Patents

Literature

612 results about "Sialon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SiAlON ceramics are a specialist class of high-temperature refractory materials, with high strength at ambient and high temperatures, good thermal shock resistance and exceptional resistance to wetting or corrosion by molten non-ferrous metals, compared to other refractory materials such as, for example, alumina. A typical use is with handling of molten aluminium. They also are exceptionally corrosion resistant and hence are also used in the chemical industry. SiAlONs also have high wear resistance, low thermal expansion and good oxidation resistance up to above ~1000 °C. They were first reported around 1971.

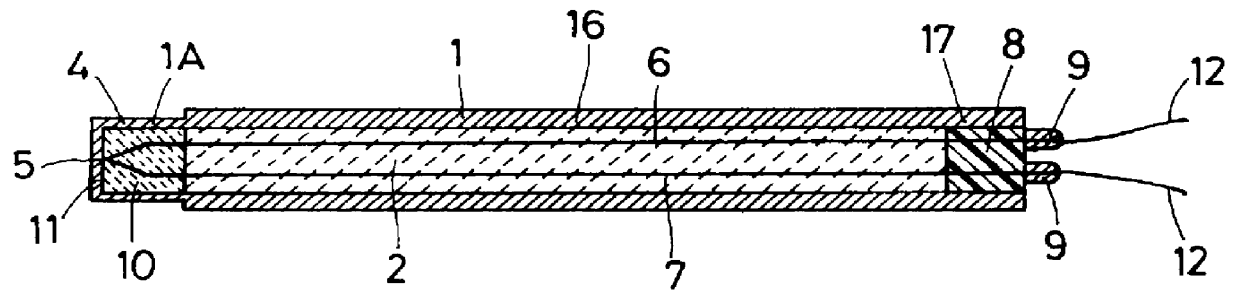

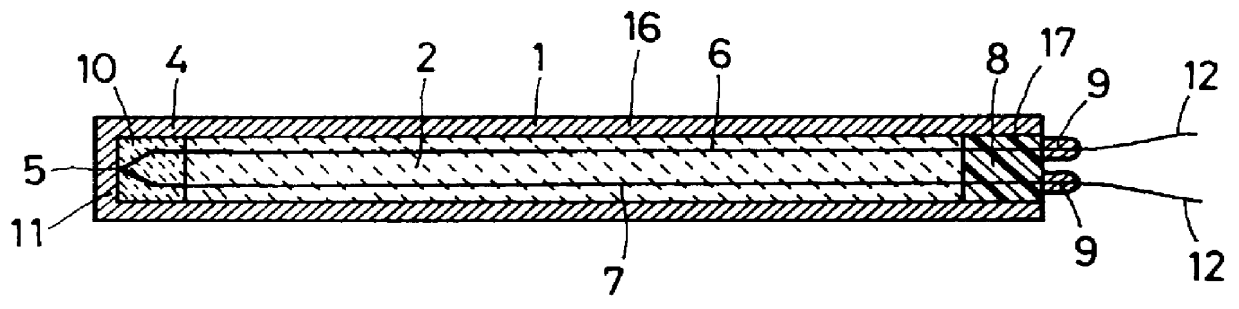

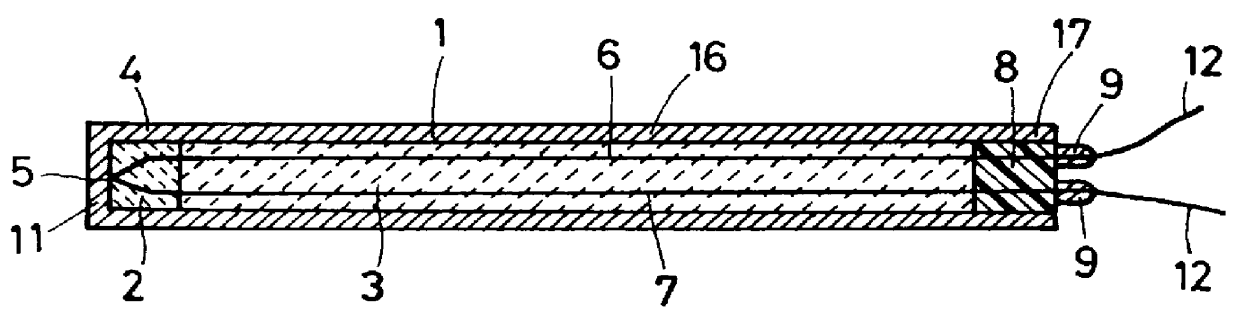

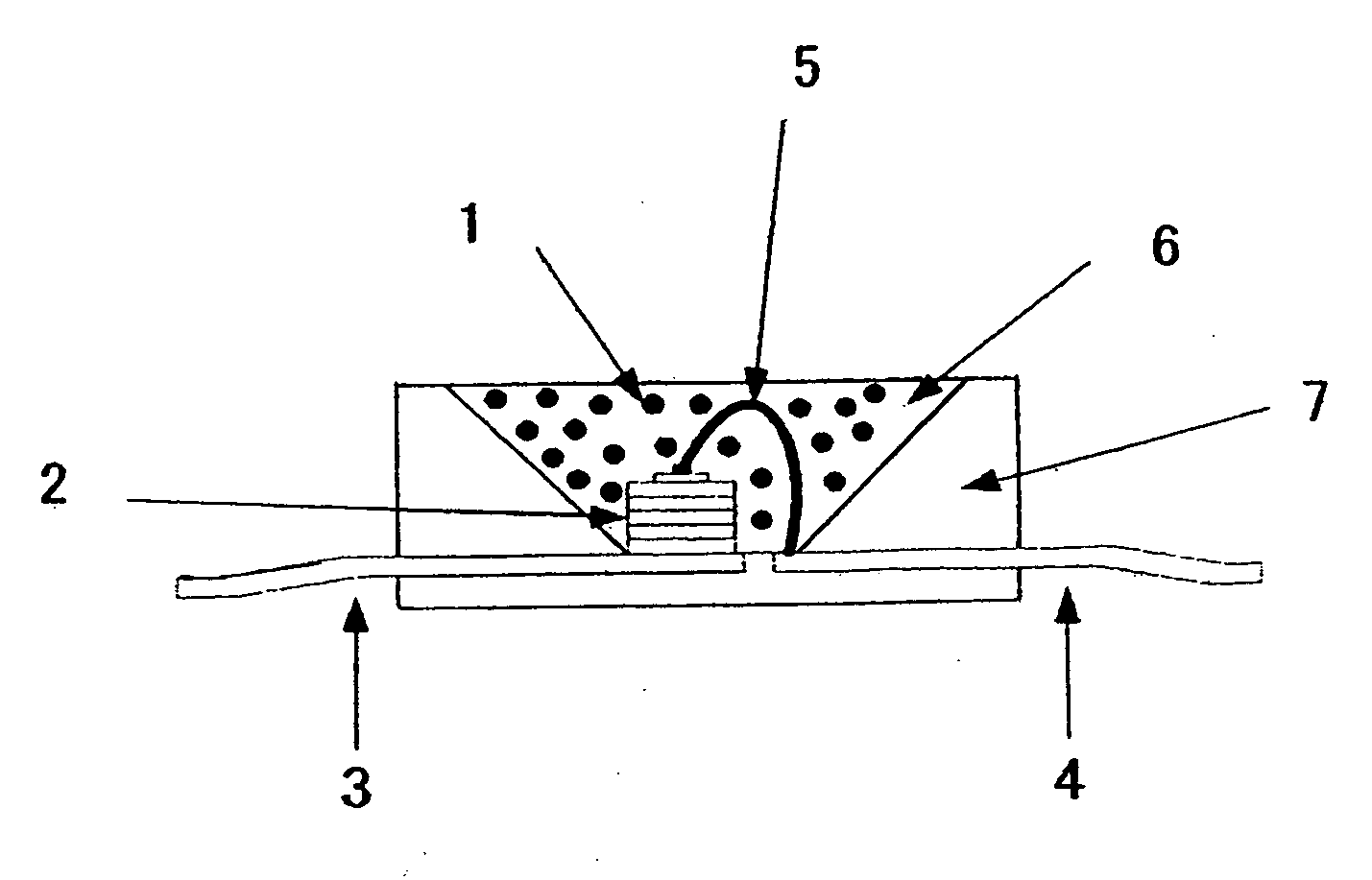

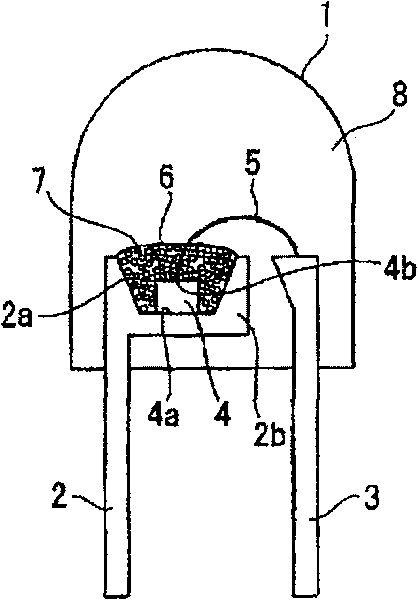

