Patents

Literature

46results about How to "Meeting Packaging Needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medicinal neutral borosilicate glass tube and preparing method thereof

InactiveCN105036553AGood visible light transmittanceImprove UV transmittanceLithium oxideUltraviolet lights

The invention discloses a medicinal neutral borosilicate glass tube and a preparing method thereof. Manganese dioxide ingredients, titanium oxide ingredients and ferric oxide ingredients are added into preparing raw materials of the glass tube. One hundred parts of the raw materials comprise, by mass, 65 parts to 75 parts of silicon dioxide, 5.0 parts to 7.0 parts of aluminum oxide, 8.2 parts to 11.6 parts of diboron trioxide, 0.5 part to 2.4 parts of calcium oxide, 0.3 part to 3.4 parts of potassium oxide, 4.5 parts to 7.6 parts of sodium oxide, 0.2 part to 1.0 part of lithium oxide, 0.5 part to 7.0 parts of manganese dioxide, 0.4 part to 5.0 parts of titanium oxide and 0.2 part to 2.5 parts of ferric oxide. By means of the medicinal neutral borosilicate glass tube and the preparing method, the performance indexes such as the visible light transmittance, the ultraviolet light transmittance and the chrominance of an existing neutral borosilicate glass tube are improved, and the requirement for visible-light and ultraviolet-light sensitive medicine packages is met.

Owner:沧州四星玻璃股份有限公司

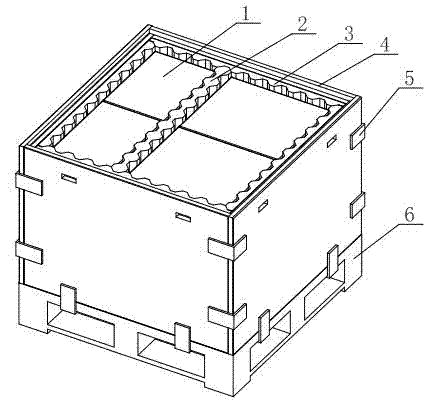

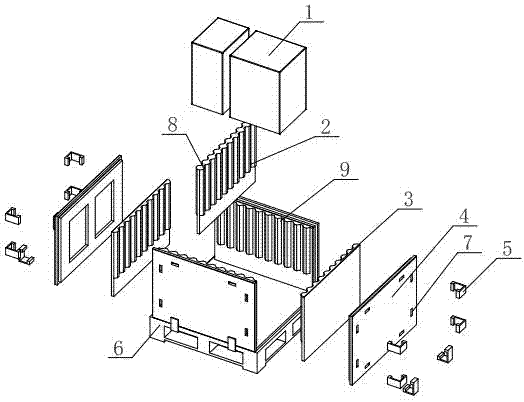

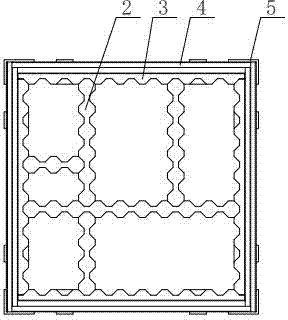

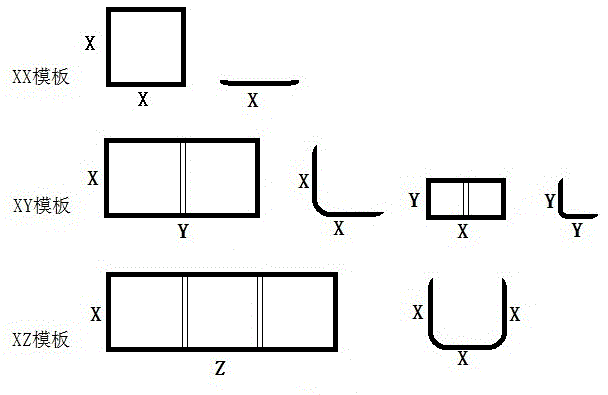

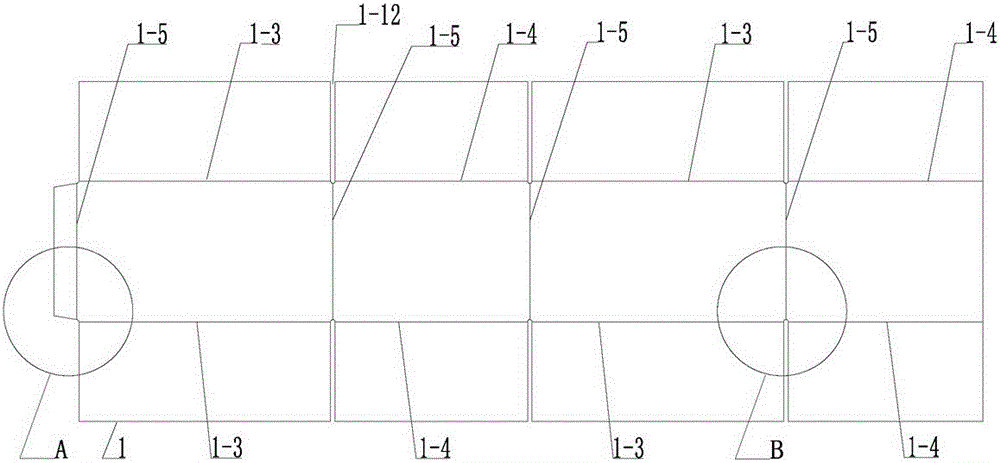

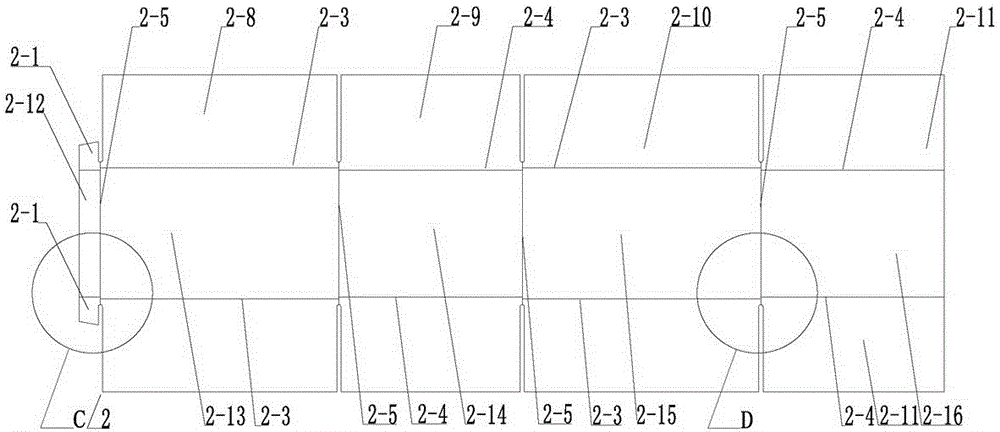

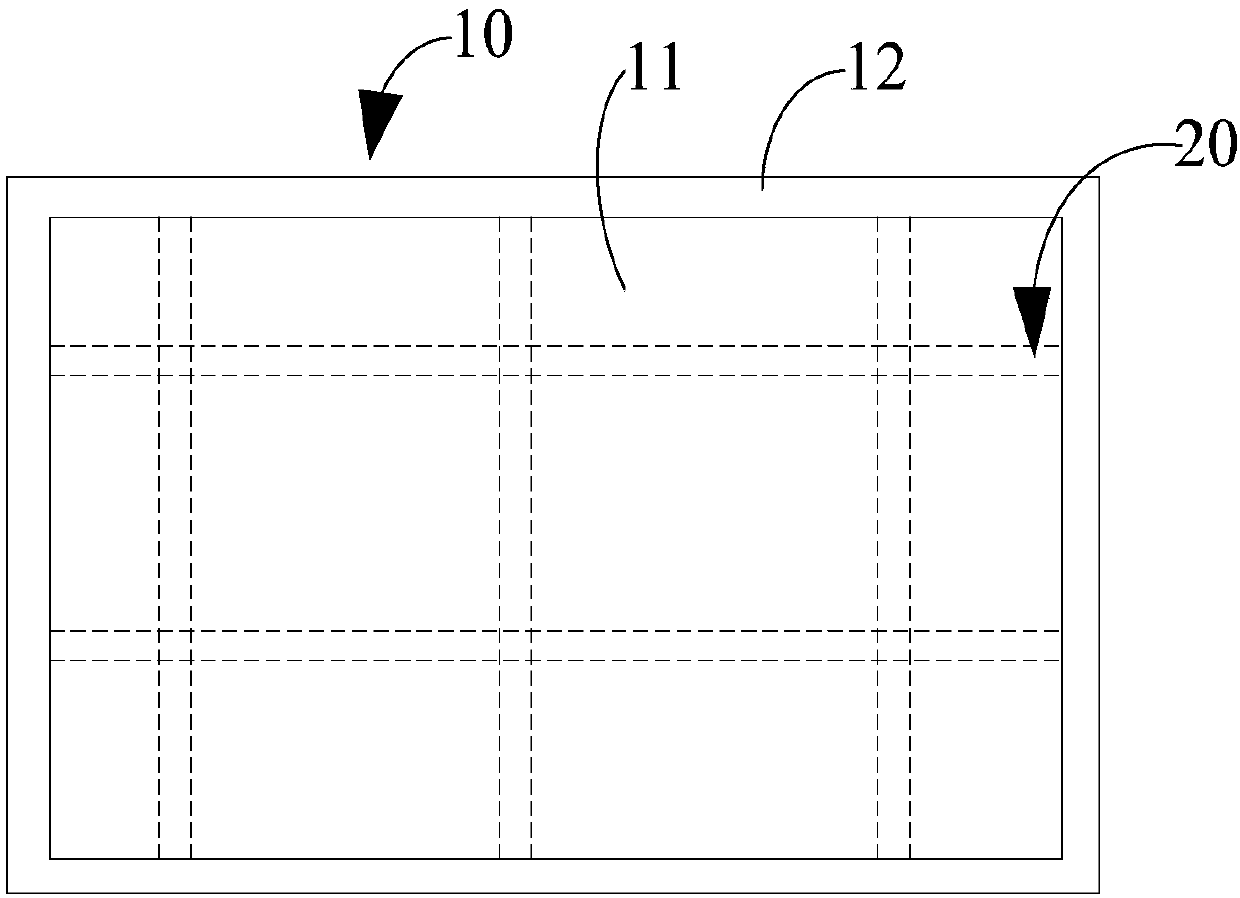

Multi-combination packaging box with variable volume

InactiveCN102530357AMeeting Packaging NeedsOptimize volumeVariable capacity containersExternal fittingsPrismEngineering

The invention discloses a multi-combination packaging box with variable volume. The multi-combination packaging box comprises a box bottom, a box cover top plate and side plates on the four sides, wherein the adjacent plates are connected and fixed through connecting parts, the interior of the box body is divided into a plurality of units through built-in partition plates, continuous trapezoidal grooves are distributed on the inner sides of the side plates and the two side plate surfaces of the built-in partition plates, the built-in partition plates form a plurality of hexagonal prisms which are connected in series and arranged at equal distances, and the positioning of the built-in partition plates is realized by embedding and combining the prism surface of the hexagonal prisms with the trapezoidal grooves of the orthogonal plates. The volume of each unit in the box can be changed through a free insert plate structural form so as to realize multiple combinations, not only optimize the volume, but also maximize the utilization rate of space; furthermore, the multi-combination packaging box with the variable volume can meet the packaging demands of products in different specifications and sizes and effectively improve the protection performance of all the products in the packaging box; and the multi-combination packaging box with the variable volume, disclosed by the invention, can be recycled multiple times and greatly reduce logistics cost and material cost, and is further green and environment-friendly.

