Patents

Literature

119results about How to "Stable spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

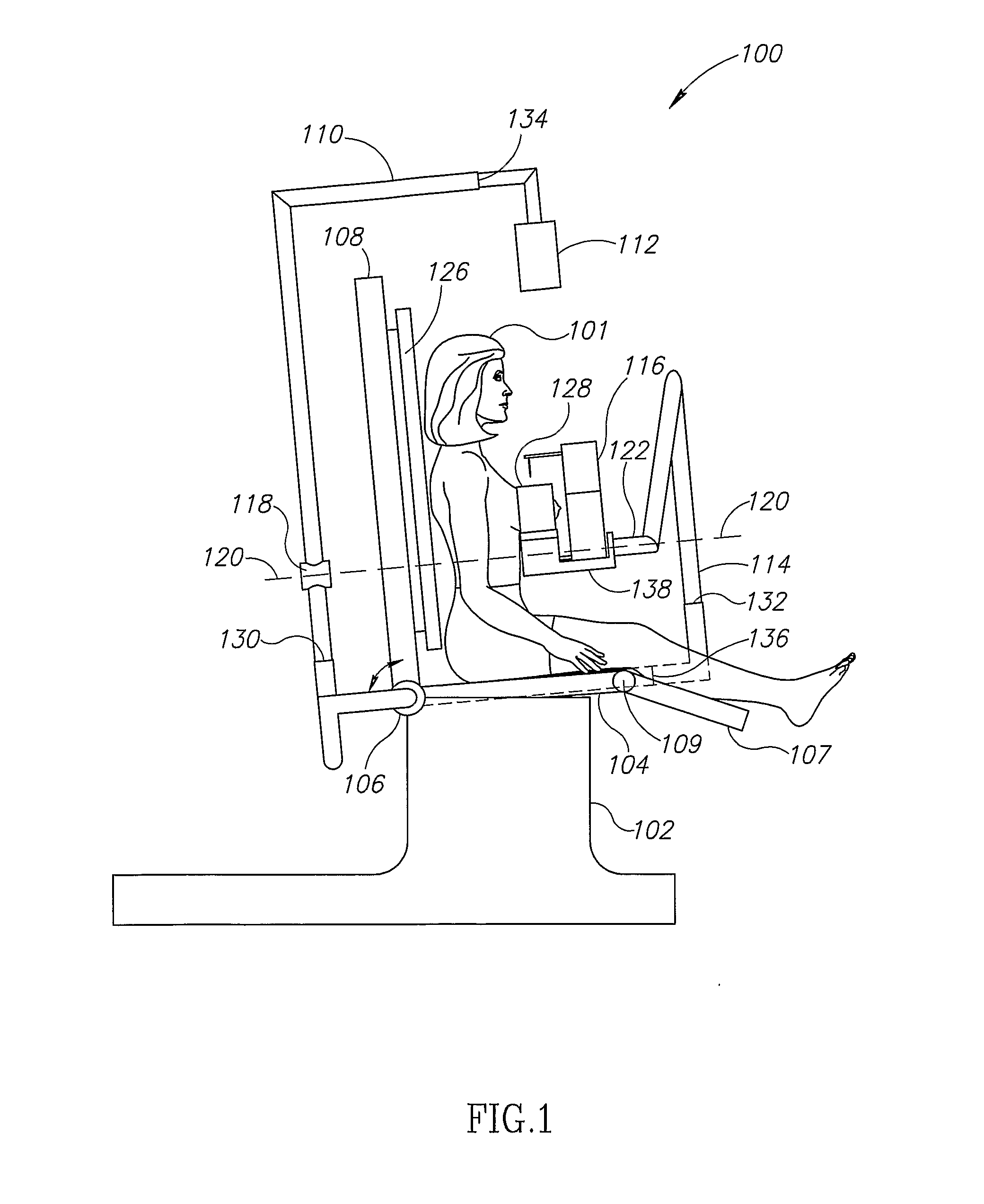

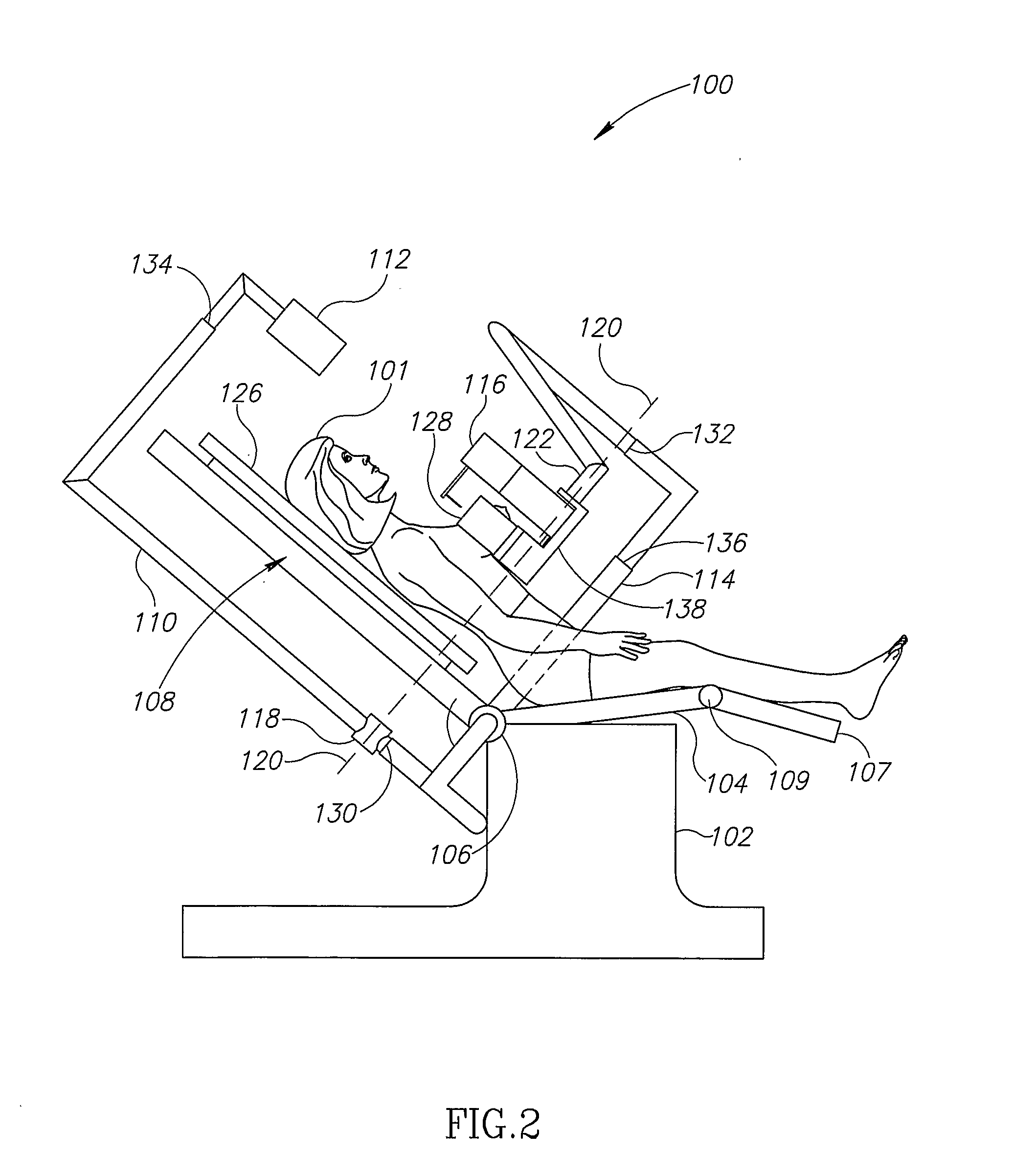

Breast Cancer Detection And Biopsy

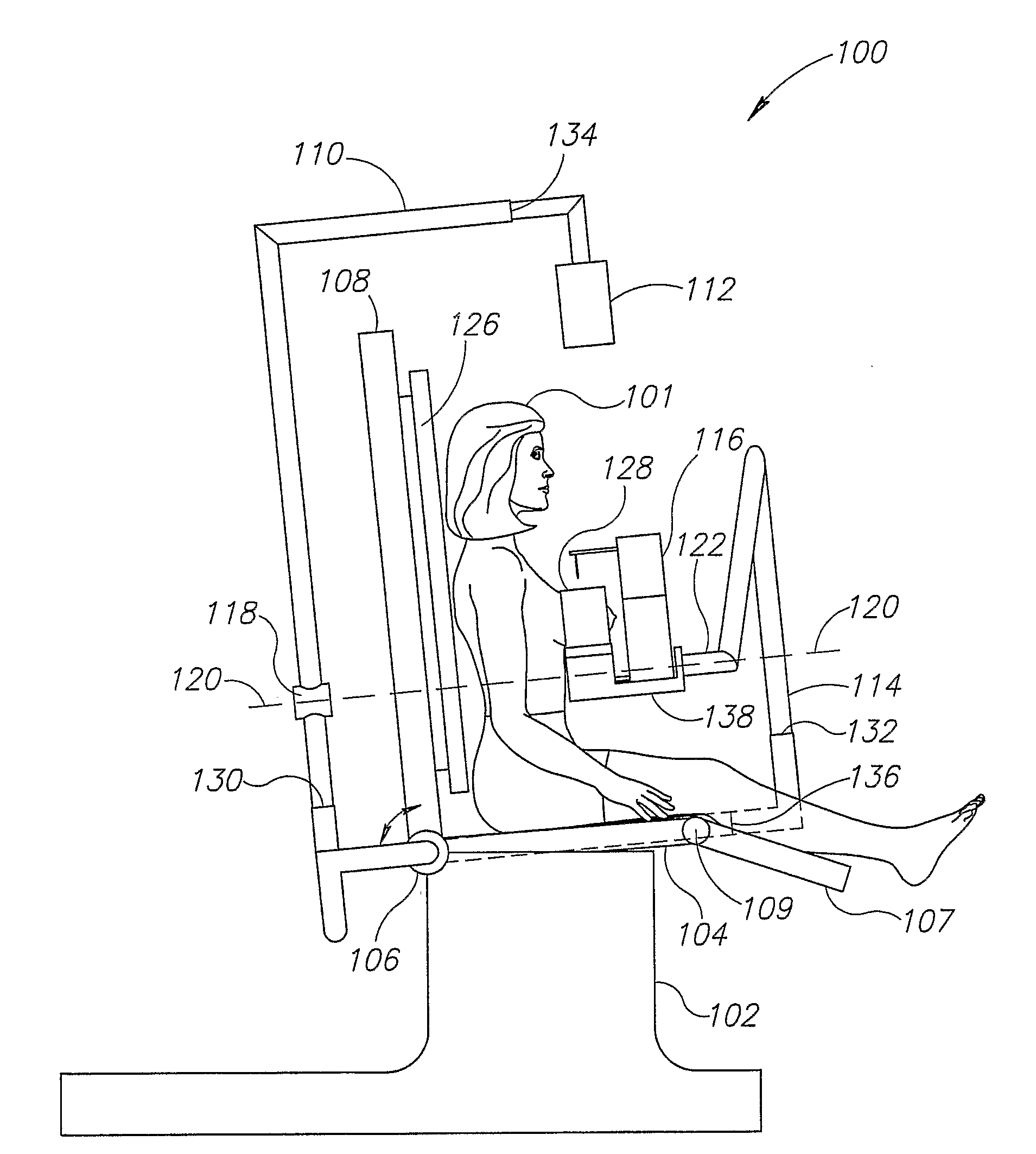

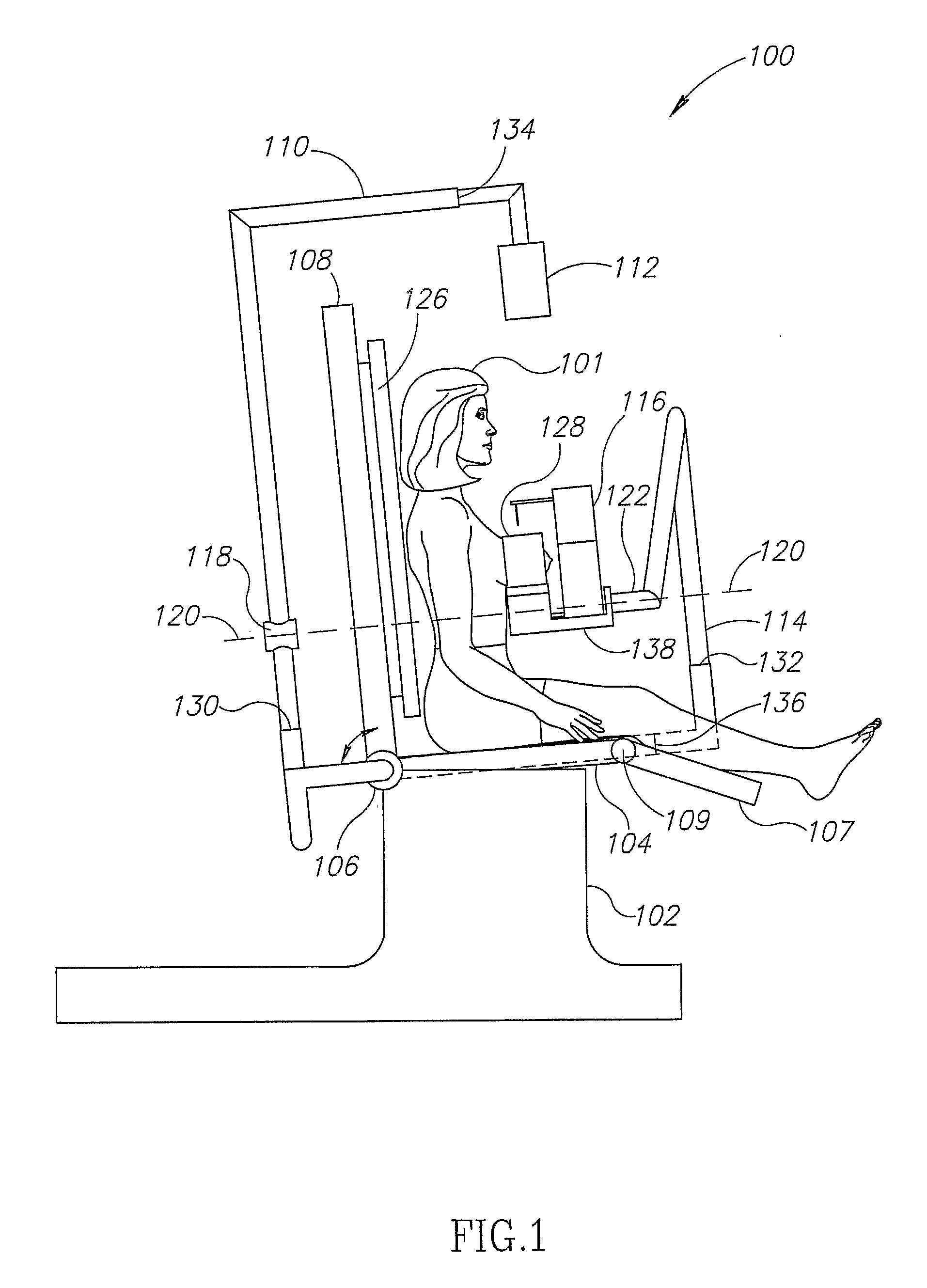

InactiveUS20080103387A1Easy to fixMore comfortable for the patientUltrasonic/sonic/infrasonic diagnosticsSurgical needlesX-ray guided biopsyBiopsy

A breast compression device suitable for compressing a breast for an x-ray guided biopsy, the device comprising:a) a base for contacting a portion of the surface of the breast;b) a flexible band, anchored to the base, adapted to be positioned on a side of the breast opposite the base, when the breast is inserted between the base and the band, which band is adapted to be wrapped at least part way around the breast; andc) a tensioning device, adapted to tension the flexible band around the inserted breast when the flexible band is anchored to the base, thereby compressing the breast between the flexible band and the base.A system for performing a biopsy of a breast lesion of a patient in a reclining position, the system comprising:a) a chair with a back that has an upright position and at least one reclining position;b) a compression device adapted to hold a breast of the patient seated in the chair in a compressed state, when the chair back is in the upright position or in at least one reclining position; andc) a biopsy unit having a biopsy element and being coupled to the chair back at least in a reclining position.

Owner:SCI BIOPSY

Breast Cancer Detection and Biopsy

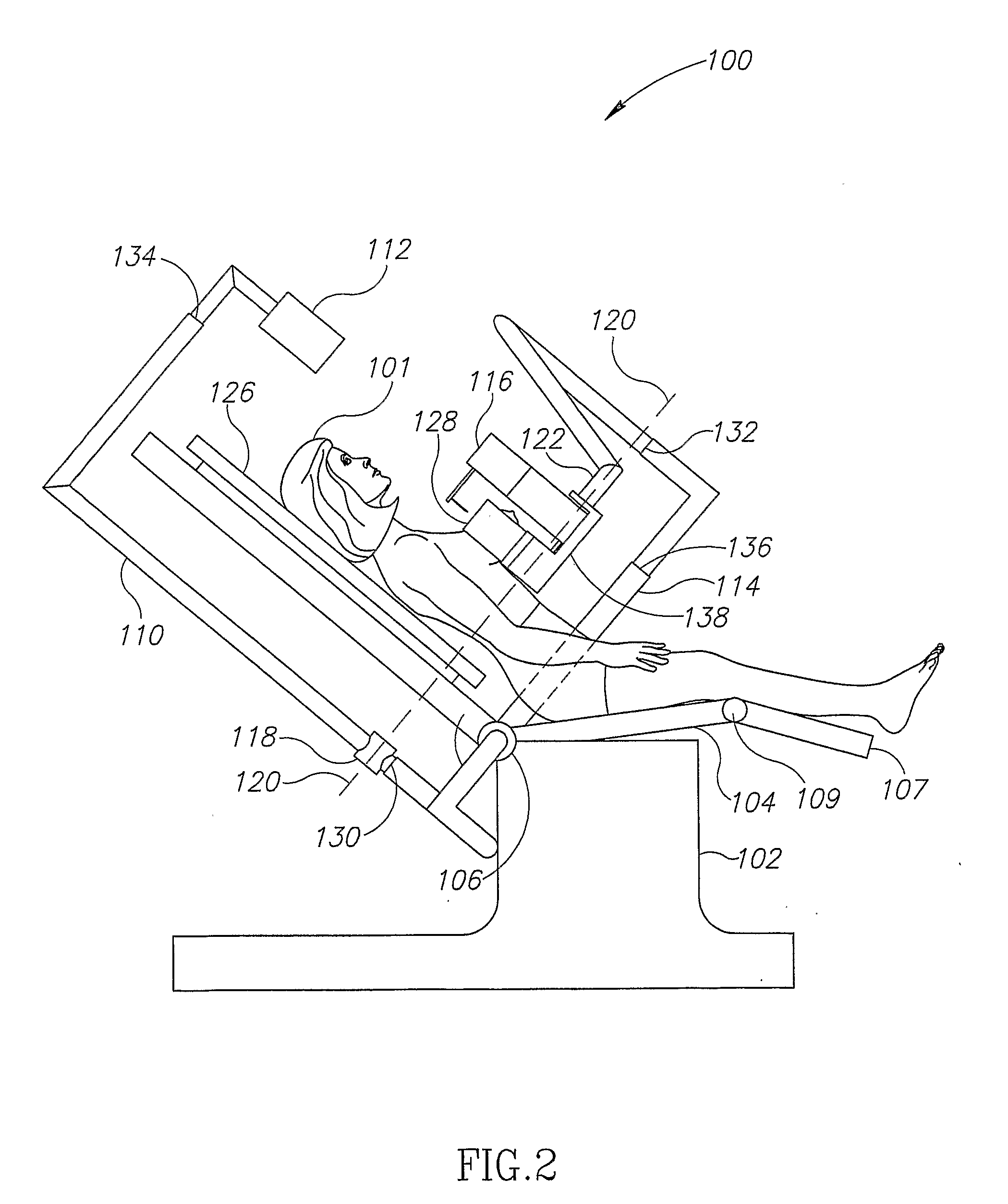

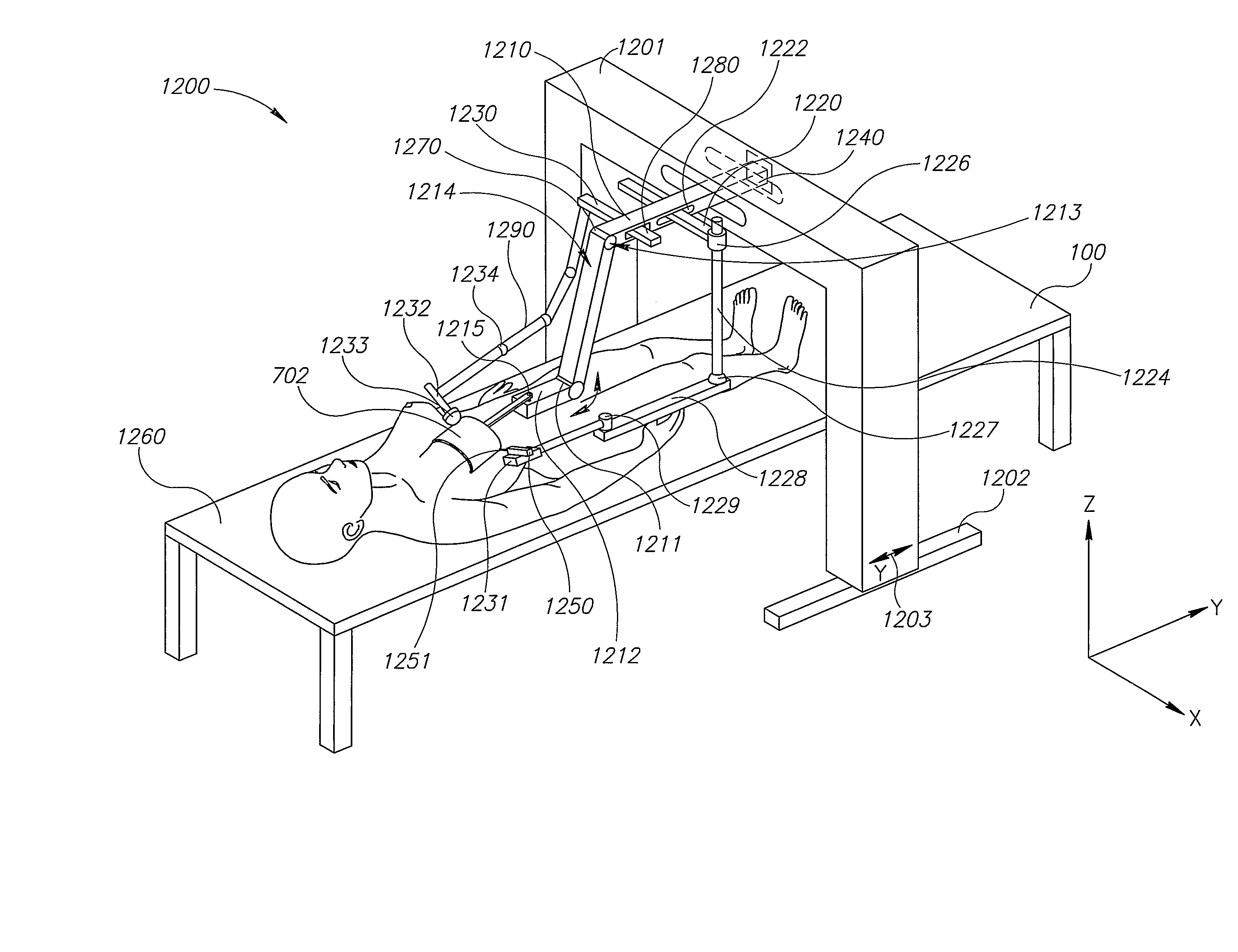

InactiveUS20080004526A1Fit contour of breastUniform compressionUltrasonic/sonic/infrasonic diagnosticsVaccination/ovulation diagnosticsUltrasound imagingLesion

A system for performing a breast biopsy. The system includes a breast compression device, an ultrasound imaging unit and a biopsy module capable directing a biopsy needle to a lesion in the breast, guided at least in part by ultrasound images. The system may optionally include a piece of furniture, such as table or a reclining chair.

