Patents

Literature

595results about How to "Reduce equipment investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

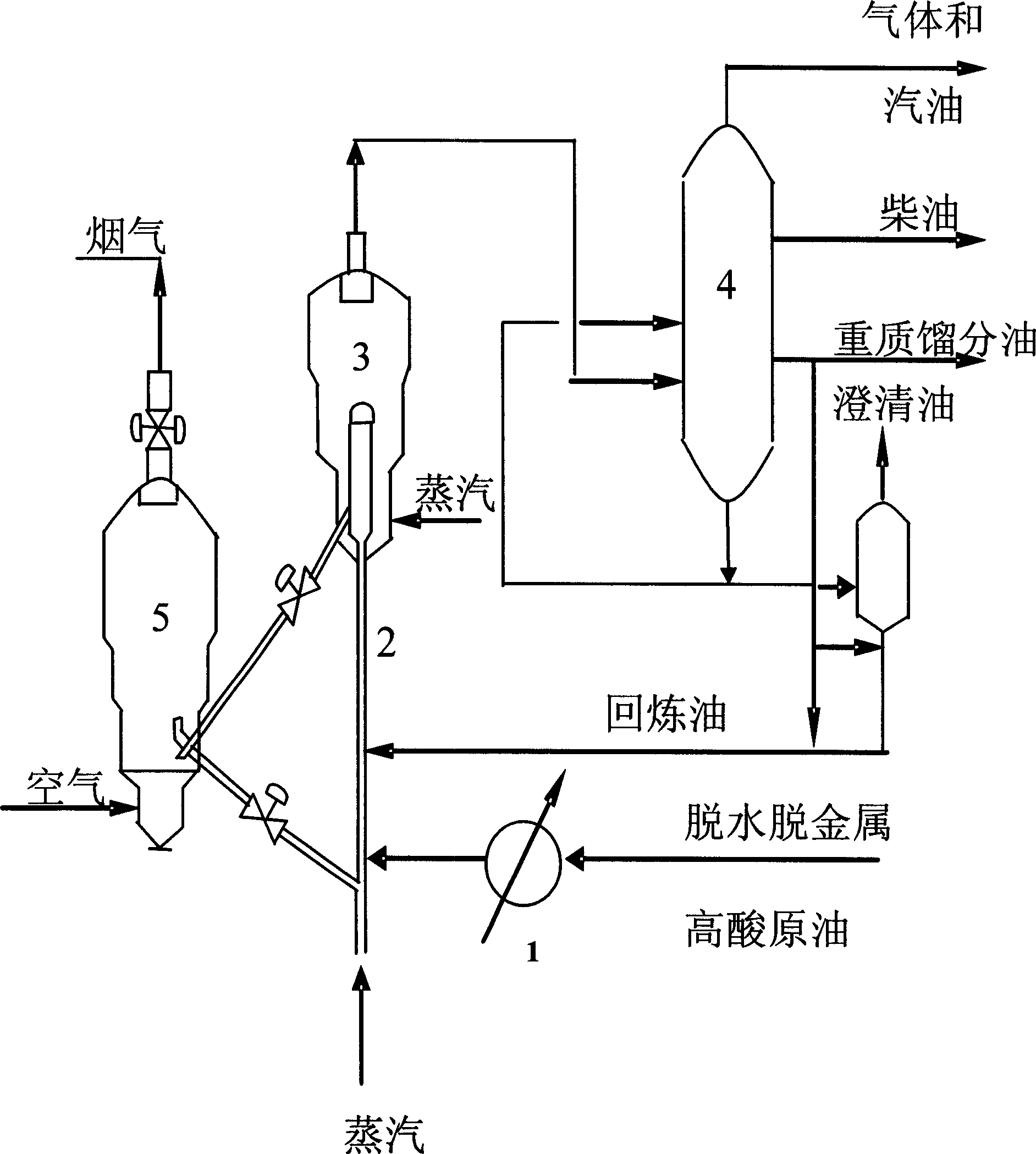

Method for processing crude oil with high acid value

ActiveCN1827744AEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

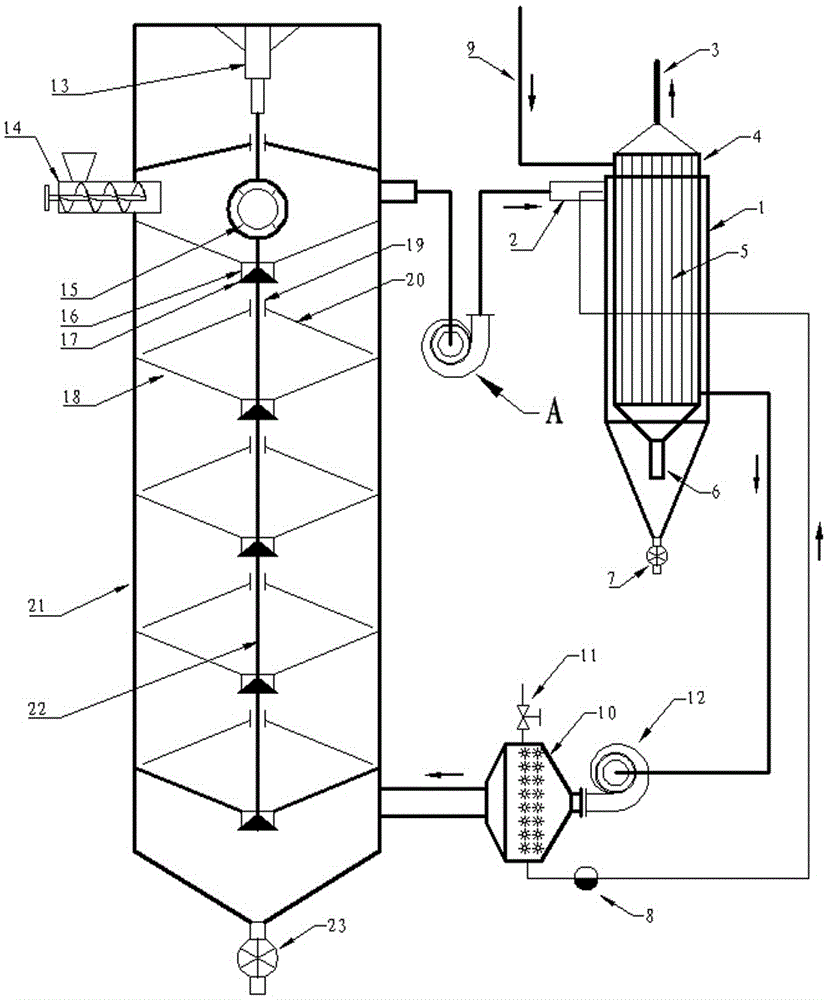

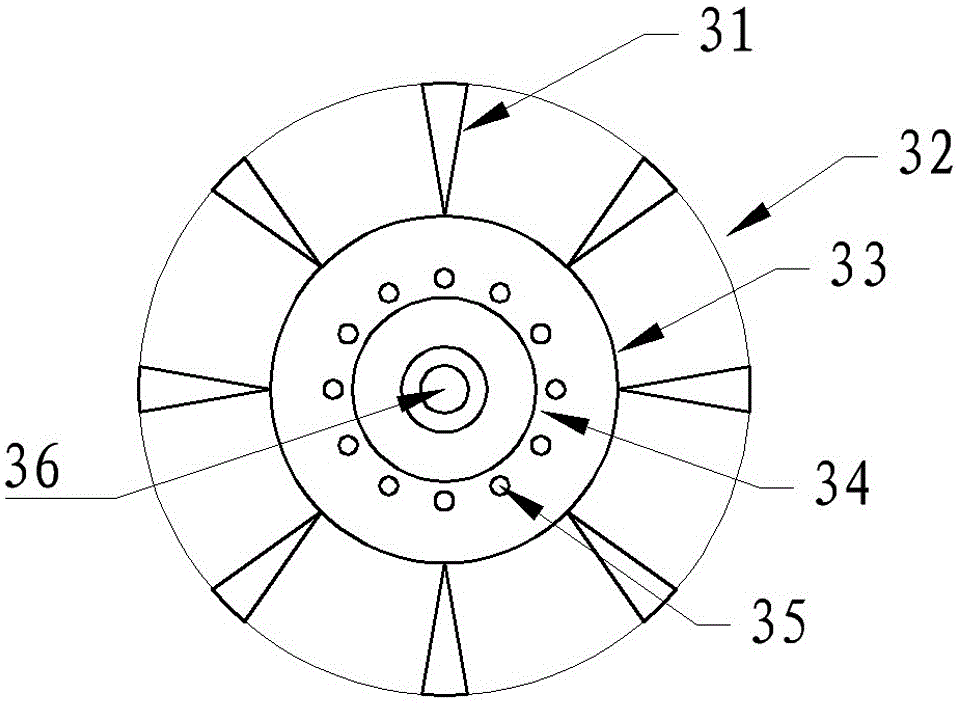

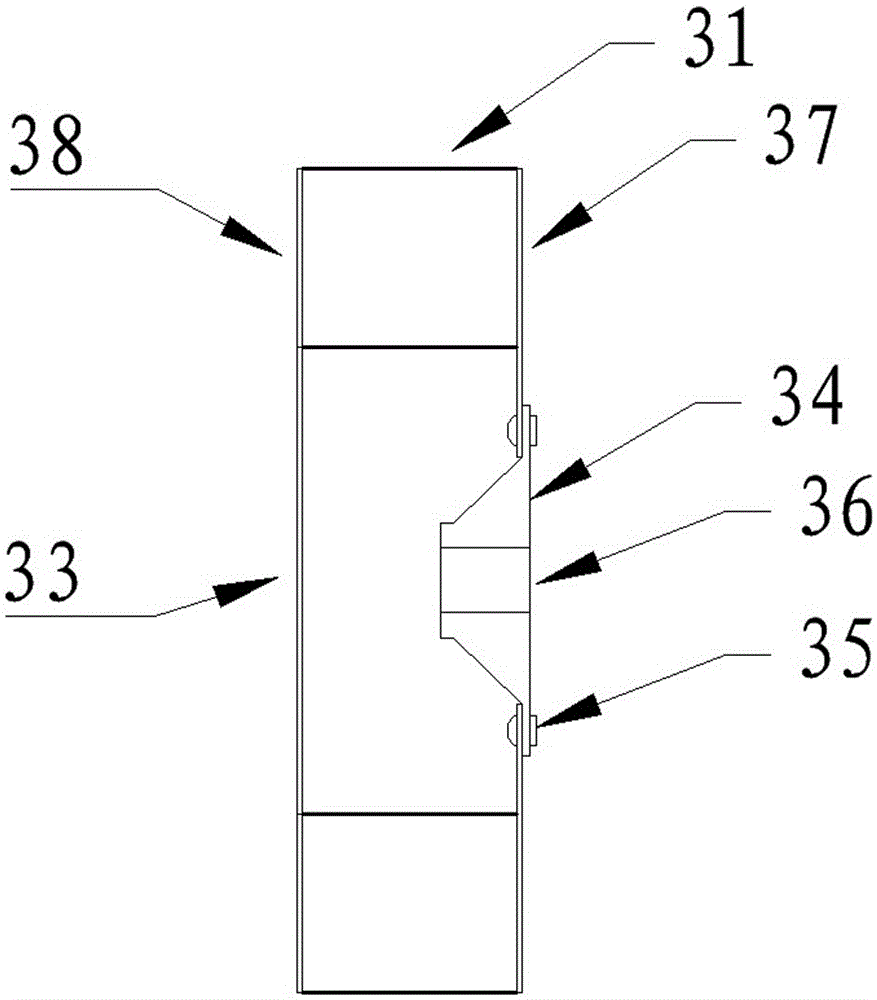

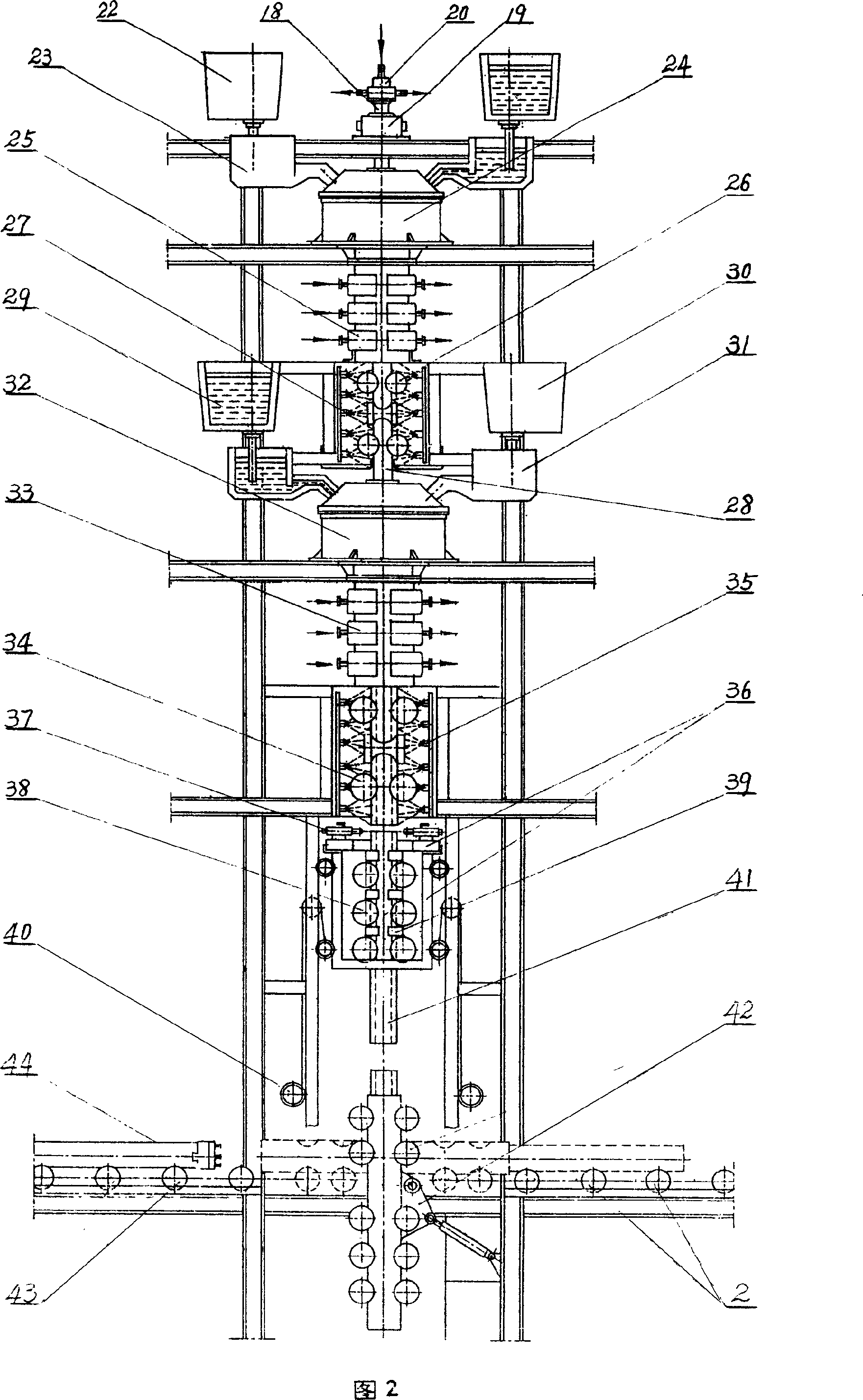

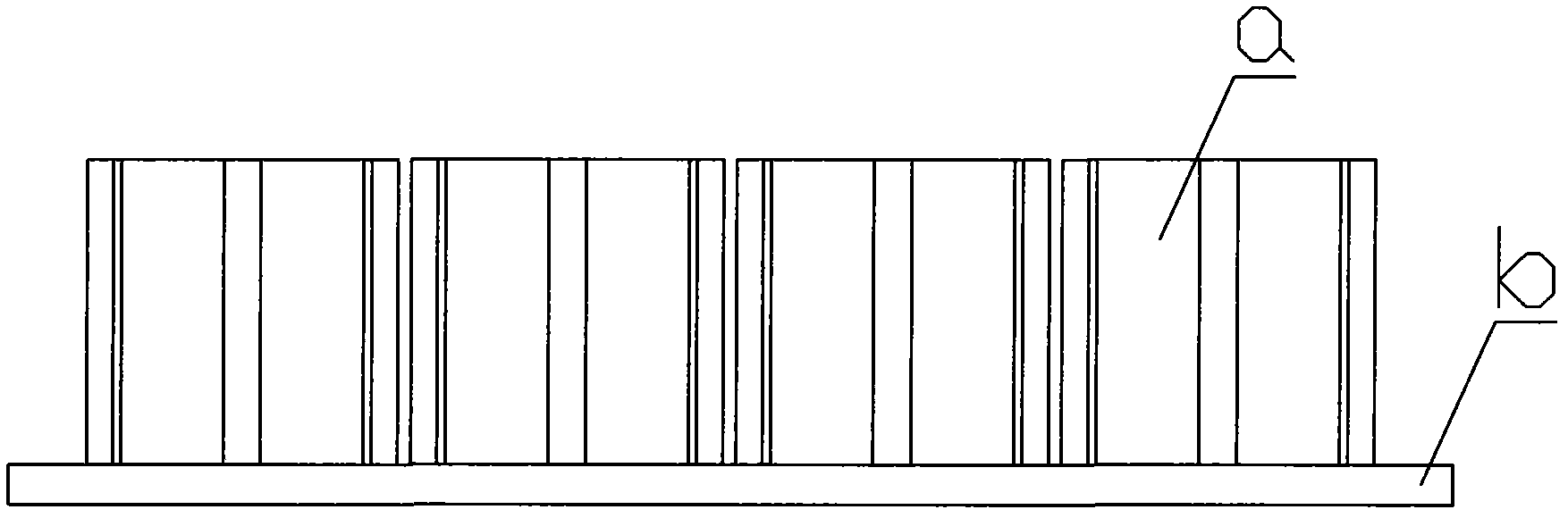

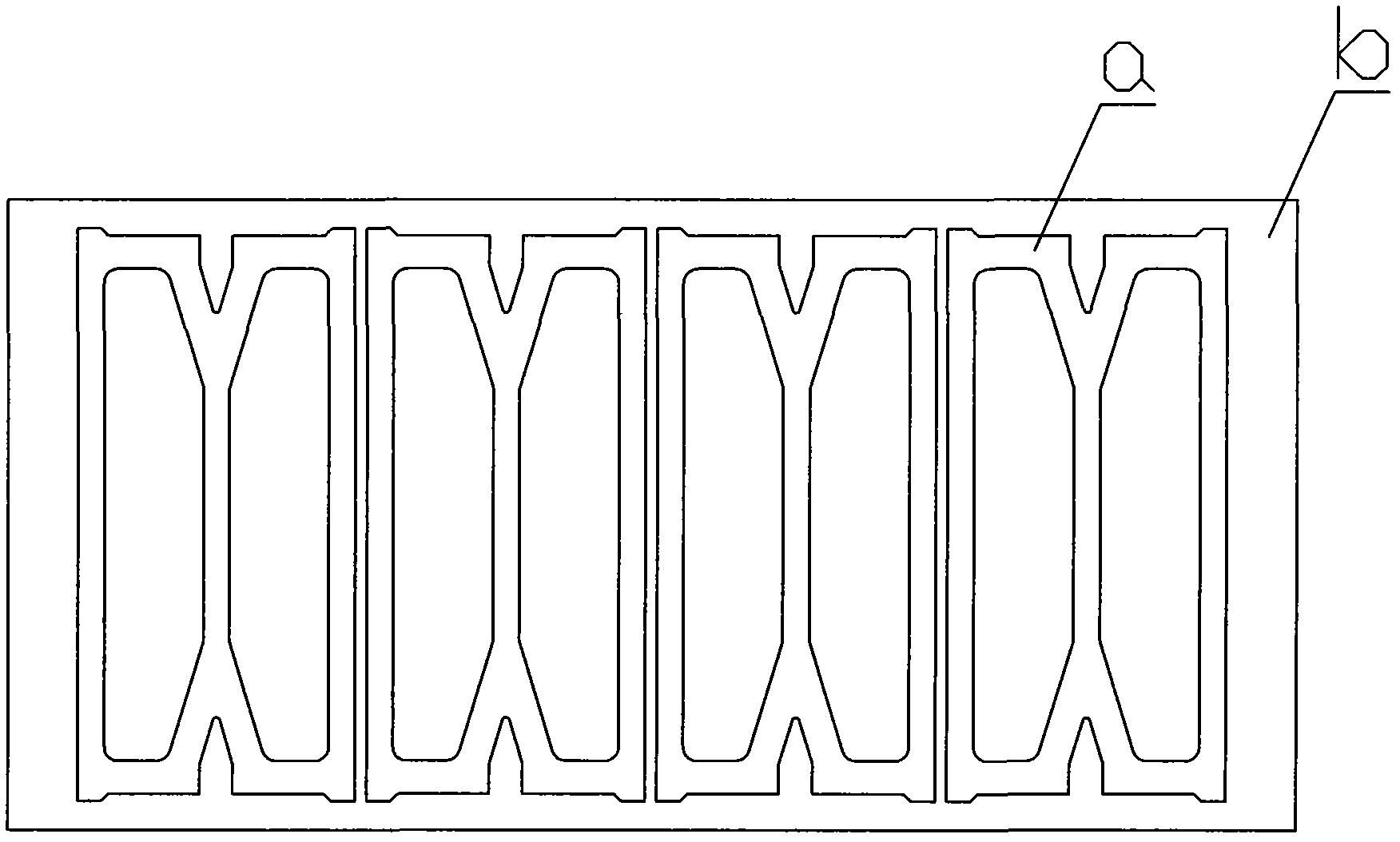

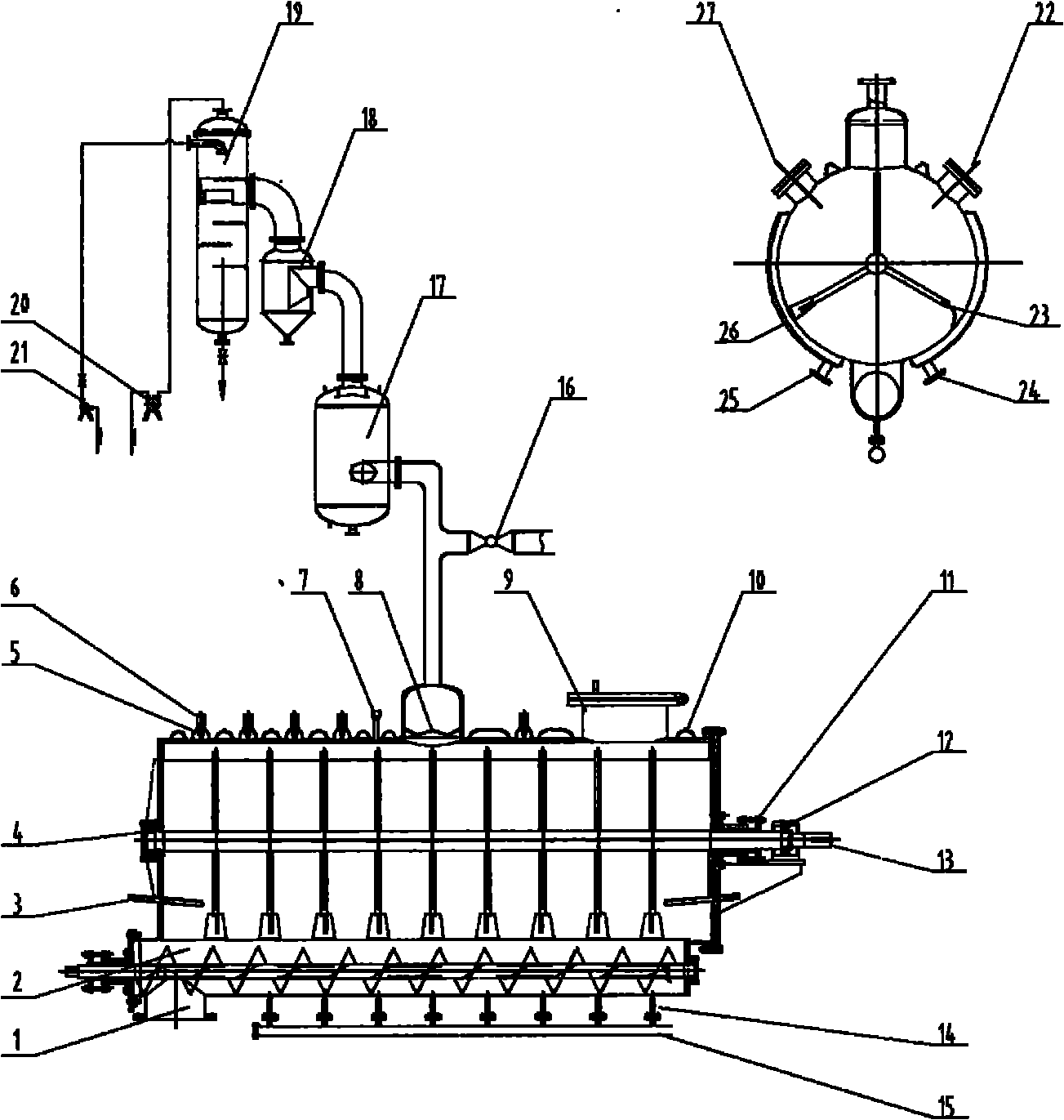

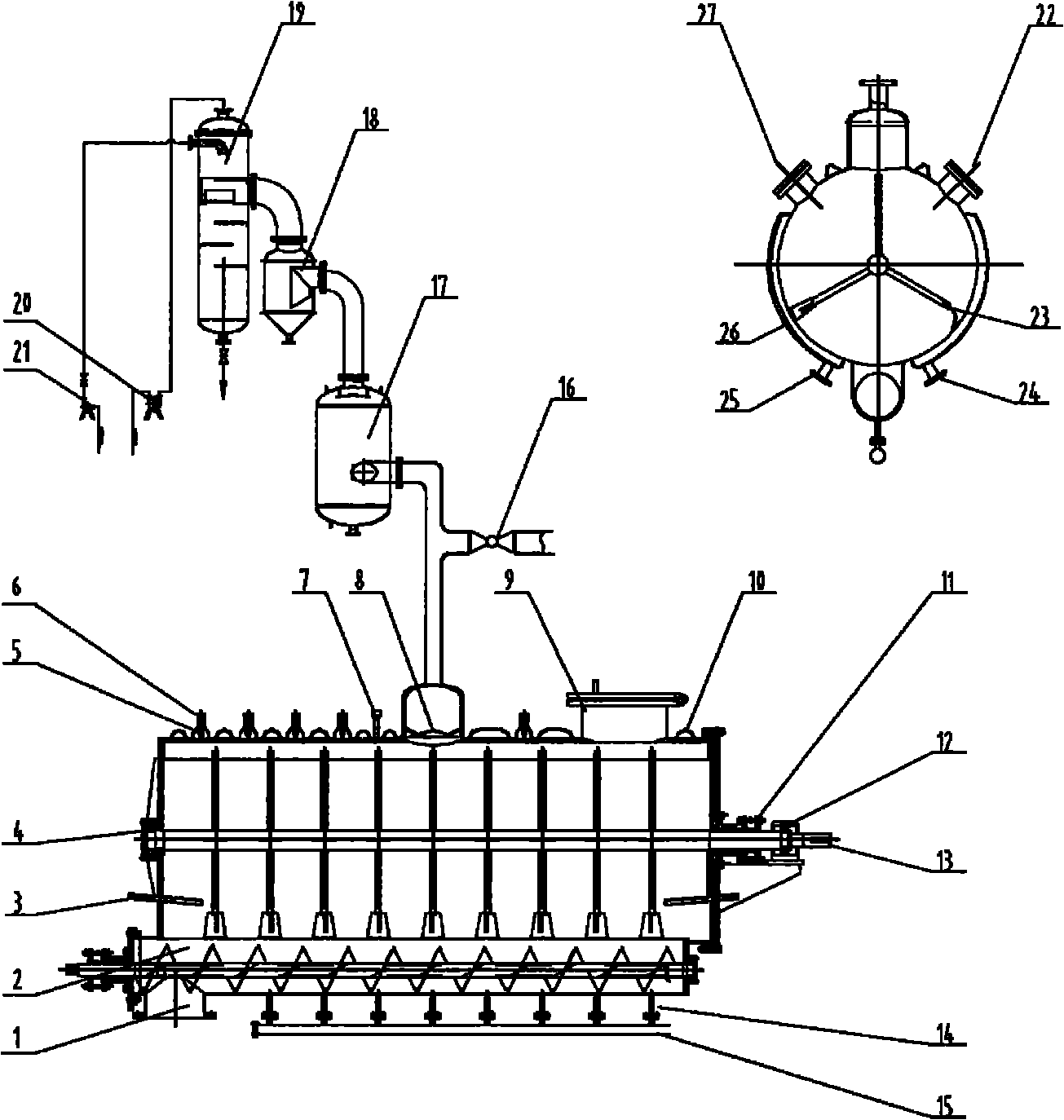

Hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization

ActiveCN105021012AReduce equipment investmentImprove work efficiencyDrying gas arrangementsImpellerWhirlwind

The invention discloses a hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization. The upper portion of a drying tower is connected with an induced draft fan, and the induced draft fan is connected with a cyclone dust removing waste heat efficient recoverer formed by a tube-type heat exchanger and a cyclone dust collector in an overlapped manner in the tangent direction and then is emptied; the air inlet end of the shell side of the tube-type heat exchanger is communicated with the atmosphere, and the air outlet end of the shell side of the tube-type heat exchanger is connected with the lower portion of the drying tower through an air blower and a steam finned heater; and an impeller of the induced draft fan is of a structure that blades are in a hollow and wedged shape, and the contour line of the appearance of the induced draft fan is an involute. According to the hot-air drying machine capable of utilizing the waste heat and achieving the penetrating countercurrent fluidization, creative integration is conducted on waste heat utilization and dust removal, the cyclone dust removing waste heat efficient recoverer is designed out, the equipment input is reduced, and the work efficiency is improved; and due to the fact that sieve mesh cone covers, sieve mesh cone discs, discharging tubes, a stretching vibration transmission shaft and conical plugs are arranged, penetrating, countercurrent, boiling and fluidization drying of materials are exquisitely and perfectly achieved, more energy is saved, the drying quality is higher, the power consumption of the induced draft fan is lower, and the application prospect is wider.

Owner:常州新舜干燥工程有限公司

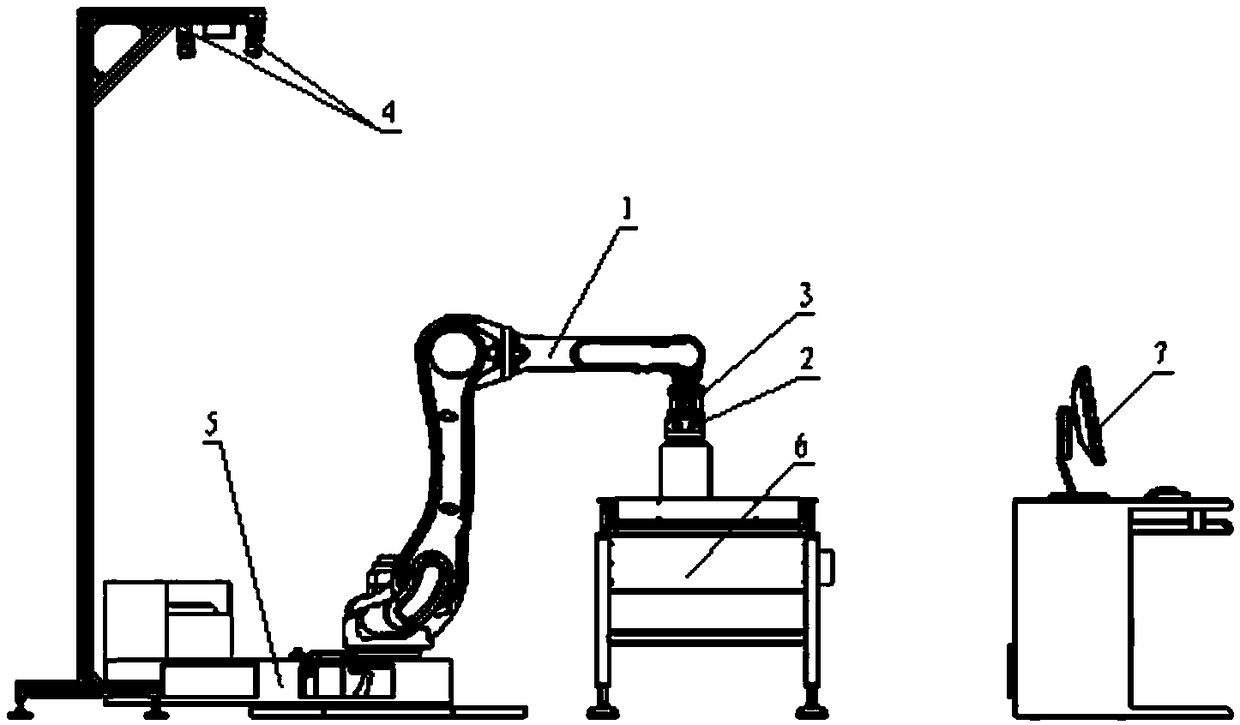

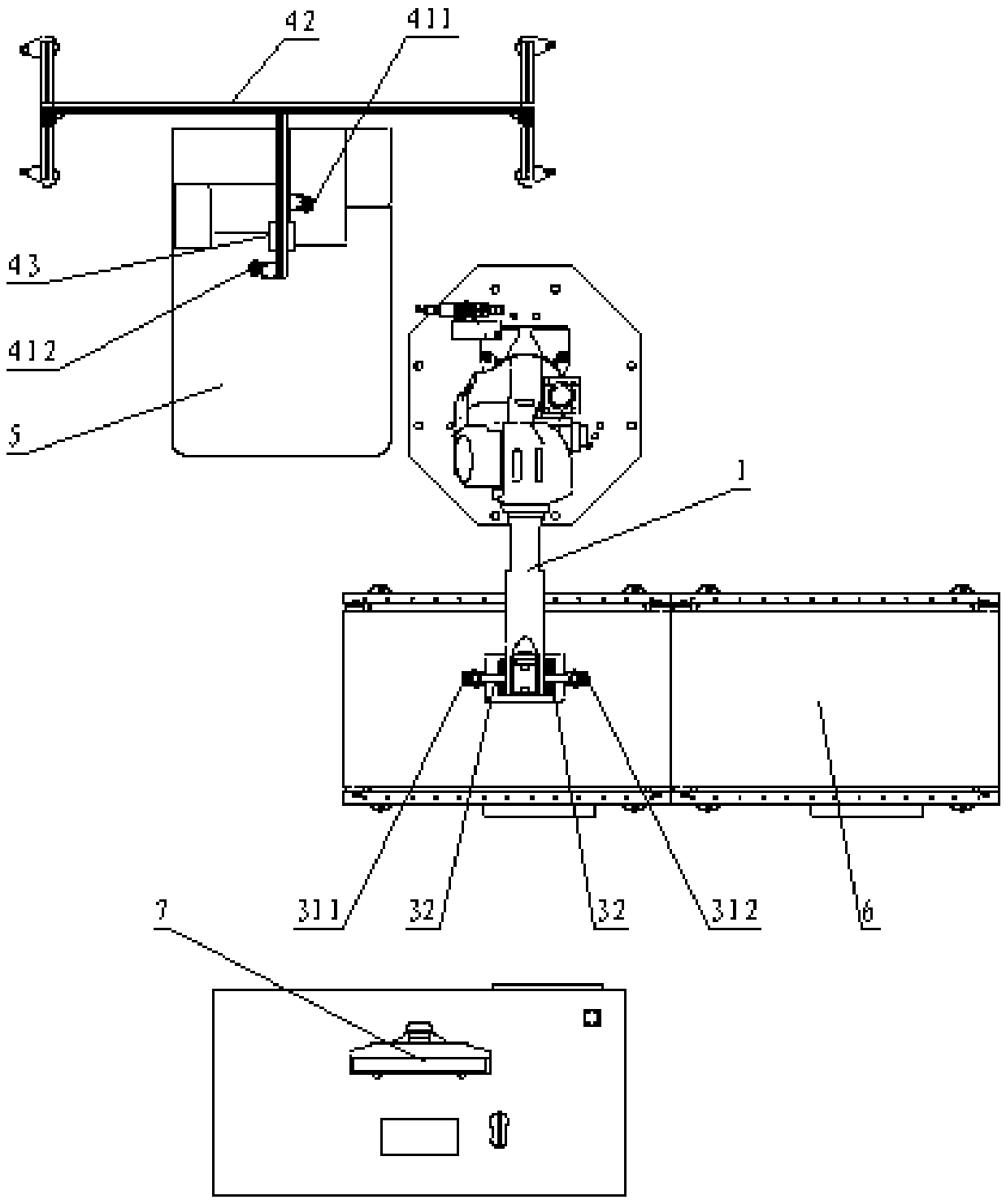

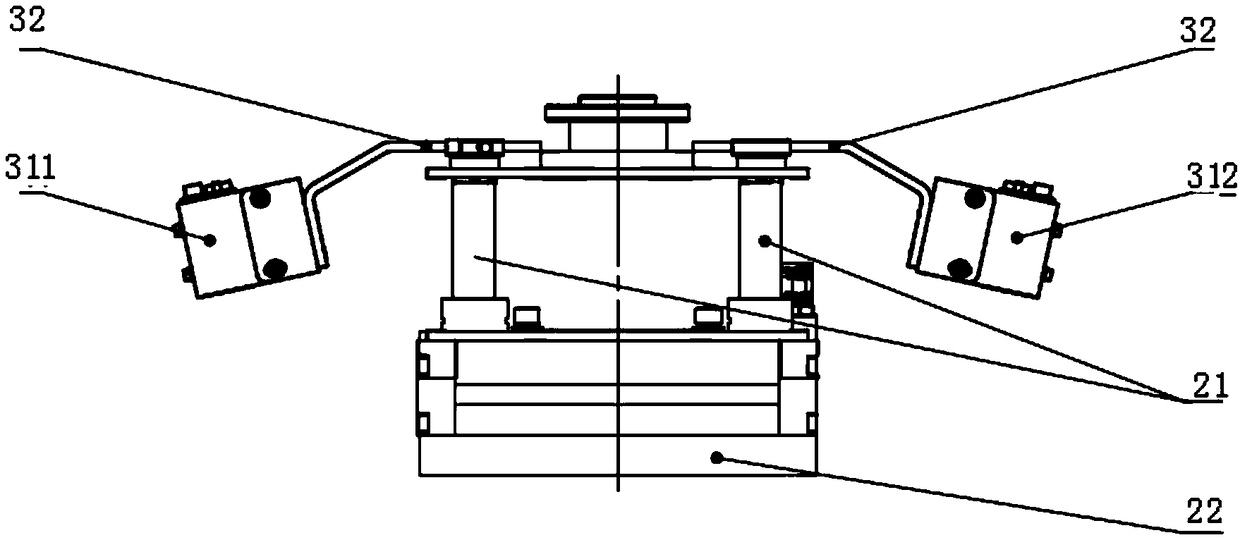

Unstacking robot system and method based on information collection of mixed materials

PendingCN109230580AWide applicabilityHigh degree of intelligenceConveyorsControl devices for conveyorsRobotic systemsBarcode

