Patents

Literature

457 results about "Polymer alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveUS20060057350A1Less spreadingWide applicationSynthetic resin layered productsFilament/thread formingPolymer sciencePolymer alloy

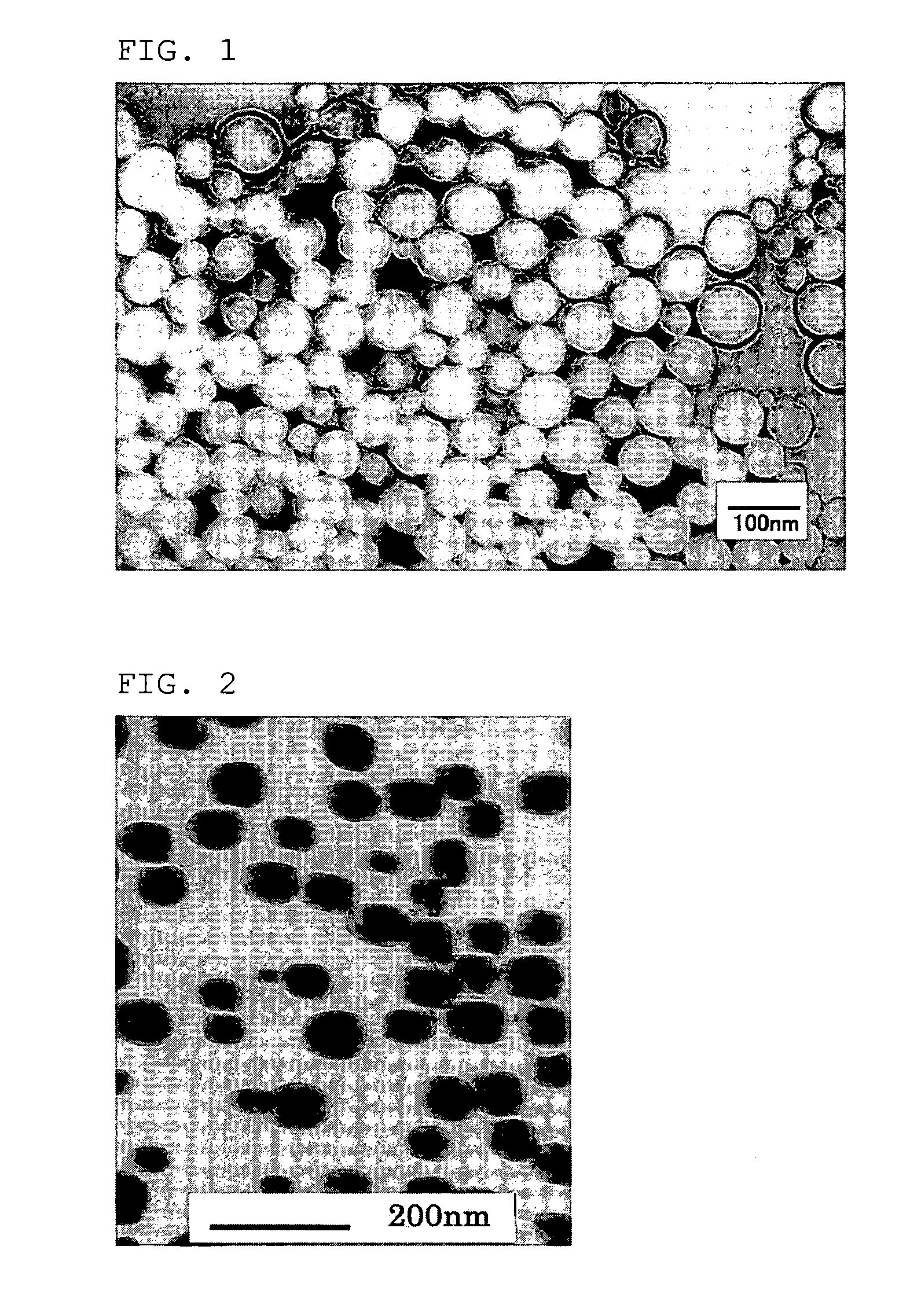

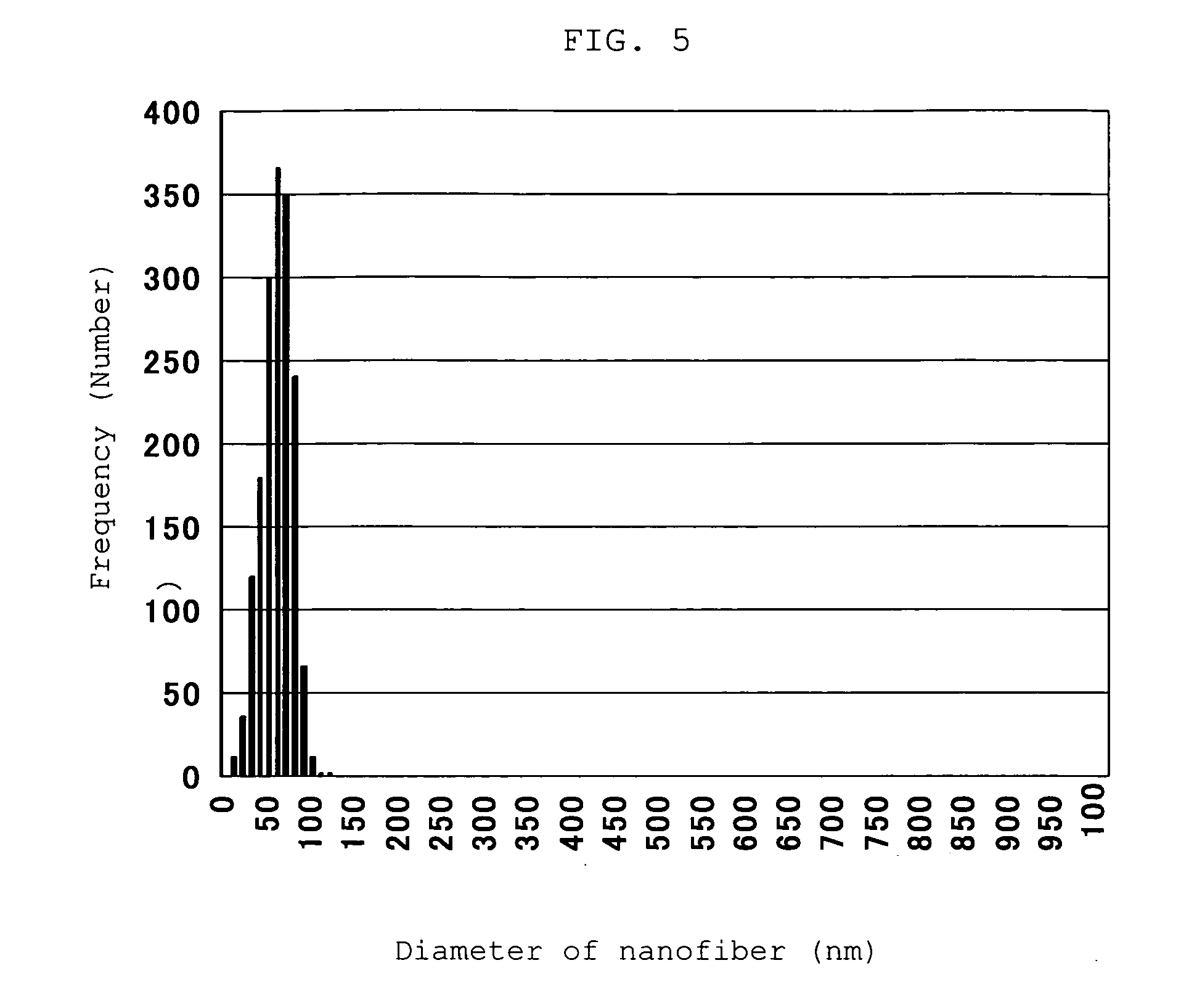

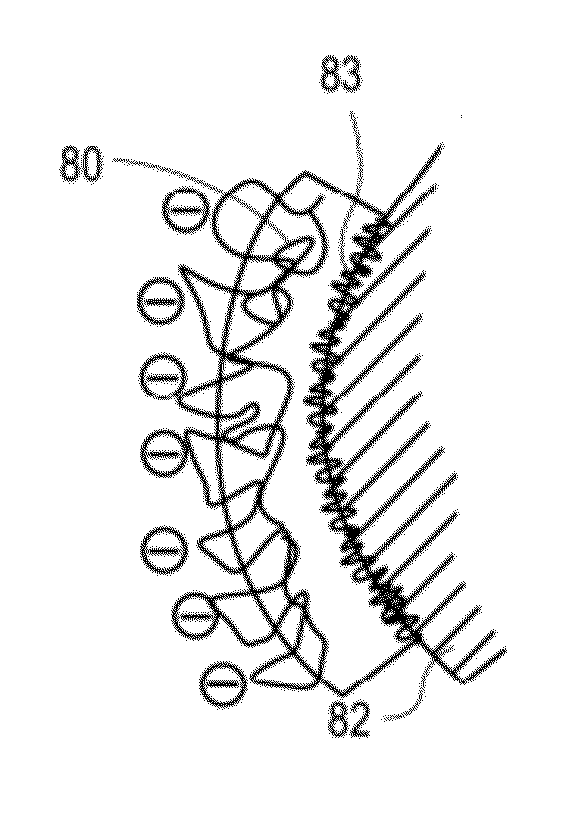

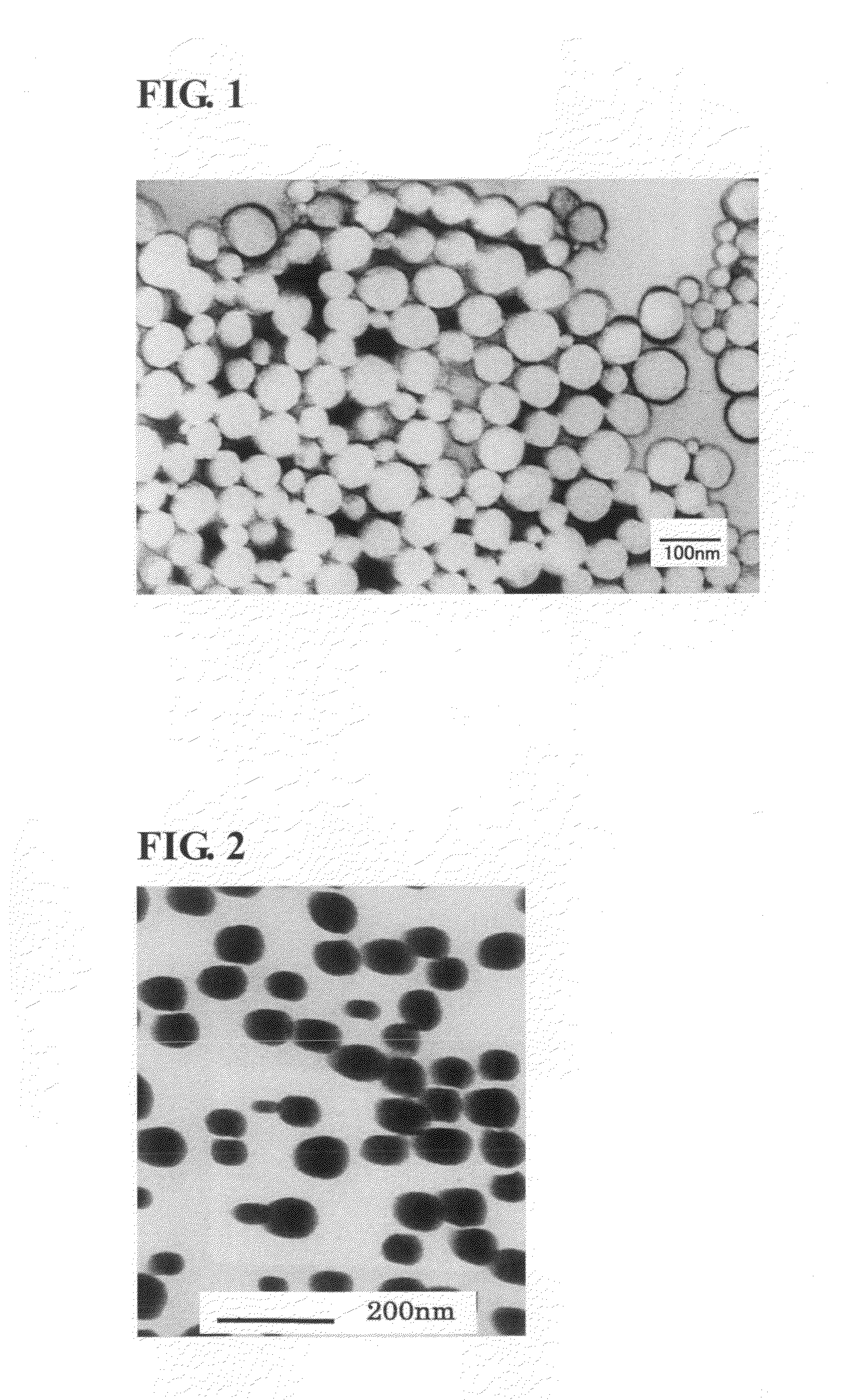

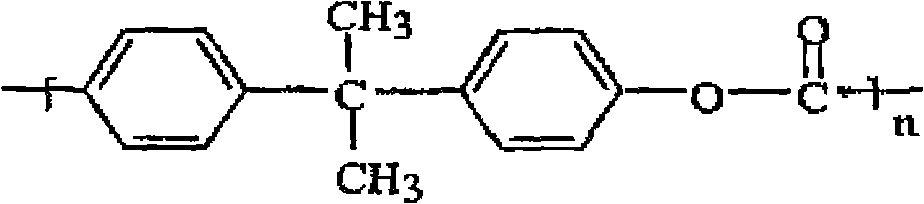

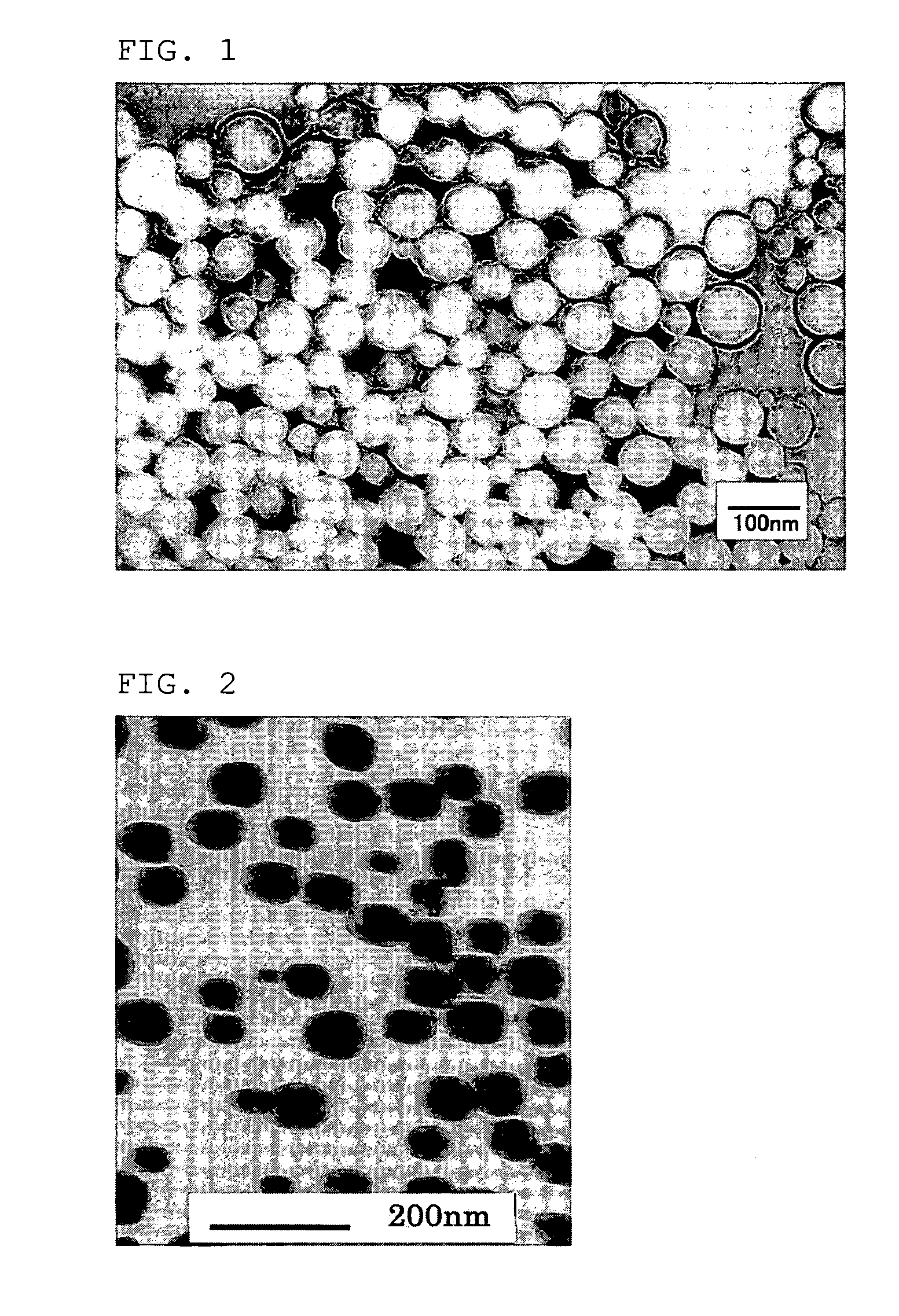

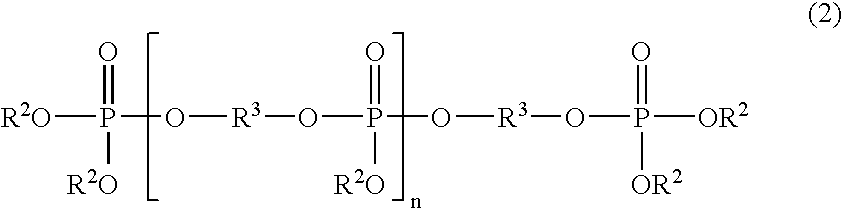

The present invention provides an aggregate of nanofibers having less spread of single fiber fineness values that can be used in wide applications without limitation to the shape and the kind of the polymer, and a method for manufacturing the same. The present invention is an aggregate of nanofibers made of a thermoplastic polymer having single fiber fineness by number average in a range from 1×10−7 to 2×10−4 dtex and single fibers of 60% or more in fineness ratio have single fiber fineness in a range from 1×10−7 to 2×10−4 dtex.

Owner:TORAY IND INC

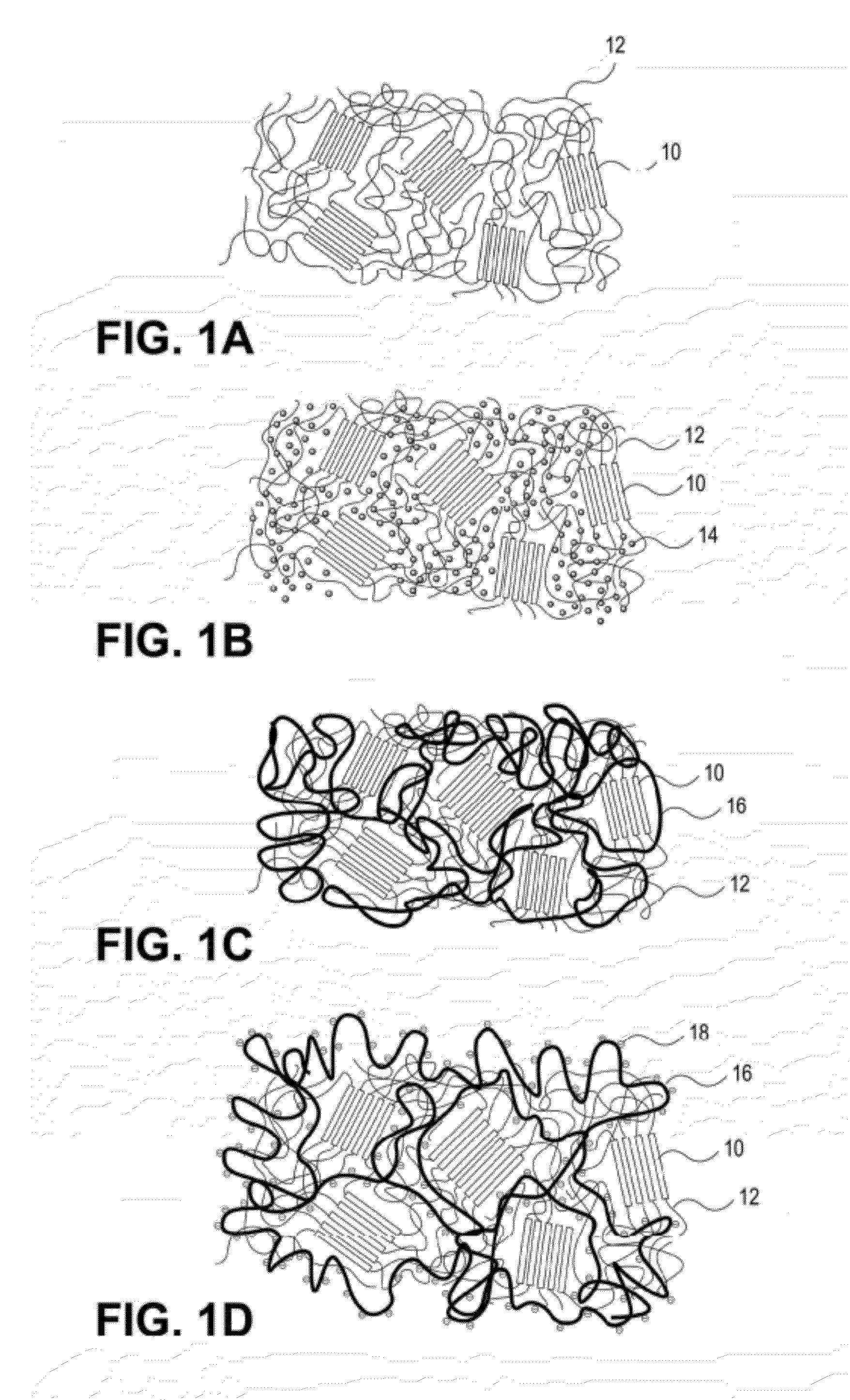

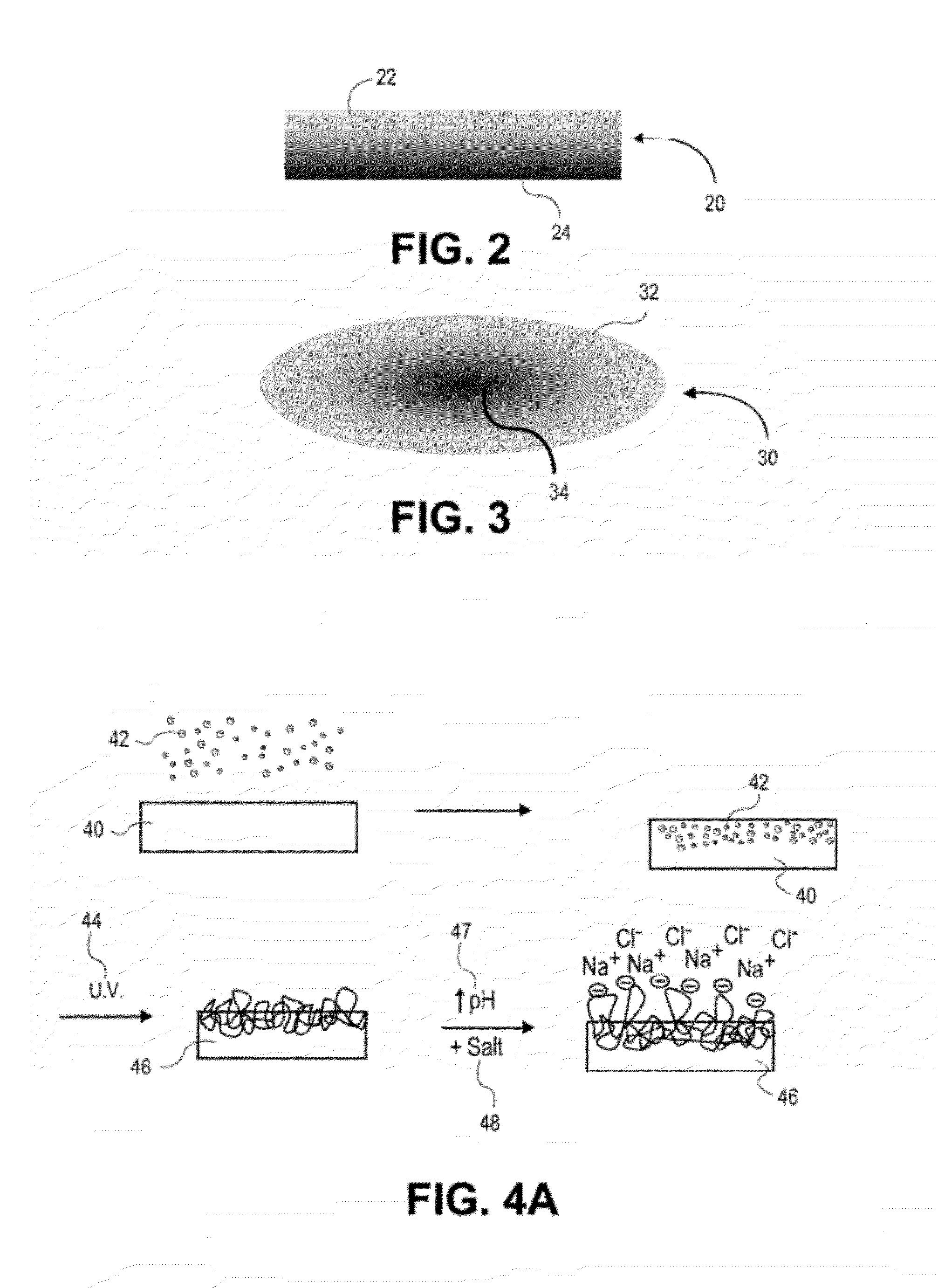

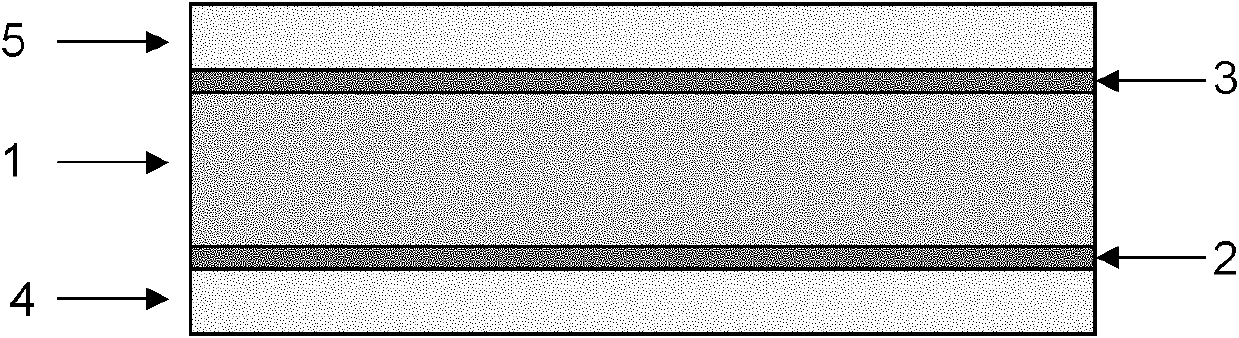

Orthopedic implants having gradient polymer alloys

InactiveUS20120209396A1High mechanical strengthFinger jointsWrist jointsPolymer alloyPlastic surgery

