Patents

Literature

145results about How to "Minimize impact on product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

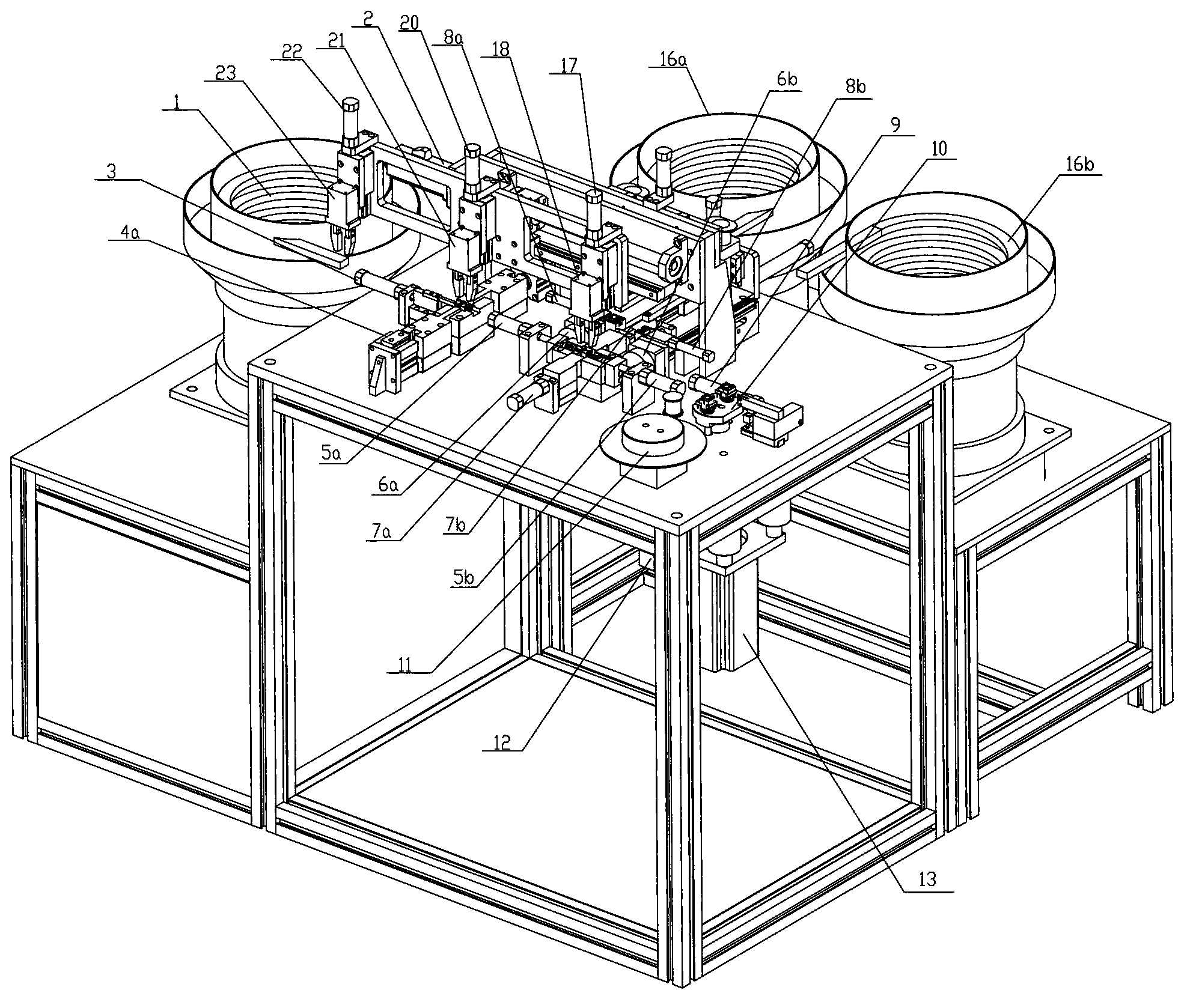

Automatic glue spreading machine

ActiveCN101920238AIncrease productivityPrecise positioningLiquid surface applicatorsCell electrodesManipulatorEngineering

The invention discloses an automatic glue spreading machine which comprises a stand, a mechanical hand arranged on the stand, a feeding turntable, a positioning device and a glue spreading device, wherein one station of the mechanical hand is aligned to a conveyer belt, and another station of the mechanical hand is aligned to a feeding station of the feeding turntable; the positioning device is aligned to a positioning station of the feeding turntable and used for positioning a workpiece; the glue spreading device is aligned to a glue spreading station of the feeding turntable and used for spreading glue on the workpiece; all the stations of the feeding turntable are respectively provided with a set of rotating clamps; and the positioning device and the glue spreading device are both provided with a clamping rotating mechanism for driving the rotating clamps to rotate. The automatic glue spreading machine not only realizes the full automatic operations of feeding, positioning, glue spreading, detecting and blanking of the workpiece and improves the production efficiency, but also meets the glue spreading requirement of cylindrical cells in different specifications, has the advantages of accurate positioning, high glue spreading precision and good consistency, reduces the influences of anthropic factors on the product quality and guarantees the glue spreading quality.

Owner:DONGGUAN AMPEREX TECH +1

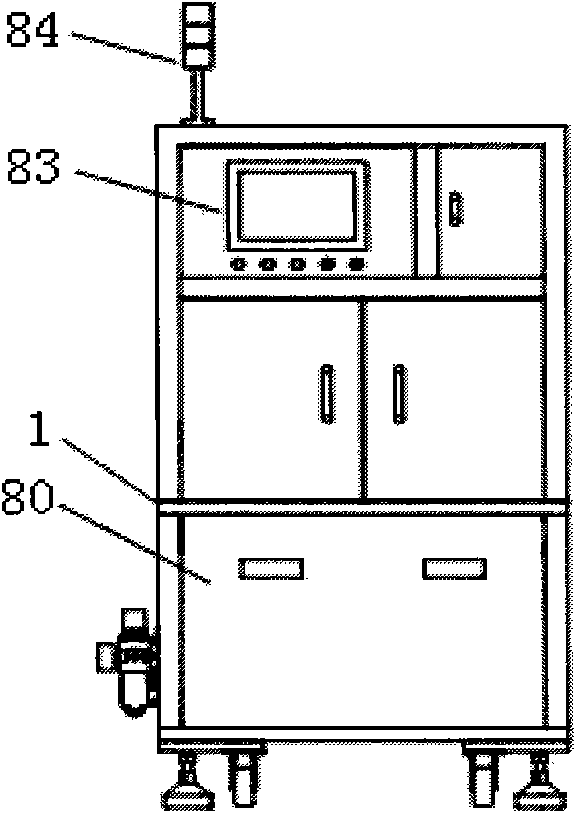

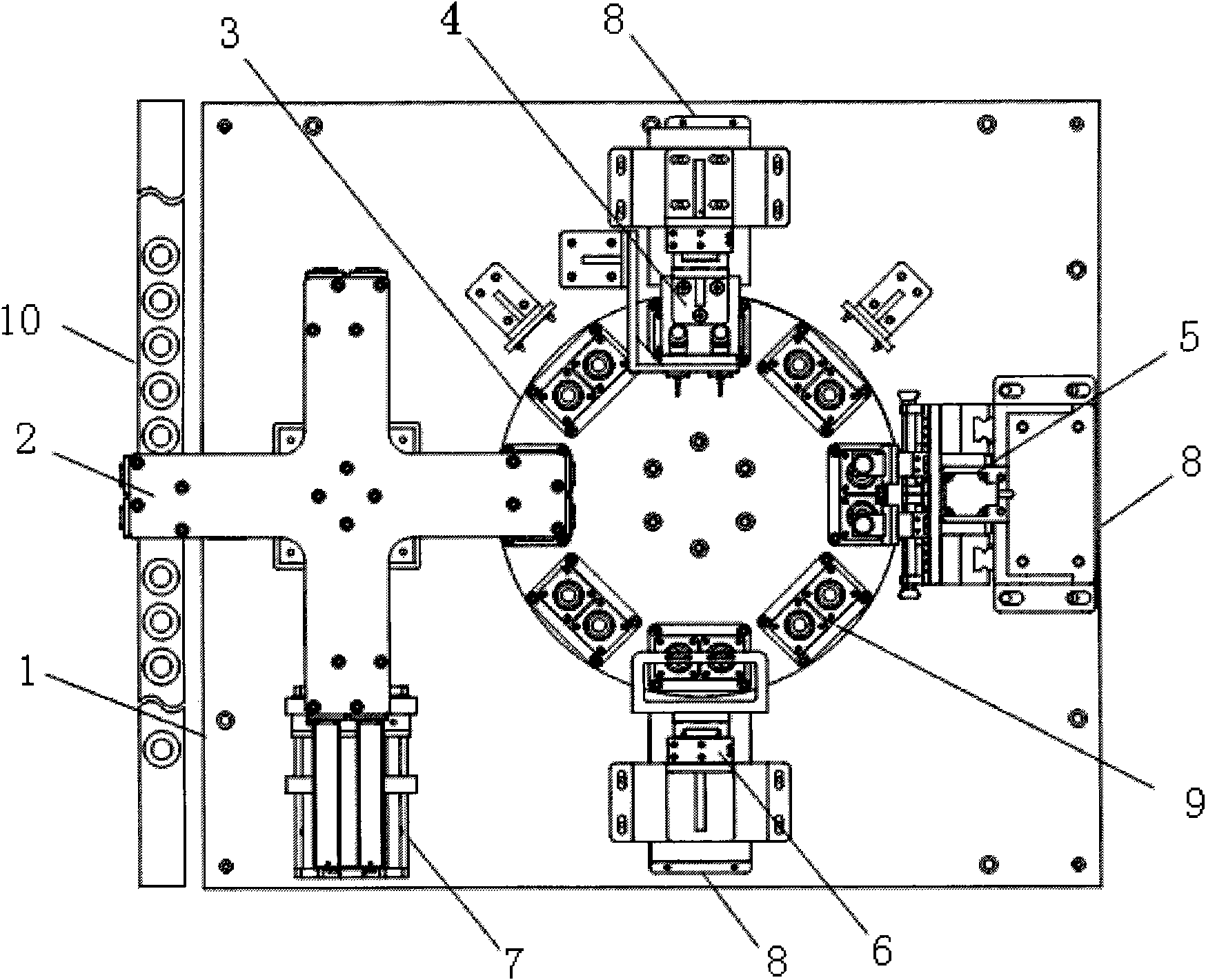

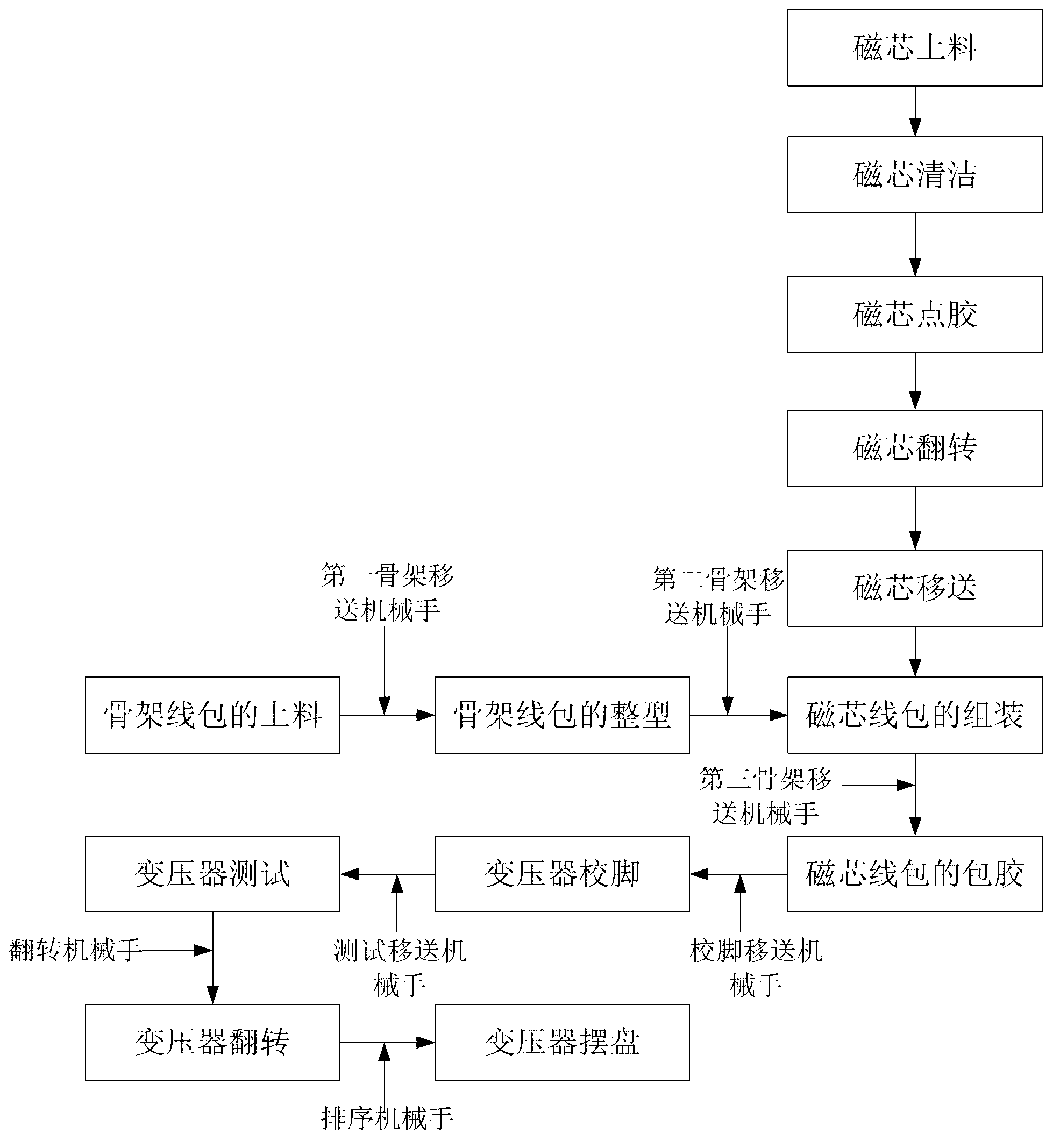

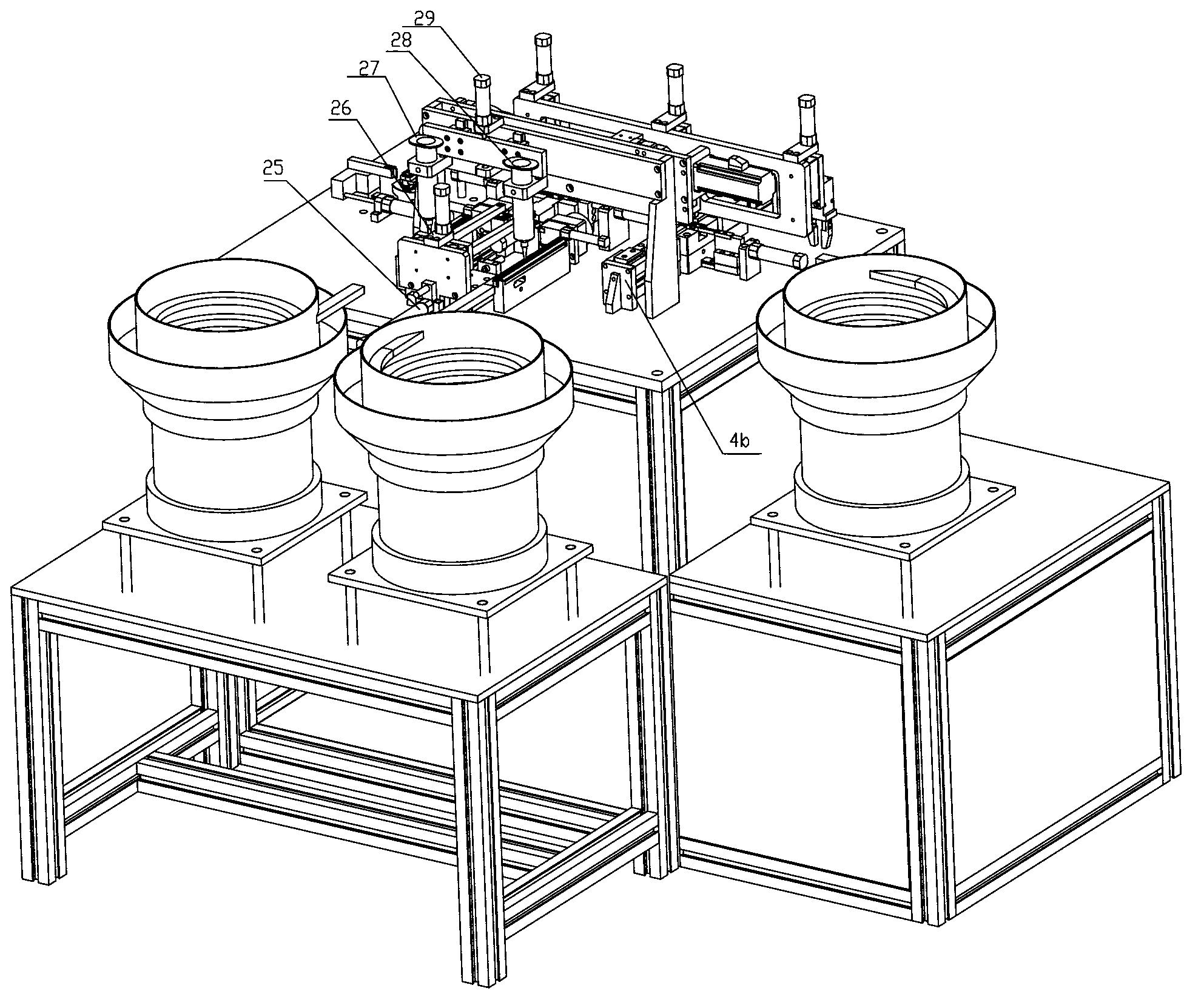

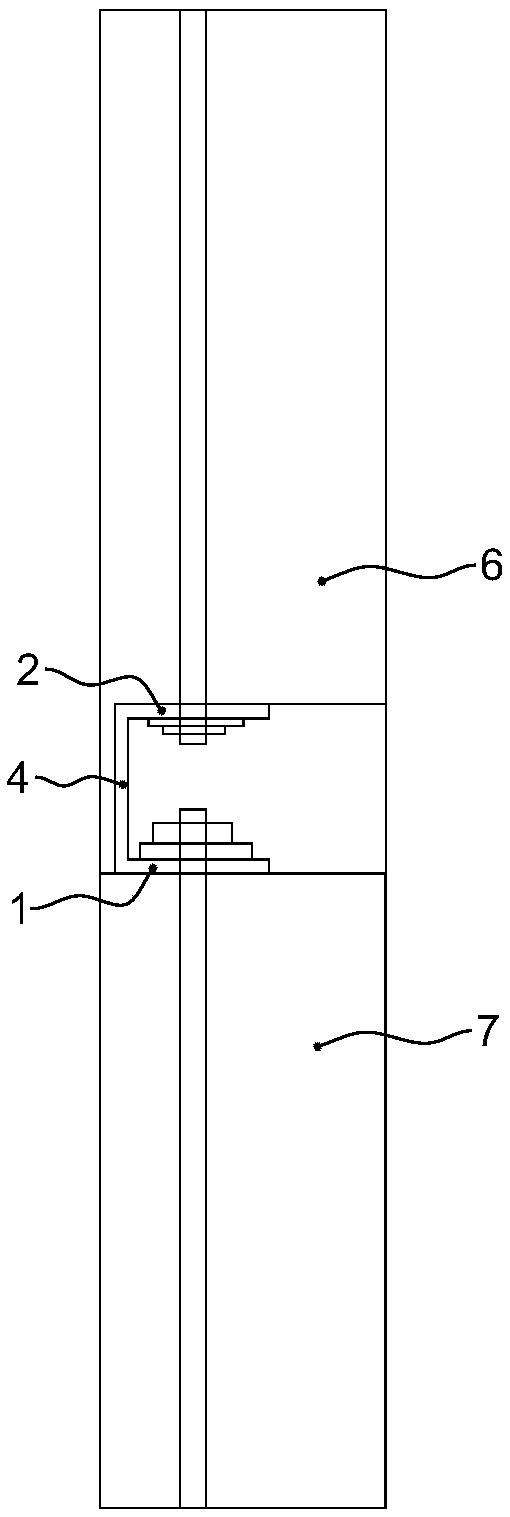

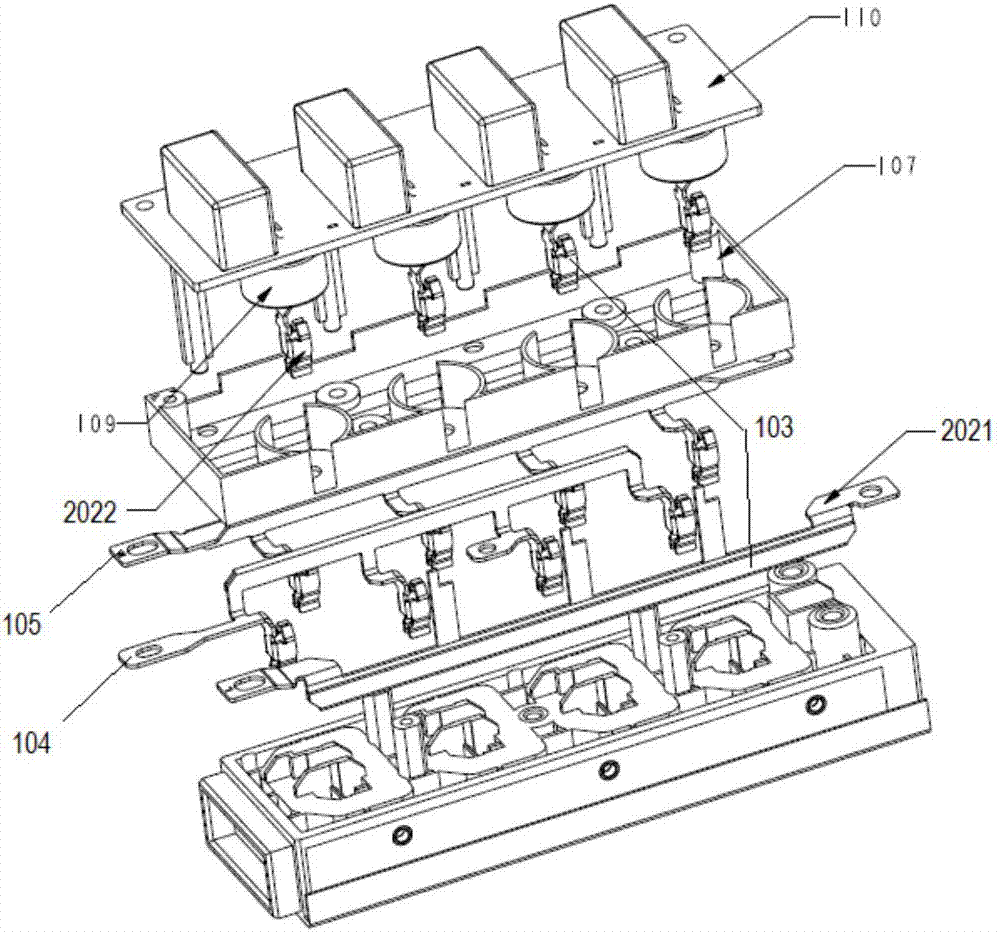

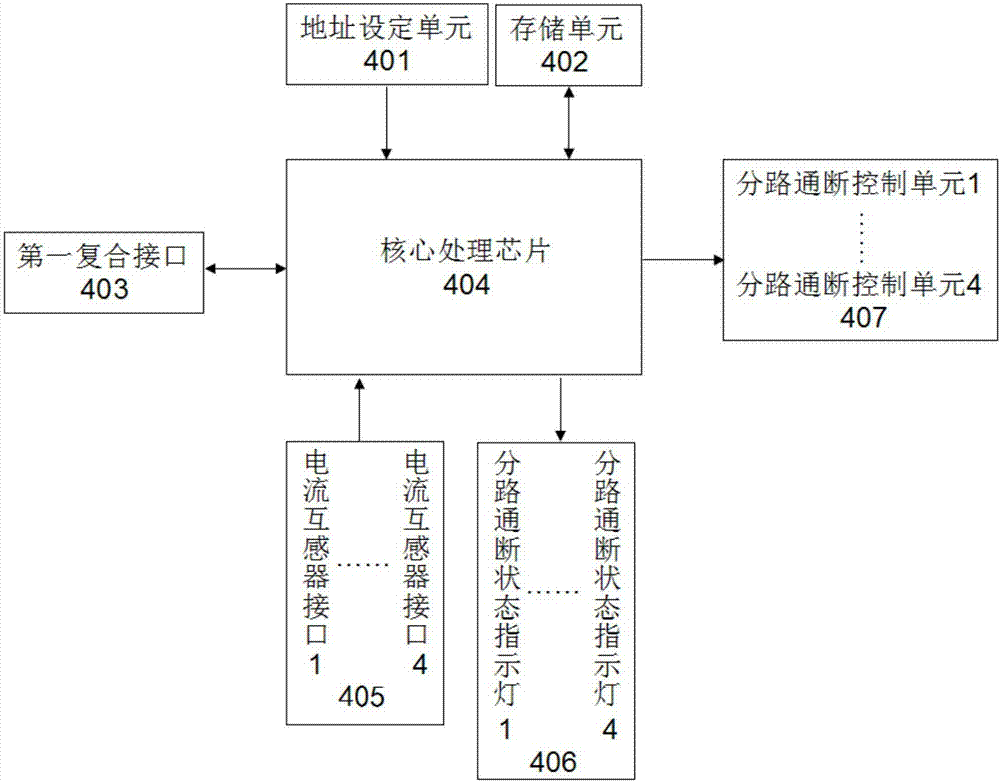

Assembly method and assembly production line of transformer

ActiveCN102842416AImprove assembly efficiencyMinimize impact on product qualityCoils manufactureProduction lineTransformer

The invention discloses an assembly method and an assembly production line of a transformer. The assembly method comprises the following steps: a shaping step implemented by use of an inner shaping clamp which is automatically sleeved in a middle hole of a skeleton wire packet and a front shaping cylinder and a back shaping cylinder which clamp the skeleton wire packet from the front side and the back side; a magnetic core skeleton assembling step of starting a left assembling cylinder and a right assembling cylinder to push the left magnet core and the right magnet core to be sleeved in the middle hole; and a tape wrapping step of winding the tape on a loading turntable around the outer peripheries of the left magnet core and the right magnetic core by driving a tape wrapping fixture to be rotated preset circles. With the adoption of the assembly method and the assembly production line of the transformer, shaping of the skeleton wire packet, assembling of the magnetic core skeleton and tape wrapping of the magnetic core skeleton can be at least completed, the assembling efficiency can be increased greatly, and the influence of the human factors on the product quality can be reduced.

