Patents

Literature

70results about How to "Realize quantitative filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

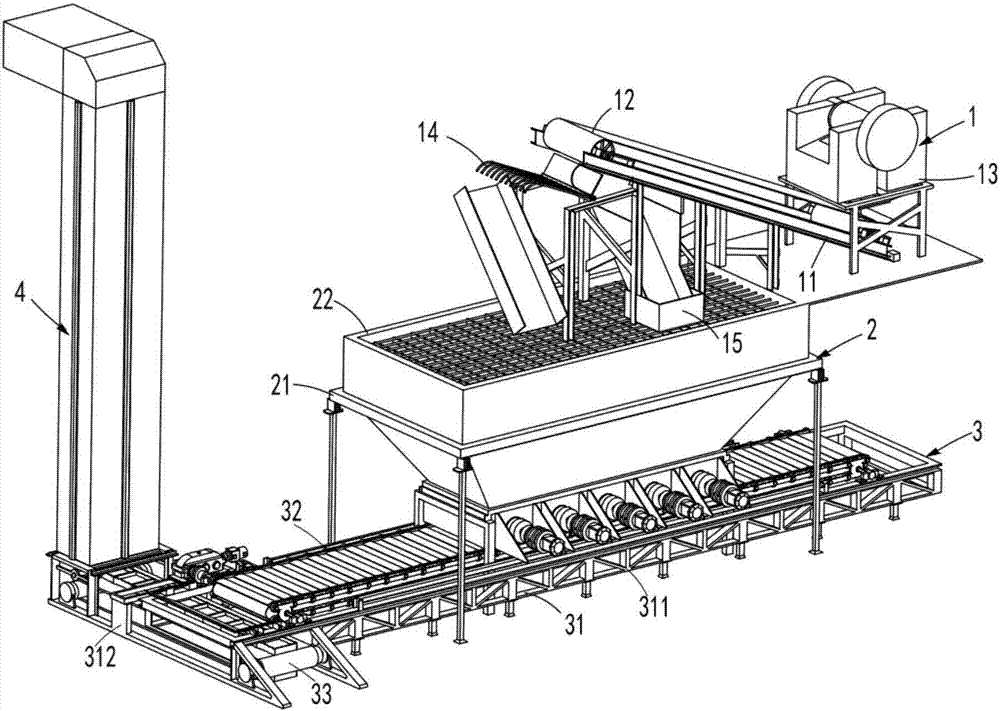

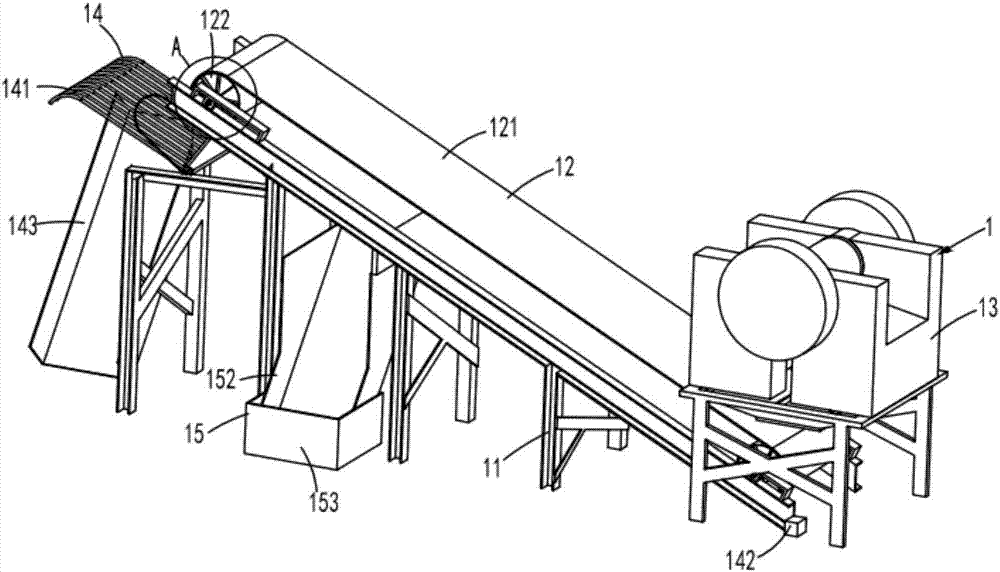

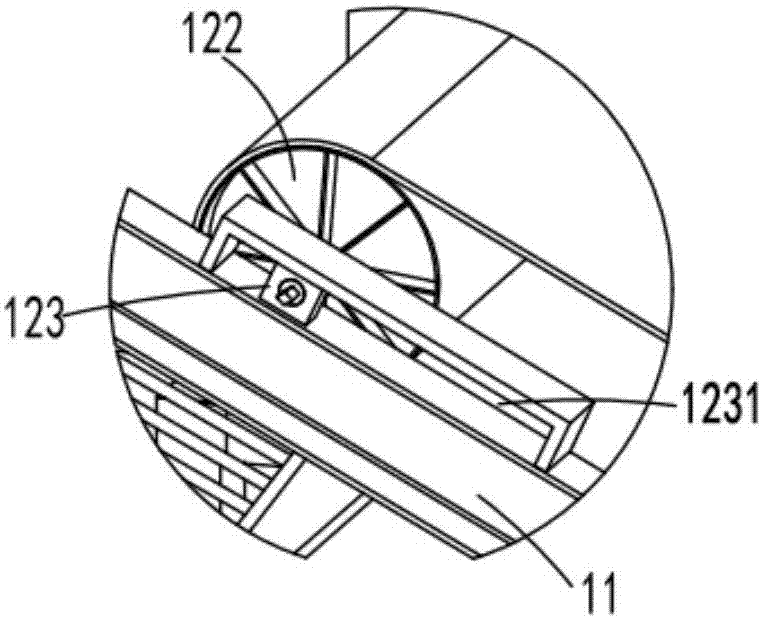

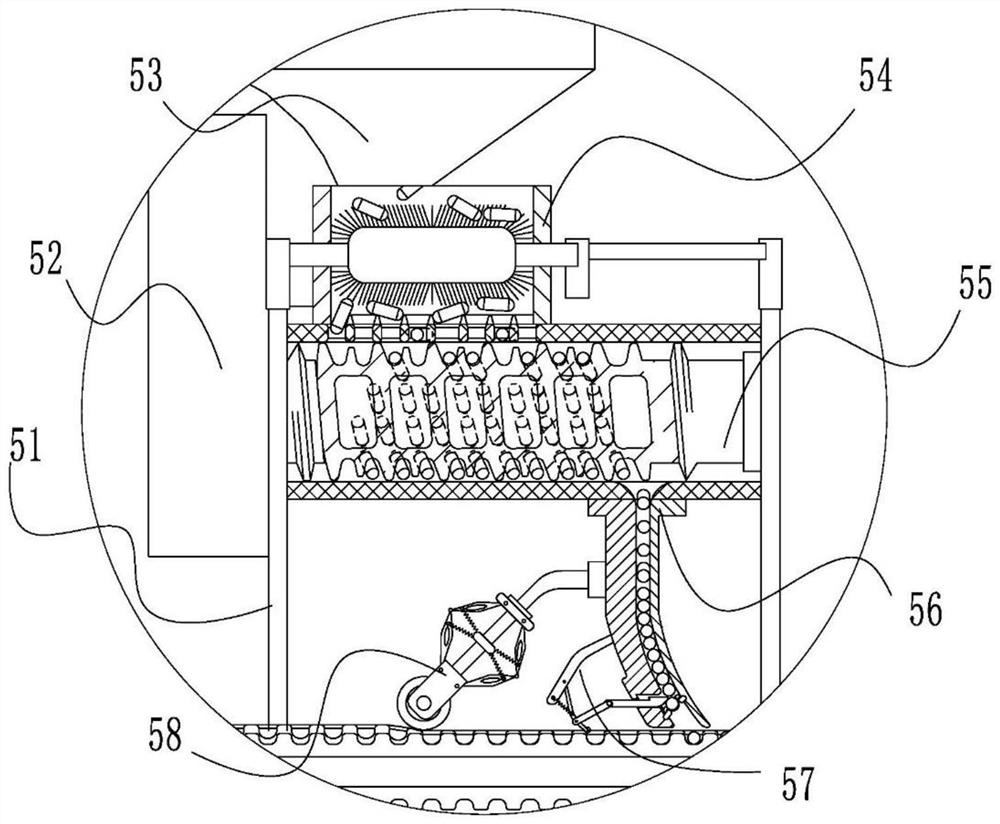

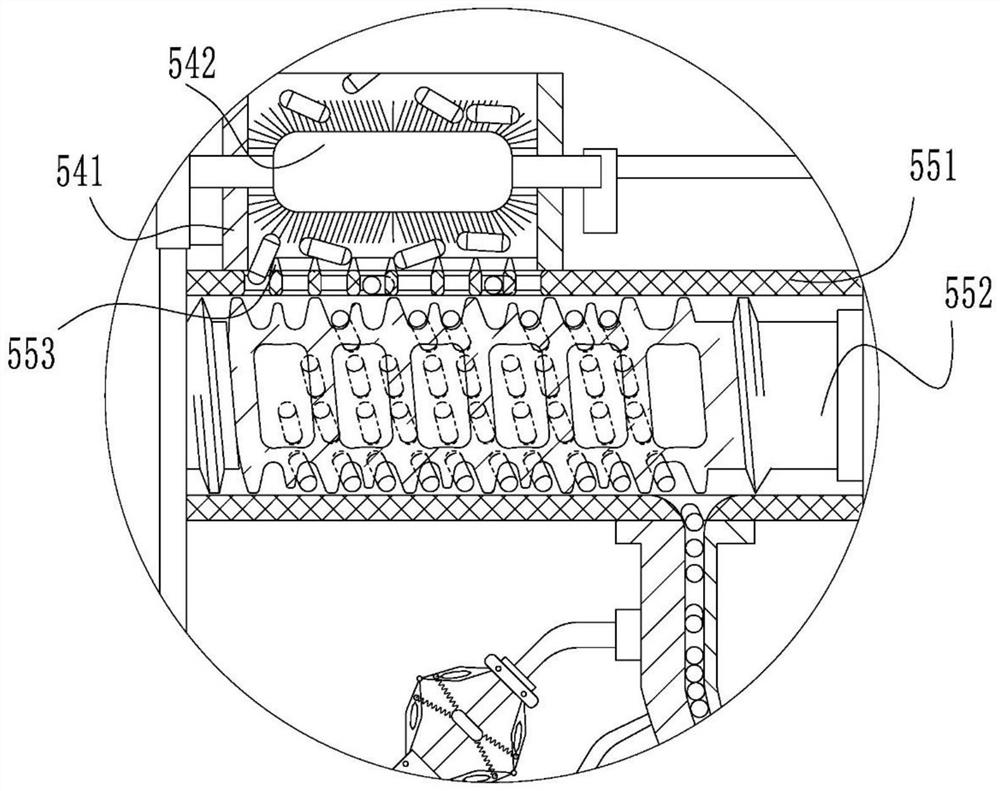

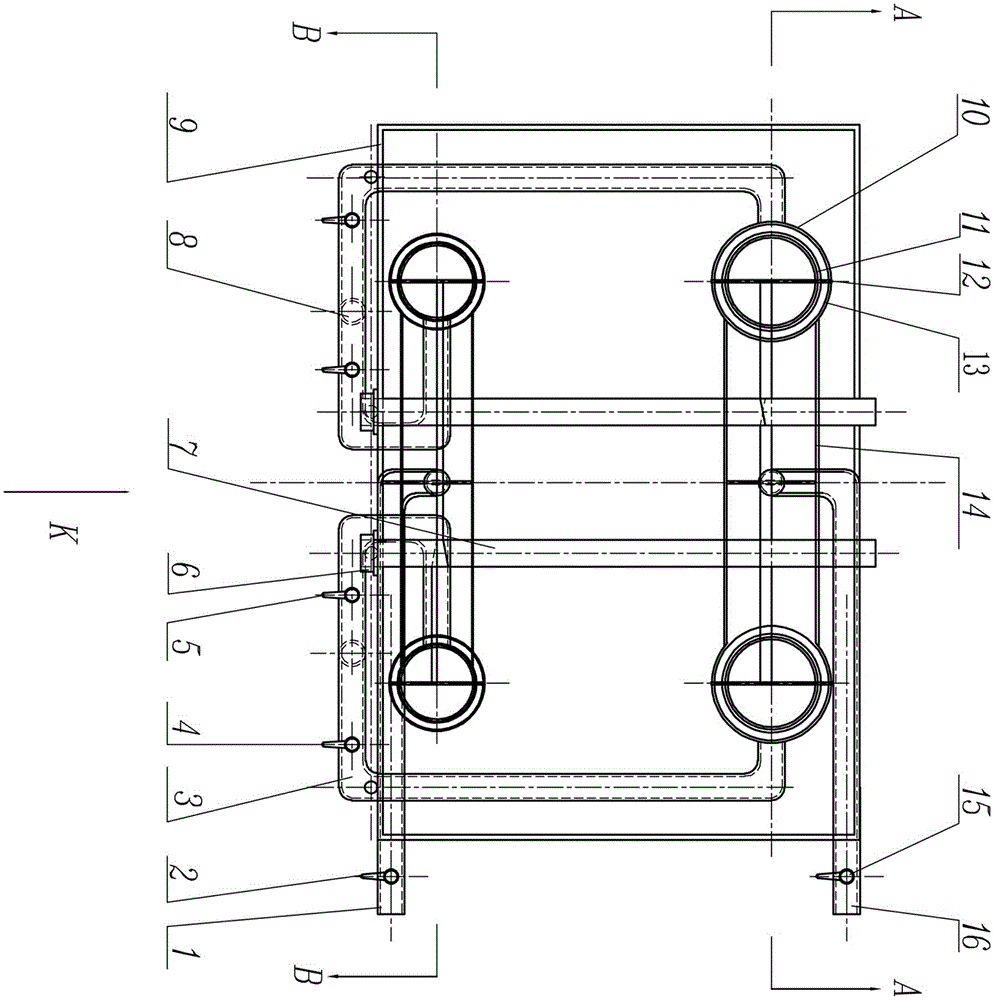

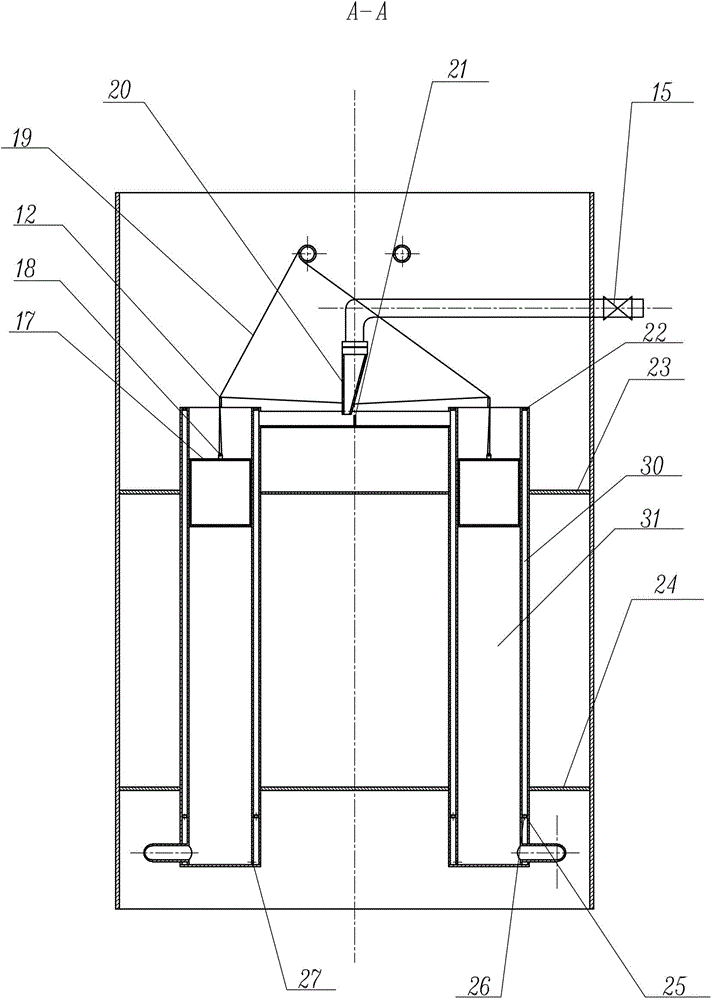

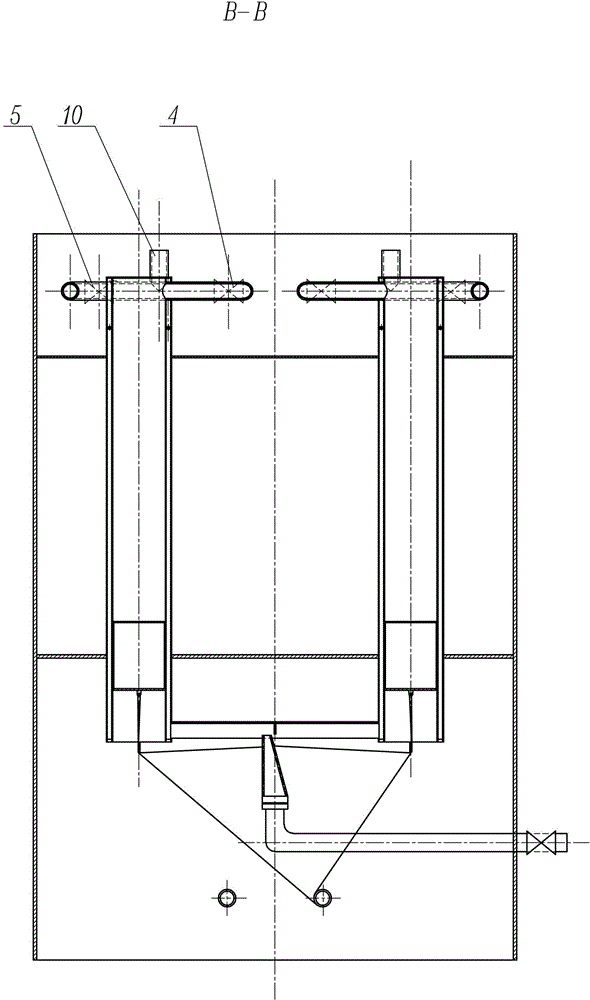

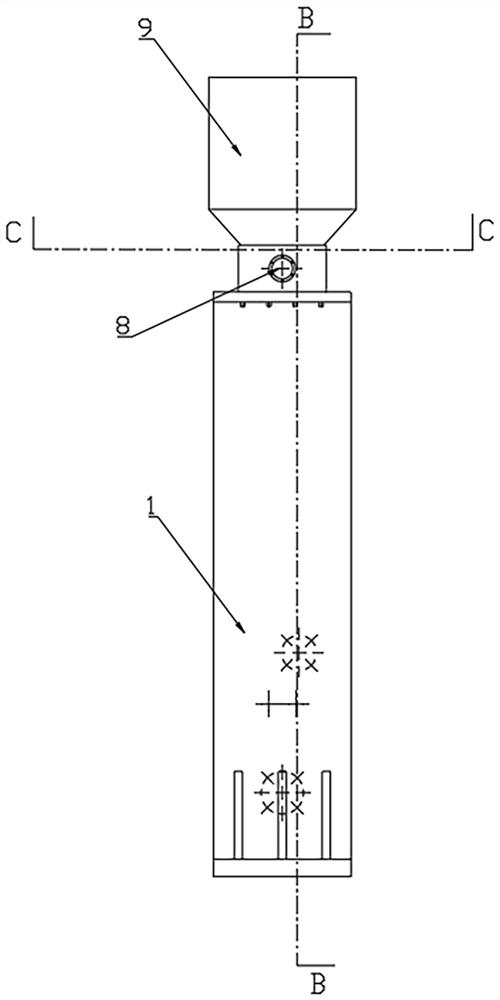

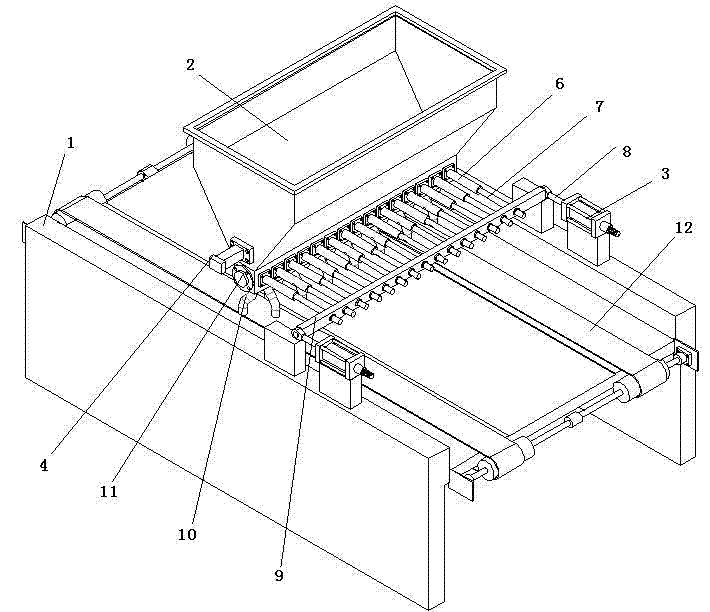

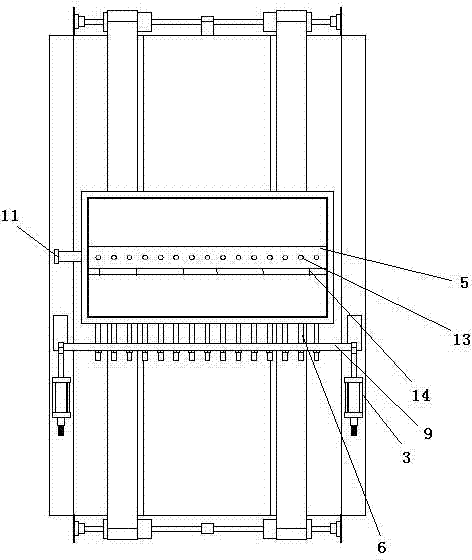

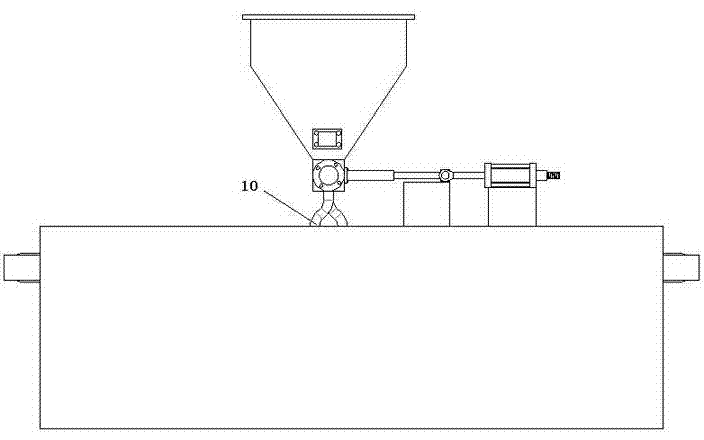

Heavy metal pollution soil treatment system and process

InactiveCN107309256ASimple structureClean thoroughlyContaminated soil reclamationMagnetic separationSoil treatmentPollution soil