Ceramic sheath type thermocouple

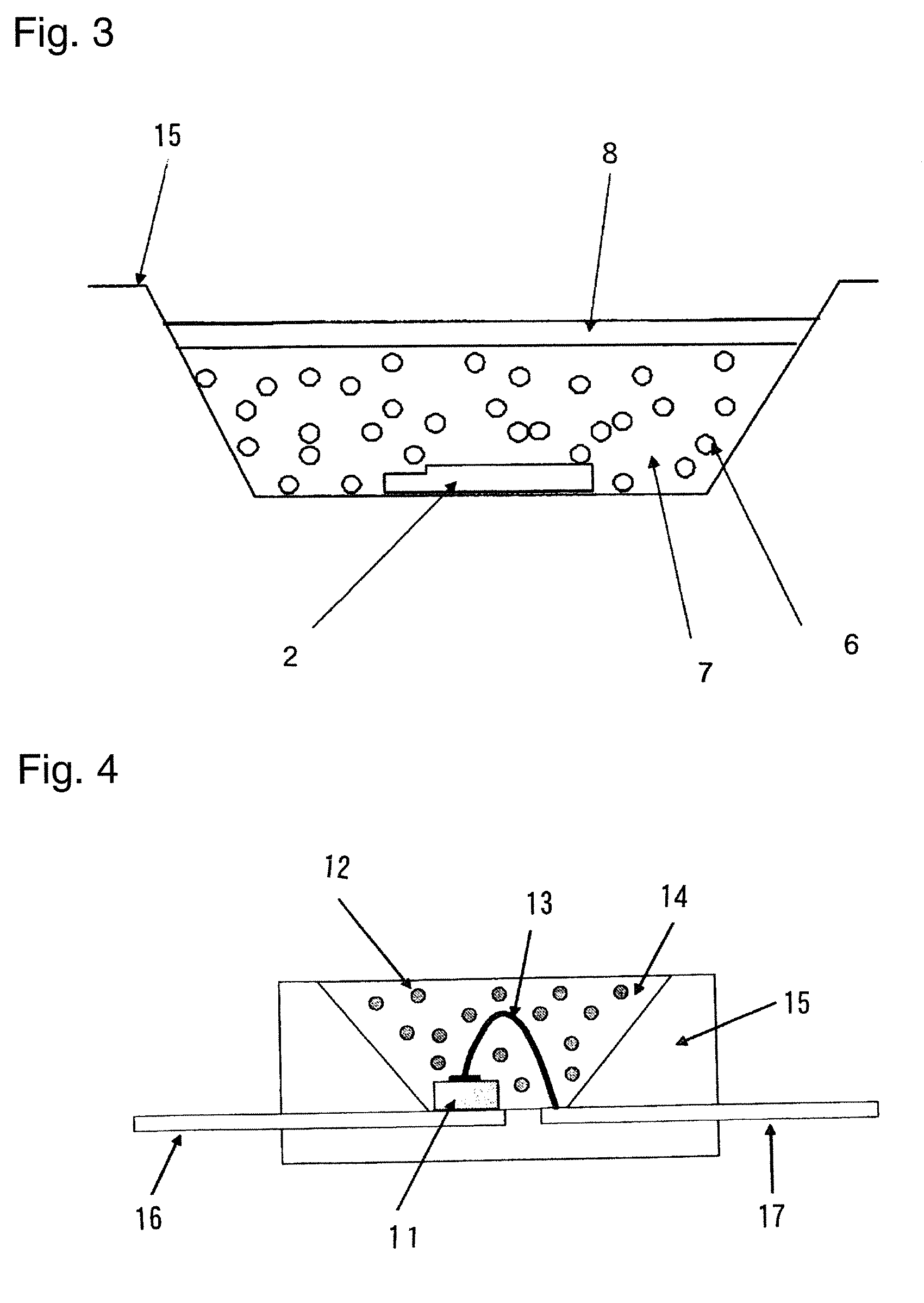

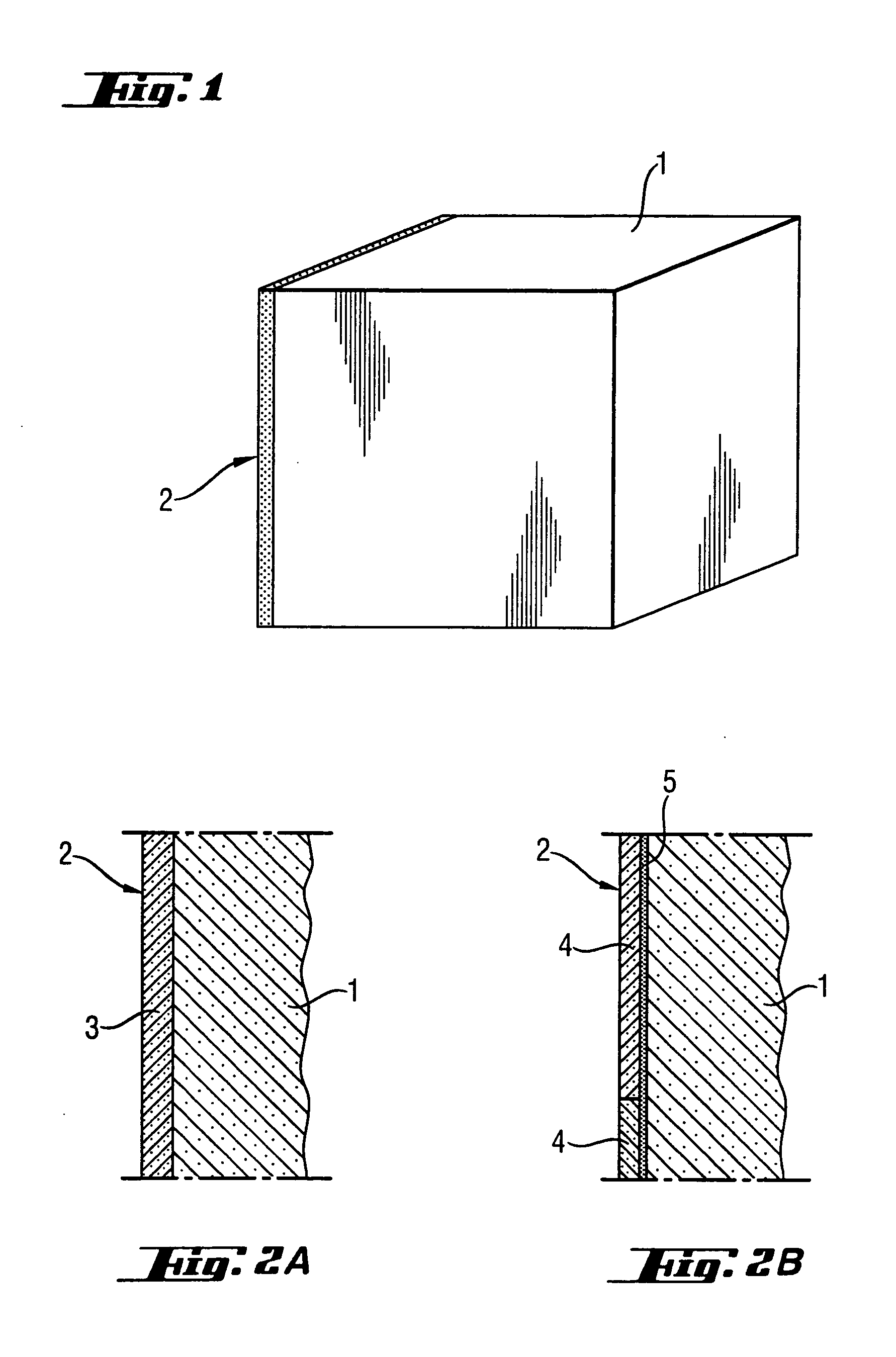

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

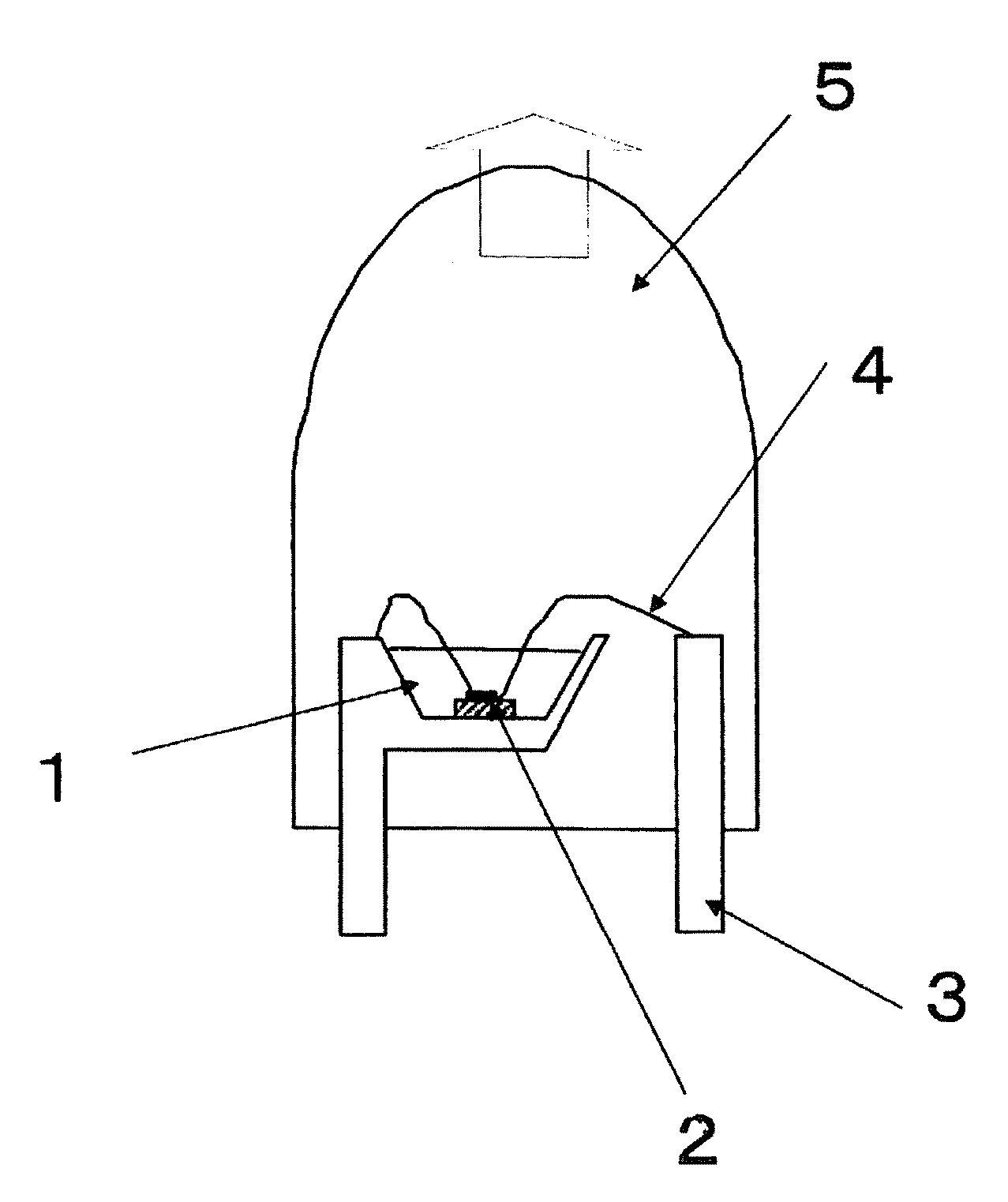

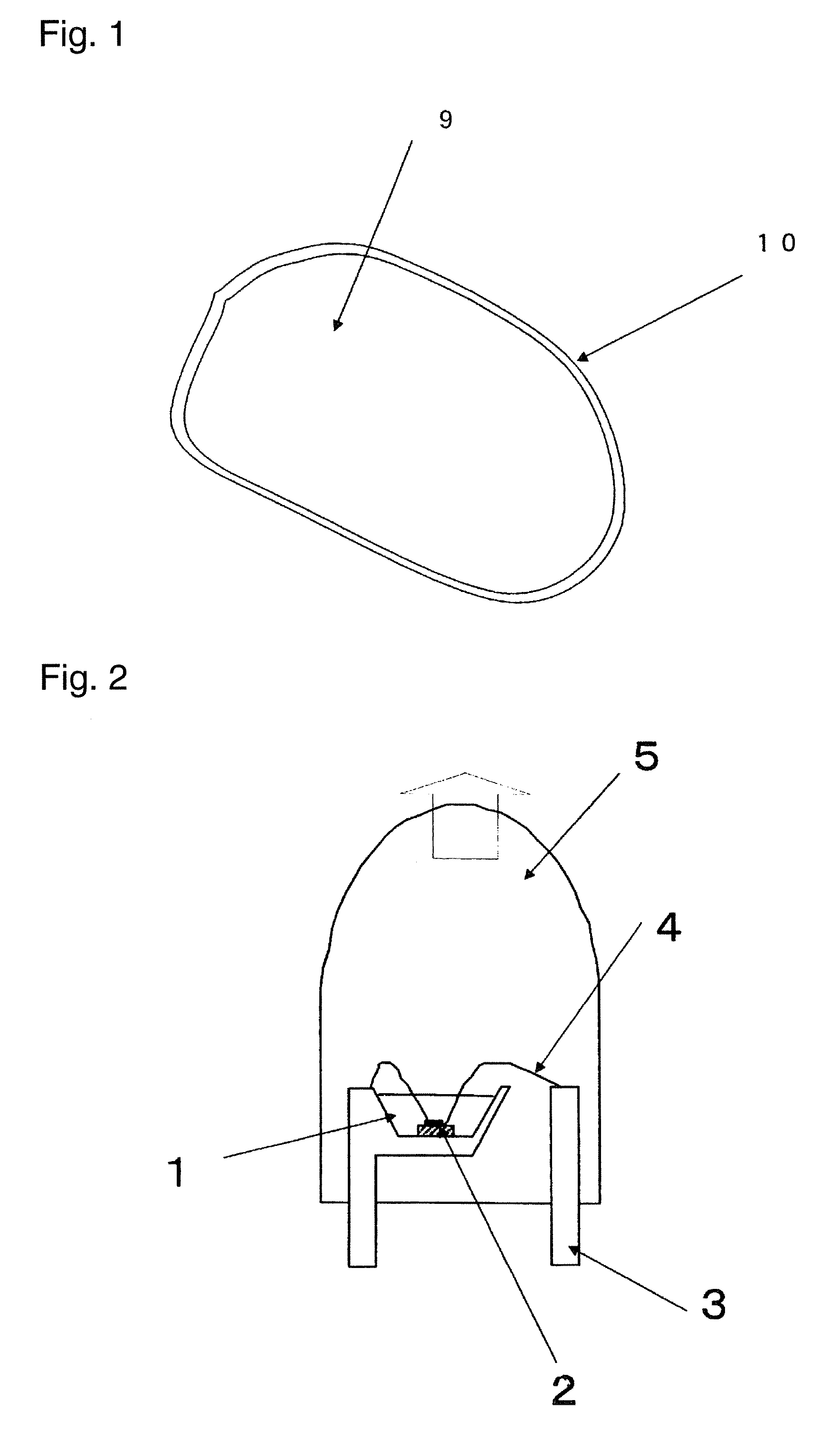

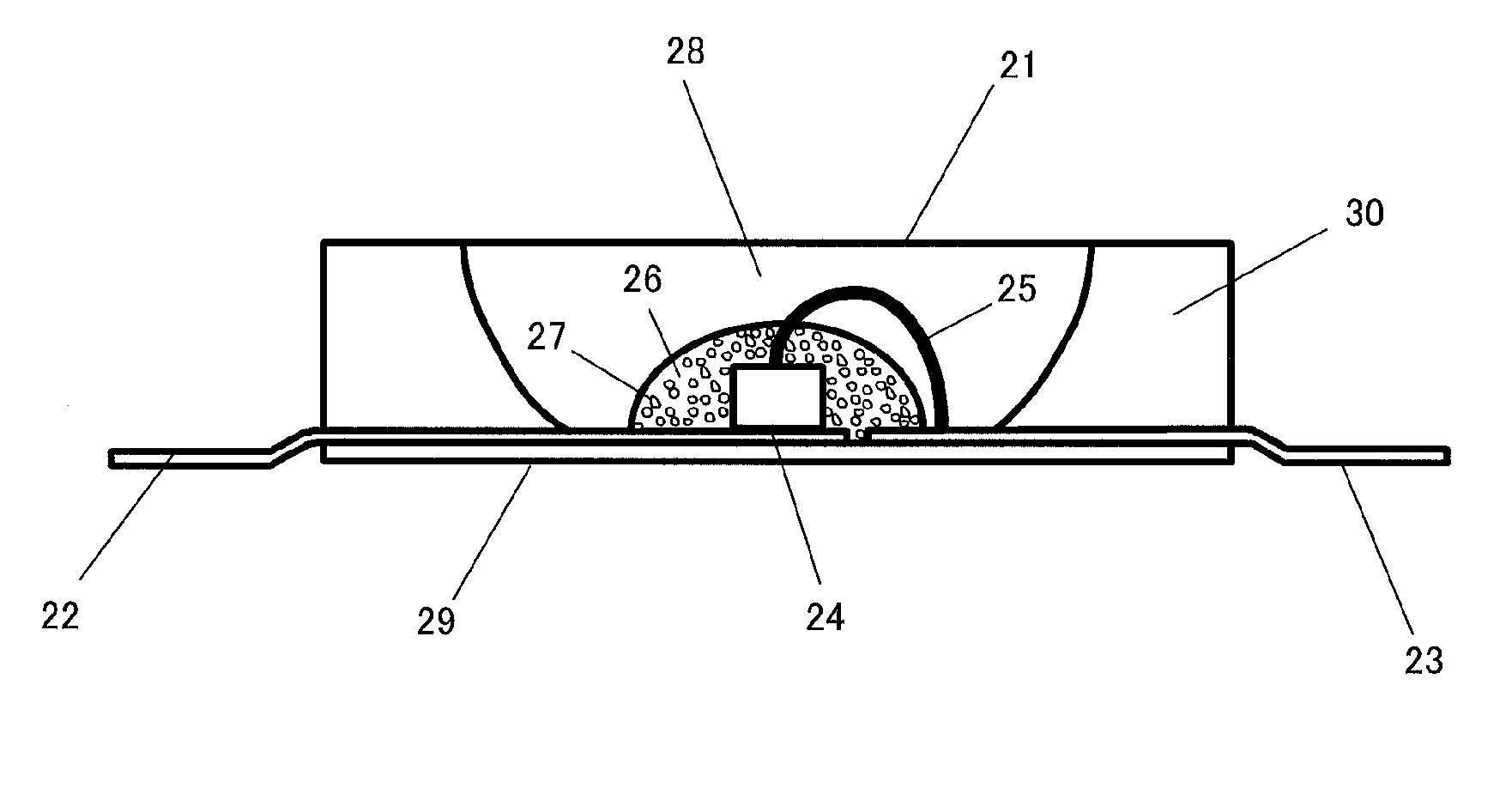

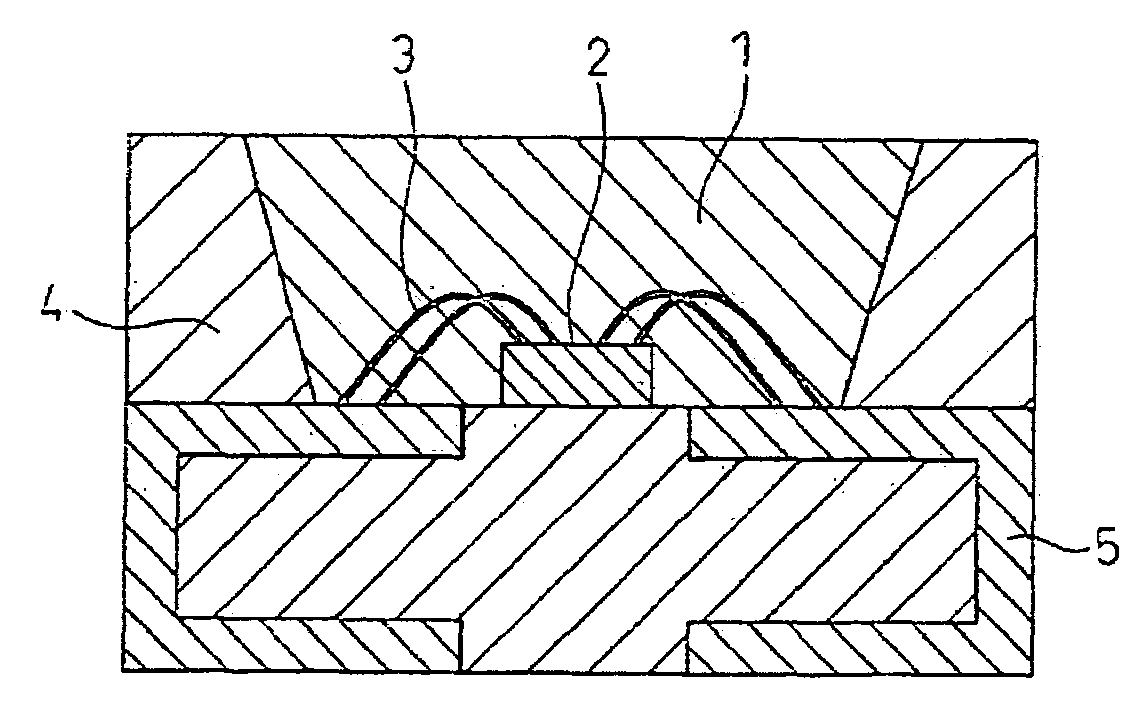

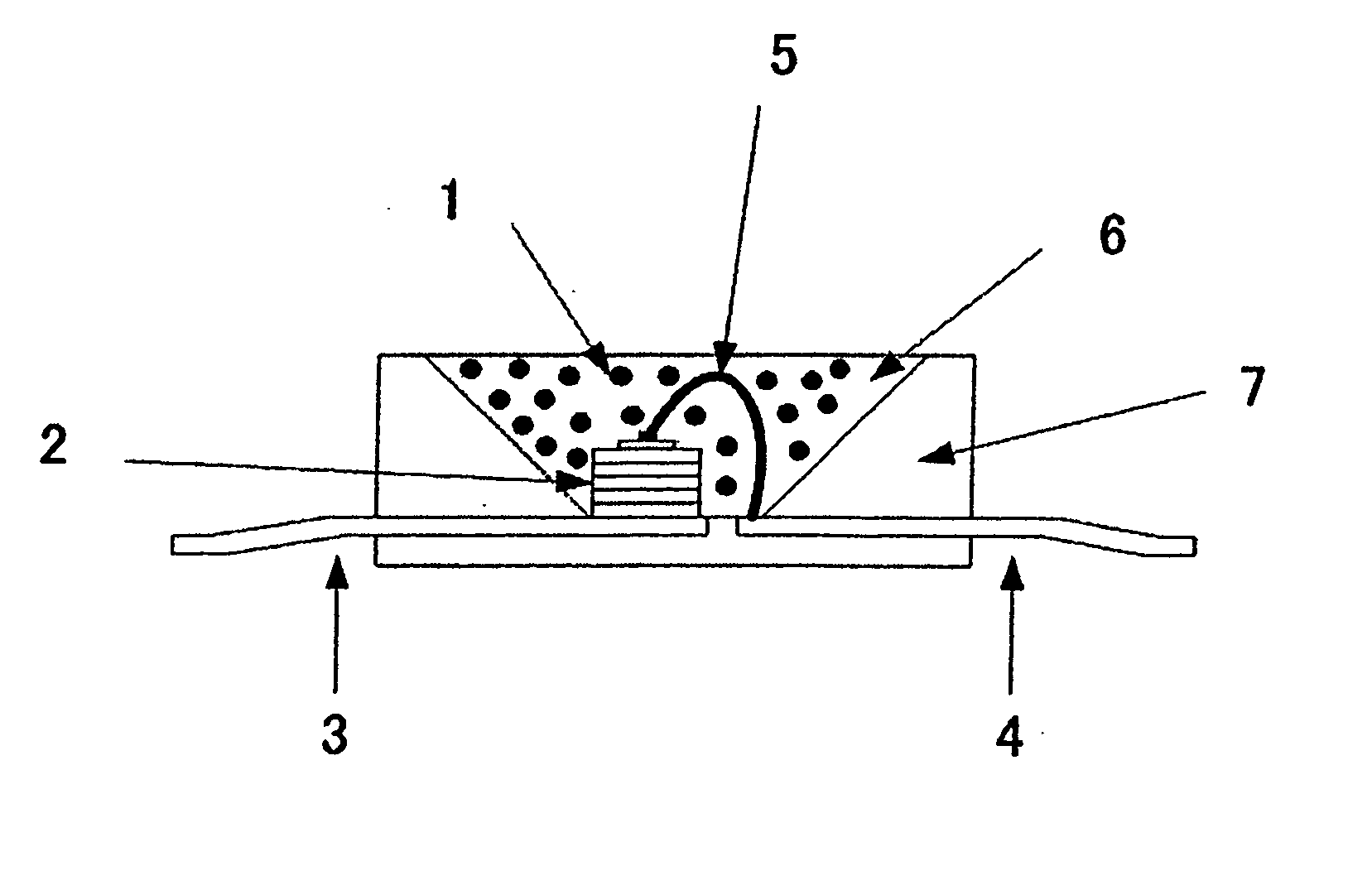

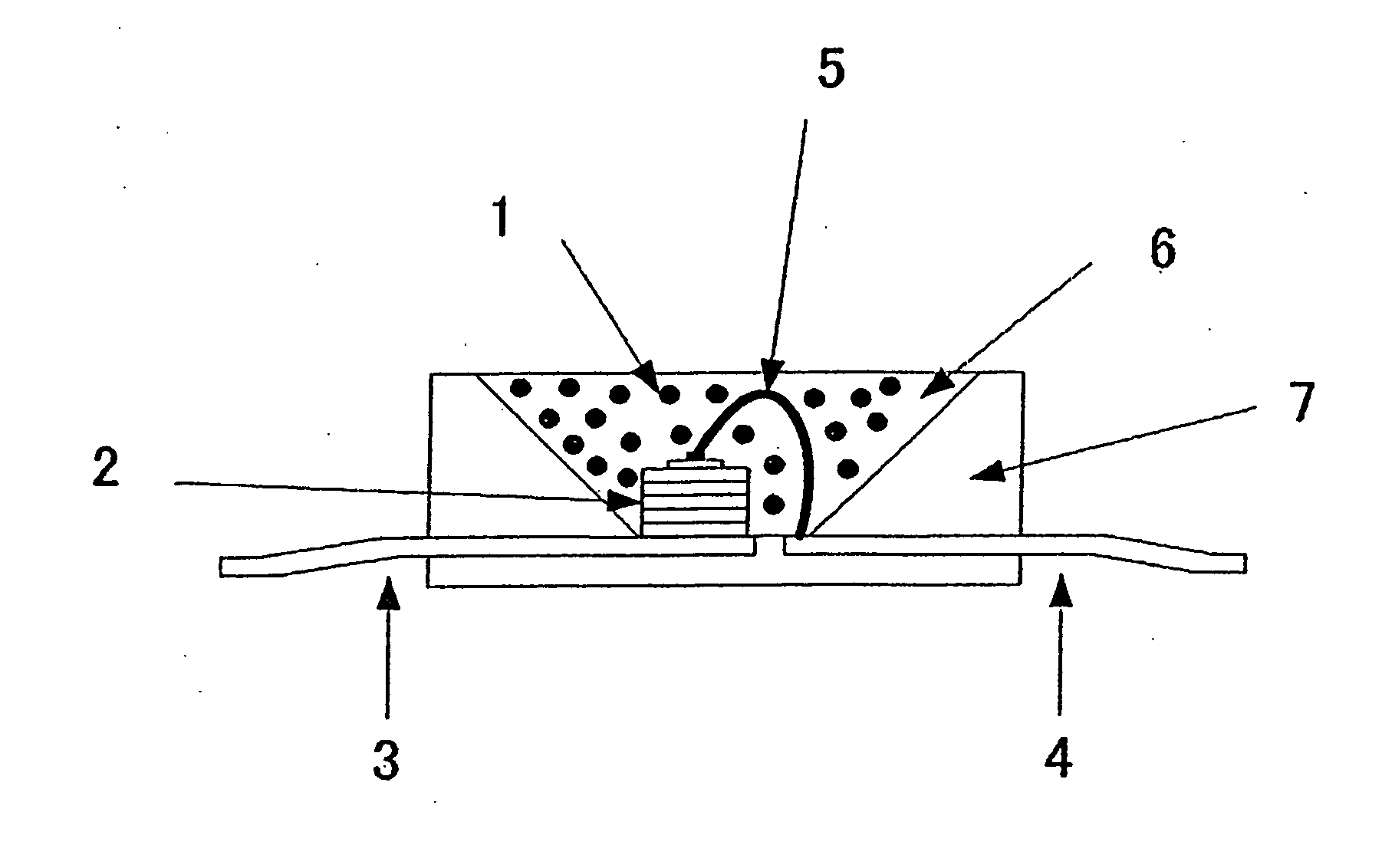

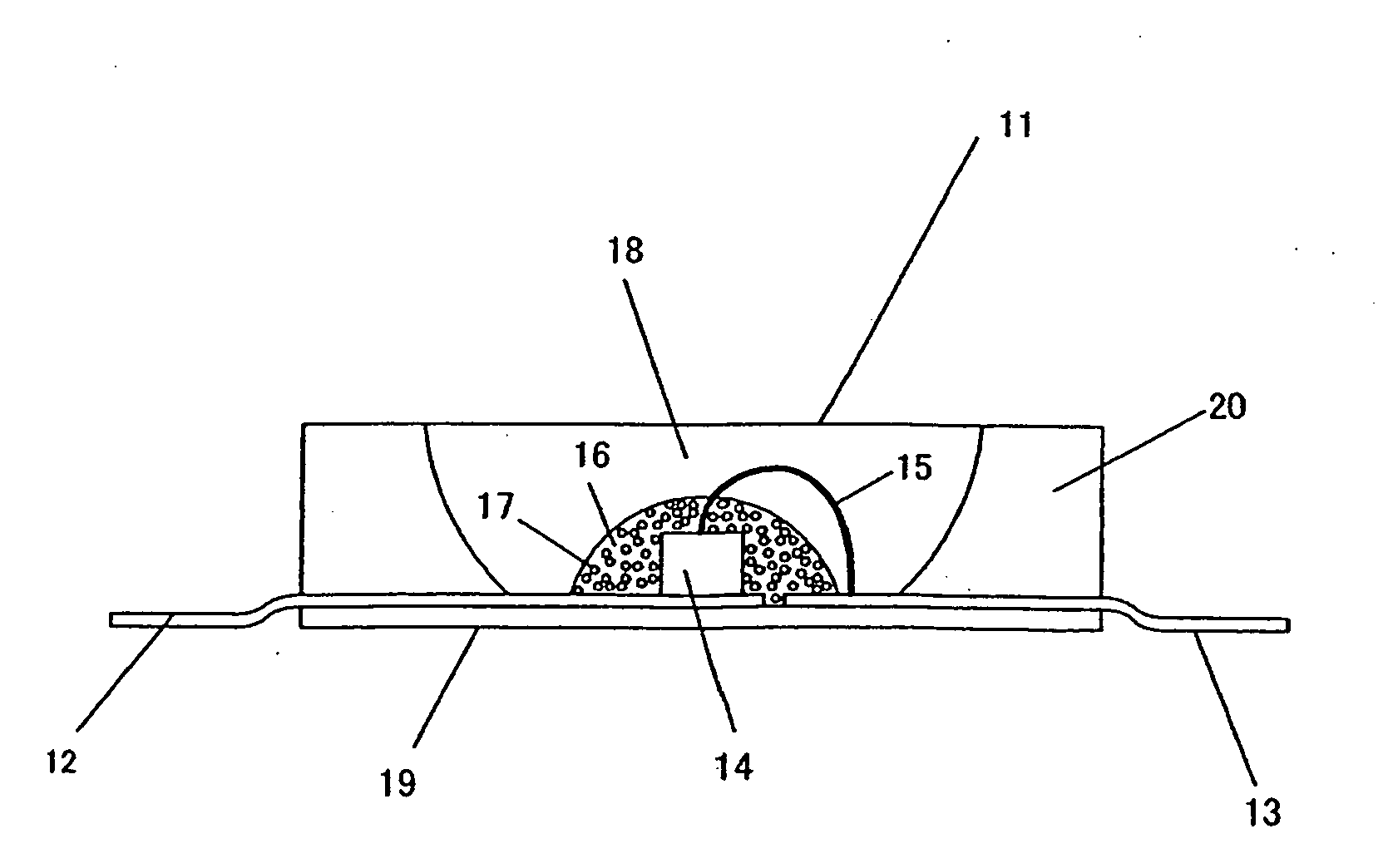

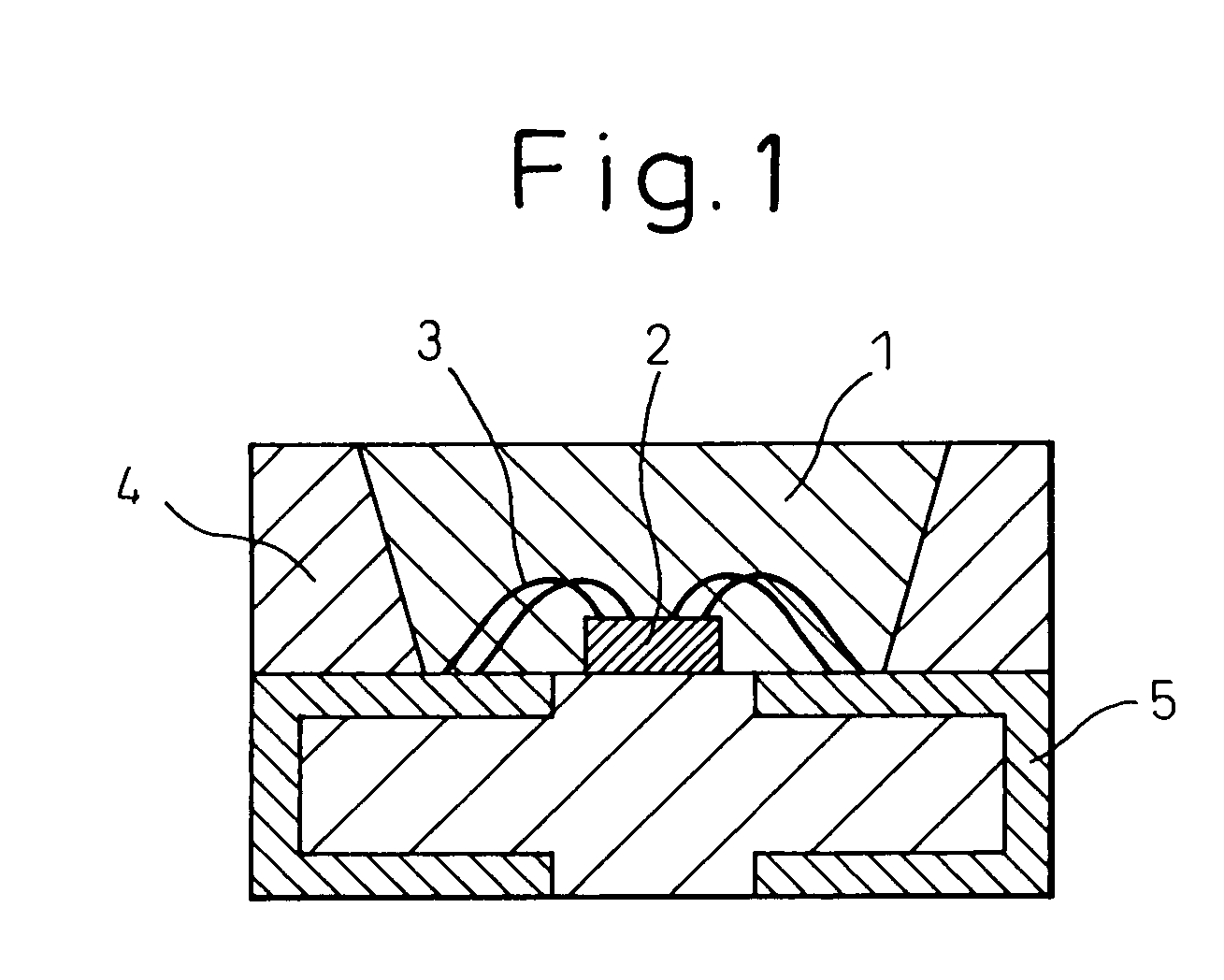

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

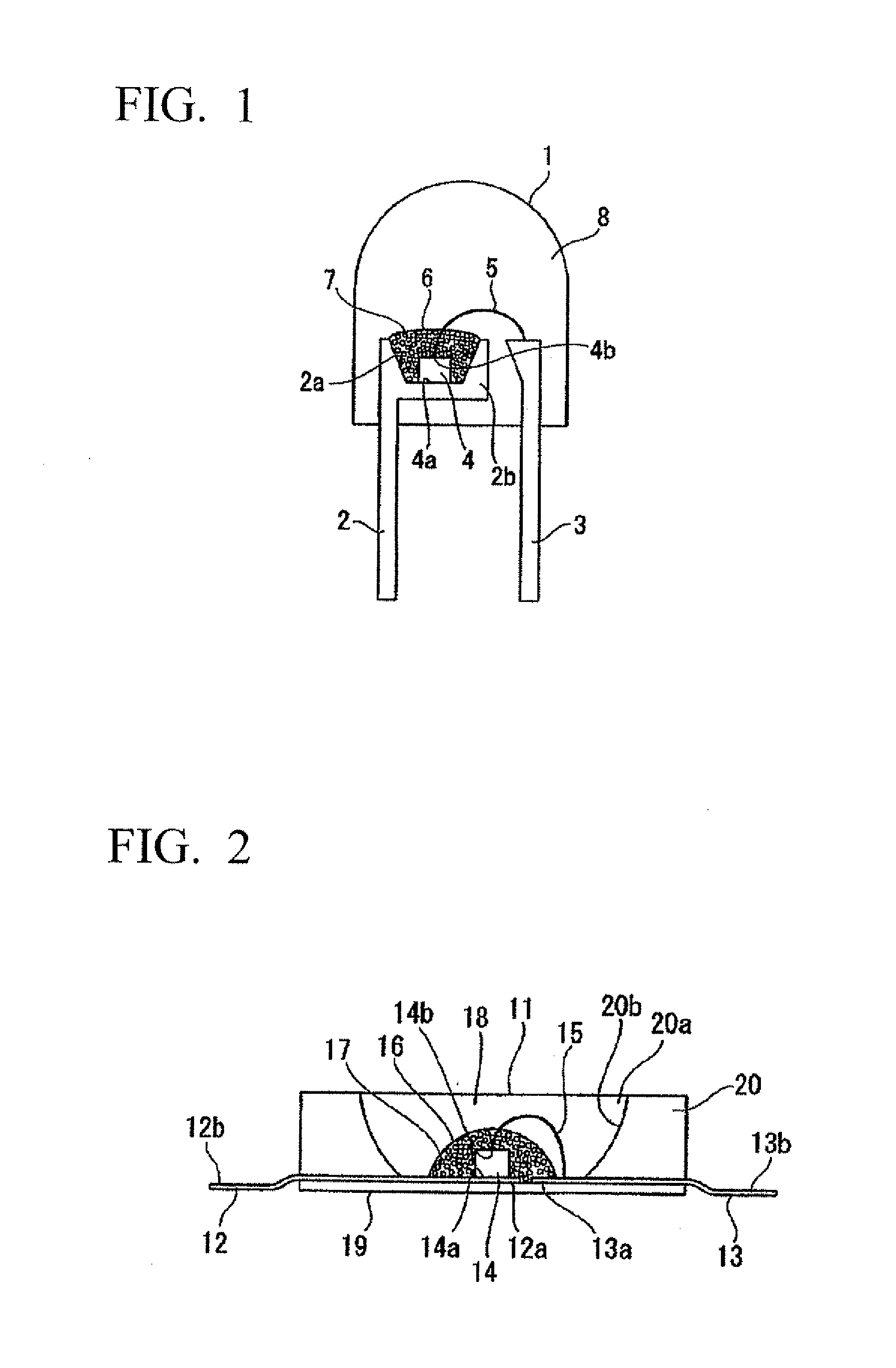

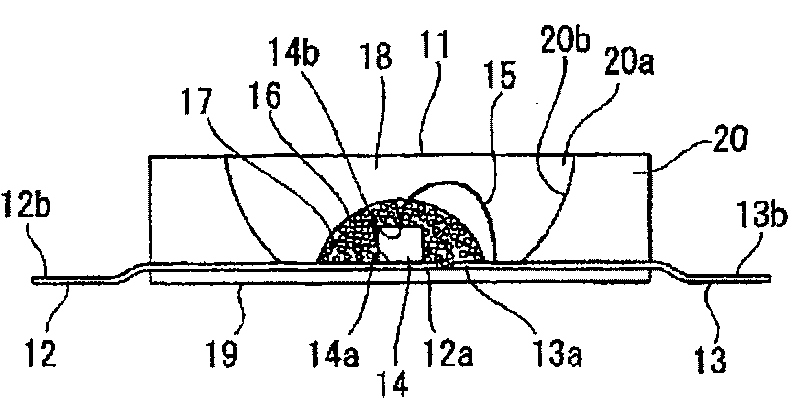

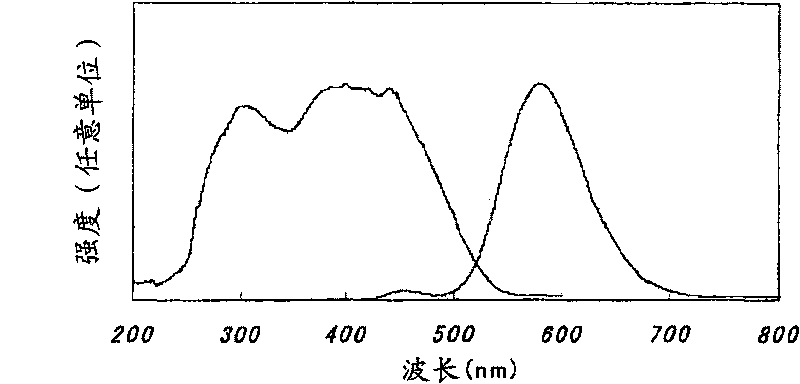

Phosphor and light-emitting equipment using phosphor

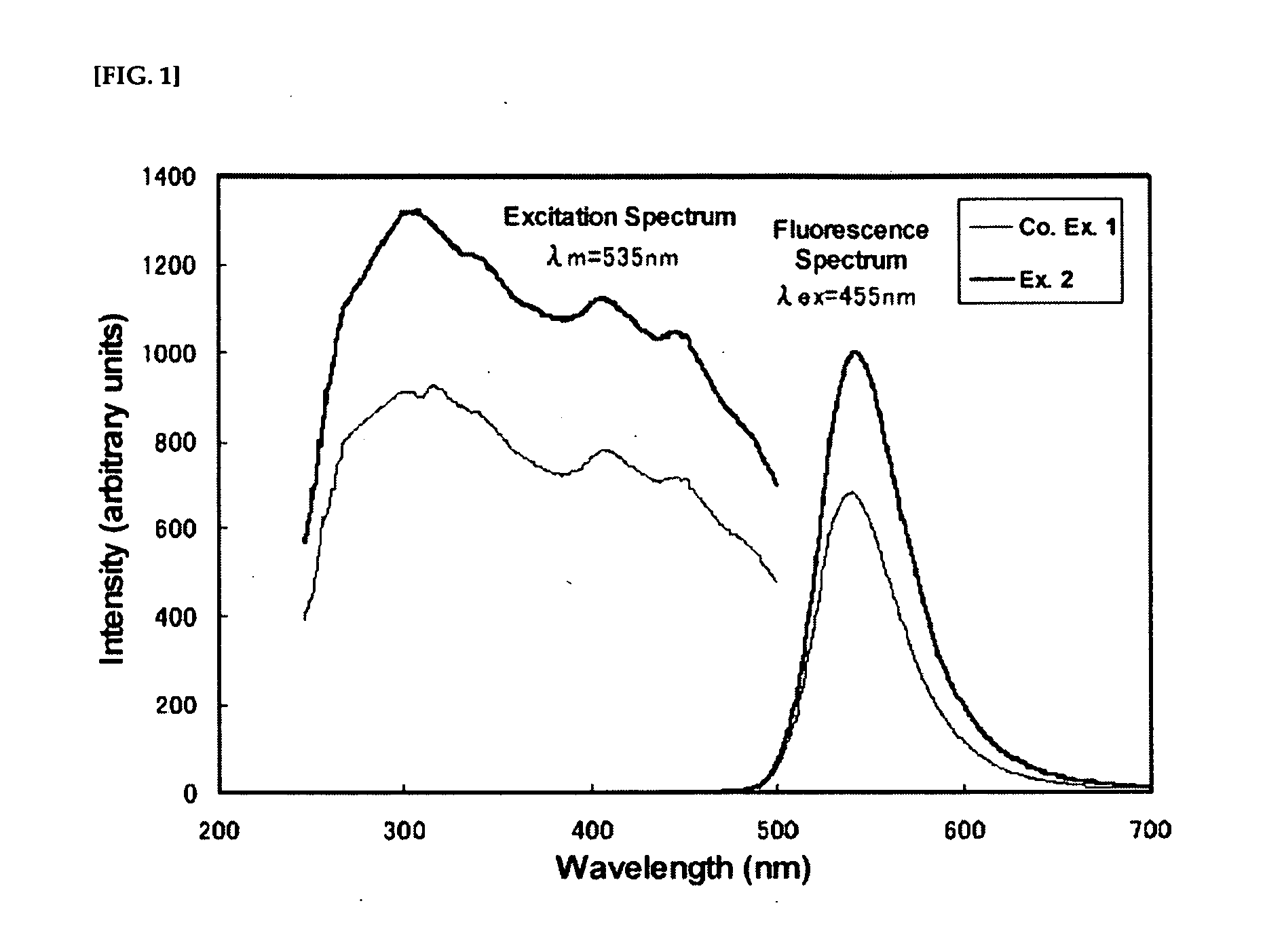

ActiveUS20070007494A1Increase brightnessGood colorOther chemical processesNitrogen-metal/silicon/boron binary compoundsFluorescenceRare earth

