Patents

Literature

97results about How to "High low temperature impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature impact-resistant polyamide-based stretch-oriented multilayer film

InactiveUS7018719B2High low temperature impact resistanceImprove mechanical propertiesFlexible coversWrappersSurface layerPolyamide

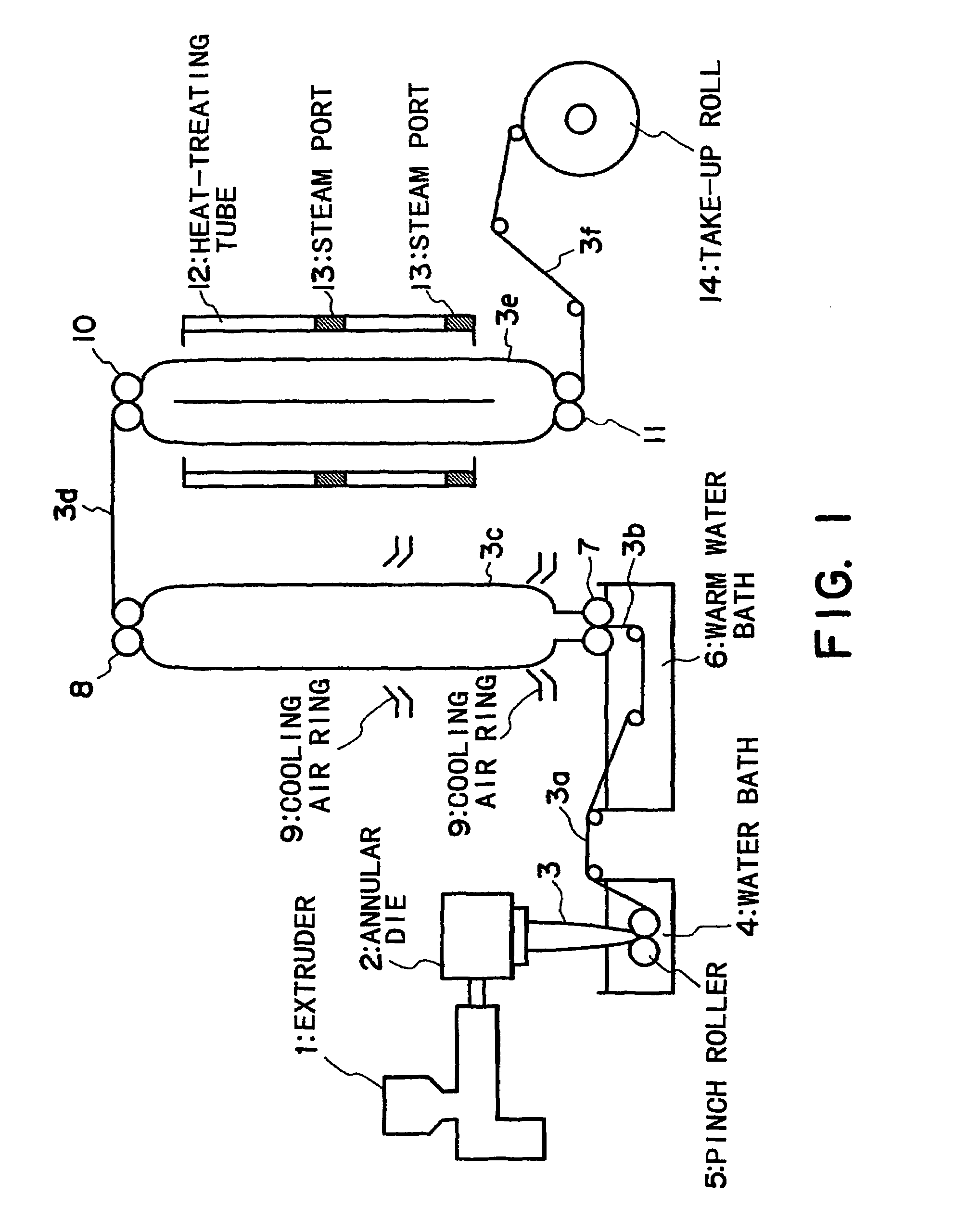

A stretch-oriented multilayer film suited for use as a freeze packaging material, a deep drawing packaging material, a vertical pillow packaging material, etc., is provided as a stretch-oriented multilayer film, comprising at least three layers including a surface layer (a) comprising a thermoplastic resin, an intermediate layer (b) comprising a polyamide resin and a surface layer (c) comprising a sealable resin, said multilayer film exhibiting an impact energy of at least 1.5 Joule at a conversion thickness of 50 μm at −10° C. The multilayer film is produced through an inflation process using water having a large capacity as a cooling and a heating medium and including a combination of a high degree of stretching and a high degree of relaxation heat treatment not exercised heretofore.

Owner:KUREHA KAGAKU KOGYO KK

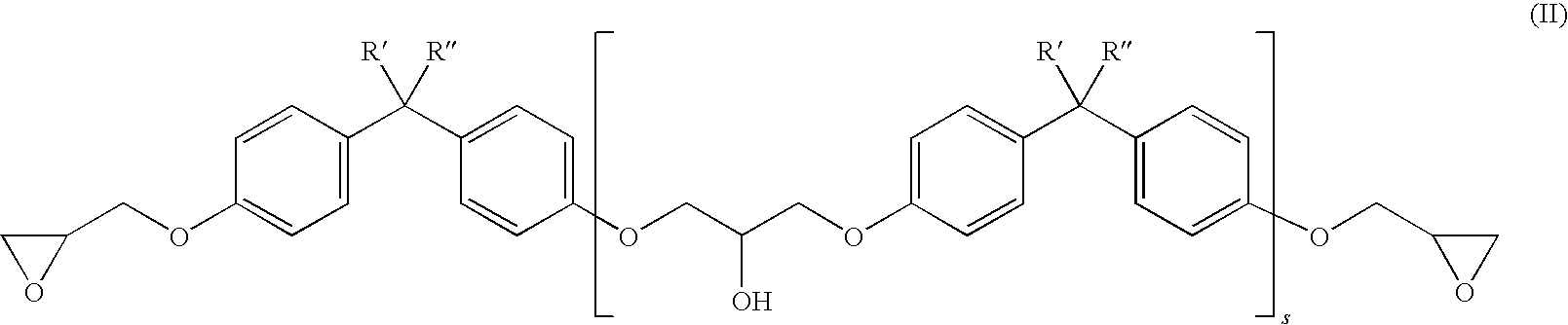

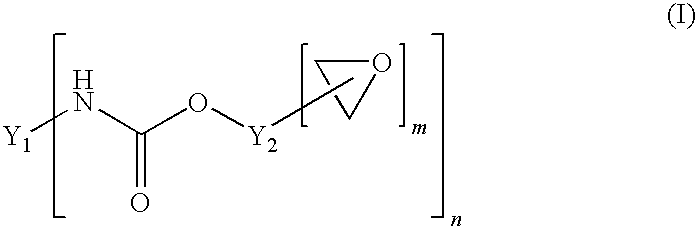

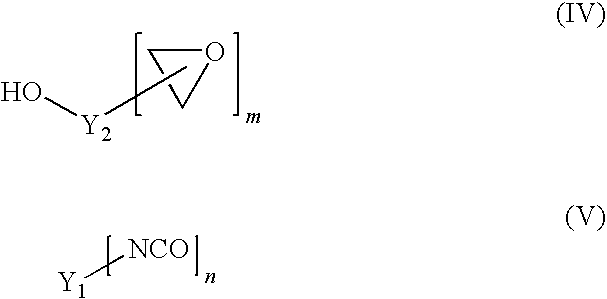

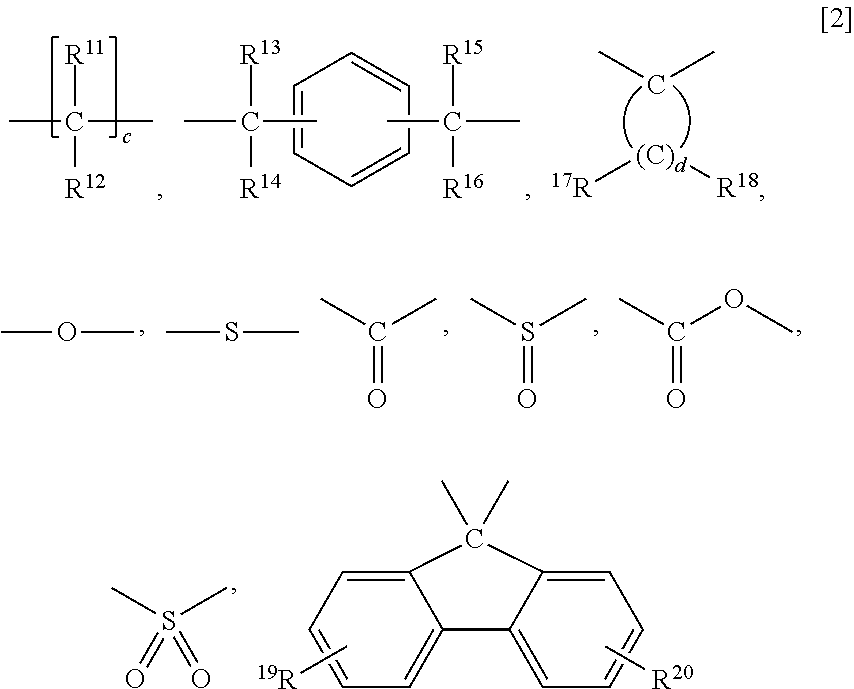

Low-temperature impact resistant thermosetting epoxide resin compositions with solid epoxide resins

InactiveUS8062468B2High low temperature impact resistanceEasy to prepareSynthetic resin layered productsThin material handlingEpoxyAdhesive

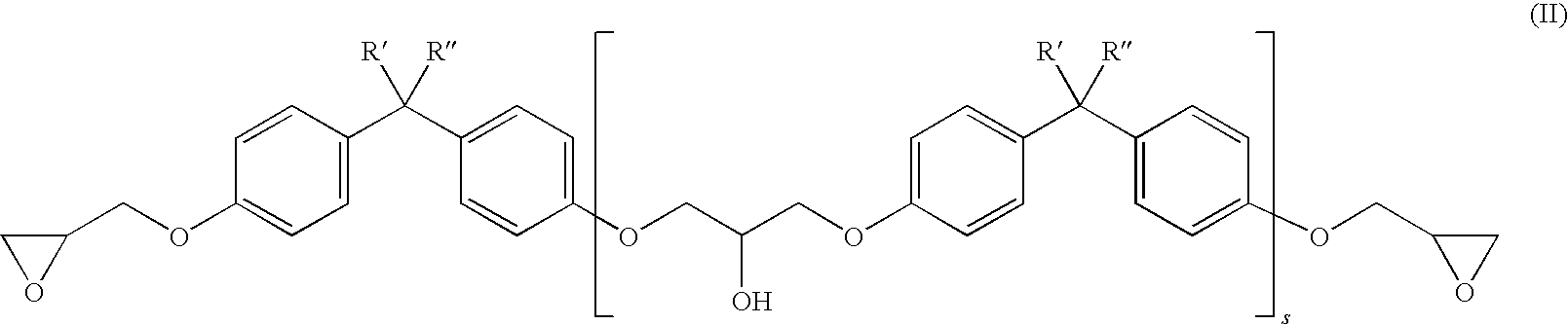

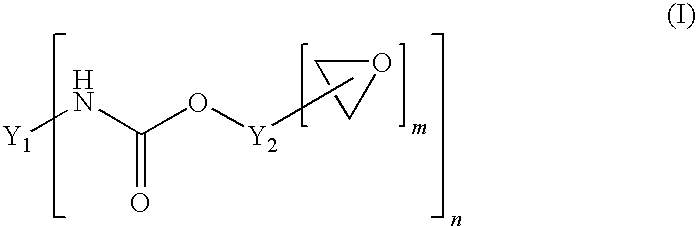

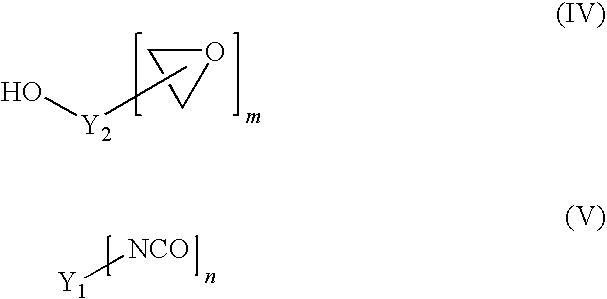

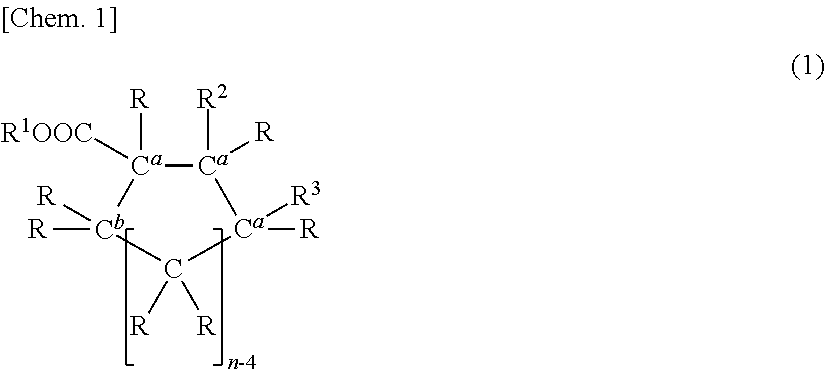

The invention relates to compositions containing at least one solid epoxide resin A, at least one polymer B of formula (1), at least one thixotropic agent C made from a urea derivative and at least one curing agent for epoxide resins D activated by high temperatures. The compositions are particularly suitable for use as adhesives. Low-temperature impact-resistant adhesives can be produced for use in particular as structural adhesives.

