Grading method of fluidized bed catalyst

A catalyst and ebullating bed technology, which is applied in the gradation field of ebullating bed catalysts, can solve the problems of limiting the depth of hydrogenation reaction and the catalyst structure can not be well matched, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

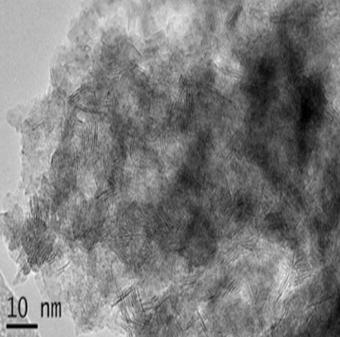

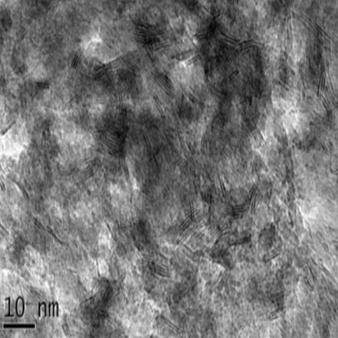

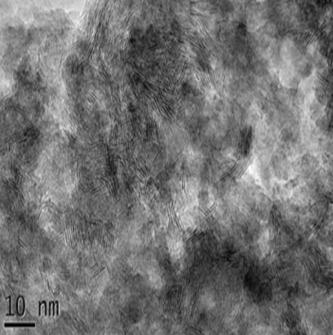

Image

Examples

Embodiment 1

[0041] This example provides a catalyst gradation combination and the preparation process of the gradation catalyst. Catalyst grading scheme is adopted, the catalyst is loaded in the reactor, and the bed is filled with hydrogenation catalyst I, hydrogenation catalyst II and hydrogenation catalyst III from top to bottom.

[0042] The preparation method of hydrogenation catalyst Ⅰ is as follows: the carrier Ⅰ is made of MoO 3 , NiO active components were supersaturated impregnated to obtain a catalyst precursor, which was dried at 250°C for 4h, heated to 580°C at 5°C / min, and roasted at constant temperature for 4.5h to obtain the desired catalyst. The catalyst MoO 3 is 21.5%, NiO is 5.9%; the specific surface area is 100m 2 / g, the pore diameter is 17.8nm, the bulk density is 0.85g / mL, and the particle diameter is 3.0mm. Load the catalyst into the vulcanization reactor, introduce sulfurized oil into it, and wet the catalyst bed; then adjust the bed temperature to 170°C, and i...

Embodiment 2

[0046] With embodiment 1, only the preparation method of hydrogenation catalyst I, II and III is different, specifically:

[0047] The preparation method of hydrogenation catalyst Ⅰ is as follows: the carrier Ⅰ is made of MoO 3 , NiO active components were supersaturated impregnated to obtain a catalyst precursor, which was dried at 300°C for 5h, heated to 550°C at 4°C / min, and roasted at constant temperature for 4.5h to obtain the desired catalyst. The catalyst MoO 3 is 23.5%, NiO is 5.9%; the specific surface area is 130m 2 / g, the pore diameter is 21.5nm, the bulk density is 0.80g / mL, and the particle diameter is 2.5mm. Load the catalyst into the vulcanization reactor, introduce sulfurized oil into it, and wet the catalyst bed; then adjust the bed temperature to 170°C, and inject the vulcanizing agent; after the hydrogen sulfide penetrates the catalyst bed, the catalyst bed The bed temperature was raised to 260°C at a rate of 3°C / h and kept at a constant temperature for ...

Embodiment 3

[0051] Same as Example 2, only the preparation method of the hydrogenation catalyst III is different, specifically: the preparation method of the hydrogenation catalyst III is as follows: the carrier III is used to contain MoO 3 , NiO active components and lactose (the amount is 17% of the mass of the catalyst carrier) mixed solution saturated impregnation to obtain a catalyst precursor, the precursor was dried at 120 ° C for 1.5 h to obtain the desired catalyst. The catalyst MoO 3 is 11.9%, NiO is 3.0%; the specific surface area is 198m 2 / g, the pore diameter is 8.1nm, the bulk density is 0.67g / mL, and the particle diameter is 0.45mm. Load the catalyst into the vulcanization reactor, introduce sulfurized oil into it, and wet the catalyst bed; then adjust the bed temperature to 160°C, and inject the vulcanizing agent; after the hydrogen sulfide penetrates the catalyst bed, the catalyst bed The bed temperature was raised to 200°C at a rate of 15°C / h and kept constant for 4.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com