Patents

Literature

205results about How to "High color temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

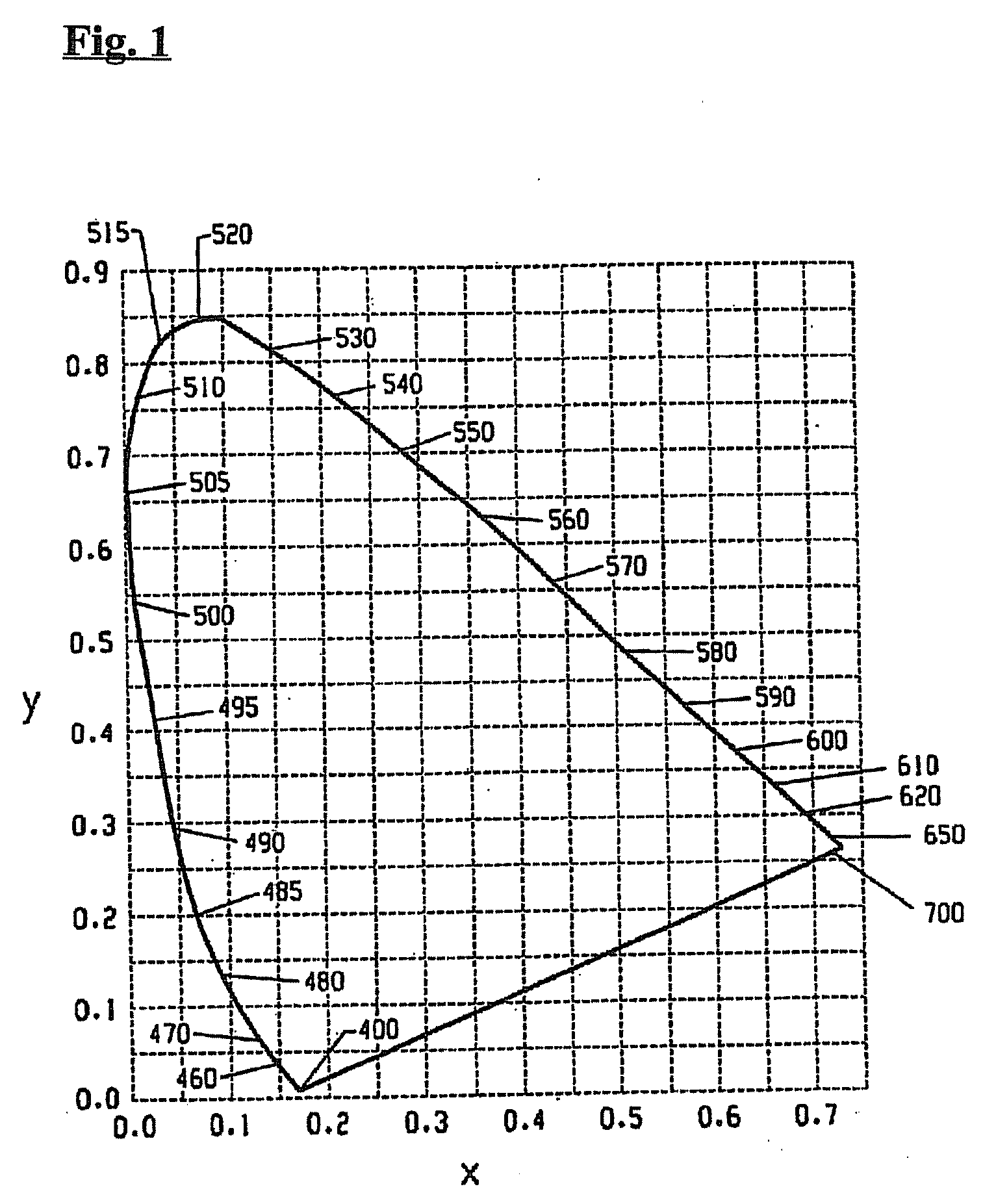

Lighting devices, methods of lighting, light filters and methods of filtering light

ActiveUS20080259589A1Attractive white lightHigh color temperatureMechanical apparatusLight source combinationsEffect lightLight filter

A lighting device comprising a white light source, a filter which filters blue light from the white light, and a second light source which emits red light and / or reddish-orange light. In some embodiments, the white light source comprises a solid state light emitter. A method of lighting, comprising illuminating a white light source, illuminating a red and / or reddish-orange light source, the light sources being positioned and oriented such that the light mixes, and filtering blue light from the mixed light. A method of lighting, comprising illuminating a white light source, filtering blue light from the white light, and illuminating a red and / or reddish-orange light source. A light filter, comprising a first filter component which has a wall region and a window region, and a second filter component comprising two or more reflection regions. Also, methods of filtering.

Owner:IDEAL IND LIGHTING LLC

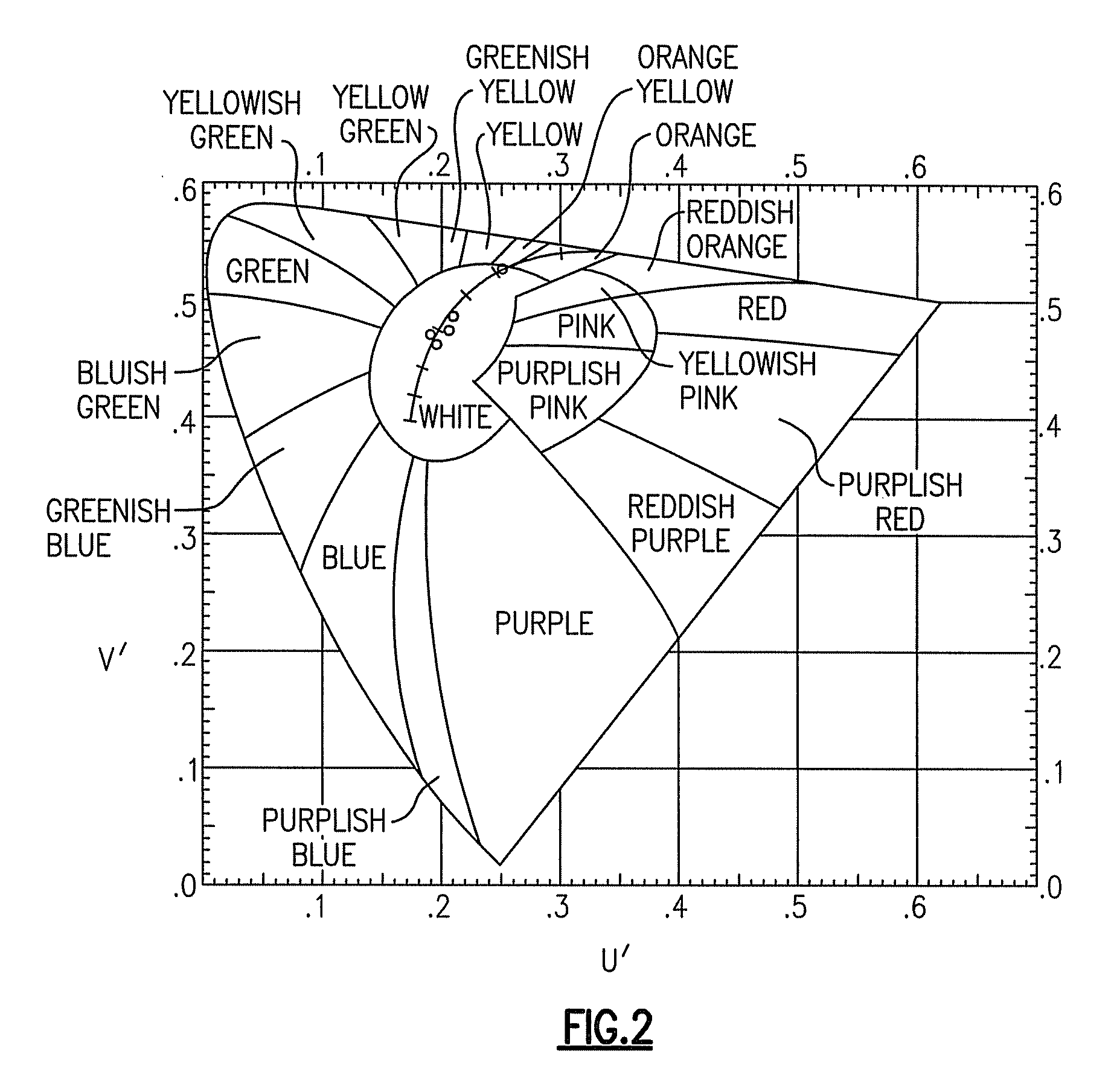

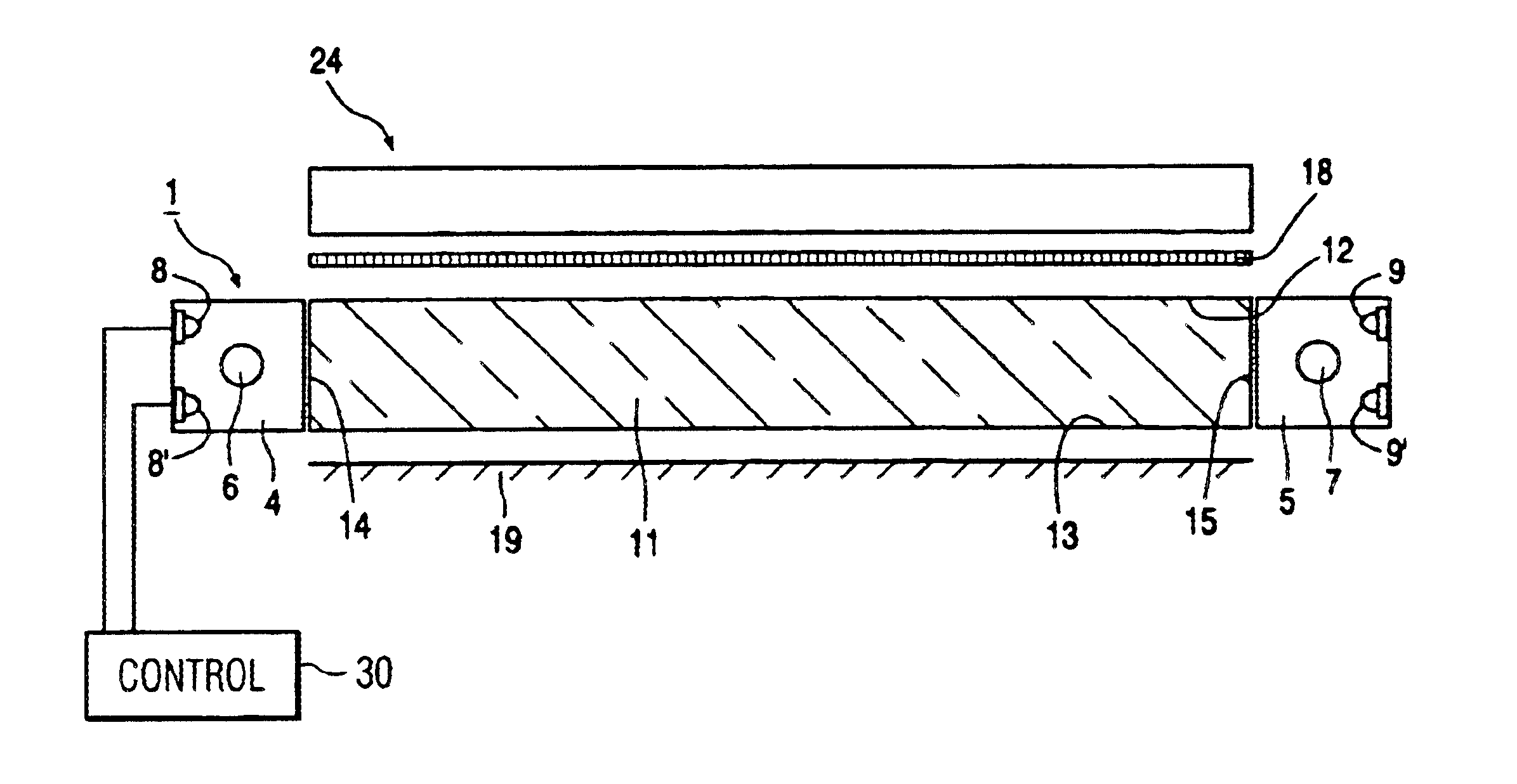

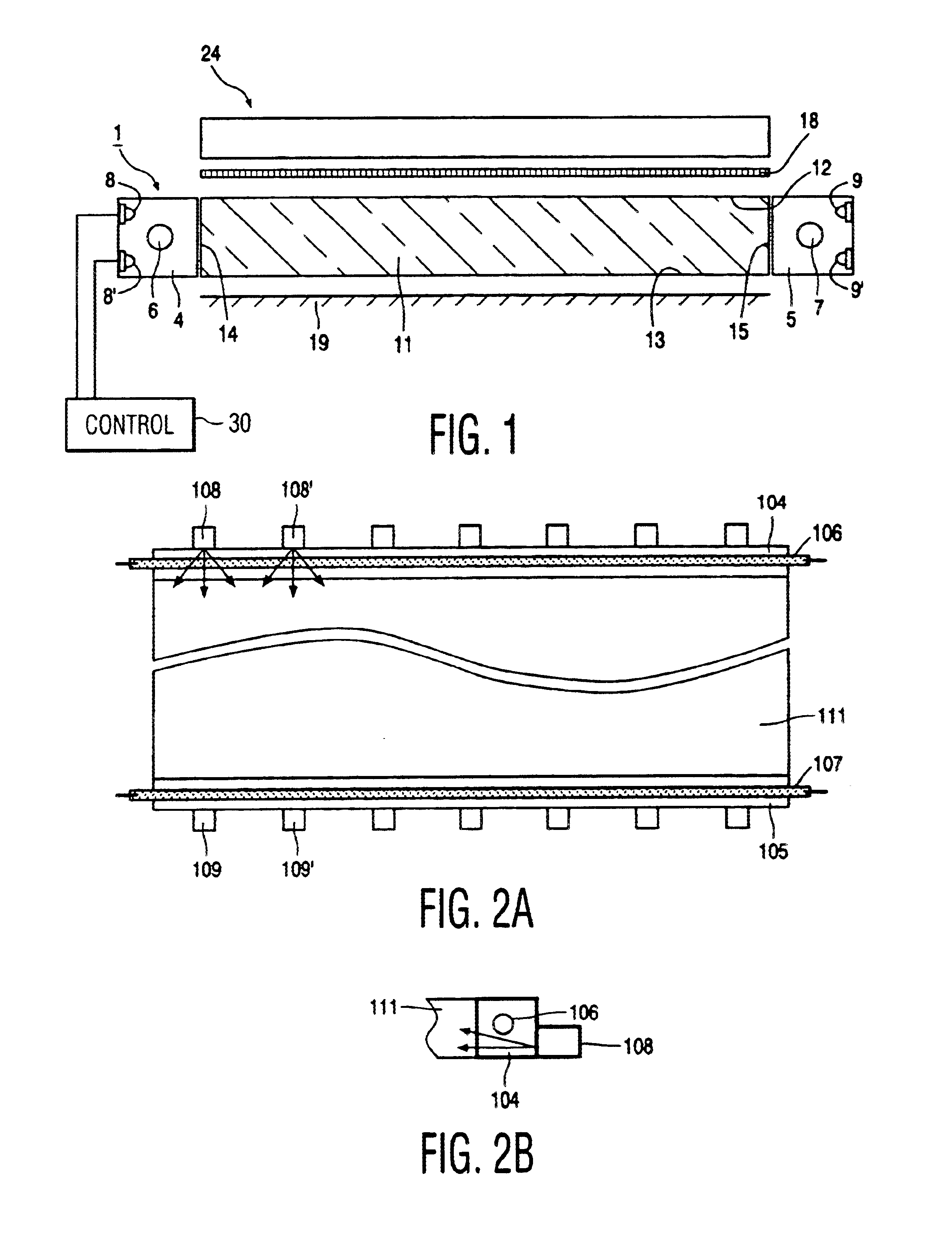

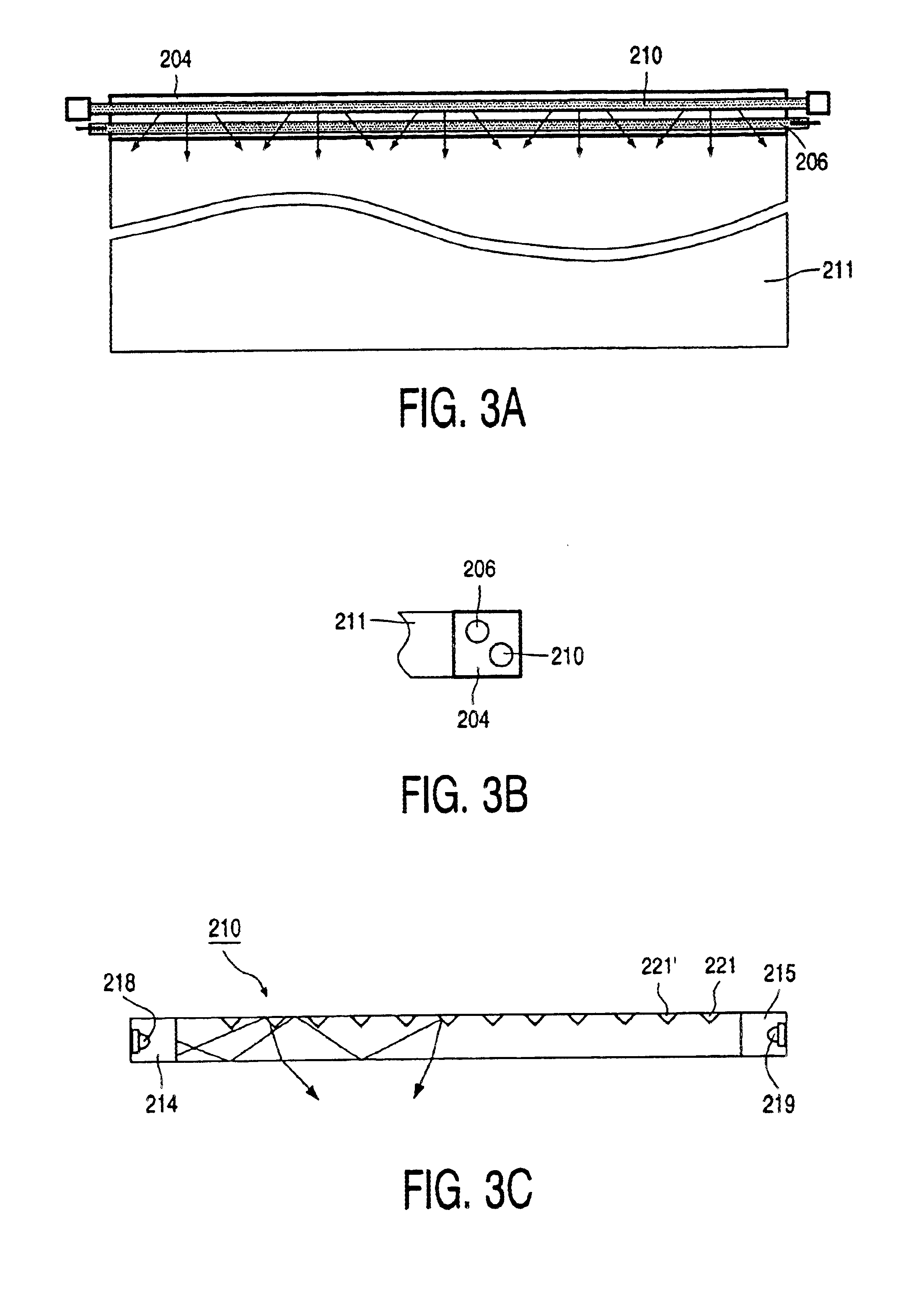

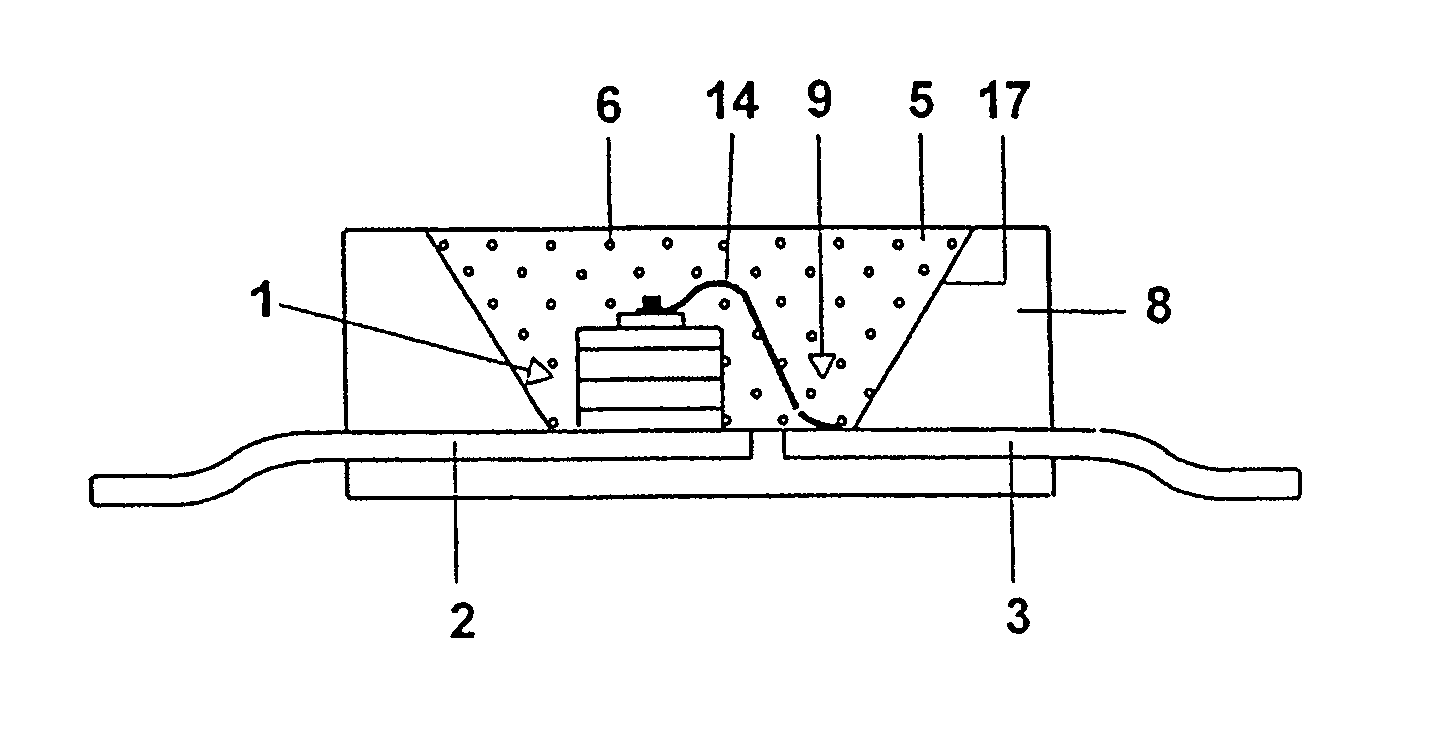

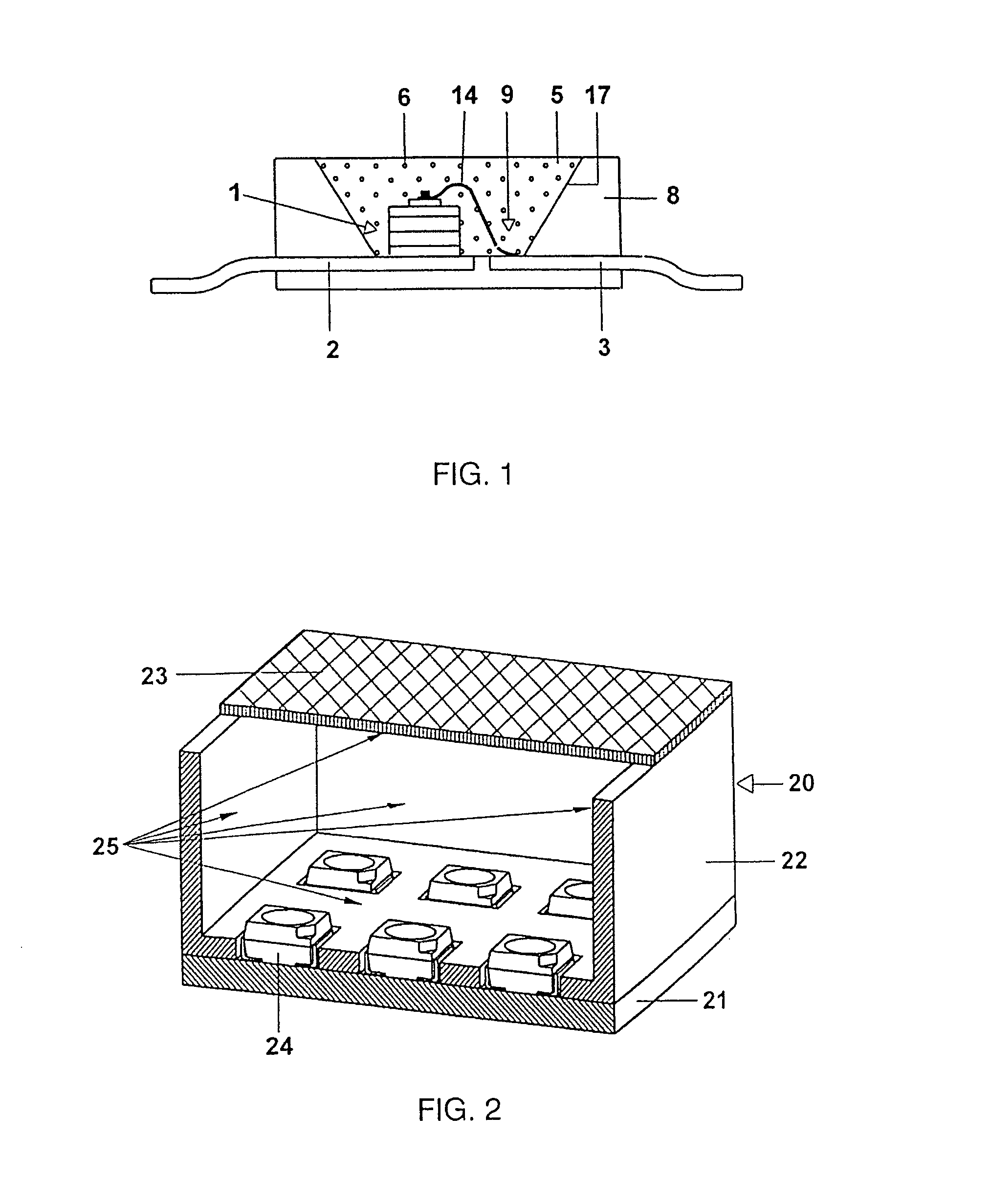

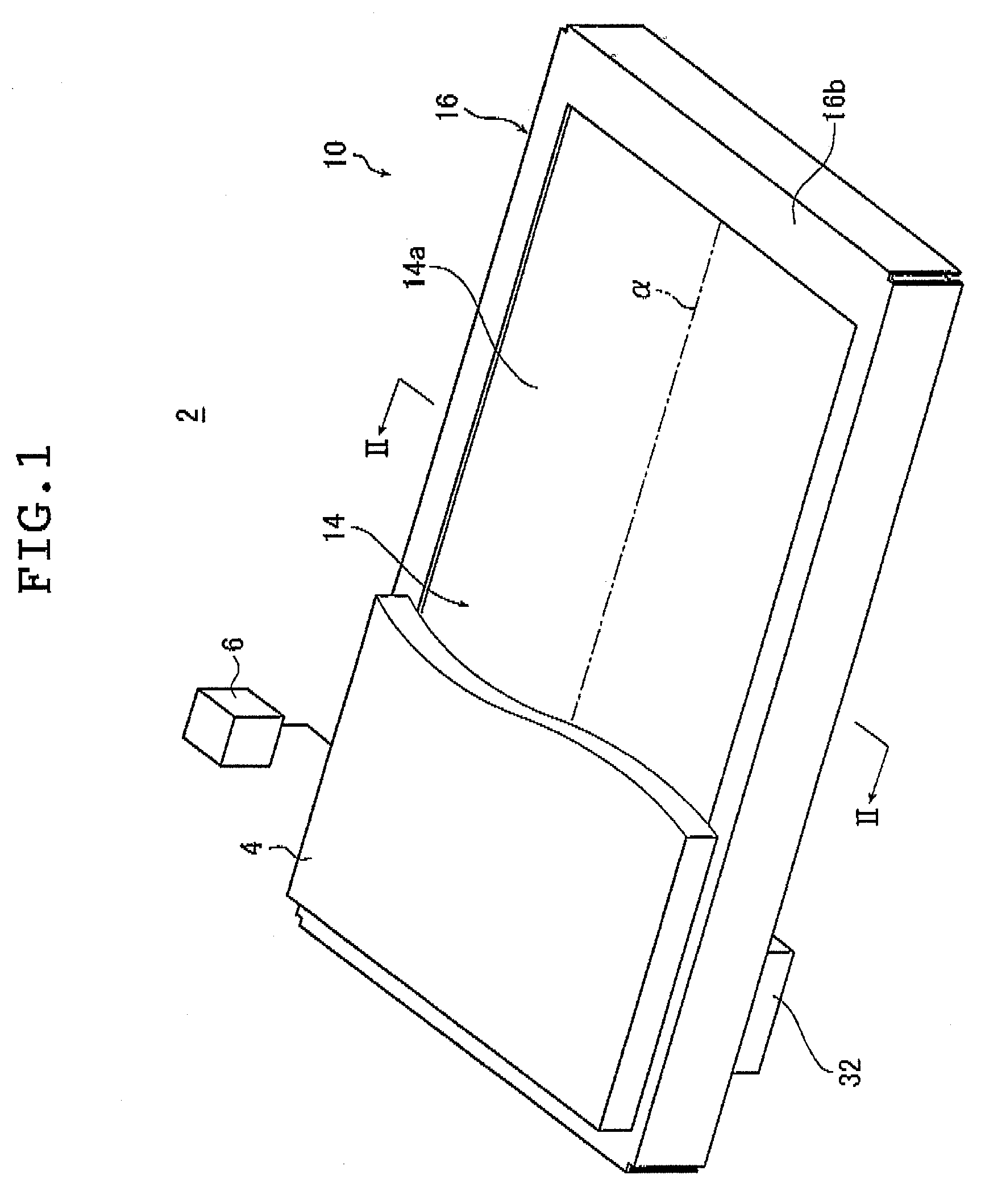

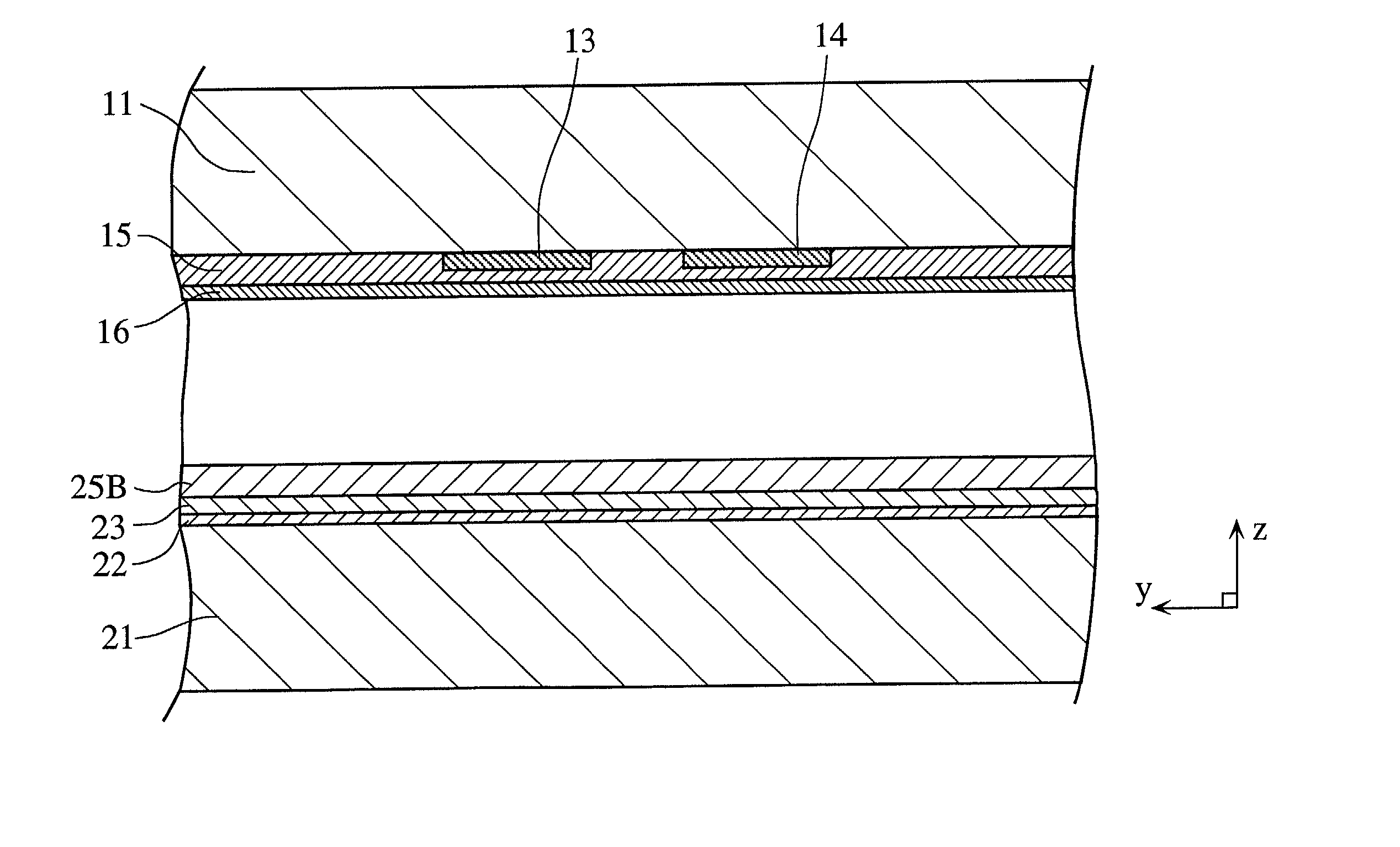

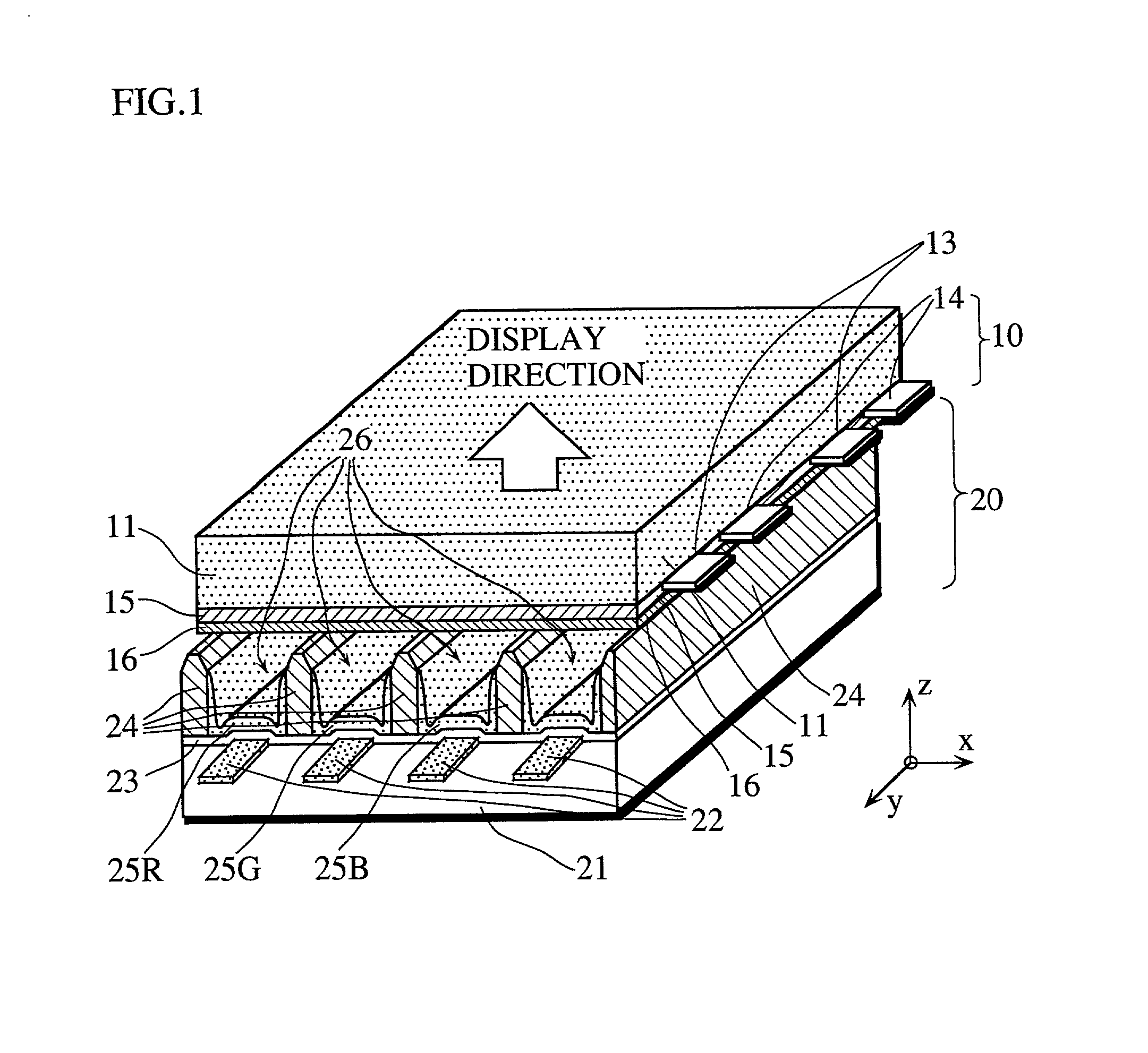

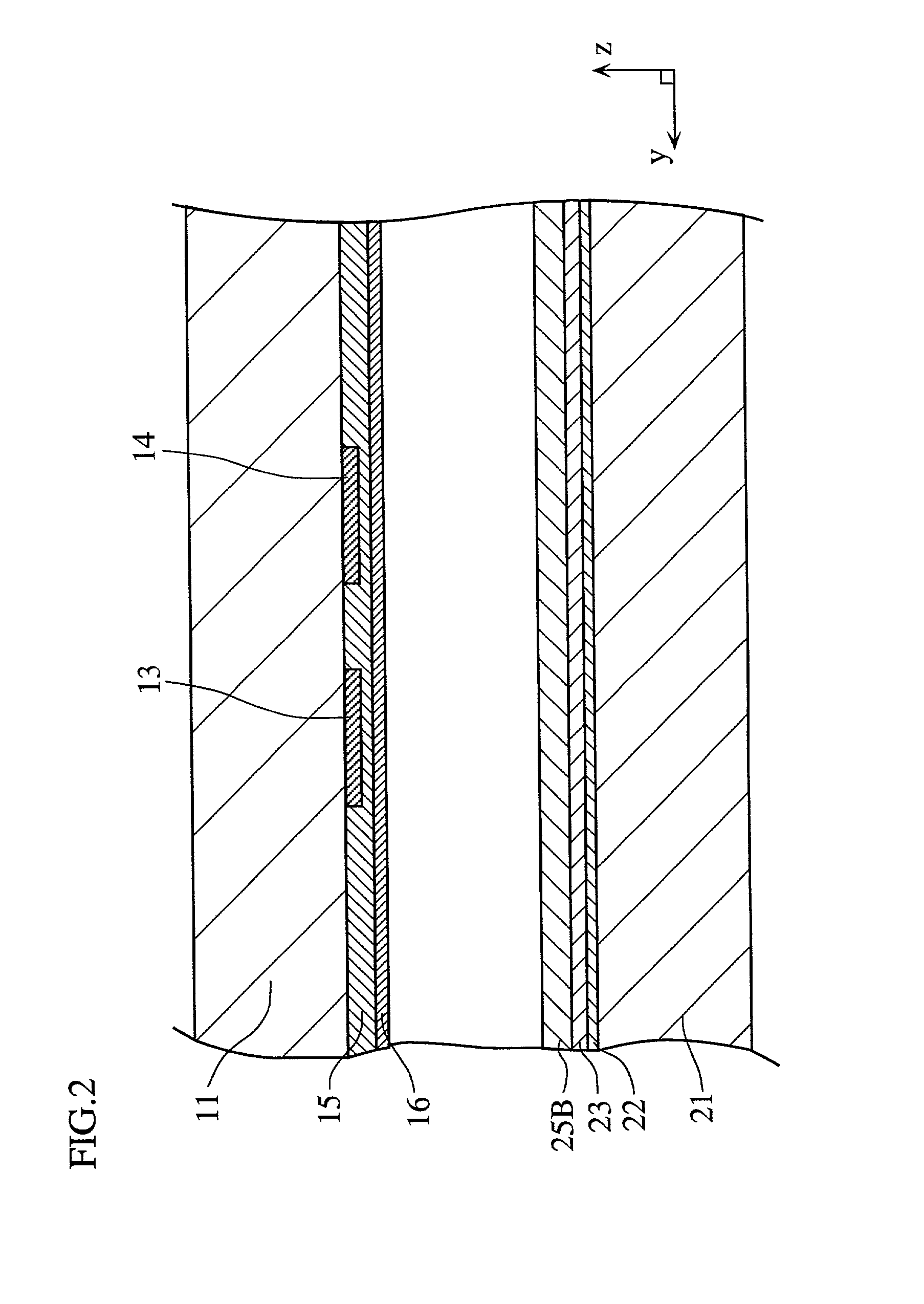

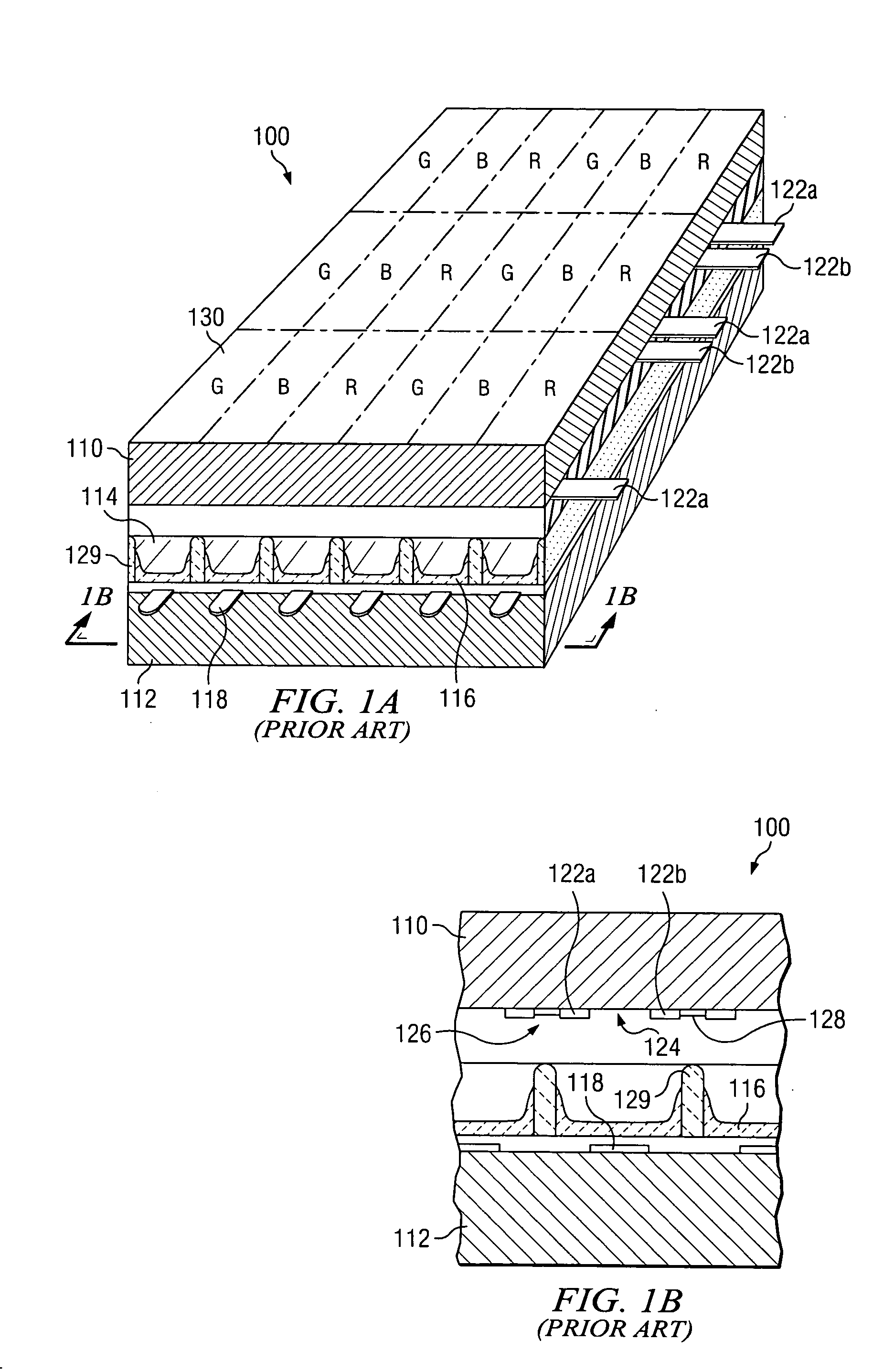

Illumination system and display device

InactiveUS6840646B2Improve image contrastSharp contrastLighting applicationsMechanical apparatusDisplay deviceLuminous flux

