Patents

Literature

75results about How to "Reduce steric hindrance effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

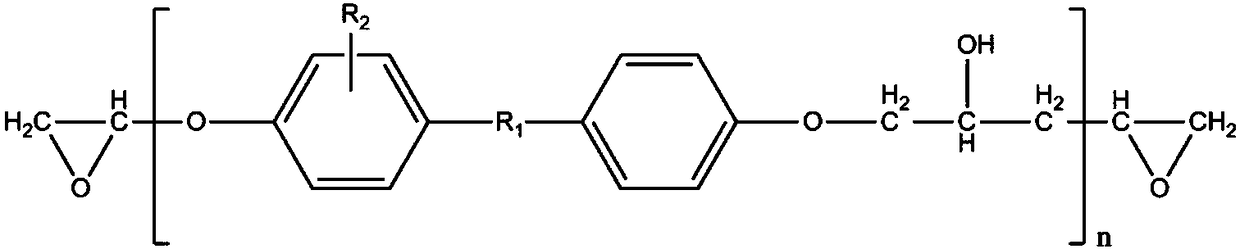

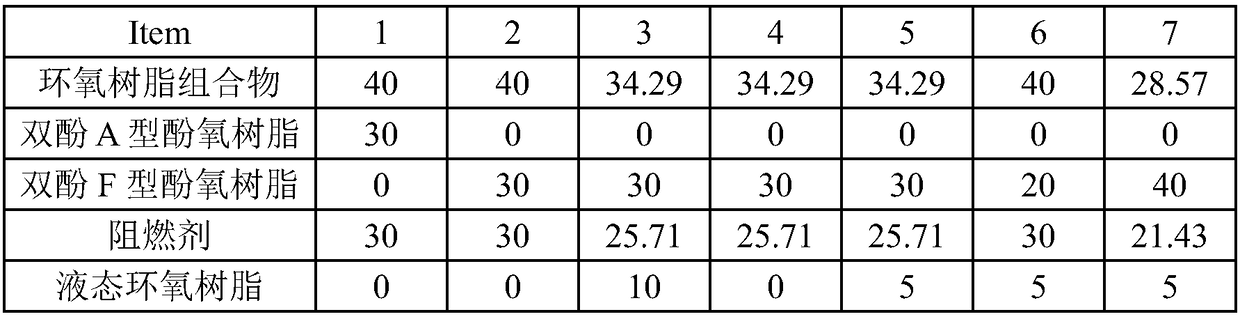

Halogen-free resin composition and low-fluidity prepreg thereof

The invention discloses a halogen-free resin composition and a low-fluidity prepreg thereof. The halogen-free resin composition comprises, by weight, 20-80 parts of an epoxy resin composition, 10-50 parts of phenoxy resin, 10-50 parts of a flame retardant, 3-30 parts of a toughening agent, 10-80 parts of an inorganic filler, 1-10 parts of a curing agent, 0-5 parts of an accelerator and 0-80 partsof an additive. The halogen-free resin composition obtained by modifying common epoxy resin with bisphenol F phenoxy resin, liquid epoxy resin and long chain-containing aliphatic epoxy resin has low viscosity and good wettability, and the low-fluidity prepreg produced from the halogen-free resin composition has the advantages of high flexibility, high Tg and bonding strength, excellent heat resistance, greenness, environmental protection, no resin dust, and realization of long-term preservation.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

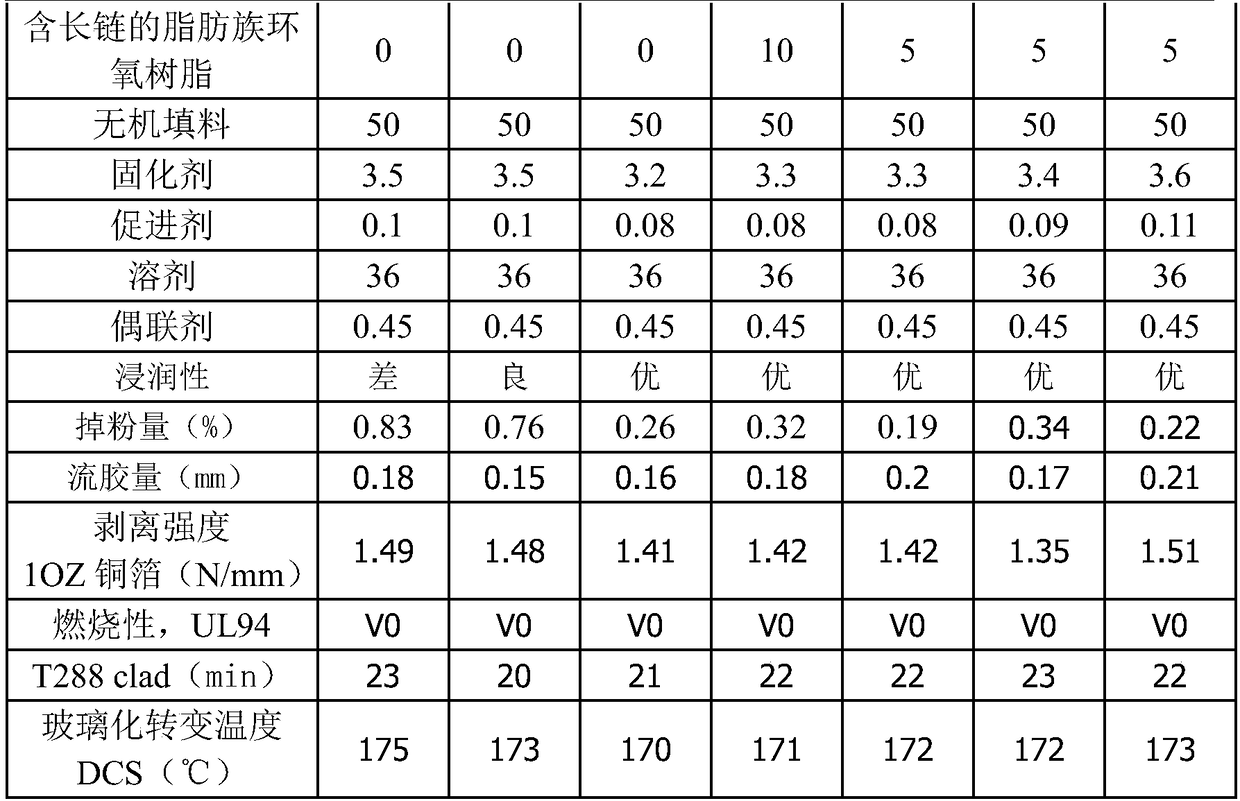

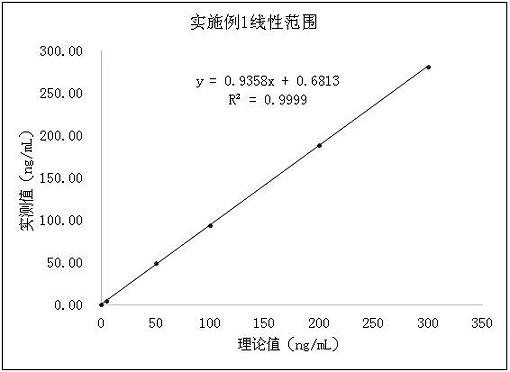

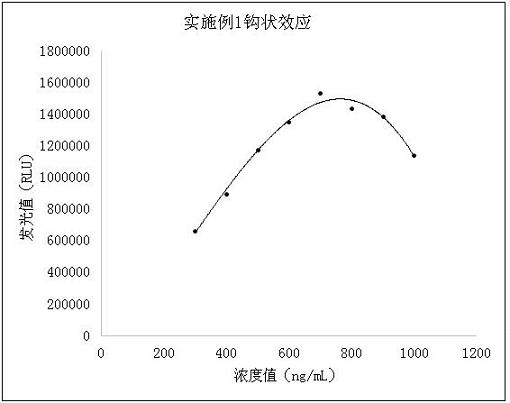

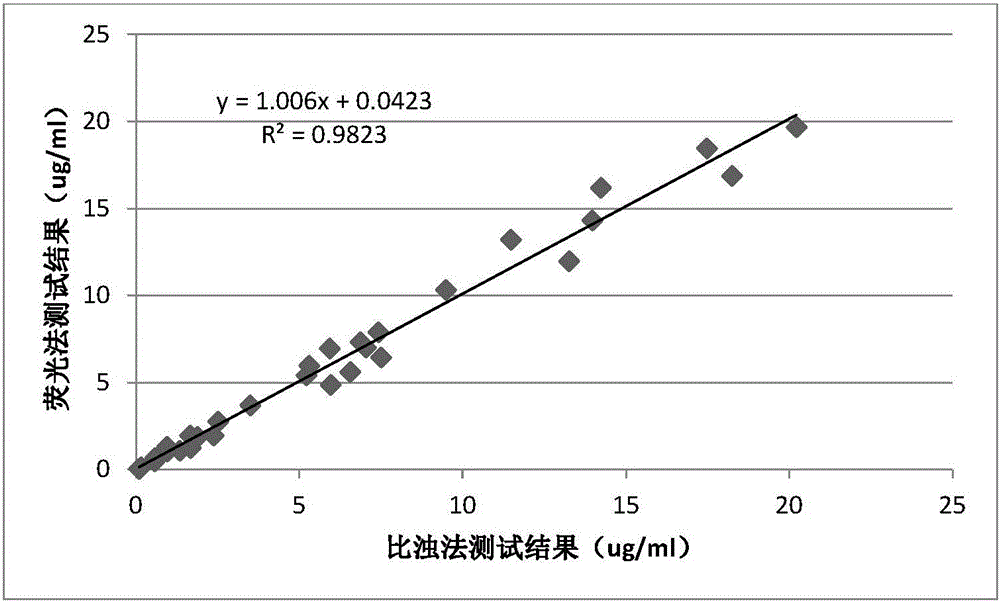

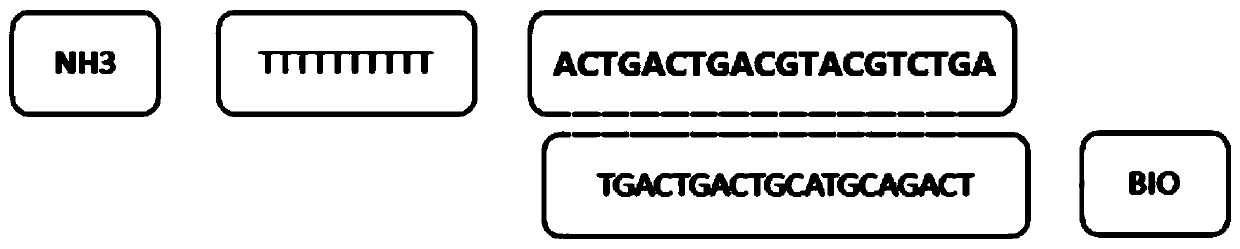

HBP magnetic particle chemiluminiscence method detection kit and preparation method thereof

ActiveCN111679086AReduce dosageLow costChemiluminescene/bioluminescenceDisease diagnosisBovine serum albuminStreptavidin

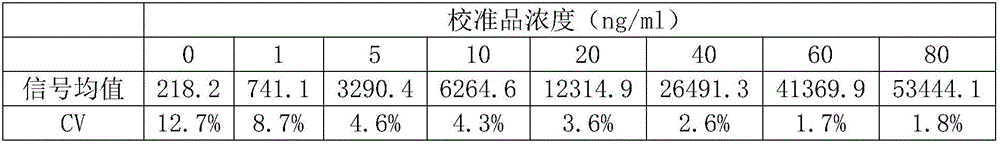

The invention discloses a magnetic particle chemiluminiscence detection kit for heparin-binding protein, a preparation method of the magnetic particle chemiluminiscence detection kit and application of the magnetic particle chemiluminiscence detection kit to immunological detection of the heparin-binding protein. The magnetic particle chemiluminiscence detection kit comprises a streptavidin-coatedmagnetic particle suspension solution, a biotin-labeled heparin-binding protein capture antibody and biotin-labeled bovine serum albumin mixed solution, a luminous marker coupled heparin-binding protein detection antibody solution, a heparin-binding protein series calibration product and a quality control product. The kit provided by the invention utilizes the advantages of a magnetic particle chemiluminescence detection method, and has the characteristics of simple operation, strong specificity, high sensitivity, wide linear range and the like when a full-automatic chemiluminescence immunoassay analyzer is used for detecting the heparin-binding protein in a specimen.

Owner:SUZHOU KANGHESHUN MEDICAL TECH

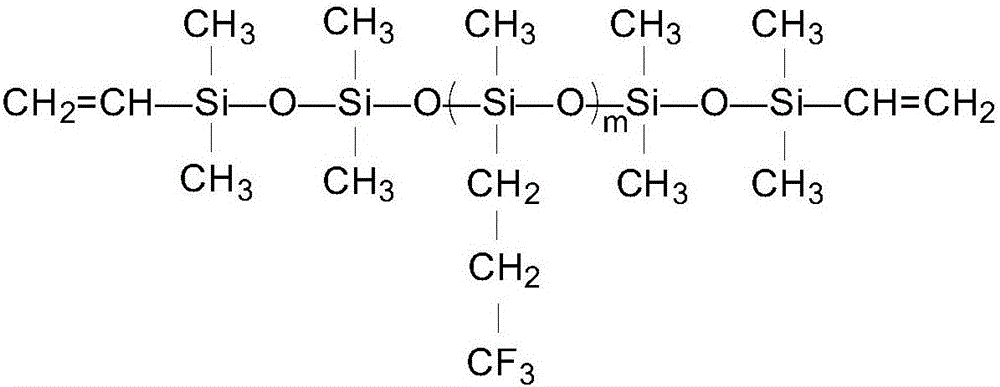

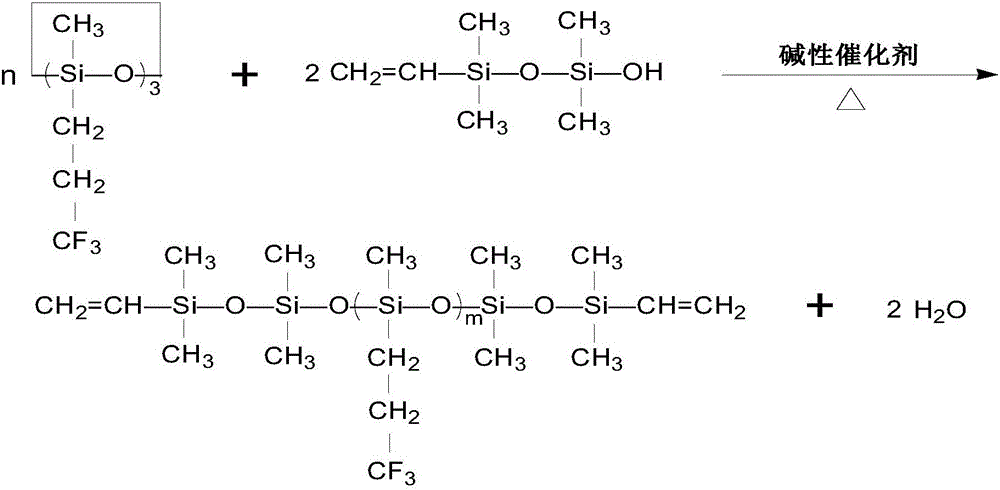

Addition type liquid fluorinated silicone rubber base rubber and preparation method thereof

The invention relates to addition type liquid fluorinated silicone rubber base rubber and a preparation method thereof. The base rubber has following structural general formula of Vi(Me)2SiO-Si(Me)2O-[Si(Rf)(Me)O]m-Si(Me)2Vi, wherein Me represents CH3-, Vi represents CH2=CH-, Rf represents CF3CH2CH2-, and m represents an integer of 18-2000. According to the preparation method, 1-vinyl-3-hydroxy-1,1,3,3-tetramethyldisiloxane is taken as an end-capping agent, and two dimethyl siloxane chains are linked with vinyl, so that the screening effect of trifluoropropyl groups on vinyl at terminals of molecular chains is reduced, the steric-hinerance effect is reduced, the crosslinking activity of vinyl is guaranteed, and the oil resistance of the fluorinated silicone rubber is not damaged.

