Patents

Literature

55results about How to "Prevent excessive aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isolated population of plant single cells and method of preparing the same

ActiveUS8053238B2Stable productionAvoid excessive changesFermentationPlant cellsPlant SourcesCell growth

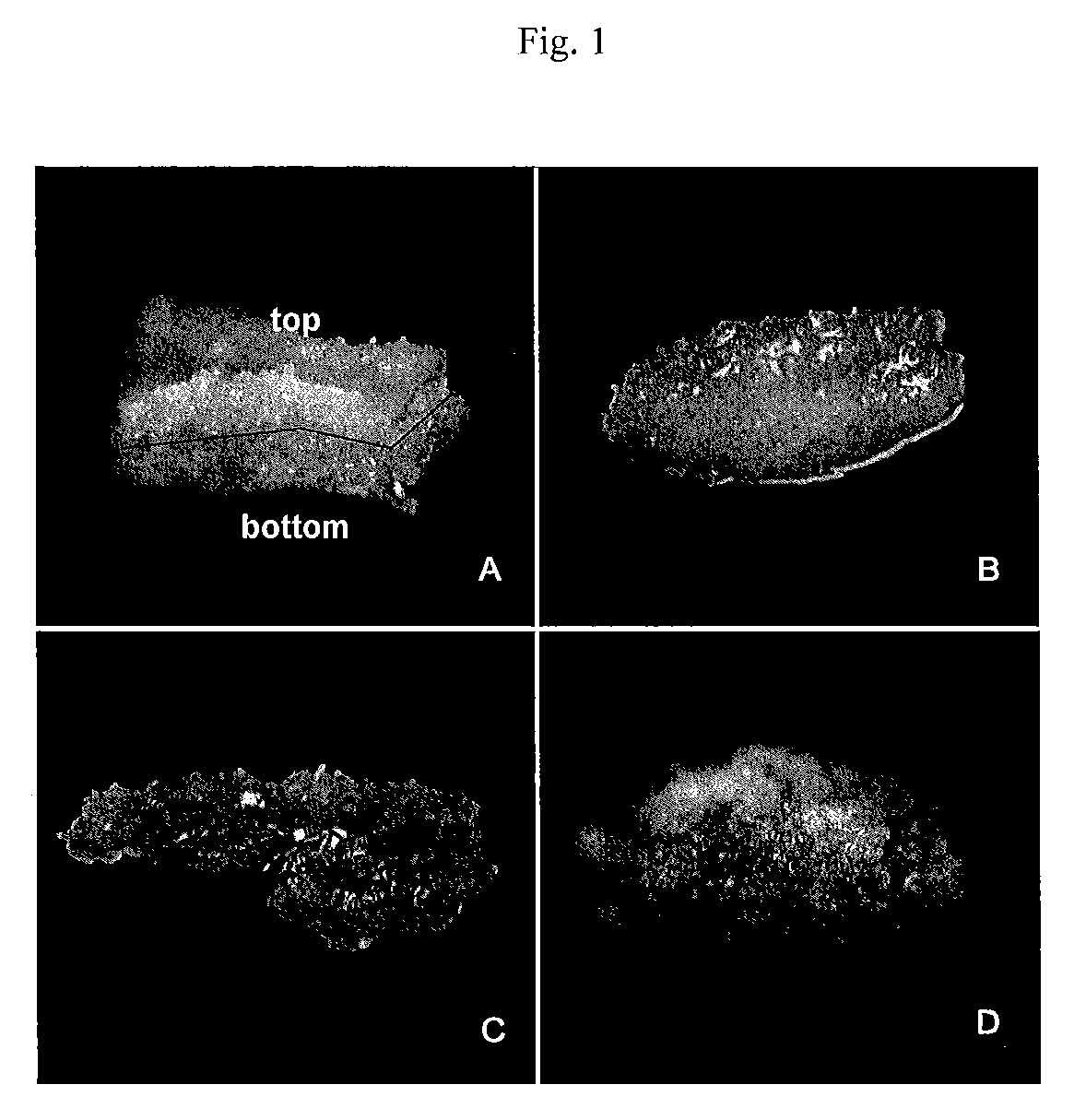

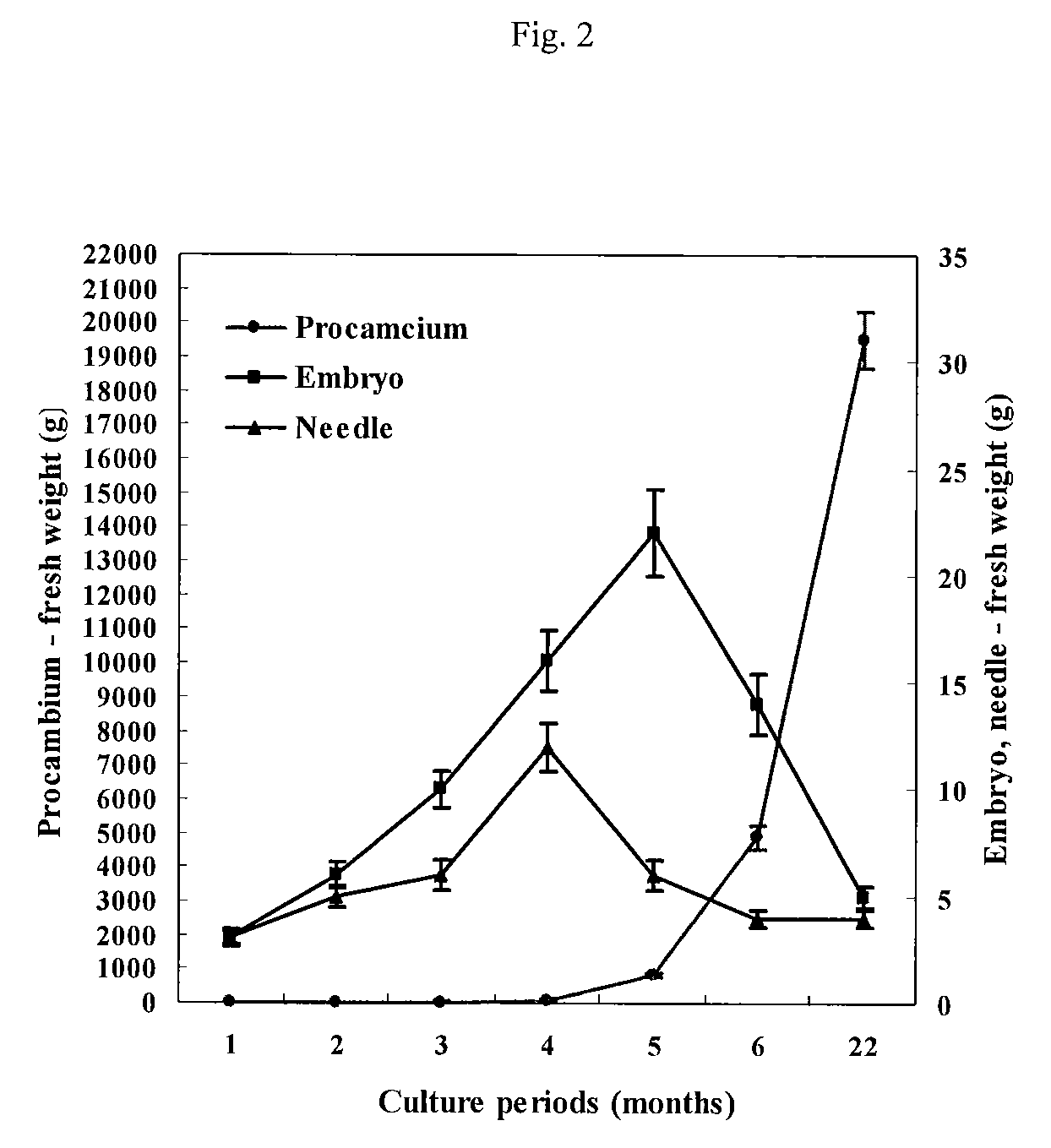

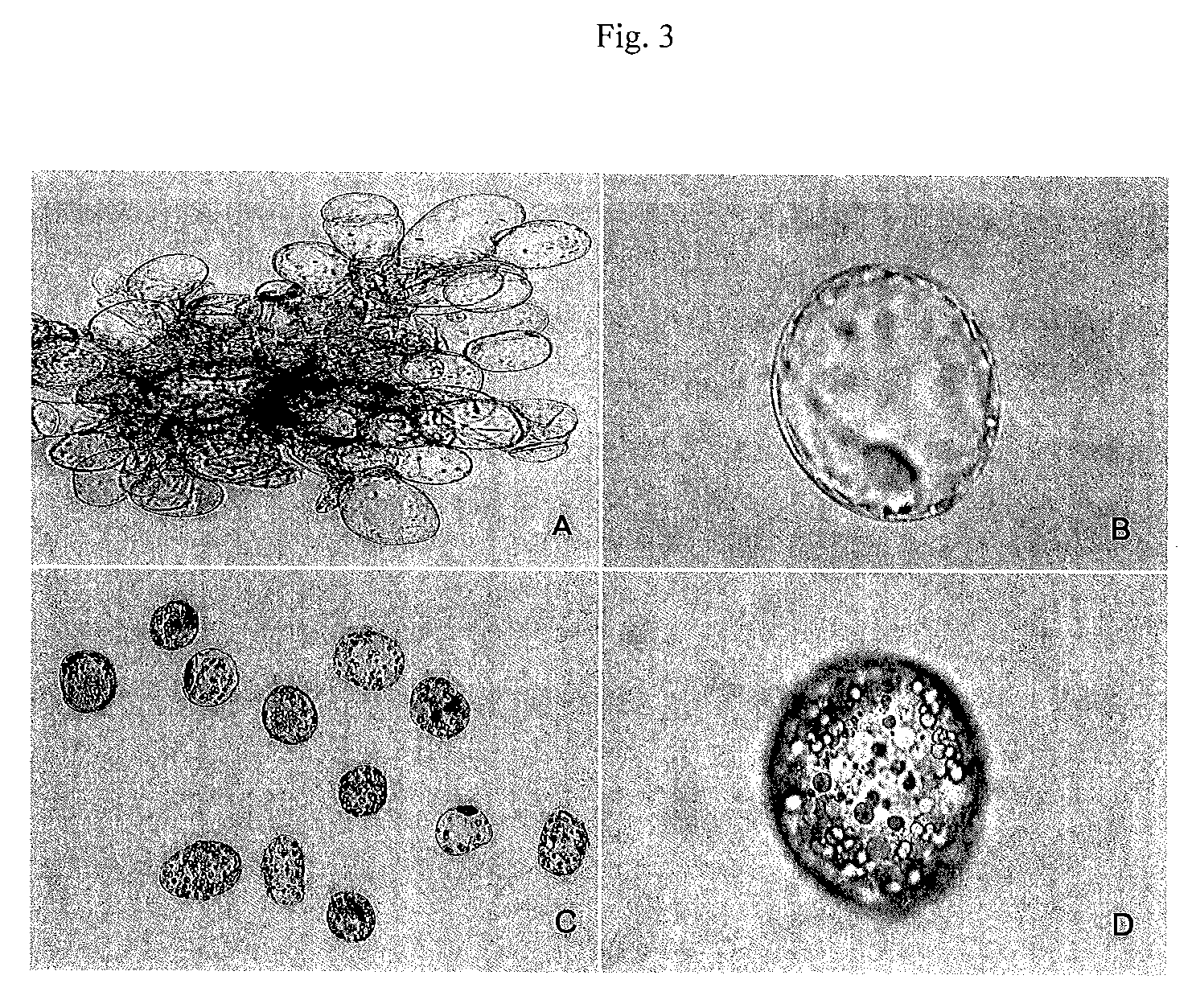

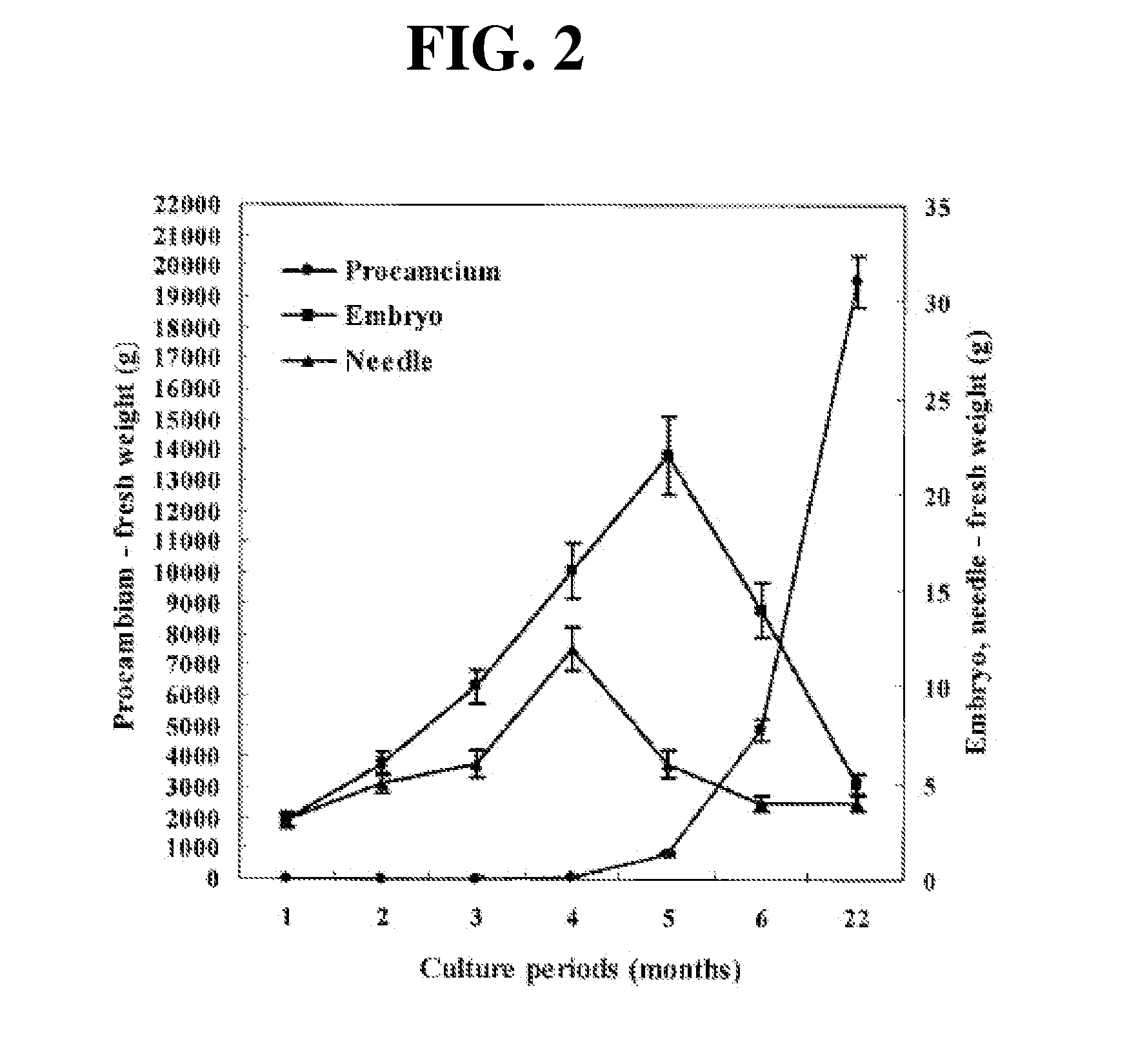

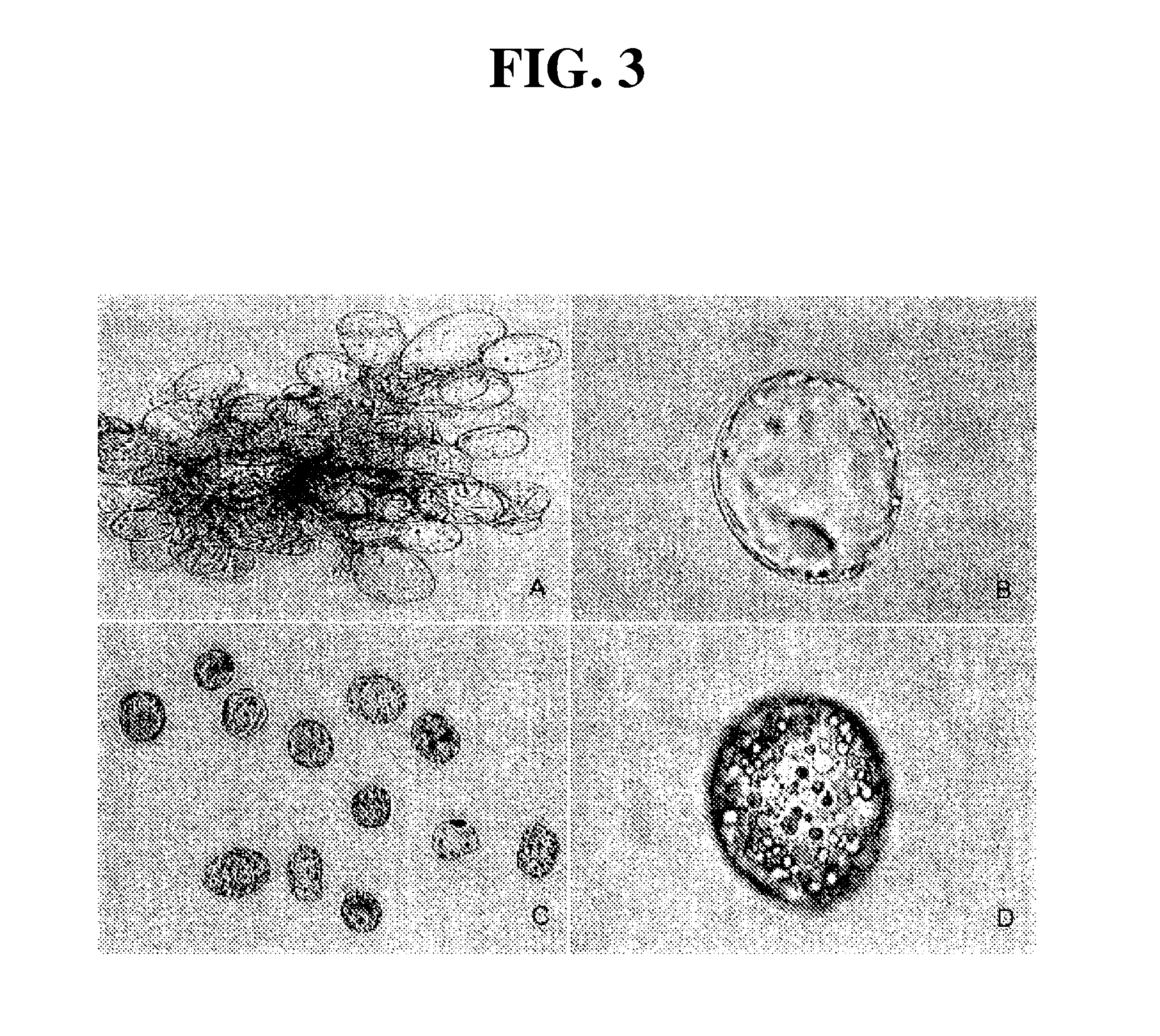

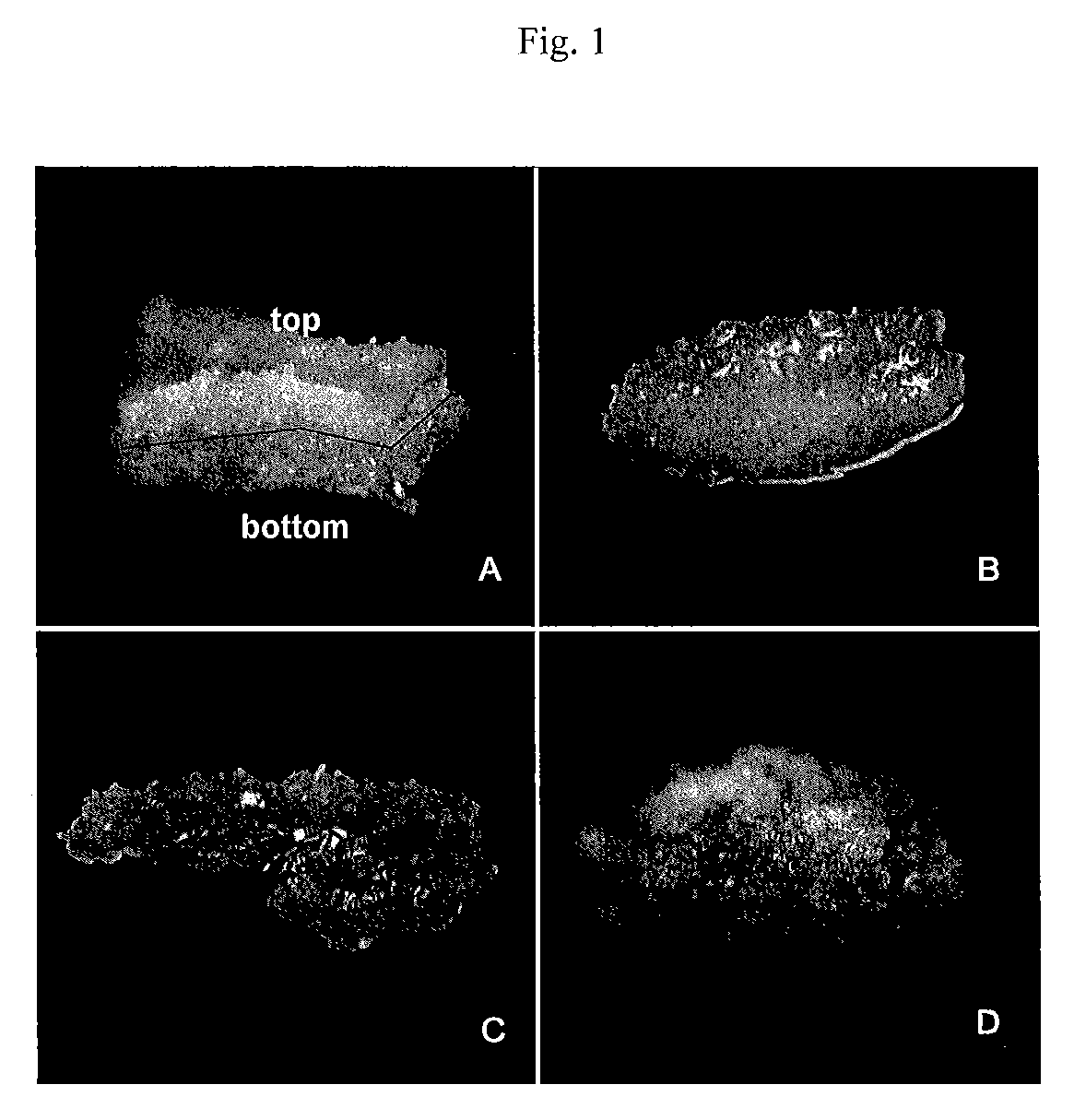

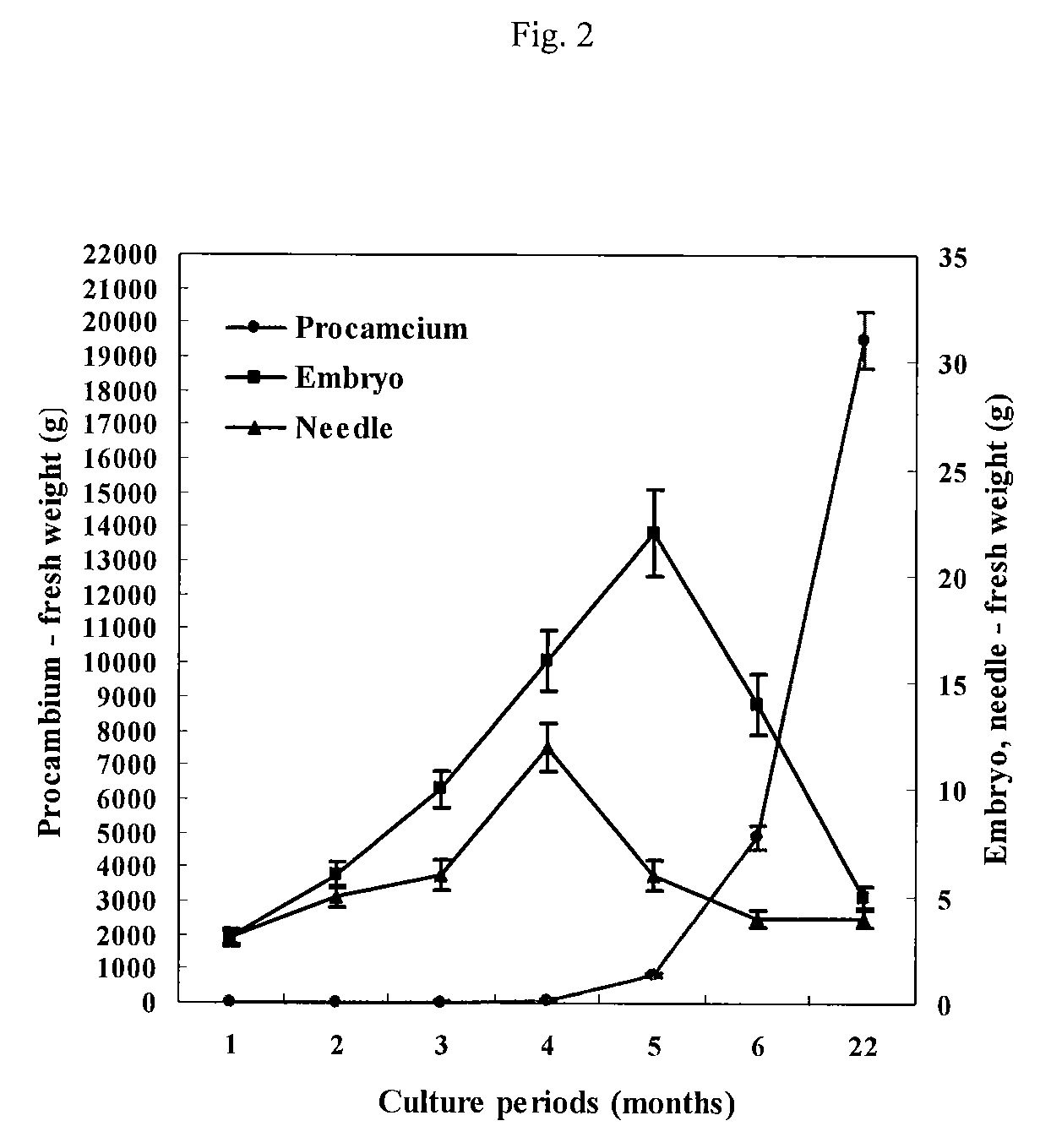

This invention is a method of minimizing the variation of cell growth and production through homogeneous cell line development. To be more specific, it is the method of isolating and proliferating single cell clone from the procambium to promote the stability of the plant-derived biologically active substances production by solving the problems of decrease in cell growth and the productivity during the long term culture.