Owner:JIANGNAN UNIV

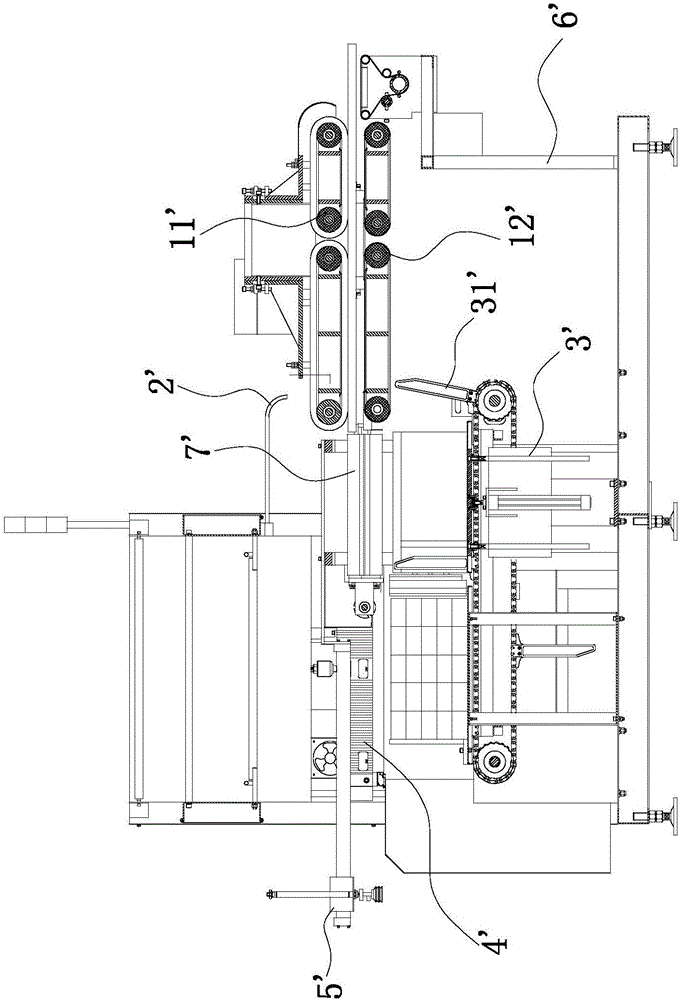

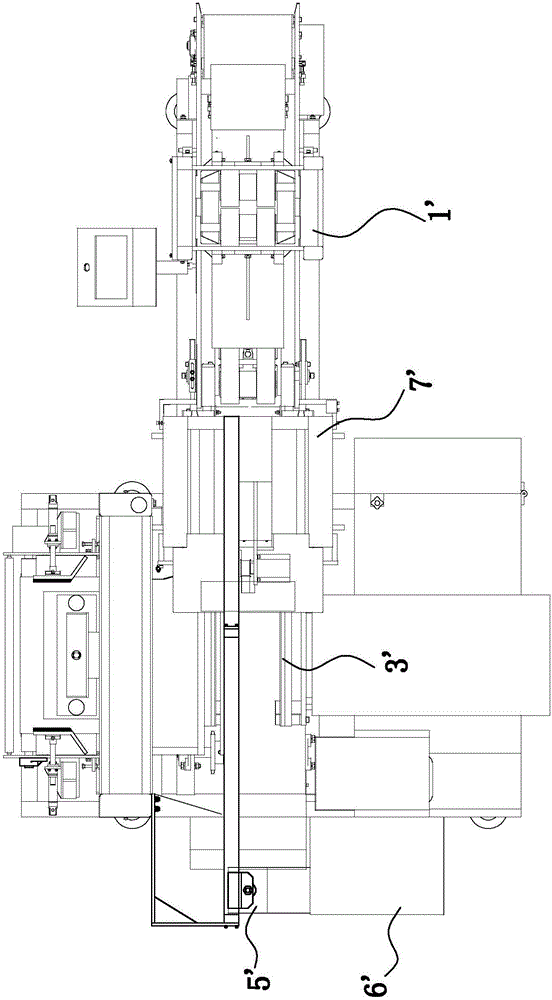

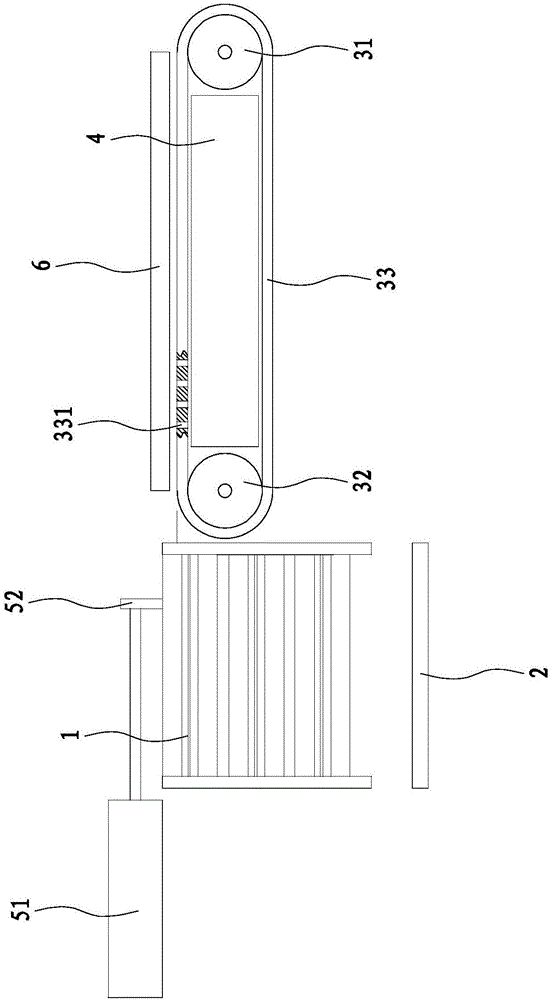

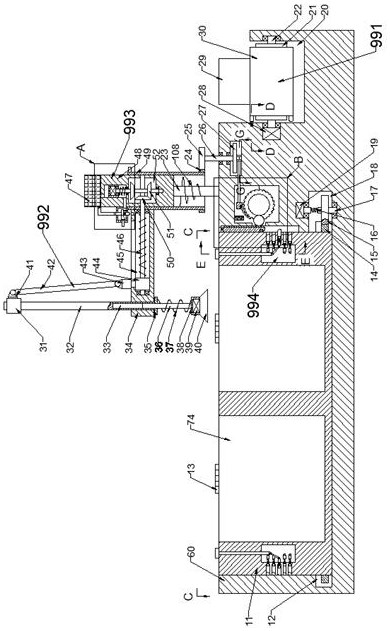

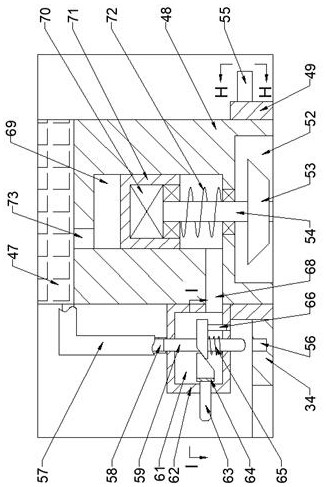

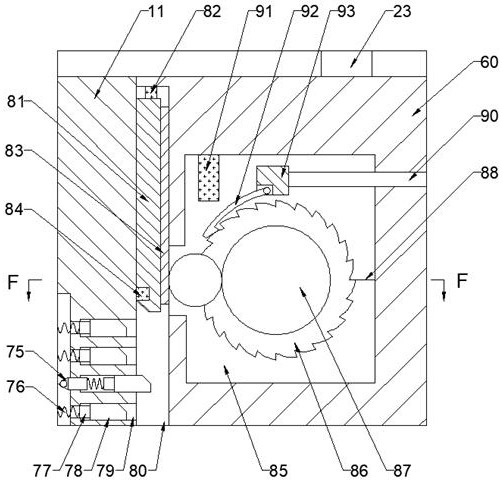

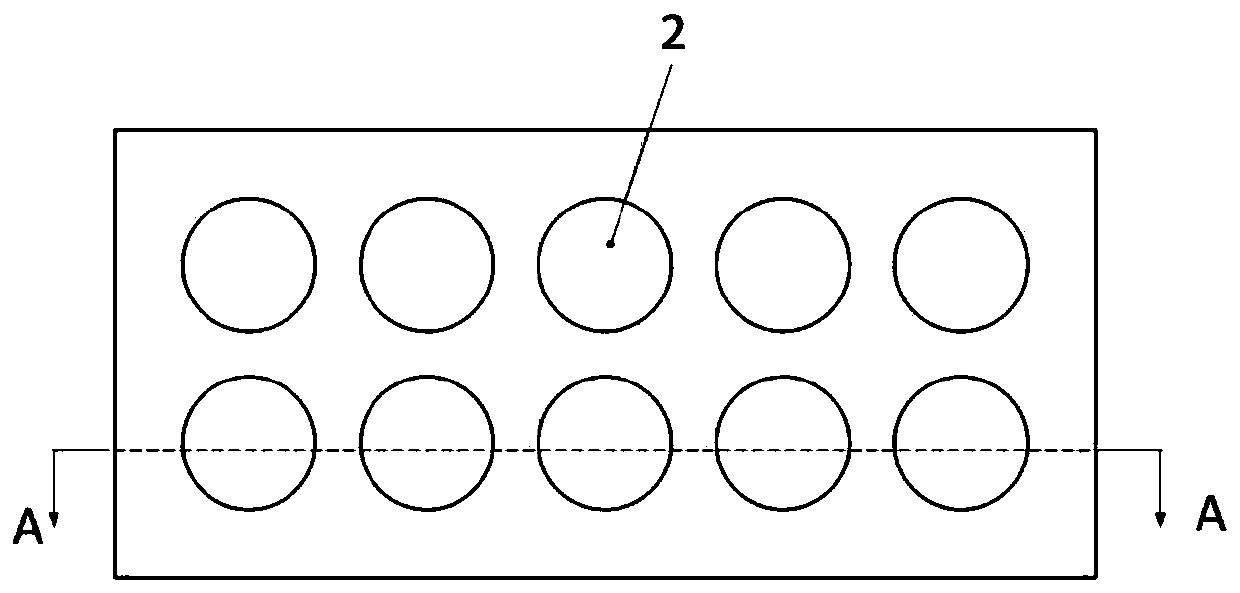

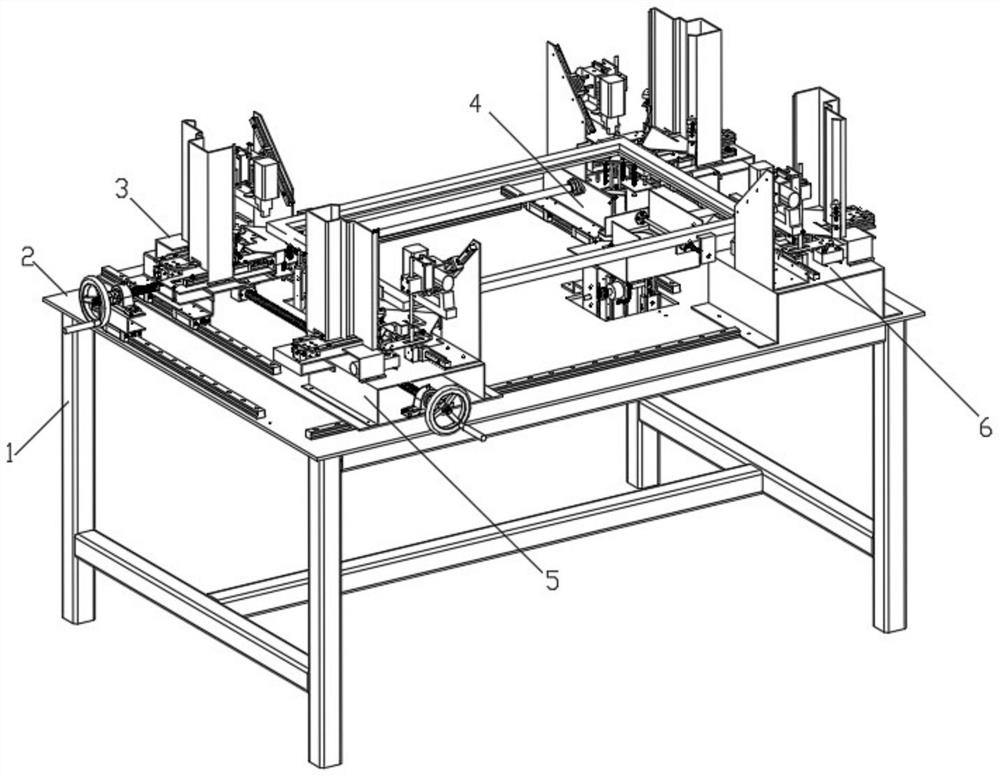

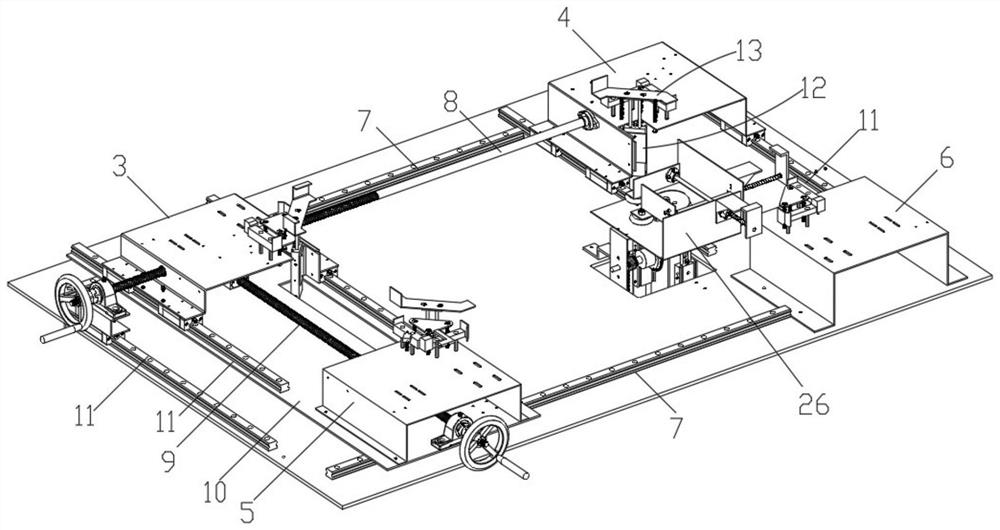

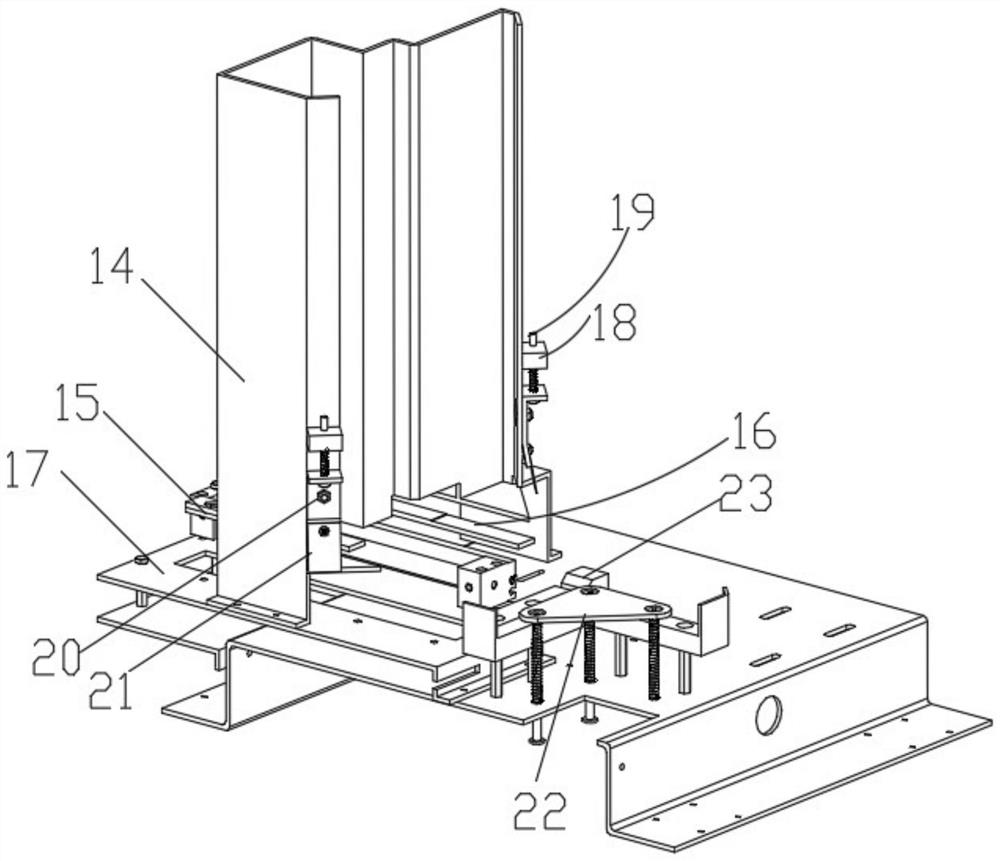

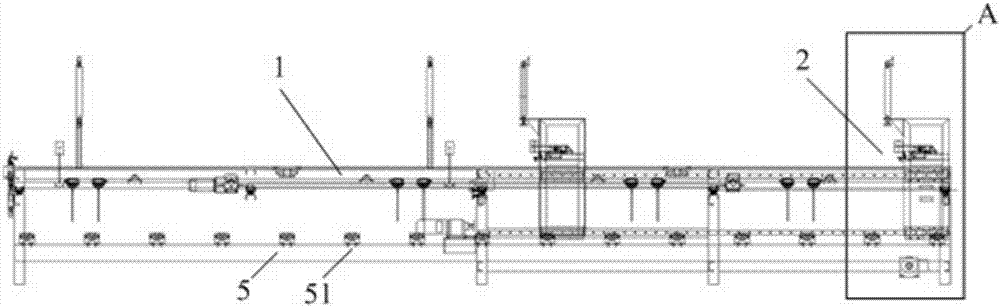

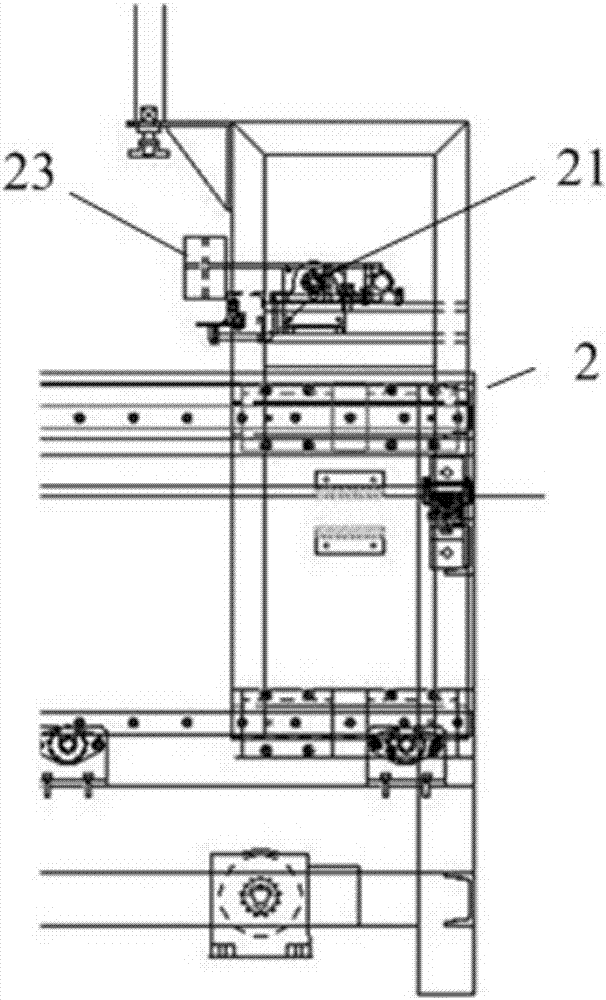

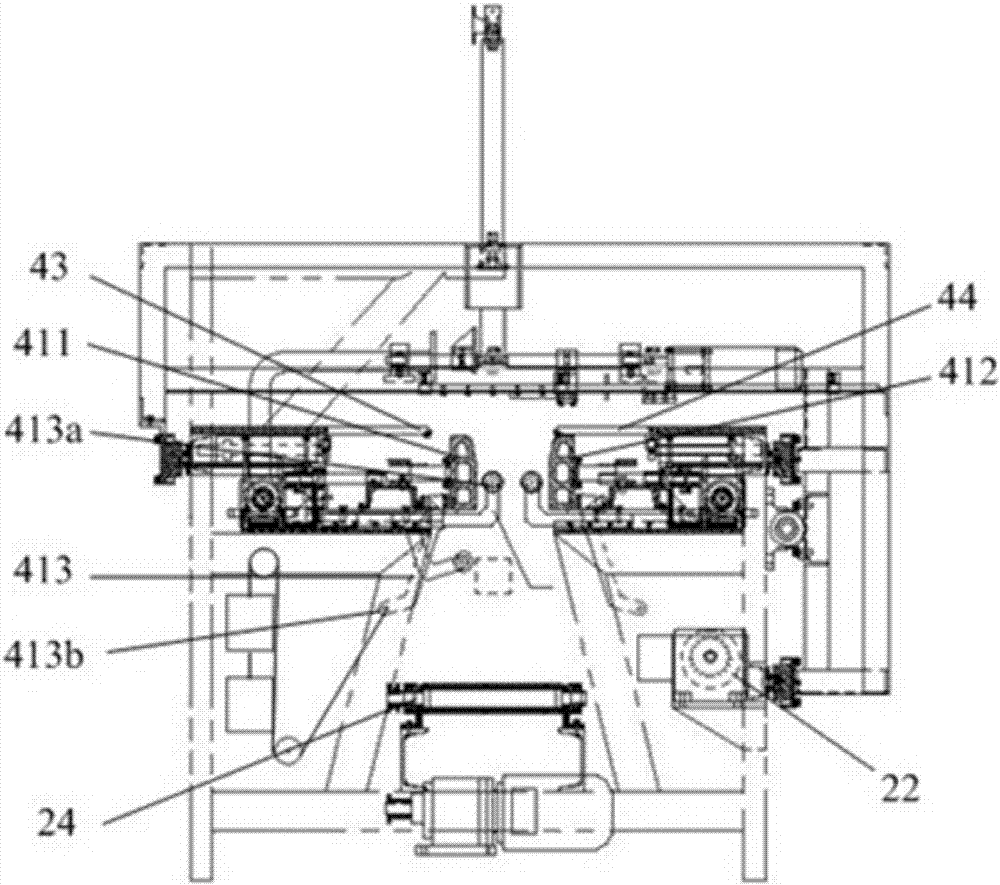

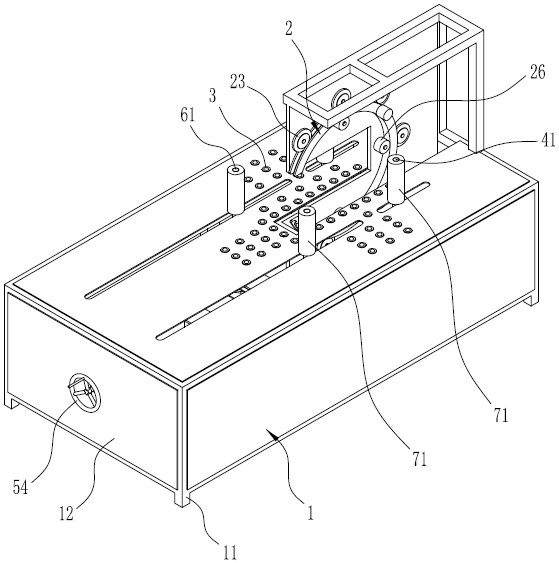

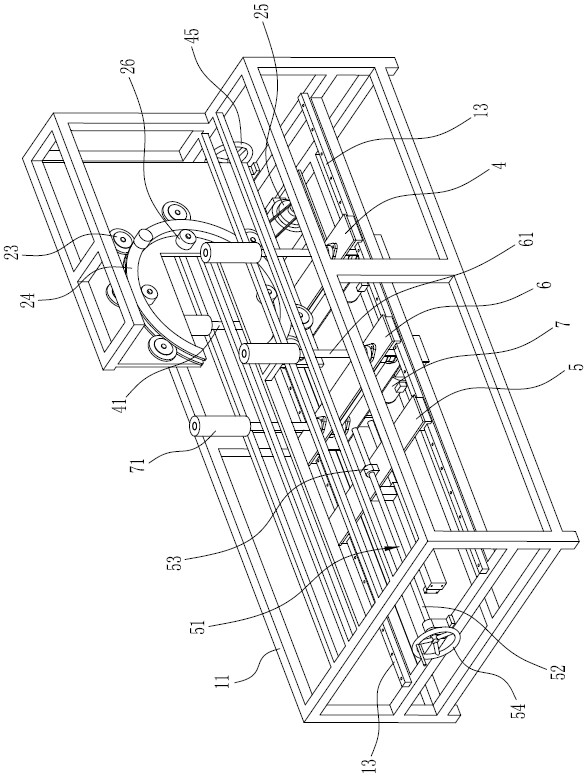

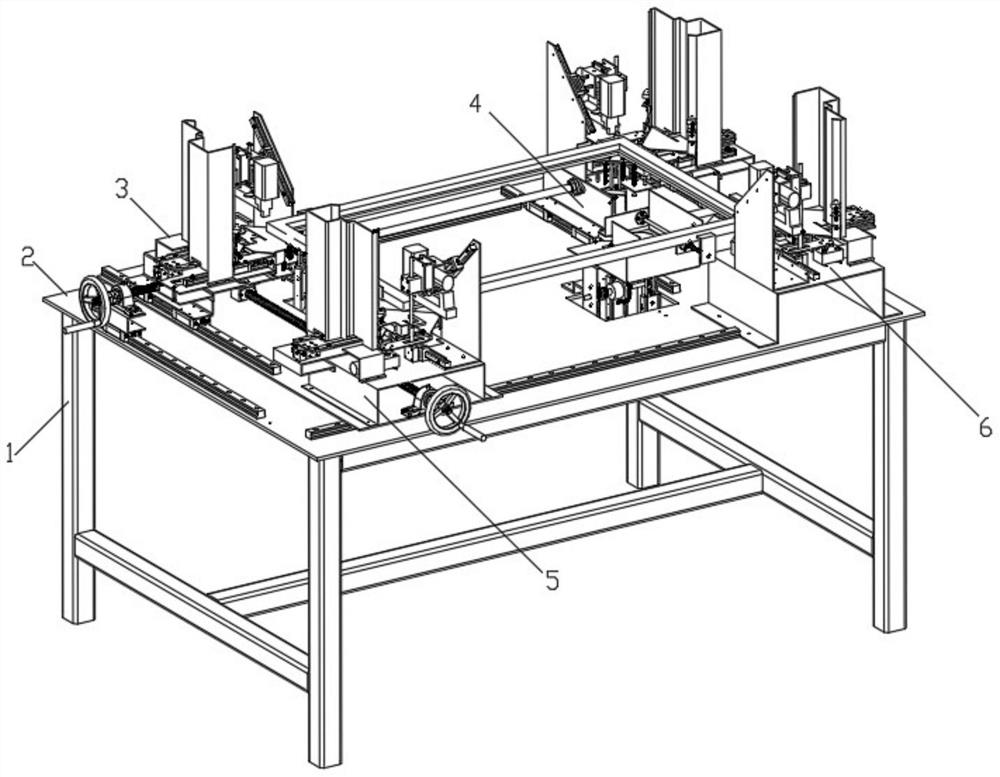

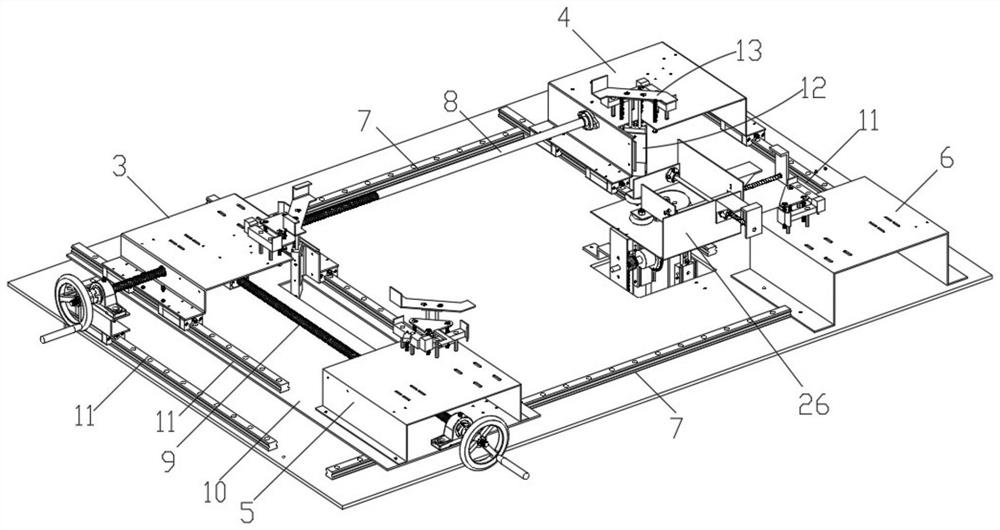

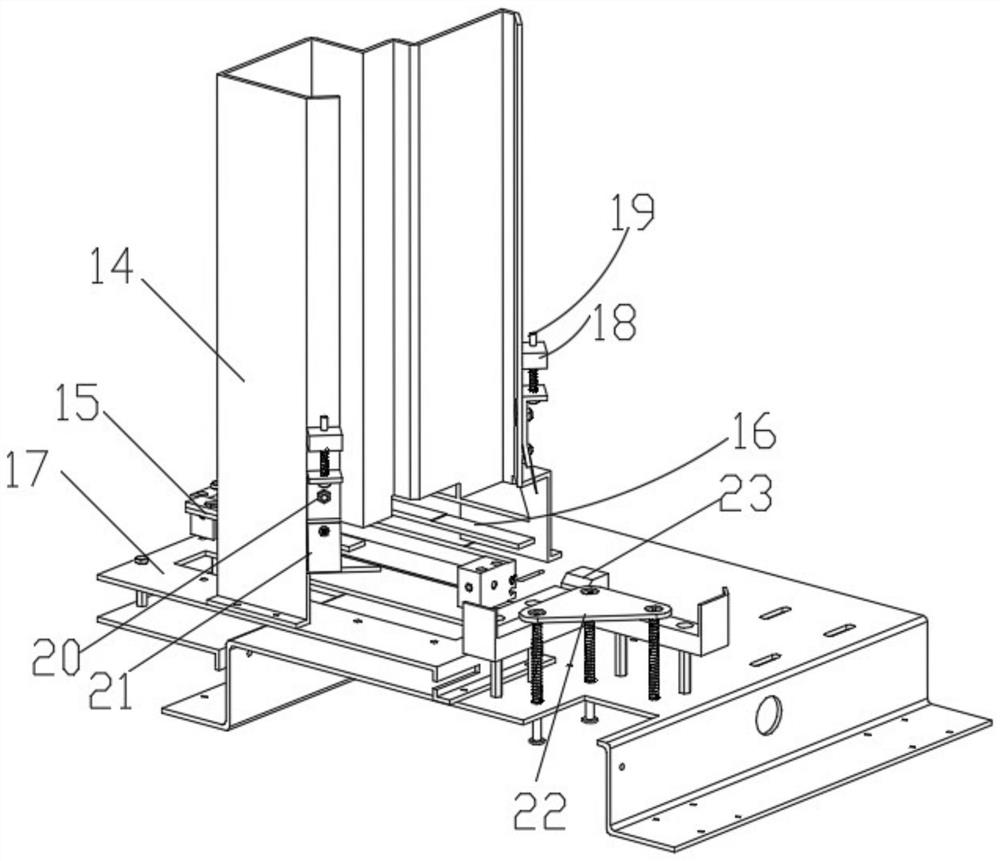

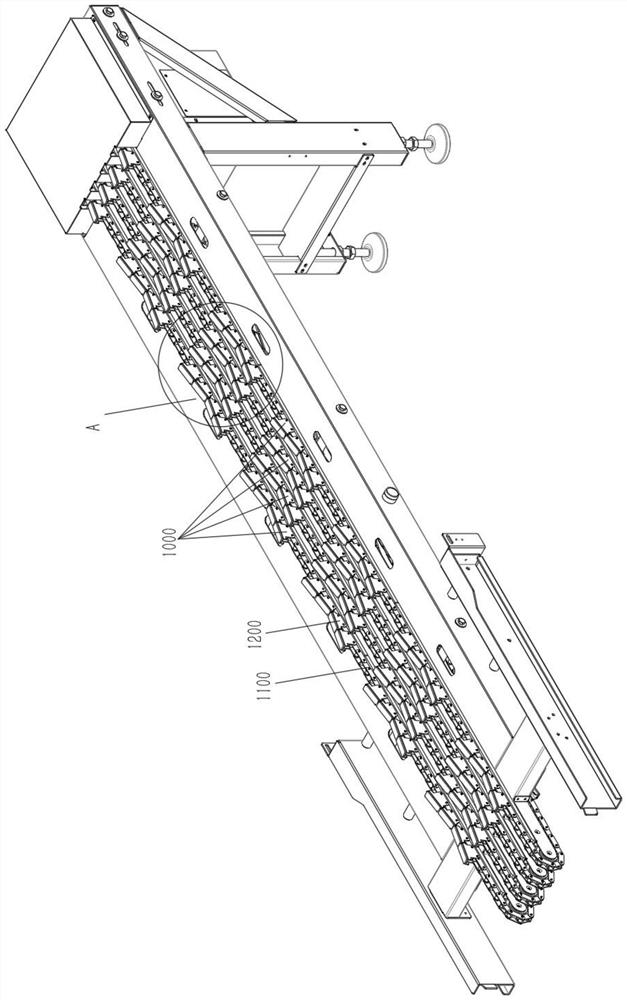

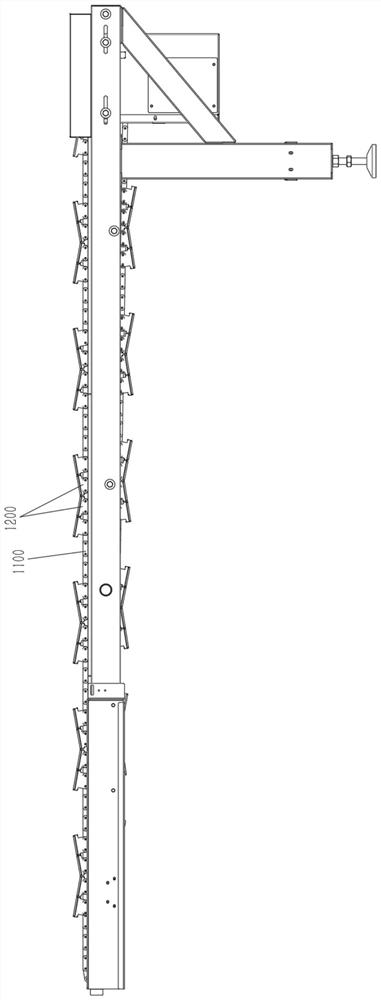

Machine for conducting mixed package on special-shaped cigarettes and conventional cigarettes

PendingCN106043806AStable spacingMeeting Packaging NeedsPackagingElectrical controlStructural engineering

The invention relates to a machine for conducting mixed package on special-shaped cigarettes and conventional cigarettes. The machine comprises a rack, an inputting and conveying device, an overturning device, an outputting station and an electric control system, wherein the inputting and conveying device, the overturning device, the outputting station and the electric control system are arranged on the rack. The outputting station is arranged below the overturning device. The inputting and conveying device comprises a driving wheel, a driven wheel, a conveying belt and a driving device, wherein the driving wheel and the driven wheel are rotatably arranged on the rack; the conveying belt wraps the driving wheel and the driven wheel; and the driving device drives the driving wheel. A plurality of through holes which are used for allowing air flow to pass through are formed in the conveying belt. A negative pressure adsorption chamber used for adsorbing articles is formed in the portion, within the wrapping range of the conveying belt, on the rack. The negative pressure adsorption chamber, the driving device and the overturning device are each connected with the electric control system.

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

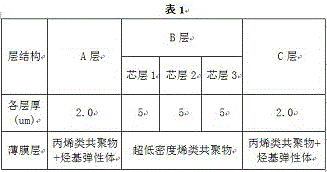

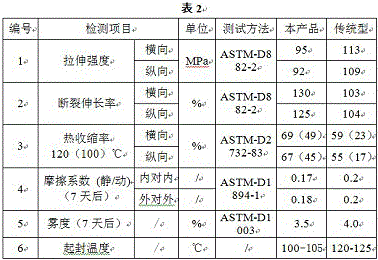

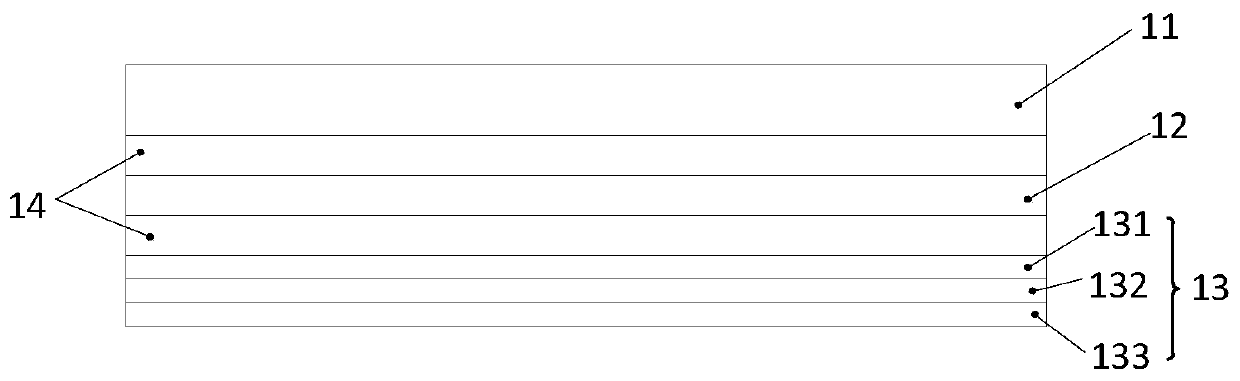

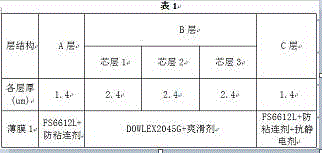

Polyolefin bidirectional stretching film and preparation method thereof

