Assembly method and assembly production line of transformer

An assembly method and transformer technology, applied in the manufacture of inductors/transformers/magnets, coils, electrical components, etc., can solve problems such as reduced production efficiency, tape tightness and discomfort, and poor inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

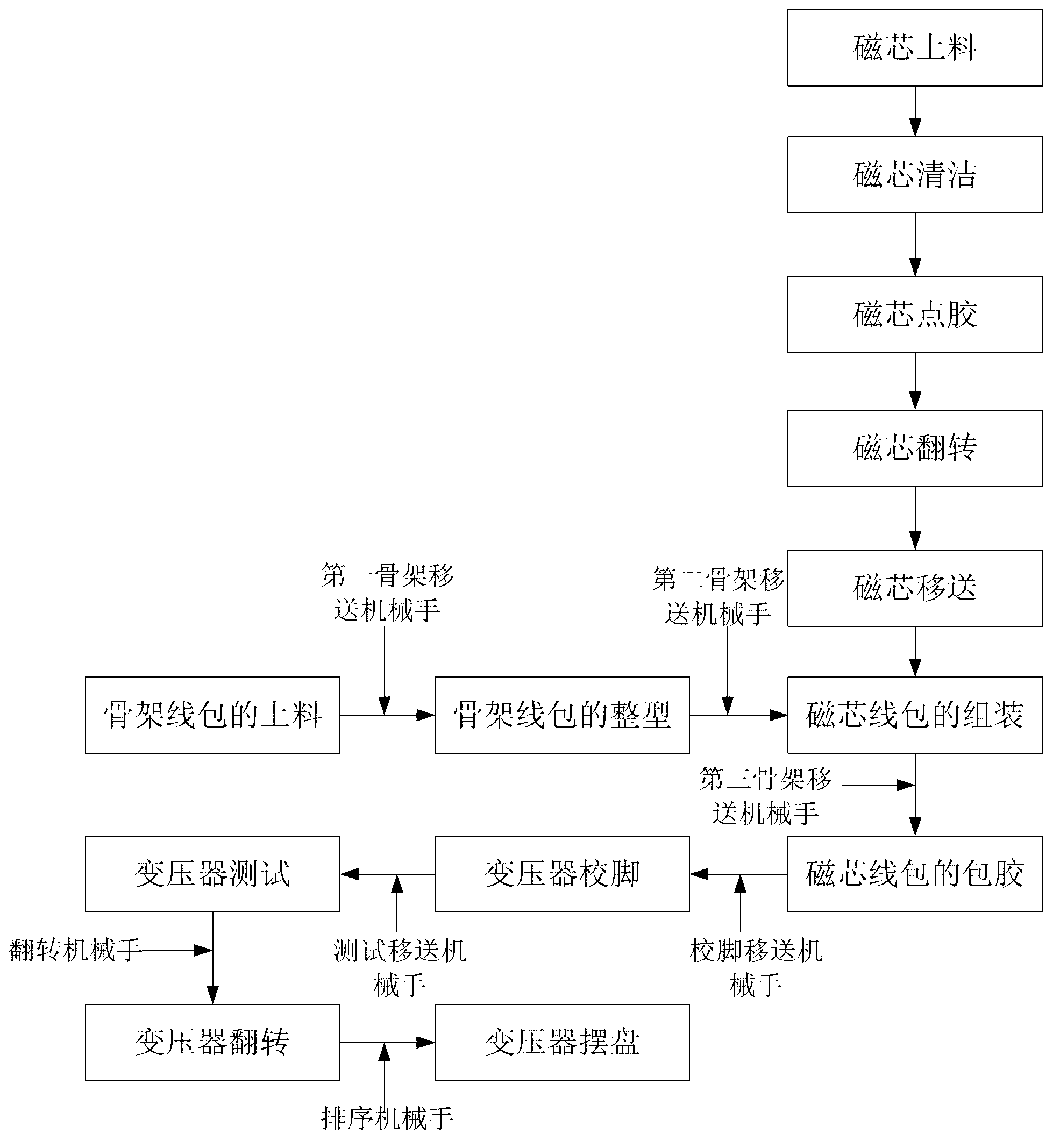

[0047] Transformer assembly broadly includes such as figure 1 In the steps shown, one branch is from the loading of the skeleton wire package to the shaping of the skeleton wire package, and the other branch completes the feeding of the magnetic core (including the left and right magnetic core), magnetic core cleaning, and magnetic core dispensing in sequence. (This step may be performed after the core bobbin is coated and before the transformer foot calibration is performed. This dispensing method is referred to as the second dispensing method in the following), magnetic core flipping and magnetic core transfer, through two branches Arriving at the assembly area, the bobbin package and magnetic core complete the assembly of the core bobbin, and then complete the encapsulation of the magnetic core bobbin, transformer leg calibration, transformer testing, transformer flipping, and transformer panning in sequence. The assembly method of the present invention can at least realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com