Owner:SUIZHOU RUISHUO ELECTRONIC CO LTD

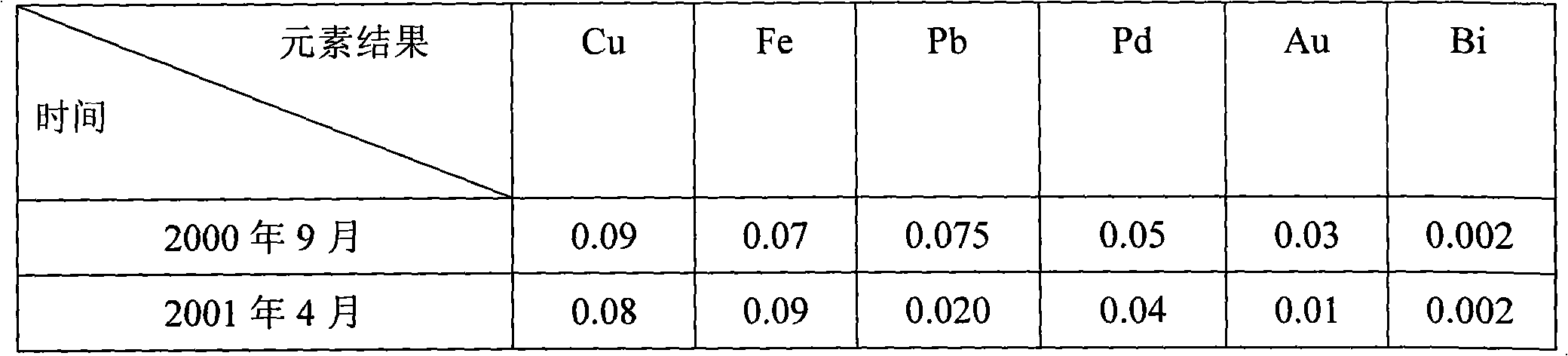

Method for producing high-purity silver nitrate

InactiveCN102040240AReduce contentMinimize impact on product qualitySilve compoundsEvaporationHydrolysis

The invention discloses a method for producing high-purity silver nitrate, comprising the following steps of: (1) reacting: flushing silver with purified water, placing the flushed silver in a reaction kettle, adding pure nitric acid, keeping the silver to be excessive, heating to 70DEG C, removing excessive nitrides and adjusting the pH value of a reaction solution; (2) hydrolyzing: adding the reaction solution in a hydrolysis kettle, flushing and diluting until the density is 1.6-1.7g / cm<3>, adding an impurity removing agent, standing for 10-16 hours and filtering to obtain filtrate; (3) evaporating and crystallizing: carrying out the pressure reduction and evaporation on the filtrate subjected to the impurity removal and cooling and crystallizing when the specific gravity is 3.2g / cm<3>; and (4) centrifuging and drying: after centrifuging and separating a crystal which is crystallized and separated out, allowing a solid to enter vacuum drying equipment, heating, decompressing and drying for 24 hours to obtain a pure silver nitrate finished product. The silver nitrate produced by the method has low metal content and high quality.

Owner:中科铜都粉体新材料股份有限公司

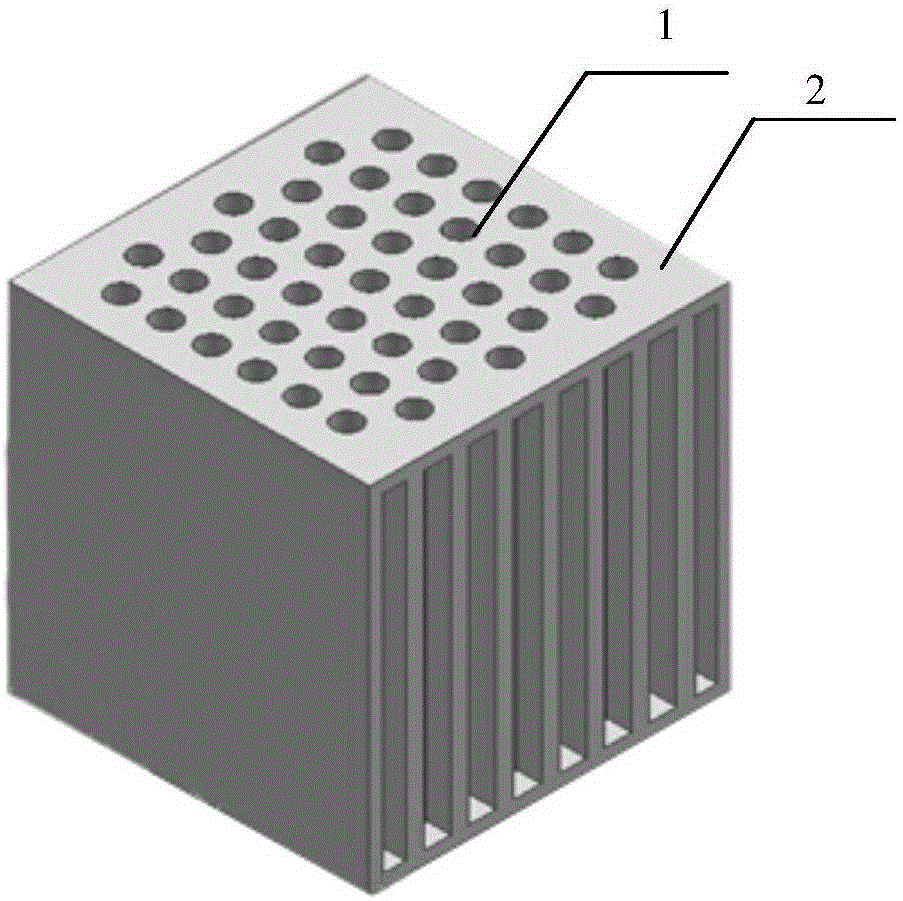

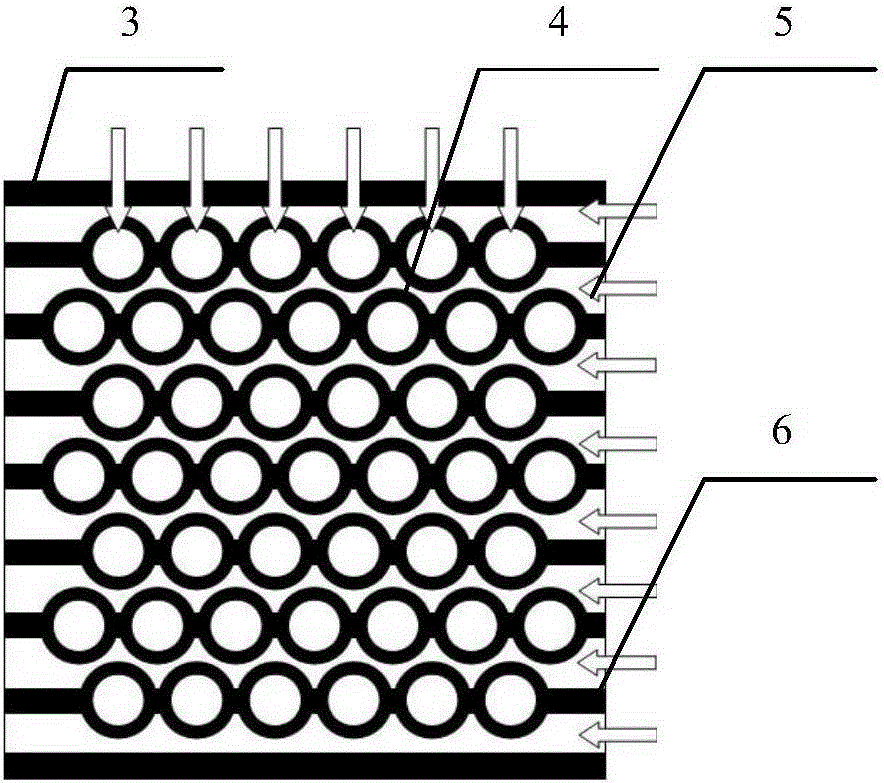

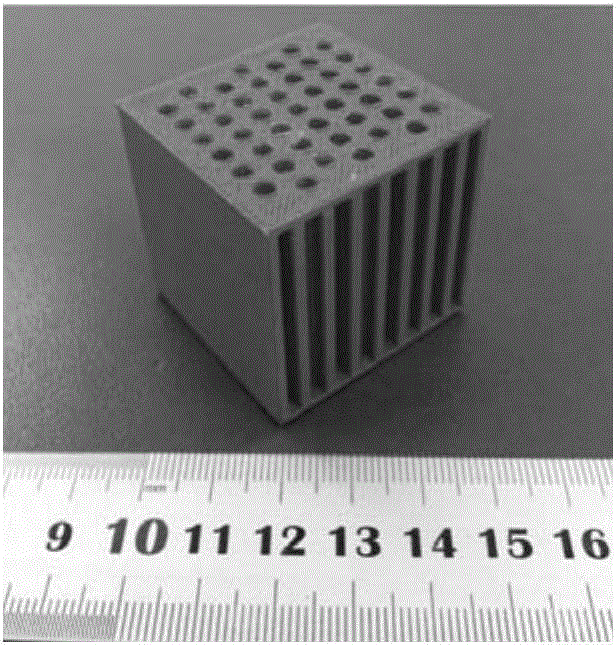

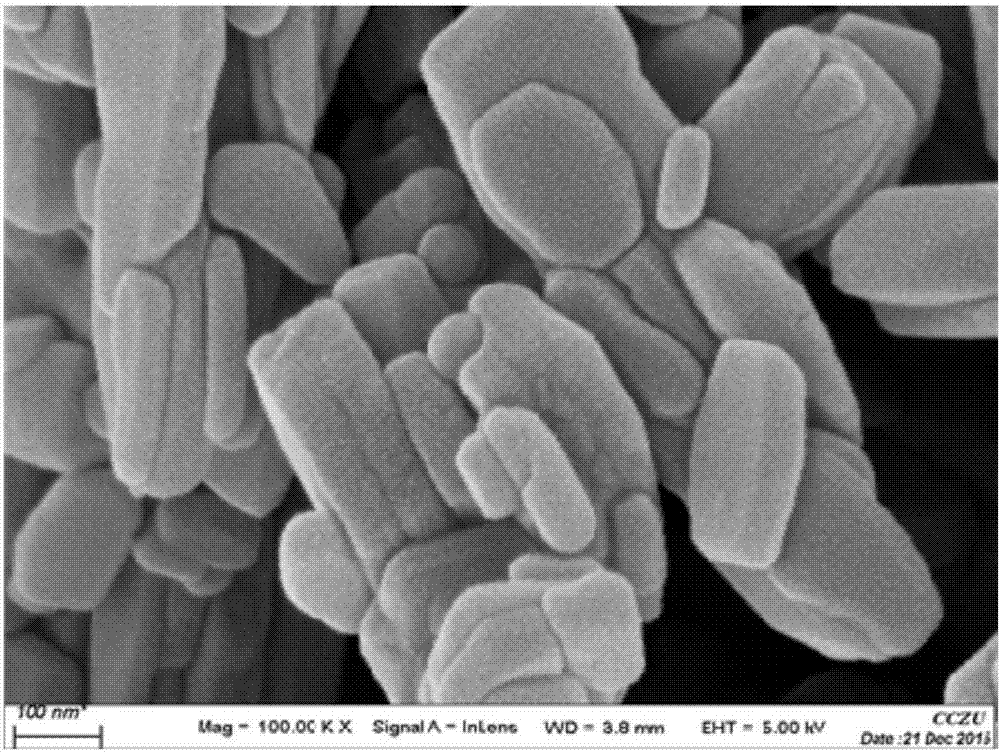

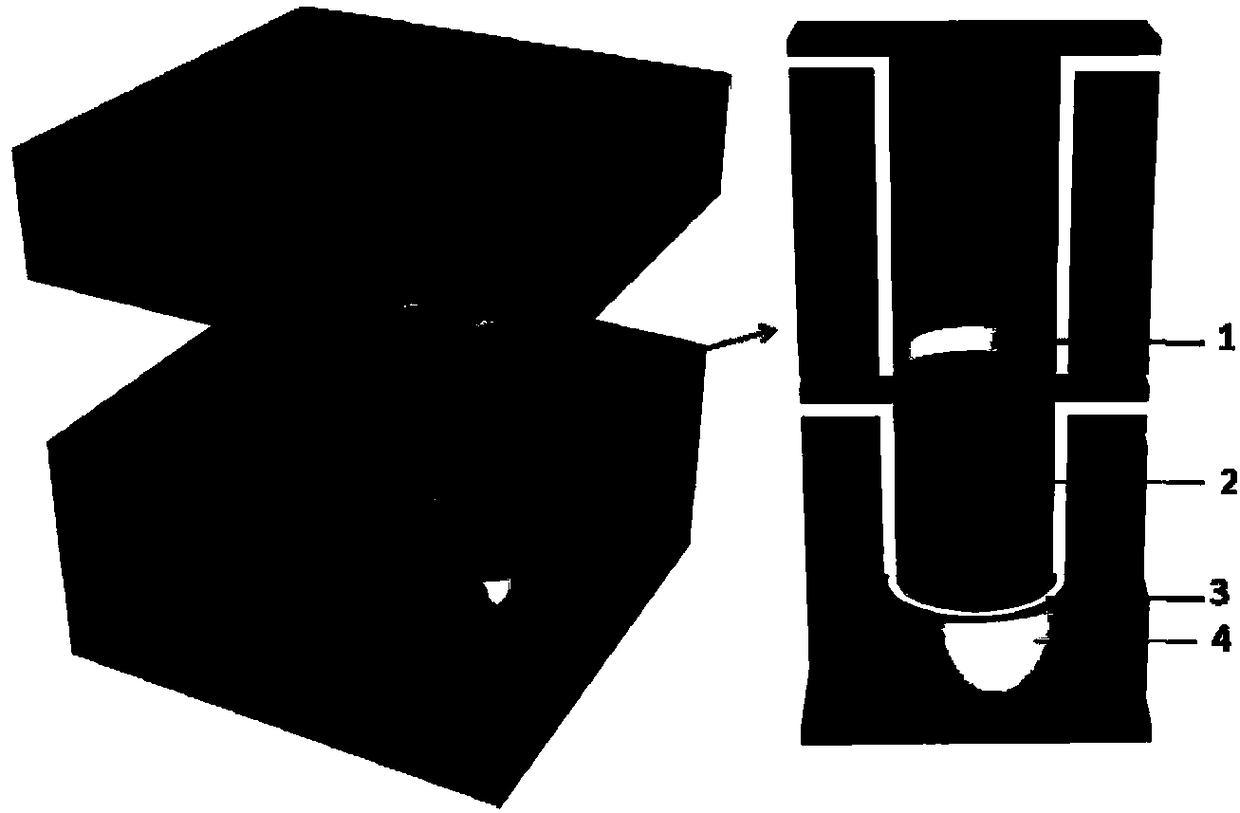

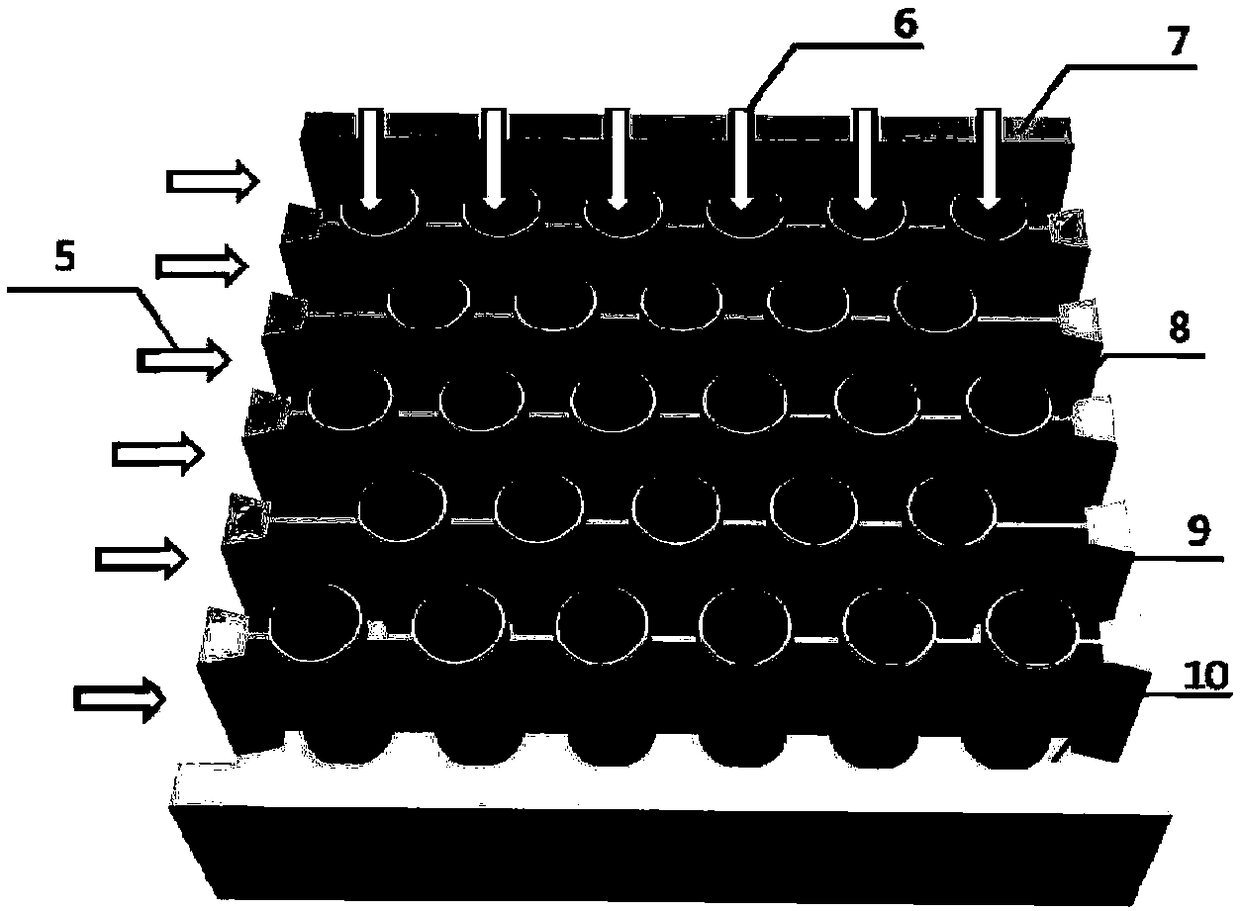

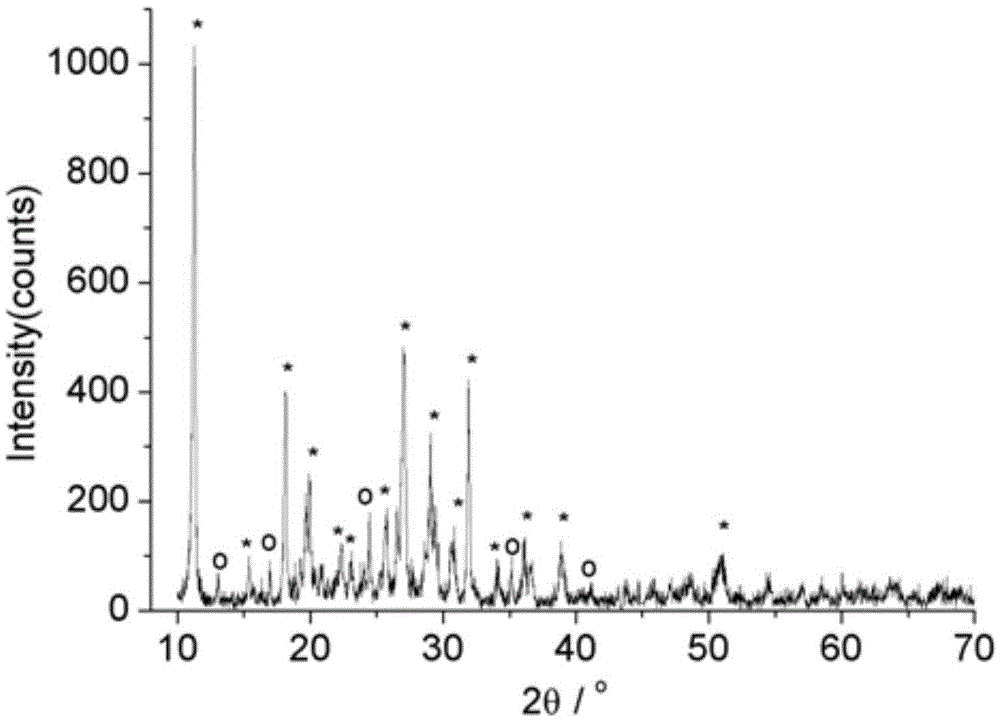

Method for three-dimensionally printing honeycomb-type solid oxide fuel cell with three-dimensional channel

ActiveCN105355947AFast mass transferShort processCell electrodesSolid electrolyte fuel cellsMaterials scienceRaw material

The invention relates to a method for three-dimensionally printing a honeycomb-type solid oxide fuel cell with a three-dimensional channel, and belongs to the technical field of solid oxide fuel cells. According to the method, positive pole ceramic powder or negative pole ceramic powder serves as a raw material, a structure is designed through three-dimensional mapping software, outputting is carried out through a ceramic three-dimensional printer, and a green body of a honeycomb-type positive pole support body or a negative pole support body with a three-dimensional channel structure is printed and prepared with a one-step method; after the green body is sintered, the positive pole support body or the negative pole support body is obtained; an electrolyte layer and a negative pole layer are sequentially deposited on the positive pole support body to form a positive-pole honeycomb-type solid oxide fuel cell with an emulsion impregnation method; an electrolyte layer and a positive pole layer are sequentially deposited on the negative pole support body to form a negative-pole honeycomb-type solid oxide fuel cell with an emulsion impregnation method. According to the method, preparing is efficient, cost is saved, the mass transfer rate is greatly increased, the automation degree is high, and the batch is stable.