ActiveCN106626654AWide sealing temperature rangeMeeting Packaging NeedsFlexible coversWrappersLow-density polyethyleneElastomer

The invention discloses a polyolefin bidirectional stretching film and a preparation method thereof, wherein the polyolefin bidirectional stretching film comprises five layers of layered structures including an upper surface layer, three core layers and a lower surface layer in sequential distribution, wherein the upper surface layer and the lower surface layer are prepared from the following ingredients including 50 to 80 parts of propylene copolymers, 20 to 40 parts of alkylene elastomers, 1 to 6 parts of anti-adhesion agents and 1 to 4 parts of slipping agents; each of the three core layers is prepared from the following ingredients including 69 to 100 parts of ultra-low density polyethylene, 0.1 to 30 parts of vinyl copolymers and 0.01 to 1 part of slipping agents. The technical scheme provided by the invention has the advantages of low hot sealing temperature, wide hot sealing temperature range, soft product hand feeling and high flexibility; the shrinkage effect and the hot sealing performance of the film can be obviously improved; the product performance is improved.

Owner:聚银塑料包装制品(深圳)有限公司

Air column type protection device

ActiveCN105109825AMeeting Packaging NeedsPrevent too narrowContainers to prevent mechanical damageEngineering

Owner:江阴艾尔克缓冲材料有限公司

Medical packaging material and preparation method thereof

InactiveCN106243653AImprove high temperature resistanceHigh tensile strengthDichlorodifluoromethaneAcrylic resin

The invention discloses a medical packaging material. The medical packaging material is prepared from, by weight, 12-23 parts of polycarbonate, 8-18 parts of polyurethane, 0.5-1.2 parts of polyethylenimine, 0.5-1.2 parts of polydimethylsiloxane diquaternary amine, 0.4-1 part of trichlorofluoromethane, 4-9 parts of dichlorodifluoromethane, 15-28 parts of polylactide, 1.5-6 parts of calcium carbonate, 0.5-1 part of sodium dibutyl naphthalene sulfonate, 15-30 parts of polyethylene glycol, 6-12 parts of acrylic resin, 4-9 parts of vinyl-vinyl acetate copolymer and 2.5-6 parts of borax. Compared with the prior art, the medical packaging material has strong resistance to high temperature and high tensile strength, does not easily deform after high temperature and high pressure sterilization treatment and is especially suitable for the medical field.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

