Circuit-breaker bundling type moveable contact special mounting tool

An installation tool and bundled technology, applied in the manufacture of circuits, emergency protection devices, emergency protection devices, etc., can solve problems such as time-consuming and labor-intensive efficiency, difficulty in checking switch distance and phase spacing, and affecting the accuracy of circuit breaker dimensions. Achieve the effect of good assembly quality and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

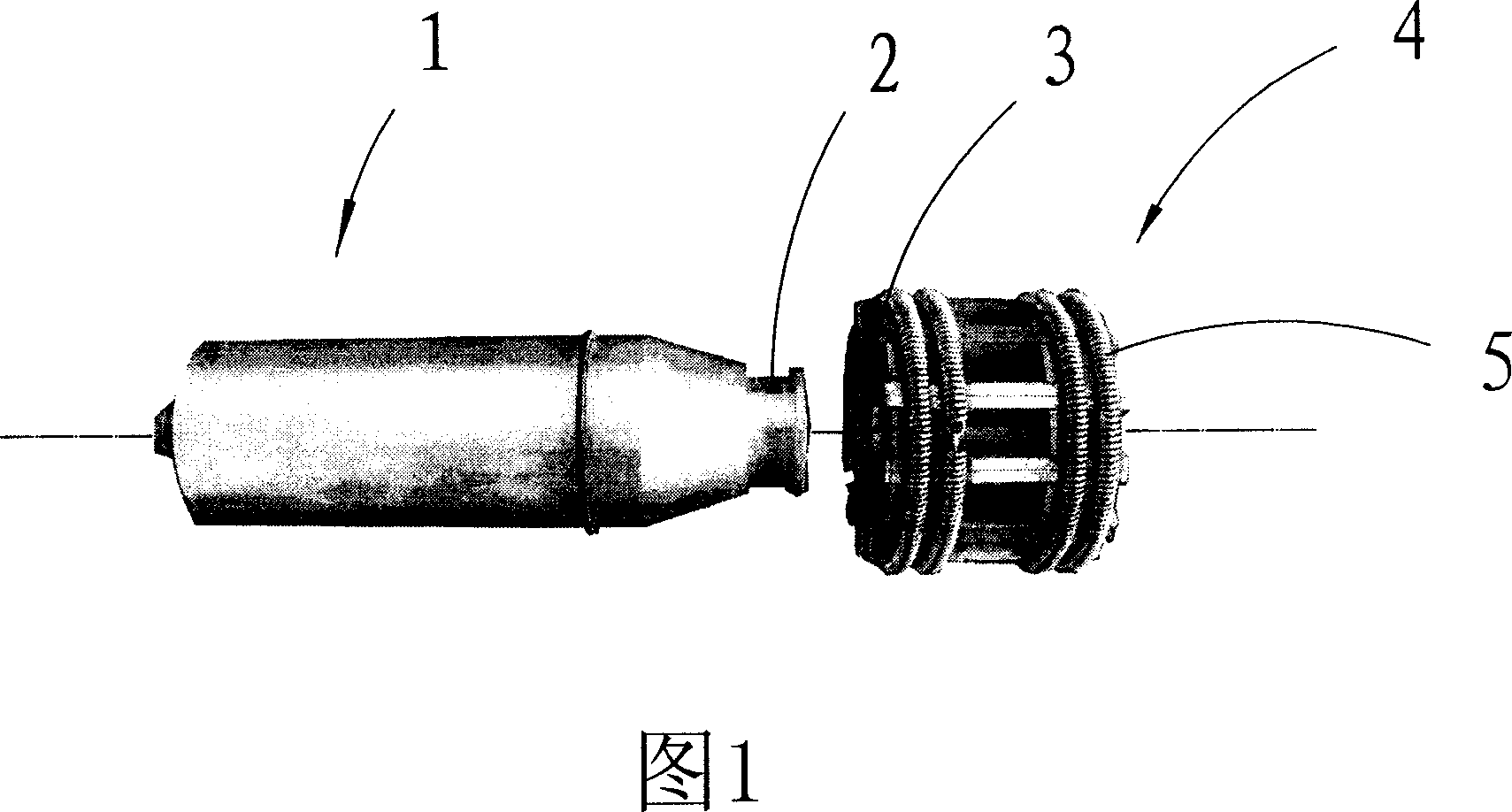