Owner:WELLKEY HLDG LTD

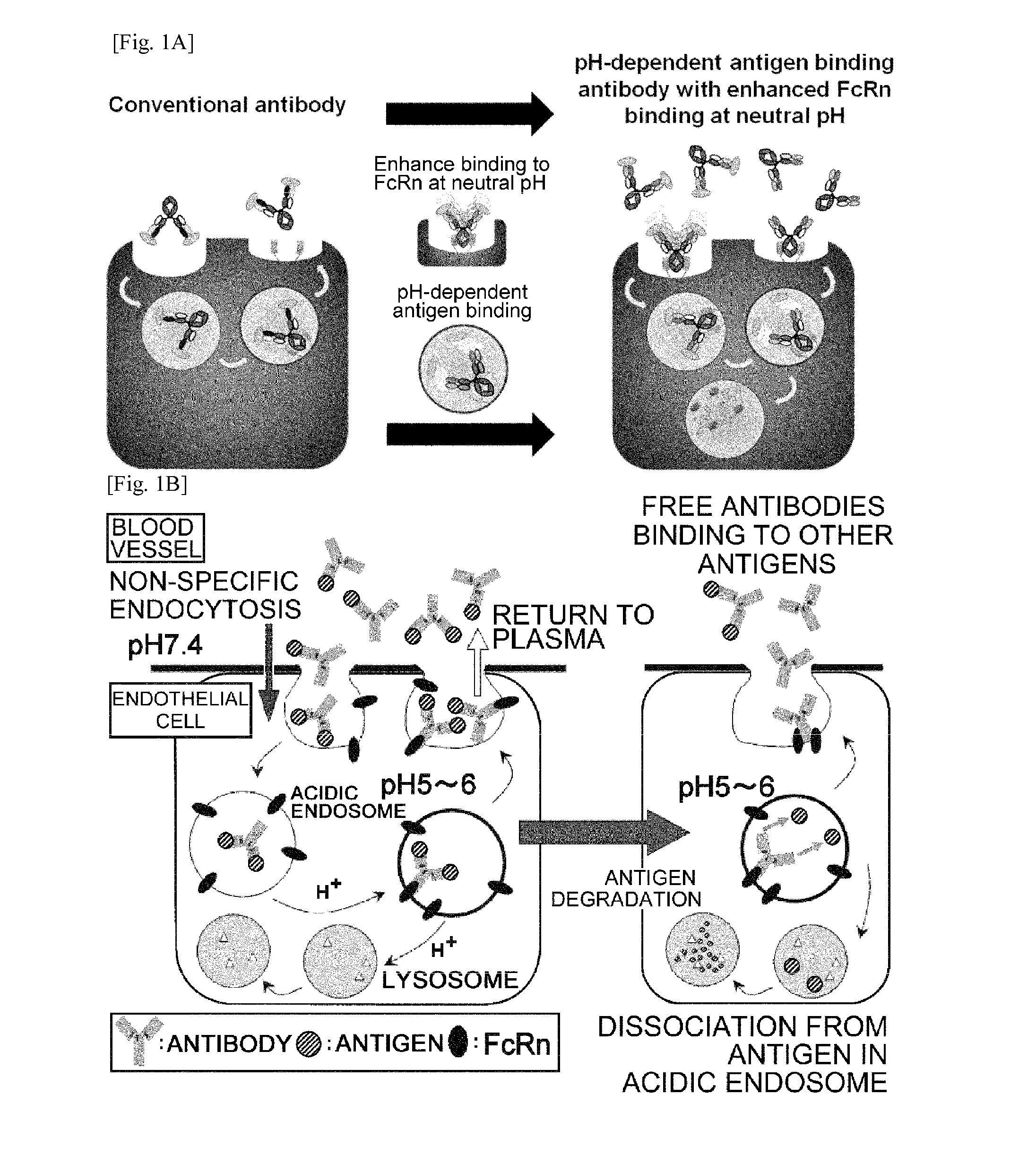

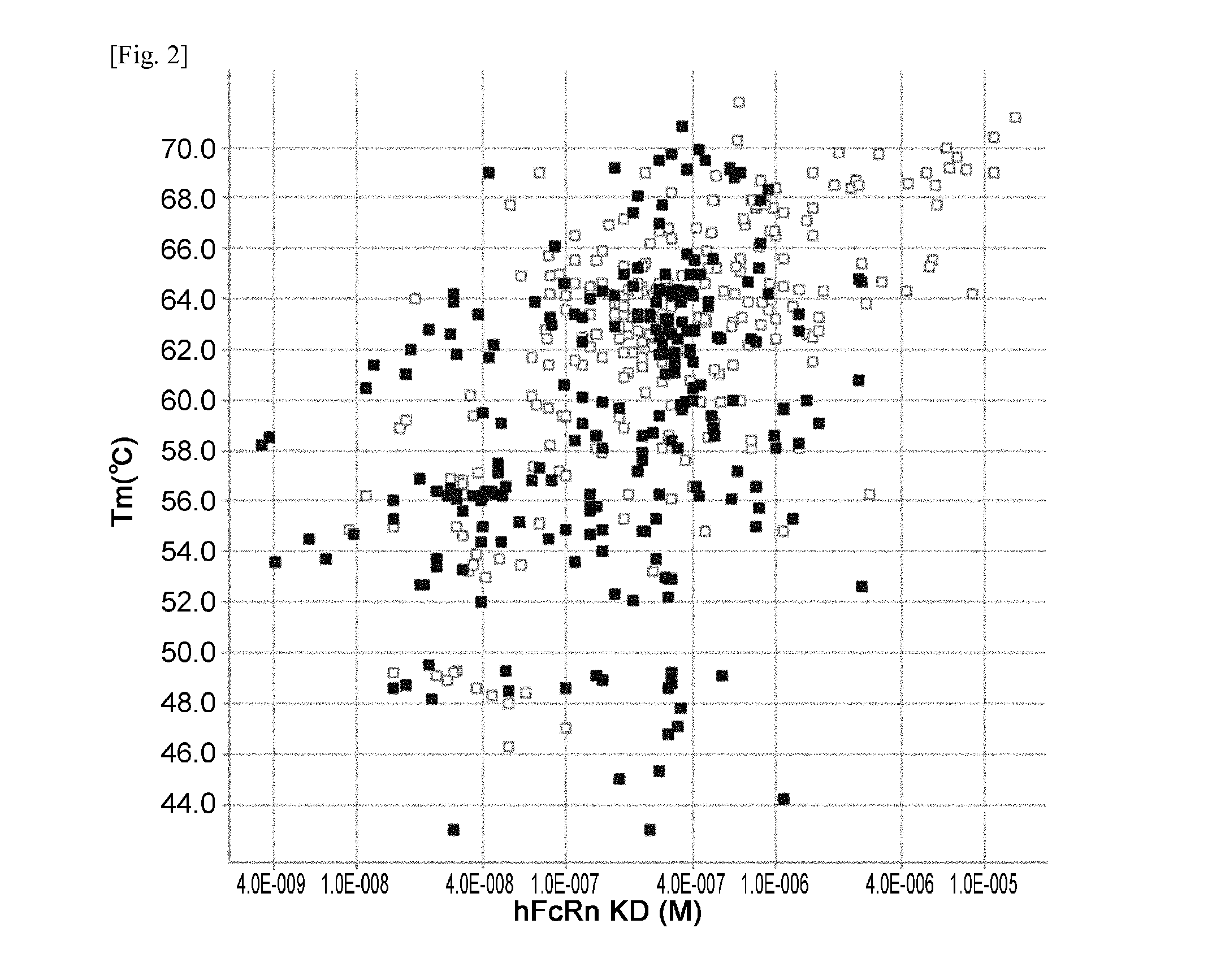

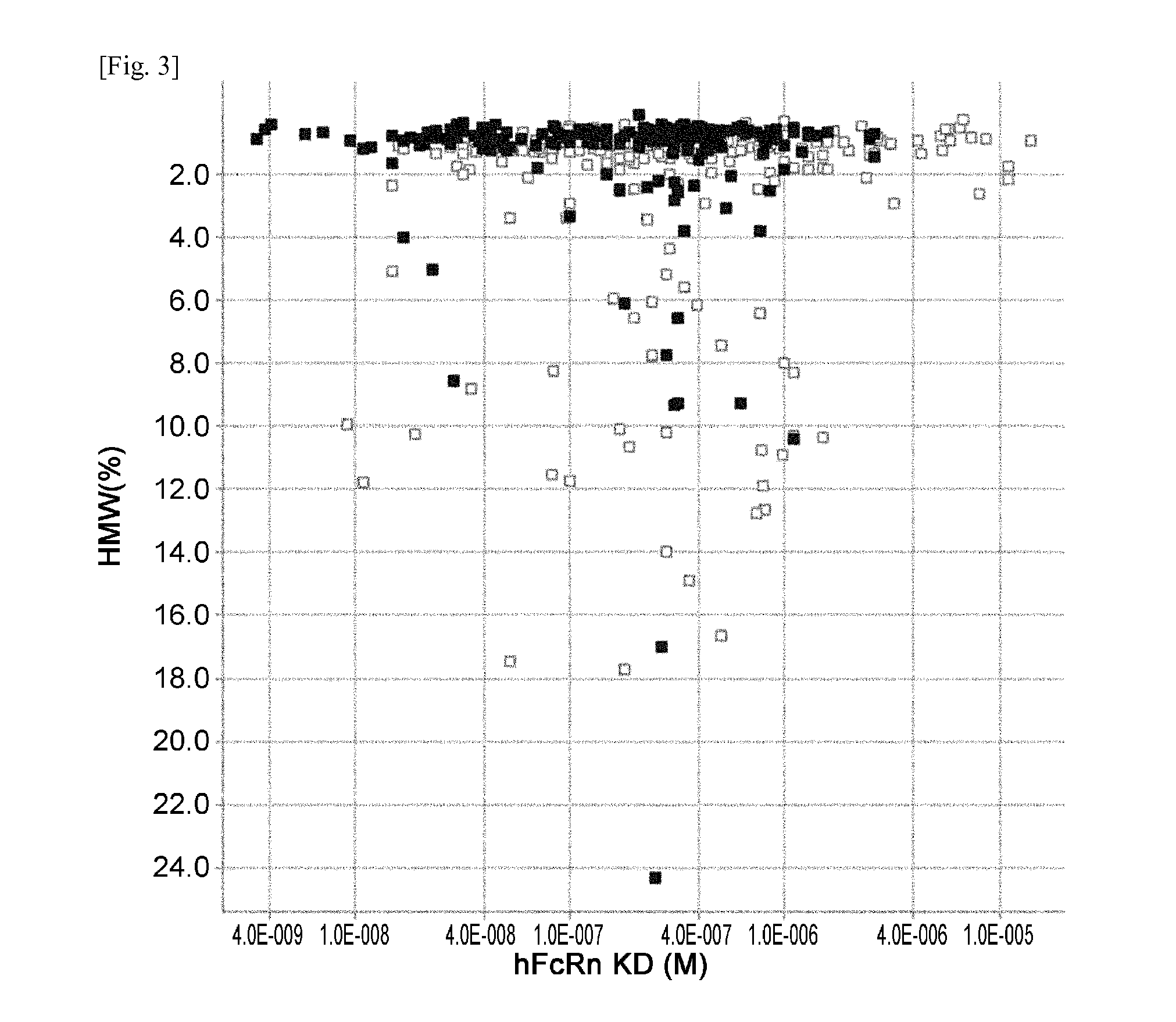

THERAPEUTIC ANTIGEN-BINDING MOLECULE WITH A FcRn-BINDING DOMAIN THAT PROMOTES ANTIGEN CLEARANCE

ActiveUS20140363428A1Low immunogenicityImprove stabilityAntipyreticAnalgesicsFc(alpha) receptorNeutral ph

The present invention provides: a modified FcRn-binding domain having an enhanced affinity for the Fc Receptor neonatal (FcRn) at neutral pH; an antigen-binding molecule comprising said FcRn-binding domain, which has low immunogenicity, high stability and form only a few aggregates; a modified antigen-binding molecule having an increased FcRn-binding activity at neutral or acidic pH without an increased binding activity at neutral pH for a pre-existing anti-drug antibody; use of the antigen-binding molecules for improving antigen-binding molecule-mediated antigen uptake into cells; use of the antigen-binding molecules for reducing the plasma concentration of a specific antigen; use of the modified FcRn-binding domain for increasing the total number of antigens to which a single antigen-binding molecule can bind before its degradation; use of the modified FcRn-binding domain for improving pharmacokinetics of an antigen-binding molecule; methods for decreasing the binding activity for a pre-existing anti-drug antibody; and methods for producing said antigen-binding molecules.