The invention discloses an unstacking robot system and method based on information collection of mixed materials. The unstacking robot system comprises a multi-degree-of-freedom robot, a local binocular vision device, a global binocular vision device and an industrial computer, wherein an end effector unstacks the materials and places the materials at a designated position; the local binocular vision device is used for detecting the three-dimensional shape of the to-be-grabbed materials, obtaining the volume information of the materials, and identifying label barcode information; the global binocular vision device photographs the shaped of a material stack through at least two cameras arranged above an unstacking station, and extracts spatial coordinate positions and attitude information of the to-be-grabbed materials; the industrial computer is connected with the multi-degree-of-freedom robot, the global binocular vision device and the local binocular vision device and used for transmitting data and other information. The system can reduce labor and equipment investment; the applicability is wider, and the intelligence is higher.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

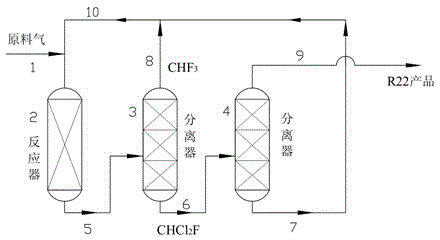

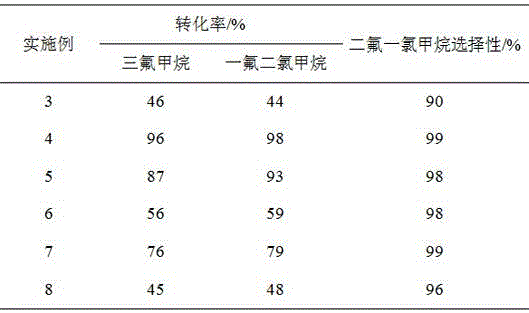

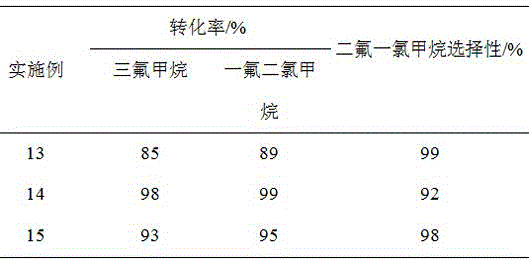

Method for resource utilization of fluoroform

ActiveCN104628513AReduce processing costsReduce equipment investmentPreparation by halogen replacementChemical recyclingHalohydrocarbonResource utilization

The invention discloses a method for resource utilization of fluoroform. The method is characterized by mixing fluoroform with one or a plurality of halohydrocarbon, converting the mixture into a product containing monochlorodifluoromethane in the presence of a catalyst, and reacting unreacted fluoroform with other reaction products in a reactor. According to the method, chlorofluorocarbon containing chlorine or bromine or chlorofluorocarbon which contains chlorine or bromine and needs to be processed during a production process is utilized as reaction material to perform chlorine / fluorine exchange reaction with fluoroform to prepare monochlorodifluoromethane, better economic benefits and social benefits are provided; and in products, monochlorodifluoromethane can be recycled though separation, remained waste gas does not need to be processed, and can still enter the reactor as gas reacted with fluoroform, the conversion rate of reactants is improved, and zero-discharge is realized.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

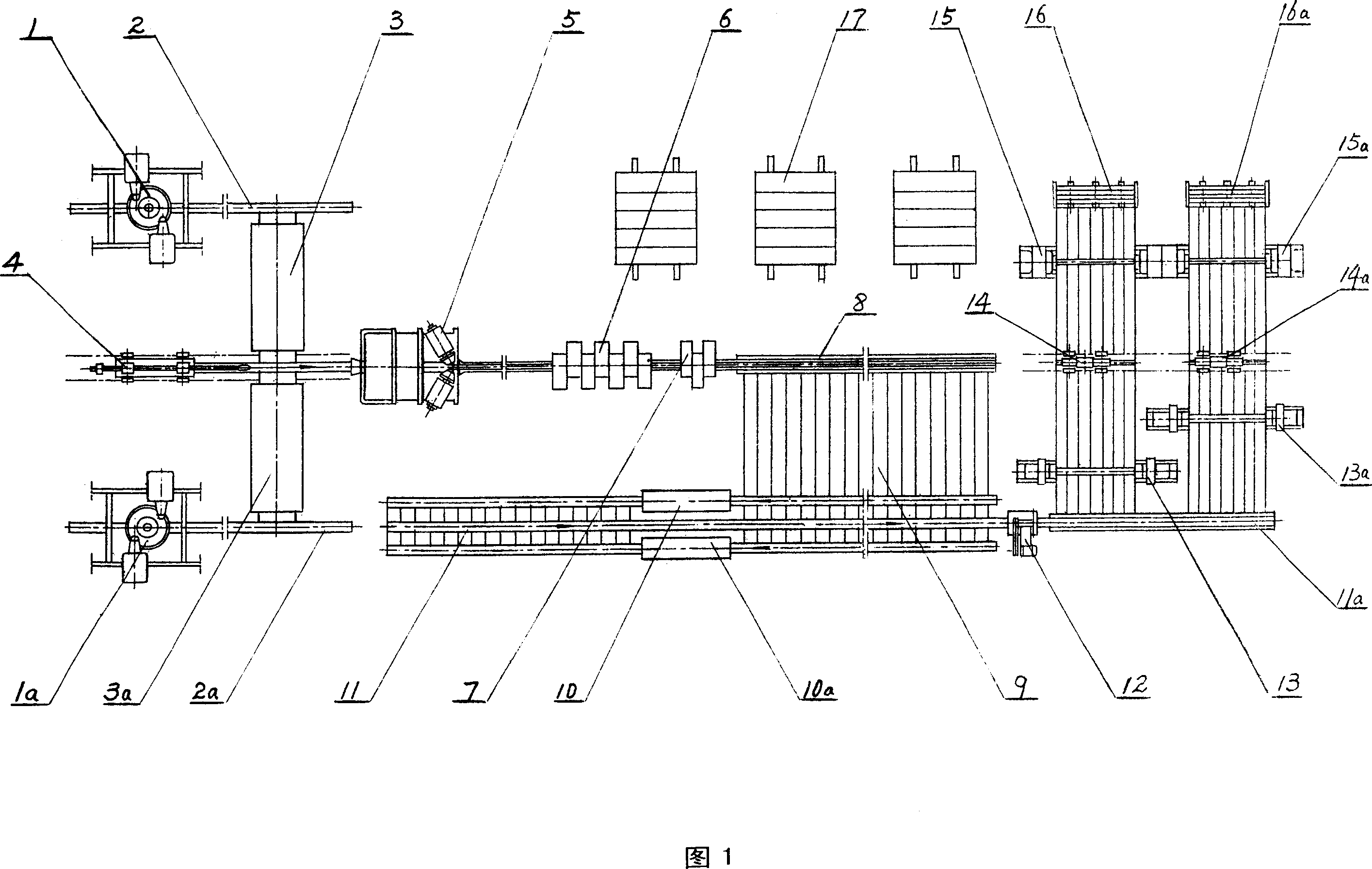

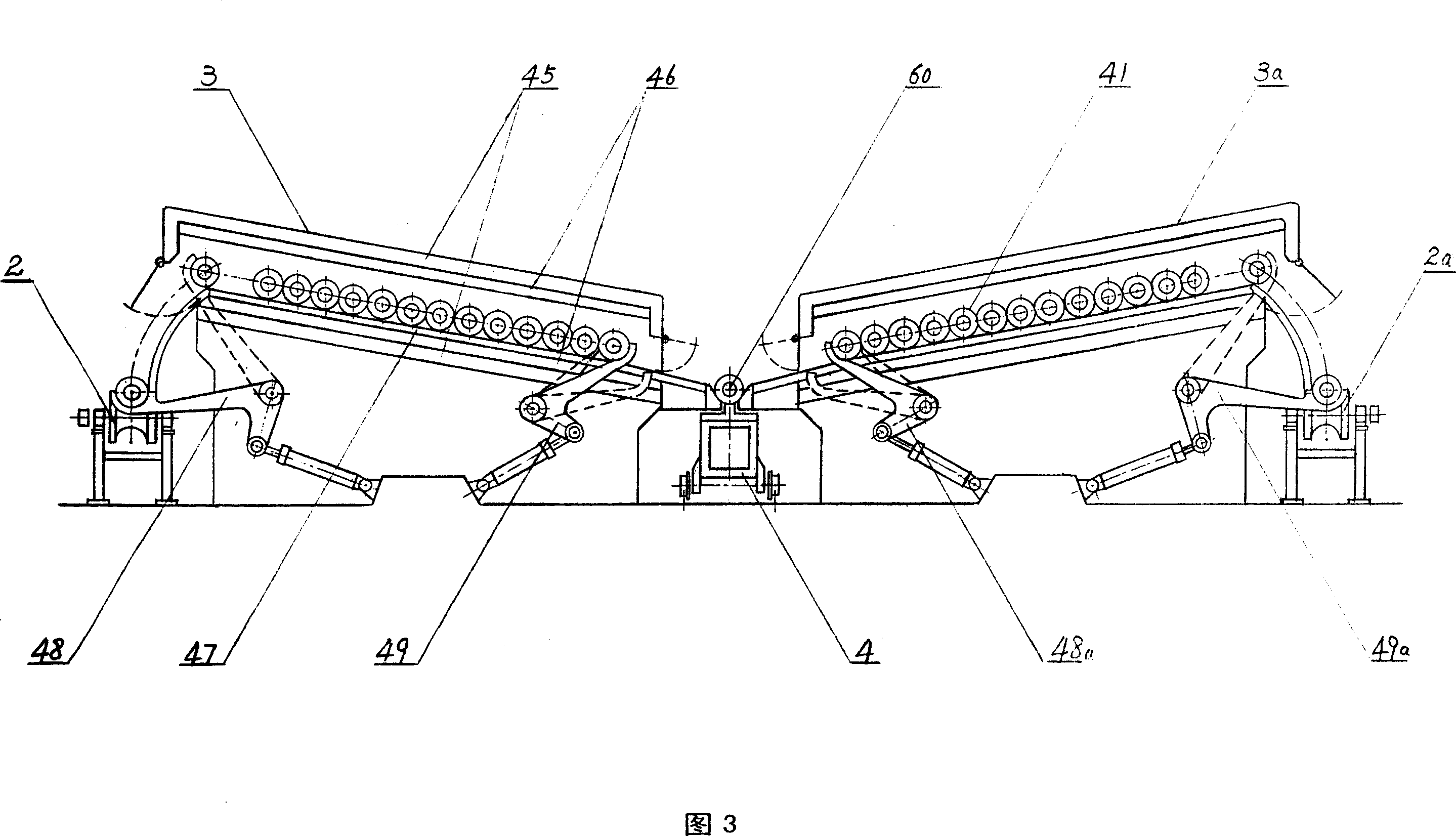

Continuous casting, continuous solling production method and apparatus for stainless steel seamless composite pipe

InactiveCN101024229AShort production processReduce equipment investmentMetal rolling arrangementsSteel tubeEnergy source

The invention relates to stainless steel seamless composite tube continuous casting tandem rolling producing method and device. Its features are that it uses two parallel vertical type hollow bloom continuous casting machines to directly cast out stainless steel composite hollow bloom, cut the high temperature tube blank into given size, and put into sloping bottom die casting furnace to adjust temperature; then the tube blank is taken out to sent into roller trio planet skew rolling mill, tension reducing mill, sizing mill to form finished tube; the finished tube is processed cooling, strengthening, scaling, packing. The invention can shorten production flow, reduce device investment, save energy sources, and increase production efficiency and steel tube rolling quality.