Owner:SCI BIOPSY

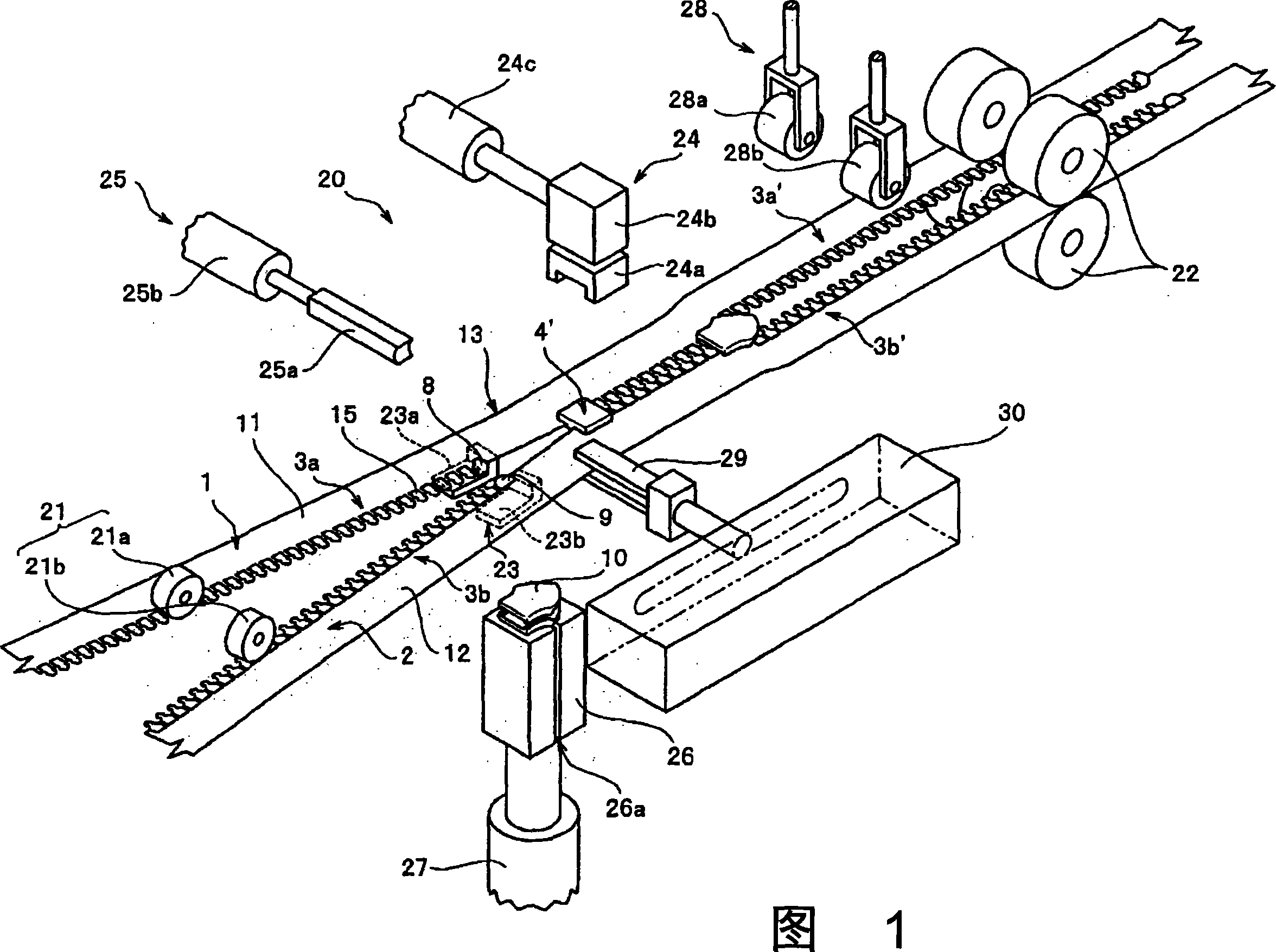

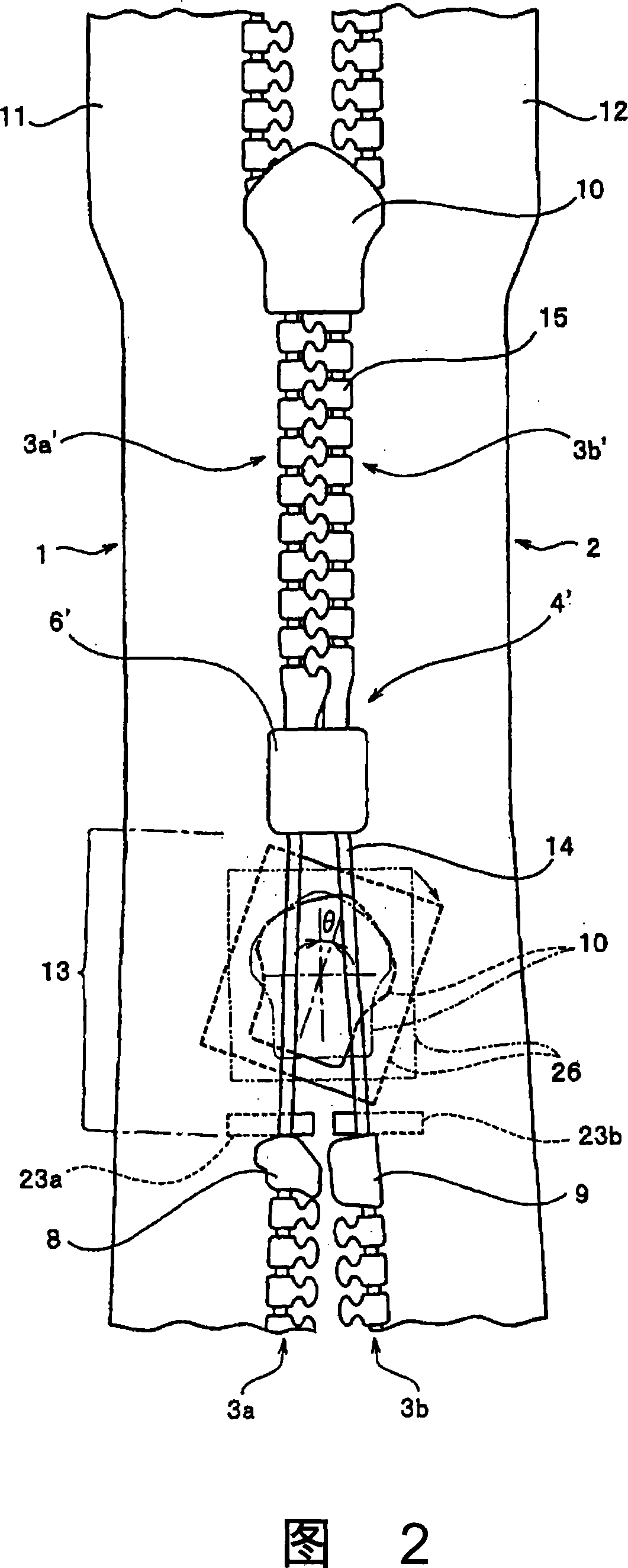

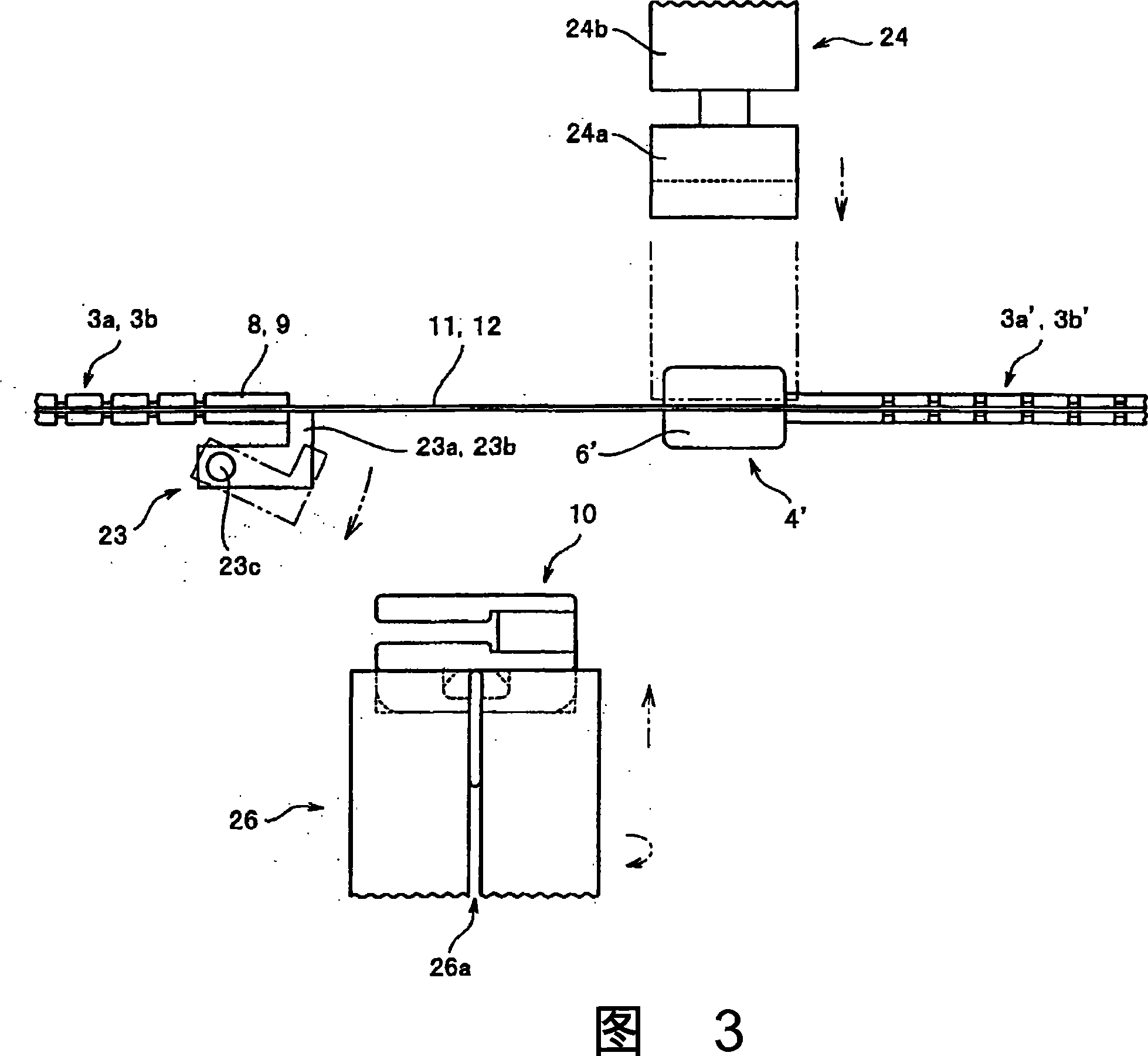

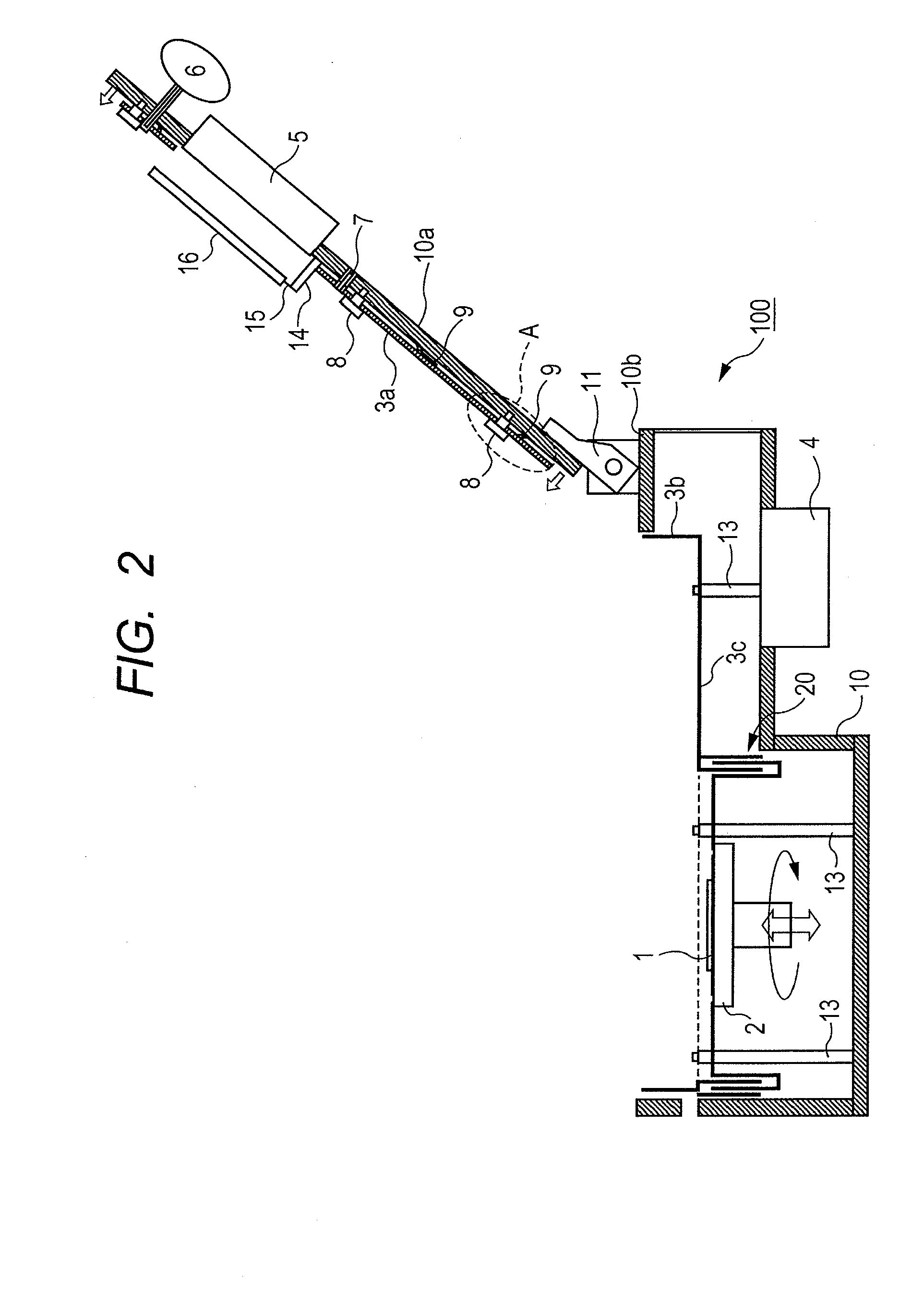

Fastener head covered method and fastener head covered device

The present invention provides a method of setting a set of left-and-right slide fastener's vertical-line slider,making one end which is automatically set at the chain tooth line possess detachable bottom stop block,and making the other side of the slide fastener possess top stop block.Following the present invention the method of setting the slide fastener's slider is setting the slider(10) on the chain tooth lines(3a,3b) between the first and second vertical strip(1,2),includes: the first working procedure of orienting the direction of the chain tooth lines(3a,3b) to make the first and the second vertical line of the slide fastener(1,2) in a right-and-left curving state;the second woking procedure of moving the slider(10) to make the first vertical strip(1) located on the side of the slider(10) and make the second vertical strip(2) linking to the below wing board(18);the third woking procedure of jointing the first vertical strip(1) to the slider(10);the fourth working procedure of moving the first and the second vertical strip ahead to joint the box-shaped pin(5) to the slider(10);and the fifth working procedure of countermarching the inserted pin(7) when it has moved to the frontage of the slider(10) to make the slider(10) setting on the right-and-left chain tooth line.

Owner:YKK CORP

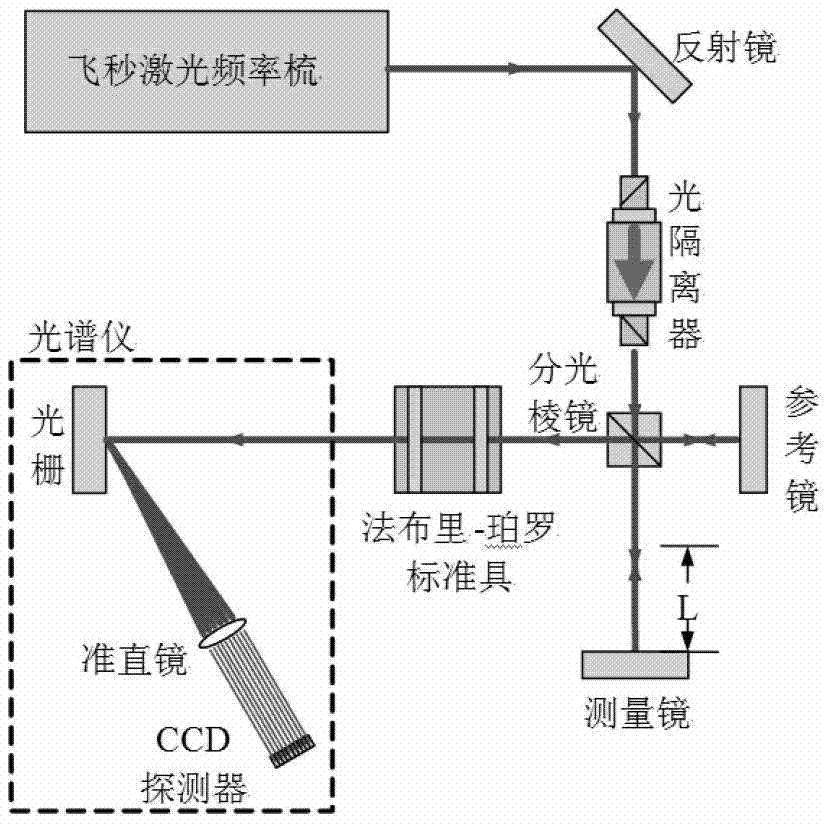

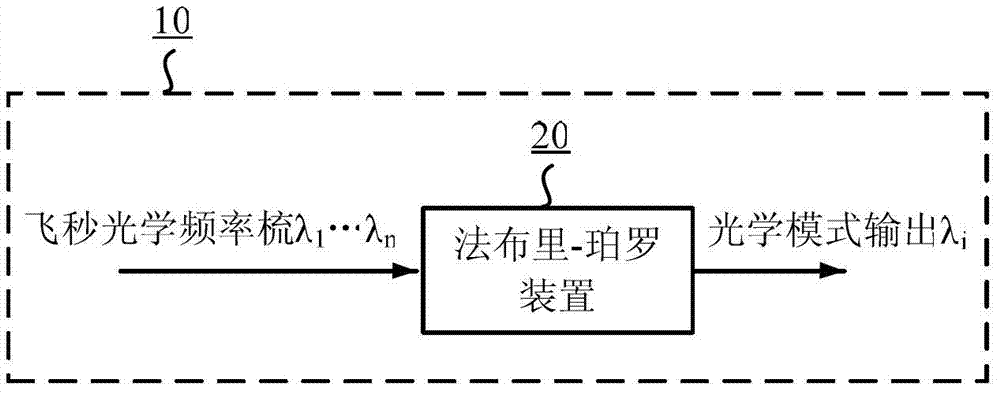

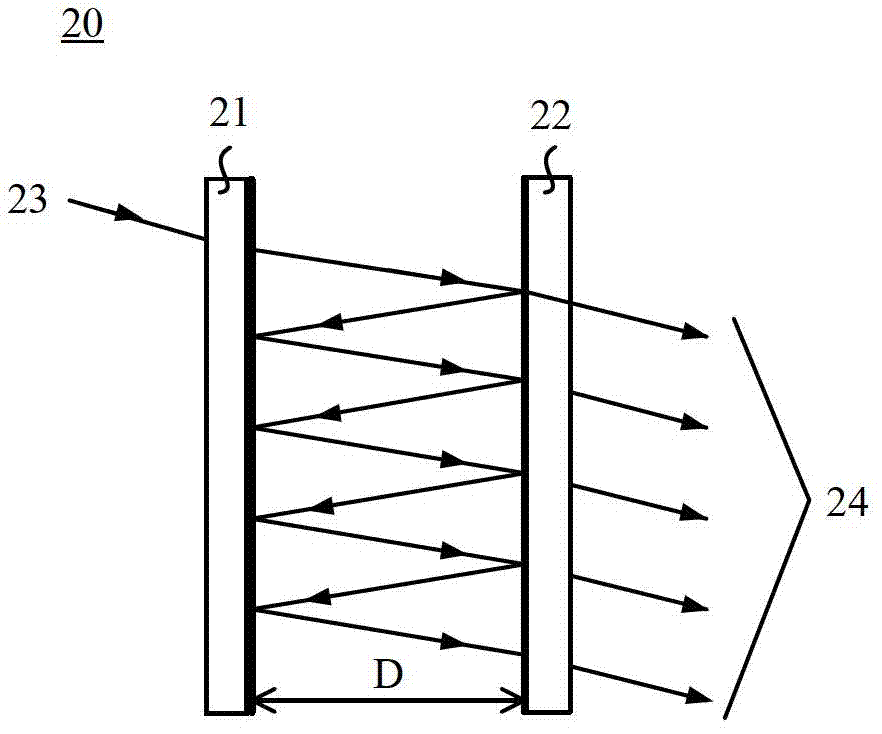

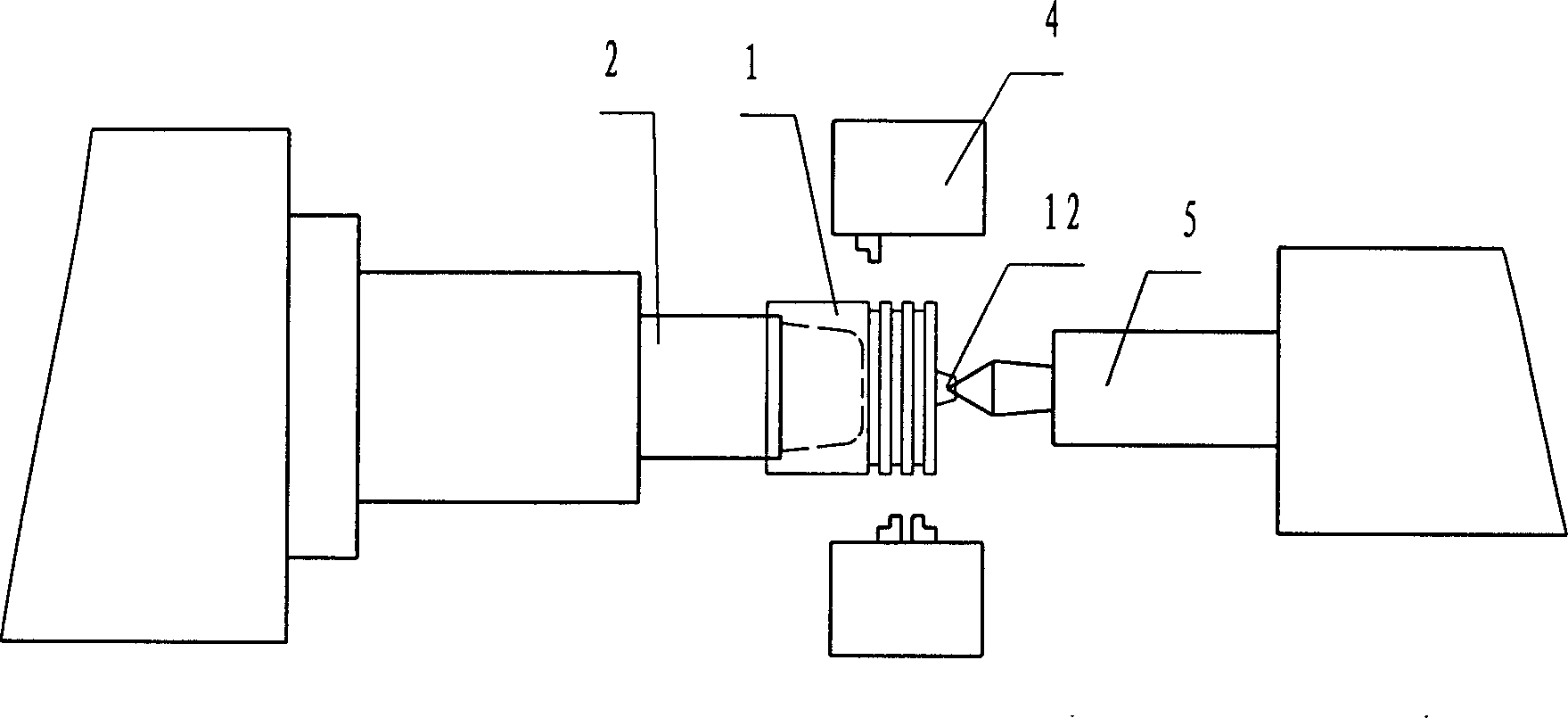

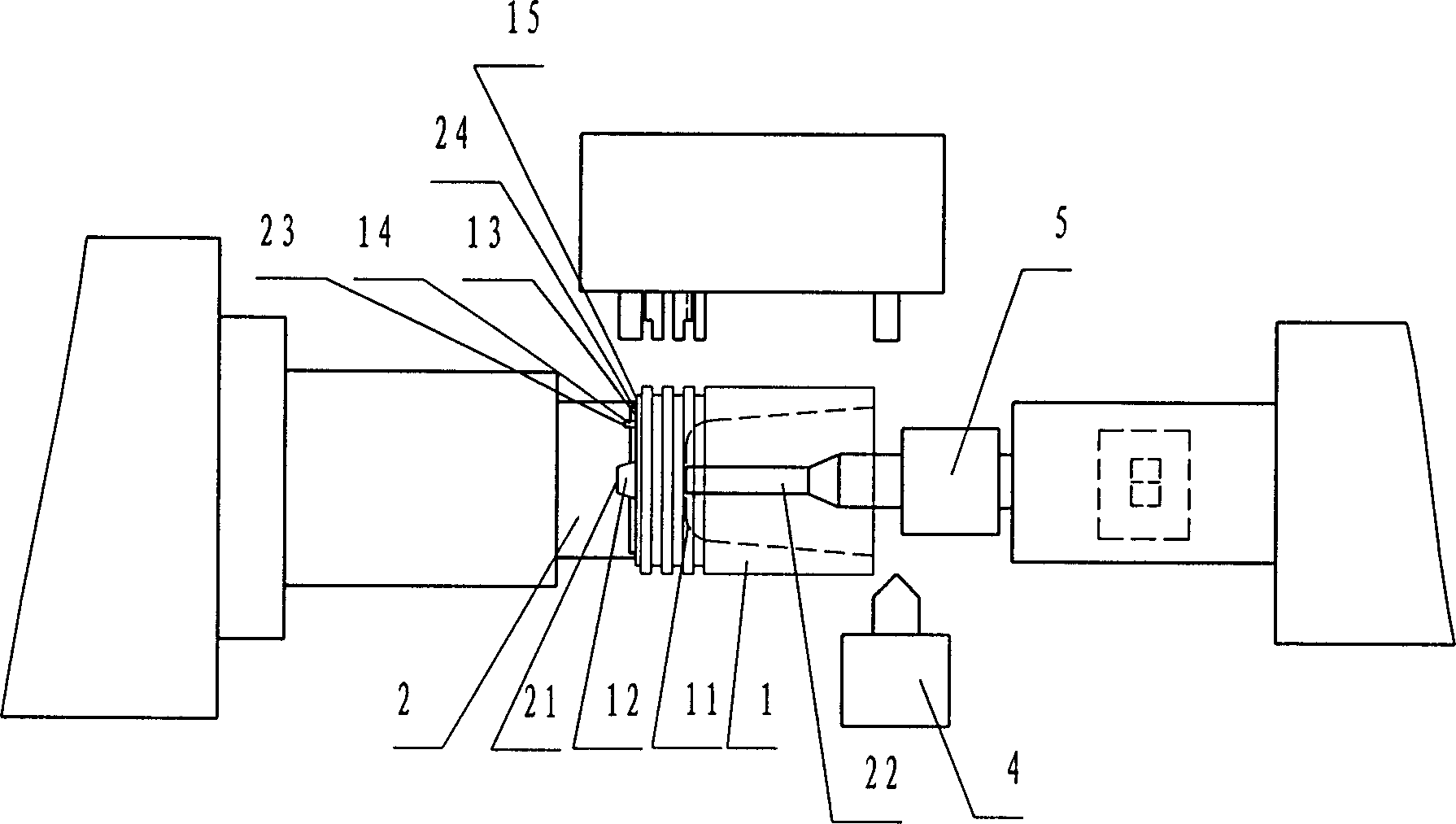

Femtosecond laser frequency comb ranging device and method

InactiveCN103196419AReduce the impactGuaranteed accuracyOptical rangefindersSpectrographLaser frequency

The invention provides a femtosecond laser frequency comb ranging device and device. The device comprises a Fabry Perot device behind a Michelson interference optical path and in front of a spectrograph. The Fabry Perot device performs optical filtering on light of a femtosecond laser frequency comb, and reduces the frequency mode density of the optical frequency comb, so that each pixel of a CCD (charge coupled device) linear array detector of the spectrograph receives an interference signal in a single frequency mode. The device and the method achieve optical filtering of the femtosecond laser frequency comb within a broad spectrum range, and guarantee the accuracy and the stability of an interval and parallelism between optical plane reflection mirrors of the device; and the device is simple in design and structure, easy to regulate and low in cost.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

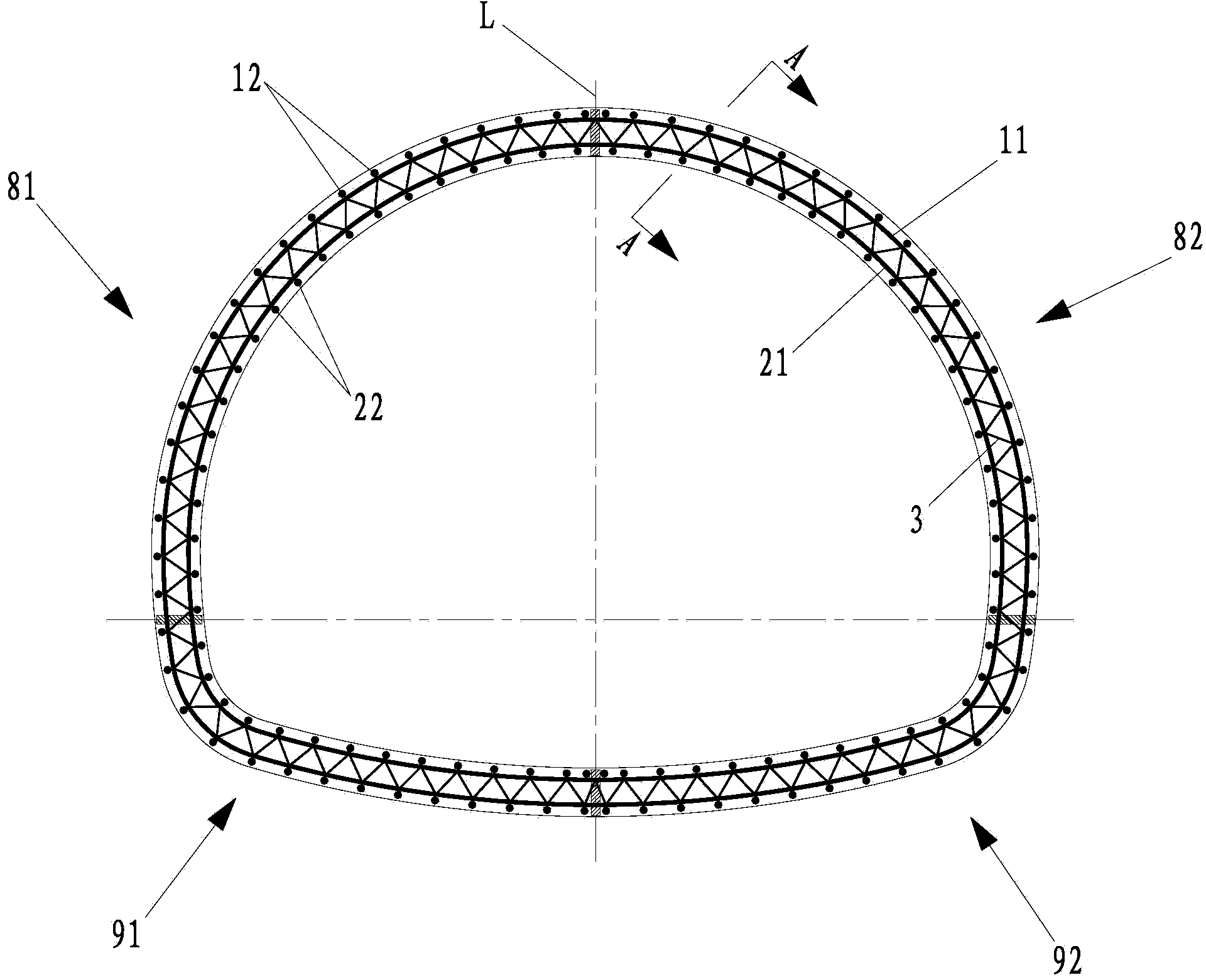

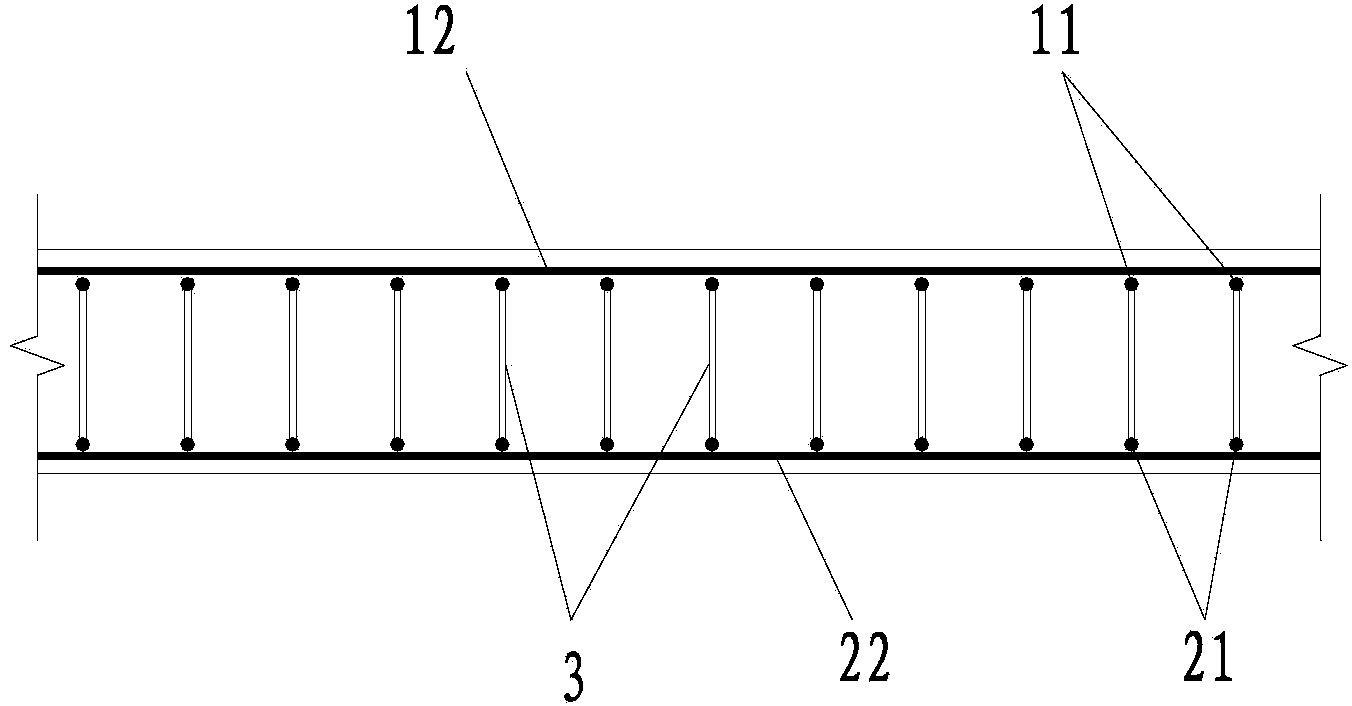

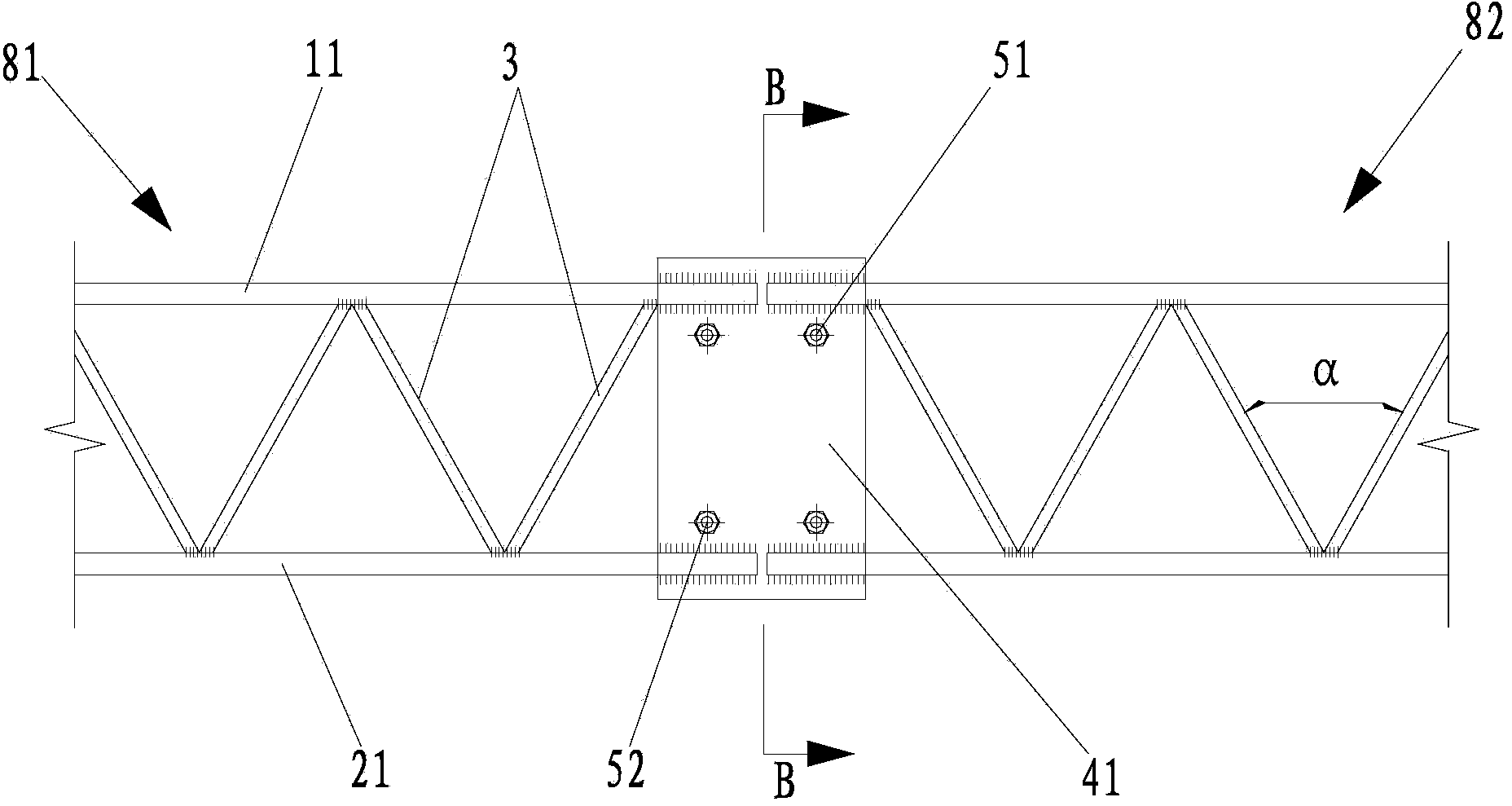

Steel bar construction for secondary lining of tunnel

InactiveCN104061004AEnsure safetyGuaranteed aestheticsUnderground chambersTunnel liningRebarProtection layer

The invention discloses a steel bar construction for secondary lining of a tunnel. The steel bar construction for the secondary lining of the tunnel comprises outer layer bar-mat reinforcement and inner layer bar-mat reinforcement, the outer layer bar-mat reinforcement comprises multiple outer layer annular main reinforcing bars which are laid in the longitudinal extending direction of the constructed tunnel and outer layer longitudinal connecting ribs which are bound to the outer layer annular main reinforcing bars, and the inner layer bar-mat reinforcement comprises multiple inner layer annular main reinforcing bars which are laid in the longitudinal extending direction of the constructed tunnel and inner layer longitudinal connecting ribs which are bound to the inner layer annular main reinforcing bars. The steel bar construction for the secondary lining of the tunnel further comprises interlayer connecting ribs connecting the outer layer bar-mat reinforcement with the inner layer bar-mat reinforcement, and each interlayer connecting rib is fixed between the corresponding outer layer annular main reinforcing bar and the corresponding inner layer annular main reinforcing bar of the same layer in a welding mode. Sinking of the outer layer bar-mat reinforcement and the inner layer bar-mat reinforcement can be effectively controlled by adding the interlayer connecting ribs which are fixed between the outer layer annular main reinforcing bars and the inner layer annular main reinforcing bars in the welding mode, the stability of the interval between an inner reinforcing steel bar layer and an outer reinforcing steel bar layer of a reinforcement cage is maintained, the thickness of a protection layer is guaranteed, safety and attractiveness of the tunnel structure are guaranteed, and working efficiency is improved.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Positioning and clamping method for processing piston and processing technique

A locating and clamping method for machining piston includes providing machine-tool, cutter and fixture, using the top of the inner cavity of the piston to be machined as the point to be clamped, and using the external end face and locating boss of the piston as the locating surface. Its advantages are no deformation caused by clamping, high locating precision, and high productivity and quality.

