Patents

Literature

238 results about "Lamellar crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

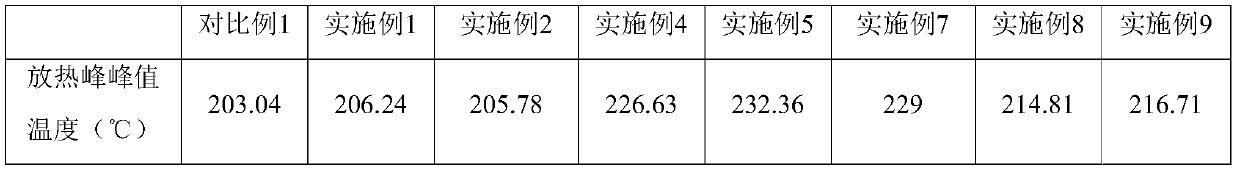

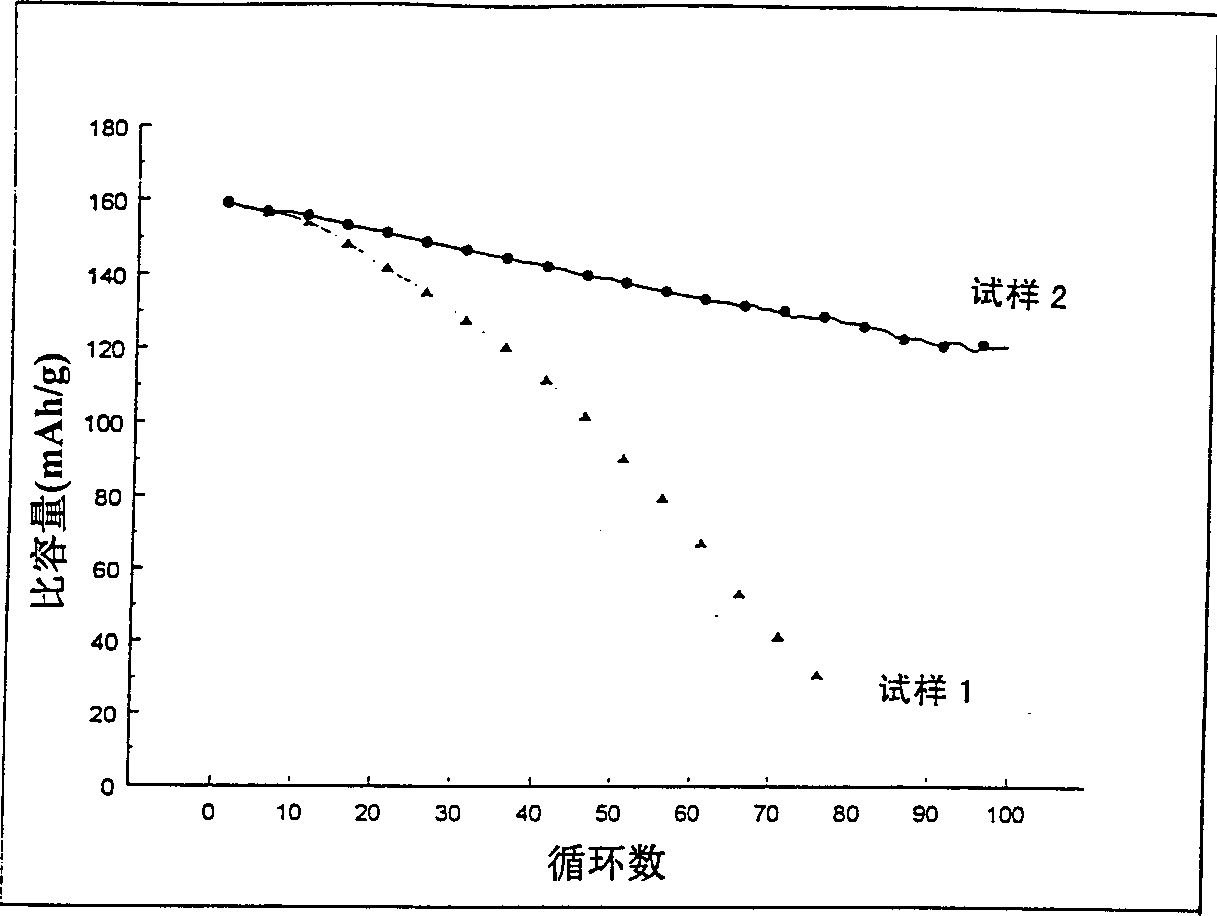

Method for preparing aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material

ActiveCN103178258AAdvantages of preparation methodInhibition of agglomerationCell electrodesManganates/permanganatesLamellar crystalsReaction temperature

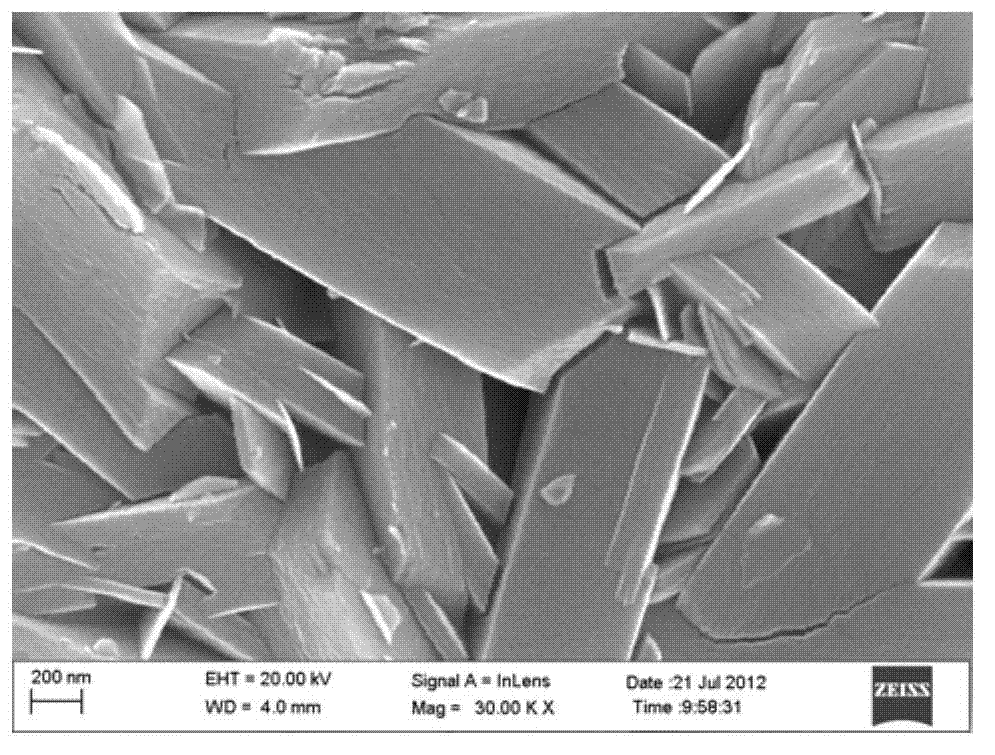

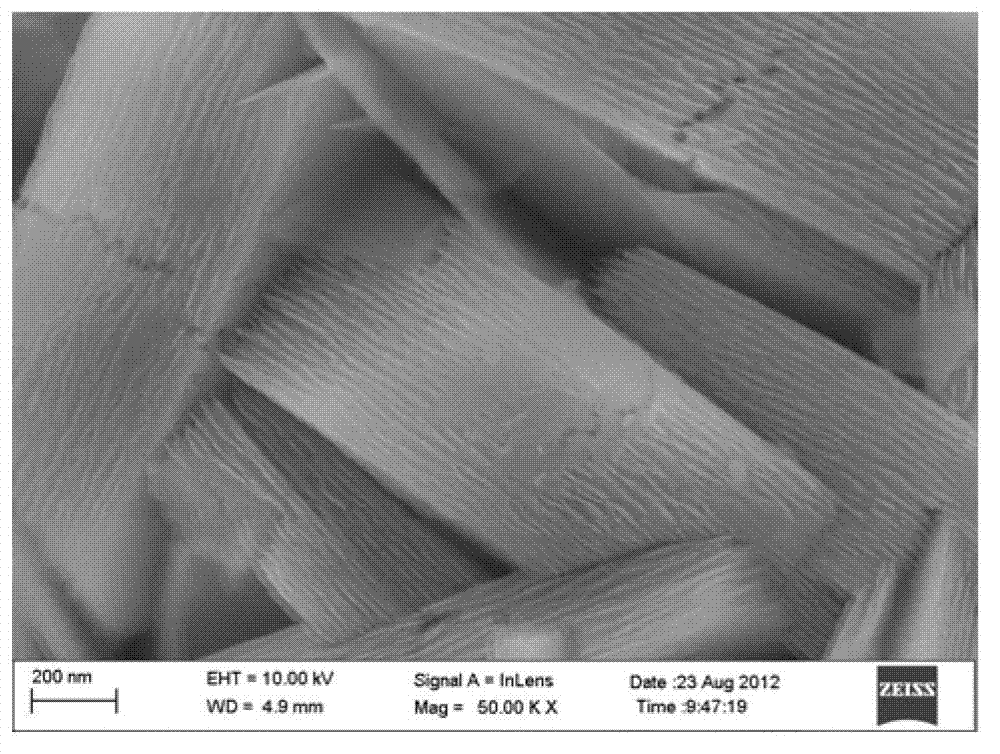

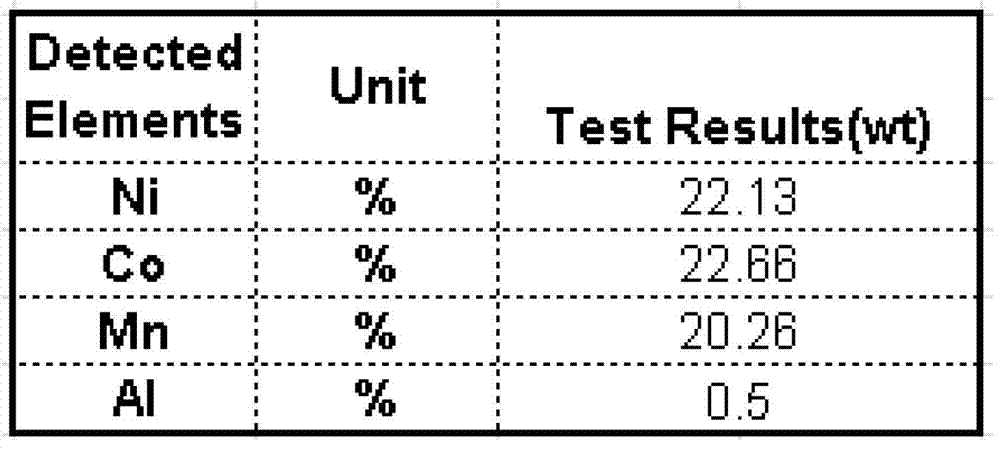

The invention discloses a method for preparing an aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material. The method comprises the following steps of: (1) preparation of a precursor: mixing water-soluble metallic nickel salt, cobalt salt and manganese salt into a mixed solution, dripping the mixed solution, a precipitator and a morphological control agent into a reaction container, controlling the pH value and reaction temperature of a system, and performing filtering, washing and vacuum drying after reaction to obtain a (NixCoyMn1-x-y)(OH)2 precursor, wherein x, y and x+y are more than 0 and less than 1; (2) preparation of an aluminum oxide coated precursor: dispersing the (NixCoyMn1-x-y)(OH)2 precursor, water-soluble aluminum salt and a disperser into deionized water, stirring while heating until the disperser is hydrolyzed, filtering to obtain an Al(OH)3-coated (NixCoyMn1-x-y)(OH)2 precursor, roasting the precursor in a sintering furnace to obtain Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder; and (3) uniformly mixing the Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder with lithium salt powder, and calcinating at high temperature to obtain an aluminum oxide coated modified Li(NixCoyMn1-x-y)O2 cathode material with a lamellar crystal structure.

Owner:NINGDE AMPEREX TECH

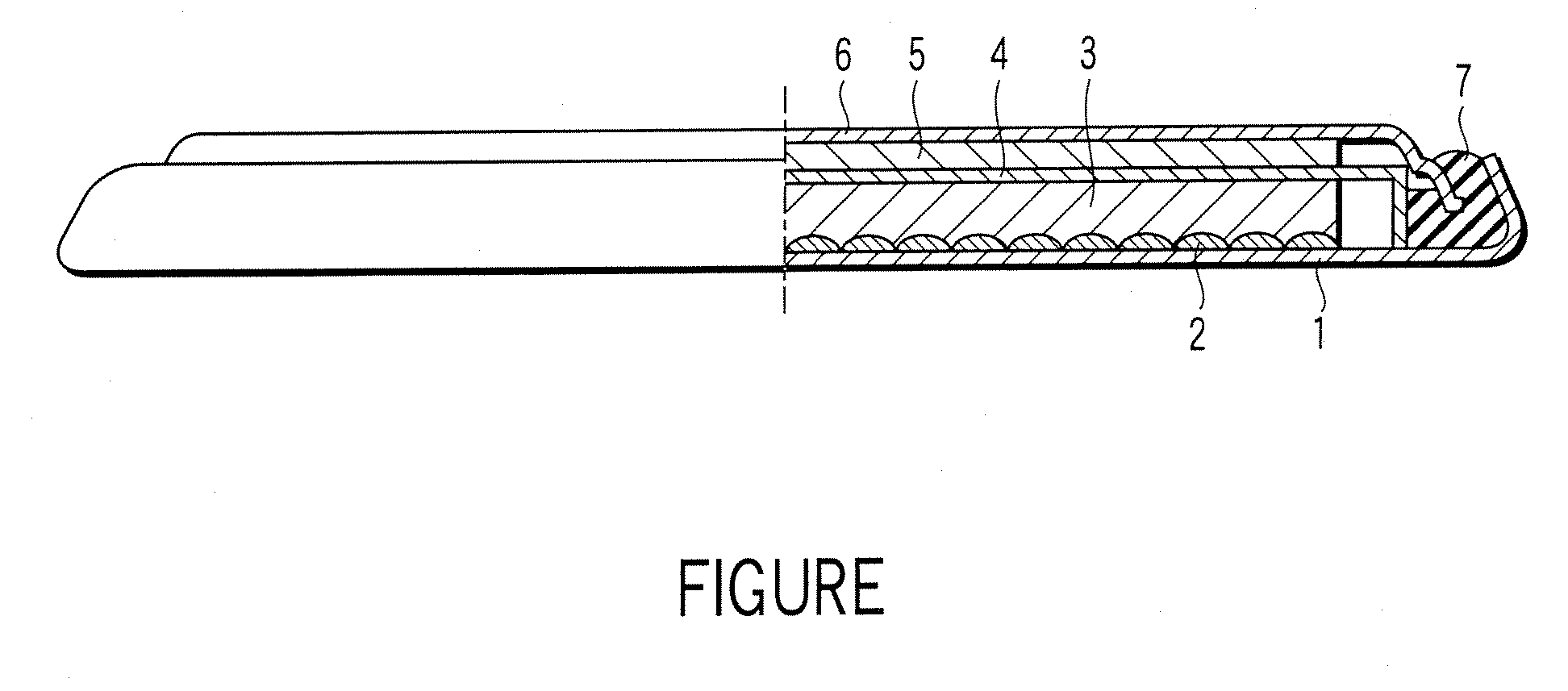

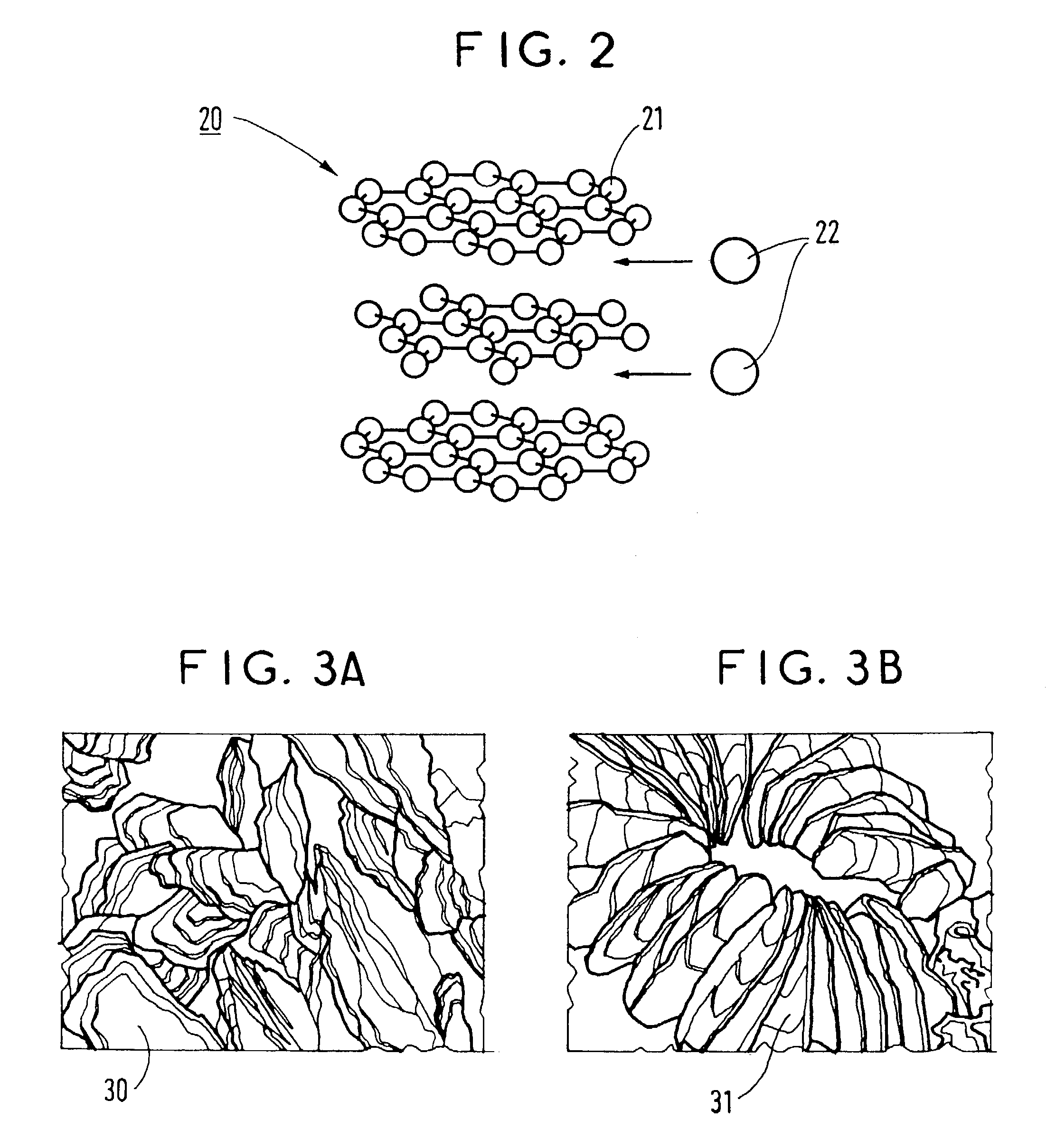

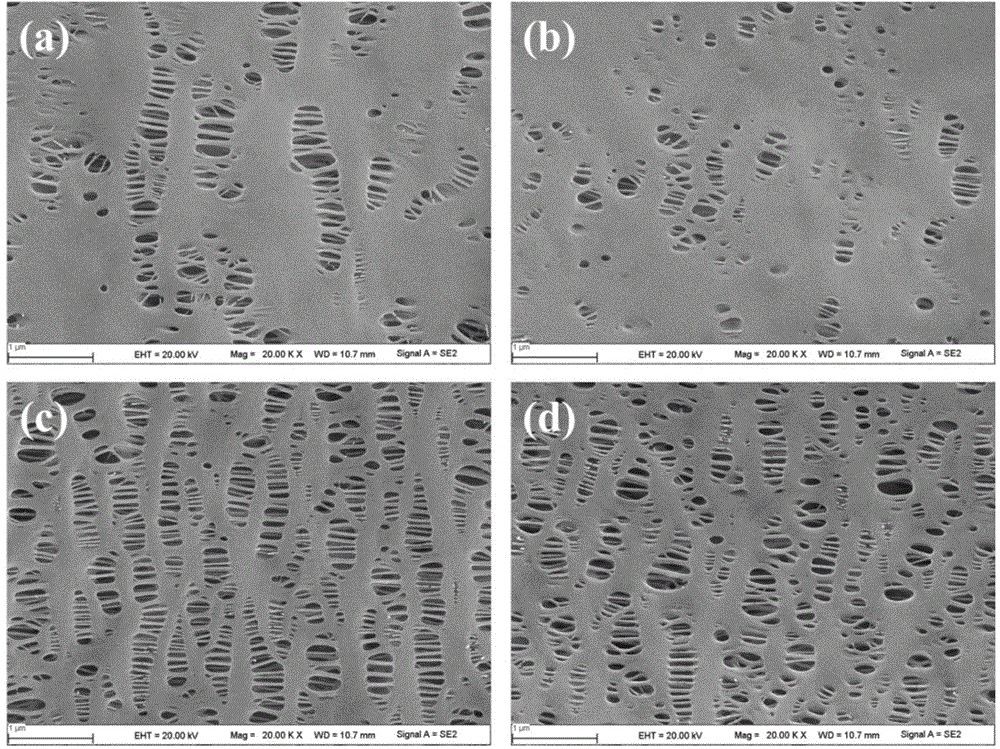

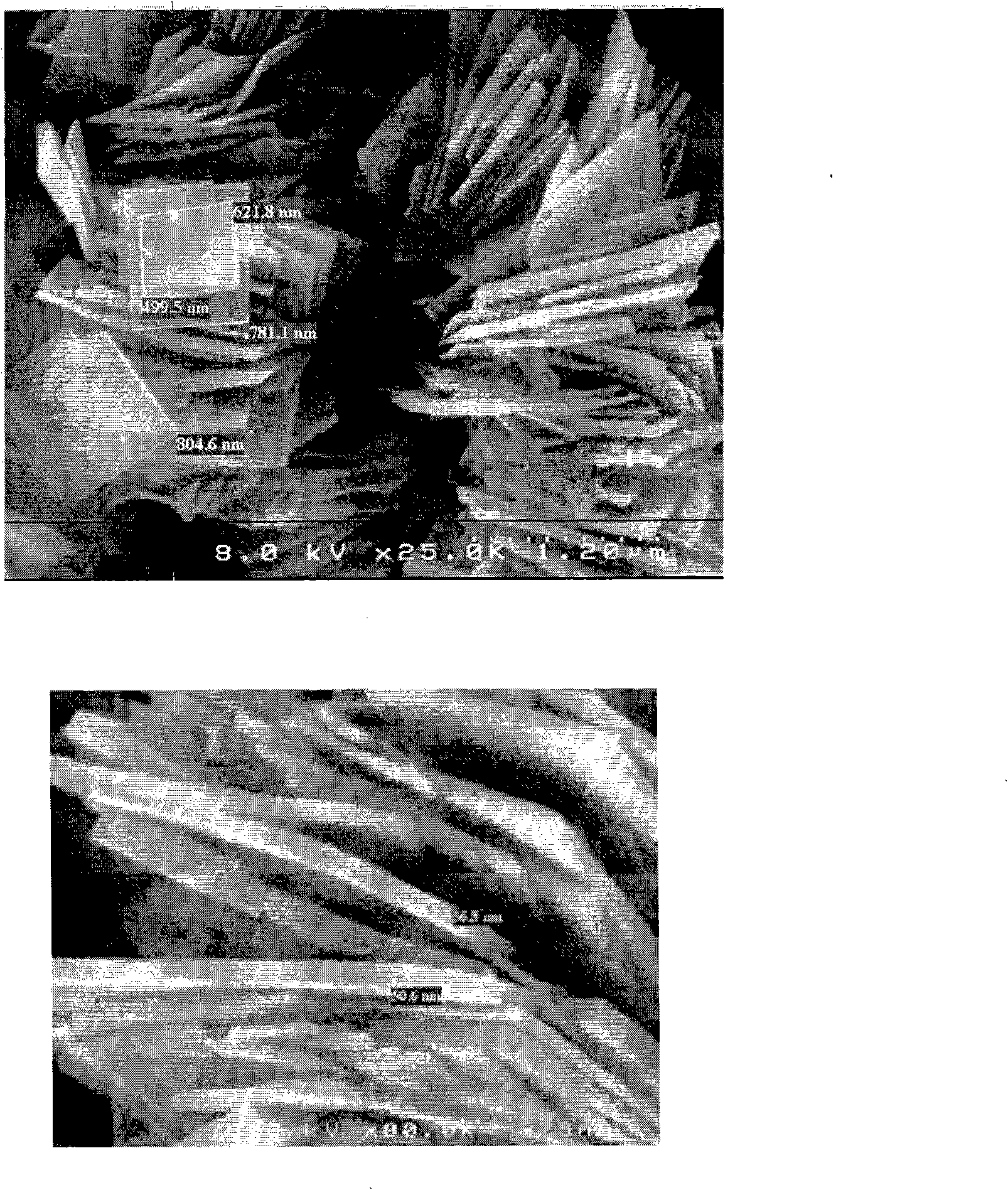

Polyolefin microporous membrane, separator for non-aqueous secondary battery, non-aqueous secondary battery and method of producing polyolefin microporous membrane

ActiveUS20120115008A1Improve propertiesImprove securityFinal product manufactureSynthetic resin layered productsLamellar crystalsPolyolefin

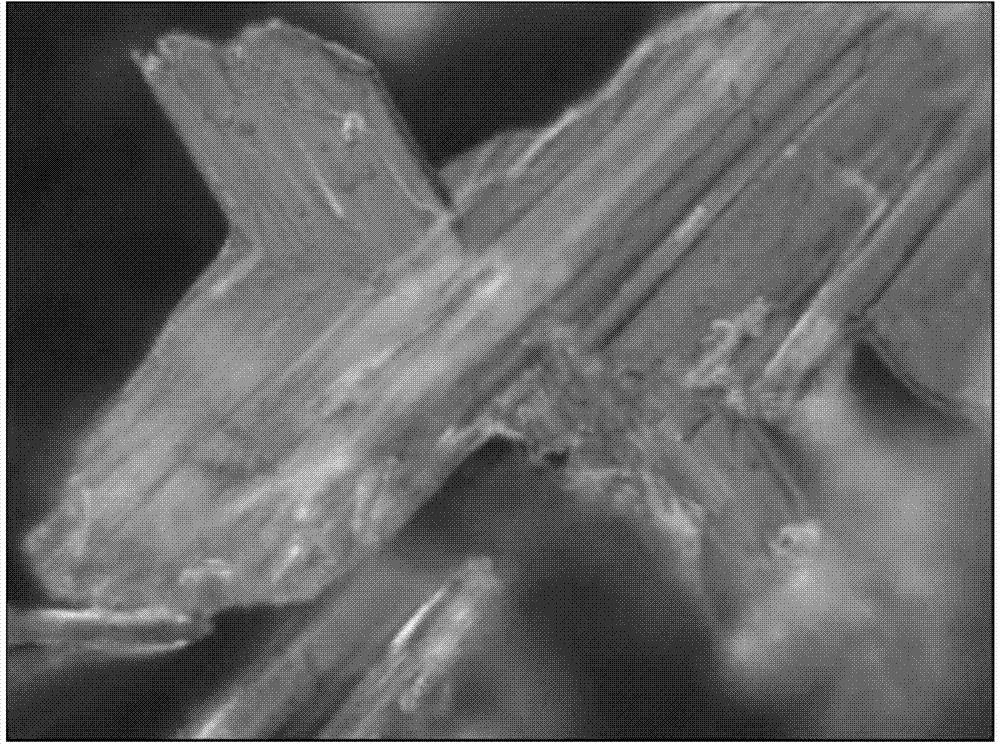

A polyolefin microporous membrane, the membrane having, when measured by DSC, a degree of crystallinity of from 65 to 85%, a lamellar crystal / crystal ratio of from 30 to 85%, a crystal length of from 5 nm to 50 nm and an amorphous length of from 3 nm to 30 nm, and a polyolefin microporous membrane, the membrane having, when measured by X-ray diffractometry, crystal size of from 12.5 nm to 13.5 nm and a degree of crystallinity of from 64 to 68%.