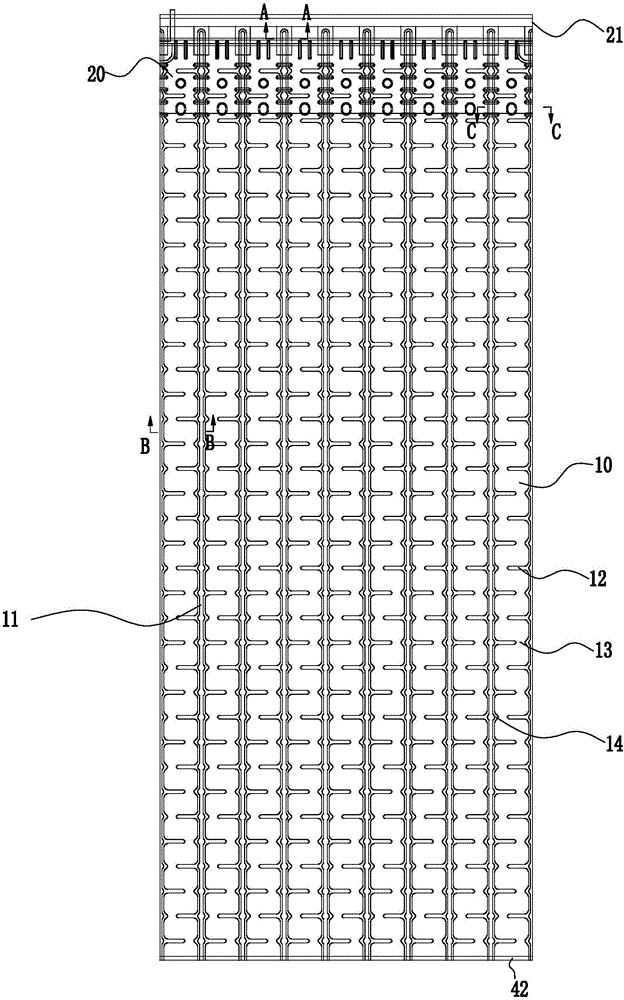

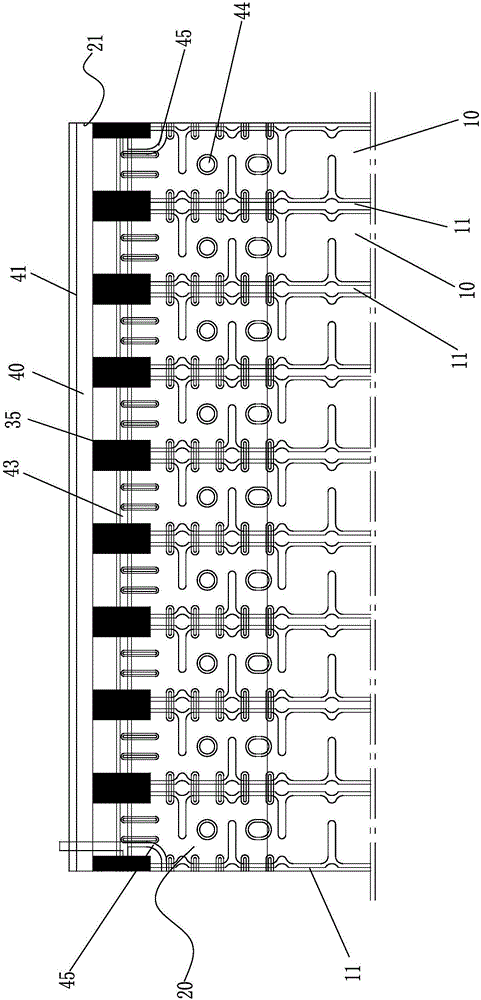

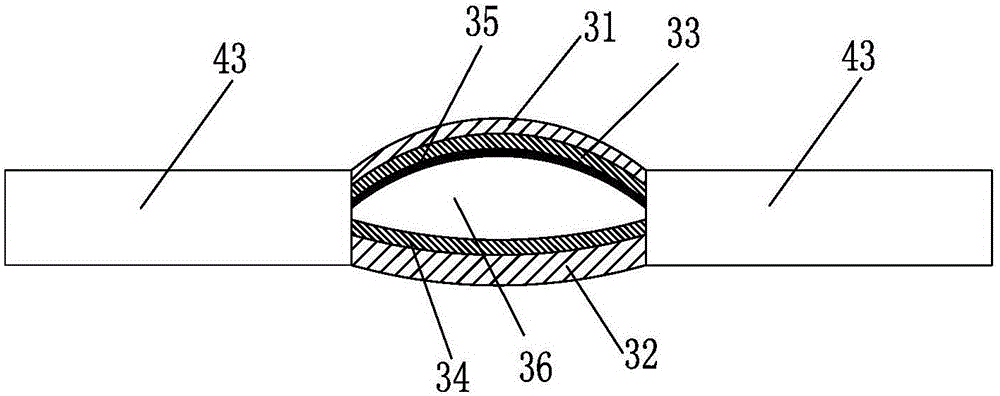

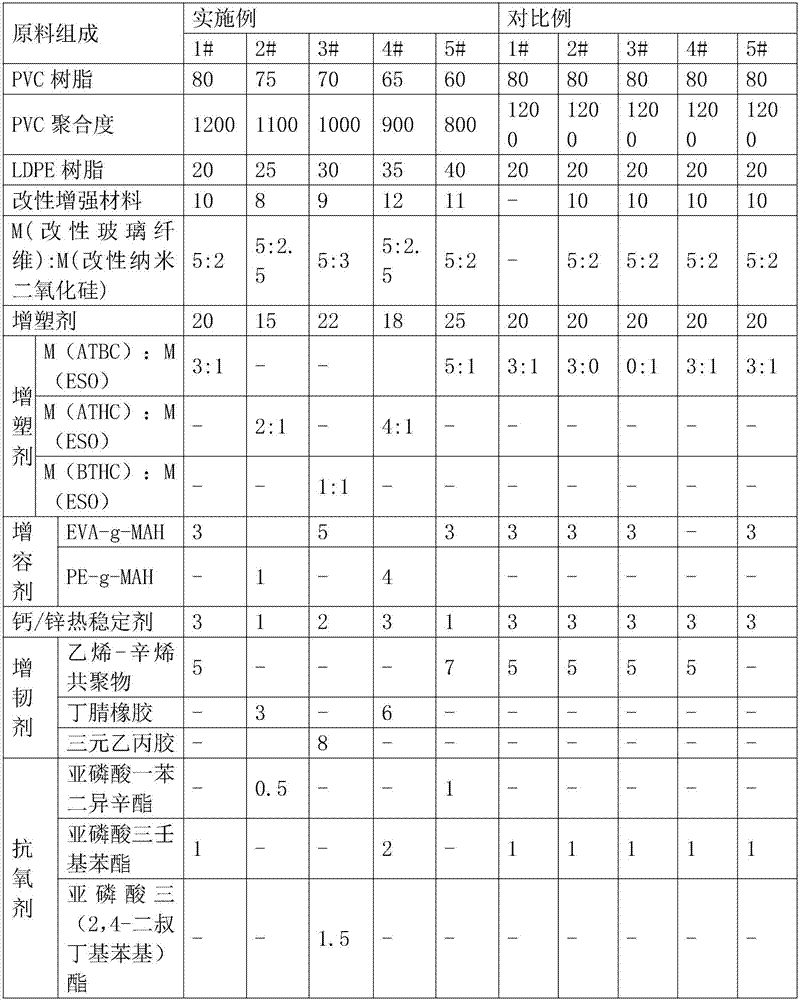

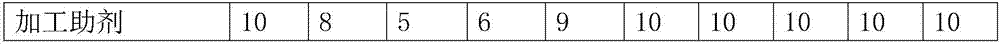

PVC/LDPE drug packaging material and preparation method thereof

The invention belongs to the field of packaging materials, and relates to a packaging material and a preparation method thereof, in particular to a PVC / LDPE drug packaging material and a preparation method thereof. The packaging material is prepared from 60-80 parts of PVC resin, 20-40 parts of LDPE resin, 8-12 parts of modified and reinforced materials, 15-25 parts of plasticizers, 0.5-2.5 parts of antioxidants, 1-5 parts of compatibilizers, 1-3 parts of calcium / zinc heat stabilizers, 3-8 parts of toughening agents and 5-10 parts of processing promoters. The PVC / LDPE drug packaging material is excellent in toughness and impact strength, high in break elongation rate, good in biocompatibility, high in oxygen permeability, especially suitable for the field of medical treatment, simple in preparation method, high in production efficiency, and easy to industrialize and produce at a large scale.

Owner:江苏凯威药用包装有限公司

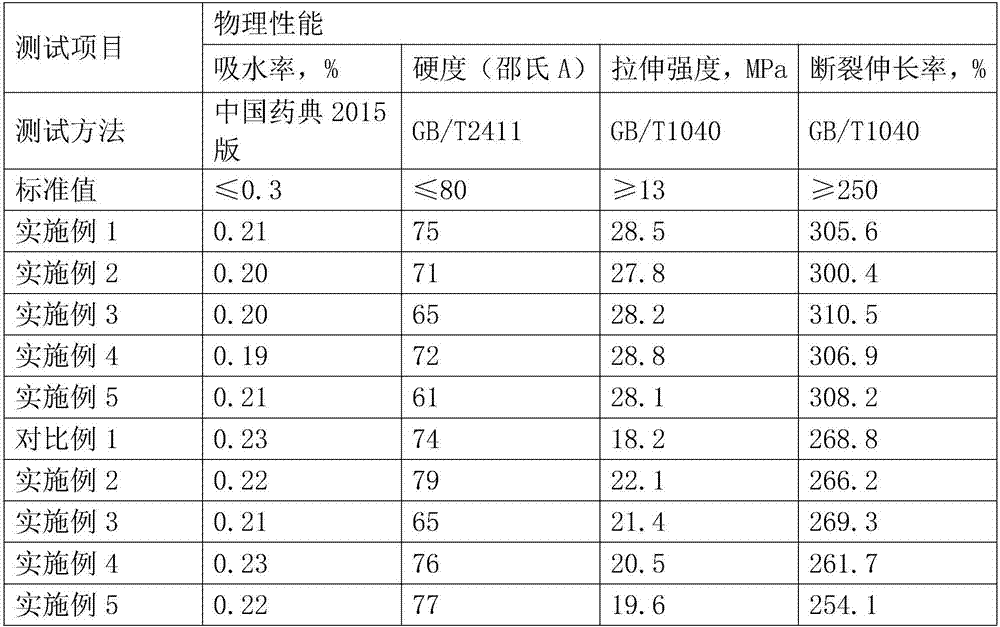

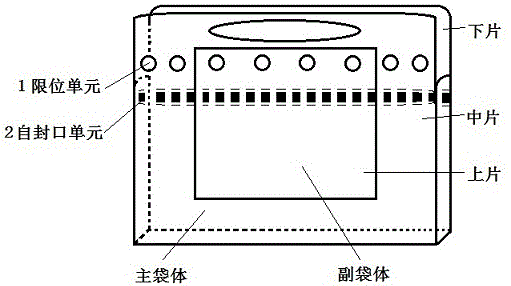

Logistics express delivery packaging method and device

InactiveCN104891003ARealize off-site security openingImprove securityLocking devicesLogistics managementComputer science

The invention discloses a logistics express delivery packaging method and device. The logistics express delivery packaging method and device are characterized in that a cryptographic device is used for achieving limited sealing delivery packaging in the method, and the device comprises a commonly-used packaging box, a commonly-used packaging bag and the novel cryptographic device. The cryptographic device is used for achieving limited sealing, safety sealing of packages is guaranteed, time and space limitations are overcome, and different-place opening of the packages is achieved. According to the device, assembling and disassembling can be completed immediately and quickly, safety of goods is guaranteed, and long-term recycling can be achieved immediately and effectively; the commonly-used device and cipher sealing logistics express delivery packaging are used, the disposable using current situation of traditional packaging is improved, resource waste is reduced to a great extent, and saved resources are immeasurable to a certain degree. In the whole process, the links that packages arrive at customers are reduced, and thus the packaging cost added to products is lowered; excessive packaging is eliminated, quick service of logistics express delivery can be enjoyed by people, and meanwhile environmental pollution is avoided.

Owner:张登高

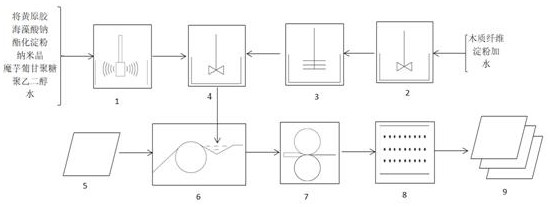

Nanocrystalline antibacterial packaging paper and preparation method

InactiveCN111608008ATightly boundAdhesivelyVegetable material additionPaper/cardboardFiberPolymer science

The invention provides a nanocrystalline antibacterial packaging paper and a preparation method thereof. Silica sol, xanthan gum, sodium alginate, nanocrystals, konjac glucomannan, polyethylene glycoland water are subjected to ultrasonic dispersion to obtain fine pulp, wood fibers, pre-gelatinized starch and water are mixed to prepare a pulping material, then the pulp and the pulping material aremixed to prepare an antibacterial coating solution, and finally the antibacterial coating solution is blade-coated and pressed on the surface of base paper to obtain the nanocrystalline antibacterialpackaging paper. The nanocrystals are dispersed in the silica sol, then are uniformly dispersed in the paper pulp, and are combined on the surface of the base paper through blade coating and wet pressing, so that not only is the use of an organic adhesive reduced, but also the nano-crystals are firmly bonded by silica sol and do not fall off, the antibacterial effect can be fully exerted, and meanwhile, the coating wood pulp ensures that the packaging paper is better in bursting strength and strength and meets packaging requirements.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

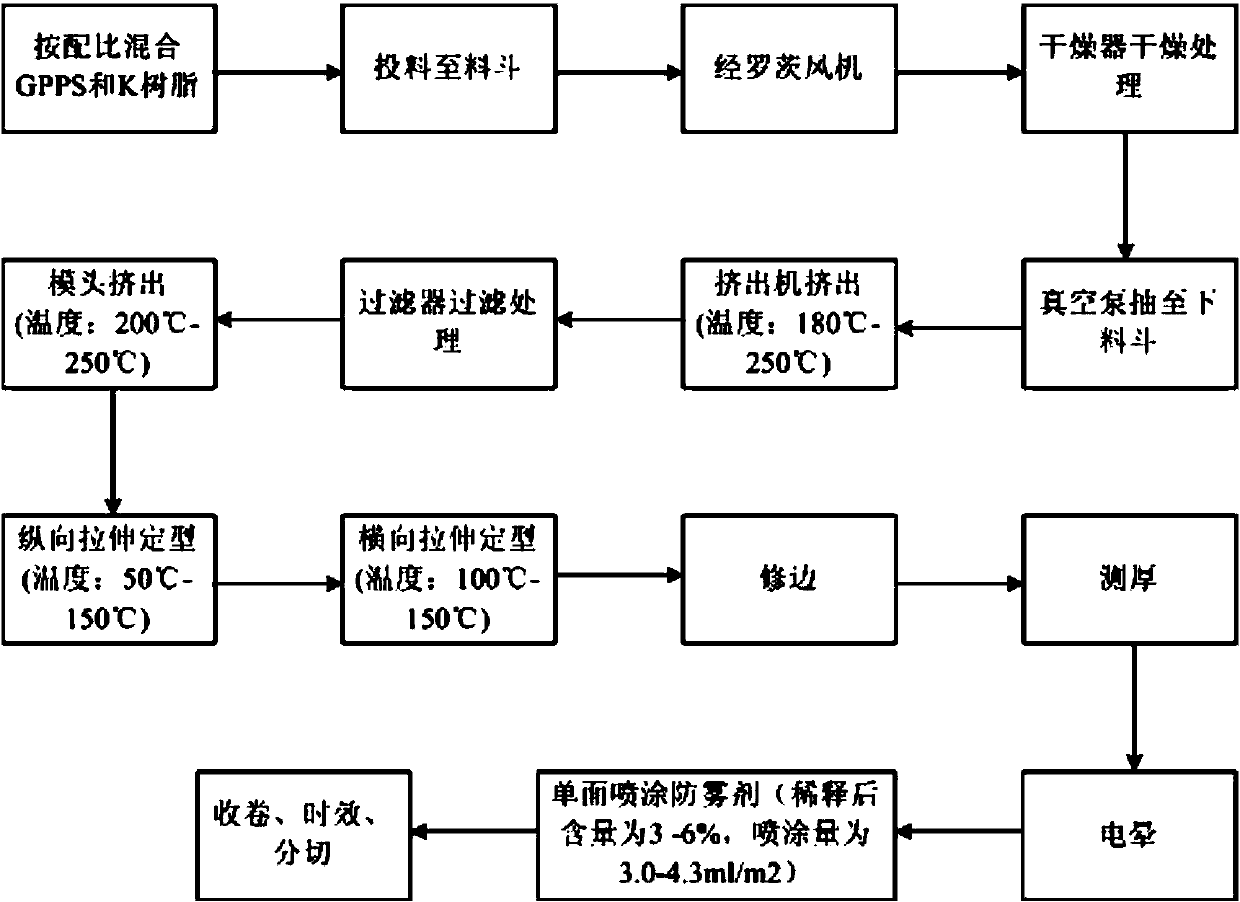

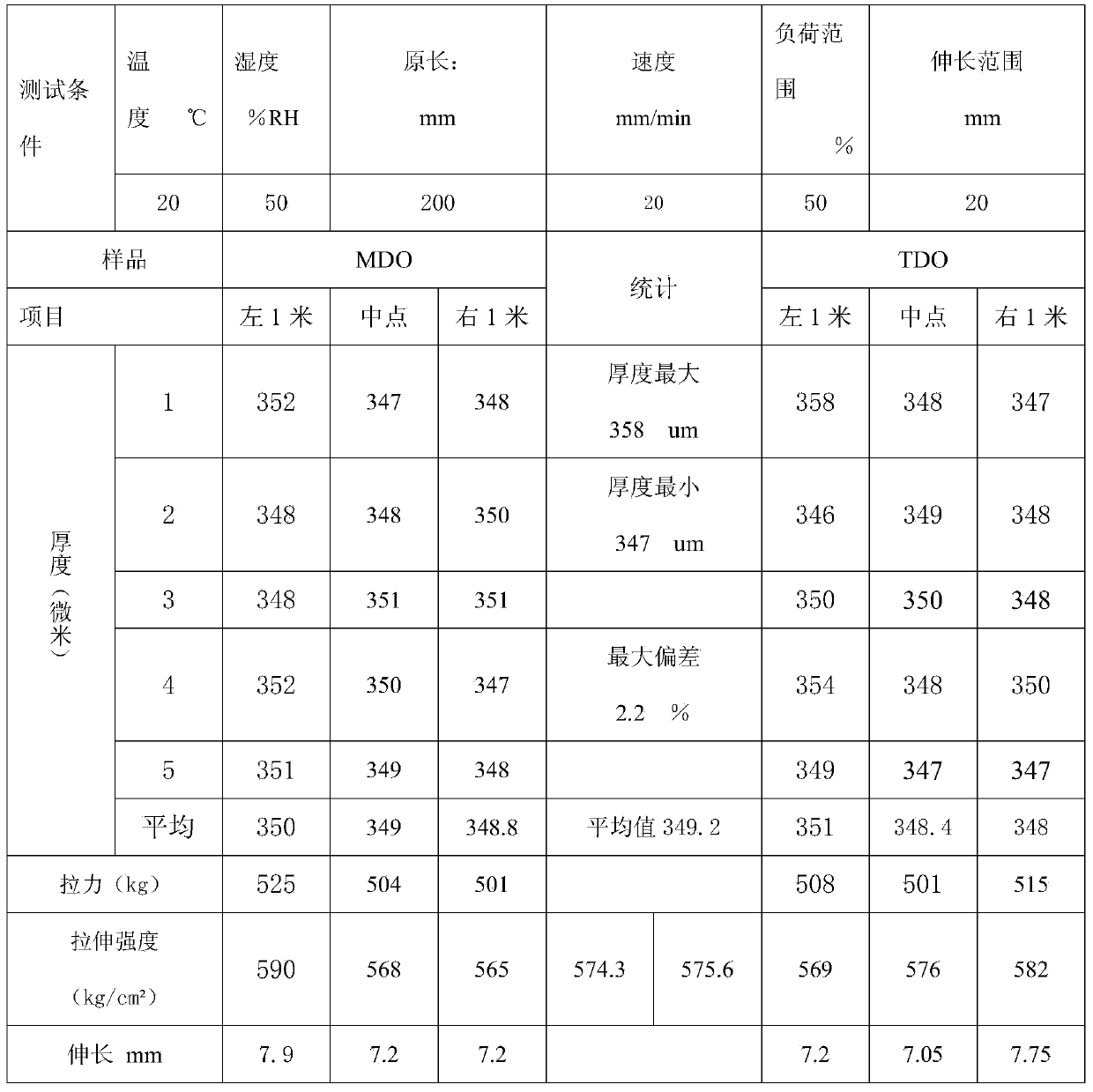

High-antifogging polystyrene sheet suitable for special food packaging and manufacturing method thereof

InactiveCN104004285AGood anti-fog performanceMeeting Packaging NeedsFlexible coversWrappersPolystyreneFood packaging

The invention discloses a high-antifogging polystyrene sheet suitable for special food packaging and a manufacturing method thereof. The high-antifogging polystyrene sheet is prepared from the following raw materials in percentage by weight: 90-95% of general-grade polystyrene, and 5-10% of resin K. The manufacturing method comprises the following steps: mixing the raw materials in proportion; carrying out melt extrusion on the obtained mixture by an extruder; feeding a melt into a die head, so that the melt is cast into a thick sheet; sequentially carrying out longitudinal and transverse stretching and sizing on the thick sheet, so that a thin sheet is obtained; carrying out edge trimming, thickness measuring and aureoling on the thin sheet; spraying an antifogging agent on one surface of the thin sheet, wherein the content of the antifogging agent is 3-6% after being diluted by water, and the spraying amount is 3.0-4.3 ml / m<2>; and rolling, aging and slitting the thin sheet. According to the invention, in the process of sheet production, a reasonable amount of a diluted antifogging agent is sprayed on the surface of a sheet, so that the antifogging performance of the sheet is greatly improved, the antifogging grade can be as high as 5-grade, the sheet also can be completely transparent and has no formed fog after packaging food, therefore, the sheet meets the packaging requirements of special foods, and has a broad market prospect.

Owner:WINKO PLASTICS

Corrugated carton forming process

InactiveCN106273653AHigh compressive strengthMeeting Packaging NeedsContainer making machineryPaperboardEngineering

The invention discloses a corrugated carton forming process. The problems of carton corner leakage, carton corner wrapping and the like caused in the forming process of a corrugated carton are effectively solved. According to the technical scheme, the corrugated carton forming process includes the following steps that a die cutting flow chart of the corrugated carton is designed, a die cutting unit of a printing die cutting slotting machine or an automatic flat pressing machine is used for producing and manufacturing corrugated paperboards, the corrugated paperboards are bonded to be formed according to the technological requirements, and the corrugated carton bonded to be formed is reinforced. By means of living example testing of the corrugated carton manufactured through the method, the effect that the carton corner leakage of the corrugated carton cannot be caused is guaranteed, and meanwhile materials are not changed, so that the overall compressive strength of the corrugated carton is improved by 10%-15%, and the packaging needs of precision instruments, electronic products, food, powder-shaped objects and the like can be met completely. Meanwhile, technical support can be provided for light-weight technological design of the corrugated carton, and cost can be effectively saved.

