Patents

Literature

461results about How to "Eliminate secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

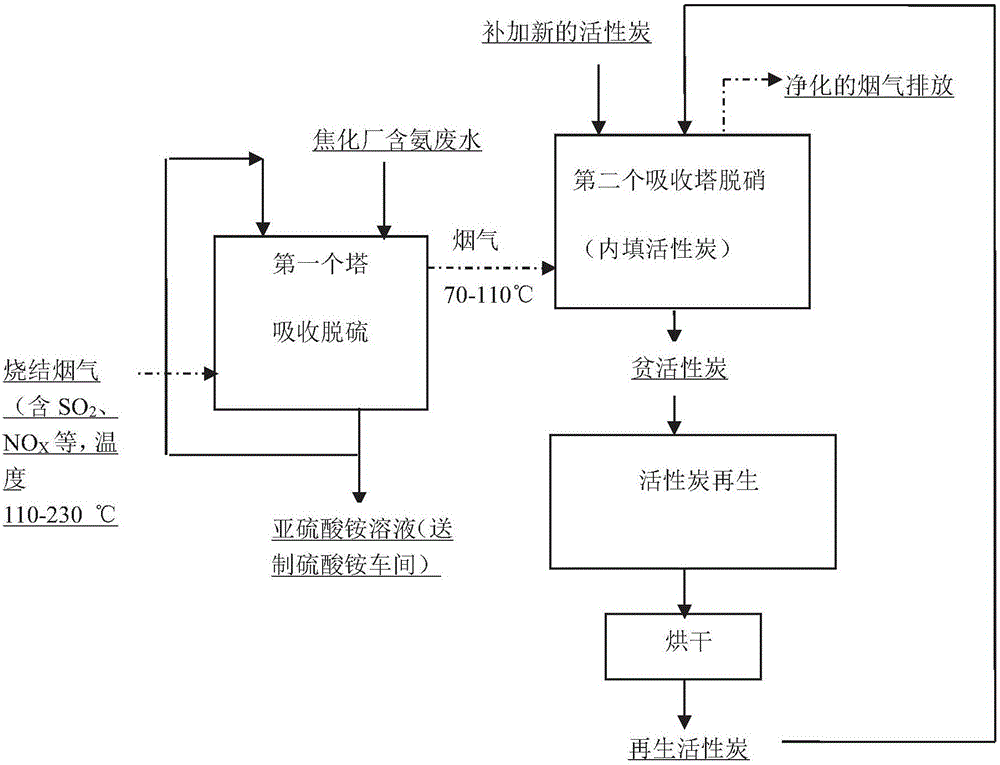

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

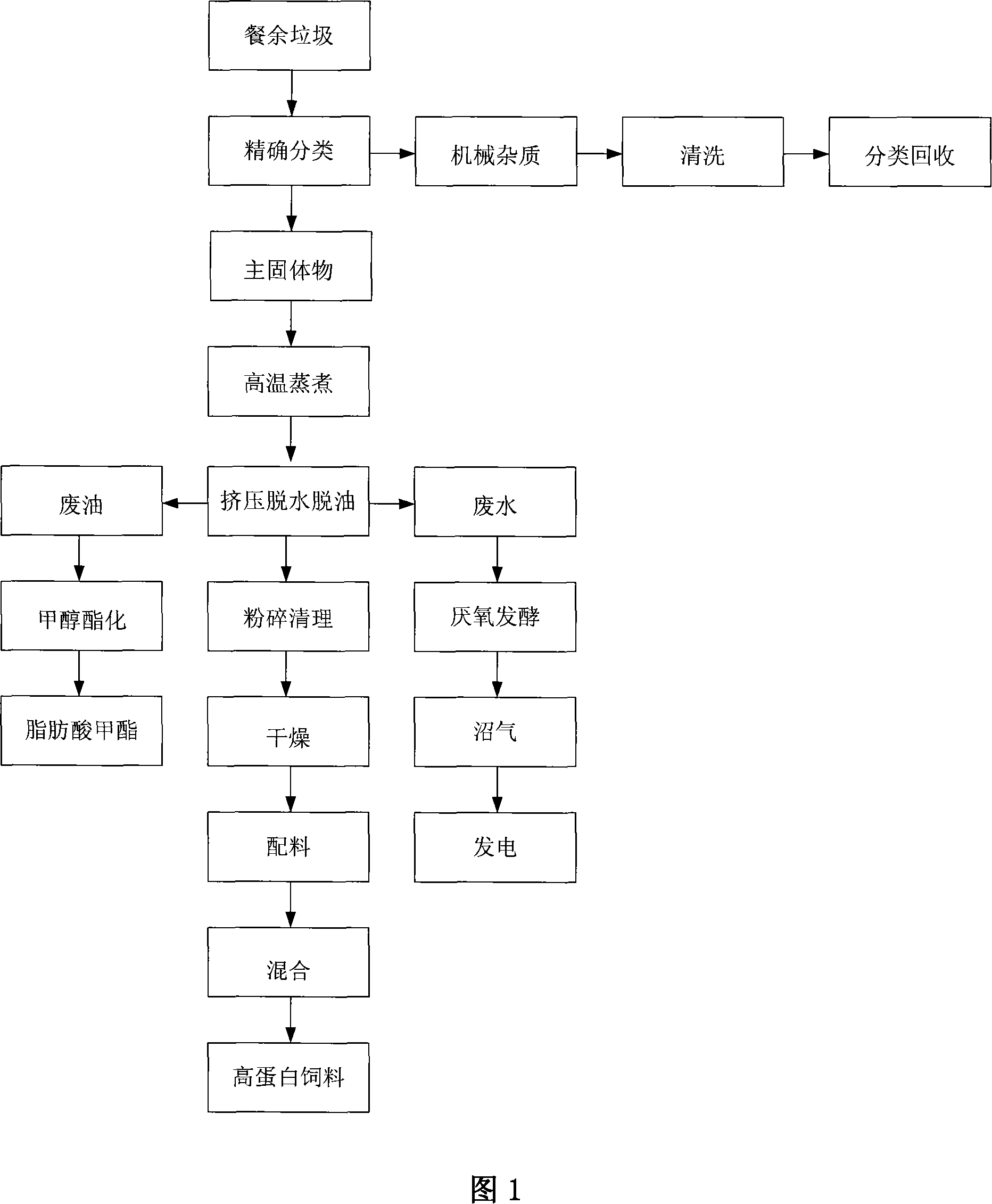

Method for comprehensive processing garbage of food and recycling to use

ActiveCN101130194AAccurate classificationRealize resource processingFood processingSolid waste disposalWaste oilFatty acid methyl ester

The invention discloses a synthetic processing recycling reusing method of residual dining rubbish, which comprises the following steps: cutting to remove package bag, waste table cloth and plastic bag; vibrating and sieving to pick chopstick; using magnet to attract bottle cap; washing the separated materials mechanically; collecting splitly; boiling main solid material under 130-150 deg. c for 30-60 min; squeezing the boiled material to separate solid from liquid; proceeding oil-water separation for the squeezed water and oil through centrifuging; doing anaerobic ferment for the waste water to produce methane; esterifying waste oil and carbinol to prepare fatty acid methyl ester. The invention eliminates secondary pollution during environmental protection and disposal, which is a reasonable, industrial, scaling, non-harmful, resourcing disposing pattern for the dining rubbish with good applying prospect.

Owner:鲁控环保(苏州)有限公司

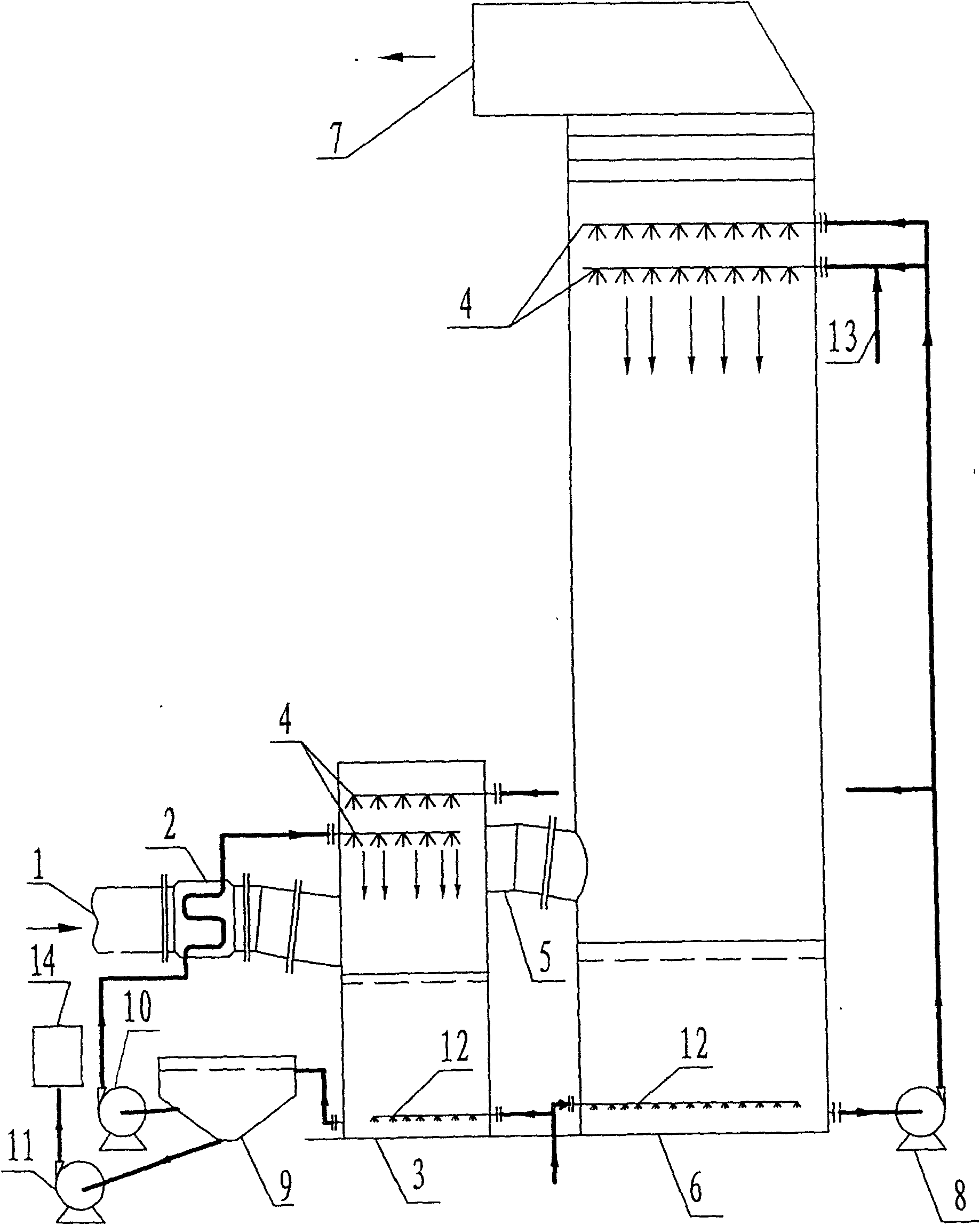

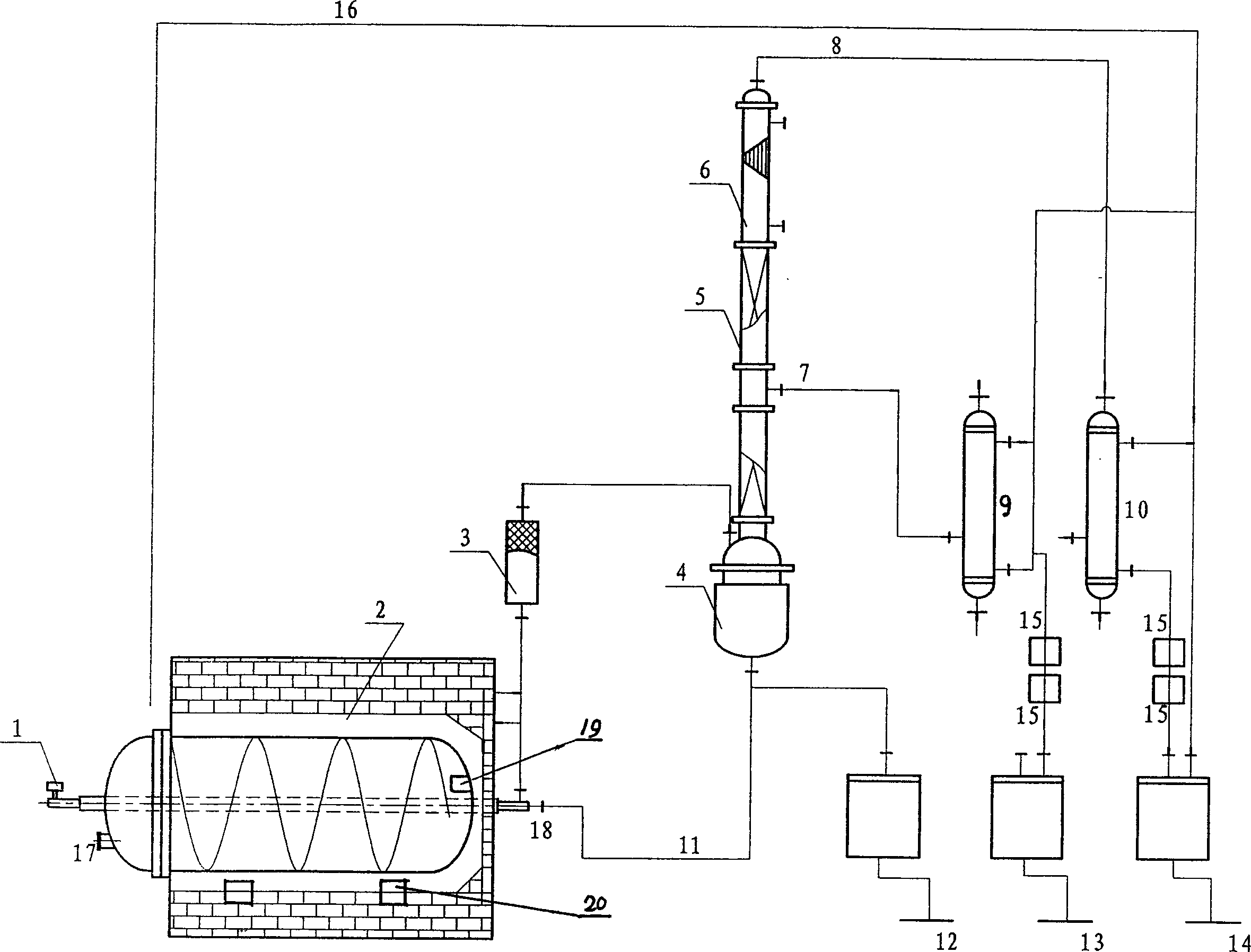

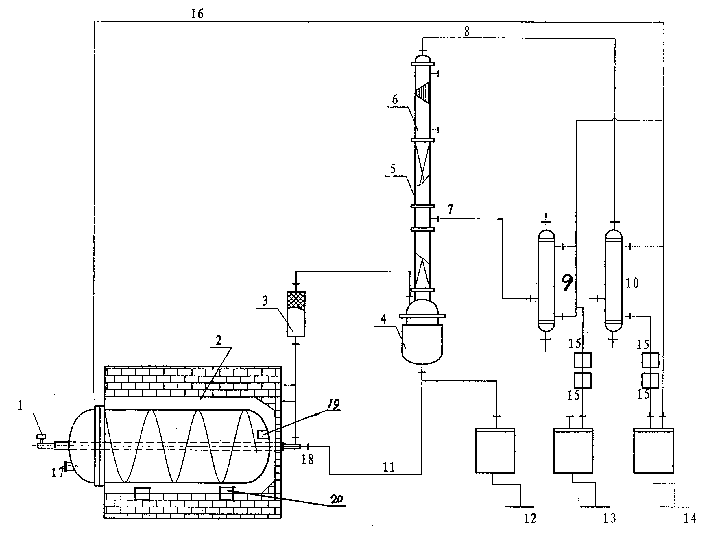

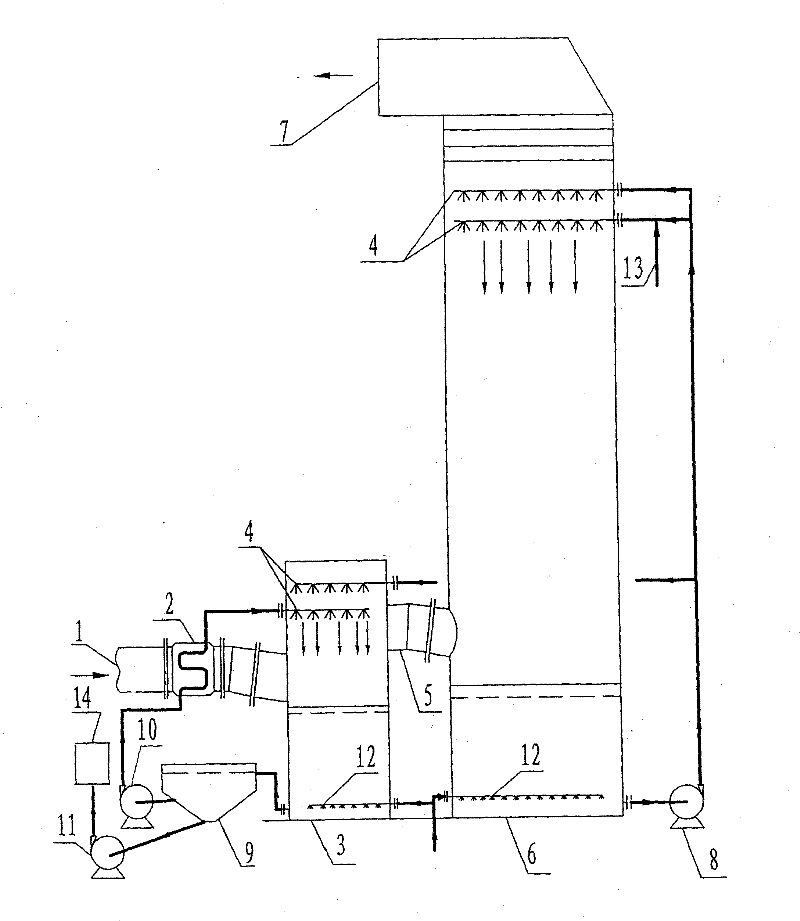

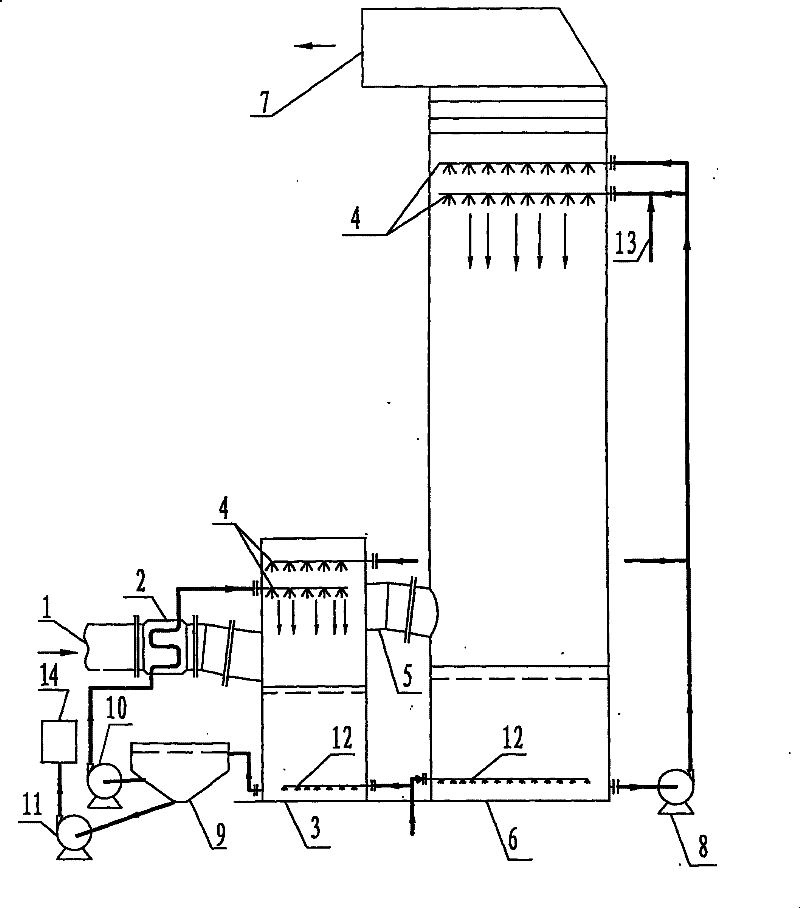

Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

ActiveCN101670231ASolve the strength problemSolve highDispersed particle separationSolution crystallizationMagmaDistributor