Owner:TEIJIN LTD

Electrochemical device

InactiveUS20060210876A1Excellent in charge-discharge cycle characteristicHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorLamellar crystalsHydrogen atom

An electrochemical device includes a case, a nonaqueous electrolyte filled in the case and containing a room temperature molten salt in an amount of 1 to 50 vol %, a first electrode housed in the case, and a second electrode housed in the case and containing a substance having a lamellar crystal structure. The room temperature molten salt contains a cation represented by formula (1) or formula (2) given below. R1 includes a carbonic acid ester group. Each of R2 and R3 denotes a substituent having an acyclic structure and having 4 or less carbon atoms, or R2 and R3 are combined to denote a substituent having a cyclic structure and having 4 or 5 carbon atoms. R4 includes a carbonic acid ester group, R5 has an acyclic structure and has 4 or less carbon atoms, and R6 denotes a hydrogen atom or a methyl group.

Owner:KK TOSHIBA

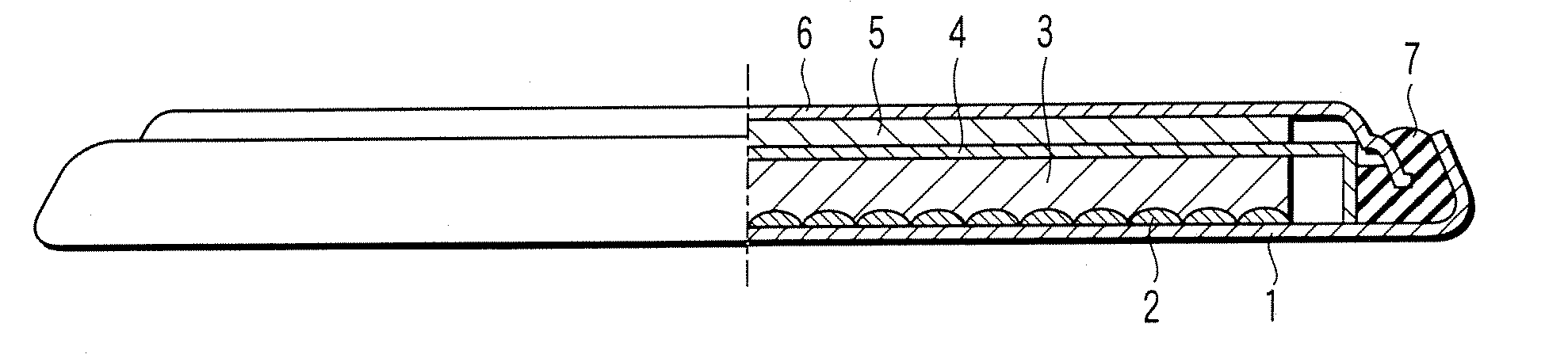

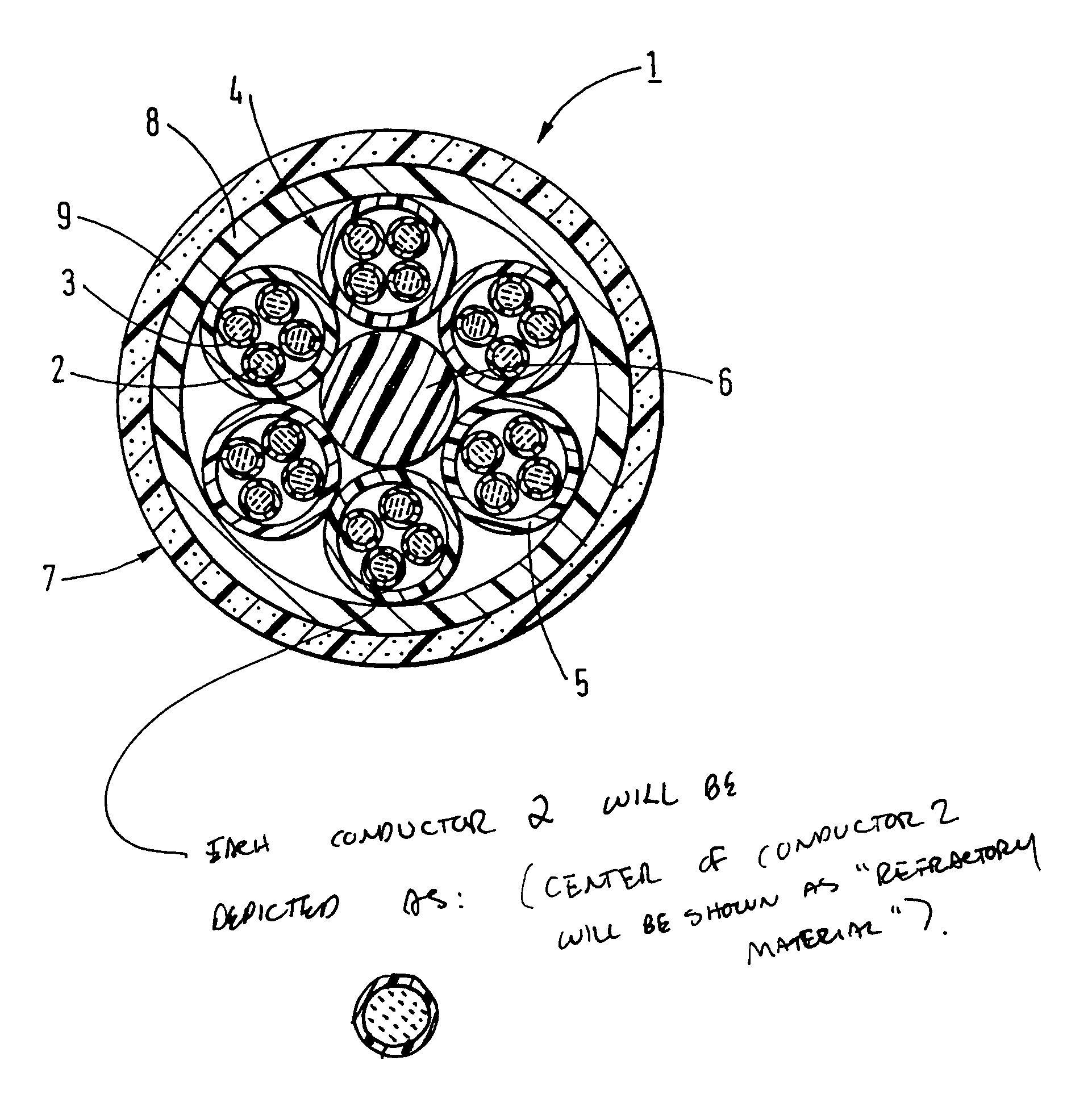

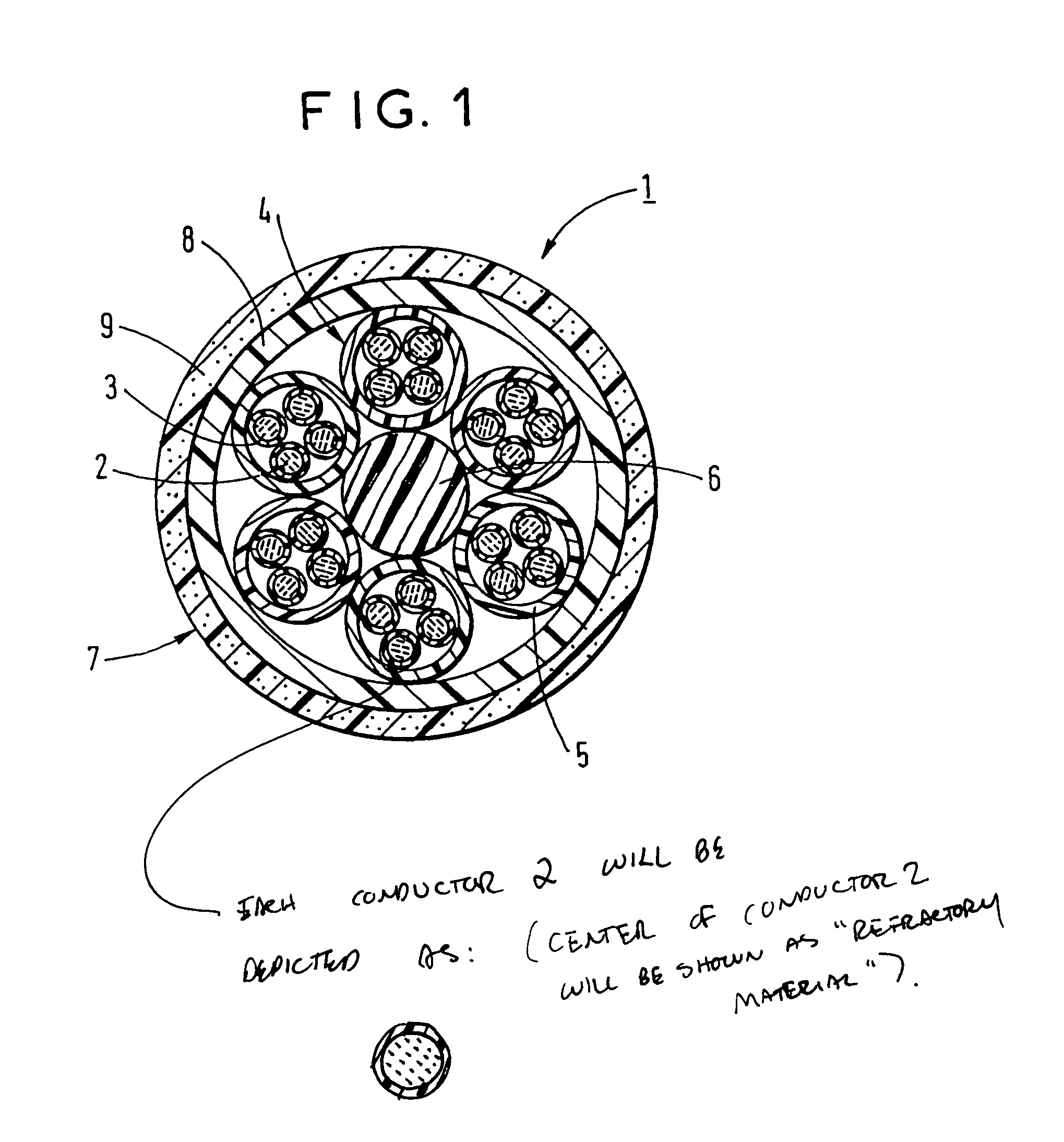

Cable sheath including a halogen-free intumescent composition

InactiveUS6998536B2Improve flame retardant performanceLow densityPlastic/resin/waxes insulatorsInsulated cablesLamellar crystalsPolyamide

The present invention relates to a sheath (7) for a cable (1), where the sheath contains, at least in part, a halogen-free intumescent composition. The composition of the sheath contains a mixture of a polymer matrix chosen from a polyethylene, a polypropylene, an ethylene copolymer, a propylene copolymer, a silicone, a polyamide, and a mixture thereof and at least one flame-retardant additive. The flame retardant additive has a first inorganic compound having a lamellar crystal structure, and a second inorganic compound inserted between the lamellae of the first compound, where the second compound causes the lamellae to move apart under the application of heat.

Owner:DRAKA COMTEQ BV

Flaky nanometer molybdenum disulfide material, nanometer composite metal anticorrosive coating material and preparation method of flaky nanometer molybdenum disulfide material and nanometer composite metal anticorrosive coating material

InactiveCN104176781AEasy to prepareImprove efficiencyMaterial nanotechnologyAnti-corrosive paintsLamellar crystalsMetallic materials

The invention discloses a preparation method of a flaky nanometer molybdenum disulfide material. The preparation method comprises the steps of dispersing a raw material, namely molybdenum disulfide with a lamellar crystal structure, into a mixed solution of nitric acid and hydrochloric acid; carrying out liquid phase separation by using a heating or ultrasound method; and reacting to obtain the flaky nanometer molybdenum disulfide material. The invention also discloses a nanometer composite metal anticorrosive coating material and a preparation method thereof. The nanometer composite metal anticorrosive coating material is prepared by compounding flaky nanometer molybdenum disulfide and nanometer silicon dioxide sol. The preparation method disclosed by the invention is simple; the raw material is easily available; the flaky nanometer molybdenum disulfide material and the nanometer composite metal anticorrosive coating material are widely applied to the antirust treatment and performance improvement of metal materials; the service life of metal is prolonged; and the energy consumption is reduced.

Owner:EAST CHINA NORMAL UNIV

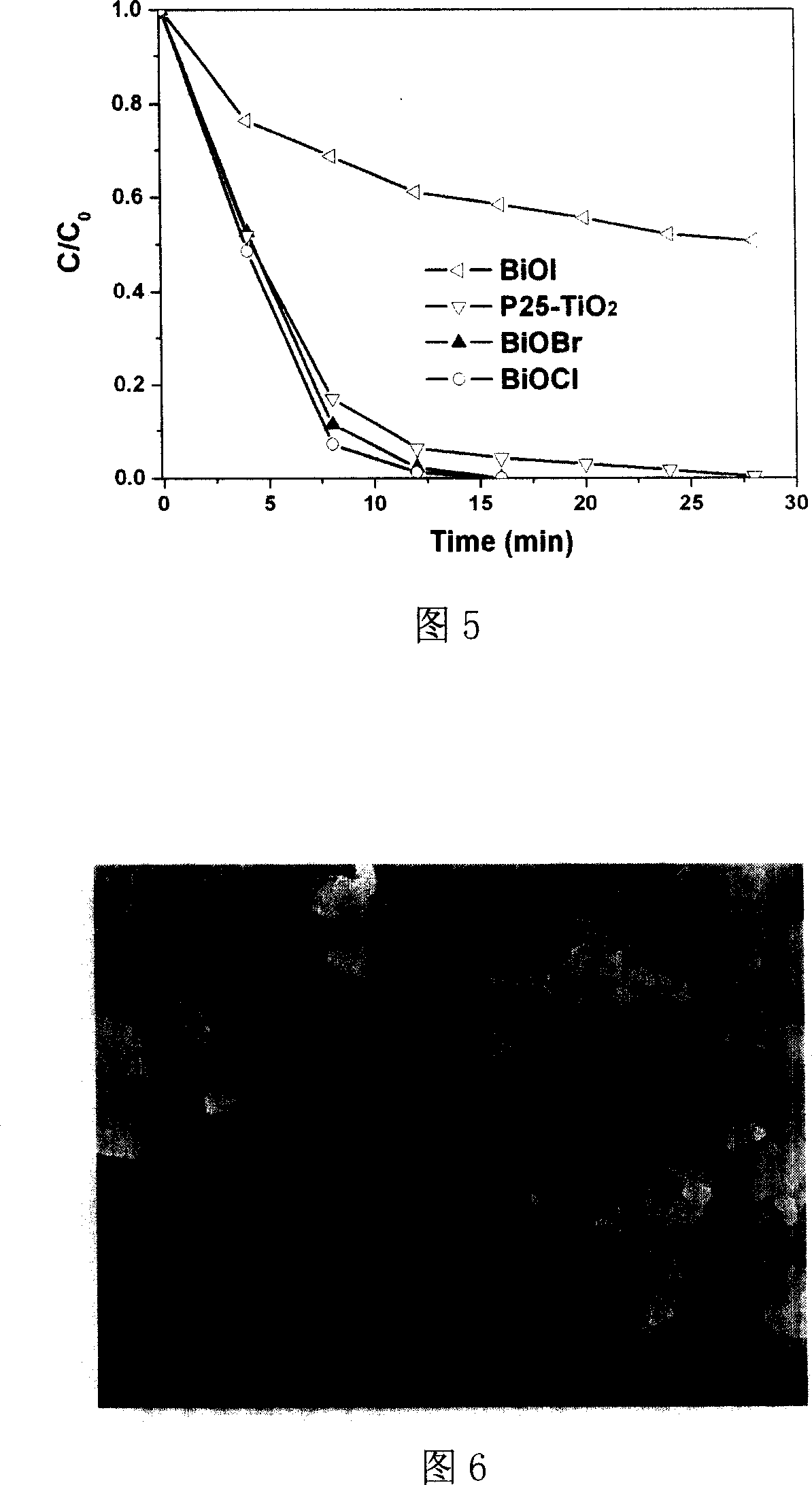

Halogen-oxide photocatalytic material and preparing method

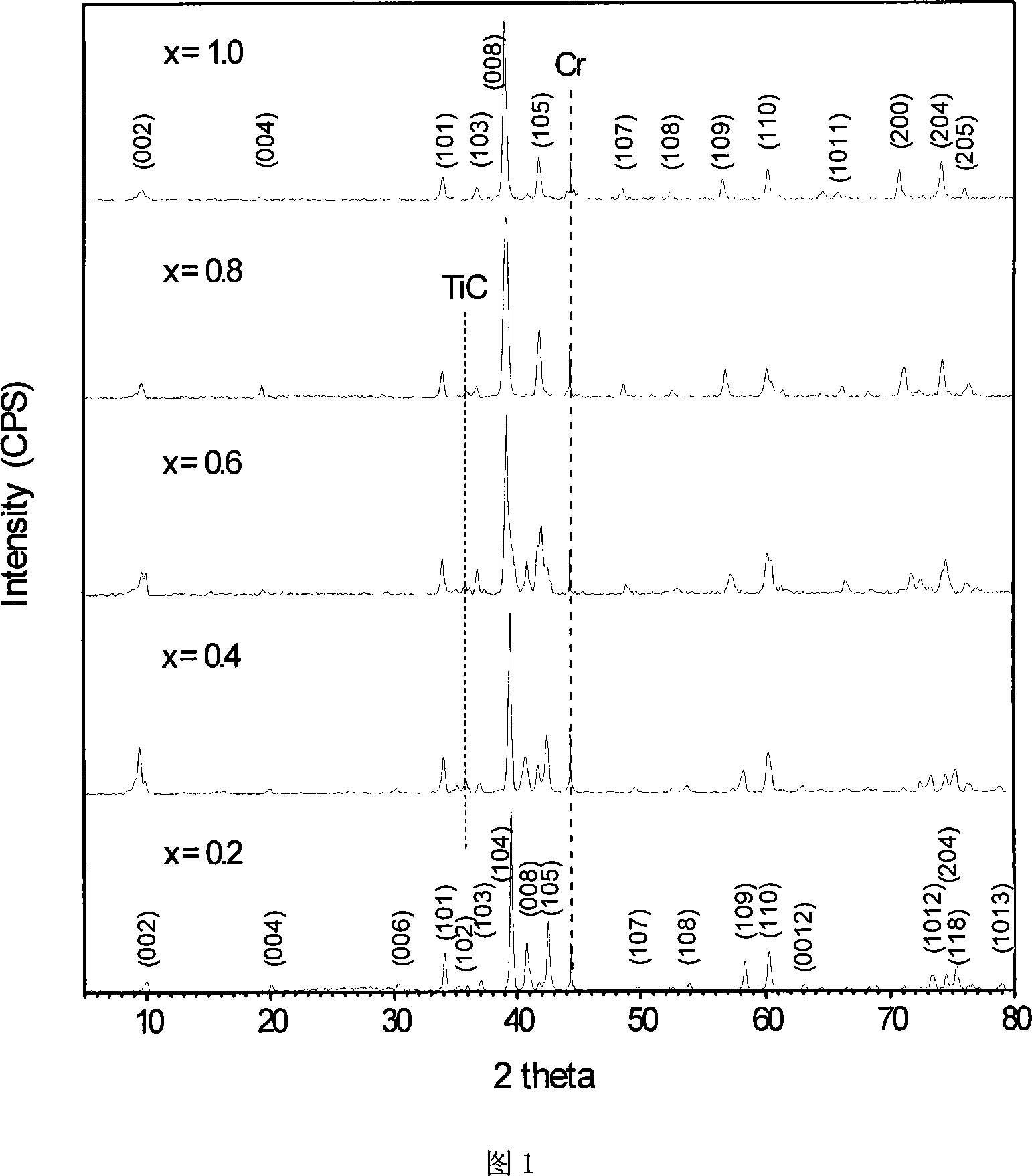

InactiveCN101024188AExcellent ability to degrade organic pollutantsPhysical/chemical process catalystsHydrogenChemical composition