Orthopedic implants having a bone interface member and a water swellable IPN or semi-IPN with a stiffness, hydration, and / or compositional gradient from one side to the other and physically attached to the bone interface member. The invention also includes an orthopedic implant system including an implant that may conform to a bone surface and a joint capsule. The invention also includes orthopedic implants with water swellable IPN or semi-IPNs including a hydrophobic thermoset or thermoplastic polymer first network and an ionic polymer second network, joint capsules, labral components, and bone interface members. The invention also includes a method of inserting an orthopedic implant having a metal portion and a flexible polymer portion into a joint, including inserting the implant in a joint in a first shape and changing the implant from a first shape to a second shape to conform to a shape of a bone.

Owner:HYALEX ORTHOPAEDICS INC

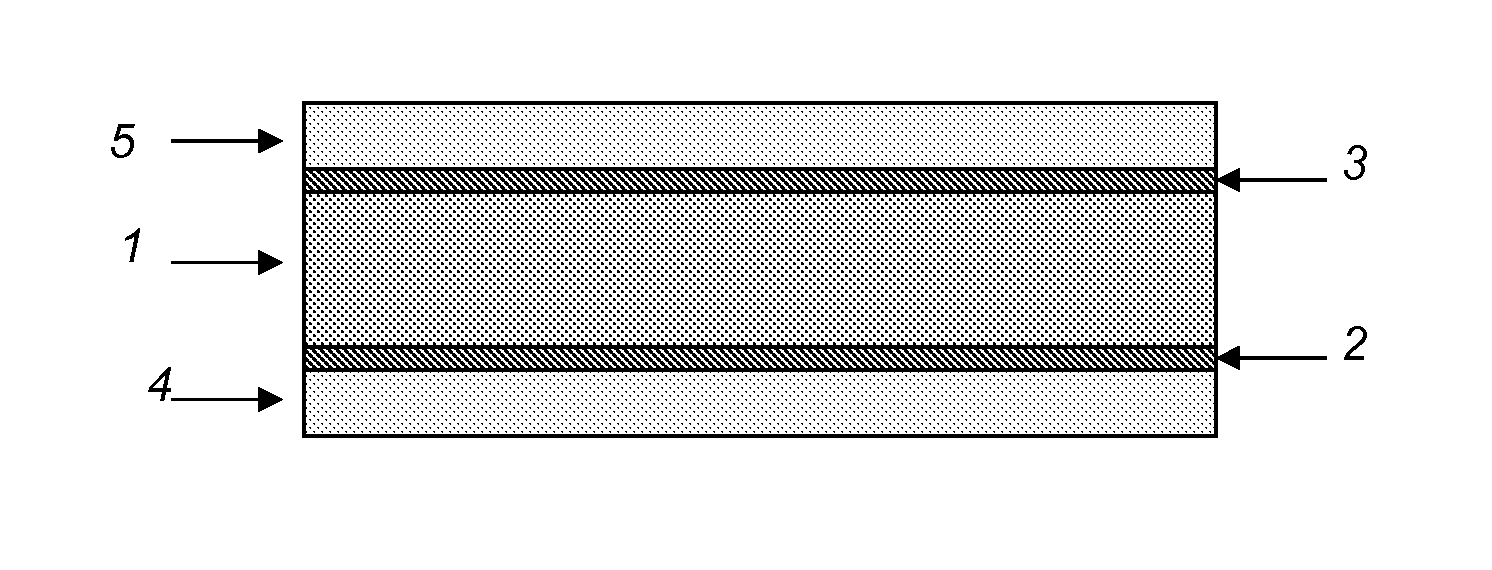

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Glass reinforced nylon blend with improved knitline strength

The present invention provides a polymer alloy including from about 40% to about 75% by weight of at least one polyamide, from about 10% to about 50% by weight polypropylene, from about 0.01% to about 1.0% by weight of at least one block copolymer including a vinyl aromatic monomer and a conjugated diene, and also includes an unsaturated dicarboxylic reagent, from about 0.1% to about 5.0% by weight of at least one block copolymer or terpolymer, wherein the terpolymer may have an unsaturated dicarboxylic reagent grafted thereto, from about 0.01% to about 7.5% of a compatibilizing agent, and from about 5% to about 50% by weight of a filler. The alloy of the present invention exhibits improved knitline strength and improved drop impact results compared with prior art fiberglass-reinforced nylon blends.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

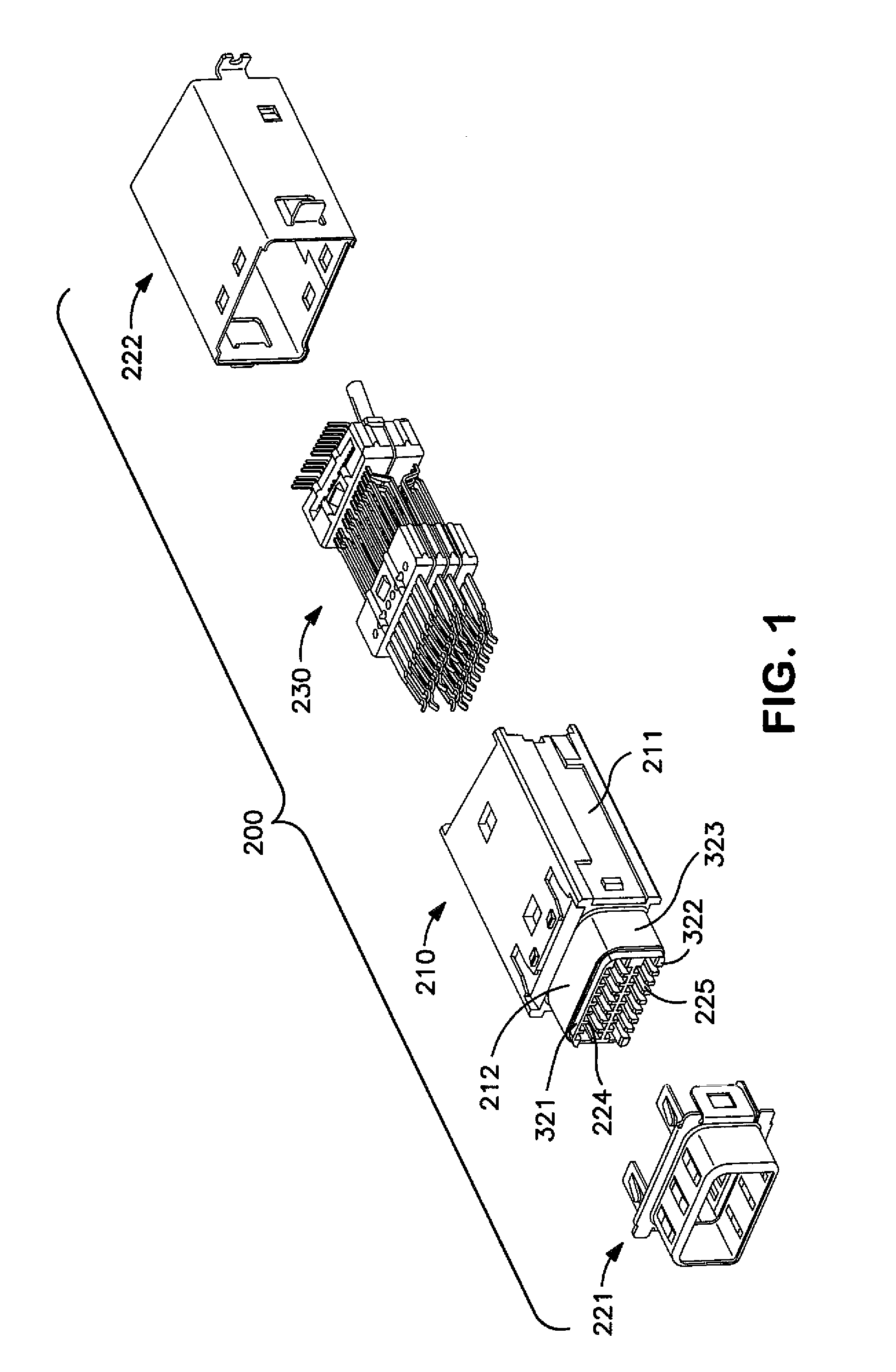

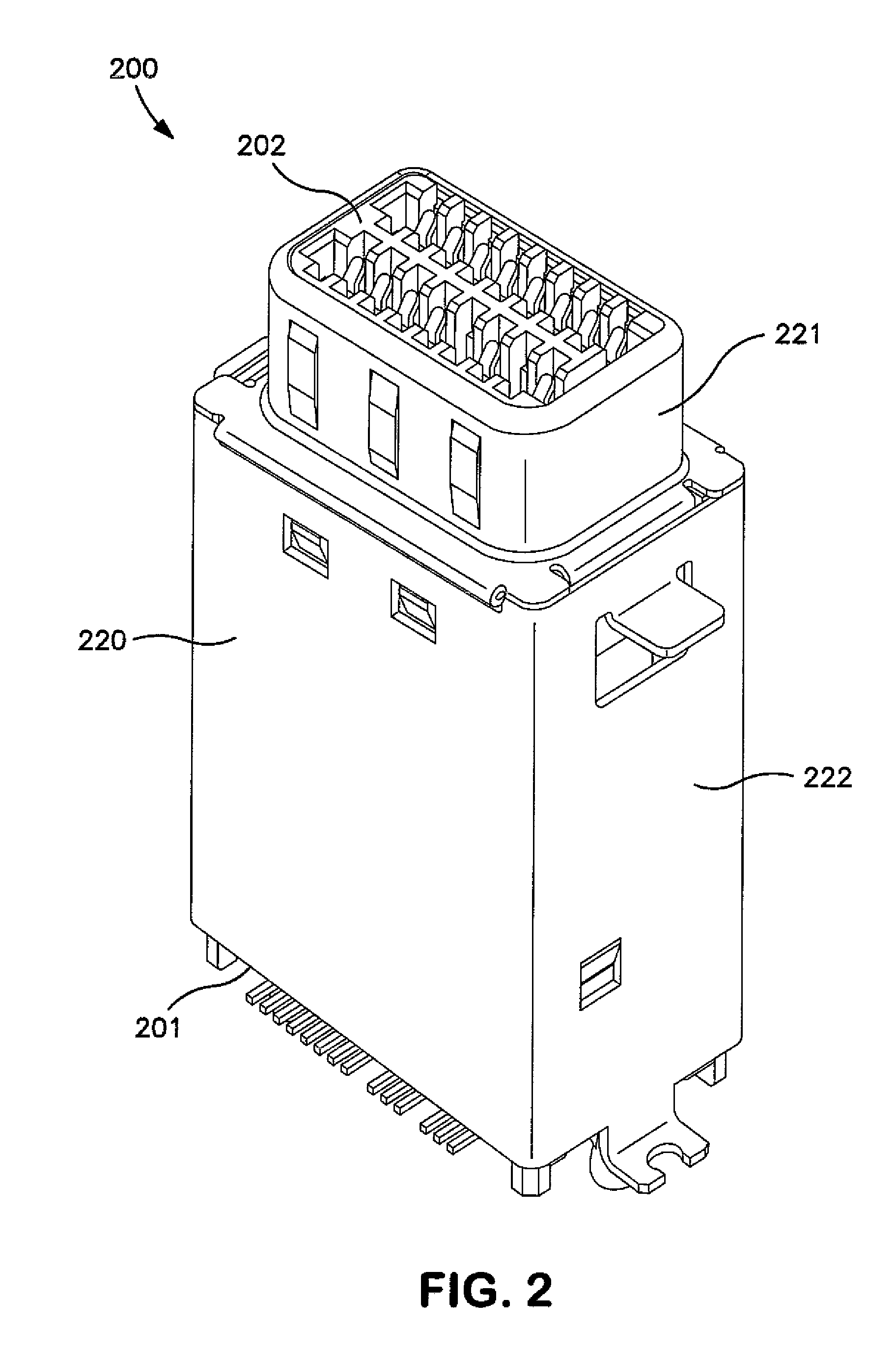

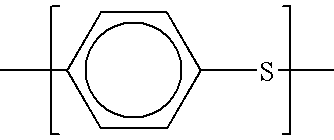

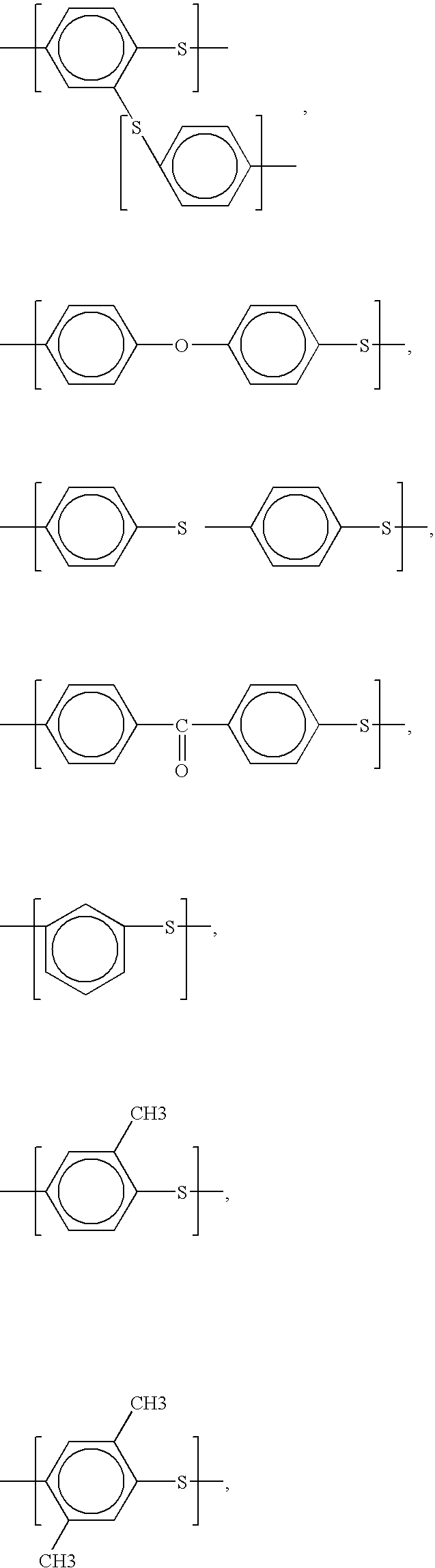

Polyarylene Sulfide/Liquid Crystal Polymer Alloy and Compositions Including Same

Polyarylene sulfide / liquid crystal polymer alloys are described as are methods of forming the polyarylene sulfide / liquid crystal polymer alloys. The polyarylene sulfide / liquid crystal polymer alloys are formed according to a melt processing method that includes melt processing a polyarylene sulfide with a reactively functionalized disulfide compound and a liquid crystal polymer in a one or two step process. The reactively functionalized disulfide compound is added in a stoichiometric amount to react with a portion of the polyarylene sulfide. The melt processing forms a polyarylene sulfide / liquid crystal polymer copolymer that is a compatibilizer in the alloy. The polyarylene sulfide / liquid crystal polymer alloys may provide low chlorine content products having excellent strength characteristics.