The invention belongs to the technical field of environment protection, and relates to a device and a process for temperature difference crystallizing ammonia process desulfurization, which is especially suitable for the ammonia process modification and newly-built desulfurization of the original calcium process desulfurization device. The device comprises a desulfurization tower, a densifying device, a gas-liquid heat exchanger, a circulating pump, a concentration circulating pump, a magma pump, a concentration crystallization tank and a drying system, wherein the desulfurization tower, the circulating pump, the magma pump and the drying system adopt the devices in the original calcium process desulfurization; the lower part of the densifying device is provided with a gas distributor, andthe upper part thereof is provided with spray heads which are arranged in 2-3 layers; spray heads in the desulfurization tower are arranged in 2-4 layers, a liquid supplementation pipe is connected with the spray heads at the lowest layer in the desulfurization tower; the concentration crystallization tank is a tank with a conical bottom part; and the upper part of the concentration crystallization tank is provided with a pipeline to be connected with the bottom of the densifying device, the middle of the concentration crystallization tank is provided with a pipeline to be connected with theconcentration circulating pump, and the bottom is provided with a pipeline to be connected with the magma pump. The invention can farthest utilize the original devices on the premise of guaranteeing the normal desulfurization efficiency, thereby saving the investment, reducing the energy consumption and eliminating the secondary pollution.

Owner:江苏世纪江南投资有限公司

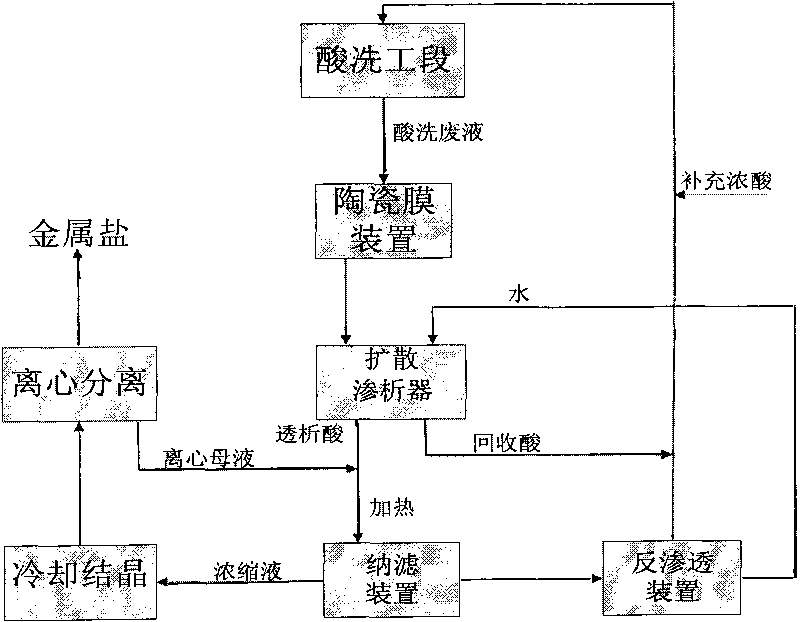

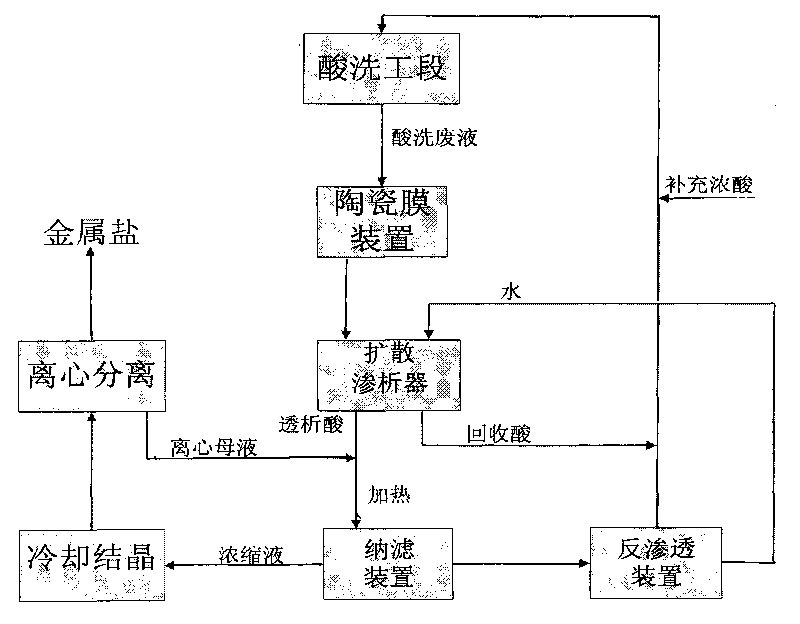

Process for recovering heavy metallic salt and inorganic acid in pickling waste liquid

ActiveCN101759250AOptimizing the integration processReduce pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisLiquid wasteIron salts

The invention relates to a process for separating and recovering heavy metallic salt and inorganic acid in pickling waste liquid by a membrane method, which comprises the following concrete steps: filtering and removing solid suspended substances in pickling waste liquid through an inorganic ceramic membrane; separating acid from salt in the ceramic membrane penetrating liquid through diffusion dialysis; and heating the dialysis liquid of a diffusion dialyzer, then introducing the dialysis liquid into a nanofiltration membrane, and cooling and crystallizing the concentrated liquid of a nanofiltration device and then centrifuging the crystal of the concentrated liquid to obtain iron salt, wherein the penetrating liquid of the nanofiltration device passes through a reverse osmosis membrane device, the concentrated liquid of the reverse osmosis device returns to a pickling section, and the water discharged from the reverse osmosis device enters a diffusion dialysis section for recycling. The invention has the characteristics that the pickling waste liquid is completely used as resources, the recovery process is simple, the recovery ratio of metallic salt and acid is high, and water is recycled. The process of the invention can be coupled with various pickling sections to realize continuous and stable automated operation, and the supplemented acid amount can be quantitatively controlled according to the acid amount consumed by the crystallized metallic salt.

Owner:NANJING UNIV OF TECH +1

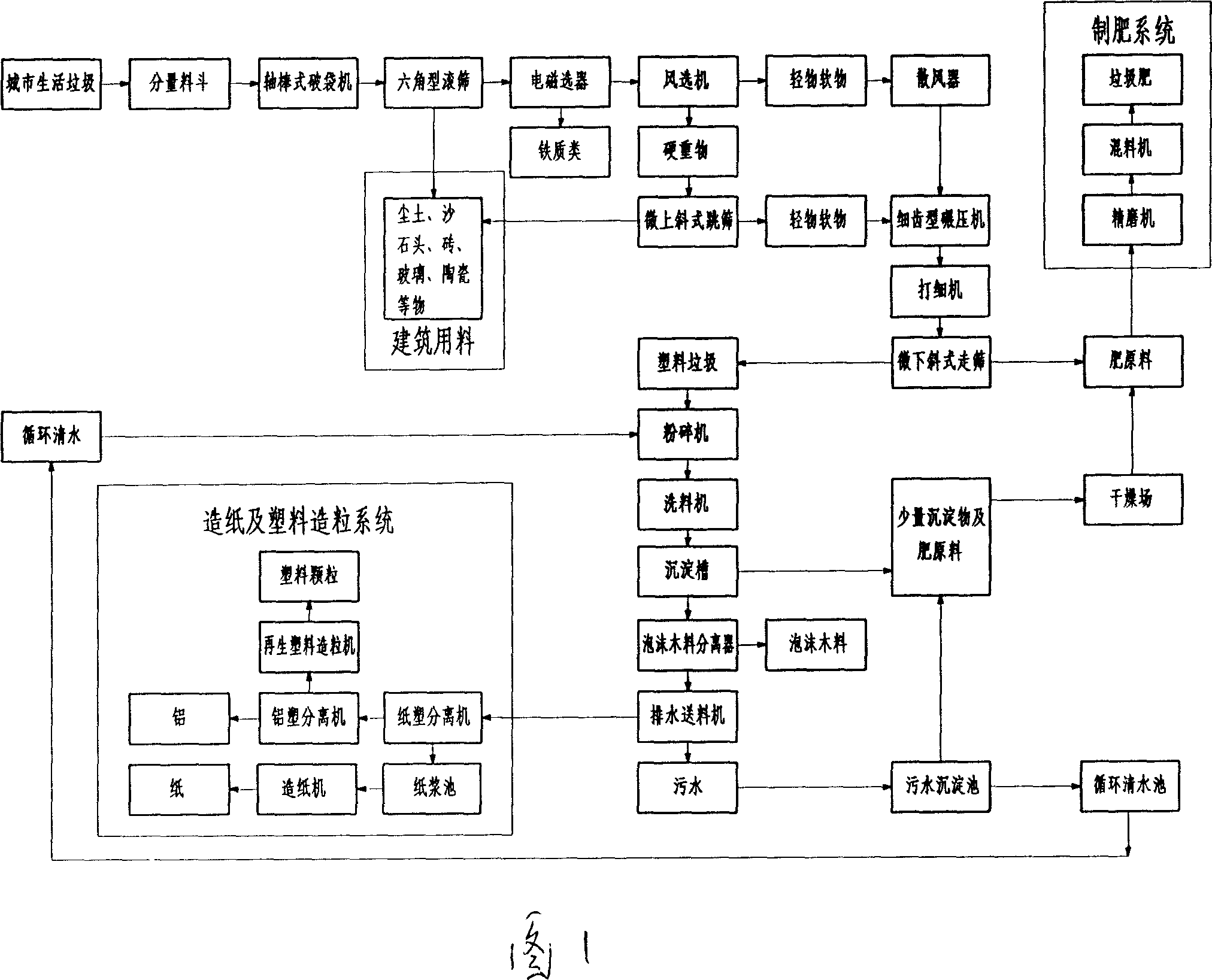

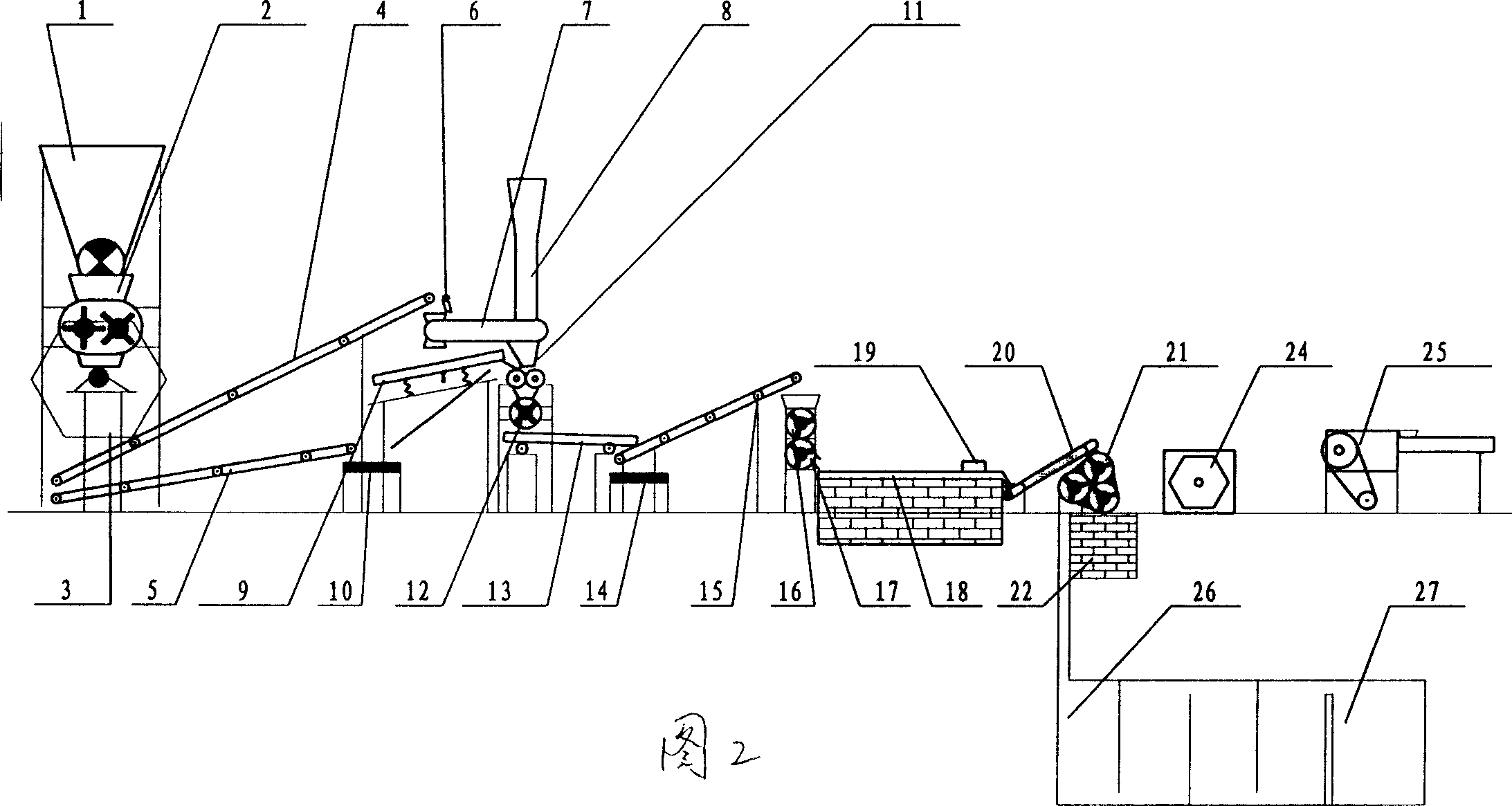

Method and apparatus for treating urban domestic refuse

InactiveCN101028627AReduce consumptionEliminate pollutionGas current separationSolid waste disposalLitterEngineering

An apparatus for reclaiming the city life garbage is composed of feeding hopper, rod-type bag breaker, hexagonal rolling sieve, conveying belt, electromagnetic separator, drum-type pneumatic separator, wind distributor, jump sieve, fine-teeth rolling machine, beater, moving sieve, pulverizer, washing unit, paper-plastics separator, Al-plastics separator, granulating unit, grinder, mixer and paper-making machine. Its method is also disclosed.