Owner:CHUGAI PHARMA CO LTD

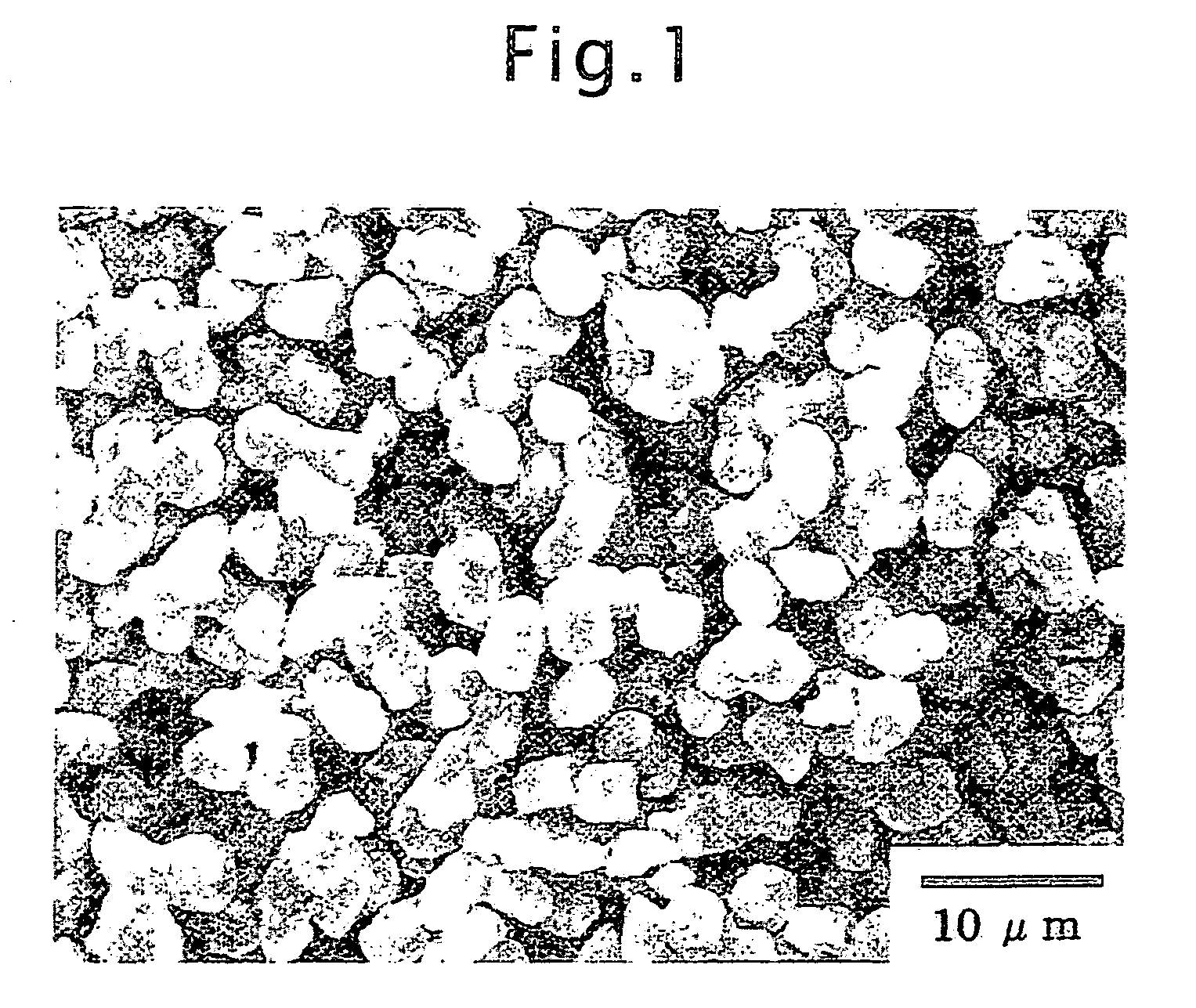

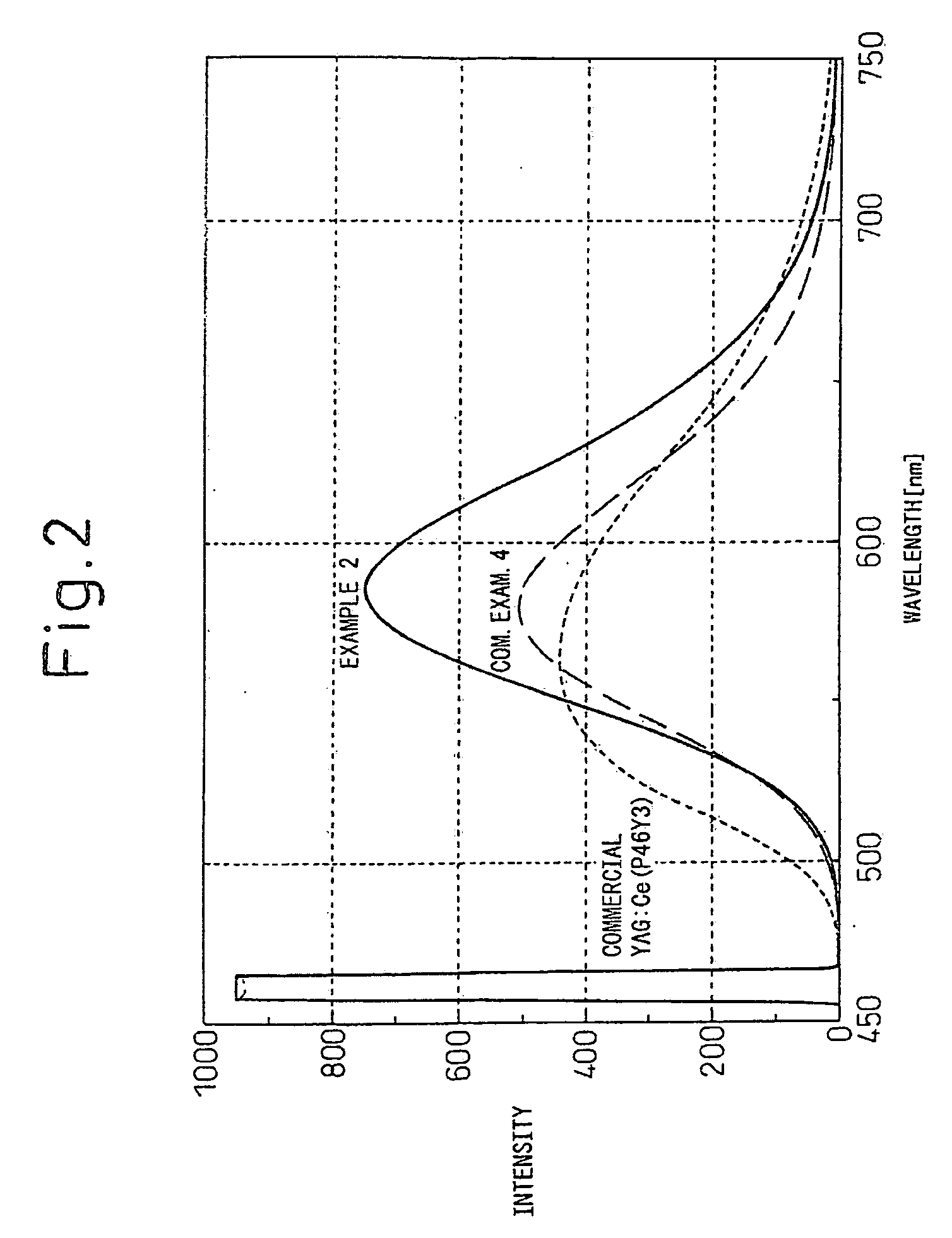

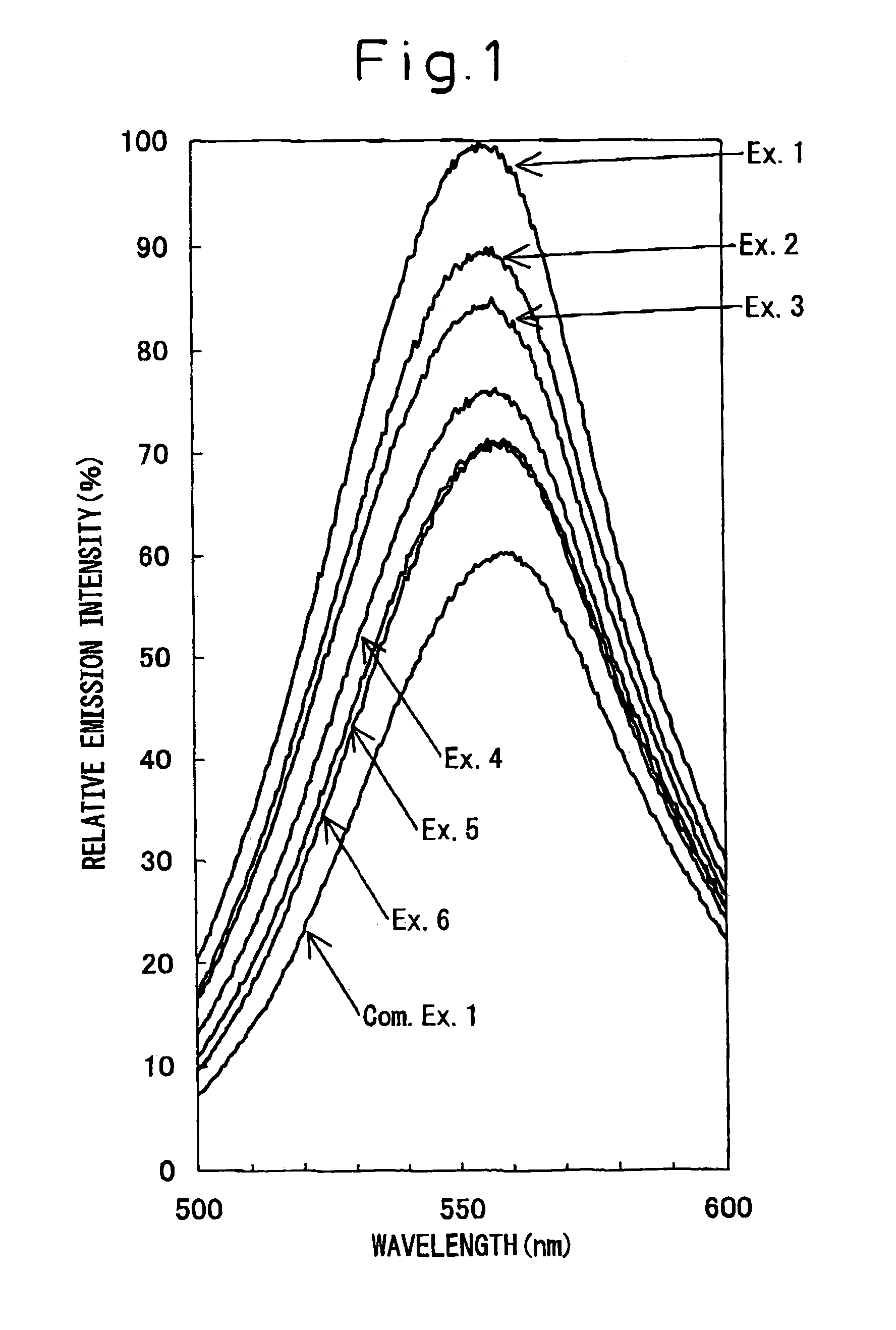

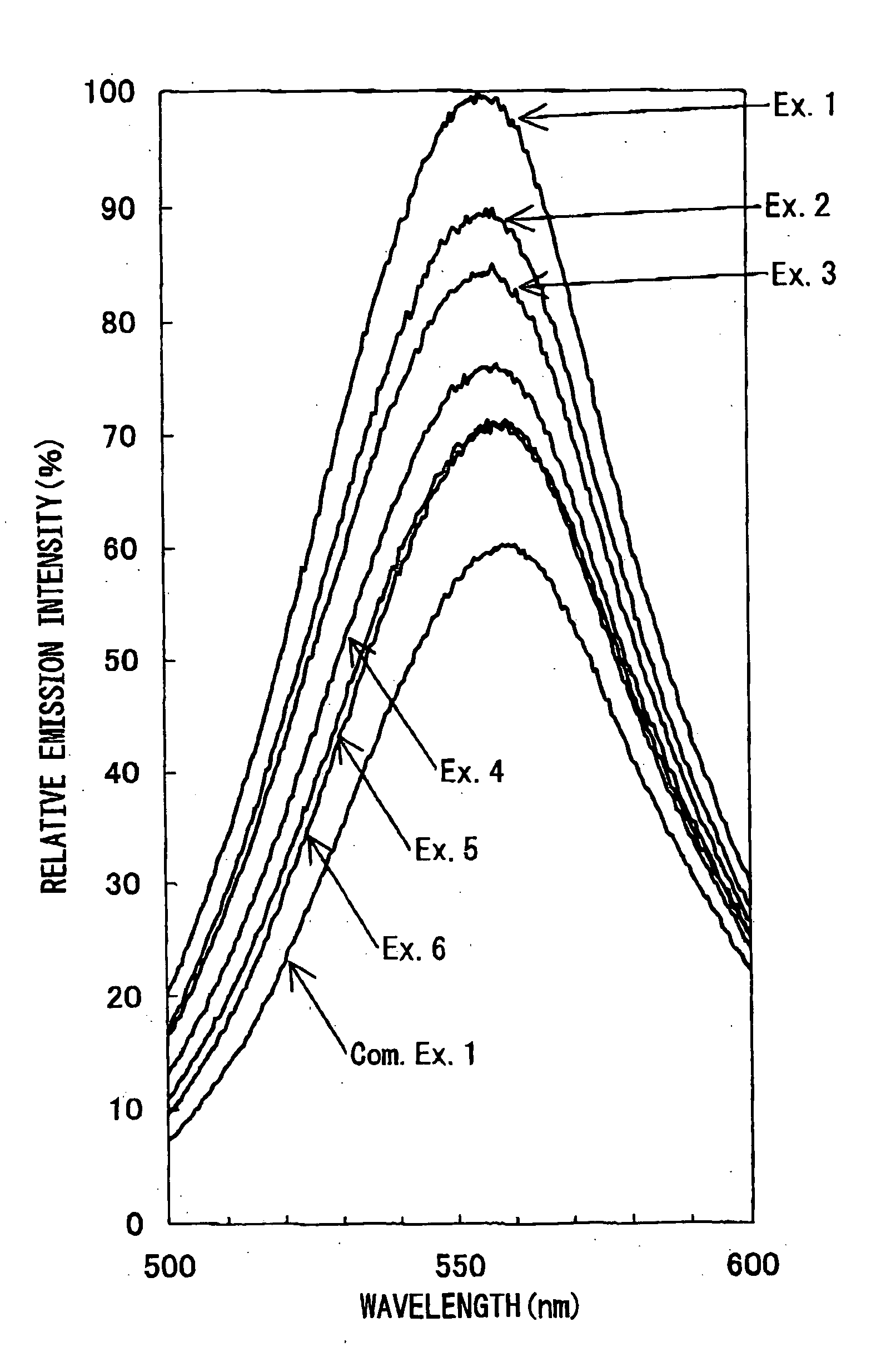

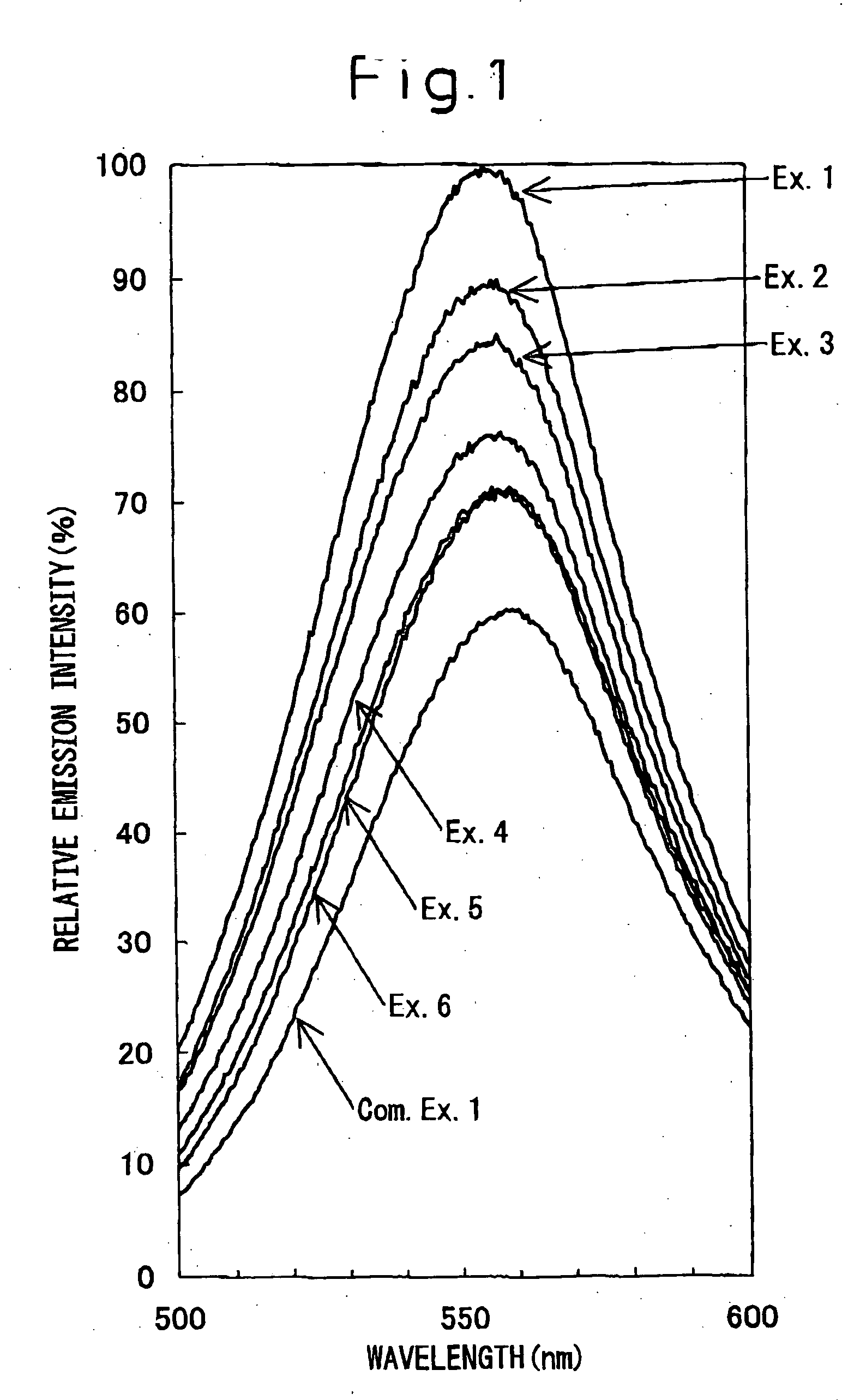

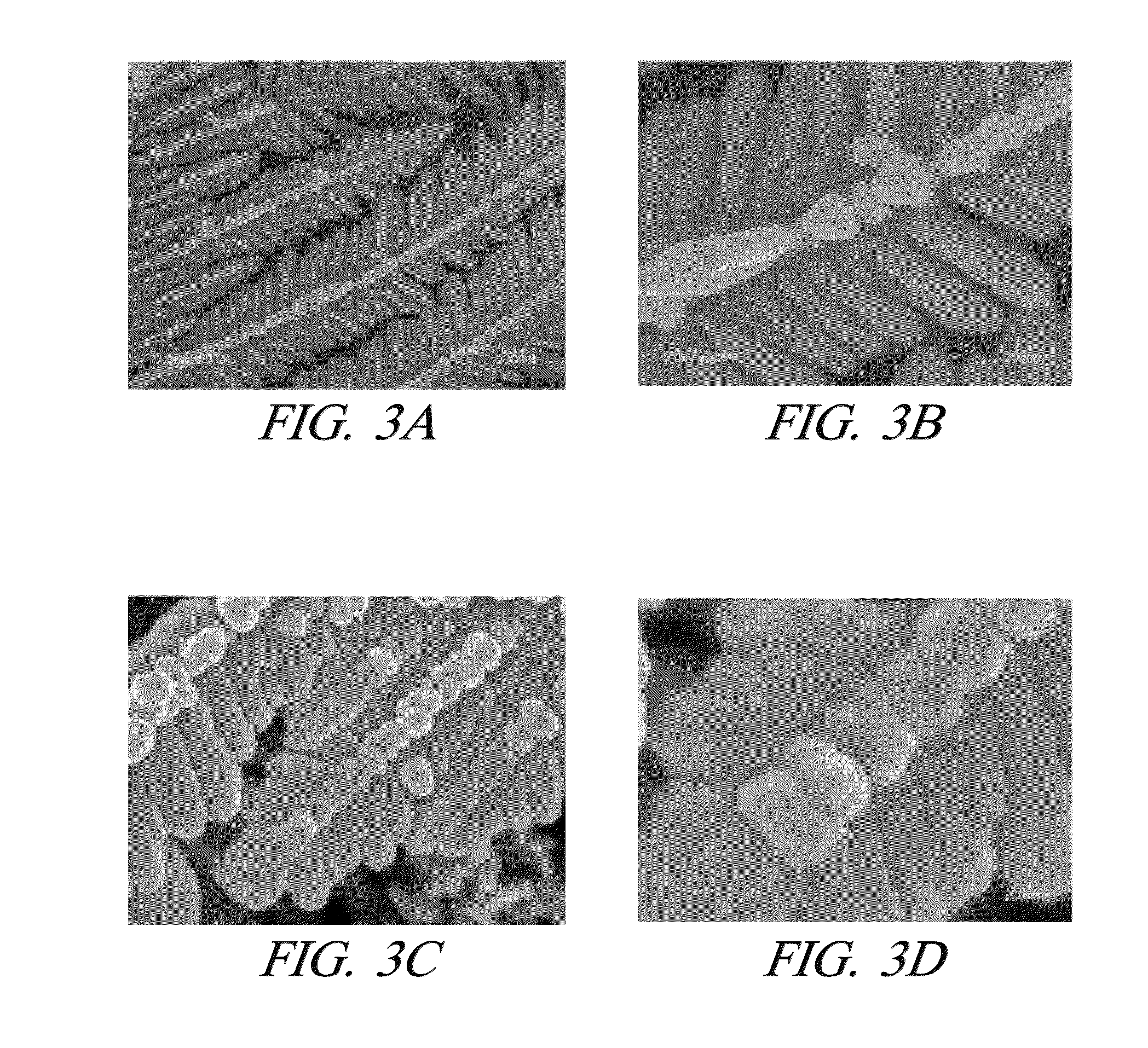

Sialon-based oxynitride phosphor and production method thereof

InactiveUS20090284948A1Prevent excessive aggregationLess fusionDischarge tube luminescnet screensElectric discharge tubesLanthanideElectron

The present invention relates to an oxynitride phosphor comprising an α-sialon as the main component, which is represented by the general formula: MxSi12−(m+n)Al(m+n)OnN16−n:Lny (wherein 0.3≦x+y<1.5, 0<y<0.7, 0.3≦m<4.5, 0<n<2.25, and assuming that the atomic valence of the metal M is a and the atomic valence of the lanthanide metal Ln is b, m=ax+by) and in which the aggregation index, A1=D50 / DBET≦3.0 or the aggregation index A2=D50 / Dparticle≦3.0; and a production method and usage of the phosphor.The phosphor of the present invention has less aggregation and a narrow particle size distribution, and therefore is easy to uniformly mix with a resin or the like, and a high-brightness white LED can be easily obtained.D50 [μm]: The median diameter in the grain size distribution curve.DBET [μm]: The equivalent-sphere diameter calculated on the basis of a BET specific surface area.Dparticle [μm]: The primary particle diameter measured by the image analysis of a scanning electron micrograph.

