Suspension beam assembly for rear suspension

A suspension beam and rear suspension technology, which is applied to the upper structure, the upper structure of the truck, transportation and packaging, etc., can solve the problems of poor stability and the inability to ensure the accuracy of the cab's whereabouts and fixation, and achieve strong stability, The effect of strong fixed effect and strong buffer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

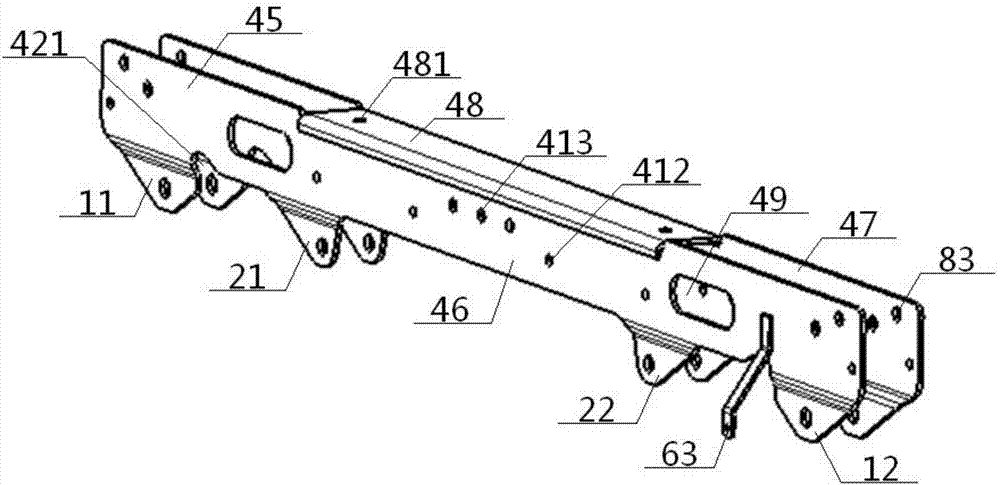

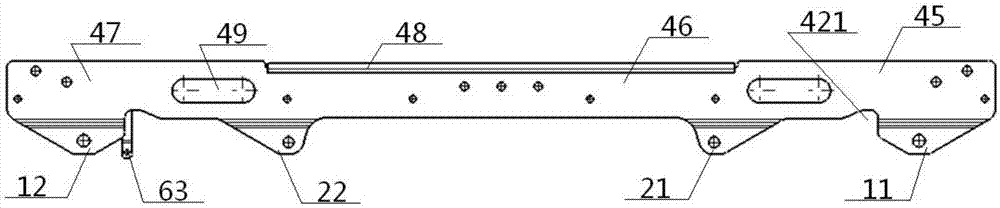

[0049] see Figure 1 to Figure 9 , a suspension beam assembly for rear suspension, comprising a suspension beam body 4 and a left first connecting portion 11, a left second connecting portion 21, a right second connecting portion 22, and a right first connecting portion 12 connected sequentially along the bottom of the suspension beam, the The first left connecting part 11 and the first right connecting part 12 are respectively hinged with the top of a vertical shock absorber 1, and the second left connecting part 21 and the second right connecting part 22 are respectively hinged with the top of a transverse shock absorber 2 ;

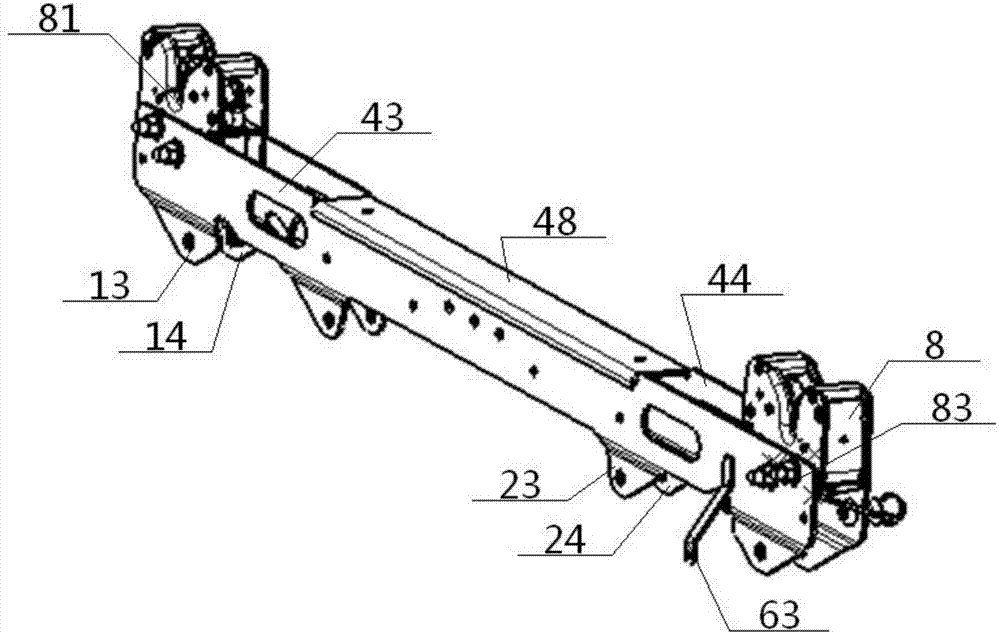

[0050] The suspension beam body 4 is sandwiched by two front floating beam plates 43 and rear floating beam plates 44 with the same structure. A hydraulic lock 8 is respectively clamped between the left and right ends of the rear floating beam plate 44, and a concave lock groove 81 is opened in the position above the suspension beam body 4 on the hydr...

Embodiment 2

[0052] Basic content is the same as embodiment 1, the difference is:

[0053] The structures of the first connecting part 11 on the left and the connecting part 12 on the right are consistent, and both include front and rear symmetrical front fins 13 and rear fins 14, and the front fins 13 are connected with the rear fins 14 through the first rotating shaft 15. The middle part of the No. 1 rotating shaft 15 is hinged to the top of the vertical shock absorber 1 sleeved on it; the second left connecting part 21 and the second right connecting part 22 have the same structure, and both include front and rear symmetrical front two wings 23 , the rear two fins 24, the front two fins 23 are connected with the rear two fins 24 by the second rotating shaft 25, and the middle part of the second rotating shaft 25 is hinged with the top of the horizontal shock absorber 2 sleeved thereon. Preferably, the type of the vertical shock absorber 1 and the transverse shock absorber 2 is a spring ...

Embodiment 3

[0055] Basic content is the same as embodiment 1, the difference is:

[0056] Described front floating beam plate 43, rear floating beam plate 44 all comprise left flat plate 45, middle flat plate 46 and right flat plate 47 connected successively, the width of left flat plate 45, right flat plate 47 is all greater than the width of middle flat plate 46, front floating beam The top of the middle plate 46 in the plate 43 is connected with the top of the middle plate 46 in the rear floating beam plate 44 by the cover plate 48, and the two ends of the cover plate 48 are provided with cover holes 481, and the left plate 45, the right plate 47 There are fixed lock holes 83 connected with the hydraulic lock 8 on the top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com