Owner:新元化学(山东)股份有限公司

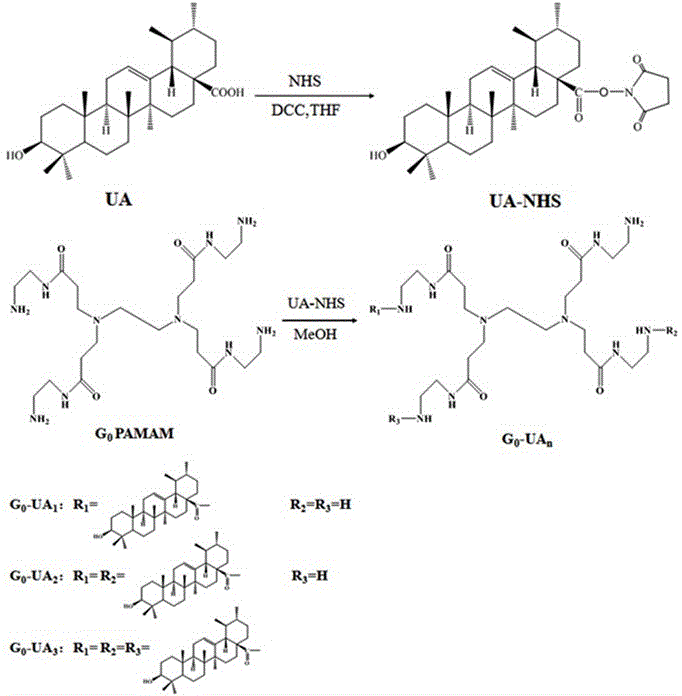

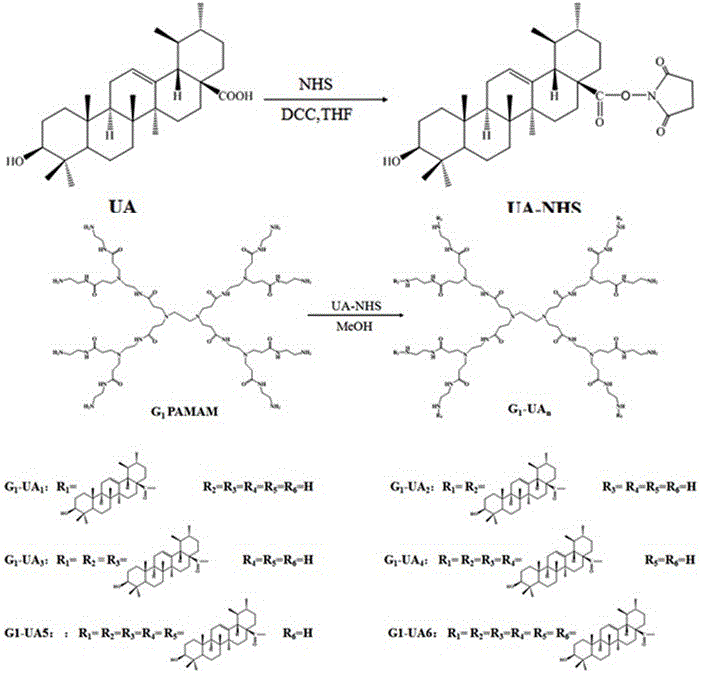

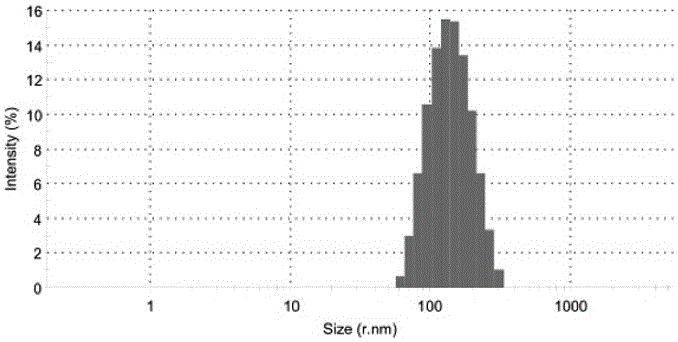

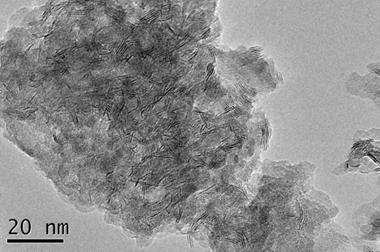

Amphiphilic self-assembled nanomicelle based on nano Low-generation PAMAM (polyamidoamine) dendrimer and application thereof

InactiveCN105854027AThe synthesis steps are simpleLow costOrganic active ingredientsPharmaceutical non-active ingredientsSolubilityNanocarriers

The invention relates to an amphiphilic self-assembled nanomicelle based on nano Low-generation PAMAM (polyamidoamine) dendrimer and application thereof, particularly obtained conjugating low-generation PAMAM dendrimer and a hydrophobic agent and self-assembling in water via ultrasonic vibration. The nanomicelle has active molecules or a prodrug with drug loading capacity; the chemical conjugation of the hydrophobic agent and the low-generation PAMAM dendrimer helps improve the defects of poor solubility of the hydrophobic drug and low bioavailability, and a new idea is provided to solve the problem that traditional clinical chemotherapeutics are high in toxicity and low in safety coefficient; the nanomicelle can also function as a nanocarrier to carry other hydrophobic drugs, enabling joint use of drugs and enhancing therapeutic effect.

Owner:FUZHOU UNIV

Preparation method of surface-heparinized anticoagulation medical device based on ionic bond-covalent bond synergistic action

The invention relates to the field of medical devices, in particular to a preparation method of a surface-heparinized anticoagulation medical device based on ionic bond-covalent bond synergistic action. The method comprises the following steps: firstly, fixing heparin on the surface of a medical device by utilizing a hydrophilic polymer modified by low-molecular-weight hyperbranched polyethyleneimine as a side chain in an ionic bond combination manner; and furthermore, grafting a stable heparin coating through covalent bonds, so as to obtain the anticoagulant biomedical device with high anticoagulant activity and high anticoagulant stability. The device has a wide application value in the field of biomedical treatment. The method is simple in preparation process, high in controllability and low in material price, does not involve toxic reagents in the experiment process, has universality for various medical device structures, and is suitable for industrial production.

Owner:JIANGSU STMED TECH CO LTD

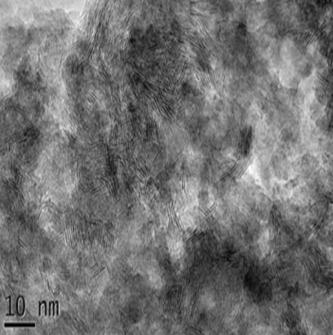

Deep desulfurization hydrotreatment method of diesel oil

ActiveCN111073688AIncrease profitAddress reactivityHydrocarbon oils treatmentRefining to eliminate hetero atomsLamellar crystalsPtru catalyst

The invention discloses a deep desulfurization hydrotreatment method of diesel oil. The method comprises the following steps that a diesel oil raw material enters a hydrogenation reactor and contactsa hydrogenation catalyst bed layer to carry out a hydrogenation reaction, and the reaction product flows out of the reactor, wherein the hydrogenation catalyst bed layer is filled with at least two stages of vulcanization-state hydrogenation catalysts in a grading manner along the material flow direction, the metal active phase crystal lengths of each stage of the vulcanization-state hydrogenationcatalyst are increased stage by stage along the material flow direction, and the lamellar crystal layer number is reduced stage by stage. According to the catalyst grading method disclosed by the invention, the matching reaction of the molecular size and structure of the reactants in each section and an active phase structure can be fully realized so as to effectively utilize the active center ofthe catalyst, improve the coupling reaction performance of the active center structure and the molecular structure, substantially improve the desulfurization activity and the stability of the whole system on reactants, significantly improve the desulfurization depth of diesel oil and produce ultralow-sulfur diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

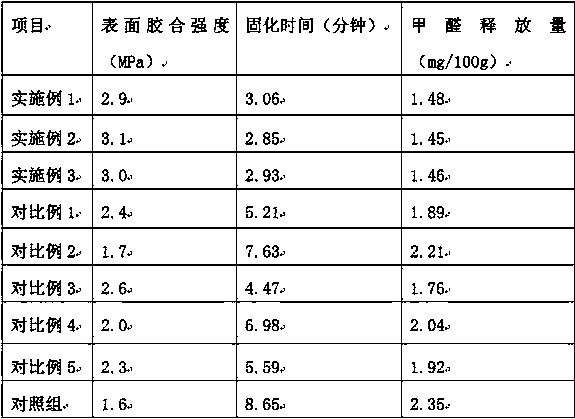

Method for preparing grape skin tannin modified phenolic resin adhesive

ActiveCN107841268AImprove performanceSimple preparation processAldehyde/ketone condensation polymer adhesivesWood veneer joiningSulfiteTannin

The invention relates to a method for preparing a grape skin tannin modified phenolic resin adhesive. The method comprises the following process steps: (1) preparation of a grape skin tannin extract:(2) biodegradation of the grape skin tannin extract: obtaining the grape skin tannin extract with a low molecular weight and low degree of polymerization by sulfite extraction and biodegradation; (3)preparation of tannin modified phenolic resin: using the grape skin tannin extract, phenol, formaldehyde, an alkali solution and water as raw materials, performing a secondary polycondensation reaction by a secondary charging method of the formaldehyde and the alkali solution to prepare the grape skin tannin modified phenolic resin adhesive; (4) preparation of a plywood. The method has the advantages that: (1) condensed tannins with low molecular weight and low degree of polymerization are prepared by a sulfite extraction and biodegradation combination method, so that the space steric effect in the polycondensation reaction is reduced and the adhesive forming properties of phenolic resin are improved; (2) the preparation process is simple, the operation is easy, and the prepared phenolic resin has good properties.

Owner:NANJING FORESTRY UNIV

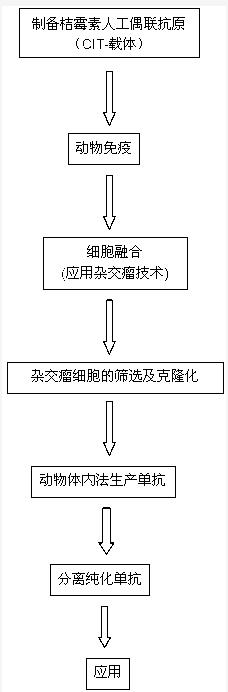

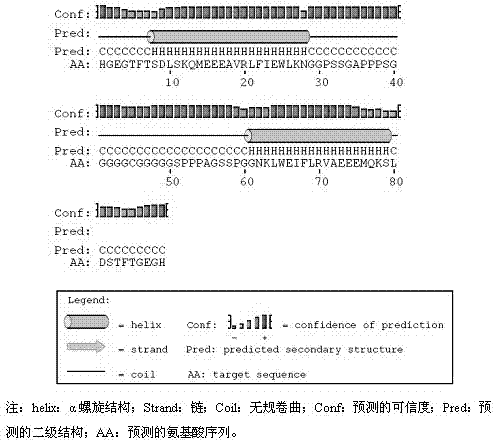

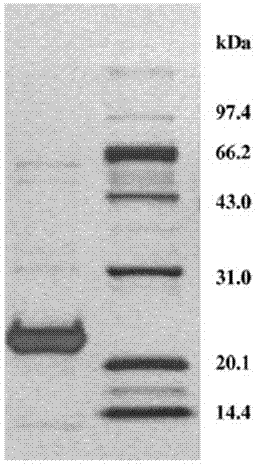

Double-cross-linking chemical synthesis method of citrinin-protein-coupled antigen and preparation method of anti-citrinin monoclonal antibody

InactiveCN101845094AReduce steric hindrance effectCompact structureOvalbuminSerum albuminAntigenAscitic fluid

The invention relates to a double-cross-linking chemical synthesis method of a citrinin-protein-coupled antigen and a preparation method of an anti-citrinin monoclonal antibody, belongs to the field of biotechnology. The synthesis method of the citrinin-protein-coupled antigen comprises the following steps that: the citrinin and a double-cross-linking agent (C2H3O)-(CH2)n-(C2H3O) react at first and is then coupled with a carrier, glycine is used for occlusion after reaction, and separation and purification are carried out finally, thereby obtaining the citrinin-carrier-coupled antigen. The preparation method of the anti-citrinin monoclonal antibody comprises the following steps: carrying out cell fusion and screening with the hybridoma technique to obtain a hybridoma cell line of the anti-citrinin monoclonal antibody with stable secretion, preparing ascitic fluid, and purifying, thereby obtaining the anti-citrinin monoclonal antibody. The invention has the advantages of mild preparation conditions, simple operation and controllable process. The obtained anti-citrinin monoclonal antibody has high specificity and high affinity, and can be further used for preparation of the enzyme linked immunosorbent assay kit or test paper card for citrinin detection.

Owner:FUZHOU UNIVERSITY

Heavy oil hydrotreatment method

ActiveCN111073689AIncrease profitEasy to removeHydrocarbon oils treatmentRefining to eliminate hetero atomsLamellar crystalsPtru catalyst

The invention discloses a heavy oil hydrotreatment method, which comprises the following steps that a heavy oil raw material enters a hydrogenation reactor and contacts a hydrogenation catalyst bed layer to carry out a hydrogenation reaction, and the reaction product flows out of the reactor, wherein the hydrogenation catalyst bed layer is filled with at least two stages of vulcanization-state hydrogenation catalysts in a grading manner along the material flow direction, the average length of the metal active phase crystals of each stage of the vulcanization-state hydrogenation catalyst is increased stage by stage along the material flow direction, the average layer number of the lamellar crystals is reduced stage by stage, the content of the active components is increased stage by stage,and the probable pore diameter is reduced stage by stage. According to the method, the specific catalyst gradation is adopted, so that the active center of the catalyst can be effectively utilized, the coupling reaction performance of an active center structure and a reactant molecular structure is improved, the stability of hydrogenation reaction, such as demetalization, desulfurization, denitrification and the like, of the whole system is greatly improved, and deep hydrogenation of heavy oil is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drug fusant of specific binding GLP-1 (Glucagon-like peptide-1) receptor

InactiveCN102949730AEnsure degrees of freedomReduce steric hindrance effectFungiBacteriaDiabetes mellitusReceptor