Owner:李铁铎

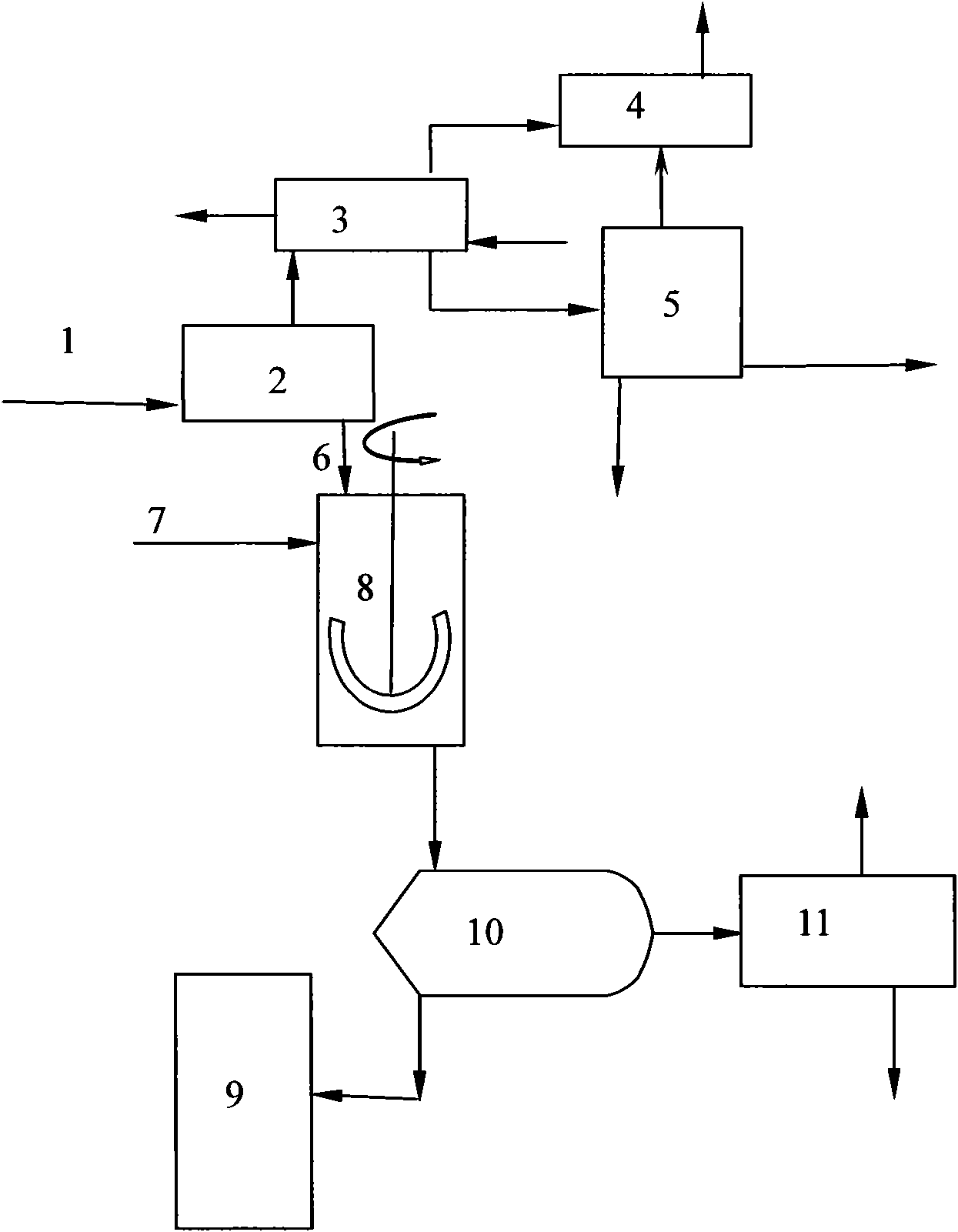

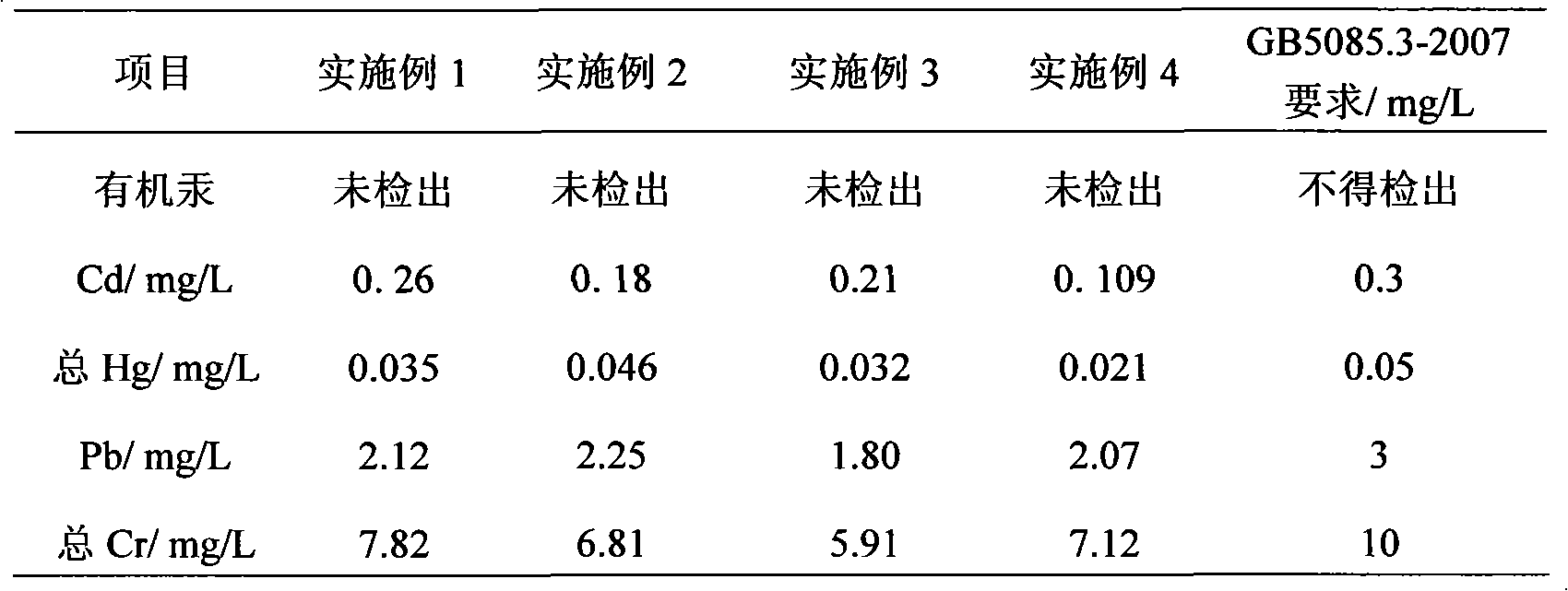

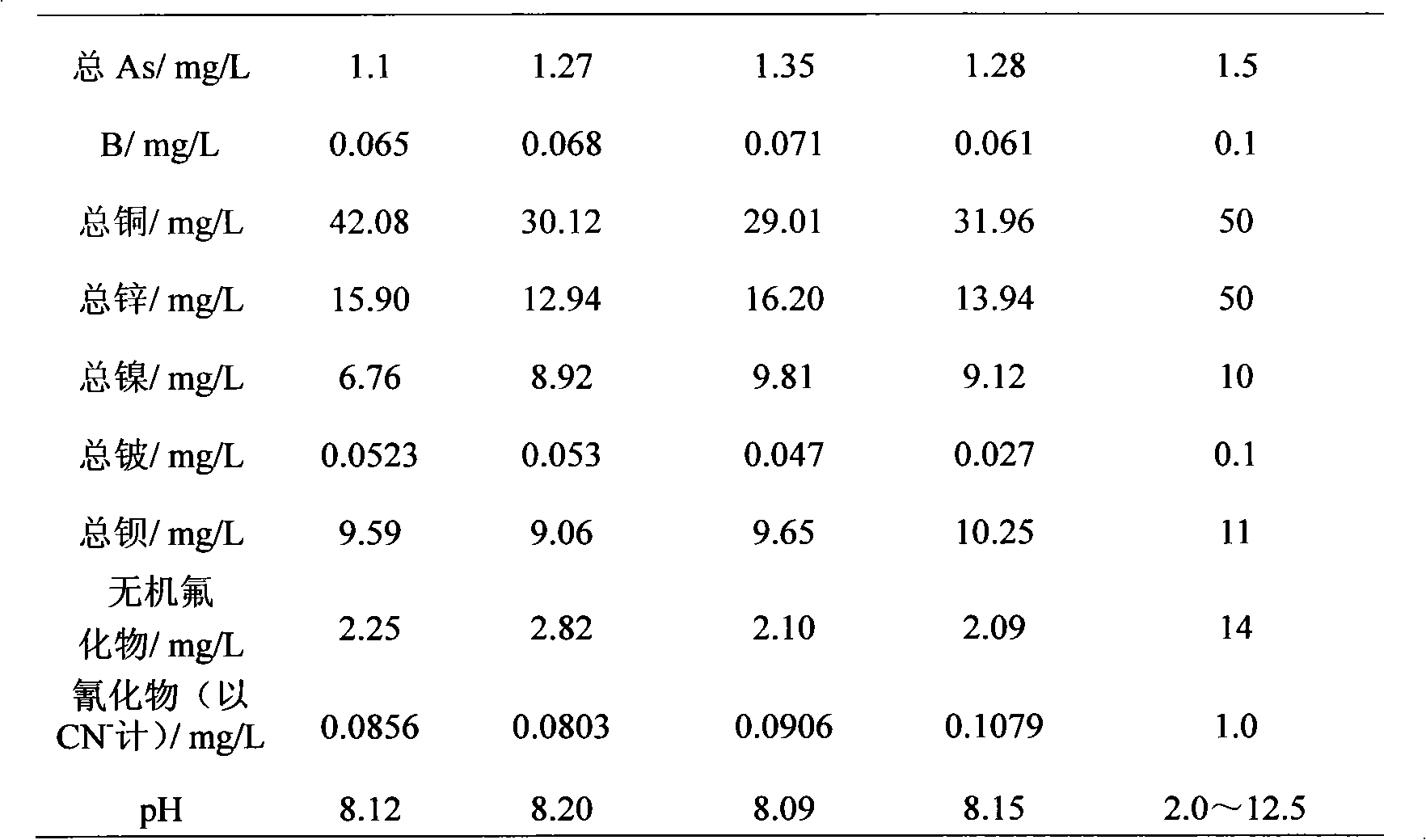

Treatment method of oily sludge

ActiveCN102050556AReduce volumeReduce quality problemsThermal non-catalytic crackingSludge treatment by de-watering/drying/thickeningTherapeutic effectOil sludge

The invention relates to a treatment method of oily sludge, which is particularly suitable for oily sludge generated during the sewage treatment process of a refinery plant. The method comprises the following steps: after centrifugal dewatering, the oily sludge is dehydrated through rotary dehydration equipment under the control of a certain negative pressure and a certain temperature, so as to destroy the water, oil and solid stable system in the oily sludge; parts of oil and water in the oily sludge are distilled out; the coke generated after dehydration is extracted with a solvent; after extraction, the material undergoes the solid-liquid separation; the separated liquid phase is delivered to a delayed coking device; the separated solid phase is dehydrated to form the residues that meet the discharge standards for solids; and the wastewater generated during the process is biochemically treated and then discharged after reaching the discharge standards. The invention is mainly characterized in that the sludge treatment process is short, the speeds and the efficiencies of sludge dehydration and extraction are high, the effect is good, the operational condition is moderate, the energy consumption is reduced, the oily sludge treatment effect is good, and the operating maintenance of the equipment is simple.