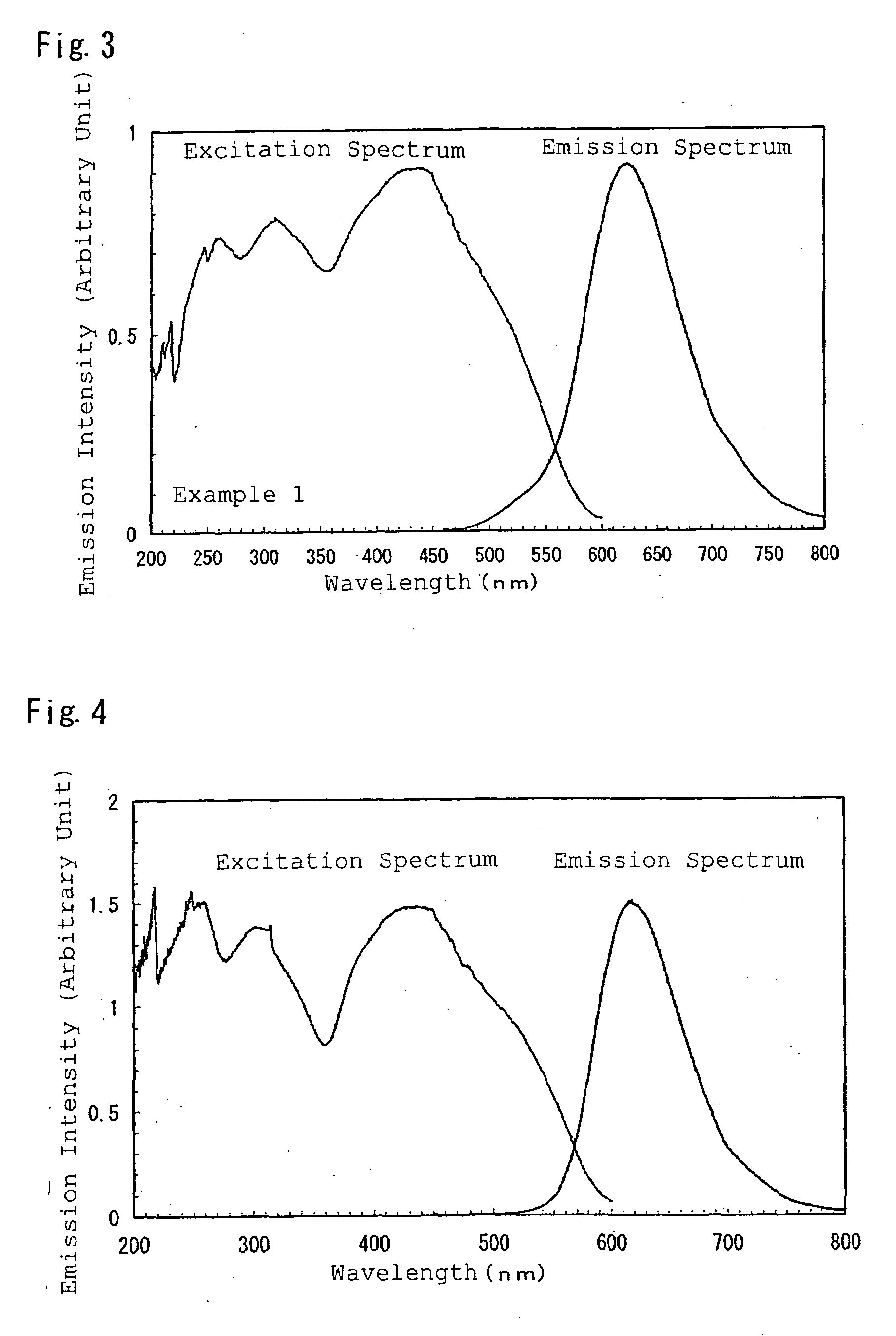

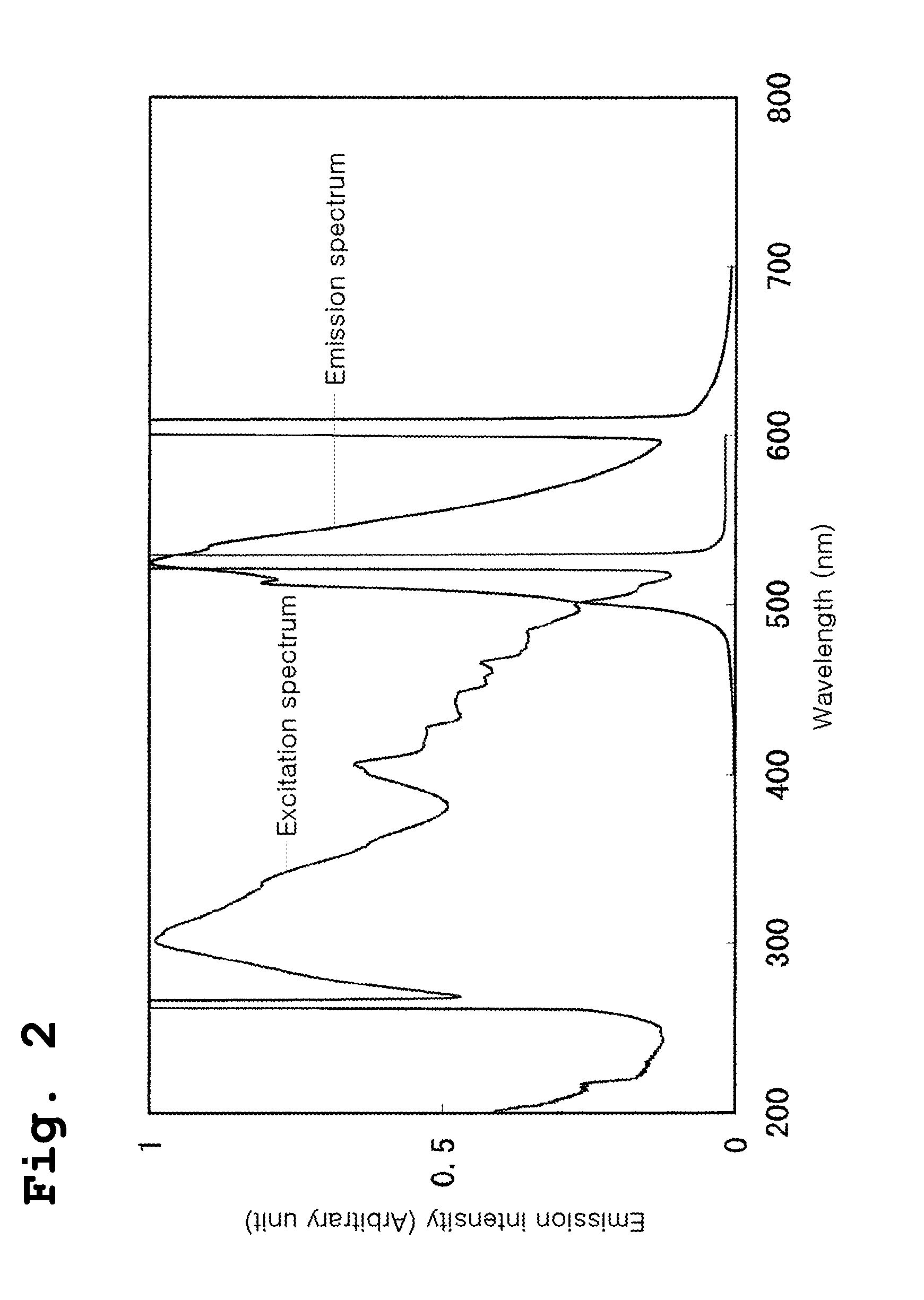

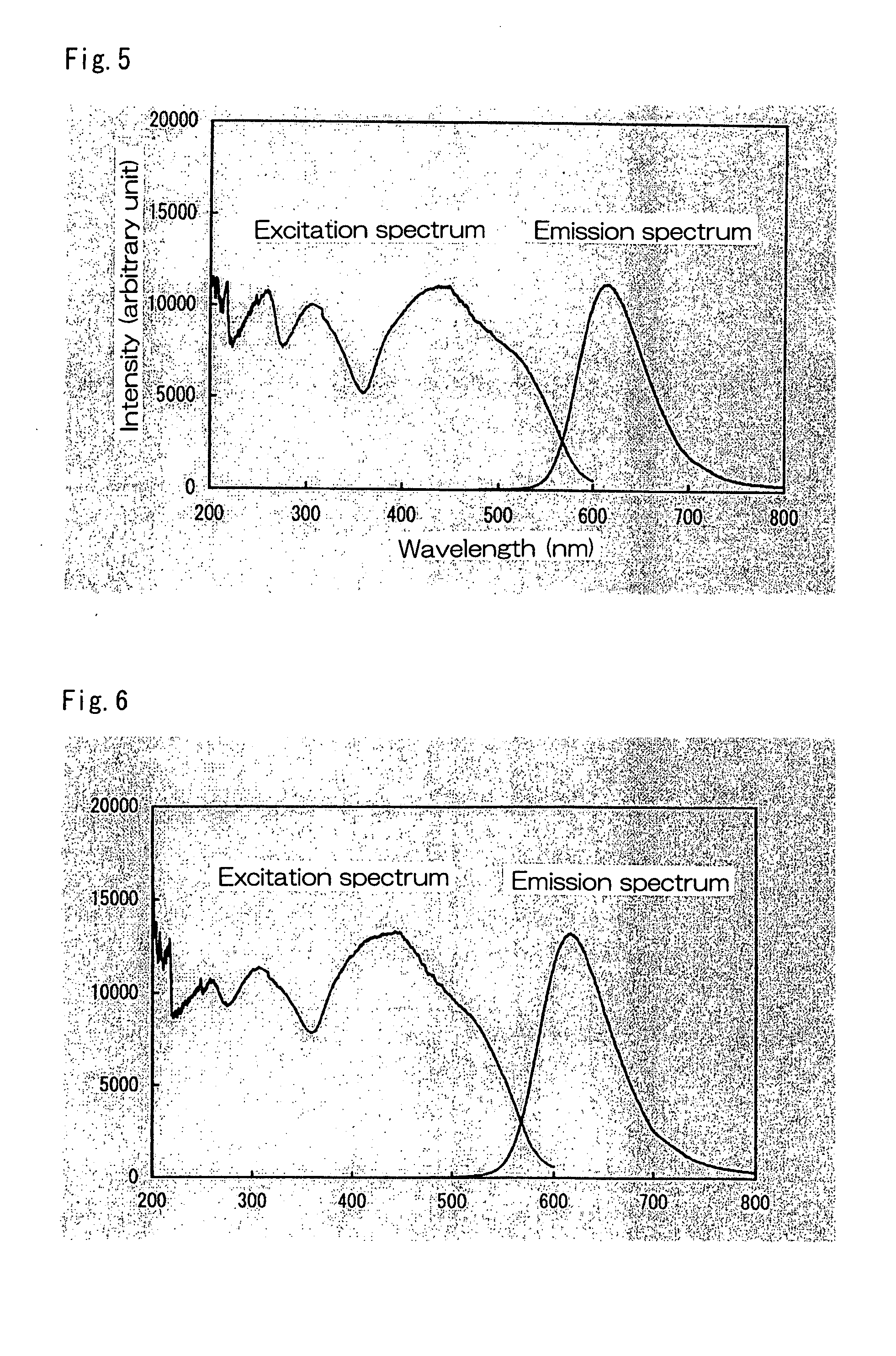

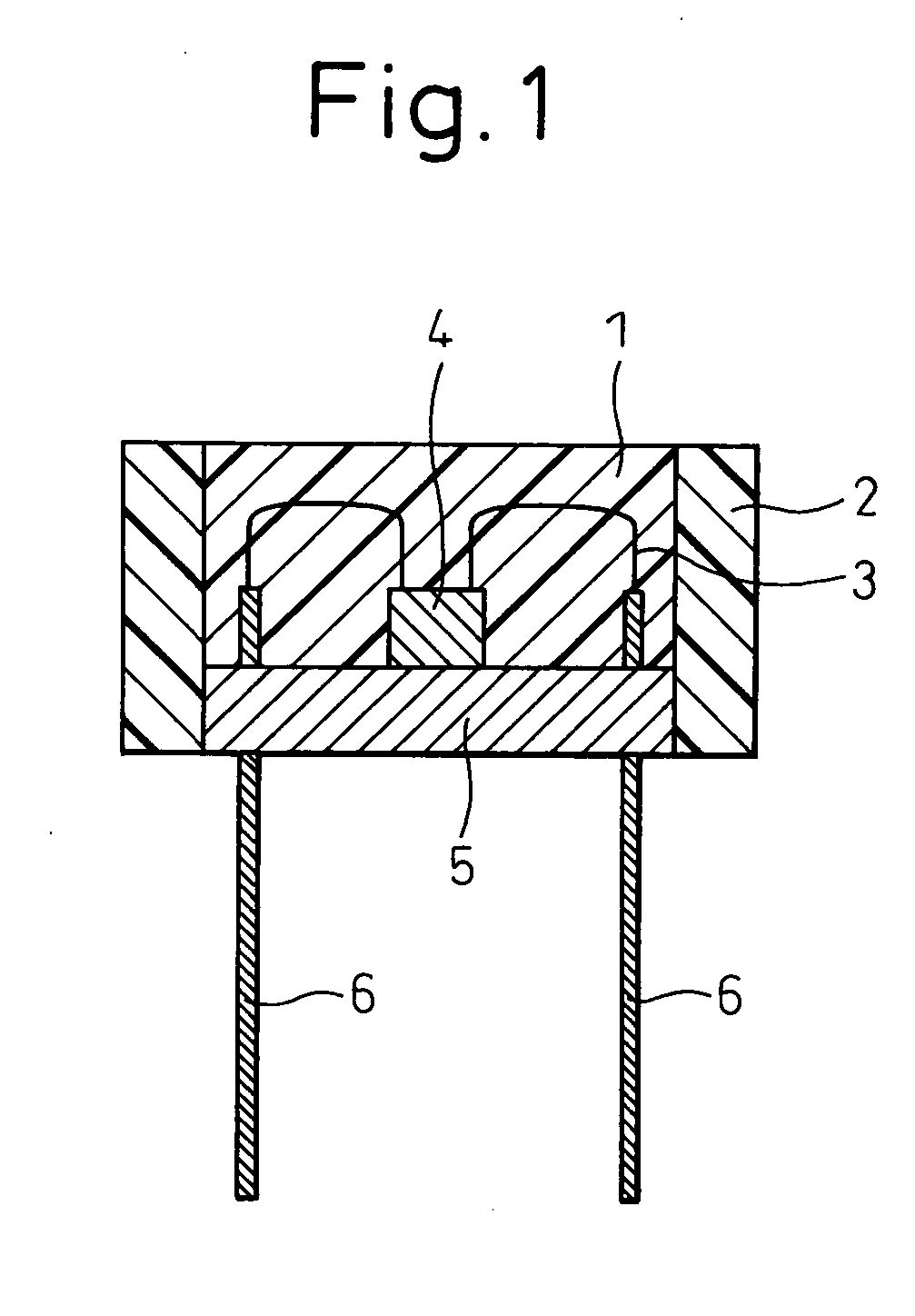

An object of the present invention is to provide an inorganic phosphor having fluorescence properties emitting an orange or red light which has a longer wavelength as compared with the cases of conventional sialon phosphors activated with a rare earth. The invention relates to a design of white light-emitting diode rich in a red component and having good color-rendering properties by employing a solid solution crystal phase phosphor which uses as a host crystal an inorganic compound having the same crystal structure as that of a CaSiAlN3 crystal phase and to which M Element (wherein M Element is one or two or more elements selected from the group consisting of Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) is added as an emission center.

Owner:NICHIA CORP +1

Fluorescent substance and process for producing the same, and luminescent element using the same

ActiveUS20090021141A1Improve luminous performanceLarge intensityMaterial nanotechnologyAluminium silicatesFluorescencePhosphor

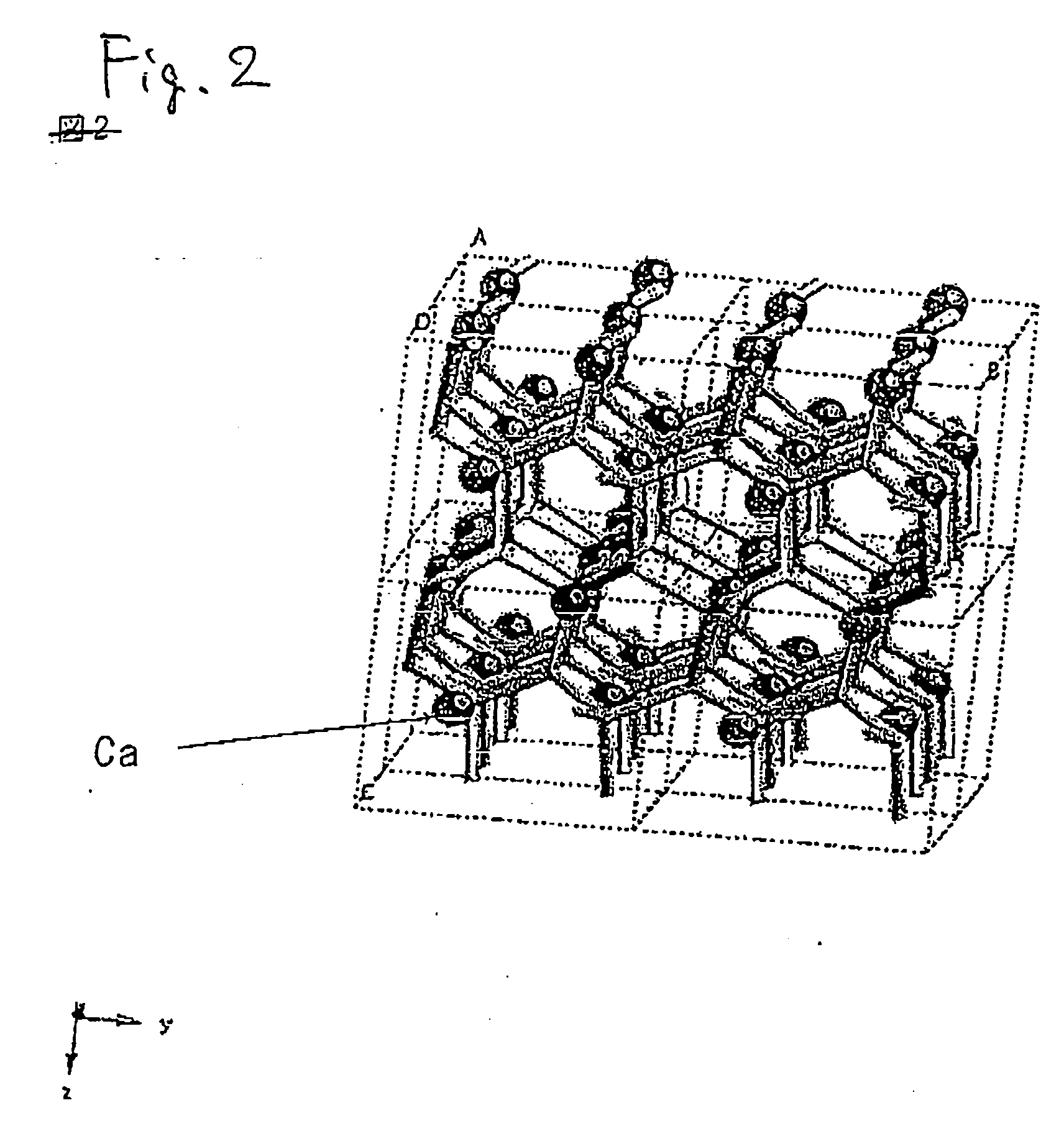

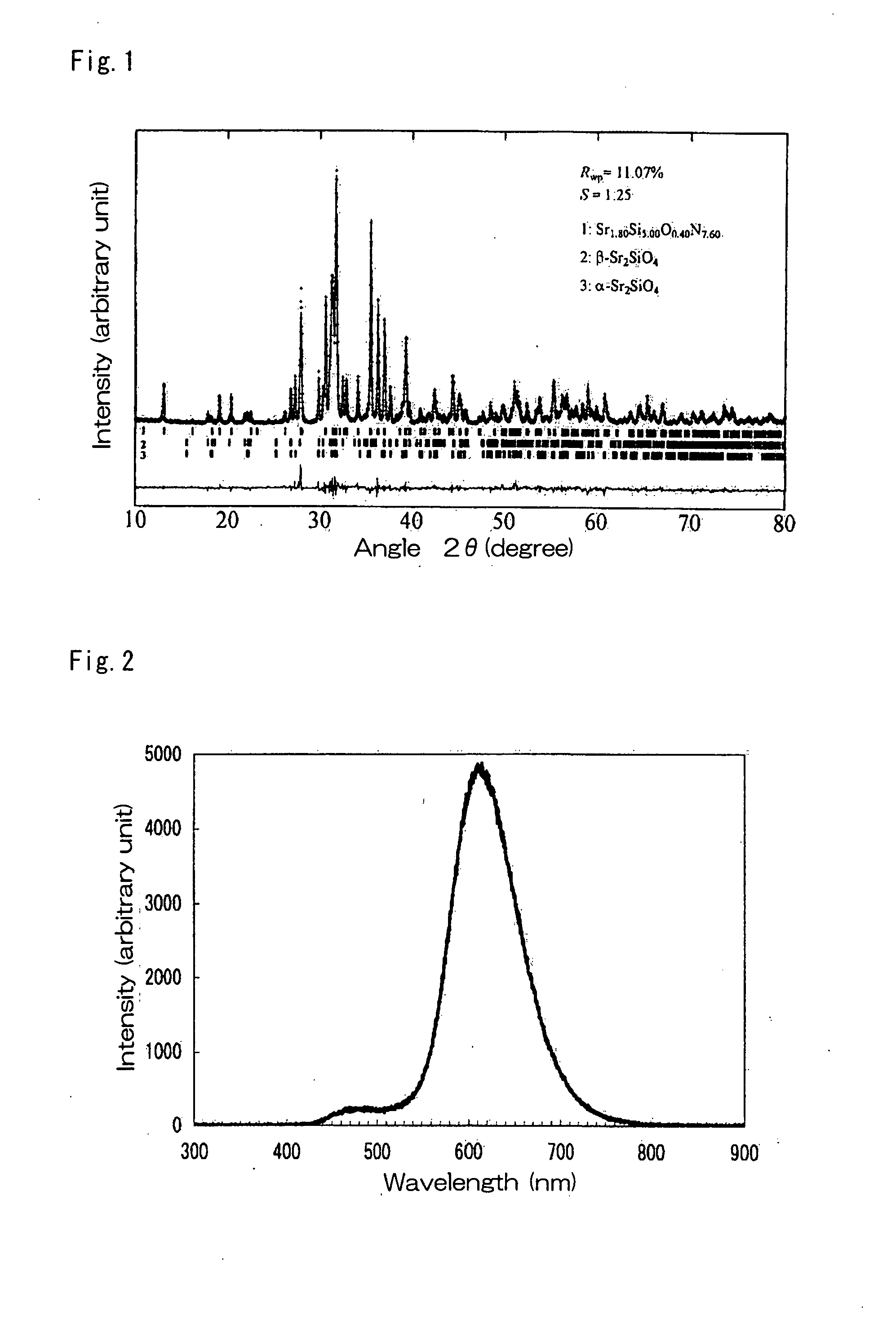

Provided is a phosphor material for a white LED with a blue LED or ultraviolet LED as a light source.A phosphor comprises an α-sialon represented by the formula: (M1)X(M2)Y(Si)12−(m+n)(Al)m+n(O)n(N)16−n where M1 is at least one element selected from the group consisting of Li, Mg, Ca, Y and lanthanide metals (except for La and Ce), M2 is at least one element selected from Ce, Pr, Eu, Tb, Yb and Er, 0.3≦X+Y≦1.5, 0<Y≦0.7, 0.6≦m≦3.0, 0≦n≦1.5 and X+Y=m / 2; and the oxygen content in a powder of the α-sialon is at most 0.4 mass % larger than a value calculated based on the formula.

Owner:DENKA CO LTD

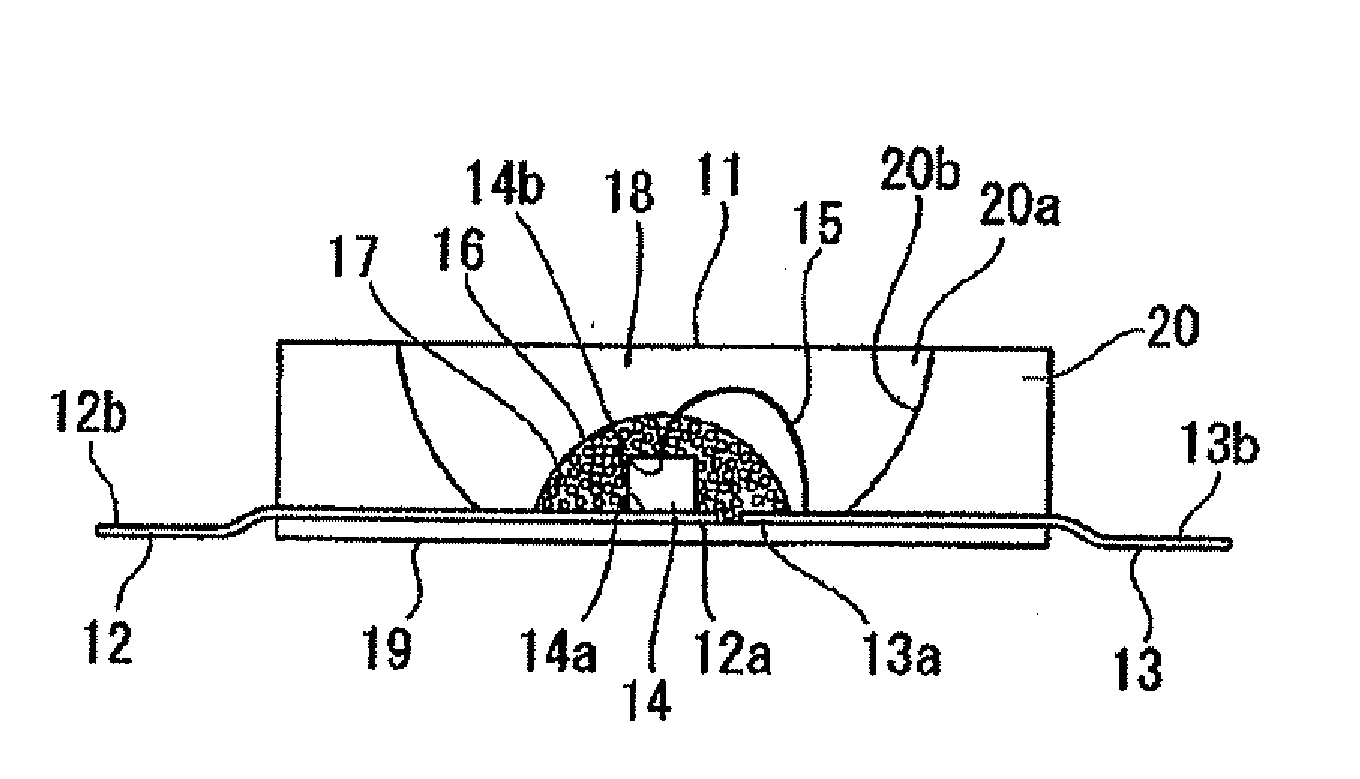

Fluorescent substance, method for producing the same, and light-emitting device using the same

ActiveUS20100164367A1High emission intensityGood dispersionLayered productsSolid-state devicesFluorescenceCrystal structure

The present invention provides a fluorescent substance exhibiting higher brightness as compared to conventional fluorescent substances, a method for producing the same, and a light-emitting device using such a fluorescent substance. Specifically, the fluorescent substance comprises an α-sialon crystal structure having the same crystal structure with an α-type silicon nitride crystal, which includes at least an M(0) element (where M(0) represents one or two elements selected from Sr and La), an M(1) element (where M(1) represents one or more elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb), Si, Al, and nitrogen.

Owner:NAT INST FOR MATERIALS SCI

Fluorophor and method for production thereof and illuminator

ActiveUS20090091237A1Small temperature fluctuationsImprove efficiencyDischarge tube luminescnet screensLamp detailsPhosphorNitrogen

A fluorophor which comprises as a main component, an α type sialon crystal containing at least Li, A element (wherein A represents one or more elements selected from among Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Er, Tm and Yb), M element (wherein M represents one or more metal elements except Li and the A element), Si, Al, oxygen and nitrogen. The fluorophor has an a type sialon crystal structure which is represented by the general formulae: (Lix1, Ax2, Mx3)(Si12−(m+n)Alm+n)(OnN16−n) 1.2≦x1≦2.4 (1) 0.001≦x2≦0.4 (2) and 0≦x3≦1.0 (3), and has a luminescence peak at a wavelength in the range of 400 to 700 nm. The above phosphor is reduced in the lowering of brightness, and can be suitably used for a white LED and the like.

Owner:NAT INST FOR MATERIALS SCI

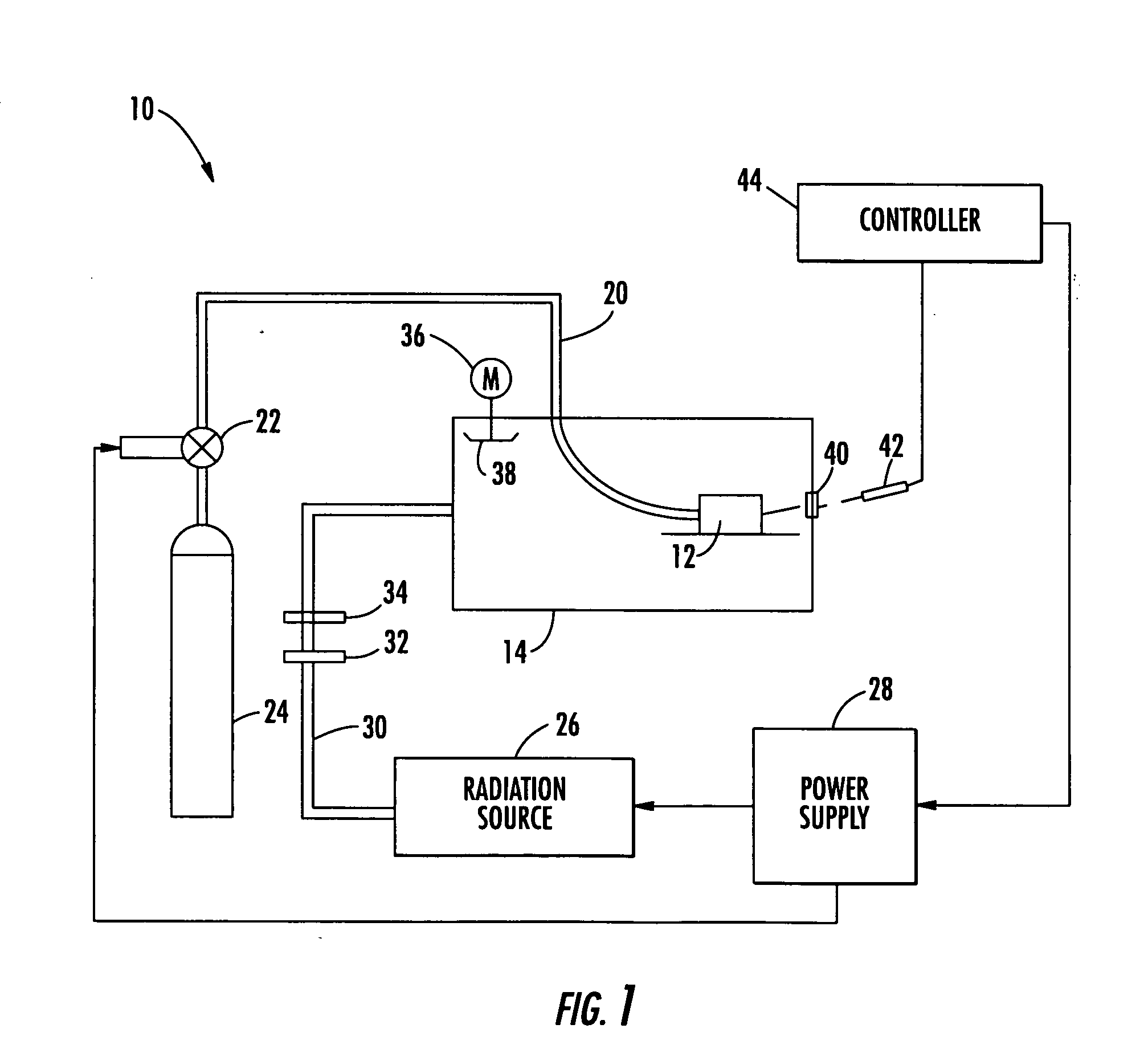

Plasma-assisted coating

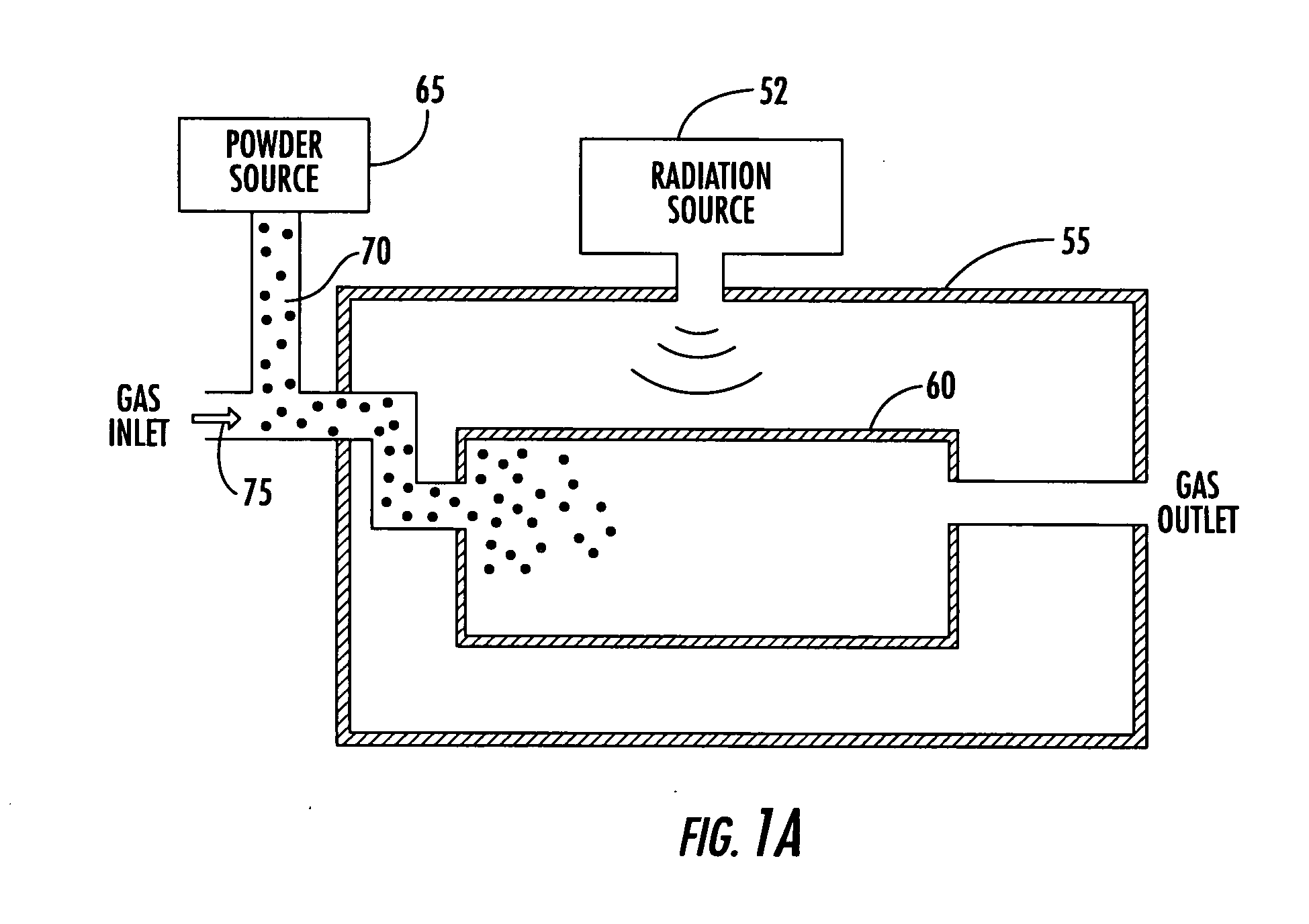

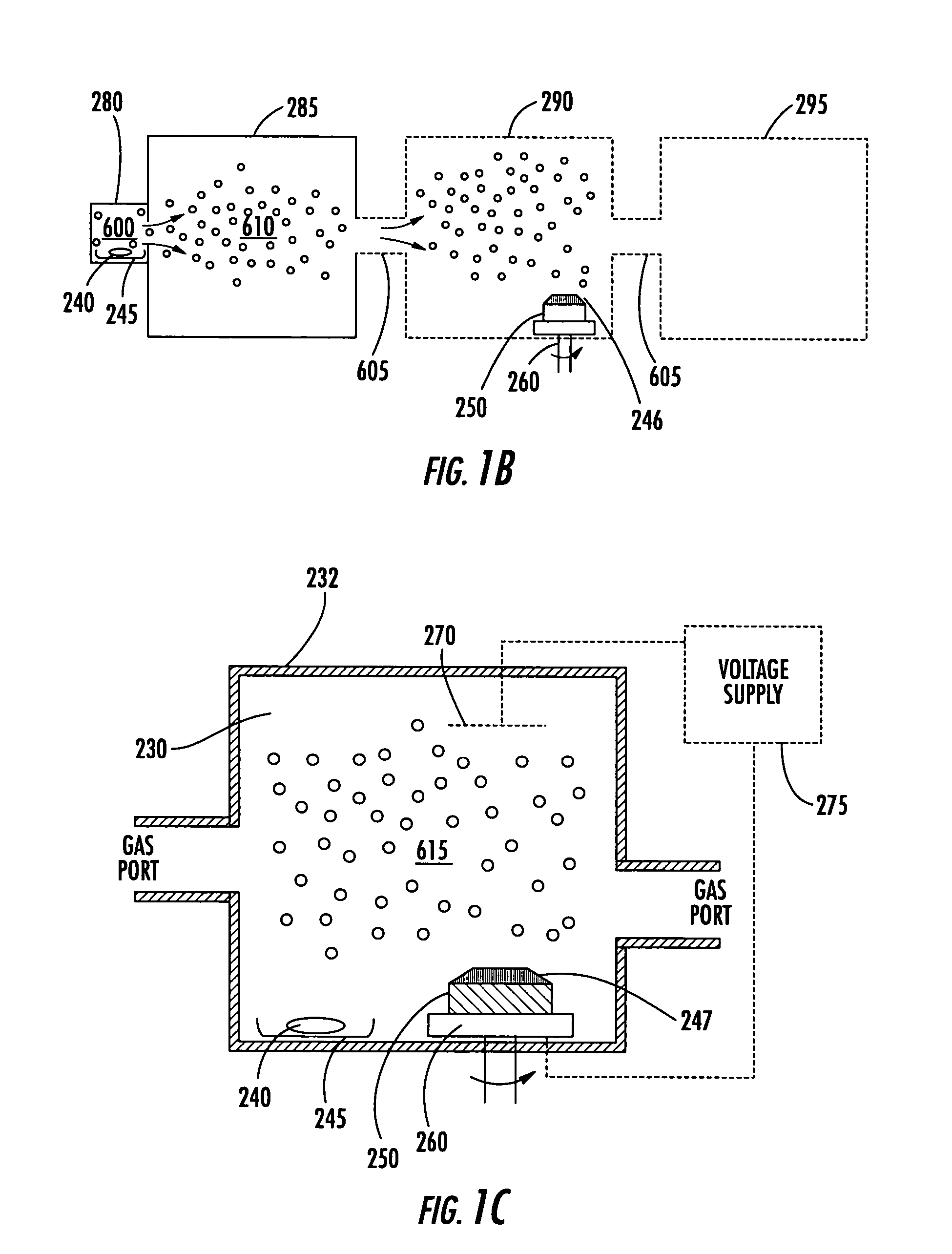

InactiveUS20060228497A1Material nanotechnologyElectric discharge tubesCarbon nanotubeElectromagnetic radiation