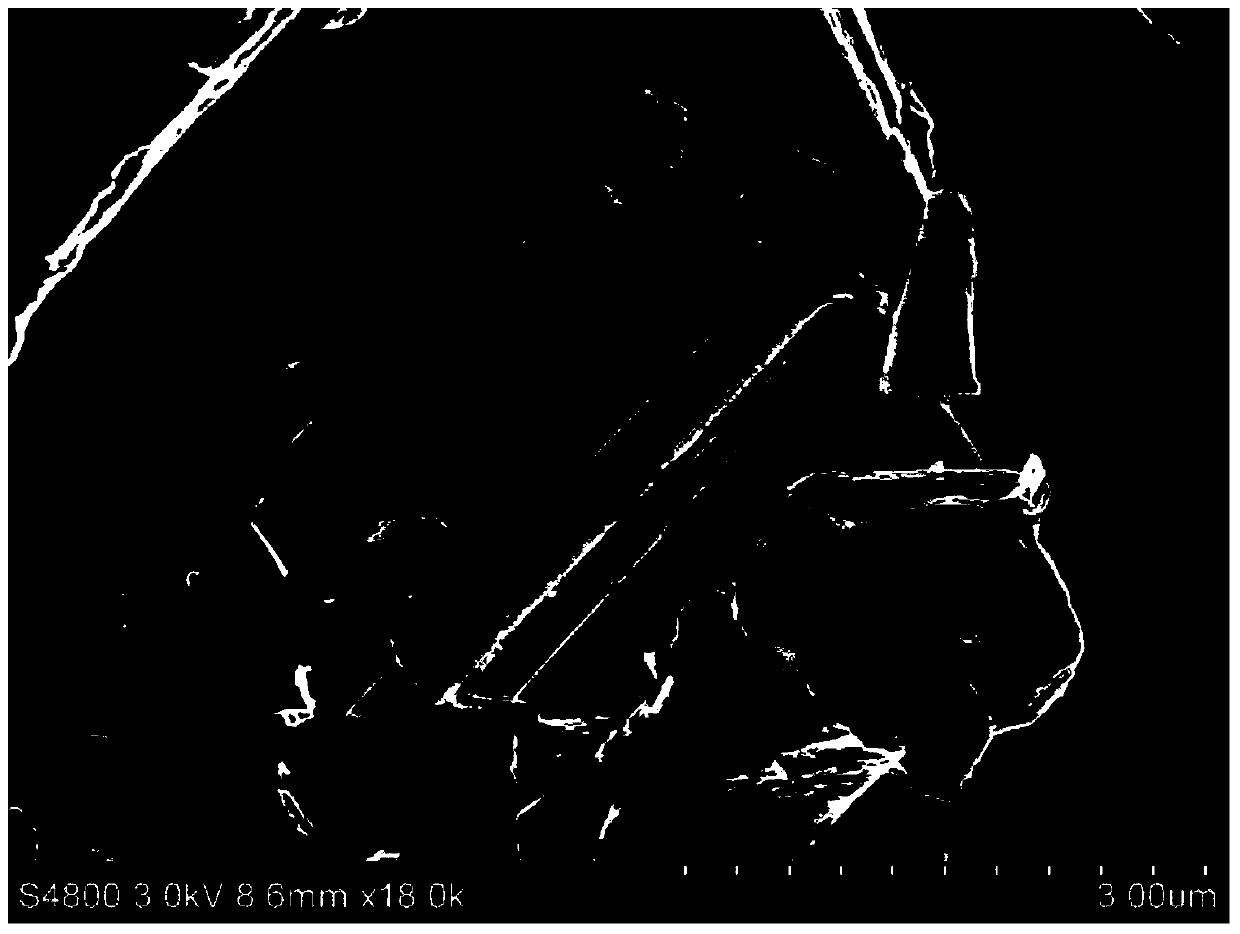

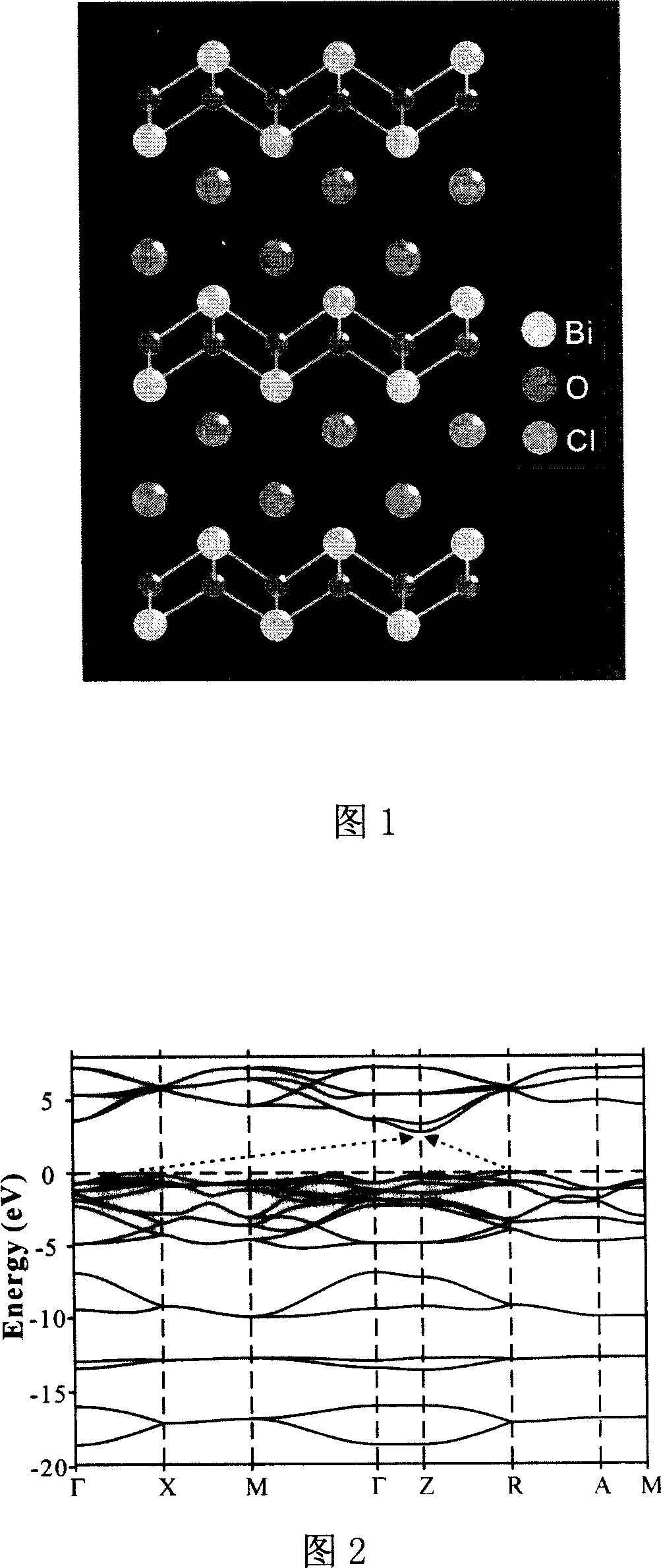

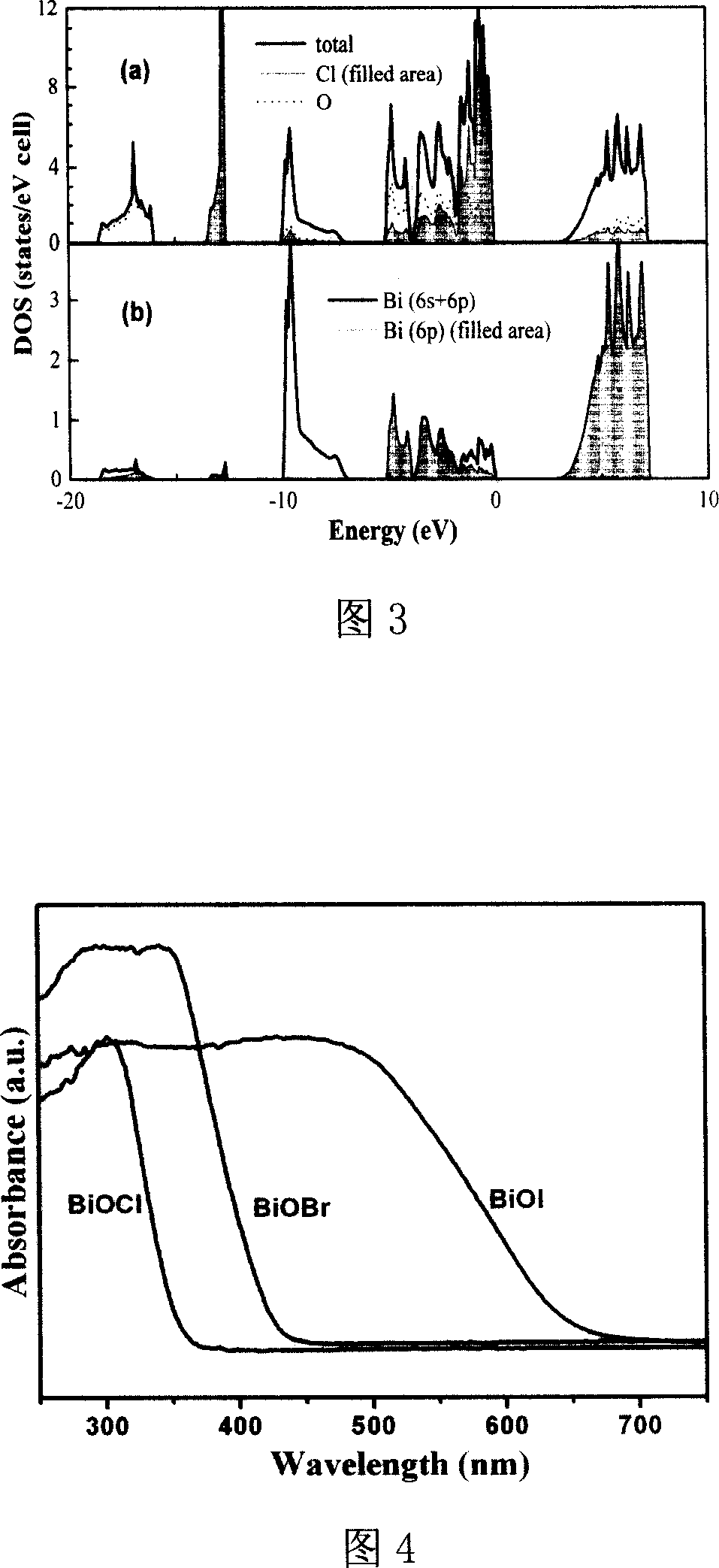

This invention relates to oxyhalogenide photocatalytic materials and their preparation methods, belongs to photocatalytic materials area. This invention using solid phase or liquid phase prepared oxyhalogenide photocatalytic materials, characterized in its chemical composition of BiOX, X=Cl, Br, I, [Bi2O2]with[X] structure layer along the c-axis direction mutual piled up a layered crystal structure. BiOX (X = Cl, Br, I) of preparation have superior photocatalytic properties; can degraded organic dyes and organic hazardous gases, sterilization and photolysis aquatic hydrogen. Load Ag and Pt and other electronic affinity metal nm particles, can greatly enhance the material photocatalytic properties.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

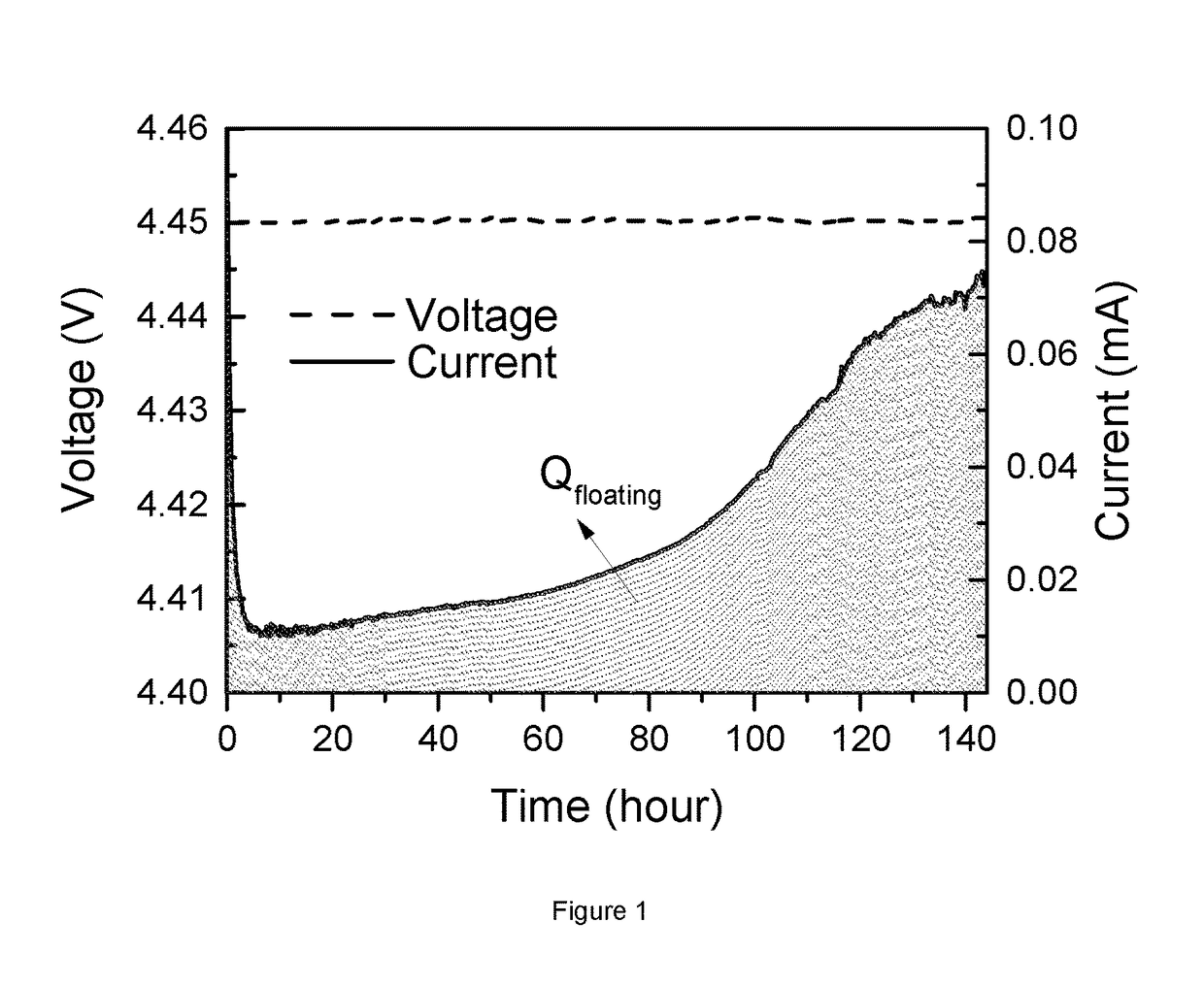

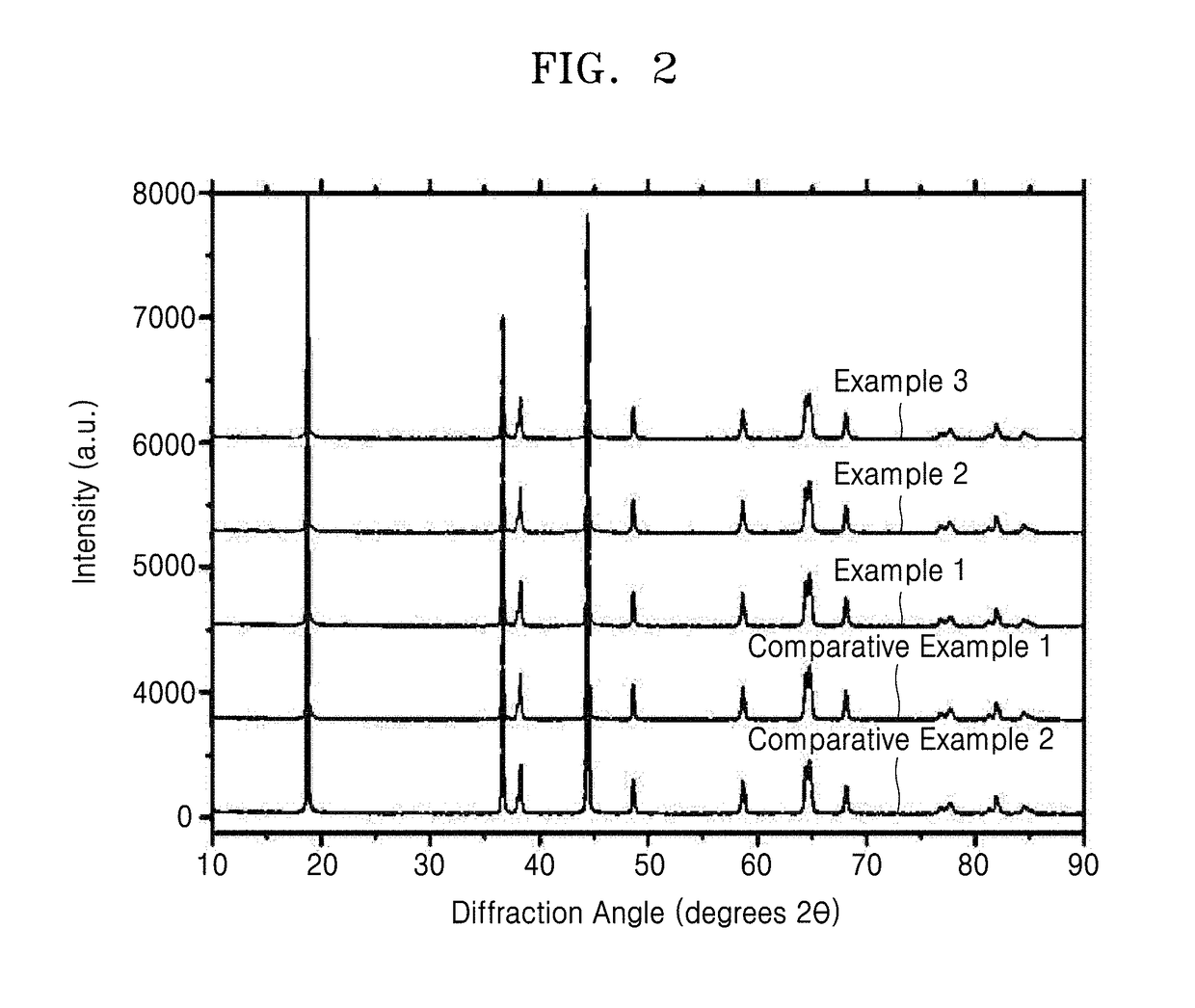

High-capacity cathode active material and lithium secondary battery including the same

ActiveUS20130224585A1Large capacityImprove featuresElectrode carriers/collectorsConductive materialManganeseConductive materials

Provided is a cathode active material including lithium manganese-based oxide, wherein the lithium manganese-based oxide has a layered crystal structure, has a content of manganese (Mn) greater than contents of other transition metal(s), includes 1 mole or more of lithium (Li) with respect to 1 mole of lithium transition metal oxide, has a plateau potential range in which lithium deintercalation as well as oxygen release occurs during initial charging in a high voltage range of 4.4 V or more, has domains included in the layered crystal structure exhibiting electrochemical activity due to a structural change in a potential range of 3.5 V or less after the initial charging, and includes conductive materials for improving electrical conductivity of the lithium manganese-based oxide in a potential range of 3.5 V or less after the initial charging.

Owner:LG ENERGY SOLUTION LTD

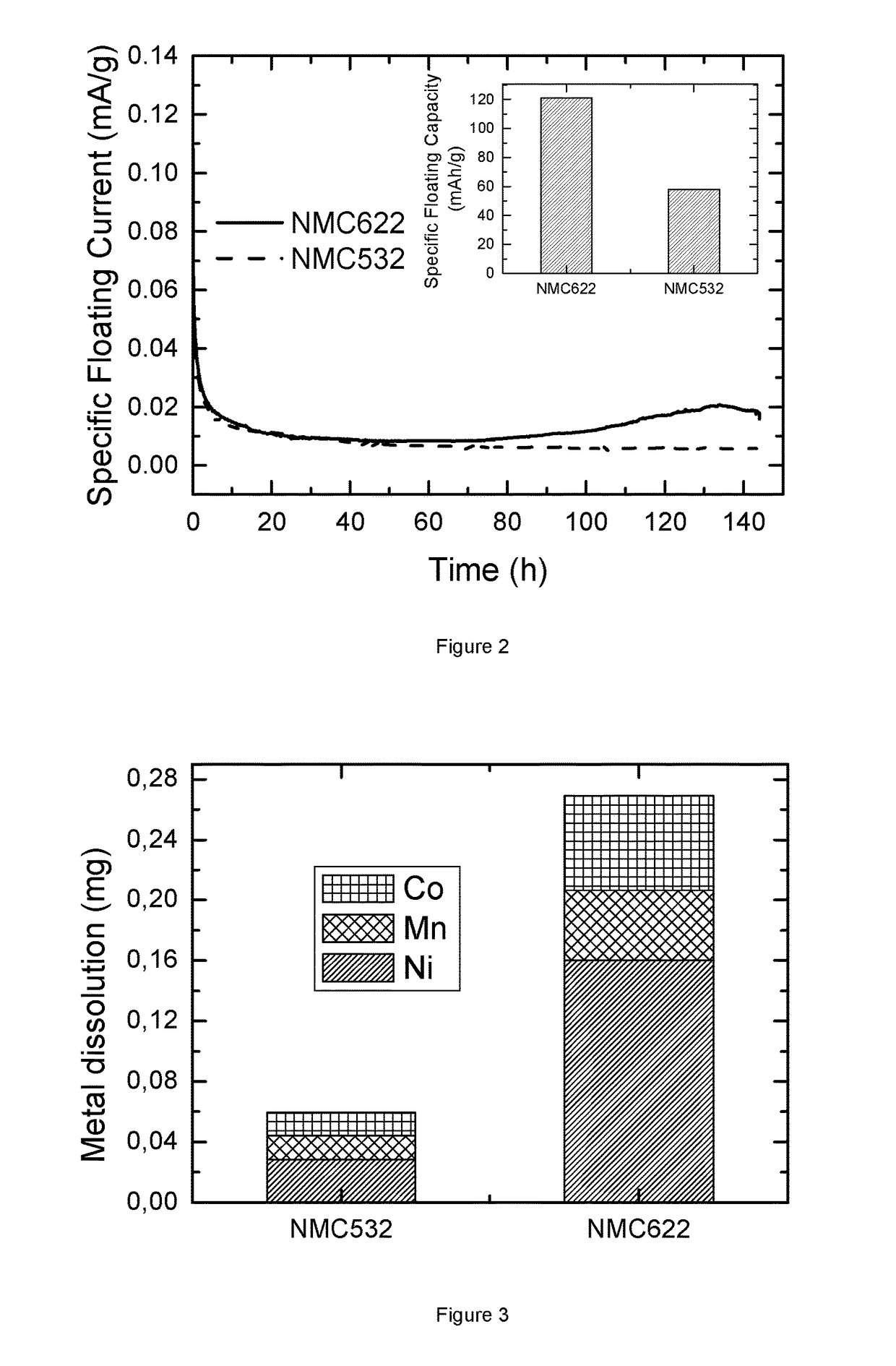

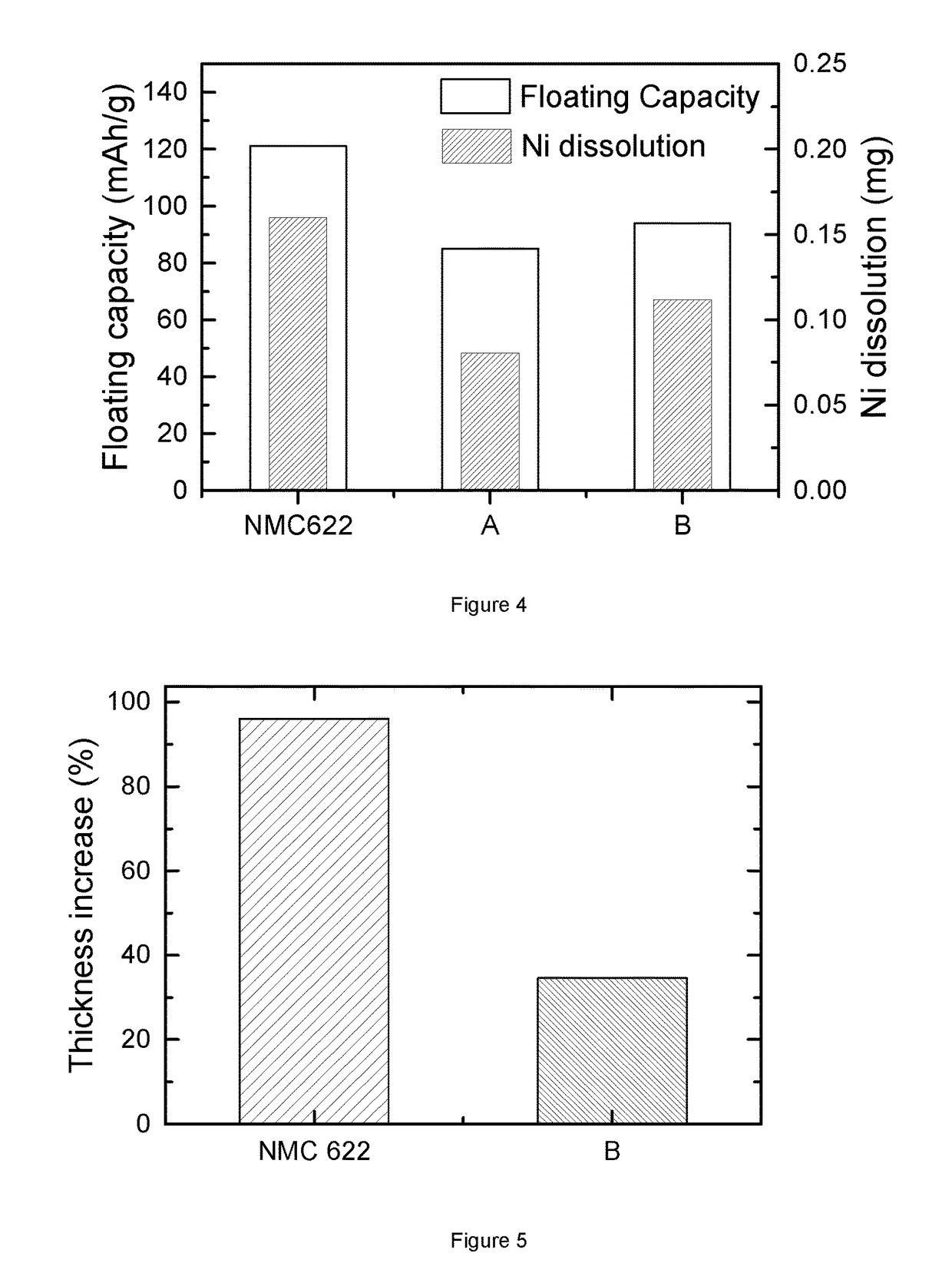

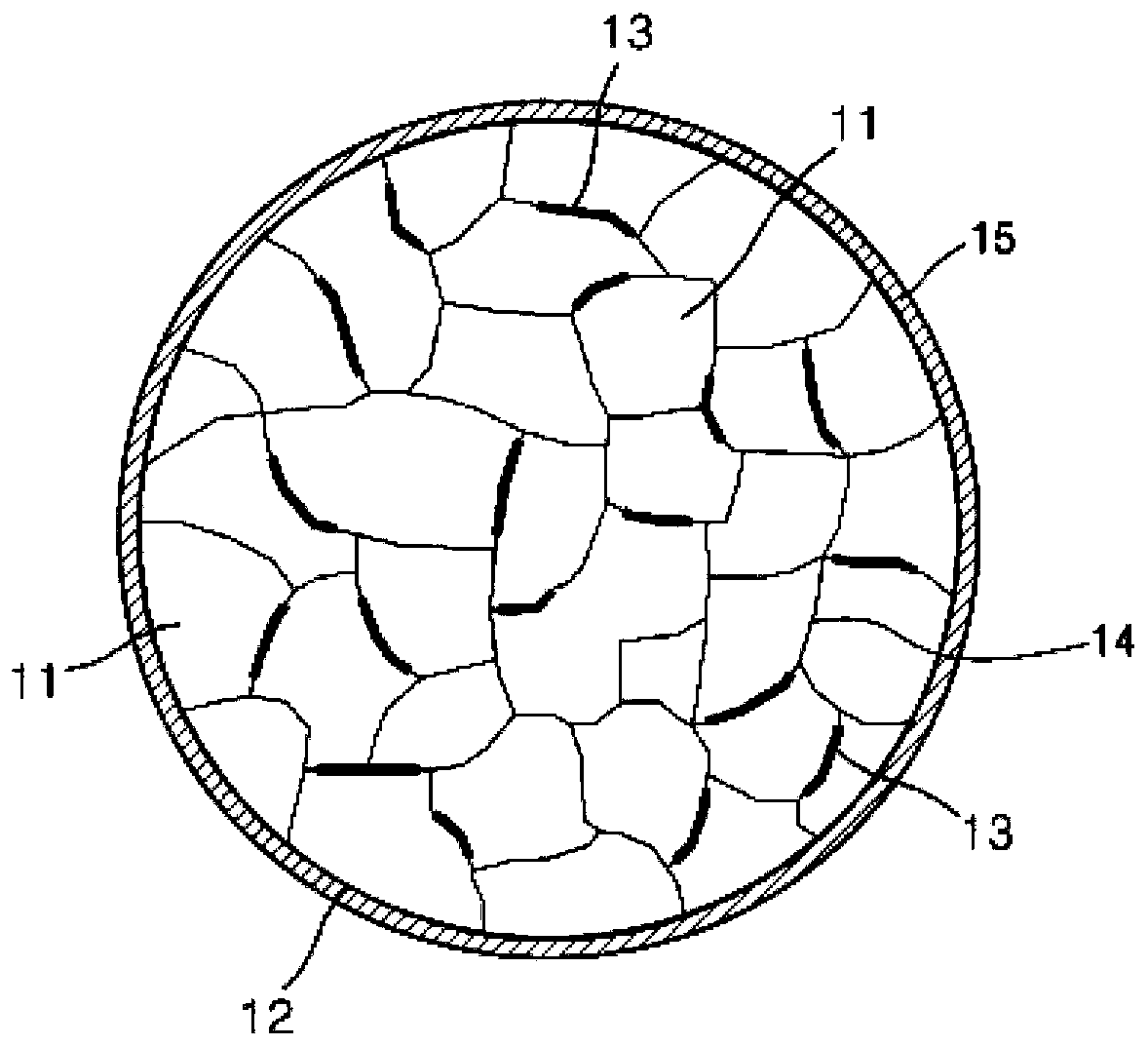

Lithium Metal Oxide Cathode Powders for High Voltage Lithium-Ion Batteries

ActiveUS20180034045A1Raise the ratioAlter electrical propertyElectrode thermal treatmentSecondary cellsLithium metalOxide cathode