Owner:SIKA TECH AG

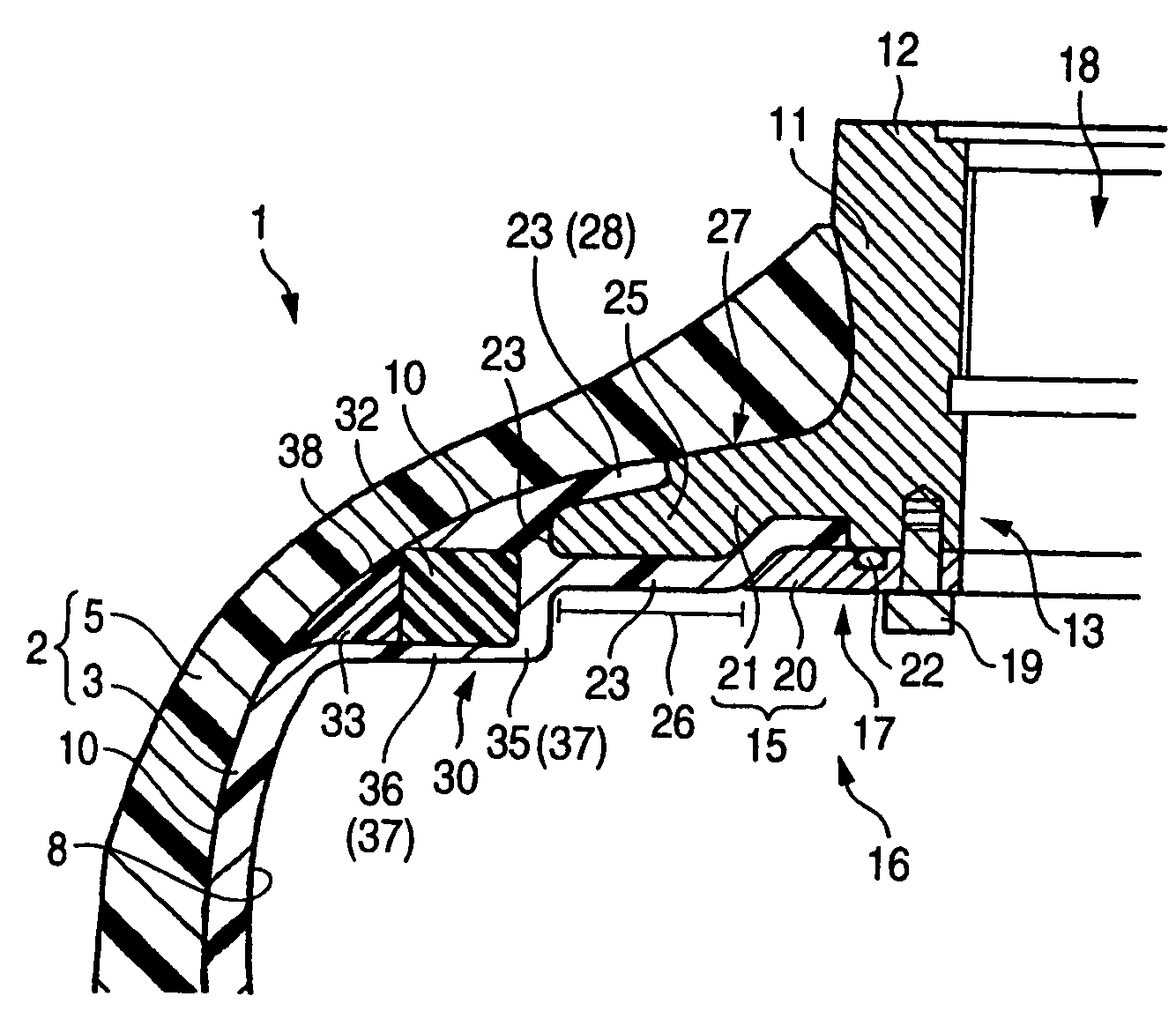

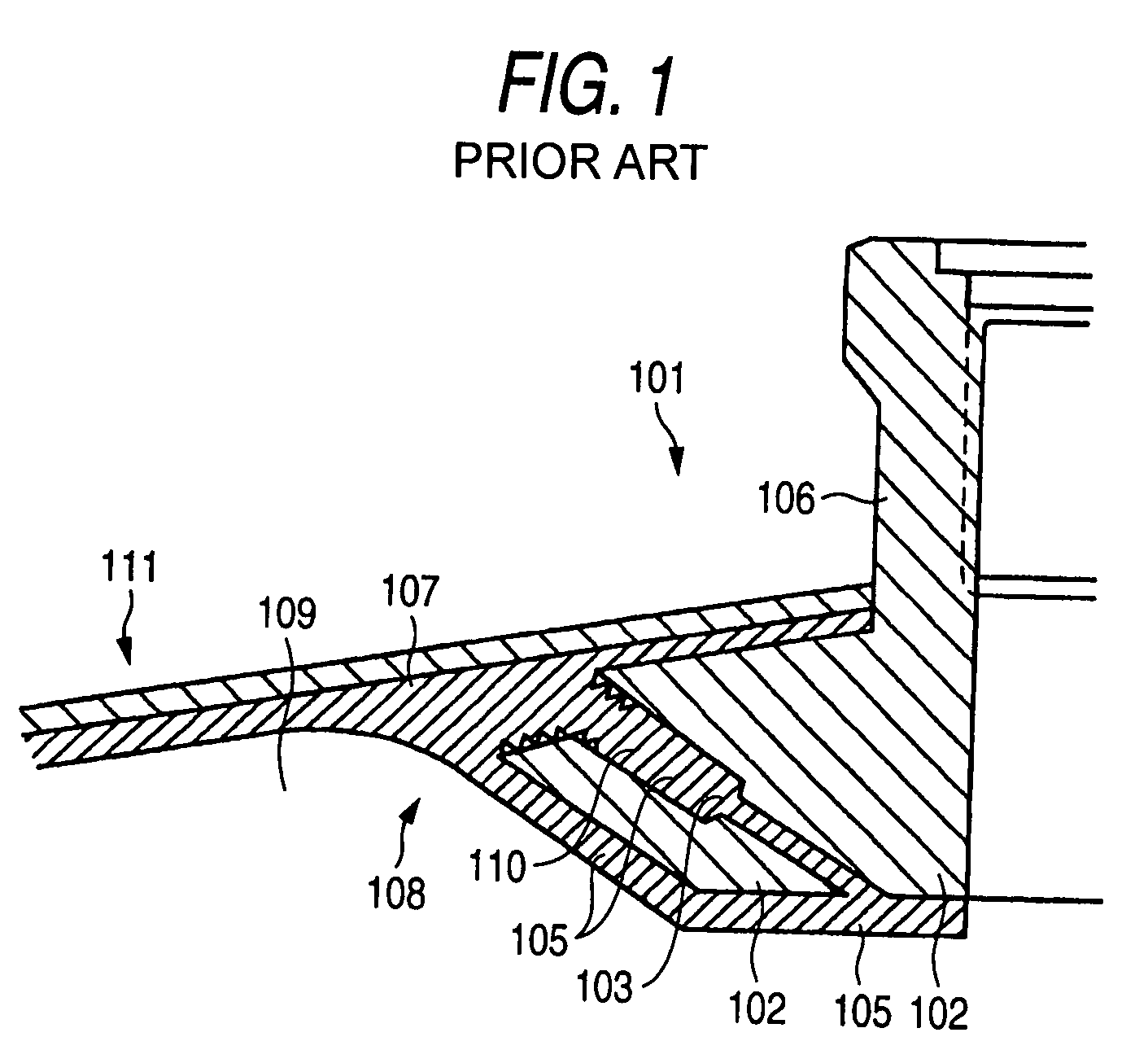

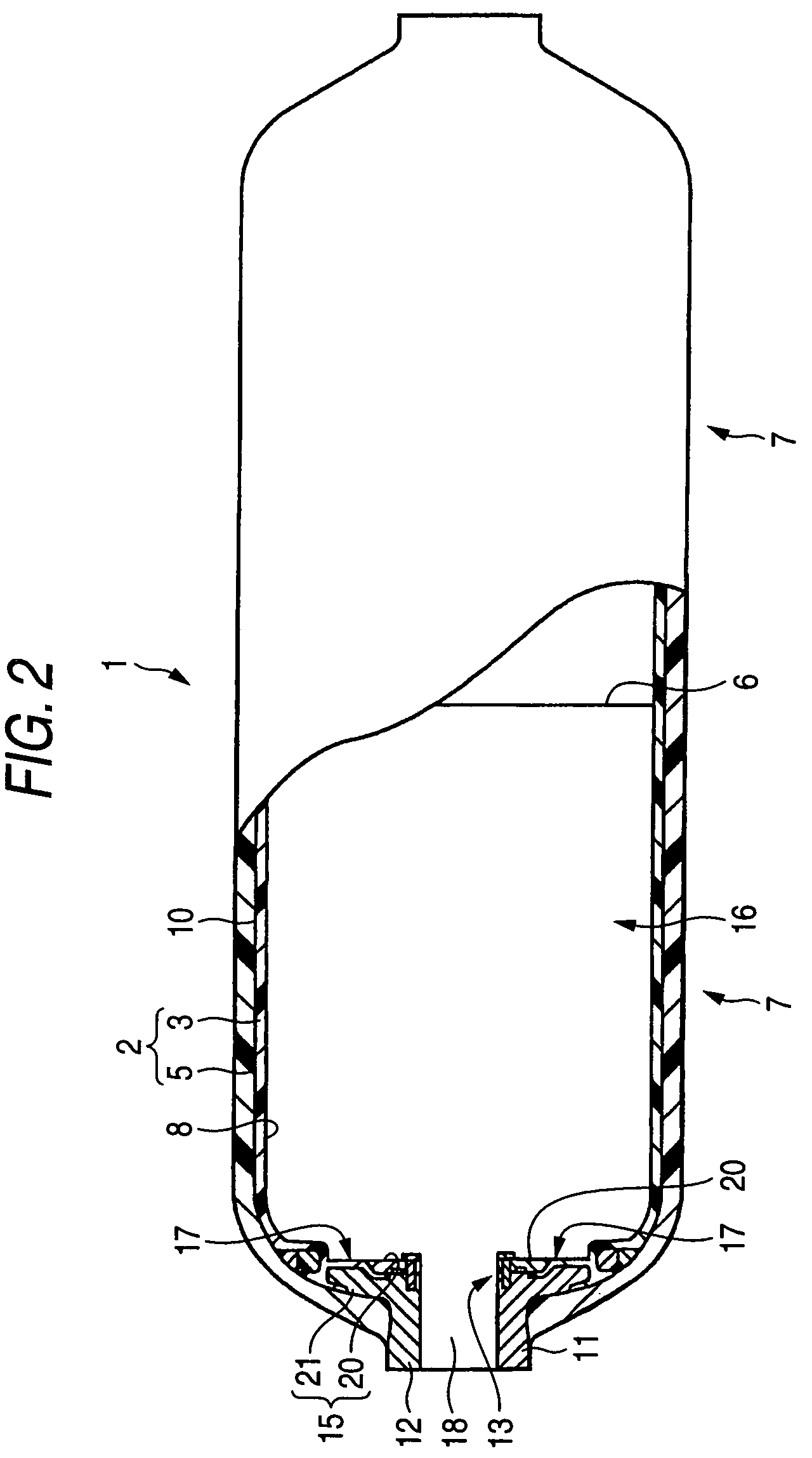

Pressure container

InactiveUS7549555B2Improve sealingImprove relationshipVessel mounting detailsVessel wallsEngineeringShape constraint

A flange is provided at the opening metal of a pressure container, and it extends toward the periphery of the container body at the bonding part thereof at which it bonds to the container body. The liner of the pressure container has a self-sealing part at which it abuts the flange to be sealed up together. On the outer peripheral side of the self-sealing part, a ring-shaped constraint member is provided in the outer periphery of the liner, and the constraint member is to restrict the diameter expansion of the liner to be caused by the expansion of the container body. The liner has an easily-displaceable part that is readily elongable and deformable, at the outer periphery thereof in the radial direction of the self-sealing part.

Owner:TOYODA GOSEI CO LTD

Preparation method of large-grain size latex particles

InactiveCN102115506AHigh low temperature impact resistanceConducive to particle size growth controlAlkaneReaction temperature

The invention relates to a preparation method of latex particles with grain sizes from 500nm to 1000nm. Agglomerating agent is copolymer of alkyl acrylate and carboxyl monomer, wherein the weight percentage of the carboxyl monomer is 3-60%, and the weight percentage of the alkyl acrylate is 97-40%; mixed emulsifying agent is fatty acid soap and alkane sulfonate, ferrous sulfate, rongalit, ethylenediaminetetraacetic acid tetrasodium salt and sodium hydrogensulfite are reducing agent, the reaction temperature is 75 DEG C, a first section of initiating agent is water-soluble initiating agent, a second section of initiating agent is oil-soluble initiating agent, and the average grain diameters are adjusted by cross-linking agent from 50 to 250nm to obtain the agglomerating agent; and the large-grain size latex comprises the components based on the parts by weight: 100 parts of the primary latex, 0.5-4 parts of the agglomerating agent, and 0.05-0.8 part of KOH solution under the agglomerating temperature of 20-80 DEG C. The method is used for preparing the large-grain size latex of synthetic resin, so that the low-temperature shock resistance of the resin can be improved, and the processed large-grain size latex can be used for producing the high-grade automobile lamp.