Owner:SHANDONG UNIV OF TECH

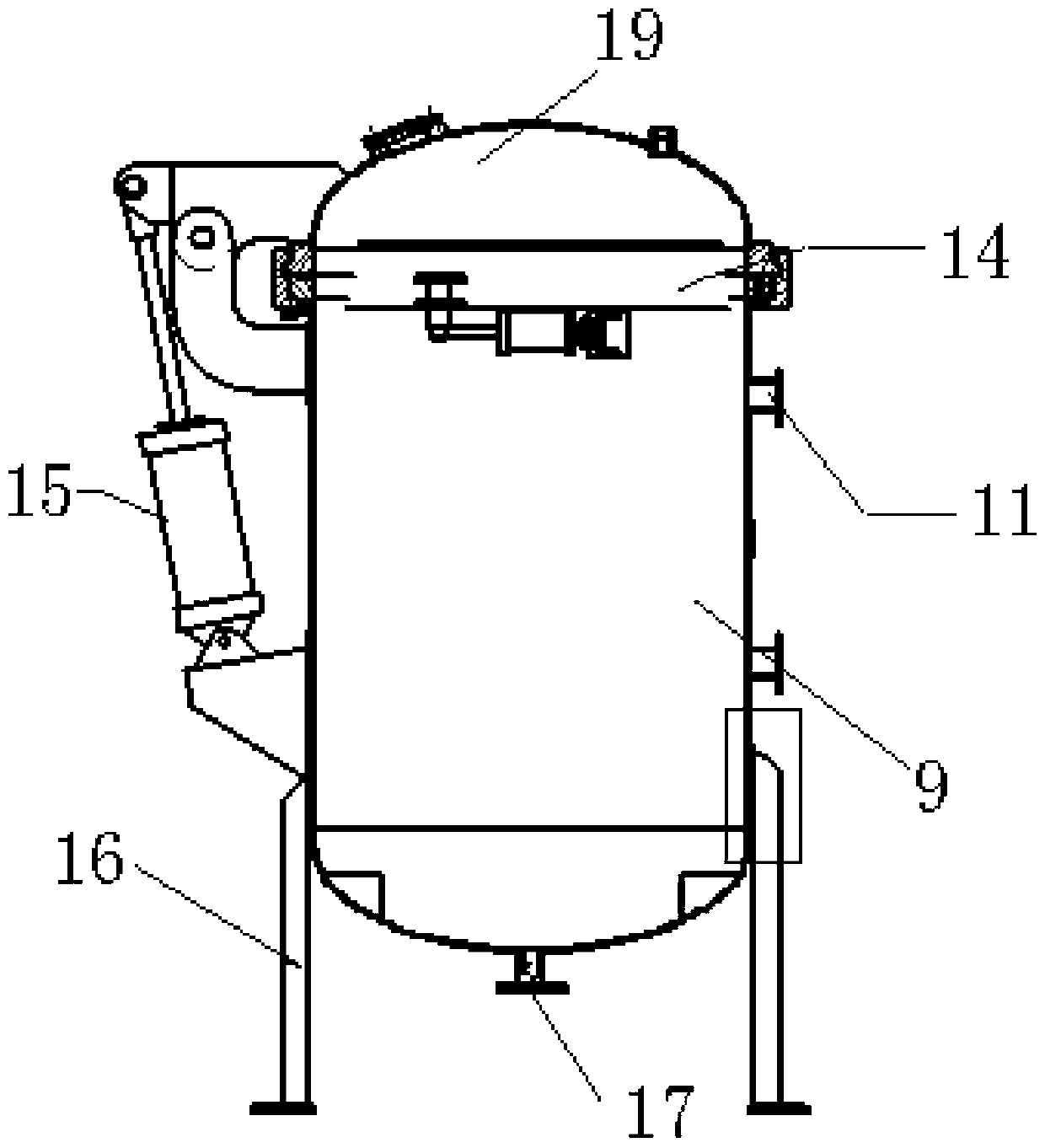

Infiltration technique and device

ActiveCN103341434AHigh surface finishHigh shape and size accuracyLiquid surface applicatorsCoatingsCooking & bakingRelative motion

The invention relates to an infiltration technique and device. The technique comprises three phases, namely infiltration preprocessing, infiltration processing and infiltration postprocessing. The infiltration device comprises an infiltration basket, a hoist hook, a degreasing pot, a cleaning pot, a centrifugal pot, a baking oven, an infiltration pot, a vacuum pump, a glue storing pot, an air compressor, a washing pot, a solidifying pot and a pressure test device, wherein all the components are arranged in a straight line. Due to the fact that the infiltration pot is cylindrical, influence of sewage on a production site can be effectively avoided. Due to the fact that the infiltration pot is locked with a method that a sealing lock ring is inflated by a lock ring cylinder and both a toothed ring of a pot cover and the lock ring are manufactured with whole materials, sealing performance is good, operation is safe and fast, the pot cover can be opened and closed automatically and fast, no relative motion exists between the pot cover and a sealing ring, friction does not exist, opening is flexible, and the service life is long. The infiltration technique and device have the advantages that the device is compact and reasonable in structure, the whole production site is beautiful, logistics is smooth, and fixed location management and civilization and cleanliness of the production site can be ensured.

Owner:NANTONG NINGYUAN AUTOMATION TECH

Method of producing rice fertilizer

InactiveCN101033163AThe amount of adsorption is easy to controlReduce lossFertiliser formsUrea compound fertilisersFertilizerUrea

This invention discloses a production method for rice fertilizers , namely a production method for SCU, in which, large grains of urea pass through flowing melt sulfur to realize coating to urea, then melt olefin is sprayed to it to be cooled to room temperature , then a conditioner is added to the rice fertilizer, and the conditioner is dolomite powder or diatomite adsorbed on the surface of the rice fertilizer grain in the 1.5-2.5% volume of the weight of the rice fertilizer, the conditioner is added in a roller screen, in which, substances on the screen are finished products and conditioners below the screen is fed back to the feeding port by a screw feed machine, the rice fertilizer processed by this method alters surface structure of SCU grains and increases spreading speed of water on the grain surface.

Owner:汉枫缓释肥料(江苏)有限公司

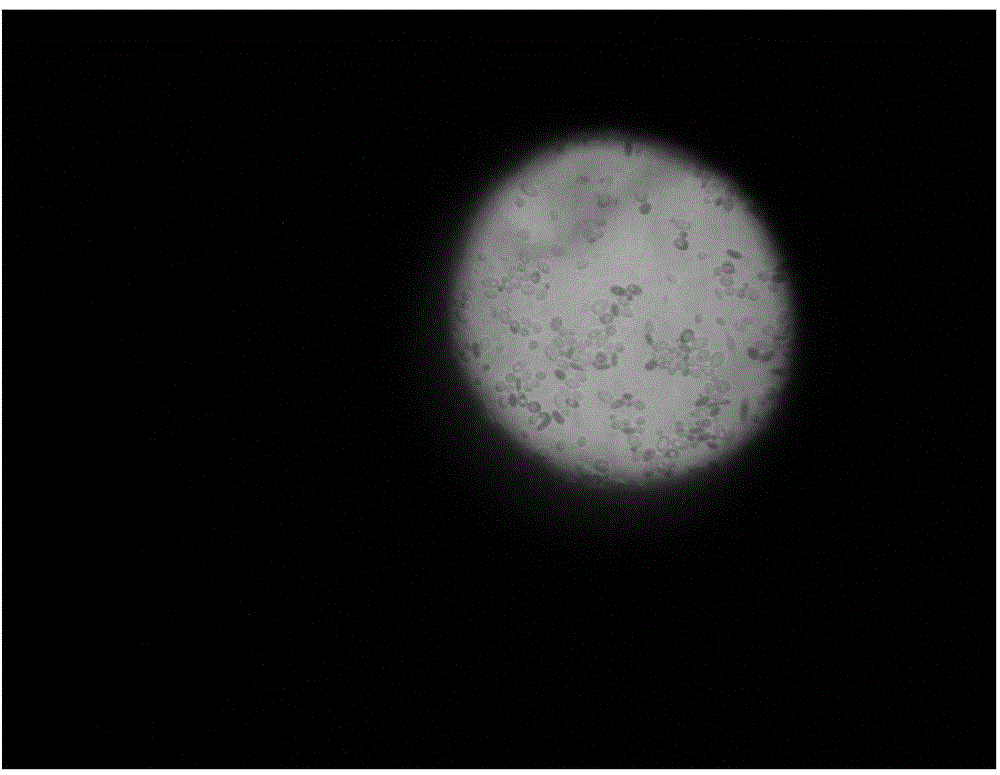

Preparation method of loquat distilled liquor

ActiveCN104371878AEasy to drinkGood for healthMicroorganism based processesAlcoholic beverage preparationPectinaseSaccharum

The invention relates to a preparation method of loquat distilled liquor. The preparation method comprises the following steps: (1) cleaning a fresh loquat fruit, removing a pit, and beating to obtain loquat slurry; (2) adding saccharose which accounts for 10wt%-12wt% of the loquat slurry, and uniformly stirring in time; (3) adding pectinase which accounts for 0.01wt%-0.015wt% of the loquat slurry, and uniformly stirring in time; (4) inoculating a self-made fresh loquat bran saccharomycete which accounts for 0.4wt%-0.6wt% of the loquat slurry, and uniformly stirring in time, wherein the fresh loquat bran saccharomycete is prepared from saccharomyces cerevisiae 2.145 (CGMCC NO.9753); (5) carrying out closed anaerobic fermentation on the loquat slurry at 28-30 DEG C for about 25-30 days to obtain fermentation liquor; and (6) distilling the fermentation liquor to obtain the distilled white liquor. The loquat distilled liquor produced through the preparation method disclosed by the invention is strong in loquat fruit flavor and mellow in liquor body and can be used for effectively reducing the influence of a fermenting metabolic waste on the product quality.

Owner:重庆市南岸区广阳镇回龙枇杷种植观光园

Three-dimensional printing method for honeycomb type electric catalyzing membrane reactor with three-dimensional channel

ActiveCN105500493AFast mass transferMass transfer automationCellsAdditive manufacturing apparatusMembrane reactorElectrolyte

The invention relates to a three-dimensional printing method for a honeycomb type electric catalyzing membrane reactor with a three-dimensional channel, and belongs to the technical field of solid oxide electrolytic tanks. The method is characterized in that the three-dimensional printing forming technology of a ceramic material is utilized, an electrolytic ceramic powder is used as a raw material, a three-dimensional drawing software is adopted, and a ceramic three-dimensional printer can perform output, so as to print and form a green body of the honeycomb type electric catalyzing membrane reactor with the three-dimensional channel by one step; the green body is subjected to sintering treatment to obtain an electrolyte supporting body; a cathode and an anode or the anode and the cathode are correspondingly deposited on the upper inner side and the upper outer side of the electrolyte supporting body by the emulsion impregnation method, thus forming the honeycomb type electric catalyzing membrane reactor with the three-dimensional channel. The method is efficient in preparation, can save the cost and greatly improve the mass transfer rate, and is high in automation degree, and stable in batch.

Owner:SHANDONG UNIV OF TECH

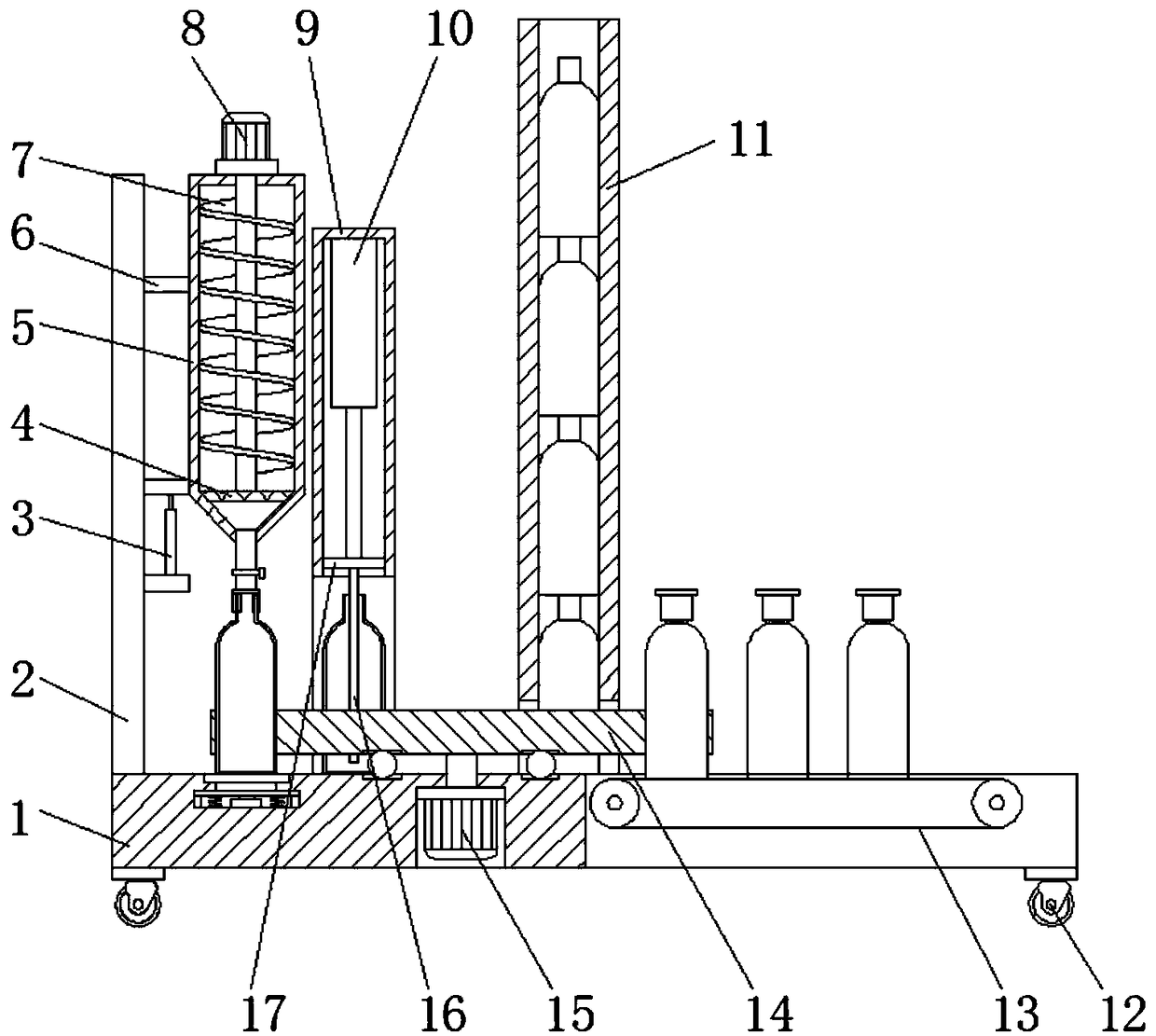

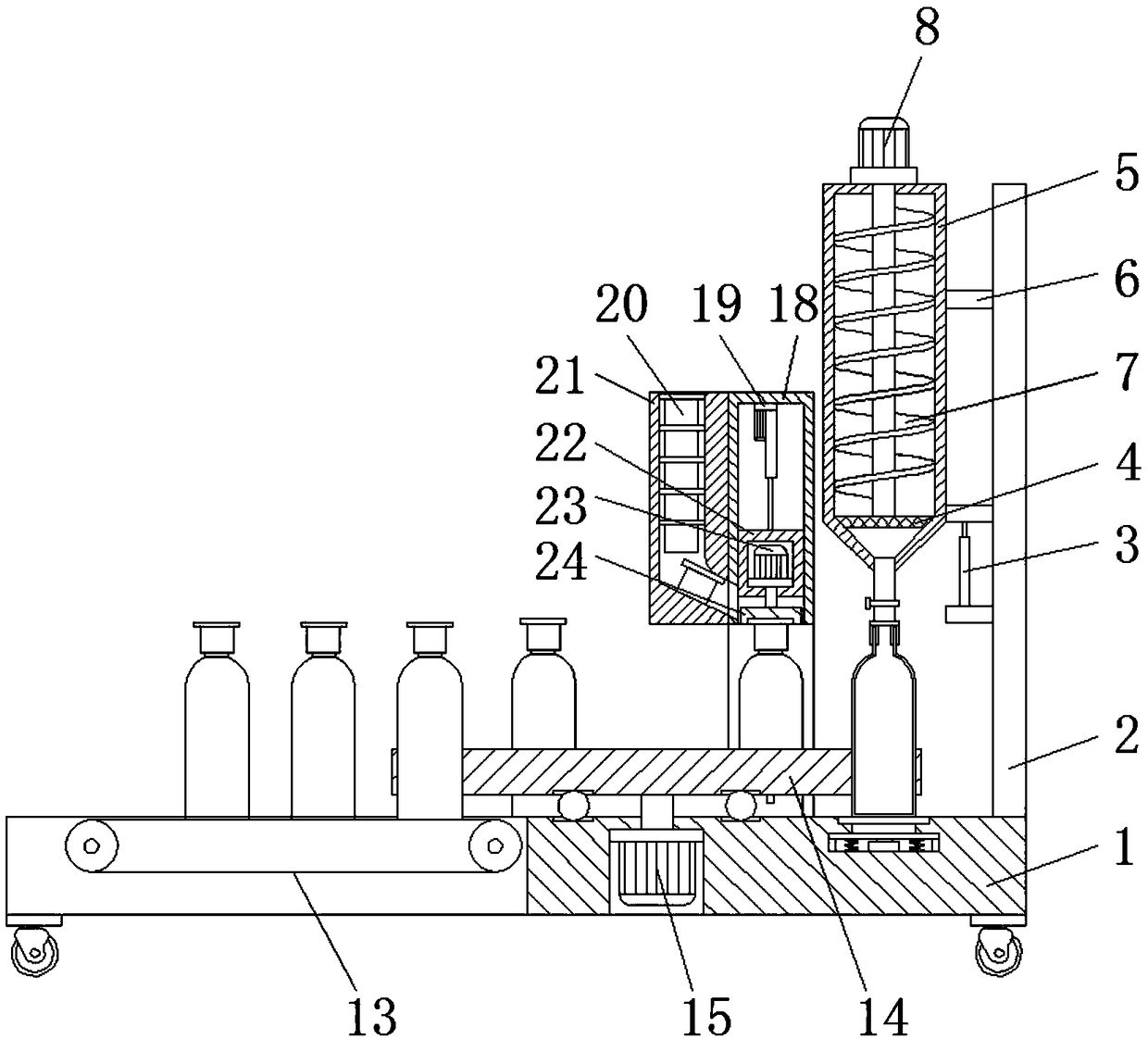

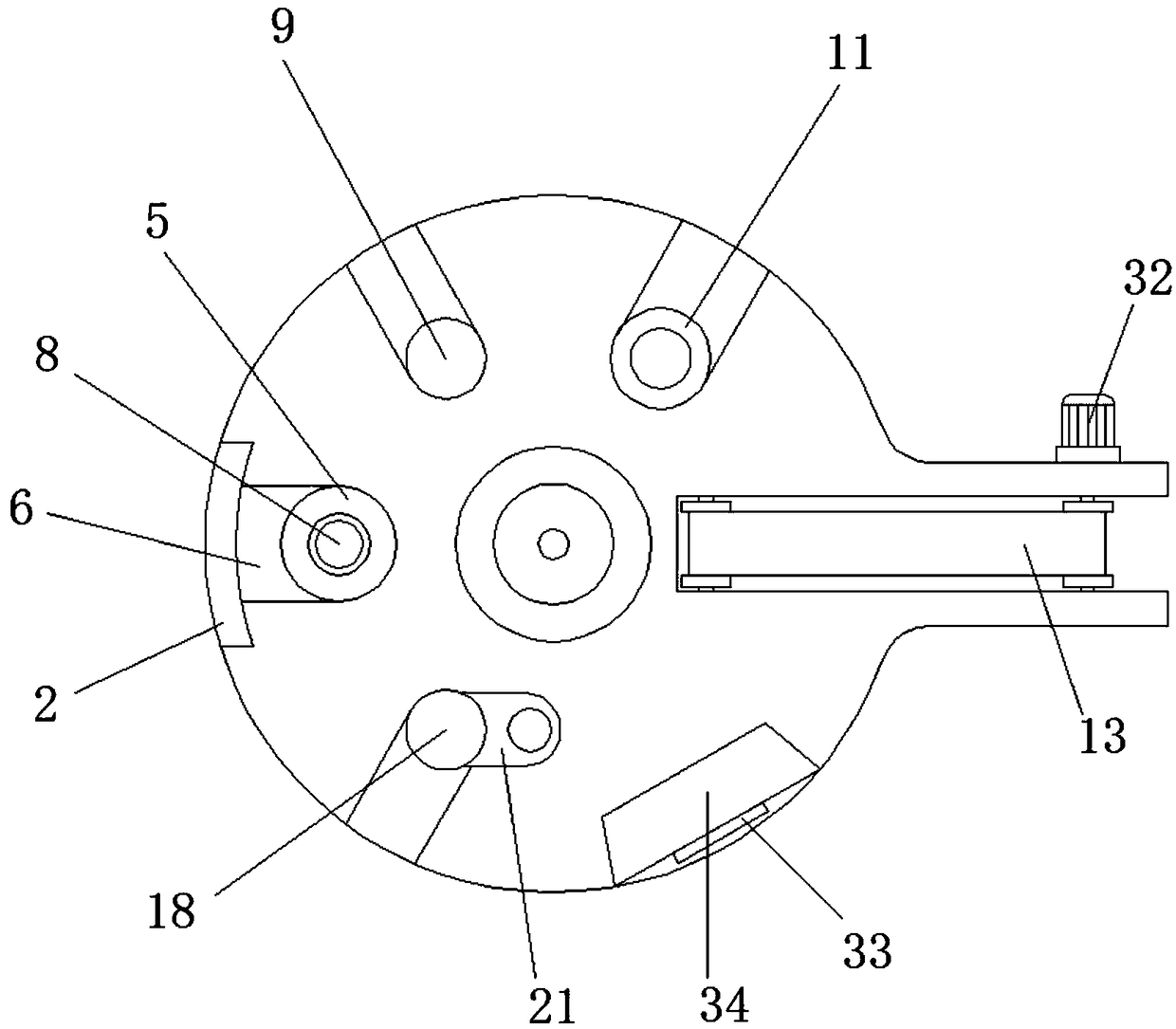

Automatic shampoo filling equipment for production of personal hygiene products

ActiveCN109160474AWeight real-time monitoringAvoid waste of raw materialsLiquid bottlingCouplingElectric machinery

The invention belongs to the technical field of shampoo production and in particular relates to automatic shampoo filling equipment for production of personal hygiene products. Aiming at the problem that the conventional shampoo filling equipment is inconvenient for quantitative filling, the following scheme is provided. The automatic shampoo filling equipment comprises a base, wherein universal wheels are fixed at four corners of the outer wall of the bottom of the base by virtue of screws; supporting shaft mounting holes are formed in outer walls of the top of the base; the inner walls of the supporting shaft mounting holes are connected with a supporting shaft by virtue of a bearing; a rotating table is connected with the top of the outer wall on one side of the supporting shaft by virtue of keys; a drive motor is fixed on the inner wall of the top of the base by virtue of screws; the output shaft of the drive motor is fixed on the outer wall at one end of the supporting shaft by virtue of a coupling. According to the equipment disclosed by the invention, the phenomenon that raw materials are wasted due to bottle-free filling can be effectively avoided, the filling amount is conveniently controlled, the occurrence probability of a phenomenon that the discharge pipe is blocked by the raw materials is reduced, the labor intensity of workers is reduced, and the influence of dust impurities in air on the product quality is reduced.