Owner:PETROCHINA CO LTD

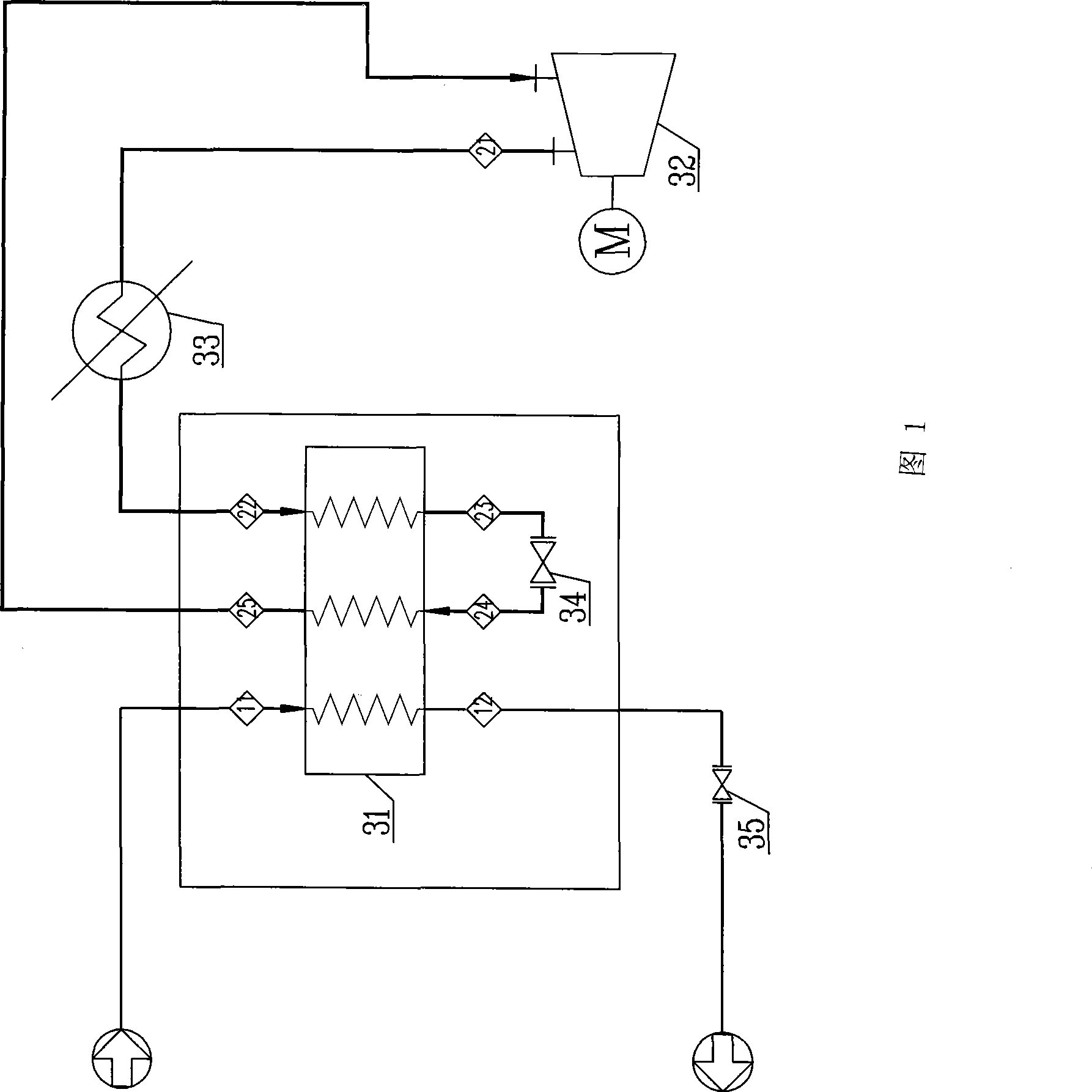

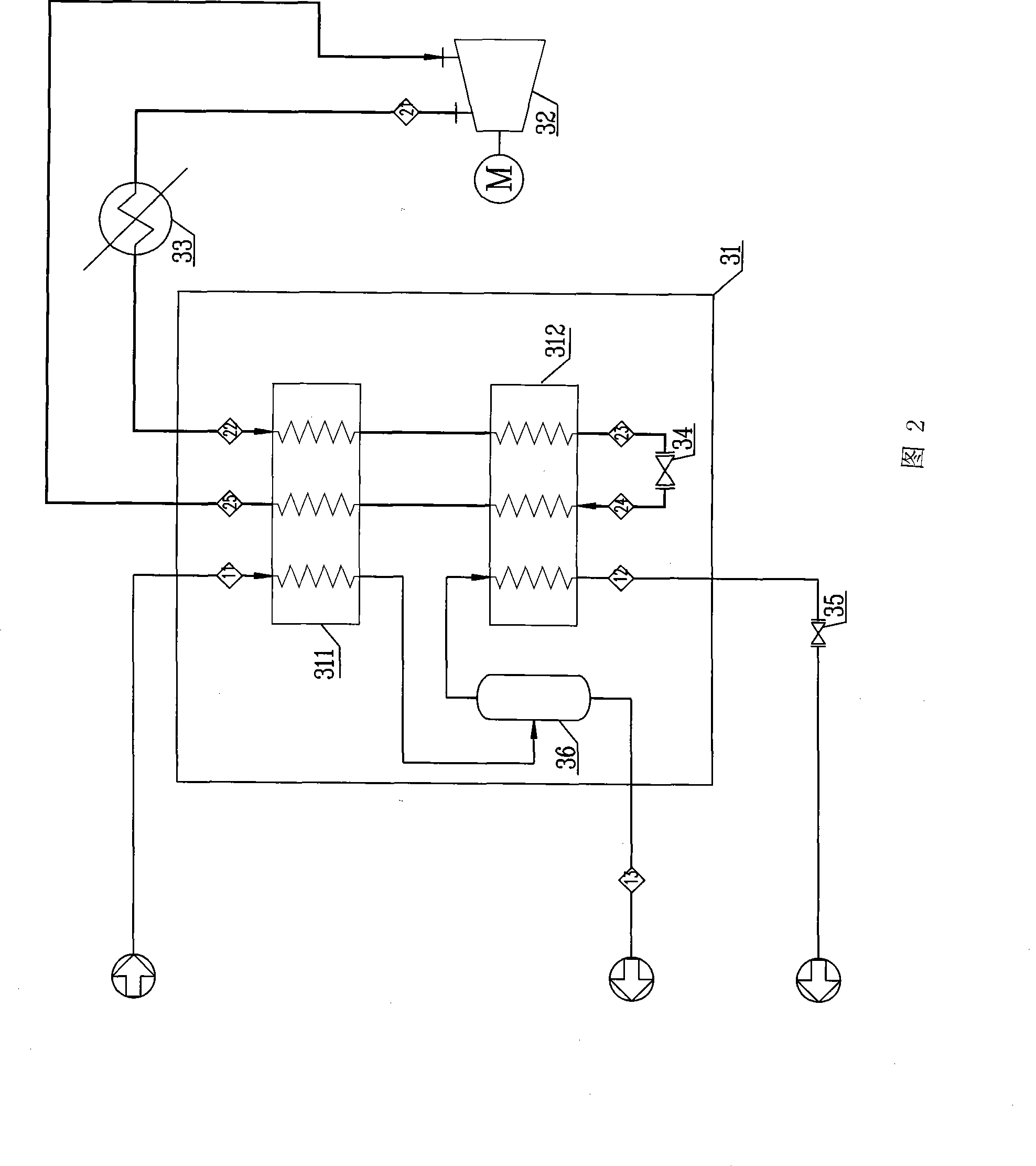

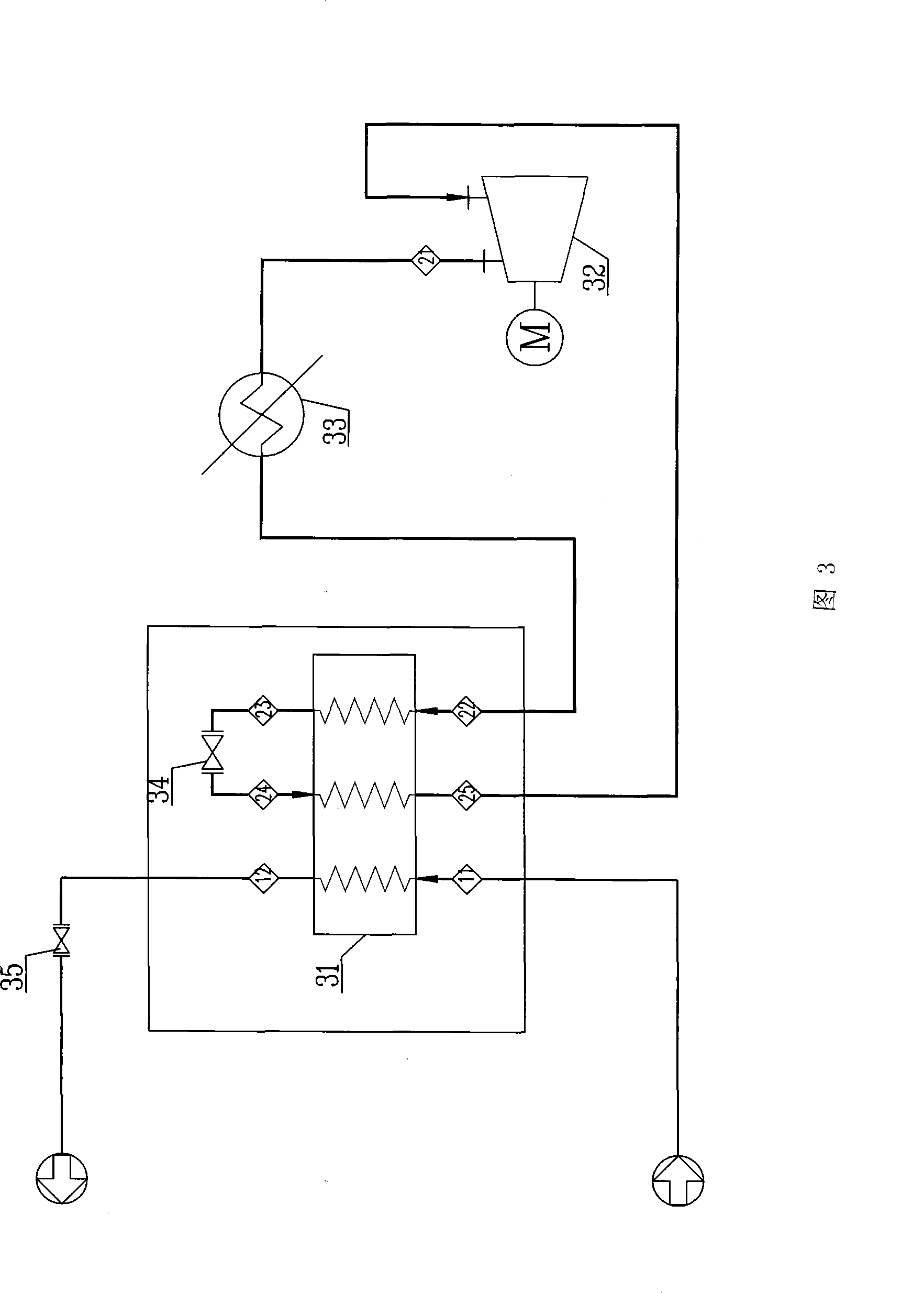

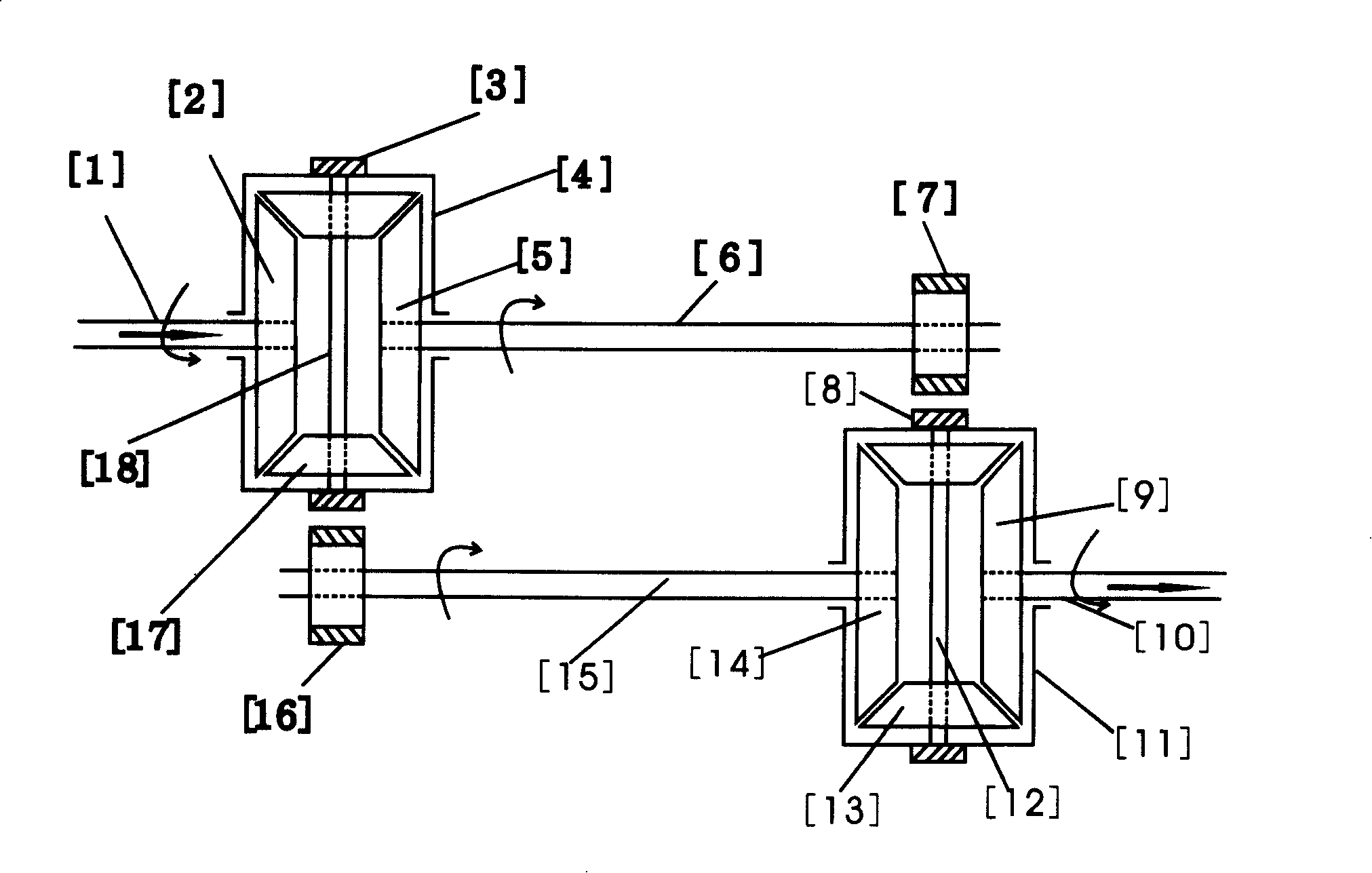

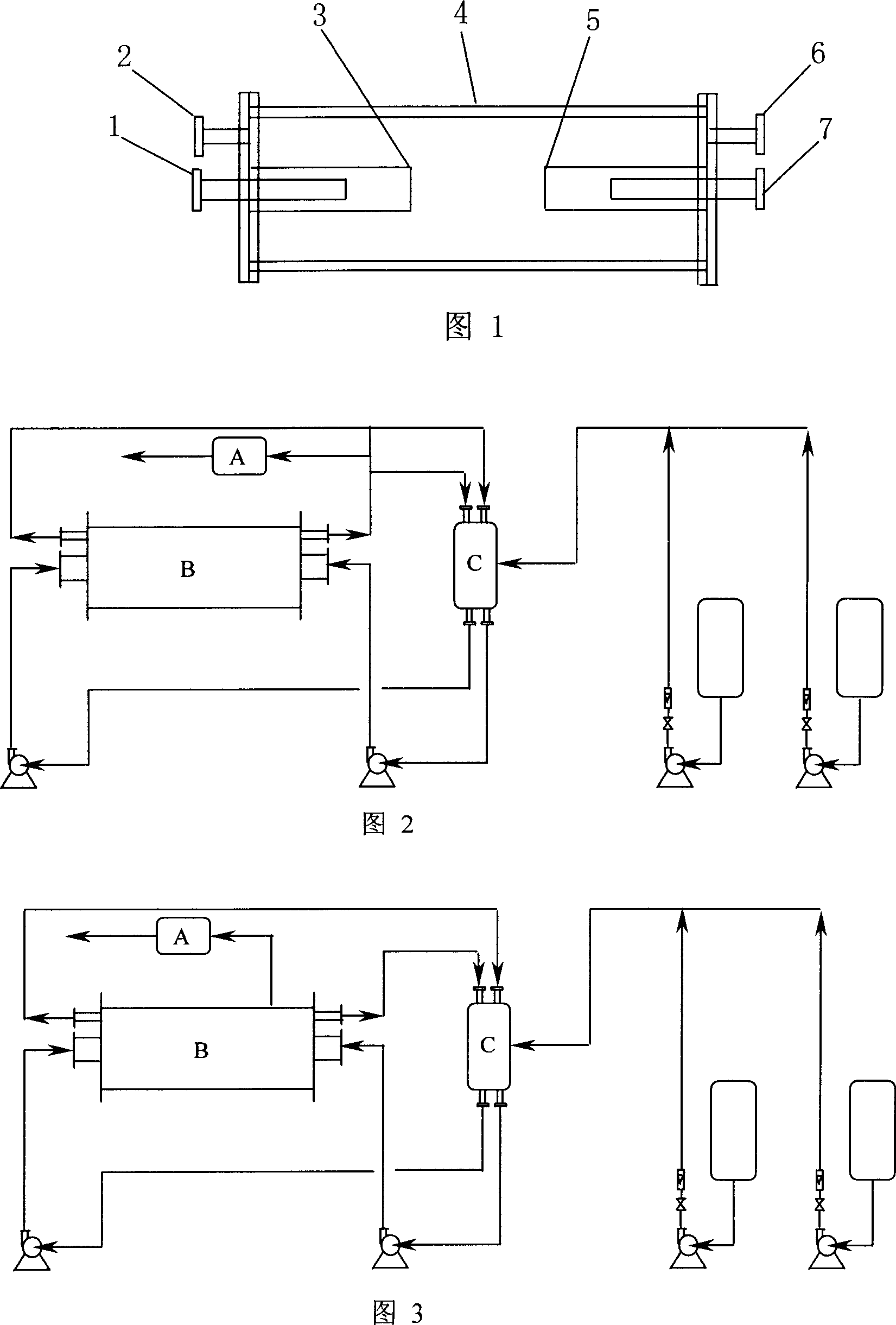

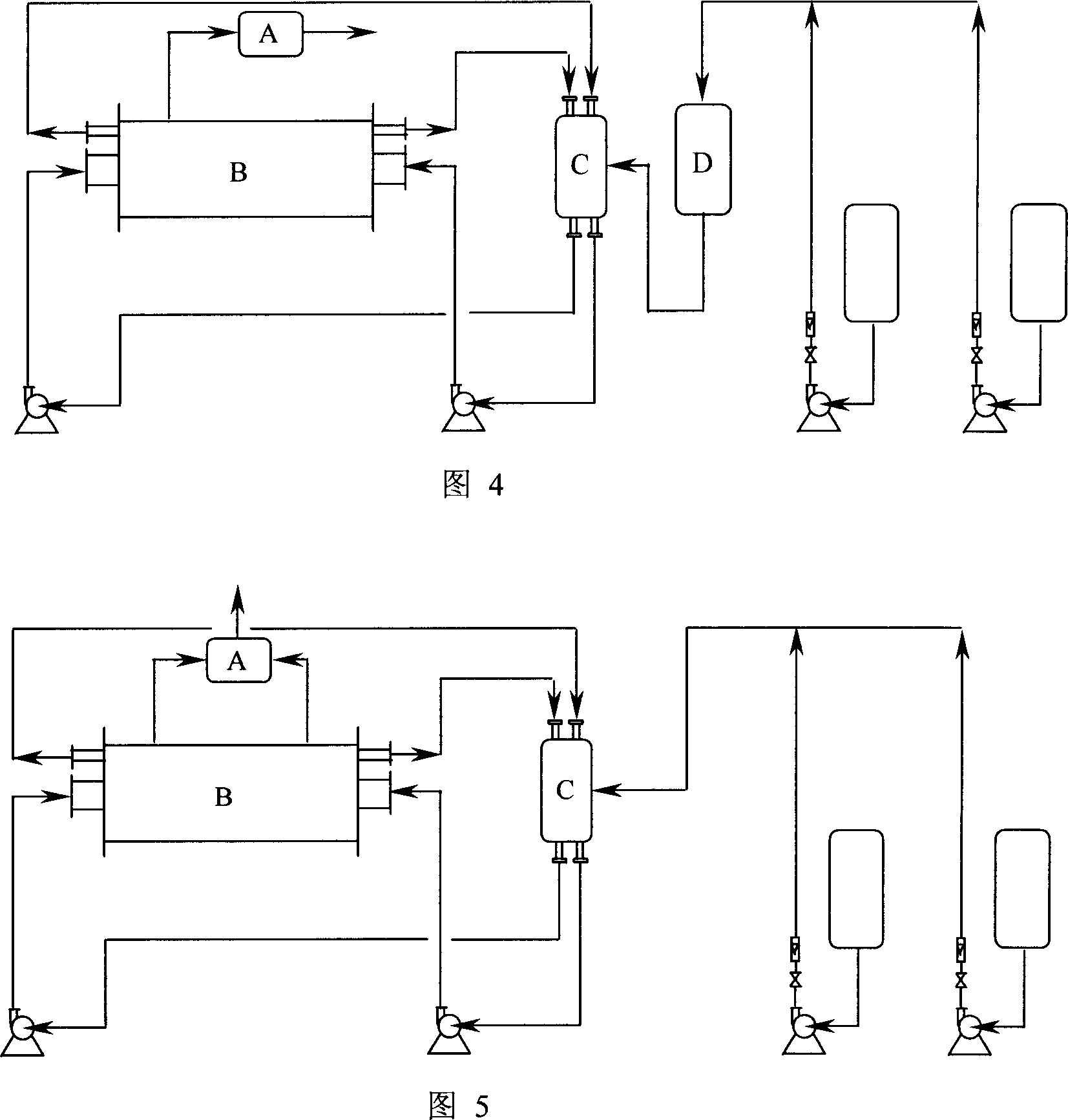

Method and apparatus for single-stage mixing cryogen refrigerating cycle liquefied natural gas

InactiveCN101413749AReduce equipment investmentSimplify cycle flow and operational controlSolidificationLiquefactionRefrigerantChiller

The invention discloses a method for liquefying natural gas by the refrigeration cycle of a single stage mixed refrigerant, which comprises the following steps: raw natural gas passes through a heat exchanger in an ice chest to exchange heat with the mixed refrigerant, and is cooled and liquefied; wherein, in sequence, the mixed refrigerant is first pressurized by a compressor, cooled by a cooler, directly enters the heat exchanger to be precooled without gas-liquid separation, goes out of the heat exchanger for depressurization and temperature reduction and then returns to the heat exchanger to exchange the heat of the natural gas and liquefy the natural gas, as well as is vaporized to gaseous mixed refrigerant and returns to the compressor for the next cycle; by reducing the outlet pressure of the compressor, or boosting the position of the outlet cooler of the compressor or using a way that the mixed refrigerant goes in and out of the ice chest both from the lower part, the method solves the problem of two phase flow of gas and liquid; can reduce the investment of the equipment such as a gas-liquid separator, a pump and the like, simplify the cycle process and operation control and reduce the manufacture cost as well. The invention also discloses a device applied to the method.

Owner:CHENGDU SEPMEM SCI & TECH

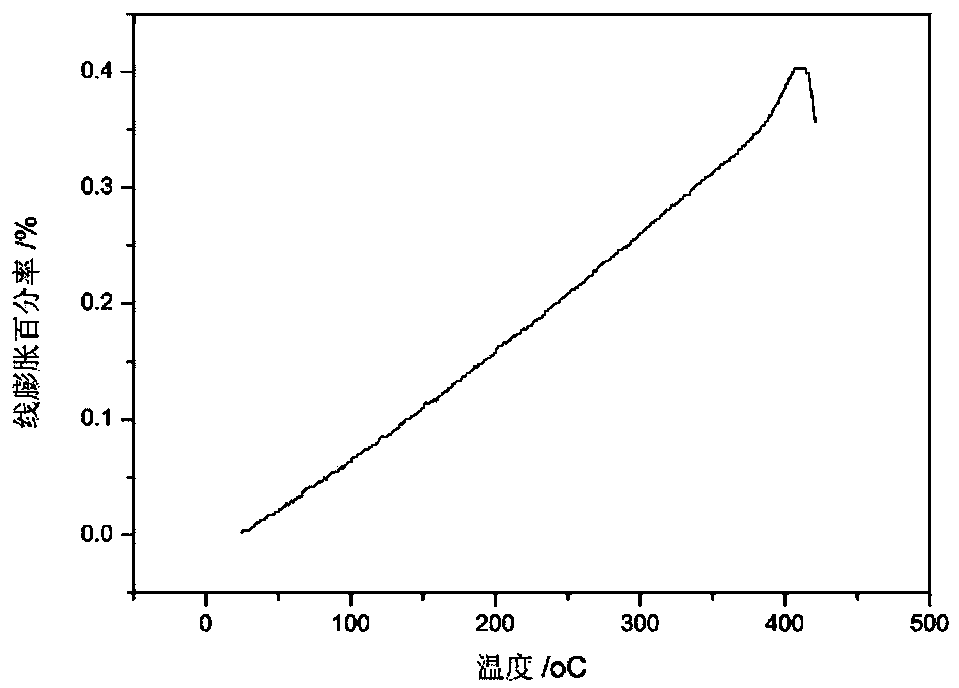

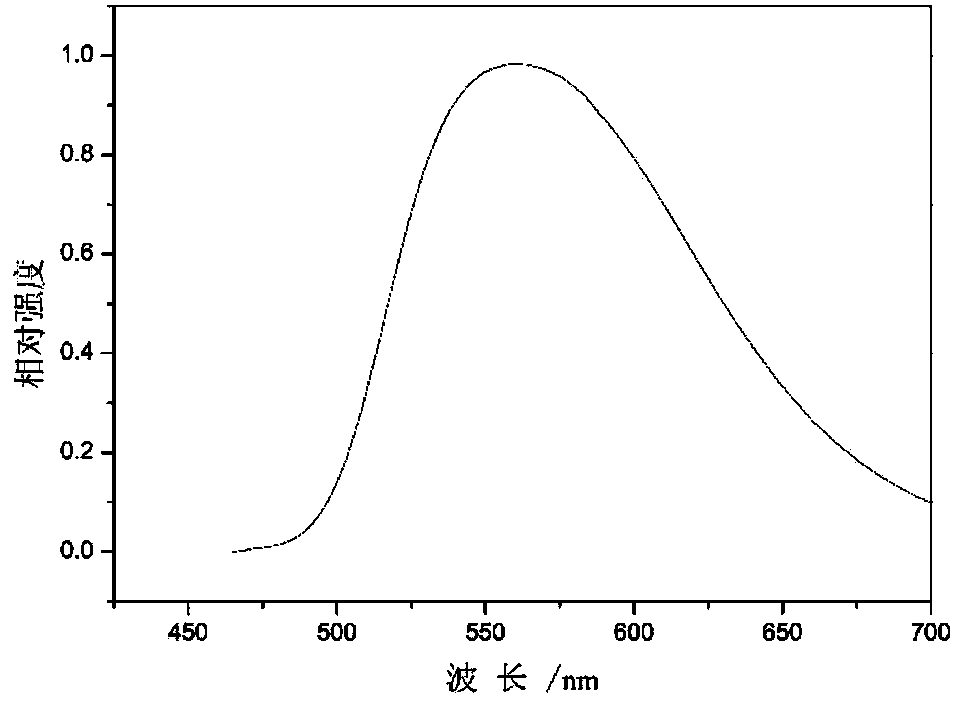

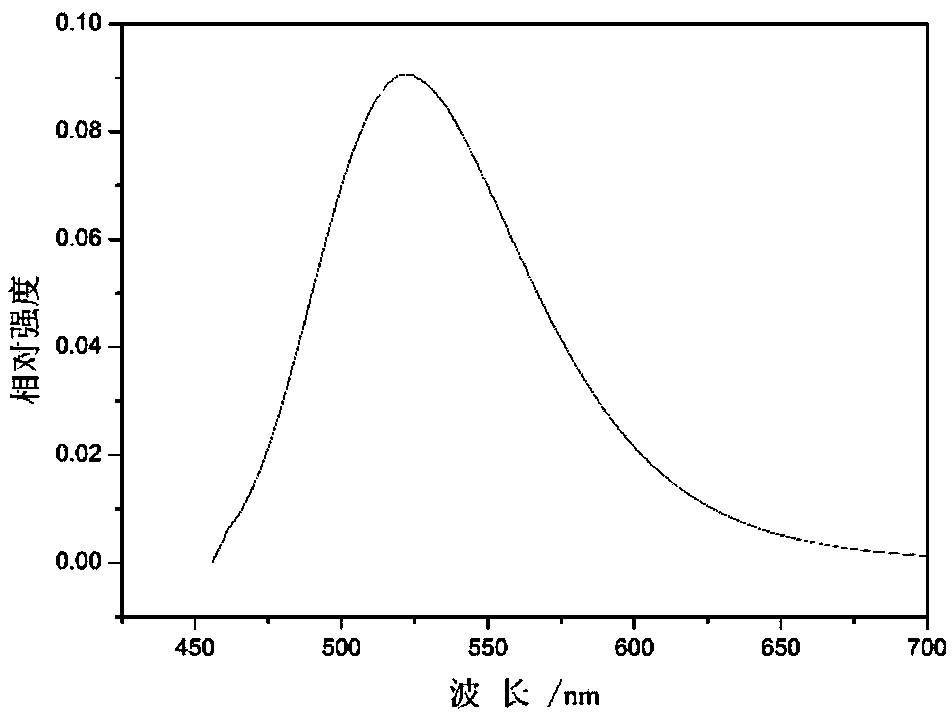

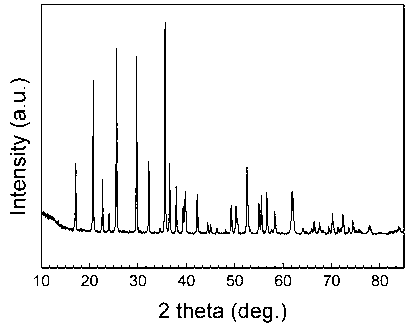

Semitransparent fluorescent powder/glass composite luminescent ceramic wafer and preparation method thereof

The invention relates to a semitransparent fluorescent powder / glass composite luminescent ceramic wafer and a preparation method thereof. The semitransparent fluorescent powder / glass composite luminescent ceramic wafer is obtained by carrying out 'pelletizing, compression moulding and sintering' on fluorescent powder and low-melting-point glass powder, wherein content of the fluorescent powder is 30-85wt%, and the content of the low-melting-point glass powder is 70-15wt%. The preparation method of the semitransparent fluorescent powder / glass composite luminescent ceramic wafer comprises the following steps: firstly, uniformly mixing fluorescent powder with glass powder in certain proportion, and adding a binding agent required by pelletizing and demoulding, so that pelletized powder of 60-100 meshes is obtained; secondly, carrying out compression moulding on the obtained pelletized powder by virtue of a mould, so that a green body of a certain shape is obtained; thirdly, carrying out heat treatment, namely carrying out glue drainage on the green body for 2-4 hours at the temperature of 300-395 DEG C, and sintering for 1-2 hours at the temperature of 395-410 DEG C, wherein the whole heat treatment process is carried out in the air atmosphere; and finally the fluorescent powder / glass composite luminescent ceramic wafer is obtained.