This invention discloses a lithium metal oxide powder for a cathode material in a rechargeable battery, consisting of a core and a surface layer, the core having a layered crystal structure comprising the elements Li, M and oxygen, wherein M has the formula M=(Niz(Ni1 / 2Mn1 / 2)yCox)1-kAk, with 0.15≦x≦0.30, 0.20≦z≦0.55, x+y+z=1 and 0≦k≦0.1, wherein A is a dopant, wherein the Li content is stoichiometrically controlled with a molar ratio 0.95≦Li:M≦1.10; and wherein the surface layer comprises the elements Li, M′ and oxygen, wherein M′ has the formula M′=(Niz′(Ni1 / 2Mn1 / 2)y′Cox′)1-k′Ak′, with x′+y′+z′=1 and 0≦k′≦0.1, and wherein y′ / (y′+2z′)≧1.1*[y / (y+2z)]. The surface layer may also comprise at least 3 mol % Al, the Al content in the surface layer 10 being determined by XPS.

Owner:UMICORE AG & CO KG +1

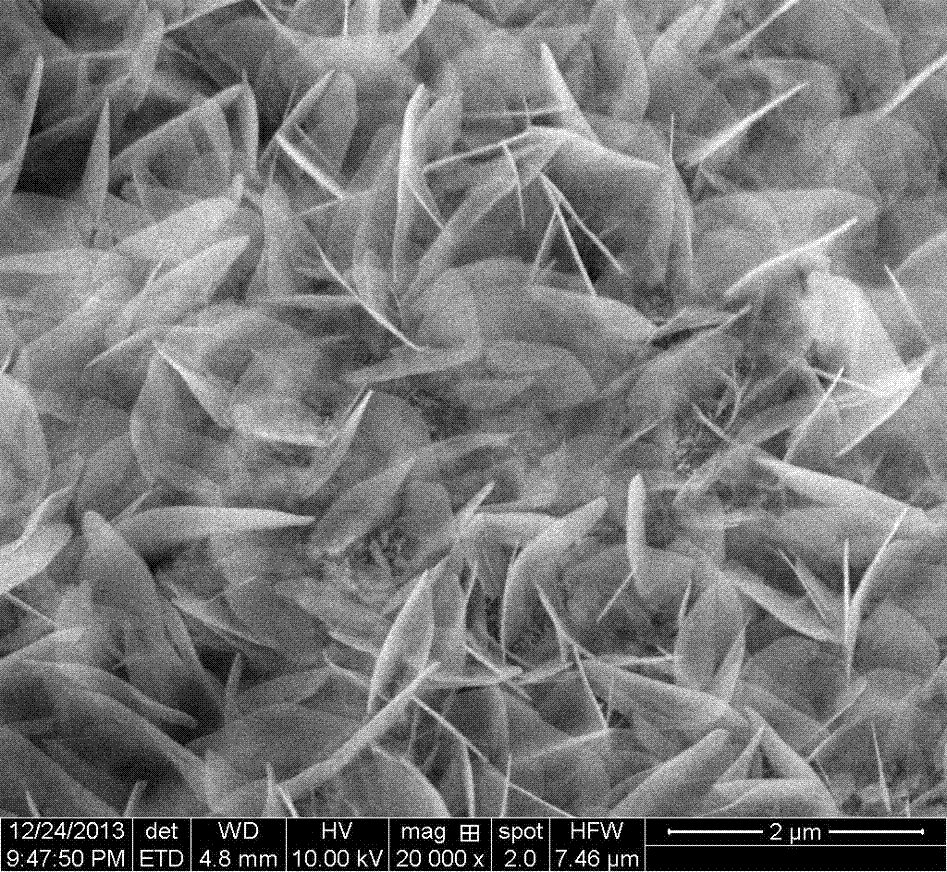

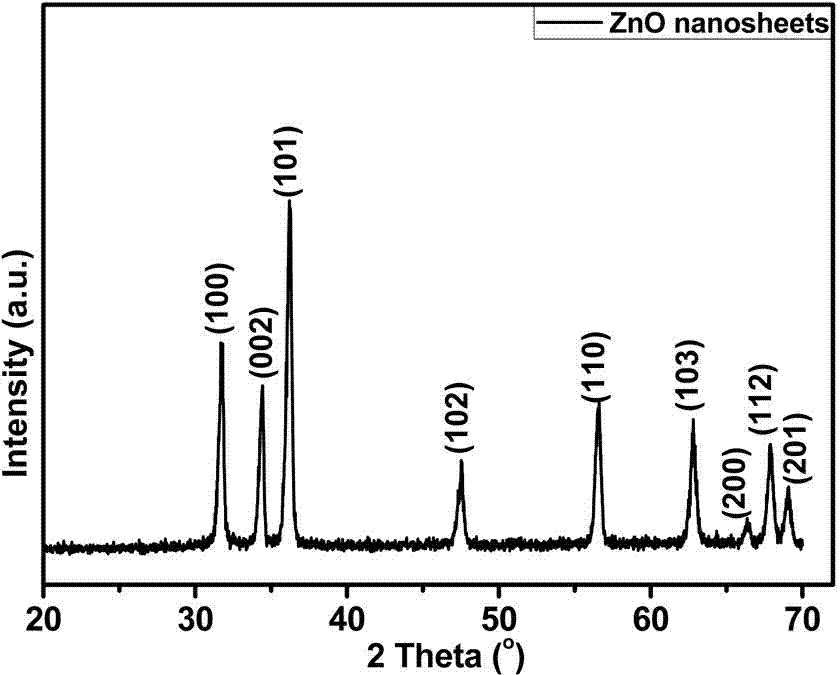

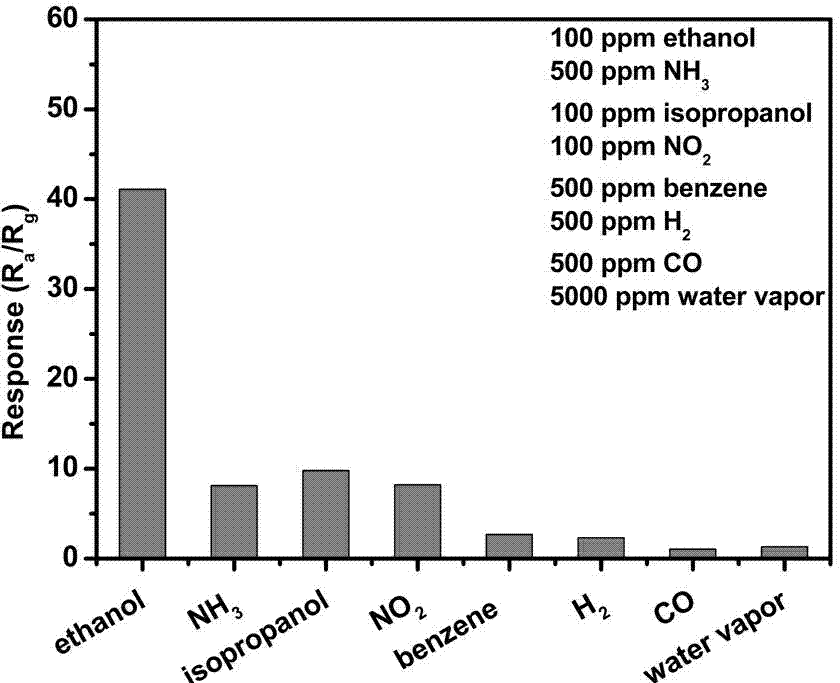

Method for in-situ growth of two-dimensional lamellar structured nano-zinc oxide on ceramic tube

ActiveCN103880064ASimple stepsShort timeZinc oxides/hydroxidesMaterial analysis by electric/magnetic meansLamellar crystalsZno nanoparticles

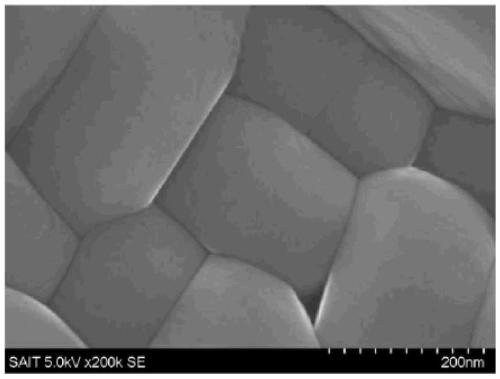

The invention relates to a method for in-situ growth of two-dimensional lamellar structured nano-zinc oxide on a ceramic tube, and belongs to the technical field of preparation of nano sensors. The method comprises the following steps: preparing a zinc oxide seed crystal layer on an aluminum oxide ceramic tube taken as a substrate by utilizing an impregnation method; and growing a mixed solution of zinc nitrate and hexamethylene tetramine on the aluminum oxide ceramic tube containing the zinc oxide seed crystal layer by utilizing a hydrothermal method so as to obtain zinc oxide nanosheets. According to the method, the two-dimensional lamellar structured nano-zinc oxide is grown in an aqueous solution at a high temperature and under a high pressure; and convection flows of the solution are generated by controlling the temperature difference of the solution in a high-pressure autoclave so as to form a hypersaturated state, thereby growing a lamellar crystal. The two-dimensional lamellar structured nano-zinc oxide grown on the aluminum oxide ceramic tube is controllable in shape, wherein the nanosheets are of a wurzite hexagonal structure and are uniform in size, namely, each of nanosheets is about 1 to 2 microns in size; and the nanosheets are mutually connected to form a network. In addition, the response of the nano-zinc oxide to the ethyl alcohol can reach 40; and the nano-zinc oxide has the good selectivity to the ethyl alcohol.

Owner:UNIV OF JINAN

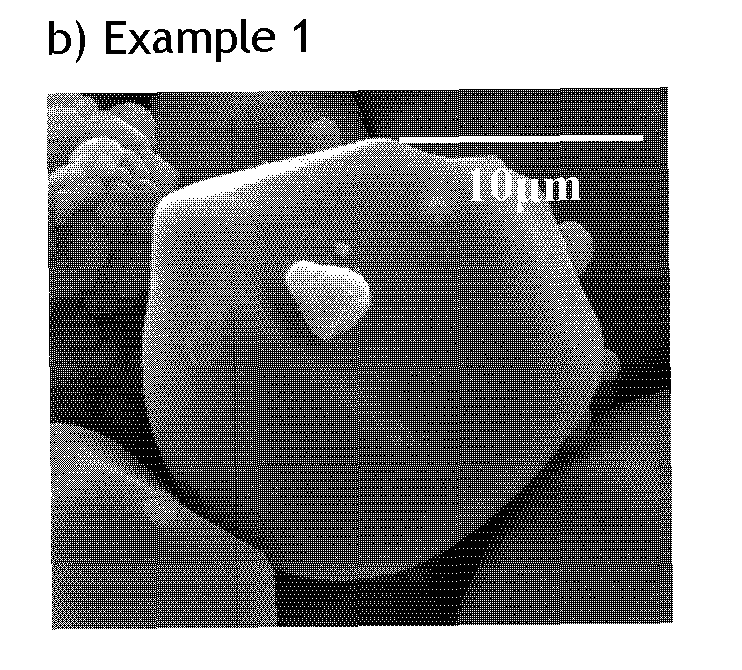

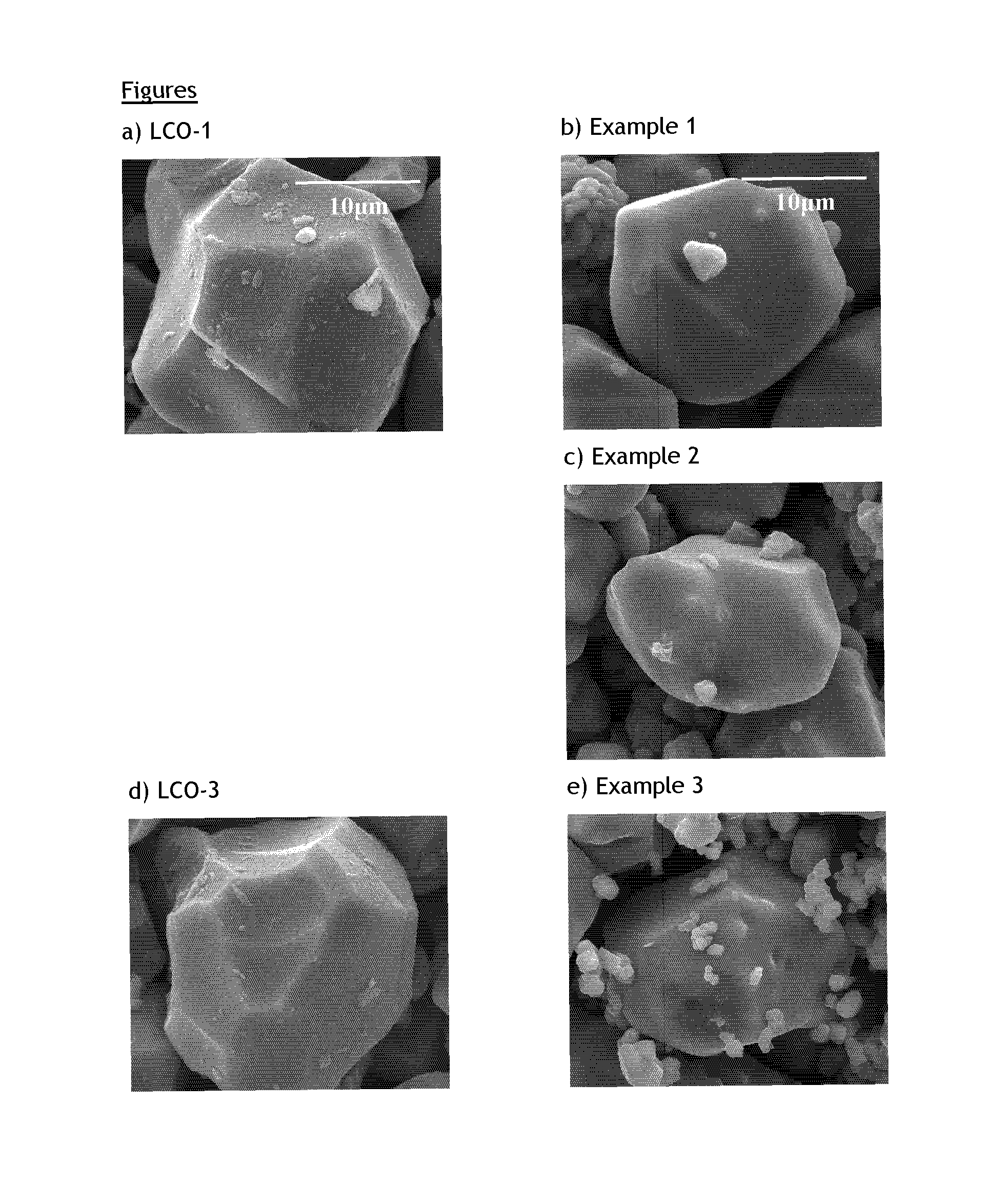

Lithium Metal Oxide Particles Coated with a Mixture of the Elements of the Core Material and One or More Metal Oxides

ActiveUS20150380722A1High bulk densityImprove discharge performanceFinal product manufacturePositive electrodesSurface layerLithium metal

A lithium metal oxide powder for use as a cathode material in a rechargeable battery, consisting of a core material and a surface layer, the core having a layered crystal structure consisting of the elements Li, a metal M and oxygen, wherein the Li to M molar ratio is between 0.98 and 1.01, and preferably between 0.99 and 1.00, wherein the metal M has the formula M=Co1-aM′a, with 0≦a≦0.05, wherein M′ is either one or more metals of the group consisting of Al, Ga and B; and the surface layer consisting of a mixture of the elements of the core material and inorganic N- and N′-based oxides, wherein N is either one or more metals of the group consisting of Mg, Ti, Fe, Cu, Ca, Ba, Sn, Sb, Na, Zn, and Si; and wherein N′ is either one or more metals of the group consisting of Y, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd, Sc, Ce, Pr, Nd, Gd, Dy, and Er.

Owner:UMICORE AG & CO KG +1

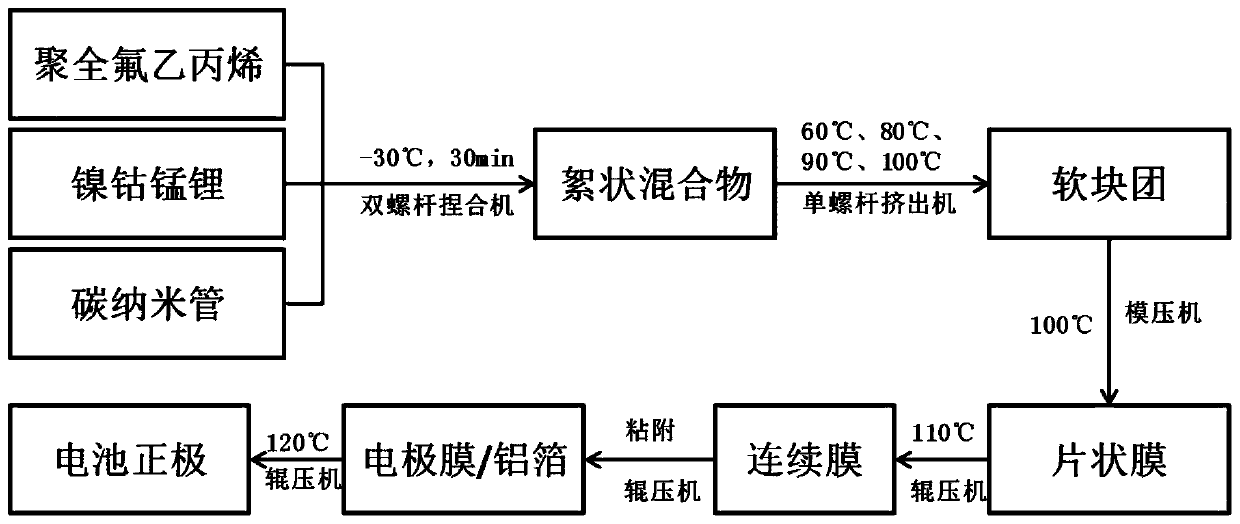

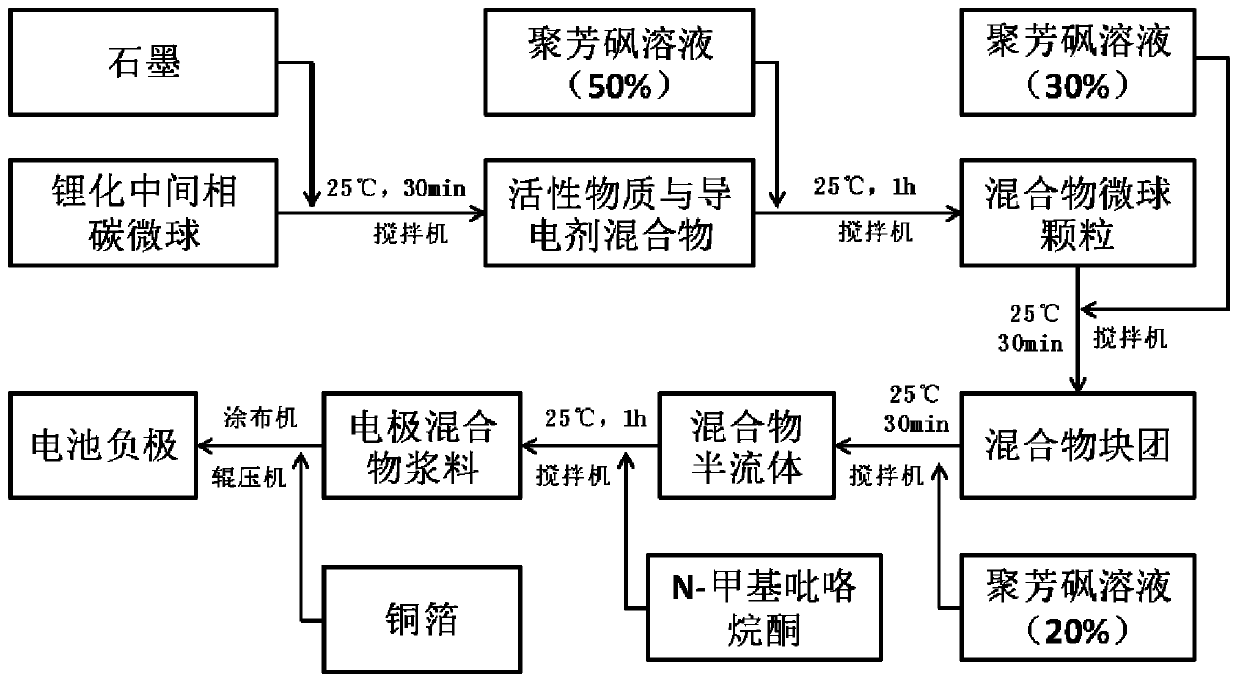

Electrode preparation method and battery

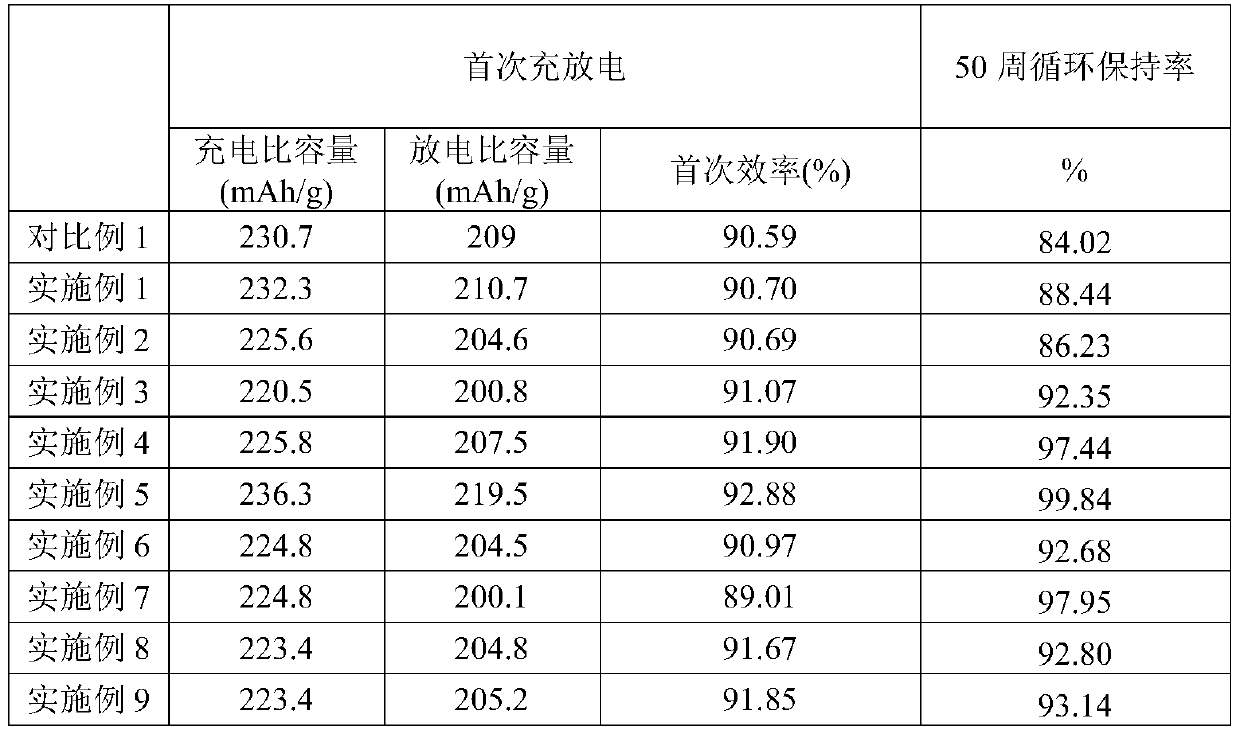

ActiveCN109841796AIncrease areal densityImprove structural stabilityElectrode manufacturing processesSecondary cellsLamellar crystalsInternal resistance

The invention discloses an electrode preparation method and a battery. The battery anode is prepared by pasting an electrode film prepared from an active substrate, a conductive agent and a binder toa current collector, the surface density of a pole piece is improved, the electrode capacity and the pole piece stability are improved, and the internal resistance is reduced. In the preparation process of the electrode film, lamellar crystals of the binder are stretched to paste the active substance and conductive agent, influence of expansion and contraction of the active substance caused by ionembedding and separating is reduced. The battery cathode is prepared by coating a slurry prepared from a pre-lithium active substance, a binder and a conductive agent on the current collector, the active substrate and conductive agent of the cathode are wetted rapidly, dispersed ultra-finely and homogeneous in a binder solution, the amount of the solvent for slurry dispersion is reduced, energy consumption for drying is reduced, the electrode process is shortened, and the load capacity of the cathode active substance is improved. The anode and cathode of the battery can be designed in an integrated way, and energy storage of the battery is improved. The electrode preparation method is simple, production and manufacture are realized by means of existing equipment, and the method is easy topopularize.