Owner:BTU INTERNATIONAL

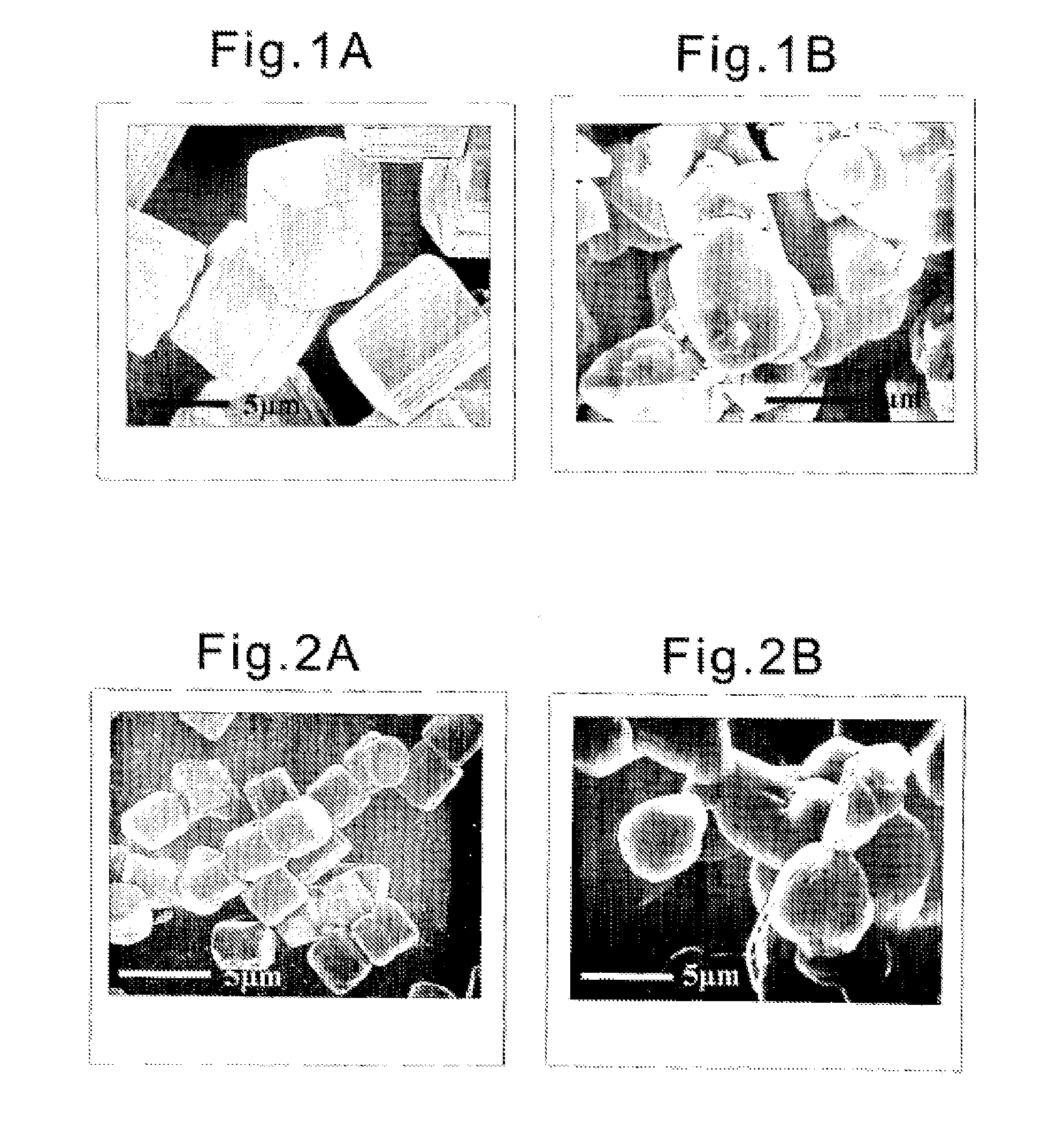

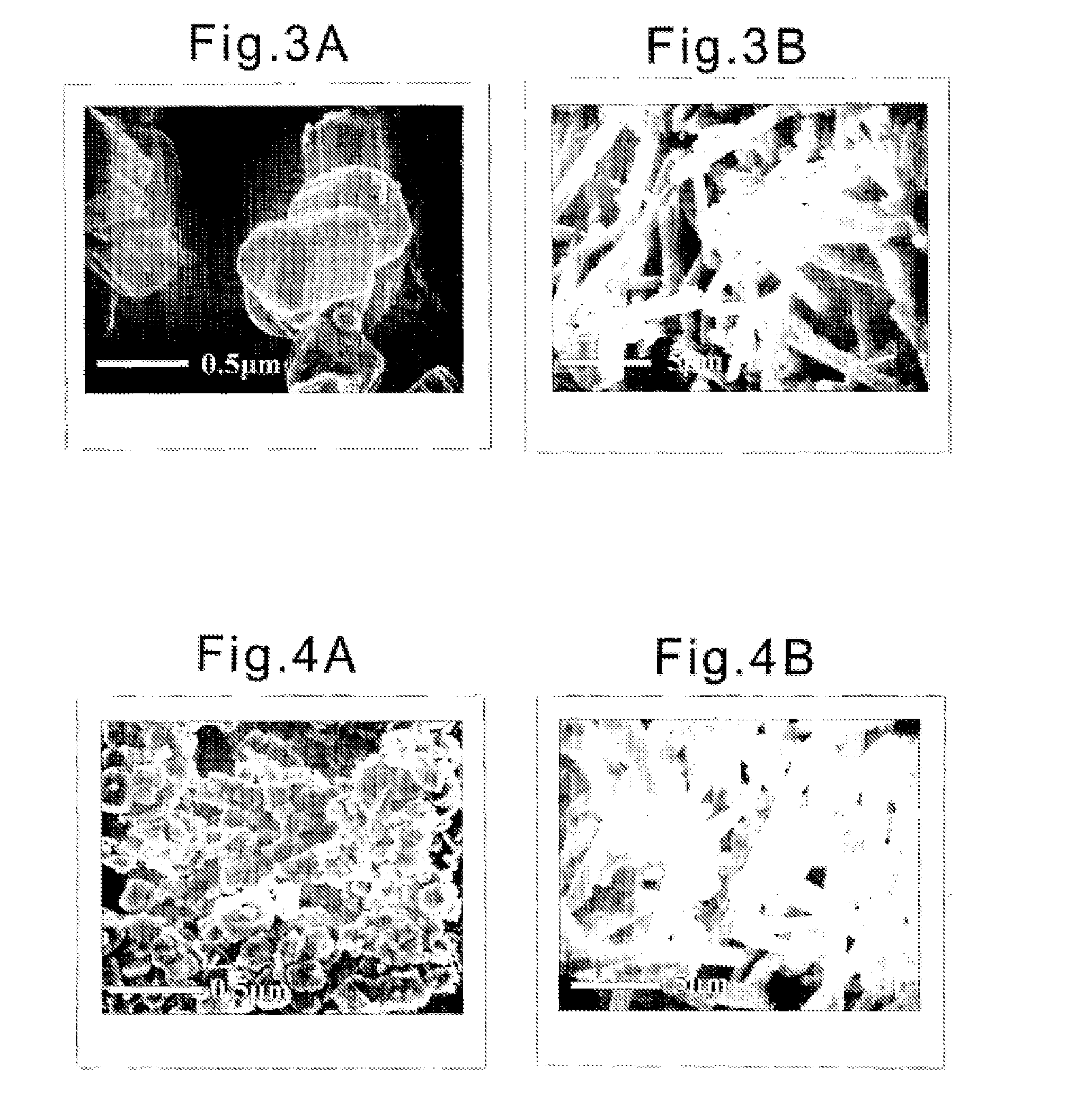

Sialon-based oxynitride phosphor and production method thereof

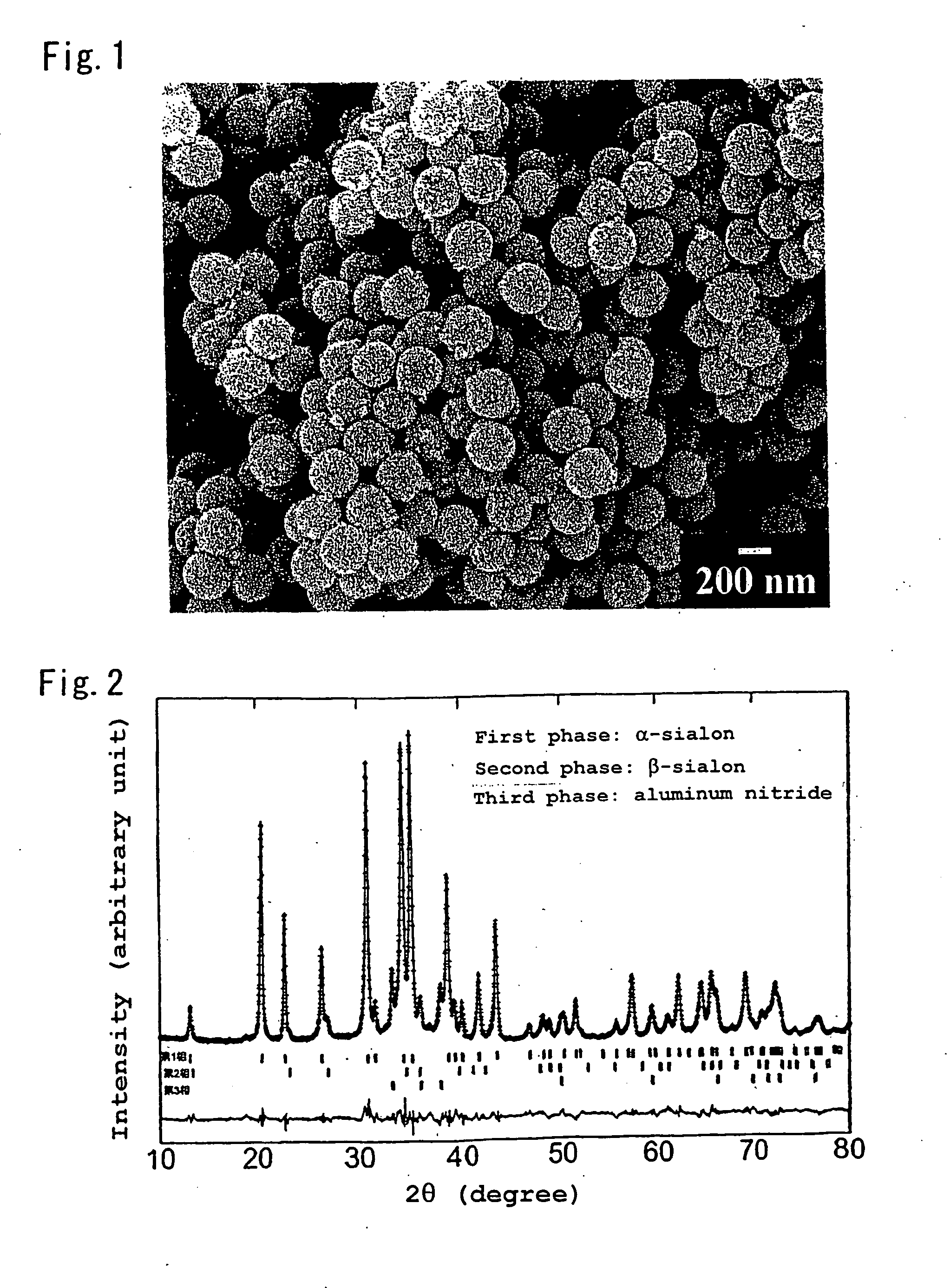

InactiveUS20090284948A1Prevent excessive aggregationLess fusionDischarge tube luminescnet screensElectric discharge tubesLanthanideElectron

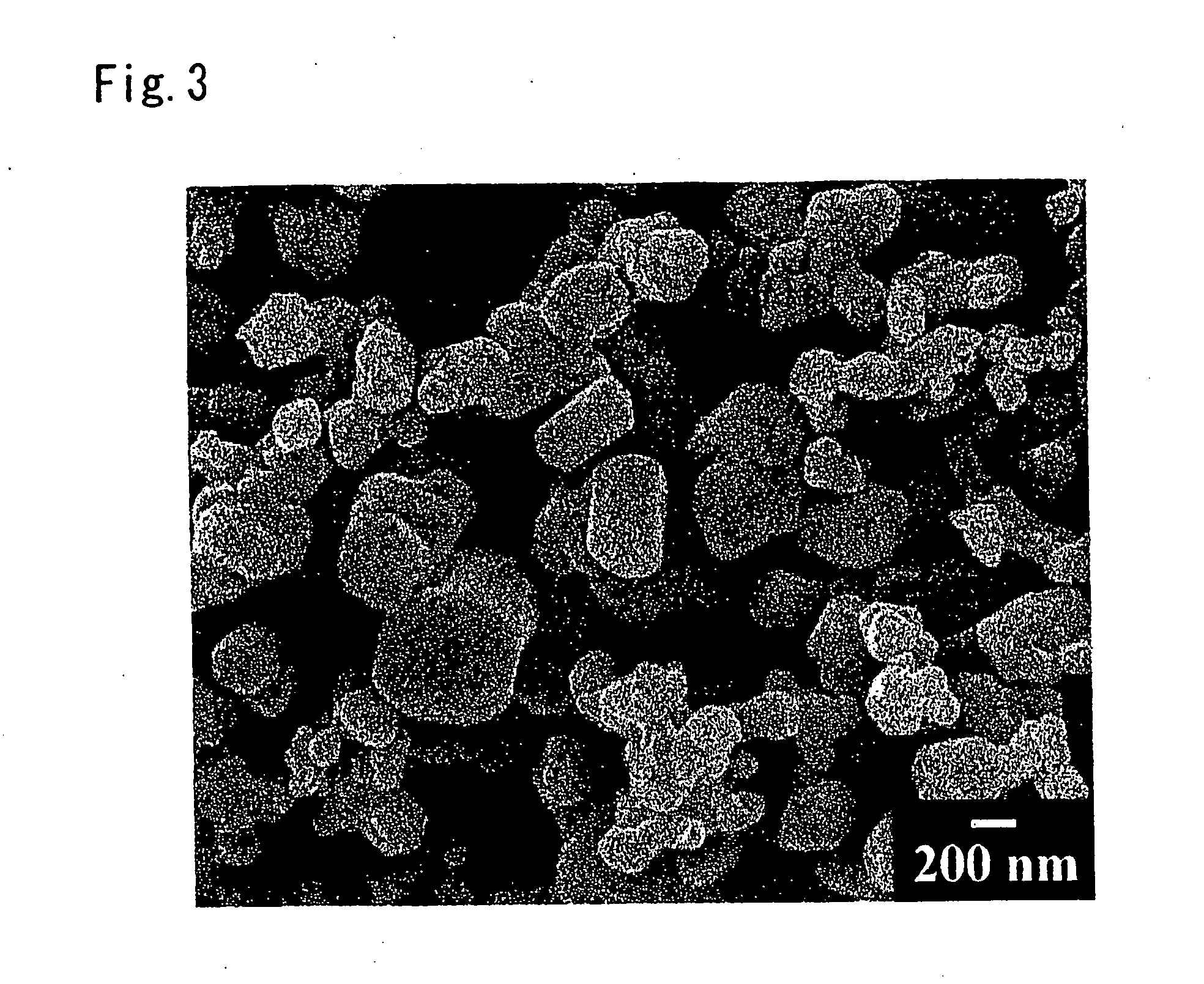

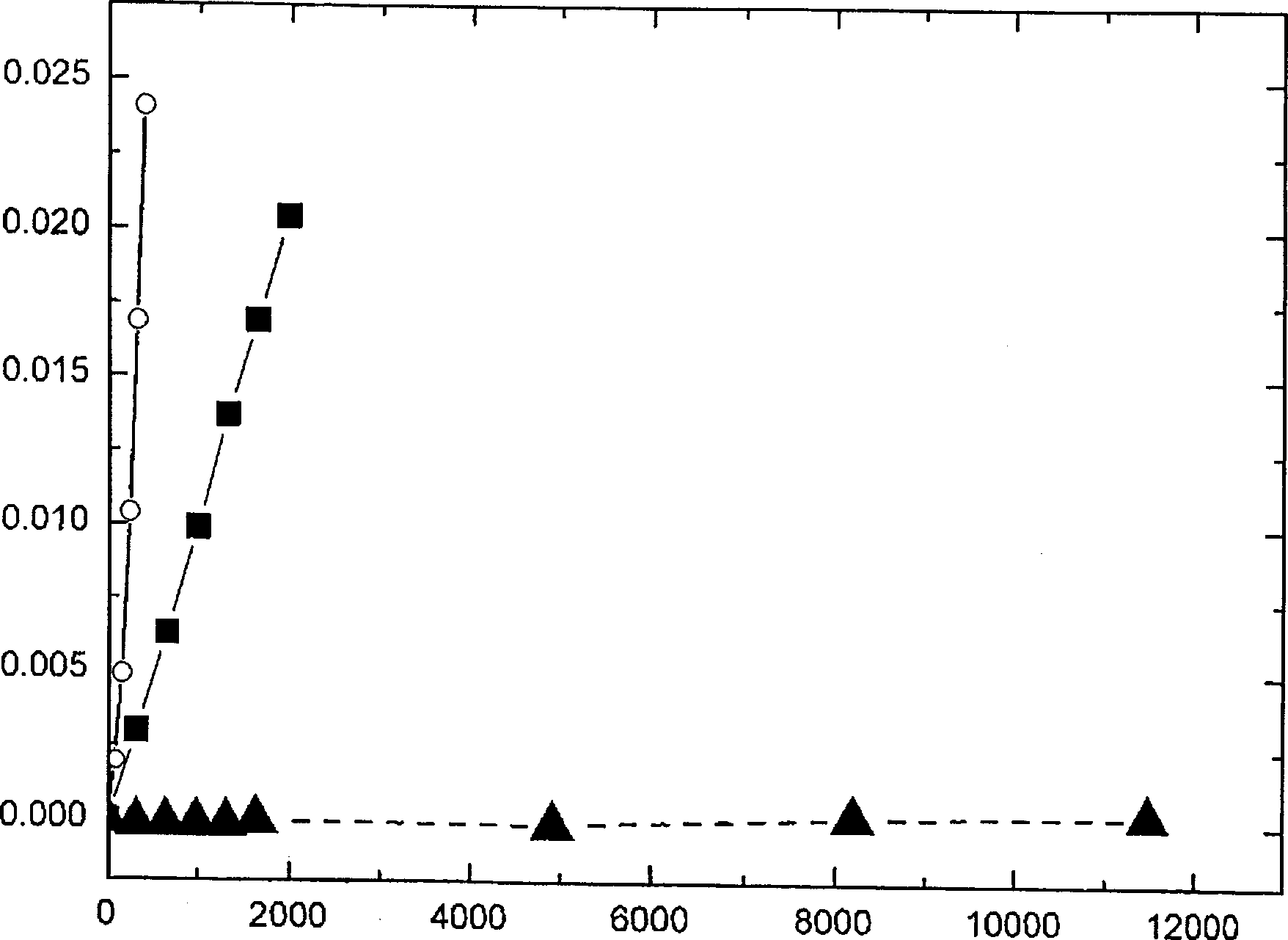

The present invention relates to an oxynitride phosphor comprising an α-sialon as the main component, which is represented by the general formula: MxSi12−(m+n)Al(m+n)OnN16−n:Lny (wherein 0.3≦x+y<1.5, 0<y<0.7, 0.3≦m<4.5, 0<n<2.25, and assuming that the atomic valence of the metal M is a and the atomic valence of the lanthanide metal Ln is b, m=ax+by) and in which the aggregation index, A1=D50 / DBET≦3.0 or the aggregation index A2=D50 / Dparticle≦3.0; and a production method and usage of the phosphor.The phosphor of the present invention has less aggregation and a narrow particle size distribution, and therefore is easy to uniformly mix with a resin or the like, and a high-brightness white LED can be easily obtained.D50 [μm]: The median diameter in the grain size distribution curve.DBET [μm]: The equivalent-sphere diameter calculated on the basis of a BET specific surface area.Dparticle [μm]: The primary particle diameter measured by the image analysis of a scanning electron micrograph.

Owner:UBE IND LTD

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Oxynitride phosphor and light-emitting instrument

InactiveUS20070018567A1Increase brightnessReduced in material deterioration and luminance dropAddress electrodesSustain/scan electrodesRare-earth elementPhosphor