Owner:UBE IND LTD

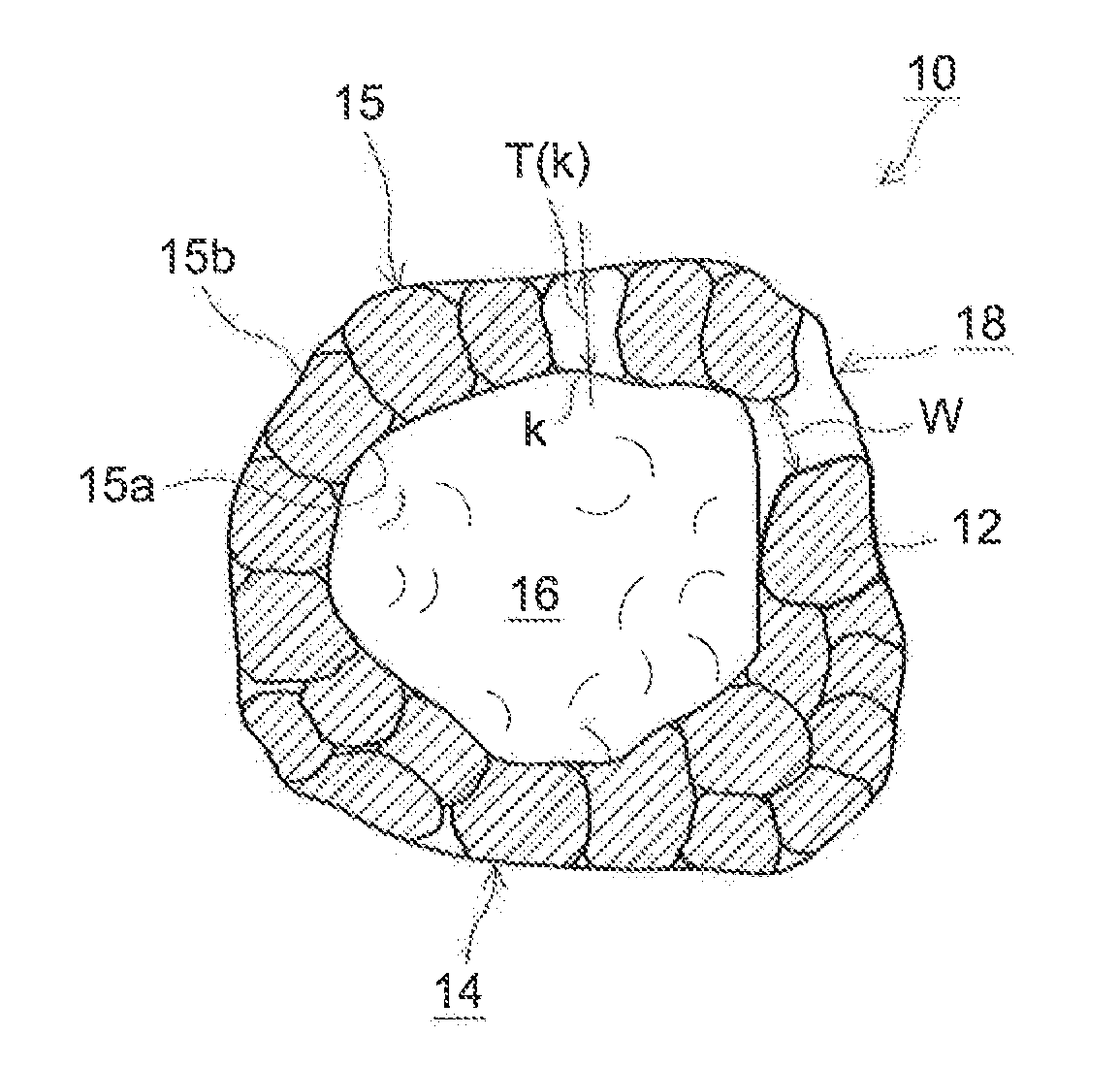

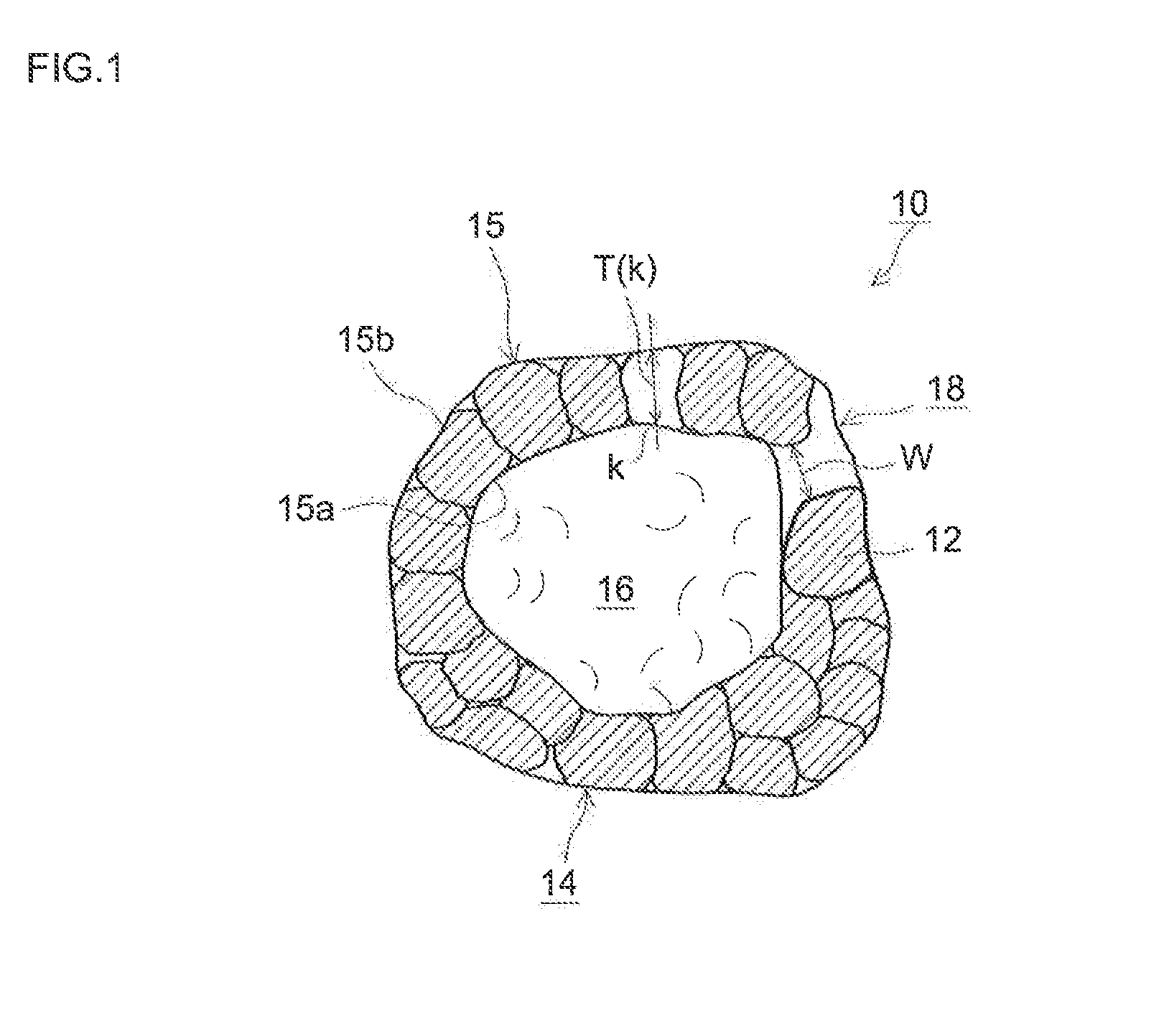

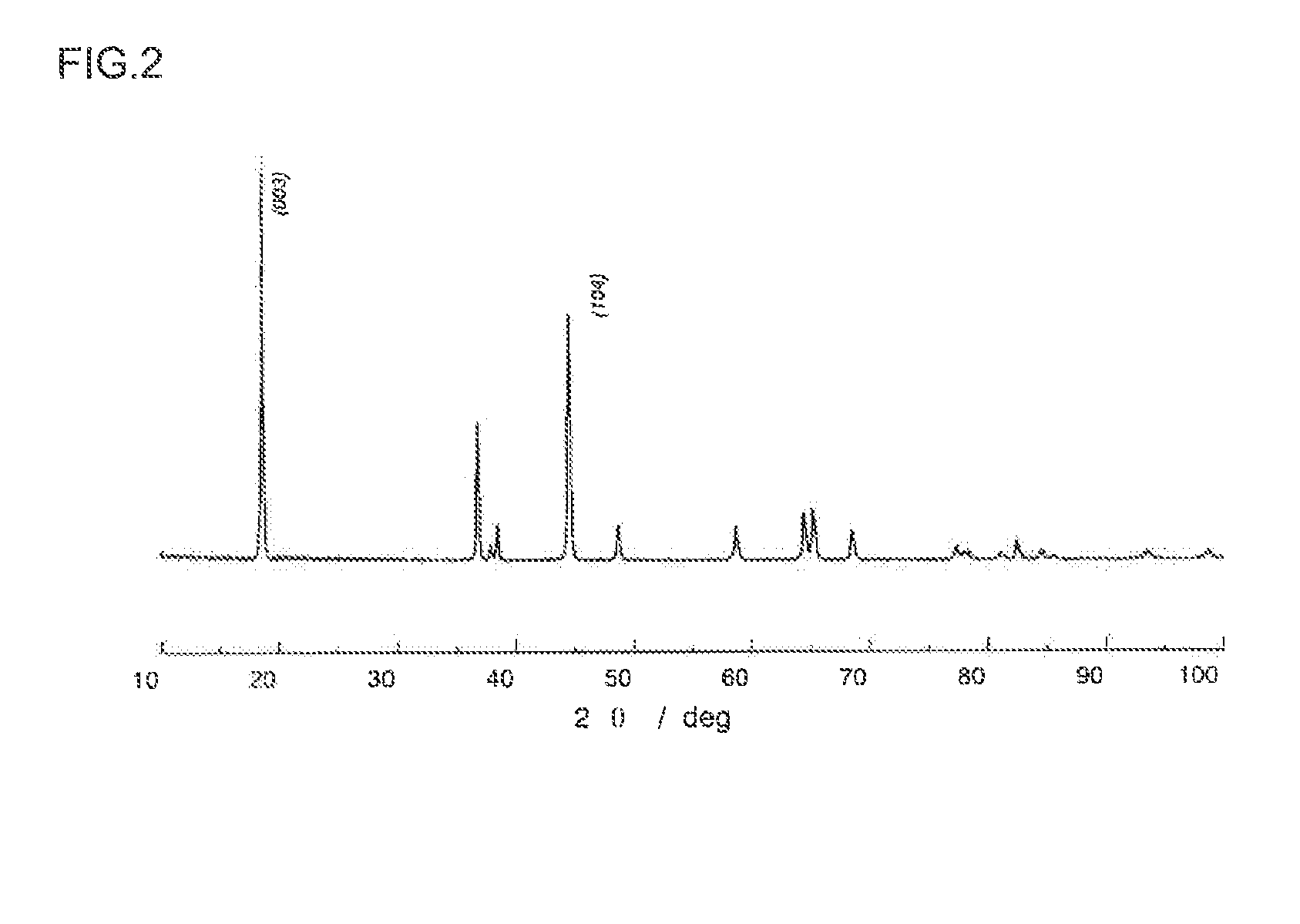

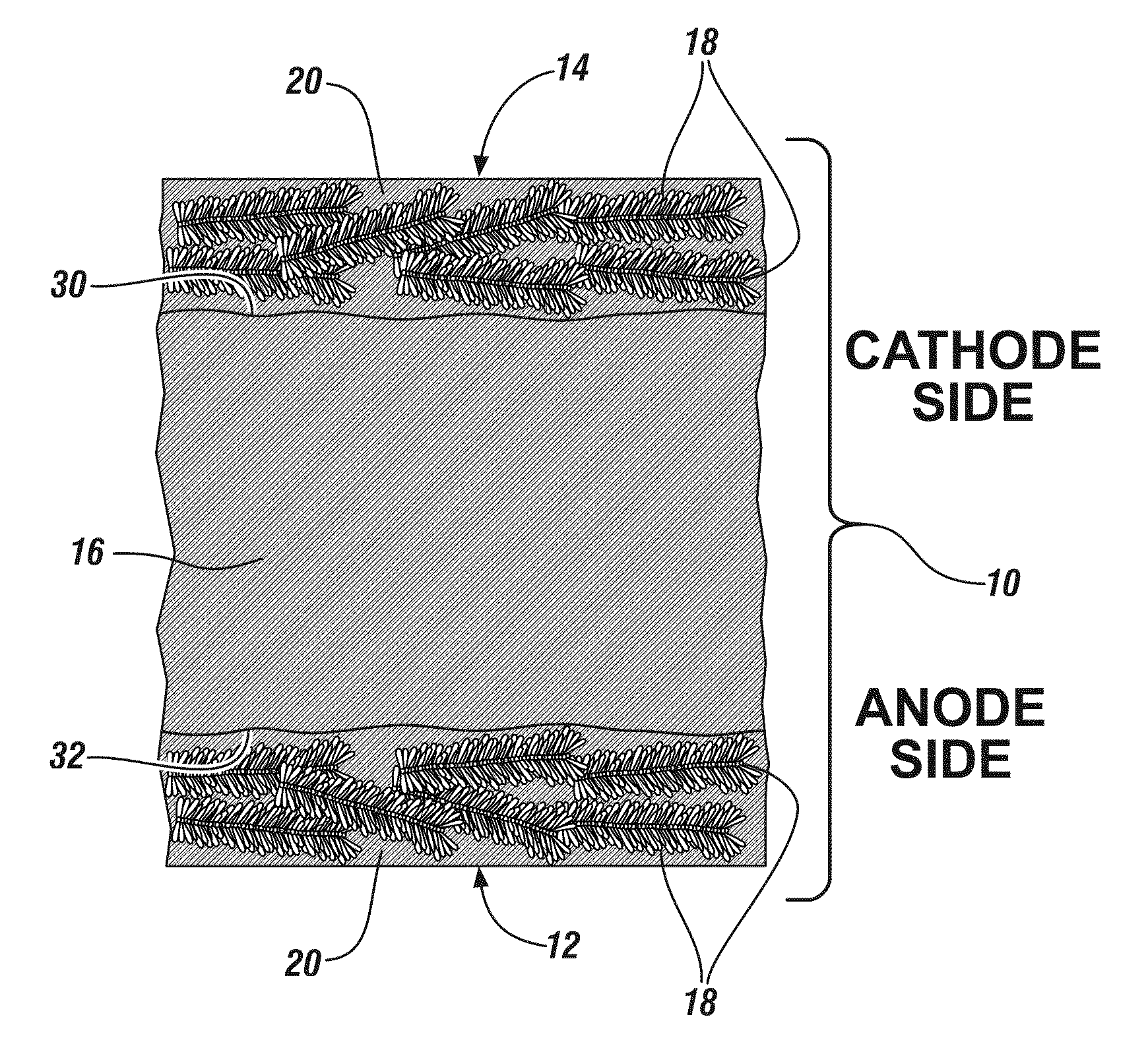

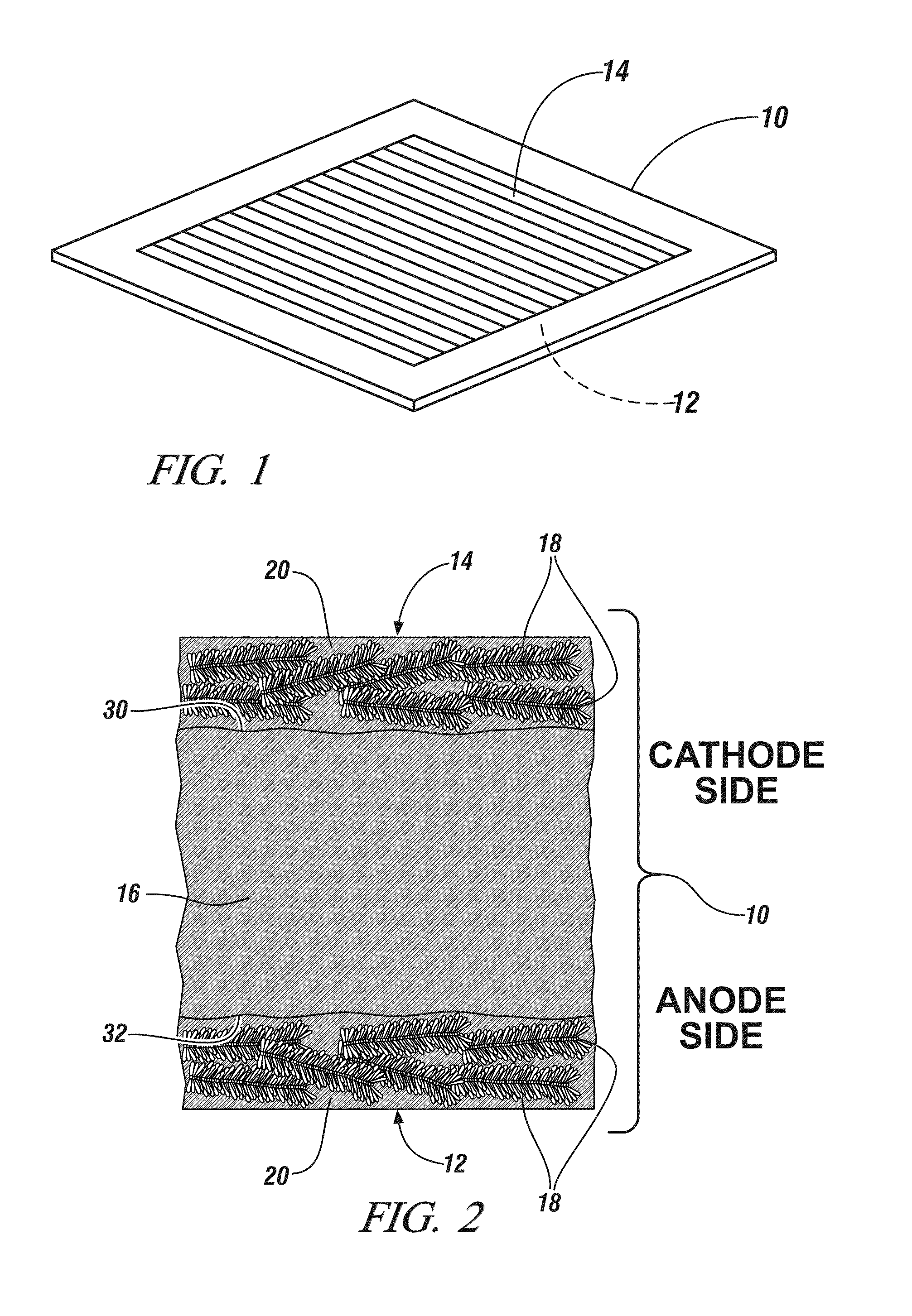

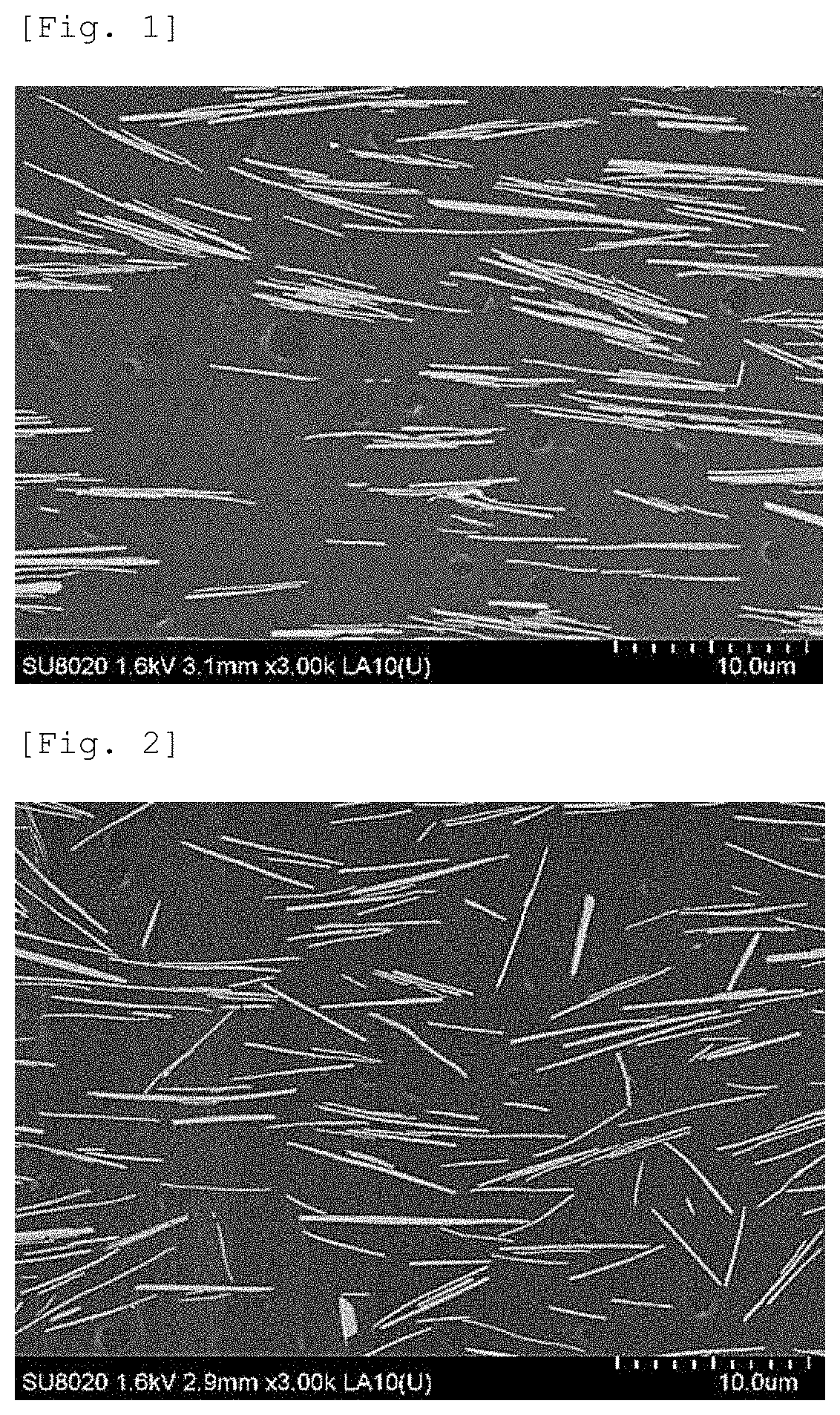

Lithium rechargeable battery

ActiveUS20140205901A1Guaranteed uptimeOperation can be performedFinal product manufactureActive material electrodesLithiumX-ray

Owner:TOYOTA JIDOSHA KK

Rubber composition and method of manufacturing the same

InactiveUS20020177641A1Reduce rolling resistanceImprove braking effectSpecial tyresPolymer scienceSilicon dioxide

Owner:BRIDGESTONE CORP

Aqueous dispersion of metal oxide fine particles and method for producing the same

InactiveUS20080242745A1Prevent excessive aggregationPrevent decrease of sumMaterial nanotechnologyOxygen/ozone/oxide/hydroxideTransmittanceCarboxylic acid

An aqueous dispersion of metal oxide fine particles, including metal oxide fine particles, a carboxylic compound and an acid compound containing a bulky anion having B value of −0.01 or less in Equation (1), wherein the metal oxide fine particles, the carboxylic compound and the acid compound containing a bulky anion are dispersed in an aqueous solution, and the aqueous dispersion of metal oxide fine particles has a light transmittance at 800 nm wavelength of 90% or more:η=η0(1+A√c+Bc) Equation (1)where η represents a viscosity of a solution, η0 represents a viscosity of a solvent, A and B respectively represent an inherent constant value of an acid, and c represents a concentration of the solution.

Owner:FUJIFILM CORP

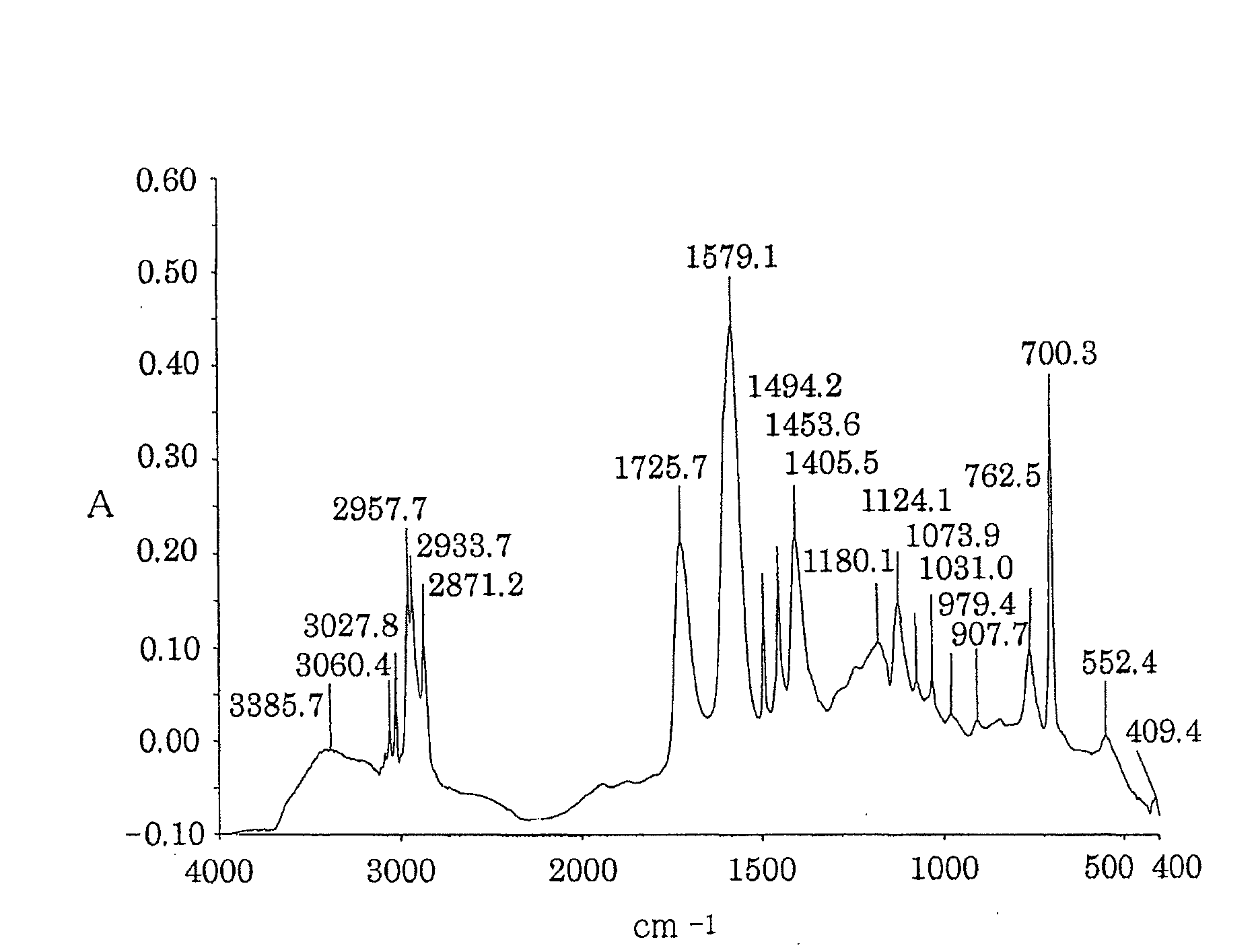

Aqueous-dispersion-type pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveUS20090186221A1Excellent stability against mechanical shearImprove productivityNatural rubber adhesivesLayered productsEmulsionPolymer science

The present invention provides an aqueous-dispersion-type pressure-sensitive adhesive composition and a pressure-sensitive adhesive sheet formed thereof. This composition comprises a rubber latex, a tackifier resin emulsion, a dispersant composed primarily of a polycarboxylic acid (salt) having a hydrophobic side chain, and an emulsifier composed primarily of a polyoxyethylene alkyl ether sulfuric acid ester having an average polymerization degree of 16 to 80. A preferred dispersant contains carboxyl group at 2 to 6 mmol / g and an aqueous solution thereof at 1% by mass has a surface tension of 25 to 45 mN / m.

Owner:NITTO DENKO CORP

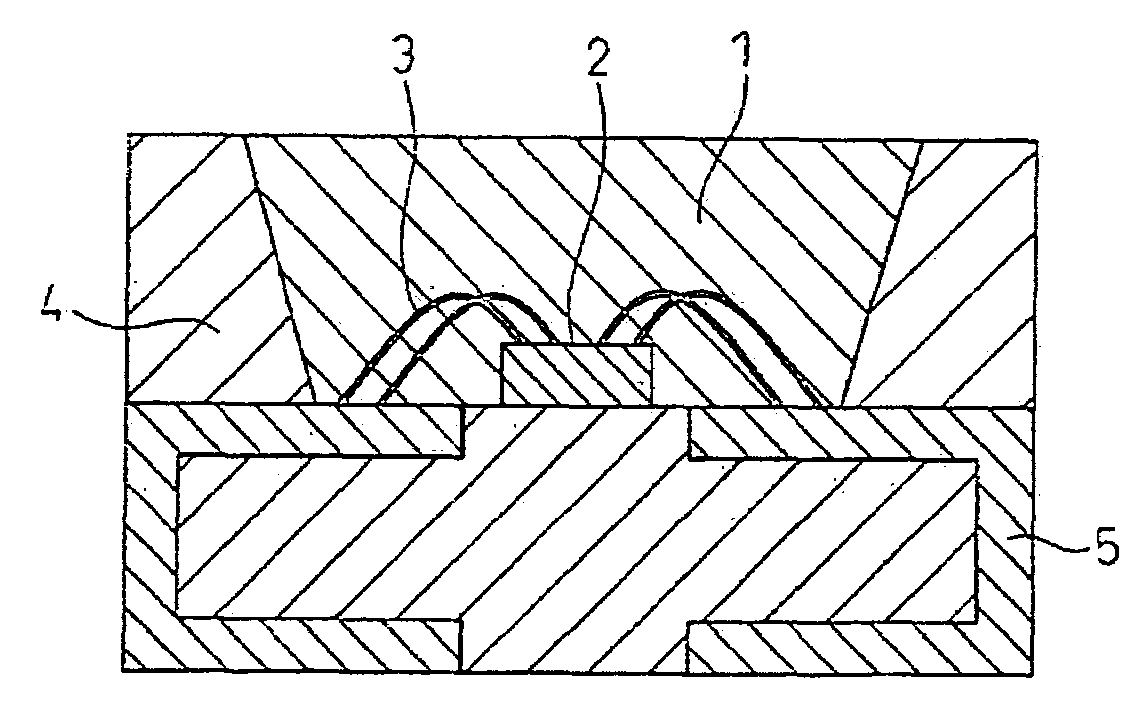

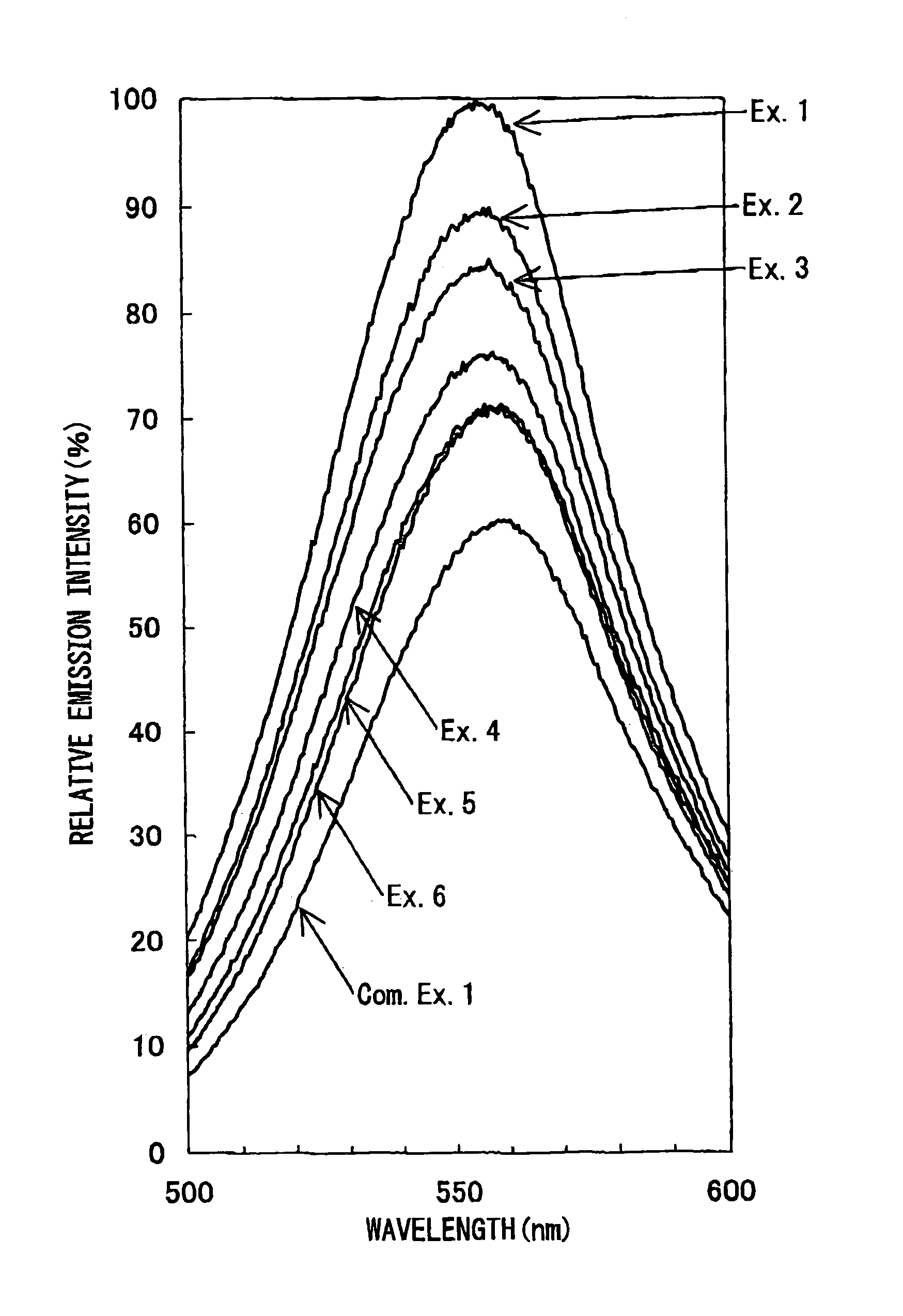

Production method of sialon-based phosphor, and sialon-based phosphor

ActiveUS7258818B2Prevent excessive aggregationSemiconductor/solid-state device manufacturingLuminescent compositionsPhotoluminescenceLanthanide

To provide a sialon-based phosphor capable of forming a thin film by mixing it with a resin, and giving a uniform photoluminescent light with high light emission intensity, and to provide a method for producing a sialon-based phosphor not having excessively large agglomerated particles and a wide particle size distribution, there is provided a method for producing an α-sialon based phosphor represented by the formula:MxLnySi12−(m+n)Al(m+n)OnN16−nwherein M is at least one metal selected from Ca, Mg, Y and Li, Ln is at least one lanthanide metal selected from Eu, Dy, Er, Tb, Yb and Ce, ax+by=m (assuming that the valence of metal M is a and the valence of lanthanide metal Ln is b), 0<x≦1.5, 0.3≦m≦4.5, and 0<n<2.25), wherein the silicon nitride raw material used as the raw material is a silicon nitride raw material powder comprising amorphous silicon nitride and crystalline silicon nitride.