Owner:邵道德

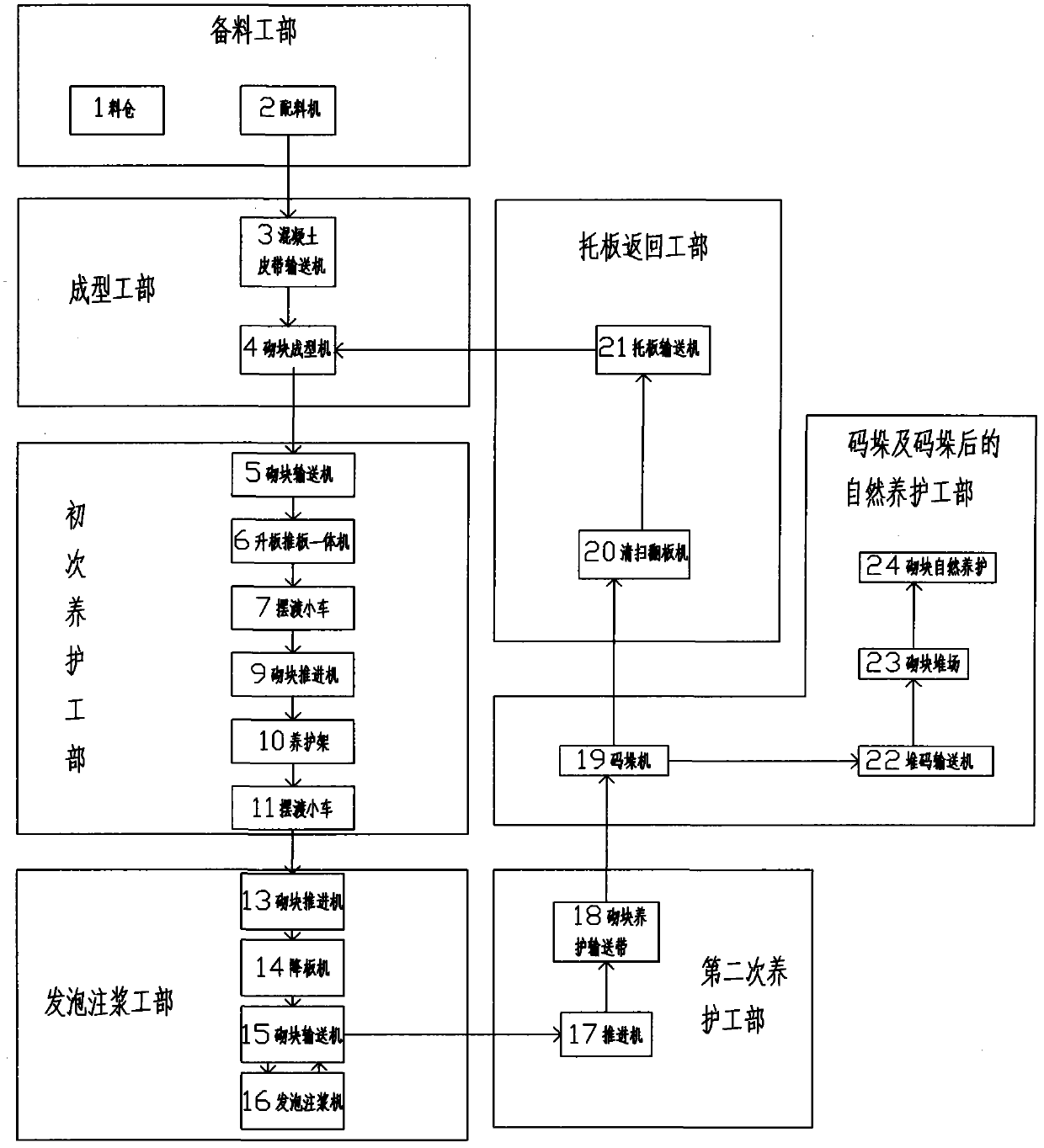

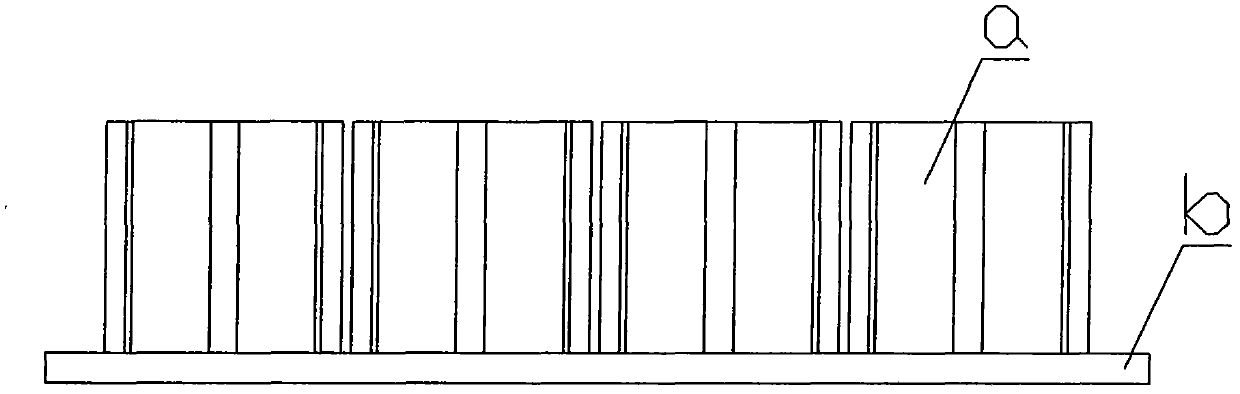

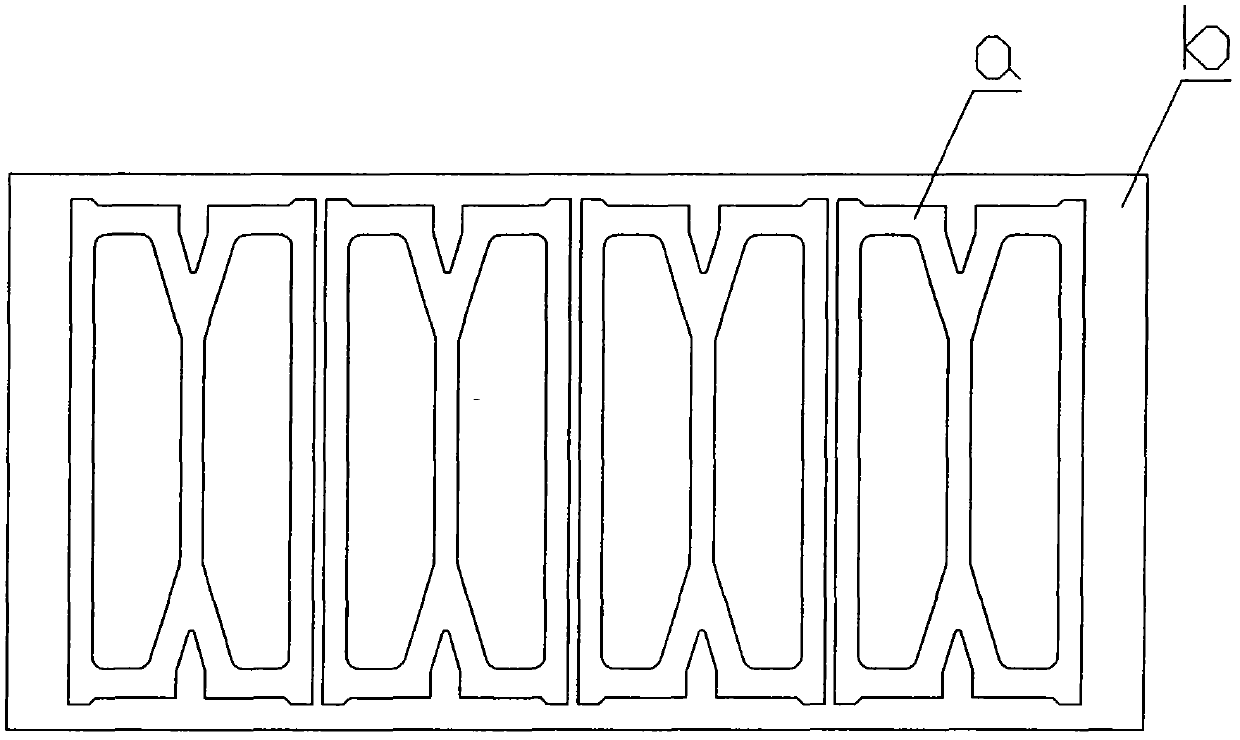

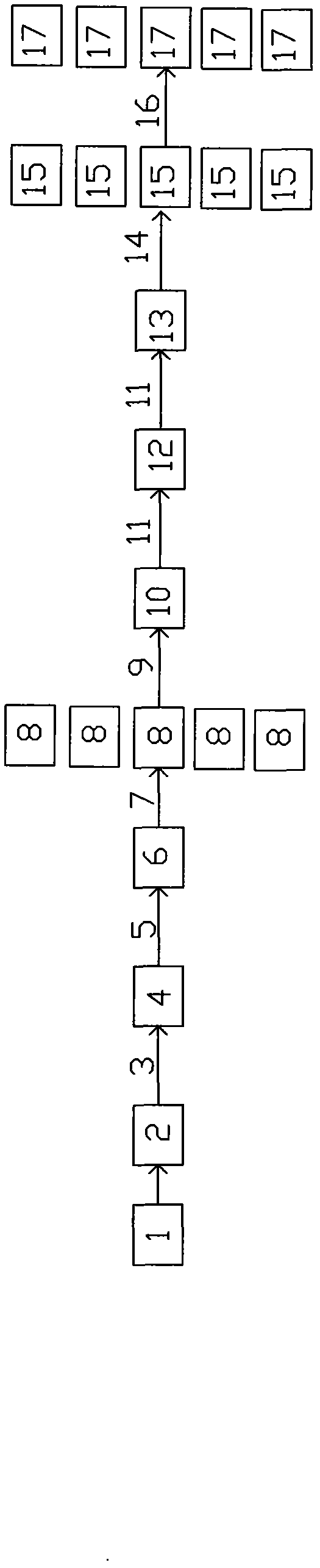

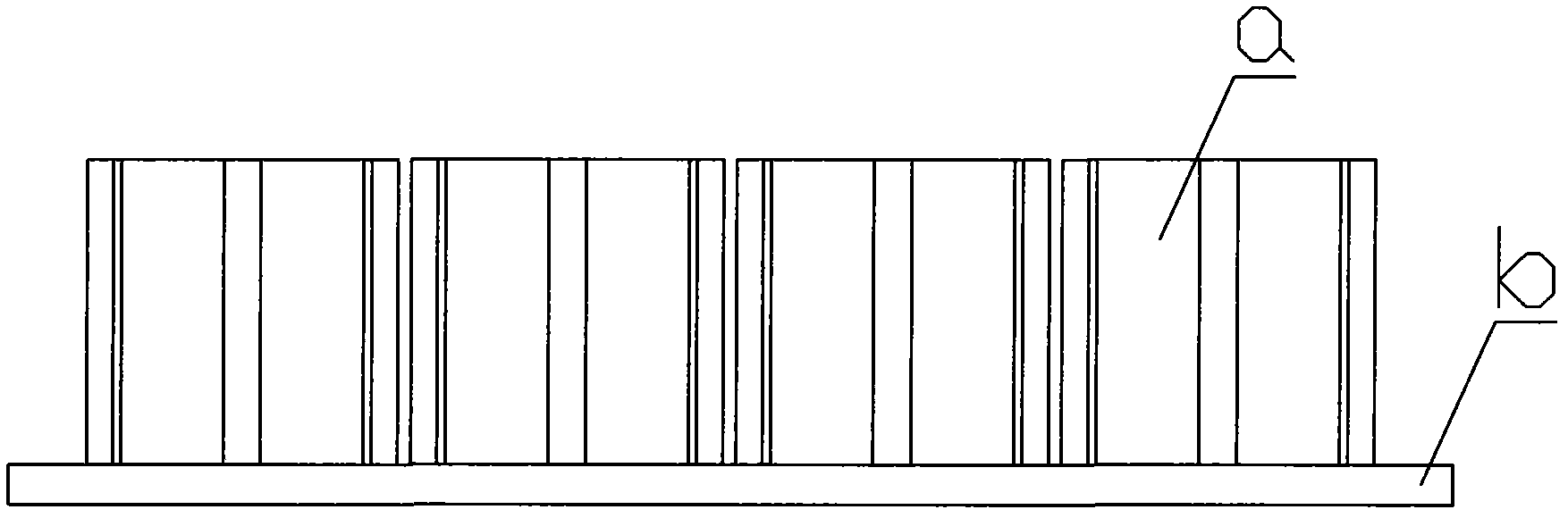

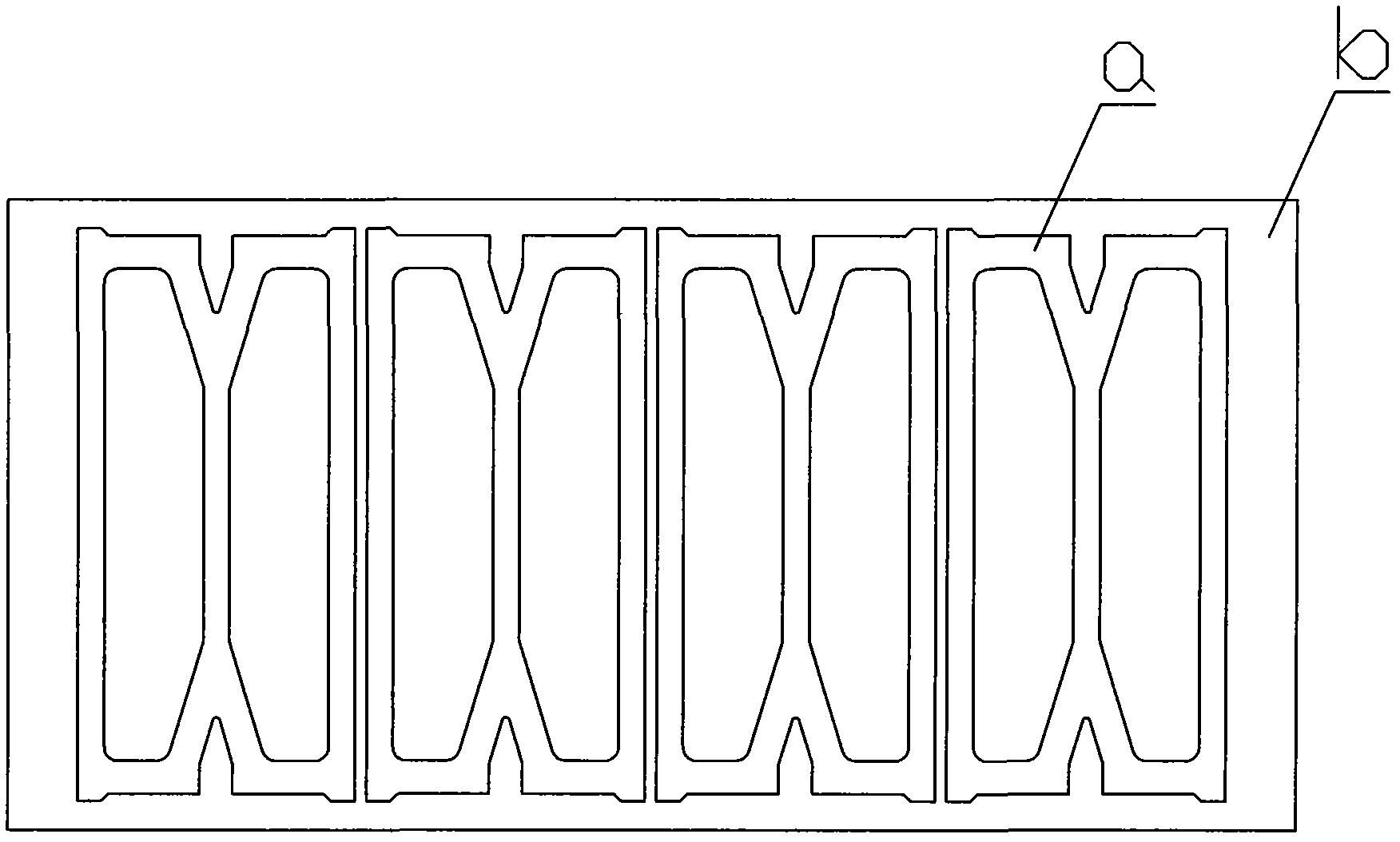

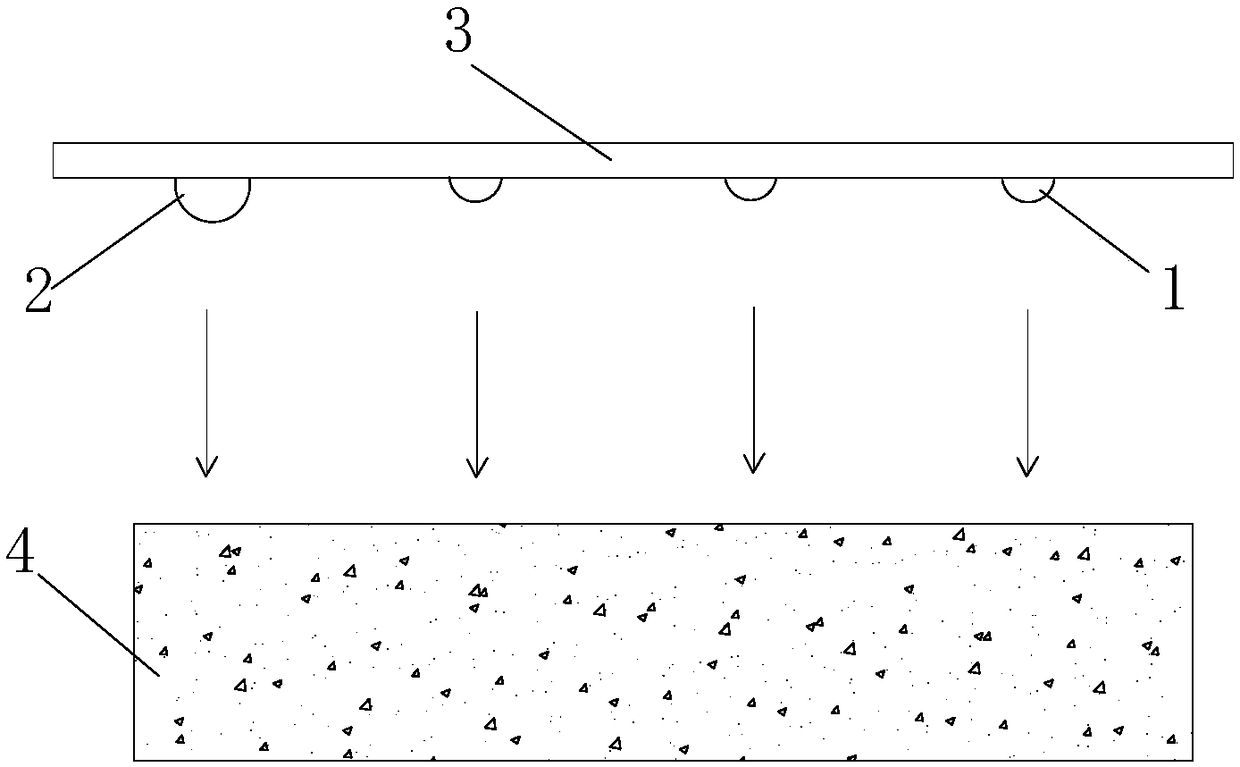

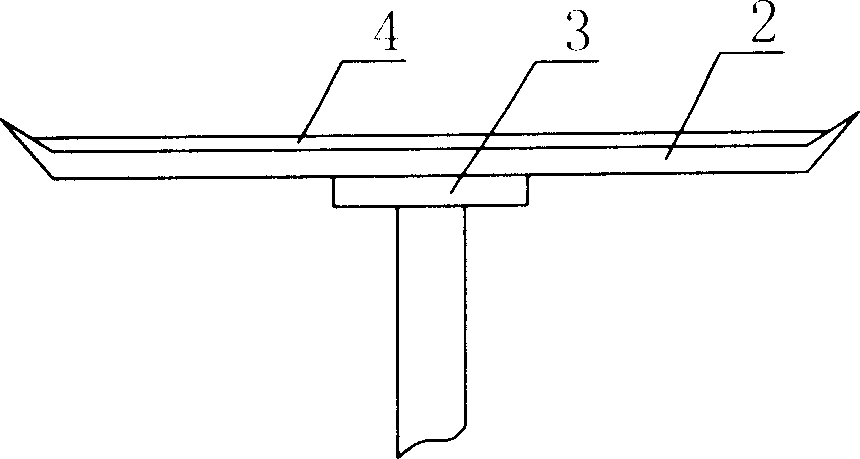

Production method of foam slurry core-filled building block capable of being quickly condensed under steam-curing-free condition

ActiveCN102632548AEliminate secondary pollutionRealize "Secondary Energy SavingConstruction materialCeramic shaping plantsMaterials preparationMaterials science

