Special-shape vacuum suction disc sucking and lifting device and method

A technology of vacuum suction cups and vacuum slings, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of increasing the success rate of operation and positioning, shortening the operation and positioning time, and being easy to be pulled off, so as to reduce personnel operations and protect Safety, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

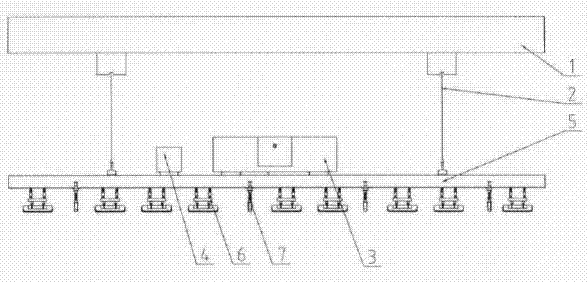

[0043] see Figure 1 to Figure 7 , The special-shaped corner material vacuum suction cup spreader of the present invention is mainly composed of a lifting crane 1, a wire rope hook 2, a vacuum pump and a control system 3, an electrical control box 4, a main beam of the vacuum spreader 5, a vacuum suction cup set 6 and a centering guide mechanism 7 composition. The vacuum suction cup group 6 is installed on the main beam 5 of the vacuum lifter. At least two sets of centering guide mechanisms 7 are installed on the main beam 5 of the vacuum lifter.

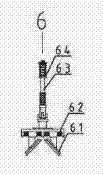

[0044] The vacuum chuck group 6 comprises two vacuum chucks 61, a lateral adjustment spring 62, a vertical guide shaft 63, and a vertical adjustment spring 64. The horizontal adjustment spring 62 is arranged between the two vacuum chucks 61 to adjust the lateral displacement between them, and the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com