Owner:UBE CORP

Production method of sialon-based phosphor, and sialon-based phosphor

ActiveUS20050116244A1Prevent excessive aggregationHigh luminous intensitySemiconductor/solid-state device manufacturingLuminescent compositionsLanthanideCrystalline silicon

To provide a sialon-based phosphor capable of forming a thin film by mixing it with a resin, and giving a uniform photoluminescent light with high light emission intensity, and to provide a method for producing a sialon-based phosphor not having excessively large agglomerated particles and a wide particle size distribution, there is provided a method for producing an α-sialon based phosphor represented by the formula: MxLnySi12-(m+n)Al(m+n)OnN16-n wherein M is at least one metal selected from Ca, Mg, Y and Li, Ln is at least one lanthanide metal selected from Eu, Dy, Er, Tb, Yb and Ce, ax+by=m (assuming that the valence of metal M is a and the valence of lanthanide metal Ln is b), 0<x≦1.5, 0.3≦m≦4.5, and 0<n<2.25), wherein the silicon nitride raw material used as the raw material is a silicon nitride raw material powder comprising amorphous silicon nitride and crystalline silicon nitride.

Owner:UBE IND LTD

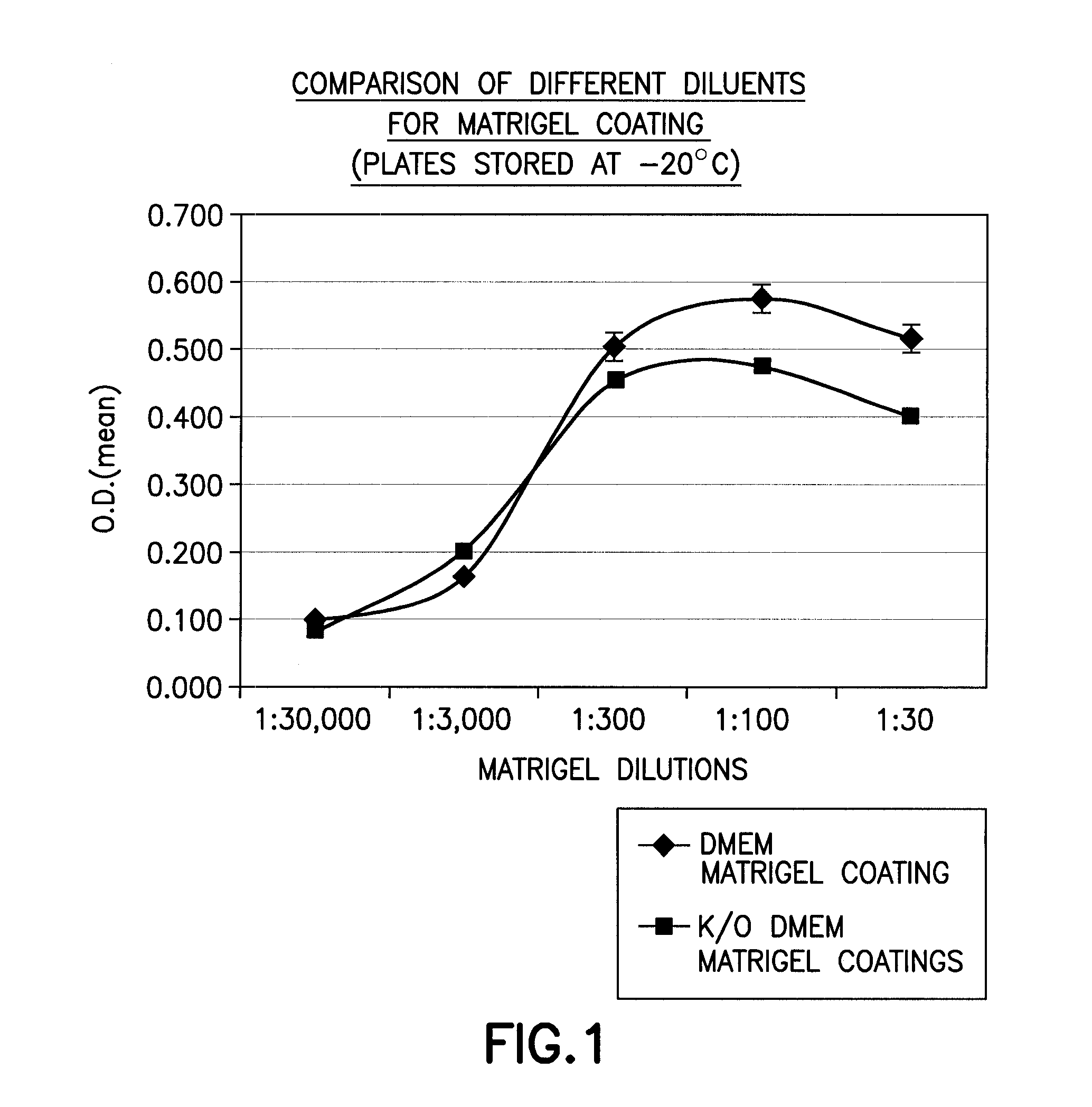

Extracellular matrix coated surface for culturing cells

ActiveUS8241908B2Maintaining their self-renewal and pluripotency characteristicsPrevent excessive aggregationBioreactor/fermenter combinationsBiological substance pretreatmentsCoated surfaceCell-Extracellular Matrix

A cell culture product is provided for propagating embryonic stem cells, and maintaining their self-renewal and pluripotency characteristics for extended periods of time in culture. The cell culturing, product includes a substrate; and a coating thereon deposited, from a coating solution. The coating solution includes a mixture of extracellular matrix proteins and an aqueous solvent, wherein the total protein concentration in the coating solution is about 10 μg / ml to about 1 mg / ml.

Owner:CORNING INC

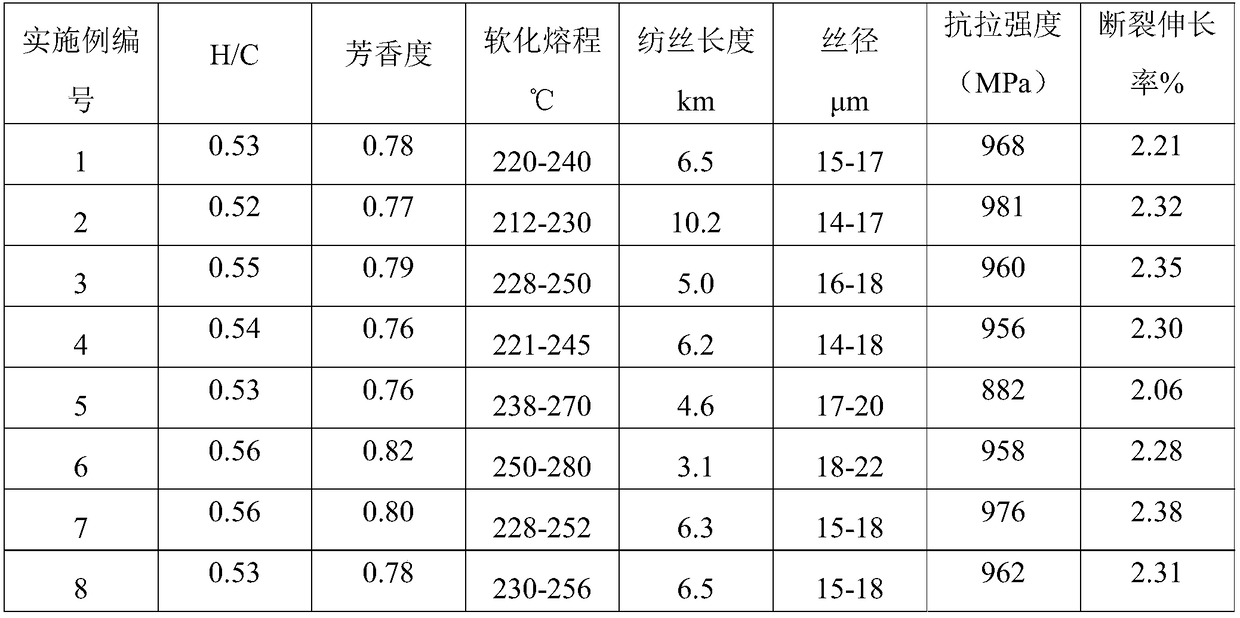

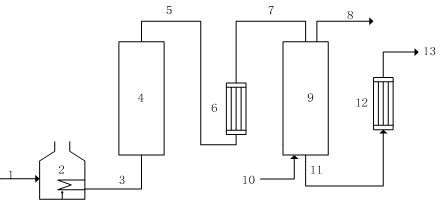

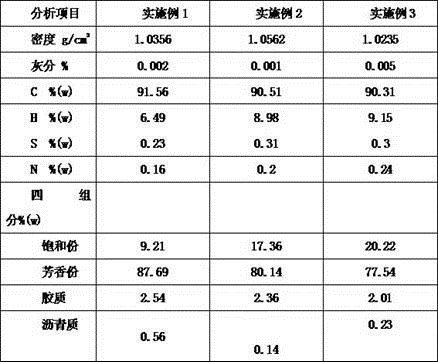

Method for preparing spinnable pitch from coal tar pitch

ActiveCN109181733AHigh yieldHigh overall yield (27-32%), softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansFiltrationNitrogen

A method for preparing spinnable pitch from coal tar pitch comprises the following steps: crushing medium-low-temperature coal tar pitch to 20 meshes or below, performing extracting by using tetrahydrofuran, performing filtration to obtain a medium-low-temperature coal tar pitch soluble component, and recovering the tetrahydrofuran solvent from the soluble component to obtain refined pitch; and mixing the refined pitch with petrolatum, adding the obtained mixture into a reactor, introducing nitrogen under normal pressure, heating the reactor to 180-220 DEG C at a heating rate of 1-10 DEG C / min, switching to air, introducing the air into the reactor at a rate of 10-60 mL / min.g, heating the reactor to 280-350 DEG C at a heating rate of 1-10 DEG C / min, and allowing the obtained mixture to stay for 1-10 h to obtain the spinnable pitch. The method has the advantages of high yield, low price and moderate thermal polycondensation temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

