Patents

Literature

2563results about "Sparking plugs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

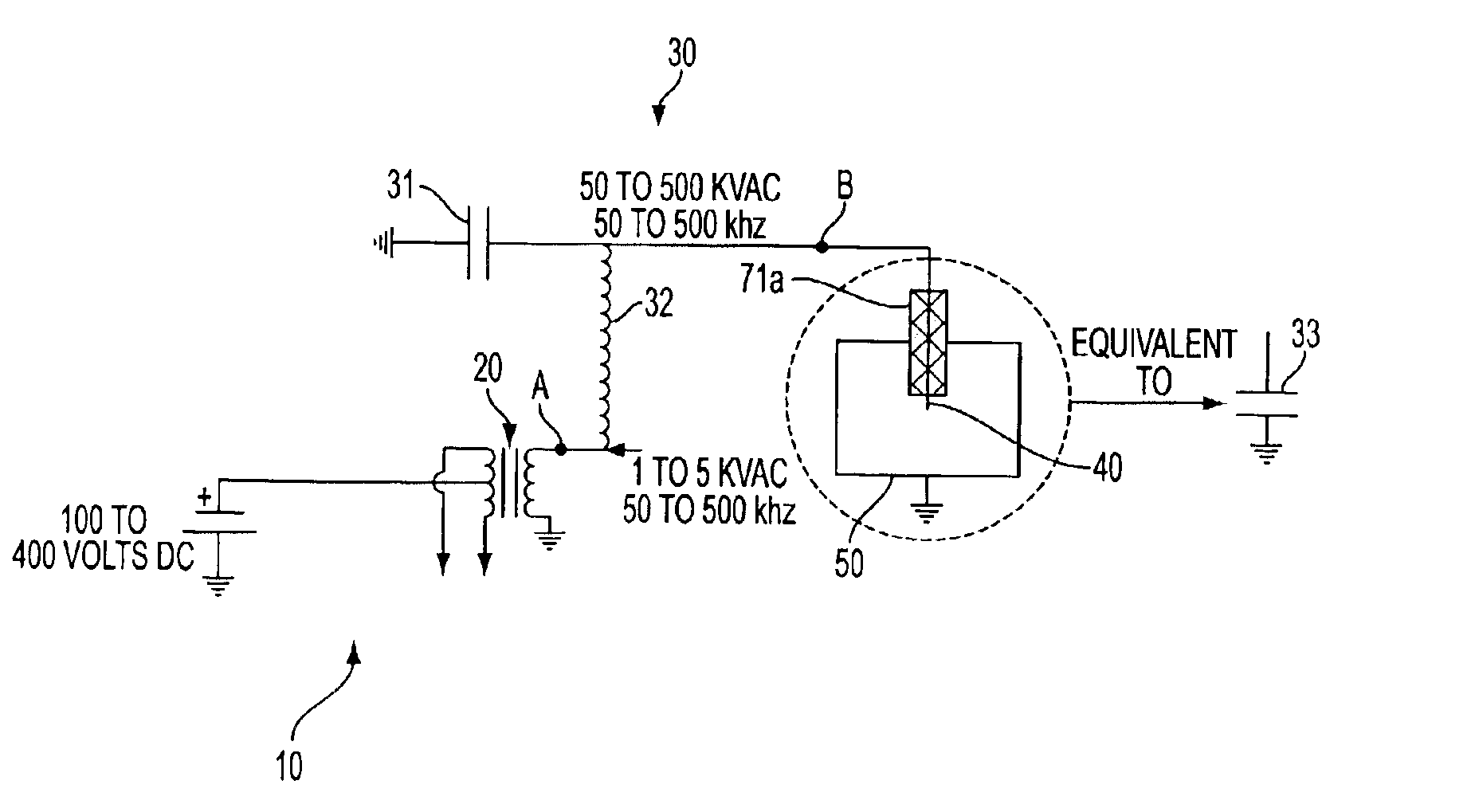

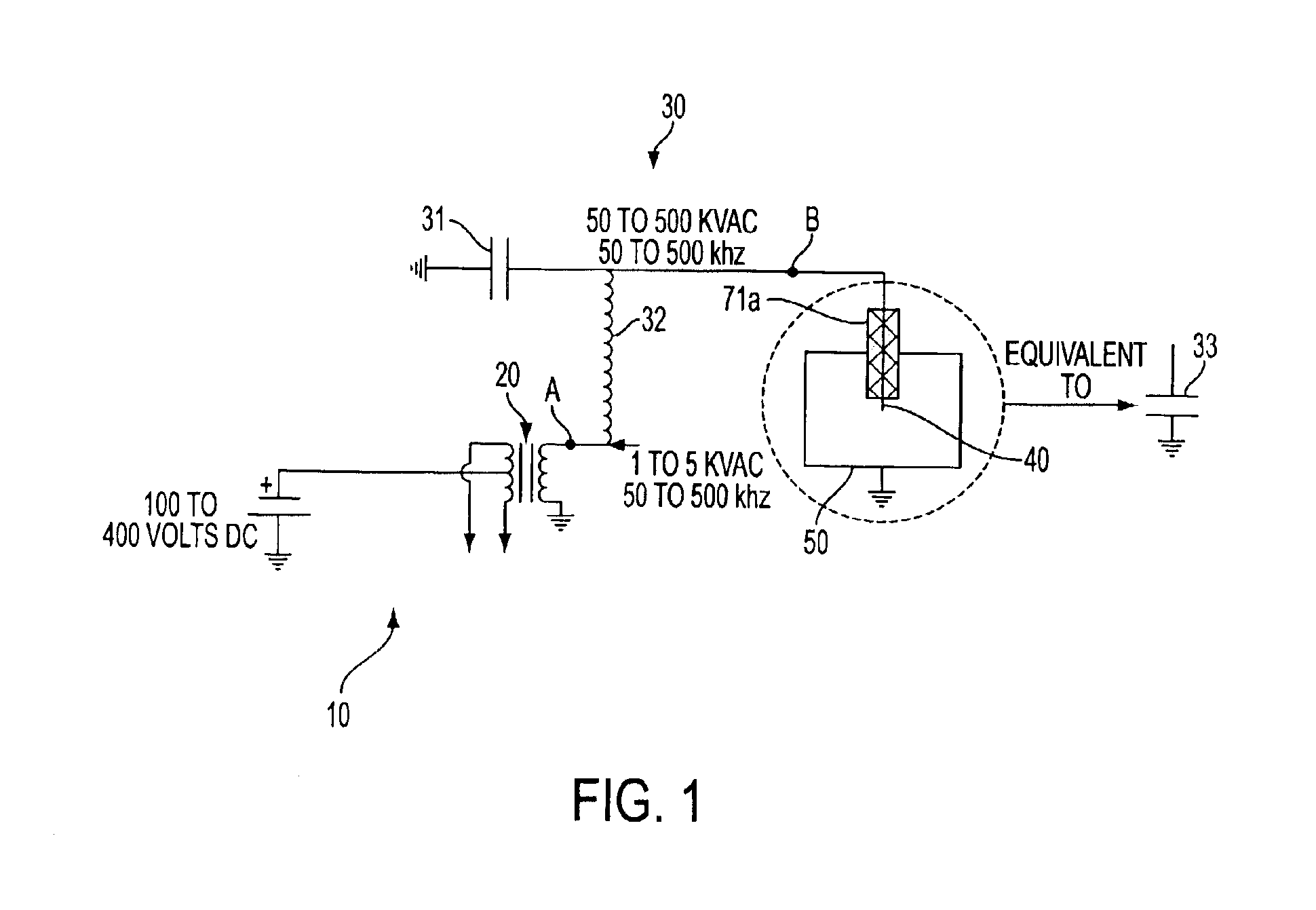

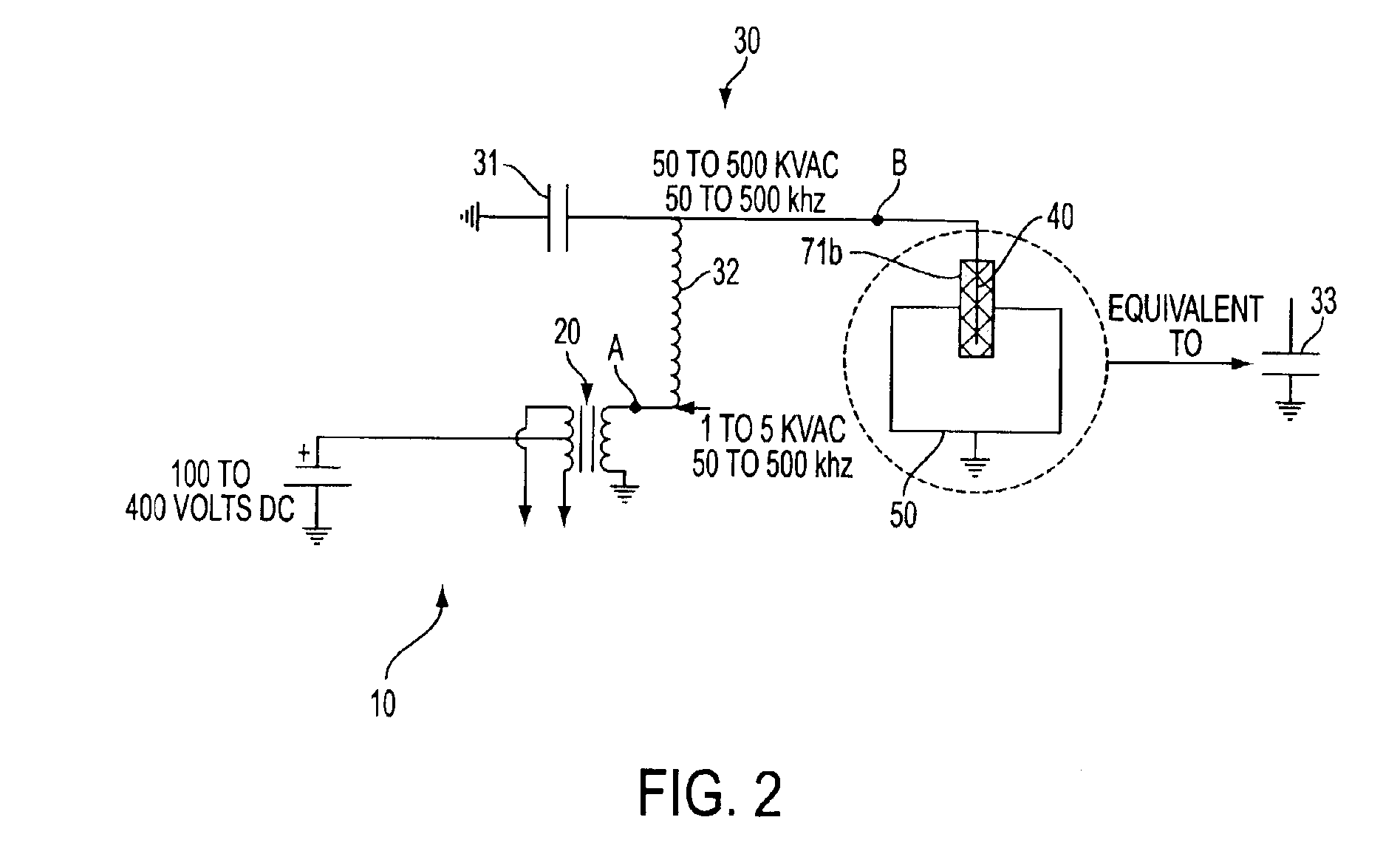

System and method for generating and sustaining a corona electric discharge for igniting a combustible gaseous mixture

InactiveUS6883507B2Sufficient energySparking plugsCombustion enginesCombustion chamberElectric discharge

The invention relates to a system for igniting a fuel-air mixture in a combustion chamber with a corona discharge. The system comprises an electrode inside of the combustion chamber, an electric circuit which provides radio frequency electric power to the electrode, and a ground formed by the combustion chamber walls. A radio frequency voltage differential formed between the electrode and the ground produces a radio frequency electric field therebetween which causes a fuel-air mixture to ionize resulting in combustion of the fuel-air mixture. The system can be utilized in engines such as internal combustion engines or gas turbine engines, for example.

Owner:BORGWARNER INC

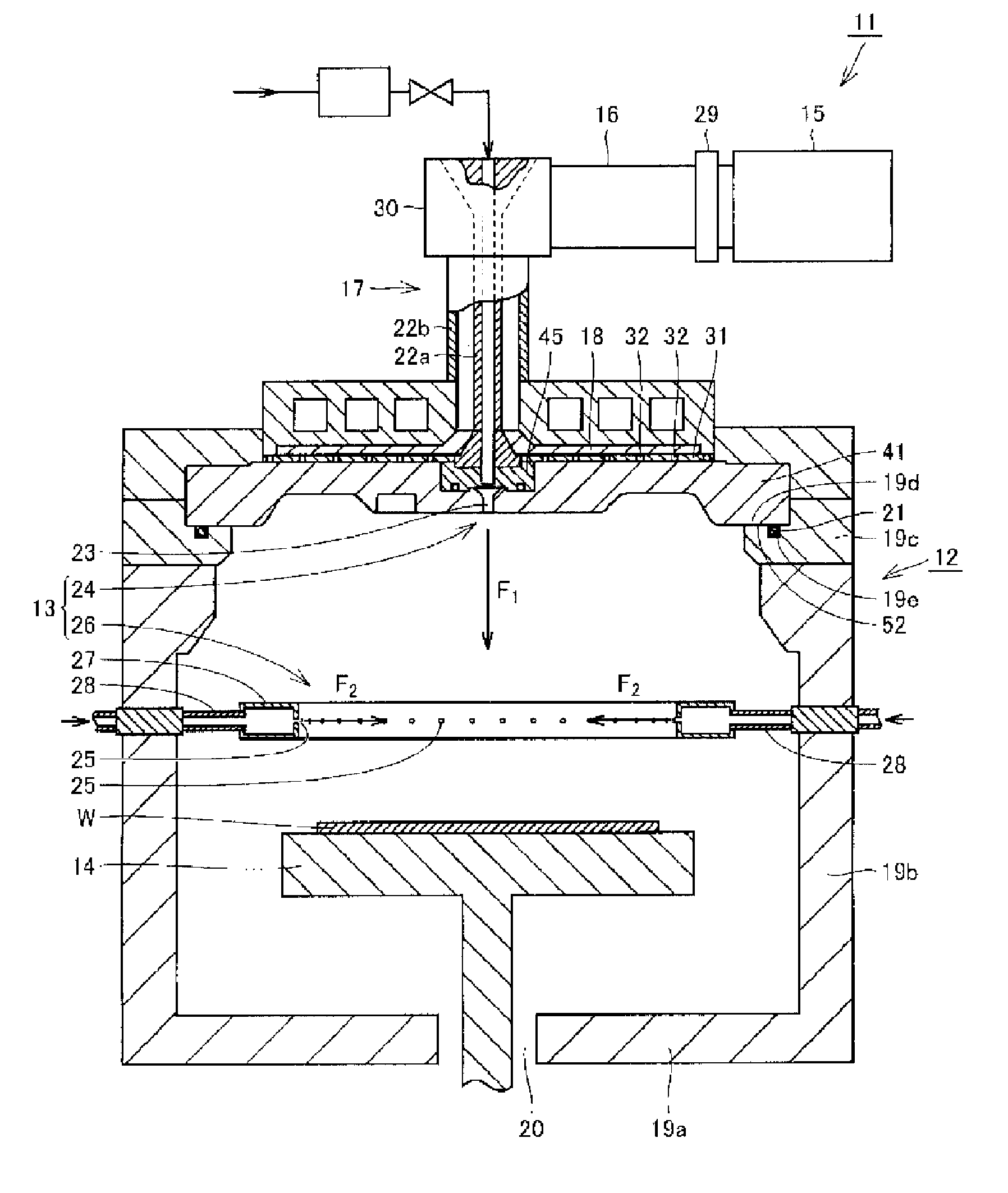

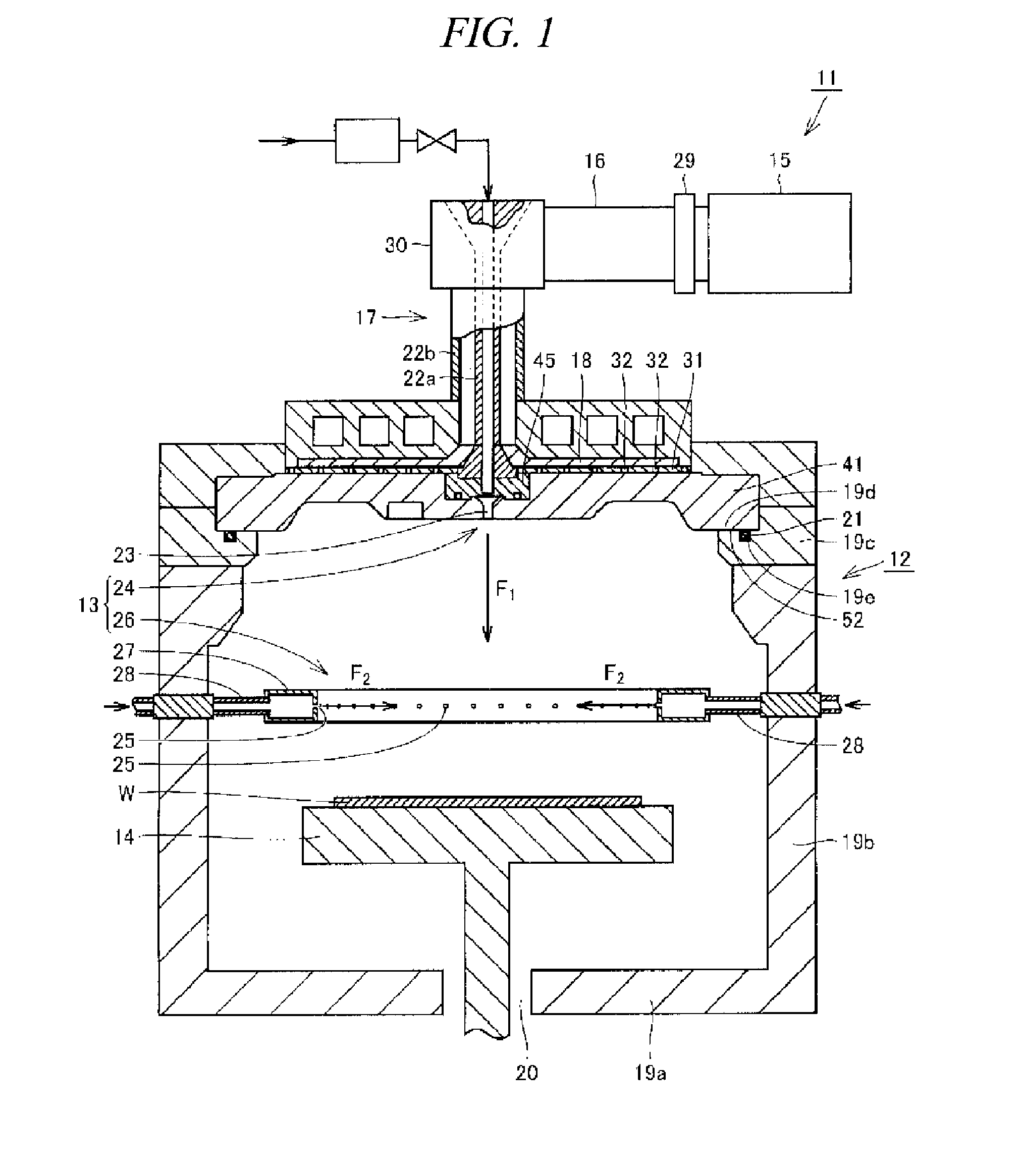

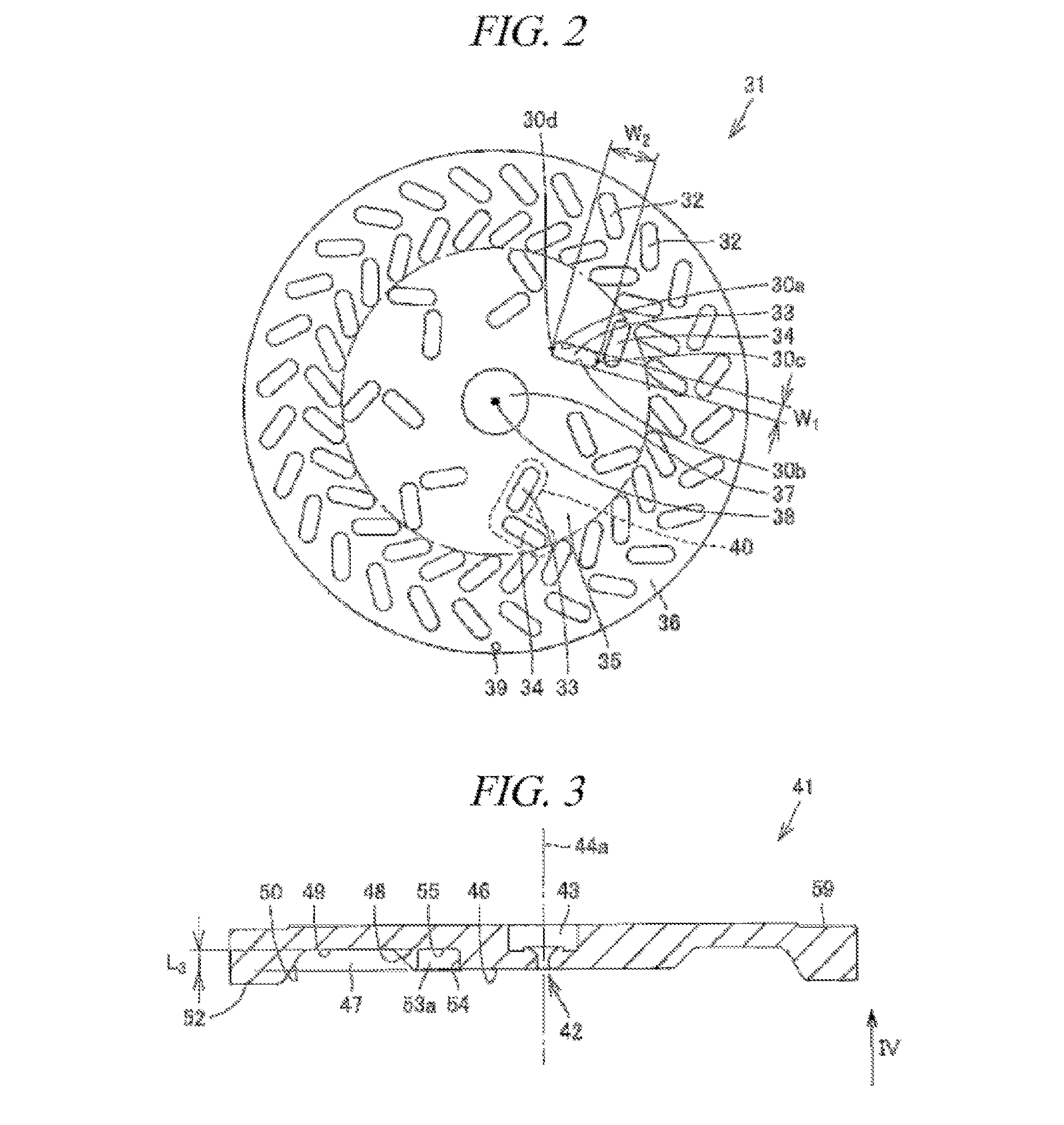

Dielectric window for plasma processing apparatus, plasma processing apparatus and method for mounting dielectric window for plasma processing apparatus

ActiveUS20130093321A1High plasma stabilityAppropriate thicknessSparking plugsSemiconductor/solid-state device manufacturingDielectricPlasma processing

In a dielectric window 41 for a plasma processing apparatus, a first dielectric window recess 47 is formed on an outer region of a surface of the dielectric window 41 in a diametrical direction of the dielectric window 41 at a side where plasma is generated, and the first dielectric window recess 47 is extended in a ring shape and has a tapered shape inwardly in a thickness direction of the dielectric window 41. A multiple number of second dielectric window recesses 53a to 53g are formed between the center of the dielectric window 41 and the first dielectric window recess 47, and each of the second dielectric window recesses 53a to 53g is recessed inwardly in the thickness direction of the dielectric window 41 from the surface of the dielectric window 41.

Owner:TOKYO ELECTRON LTD

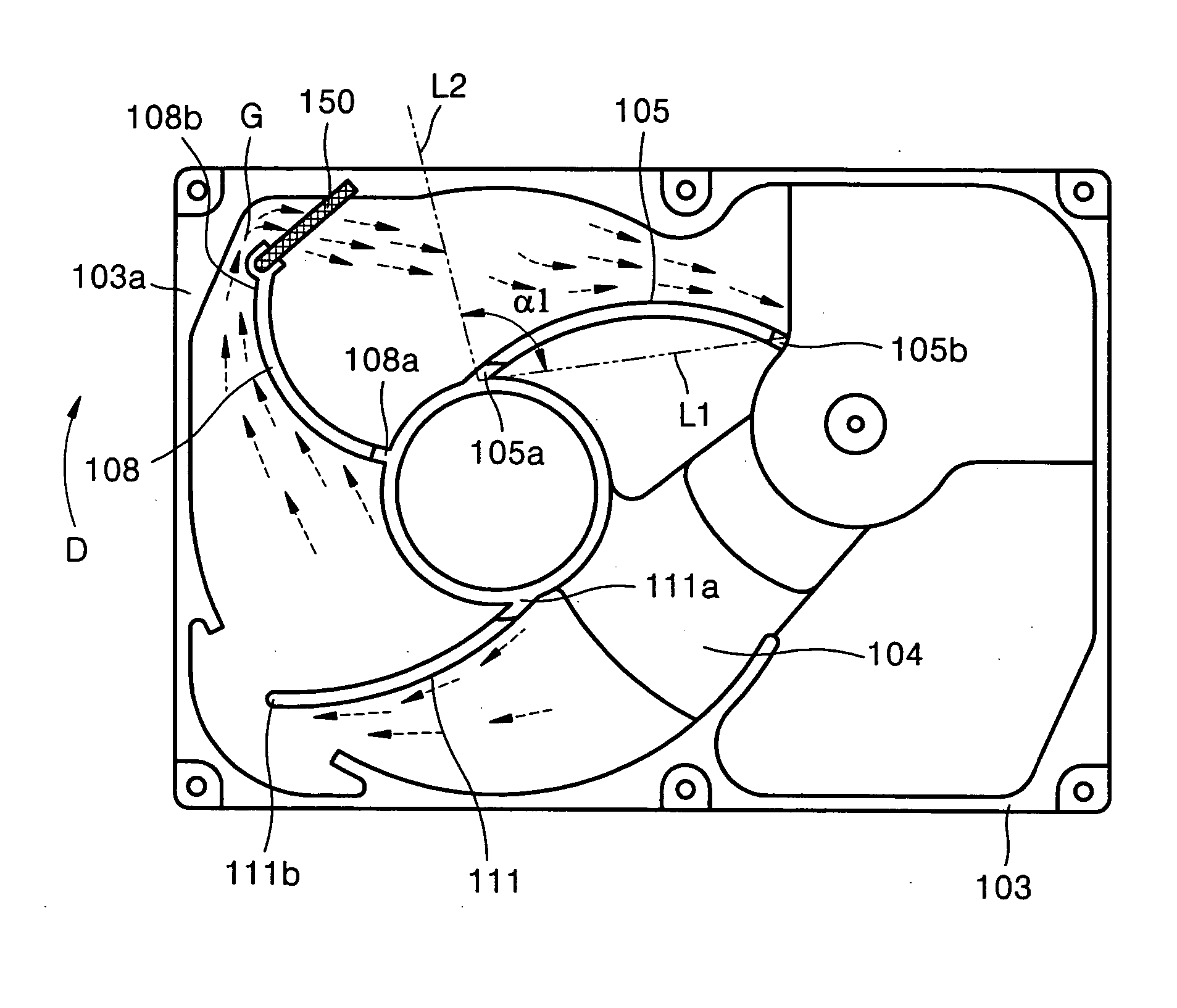

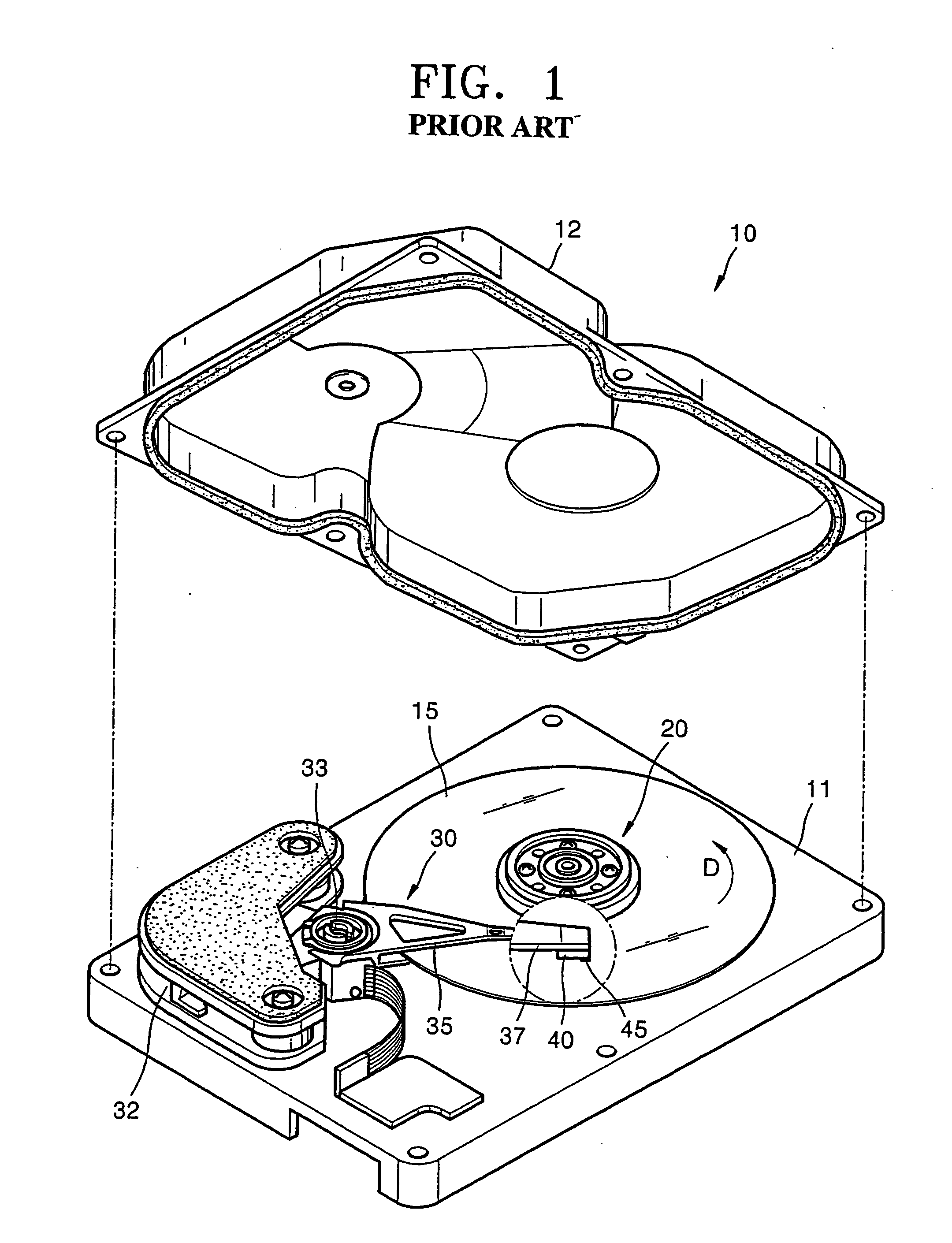

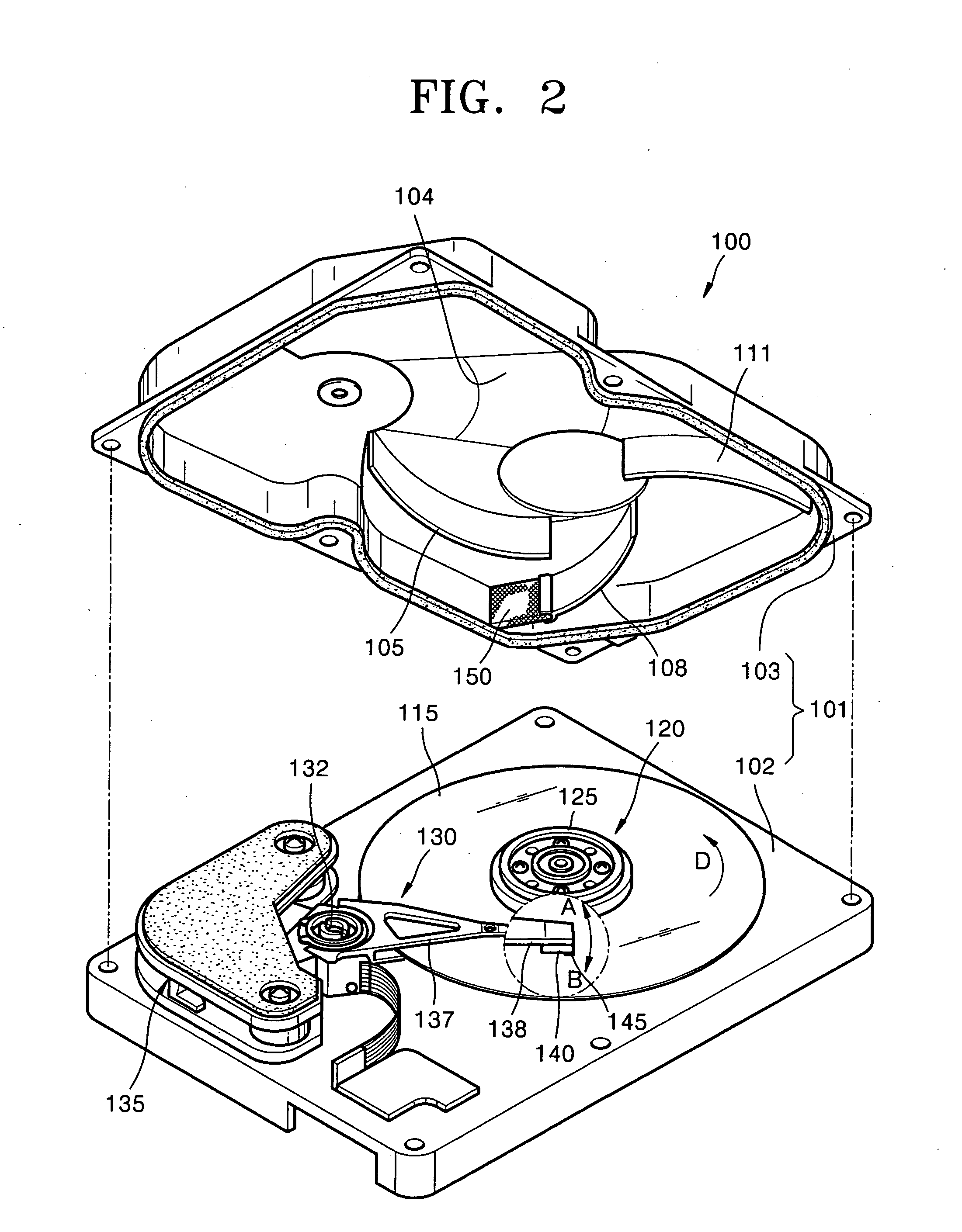

Hard disk drive

A hard disk drive having a housing with a base and a cover connected to each other, a spindle motor connected to the base, a disk mounted on the spindle motor and rotating with respect to the base, and an actuator rotatably connected to the base and supporting a slider with a magnetic head mounted on a front end thereof. The magnetic head writes and / or reads data to and / or from the disk. The hard disk drive also has a blade protruding from a surface of the base and / or a portion of the cover facing the disk. The blade guides an air flow caused by rotation of the disk toward an outer edge of the disk.