Owner:BC P INC CHINA NAT PETROLEUM CORP

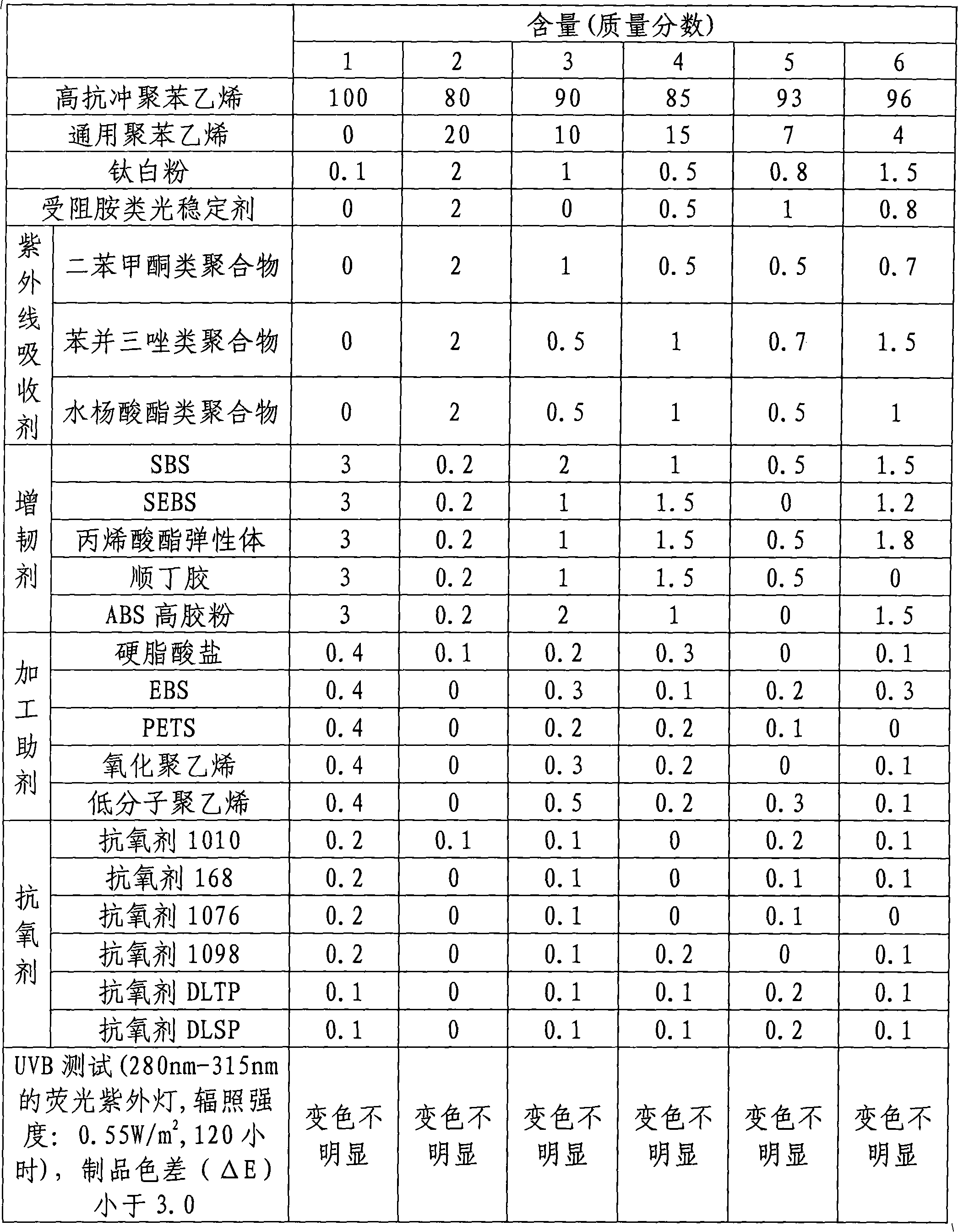

Weather-resistant high impact polystyrene material and preparation method thereof

The invention discloses a weather-resistant high impact polystyrene material, which is characterized by comprising high impact polystyrene resin, an anti-ultraviolet agent, a toughener, an antioxidant, and a processing aid, and comprising the following components in part by mass: 80 to 100 parts of high impact polystyrene resin, 0 to 20 parts of general purpose polystyrene, 0.1 to 10 parts of light stabilizer, 1 to 15 parts of toughener, 0.1 to 1 part of antioxidant and 0.1 to 2 parts of processing aid. The weather-resistant high impact polystyrene material has high weather resistance and stable performance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Cold-resistant flame-retardant polycarbonate alloy material and preparation method thereof

InactiveCN102093690AImprove low temperature toughnessHigh low temperature impact resistanceWeather resistanceAntioxidant

The invention discloses a cold-resistant flame-retardant polycarbonate alloy material. The cold-resistant flame-retardant polycarbonate alloy material is characterized by comprising 100 mass parts of polycarbonate resin, 2 to 30 mass parts of toughening agent, 3 to 20 mass parts of flame retardant, 1 to 5 mass parts of flame-retardant synergist, 0 to 2 mass parts of antioxidant, and 0 to 3 mass parts of weather-resistant agent. The cold-resistant flame-retardant polycarbonate alloy material has high flame-retardant efficiency, good low-temperature impact resistance and good weather resistance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

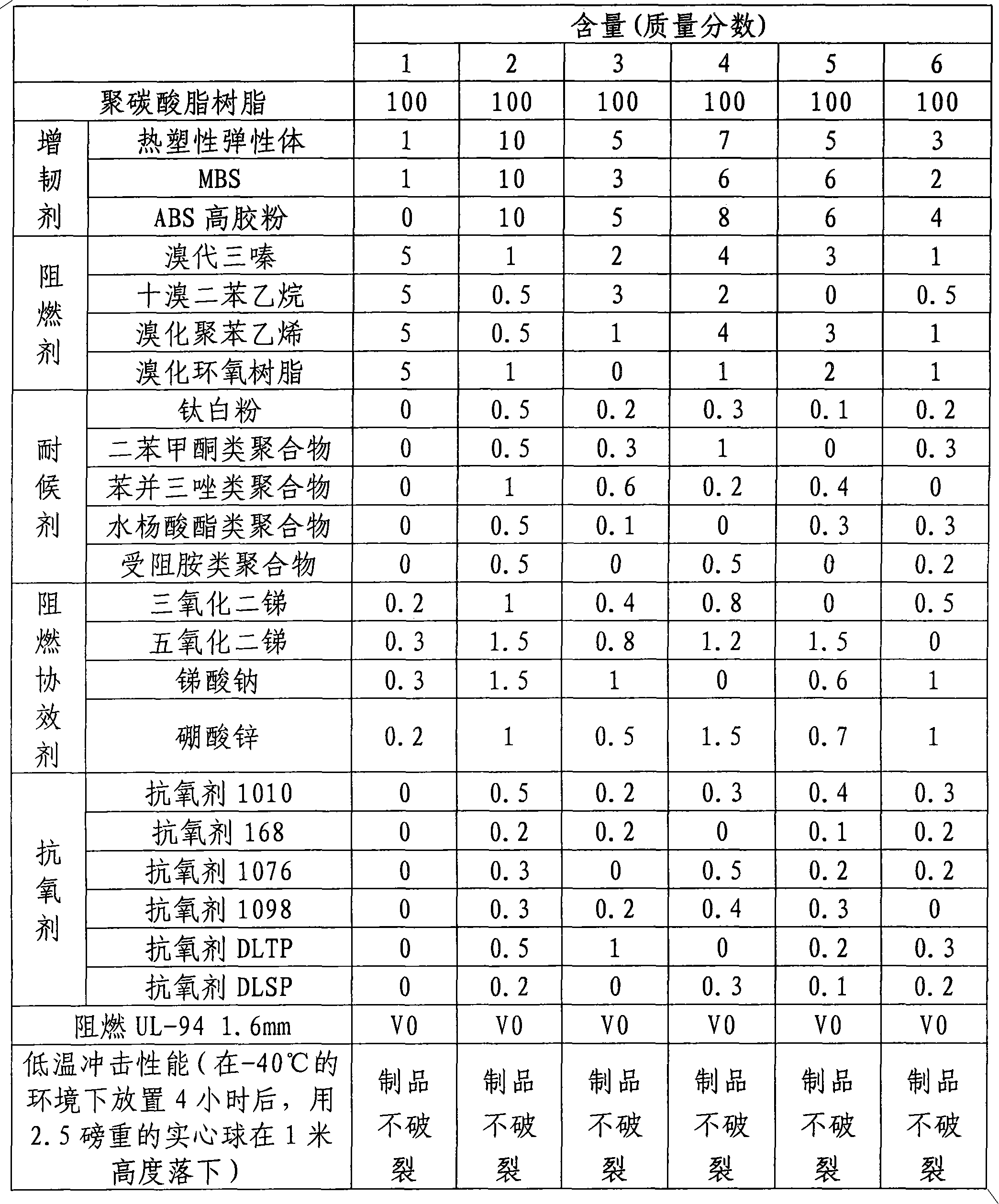

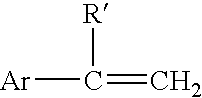

Mass polymerized rubber-modified monovinylidene aromatic copolymer composition

ActiveUS20070106028A1High low temperature impact resistanceDesirable of aesthetic propertyClosuresClosure using stoppersMechanical propertyPhysical chemistry

Owner:TRINSEO EURO GMBH +1

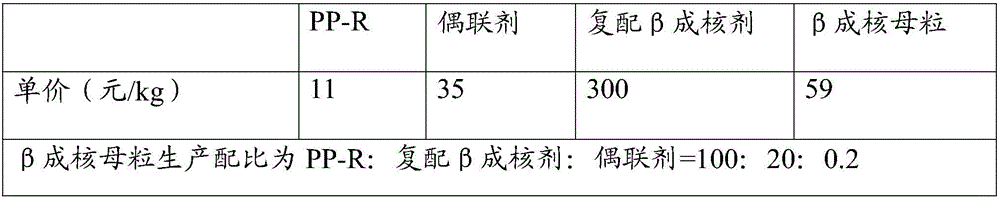

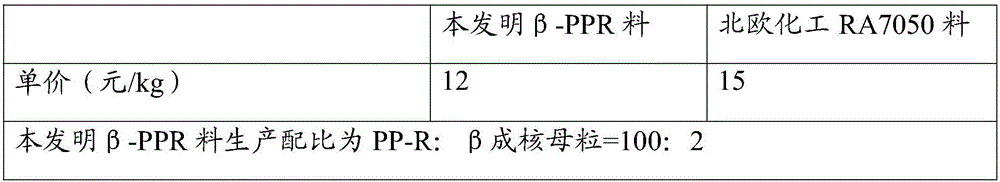

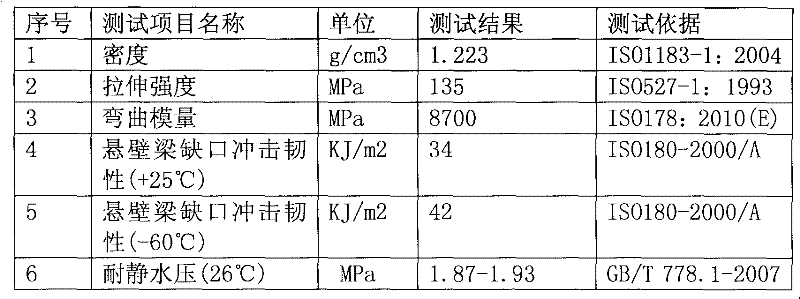

Beta-PPR tube and preparation method thereof

ActiveCN105860275AHigh low temperature impact resistanceReduce brittle crackingShock resistanceMaterials science

The invention relates to a beta-PPR tube and a preparation method thereof. The beta-PPR tube is prepared from the following raw materials in parts by mass: 100 parts of PP-R resin and 1-5 parts of beta nucleated master batch, wherein the beta nucleated master batch is prepared from the following raw materials in parts by mass: 100 parts of PP-R resin, 0.1-1 part of coupling agent and 10-30 parts of beta nucleator. The beta-PPR tube improves the low-temperature shock resistance of the tube and greatly reduces the problem of brittle cracking of the tube, and the preparation method has simple technique, reduces the raw material cost and is favorable for ordinary popularization and use.

