Mobile phone camera LED part automatic assembly machine

A technology for automatic assembly machines and mobile phone cameras, which is applied to assembly machines, connecting components, mechanical equipment, etc., and can solve problems such as poor assembly accuracy, unstable dispensing accuracy, and low feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

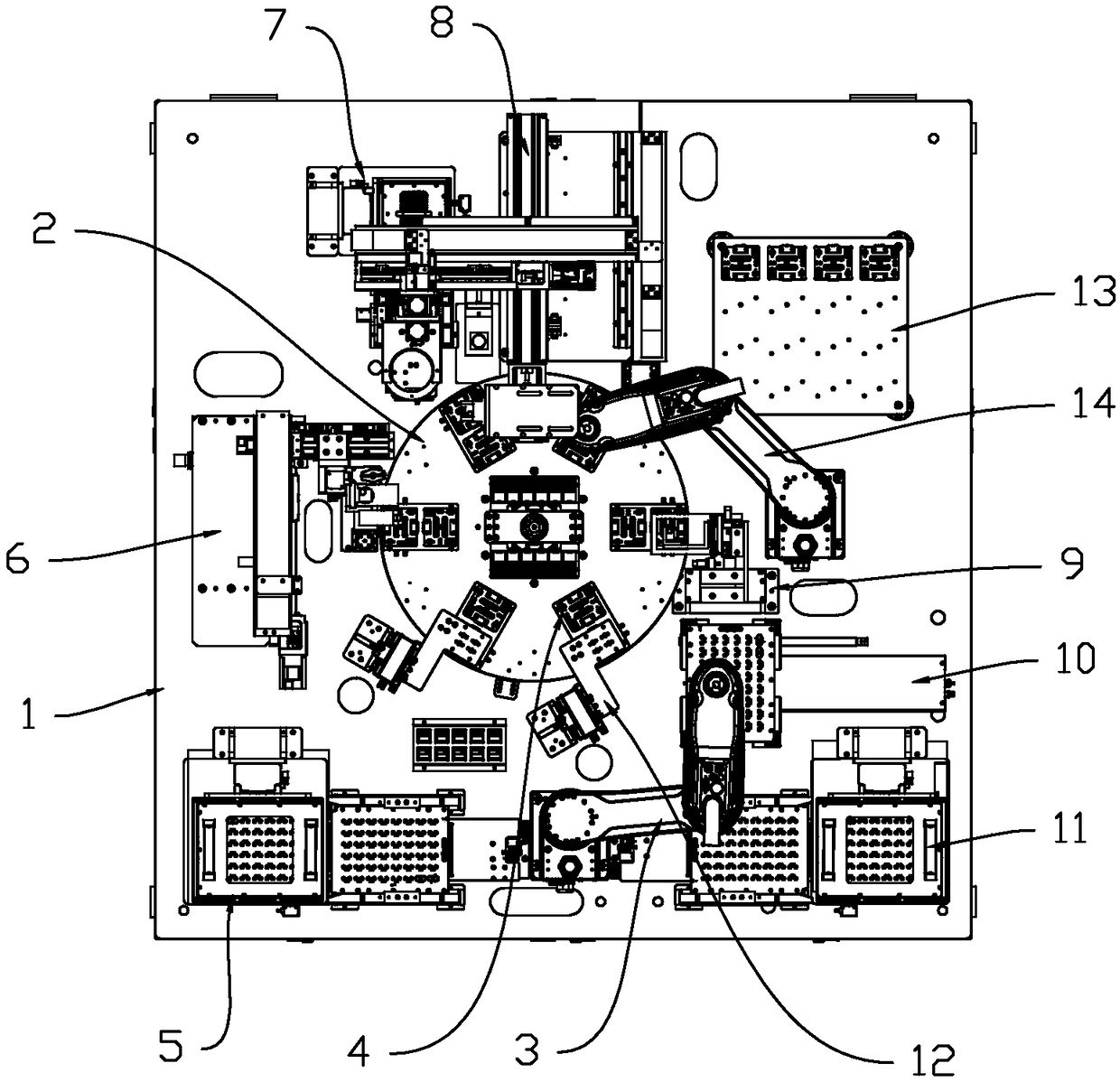

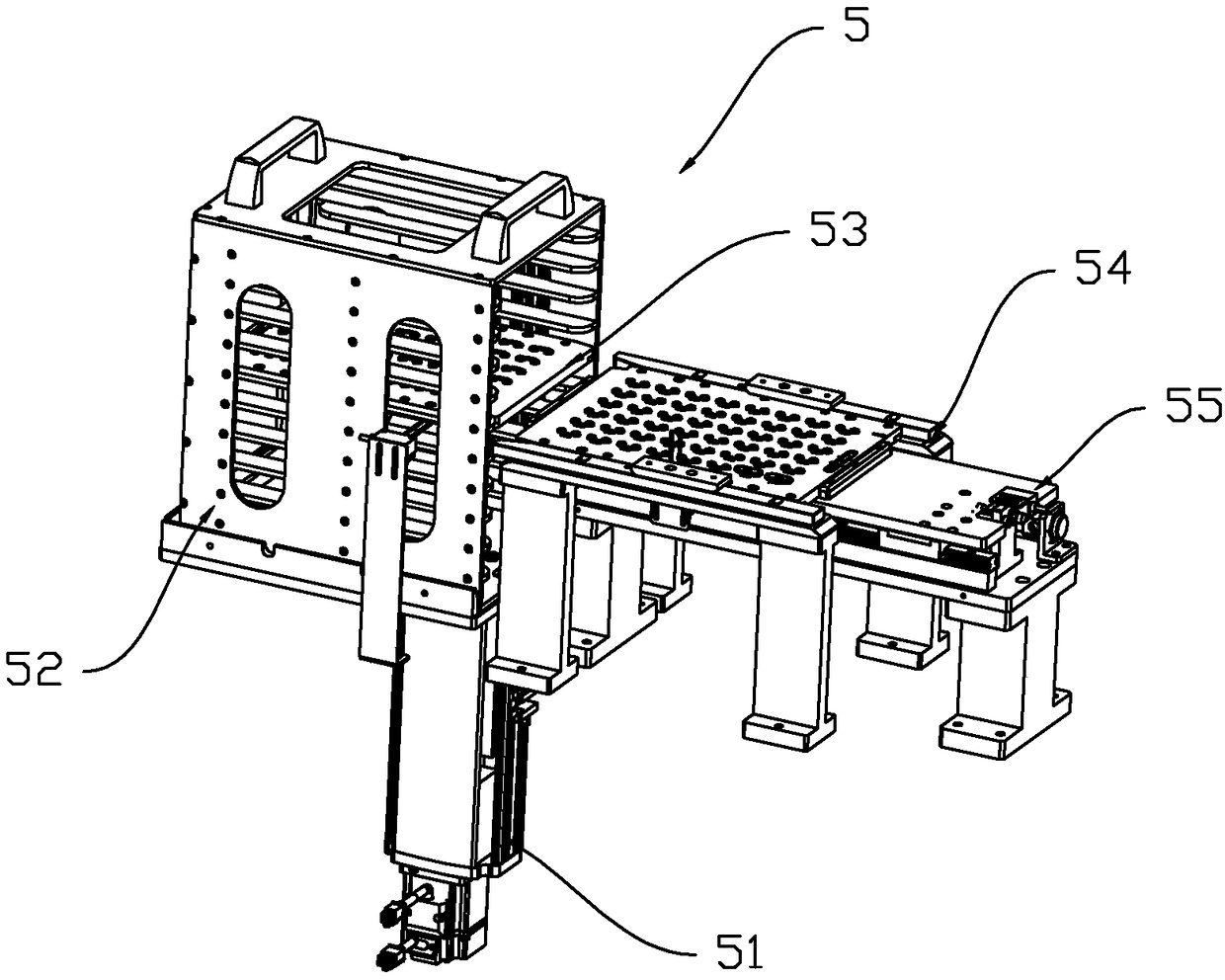

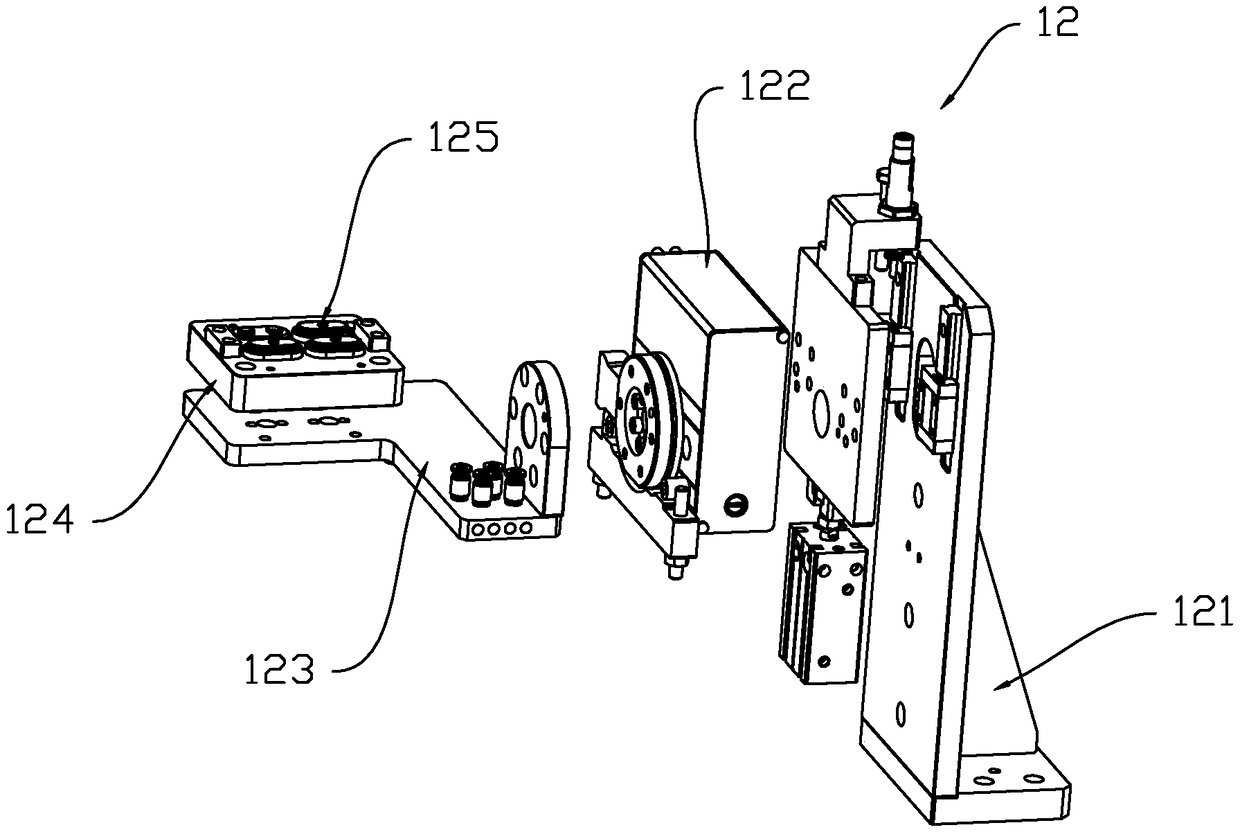

[0027] refer to Figure 1 to Figure 9 , the present invention is an automatic assembly machine for mobile phone camera LED parts, including a workbench 1, a turntable device 2 and a manipulator 3 for loading and unloading are arranged on the workbench 1, and the execution end of the manipulator 3 is a camera end that can absorb The suction head of the cover, the turntable device 2 is provided with a number of auxiliary jigs 4 for placing the camera end cap, and the workbench 1 is surrounded by the turntable device 2. The camera end cover feeding device 5, the glue dispensing device 6, and the LED parts are arranged in turn. Feeding device 7, LED assembly device 8, finished product inspection mechanism 9, defective product placement area 10 and finished product unloading device 11, a number of turning mechanisms 12 are arranged between the camera end cover feeding device 5 and the turntable device 2, and the turning mechanism 12 It includes a rotatable rotating arm 123, on whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com