Owner:绿建科技集团新型建材高技术有限公司

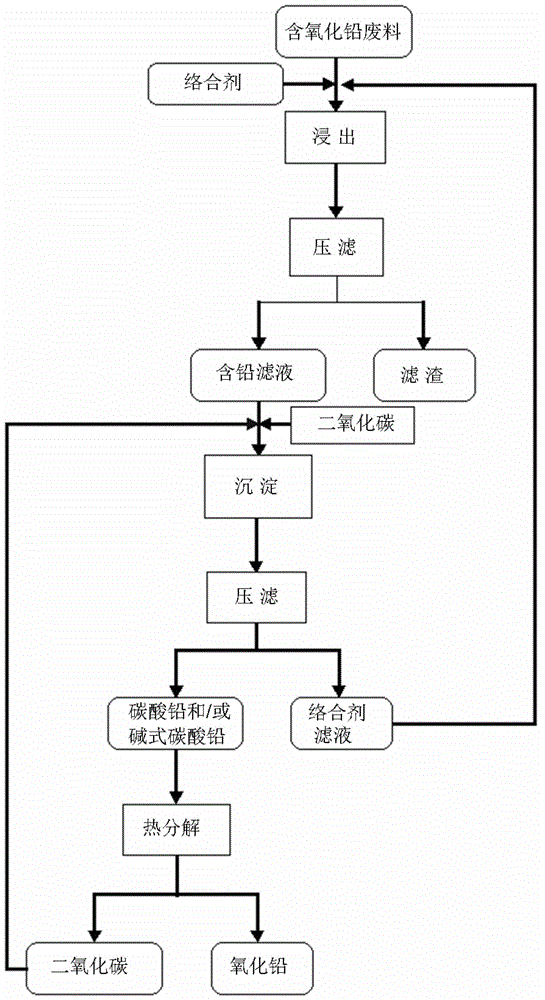

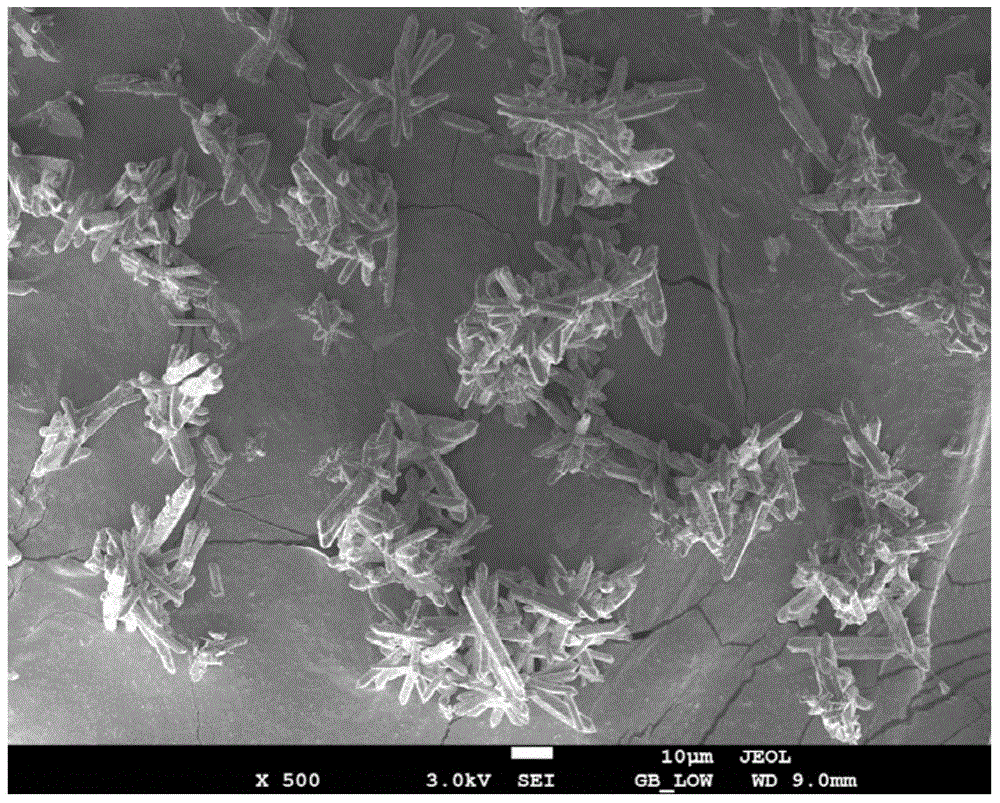

Method for recovering lead oxide from waste containing lead oxide

ActiveCN104789776AShort processEliminate secondary pollutionEnergy inputProcess efficiency improvementChemistryScrap

The present invention provides a method for recovering lead oxide from waste containing lead oxide. The method comprises: (1) contacting waste containing lead oxide and a complexing agent solution, and carrying out solid-liquid separation on the contacting mixture to obtain the lead-containing filtrate and the filter residue; (2) carrying out a reaction of the lead-containing filtrate and a precipitating agent, carrying out solid-liquid separation on the obtained reaction product to obtain a lead salt precipitate and a regenerated complexing agent filtrate, and returning the complexing agent filtrate to the dissolving process of the step (1); and (3) carrying out desalination decomposition on the lead salt precipitate to obtain PbO. With the method of the present invention, the PbO in the waste containing lead oxide can be efficiently and selectively recovered, the impurities can be effectively removed, and the high-purity PbO can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

Semi-automatic production method of foam slurry core-filling building blocks

ActiveCN102672796AEliminate secondary pollutionReduce equipment investmentCeramic shaping plantsBatch machineFully automatic

Owner:绿建科技集团新型建材高技术有限公司

Biological sediment modifier for fishpond

InactiveCN102963986AEliminate secondary pollutionEliminate self-pollution and deteriorationClimate change adaptationPisciculture and aquariaGramEnvironmental chemistry

The invention discloses a biological sediment modifier for a fishpond, belonging to the technical field of water quality purification of fishponds. The biological sediment modifier is prepared from the following raw materials in parts by weight: 3-8 parts of bacillus subtilis powder, 3-8 parts of nitrifying bacteria powder, 3-8 parts of denitrifying bacteria powder, 3-8 parts of sulfurizing bacteria powder, 10-40 parts of zeolite powder, 40-70 parts of sodium humate, and 0.5-3 parts of calcium peroxide, wherein the total content of viable bacteria is 2*10<8>-2*10<9> per gram. The biological sediment modifier disclosed by the invention can be used for absorbing the nutrition of sediment, and forming a bacterium membrane on the sediment via fermentation, breeding and bacterial community expansion, so as to cover the sediment and prevent the sediment from polluting water quality, thus benefiting the growth of aquatic animals, greatly increasing a degradation rate, and avoiding the secondary pollution of chemical degradation to a water body.

Owner:沧州旺发生物技术研究所有限公司

Thallium-containing heavy metal wastewater advanced treatment method

ActiveCN103693819AEliminate secondary pollutionLow costMultistage water/sewage treatmentPretreatment methodFiltration

The invention belongs to a thallium-containing heavy metal wastewater advanced treatment method. The method comprises the following steps: (1) pretreating thallium-containing heavy metal wastewater: adjusting the pH value of wastewater to 9.5-11.5 with alkaline, and adding a chemical thallium removing agent according to the mass ratio of the chemical thallium removing agent to thallium of (0.5-1.5):1; (2) medicating according to the mass ratio of the chemical thallium removing agent to wastewater after the reaction in step (1) for 15-30 minutes, and carrying out mixed reaction for 15-30 minutes; (3) adding liquid alkaline into the solution obtained from the step (2), adjusting the pH value to 11.0-11.5, reacting for 10-20 minutes, adding 5-50g / m<3> of flocculating agents, reacting for 10-20 minutes, carrying out solid-liquid separation by oblique plate deposition or plate frame press filtration, standing for 1-2 hours, and discharging or recycling supernate. The thallium contained heavy metal wastewater treatment method is simple in process, has no secondary pollution, is high in treatment efficiency, runs stably and low in cost, and has very high practicability.

Owner:CENT SOUTH UNIV +1

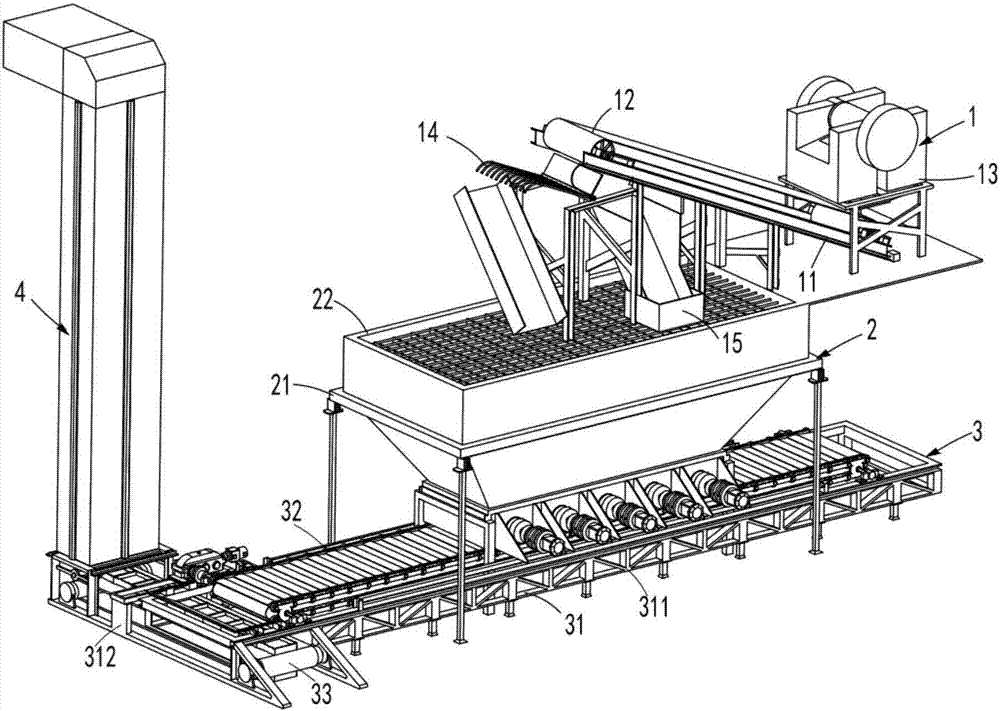

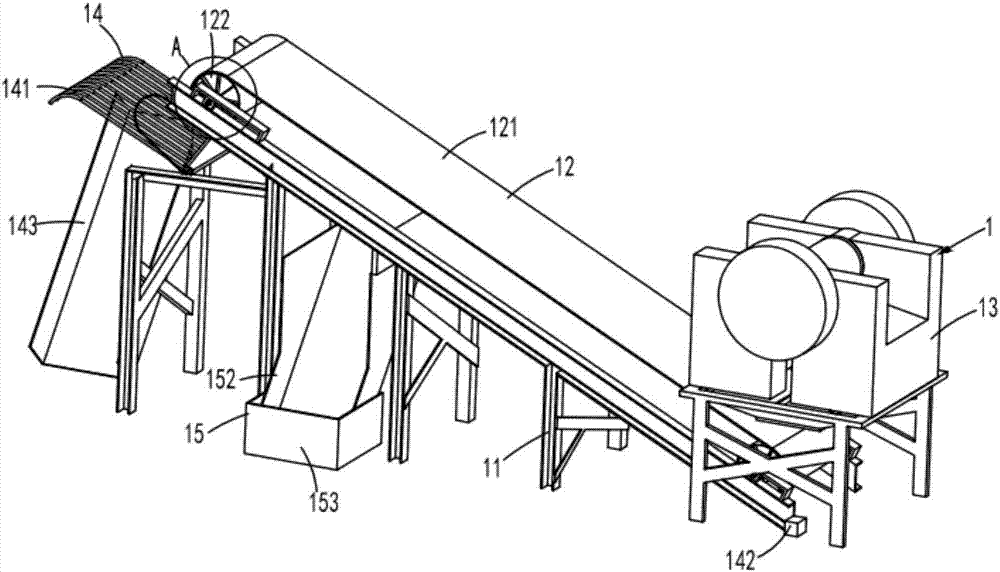

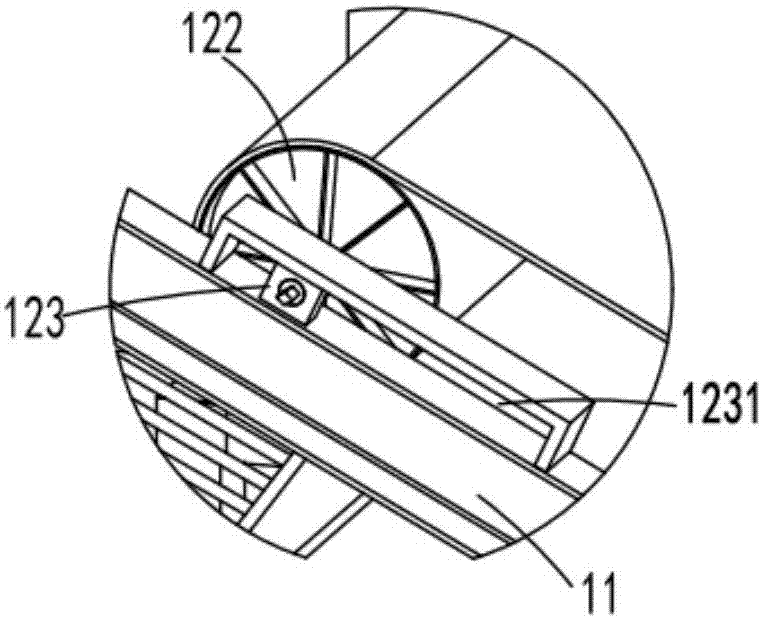

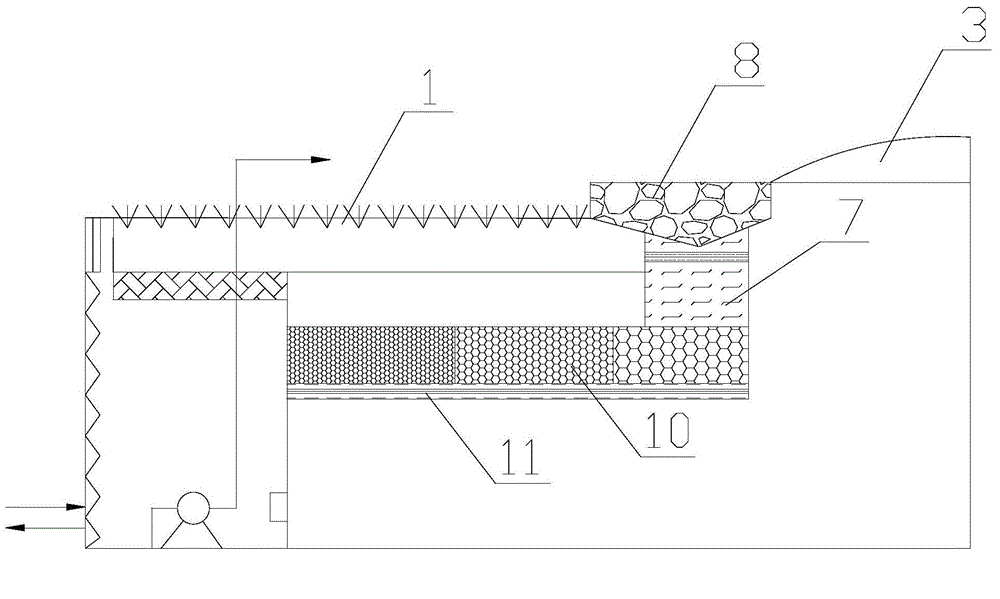

Heavy metal pollution soil treatment system and process

InactiveCN107309256ASimple structureClean thoroughlyContaminated soil reclamationMagnetic separationSoil treatmentPollution soil

The invention discloses and provides a heavy metal polluted soil treatment system and process, aiming to solve the screening problem of magnetic heavy metal pollutants in polluted soil, which includes a first crushing and screening mechanism, a second crushing and screening mechanism, and a transfer and conveying mechanism And the lifting mechanism, through the oblique lifting and throwing of the heavy metal contaminated soil after the initial crushing to the screening rake with magnetic adsorption, the secondary crushing of the heavy metal contaminated soil is carried out by the screening rake, and the heavy metal contaminated soil is sucked out by magnetic adsorption The magnetic heavy metals contained in it improve the quality and efficiency of heavy metal pollutants in the subsequent treatment process.

Owner:浙江明境环保科技集团有限公司

Traditional Chinese medicine aldehyde-removing air purifying agent and preparation method thereof

ActiveCN103721288AEliminate secondary pollutionEasy to useBiocideDispersed particle separationGynostemmaHoneysuckle

The invention discloses a traditional Chinese medicine aldehyde-removing air purifying agent and a preparation method thereof. The air purifying agent is prepared from the following raw materials in parts by weight: 15-20 parts of holy basil, 10-15 parts of fiveleaf gynostemma herb, 10-15 parts of mint, 16-22 parts of folium eucalypti, 12-18 parts of cortex cinnamomi, 5-10 parts of fernleaf hedge bamboo, 8-14 parts of ficus benjamina, 15-20 parts of pomegranate leaves, 10-15 parts of green bonnie flowers, 6-12 parts of marigold, 13-19 parts of tuberose, 10-15 parts of litsea cubeba, 5-10 parts of mangnolia officinalis, 11-17 parts of radix dichroa, and 8-14 parts of honeysuckle. The aldehyde-removing air purifying agent is prepared from pure plants, can enable indoor toxic dust to be quickly precipitated, and can quickly remove methanal and other residual hazardous substances indoors or in furniture, the removal ratio reaches over 96%, and the secondary pollution is avoided; in addition, the harmful bacteria in indoor air can be inhibited and killed, and the pungent peculiar smell can be quickly removed; the air purifying agent contains no chemical preparation, is free from corrosion, non-toxic, free from contamination, convenient to use, safe and environmental-friendly, and causes no toxic or side effects on human bodies.

Owner:SUZHOU JUNCHUANG JIAMEI ENVIRONMENTAL PROTECTION SCI & TECH

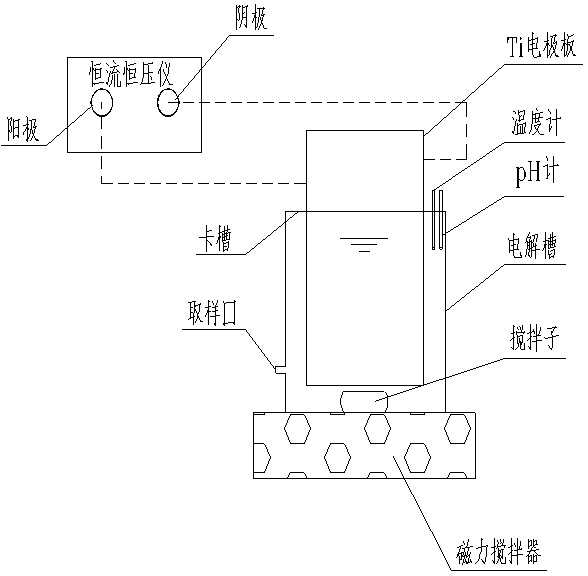

Method for removing harmful algae in water body by adopting electro-Fenton

InactiveCN101962216AStable in natureNo electrocoagulationWater/sewage treatment by oxidationFerric hydroxideElectrolysis

The invention belongs to the technical field of environmental protection and in particular relates to a method for removing harmful algae pollution in water body by adopting electro-Fenton. Hydrogen peroxide and ferrous ions in a reactor react to generate hydroxyl radicals, at the same time, the ferrous ions are regenerated from iron ions and iron hydroxide in the cathode region for electrolysis through reduction, thus continuously generating vast hydroxyl radicals, efficiently inactivating algae cells, simultaneously rapidly carrying out oxidation degradation on the microcystins and effectively avoiding secondary pollution. The body part of the reactor comprises a power source, electrodes, an electrolytic bath and a magnetic stirrer. After the algae liquid to be treated is introduced to the electrolytic bath, the magnetic stirrer at the bottom of the electrolytic bath is used for ensuring the algae liquid to be uniformly distributed in the whole reactor. Under the set process parameters, the method can realize rapid inactivation of the harmful algae and simultaneously realize efficient degradation of the microcystins.