Owner:HAISCO PHARMA GRP INC

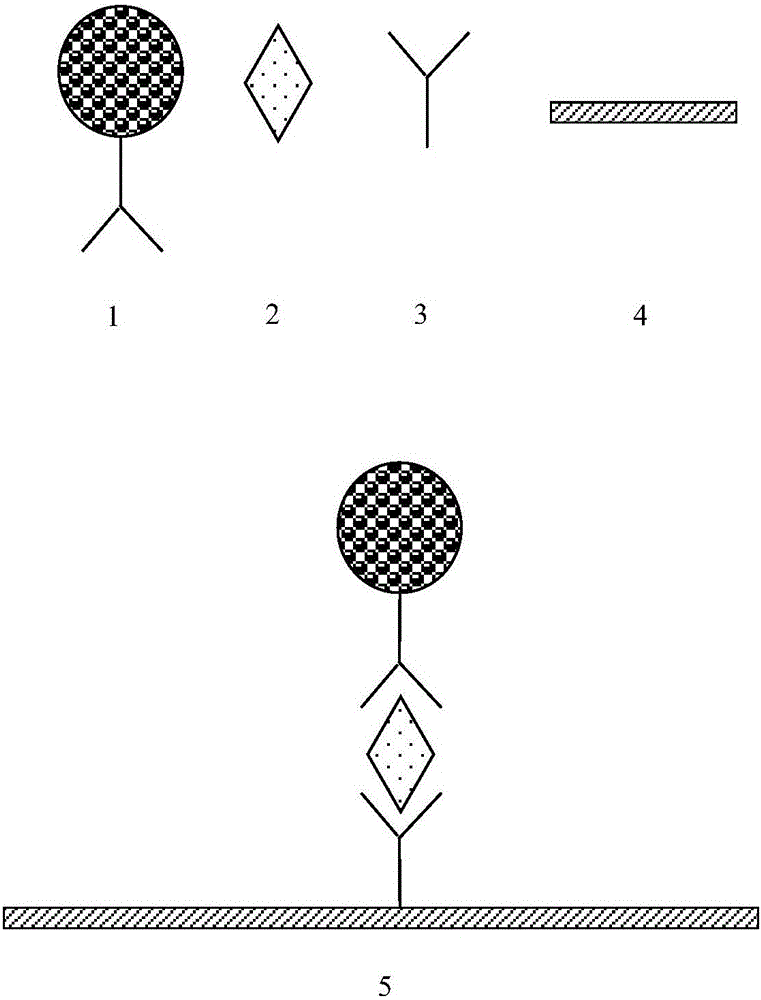

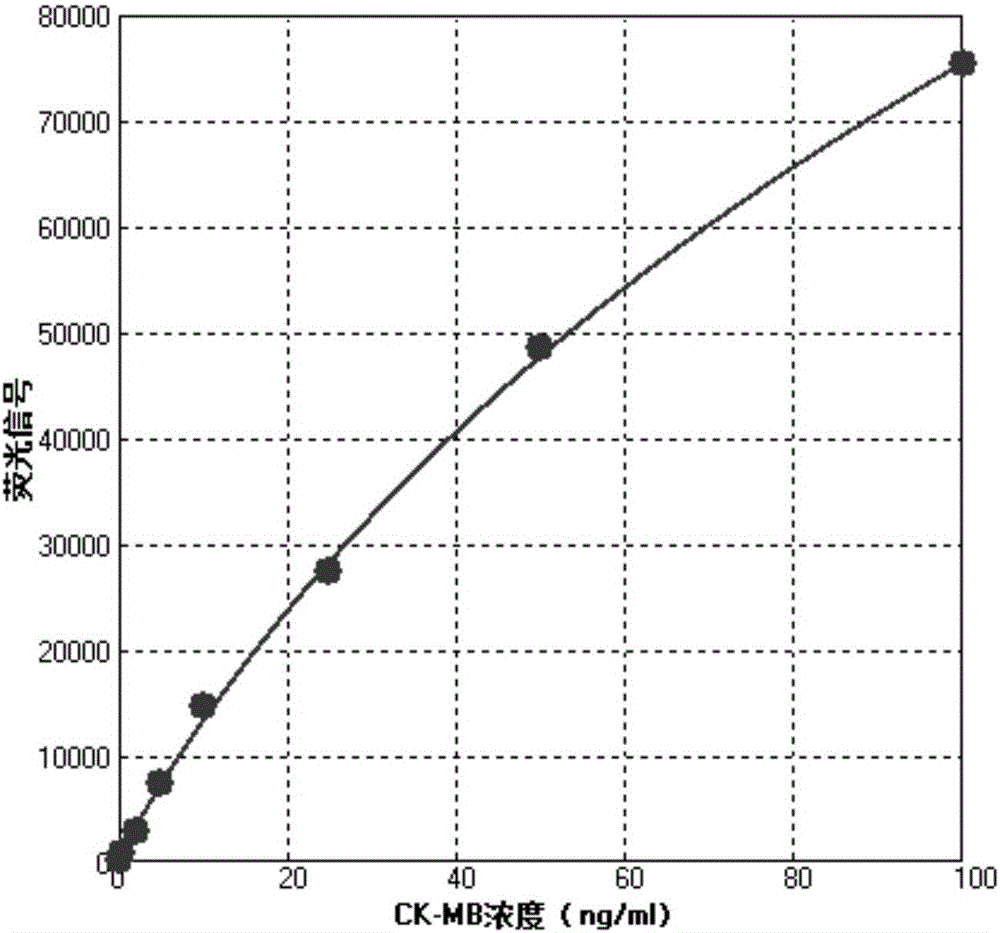

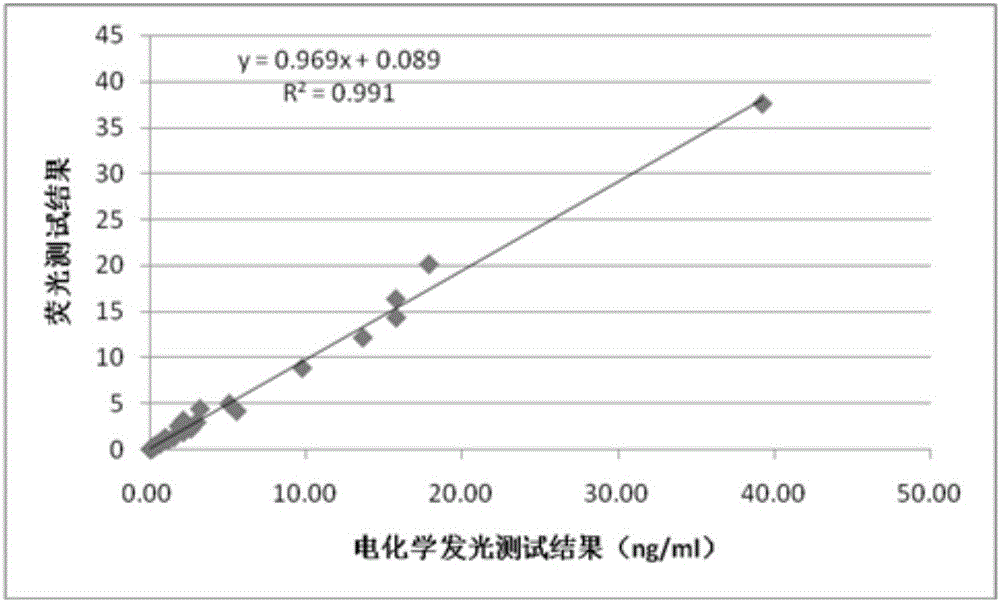

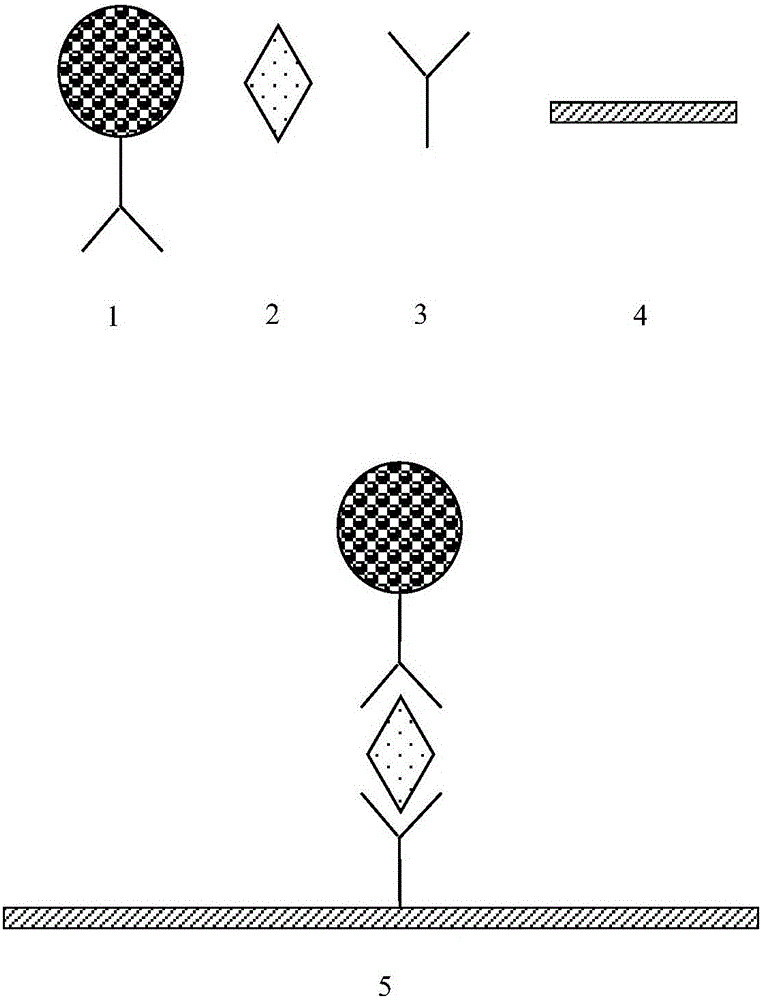

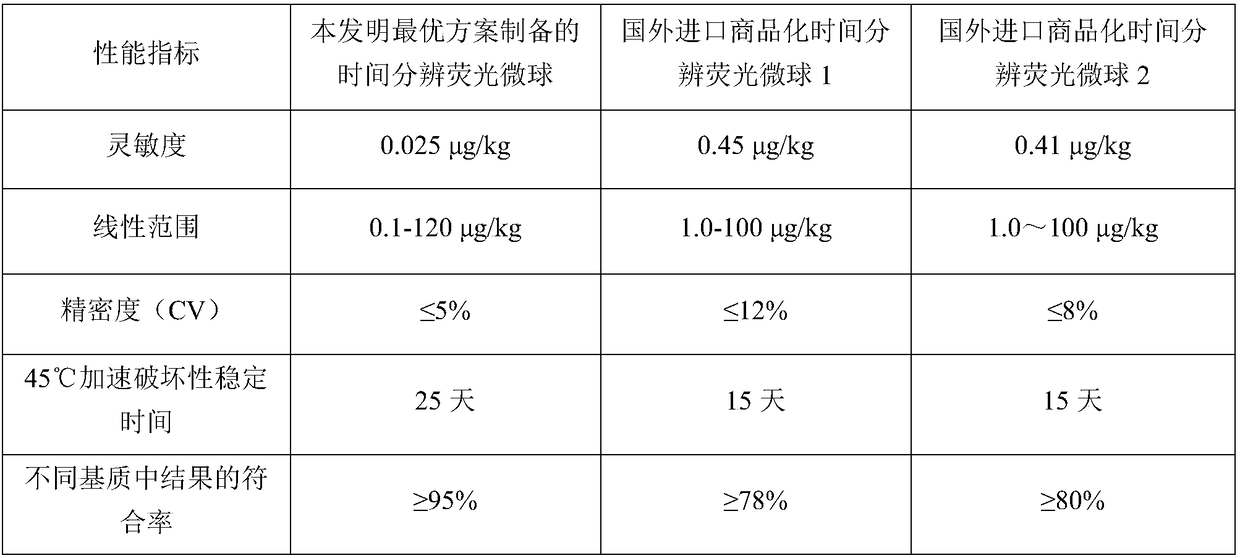

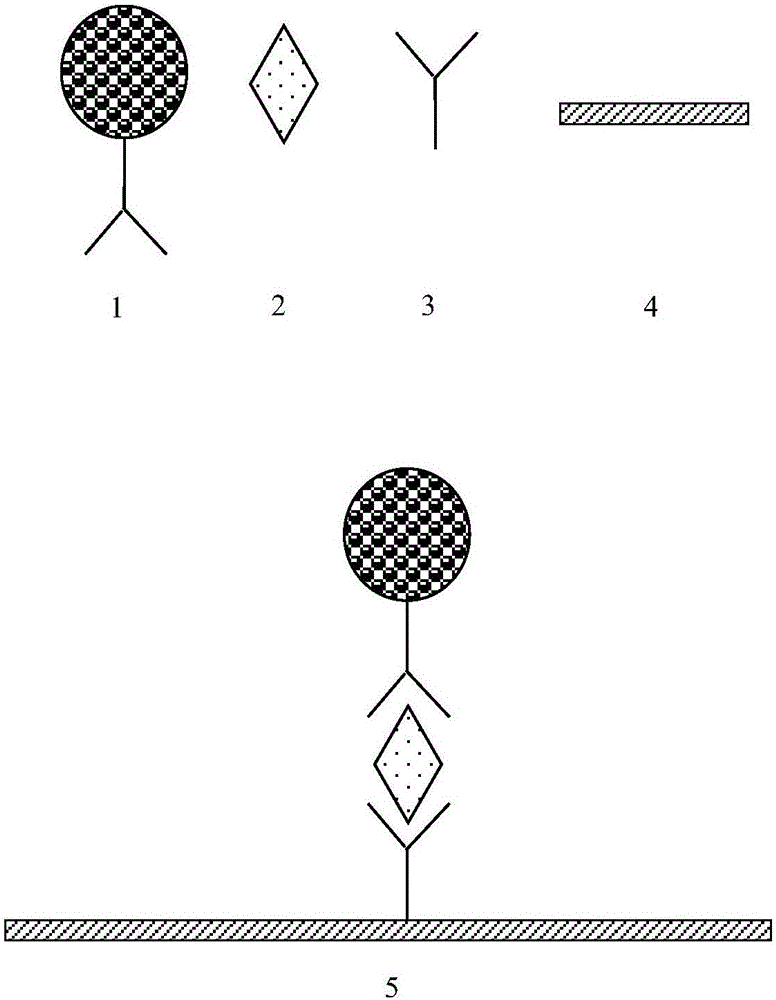

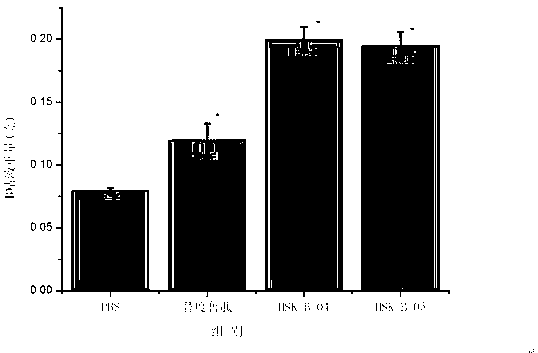

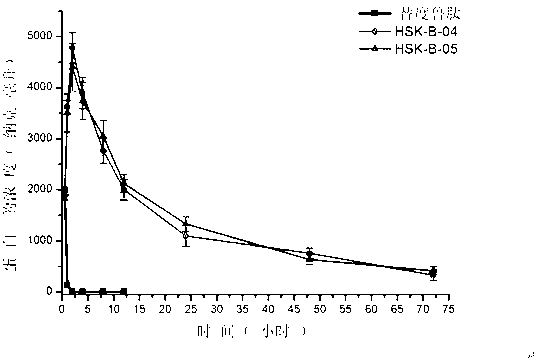

Microballoon-based cup-type time resolution fluorescent procalcitonin analysis kit, preparation method and application thereof

InactiveCN105758832ASimplify time-resolved fluorescence detection stepsShorten detection timeFluorescence/phosphorescenceSpecific detectionFluorescence

The invention belongs to the field of clinical medical diagnosis and especially relates to a microballoon-based cup-type time resolution fluorescent procalcitonin analysis kit, a preparation method and an application thereof. The kit comprises a detection reaction cup, a fluorescence labeling antibody and a cleaning fluid. The method comprises the following steps of: in specific detection process, firstly drawing a standard curve; adding a to-be-detected sample into the detection reaction cup; adding the fluorescence labeling antibody; incubating at 30-40 DEG C; washing with the cleaning fluid and removing the uncombined antibody and fluorescence labeling antibody; and comparing a fluorescence signal with the standard curve, thereby acquiring the concentration of procalcitonin of the to-be-detected sample. The detection method for the procalcitonin is ultrahigh in sensitivity, so that the automatic operation can be easily realized; the reaction temperature is uniform; the method is not influenced by the environmental factor; the accuracy is better; the precision is excellent.

Owner:SHANGHAI UPPER BIO TECH PHARMA

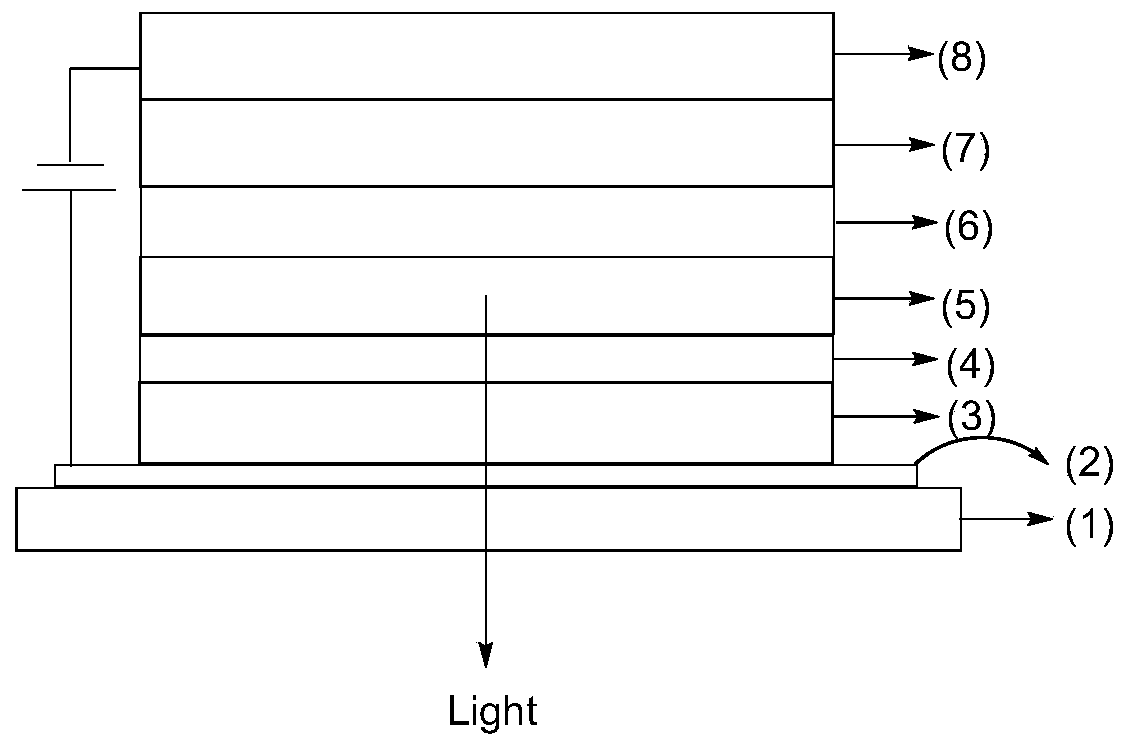

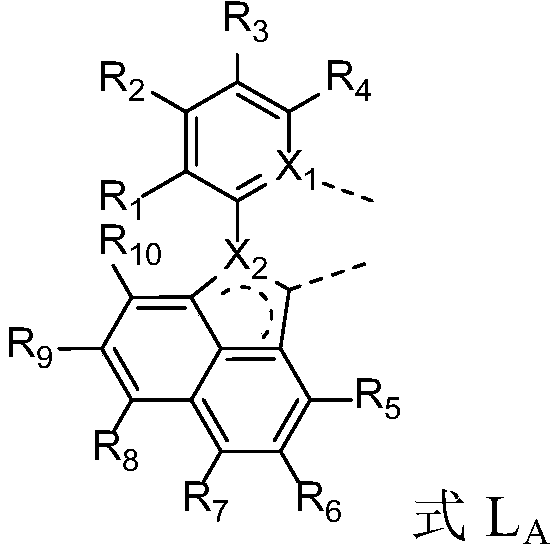

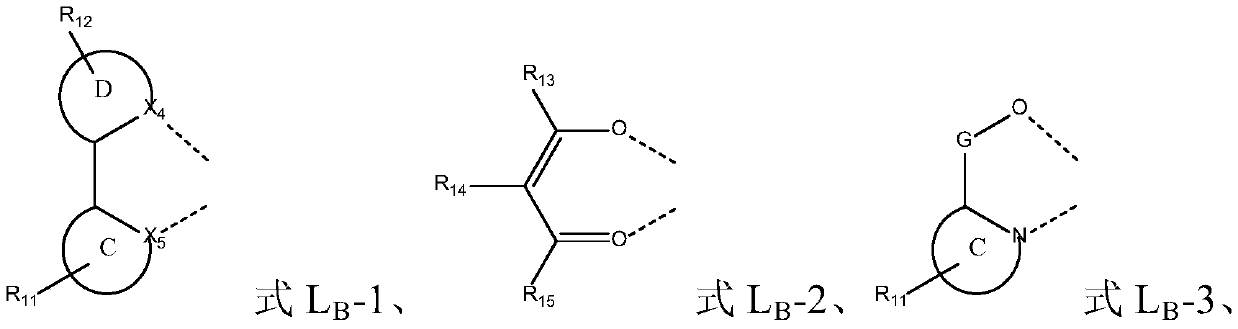

Metal complex, material containing the same and organic electroluminescent device

ActiveCN110317231AImprove luminous efficiencyReduce steric hindrance effectIndium organic compoundsSolid-state devicesOrganic electroluminescenceLuminescent material

The invention provides a metal complex whose molecular formula is [M(L)<x>(L)<y>]<a+>[Z<b->]<r>, wherein M is a metal element with the atomic weight more than 40, L is a ligand, L is an auxiliary ligand, and Z<b-> is an anion. Under the condition of electroluminescence, the metal complex can emit dark blue light, the luminous efficiency is high, the stability is good, raw materials areeasy to prepare and purify, and the metal complex is an ideal choice for making the luminescent materials used for organic electroluminescent devices.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