Owner:薛玉田

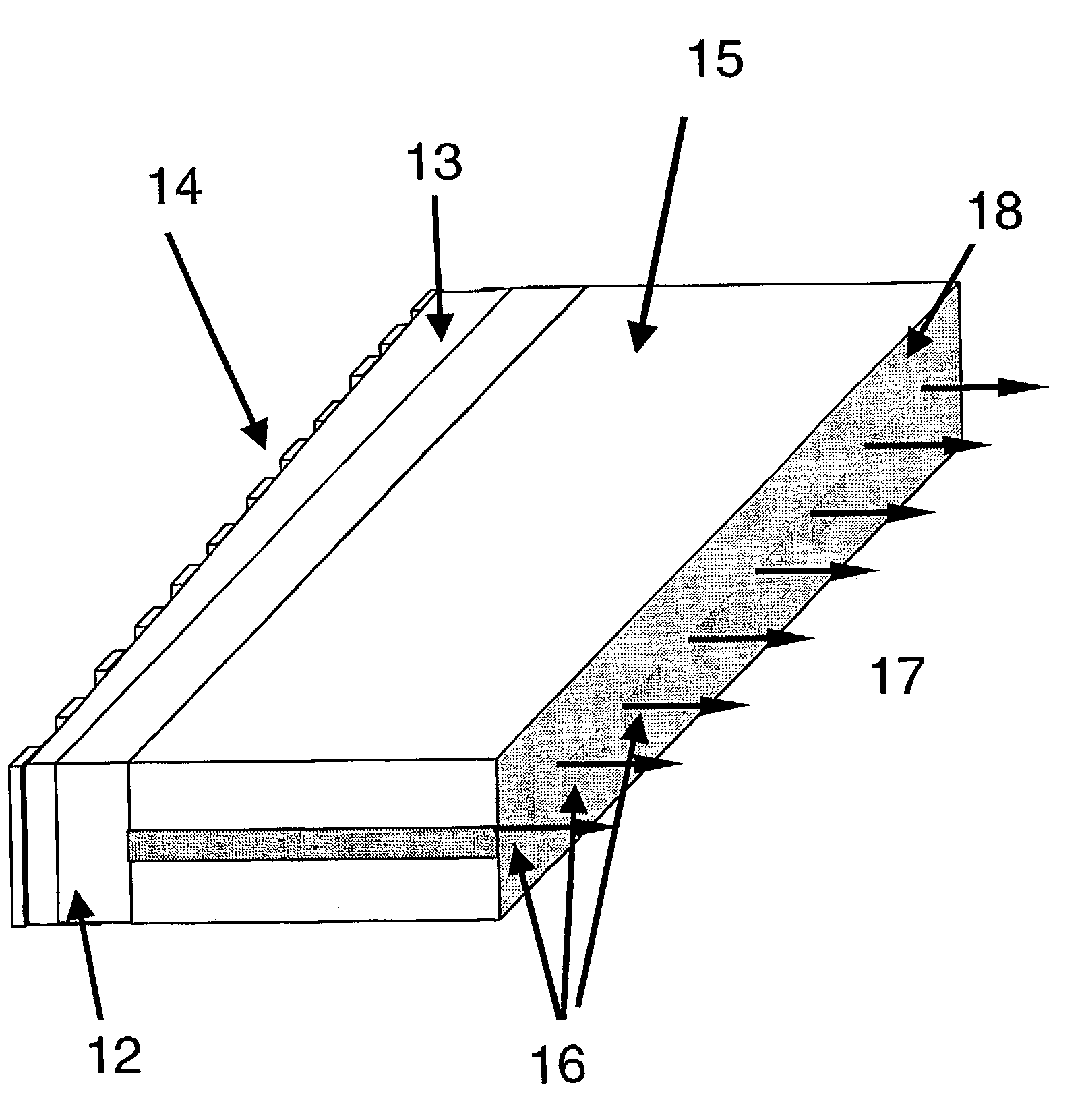

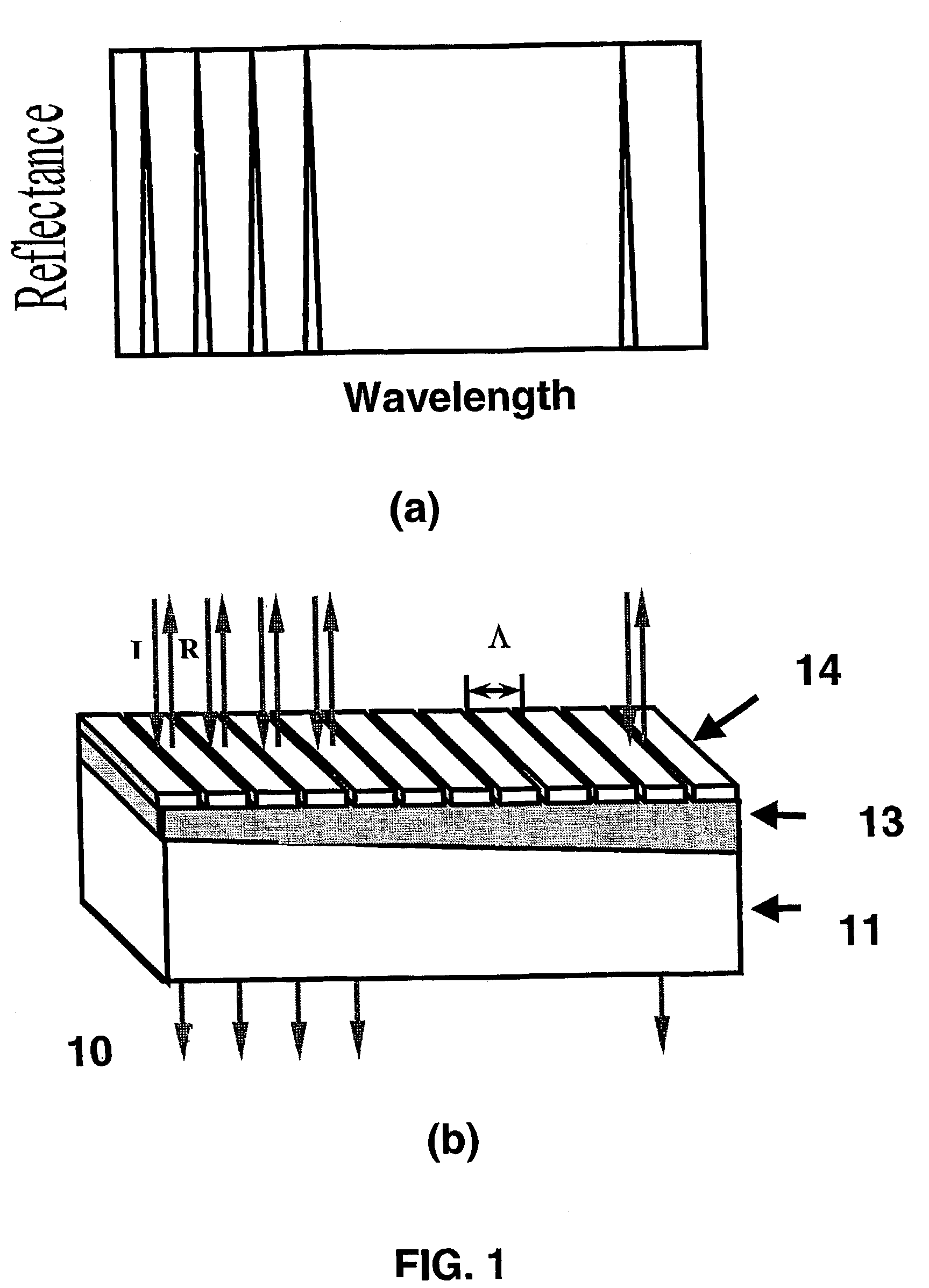

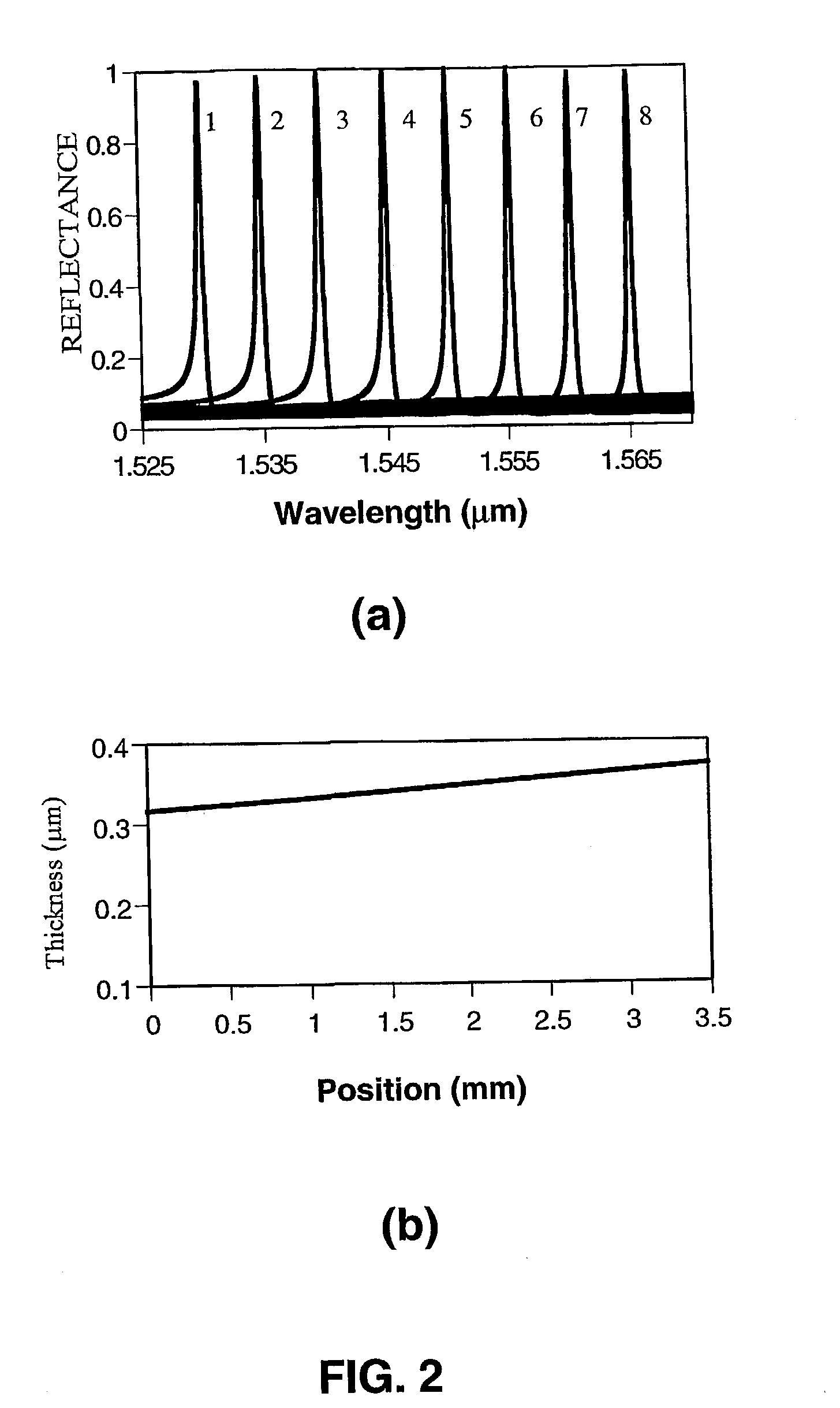

Laser array for generating stable multi-wavelength laser outputs

InactiveUS7106920B2Improve line shapeImprove thermal stabilitySemiconductor laser arrangementsOptical resonator shape and constructionLaser arrayLength wave

A multi-wavelength laser array is achieved by using a wavelength selectable optical device as a feedback mirror for a plurality of lasers. The wavelength of reflected light from the optical device depends upon the parameters in the local reflection positions of the optical device along the direction as determined by guided-mode resonance. Thus, the multi-wavelength laser array is able to emit a plurality of laser beams with desired wavelengths, each within the gain curve of its active element.

Owner:LIU ZHONGSHAN

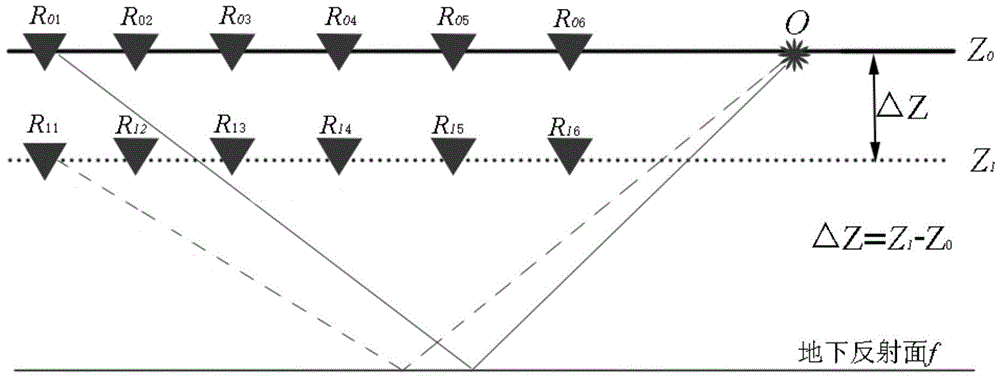

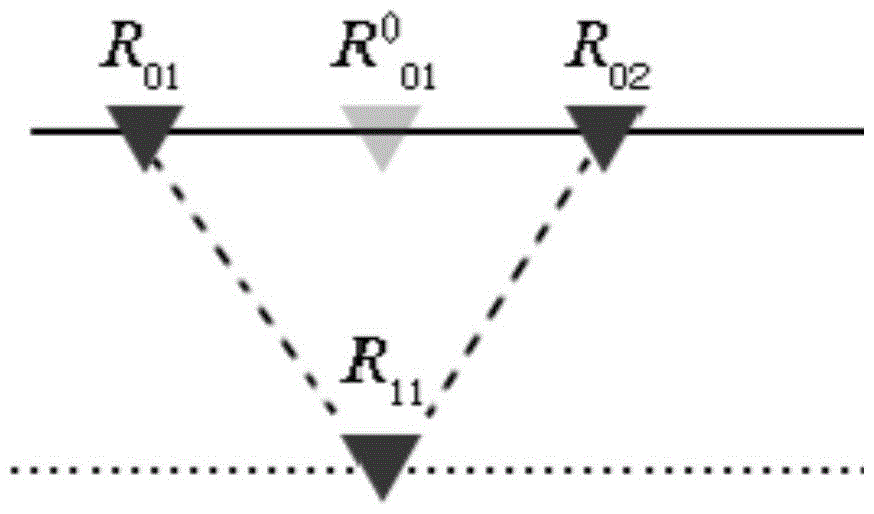

True amplitude migration imaging method

ActiveCN104991268AStable spacingStable data supportSeismic signal recordingSeismic signal processingContinuationData acquisition

The invention discloses a true amplitude migration imaging method, in particular, an onshore double / multi-detector total sound wave equation true amplitude pre-stack depth migration method. The method includes the following steps that: a plurality of detection layers are arranged on a ground surface or below the ground surface; seismic signal data are acquired; the partial derivatives of wave fields at the ground surface relative to depth are calculated; wave field continuation is performed a detection point wave field and a shot point wave field; and cross-correlation correlation imaging principles or reflection coefficient imaging principles are utilized to image the continued detection point wave field and shot point wave field. With the method of the invention adopted, a defect that an existing seismic data acquisition system can only record the values of wave fields at the ground surface and cannot accurately solve an acoustic wave equation at the depth domain can be eliminated; an acoustic wave equation can be utilized to accurately solve seismic wave field information; reliable subsurface structure and lithological information can be provided for subsequent geological interpretation personnel; the confidence level of geological interpretation and seismic inversion analysis can be improved; migration imaging can be performed on various kinds of wave fields; and the true amplitude migration of the lithological changes of subsurface structures can be reflected.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