Owner:TICONA LLC

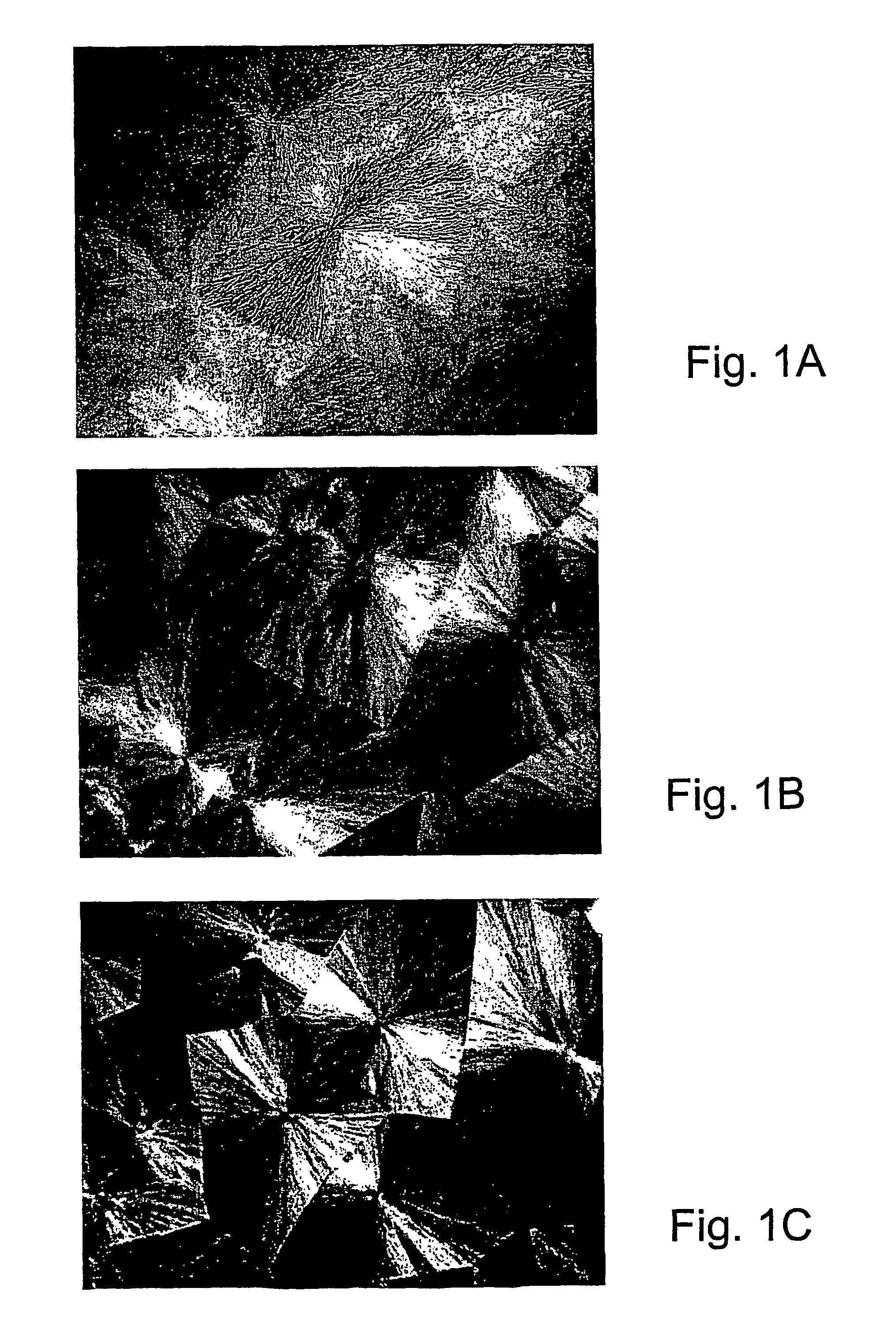

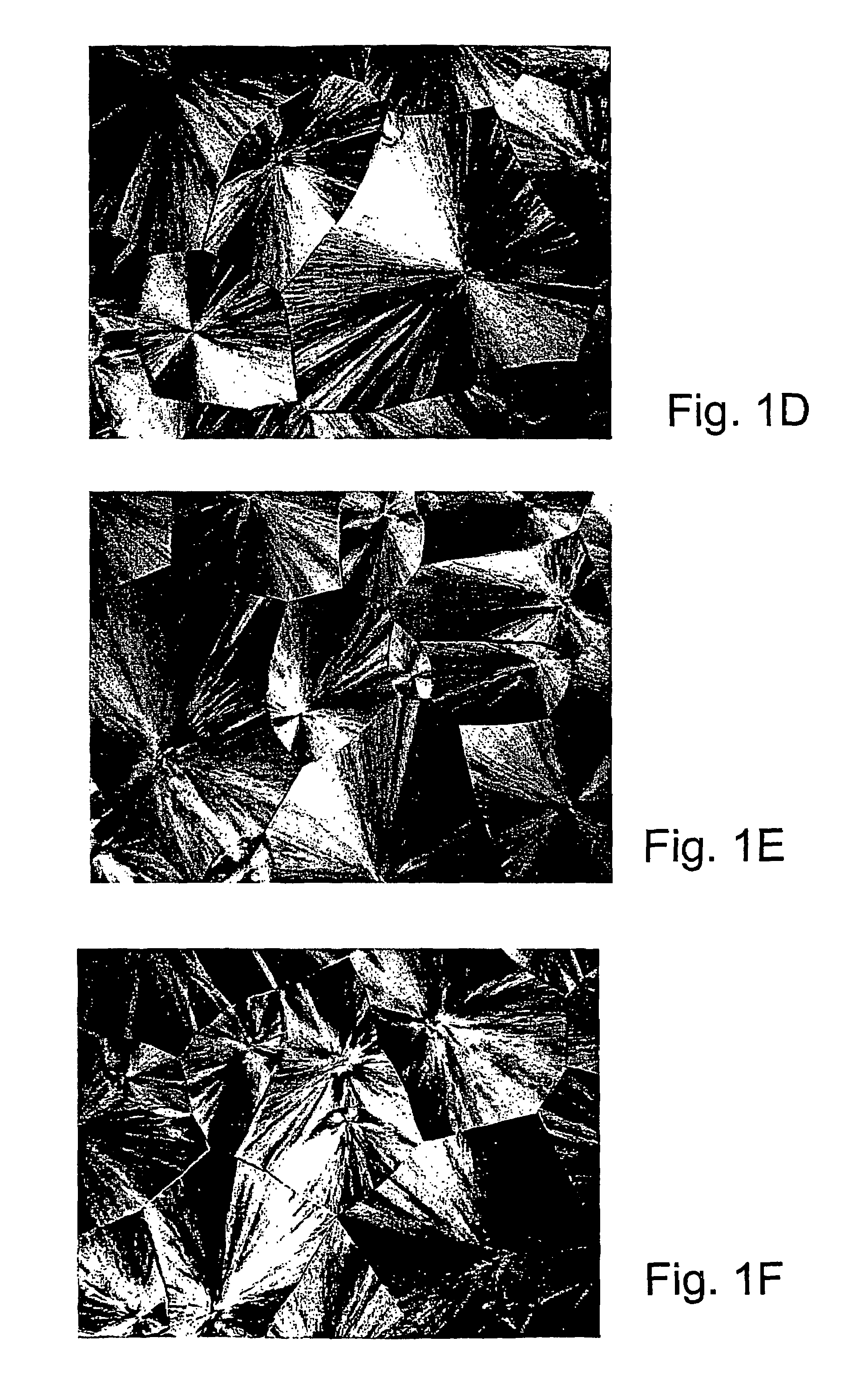

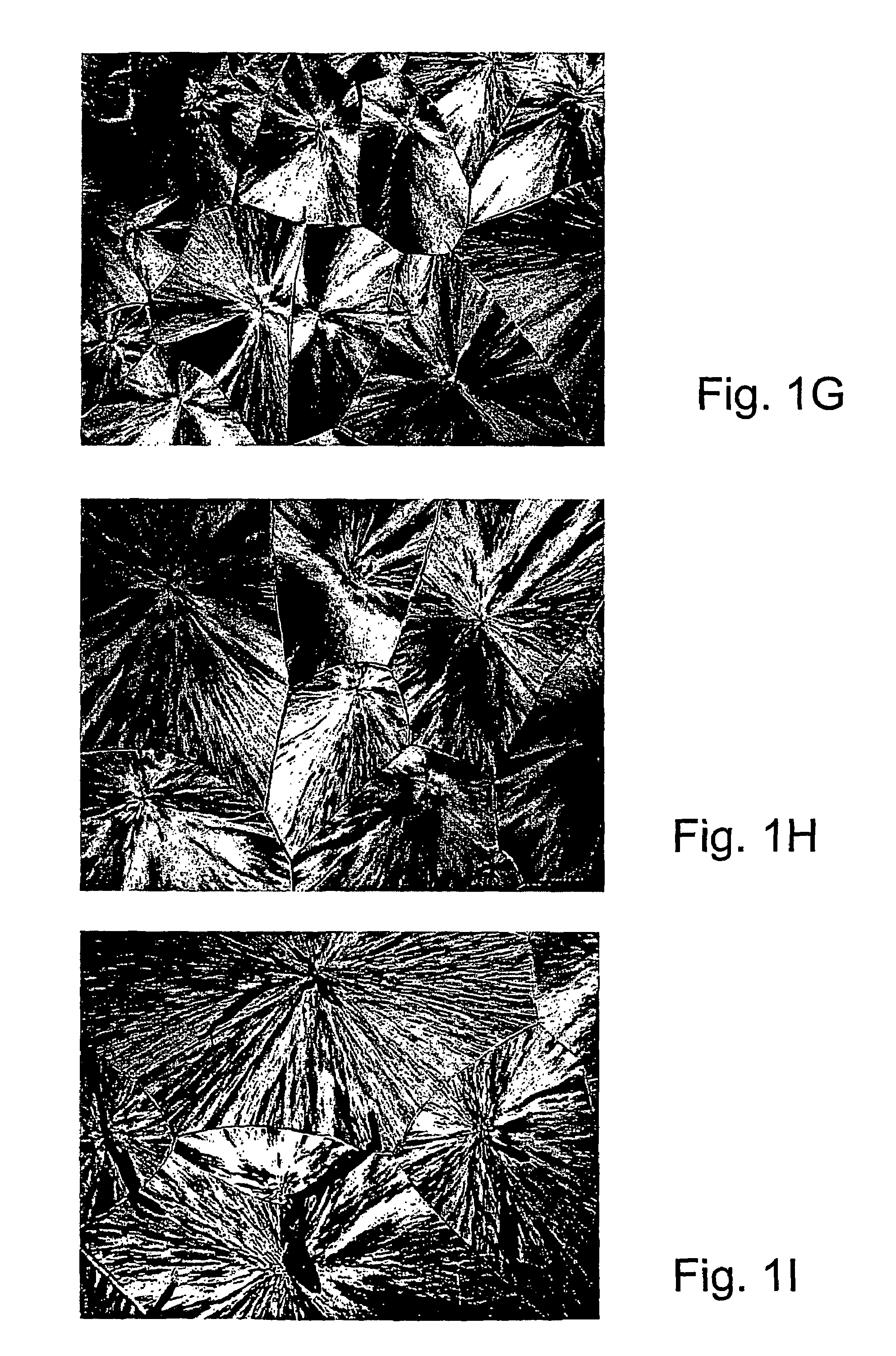

Polymeric blends for optical devices and method of manufacture thereof

A method for manufacturing a film or sheet comprises deforming a polymeric alloy at a temperature effective to impart to the deformed alloy a birefringence retardation of greater than or equal to about 350 nanometers. A method of substantially eliminating comets and veins in an optical film or sheet comprises annealing the film or sheet comprising a polymeric alloy to a temperature proximate to a glass transition temperature of a polymeric resin contained in the alloy. A composition comprises a first polymeric resin in an amount of about 1 to about 99 wt %; and a second polymeric resin in an amount of about 1 to about 99 wt %, wherein the polymeric resins are treated with a deforming force or with an energy effective to produce a polymeric alloy having a birefringence retardation of greater than or equal to about 350 nanometers or with a birefringence retardation of less than or equal to about 150 nanometers.

Owner:SABIC INNOVATIVE PLASTICS IP BV

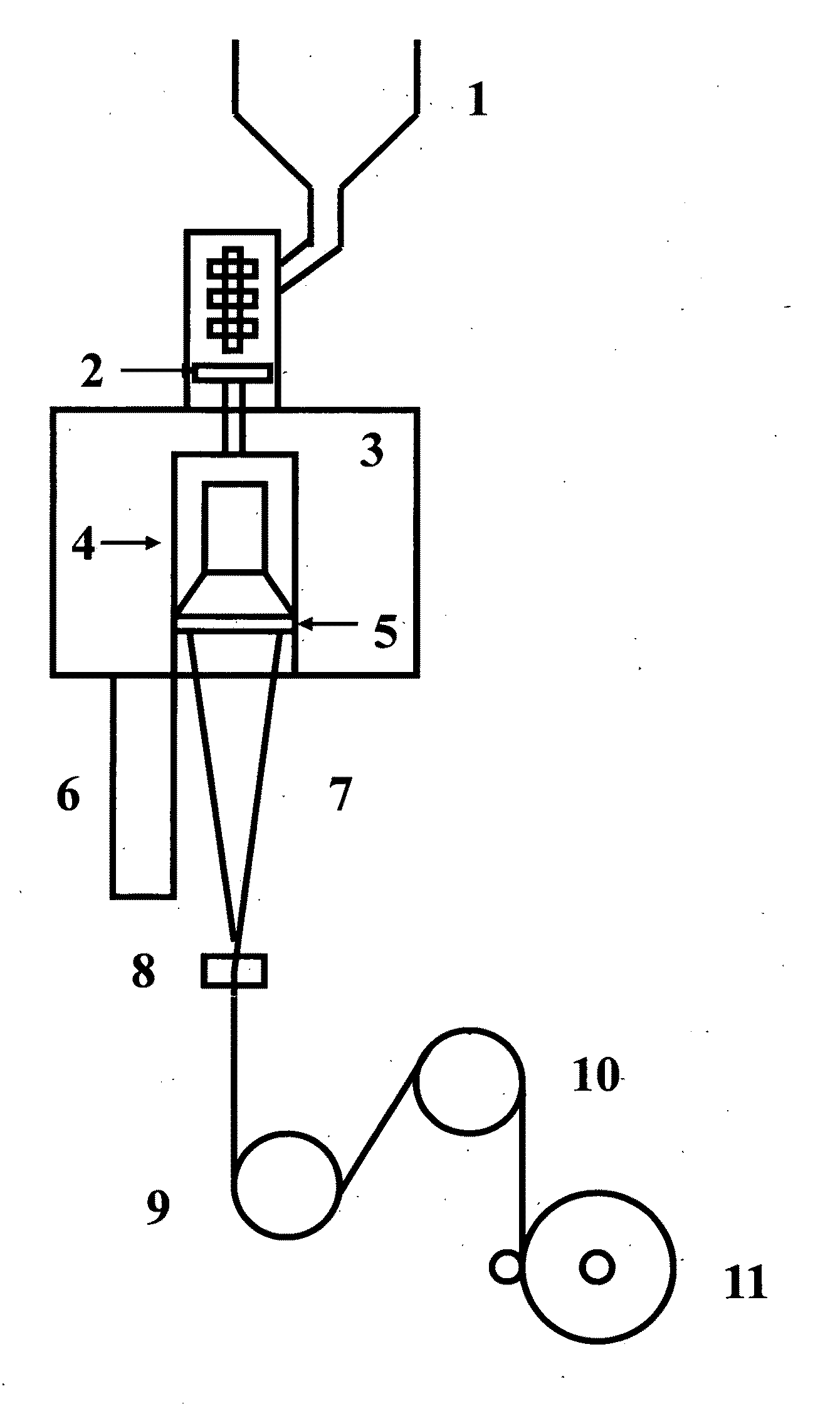

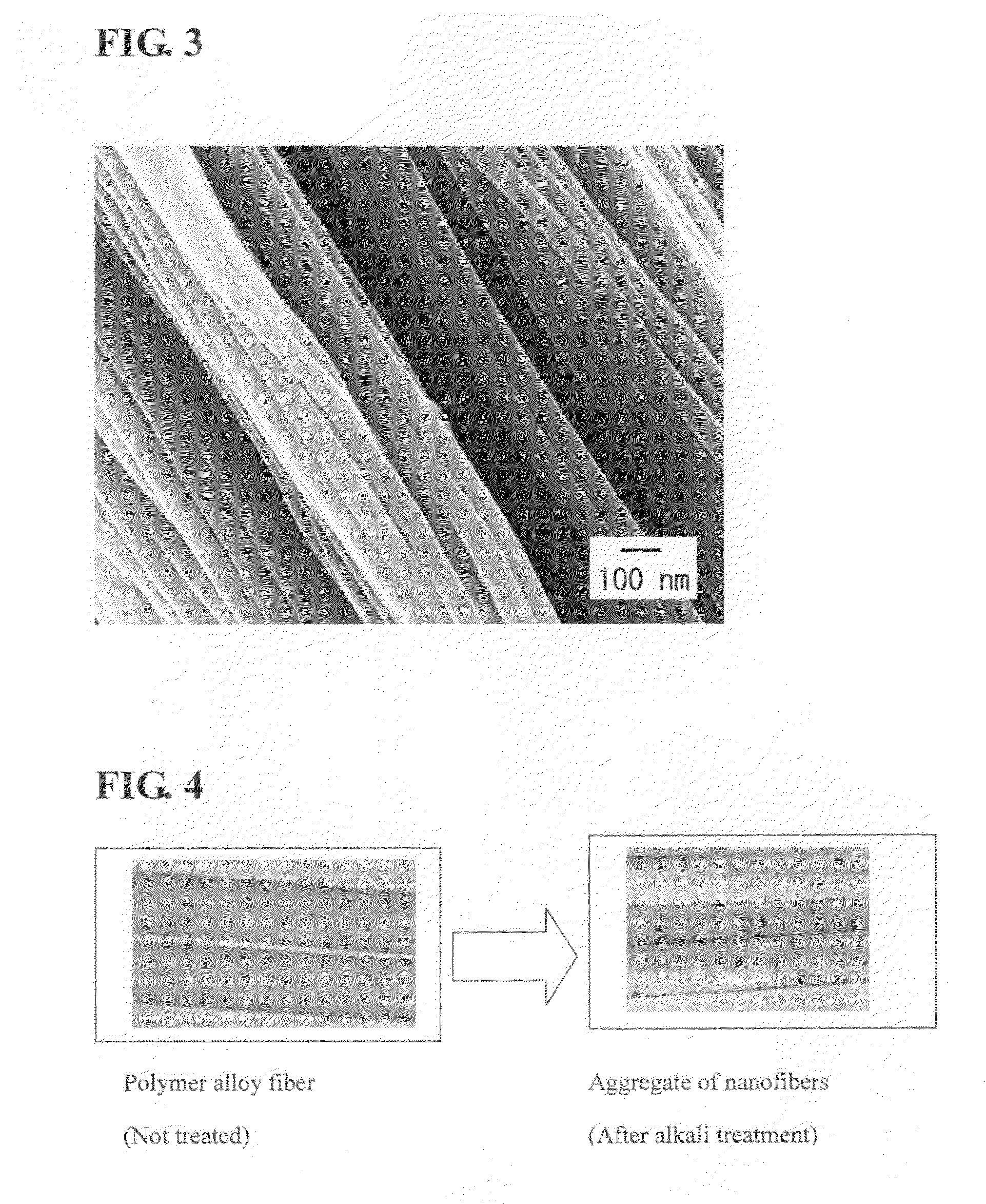

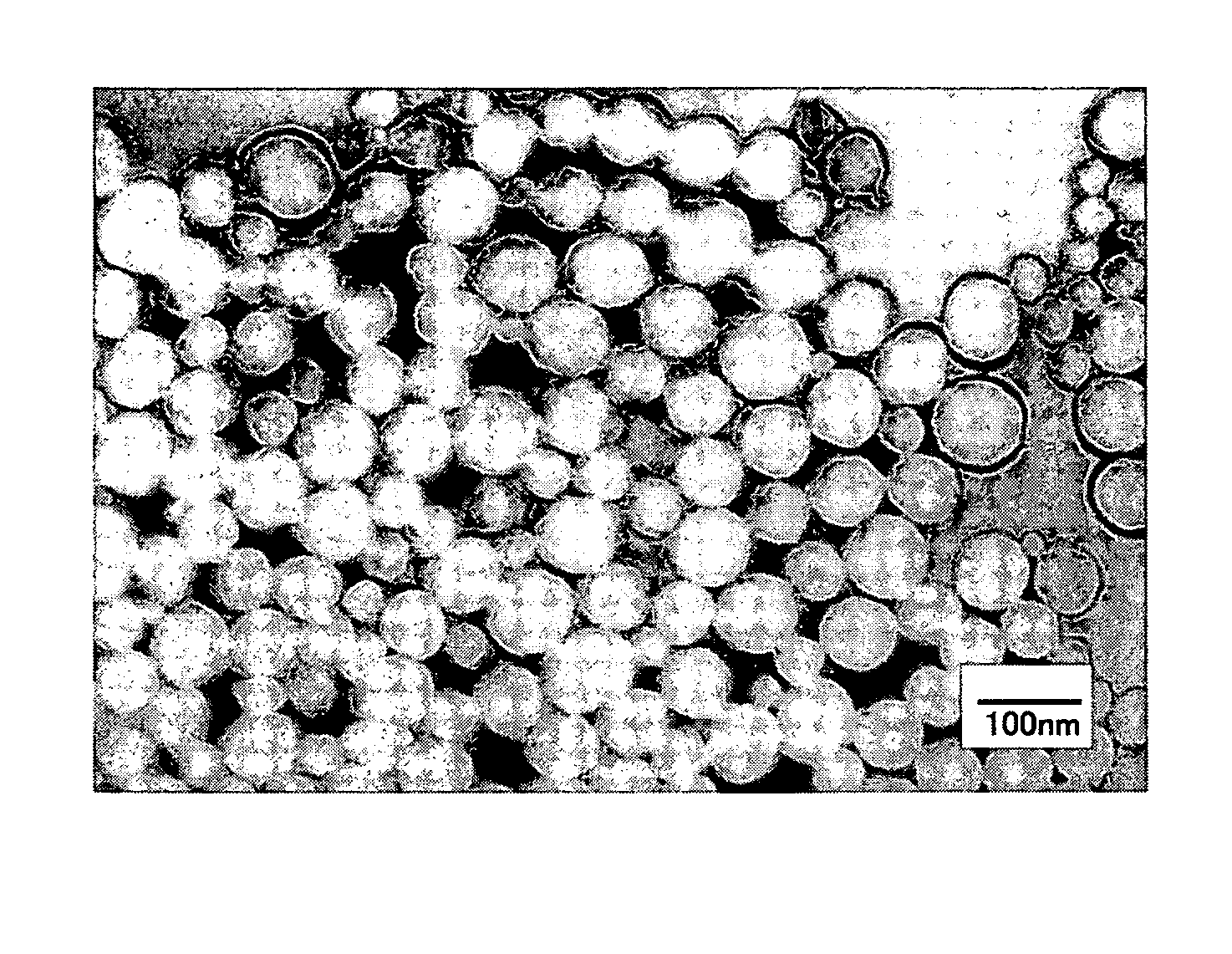

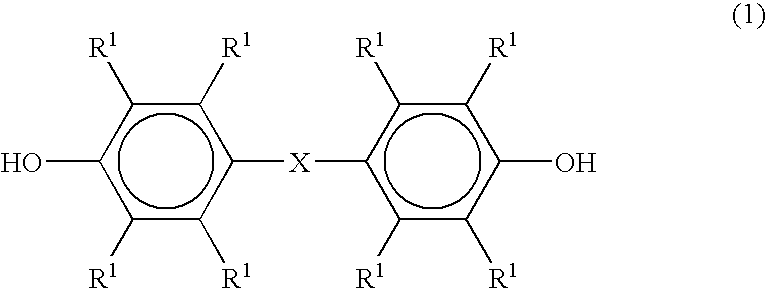

Polymer alloy fiber, fibrous material, and method for manufacturing polymer alloy fiber

InactiveUS20110183563A1Less spreadingWide applicationWarp knittingFilament/thread formingSolubilityPolymer science

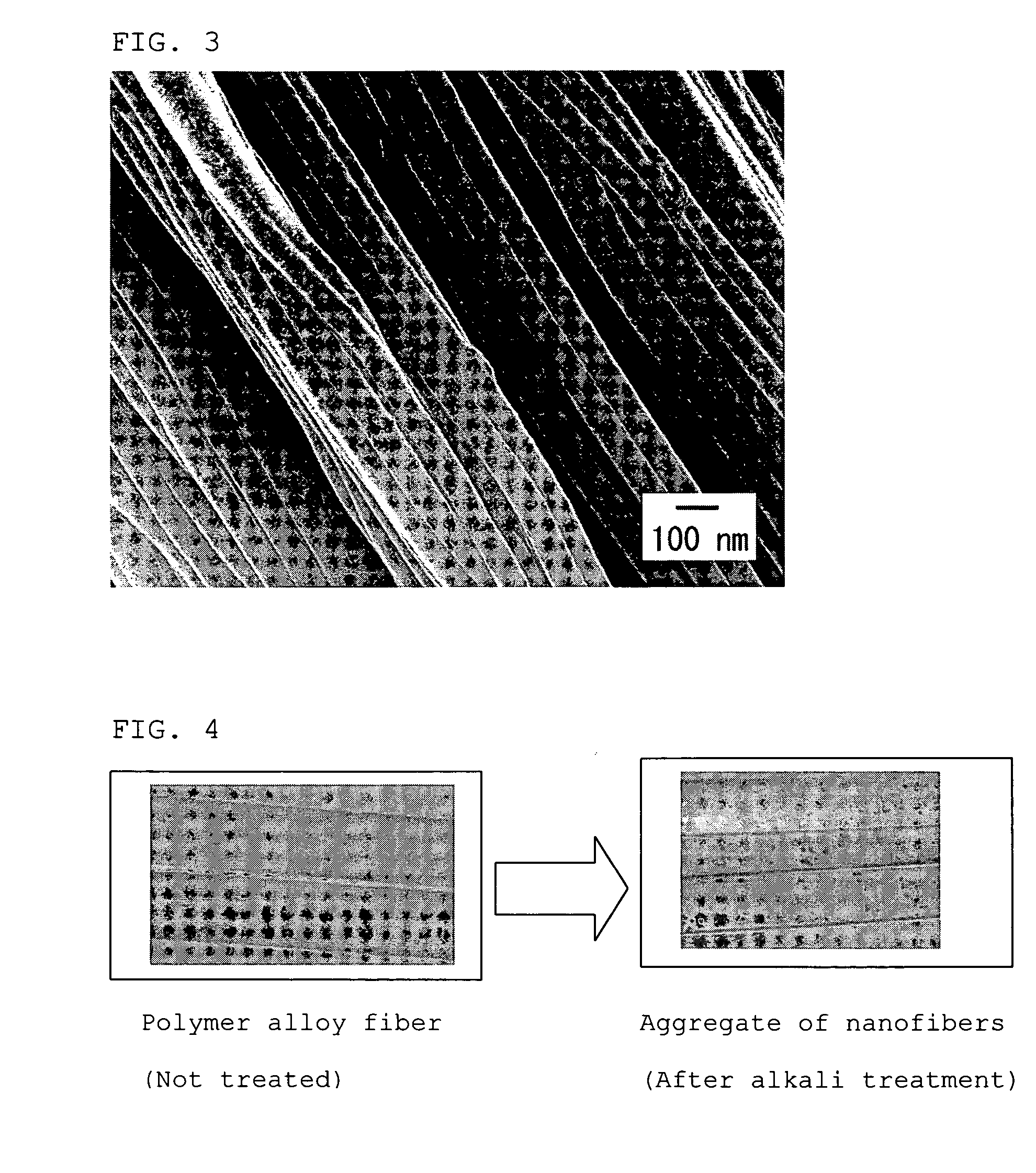

A polymer alloy fiber that has an islands-in-sea structure of two or more kinds of organic polymers of different levels of solubility, wherein the island component is made of a low solubility polymer and the sea component is made of a high solubility polymer, while the diameter of the island domains by number average is in a range from 1 to 150 nm, 60% or more of the island domains in area ratio have sizes in a range from 1 to 150 nm in diameter, and the island components are dispersed in a linear configuration. A method for manufacturing the polymer alloy fiber includes melt spinning of a polymer alloy that is made by melt blending of a low solubility polymer and a high solubility polymer.