Owner:CHINA FIRST AUTOMOBILE

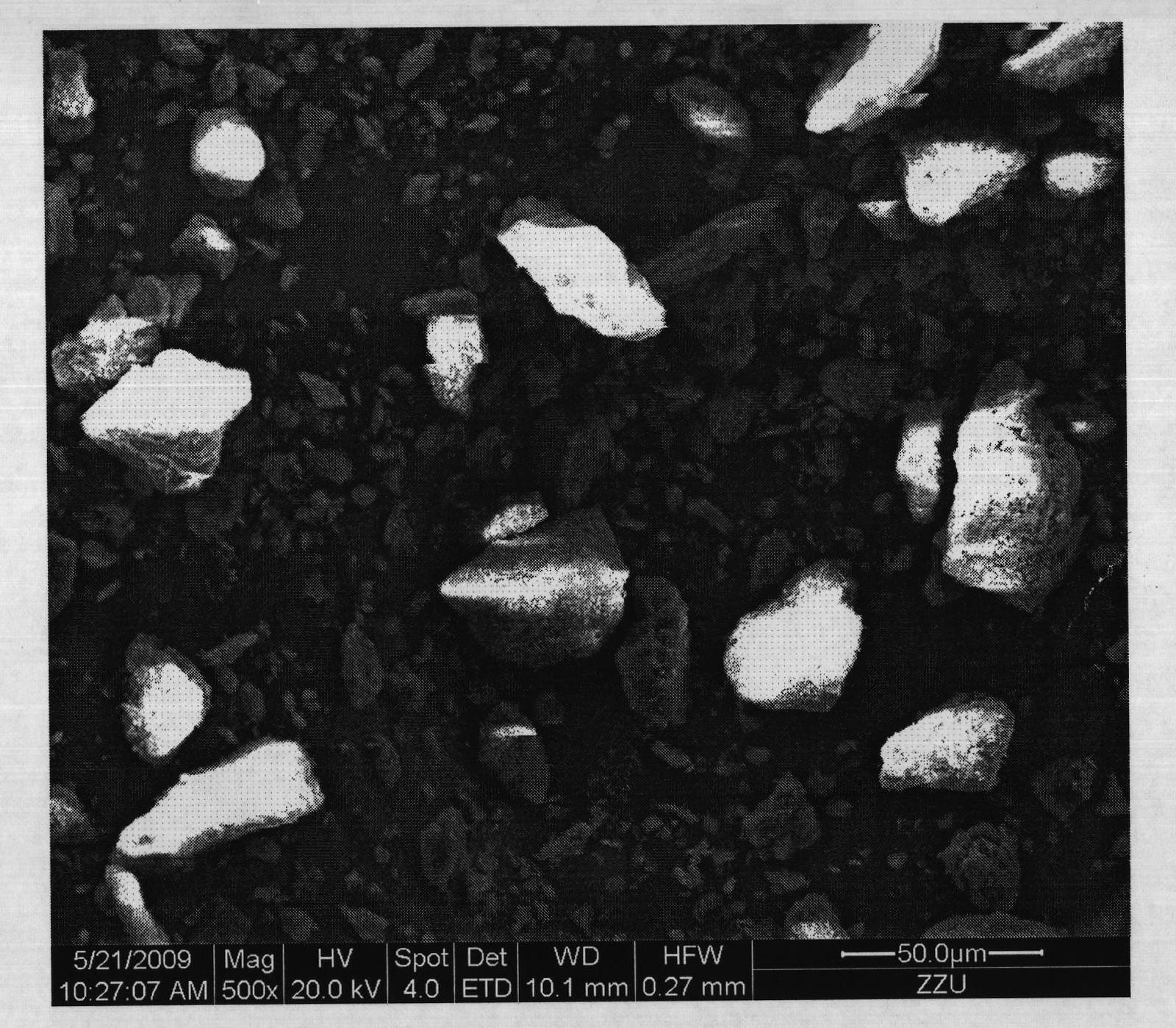

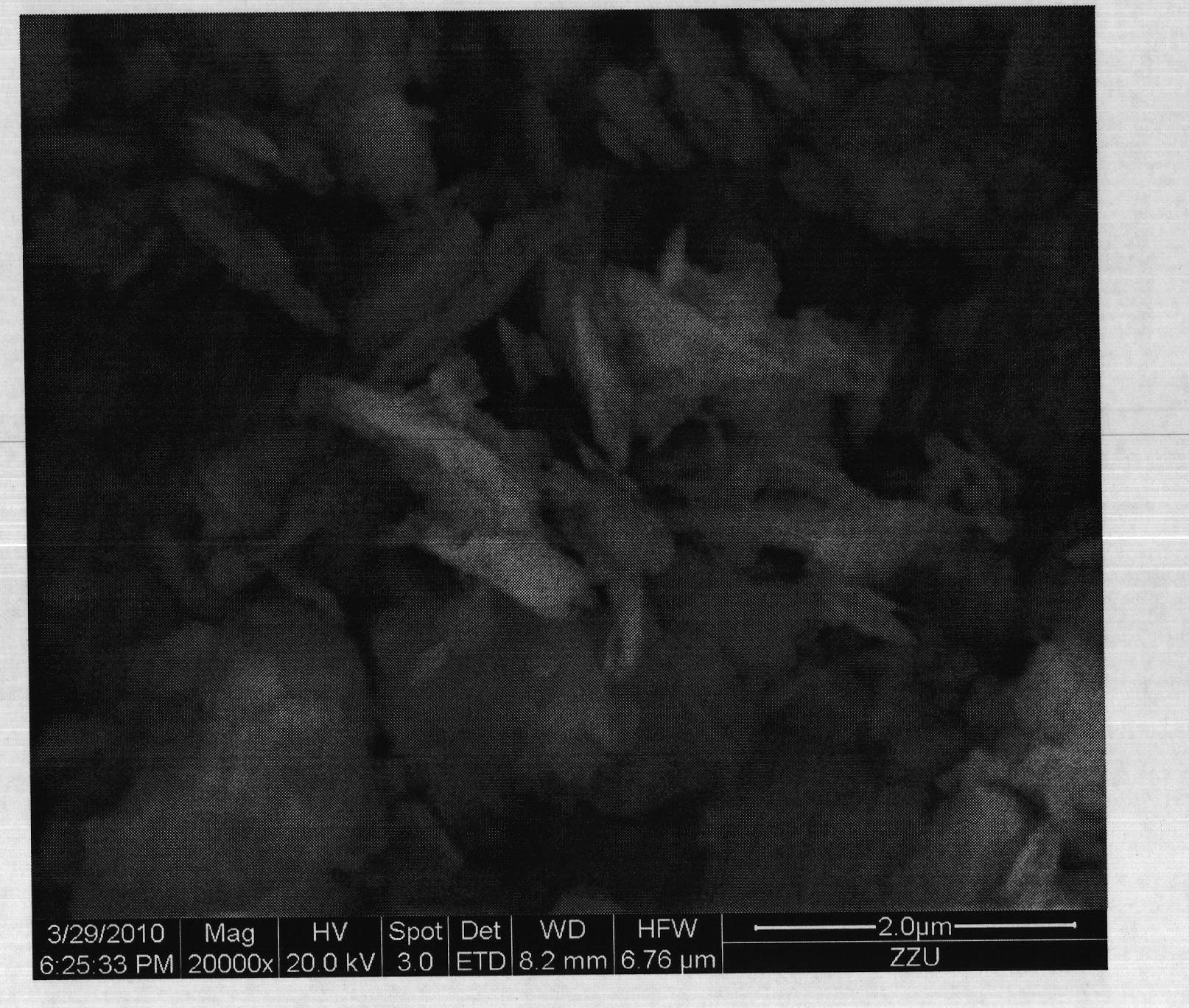

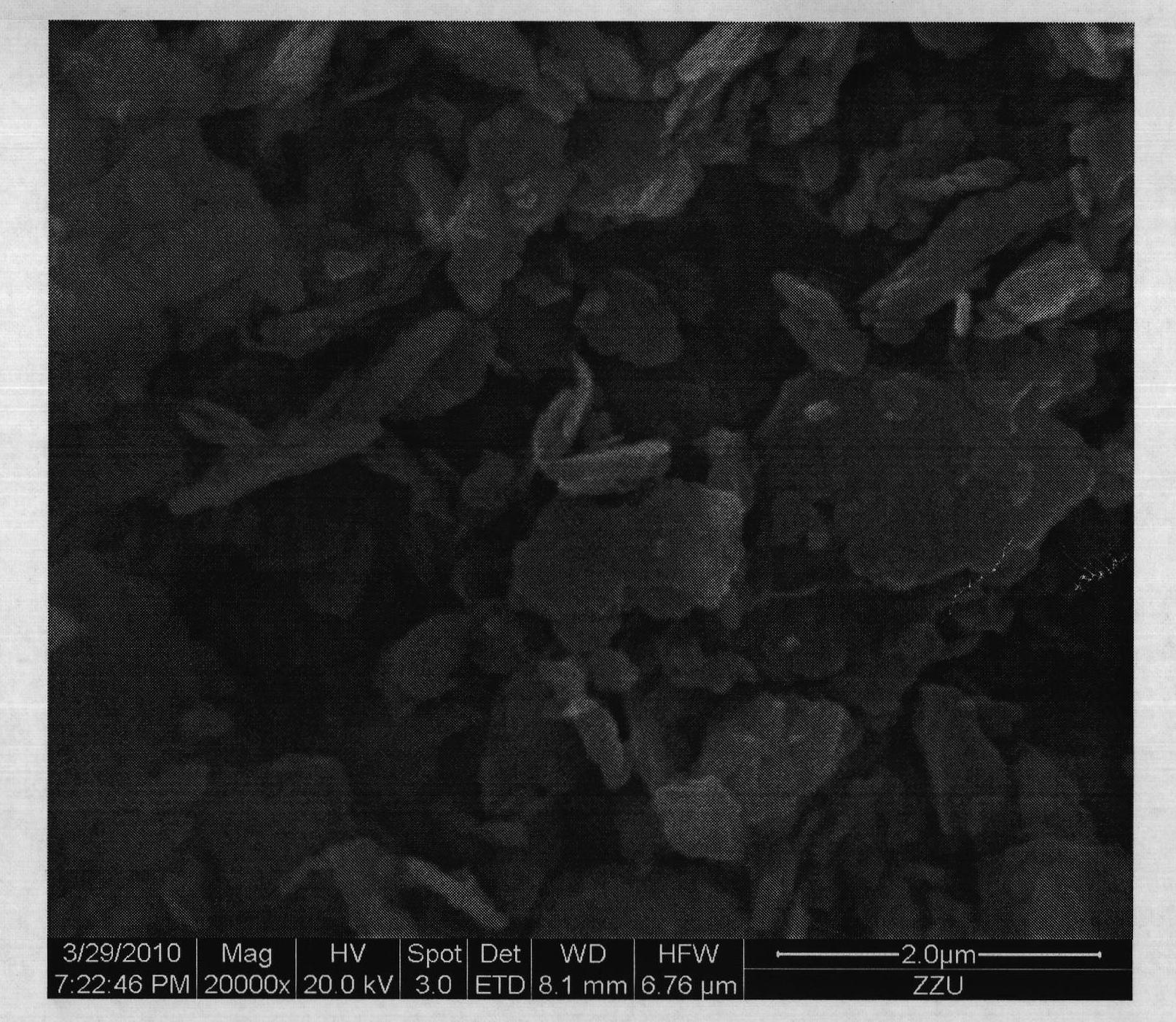

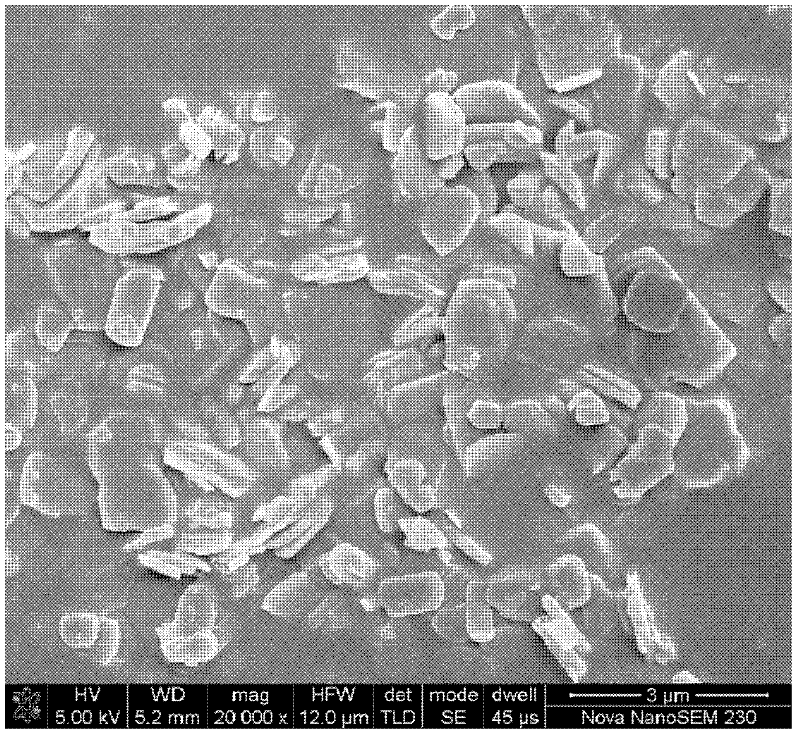

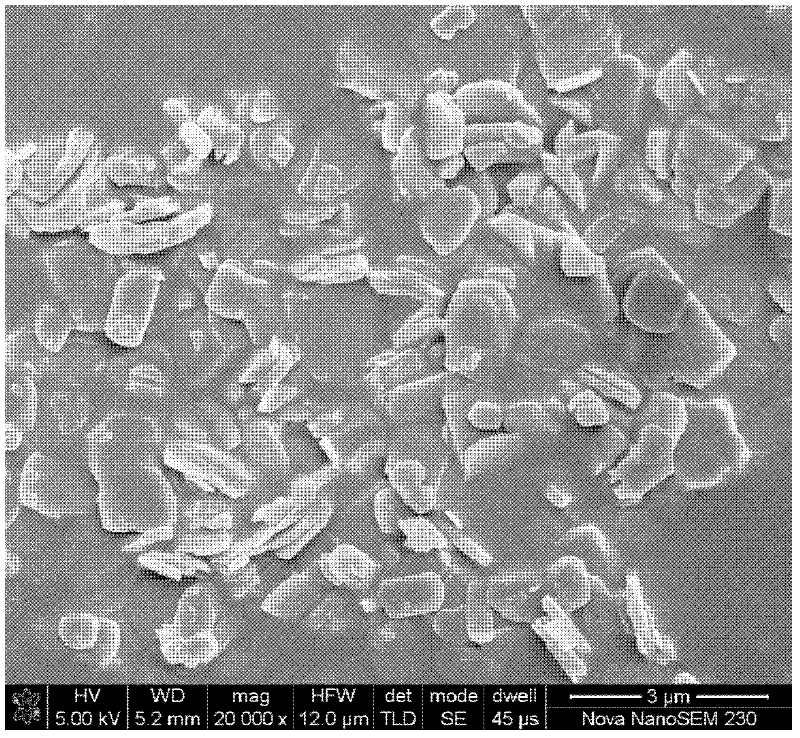

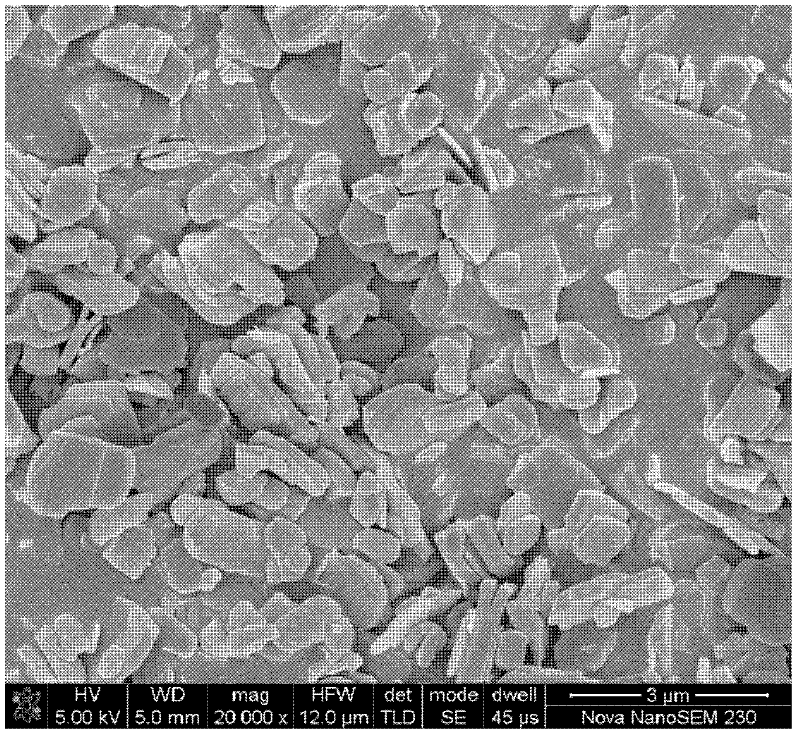

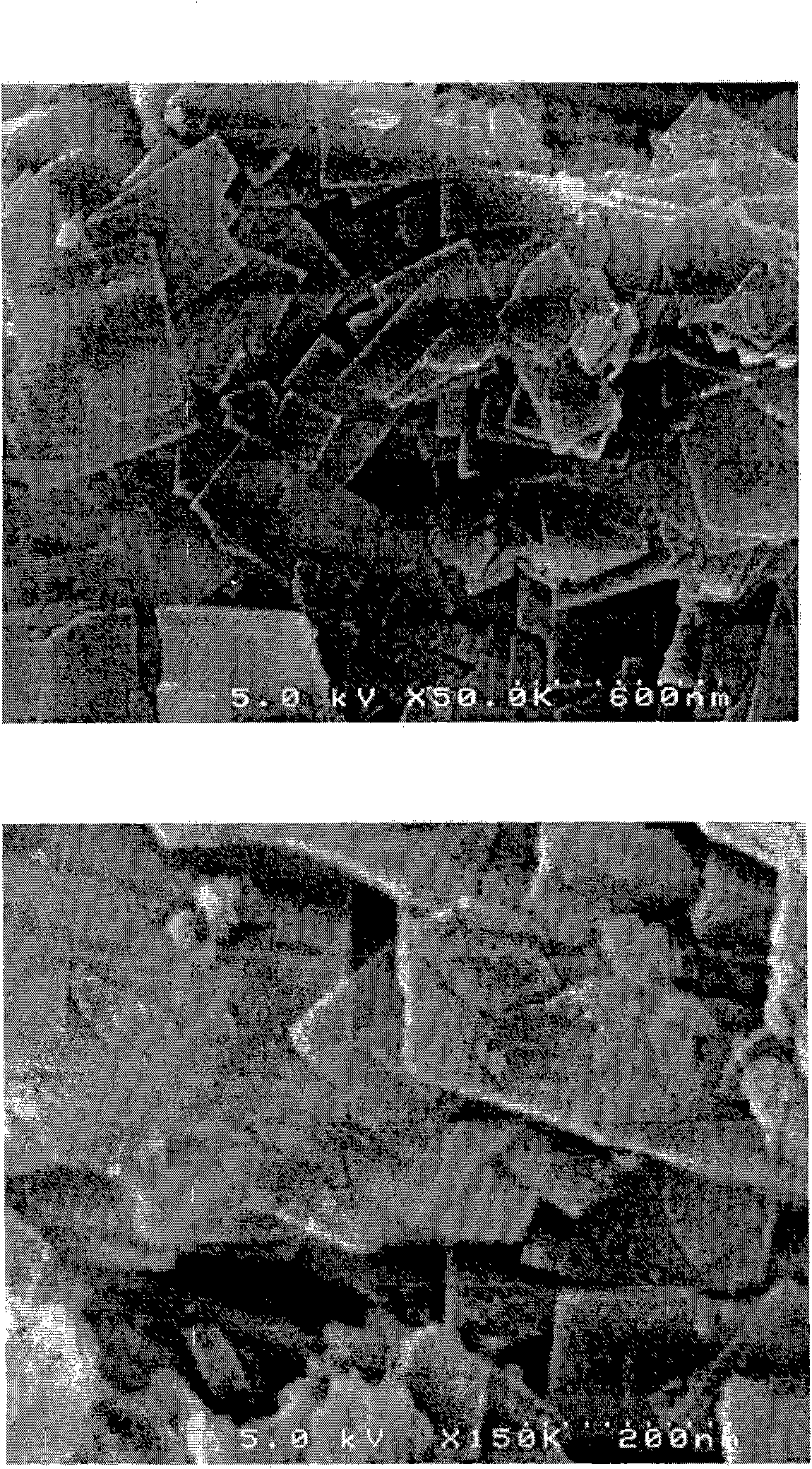

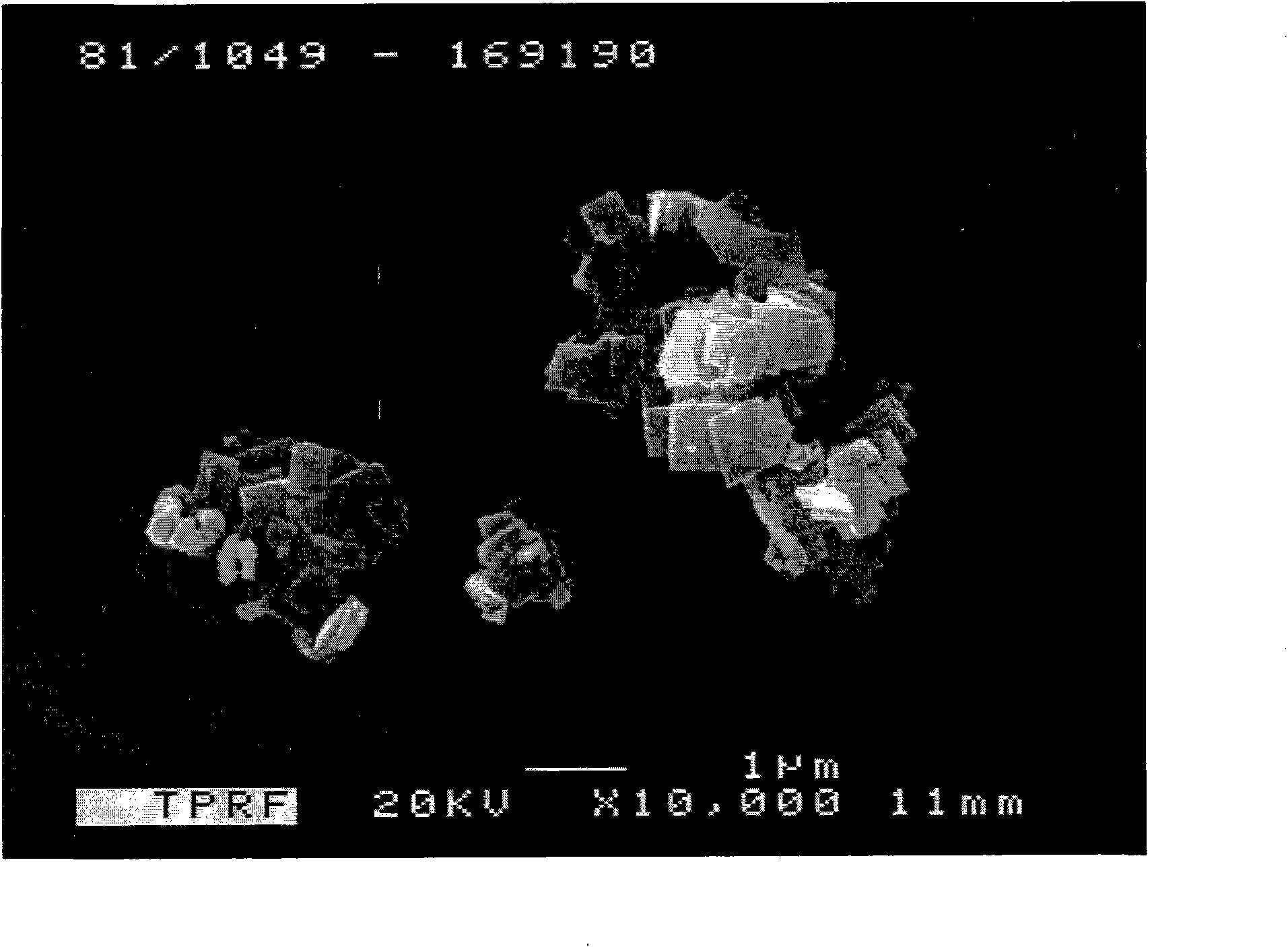

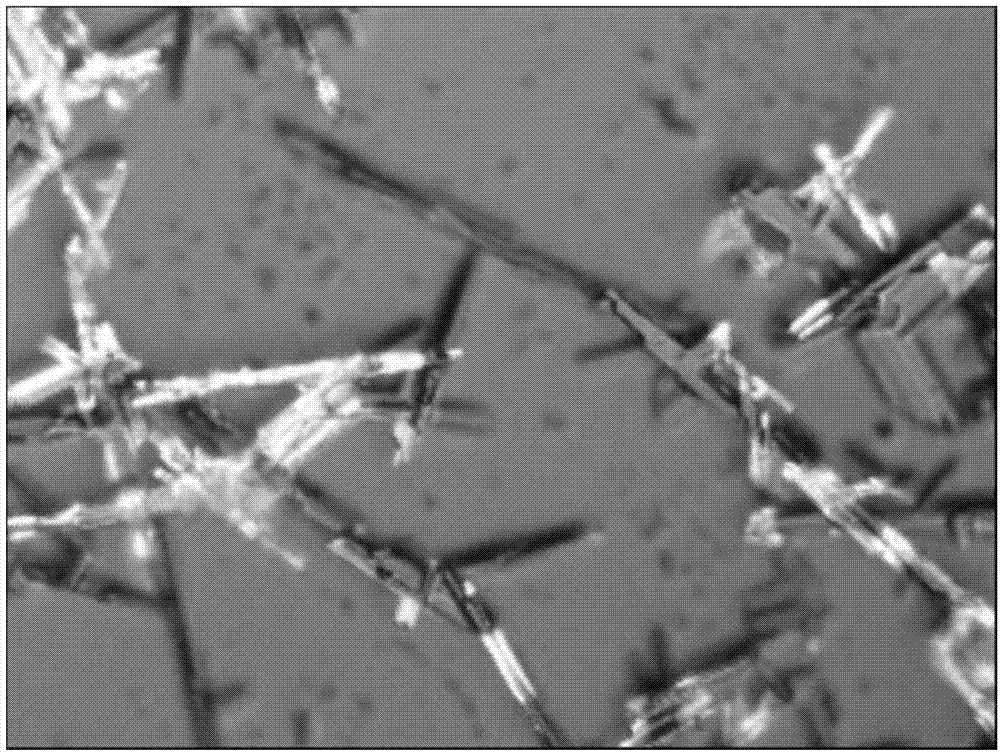

Kaolinite lamellar crystal and preparation method thereof

InactiveCN101844776AIncreased particle size limitReduce upfront processing costsSilicon compoundsLamellar crystalsKaolinite

The invention belongs to the field of kaoline deep processing technology, particularly relates to a kaolinite lamellar crystal and a preparation method thereof. The kaolinite lamellar crystal has the diameter less than 2 microns, the average diameter of 500-800nm, the thickness of less than 700nm, the average thickness of 80-300nm, and the specific surface area of 32.7-49.8m<2> / g. When the kaolinite lamellar crystal is prepared, a chemical intercalation method, a mechanical grinding method and a calcine treatment method are adopted in a combined way. The preparation method comprises the following steps of: taking the traditional common kaoline or coal series kaoline as main raw material, and firstly using dimethyl sulfoxide as intercalation agent for preparing kaoline / dimethyl sulfoxide intercalation compound; then, taking urea as the intercalation agent, and preparing kaoline / urea intercalation compound by substituting dimethyl sulfoxide molecule; and finally, carrying out mechanical grinding on the kaoline / urea intercalation compound, then carrying out calcine treatment and ultrasonic processing so as to realize lamellar stripping of the kaoline, and obtaining the kaolinite lamellar crystal with good crystalline form.

Owner:ZHENGZHOU UNIV

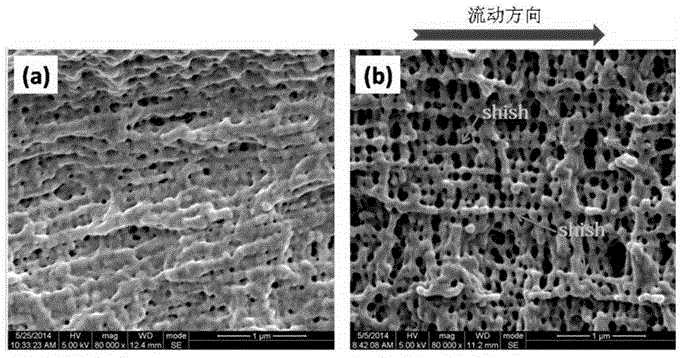

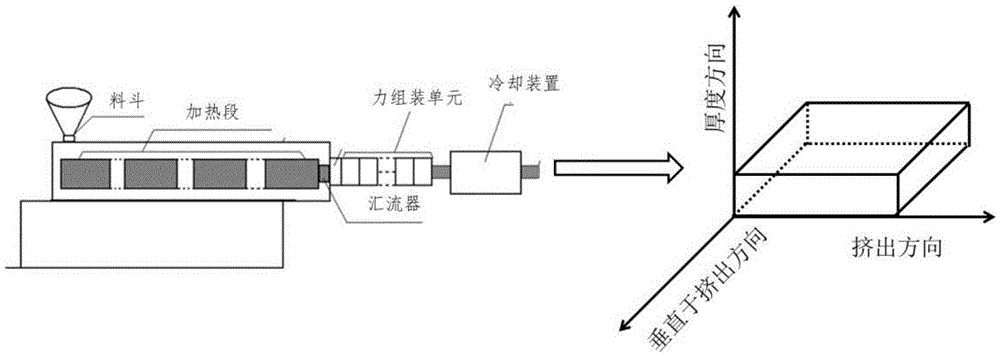

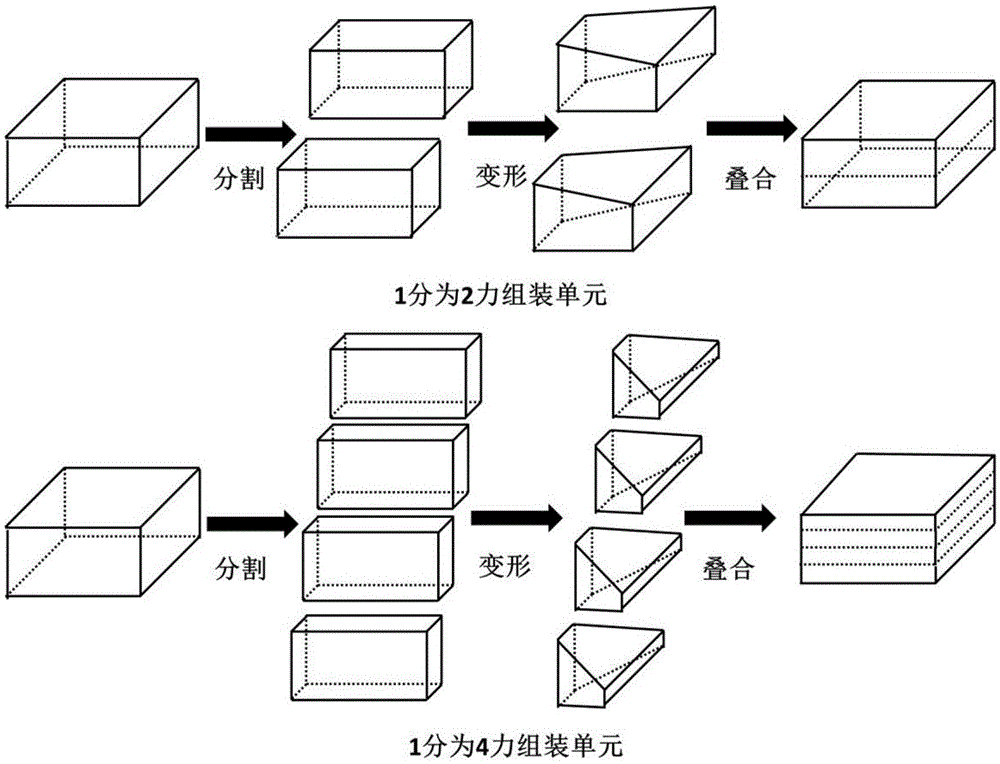

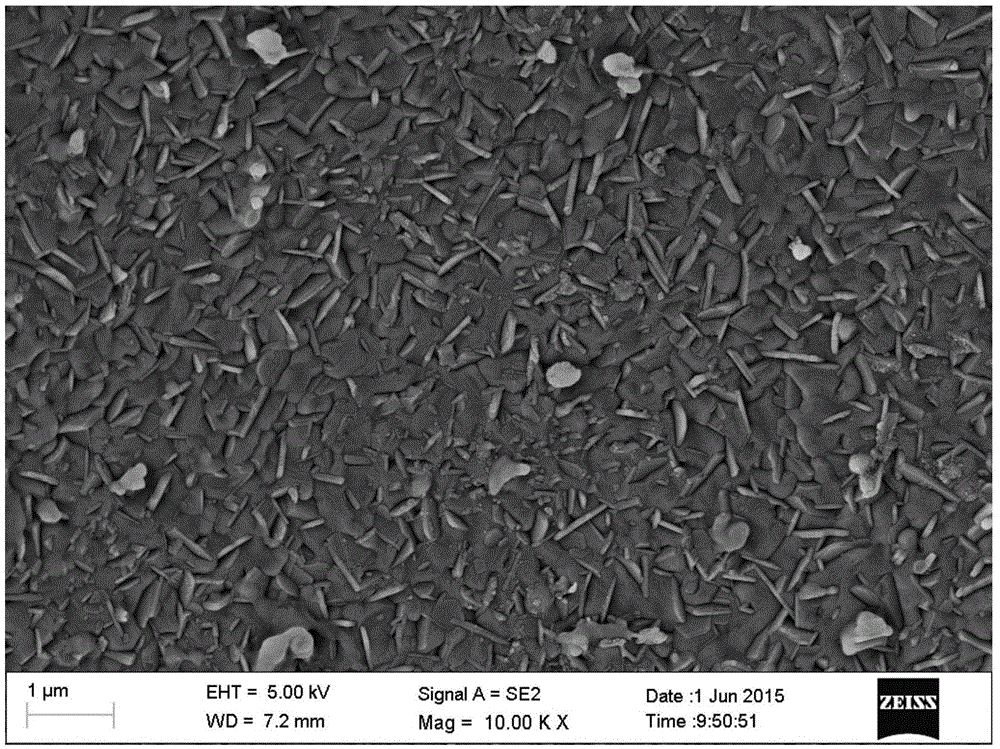

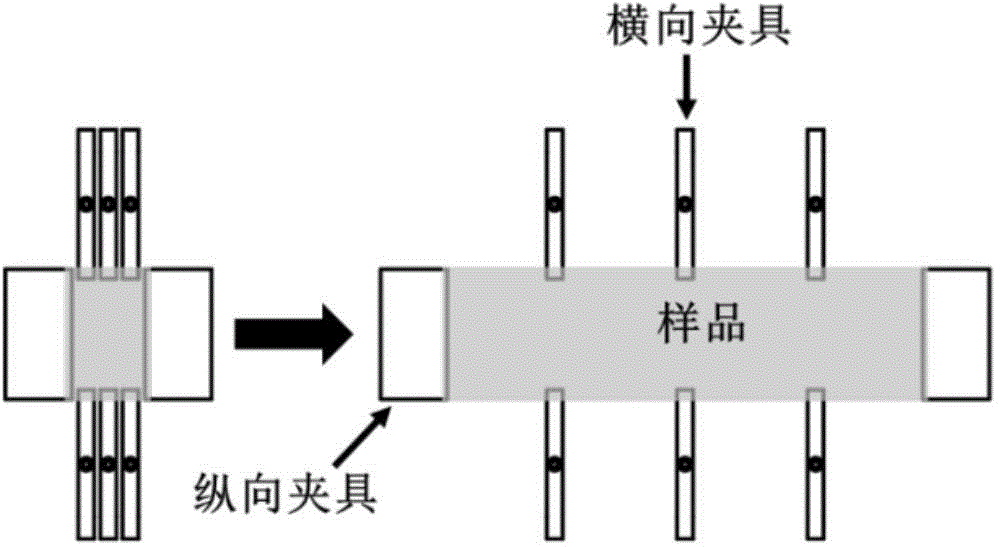

Preparation method of reinforced and toughened polylactic acid

The invention discloses a preparation method of reinforced and toughened polylactic acid. The preparation method is characterized in that during the processing process, the crystallized morphology of the polylactic acid is controlled so as to improve the mechanical property of the polylactic acid. Particularly, during the processing process, certain shearing force fields and certain bidirectional drawing force fields are applied on a polylactic acid melt in different directions through the control of the number and the type of force assembling units, when the shearing and drawing action force is large enough, polylactic acid molecules are directionally arranged in the force field direction at first to form shish, then polylactic acid lamellar crystals are arranged in a direction perpendicular to the shish, and at least, an shish-kebab crystallization structure is formed; and the sizes of crystalline grains are small, besides, a large amount of interfaces are introduced in a polylactic acid material, so that the strength and the toughness of the polylactic acid material are remarkably improved. The more the number of the force assembling units with higher melt deformation degrees is, the higher the strength of the bidirectional drawing force field in the direction perpendicular to the extrusion direction is, and the smaller the mechanical strength difference of the prepared polylactic acid product in the extrusion direction and the direction perpendicular to the extrusion direction is. The preparation method has the advantages that the force assembling units are additionally arranged on a traditional extrusion device, the preparation method is simple in operation, can be produced continuously, is convenient to control, stable in quality, and high in production efficiency, has a good industrial and market prospect, can be widely applied to the preparation of a polylactic acid plate, a polylactic acid sheet and a polylactic acid film material, with high strength and toughness.

Owner:SICHUAN UNIV

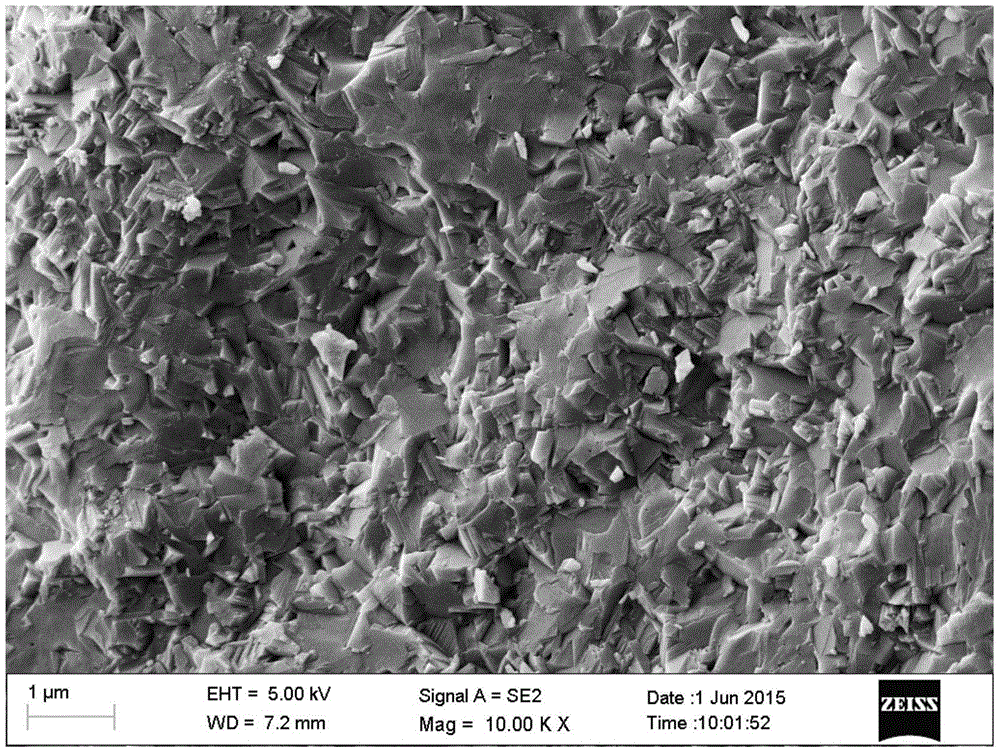

Alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as preparation method for ceramic particles and application of ceramic particles

InactiveCN105622071AGood application effectGood grinding performanceLamellar crystalsCrystal morphology