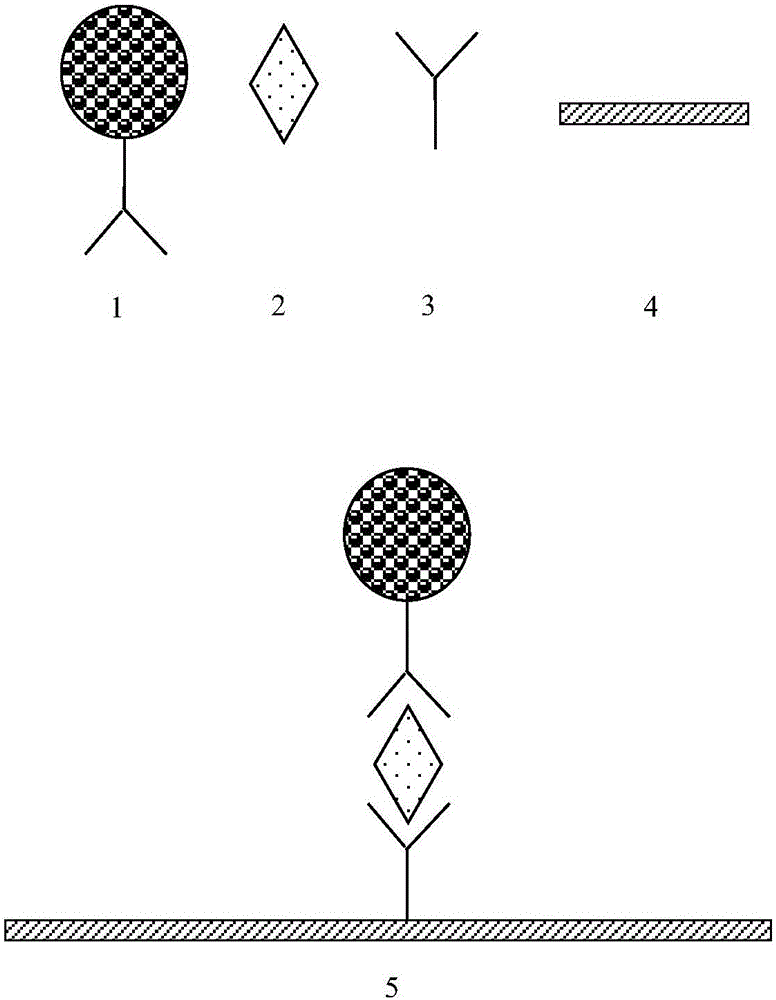

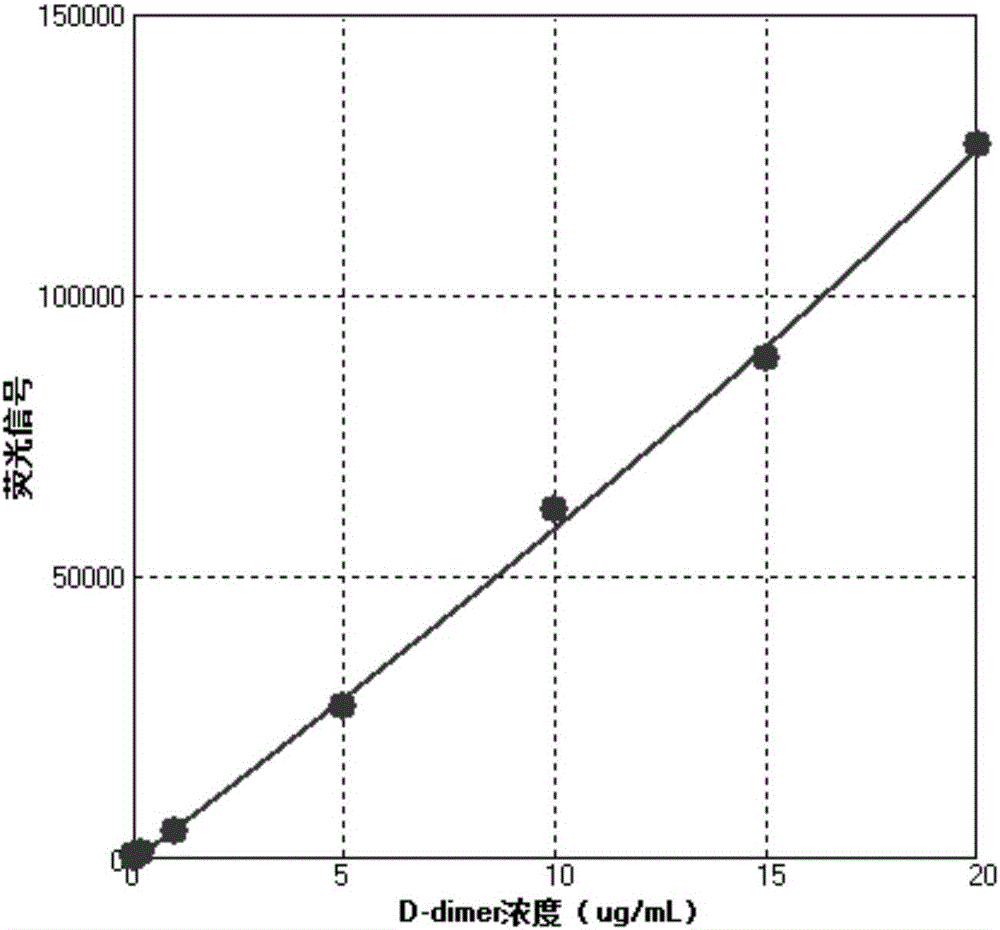

Cup type time-resolved fluorescence D-dimer analysis method and reagent kit based on microspheres

InactiveCN105891176ASimplify time-resolved fluorescence detection stepsShorten detection timeBiological testingFluorescence/phosphorescenceCross-linkMicrosphere

The invention discloses a cup type time-resolved fluorescence D-dimer analysis method and a reagent kit based on microspheres. The method includes the steps that the inner surface of a detection reaction cup is coated with D-dimer monoclonal antibodies or polyclonal antibodies; the time-resolved fluorescence microspheres and the D-dimer monoclonal antibodies or polyclonal antibodies are subjected to covalent bond cross-linking to prepare fluorescence-labeled antibodies; a D-dimer sample to be detected is added into the coated detection reaction cup, then the fluorescence-labeled antibodies are added, and incubation is carried out at 25-40 DEG C; cleaning is carried out to remove unbound antigens and fluorescence-labeled antibodies, and fluorescence signals in the detection reaction cup are tested under the excitation of 340-380 nm exciting light; the fluorescence signals are compared with a standard curve, and the D-dimer concentration of the D-dimer sample to be detected is obtained. By means of the method, detection can be completed within a short detection time, the detection time is shortened, and the detection sensitivity is effectively improved.

Owner:SHANGHAI UPPER BIO TECH PHARMA

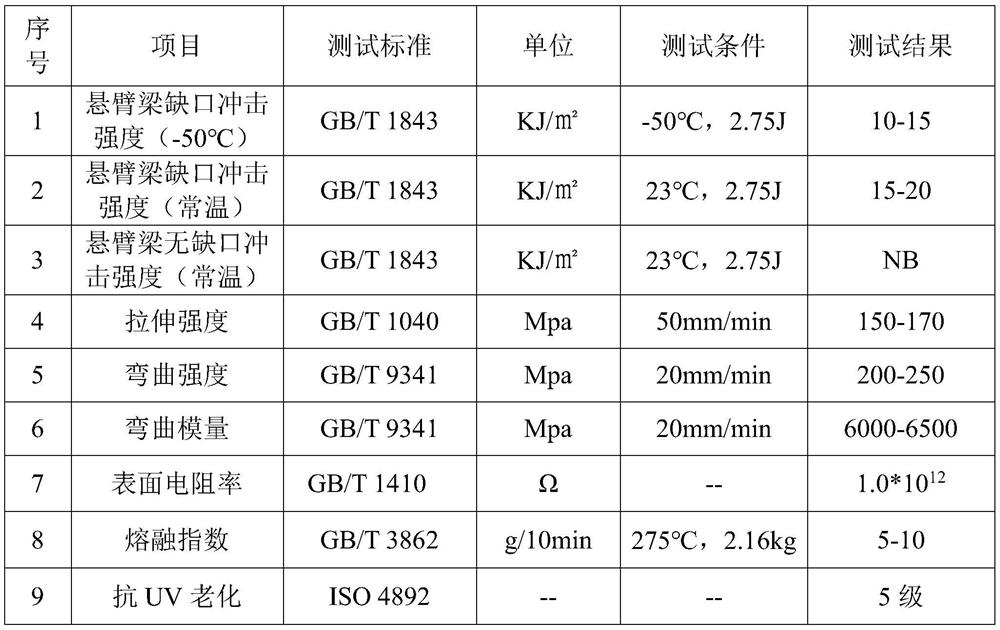

Nylon material for pin type composite insulator cap-shaped connector for power grid power transmission and distribution line and forming method

PendingCN111621149AImprove mechanical propertiesImprove liquidityInsulatorsGlass fiberNylon material

The invention relates to a nylon material of a pin-type composite insulator cap-shaped connector for a power grid power transmission and distribution line and a forming method. The nylon material comprises the following components in percentage by mass: 62%-66% of nylon resin, 28%-33% of glass fiber, 3%-6% of a toughening agent, 0.2%-0.5% of a main antioxidant, 0.2%-0.5% of an auxiliary antioxidant, 0.2%-0.5% of an ultraviolet absorbent, 0.2%-0.5% of a light stabilizer and 1%-3% of a wear-resistant additive, the viscosity of the nylon resin is 3.2 + / -0.01; the grafting rate of the toughening agent is 0.8 to 1.2%; the nylon resin is PA66 polyhexamethylene adipamide, PA6 polyamide 6 or a mixture of the PA66 polyhexamethylene adipamide and the PA6 polyamide 6. After polymerization processing,the material performance is excellent, the mechanical performance, the electrical performance, the environmental aging resistance, the high and low environmental temperature resistance and the material wear resistance of the composite product are excellent, and the safe use condition of the product is met.

Owner:XIAN WEISHI TRANSMISSION & DISTRIBUTION TECH CO LTD

Grading method of fluidized bed catalyst

ActiveCN111690432AIncrease profitAddress reactivityTreatment with hydrotreatment processesLamellar crystalsPtru catalyst

The invention discloses a fluidized bed catalyst grading method which comprises the following steps: heavy oil raw materials and hydrogen enter from the bottom of a reactor and are in contact with a hydrogenation catalyst bed layer for hydrogenation reaction, and a reaction product flows out from the top of the reactor; wherein the grading is filled with at least two stages of sulfurized hydrogenation catalysts; wherein from bottom to top in the material flow direction of the sulfurized hydrogenation catalysts at each stage, the average length of metal active phase crystals is gradually increased, the average number of lamellar crystal layers is gradually reduced, the content of active components is gradually reduced, the probable pore diameter is gradually reduced, the stacking density isgradually reduced, and the particle diameter is gradually reduced. The metal active phase is active metal sulfide. According to the method, the specific catalyst gradation is adopted, so that the active center of the catalyst can be effectively utilized, the coupling reaction performance of an active center structure and a reactant molecular structure is improved, the stability of hydrogenation reaction, such as demetalization, desulfurization and denitrification, of the whole system is greatly improved, and deep hydrogenation of heavy oil is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

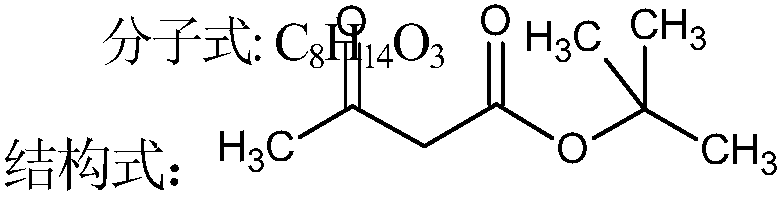

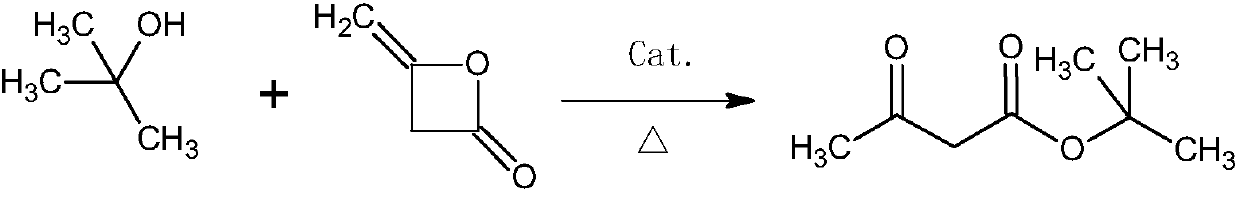

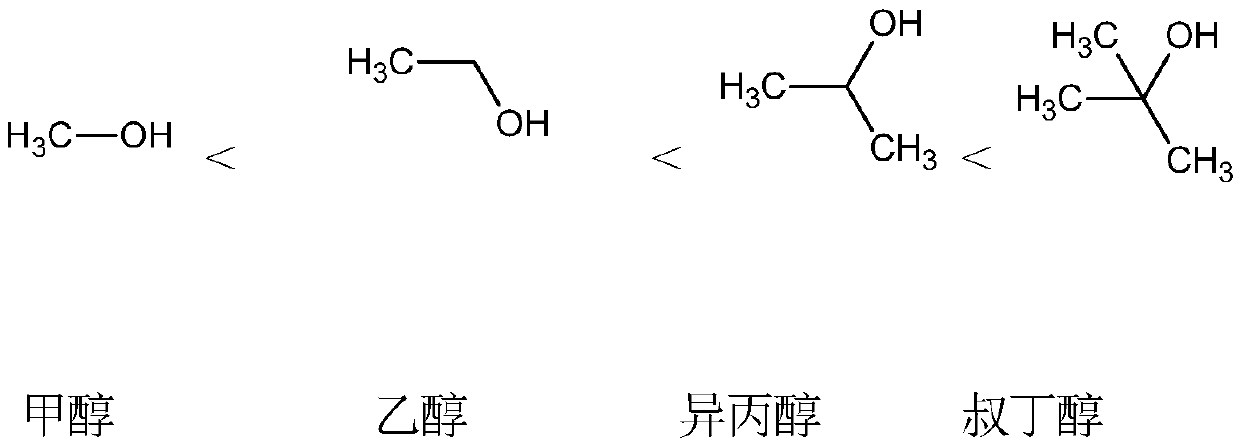

Synthesis method of tert-butyl acetoacetate

InactiveCN107827749AHigh reactivityReduce steric hindrance effectPreparation from ketenes/polyketenesCorrosionFatty amine

The invention discloses a synthesis method of tert-butyl acetoacetate. The method comprises the following steps that tertiary butanol and catalysts are added into a reaction container; the catalysts are selected from aliphatic amine catalysts or tertiary amine catalysts; or the catalysts are fatty amine catalysts and tertiary amine catalysts; the catalysts are one kind of catalysts or several kinds of catalysts proportioned at any proportion; the temperature is raised to 20 to 120 DEG C; diketene is dropwise added; in the reaction process, the reaction temperature is controlled to be 20 to 150DEG C; after the dripping is completed, the temperature is controlled at 20 to 150 DEG C; heat insulation is performed for 0.5 to 8 hours to obtain tert-butyl acetoacetate raw ester; the mole ratio of the tertiary butanol to the diketene is (1 to 2) to1; the addition of the catalyst is 0.1 weight percent to 2 weight percent of the total amount. The process is used for synthesizing the tert-butylacetoacetate; the conversion rate of the diketene reaches 100 percent; the finished product yield reaches 94 percent or higher; the product content reaches 99 percent or higher. By using the process,the synthesis yield is greatly improved; the preparation cost is reduced; meanwhile, the three-waste quantity is reduced; no corrosion is caused on the equipment; better economic and environment-friendly effects can be achieved.