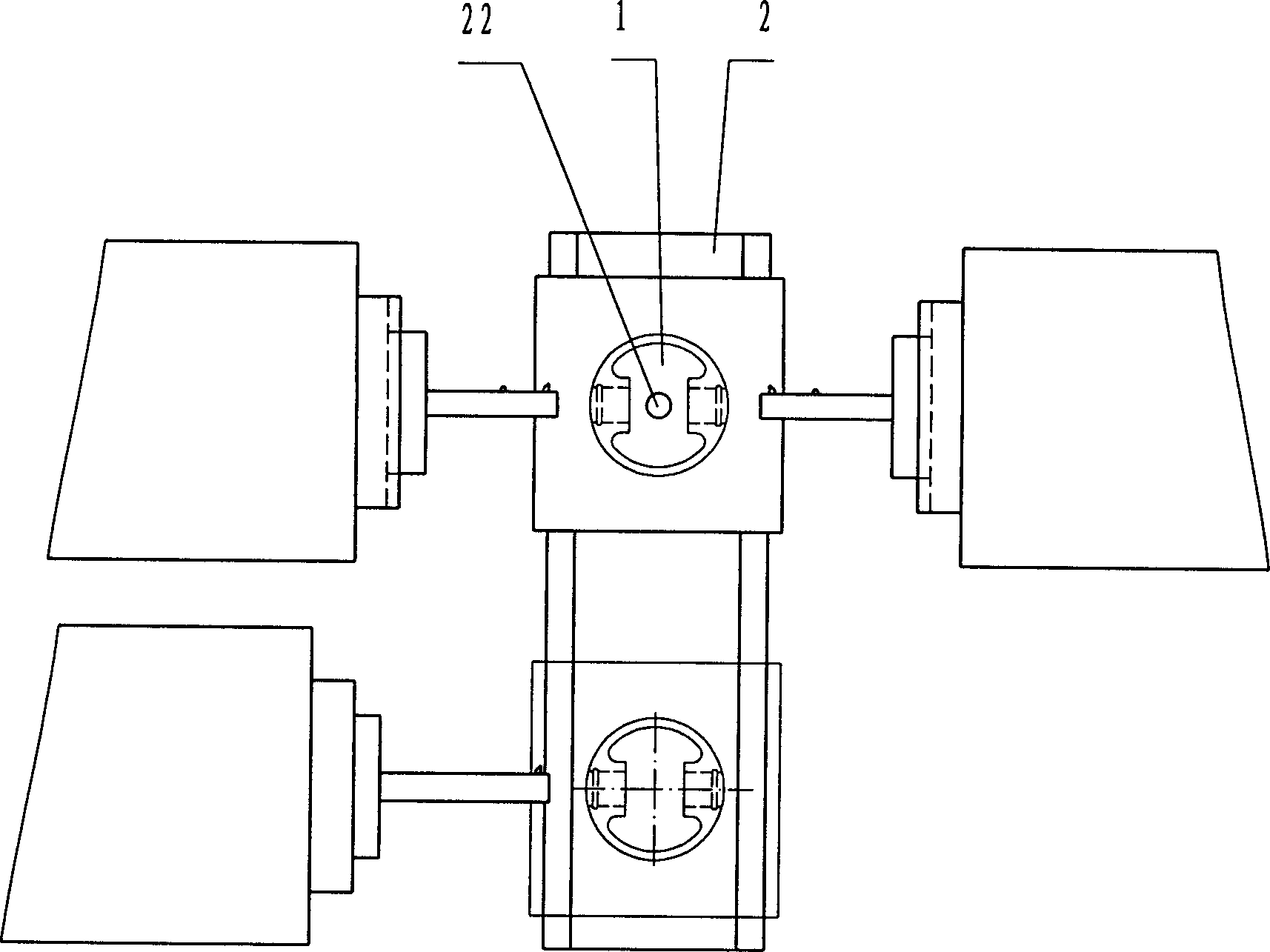

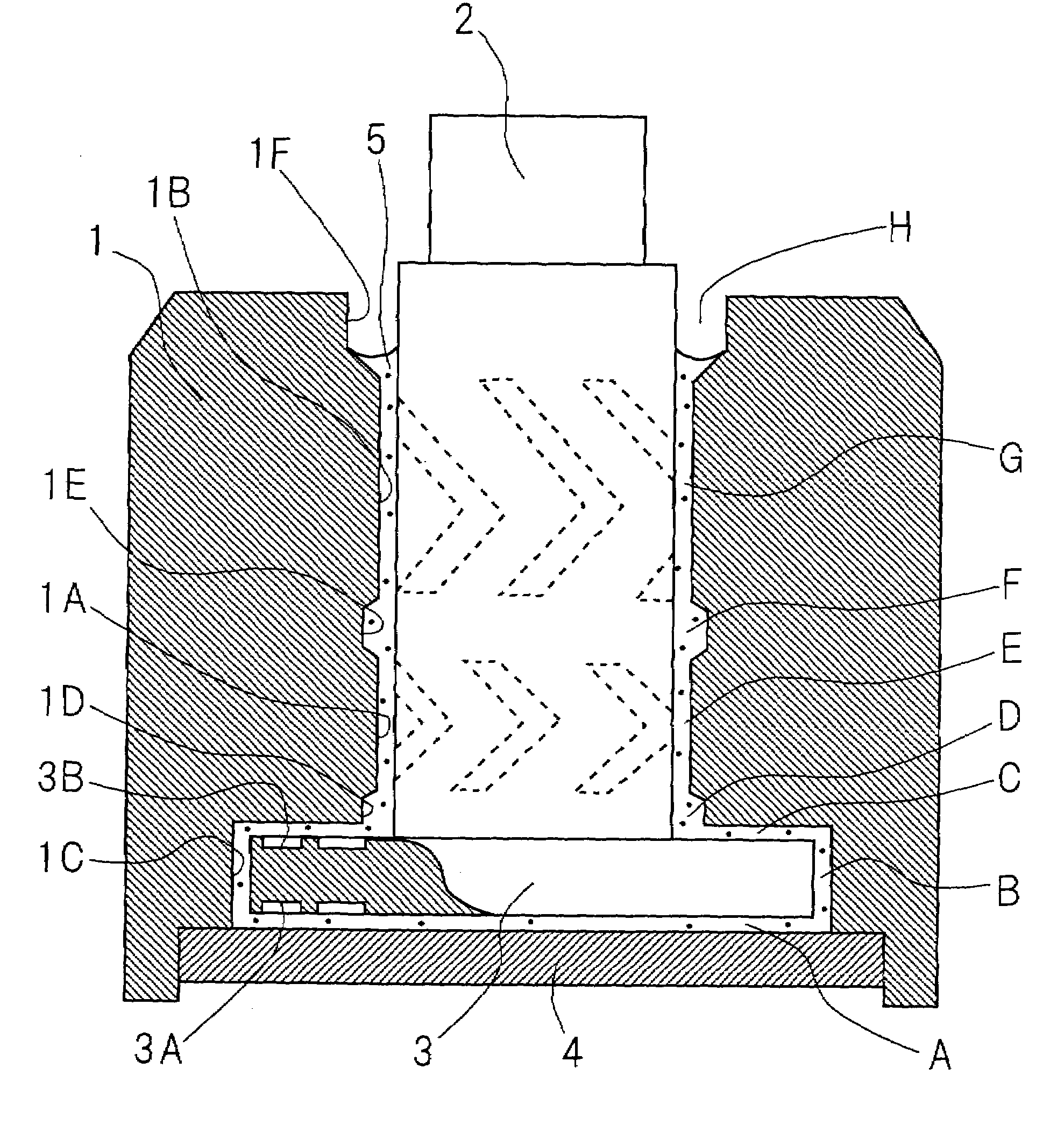

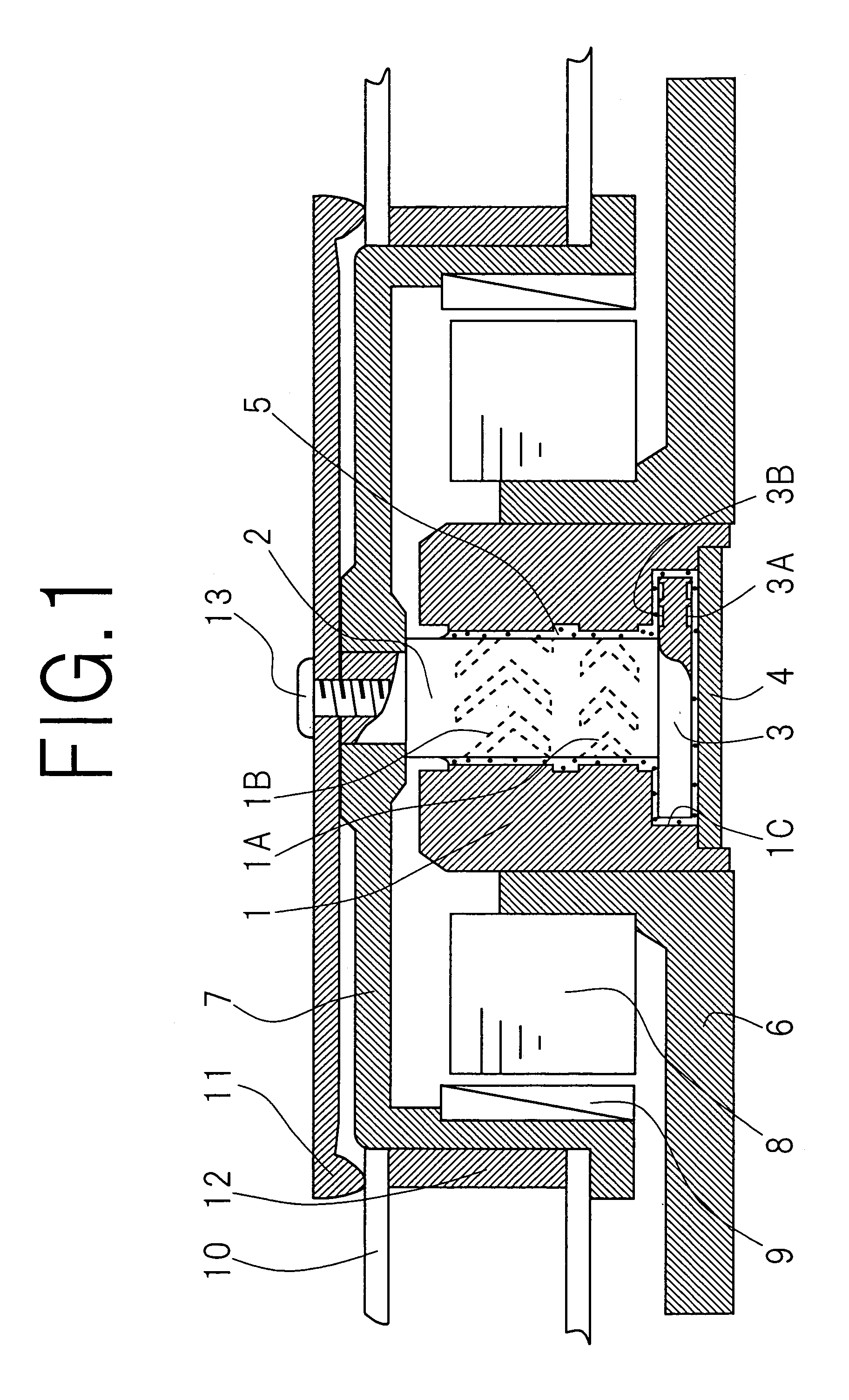

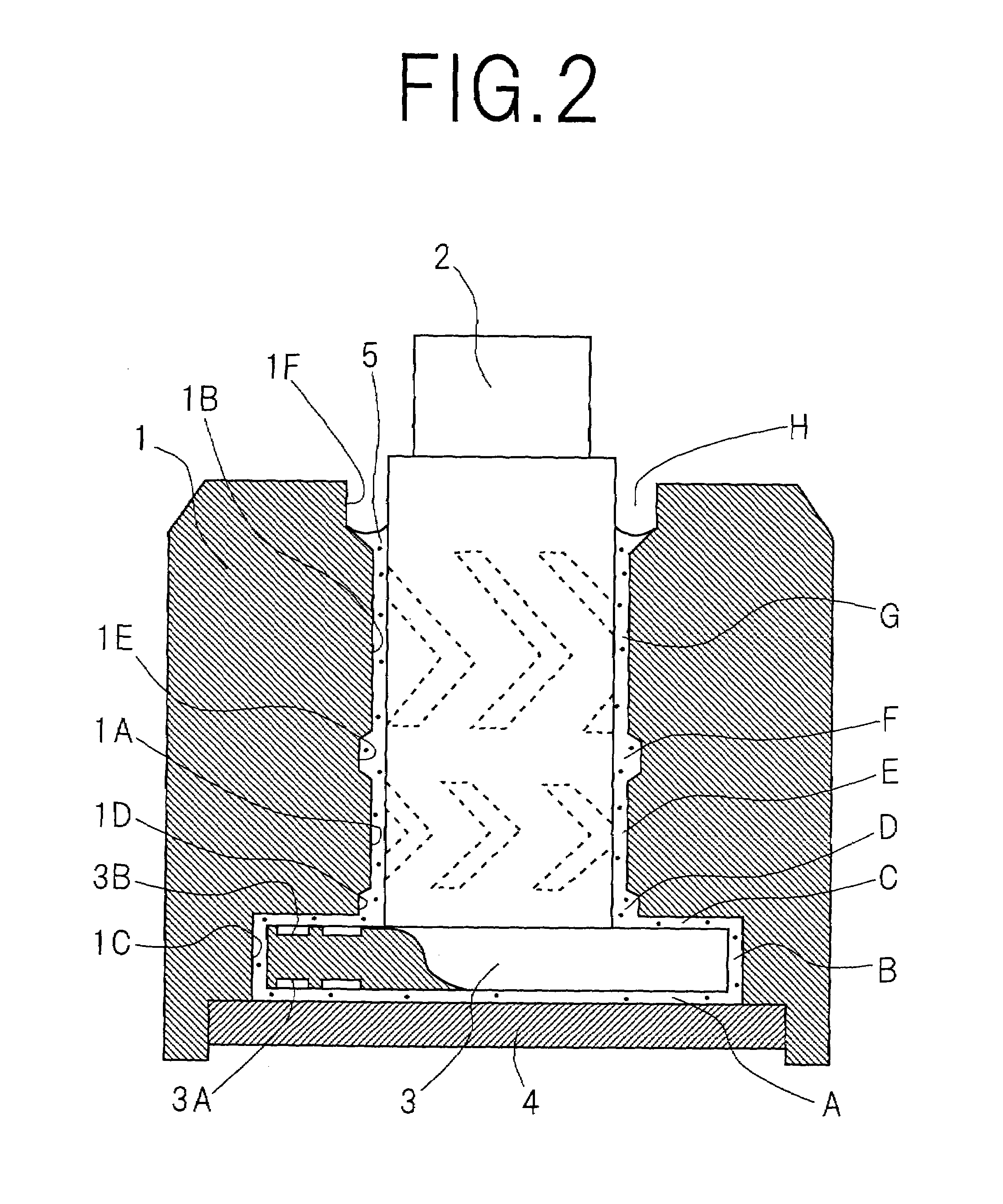

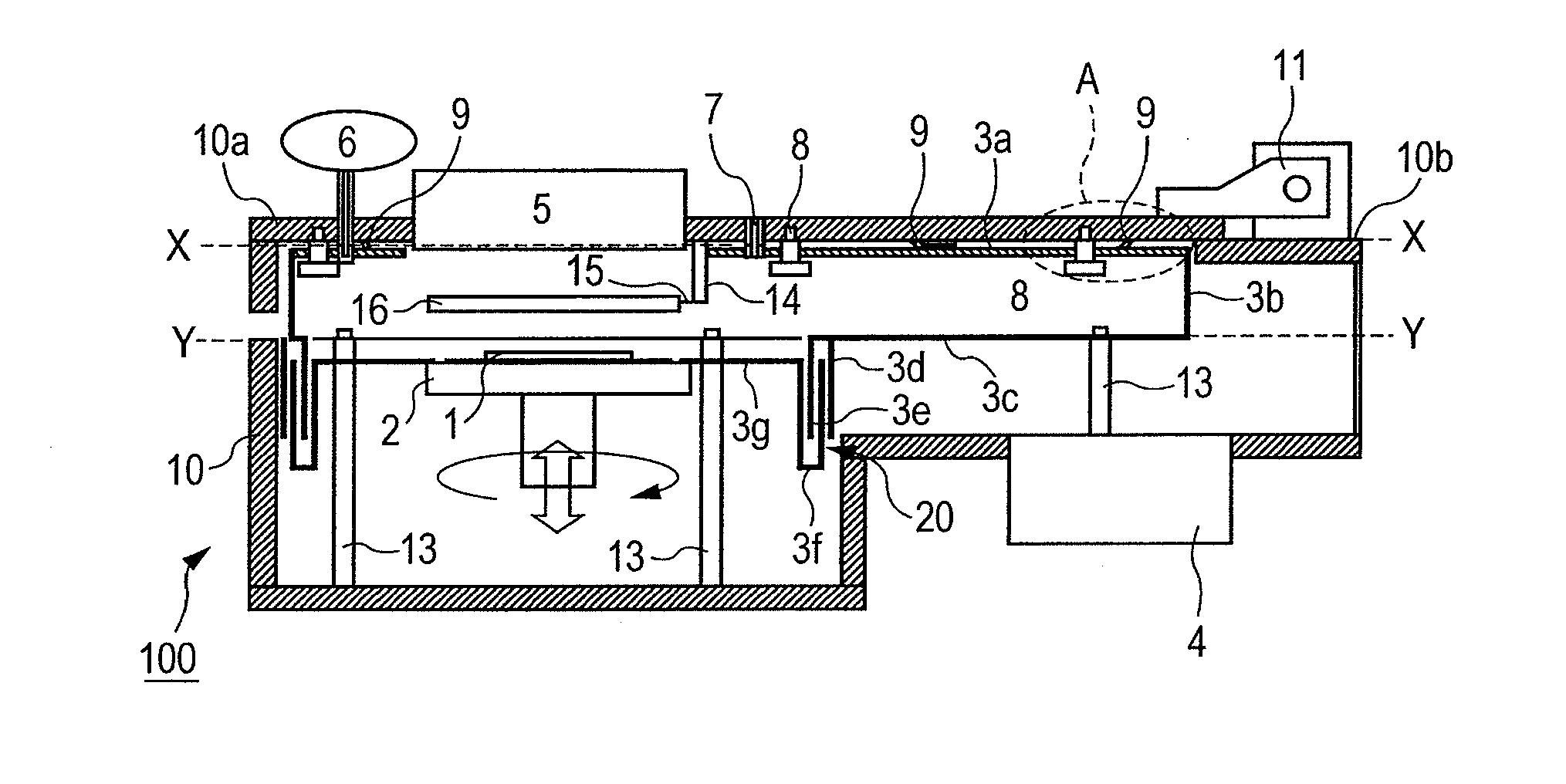

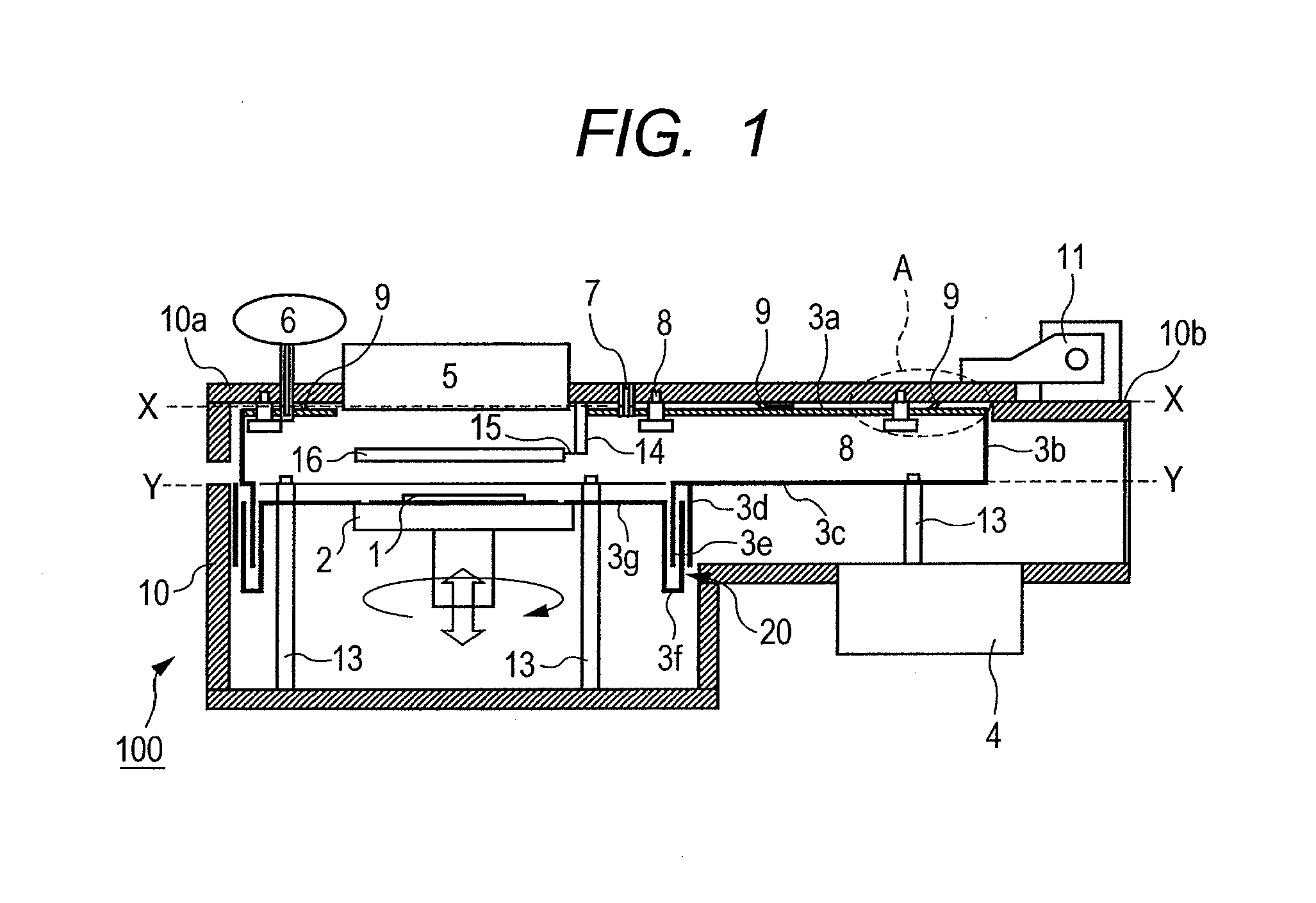

Hydrodynamic bearing and disk recording/reproducing apparatus

ActiveUS7102851B2Improve reliabilityInhibition of agglomerationShaftsRecord information storageEngineeringDynamic pressure

A sleeve 1 is fixed on a base. Radial dynamic-pressure generating grooves 1A and 1B are provided on an inner surface of the sleeve 1. A thrust plate 4 hermetically seals a lower opening end of the sleeve 1. A shaft 2 is inserted inside the sleeve 1, being allowed to revolve. A flange 3 is fixed at the bottom end of the shaft 2, and its lower surface is placed close to an upper surface of the thrust plate 4. Thrust dynamic-pressure generating grooves 3A and 3B are provided on the surfaces of the flange 3. Gaps A–H among the sleeve 1, the shaft 2, the flange 3, and the thrust plate 4 are filled with a lubricant 5. Hollows 1C–1F are provided on the inner surface of the sleeve 1. The gaps A and C over the thrust dynamic-pressure generating grooves 3A and 3B and their vicinities are narrower than the surrounding gaps B and D (A<B, A<D, C<B, and C<D), and the surrounding gaps B and D are narrower than the gap H in the upper opening end of the sleeve 1 and its vicinity (B<H and D<H). The gaps E and G over the radial dynamic-pressure generating grooves and their vicinities are narrower than the surrounding gaps D and F (E<D, E<F, G<D, and G<F), and the surrounding gaps D and F are narrower than the gap H in the upper opening end of the sleeve 1 and its vicinity (D<H and F<H).

Owner:PANASONIC CORP

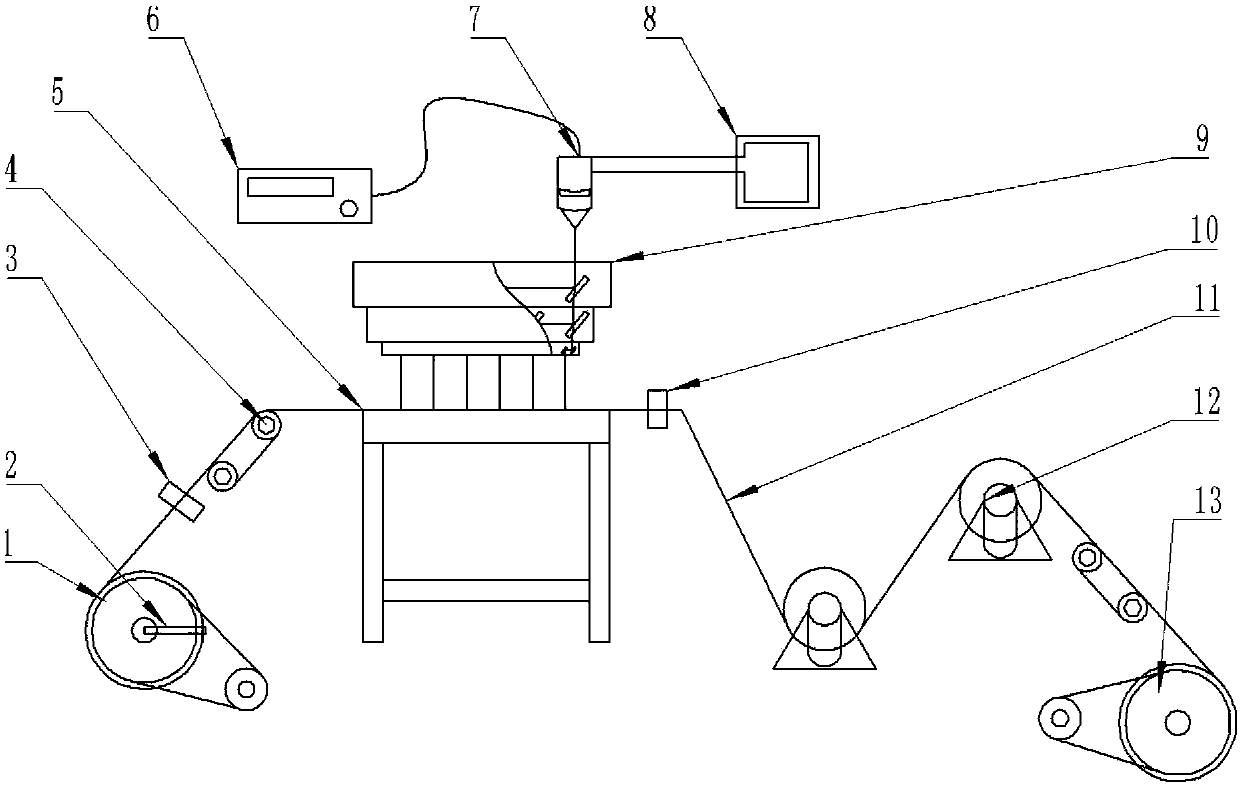

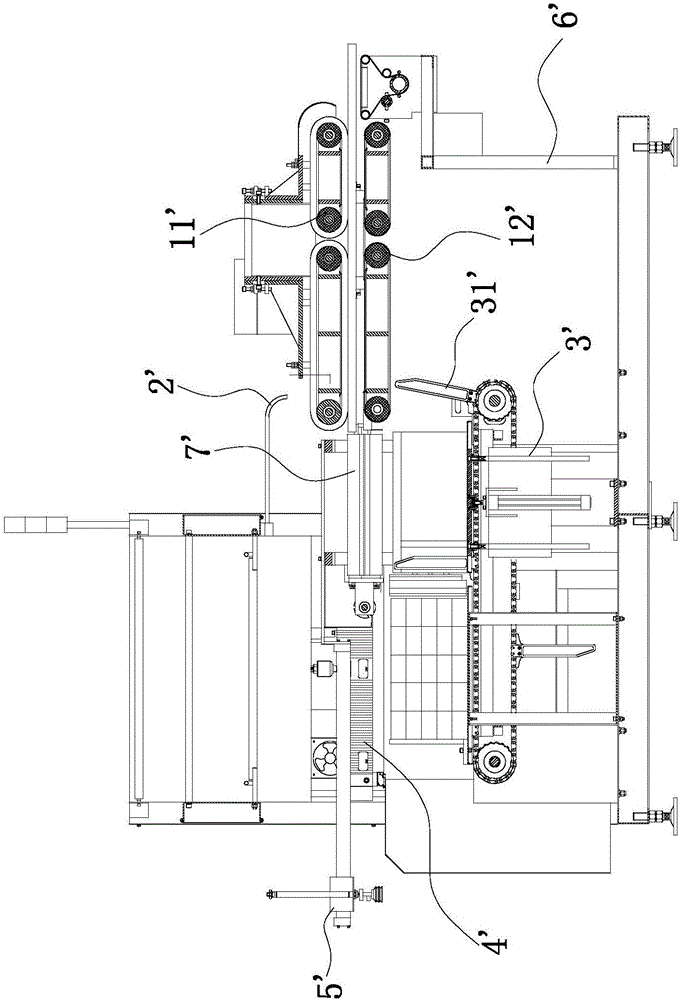

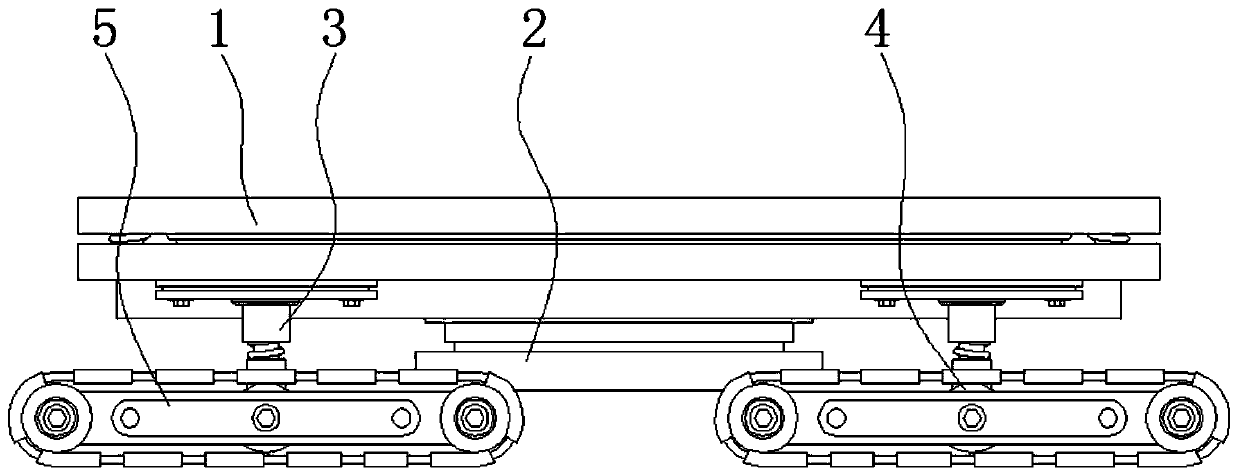

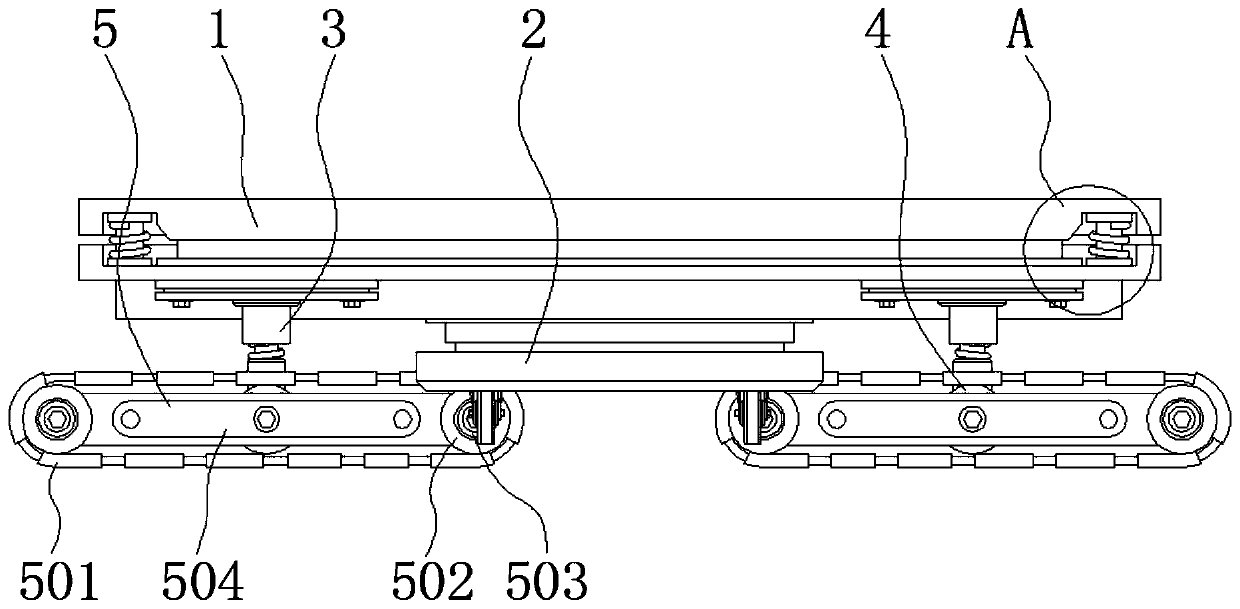

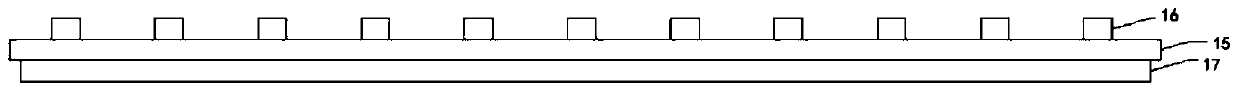

Device for machining copper foil hole through laser

InactiveCN108044242AElongation stabilityStable spacingWelding/soldering/cutting articlesLaser beam welding apparatusPunchingControl system

The invention discloses a device for machining a copper foil hole through a laser. The device for machining the copper foil hole through the laser comprises a control system, a laser device and a motion system. The control system is used for controlling the motion system to work. The motion system is used for driving copper foil to pass through a laser punching point of the laser device. The motion system comprises a copper foil conveying mechanism and a supporting frame. The top of the supporting frame is provided with a punching worktable. The copper foil conveying mechanism is used for making the copper foil sequentially pass through the punching worktable. The device for machining the copper foil hole through the laser further comprises a tension sensor. The tension sensor is used fordetecting the tension on the copper foil in the conveying process of the copper foil, and the data output end of the tension sensor is connected with the signal input end of the control system. The control system controls a working state of the copper foil conveying mechanism according to tension data obtained by the tension sensor. The device for machining the copper foil hole through the laser is used for conducting laser punching machining on the copper foil, and the obtained hole in the copper foil can be made to have higher position precision.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

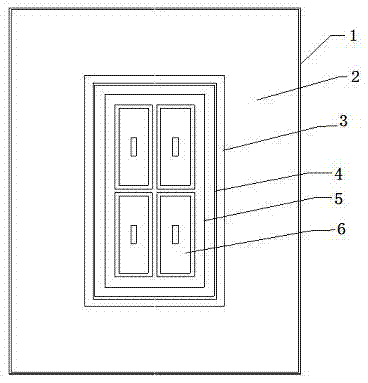

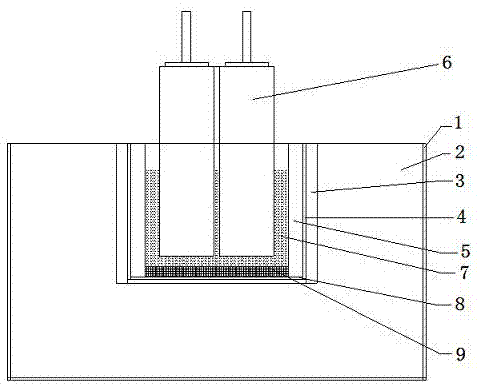

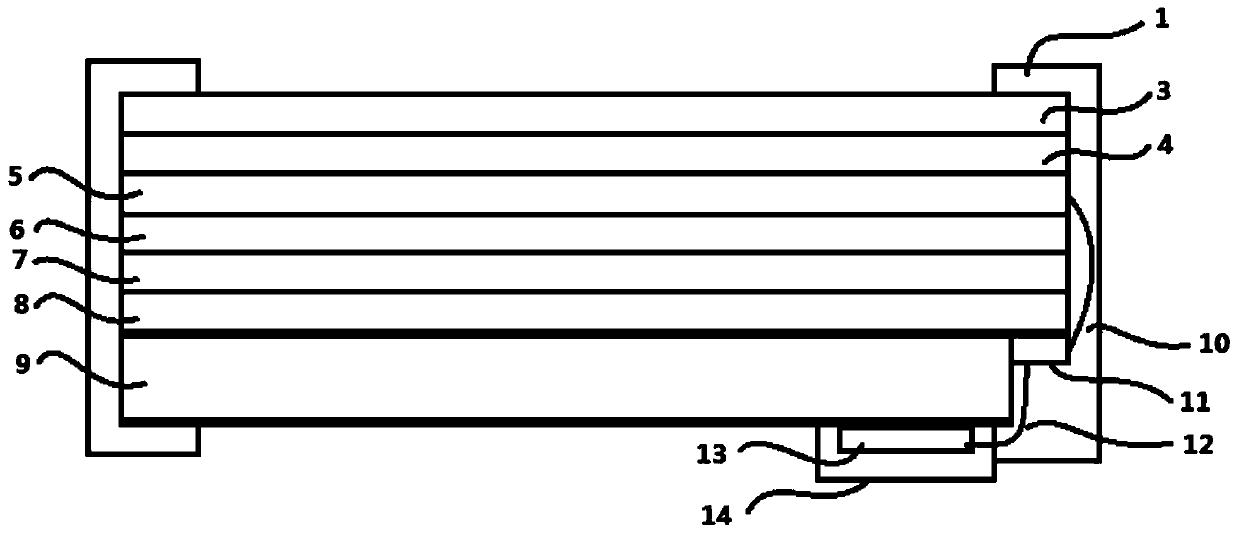

Rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using liquid cathode

InactiveCN105441987AImprove current efficiencyExtended service lifeCellsElectrodesRadiative heat lossRare-earth element

The invention discloses a rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using a liquid cathode. The rare earth fused-salt electrolysis cell mainly comprises an electrolysis cell body, an anode and the liquid cathode; the anode and the cathode are provided with horizontal planes parallel to and facing each other; the anode is vertically inserted in the electrolysis cell body; the liquid cathode is a liquid metal electrolyzed at the bottom; a tungsten plate is inlaid in the internal bottom of the electrolysis cell body; a molybdenum plate or a niobium plate can be taken as a cathode bottom plate or a rare earth metal catcher for an electrolytic product separated out on the cathode. The rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using the liquid cathode has the advantages of high current efficiency, low radiant heat losses, high anode utilization rate, long electrolysis cell service life and low investment of the electrolysis cell body; the single plant capacity can reach above 100 KA, the energy consumption per unit product is greatly reduced, and produced products are stable in quality, low in production cost and relatively closed.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

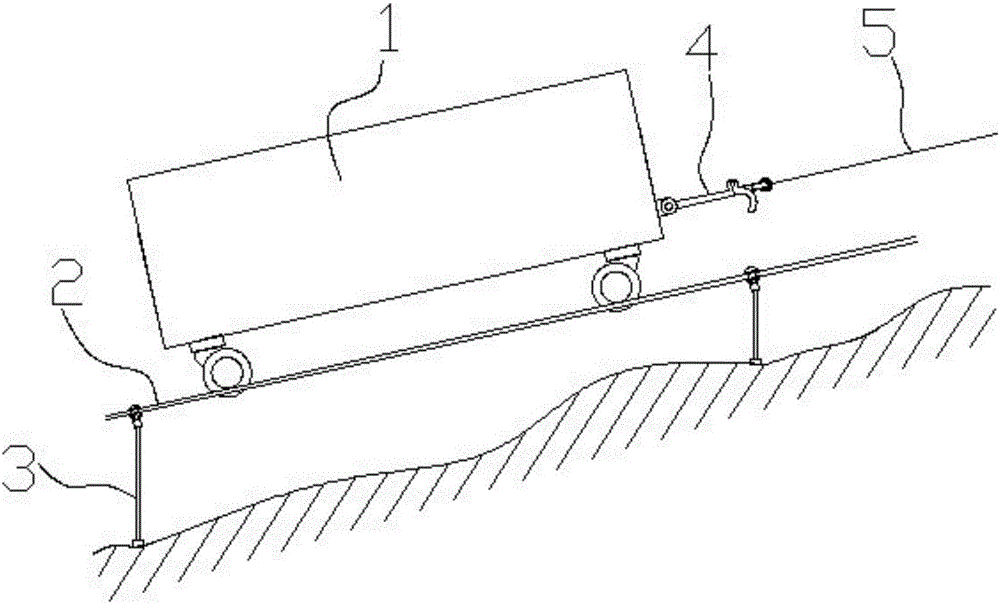

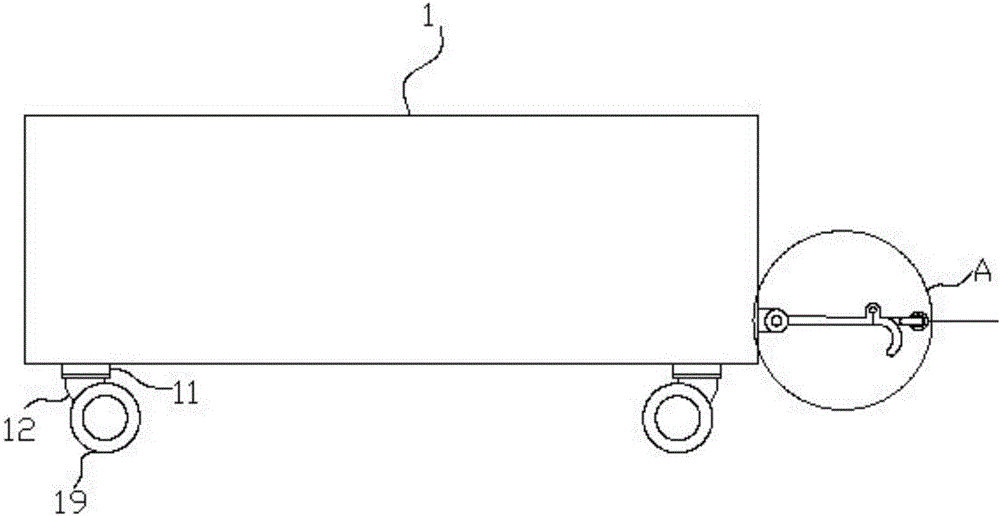

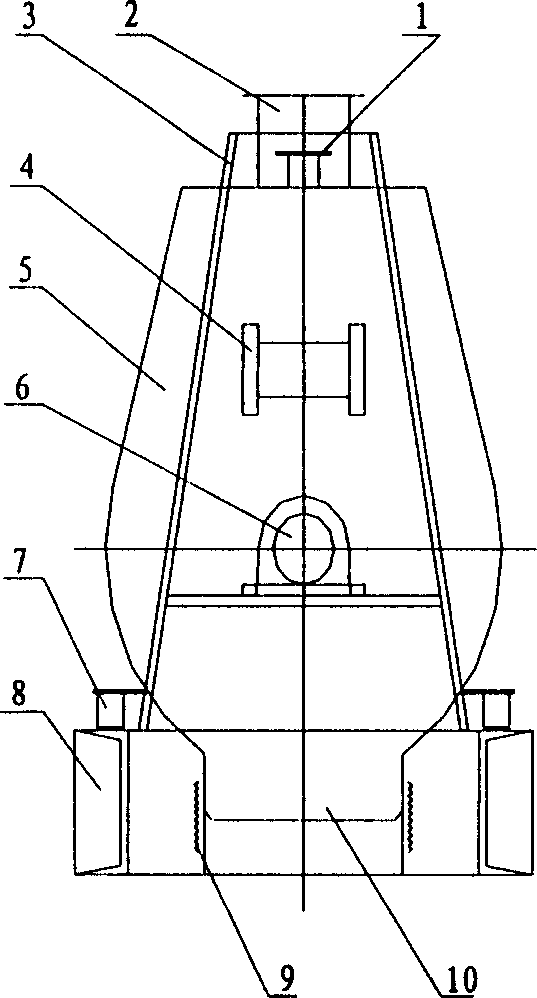

Steel wire rail transportation mechanical equipment system for mountain land

ActiveCN106241235AImprove smoothness of movementExtended range of movementMechanical conveyorsMechanical equipmentFlange

The invention discloses a steel wire rail transportation mechanical equipment system for mountain land. The system comprises travelling mechanisms at the bottom a compartment. The travelling mechanisms travel on steel cable tracks. The steel cable tracks are mounted on the mountain land through track fixing devices. The compartment is connected with a traction machine through a traction steel cable. Each pair of travelling mechanisms comprise two mounting bases. A rotating head is arranged at the lower end of each mounting base. A cylindrical rolling wheel is arranged at the lower end of each rotating head. A flange disc is arranged at one end of each cylindrical rolling wheel. Each rotating head is provided with an oriented steel wire rope. An extension spring is connected between every two oriented steel wire ropes. Each track fixing device comprises a steel cable fixing bracket and a ground fixing bracket. Each steel cable fixing bracket and the corresponding ground fixing bracket are tensioned through tensioning steel cables. The steel cable fixing brackets are uniformly arranged between the steel cable tracks. Clamping devices are arranged at the two ends of each steel cable fixing bracket, and an auxiliary rolling wheel is arranged in the middle of each steel cable fixing bracket. By means of the steel wire rail transportation mechanical equipment system for the mountain land, suspended transportation conducted between the mountain land and a road is achieved; efficiency of transporting goods and materials among areas of the mountain land can be greatly improved; labor intensity is lowered; and the system is easy to operate and stable in operation.