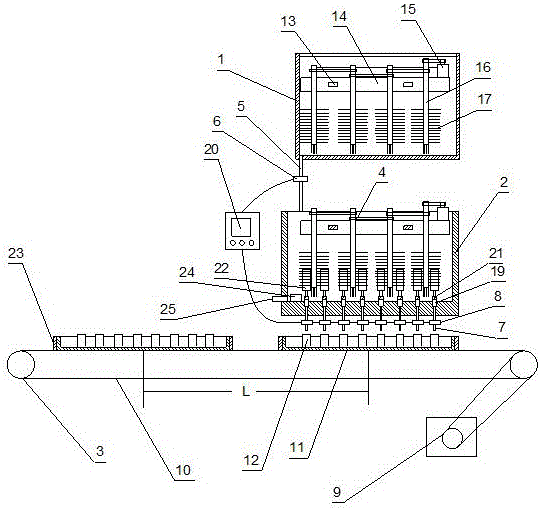

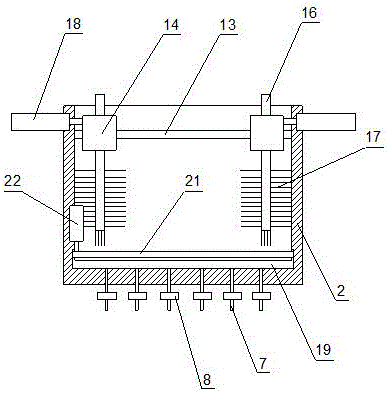

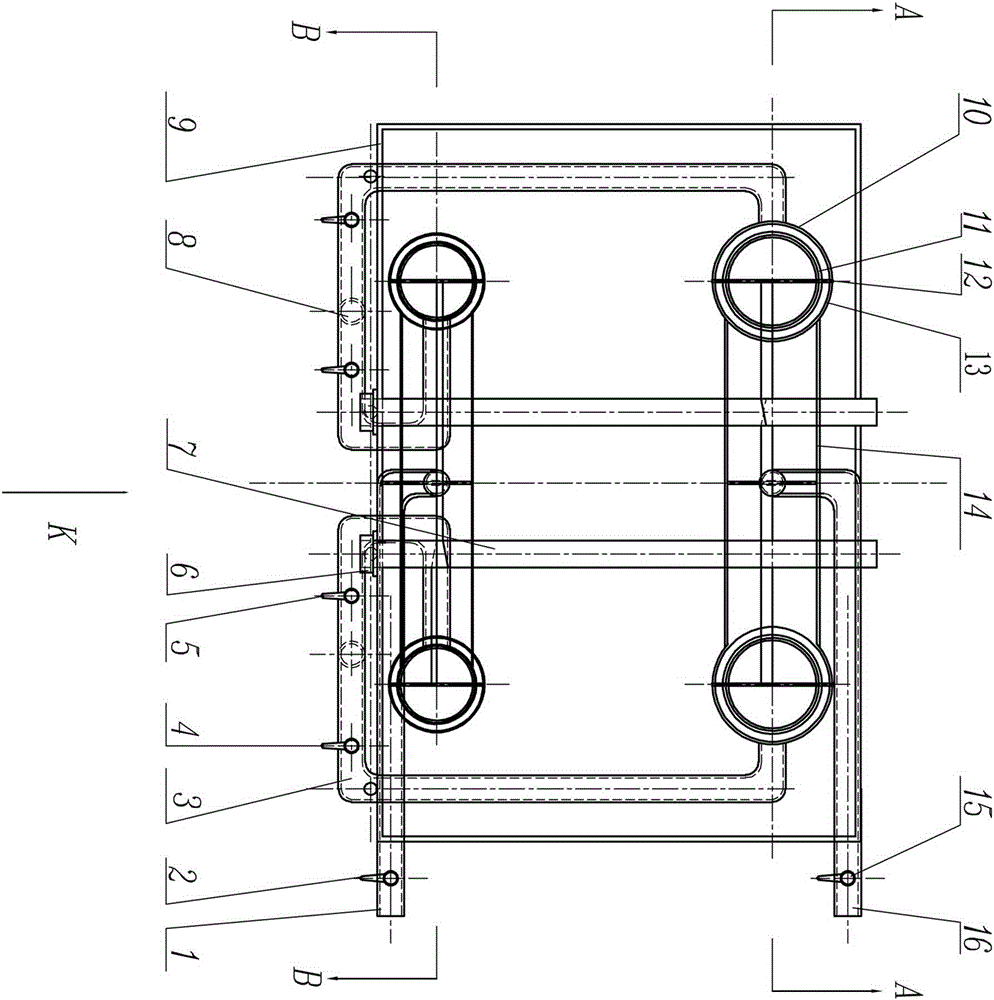

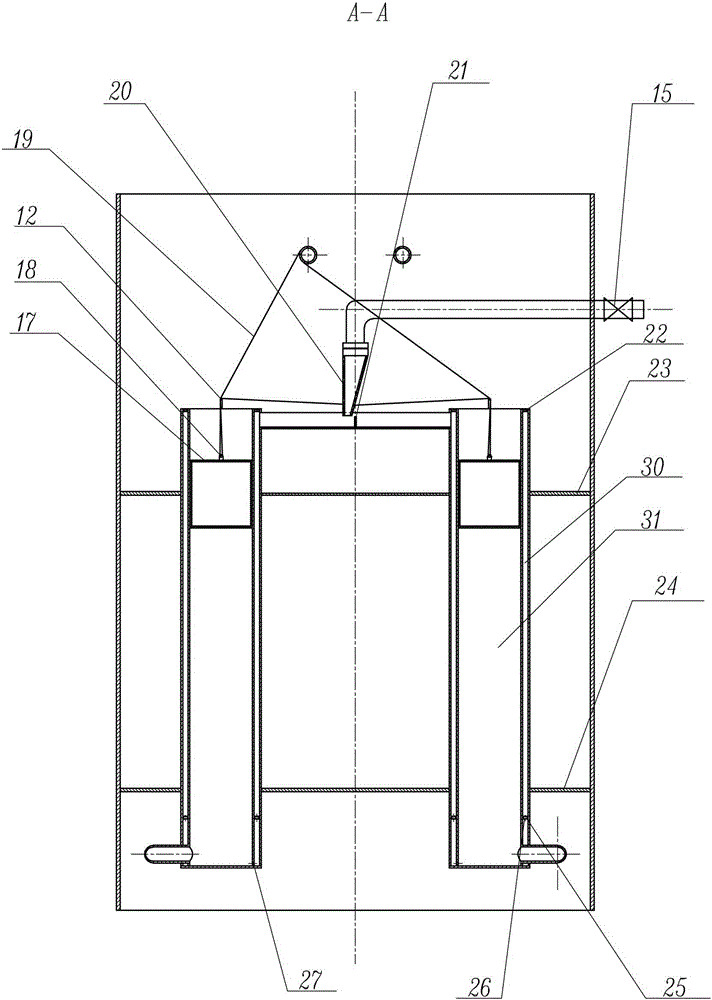

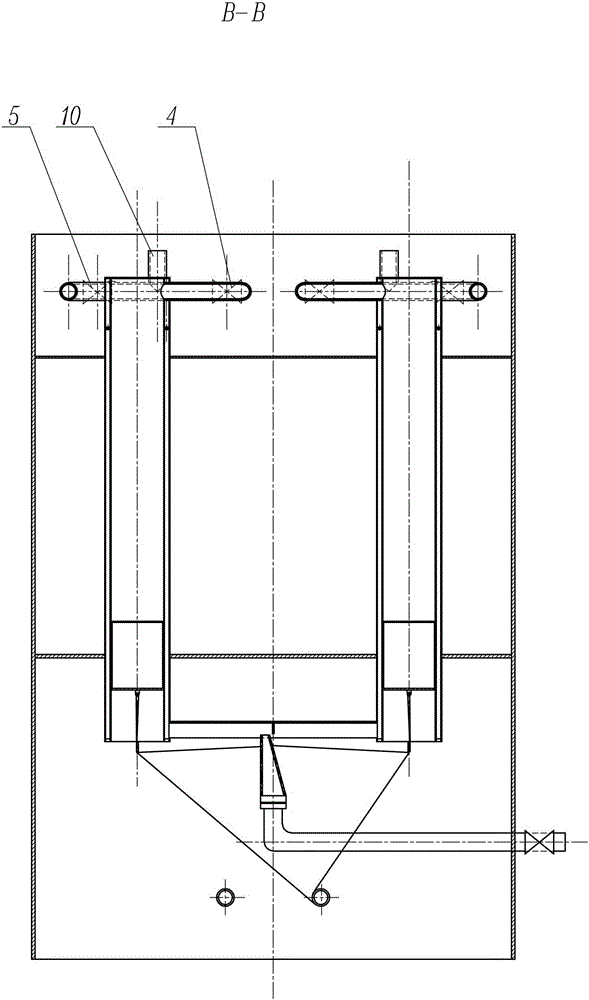

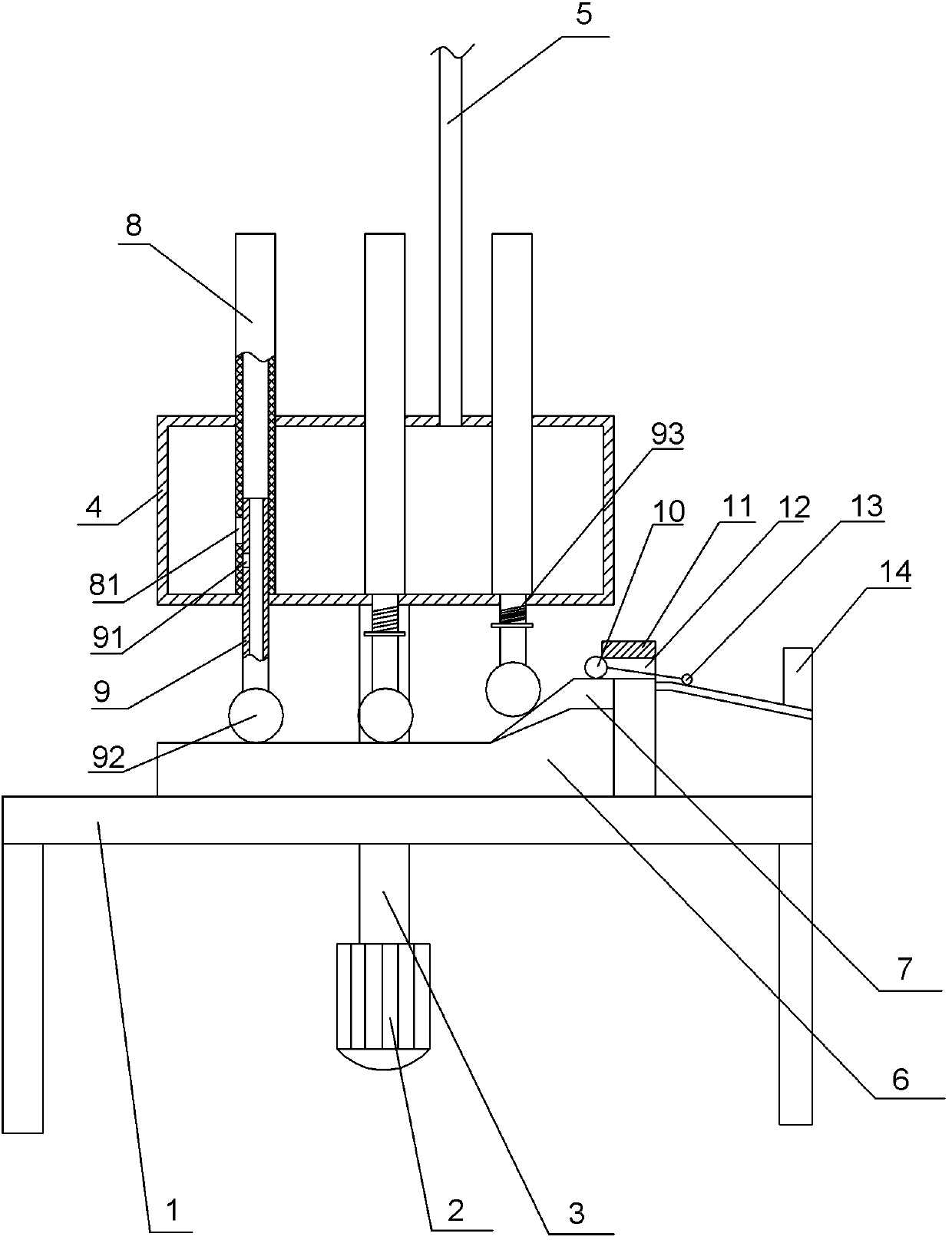

The invention discloses and provides a heavy metal polluted soil treatment system and process, aiming to solve the screening problem of magnetic heavy metal pollutants in polluted soil, which includes a first crushing and screening mechanism, a second crushing and screening mechanism, and a transfer and conveying mechanism And the lifting mechanism, through the oblique lifting and throwing of the heavy metal contaminated soil after the initial crushing to the screening rake with magnetic adsorption, the secondary crushing of the heavy metal contaminated soil is carried out by the screening rake, and the heavy metal contaminated soil is sucked out by magnetic adsorption The magnetic heavy metals contained in it improve the quality and efficiency of heavy metal pollutants in the subsequent treatment process.

Owner:浙江明境环保科技集团有限公司

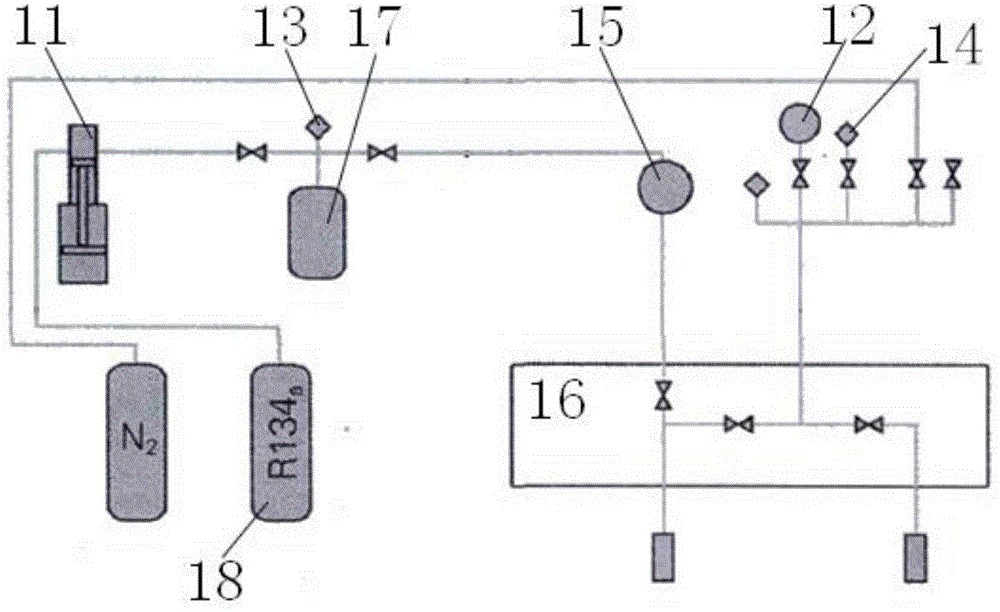

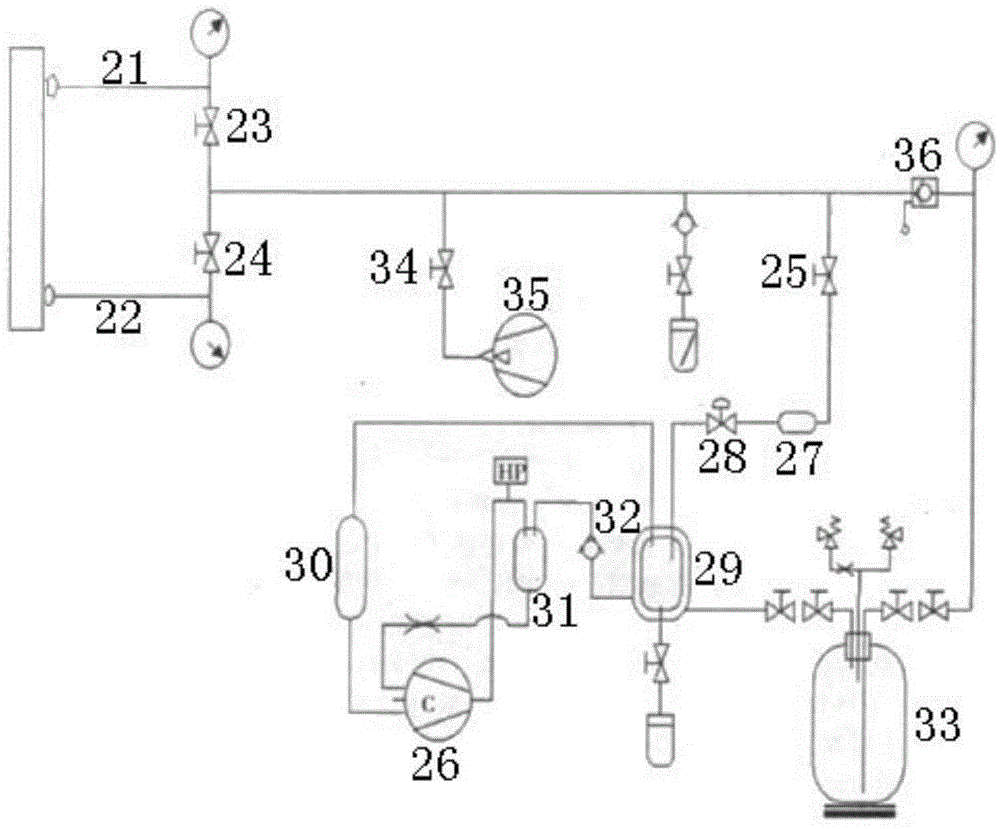

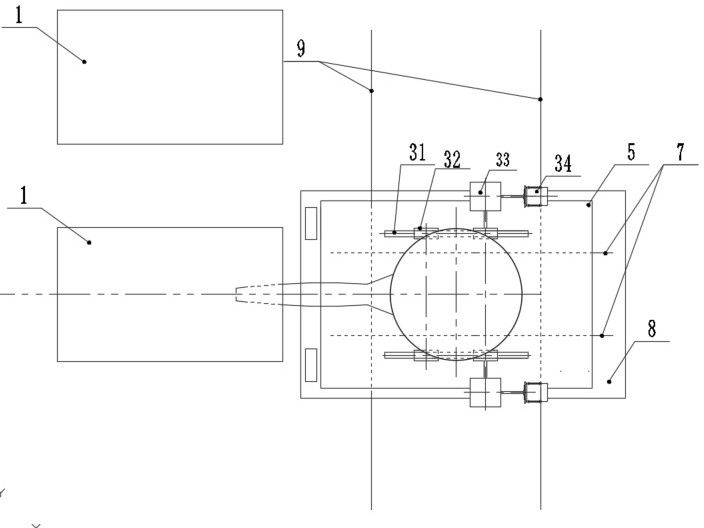

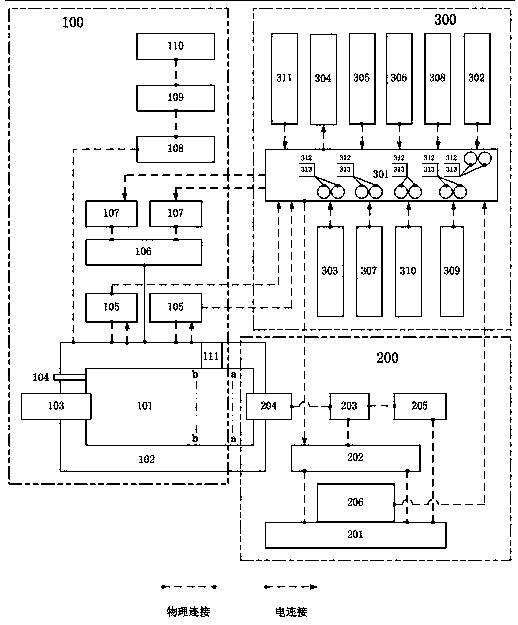

Refrigerating agent filling and recovering system and refrigerating agent filling and recovering method for vehicle air conditioner test system

The invention discloses a refrigerating agent filling and recovering system and a refrigerating agent filling and recovering method for a vehicle air conditioner test system. The refrigerating agent filling and recovering system comprises a liquid storage tank, a vacuum pump, a vacuum gauge, a first pipeline, a second pipeline, a filling tank, a recovering tank, a temperature control tank, a heater, a cooler, a weighing device and a control unit, wherein the filling tank which is arranged in a first temperature control box is connected with the liquid storage tank by virtue of a refrigerating agent replenishing valve and connected with the first pipeline by virtue of a filling valve; the recovering tank which is arranged in a second temperature control box is connected with a second pipeline by virtue of a recovering valve; the heater and the cooler are respectively used for controlling the temperature of the first temperature control box and the second temperature control box, and the two temperature control boxes are arranged on the weighing device; a low pressure pipeline and the second pipeline are respectively connected with the vacuum pump by virtue of a low-pressure vacuum valve and a high-pressure vacuum valve, a communication valve is arranged between the filling tank and the recovering tank, and one of the filling tank and the recovering tank is connected with the vacuum pump by virtue of a filling recovering vacuum valve; the control unit is connected with the weighing device, the heater, the cooler, the vacuum gauge and all valves. By adopting the system and the method, quantitative filling and temperature control can be accurately realized, and the reutilization of the refrigerating agent can be realized by switching the state of the temperature control boxes.

Owner:上海佐竹冷热控制技术有限公司

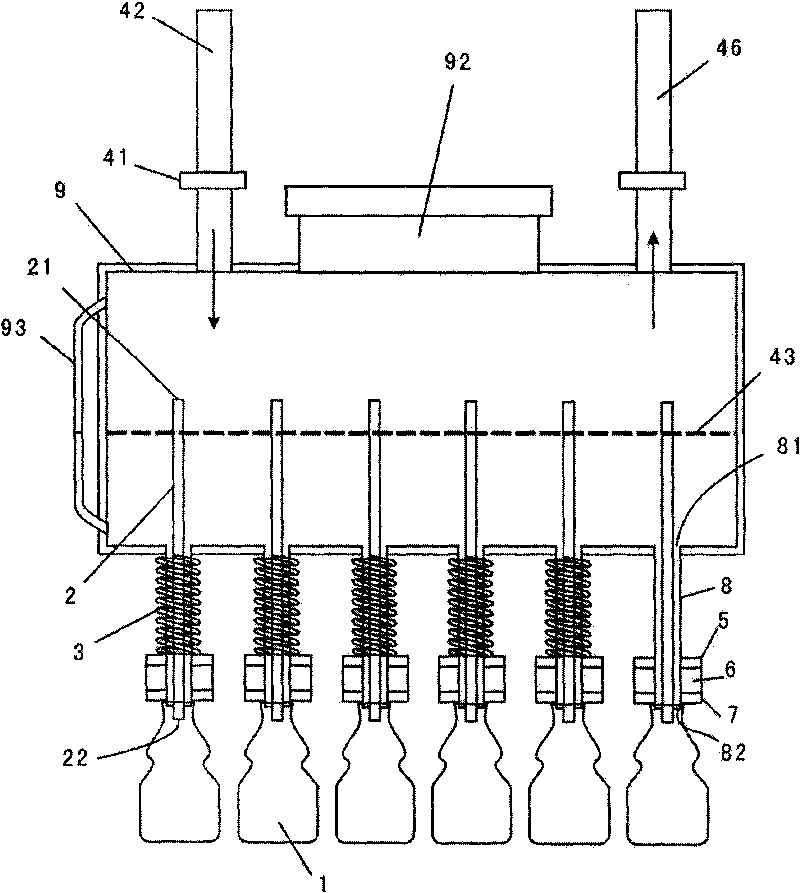

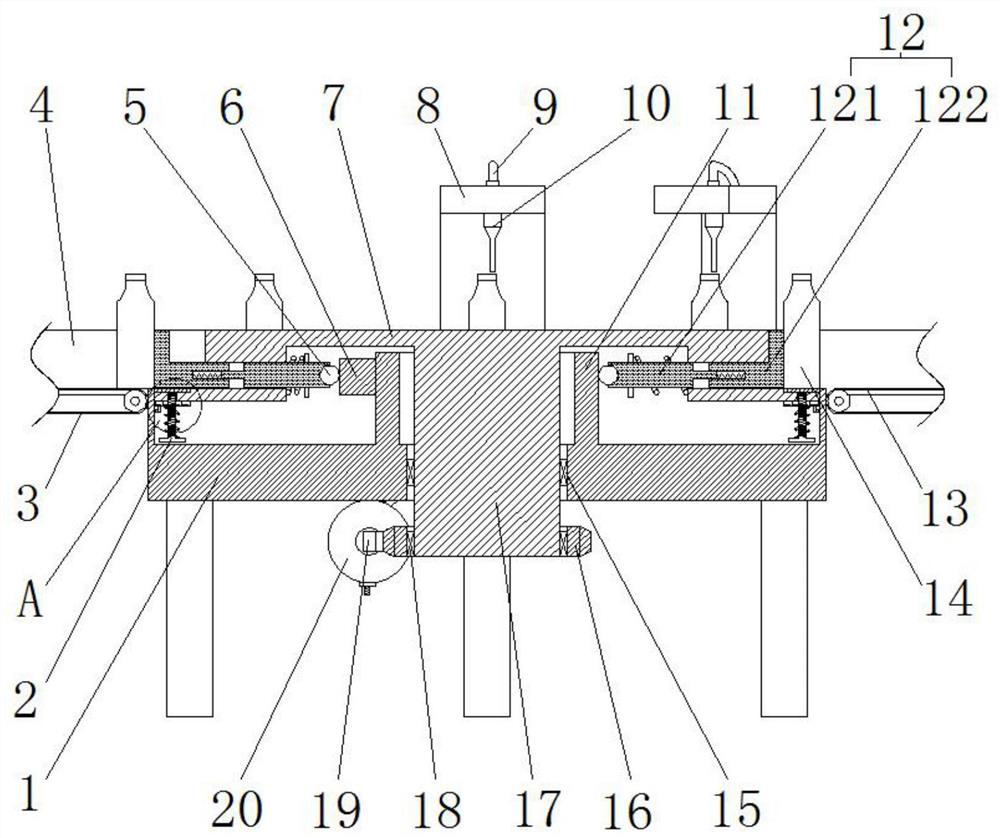

Method and equipment for vacuum quantitative filling of filling and sealing machine

ActiveCN101704495AHigh degree of automationLarge amount of processingFilling using suctionBottle-handling machinesLiquid productEngineering

The invention relates to a method and equipment for vacuum quantitative filling of a filling and sealing machine. The method comprises the following steps: a plurality of bottle holding plates are fixed on a driving chain and the driving chain is driven by a bottle holding plate to run; filling bottles are placed in all bottle holding holes of the bottle holding plates; the driving chain stops running when the bottle holding plates run to the lower part of a fluid reservoir, and at the moment, the filling bottles are supported on bottle mouth pressing plates by bottle supporting devices, and liquids flow into the filling bottles from lower openings of filling nozzles; and when the liquids inside the filling bottles are filled to liquid surfaces and parallel and level to lower openings of suction pipes, surplus liquids can be suctioned away by vacuum suction pipes, thus realizing quantitative filling. The filling nozzles, the bottle supporting devices and a transmission system all have specific structures, high degree of automation, and also large treatment quantity and extremely high efficiency. The structure is easy to demount and wash, thus guaranteeing sanitation indexes. The equipment and the method can be used for filling all liquid products.