Owner:厦门百嘉祥微晶材料科技股份有限公司

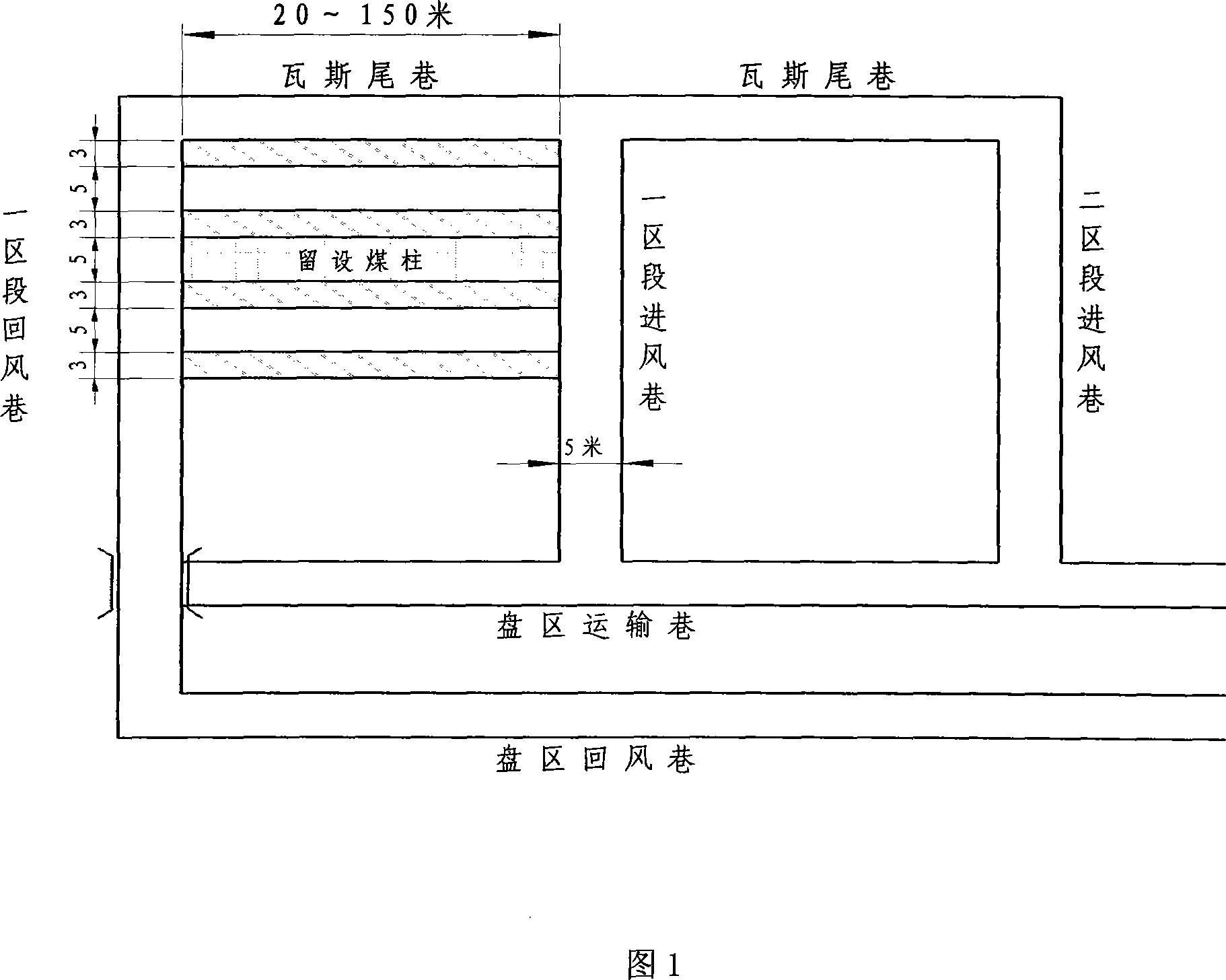

Method for coal mine downhole reproduction and back production

InactiveCN101025085AReduce equipment investmentShort construction periodUnderground miningBlastingResource depletionCoal pillar

The invention provides a coal mine underground coal remining and extracting method, comprising: laneway disposing, mining, coal dropping, and adopting the processes of coal loading, coal conveying and timbering by a coal loading, coal conveying and anchor rod timbering mechanical integrated device and recovering from two wings, where the laneway disposing divides several segments in a mining section and disposes two preparing laneways in each segment, one as air inlet lane and the other as air return lane, after all coal in the previous segment has been mined, the air inlet lane of the previous segment can act as an air return lane for the next segment, and the next segment is made with only one air return lane, it disposes a strip house pillar in the middle of the two preparing laneways, arranges mining house, mining pillar and remains coal pillars, and determines the sizes of the mining house and mining pillar according to the characteristics of the top plate, and implements mine underground mechanical mining, makes medium-sized and small-sized mines whose 'resources have dried up' implement remining, and makes coal pillars and corner coal recovered in large-sized and medium-sized mines and makes the coal extraction ratio up to 50%-70%.

Owner:闫振东

Semi-automatic production method of foam slurry core-filling building blocks

ActiveCN102672796AEliminate secondary pollutionReduce equipment investmentCeramic shaping plantsBatch machineFully automatic

Owner:绿建科技集团新型建材高技术有限公司

Vanadium nitrogen microalloy additive and its preparing method

A V-N microalloying additive is prepared from vanadate or vanadium oxide, carbon reducing agent, and density intensifier through die pressing to become blocks, loading in high-temp furnace, introducing N2, and reduction reacting which nitrifying. It contains V (77-82%), nitrogen (11-16%) and C (2-7%).

Owner:NORTHEASTERN UNIV

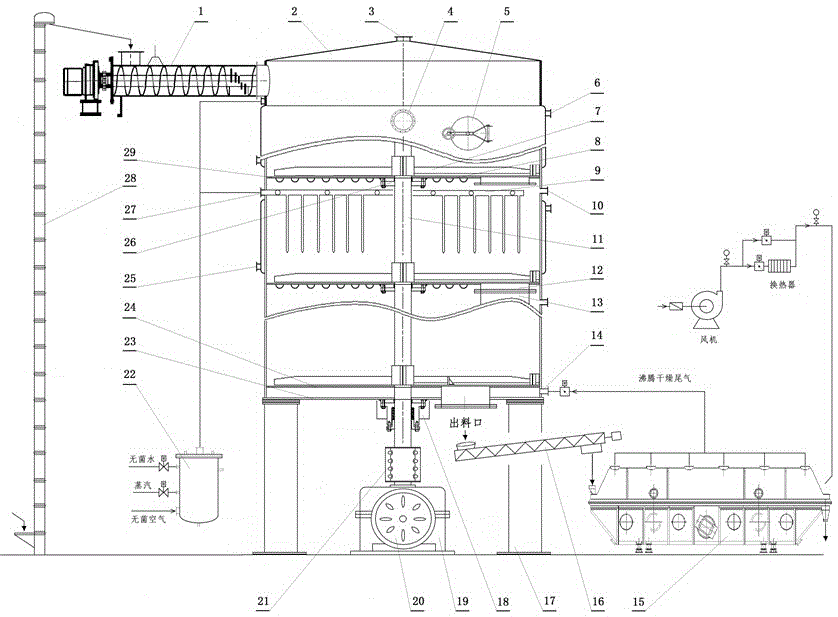

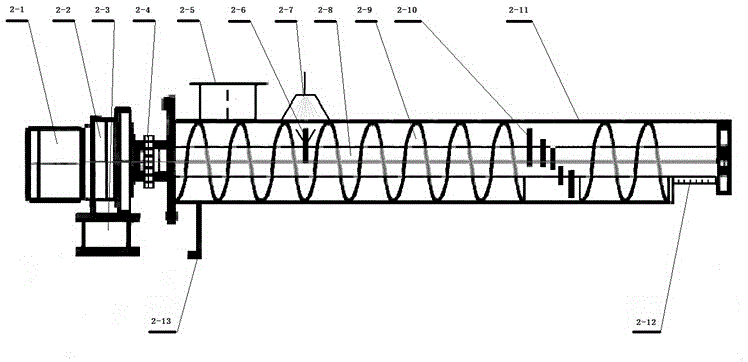

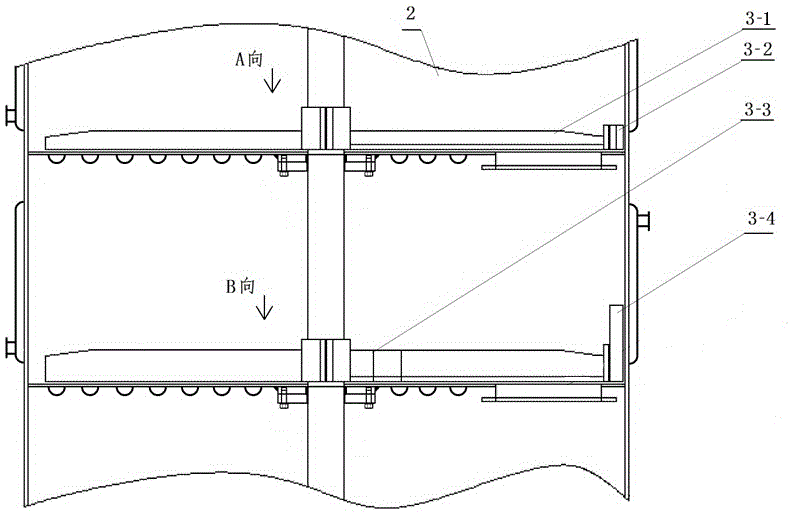

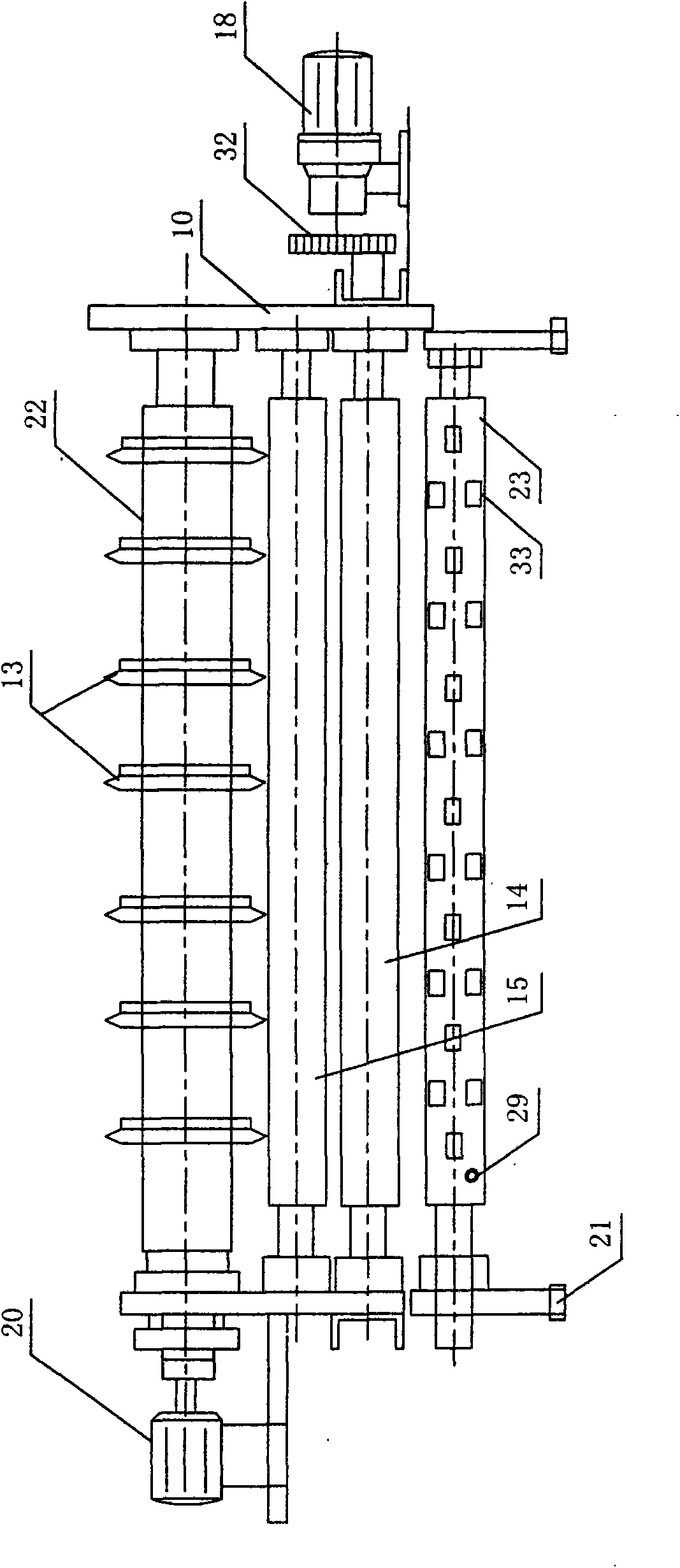

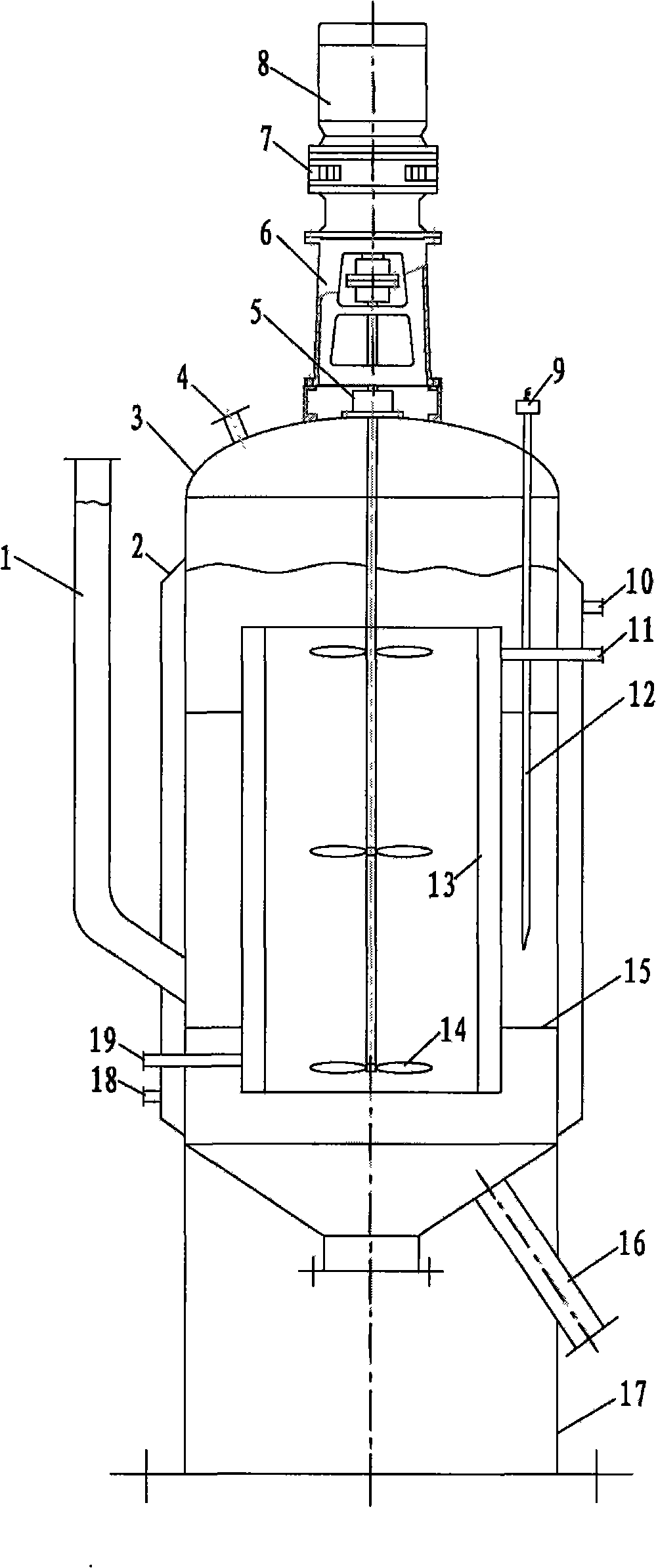

Full-automatic control multifunctional solid-state fermentation tank

ActiveCN106701563ARealize mechanized controlRealize temperature controlBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlControl system

The invention discloses a full-automatic control multifunctional solid-state fermentation tank, comprising a round vertical fermentation tank main body and a fermentation control system, wherein a loading auger is arranged at one side of the upper end of the fermentation tank main body; multiple clapboards are arranged in the fermentation tank main body; a high-material-bed material level automatic control device is arranged in each fermentation layer; a sterile air distribution system is arranged in each fermentation layer and is connected with a sterile air generation tank positioned at the outer side of the fermentation tank main body; a main shaft is rotationally arranged in the fermentation tank main body; and the upper ends of the clapboards are provided with stirring blades. The full-automatic control multifunctional solid-state fermentation tank disclosed by the invention integrates eight functions including dry material mixing, watering material mixing, steam sterilization, inoculation, automatic fermentation control, low-temperature drying, raw material crushing, automatic discharging and finished product smashing, and enables all operations of solid-state fermentation to be completed in a multifunctional biological solid-state fermentation tank; and by virtue of the equipment disclosed by the invention, the fermentation and production preparation processes of solid biological products can be continuously completed.

Owner:郑州良源分析仪器有限公司

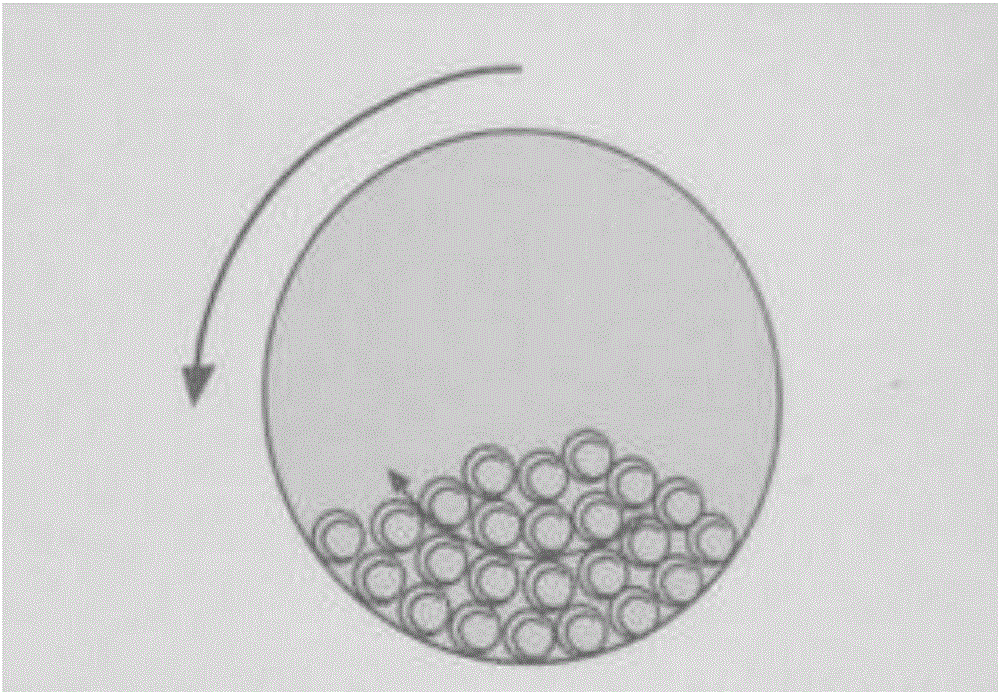

Multifunctional biological solid fermentation tank

InactiveCN101955883AUniform inoculation and humidity controlSolve the single functionBioreactor/fermenter combinationsBiological substance pretreatmentsPropellerSteam sterilization

The invention relates to a multifunctional biological solid fermentation tank. The main body structure of the fermentation tank is a horizontal propeller, and spiral auger propeller blades are installed below the tank bottom. An auger is directly communicated with steam for sterilizing form the bottom of the tank and communicated with air for cooling, a spray tube on the upper part of the tank body sprays bacterial liquid for inoculation and can also spray water mist for humidity regulation, and thus, uniform inoculation and humidity control can be realized. The unique tank body horizontal type propeller and the auger coordination system below the tank body are utilized, and the circular flowing and the thorough mixing of a solid material in the tank body during fermentation are realized by controlling the rotating speed and the rotating direction; stirring nonuniformity caused by using a motor to rotate forwards or backwards repeatedly is avoided, automatic material discharge can be realized after fermentation, and material discharge is clean and complete. The operations of sterilization, cooling, inoculation, fermentation, temperature control, humidity control, ventilation, vacuum drying and the like required by solid fermentation can all be completed in the biological solid fermentation tank. The biological solid fermentation tank has the advantages of hardly no bacterial contamination, small occupied space, high automation degree, labor saving, investment saving and the like.

Owner:JIANGNAN UNIV

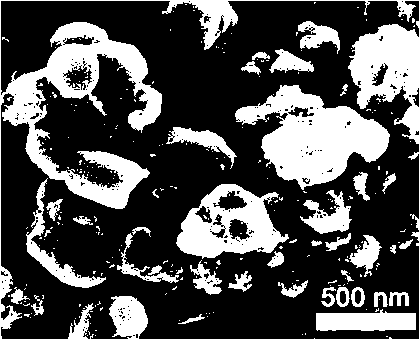

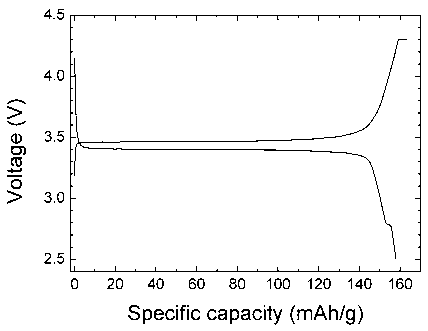

Method for recycling positive material of waste lithium iron phosphate battery

InactiveCN102709620ASimple recycling processReduce equipment investmentWaste accumulators reclaimingBattery recyclingPre treatmentScrap

The invention discloses a simple and easy method for recycling positive material of a waste lithium iron phosphate battery, and the method can be used for the industrial production. The method comprises the following steps: firstly, carrying out total discharge (0.05V) on the waste lithium iron phosphate battery, then mechanically disassembling the battery in a fume hood and screening a positive plate; and placing the positive material into water to carry out ultrasonic stirring, sieving out an aluminium foil, drying the residual solution and material, carrying out ball milling, carrying out elemental analysis, matching the obtained material with a novel raw material and carrying out sintering to obtain the lithium iron phosphate positive material with superior performances. The method has the significance that according to the simple method for recycling the lithium iron phosphate positive material which can be used for the industrial production, the positive material with the superior performances can be obtained by utilizing additives in wastes, such as acetylene black and the like, without carrying out the pretreatment.