Owner:LOOBI GUANGZHOU HEALTH IND CO LTD +1

A brewing method of low-methanol-content Chinese date wine

ActiveCN106085699AIncrease contentIncrease the juice yieldAlcoholic beverage preparationPectin esteraseFruit juice

The invention relates to a brewing method of low-methanol-content Chinese date wine, and belongs to the technical field of brewing. The method includes sorting Chinese dates, cleaning, stoning, soaking with hot water, pulping, adding pectin esterase and cellulase, performing enzymatic hydrolysis, stirring and cooking in an air-lift combined mechanical manner, centrifuging, separating supernatant, adjusting the supernatant with white sugar and citric acid, sterilizing, inoculating, fermenting, clarifying, filtering, adding a clarifying agent, and aging by using an oak barrel. The method degrades cell walls of fruit tissues by using the pectin esterase and the cellulase, degrades polysaccharides to allow effective components inside the Chinese dates to dissolve out, and increases the content of juice nutrients and the juice yield. Through stirring and cooking in the air-lift combined mechanical manner, methanol produced by pectin substance zymolysis through the pectin esterase and methanol produced by other reasons are separated along with stirring, cooking and high-pressure air blowing, thus reducing the methanol content in Chinese date juice pulp.

Owner:河北九维生物科技开发有限公司

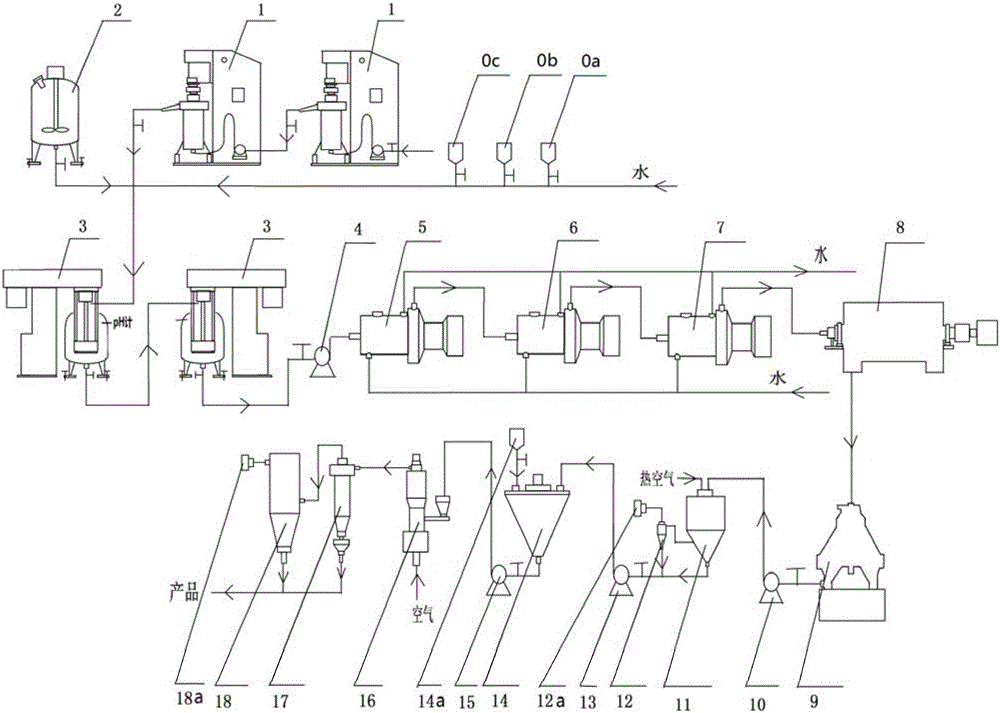

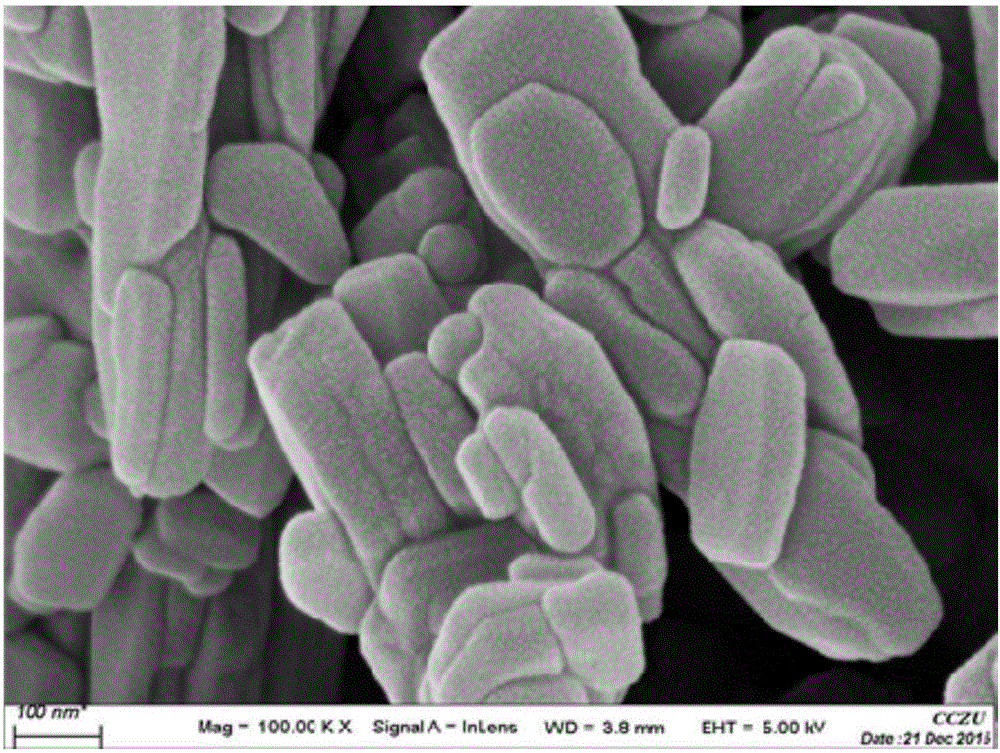

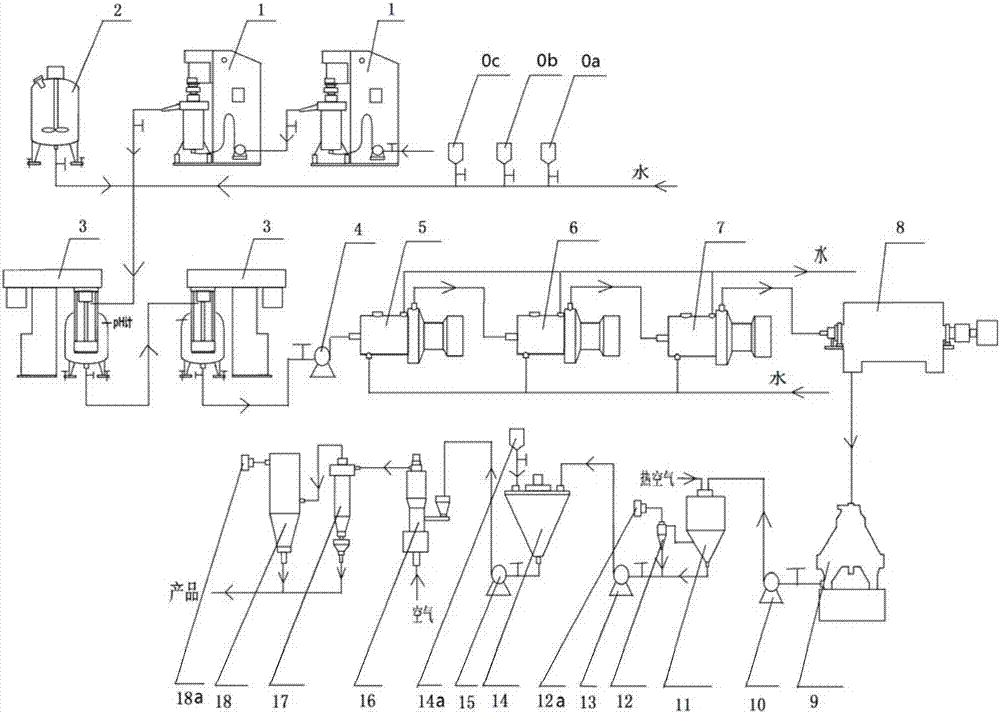

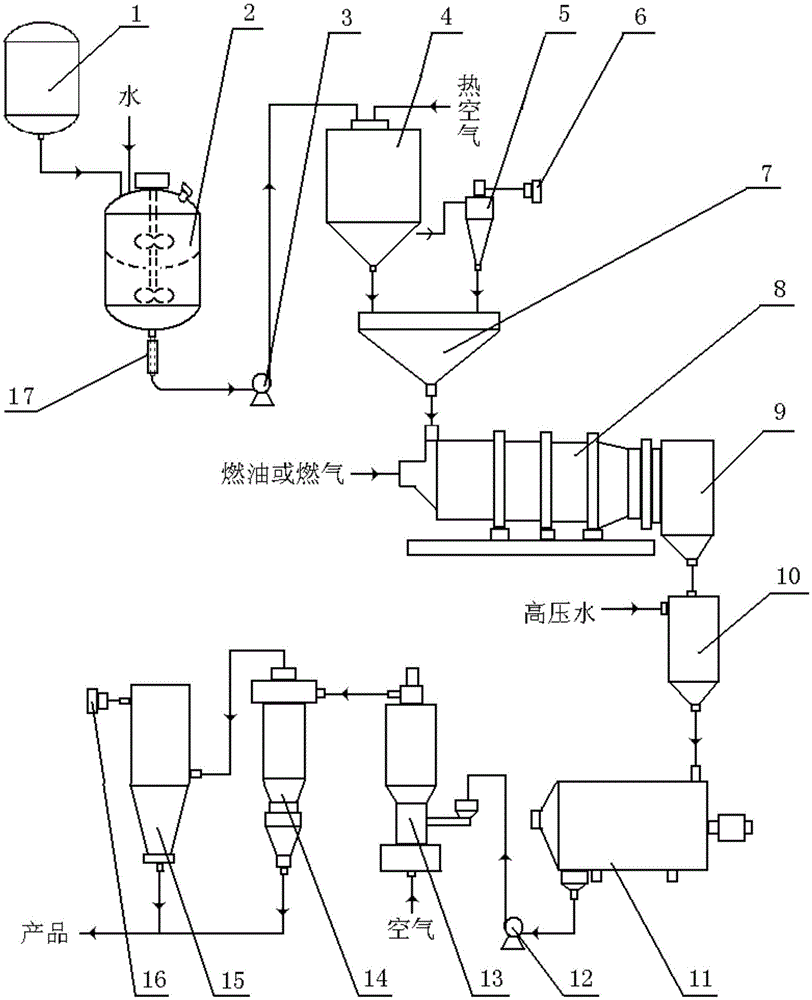

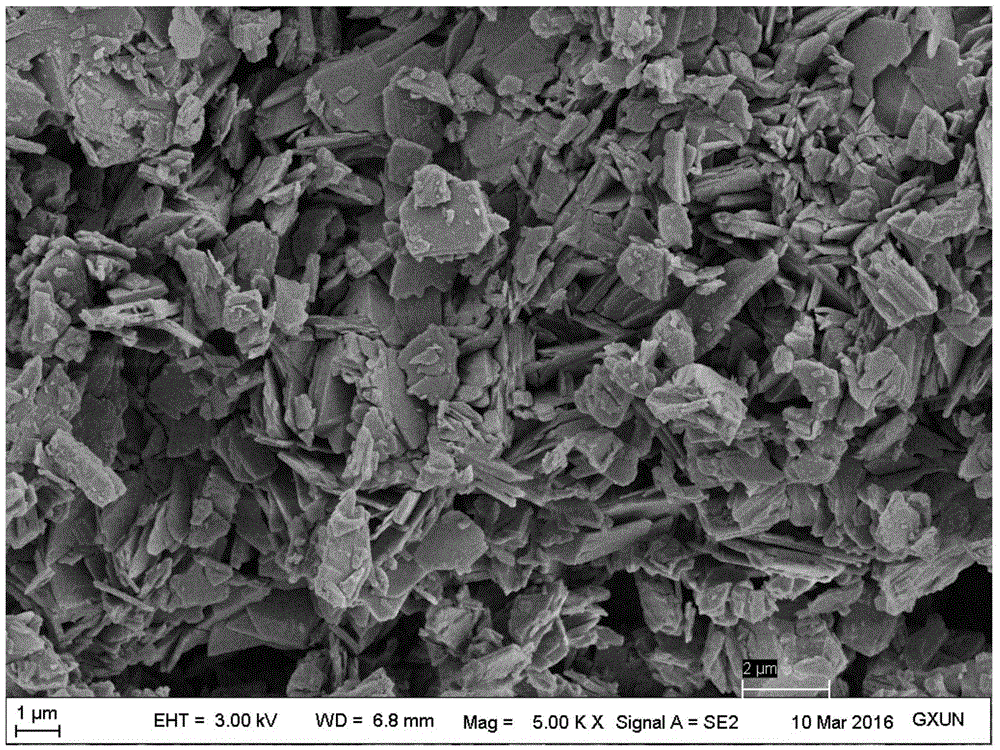

Nanometer zinc phosphate antirust pigment continuous production method and device

InactiveCN105694570AGood uniformityIncrease productivityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsAutomatic controlPhosphoric acid

The invention provides a nanometer zinc phosphate antirust pigment continuous production method and device. Zinc oxide and phosphoric acid are used as raw materials, under the synergistic effect of multiple auxiliaries such as a template agent and a dispersing agent, the contact reaction surface between zinc oxide and phosphoric acid is continuously updated by means of three-level serial grinding, particle shape and size control is conducted, and nanometer zinc phosphate antirust pigments with a uniform particle size are obtained by means of dehydration, spray drying, modification and smashing. Full-automatic control is adopted, production is convenient and fast, the obtained nanometer zinc phosphate antirust pigments are uniform in particle size and stable in product quality, and the antirust performance is improved by 20% compared with existing imported zinc phosphate.