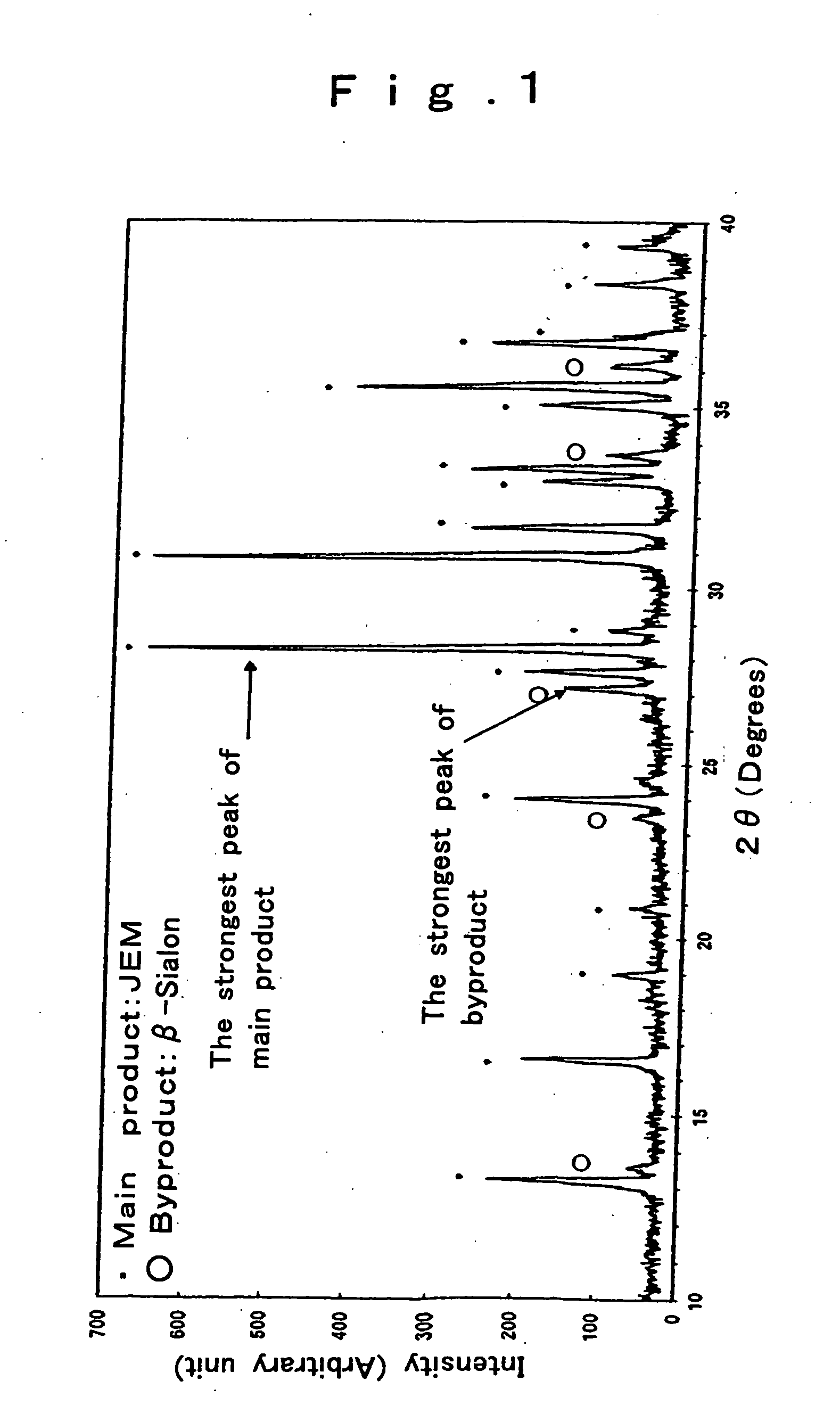

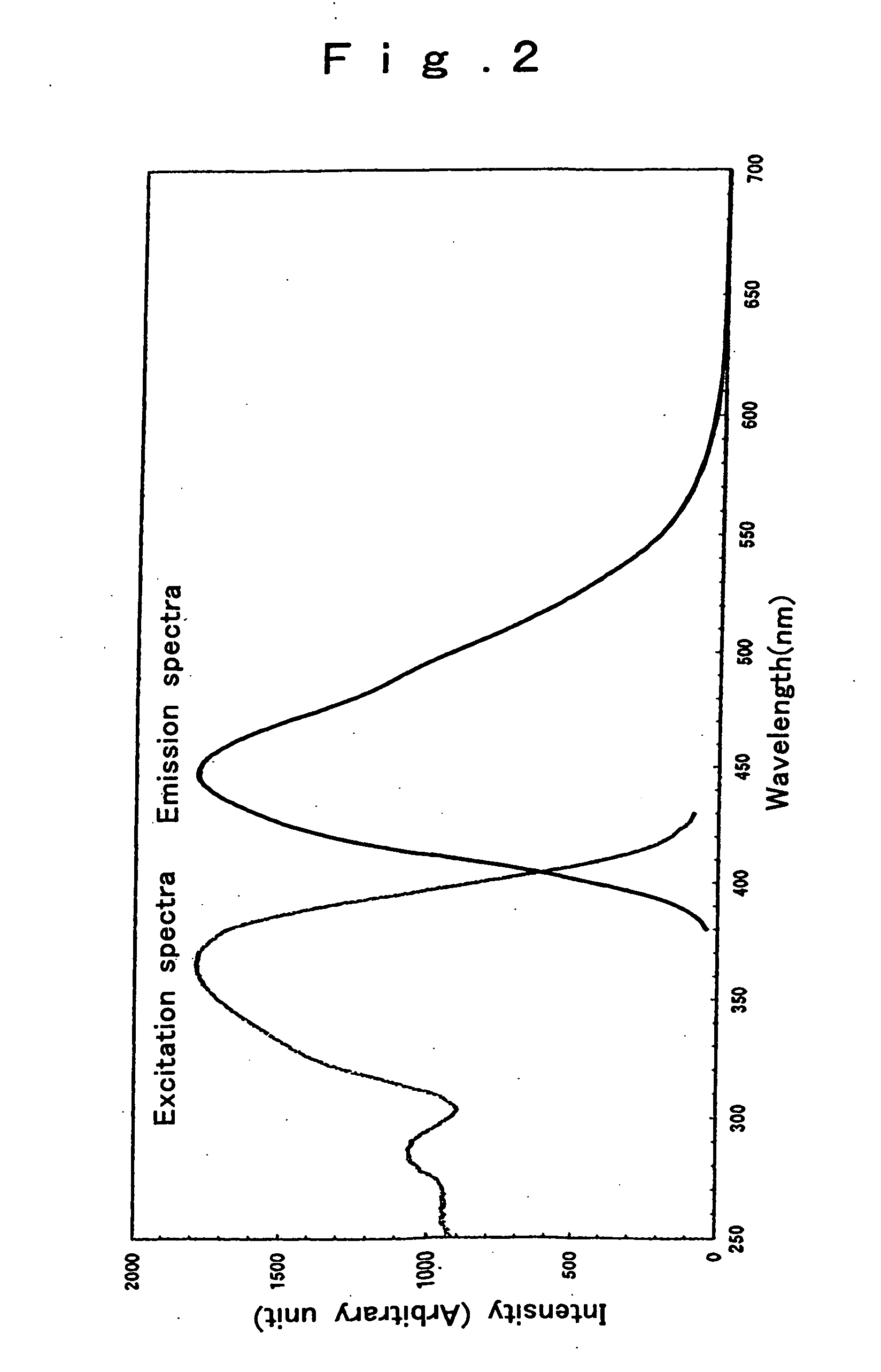

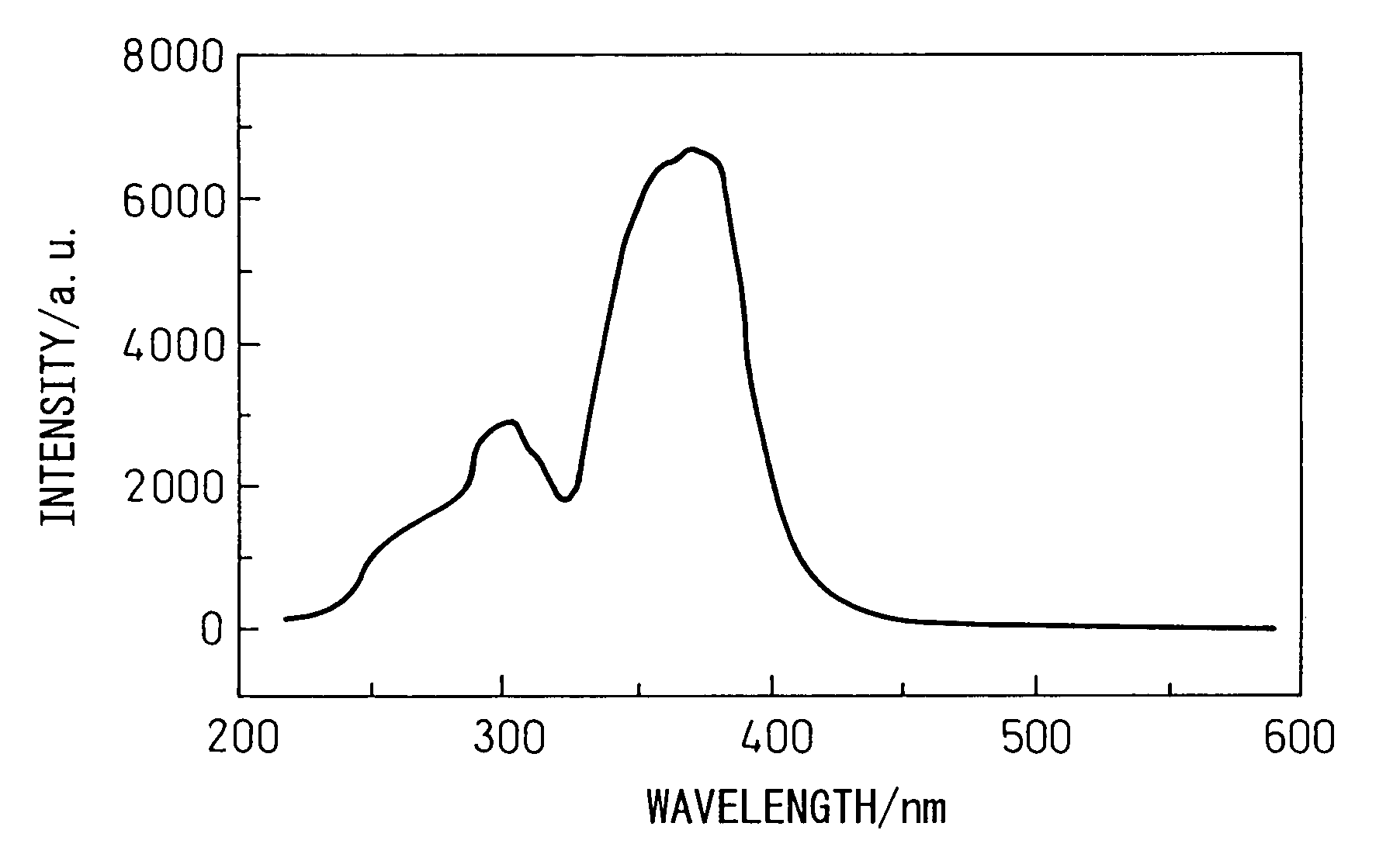

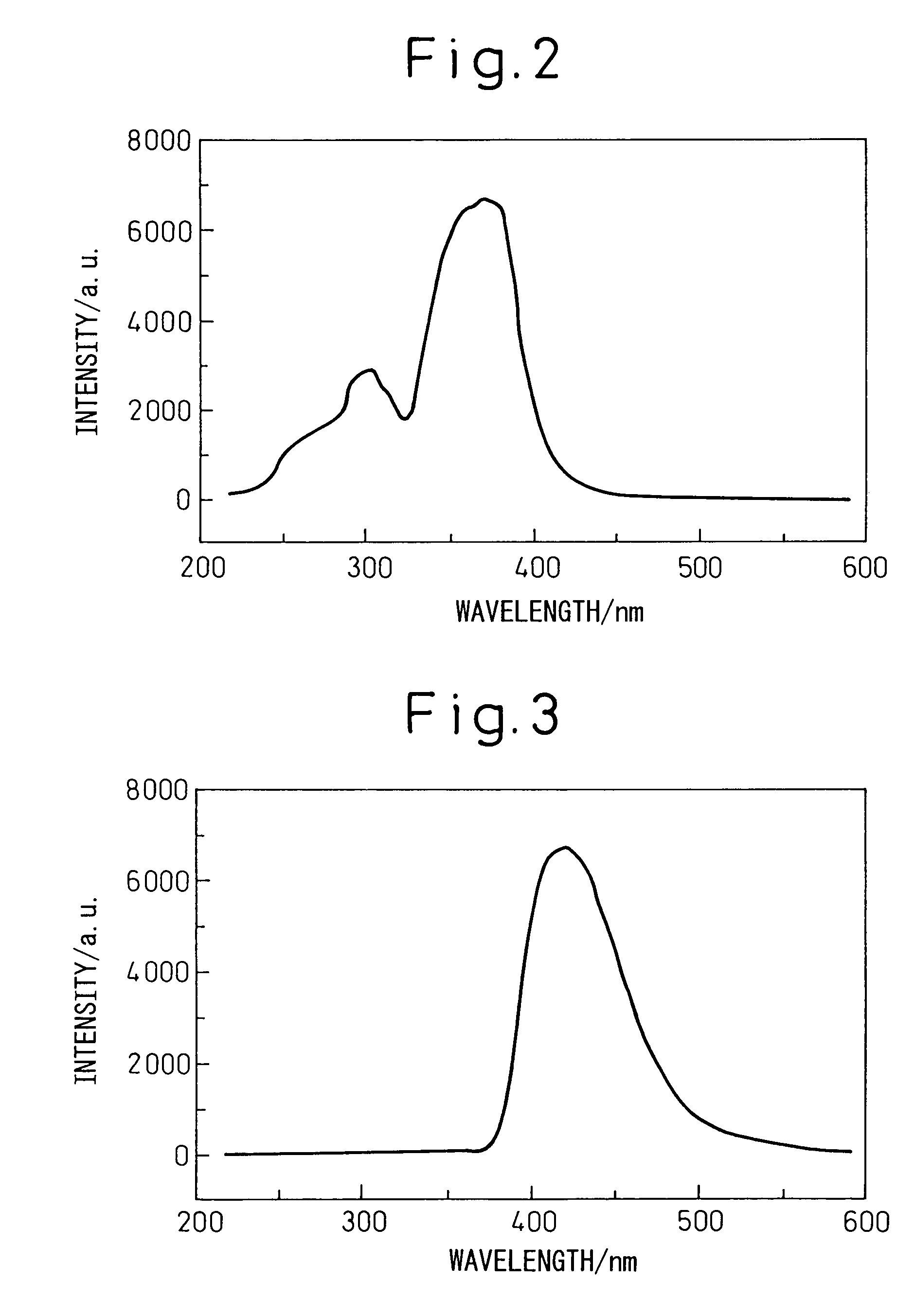

The invention has for its object the provision of an oxynitride fluorescent material has higher emission luminance than conventional rare earth element-activated sialon fluorescent materials. To this end, an oxynitride fluorescent material is designed in such a way as to contain as the primary constituent a JEM phase represented by a general formula MA1(Si6−zAlz)N10−zOz wherein M is one or two or more elements selected from the group consisting of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu. For instance, this fluorescent material has a fluorescent spectrum maximum emission wavelength of 420 nm to 500 nm inclusive and an excitation spectrum maximum emission excitation wavelength of 250 nm to 400 nm inclusive.

Owner:NAT INST FOR MATERIALS SCI

Oxynitride phosphor and light-emitting device

ActiveUS20060192178A1Increase brightnessNot easy to deteriorateIncadescent screens/filtersDischarge tube luminescnet screensRare-earth elementPhosphor

A phosphor which is excited by a blue light and emits a yellow light has been conventionally known as a SiAlON phosphor wherein a rare earth element such as Eu ion is activated. The present invention provides an oxynitride phosphor having emission characteristics of more various wavelengths and a light-emitting device using such an oxynitride phosphor. The oxynitride phosphor mainly contains a crystalline phase of the general formula: La3Si8N11O4 or a crystalline phase of the general formula: La3Si8−xAlxN11−xO4+x (0<x≦4), and an optically active element (M) composed of one or more elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu is added thereto as a luminescent center component.

Owner:NAT INST FOR MATERIALS SCI

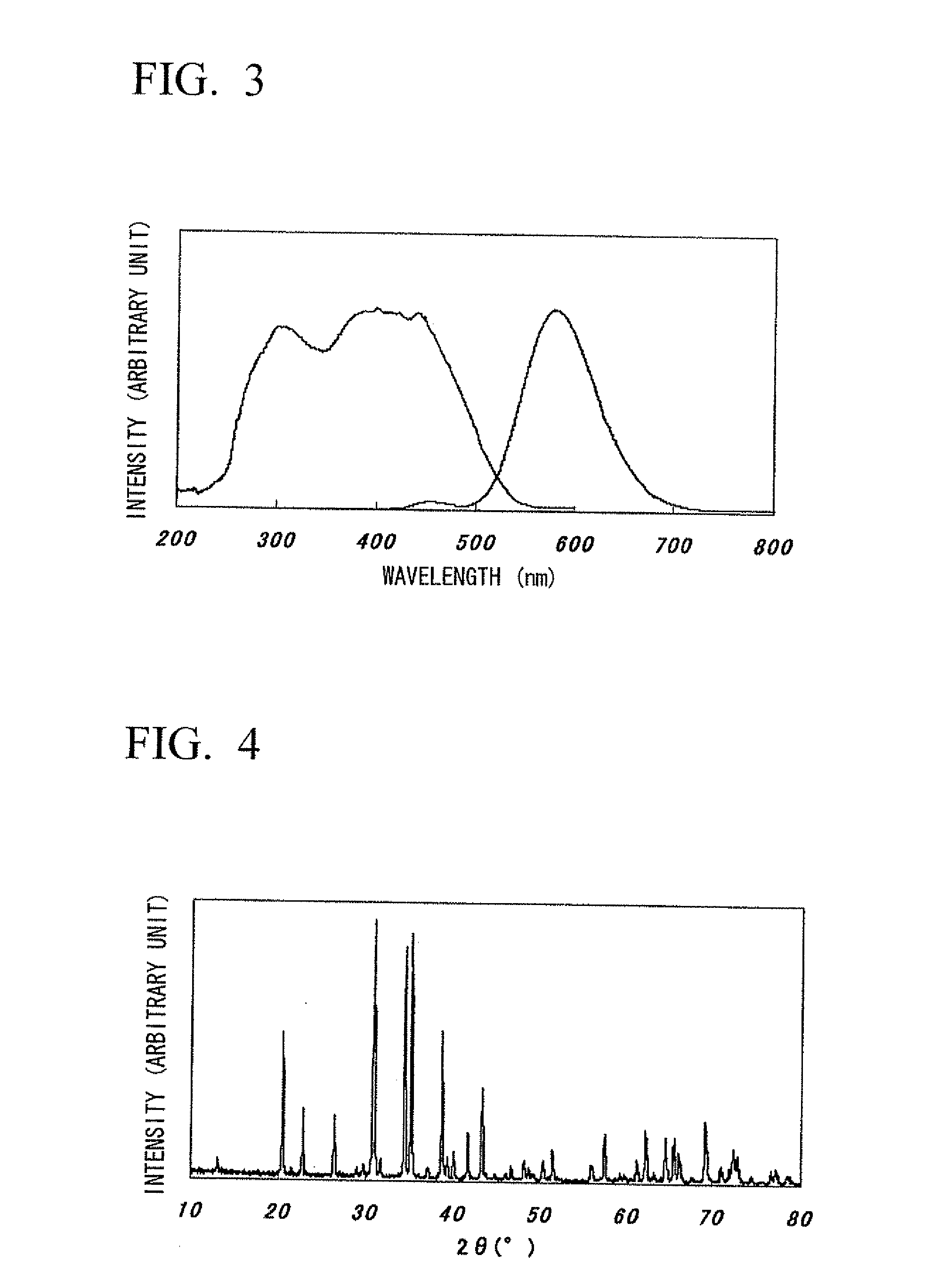

Fluorescent substance and production method thereof, and light emitting device

ActiveUS20100053932A1Excels substanceImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceUltraviolet lights

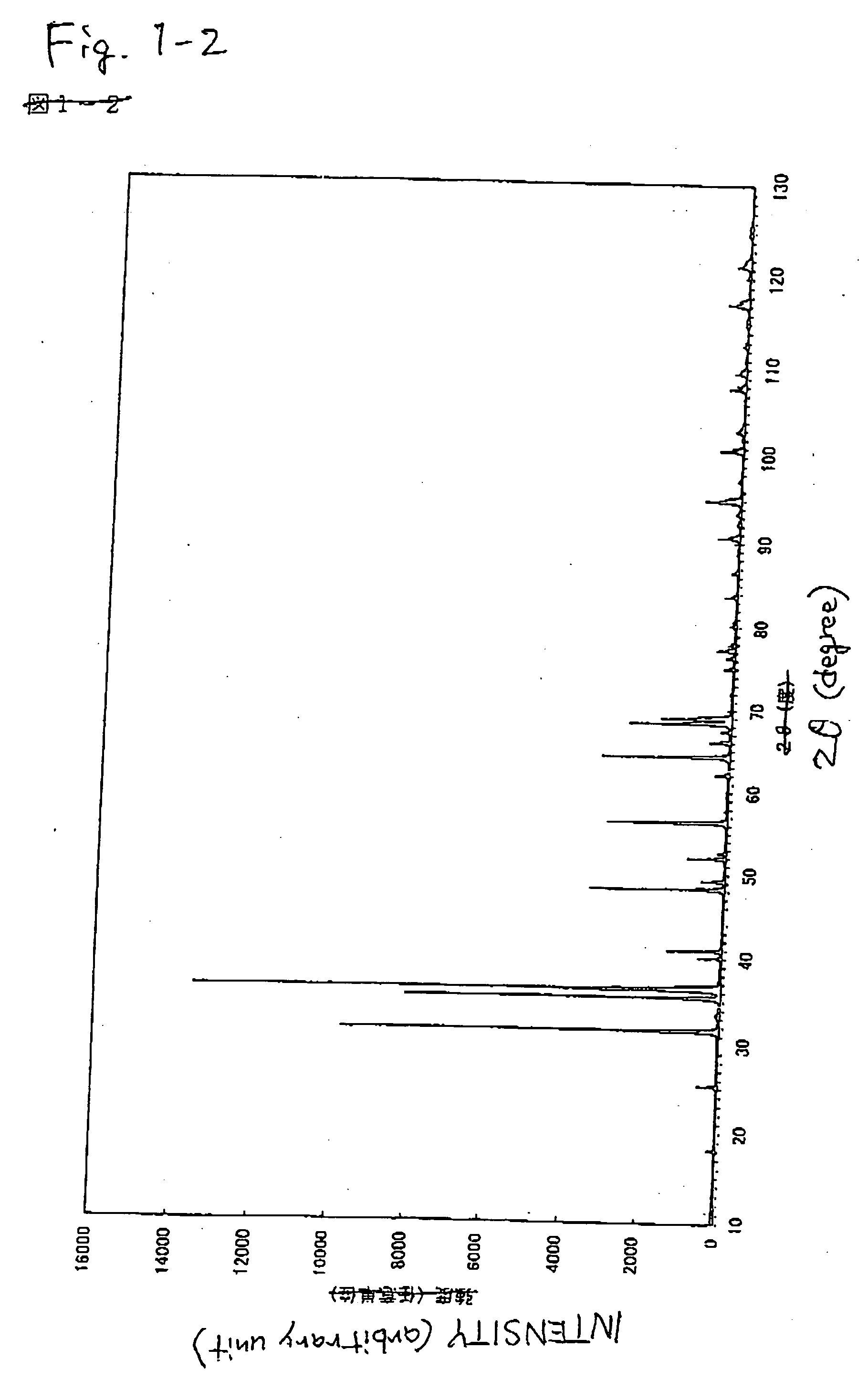

Offered is a fluorescent substance consisting of Eu-activated β-sialon and capable of enhancing the brightness of a light emitting device such as a white LED using blue or ultraviolet light as a light source. The fluorescent substance has as its main constituent a β-sialon represented by the general formula Si6-zAlzOzN8-z and containing Eu, wherein the spin density is 2.0×1017 / g or less as measured by electron spin resonance spectroscopy corresponding to an absorption of g=2.00±0.02 at 25° C. In the above fluorescent substance, it is preferable that lattice constant a of the β-sialon be 0.7608-0.7620 nm, the lattice constant c be 0.2908-0.2920 nm, and the Eu content be 0.1-3 mass %.

Owner:DENKA CO LTD

Phosphor and Light Emitting Instrument

ActiveUS20080303409A1Without luminance deteriorationLong wavelengthSustain/scan electrodesDischarge tube luminescnet screensPhosphorRare earth

The present invention aims at providing a chemically stabilized inorganic phosphor which emits orange light or red light at wavelengths longer than the conventional rare-earth activated sialon phosphor and which has a higher luminance.The solving means resides in an inorganic phosphor design represented by a composition formula MaAbDcEdNeOfXg and containing: an M element (M is one kind or two or more kinds of element(s) selected from Mn, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu); a divalent A element (A is one kind or two or more kinds of element(s) selected from Mg, Ca, Sr, and Ba); a trivalent E element (E is one kind or two or more kinds of element(s) selected from B, Al, Ga, and In); a tetravalent D element (D is one kind or two or more kinds of element(s) selected from Si, Ge, and Sn); nitrogen; oxygen (including an oxygen absent condition); and another X element (including an X absent condition); wherein the parameters a, b, c, d, e, f, and g included in the equation are adjusted to and set at particular regions to provide an inorganic phosphor which emits orange light at wavelengths of 570 nm or longer or red light at wavelengths of 600 nm or longer with excellent color rendering property.

Owner:NAT INST FOR MATERIALS SCI

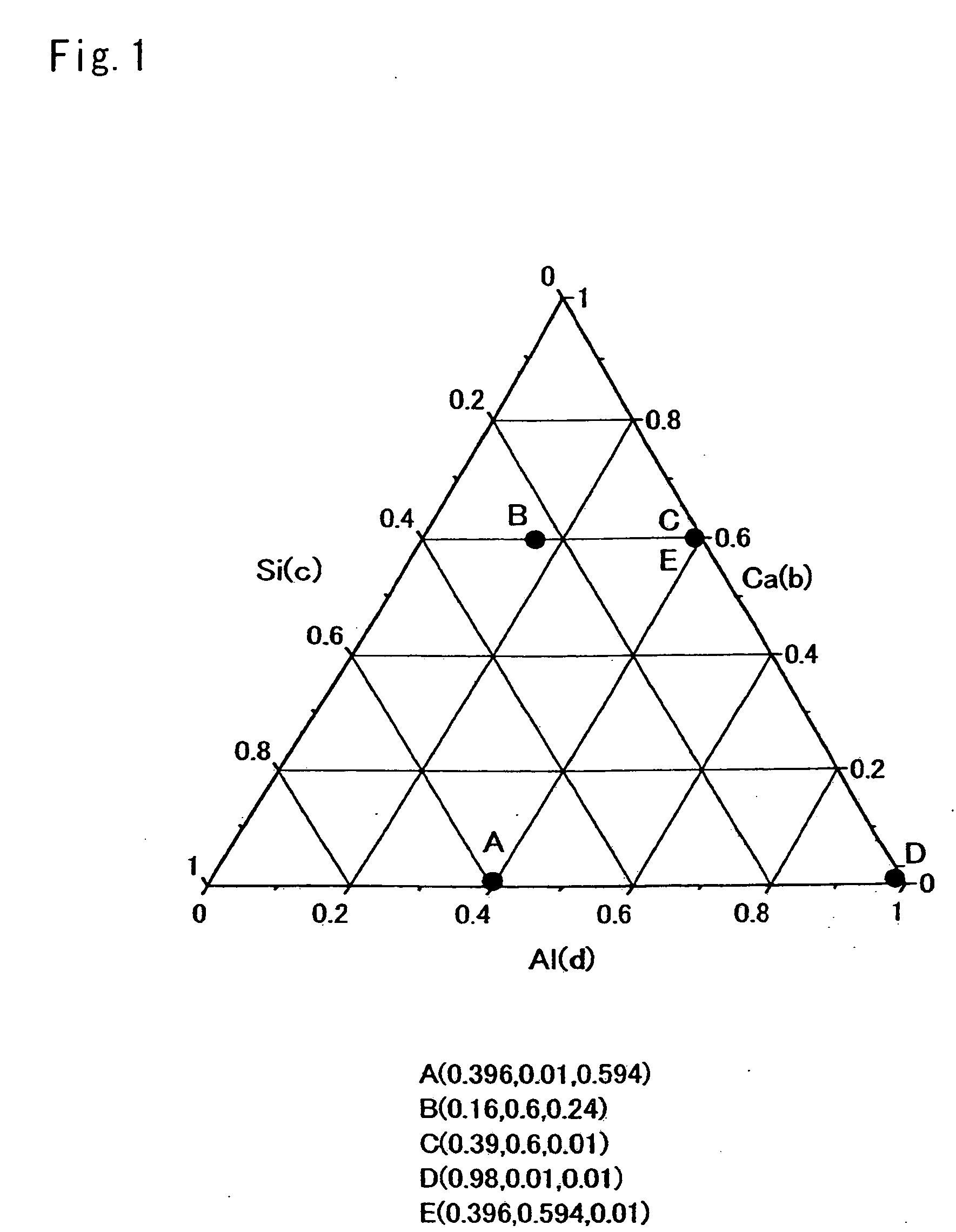

Phosphor, Production Method Thereof and Light Emitting Instrument

ActiveUS20080143246A1Without luminance deteriorationIncrease production capacityDischarge tube luminescnet screensCathode ray tubes/electron beam tubesAlkaline earth metalRare earth

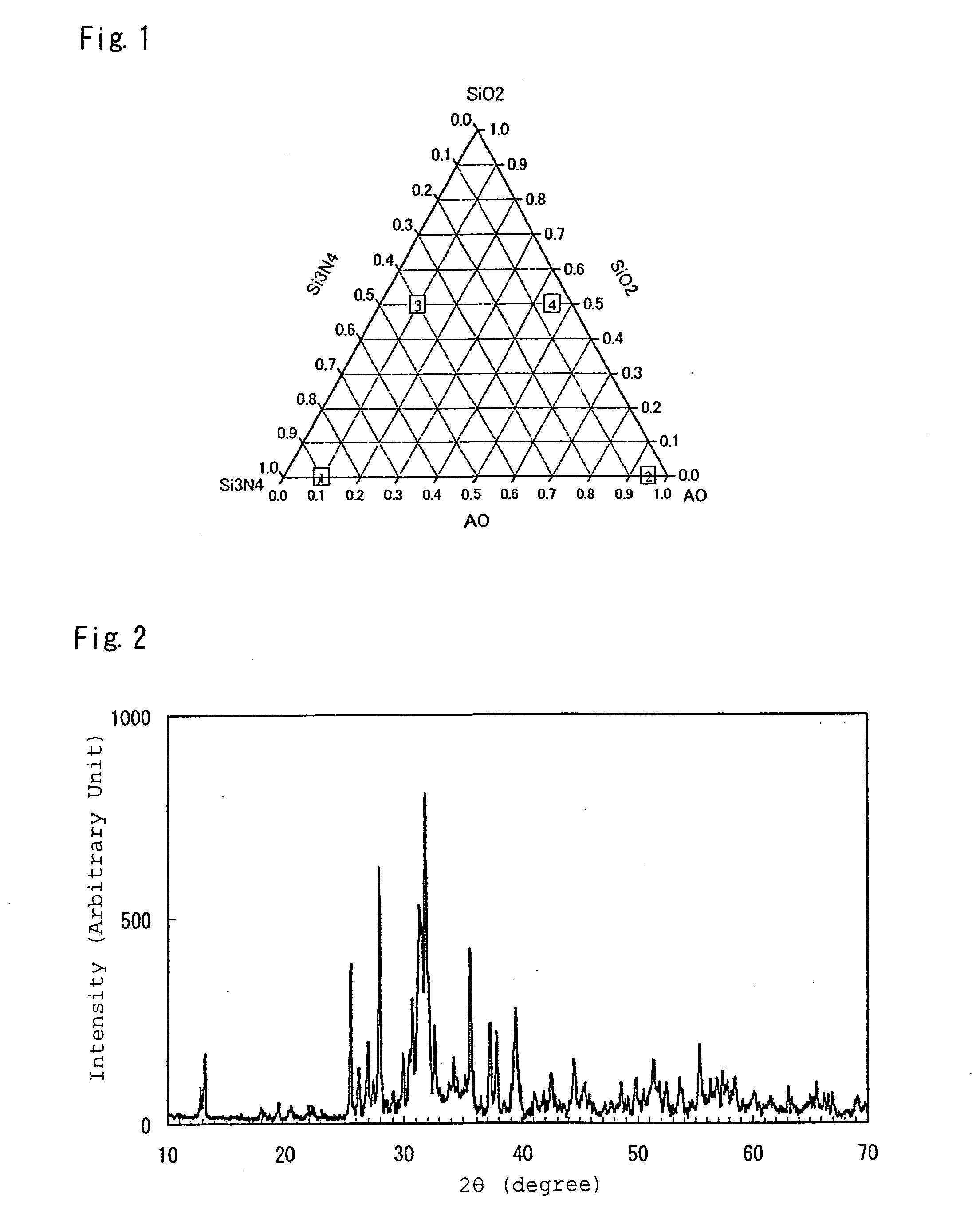

The present invention aims at providing a chemically stabilized inorganic phosphor, among oxynitride phosphors including alkaline earths, which oxynitride phosphor emits orange or red light at longer wavelengths at higher luminance than conventional sialon phosphors activated by rare earths. The present invention further aims at providing a light emitting instrument based on the phosphor, for a lighting instrument excellent in color rendering property and for an image displaying apparatus excellent in durability.The solving means resides in provision of a fundamental phosphor comprising:a composition on a pseudo-ternary phase diagram including AO (A is one kind or two or more kinds of element(s) selected from Mg, Ca, Sr, and Ba; and AO is oxide of A), Si3N4, and SiO2 as end members, respectively, and satisfying all of the following conditions:in a composition formula, pAO-qSi3N4-rSiO2 (p+q+r=1),0.1≦p≦0.95, (1)0.05≦q≦0.9, and (2)0≦r≦0.5, and (3)at least a metallic element M (M is one kind or two or more kinds of element(s) selected from Mn, Ce, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) dissolved, in a solid state, in the composition.

Owner:NAT INST FOR MATERIALS SCI

Oxynitride powder and production method thereof

ActiveUS20070166218A1Low oxygenHigh nitrogen contentAluminium compoundsAluminium silicatesPhosphorNitrogen

It is aimed at providing an oxynitride powder, which is suitable for usage as a phosphor, is free from coloration due to contamination of impurities, and mainly includes a fine α-sialon powder. An oxynitride powder is produced by applying a heat treatment in a reducing and nitriding atmosphere, to a precursor compound including at least constituent elements M, Si, Al, and O (where M is one element or mixed two or more elements selected from Li, Mg, Ca, Sr, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), thereby decreasing an oxygen content and increasing a nitrogen content of the precursor.

Owner:NAT INST FOR MATERIALS SCI

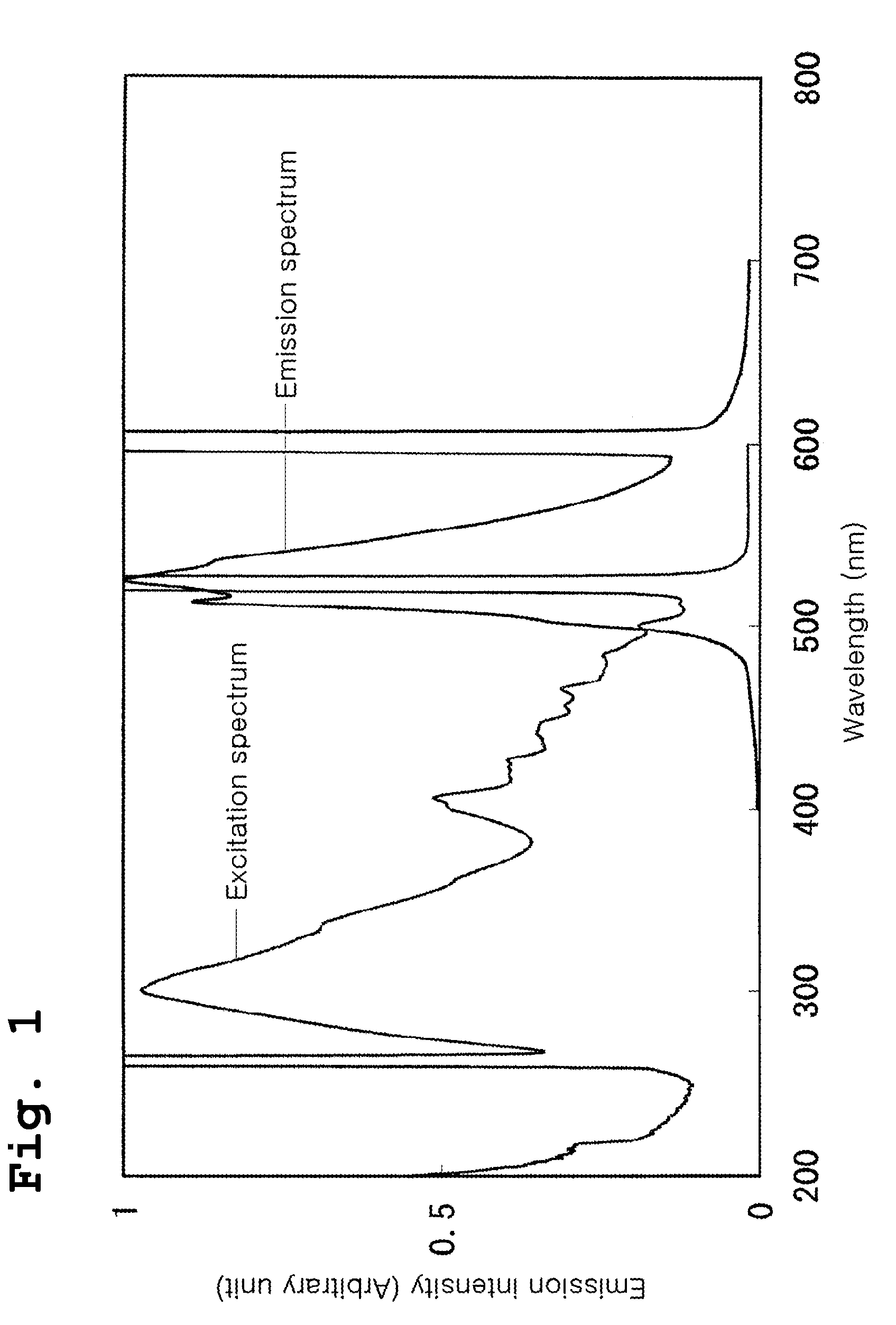

Phosphor, process for producing the same, and luminescent device

ActiveUS20110121234A1Narrow peak widthIncrease brightnessElectric discharge tubesSolid-state devicesRare earthGreen-light

A green phosphor for emitting light, a spectrum of which is sharp, in an ultraviolet and visible light region, which has higher green light brightness than the conventional rare earth-activated sialon phosphor and has higher durability than the conventional oxide phosphor, is provided. The phosphor being characterized in that Al and a metal element M (here, M is Eu) are incorporated into a crystal of a nitride or oxynitride having a βSi3N4 crystal structure as a solid solution, the content of oxygen in the crystal does not exceed 0.8% by mass, and that the phosphor emits a visible light having a luminescence peak wavelength in the range of 450 nm to 650 nm upon exposure to an excitation source is provided. This luminescence spectrum has a sharp spectrum shape. A manufacturing method of the phosphor, a lighting device and an image display device utilizing the phosphor are also provided.