Owner:SAMSUNG ELECTRONICS CO LTD

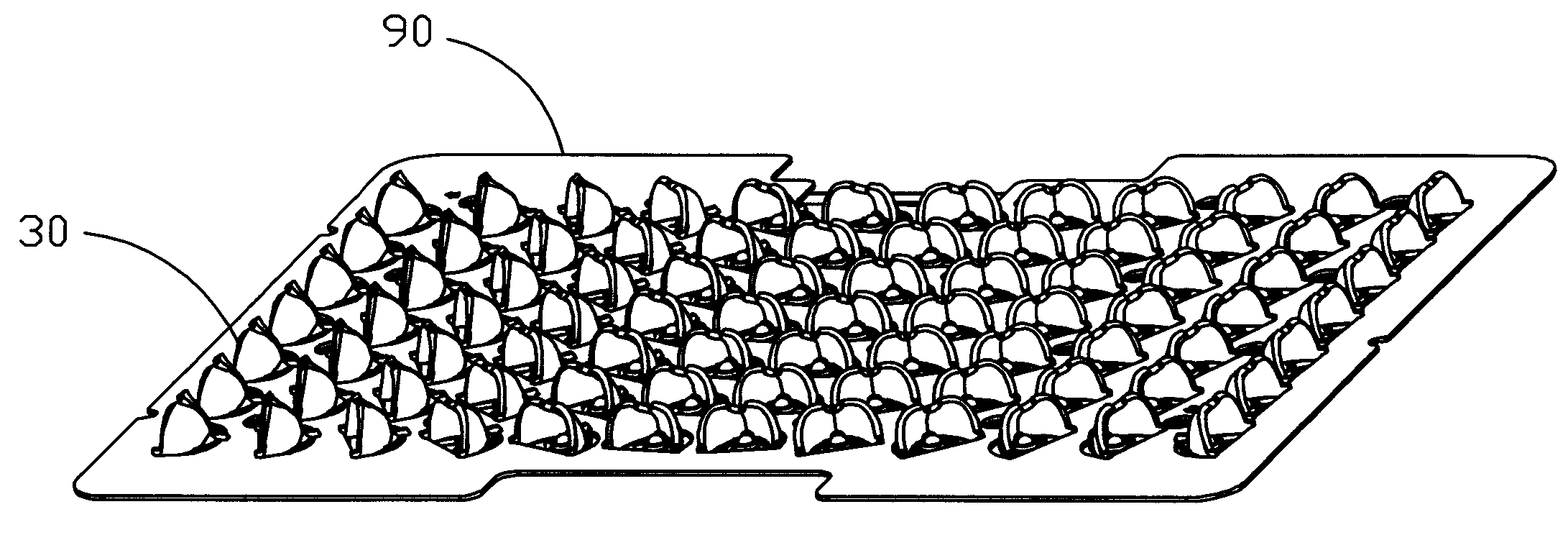

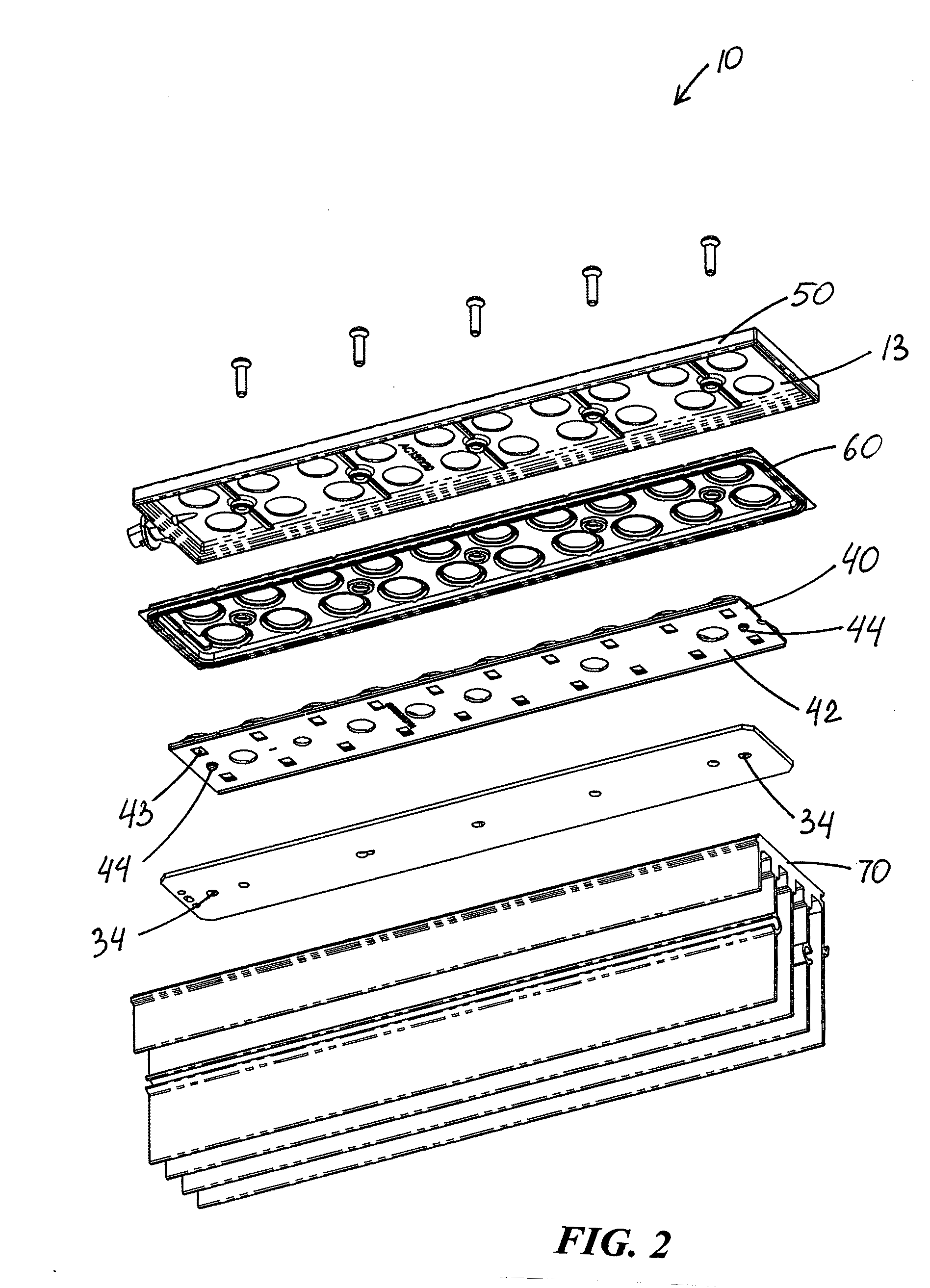

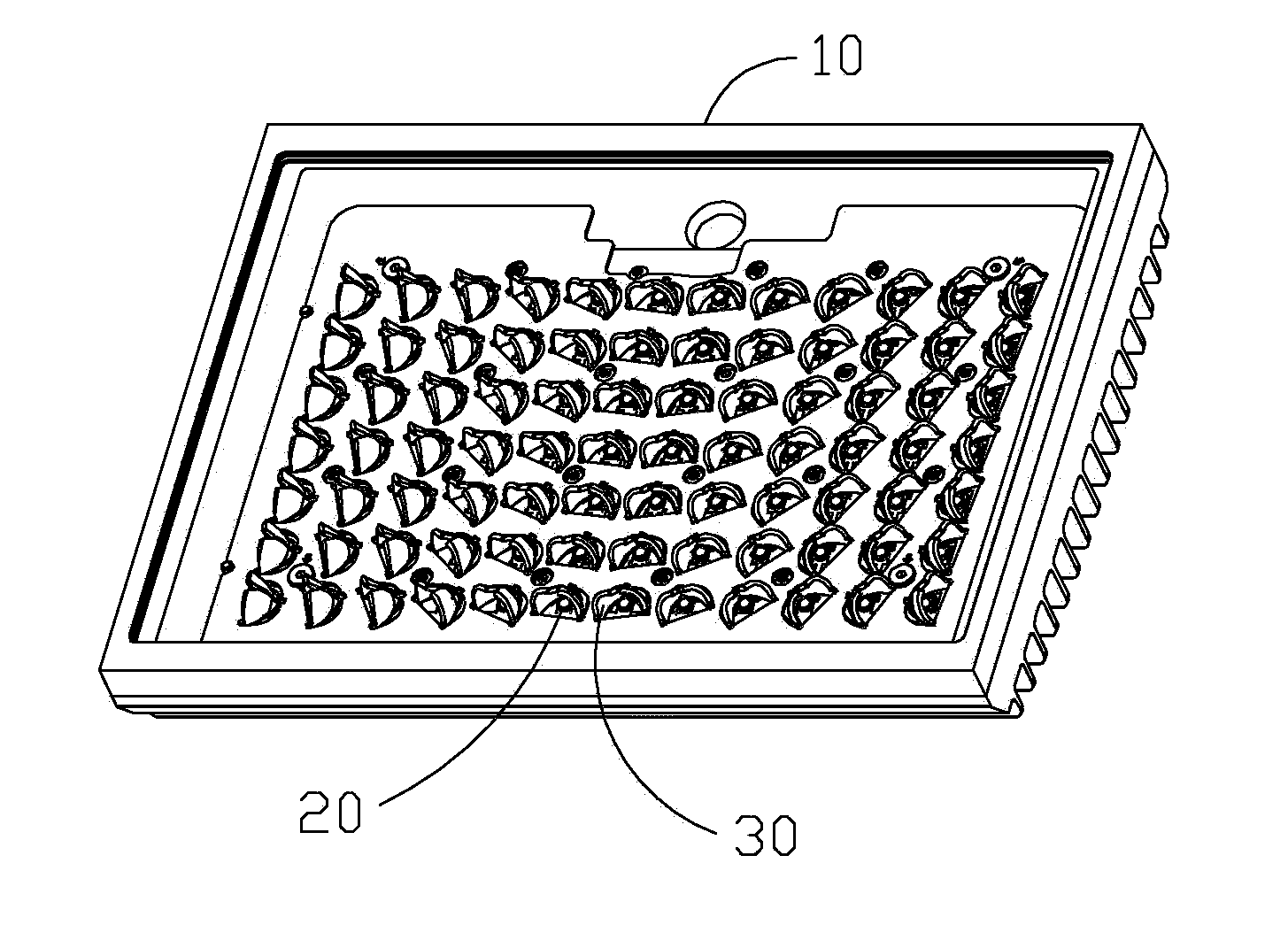

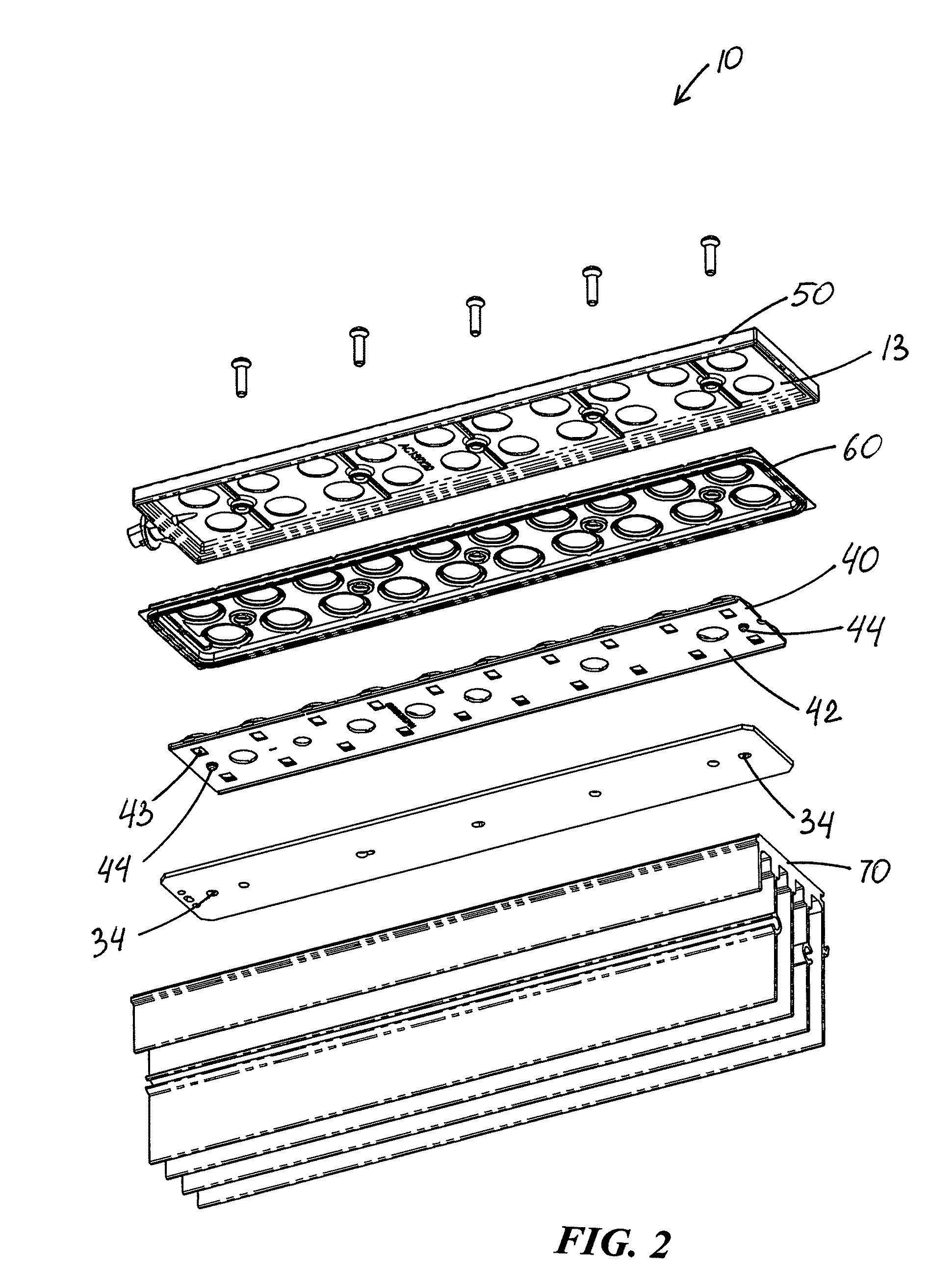

Method, system and apparatus for highly controlled light distribution from light fixture using multiple light sources (led's)

ActiveUS20090323330A1Easily pre-aimedAccurately establishedPlanar light sourcesMechanical apparatusLight equipmentBeam pattern

An apparatus, method, or system of lighting units comprising a plurality of lighting elements, such as one or more LEDs, each element having an associated optic which is individually positionable. In embodiments of the present invention, one or more optics are developed using optimization techniques that allow for lighting different target areas in an effective manner by rotating or otherwise positioning the reflectors, refractive lenses, TIR lenses, or other lens types to create a composite beam. The apparatus, method, or system of lighting herein makes it possible to widely vary the types of beams from an available fixture using a small number of inventoried optics and fixtures. In some cases, by using a combination of individual beam patterns, a small set of individual optics would be sufficient to create a majority of the typical and specialized composite beams needed to meet the needs of most lighting projects and target areas.

Owner:MUSCO

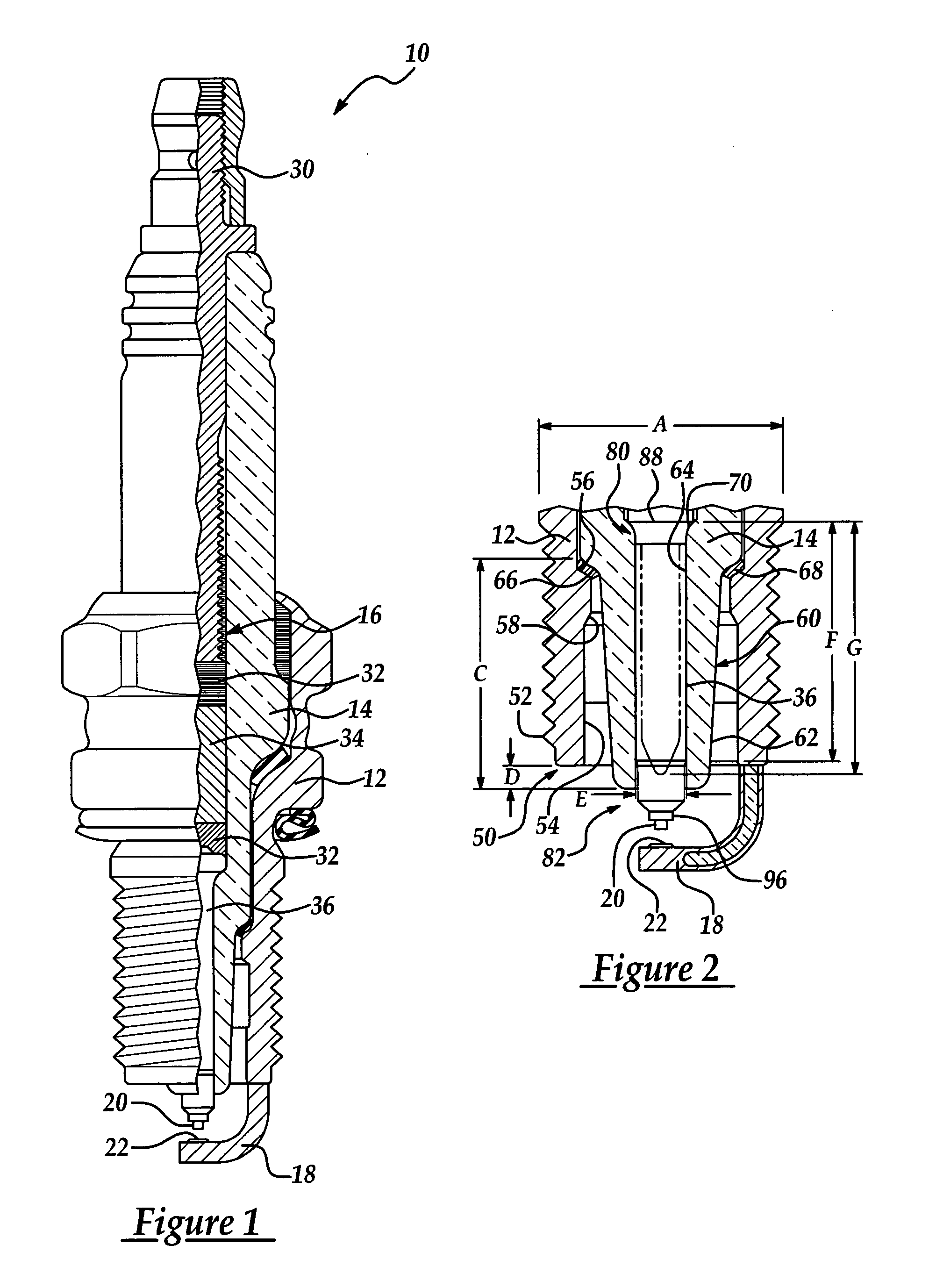

Spark plug

InactiveUS6495948B1Improve fuel efficiencyIncrease combustion pressureSparking plugsFuel injection apparatusInternal combustion engineSpark plug

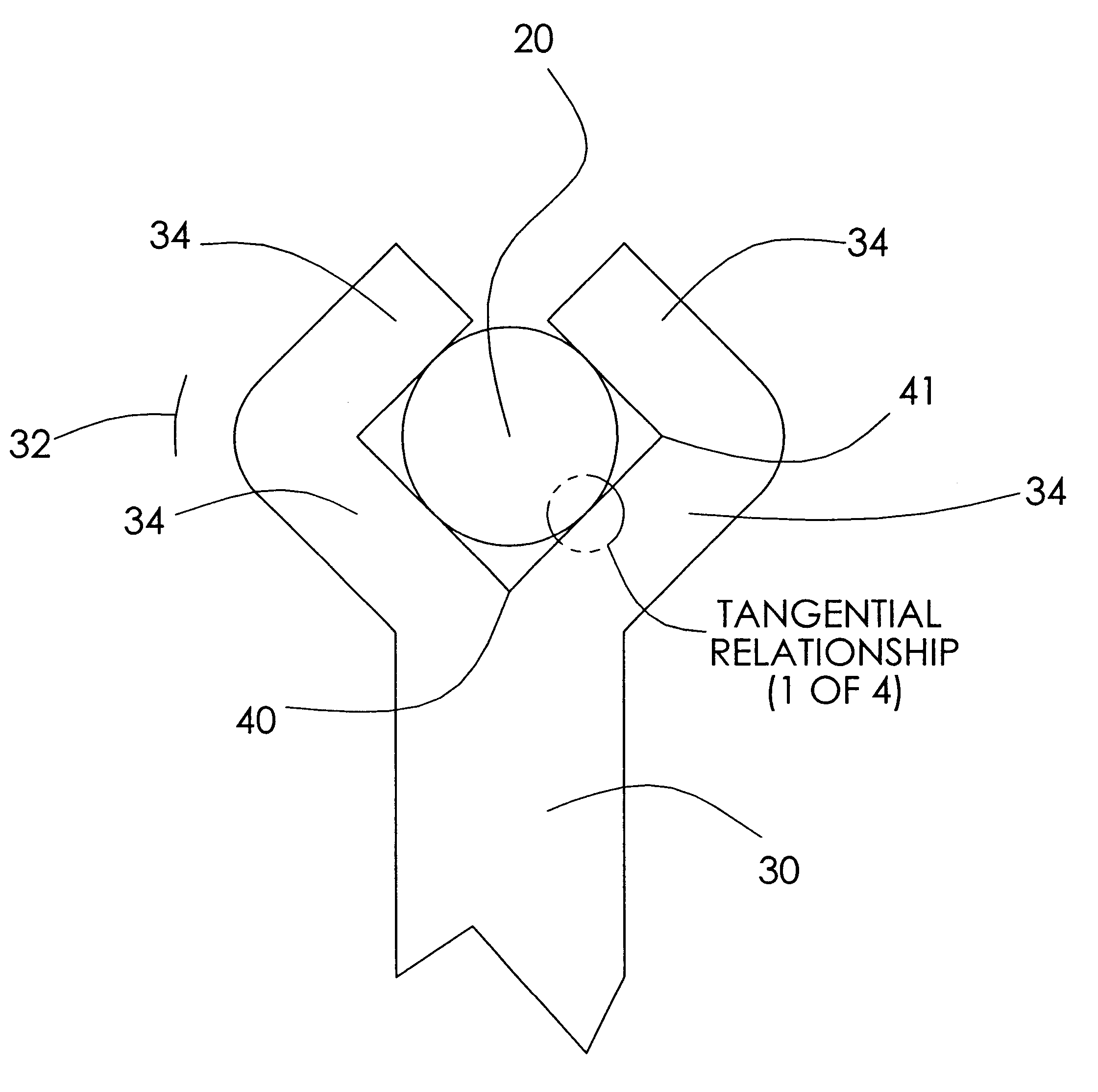

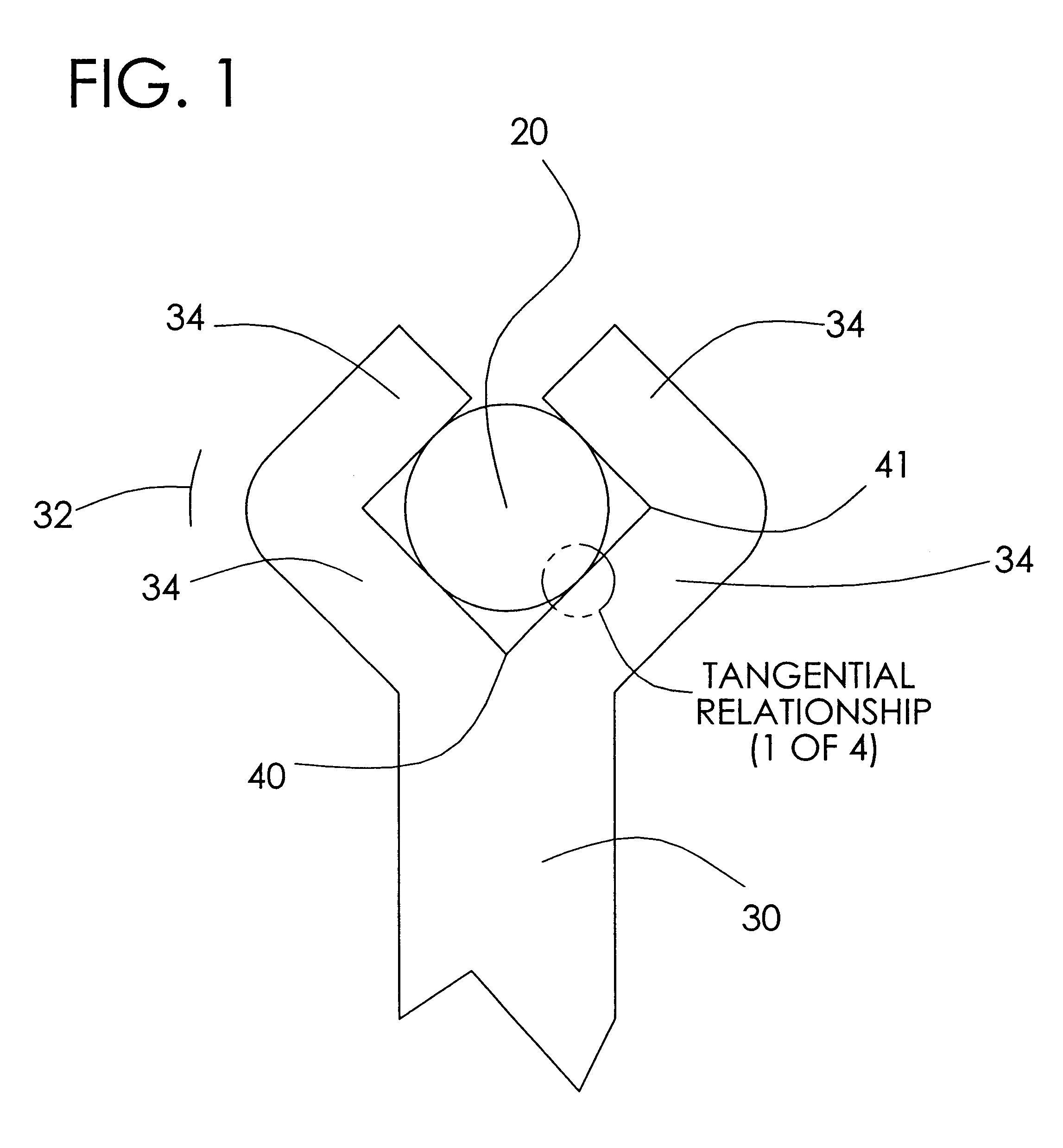

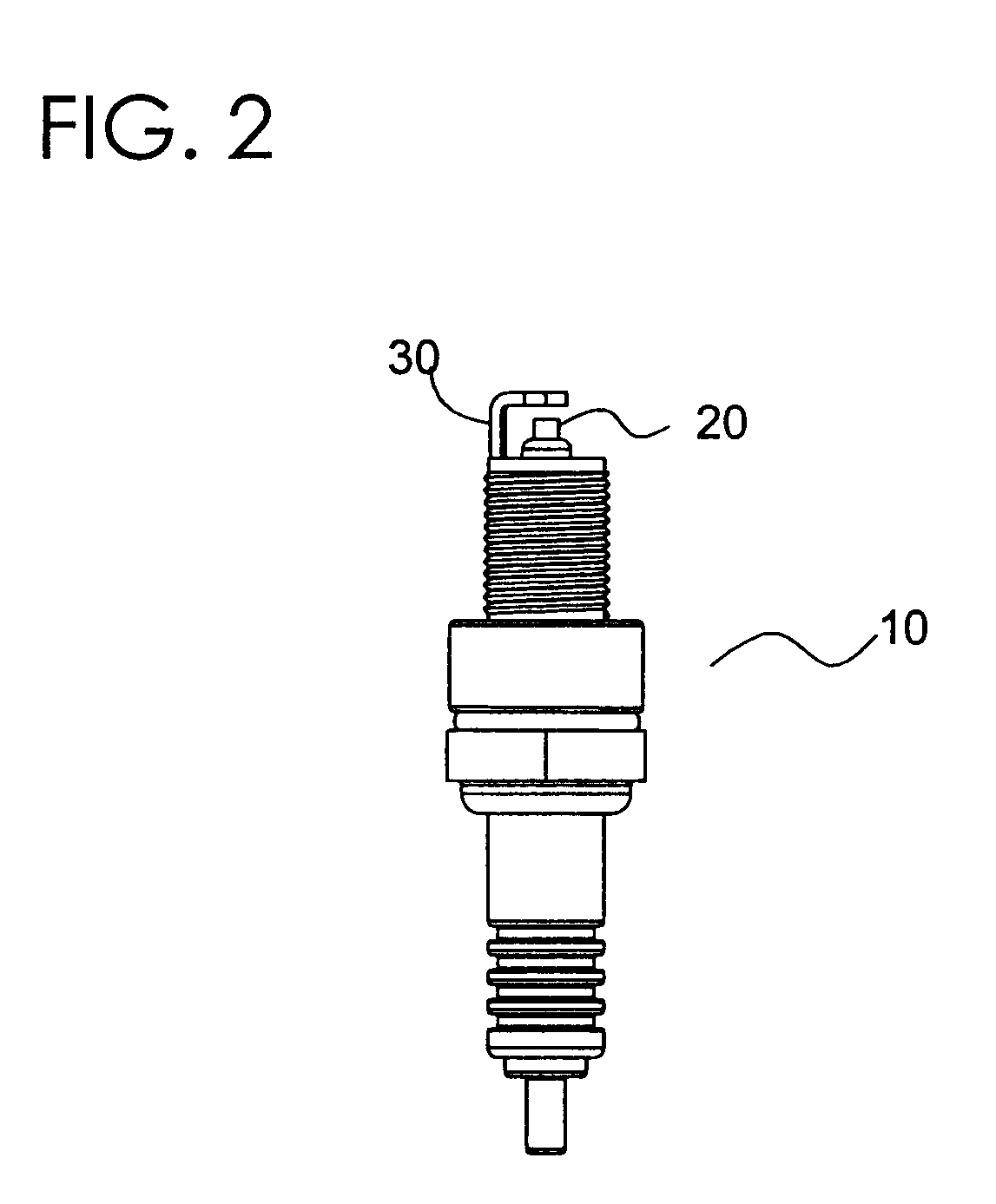

The present invention relates to improved spark plugs for igniting a fuel charge in an internal combustion engine, and is particularly concerned with an improved spark plug construction which improves combustion pressure and fuel mileage and diminishes exhaust pollution. The spark plug includes a center electrode and a ground electrode. In one embodiment, the ground electrode has an elongate edge that extends past the major dimension of the center electrode. The elongate edge can either be positioned substantially tangentially to or within a "zone" outside of the center electrode's periphery. Preferably, the edge of the center electrode and the lower interior edge of the ground electrode will be presented towards one another such that the edges are or are among the closest portions within the sparking region.

Owner:PYROTEK E3 LLC

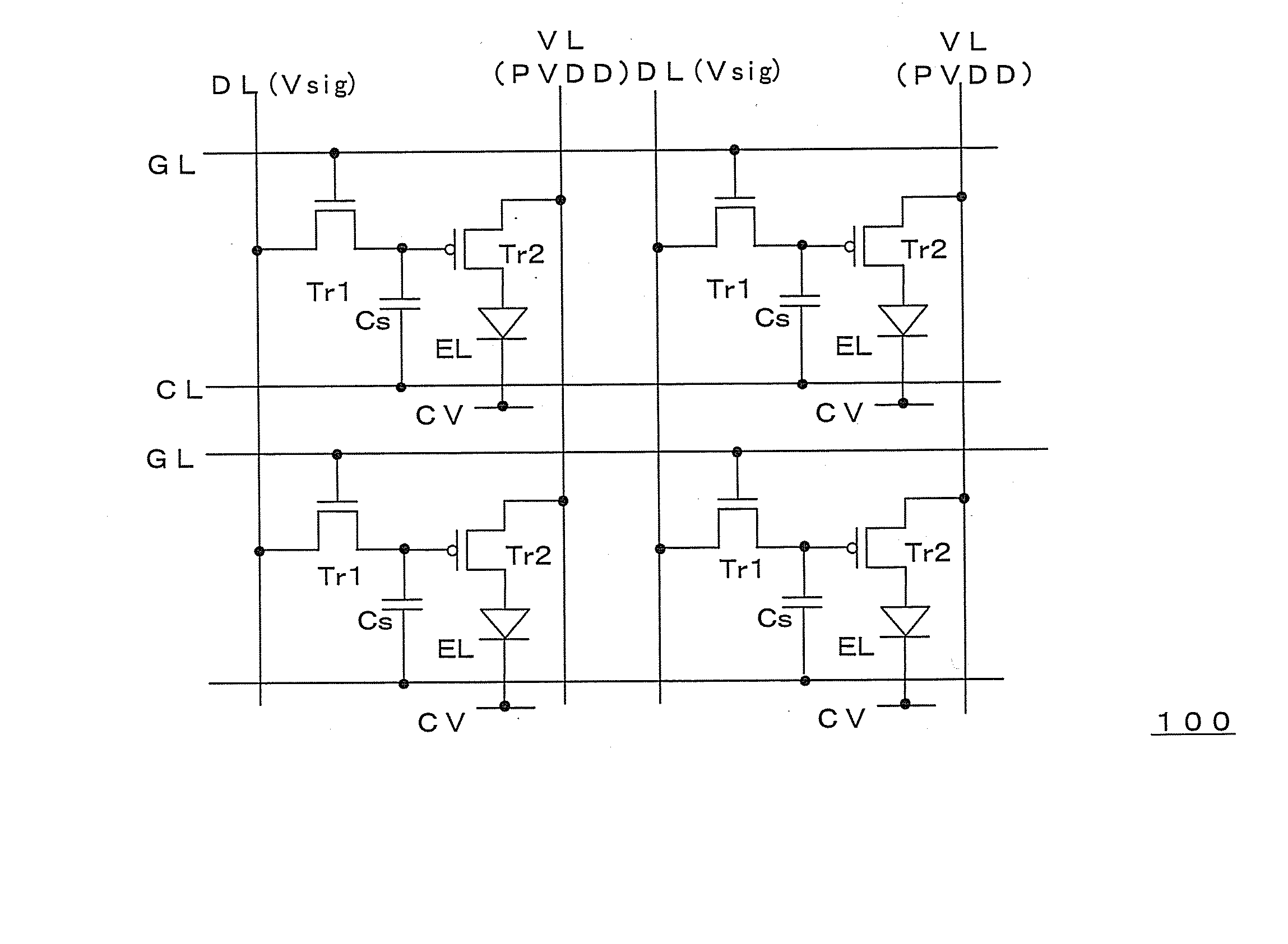

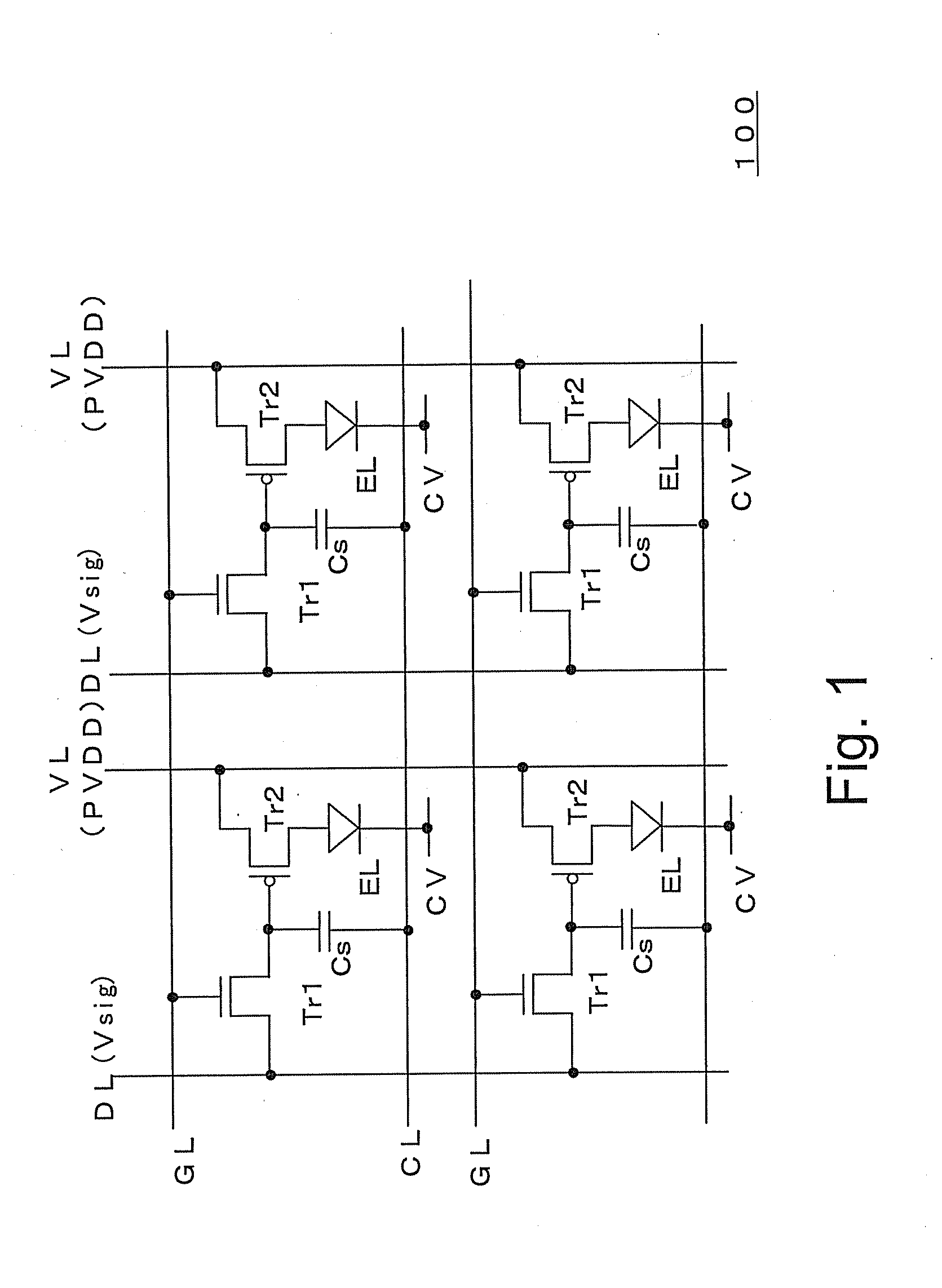

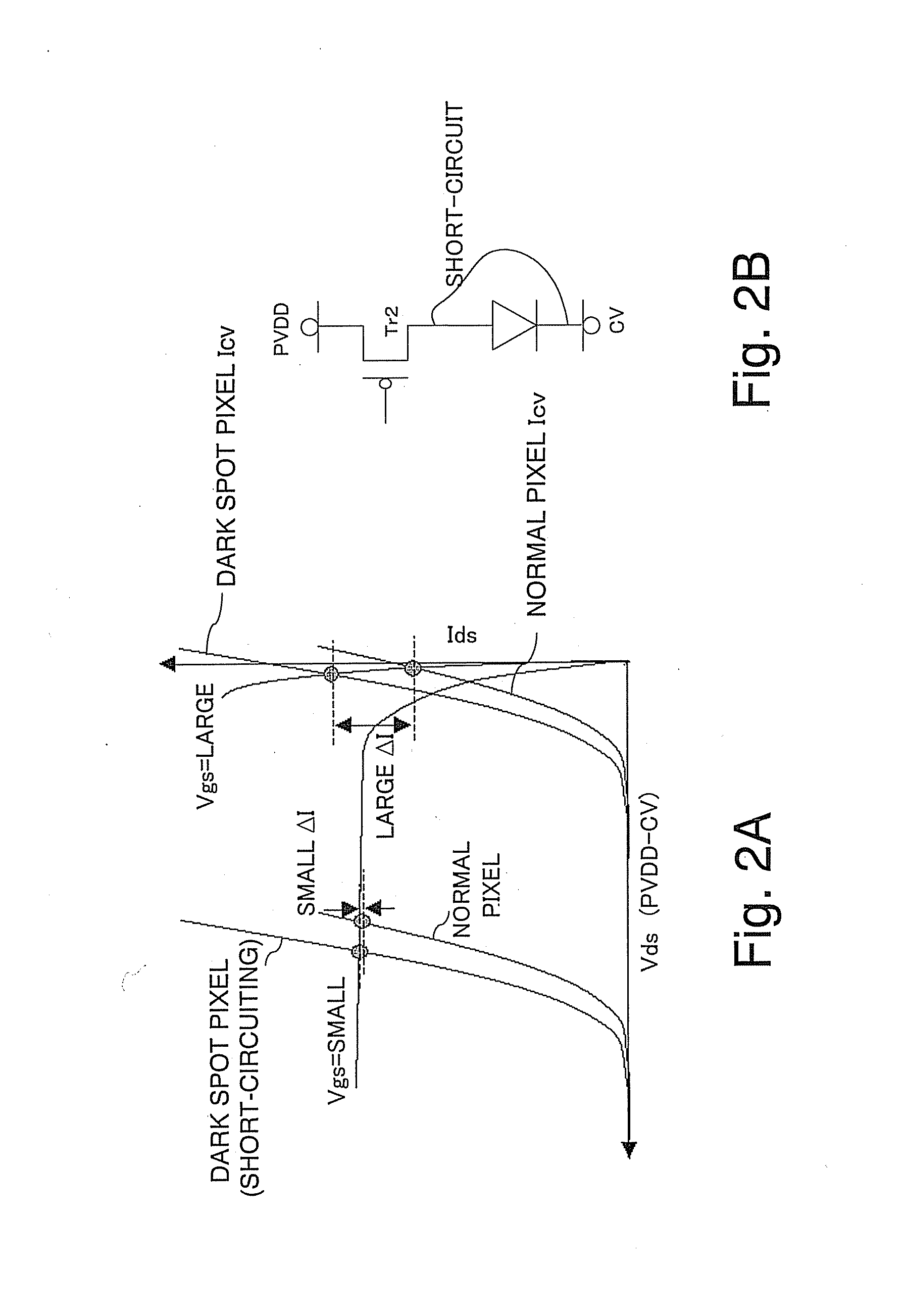

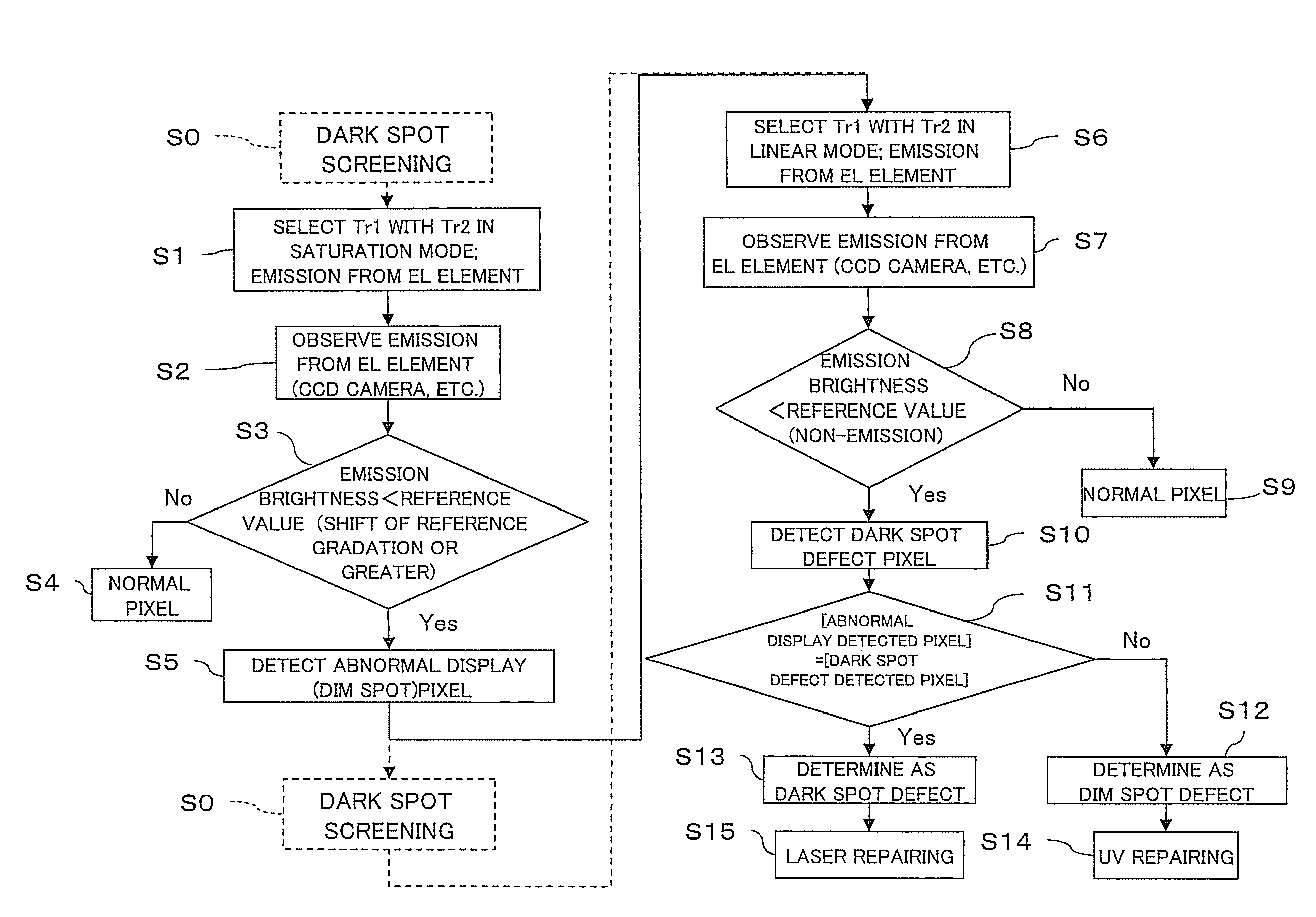

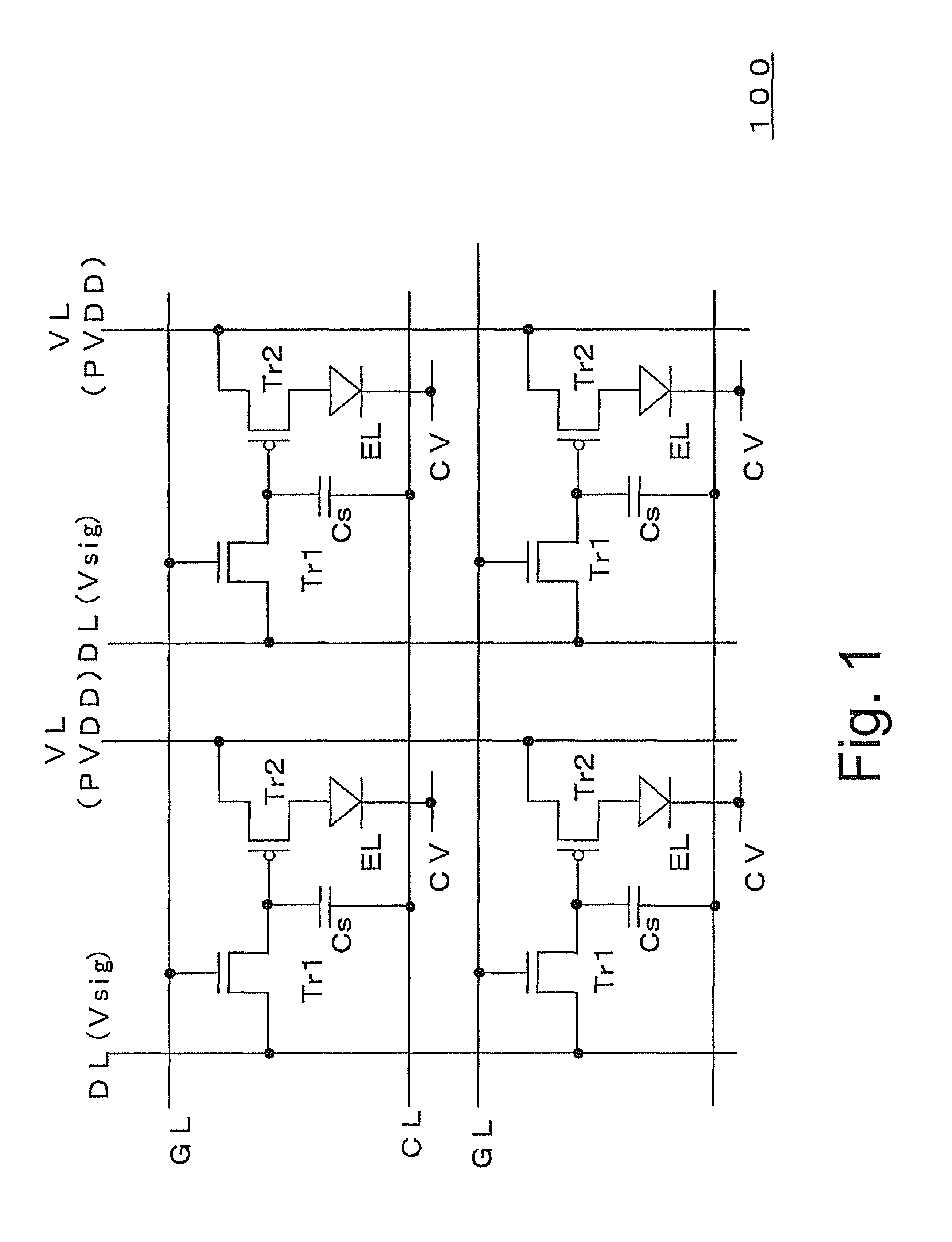

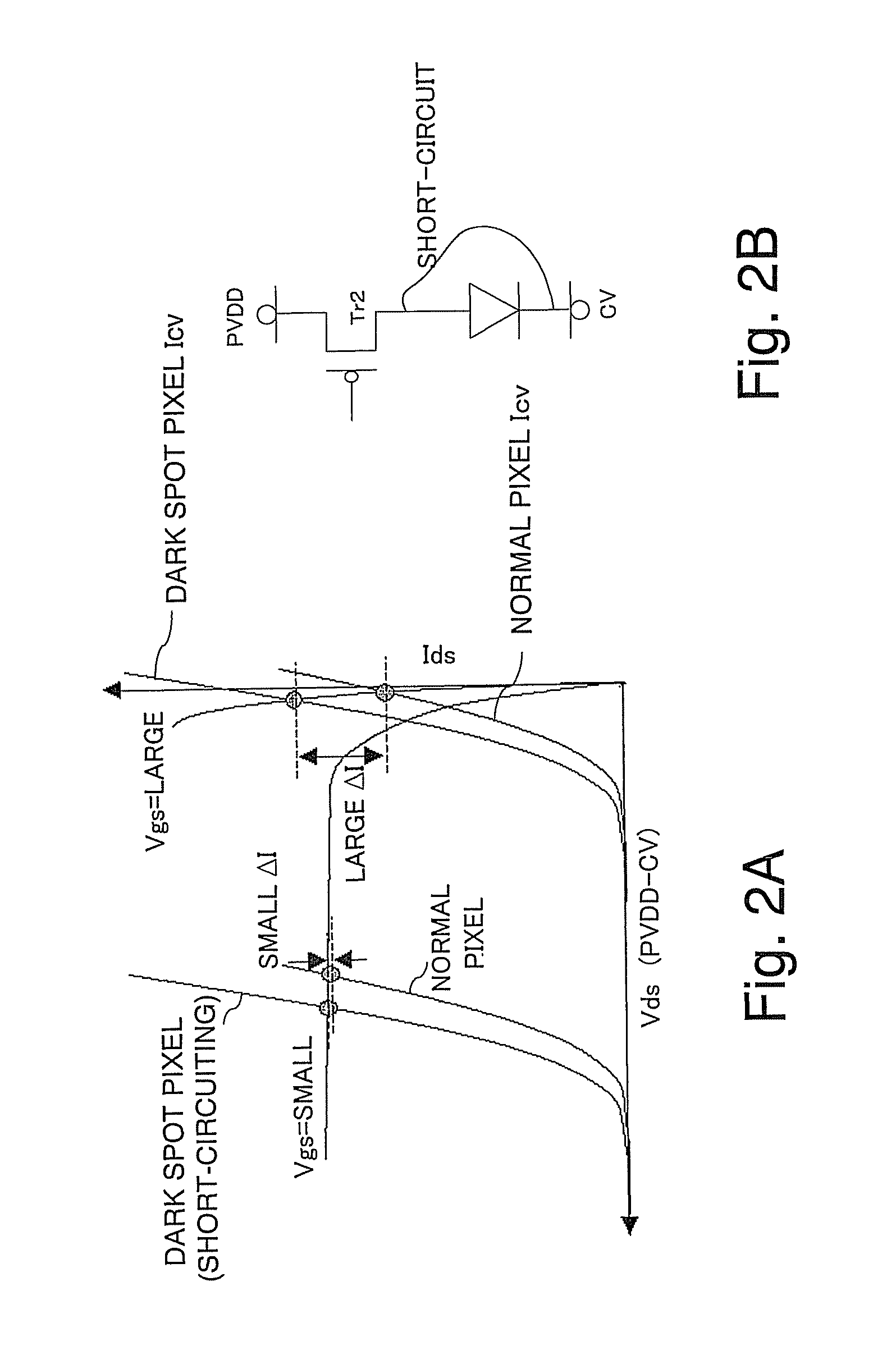

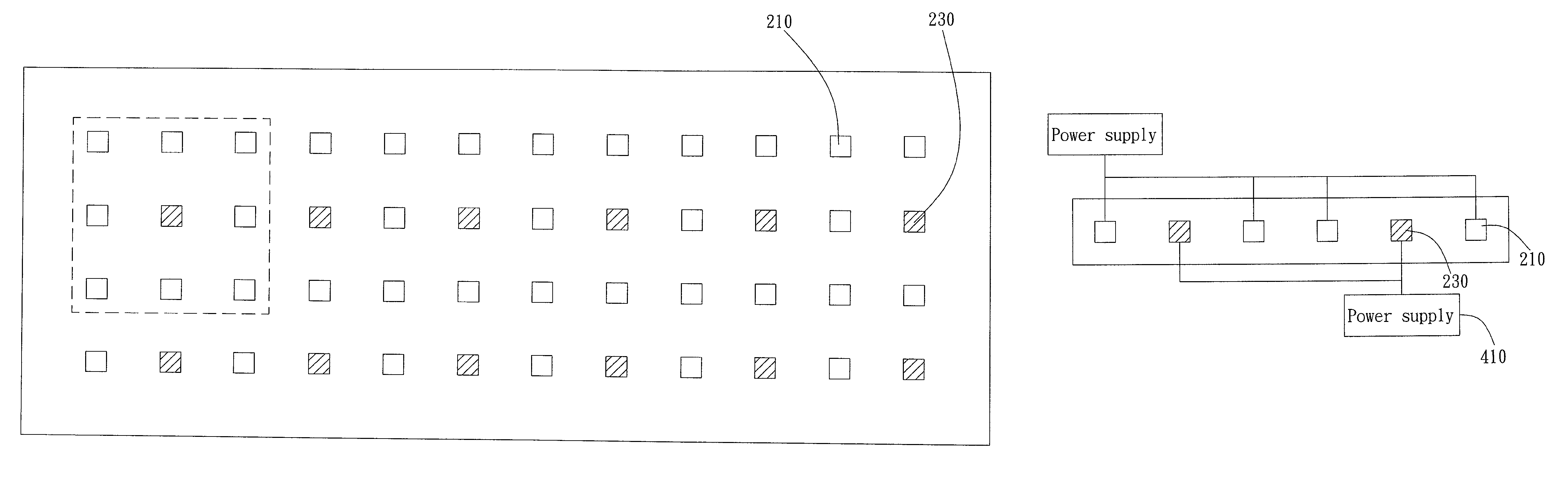

Method of inspecting defect for electroluminescence display apparatus, defect inspection apparatus, and method of manufacturing electroluminescence display apparatus using defect inspection method and apparatus

A dark spot defect caused by short-circuiting of an EL element is detected based on an emission brightness or a current flowing through the EL element when an element driving transistor which controls a drive current to be supplied to the EL element is operated in its linear operating region and the EL element is set to an emission level. A dim spot defect caused by a characteristic variation of the element driving transistor can be detected based on a current flowing through the EL element when the element driving transistor is operated in its saturation operating region and the EL element is set to the emission level. When an abnormal display pixel is detected based on an emission brightness, a pixel which is determined as an abnormal display pixel and which is not determined as a dark spot defect during a dark spot inspection is determined, and the pixel is detected as a dim spot defect caused by the characteristic variation of the element driving transistor.