Owner:钦永富

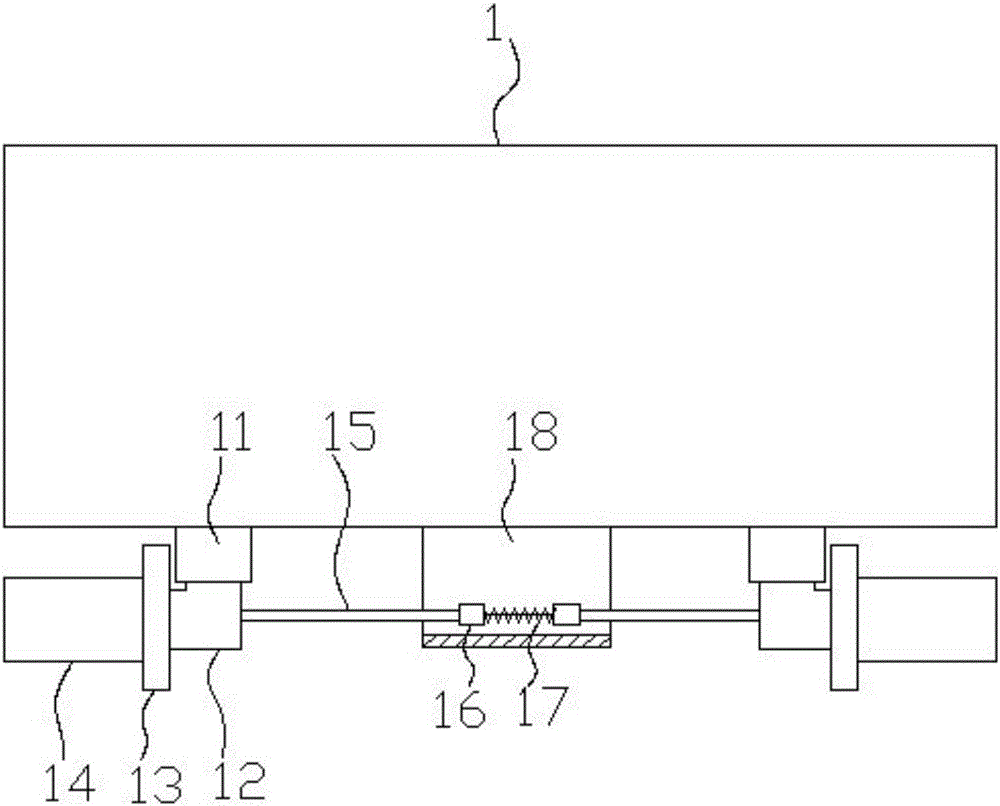

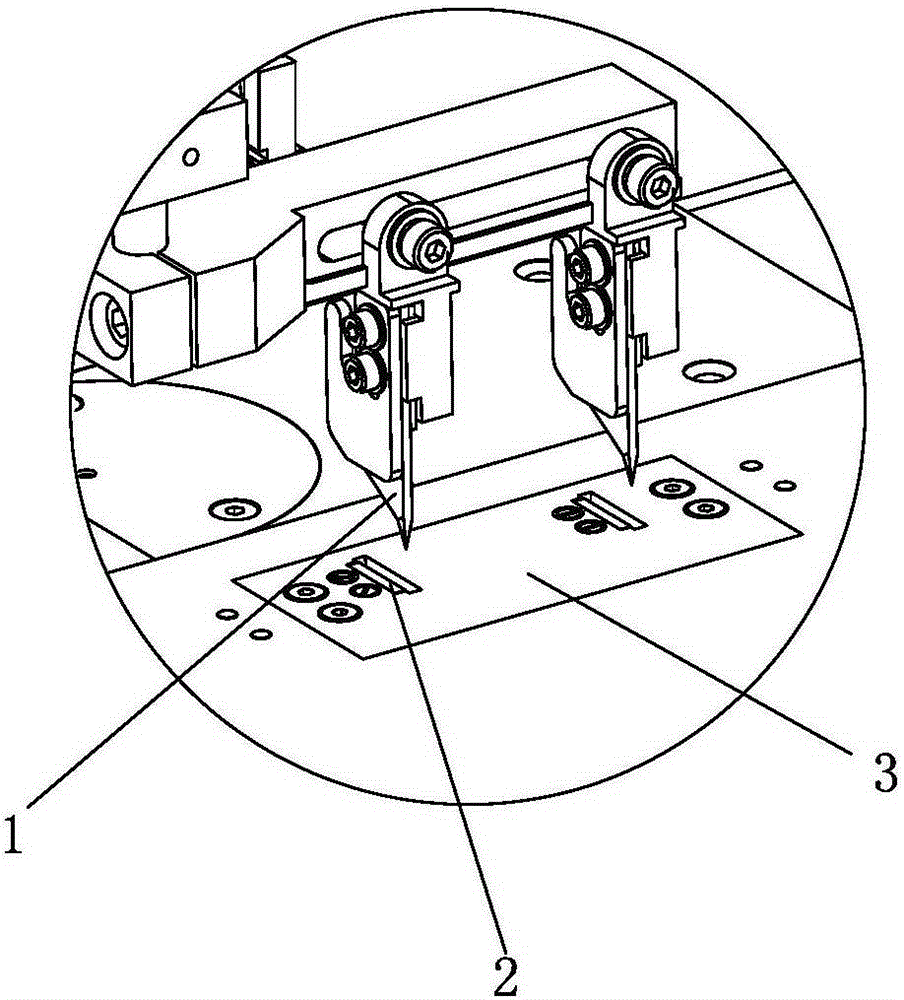

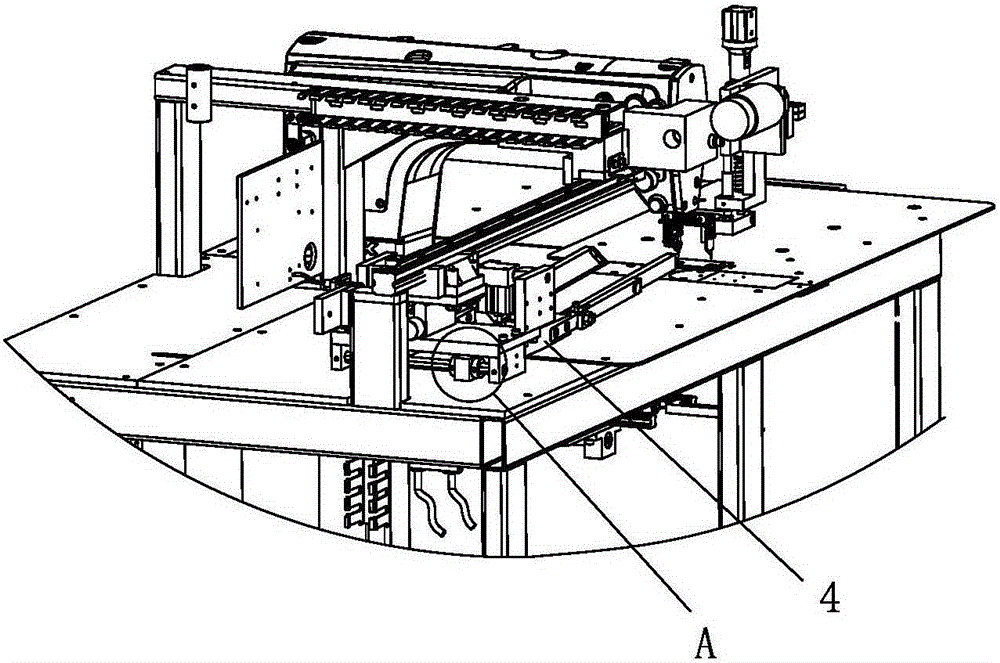

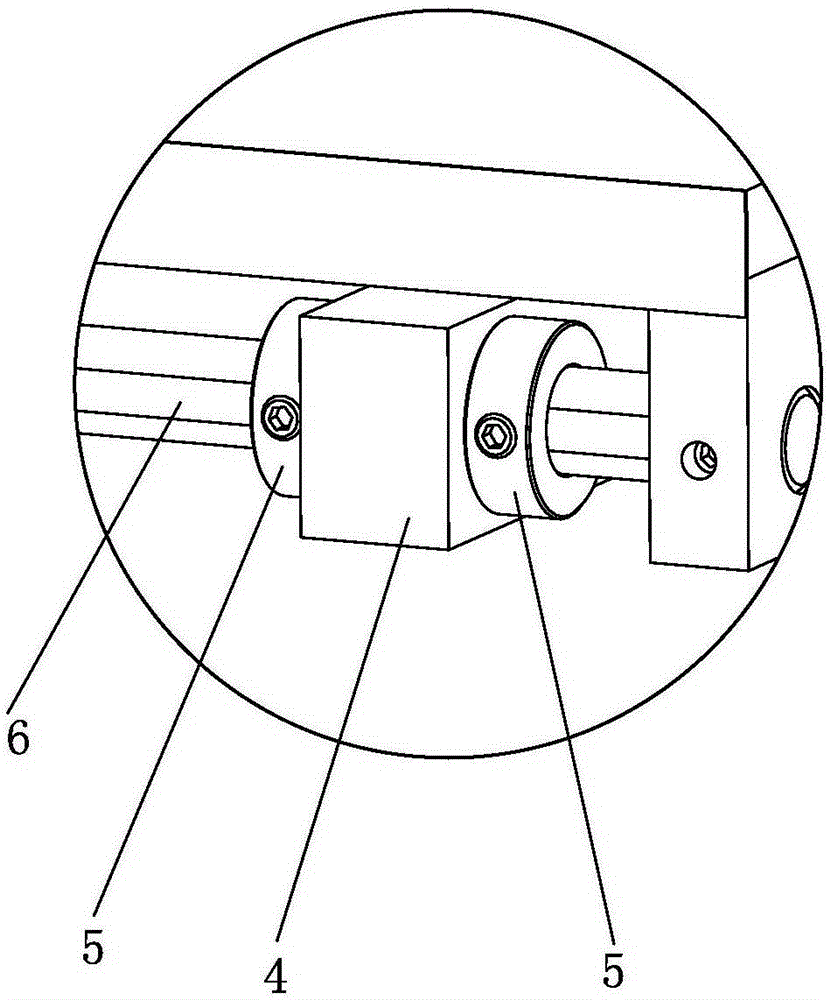

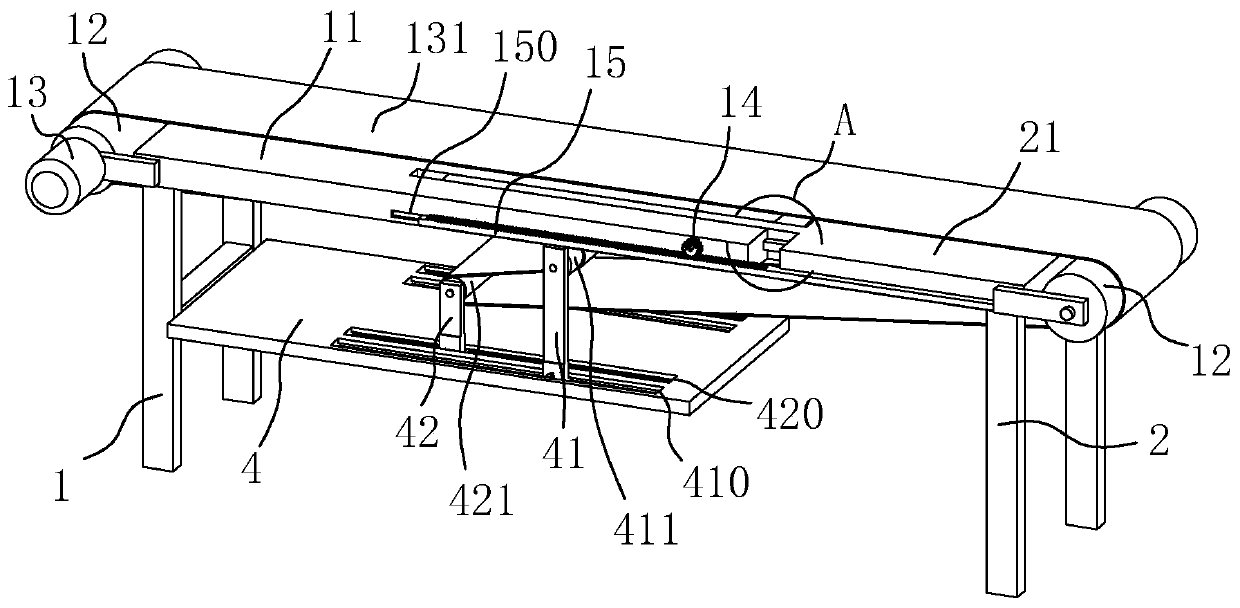

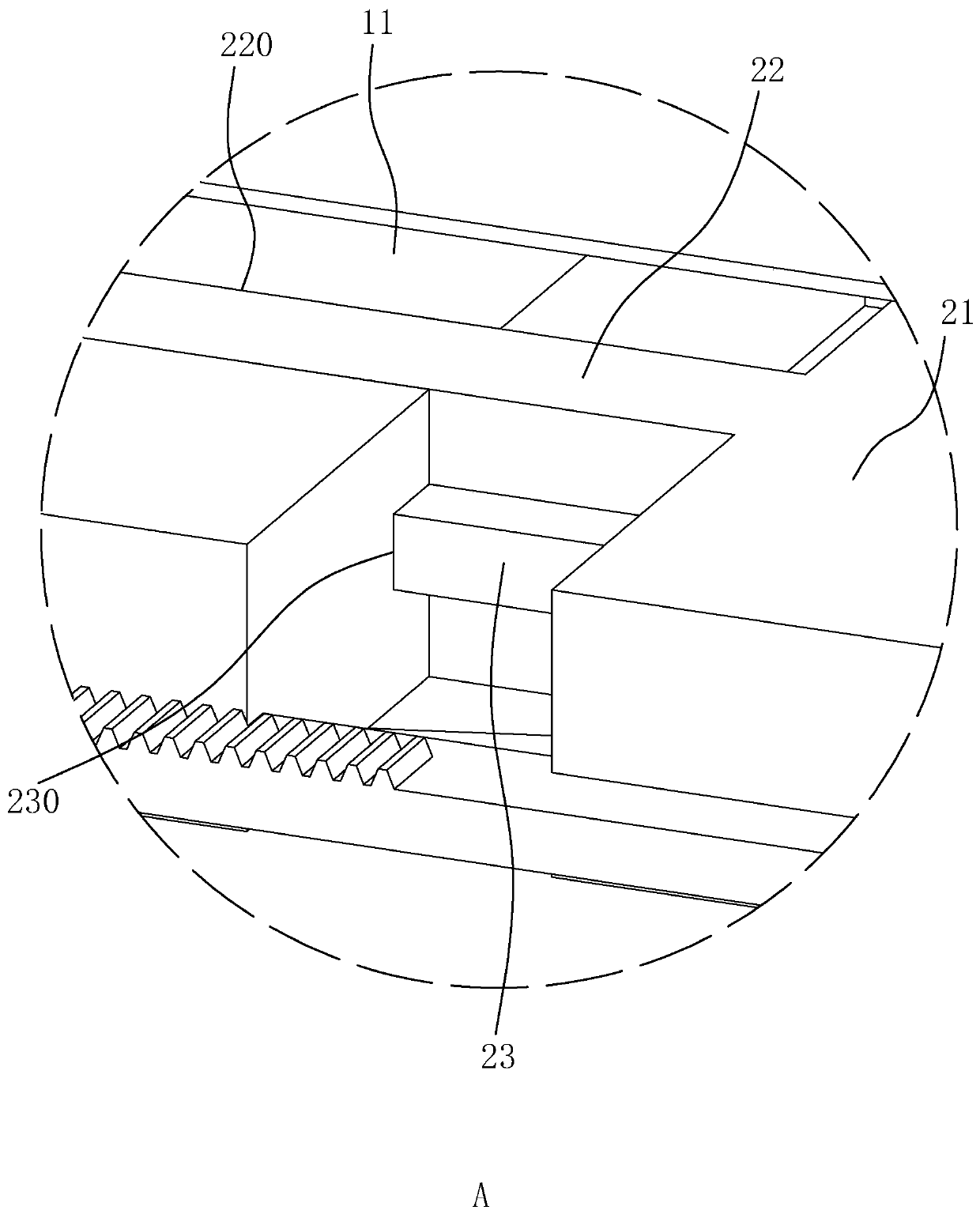

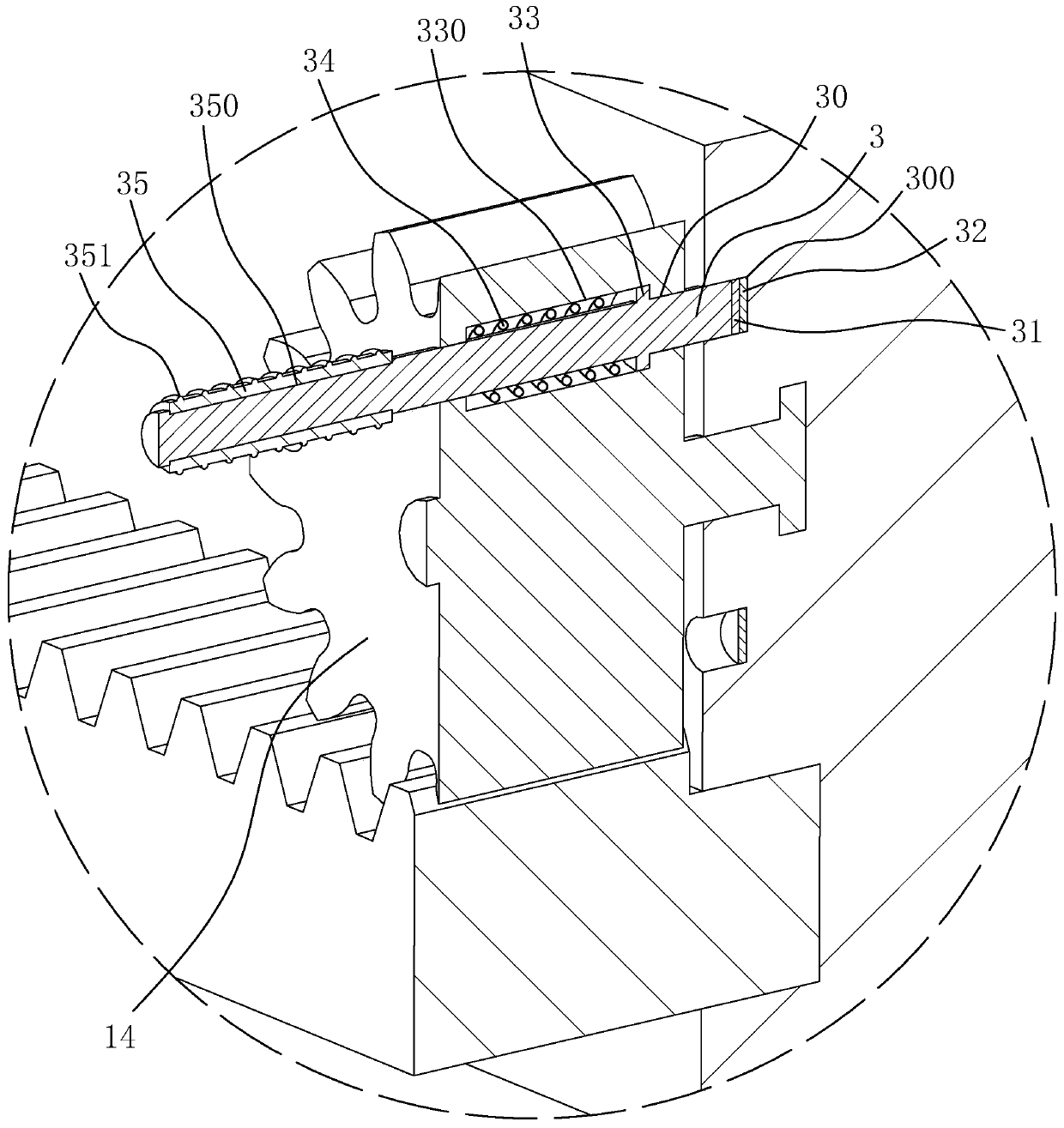

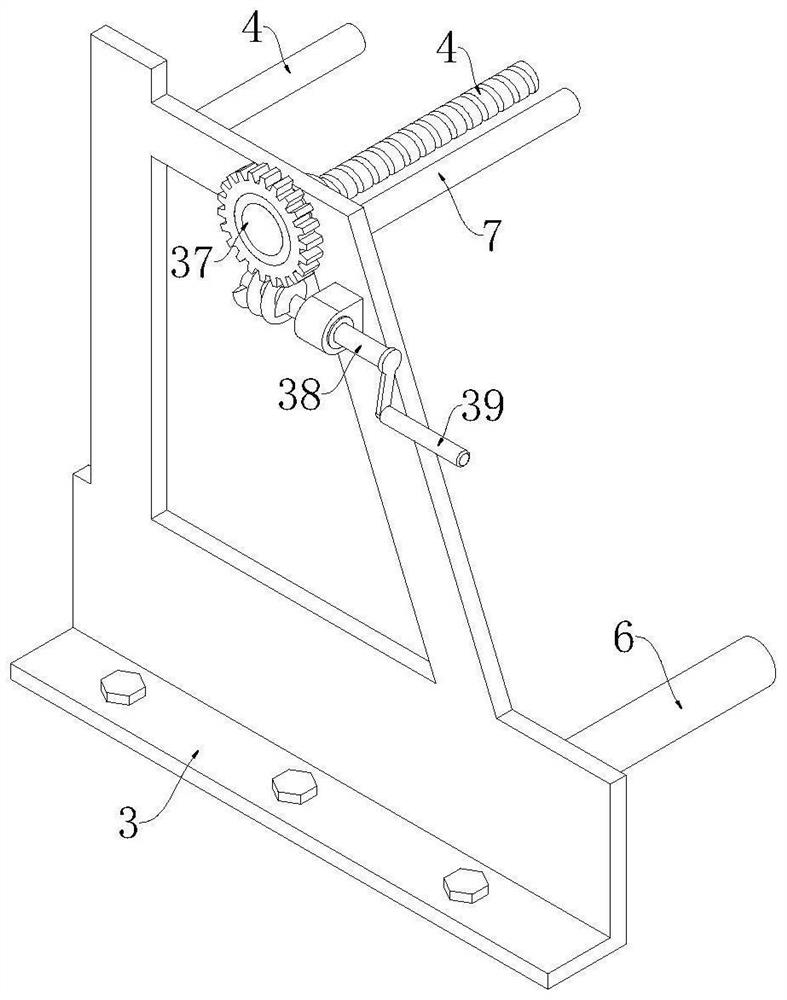

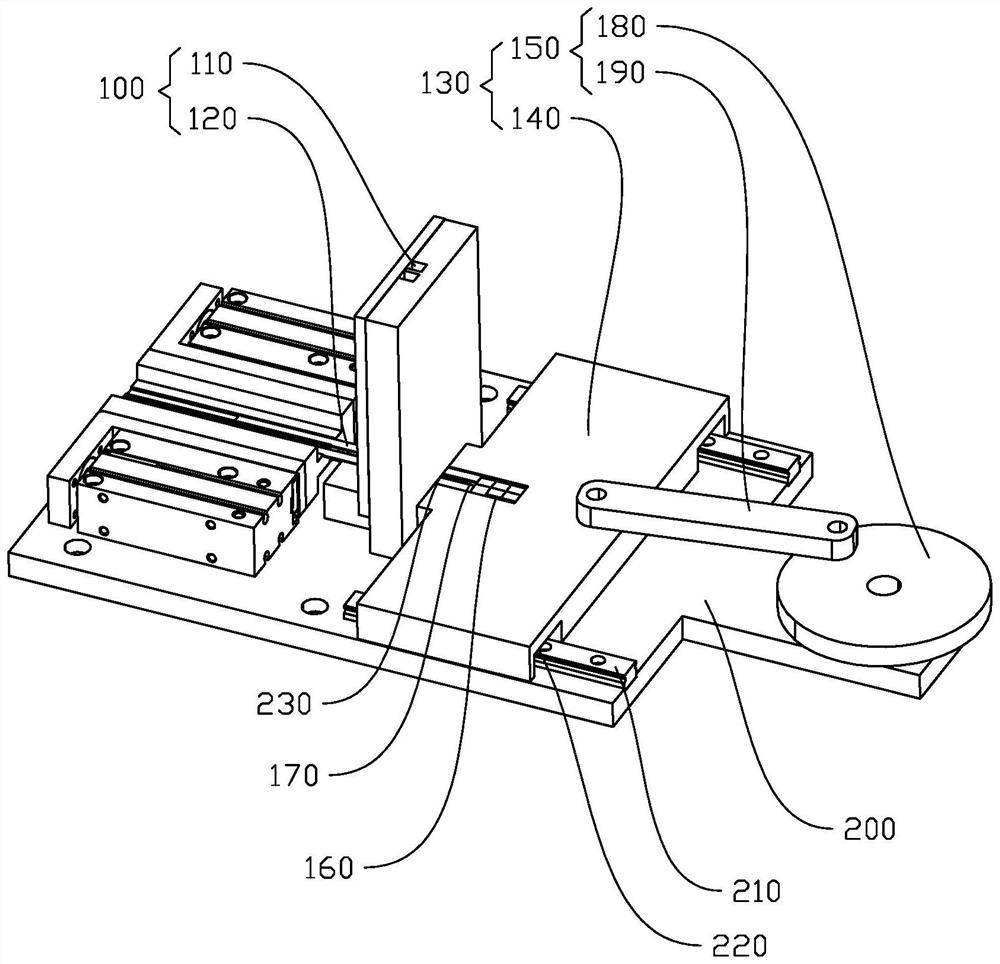

Placket machine presser foot automatic adjustment mechanism and control method thereof

ActiveCN105200675APrecise control of presser foot spacingEasy to adjustSewing-machine control devicesPressersPhysical medicine and rehabilitationSewing machine

The invention belongs to the technical field of placket machines, in particular to a placket machine presser foot automatic adjustment mechanism and a control method thereof. The placket machine presser foot automatic adjustment mechanism comprises a left presser foot arm and a right presser foot arm, as well as a left presser foot and a right presser foot which are arranged on the left presser foot arm and the right presser foot arm, wherein an adjustment mechanism body is arranged on a presser foot mounting frame, the left and right presser foot arms are connected with the adjustment mechanism body, the adjustment mechanism body acts for adjusting the space between the left and right presser foot arms to further adjust the space between the left and right presser feet, and the action of the adjustment mechanism body is electrically controlled through a sewing machine; the method comprises the steps of (1) left and right presser feet resetting; (2) adjusting the space between the left and right presser feet; (3) automatically pressing cloth; (4) automatically lifting the presser feet; the whole working process of the mechanism is that after the width of a placket is changed, a system calculates the angles of positive and negative rotation and rotating of a motor according to the width, and a screw rod is driven to rotate under the driving of the motor, so as to automatically adjust the space between the two presser feet and accurately control the space between the presser feet without performing manual adjustment like a traditional method, and the adjustment is simple and convenient.

Owner:BULLMER ELECTROMECHANICAL TECH

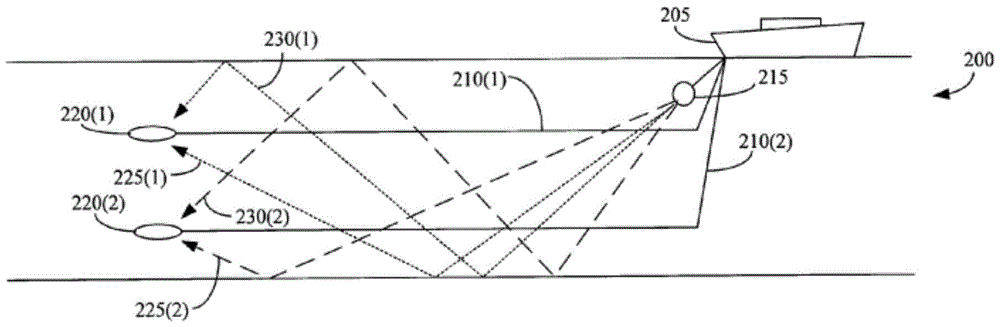

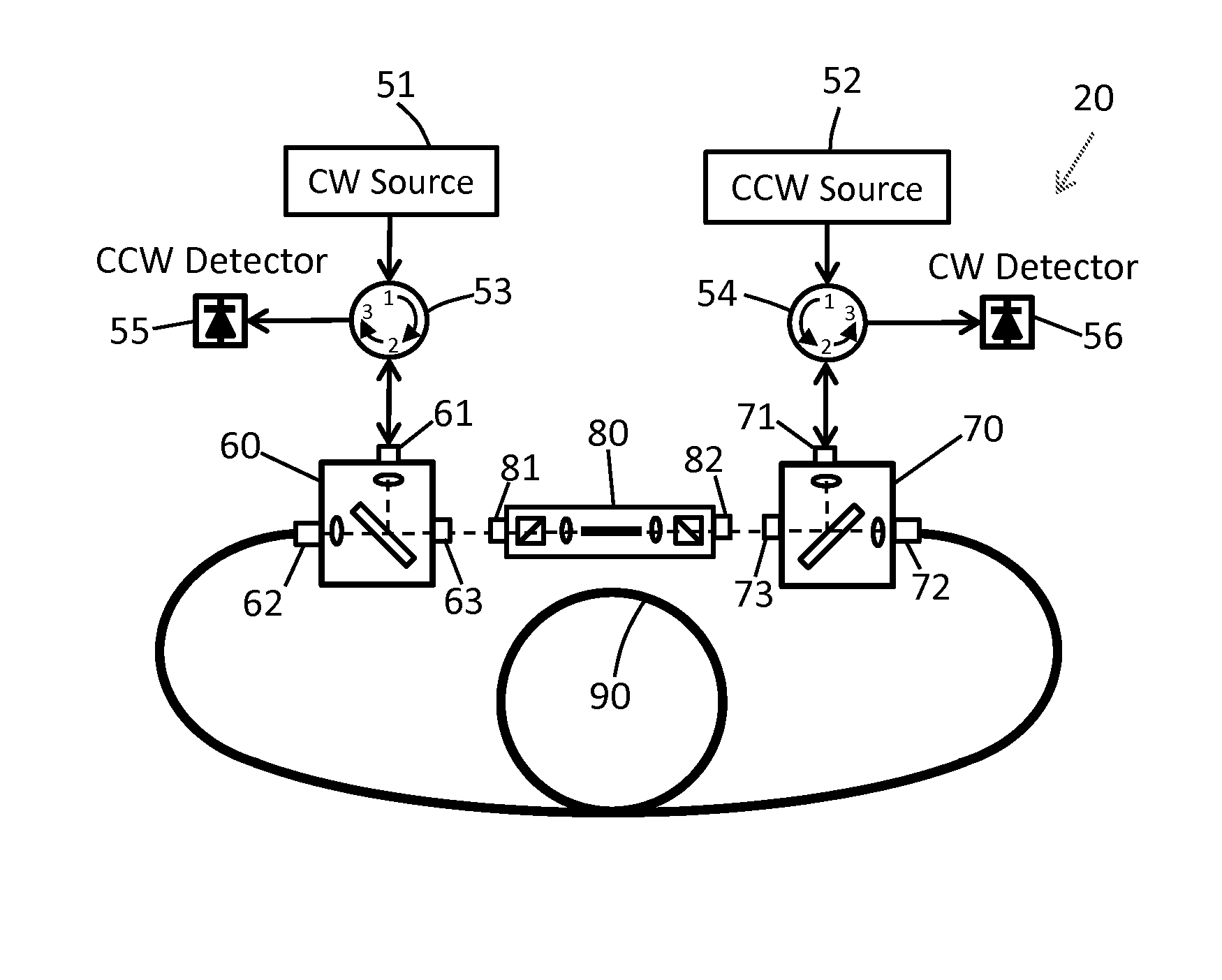

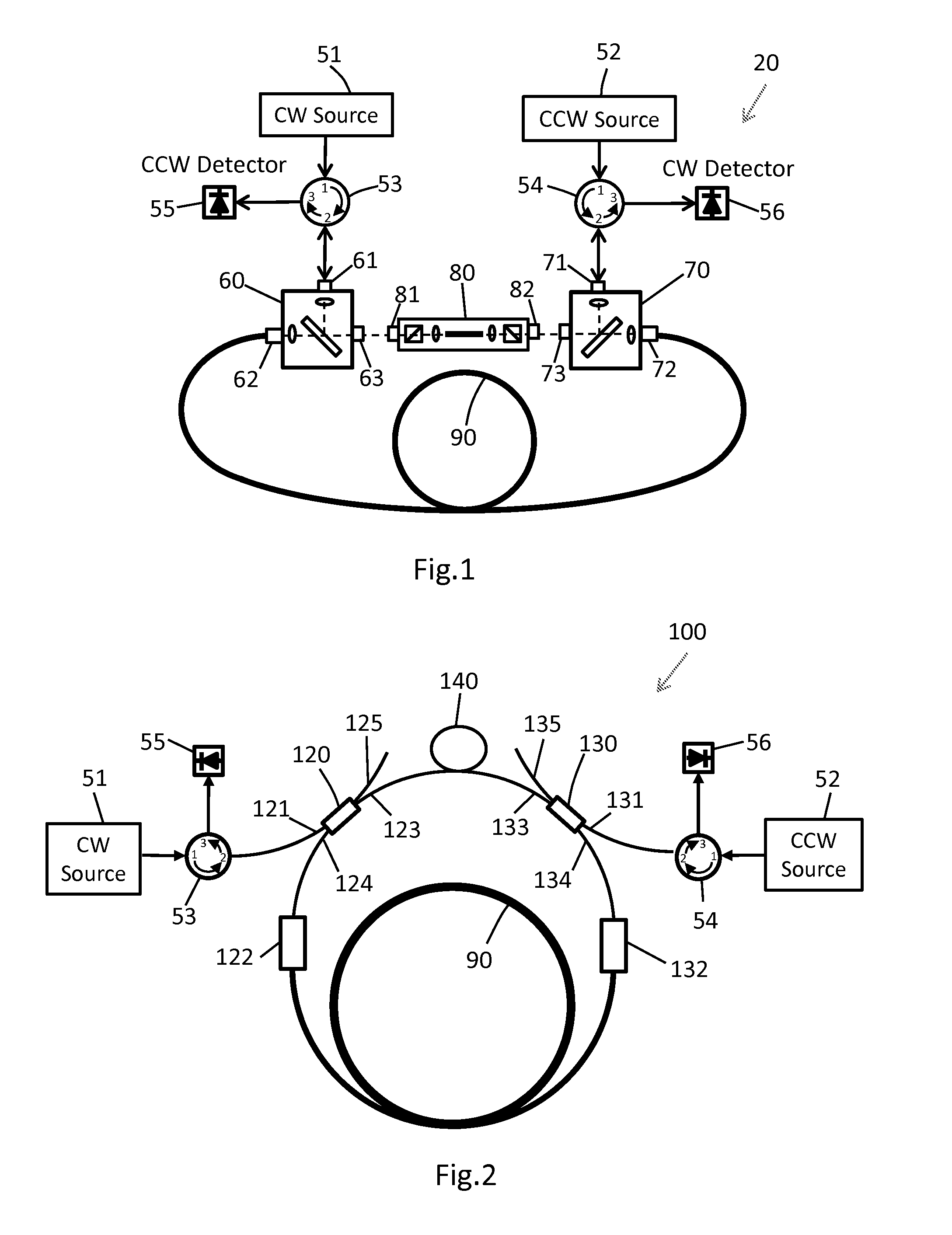

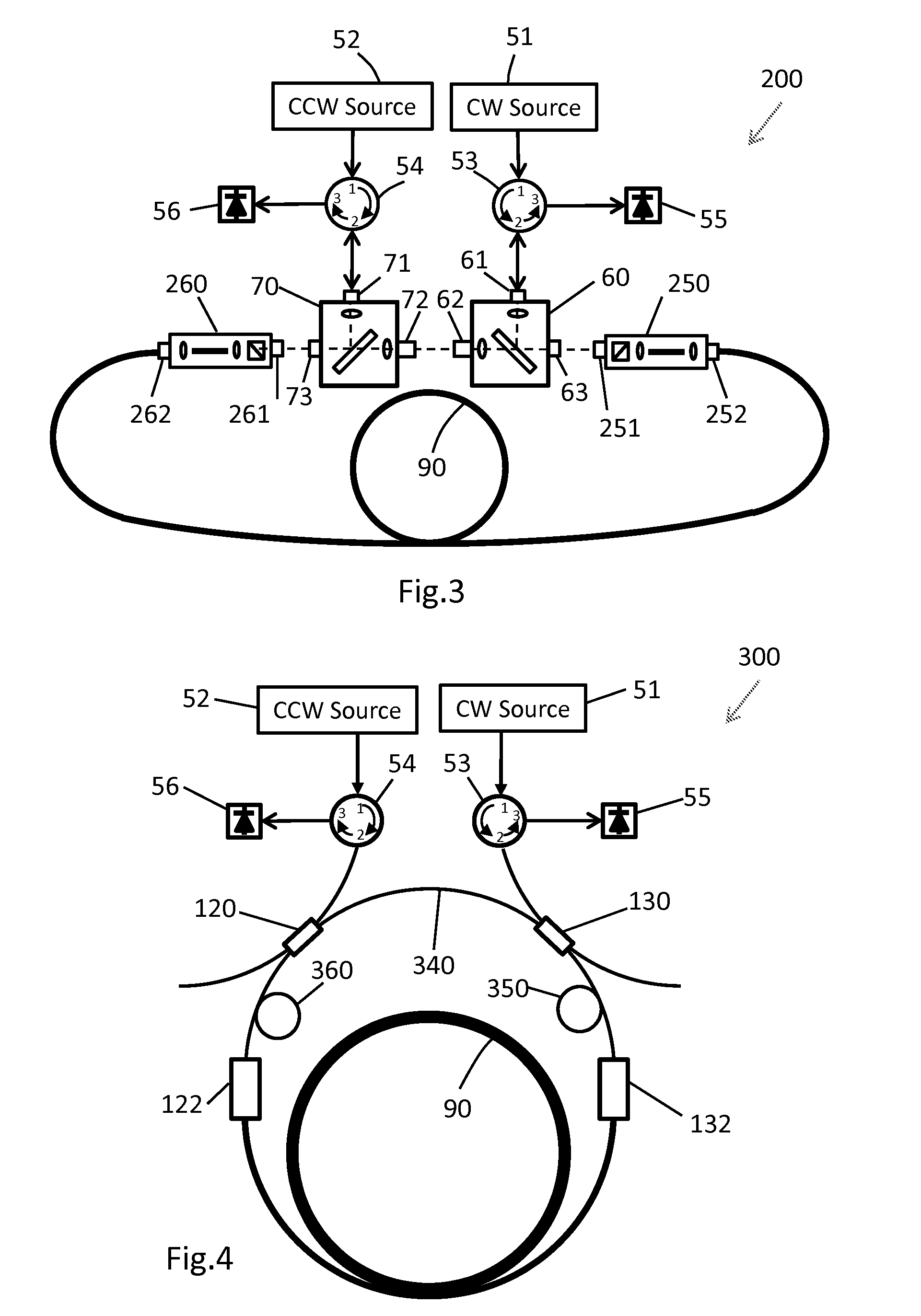

Resonator fiber optic gyroscope (RFOG) with reduced bias error from high order spatial modes

ActiveUS8098380B2Reduces/removes impactReduce impactSpeed measurement using gyroscopic effectsSagnac effect gyrometersGyroscopePhotodetector

Multiple resonator fiber optic gyroscope (RFOG) configurations comprising one or more mode filters inside the resonator are adopted to effectively suppress unwanted high order spatial modes which can be a significant source of gyro bias errors. The resonator comprises at least a loop fiber, either two or more in / out coupling elements, and connectors that link elements into a circulating loop. Directional elements may be used to separate output light from input light in some of the embodiments. In all embodiments, mode filters are placed in the resonator to guarantee that the light reaching the photodetector is filtered by at least one mode filter in the resonator at least once. The mode filters may contain both spatial mode filters (such as single mode fibers or waveguides) and polarization mode filters (such as polarizing elements) so that both spatial and polarization mode filtering can be implemented simultaneously.

