Patents

Literature

941results about "Working-up pitch/asphalt/bitumen by chemical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

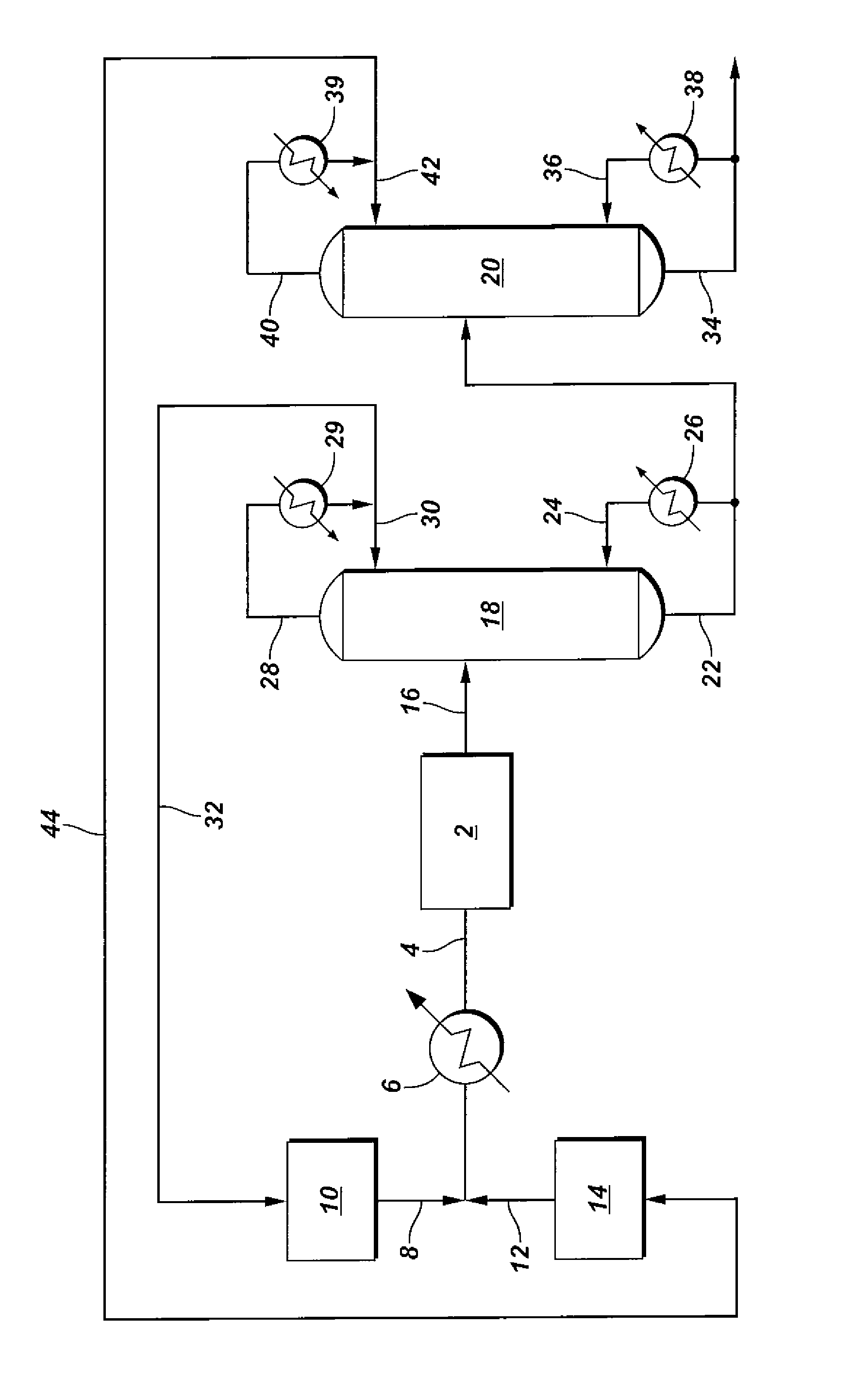

Process for converting carbon-based energy carrier material

InactiveUS20090308787A1Thermal non-catalytic crackingCatalytic crackingPtru catalystPhysical chemistry