Owner:SEMICON COMPONENTS IND LLC

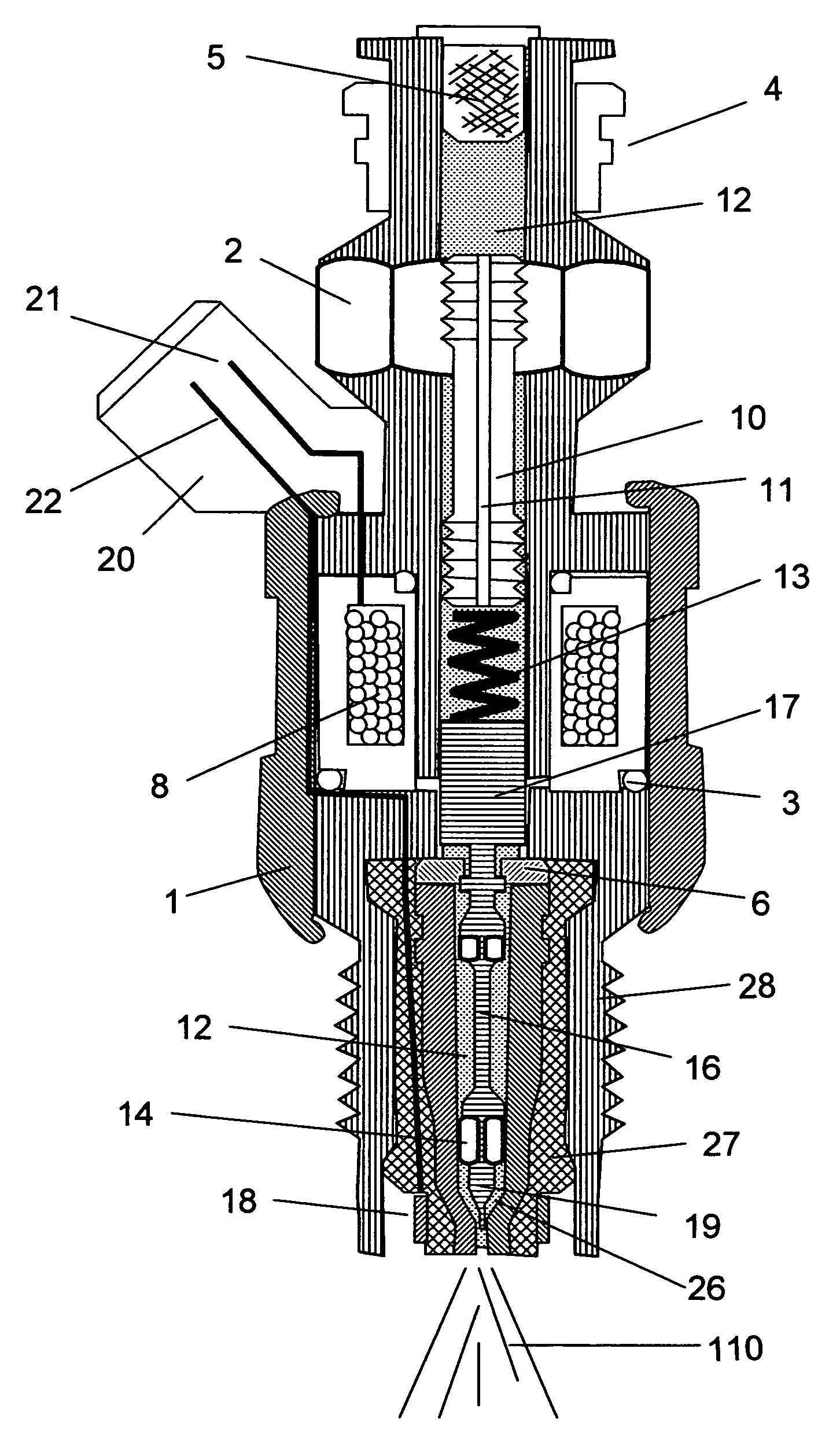

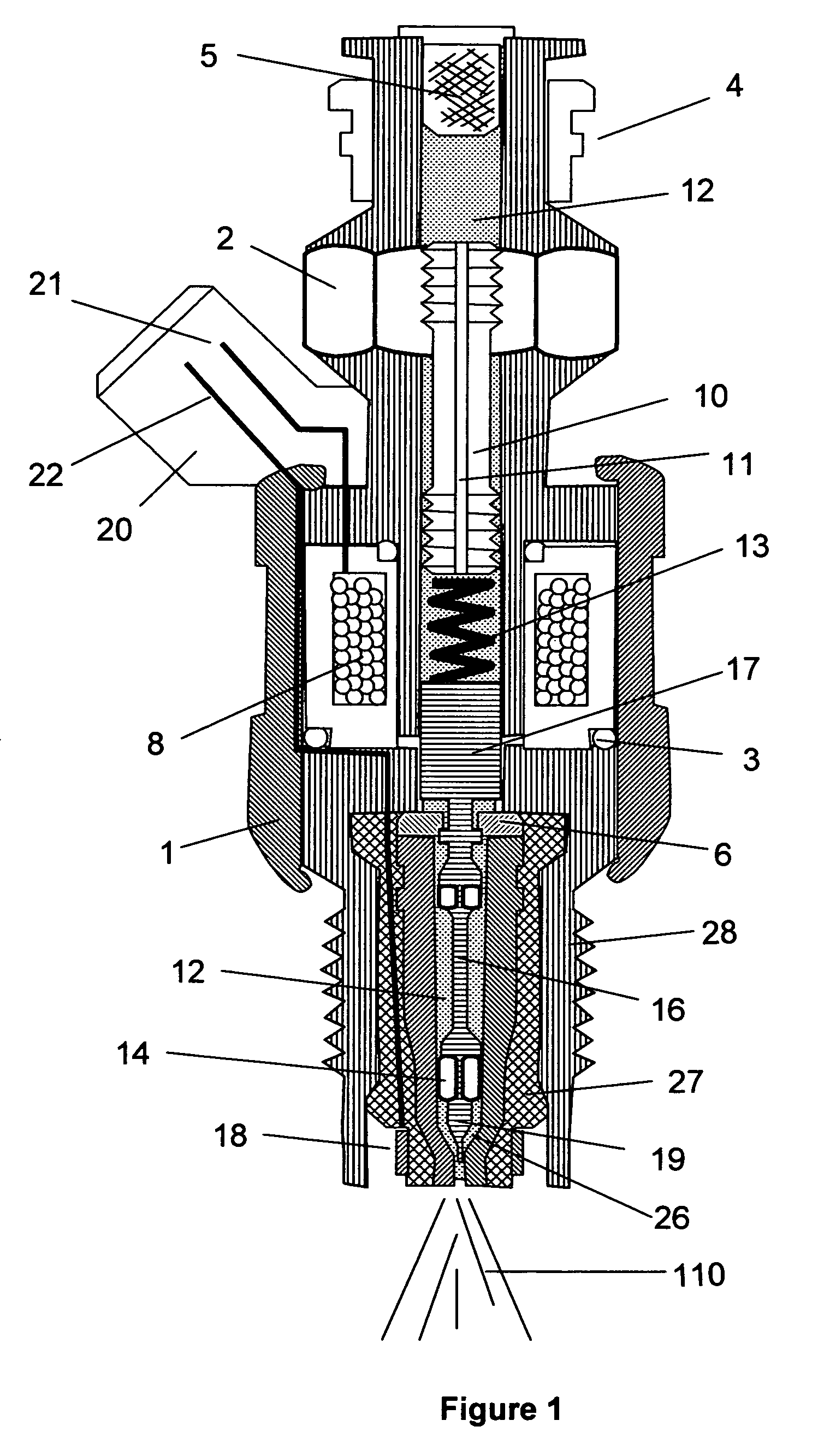

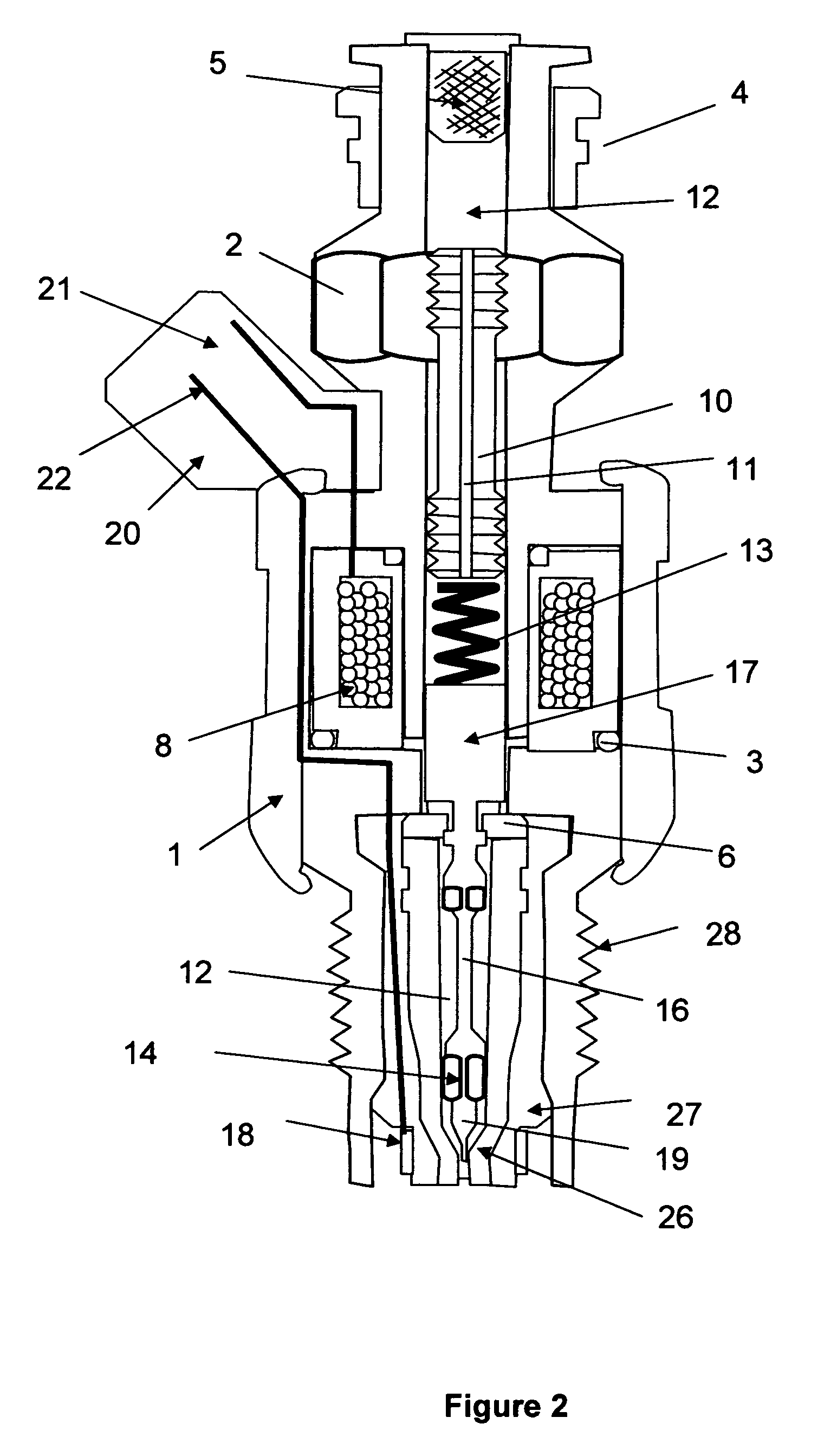

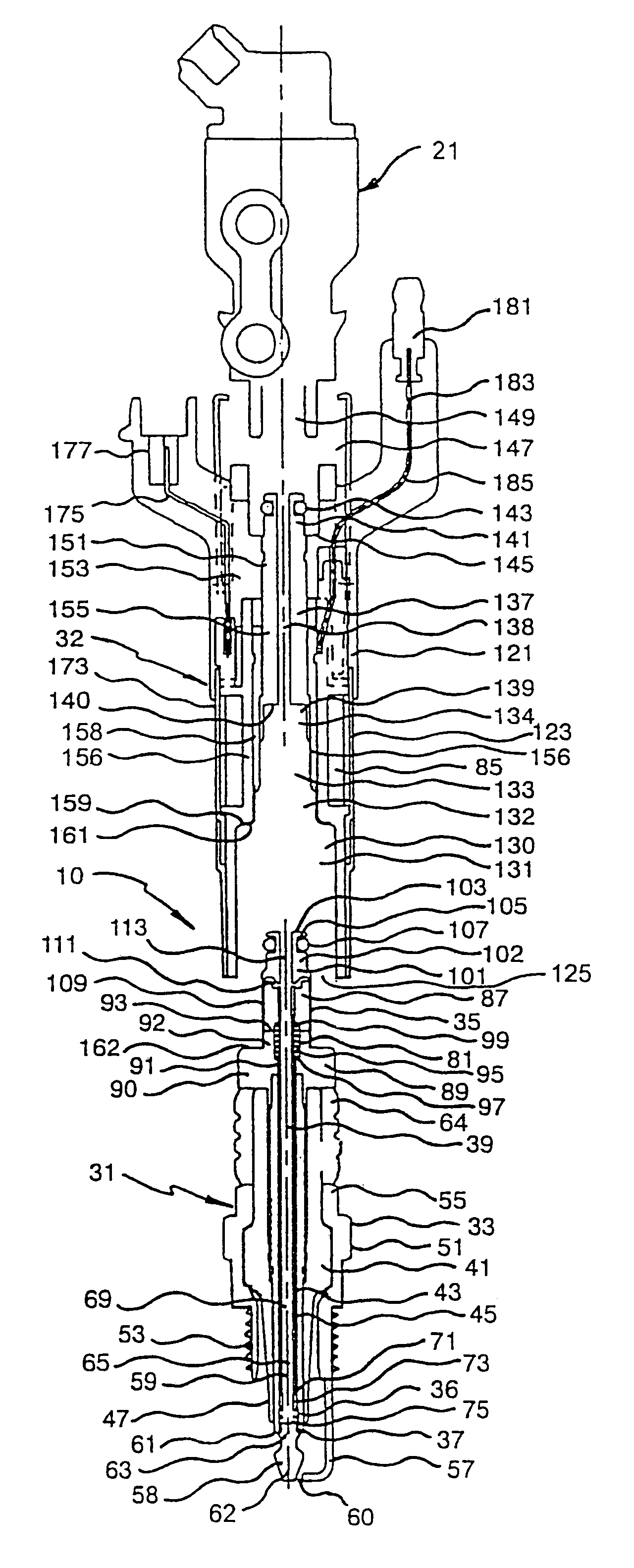

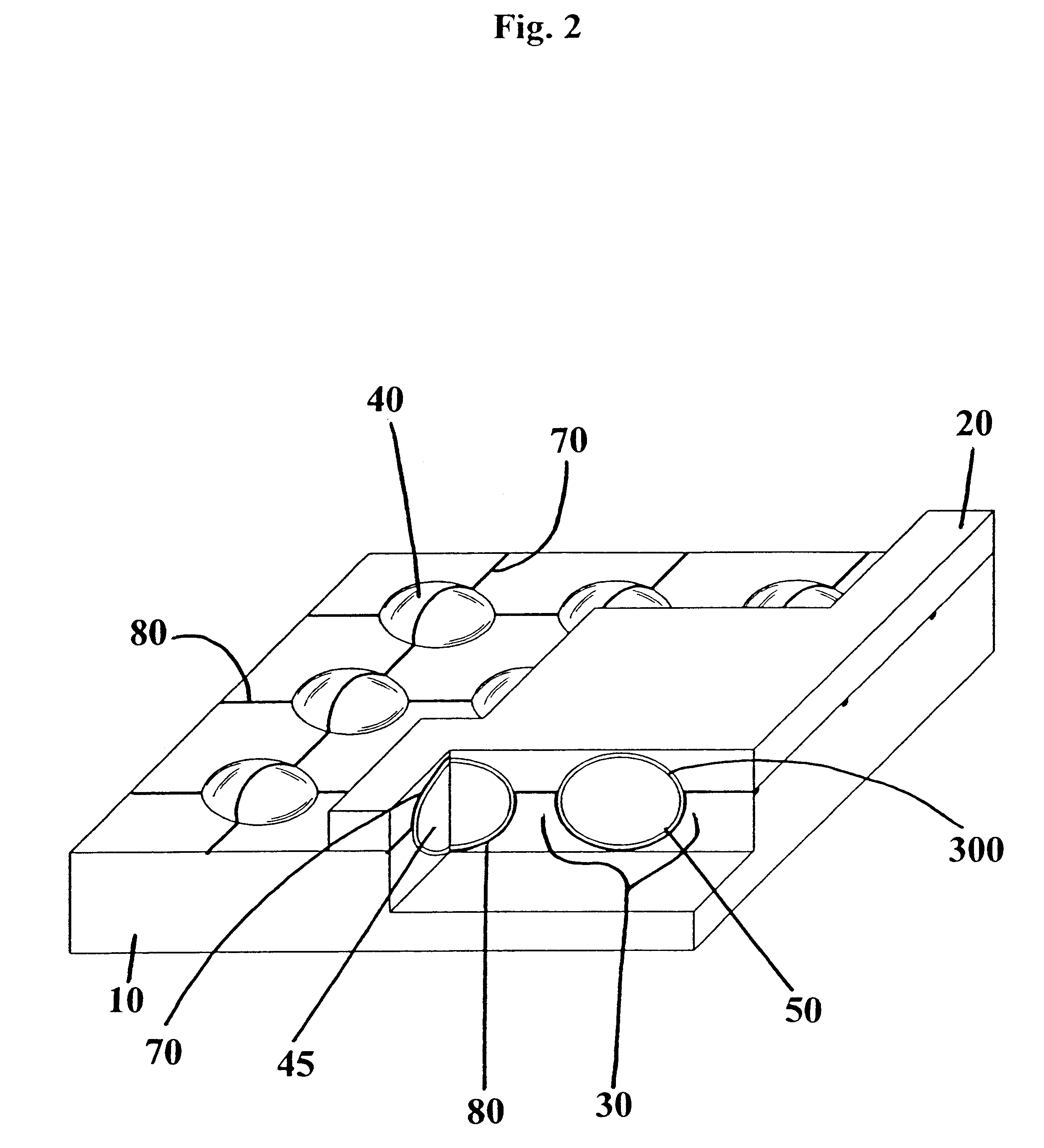

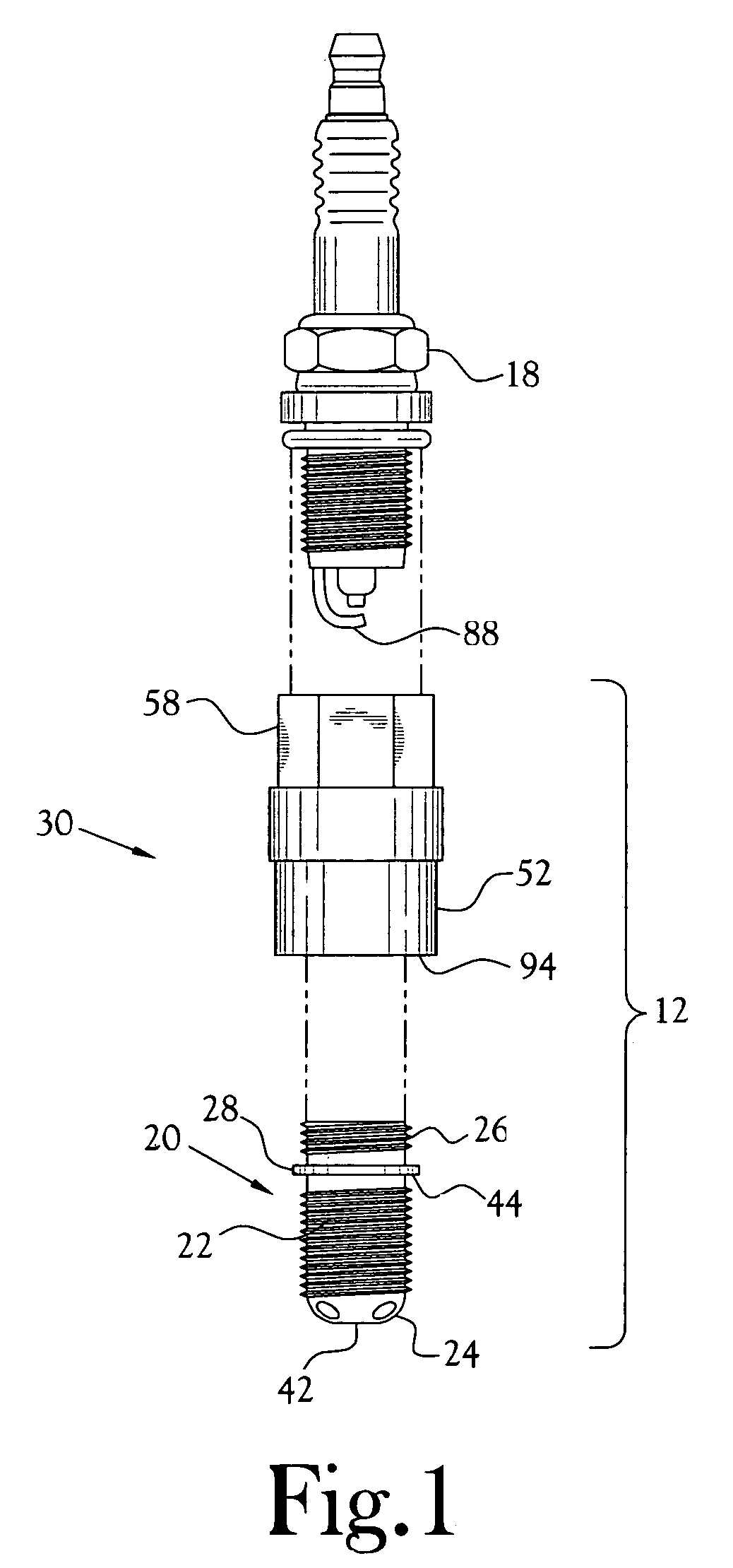

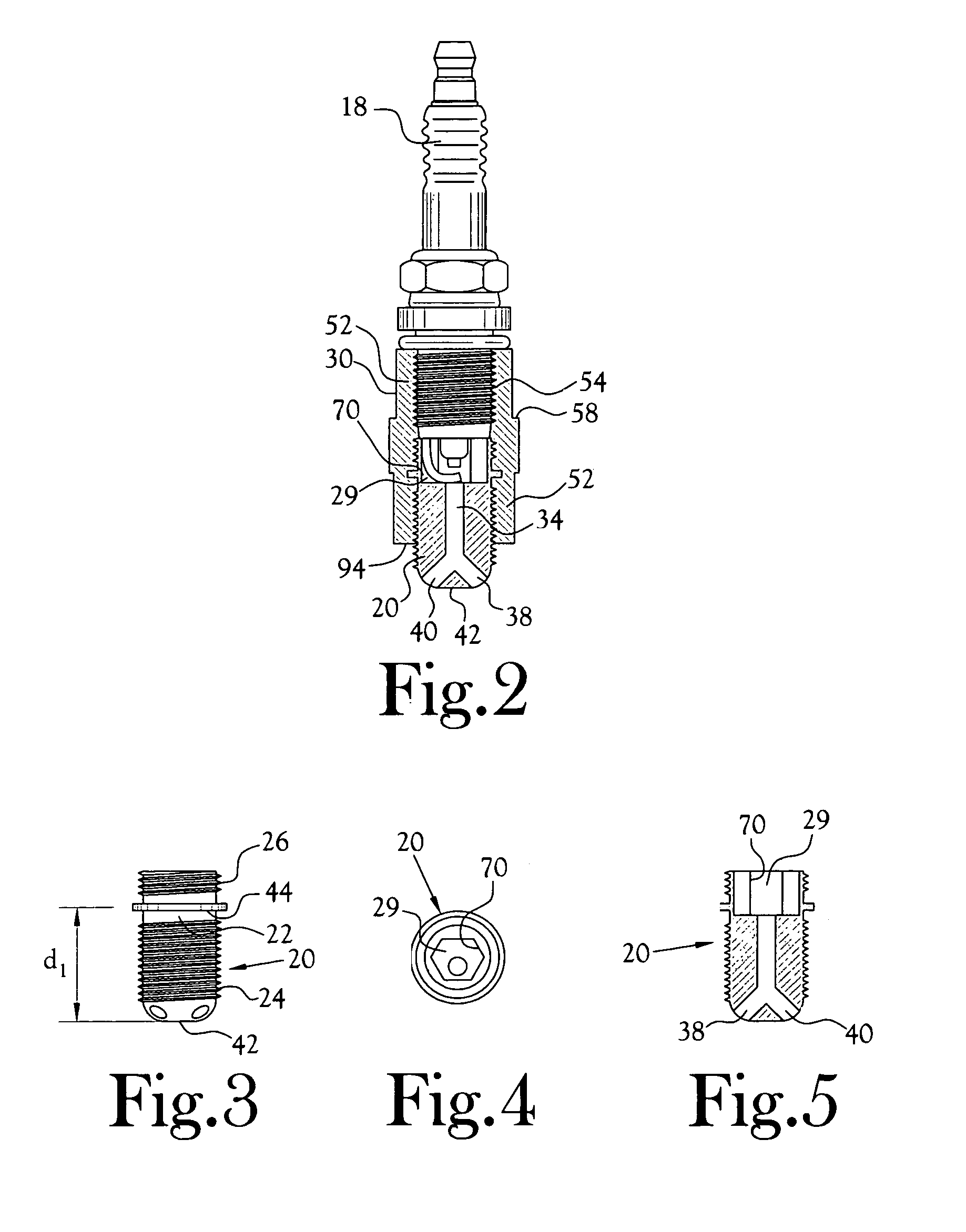

Fuel injector spark plug

InactiveUS6955154B1Eliminates excess fuel useRemove heatSparking plugsFuel injection apparatusCombustionEngineering

A spark plug and fuel injector combination. The spark plug has a central channel that funnels fuel into the lower portion of the spark plug, where it is superheated. A solenoid system causes a needle valve to rise up to allow a measured quantity of fuel to be injected into a cylinder through a nozzle, where it vaporizes upon exiting the spark plug. A spring releases the needle valve to close the nozzle. The spark plug also has an ignition ring on the base. The ignition ring produces an encompassing spark, which produces complete combustion of the vaporized fuel. This produces more power and better fuel economy.