Owner:NAT INST FOR MATERIALS SCI

Low cost process of synthesizing sialon ceramic powder

The method for synthesizing sialon ceramic powder material by low cost is characterized by using metallurgical furnace slag or limestone or fly ash industrial waste material or cheap natural mineral as raw material, adding metal silicon powder, aluminium powder and partial crystal seed through the processes of ball grinding, drying, high-temp. self spreading and other treatment to obtain the invented single-phase alpha-sialon powder material. Said powder material possesses excellent sintering property, can be sintered without pressure at 1600-1800 deg.C, its density is up to 3.07g / se.cm, hardness is 15.53 GPa, and its toughness is 4.72 Mpa.m(1 / 2), as compared with Al2O3, ZrO2 and SiC ceramics its erosion resistance is excellent.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Refractory metal core coatings

InactiveUS7575039B2Trend downImprove the immunityFoundry mouldsFoundry coresTitanium nitrideDissolution

Owner:RTX CORP

Manufacture method of silicon carbide refractory ceramics material

The invention discloses a preparing method of carbofrax fireproof ceramic material combined by beta-Sialon host phase, which comprises the following steps: adopting predisposal clay mineral raw material, industrial carbon powder and gas with nitrogen as main raw material to form beta-sialon hose combining phase; adding reacting accelerating addictive; adding different particle grades to allocate SiC particle; blending evenly with organic adhesive; moulding biscuit through ceramic moulding method; drying; loading in the high-temperature kiln-furnace with nitrogen; setting the reacting temperature under 1300-1550 deg.c for 3-36h; proceeding carbon heat-nitrogenizing reaction; setting each reacting sintering period at 10-100h; synthesizing the product.

Owner:QINGDAO UNIV

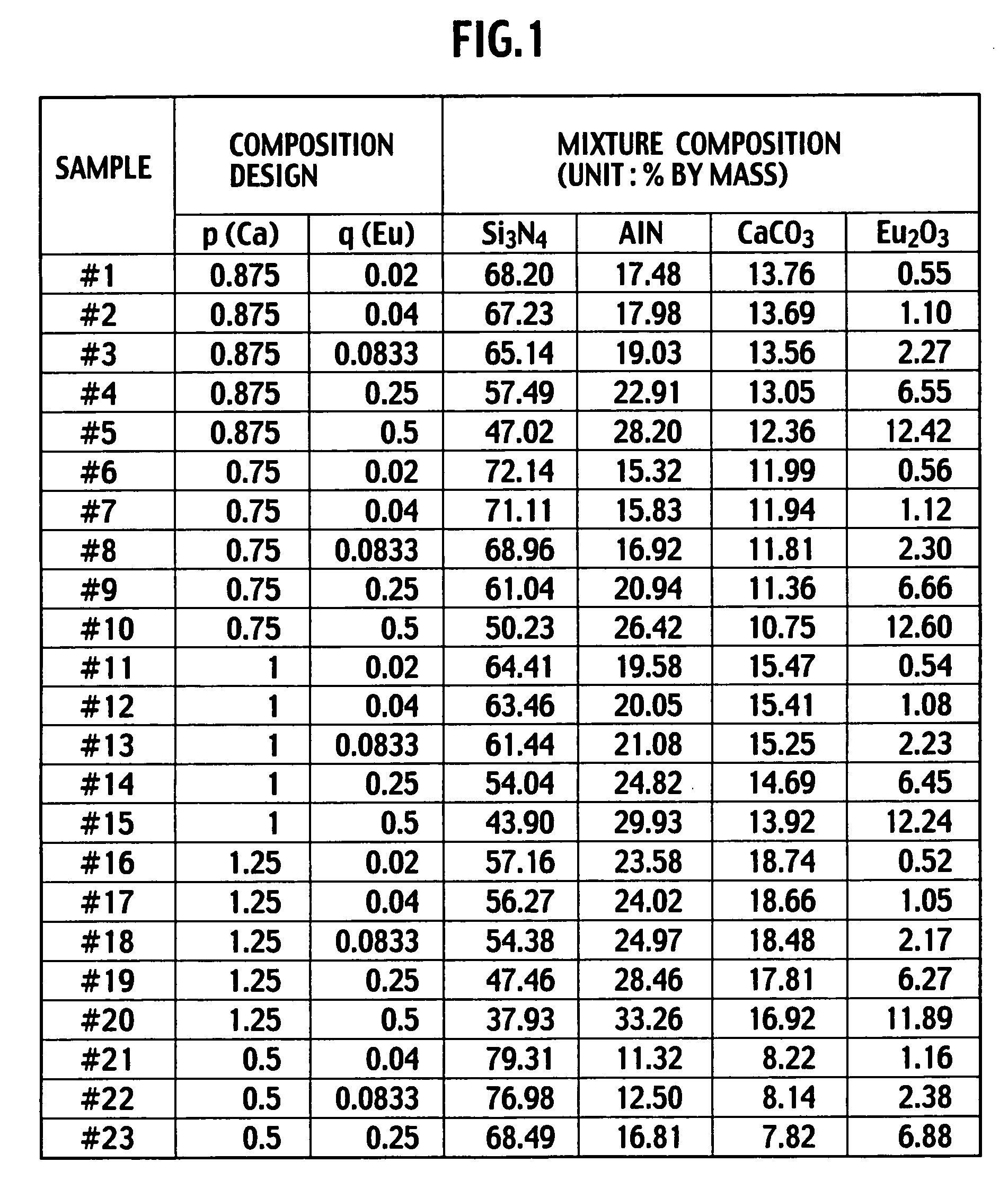

Phosphor, its Production Method, and Light Emitting Apparatus

ActiveUS20080197321A1Improve luminanceIncrease brightnessNitrogen compoundsSolid-state devicesRare earthNitrogen gas

An object of the present invention is to provide an inorganic phosphor, particularly, an oxynitride phosphor containing alkaline earths which has a higher luminance than that of conventional sialon phosphors activated with a rare earth, and is chemically stable.By baking a raw material mixture containing at least silicon nitride powder, M element containing inorganic substance, and A element containing inorganic substance at a temperature range of 1200° C. to 2200° C. in a nitrogen atmosphere, a phosphor comprising an inorganic composition containing at least M Element, A Element, silicon, oxygen, and nitrogen (wherein M Element is one or two or more elements selected from the group consisting of Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb, A Element is one or two or more elements selected from the group consisting of Mg, Ca, Sr, and Ba) and containing at least crystal having the same crystal structure as that of A2Si5N8 and A element-containing crystal is obtained.

Owner:NAT INST FOR MATERIALS SCI

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

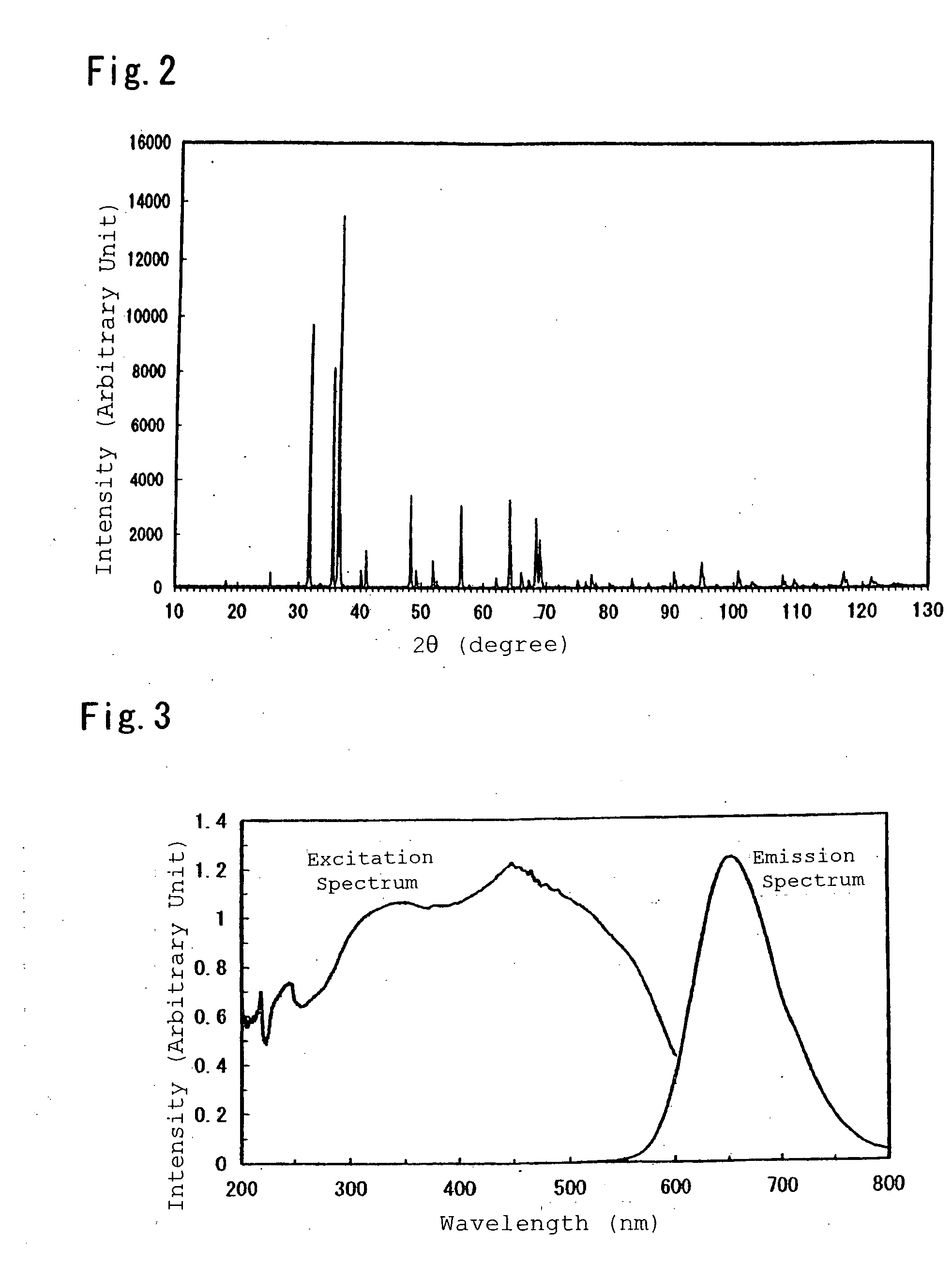

Sialon-based phosphor and its production method

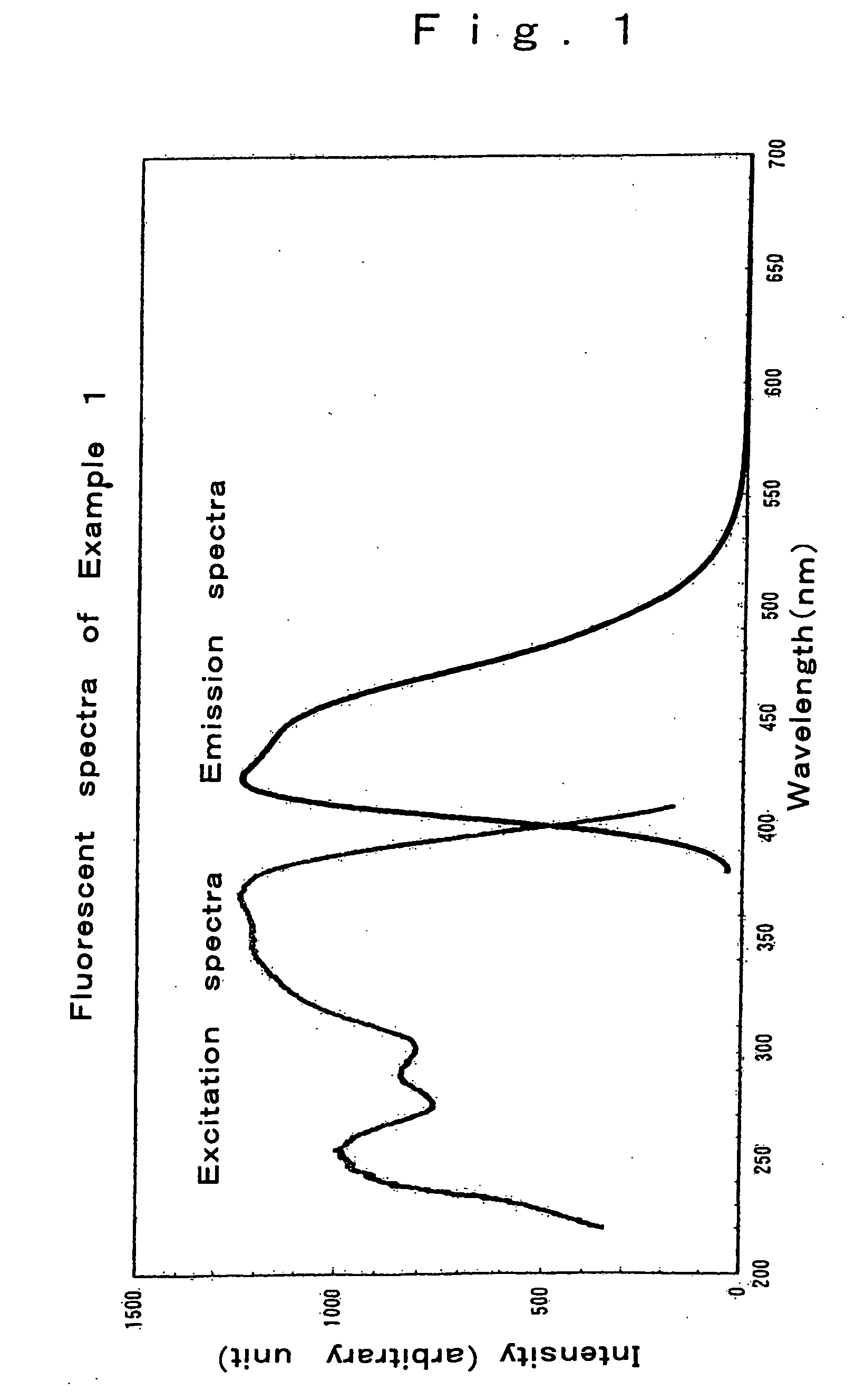

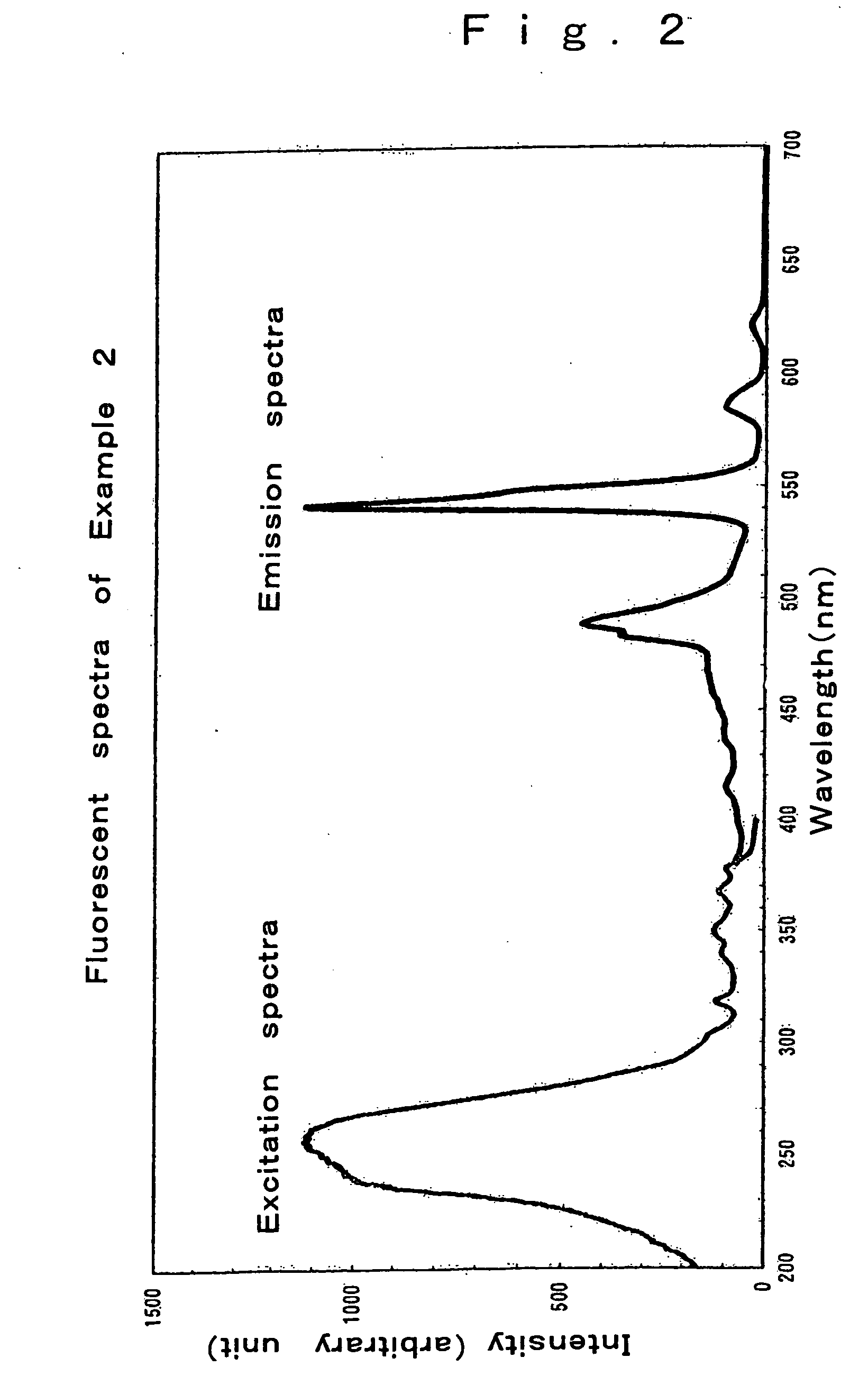

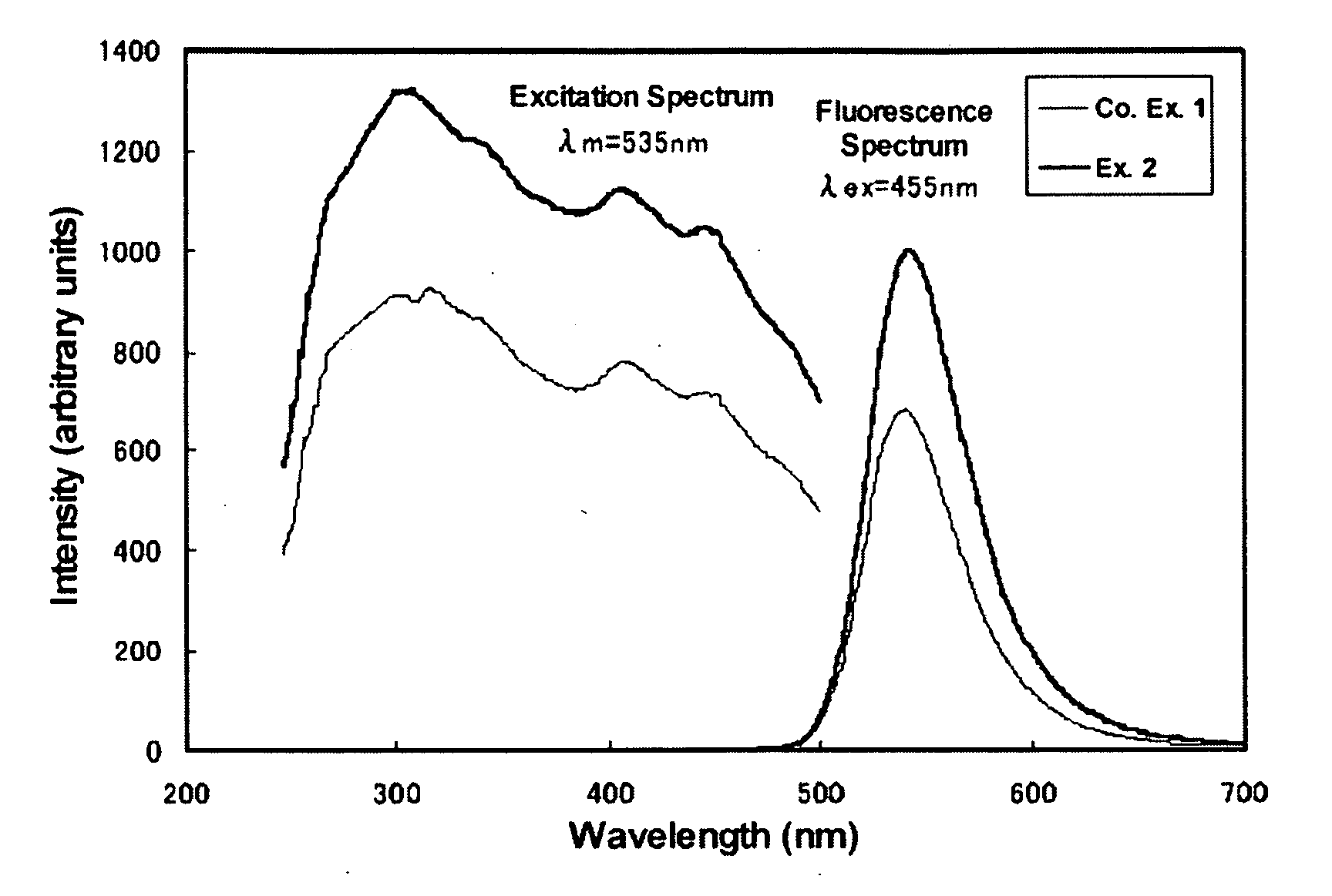

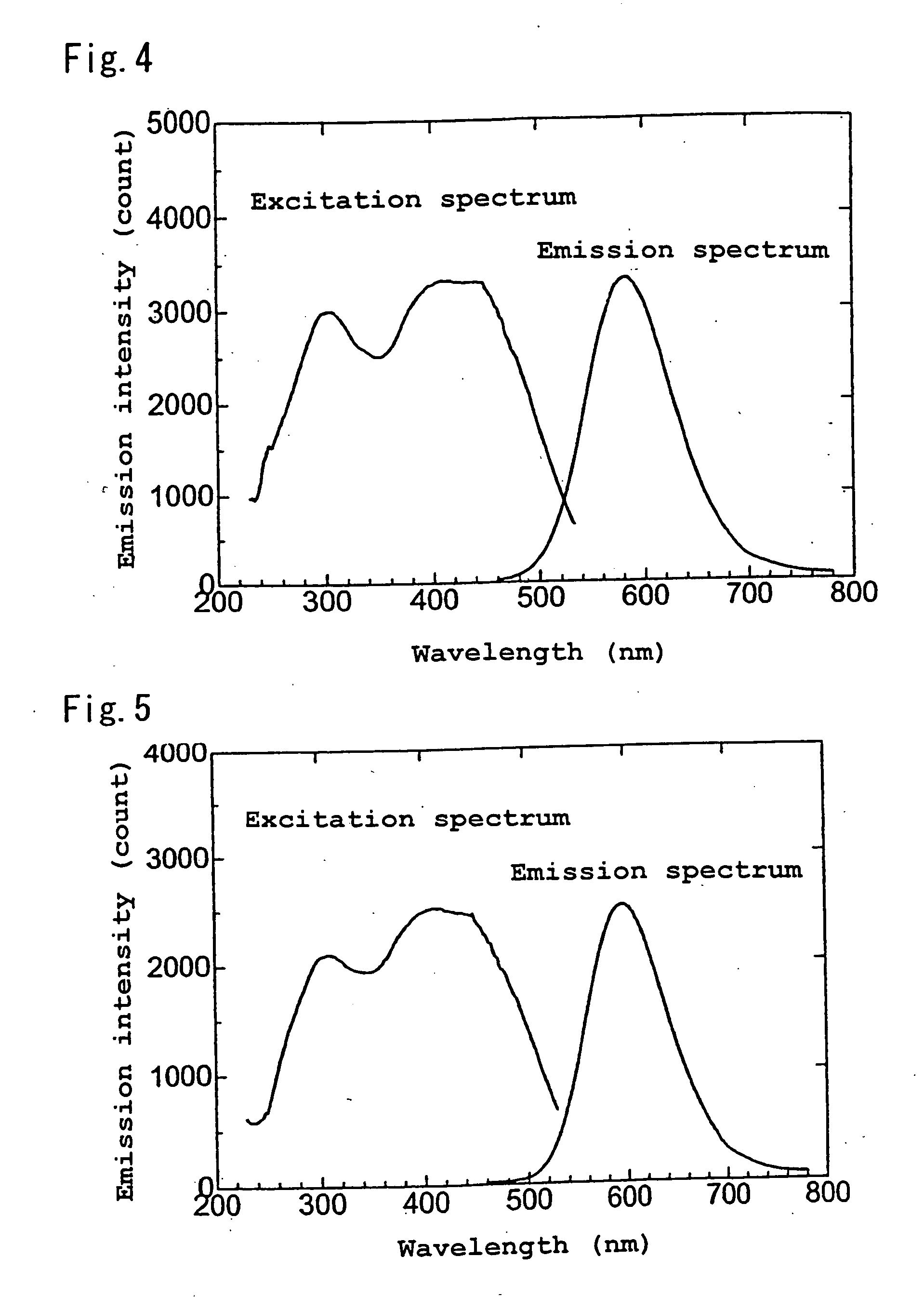

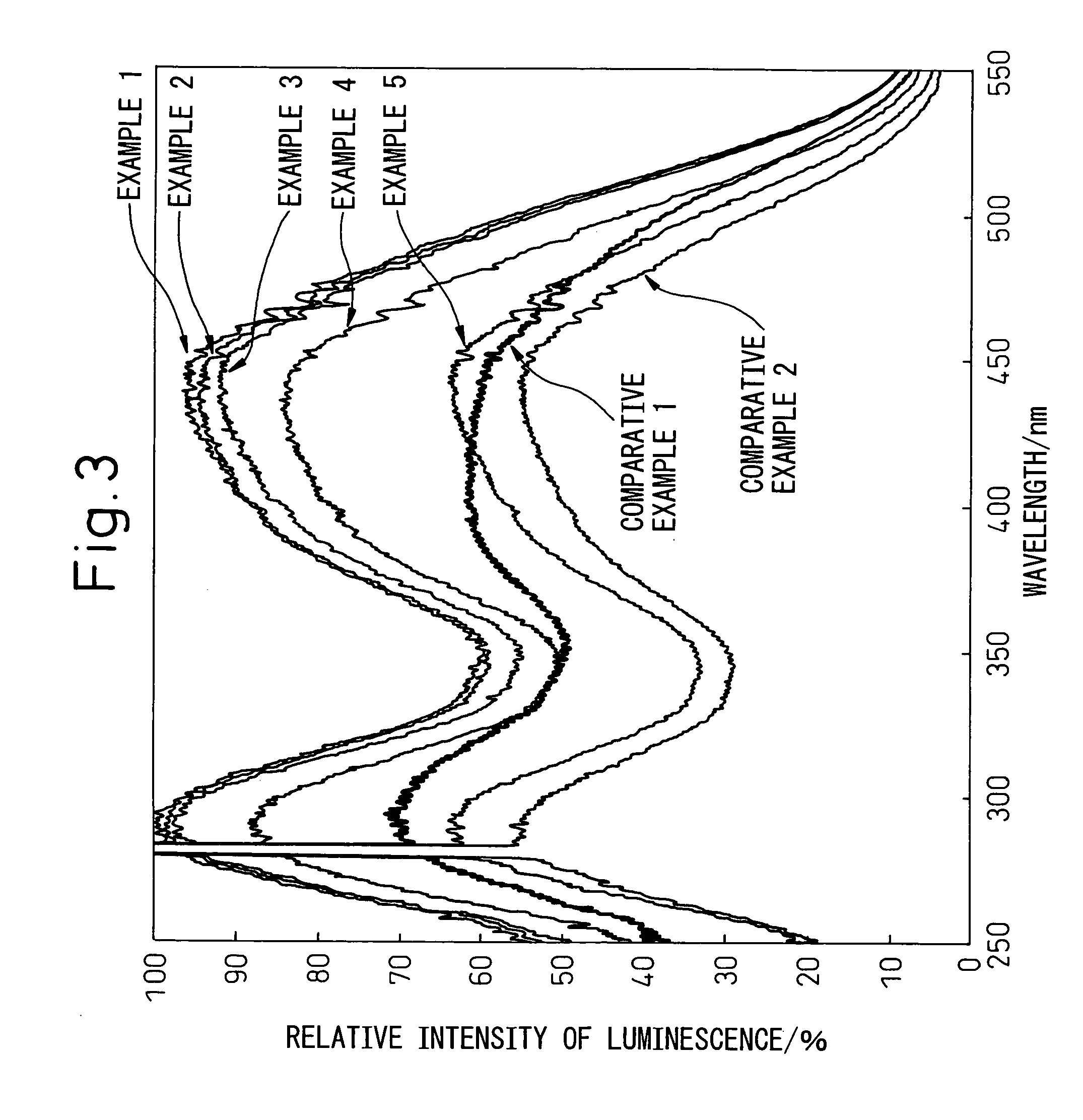

ActiveUS20050012075A1Efficiently obtainedEnhanced photoluminescence intensityDischarge tube luminescnet screensLamp detailsPhosphorLanthanide

To provide a Sialon-based phosphor having a high photoluminescent intensity, which can realize a high brightness LED, particularly a white LED using a blue LED as the light source, and a production method of the Sialon-based phosphor. The α-Sialon based phosphor of the present invention is represented by the formula: LixMyLnzSi12−(m+n)Al(m+n)OnN16−n (I) wherein M is at least one metal selected from Ca, Mg and Y, Ln is at least one lanthanide metal selected from Eu, Dy, Er, Tb, Yb and Ce, x+ay+bz=m (assuming that the valence of metal M is a and the valence of lanthanide metal Ln is b), 0<x≦0.8, 0<y, 0<z, 0.3≦m<4.5, and 0<n<2.25.

