Polyphenylene oxide resin alloy material and preparation method and application thereof

A polyphenylene ether resin and alloy material technology, which is applied in the field of polyphenylene ether resin alloy materials, can solve problems such as deformation of the battery case and cracking of the electrode connection of the battery case, and achieve the effects of not easy to crack, low cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

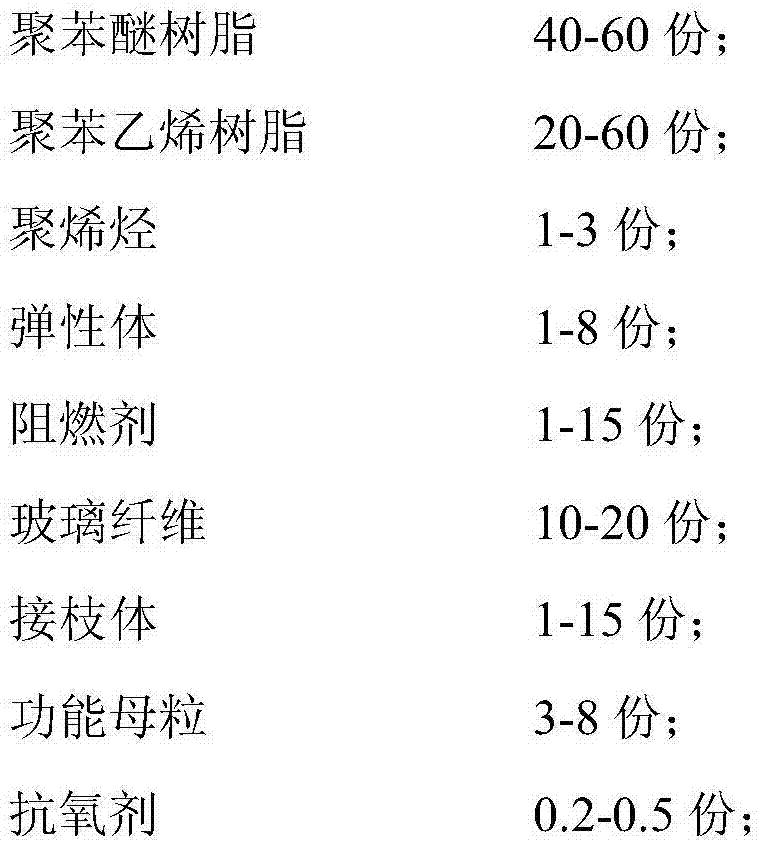

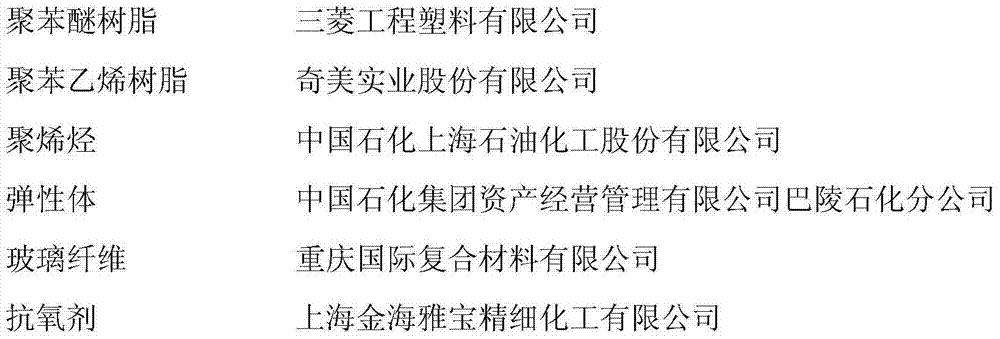

[0033] See Table 1 for the raw materials and consumption used in the present embodiment, wherein:

[0034] Polyphenylene ether resin: a polymer selected from 2,6-dimethylphenol with an intrinsic viscosity of 0.4 dl / g;

[0035] Polystyrene resin: selected from high impact polystyrene;

[0036] Polyolefin: It is composed of polyethylene and polypropylene in a weight ratio of 2:1;

[0037] Elastomer: It is composed of styrene-butadiene rubber and hydrogenated styrene-butadiene rubber elastomer in a weight ratio of 1:1;

[0038] Flame retardant: composed of phosphorus-based flame retardant and nitrogen-based flame retardant in a weight ratio of 3:1, wherein the phosphorus-based flame retardant is a phosphate ester flame retardant, and the nitrogen-based flame retardant is melamine;

[0039] Glass fiber: PPO special alkali-free glass fiber.

[0040] Graft: a mixture of polyphenylene ether resin, polyethylene resin, and polyolefin in a weight ratio of 7:2:1 is used as the base ma...

Embodiment 2

[0047] The raw materials and amounts used in this example are shown in Table 1, and the raw materials other than polyphenylene ether resin, polystyrene resin, and polyolefin are the same as those in Example 1.

[0048] In this example, polyphenylene ether resin: a polymer of 2,6-dimethylphenol, a copolymer of 2,6-dimethylphenol and 2,3,6-trimethylphenol in a weight ratio of 1: 1 composition with an intrinsic viscosity of 0.6 dl / g;

[0049] In this example, polystyrene resin: composed of polystyrene and high-impact polystyrene in a weight ratio of 1:1;

[0050] In this example, polyolefin: consists of polyethylene, ethylene propylene copolymer, and polybutene in a weight ratio of 3:1:1;

[0051] In this embodiment, the preparation method of the polyphenylene ether resin alloy material is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0053] The raw materials and amounts used in this example are shown in Table 1. The raw materials other than the elastomer, the flame retardant, and the functional masterbatch are the same as those in Example 1.

[0054] In this example, the elastomer: selected from styrene-butadiene rubber;

[0055] In this example, the flame retardant is composed of a phosphorus-based flame retardant and a nitrogen-based flame retardant in a weight ratio of 4:1, wherein the phosphorus-based flame retardant is an ammonium polyphosphate flame retardant and a nitrogen-based flame retardant. is melamine;

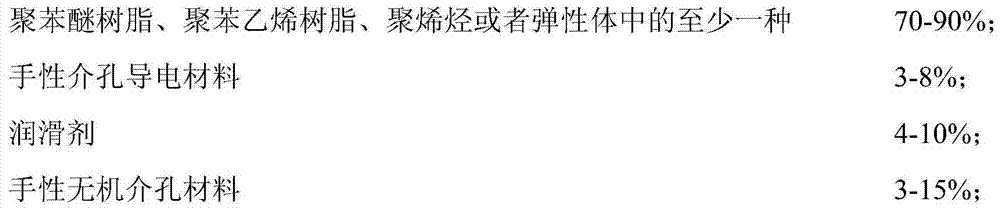

[0056] In this example, functional masterbatch: self-made, with a mixture of polystyrene resin and elastomer in a weight ratio of 5:1 as the base material, loaded with chiral mesoporous conductive materials, lubricants, and chiral inorganic mesoporous materials Formed together, in terms of weight percentage, the base material accounts for 80%, the chiral mesoporous conductive material is polyan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com