Owner:DOUGLAS DENIS

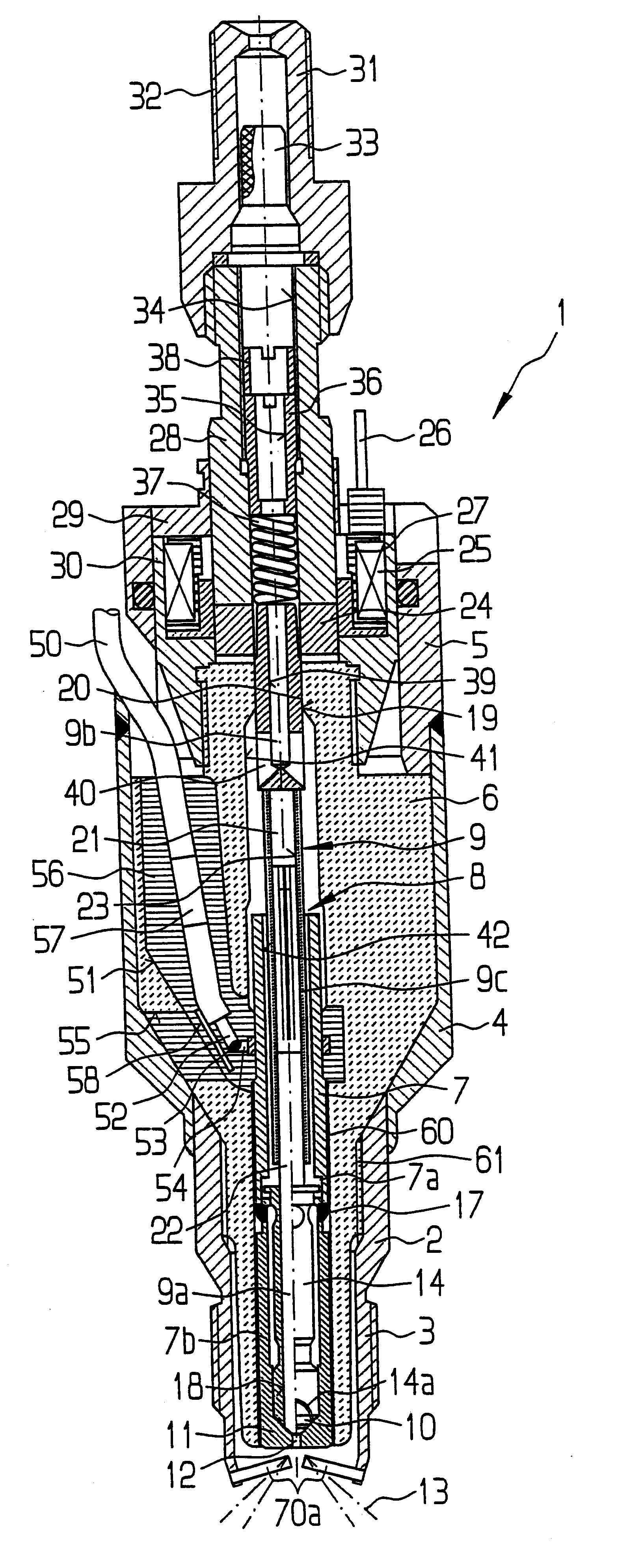

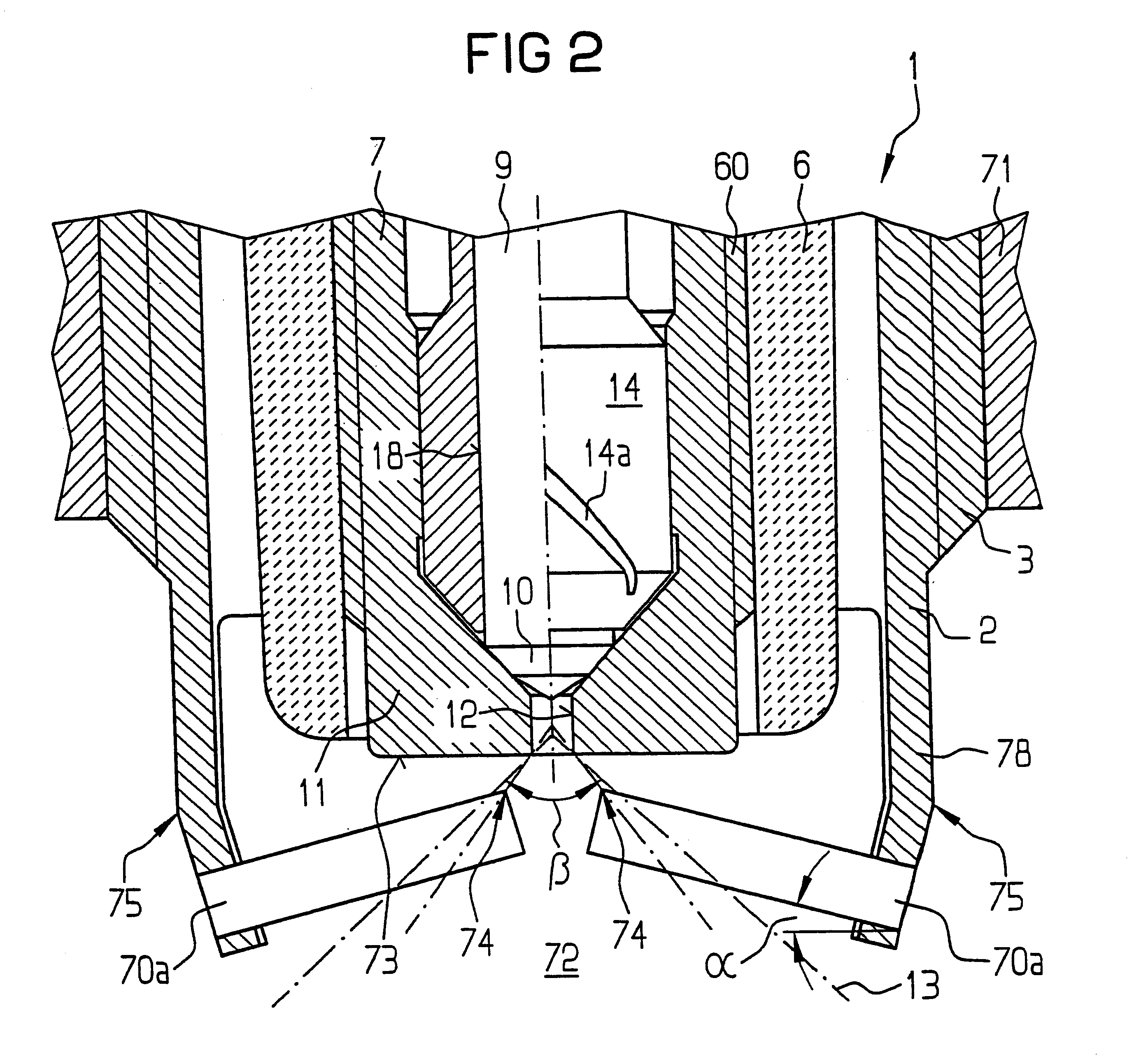

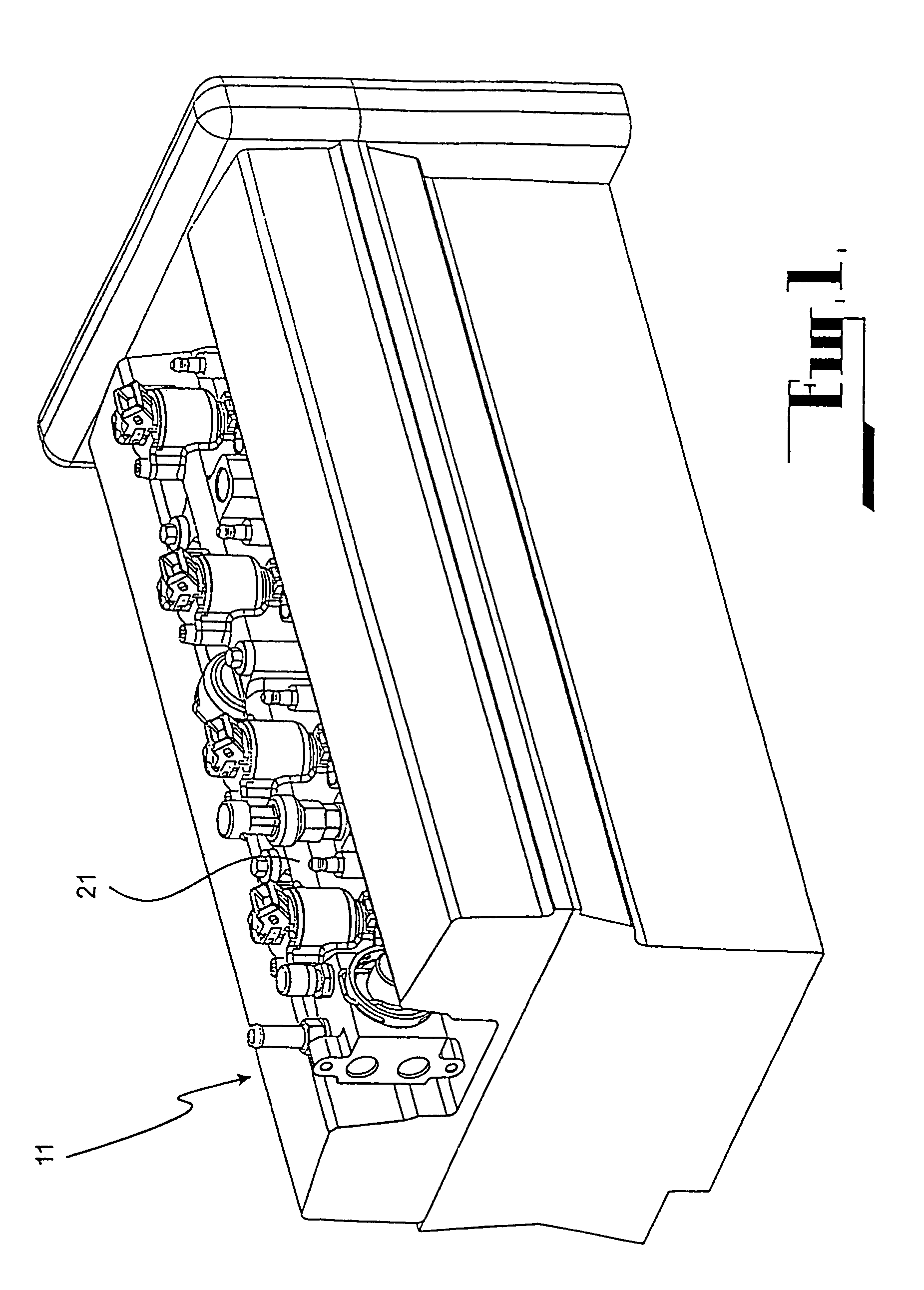

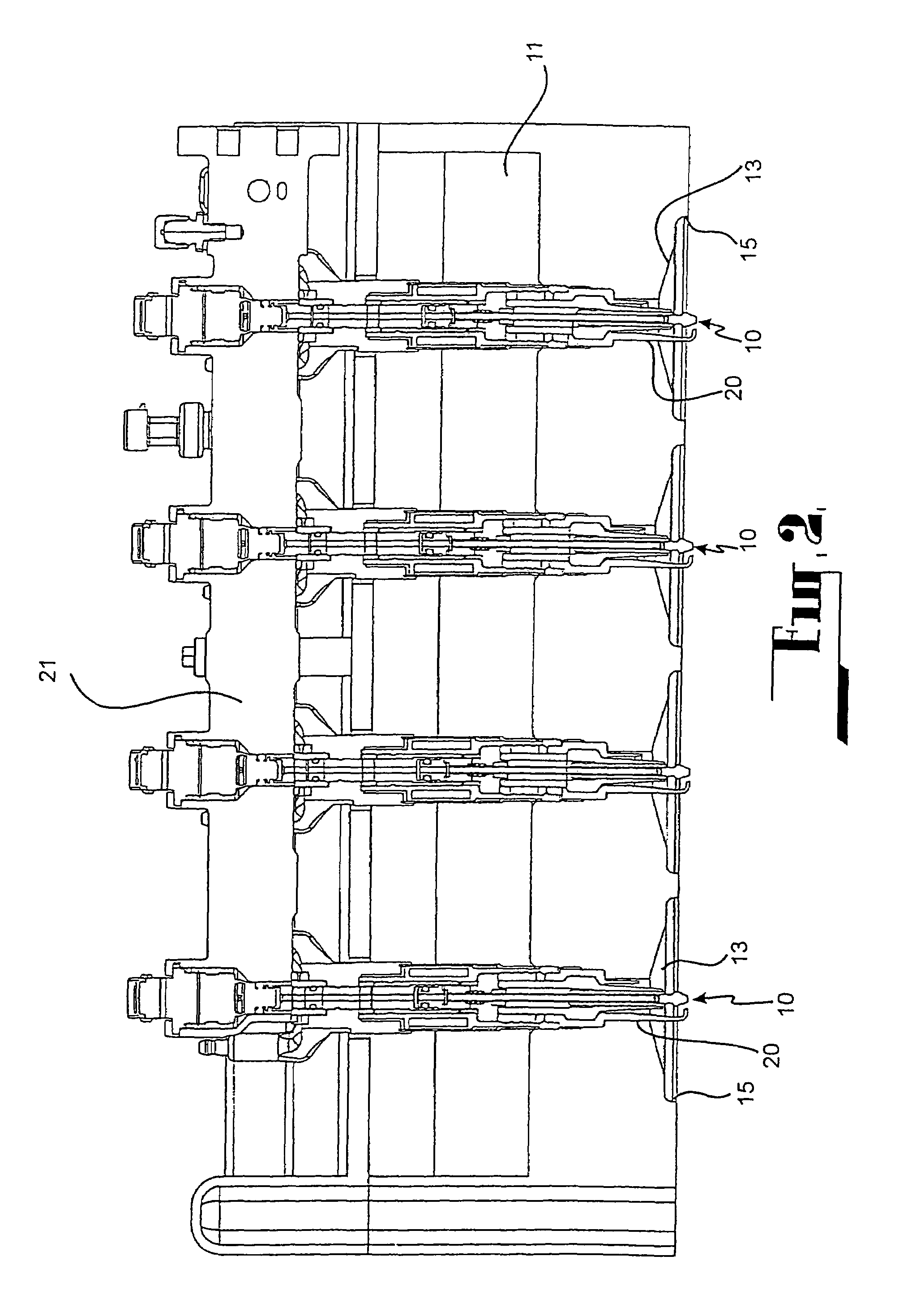

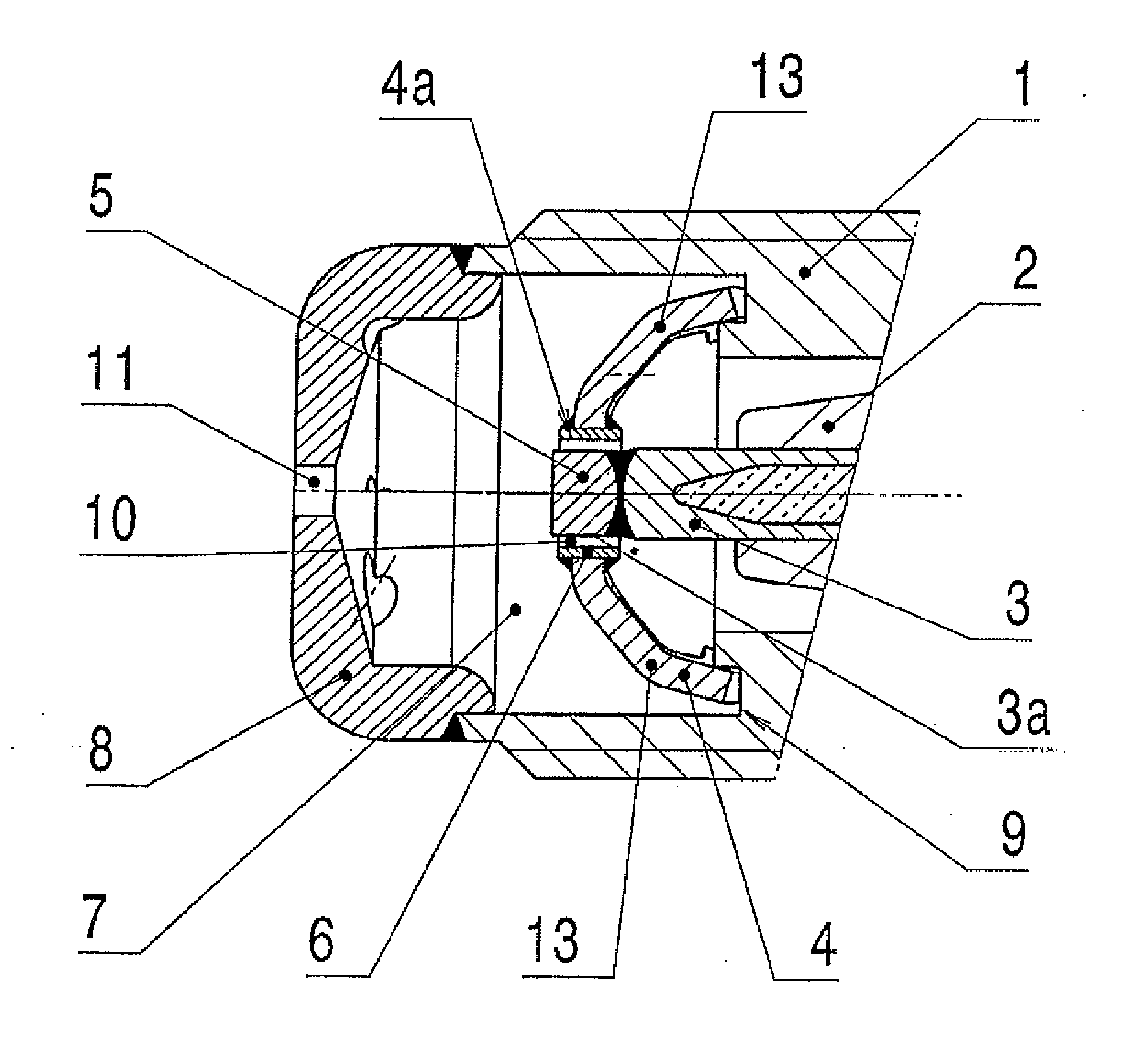

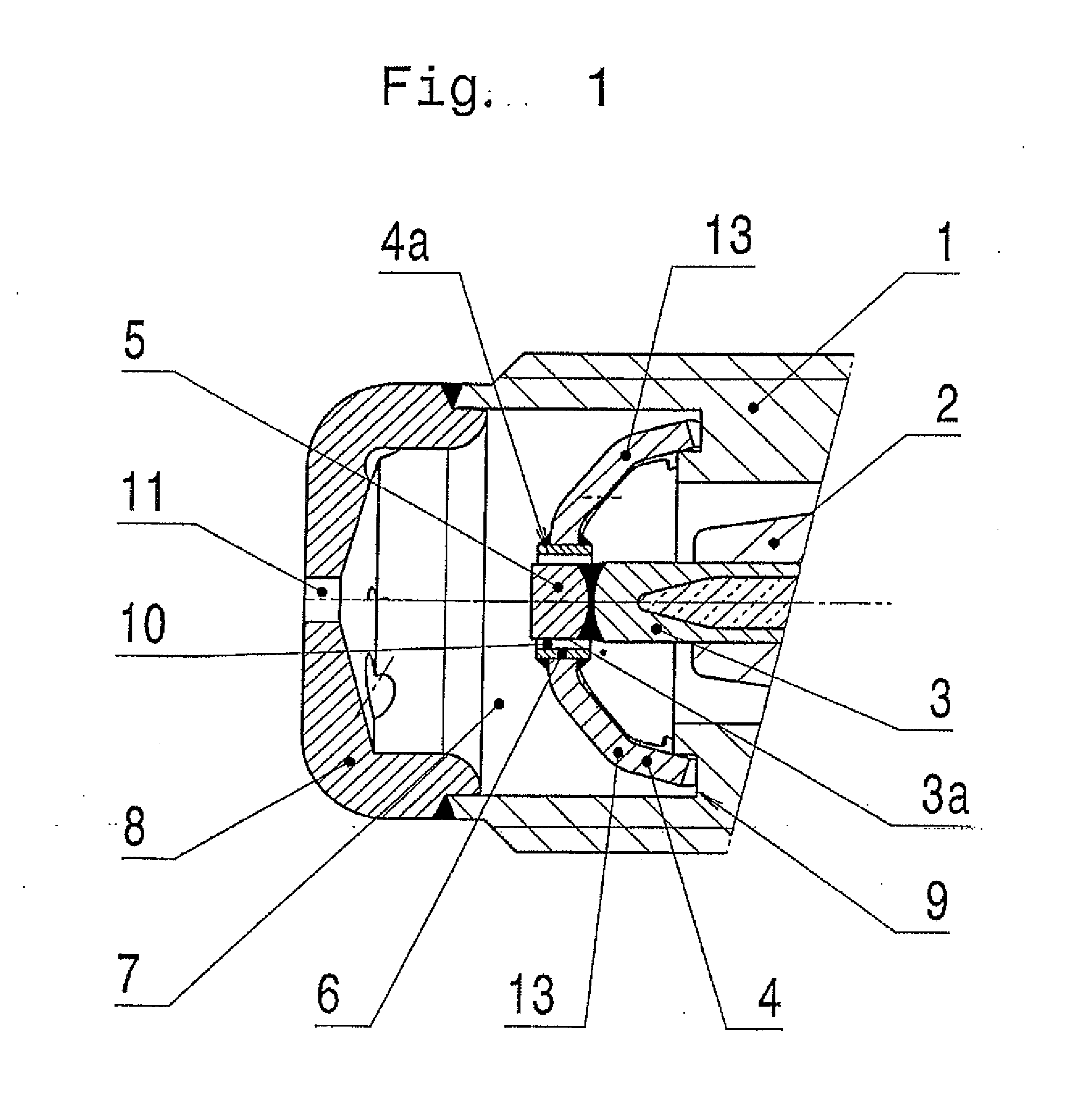

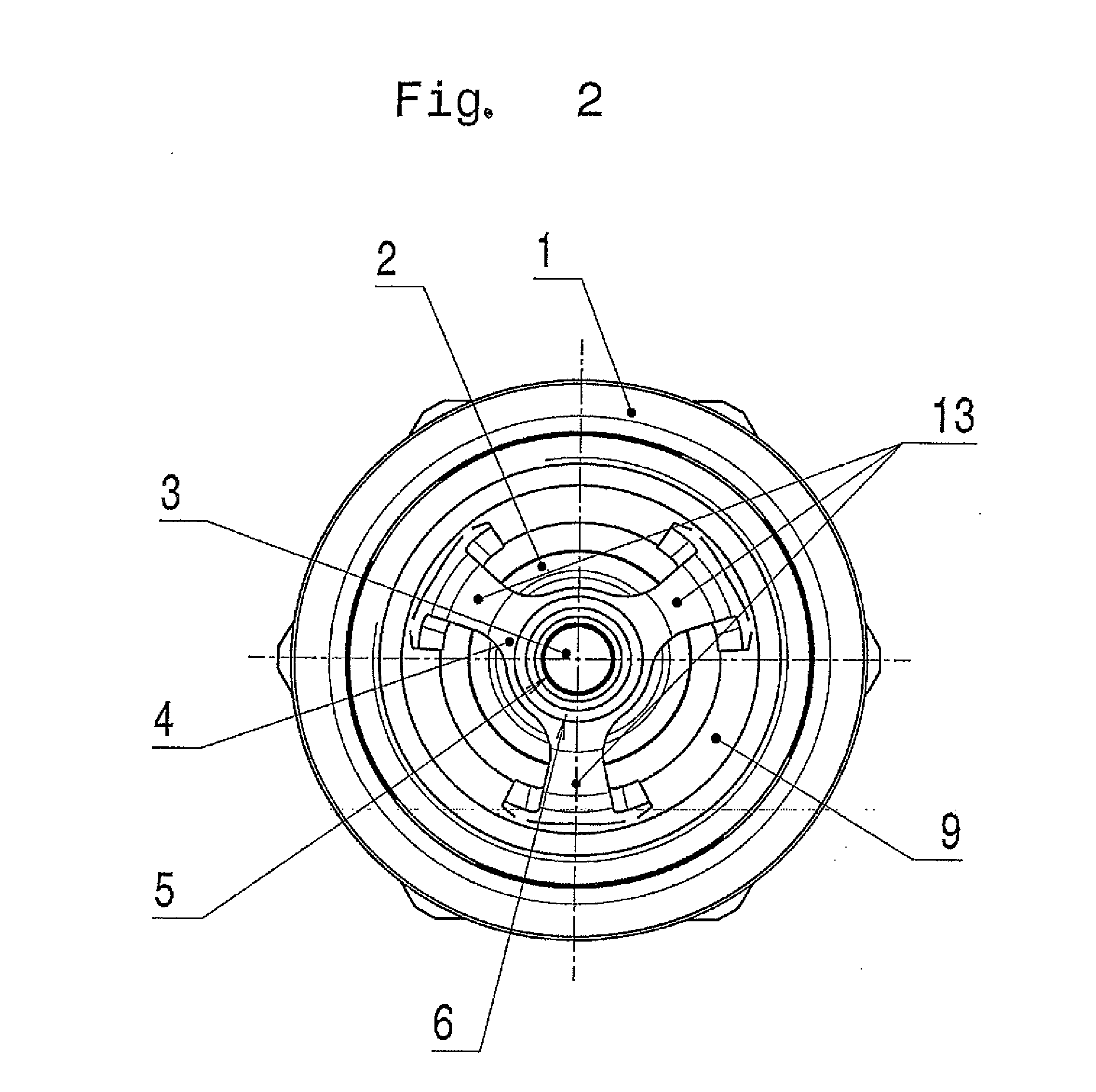

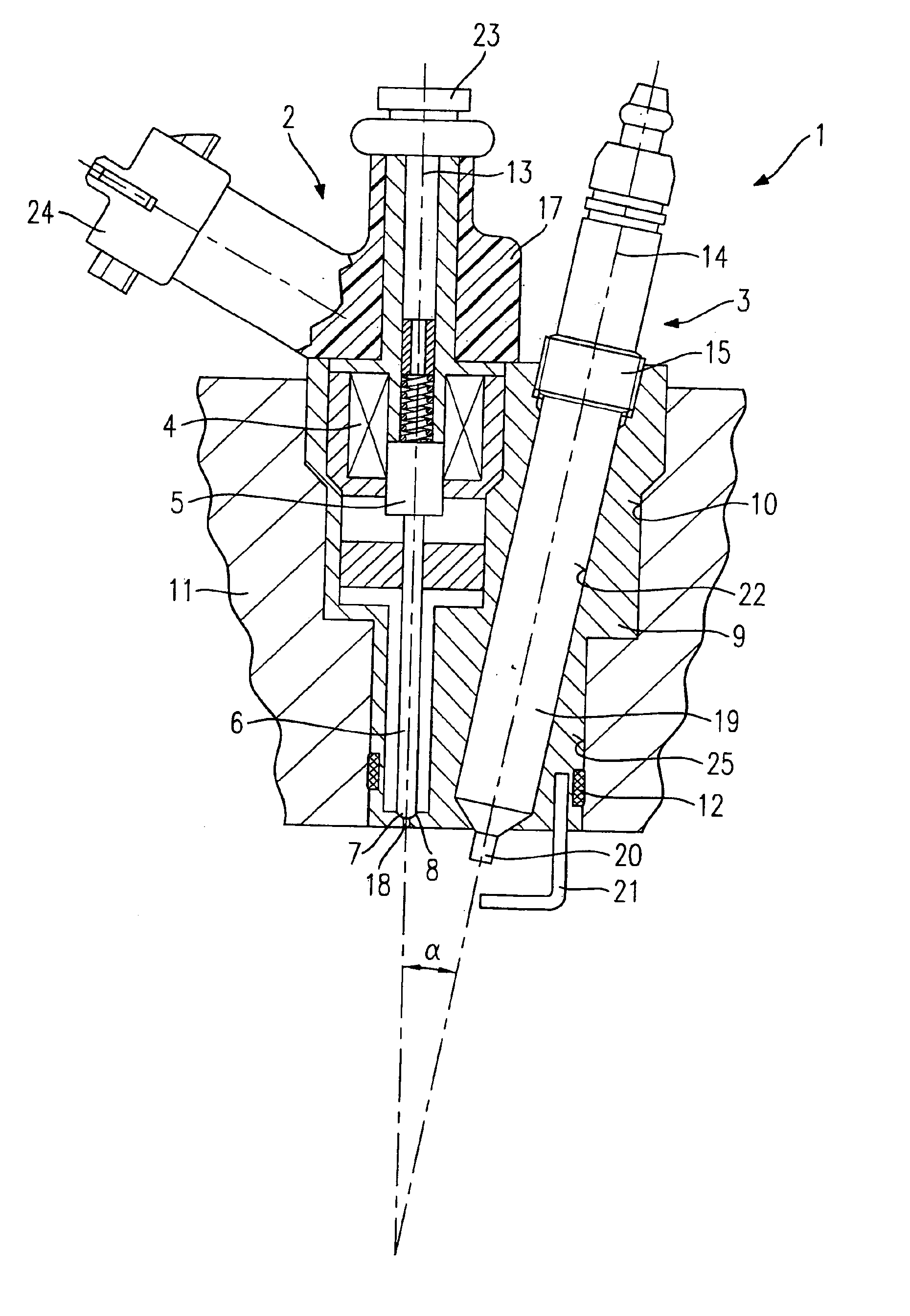

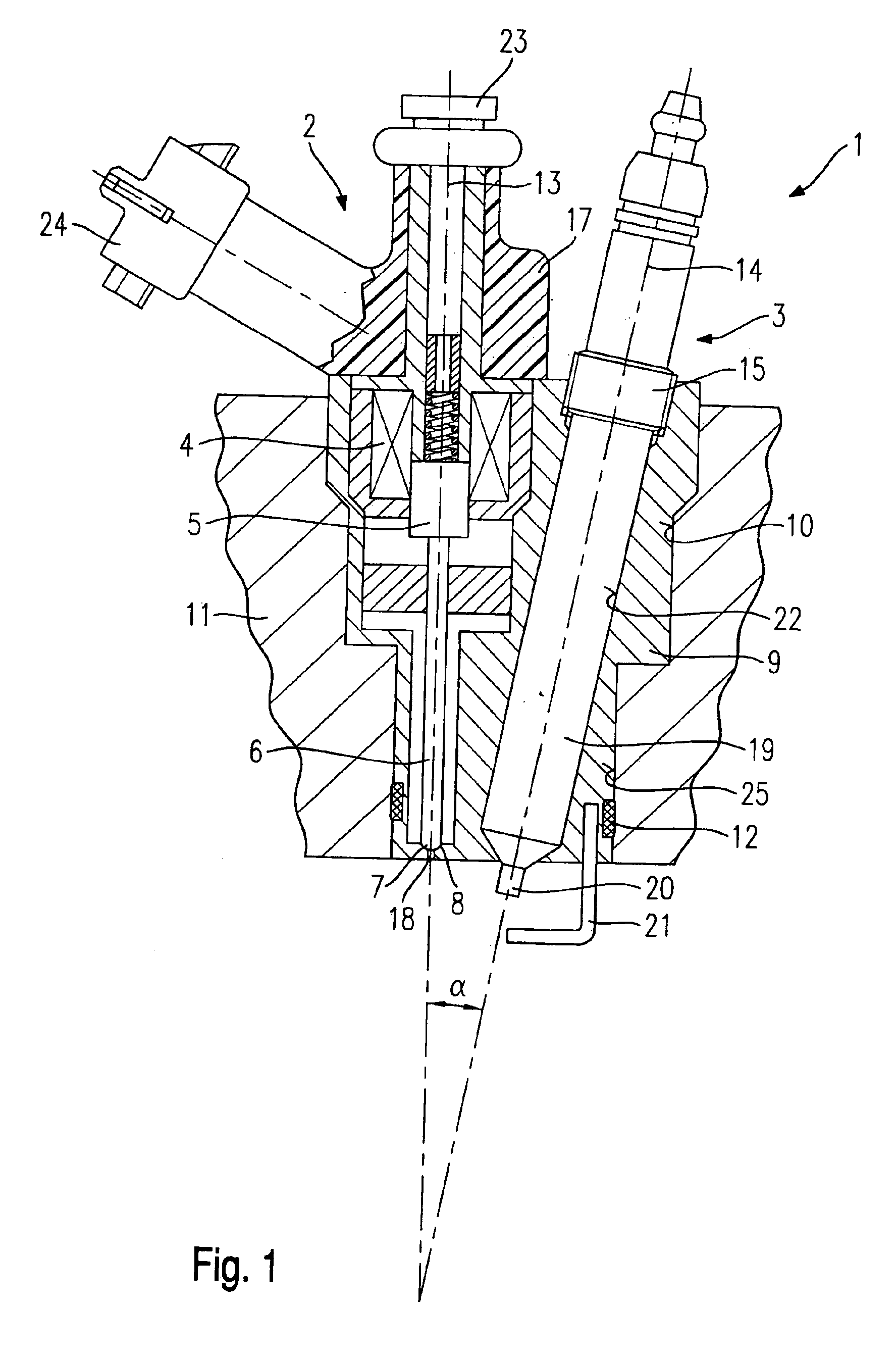

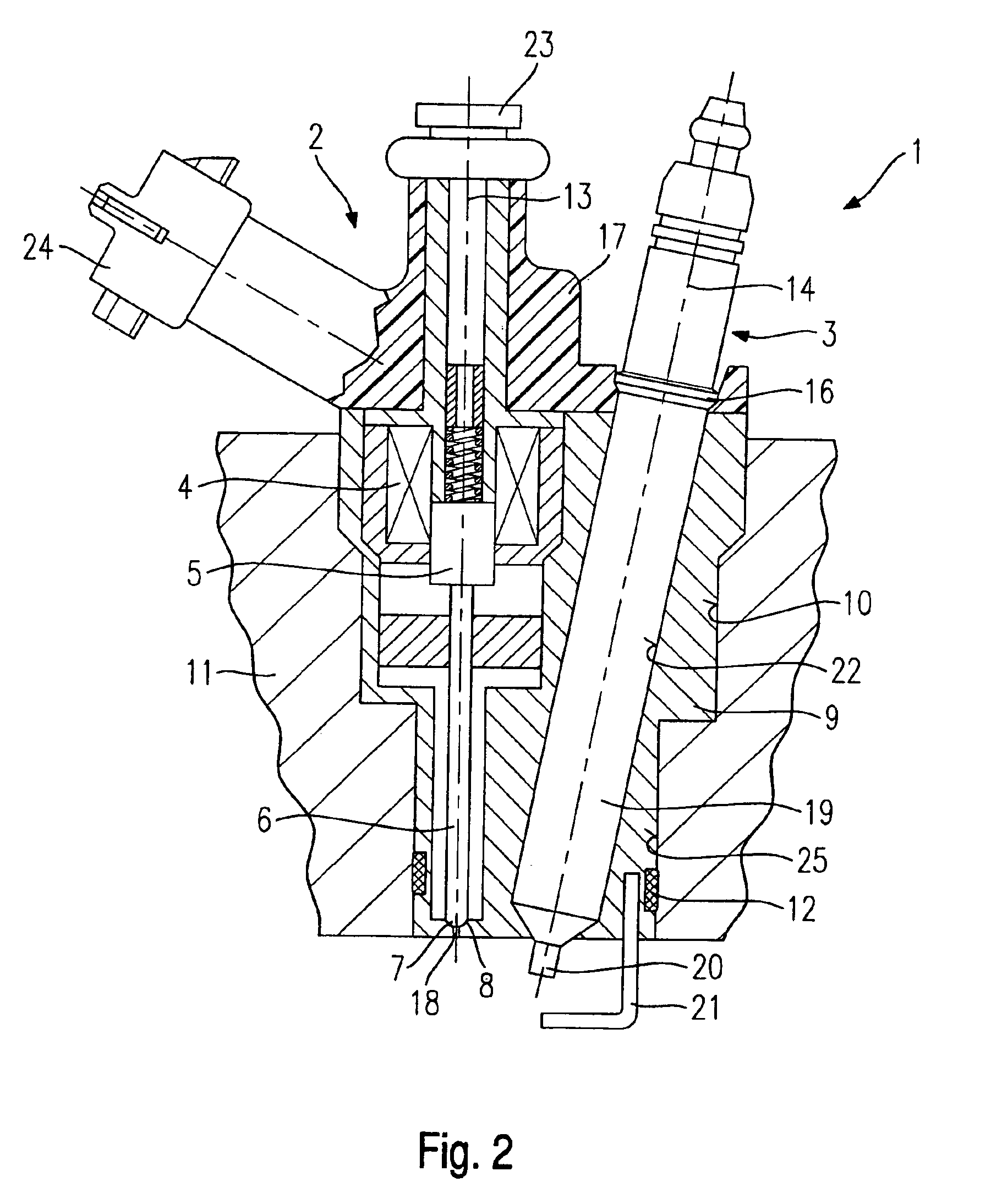

Fuel injection valve with integrated spark plug

A fuel injector having an integrated spark plug (1) for injecting fuel directly into a combustion chamber (72) of an internal combustion engine and for igniting the fuel that is injected into the combustion chamber (72) has a valve body (7), which, together with a valve-closure member (10), forms a sealing seat. Disposed contiguously to the sealing seat is a discharge orifice (12), which discharges at a valve-body (7) end face (73) facing the combustion chamber (72). Provision is also made for a housing body (2) that is insulated from the valve body (7), and for an ignition electrode (70a) that is connected to the housing body (2). In this context, a spark arc-over is produced between the valve body (7) and the ignition electrode (70a). The ignition electrode (70a) and the valve body (7) are formed in such a way that the spark arc-over takes place between the end face (73) of the valve body (7) facing the combustion chamber (72) and the ignition electrode (70a). In the vicinity of the discharge orifice (12), the ignition electrode (70a) has an edge (74) in order to reproducibly define the position of the spark arc-over at the end face (73) of the valve body (7) with respect to the position of the discharge orifice (12).

Owner:ROBERT BOSCH GMBH

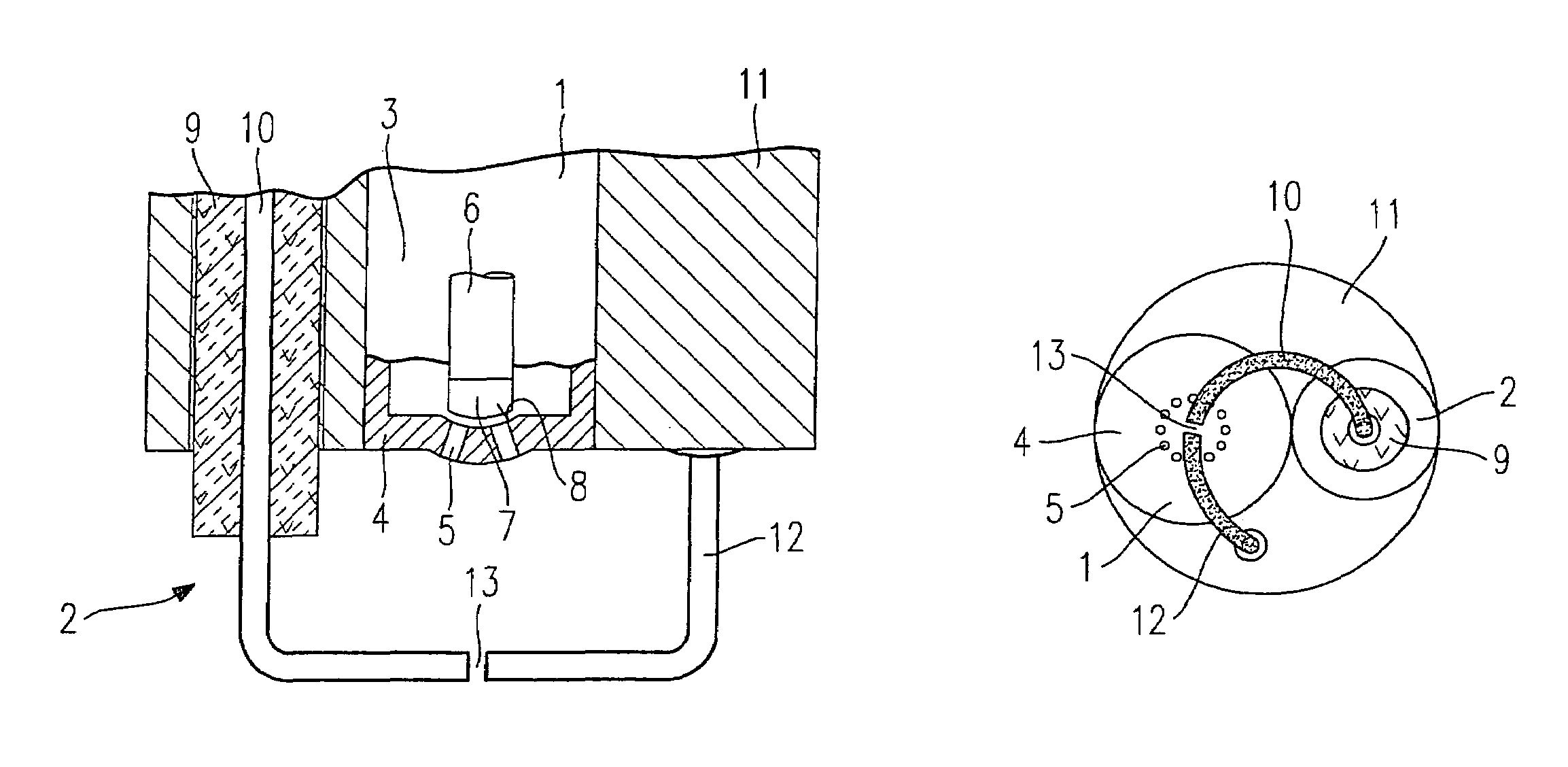

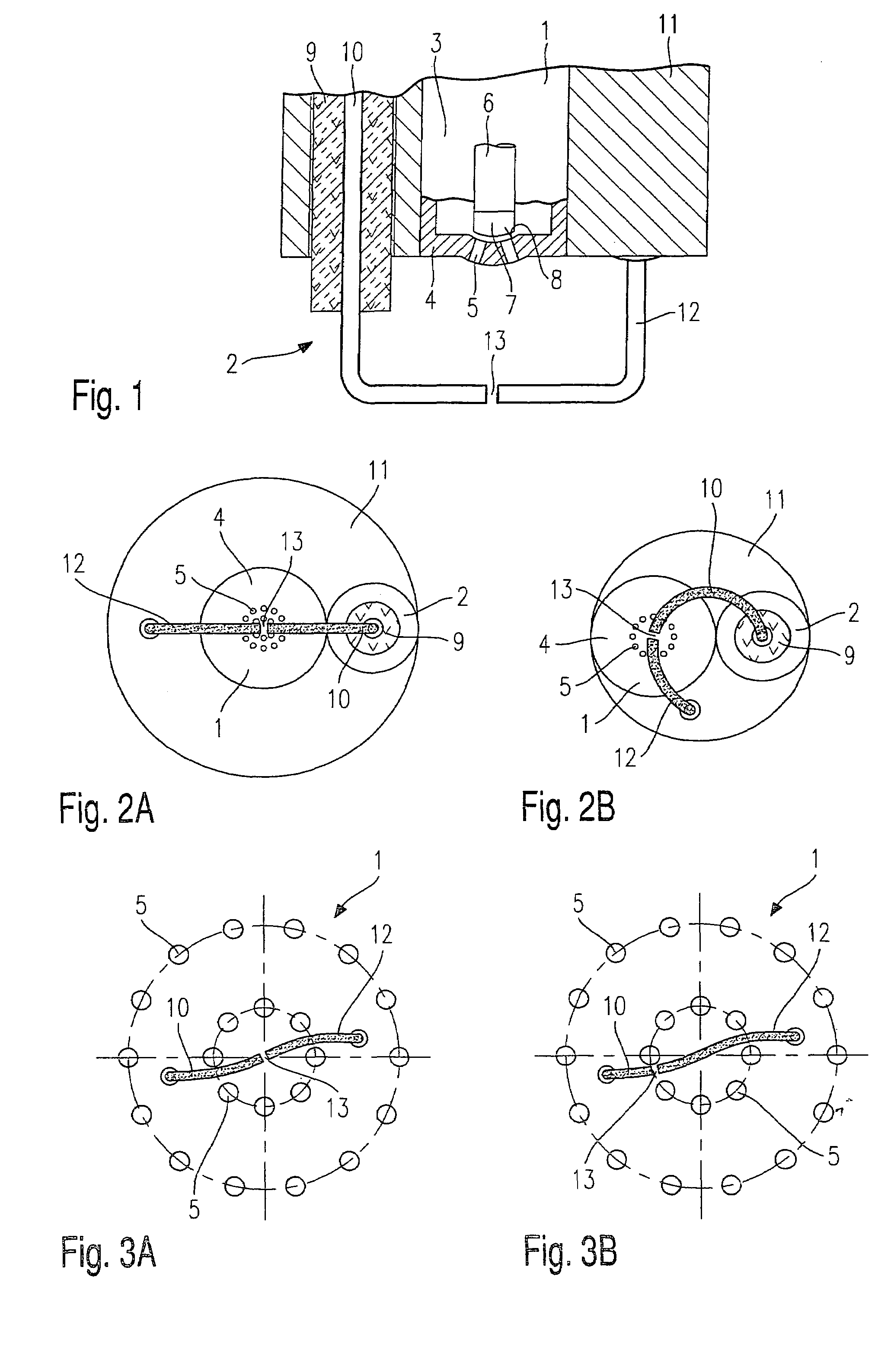

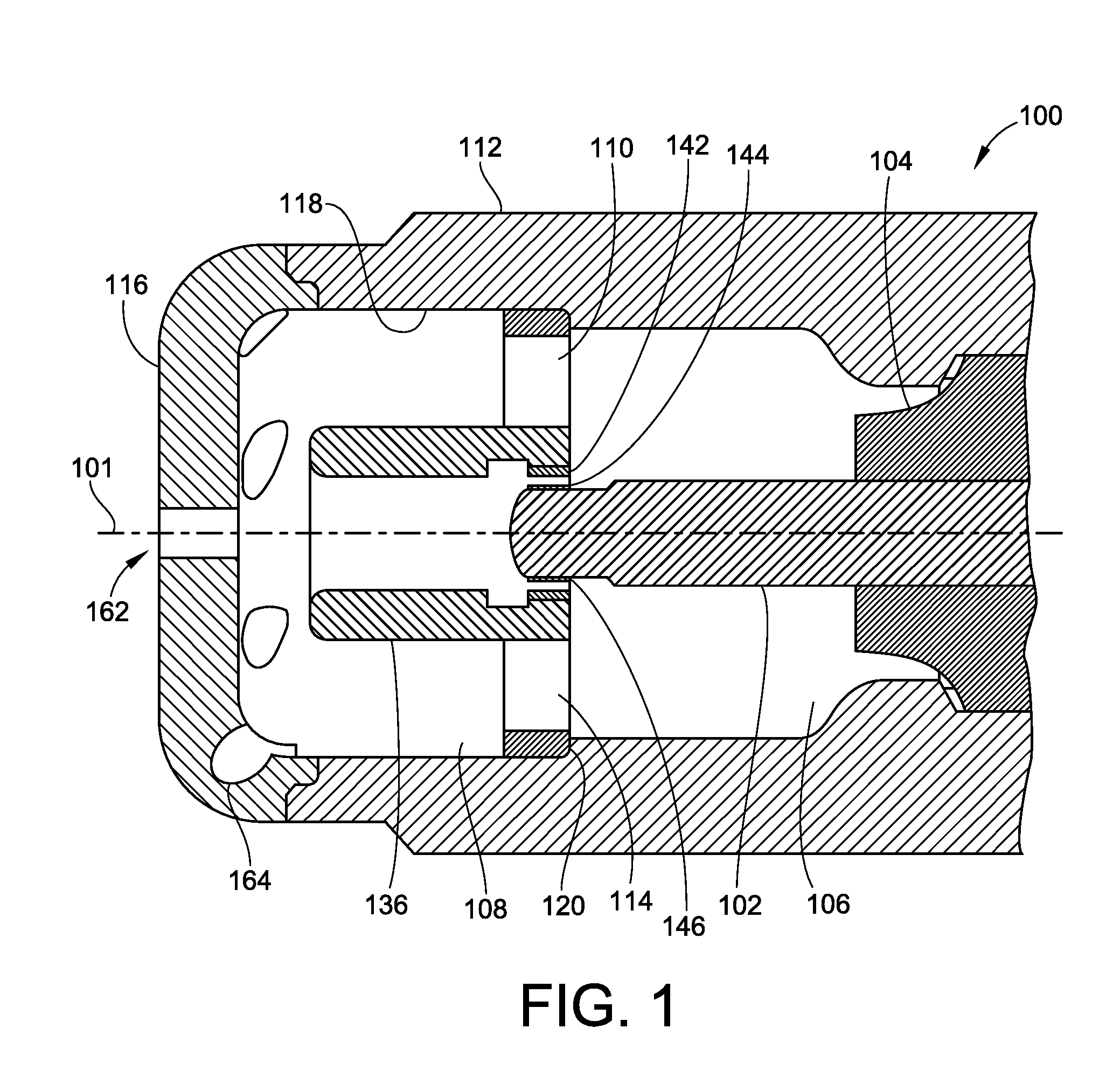

Combined fuel injection valve-ignition plug

InactiveUS7077100B2Sparking plugsFuel injection apparatusCombustion chamberInternal combustion engine

A fuel injector having an integrated spark plug is provided, the fuel injector providing direct injection of fuel into a combustion chamber of an internal combustion engine, and the spark plug for igniting the fuel injected into the combustion chamber. Also provided is a spark-plug insulator that insulates a first electrode and a second electrode which is set apart from the first electrode by a spark gap, the fuel injector and the spark-plug insulator of the spark plug being arranged in a shared housing. The spark gap has a width of 50 to 300 μm and is disposed in front of the fuel injector at a distance of 3 to 10 mm.