A back lighting system for illuminating a display device comprises a light-emitting panel (1) and a light source (6) for coupling light into the light-emitting panel. The light source comprises a low-pressure discharge lamp (6; 7). The light source additionally comprises a plurality of LEDs (8, 8′, . . . ; 9, 9′, . . . ) for selectively setting the color temperature of the light emitted by the light source. Preferably, the LEDs increase the color temperature of the light emitted by the light source. Preferably, the light emitted by the back lighting system ranges from 6,000 to 10,500 K. Preferably, the LEDs are blue light emitting LEDs, each preferably having a luminous flux of at least 5 lm. The color point of an image to be displayed on a display screen of the display device is set by the back lighting system, thus enabling an optimum contrast to be achieved for the image to be displayed by the display device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

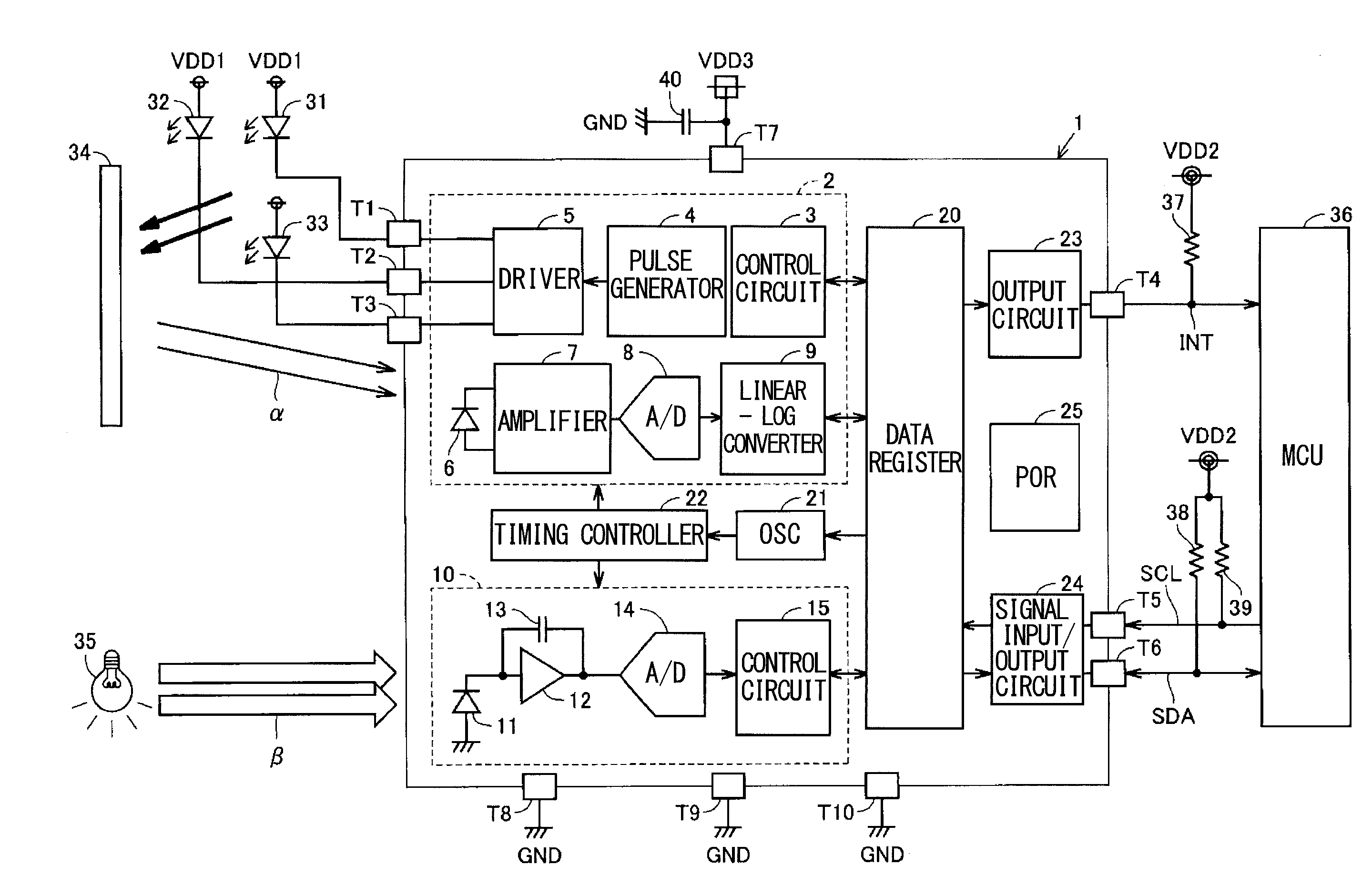

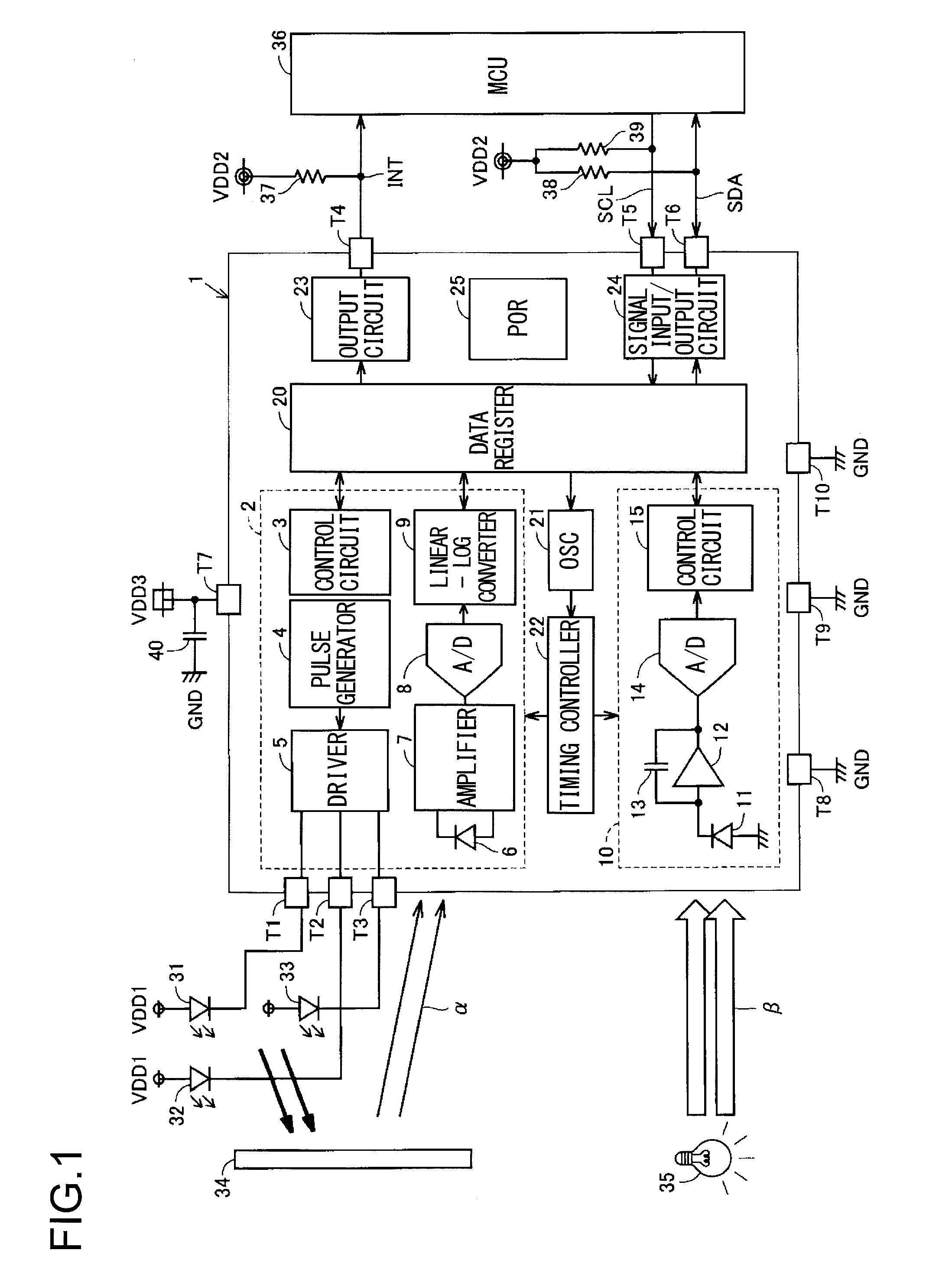

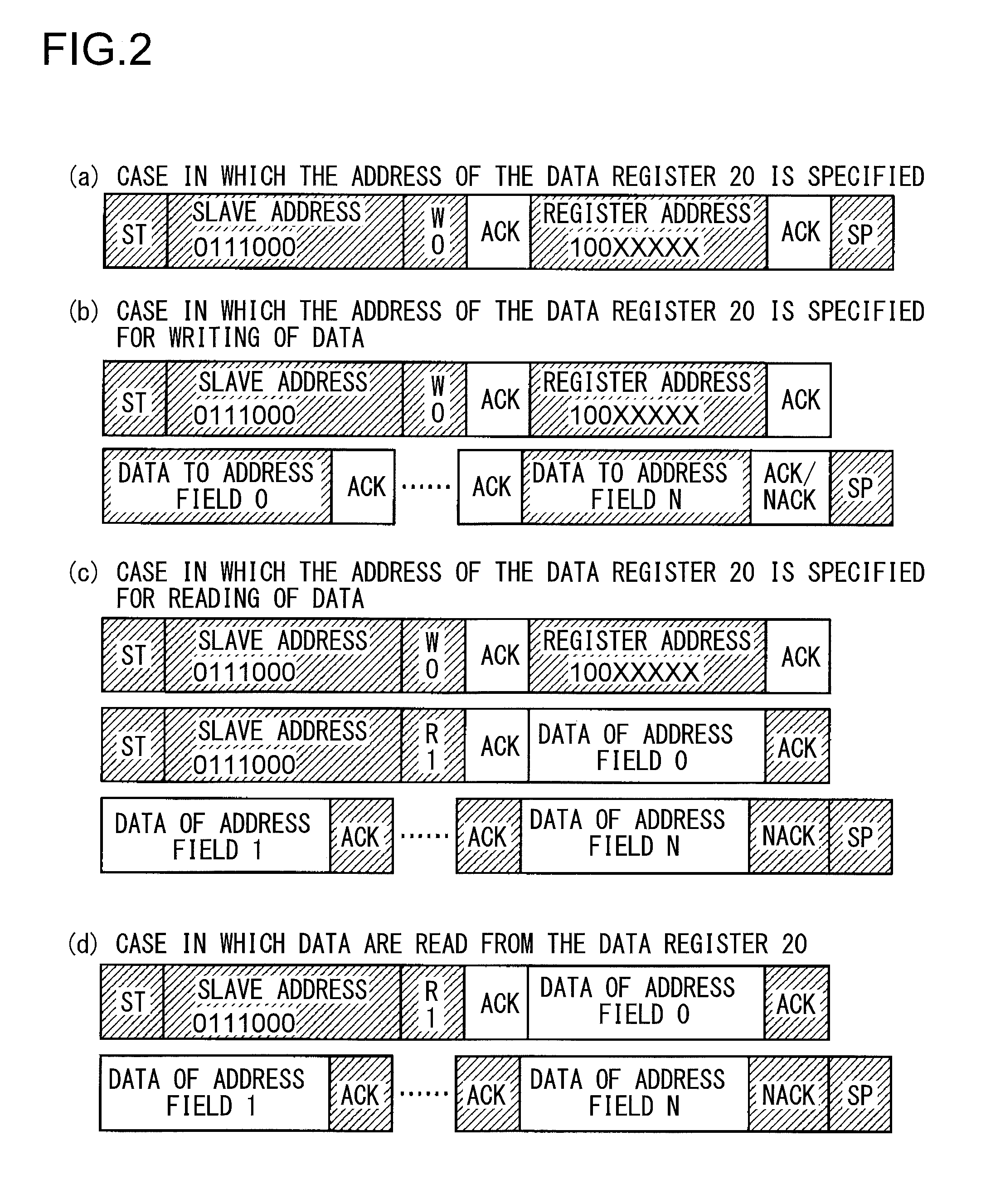

Illumination device

InactiveUS20120019165A1Low color temperatureHigh color temperatureTransmission systemsElectrical apparatusOptoelectronicsControl unit

The illumination device disclosed in the present specification has a light source, a touchless sensor for detecting proximity and movement of an object without contact, and a control unit for controlling the driving of the light source on the basis of an output of the touchless sensor.