Owner:DENKA CO LTD

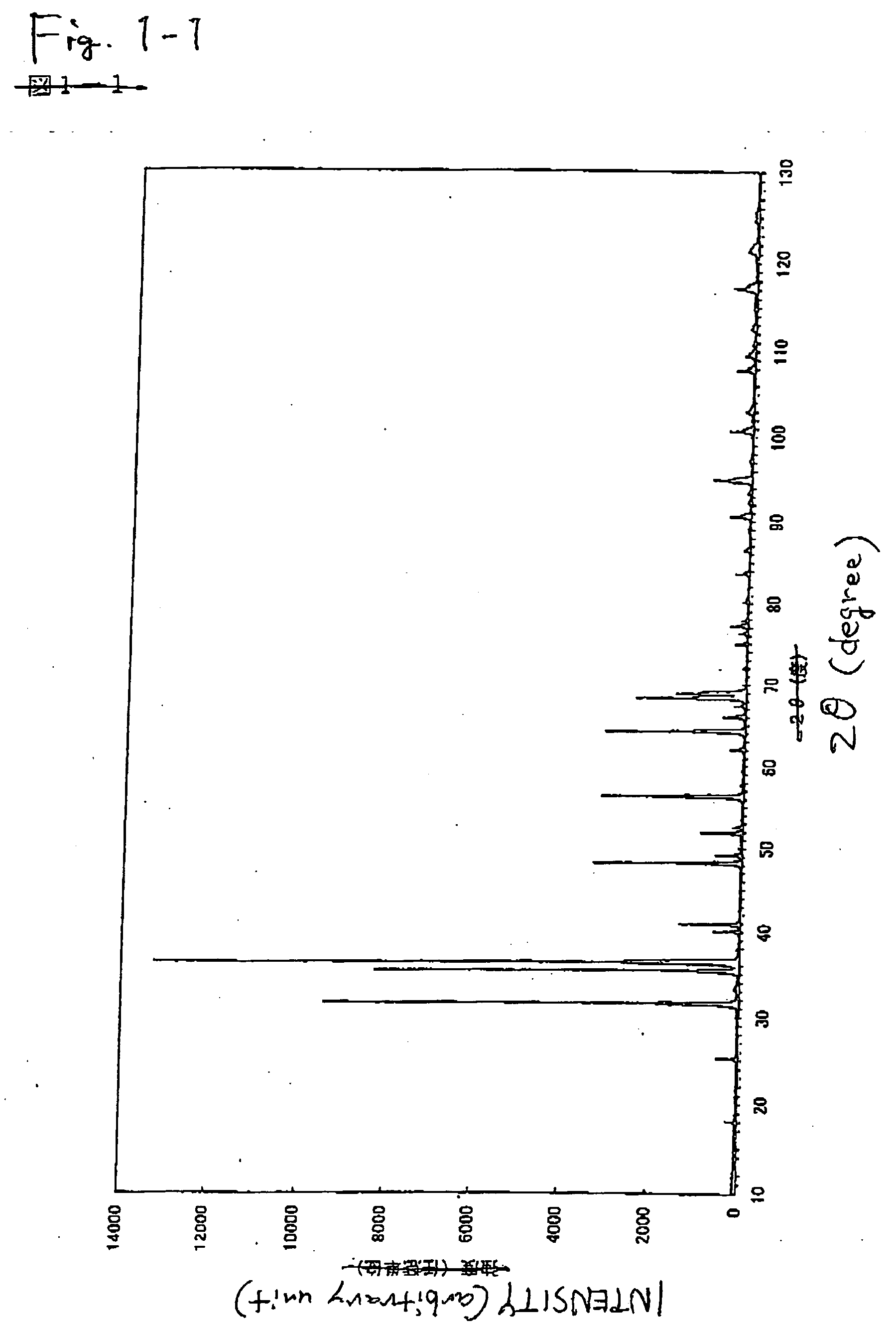

Beta-sialon phosphor powder and production method thereof

ActiveUS20100213820A1Small aspect ratioIncrease brightnessDischarge tube luminescnet screensElectroluminescent light sourcesGreek letter betaCrystal structure

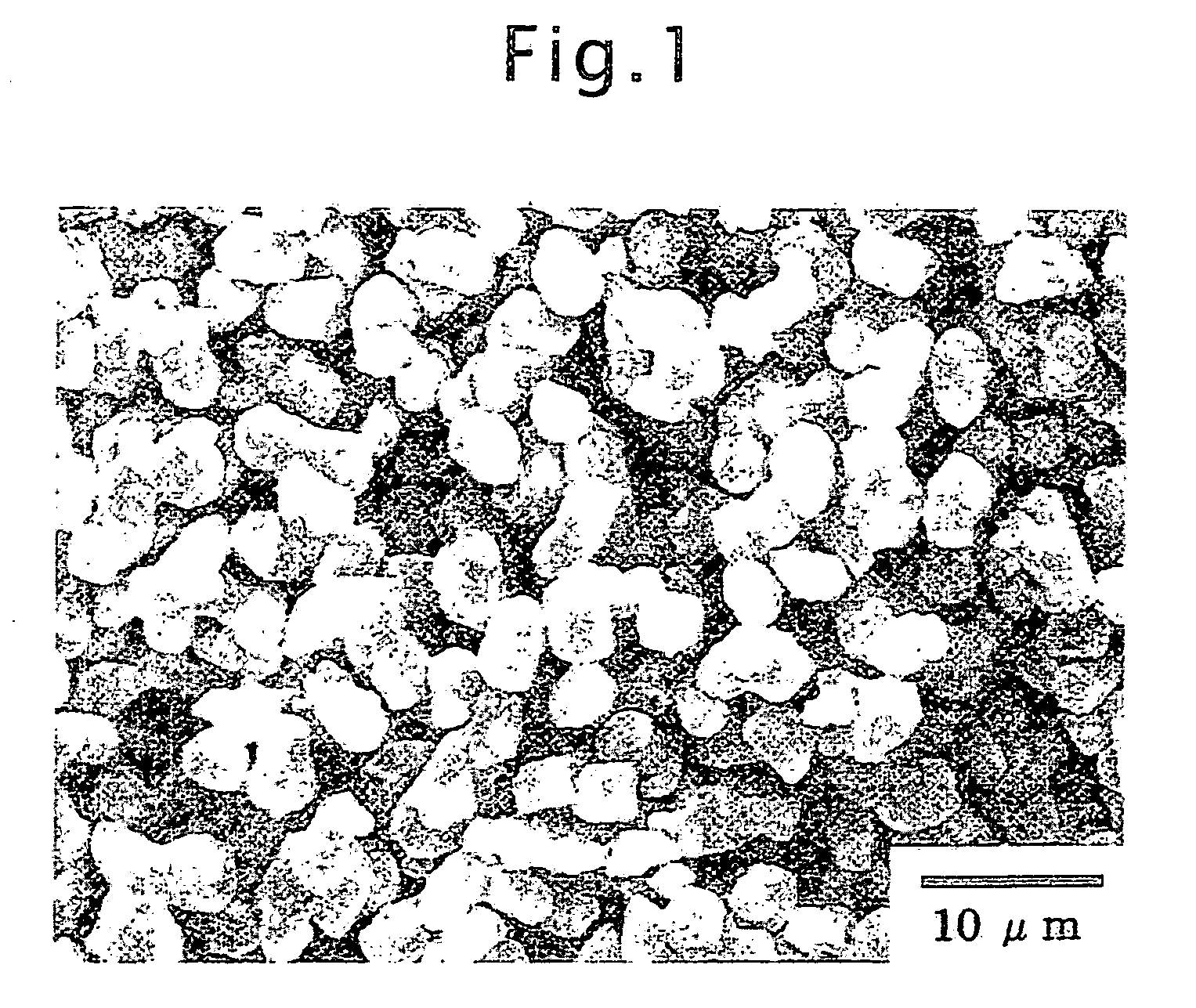

A β-sialon phosphor particle in which Eu (europium) is solid-soluted in a crystal having a β-type Si3N4 crystal structure, wherein the median diameter (D50) in the particle size distribution curve of the primary particle is from 3.0 to 10 μm and the aspect ratio is less than 1.5.

Owner:DENKA CO LTD

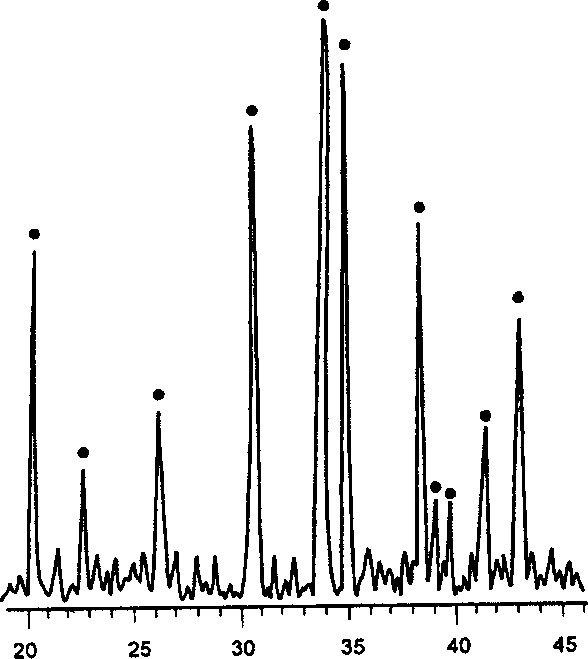

Sialon-based oxynitride phosphor, process for its production, and use thereof

ActiveUS7074346B2Increase brightnessDischarge tube luminescnet screensLamp detailsPhosphorMetal impurities

An α-sialon-based oxynitride phosphor characterized in that the content of α-sialon represented by the general formula: MxS12−(m+n)Al(m+n)OnN16−n:Lny (wherein M is at least one metal selected from among Li, Ca, Mg, Y or lanthanide metals excluding La and Ce, Ln is at least one lanthanide metal selected from among Ce, Pr and La or at least one lanthanide metal selected from among Eu, Dy, Er, Tb and Yb, 0.3≦x+y<1.5, 0<y<0.7, 0.3≦m<4.5, 0<n<2.25, and m=ax+by, where a is the valence of the metal M and b is the valence of the lanthanide metal Ln), wherein all or a portion of the metal M dissolved in the α-sialon is replaced with the lanthanide metal Ln as the luminescence center, is 75 wt % or greater when the lanthanide metal Ln is at least one lanthanide metal selected from among Ce, Pr and La and 90 wt % or greater when the lanthanide metal Ln is at least one lanthanide metal selected from among Eu, Dy, Er, Tb and Yb, and in that the content of metal impurities other than the metal M, lanthanide metal Ln, silicon, IIIA elements (aluminum, gallium), oxygen and nitrogen, is no greater than 0.01 wt %.

Owner:UBE CORP

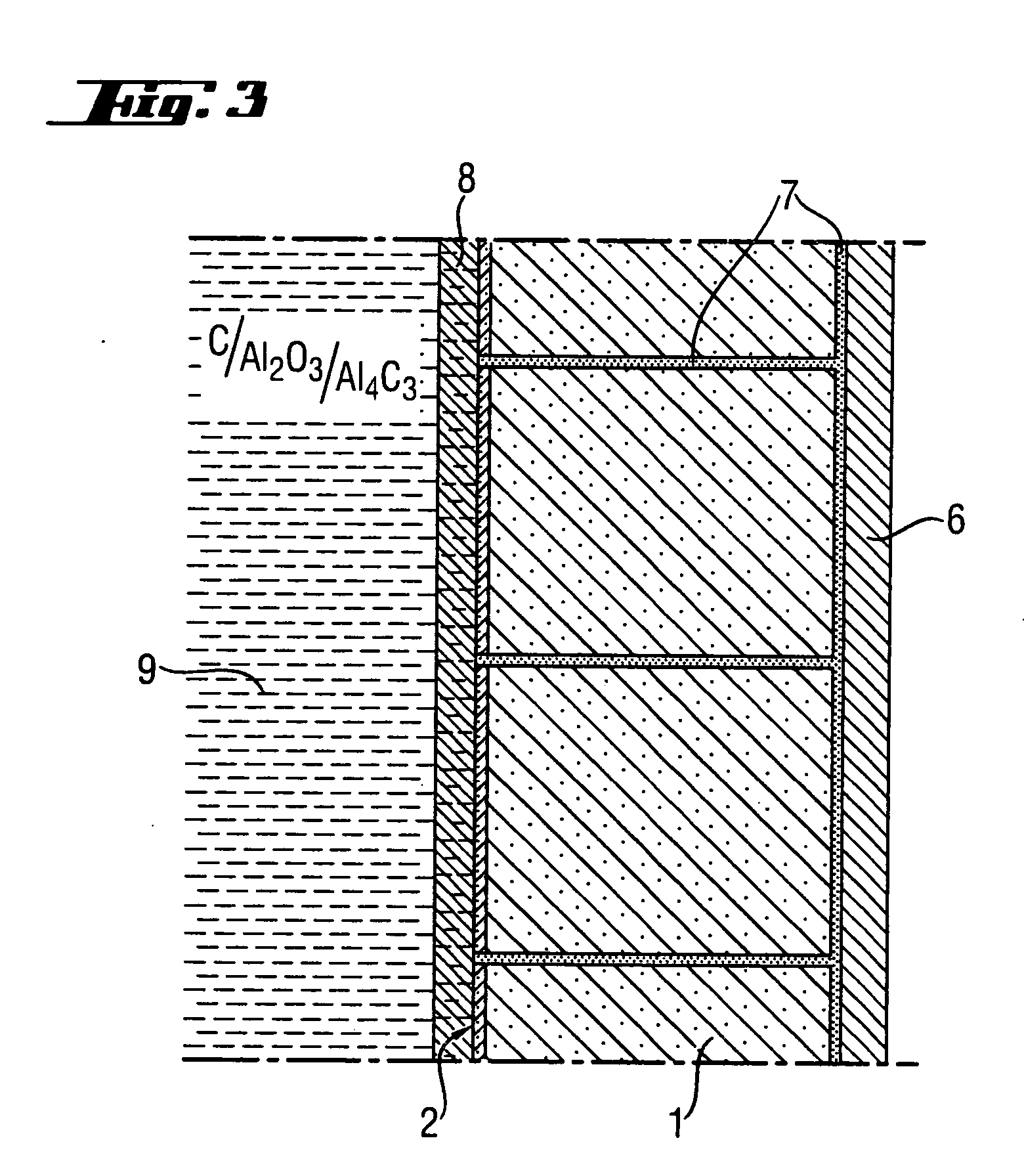

Lining for carbothermic reduction furnace

InactiveUS20050254543A1Effective heat dissipation systemOvercome disadvantagesElectric discharge heatingLinings repairRefractoryGraphite

An inner lining for the steel shell of a carbothermic reduction furnace for the production of alumina has a base layer of graphite and a coating layer of refractory material. The refractory material is corundum (Al2O3) bound by Sialon (Si.Al.O.N). The lining structure provides protection against the molten slag and it is not attacked by the CO-rich melt furnace atmosphere. Further, the lining does not contaminate the melt and it provides an effective heat dissipation system in case of a power shut-off.

Owner:SGL CARBON SE

SiAION material and cutting tools made thereof

A SiAlON-based ceramic particularly suited for use as a cutting tool in the high speed chip forming machining of metals composed of a SiAlON matrix including a) a phase of alpha′ SiAlON represented by the general formula of Mx(Si,Al)12(O,N)16, wherein 0<x<2 and M is at least two cationic elements, a first cationic element being 0.2 to 4 weight percent Mg and optionally between 0.5 and 15 weight percent of one or more of Ca, Sr, and Ba calculated as oxide, based on the SiAlON matrix, and a second cationic element being one or more of Y, Sc, La and the rare earth (RE) elements; b) a phase consisting of beta′ SiAlON represented by the general formula Si6-zAlzOzN8-z wherein 0<z<4.2; and c) a component containing glass, and at least one additional intergranular crystal phase that is detectable using X-ray diffraction techniques is provided.