Owner:NANTONG ACETIC ACID CHEM

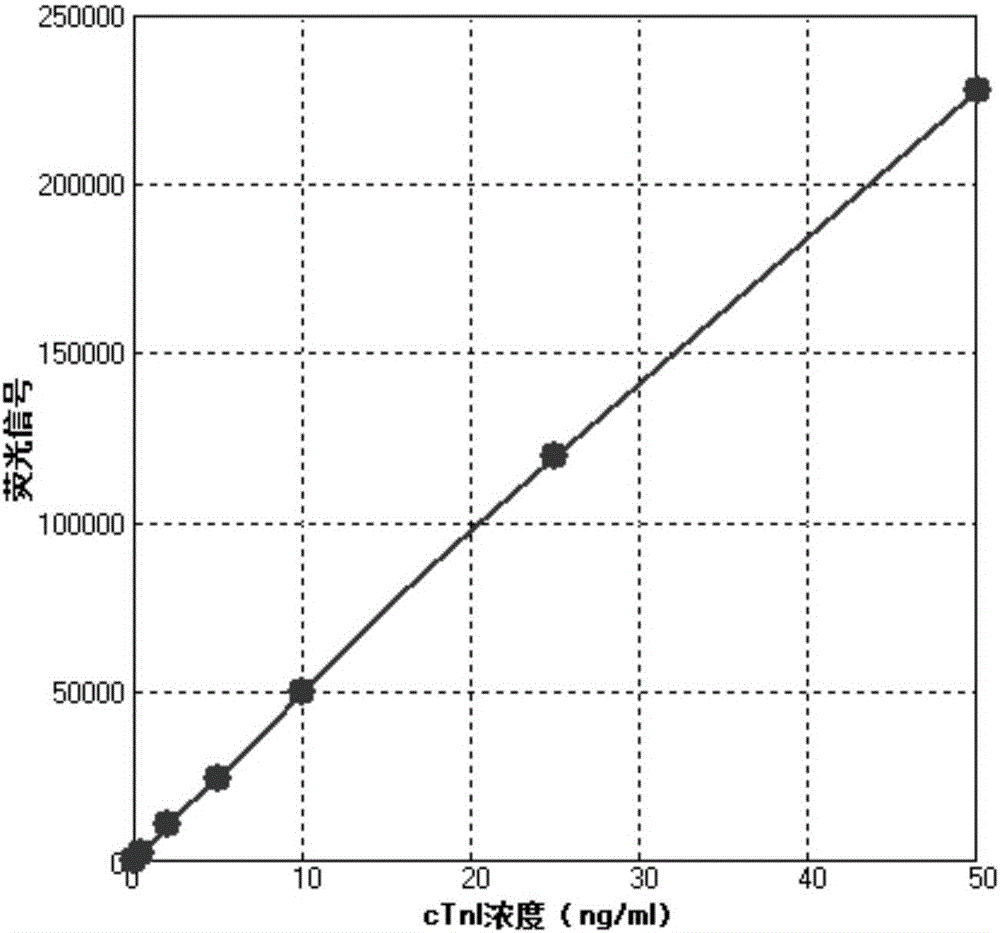

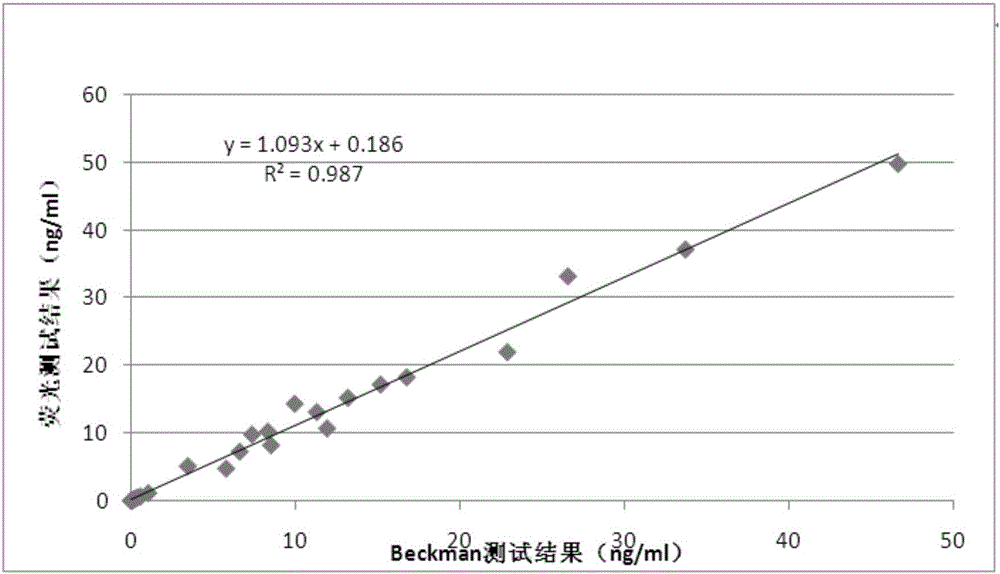

Microballoon-based cup-type time resolution fluorescent troponin I analysis kit as well as preparation method and application thereof

InactiveCN105758833ASimplify time-resolved fluorescence detection stepsShorten detection timeBiological testingFluorescence/phosphorescenceSpecific detectionMicrosphere

The invention belongs to the field of clinical medical diagnosis and especially relates to a microballoon-based cup-type time resolution fluorescent troponin I analysis kit as well as a preparation method and application thereof. The kit comprises a detection reaction cup, a fluorescence labeling antibody and a cleaning fluid. The method comprises the following steps of: in a specific detection process, firstly drawing a standard curve; adding a to-be-detected sample into the detection reaction cup; adding the fluorescence labeling antibody; incubating at 30-40 DEG C; washing with the cleaning fluid and removing the uncombined antibody and fluorescence labeling antibody; comparing a fluorescence signal with the standard curve, thereby acquiring the concentration of troponin I of the to-be-detected sample. The detection method for the troponin I is ultrahigh in sensitivity, so that the automatic operation can be easily realized; the reaction temperature is uniform; the method is not influenced by the environmental factor; the accuracy is better; the precision is excellent.

Owner:SHANGHAI UPPER BIO TECH PHARMA

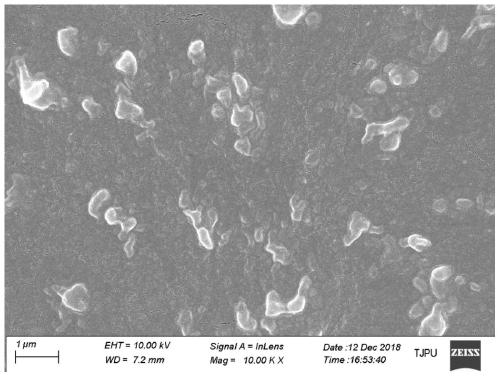

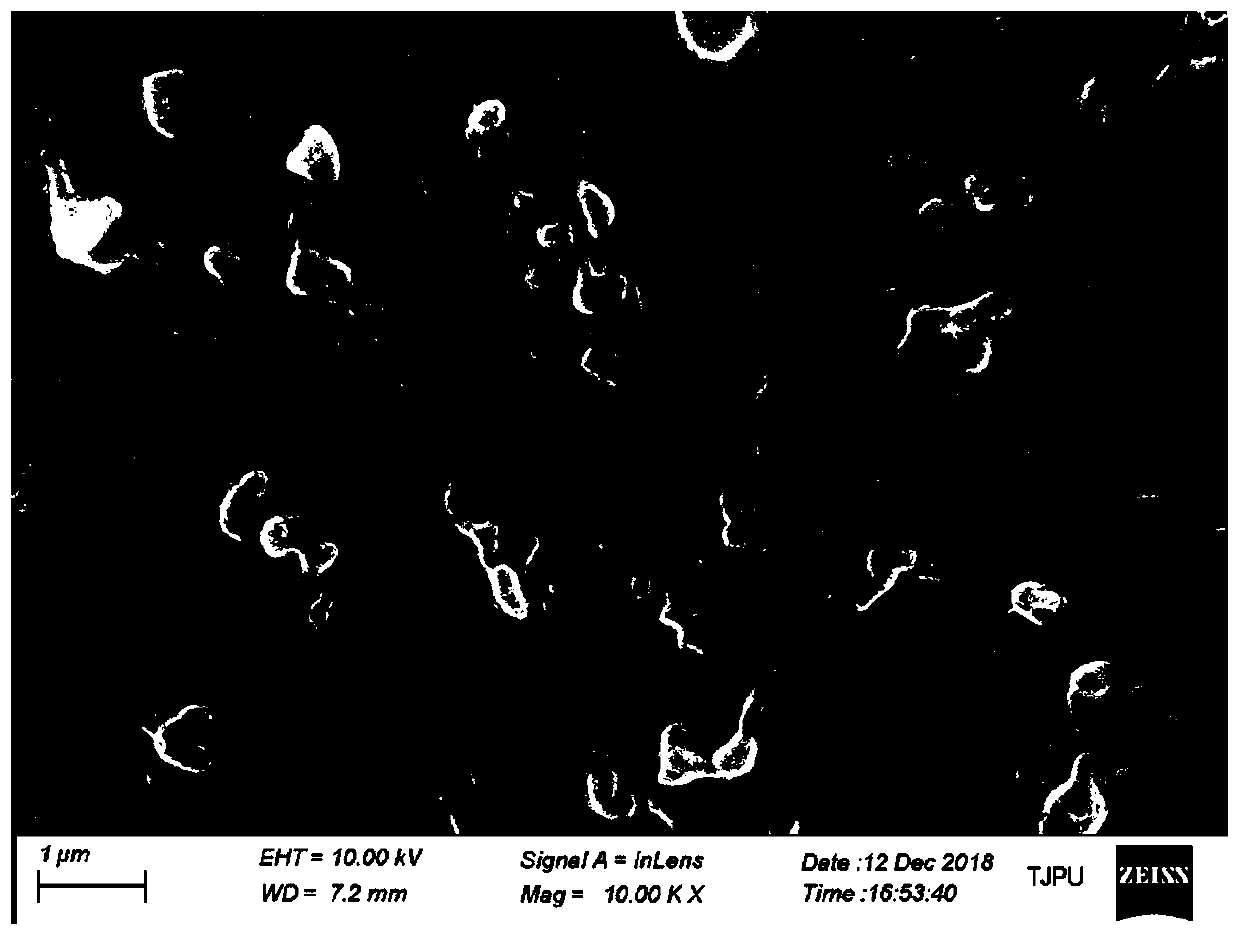

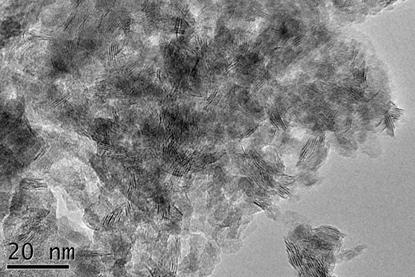

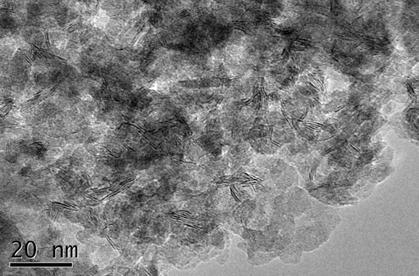

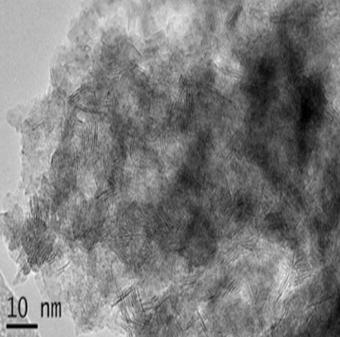

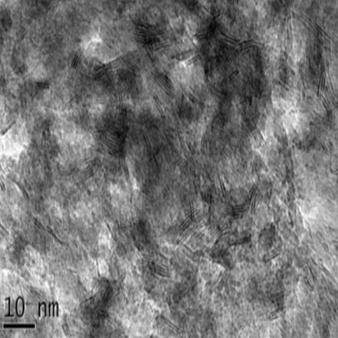

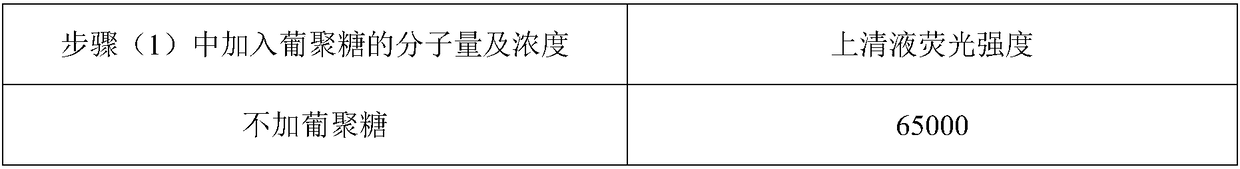

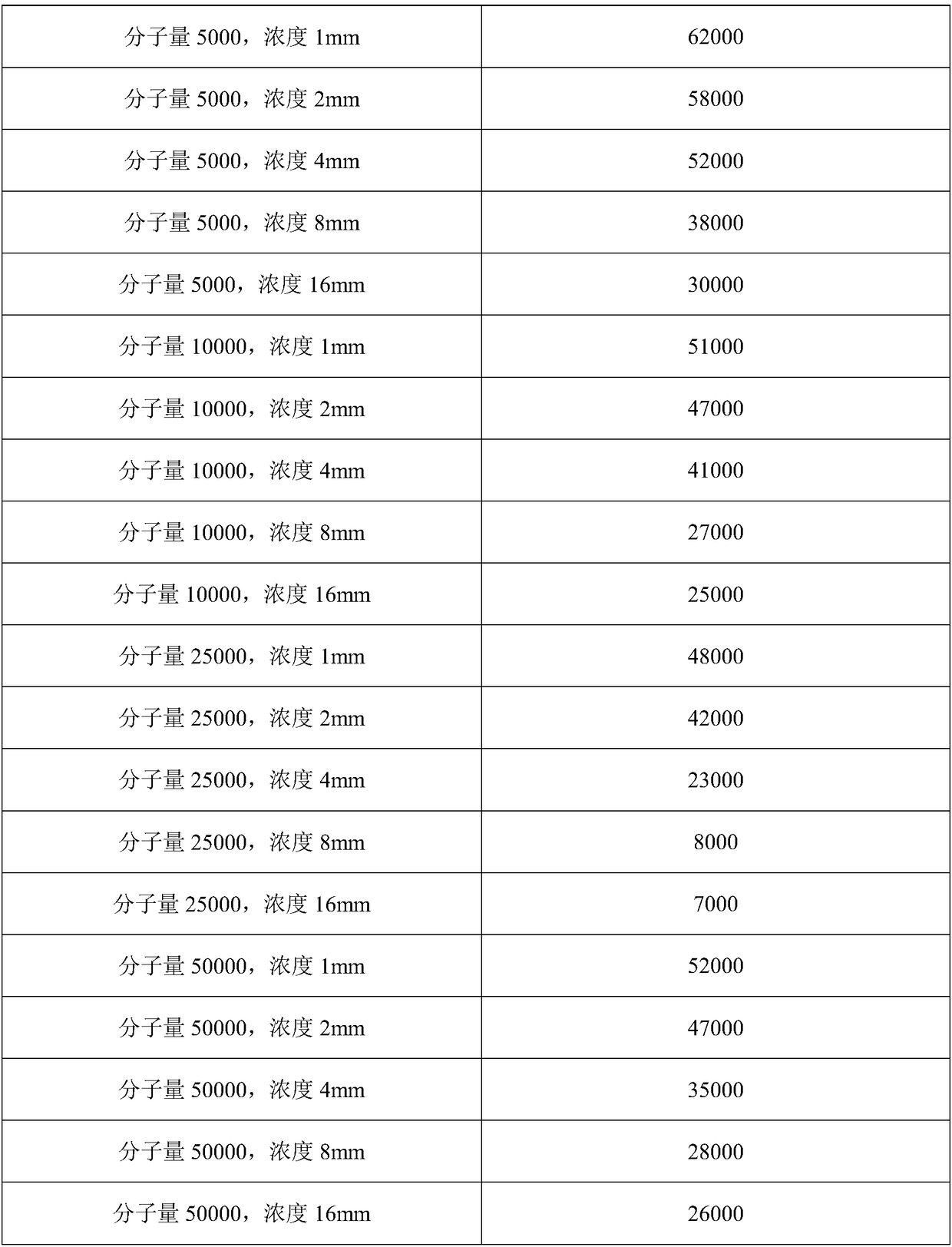

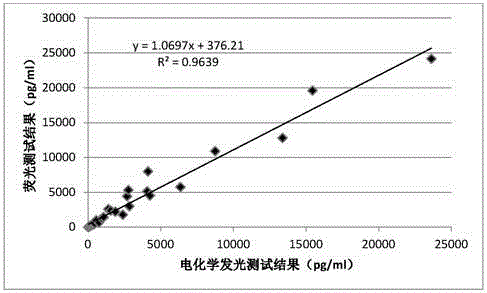

Preparation method and application of high-performance time resolved fluorescence microspheres

InactiveCN108445219AImprove stabilityHigh fluorescence intensityFluorescence/phosphorescenceMicrospherePolystyrene

The invention relates to the technical field of detection and in particular relates to a preparation method and application of high-performance time resolved fluorescence microspheres. The preparationmethod comprises the following steps: (1) preparing high-stability polystyrene nano-microspheres; (2) preparing europium ion chelates doped with different ions; (3) preparing nano microspheres with high fluorescence intensity; (4) carrying out stereo-hindrance effect removing effect modification on the surfaces of the fluorescence microspheres. The time resolved fluorescence microspheres providedby the invention have the characteristics of high fluorescence intensity, low stereo-hindrance effect, good stability and the like; a time resolved fluorescence immunochromatography technology developed based on the microspheres has the advantages of high detection sensitivity, wide linear range, high precision, wide sample applicable range and the like, and hypersensitive, rapid and quantitativedetection and analysis of a substance to be detected can be realized.

