Quantitative filling feed packaging equipment and packaging method

A technology for packaging equipment and feed, applied in packaging, biological packaging, transportation packaging, etc., can solve the problems of high use cost, many equipment, and large space, and achieve the effect of avoiding dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

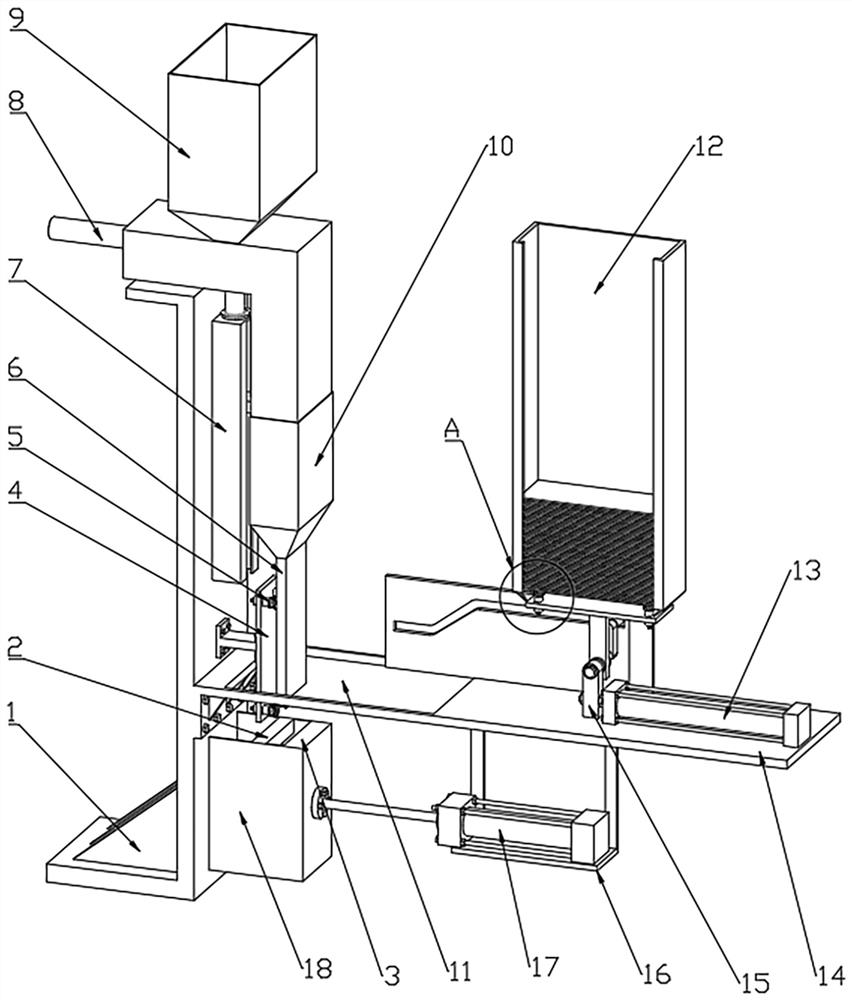

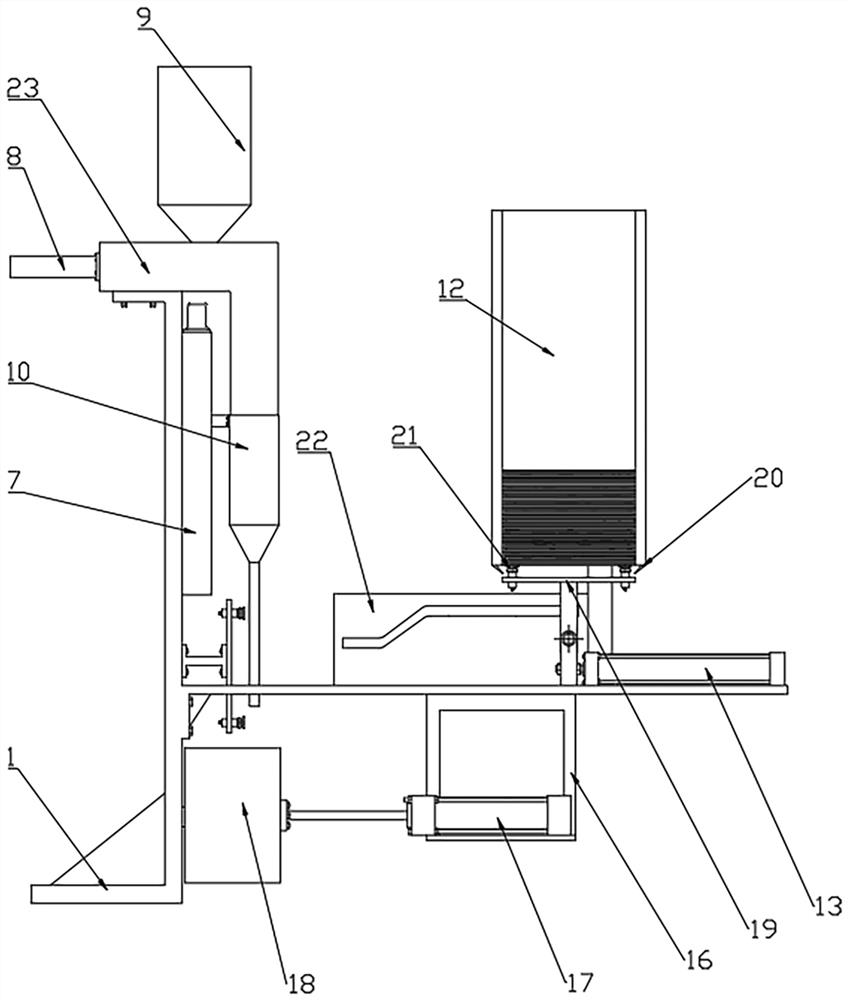

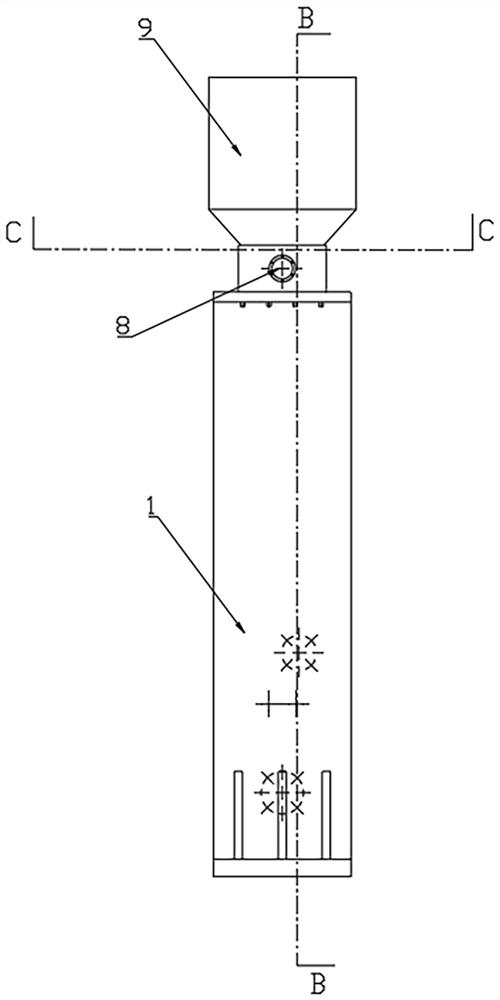

[0040] see figure 1 , 2 , 4, 7 and 8, a feed packaging equipment for quantitative filling, including a support frame 1, the top lateral part of the support frame 1 is provided with a quantitative unloading assembly, and the quantitative unloading assembly includes a first cylinder 8, a storage tank 9, L-shaped material guide cylinder 23, blanking slide plate 26 and quantitative groove 27, the blanking hole place that L-shaped material guide cylinder 23 top middle end offers is provided with storage cylinder 9, and L-shaped material guide cylinder 23 lateral parts outer walls are provided with There is a first cylinder 8, and the telescopic end of the first cylinder 8 is provided with a blanking slide 26. The shape of the blanking slide 26 is square. One side of the blanking slide 26 is provided with a quantitative groove 27, and the blanking slide 26 drives the quantitative groove 27 to move When the L-shaped material guide cylinder 23 is directly above the upright position, ...

Embodiment 2

[0053] On the basis of embodiment 1, see Figure 11 As shown, the transverse support plate 14 is provided with a pushing plate 34, and the L-shaped connecting plate 24 moves to the third cylinder 17, and the pushing plate 34 pushes out the feed bag in the L-shaped connecting plate 24 to realize automatic discharge.

[0054] During specific use, at first the feed bags are stacked in order in the material storage frame 12 of the bag storage assembly, and the inclined limit plate 20 limits the position of the lowermost feed bag, which is beneficial to the feed bags being taken out one by one; secondly, the first bag of the bag assembly The second cylinder 13 drives the slide plate 15 to move, the slide plate 15 drives the Z-shaped shaft 32 to rotate into the second lateral movement chute 31 of the guide plate 22, the Z-shaped shaft 32 drives the connecting straight plate 33 upwards, and the connecting straight plate 33 drives the second sucker mounting plate 19 upwards, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com