Owner:ZHEJIANG UNIV

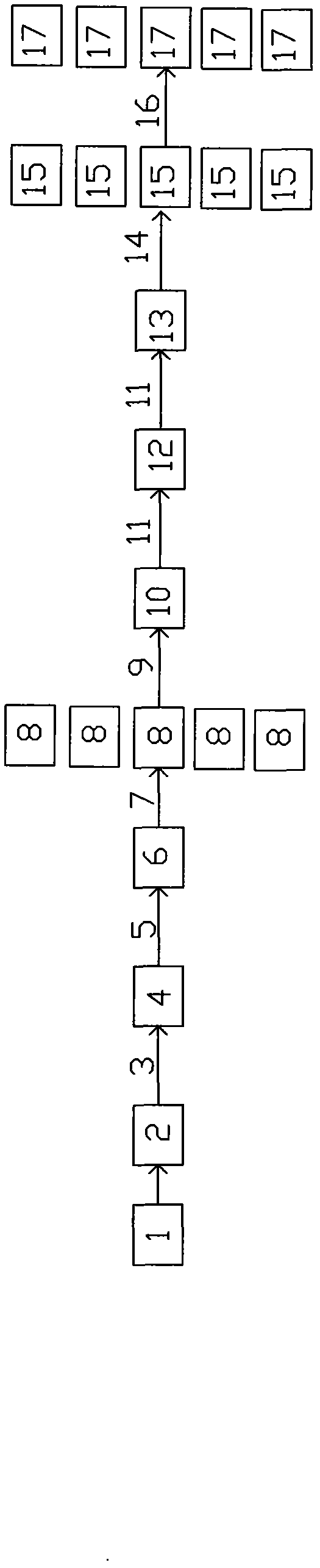

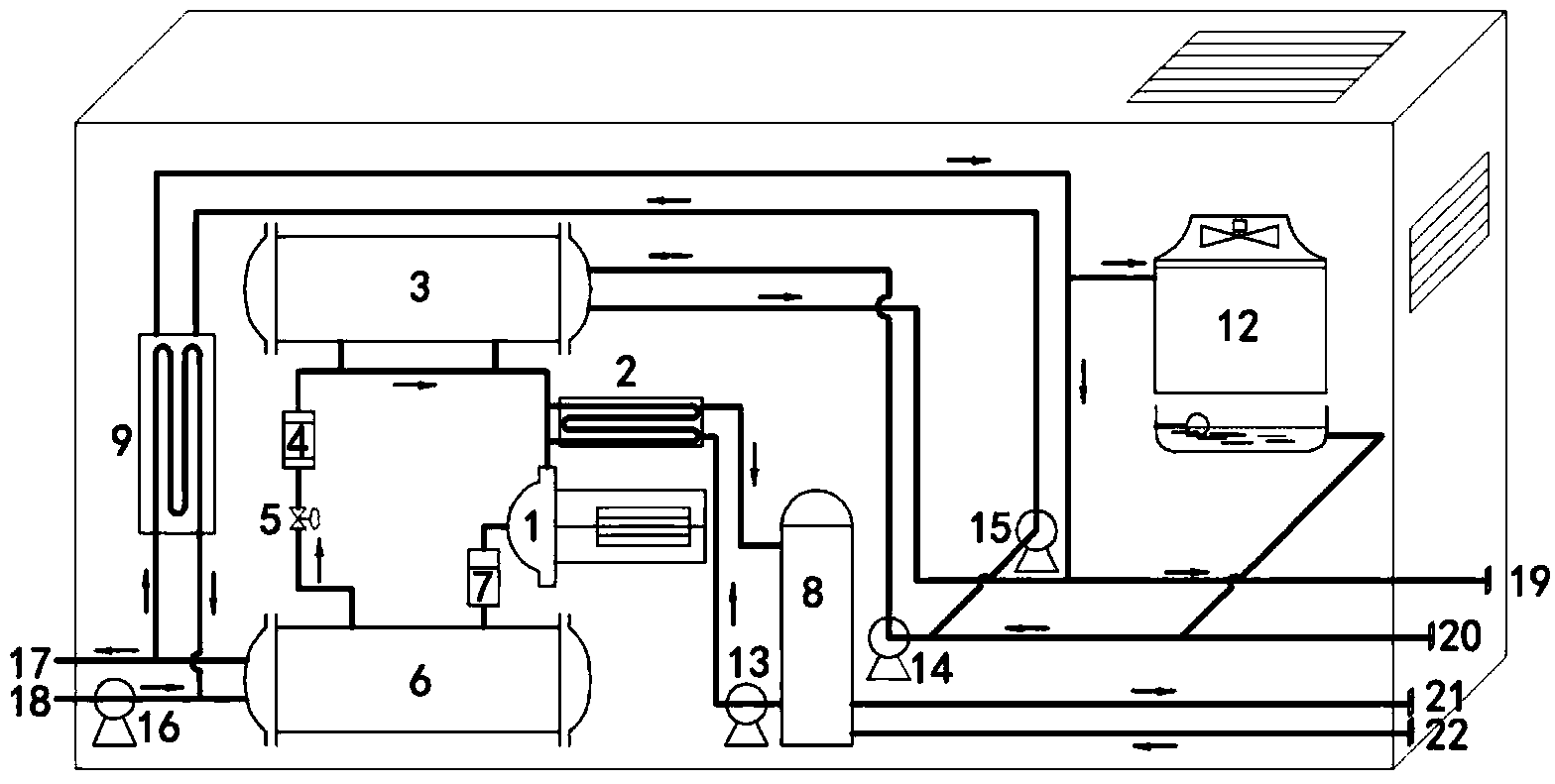

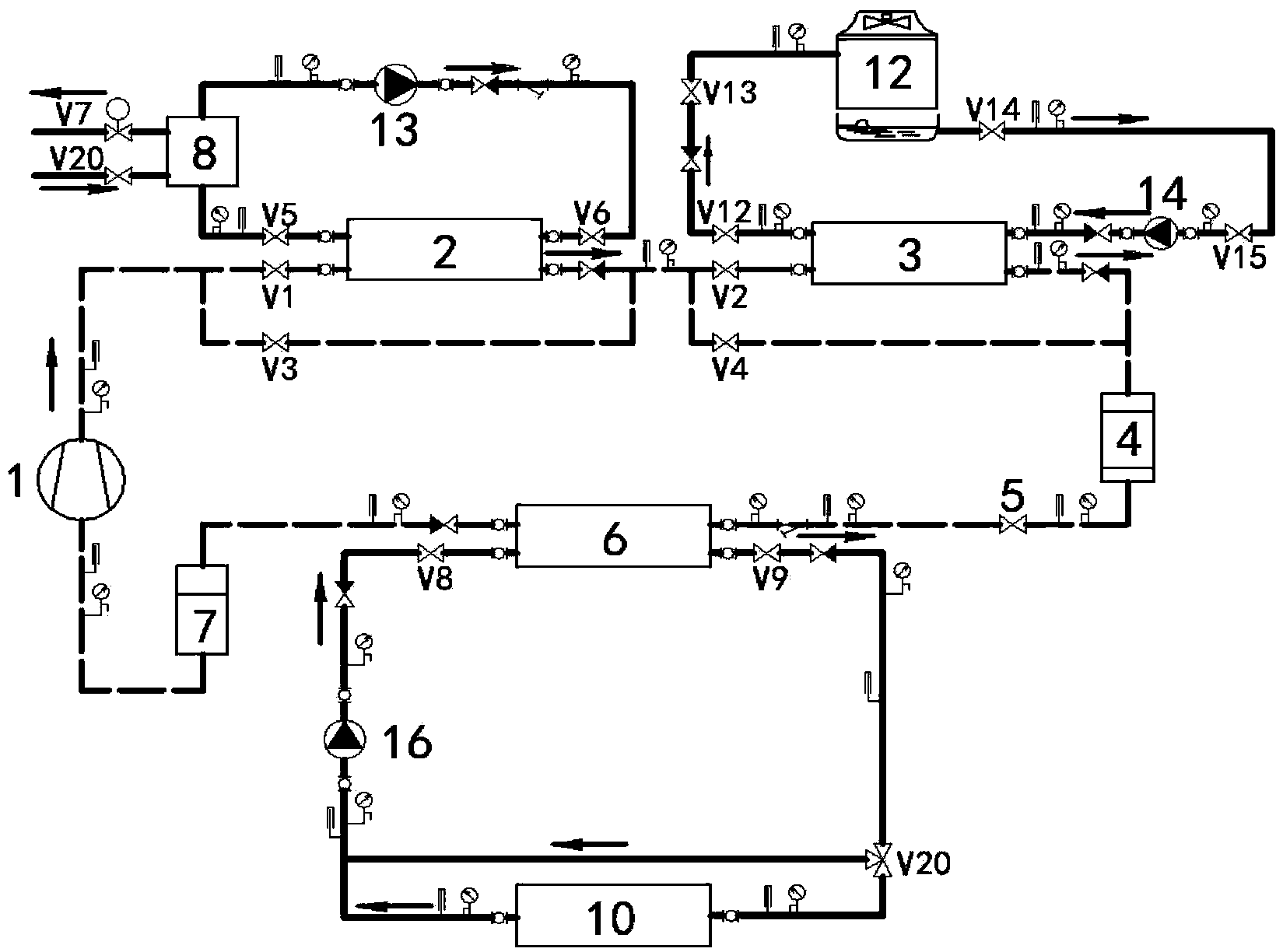

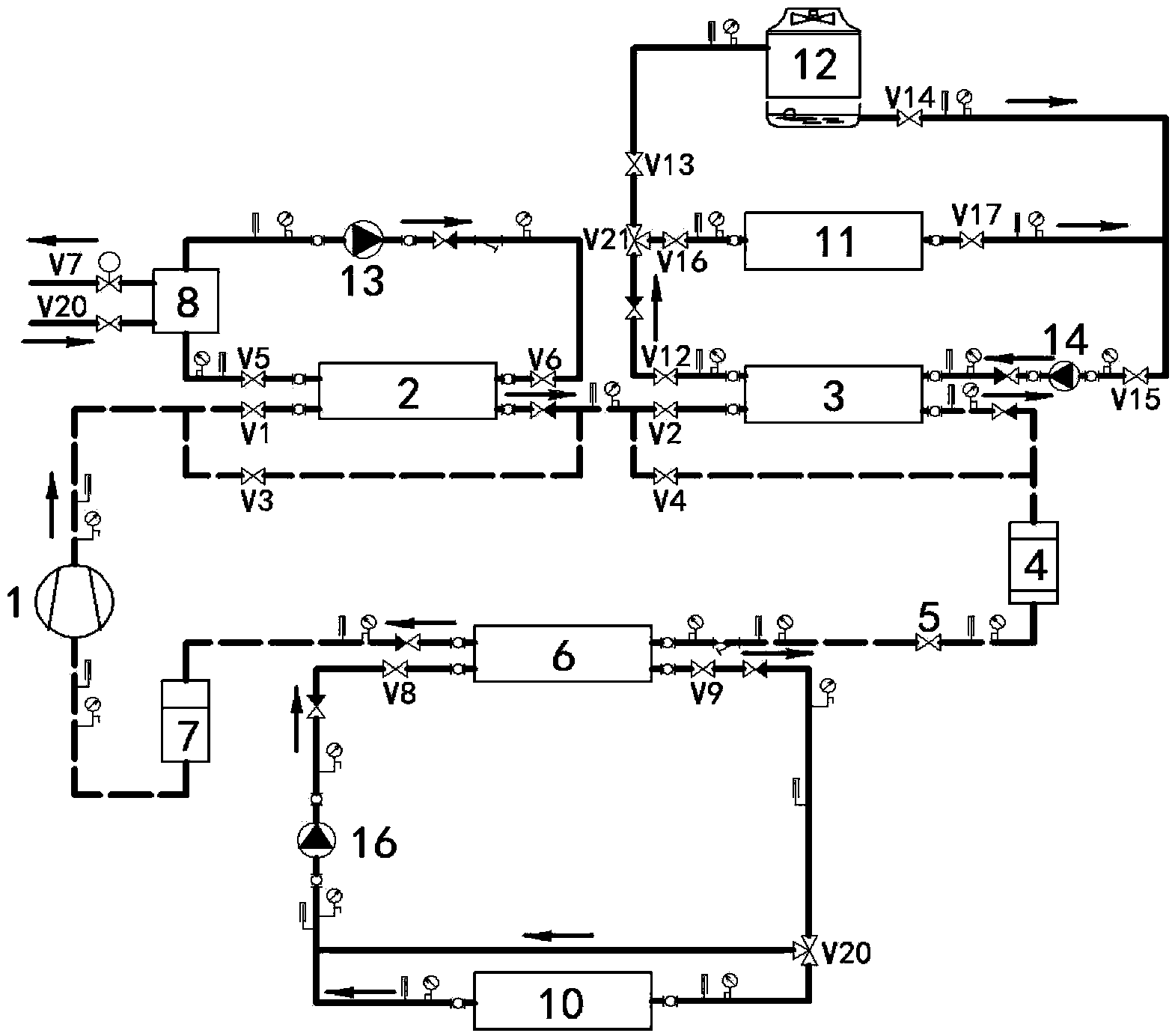

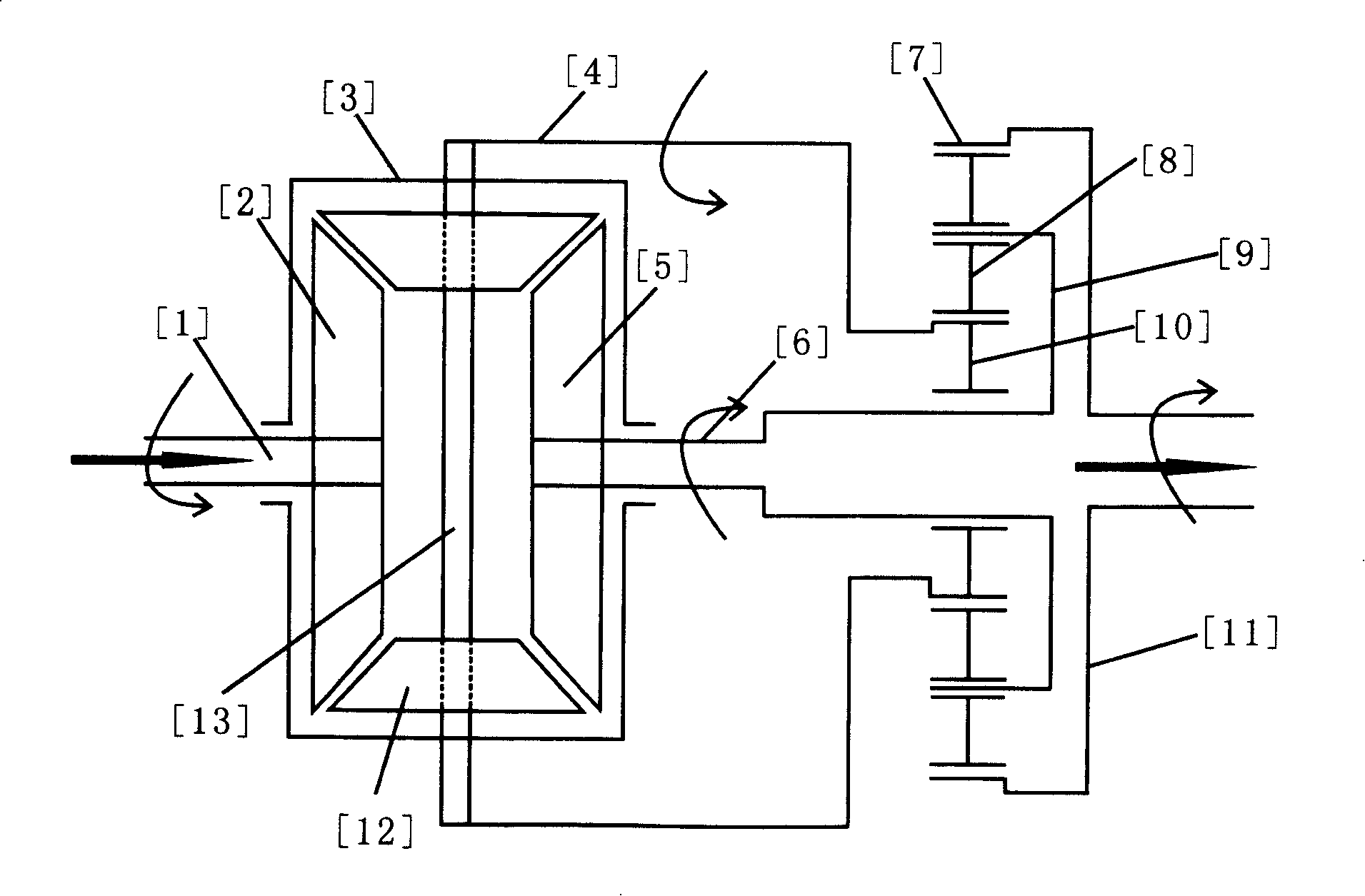

Multifunctional combined supply type integrated air conditioner unit for data rooms

InactiveCN103940145AReduce volumeImprove energy efficiencySpace heating and ventilation detailsHeating and refrigeration combinationsPlate heat exchangerCooling tower

The invention discloses a combined supply type air conditioner unit integrating the refrigerating function, the high-temperature hot water preparation function, the low-temperature hot water preparation function and the like. The air conditioner unit is mainly composed of a compressor 1, a high-temperature heat recovery device 2, a low-temperature heat recovery device 3, a dry filter 4, a throttling valve 5, an evaporator 6, a gas-liquid separator 7, a heat storage water tank 8, a plate heat exchanger 9, a cooling tower 12, a hot water circulating pump 13, a circulating pump 14, a cooling water pump 15, a chilled water pump 16, a chilled water outlet 17, a chilled water inlet 18, a low-temperature hot water outlet 19, a low-temperature hot water inlet 20, a high-temperature hot water outlet 21 and a heat storage water tank water adding opening 22, wherein all the components are connected through pipelines and are switched and adjusted through valves. According to the combined supply type air conditioner unit, circulated waste heat is refrigerated as a heat source by means of the high-temperature heat recovery device and the low-temperature heat recovery device, and user heat loads are borne through heat recovery. In addition, cooling free of charge can be achieved, and the combined supply type air conditioner unit has the good applicability and adaptability for the data room and the like needing perennial cooling.

Owner:CHONGQING UNIV

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

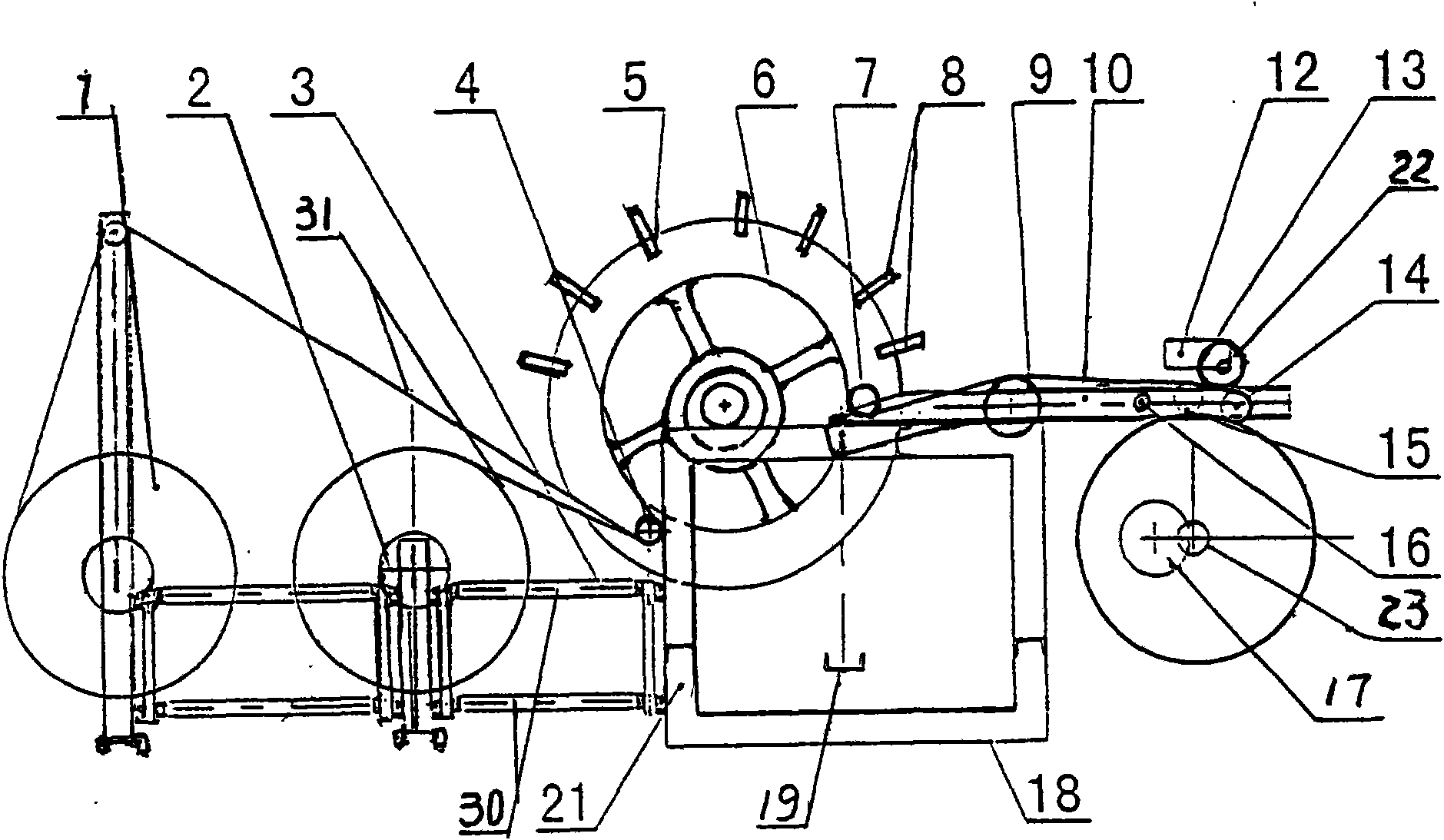

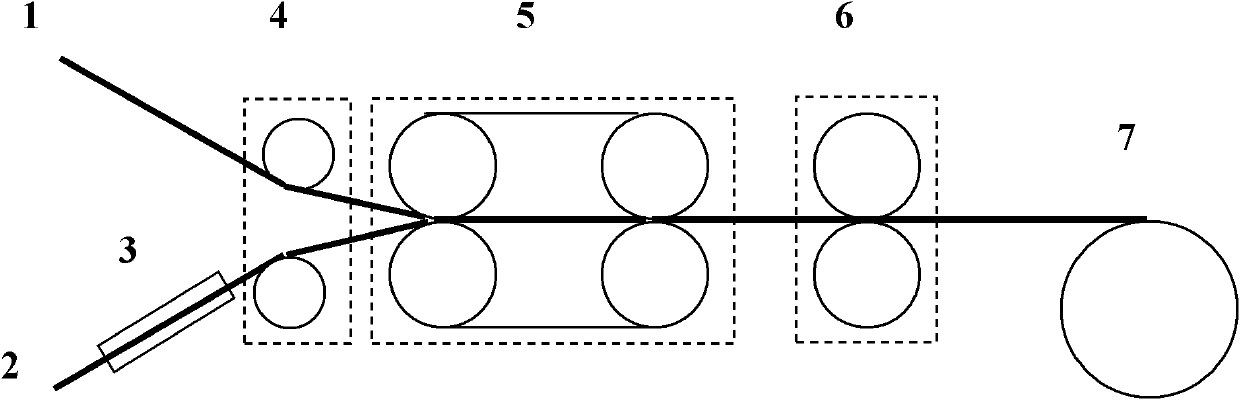

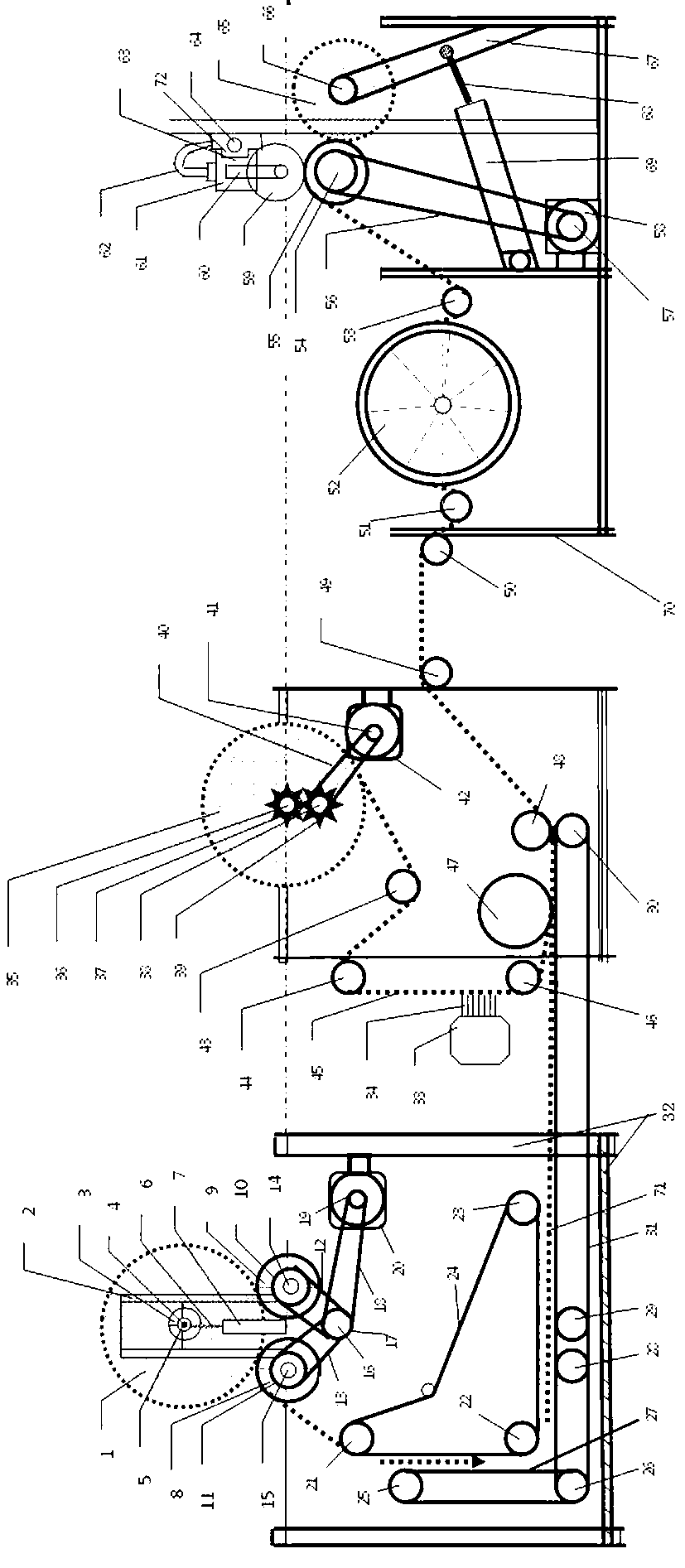

Electret, dividing and cutting machine for non-weaving cloth

InactiveCN101581032AReasonable designCompact structureSevering textilesUltrasonic/sonic fibre treatmentEngineeringNonwoven fabric

The invention discloses an electret, dividing and cutting machine for non-weaving cloth, and relates to an electret, dividing and cutting device for non-weaving cloth which is also named as non-woven cloth. The device comprises an unreeling rack, a winding roller, a cloth pressing roller, an electret tank, an electret cylinder, a pressing cloth guide roller, a cloth guide roller, a swing rack, an adjustable cloth cutting knife rest, a cloth cutter, a cloth cutter shaft, a cloth pressing roller, a cloth support roller, a cloth inspection light source, a rolling tension controller, a main transmission motor, a counterweight component, a cutter shaft motor, a stander braking controller, a quick clamping device and an air expanding shaft, wherein two ends of the winding roller are arranged on the unreeling rack, the outside of the electret cylinder is provided with the electret tank which is provided with a plurality of rows of high-pressure discharge brushes, and a stander is grounded; the cloth pressing roller and the pressing cloth guide roller are arranged on the standers at two sides of the electret cylinder respectively, the swing rack is movably arranged at two sides of the stander, the lower part of the swing rack is provided with the counterweight component, and the cloth guide roller, the cloth support roller and the cloth pressing roller are arranged at the upper part of the swing rack in turn; and the air expanding shaft is arranged on the stander at the lower part of the swing rack through a bearing block, and the swing rack at one end of the cloth pressing roller is provided with the main transmission motor.