Owner:OCHI TAKASHI +1

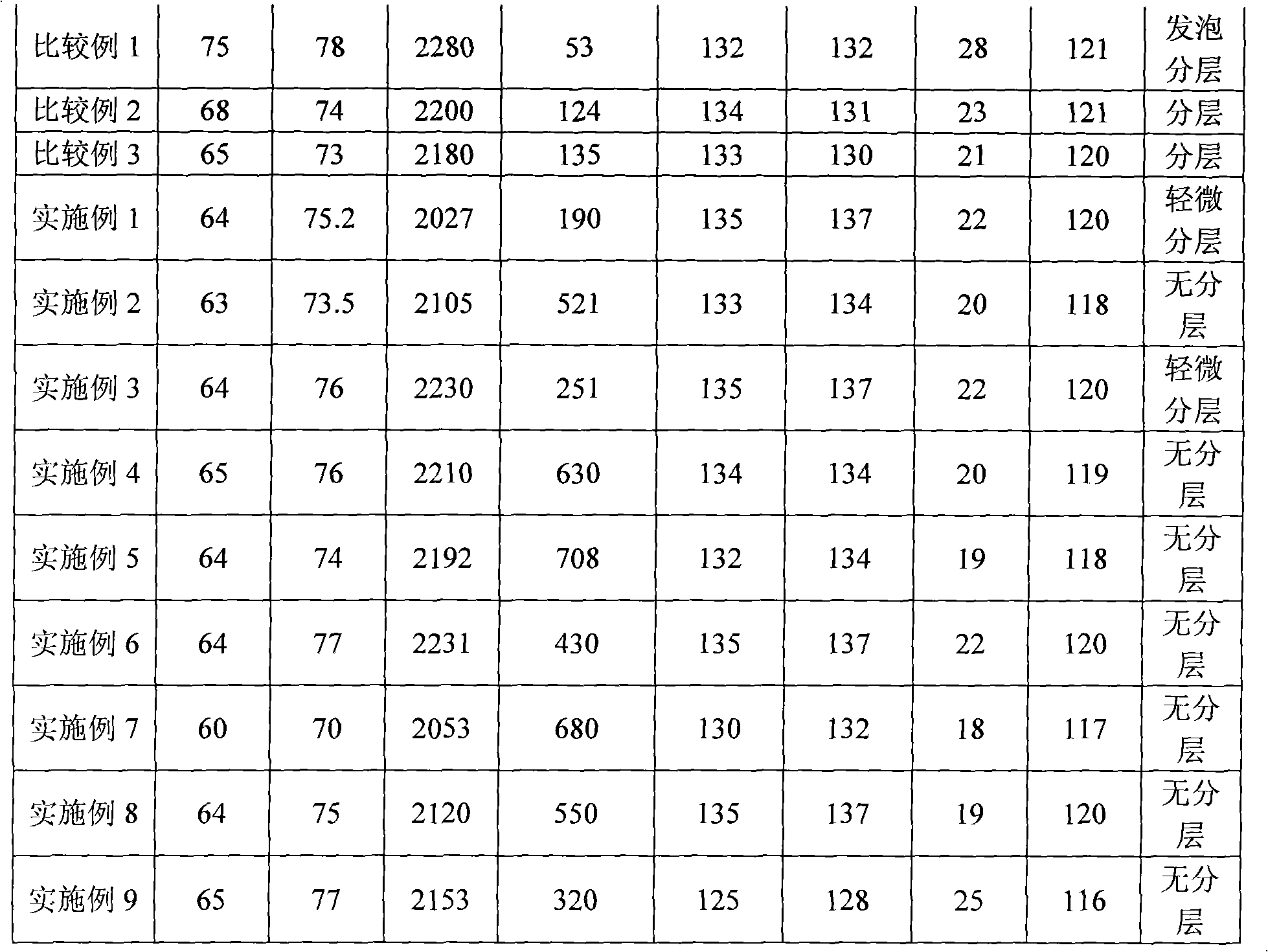

Polycarbonate/polyamide alloy and preparation method thereof

The invention relates to a polycarbonate / polyamide alloy and a preparation method thereof. The alloy contains the following components by weight percentage: 30-80 of polycarbonate, 20-70 of polyamide, 5-30 of toughening agent, 1.5-15 of compatibilizer and 0.2-3 of assistant; wherein the contents of the toughening agent, the compatibilizer and the assistant are based on the total weight of the polycarbonate and the polyamide. Compared with the prior art, due to the blending of the polycarbonate and the polyamide with the excellent compatibilizer in the preparation method, the preparation process is reasonable, the prepared polymer has good paint adhesion, solvent resistance and impact resistance and simultaneously combines the low moisture absorption, heat resistance, wear resistance and self-lubricity of the polycarbonate, and the polycarbonate / polyamide alloy can be widely applied in automobiles (front and rear baffles, column covers, wheel covers and instrument covers), electronic appliances (electric tool housings, wiring devices and relays) and other fields.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Thermoplastic Resin Composition with High Thermal Conductivity

InactiveUS20080277619A1Good molding effectReduce the amount requiredThermal insulationBuilding constructionsGeneral purposePolymer alloy

There are provided an inorganic compound-containing thermoplastic resin composition that practically retains various properties of a general-purpose resin such as mechanical properties and moldability and has excellent thermal conductivity, and a highly thermally conductive molded article molded using the resin composition.In a polymer alloy comprising a thermoplastic resin excluding a thermoplastic polyester resin, a thermoplastic polyester resin and a highly thermally conductive inorganic compound, the thermoplastic polyester resin forms a continuous phase and the highly thermally conductive inorganic compound is preferentially present in a phase other than the thermoplastic resin excluding a thermoplastic polyester resin. Therefore, the composition and the highly thermally conductive molded article molded using the resin composition can have a thermal conductivity improved only by adding a relatively small amount of the highly thermally conductive inorganic compound.

Owner:KANEKA CORP

Random and non-random alkylene oxide polymer alloy compositions

ActiveUS20060100370A1Easy to eliminateMinimal adverse reactionOrganic active ingredientsImpression capsWaxPolymer alloy

A polymeric material comprised of (i) at least one random copolymer comprised of ethylene oxide and one or more other alkylene oxide(s) and (ii) at least one non-random polymer comprised of one or more poly(alkylene oxide)s has been discovered. Preferably, it is a polymer alloy. Alkylene oxide homo-polymers or block copolymers may be the non-random polymer. In a related discovery, an adhesive material can be made by suspending (a) particles in (b) a matrix of at least one poly(ethylene oxide) copolymer of ethylene oxide and propylene oxide, or a combination thereof. The handling characteristics may be adjusted for different utilities (e.g., from runny oil to hard wax). Applications include use as adhesive, cohesive, filler, lubricant, surfactant, or any combination thereof. In particular, the hard materials may be used for cleaning or waxing.

Owner:SYNCERA

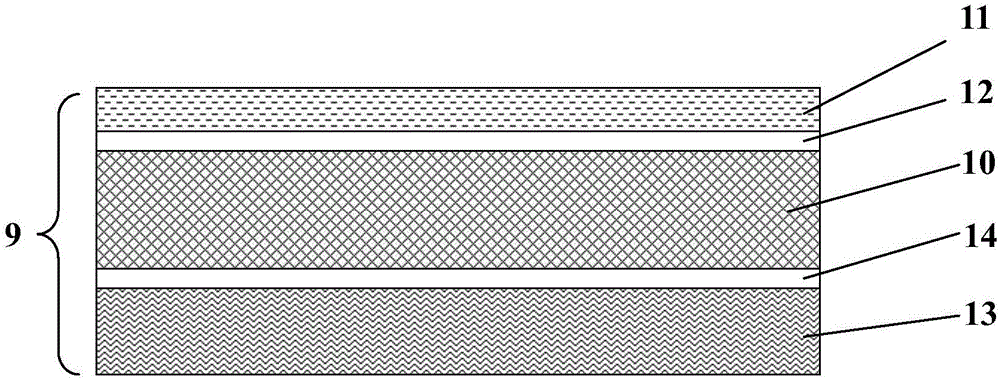

Polymer backsheet of solar cell assembly and manufacturing process thereof

InactiveUS20130209795A1Easy to processExcellent material mechanical performanceFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolymer alloy

A solar module polymer backsheet comprising a basement layer, tie layer on each side of the basement layer, a fourth film layer and a fifth film layer on the other side of the tie layer, the basement layer comprises at least one of the following components: polyamide polymers, polypropylene and propylene polymers, polyethylene and vinyl polymers, poly(vinylidene chloride), styrene polymers, ABS resins, liquid crystal polymers, acrylic polymers, polyphenylene oxides, polycarbonates, and polymer alloys of polycarbonates with poly(C2-6 alkylene glycol phthalates). The manufacturing process of the backsheet was provided, one polymer or a mixture of more polymers are used to form the film configuration in place of the former PET layer, thus excellent processability, material mechanical performances, barrier property and ageing resistance can be obtained; furthermore, the laminated films of the backsheet are formed via melt co-extrusion or extrusion composite process, which significantly upgraded the adhesion strength between the laminated films, and simplified manufacturing process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Crimped yarn, method for manufacture thereof, and fiber structure

InactiveCN101313091AImprove wear resistanceImprove qualityConjugated synthetic polymer artificial filamentsMonocomponent polyesters artificial filamentYarnPolymer alloy

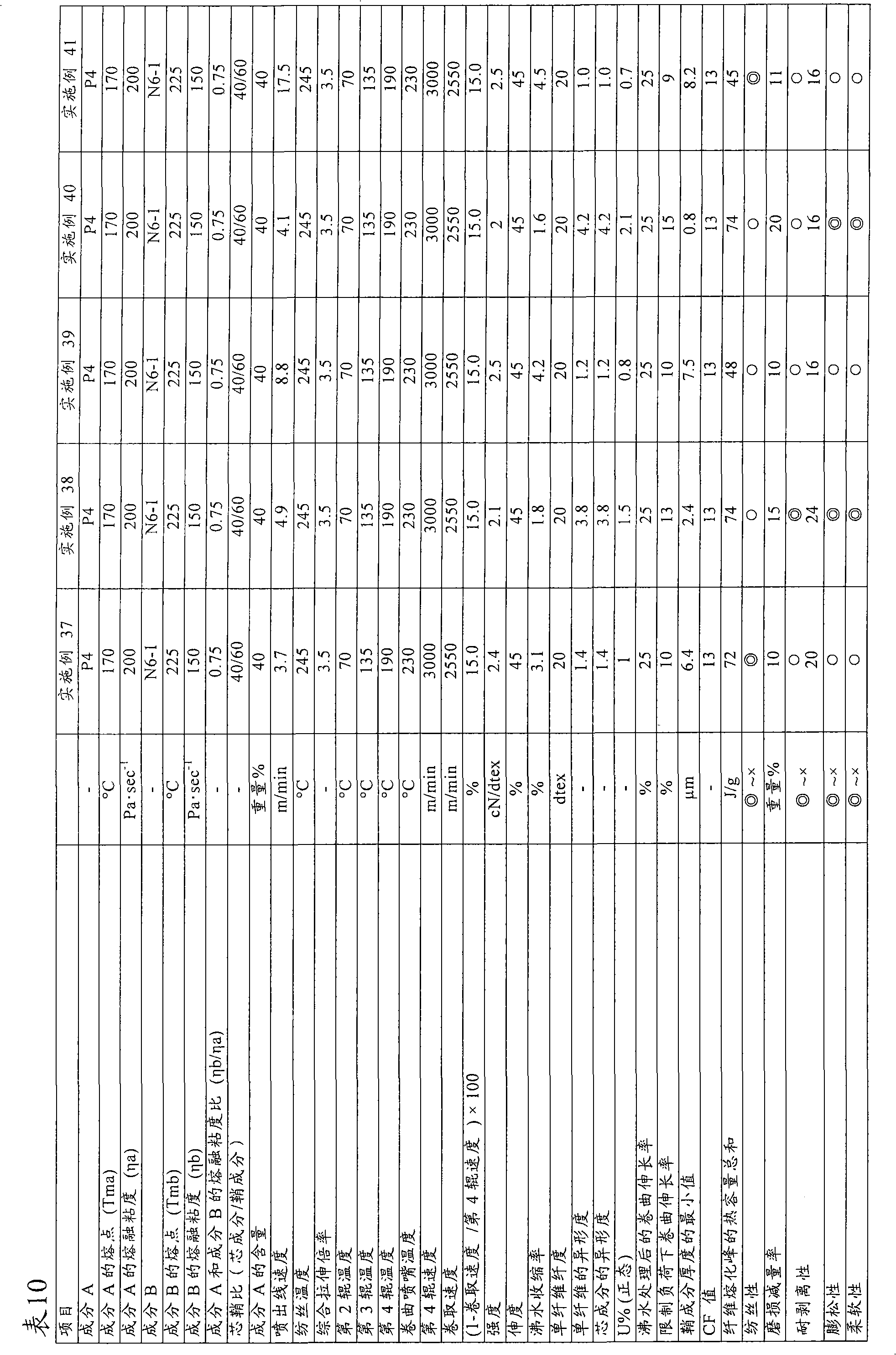

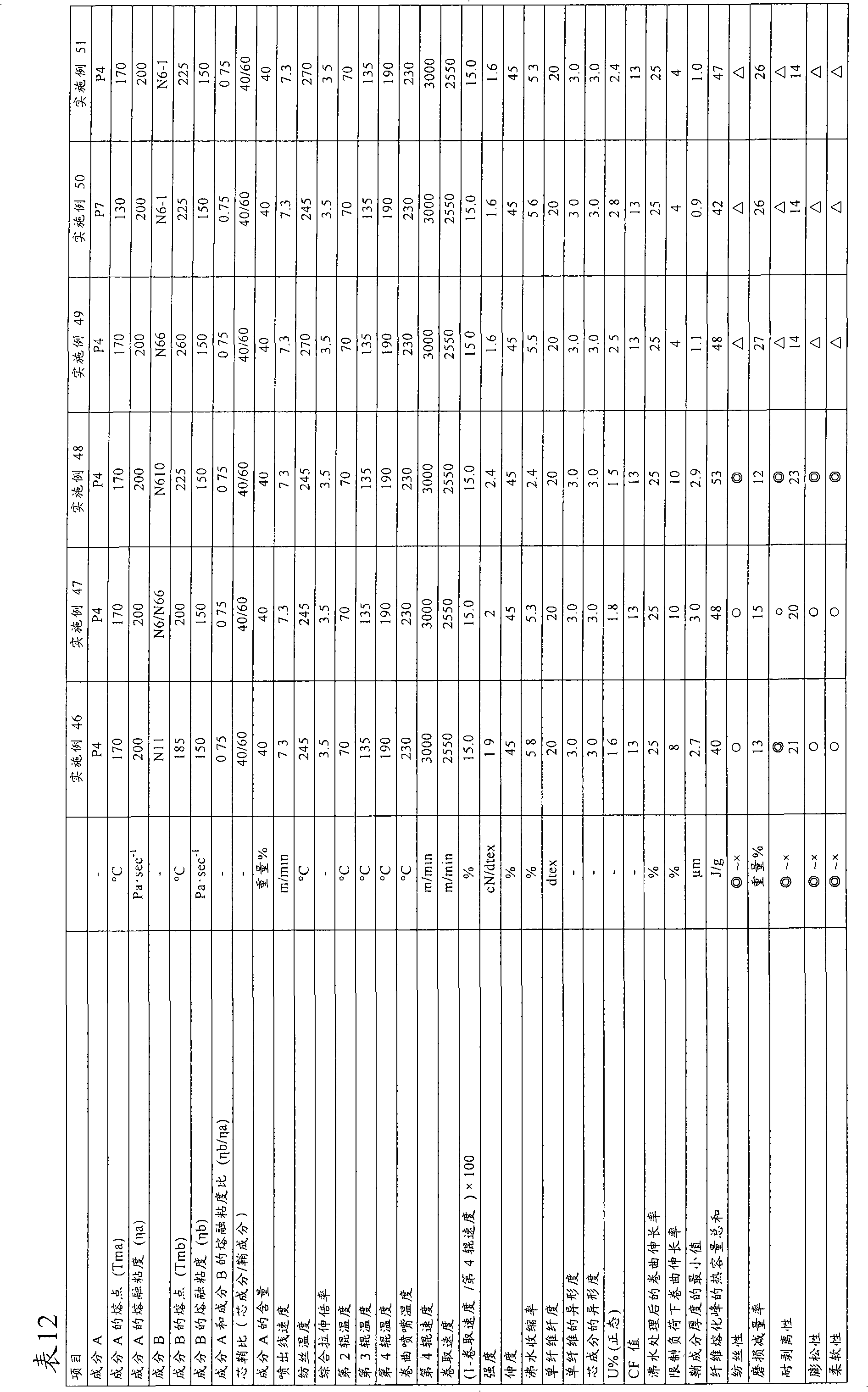

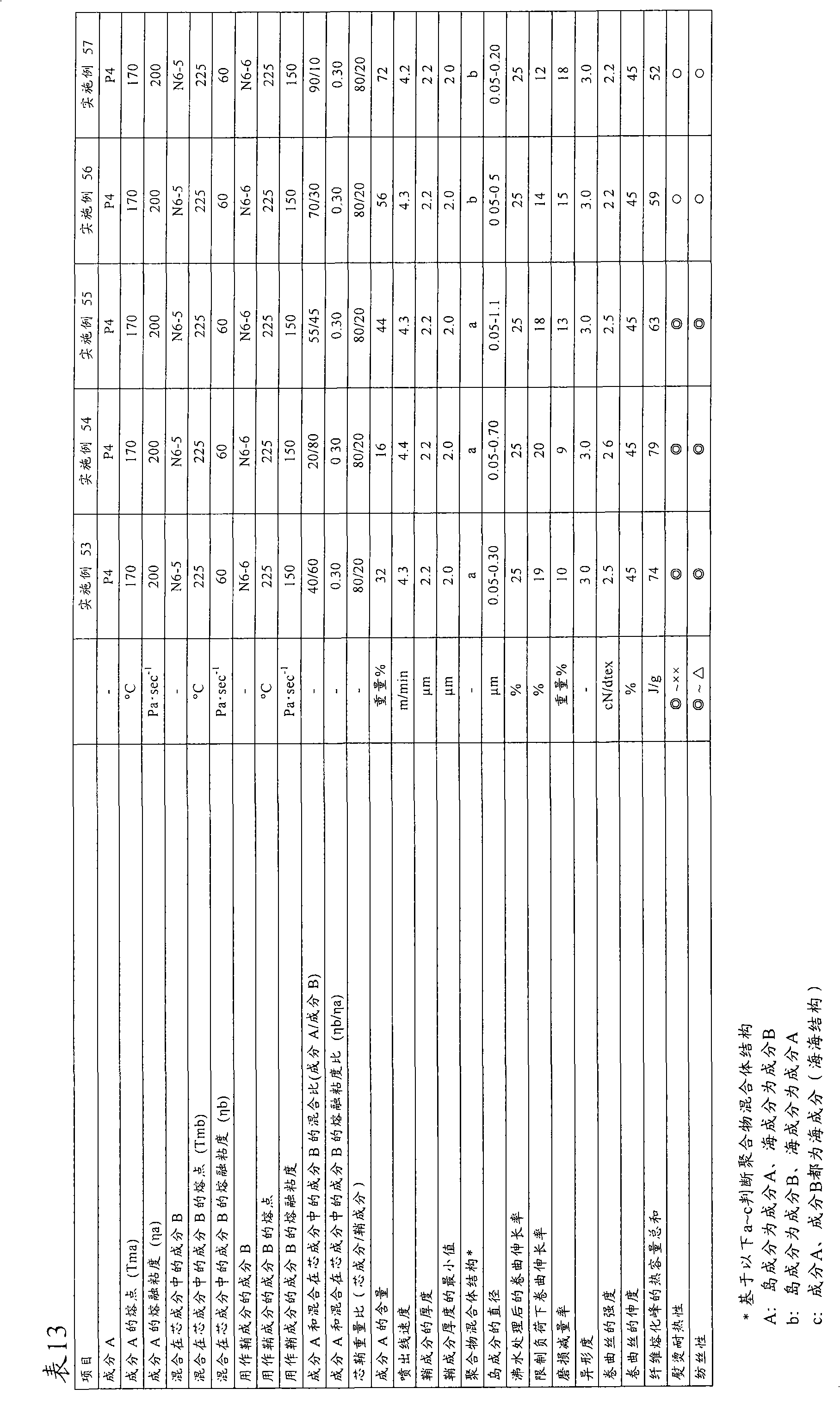

The invention relates to a crimped yarn and a fiber structure. The crimped yarn is characterized in that: a multifilament yarn composed of a synthetic fiber is crimped to obtain the crimped yarn; the synthetic fiber is composed of an aliphatic polyester resin (A) and a thermoplastic polyamide resin (B); the ratio of the exposed surface area of the aliphatic polyester resin (A) to the surface area of the fiber is below 5%. The fiber structure is characterized in that at least part of the fiber structure comprises the crimped yarn. The invention also relates to the crimped yarn and the fiber structure. The crimped yarn is composed of a polymer alloy synthetic fiber or core-sheath-type composite fiber. The polymer alloy synthetic fiber is composed of the aliphatic polyester resin (A) and the thermoplastic polyamide resin (B). The core component of the core-sheath-type composite fiber is composed of the aliphatic polyester resin (A) or a polymer alloy composed of the aliphatic polyester resin (A) and the thermoplastic polyamide resin (B). The sheath component is composed of the thermoplastic polyamide resin (B). The fiber structure is characterized in that at least part of the fiber structure comprises the crimped yarn.