Owner:FUDAN UNIV

Method for recovering rare earth from catalyst waste residues

InactiveCN102242270ARealize resourcesEliminate secondary pollutionProcess efficiency improvementFiltrationRare earth

The invention relates to a method for recovering rare earth from catalyst waste residues. The method, which can be adopted to reach the purpose of waste utilization, comprises the following steps of: carrying out a reaction between catalyst waste residues containing rare earth and acid, dissolving rare earth and some metal ions, followed by filtration separation, separating rare earth from the filtrate by the solvent extraction separation method or the oxalic acid precipitation method, removing aluminium by the form of aluminium salt, mixing the extractant and the filtered solid substance, followed by a reaction among the mixture, the aluminium salt and an alkaline substance, aging, carrying out filtration washing and drying to obtain a porous material with the specific surface area being not less than 150m<2> / g, the pore volume being not less than 0.2ml / g and the most probable aperture of meso pores being 4-20nm.

Owner:于向真

Oil refining procss from waste plastic and equipment

The present invention discloses an oil refining process and equipment with waste plastic. Inside an industrial furnace painted with far infrared material to increase radiation heat by 20 %, there are the first or horizontal catalytic cracking reactor and hating space around it. The catalytically cracking produced oil gas is deeply cracked and recombined in the second catalytic cracking reactor and fractionized, condensed and oil-water separated. The separated gasoline and diesel oil are fed to storage tanks separately, heavy oil is returned to the furnace for refining for the second time, the light hydrocarbon gas is backed to the furnace for burning, and the coke slag produced in catalytic cracking is exhausted via spiral slag drainer. The present invention can change waste plastic into qualified gasoline or diesel oil product.

Owner:吴克斌

Rainwater collecting and recycling system for urban green land and plaza

ActiveCN104480994AImplement automatic poolingAchieve recyclingWater/sewage treatment by irradiationSewerage structuresWater resourcesEngineering

The invention discloses a rainwater collecting and recycling system for an urban green land and a plaza; the rainwater collecting and recycling system comprises the green land, roads around the green land and the plaza; the green land is of a sunken structure which is lower than the roads and the plaza; the plaza is of a dome structure which is slightly lower at four sides; and the roads are of arched structures which are higher at the middle and slightly lower at two sides; rainwater on the roads and the plaza enters a water collecting well which is connected with a covered filtering channel; the water drain end of the covered filtering channel is connected with an underground impounding reservoir; a concrete cover plate layer is arranged at the upper part of the impounding reservoir; the green land is arranged at the upper part of the concrete cover plate layer; a water pump is arranged in the underground impounding reservoir; and the water outlet of the water pump is connected with a green land irrigation spray head. The rainwater collecting and recycling system for the urban green land and the plaza relieves the pressures on sewage disposal, municipal water supplying and shortage of urban water sources, realizes rainwater recovery and gives full play to the ideas of energy conservation, emission reduction and sustainable development.

Owner:广东银湖湾建设科技有限公司

Biochar soil remediation agent and preparation method thereof

InactiveCN108640791AImprove organic matterIncrease microbial contentSuperphosphatesAlkali orthophosphate fertiliserMicroorganismSoil remediation

The invention discloses a biochar soil remediation agent and a preparation method thereof. The biochar soil remediation agent is prepared from titanium dioxide supported biochar, compost materials, compound fertilizer, a biological bacteria solution, clay, a binder and microelements; the preparation method of the biochar soil remediation agent comprises steps as follows: preparation of titanium dioxide supported biochar, preparation of the compost materials, preparation of the biological bacteria solution, preparation of the clay, preparation of a mixed material coated with biochar, pelletizing and drying. The preparation process is environmentally friendly and simple to operate, the raw materials are widely sourced, the prepared soil remediation agent not only can adsorb and degrade pollutants in soil, but also increases content of organic matter and microorganisms in the soil, and accordingly, economic benefit and environmental benefit are remarkably increased.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

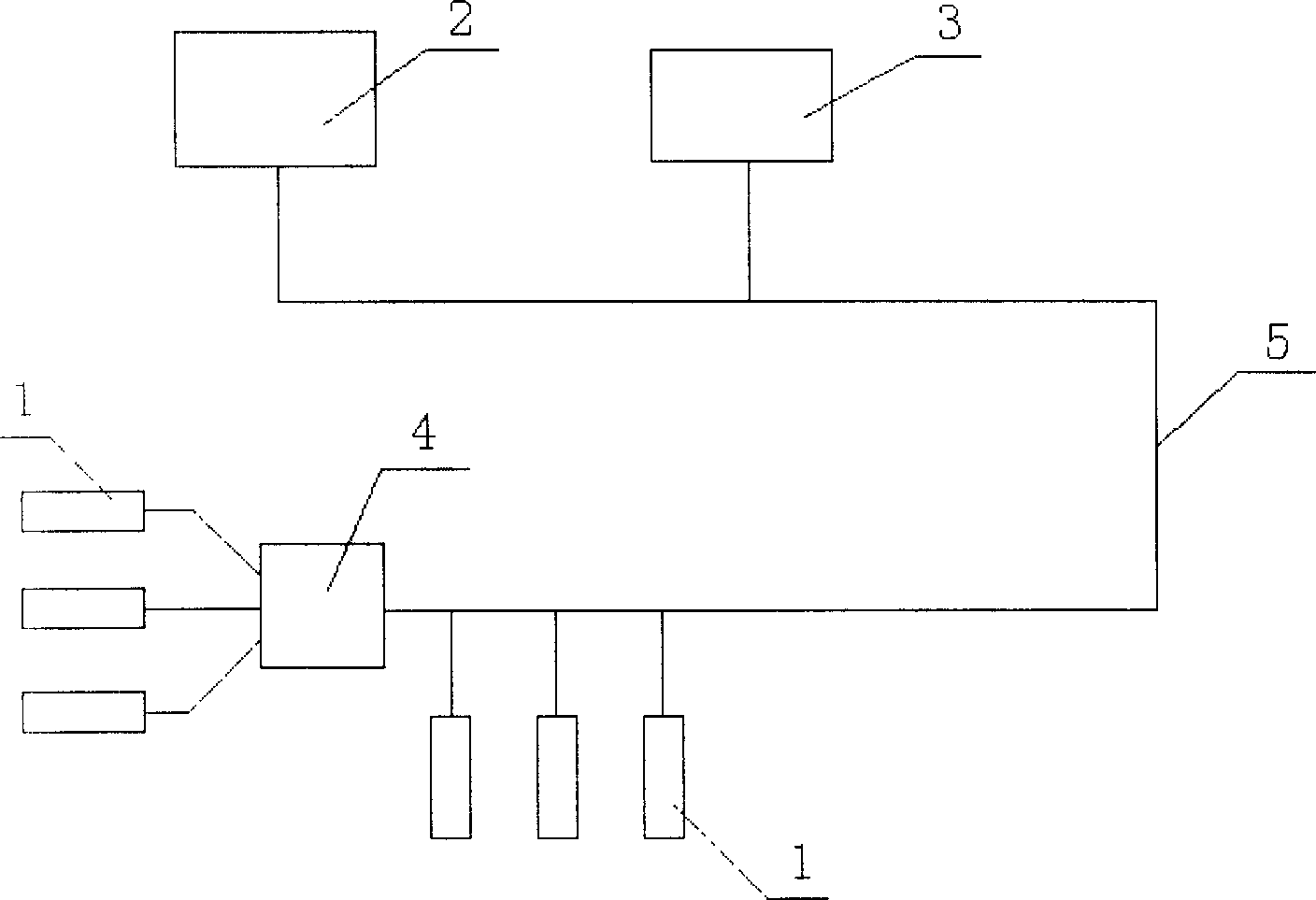

Garbage collecting station with remote control and diagnosis device

InactiveCN1629058AGood logistics effectLow running costRefuse transferringStorage devicesRemote controlMarine engineering

This invention relates to garbage collection stop with remote control and diagnose device, which comprises the following: multiple garbage compression stops; garbage process and control device, remote diagnose servo, remote management and control end and inter processor. The said control device is located on the compression stop and is connected to the hydraulic pressure and electron device in the compression stop. The said garbage control device is used as remote control terminal and is connected to the remote management control terminal through wire or wireless diagnose servo.

Owner:SHANGHAI RUIHUA GRP CORP

Method for treating acid wastewater of titanium white

ActiveCN101050010AReduce processing costsIncrease profitWater/sewage treatment by neutralisationWastewaterTitanium

This invention discloses a method for treating acidic wastewater produced during titanium dioxide production by H2SO4 method by using quicklime. The method comprises: wet-grinding quicklime digestion dreg into 60 mesh slurry (90%), and pre-neutralizing the acidic wastewater of titanium dioxide with the slurry. The method has such advantages as high quicklime utility, and no secondary pollution.

Owner:ANHUI ANNADA TITANIUM IND CO LTD

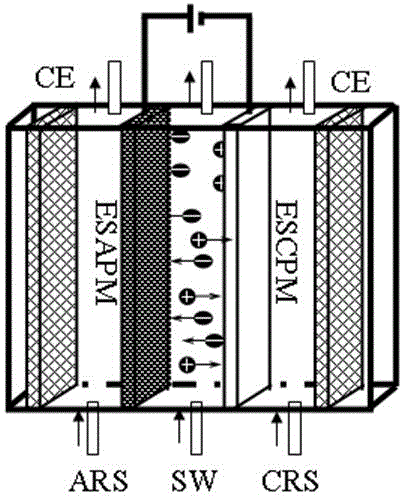

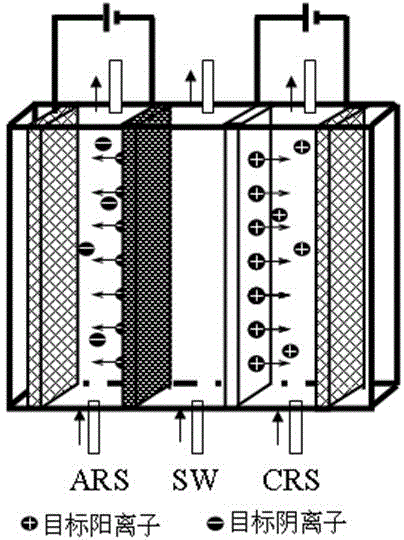

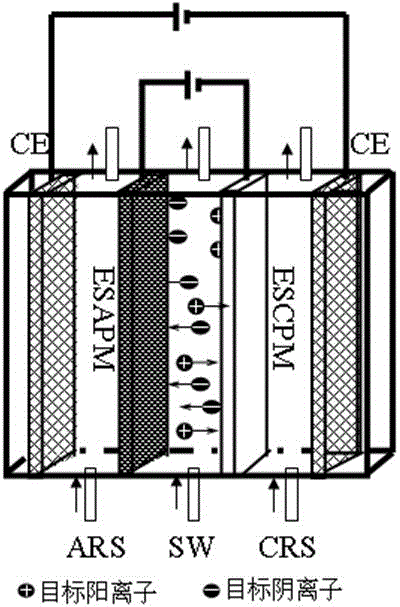

Separation process of electronic control ion selective permeable membrane

ActiveCN102718292AImprove osmotic diffusion transfer rateAchieve selective separationDispersed particle separationElectrode potentialIon exchange

The invention discloses a separation process of an electronic control ion selective permeable membrane. An electronic control ion exchange performance and an electronic control ion selective permeability of a membrane electrode are utilized in a double-diaphragm electrode reactor, oxidation-reduction potentials are alternately imposed on the double-diaphragm electrode reactor to control a synchronously imbedding and a synchronously releasing of targeted negative ions and positive ions, and under the action of field stress imposed by an auxiliary electrode, a separation and a recycle of the negative and positive ions in a dilute solution are achieved. According to the separation process of the electronic control ion selective permeable membrane, by means of the electronic control ion exchange performance of the selective permeable membrane electrode, targeted ions can selectively penetrate through a diaphragm by controlling electrode potentials of the membrane electrode, and thereby the efficient, synchronous, controllable and continuous separation and recycle of the negative and positive ions can be achieved.

Owner:山西翌佳环保科技有限公司

Sterilization module and sterilization equipment

ActiveCN108452362ARealize the function of purifying VOCsRealize green purificationGas treatmentDispersed particle separationUltraviolet lightsLight-emitting diode

The invention relates to the sterilization field, in particular to a sterilization module and sterilization equipment. The sterilization module comprises a light emitting diode lamp bank, photocatalytic materials and a deep ultraviolet lamp element, wherein the light emitting diode lamp bank, the photocatalytic materials and the deep ultraviolet lamp element are arranged on the front side of a substrate; the light emitting diode lamp bank is used for emitting visible light of 400 nanometers or above or ultraviolet light of 300-400 nanometers to the photocatalytic materials; the photocatalyticmaterials are used for receiving the light wave of the light emitting diode lamp bank and generating a free radical with high oxidability; the deep ultraviolet lamp is arranged on the front side of the substrate and is used for emitting deep ultraviolet 300 nanometers or below to the photocatalytic materials. According to the sterilization module, the light emitting diode lamp element serves as the motivation light source of the photocatalytic materials and is used for emitting visible light of 400 nanometers or above or ultraviolet light of 300-400 nanometers to the photocatalytic materials,the photocatalytic materials are used for receiving the light wave of the light emitting diode lamp bank and generating the free radical with the high oxidability, sterilization and VOCs (Volatile Organic Compounds) purification are realized, and an effect on thoroughly purifying indoor gas pollutant is achieved.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Method for preparing coconut shell activated carbon with silver controlled-release sterilizing function through hydrothermal reaction

InactiveCN104307475AWell-developed pore structureLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesActivated carbonControl release

A method for preparing coconut shell activated carbon with a silver controlled-release sterilizing function through hydrothermal reaction is characterized in that: using coconut shell activated carbon as a raw material and silver nitrate as an impregnating liquid, preparing silver-carried activated carbon through hydrothermal reaction, and forging at a high temperature under nitrogen protecting conditions to obtain the product. The operating technology has the main characteristics that the coconut shell activated carbon is used as the raw material, the absorption capacity is high, the speed is high, and the product is durable and regenerative; silver is more effectively loaded on the activated carbon through hydrothermal reaction preparation, and high specific surface area (1000m<2> / g) and high antibacterial activity (the sterilizing time of 107 / mL is 35 minutes) are obtained; high-temperature forging is favorable to the reactivation of the silver-carried activated carbon, silver granules are more uniformly distributed on the surface of the activated carbon, and a silver controlled-release function is realized.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