The invention relates to alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as a preparation method for the ceramic particles and an application of the ceramic particles. The alpha-Al2O3 ceramic particles comprises magnetoplumbite lamellar crystals and aluminum oxide crystals, and the magnetoplumbite lamellar crystals are inserted in the aluminum oxide crystals in a penetration manner. The specific preparation method comprises the following steps: 1) dispersing low-cost industrial grade pseudo-boehmite to form slurry, then adding aqueous solutions of acid and additives, and stirring uniformly; 2) performing heat treatment on the slurry at 180-240 DEG C for 24-72 hours to obtain gel; 3) drying the gel, and grinding and screening the gel to form semi-finished products with different particle sizes; and 4) slowly heating the semi-finished products to 1,500-1,600 DEG C in a vacuum state, and keeping a target temperature for 2-4 hours to obtain the alpha-Al2O3 ceramic particles containing the lamellar microcrystals. The alpha-Al2O3 ceramic particles containing the lamellar microcrystals are good in toughness and good in primary crystal morphology controllability, and have excellent grinding performance; and the hardness value of the ceramic particles is greater than 20GPa and the ball-milling toughness of the ceramic particles is greater than 76%.

Owner:SHANDONG UNIV

Modified polyformaldehyde resin and its preparation method

This invention relates to a polyformaldehyde resin with high heat stability, high intensity, high modulus and its preparations. The feature of this invention is mixing formaldehyde resin, free radical catcher, formaldehyde catcher, formic acid catcher and inorganic compound with lamerllar crystal structure together, and then melting, compounding and palletizing by Screw Extruder. This polyfomaldehyde resin can be used in the fields of high demanding of intensity and rigidity, such as auto making, electricity and electronic machine, office equipment, industrial machine and so on.

Owner:重庆云天化天聚新材料有限公司 +1

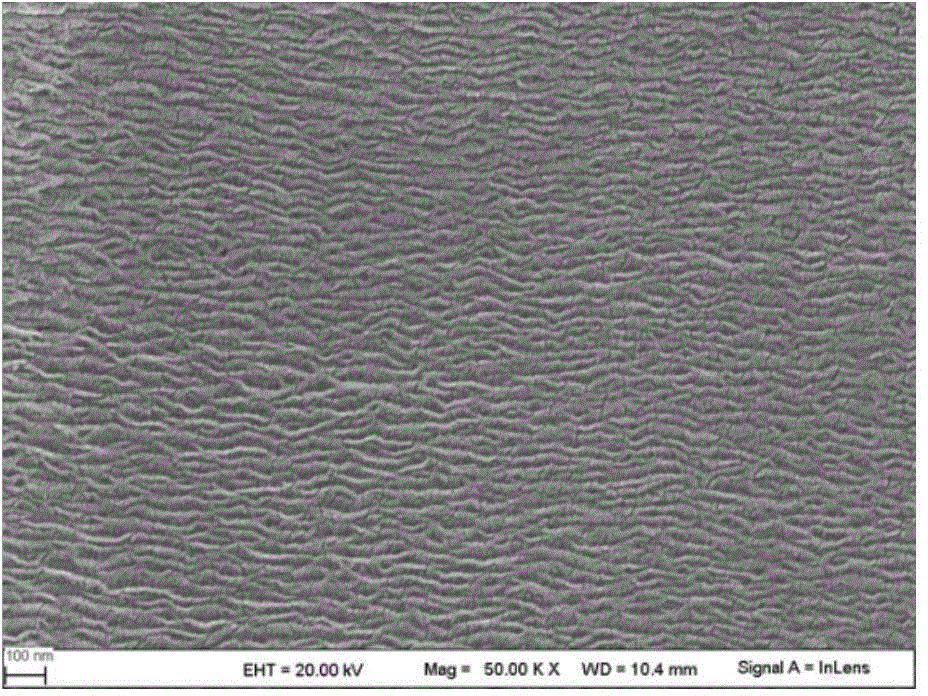

A preparing method of a polyolefin microporous separating membrane

ActiveCN104835930AOrderly rowsUniform pore sizeCell component detailsFlat articlesLamellar crystalsPorosity

A preparing method of a novel polyolefin microporous separating membrane is provided. The method includes steps of preparing polyolefin into a prefabricated membrane with a row-arranged lamellar crystal structure by melting, extruding, casting and drawing; annealing the prefabricated membrane; and performing limited uniaxial cold drawing, limited uniaxial hot drawing and heat setting in order by adoption of a banner wide uniaxial drawing device to obtain the microporous separating membrane. The polyolefin microporous separating membrane prepared by the limited uniaxial drawing is characterized in that porosity is high; the ratio of through holes is high, namely air permeability is good; skeleton lamellar crystal clusters and rows are neatly arranged; transverse mechanical strength is enhanced; and the difference between transverse and longitudinal hot-shrinkage rates is reduced. By adjusting the casting and drawing ratio, the limited uniaxial cold drawing speed and the limited uniaxial cold drawing ratio, regulation and control of the porosity of the microporous separating membrane can be achieved. The disadvantages of polyolefin microporous separating membranes prepared by dry uniaxial drawing methods at present, namely low transverse mechanical strength, large difference between transverse and longitudinal hot-shrinkage rates, easily slidable lamellar crystal cluster skeletons, and the like, can be overcome.

Owner:UNIV OF SCI & TECH OF CHINA

Electrically conductive thin films

ActiveUS20150166340A1High light transmittanceGood flexibilitySynthetic resin layered productsTitanium suboxidesLamellar crystalsThin membrane

According to example embodiments, a transparent electrically conductive film including a compound that has a two-dimensional electron gas layer, and has a product of an absorption coefficient (α) for light having a wavelength of about 550 nm at 25° C. and a resistivity value (ρ) thereof of less than or equal to about 30 Ω / sq is provided. The electrically conductive film may be a layered crystal structure of the compound.