Owner:DONG GUAN SHI LONG JIN WEI BEVERAGE & FOOD

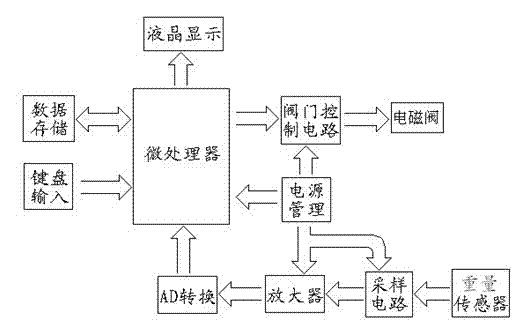

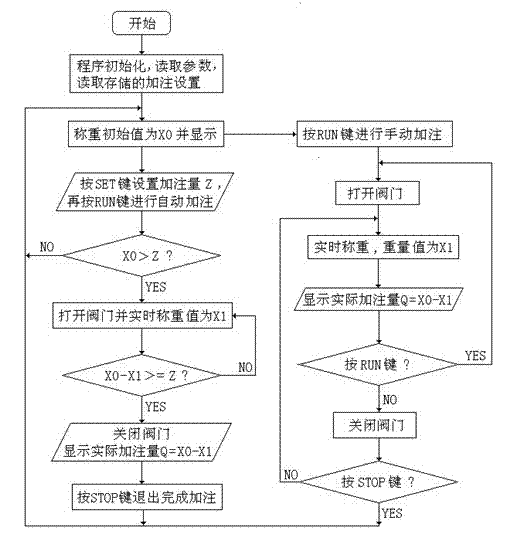

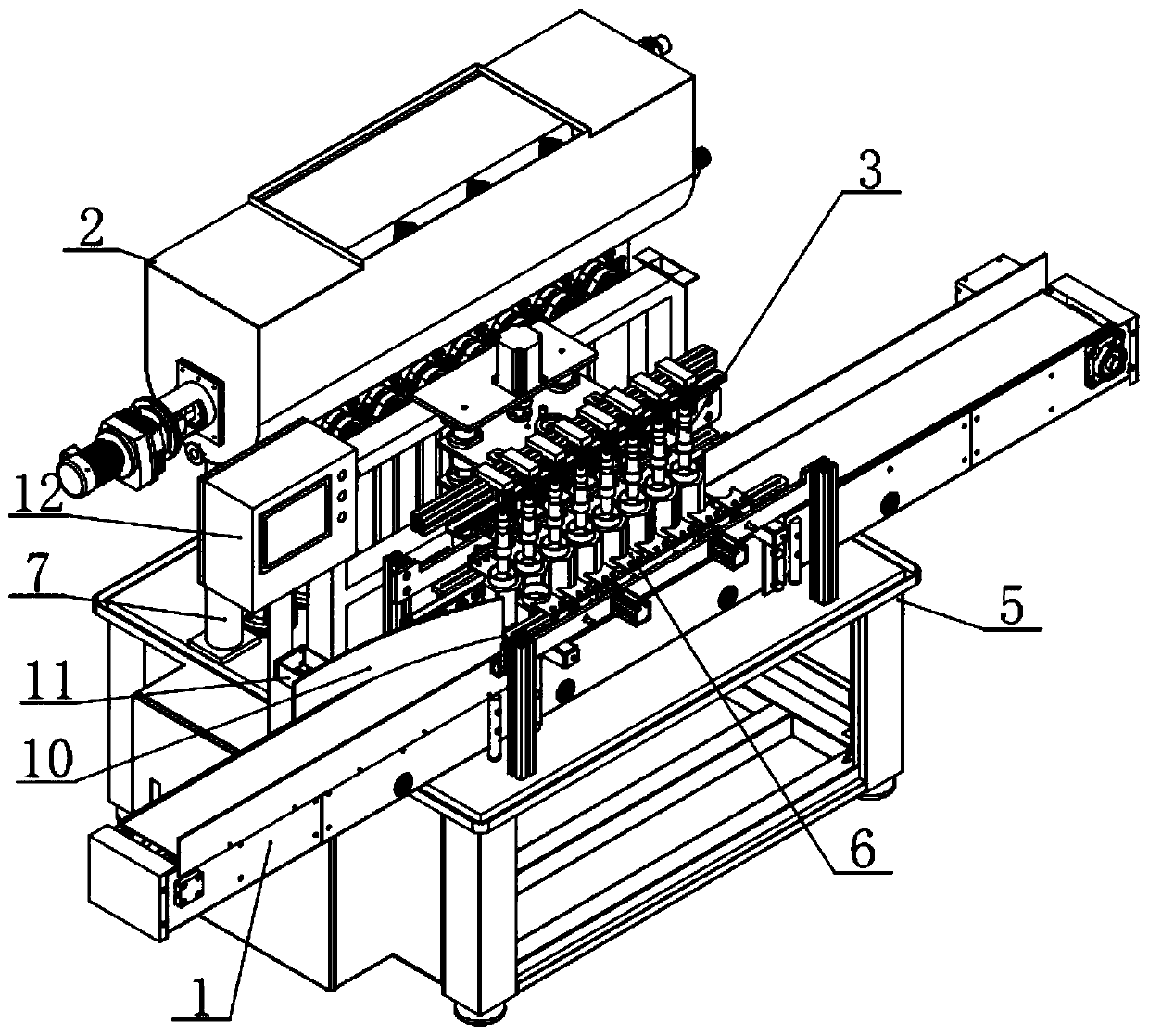

Electronic scale capable of quantitatively adding liquid and method for quantitatively adding liquid

InactiveCN103090937ARealize quantitative fillingRealize subpackageWeighing apparatus with automatic feed/dischargeAudio power amplifierEngineering

The invention discloses an electronic scale capable of quantitatively adding liquid. The electronic scale capable of quantitatively adding the liquid comprises a tray. A weight sensor is connected with the tray and arranged below the tray. The weight sensor is connected with an operating circuit board through a shielded wire. The operating circuit board controls an electromagnetic valve to be opened and closed. The operating circuit board comprises a microprocessor. Output signals of the weight sensor are transmitted to an amplifier through a sampling circuit. After the output signals are processed through the amplifier, the output signals are input the microprocessor through an analog to digital (A / D) transition circuit. The microprocessor controls the electromagnetic valve to be opened and closed through a valve control circuit. According to the electronic scale capable of quantitatively adding the liquid, accurate and automatic filling of air conditioner refrigerants can be achieved, and a price is more reasonable. Further disclosed is a method for quantitatively adding the liquid. The electronic scale is adopted in the method for quantitatively adding the liquid.

Owner:TAIZHOU LANGXUN MACHINERY

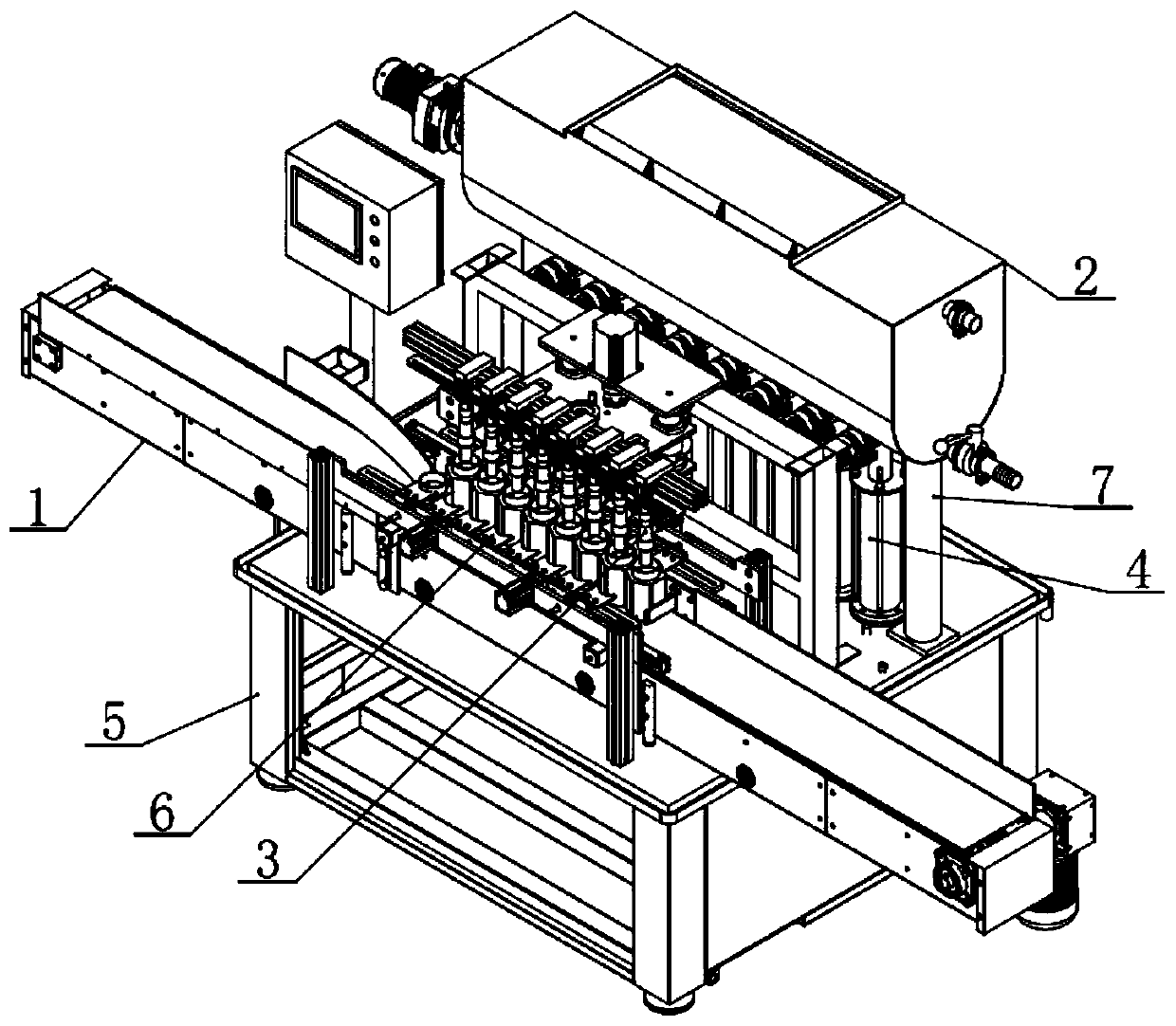

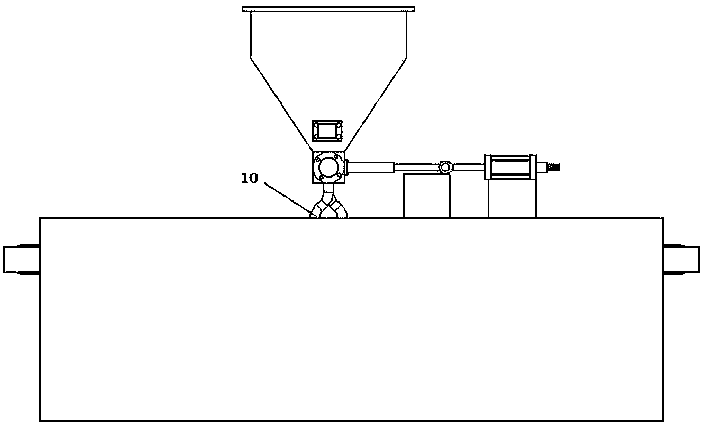

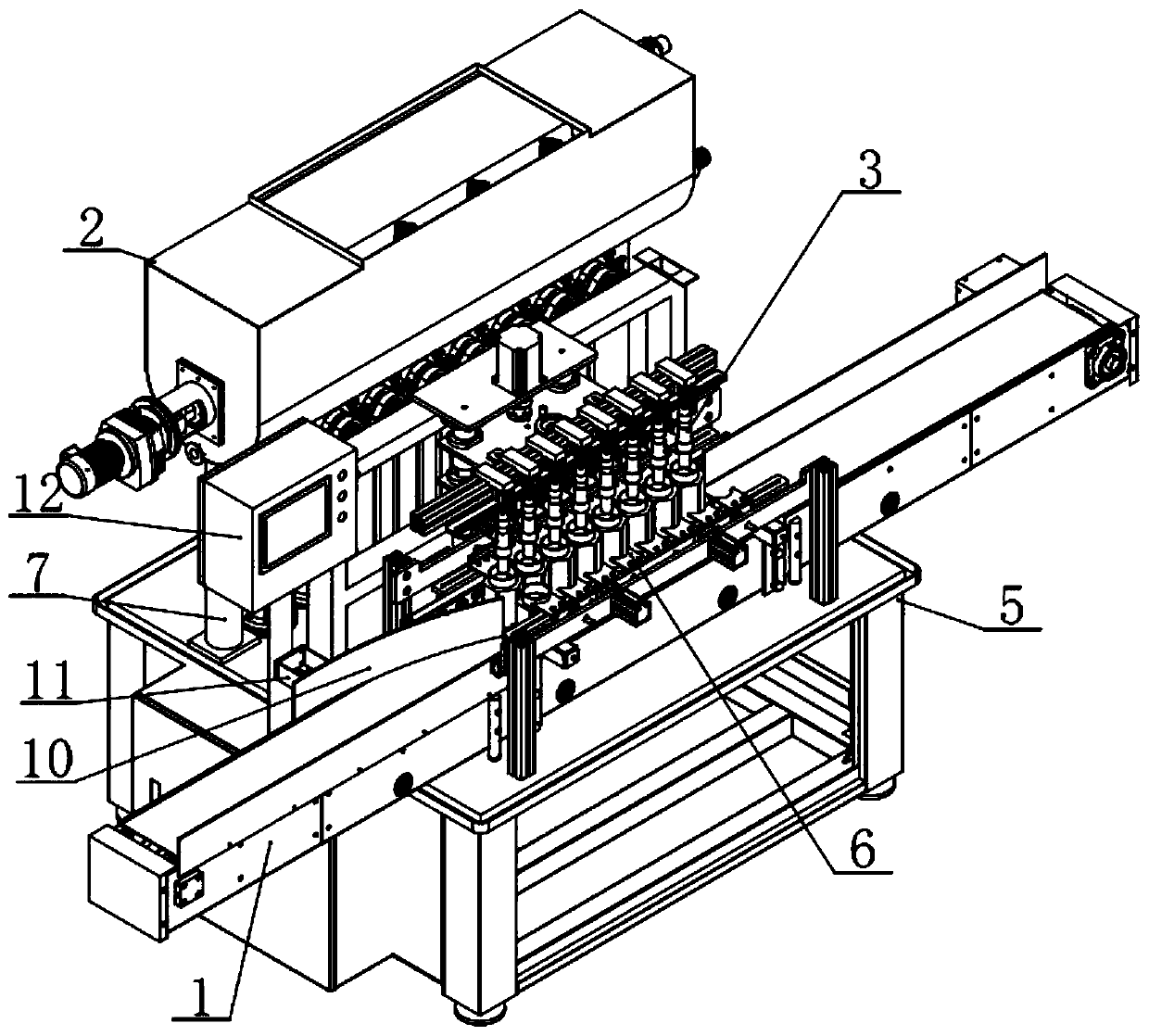

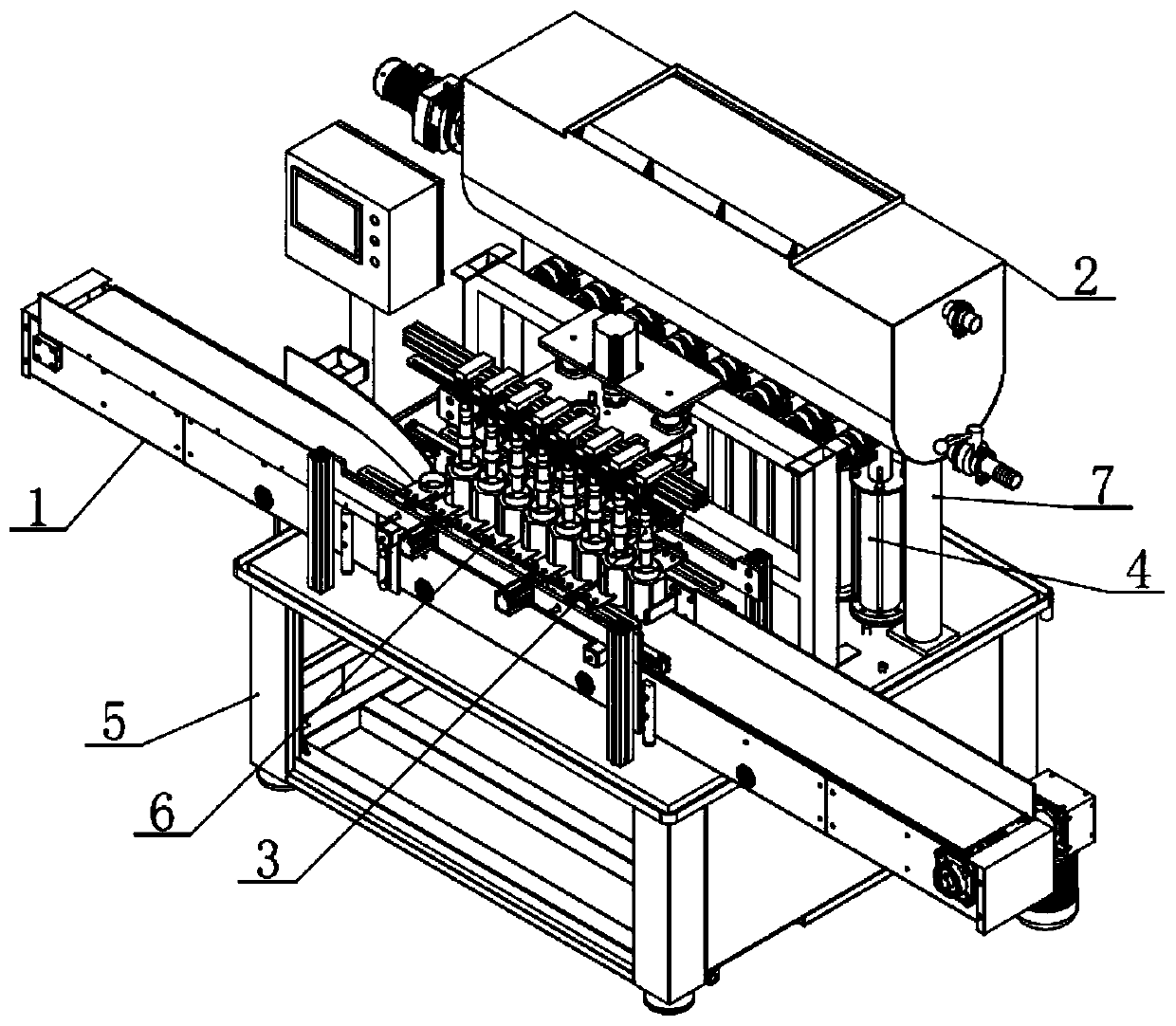

Passion fruit linear type filling machine

The invention discloses a passion fruit linear type filling machine. The passion fruit linear type filling machine comprises a conveying mechanism, a stirrer, a filling mechanism and metering cylinders. The conveying mechanism is installed on the transverse front side of the upper end of a base, and a bottle opening limiting mechanism and the filling mechanism are installed on the front side and the rear side of the middle of the conveying mechanism. The filling mechanism is connected to the discharging ends of the metering cylinders through pipelines, and the feeding ends of the metering cylinders are connected to the bottom of the stirrer. The stirrer is fixedly connected to the rear side of the base through a supporting frame, piston rods of the metering cylinders are connected with a metering adjusting mechanism, and the metering adjusting mechanism is installed on the base. The metering adjusting mechanism in the passion fruit linear type filling machine adjusts the stir uniform feeding of the stirrer and the discharging operation of the metering cylinders and controls the feeding operation of the metering cylinders, and after the metering cylinders are filled with passion fruit juice, the filling mechanism is controlled to multiple filling bottles conveyed by the conveying mechanism to conduct discharging and filling operation. The bottle opening limiting mechanism is adopted to conduct automatic quick limiting, the bottles are pushed to the filling positions to be subjected to quick filling, and therefore the bottle output waiting time is shortened, and the production efficiency is improved.

Owner:GUIZHOU UNIV

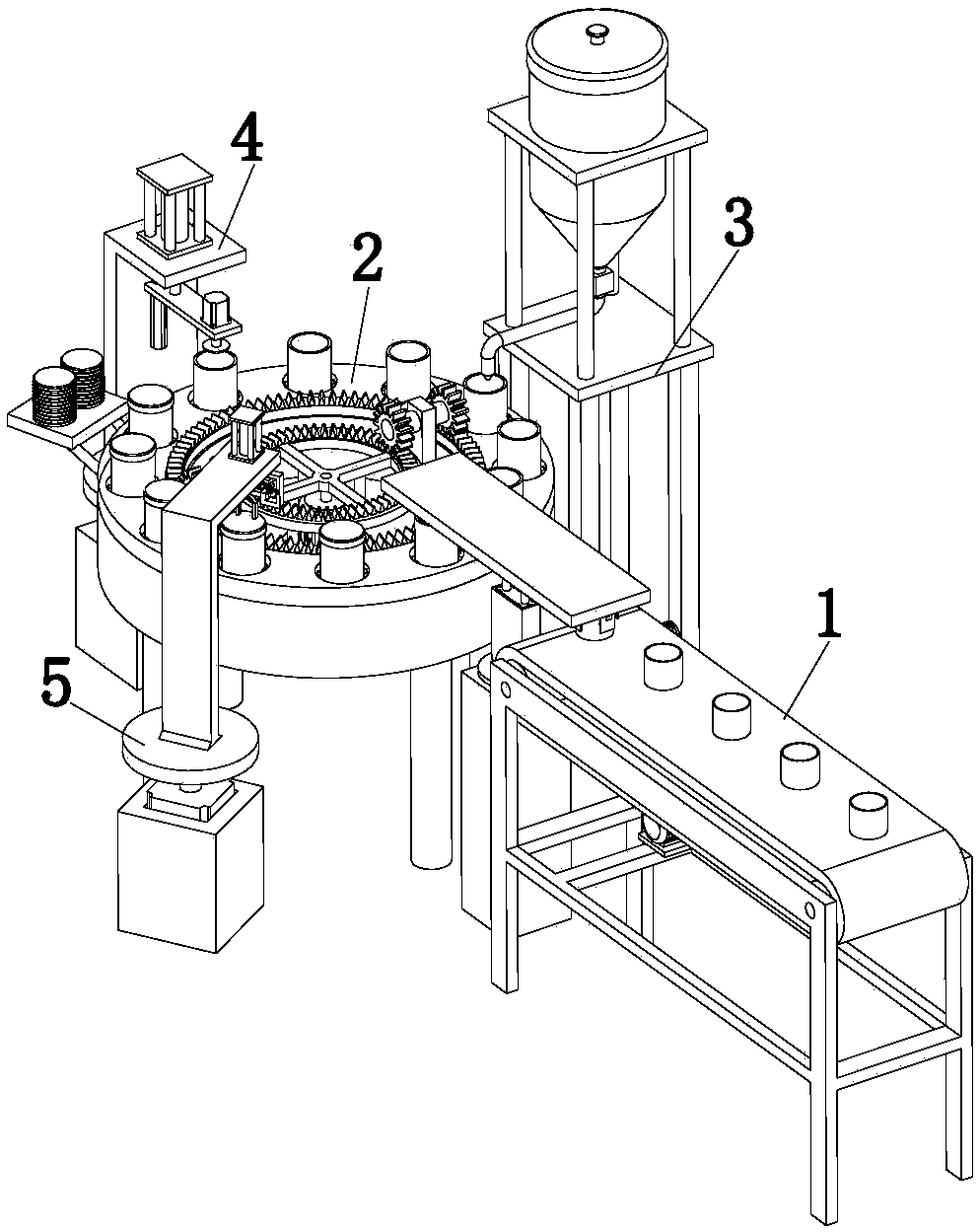

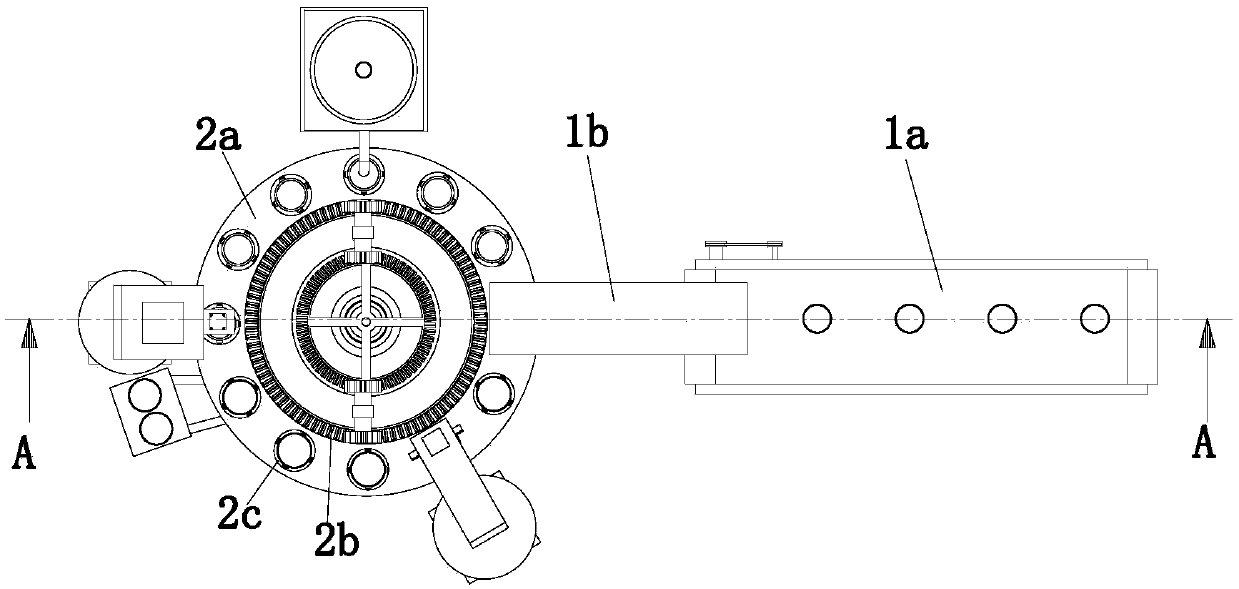

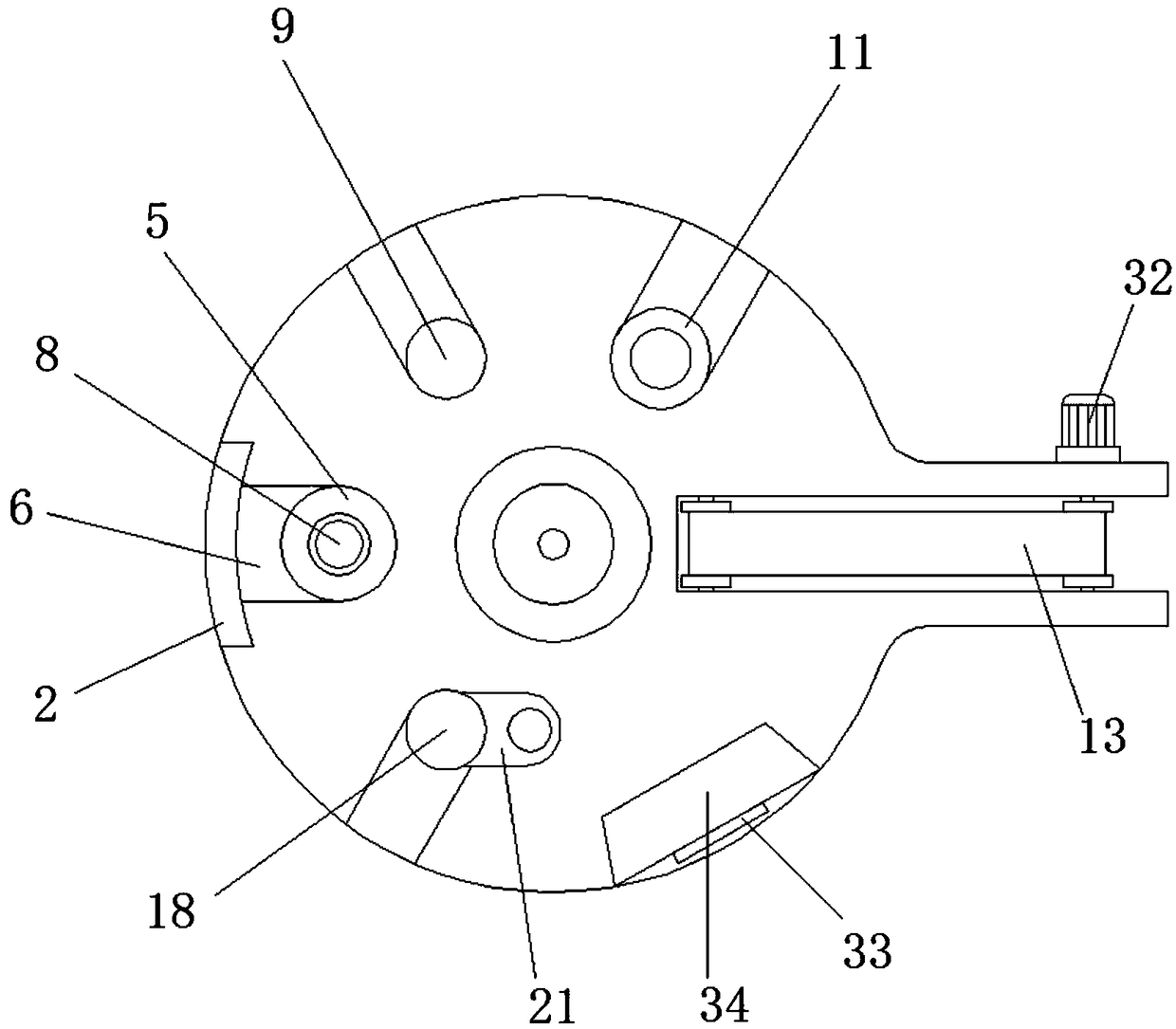

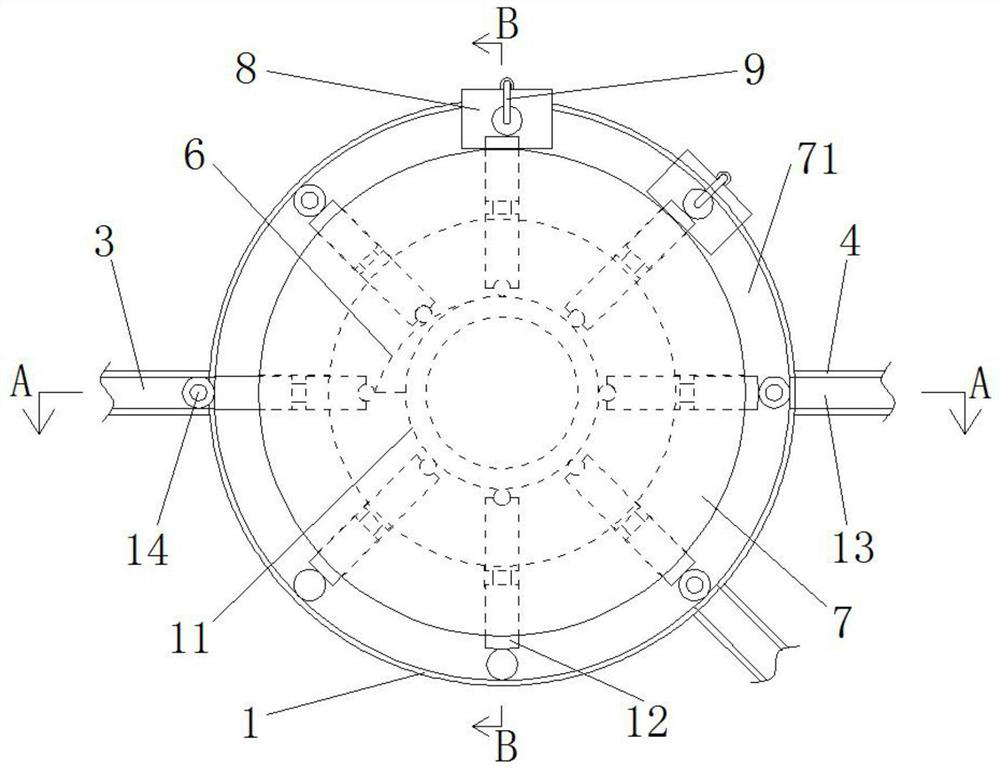

Filling and sealing device for filling food

ActiveCN109573922AFilling operation realizedIncrease productivitySynchronising machinesLiquid bottlingEngineeringFood packaging