Owner:TORAY IND INC

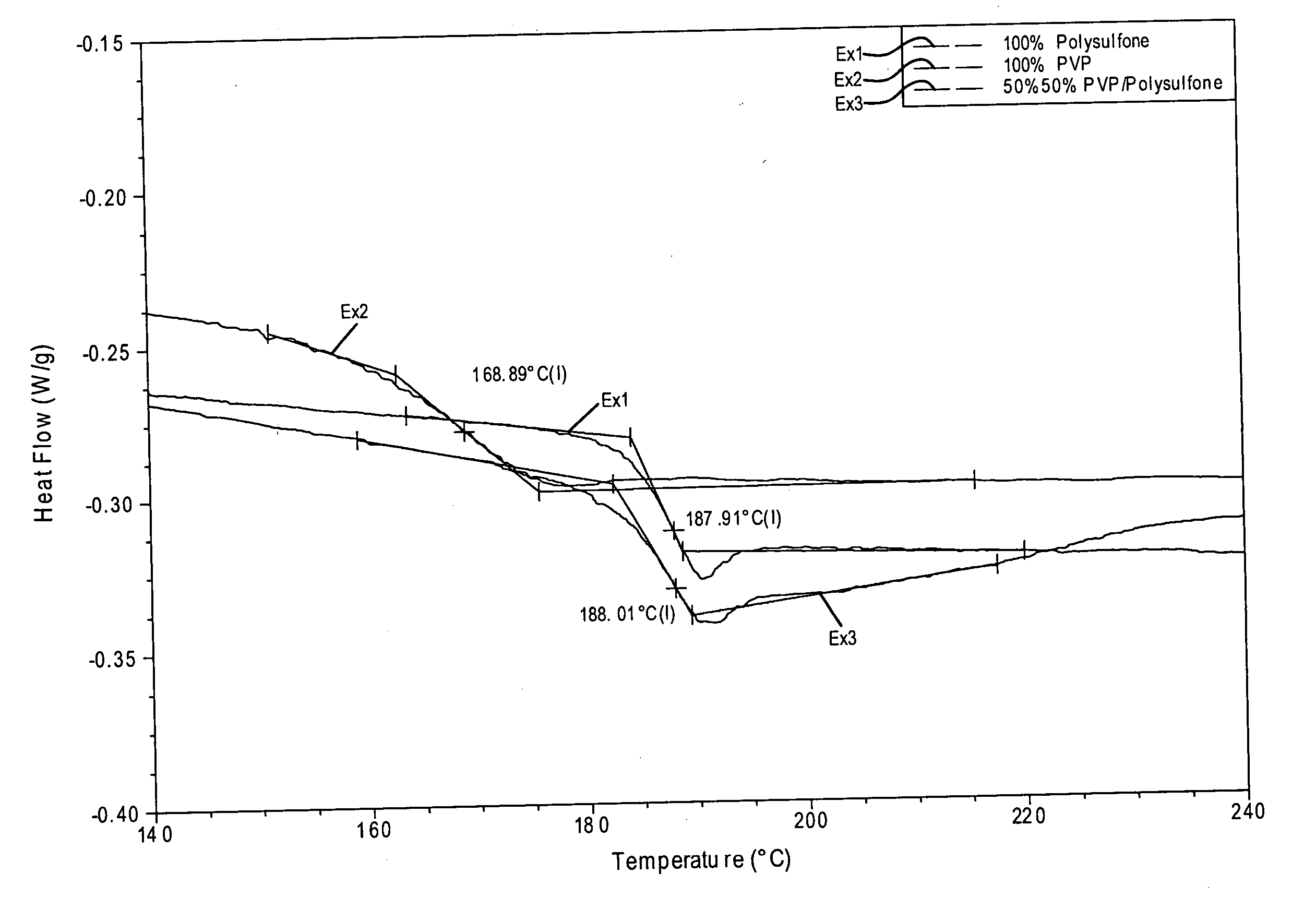

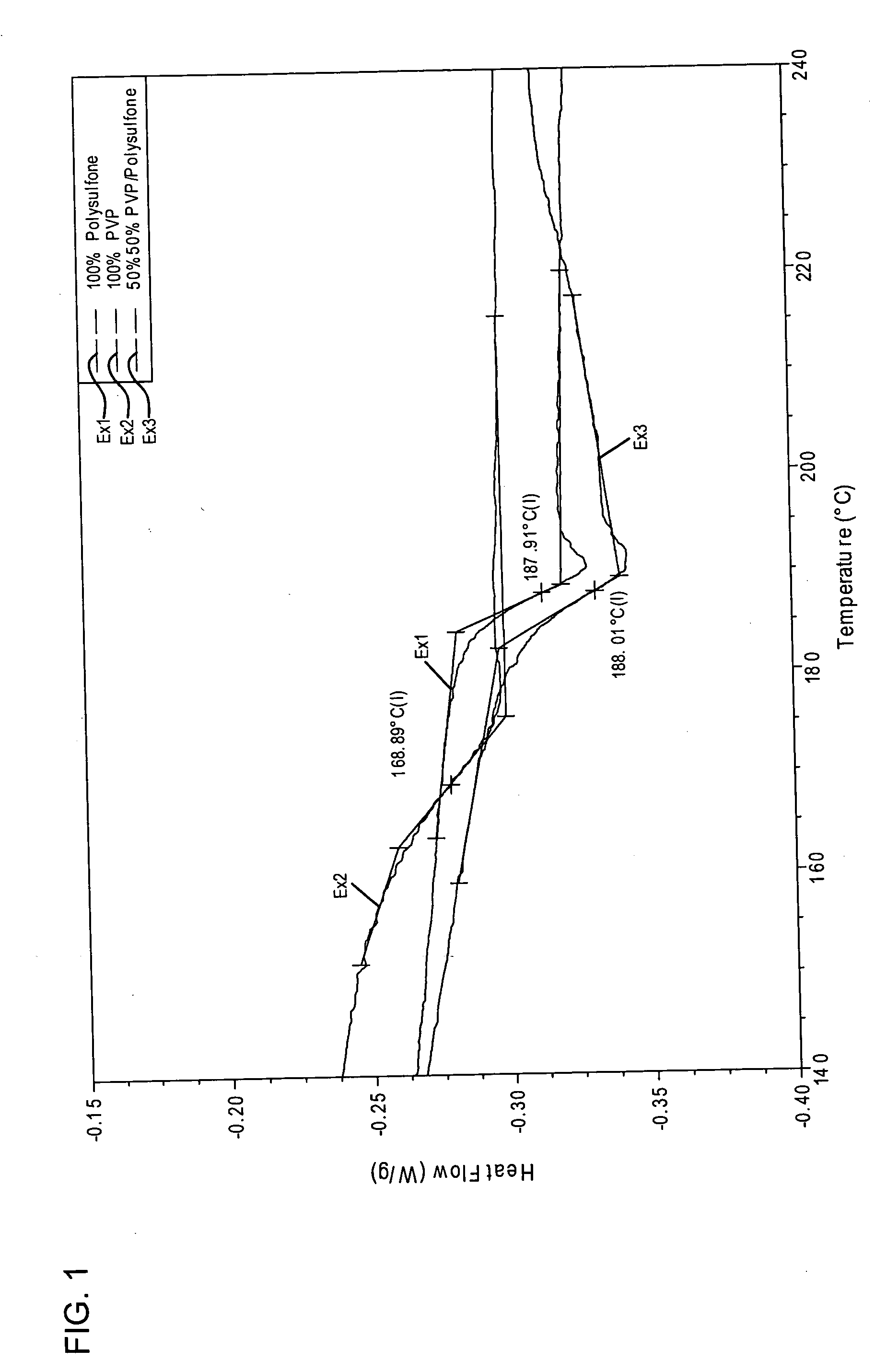

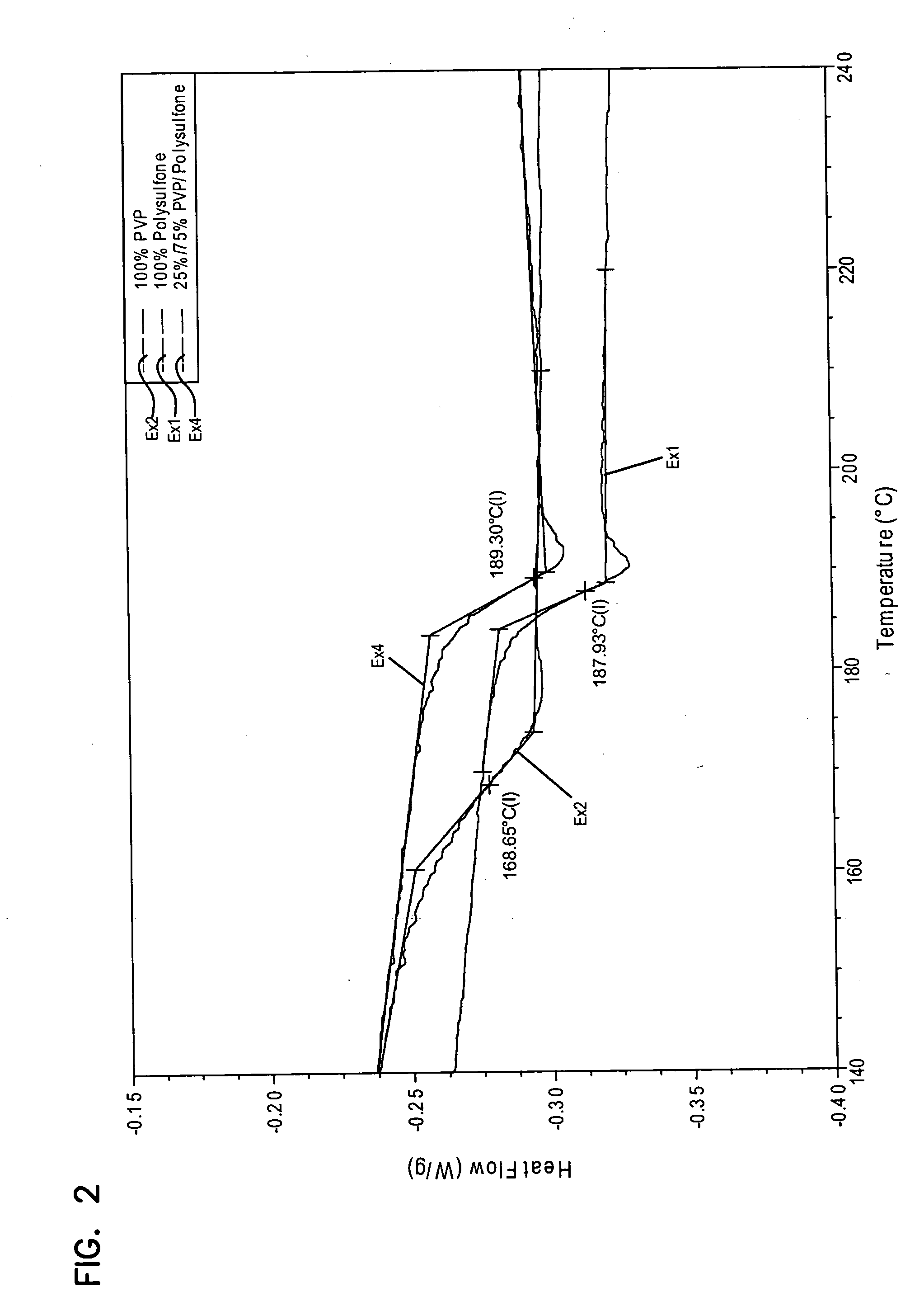

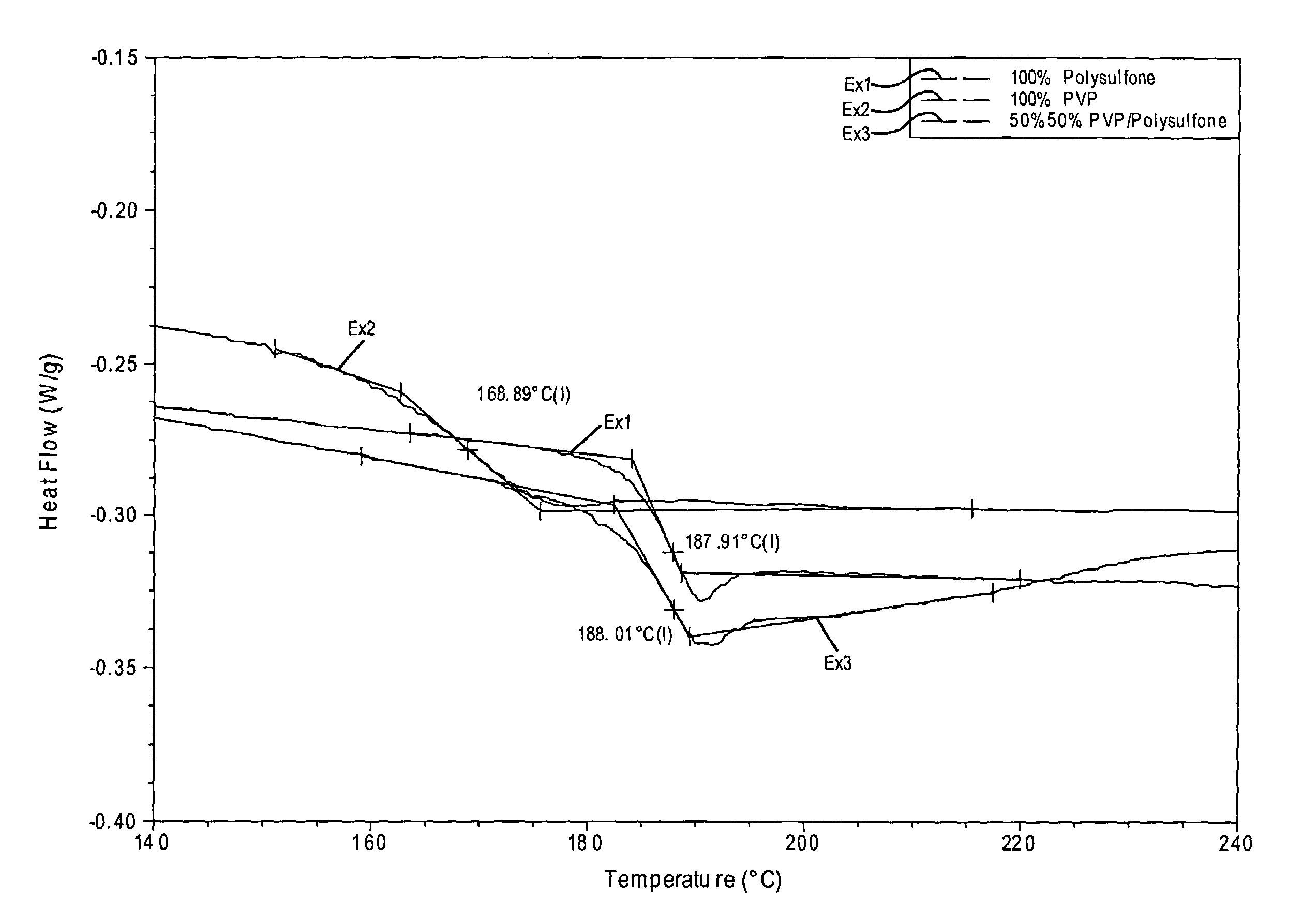

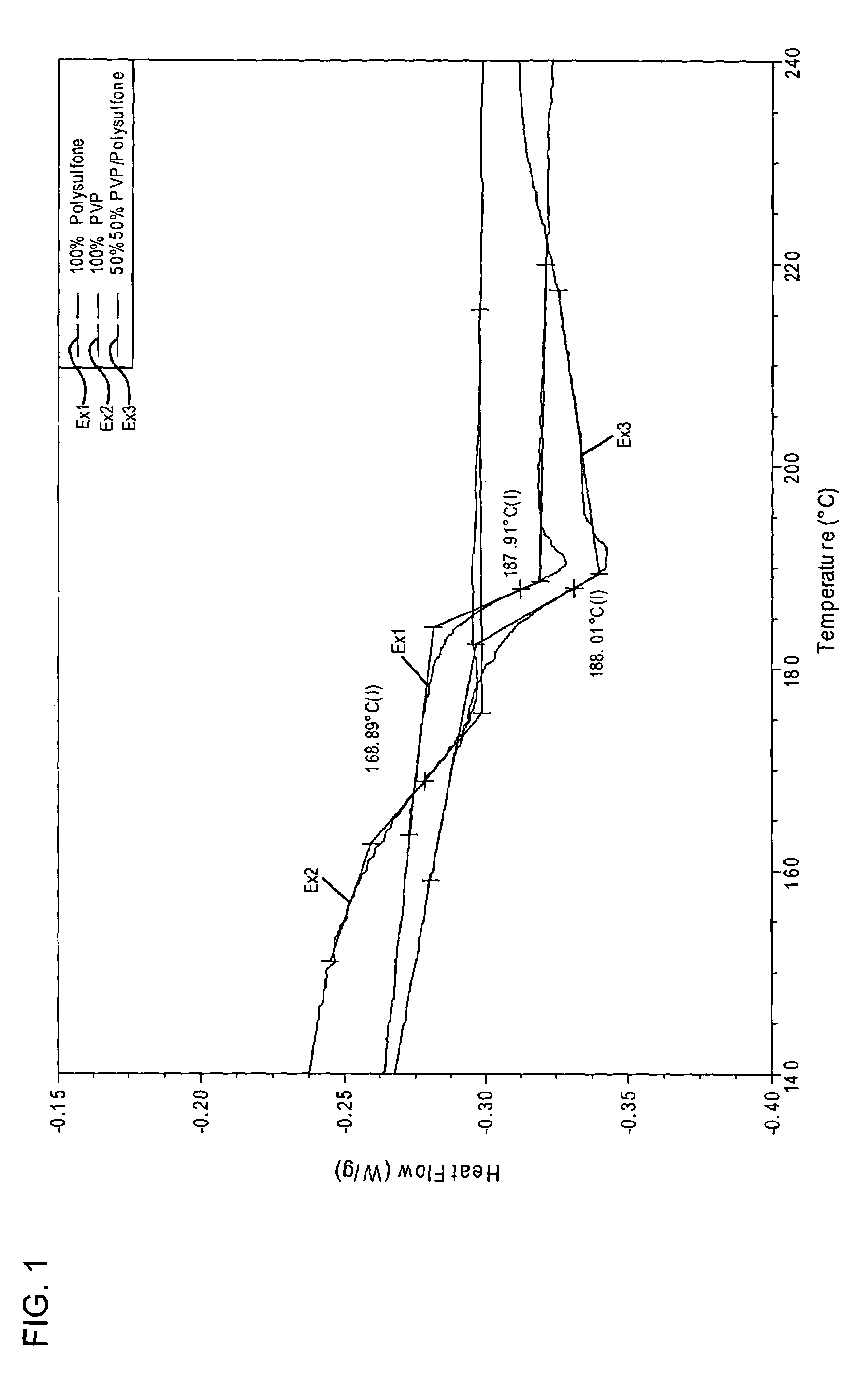

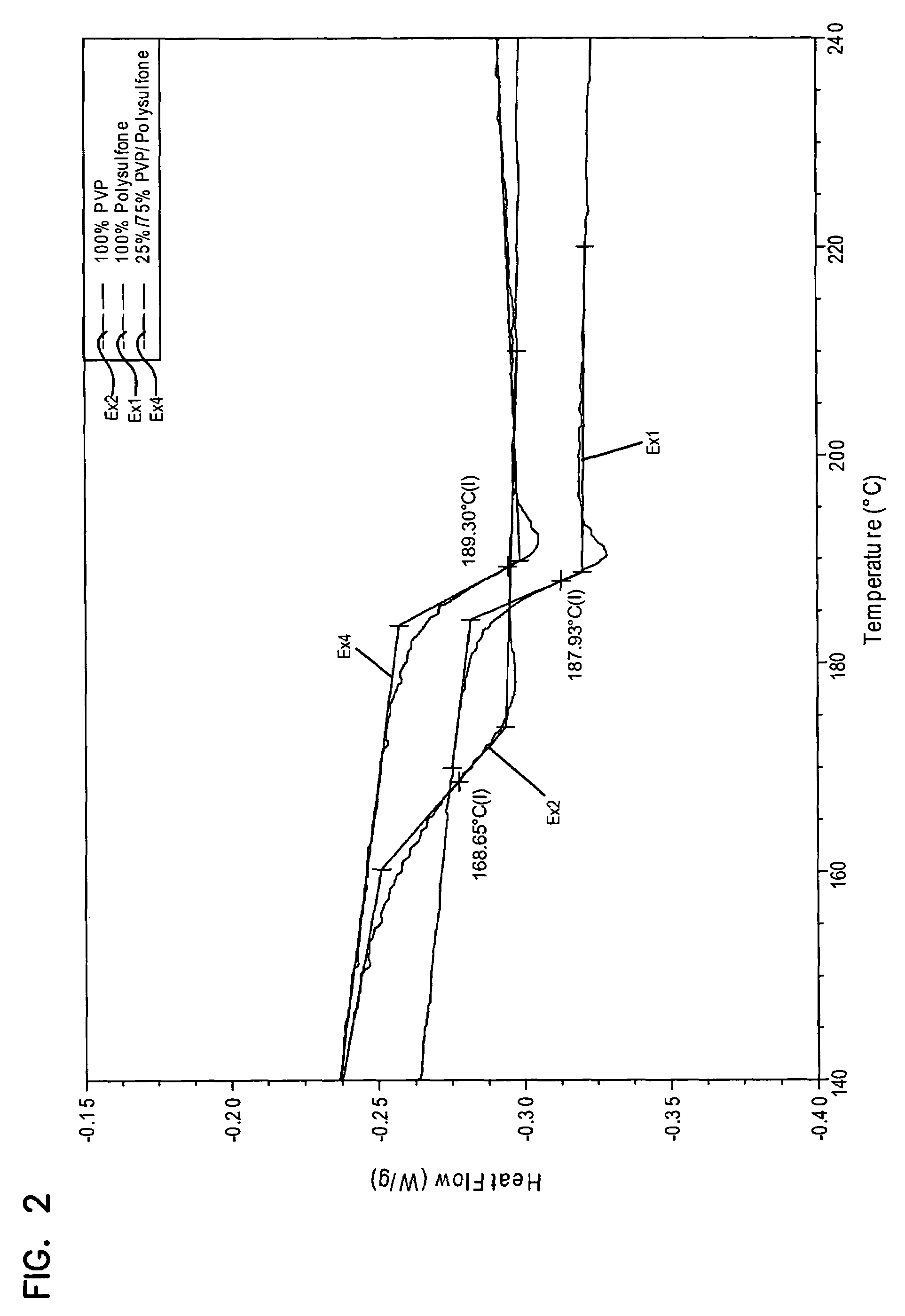

Polysulfone and poly(N-vinyl lactam) polymer alloy and fiber and filter materials made of the alloy

ActiveUS20070102372A1Substantial surface loadingHigh initialSemi-permeable membranesDispersed particle filtrationPolymer sciencePolymer alloy

Owner:DONALDSON CO INC

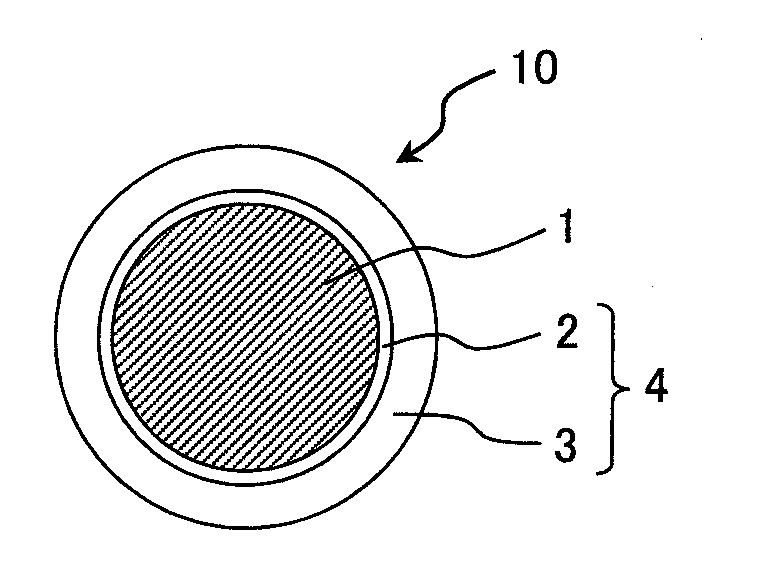

Insulated wire

InactiveUS20110192632A1AdhesionImprove adhesionInsulated cablesInsulatorsTetrafluoroethylenePolymer alloy

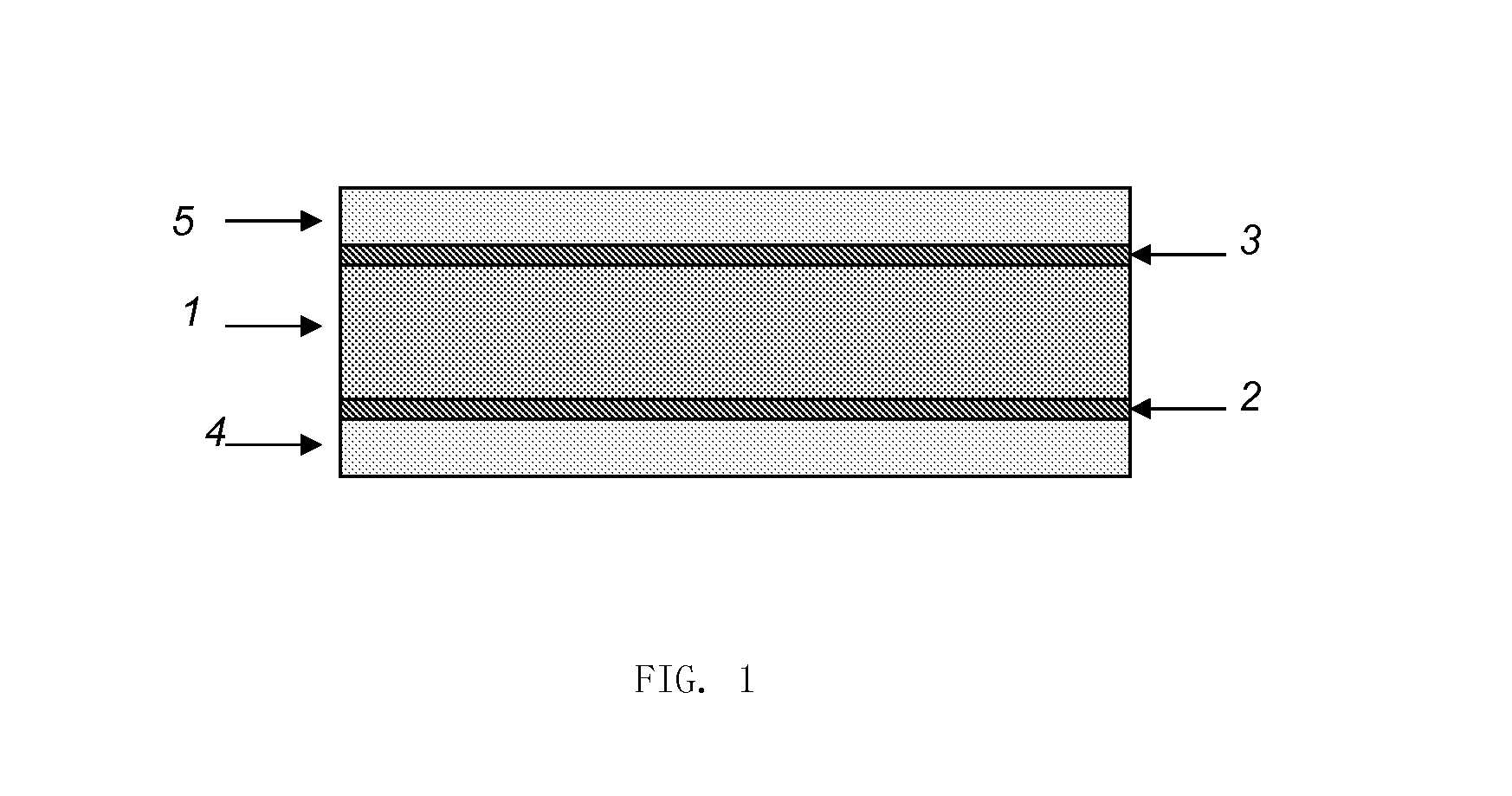

There is provided an insulated wire having an insulation film composed of a plurality of layers provided on a conductor, in which: the insulation film includes a first film layer and a second film layer; the first film layer is made of a first resin composition formed by graft-polymerizing a graft compound with an ethylene-tetrafluoroethylene copolymer and is provided on a circumference of the conductor; and the second film layer is made of a second resin composition being a polymer alloy made of a polyphenylene sulfide resin and a polyamide resin, or being a polymer alloy made of a polyether ether ketone resin and a polyamide resin and is provided on a circumference of the first film layer.