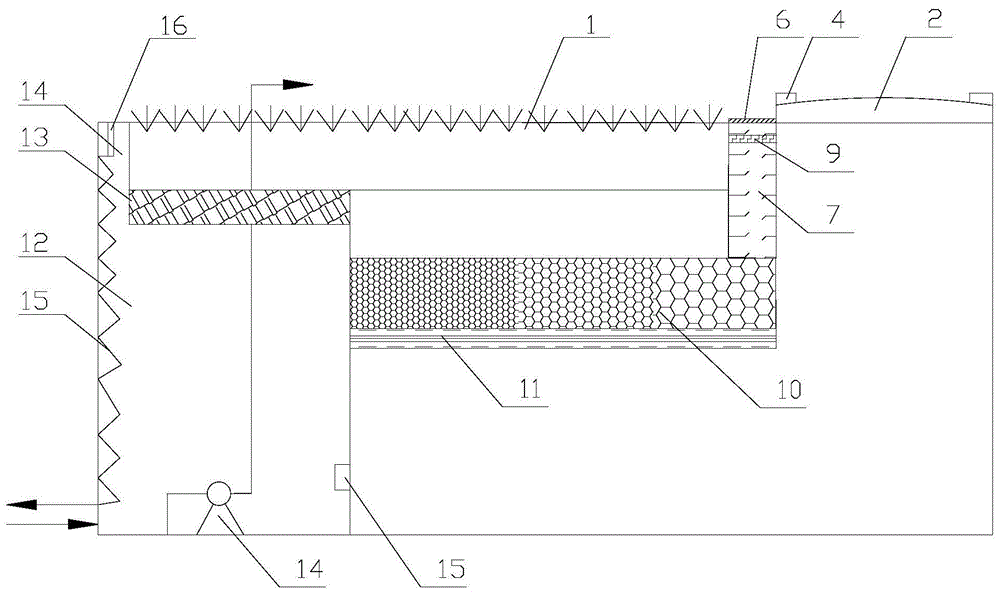

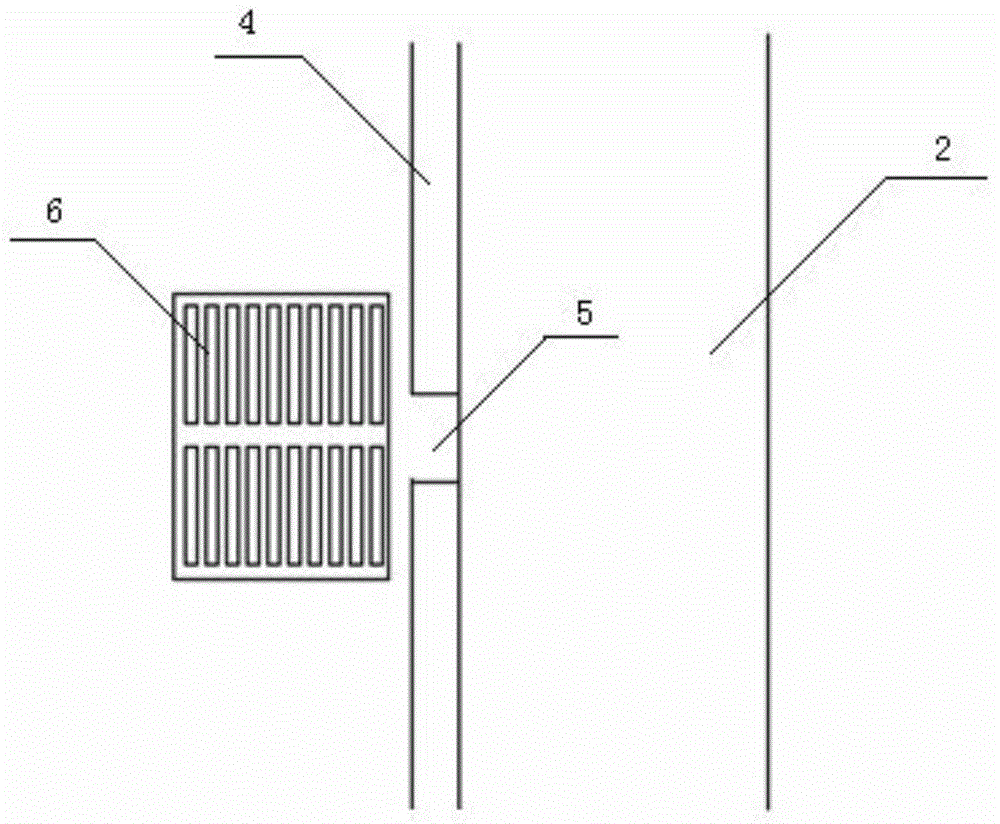

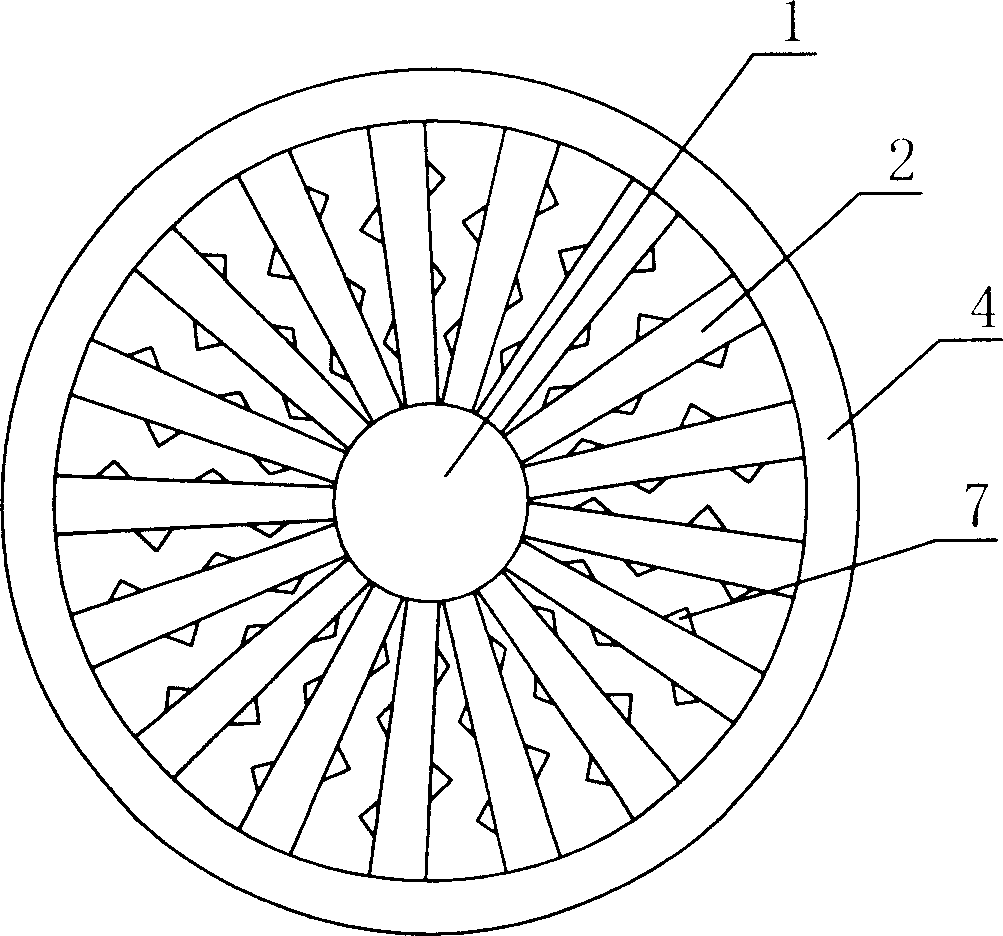

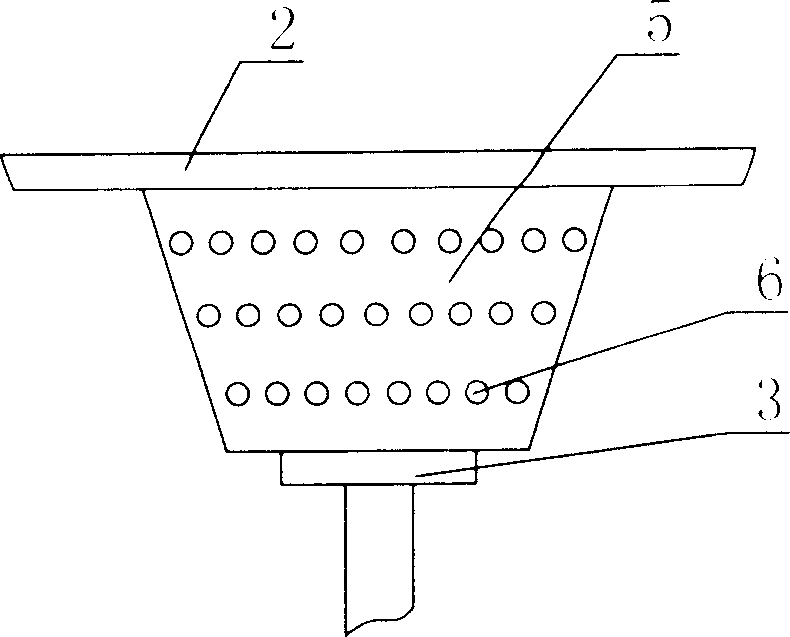

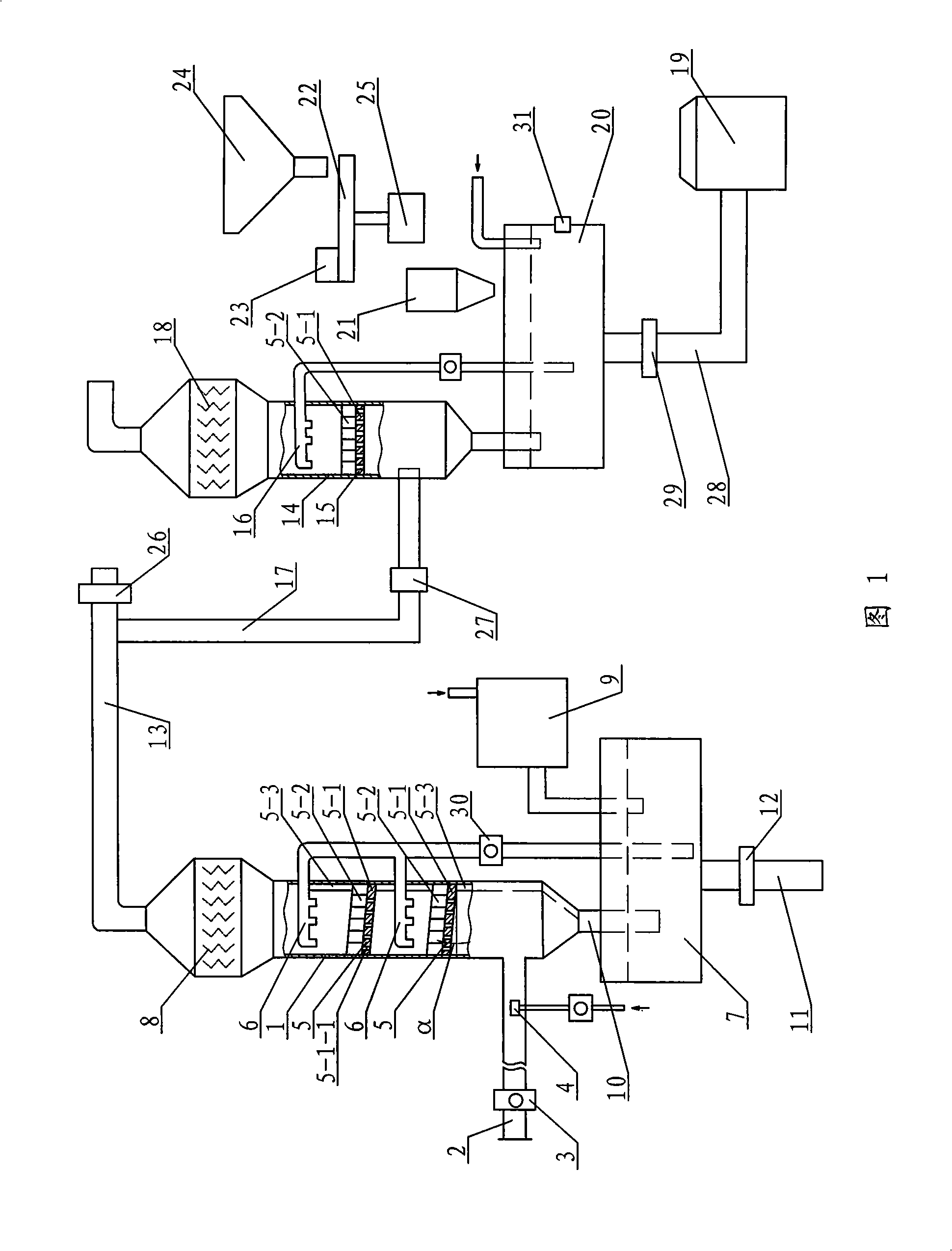

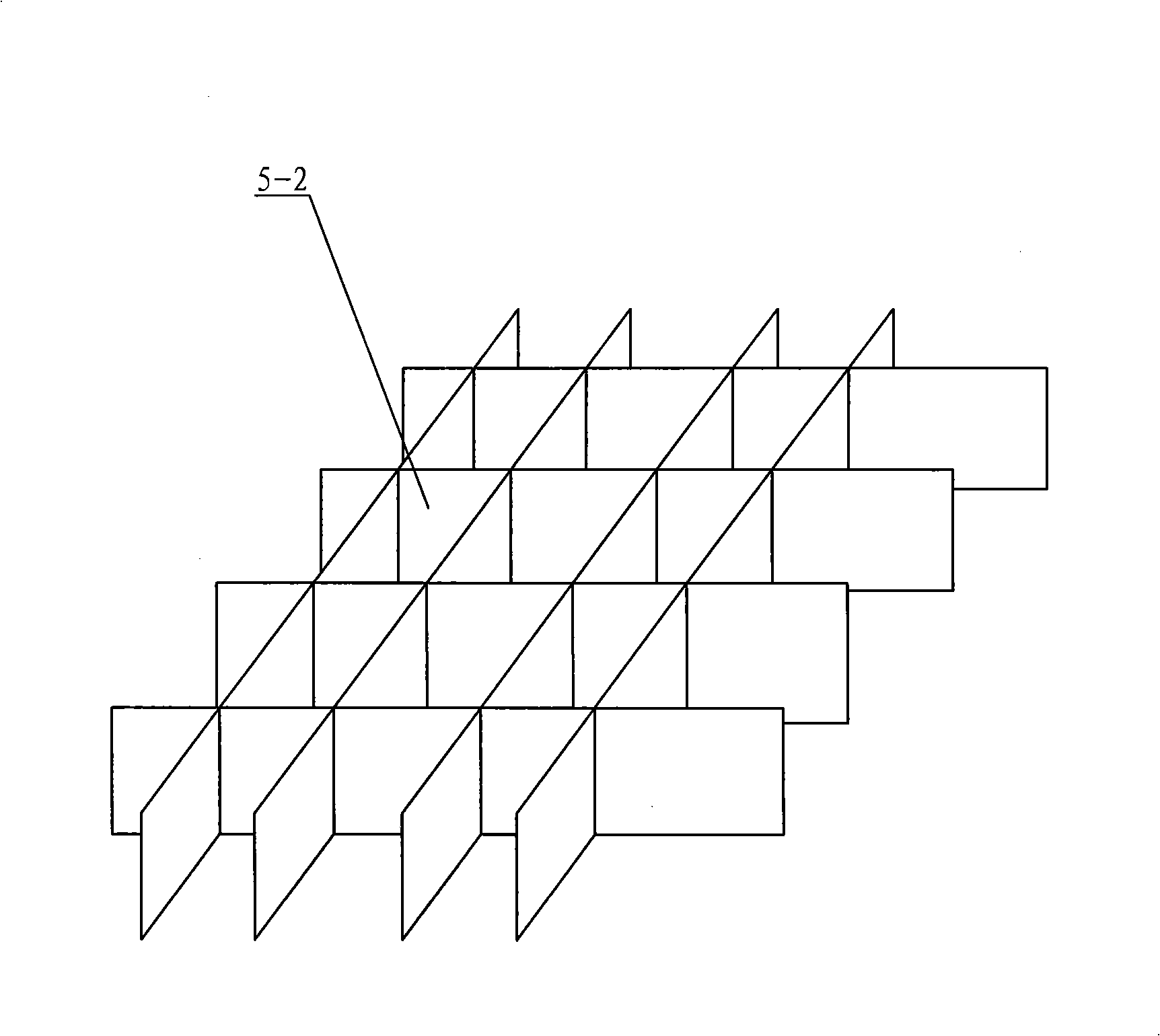

Liquid blast furnace slag pelletizing method and apparatus for heat recovering process

InactiveCN1888081AGuaranteed heat effectHigh activityOther heat production devicesRecycling and recovery technologiesLiquid slagProduct gas

The present invention is liquid blast furnace slag pelletizing method and apparatus for heat recovering process, and features that the liquid slag blast furnace discharges in downward flow is crushed into grains with the pelletizing apparatus in high speed rotation to produce centrifugal force of throwing the liquid slag. Crushing the liquid slag into relatively homogeneous fine grains can ensure the effective heat exchange between slag and gas. The pelletizing apparatus is one wheel spoke type disc or cup structure capable of ensure the effective recovering of heat from the liquid blast furnace slag.