The invention discloses a filling and sealing device for filling food, and belongs to the technical field of food packaging machinery. The filling and sealing device comprises a feeding component, a rotating component, a filling component, a packaging component and a discharging component; the feeding component, the filling component, the packaging component and the discharging component are all arranged around the axis of the rotating component, and the feeding component comprises a conveying assembly and a transfer assembly; the conveying assembly is arranged at the discharging end of the transfer assembly, and the rotating component comprises a rotating assembly, a support assembly and a limit assembly; the rotating assembly is arranged on the support assembly, and the limit assembly isarranged on the rotating assembly; and in the working state, the transfer assembly, the filling component, the packaging component and the discharging component are all in but joint with the limit assembly. According to the filling and sealing device, filling bottles in different sizes can be clamped through movement of four pneumatic clamps, and the fixation of the filling bottles in different sizes can be achieved through movement of four springs and four stop blocks; and the sealing operation of the filling bottles in different sizes is achieved through the sealing device.

Owner:中山市正友机械制造有限公司

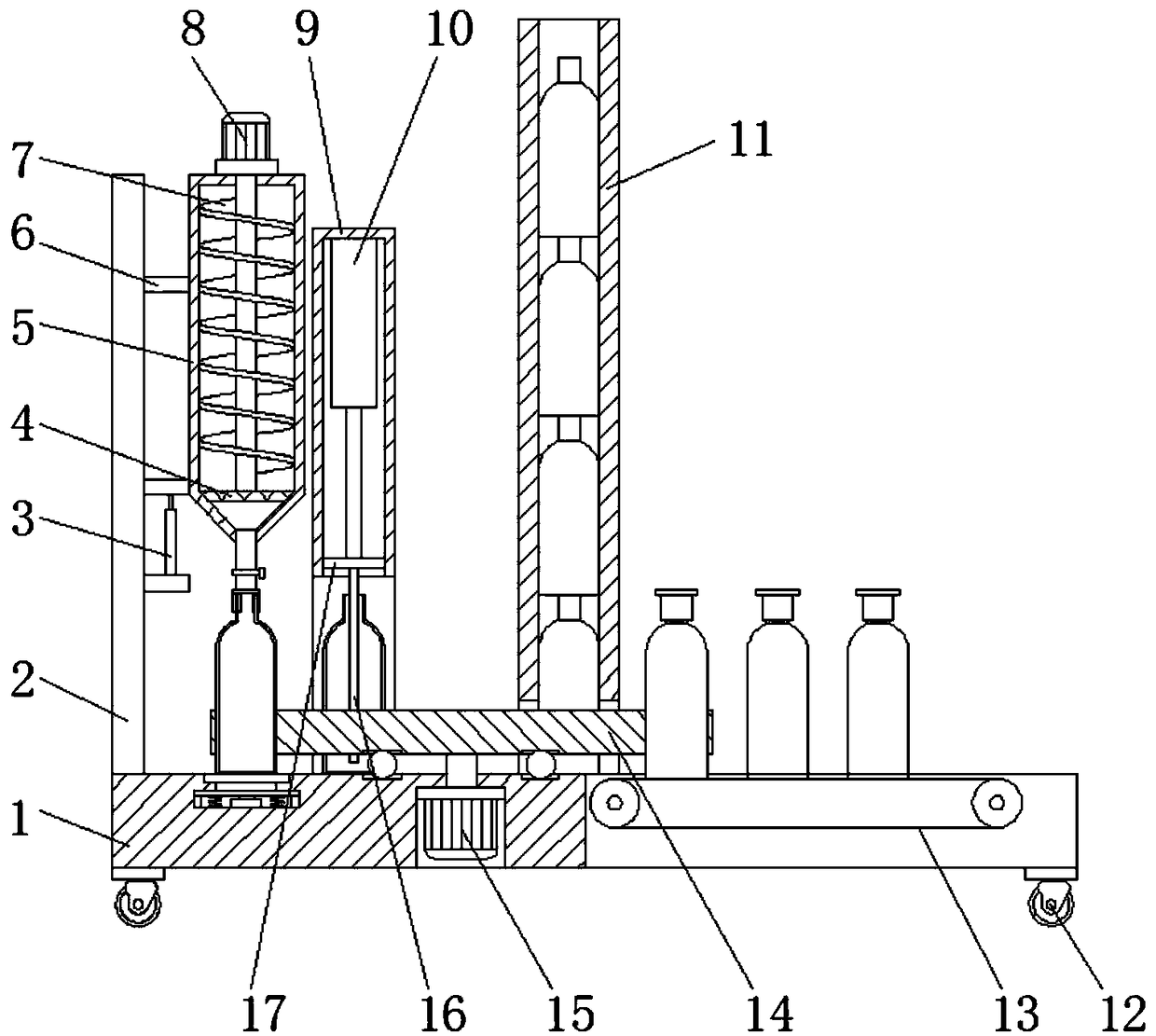

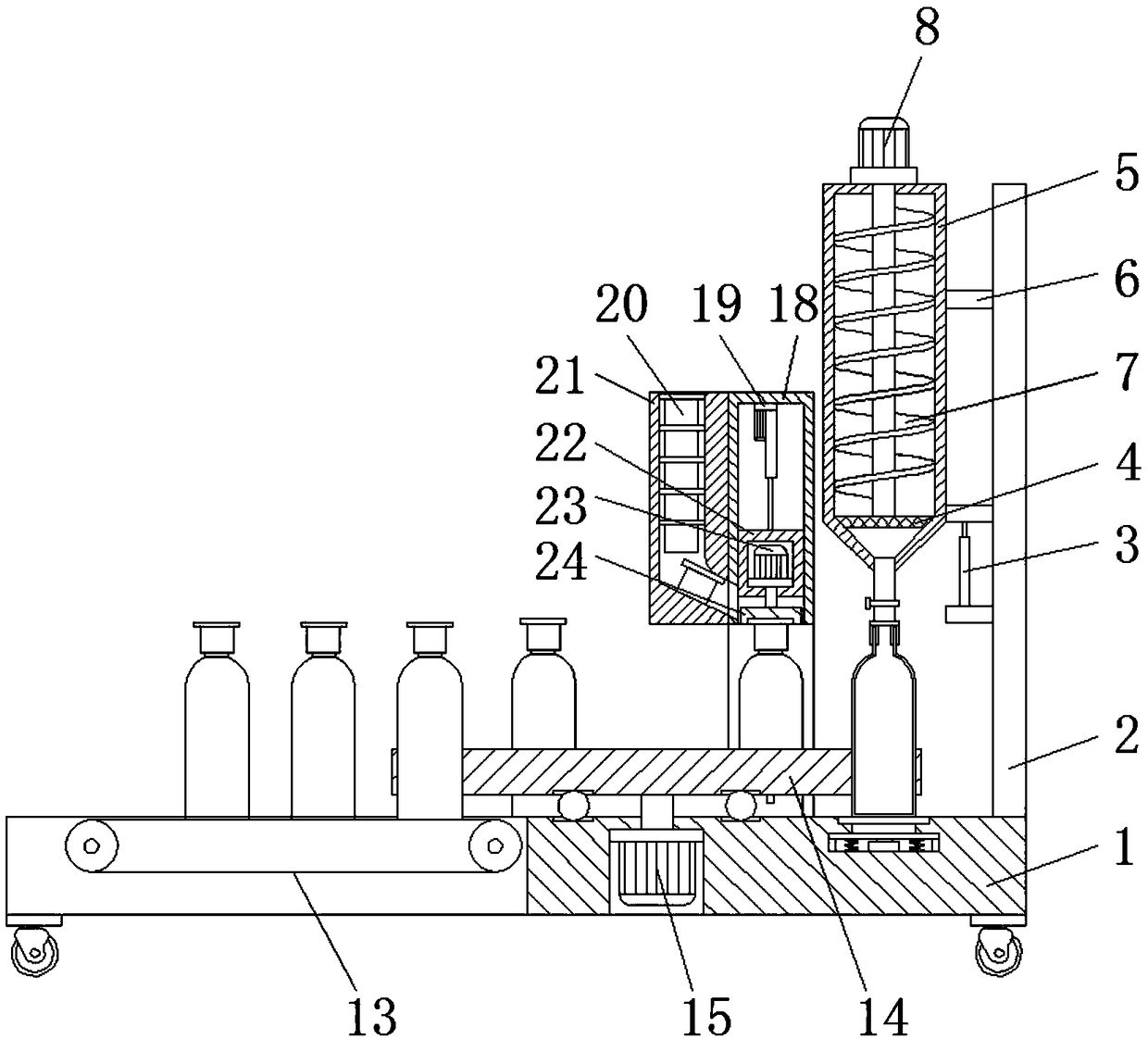

Automatic shampoo filling equipment for production of personal hygiene products

ActiveCN109160474AWeight real-time monitoringAvoid waste of raw materialsLiquid bottlingCouplingElectric machinery

The invention belongs to the technical field of shampoo production and in particular relates to automatic shampoo filling equipment for production of personal hygiene products. Aiming at the problem that the conventional shampoo filling equipment is inconvenient for quantitative filling, the following scheme is provided. The automatic shampoo filling equipment comprises a base, wherein universal wheels are fixed at four corners of the outer wall of the bottom of the base by virtue of screws; supporting shaft mounting holes are formed in outer walls of the top of the base; the inner walls of the supporting shaft mounting holes are connected with a supporting shaft by virtue of a bearing; a rotating table is connected with the top of the outer wall on one side of the supporting shaft by virtue of keys; a drive motor is fixed on the inner wall of the top of the base by virtue of screws; the output shaft of the drive motor is fixed on the outer wall at one end of the supporting shaft by virtue of a coupling. According to the equipment disclosed by the invention, the phenomenon that raw materials are wasted due to bottle-free filling can be effectively avoided, the filling amount is conveniently controlled, the occurrence probability of a phenomenon that the discharge pipe is blocked by the raw materials is reduced, the labor intensity of workers is reduced, and the influence of dust impurities in air on the product quality is reduced.

Owner:LOOBI GUANGZHOU HEALTH IND CO LTD +1

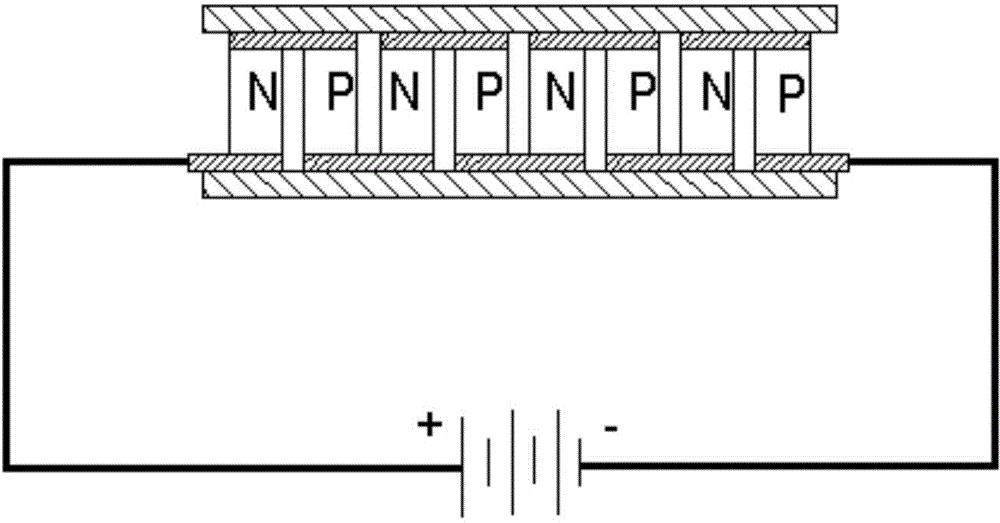

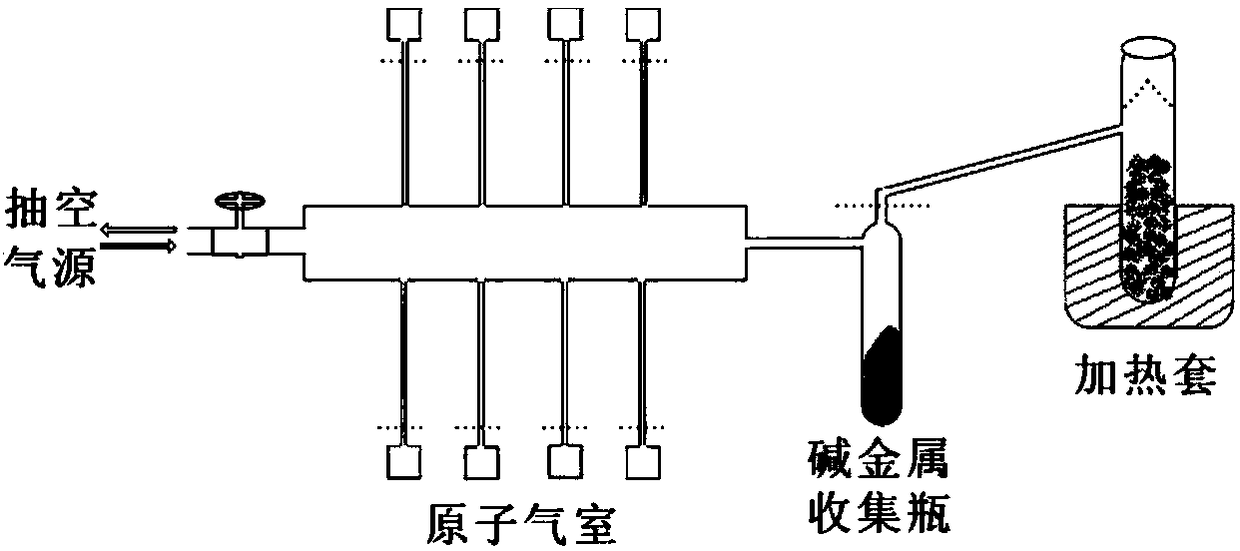

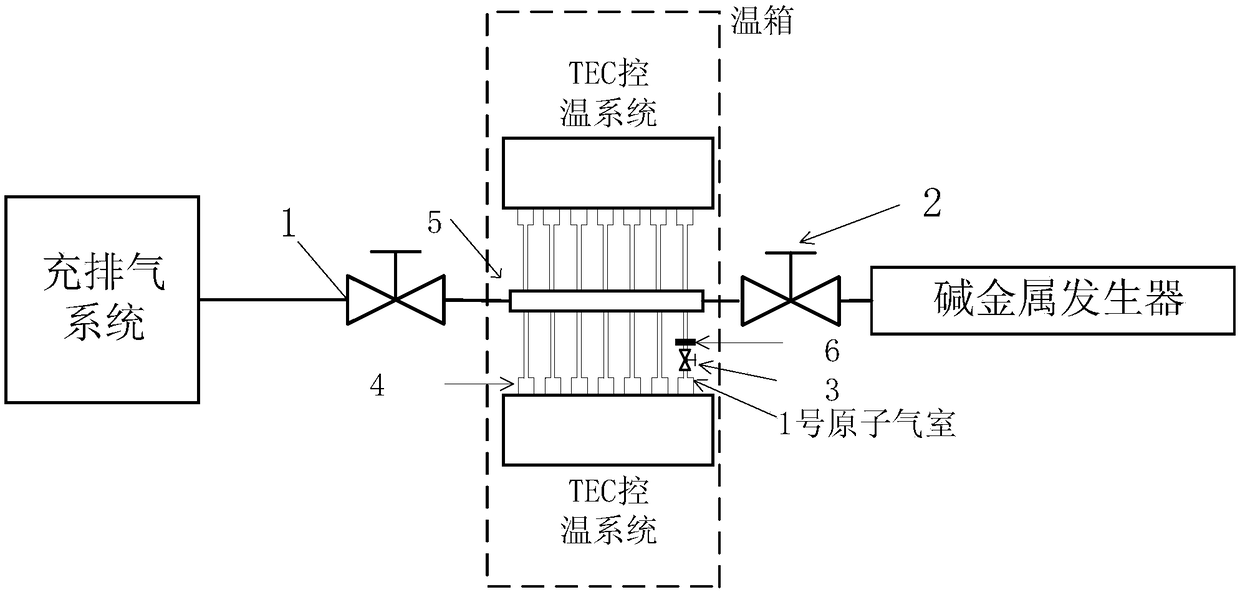

Atom air chamber preparation device and preparation method with quantitative filling of alkali metal

ActiveCN108411253AGuaranteed uniformityEfficient use ofVacuum evaporation coatingSputtering coatingBatch productionEngineering

The invention discloses an atom air chamber preparation device with quantitative filling of alkali metal. The preparation device comprises a gas filling and exhausting system, N atom air chambers, analkali metal split charging vessel, a temperature tank, a TEC temperature control system, an alkali metal generator, a vacuum valve 1 used for being connected with the gas filling and exhausting system and the alkali metal split charging vessel, a vacuum valve 2 used for being connected with the alkali metal split charging vessel and the alkali metal generator and a vacuum valve 3 used for being connected with the alkali metal split charging vessel and a first atom air chamber. For the atom air chamber preparation device and method provided by the invention, by actively and accurately controlling temperature distribution in the alkali metal split charging vessel, orientated deposition of the alkali metal is realized; by utilizing calibration of the deposition rate of some an atom air chamber, quantitative filling of the alkali metal is realized; and compared with the traditional filling mode, quantitative control of the filled alkali metal is realized, the filling consistency is improved at the same time, and a feasible solution is more provided to batch production of the atom air chambers.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