Owner:RIFENG TECH CO LTD +1

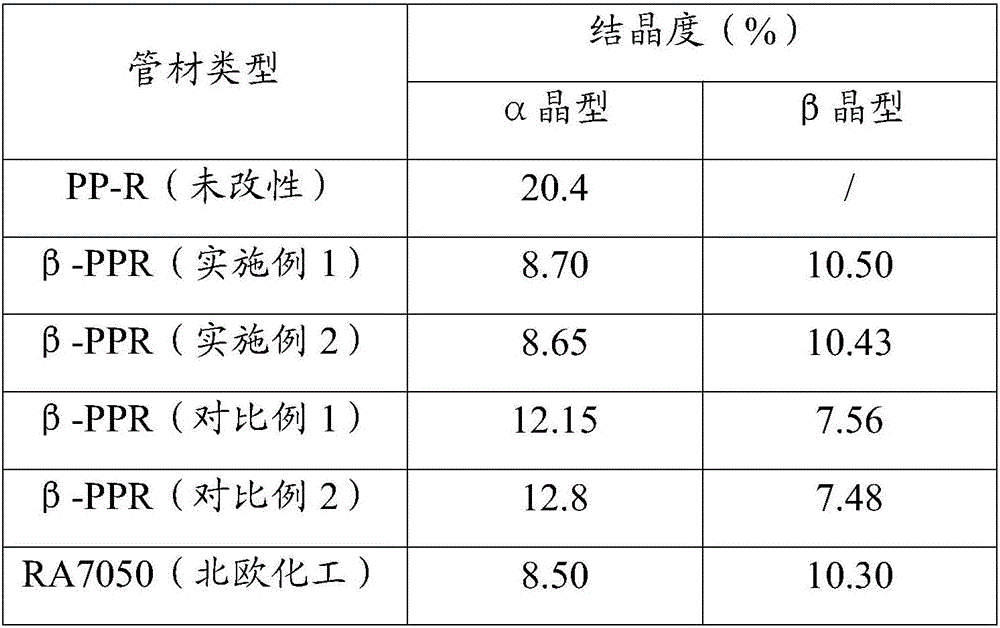

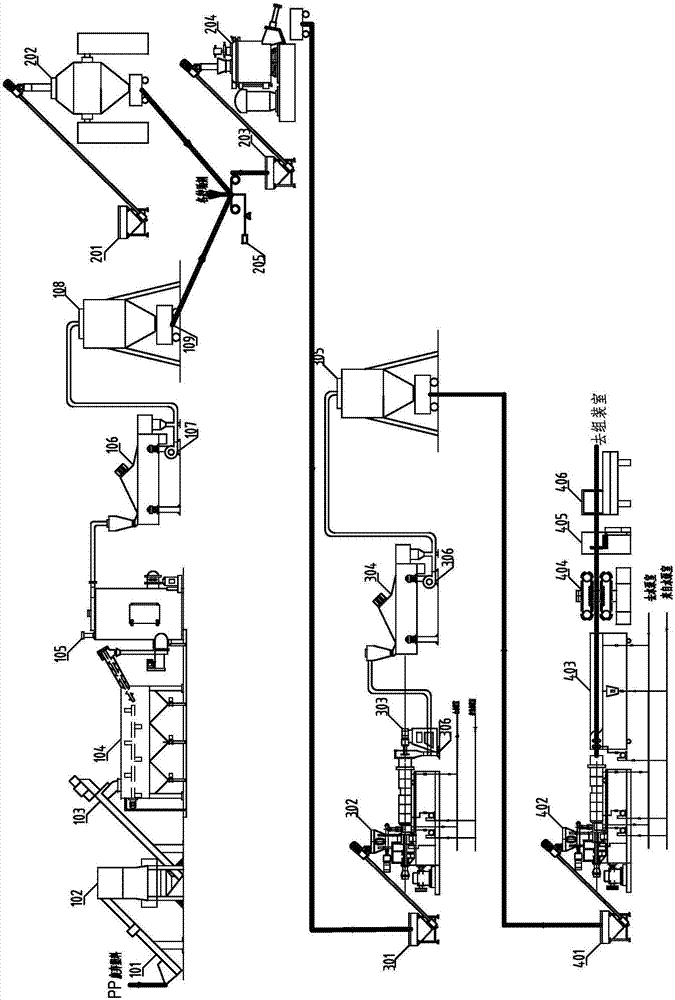

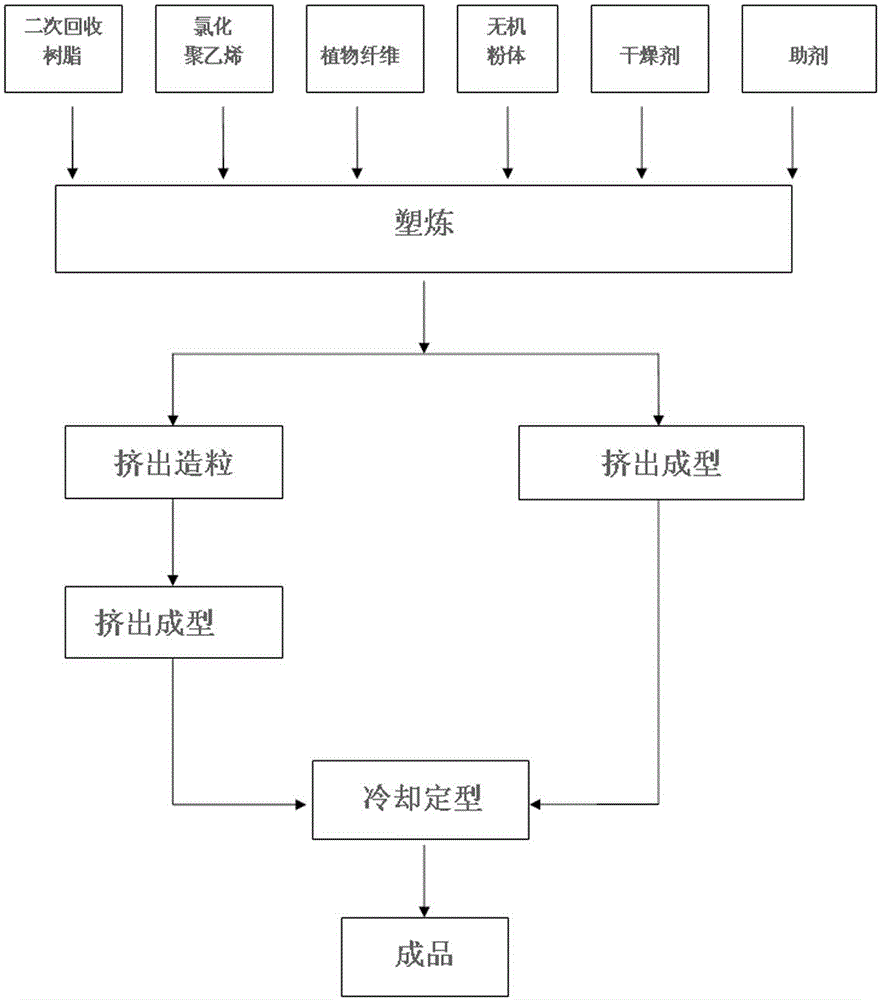

Formulation of wood-plastic profile as well as preparation method and manufacturing device thereof

InactiveCN107189216AImprove impact performance at room temperatureHigh low temperature impact resistanceHeat resistanceAntioxidant

The invention particularly relates to a formulation of wood-plastic profile as well as a preparation method and a manufacturing device thereof. The formula is characterized by being prepared from the following raw materials in parts: 100 parts of PP waste plastic with good mobility, 20 to 75 parts of wood powder, 5 to 15 parts of flexibilizer; 2 to 10 parts of compatibilizer; 1 to 10 parts of lubricant; 0.1 to 1 part of main antioxidant; 0.1 to 0.5 part of auxiliary antioxidant; 0.02 to 0.5 part of light stabilizer and 0.1 to 4 parts of antibacterial agents; the preparation method is characterized by comprising the following steps:(1) recycling the PP waste plastic with good mobility; (2) cleaning, crushing and drying; 3) drying the wood powder; 4) extruding and granulating; and 5) extruding and molding; and the manufacturing device is characterized by comprising a plastic cleaning device, a wood powder drying device, a weighing device, a mixing device, an extrusion granulation device and an extrusion molding device. The invention has the advantages of low cost, durability, long life, good heat resistance, good resistance to ultraviolet rays, high hardness and high load capacity.

Owner:YANTAI UNIV

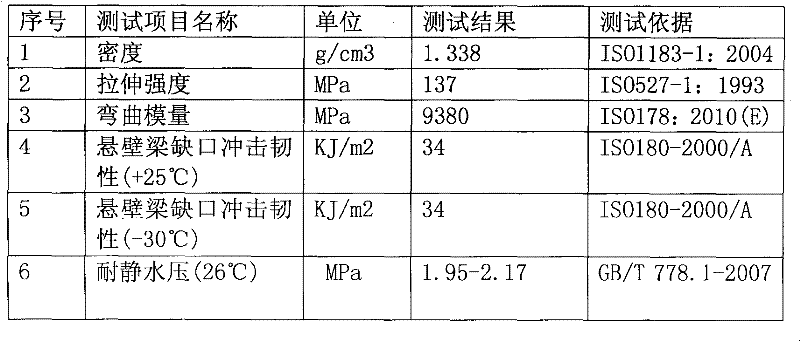

Long glass fiber enhanced polypropylene composite material water meter casing and manufacture method thereof

InactiveCN102504405AGood low temperature resistanceHigh low temperature impact resistanceVolume meteringHeavy metalsAntioxidant

The invention discloses a long glass fiber enhanced polypropylene composite material water meter casing and a manufacture method of the long glass fiber enhanced polypropylene composite material water meter casing. A thermal plastic composite material water meter casing comprises the following ingredients: blending alloy, auxiliary agents, color powder, antioxidants and ultraviolet absorbers, wherein the blending alloy consists of glass fiber, polypropylene and / or polypropylene modified materials. The thermal plastic composite material water meter casing made by adopting an injection molding forming process has the characteristics of high-temperature resistance, low-temperature resistance, impact resistance, creep deformation resistance, water pressure resistance, hydrolysis resistance, no heavy metal, long service life, low cost, environmental-friendly effect and the like, is easy to process and conforms to the industrial standard of the national plastic water meter casing material, so the thermal plastic composite material water meter casing is particularly suitable for large-scale industrial production and wide popularization and application.

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

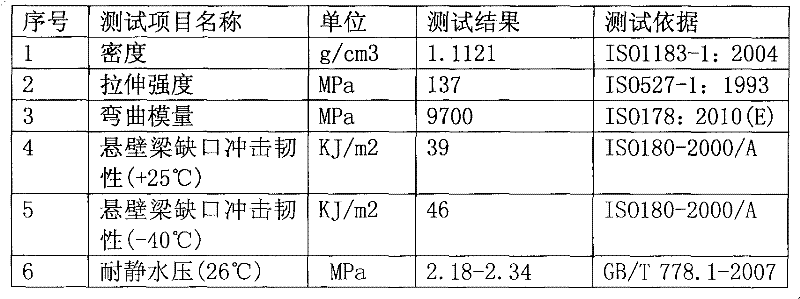

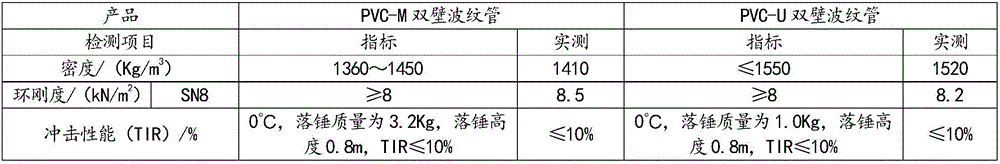

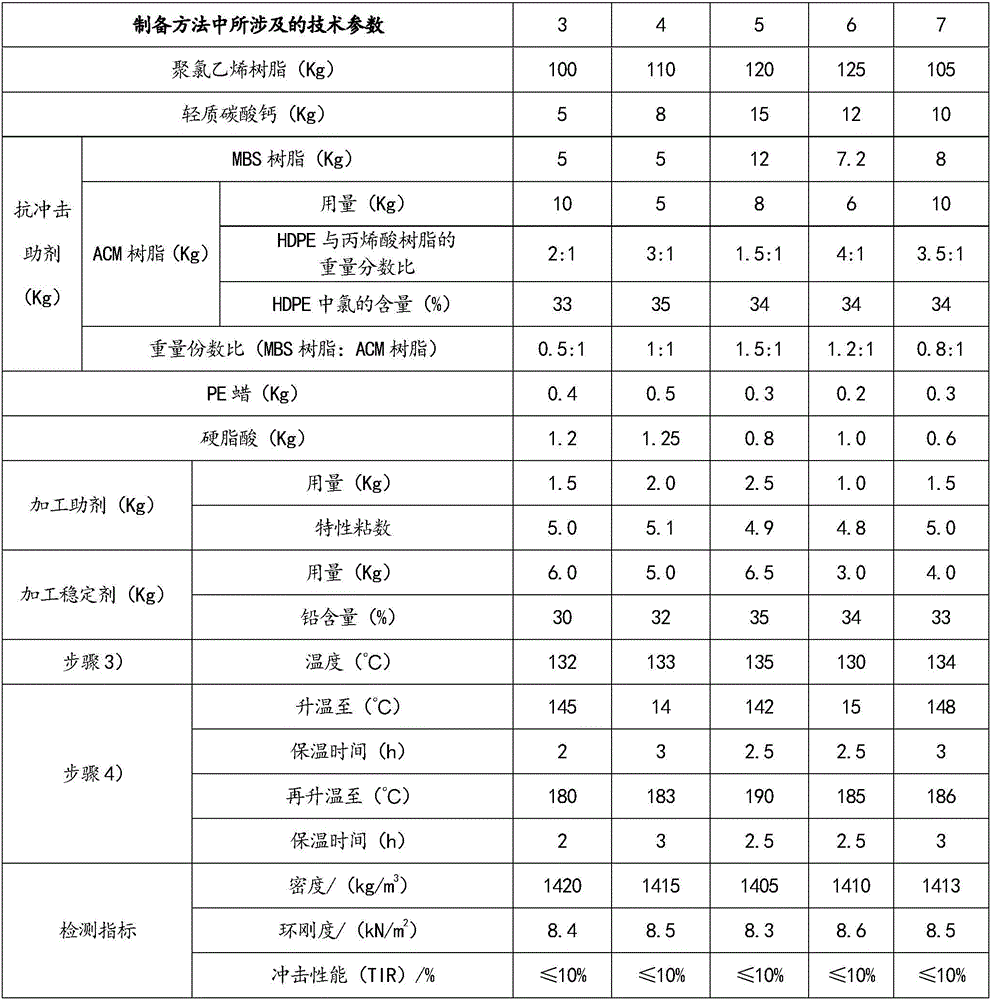

High-impact-resistant-polyvinyl-chloride double-wall corrugated pipe and preparing method thereof

InactiveCN106432951AHigh strengthImproved low temperature impact resistanceTubular articlesWaxProcedure Agents

The invention discloses a high-impact-resistant-polyvinyl-chloride double-wall corrugated pipe and a preparing method thereof. The high-impact-resistant-polyvinyl-chloride double-wall corrugated pipe is prepared from polyvinyl-chloride resin, light calcium carbonate, an impact-resistant assistant, PE wax, stearic acid, a processing agent and a processing stabilizer. The polyvinyl-chloride resin is a main raw material, and is subjected to physical modification and extruded and produced, and the high-impact-resistant-polyvinyl-chloride double-wall corrugated pipe is obtained. The high-impact-resistant-polyvinyl-chloride double-wall corrugated pipe has the excellent low-temperature impact-resistant performance, and the high-impact-resistant-polyvinyl-chloride double-wall corrugated pipe and the preparing method thereof are suitable for preparing the high-impact-resistant double-wall corrugated pipe.