Owner:江苏金美达新材料有限公司

Process method for preparing polyoxymethylene dimethyl ethers

ActiveCN105566077AAvoid cloggingAchieve dehydrationOrganic compound preparationCarbonyl compound separation/purificationCyclic processLiquid water

The invention discloses a process method for preparing polyoxymethylene dimethyl ethers. The method includes the steps that formaldehyde gas is cooled to 100 DEG C and below, so that vapor is removed; dehydrated gas formaldehyde is directly absorbed by a mixture of polyoxymethylene dimethyl ethers DMM1-2 and polyoxymethylene dimethyl ethers DMM6-10 of different degrees of polymerization, then a reaction is conducted, polyoxymethylene dimethyl ethers DMM 3-5 are prepared, and DMM1-2 and DMM 6-10 with the DMM 3-5 separated continuously serve as raw materials and are recycled. According to the method, formaldehyde gas generated by methanol oxidation is cooled to 100 DEG C and below, vapor is condensed into liquid water, the purpose of dehydration is achieved, and due to the fact that water in the formaldehyde is removed before being absorbed by reactant, and the situations that a polycondensation reaction occurs and device is blocked by paraformaldehyde generated by formaldehyde polycondensation are avoided; the mixture of the DMM1-2 and DMM6-10 also participates in a polymerization reaction and a depropagation reaction in the cyclic process and is finally converted to the polyoxymethylene dimethyl ethers DMM3-5 of the target degree of polymerization. The method is simple in process and easy to operate, the speed for generating the DMM3-5 is high, the conversion rate of the DMM3-5 is high, and energy consumption and equipment investment are lowered.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Preparation method of addition type liquid fluorinated silicone rubber

The invention relates to a preparation method of addition type liquid fluorinated silicone rubber. D3F, ViD4 and MM with the purity larger than 99.5% are adopted as raw materials and evenly mixed according to a certain ratio, and vinyl fluorosilicone oil is obtained; the vinyl fluorosilicone oil is used as base gum, a reinforcement agent, a cross-linking agent and a catalyst are added in the vinyl fluorosilicone oil, kneading, grinding, tabletting and other technologies are performed, and the liquid fluorinated silicone rubber (FSR) is obtained; the insulation performance, hydrophobic property, the high-temperature resistance and the like of the LSR are better than that of liquid silicone rubber (LSR) with the same technology and formula. The preparation method is short in production period, the product has the good heat tear resistance, demolding is convenient, various machining ways of mold pressing, extrusion, injection molding and the like can be achieved, and automatic production materials can be achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Method for gasifying carbonaceous organic materials and gasification furnace

ActiveCN103555370AReduce consumptionRaise the reaction temperatureGranular/pulverulent flues gasificationMetallurgyReaction temperature

The invention provides a method for gasifying carbonaceous organic materials. The method comprises a co-gasification step of simultaneously gasifying a slurry carbonaceous organic material and a powder carbonaceous organic material in a same gasification furnace according to a certain proportion, and a co-gasification fine adjustment step of adjusting the material conveying proportion of a gasifying agent, the powder carbonaceous organic material and the slurry carbonaceous organic material according to the coal gas temperature at an outlet of the gasification furnace. The invention also provides a gasification furnace used in the method for gasifying the carbonaceous organic materials, and the gasification furnace comprises a temperature feedback control module. By adopting the method and the gasification furnace provided by the invention, the consumption of water is reduced, the gasification efficiency is improved, the reaction temperature of the gasification furnace is improved at the same time, and then a number of gasification raw materials which can not be gasified by the prior art due to a high ash fusion point can be gasified, so that the selection range of coal types can be improved through the method and the gasification furnace provided by the invention. Furthermore, by adopting the gasification furnace, the injection ratio of the gasifying agent to each gasification raw material according to the temperature of the outlet coal gas can be adjusted, so that the fine adjustment of co-gasification can be realized.

Owner:ENN SCI & TECH DEV

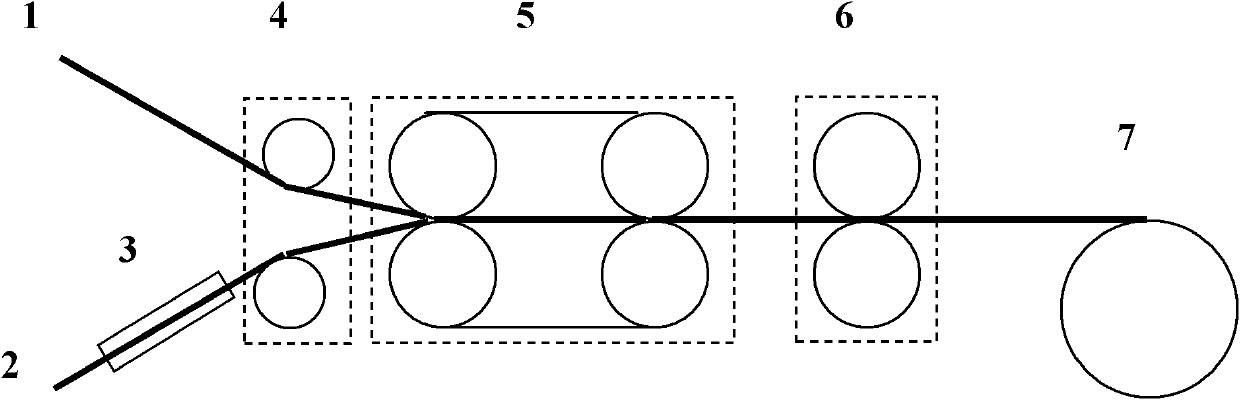

Manufacturing method of fiber cloth reinforced thermoplastic resin composite material

The invention relates to a manufacturing method of a fiber cloth reinforced thermoplastic resin composite material, comprising the following steps of: firstly, pre-treating fiber cloth; then, pre-treating a thermoplastic resin thin film; and then, tightly sticking the pre-heated fiber cloth on the thermoplastic resin thin film and overlapping; introducing into a calendering hot roller pressurizing device, melting and immersing the fiber cloth; and finally, treating the immersed fiber cloth by a cooling rolling device and then introducing into a drawing and winding device for winding and molding. According to the manufacturing method provided by the invention, the problem of immersing the fiber cloth by the thermoplastic resin is solved and various fiber cloth reinforced thermoplastic resin composite materials which are completely immersed and contain 40-80% of the fiber are prepared; and the performance of the fiber cloth reinforced thermoplastic resin composite materials is greatly improved compared with the same type of long fiber or unidirectional fiber cloth reinforced thermoplastic resin composite materials. The resin content of the fiber cloth reinforced thermoplastic resin composite material can be controlled and adjusted. According to the manufacturing method provided by the invention, the continuous production can be realized by the process, the production efficiency is greatly improved and the production cost is greatly reduced. The manufacturing method provided by the invention is low in equipment investment, simple in process, and economical and practical.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

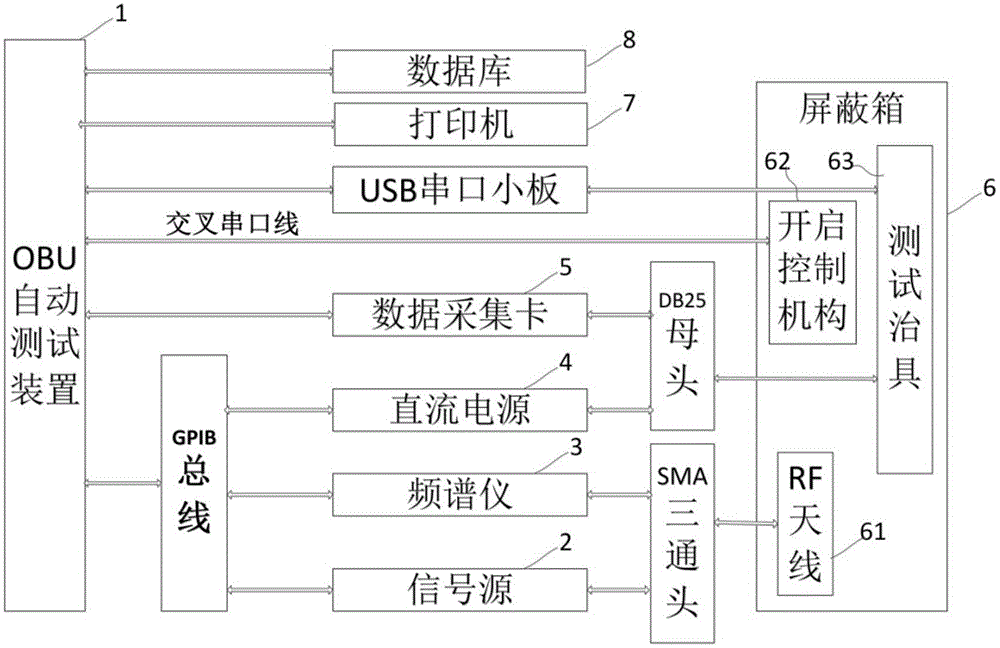

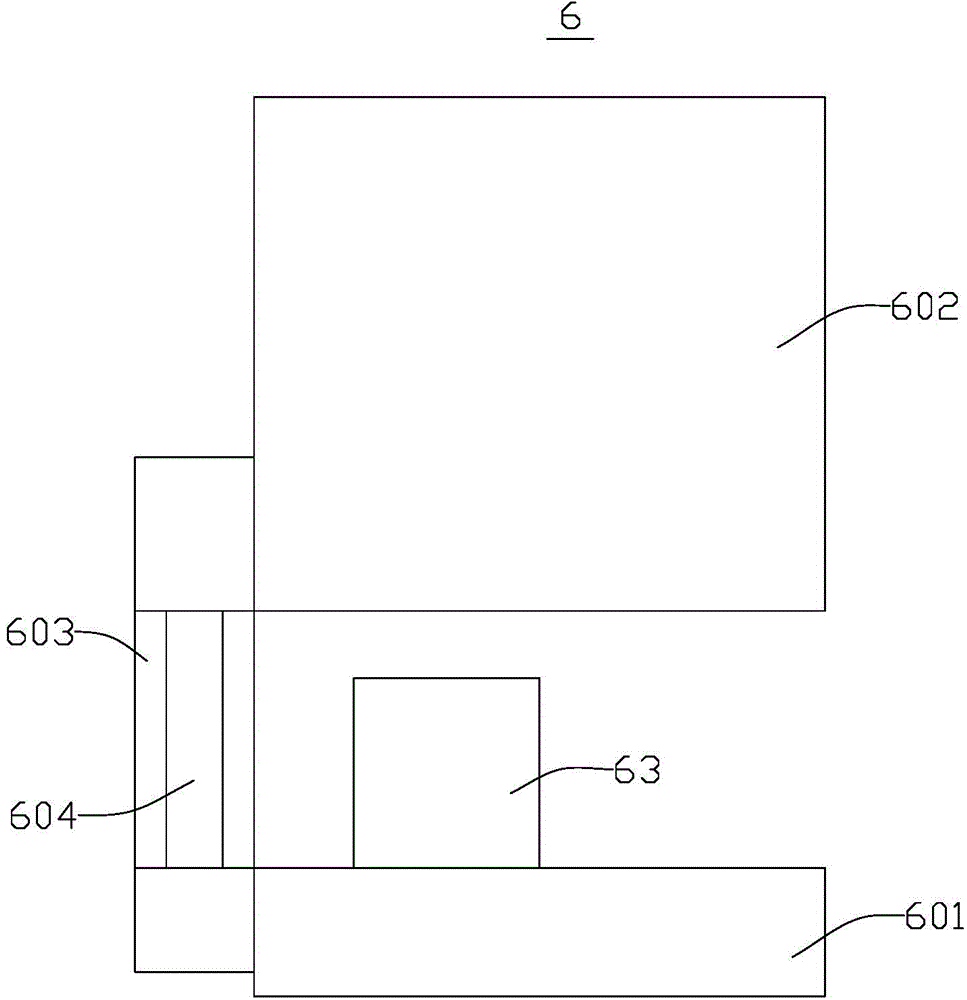

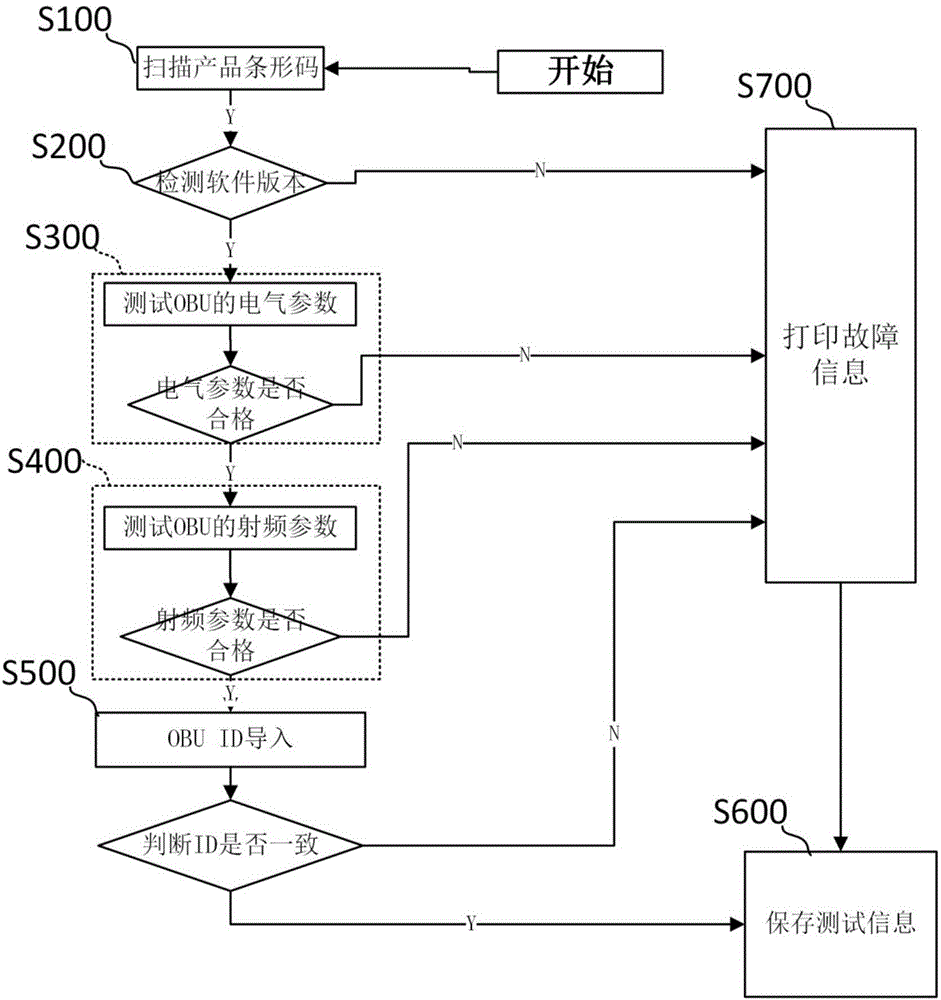

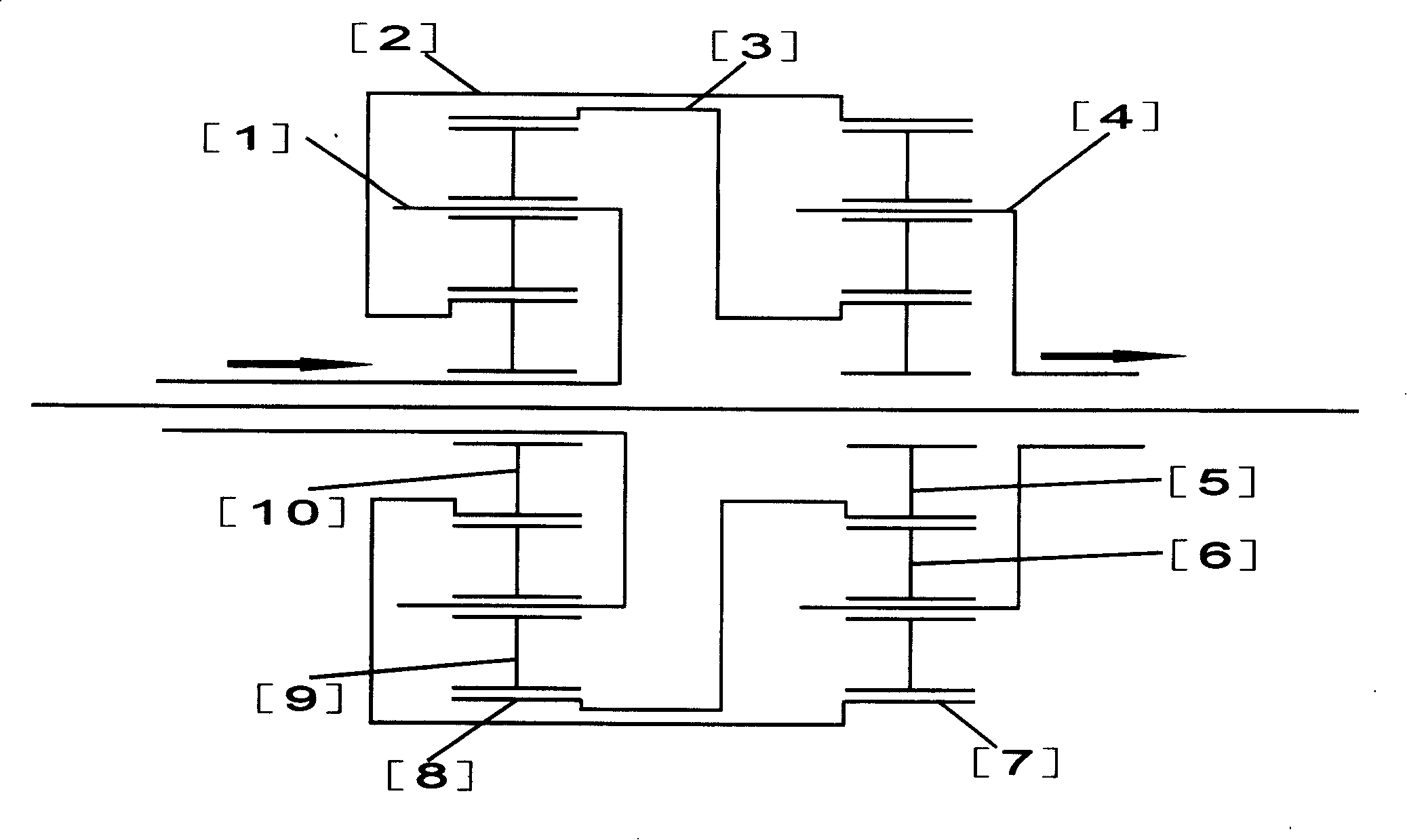

OBU automatic testing control method and device and OBU automatic testing system

ActiveCN104569676ARealize one-stop automatic testingLower performance requirementsElectrical testingFrequency spectrumData collecting

The invention relates to an OBU automatic testing control method and device and an OBU automatic testing system. The control method includes the steps that corresponding instructions are sent to a tested OBU, a data collecting unit of the testing system and / or a direct-current power source so that corresponding electrical parameters of the tested OBU can be obtained; corresponding instructions are sent to the tested OBU, a signal source of the testing system and / or a frequency spectrum measuring unit so that corresponding radio frequency parameters of the tested OBU can be obtained; a testing result is processed. The control device comprises an electrical parameter testing module, a radio frequency parameter testing module and a managing module. The testing system comprises the OBU automatic testing control device, a shielding box, a testing jig, an RF antenna, the signal source, the frequency spectrum measuring unit, the direct-current power source and the data collecting unit, wherein the testing jig and the RF antenna are arranged inside the shielding box. Program control is adopted for testing all electrical parameters and radio frequency parameters of the tested OBU, so that the various electrical parameters and the radio frequency parameters of the OBU are automatically tested in a one-stop mode.

