Coated pigment

a technology of coating pigment and pigment, applied in the direction of coating, transportation and packaging, chemical coating, etc., can solve the problems of blackening or hydrogen gas of aluminum pigment, and achieve the effect of reducing the number of aggregates (few aggregates, aggregated particles)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

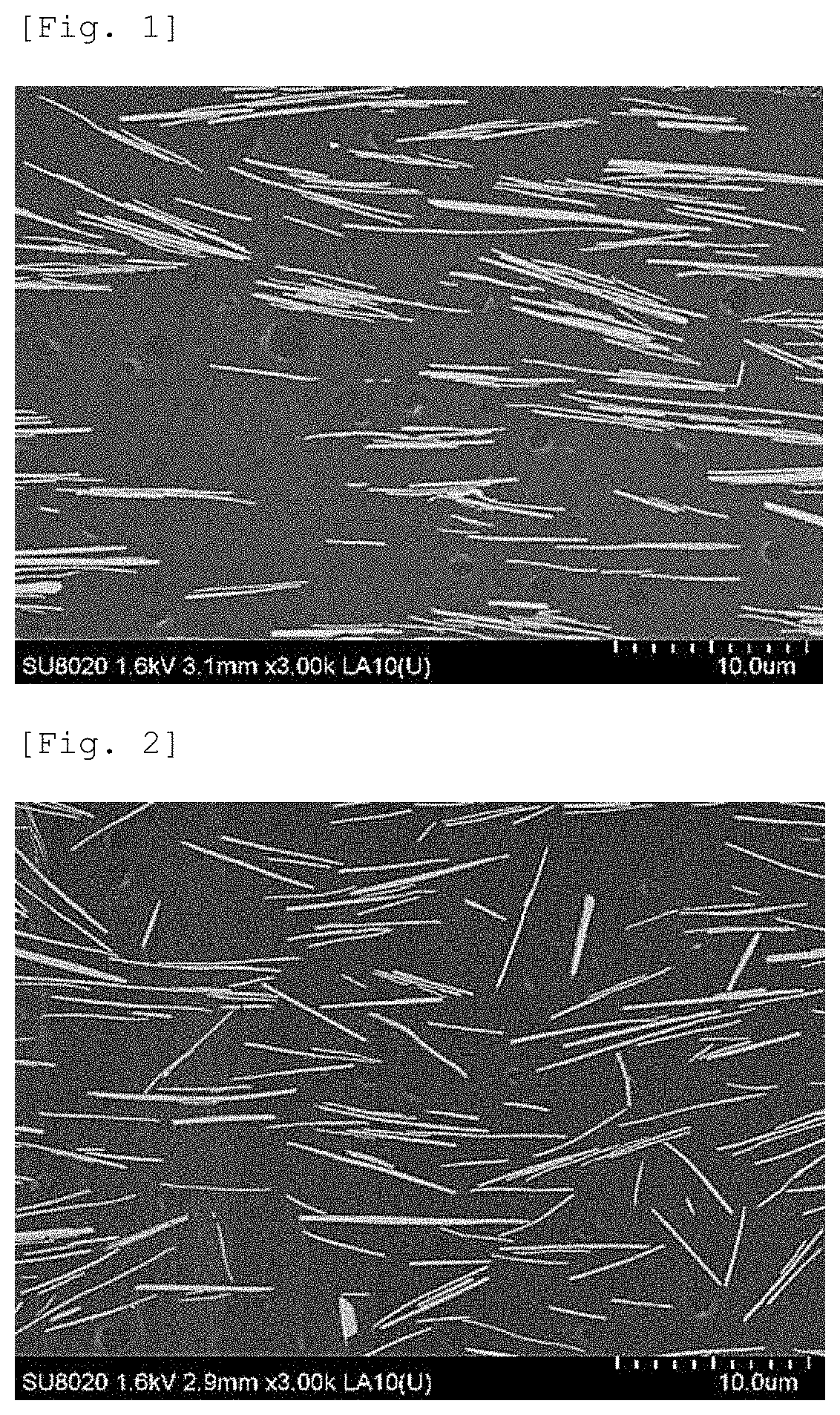

example 1

[0137]First, commercial aluminum pigment flakes (product name “7670NS”, manufactured by Toyo Aluminum K.K., average particle diameter 15 μm, aspect ratio 68) in the amount of 100 g as solids were added to 1,000 g of isopropyl alcohol, and thoroughly mixed to prepare an aluminum slurry. At this point the aluminum slurry had a viscosity of about 10 mPa·s (25° C.), and a liquid density of about 830 kg / m3 (25° C.). This aluminum slurry was placed in a roughly 4.5 L round-bottomed flask, and heated to 50° C. under stirring with a three-bladed propeller stirrer (Tokyo Rikakikai Co., Ltd., marine blade) so that the stirring Reynolds number was 19,000. In the following steps, stirring was also performed so as to maintain the same stirring Reynolds number.

[0138]Next, 0.5 g of metal molybdenum powder was added bit by bit to 10 g of hydrogen peroxide water containing 30% hydrogen peroxide, and reacted to prepare a solution. The resulting aqueous solution containing molybdenum was added gradual...

example 2

[0142]A coated aluminum pigment was obtained by the same operations as in Example 1 except that the stirring Re number was 14,000.

example 3

[0143]A coated aluminum pigment was obtained by the same operations as in Example 1 except that the stirring Re number was 10,005.

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser diffraction particle size distribution analyzer | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com