A kind of tensile composite film cement packaging bag and preparation method thereof

A technology for tensile lamination and packaging bags, which is applied in the field of packaging bag processing, can solve the problems of easily damaged cement packaging bags and poor barrier performance, and achieves the effect of meeting the requirements of cement packaging, good barrier performance and good cement packaging requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

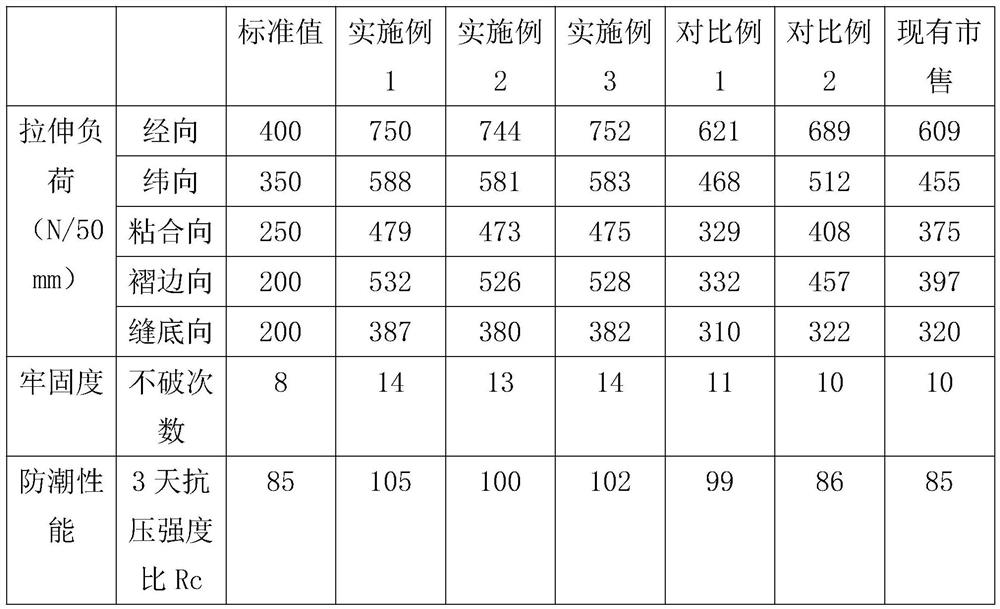

Examples

Embodiment 1

[0027] The preparation method of plastic woven bag layer comprises the steps:

[0028] (1) Take 6 parts of chitosan in parts by mass, dissolve chitosan in water with twice the quality under stirring, then stir at high speed for 2h and vacuum degassing to obtain chitosan slurry;

[0029] (2) Weigh 80 parts of polylactic acid in parts by mass, premix the chitosan slurry with polylactic acid for 1 min, then add 2 parts of whitening agent DT to mix and co-extrude the polylactic acid base material; use a twin-screw extruder Extrude, set the temperature at 170°C, and the screw speed at 320r / min; the extruded pellets are dried at 80°C for 1 hour;

[0030] (3) Weigh 3 parts of glass filaments, blend and extrude the glass filaments and the polylactic acid base material, set the extrusion temperature at 180°C, and the speed at 60m / min, cool naturally, shape, and roll to make a plastic woven bag layer; Among them, the diameter of the glass filament is 0.4mm;

[0031] The preparation me...

Embodiment 2

[0038] The preparation method of plastic woven bag layer comprises the steps:

[0039] (1) Take 10 parts of chitosan in parts by mass, dissolve chitosan in water with twice the quality under stirring, then stir at high speed for 2.5h and vacuum degassing to obtain chitosan slurry;

[0040] (2) Weigh 90 parts of polylactic acid in parts by mass, premix the chitosan slurry with polylactic acid for 3 minutes, then add 3 parts of whitening agent DT to mix and co-extrude the polylactic acid base material; use a twin-screw extruder Extrude, set the temperature at 190°C, and the screw speed at 350r / min; the extruded pellets are dried at 90°C for 1-3 hours;

[0041] (3) Weigh 8 parts of glass filaments, blend and extrude the glass filaments and the polylactic acid base material, set the extrusion temperature to 180°C, and the speed to 60m / min, cool naturally, shape, and roll to make a plastic woven bag layer; Among them, the diameter of the glass filament is 0.6mm;

[0042] The prep...

Embodiment 3

[0049] The preparation method of plastic woven bag layer comprises the steps:

[0050] (1) Take by weighing 8 parts of chitosan in parts by mass, dissolve chitosan in water of twice the quality under stirring, then stir at high speed for 2h and vacuum degassing to obtain chitosan slurry;

[0051] (2) Weigh 85 parts of polylactic acid in parts by mass, premix the chitosan slurry with polylactic acid for 2 minutes, then add 2.5 parts of whitening agent DT to mix and co-extrude the polylactic acid base material; use a twin-screw extruder Extrude, set the temperature at 180°C, and the screw speed at 330r / min; the extruded pellets are dried at 85°C for 2 hours;

[0052] (3) Weigh 5 parts of glass filaments, blend and extrude the glass filaments and the polylactic acid base material, set the extrusion temperature to 180°C, and the speed to 60m / min, cool naturally, shape, and roll to make a plastic woven bag layer; Wherein, the diameter of the glass filament is 0.5mm;

[0053] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com