Owner:ROBERT BOSCH GMBH

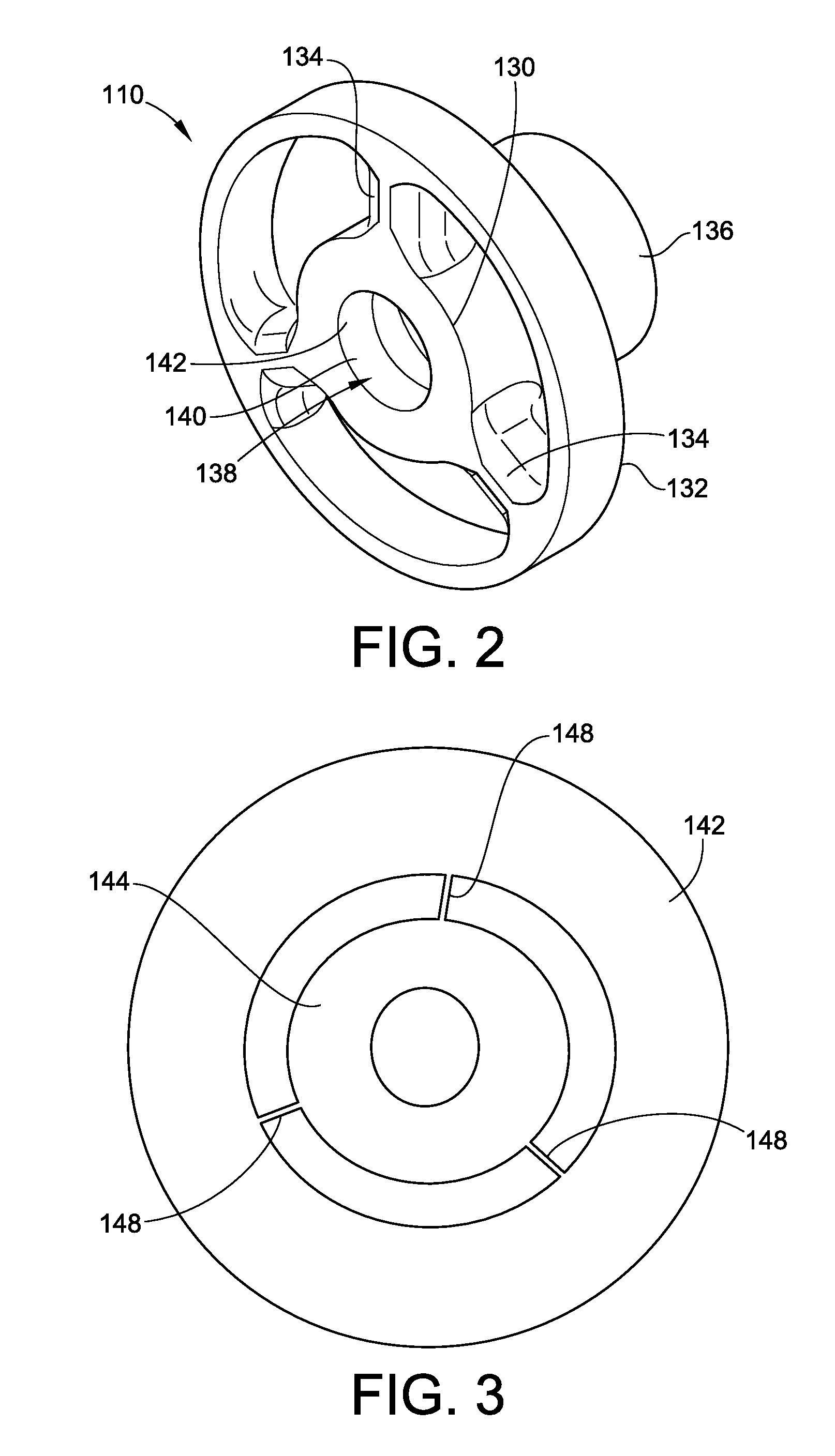

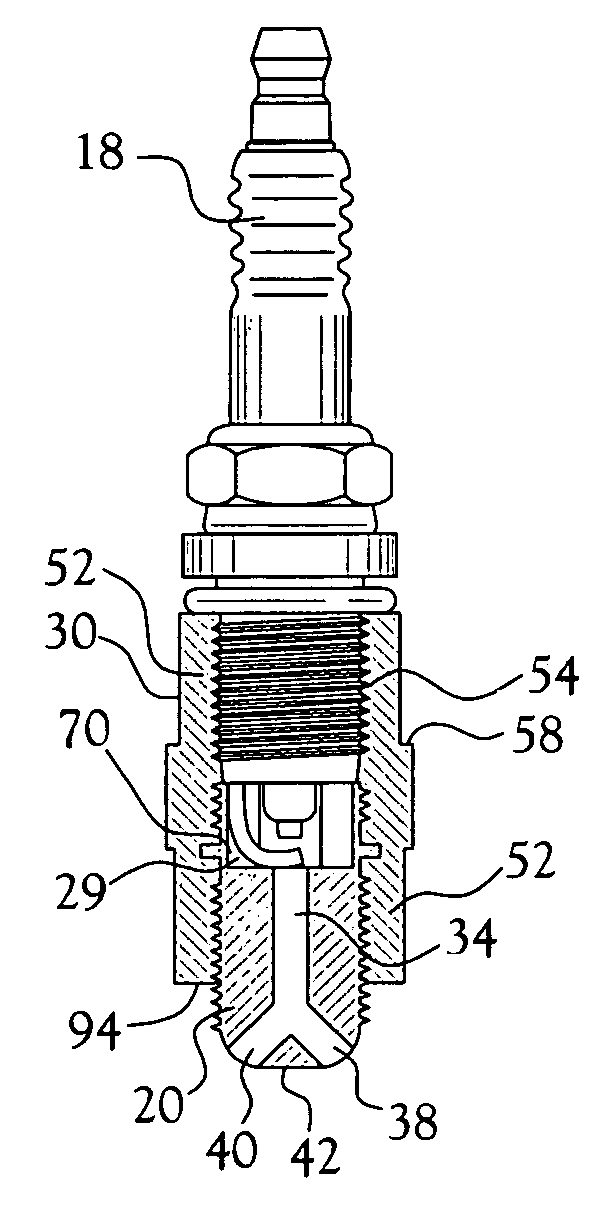

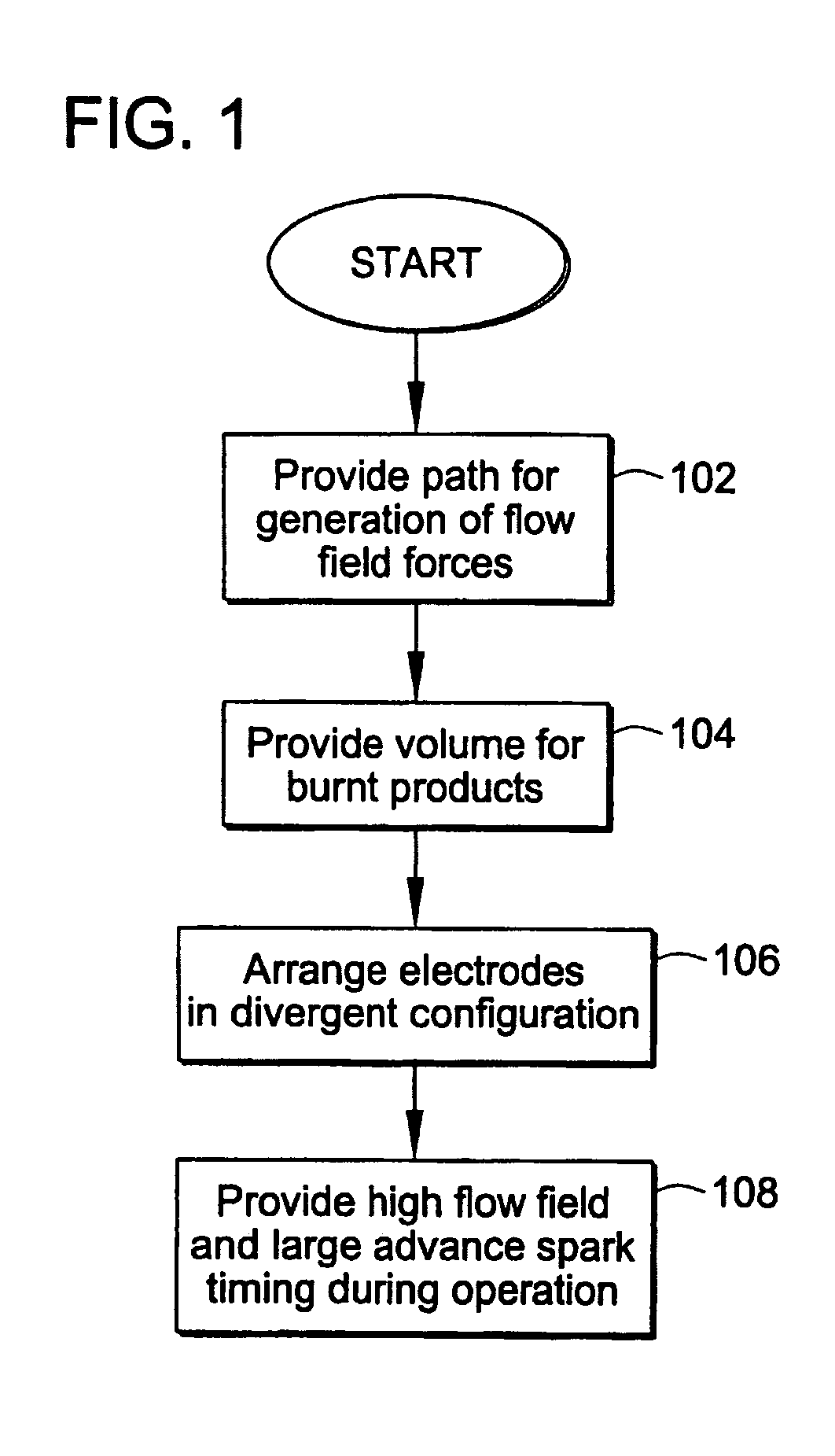

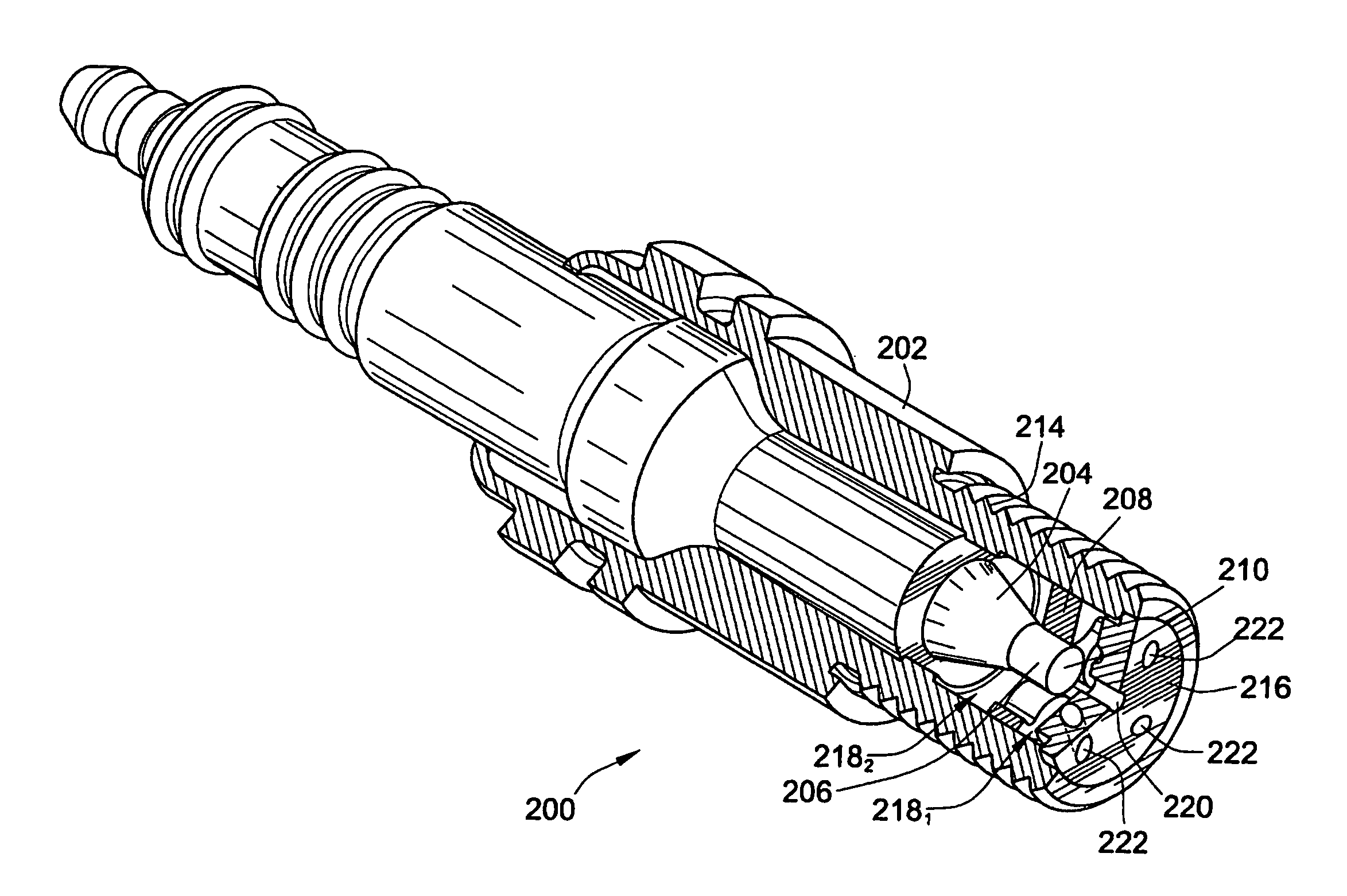

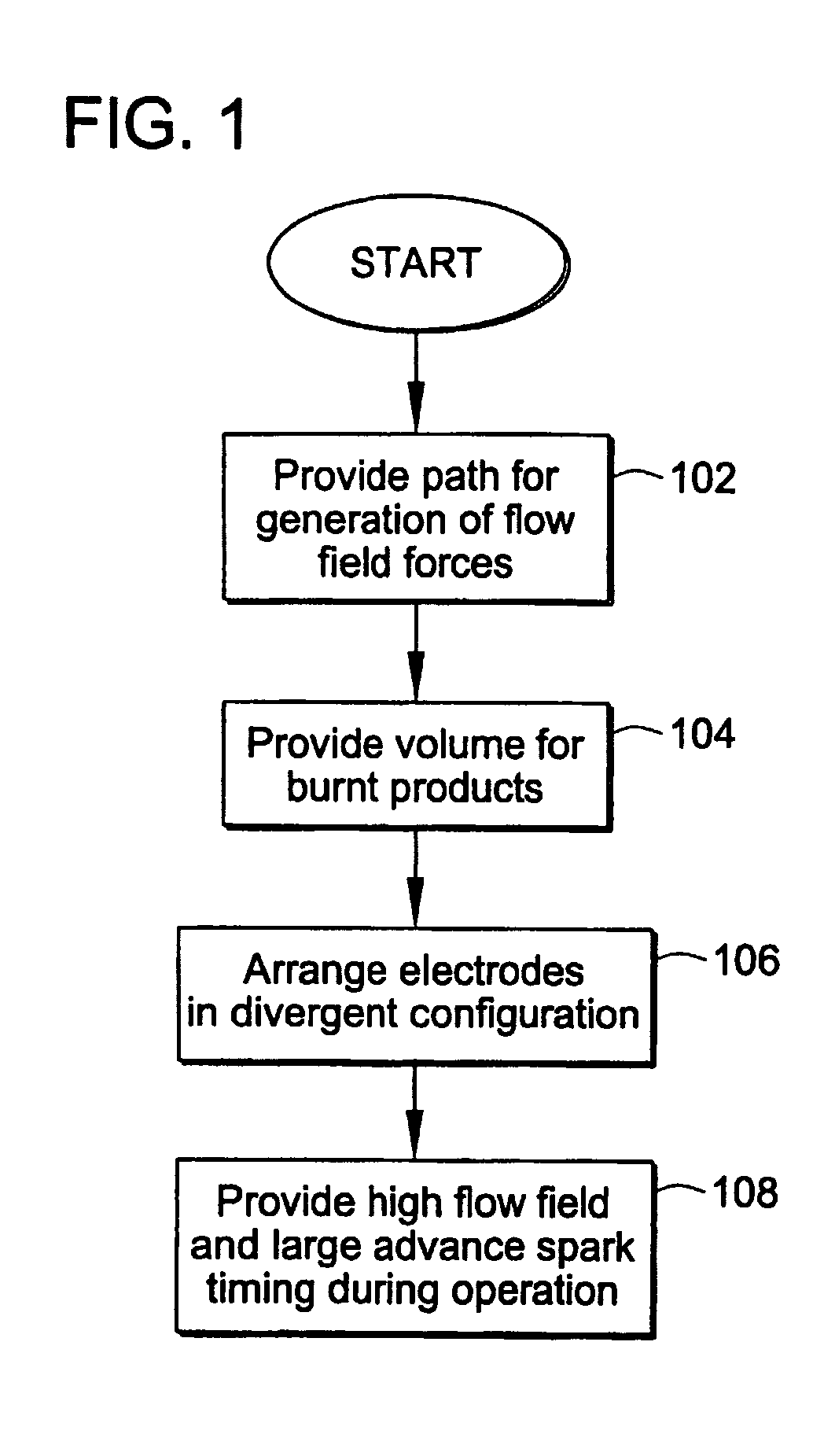

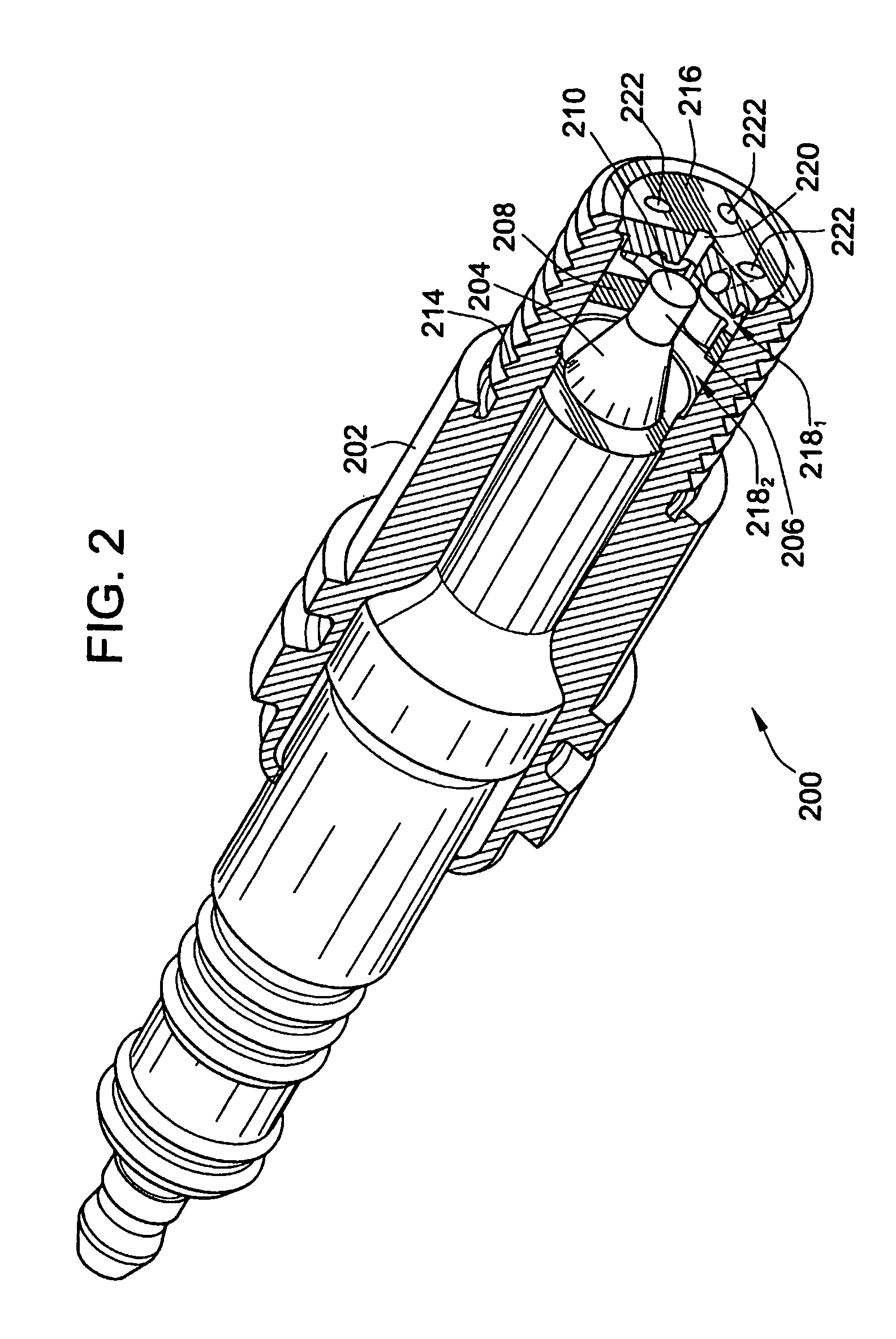

Controlled Spark Ignited Flame Kernel Flow in Fuel-Fed Prechambers

ActiveUS20120125287A1Improve flowHigh trafficSparking plugsInternal combustion piston enginesAlloyEngineering

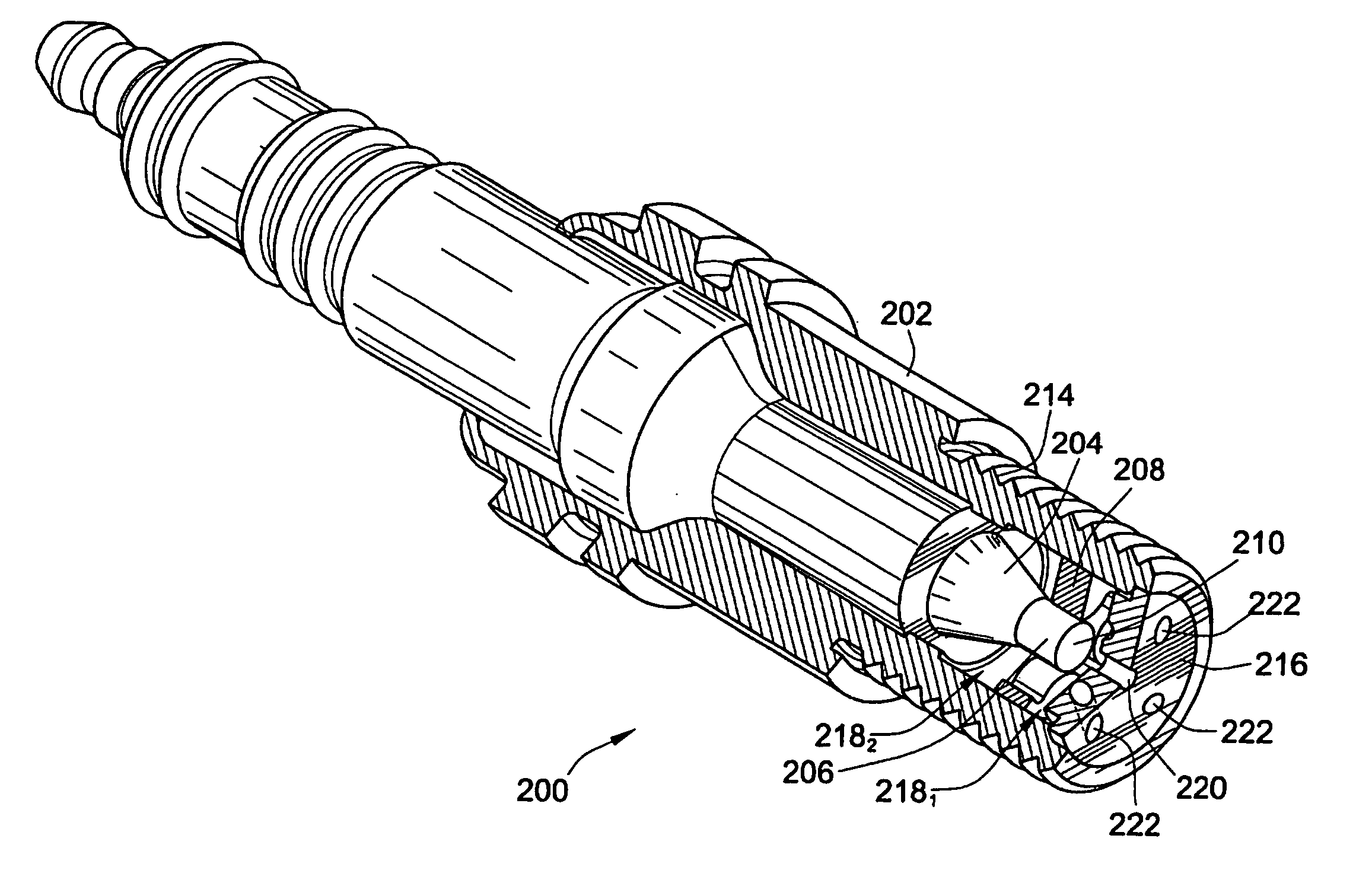

A pre-chamber spark plug that includes a shell. Additionally, the pre-chamber spark plug includes an insulator disposed within the shell. In a particular embodiment, a center electrode has a first portion surrounded by the insulator, and a second portion that extends from the insulator into a pre-chamber. The pre-chamber defined by the shell. In a further embodiment, a ground electrode is attached to the insulator. In particular embodiments, the ground electrode is tubular in shape and includes an inner spark surface ring spaced in surrounding relation to the center electrode to create a spark gap, an outer ring attached to the shell, and a plurality of rounded spokes connecting the inner and outer rings. In a particular embodiment, the ground and center electrodes accommodate attachment of precious metal alloys to increase electrode surface life. In another embodiment the ground electrode and insulator is coaxial to the center electrode.