Owner:SAMSUNG ELECTRONICS CO LTD

Quaternary positive electrode material, positive electrode and battery

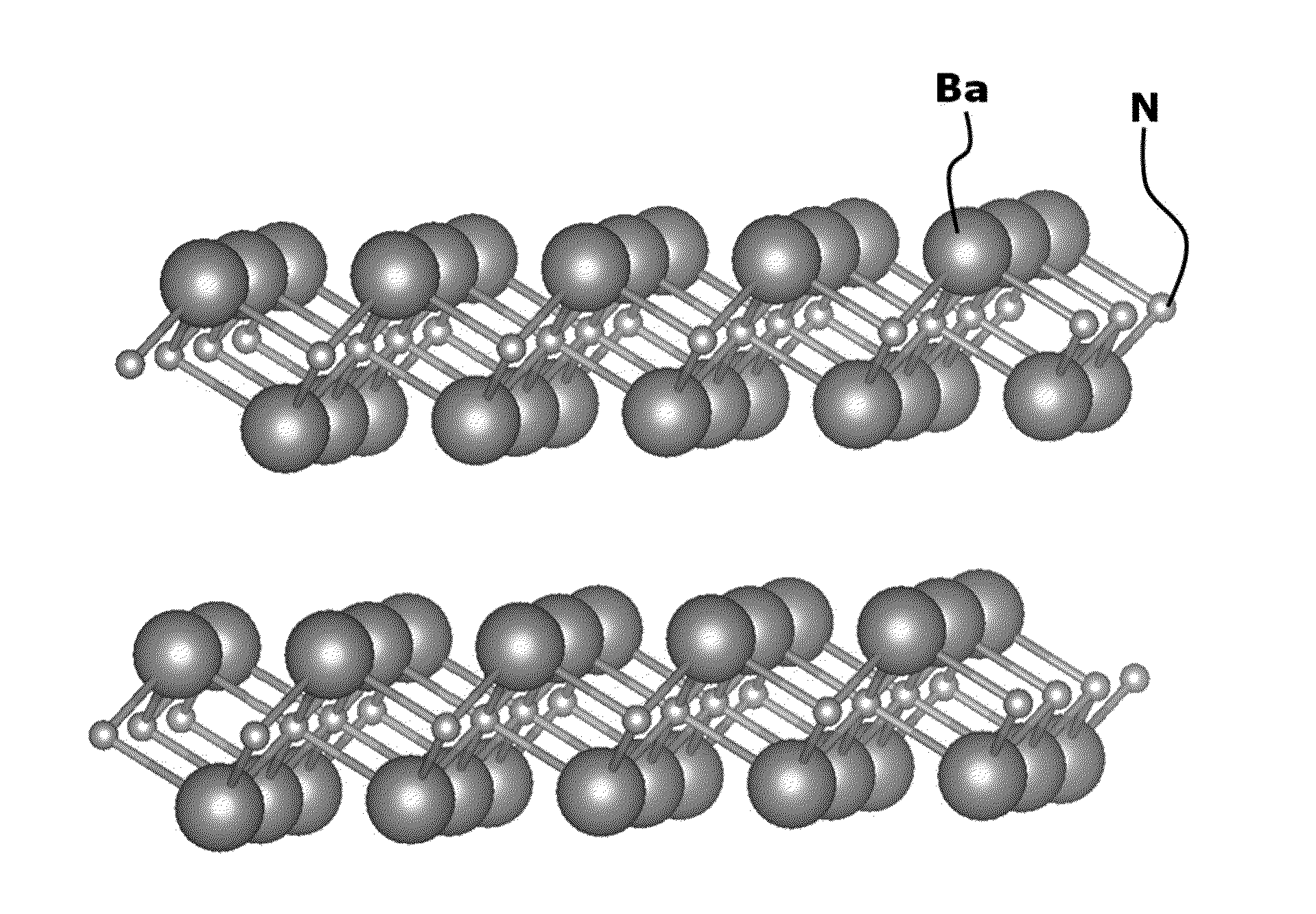

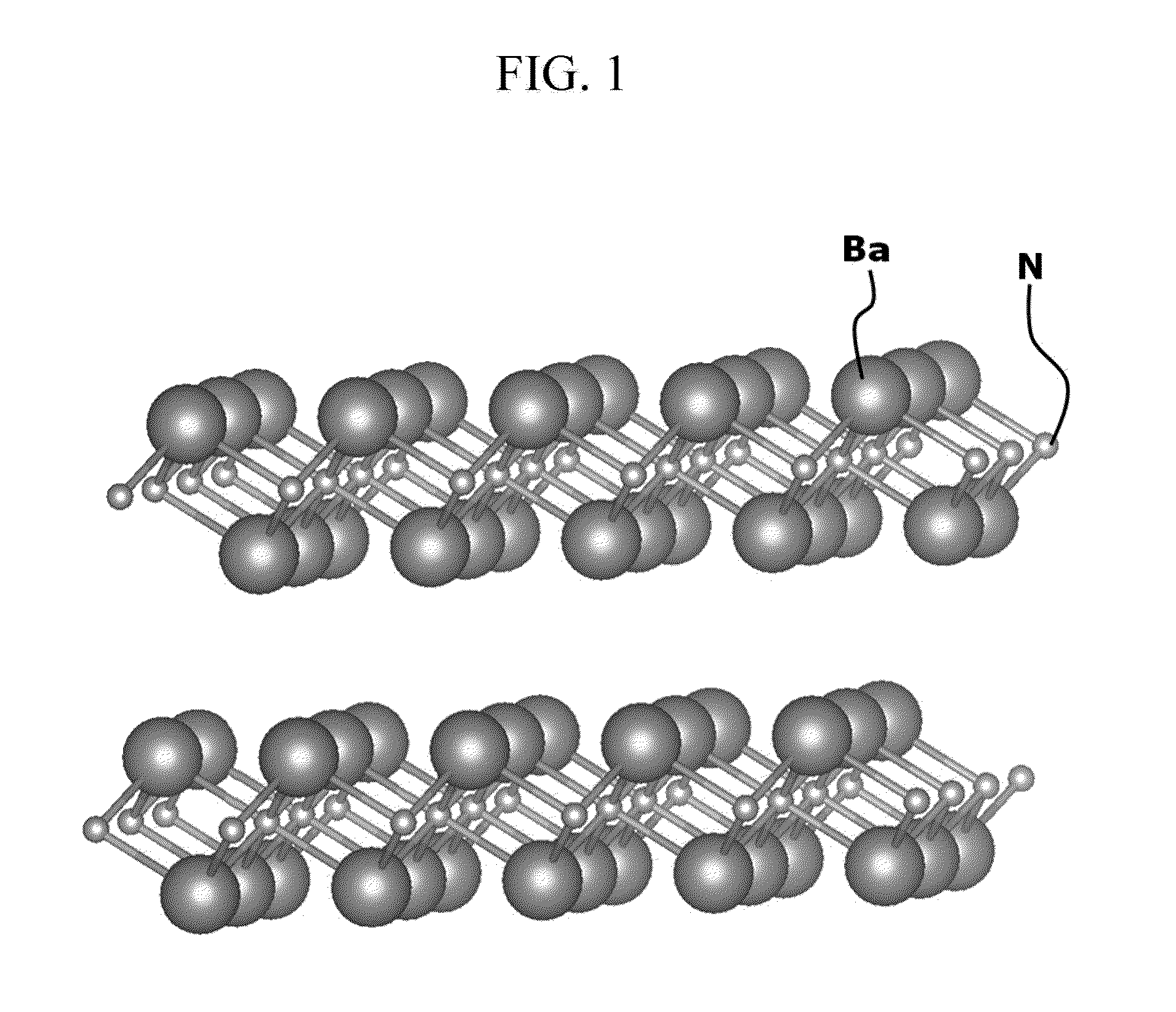

ActiveCN111435743AImprove structural stabilityGood layered crystal structurePositive electrodesLi-accumulatorsLamellar crystalsCrystallography

The invention discloses a quaternary positive electrode material, a positive electrode and a battery. Specifically, the invention provides a quaternary positive electrode material. The chemical structural general formula of the quaternary positive electrode material is shown in the specification, wherein x is larger than or equal to 1 and smaller than or equal to 1.05, y is larger than 0 and smaller than or equal to 0.025, a is larger than or equal to 0.3 and smaller than or equal to 0.95, b is larger than or equal to 0.03 and smaller than or equal to 0.1, c is larger than or equal to 0.01 andsmaller than or equal to 0.05, d is larger than or equal to 0.01 and smaller than or equal to 0.05, and a+b+c+d=1; M is a doping agent and comprises one or more of Zr, Al, B, Ti, Mg, Nb, Ba, Si, P, W, Sr and F; the quaternary positive electrode material has an [alpha]-NaFeO2 type crystal structure, the space group of an X-ray diffraction pattern of the quaternary positive electrode material is R-3m, and the relationship between the cell parameter c of the c axis and the cell parameter a of the a axis meets the condition that c / a is greater than 4.943. Therefore, the dopant can better improvethe structural stability of the quaternary positive electrode material, and the quaternary positive electrode material has a better layered crystal structure, so that the cycling stability and the thermal stability of a battery using the quaternary positive electrode material can be improved, the battery specific capacity of the battery is improved, and the cycle life of the battery is prolonged.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method of lamellar crystal light calcium carbonate for paper making coating

InactiveCN1657413AEasy to operateEasy to industrializeCalcium/strontium/barium carbonatesLamellar crystalsCarbonate

A process for preparing the light-weight flaky calcium carbonate used for coating on paper includes such steps as preparing the solution of soluble Ca salt, preparing the solution of soluble carbonate, slowly adding one to another, reaction to obtain crystal seeds of calcium carbonate, adding them along with mother liquid to refined lime milk, stirring, filling CO2, carbonizing, filtering and drying.

Owner:TIANJIN CHEM RES & DESIGN INST

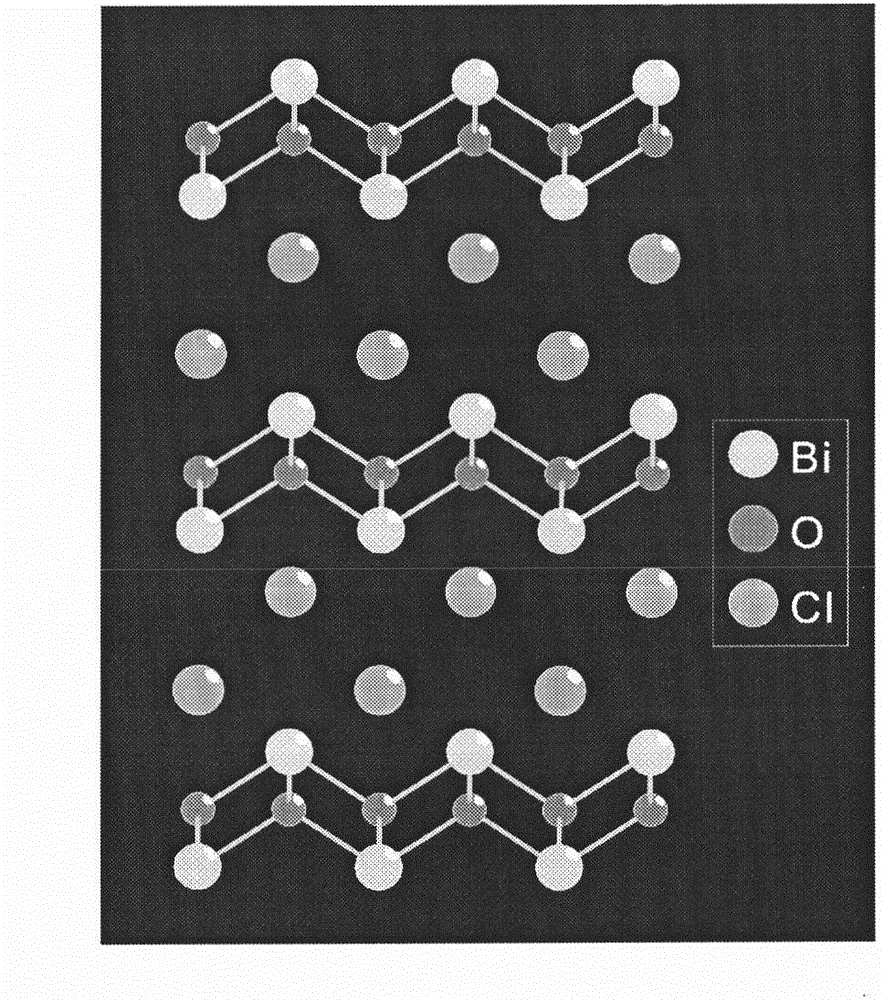

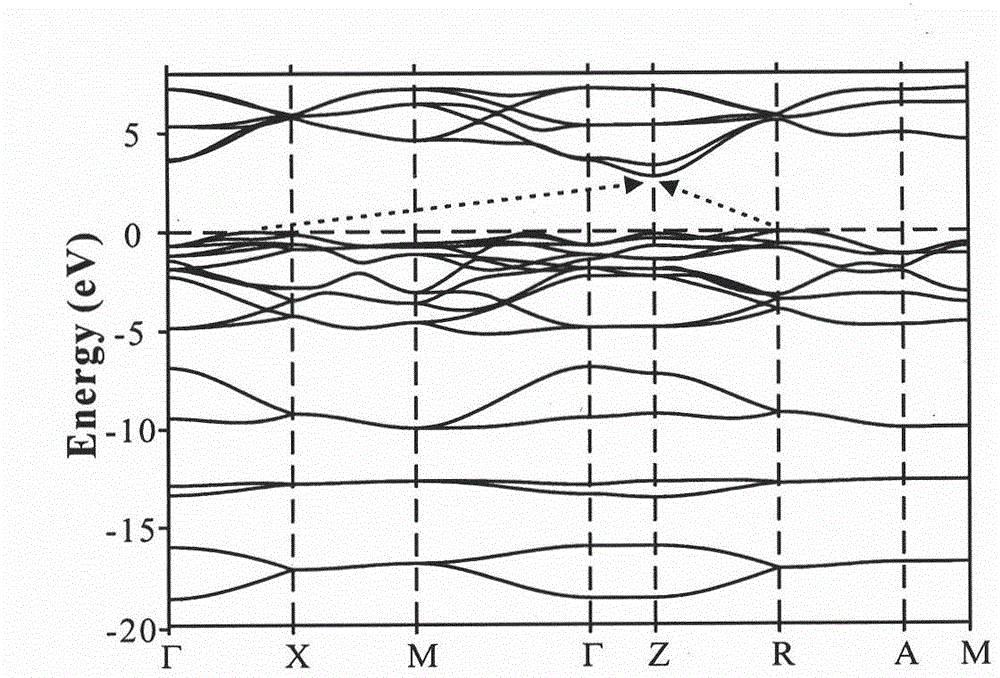

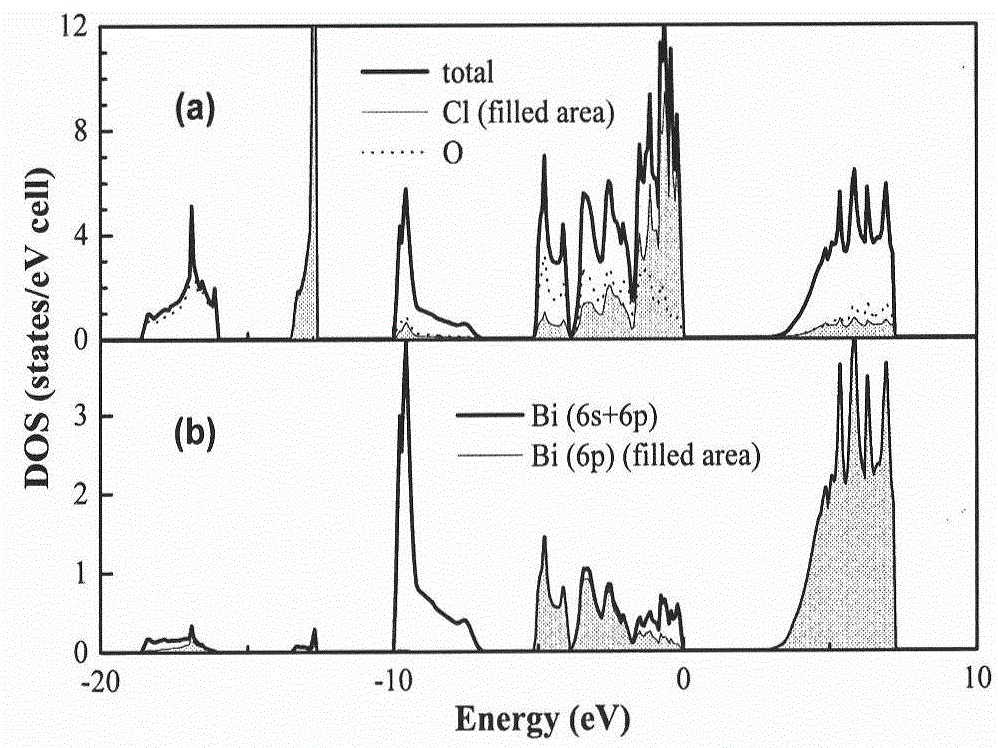

Oxyhalide photo-catalytic material and preparation method thereof

ActiveCN102794186AExcellent ability to degrade organic pollutantsPhysical/chemical process catalystsDispersed particle separationLamellar crystalsChemical composition

The invention relates to an oxyhalide photo-catalytic material and a preparation method thereof, and belongs to the field of photo-catalytic materials. The oxyhalide photo-catalytic material is prepared by using a solid phase or liquid phase method. The photo-catalytic material is characterized in that the chemical composition of the material is BiOX, wherein X is Cl, Br or I; and [Bi2O2] and [X] structural layers are alternately and mutually stacked along the c axis to form a lamellar crystal structure. The prepared BiOX (X is Cl, Br or I) has excellent photo-catalytic performance, and can be used for degrading organic dyes, degrading harmful gases, sterilizing and photolyzing water to produce hydrogen. By supporting nano metal particles with high electron affinity such as Ag and Pt, the photo-catalytic performance of the material can be greatly improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of flaky potassium hexatitanate

InactiveCN102390864ANo pollution in the processEasy to controlTitanium compoundsLamellar crystalsPotassium

The invention discloses a preparation method of flaky potassium hexatitanate, belonging to the field of preparation of reinforced materials, frictional materials and heat-resisting materials. The preparation method comprises the following steps of: with potassium magnesium titanate lamellar crystals as a precursor, carrying out acid washing, alkaline washing, hydrothermal treatment, and calciningto generate the potassium magnesium titanate laminar crystals with the average diameter size of 2-3.5 mum and thickness of 100-200nm. The potassium hexatitanate produced by utilizing the preparation method disclosed by the invention has the advantages of small size, good dispersibility, high crystallinity, uniform shapes and benefit to industrial production.

Owner:CENT SOUTH UNIV

Method for preparing metalloaluminophosphate (MEAPO) molecular sieve

InactiveCN101679054AIncrease productionIncrease flexibilityMolecular sieve catalystsMolecular sieve catalystLamellar crystalsCrystal morphology

The present invention also relates to a method for preparing metalloaluminophosphate (MeAPO) molecular sieve said method comprising : a) forming a reaction mixture containing a texture influencing agent (TIA), an organic templating agent (TEMP), at least a reactive inorganic source of MeO2 insoluble in the TIA, reactive sources of Al2O 3 and P2O5, b) crystallizing the above reaction mixture thus formed until crystals of the metalloaluminophosphate are formed, c) recovering a solid reaction product, d) washing it with water to remove the TIA and e) calcinating it to remove the organic template.In a usual embodiment said reaction mixture has a composition expressed in terms of molar oxide ratios of: TEMP / Al2O3=0.3-5, more desirable 0.5-2 MeO2 / Al2O3= 0.005-2.0, more desirable 0.022-0.8 P2O5 / Al2O3=0.5-2, more desirable 0.8-1.2 TIA / Al2O3=3-30, more desirable 6-20. In a usual embodiment the metalloaluminophosphate (MeAPO) molecular sieves made with the above method have a lamellar crystal morphology having an empirical chemical composition on an anhydrous basis, after synthesis and calcination, expressed by the formula HxMeyAlzPkO2 wherein, y+z+k=1, x<=y, y has a value ranging from 0.0008 to 0.4 and more desirable from 0.005 to 0.18, z has a value ranging from 0.25 to 0.67 and more desirable from 0.38 to 0.55, k has a value ranging from 0.2 to 0.67 and more desirable from 0.36 to 0.54, said molecular sieve having predominantly a plate crystal morphology. In an advantageous embodiment the MeAPO made by the method of the invention have essentially a structure CHA or AEI or a mixture thereof. Preferably they have essentially the structure SAPO 18 or SAPO 34 or a mixture thereof. The present invention also relates to catalysts consisting of the above MeAPO molecular sieves madeby the method of the invention or comprising the above MeAPO molecular sieves made by the method of the invention.