Owner:HENAN HUALI PAPER IND

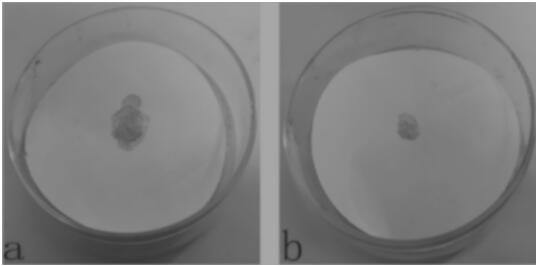

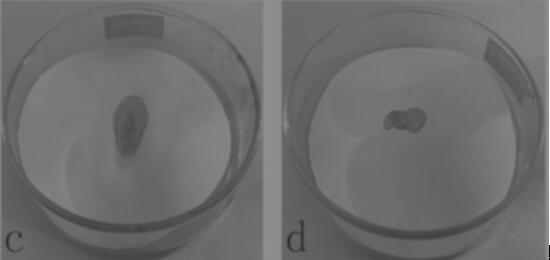

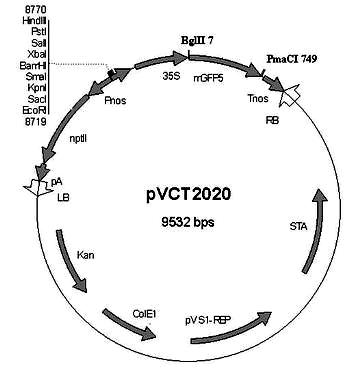

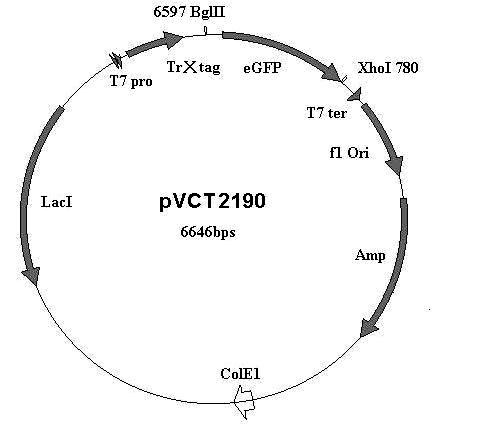

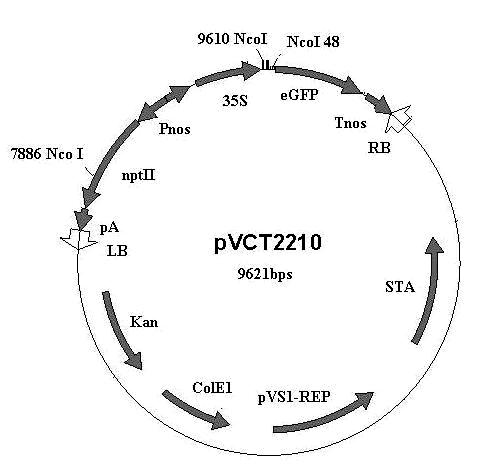

Virulence auxiliary vector for agrobacterium tumefaciens-mediated high molecular weight T-DNA (Transfer-Deoxyribonucleic Acid) transformation and preparation method as well as application thereof

InactiveCN102321667AMeeting Packaging NeedsFacilitate genetic transformationFermentationVector-based foreign material introductionRepliconOperon

The invention relates to the field of gene engineering, in particular to a virulence auxiliary vector for agrobacterium tumefaciens-mediated high molecular weight T-DNA (Transfer-Deoxyribonucleic Acid) transformation. In the invention, VirE2 protein can be over-expressed in agrobacterium tumefaciens by constructing a vector containing virE-virG chimeric operon and agrobacterium tumefaciens replicon oriV. The invention also discloses a preparation method of the vector. The vector disclosed by the invention is used in agrobacterium tumefaciens-mediated genetic transformation, so that a sufficient amount of VirE2 protein wraps high molecular weight T-DNA when the T-DNA with length of over 25kb is transformed into plant genome, and the high molecular weight T-DNA is not degraded by nuclease and can be completely integrated into the plant genome to realize multi-gene genetic transformation.

Owner:SOUTHWEST UNIV

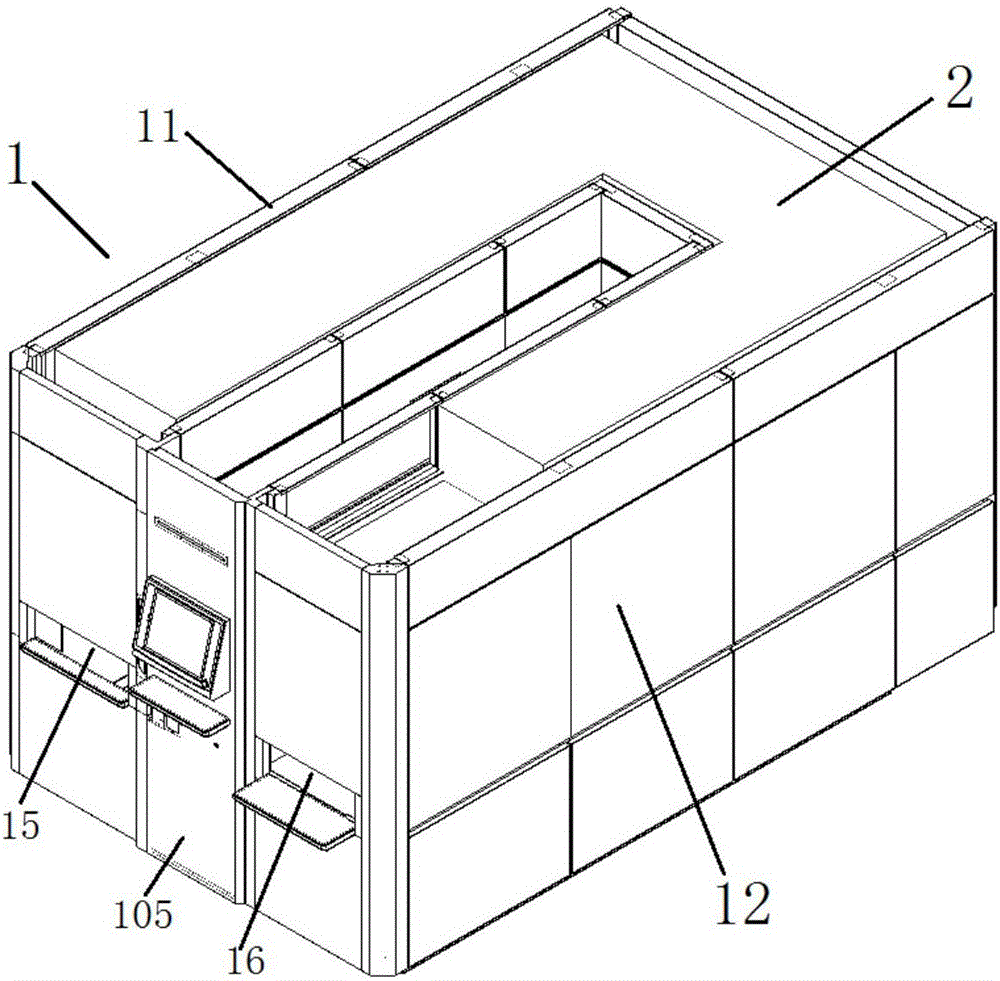

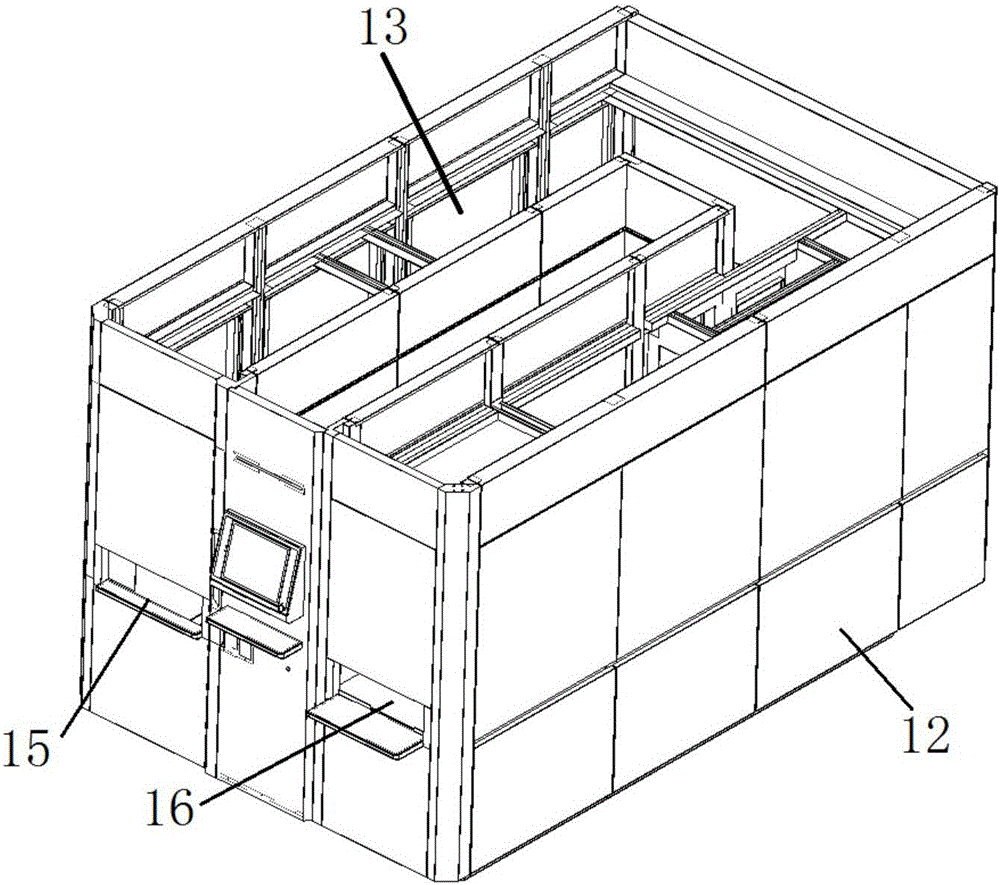

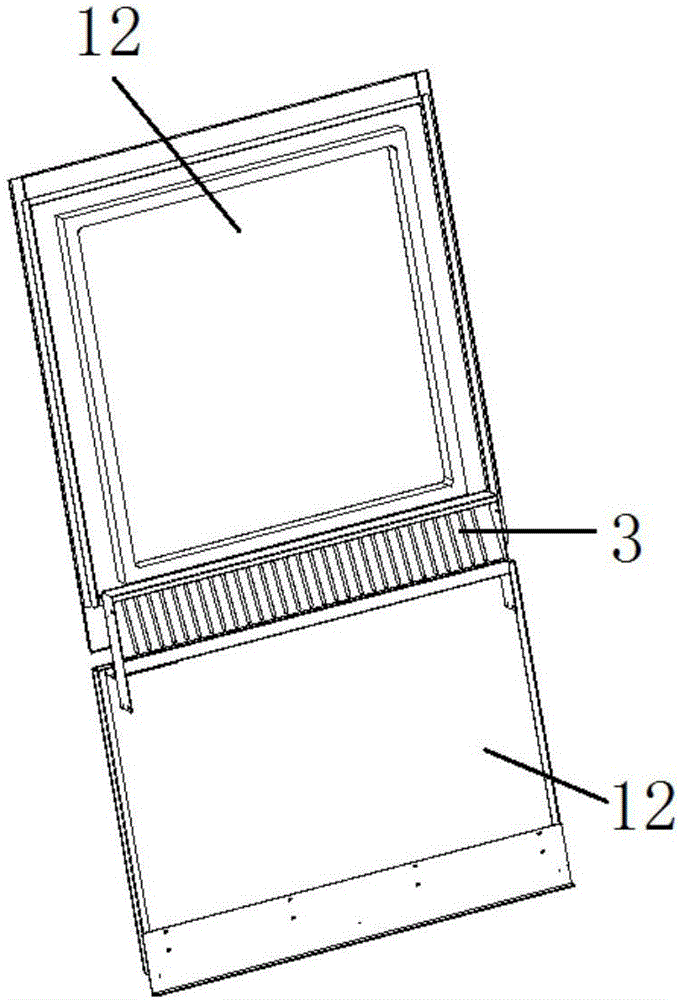

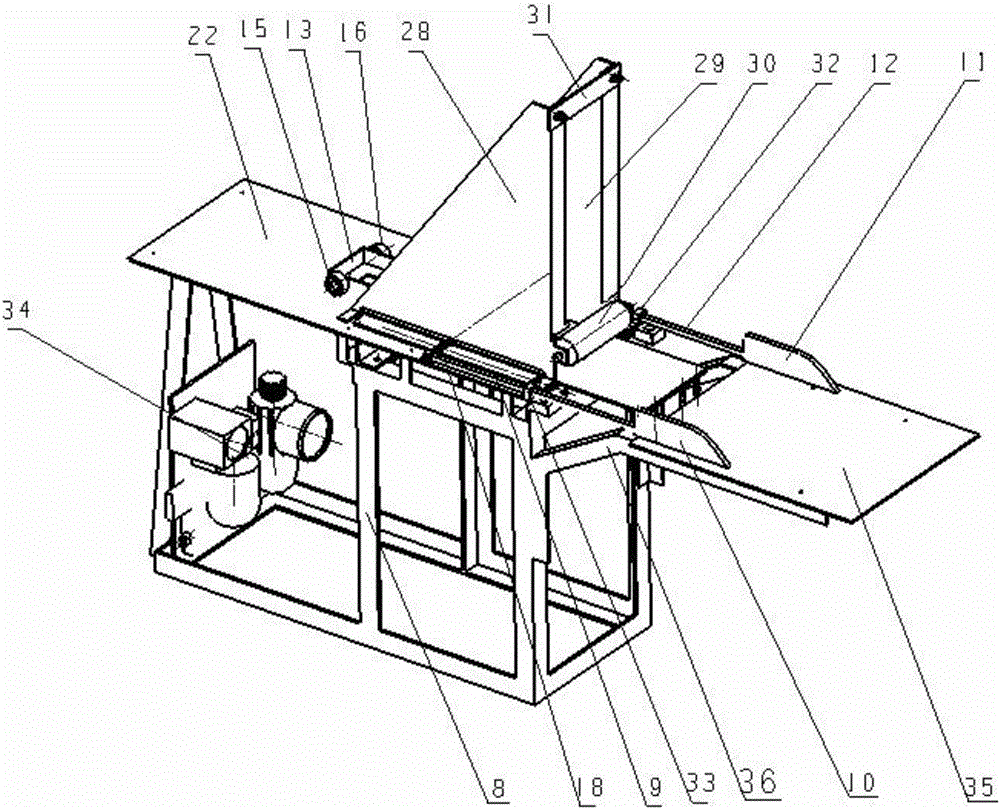

Packaging equipment and packaging process under clean environment

ActiveCN106829035AExtended shelf lifeFully automatedWrapper twisting/gatheringPackaging protectionPositive pressureEngineering

The invention provides packaging equipment and a packaging process under the clean environment. The packaging equipment comprises a rack assembly, a wind feeding device, an exhaust structure and a first heat sealing mechanism; the rack assembly is provided with a mounting cavity provided with an opening in the top; the wind feeding device is used for blowing in air with required cleanliness to the mounting cavity along the vertical direction via air inlets; the exhaust structure is arranged on the rack assembly and is used for exhausting the air in the mounting cavity out and combining with the wind feeding device to form positive pressure environment in the mounting cavity; the first heat sealing mechanism is used for heat-sealing a cover of an acquired material on the top opening of a box. The packaging process is performed by adopting the above packaging equipment. Wind feeding speed of an exhaust assembly is controlled so as to be greater than wind exhausting speed of the exhaust structure, the positive pressure environment is formed in the mounting cavity, the required clean environment is achieved, the cover of the required material is heat-sealed in the top opening of the box through the heat sealing mechanism, and packaging of biological tissue or oranges under the clean environment is realized.

Owner:苏州奥特科然医疗科技有限公司

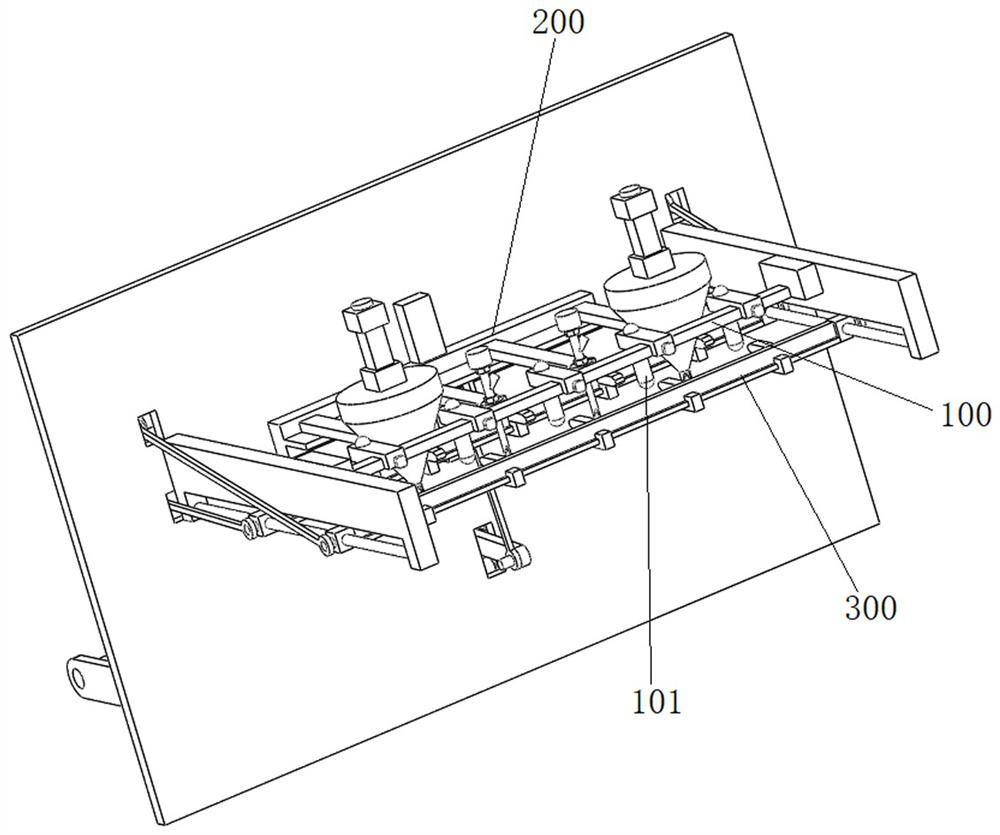

Intelligent sorting and grabbing equipment

InactiveCN111846377AMeeting Packaging NeedsShorten the timeIndividual articlesIndustrial engineeringMaterial storage

The invention relates to the related field of product packaging, in particular to intelligent sorting and grabbing equipment. The intelligent sorting and grabbing equipment comprises a machine body, aconveying cavity with an upward opening is formed in the upper end wall of the machine body, a conveying device used for conveying packaging boxes is arranged in the conveying cavity, the conveying device can convey the packaging boxes front and back, a material storage rotary plate is rotatably arranged in the upper end wall of the machine body, and a sorting power cavity with a leftward openingis formed in the right side of the material storage rotary plate. A grabbing device is arranged in the equipment itself, products can be automatically grabbed from the material storage cavity and then put into a packaging box, manual grabbing of workers does not needed, the time and labor consumed for grabbing the products during the product packaging are saved, a plurality of material storage cavities are formed in the storage rotary plate, various different products can be placed, the number of each product can be controlled in the grabbing process, the packaging requirements of different product packages of merchants can be efficiently met at the same time, use is flexible, and the purpose of intelligent sorting is achieved.

