Machine for conducting mixed package on special-shaped cigarettes and conventional cigarettes

A special-shaped cigarette and packaging machine technology, applied in packaging and other directions, can solve the problems of front and rear cigarette clamping force deformation, unpackable, mutual extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

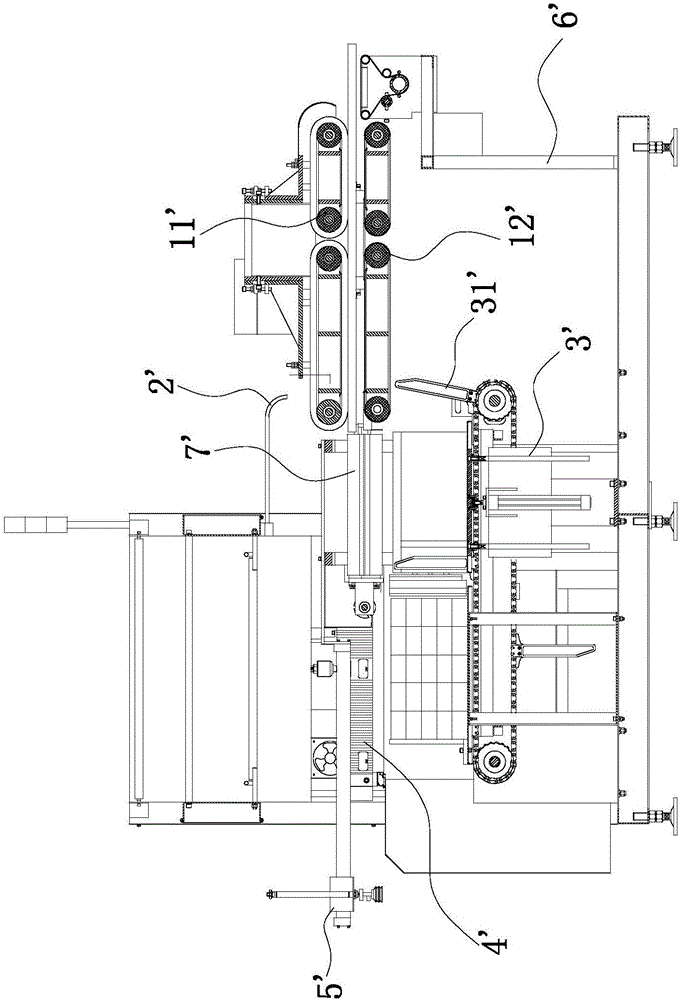

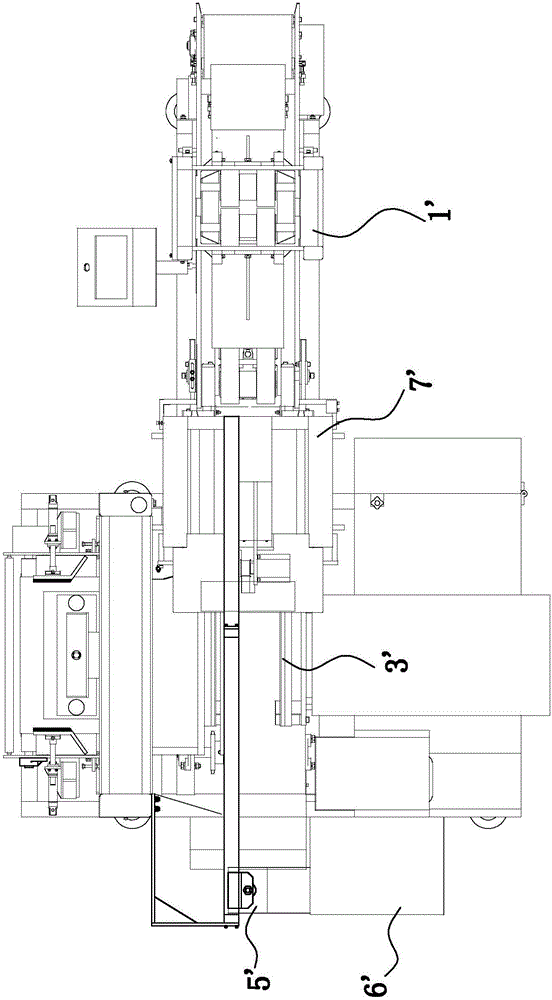

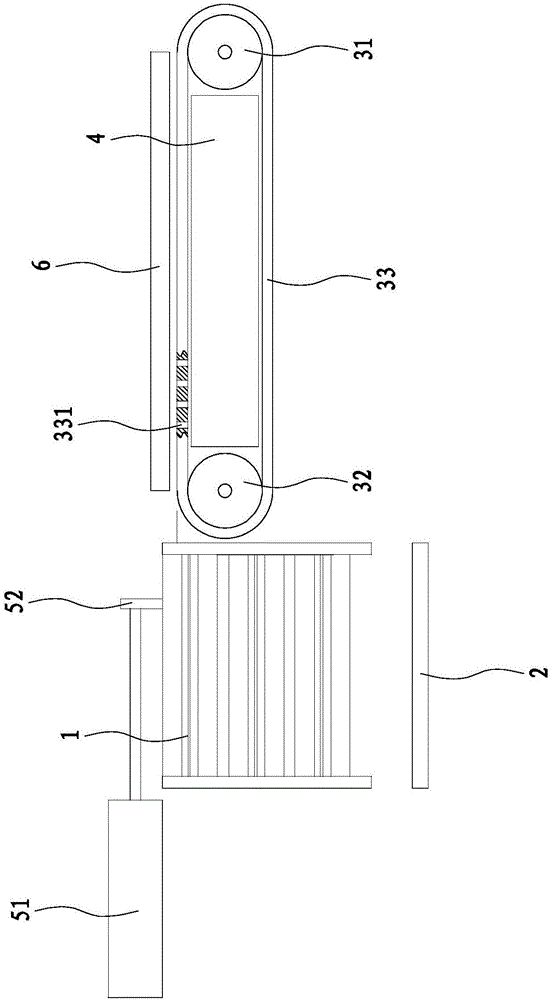

[0014] refer to image 3 , the present embodiment provides a mixed packaging machine for special-shaped cigarettes and conventional cigarettes, including a frame and an input and conveying device arranged on the frame, a turning device 1, an output station 2, and an electrical control system, and the output station 2 is set Below the turning device 1, the input conveying device includes a driving wheel 31 and a driven wheel 32 rotatably arranged on the frame, a conveyor belt 33 covering the driving wheel 31 and the driven wheel 32, and a driving device for driving the driving wheel , the conveyer belt 33 is provided with a plurality of through holes 331 for airflow to pass through, and the negative pressure adsorption chamber 4 for absorbing articles is provided on the frame within the covering range of the conveyer belt 33 , and the turning device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com