Owner:TOTAL RES & TECH FELUY +1

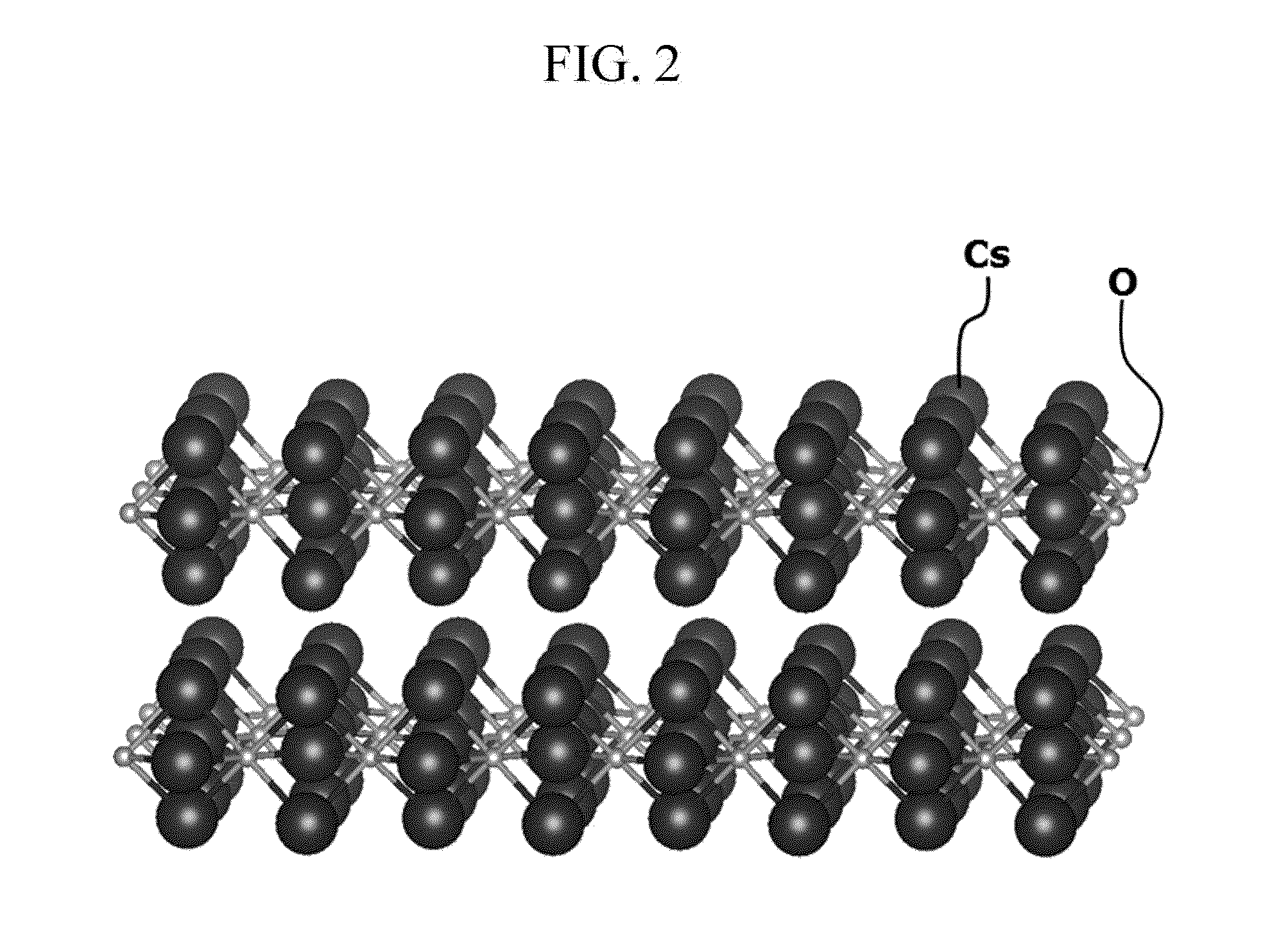

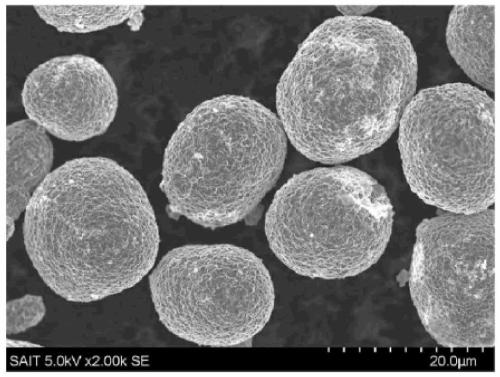

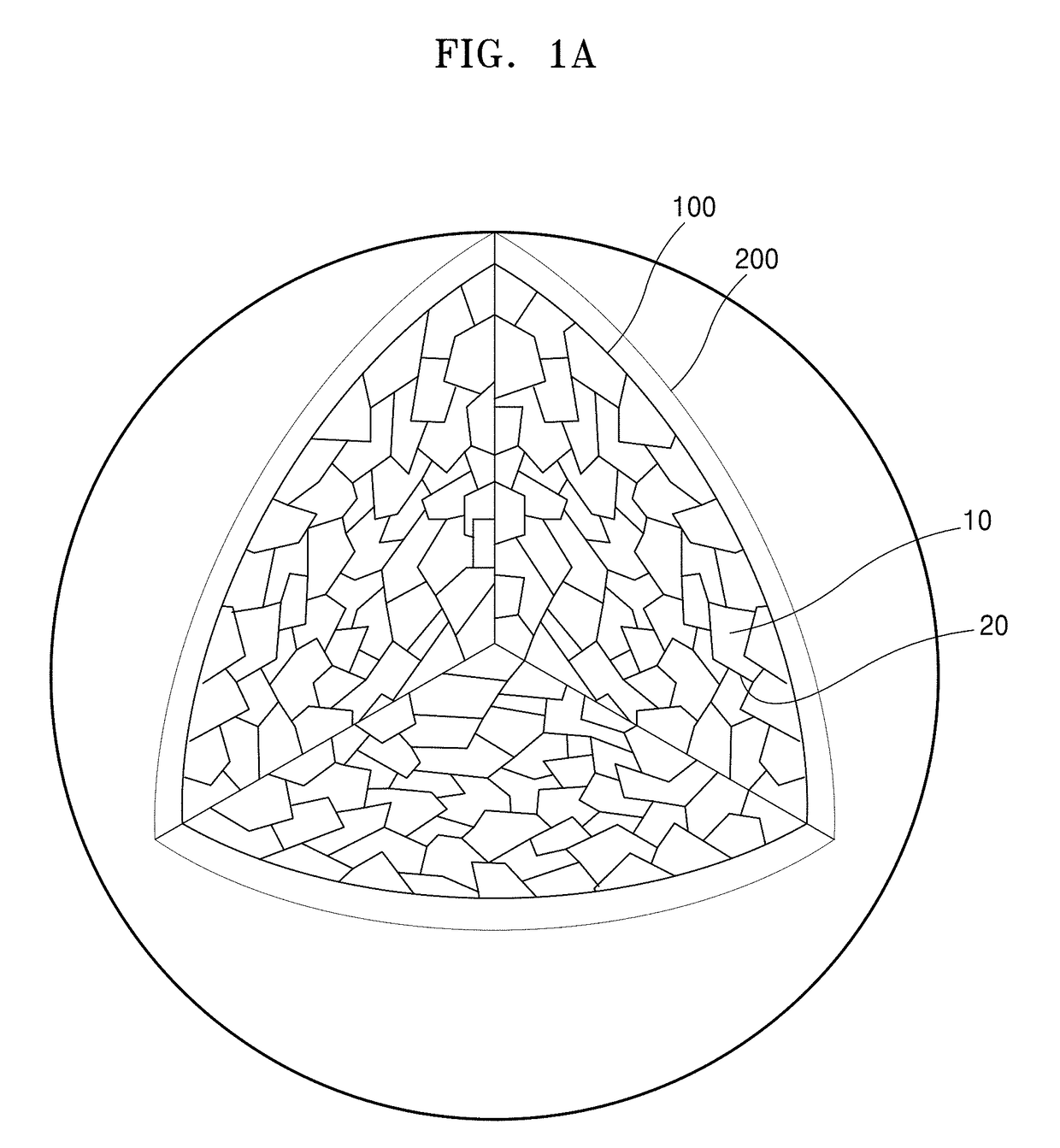

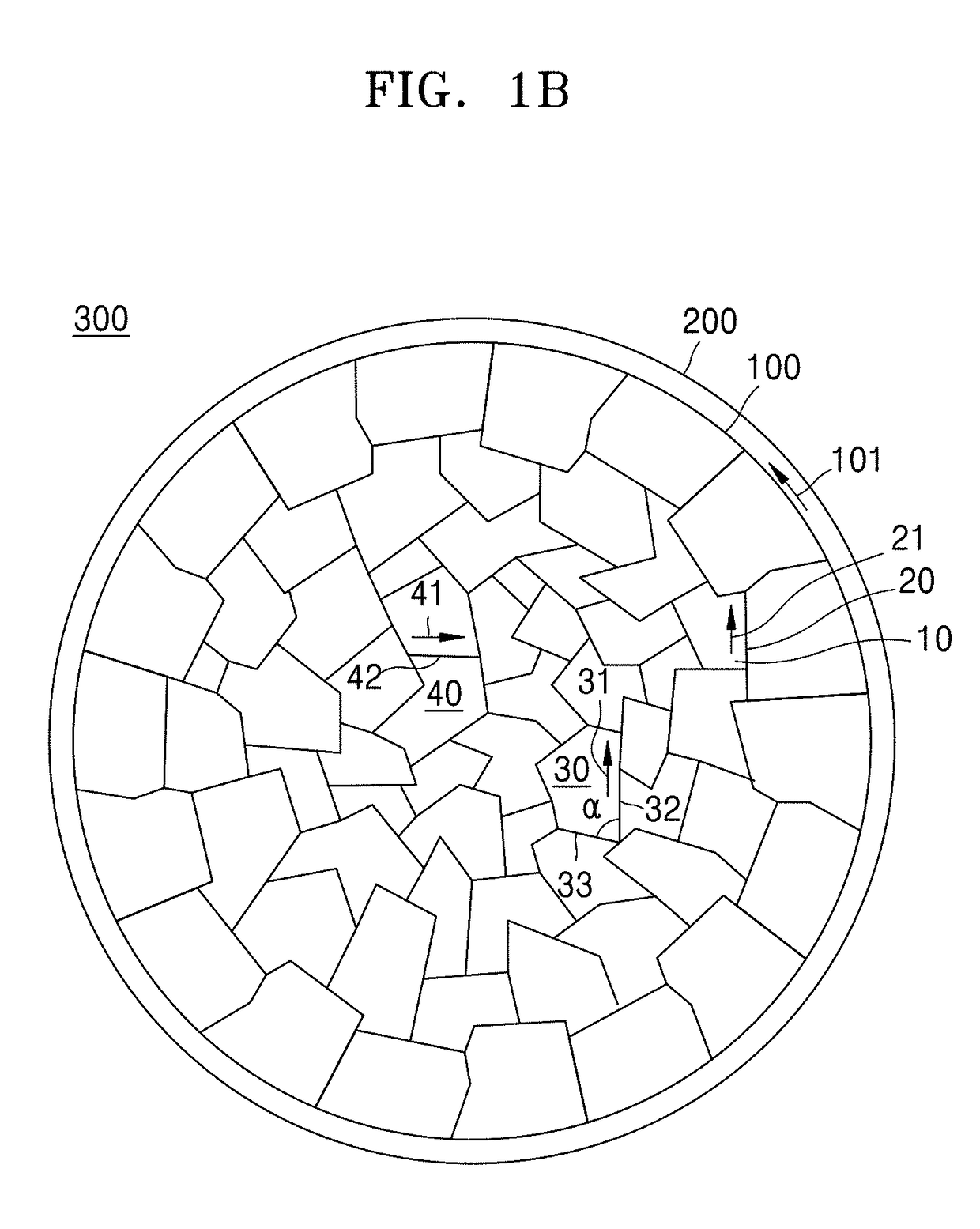

Composite cathode active material, cathode and lithium battery each including the same, and method of preparing composite cathode active material

PendingCN111106328AMangesium aluminatesElectrode thermal treatmentLamellar crystalsComposite cathode

The invention relates to a composite cathode active material, a cathode and a lithium battery each including the same, and a method of preparing the composite cathode active material. The composite cathode active material includes a secondary particle; and a coating on a surface of the secondary particle, wherein the secondary particle comprises a plurality of primary particles, and the pluralityof primary particles include a lithium nickel transition metal oxide having a layered crystal structure; and a grain boundary between primary particles of the plurality of primary particles, the grainboundary including a lithium metal oxide having a crystal structure different from the lithium nickel transition metal oxide having a layered crystal structure, wherein the coating on the surface ofthe secondary particle includes a metal oxide including cobalt, and a Group 2 element, a Group 12 element, a Group 13 element, or a combination thereof

Owner:SAMSUNG ELECTRONICS CO LTD +1

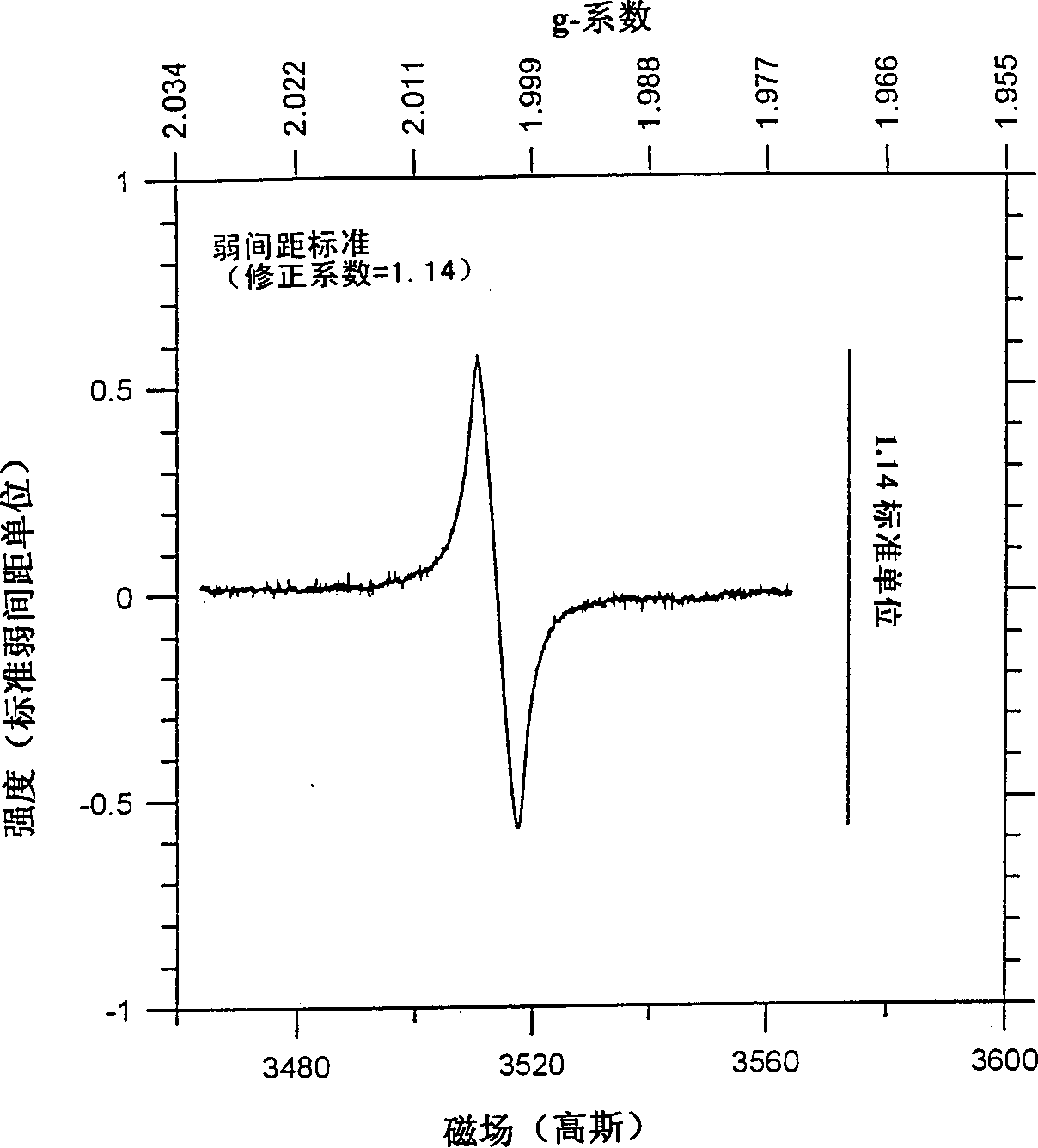

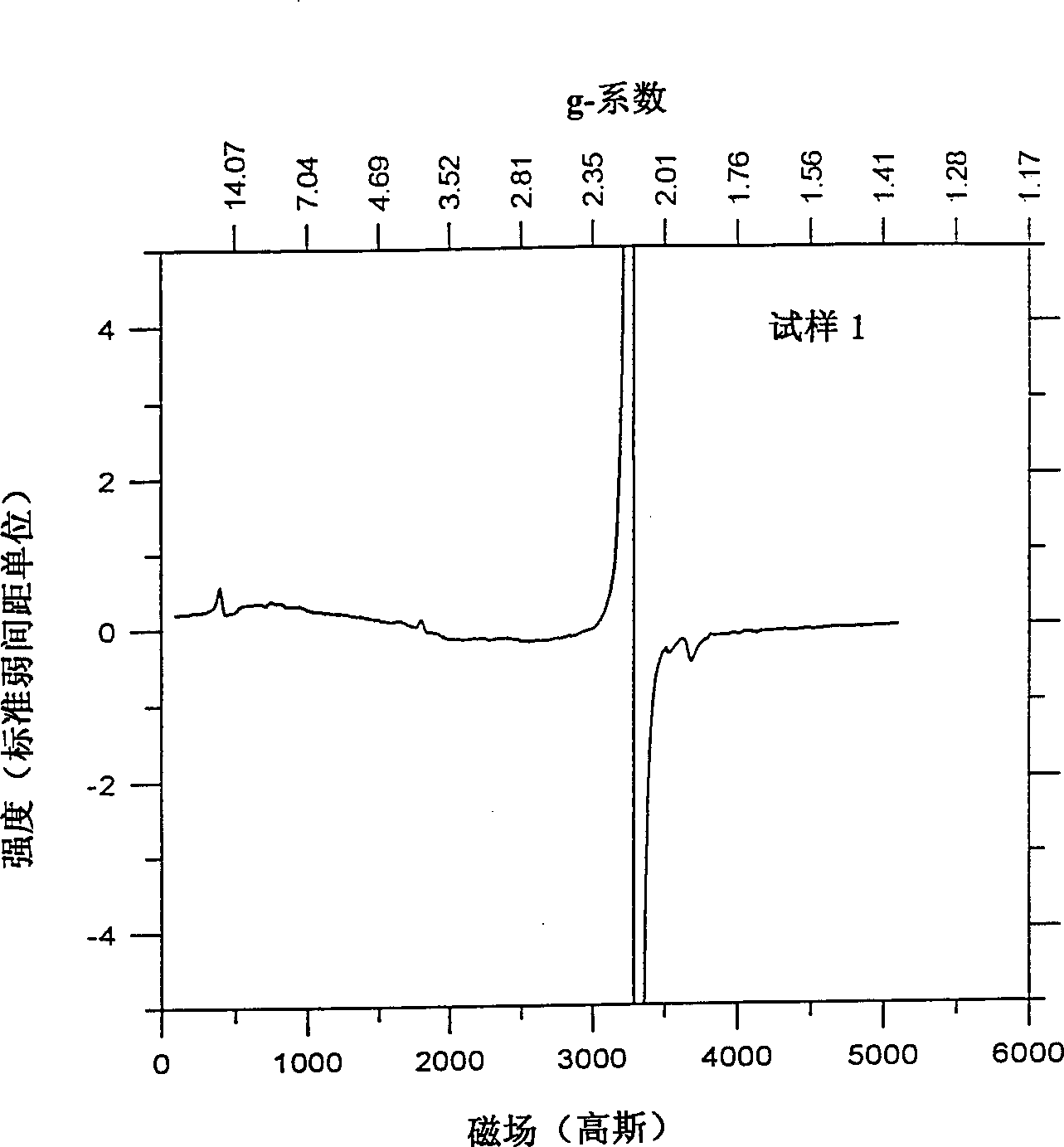

Catalyst for selective hydrodesulfurization and preparation method thereof

ActiveCN101816939AGood desulfurization selectivityRefining with metal oxidesMetal/metal-oxides/metal-hydroxide catalystsLamellar crystalsHydrodesulfurization

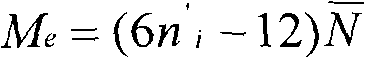

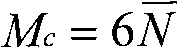

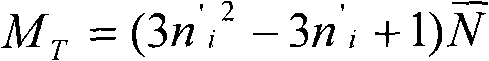

The invention discloses a catalyst for selective hydrodesulfurization. The catalyst contains a carrier and at least one VIB group metal component with hydrogenation activity and at least one VIII group metal component with hydrogenation activity. In the invention, a sulfide of the catalyst is used as a sample, and TEM method is used for characterization, the f value of the catalyst is 7 to 10 and f is equal to fe / fc, wherein fe is the ratio of the edge atomicity of the lamellar crystal of the active phase of the VIB group metal component with hydrogenation activity to the total atomicity of the lamellar crystal; and fc is the ratio of the angular atomicity of the lamellar crystal of the active phase of the VIII group metal component with hydrogenation activity to the total atomicity of the lamellar crystal. Compared with the conventional catalyst, the catalyst provided by the invention has higher desulfuration selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic blending additive in use for producing ultrathin two-faced bright electrolytic copper foil

InactiveCN1958864ASolve the technical problem of rough surface roughnessReduce manufacturing costElectroforming processesLamellar crystalsElectrolysis

This invention discloses an organic composite additive for manufacturing ultra-thin double-side-smooth electrodeposited copper foil. The organic composite additive is composed of (per unit): poly(ethylene glycol) 5-20 g / L, sodium polydithio-dipropyl sulfonate 500-1000 mg / L, thiourea 100-500 mg / L, and sodium 3-[[(dimethylamino)thioxomethyl]thio]propanesulfonate 30-70 mg / L. The electrodeposited copper foil manufactured by using the organic composite additive has surface roughness less than 0.25 mums. The individual grain of the electrodeposited copper foil is lamellar crystal, and the surface is mirror-like. The electrodeposited copper foil has high tensile strength and high elongation percentage, and can be used as a substitute for calendered copper foil for application in soft printed circuit board and polymeric Li-ion battery. The method for manufacturing the electrodeposited copper foil is simple and low cost compared with that for manufacturing calendered copper foil. Besides, the costs for manufacturing soft printed circuit board and polymeric Li-ion battery can be largely reduced.

Owner:SUXI CHINA COPPER FOILS

Powder body of solid solution among interlayer of titanium, silicon, aluminum, carbon, and preparation method

This invention discloses a method for preparing Ti-Si-Al-C lamellar solid solution powder. The powder is composed of: Ti3Siy-xAlxCz (wherein, 0 less than x less than y; y is 1-1.2; z is 1.8-2) higher than 96 vol.%, and impurities lower than 4 vol.%. Ti3Siy-xAlxCz has the same lamellar crystal structure as Ti3SiC2 and Ti3AlC2. Si and Al atoms are set between two Ti3Cz lamellae. The crystal constants c and a increase with the increase of x. The method comprises: mixing Ti, Si, Al and graphite powder at a mol. ratio of 3.0:(0.1-1.1):(0.1-1.1):(1.8-2.0), ball-milling, pressing into a block, placing in a high-temperature furnace, calcining at 1400-1500 deg.C under Ar protection, keeping the temperature for 5-10 min, cooling to obtain loose block product, pulverizing, and ball-milling. The powder can be used to prepare composite or mono-phase Ti-Si-Al-C block material.

Owner:BEIJING JIAOTONG UNIV

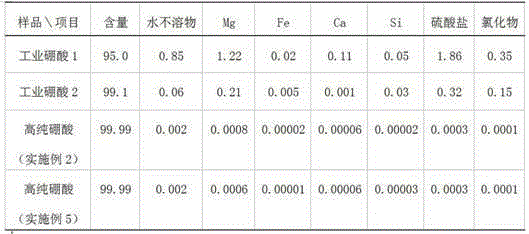

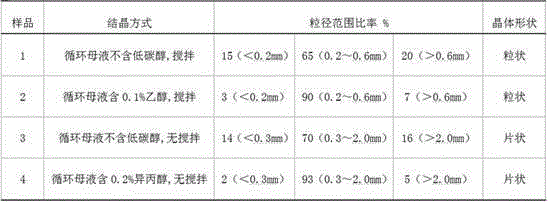

Preparation method of high-purity boric acid

ActiveCN105347353ANo pollution in the processSimple processBoron oxyacidsLamellar crystalsPhysical chemistry

The invention provides a preparation method of high-purity boric acid. The preparation method comprises the following steps: putting industrial boric acid into a mixed solution of circulating mother liquor and trace inorganic acid, stirring, and heating for dissolution; performing thermal reaction for 1-2 hours in a temperature range of 80-95 DEG C; cooling to obtain wet boric acid crystals; respectively washing the crystals by virtue of mother liquor alternately purified by a cation exchange resin column and an anion exchange resin column; and drying to prepare high-purity boric acid. Compared with the prior art, the technical scheme provided by the invention has the technical advantages of being simple in process flow, having no environmental pollution, being high in crystal purity and low in manufacturing cost, selecting between granular or lamellar crystals, and the like; moreover, the crystal particle size distribution can be greatly improved.

Owner:DANDONG CHEM REAGENT FACTORY

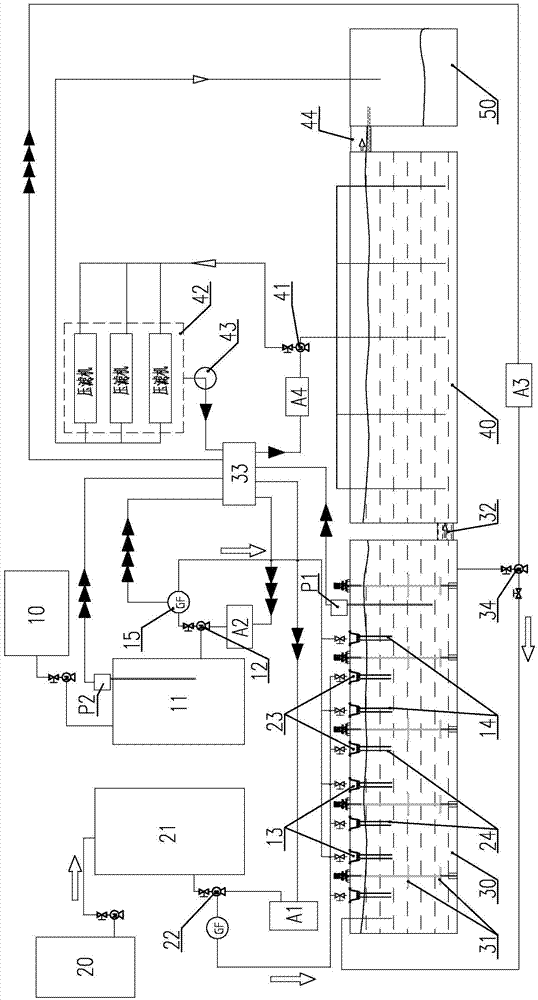

Production method of calcium sulphate dehydrate and production device thereof

ActiveCN103693670AReduce pollutionEasy to recycleCalcium/strontium/barium sulfatesWater/sewage treatment by neutralisationLamellar crystalsCalcium hydroxide

The invention relates to a production method and device of calcium sulphate dehydrate. The method comprises the following steps: mixing an acid solution containing waste sulfuric acid with alkaline liquor containing calcium hydroxide, and adding to a neutralization pond; carrying out neutralization crystallization under full agitation of a propeller; controlling the concentration of the sulfuric acid added to the acid solution and the concentration of the calcium hydroxide added to the alkaline liquor within the range of 0.05-0.4mol / L; simultaneously, controlling the pH value of the mixed solution in the neutralization pond to be neutral, and controlling the detention pond time of the mixed solution in the neutralization pond for 20 minutes to 2 hours; outputting the mixed solution after neutralization crystallization through a liquid outlet formed at the lower part of the rear section of the neutralization tank as filtered water. By adopting the production method, flake crystal which is more beneficial to subsequent filtering is generated by a neutralization condition of controlling the acid and base of the liquid phase, and growth of the crystal in a flake form is kept, so that lamellar crystal capable of effectively reducing the moisture content after being filtered is provided for subsequent filtering, the filtering efficiency can be improved, the baking cost is reduced, and the transportation cost also can be further reduced, the transportation efficiency is improved, and recycling of renewable resources is powerfully facilitated.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Layered lithium metal oxides free of localized cubic spinel-like structural phases and methods of making same

The present invention includes substantially single-phase lithium metal oxide compounds having hexagonal layered crystal structures that are substantially free of localized cubic spinel-like structural phases. The lithium metal oxides of the invention have the formula LialphaMbetaAgammaO2, wherein M is one or more transition metals, A is one or more dopants having an average oxidation state N such that +2.5<=N<=+3.5, 0.90<=alpha<=1.10, and beta+gamma=1. The present invention also includes dilithiated forms of these compounds, lithium and lithium-ion secondary batteries using these compounds as positive electrode materials, and methods of preparing these compounds.

Owner:UMCORE

Composite cathode active material, cathode and lithium battery including the same, and method of preparing the composite cathode active material

PendingUS20190006669A1Inhibit deteriorationInhibit side effectsElectrode thermal treatmentNegative electrodesComposite cathodeCrystal structure

A composite cathode active material and a cathode and a lithium battery including the composite cathode active material. The composite cathode active material has a core including a plurality of primary particles including a nickel-containing first lithium transition metal oxide having a layered crystal structure; a grain boundary disposed between adjacent primary particles of the plurality of primary particles; and a shell on the core, the shell including a second lithium transition metal oxide having a spinel crystal structure, wherein the grain boundary includes a first composition having a spinel crystal structure.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com