Owner:公元管道(上海)有限公司

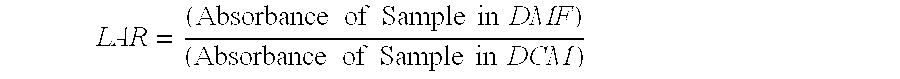

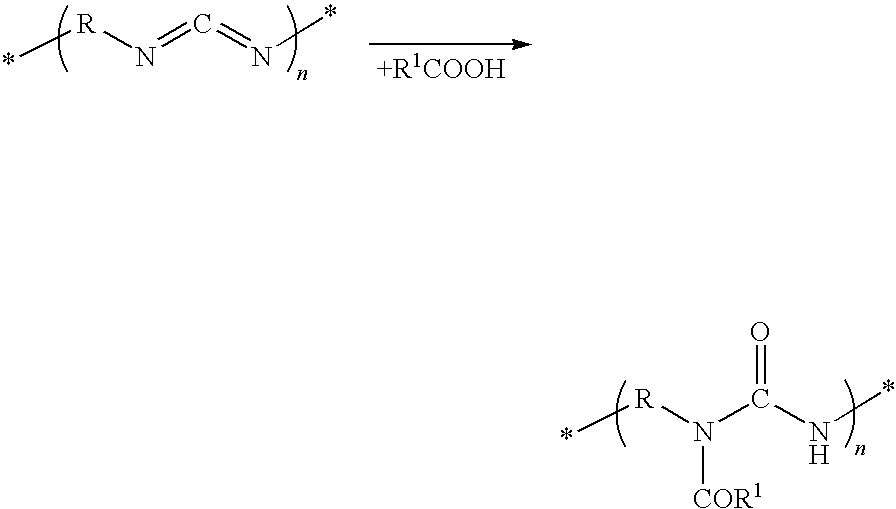

Resin modifier and polar group-containing polymer composition containing the same

ActiveUS7754813B2High low temperature impact resistanceOther chemical processesPolyolefinPolymer science

A resin modifier (C) obtained by reacting a polyolefin (A) having a group which reacts with a carbodiimide group, and a carbodiimide group-containing compound (B), wherein the content of the carbodiimide group is from 1 to 200 mmol per 100 g of the resin modifier, and a polar group-containing polymer composition (F) comprising from 1 to 30% by weight of the resin modifier (C), from 99 to 20% by weight of a polar group-containing polymer (D), and from 0 to 80% by weight of an olefin polymer (E). The modifier can provide improved low-temperature impact resistance of a polymer alloy including a polar group-containing polymer and an olefin polymer (such as polylactic acid and polypropylene), and can provide a molded article with smooth surface when the polymer alloy is molded. A polar group-containing polymer composition is also set forth.

Owner:MITSUI CHEM INC

Nano polyvinyl chloride pipe and preparation method thereof

InactiveCN101157784AShorten plasticizing timeGood uniformity of plasticizationPolyvinyl chlorideResin-Based Composite

The invention relates to a nanometer polyvinyl chloride pipe and a preparation method thereof. According to weight ratio, raw materials of the nanometer polyvinyl chloride pipe comprise nanometer polyvinyl chloride resin, calcium carbonate, and PME-100 strengthening and toughening agent, etc. The preparation method is that: first, the raw materials needed are fully mixed in a high level mixing pot and a low level mixing pot; then the materials mixed are transported to an extruder production line to do extruding molding, thereby gaining the nanometer polyvinyl chloride pipe. The invention is characterized in that the invention is not only environment-friendly, but also solves the problems of insufficiency of thermal stability, initial coloring and products reddened and zinc burned, bad weather resistance and copper erosion, etc. During the mixing process of the preparation method, the plasticizing time is shortened, leading to a good plasticizing uniformity and being in favor of the basic extrusion molding process to the modification polyvinyl chloride. The mechanical property of the invention is distinctively higher than the common polyvinyl chloride resin and nanometer blending composite resin. The anti-impact performance and other performances are greatly enhanced The shock strength is two times the common resin products, and in particular the products has good shock strength in low temperature; in addition, the invention has good bending performance, thus being applied to no digging laying and repairing, etc.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK

Propylene resin sheet and heat processing packaging body using same

InactiveUS20130177721A1Increase flexibilityIncrease resistanceSynthetic resin layered productsBagsPolymer scienceCopolymer

The invention discloses a propylene resin sheet and a heat-treatable packaging material which have an excellent transparency, flexibility and very-low-temperature impact resistance, and which reduce the thickness variation during lamination, suppress appearance defects such as interfacial roughness. A propylene resin sheet composed of at least one layer, the main layer being made up of a resin composition containing: (1) 50 to 90 wt % of a propylene resin composition (A) which includes from 30 to 70 wt % of a propylene-α-olefin random copolymer component (A1) having a melting peak temperature of 120 to 150° C., and from 70 to 30 wt % of a propylene-α-olefin random copolymer component (A2) having a C2 or C4-8 α-olefin content of at least 10 wt % but less than 20 wt %; and (2) 10 to 50 wt % of a specific ethylene-α-olefin copolymer (B).

Owner:JAPAN POLYPROPYLENE CORP

Anti-impact-resistant modified polypropylene bumper material

The invention discloses an anti-impact-resistant modified polypropylene bumper material and an automobile bumper prepared therefrom. The bumper material comprises propylene, tetra(2,6-dimethylphenyl)-m-resorcinol diphosphate, tetra-(2,6-dimethylphenyl)-p-resorcinol diphosphate, a metallocene polyolefin elastomer, nylon, maleic anhydride, thermoplastic polyurethane, inorganic composite particles, vinyl triethoxyl silane, ethylene propylene rubber, polyethylene, a shear thickening agent, polyisophthaloyl metaphenylene diamine fiber, an anti-static agent, an anti-oxidant, a dispersing agent, a plasticizer and a UV absorber. The bumper material is low in shrinkage rate, is high in flowability, is good in weather resistance and is excellent in paint performance, and meanwhile is high in toughness, strength, elongation at break and heat deflection temperature. The automobile bumper prepared from the bumper material is free of being broken even an automobile is slightly impacted.

Owner:CHONGQING JIAOTONG UNIVERSITY

Low-Temperature Impact Resistant Thermosetting Epoxide Resin Compositions With Solid Epoxide Resins

InactiveUS20100116433A1Easy to makeHigh impact strengthSynthetic resin layered productsEpoxy resin adhesivesEpoxyAdhesive

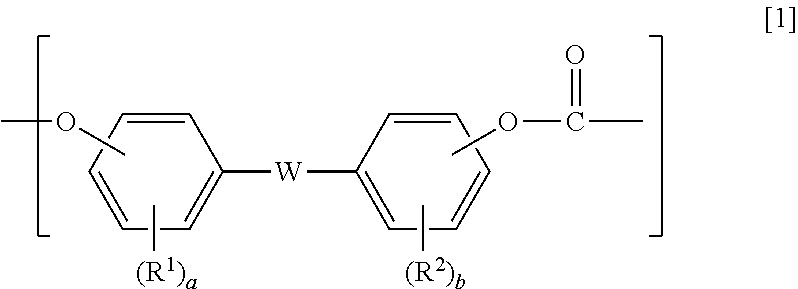

The invention relates to compositions containing at least one solid epoxide resin A, at least one polymer B of formula (I), at least one thixotropic agent C made from a urea derivative and at least one curing agent for epoxide resins D activated by high temperatures. The compositions are particularly suitable for use as adhesives. Low-temperature impact-resistant adhesives can be produced for use in particular as structural adhesives.