Owner:TIANJIN FENGWEI PACKAGING PROD SALES CO LTD

Graphene composite material membrane and preparation method thereof

InactiveCN108641107AOxygen permeability coefficient decreasedImprove barrier propertiesPolyvinyl alcoholColloid

The invention discloses a graphene composite material membrane and a preparation method thereof. The preparation method includes the following steps that S10,graphene oxide colloid suspension liquid is prepared,wherein graphene oxide and nanometer titania are added into deionized water,and the mixture is subjected to even ultrasonic dispersion; S20,graphene dispersion liquid is prepared,wherein the graphene oxide colloid suspension liquid is irradiated for 2-3 h under an ultraviolet mercury lamp; S30,polyvinyl alcohol powder is added into the graphene dispersion liquid in the step S20,the mixture is stirred evenly,then graphene-polyvinyl alcohol complex liquid is obtained,a mold is smeared with the graphene-polyvinyl alcohol complex liquid,and finally the graphene composite material membrane is obtained after drying and mold release. In the embodiment of the preparation method of the graphene composite material membrane,the oxygen-permeable coefficient of the graphene composite material membrane is lowered by 99% to the highest degree,the barrier property is good,and package requirements of kinds of foods,medicine and other products can be met. According to the preparation technology,the embodiment of the graphene composite material membrane is simple,and production is convenient to expand.

Owner:苏州傅里烨新材料科技有限公司

Soft bag filling device

PendingCN111806741AApplicable use requirementsMeeting Packaging NeedsSolid materialLiquid materialMechanical engineeringEngineering

The invention discloses a soft bag filling device, and relates to the technical field of automatic packaging. The soft bag filling device comprises a guiding device and a filling device; the guiding device comprises a plurality of guiding rods, the filling device comprises a plurality of filling heads, the plurality of guiding rods and the plurality of filling heads are arranged in a line, and onefilling head is arranged between every two adjacent guiding rods; and guiding lines are formed at the bottom ends of the plurality of guide rods, and the bottom ends of the filling heads can ascend to the positions above the guiding lines or descend to the positions below the guiding lines. The soft bag filling device can be perfectly refitted to an existing automatic filling machine, and the production requirements of the filling heads with different types and specifications for multi-split bag product filling are met.

Owner:JIANYANG CHENGCHUANG PACKAGING MACHINERY

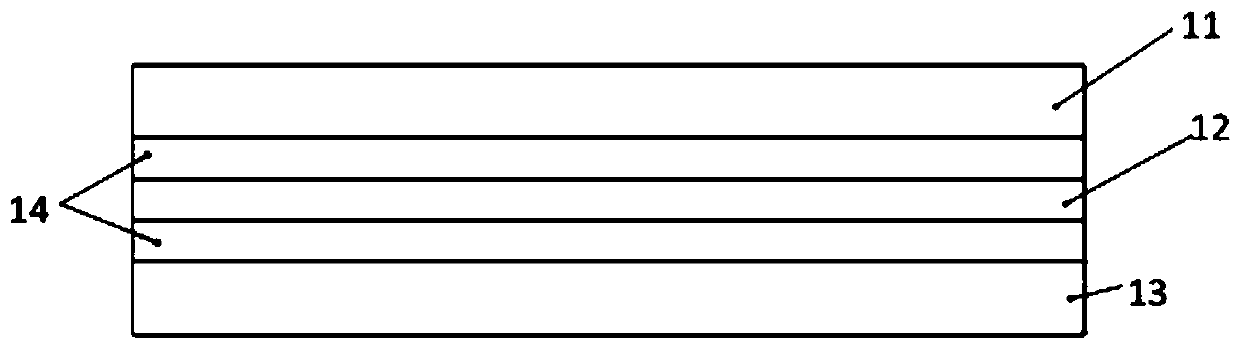

Composite sheet for medicine packaging, and Chinese herbal honeyed pill wrappage prepared from composite sheet

PendingCN110861377AHigh breaking forceLarge cupping valueSynthetic resin layered productsWrappingPolyamideThin membrane

The invention provides a composite sheet for medicine packaging and a Chinese herbal honeyed pill wrappage prepared from the composite sheet. The composite sheet is suitable for cold stamping formingand comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is a polyamide film, the middle layer is an aluminum foil, the inner layer is a heat sealing layer, and the inner layer is composed of a co-extruded composite film formed by the same or different resins. The composite sheet is large in breaking force, high in cupping test value, high in heat sealing strength,high in peel strength and excellent in barrier properties, and is particularly suitable for preparing Chinese herbal honeyed pill wrappages.

Owner:SHANXI GUANGHUAYUAN MEDICINAL PACKAGING

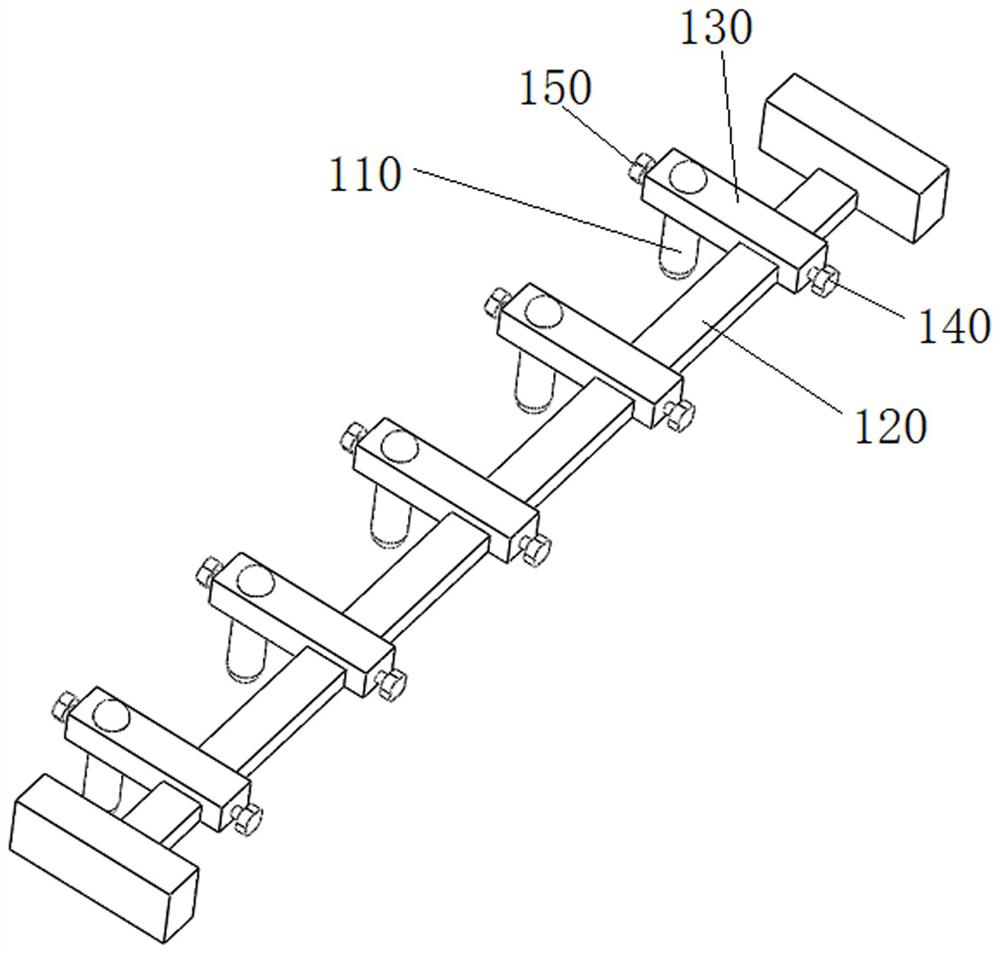

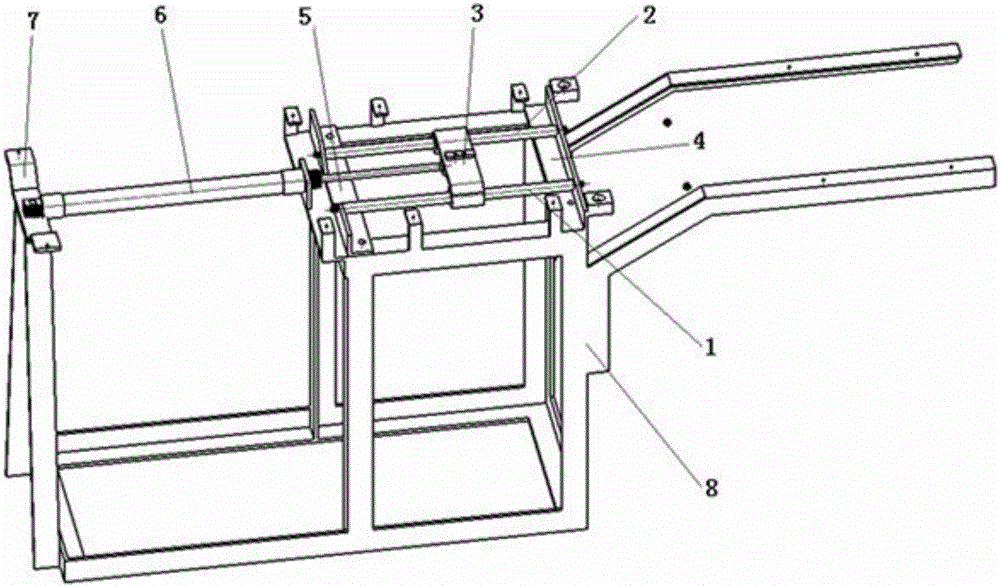

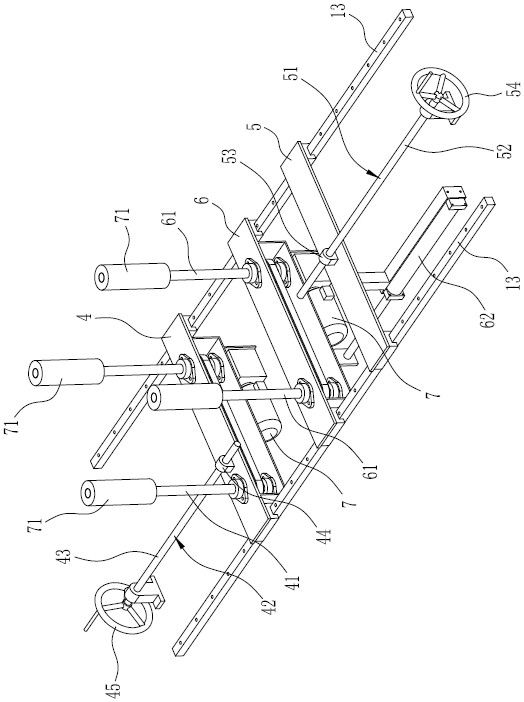

Automatic packing machine for four corners of photo album

The invention provides an automatic packing machine for four corners of a photo album. The automatic packing machine comprises a machine frame, a workbench, a stroke adjusting mechanism arranged on the workbench, a plurality of paper corner pushing mechanisms, a plurality of yard nailing mechanisms and a positioning downward pressing mechanism, wherein the stroke adjusting mechanism comprises a first boss, a second boss, a third boss, a fourth boss, a transverse screw and a longitudinal screw. The automatic packing machine is simple in structure and high in practicality, the positions of the four bosses can be adjusted through the stroke adjusting mechanism, and accordingly, packing of different sizes of photo albums is achieved; the paper corners are pushed onto a placement table throughthe paper corner pushing mechanisms, in addition, it can be achieved that only one paper corner is pushed out when a paper corner pushing air cylinder moves rightwards every time, and accordingly, thepacking requirements are met; and through mutual cooperation of a double connection rod air cylinder, a photo album lifting air cylinder and the paper corner placement table, folding of a first edge,a second edge and a third edge of each paper corner is achieved, and through the yard nailing mechanisms, folding and yard nailing of a fourth edge and a fifth edge are achieved.

Owner:WUYI UNIV

Automatic aluminum material packaging machine

InactiveCN107140254ASave on packaging materialsImprove efficiencyWrappingPackaging automatic controlEngineeringConductor Coil

The invention discloses an automatic packaging machine for aluminum materials, which includes a frame, a paper feeding mechanism, a material feeding mechanism and a packaging mechanism; the packaging mechanism includes a trough, a large push rod, a left push plate and a right push plate, The plate and the right push plate can cooperate with each other and slide horizontally against the upper surface of the chute. In the present invention, the aluminum material is covered and packaged through the cooperation of the material trough, the left push plate and the right push plate. The area of the packaging paper consumed by the packaging is only the surface area of the aluminum material plus the area of the straight line overlap of the packaging paper. Compared with the roll paper packaging, it is greatly The packaging material is saved; moreover, the packaging speed of the automatic aluminum packaging machine provided by the invention has nothing to do with the length of the aluminum material, and the packaging of the aluminum material is completed at one time, with excellent quality, and the production efficiency is 5 times higher than that of manual packaging.

Owner:郭善财

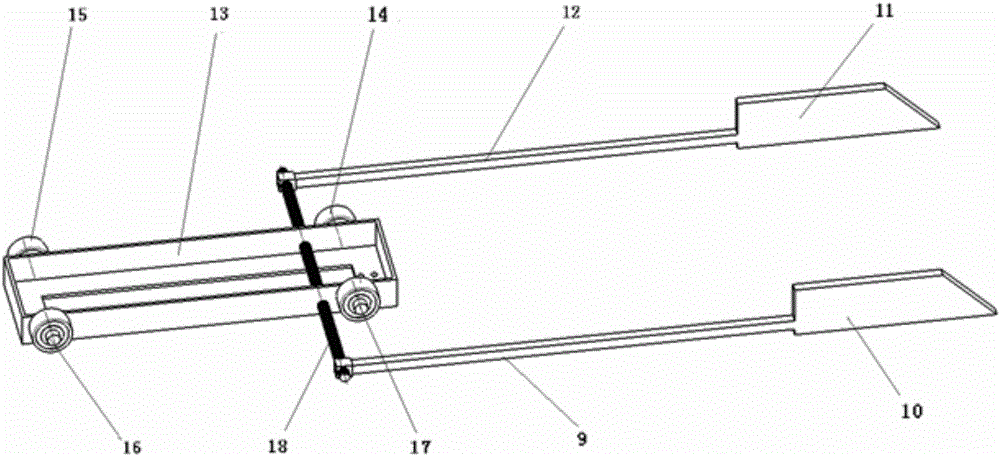

Pneumatic linked book bagging device

A pneumatic linked book bagging device comprises a pneumatic transmission mechanism, a book-pushing bag-opening linkage mechanism, a book-pressing baffle mechanism, a bag opening fixing mechanism, a book pushing workbench and a bagging workbench. Books are placed on the book pushing workbench, and a cylinder of the pneumatic transmission mechanism provides power for the book-pushing bag-opening linkage mechanism which reciprocates on the book pushing workbench. When the books are pushed to move forwards, a bag opening inserting piece is inserted into a bag opening to prop open the bag opening, after the bag opening is propped open, the books are immediately pushed into a book bag, and then the actions are repeated. The pneumatic linked book bagging device provided by the invention is stable and reliable in performance and high in bag opening efficiency, and the problems of high labor intensity and low work efficiency of manual bagging are solved.

Owner:GUANGXI UNIV

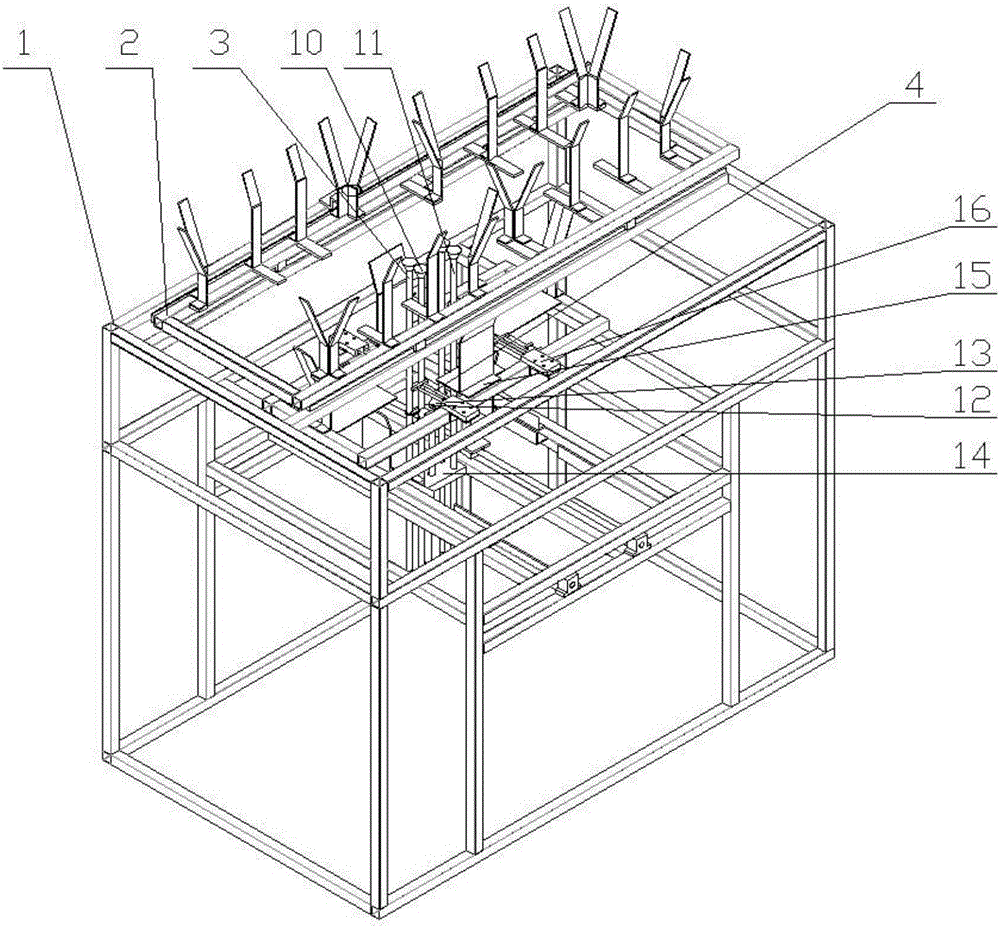

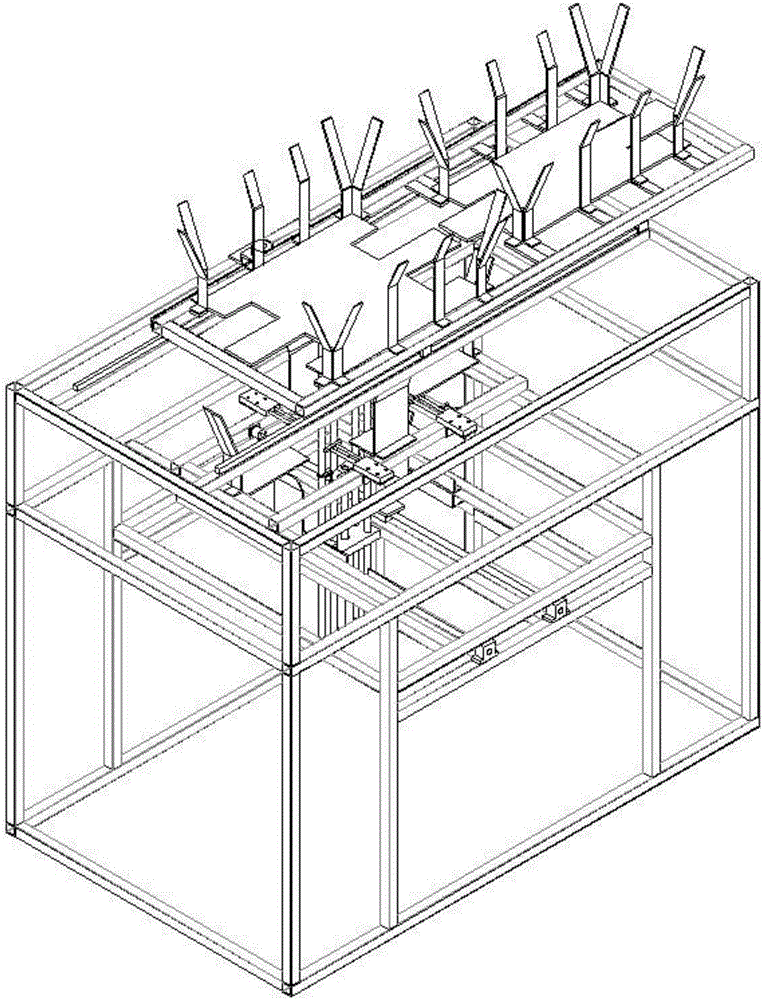

Automatic switching box folding machine for paper boxes having various specifications

The invention discloses an automatic switching box folding machine for paper boxes having various specifications. An automatic adjustable paperboard groove includes an upper box paperboard storage groove and a lower box paperboard storage groove; an upper box and a lower box are different, and the lower box has 2 more folds than the upper box; the upper box paperboard storage groove and the lower box paperboard storage groove can be automatically adjusted according to the size of an upper box paperboard and a lower box paperboard so as to adapt to various specifications of the upper box paperboards and the lower box paperboards; the automatic adjustable paperboard groove is arranged on the top of a rack, the paperboard grooves can move back and forth on the rack to automatically switch the paperboard grooves; when the paperboard grooves move to a folding station, a sucker device sucks paperboards and pulls the paperboards to a first fold station, an automatic folding device is automatically adjusted according to the specifications of the paperboards to complete the first fold, the shape specifications of the upper box paperboard and the lower box paperboard are identical after the first fold. According to the invention, various specifications of paper boxes can be folded through the same box folding machine, and the automatic switching box folding machine is convenient and rapid, can meet the demands of packaging, and can improve the packaging efficiency.