Owner:GUANGXI UNIV FOR NATITIES

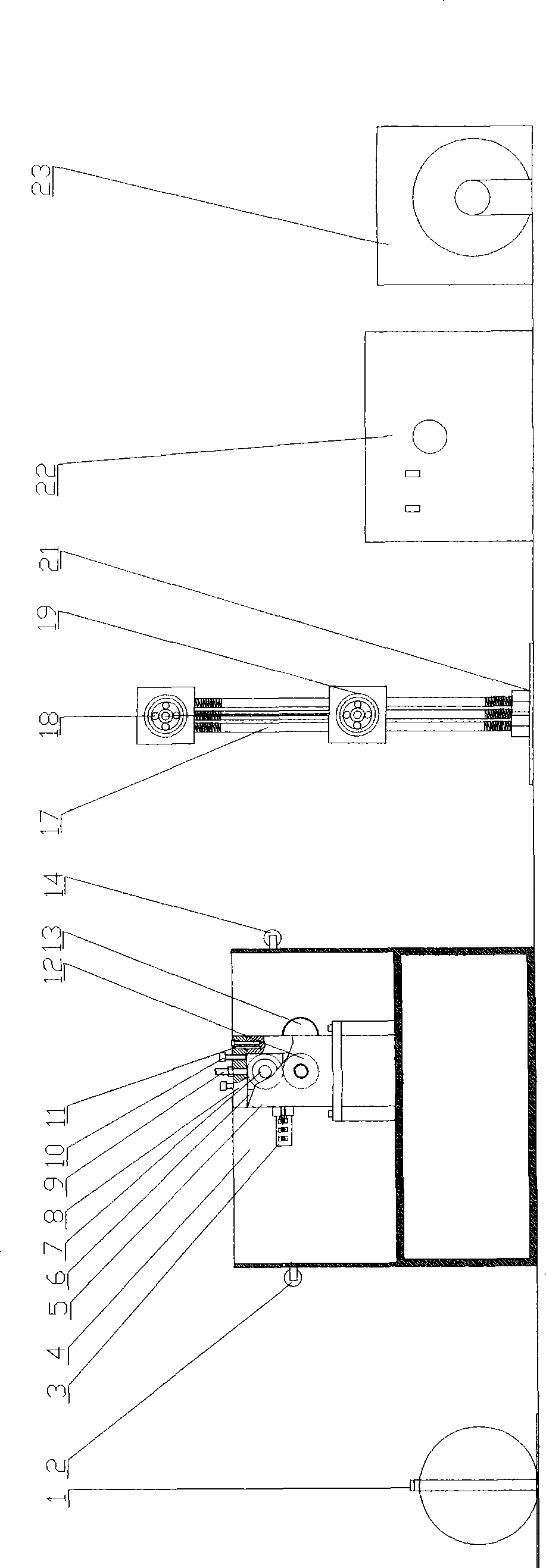

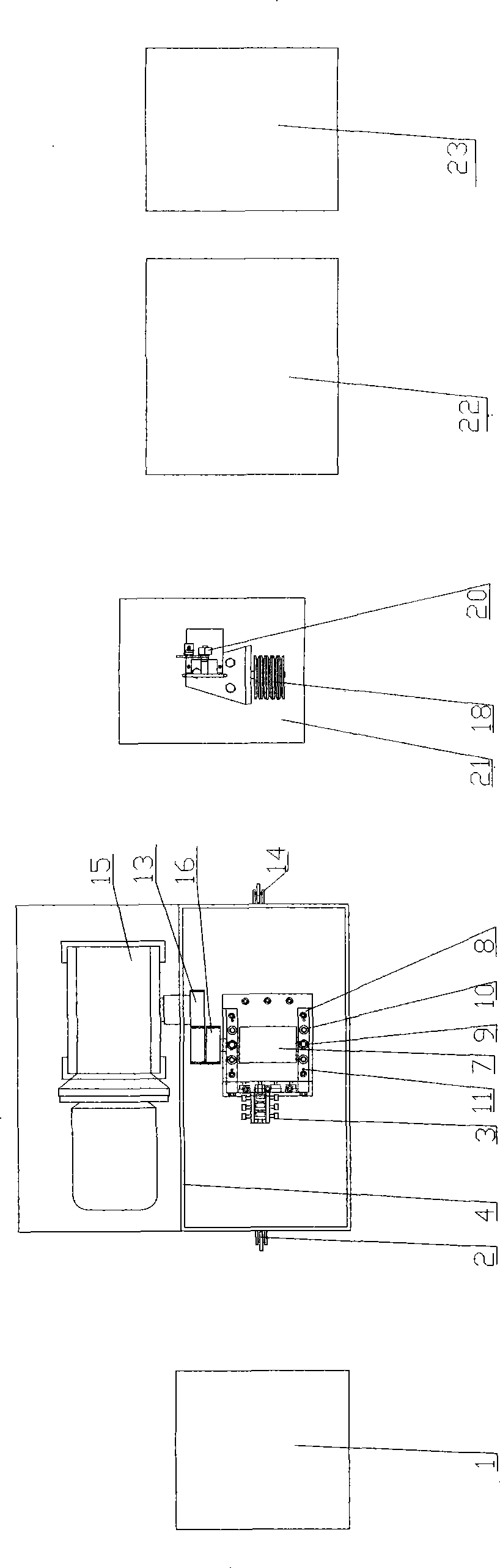

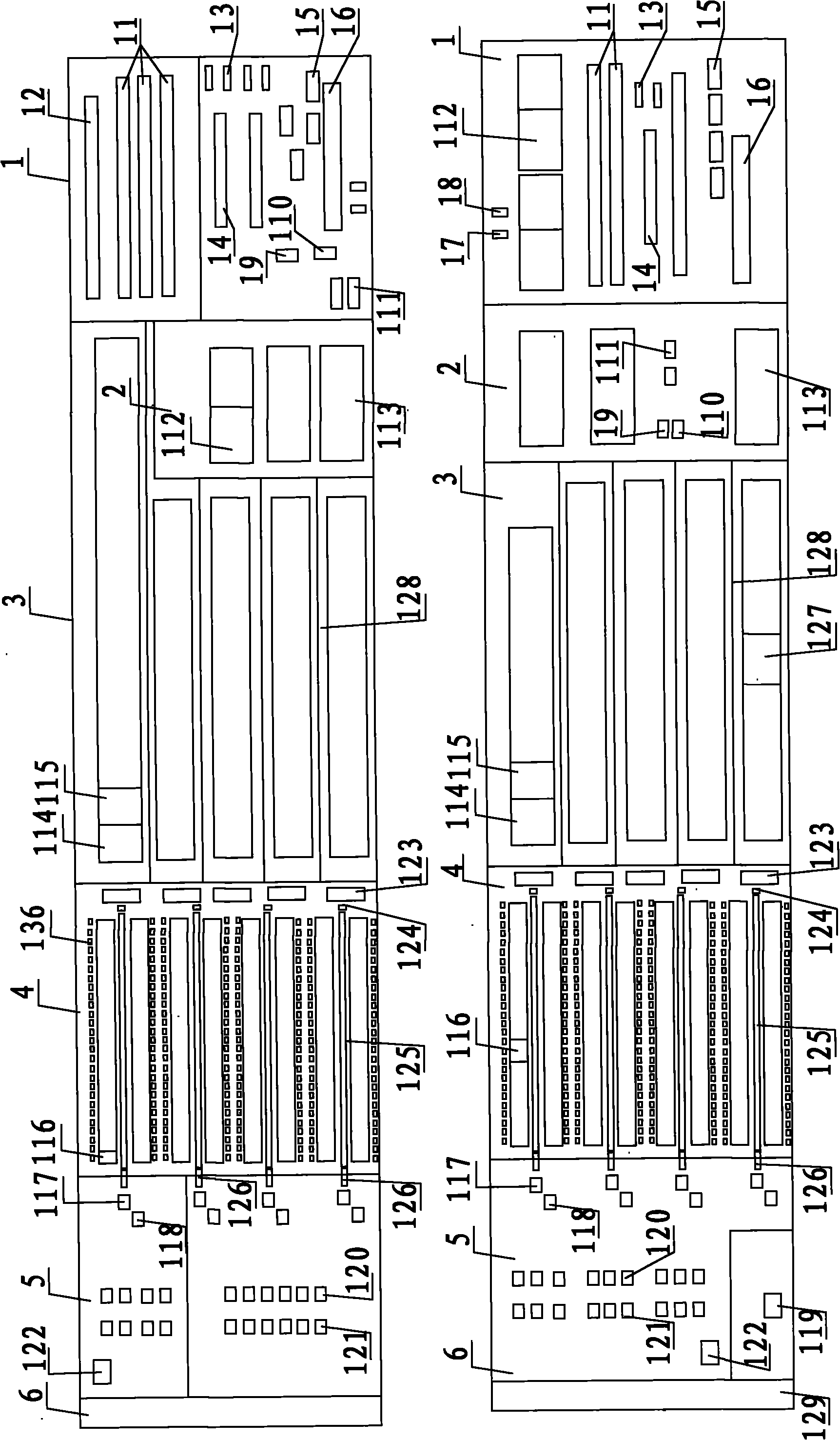

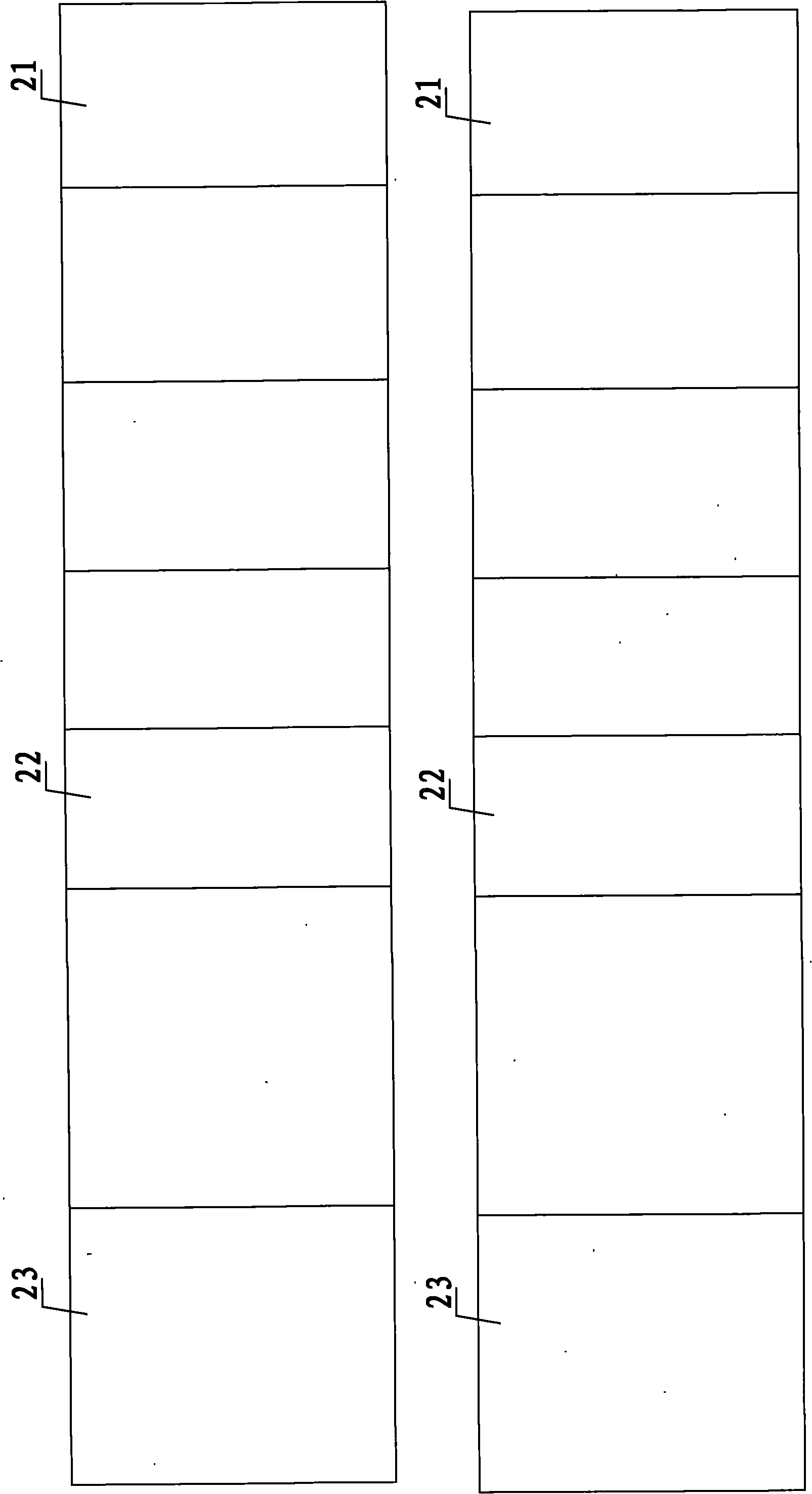

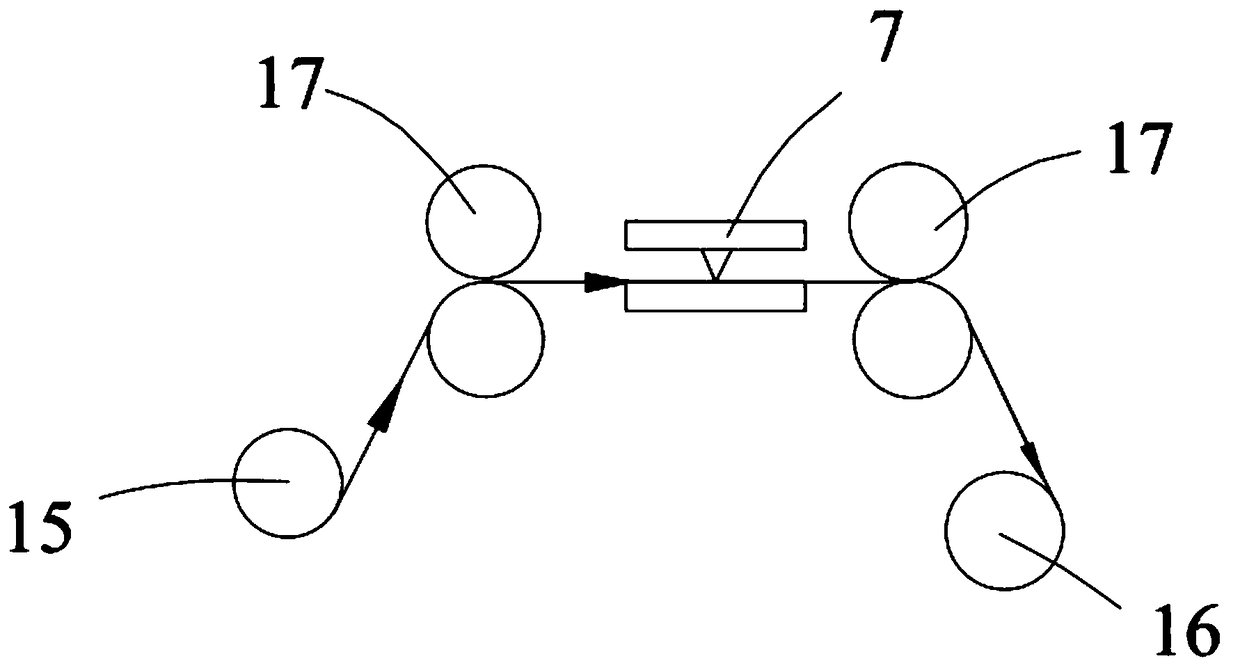

Equipment for producing small-sized copper flat wire

InactiveCN101486146AControl and stabilize rolling accuracyTension adjustable and stableOther manufacturing equipments/toolsCable/conductor manufactureCopper wireRolling mill

The invention relates to a device for producing small flat copper wires, which consists of a paying-off machine (1), a rolling mill (4), a drawing and rolling adapter (21), a wire drawing machine (22) and a wire-rewinding machine (23) which are orderly arranged according to the operating direction. The device uses a die tensioner to control and stabilize the backward tension of flat copper wire blanks after entering a roller to be a fixed value so as to control and stabilize the rolling precision of the flat copper wires. The device adopts the drawing and rolling adapter and changes two separated technological processes of rolling and drawing into a continuous technological process so as to improve the production efficiency; and the device simultaneously avoids adverse effect of the tension with large fluctuation of the paying-off machine on the forward tension of rolling pieces of the rolling mill, and greatly improves the rolling precision of the flat copper wires. Moreover, the device can produce the small flat copper wires with a thickness between 0.50 and 0.08 millimeter, a thickness deviation of + / -0.009 millimeter and a width deviation of + / -0.015 millimeter, and the produced small flat copper wires accord with the requirements of production of flat enamelled copper wires.

Owner:珠海蓉胜扁线有限公司 +2

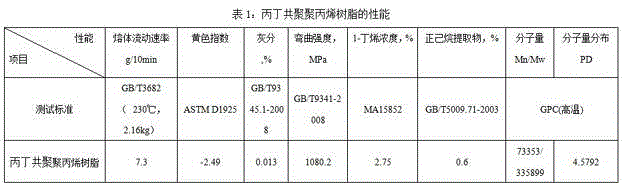

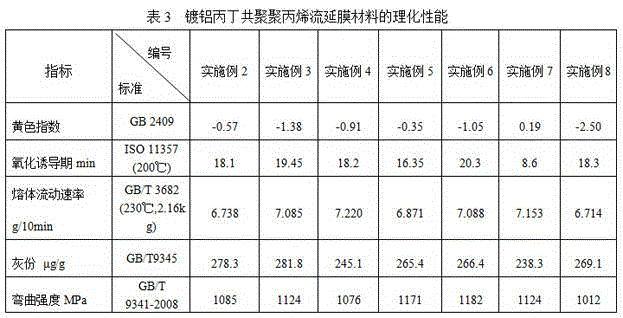

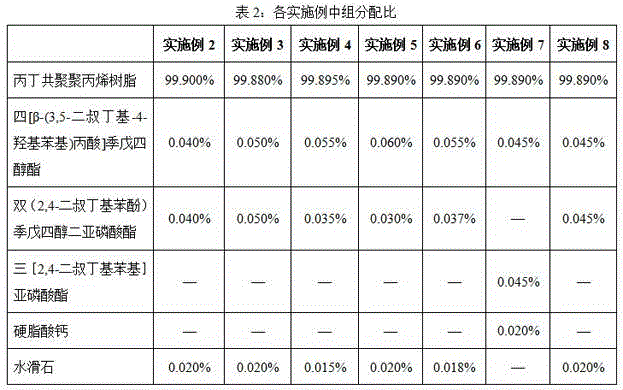

Aluminum-plated propylene and butylene co-polypropylene tape casting membrane material and preparation method thereof

ActiveCN104479228AReduce film surface tension decayMeet the mechanical performance requirementsPolypropyleneComonomer

The invention discloses an aluminum-plated propylene and butylene co-polypropylene tape casting membrane material. The preparation raw materials include polypropylene resin, an antioxidant and a halogen absorbent, wherein the polypropylene resin is propylene and butylene co-polypropylene resin and is prepared by adopting the following method: by taking propylene as a raw material and 1-butene as a copolymerization monomer, copolymerizing in a circular tube reactor to obtain propylene and butylene co-polypropylene resin, wherein the reaction temperature is at 70+ / -1DEG C, the reaction pressure is under 3.4-3.8MPa, the concentration of hydrogen is 800-1500ppm, and the concentration of 1-butene is 1%-5%. The invention further discloses a preparation method of the tape casting membrane material. An aluminum-plated tape casting membrane prepared by the tape casting membrane material has good processability, optical performance, mechanical performance and aluminum plating performance, and the production requirement of a tape casting membrane packaging factory on the aluminum-plated tape casting membrane can be met.

Owner:CHINA PETROLEUM & CHEM CORP

Method for extracting and separating metallic oxide from flue gas denitration catalyst

ActiveCN106277043AResolve disposal issuesHigh purityTitanium dioxideVanadium oxidesFiltrationAmmonium metavanadate

The invention relates to a waste recycling method, and particularly relates to a method for extracting and separating metallic oxide from a flue gas denitration catalyst. The method comprises the following steps: sequentially performing physical pretreatment, pulverization and high-temperature roasting on the flue gas denitration catalyst, then performing leaching by use of dilute acid, and further performing acidolysis treatment by use of concentrated sulfuric acid; aging reactants obtained after acidolysis treatment, performing filtration, then performing boiling hydrolytic treatment on a filtrate so that titanium dioxide is subjected to hydrolytic precipitation, and performing solid-phase separation on liquid obtained by leaching, regulating the pH of the obtained filtrate to 2.0-2.5 by use of aqueous ammonia, then performing organic extraction, and further performing back extraction by use of dilute sulphuric acid; oxidizing vanadium in strip liquor from quadrivalence to quinquevalence by use of sodium chlorate; then adding aqueous ammonia to regulate the pH to 1.9-2.2, and performing precipitation separation on vanadium in an ammonium metavanadate form; and performing pyrolysis on a precipitate, thereby obtaining vanadic oxide. The method provided by the invention has the advantages of simple process, high recovery efficiency, good product technical index and the like.

Owner:ZHEJIANG UNIV

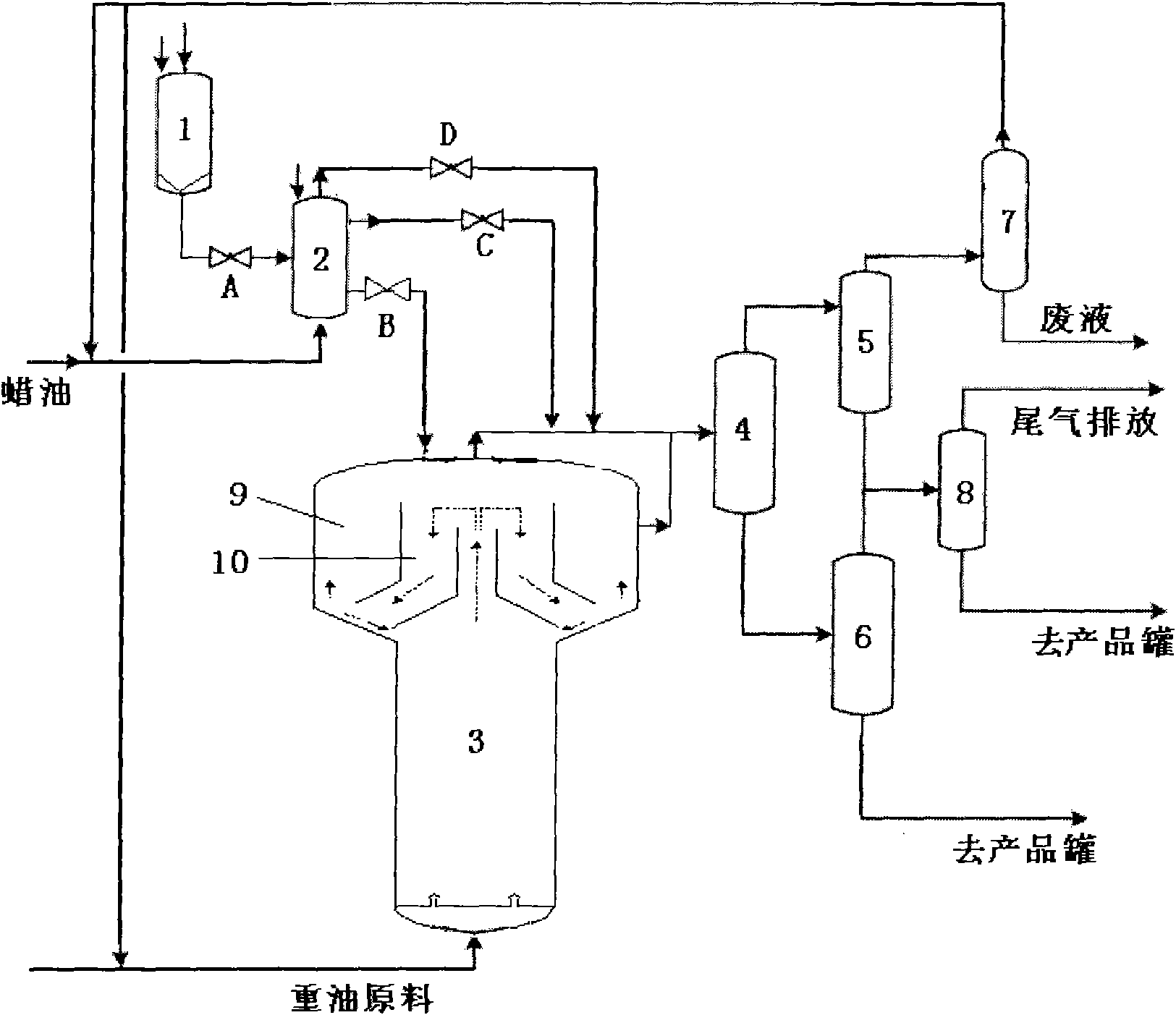

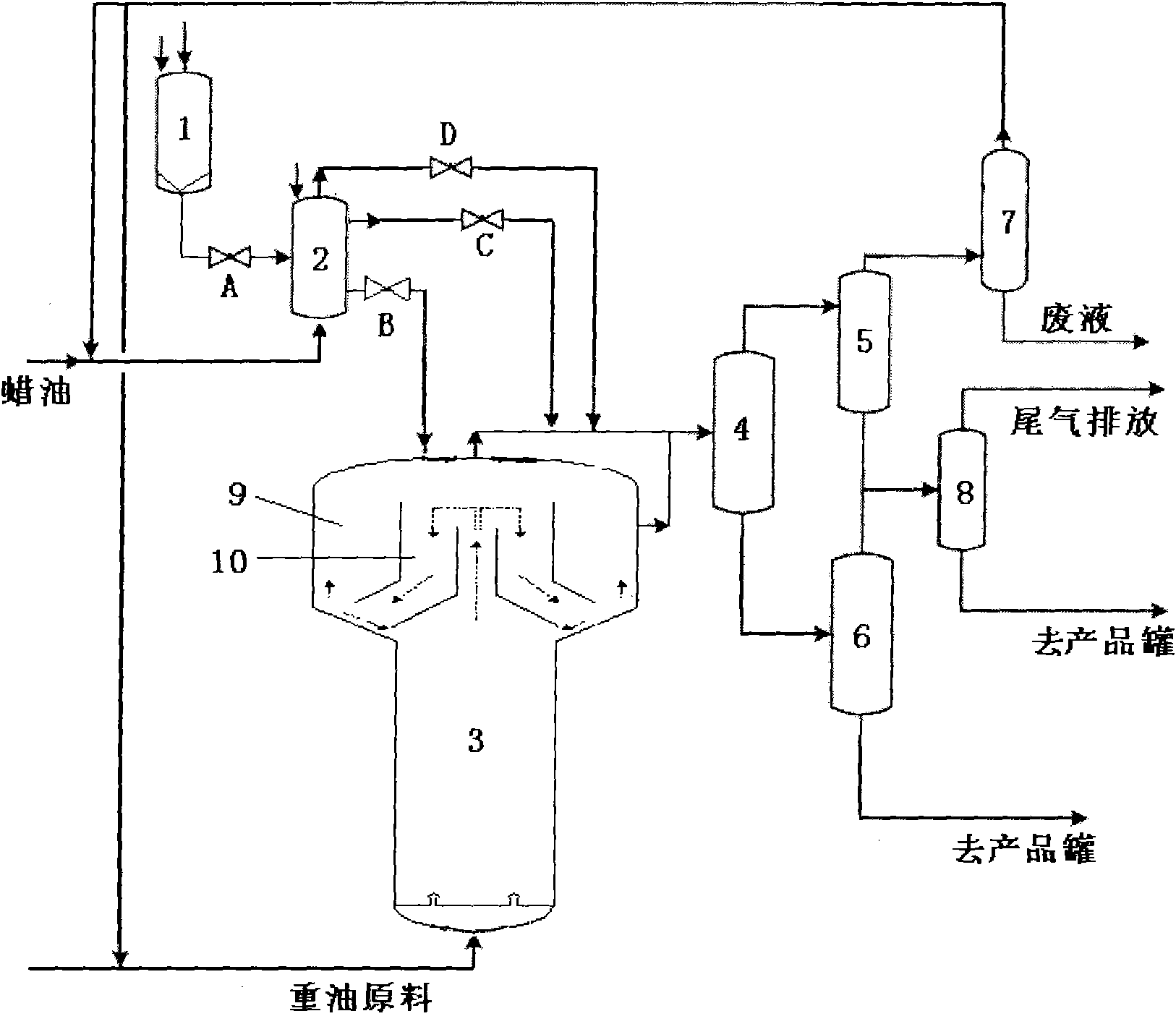

Method for charging boiling bed catalyst on line

The invention relates to a method for charging a boiling bed catalyst on line. In the method, a catalyst charging tank is set into a vulcanizing bed; and wax oil is produced by system recycle hydrogen and a device. The method comprises the following steps of: firstly, washing, moistening and vulcanizing the boiling bed catalyst to be added; and then under the action of a pressure difference of the catalyst charging tank and a reactor, conveying of the wax oil and the gravity, charging the required catalyst into the reactor. Compared with the prior art, the method has the advantages that the investment can be reduced and the operation can be simplified; meanwhile, the wax oil is used as vulcanized oil of the boiling bed catalyst, has wide sources and is convenient to process, and the possibility of adopting residual oil or heavy oil raw materials to coke on a pipeline is reduced; and before charging, a temperature of the catalyst is risen to a temperature of the reactor, so that the perturbation of on-line charging on a reaction temperature of a boiling bed and the influence of operation instability of the device on the product quality in the prior art are reduced. The method for charging the catalyst on line, which is disclosed by the invention, is particularly suitable for a hydrogenation process of the boiling bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

A continuous production method and production device of nano-zinc phosphate antirust pigment

InactiveCN105694570BImprove uniformityMinimize impact on product qualityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsThree levelAutomatic control

The invention provides a nanometer zinc phosphate antirust pigment continuous production method and device. Zinc oxide and phosphoric acid are used as raw materials, under the synergistic effect of multiple auxiliaries such as a template agent and a dispersing agent, the contact reaction surface between zinc oxide and phosphoric acid is continuously updated by means of three-level serial grinding, particle shape and size control is conducted, and nanometer zinc phosphate antirust pigments with a uniform particle size are obtained by means of dehydration, spray drying, modification and smashing. Full-automatic control is adopted, production is convenient and fast, the obtained nanometer zinc phosphate antirust pigments are uniform in particle size and stable in product quality, and the antirust performance is improved by 20% compared with existing imported zinc phosphate.

Owner:GUANGXI UNIV FOR NATITIES

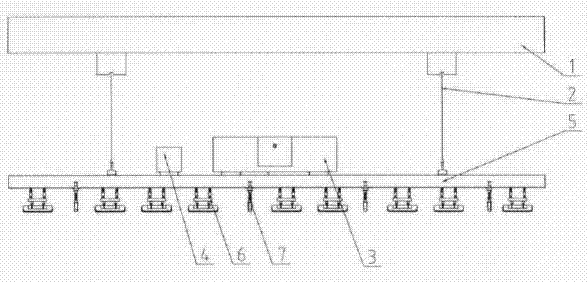

Special-shape vacuum suction disc sucking and lifting device and method

InactiveCN102774736AReduce stepsProtection securityLoad-engaging elementsWire ropeDownward displacement

The invention relates to a special-shape vacuum suction disc sucking and lifting device and method. A vacuum suction disc group and at least two groups of centering guiding mechanisms are arranged on the main beam of the vacuum lifting device; a transverse adjustment spring is arranged between two vacuum suction discs in the vacuum suction disc group so as to adjust the mutual transverse displacement of the vacuum suction discs; each centering guidng mechanism is provided with more than four rolling wheels; the rolling wheels are arranged on a reversed V-shaped support leg; a guiding sleeve is arranged on the upper part of the reversed V-shaped support leg; a spring which guiding downwards is supported and arranged in the guiding sleeve; the top of the guiding sleeve is provided with a guiding shaft; a downward displacement adjustment rod is hung in the upper component of the guiding sleeve. One or more groups of vacuum suction discs are distributed in the length direction of a special-shape angel section, a crane trolley is started, the vacuum suction disc group is make to descend to cling to the special-shape angel section through a steel wire rope to form a sealed vacuum cavity, and the special-shape angel section is lifted. Due to the adoption of the special-shape vacuum suction disc sucking and lifting device, the production efficiency is improved, the security is improved, and the influence of the human factors to the product quality is reduced.