Owner:HITACHI CABLE +1

Flame-retardant cold-resistant PVC/ABS alloy and preparation method thereof

The invention belongs to the technical field of polymer alloy, and relates to polyvinyl chloride / acrylonitrile-styrene-butadiene copolymer alloy and a preparation method thereof; the polyvinyl chloride / acrylonitrile-styrene-butadiene copolymer alloy comprises the following components by weight: 100 parts of polyvinyl chloride, 30-100 parts of acrylonitrile-styrene-butadiene copolymer, 10-50 parts of a cold-resistant plasticizer, 15-30 parts of a fire retardant, 6-20 parts of a compatilizer, 1-10 parts of a heat stabilizer, 0.2-2 parts of an anti-oxidant, and 0.2-10 parts of an processing additive. The PVC / ABS alloy of the invention has a short process flow, has both maintained PVC flame retardancy and increased product cold resistance, and has enlarged product application scope.

Owner:HEFEI GENIUS NEW MATERIALS

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveCN1720358AFibre treatmentMonocomponent synthetic polymer artificial filamentPolymer alloyPolymer science

The invention provides an aggregate of nanofibers which is not limited in shape or material polymer, is widely applicable and developable, and has a small dispersion of single fiber fineness, and a process for the production thereof. The invention relates to an aggregate of nanofibers which have a number-average single fiber fineness of 1 x 10<-7> to 2 x 10<-4> dtex and a proportion of single fibers having single fiber fineness ranging from 1 x 10<-7> to 2 x 10<-4> dtex of 60 % or above and which are made of a thermoplastic polymer.

Owner:TORAY IND INC

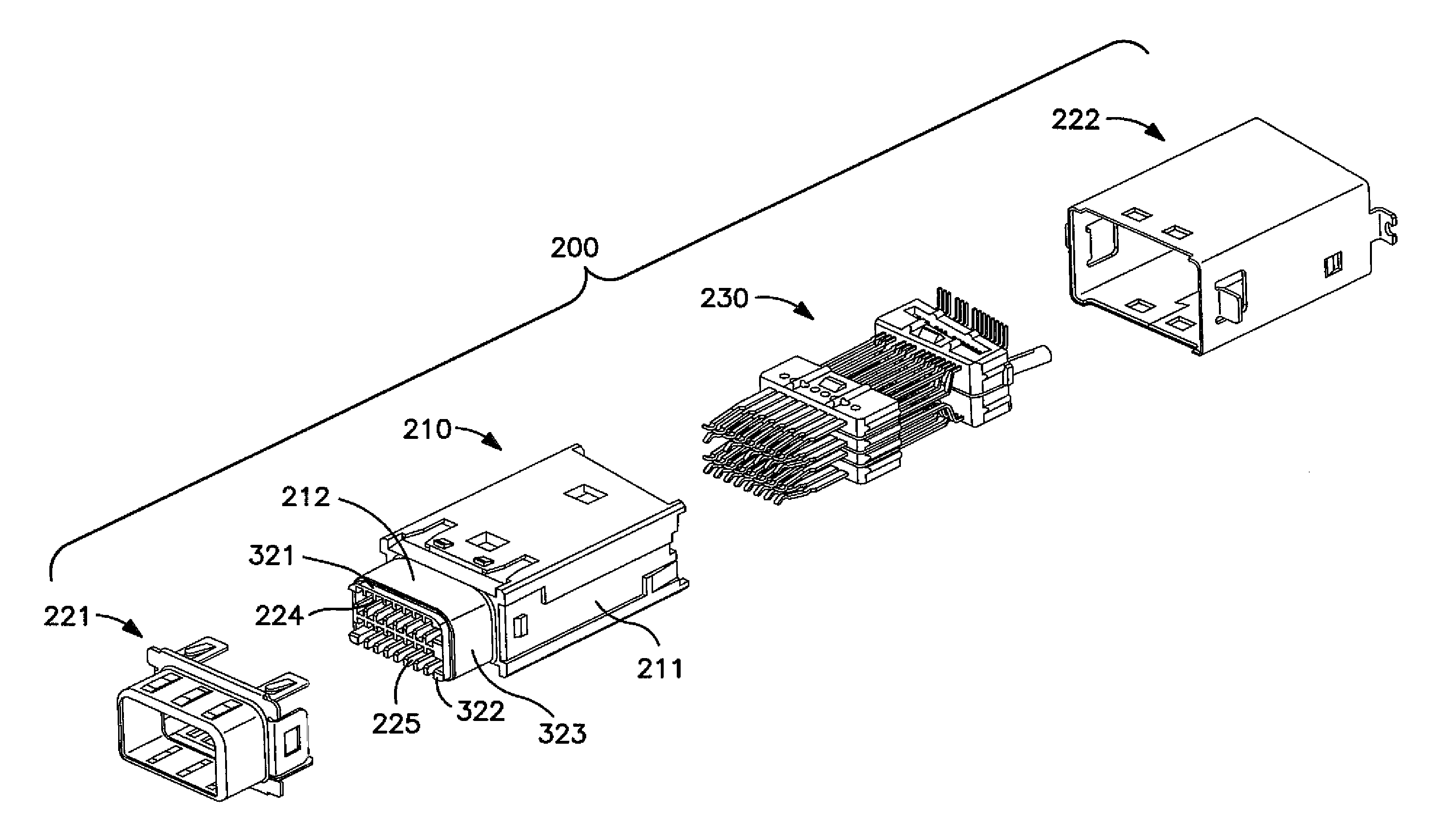

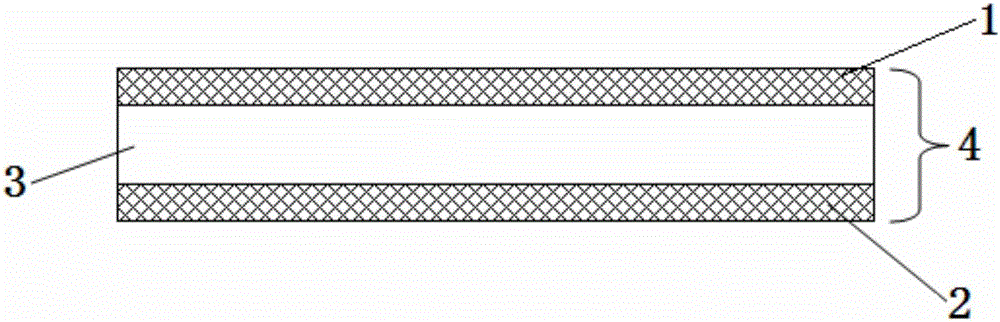

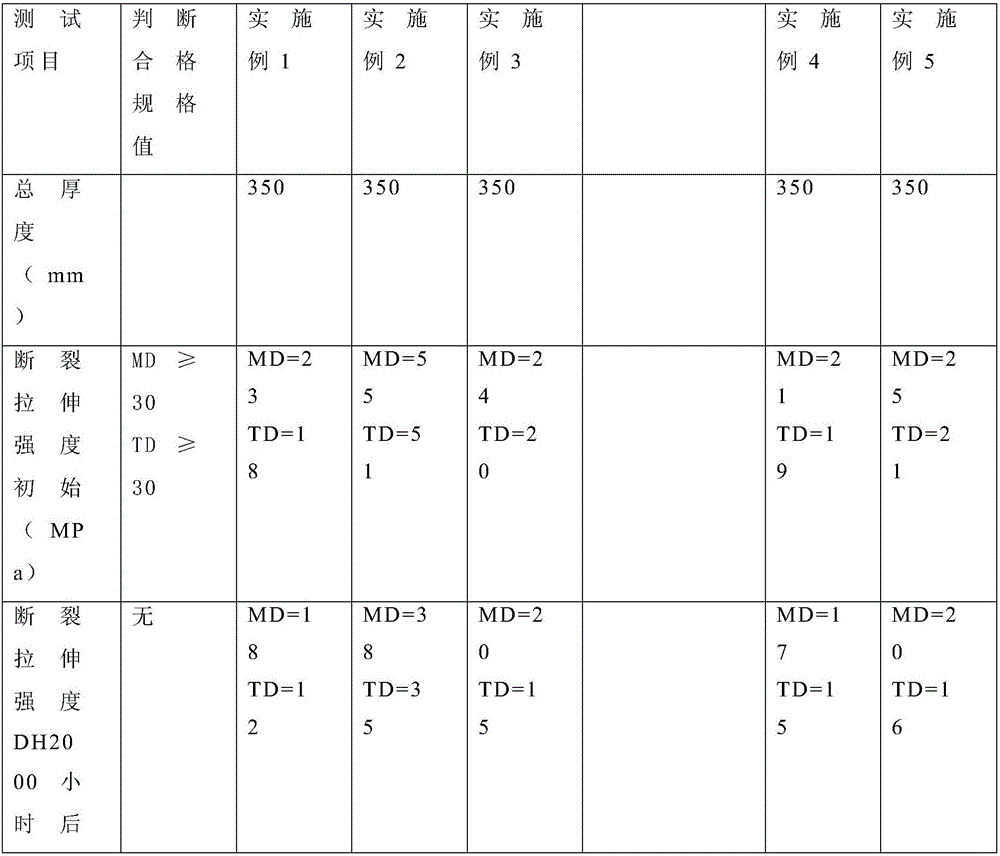

Co-extruded one-time formed backplate with three-layer structure for solar cell module

ActiveCN105870237ASynthetic resin layered productsElectrical equipmentBreaking strengthPolymer alloy

Owner:CYBRID TECHNOLOGIES INC

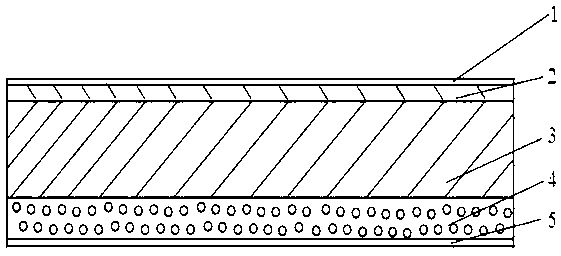

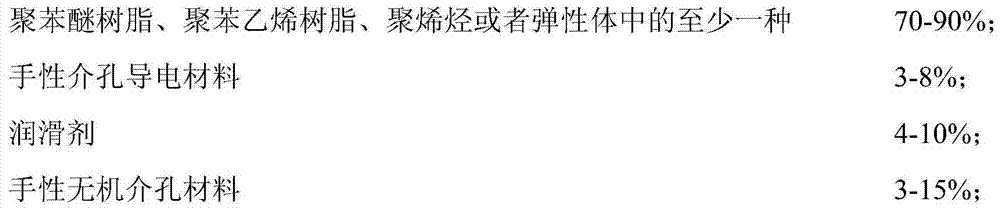

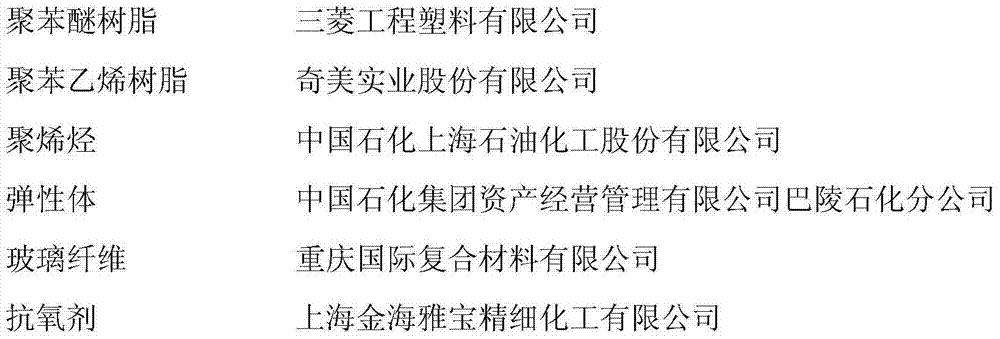

Functional co-extrusion composite alloy material floor-heating floor and manufacturing method thereof

ActiveCN103628652ASimple processImprove thermal conductivityAntifouling/underwater paintsSynthetic resin layered productsPolymer alloyAlloy

The invention discloses a functional co-extrusion composite alloy material floor-heating floor and a manufacturing method thereof. The floor is of a five-layer composite structure, a board vacuum coating reflection layer is arranged on the bottommost layer, a heating layer which is the conductive heating plastic layer is arranged above the reflection layer, a PVC-based polymer alloy composite material layer is arranged above the heating layer, and a co-extrusion composite decorative layer is arranged above the PVC-based polymer alloy composite material layer. The heating layer, the PVC-based polymer alloy composite material layer and the co-extrusion composite decorative layer integrally form the whole structure through the co-extrusion technology, and a transparent layer protective layer processed through UV anti-microbial wear-resistance processing is arranged on the topmost layer. The manufacturing method of the functional co-extrusion composite alloy material floor-heating floor comprises the following steps of (1) mixture and manufacturing of the PVC-based polymer alloy composite material layer, (2) on-line co-extrusion composite of the heating layer, the co-extrusion composite decorative layer and the PVC-based polymer alloy composite material layer, (3) surface one-line knurling processing of the co-extrusion composite decorative layer, (4) vacuum coating conducted on the surface of boards and (5) surface layer UV anti-microbial wear-resistance processing. The manufacturing method of the functional co-extrusion composite alloy material floor-heating floor is simple in process, and the functional co-extrusion composite alloy material floor-heating floor manufactured by the method has the good floor heating conductivity, good size stability, anti-fouling environmental protection performance and using durability.

Owner:安徽圣源橡塑科技有限公司

Polysulfone and poly(N-vinyl lactam) polymer alloy and fiber and filter materials made of the alloy

ActiveUS7641055B2Maintain good propertiesIncrease resistanceSemi-permeable membranesDispersed particle filtrationPolymer alloyPolymer science

Owner:DONALDSON CO INC

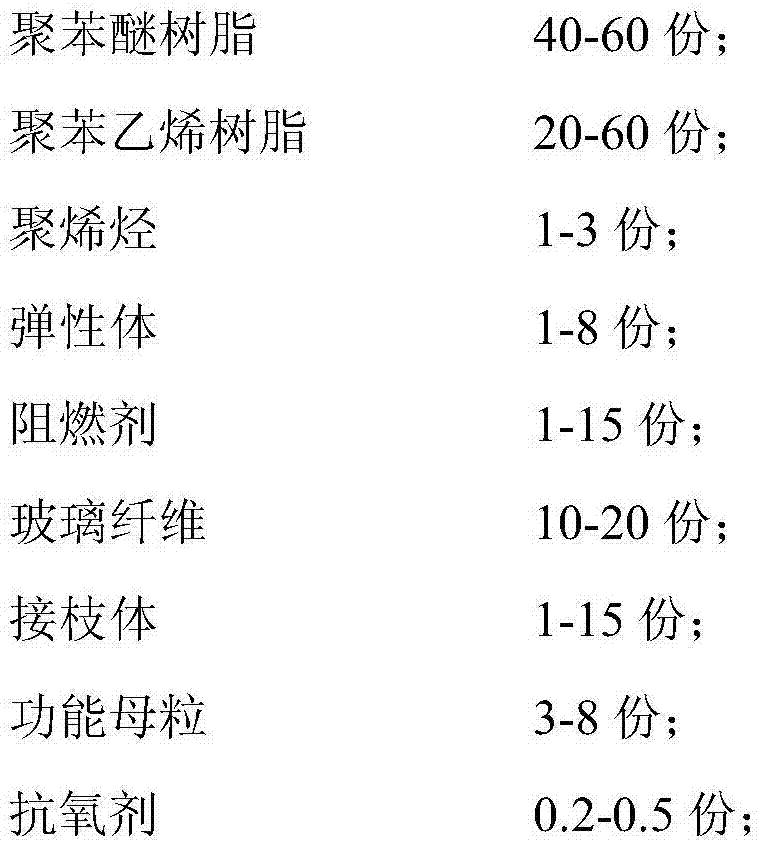

Polyphenylene oxide resin alloy material and preparation method and application thereof

The invention belongs to the field of polymer alloy material and particularly relates to polyphenylene oxide resin alloy material for machining cases of electric car lithium batteries and a preparation method of the material. The polyphenylene oxide resin alloy material comprises, by weight, 40-60 parts of polyphenylene oxide resin, 20-60 parts of polystyrene resin, 1-3 parts of polyolefin, 1-8 parts of elastomer, 1-15 parts of flame retardant, 10-20 parts of glass fiber, 1-15 parts of graft body, 3-8 parts of functional master batch and 0.2-0.5 part of antioxidant. The process of the polyphenylene oxide resin alloy material is optimized through reasonable formula combination, and the problem that the cases of the electric car lithium batteries deforms and electrode connections of the batteries crack after long-term use of electric cars is solved.

Owner:江苏沃特新材料科技有限公司

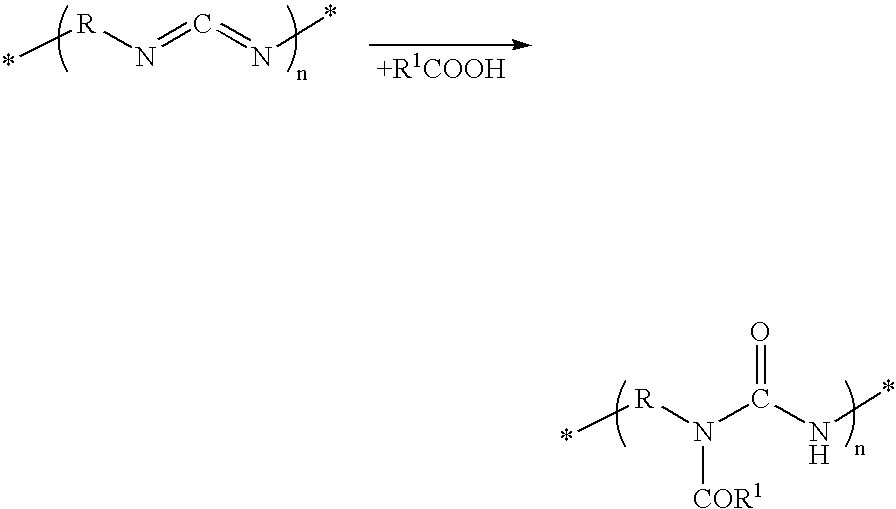

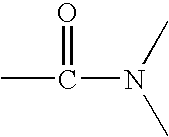

Novel resin modifier and polar group-containing polymer composition containing the same

ActiveUS20070173603A1High low temperature impact resistanceCompatibilityOther chemical processesPolymer sciencePolyolefin

An object to be solved Disclosed is a novel resin modifier which enables to improve the low-temperature impact resistance of a polymer alloy including a polar group-containing polymer and an olefin polymer and enables to obtain a molded article with smooth surface when the polymer alloy is molded. Also disclosed is a polar group-containing polymer composition including the resin modifier. The polar group-containing polymer composition which is suitable in the invention is a resin composition of a polylactic acid and a polypropylene. Means for solving the object A resin modifier (C) obtained by reacting a polyolefin (A) having a group which reacts with a carbodiimide group, and a carbodiimide group-containing compound (B), wherein the content of the carbodiimide group is from 1 to 200 mmol per 100 g of the resin modifier, and a polar group-containing polymer composition (F) comprising from 1 to 30% by weight of the resin modifier (C), from 99 to 20% by weight of a polar group-containing polymer (D), and from 0 to 80% by weight of an olefin polymer (E).

Owner:MITSUI CHEM INC

Polymer alloy with added wood (bamboo) powder and flake material and preparation method thereof

InactiveCN102134367ASmall coefficient of linear expansionImprove temperature stabilityPolymer alloyPolymer science

The invention provides a polymer alloy with added wood (bamboo) powder and a flake material, which comprises the wood (bamboo) powder, a polymer material (ABS (Acrylonitrile Butadiene Styrene) / PVC (Polyvinyl Chloride) alloy, PC (Polycarbonate) / PE (Polyethylene) alloy, PP (Polypropylene), PE (Polyethylene), PVC (Polyvinyl Chloride), PS (Polystyrene), a coupling agent, an impact modifier, a stabilizer, a plasticizer, a foaming agent, a flame retardant, a compatilizer, a dispersing agent, a lubricating agent and an ultraviolet absorbent, wherein 5-35 parts by weight of surface modified flake glass or surface modified metal flake or surface modified organic resin flake and 15-40 parts by weight of the wood (bamboo) powder are added into the polymer material.