Owner:IRIS OHYAMA

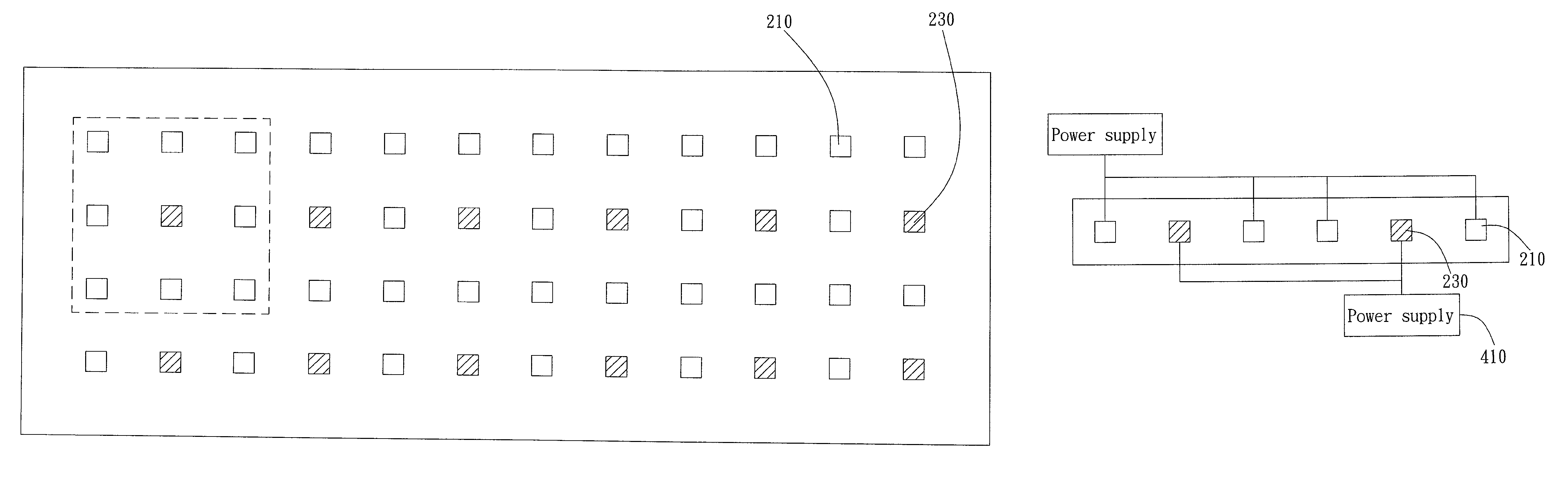

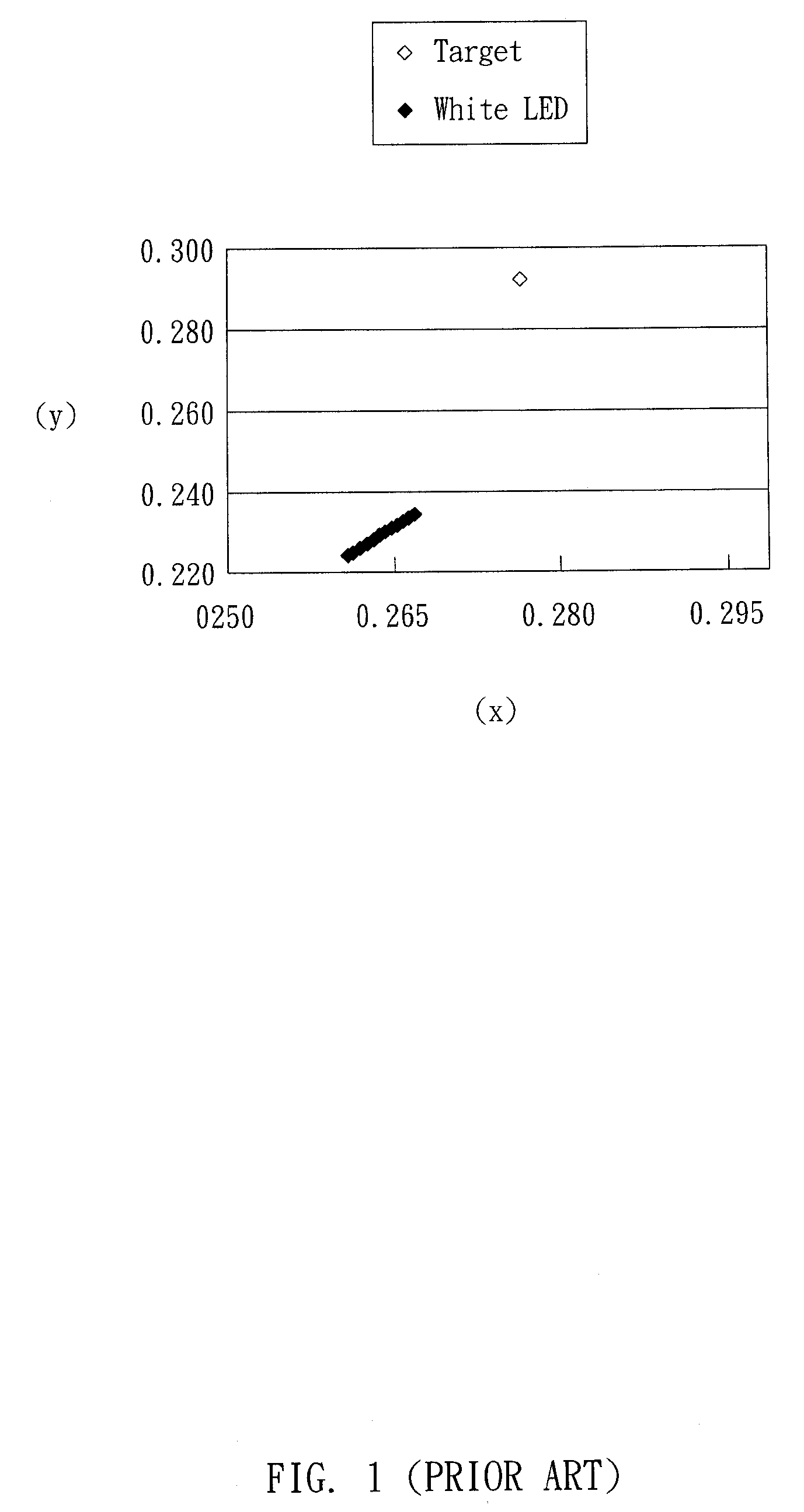

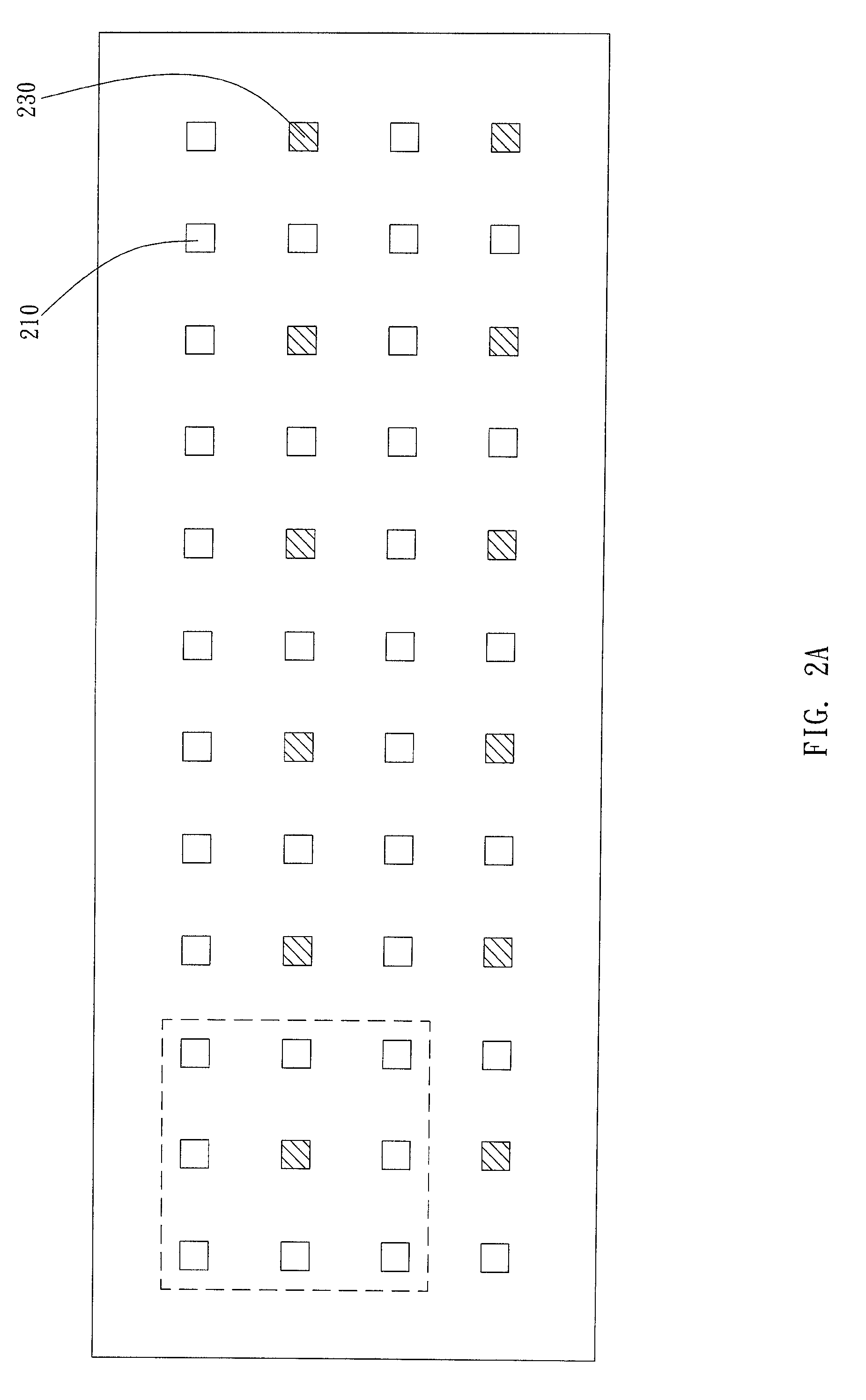

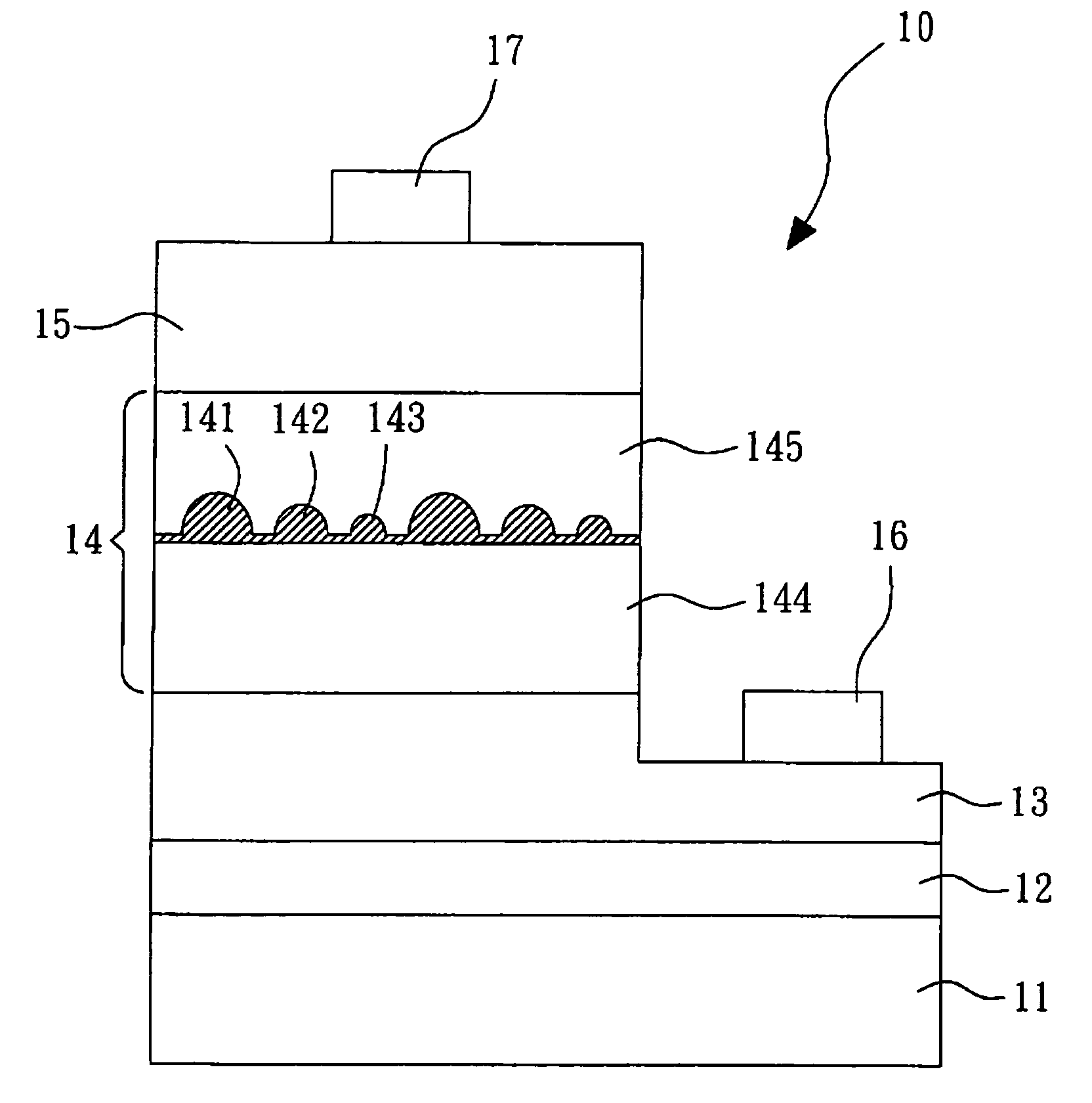

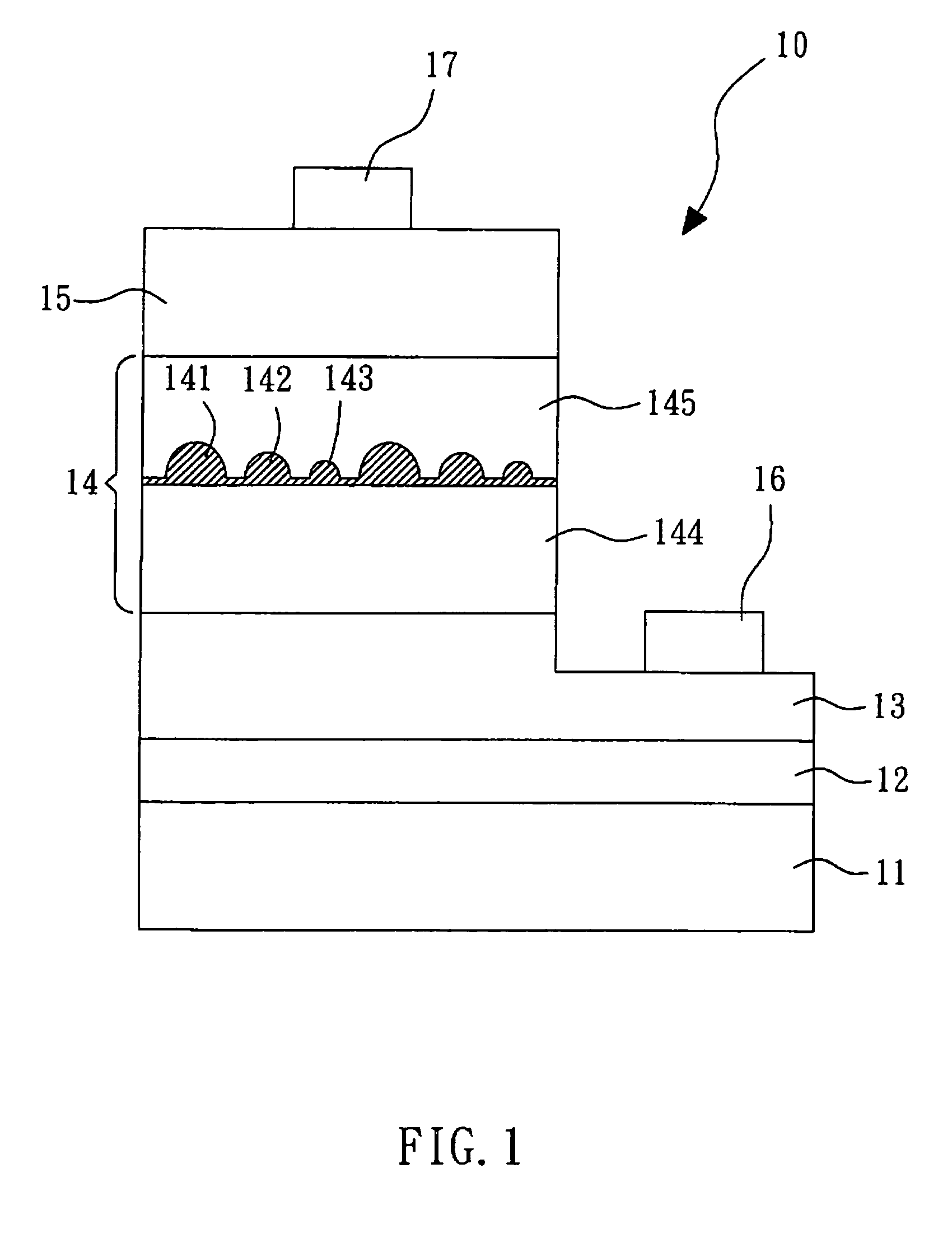

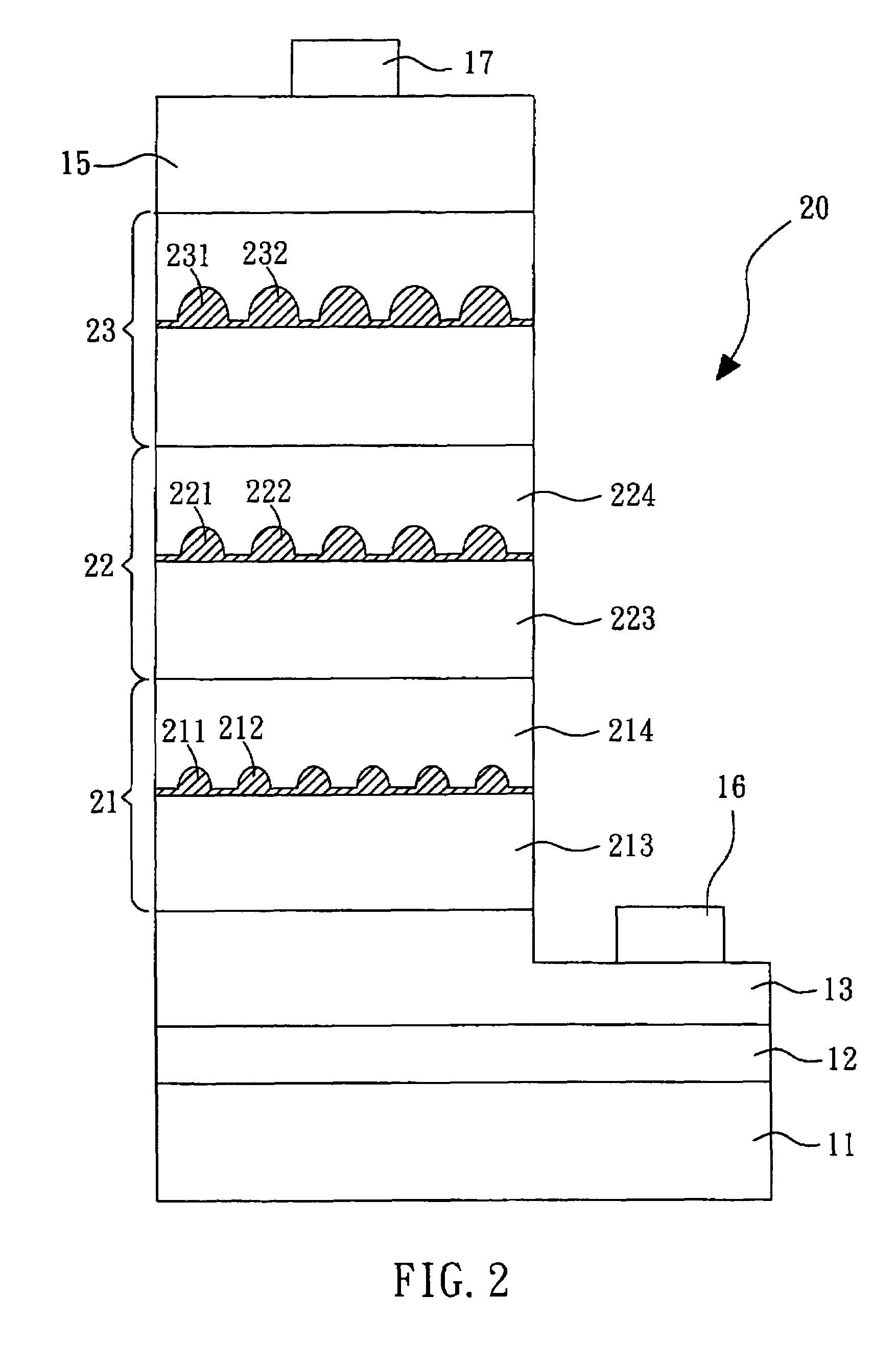

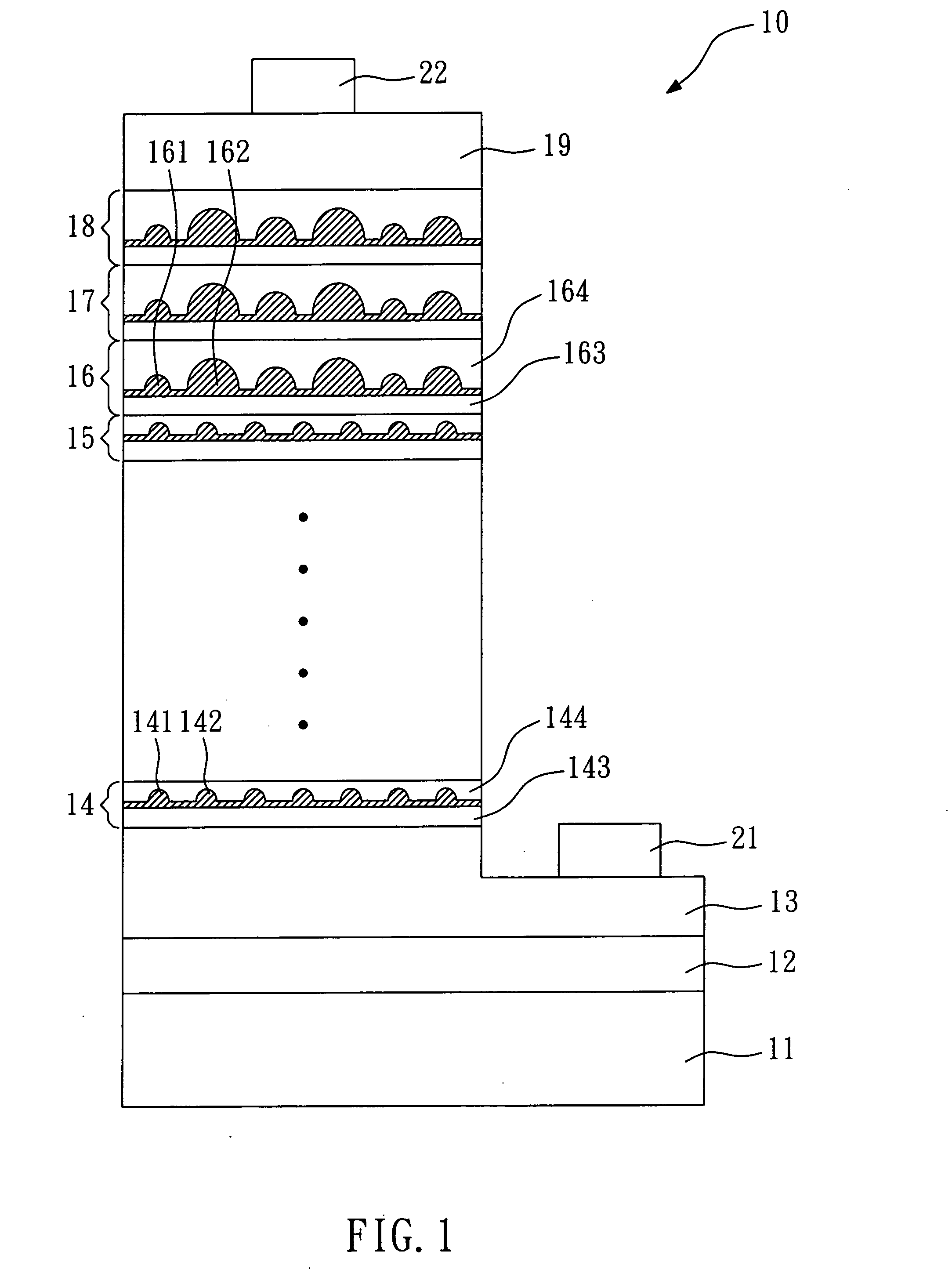

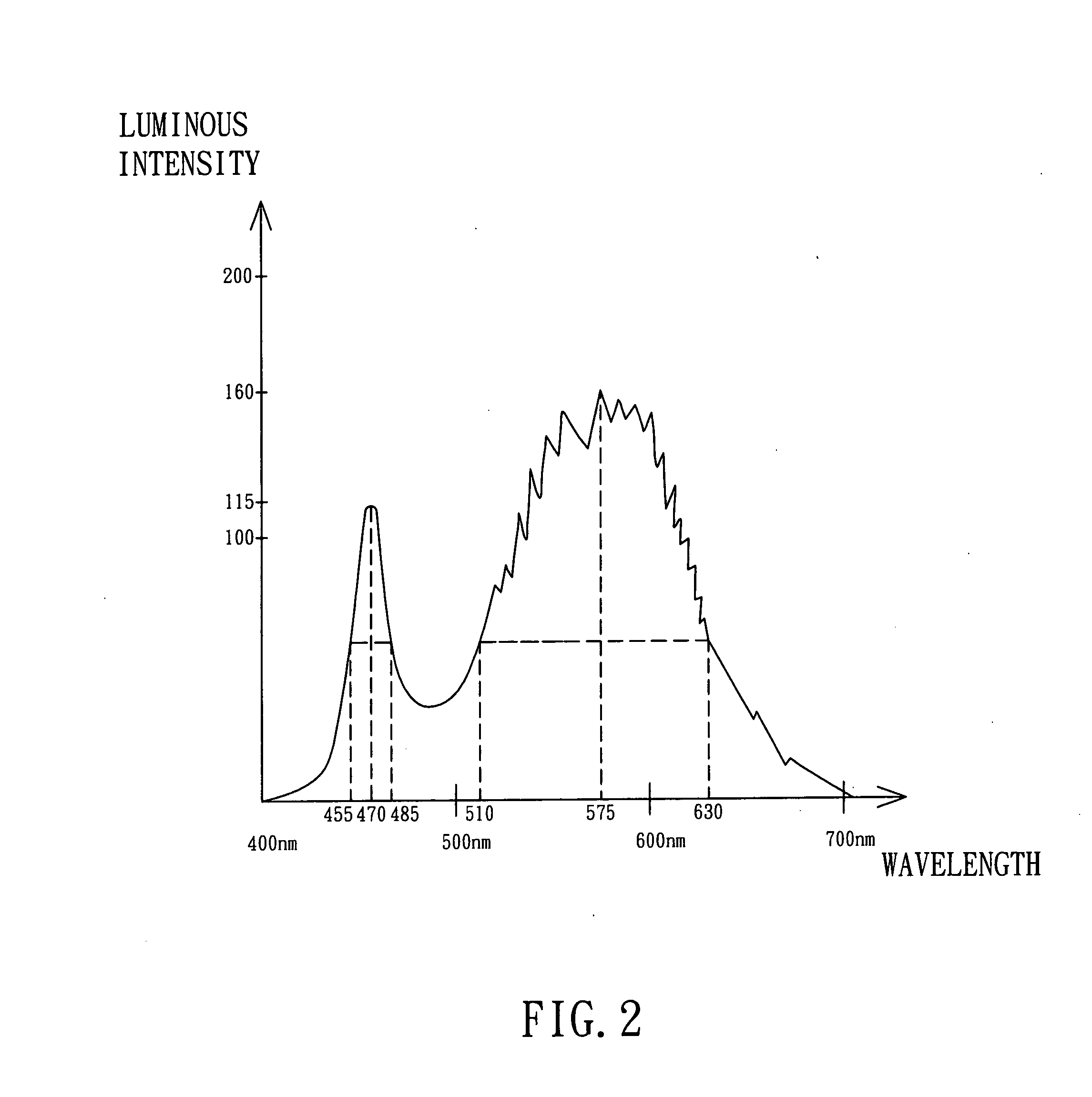

Illuminant system using high color temperature light emitting diode and manufacture method thereof

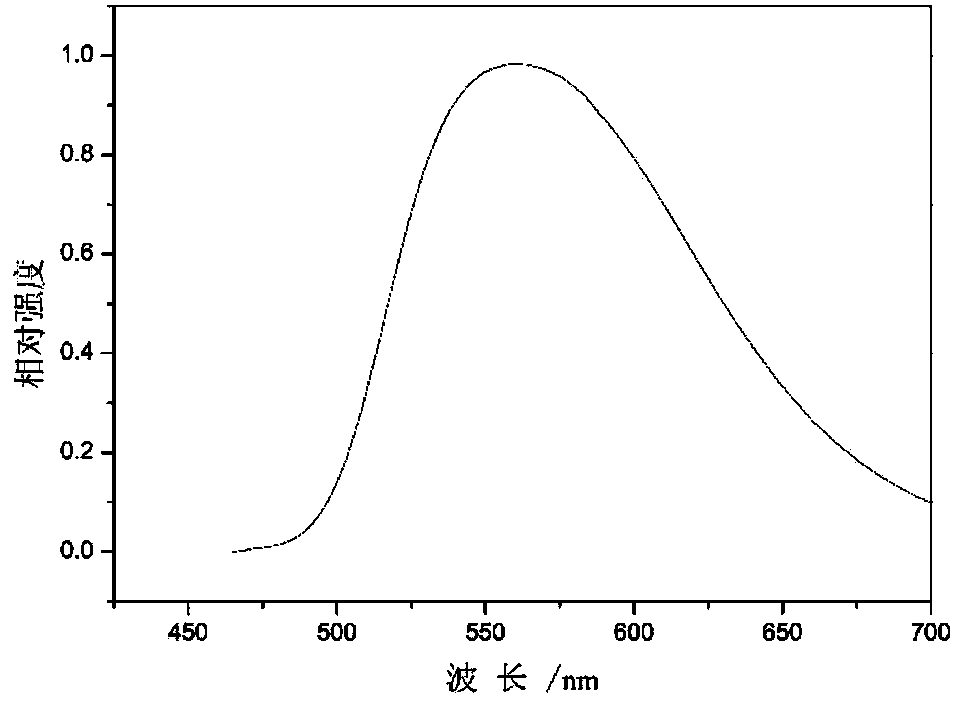

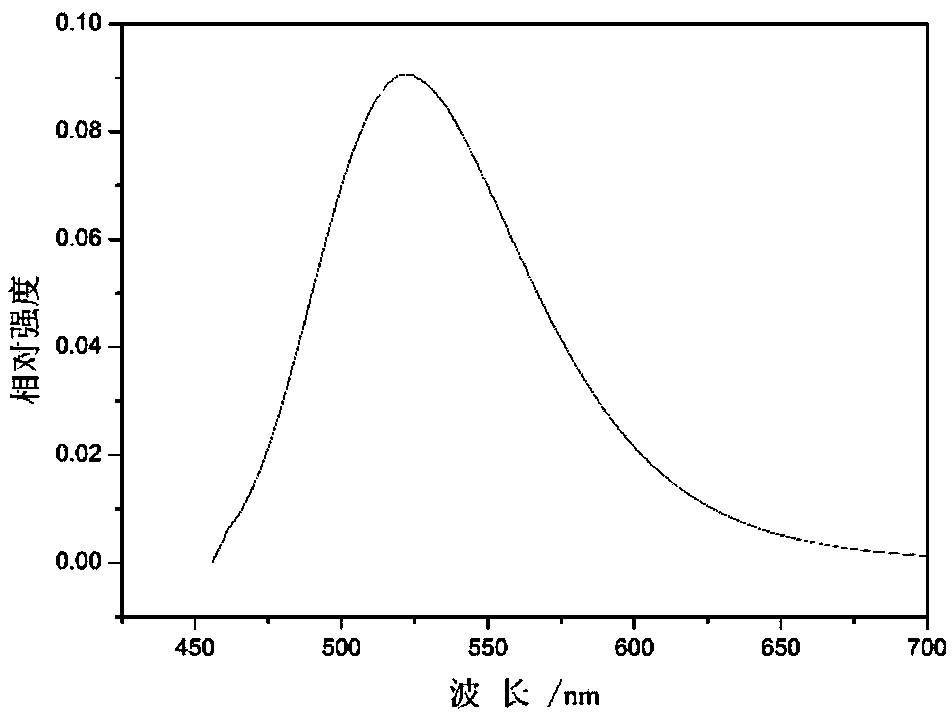

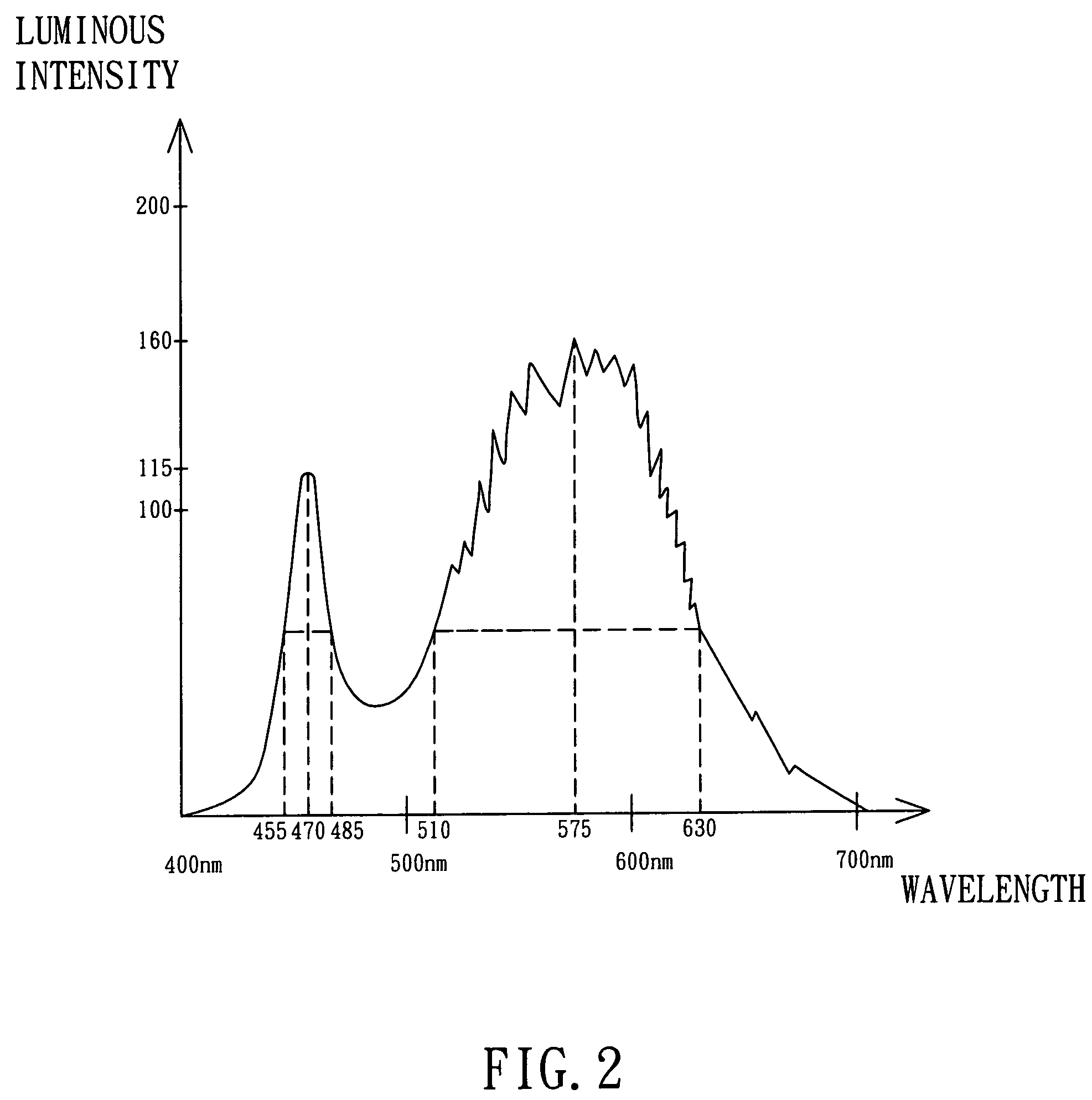

ActiveUS8109650B2High color temperatureSparking plugsDischarge tube luminescnet screensHigh colorGreen-light

A light emitting diode (LED) illuminant system, a manufacture method thereof, and a backlight module using the same are provided. The LED illuminant system includes a plurality of white light illuminants and at least one green light illuminant mixed in the white light illuminants. A light power ratio of the green light illuminant to the white light illuminants is in between ⅕ to 1 / 20. The color temperature of the whole illuminant system will be enhanced to a certain extent by mixing the green light illuminant and the white light illuminants. The manufacture method includes the following steps: obtaining a transmission spectrum of the white light illuminants; analyzing the transmission spectrum to determine n supplemental amount of a green light; and disposing at least one green illuminant in accordance with the supplemental amount of the green light.

Owner:OPTRONIC SCI LLC

Broad-spectrum A1(1-x-y)InyGaxN light emitting diodes and solid state white light emitting devices

ActiveUS7005667B2High luminous intensityHigh indexSolid-state devicesNanoopticsIndiumLuminous intensity

A broad-spectrum Al(1-x-y)InyGaxN light emitting diode (LED), including: a substrate, a buffer layer, an N-type cladding layer, at least one quantum dot emitting layer, and a P-type cladding layer. The buffer layer is disposed over the substrate. The N-type cladding layer is disposed over the buffer layer to supply electrons. The quantum dot emitting layer is disposed over the N-type cladding layer and includes plural quantum dots. The dimensions and indium content of the quantum dots are manipulated to result in uneven distribution of character distribution of the quantum dots so as to increase the FWHM of the emission wavelength of the quantum dot emitting layer. The P-type cladding layer is disposed over the quantum dot emitting layer to supply holes. A broad-spectrum Al(1-x-y)InyGaxN yellow LED may thus be made from the LED structure of this invention, with an emission wavelength at maximum luminous intensity falling within a range of 530˜600 nm, and FWHM within a range of 20˜150 nm. After packaging an Al(1-x-y)InyGaxN blue LED to form a solid state white light emitting device, the mixing of blue light and yellow light would generate white light with a high CRI index, high luminous intensity and capable of various color temperature modulation.

Owner:GENESIS PHOTONICS

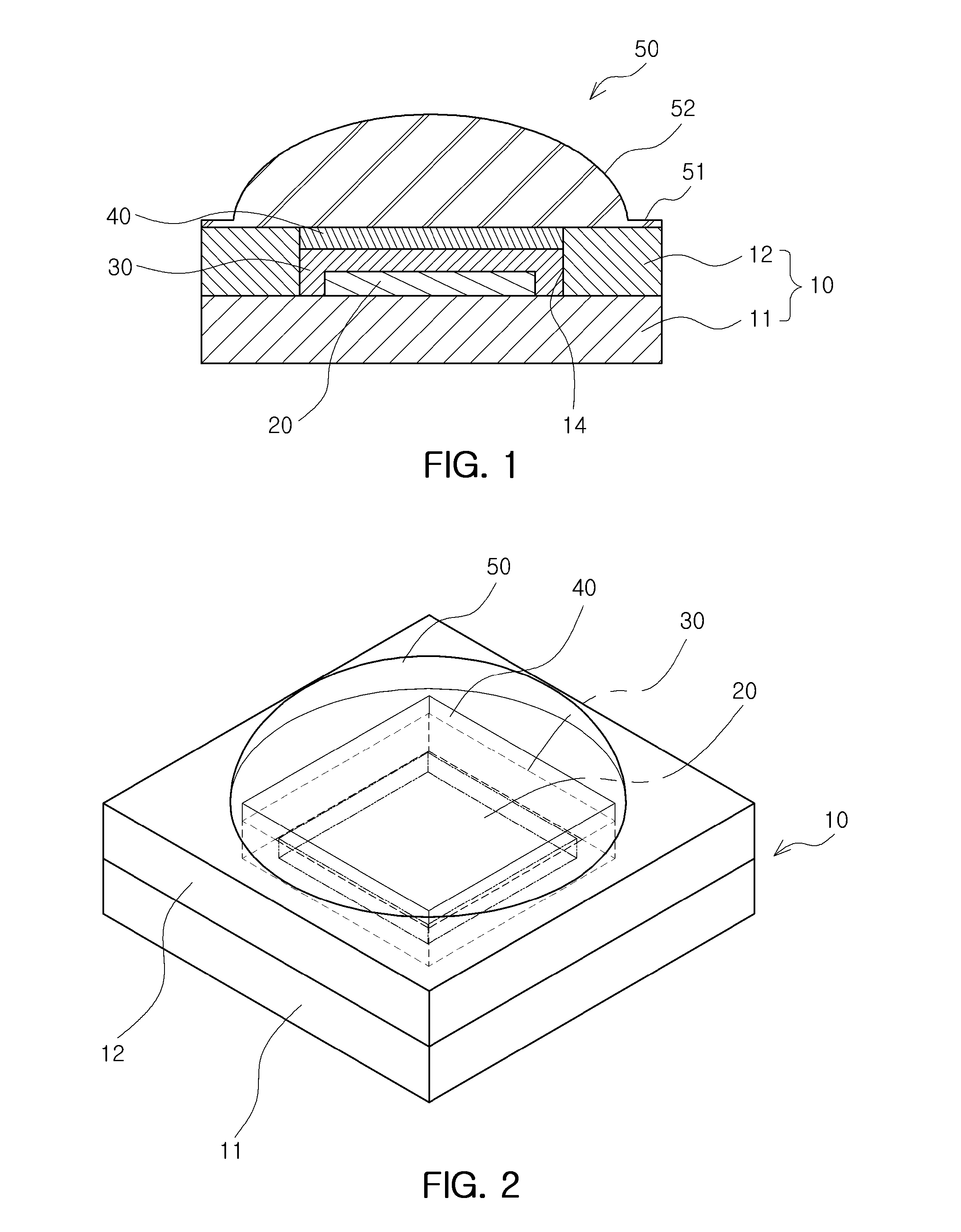

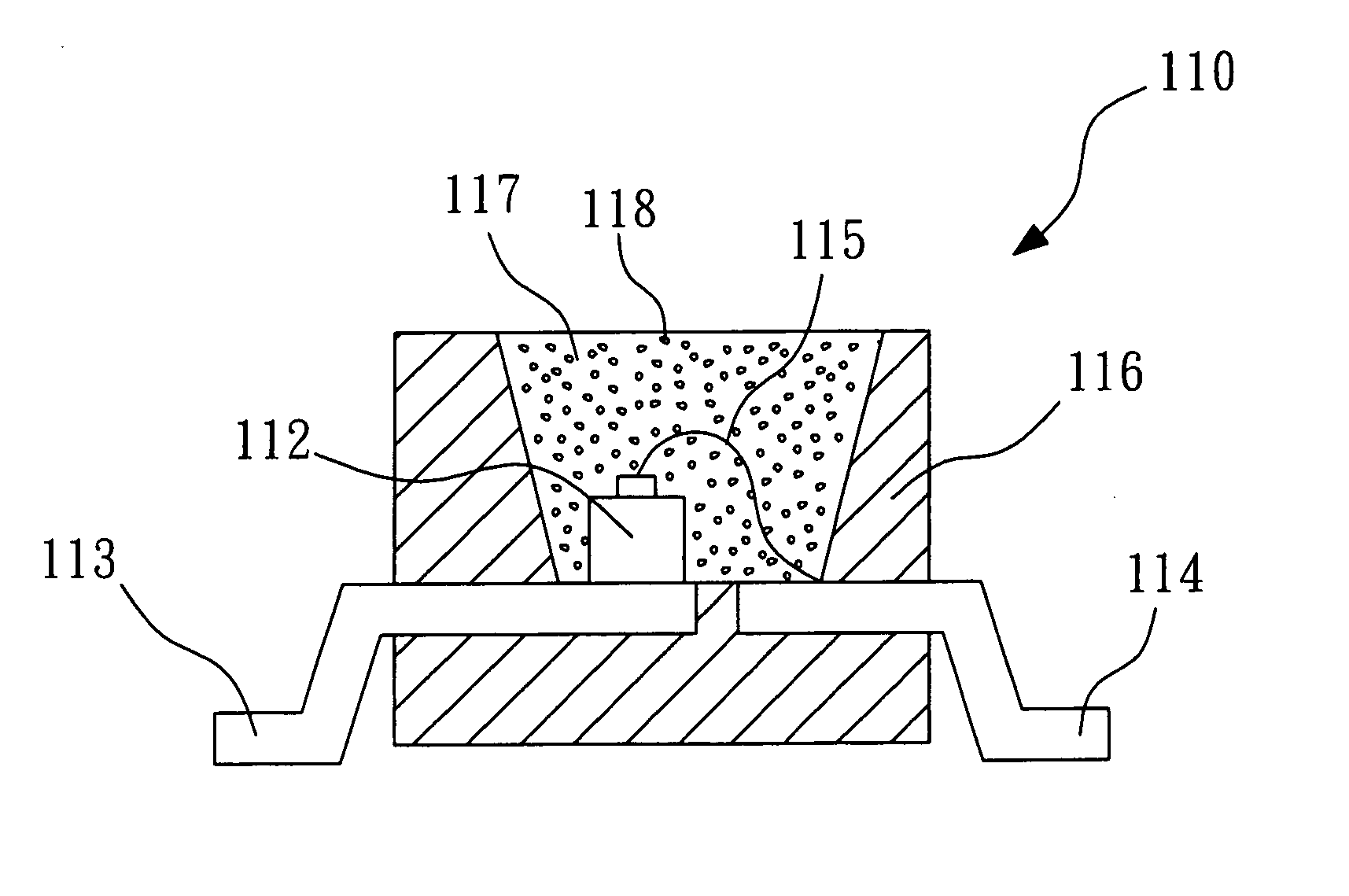

Light emitting device package and manufacturing method thereof

InactiveUS20120305970A1High color temperatureReduce deviationSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLength wave

There is provided a light emitting device package including a substrate having a cavity therein; alight emitting device mounted on a bottom surface of the cavity; a first wavelength conversion part including a first phosphor for a wavelength conversion of light emitted from the light emitting device and covering the light emitting device within the cavity; and a second wavelength conversion part including a second phosphor allowing for emission of light having a wavelength different to that of the first phosphor and formed as a sheet on the first wavelength conversion part.

Owner:SAMSUNG ELECTRONICS CO LTD

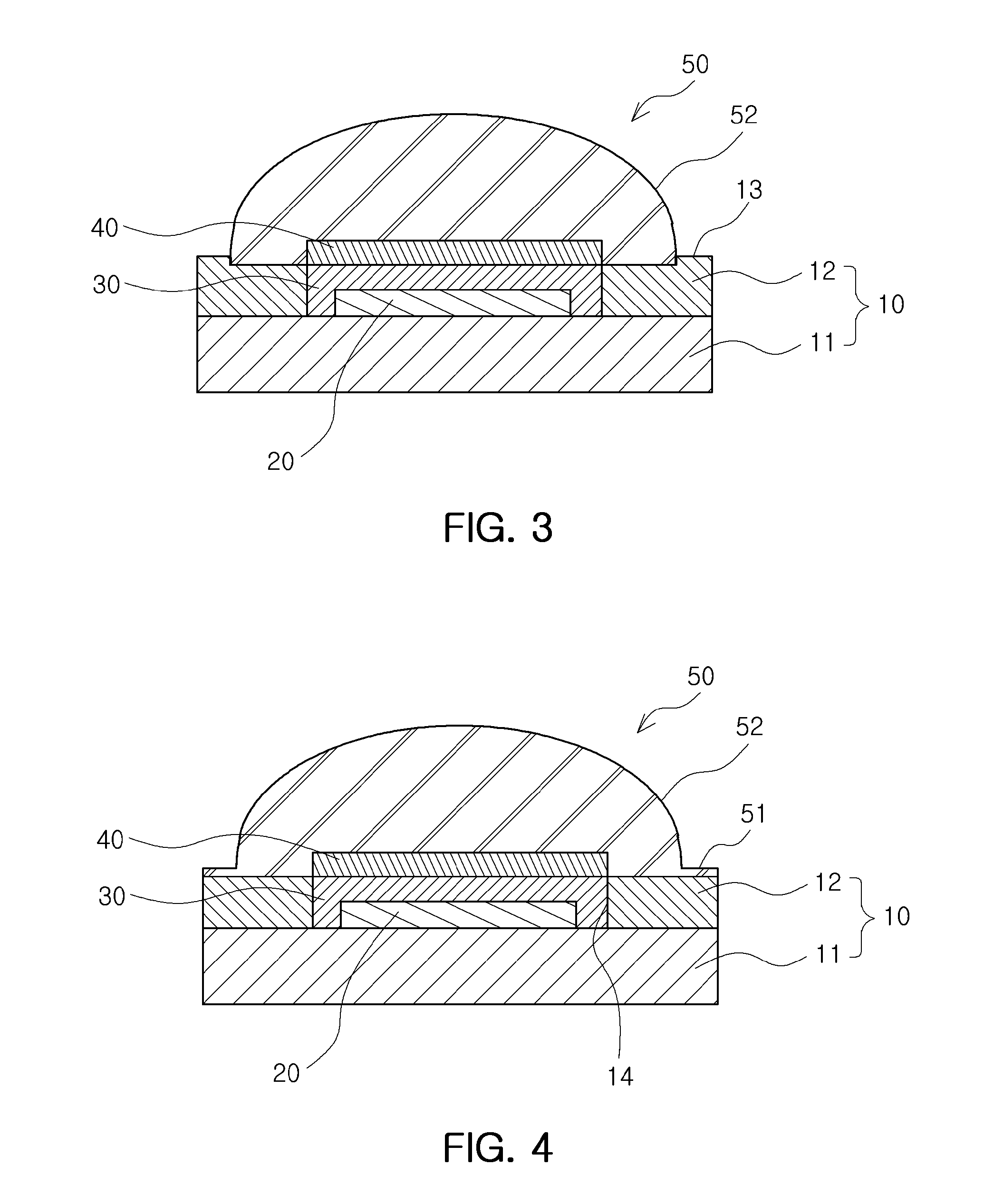

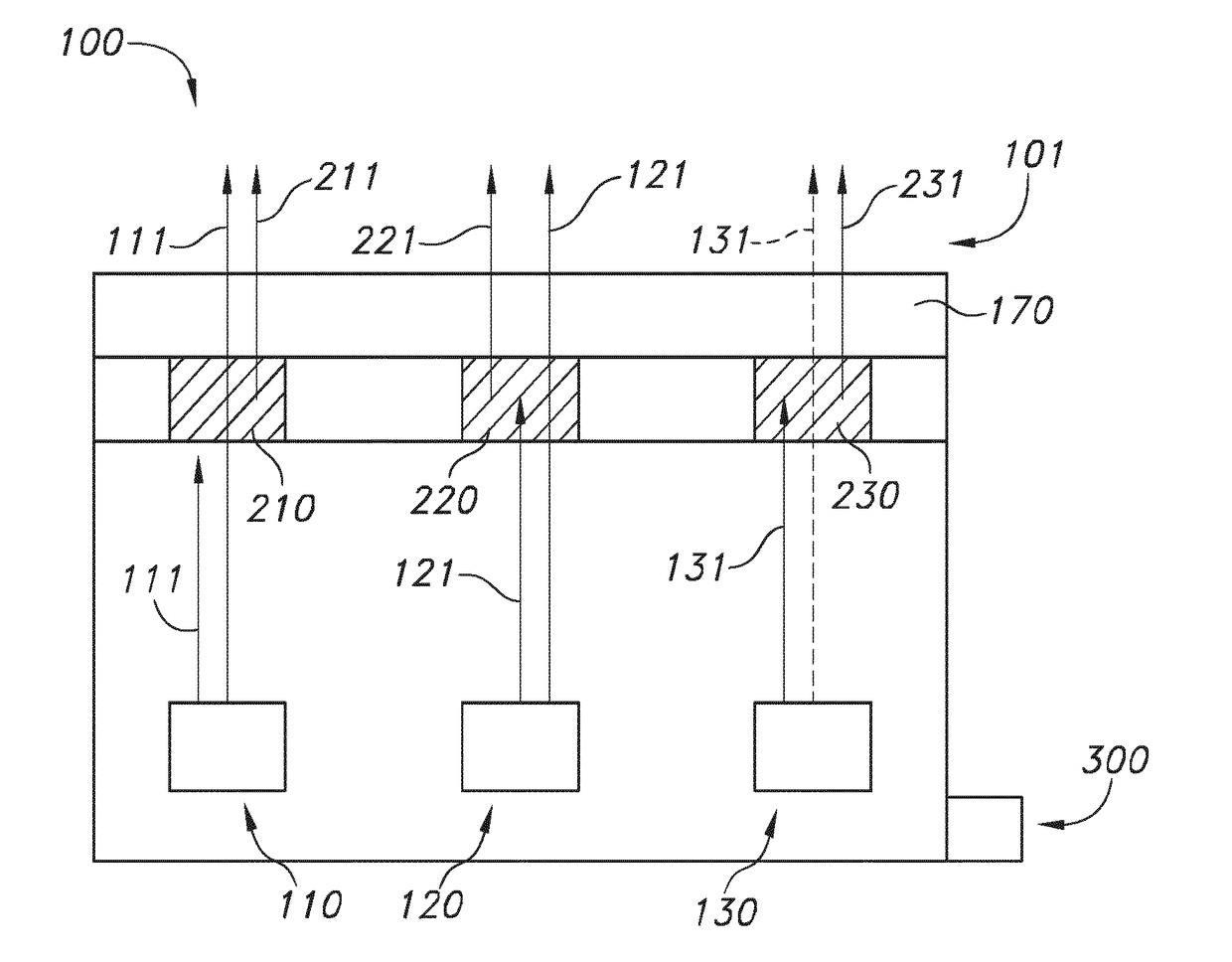

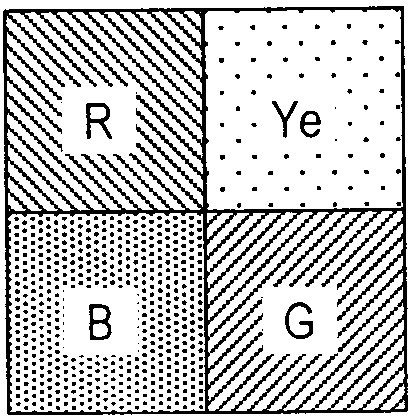

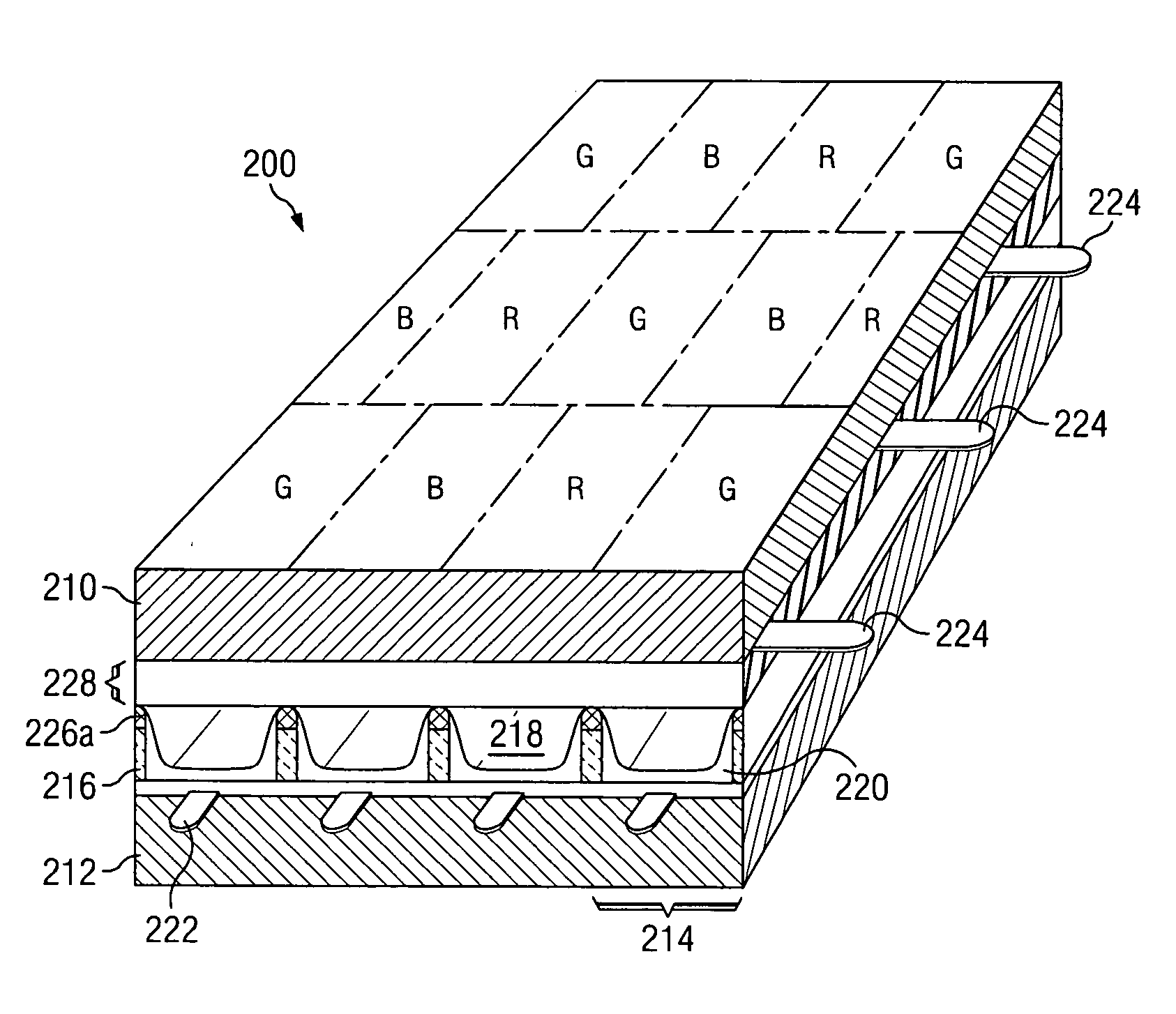

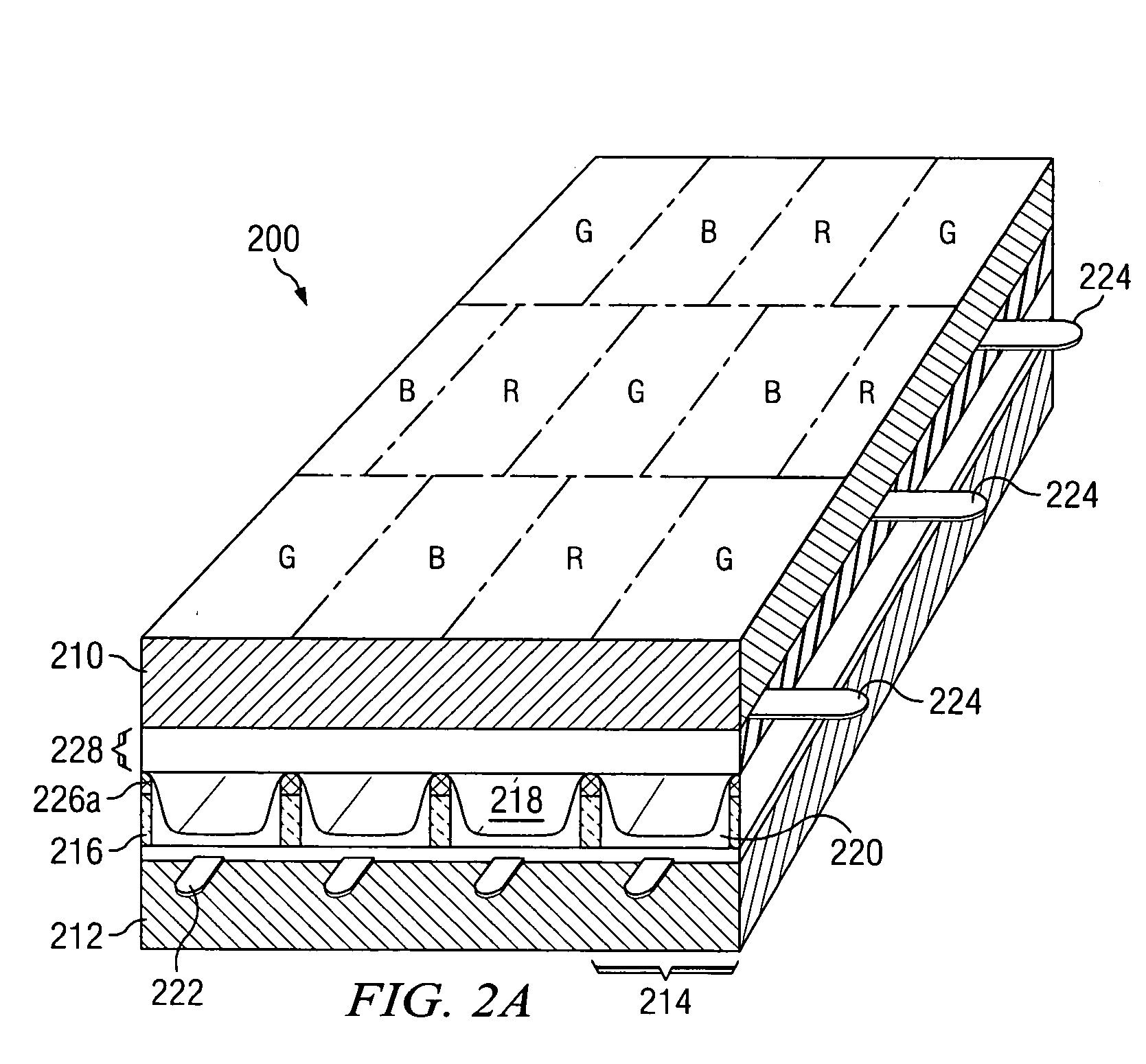

Illumination system and display device

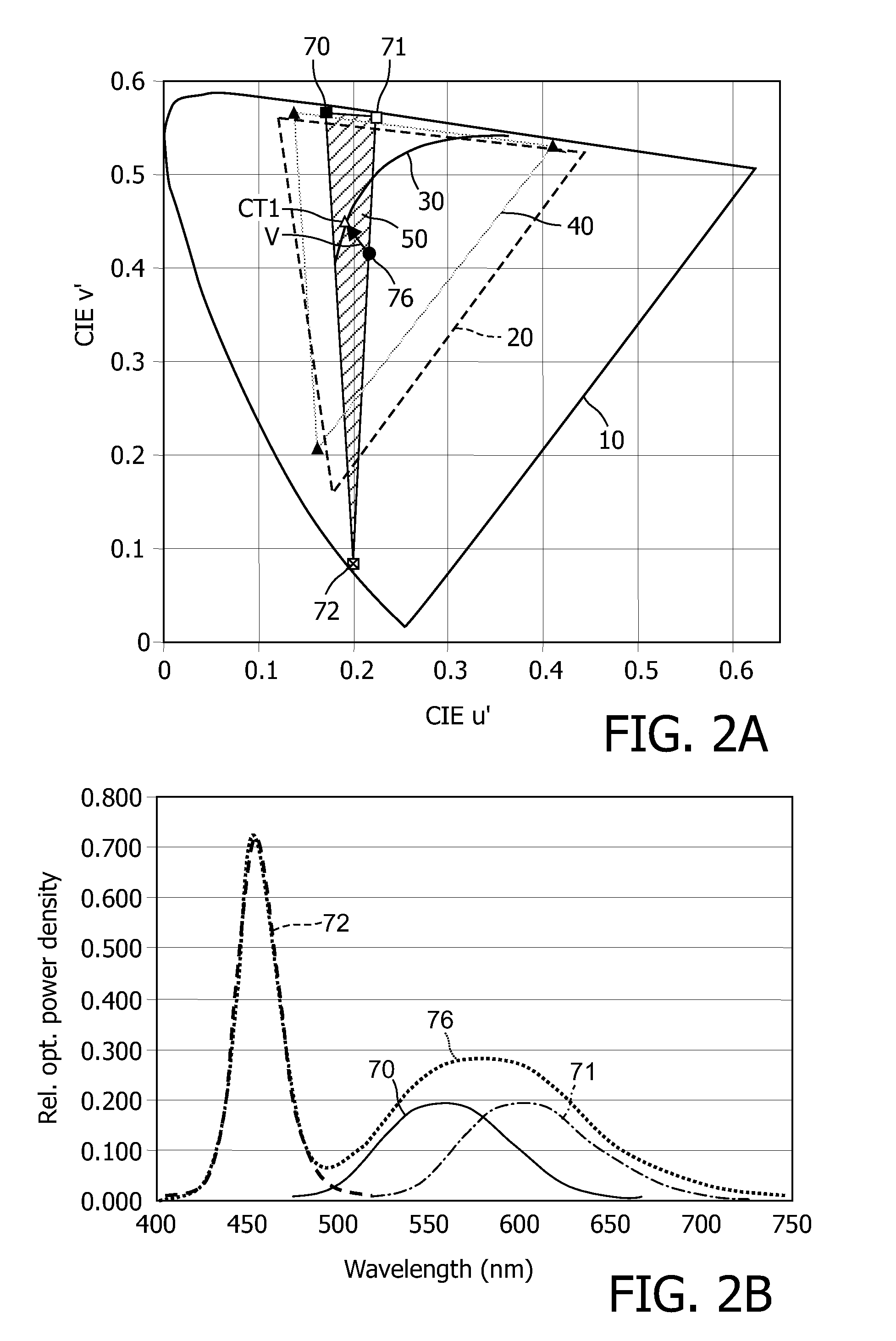

ActiveUS20100067214A1Improve color temperatureHigh color temperatureDischarge tube luminescnet screensElectroluminescent light sourcesLighting systemCerium

The invention relates to an illumination system, a luminaire and a display-device (200) comprising the illumination system. The illumination system (100, 101) comprises a light emitting diode (D1, D2), a light exit window (105) and a luminescent layer (120) arranged between the light emitting diode and the light exit window. The light emitting diode emits light of a first primary color (72, 75). The luminescent layer is arranged between the light emitting diode and the light exit window for converting part of the light emitted by the light emitting diode into light of a second primary color. The luminescent layer comprises a garnet luminescent material comprising at least Lutetium, Cerium, Silicon and Nitrogen (73), or it comprises a combination of a garnet luminescent material comprising at least Lutetium and Cerium (70) and a garnet luminescent material comprising at least Cerium and at least one element of the group comprising Yttrium and Gadolinium (71, 74). The light exit window emits light generated by the illumination system towards the display device.