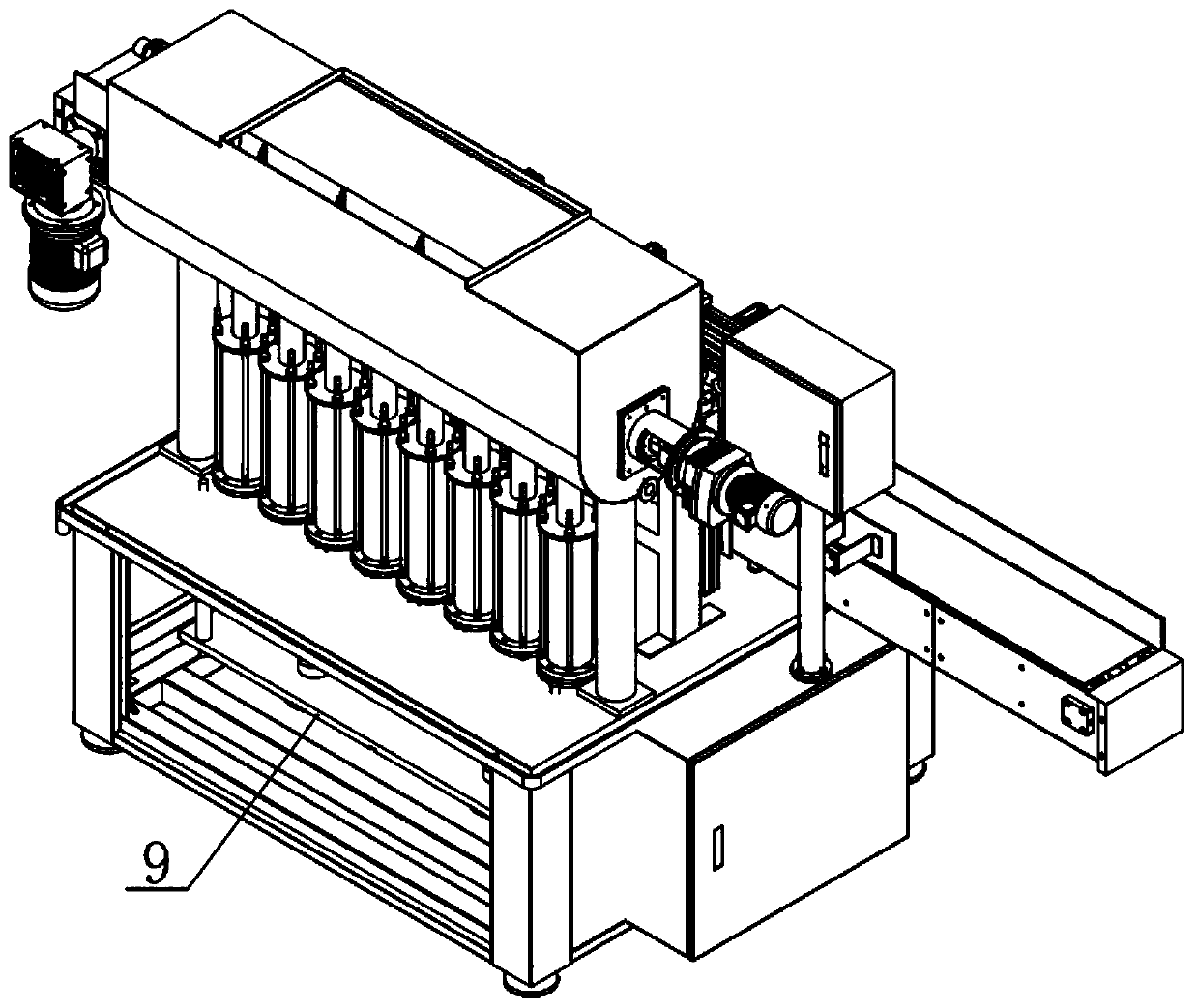

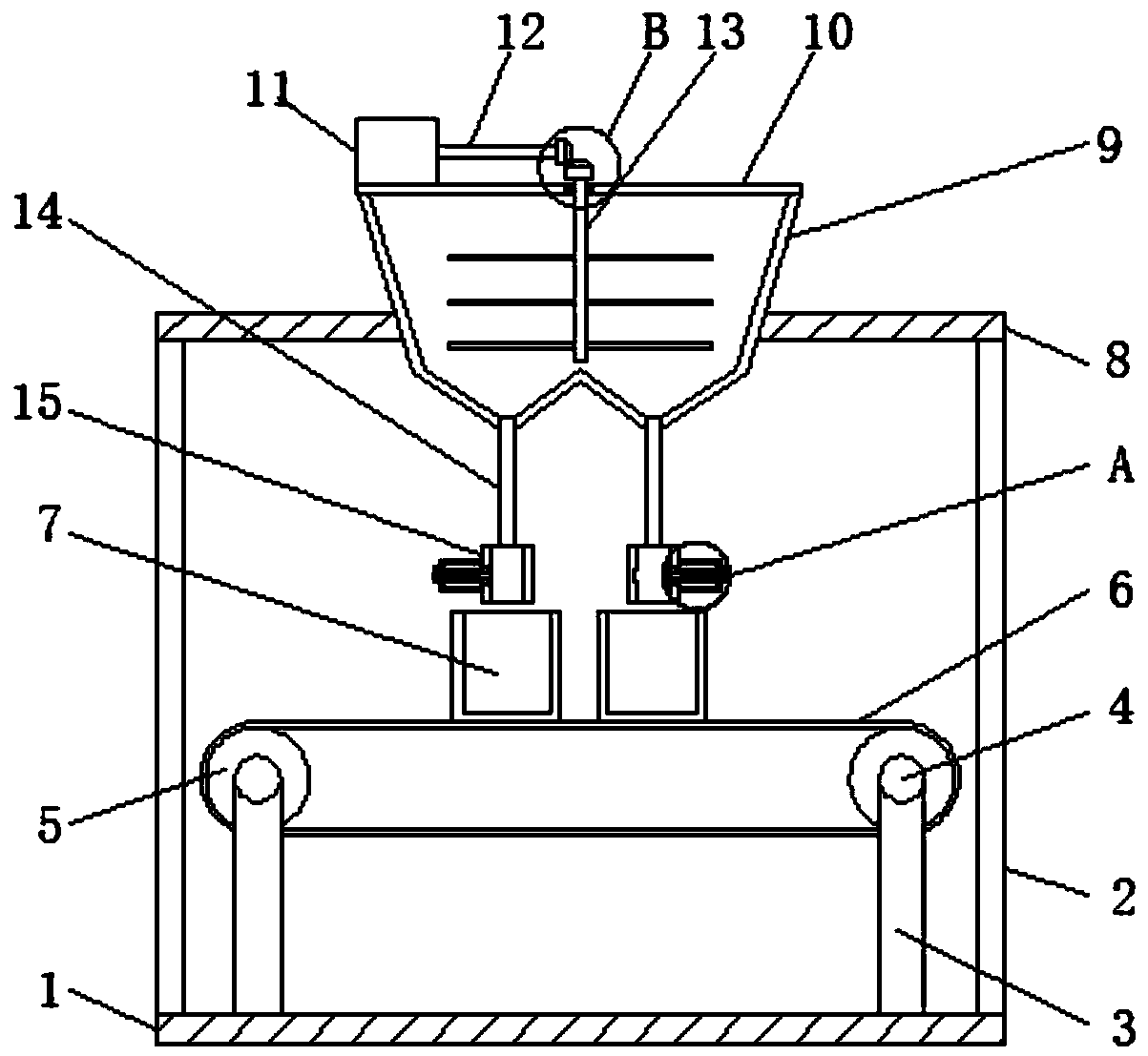

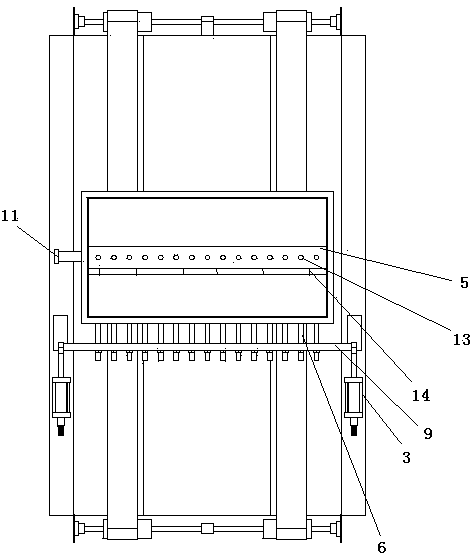

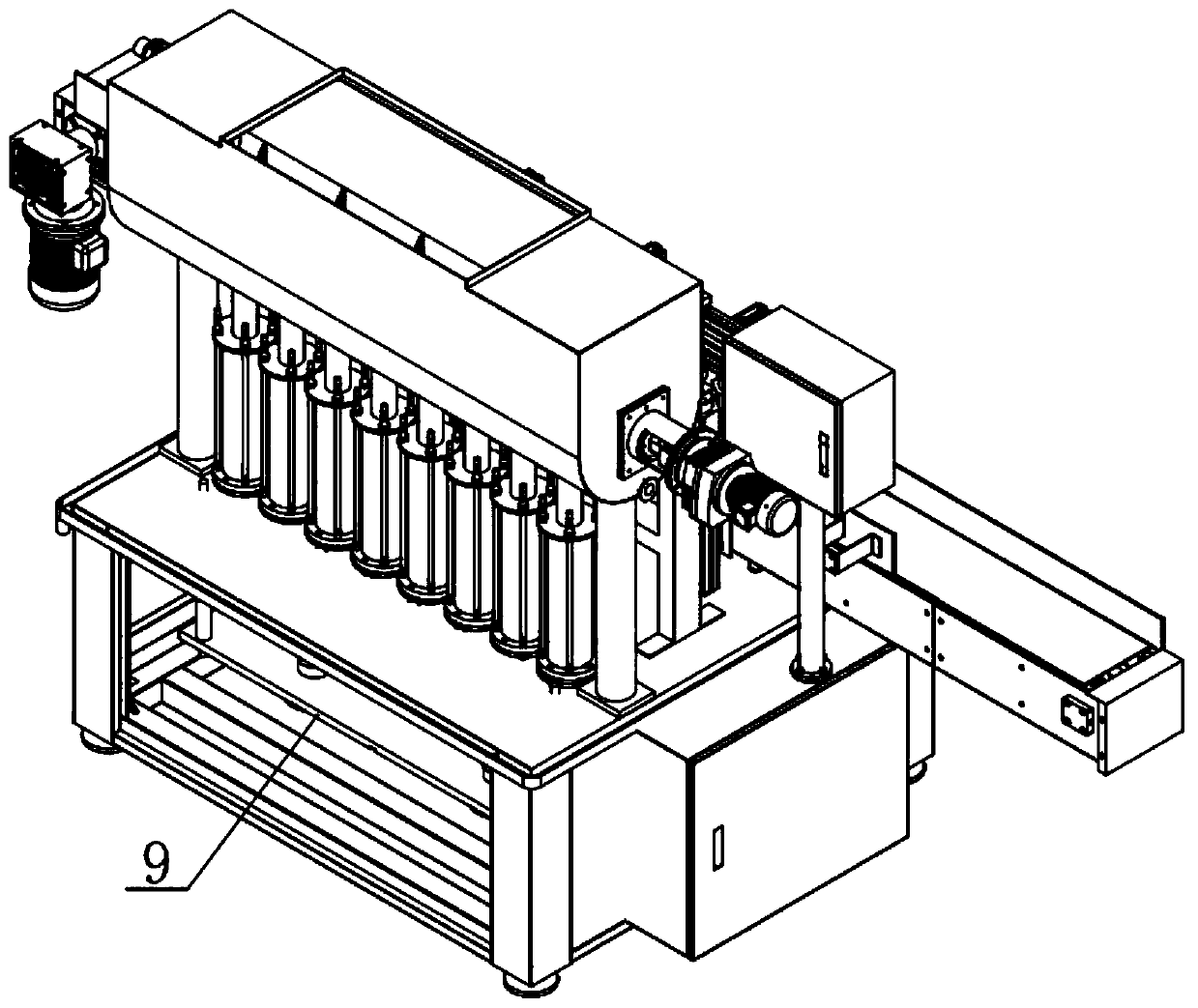

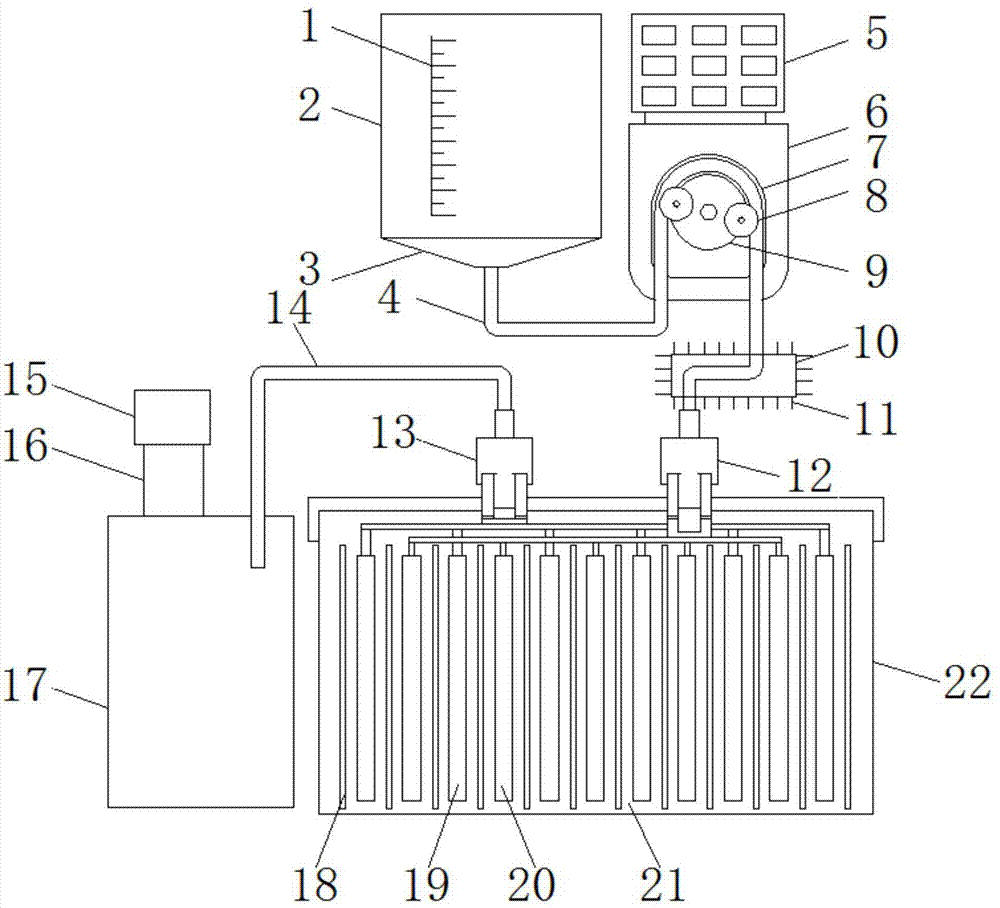

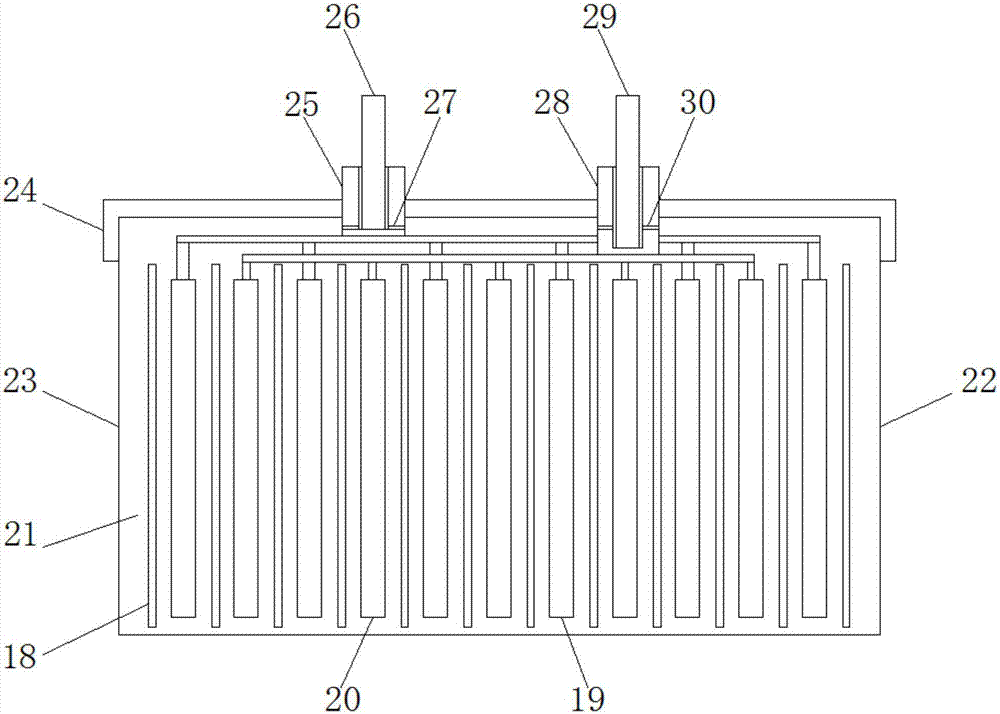

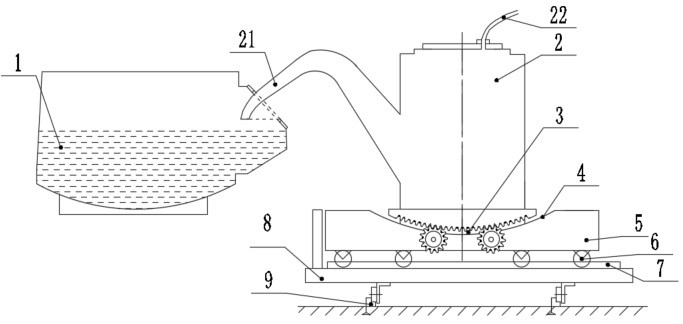

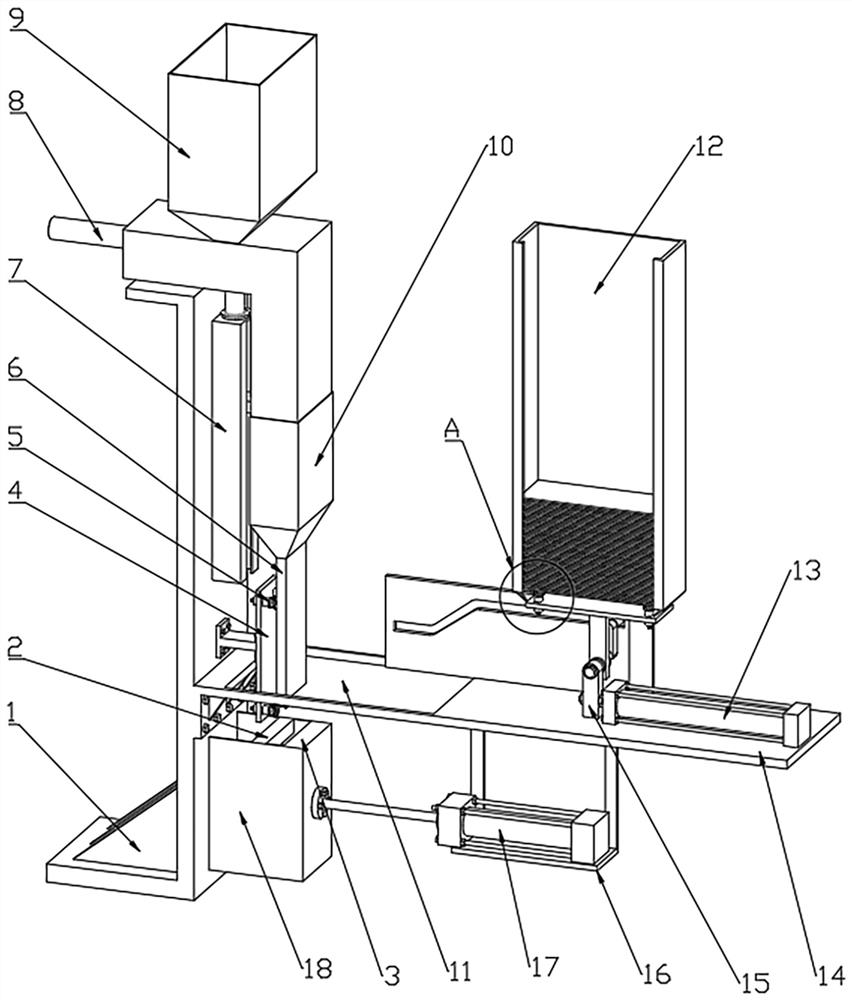

Automatic quantitative filling system for tissue culture solution

The invention discloses an automatic quantitative filling system for a tissue culture solution. The automatic quantitative filling system comprises a high configuration tank, a low storage tank and a transmission device, wherein a stirring device is arranged in each of the high configuration tank and the low storage tank; the high configuration tank communicates with the lower storage tank through a conveying tube; a solenoid valve is arranged on the conveying tube; a plurality of liquid outlet tubes which are uniformly arranged are arranged on the bottom of the low storage tank; the liquid outlet tubes are vertically arranged, and the lower ends of the liquid outlet tubes penetrate through a bottom plate of the storage tank; an electromagnetic flow control valve is arranged on each liquid outlet tube; the electromagnetic flow control valves are electrically connected with a control device; the transmission device comprises a step motor and a transmission belt; a plurality of supporting boxes are arranged on the conveyor belt; distance between adjacent two supporting boxes is equal; a plurality of tissue culture bottles which are uniformly distributed are arranged in the supporting boxes; quantity of the tissue culture bottles is consistent with that of the liquid outlet tubes; and each tissue culture bottle can move to a position below certain liquid outlet tube along with the conveyor belt. The system realizes quantitative filling, and ensures that nutrition of the tissue culture solution in each tissue culture bottle is uniform and consistent.