Owner:王广武

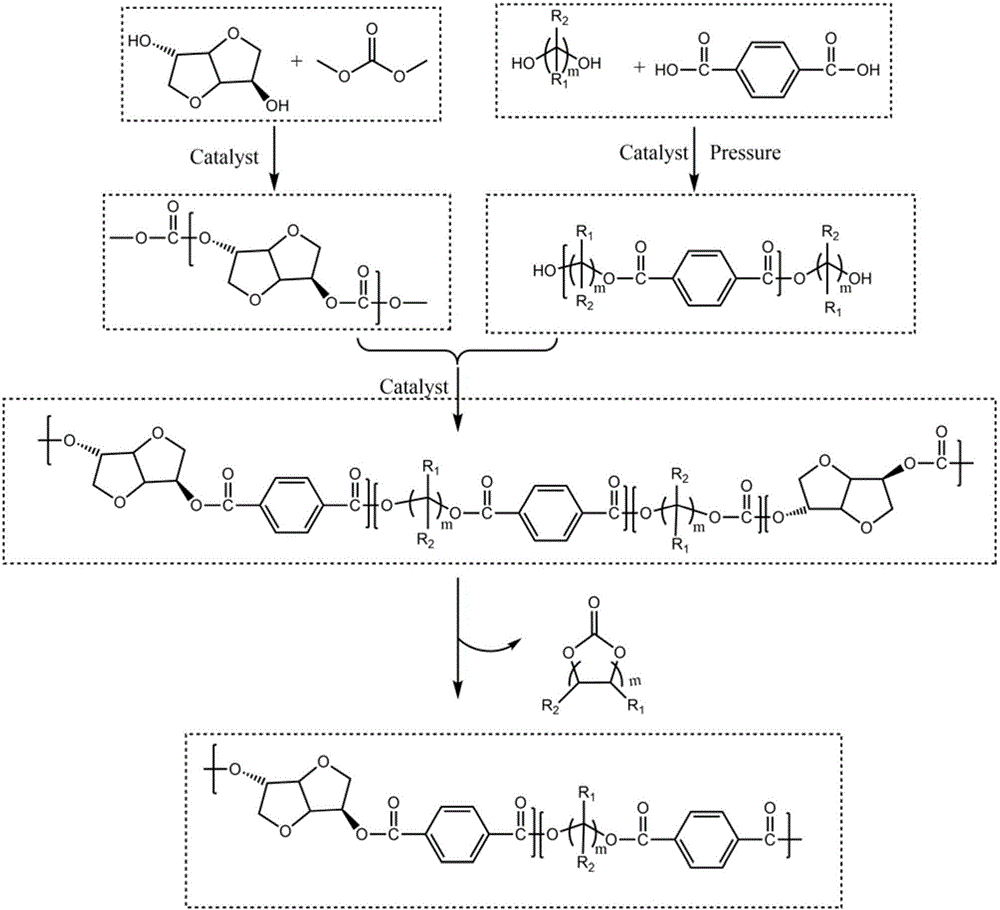

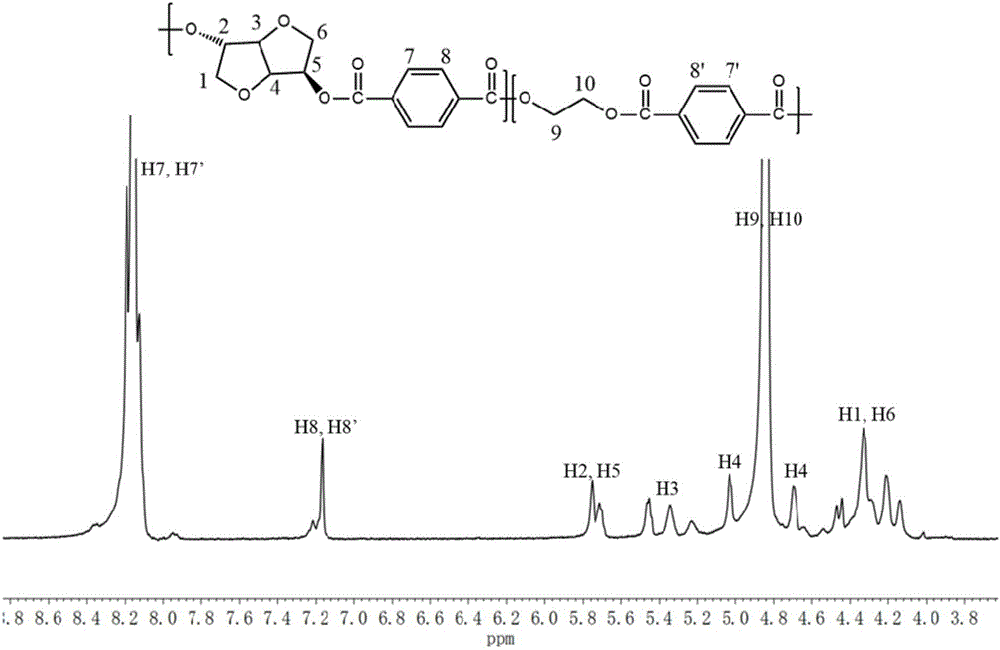

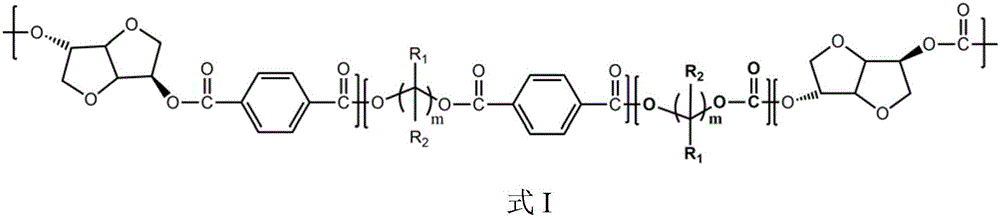

Preparation method of high heat resistance isosorbide type random copolyester

ActiveCN106800643AImprove heat resistanceOvercoming the problem of low reactivityFiberPolymer science

The invention relates to a preparation method of high heat resistance isosorbide type random copolyester. As for the high heat resistance isosorbide type random copolyester, by controlling the feed molar ratio of a monomer, a short-chain alkyl carbonate structure is constructed between aromatic dibasic acid and isosorbide, and then cyclic allyl ester carbonate is removed under a certain condition to realize linkage of the aromatic dibasic acid and an isosorbide structure unit. The prepared isosorbide type random copolyester has high glass transition temperature which decides that the high heat resistance isosorbide type random copolyester has good heat resistance and is low in preparation cost and environment-friendly in preparation process. The random copolyester has the viscosity being 0.6-1.0dL / g and the glass transition temperature being 90-190 DEG C, is excellent in comprehensive performance and can be used for preparing polymer blends, polymer alloy, heat resistant vessels, bottles, films, fibers, sheets, optical products and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

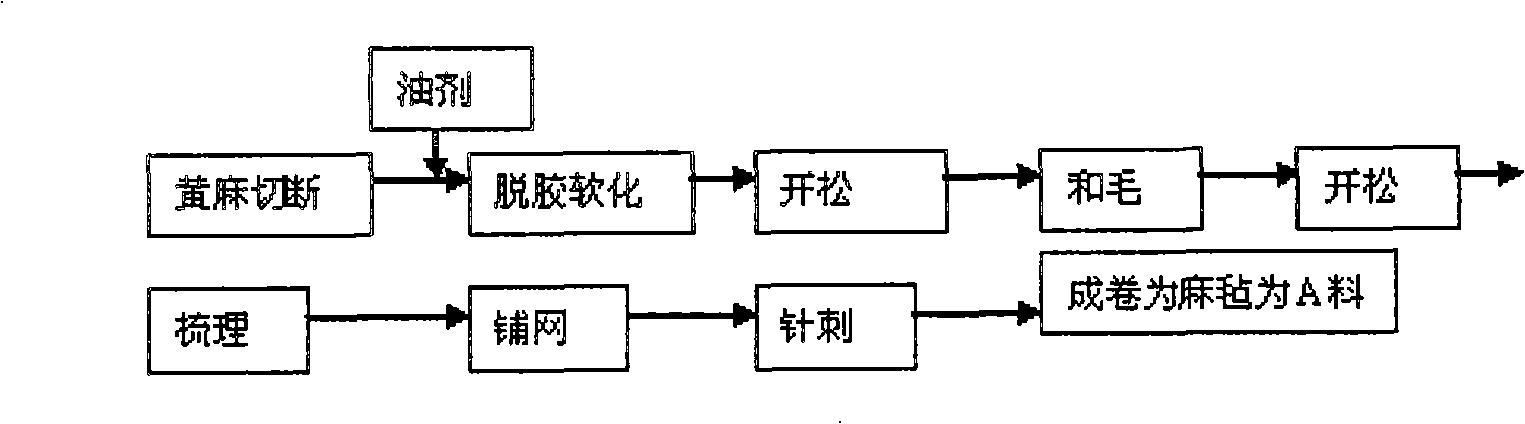

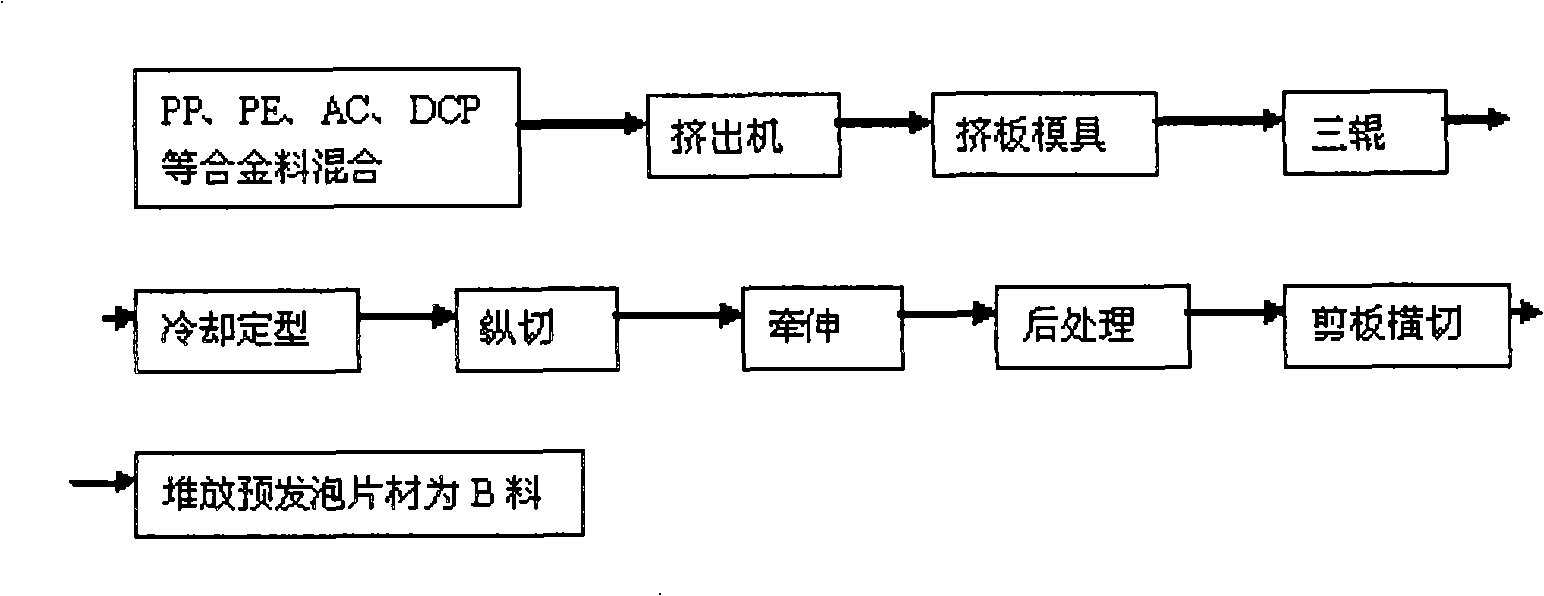

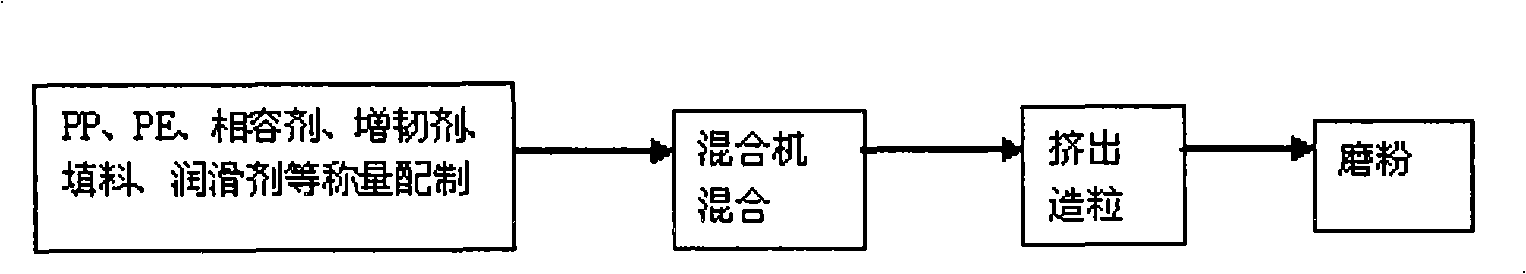

Light jute fiber reinforced polypropylene alloy composite plate and machining process thereof

InactiveCN101537713ACause wasteImprove performance indicatorsFlat articlesNon-woven fabricsFiberCross-link

The invention relates to a light jute fiber reinforced polypropylene alloy composite plate. Main raw materials of the composite plate are jute and a polymer material. In a manufacturing process, polypropylene, polyethylene, compatibilizer (such as reactive-type polymer compatibilizer MPP), toughening agent (such as rubber-like EPDM ) and filler are added to the polymer alloy raw material, wherein the filler is talcum powder, CaCO3, lubricant (WAX), foaming agent (AC) for facilitating lightweight foaming, cross-linking agent (DCP) and the like. The composite plate is manufactured through a special machining process. Because various raw materials adopted in the invention are all nontoxic, no pollution can be caused to workshops or ecological environment during manufacture; due to pipeline operation, no raw materials can be wasted; due to the special machining process and coupling-agent treatment performed on the related raw materials, all performance indexes of a light jute fiber reinforced low-foamed alloy plate are greatly improved; and due to the promotion of product performance, the composite plate can be used to be made into automobile inner decoration materials in various shapes, and can be particularly used as an automobile ceiling, a front / back top plate, a back panel, a side panel, an airduct and the like.