Owner:SIGNIFY HLDG BV

Single-chip white light emitting device

ActiveUS20050194608A1Enhance color temperature modulation capabilityReduce packaging costsNanoinformaticsSolid-state devicesQuantum dotLength wave

A single-chip white light emitting device, including: a substrate, a buffer layer, a first conductive cladding layer, a second conductive cladding layer, at least one broad-spectrum blue-complimentary light quantum dot emitting layer and at least one blue light emitting layer. The buffer layer is disposed over the substrate. The first conductive cladding layer is disposed over the buffer layer. The broad-spectrum blue-complimentary light quantum dot emitting layer is disposed between the first conductive cladding layer and the second conductive cladding layer. The blue-complimentary light quantum dot emitting layer includes plural quantum dots with an uneven character distribution, so as to increase FWHM of emission wavelength of the quantum dot emitting layer. The blue light emitting layers is disposed between the first and second conductive cladding layers, such that mixing of blue light and blue-complimentary light would generate white light. According to the single-chip white light emitting device of this invention, a single LED laminar structure is provided therein with a broad-spectrum blue-complimentary light quantum dot emitting layer and a blue light emitting layer, which are mixed to form an Al(1-x-y)InyGaxN single-chip white light emitting device with a high CRI, and high emission and are capable of color temperature modulation.

Owner:GENESIS PHOTONICS

Broad-spectrum A1(1-x-y)InyGaxN light emitting diodes and solid state white light emitting devices

ActiveUS20050092980A1High luminous intensityHigh indexSolid-state devicesNanoopticsIndiumLuminous intensity

A broad-spectrum Al(1-x-y)InyGaxN light emitting diode (LED), including: a substrate, a buffer layer, an N-type cladding layer, at least one quantum dot emitting layer, and a P-type cladding layer. The buffer layer is disposed over the substrate. The N-type cladding layer is disposed over the buffer layer to supply electrons. The quantum dot emitting layer is disposed over the N-type cladding layer and includes plural quantum dots. The dimensions and indium content of the quantum dots are manipulated to result in uneven distribution of character distribution of the quantum dots so as to increase the FWHM of the emission wavelength of the quantum dot emitting layer. The P-type cladding layer is disposed over the quantum dot emitting layer to supply holes. A broad-spectrum Al(1-x-y)InyGaxN yellow LED may thus be made from the LED structure of this invention, with an emission wavelength at maximum luminous intensity falling within a range of 530˜600 nm, and FWHM within a range of 20˜150 nm. After packaging an Al(1-x-y)InyGaxN blue LED to form a solid state white light emitting device, the mixing of blue light and yellow light would generate white light with a high CRI index, high luminous intensity and capable of various color temperature modulation.

Owner:GENESIS PHOTONICS

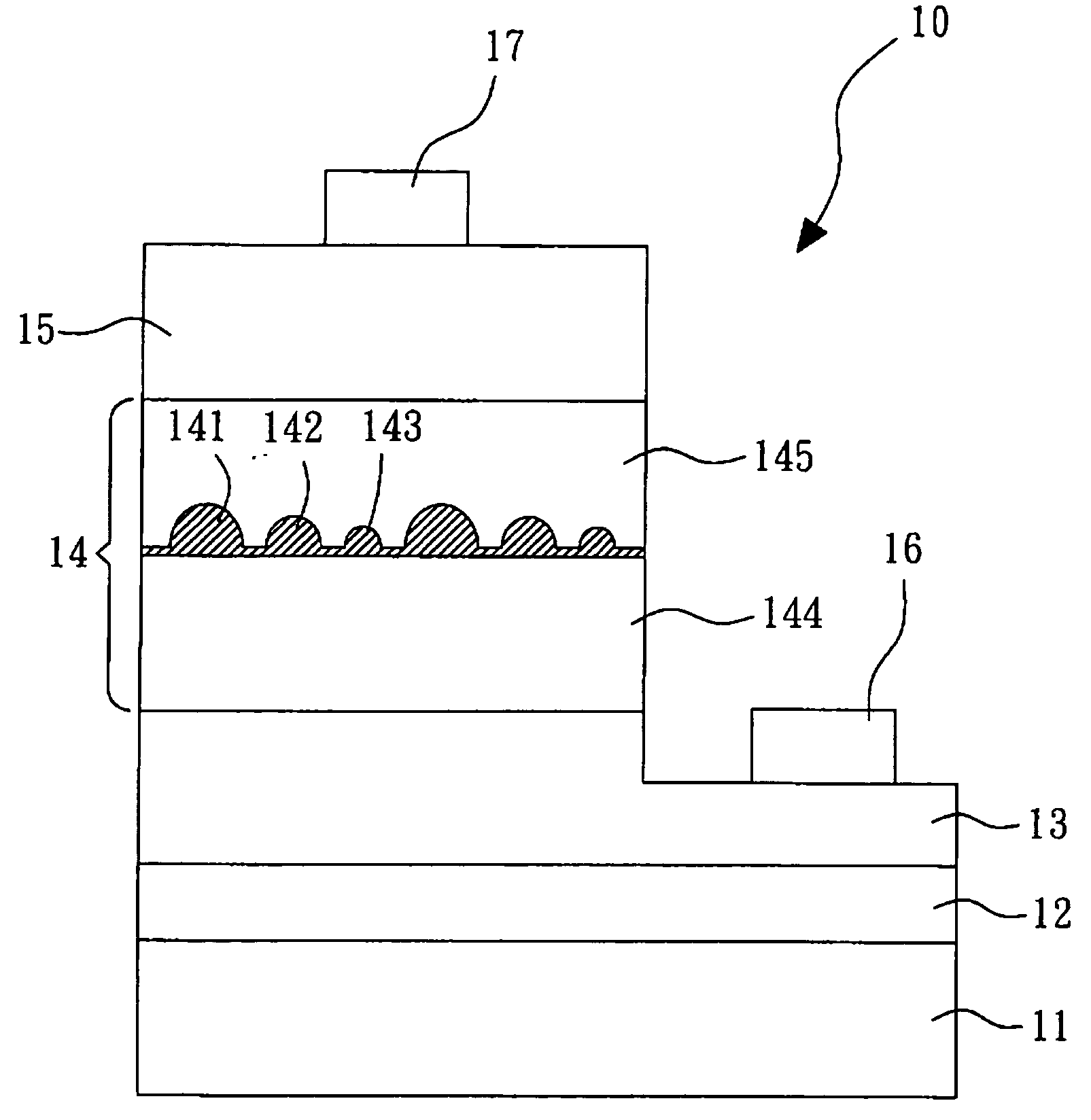

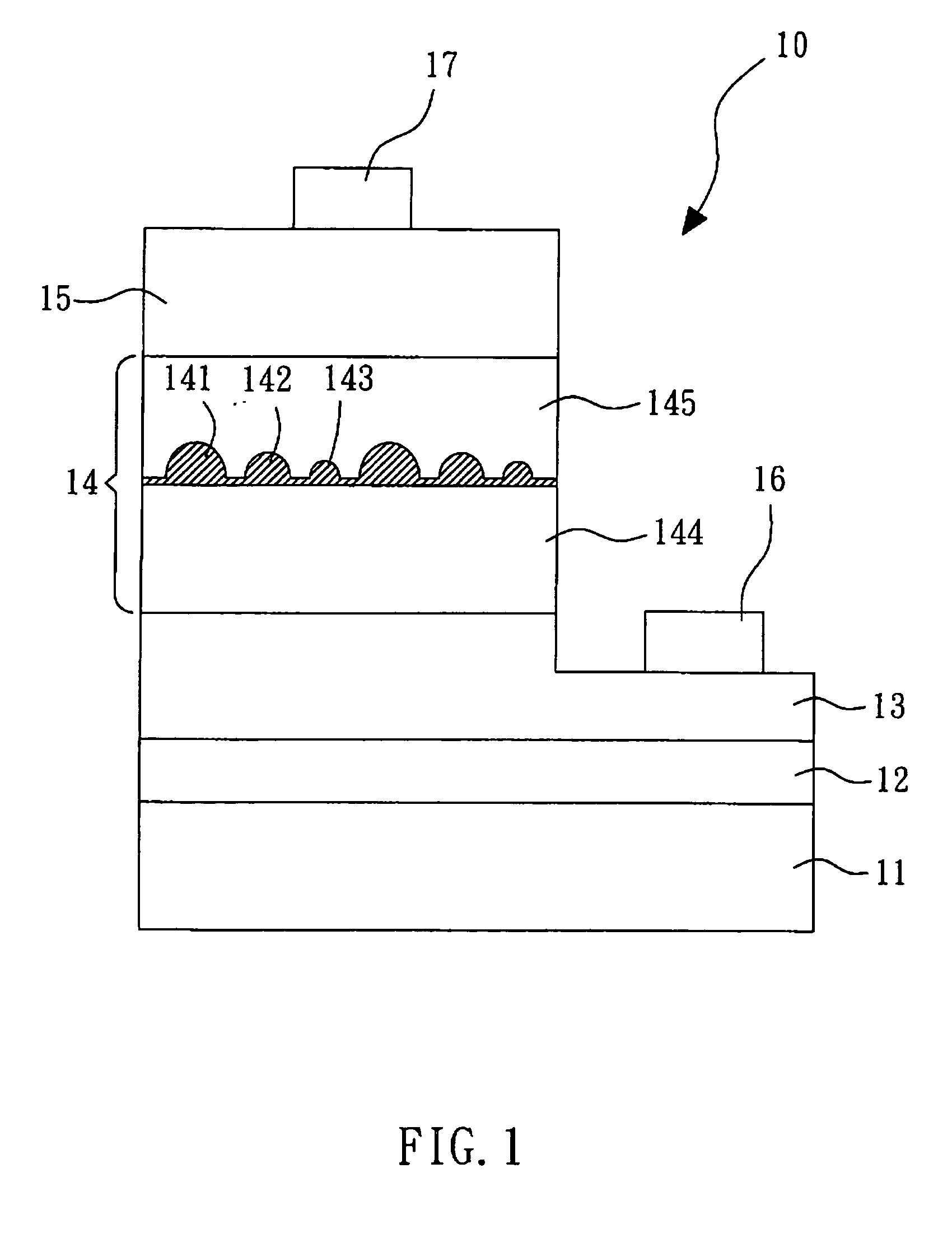

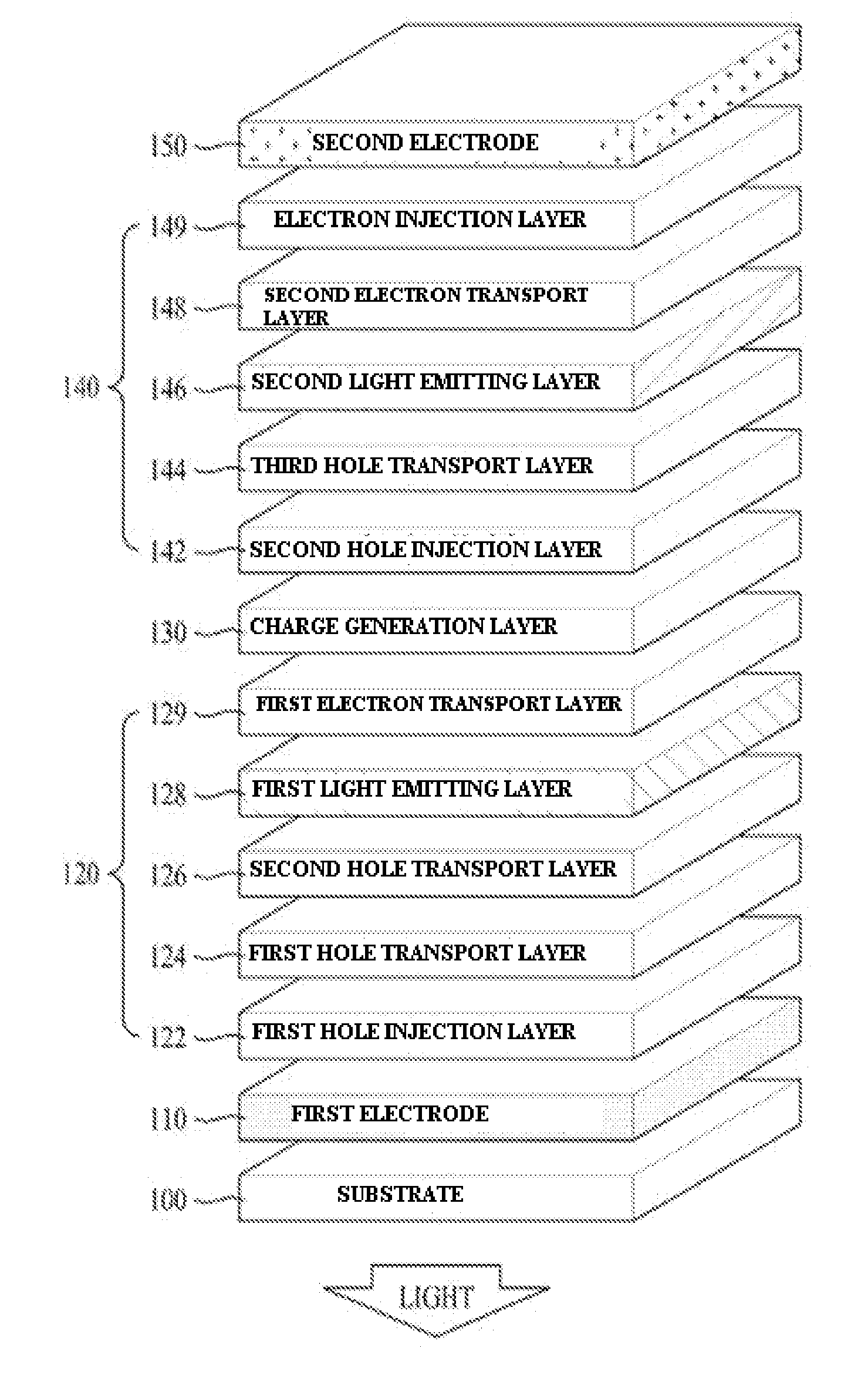

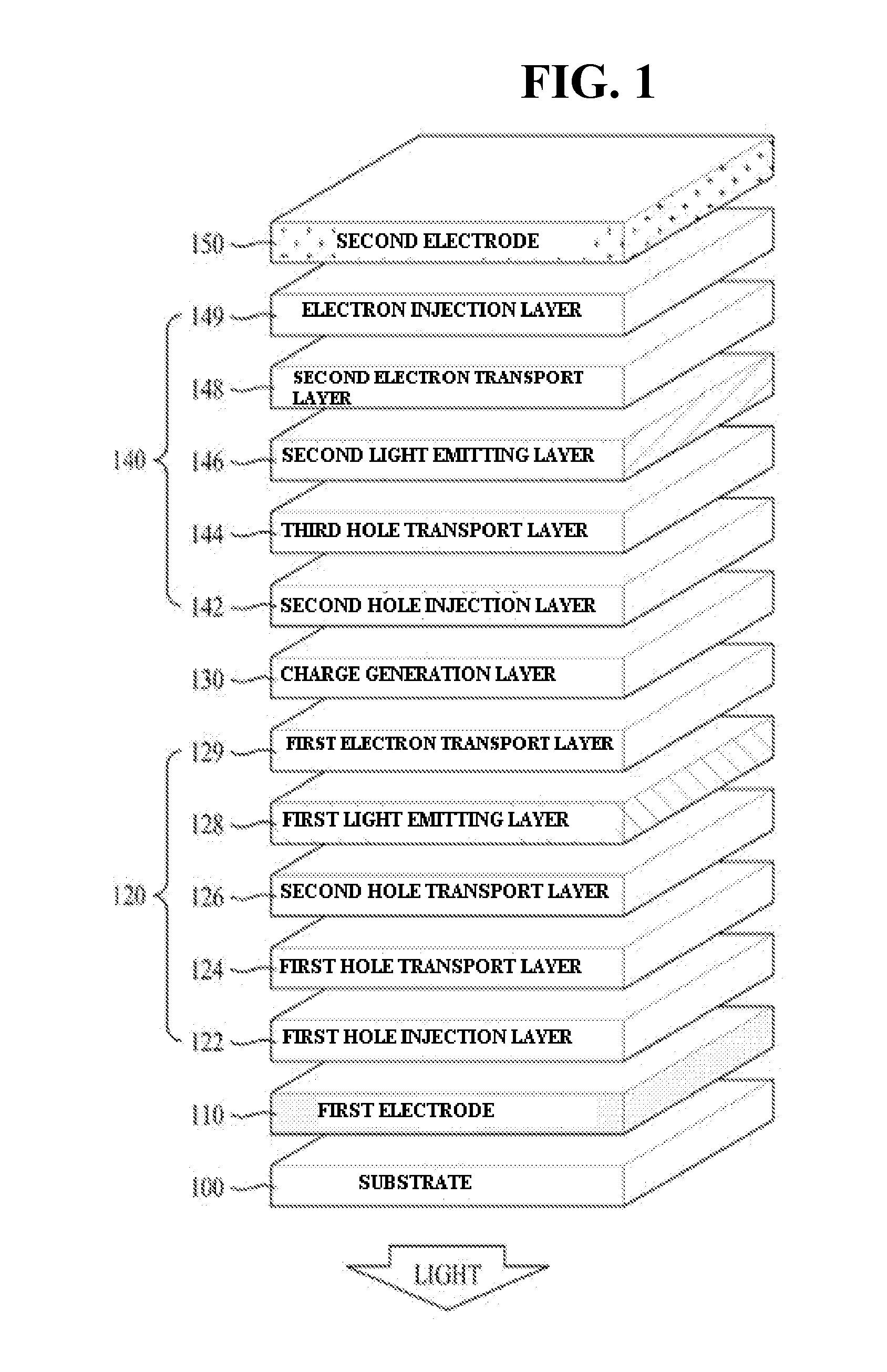

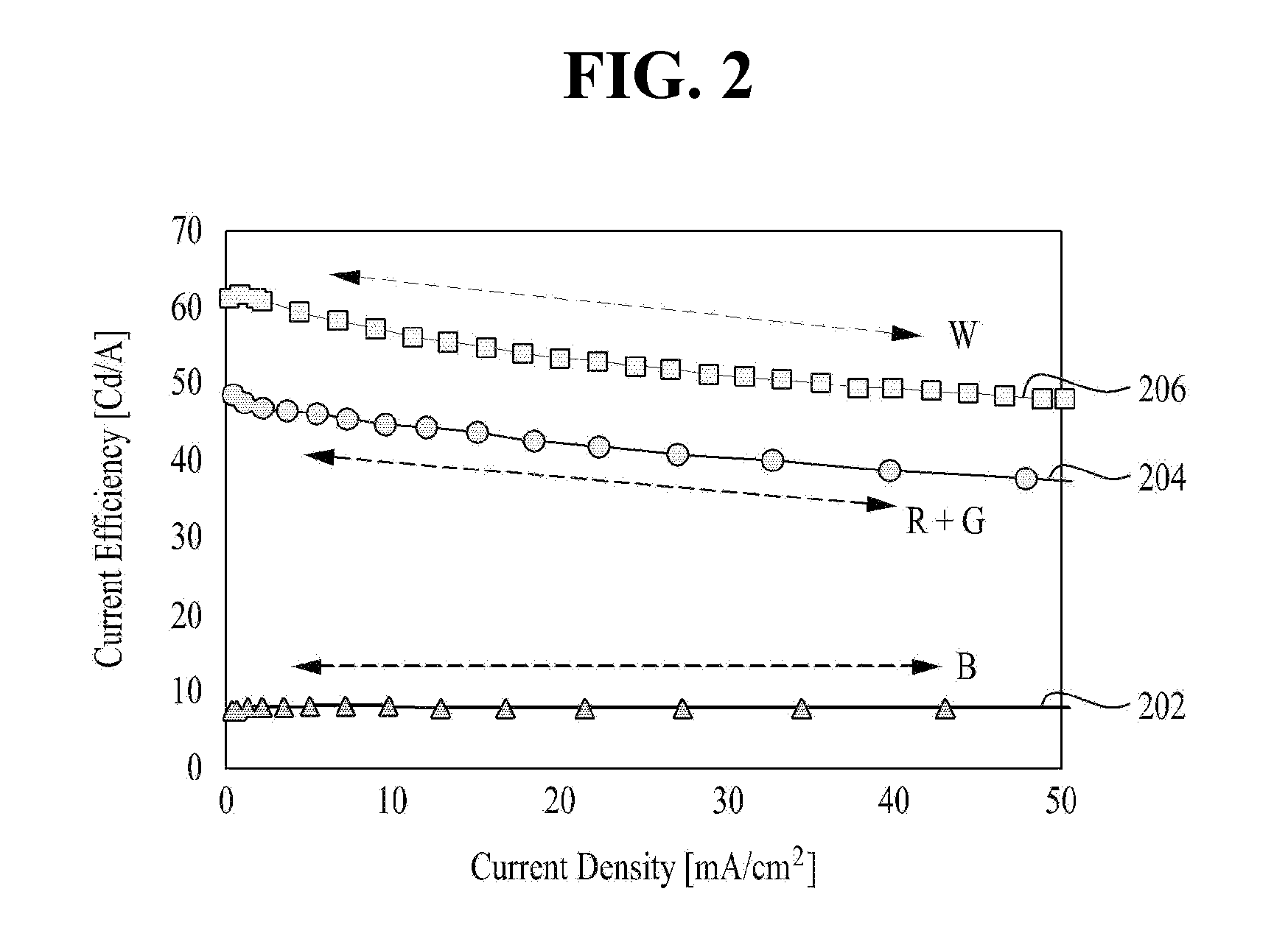

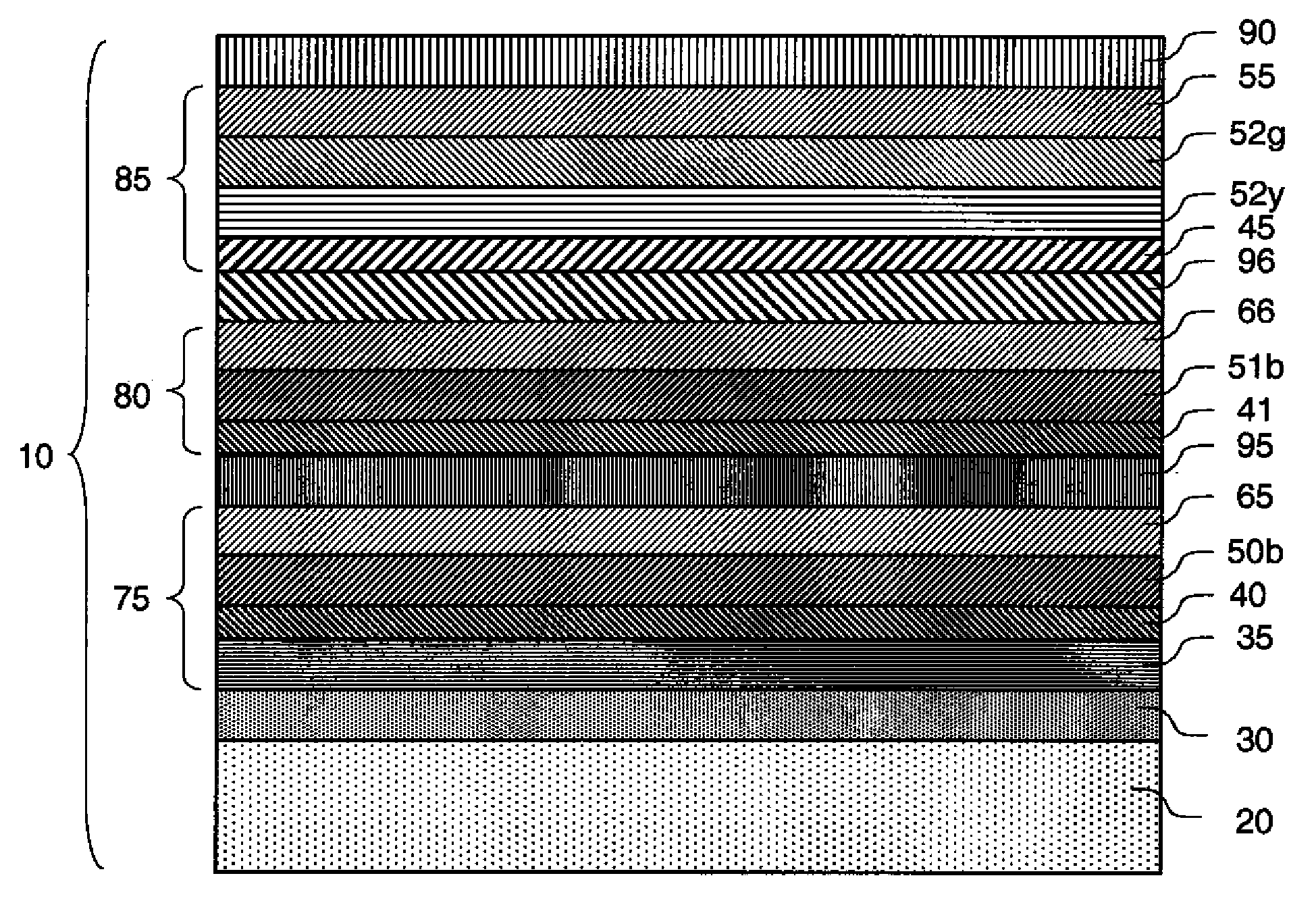

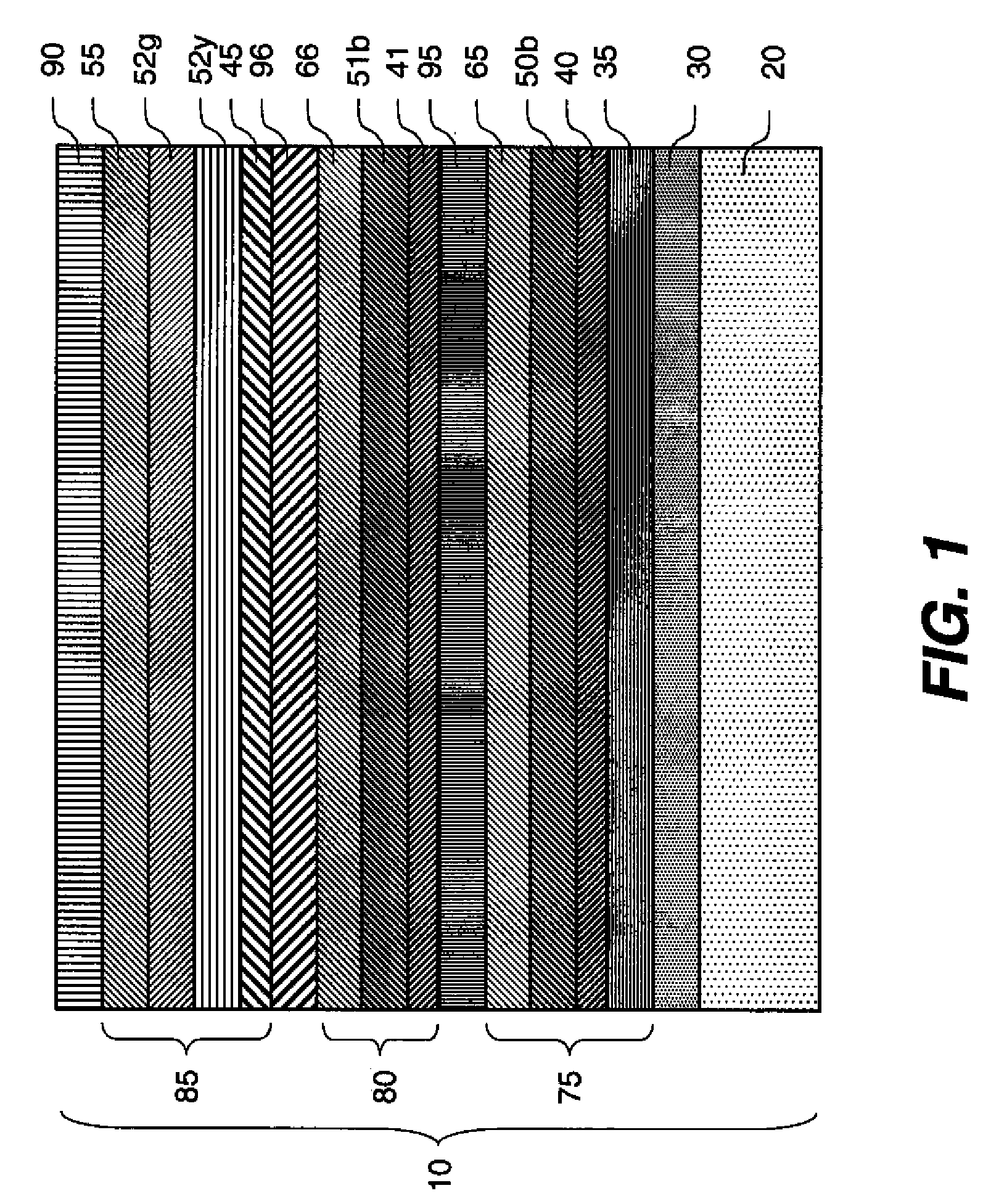

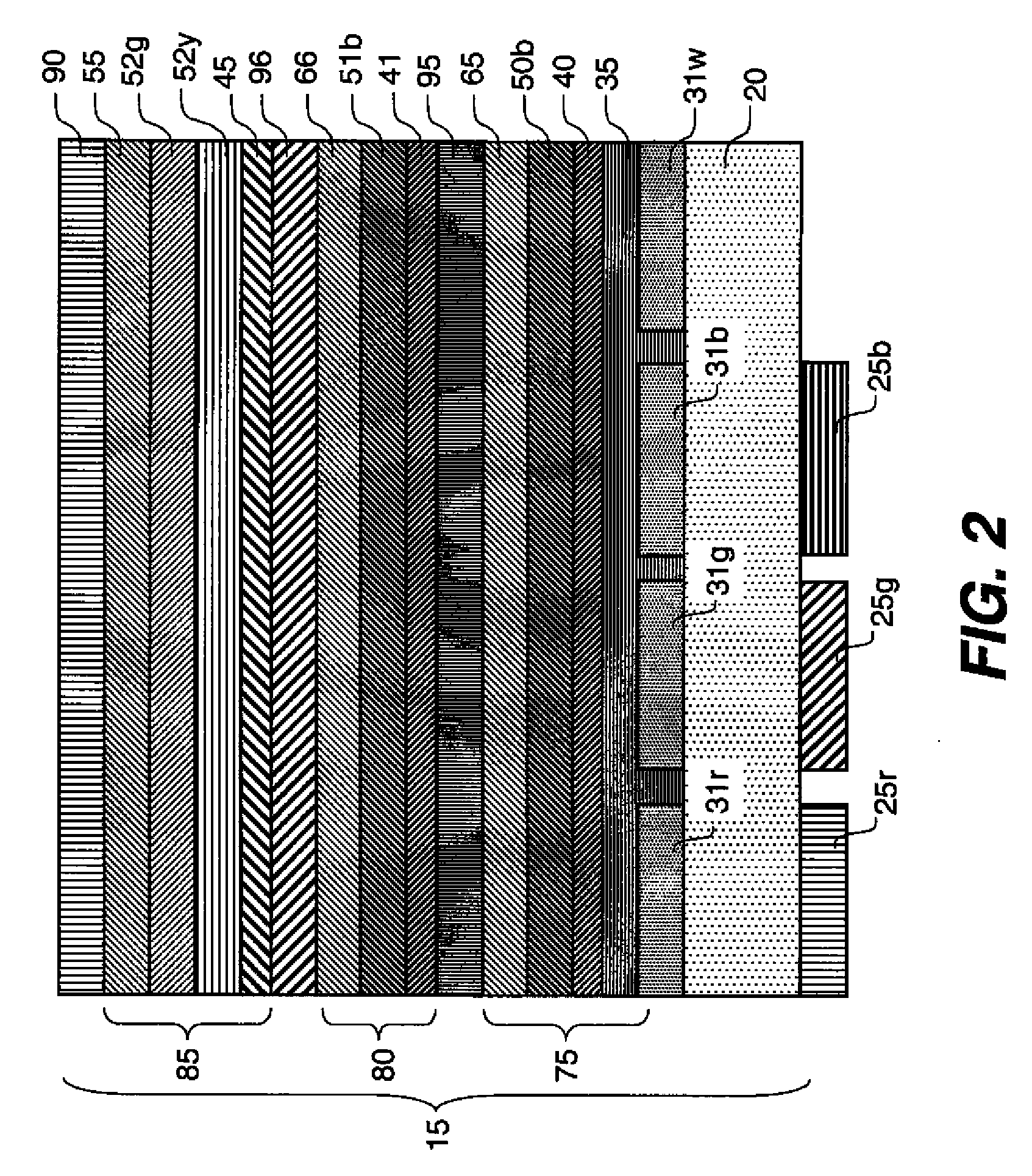

White Organic Light Emitting Device

ActiveUS20120097998A1Minimize diffusionHigh color temperatureSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceHigh color

A white organic light emitting device which has high color temperature characteristics and no change in color coordinates according to luminance change, includes a first electrode and a second electrode opposite to each other on a substrate, a charge generation layer formed between the first electrode and the second electrode, a second stack including a second light emitting layer formed between the charge generation layer and the second electrode, and a first stack including a first light emitting layer formed between the first electrode and the charge generation layer, wherein the first emitting layer has low singlet-triplet exchange energy to change triplet excitons into a singlet state by triplet-triplet annihilation and a dopant concentration of the first light emitting layer is adjusted according to a luminance change curve of the second stack.