Owner:BEIJING UNIV OF TECH

Bi-axially oriented static polyolefin film and preparation method thereof

ActiveCN106585013AReduce usageReduce pollutionSynthetic resin layered productsAntistatic agentPolyolefin

The invention discloses a bi-axially oriented static polyolefin film and a preparation method thereof. The bi-axially oriented electrostatic polyolefin film adopts a five-layer structure comprising an upper surface layer, three core layers and a lower surface layer which are distributed in sequence, wherein the upper surface layer is prepared from components as follows: 93-97 parts of propylene copolymers and 3-7 parts of an anti-adhesion agent; each core layer is prepared from components as follows: 99-100 parts of linear low-density alkene copolymers and 0.1-1 part of a slipping agent; the lower surface layer is prepared from components as follows: 88-97 parts of propylene copolymers, 2-7 parts of the anti-adhesion agent and 1-5 parts of an antistatic agent. According to the technical scheme, transparency and thermal sealing property of a product can be remarkably improved, and by means of matching with a static sealing mode, materials can be effectively utilized, waste of leftover materials is reduced, and environment is not polluted; the bi-axially oriented static polyolefin film can meet packaging requirements of high-speed packaging and static sealing, keeps the thermal sealing property, can be applicable to traditional thermal sealing and meets requirements of different packaging modes.

Owner:聚银塑料包装制品(深圳)有限公司

Multipurpose winding packaging machine

ActiveCN113636131ALarge clamping rangeMeeting Packaging NeedsWrappingControl engineeringControl theory

The invention discloses a multipurpose winding packaging machine. The multipurpose winding packaging machine comprises a machine frame, a rotating ring mechanism is arranged on the machine frame, a supporting universal ball set is laid on the machine frame, a positioning sliding seat and a clamping secondary sliding seat which are oppositely arranged are slidably installed on the machine frame, and a clamping primary sliding seat is further slidably installed on the side, away from the positioning sliding seat, of the clamping secondary sliding seat on the machine frame. Two positioning rotating shafts are rotatably installed on the positioning sliding seat, a clamping rotating shaft is rotatably installed on the clamping secondary sliding seat, a positioning regulator is arranged between the positioning sliding seat and the machine frame, a clamping regulator is arranged between the clamping primary sliding seat and the machine frame, and a clamping driving cylinder is arranged between the clamping secondary sliding seat and the clamping primary sliding seat; and conveying drivers are arranged between the two positioning rotating shafts and the positioning sliding seat and / or between the clamping rotating shaft and the clamping secondary sliding seat. The multipurpose winding packaging machine can meet the packaging requirements of strip-shaped and annular products at the same time, can meet the packaging requirements of more sizes in annular products, and is good in packaging effect.

Owner:昌乐县富杰塑料机械有限公司

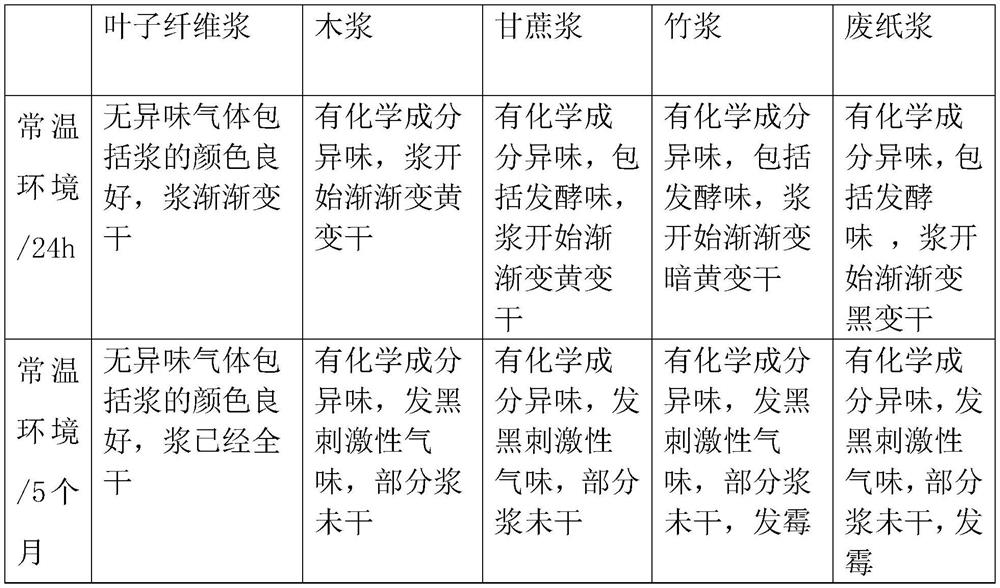

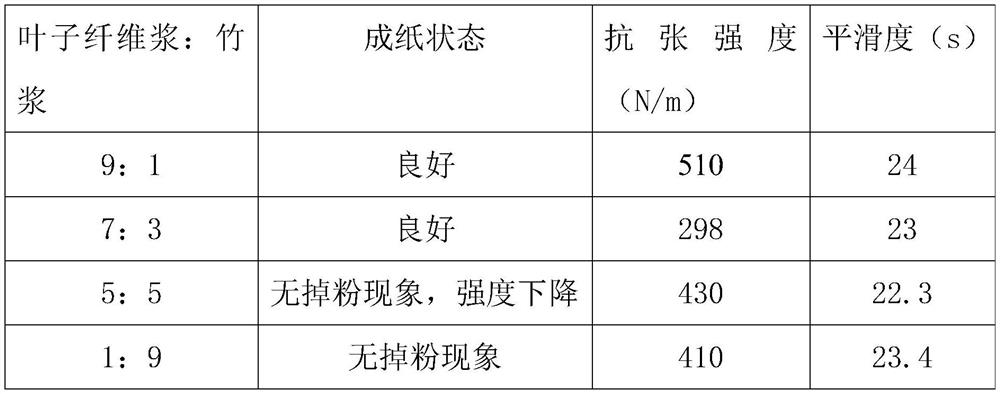

Raw paper pulp

InactiveCN111851124AGood strength propertiesHigh strengthSecondary cellulose fibresNon-woody plant/crop pulpFiberDicotyledon

The invention discloses raw paper pulp. The raw paper pulp comprises leaf fiber pulp of dicotyledonous plants, wherein the leaf fiber pulp comprises celtis plant leaf fiber pulp, oak plant leaf fiberpulp, populas plant leaf fiber pulp and fagus plant leaf fiber pulp. The raw paper pulp has the beneficial effects that the raw paper pulp has good strength characteristics; the strength of a paper material can be improved by 30%-40% after the raw paper pulp is mixed with poor pulp for use; the raw paper pulp can also be independently used for preparation of a paper material; and the prepared paper material is high in hardness and attractive in appearance, meets the packaging requirements of industrial products is met, and can be recycled after being discarded.

Owner:广东叶囵生物科技发展有限公司

Photo album four-corner automatic packaging machine

The invention provides a photo album four-corner automatic packaging machine, which includes a frame, a workbench, a stroke adjustment mechanism arranged on the workbench, a plurality of paper corner pushing mechanisms, a plurality of coding nail mechanisms, and a positioning and pressing mechanism. Wherein, the stroke adjustment mechanism includes a first boss, a second boss, a third boss, a fourth boss, a transverse screw rod and a longitudinal screw rod. The present invention has simple structure and strong practicability. Adjust the positions of the four bosses to meet the packaging of photo frames of different sizes; the present invention pushes the paper corners to the placement platform through the paper corner pushing mechanism, and can only push out the paper corners every time the cylinder moves to the right once A piece of paper corner; thereby satisfying the packaging requirements; the present invention realizes the folding of the first boundary, the second boundary, and the third boundary of the paper corner through the mutual cooperation of the double-link cylinder, the photo frame lifting cylinder, and the paper corner placement table. The coding nail mechanism realizes the folding and coding of the 4th border and the 5th border.