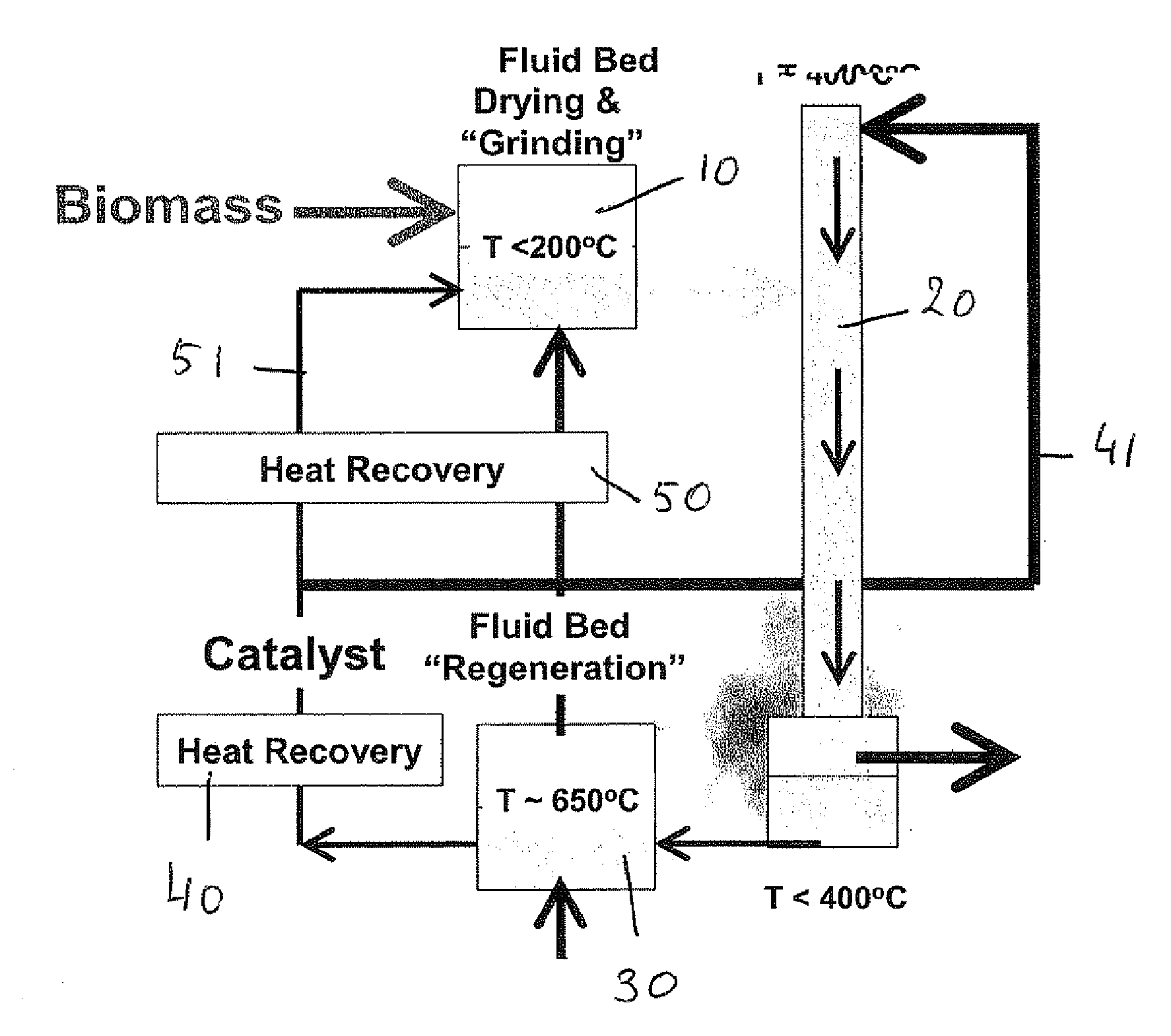

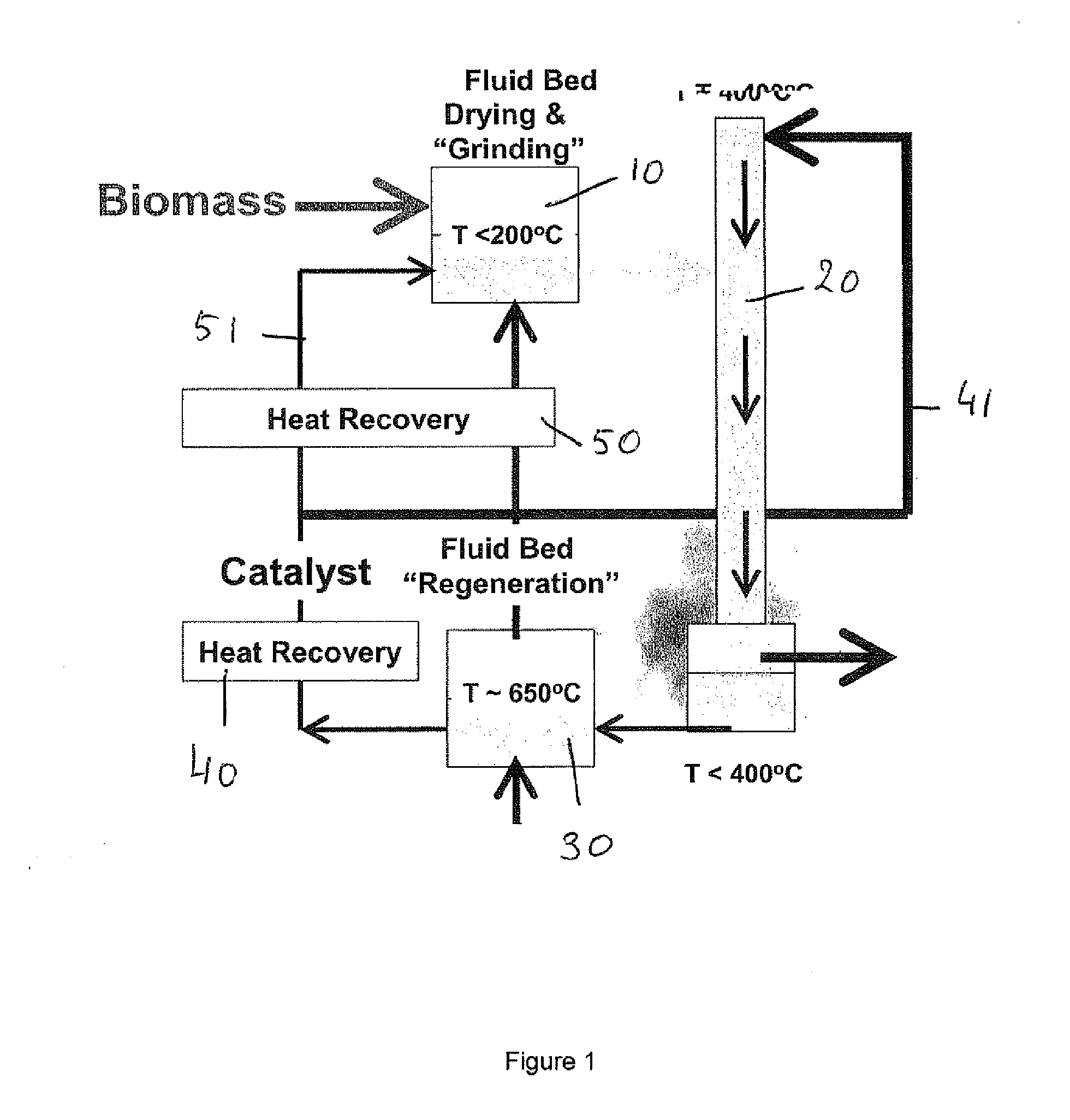

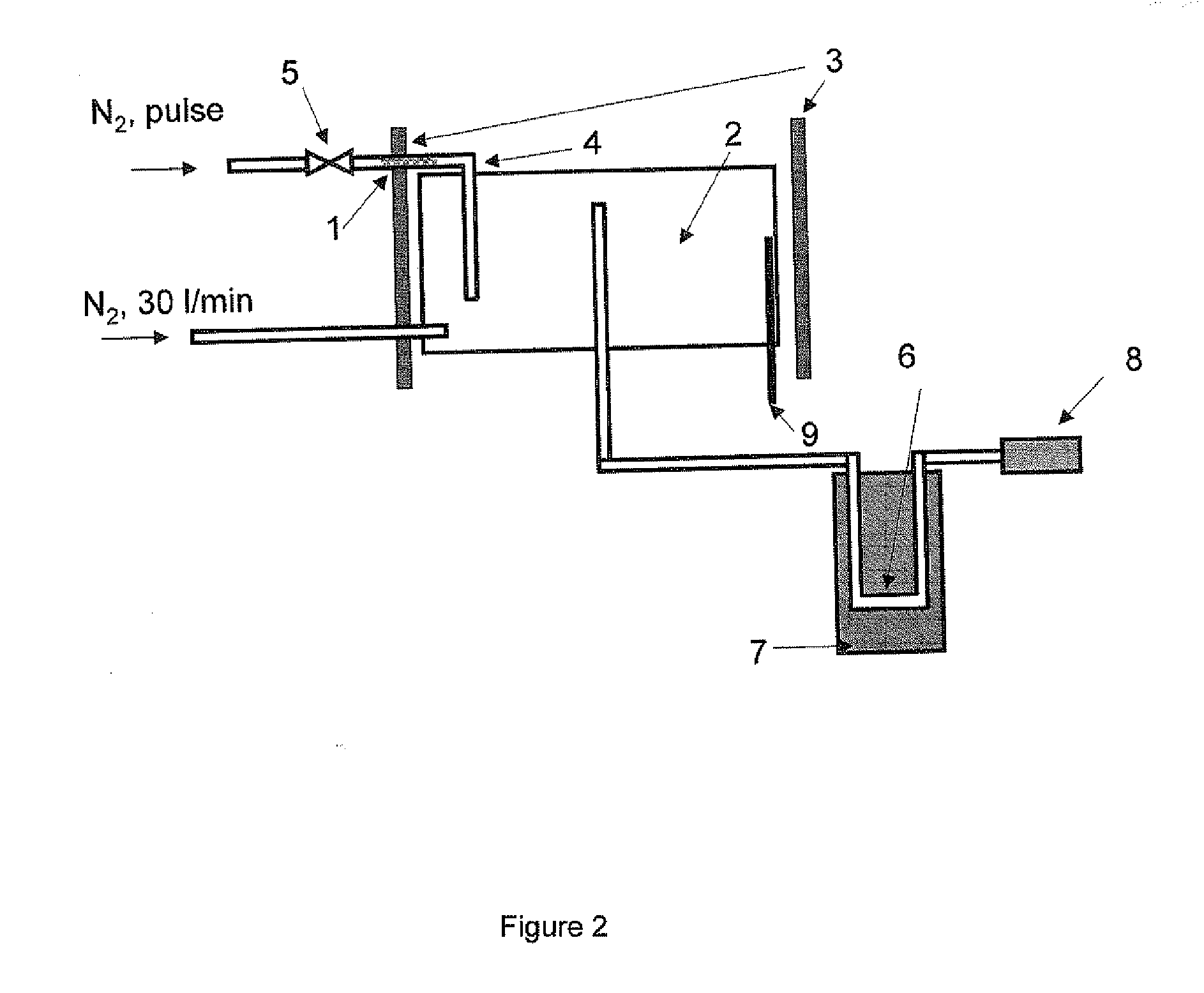

A process is disclosed process for converting a solid or highly viscous carbon-based energy carrier material to liquid and gaseous reaction products, said process comprising the steps of: a) contacting the carbon-based energy carrier material with a particulate catalyst material b) converting the carbon-based energy carrier material at a reaction temperature between 200° C. and 450° C., preferably between 250° C. and 350° C., thereby forming reaction products in the vapor phase. In a preferred embodiment the process comprises the additional step of: c) separating the vapor phase reaction products from the particulate catalyst material within 10 seconds after said reaction products are formed; In a further preferred embodiment step c) is followed by: d) quenching the reaction products to a temperature below 200° C.

Owner:MARD INC

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing mesophase asphalt by coal liquefaction residue

ActiveCN101580729AHigh C/H atomic ratioLow ashWorking-up pitch/asphalt/bitumen by chemical meansSolventChemistry