Owner:LG DISPLAY CO LTD

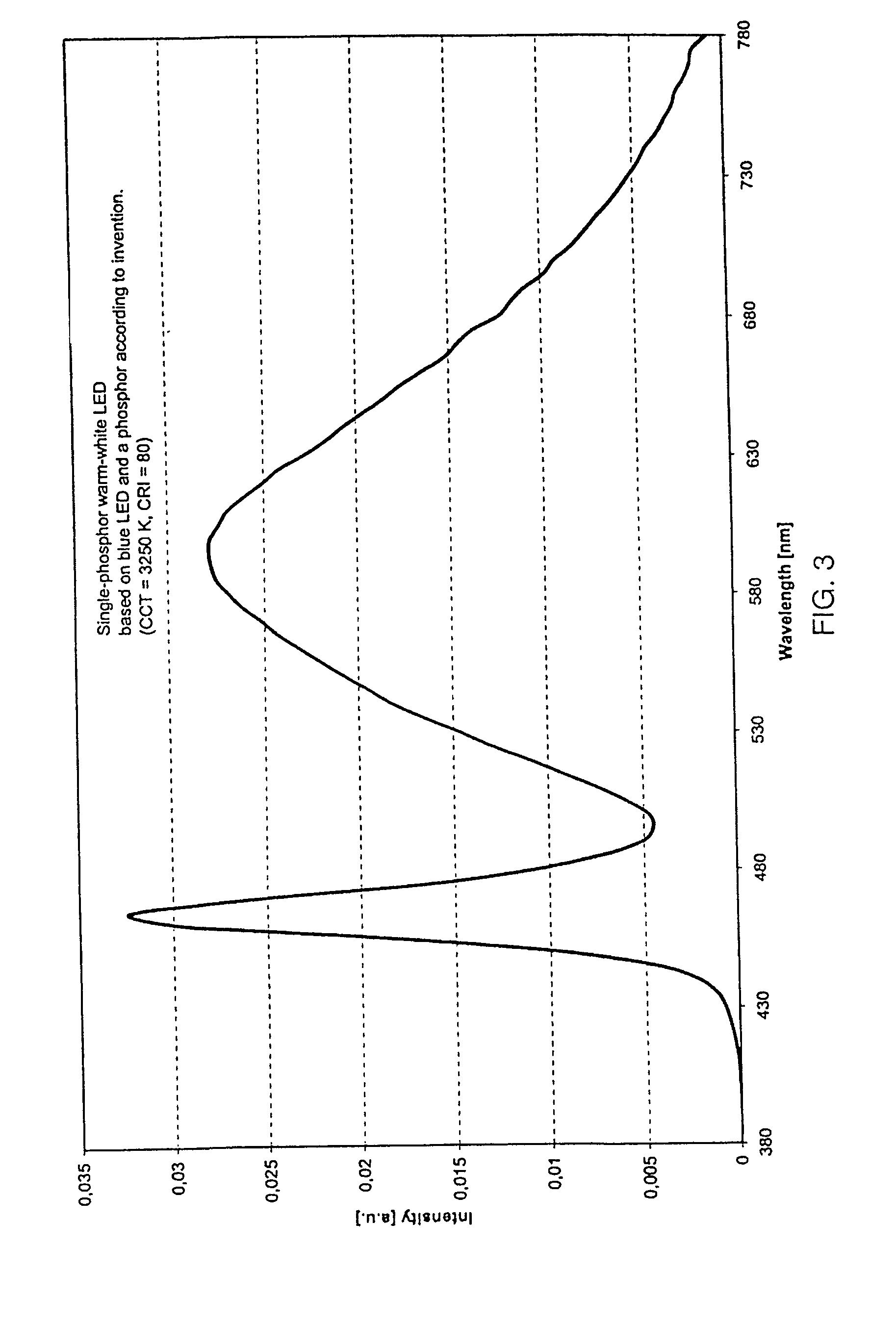

Phosphor and light source comprising such a phosphor

ActiveUS20050242329A1Improve quantum efficiencyReduce contentConductive materialSolid-state devicesPhosphorWavelength

Owner:RIKEN CO LTD +3

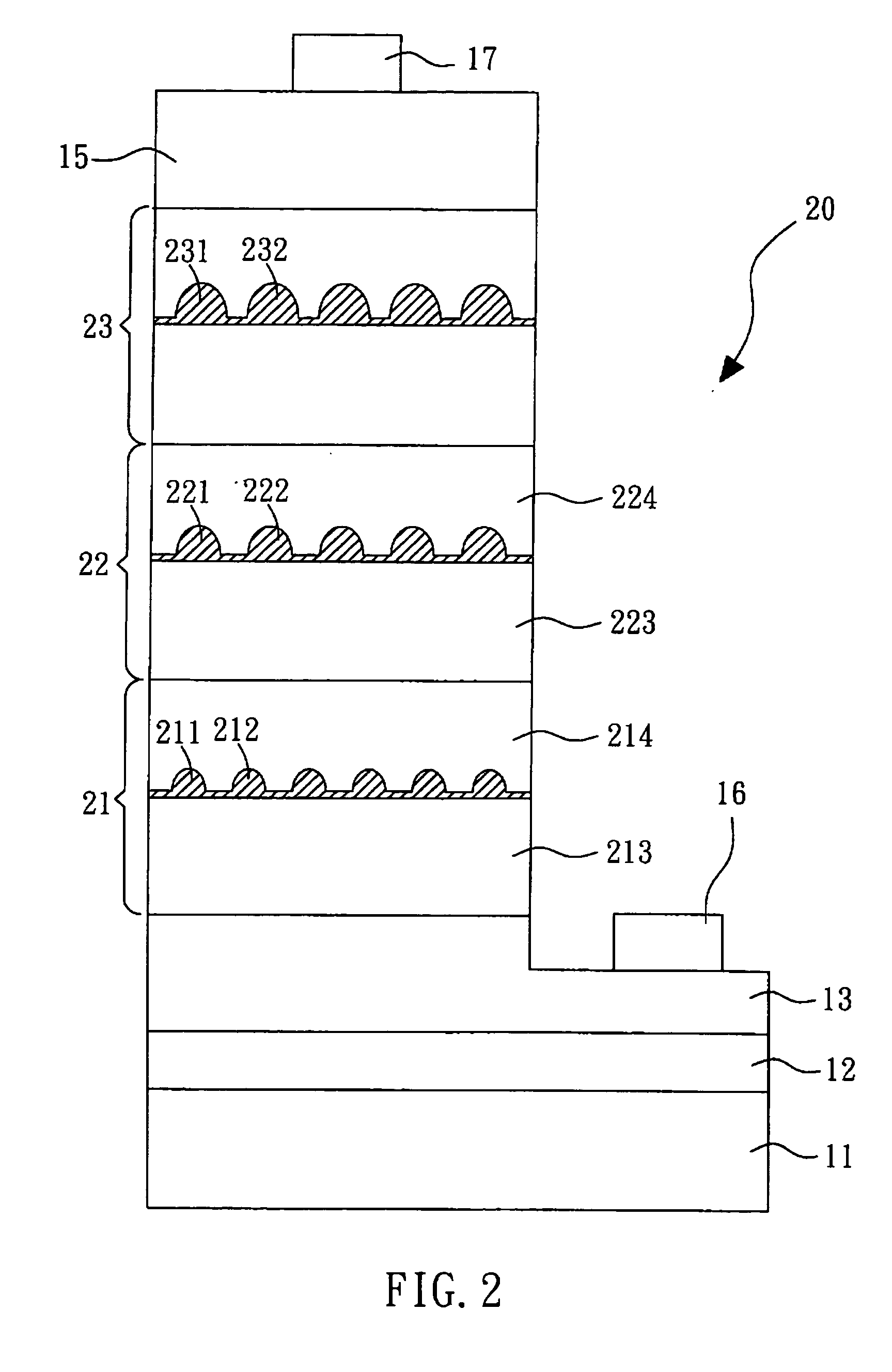

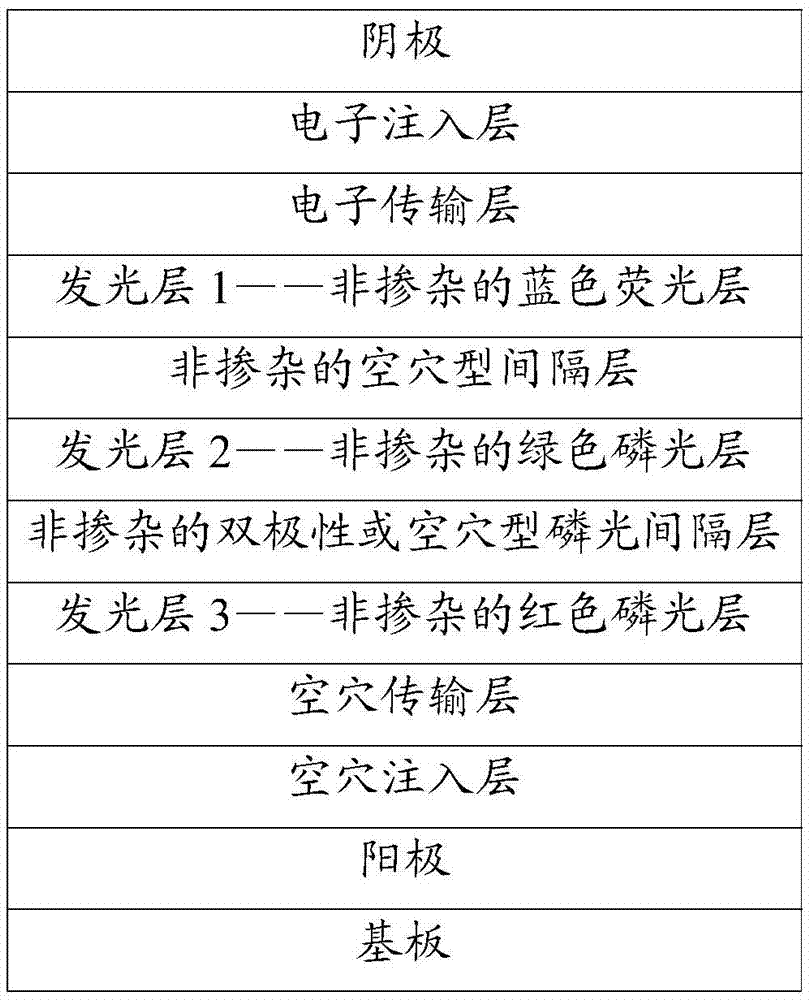

High-color-temperature tandem white OLED

ActiveUS20100066239A1Improve color temperatureLarge displayDischarge tube luminescnet screensLamp detailsColor temperatureHigh color

An OLED device having two spaced electrodes including: first, second, and third light-emitting units disposed between the electrodes, the first light-emitting unit produces light that has multiple peaks at wavelengths longer than 500 nm and substantially no emission at wavelengths shorter than 480 nm, and the second and third light-emitting units produce light that has substantial emission at wavelengths shorter than 500 nm; intermediate connectors respectively disposed between the first and second light-emitting units, and between the second and third light-emitting units; and wherein the OLED device emits light with a color temperature greater than 7,000K.

Owner:GLOBAL OLED TECH

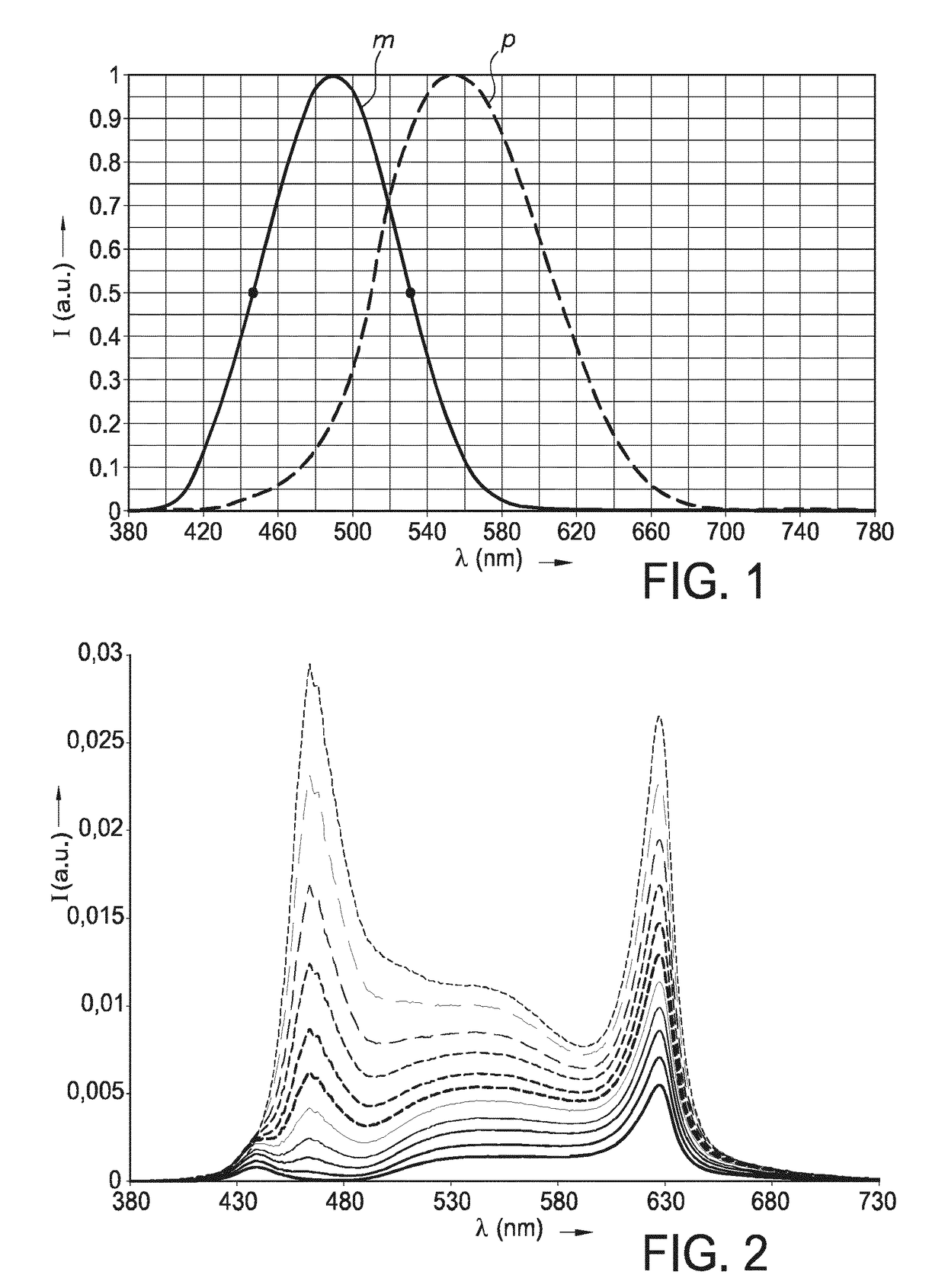

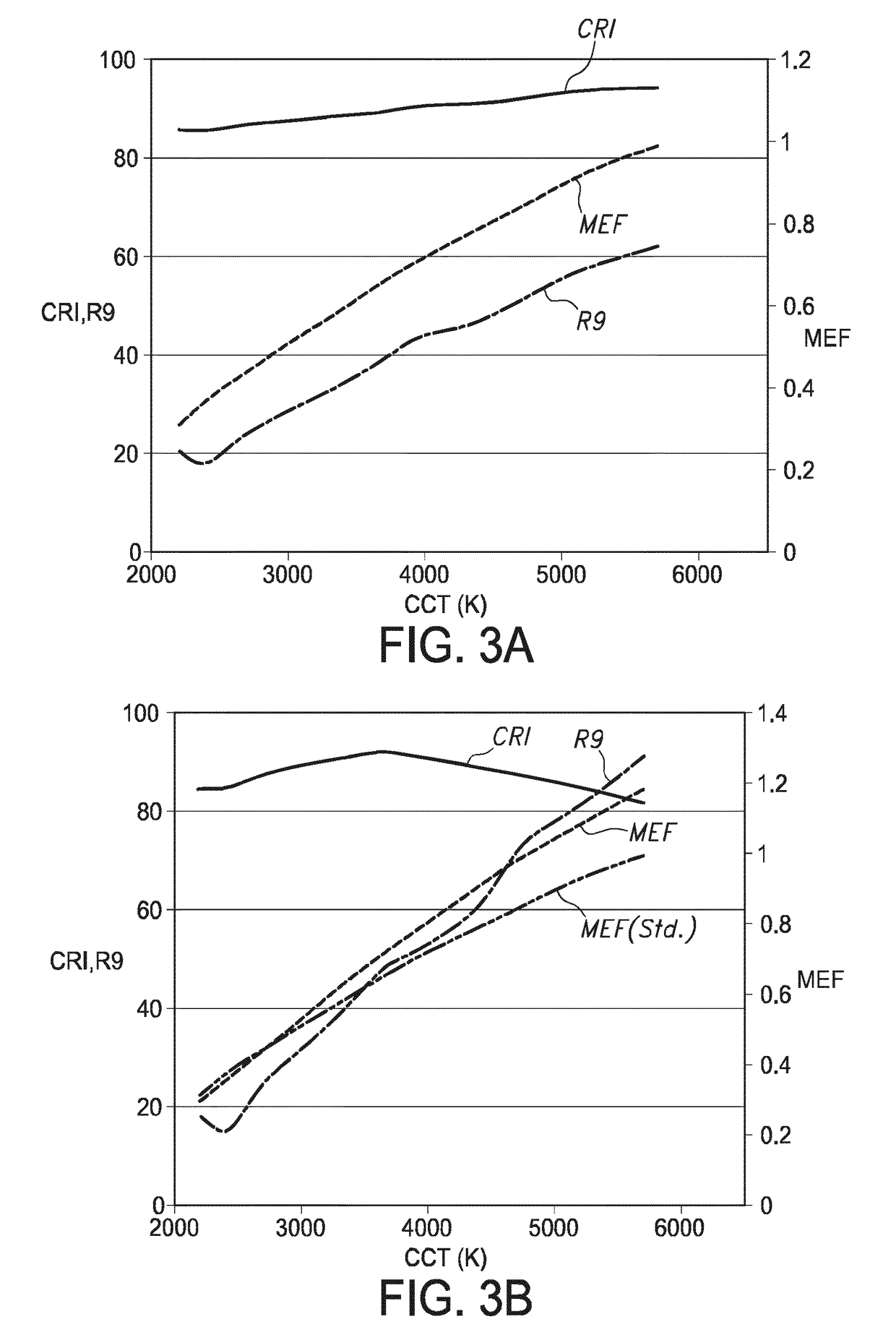

Bio hue lamp

ActiveUS20180056027A1Suppresses melatonin productionImprove sleepingLight source combinationsElectrical apparatusHuman Circadian RhythmsPhosphor

The invention provides a three-channel lighting apparatus with the option to support the human circadian rhythm. By choosing especially the blue LED and green phosphor, the range of biological activity that can be changed is optimized. By adjustment of the LED spectra a bigger range in melanopsin effectiveness factor, at the same CCT range (from daylight like CCT down to dimmed halogen), can be obtained.

Owner:SIGNIFY HLDG BV

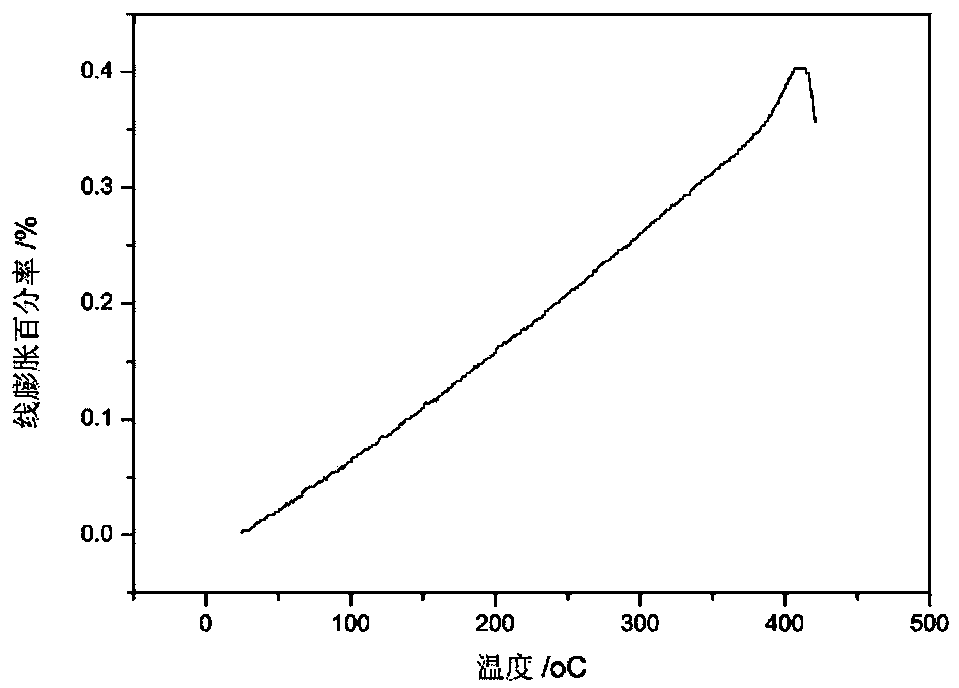

Semitransparent fluorescent powder/glass composite luminescent ceramic wafer and preparation method thereof

The invention relates to a semitransparent fluorescent powder / glass composite luminescent ceramic wafer and a preparation method thereof. The semitransparent fluorescent powder / glass composite luminescent ceramic wafer is obtained by carrying out 'pelletizing, compression moulding and sintering' on fluorescent powder and low-melting-point glass powder, wherein content of the fluorescent powder is 30-85wt%, and the content of the low-melting-point glass powder is 70-15wt%. The preparation method of the semitransparent fluorescent powder / glass composite luminescent ceramic wafer comprises the following steps: firstly, uniformly mixing fluorescent powder with glass powder in certain proportion, and adding a binding agent required by pelletizing and demoulding, so that pelletized powder of 60-100 meshes is obtained; secondly, carrying out compression moulding on the obtained pelletized powder by virtue of a mould, so that a green body of a certain shape is obtained; thirdly, carrying out heat treatment, namely carrying out glue drainage on the green body for 2-4 hours at the temperature of 300-395 DEG C, and sintering for 1-2 hours at the temperature of 395-410 DEG C, wherein the whole heat treatment process is carried out in the air atmosphere; and finally the fluorescent powder / glass composite luminescent ceramic wafer is obtained.

Owner:厦门百嘉祥微晶材料科技股份有限公司

Single-chip white light emitting device

ActiveUS7217959B2Improve reliabilityHigh indexNanoinformaticsSolid-state devicesQuantum dotLength wave

Owner:GENESIS PHOTONICS

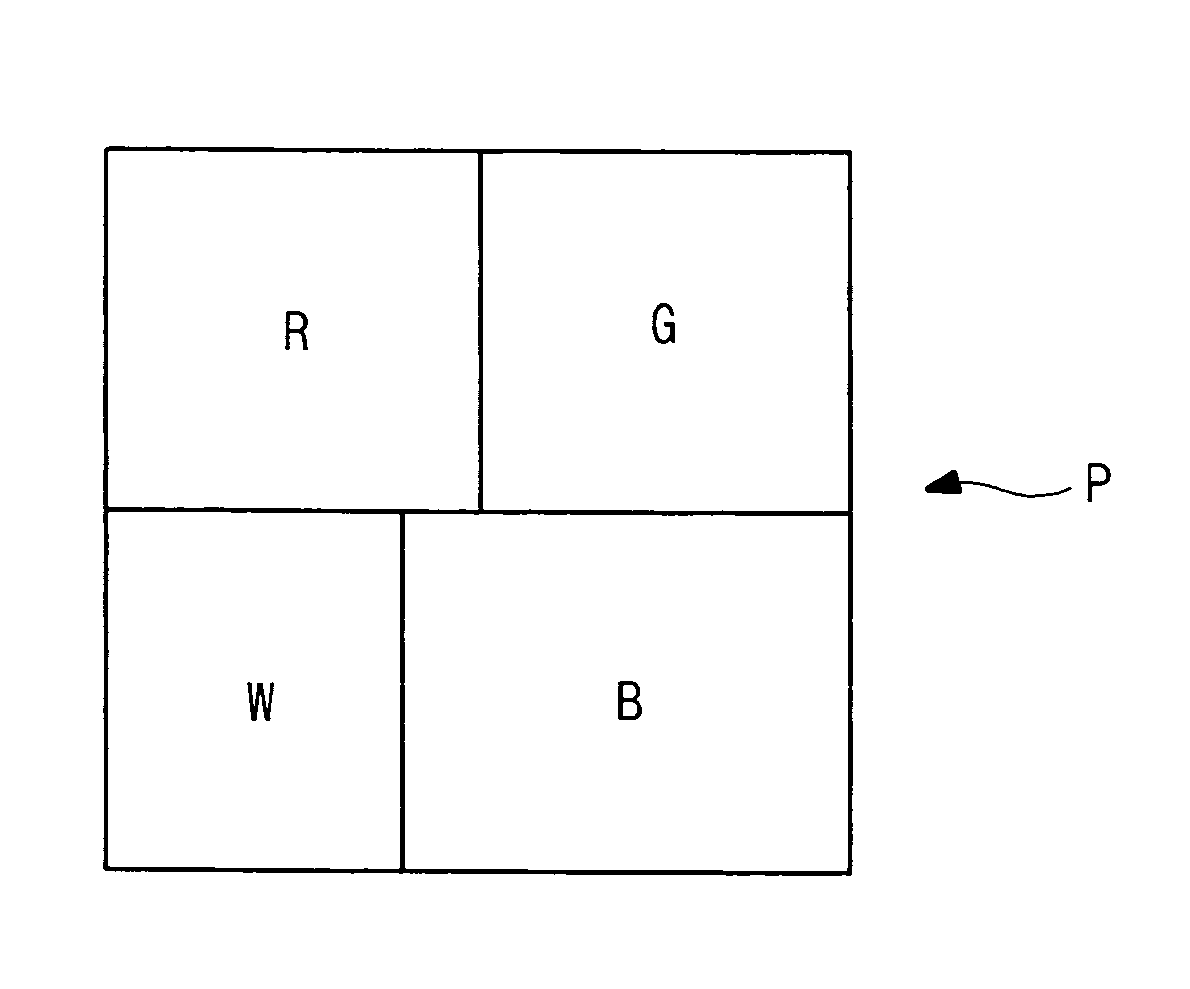

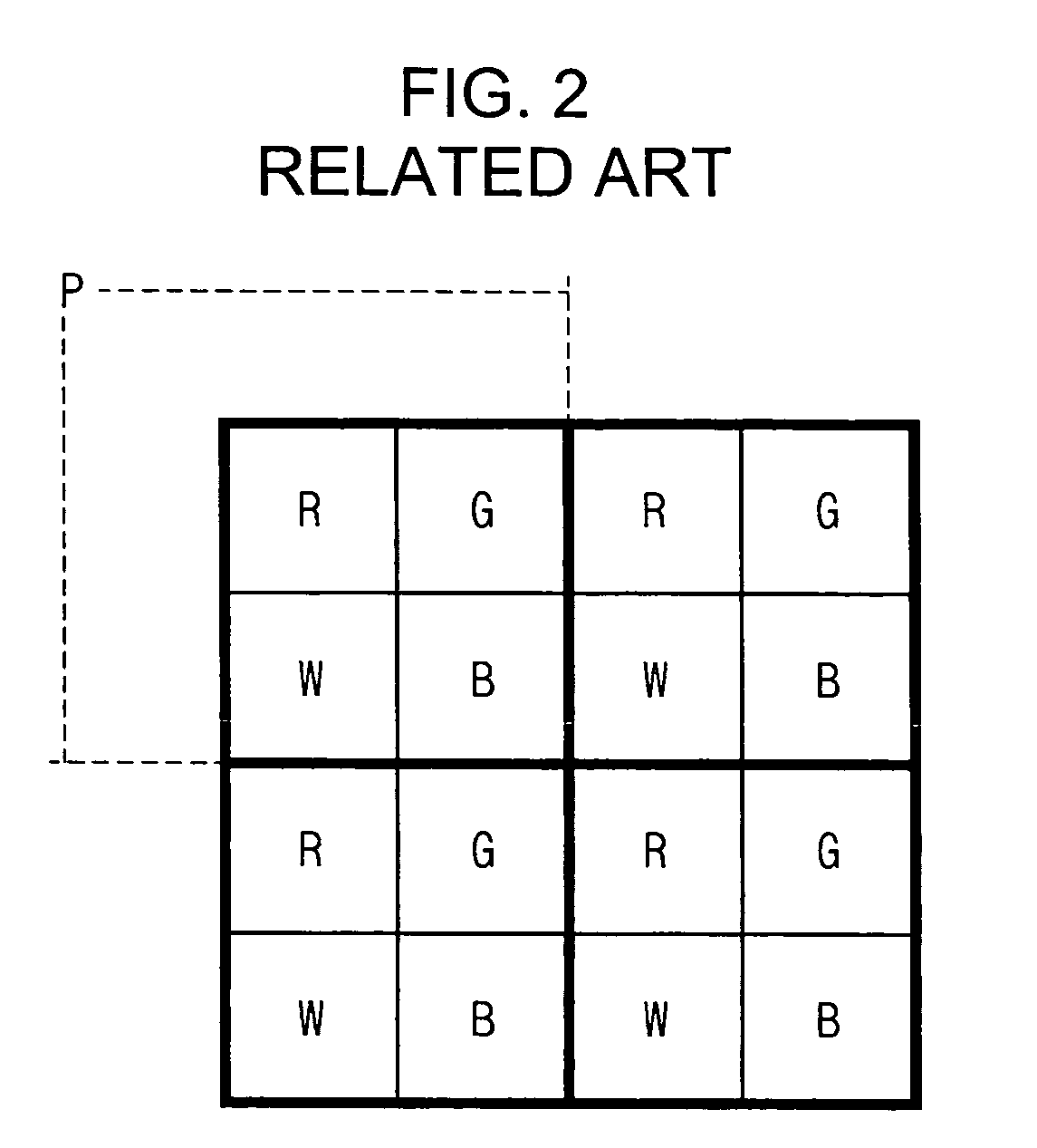

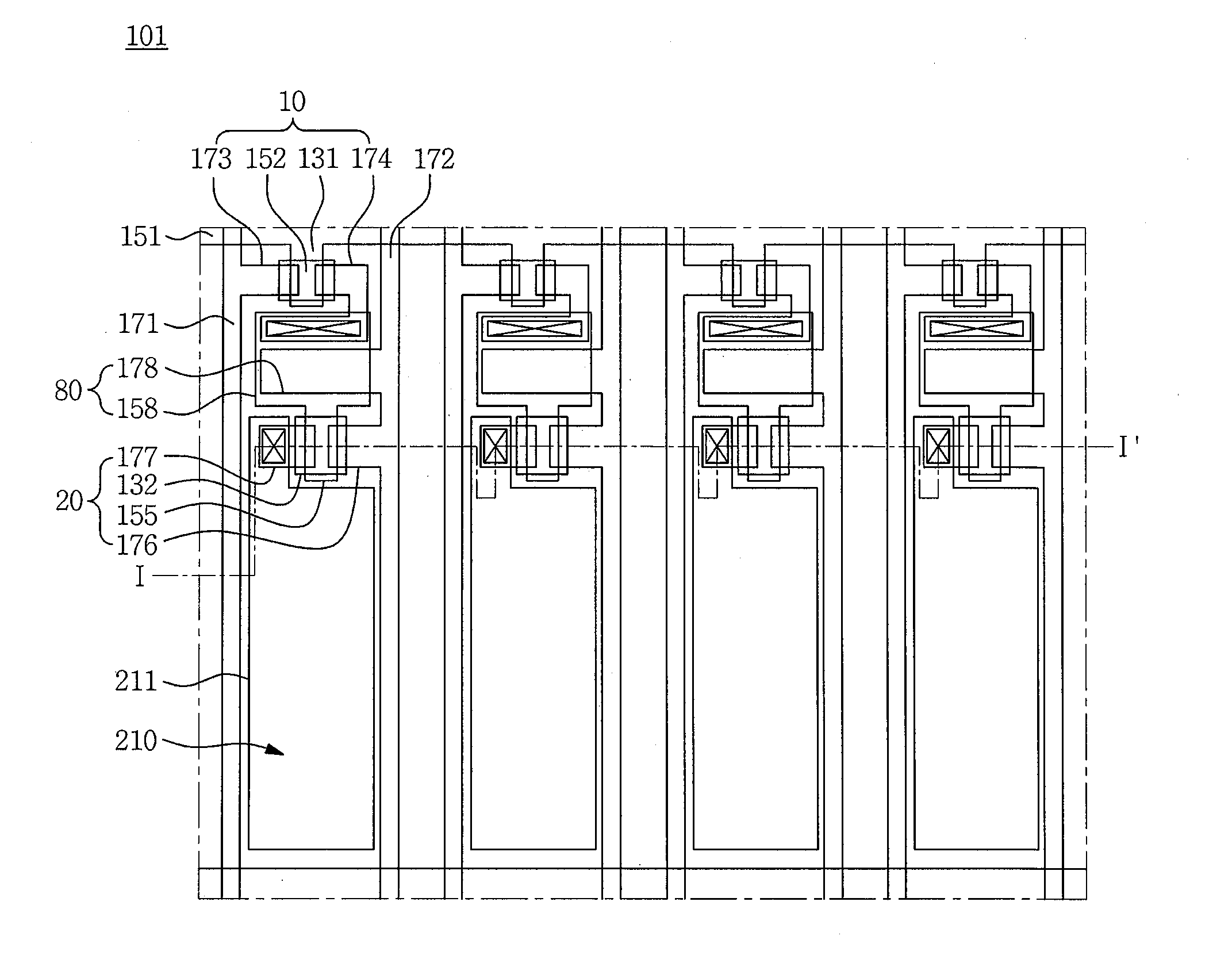

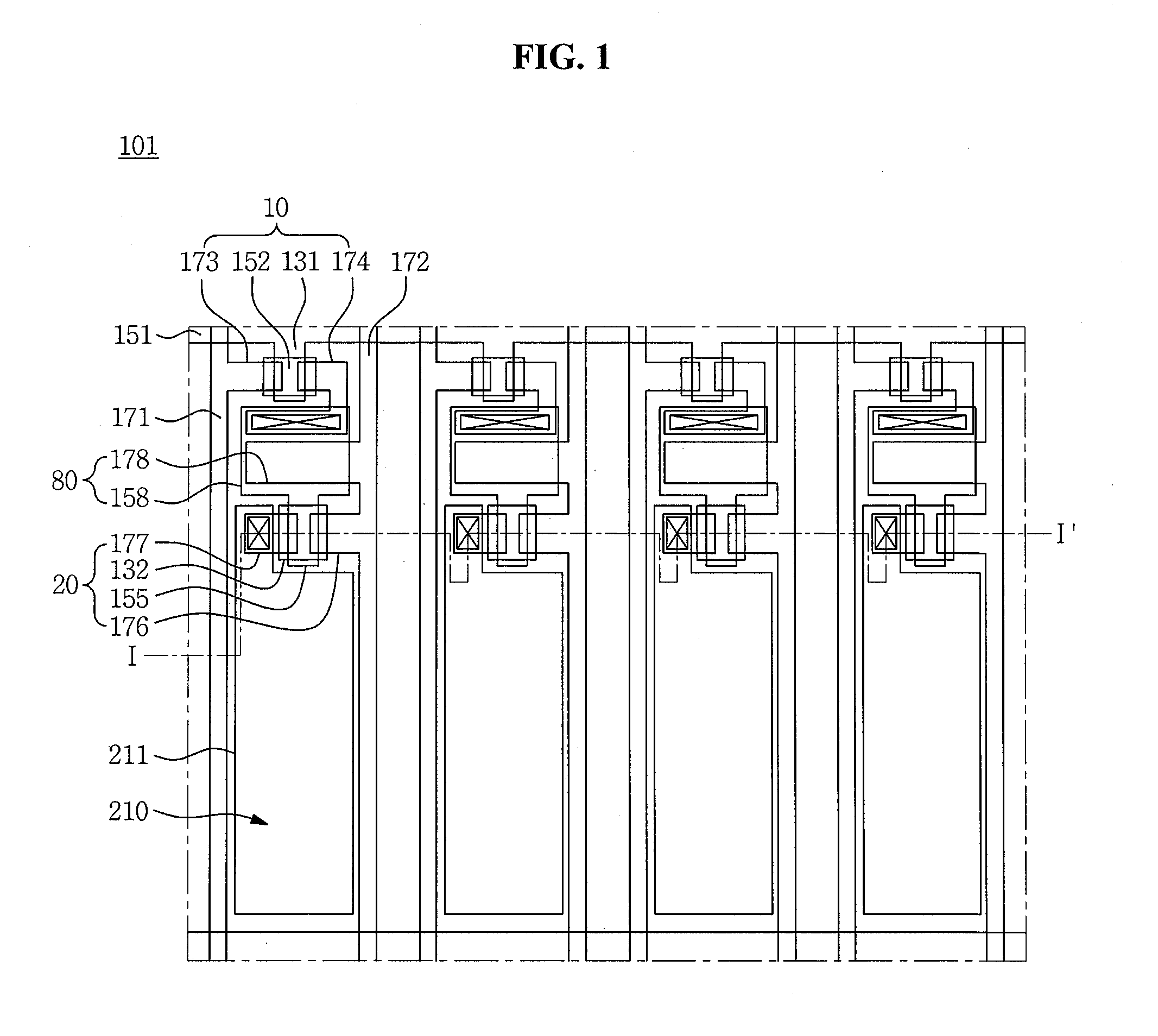

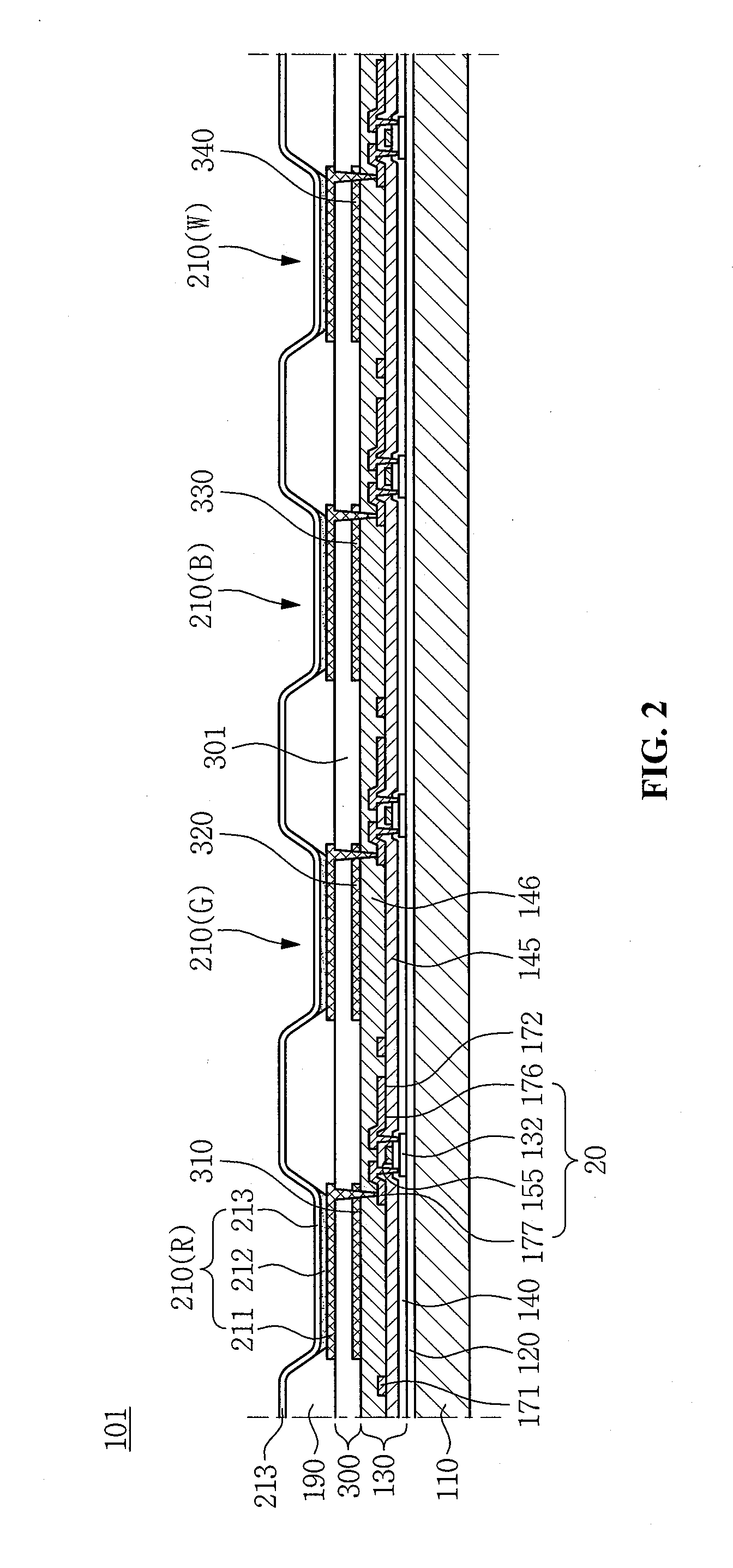

Liquid crystal display device

A liquid crystal display device includes a red sub-pixel having a first area, a green sub-pixel having a second area, a blue sub-pixel having a third area, a white sub-pixel having a fourth area, and a backlight supplying a light to the red, green, blue, and white sub-pixels. The fourth area is smaller than the third area.

