Heavy metal pollution soil treatment system and process

A heavy metal-contaminated soil and treatment system technology, applied in the restoration of contaminated soil, grain treatment, magnetic separation, etc., to achieve the effect of eliminating secondary pollution, realizing automatic transportation, and realizing quantitative filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

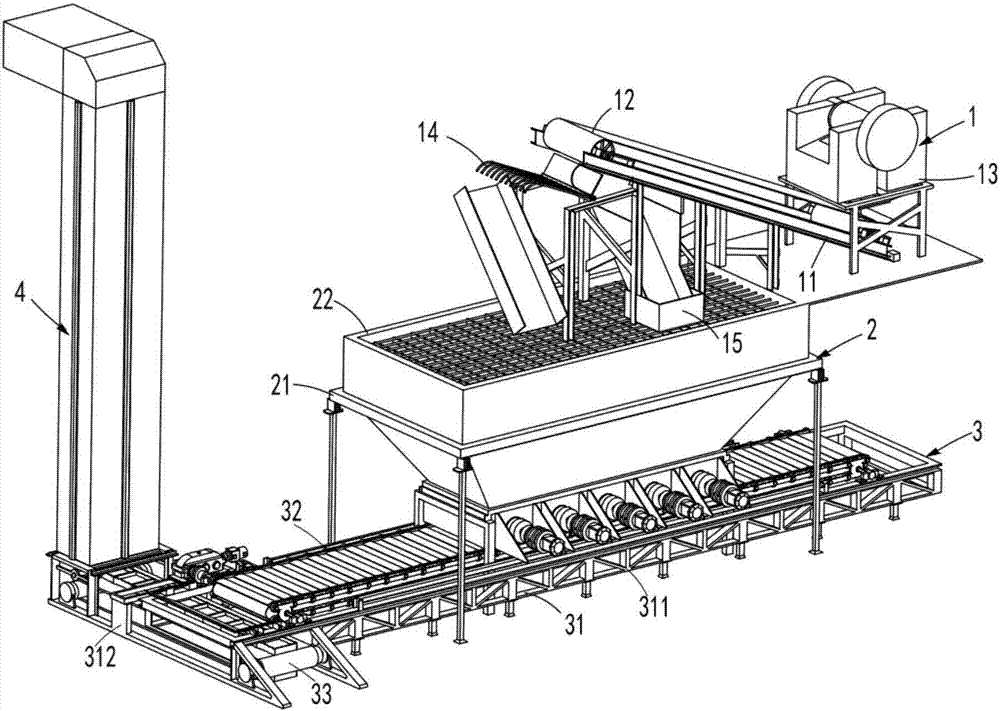

[0077] Such as figure 1 As shown, a heavy metal-contaminated soil treatment system includes:

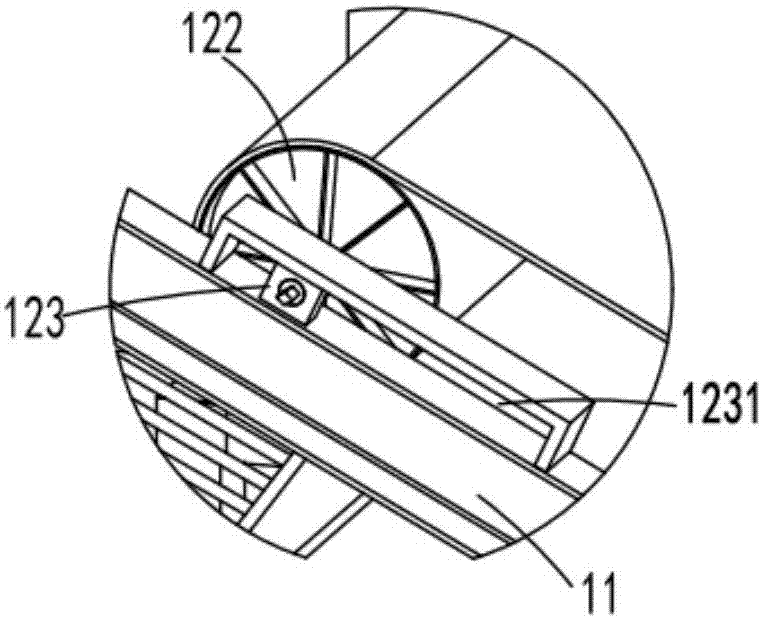

[0078] The first crushing and screening mechanism 1, the first crushing and screening mechanism 1 includes a first mounting frame 11 arranged obliquely and a first conveying assembly 12 arranged along the inclined surface of the first mounting frame 11, the first conveying assembly 12 The upper part is the output end, and its lower part is the input end, and the input end of the first conveying assembly 12 is equipped with the initial crushing assembly 13, and the output end of the first conveying assembly 12 is equipped with the first crushing and screening assembly 14;

