Equipment for assembling contactor contact

A contactor and contact technology, which is used in the manufacture of relays, emergency protection devices, and emergency protection devices, etc., can solve the problems that cannot meet the large-scale industrial production of enterprises, it is difficult to ensure that the contacts are installed in place, and the assembly is time-consuming and laborious. Market application value, the effect of increasing production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

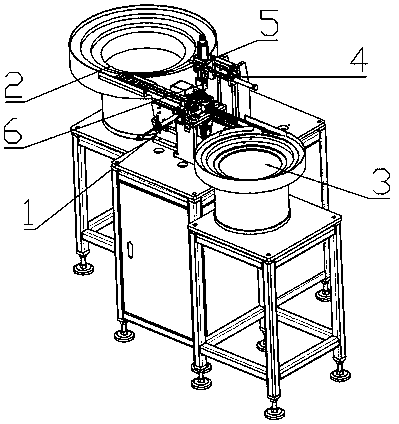

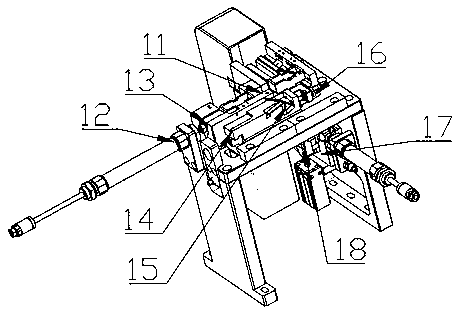

[0023] Such as figure 1 , figure 2 As shown, Embodiment 1 of the present invention: a device for assembling contacts of a contactor, including a workbench, a housing feeding mechanism 2, a contact feeding mechanism 3, a shifting mechanism 1, a contact grasping and pressing mechanism and control box, the displacement mechanism 1 is arranged in the middle of the workbench, the shell feeding mechanism 2 is arranged on the left side of the displacement mechanism 1, and the contact feeding mechanism 3 is arranged on the The right side of the displacement mechanism 1, the contact pressing mechanism is arranged on the rear side of the displacement mechanism 1, and the displacement mechanism 1 includes a housing displacement device and a contact receiving top that are both arranged on the displacement bracket. Lifting device, the housing shifting device is connected to the outlet of the first material guide groove of the housing feeding mechanism 2, and the contact receiving jacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com