Owner:CHONGQING UNIV

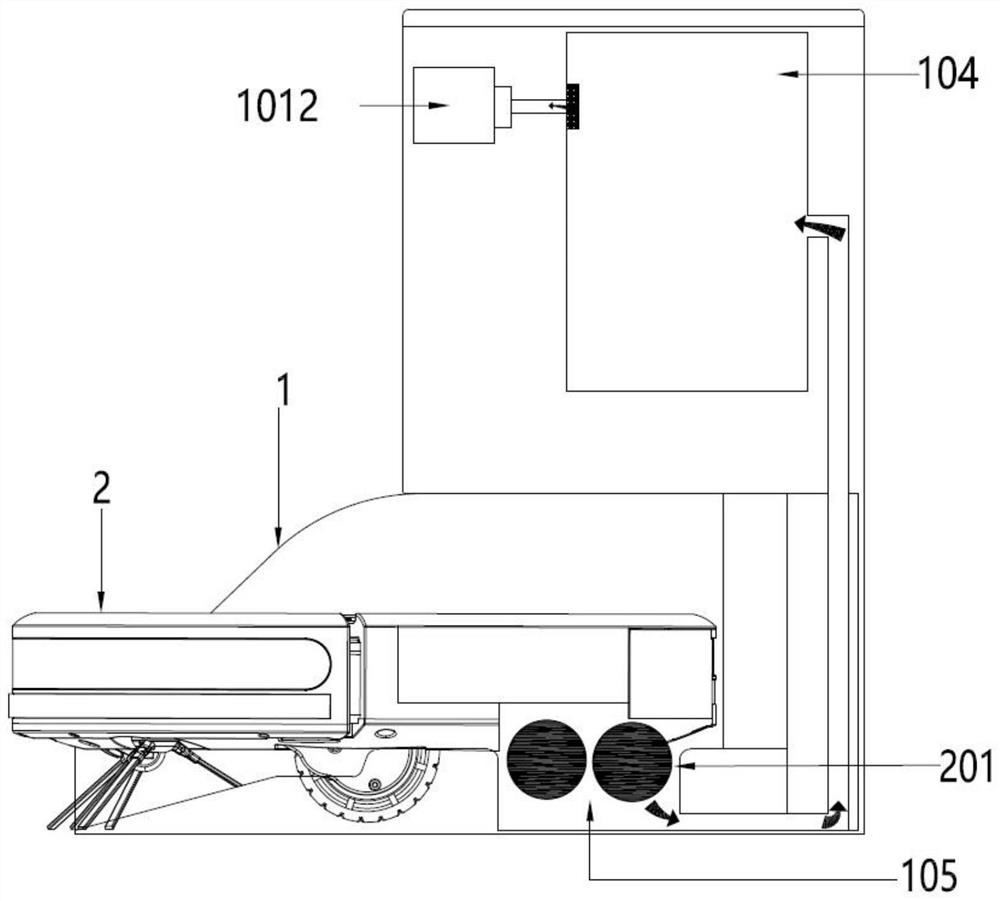

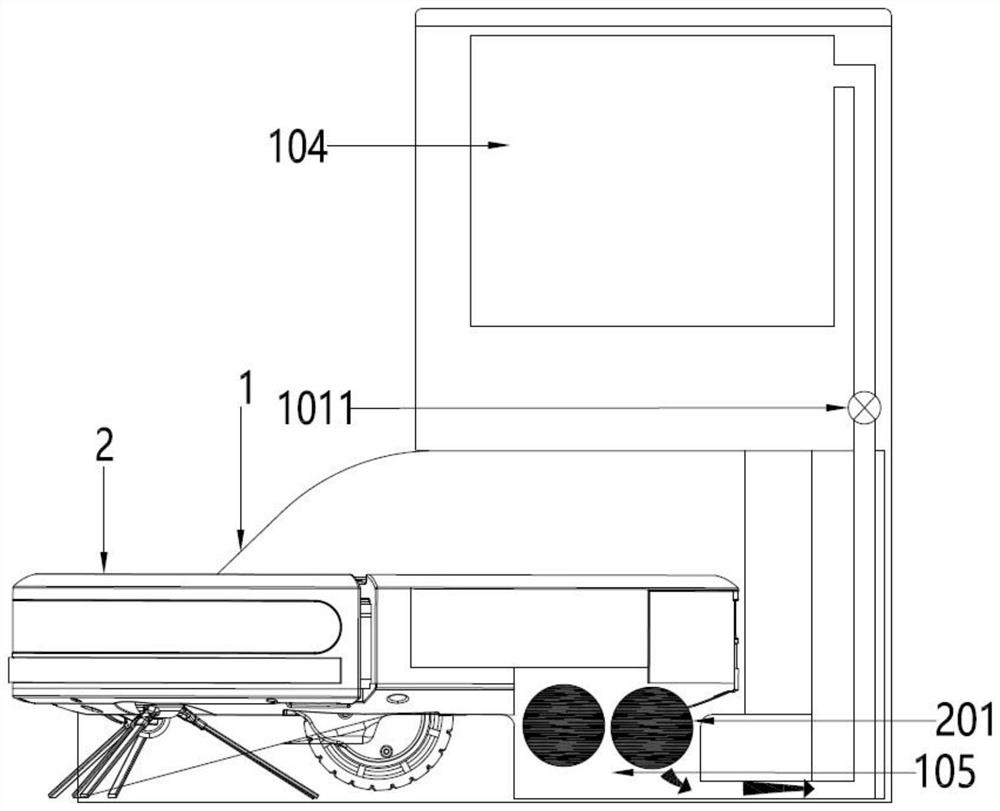

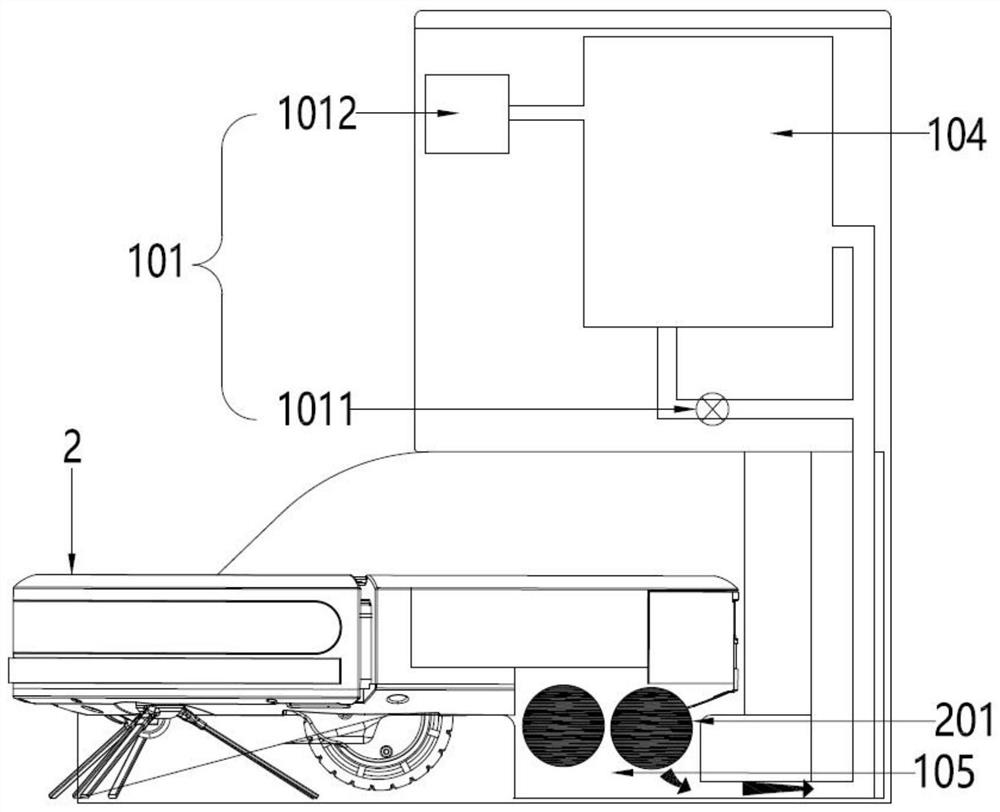

Cleaning station of cleaning robot

PendingCN112006618AEasy to absorb and handleRealize centralized suction processingCarpet cleanersFloor cleanersWater storage tankProcess engineering

The invention discloses a cleaning station of a cleaning robot. The cleaning station is independently arranged relative to the cleaning robot, and the cleaning station is at least used for cleaning arotary mopping piece used for mopping the ground on the cleaning robot; the rotary mopping piece is arranged to mop and clean the ground, the rotary mopping piece is located at the bottom of the cleaning robot and can rotate and roll relative to the ground to mop and clean the ground, and when the rotary mopping piece makes contact with the ground, a plane structure is formed by the contact portion of the rotary mopping piece and the ground; the rotary mopping piece is automatically cleaned when the cleaning robot is located on the cleaning station by utilizing a rotatable rolling structure ofthe rotary mopping piece; a clean water tank can automatically supply water to the rotary mopping piece, a sewage tank automatically collects sewage and garbage after the rotary mopping piece is cleaned, water is automatically added into the water storage tank on the cleaning robot, the cleaning robot can automatically complete mopping cleaning, rotary mopping piece cleaning and automatic water adding without more participation of a user, and the mopping cleaning effect is better.

Owner:杭州匠龙机器人科技有限公司

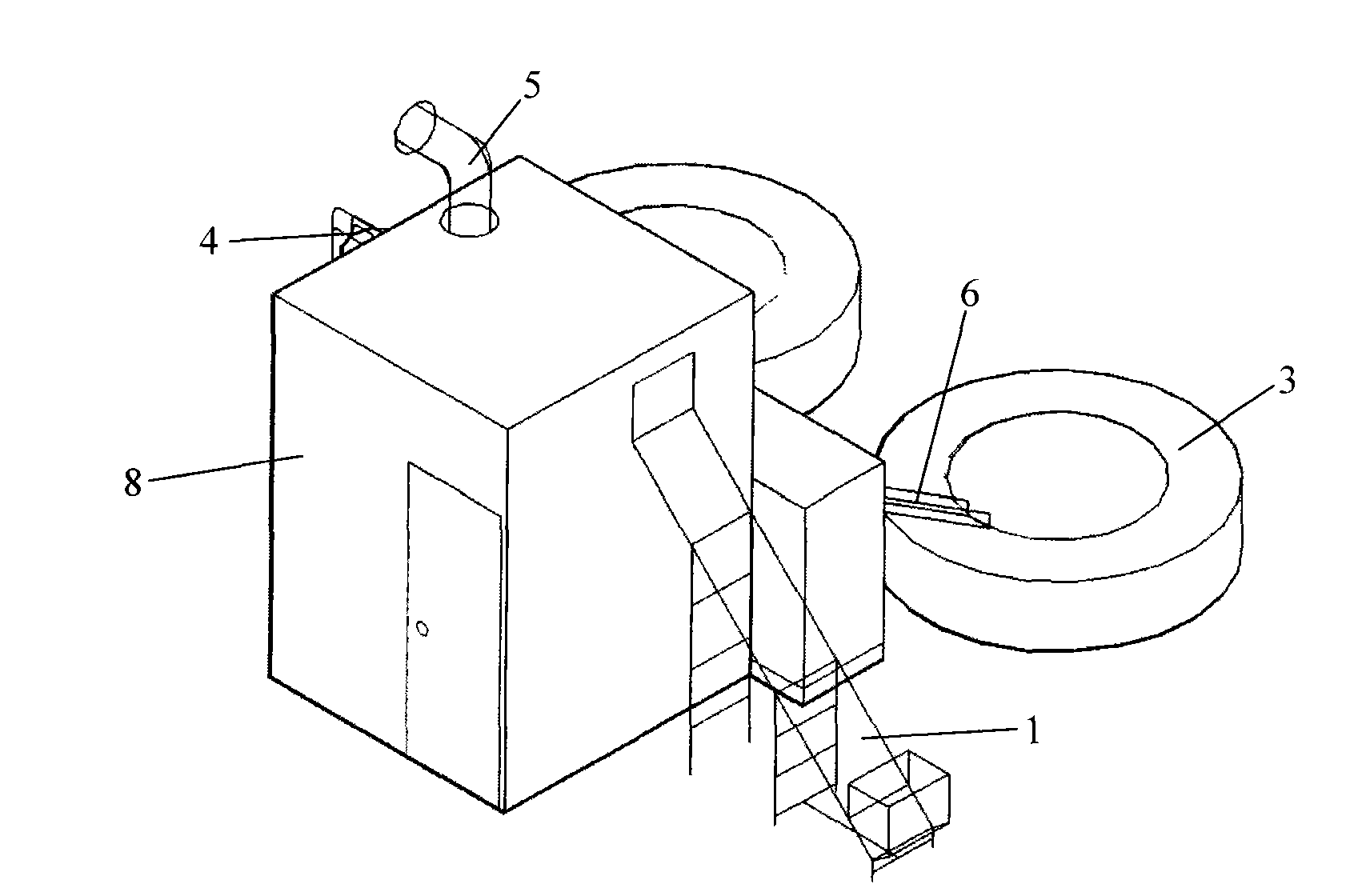

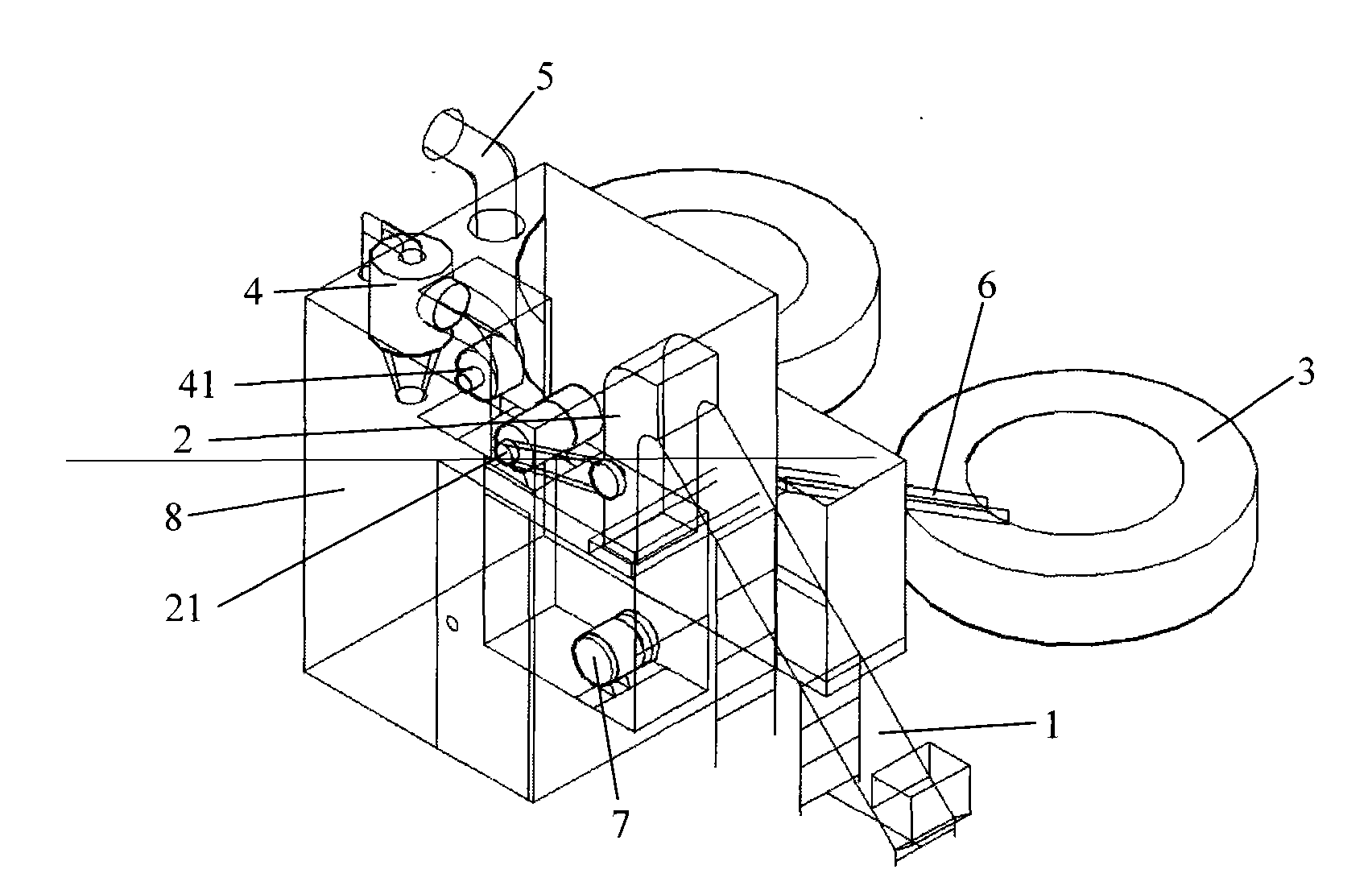

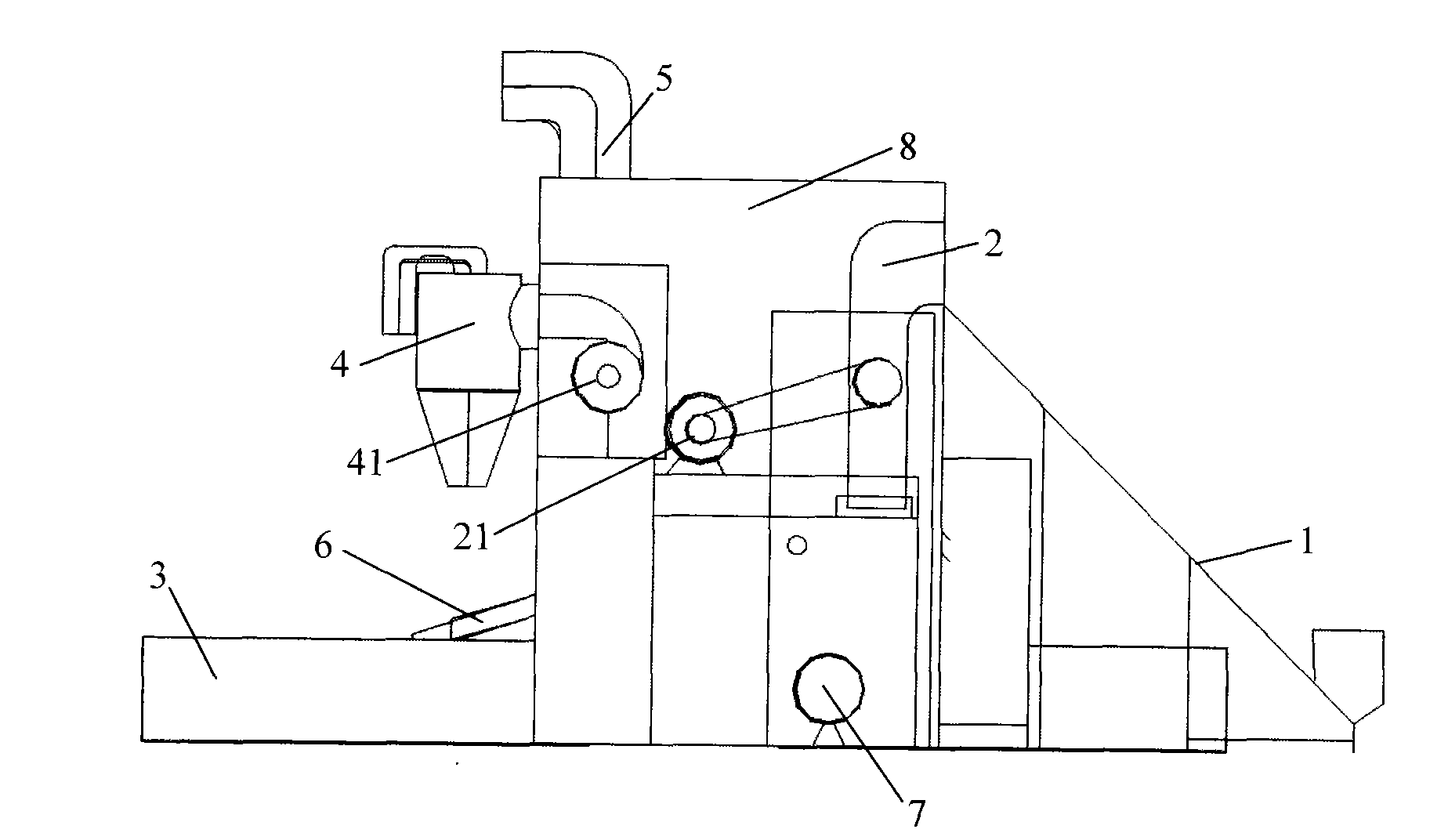

Recycling separation system of lithium battery component materials

ActiveCN102029283AAvoid burnsAvoid explosionSolid waste disposalWaste accumulators reclaimingElectricityEnvironmental resistance

The invention relates to a recycling separation system of lithium battery component materials. A feed conveying device of the system is matched with the feeding hole of a crushing device, a spray device is arranged in the crushing device, a middle conveying device is matched with the discharge hole of the crushing device and the inlet of a centrifugal separation device, the drainage port of the centrifugal separation device is connected with a precipitation device, a solid collecting device is matched with the centrifugal separation device, a waste gas collecting device is communicated with the crushing device, a control device is electrically connected with other devices except the precipitation device, and preferably, the spray device is arranged in the discharge hole of the crushing device; the middle conveying device comprises a chute, a water pump and an overflow storage tank; and the system also comprises a sound insulation device. The recycling separation system of the lithium battery component materials has skilful and reasonable design, is safe, efficient and environmentally-friendly, can eliminate the hidden dangers of combustion and explosion and the secondary pollution problem caused by the residual electric quantity, is convenient for recycling the crushed materials, and is suitable for large-scale popularization and application.