Owner:上海优乐博特自动化工程有限公司

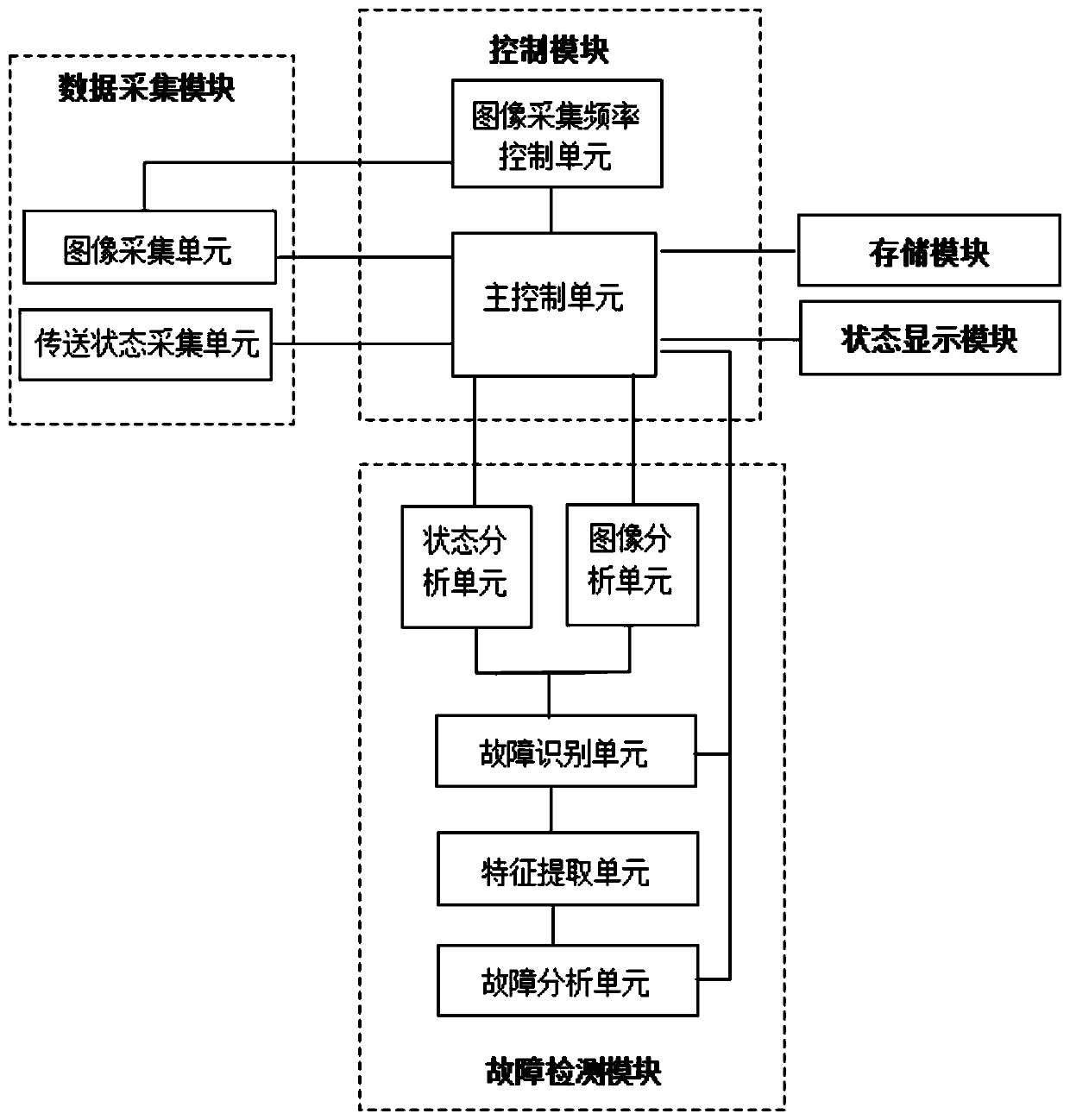

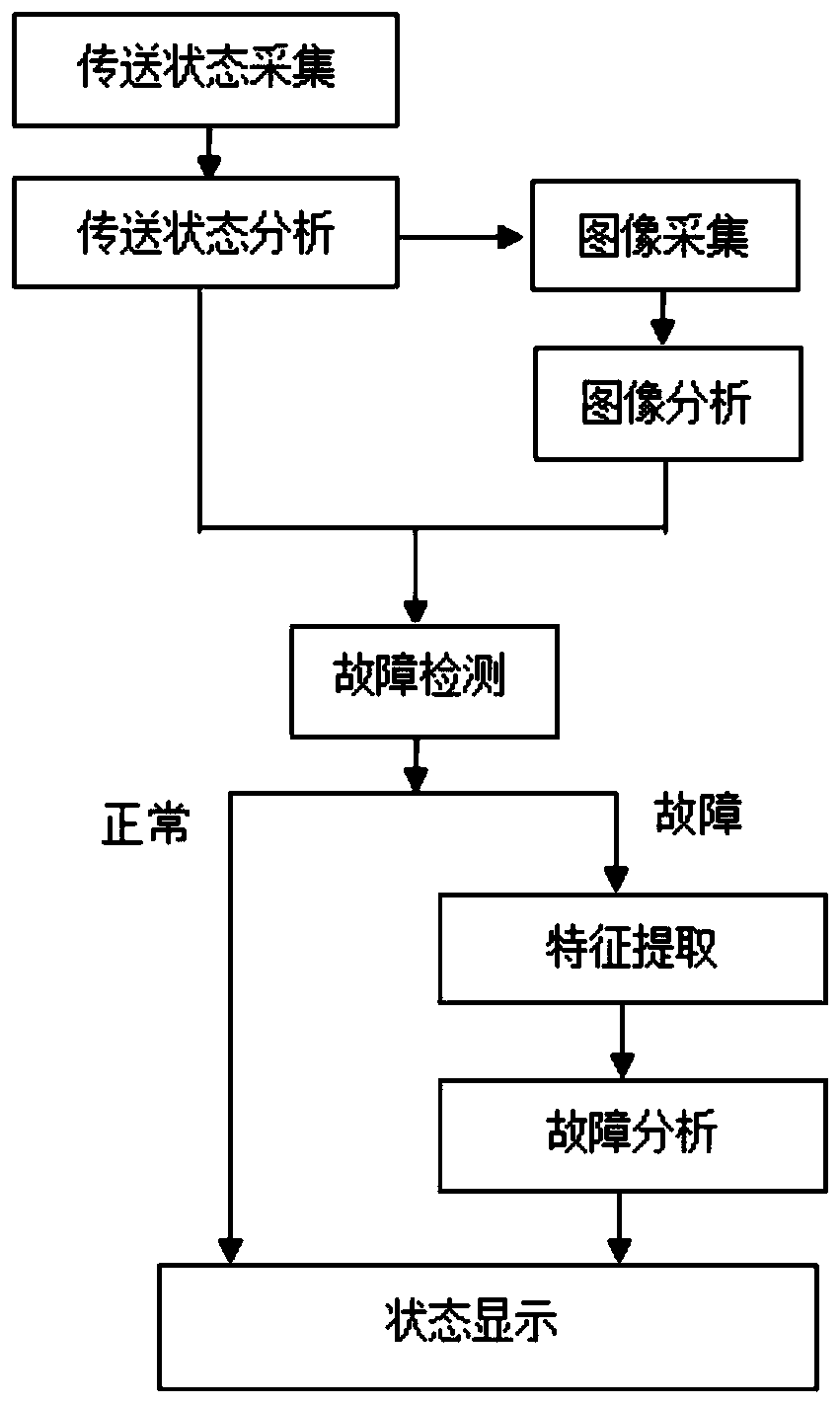

Intelligent spinning packaging production line fault detection system

ActiveCN111552243AReduce the impactReal-time monitoring of transmission statusTotal factory controlProgramme total factory controlYarnBobbin

The invention discloses a fault detection system for an intelligent spinning and packaging production line. The system comprises a data acquisition module, a control module, a fault detection module,a storage module, a state display module and an information transmission module, wherein the control module is connected with the data acquisition module, the fault detection module, the storage module and the state display module through the information transmission module; the data acquisition module is used for acquiring the conveying state of each bobbin and images of the bobbins before and after single yarn packaging in real time, and the fault detection module is used for analyzing and detecting fault reasons. By means of the mode, the conveying states of all links on the packaging production line can be monitored in real time, faults can be found in time and automatically analyzed, measures can be conveniently taken in time, and the influence of the faults is reduced; in addition, image acquisition and analysis can be carried out on bobbins before and after single yarn packaging, faults of overturning and single yarn packaging links are further detected, the fault detection rateis increased, and the product packaging quality is guaranteed.

Owner:武汉裕大华纺织有限公司

Method for preparing connector-free positive electrode-supported solid oxide fuel cell stack by 3D printing

ActiveCN108598521AGuaranteed StrengthIncrease mass transfer rateAdditive manufacturing apparatusCell electrodesElectrical batteryMaterials science

Owner:SHANDONG UNIV OF TECH

Connecting box and processing method thereof

InactiveCN109403551AIncrease productivityReduce welding partsBuilding reinforcementsEngineeringSteel bar

The invention discloses a connecting box. The connecting box comprises a base plate, a top plate, two side plates and a back plate, the base plate, the top plate and the two side plates are formed bycutting rectangular steel tubes, the back plate is simultaneously welded and fixed to the base plate, the top plate and the side plates, and the base plate and / or the top plate are / is provided with through holes used for allowing steel bars to be arranged in a penetrating mode. In addition, the invention further relates to a processing method for the connecting box. According to the connecting boxand the processing method thereof, the base plate, the top plate and the two side plates of the connecting box are all from the rectangular steel tubes, so that the integrality is greatly improved, only the back plate needs to be welded, so that the welding positions of the connecting box is reduced, and the influence of human factors on the product quality is reduced; the overall rigidity and strength of the connecting box are superior to the overall rigidity and strength of a fully-welded connecting box in the prior art; meanwhile, the production efficiency of the connecting box is improved.

Owner:BROAD HOMES IND SHANGHAI CO LTD

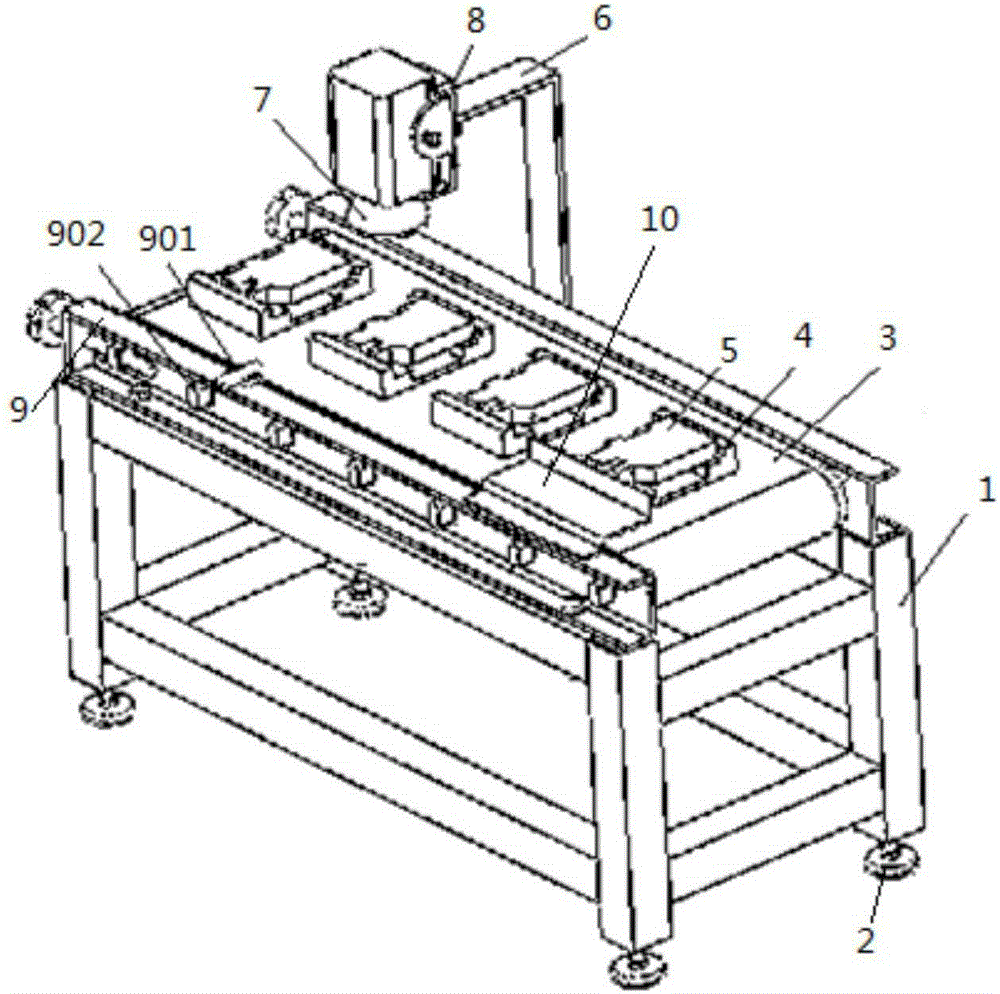

Visual detection machine of automobile lock catch rivet point

InactiveCN105258648AMinimize impact on product qualityReduce human inputUsing optical meansExternal cameraEngineering

The invention discloses a visual detection machine of an automobile lock catch rivet point. A conveyer which is taken as a working bench is arranged above a rack. A carrying tool is arranged on the conveyer. A lockset is placed in the carrying tool. A support fine tuning apparatus is installed on a camera fixing support. The camera is fixed on the support fine tuning apparatus. The camera is located above the conveyer. A lens of the camera is directed at the lockset. The camera is connected to an external upper computer through a data line. A detection apparatus is fixed to a side surface of the conveyer. The detection apparatus is connected to an external camera detection system through the data line. The detection apparatus is formed by an infrared probe and an installation table. When the infrared probe detects that the carrying tool is passed, a detection result is emitted to the camera detection system. By using the detection machine of the invention, there are the following advantages that the camera carries out acquisition and analysis on an image of the automobile lock catch rivet point through a visual detection system; simultaneously, influences of a sub-quality product and a man-made factor on product quality are effectively reduced; manpower investment is reduced, work efficiency is increased and detection cost is saved.

Owner:HUBEI UNIV OF TECH

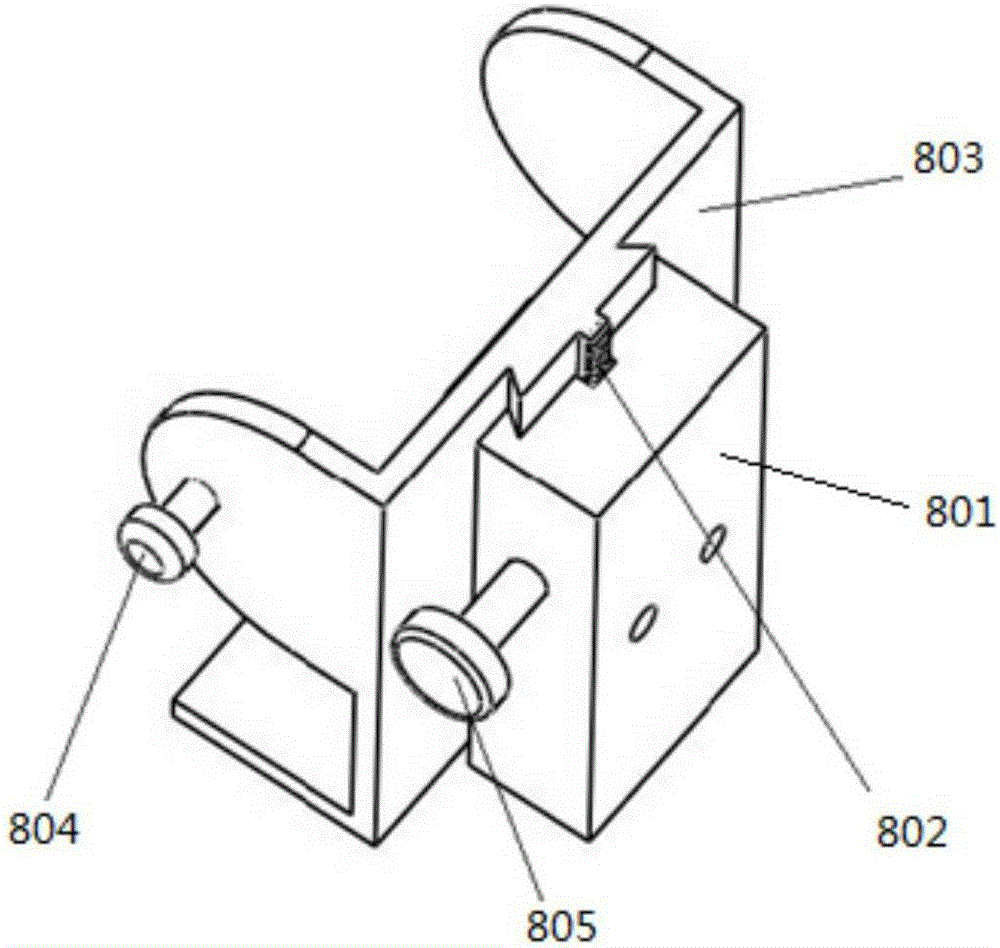

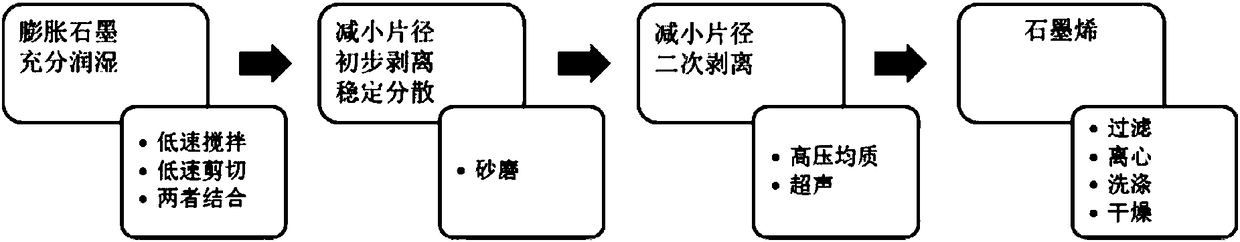

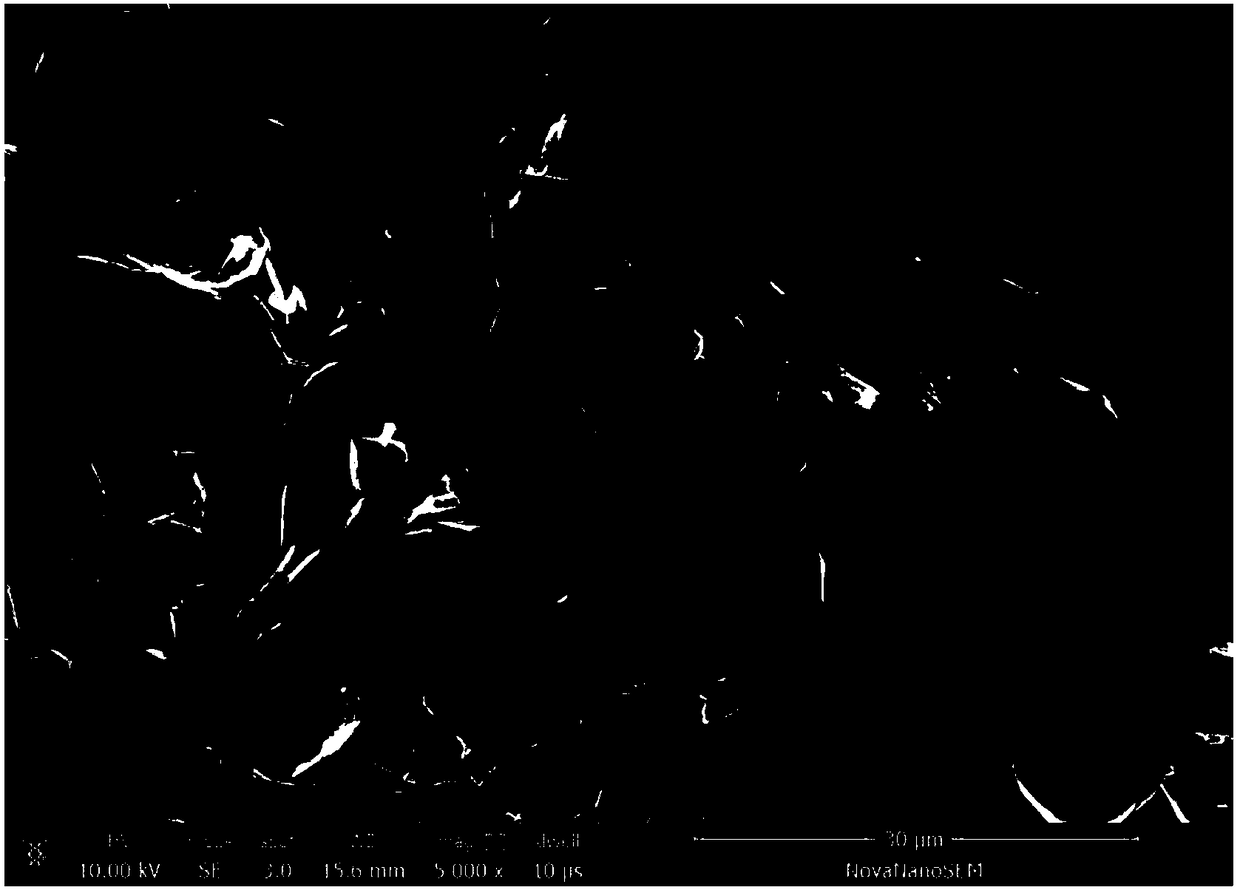

Method and device for continuously producing graphene on large scale and graphene prepared through method

ActiveCN108622888AExcellent physical and chemical propertiesQuality improvementGrapheneGraphiteSolvent

The invention provides a method and device for continuously producing graphene on a large scale and the graphene prepared through the method. The method comprises the following steps of a) carrying out full wetting, specifically, mixing the graphite with a solvent, and carrying out low-speed stirring treatment and / or low-speed shearing treatment at least once so as to obtain graphite dispersion liquid; b) carrying out preliminary stripping, specifically, carrying out sanding treatment on the graphite dispersion liquid obtained in the step a) at least once so as to obtain graphene dispersion liquid subjected to preliminary stripping; and c) carrying out secondary stripping, specifically, carrying out high-pressure homogenization treatment and / or ultrasonic treatment on the graphene dispersion liquid subjected to preliminary stripping obtained in the step b) at least once so as to obtain single-layer or few-layer graphene dispersion liquid. The method has the advantages that the high-quality graphene can be further obtained on the premise of environmental protection, and the process difficulty and the cost can be lowered. The device has the advantage that the existing problem that graphene is difficult to produce on a large scale can be solved. The graphene prepared through the method has the advantages of being high in purity, thin in thickness, large in specific surface area, low in resistivity and low in metal impurity content.