Owner:XUANWEI NONGSHUO AGRI SPECIAL PROD DEV CO LTD

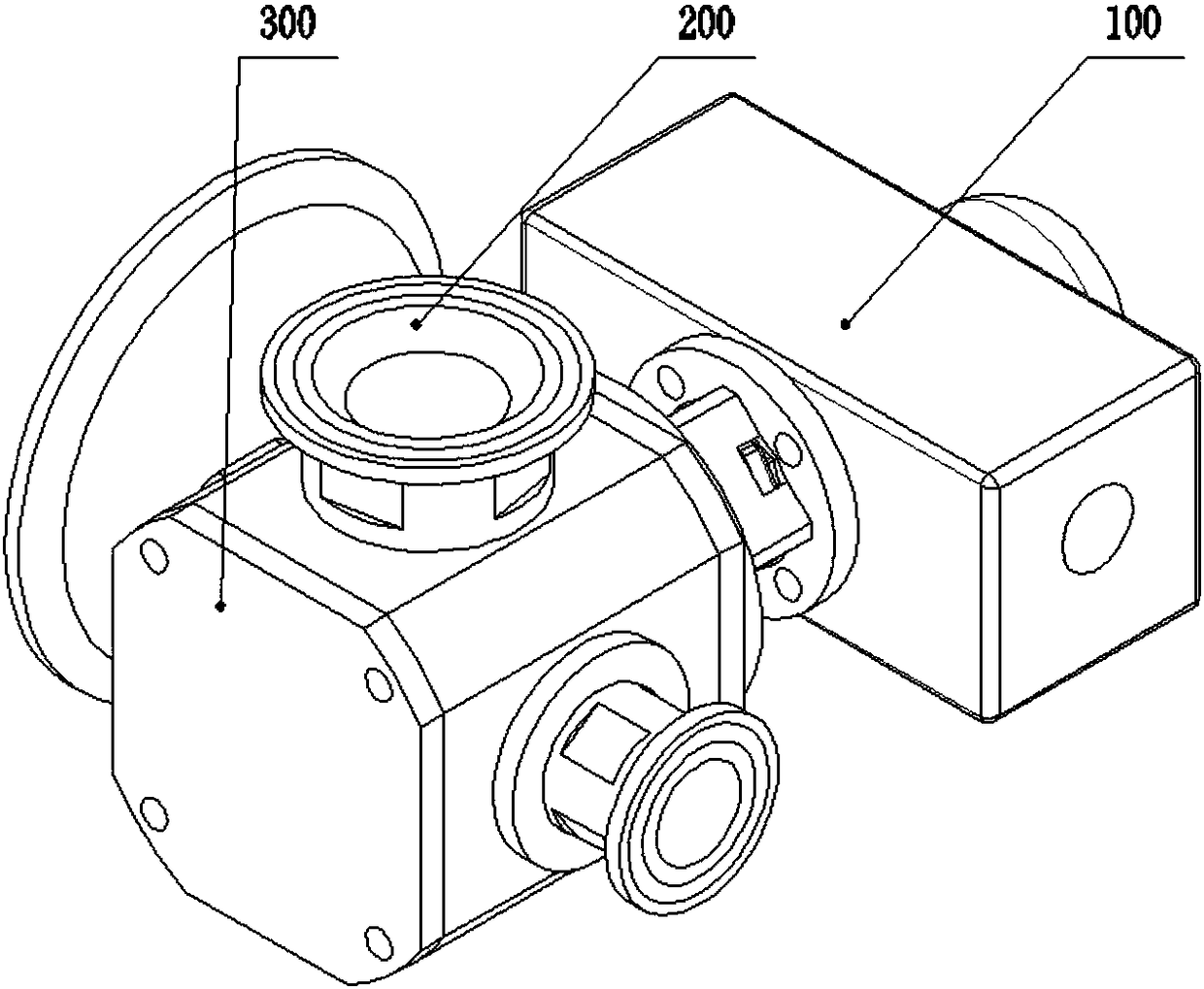

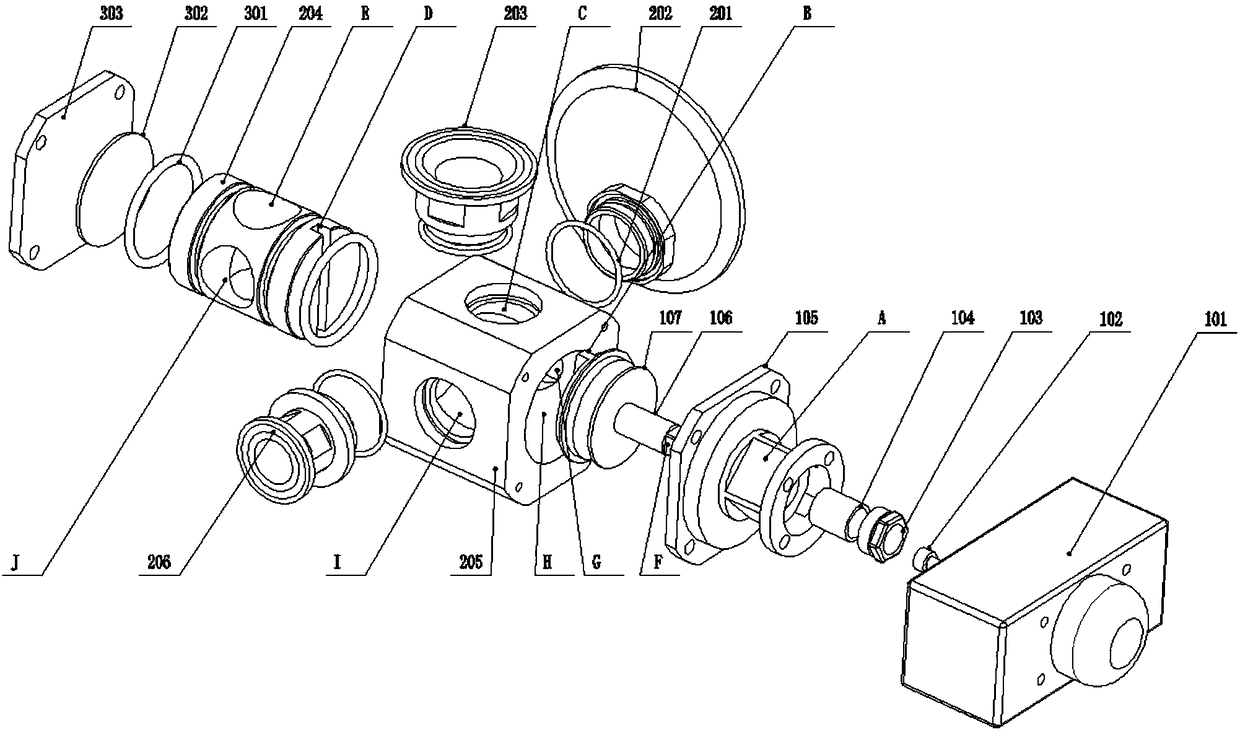

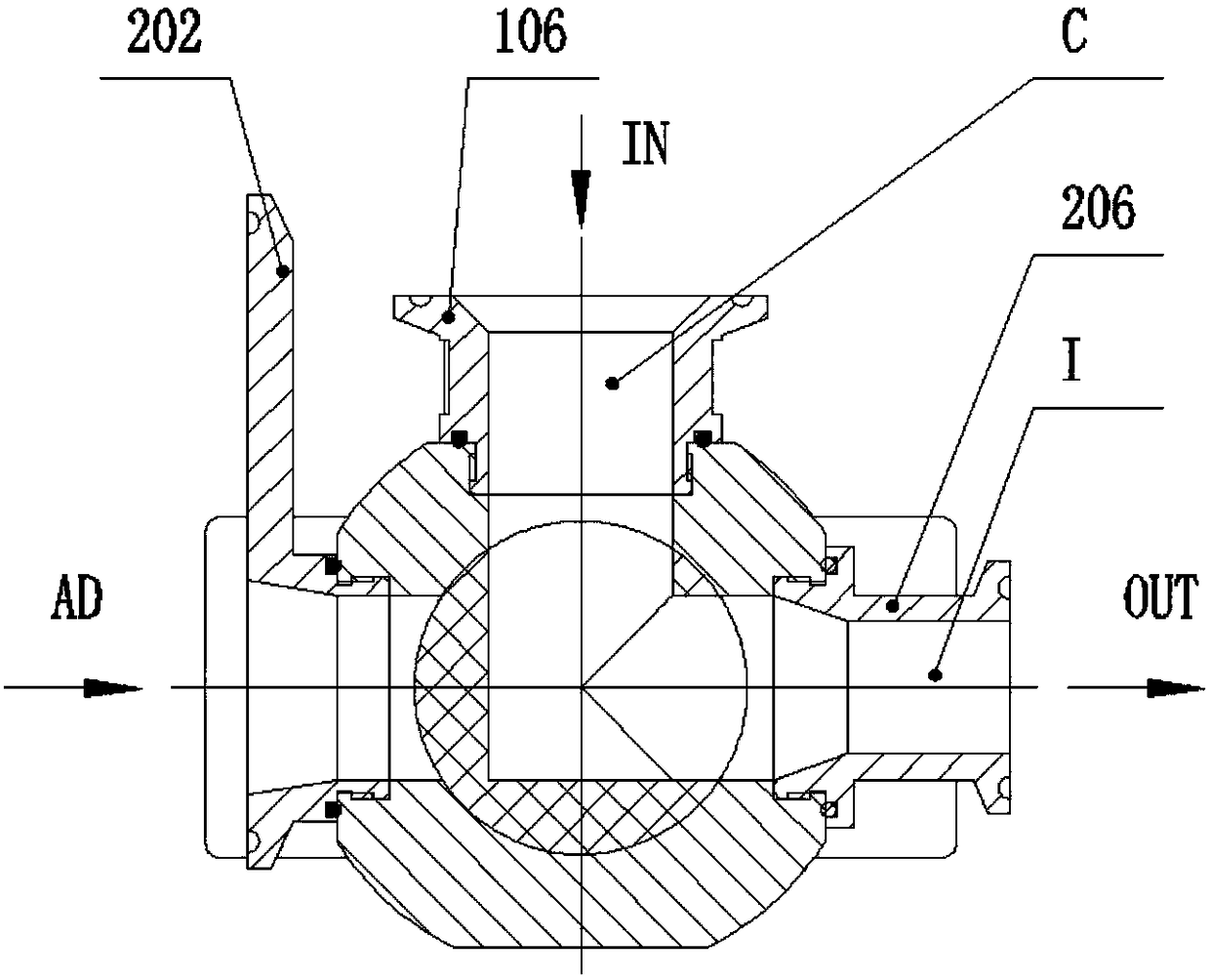

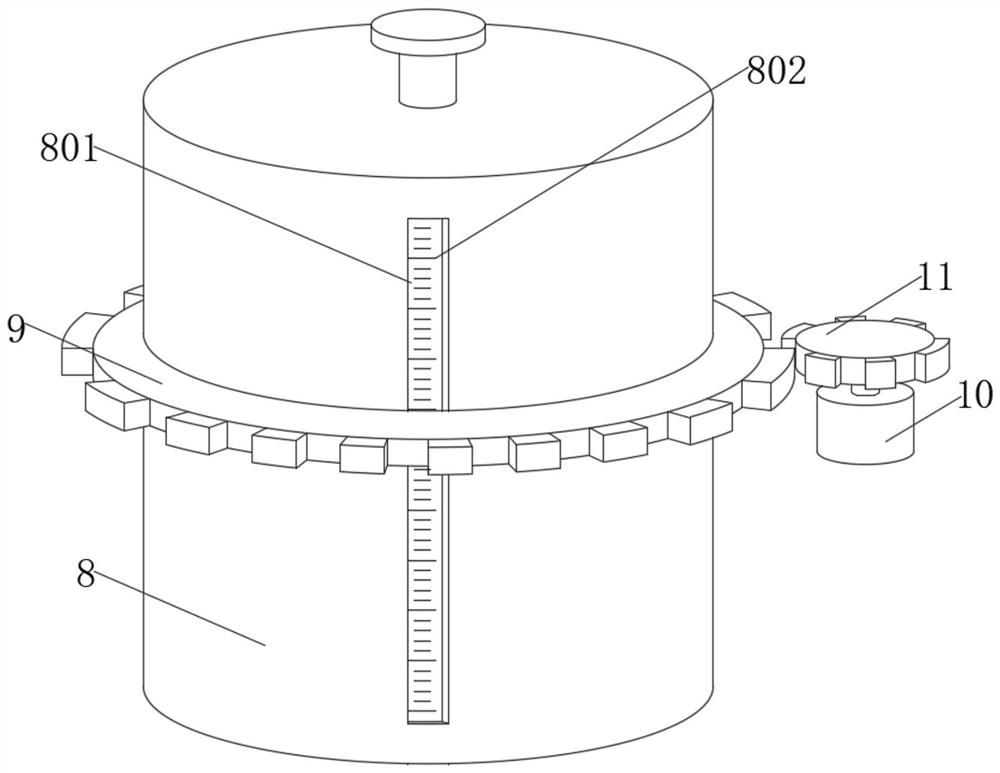

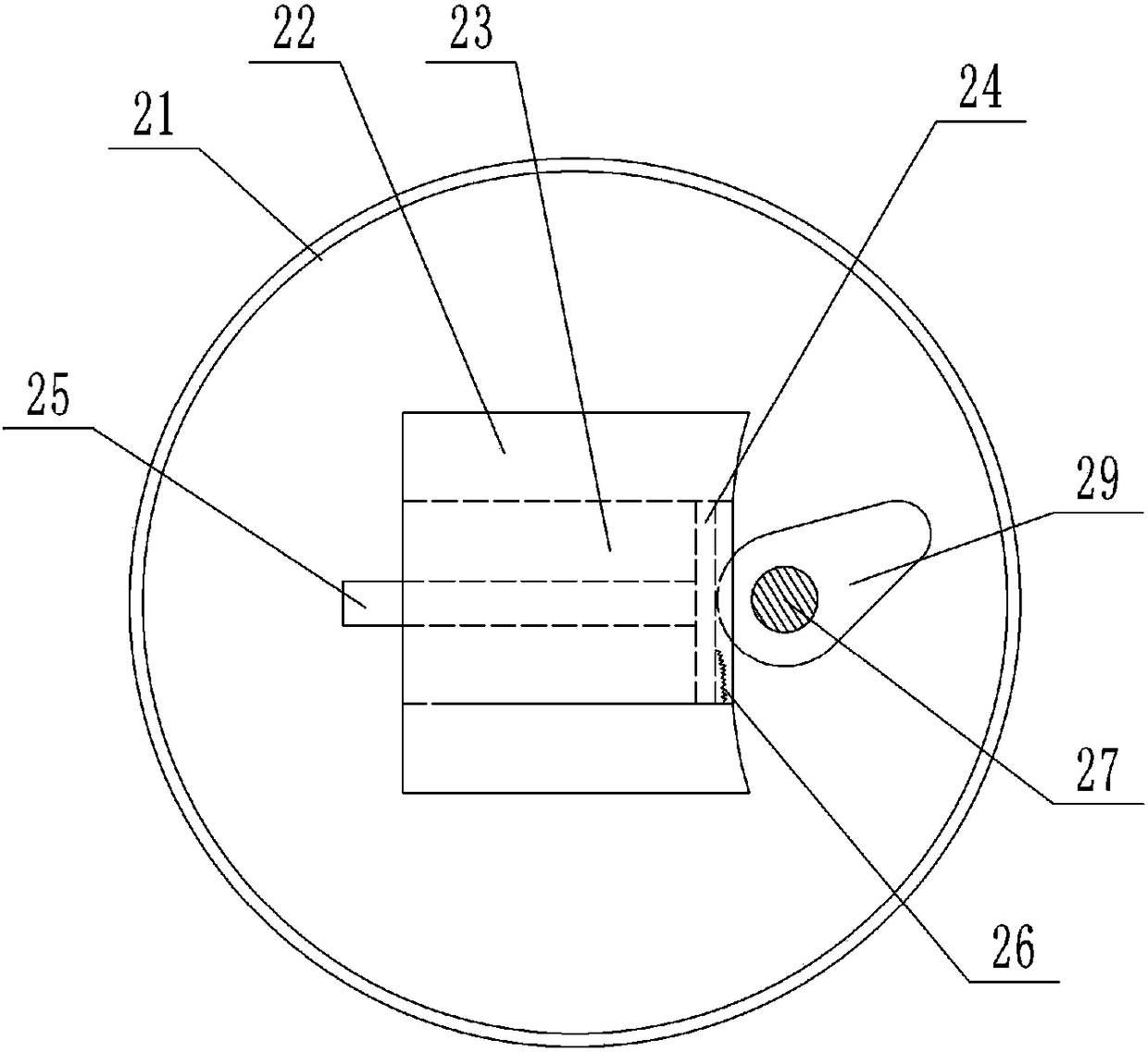

High viscosity paste quantitative filling ceramic rotary valve

InactiveCN108547978ARealize quantitative fillingImprove working precisionOperating means/releasing devices for valvesMultiple way valvesProduction lineRotary valve

The invention provides a high viscosity paste quantitative filling ceramic rotary valve. The high viscosity paste quantitative filling ceramic rotary valve mainly comprises a rotary part, a reversingpart and a sealing part. High viscosity paste is transferred to a valve body by using high atmospheric pressure; the valve body is made of ceramic; and with the help of the high hardness and wear resistance of the ceramic, the working accuracy of the valve body is improved, and the service life of the valve body is prolonged. An air cylinder rotates to drive a valve core to rotate, so that the quantitative filling of the paste can be realized in a discharging hole. The high viscosity paste quantitative filling ceramic rotary valve is suitable for the filling of high viscosity paste, is mainlyapplied to the filling of high viscosity paste which is not easy to fill, such as medicines, food and daily necessities, has high filling accuracy, can work independently and can also be used in conjunction with a large-scale automatic filling production line.

Owner:GUANGZHOU XUEBA SPECIAL EQUIP CO LTD

Quantitative coating filling device

The invention discloses a quantitative coating filling device. A bottom plate is included, and four supporting rods are symmetrically and fixedly connected to the top wall of the bottom plate; two fixing rods are symmetrically and fixedly connected to the top wall of the bottom plate; the two fixing rods are located between the four supporting rods; the top ends of the two fixing rods are each provided with a rotating shaft; the two rotating shafts are each provided with a rolling wheel; a conveying belt is wound on the two rolling wheels jointly; two storage tanks are placed on the conveyingbelt; and the top ends of the four supporting rods are jointly and fixedly connected with a carrying plate. The device is provided with a flow adjusting device, a threaded rod is rotated, the threadedrod is provided with a limiting ring which limits the movement of the threaded rod, and the threaded rod and a linkage rod are engaged through threads; and when the threaded rod is rotated, only thelinkage rod moves, and therefore the purpose of controlling the coating flow is achieved, and then quantitative filling on coating is achieved.

Owner:吴嘉伟

Efficient filling machine for clothing detergent processing and processing technology of efficient filling machine

PendingCN112850614AHigh precisionPracticalRotating receptacle mixersLarge containersMachining processManufacturing engineering

The invention discloses an efficient filling machine for clothing detergent processing and a processing technology of the efficient filling machine, and belongs to the field of detergent production. According to the technical scheme, the efficient filling machine comprises a workbench, the top of the workbench is fixedly connected with a frame, and the bottom of the workbench is fixedly connected with a first motor. An output shaft of the first motor penetrates through the workbench and is fixedly connected with a containing disc, filling bottles which are uniformly distributed are arranged at the top of the containing disc, penetrate through the containing disc and extend to the outside of the containing disc, a controller is fixedly connected to the bottom of the workbench, a storage hopper is fixedly connected to the inner wall of the frame, and a pretreatment tank is rotationally connected to the top of the frame. According to the efficient filling machine, by arranging pressing devices, under driving of electric push rods and fixing plates, perfect contact between pressing plates and the filling bottles is achieved, a third electromagnetic valve enters the filling bottles, the filling precision is high, the situation of drip leakage in the filling process is avoided, and practicability is high.

Owner:时协全

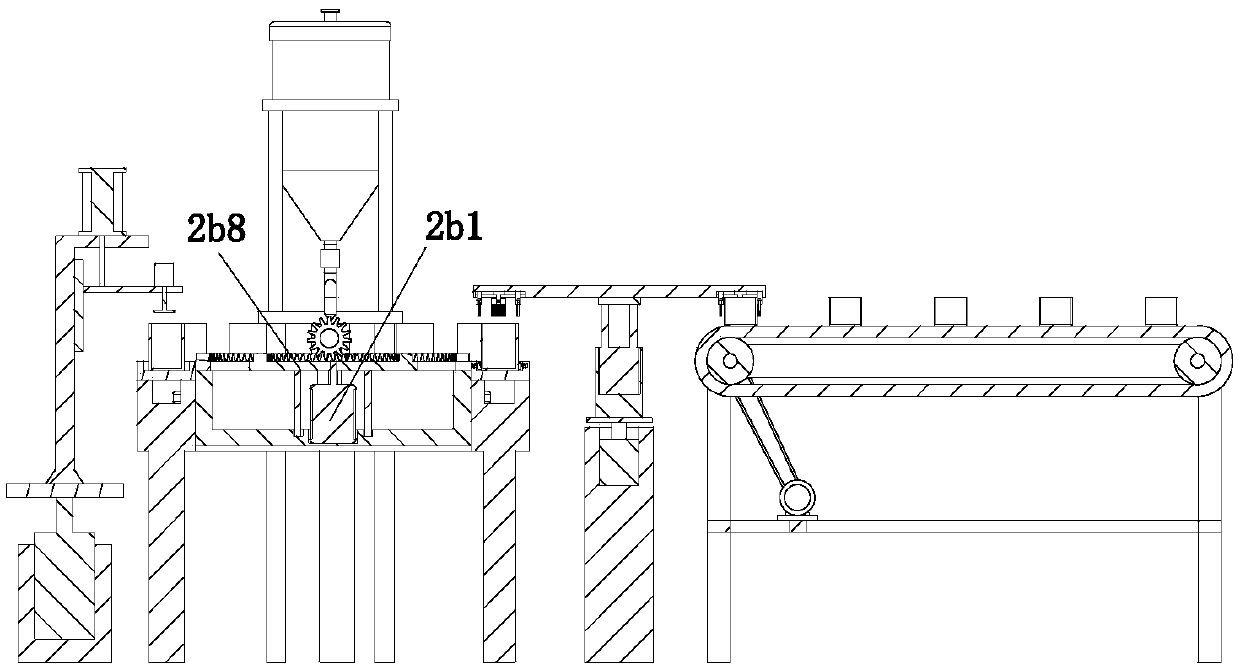

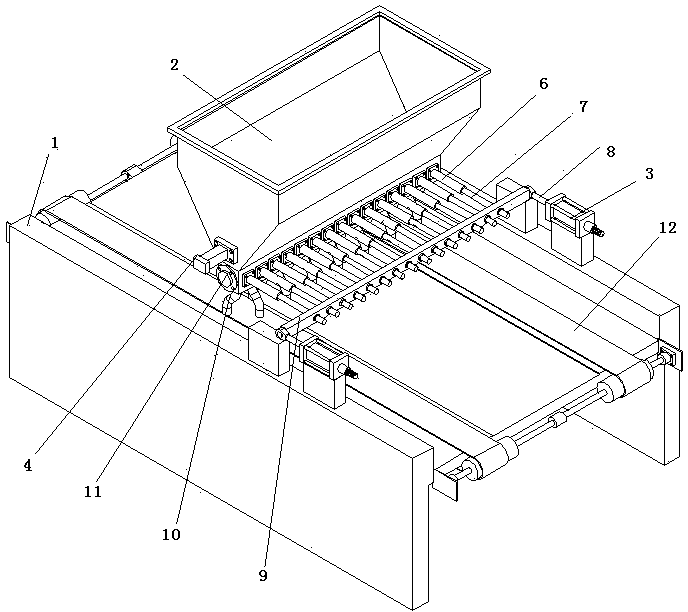

Rice crust forming machine

InactiveCN103637089ARealize quantitative fillingUniform outputFood shapingFood preparationReciprocating motionElectric machinery

The invention relates to a rice crust forming machine, in particular to a forming machine for rice crust preparation. The forming machine comprises a frame, which is provided with a feed bin for storing a rice crust green body liquid and an air cylinder for controlling the outflow of rice crust green body liquid to undergo forming. Horizontally, two sides of the feed bin are provided with stirring motors for stirring the rice crust green body liquid. The lower part of the feed bin is equipped with a discharge area for outflow of the rice crust green body liquid and a conversion valve for controlling the connection or shut condition between the discharge area and the feed bin. The discharge area is communicated with piston cylinders that are disposed outside the feed bin to absorb and accommodate the rice crust green body liquid in the feed bin. The piston cylinders are communicated with filling ports arranged at the bottom of the feed bin. Also, the air cylinder is internally equipped with reciprocating pneumatic heads that are in connection with a pull rod, the pull rod is connected to piston rods used for driving the piston cylinders to absorb or discharge the rice crust green body liquid, and the piston cylinders are sleeved outside the piston rods. The device provided by the invention can realize quantitative filling and uniform output of the rice crust green body liquid.

Owner:HUZHOU ZHENYUANTONG FOOD

Ficus carica linn juice quantitative filling device

InactiveCN107117338ARealize quantitative fillingImprove work efficiencyJuice extractionLiquid materialFruit juiceEngineering

The invention discloses a ficus carica linn juice quantitative filling device. The ficus carica linn juice quantitative filling device comprises a shell body. A filling opening is formed in one side of the top end of the shell body. An installation frame is welded to the filling opening. A driving motor is fixed to the installation frame through a screw. A perpendicularly-arranged rotating shaft is connected to an output shaft of the driving motor and located in the shell body. Cutting blades are installed on the peripheral side walls of the rotating shaft. The shell body is internally provided with a plurality of perpendicularly-arranged first filtering nets. The first filtering nets are located on one sides of the cutting blades. A fixed frame is welded to the side wall of the top end of the shell body. A push rod motor is fixed to the fixed frame through a screw. A perpendicularly-arranged connecting rod is connected to an output shaft of the push rod motor. A piston barrel is welded to the side wall of the shell body and located under the push rod motor. A piston block is slidably connected in the piston barrel in a sealed mode. According to the ficus carica linn juice quantitative filling device, ficus carica linn juice extracting, filtering and filling can be integrated, and juice quantitative filling is achieved.

Owner:滨海康之源生态农业科技有限公司

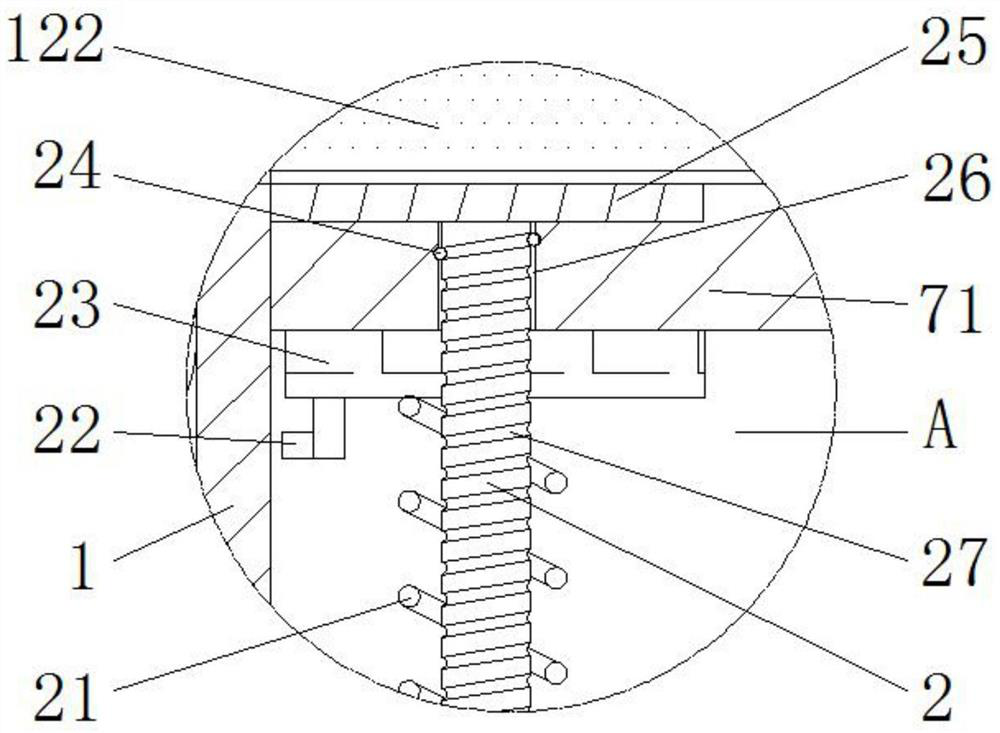

Passion fruit juice filling mechanism

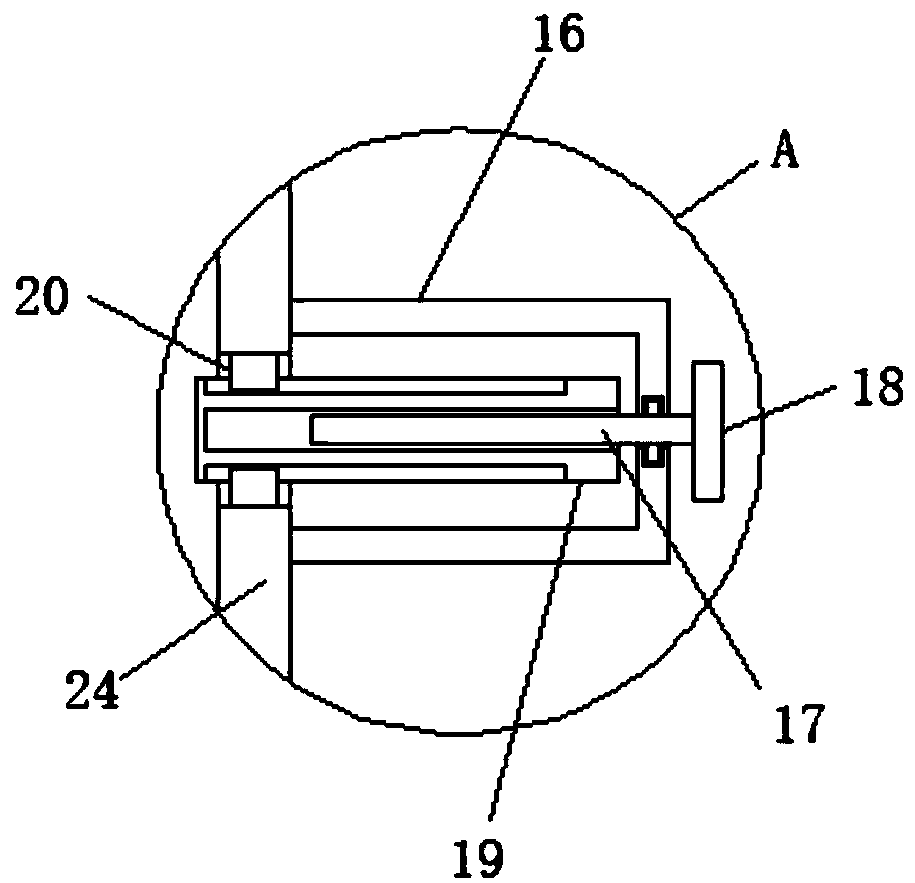

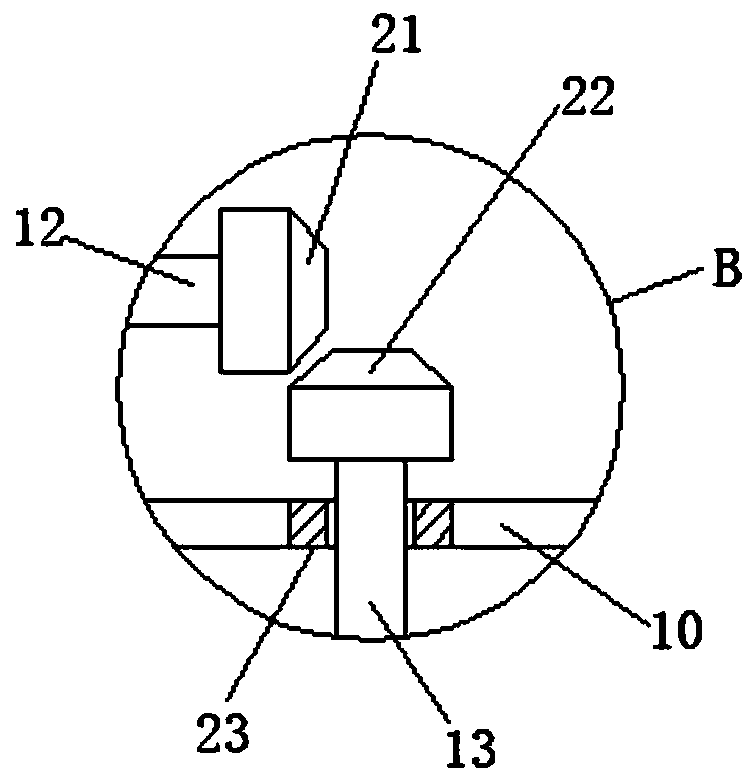

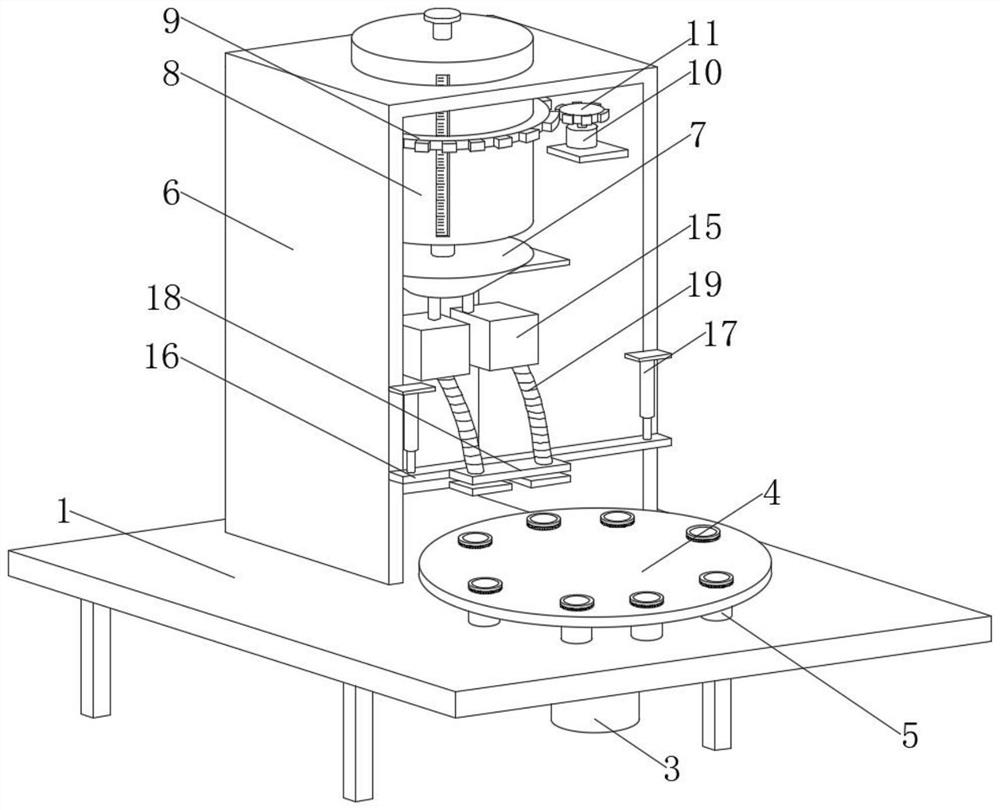

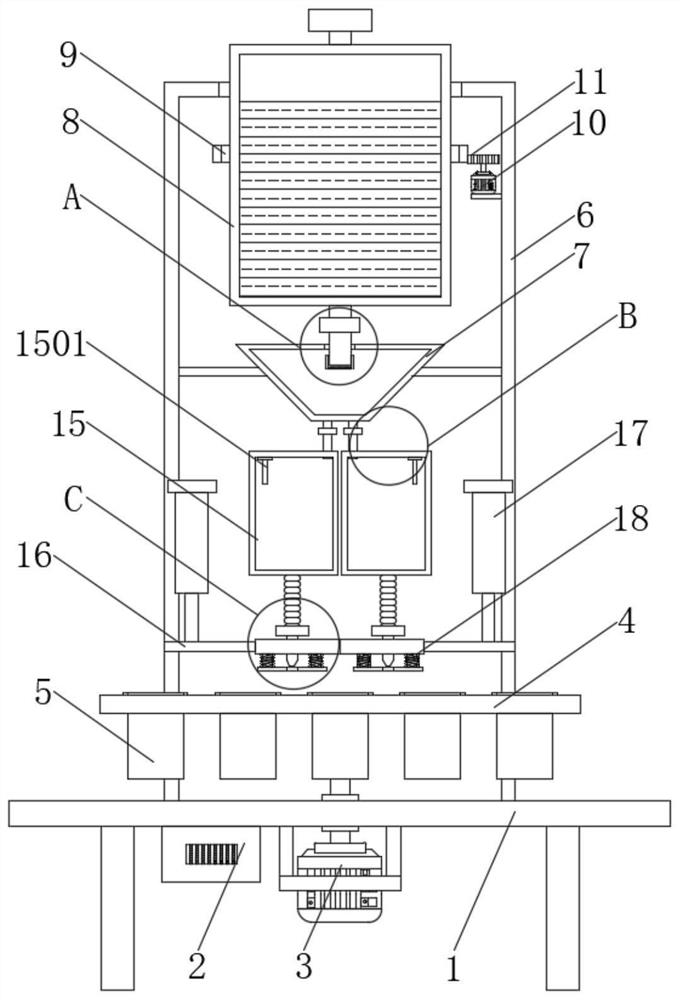

PendingCN110407147AHigh precision of lifting adjustmentLifting is stable and reliableRotary stirring mixersLiquid bottlingElectric machineryEngineering

The invention discloses a passion fruit juice filling mechanism. The mechanism comprises a filling valve, a connecting plate and a lifting mechanism, the feeding end of the filling valve is connectedto a metering cylinder, the upper end of the filling valve is fixedly connected to a cross beam through the connecting plate, and the cross beam is connected to the lifting mechanism through a supporting plate. The lifting mechanism comprises a sliding plate, a first screw and nut pair, a first linear bearing and a lifting motor, the two sides of the sliding plate are connected with two linear bearings, the middle of the sliding plate is connected with a nut of the first screw and nut pair, the upper end and the lower end of a first guide column matched with the first linear bearing are fixedly connected with an upper fixing plate and a lower fixing plate respectively, the two ends of a screw of the screw and nut pair are rotationally connected to the upper fixing plate and the lower fixing plate, the upper end of the screw extends out and is connected with a motor shaft of the lifting motor, the lifting motor is fixedly connected to the upper fixing plate, the upper fixing plate and the lower fixing plate are fixedly connected to a door frame, and the door frame is fixedly connected to a base. According to the mechanism, filling and quantitative constant-speed filling can be carried out on a plurality of filling bottles, ascending and descending are stable and reliable, the ascending and descending adjustment precision is high, and the ascending and descending are rapid.

