Nylon material for pin type composite insulator cap-shaped connector for power grid power transmission and distribution line and forming method

A technology of pin insulators and power transmission and distribution lines, which is applied to circuits, insulators, electrical components, etc., and can solve problems such as high energy consumption, worn wires, and sassafras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

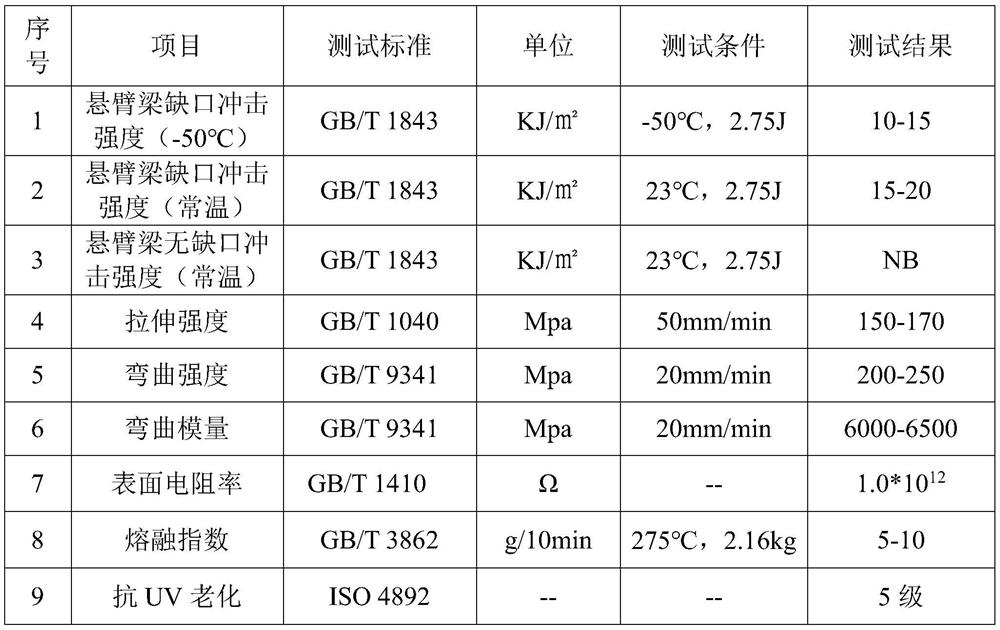

Image

Examples

Embodiment 1

[0034] Step 1: Mix 71% nylon resin PA66 with 29% nylon resin PA6. Add white oil and stir for 10min-12min, then add all the components of the pellets according to the ratio into a high-speed mixer and stir for 15min-18min to obtain a premix; the specific components are (mixed nylon resin 62% ~ 66%; MAH toughening Agent 3%~6%; main antioxidant 0.2%~0.5%, auxiliary antioxidant 0.2%~0.5%, ultraviolet absorber 0.2%~0.5%, light stabilizer 0.2%~0.5%, wear resistance additive 1 %~3%)

[0035] Step 2: Put the premix into the main feeding hopper of the twin-screw extruder, and add the glass fiber to the auxiliary hopper of the co-extrusion. The added amount accounts for 28% to 33% of the total mass of the formula. Simultaneous extrusion and granulation; Extrusion temperature: feeding Material section 220-240℃, shearing plasticization section 240-260℃, head 250-280℃;

[0036] Step 3: Dry the granulated particles in a blast drying oven at 130°C for 4h-5h;

[0037] Step 4: The temperature of e...

Embodiment 2

[0042] Step 1: Mix 71% nylon resin PA66 with 29% nylon resin PA6. Add white oil and stir for 10min-12min, then add all the components of the pellets according to the ratio into a high-speed mixer and stir for 15min-18min to obtain a premix; the specific components are (mixed nylon resin 62% ~ 66%; MAH toughening Agent 3%~6%; main antioxidant 0.2%~0.5%, auxiliary antioxidant 0.2%~0.5%, ultraviolet absorber 0.2%~0.5%, light stabilizer 0.2%~0.5%, wear resistance additive 1 %~3%)

[0043] Step 2: Put the premix into the main feeding hopper of the twin-screw extruder, and add the glass fiber to the auxiliary hopper of the co-extrusion. The added amount accounts for 28% to 33% of the total mass of the formula. Simultaneous extrusion and granulation; Extrusion temperature: feeding Material section 220-240℃, shearing plasticization section 240-260℃, head 250-280℃;

[0044] Step 3: Dry the granulated particles in a blast drying oven at 130°C for 4h-5h;

[0045] Step 4: The temperature of e...

Embodiment 3

[0050] Step 1: Combine nylon resin PA66 with toughening agent MAH. Add white oil and stir for 10min-12min, then add all the components of the pellets according to the ratio into a high-speed mixer and stir for 15min-18min to obtain a premix; the specific components are (PA66 nylon resin 62%~66%; MAH toughening Agent 3%~6%; main antioxidant 0.2%~0.5%, auxiliary antioxidant 0.2%~0.5%, ultraviolet absorber 0.2%~0.5%, light stabilizer 0.2%~0.5%, wear resistance additive 1 %~3%)

[0051] Step 2: Put the premix into the main feeding hopper of the twin-screw extruder, and add the glass fiber to the auxiliary hopper of the co-extrusion. The added amount accounts for 28% to 33% of the total mass of the formula. Simultaneous extrusion and granulation; Extrusion temperature: feeding Material section 220-240℃, shearing plasticization section 240-260℃, head 250-280℃;

[0052] Step 3: Dry the granulated particles in a blast drying oven at 130°C for 4h-5h;

[0053] Step 4: The temperature of eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com