Owner:伟翔环保科技发展(上海)有限公司

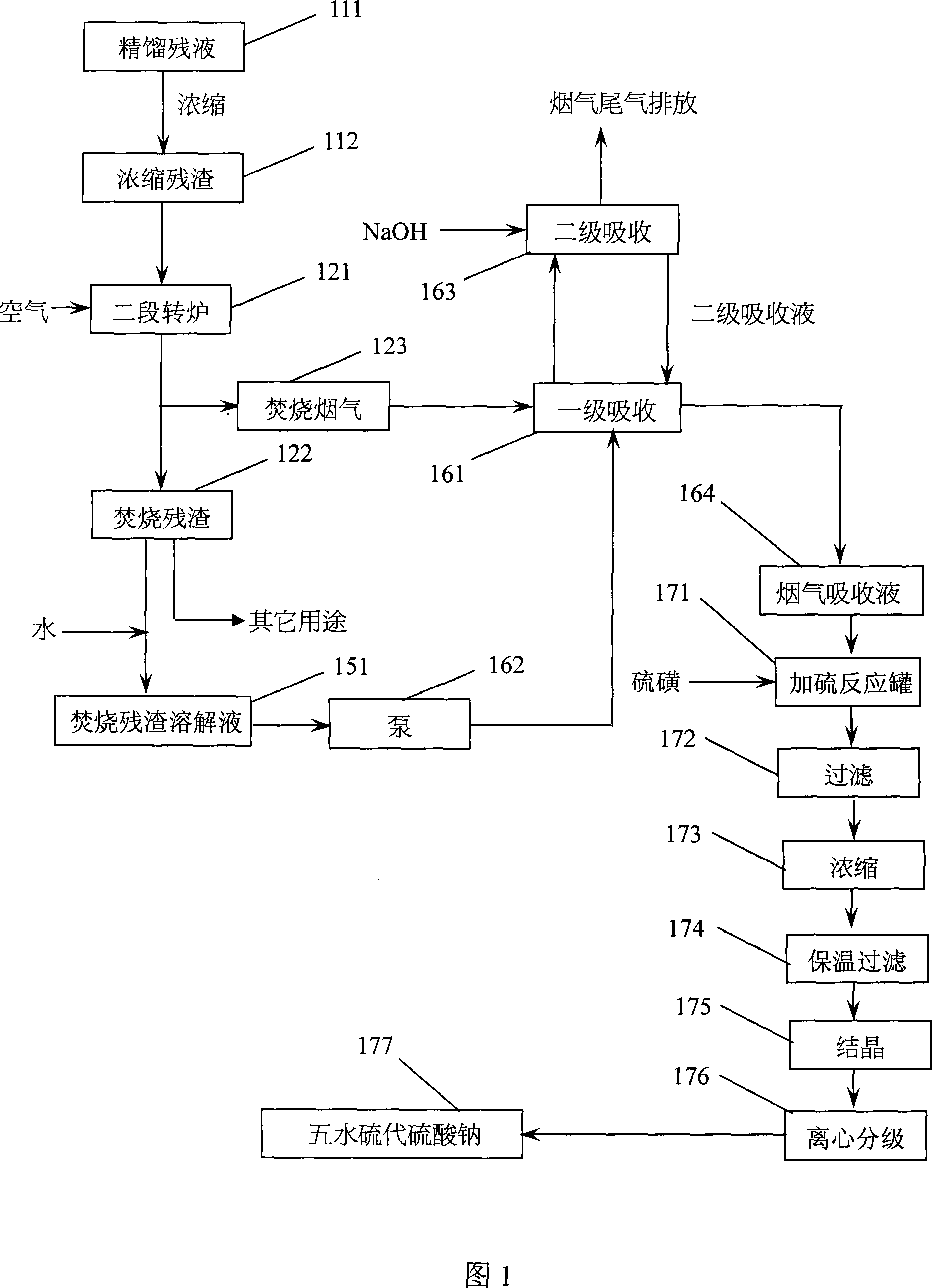

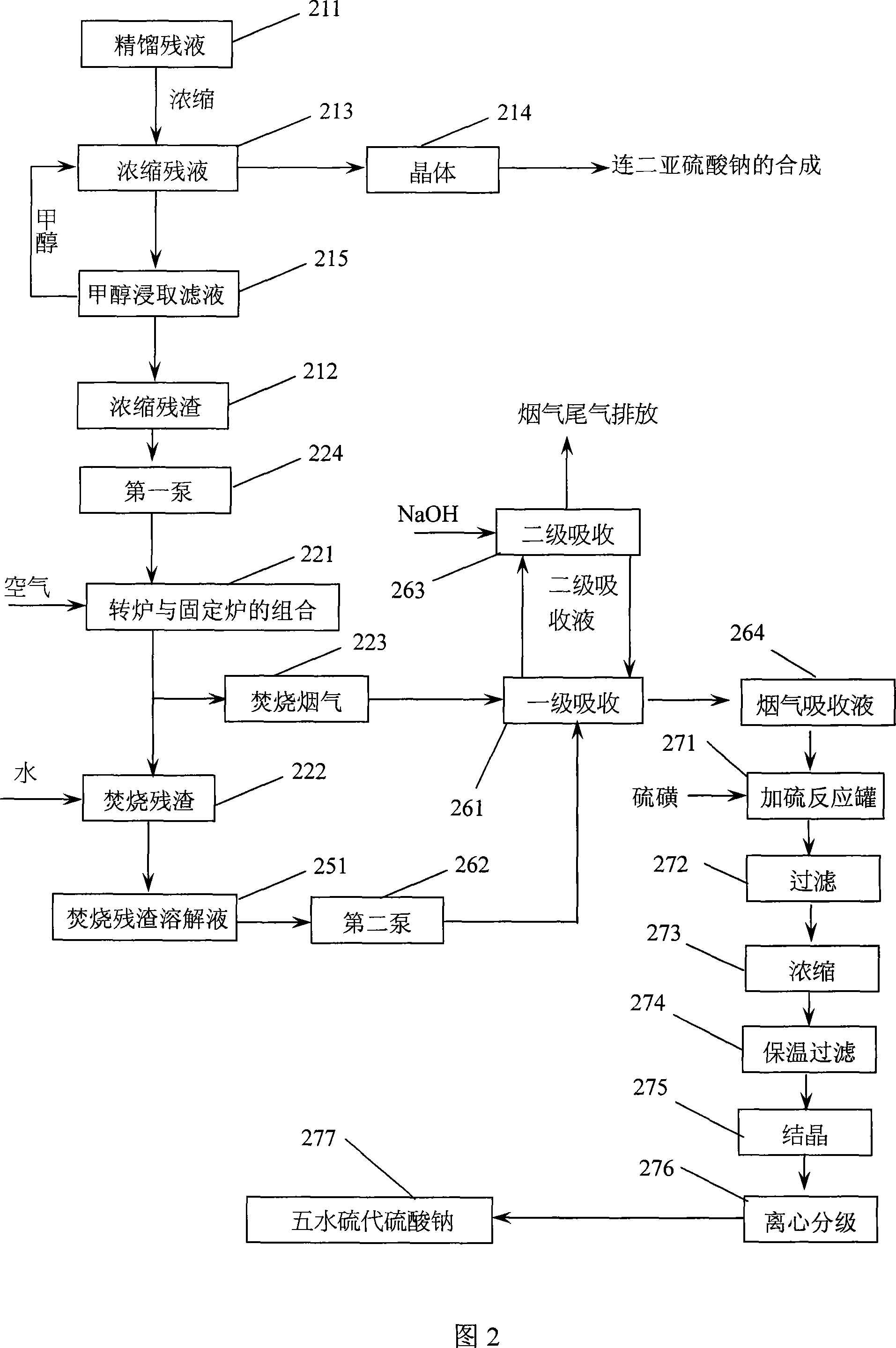

Method for treating residual liquid after mother liquor distillation methanol recovery during production of sodium sulphoxylate by sodium formate process

InactiveCN101081715AEliminate secondary pollutionRecycling resourcesThiosulfates/dithionites/polythionitesDispersed particle separationDithionous acidSulfite salt

The present invention is process of treating mother liquid residue from sodium formate method to produce sodium hyosulfate and after being rectified to recover methanol. The process includes the following steps: 1. concentrating to obtain concentrated residue with or without sodium formate recovery; 2. incinerating the concentrated residue in a converter or one combined furnace to obtain incinerated clinker; 3. discharging high temperature clinker; 4. dissolving the clinker to form water solution; 5. absorbing SO2 from the incinerating fume with the water solution; and 6. adding sulfur to the absorbed solution to prepare sodium thiosulfate. The process can eliminate pollutant while producing sodium thiosulfate as chemical material.

Owner:GUANGDONG ZHONGCHENG CHEM INC LTD

Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

ActiveCN101670231BEliminate secondary pollutionImprove environmental performanceDispersed particle separationSolution crystallizationMagmaDistributor

The invention belongs to the technical field of environment protection, and relates to a device and a process for temperature difference crystallizing ammonia process desulfurization, which is especially suitable for the ammonia process modification and newly-built desulfurization of the original calcium process desulfurization device. The device comprises a desulfurization tower, a densifying device, a gas-liquid heat exchanger, a circulating pump, a concentration circulating pump, a magma pump, a concentration crystallization tank and a drying system, wherein the desulfurization tower, the circulating pump, the magma pump and the drying system adopt the devices in the original calcium process desulfurization; the lower part of the densifying device is provided with a gas distributor, and the upper part thereof is provided with spray heads which are arranged in 2-3 layers; spray heads in the desulfurization tower are arranged in 2-4 layers, a liquid supplementation pipe is connected with the spray heads at the lowest layer in the desulfurization tower; the concentration crystallization tank is a tank with a conical bottom part; and the upper part of the concentration crystallization tank is provided with a pipeline to be connected with the bottom of the densifying device, the middle of the concentration crystallization tank is provided with a pipeline to be connected with theconcentration circulating pump, and the bottom is provided with a pipeline to be connected with the magma pump. The invention can farthest utilize the original devices on the premise of guaranteeing the normal desulfurization efficiency, thereby saving the investment, reducing the energy consumption and eliminating the secondary pollution.

Owner:江苏世纪江南投资有限公司

Water-washing type air purification device

InactiveCN101342435AEliminate secondary pollutionLow costLighting and heating apparatusUsing liquid separation agentEngineeringExhaust pipe

The present invention relates to an air purifier, in particular to a water washing type air purifier. The present invention resolves the problems of the prior devices, including low concentration of attached pollutants and incapability of thoroughly eliminating the secondary pollution. First nozzles are communicated with a buffer tank through a pipeline; an ozone water machine is communicated with the buffer tank through a pipeline; the bottom of the buffer tank is provided with a first drainpipe, which is provided with a first drainage control valve; an exhaust pipe is arranged on the top of a purification tower; the inflow end of a waste pipe is connected with the bottom of the purification tower; the outflow end of the waste pipe is arranged inside the buffer tank; and a first purifier arranged in the purification tower is inclined relative to the horizontal plane of the purification tower at an angle between 10 degrees and 15 degrees. The air purifier utilizes the ozone water produced by the ozone water machine to clean and disinfect the foul air in the purification tower, thus cleaning out pollutants, and since the first purifier is obliquely arranged in the purification tower, the disinfected sewage can flow into the buffer tank, so the secondary pollution is eliminated.

Owner:NORTHEAST FORESTRY UNIVERSITY

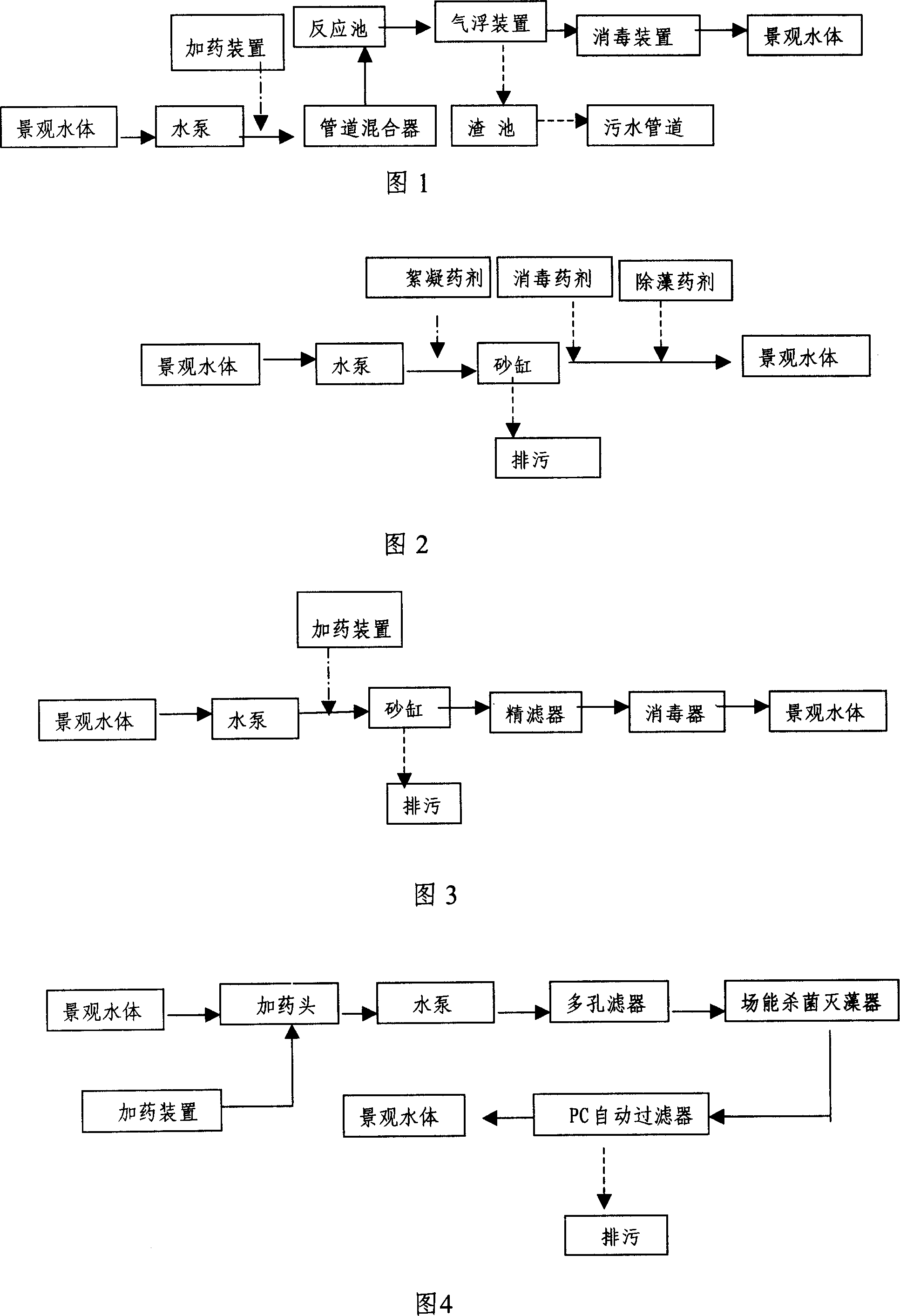

Landscape water treatment technology

InactiveCN101085685ALow costReduce processWater/sewage treatment bu osmosis/dialysisWater/sewage treatment using germicide/oligodynamic-processForeign matterMedicine

The invention relates to a water treatment process, which in detail is a process of treating landscape water. It comprises following steps: feeding landscape water into water pump through medicine dosing port; medicine dosing injecting medicine from medicine dosing device into landscape, mixing medicine with landscape water; killing the bacteria, microbe and algae and degrading organic pollutant in the mixing liquid by using disinfecting and algae removal device, the medicine and foreign matter in mixing liquid coagulating and forming colloidal cluster with bacteria and algae; filtering with PC automatic filter with the filtering precision being equal to or less than 50 um, back flushing by using pressure difference, discharging through discharging port, and feeding treated water into landscape river. The invention is characterized by simplified process and no secondary pollution.

Owner:上海舜禹环保工程成套技术有限公司 +1

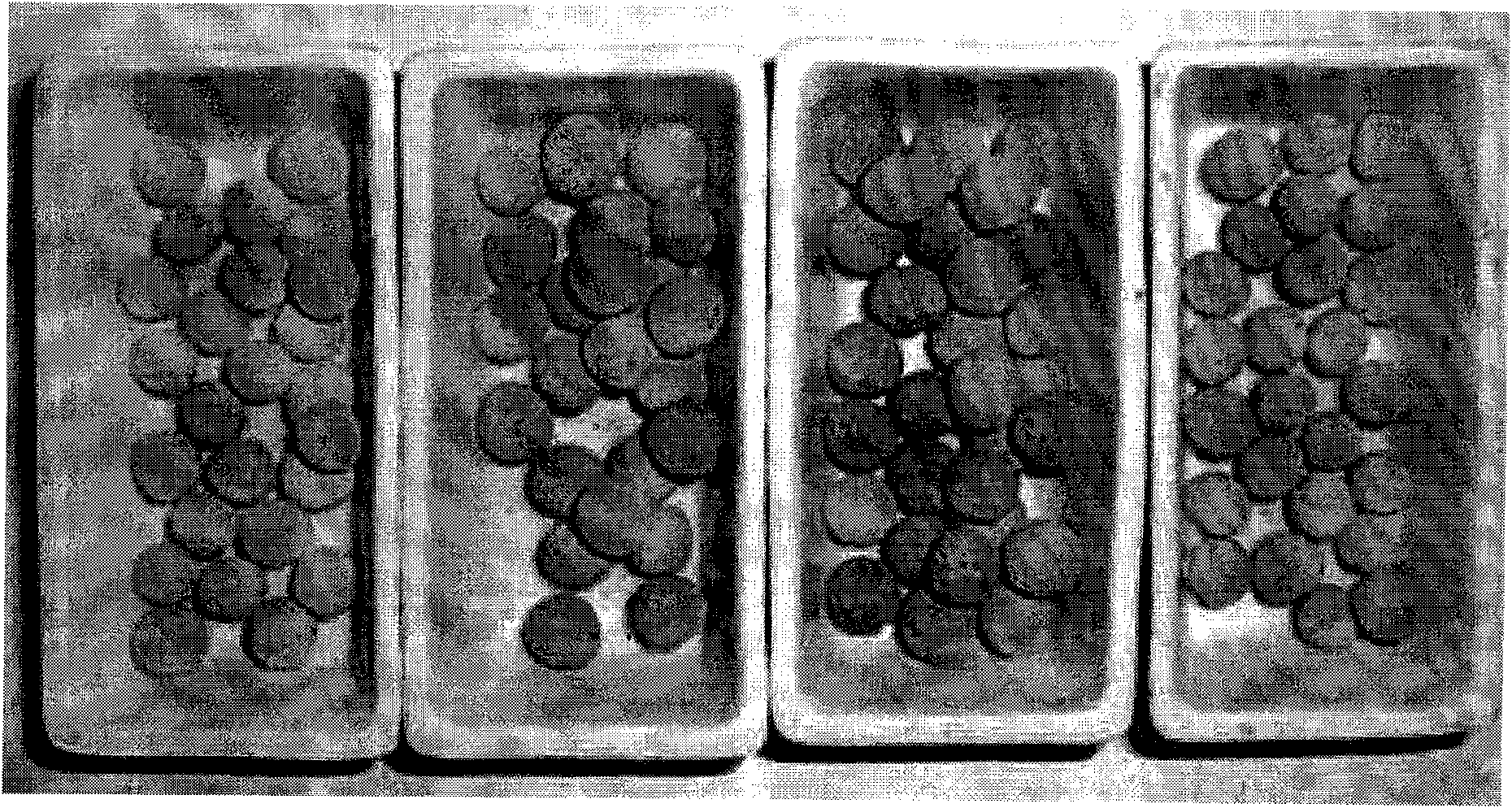

Method for preparing light ceramsite by adopting DSD acid industrial sludge

InactiveCN101638312AEliminate secondary pollutionLow costCeramic materials productionCeramicwareChemistryAdhesive

The invention provides a method for preparing light ceramsite by adopting DSD acid industrial sludge, which is characterized in that the following raw materials are utilized in the method: DSD acid sludge, binders, fluxing agents and expanding agents. The method comprises the following steps: (1) respectively grinding the dried DSD acid sludge and the binders and sieving the substances with 100-mesh sieves; (2) sieving the fluxing agents and the expanding agents with 300-mesh sieves; (3) weighing the binders, the fluxing agents, the expanding agents and the dried DSD acid sludge in a weight ratio of 3-5:0.5:0.5:4-6 and pelletizing the substances in a drum-type pelletizer with water as an adhesive to prepare raw pellets with the diameter being about 5mm; (4) drying the raw pellets at normaltemperature; (5) placing the raw pellets into box-type resistance furnaces, transferring the raw pellets into tube-type resistance furnaces to be fired after preheating and cooling the ceramsite at room temperature, thus obtaining the DSD acid sludge light ceramsite. The method lowers the cost on sludge treatment, avoids environmental pollution and features simple preparation process. The prepared DSD acid sludge light ceramsite has the characteristics of light weight, low water absorption, large specific surface area and the like.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com