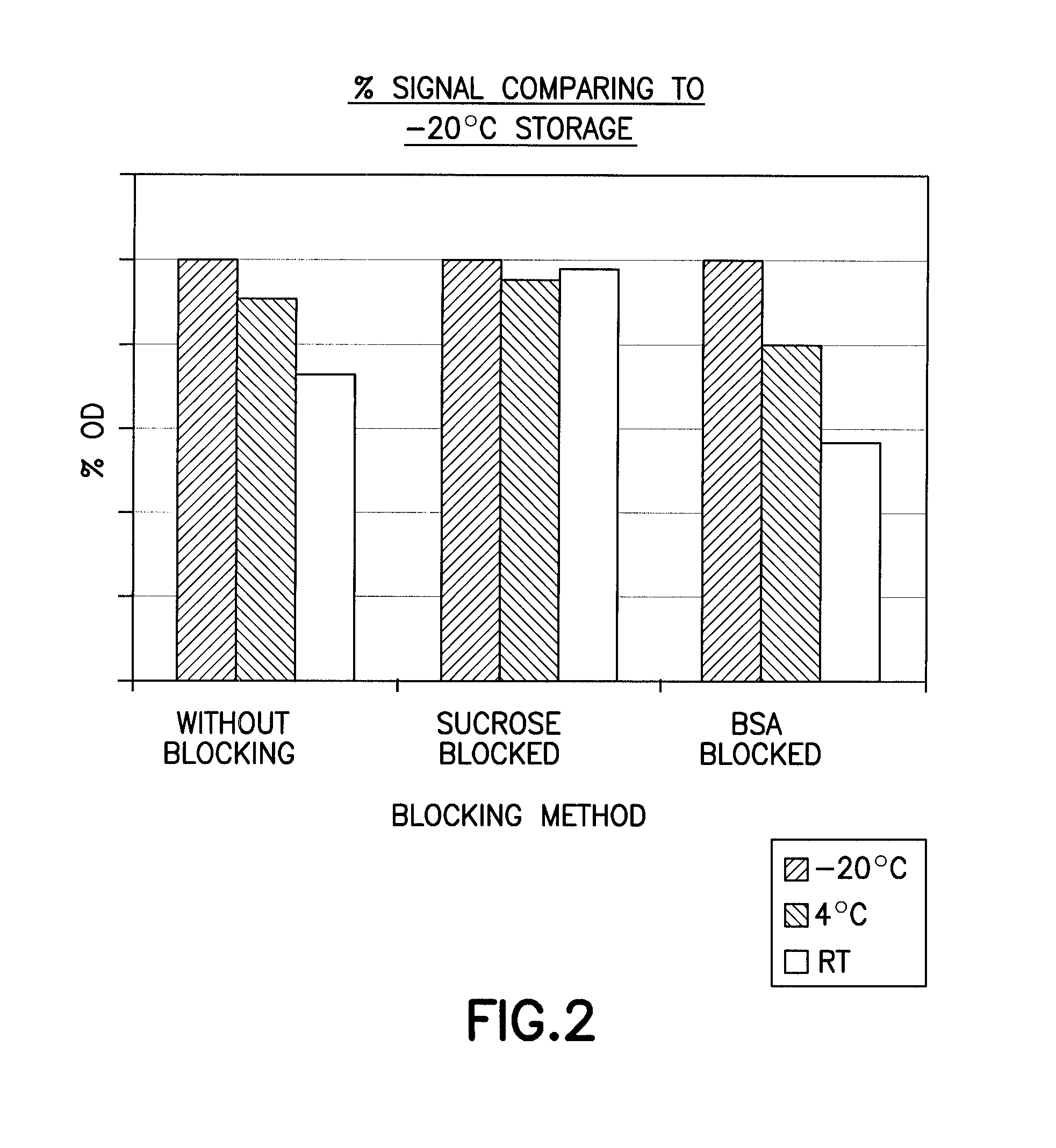

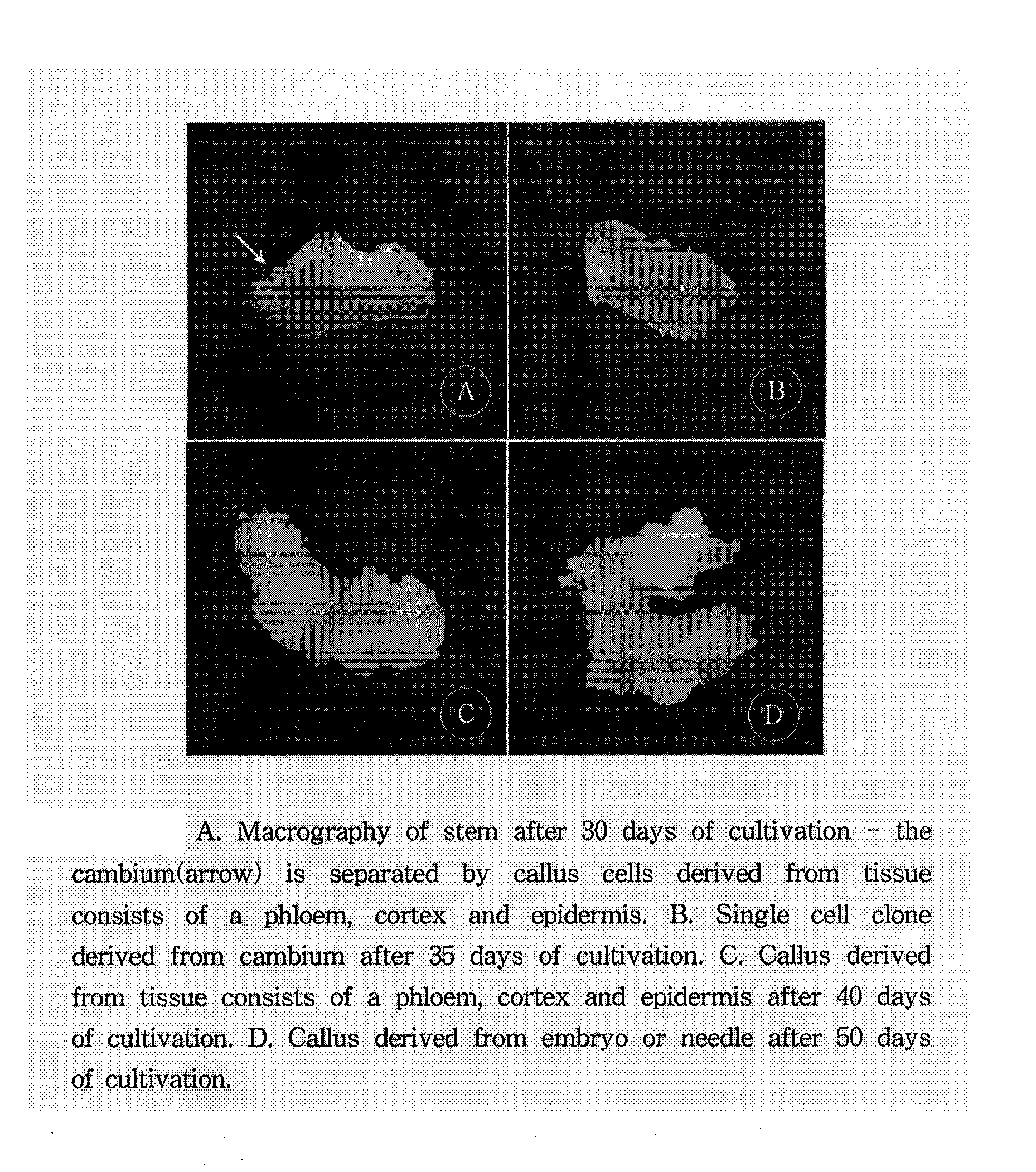

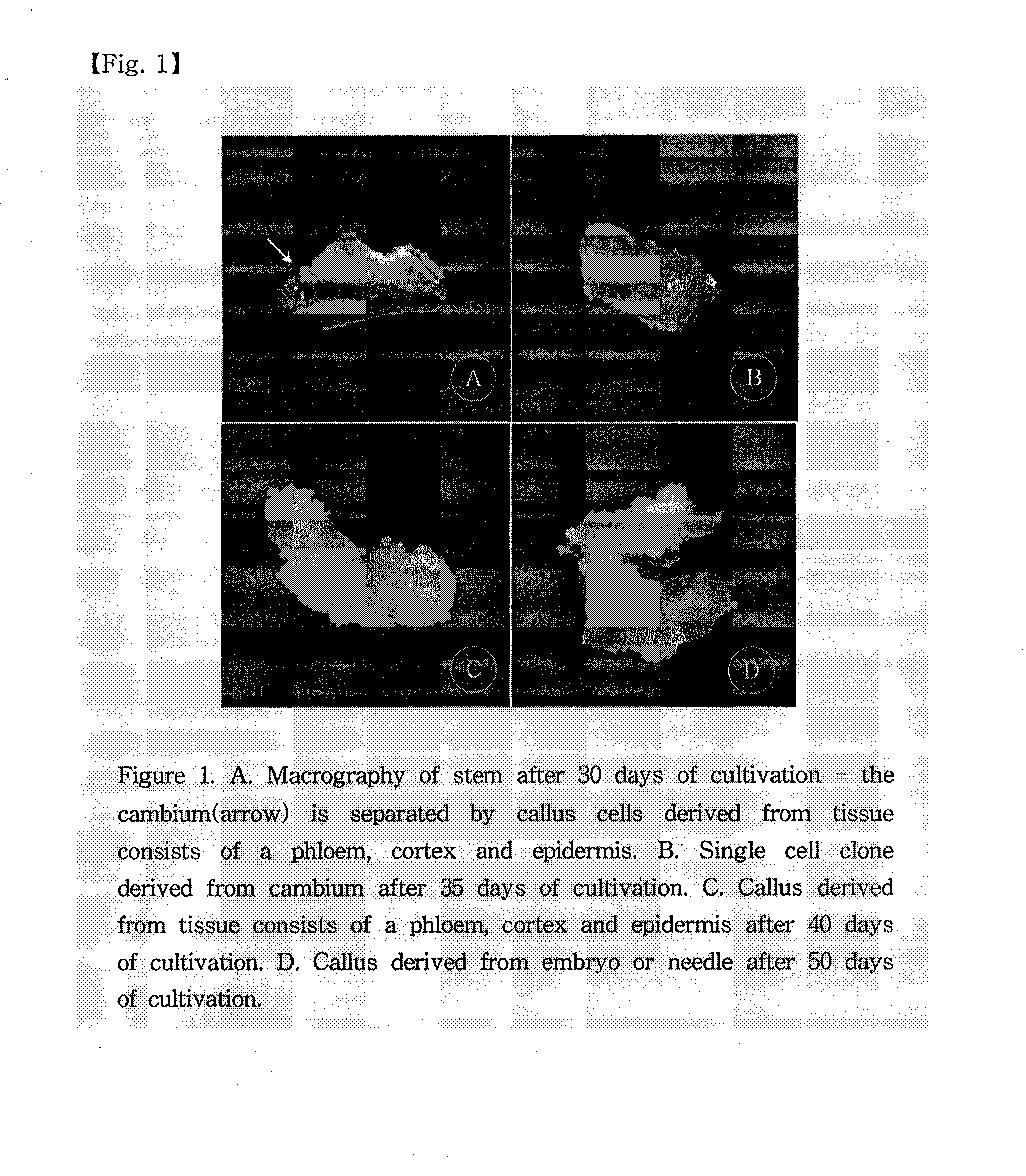

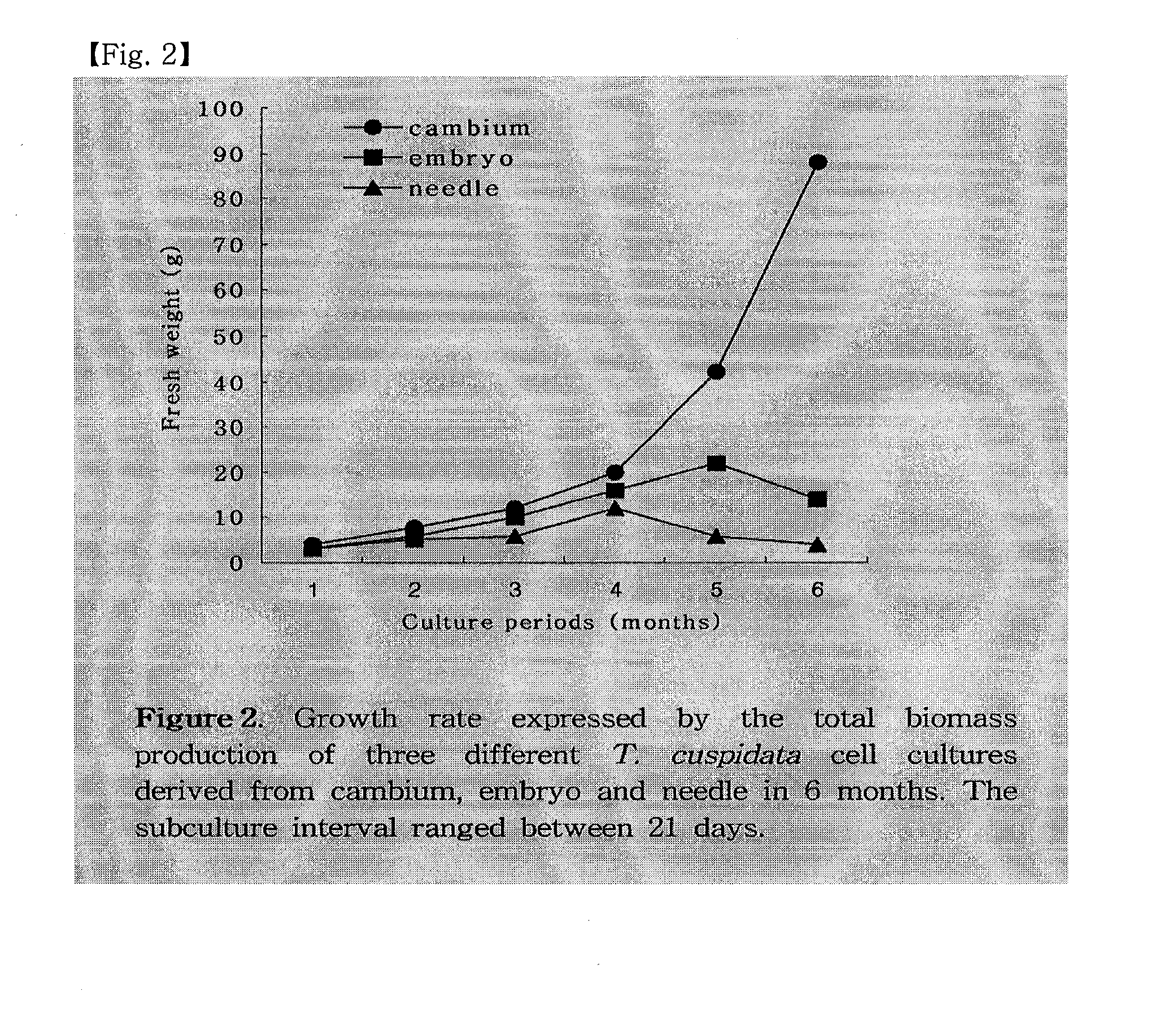

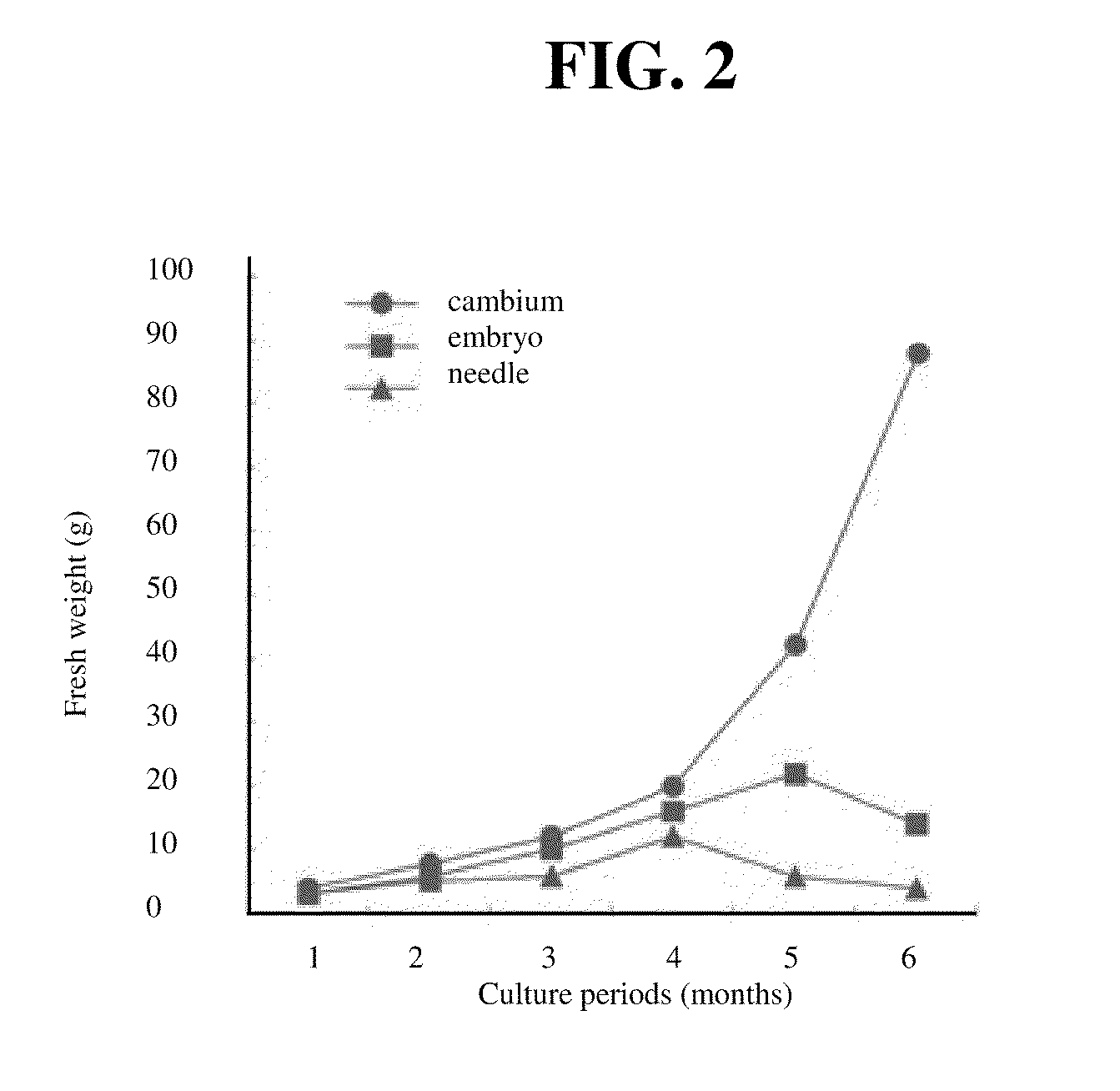

Stability of Secondary Metabolite Mass Production Through Synchronized Plant Cell Cultures

ActiveUS20080194025A1Stable productionLess changePlant cellsBiologically active substancesPlant cell culture

This invention is a method of minimizing the variation of cell growth and production through homogeneous cell line development. To be more specific, it is the method of isolating and proliferating single cell clone from the procambium or cambium to promote the stability of the plant-derived biologically active substances production by solving the problems of decrease in cell growth and the productivity during the long term culture. Key words: Procambium or cambium, single cell clone, cell aggregation, dedifferentiation, cryoperservation, variability.

Owner:WELLKEY HLDG LTD

Isolated population of plant single cells and method of preparing same

InactiveUS20110033903A1Stable productionAvoid excessive changesFermentationPlant cellsCambiumPlant Sources

This invention is a method of minimizing the variation of cell growth and production through homogeneous cell line development. To be more specific, it is the method of isolating and proliferating single cell clone from cambium to promote the stability of the plant-derived biologically active substances production by solving the problems of decrease in cell growth and the productivity during the long term culture.