Owner:SHENZHEN GENVICT TECH

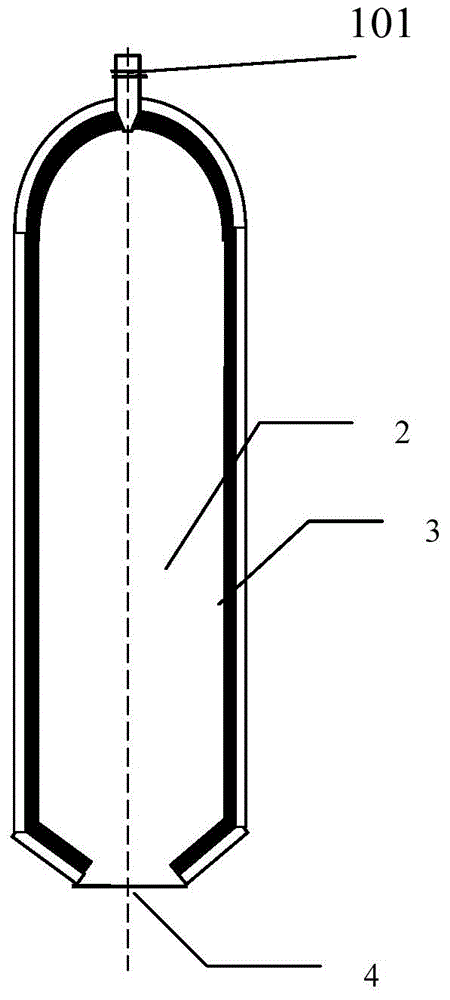

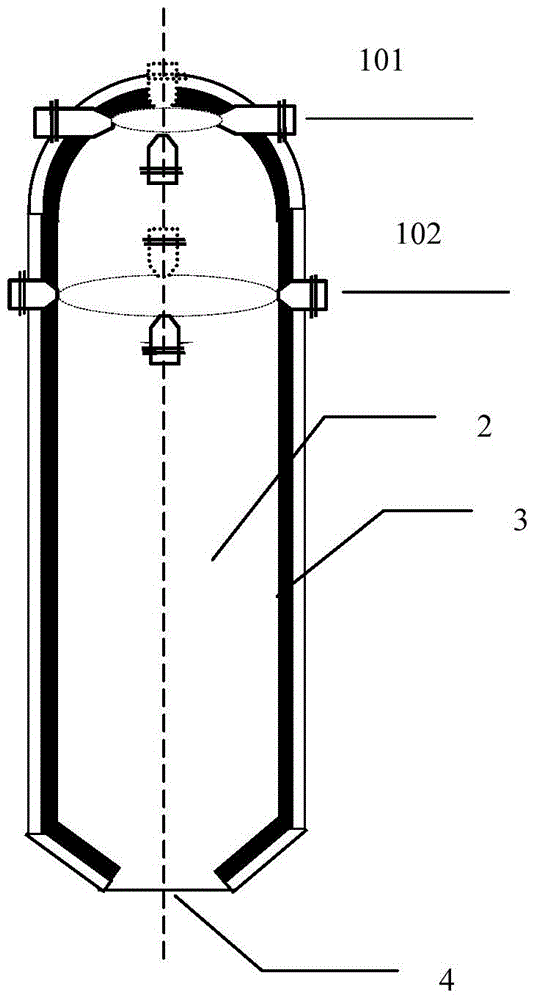

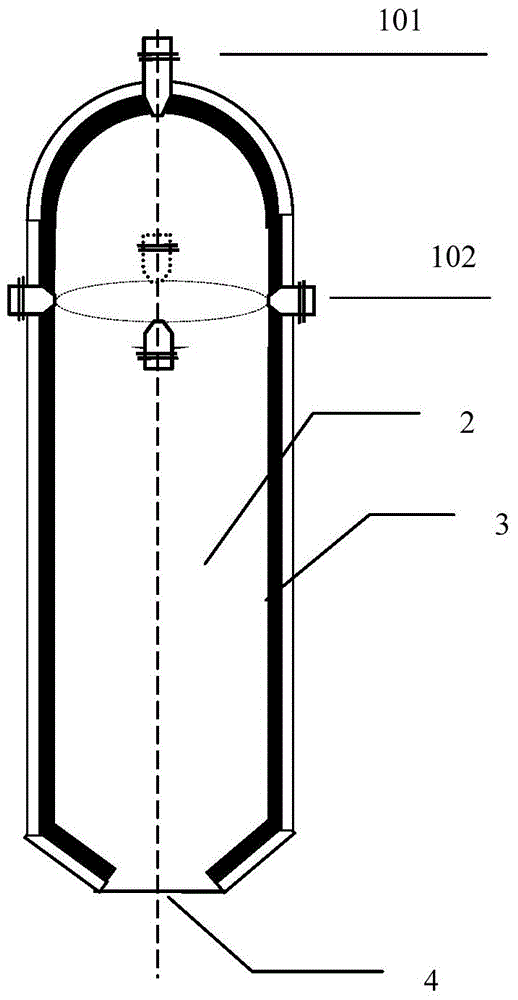

Reactor for producing acid phase with diphasic anaerobic digestion of urban biomass garbage

InactiveCN101402096AGood energy saving and environmental protection characteristicsLow consumption and efficient operationBiological substance pretreatmentsSolid waste disposalFermentationMaterials science

The invention discloses a two-phase anaerobic digestion acidogenic phase reactor for municipal biomass waste. The acidogenic phase reactor is provided with an enclosed vertical kettle formed with a thin corrosion resistant stainless steel inner barrel and a common carbon steel outer barrel. The kettle is welded with a dimple jacket outside, and is fixed with a hollow guiding barrel inside, and the insides of the dimple jacket and the hollow guiding barrel both have a heating medium so as to realize heating insulation operation under the combination control of a temperature sensing probe and a temperature controller. A multi-layer push type propeller blade with less flow resistance is used to perform mechanical stirring of the biomass waste entering the reactor, and meanwhile low consumption and high efficiency mixing of material and liquid can be realized with the forced current limit of the guiding barrel. The rotating inner stirring device and the resting kettle are mechanically sealed through a movable sealing element. The acidogenic phase reactor integrates the functions of stirring, mixture, reaction, fermentation, heating and insulation has good energy-saving and environmental-protection property, which can digest the high solid municipal biomass waste into small molecule organic acids that can be used by methanogens bacteria directly.

Owner:ZHEJIANG UNIV

Dispersed tablet of proton pump inhibitor

InactiveCN101066251ASolve quality problemsSolve the costOrganic active ingredientsDigestive systemSodium bicarbonateDuodenal ulcer

The dispersed tablet of proton pump inhibitor is used for treating gastric ulcer, duodenal ulcer, stomal ulcer and other indications. It contains at least one kind of proton pump inhibitor and at least one kind of biologically acceptable buffering agent in the weight ratio of 1 to 10-200. The proton pump inhibitor is one selected from omeprazole, S-omeprazole, pantoprazole, lansoprazole, rabeprazole, leminoprazole, tenatoprazole and their salts. The biologically acceptable buffering agent is sodium bicarbonate, sodium carbonate, magnesium carbonate, etc or their mixture.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Planetary gear multipath transmission stepless speed changer

InactiveCN101235878ARealize the task of continuously variable speed and torqueImprove transmission efficiencyToothed gearingsDifferential gearingsAutomatic transmissionGear wheel

The invention discloses a stepless transmission for planetary gear multi-path drive, which is designed according to the principle of differently distributing the moment and revolution rate because the planetary gear provides rotation and revolution to different extent under different environment and control. The invention is composed of two rotating members with planetary gear component, one set of the rotating members is used as input step and a rotating member is used to serve as a main input gear for connecting an input moment, and the other set is used as output step and a rotating member serves as a main output gear for driving rear-step driving mechanism. The middle of the other two rotating members of the input step and the output step are connected in pair by different drive ratio, thereby respectively forming two drive paths for reducing speed and increasing moment and increasing speed and reducing moment. Stepless change to driving of input moment is accomplished by forward and reverse rotation modes of the drive path for increasing speed and reducing moment, constantly variable rotating speed of the two moment driving paths and proper control to rotation speed of the two movement driving paths. The stepless transmission for planetary gear multi-path drive is a stepless transmission for gears with fixed number of teeth, has high drive efficiency and strong drive capacity, which is produced with prior art and products with low device investment, and has manufacturing cost much lower than existing stepless transmission and automatic transmission.

Owner:龙宏元

Manufacture method of capacitive touch screen

InactiveCN102096535ALow costReduce equipment investmentInput/output processes for data processingCapacitancePhotosensitizer

The invention relates to a manufacture method of a capacitive touch screen. The method is characterized by comprising the steps: 1. respectively plating conducting layers on the surface a and the surface b of a baseplate; 2. coating a photoresist on the surface a; 3. exposing and developing the photoresist on the surface a; 4. passivating the photoresist on the surface a: i.e. decomposing the photosensitizer of the photoresist in a heating way at an infrared tunnel furnace, wherein the heating temperature is within the range of 115- 150 DEG C, and the heating time is within the range of 120-3600 seconds; 5: coating a photoresist on the surface b; 6. exposing and developing the photoresist on the surface b; 7. hardening the photoresist coated on the surface b in a heating way, wherein the heating temperature is within the range of 100 DEG C to 150 DEG C, and the heating time is within the range of 120-3600 seconds; 8. simultaneously etching transparent conducting materials at two surfaces; and 9. removing the photoresists at the two surfaces. The method has the advantages that since the photoresist on the surface a is passivated, the photosensitizer of the photoresist on the surface a is decomposed, and the transparent conducting patterns at the two surfaces are simultaneously etched, therefore, the production process can be reduced, the flow time can be saved, the material cost can be reduced, and the equipment investment can be reduced.

Owner:安徽晟光科技有限公司

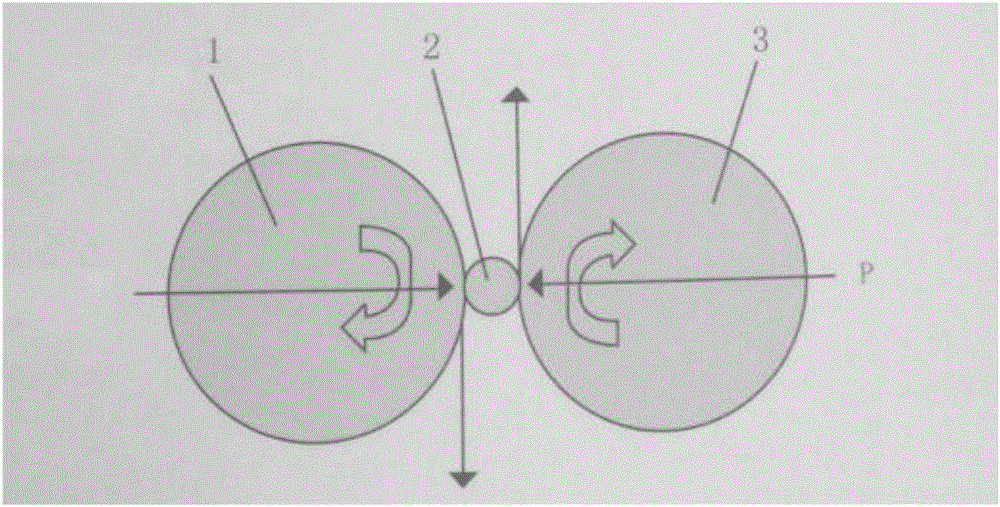

Production process of biological diesel oil

ActiveCN1952048AImprove conversion rateAvoid Catalyst SeparationBiofuelsLiquid hydrocarbon mixture productionChemistryTransformation efficiency

The invention relates to a producing process of biological diesel oil by making the animal oil (or esters), vegetable oil (or esters) and low-carbon alcohol carry out the eater exchanging reaction in striking admixer to produce the biological diesel oil. Charge the animal oil (or esters), vegetable oil (or esters) and low-carbon alcohol into the striking admixer according to the reacting ratio, control the temperature and pressure of the admixer to make the materials mix and react quickly. The invention can be used in successive production and has high transformation efficiency in malacipeous conditions. Compared to the present technologies, the invention has the advantages of simple procedures, malacipeous conditions, high transformation efficiency and less by-products; besides, the invention can be used to produce diesel oil with different kinds of animal oil (or esters) and vegetable oil (or esters).

Owner:CHINA PETROLEUM & CHEM CORP +1

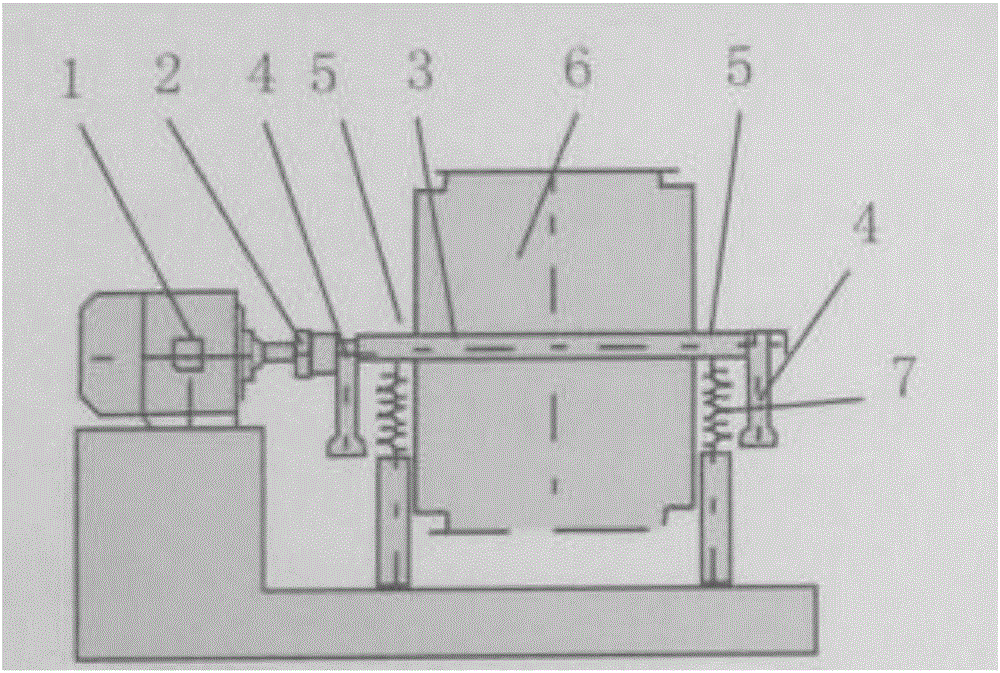

Wall-breaking and superfine grinding process and device for better ground traditional Chinese medicine decoction piece

ActiveCN105344428AImprove qualityStable and controllable qualityGrain treatmentsLiquid-crystal displayMedicine

The invention belongs to the field of medicinal material grinding and smashing equipment and method, and particularly relates to a wall-breaking and superfine vibration grinder for a better ground traditional Chinese medicine decoction piece, a traditional Chinese medicine decoction piece preparation method adopting the grinder, and the better ground traditional Chinese medicine decoction piece. The grinder comprises a motor (1), a coupler (2), a rotating spindle (3), a bearing pedestal (4), a drum holder (5), a drum (6), a supporting spring (7), a base, an excitation vibration absorber, a controller, a timer, a liquid crystal display operating panel, a central processing unit and a silencing case. By means of the specific rotating speed and the specific motion trace of the motor of the grinder, the grinder achieves the advantages of energy conservation, high efficiency and smaller sizes of smashed grains.

Owner:SHAANXI NIANQINGBAO PHARMA CO LTD

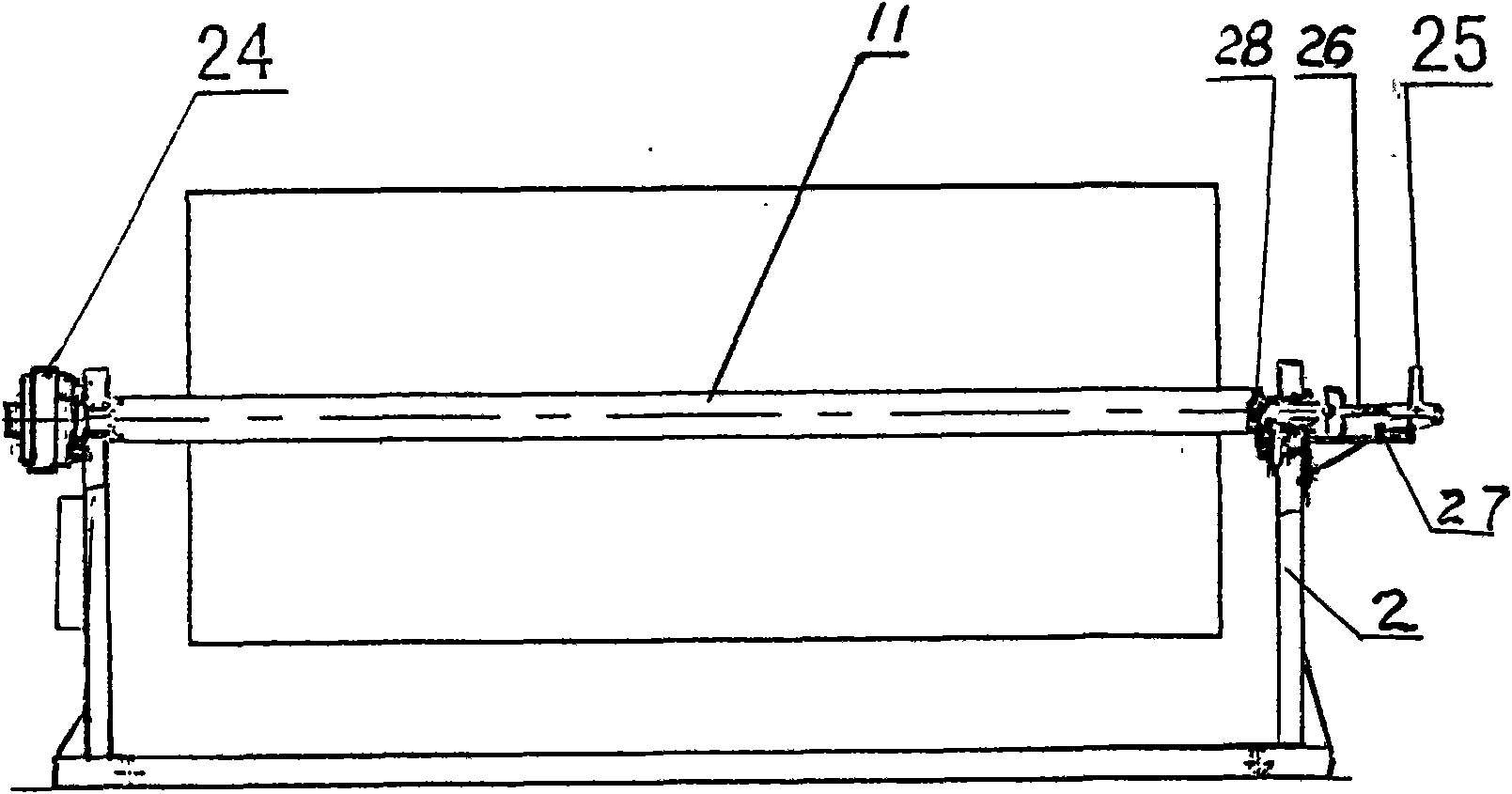

Compounding and cutting machine of hot melt adhesive

InactiveCN103009779AReasonable designCompact structureLamination ancillary operationsLaminationSprayerEngineering

The invention discloses a compounding and cutting machine of a hot melt adhesive, and relates to a compounding and cutting device of non-weaving cloth namely non-woven fabric suitable for compounding and cutting between spunbond cloth, melt-blown web and hot air cloth manufactured by a high-molecular polymer. The compounding and cutting machine comprises a frame, an unwinding part, a conveying part, a glue spray part, a compound part, a cutting part and a winding part; the unwinding part is composed of a melt-blown web unwinding mechanism and a spunbond cloth unwinding mechanism; the conveying part is composed of a melt-blown web conveying mechanism and a spunbond cloth conveying mechanism; the glue spray part comprises a glue sprayer; a glue spraying head is arranged on the glue sprayer; the compounding part comprises a cloth guide roller 2, a cloth pressing roller 2, a cloth pressing roller 3, a cloth guide roller 3, a cloth guide roller 4, a cloth pressing roller 4, a roller and a cloth pressing roller 5; the cutting part comprises a cutter holder, a pneumatic cutter, a knife resisting shaft, a knife resisting shaft driving motor, a drive chain and a drive chain wheel; and the winding part comprises a frame, a winding roller, a winding bracket, a cylinder and a pneumatic piston rod.

Owner:江苏金美达新材料有限公司

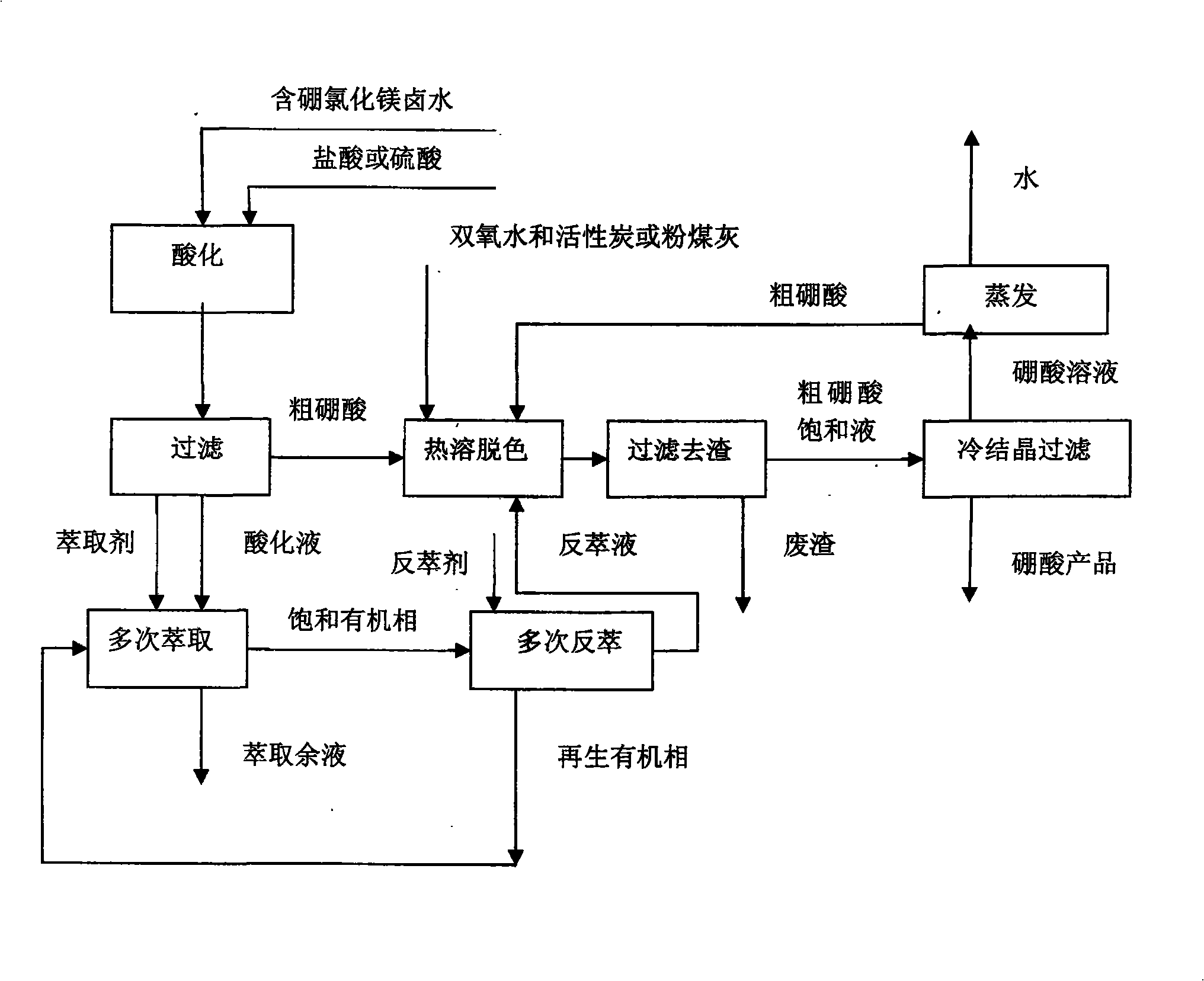

Method for extracting boric acid from boron-containing magnesium chloride solution by using an acidification-extraction method

The invention belongs to the field of inorganic chemical technology, and particularly relates to a method for extracting boric acid from boron-containing magnesium chloride solution by using an acidification-extraction method. The method is characterized in that: (a) the process flows comprise acidification, filtering, and multiple extraction, and also have four processes, namely thermosol colorization, slag removal by filtration, cold crystallization filtration, and evaporation, and then a boric acid product is obtained after the crystallization filtration; and (b) the process conditions comprises that hydrochloric acid or sulfuric acid is added into boron-containing magnesium chloride brine in acidification, thereby leading the pH-value of brine to be 0-3; the acidification temperature is room temperature; the acidification time is 10-60 minutes; the mass percent of crude boric acid: industrial hydrogen peroxide: active carbon or fly ash in thermosol colorization is 100:0.01-5:0.5-5; and the heating temperature in thermosol colorization is 80-95 DEG C. The method is fully applicable to the industrial production need of the existing salt lake brine boron extract, greatly lowers the production cost and equipment investment, and lays down solid technology basis for the large-scale industrial salt lake brine extract.

Owner:青海中信国安科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com