Owner:HONEYWELL INT INC

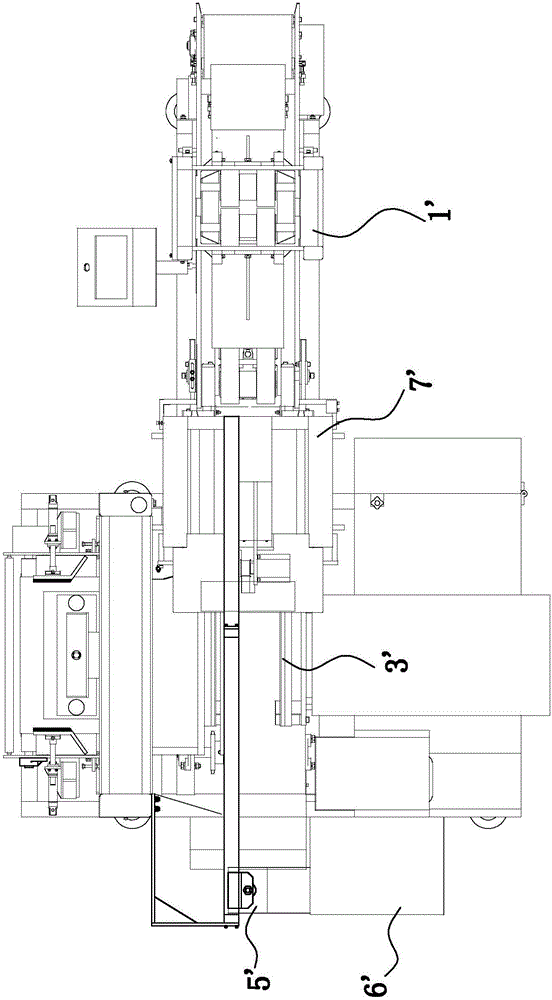

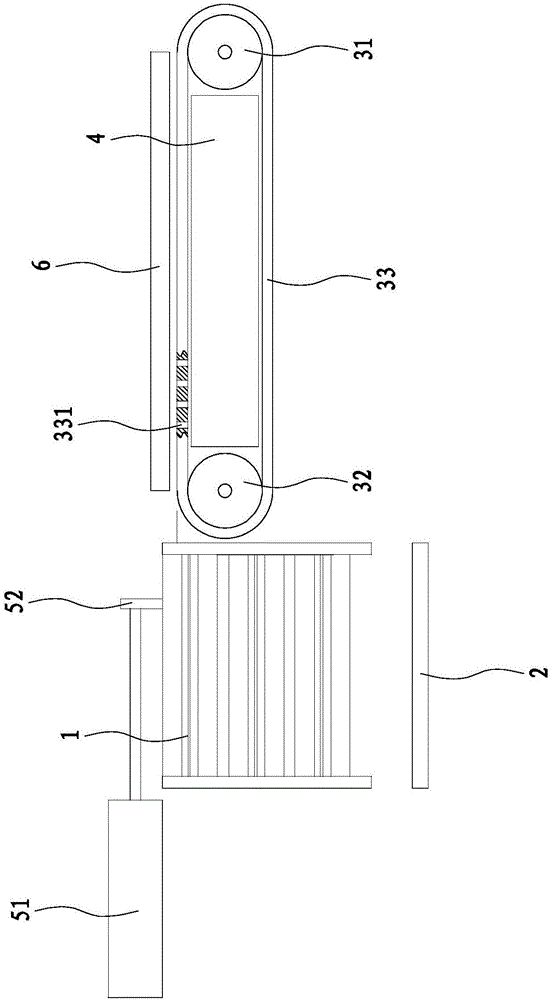

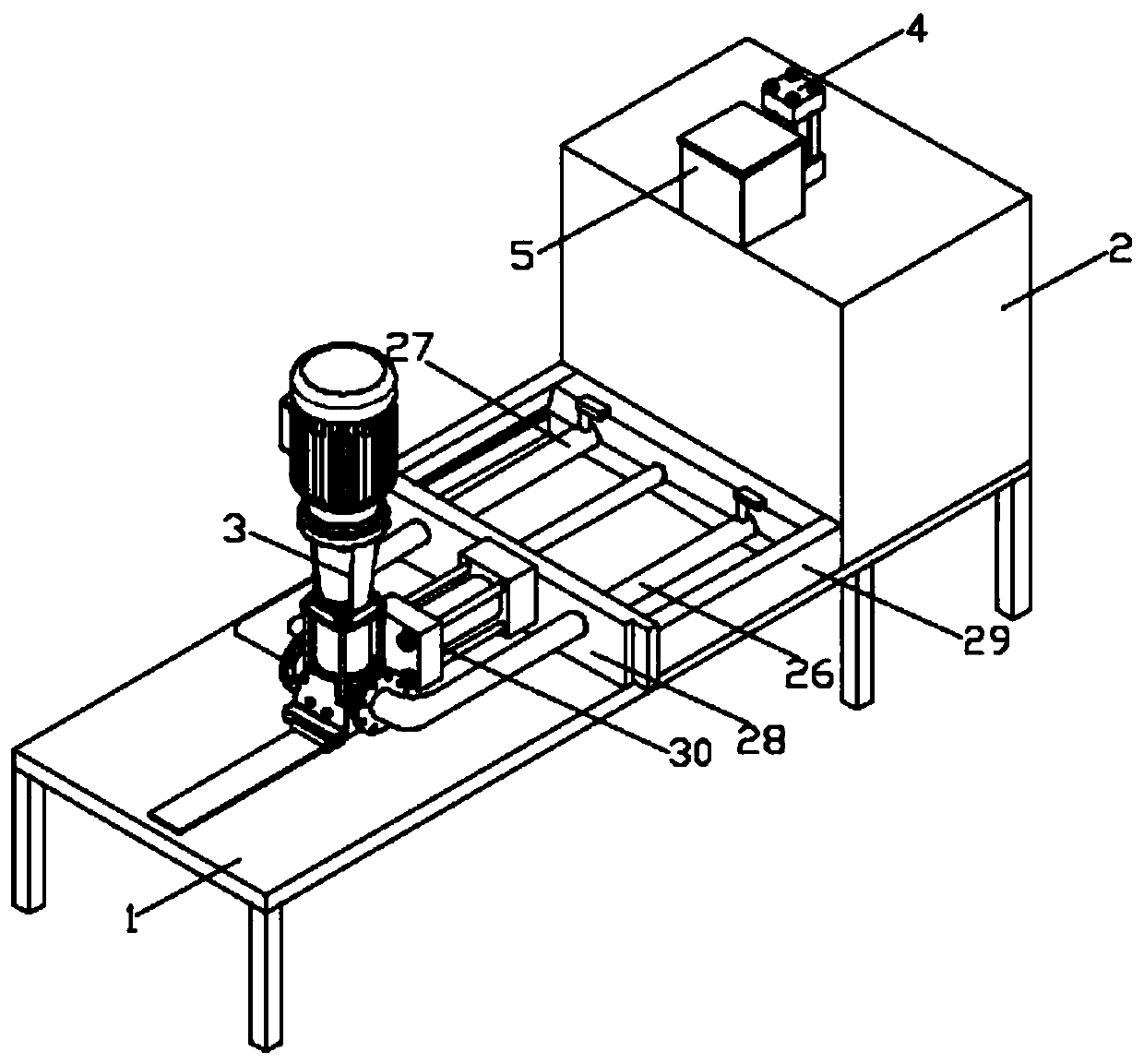

Machine for conducting mixed package on special-shaped cigarettes and conventional cigarettes

PendingCN106043806AStable spacingMeeting Packaging NeedsPackagingElectrical controlStructural engineering

The invention relates to a machine for conducting mixed package on special-shaped cigarettes and conventional cigarettes. The machine comprises a rack, an inputting and conveying device, an overturning device, an outputting station and an electric control system, wherein the inputting and conveying device, the overturning device, the outputting station and the electric control system are arranged on the rack. The outputting station is arranged below the overturning device. The inputting and conveying device comprises a driving wheel, a driven wheel, a conveying belt and a driving device, wherein the driving wheel and the driven wheel are rotatably arranged on the rack; the conveying belt wraps the driving wheel and the driven wheel; and the driving device drives the driving wheel. A plurality of through holes which are used for allowing air flow to pass through are formed in the conveying belt. A negative pressure adsorption chamber used for adsorbing articles is formed in the portion, within the wrapping range of the conveying belt, on the rack. The negative pressure adsorption chamber, the driving device and the overturning device are each connected with the electric control system.

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

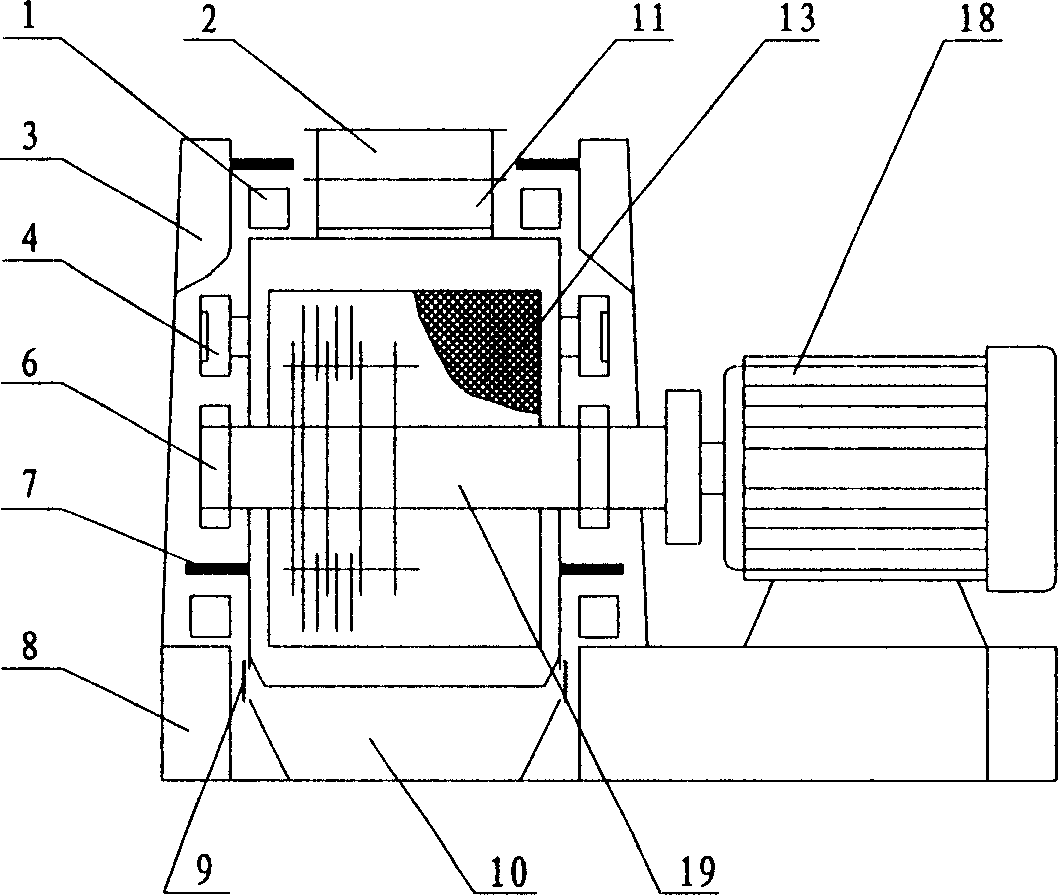

Crushing machine

InactiveCN1651145AReduce consumptionEliminate loosening problemsGrain treatmentsMetallic materialsEngineering

A pulverizer without pollution and noise is composed of mainshaft, rotor, hammer plates, feeding inlet, discharging outlet, sieving plate, base, supporting frame, vibrators, seated vibration damper between base and the assemblage consisting of toothed plate, sieving plate, gate and said inlet and outlet, and the pressing vibration damper between supporting frame and assemblage.

Owner:JIANGSU MUYANG GRP CO LTD

Retractable belt conveyor

ActiveCN110104384AThe conveying distance can be adjustedWide applicabilityConveyorsEngineeringBelt conveyor

The invention discloses a retractable belt conveyor, relates to the technical field of material conveying equipment, and aims to solve the technical problem that the conveying distance is not adjustable. According to the technical scheme, the retractable belt conveyor comprises a fixed frame and a movable frame, wherein a fixed supporting plate is arranged on the fixed frame, and a movable supporting plate is arranged on the movable frame; one end, away from the movable supporting plate, of the fixed supporting plate is rotatably connected with a driving roller; one end, away from the fixed supporting plate, of the movable supporting plate is rotatably connected with another driving roller; a driving part used for driving the driving roller connected with the fixed supporting plate to rotate is arranged on the fixed supporting plate; conveying belts wind around the outer sides of the two driving rollers; the fixed supporting plate and the movable supporting plate are able to be slidably adjusted in the horizontal direction, thus, the conveying distance can be adjusted by adjusting the distance between the two driving rollers, and the applicability of the retractable belt conveyor is wide.

