Powder body of solid solution among interlayer of titanium, silicon, aluminum, carbon, and preparation method

A solid solution, titanium-silicon-aluminum technology, applied in the field of titanium-silicon-aluminum-carbon interlayer solid solution powder and its preparation, to achieve the effect of simple method and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

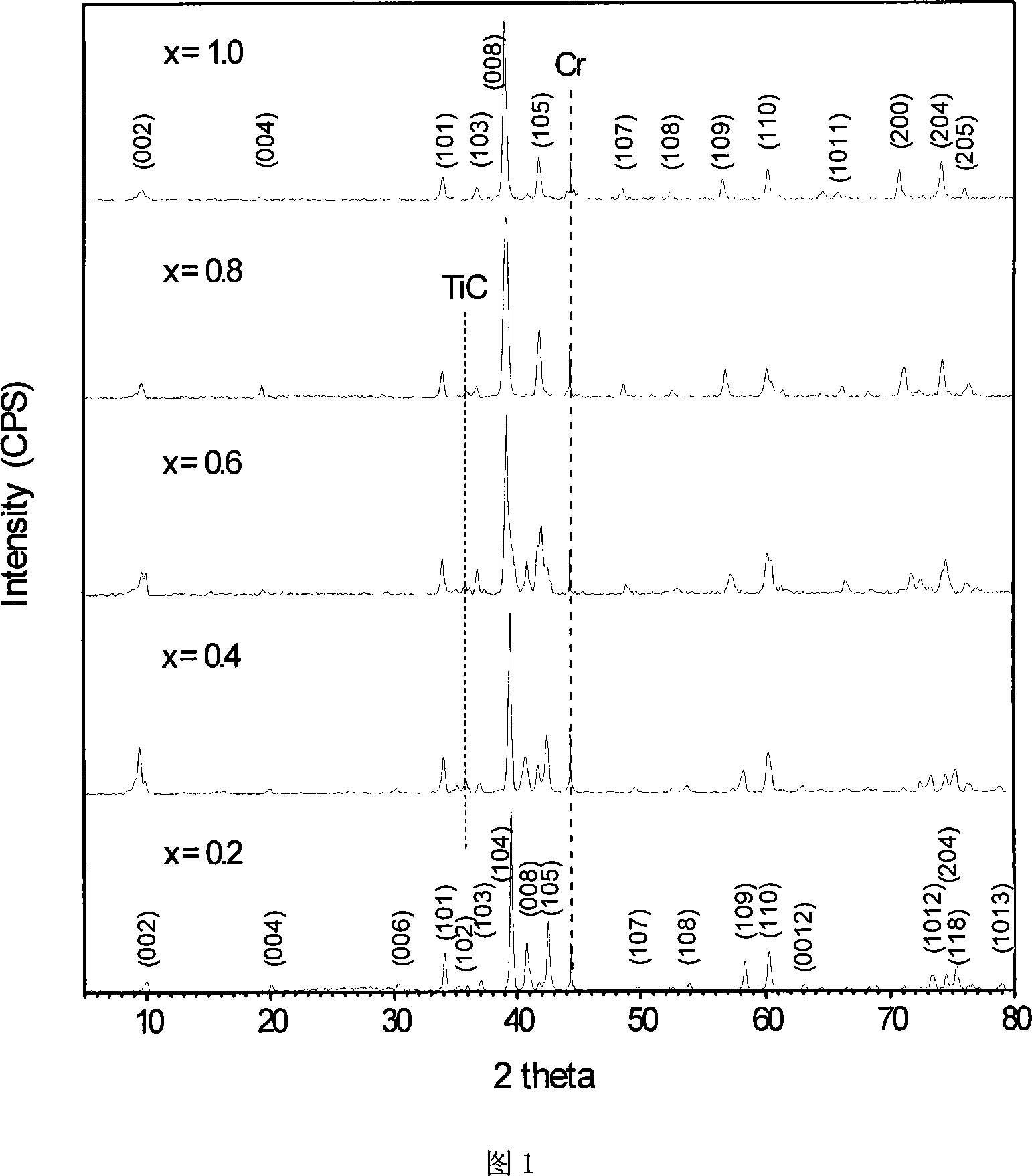

Embodiment 1

[0023] Weigh 14.455 grams of Ti powder, 2.827 grams of Si powder, 0.543 grams of Al powder, and 2.175 grams of graphite powder. After mixing, add 15 ml of absolute ethanol and 40 grams of agate balls, mix the mixture for 2 hours, and then dry it in an oven at 70 ° C. , crushed, passed through a 100-mesh sieve, pressed into a block-shaped green body, put into a graphite crucible, and then moved into a high-temperature furnace. Under the protection of argon, the temperature was raised to 1470°C at a rate of 20°C / min, kept for 5 minutes, and then cooled. The loose massive product that reaction generates is taken out, pulverizes, ball mills, promptly obtains that the main phase of the present invention is Ti 3 Si 1.0 al 0.2 C 1.8 Titanium silicon aluminum carbon solid solution powder.

Embodiment 2

[0025] Weigh 14.471 grams of Ti powder, 2.264 grams of Si powder, 1.087 grams of Al powder, and 2.178 grams of graphite powder. After mixing, add 15 ml of absolute ethanol and 40 grams of agate balls, mix the mixture for 2 hours, and then dry it in an oven at 70 ° C. , crushed, passed through a 100-mesh sieve, pressed into a plate-shaped green body, put into a graphite crucible, and then moved into a high-temperature furnace. Under the protection of argon, the temperature was raised to 1450°C at a rate of 20°C / min, kept for 5 minutes, and then cooled. The loose massive product that reaction generates is taken out, pulverizes, ball mills, promptly obtains that the main phase of the present invention is Ti 3 Si 0.8 al 0.4 C 1.8 Titanium silicon aluminum carbon solid solution powder.

Embodiment 3

[0027] Weigh 14.487 grams of Ti powder, 1.70 grams of Si powder, 1.63 grams of Al powder, and 2.18 grams of graphite powder. After mixing, add 15 ml of absolute ethanol and 40 grams of agate balls, mix the mixture for 3 hours, and then dry it in an oven at 70 ° C. , crushed, passed through a 70-mesh sieve, pressed into a block green body, put into a graphite crucible, and then moved into a high-temperature furnace. Under the protection of argon, the temperature was raised to 1450°C at a rate of 30°C / min, kept for 5 minutes, and then cooled. The loose massive product that reaction generates is taken out, pulverizes, ball mills, promptly obtains that the main phase of the present invention is Ti 3 Si 0.6 al 0.6 C 1.8 Titanium silicon aluminum carbon solid solution powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com