Sialon-based oxynitride phosphor and production method thereof

a technology of oxynitride phosphor and sialon, which is applied in the direction of luminescent compositions, discharge tubes, lighting and heating apparatus, etc., can solve the problems of not being suited light is slightly blue-tinged, and not being suitable for use as phosphor powders, etc., to achieve excellent miscibility with resin, good miscibility with resin, and little scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0179]Silicon diimide (Si(NH)2) obtained by reacting silicon tetrachloride with ammonia at a temperature lower than room temperature was decomposed under heating at 700 to 1,200° C. to obtain silicon nitrogen imide (Si2N2NH) and / or amorphous silicon nitride powder. The metal impurity content of the silicon nitrogen imide (Si2N2NH) and / or amorphous silicon nitride powder was 10 ppm or less. A blend obtained by blending a compound(s) as a silicon nitride source(s) selected from nitrogen-containing silane compounds (silicon diimide (Si(NH)2) and silicon nitrogen imide (Si2N2NH)), amorphous silicon nitride and crystalline silicon nitride to give a chemical composition shown in Table 1 was used as the silicon nitride raw material. A europium oxide (Eu2O3) powder, a lithium carbonate (Li2CO3) powder and a calcium carbonate (CaCO3) powder were weighed and added to the silicon nitride raw material to give a chemical composition of Si9.25Eu0.15Ca0.62Li0.10O0.89N12.33 after firing, and these ...

example 2

[0186]An α-sialon-based oxynitride phosphor was obtained by repeating the same operation as in Example 1, except that the blending ratio of the compound(s) working as a silicon nitride source(s) selected from nitrogen-containing silane compounds (silicon diimide (Si(NH)2) and silicon nitrogen imide (Si2N2NH)), amorphous silicon nitride and crystalline silicon nitride and the firing conditions in the first and second steps were slightly changed. The conditions in the synthesis of the α-sialon-based oxynitride phosphor comprising first and second steps are shown in Table 1, and the powder properties and fluorescent properties of the obtained oxynitride phosphor are shown in Table 2.

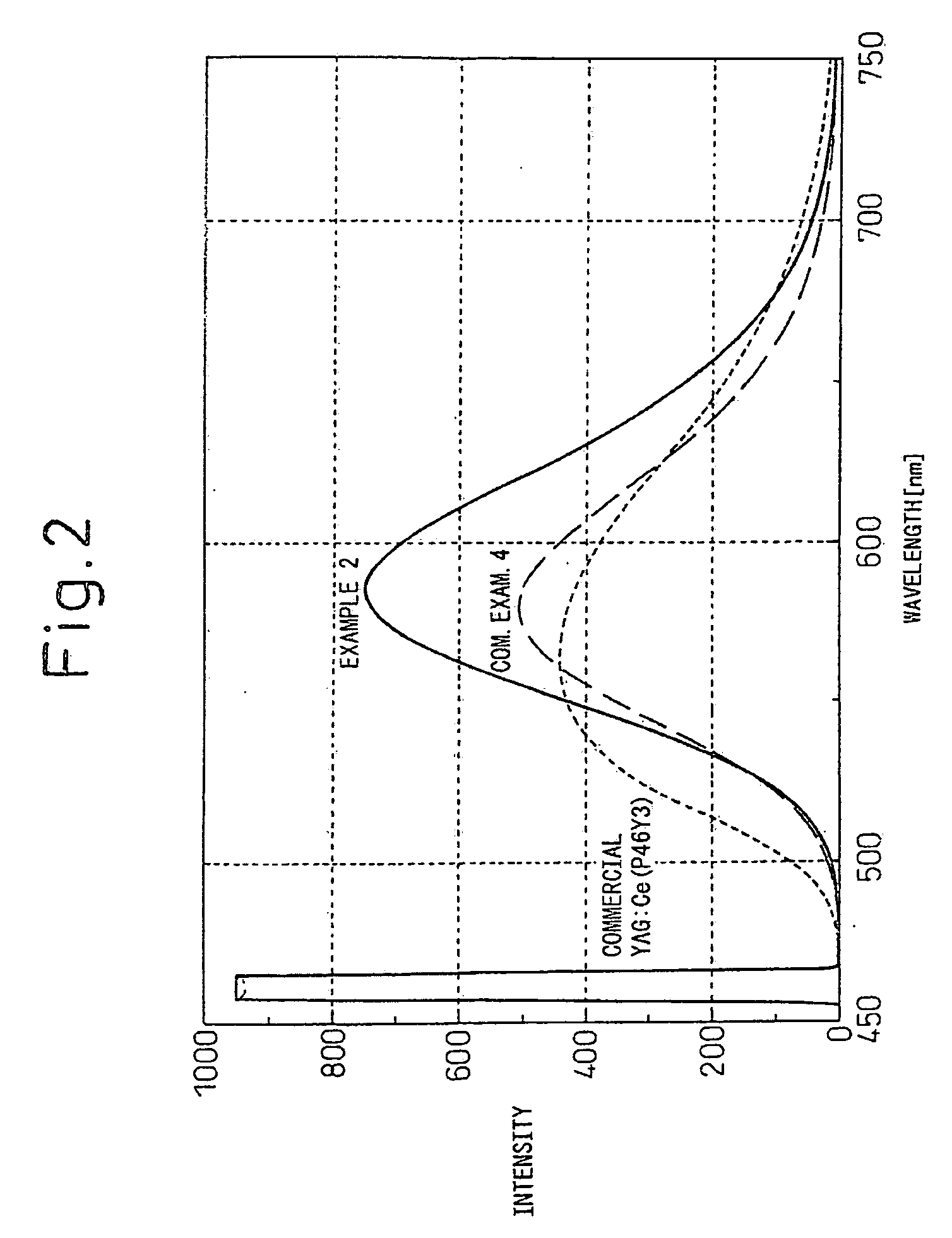

[0187]FIG. 2 illustrates the emission spectrum at an excitation wavelength of 450 nm of the α-sialon-based oxynitride phosphor obtained in Example 2 together with the emission spectra of the α-sialon-based oxynitride phosphor obtained in Comparative Example 4 and a commercially available YAG:Ce-based fluore...

examples 3 to 15

[0188]Similarly to Example 1, those obtained by blending a compound(s) working as a silicon nitride source(s) selected from nitrogen-containing silane compounds (silicon diimide (Si(NH)2) and silicon nitrogen imide (Si2N2NH)), amorphous silicon nitride and crystalline silicon nitride to give a chemical composition shown in Table 1 were used as the silicon nitride raw material. A europium oxide (Eu2O3) powder and a lithium oxide precursor powder were weighed and added to the silicon nitride raw material to give a chemical composition of Si12−(m+n)EuyLix′O0.5x′+1.5y−δN16−4(m+n) / 3 (wherein 0≦δ≦0.5y), and these were mixed by a vibration mill under the conditions shown in Table 1 in a nitrogen atmosphere.

[0189]The mixed powder was filled in a silicon nitride-made crucible, the crucible was set in an electric furnace of resistance heating system, and the furnace was heated in a nitrogen gas atmosphere by a temperature-rising schedule of holding the furnace at from temperature to 1,150° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| equivalent-sphere diameter DBET | aaaaa | aaaaa |

| primary particle diameter Dparticle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com