Owner:北京地泽科技有限公司

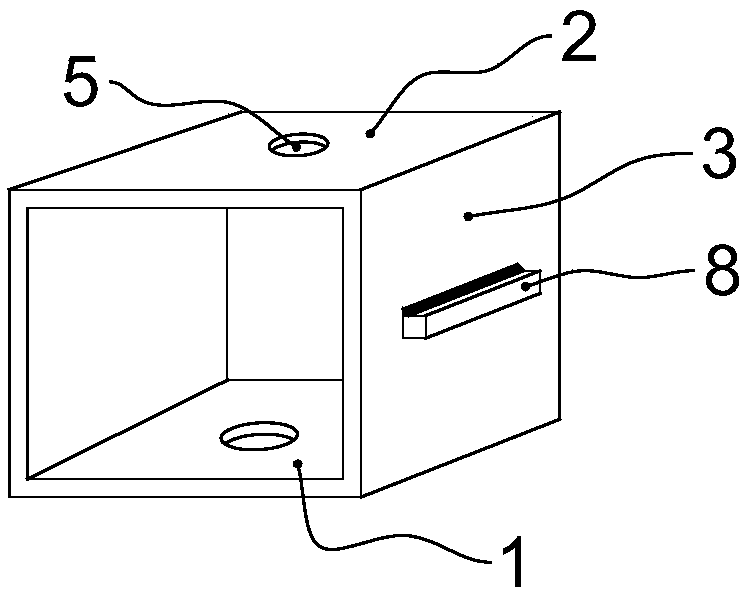

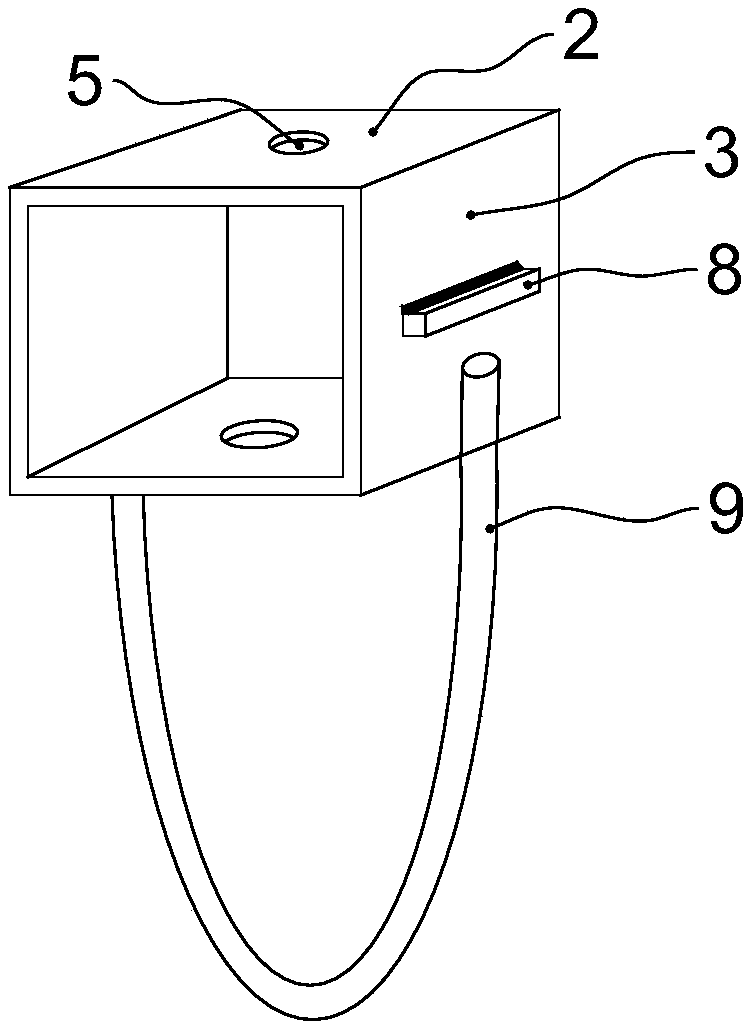

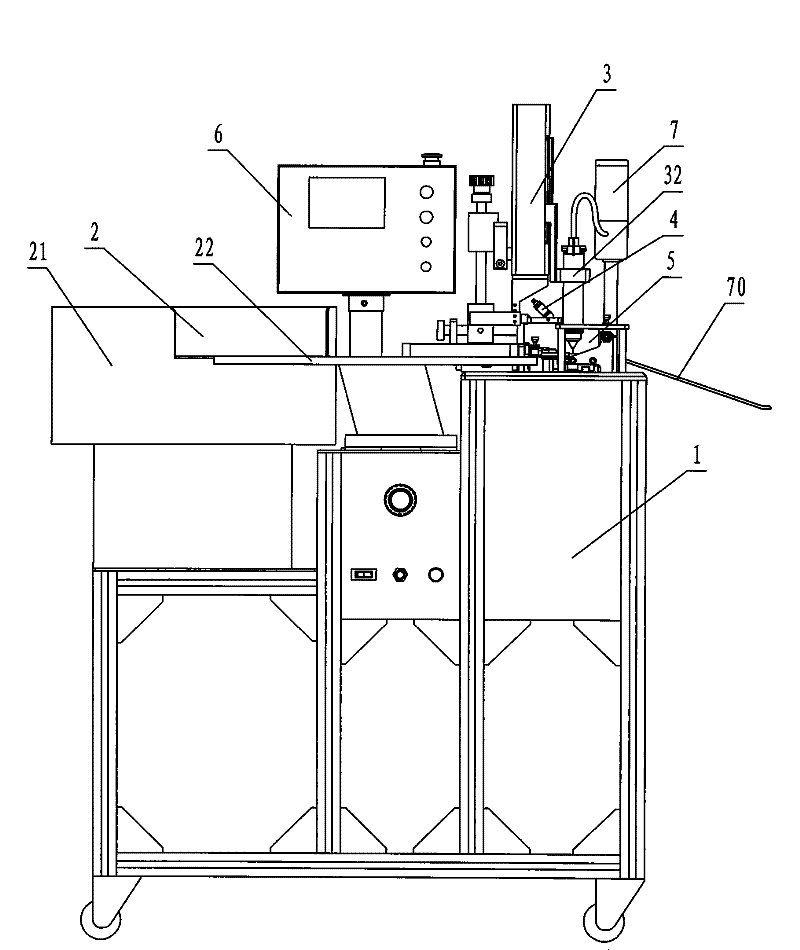

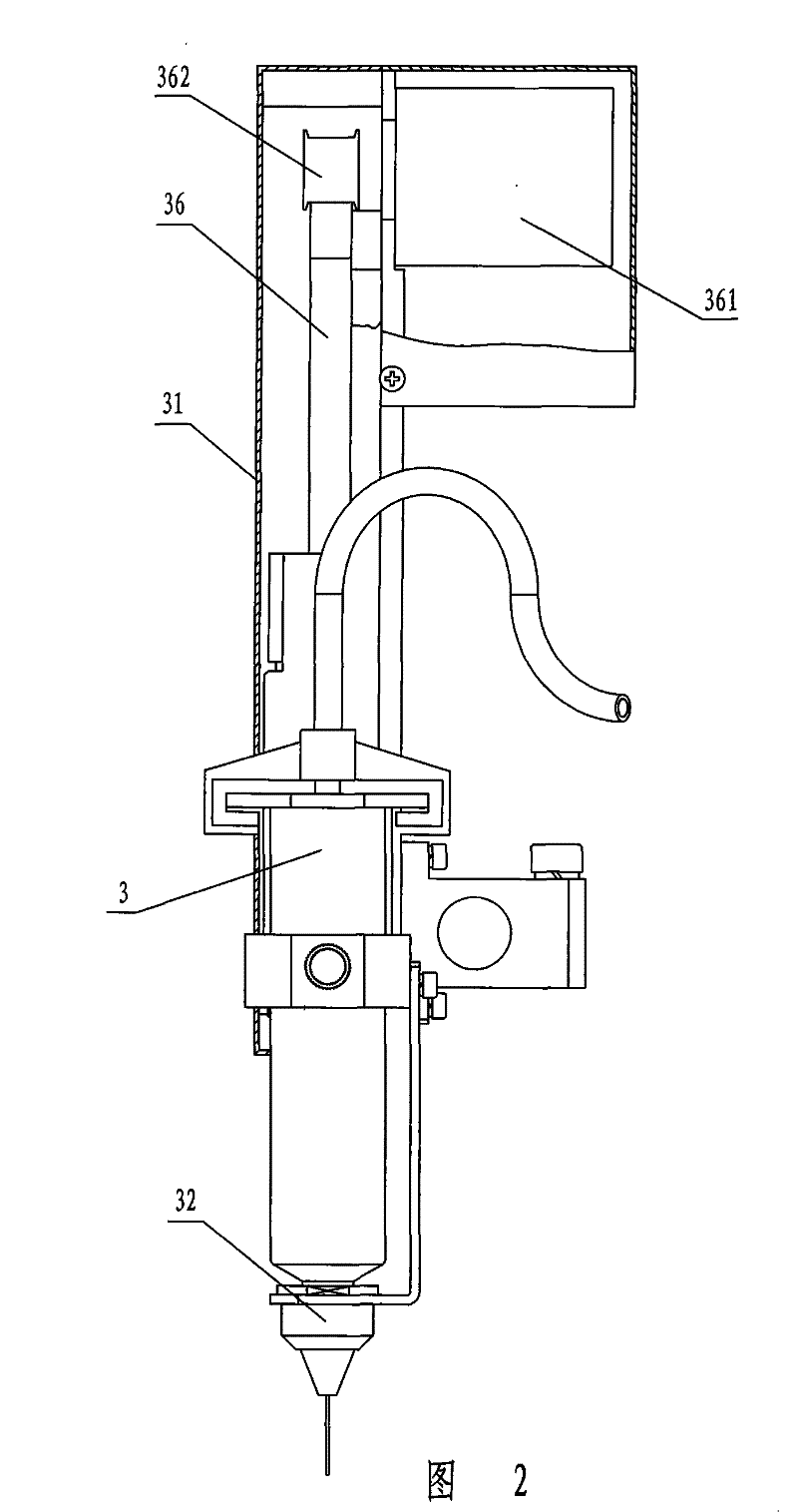

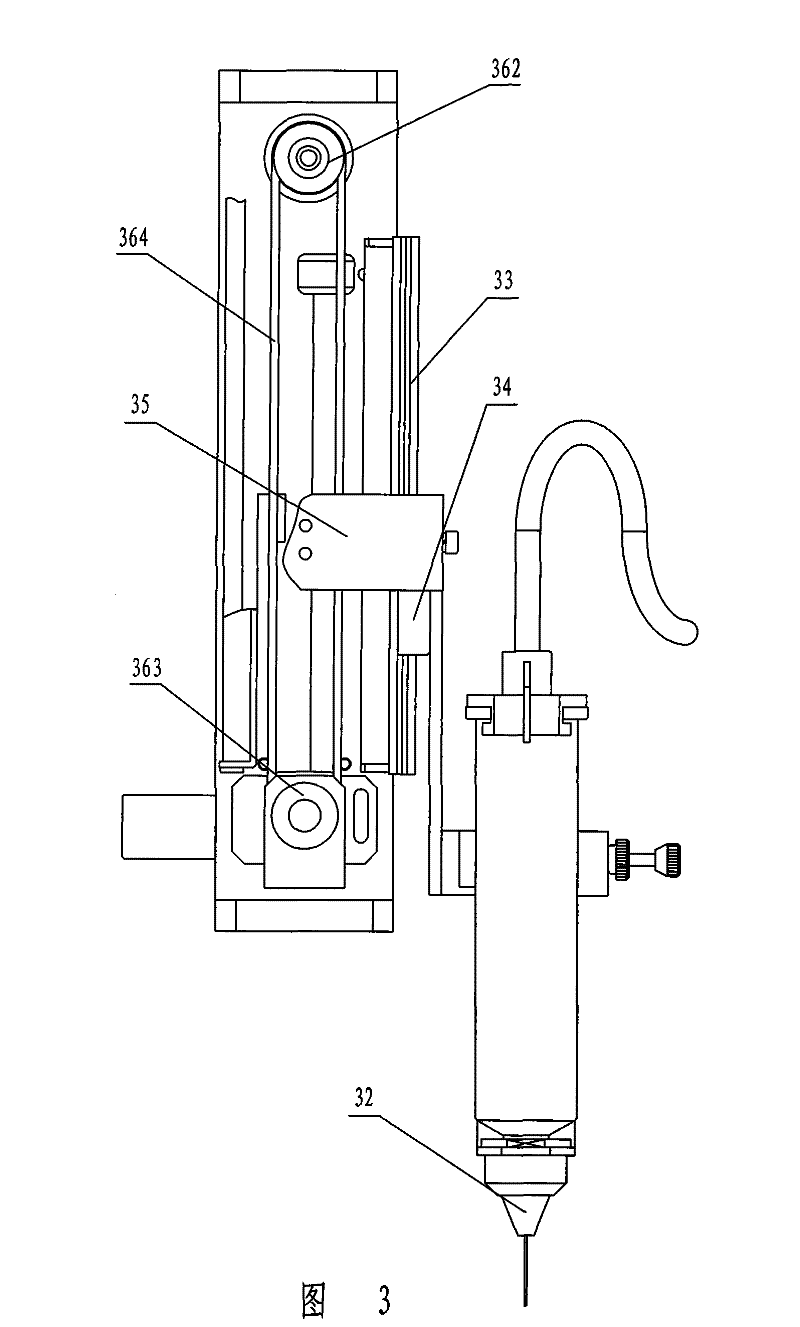

Full-automatic glue-dropping machine

ActiveCN101502825BEasy to operateRealize fully automatic operationElectrical transducersLiquid surface applicatorsProcess engineeringMachine

The invention discloses a fully automatic glue dispenser used for spreading glue on the bracket of a magnetic-induction circular loudspeaker, comprising a machine frame. The machine frame thereon is provided with a feeding device, a glue dispensing device and a locating device for locating a work piece. The glue dispensing device thereon is provided with a glue spreading head. The locating devicethereon is provided with a material receiving channel, a fixed work piece and a rotating fixture capable of driving the work piece to rotate. The material receiving channel receives the work piece sent from a material sending device, the work piece is located on the rotating fixture and then the glue spread surface of the work piece is aligned with the glue spreading head on the glue dispensing device. In the glue spreading process, the rotating fixture drives the work piece to rotate for a set number of turns, and the glue spreading head moves downwards to a specified position and then spreads glue on the glue spread surface of the work piece. By using above structure, the invention can realize fully automatic operations of feeding and locating the work piece, spreading glue and blankingthe work piece. The invention feeds material stably, accurately locates the work piece, and can be synchronously applied to the glue spreading requirement of work pieces of different specifications. The whole machine runs reliably, is in favor of improving production efficiency and ensuring product quality, and reduces influence of personal factor on the product quality.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Micro-spherical fossilized complex enzyme and process for preparing edible gelatine by enzymolysis of leather

InactiveCN101665784AEasy to recycleReduce pollutionOn/in inorganic carrierAnimal proteins working-upAdditive ingredientFiltration

The invention relates to a micro-spherical fossilized complex enzyme and a process for preparing edible gelatine by enzymolysis of leather, wherein the micro-spherical fossilized complex enzyme is prepared from the following constituents according to parts by weight through absorption, cross linking and embedding: 2-8 parts of complex enzyme, 70-90 parts of fossilizing carrier, 0.5-1.5 parts of cross linking agent, 10-18 parts of embedding agent, and 0.5-1.5 parts of pH buffer agent. The process comprises the steps of enzymolysis, filtration and separation and gelatine dissolution, wherein thespecific steps are as follows: placing leather pieces cut after pre-treatment into an enzymolysis wooden rotating drum and rotating the drum by using water that has the volume of 0.5-1.5 times that of the drum; then adding the micro-spherical fossilized complex enzyme to the drum for enzyme bath at the temperature of 30 to 42 DEG C till the smooth belt of the leather pieces becomes transparent; then separating the primer, filtering and separating the enzyme solution for reuse and washing the primer in the water; and then continuing with the normal operations. The fossilizing enzyme is not soluble in the water, therefore, the fossilizing enzyme is easy to be recycled and can be repeatedly used; and the actual cycle for production of a ton of gelatine is shortened by 90%, the water consumption is reduced by 87.5-90%, the cost is lowered by 28-36%, the yield is increased by 10-20%, and the gelatine strength is increased by 20-30%.

Owner:危冬发

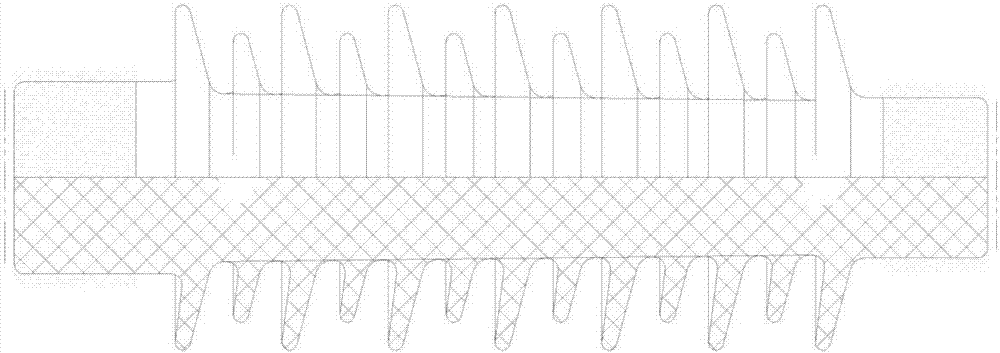

Intensive ultra-large-scale radial tire production system of high-performance car

ActiveCN102152484AReduce transportation distance or timeImprove product qualityTyresWork in processRadial tire

The invention relates to a radial tire production system, in particular to an intensive ultra-large-scale radial tire production system of a high-performance car. The intensive ultra-large scale radial tire production system of the high-performance car provided by the invention comprises three layers of building plant, wherein the first layer is sequentially provided with a semi-finished product extrusion calendaring region, a cutting region, a molding region, a vulcanizing region, a finished product inspection region and a storage and transportation shipping region; the second layer sequentially comprises a mixing rubber storage region, a semi-finished product production region, a green tire spraying region, a green tire storage region and a finished tire storage region; the semi-finished product production region is provided with multiple triangular rubber pasting machines and multiple steel ring extrusion and rolling production lines; the third layer comprises a tire edge polishingregion, a tire inflation region and a tire maintenance region; the total area of the production system is larger than or equal to 250,000 m<2>, the total height is larger than or equal to 23.5m, the length is larger than or equal to 450m and the width is larger than or equal to 190m; and the temperature of the molding region is controlled to be 23+ / -5 DEG C and the humidity is controlled to be less than or equal to 70%. The tire production system provided by the invention has the intensive and ultra-large-scale characteristics.

Owner:ZHONGCE RUBBER GRP CO LTD

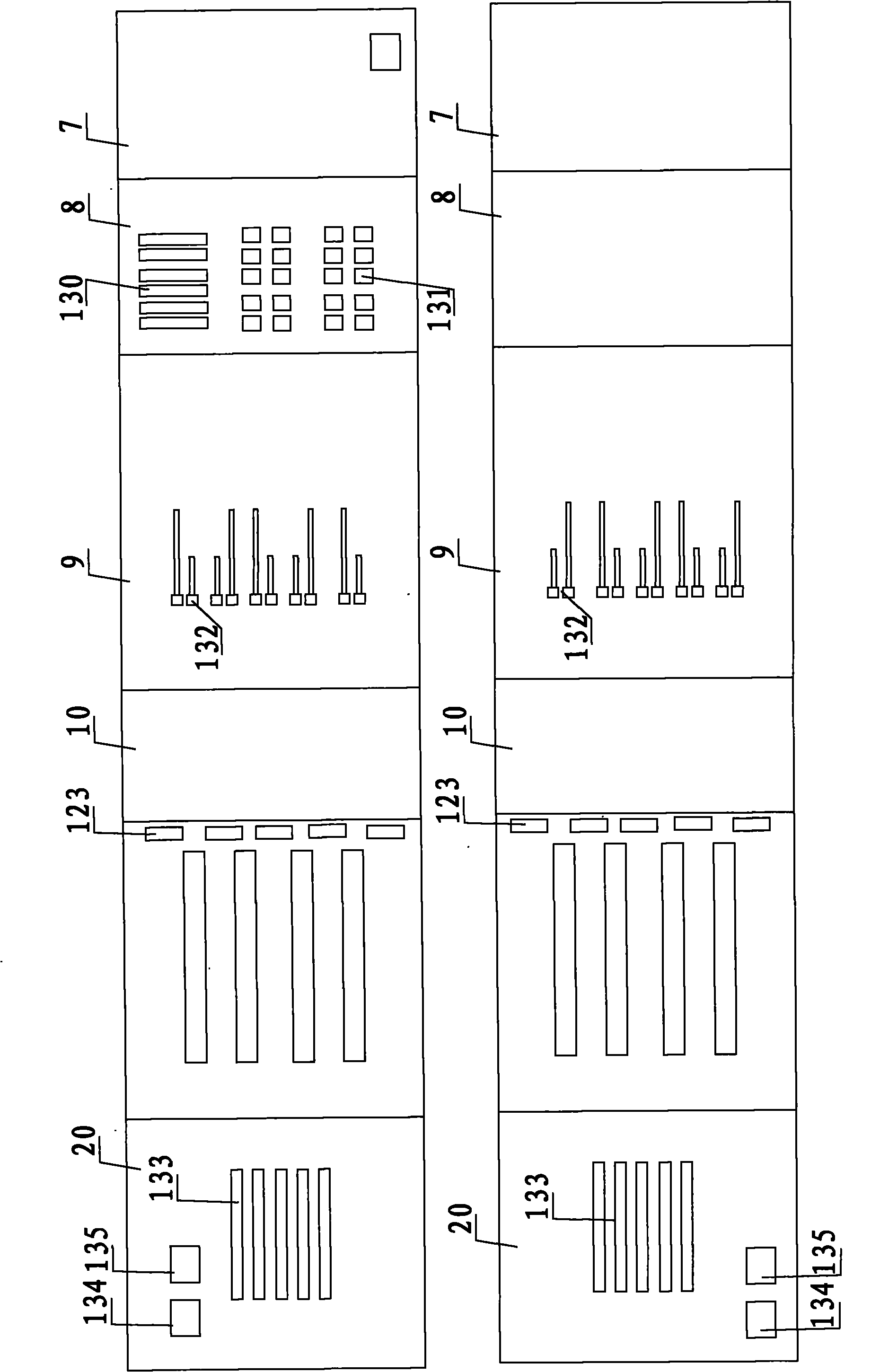

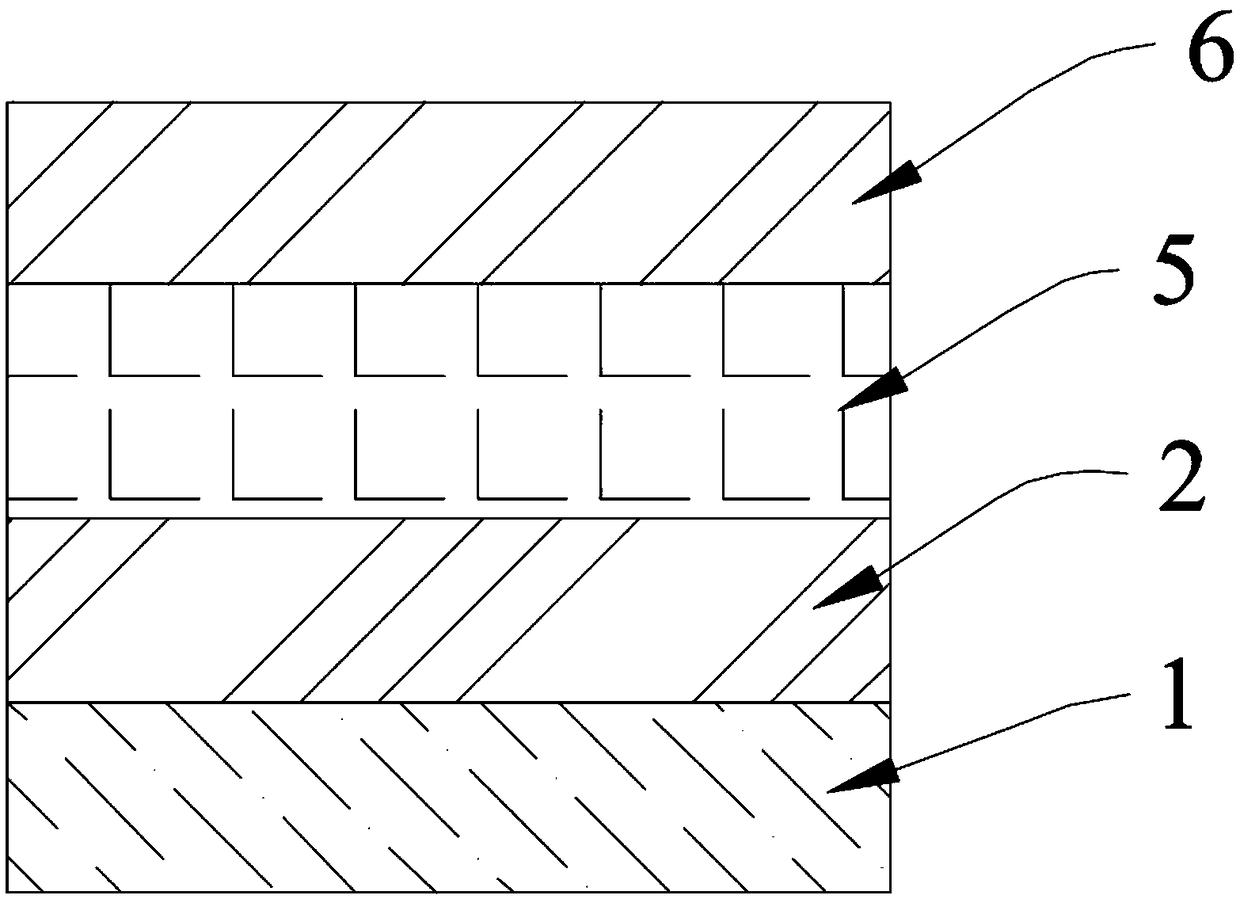

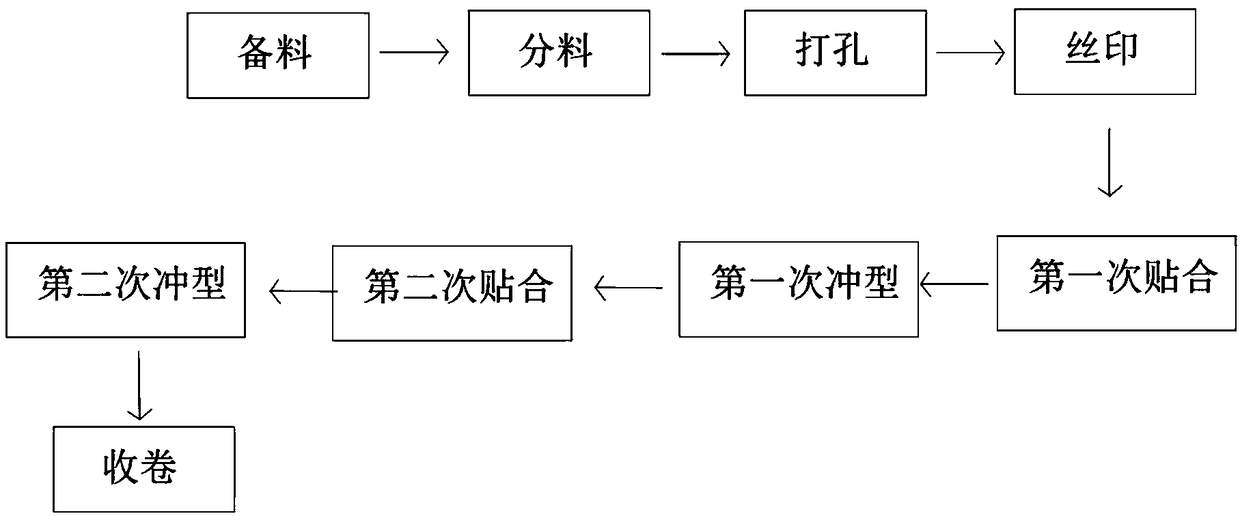

Production method of silk-screen gum

InactiveCN109233665AReduce labor intensityIncrease productivityFilm/foil adhesivesPolyesterBiochemical engineering

The invention discloses a production method of a silk-screen gum. The production method comprises the following steps: step one, preparing production raw materials; step two, carrying out slitting orstripping on the raw materials according to production standard; step three, punching location holes in a double-sided laminated PET film; step four, carrying out silk screen on the double-sided laminated PET film; step five, adhering a double-sided adhesive tape and a first OPP protective film onto the double-sided laminated PET film respectively to obtain a first semi-finished product; step six,punching the first semi-finished product to obtain a second semi-finished product; step seven, removing waste materials, then adhering a release film, a black silicone polyester tape and a second OPPprotective film onto the second semi-finished product respectively to obtain a third semi-finished product; step eight, punching the third semi-finished product to obtain a fourth semi-finished product; and step nine, after removing the waste materials, carrying out rolling to obtain the silk-screen gum film. According to the production method, automatic lamination and stamping for the silk-screen gum can be realized, integral automation production is realized, the production efficiency is high, the influence of artificial factors on the product is reduced, and the product quality is improved.