Owner:UNHWA CORP

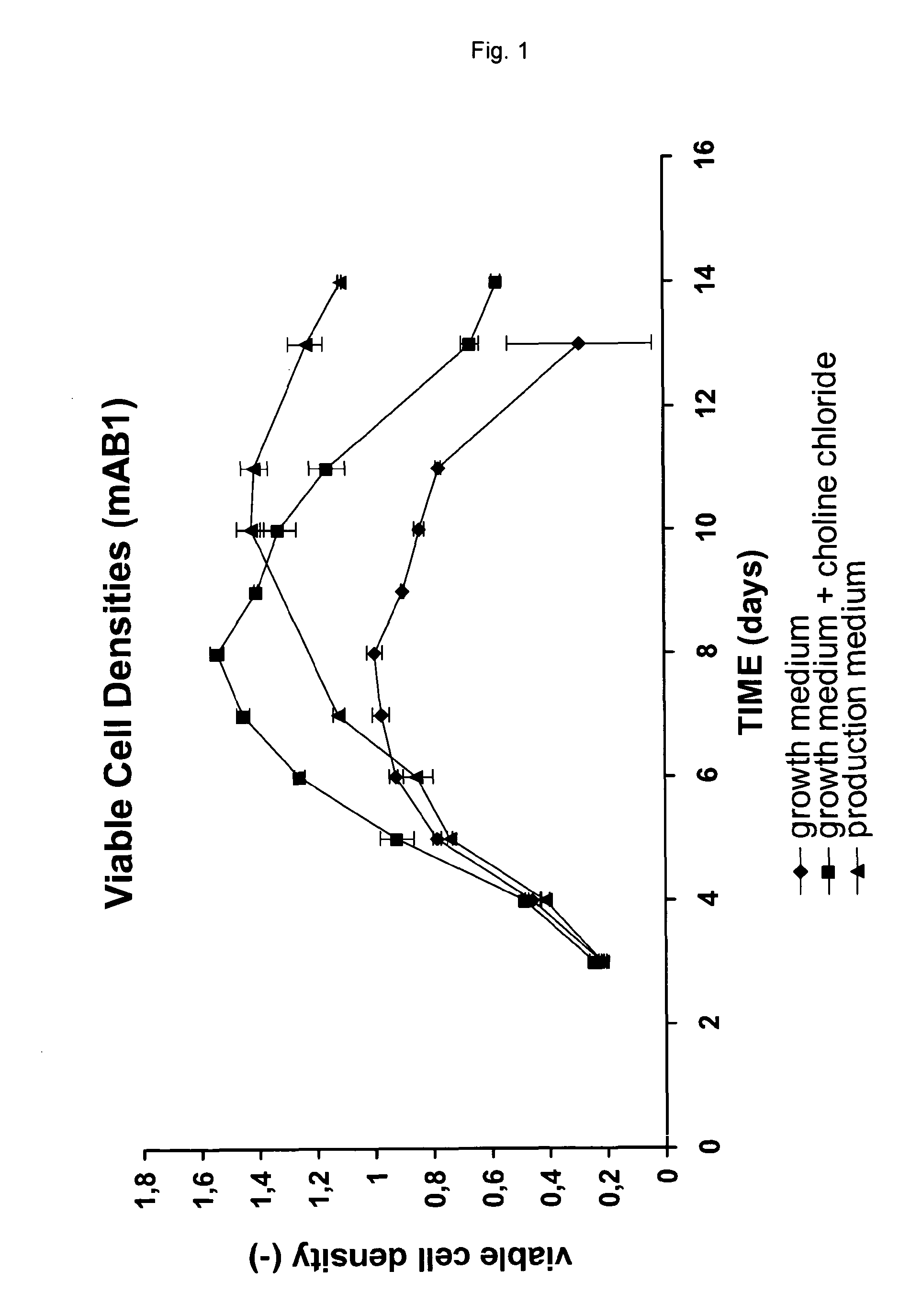

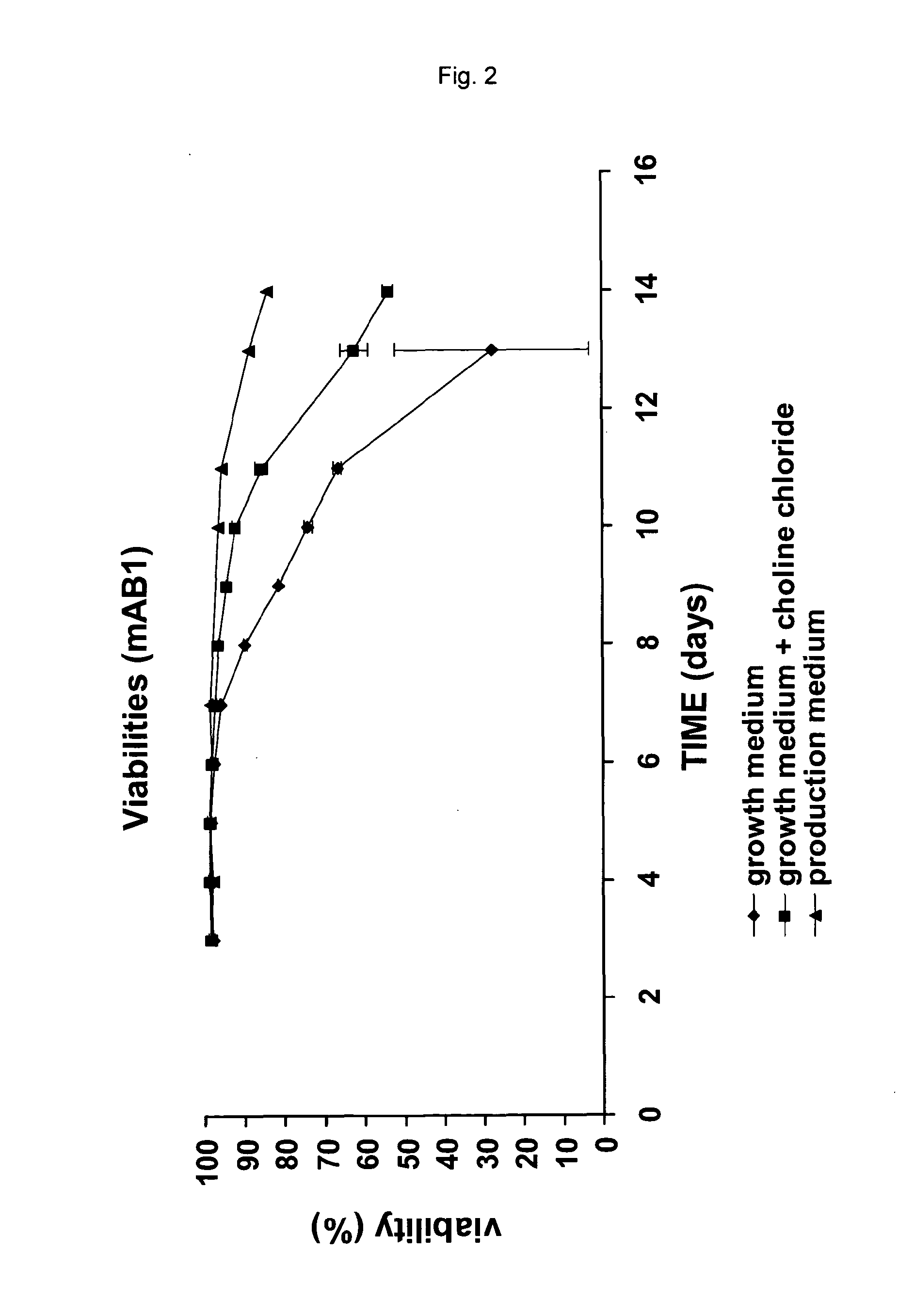

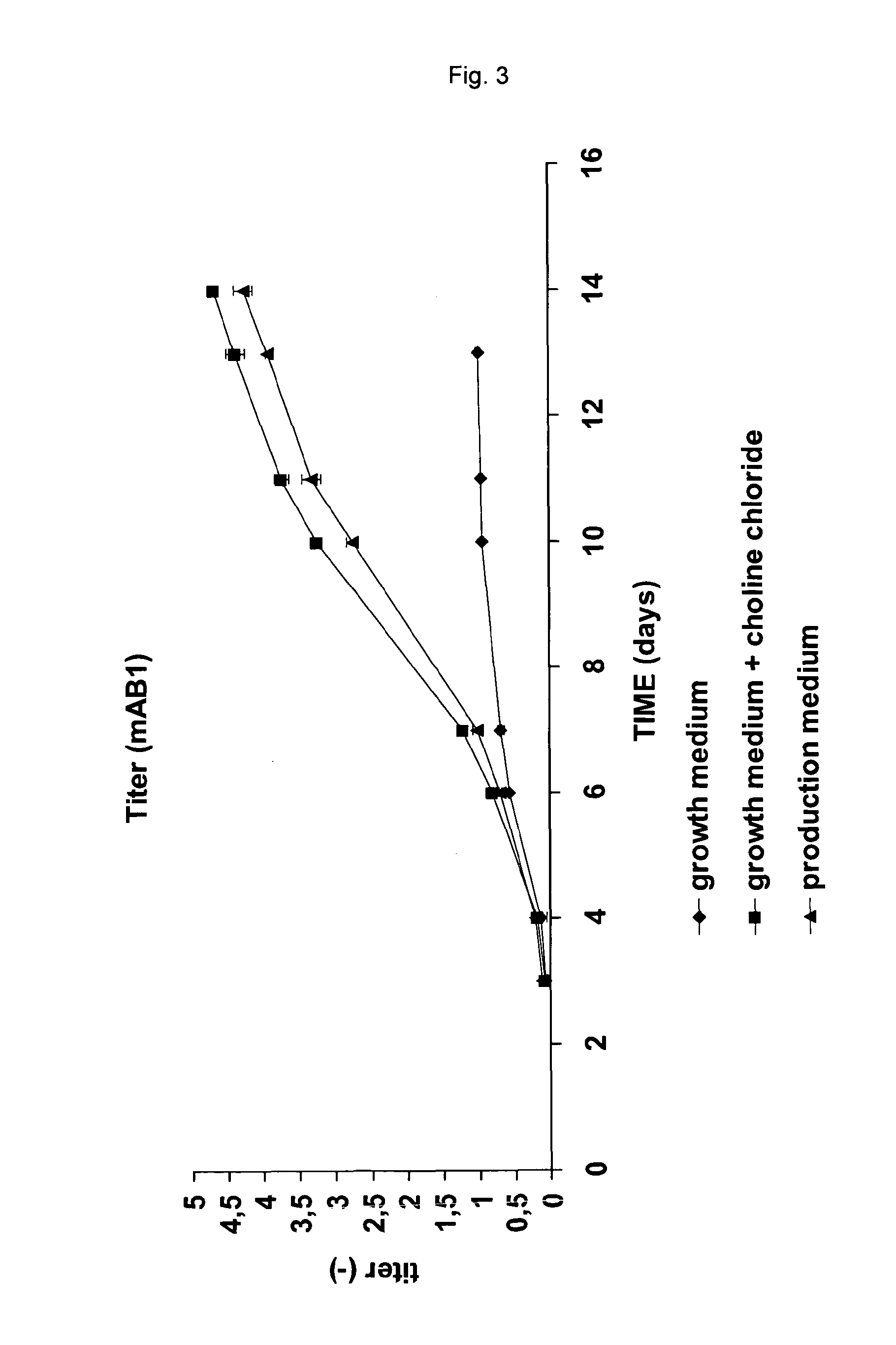

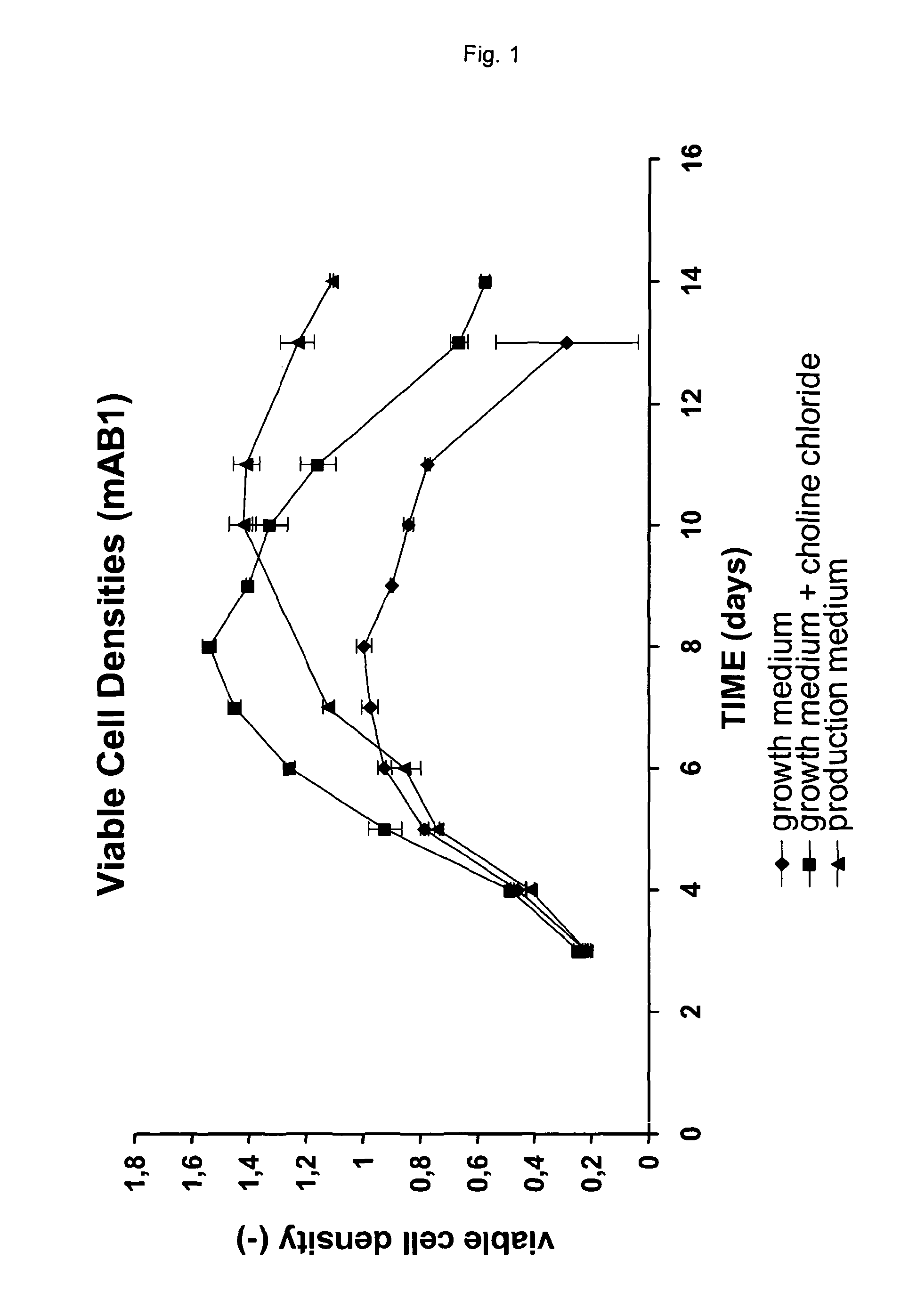

Cell culture medium

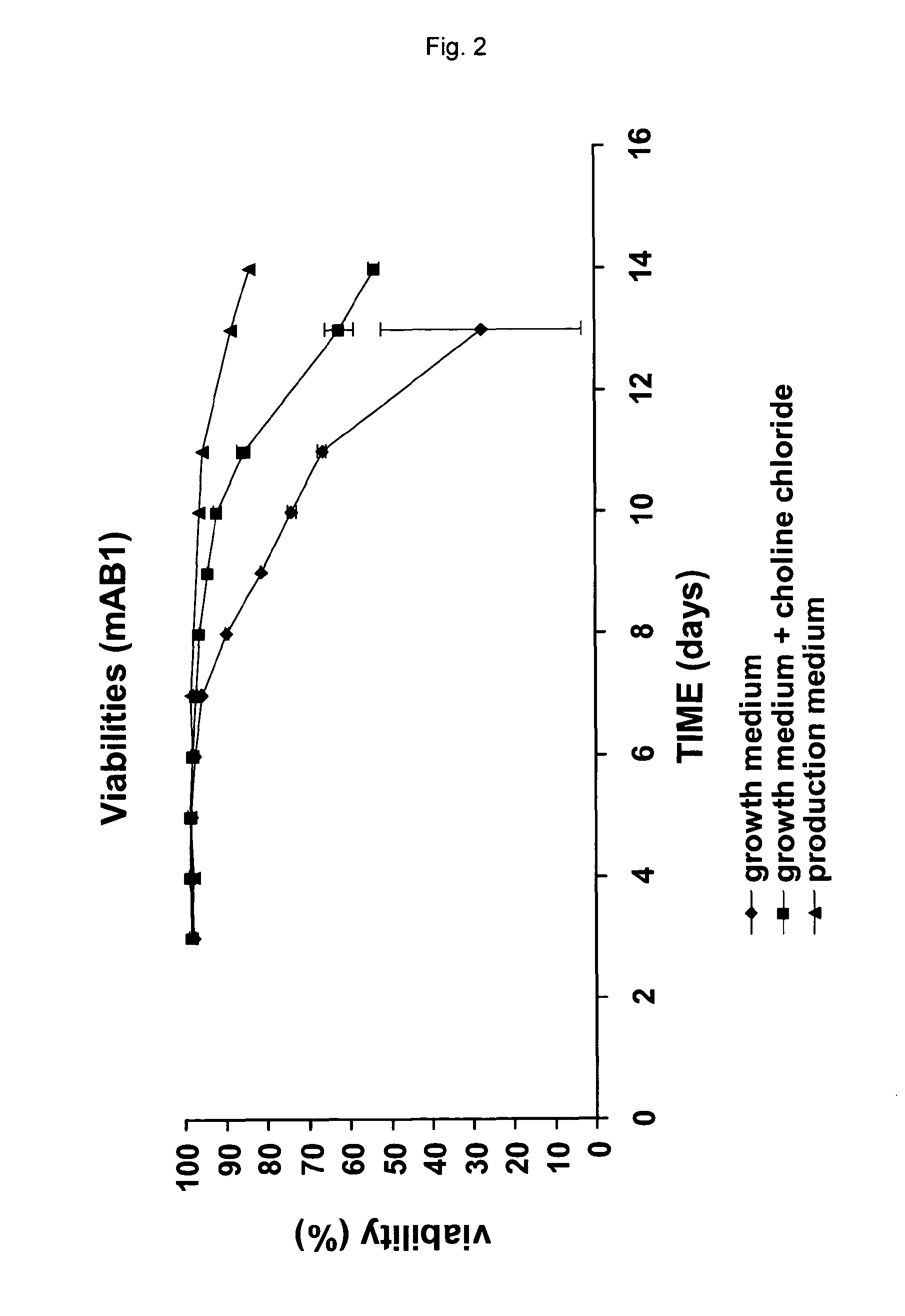

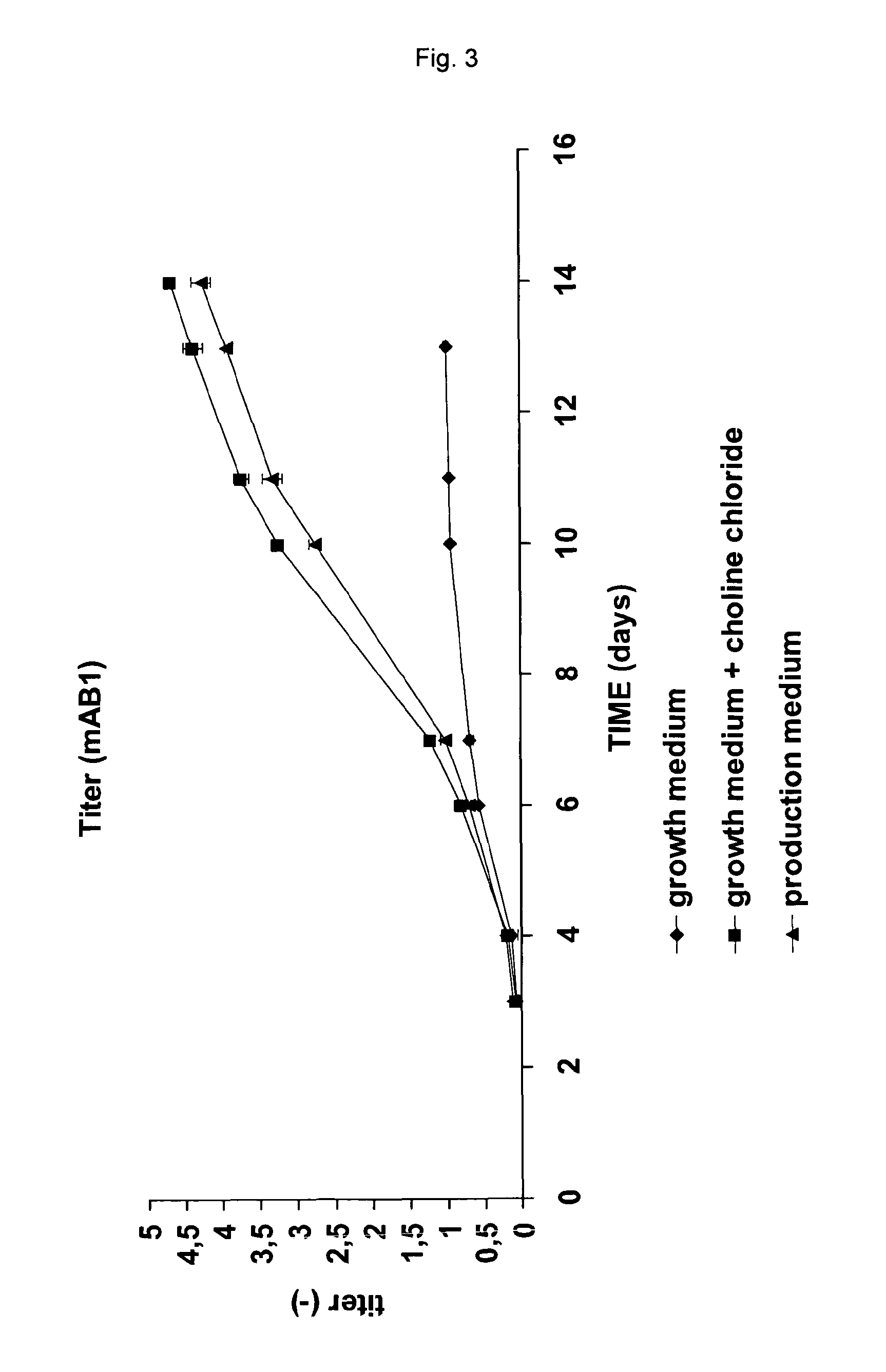

ActiveUS20130102032A1Increase productivityImprove viabilityGenetically modified cellsCulture processCell culture mediaTiter

A cell culture medium with high content of choline chloride is provided. The cell culture media further comprise only moderate amounts of amino acids, in particular the amount of glutamine in the cell culture media is limited. The cell culture media can be used for large scale production of polypeptides using cell cultures. The cell culture media with high content of choline chloride are particularly suitable for fed-batch cell culture whereby cell viabilities stay at a higher level for a longer time and high polypeptide titers although limited amounts of amino acids are used.

Owner:NOVARTIS AG

Dispersion of metal oxide fine particles and method for producing the same

InactiveUS20080242746A1Prevent excessive aggregationPrevent particle aggregationMaterial nanotechnologyOxygen/ozone/oxide/hydroxideAlcoholStrong acids

A dispersion of metal oxide fine particles, containing metal oxide fine particles, a strong acid and an aqueous solution, wherein the metal oxide fine particles and the strong acid are dispersed in an aqueous solution containing alcohol, and the dispersion of metal oxide fine particles has a light transmittance at 800 nm wavelength of 90% or more.

Owner:FUJIFILM CORP

Isolated population of plant single cells and method of preparing same

ActiveUS20110039312A1Stable productionAvoid excessive changesFermentationPlant cellsPlant SourcesCell growth

This invention is a method of minimizing the variation of cell growth and production through homogeneous cell line development. To be more specific, it is the method of isolating and proliferating single cell clone from procambium to promote the stability of the plant-derived biologically active substances production by solving the problems of decrease in cell growth and the productivity during the long term culture.

Owner:WELLKEY HLDG LTD

Stability of Secondary Metabolite Mass Production Through Synchronized Plant Cell Cultures

ActiveUS20090011477A1Stable productionAvoid excessive changesFermentationPlant cellsSecondary metaboliteCell growth

This invention is a method of minimizing the variation of cell growth and production through homogeneous cell line development. To be more specific, it is the method of isolating and proliferating single cell clone from the procambium to promote the stability of the plant-derived biologically active substances production by solving the problems of decrease in cell growth and the productivity during the long term culture.

Owner:WELLKEY HLDG LTD

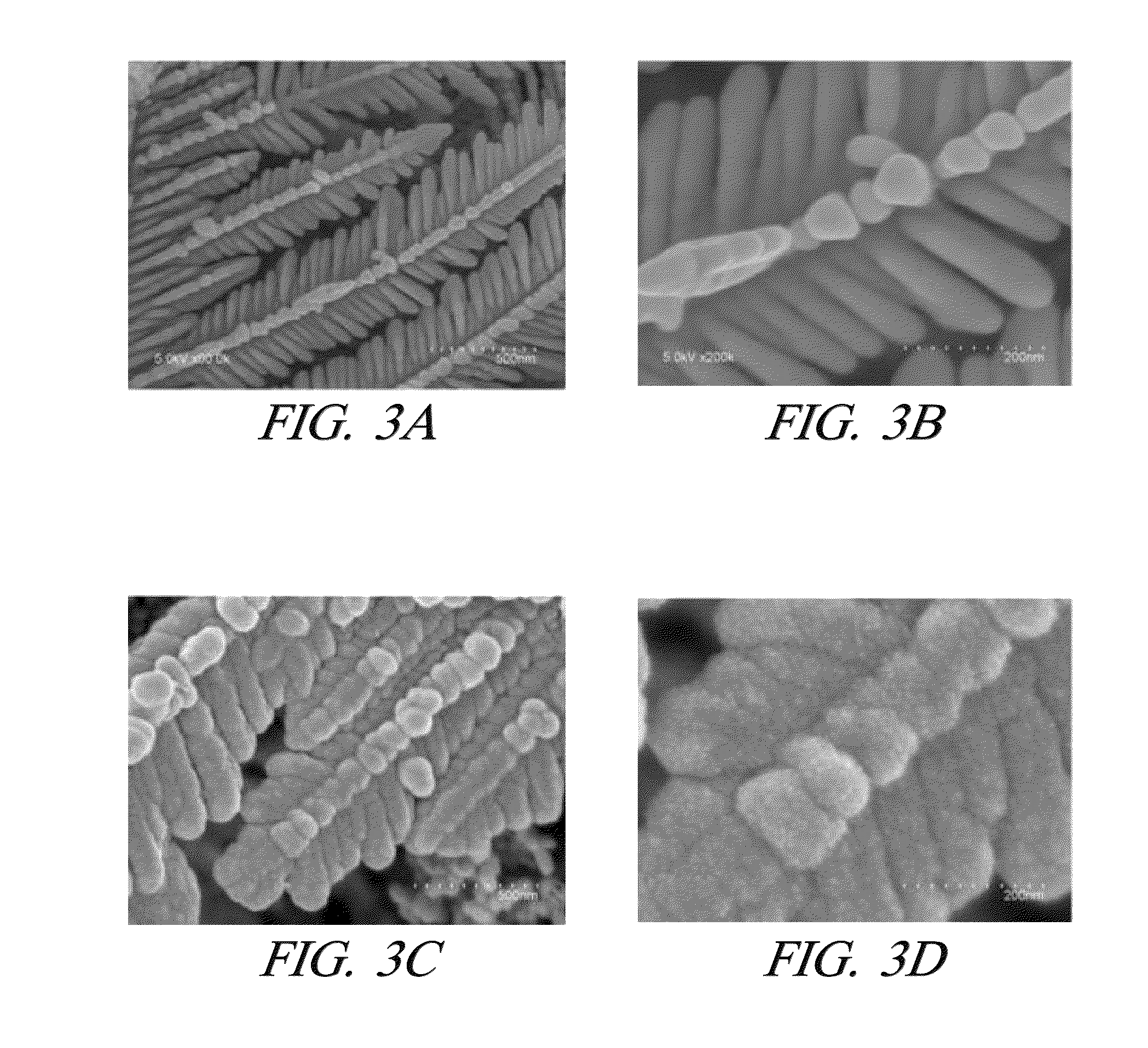

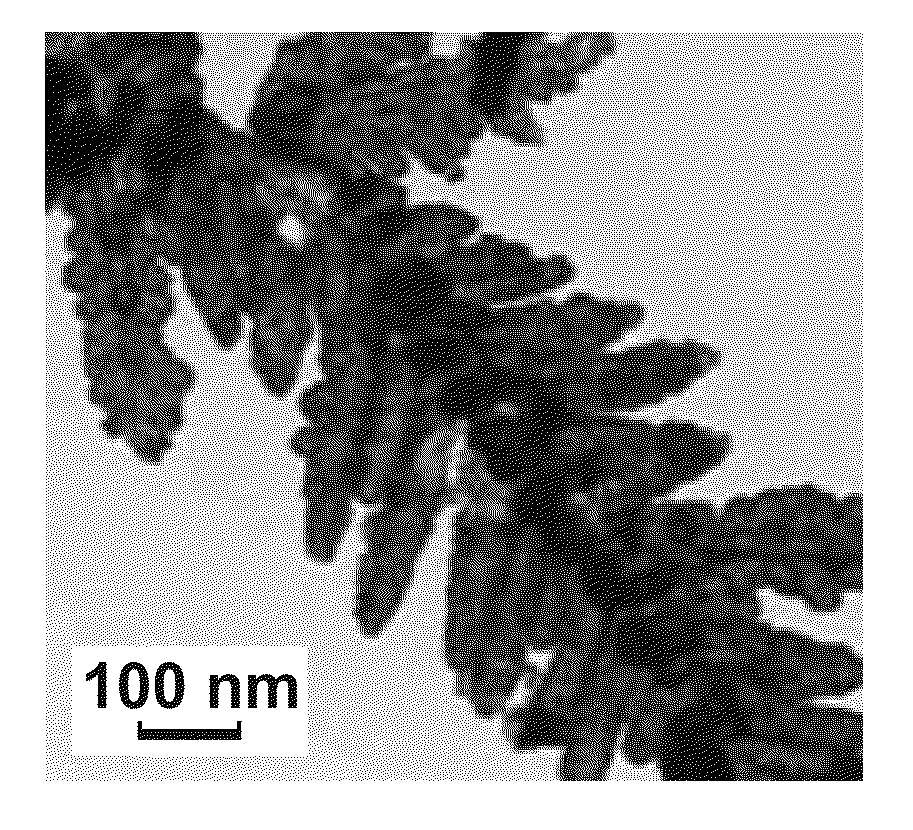

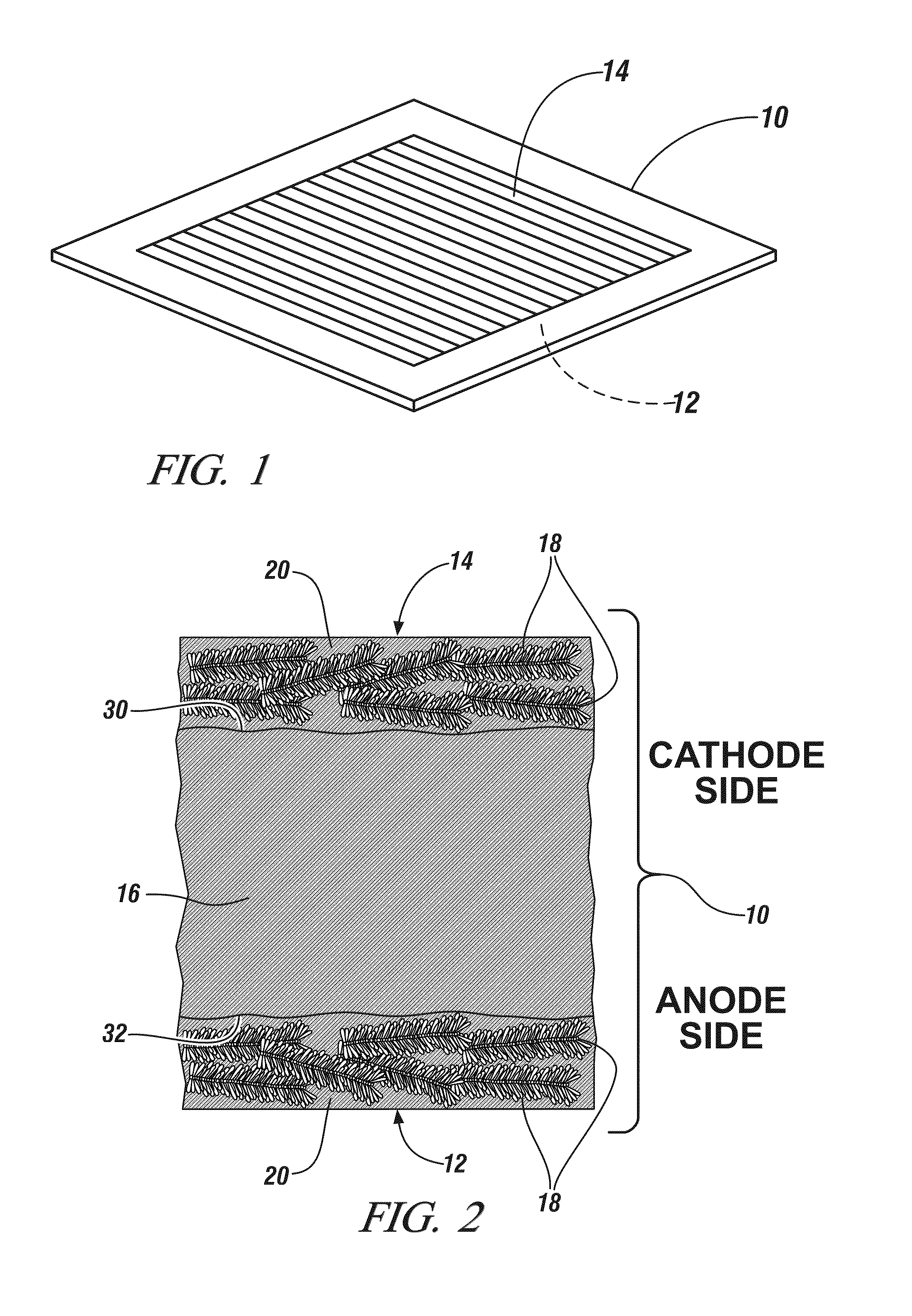

Porous dendritic platinum tubes as fuel cell electrocatalysts

InactiveUS20120003563A1Increased durabilityImprove electrocatalytic activityMaterial nanotechnologyCell electrodesPolymer electrolytesFuel cells

Platinum particles have been formed as porous, hollow tubular dendrites by using silver dendrite particles in a galvanic replacement reaction conducted in an aqueous solution of a platinum compound. The dendritic platinum particles have been found useful as catalysts and particularly useful as a hydrogen-oxidation electrocatalyst and / or an oxygen-reduction catalyst in a polymer electrolyte membrane fuel cell.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

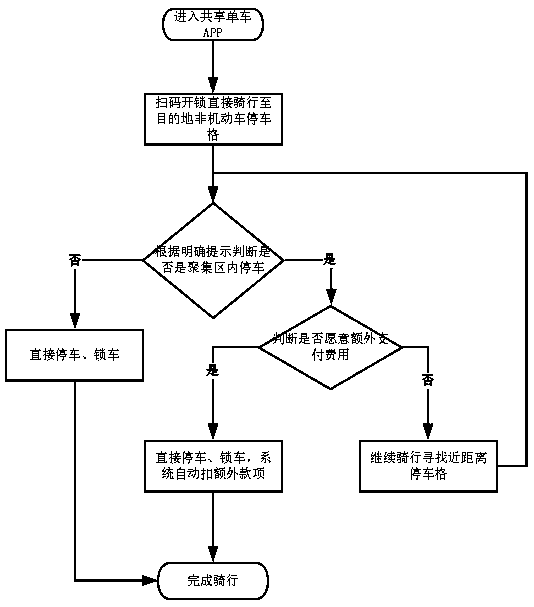

Guiding method for avoiding excessive gathering and parking of shared bikes

PendingCN109559502AIncrease operating costsReduce experience effectRoad vehicles traffic controlBuying/selling/leasing transactionsSingle vehicleOperational costs

The invention discloses a guiding method for avoiding excessive gathering and parking of shared bikes, and aims at enabling users to park shared bikes outside gathering areas through an economic way.According to the method, users can decide whether to allow extra price for continuously parking the shared bikes in gathering areas or not according to clear hints; and meanwhile, a bike transfer service function is added in a shared bike APP to encourage the users to move the shared bikes out from the gathering and parking areas via short time and short distance and then obtain red packets. According to the method, the operation cost of shared bike enterprises is greatly reduced, and the shared bikes are distributed more reasonably and naturally on the basis of not increasing the operation cost, so that the phenomenon that the shared bikes are excessively gathered and parked is avoided.

Owner:唐尧

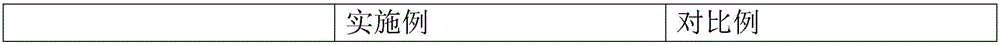

High barrier PET/PP film

ActiveCN106117527AImprove activation performanceGood weather resistanceSynthetic resin layered productsLaminationBenzodioxolesCo extrusion

The invention discloses a high barrier PET / PP film, which is prepared by adding PP plastic particles and PET plastic particles into a co-extrusion casting film machine, and comprises a PET layer and a PP layer, wherein the PP plastic particles are prepared through blending modification, N,N'-(4,4'-methylenebiphenyl)bismaleimide, methylolpropane trimethyl acrylate, and 4,4'-dihydroxy diphenyl sulfide are added to improve the barrier property, the PET plastic particles are modified through a synthetic modification method, terephthalic acid and ethylene glycol are adopted as base materials, and 2-amino terephthalic acid, 2-nitro-terephthalic acid-4-methyl ester, 1,4-diacetoxybenzene, 1,4-benzenedimethanol, 2,2-dimethyl-1,3-propanediol, 2,3-dibromo-2-butene-1,4-diol, dimethyl 2-bromoterephthalate, 2,2-difluoro-1,3-benzodioxole, and magnesium fluorosilicate are added to adjust the performance. According to the present invention, the PET plastic particles and the PP plastic particles are extruded through the co-extrusion casting cast film machine to prepare the multi-layer casting film, wherein the effects of good high-barrier, fire retardation and bacterial resistance can be achieved through the complementation between the two materials.