Owner:LG DISPLAY CO LTD

Display device comprising gray color filter

ActiveUS20160087247A1Suppress light reflectionHigh color temperatureSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceGreen-light

A display device may include a substrate, a color filter layer, on a first surface of the substrate, including a red color filter, a green color filter, a blue color filter, and a gray color filter, and an organic light emitting diode on the color filter layer. The gray color filter may have a blue light transmittance higher than red and green light transmittances.

Owner:SAMSUNG DISPLAY CO LTD

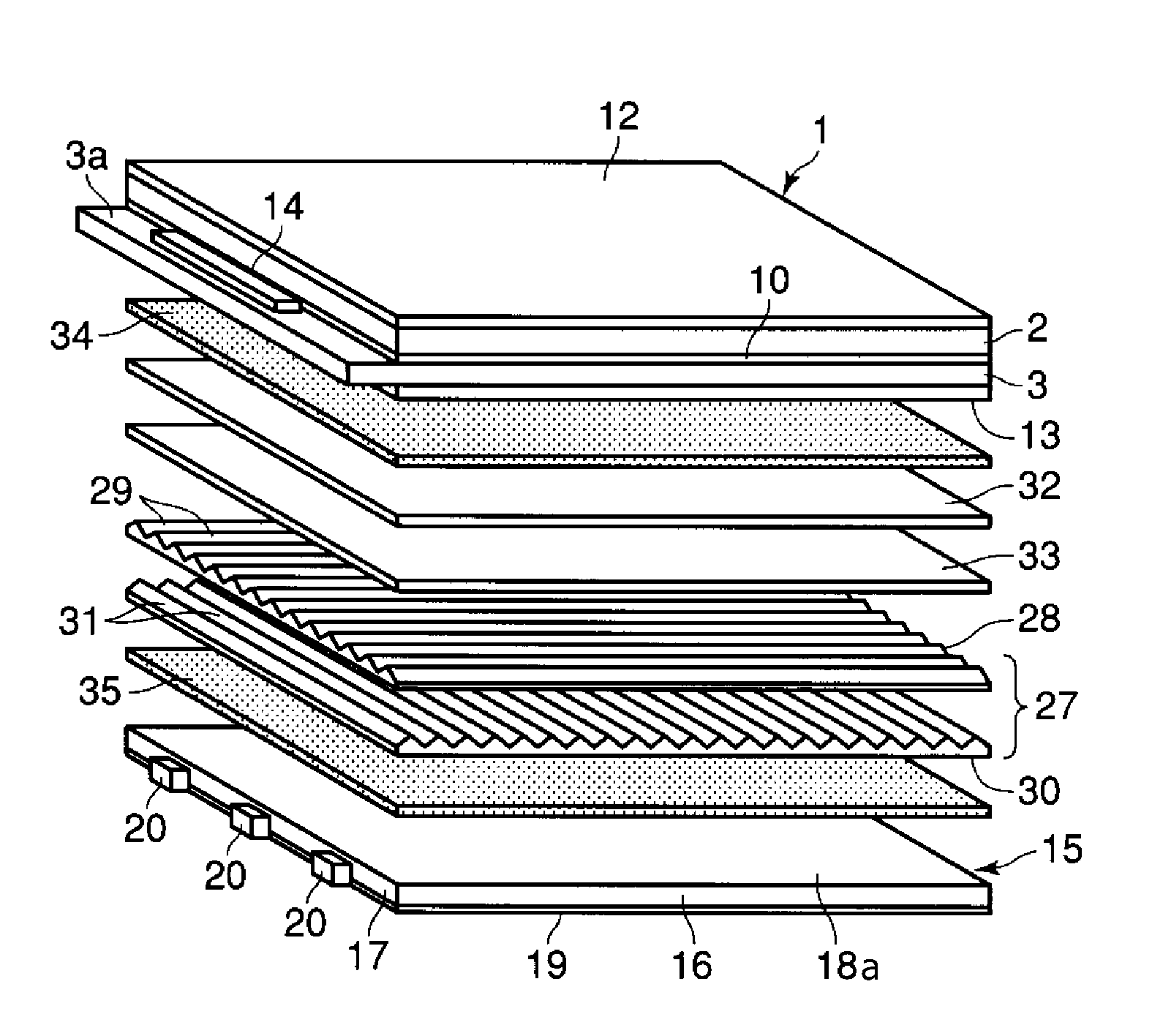

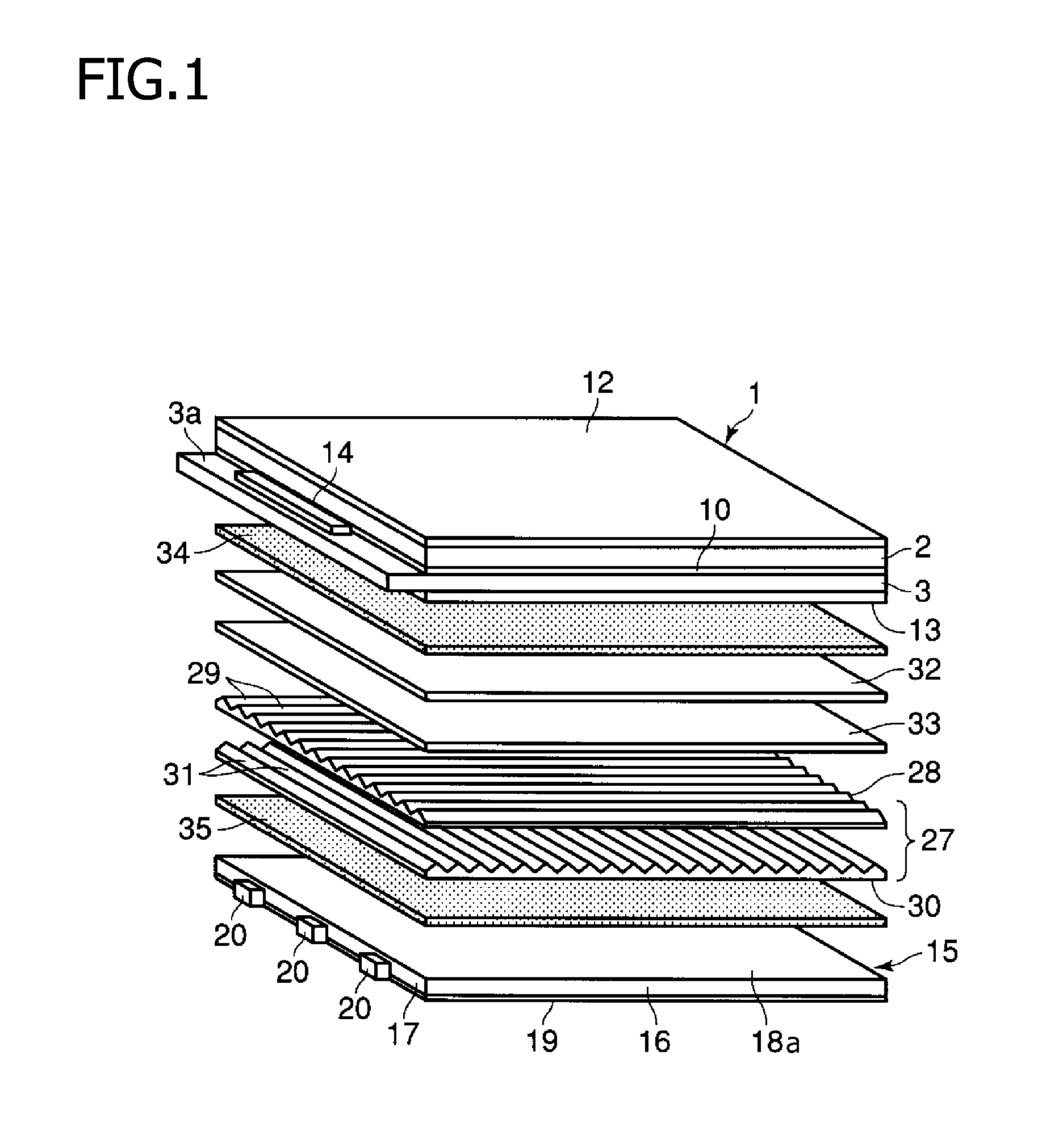

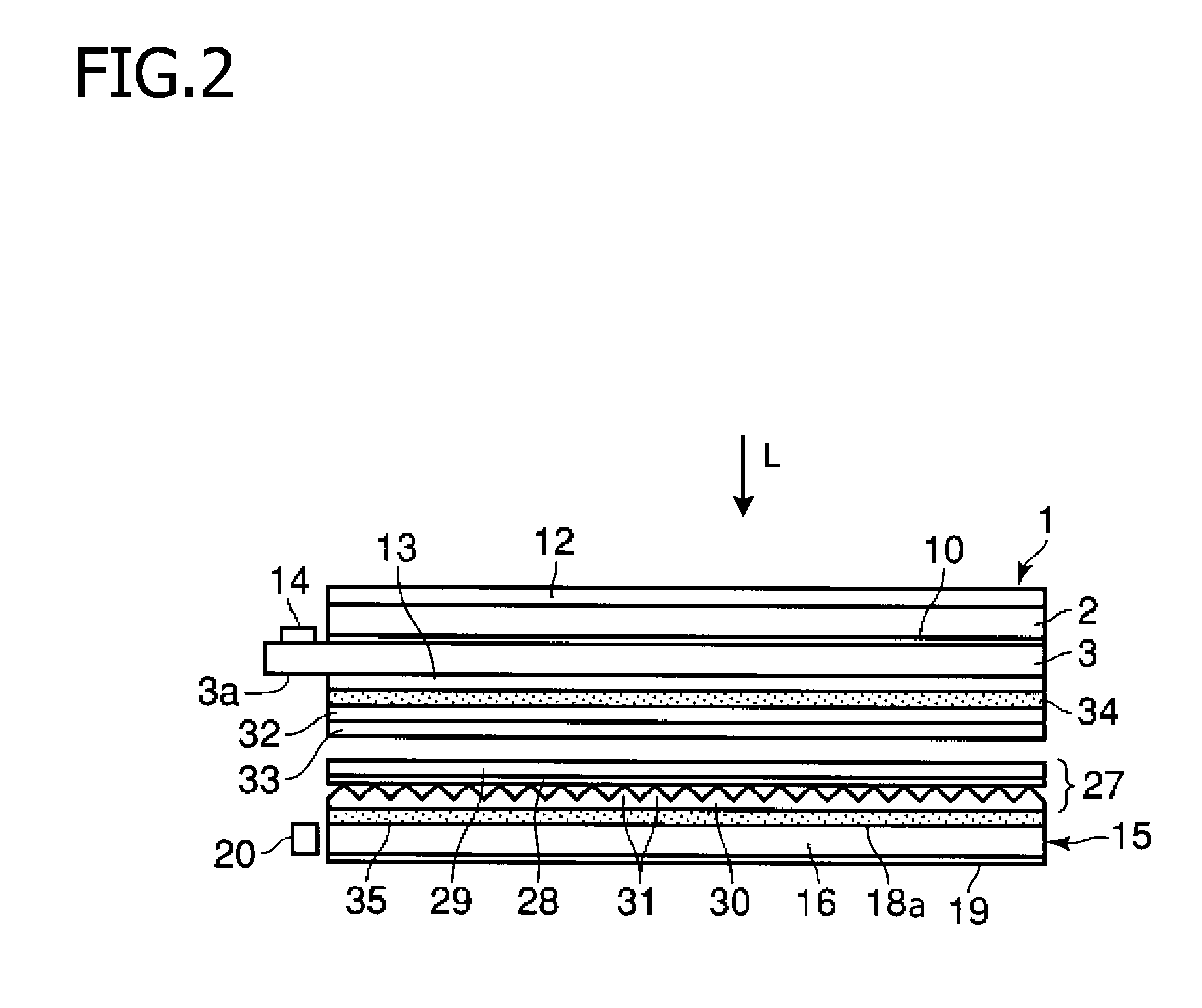

Liquid crystal display device

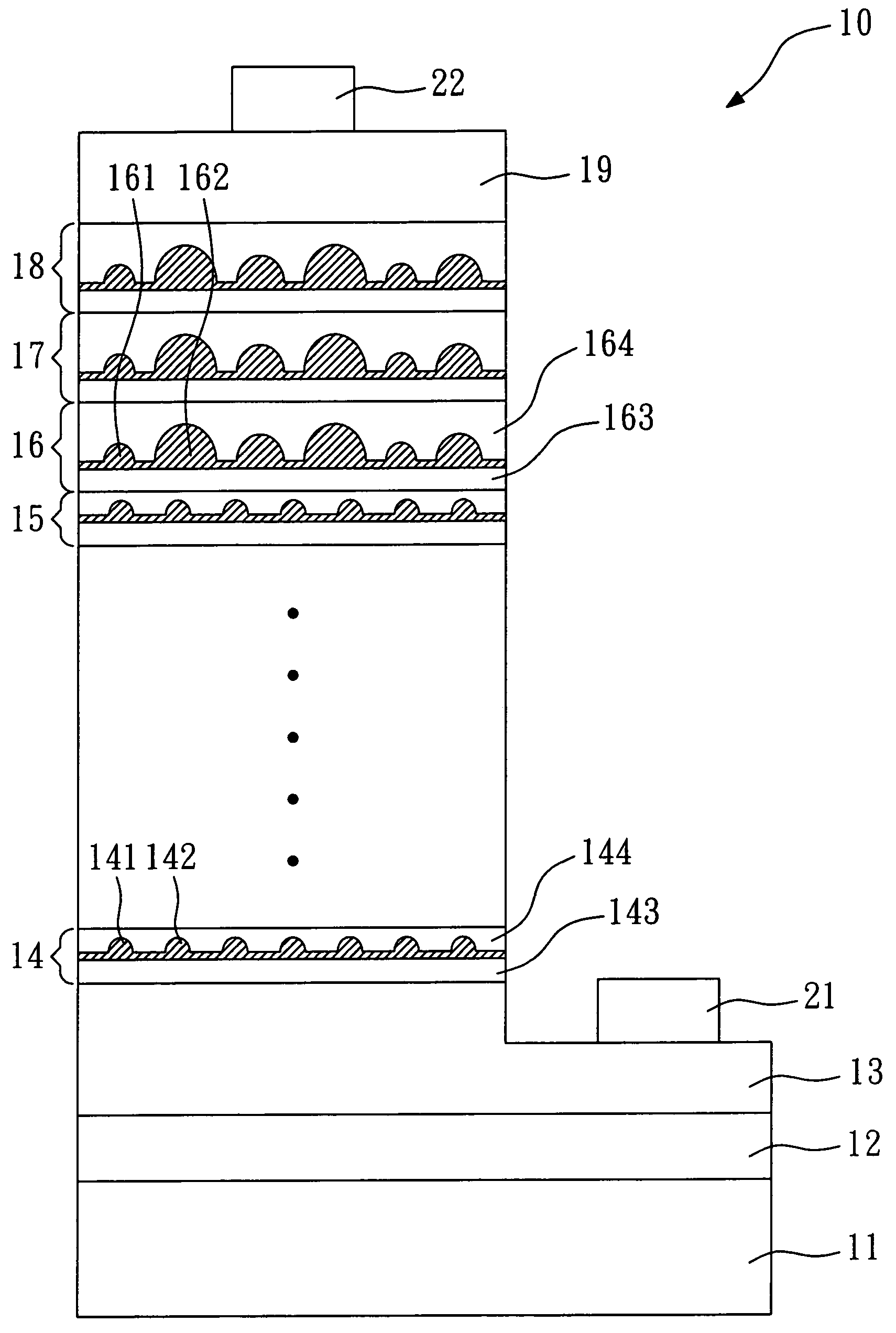

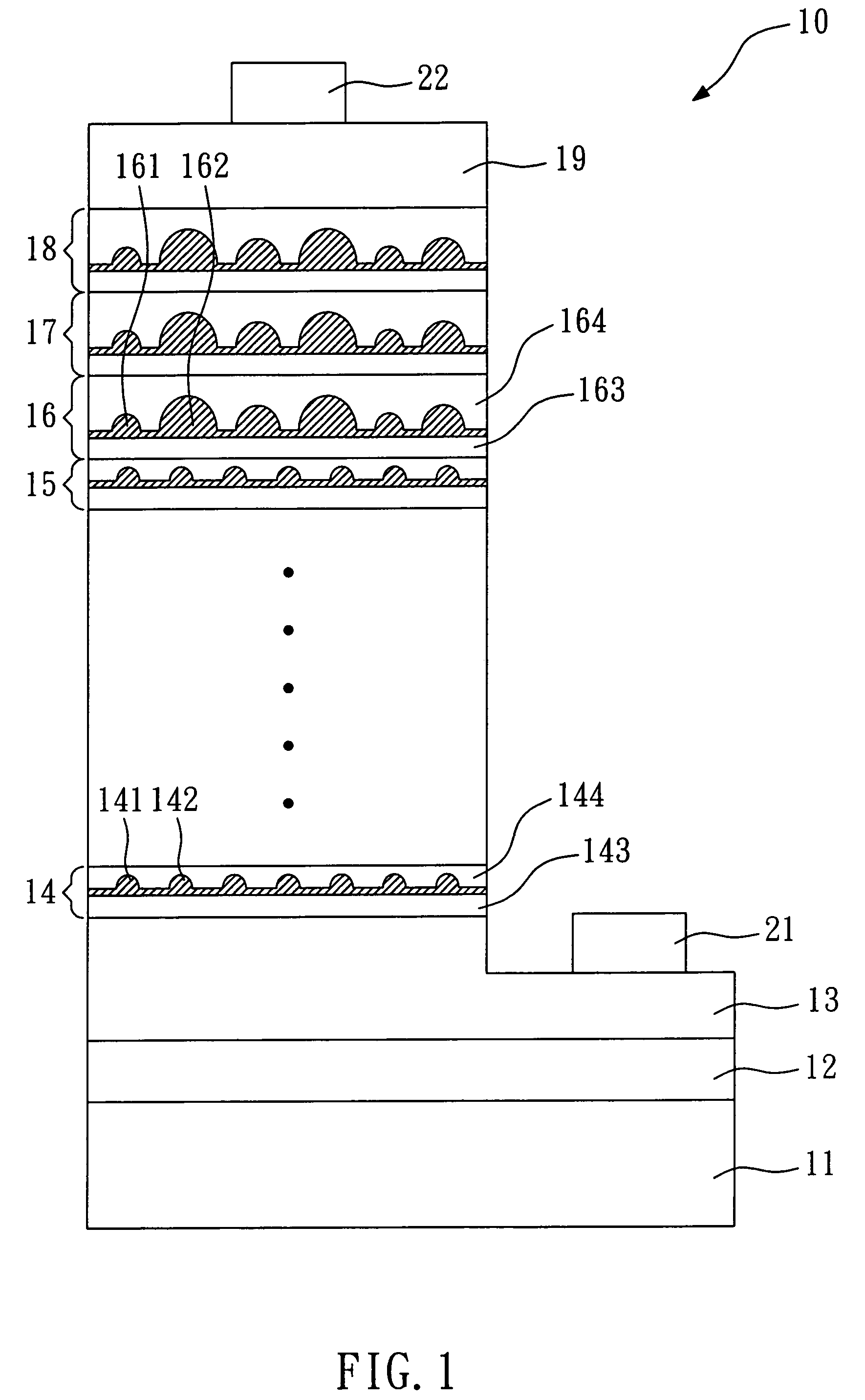

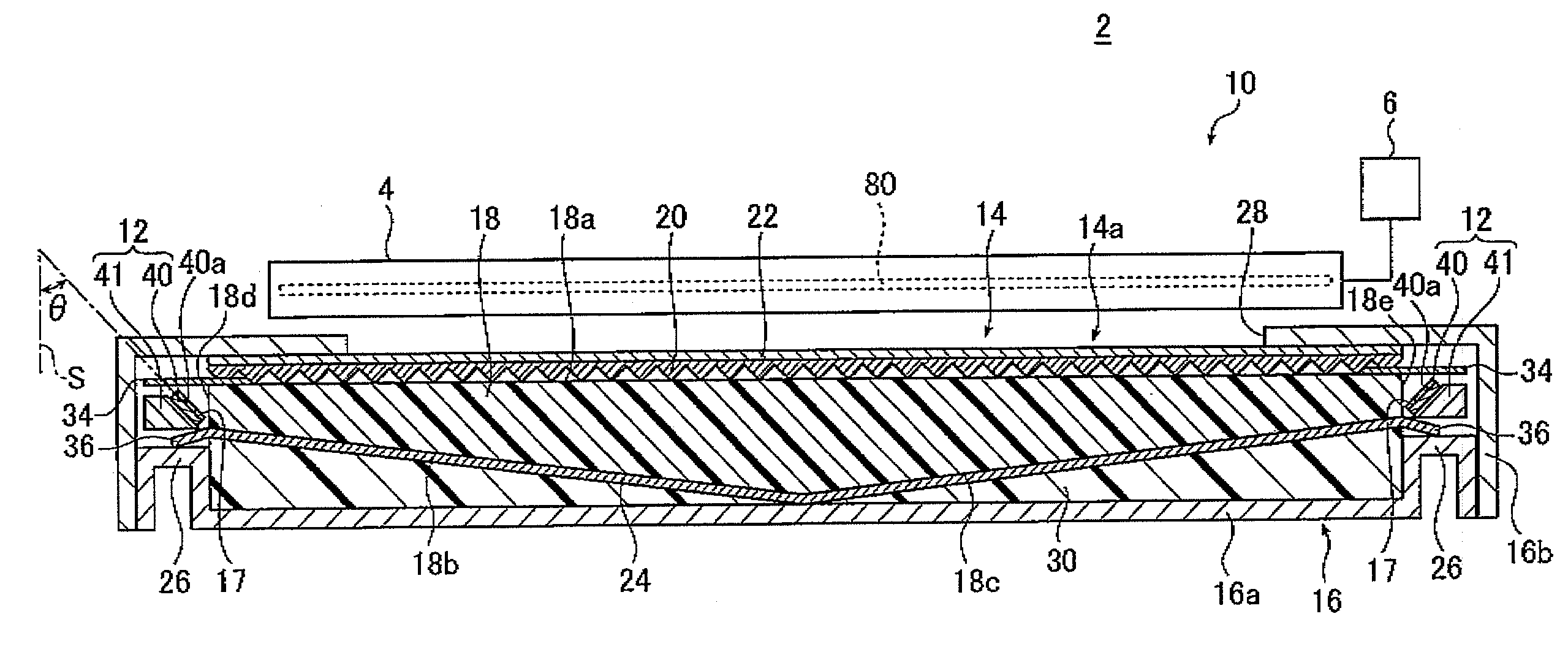

ActiveUS20080198300A1High color temperatureHigh color reproductionOptical light guidesNon-linear opticsExit planeLiquid-crystal display

The liquid crystal display device with a simple configuration is capable of emitting light with a desired color temperature, achieving high light use efficiency, and displaying high quality images. The liquid crystal display device includes a planar lighting device and a liquid crystal display panel. The planar lighting device includes a light source having LED chips for emitting blue light, a transparent light guide plate having a light entrance plane admitting light emitted by the light source and a light exit plane emitting planar light, and a fluorescent member disposed between the light emission plane and the light entrance plane and having one or more fluorescent substance coated areas for emitting white light by converting blue light from the light source into white light and one or more blue light passing areas passing blue light as blue light. The liquid crystal display panel essentially includes red, green and blue filters.

Owner:FUJIFILM CORP

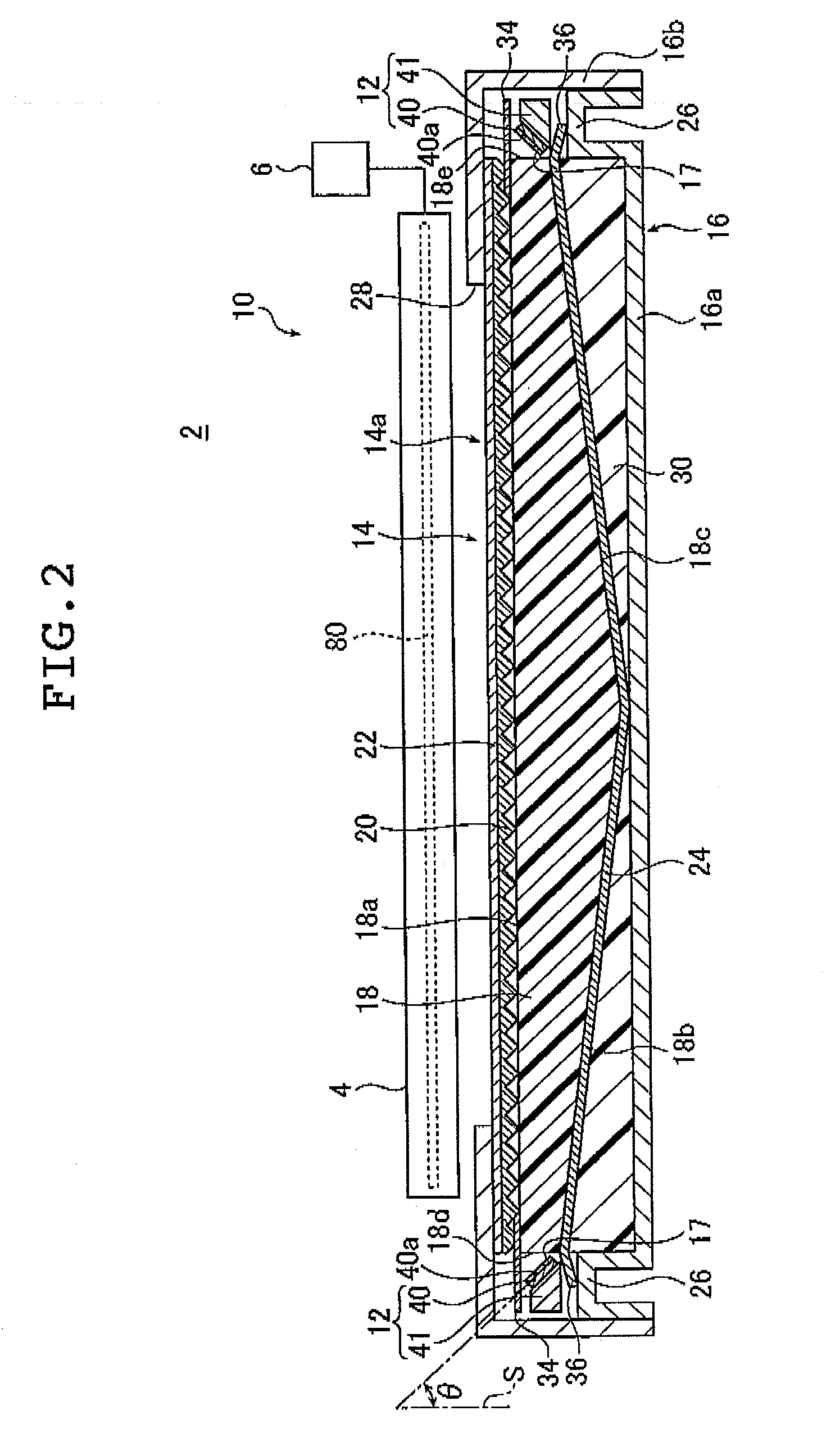

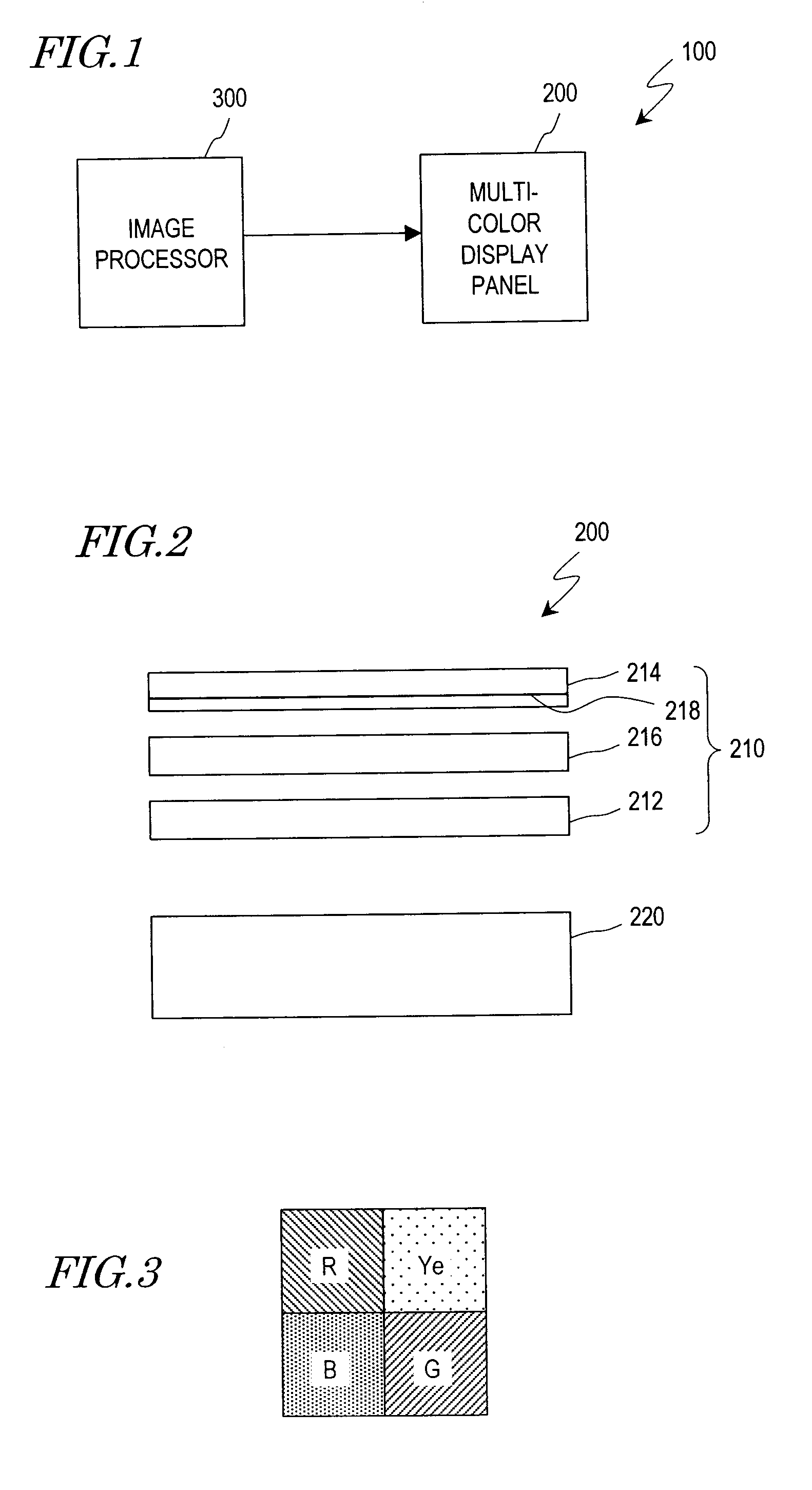

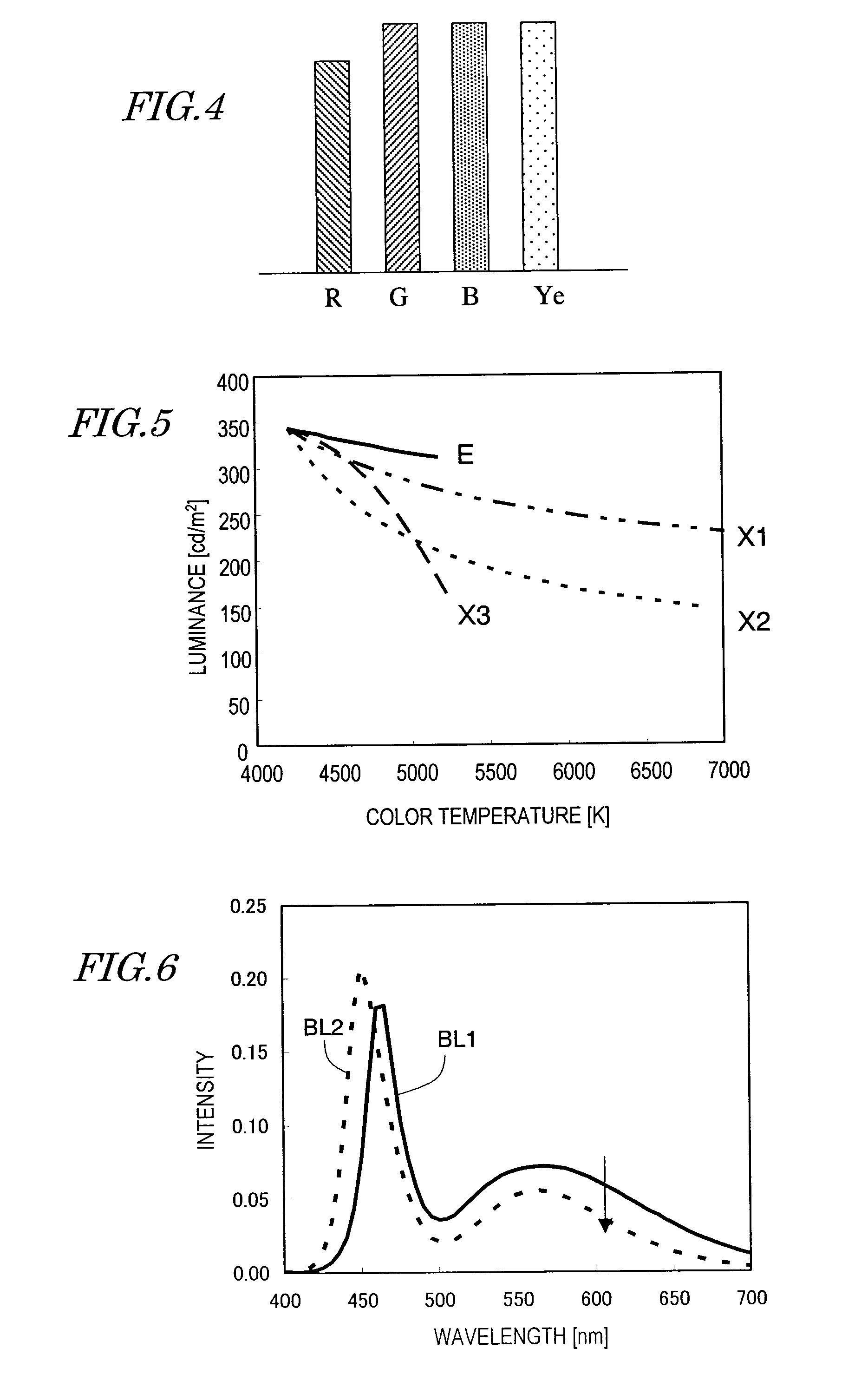

Display

ActiveUS20090273607A1Wide color reproduction rangeHigh color temperatureOpticsCathode-ray tube indicatorsDisplay deviceComputer science

A display device has a pixel that is defined by a plurality of sub-pixels. The sub-pixels include a red sub-pixel representing red, a green sub-pixel representing green, a blue sub-pixel representing blue and a yellow sub-pixel representing yellow. When the pixel represents white, the luminance of the red sub-pixel is lower than its luminance corresponding to the highest gray scale level. In one embodiment, when the pixel represents white, the luminance of the red sub-pixel is preferably in the range of 25% to 96% of its luminance corresponding to the highest gray scale level. Also, the color temperature of white represented by the pixel is preferably higher than 4200 K, more preferably higher than 5000 K.

Owner:SHARP KK

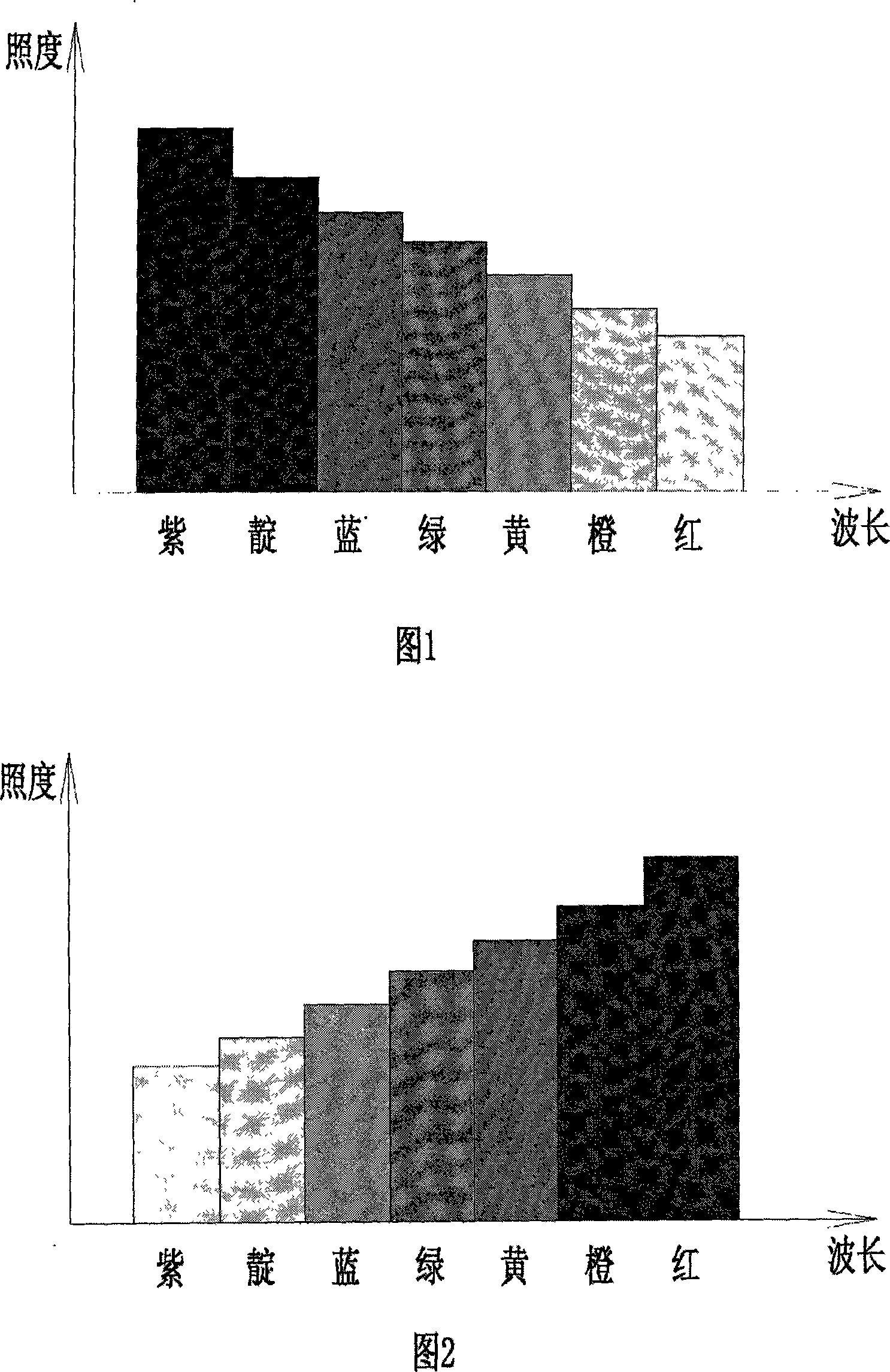

Colour, temperature adjustable operation lamp

InactiveCN101025257AHigh color temperatureRelieve visual fatigueTreatment roomsMedical lightingLuminous intensityIlluminance

The invention relates to an operating-lamp which can adjust the color temperature. It is made up of a white light luminous series which is cold color, the white light luminous series which is warm color and a controller to adjust the luminous intensity. So the operating-lamp has the uniform light spectrum change, the color temperature and the light intensity can be adjusted, also it has the simple structure and easy operation.