Owner:南京微测生物科技有限公司

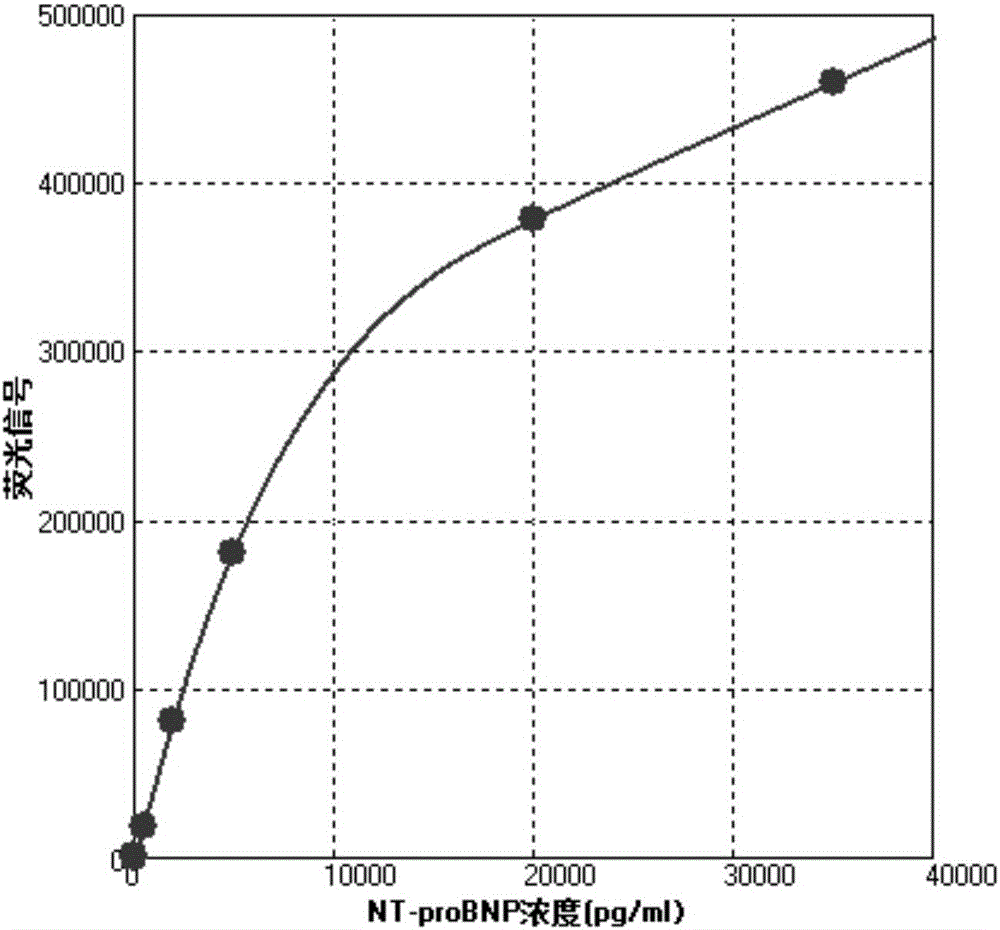

Cup-type time-resolved fluorescent analysis method and kit for NT-proBNP based on microspheres

InactiveCN105911283ASimplify time-resolved fluorescence detection stepsShorten detection timeFluorescence/phosphorescencePolyclonal antibodiesLength wave

The invention discloses a cup-type time-resolved fluorescent analysis method and kit for NT-proBNP based on microspheres. The method comprises the following steps: coating the interior surface of a detection reaction cup with a NT-proBNP monoclonal or polyclonal antibody; subjecting time-resolved fluorescent microspheres and the NT-proBNP monoclonal or polyclonal antibody to crosslinking via a covalent bond so as to prepare a fluorescence-labeled antibody; adding a to-be-detected NT-proBNP sample into the coated detection reaction cup, then adding the fluorescence-labeled antibody and carrying out incubation at 25 to 40 DEG C; carrying out cleaning to remove unbounded antigen and fluorescence-labeled antibody and testing a fluorescence signal in the detection reaction cup under the condition of excitation by exciting light with a wavelength of 340 to 380 nm; and comparing the fluorescence signal with a standard curve so as to obtain the concentration of NT-proBNP in the to-be-detected NT-proBNP sample. The method and kit provided by the invention can complete detection in short detection time, shortens detection time and improves detection sensitivity.

Owner:SHANGHAI UPPER BIO TECH PHARMA

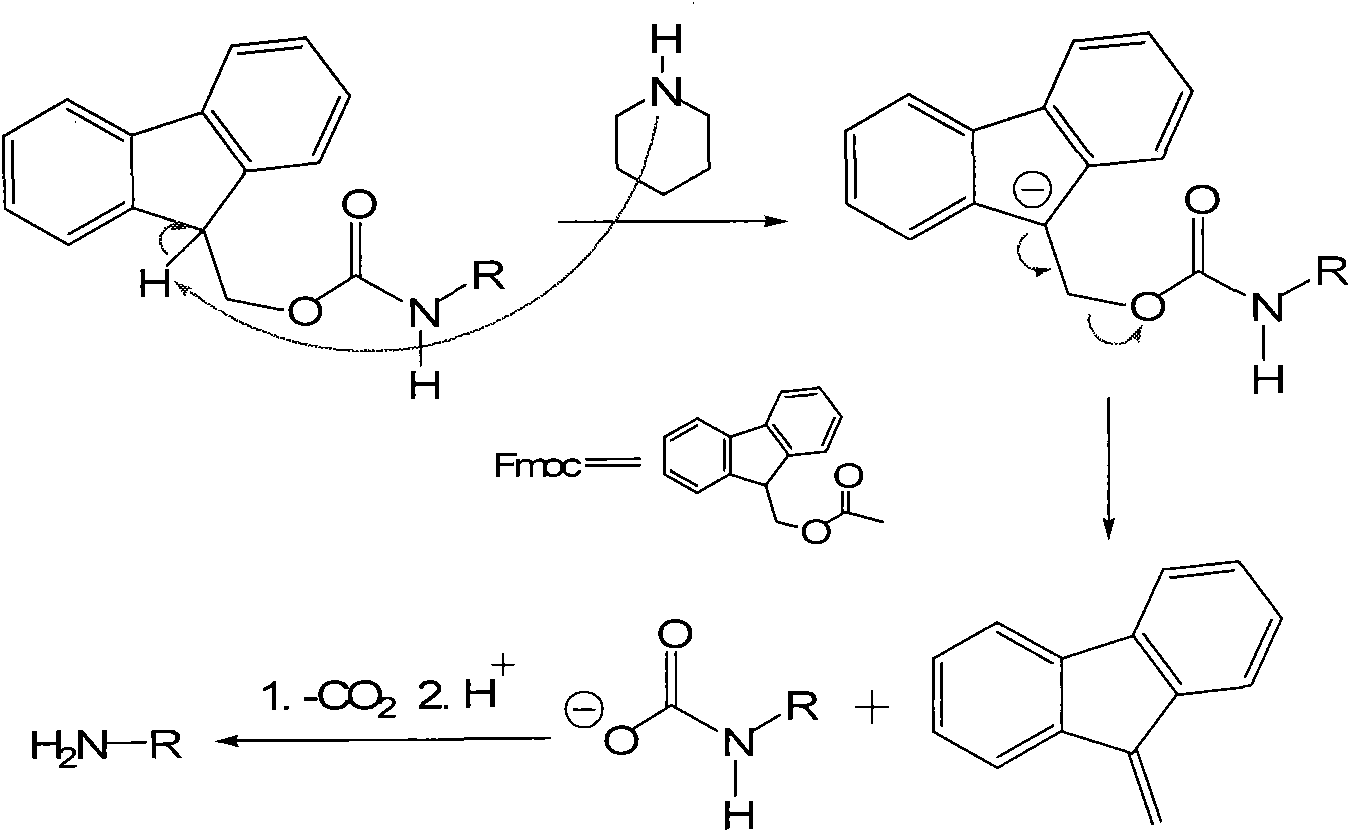

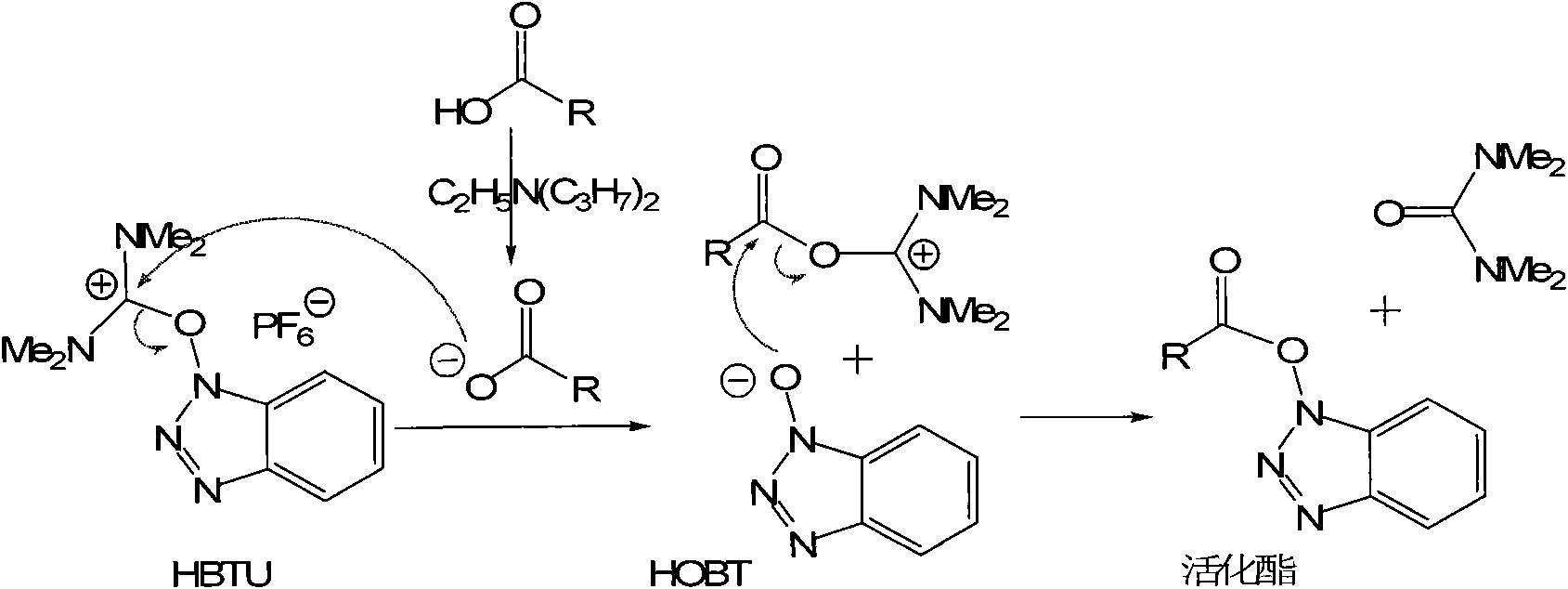

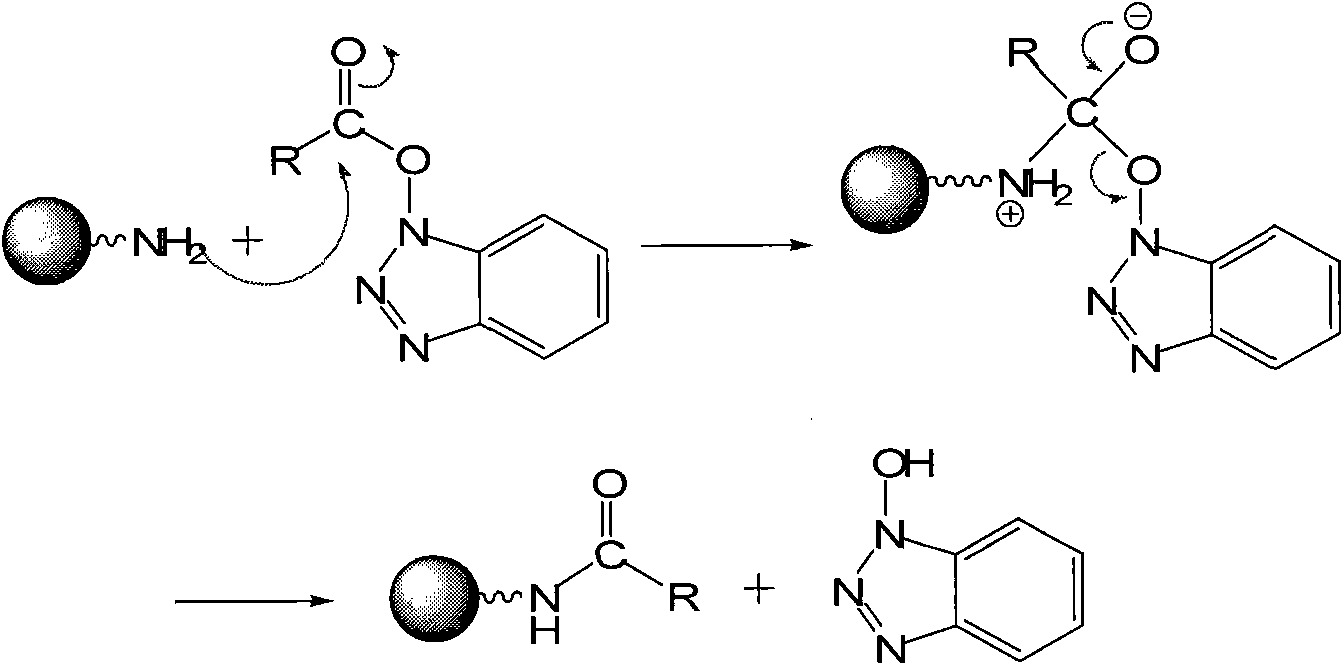

Formula and application of xylene solvent for improving solid phase synthesis efficiency of polypeptide

InactiveCN101880311ALess impuritiesSynthesis speedPeptide preparation methodsSide chainCombinatorial chemistry

The invention relates to a formula and application of a xylene solvent for improving solid phase synthesis efficiency of polypeptide, which is characterized in that the formula of the xylene solvent comprises dimethylformamide DMF, dichloromethane DCM and xylene DMB at a volum ratio of 1:1.5-2.5:0.15-1.0. The invention effectively reduces the cost for synthesizing the polypeptide, reduces the steric hindrance effect of hydrophobic lateral chains and blocking groups of amino acid, shortens the reaction time and accelerates the polypeptide synthesizing speed, and the polypeptide has high yield and few impurities.

Owner:JILIN UNIV

Application of Phage Chip as Protein Chip or Gene Chip

InactiveCN101059515BParticle stabilizationAvoid degradationMicrobiological testing/measurementAntigen epitopeAntigen

The invention discloses the application of a phage chip as a protein chip or a gene chip. The present invention obtains phage clones displaying specific exogenous peptides (or antigenic epitopes) by screening phage peptide libraries or constructing phage display libraries, and displays different exogenous peptides in an automatic or non-automatic manner according to a pre-designed array pattern. The phages were directly coupled to the same chip substrate to obtain a phage chip. The chip can be used not only as a protein chip displaying exogenous peptides, but also for the detection, screening and identification of antibodies, ligands and specific binders in natural or synthetic compounds in various samples of human and experimental animals, and as a clone The gene chip of related genes is used for the detection of related genes. The phage chip has the remarkable characteristics of low cost, simple preparation, high stability, high specificity, easy long-term storage and the like.

Owner:XI AN JIAOTONG UNIV

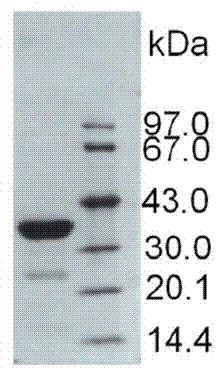

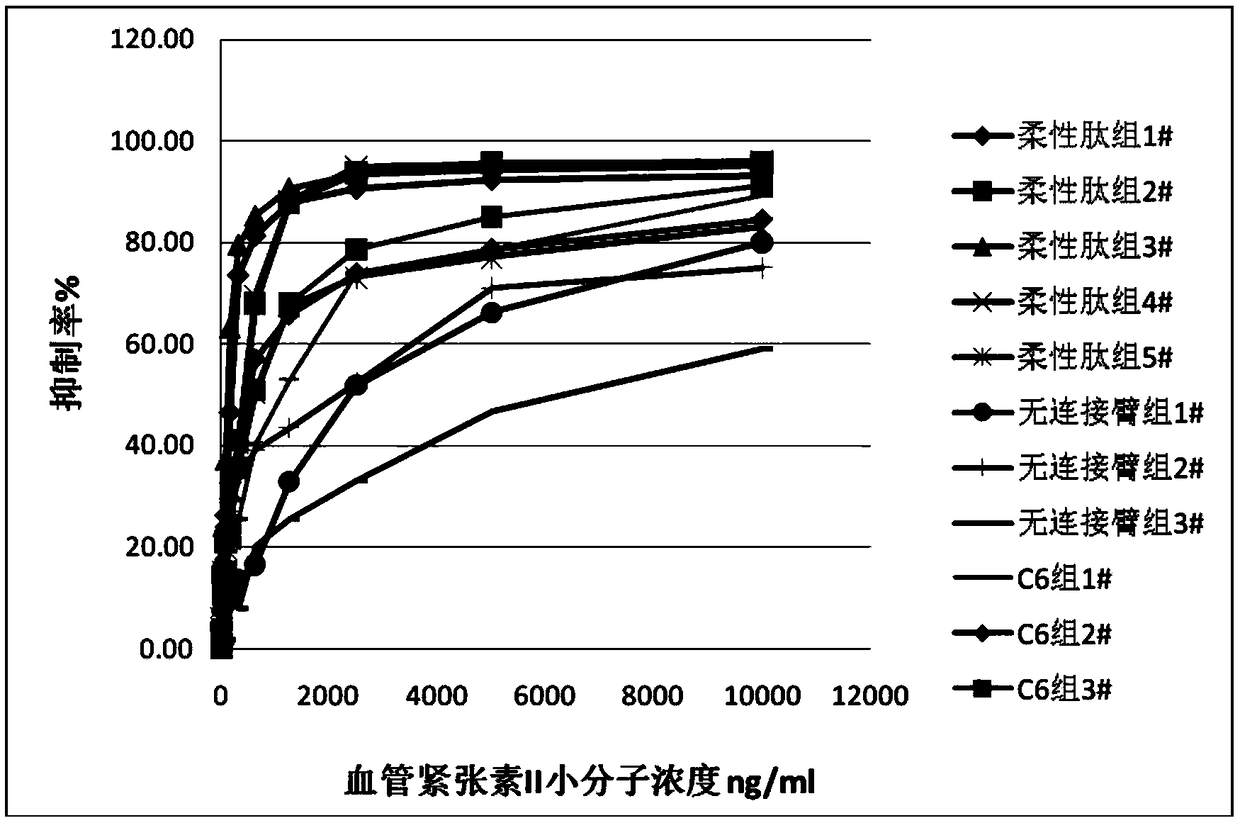

Angiotensin II immunogen and preparation method thereof

ActiveCN109265554AReduce steric hindrance effectEliminate the effects ofAngiotensinsSerum immunoglobulinsSolubilitySide chain