Owner:WOODWARD GOVERNOR CO

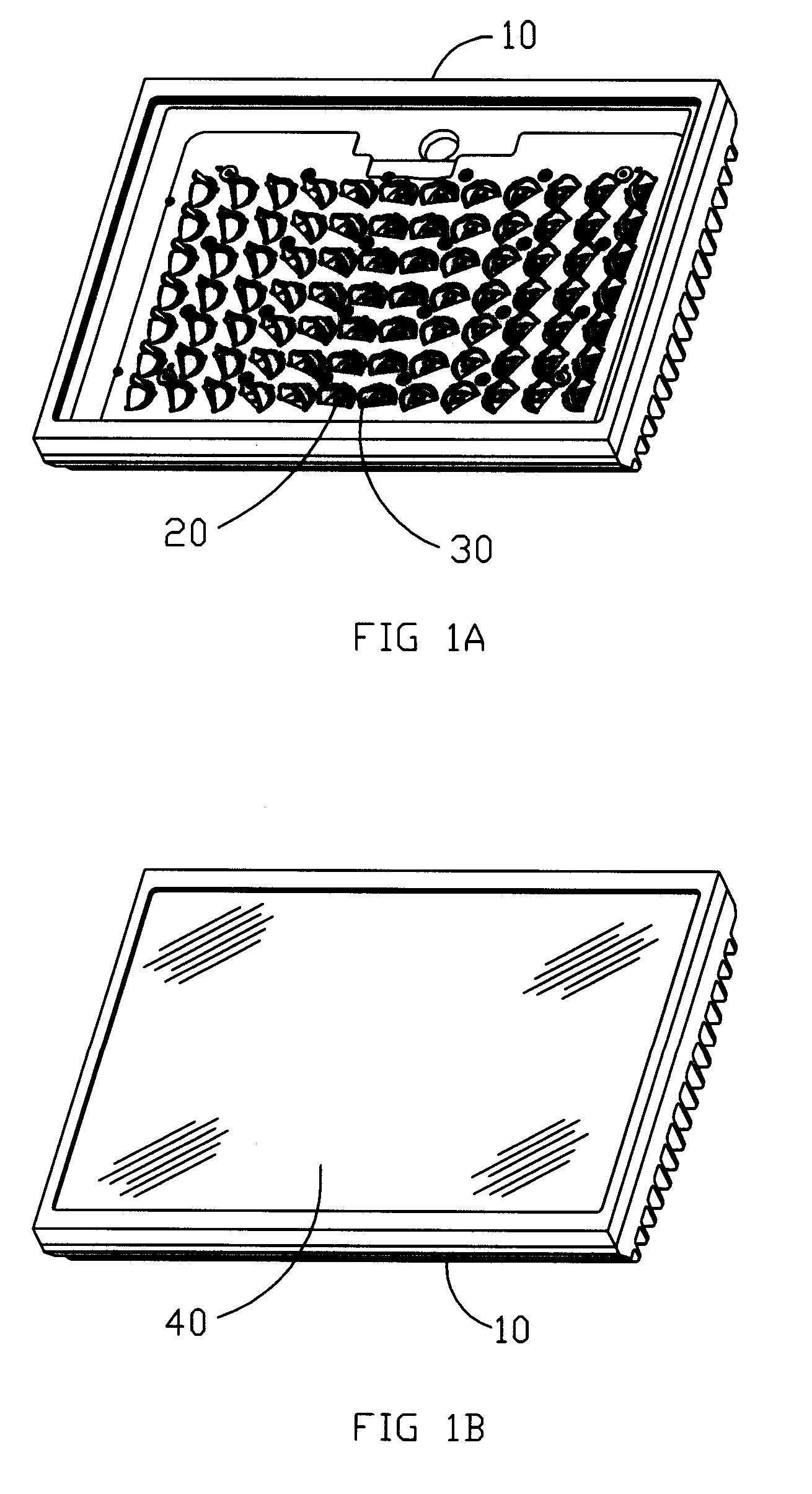

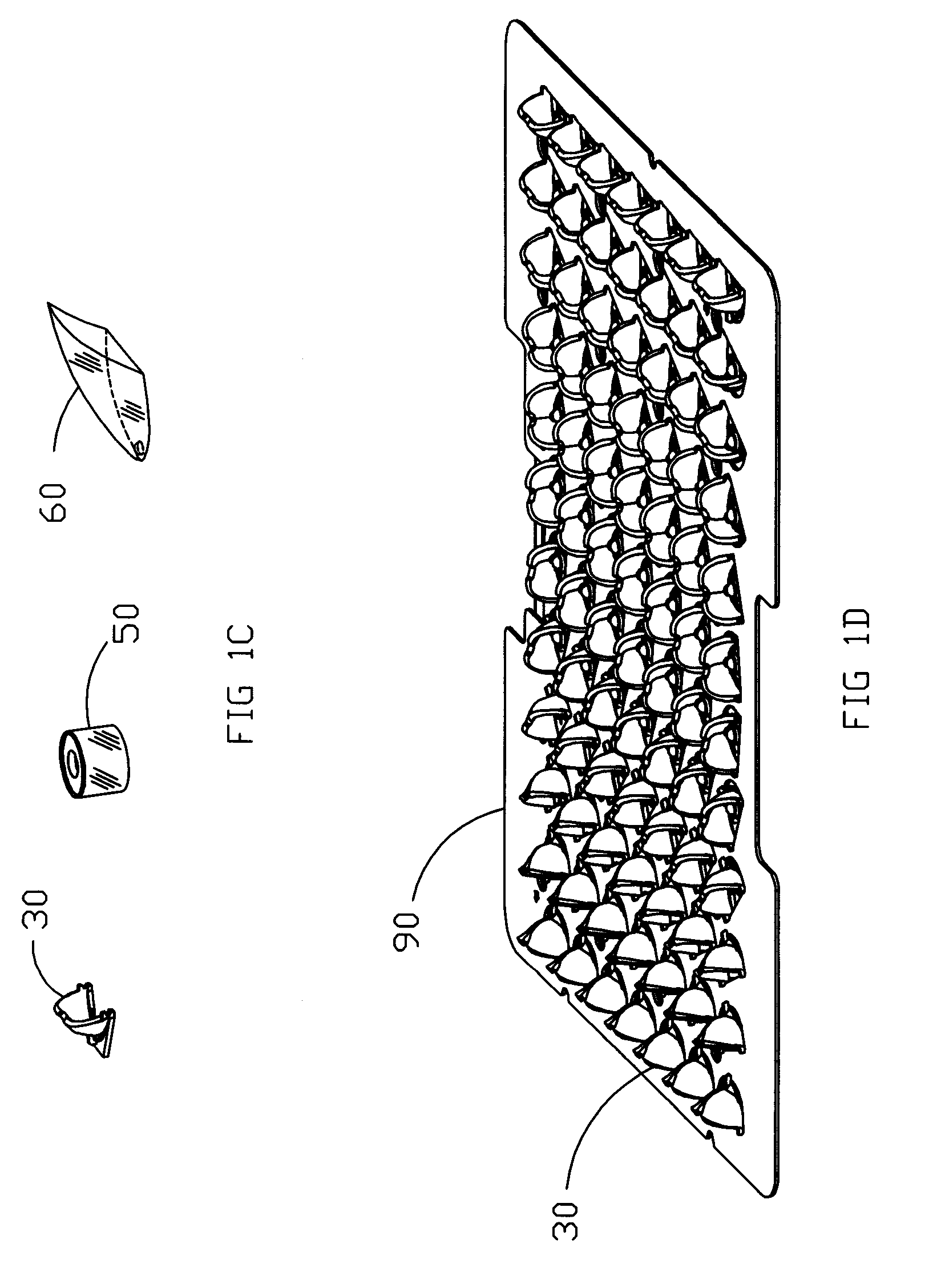

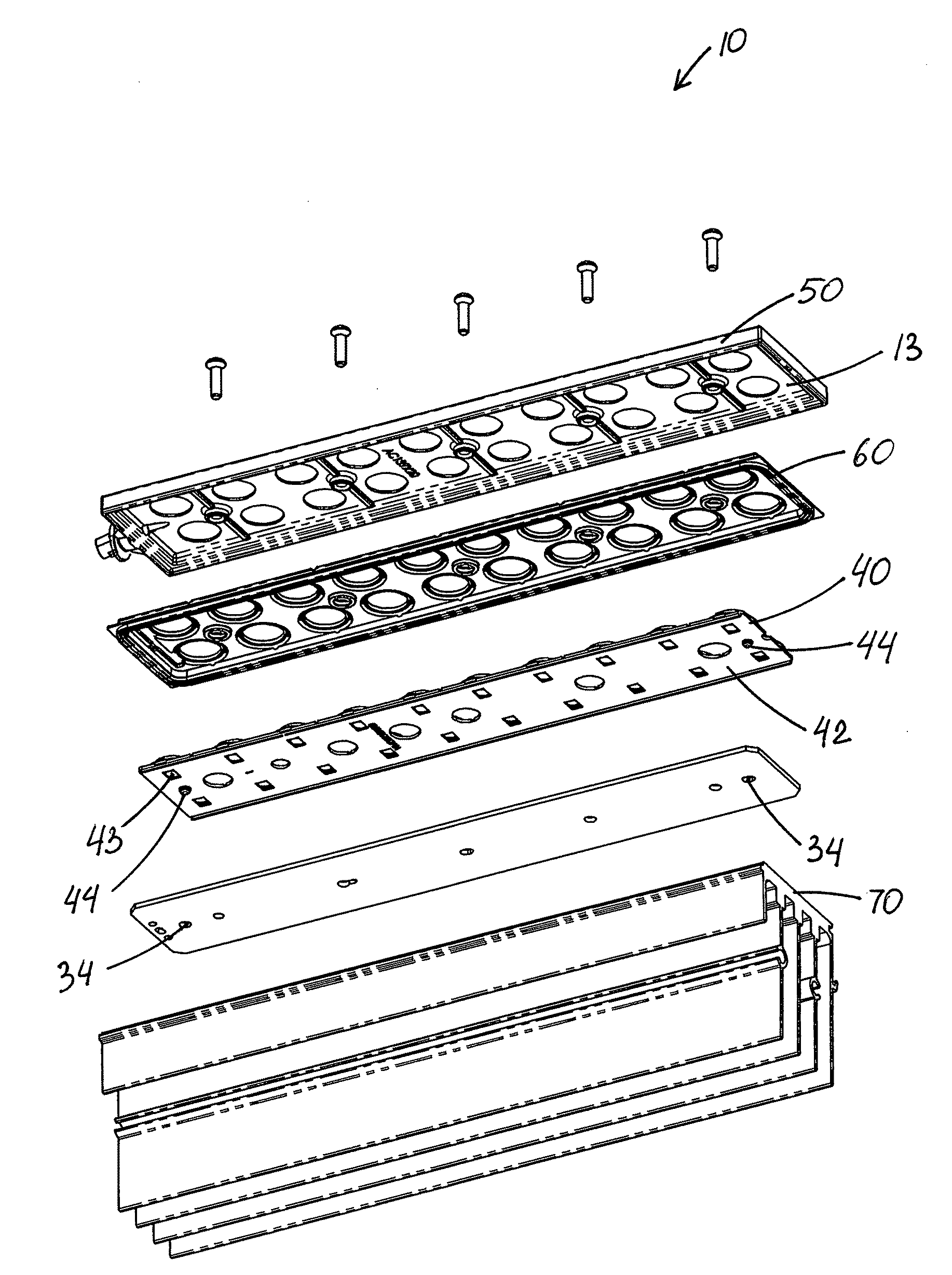

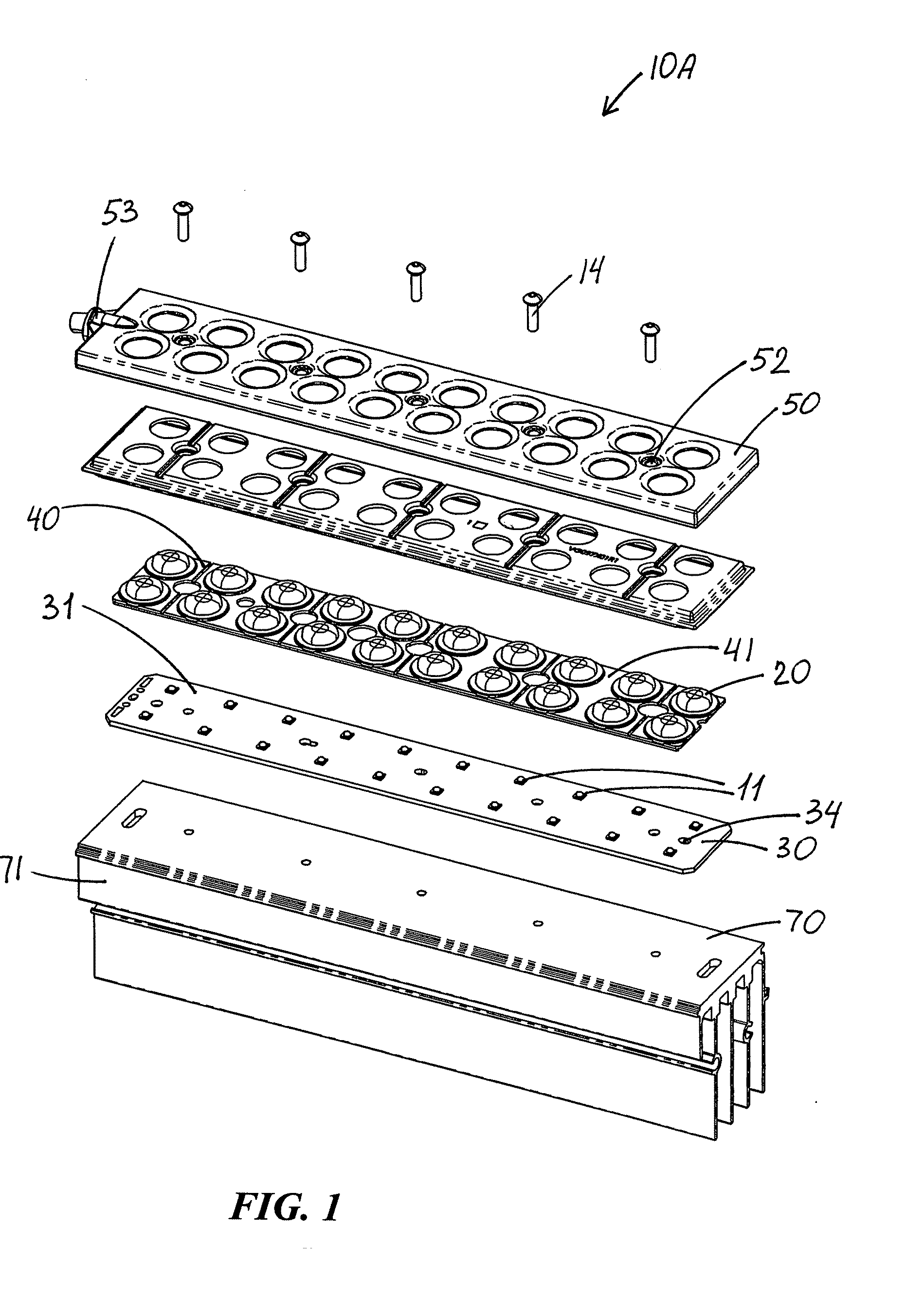

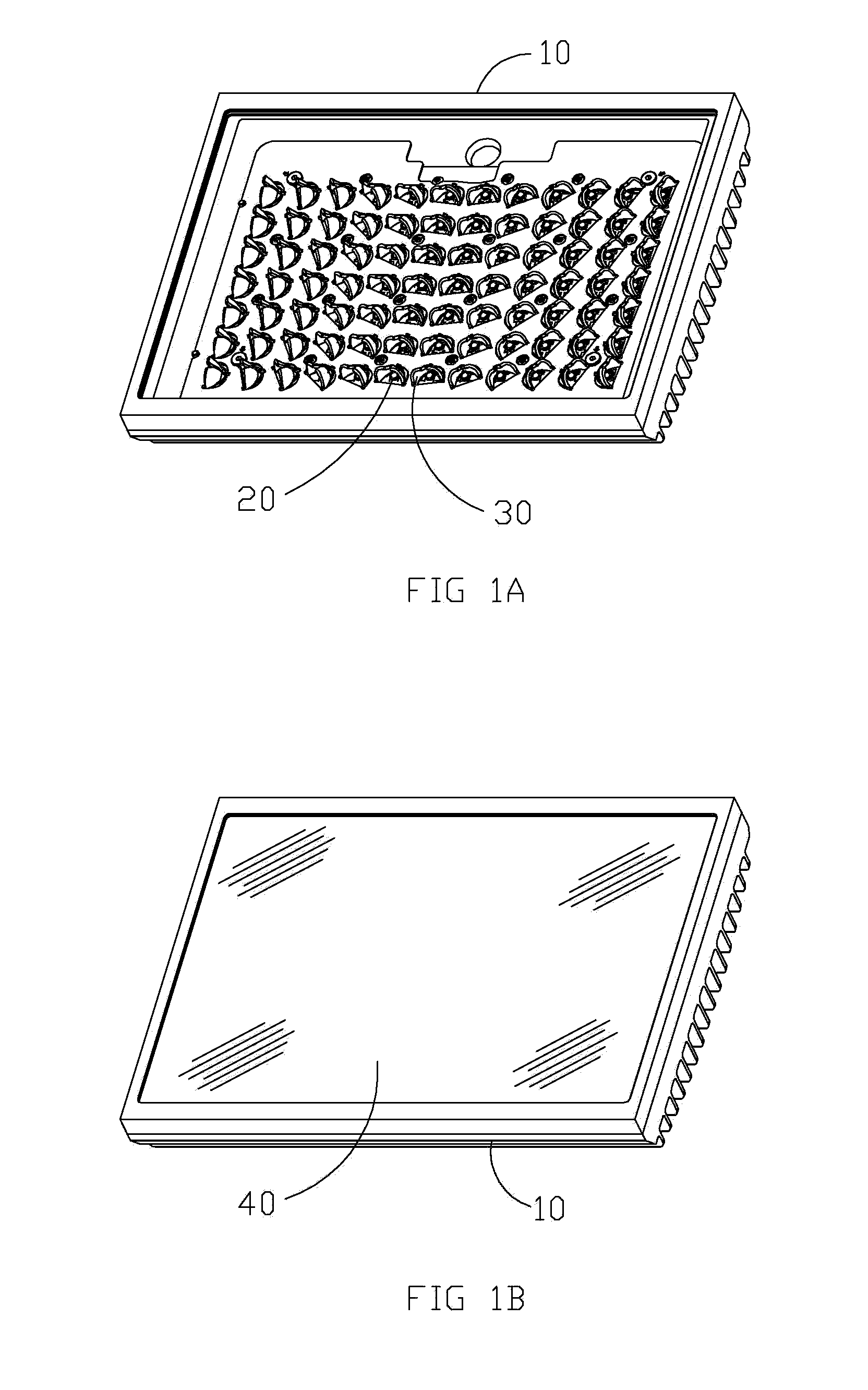

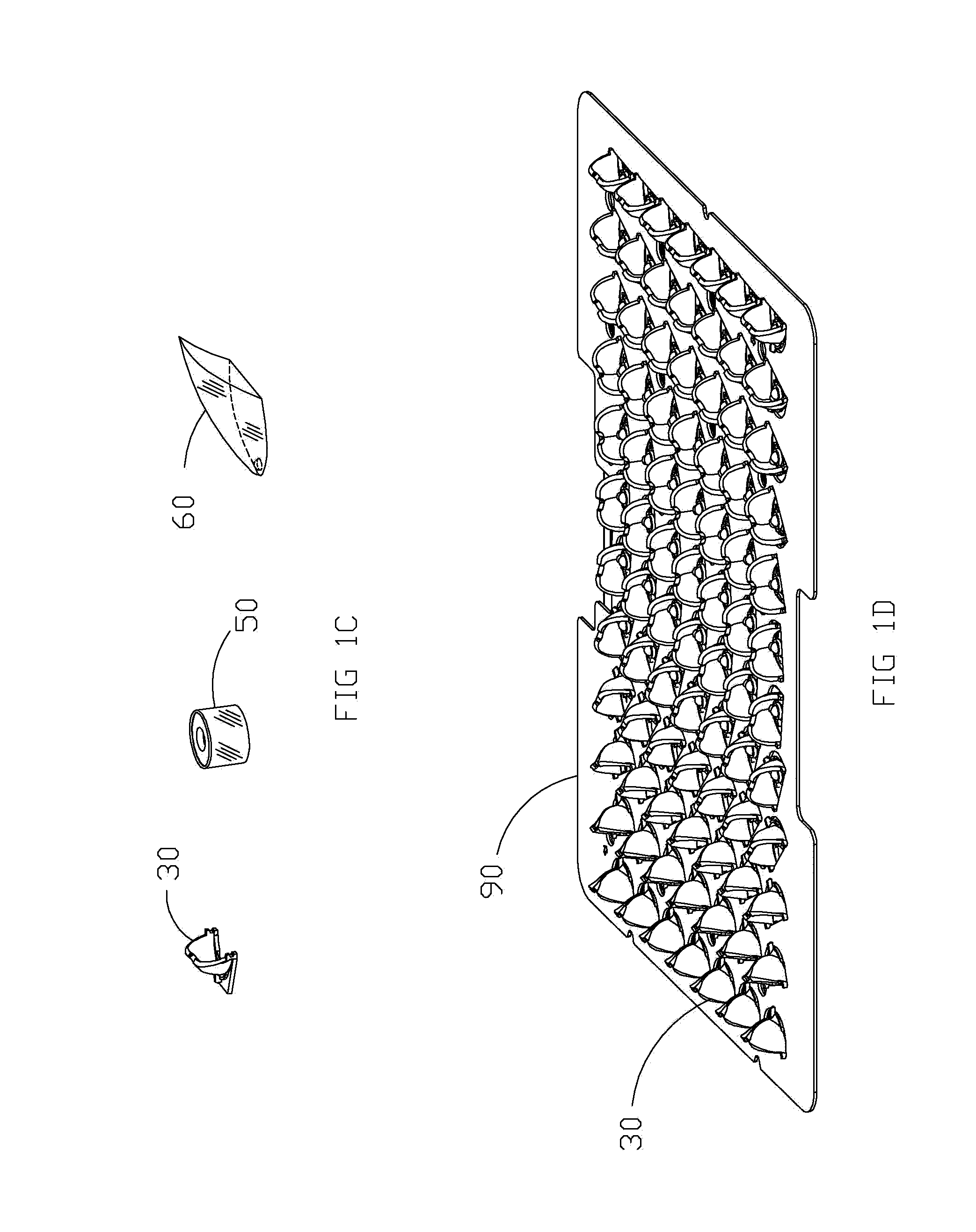

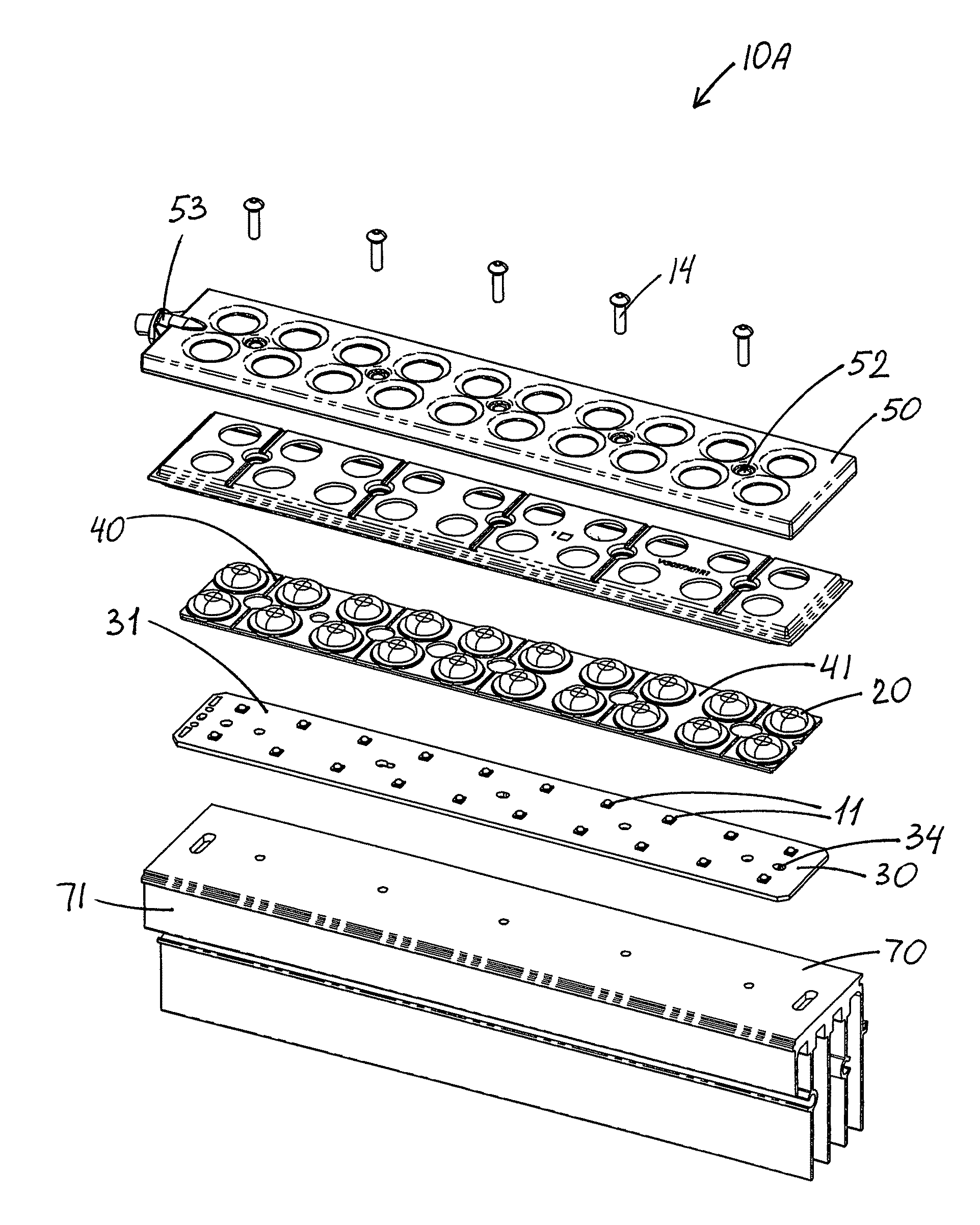

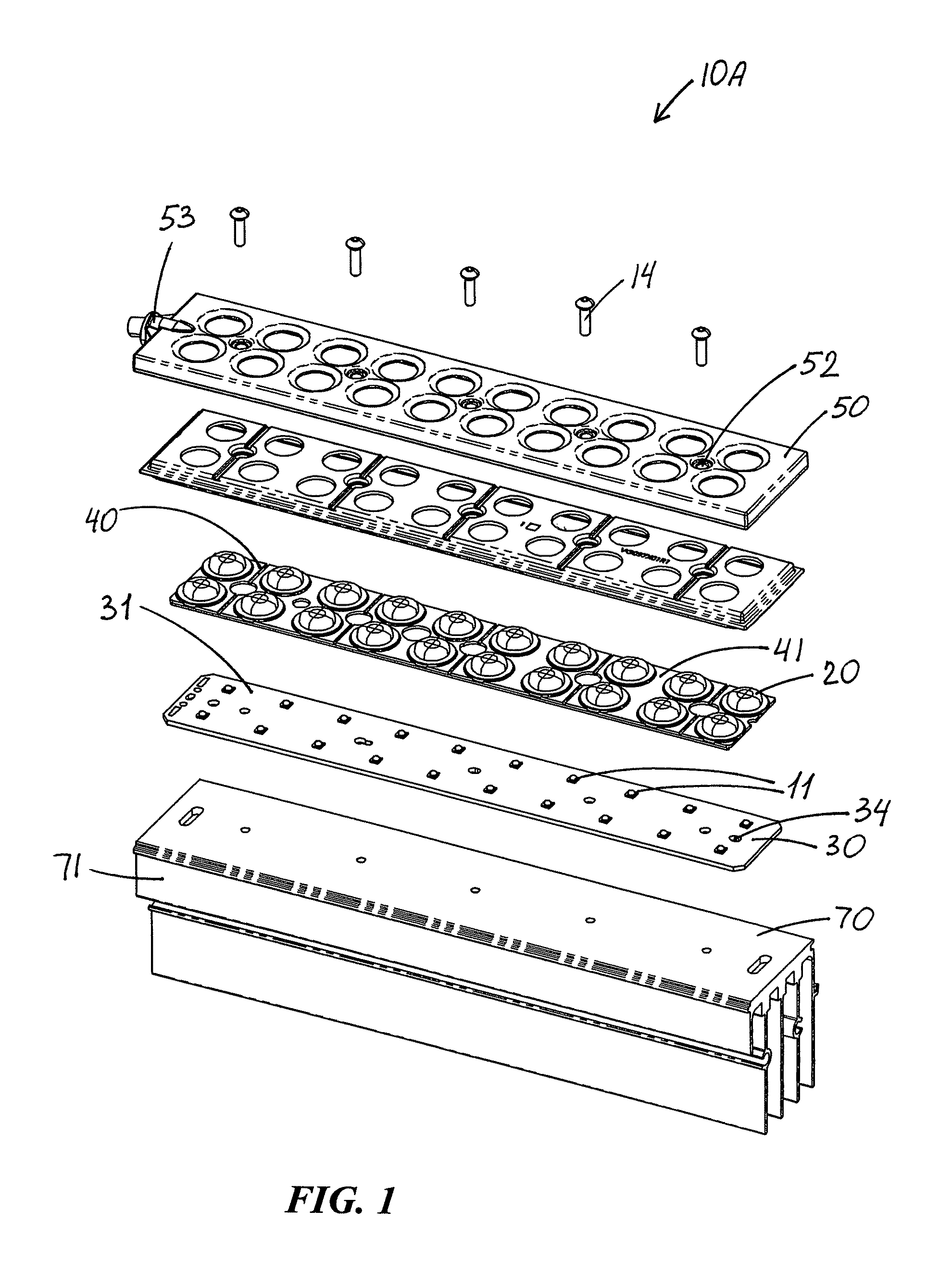

LED apparatus and method for accurate lens alignment

ActiveUS20110103051A1Accurate shapeLoss efficiency of distributionPlanar light sourcesMechanical apparatusLed arrayEngineering

An LED apparatus of the type including (a) a mounting board having an LED-supporting surface with an LED device thereon and (b) a lens member over the LED device establishing a light path therebetween. The inventive LED apparatus includes a lens-aligning member having front and back surfaces and defining an aperture receiving the LED device therethrough such that the LED device protrudes beyond the front surface. The lens member includes a lens portion and a flange thereabout, the flange being attached to the front surface of the lens-aligning member such that the lens portion substantially surrounds the protruding LED device. The lens-aligning member has a first mating feature which is positioned and arranged for mating engagement with a second mating feature of the mounting board, thereby accurately aligning the lens member over the LED device by accurately aligning the lens-alignment member with the mounting board. Other aspects of the invention is a method for LED-apparatus assembly and a method for manufacturing custom high-efficiency LED lensing for LED-array modules.

Owner:IDEAL IND LIGHTING LLC

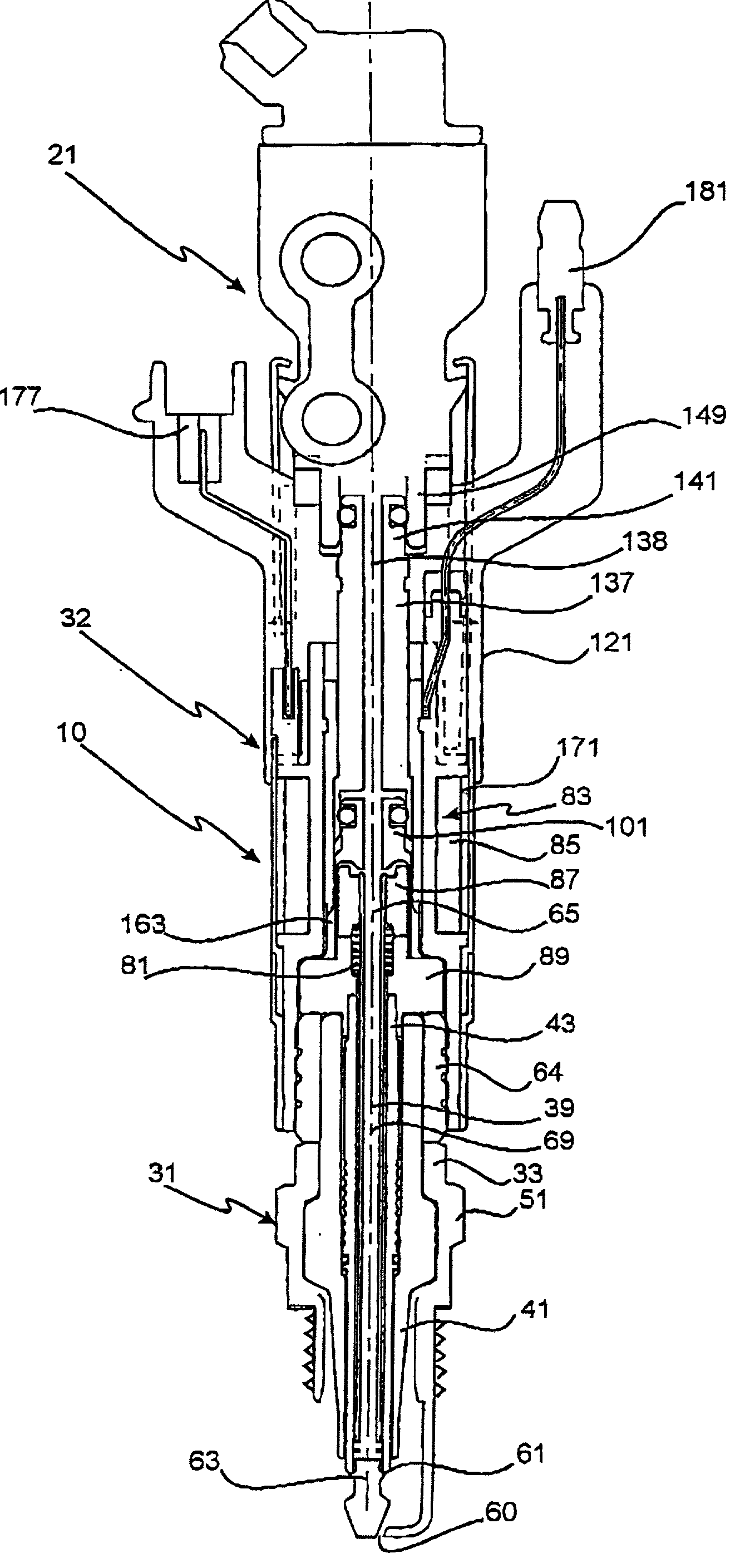

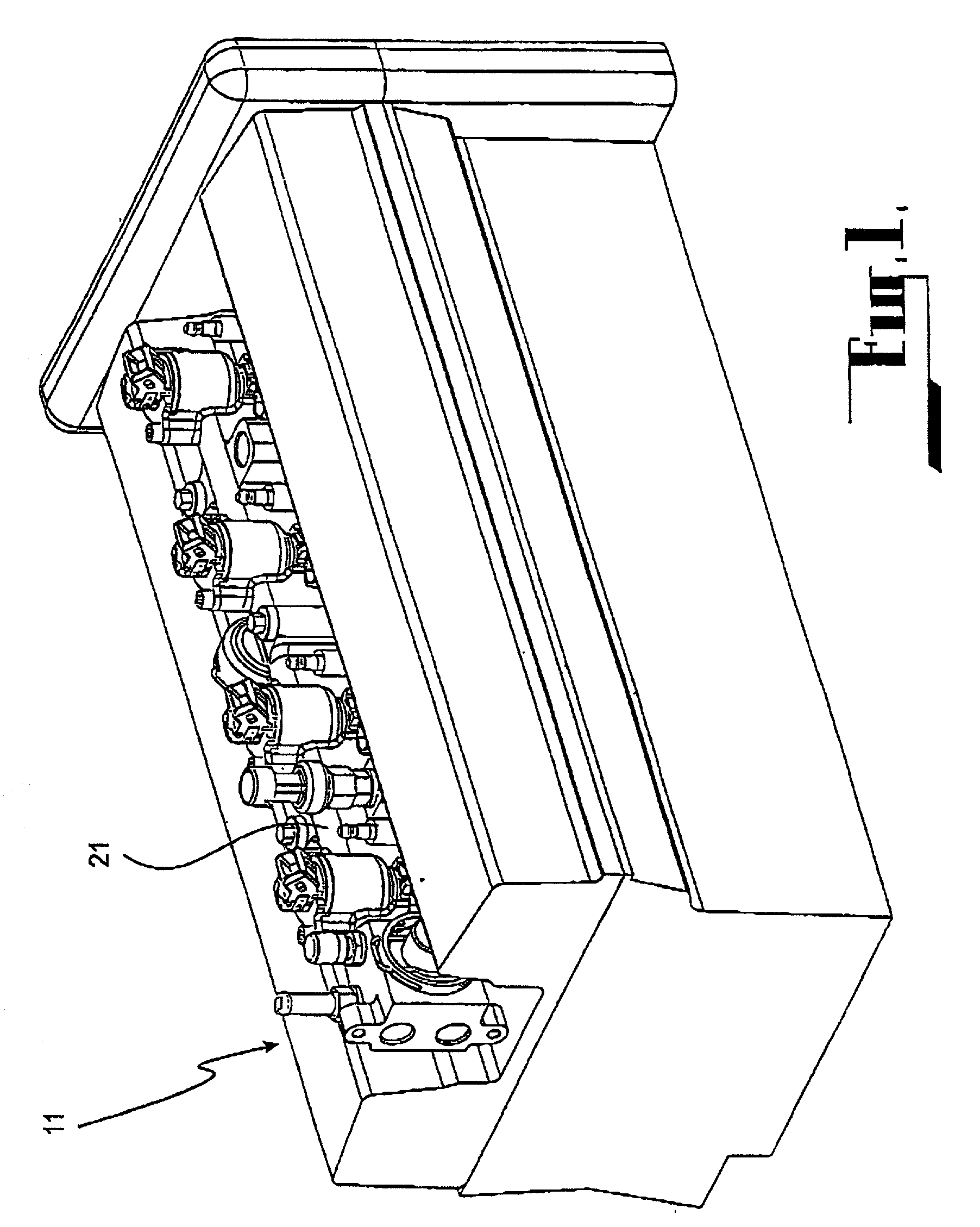

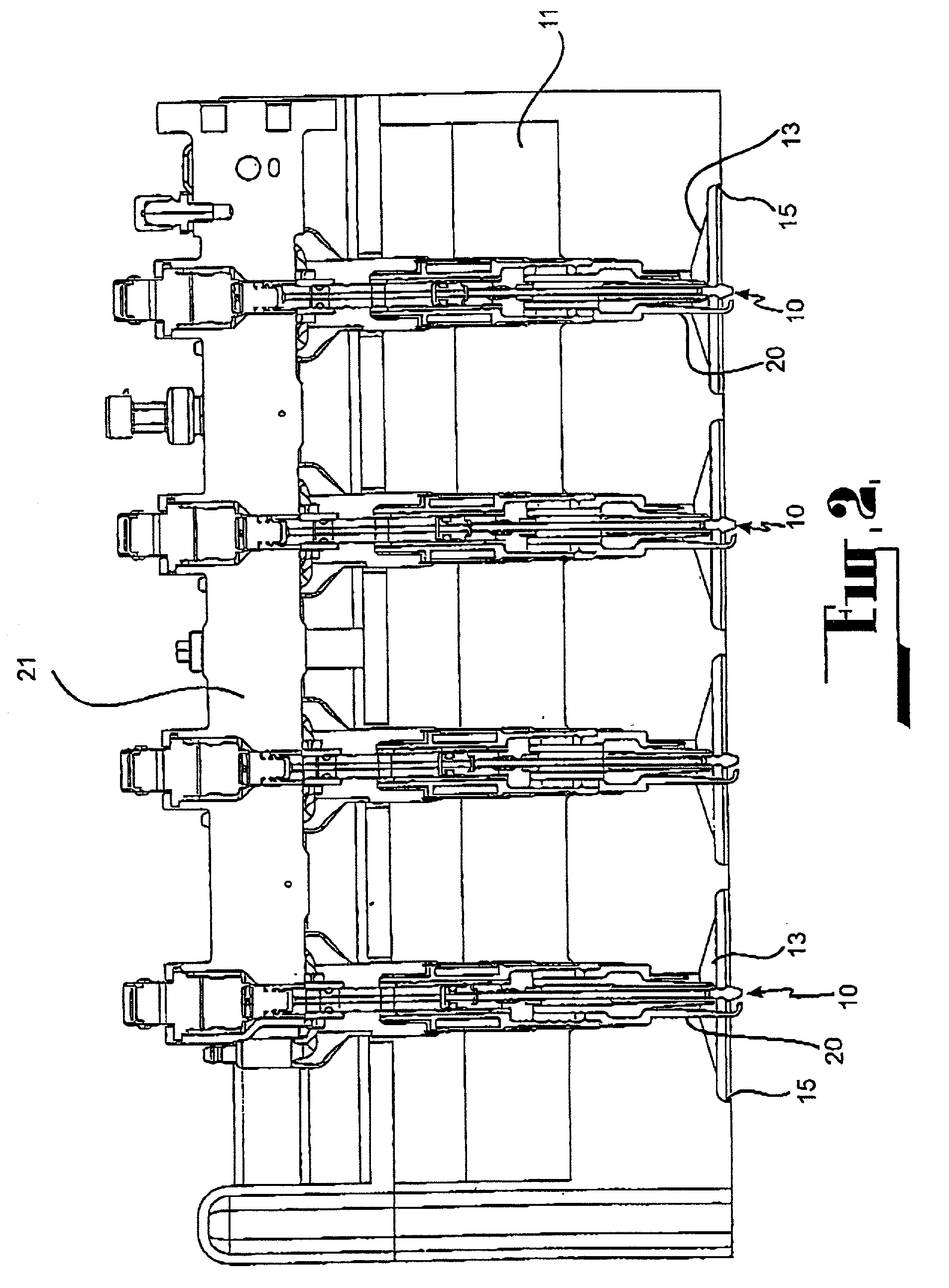

Direct injection of fuels in internal combustion engines

A fuel delivery injector for an internal combustion engine is provided. A fuel injector forms part of a device which provides a combined injection and ignition. The fuel delivery injector comprises first and second portions adapted to be detachably connected together. The first portion incorporates a valve structure having a valve member movable with respect to a valve seat for opening and closing a delivery port, and an actuating member operatively connected to the valve member. An actuator is provided in the second portion. When the first and second portions are connected together, the actuator is operably associated with the actuating member to provide an actuating assembly. Typically, the actuating assembly comprises an electromagnetic device in which the actuating member comprises a solenoid armature and the actuator comprises a solenoid coil, whereby connection of the first and second portions together completes assembly of the electromagnetic device.

Owner:ORBITAL ENGINE CO PTY LTD

Method of inspecting defect for electroluminescence display apparatus, defect inspection apparatus, and method of manufacturing electroluminescence display apparatus using defect inspection method and apparatus

ActiveUS8493296B2Sparking plugsSemiconductor/solid-state device testing/measurementDriving currentElectricity

A dark spot defect of an EL element is detected based on an emission brightness or a current flowing through the EL element when an element driving transistor which controls a drive current to be supplied to the EL element is operated in its linear operating region and the EL element is set to an emission level. A dim spot defect caused can be detected based on a current flowing through the EL element when the element driving transistor is operated in its saturation operating region and the EL element is set to the emission level. When an abnormal display pixel is detected based on an emission brightness, a pixel which is determined as an abnormal display pixel and which is not determined as a dark spot defect is determined, and the pixel is detected as a dim spot defect caused by the characteristic variation of the element driving transistor.

Owner:SEMICON COMPONENTS IND LLC

Spark Plug for a Gas-Operated Internal Combustion Engine

ActiveUS20110148274A1Extended service lifeIncrease volumeSparking plugsExternal combustion engineEngineering

The invention relates to a spark plug for a gas-fired internal combustion engine, and Includes a metallic body, with an insulator fastened in the body. A central electrode, leads through the insulator and includes a protruding end of a precious metal alloy. An annular ground electrode is fastened to the body and surrounds the end of the central electrode which, at the inside thereof facing the central electrode is provided with a precious metal or with a precious metal alloy. The mutually facing surfaces of the central electrode and ground electrode formed by the precious metal or the precious metal alloy are coaxially disposed cylinder surfaces. A cap is provided and attached to the body and which, after installation of the spark plug into a combustion chamber of the internal combustion engine, shields the central electrode and the ground electrode from the combustion chamber. Together with the body of the spark plug, the central electrode forms an ante-chamber, in which the central electrode and the ground electrode are disposed. The cap having at least one opening, which enables a gas exchange between the ante-chamber and the space outside of the ante-chamber. According to the invention, a deviation of the cylinder surfaces from the ideal cylinder geometry is less than +−20 μm, and a deviation of the positions of the axes of the cylinder surfaces from their ideal coaxial position is less than +−50 μm.

Owner:FEDERAL MOGUL IGNITION

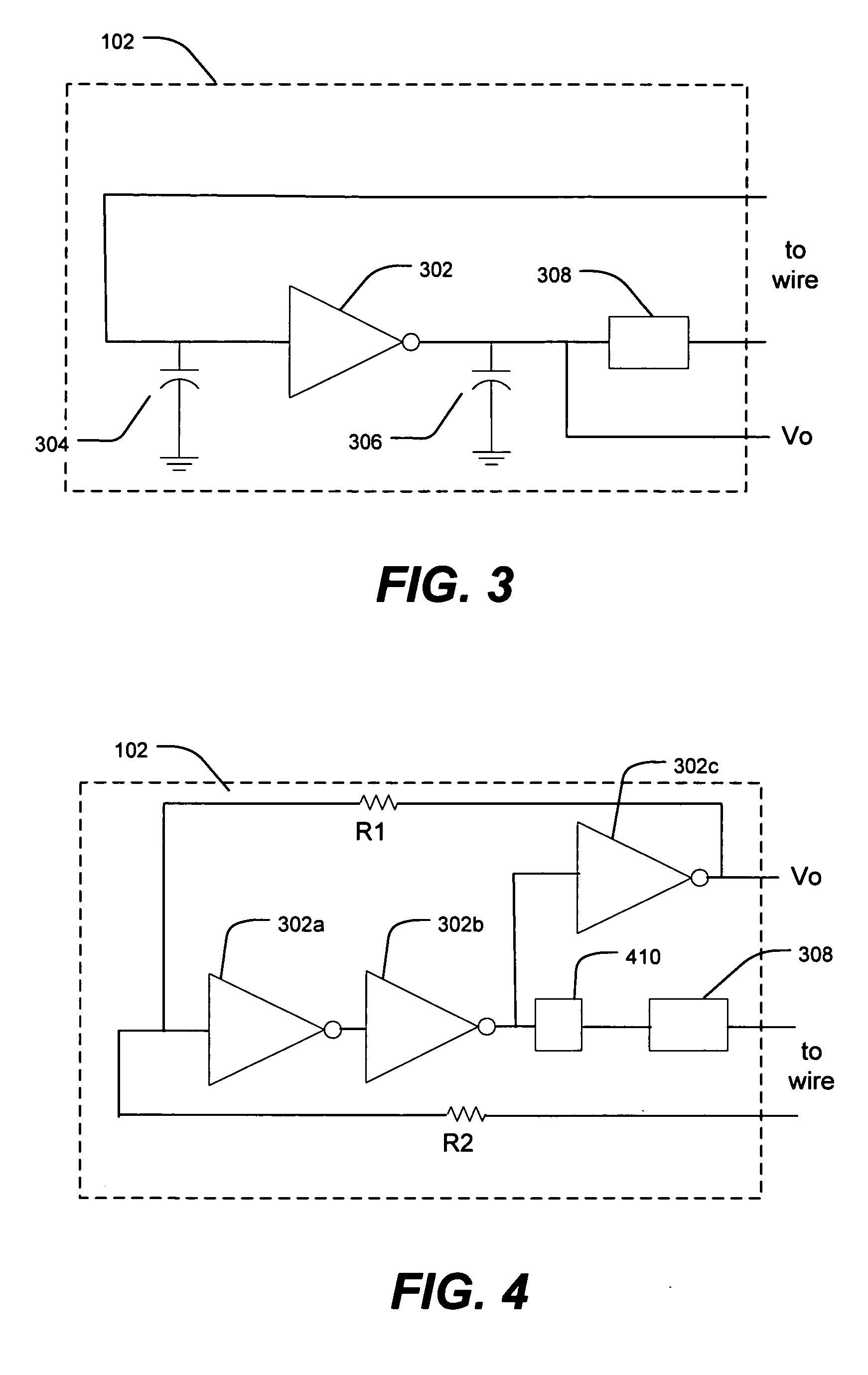

Device and method for detecting anomolies in a wire and related sensing methods

ActiveUS20060061368A1Multiple-port networksSparking plugsElectrical and Electronics engineeringShort circuit

Owner:UNIV OF UTAH RES FOUND

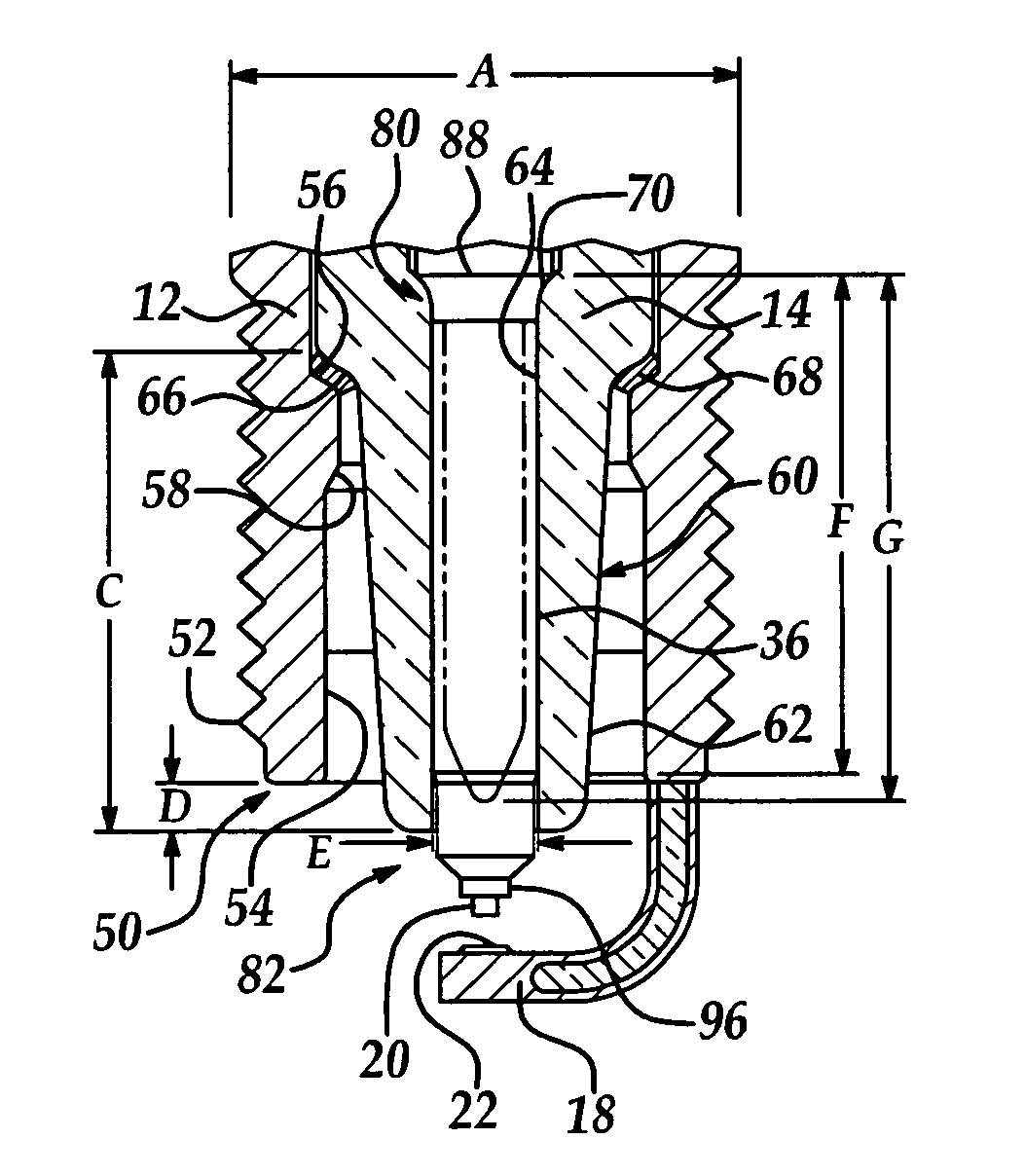

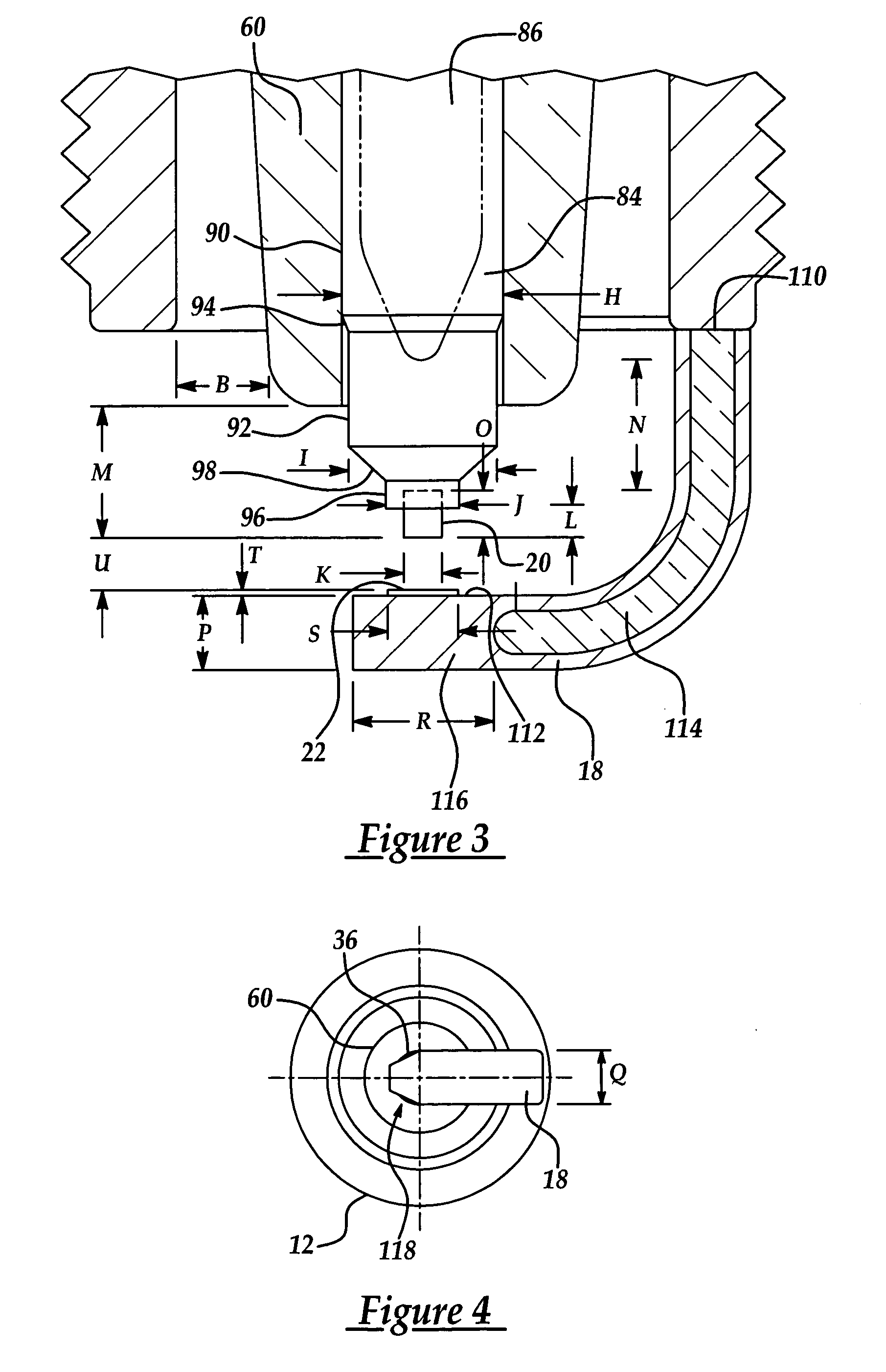

Spark plug configuration having a metal noble tip

A spark plug having a particular firing end configuration that satisfies numerous dimensional ranges for improved performance. The spark plug generally includes a shell, an insulator, and center and ground electrodes, with the electrodes each having a copper core for improved thermal conductivity and a noble metal insert for improved erosion and corrosion resistance. The noble metal insert for the center electrode is preferably in the form of a cylindrical Ir-based tip, which is received within a complimentary recess formed in the center electrode. The noble metal insert for the ground electrode is in the form of a flat Pt-based pad attached to a surface of the ground electrode. Various dimensional ranges are provided for the various components of the spark plug assembly, both individually and in combination with other dimensions.

Owner:FEDERAL MOGUL IGNITION UK

Method for testing a light-emitting panel and the components therein

InactiveUS6620012B1Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringIonization

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. A method of testing a light-emitting panel and the component parts therein is also disclosed, which uses a web fabrication process to manufacturing light-emitting panels combined with inline testing after the various process steps of the manufacturing process to produce result which are used to adjust the various process steps and component parts.

Owner:LEIDOS

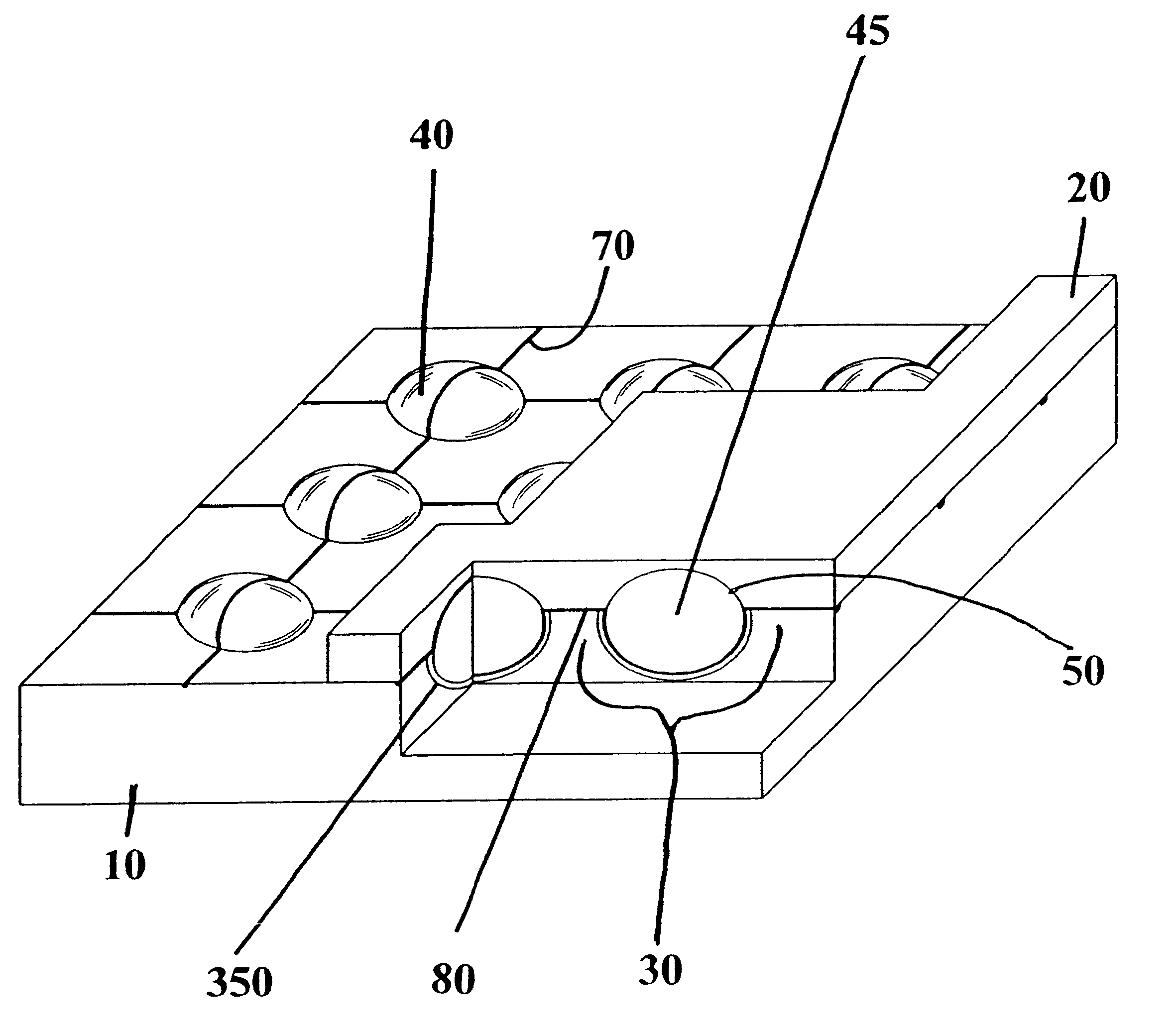

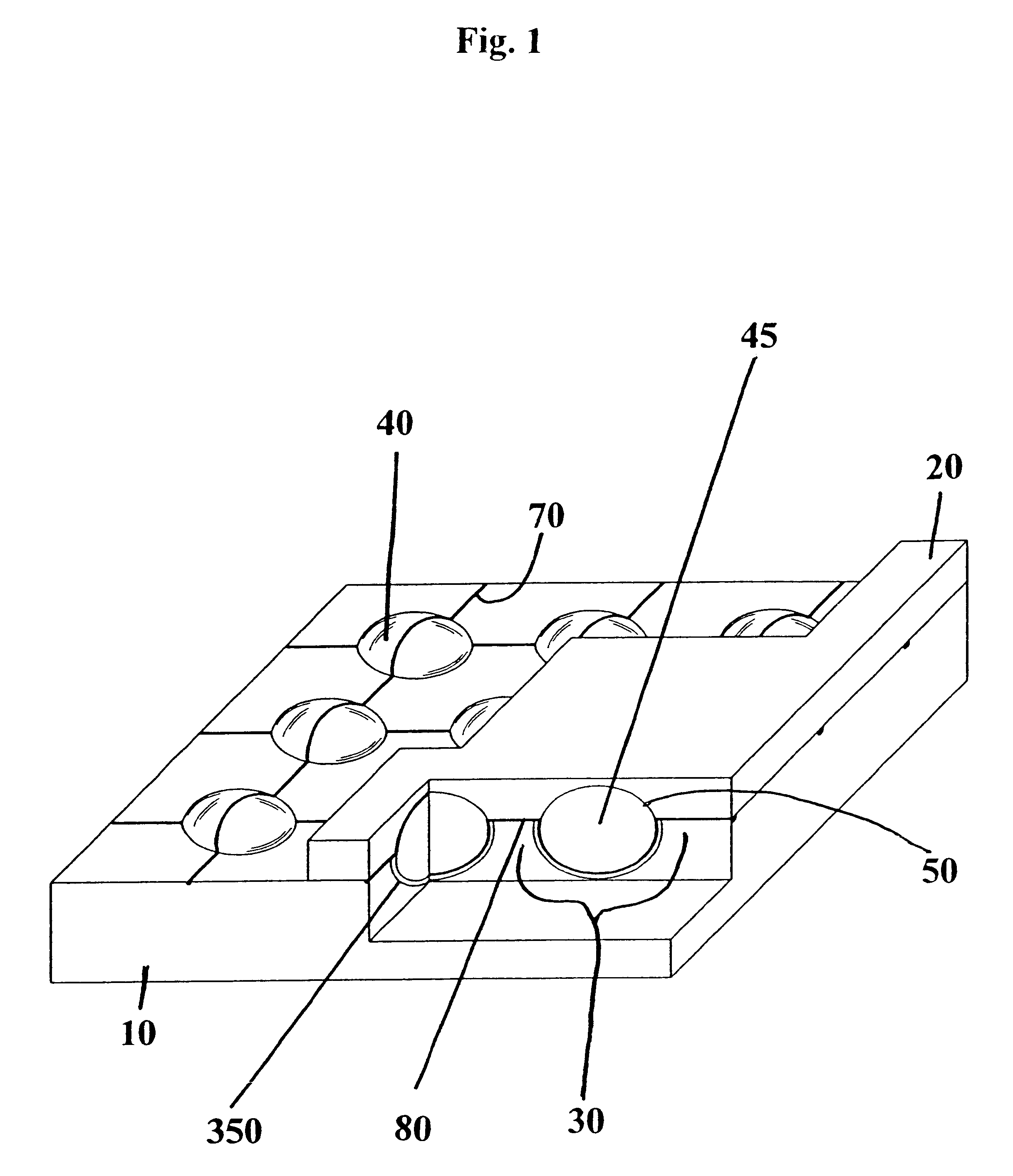

Spark ignition modifier module and method

InactiveUS7104246B1Easy to operateSparking plugsInternal combustion piston enginesCylinder blockSpark plug

A multi-part module including a flame cone and a connector adapted to be interposed between the normal spark plug port in an internal combustion engine block and a spark plug suitable for use with the engine in question. In the method, a quantity of fuel / air mixture is captured in a chamber which also houses the electrode of a spark plug. Upon generation of a spark from the spark plug, this quantity of fuel / air mixture ignites, generating a flame which propagates through one or more channels in a flame cone interposed between the spark plug and the cylinder of the engine and exits into the cylinder through multiple directionally oriented ports, whereupon the flame fronts rapidly ignite substantially all the fuel / air mixture held within the cylinder.