Owner:南通贝源机械制造有限公司

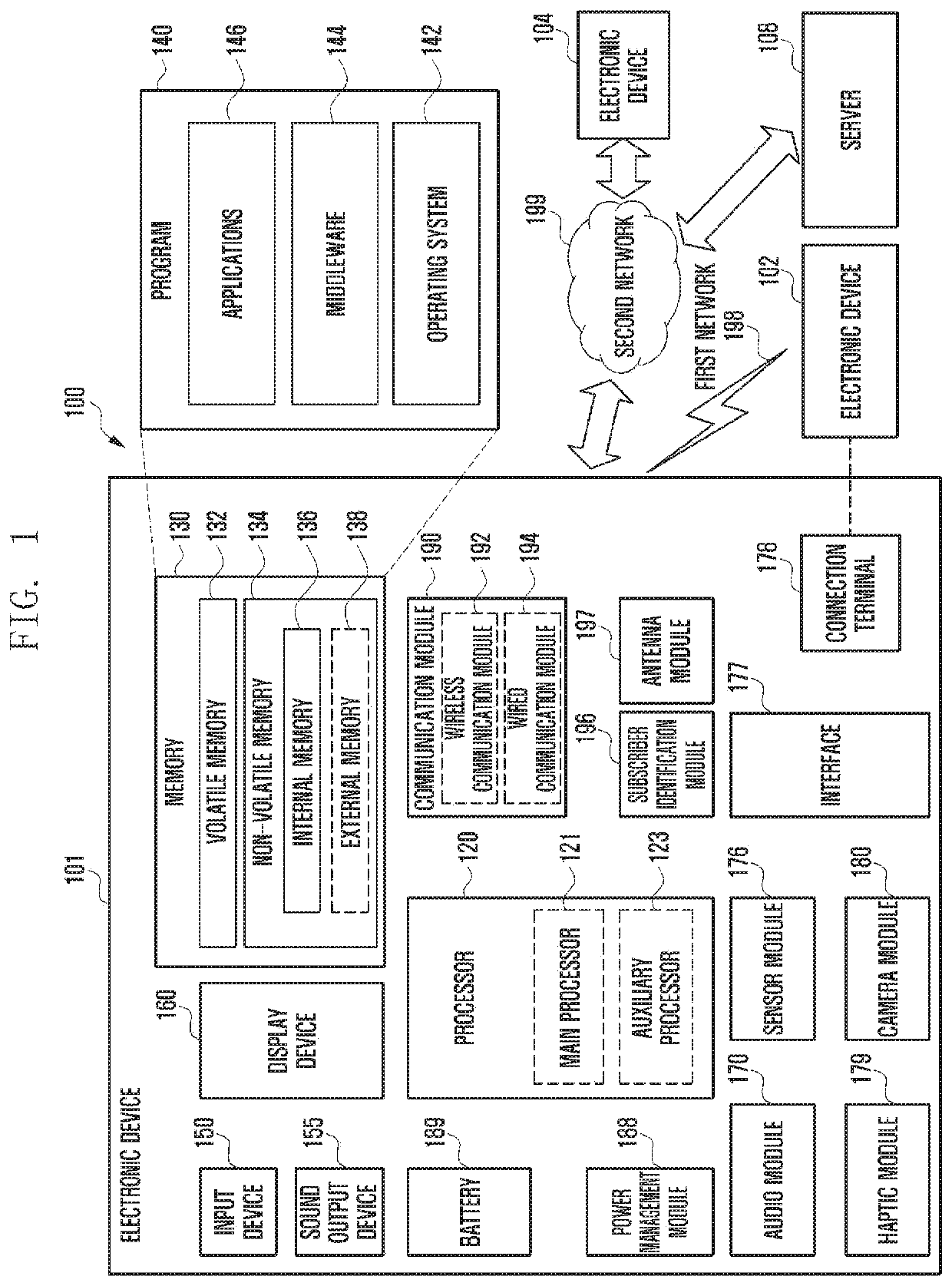

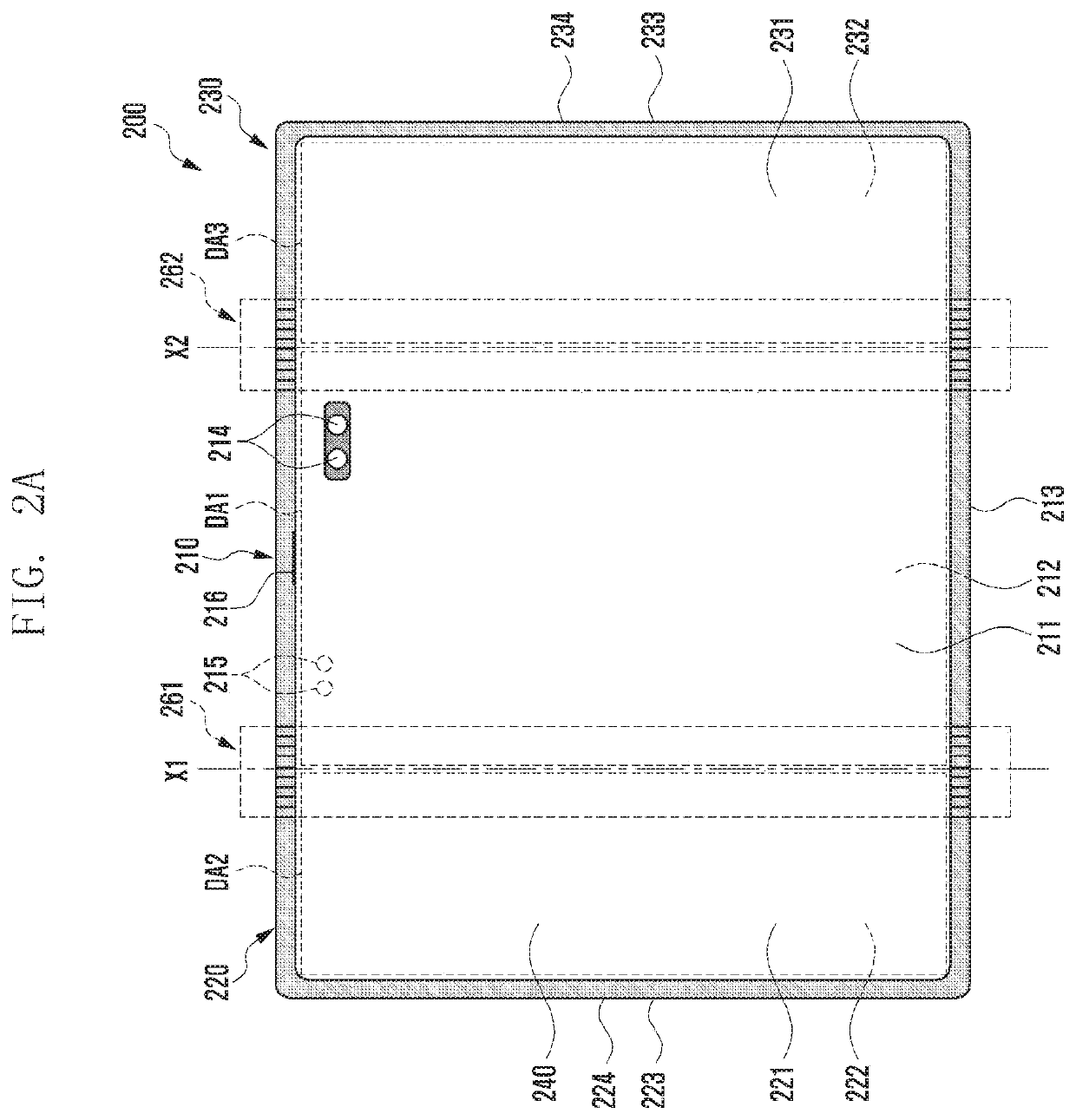

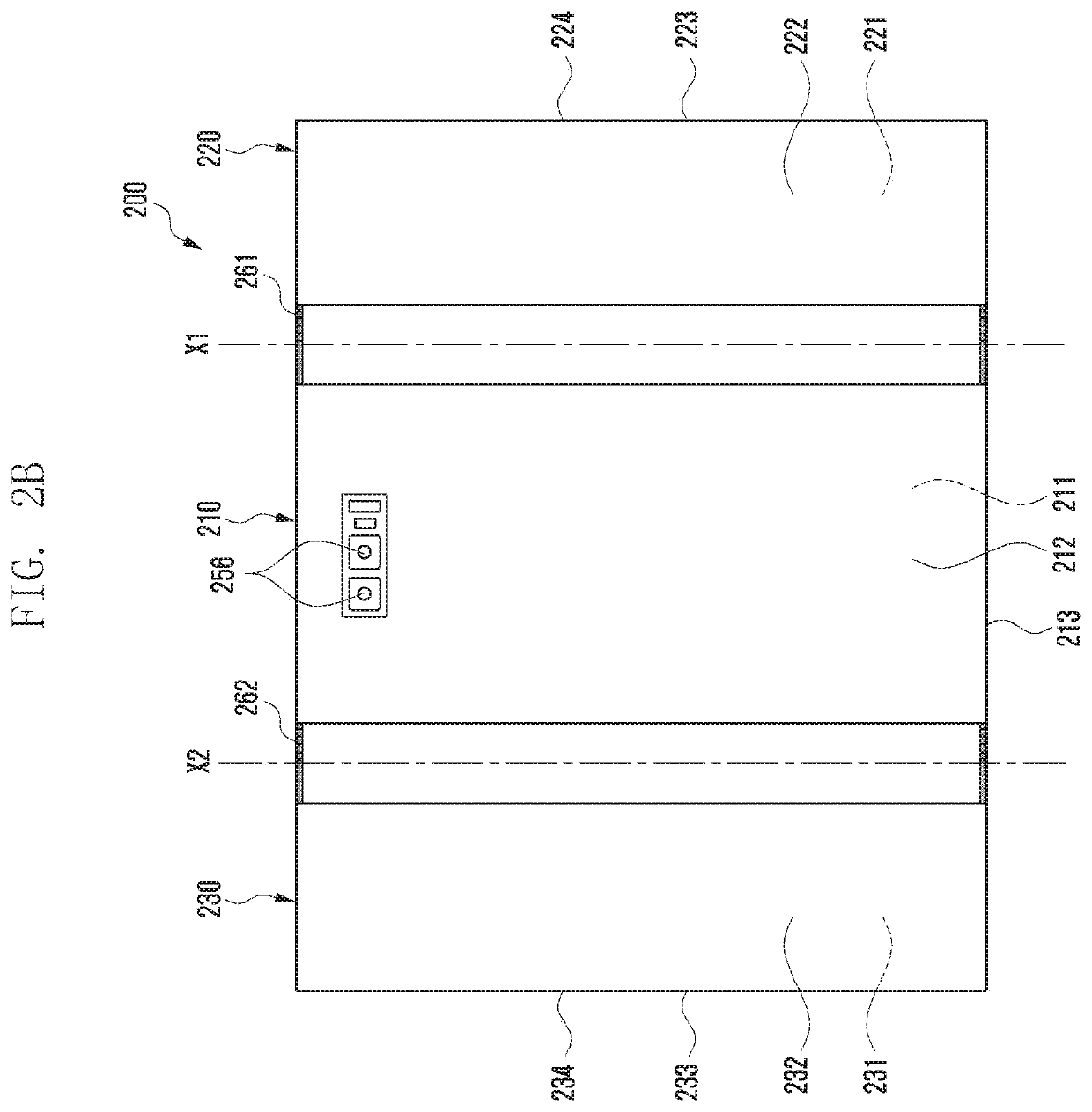

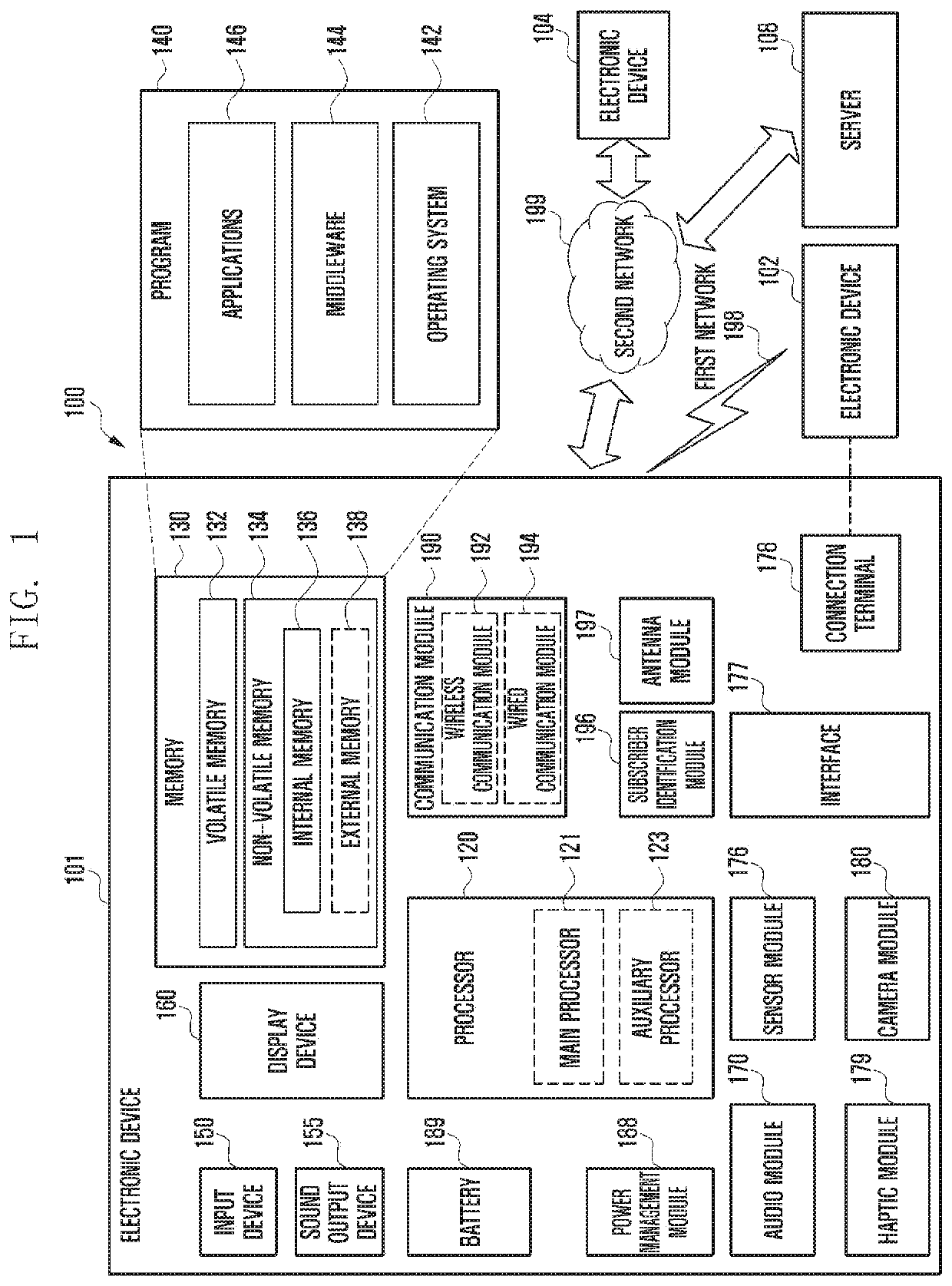

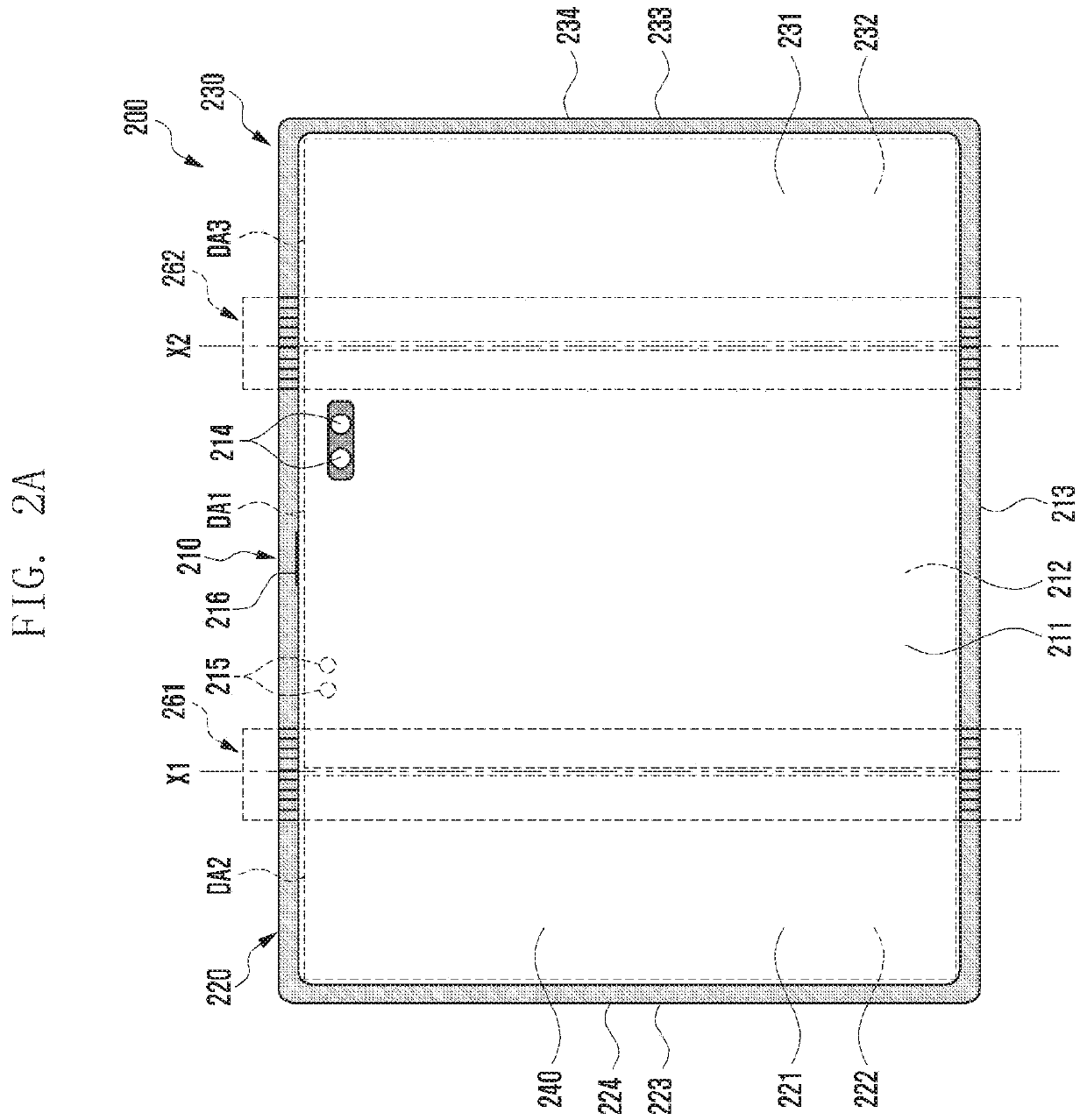

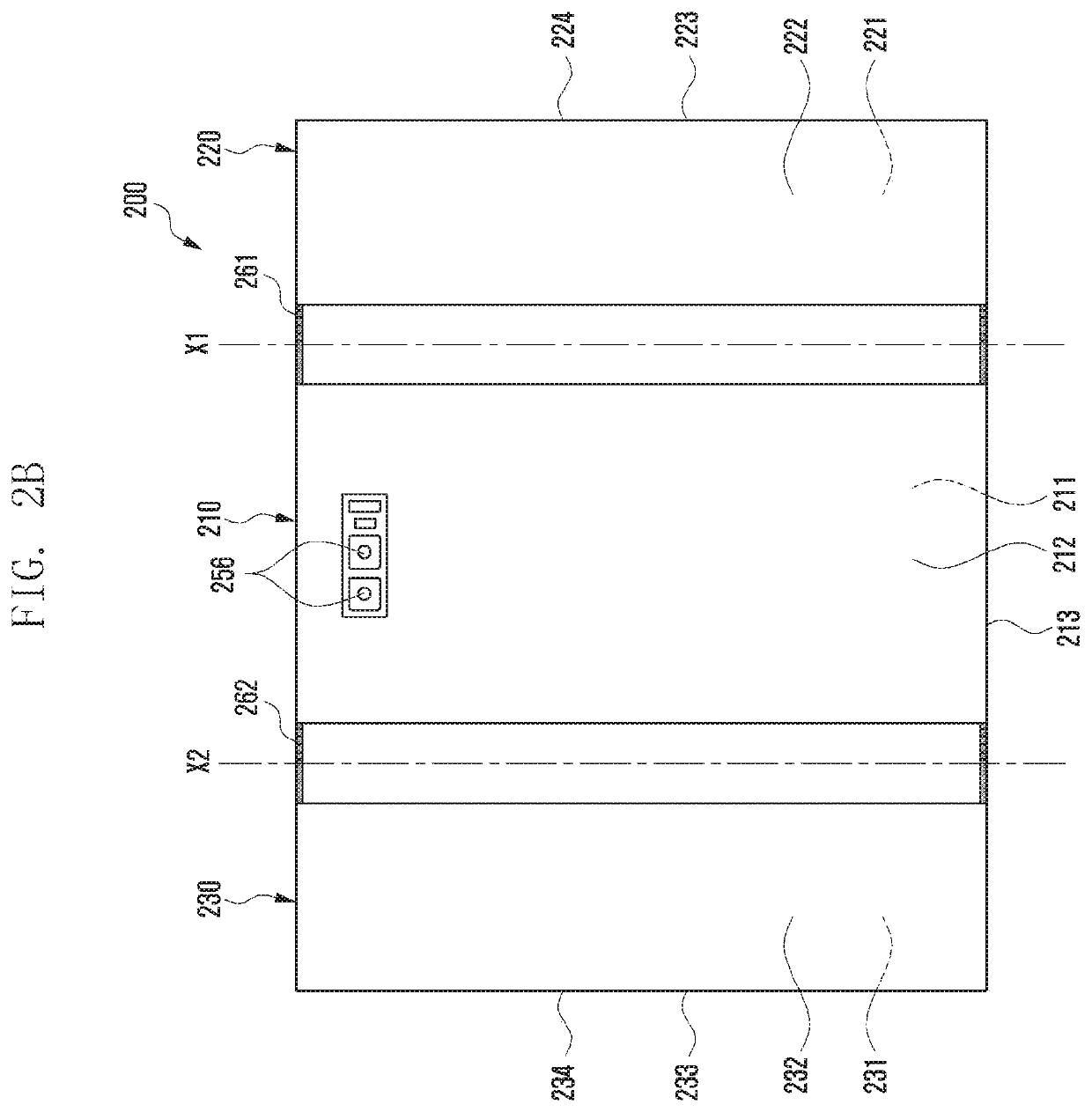

Foldable electronic device including elecronic pen

ActiveUS20210116962A1Improve portabilityPrevents for loss and unintentional movementCircuit arrangementsDetails for portable computersComputer hardwareEmbedded system

Owner:SAMSUNG ELECTRONICS CO LTD

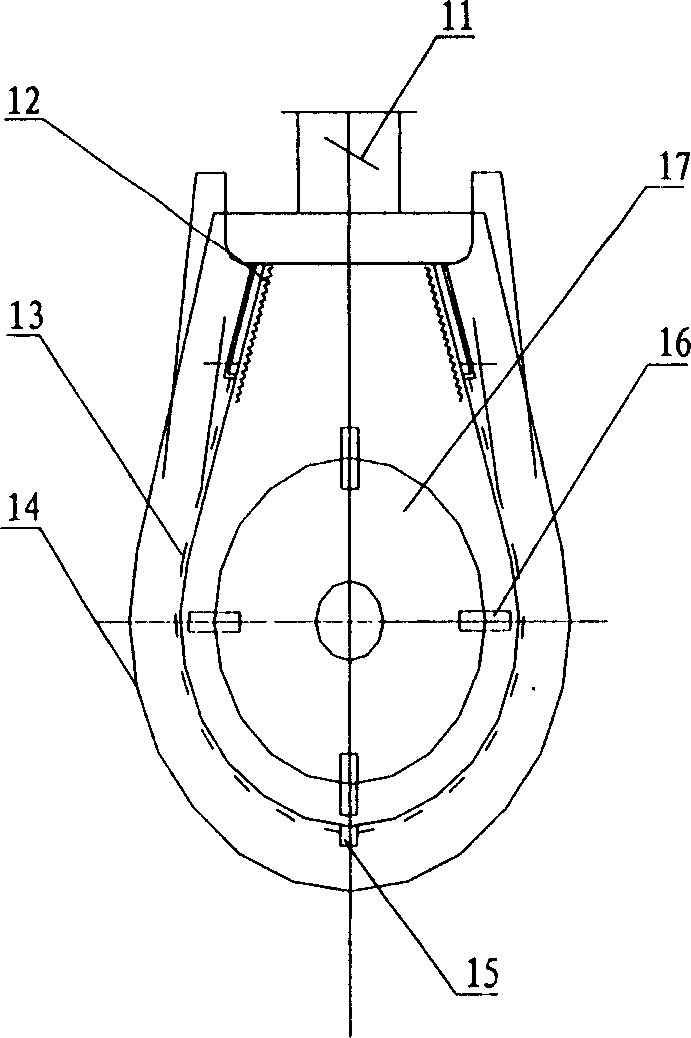

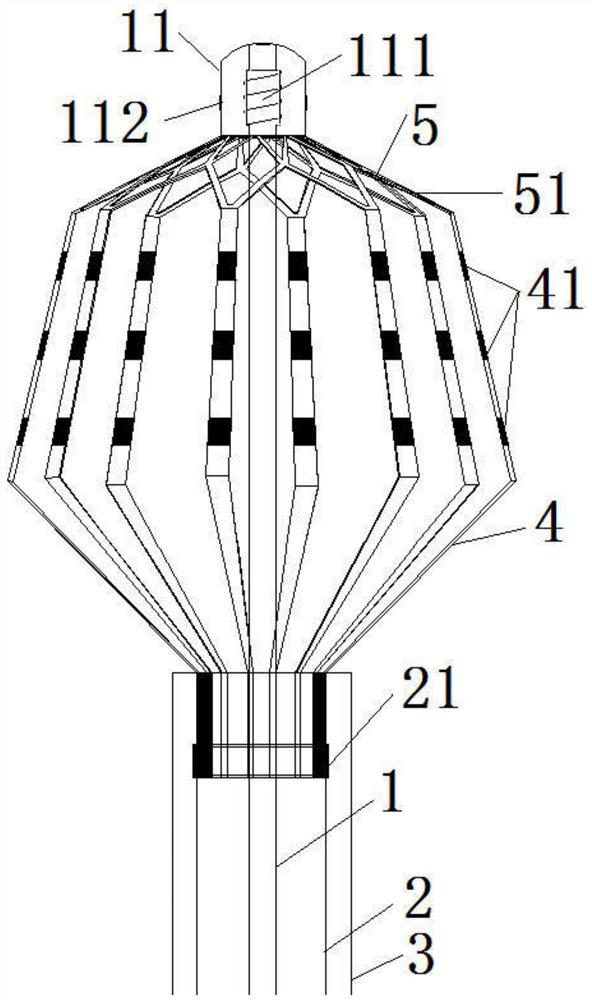

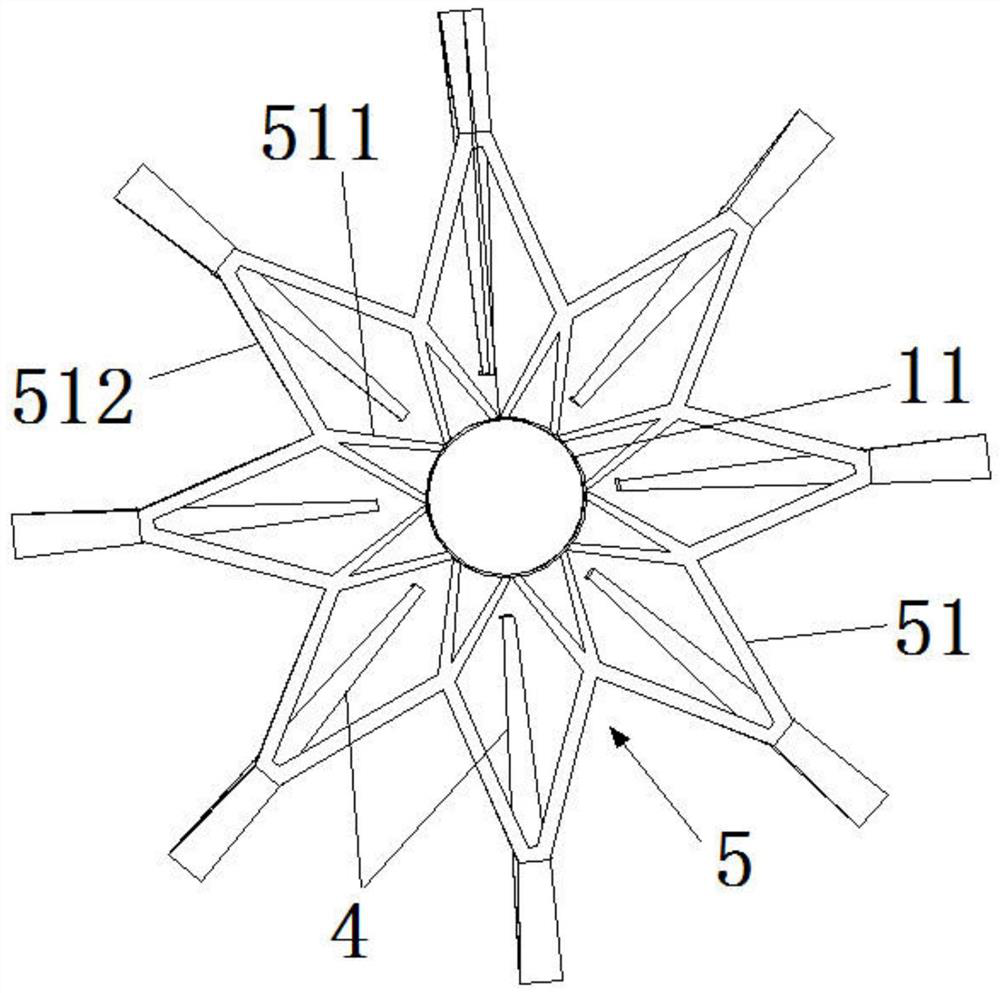

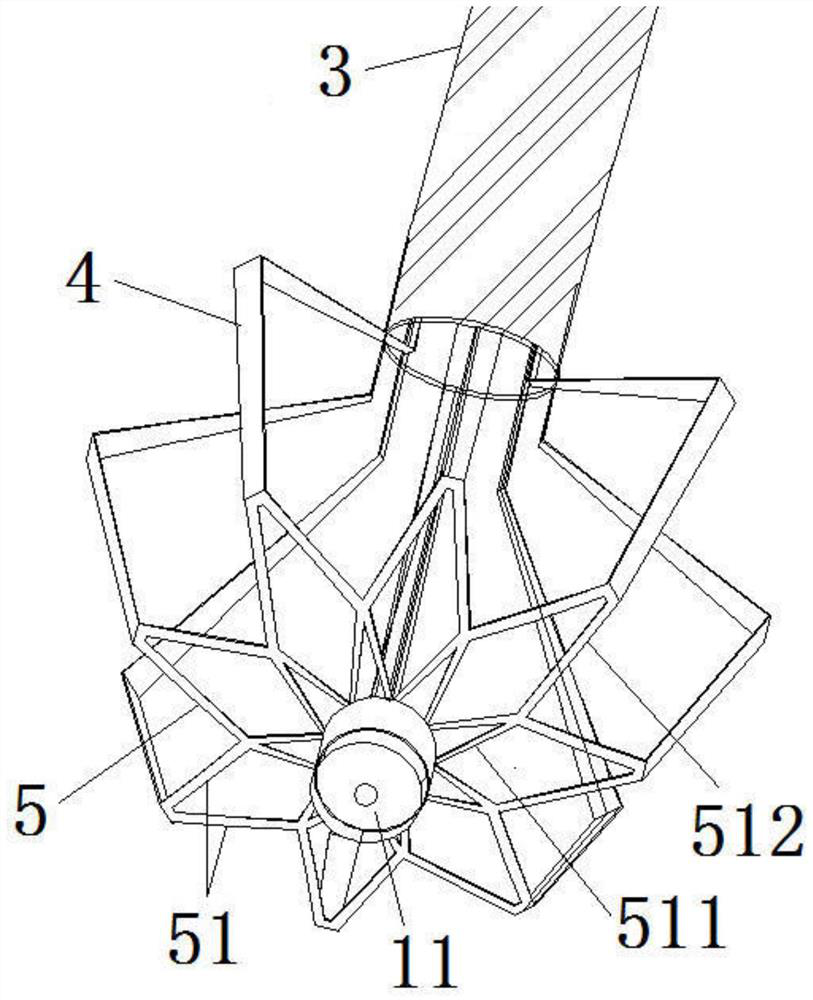

Ablation catheter

PendingCN113081241AImprove securityImprove stabilitySurgical instruments for heatingCatheterBiomedical engineering

The ablation catheter comprises an inner tube, a middle tube, an outer tube and an ablation device, the inner tube, the middle tube and the outer tube are arranged in a sleeved mode, the ablation device comprises at least two electrode arms, and each electrode arm is provided with at least one electrode; the near end of the electrode arm is fixedly connected with the middle tube, and an electric wire communicated with the electrode is located between the middle tube and the outer tube; a support structure is arranged at the far end of the electrode arm; the supporting structure comprises a plurality of supporting arms, the far end of each electrode arm is connected with at least two supporting arms, and the other end of each supporting arm is fixedly connected with the inner tube; an included angle exists between each supporting arm and the electrode arm connected with the supporting arm, and at least one supporting arm and other supporting arms are located on the different sides of the plane formed by the electrode arm and the inner pipe. According to the ablation catheter, the far ends of the electrode arms and the inner tube are connected through the supporting structures, the distance between the adjacent electrode arms is kept stable, and safety and stability are improved.

Owner:APT MEDICAL HUNAN INC

Foldable electronic device including electronic pen

ActiveUS11281254B2Prevents for loss and unintentional movementImprove portabilityCircuit arrangementsDetails for portable computersComputer hardwareEmbedded system

Owner:SAMSUNG ELECTRONICS CO LTD

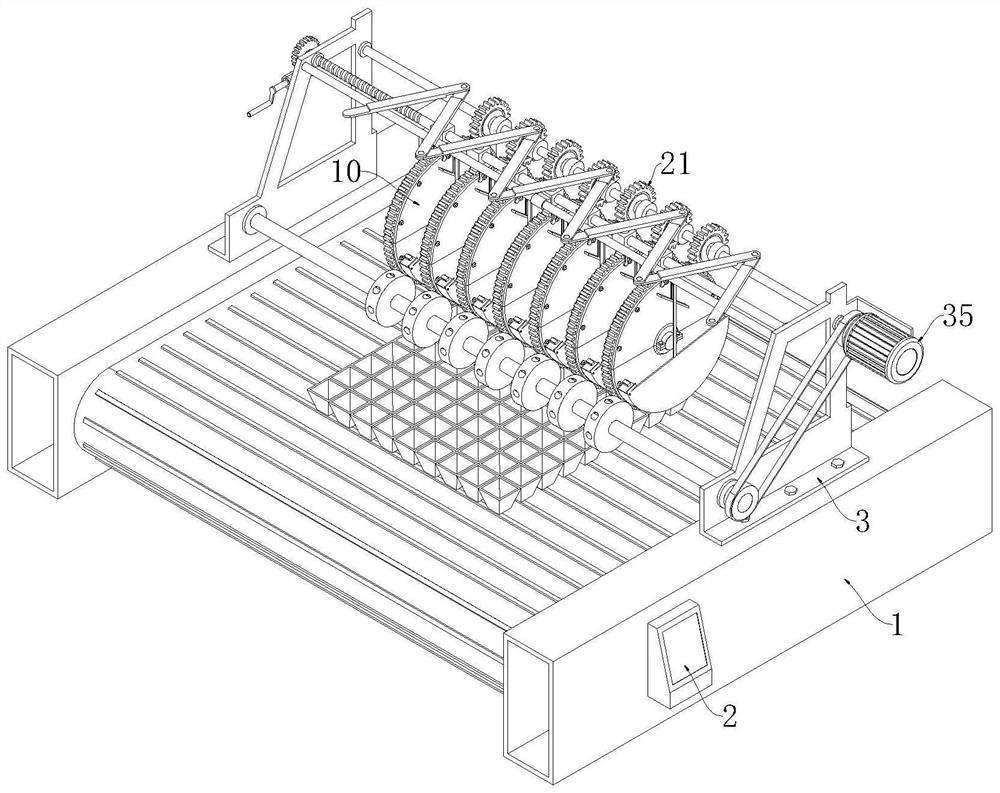

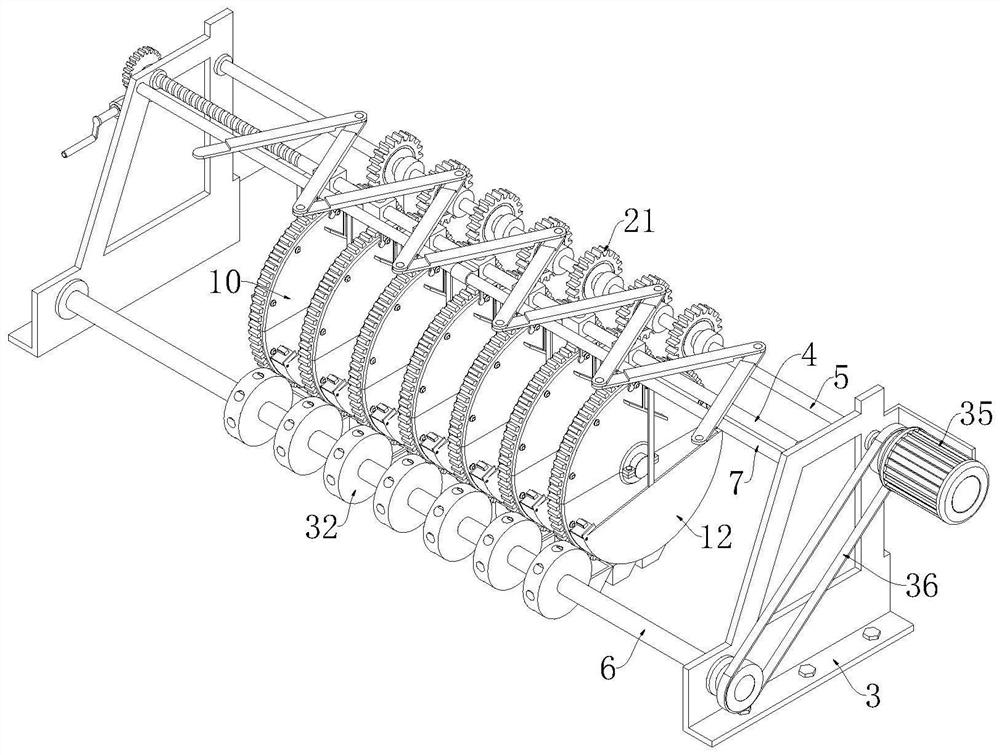

Intelligent agricultural seeding machine

InactiveCN114342607AAvoid easy cloggingNot easy to cause blockageSeed depositing seeder partsSingle grain seedersAgricultural scienceAgricultural engineering

The invention discloses an intelligent agricultural seeding machine which comprises a conveying device and a PLC, the top of the conveying device is fixedly connected with two racks, a plurality of seeding parts distributed in the axial direction are arranged on a guide shaft, and an adjusting part for adjusting the distance between every two adjacent seeding parts is arranged between the two racks. According to the device, the driving piece drives the rotating disc assembly to rotate, the suction head sucks seeds and moves the seeds to pass through the first check block and the second check block, the seeds move back and forth on the suction head under the blocking effect of the two check blocks, therefore, redundant seeds are separated from the suction head due to extrusion, the two check blocks extrude the seeds from the upper direction and the lower direction respectively, and the seeds are separated from the suction head. And the suction head covers half of the area of the air inlet end of the suction head, so that the device can effectively remove the seeds which are adsorbed on the suction head and have smaller particle sizes, the effects of saving the seeds and reducing the cost are achieved, and the normal development and growth of the seeds are facilitated.

Owner:王少平 +2

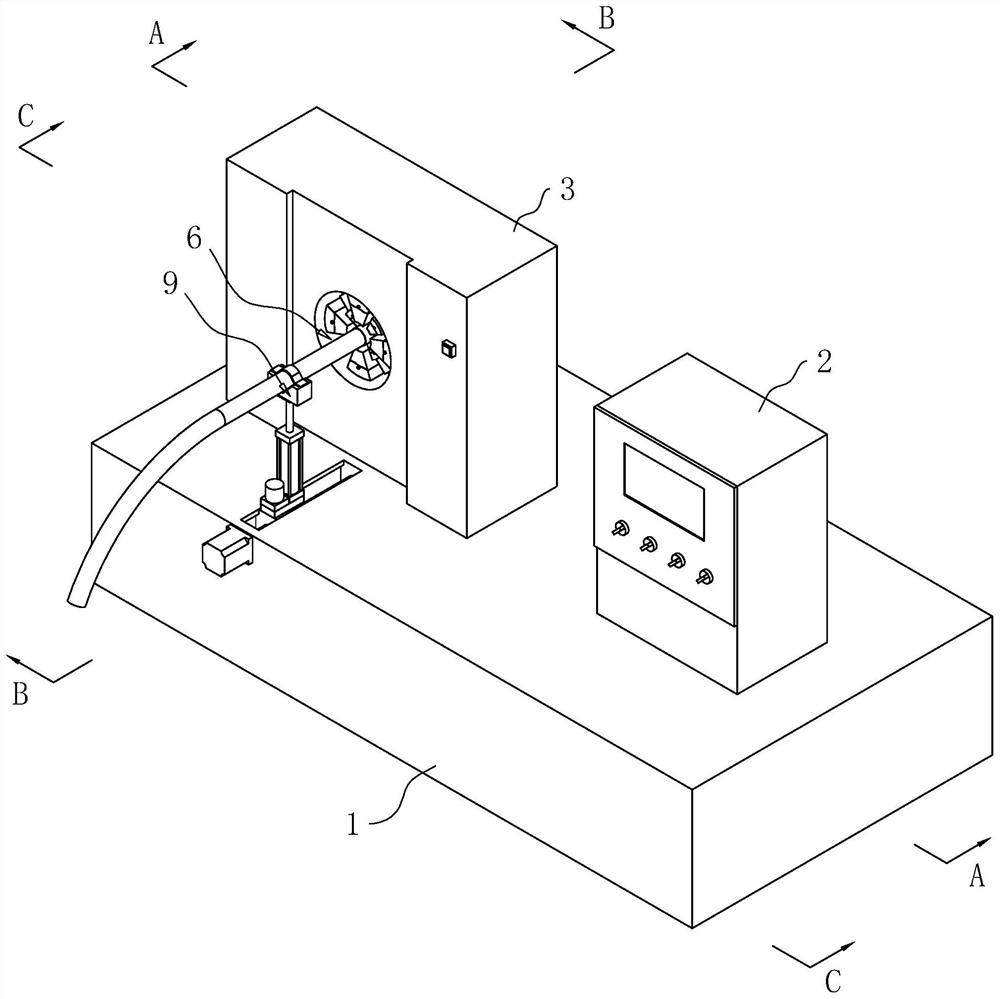

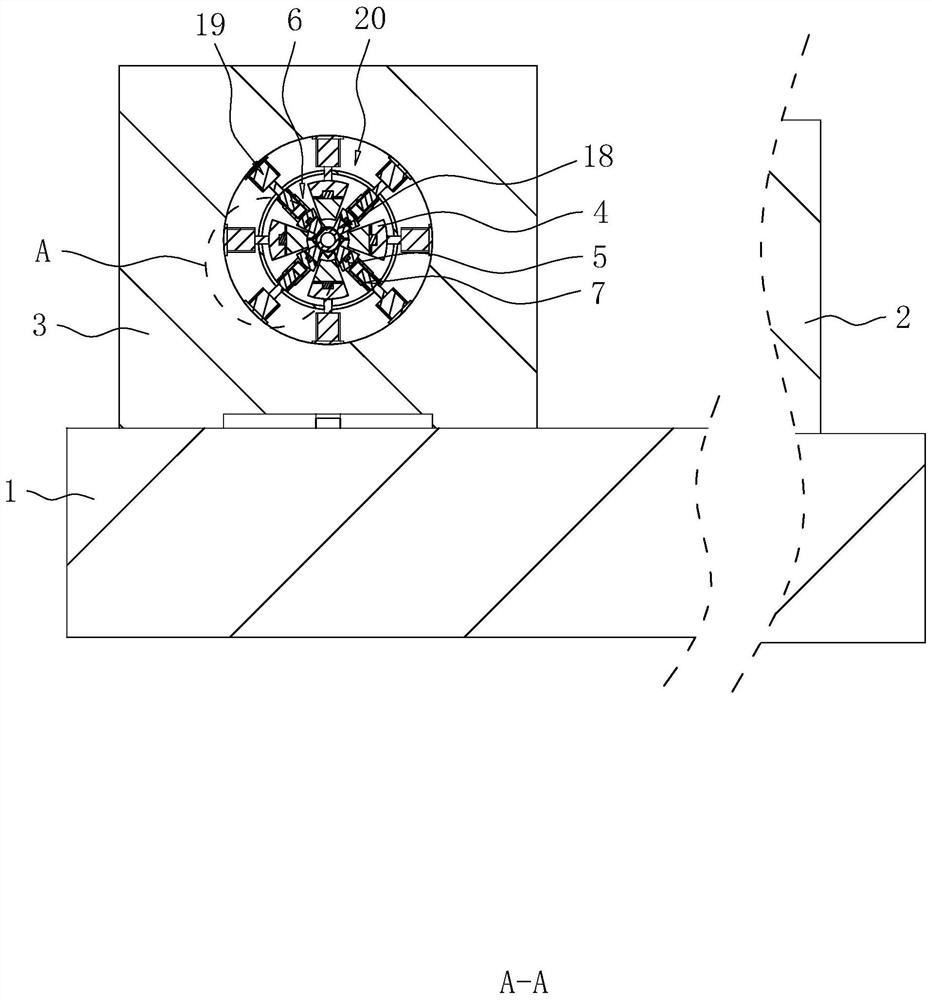

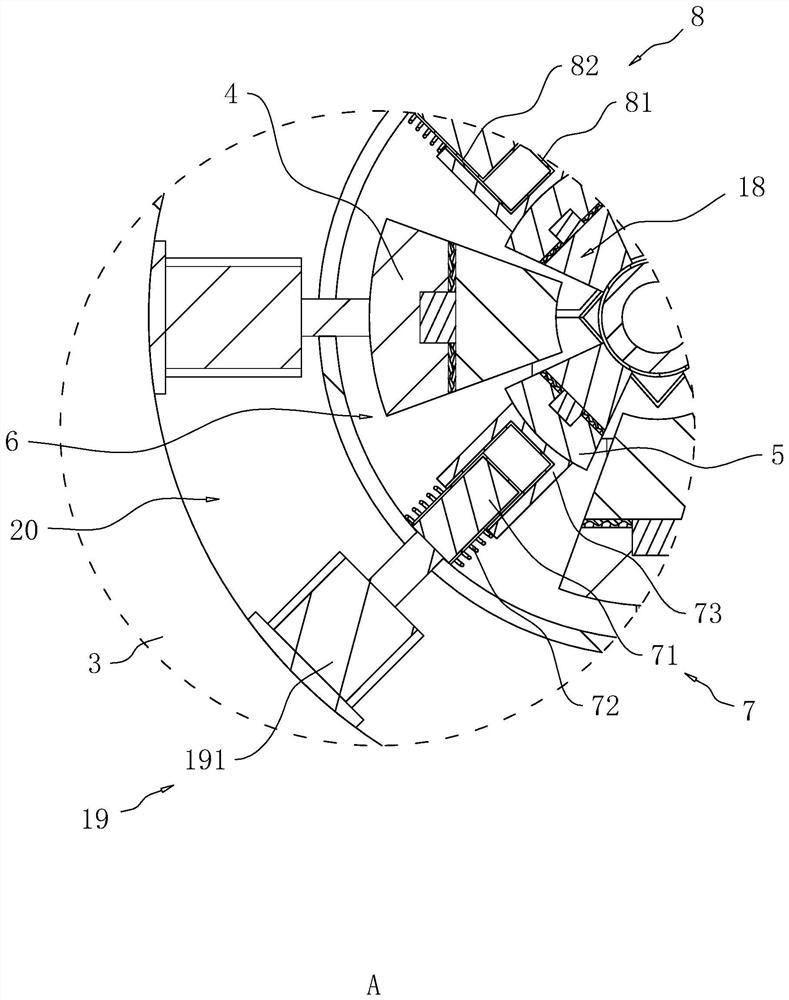

Hydraulic system hose withhold machine

The invention provides a hydraulic system hose withhold machine and relates to the field of withhold machines. The hydraulic system hose withhold machine comprises a working table, and further comprises a pipe clamping base mounted on the working table, a plurality of first arc blocks arrayed in the circumferential direction of a hose and second arc blocks located between the adjacent first arc blocks. The sidewall of the pipe clamping base is provided with clamping grooves for accommodating the first arc blocks and the second arc blocks. Elastic guide assemblies used for driving the second arc blocks to move in the radial direction of the clamping grooves are arranged on the groove walls of the clamping grooves. A locating and retaining assembly used for bearing the hose is arranged on the working table. The outer arc walls of the first arc blocks and the second arc blocks are all provided with abutting assemblies abutting against the outer wall of a joint. The pipe clamping base is internally provided with a cavity communicating with the clamping grooves. A driving assembly used for driving the first arc blocks and the second arc blocks to slide in the radial direction of the sliding grooves is arranged in the cavity. The hydraulic system hose withhold machine has the advantages of preventing extrusion deformation and poor airtightness caused by looseness between the joint and the rubber hose and improving the withhold precision and efficiency.