Owner:汕头市夏野电器有限公司

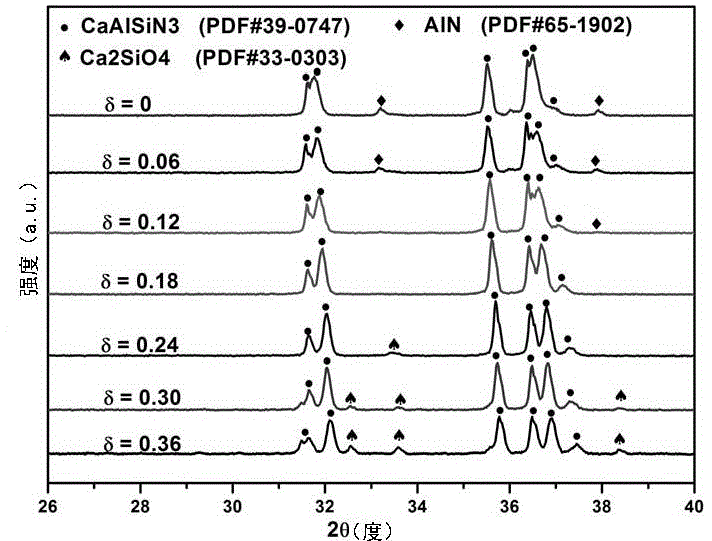

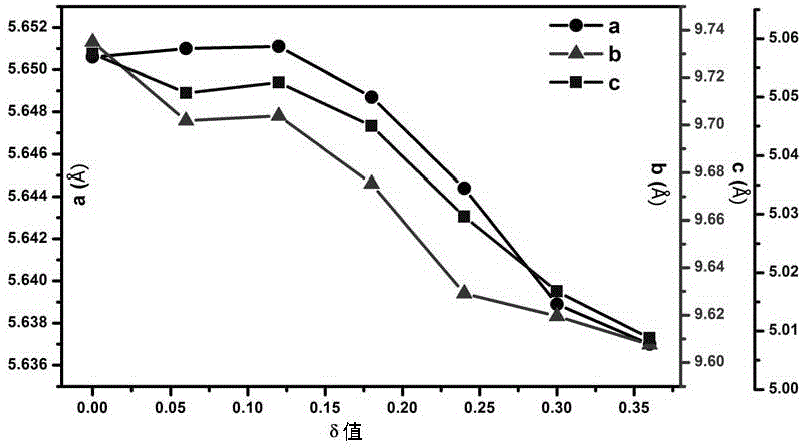

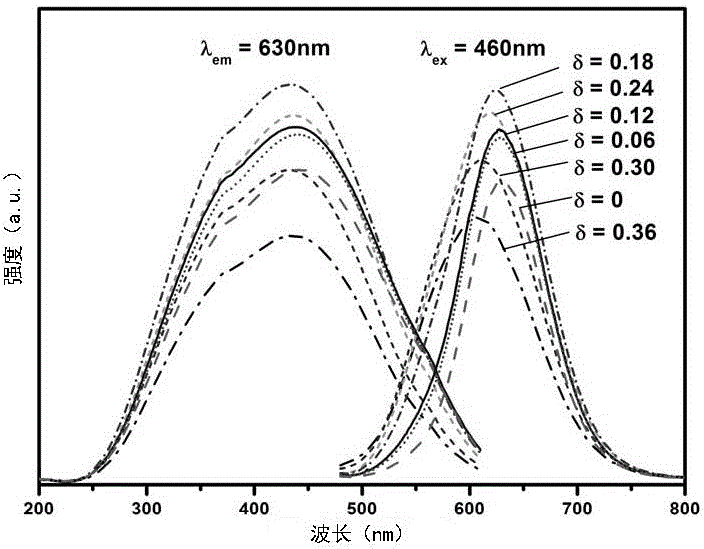

Red fluorophor as well as carbothermal reduction nitridation preparation method and application of red fluorophor

ActiveCN104087293ASimple processLow costEnergy efficient lightingLuminescent compositionsNitrogen gasReducing agent

The invention relates to a red fluorophor as well as a carbothermal reduction nitridation preparation method and an application of the red fluorophor. The red phosphor is formed by carrying out solid solution on an activator A in the Ca[1-y]SryAlaSibNcOd substrate having the same crystal structure as that of the CaAlSiN3 crystalline phase, the chemical formula of red phosphor is Ca[1-vx / 2-y]SryAxAlaSibNcOd, wherein x is greater than 0 and less than or equal to 0.2, y is equal to or greater than 0 and less than or equal to 0.8, a is equal to or greater than 0.52 and less than or equal to 1, b is equal to or greater than 1 and less than or equal to 1.36, c is greater than 2.85 and less than or equal to 3 and d is equal to or greater than 0 and less than or equal to 0.2, the element A is at least one element selected from Eu, Mn, Yb, Ce, and Tb and v is representative of the electrovalence of the activator A ion and the preparation method of the red fluorophor comprises the following steps of maintaining CaCO3 powder and / or CaO powders and / or CaC2O4 powder, SrCO3 and / or SrO powder, Si3N4 powder and / or SiO2 powder, AlN powder, and single metal, oxide, nitride, fluoride, chloride, carbonate and / or nitrogen oxide powder of element A as starting materials in the presence of carbon powder as a reducing agent at a mixed atmosphere nitrogen and hydrogen or a mixed atmosphere of nitrogen, hydrogen and ammonia at a temperature range of 1550-1650 DEG C and sintering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Display panel and display panel production method

InactiveUS20030071572A1Suppress DiffuseReduce diffuseAlternating current plasma display panelsVessels or leading-in conductors manufactureCooking & bakingSilver paste

The present invention has as its objective to provide a display panel with silver electrodes without yellowing, and a method of production such a display panel. After patterning and applying silver paste to form display electrodes on the substrate, glass paste is applied to form the dielectric layer, covering the electrodes, and both layers are simultaneously baked. Glass flit contained in the silver paste is chosen to have a lower softening point than the glass contained in the glass paste, and the baking process is divided into a first step, in which the baking temperature is equal to or higher than the softening point of the glass flit but lower than the softening point of the glass, and a second step, in which the baking temperature is higher than the softening point of the glass. This process allows a display panel to be produced with fewer bakings and reduced yellowing.

Owner:PANASONIC CORP

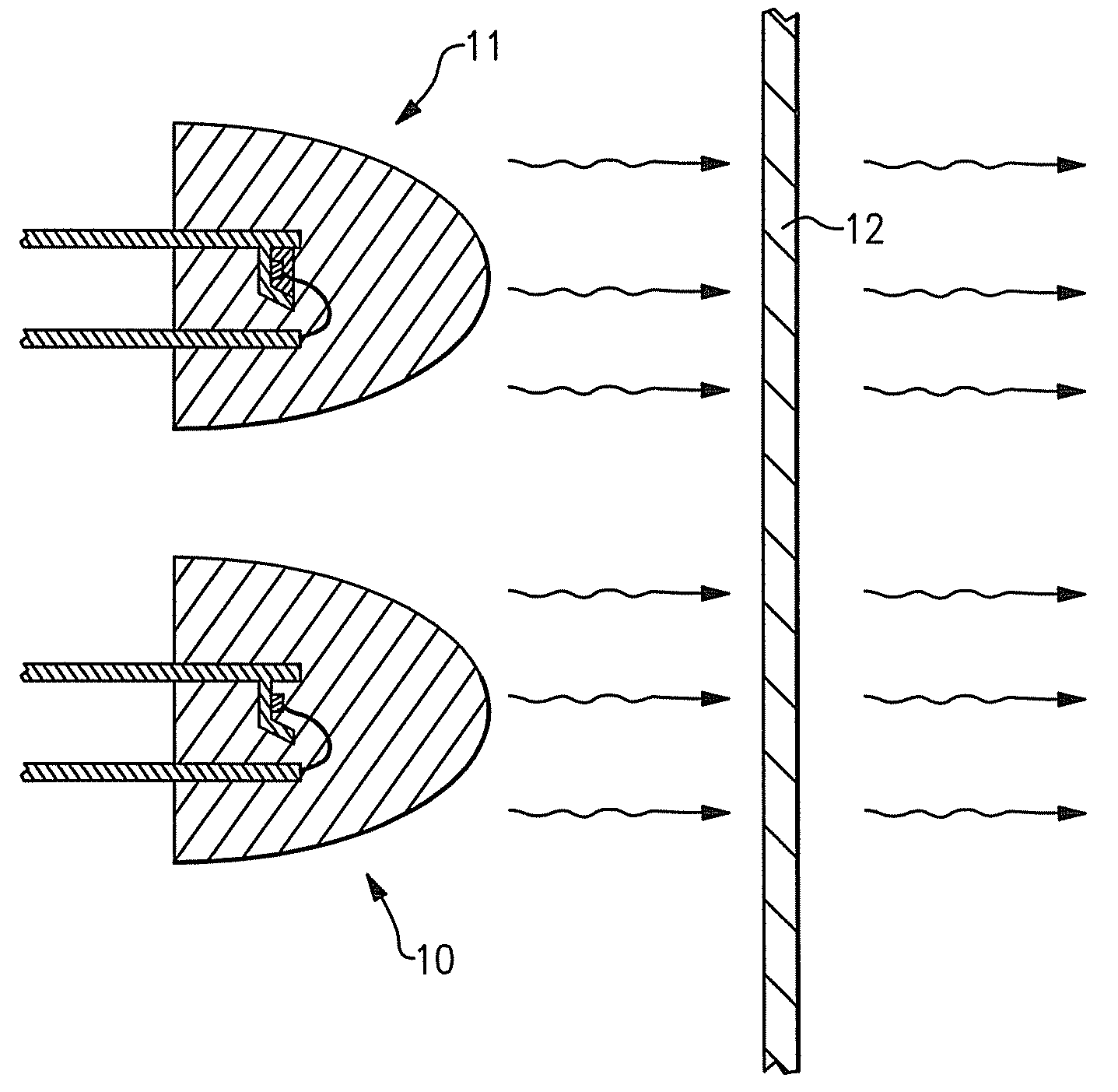

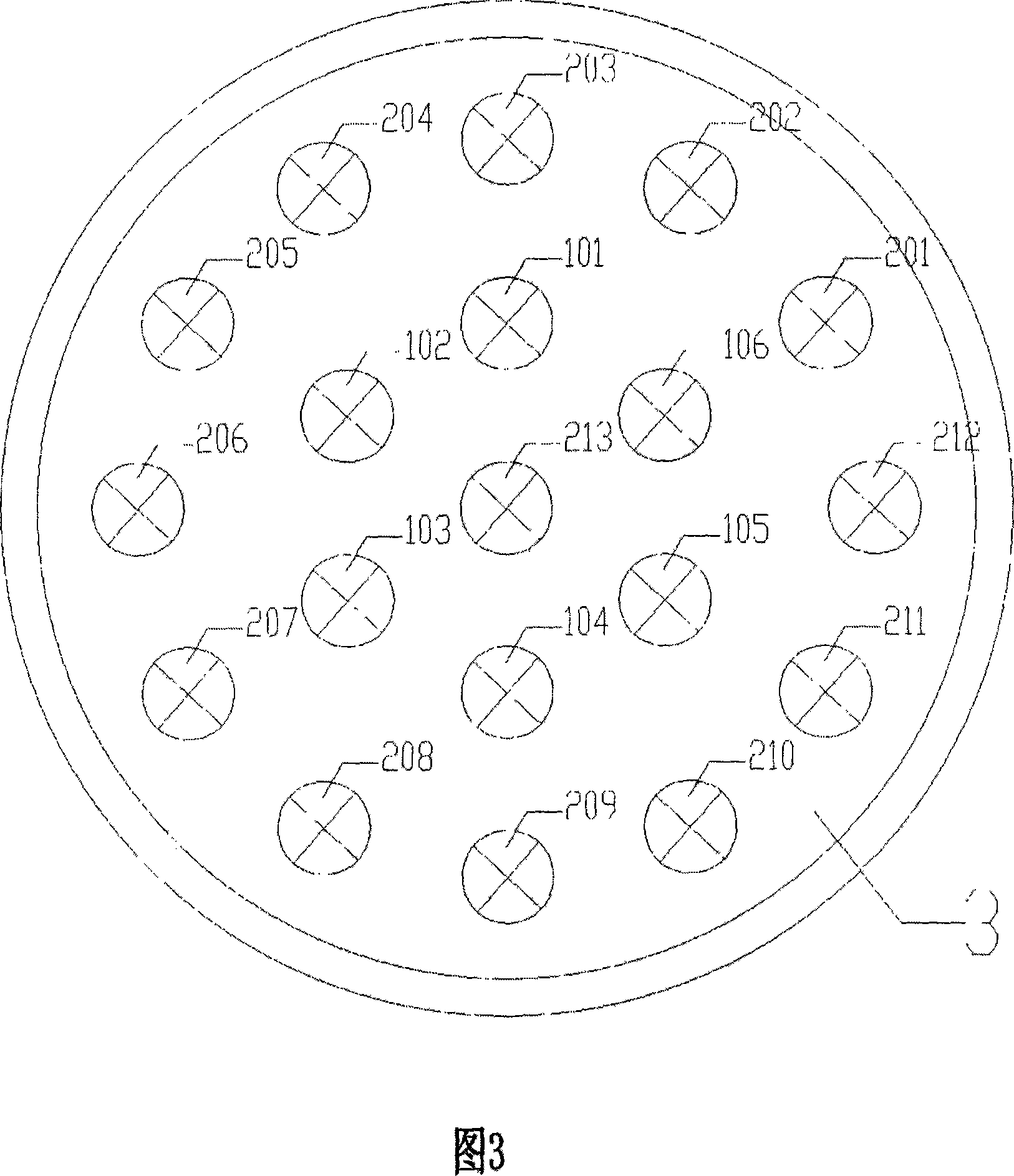

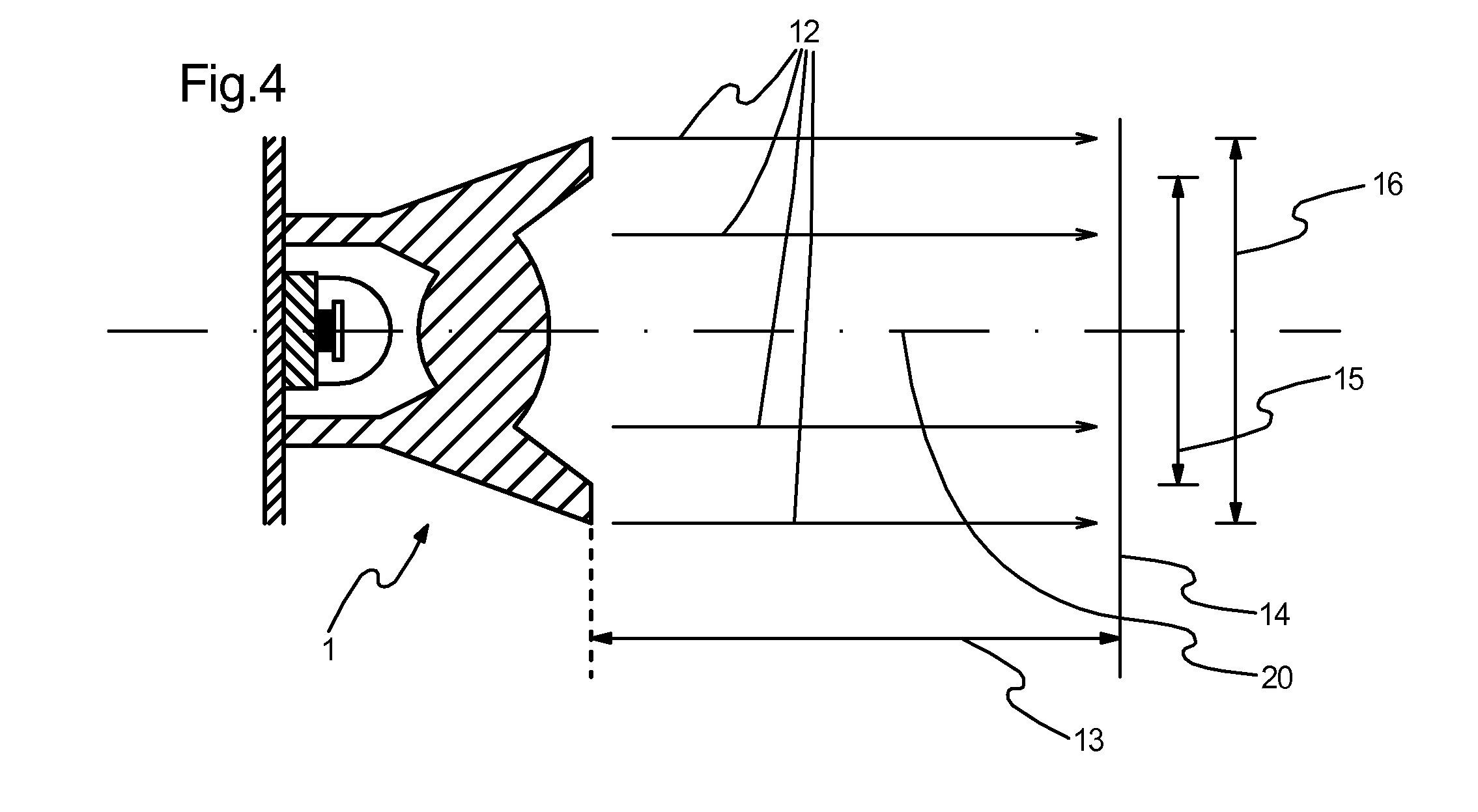

Operating light and a process for lighting an operating table by means of an operating light

ActiveUS20120106145A1Improvement of light perceptionConvenient lightingLighting applicationsMechanical apparatusOperating pointColor temperature

An operating light (36) and a process are provided for lighting an operating table via an operating light (36). The operating light (36) includes at least one first radiation source (1), which is suitable for producing light (12) with locally different, especially radially outwardly decreasing color temperature distribution (18) in a plane extending at right angles to the work area.

Owner:DRAGERWERK AG

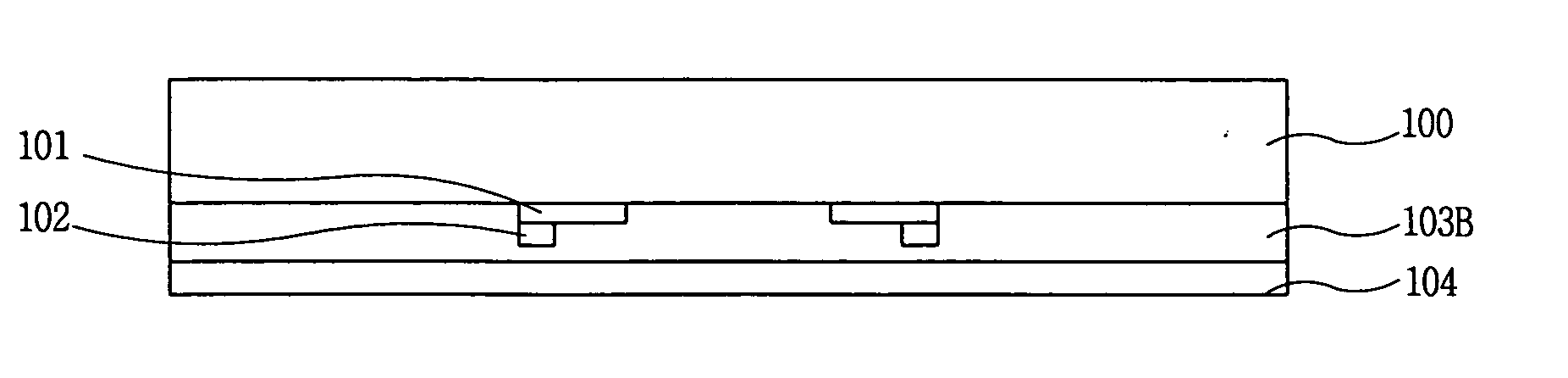

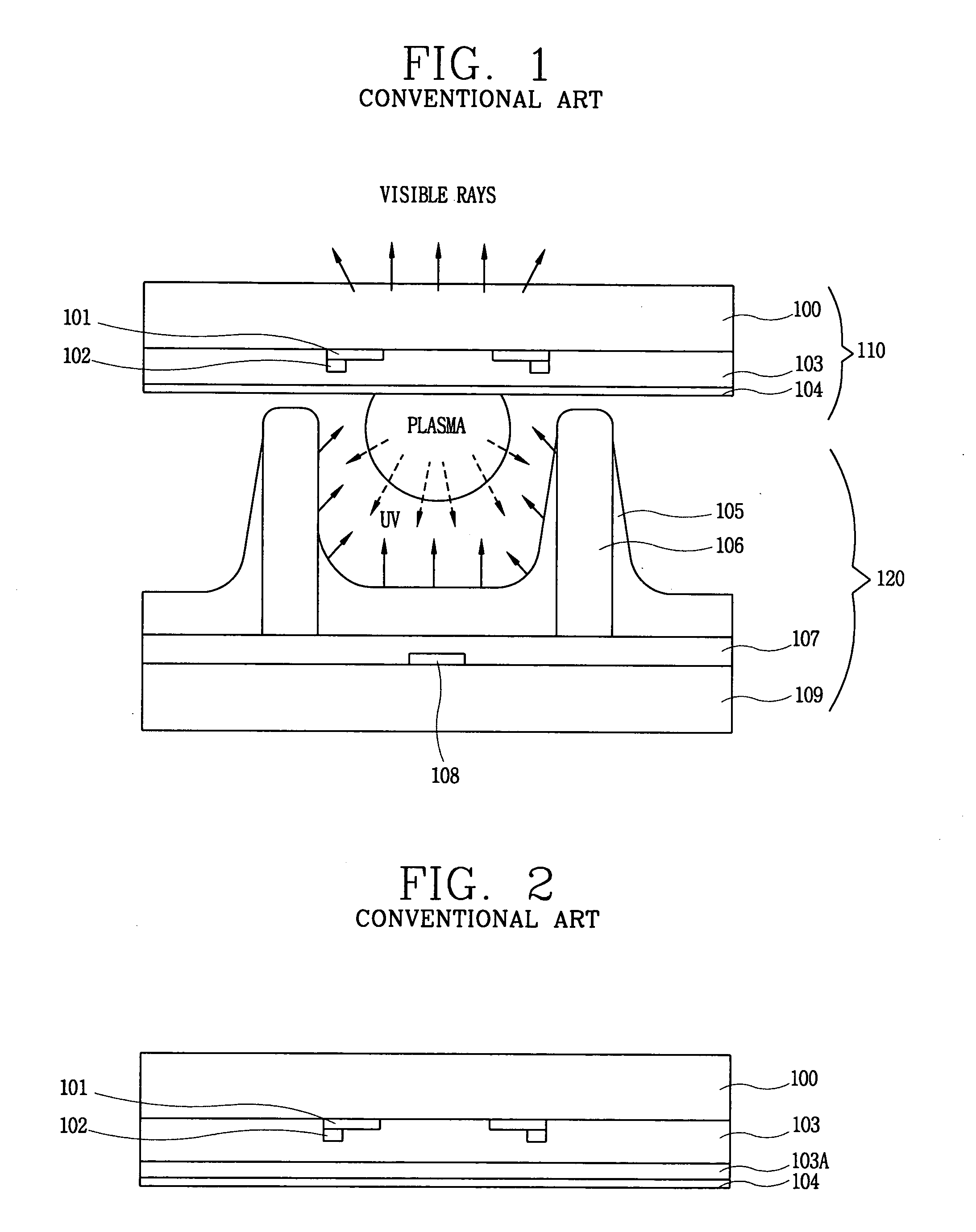

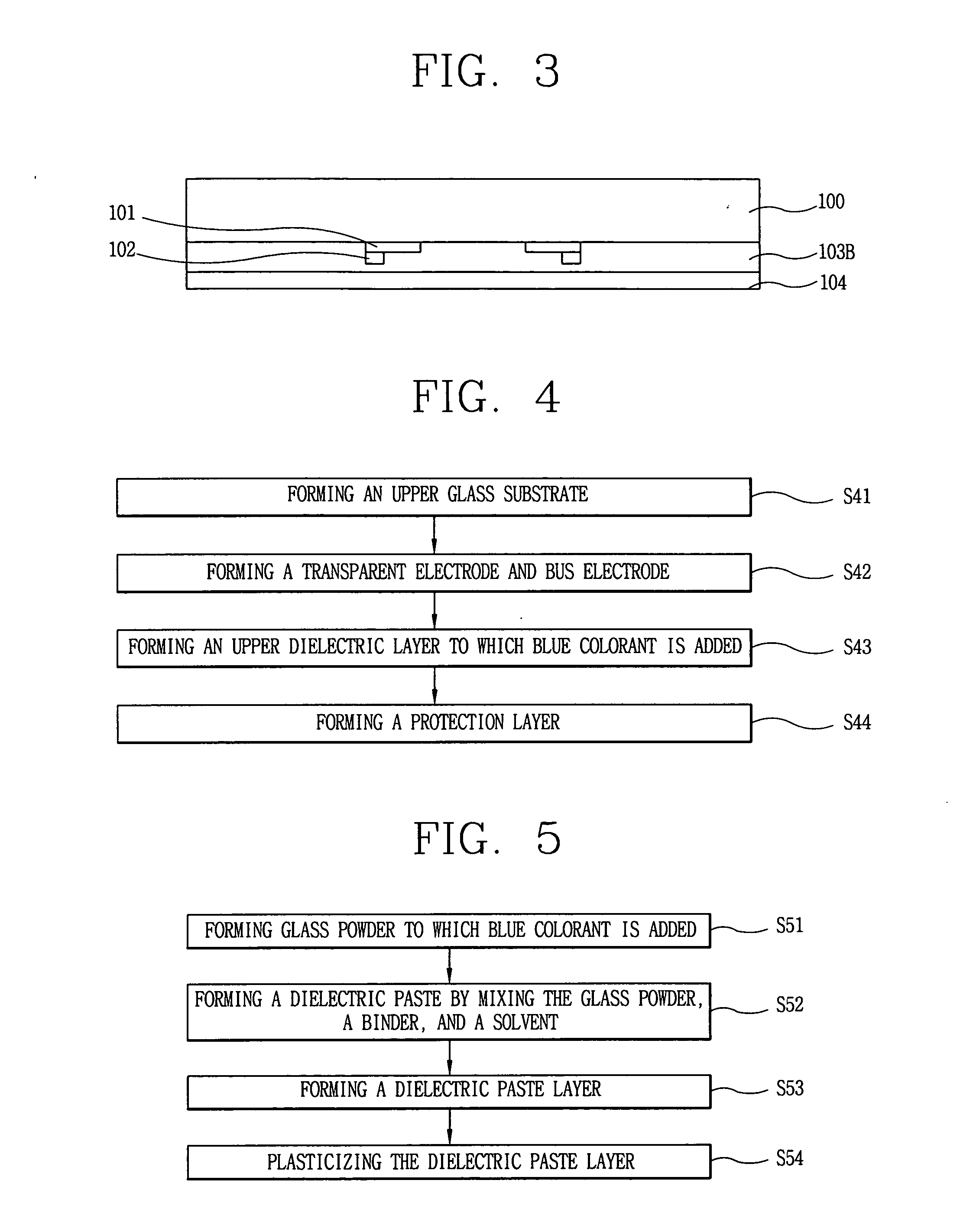

Front substrate of plasma display panel and fabricating method thereof

InactiveUS20050042364A1Good colorHigh color temperatureGas discharge electrodesAlternating current plasma display panelsDielectric layerContrast ratio

Disclosed is a front substrate of a plasma display panel and fabricating method thereof, by which color temperature, color purity, and contrast of PDP are enhanced. The present invention includes an upper dielectric layer containing a colorant therein. And, the present invention includes the step of forming an upper dielectric layer having a colorant added thereto.