Owner:SMARTPLUG

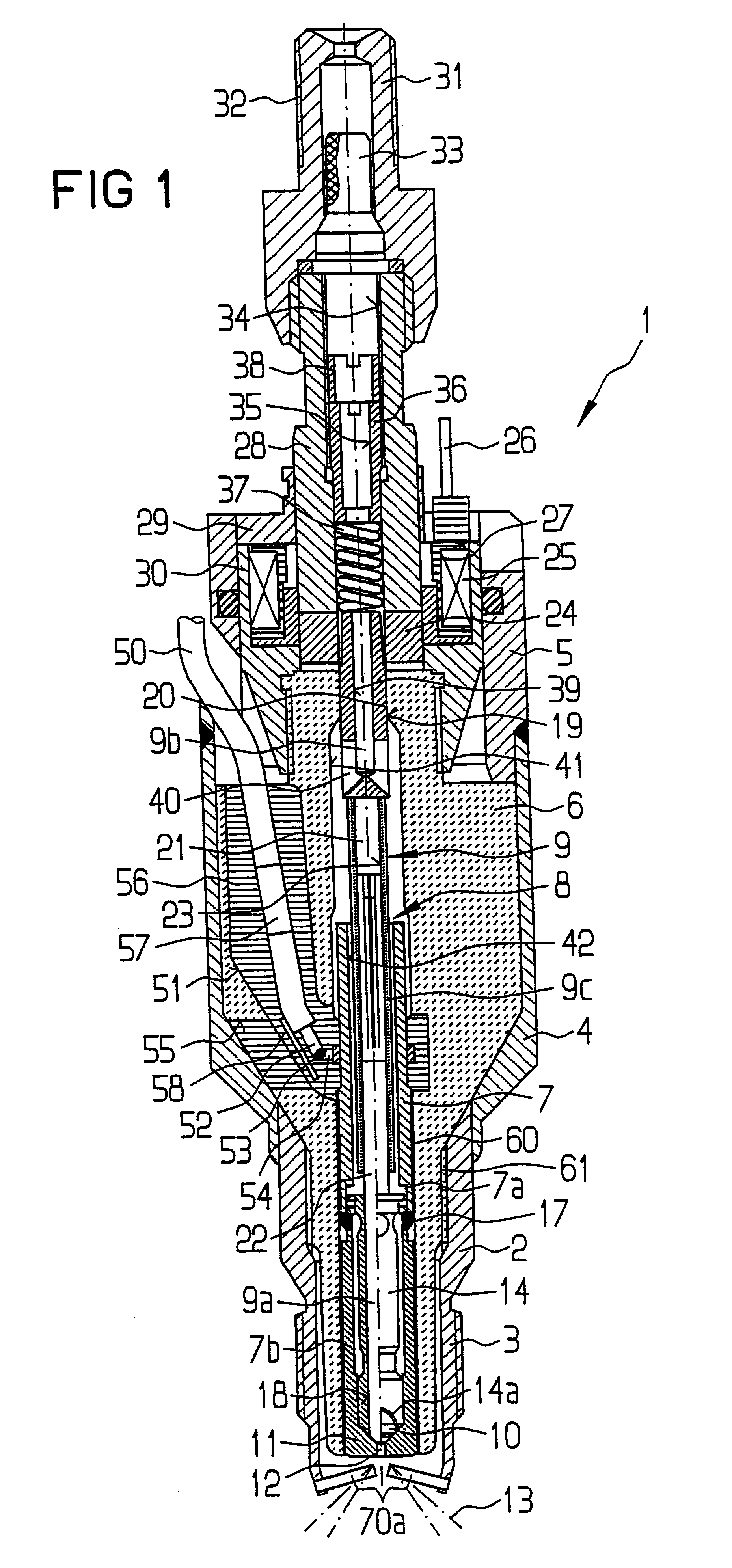

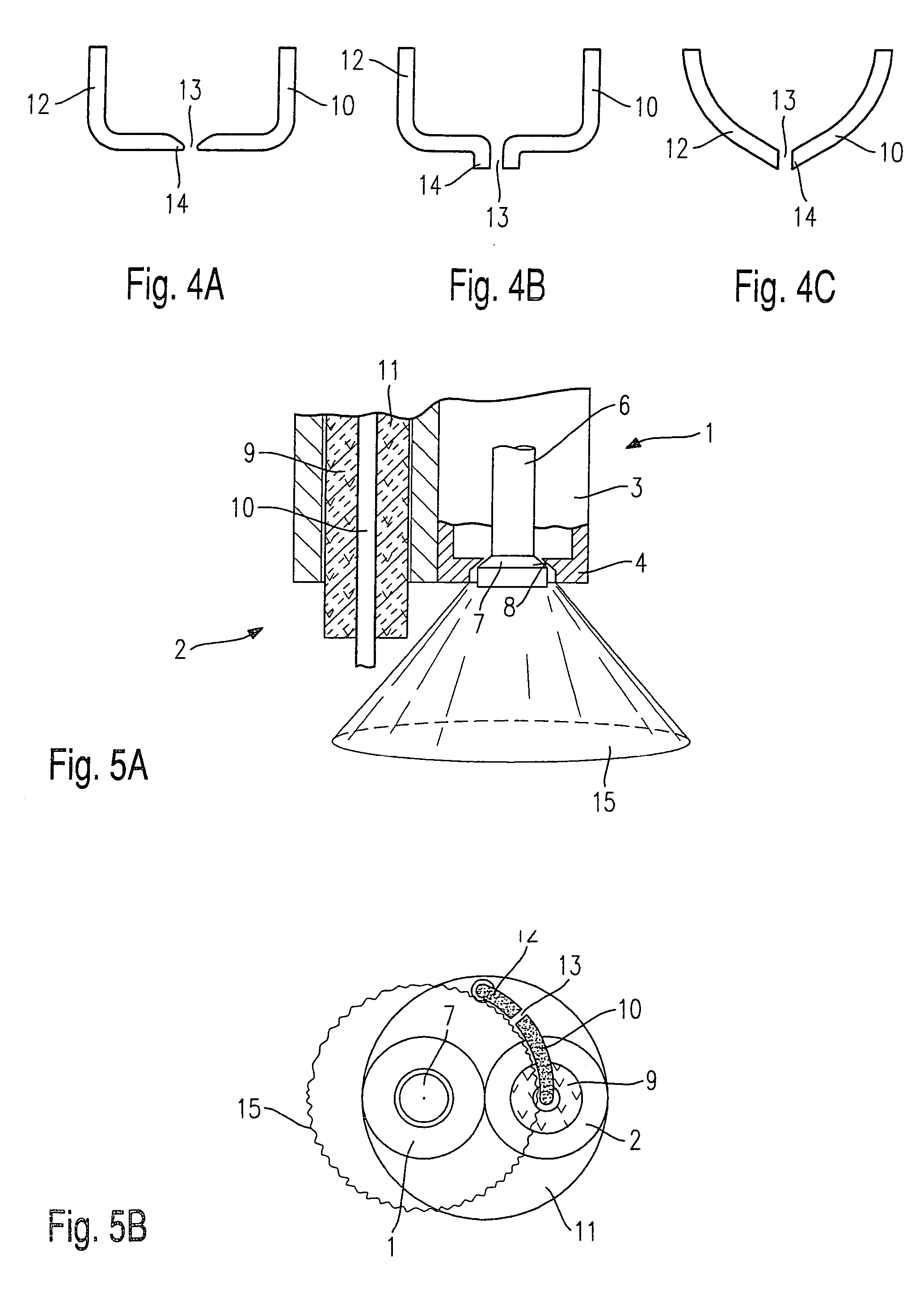

Combined fuel injection valve/ignition plug

InactiveUS6871630B2Easy to installSpace minimizationSparking plugsCombustion enginesExternal combustion engineInternal combustion engine

A fuel injector-spark plug combination comprises a fuel injector for the direct injection of fuel into a combustion chamber of an internal combustion engine and a spark plug with a spark-plug insulator, a first electrode and a second electrode for igniting the fuel injected into the combustion chamber. The fuel injector includes an actuator cooperating with an actuation device, which is in force-locking, operative connection to a valve needle, the valve needle, or a valve-closure member connected thereto, cooperating with a valve-seat surface to form a sealing seat. The valve needle of the fuel injector and the spark-plug insulator of the spark plug are positioned in a shared housing at a biaxial offset.

Owner:ROBERT BOSCH GMBH

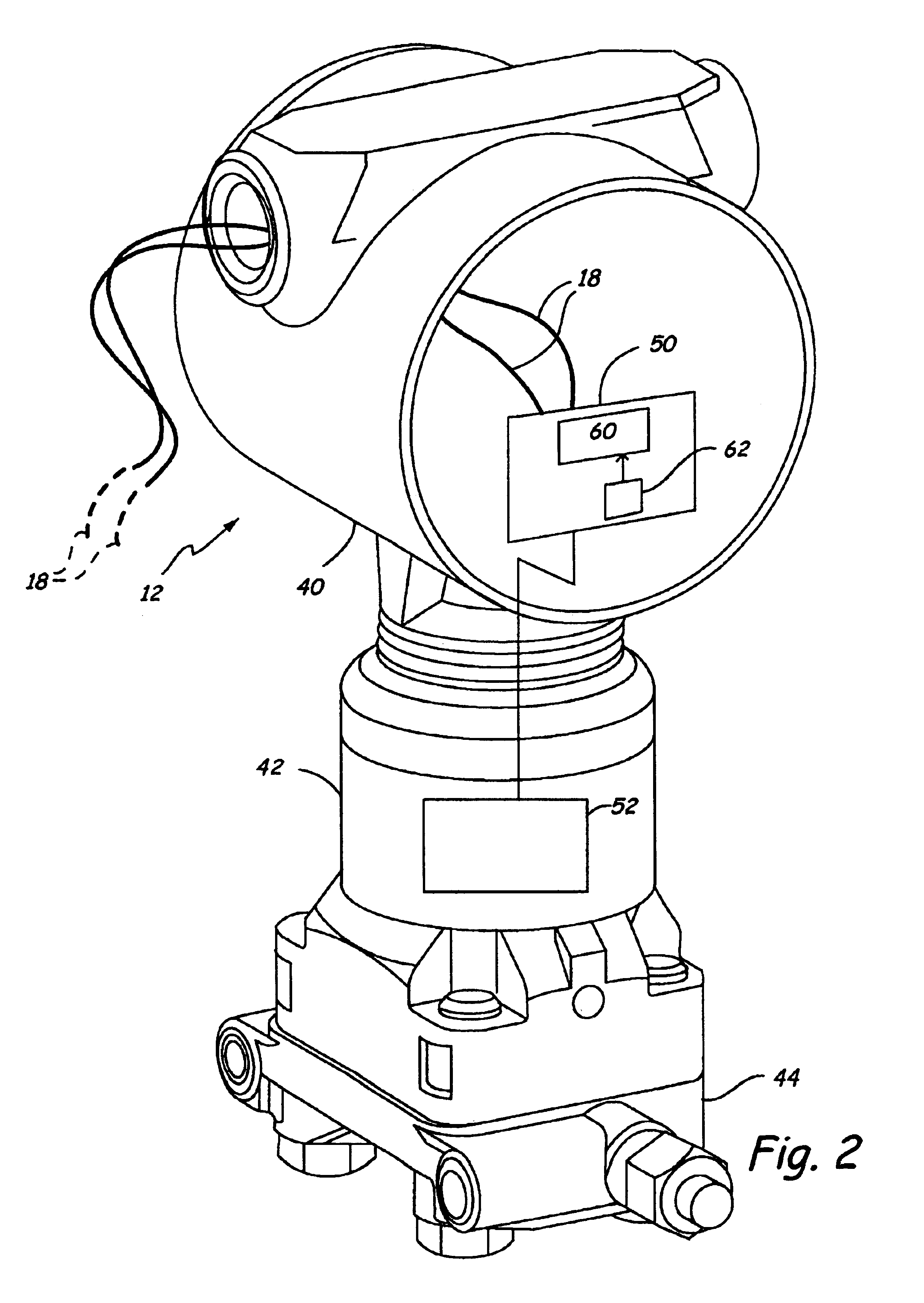

Process device with quiescent current diagnostics

A process device for use on an industrial process control system includes a quiescent current sensor configured to sense quiescent current draw of the process device. Diagnostic circuitry determines a diagnostic condition of the process device as a function of the sensed quiescent current.

Owner:ROSEMOUNT INC

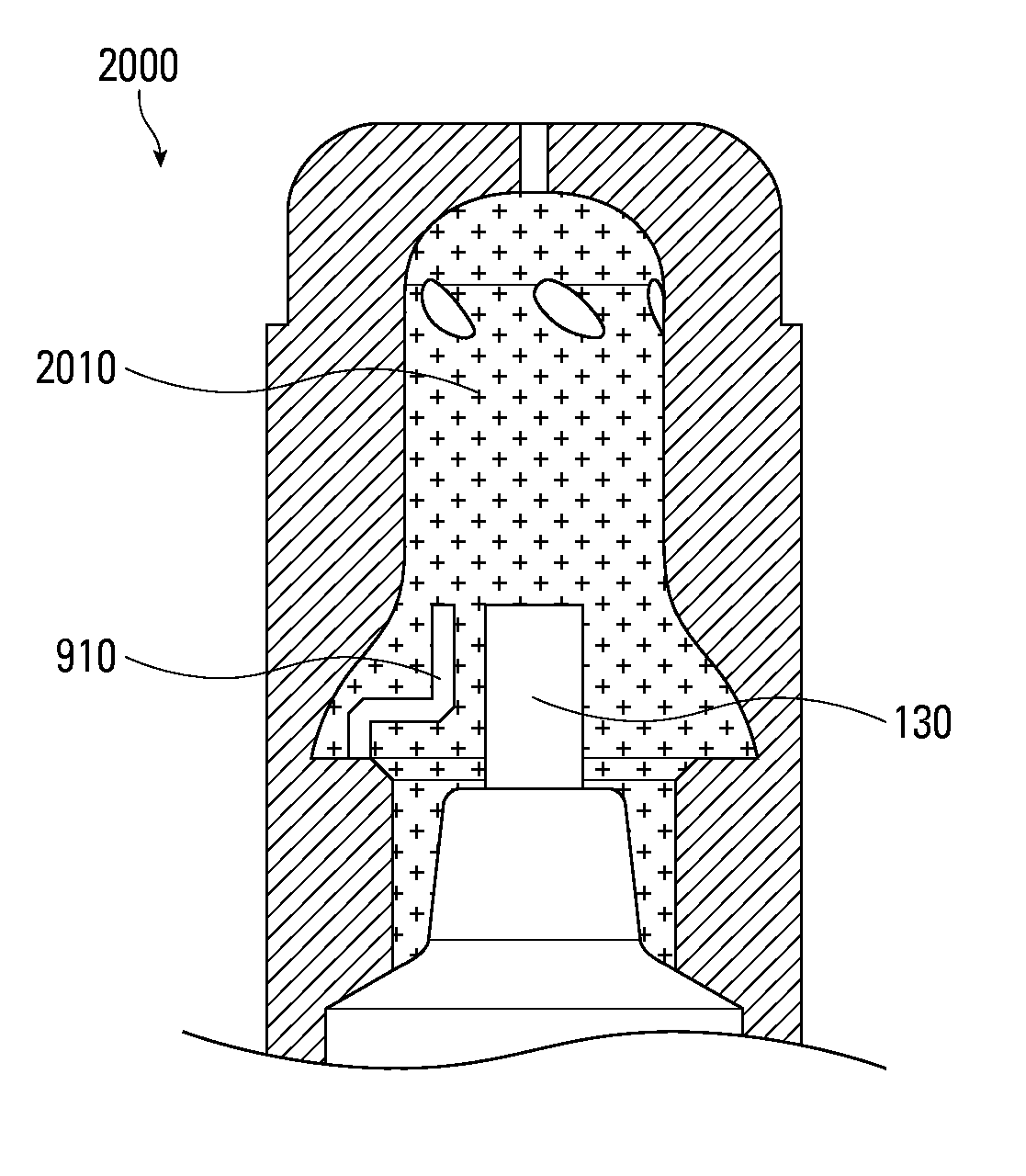

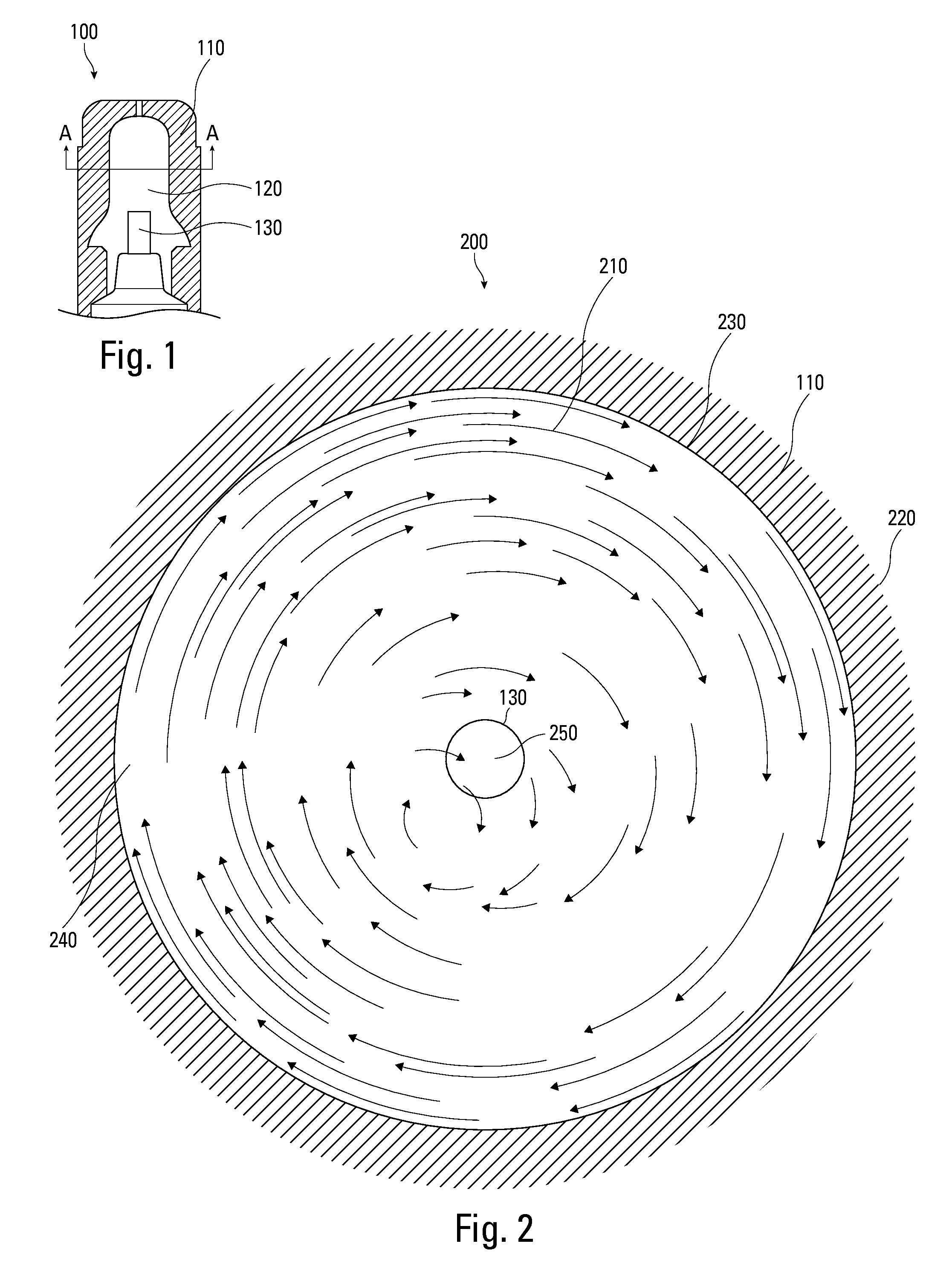

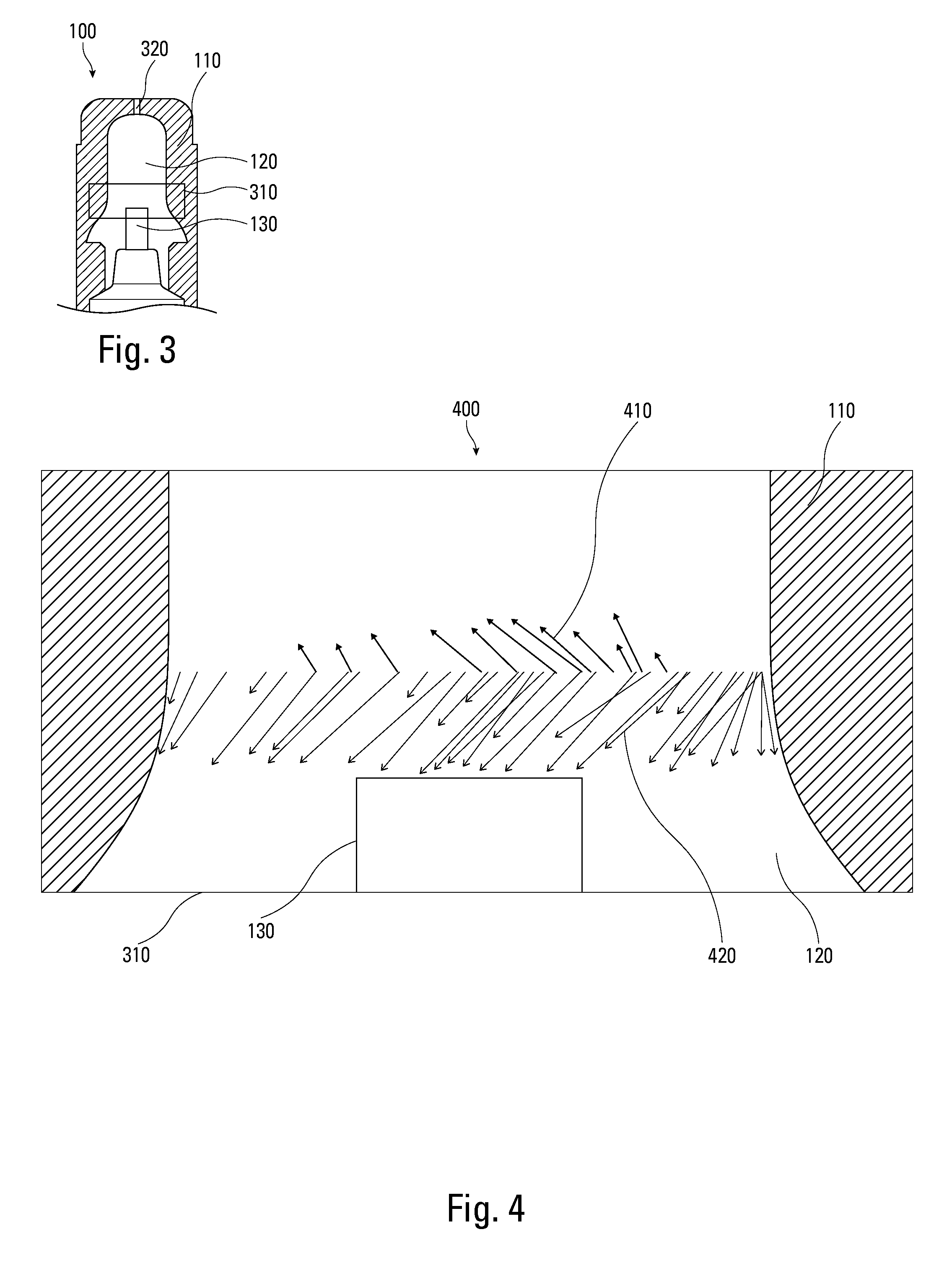

Method and apparatus for achieving high power flame jets while reducing quenching and autoignition in prechamber spark plugs for gas engines

ActiveUS20130055986A1Increase ignition delayPrevent spontaneous combustionSparking plugsInternal combustion piston enginesEngineeringQuenching

A prechamber spark plug may have a prechamber having a pre-determined aspect ratio and hole pattern to achieve particular combustion performance characteristics. The aspect ratio and hole pattern may induce a rotational flow of fuel-air in-filling streams inside the prechamber volume. The rotational flow of the fuel-air mixture may include both radial flow and axial flow characteristics based on the aspect ratio and hole pattern. Axial flow characteristics can include a first axial direction proximate the periphery of the rotational flow and a counter second axial direction approaching the center of the rotational flow. The radial and axial flow characteristics may further include radial air-fuel ratio stratification and / or axial air-fuel ratio stratification. The rotational flow, the radial flow and the axial flow may be adjusted by alteration of the aspect ratio and hole pattern to achieve particular combustion performance characteristics in relation to a wide variety of spark gap geometries.

Owner:PROMETHEUS APPLIED TECH

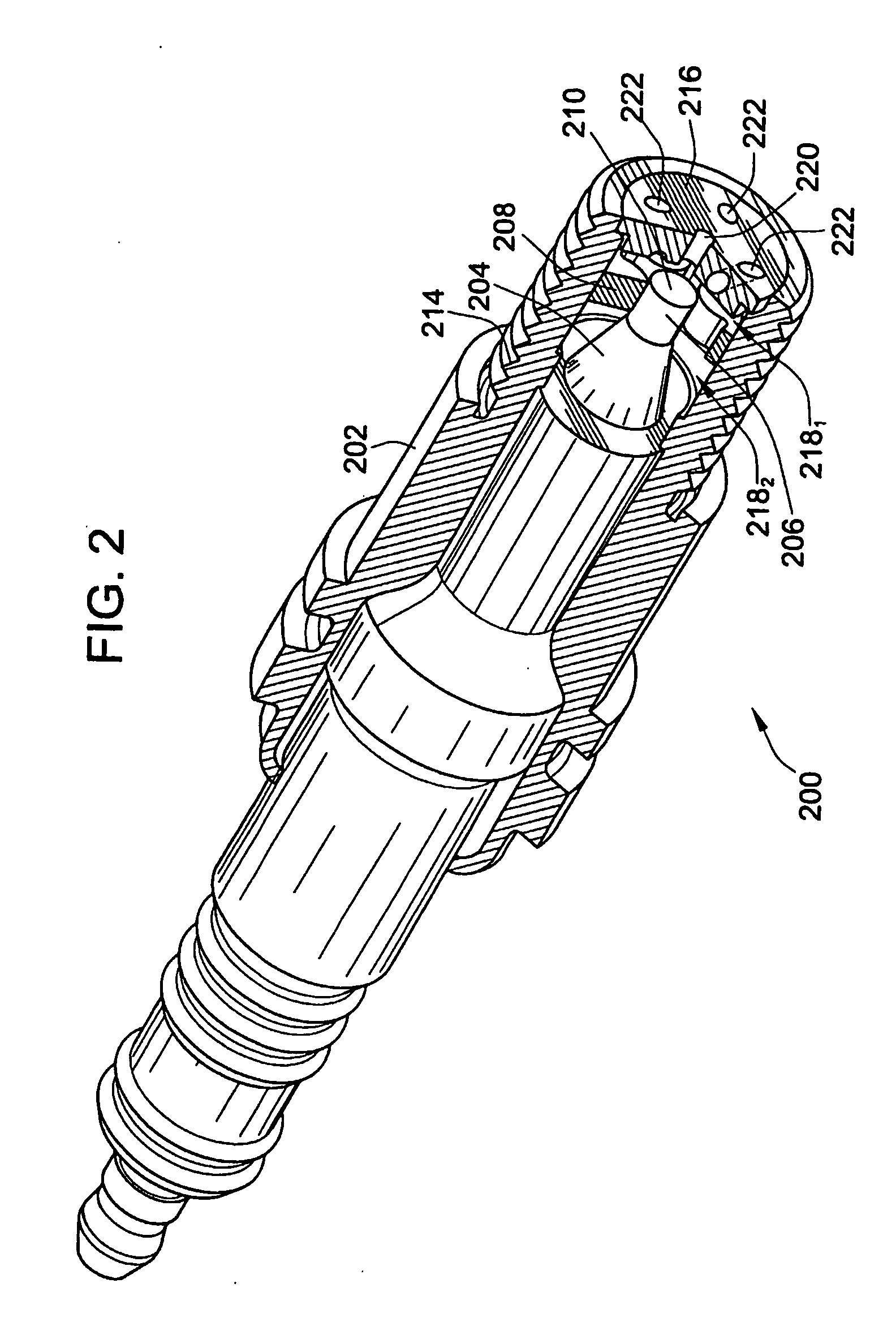

Pre-chamber spark plug

ActiveUS20070069617A1Maximize spark plug lifeReduce erosionSparking plugsInternal combustion piston enginesSpecific energyElectricity

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and preignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

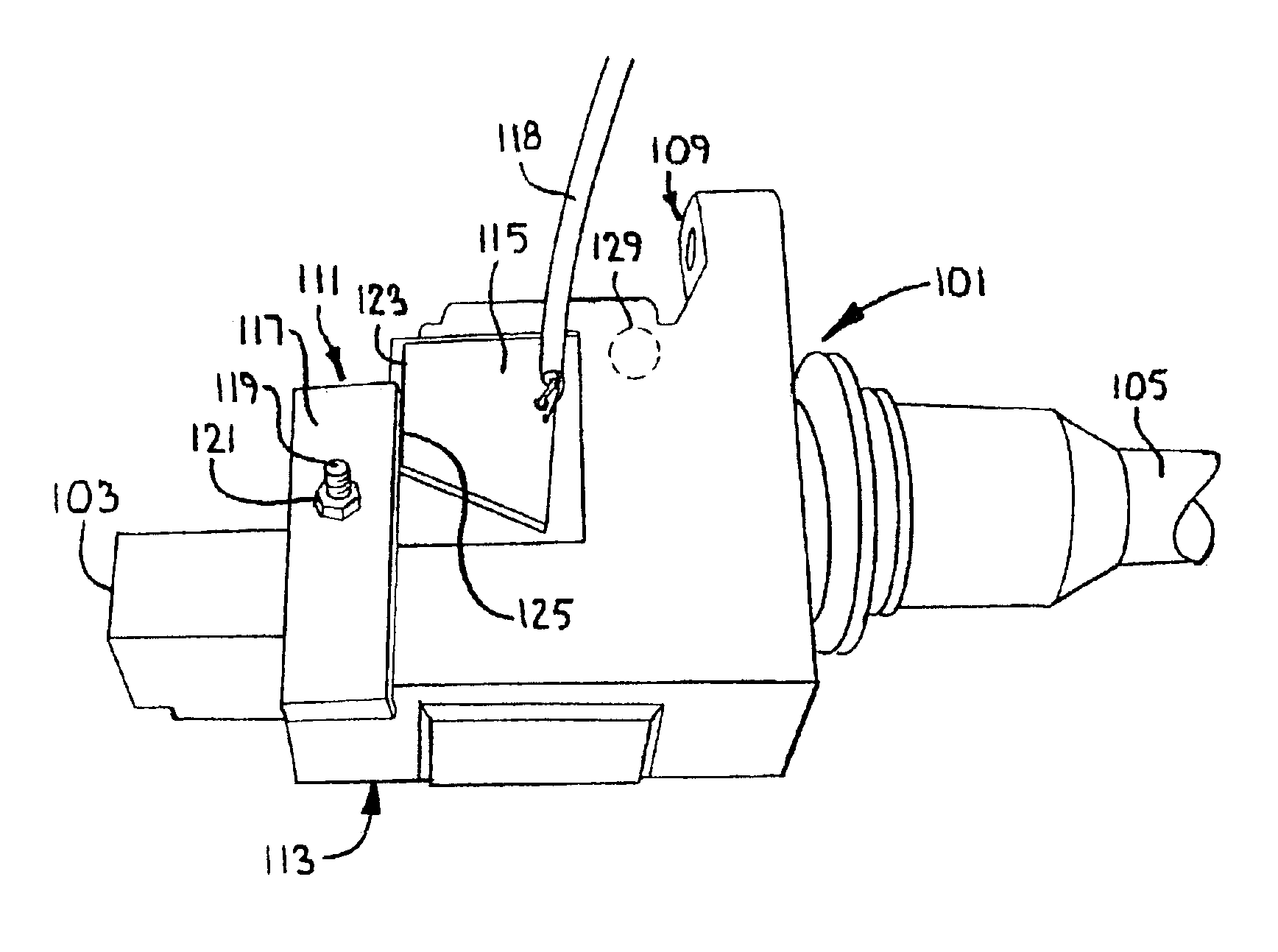

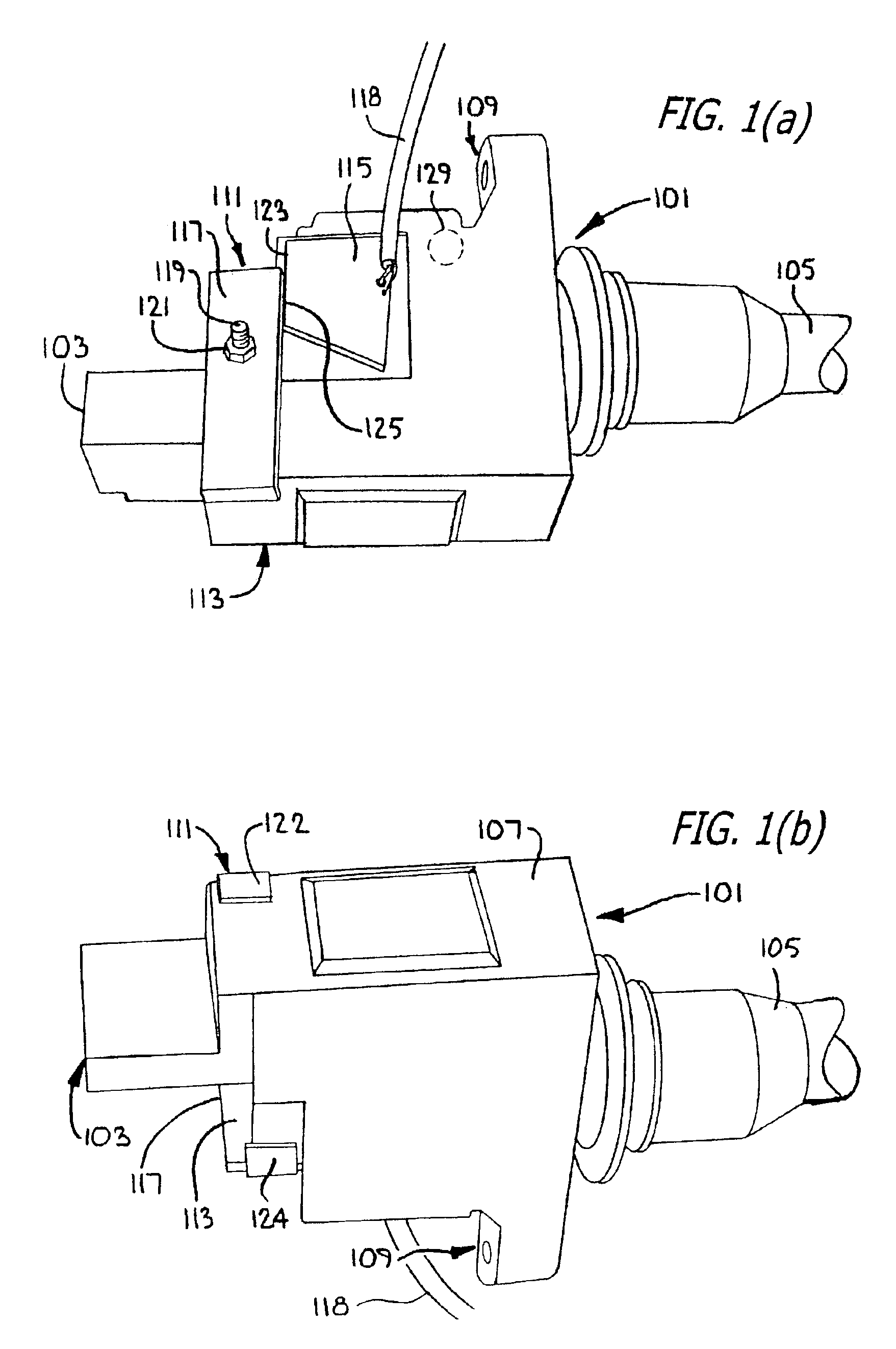

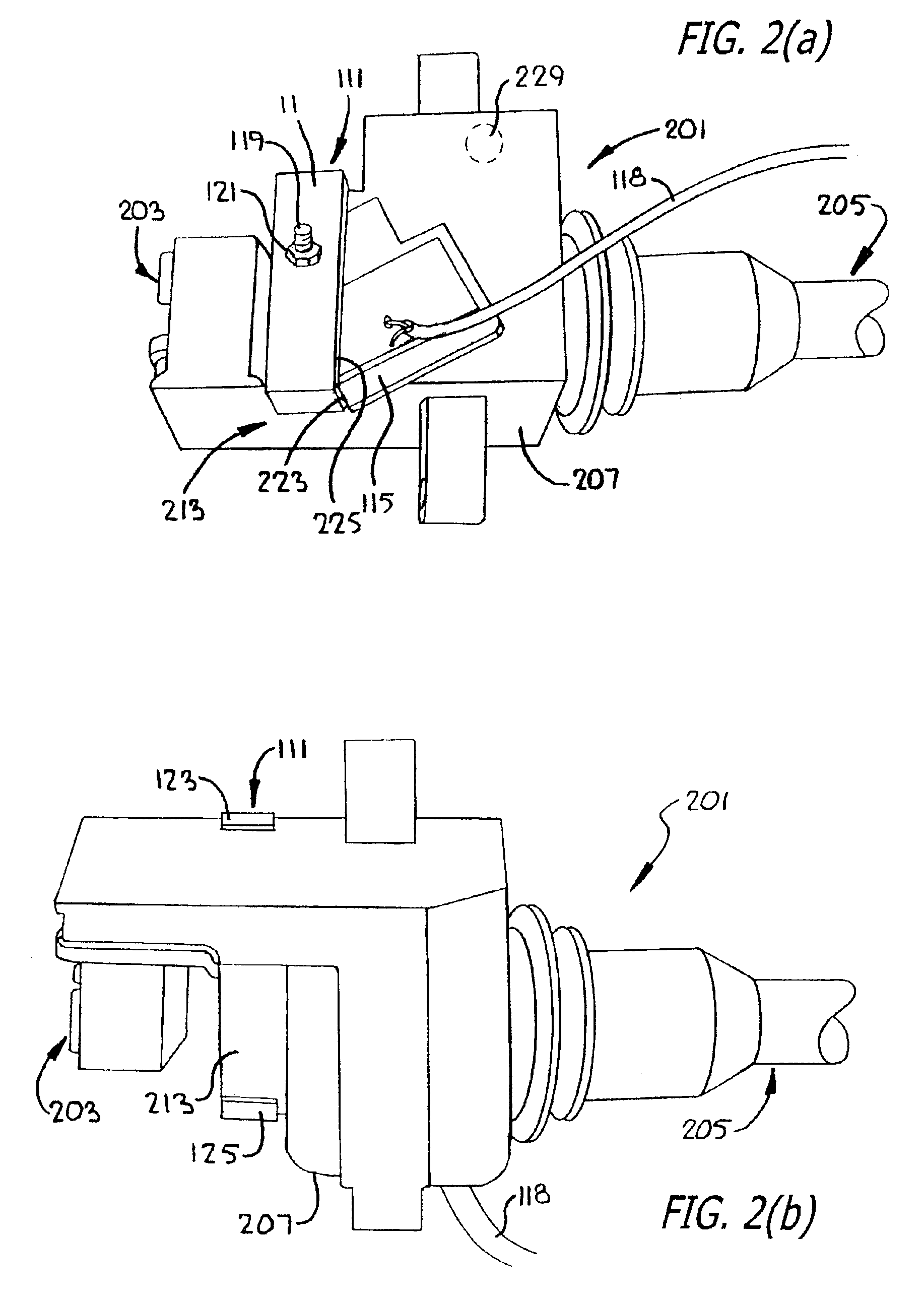

Detecting field from different ignition coils using adjustable probe

Detecting the magnetic field generated by a coil-on-plug (101) (aka coil-over-plug) using an adjustable probe (111). The probe (111) includes a signal detector (115) for detecting the field, a detachable adapter (117) configured to detachably attach to the housing (107) of the ignition coil at a specified location (113), and an adjustable connector (119 and 121) that adjustably connects the signal detector to the detachable adapter in a first predetermined position or in a second predetermined position. A detecting process and a diagnostic system using the probe are also disclosed.

Owner:SNAP ON INC

Method, system, and apparatus for highly controlled light distribution from light fixture using multiple light sources (LEDS)

InactiveUS20100110671A1High strengthHigh producedPlanar light sourcesMechanical apparatusLight beamEffect light

Disclosed herein are apparatus, methods, and systems for deriving composite beams from a plurality of light sources such as LEDs. Optical units comprising a plurality of light sources, each source having an associated optic which is individually positionable, are developed using optimization techniques that allow for lighting different target areas in an effective manner by rotating or otherwise positioning the reflectors, refractive lenses, TIR lenses, or other lens types to create a composite beam. The apparatus, methods, and systems of lighting herein make it possible to widely vary the types of beams from an available fixture using a small number of optics and fixtures. In some cases, by using a combination of individual beam patterns from the same or different types of light sources, a small set of individual optics may be sufficient to create a majority of the typical and specialized composite beams needed to meet the needs of most lighting projects and target areas.