Owner:SIKA TECH AG

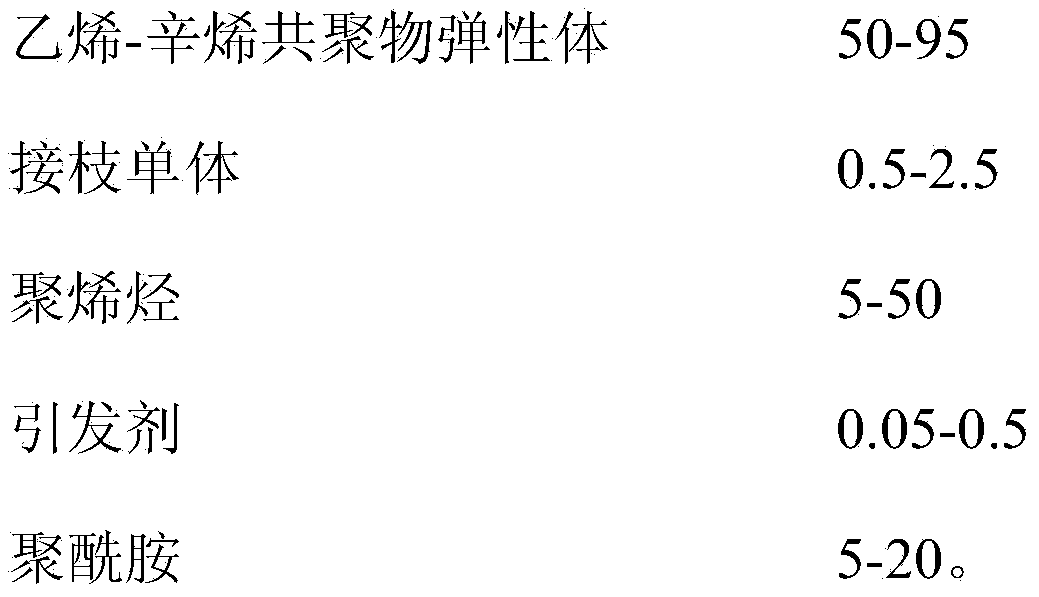

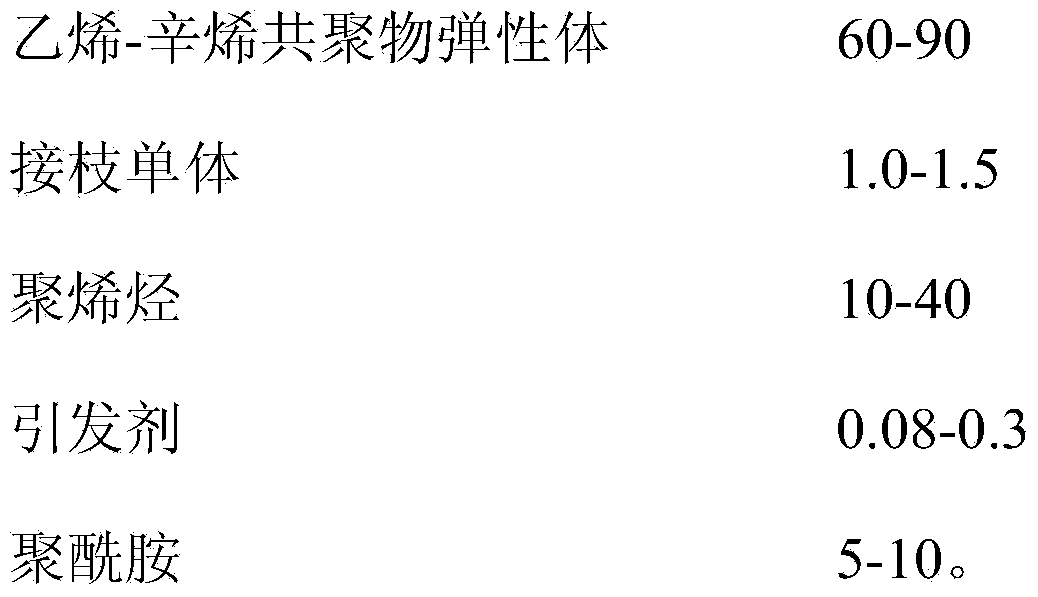

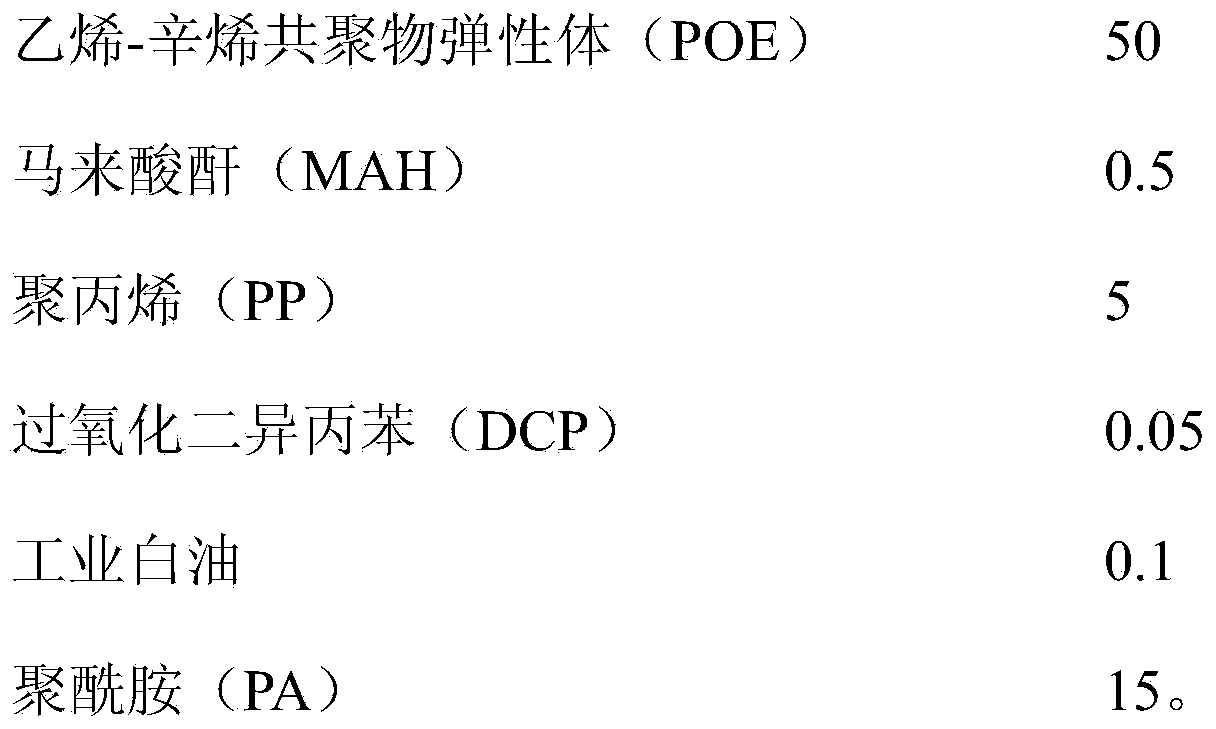

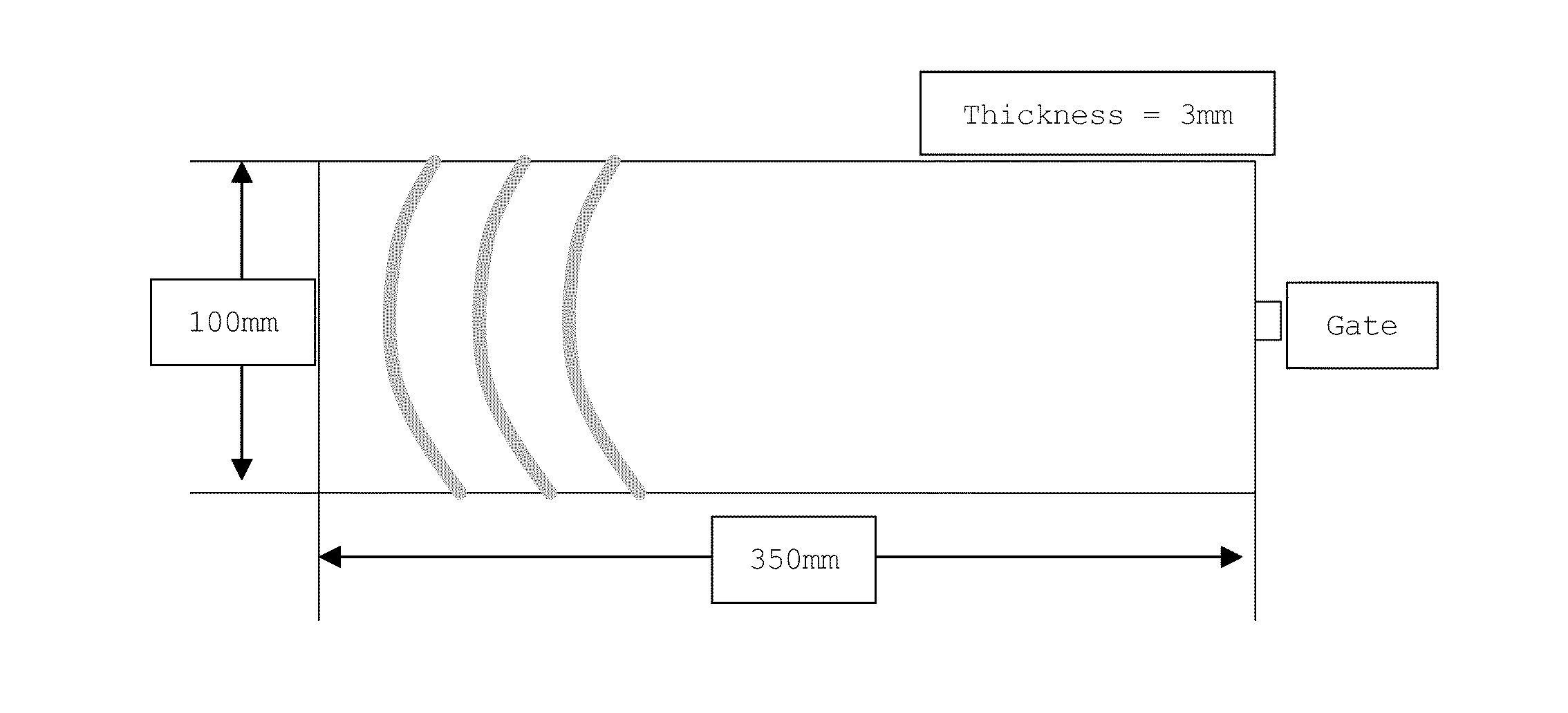

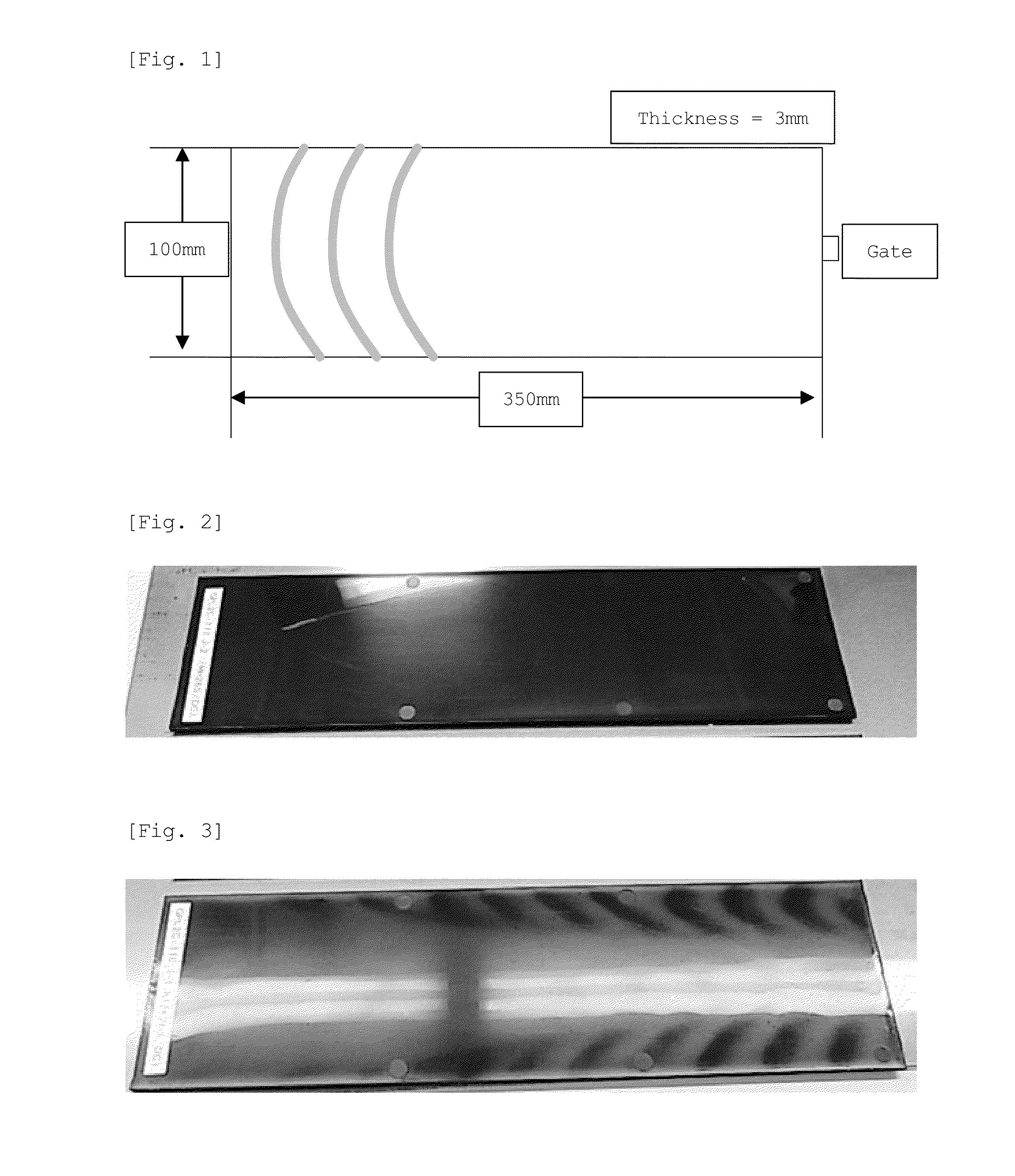

Polyamide toughening agent as well as preparation method and use thereof

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

Propylene-based block copolymer, composition containing the copolymer, and molded products obtained therefrom

ActiveUS20110172353A1High melt viscoelasticityImprove liquiditySpecial tyresPolymer scienceRoom temperature

To provide a propylene-based block copolymer which has high melt viscoelasticity, excellent balance between rigidity and impact resistance and good molding processablility and is extremely excellent in its molded product appearance, a composition containing the copolymer and molded products obtained therefrom. The propylene-based block copolymer comprises 5 to 80% by weight of a room temperature n-decane-soluble portion (Dsol) and 20 to 95% by weight of a room temperature n-decane-insoluble portion (Dinsol), with the proviso that the total amount of the Dsol and the Dinsol is 100% by weight, and satisfies the following requirements [1] to [3] at the same time: [1] the molecular weight distribution (Mw / Mn) of the Dsol is not less than 7.0 but not more than 30, [2] the molecular weight distribution (Mw / Mn) of the Dinsol is not less than 7.0 but not more than 30, and Mz / Mw thereof is not less than 6.0 but not more than 20, and [3] the pentad fraction (mmmm) of the Dinsol is not less than 93%.

Owner:MITSUI CHEM INC

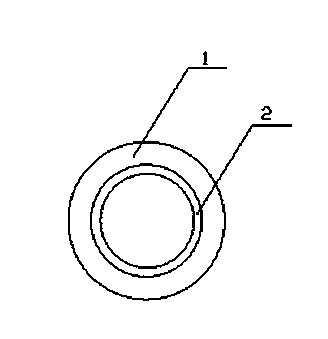

Wire protective tube with silicon core layer

InactiveCN103457208ASimple structureGood for mass productionElectrical apparatusHollow cylinderHigh-density polyethylene

The invention discloses a wire protective tube with a silicon core layer. The wire protective tube with the silicon core layer comprises a tube body and an inner core, wherein the tube body is a hollow cylinder, the outer diameter of the tube body is 40mm, the wall thickness of the tube body is 4mm, the tube body is made of high-density polyethylene materials, the temperature which can be borne by the tube body is more than 90DEG C, the pressure intensity borne by the tube body is 1.0-2.0MPa, the inner core is a silicon layer which is evenly plated on the inner wall of the tube body, and the thickness of the inner core is 1mm. According to the mode, the wire protective tube with the silicon core layer has the advantages of being simple in structure and beneficial to mass production, resisting abrasion, the high temperature and corrosion, being non-toxic, harmless, good in toughness, light in weight, good in strength, sturdy, durable, good in low-temperature impact resistance, and good in stress crack resistance performance, and having wide market prospect in popularization.

Owner:TAICANG CHENZHOU PLASTIC

Method for forming multilayer coating film

ActiveUS20180104718A1Excellent impact resistanceHigh low temperature impact resistancePretreated surfacesPolyurea/polyurethane coatingsIsocyanatePlastic materials

Provided is a method for forming a multilayer coating film giving excellent low temperature impact resistance to a substrate that comprises a metal material and a plastic material. The method for forming a multilayer coating film comprises sequential steps of forming an uncured primer coating film, an uncured first colored coating film, an uncured second colored coating film and an uncured clear coating film on a substrate; and heating the same so as to simultaneously cure these 4 coating films, wherein the aqueous first colored paint and aqueous second colored paint are each a 1-package type paint composition containing a specific hydroxyl group-containing resin and a specific blocked polyisocyanate compound.