Owner:LG ELECTRONICS INC

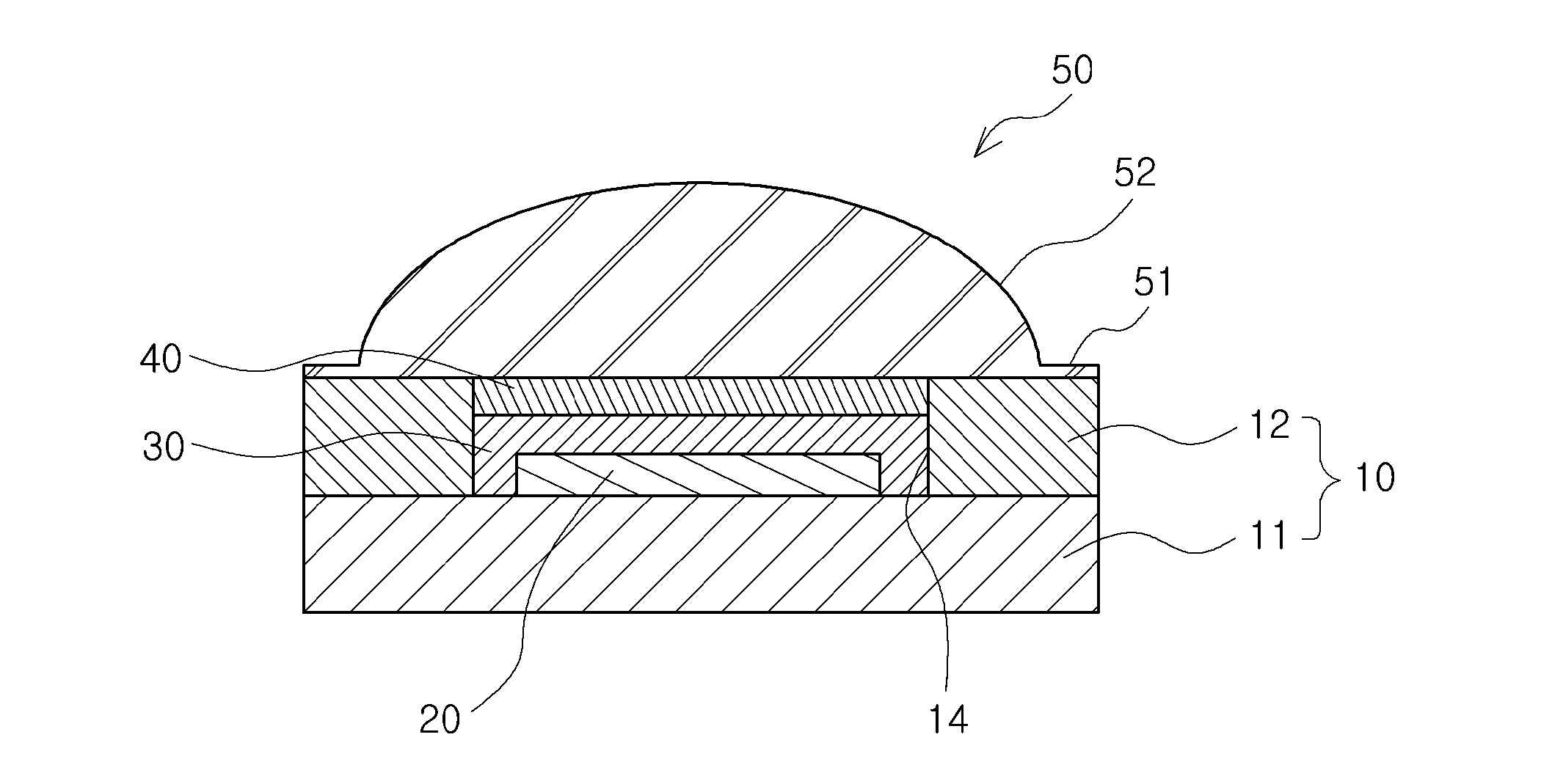

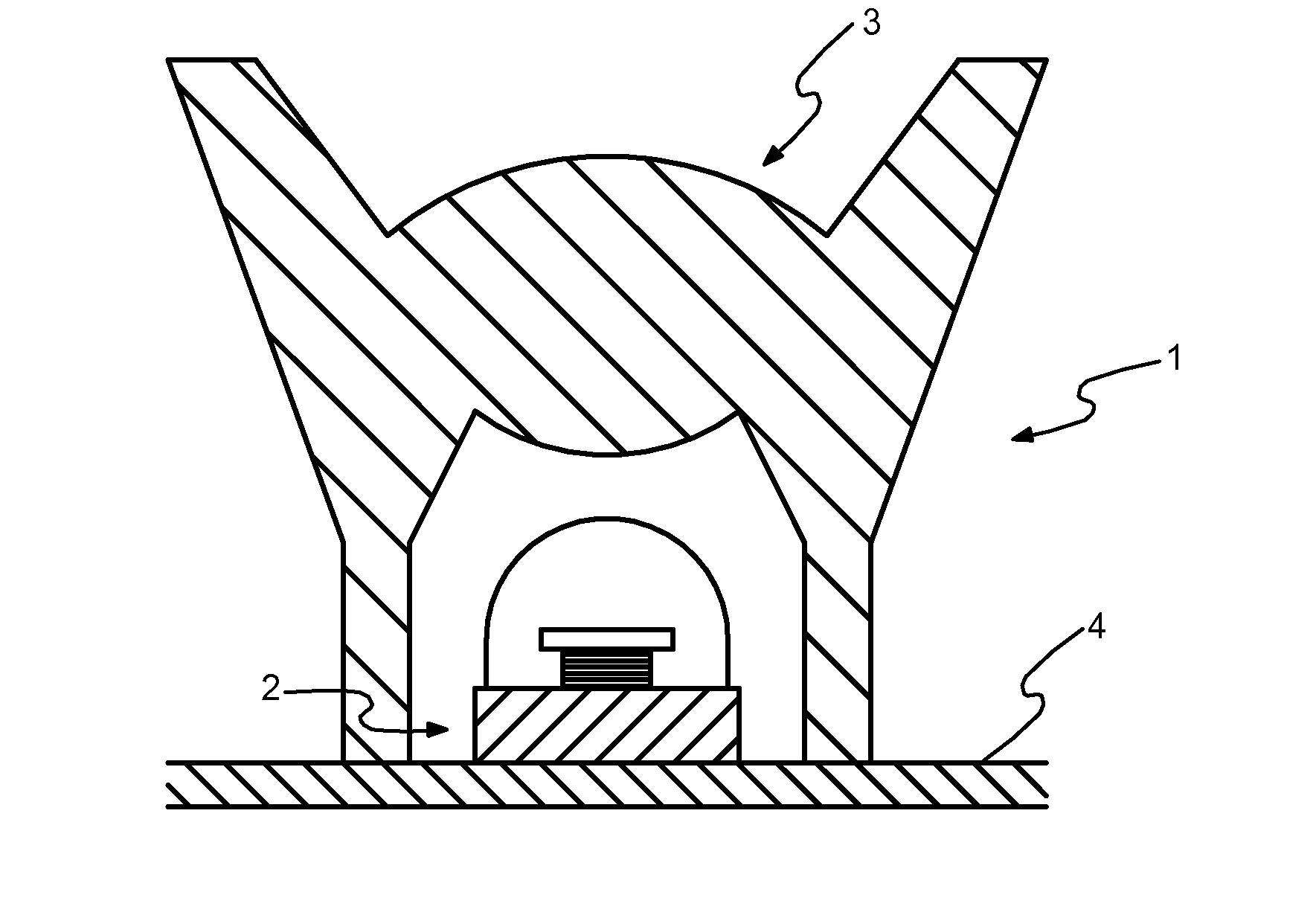

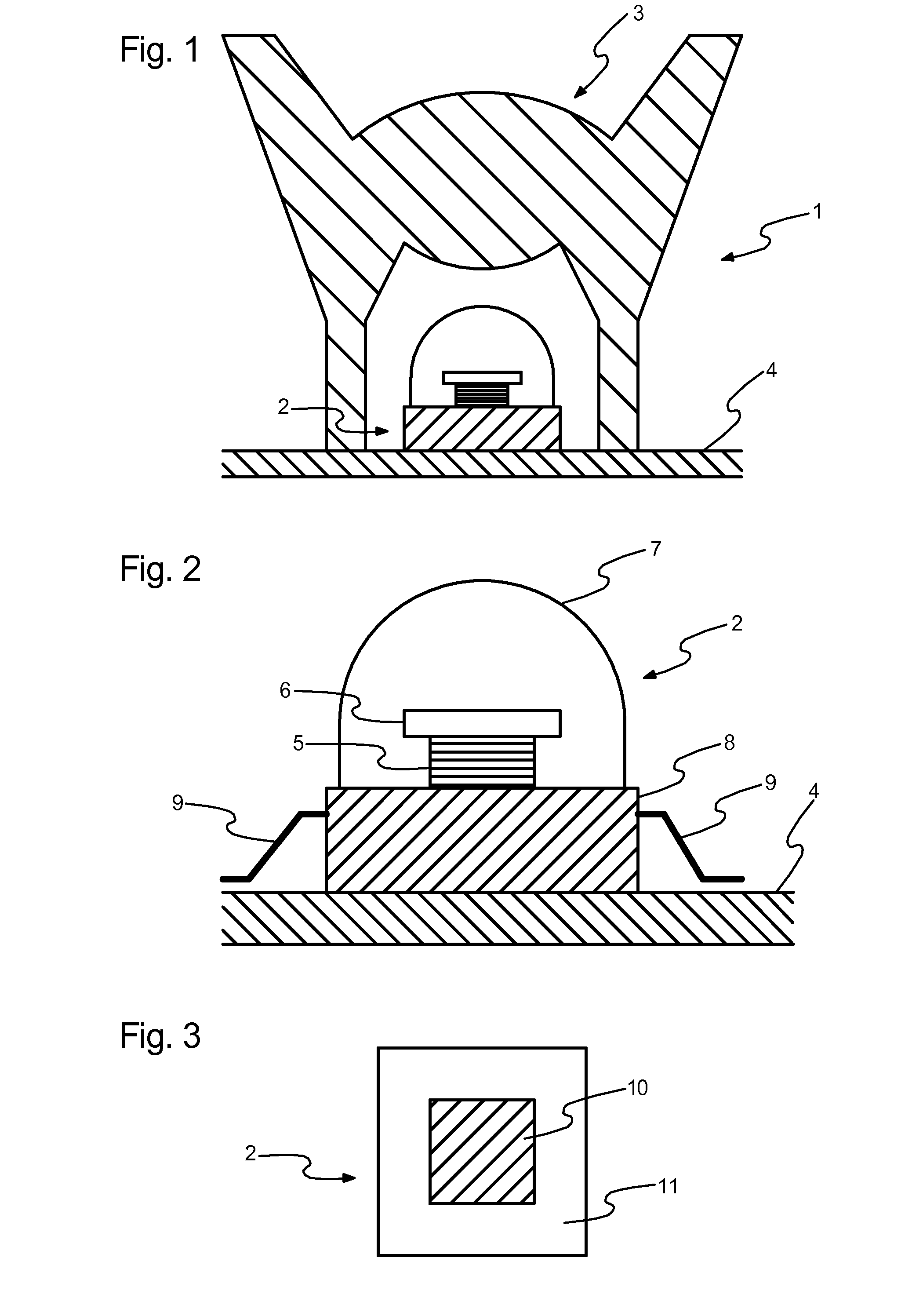

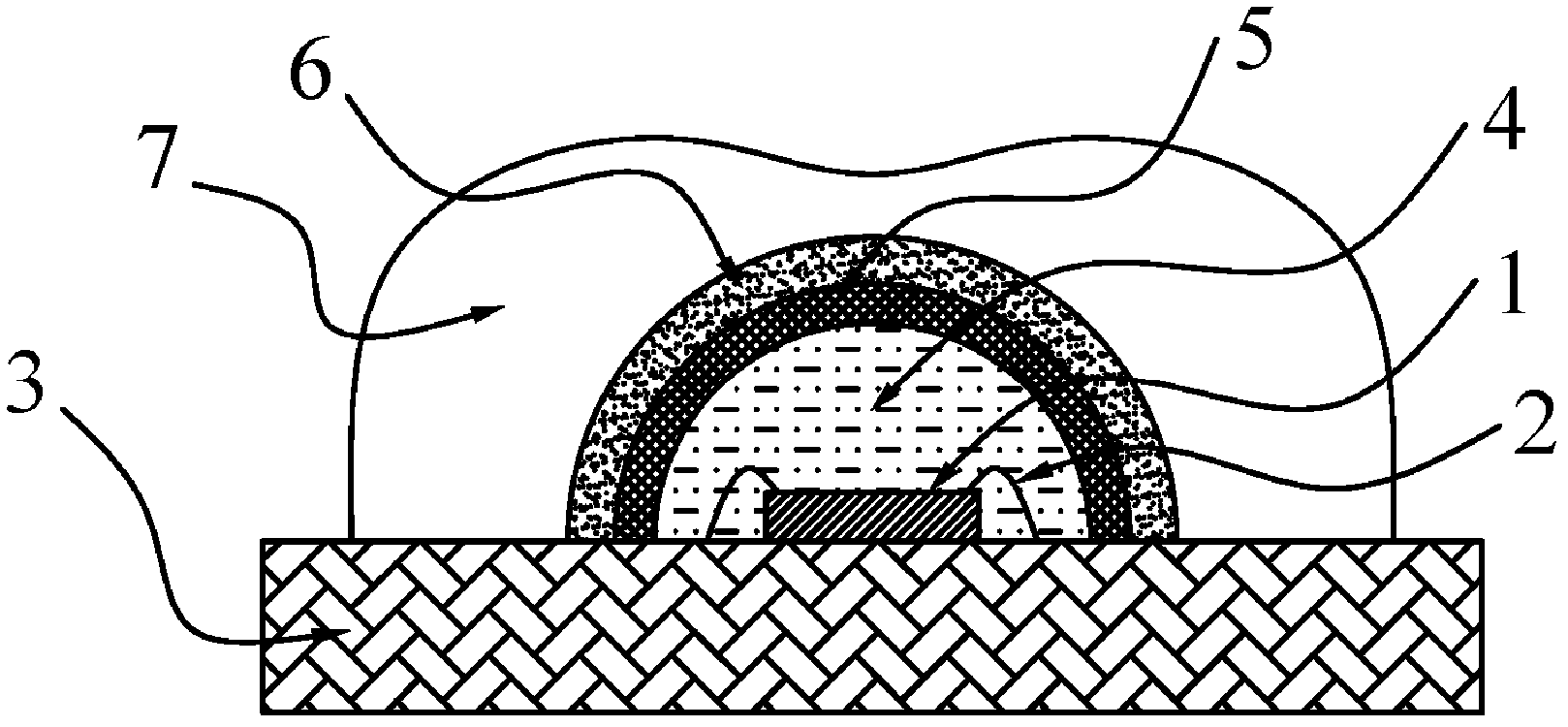

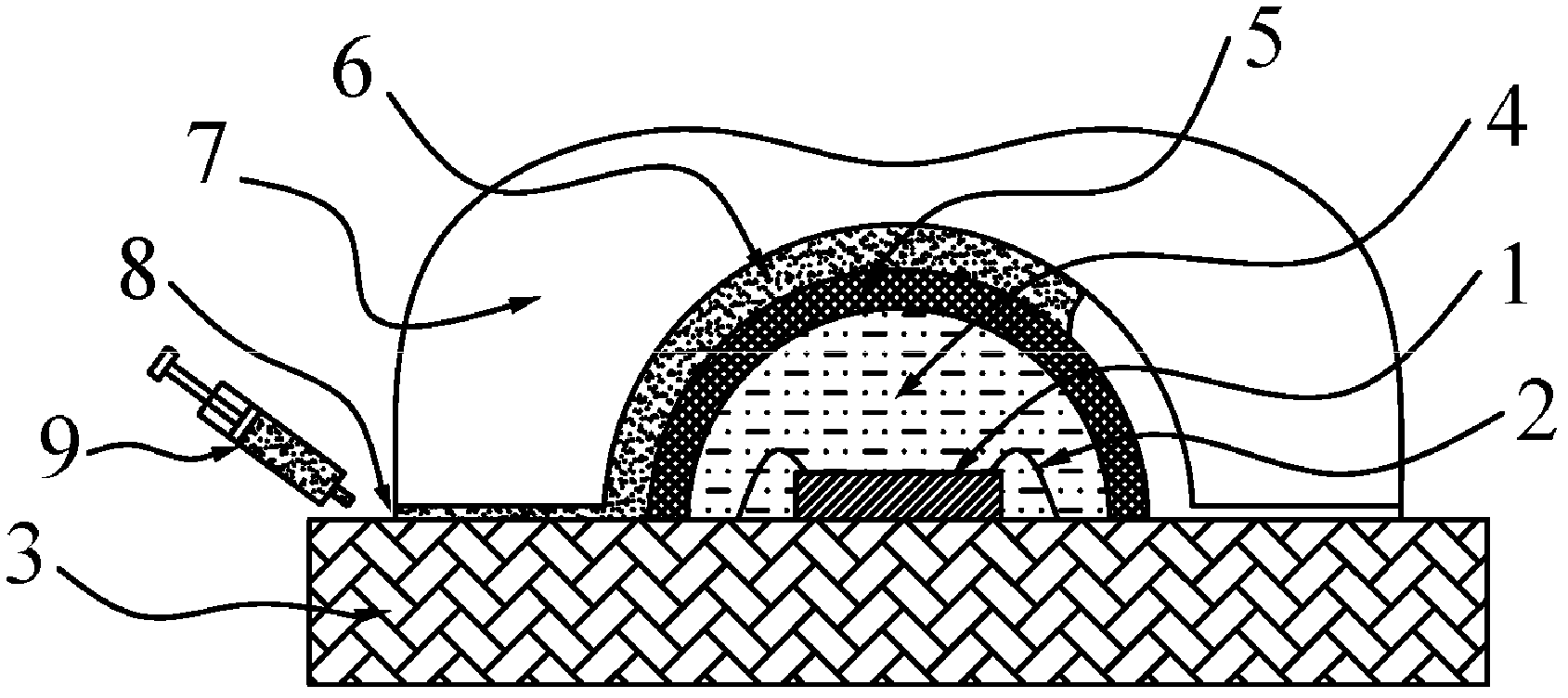

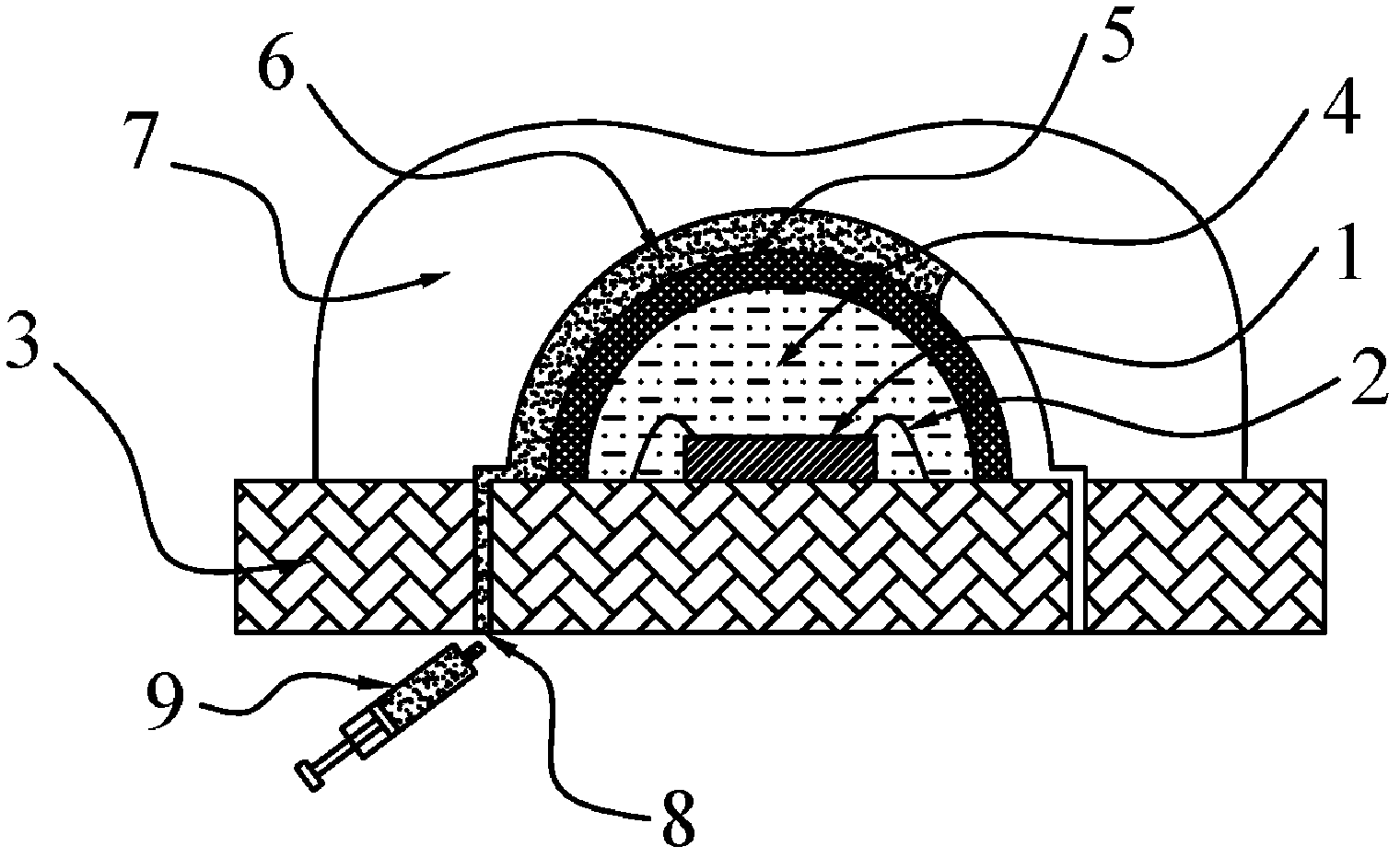

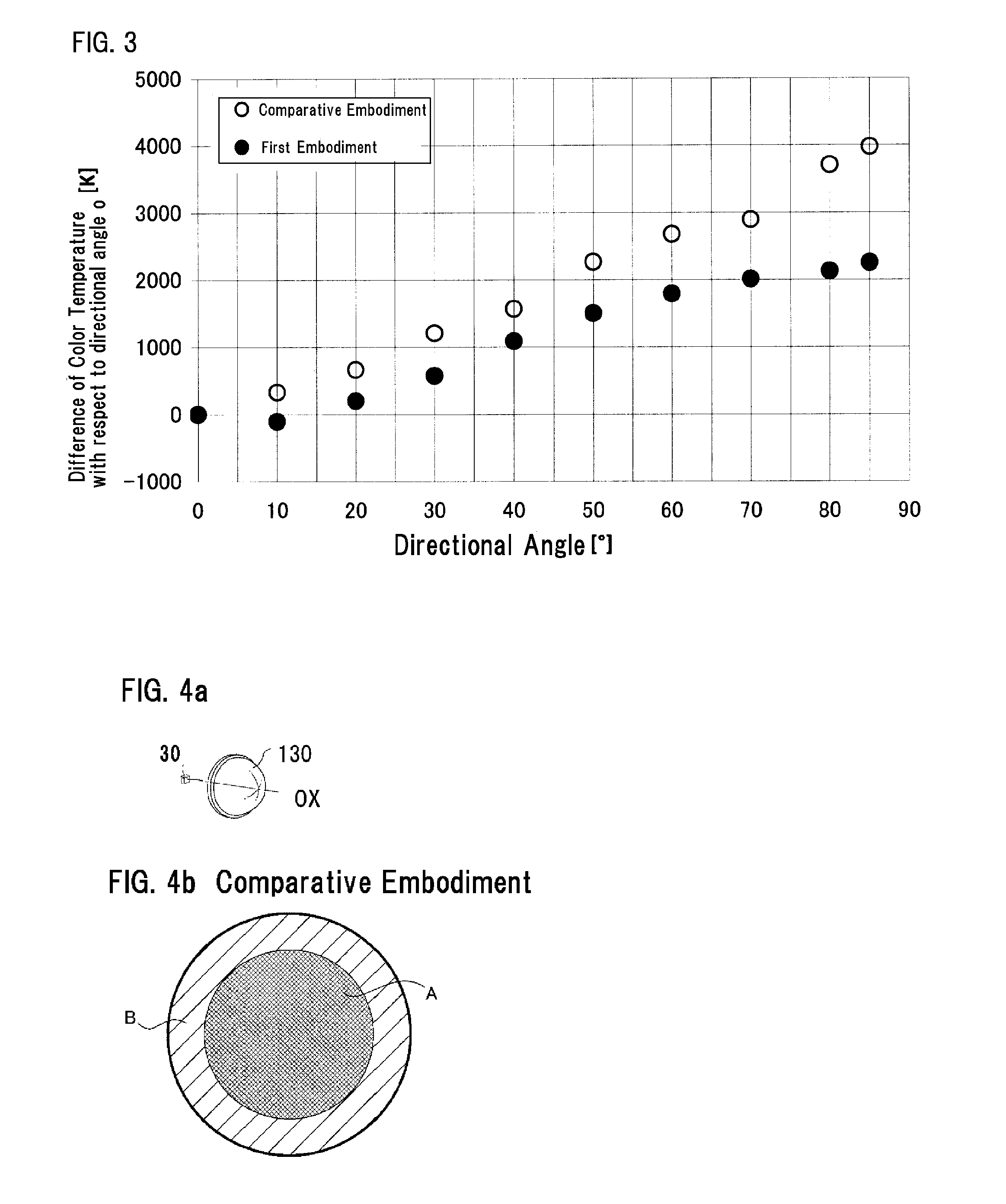

Packaging method for realizing separation of fluorescent powder glue away from coating in light emitting diode (LED) package and application

InactiveCN102569558AImprove light extraction efficiencyHigh color temperatureSemiconductor devicesLight-emitting diodeLight emission

The invention belongs to the light emitting diode (LED) packaging technology, and relates to a packaging method for realizing separation of fluorescent powder glue away from coating in LED package and an application of the method. The method is characterized in that: fluorescent powder glue is filled inside a gap between a primary lens and a secondary lens in the LED package, the thickness of the fluorescent powder glue is adjusted according to the size of the gap between the primary lens and the secondary lens to realize the uniform or nonuniform thickness. The primary lens can be semispherical or rectangular, or can be a free curved surface with internal top being a plane; and the outer surface of the secondary lens can be a free curved surface, and the inner surface of the secondary lens can be a semispherical shape, a rectangular shape, a trapezoid shape or other shapes with the top part being a plane. The packaging method can be used for controlling the geometric shape of the fluorescent powder layer in the LED package. Due to the adoption of the packaging method, the fluorescent powder glue can be away from the coating, and at the same time, the LED can satisfy the optical requirements such as brightness uniformity, high light emission efficiency, and uniformity of color temperature control and color control.

Owner:HUAZHONG UNIV OF SCI & TECH

LCD apparatus

ActiveUS20100245718A1Improve visual qualityHigh color temperatureNon-linear opticsLight guideEffect light

An LCD apparatus includes an LCD panel having a color filter for a plurality of color components and having a plurality of pixels each associated with one of the color components of the color filter, and a side lighting-type backlight unit disposed under the LCD panel. The backlight unit includes a light guide and a light source disposed at least at one lateral end of the light guide, and further includes a reflecting layer on a side opposite to a side facing the LCD panel to reflect light coming towards the reflecting layer from the light guide. The color filter is configured to compensate a change in color spectrum in the ambient light that has passed through the LCD panel and the light guide and that has been reflected by the reflecting layer back to the light guide and the LCD panel so that the color temperature of white display of the LCD panel by the ambient light remains substantially the same as the color temperature of the original ambient light.

Owner:ORTUS TECH

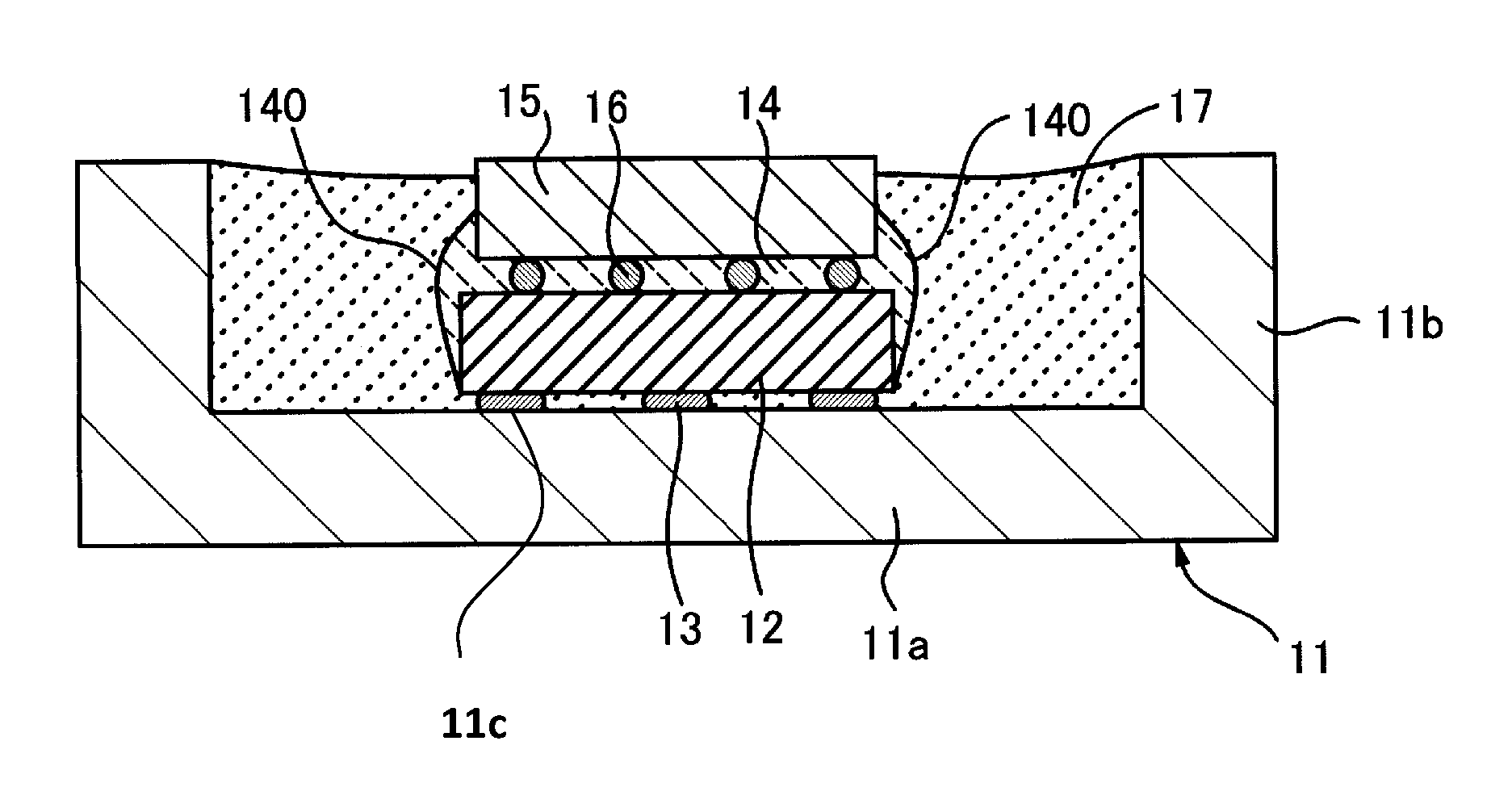

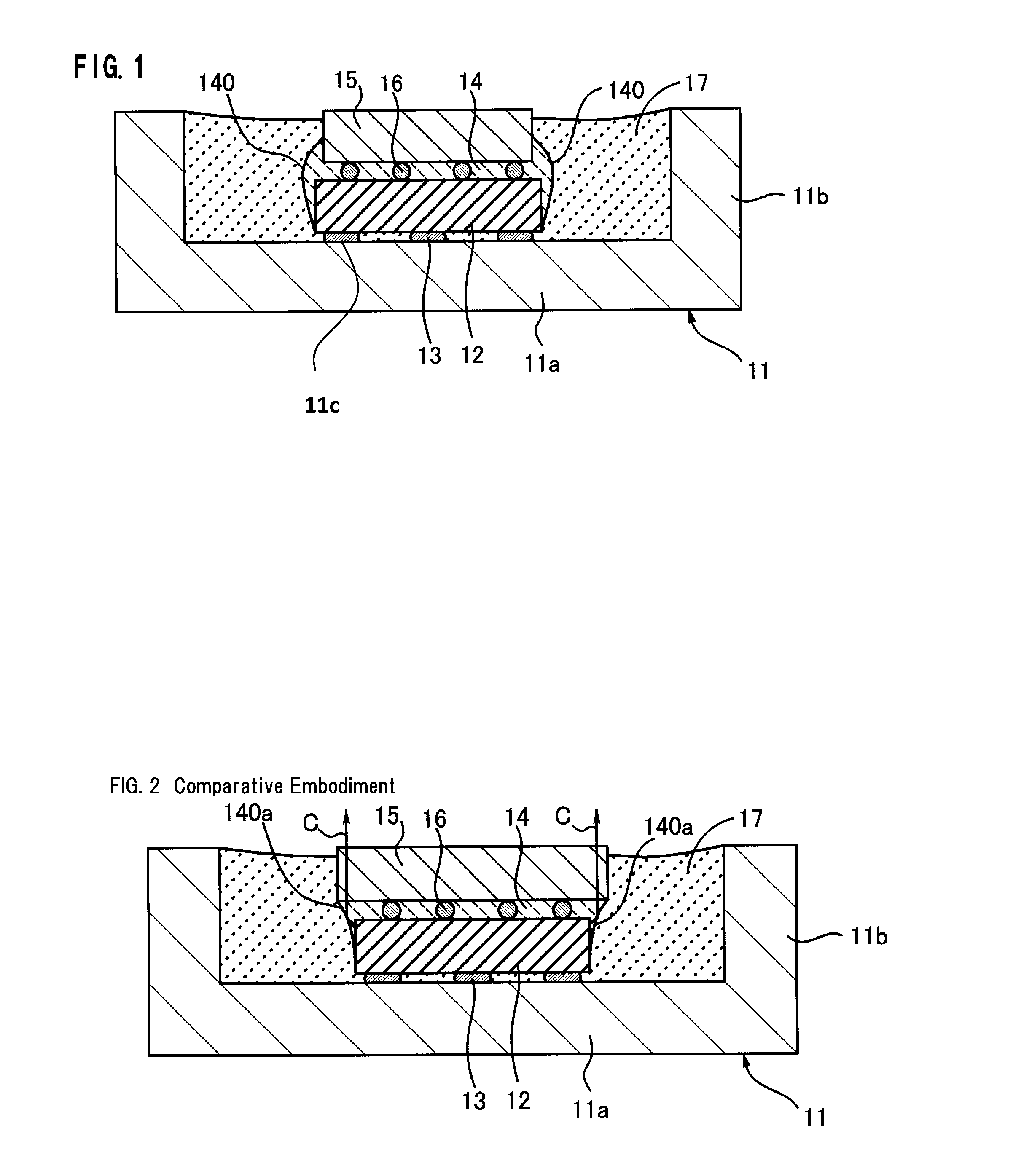

Semiconductor light-emitting device and manufacturing method

ActiveUS20130193458A1Uniform toneHigh light emitting efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringReflective layer

A semiconductor light-emitting device and a method for manufacturing the same can include a wavelength converting layer located on at least one semiconductor light-emitting chip in order to emit various colored lights including white light. The semiconductor light-emitting device can include a casing having a cavity and a mounting surface, the chip mounted on the mounting surface, a transparent plate mounted on the wavelength converting layer within a top surface of the chip and a reflective layer located in the cavity so as to surround the transparent plate, the wavelength converting layer and the chip. The semiconductor light-emitting device can be configured to improve light-colored variability and light-emitting efficiency of the chip by using the reflective layer as a reflector, and therefore can emit a wavelength-converted light having a substantially uniform color tone and a high light-emitting efficiency from a smaller light-emitting surface than the top surface of the chip.

Owner:STANLEY ELECTRIC CO LTD

Plasma display panel structure

InactiveUS20050099122A1Enhanced display contrast ratioEnhanced luminance ratioVacuum tubesAlternating current plasma display panelsComputer scienceHigh luminance

The present application describes a plasma display panel structure with high contrast ratio and high luminance. In one embodiment, display cells in the plasma display panel are arranged in a delta structure. The delta structure of display cells enhances the luminance and contrast ratio of the plasma display panel. In some embodiments, a light-shielding layer is configured to selectively exclude display cells of one or more selected colors to enhance the color temperature of the plasma display panel.

Owner:AU OPTRONICS CORP

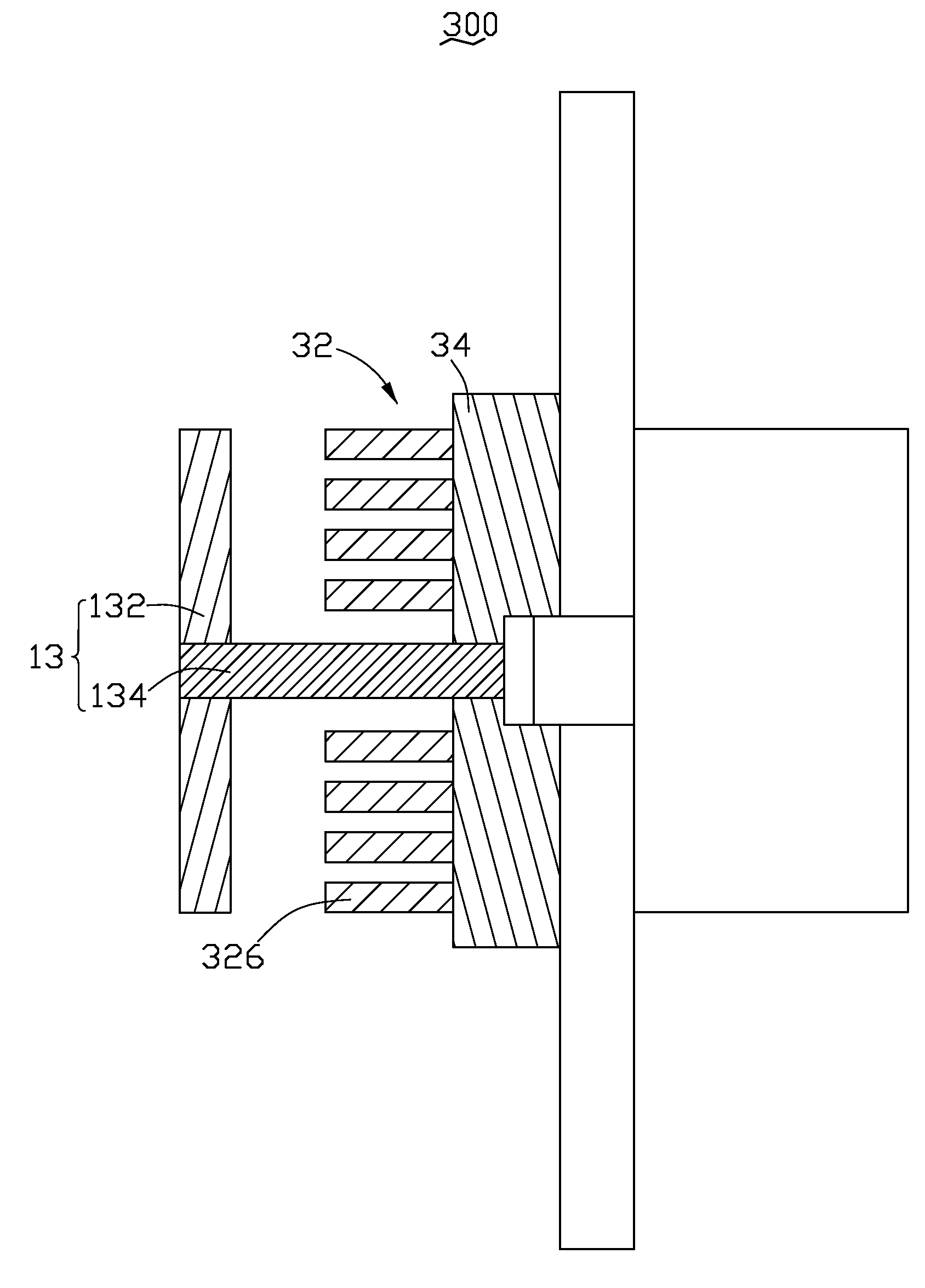

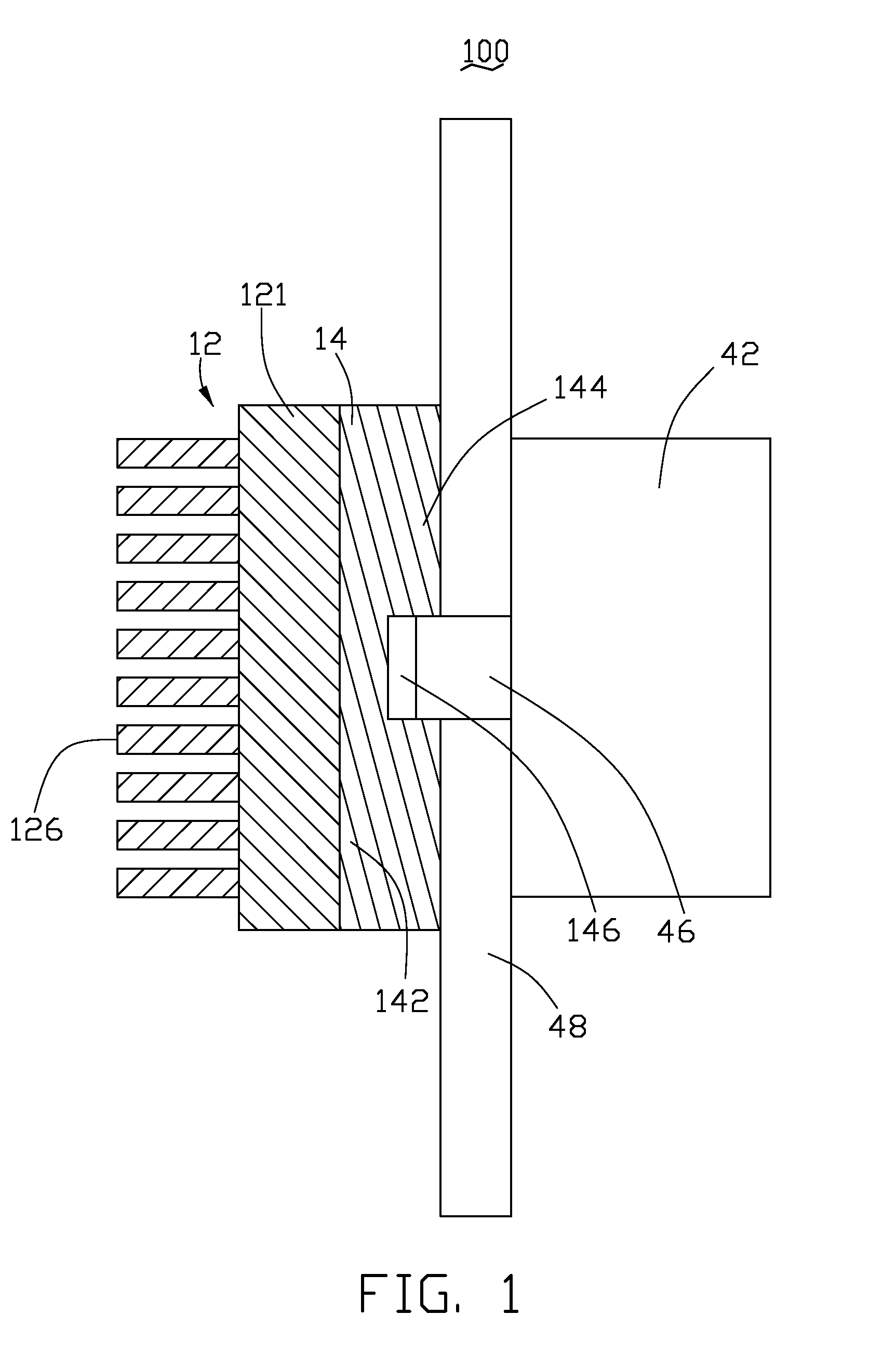

Color wheel

An exemplary color wheel includes a carrier, a color filter, a fastening plate, and a heat dissipating unit. The carrier includes a spindle extending outwardly therefrom. The fastening plate includes a first side and a second side opposite to the first side. The second side is sleeved around the spindle. The color filter is sandwiched between the fastening plate and the carrier, and sleeved around the spindle. The heat dissipating unit engages with the first side of the fastening plate for dissipating heat from the color wheel.

Owner:HON HAI PRECISION IND CO LTD

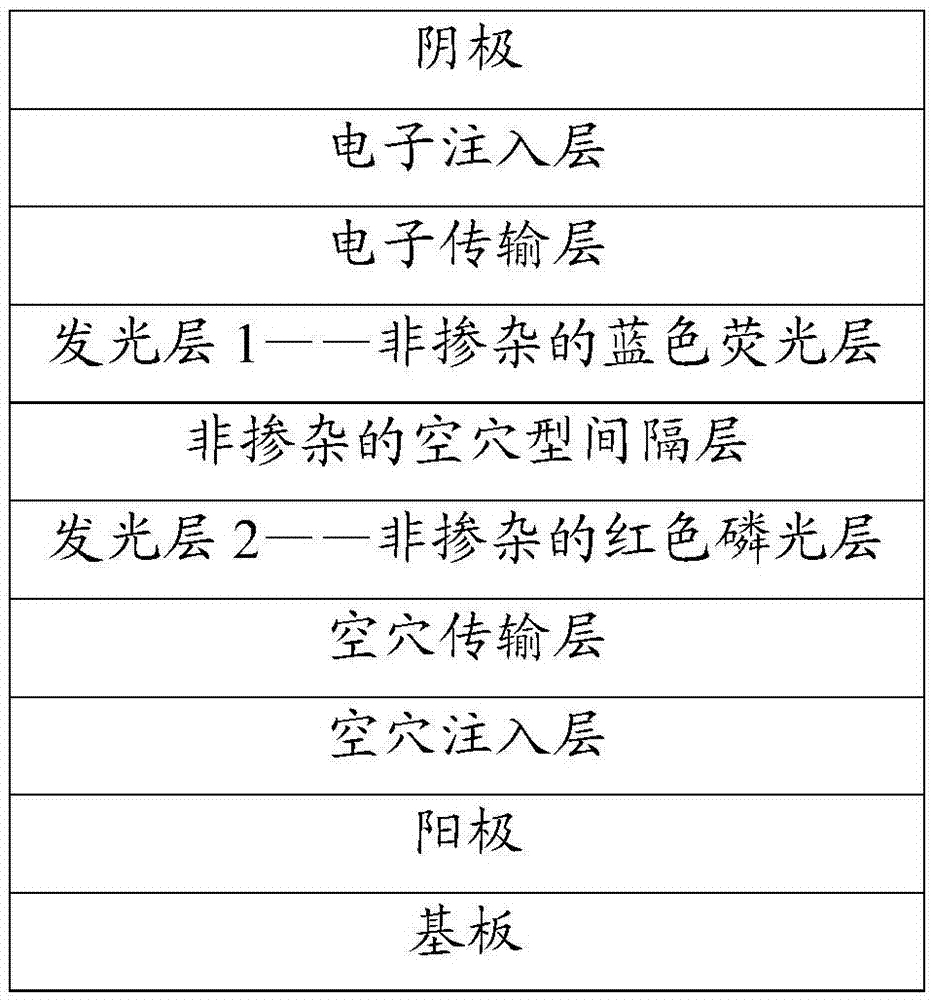

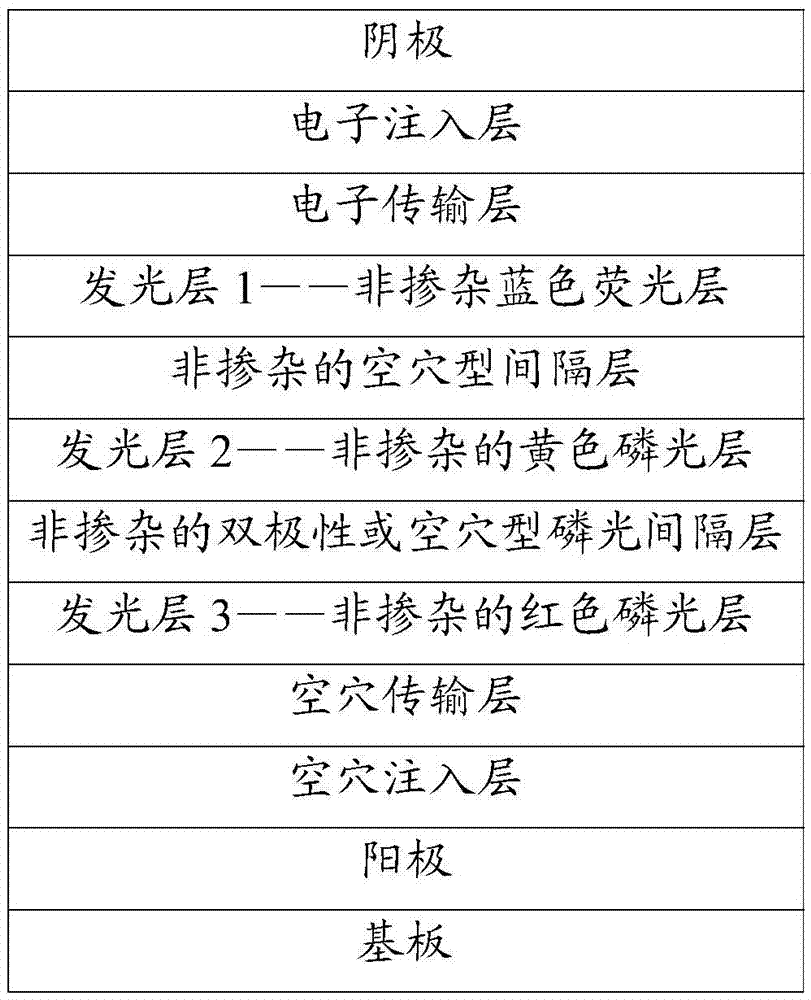

Organic electroluminescence device capable of simulating sunlight and preparation method thereof

ActiveCN105449109ASimple structureLow preparation process requirementsFinal product manufactureSolid-state devicesOrganic electroluminescenceChemistry

The invention relates to an organic electroluminescence device capable of simulating sunlight and a preparation method thereof, belonging to the technical field of electroluminescence devices. The device comprises a substrate, an anode, a cathode and an organic function layer arranged between the anode and the cathode, wherein the organic function layer comprises a blue fluorescent layer, a phosphor coating and a spacer layer, wherein the blue fluorescent layer and the phosphor coating are separated by the spacer layer; the blue fluorescent layer is made of a non-doped luminescent material with the light-emitting wavelength of smaller than 500nm; the phosphor coating comprises a red phosphor coating, wherein the red phosphor coating is made of a non-doped luminescent material with the light-emitting wavelength of greater than 585nm; and the spacer layer is formed by at least one of hole-type organic semiconductor materials whose hole mobility is greater than electronic mobility. The organic electroluminescence device has a CCT (Correlated Color Temperature) feature of the sunlight and can be prepared through a non-doped technology, and furthermore, the organic electroluminescence device has the advantages of simple structure and low requirements for the preparation process.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com