Owner:WUYI UNIV

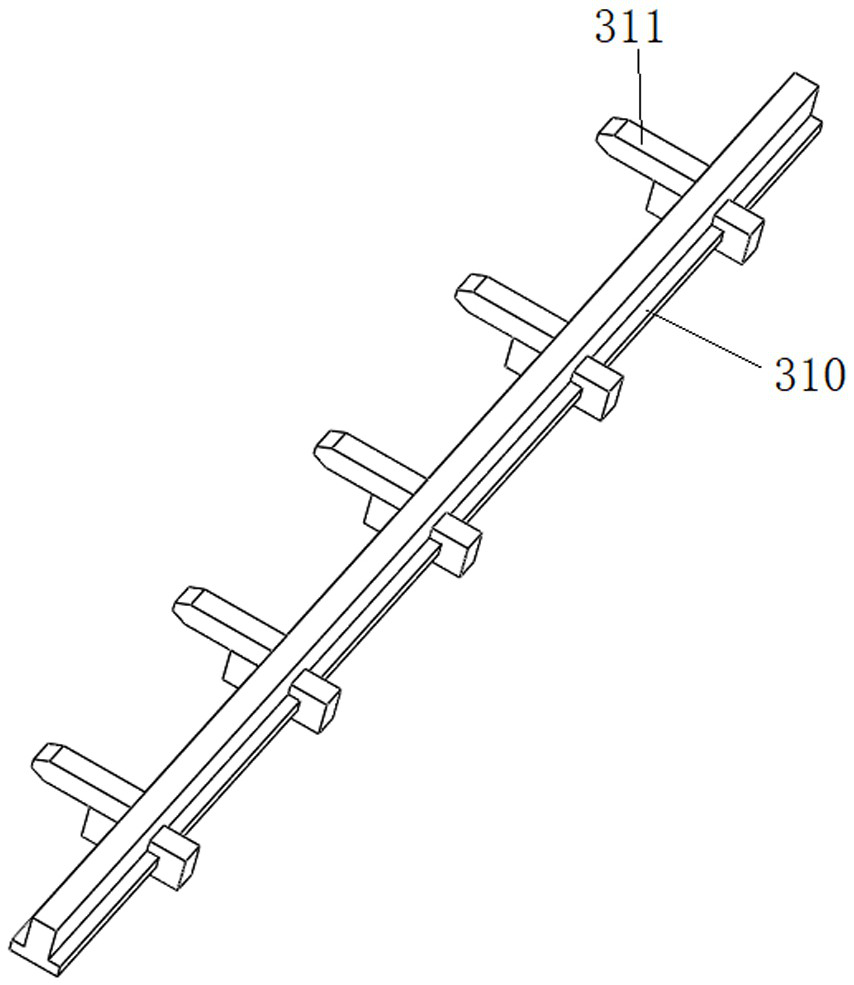

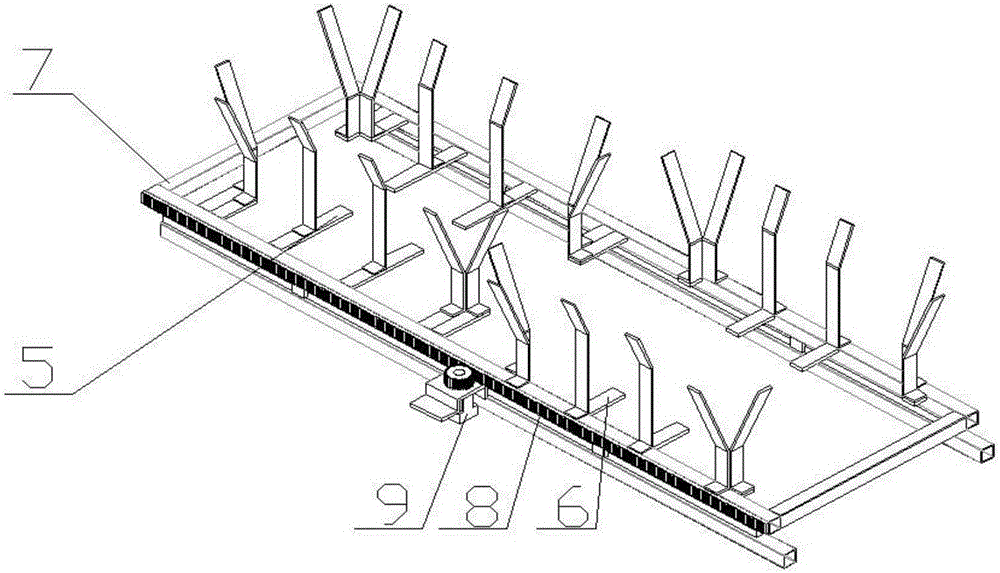

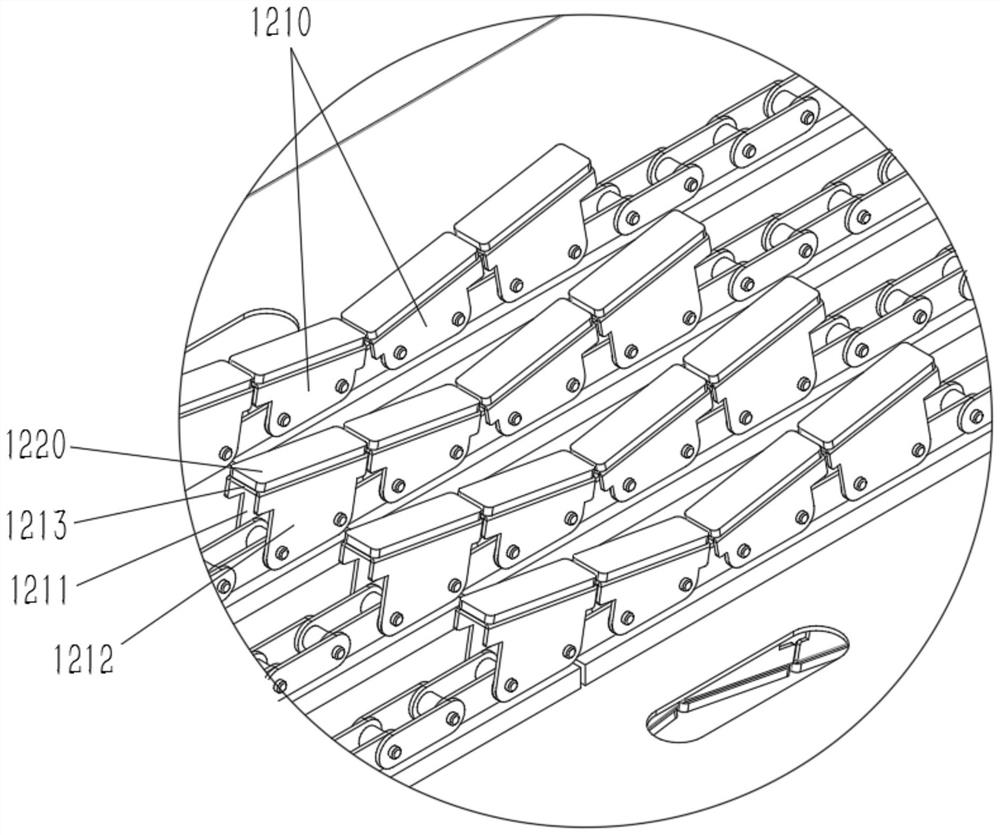

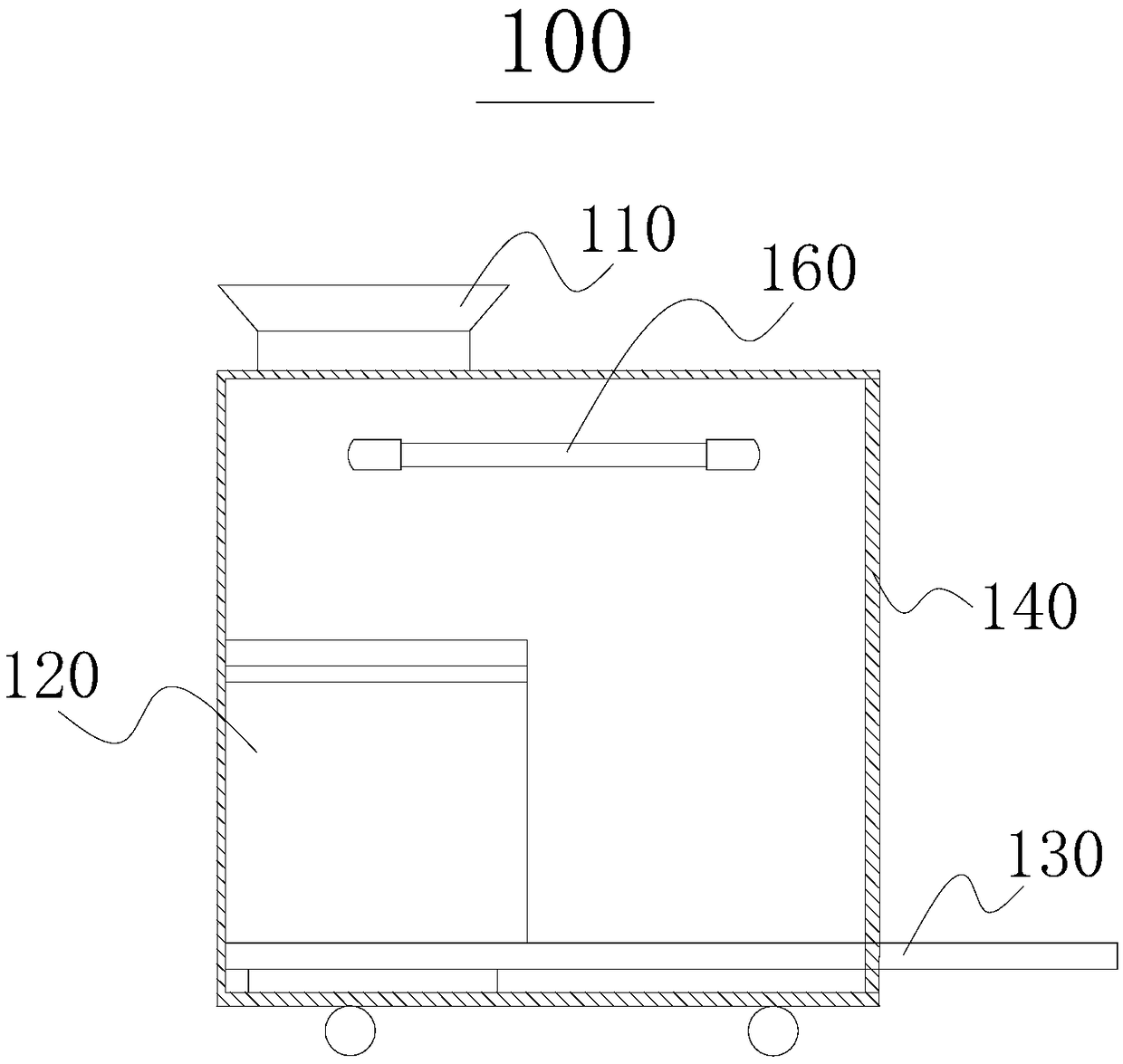

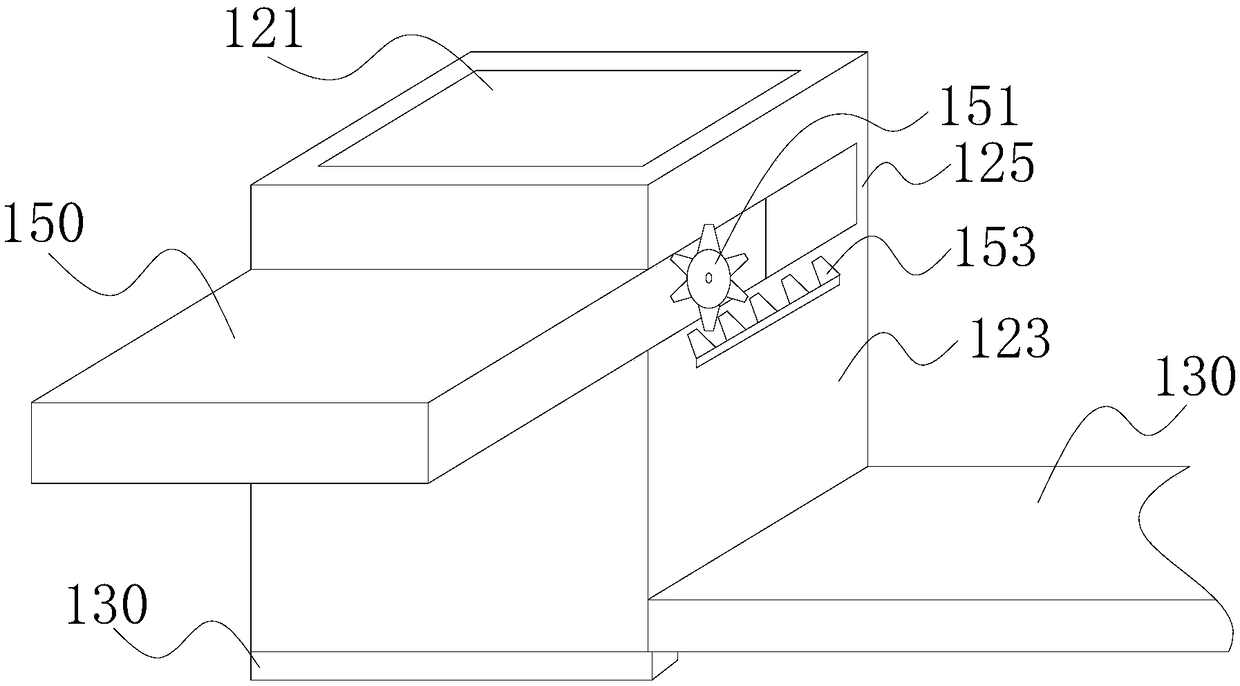

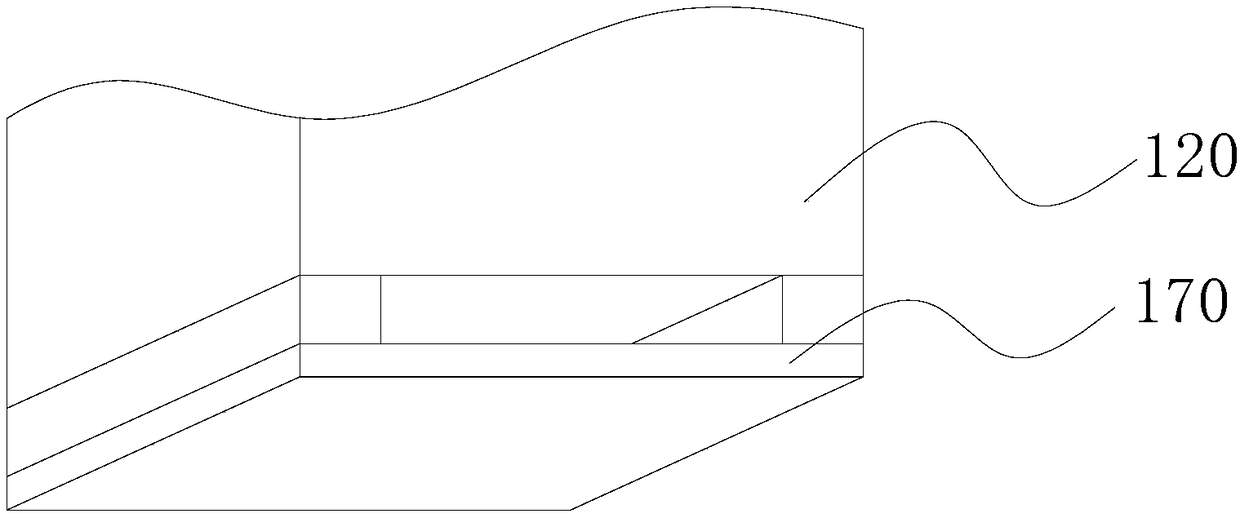

Tray-free packaging feeding device and tray-free continuous preservative film packaging machine

PendingCN113184271AMeeting Packaging NeedsRealize automatic productionWrapper twisting/gatheringAssembly lineElectrical and Electronics engineering

The embodiment of the invention discloses a tray-free packaging feeding device and a tray-free continuous preservative film packaging machine. The tray-free packaging feeding device comprises a plurality of narrow-band synchronous transmission mechanisms and a driving device; the plurality of narrow-band synchronous transmission mechanisms are arranged side by side in a mutually parallel and spaced mode; the plurality of narrow-band synchronous transmission mechanisms are connected with the driving device, so that the driving device can drive the plurality of narrow-band synchronous transmission mechanisms to rotate synchronously; each narrow-band synchronous transmission mechanism comprises a narrow-band transmission part and a plurality of bearing frames, and the bearing frames are used for bearing packaged articles and can prevent the problem that normal packaging is affected due to the fact that the positions of the packaged articles in a bare package change or even fall off in the placing and conveying process; and the plurality of bearing frames are uniformly arranged on the narrow-band transmission part. According to the tray-free packaging feeding device, continuous assembly line type fresh-keeping film bare package packaging and continuous assembly line type fresh-keeping film tray packaging can be achieved at the same time, a high-efficiency packaging mode is formed, and all packaging requirements of high-speed fresh-keeping film packaging are met; and the rear end can be in butt joint with an assembly line so as to realize automatic production.

Owner:成都市新享科技有限公司

Environment-friendly organic food packaging device

InactiveCN109264104AMeeting Packaging NeedsIncrease salesPackage sterilisationPackaging by pressurising/gasifyingWhole bodyEngineering

The invention relates to the field of food production, in particular to an environment-friendly organic food packaging device, which comprises a charging port, a charging box, a conveying belt and a shell, wherein the charging port is connected with the outer peripheral surface of the shell; the charging box is arranged in the shell; a through hole is formed in one side of the charging box, closeto the charging port; the conveying belt is connected with the bottom of the charging box; and a sealing device is arranged on one side of the charging box, away from the conveying belt. The chargingbox comprises a box body and fixing plate which are mutually connected; the sealing device comprises a moving plate and a heating device which is arranged on one side of the moving plate, close to thefixing plate; and the moving plate is slidably connected with the box body. The invention provides the environment-friendly organic food packaging device, which integrates filling, sealing and conveying functions into a whole body, meets the packaging requirement on organic food and is convenient to sell.

Owner:徐鹏

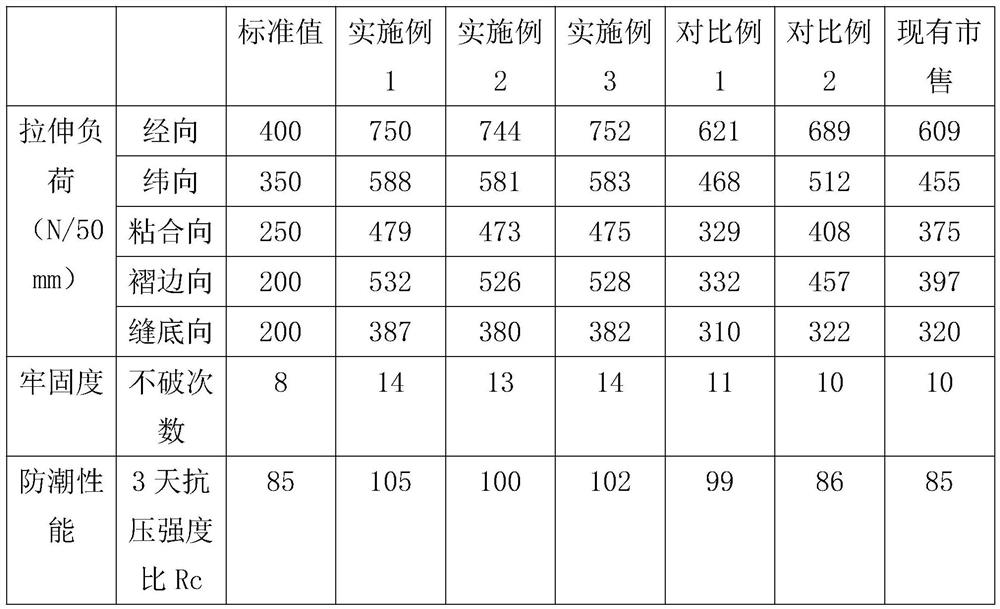

A kind of tensile composite film cement packaging bag and preparation method thereof

ActiveCN110371455BImprove mechanical propertiesGood weather resistanceBio-packagingBagsFiberPolymer science

The invention discloses a tensile composite film cement packaging bag and a preparation method thereof, and relates to the technical field of packaging bag processing. The tensile composite film cement packaging bag of the present invention comprises a plastic woven bag layer and a shrink film layer; wherein, the preparation raw materials of the plastic woven bag layer include polylactic acid, glass fiber, chitosan and whitening agent; the preparation of the shrink film Including the preparation of lipophilic modified carbon fibers. The packaging bag prepared by processing in the invention has excellent mechanical properties, better weather resistance and barrier properties than traditional cement packaging bags, and can better meet the needs of cement packaging.

Owner:安徽天元塑业有限公司

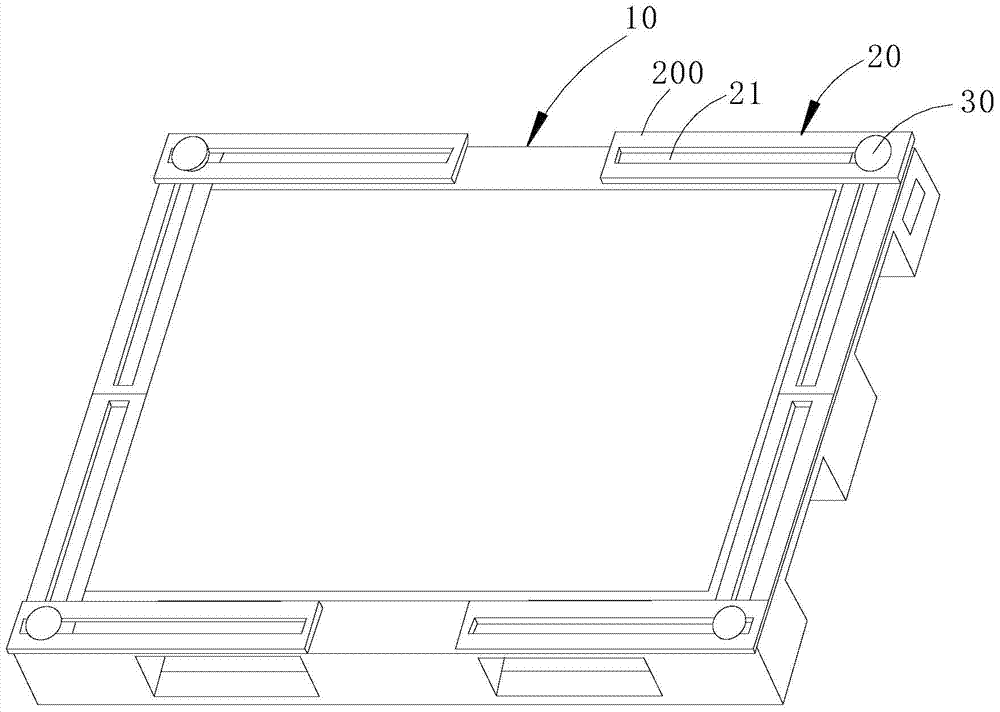

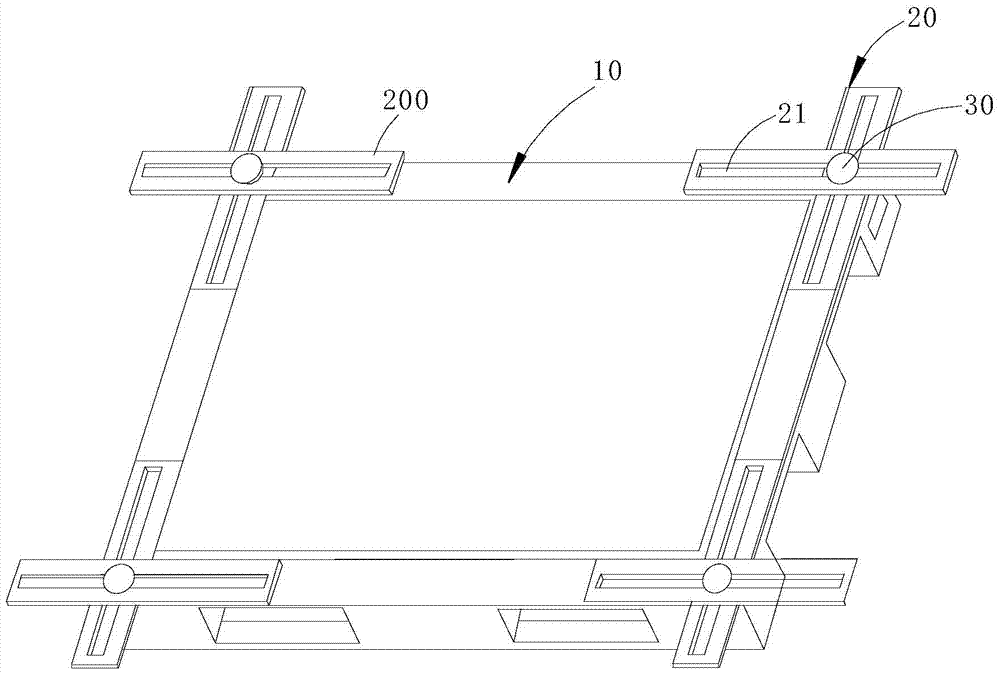

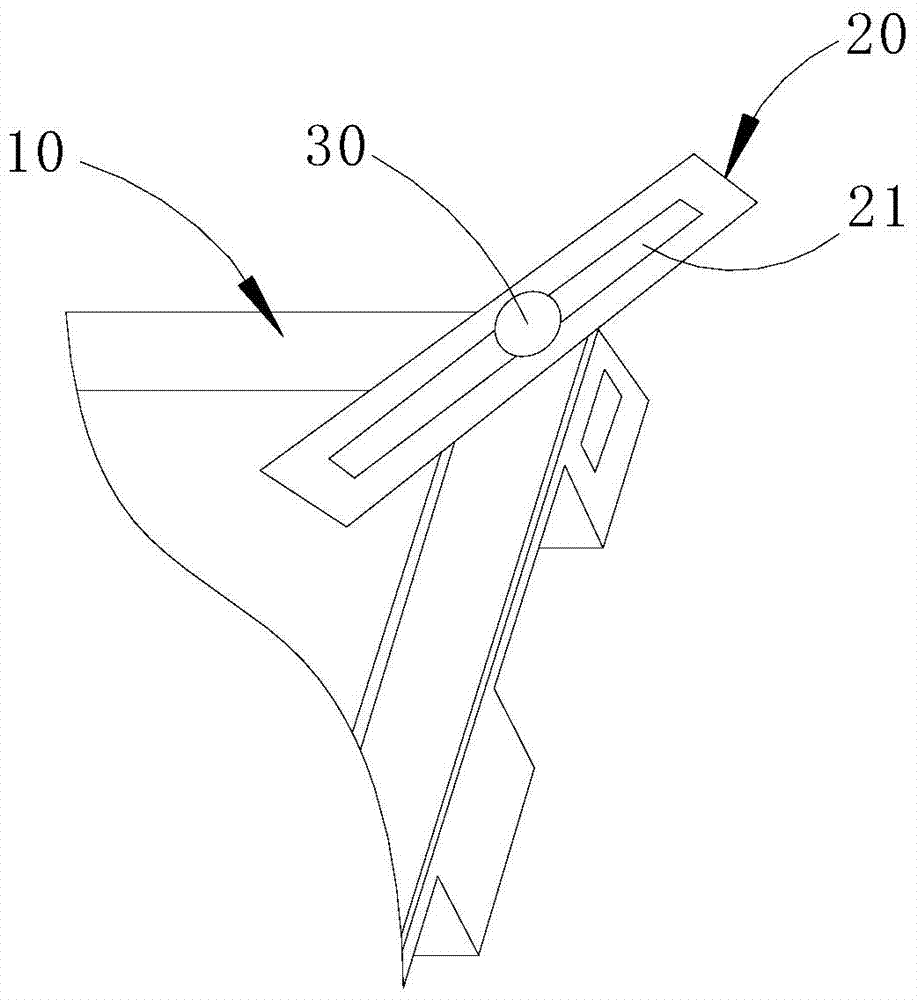

A composite pallet

The invention discloses a composite pallet which comprises a pallet body, extending arms and fixing pieces. Through holes are formed in the extending arms. The four corners of the pallet body are each provided with at least one extending arm. Each fixing piece penetrates through the corresponding through hole, and thus the corresponding extending arm is movably fixed to the pallet body. According to the composite pallet, the four corners of the pallet body are provided with the movable extending arms, the extending arms can stretch out of and retreat into the pallet body according to requirements, requirements for packaging panels with different dimensions can be met, and the design cost and manufacturing cost of the pallet are reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Large-size displayer packing box

InactiveCN108313452AMeeting Packaging NeedsMeet transportation needsRigid containersDisplay deviceEngineering

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com