Owner:KANSAI PAINT CO LTD

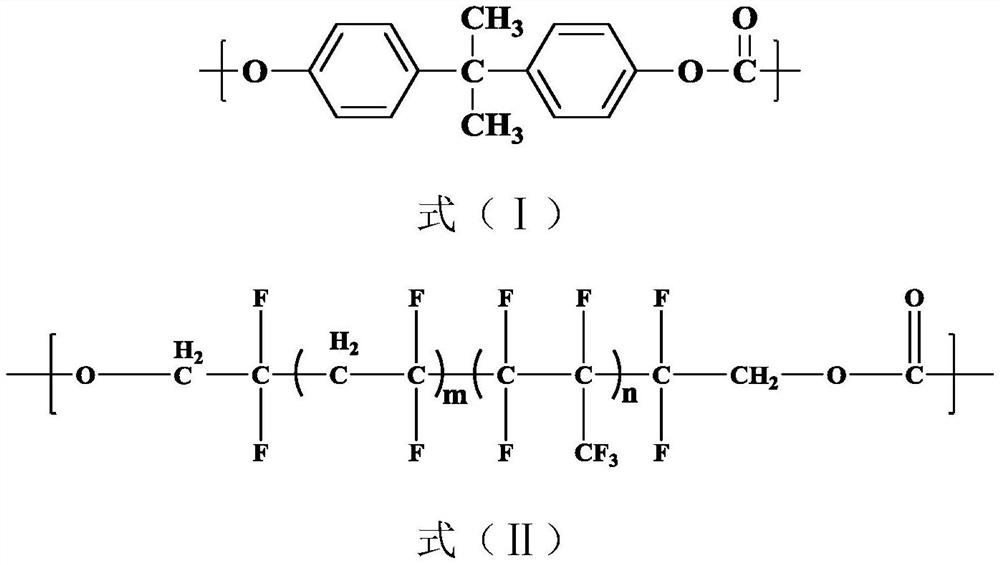

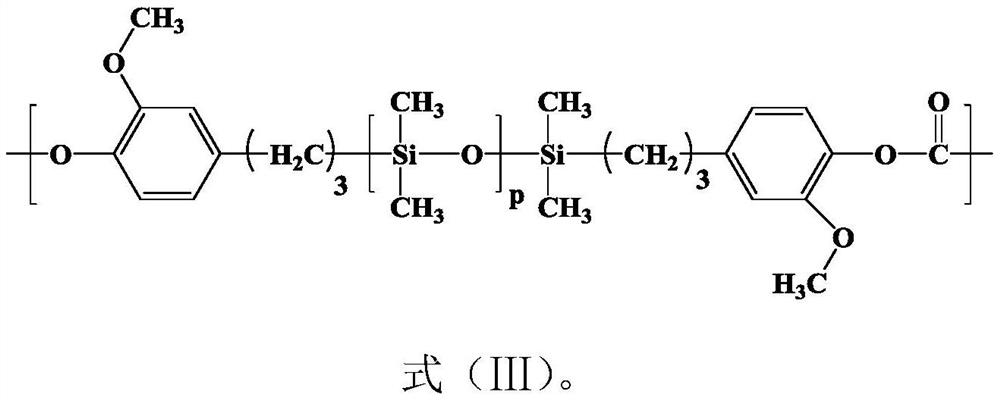

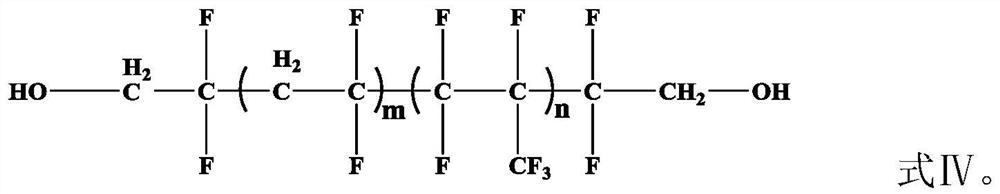

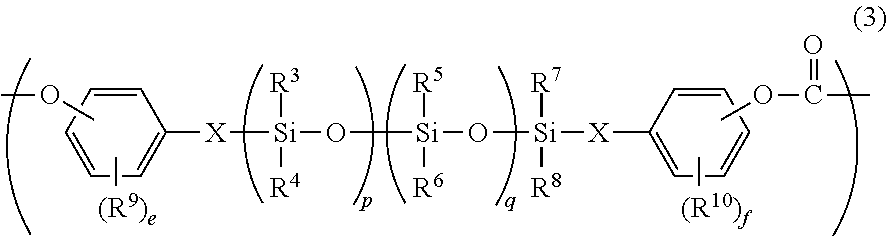

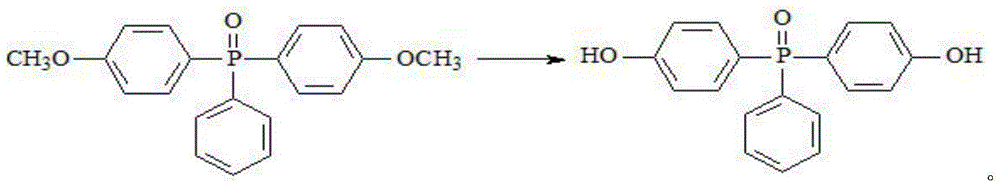

Copolycarbonate and preparation method thereof

ActiveCN112409585AExcellent heat and humidity resistanceGood solvent resistancePolymer sciencePtru catalyst

The invention relates to a copolycarbonate and a preparation method thereof. The invention particularly relates to a novel copolymer of which the molecular chain contains a fluororubber chain segment,a polysiloxane chain segment and a polycarbonate chain segment, and a preparation method thereof. The copolymer is novel in structure, and the fluororubber chain segment and the polysiloxane chain segment are introduced into the polycarbonate chain segment in a copolymerization manner so that the damp-heat aging resistance, the solvent resistance and the impact resistance of conventional polycarbonate can be improved. The copolymer is prepared by copolycondensation of the comonomer and the polycarbonate oligomer under the action of the catalyst, is easy to operate and easy to implement, and can be used in industrial production.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

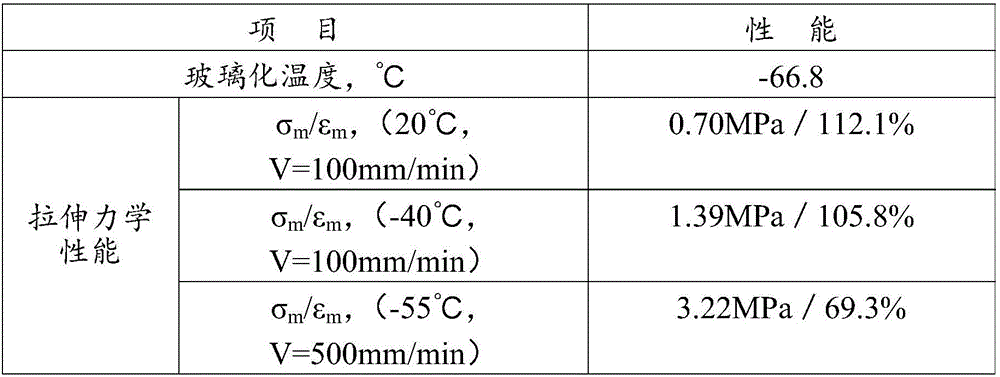

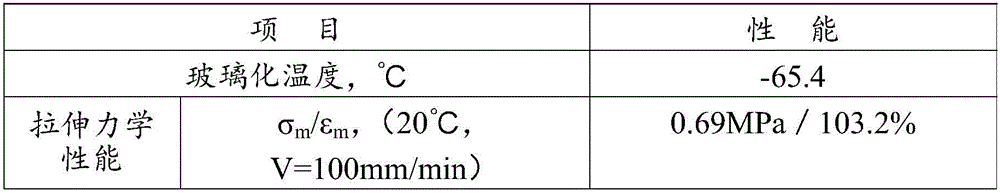

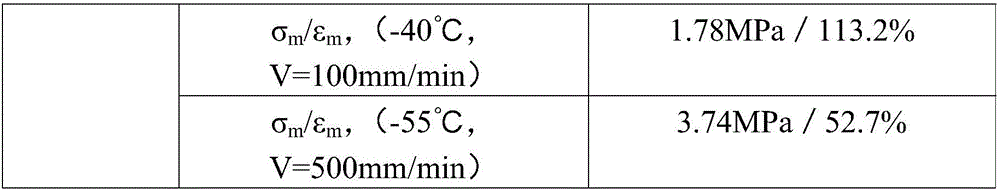

NEPE (nitrate ester plasticized polyether) propellant with good low-temperature mechanical property

ActiveCN106748601AActiveReduced low temperature performanceNon-explosive/non-thermic compositionsPressure gas generationAdhesiveTriethylene glycol dinitrate

The invention relates to a NEPE (nitrate ester plasticized polyether) propellant with good low-temperature mechanical property. The NEPE propellant is prepared from the following components in percentage by mass: 5 to 10% of adhesive, 6 to 16% of energetic plasticizer, 0 to 3% of cold-resistant plasticizer, 15 to 40% of oxidant, 20 to 41% of energetic oxidant, 0.3 to 1.0% of curing agent, and 15 to 19% of fuel, wherein the cold-resistant plasticizer is triglyceride ethyl carbonate, and the adhesive is ethylene oxide-tetrahydrofuran copolymer; the plasticizer is a nitroglycerin and triethylene glycol dinitrate mixture, and singly uses triethylene glycol dinitrate; the oxidant is ammonium perchlorate, and the energetic oxidant is octogen or hexogen; the curing agent is hexamethylene diisocyanate; the fuel is Al (aluminum). The NEPE propellant has the characteristics that the low-temperature mechanical property is good, the energy is higher, and the like; the NEPE propellant is suitable for tactical missiles with low use environment temperature, high charge ratio and large thrust.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Special material for high-toughness and high-water pressure resistance polypropylene randon copolymer (PPR) pipe material and preparation process thereof

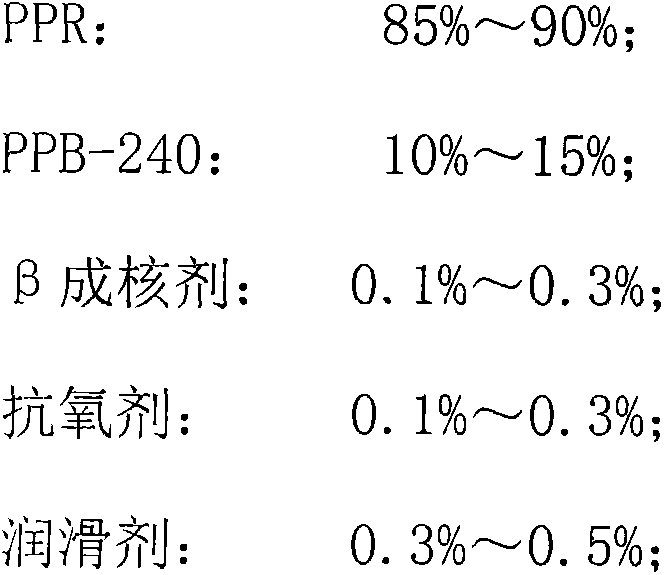

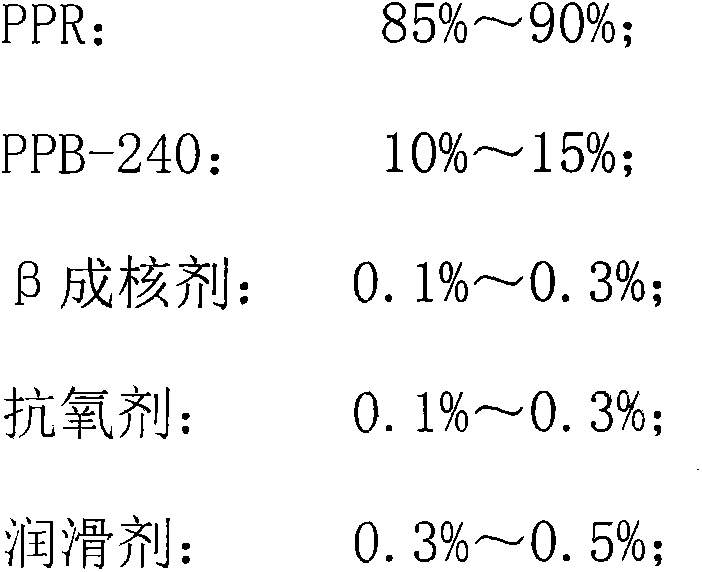

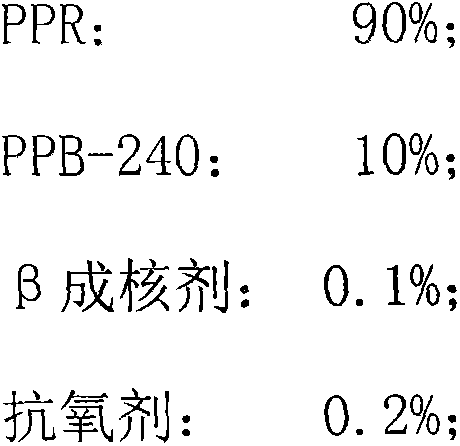

The invention relates to a special material for a high-toughness and high-water pressure resistance polypropylene randon copolymer (PPR) pipe material and a preparation process of the special material. The special material is prepared from the following raw materials in percentage by mass: 85-90% of PPR, 10-15% of PPB-240, 0.1-0.3% of a beta-nucleating agent, 0.1-0.3% of an antioxidant and 0.3-0.5% of a lubricant. The preparation process mainly comprises the steps of weighing proper amounts of PPR, PPB, a beta-nucleating agent, an antioxidant and a lubricant according to the prescription, and mixing the materials in a low-speed mixer according to an order from higher proportion to lower proportion; setting a corresponding thread combination; setting heating temperature of various sections of charging barrels of a dual-screw extruder; adding mixed raw and auxiliary materials to a storage hopper of the dual-screw extruder set; starting a lubricating oil pump, a cooling fan, a grain cutting machine, cooling water, a main motor and a feeding motor, and regulating rotating speeds of the main motor and the feeding motor; drawing the extruded materials to the grain cutting machine through a cooling water bath and a blow drying machine, regulating rotating speed of the grain cutting machine, so that the cut materials are 3 in granularity and 3mm long; and detecting various physical indicators of the produced materials in real time.

Owner:MIANYANG PENGYANG POLYMER MATERIAL

Ageing-resistant ethylene-propylene-diene monomer rubber (EPDM)/POE waterproof roll and preparation method thereof

InactiveCN106117838AHigh strengthPrevent agingFlat articlesBuilding insulationsRubber materialPolymer science

The invention discloses an ageing-resistant ethylene-propylene-diene monomer rubber (EPDM) / POE waterproof roll which is characterized by being prepared from the following raw materials in parts by weight: EPDM, butadiene styrene rubber, POE, 1,3-di(tert-butylperoxyisopropyl)benzene, triallyl isocyanurate, stearic acid, 2-mercapto benzimidazole, lanthanum oxide, di-2-ethylhexylsulfosuccinate, absolute ethyl alcohol, polyvinyl alcohol, zinc oxide, argil, nano-silica, vinyltris(beta-methoxyethoxy)silane, ethylene bis stearamide, sodium phosphate, 2,2'-dithio-dibenzo thiazole and deionized water. According to the waterproof roll disclosed by the invention, EPDM serves as a matrix, and a proper amount of POE and butadiene styrene rubber are added, so that the wear resistance of rubber materials is greatly enhanced, and the ageing resistance and oxidization resistance of the waterproof roll disclosed by the invention are improved.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

Polycarbonate resin composition and molded article thereof

ActiveUS20170335100A1Excellent flowabilityExcellent low-temperature impact resistancePolyolefinShell molding

A polycarbonate resin composition which has excellent low-temperature impact resistance and flowability high enough to enable thin molding and provides a coated molded article having a good appearance and high impact resistance. The resin composition comprises 100 parts by weight of a resin component including a polycarbonate resin (component A) and a polycarbonate-polydiorganosiloxane copolymer resin (component B) and 0.5 to 2.5 parts by weight of a polyolefin resin (component C).