Owner:CANGNAN BAOFENG PRINTING

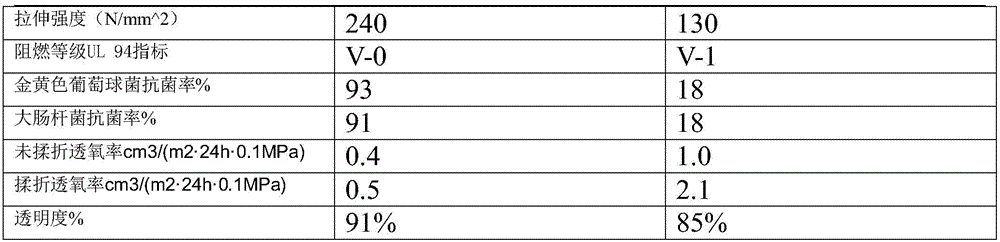

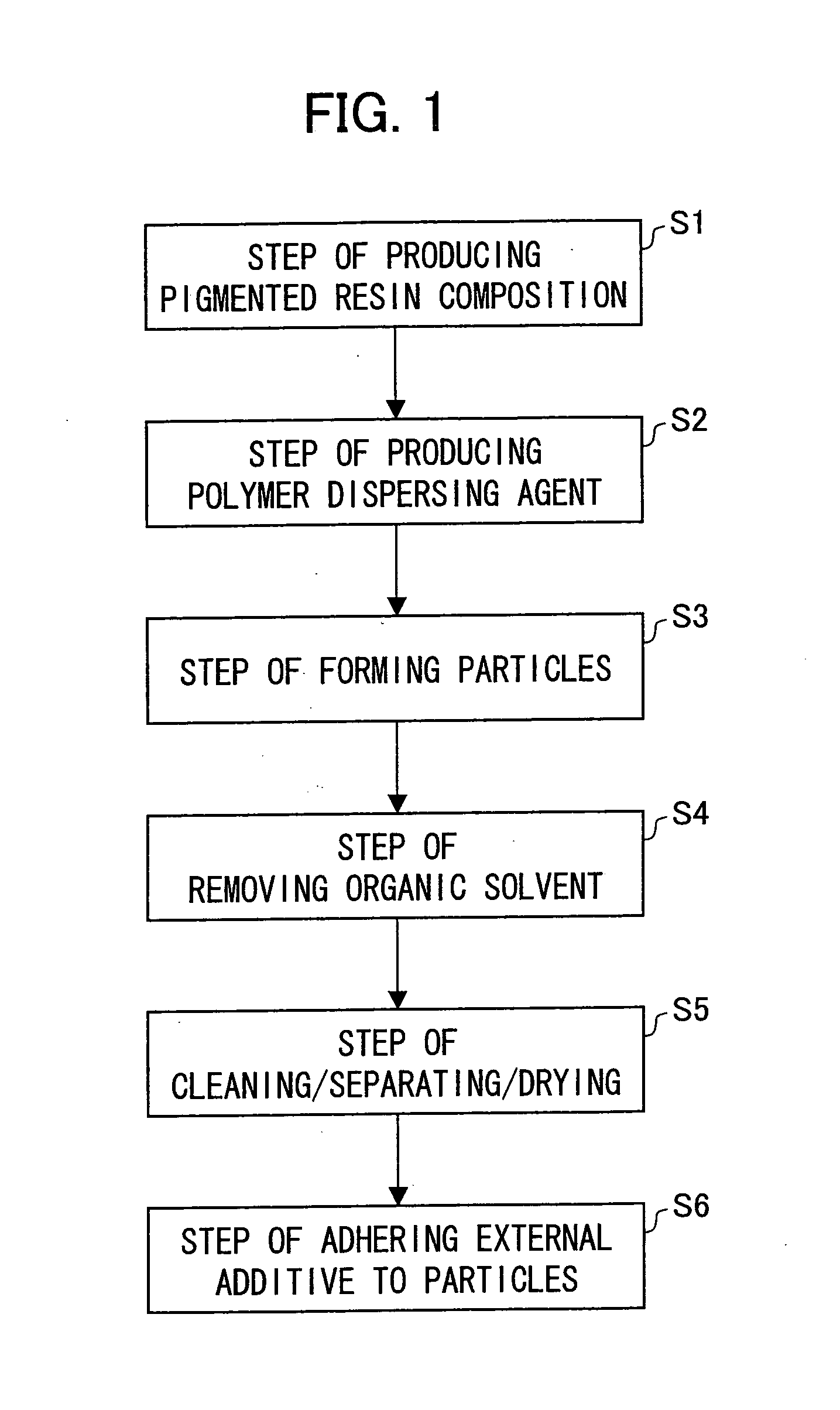

Toner for development and method of producing toner

InactiveUS20070042283A1Easily downsizedImprove moisture resistanceDevelopersVitrificationOrganic solvent

According to the method of producing toner, toner is produced by (i) forming particles of a pigmented resin by applying shear stress to a mixture of a pigmented resin composition, an organic solvent, a polymer dispersing agent, and a hydrophobic medium, the organic solvent being capable of reducing viscosity of the pigmented resin composition, and said polymer dispersing agent having a glass transition point in a range of 50° C. to 80° C. and an SP value in a range of 8.5 to 10, (ii) distilling off the organic solvent, and (iii) separating the toner from the hydrophobic medium and drying the toner. With the above arrangement, the method makes it possible to (i) easily downsize toner particle without causing thermal decomposition of a resin or separation of a release agent, and (ii) produce toner that is small in particle size, excellent in humidity-resistance, and less likely to aggregate.

Owner:SHARP KK

Preparation method of nano cuprous sulfide/polyvinyl alcohol composite conductive fiber

InactiveCN105714397APrevent excessive aggregationEvenly dispersedElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentAqueous solutionSodium thiosulfate

The invention belongs to the field of preparation of composite conductive fibers and relates to a preparation method of a polyvinyl alcohol composite conductive fiber. According to the preparation method, firstly, polyvinyl alcohol is used as a base body, copper sulfate and sodium thiosulfate are used as raw materials, nano cuprous sulfide is produced in situ through a chemical reaction in a polyvinyl alcohol aqueous solution, a nano cuprous sulfide / polyvinyl alcohol composite spinning solution is obtained, and the nano cuprous sulfide / polyvinyl alcohol composite conductive fiber with lasting conductivity is prepared from the spinning solution in a wet spinning manner. The traditional polyvinyl alcohol wet spinning technology is adopted, existing requirement is not required to be transformed or replaced, the equipment investment is low, the technological route is simple, the operability is high, and the production efficiency is high. According to the preparation technology of the conductive fiber, the conductive network is formed in the fiber, a conductive layer cannot fall off during usage, the effect of the use environment is avoided, and the conductive function is lasting.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Enriched liquid food comprising soybean protein material

InactiveUS20100297333A1Good physical propertiesLow viscosityVegetable proteins working-upFood preparationCALCIUM LACTOBIONATECalcium content

The object is to provide an enriched liquid food which comprises a soybean protein material, which has a low viscosity, which produces little aggregates, and which has good physical properties. An enriched liquid food can be prepared by using a soybean protein material having the following physical properties a) to d): a) an aqueous solution containing the soybean protein material in an amount of 5 g in terms of solid content relative to 100 g of the aqueous solution and also containing calcium lactate in an amount of 30 mg in terms of calcium content has a viscosity of 10 mPa·s or less at 20° C. after the aqueous solution is heated at 121° C. for 10 minutes, and produces precipitates in an amount of 1 vol % or less after the aqueous solution is centrifuged at 1,300×g for 5 minutes; b) a 12-wt % aqueous solution of the soybean protein material has a viscosity of 1,000 mPa·s or less at 5° C.; c) the soybean protein material can be solubilized in a 0.22 M TCA at a solubilization ratio of less than 11%; and d) the soybean protein material has a PSI (protein solubility index) value of 70 or more. The soybean protein material can be produced by heating an aqueous solution or an aqueous dispersion solution of a soybean protein raw material at pH 5.7 to 7.4 and at a temperature of 110 to 160° C. for 15 to 70 seconds.

Owner:FUJI OIL CO LTD

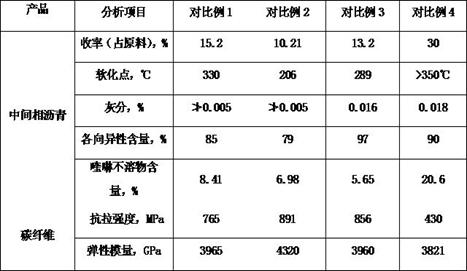

Preparation method of mesophase pitch

ActiveCN113088313AGood spinnabilityLow ash contentWorking-up pitch/asphalt/bitumen by chemical meansFiberPolymer science

The invention discloses a preparation method of mesophase pitch, the method comprises N times of thermal polymerization reactions, N is an integer greater than 1, preferably an integer greater than 2, and further preferably 2; rapid cooling treatment is carried out after each thermal polymerization reaction; the cooling rate is 20-150 DEG C / min, preferably 50-100 DEG C / min, and the temperature is rapidly reduced to 60%-90% of the temperature of the thermal polymerization reaction, preferably 60%-90%. The method can be used for continuously producing the high-purity mesophase pitch and can be used for producing high-end carbon fibers.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing environment-friendly diesel additive and preparation method thereof

InactiveCN111715280ANot easy to loseEfficient separationOrganic chemistryOrganic compound preparationPtru catalystPhysical chemistry

The invention discloses a catalyst for producing an environment-friendly diesel additive and a preparation method of the catalyst. The catalyst prepared by in-situ compounding of WO3 / ZrO2-Bi2O3 solidsuperacid and zirconium-based solid ionic liquid is prepared through the steps of preparation of a zirconium-bismuth composite oxide, preparation of the solid superacid, preparation of an ionic liquidprecursor MIMPS and in-situ loading of the zirconium-based solid ionic liquid, wherein the mass fraction of the WO3 / ZrO2-Bi2O3 solid superacid in the catalyst is 70 to 90wt%. According to the invention, the problems of difficult separation of the catalyst and a product and poor stability caused by easy loss of reactive components can be solved; the catalyst can be kept in a solid state, and the acid content and the acid strength of the catalyst are relatively moderate, so the catalyst has no corrosivity to a reactor; and the catalyst has high catalytic efficiency and is good in selectivity ofthe obtained main product.

Owner:闫英辉

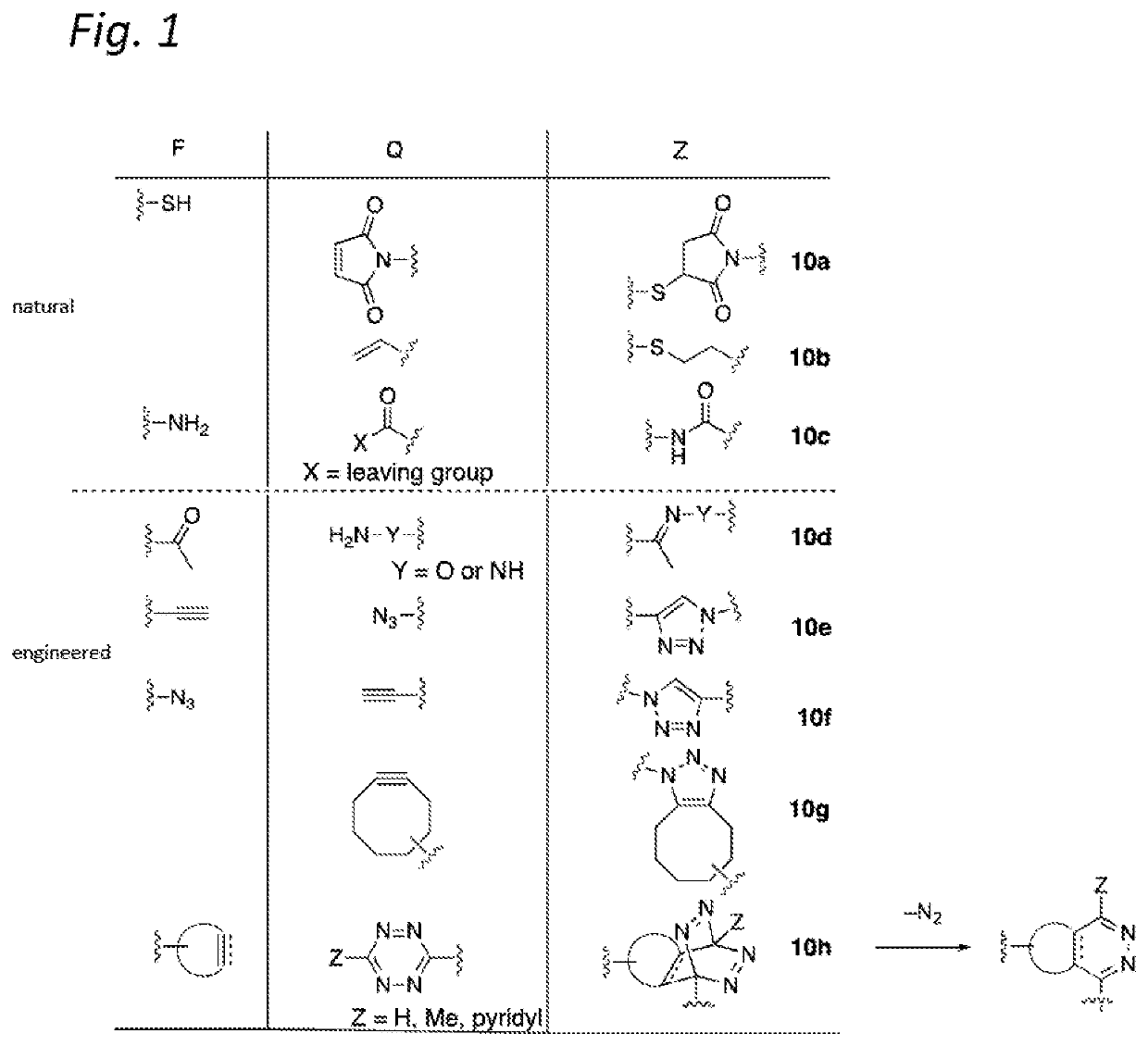

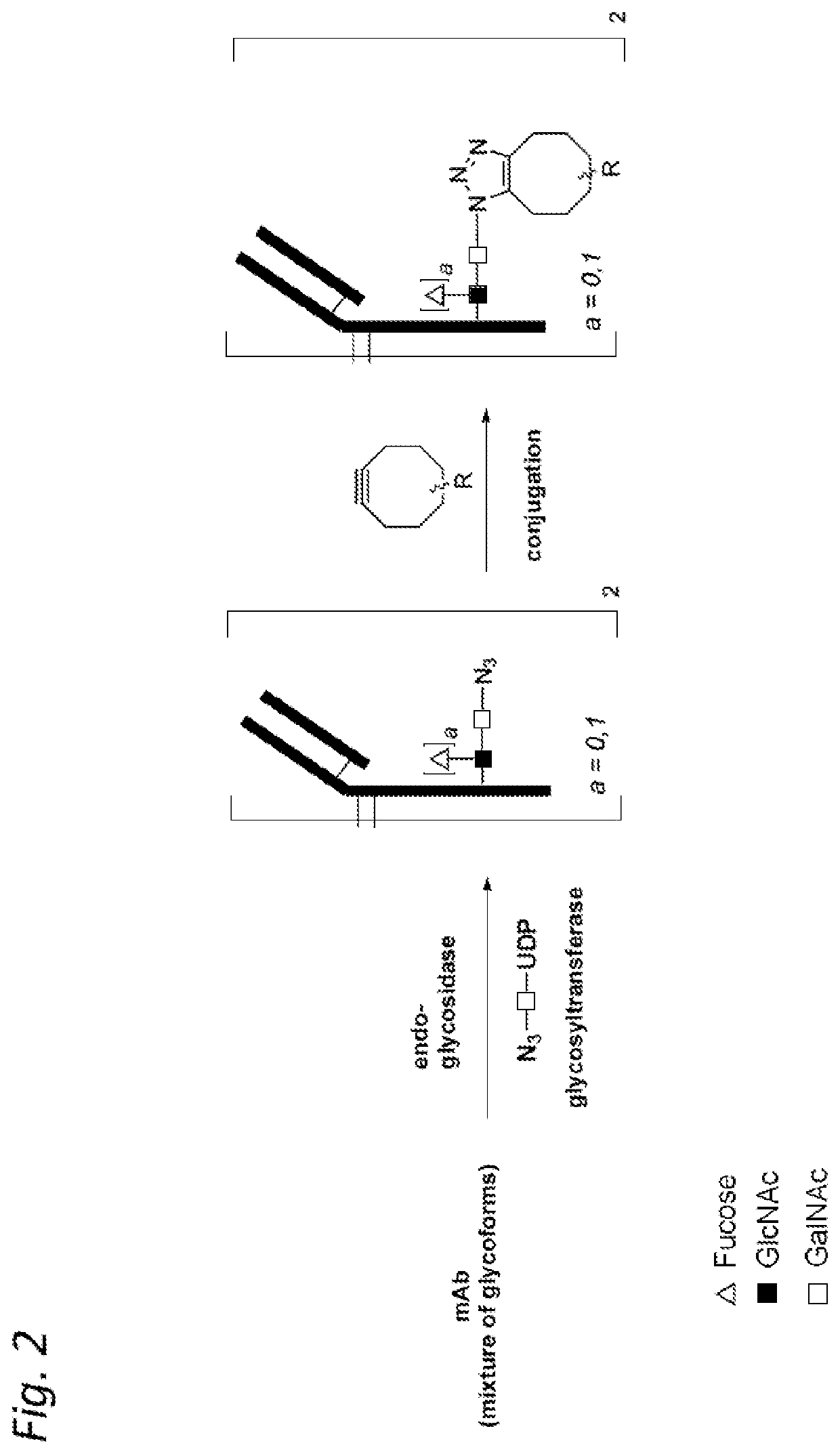

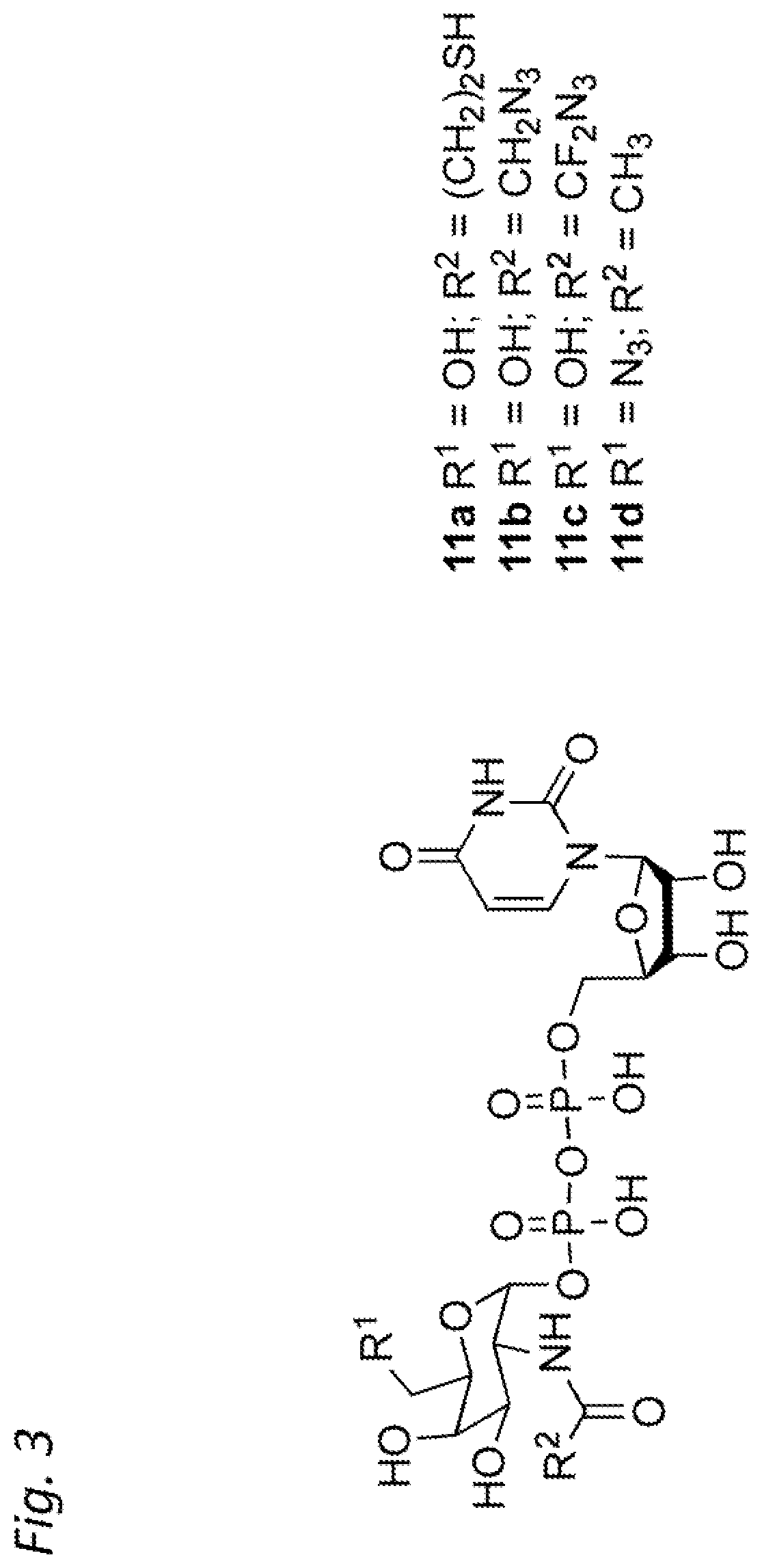

Antibody-conjugates for targeting of tumours expressing trop-2

PendingUS20210393792A1Increase polarityGood water solubilityPharmaceutical non-active ingredientsAntineoplastic agentsDimerAntibody conjugate

The present invention concerns antibody-conjugate having general structure (2):AB-[(L6)-{Z-(L1)n-(L2)o-(L3)p-(L4)q-D}xx]yy (2)wherein AB is an antibody capable of targeting Trop-2-expressing tumours and D is selected from the group consisting of taxanes, anthracyclines, camptothecins, epothilones, mytomycins, combretastatins, vinca alkaloids, maytansinoids, enediynes such as calicheamicins, duocarmycins, tubulysins, amatoxins, bleomycins, dolastatins and auristatins, pyrrolobenzodiazepine dimers, indolinobenzodiazepine dimers, radioisotopes, therapeutic proteins and peptides (or fragments thereof), kinase inhibitors, MEK inhibitors, KSP inhibitors, and analogues or prodrugs thereof. These antibody-conjugates exhibit an improved therapeutic index. The invention further concerns a process for preparing the antibody-conjugate according to the invention, a method for targeting Trop-2-expressing cells, medical uses of the antibody-conjugates according to the invention.

Owner:SYNAFFIX

Porous dendritic platinum tubes as fuel cell electrocatalysts

InactiveUS8709127B2High activityIncreased durabilityMaterial nanotechnologyCell electrodesPolymer electrolytesFuel cells

Platinum particles have been formed as porous, hollow tubular dendrites by using silver dendrite particles in a galvanic replacement reaction conducted in an aqueous solution of a platinum compound. The dendritic platinum particles have been found useful as catalysts and particularly useful as a hydrogen-oxidation electrocatalyst and / or an oxygen-reduction catalyst in a polymer electrolyte membrane fuel cell.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Coated pigment

InactiveUS20200131374A1Prevent excessive aggregationAggregated particles)Transportation and packagingMetal-working apparatusPolymer scienceMetal particle

A main object of the present invention to provide a coated pigment that is composed of a composite particle comprising a silicon compound coated on the surface of a metal particle, and that can be dispersed with relatively few aggregates.The present invention relates to a coated pigment comprising a composite particle containing a metal particle and one or two or more coating layers on the surface of the metal particle, wherein (1) at least one of the coating layers is a silicon compound-containing layer, and (2) the proportion of aggregates formed by adhesion of at least four of the composite particles with each other is not more than 35% by number.

Owner:TOYO ALUMINIUM KK

Preparation method of nano cuprous iodide/polyvinyl alcohol composite conductive fiber

InactiveCN105714398APrevent excessive aggregationEvenly dispersedElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentIodideChemistry

The invention belongs to the field of preparation of composite conductive fibers and relates to a preparation method of a nano cuprous iodide / polyvinyl alcohol composite conductive fiber. According to the preparation method, polyvinyl alcohol is used as a base body, copper sulfate, sodium thiosulfate and potassium iodide are used as raw materials, nano cuprous iodide is produced in situ through a chemical reaction in a polyvinyl alcohol aqueous solution, a nano cuprous iodide / polyvinyl alcohol composite spinning solution is obtained, and the nano cuprous iodide / polyvinyl alcohol composite conductive fiber with lasting conductivity is prepared from the spinning solution in a wet spinning manner. According to the preparation technology of the conductive fiber, the conductive network is formed in the fiber, and the conductive function is lasting. Light-color nano CuI conductive powder is selected as a conductive agent, and the fiber is prone to dyeing and has broader application prospect in fields of civil clothing, interior decoration, carpets, home textiles, micro-electronics, medicine, food, precise instruments, biotechnology and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Cell culture medium

ActiveUS8986957B2Increase productivityImprove viabilityAnimal cellsGenetically modified cells3D cell cultureCell culture media

A cell culture medium with high content of choline chloride is provided. The cell culture media further comprise only moderate amounts of amino acids, in particular the amount of glutamine in the cell culture media is limited. The cell culture media can be used for large scale production of polypeptides using cell cultures. The cell culture media with high content of choline chloride are particularly suitable for fed-batch cell culture whereby cell viabilities stay at a higher level for a longer time and high polypeptide titers although limited amounts of amino acids are used.

Owner:NOVARTIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com