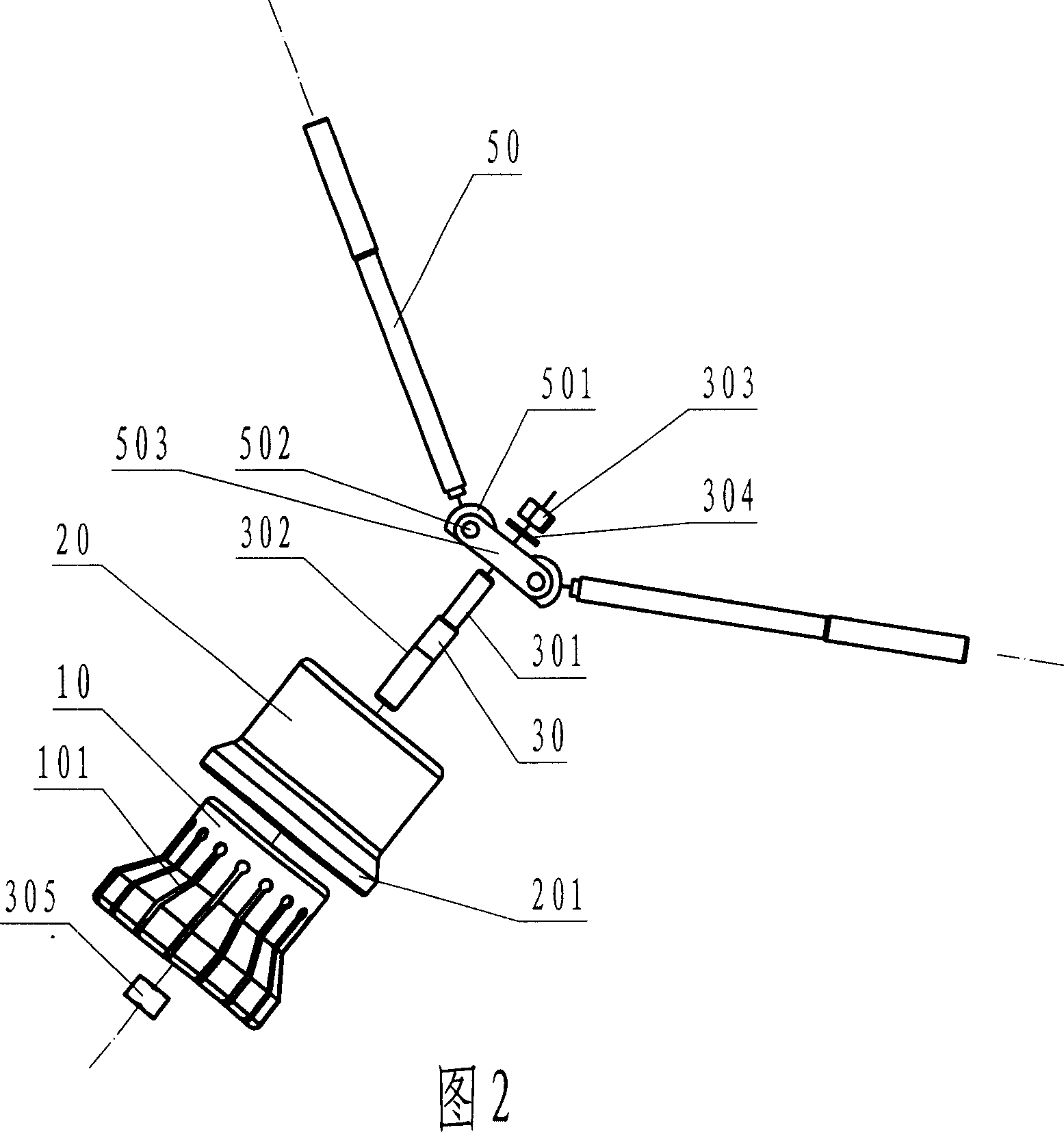

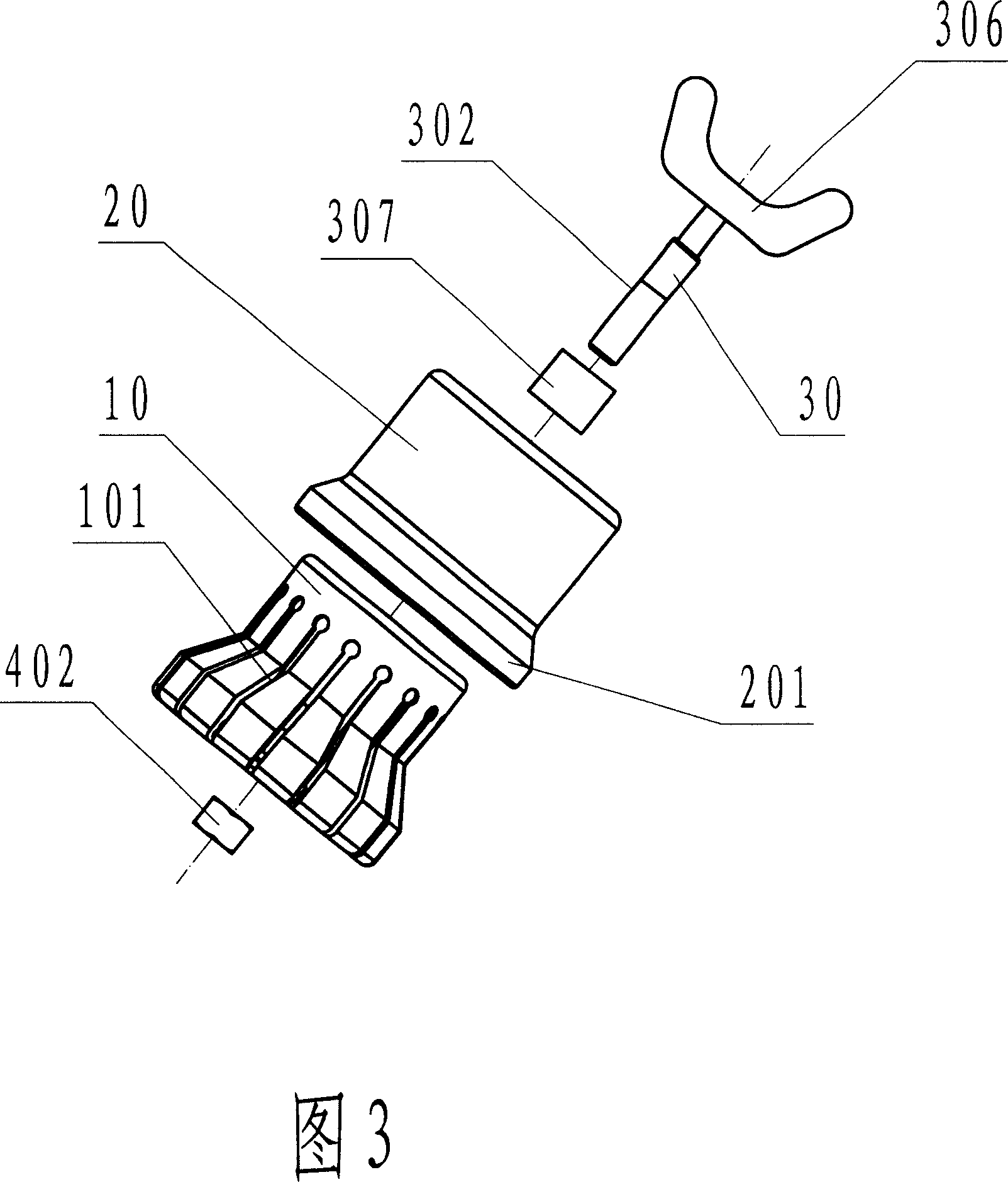

[0011] The serial numbers in the figure respectively indicate: contact arm 1, contact arm end 2, contact hole 3, contact 4, spring clip 10, scaling gap groove 101, squeeze cup 20, cup mouth 201, pull rod 30, upper shaft head 301, lower shaft head 302, nut 303, washer 304, spring clamp nut 305, handle 50, cam 501, shaft pin 502, I-shaped piece 503, rotary handle 306, pad cover 307.

[0012] Referring to FIG. 2 in conjunction with FIG. 1, FIG. 2 shows the assembly structure of an embodiment of the present invention. It consists of three parts: a spring clip 10, a squeeze cup 20 and a handle assembly. The shape of the spring clip 10 is in the shape of a lampshade, and the shape of its inner cavity matches the external shape of the contact 4 of the movable contact. Since the outermost periphery of the contact 4 is a spring, the inner edge and inner wall of the spring clip 10 should also have corresponding shape, so that the contact 4 can be put in smoothly when the spring clip 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com