Owner:INDEXABLE CUTTING TOOLS OF CANADA

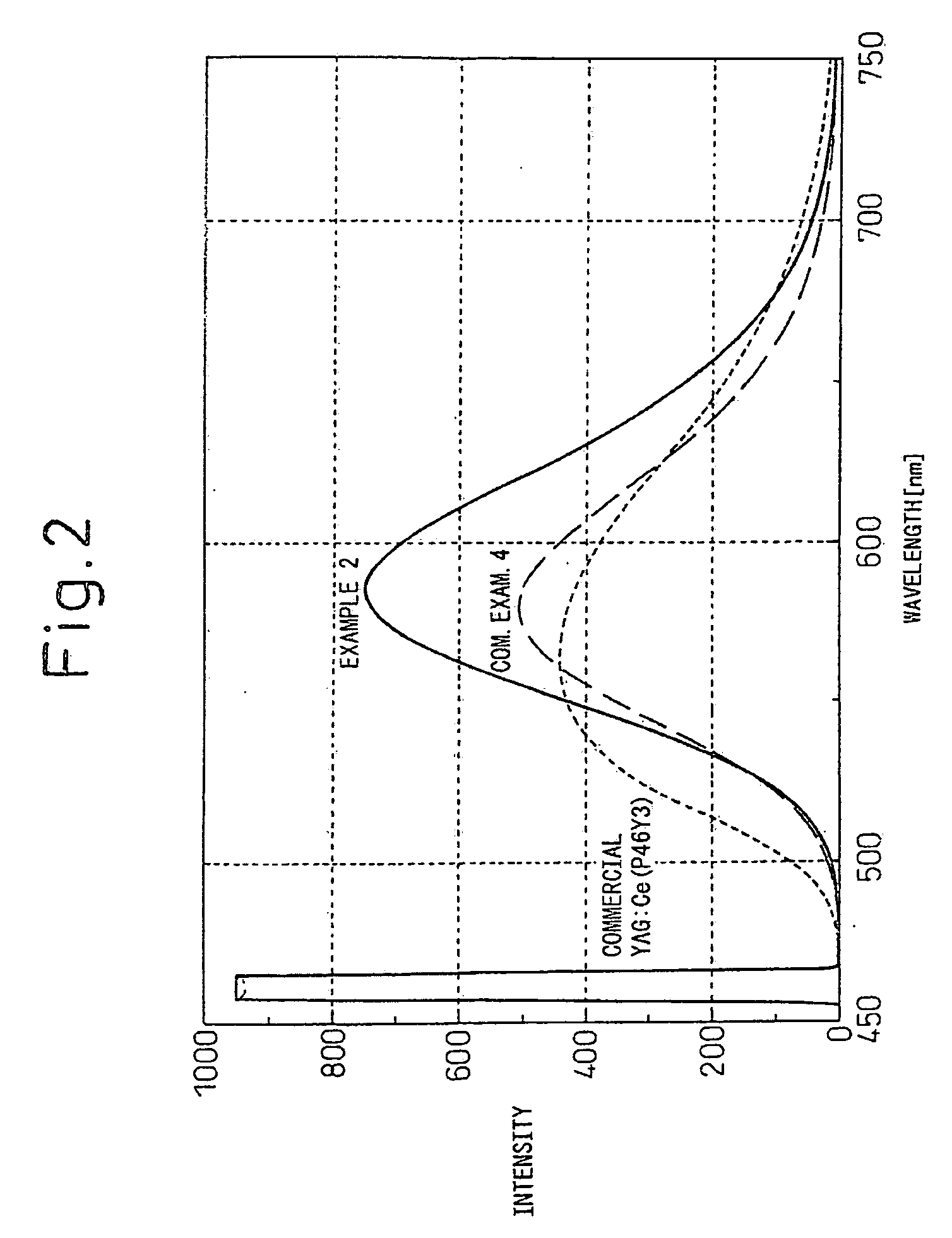

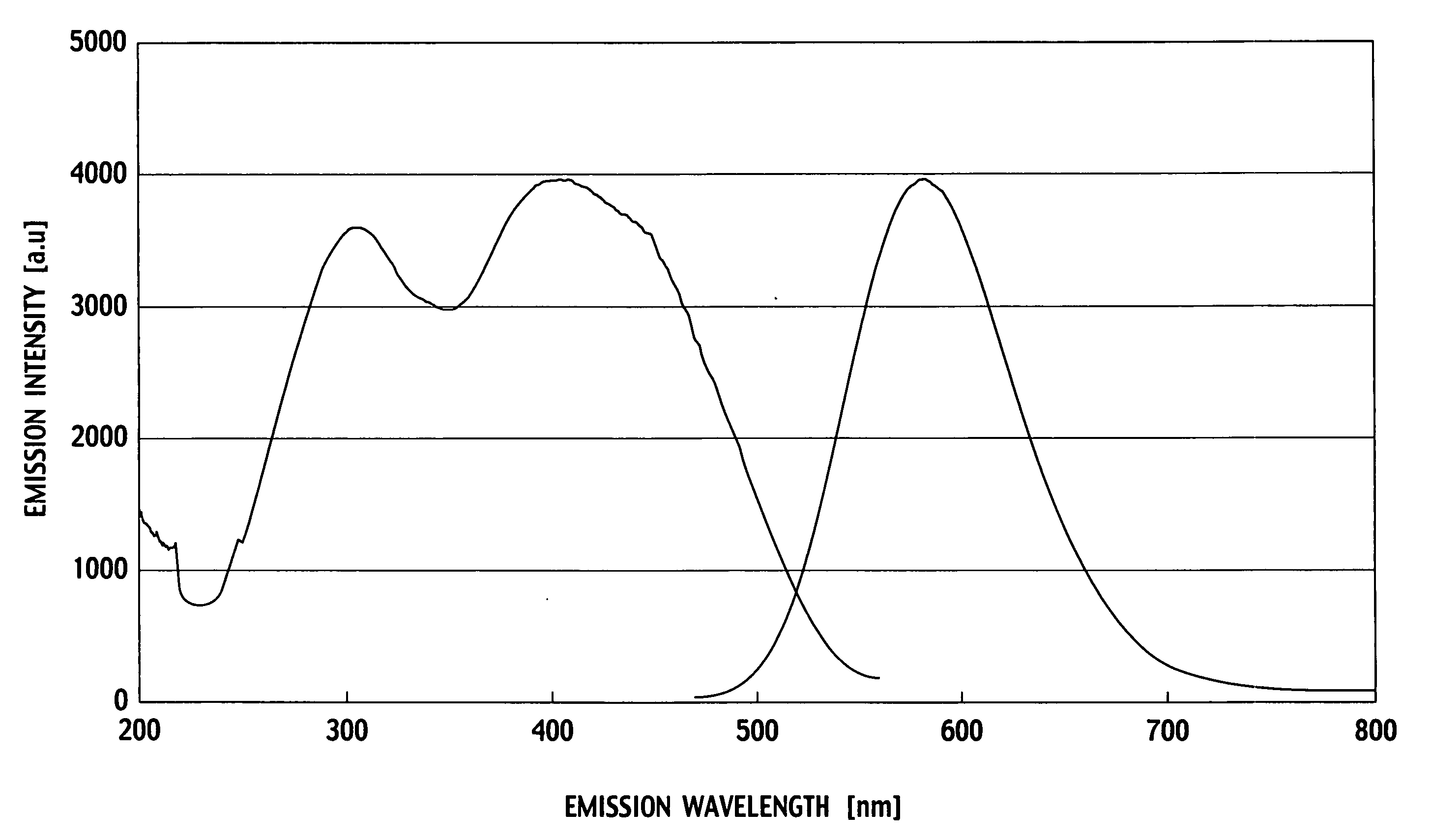

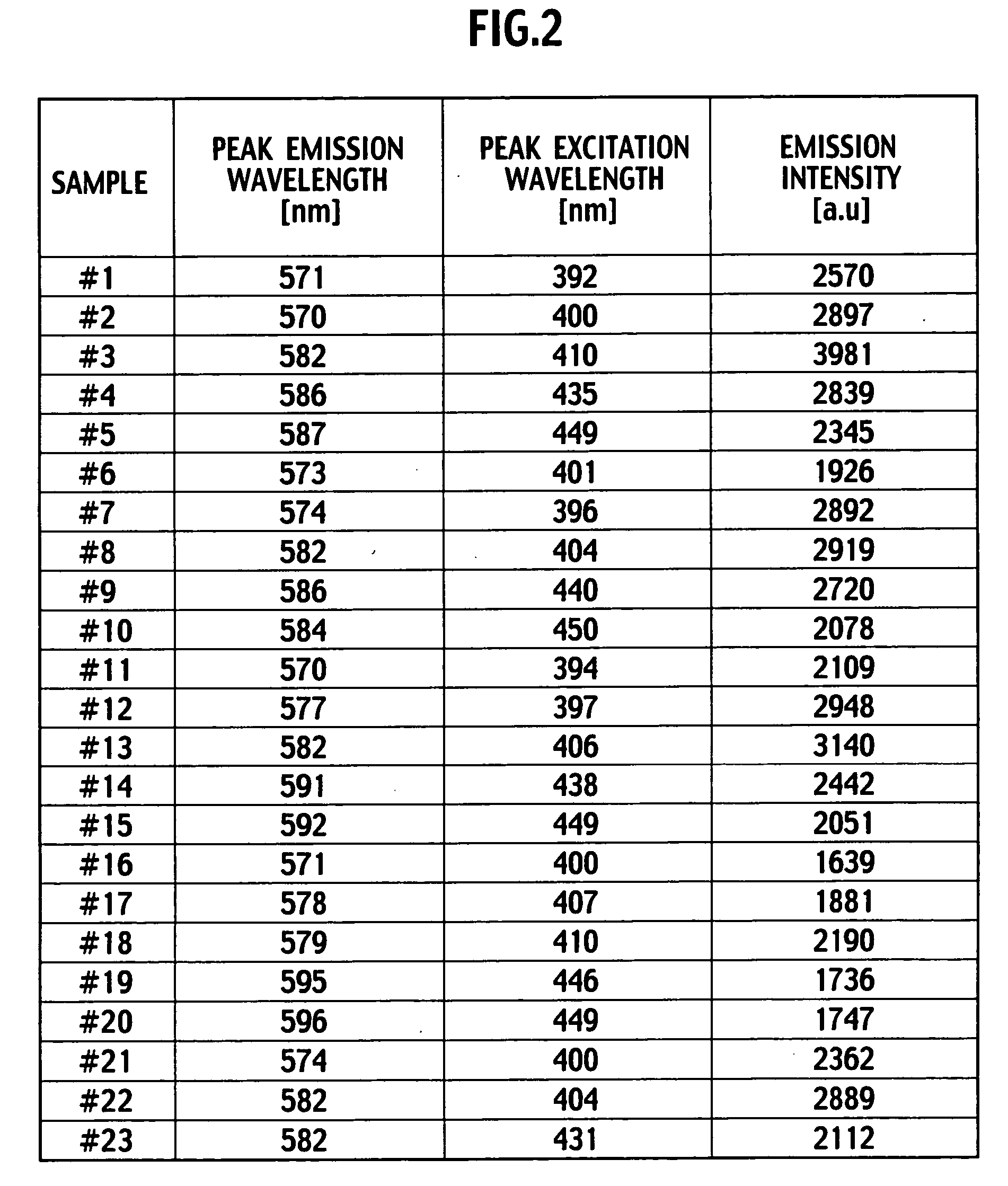

Phosphor and an incandescent lamp color light emitting diode lamp using the same

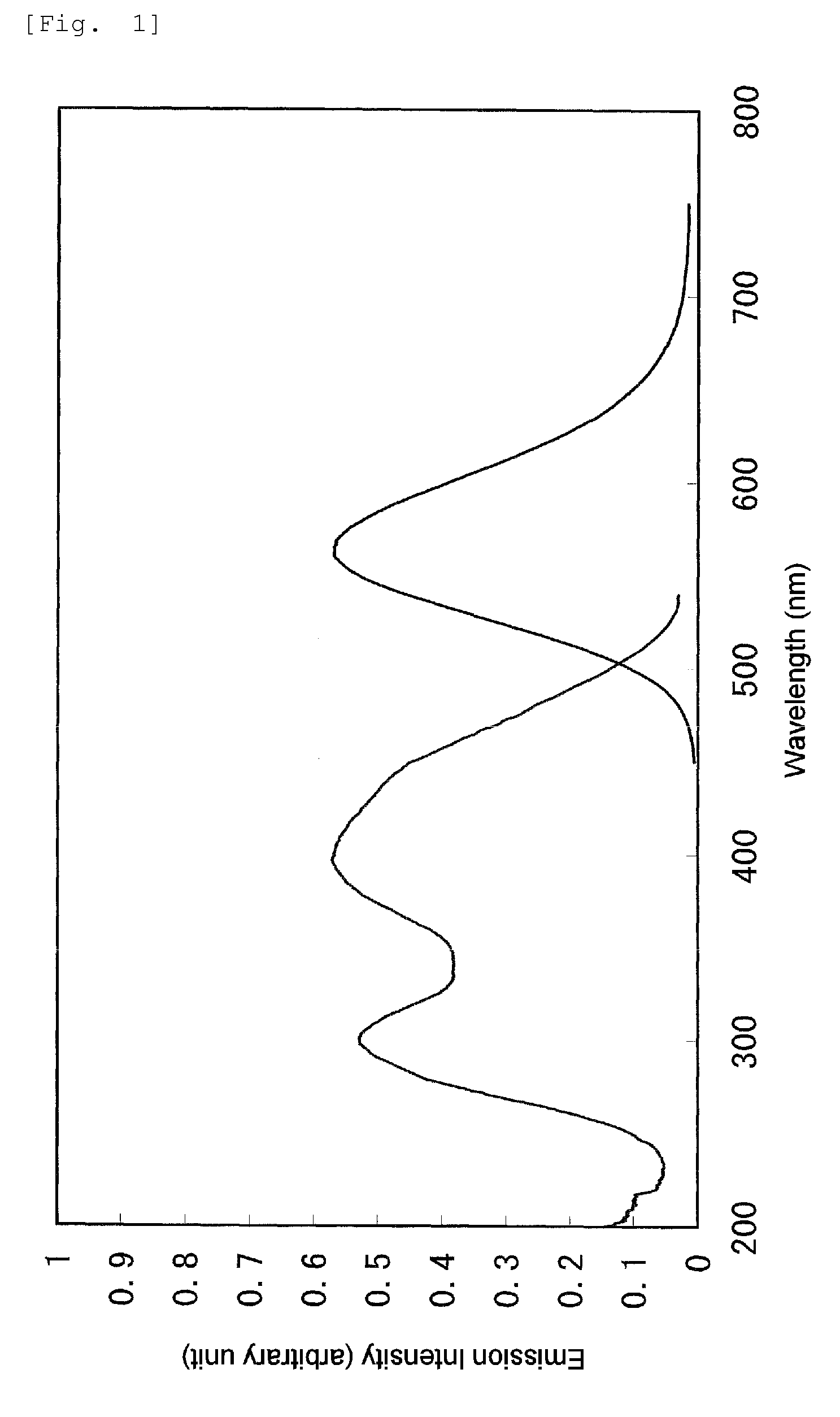

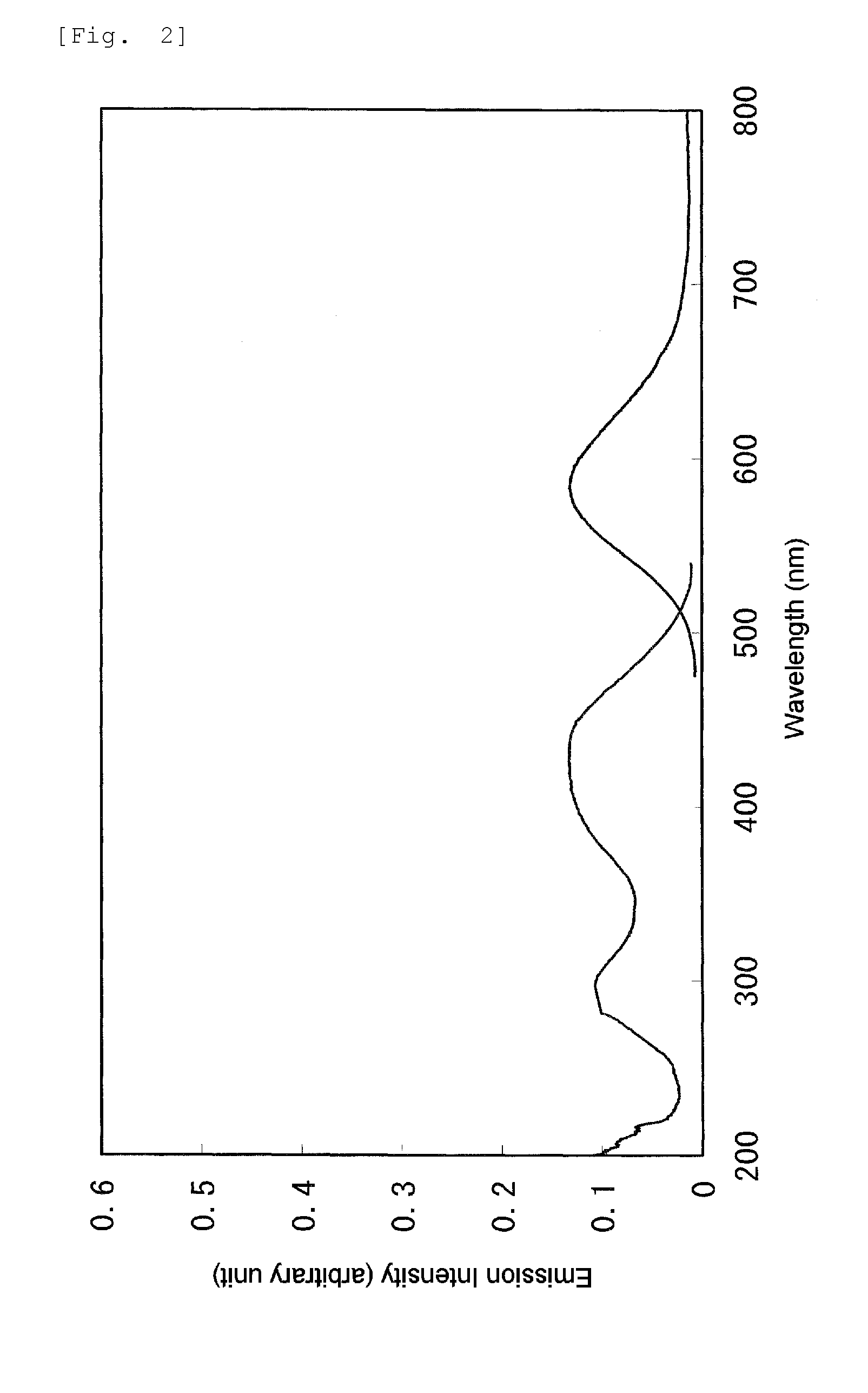

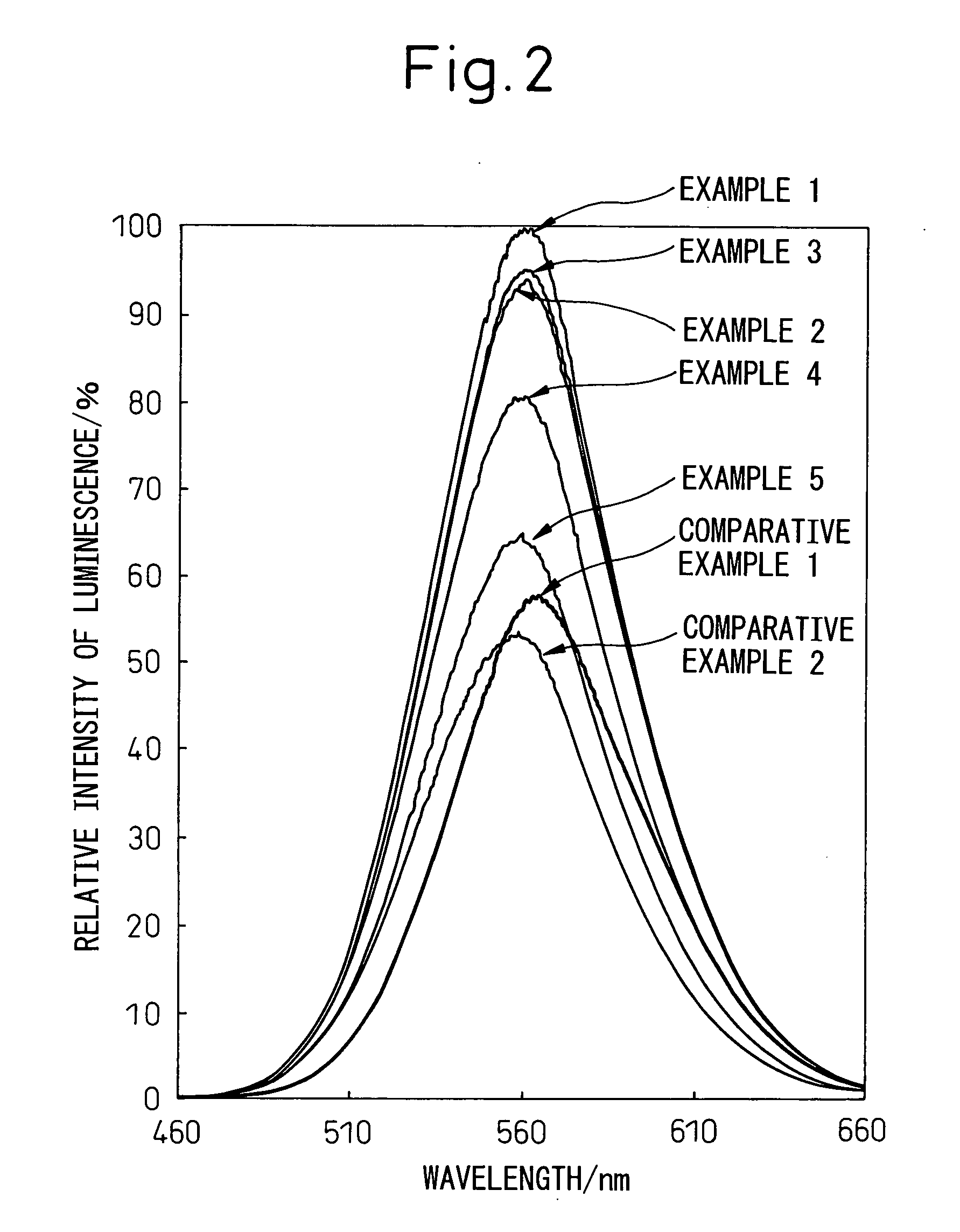

ActiveUS20060061263A1Improve emission efficiencyAppropriate chromaticityDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorLength wave

An incandescent lamp color light emitting diode lamp comprises a semiconductor blue light emitting diode chip having a center emission wavelength in a range of from 400 nm to 480 nm and a phosphor that absorbs light emitted from the diode chip to emit light having a different wavelength than the light emitted from the diode chip. The phosphor is represented by a general formula of Mp(Si, Al)12(O, N)16:Eu2+q. The main phase is an α-SiAlON phosphor having an α SiAlON structure, wherein M is at least one element of Ca, Y, Mg, Li, Sc, Pr, Nd, Pm, Sm, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, and Sr and p is from 0.75 to 1.0; and q is between 0.02 and 0.09. The diode lamp emits light having an emission color produced by a mixture of the light emitted from the semiconductor blue light emitting and the light emitted from the α-SiAlON. The chromaticity range thereof falls within the range defined by chromaticity coordinates (x, y) of (0.4775, 0.4283), (0.4594, 0.3971), (0.4348, 0.4185), and (0.4214, 0.3887) on the XYZ chromaticity diagram.

Owner:THE FUJIKURA CABLE WORKS LTD +1

Refractory Sialon corundum brick material for blast flurnace and its prepn process

The refractory sialon corundum brick material for blast furnace is prepared with corundum grain and powder 60-75 wt%, metal silicon powder 5-12 wt%, metal aluminum powder 10-15 wt%, titania powder 1-8 wt%, alumina powder 3-9 wt%, silica powder 0-2 wt%, clay 0-2 wt% temporary paper pulp or phnolic resin binding agent 2-5 wt%, and through mixing, forming, drying, sintering at nitrogen atmosphere. The refractory sialon corundum brick material has excellent alkali resistance, excellent slag resistance, high heat shock stability, high wear resistance and excellent molten iron fuse loss resistance. The refractory sialon corundum brick material may be used widely for large and medium sized blast furnaces.

Owner:WUHAN UNIV OF SCI & TECH

Process for sintering Sialong binding silicon carbide refractory by microwave tech.

InactiveCN1793038AGood physical and chemical propertiesImprove mechanical propertiesPorosityMicrowave

The invention relates to a technology that uses microwave quickly reacting nitriding sintering Sialon associated with silicon carbide refractory. The feature of the invention is that its bulk density is 2.68-3.2g / cm3, compressive strength is over 180MPa, bending strength is over 45MPa, degree of porosity is below 15%, good thermal shock resistance, good anti-oxygenic property and excellent alkali resistance. It also solves the technology problem of super thickness (100mm-200mm) Sialon nitriding reacting sintering with silicon carbide refractory material.

Owner:TSINGHUA UNIV +1

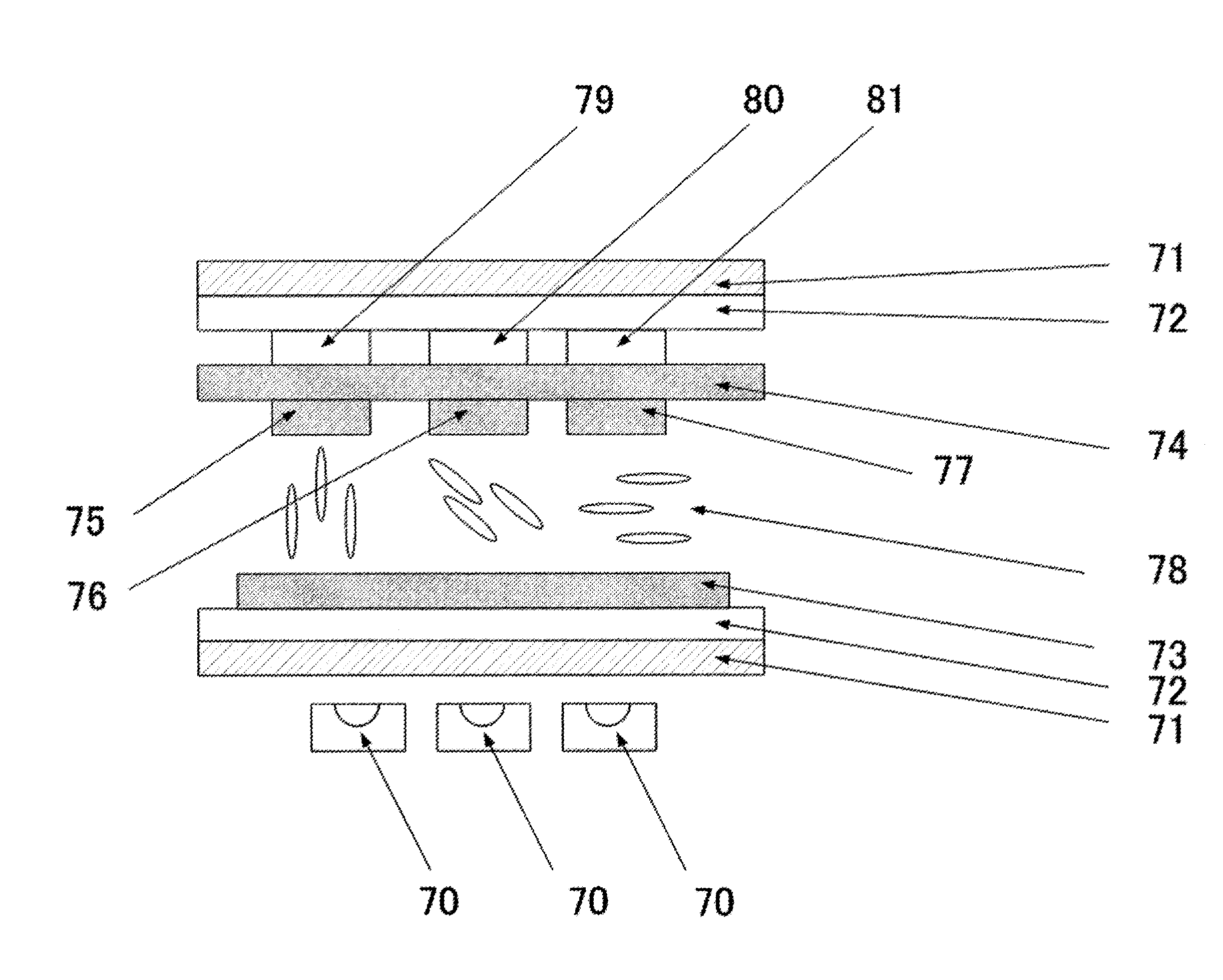

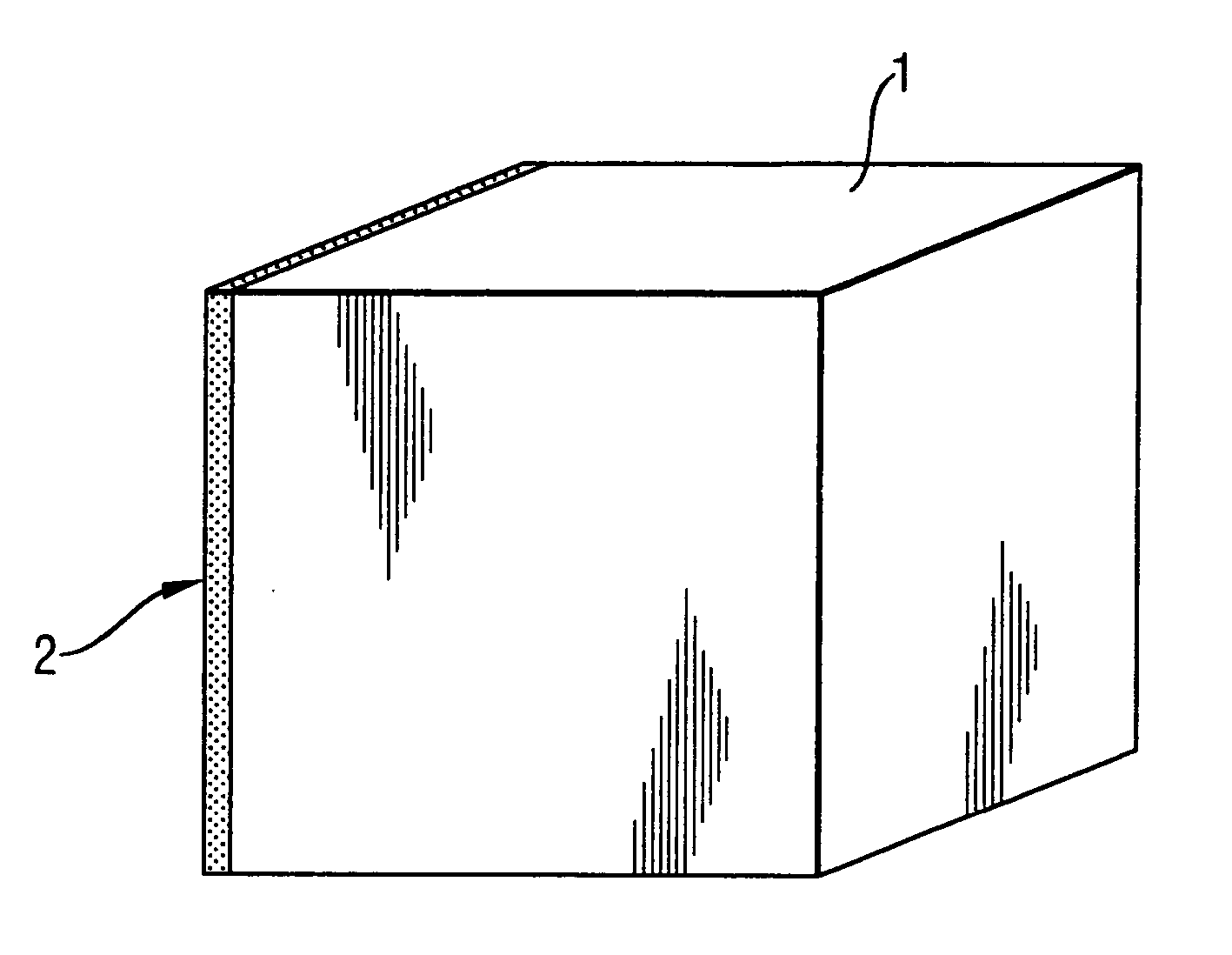

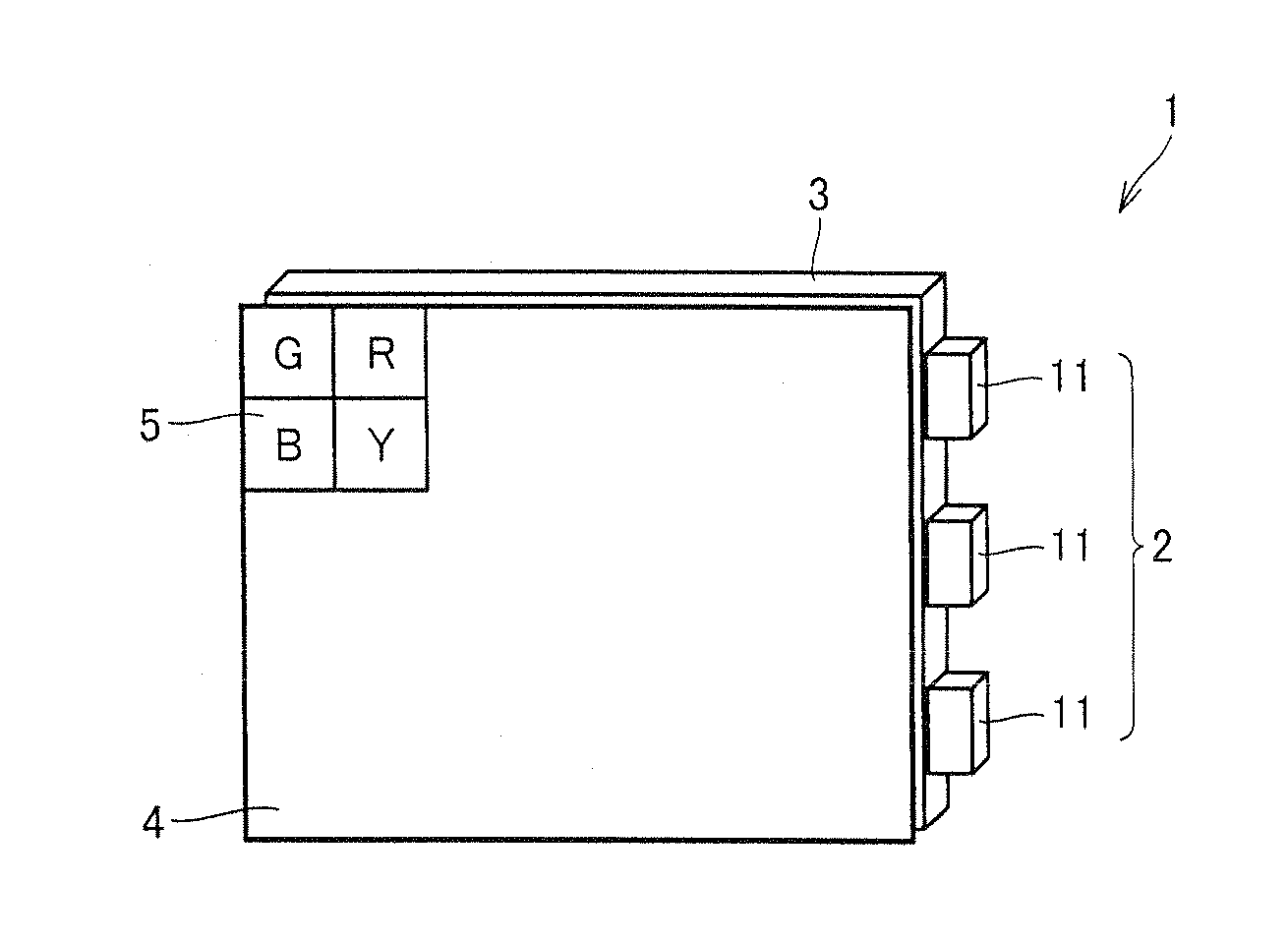

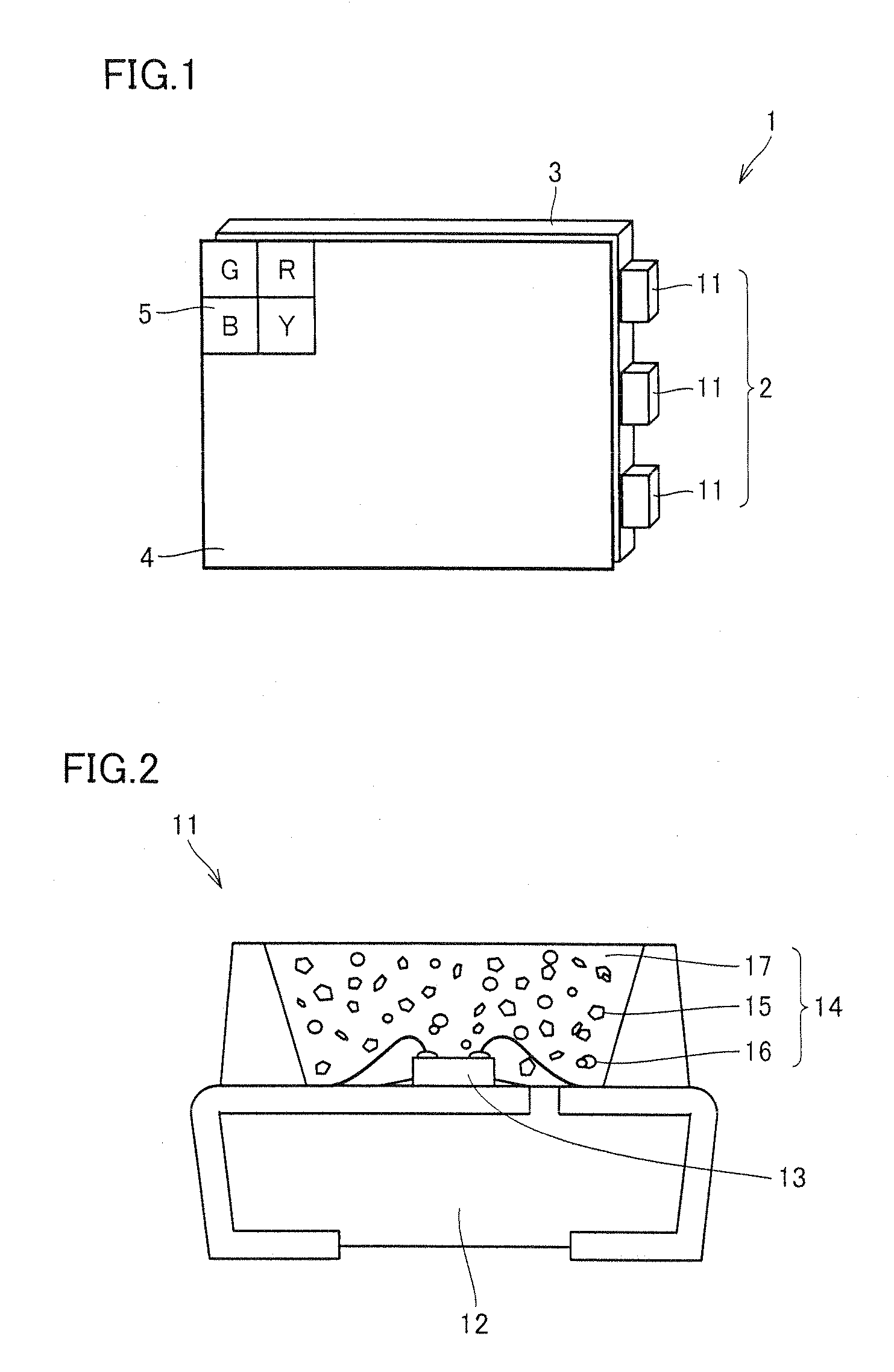

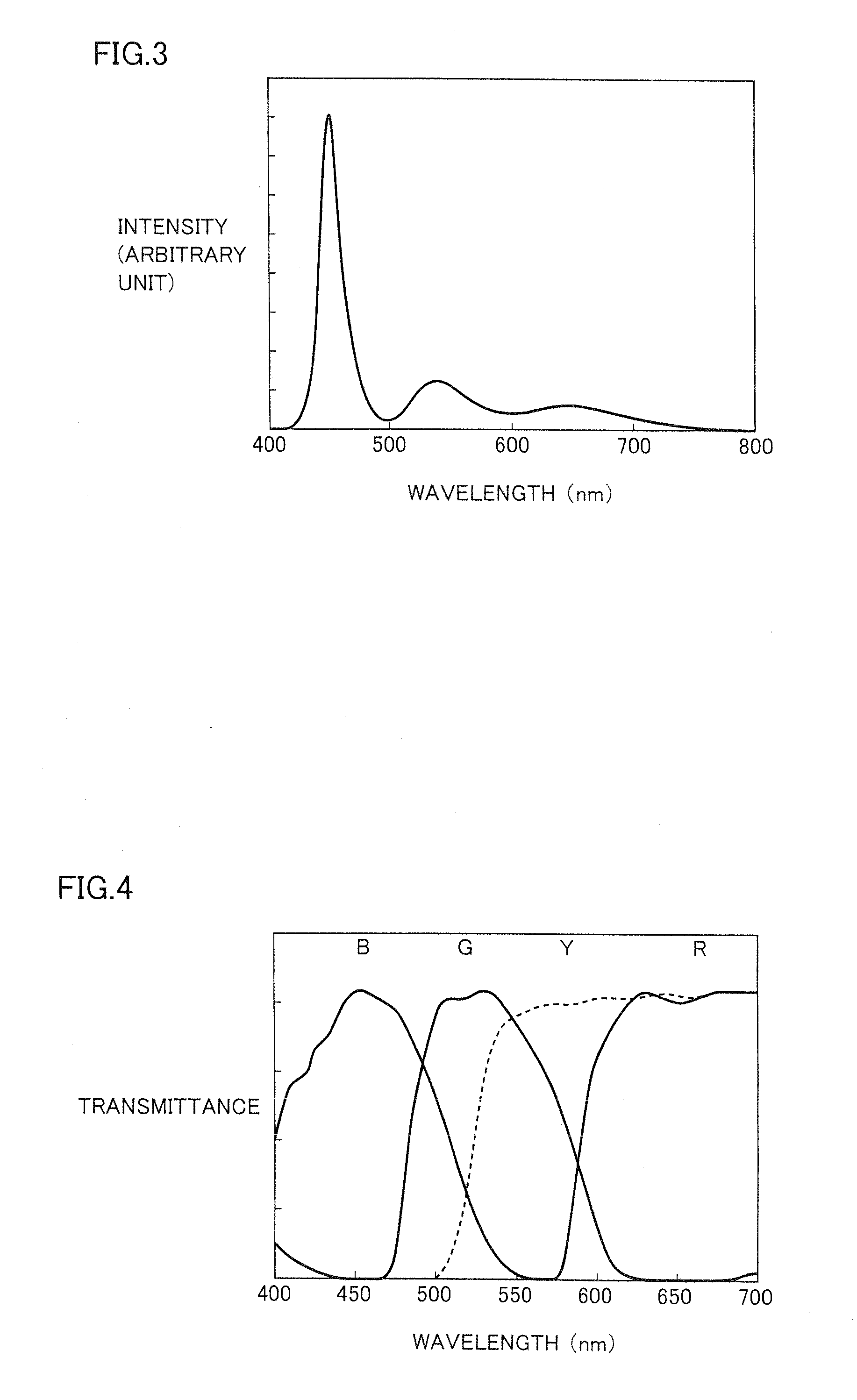

Liquid crystal display

InactiveUS20120162573A1High color reproductionBrighter displayed imageSolid-state devicesLuminescent compositionsLiquid-crystal displayPhosphor

A liquid crystal display including a backlight and a filter, the backlight including a light-emitting device having a light-emitting element emitting blue light, and a green phosphor and a red phosphor absorbing a part of primary light emitted from the light-emitting element and emitting first secondary light and second secondary light, respectively, the green phosphor being a β-type SiAlON phosphor containing Eu and Al dissolved in a crystal of a nitride or an oxynitride having a β-type Si3N4 crystal structure, and the filter including filters for colors of red (R), green (G), blue (B) and yellow (Y), respectively, arranged in a plane for subpixels provided in each pixel of the liquid crystal display, which attains excellent color reproducibility (NTSC ratio) and high luminance, can be provided.

Owner:SHARP KK

Fluorescent substance, method for production of the same, and light-emitting device using the same

ActiveCN101755030AIncrease brightnessImprove responseElectroluminescent light sourcesSolid-state devicesNitrogenCrystal structure

Disclosed is a fluorescent substance having higher brightness than that of a conventional fluorescent substance. Also disclosed is a method for producing the fluorescent substance. Further disclosed is a light-emitting device which utilizes the fluorescent substance. Specifically, the fluorescent substance comprises at least an M(0) element [wherein M(0) represents one or two elements selected from Sr and La], an M(1) element [wherein M(1) represents at least one element selected from Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb], Si, Al and nitrogen, has the same crystal structure as that of an a-type silicon nitride crystal, and comprises an alpha-sialon crystal structure.

Owner:NAT INST FOR MATERIALS SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com