Owner:MUSCO

Pre-chamber spark plug

ActiveUS7659655B2Life maximizationReduce erosionSparking plugsInternal combustion piston enginesElectricityElectrode erosion

Owner:WOODWARD GOVERNOR CO

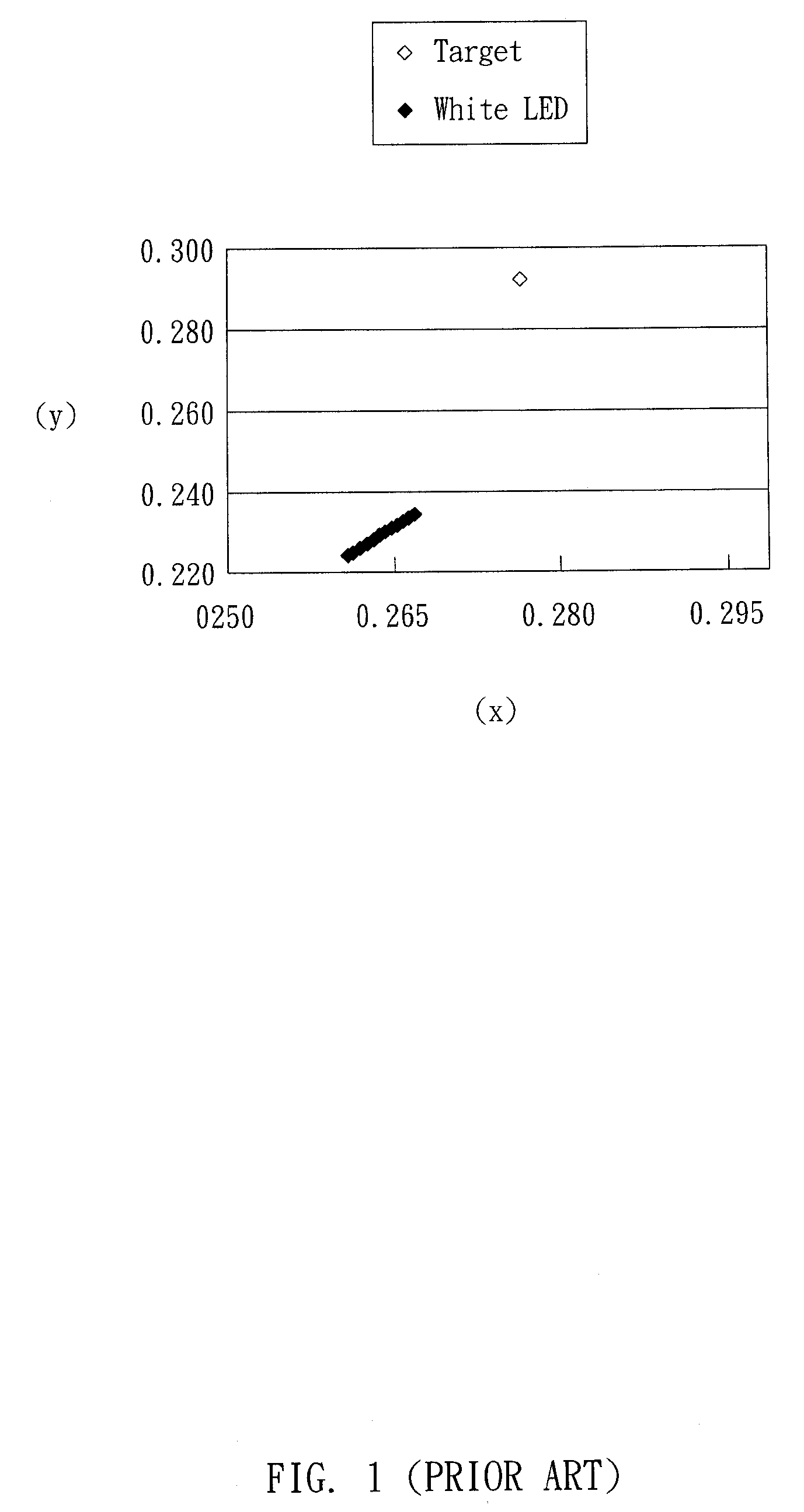

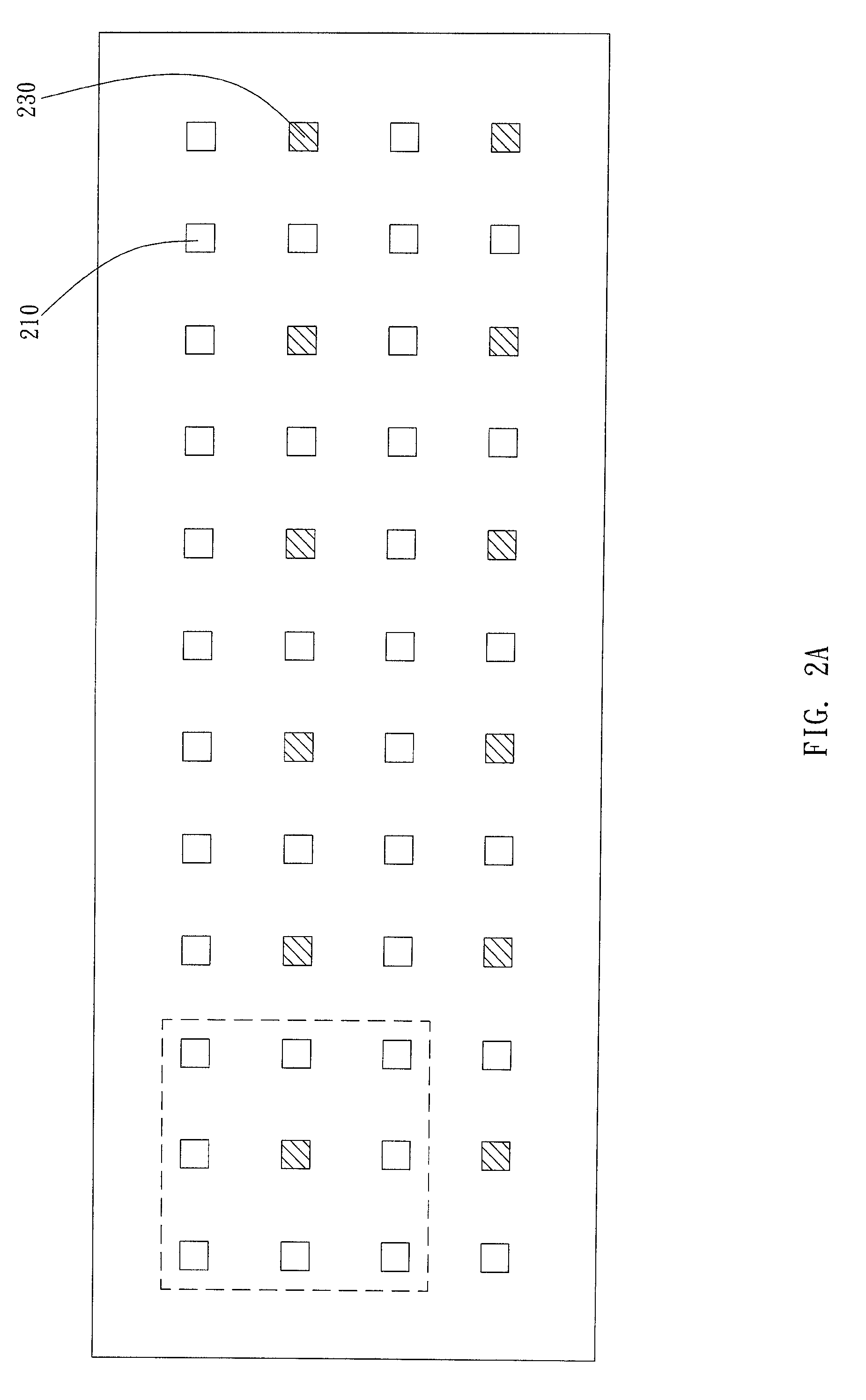

Illuminant system using high color temperature light emitting diode and manufacture method thereof

ActiveUS8109650B2High color temperatureSparking plugsDischarge tube luminescnet screensHigh colorGreen-light

A light emitting diode (LED) illuminant system, a manufacture method thereof, and a backlight module using the same are provided. The LED illuminant system includes a plurality of white light illuminants and at least one green light illuminant mixed in the white light illuminants. A light power ratio of the green light illuminant to the white light illuminants is in between ⅕ to 1 / 20. The color temperature of the whole illuminant system will be enhanced to a certain extent by mixing the green light illuminant and the white light illuminants. The manufacture method includes the following steps: obtaining a transmission spectrum of the white light illuminants; analyzing the transmission spectrum to determine n supplemental amount of a green light; and disposing at least one green illuminant in accordance with the supplemental amount of the green light.

Owner:OPTRONIC SCI LLC

LED apparatus and method for accurate lens alignment

ActiveUS8348461B2Improve efficiencyReduce manufacturing costPlanar light sourcesMechanical apparatusLed arrayEngineering

An LED apparatus of the type including (a) a mounting board having an LED-supporting surface with an LED device thereon and (b) a lens member over the LED device establishing a light path therebetween. The inventive LED apparatus includes a lens-aligning member having front and back surfaces and defining an aperture receiving the LED device therethrough such that the LED device protrudes beyond the front surface. The lens member includes a lens portion and a flange thereabout, the flange being attached to the front surface of the lens-aligning member such that the lens portion substantially surrounds the protruding LED device. The lens-aligning member has a first mating feature which is positioned and arranged for mating engagement with a second mating feature of the mounting board, thereby accurately aligning the lens member over the LED device by accurately aligning the lens-alignment member with the mounting board. Other aspects of the invention is a method for LED-apparatus assembly and a method for manufacturing custom high-efficiency LED lensing for LED-array modules.

Owner:IDEAL IND LIGHTING LLC

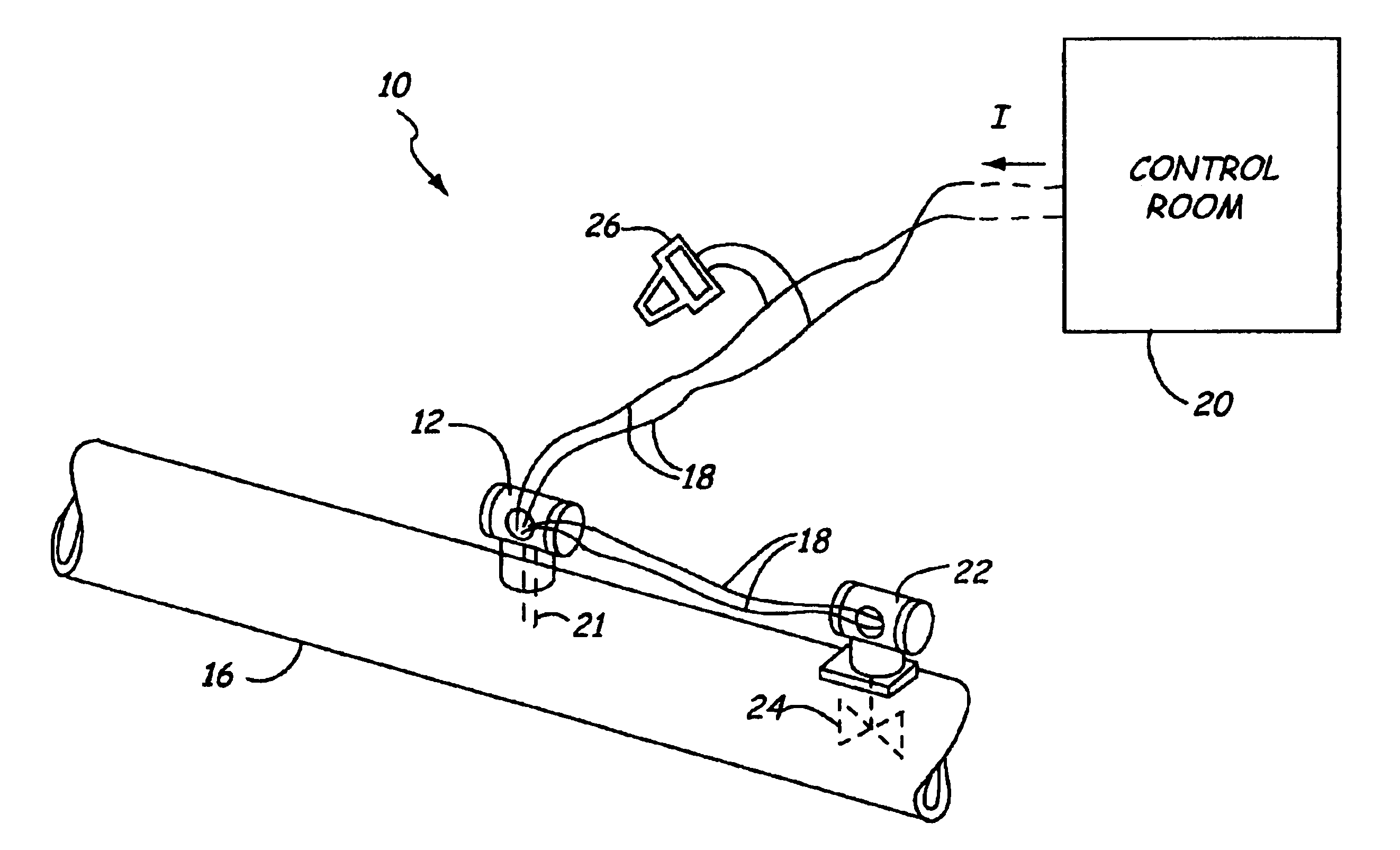

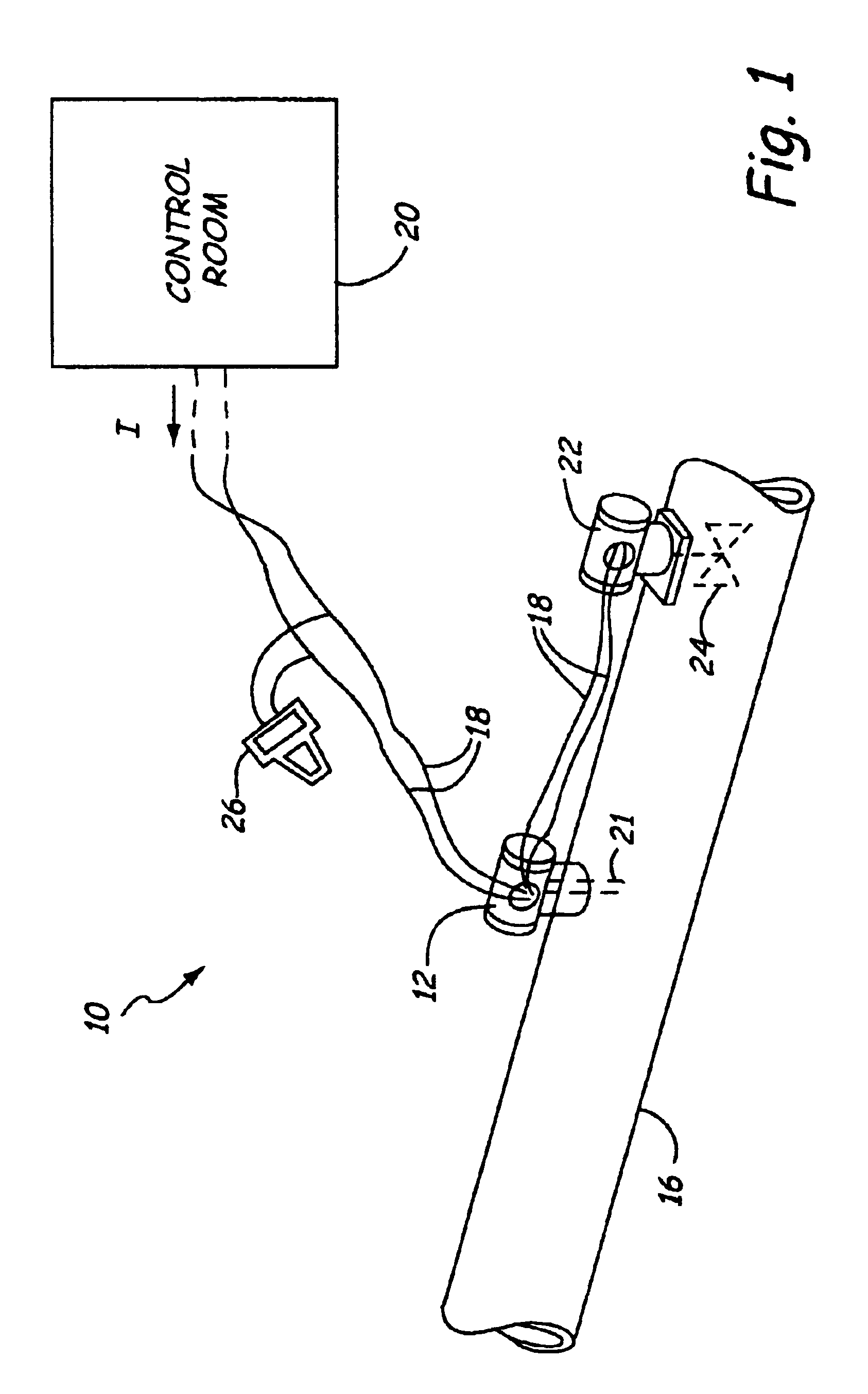

Direct injection of fuels in internal combustion engines

InactiveUS20050045146A1Maintain integritySparking plugsHigh pressure gas fuel injectionCombustionEngineering

A fuel delivery injector for an internal combustion engine. The fuel injector forms pan of a device (10) which provides a combined injection and ignition means for the engine. The fuel delivery injector comprises a first portion (31) and a second portion (32) adapted to be detachably connected together. The first portion has a delivery port (37) defined between a valve seat (61) and a valve member (63) movable with respect to the valve seat (61) for opening and closing the delivery port (37). An actuating member (87) is provided in the first portion (31) and is operatively connected to the valve member (63). An actuating means (85) is provided in the second portion (32). When the first and second portions (31, 32) are connected together, the actuating mean (85) is operably associated with the actuating member (87) to provide an actuating assembly (83). Typically, the actuating assembly (83) comprises an electromagnetic means in which the actuating member (87) comprises a solenoid armature and the actuating means (85) comprises a solenoid oil, whereby connection of the first and second portions (31, 32) together completes assembly of the electromagnetic means. Where the device (10) provides a combined fuel injector and ignition me the device (10) is provided with a primary electrode (58) which cooperates with a secondary electrode (57) to define a spark gap (60). A popper projection (62) provided on the valve member (63) is utilized to define the primary electrode (58), as well as to provide spray guidance effects on the fuel spray issuing from the delivery port (37). The device (10) providing the combined fuel injection and ignition means is also described and claimed.

Owner:ORBITAL ENGINE CO PTY LTD

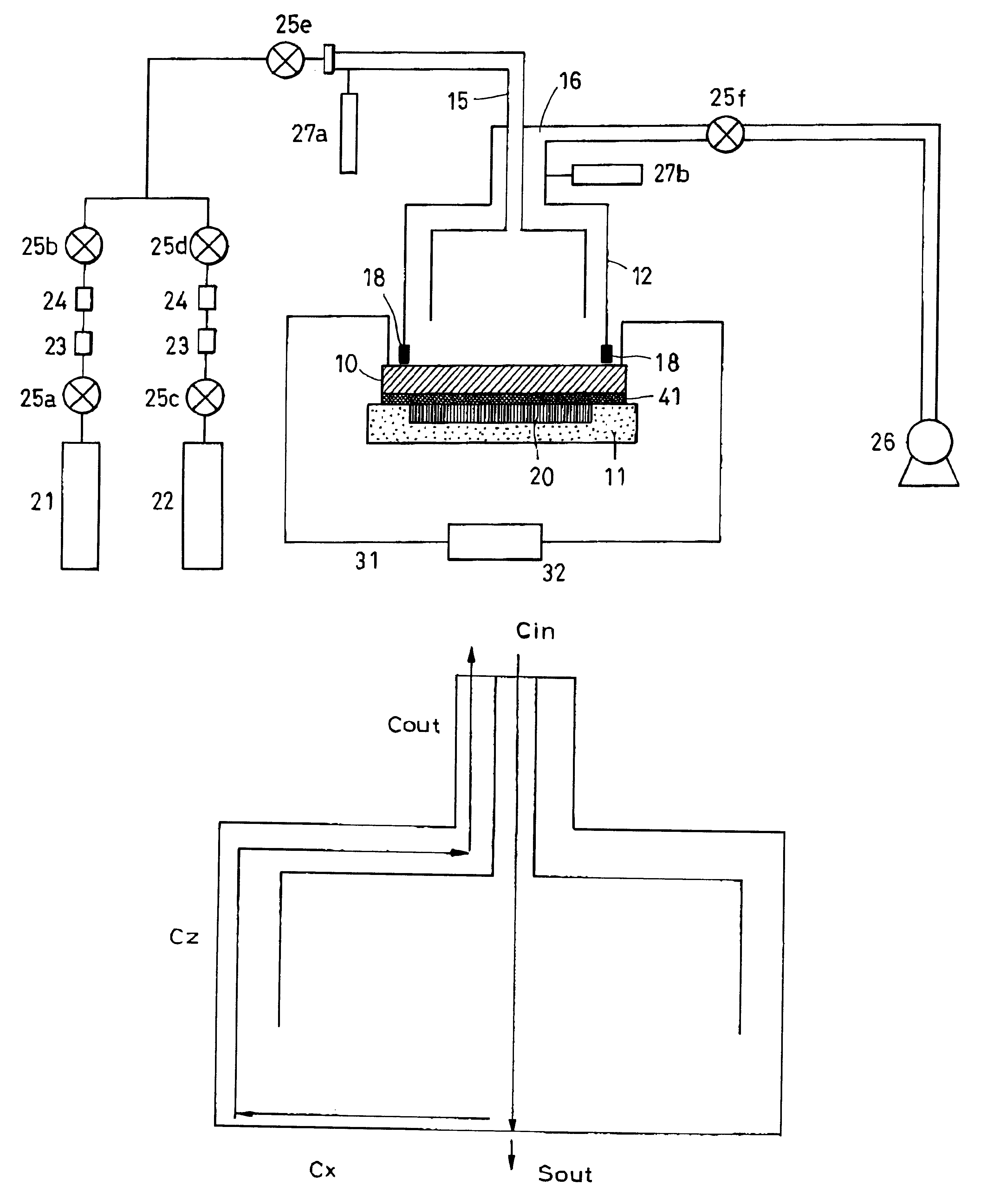

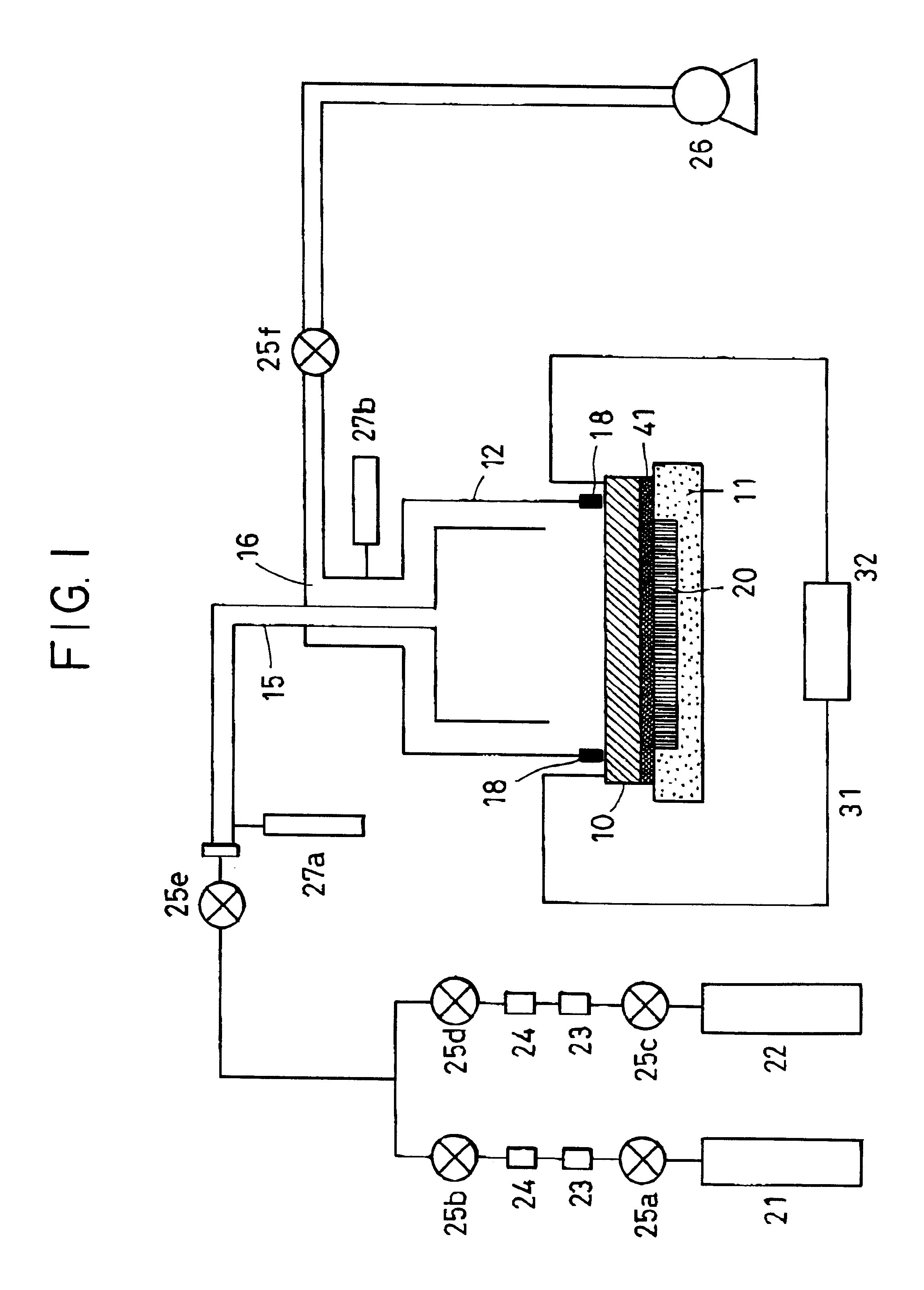

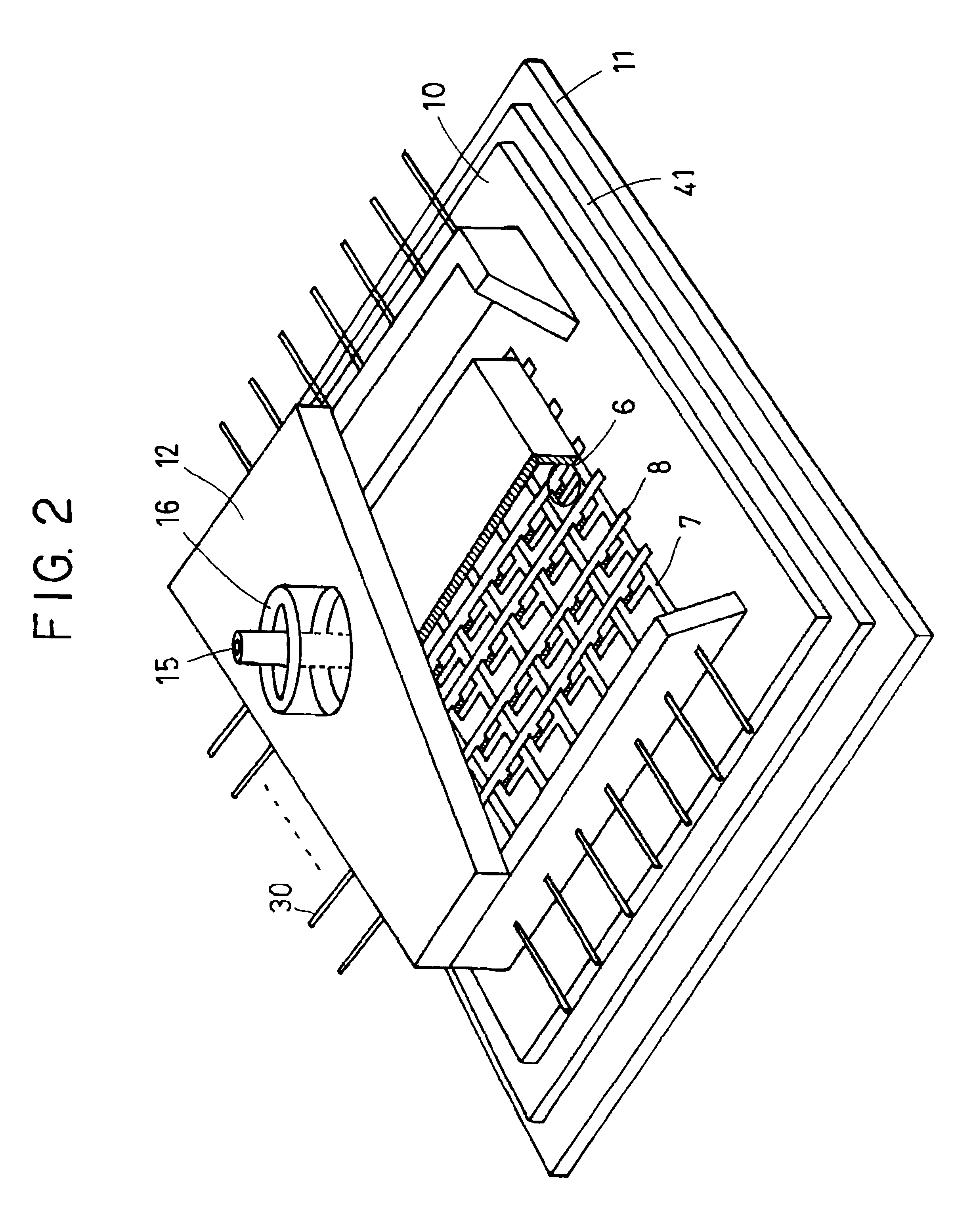

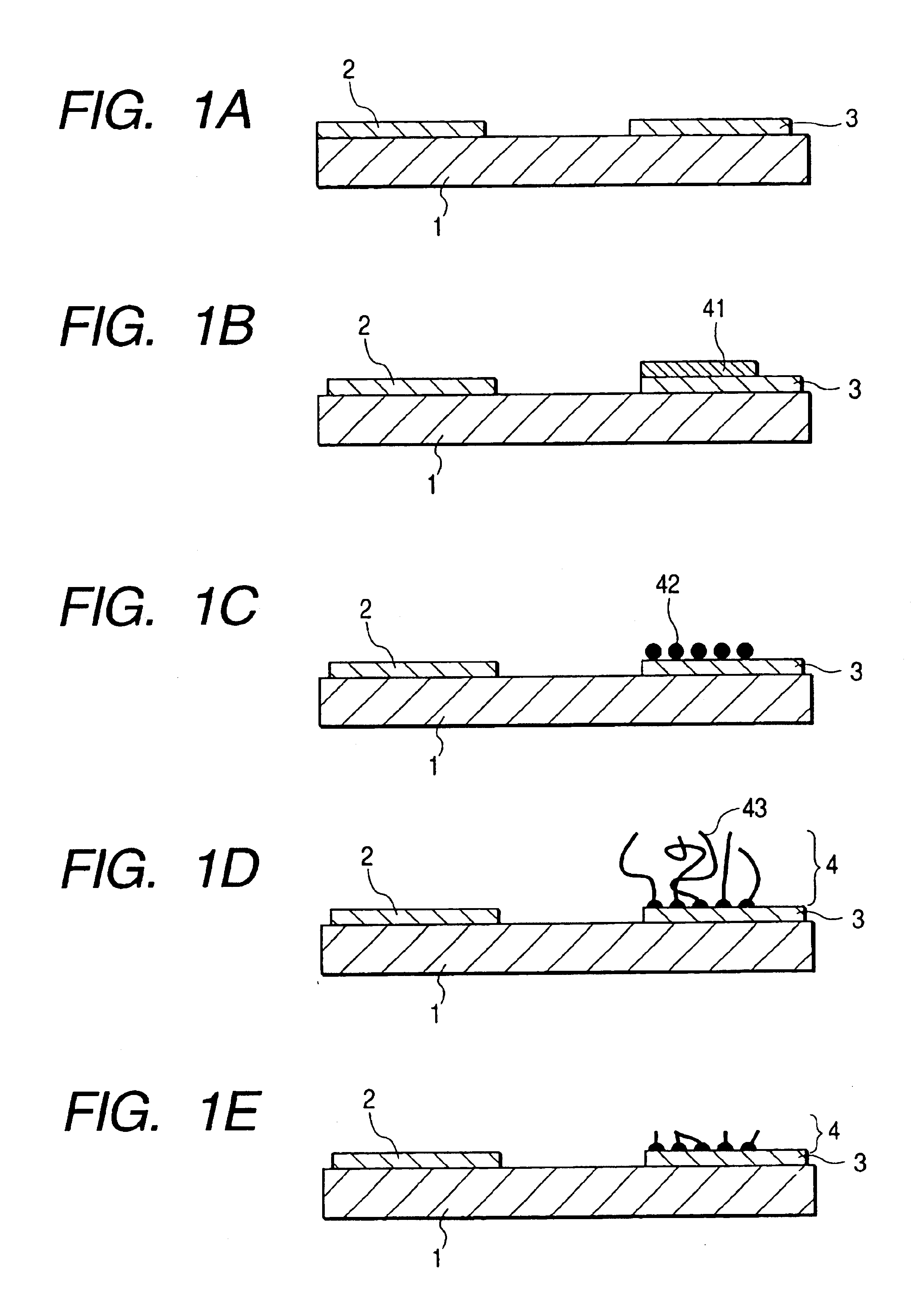

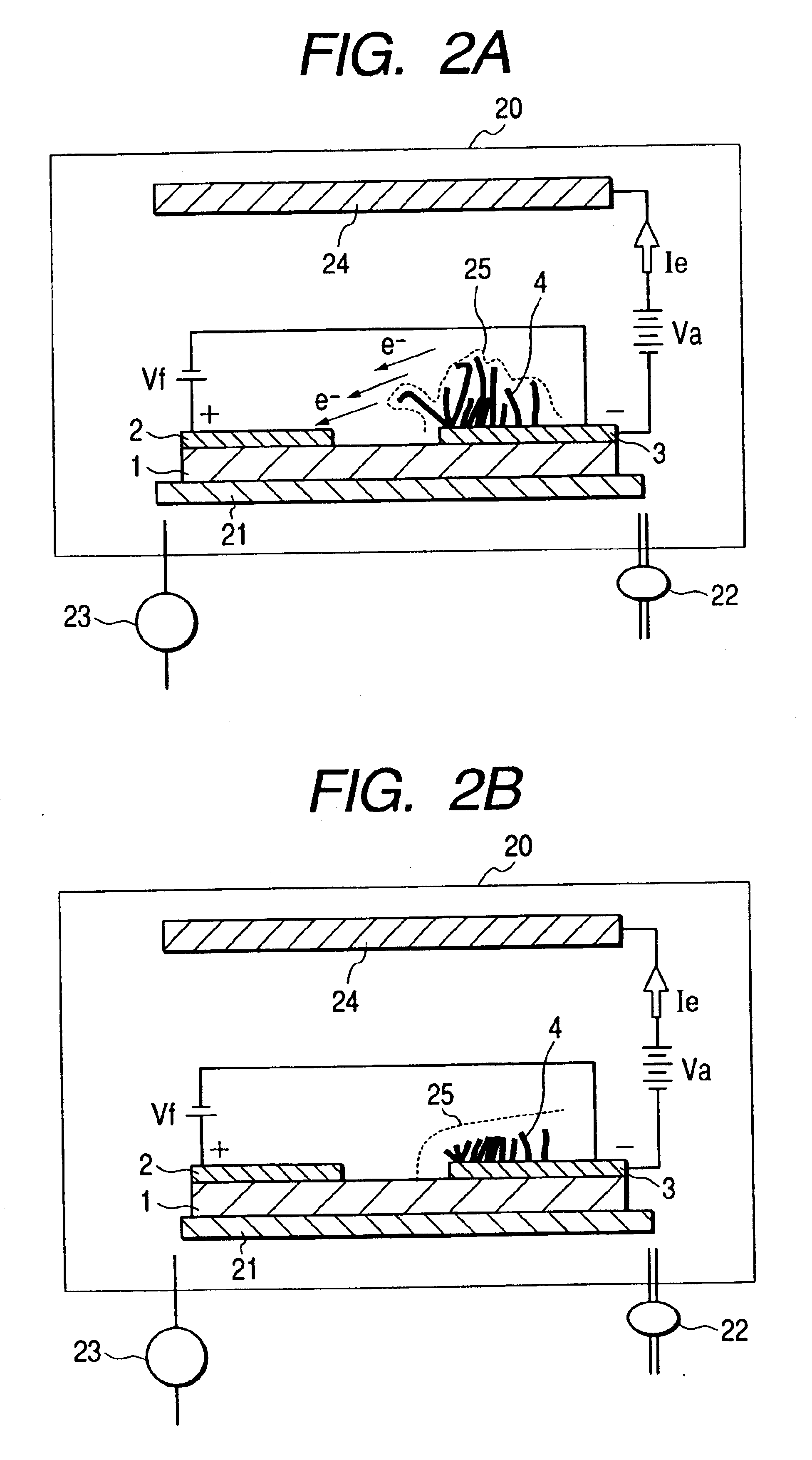

Apparatus for manufacturing electron source, method for manufacturing electron source, and method for manufacturing image-forming apparatus

InactiveUS6626718B2Sparking plugsVessels or leading-in conductors manufactureCarbon filmElectron source

A method for manufacturing an electron source includes the steps of covering a substrate provided with a first electrode and a second electrode by a container, introducing a gas composed of a carbon compound into the container, and forming a carbon film by applying a voltage between the first electrode and the second electrode. The relationship 1 / (4 / Cx-1 / Cz)>=Sout>=4Sact-Cin is satisfied, where Cin is the conductance from the gas inlet to the position of the substrate nearest to the gas inlet, Cx is the conductance from the position of the substrate nearest to the gas inlet to the position of the substrate nearest to the gas outlet, Sout is the effective exhaust rate, Sact is the consumption rate of the gas, and Cz is the conductance from the substrate to the gas outlet. An apparatus for manufacturing an electron source and a method for manufacturing an image-forming apparatus are also disclosed.

Owner:CANON KK

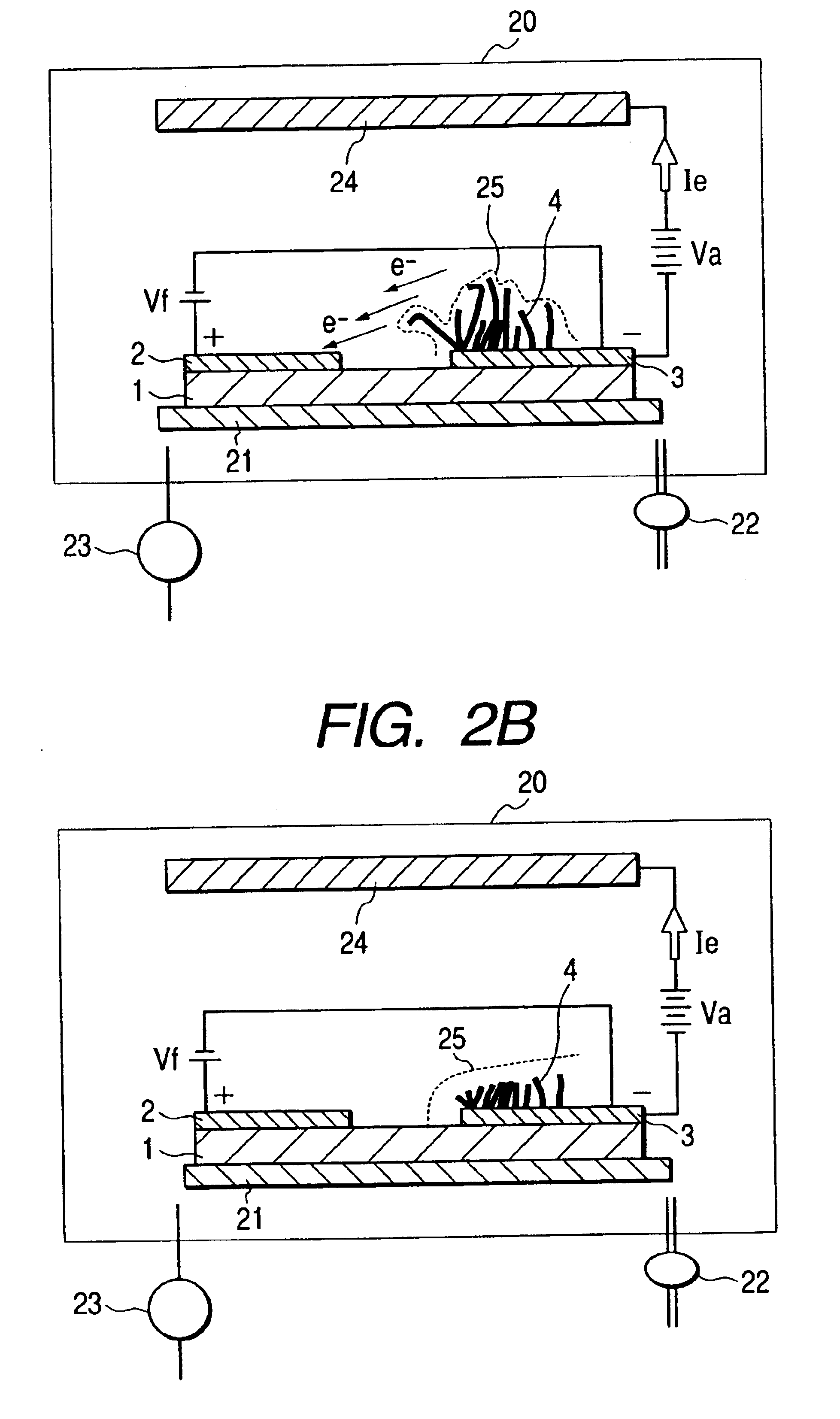

Electron-emitting device, electron source, image-forming apparatus, and method for producing electron-emitting device and image forming apparatus

InactiveUS6848962B2Reduce the differenceUniform and stableSparking plugsCathode ray tubes/electron beam tubesFiberElectron source

A method for producing a durable electron-emitting device having a uniform electron emission characteristic, an electron source, and an image-forming apparatus having a uniform display characteristic for a long period are provided. The method for producing an electron-emitting device according to the present invention includes the steps of: disposing a cathode electrode on a surface of a substrate; providing an electrode opposite the cathode electrode; disposing plural pieces of fiber containing carbon as a main component on the cathode electrode; and applying potential higher than potential applied to the cathode electrode under depressurized condition to an electrode opposite the cathode electrode.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com