Owner:惠州恒铭达电子科技有限公司

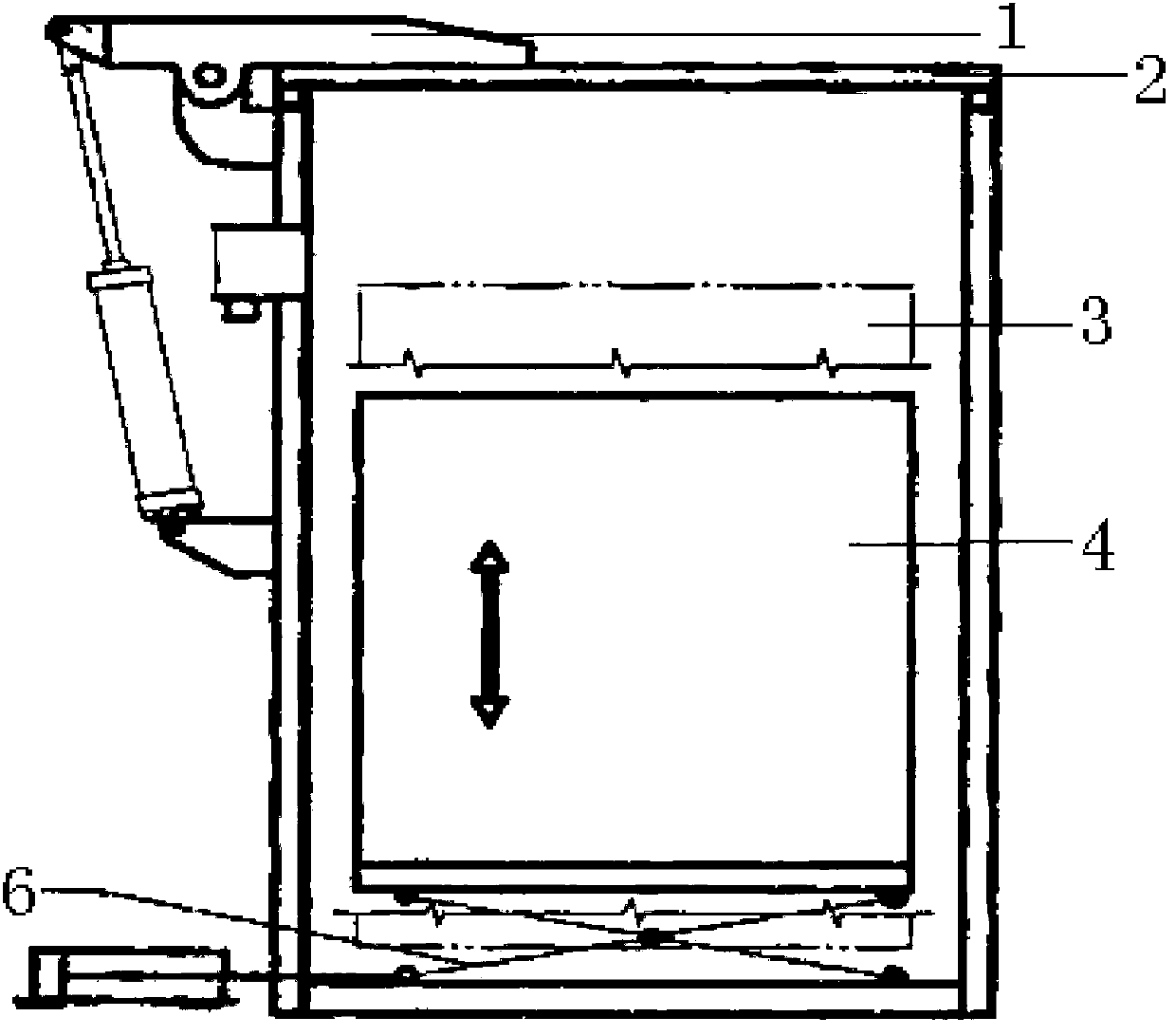

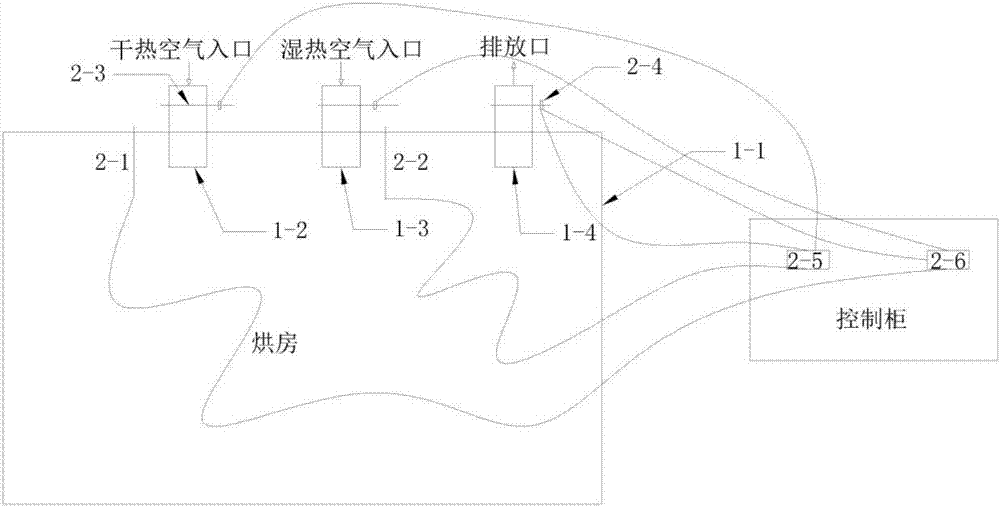

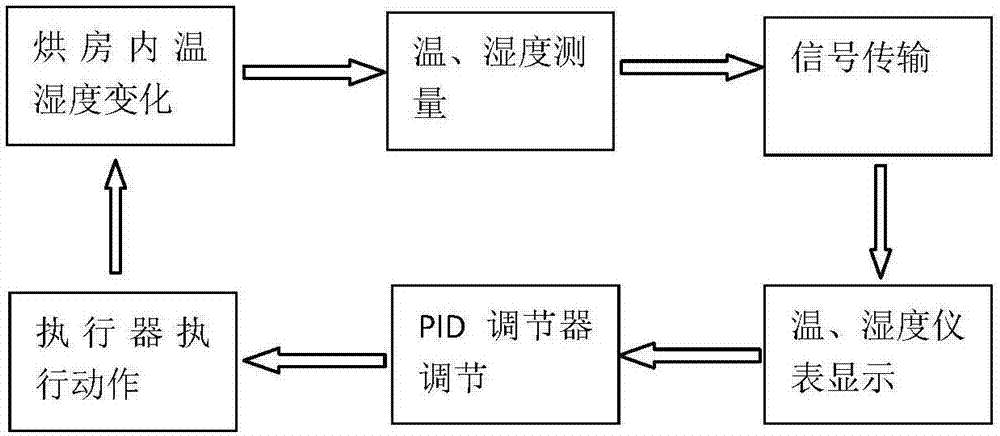

Automatic drying system of electro-porcelain blank

InactiveCN107992134ARealize automatic and precise controlMinimize impact on product qualitySimultaneous control of multiple variablesAutomatic controlControl room

The invention discloses an automatic drying system of electro-porcelain blank. An artificial operation way is changed to automatic control, firstly a temperature and humidity control gate is improved,a performer is additionally arranged on the temperature and humidity control gate, so that the rotation speed can be controlled to be accurate to 0.5 degree / Min for switch motion, and then the performer is connected to a corresponding temperature and humidity detection device; a testing part of the temperature and humidity detection device is in a drying room, and a display part is focused on a control room. In this way, so long as the drying curve is followed and a program is input before drying, the automatic drying can be conducted. The automatic drying system of electro-porcelain blank can realize automatic and accurate control, and the influence of human factors on the product quality is reduced.

Owner:湖南阳东电瓷电气股份有限公司

Aluminum dihydrogen tripolyphosphate continuous production method and device

The invention provides an aluminum dihydrogen tripolyphosphate continuous production method and device. The production method comprises the steps: preparing liquid aluminum dihydrogen phosphate by adopting activated aluminum oxide and 85% industrial phosphoric acid, centrifugally atomizing and drying to obtain aluminum dihydrogen phosphate powder, calcining, condensing, hydrating, drying and crushing to obtain aluminum dihydrogen tripolyphosphate powder. The aluminum dihydrogen tripolyphosphate continuous production method is an automatically-controlled continuous production process and is convenient in production and stable in product quality by virtue of digitalized control; and the prepared aluminum dihydrogen tripolyphosphate particles are uniform in size, the purity reaches 92 percent or more, compared with the prior art, the purity is increased by 15 to 18, and the problems of the existing two-step-method intermittent process that the automation degree is not high, the product quality is unstable and the purity is large in fluctuation are solved.

Owner:GUANGXI UNIV FOR NATITIES

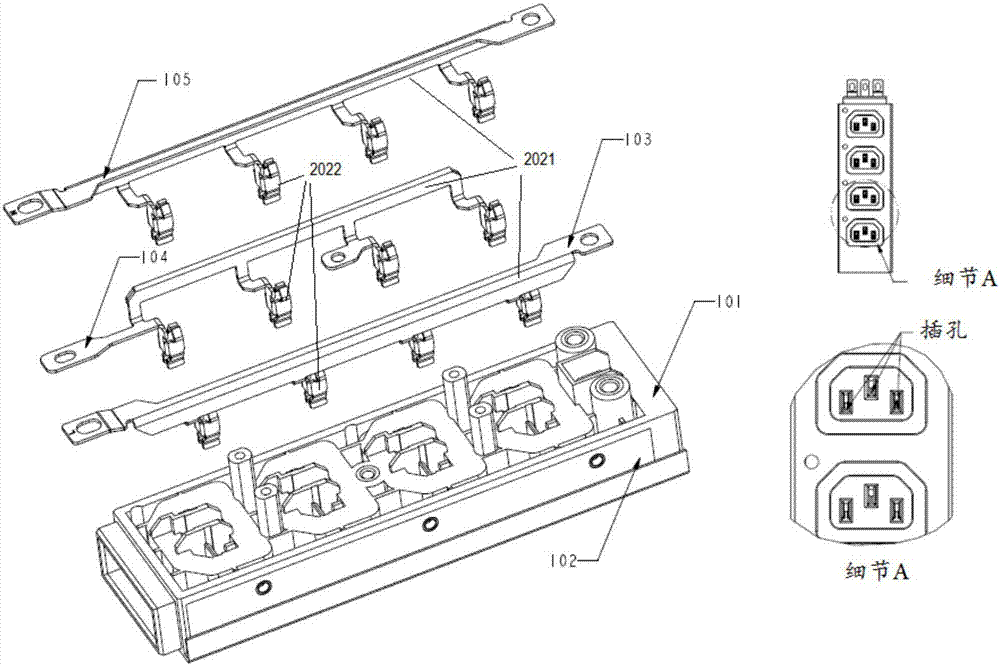

Power adaptor

ActiveCN106921077AAvoid manual connectionIncrease productivityCoupling device detailsElectricityEngineering

The embodiment of the invention provides a power adaptor. By the power adaptor, the problems of complicated production and detection process, poor reliability, poor universality and unfavorableness to mass production of the power adaptor in the prior art are solved. The power adaptor comprises a power incoming line module, wherein the power incoming line module comprises a cable and at least one socket module, the cable is electrically connected with an external power supply, the at least one socket module is electrically connected with each other, each socket module comprises a first socket conductive part, a second socket conductive part and a socket grounding part, the first socket conductive part of each socket module is electrically connected in series and is electrically connected with a live line of the cable, the second socket conductive part of each socket module is electrically connected in series and is electrically connected with a null line of the cable, and the socket grounding part of each socket module is electrically connected in series and is electrically connected with a grounding line of the cable.

Owner:哈尔滨西陆科技有限公司

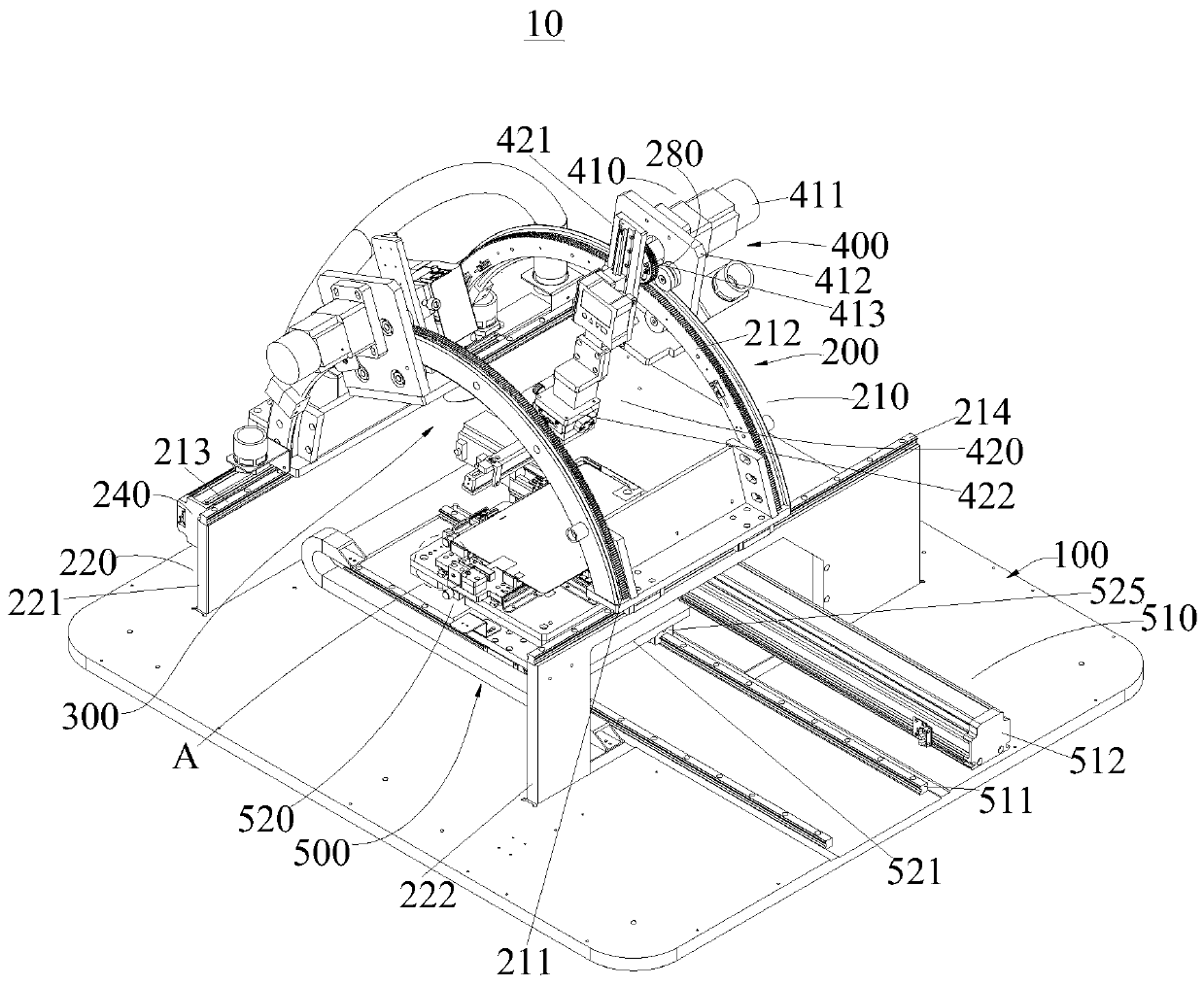

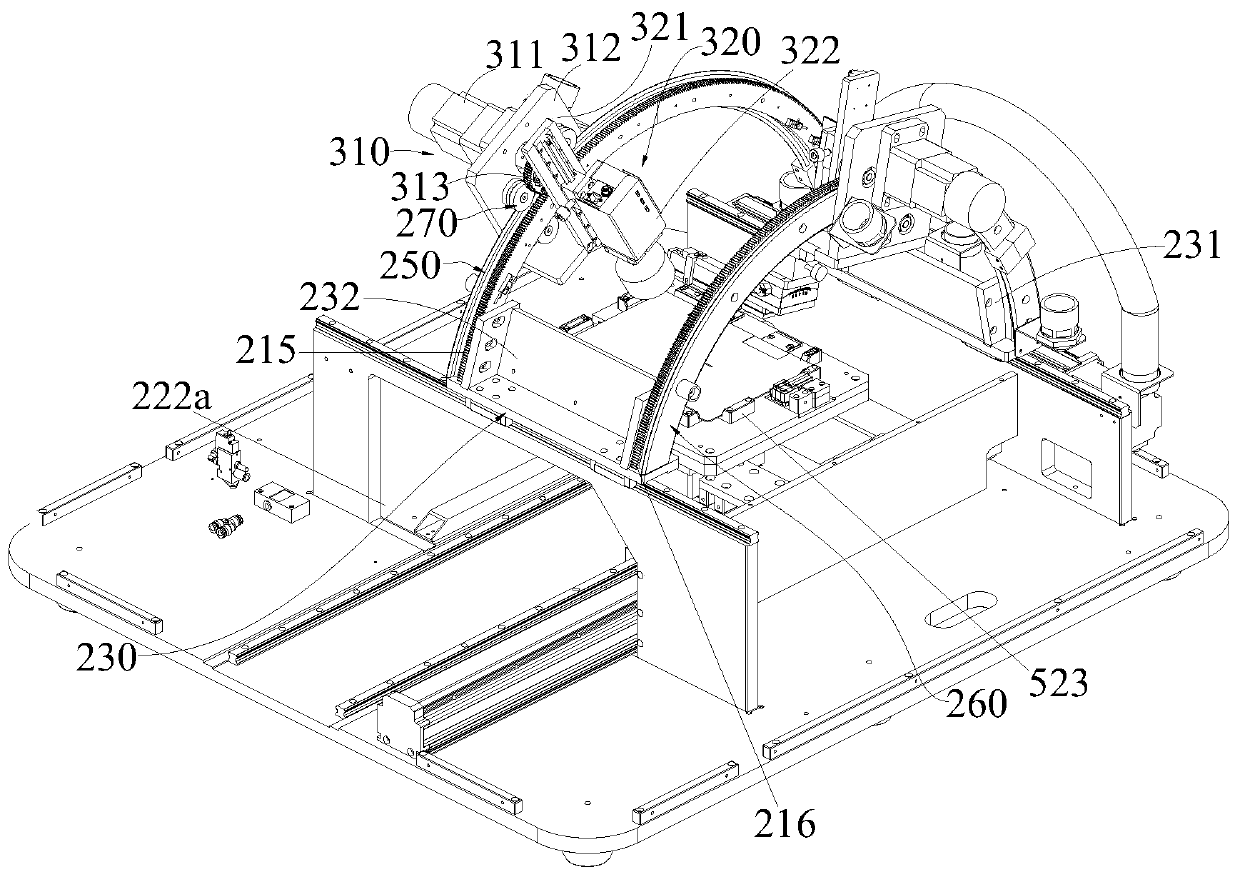

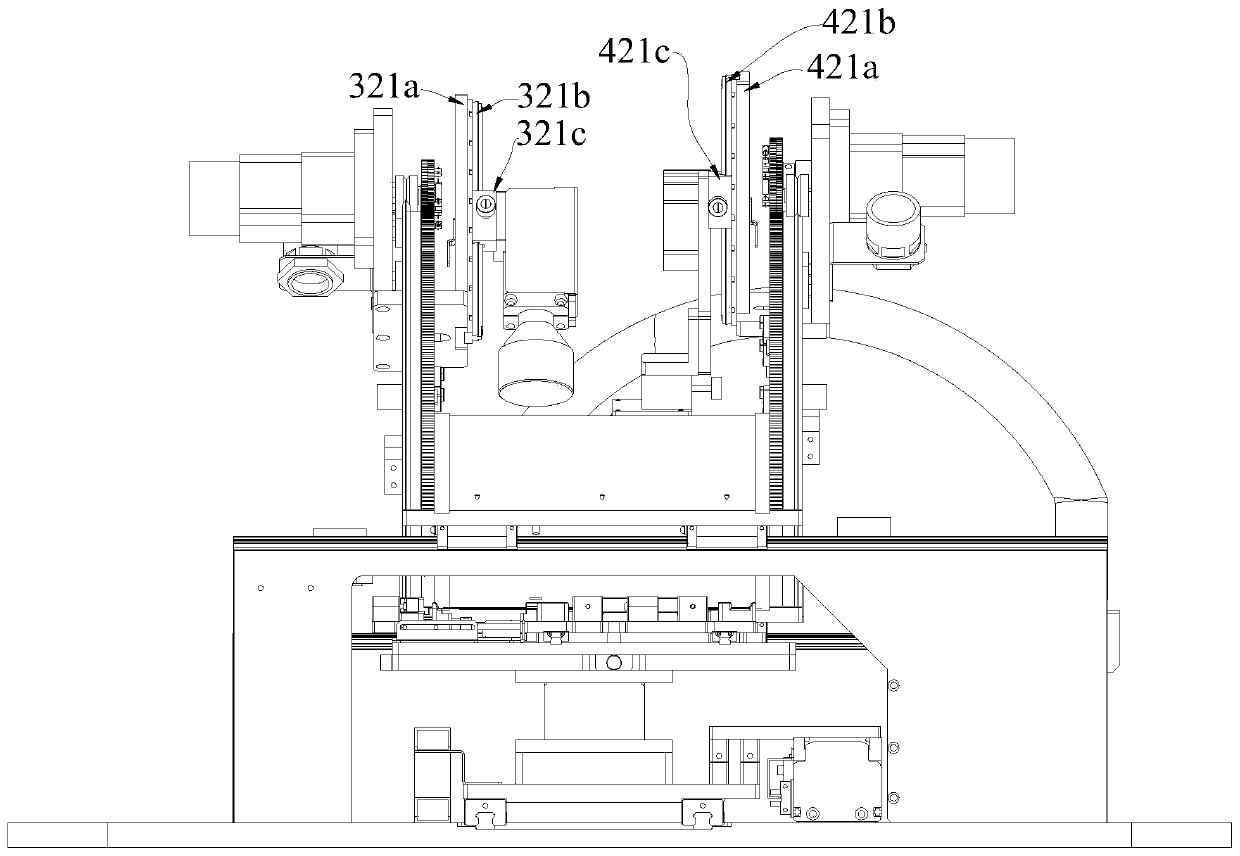

Arc motion visual detection mechanism

ActiveCN110618545AImprove consistencyIncrease productivityNon-linear opticsLiquid-crystal displayEffect light

The invention discloses an arc motion visual detection mechanism. The arc motion visual detection mechanism comprises a workbench, a sliding rail device, a visual detection device, a lighting device and a placement device, wherein the sliding rail device, the visual detection device, the lighting device and the placement device are arranged on the workbench, the visual detection device and the lighting device are arranged on the sliding rail device at intervals, the placement device is arranged below the sliding rail device, the sliding rail device is used for allowing the visual detection device and the lighting device to slide, the visual detection device is used for performing shooting detection on a liquid crystal display screen panel, the lighting device is used for providing a lightsource, and the placement device is used for placing the liquid crystal display screen panel. By combining a plurality of devices, the production efficiency is improved, the working process is accelerated, and the time is saved; and moreover, the detection accuracy and the detection standard consistency are improved, the influence of a manual factor on product quality is reduced, and the product quality is further improved.

Owner:惠州帆声智创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com