[0079] The second crushing and screening mechanism 2, the second crushing and screening mechanism 2 is arranged below the first crushing and screening mechanism 1, which includes a second mounting frame 21 and a frame fixed on the second mounting frame 21 The second crushing and screening assembly 22;

[0080] Tr...

Embodiment approach

[0099] As a preferred embodiment, the second crushing and screening assembly 22 includes:

[0100] Grid 221, described grid 221 is arranged on the below of described first installation frame 11, and it is used for crushing sludge and intercepting large particle mud block;

[0101] A crushing chamber 222, the crushing chamber 222 is arranged below the grid 221, and it is fixedly connected with the grid 221;

[0102] Several stirring motors 223, the several stirring motors 223 are arranged on the lower outer side of the crushing chamber 222, which are equidistantly arranged along the length direction of the crushing chamber 222, and are fixedly connected to the outer wall of the crushing chamber 222 , and it is connected with a rotating shaft 2231 inside the crushing chamber 222;

[0103] A plurality of stirring paddles 224 are equidistantly arranged on the rotating shaft 2231 , and are fixedly connected to the rotating shaft 2231 .

[0104] It should be noted that the grid 22...

Embodiment 2

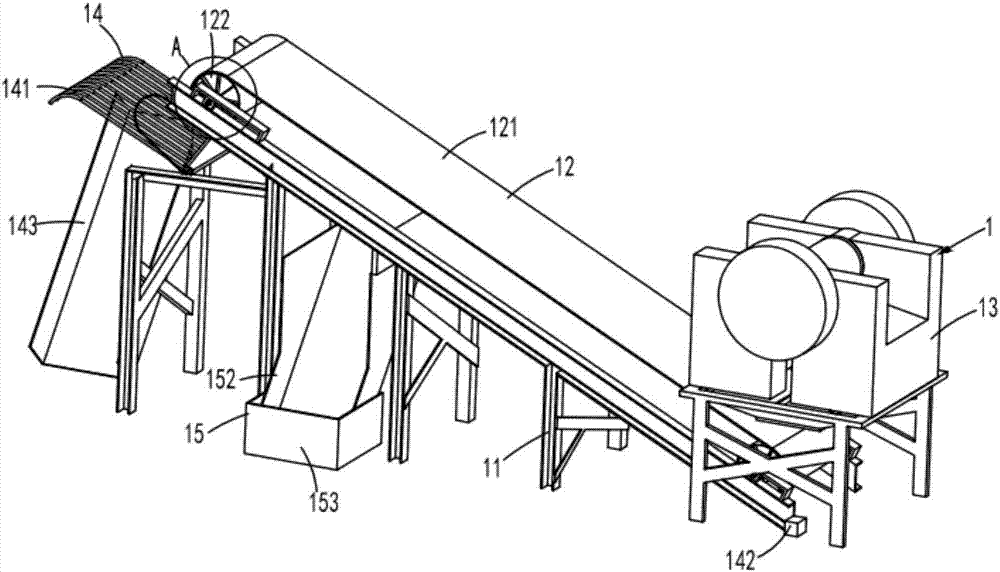

[0120] figure 2 and Figure 5 It is a kind of structural representation of embodiment two of a kind of heavy metal contaminated soil treatment system of the present invention; Figure 5 As shown, the parts identical or corresponding to the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below, and the second embodiment is different from the first embodiment. figure 1 The difference of the shown embodiment one is:

[0121] Such as figure 2 and Figure 5 As shown, a heavy metal-contaminated soil treatment system disclosed in the present invention also includes a scraping and recovery assembly 15 arranged at the rear end of the first crushing and screening assembly 14, which is located below the first conveying assembly 12, the Scraping mud recycling assembly 15 includes:

[0122] A scraper 151, the scraper 151 is arranged behind the crushing and sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com