Owner:TEIJIN LTD

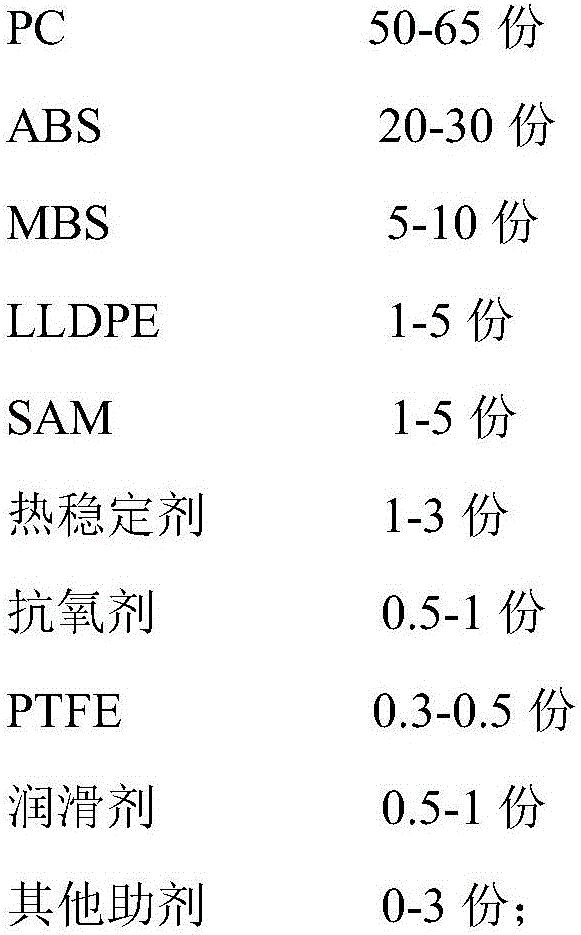

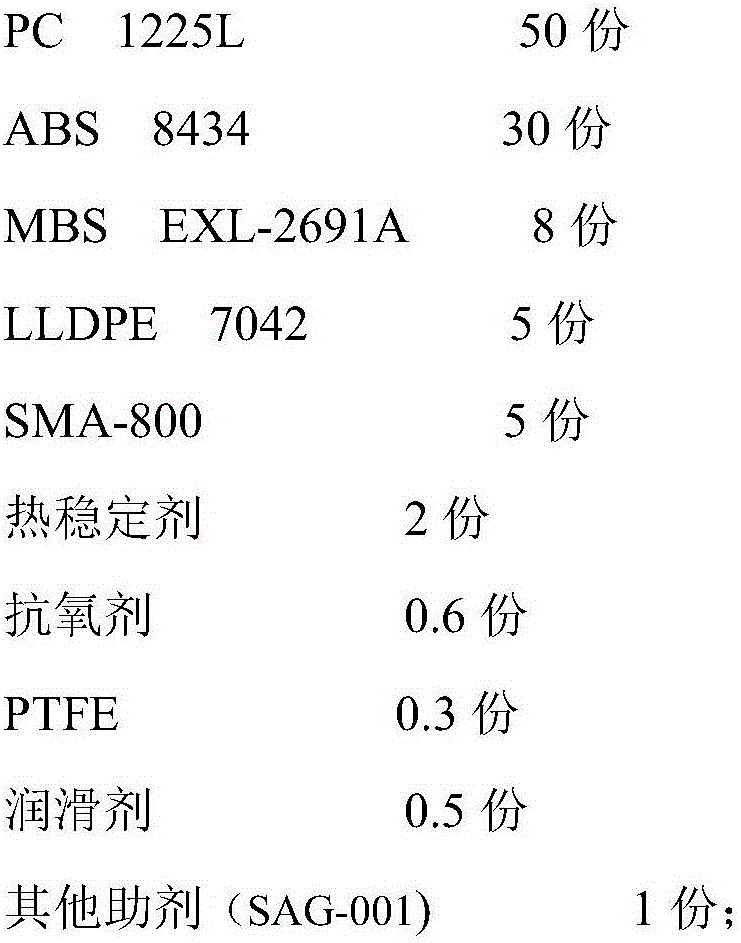

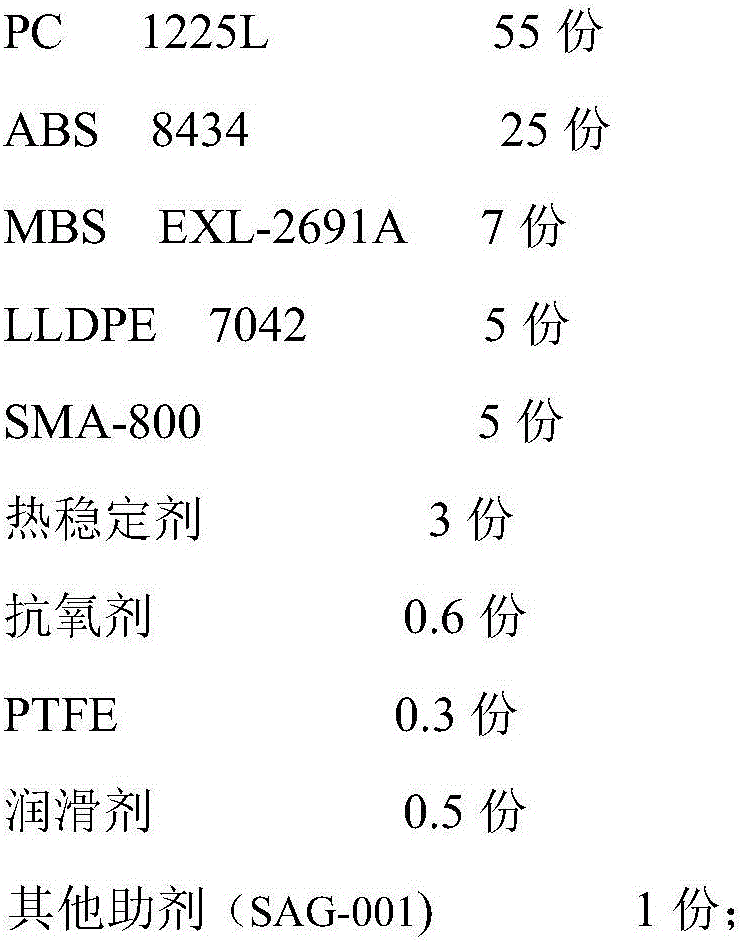

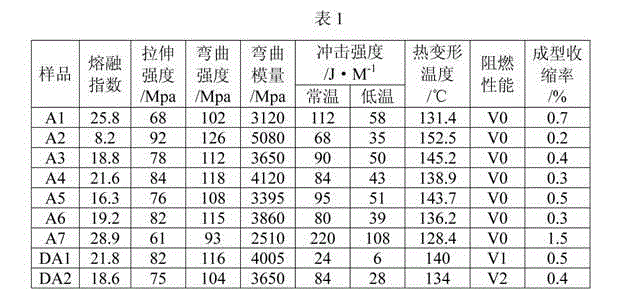

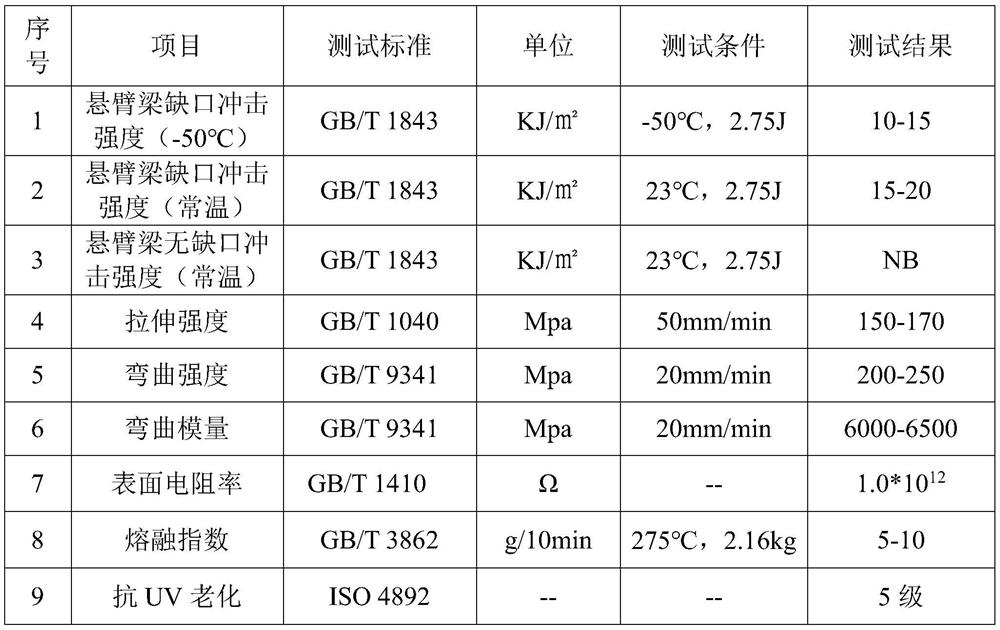

Hydrolysis-resistant and low-temperature-resistant PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composite and preparation method thereof

ActiveCN106349675AGood low temperature impact resistanceImprove hydrolysis resistancePolytetrafluoroethyleneCompatibilization

The invention provides a hydrolysis-resistant and low-temperature-resistant PC / ABS (Polycarbonate / Acrylonitrile Butadiene Styrene) composite and a preparation method thereof. The PC / ABS composite comprises the following materials in parts by weight: 50-65 parts of PC resin, 20-30 parts of ABS, 5-10 parts of an MBS flexibilizer, 1-5 parts of LLDPE (Linear Low Density Polyethylene), 1-5 parts of SAM, 1-3 parts of a heat stabilizer, 0.5-1 part of antioxygen, 0.3-0.5 part of polytetrafluoroethylene, 0.5-1 part of a lubricant, and 0-3 parts of other assistants. Due to the linear structure of the LLDPE, the shrinkage property of the polytetrafluoroethylene (PTFE) and the compatibilization of the SAM, the interfacial compatibility of the LLDPE and the PC / ABS is improved, and the low-temperature impact resistance performance, the malleability and the tearing property of the composite are greatly improved; meanwhile, the composite has the characteristics of high hydrolysis resistance, high heat stability, excellent wear resistance and excellent chemical corrosion resistance, so that the application field of a PC / ABS alloy material is greatly expanded, and the composite has broad development and application prospects.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Polyphenylether material and preparation method thereof

ActiveCN102796362AImprove flame retardant performanceHigh low temperature impact resistancePolymer sciencePolyphenyl ether

The invention provides a polyphenylether material and a preparation method thereof. The polyphenylether material comprises a main body resin, a toughening compound, a phosphatic organic substance and an assistant, wherein the main body resin is polyphenylether resin, and the toughening compound is an organosilicon-acrylate-styrene multipolymer. The polyphenylether material has the advantages of high melt index and excellent flame retardancy.

Owner:BYD CO LTD

Automobile bumper

InactiveCN104817771ALow shrinkageSpeed up the flowGroup 5/15 element organic compoundsFiberAntioxidant

The invention discloses an automobile bumper which is made of materials including polypropylene, bis (p-hydroxyphenyl) phenyl phosphine oxide, thermoplastic polyurethane, ultrafine magnesium hydroxide, polyamide, acrylonitrile-butadiene-styrene, ethylene propylene rubber, polyethylene, shear thickening fluids, poly (m-phenylene isophthalamide) fibers, antistatic agents, antioxidants, dispersing agents, plasticizers and stabilizers. The materials of the bumper are low in shrinkage, high in flowability, fine in weather resistance and fine in paint performance, and have the advantages of high flexibility, strength, breaking elongation and heat distortion temperature. The bumper cannot fracture when an automobile is slightly collided. Compared with existing bumper materials, bending modulus, tensile strength, hardness and melt flow rate are greatly increased, and low-temperature impact resistance and chemical resistance are remarkably improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Nylon material for pin type composite insulator cap-shaped connector for power grid power transmission and distribution line and forming method

PendingCN111621149AImprove mechanical propertiesImprove liquidityInsulatorsGlass fiberNylon material

The invention relates to a nylon material of a pin-type composite insulator cap-shaped connector for a power grid power transmission and distribution line and a forming method. The nylon material comprises the following components in percentage by mass: 62%-66% of nylon resin, 28%-33% of glass fiber, 3%-6% of a toughening agent, 0.2%-0.5% of a main antioxidant, 0.2%-0.5% of an auxiliary antioxidant, 0.2%-0.5% of an ultraviolet absorbent, 0.2%-0.5% of a light stabilizer and 1%-3% of a wear-resistant additive, the viscosity of the nylon resin is 3.2 + / -0.01; the grafting rate of the toughening agent is 0.8 to 1.2%; the nylon resin is PA66 polyhexamethylene adipamide, PA6 polyamide 6 or a mixture of the PA66 polyhexamethylene adipamide and the PA6 polyamide 6. After polymerization processing,the material performance is excellent, the mechanical performance, the electrical performance, the environmental aging resistance, the high and low environmental temperature resistance and the material wear resistance of the composite product are excellent, and the safe use condition of the product is met.

Owner:XIAN WEISHI TRANSMISSION & DISTRIBUTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com