Owner:GUIZHOU UNIV

Quantitative filling device for cosmetic production

The invention discloses a quantitative filling device for cosmetic production, and belongs to the field of cosmetic production equipment. The device comprises a conveying mechanism and a filling mechanism. The filling mechanism comprises a storage barrel body and a filling head communicating with the storage barrel body. The conveying mechanism comprises a fixed supporting table and a rotating table; a feeding notch, a filling station and a discharging notch are sequentially arranged on three sides of the fixed supporting platform, carrier plates are arranged on the rotating table at equal intervals, lifting rods are fixed at the bottoms of the carrier plates, and the lifting rods are connected with a rotating lifting driving mechanism; and the filling head is aligned with the eccentric position of a bottle mouth of a filling bottle below the filling head; a limiting rod is arranged in the storage barrel body, a screw rod penetrating through the storage barrel body is fixed on the limiting rod, an adjusting port is formed in the position, through which the screw rod penetrates, of the storage barrel body, and the screw rod is sleeved with a locking nut. Insufficient filling quantity caused by foam accumulation in the filling bottle can be avoided, and the reliability of the filling process is guaranteed; the primary filling amount of the filling mechanism is adjustable, so thatquantitative filling can be realized; and automatic feeding, filling and discharging can also be realized.

Owner:泉州市创智工业设计服务有限公司

Automatic oil paint filling device

InactiveCN108689375AImprove filling efficiencyEasy to operateBarrels/casks fillingElectric machineryElectromagnetic valve

The invention provides an automatic oil paint filling device which comprises a base and an oil paint barrel. Symmetrical support pillars are arranged under the oil paint barrel; the oil paint barrel is fixed onto the base through the support pillars; a rotary shaft is arranged in the oil paint barrel; screw blades are arranged on the rotary shaft and are uniformly distributed on the rotary shaft;the top end of the rotary shaft penetrates through the oil paint barrel so as to be connected with an adjustable-speed motor; an annular scraper blade is arranged in the oil paint barrel; two symmetrical push rods are connected above the annular scraper blade; telescopic air cylinders are connected to the top ends of the two push rods; two filling pipes are arranged on the bottom part of the oil paint barrel; electromagnetic valves are arranged on the filling pipes; two filling barrels are arranged on the upper side of the base and are arranged corresponding to the two filling pipes separately; weighing sensors are arranged on the bottom parts of the two filling barrels and are fixedly arranged on the base; a charging hole is formed in the upper side of the oil paint barrel; and a controlend is arranged at the right end of the upper side of the base. The automatic oil paint filling device provided by the invention is used for automatic and quantitive filling of oil paints, so that thetime and the effort are saved, and the oil paint filling efficiency is improved.

Owner:WUHU HUANGSHANSONG IND FLOOR NEW MATERIAL CO LTD

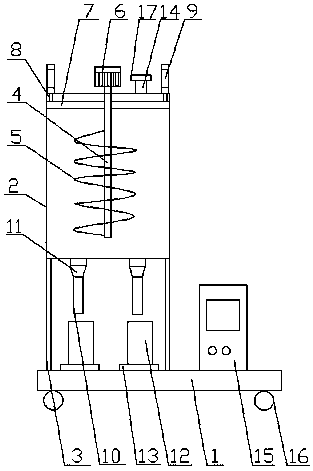

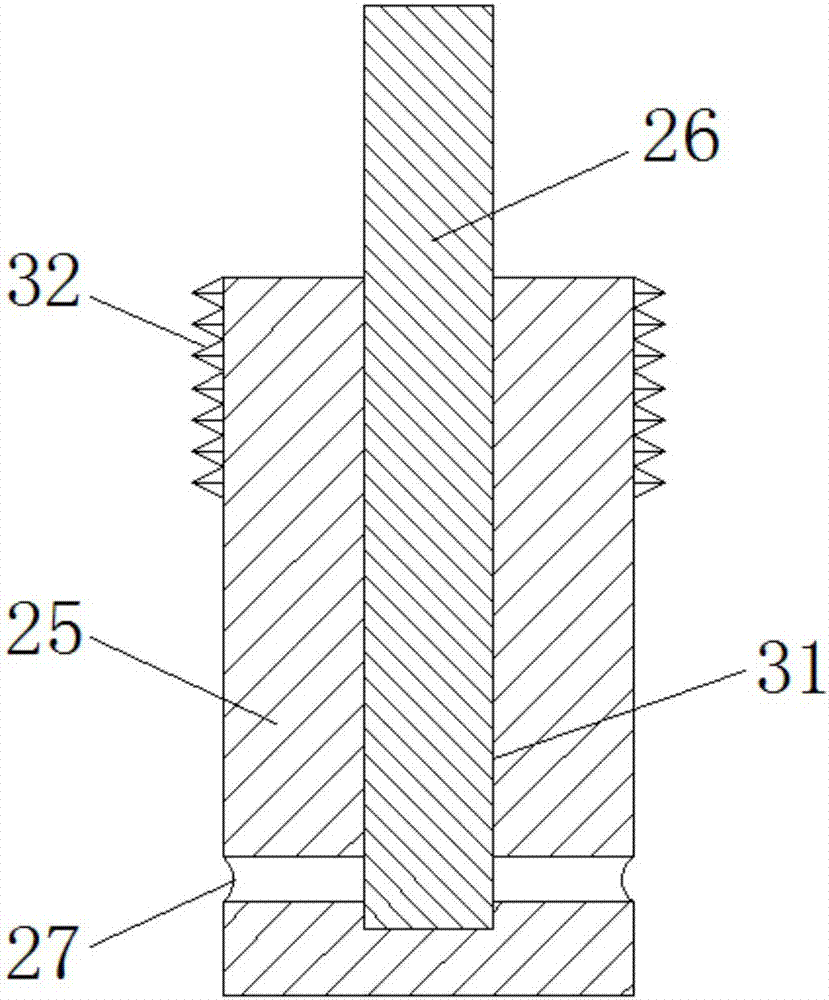

Storage battery for electric tool for garden and automatic injecting device for electrolyte of storage battery

InactiveCN107256942AEasy injectionEasy to unscrewFinal product manufactureSmall-sized cells cases/jacketsPeristaltic pumpEngineering

The invention discloses a storage battery for an electric tool for a garden and an automatic injecting device for electrolyte of a storage battery. The storage battery comprises an electrolyte storing tank, a liquid delivery pipe, a peristaltic pump, an electrolyte adding cap, a vent cap and a storage battery body, wherein the storage battery body consists of an ABS (Acrylonitrile Butadiene Styrene) casing, a top cover, a positive terminal, a negative terminal, AGM separators, positive plates and negative plates; the bottom end of the positive terminal is connected with the positive plates; the bottom end of the negative terminal is connected with the negative plates; electrode lug connecting slots of which openings face upwards are separately formed inside the positive terminal and the negative terminal; the inner part of the electrode plug connecting slot of the positive terminal is in threaded connection with a positive electrode plug; the inner part of the electrode plug connecting slot of the negative terminal is in threaded connection with a negative electrode plug. Assembly and disassembly of the positive electrode lug and the negative electrode lug, injection of the electrolyte, and exhaust of air are facilitated; by means of the peristaltic pump, the electrolyte in the electrolyte storing tank is conveniently extruded forwards by the liquid delivery pipe in the rotating direction of a center wheel, and corrosion caused by contact between the electrolyte in the liquid delivery pipe and the peristaltic pump is also effectively avoided; quantitative injecting of the electrolyte is realized.

Owner:胡沛

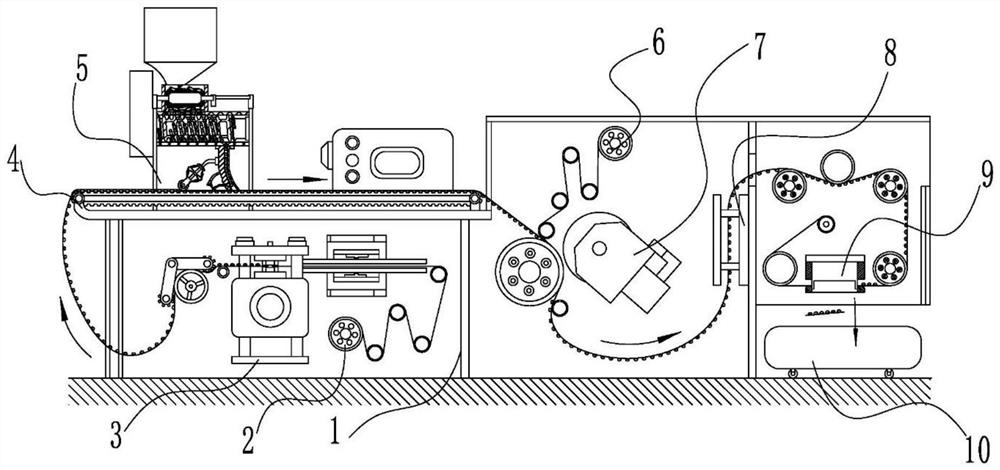

Full-automatic aluminum plastic packaging equipment for pharmacy

InactiveCN114132567AAdjustable interference storageAchieve regulationWrappingPackaging automatic controlEngineeringPlastic packaging

The invention discloses full-automatic aluminum plastic packaging equipment for pharmacy, and relates to the field of packaging. The PVC conveying part is arranged in the rack in a relatively rotating manner; the preheating forming device is fixed in the rack and is positioned above the PVC conveying piece; the belt wheel set is arranged on the upper surface of the rack in a relatively rotating mode, and grooves are evenly formed in the surface of the belt wheel set; the feeding assembly is fixed to the upper surface of the rack and located over the input end of the belt wheel set. The aluminum foil conveying piece is arranged in the rack in a relatively rotating mode and located on the side close to the output end of the belt wheel set; the heat sealing device is arranged in the rack in a relatively rotating mode and located below the aluminum foil conveying assembly; the printing device is fixed to the inner wall of the rack and located on the side, away from the belt wheel set, of the heat sealing device. And the blanking device is fixed in the rack and located on the side, away from the heat sealing device, of the printing device, and a trolley is arranged below the blanking device.

Owner:李永前

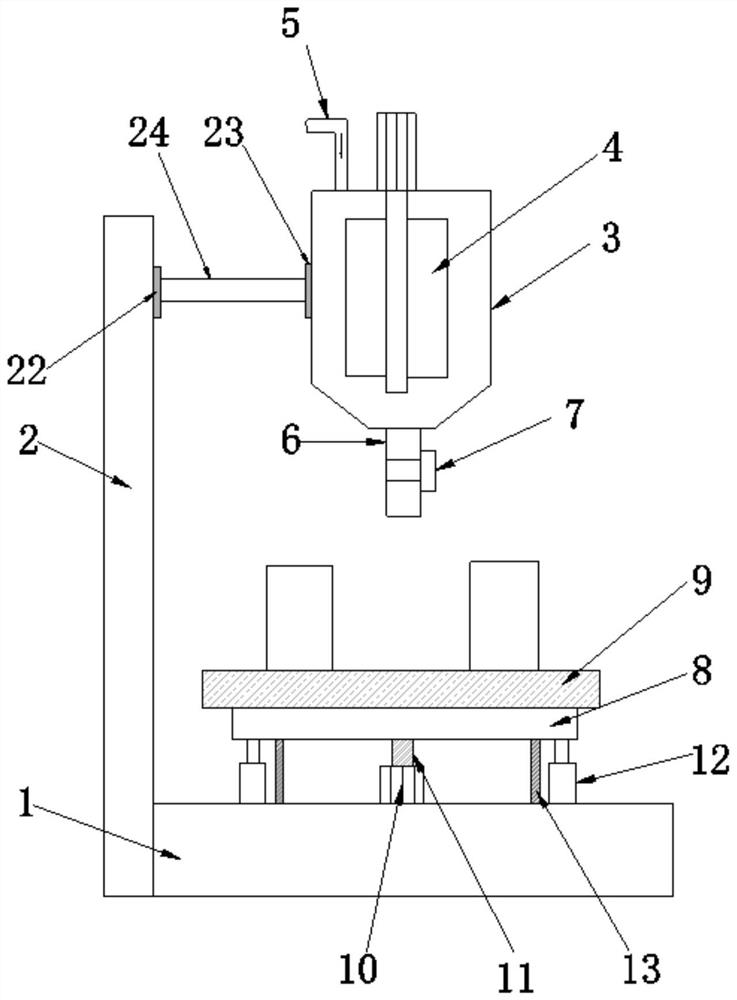

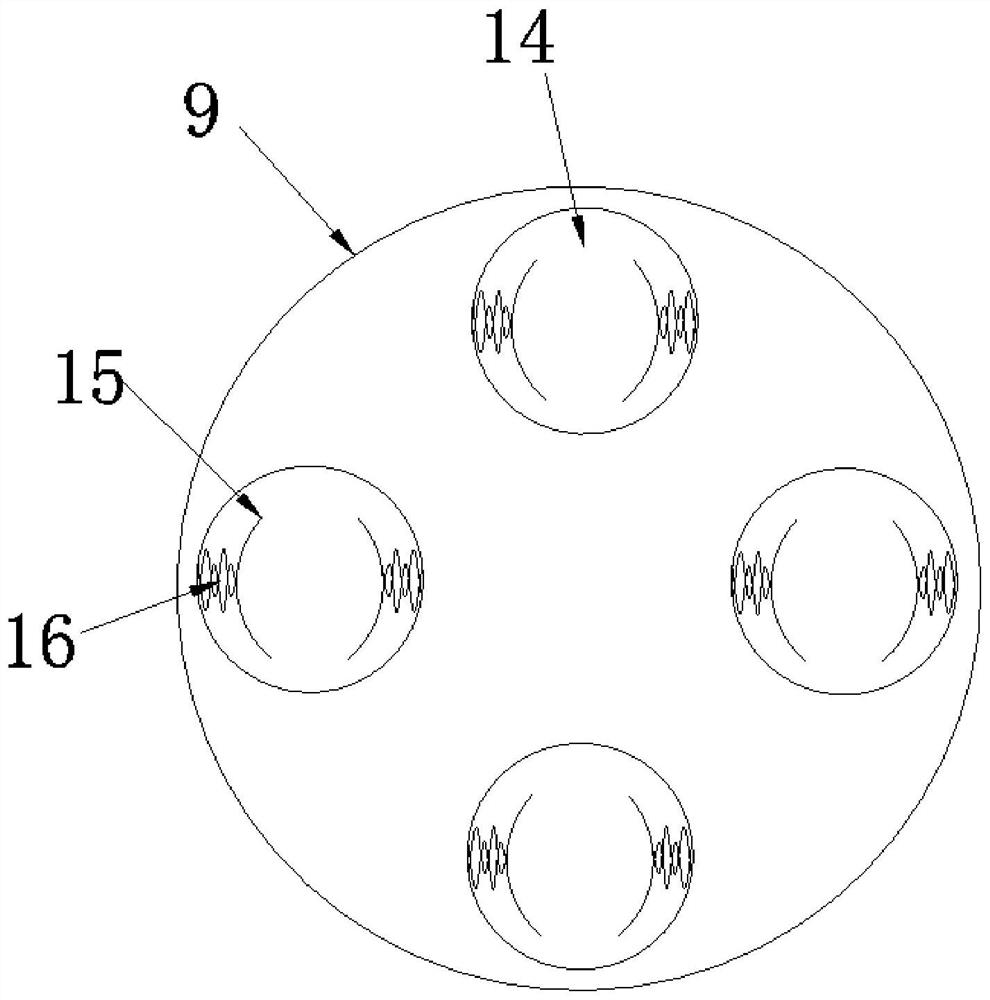

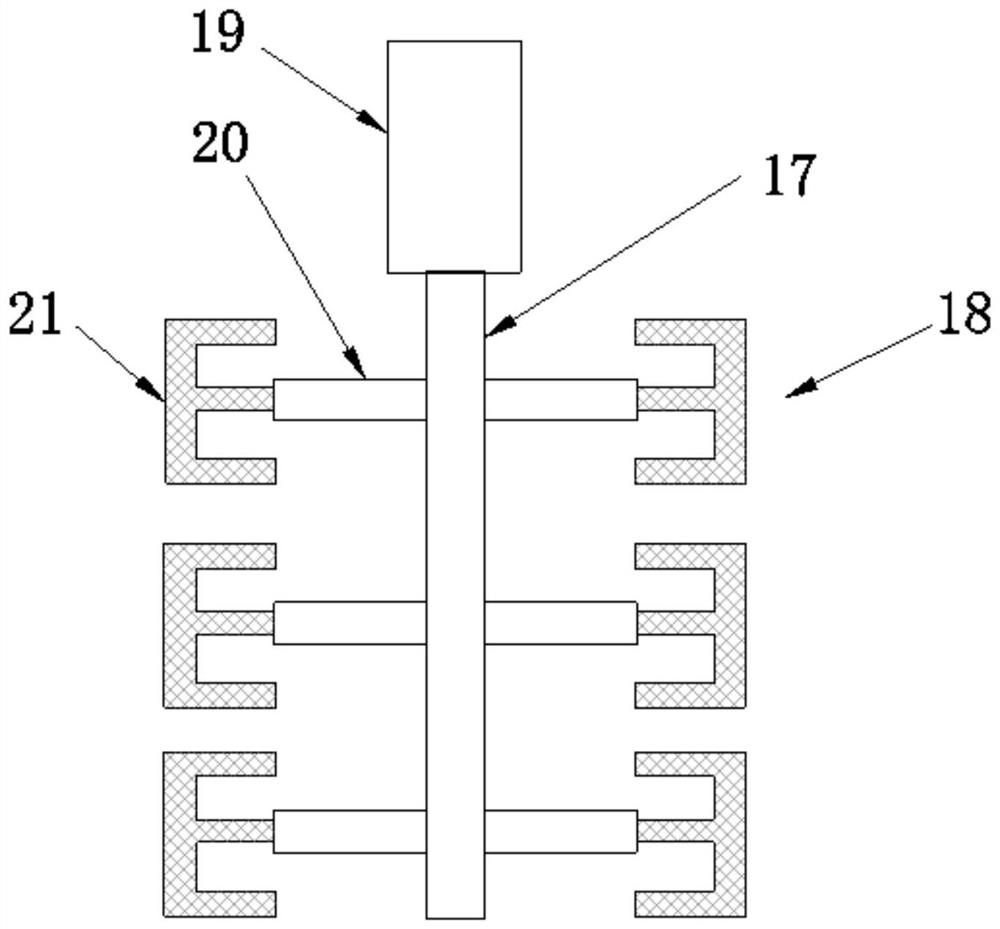

Quantitative filling device for lactarius hatsudake tanaka oil packaging

InactiveCN112209327ARealize quantitative fillingLow costBarrels/casks fillingRotary stirring mixersLactarius hatsudakeStructural engineering

The invention discloses a quantitative filling device for lactarius hatsudake tanaka oil packaging. The quantitative filling device comprises a base, a supporting column, a discharging mechanism and areceiving mechanism, the supporting column is vertically installed on one side of the base, the discharging mechanism comprises a discharging box and a stirring assembly, the stirring assembly is installed in the discharging box, and a supporting assembly is installed between the outer wall of the discharging box and the supporting column; a feeding pipe is installed at the top end of the discharging box, a discharging opening is formed in the bottom of the discharging box, a discharging pipe is installed at the discharging opening, a liquid metering valve is installed on the discharging pipe, and the receiving mechanism is installed on the base. The quantitative filling device is novel in structural design, easy to operate and capable of achieving quantitative filling of lactarius hatsudake tanaka oil, reducing the labor cost and improving the filling efficiency and precision.

