A kind of multi-layer glued toughened glass insulator and its manufacturing method

A glass insulator and manufacturing method technology, applied in insulators, adhesives, inorganic adhesives, etc., can solve the problems of high brittleness, poor mechanical properties, poor bonding force, etc., and achieve strong impact resistance, improved body toughness, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

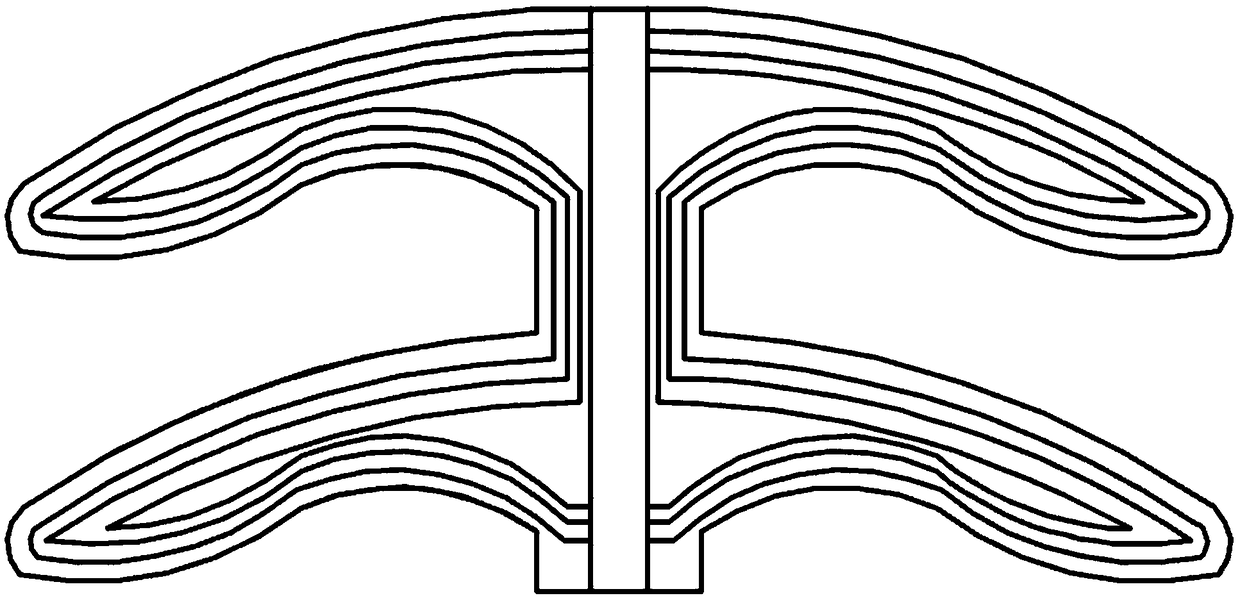

[0033] A multi-layer glued toughened glass insulator, the insulator includes multi-layer glass layers and multi-layer glue layers interspersed one by one, and the core is made of glass;

[0034] The manufacturing method of the multilayer glued toughened glass insulator comprises the following steps:

[0035] 1) Raw material preparation

[0036] ①The glass body raw materials include the following components by weight: 70 parts of silicon dioxide, 8 parts of calcium oxide, 10 parts of sodium carbonate, 3 parts of magnesium oxide powder, 3 parts of pure iron powder, 1 part of phosphorus powder, and 1 part of carbon powder;

[0037] ② The raw materials of the cement include the following components by weight: 50 parts of sodium silicate, 3 parts of acetic acid, 10 parts of silicone, and 30 parts of purified water;

[0038] ③Process auxiliary materials include: sufficient amount of release agent, sufficient amount of nitrogen;

[0039] ④Process equipment includes: a central metal...

Embodiment 2

[0058] A multi-layer glued toughened glass insulator, the insulator includes multi-layer glass layers and multi-layer glue layers interspersed one by one, and the core is made of glass;

[0059] The manufacturing method of the multilayer glued toughened glass insulator comprises the following steps:

[0060] 1) Raw material preparation

[0061] ①The glass body raw materials include the following components by weight: 80 parts of silicon dioxide, 10 parts of calcium oxide, 15 parts of sodium carbonate, 5 parts of magnesium oxide powder, 5 parts of pure iron powder, 2 parts of phosphorus powder, and 2 parts of carbon powder;

[0062] ②The raw materials of the cement include the following components by weight: 60 parts of sodium silicate, 5 parts of acetic acid, 15 parts of silicone, and 35 parts of purified water;

[0063] ③Process auxiliary materials include: sufficient amount of release agent, sufficient amount of nitrogen;

[0064] ④Process equipment includes: a central met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com