Owner:丹阳市新美龙汽车软饰件有限公司

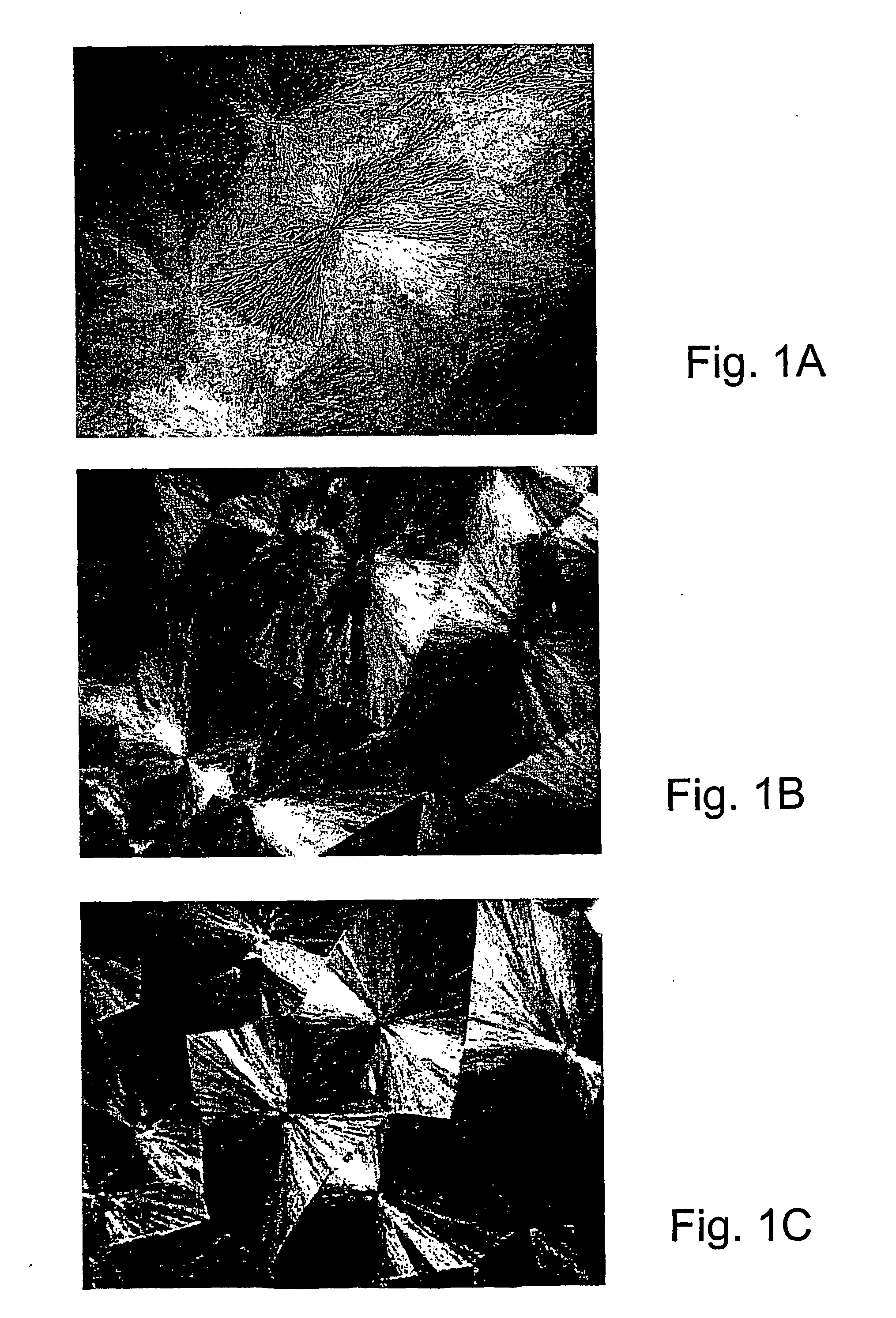

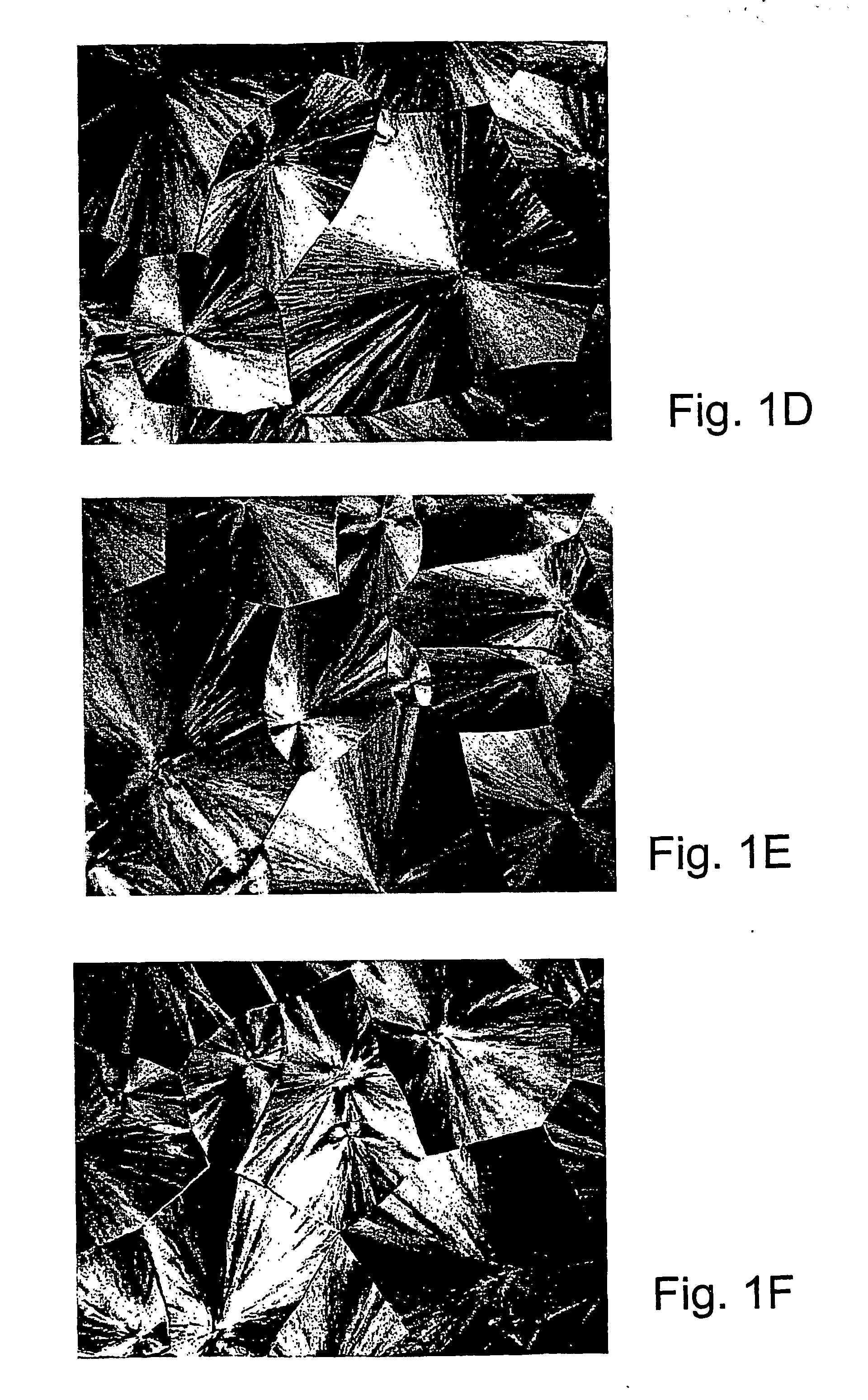

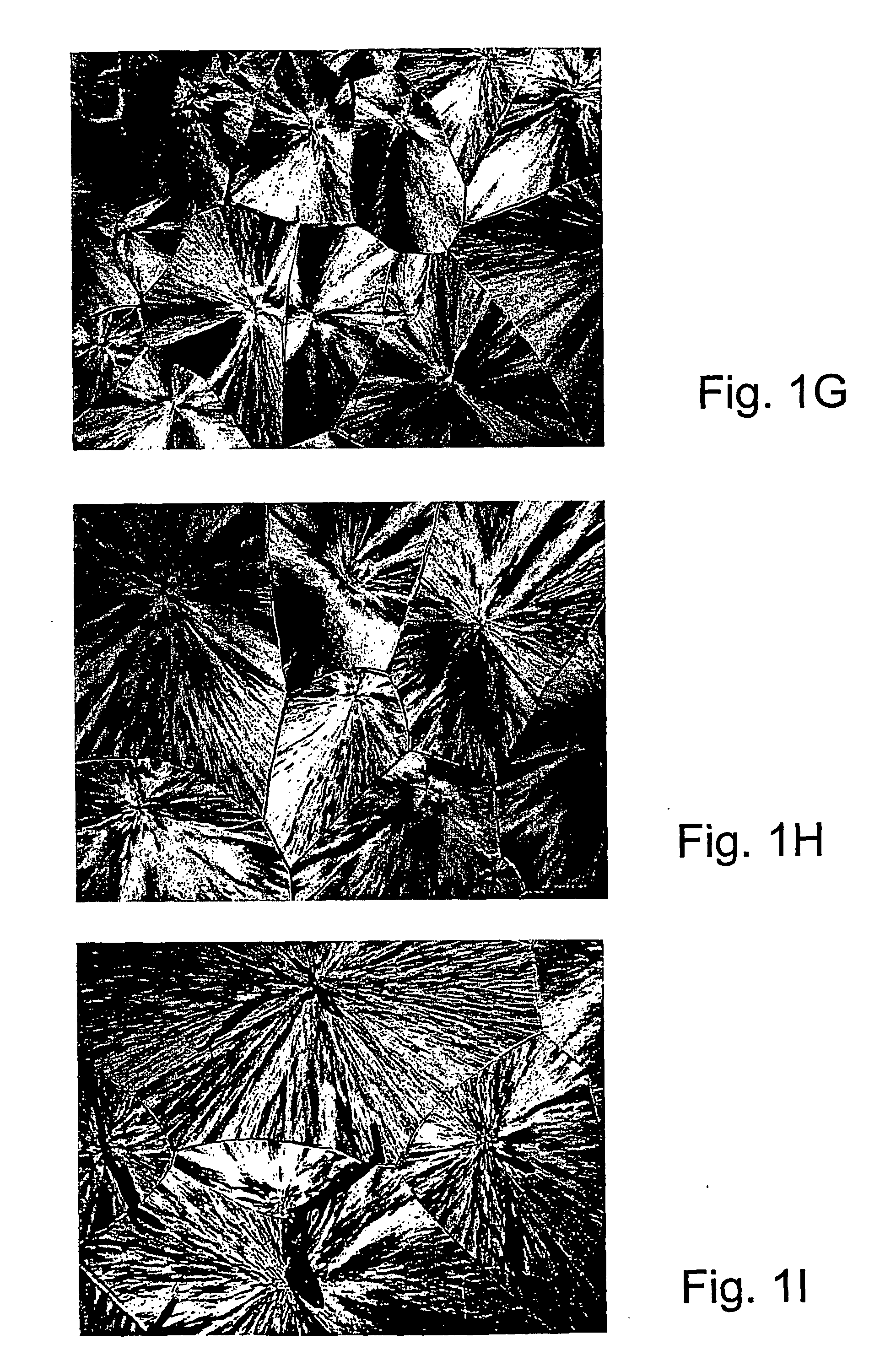

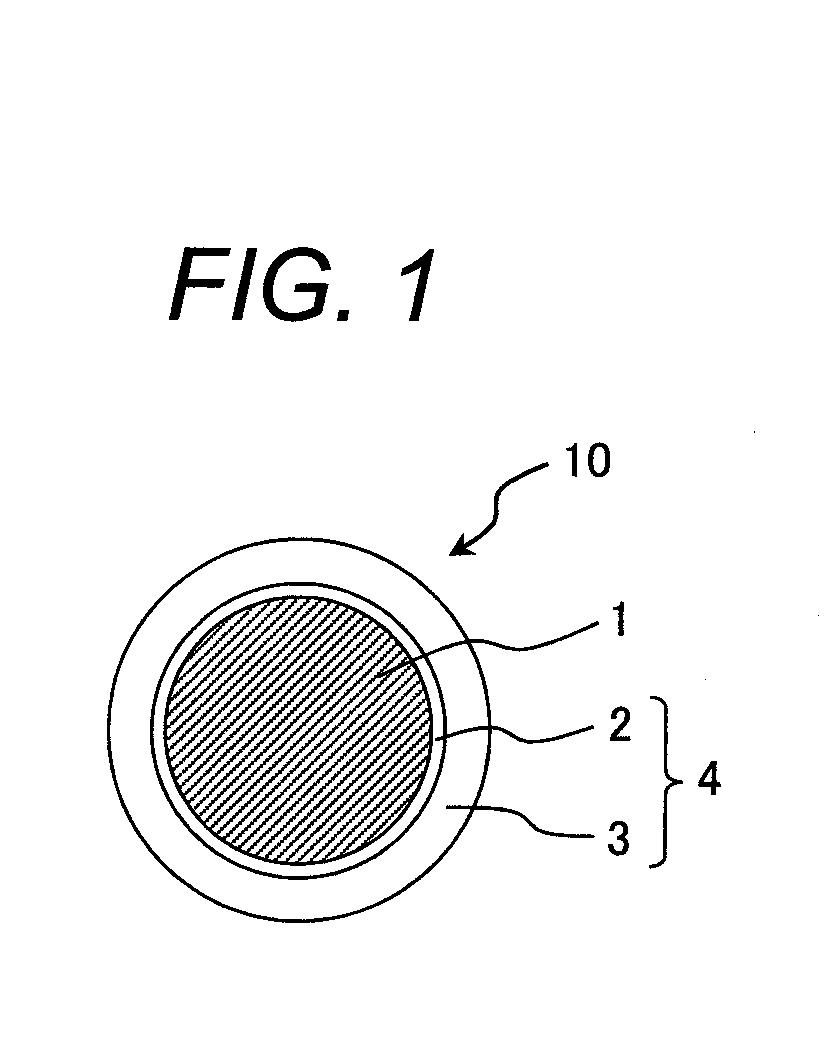

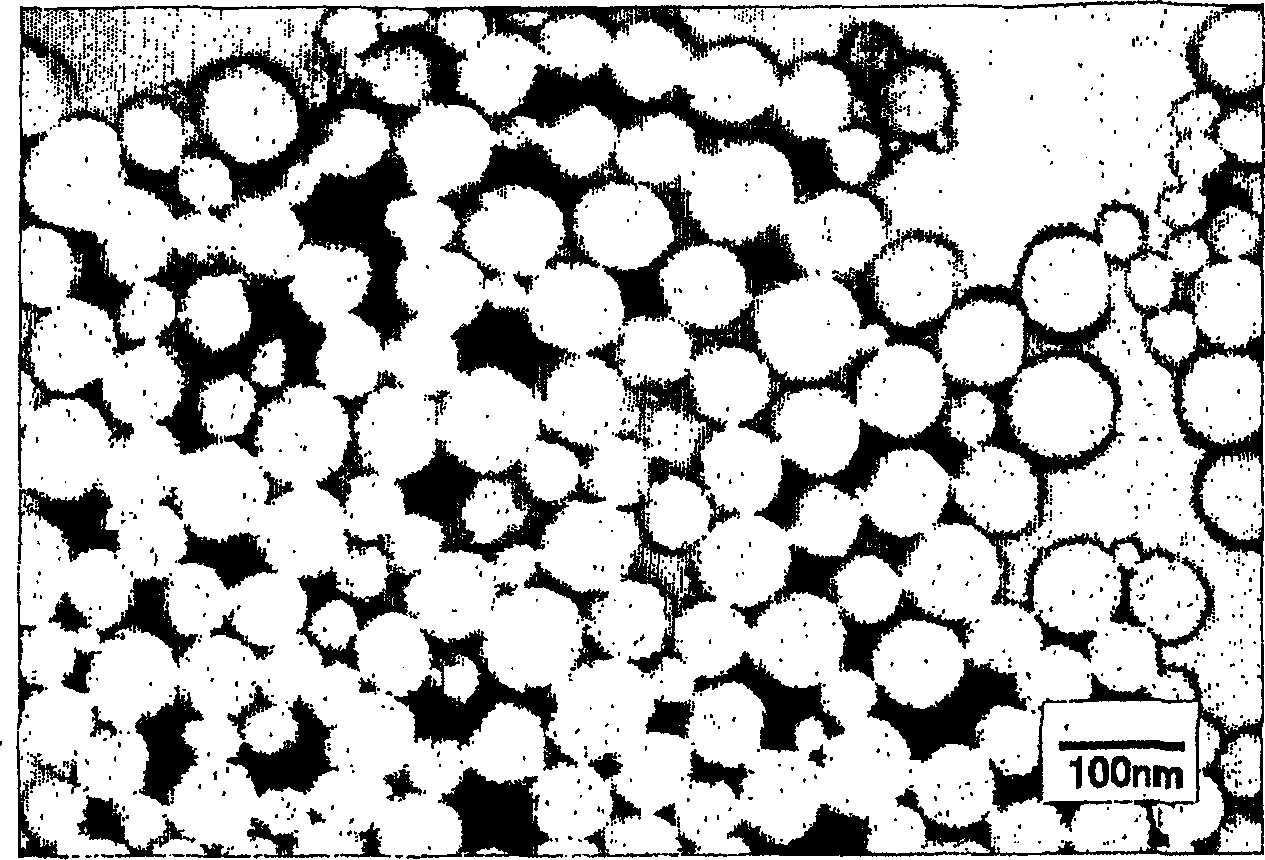

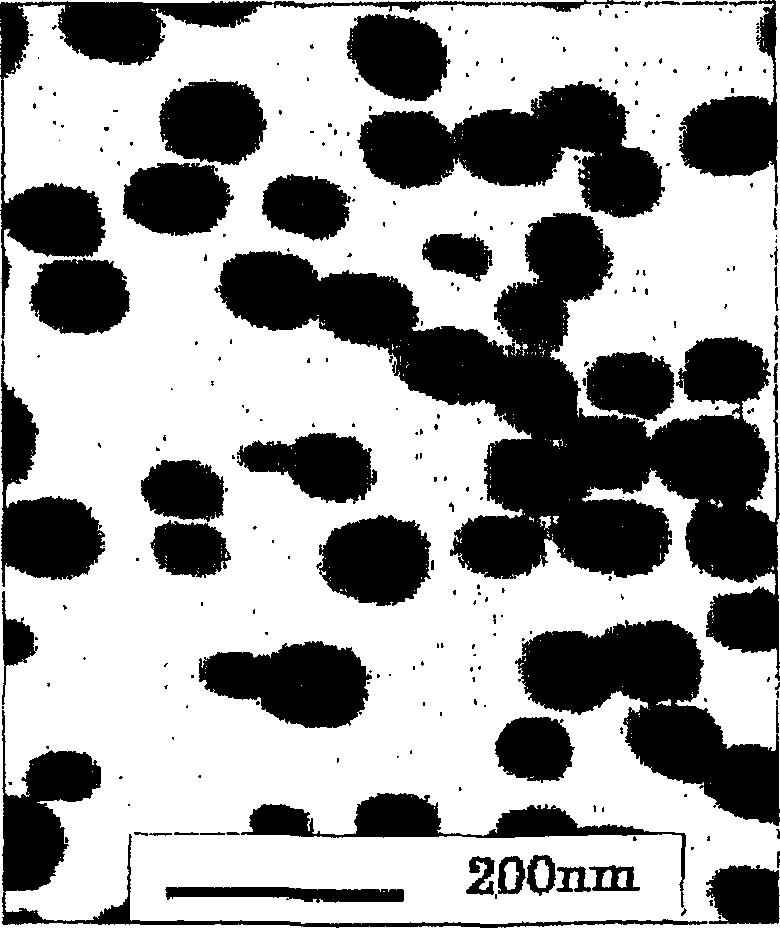

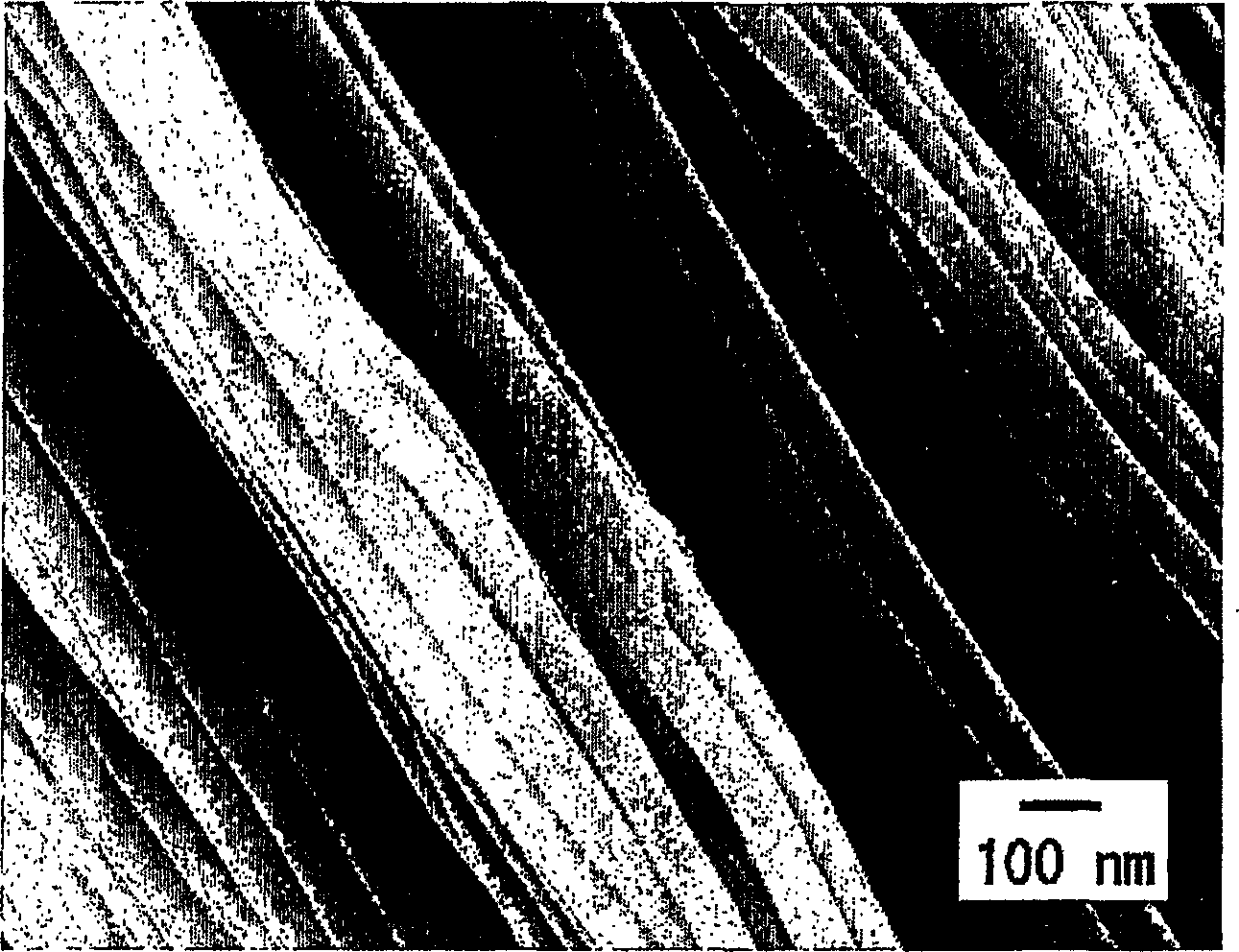

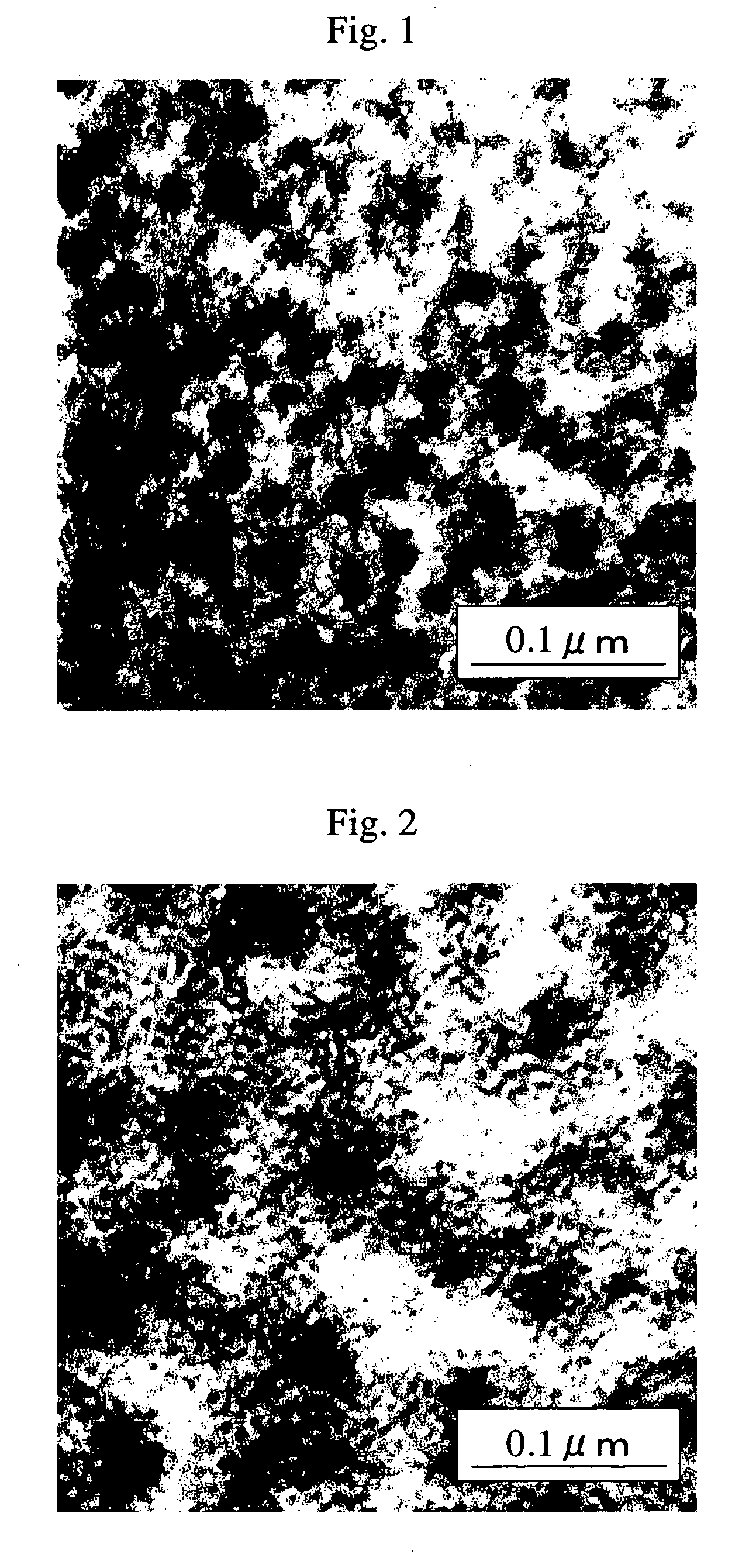

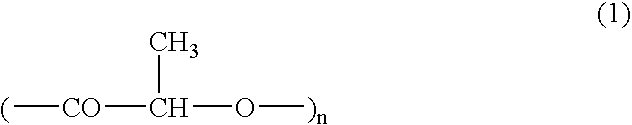

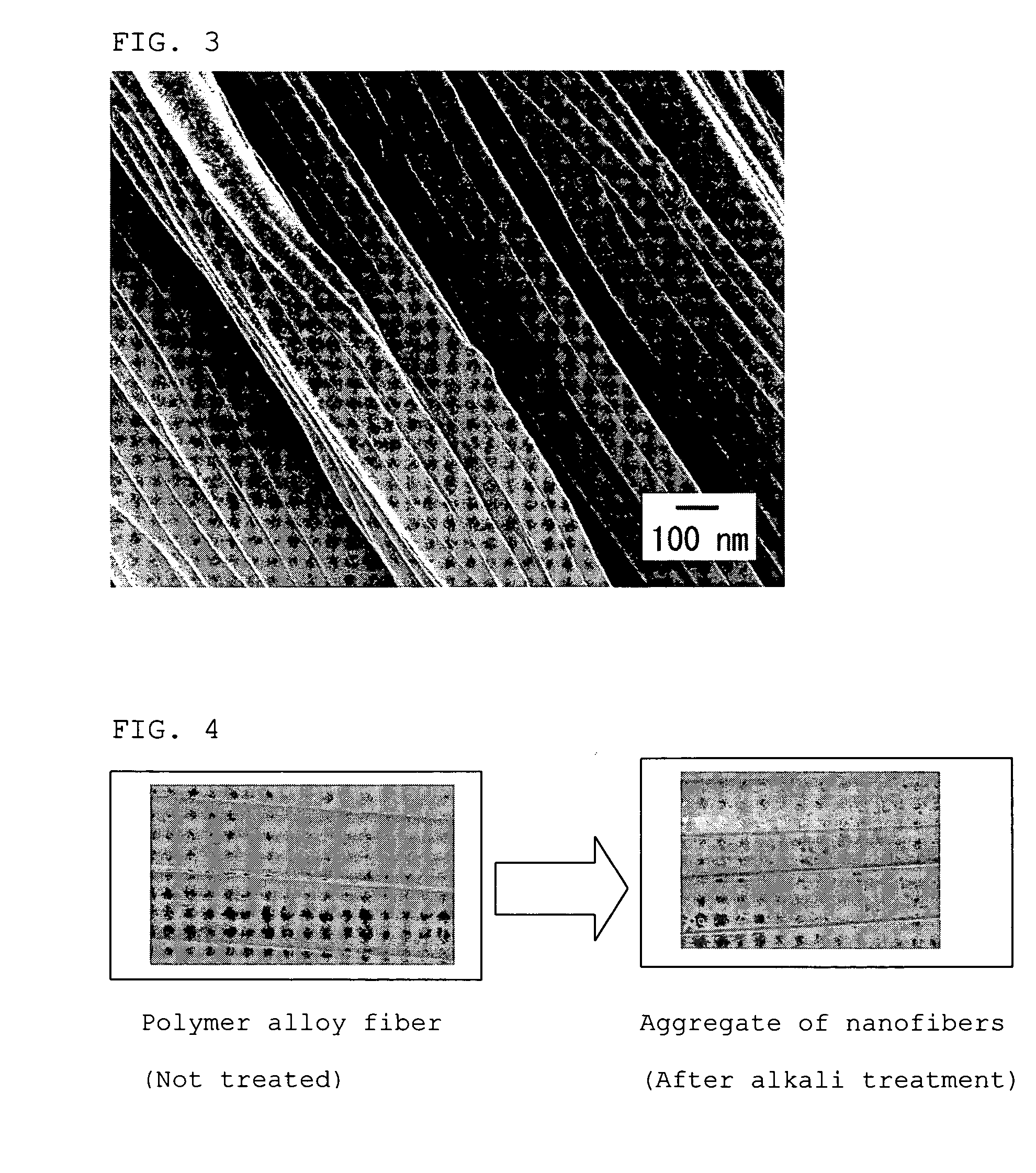

Polymer alloy and method for manufacturing polymer alloy

This invention is a method for manufacturing a polymer alloy, by making at least two resins used as components miscible, and inducing the spinodal decomposition for causing phase separation, for forming a co-continuous structure with a wavelength of concentration fluctuation of 0.001 to 1 mum or a dispersed structure with a distance between particles of 0.001 to 1 mum. This invention is also a polymer alloy manufactured by the method. The polymer alloy of this invention can provide a molded article, film, fibers and the like respectively with excellent mechanical properties at high productivity.

Owner:TORAY IND INC

Random and non-random alkylene oxide polymer alloy compositions

ActiveUS7553913B2Easy to eliminateMinimal adverse reactionOrganic active ingredientsOrganic detergent compounding agentsPolymer sciencePolymer alloy

A polymeric material comprised of (i) at least one random copolymer comprised of ethylene oxide and one or more other alkylene oxide(s) and (ii) at least one non-random polymer comprised of one or more poly(alkylene oxide)s has been discovered. Preferably, it is a polymer alloy. Alkylene oxide homo-polymers or block copolymers may be the non-random polymer. In a related discovery, an adhesive material can be made by suspending (a) particles in (b) a matrix of at least one poly(ethylene oxide) copolymer of ethylene oxide and propylene oxide, or a combination thereof. The handling characteristics may be adjusted for different utilities (e.g., from runny oil to hard wax). Applications include use as adhesive, cohesive, filler, lubricant, surfactant, or any combination thereof. In particular, the hard materials may be used for cleaning or waxing.

Owner:SYNCERA

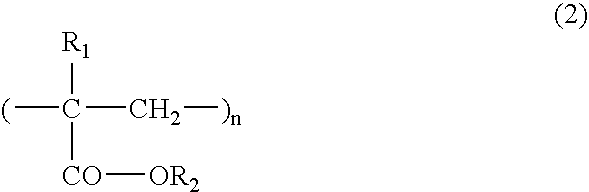

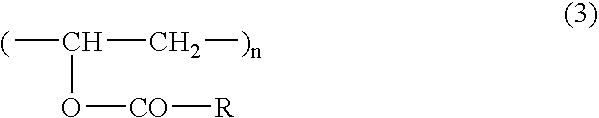

Polymer alloy including polylactic acid

InactiveUS20050192405A1No adverse effect on environmentsHighly inhibited from hydrolysisPolymer sciencePolyolefin

The object of the present invention is to provide a polymer alloy including polylactic acid which can be used in the same manner as conventional commodity plastics even in an environment of high temperature and high humidity. According to the present invention, there is provided a polymer alloy including polylactic acid comprising (A) a polylactic acid, (B) a polyalkylacrylic ester and / or a polyvinyl ester, (C) a polyolefin and (D) a block copolymer of a polyalkylacrylic ester and polyolefin and / or a block copolymer of a polyvinyl ester and a polyolefin.

Owner:HITACHI LTD

Polymer material

A polymer material, in particular for a medical instrument such as a balloon catheter, is provided. The polymer material comprising a combination at least of a first constituent comprising a partly crystalline polymer and a second constituent for increasing the flexibility of the material, wherein the polymer material is in the form of a polymer alloy, and wherein the first constituent is formed of a polyamide or a polyether block amide and the second constituent is formed at least partly by a thermoplastic elastomer based on polystyrene (TPE-S). A process for producing the polymer material and a medical device incorporating the polymer material are also provided.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveUS8460790B2Less spreadingWide applicationSynthetic resin layered productsFilament/thread formingPolymer alloyPolymer science

The present invention provides an aggregate of nanofibers having less spread of single fiber fineness values that can be used in wide applications without limitation to the shape and the kind of the polymer, and a method for manufacturing the same. The present invention is an aggregate of nanofibers made of a thermoplastic polymer having single fiber fineness by number average in a range from 1×10−7 to 2×10−4 dtex and single fibers of 60% or more in fineness ratio have single fiber fineness in a range from 1×10−7 to 2×10−4 dtex.

Owner:TORAY IND INC

Flame-retardant polyester fiber and artificial hair comprising the same

InactiveUS20050245647A1Excellent set propertyMaintain physical propertiesHair accessoriesToupeesPolyesterFiber

A flame resistant polyester fiber, while maintaining physical properties, such as heat resistance, tensile strength and elongation, etc. of usual polyester fibers, having excellent flame resistance and excellent setting property, and furthermore having controlled gloss of fiber is provided. A composition obtained by melt kneading of a polyester (A) comprising polyalkylene terephthalates, and one or more kinds of copolymerized polyesters having polyalkylene terephthalate as a principal component; a polymer alloy (B) consisting of polyalkylene terephthalates and polyarylates; phosphorus based flame resistant agents (C); and phosphite based compounds (D), and organic fine particles (E) and / or inorganic fine particles (F) are mixed thereto to obtain a composition. The obtained composition is melt spun to obtain a flame resistant polyester fiber in which the above-mentioned problems are solved, and to obtain artificial hair using the fiber.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com