Owner:湖南大熊山食品有限公司

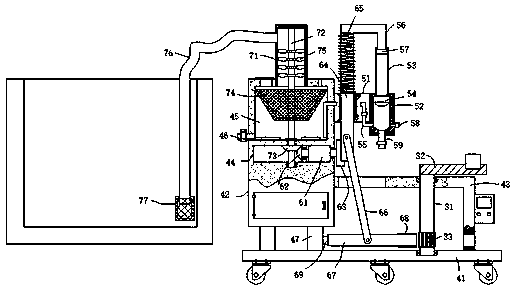

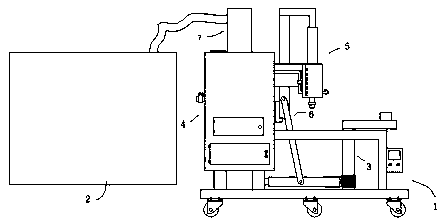

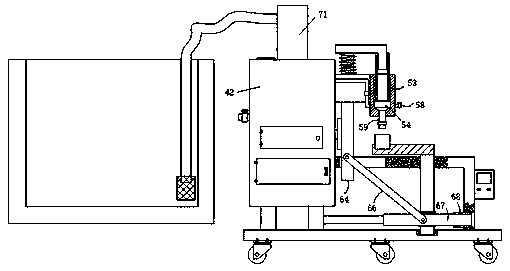

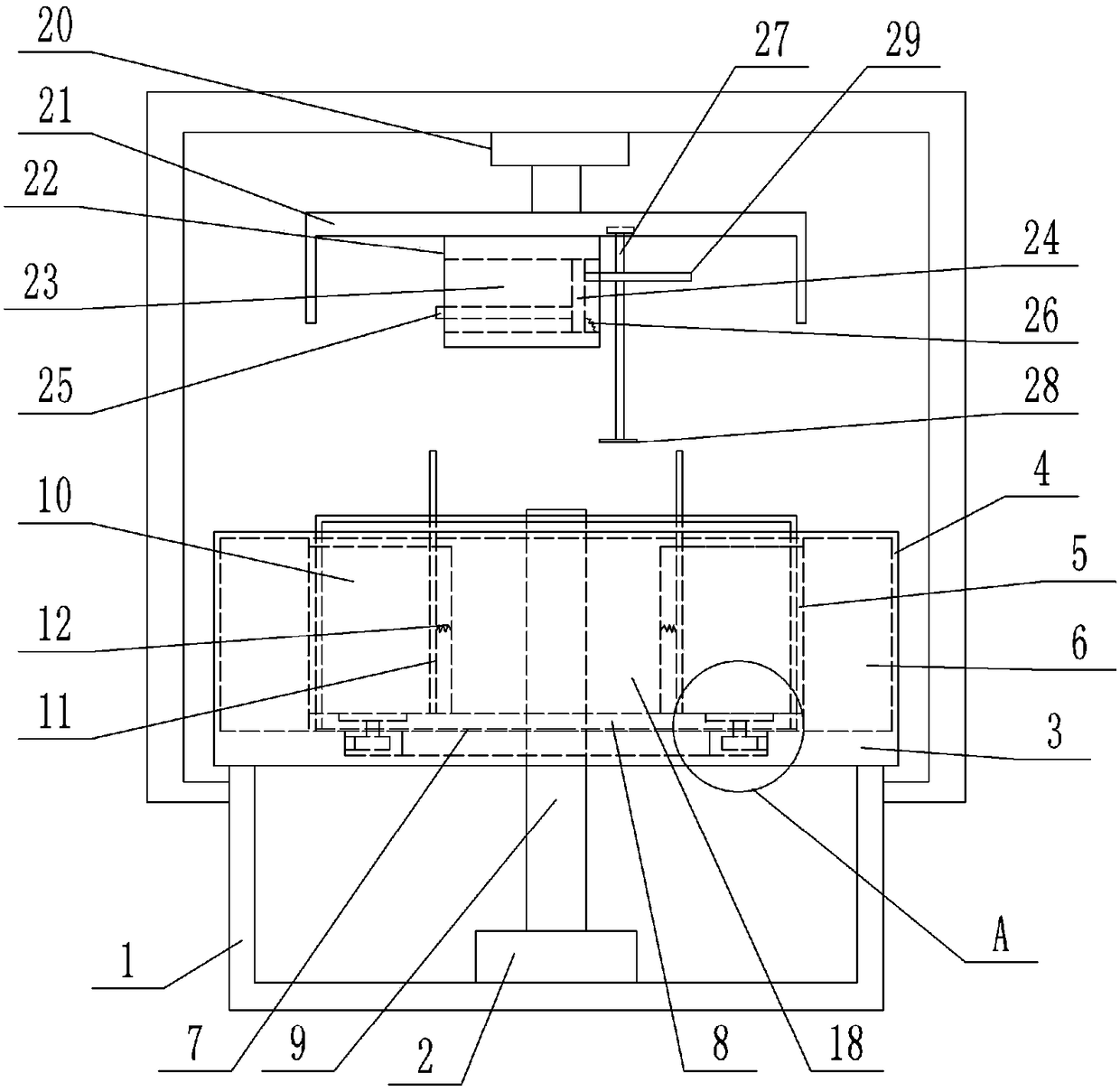

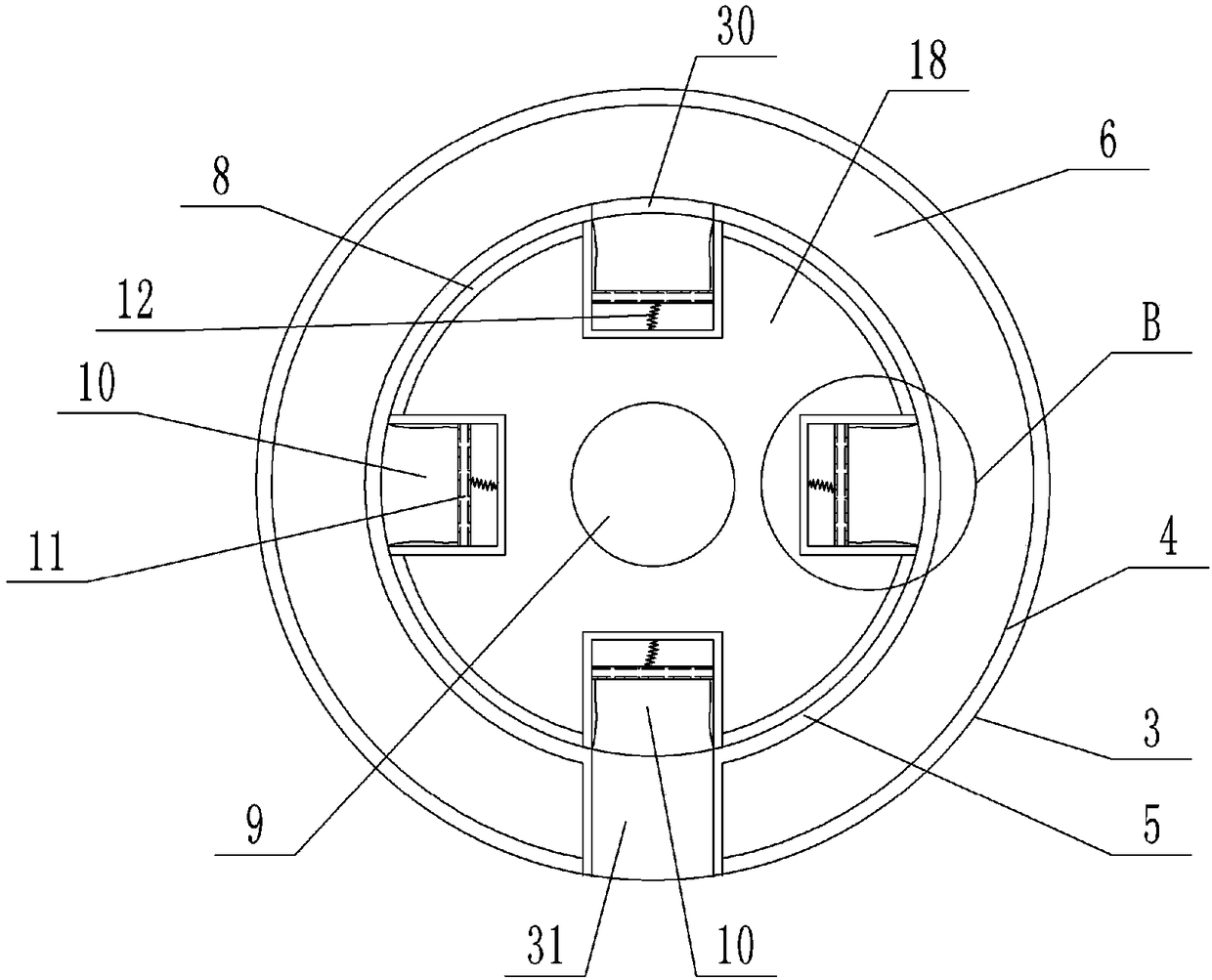

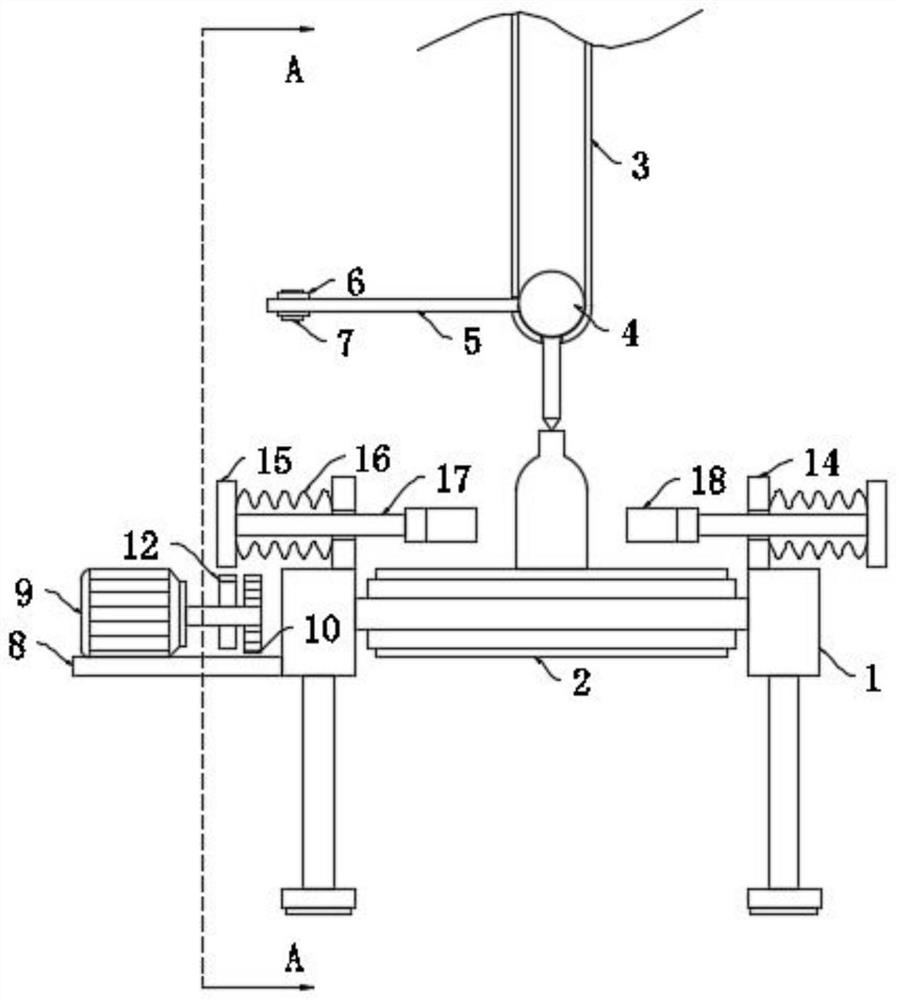

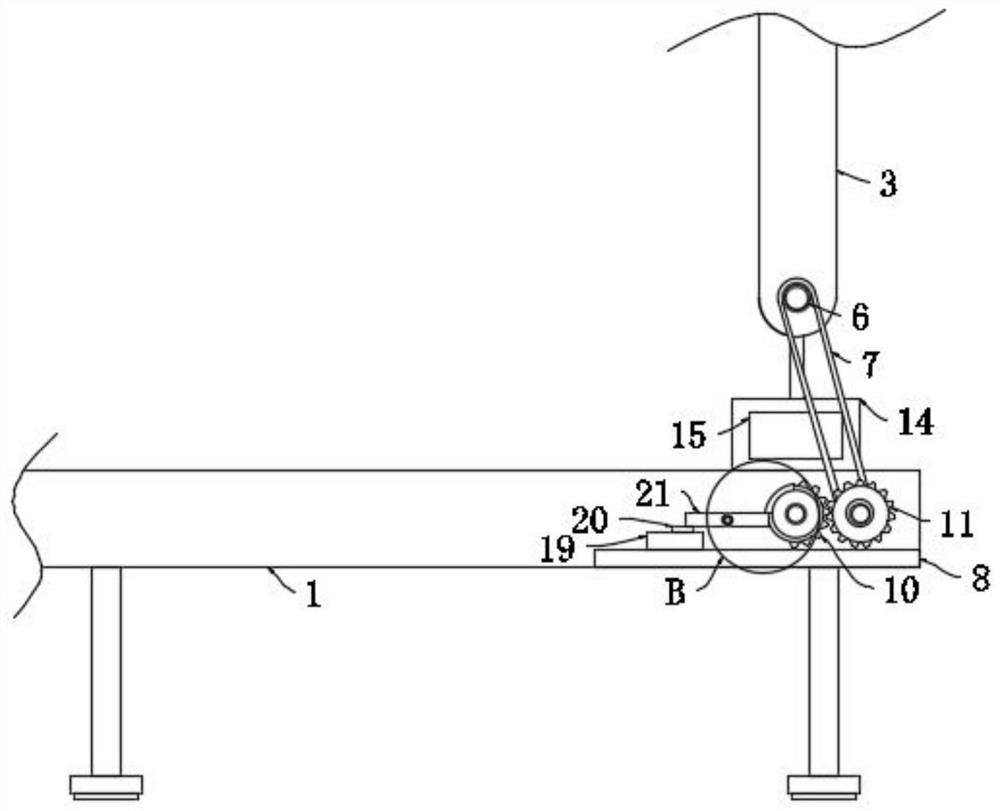

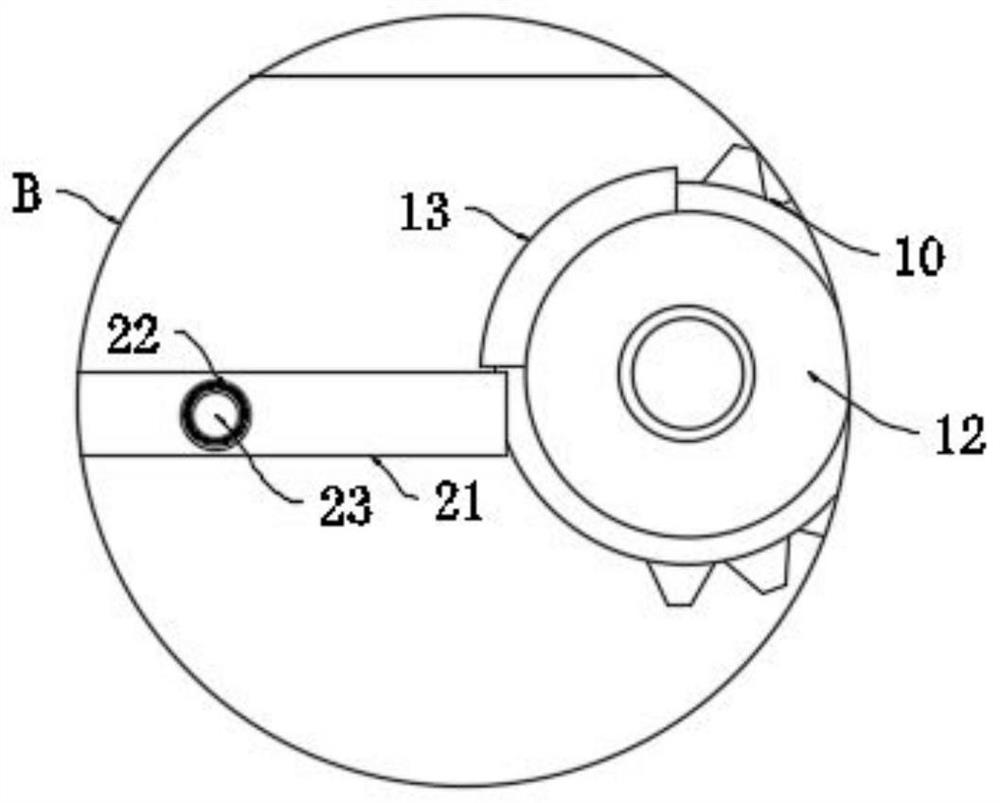

Quantitative filling device for preparing prawn shrimp head sauce based on enzymatic hydrolysis method

The invention discloses a quantitative filling device for preparing a prawn shrimp head sauce based on an enzymatic hydrolysis method, and relates to the field of shrimp head sauce processing. The device comprises a movable device body located on one side of an enzymolysis pool, wherein the device body comprises a transferring mechanism, a material processing mechanism, a filling mechanism, a driving mechanism, and a material taking mechanism, the transferring mechanism, the filling mechanism, the driving mechanism and the material taking mechanism are all mounted on the material processing mechanism, the material taking mechanism is in linkage connection with the driving mechanism and is used for sucking juice in the enzymolysis tank and filtering the juice, and the filling mechanism is mounted on the right side of the material processing mechanism and is in linkage connection with the driving mechanism for quantitative filling work. The whole device can perform the quantitative filling work, can further automatically suck the juice in the enzymolysis tank out, carry out filtering and sterilization and disinfection, and automatically carry out filling and transferring on the processed juice.

Owner:安徽新之图科技发展有限公司

Quantitative filling machine

ActiveCN108482777ARealize quantitative fillingImprove cooling effectLiquid materialCooling effectSlide plate

The invention relates to the field of food processing, and discloses a quantitative filling machine which comprises a support, a fixed disc, a rotary disc and a cover plate. The rotary disc is rotationally connected to a containing groove, the rotary disc comprises a cooling groove and a plurality of quantitative grooves, and cooling liquid is contained in the cooling groove. Extrusion plates arein sliding connection with the interior of the quantitative grooves. A stirring disc is rotationally connected to the bottoms of the quantitative grooves, a second rotary shaft is fixed to the bottomof the stirring disc, the bottom of the second rotary shaft penetrates out of the rotary disc to be fixed to a gear, a rack engaged with the gear is arranged in an annular groove, a column body is fixed to the bottom of the cover plate, a through hole is formed in the column body, a sliding plate is in sliding connection with the interior of the through hole, an ejector rod is fixed to one end ofthe sliding plate, the ejector rod abuts against the extrusion plate, a third rotary shaft is rotationally connected to the cover plate, a turbine is fixed to the bottom of the third rotary shaft, a cam is fixed to the third rotary shaft, and the cam abuts against the sliding plate. According to the scheme, quantitative filling of seasoning can be achieved, the seasoning can be cooled in the filling process, the seasoning cooling effect is enhanced, and seasoning can be more easily packaged.

Owner:重庆市长寿区可又可食品有限公司

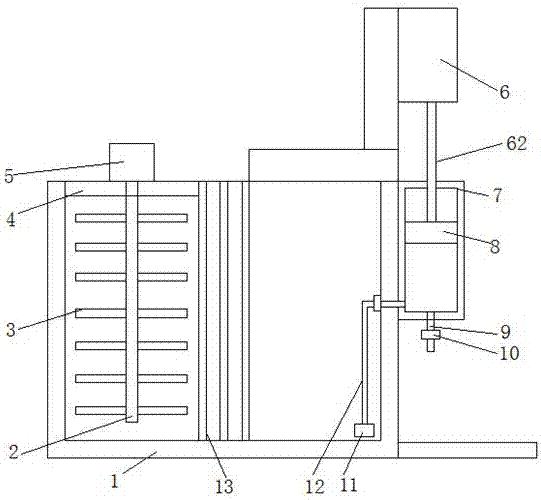

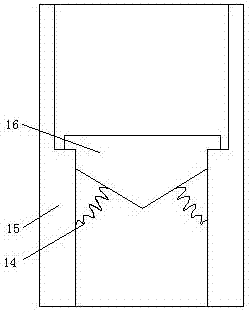

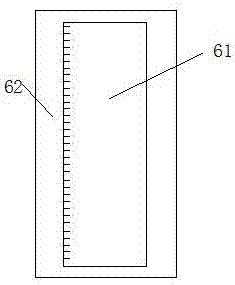

Quantitative liquid filling machine

InactiveCN104085841ASimple structureReduce manufacturing costLiquid bottlingLiquid productFixed frame

The invention discloses a quantitative liquid filling machine. The quantitative liquid filling machine consists of a fixed frame, a raw material barrel, a liquid input part, a finished liquid product output part, a quantitative adjustment device and a liquid level indication device. The quantitative liquid filling machine has the characteristics that the structure is simple; the manufacturing cost is low; quantitative filling can be realized.

Owner:张化翔

Ointment preparation device for diabetic patients

InactiveCN112299348ARealize quantitative fillingQuality assuranceLiquid bottlingDiabetic patientDrug ointment

The invention discloses an ointment preparation device for diabetic patients. The device comprises two supporting frames, wherein the opposite side walls of the two supporting frames are jointly provided with a conveying belt, a liquid inlet pipe is arranged above the conveying belt, the outward side wall of one supporting frame is fixedly connected with a containing plate, and a control mechanismused for controlling filling and conveying belt transmission is arranged on the upper side of the containing plate. The device is reasonable in structural design, quantitative filling can be achieved, manual control over the flow of liquid is replaced, accordingly, the product quality is guaranteed, unqualified products are reduced, the production efficiency is improved, the labor amount of workers is reduced, filling bottles can be clamped through electromagnets and magnets when the conveying belt intermittently stops, and liquid is prevented from flowing out of the filling bottles due to shaking of the filling bottles in the filling process, so that normal operation of the device is guaranteed.

Owner:邓建军

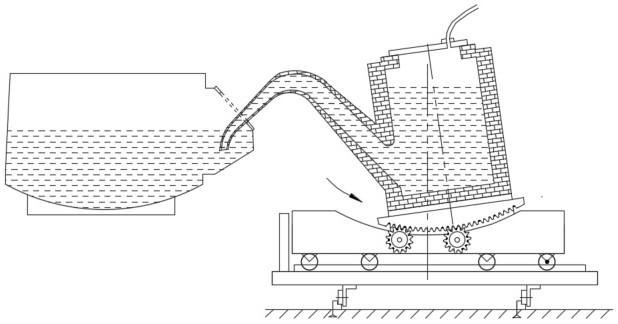

Molten aluminum transfer system

PendingCN112222378ALess agitationQuality improvementMelt-holding vesselsMolten metal supplying equipmentsMaterials scienceCompressed air

The invention discloses a molten aluminum transfer system. The molten aluminum transfer system comprises a casting ladle arranged on a supporting platform, an n-shaped molten aluminum pouring gate andan air inlet are formed in the casting ladle, the molten aluminum pouring gate can extend into the position below the molten aluminum level in a heat preservation furnace, and compressed air can be introduced into the air inlet. According to the molten aluminum transfer system, molten aluminum stirring during direct pouring can be relieved, impurities at the bottom of the heat preservation furnace are prevented from being brought into molten aluminum, and the quality of the molten aluminum is improved; and quantitative filling is achieved by controlling the compressed gas introducing time andcontrolling the adding amount of the molten aluminum.

Owner:CITIC DICASTAL

Quantitative filling feed packaging equipment and packaging method

ActiveCN114476233AFavorable to be taken out one by oneRealize automatic bag pickingBio-packagingWrapper twisting/gatheringEngineeringSupport plane

The invention provides feed packaging equipment with a quantitative filling function and a packaging method, relates to the technical field of feed packaging, and solves the problems that bag taking, filling and heat sealing of existing feed packaging are operated on different equipment, the number of the used equipment is large, the use cost is high, and the occupied space is large. According to the specific scheme, the device comprises a supporting frame, a quantitative discharging assembly is arranged on the transverse portion of the top of the supporting frame, a guiding assembly is arranged at the lower end of the quantitative discharging assembly, an adsorption assembly and a transverse supporting plate are arranged on the side wall of the supporting frame, and a bag storage assembly and a bag taking assembly are arranged on the top of the transverse supporting plate; the transverse supporting plate is provided with a heat sealing assembly. The packaging method comprises the following steps that firstly, feed bags are stacked in the feed storage frame of the bag storage assembly in sequence, and the feed bag at the lowermost end is limited through the inclined limiting plate; in this way, bag taking, quantitative filling and heat sealing are carried out on the same equipment, the number of used equipment is small, the use cost is low, and the occupied space is small.

Owner:山东天源饲料有限公司

Rice crust forming machine

InactiveCN103637089BRealize quantitative fillingUniform outputFood shapingDough extruding machinesReciprocating motionPiston cylinder

The invention relates to a rice crust forming machine, in particular to a forming machine for rice crust preparation. The forming machine comprises a frame, which is provided with a feed bin for storing a rice crust green body liquid and an air cylinder for controlling the outflow of rice crust green body liquid to undergo forming. Horizontally, two sides of the feed bin are provided with stirring motors for stirring the rice crust green body liquid. The lower part of the feed bin is equipped with a discharge area for outflow of the rice crust green body liquid and a conversion valve for controlling the connection or shut condition between the discharge area and the feed bin. The discharge area is communicated with piston cylinders that are disposed outside the feed bin to absorb and accommodate the rice crust green body liquid in the feed bin. The piston cylinders are communicated with filling ports arranged at the bottom of the feed bin. Also, the air cylinder is internally equipped with reciprocating pneumatic heads that are in connection with a pull rod, the pull rod is connected to piston rods used for driving the piston cylinders to absorb or discharge the rice crust green body liquid, and the piston cylinders are sleeved outside the piston rods. The device provided by the invention can realize quantitative filling and uniform output of the rice crust green body liquid.

Owner:HUZHOU ZHENYUANTONG FOOD

Liquid Quantitative Filling Machine

InactiveCN104085841BSimple structureReduce manufacturing costLiquid bottlingLiquid productMechanical engineering

The invention discloses a quantitative liquid filling machine. The quantitative liquid filling machine consists of a fixed frame, a raw material barrel, a liquid input part, a finished liquid product output part, a quantitative adjustment device and a liquid level indication device. The quantitative liquid filling machine has the characteristics that the structure is simple; the manufacturing cost is low; quantitative filling can be realized.

Owner:张化翔

A kind of liquor filling equipment

The invention belongs to the field of white spirit producing equipment, and particularly discloses white spirit filling equipment. The white spirit filling equipment comprises a machine frame and a spirit filling cavity rotationally connected with the machine frame. Spirit outlet pipes are arranged on the spirit filling cavity. First through holes are formed in the positions, located in the spirit filling cavity, of the spirit outlet pipes. A hollow piston guide rod is slidably connected into each spirit outlet pipe. Openings are formed in the top ends of the piston guide rods. Second through holes are formed in the piston guide rods. One of the piston guide rods is connected with a first metal ball through a first rope. The first metal ball is connected with a second metal ball through a second rope. The machine frame is fixedly provided with a first cam rail. The lower ends of the piston guide rods abut against the first cam rail. The machine frame is slidably connected with a second cam rail. The second cam rail is detachably connected with the first cam rail. The side edge of the second cam rail is fixedly connected with a baffle. A third through hole is formed in the baffle. The outer side of the baffle is provided with a magnetic part. By means of the white spirit filling equipment, continuous filling and quantitative filling of white spirit are achieved, the filling efficiency is high, and the filling effect is good.

Owner:江苏百果先农业科技有限公司

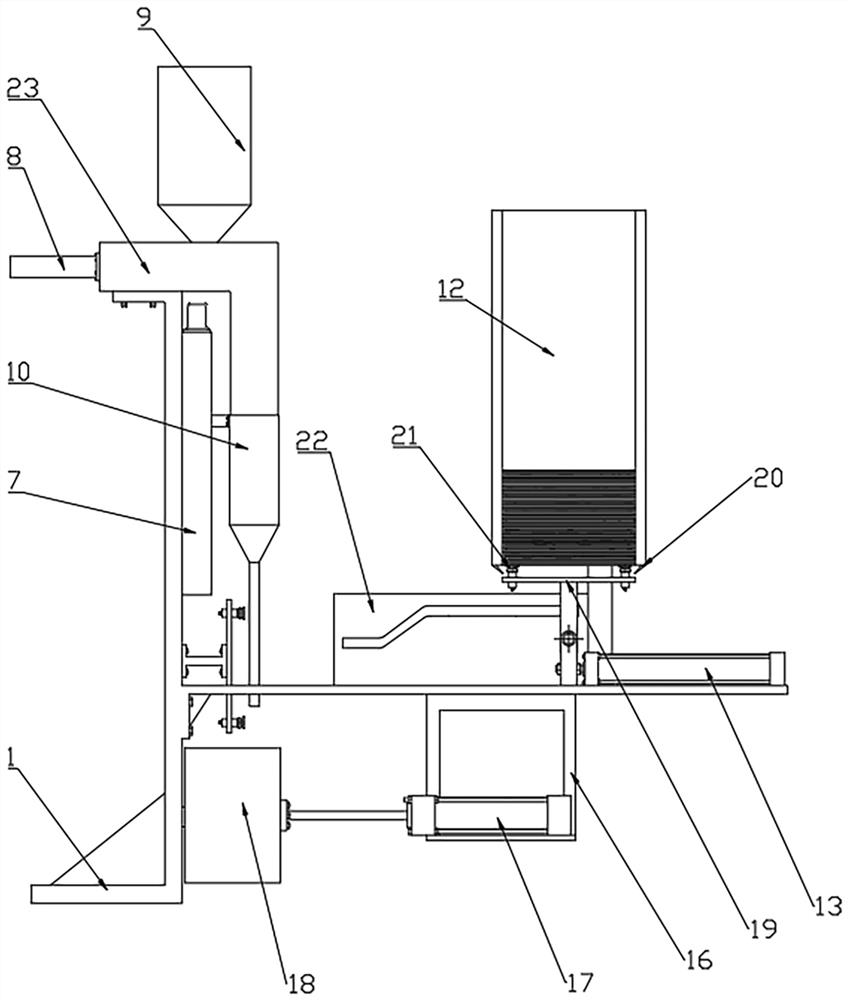

System for thermostatically preparing low-melting point alloy and quantitatively filling and application method thereof

PendingCN108251667AReduce weightSmall heat capacityMolten metal supplying equipmentsLiquid stateAlloy

The invention discloses a system for thermostatically preparing low-melting point alloy and quantitatively filling and an application method thereof. The system comprises a thermostatic preparation module, a quantitative filling module, and a control module; the thermostatic preparation module is used for preparing liquid-state low-melting point alloy and maintaining the temperature constancy; thequantitative filling module can realize quantitative filling by taking the liquid-state low-melting point alloy prepared by the thermostatic preparation module as a raw material according to a set volume filling value input by a user; the control module respectively controls the processes of preparing the thermostatic liquid-state low-melting point alloy by the thermostatic preparation module andfilling the liquid-state low-melting point alloy with quantitative volume by the quantitative filling module. The system has the features of being small in volume and convenient for carrying, and iscapable of realizing thermostatic preparation and quantitative filling, and suitable for preparing at construction field and filling the liquid-state low-melting point alloy.

Owner:XIJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com