The invention provides angiotensin II immunogen and a preparation method thereof. According to the angiotensin II immunogen and the preparation method thereof, when the N-end of angiotensin II is connected to carrier protein, a derivative of the angiotensin II is firstly synthesized, in the derivative of the angiotensin II, a segment of polypeptide is added to the N-end of the angiotensin II to serve as a connecting arm, the connecting arm comprises a flexible peptide, the flexible peptide is composed of Gly and Ser amino acid residues, the position of the Gly are distributed on the two sidesof the Ser, and therefore the torsion of the connecting arm is facilitated; and the derivative of the angiotensin II can effectively reduce the steric-hindrance effect of the carrier protein on smallmolecule hapten of the angiotensin II, and -OH on side chains of the Ser can improve the water solubility of molecules of the angiotensin II to a certain extent. The prepared angiotensin II immunogenhas the advantages of being simple in preparation method, low in cost, strong in immunogenicity and suitable for preparation of an angiotensin II antibody.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

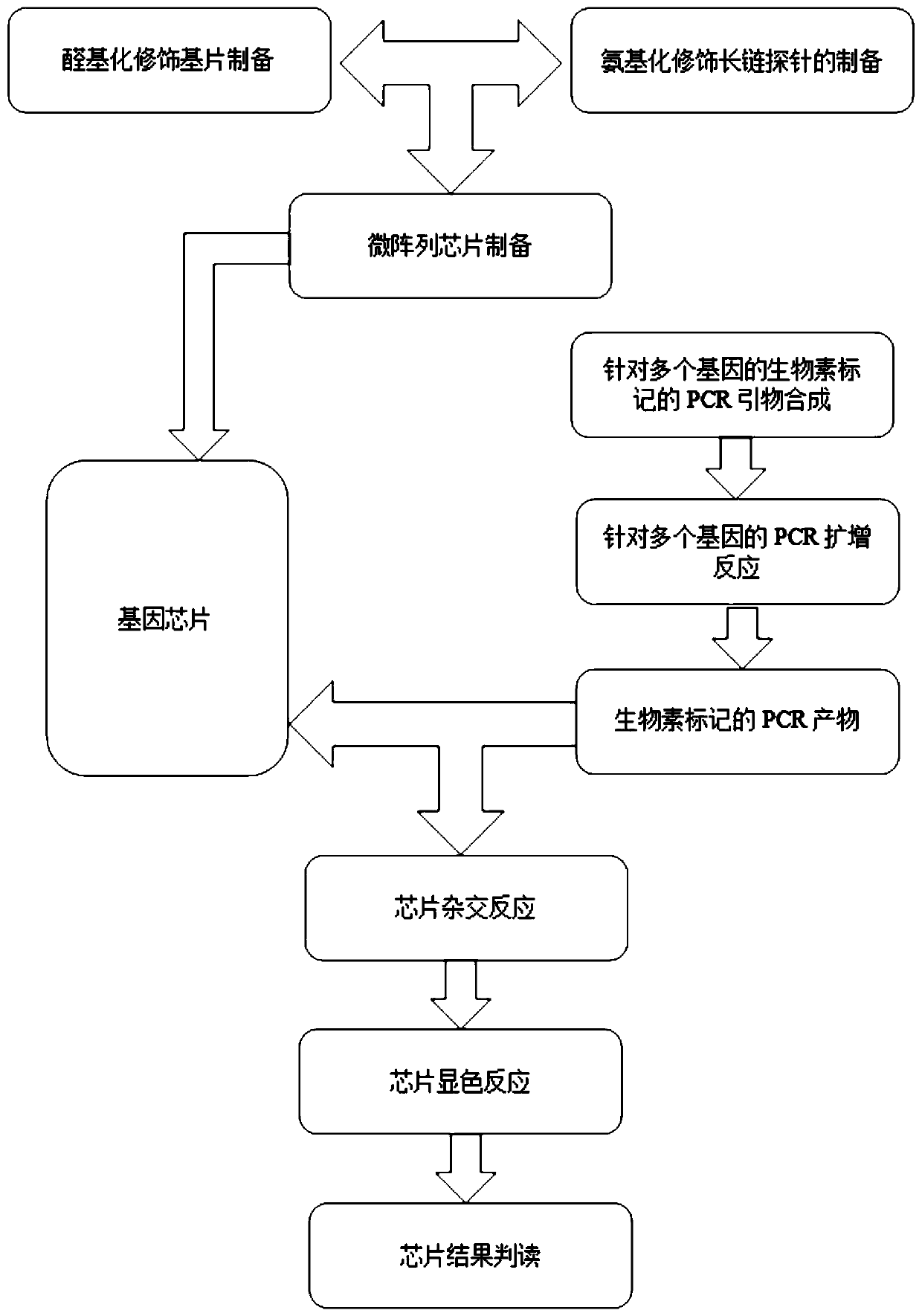

Microarray chip capable of detecting genomic DNA of various fungi and preparation method of microarray chip

PendingCN110863037AReduce steric hindrance effectReduce chip costMicrobiological testing/measurementMicroarray cghGenomic DNA

The invention relates to a microarray chip capable of detecting genomic DNA of various fungi and a preparation method of the microarray chip. The microarray chip comprises a modified chip solid-phasecarrier, and a modified gene chip probe, wherein the modified gene chip probe comprises the following structures according to the direction of 5'-3': a 5' modified group-Cn-(dT) m-oligonucleotide chain 3', oligodeoxynucleotide is selected from nucleotide sequences of genomic DNA specific regions of two or more fungi of Candida albicans, Candida glabrata, Candida parapsilosis, Aspergillus, Candidatropicalis and Cryptococcus, or complementary sequences thereof. According to the embodiment of the invention, the modified gene chip probe in the microarray chip effectively reduces the steric hindrance effect of the probe and a PCR product during specific binding, the combination of the two modification modes plays a synergistic role, and the genomic DNA of various fungi can be well detected.

Owner:BEIJING BEIER BIOENG

Method of increasing curing speed of phenolic resin adhesive

InactiveCN109369868AFast curingIncreased ortho reactivityAldehyde/ketone condensation polymer adhesivesHigh water contentTemperature resistance

The invention relates to the technical field of novel functional materials and discloses a method of increasing curing speed of phenolic resin adhesive. In the phenolic resin preparation process, phenolic aldehyde and formaldehyde are mixed in the molar ratio of 1:(1.9-2.0) for reaction; first, all phenolic resin is added to a three-neck flask, formaldehyde 17-20% in mass percentage is added, andmixing is performed to prepare a modifying catalyst; second, the residual formaldehyde is added to the reaction system; catalytic modification helps reduce steric hinderance effect, improve ortho-reaction activity of phenols, and inhibit the generation of aldehyde gas; curing performance and thermal stability of the phenolic resin adhesive are successfully improved; the problem is overcome that existing phenolic resin adhesive has high water content and hindered water molecular diffusion and therefore, is low in curing speed and poor in stability; the phenolic resin adhesive has high durability and adhesive strength, better temperature resistance and evidently extended service life.

Owner:合肥绿普包装材料有限公司

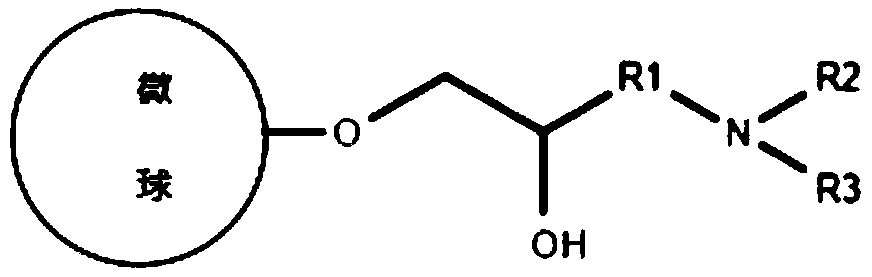

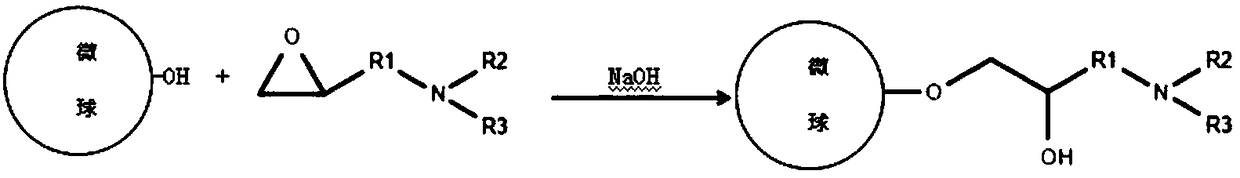

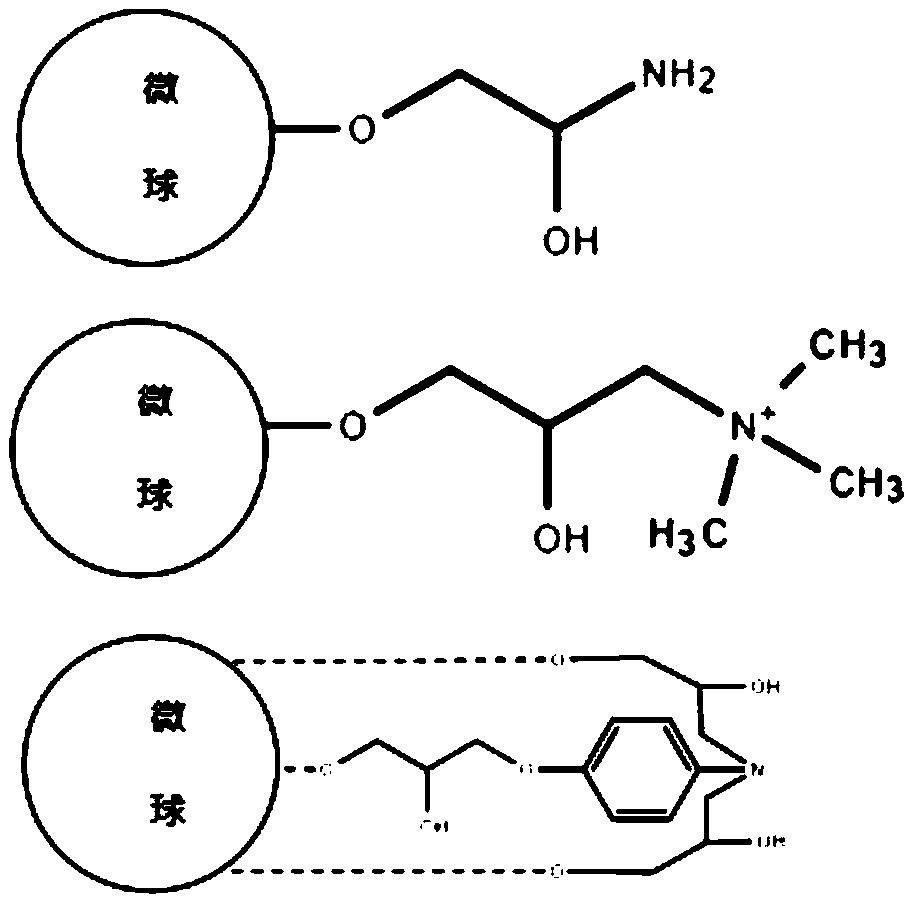

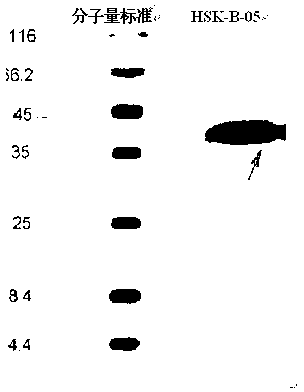

Epoxy amino chromatography medium and preparation method thereof

InactiveCN109206538AReduce steric hindrance effectIncrease protein binding capacityOther chemical processesChemistryHigh protein

The invention relates to an epoxy amino chromatography medium and a preparation method thereof. The epoxy amino chromatography medium is formed by ring-opening reaction of a polysaccharide microsphereand an amino epoxy compound. The preparation method comprises reaction of the polysaccharide microsphere and the amino epoxy compound. The epoxy amino chromatography medium has a long intermediate arm, high protein binding capacity, and simple preparation method.

Owner:WUHAN HUIYAN BIOTECH

Medicine fusion specifically bound with GLP-2 receptor

InactiveCN102949731AEnsure degrees of freedomReduce steric hindrance effectFungiBacteriaDisease irritable bowelPharmaceutical drug

The invention discloses a medicine fusion bound with GLP-2R oligopeptide, and also discloses a preparation method of the medicine fusion and a method for treating inflammatory bowel diseases, Crohn diseases and short bowel syndrome by using the medicine fusion.

Owner:HAISCO PHARMA GRP INC

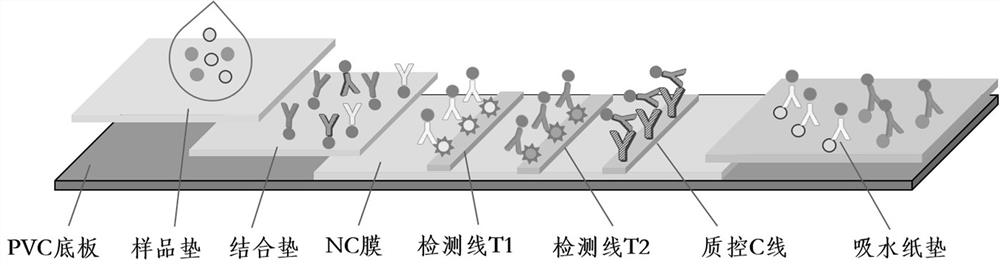

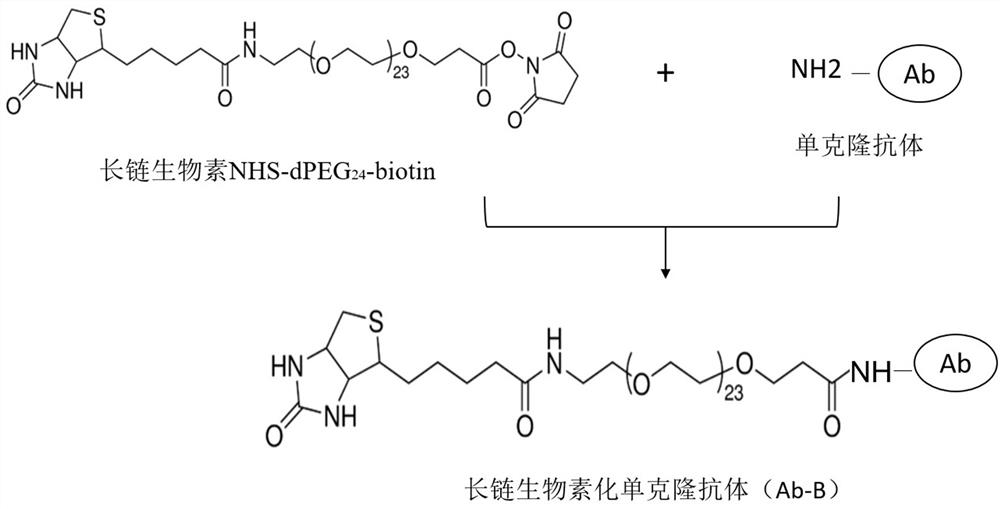

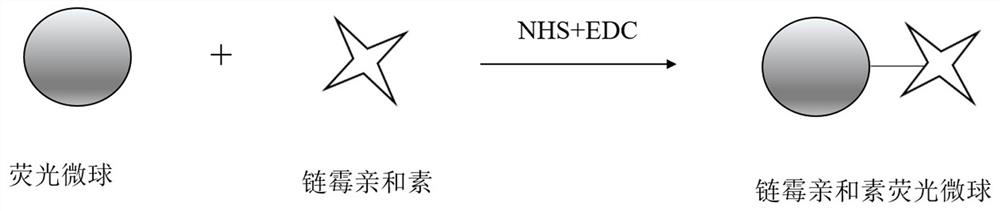

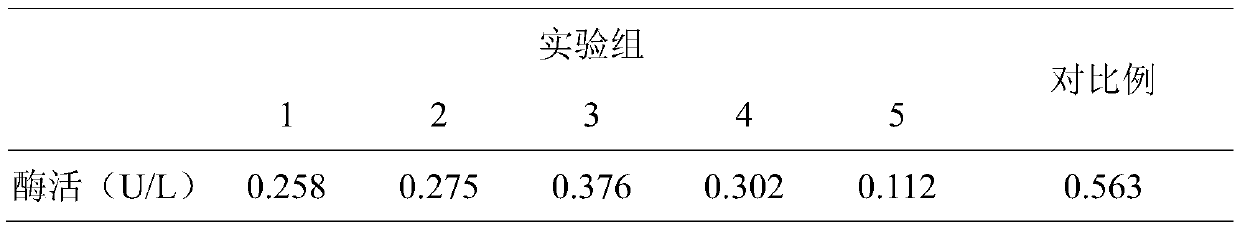

Immunofluorescence chromatography detection card and method for synchronously detecting contents of florfenicol and trimethoprim in poultry eggs

ActiveCN112798778AWith signal amplificationReduce steric hindrance effectBiological testingAnimal scienceImmunofluorescence

The invention discloses an immunofluorescence chromatography detection card and method for synchronously detecting the contents of florfenicol and trimethoprim in poultry eggs, and aims to provide an immunofluorescence chromatography detection card and method which are simple and time-saving in sample pretreatment operation, free of blow-drying, high in detection method sensitivity, suitable for on-site instant detection and capable of synchronously detecting florfenicol and trimethoprim in poultry eggs. The card is characterized by comprising a bottom plate, an absorbent paper pad, a reaction film, a combination pad and a sample pad are sequentially connected to the bottom plate from left to right, a florfenicol detection line T1, a trimethoprim detection line T2 and a quality control line C are marked on the reaction film, and florfenicol detection microspheres, trimethoprim detection microspheres and goat anti-chicken IgY polyclonal antibody labeled microspheres are coated on the combination pad; the invention belongs to the technical field of biological detection.