Owner:南京鑫姆迪克液压技术有限公司

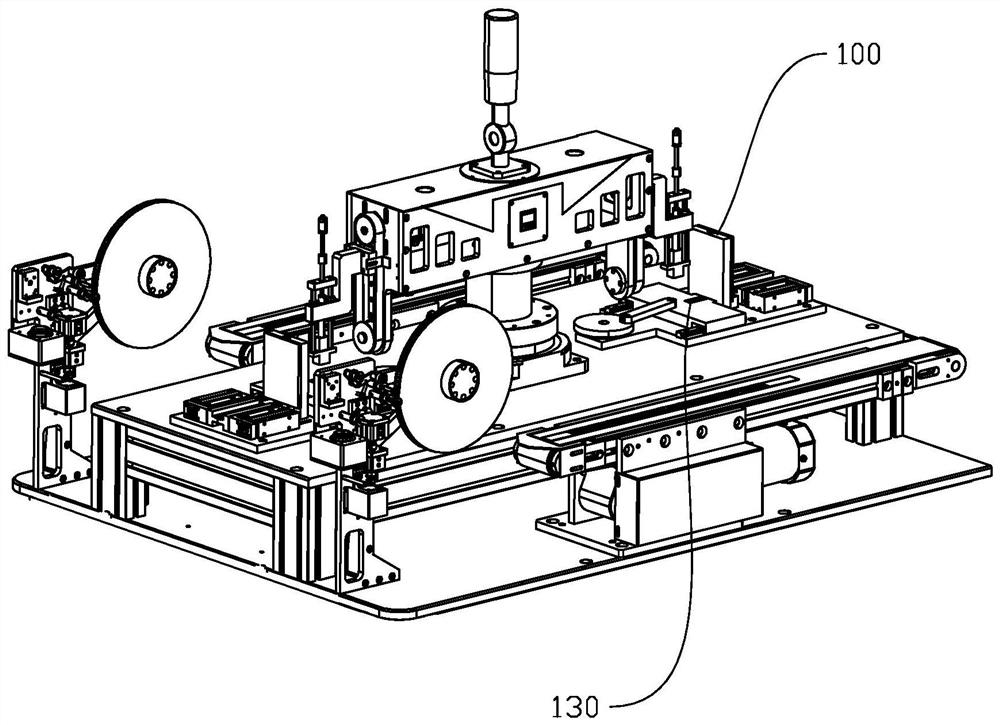

Tiling device and automatic transfer arrangement machine

PendingCN113264220AReduce the frequency of manual feedingImprove efficiencyPackagingDe-stacking articlesStructural engineeringMechanical engineering

The invention discloses a tiling device and discloses an automatic transfer arrangement machine with the tiling device. The tiling device comprises a feeding mechanism and a tiling mechanism, the feeding mechanism comprises a material bin and a material pushing part located on one side of the material bin, the material bin accommodates vertically stacked magnetic sheets, and the material pushing part is used for pushing the magnetic sheets to the other side of the material bin; and the tiling mechanism is located on the side, away from the material pushing part, of the material bin and comprises a material carrying table and a power assembly driving the material carrying table to be away from and close to the material bin, and the material carrying table is used for supporting the magnetic sheets from the material bin. According to the tiling device, the magnetic sheets can be automatically tiled and arranged, and the magnetic sheets can be tiled more orderly.

Owner:肇庆高峰机械科技有限公司

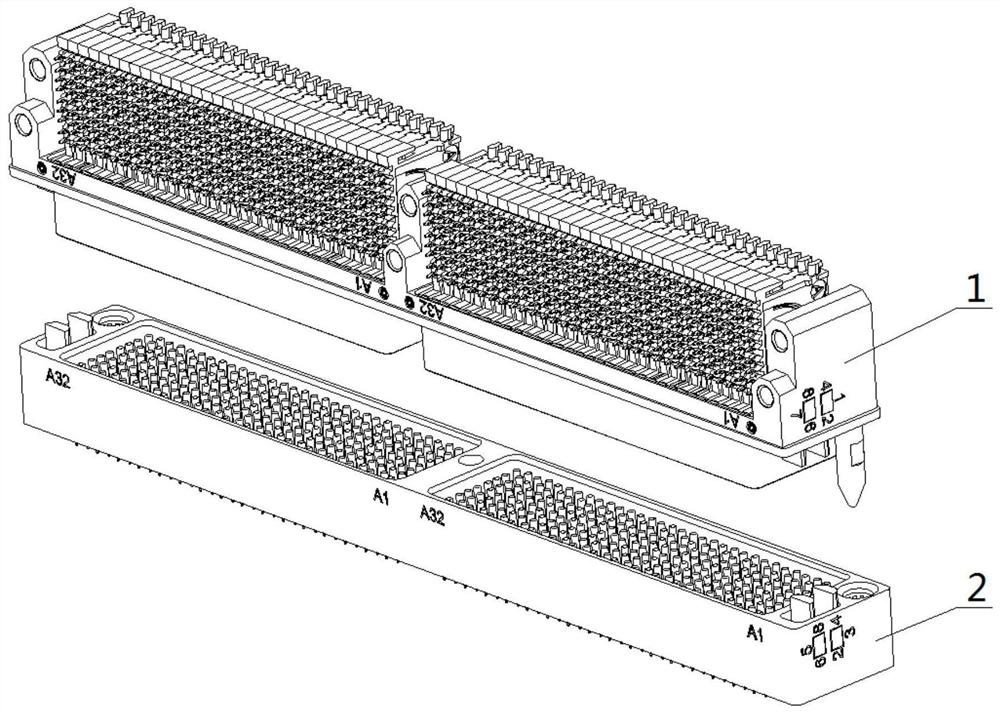

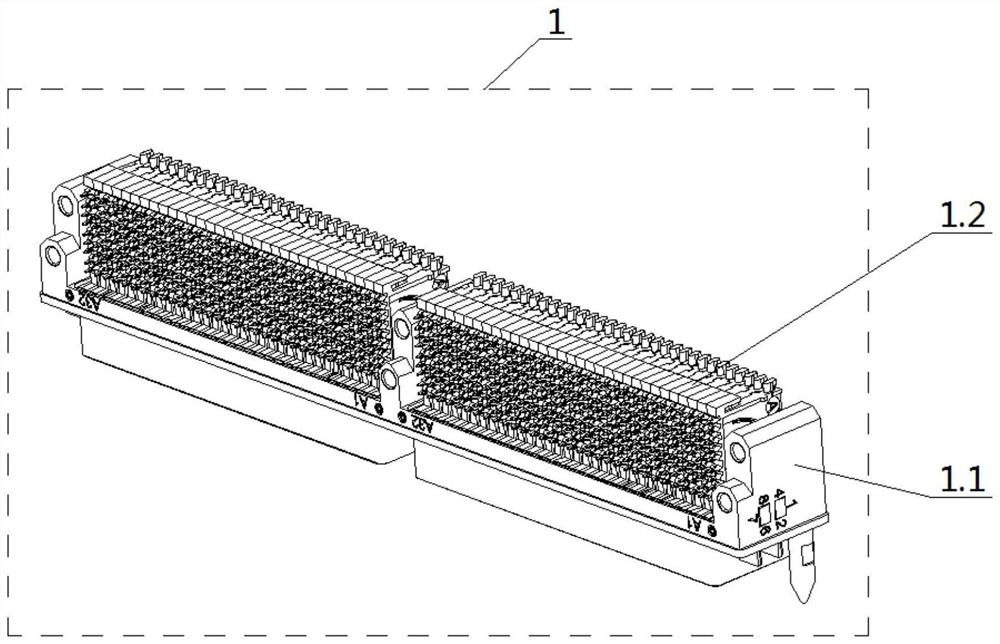

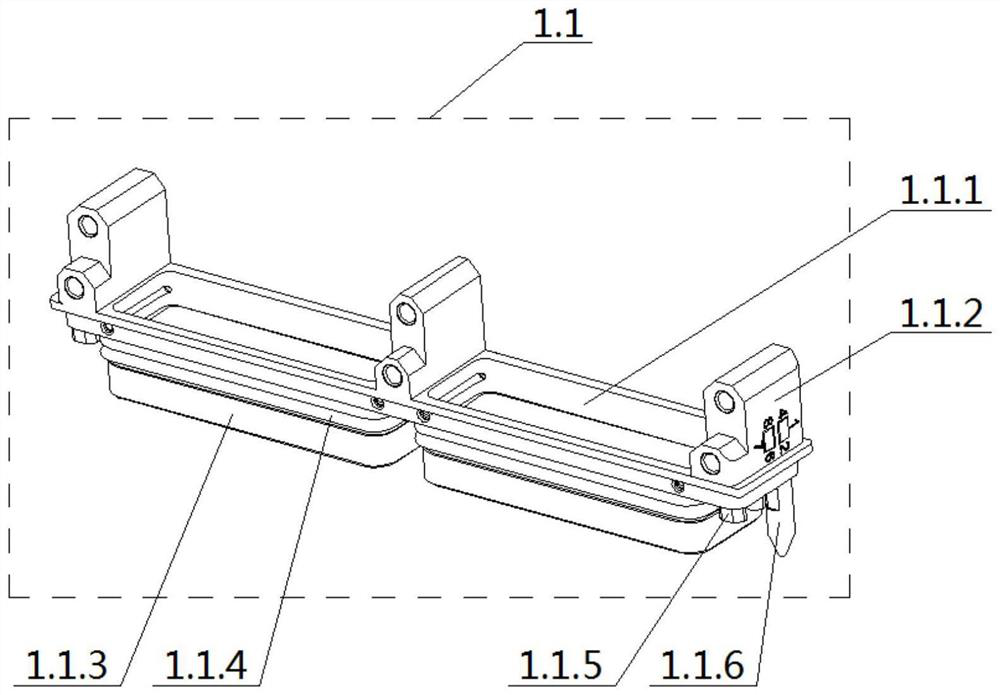

Reinforced ultrahigh-speed high-density high-reliability connector

ActiveCN111969351AImprove the problem of low impedanceImprove crosstalkSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

The invention provides a reinforced ultrahigh-speed high-density high-reliability connector, which comprises a plug and a socket, wherein the plug comprises a plurality of A-type pin groups and B-typepin groups which are formed by punching, the microstrip line sections of the A-type pin groups and the B-type pin groups are rectangular, the A-type pin groups and the B-type pin groups are providedwith a plurality of rounding pins A and rounding pins B, the socket comprises a plug sleeve, plug sleeve holes are formed in the uppermost end of the plug sleeve, an elastic contact body is arranged in the plug sleeve hole, and when the plug and the socket are plugged in a matched manner, the rounding pin A and the rounding pin B are plugged in the plug sleeve holes of the plug sleeve and are in reliable contact with the plug sleeve through the elastic contact bodies. According to the reinforced ultrahigh-speed high-density high-reliability connector of the invention, the above innovative structural design is adopted, and the connector has the advantages of being high in assembly efficiency, low in cost, stable in impedance characteristic, good in differential signal transmission coupling,small in time delay difference, small in signal transmission reflection, small in differential signal crosstalk and reliable in contact between the contact pin and the contact pin sleeve, so that thelow-cost, ultra-high-speed, high-density and high-reliability connector can be achieved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

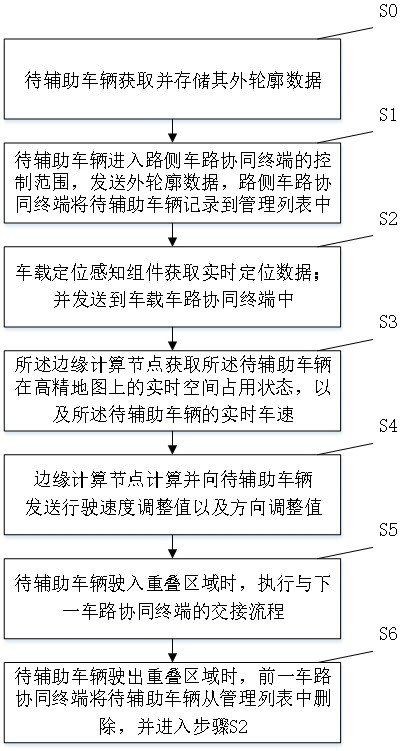

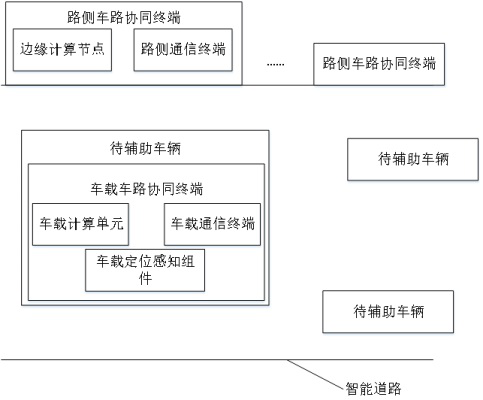

Vehicle-road cooperative auxiliary driving system and method

ActiveCN114399906APrecise Assist ControlFully grasp the situation of occupied road spaceRoad vehicles traffic controlExternal condition input parametersIn vehicleVehicle driving

The invention relates to the field of vehicle-road cooperation, in particular to a vehicle-road cooperation auxiliary driving system and method. According to the invention, the precise positioning technology and the high-precision map technology are comprehensively applied, the positioning data monitored by the vehicle-mounted positioning sensing assembly is taken as the reference, and the outer contour data of the vehicle and the precise high-precision map are superposed, so that the vehicle-road cooperation system can rapidly, accurately and comprehensively master the condition of the road space occupied by the vehicle, and the vehicle-road cooperation system can be used for the vehicle-road cooperation system. Therefore, high-precision auxiliary control of the vehicle-road cooperation system on road vehicle driving is achieved, and traffic safety and road passing efficiency are improved. According to the technical scheme of the invention, the roadside vehicle-road cooperation terminal does not need to be provided with vehicle detection and positioning equipment, and the to-be-assisted vehicle does not need to be provided with equipment such as a distance measuring sensor, so that the cost is greatly reduced.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Multi-maneuvering-mode mobile intelligent robot

The invention discloses a multi-maneuvering-mode mobile intelligent robot and relates to the technical field of intelligent robots, in particular to a multi-maneuvering-mode mobile intelligent robot.The multi-maneuvering-mode mobile intelligent robot comprises a buffering base and a stable supporting structure, wherein a hydraulic lifting structure is arranged below the buffering base; and the stable supporting structure comprises a supporting platform, a damping buffering column, a damping spring and a piston column, the damping spring is arranged in the lower end of the damping buffering column, and a power transmission structure is arranged below the stable supporting structure. According to the intelligent robot capable of being moved stably and with a carrying function, the structureis increased, the usability of the whole device is improved, the improved equipment has good buffering and damping capacity in the using process, the resonance phenomenon occurring in the moving process of the equipment is reduced as much as possible, the stability degree of carried articles is improved, the display of the equipment and the articles due to unstable gravity center can be avoided,and the use requirements of people can be effectively met.

Owner:DONGGUAN UNIV OF TECH

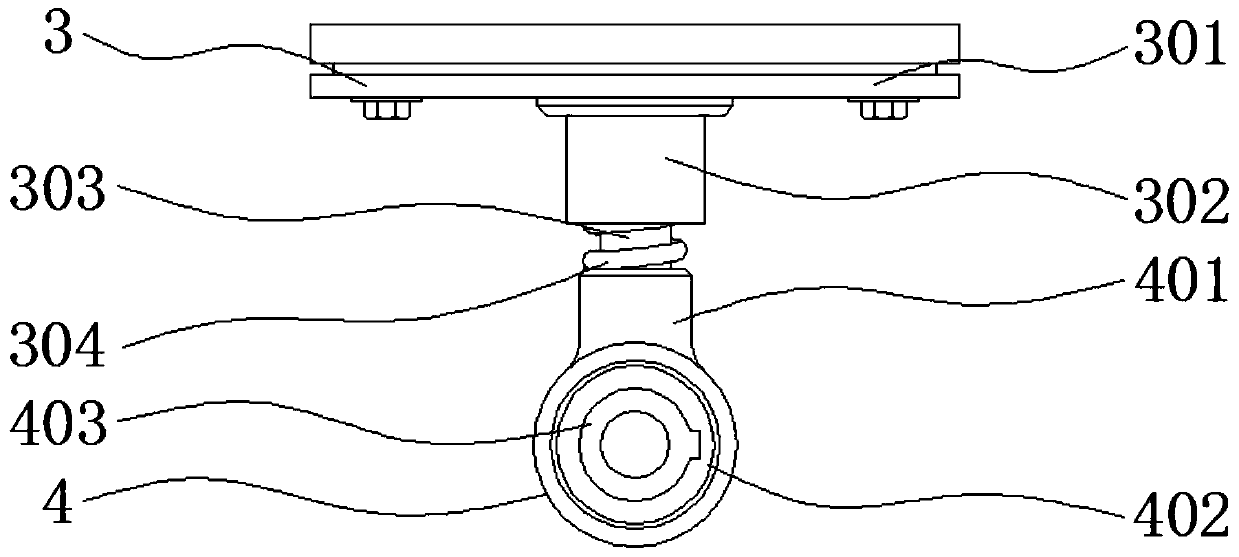

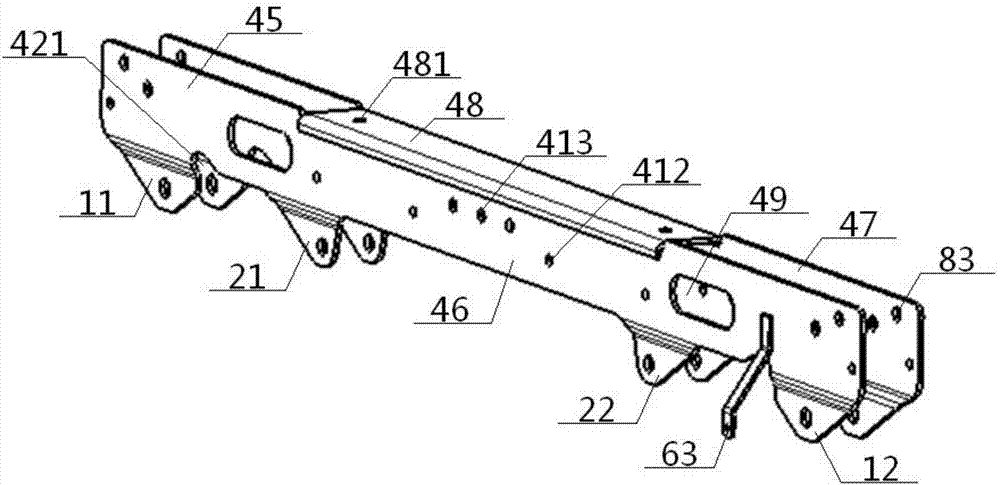

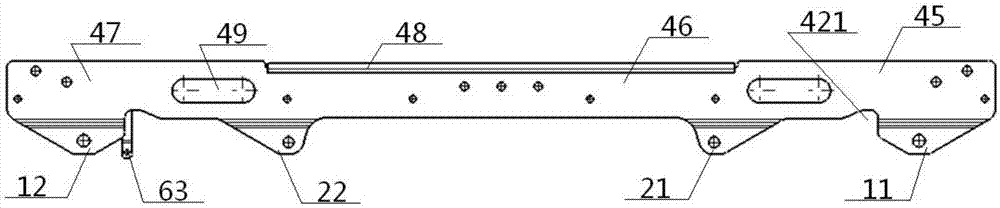

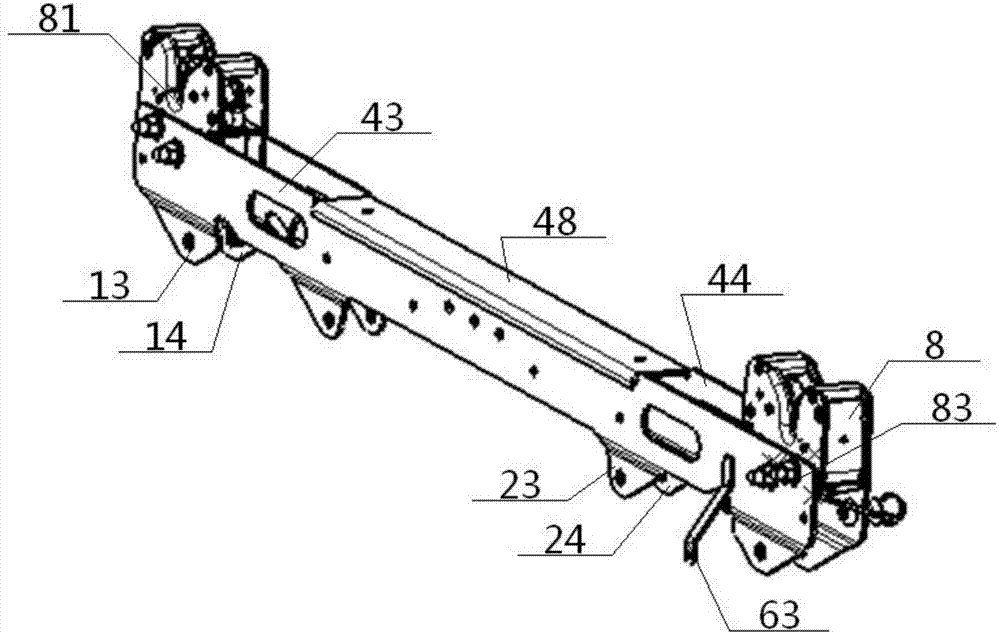

Suspension beam assembly for rear suspension

PendingCN107499396AStrong buffer functionEasy to fixLoading-carrying vehicle superstructuresClassical mechanicsStructural engineering

A suspension beam assembly for a rear suspension comprises a suspension beam body and a first left connecting portion, a second left connecting portion, a second right connecting portion and a first right connecting portion which are sequentially connected along the bottom of the suspension beam body. The suspension beam body is formed by clamping a front floating beam plate and a rear floating beam plate of the same structure, a hydraulic lock is clamped to portion between the left and right ends of the front floating beam plate, a hydraulic lock is clamped to the portion between the left and right ends of the rear floating beam plate, inward concave lock grooves are formed in the portions, located above the suspension beam body, of the hydraulic locks, lock hooks are arranged inside the lock grooves, and the front and rear floating beam plates each comprise a left panel, a middle panel and a right panel which are sequentially connected, wherein the widths of the left and right panels are larger than the width of the middle panel, and an overlay plate, a constraint hole, a pipeline gap, an oval through hole or a height valve adjusting rod support are arranged on the suspension beam body. The suspension beam assembly is good in stability, the falling fixing accuracy of a cab can be ensured, the manufacturing and installation costs are low, and functionality is high.

Owner:DONGFENG COMML VEHICLE CO LTD

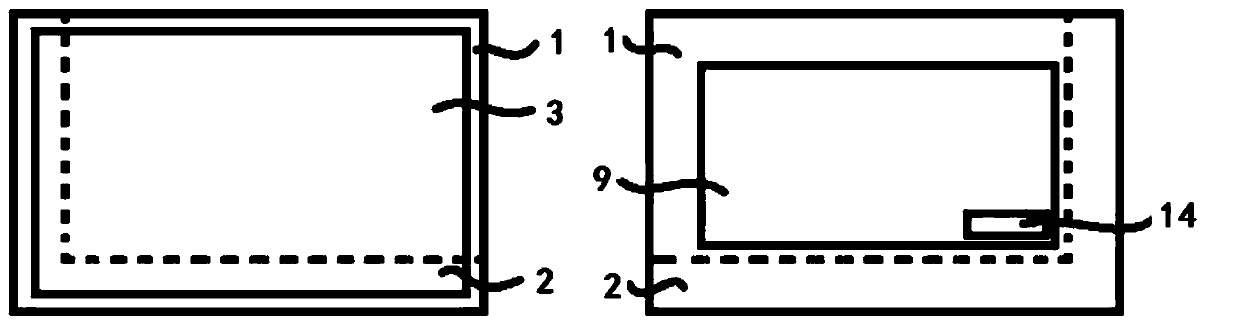

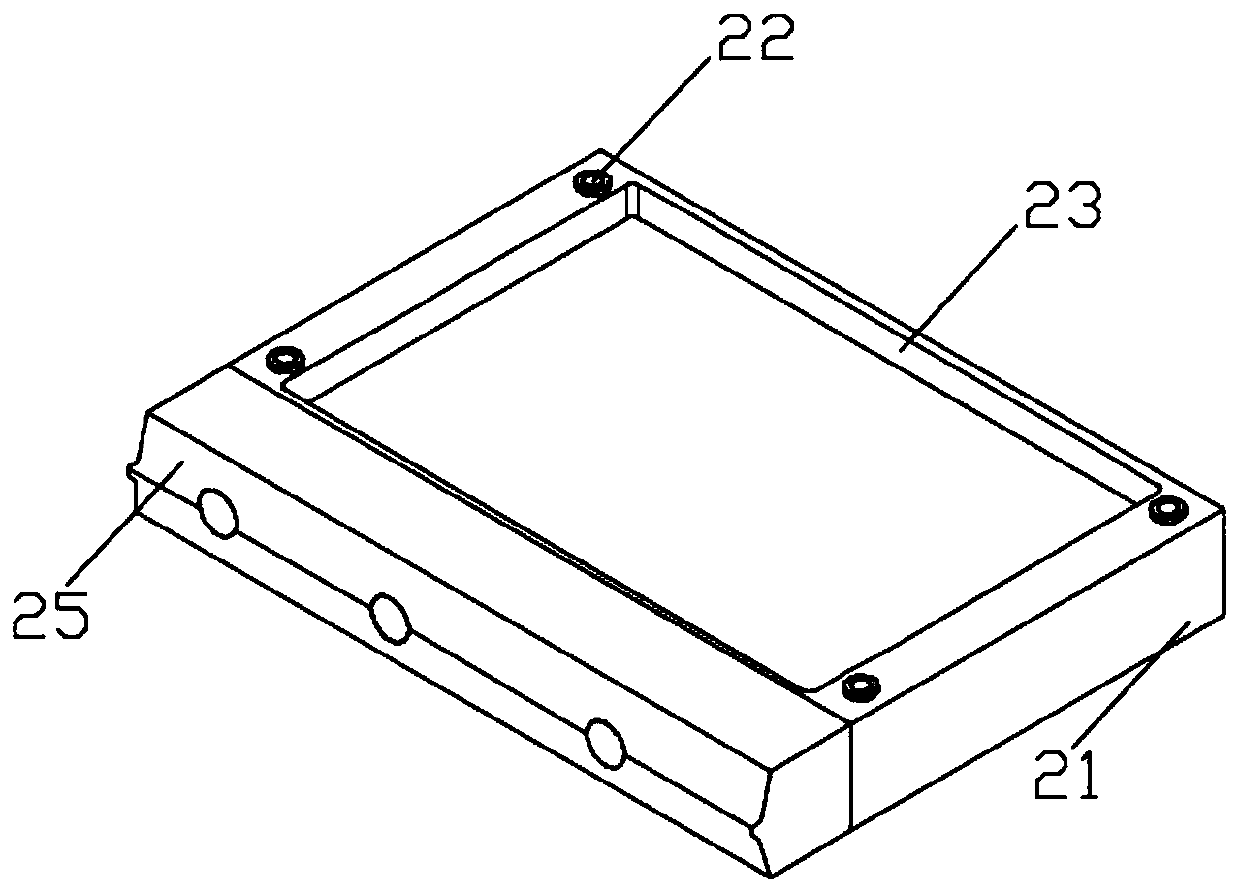

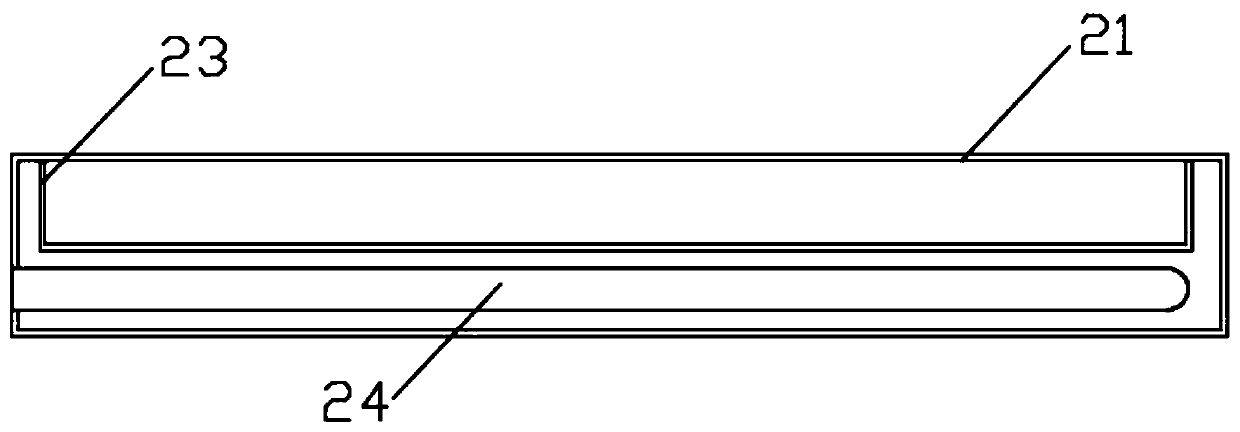

Capacitive touch white board

PendingCN110531900ASimple structureReasonable designInput/output processes for data processingWhiteboardCapacitance

The invention discloses a capacitive touch white board. The invention belongs to the technical field of touch whiteboards. The capacitive touch screen comprises a panel, a capacitive sensing layer anda supporting layer which are sequentially arranged, the capacitive sensing layer comprises a transmitting signal line and a receiving signal line which are perpendicular to each other. An intersection point of the transmitting signal line and the receiving signal line forms a micro capacitor, the transmitting signal line and the receiving signal line are both connected with the touch main board,the touch main board is used for positioning a touch position according to a capacitance change value of the micro capacitor, and the touch main board is connected with a host through an interface; the capacitive touch whiteboard is simple in structure, reasonable in design and convenient to operate, the functions of the whiteboard, the curtain and the touch control are integrated, the touch areaof the capacitive touch whiteboard covers the whole panel area, no blind area exists, overall uniform distribution is achieved, positioning accuracy is better facilitated, and practicability is high.

Owner:成都黝影科技有限公司

Low-fat chocolate and production process thereof

InactiveCN111436515AGuaranteed fluffy and smooth feelingStable spacingFood ingredient as thickening agentCocoaProtein contentAnimal science

The invention discloses low-fat chocolate and a production process thereof. By adding whey protein, the smooth mouthfeel of fat can be simulated, so that the prepared low-fat chocolate has low fat content while the mouthfeel is ensured; during treatment, the whey protein is denatured after high-speed mixing treatment and wet heat treatment; by adding xanthan gum, the whey protein is effectively stabilized; the volume increase due to whey protein aggregation in the low-fat chocolate production process is avoided; the xanthan gum can stabilize the space between particles; the fluffy and smooth feeling of the prepared low-fat chocolate is ensured; meanwhile, the effects of thickening and lubricating the mouthfeel can also be achieved; and through test measurement, the fat content of the prepared low-fat chocolate is 5-8 percent; the protein content is 12-15 percent.

Owner:安徽省好朋友食品有限公司

Substrate processing apparatus

ActiveUS20130161187A1Stable plasma spaceEasy to controlCellsElectric discharge tubesBiomedical engineering

Provided is a substrate processing apparatus including an openable and closable lid and being capable of precisely controlling a gap between multiple shields. The substrate processing apparatus includes: an openable and closable lid provided on an opening of a chamber; a first shield provided on a surface of the lid at the chamber side and having an insertion hole; an insertion section fixed to the lid while inserted through the insertion hole, and configured to support the first shield in a manner movable within a predetermined distance; a restriction section provided on an end portion of the insertion section and configured to restrict the movement of the first shield; and biasing means configured to bias the first shield to a member provided inside the chamber when the lid is closed.

Owner:CANON ANELVA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com