Owner:广州敏捷生物技术有限公司

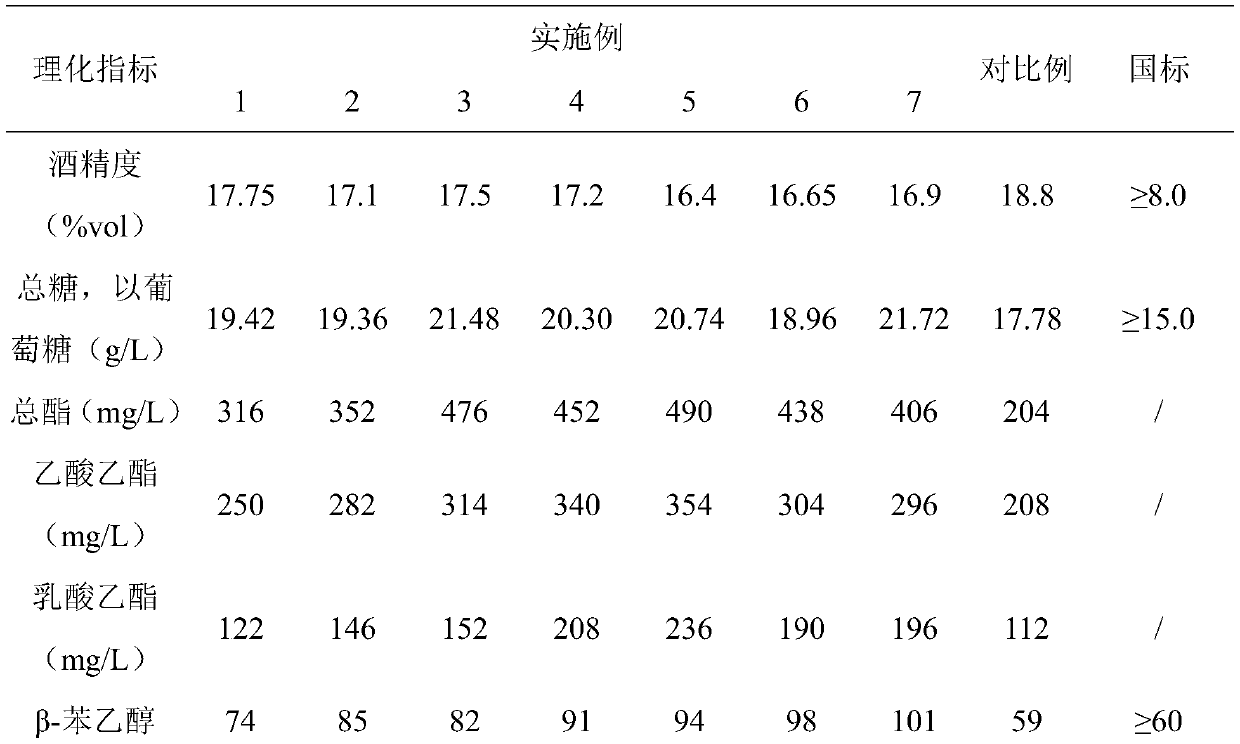

Brewing technology of low EC content yellow rice wine

InactiveCN109777682AInhibitory activityReduce generationMicroorganism based processesAlcoholic beverage preparationSynechococcusNatural aging

The invention discloses a brewing technology of low EC content yellow rice wine, belonging to the field of brewing technology, which in particular comprises the following steps: steaming material, saccharifying, pre-fermenting, post-fermenting, pressing, frying wine, filtering, natural aging for 6-12 months, and obtaining oat yellow rice wine. In addition, an arginase inhibitor and halophilic tetradiplococcus are added during the process of pre-fermenting. By the adoption of the brewing technology of the low EC content yellow rice wine, the EC content can be reduced through an interaction of various arginase inhibitors; and acetyl propionate forms a coordination compound with a binuclear manganese cluster at an active center of the arginase, zinc sulfate replaces the position of Mn<2+> byZn<2+>, lysine reaction between leaf aldehyde and an active site of enzyme is further, binding of substrate and the enzyme is hindered, the activity of the arginase is inhibited, the production of main precursor of EC is blocked, and the amount of the EC in finished wine is controlled, so that the safety of wine is improved.

Owner:枣阳市灵鹿酒业有限公司

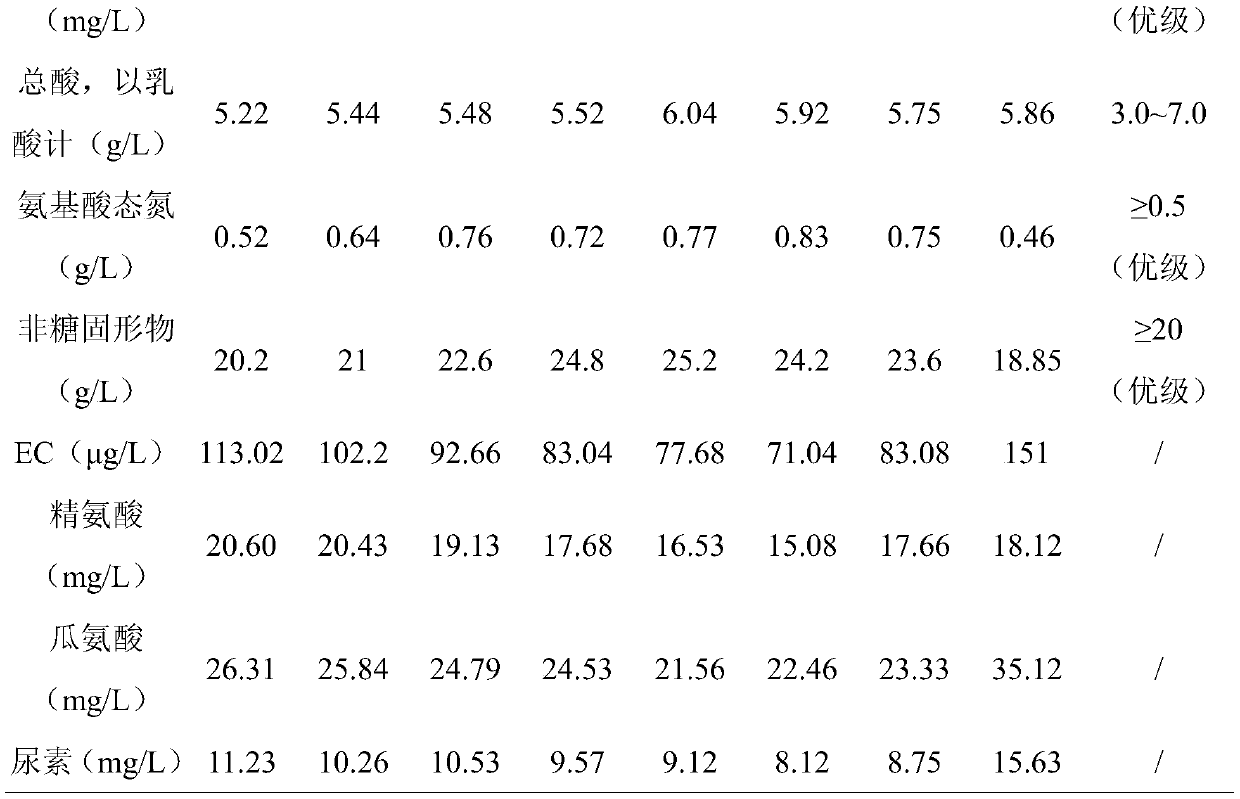

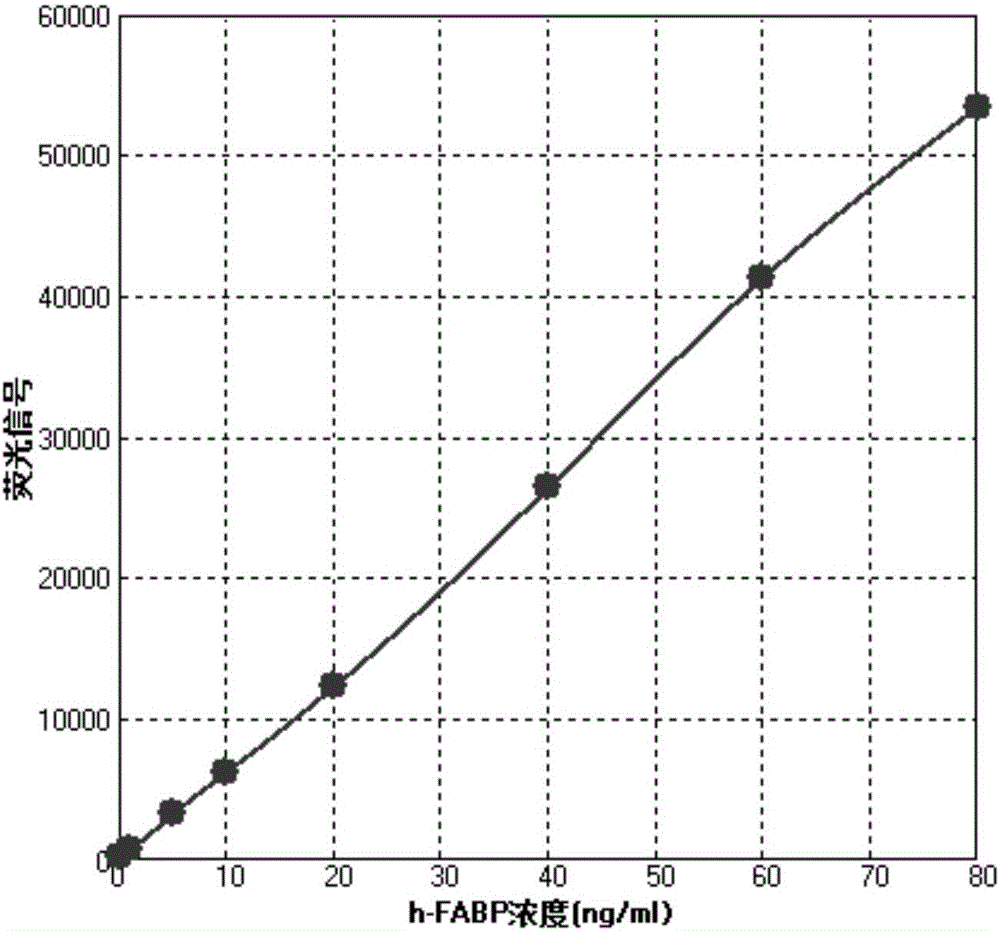

Cup type time-resolved fluorescence FABP analysis method and reagent kit based on microspheres

InactiveCN105891506ASimplify time-resolved fluorescence detection stepsShorten detection timeDisease diagnosisBiological testingCross-linkMicrosphere

The invention discloses a cup type time-resolved fluorescence FABP analysis method and a reagent kit based on microspheres. The method includes the steps that the inner surface of a detection reaction cup is coated with h-FABP monoclonal antibodies or polyclonal antibodies; the time-resolved fluorescence microspheres and the FABP monoclonal antibodies or polyclonal antibodies are subjected to covalent bond cross-linking to prepare fluorescence-labeled antibodies; an h-FABP sample to be detected is added into the coated detection reaction cup, then the fluorescence-labeled antibodies are added, and incubation is carried out at 25-40 DEG C; cleaning is carried out to remove unbound antigens and fluorescence-labeled antibodies, and fluorescence signals in the detection reaction cup are tested under the excitation of 340-380 nm exciting light; the fluorescence signals are compared with a standard curve, and the h-FABP concentration of the h-FABP sample to be detected is obtained. By means of the method, detection can be completed within a short detection time, the detection time is shortened, and the detection sensitivity is effectively improved.

Owner:SHANGHAI UPPER BIO TECH PHARMA

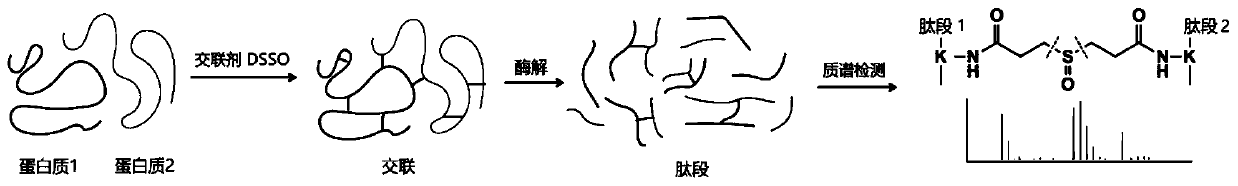

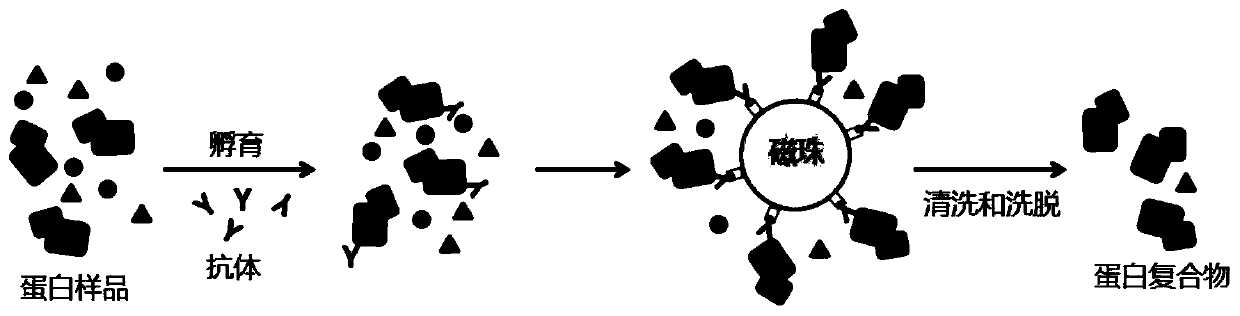

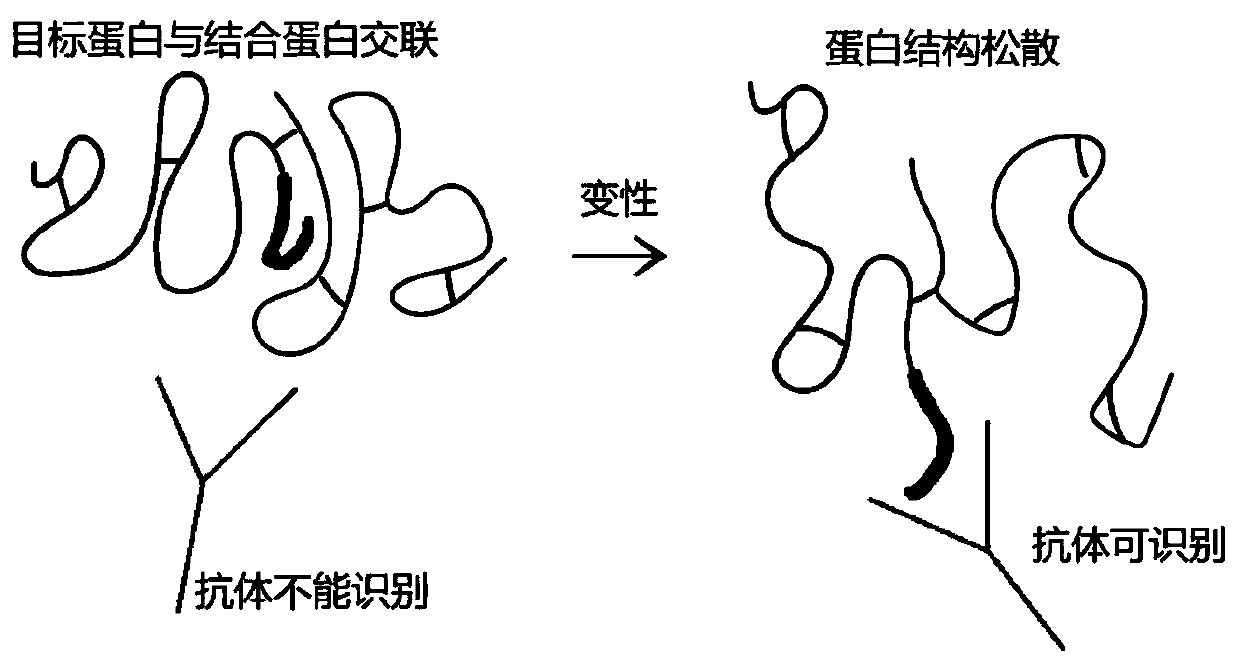

Method of detecting protein complex in biological sample

PendingCN111189904ASolve the problem of not being recognized by specific antibodiesReduce steric hindrance effectMaterial analysis by electric/magnetic meansProtein containing complexLinear epitope

The invention provides a method for detecting a protein complex in a biological sample. The method comprises the steps of: covalent crosslinking, denaturation treatment, solution replacement, co-immunoprecipitation and mass spectrometry. According to the method, a three-dimensional structure of protein is destroyed through the denaturation treatment step to disperse a peptide chain, so that the steric hindrance effect of the peptide chain is reduced, and the protein complex can be better recognized by a specific antibody. Moreover, due to denaturation treatment, an antigenic determinant buriedin a hydrophobic center of the peptide chain is exposed to serve as a linear epitope, an antibody directed at the linear epitope can be adopted for co-immunoprecipitation, and a novel thought is provided for co-immunoprecipitation. The detection method disclosed by the invention is beneficial to research on the interaction of the protein complex and the protein.

Owner:BGI CLINICAL LAB (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com