The invention relates to a method for preparing mesophase asphalt by coal liquefaction residue. In the method, the coal liquefaction residue is ground, screened and dried, and is extracted at certain temperature for certain time by using organic solvent as extracting solvent; the extracted mixed liquor is filtered, purified and evaporated; the extracting solvent in the extract liquor is evaporatedto obtain refined coal liquefaction oil asphalt, thus obtaining the mesophase asphalt by charring for 4-10 hours in a high-pressure autoclave under the conditions of 410-460 DEG C, 3-4MPa of constantpressure and stirring. The method has simple process and convenient and safe operation, the mesophase asphalt with high quality is prepared and can be used as raw materials of high power and ultra high power graphite electrode, carbon fiber and the like.

Owner:CHINA COAL RES INST +1

Compositions and methods of using same in producing heavy oil and bitumen

InactiveUS7691788B2Maximize the effectLarge volumeWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

Owner:SCHLUMBERGER TECH CORP

Compositions and Methods of Using Same in Producing Heavy Oil and Bitumen

InactiveUS20070295640A1Reduce energy consumptionMinimal heat lossWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

deposition in a formation, wellbore, near wellbore region, and production tubing. Compositions of the invention comprise an asphaltene solvent and a viscosity reducing agent, the asphaltene solvent and viscosity reducing agent present in a ratio so as to substantially reduce viscosity of an asphaltene-containing material while substantially negating deposition of asphaltenes either in a reservoir, in production tubing, or both when mixed or otherwise contacting the asphaltene-containing material Methods of the invention comprise forcing a composition comprising an asphaltene solvent and a viscosity reducing agent to contact an asphaltene-containing hydrocarbon in an underground geologic formation, and producing from the formation a production composition comprising at least some of the treatment composition and at least some of the asphaltene-containing hydrocarbon under conditions sufficient to substantially negate deposition of asphaltenes in the formation.

Owner:SCHLUMBERGER TECH CORP

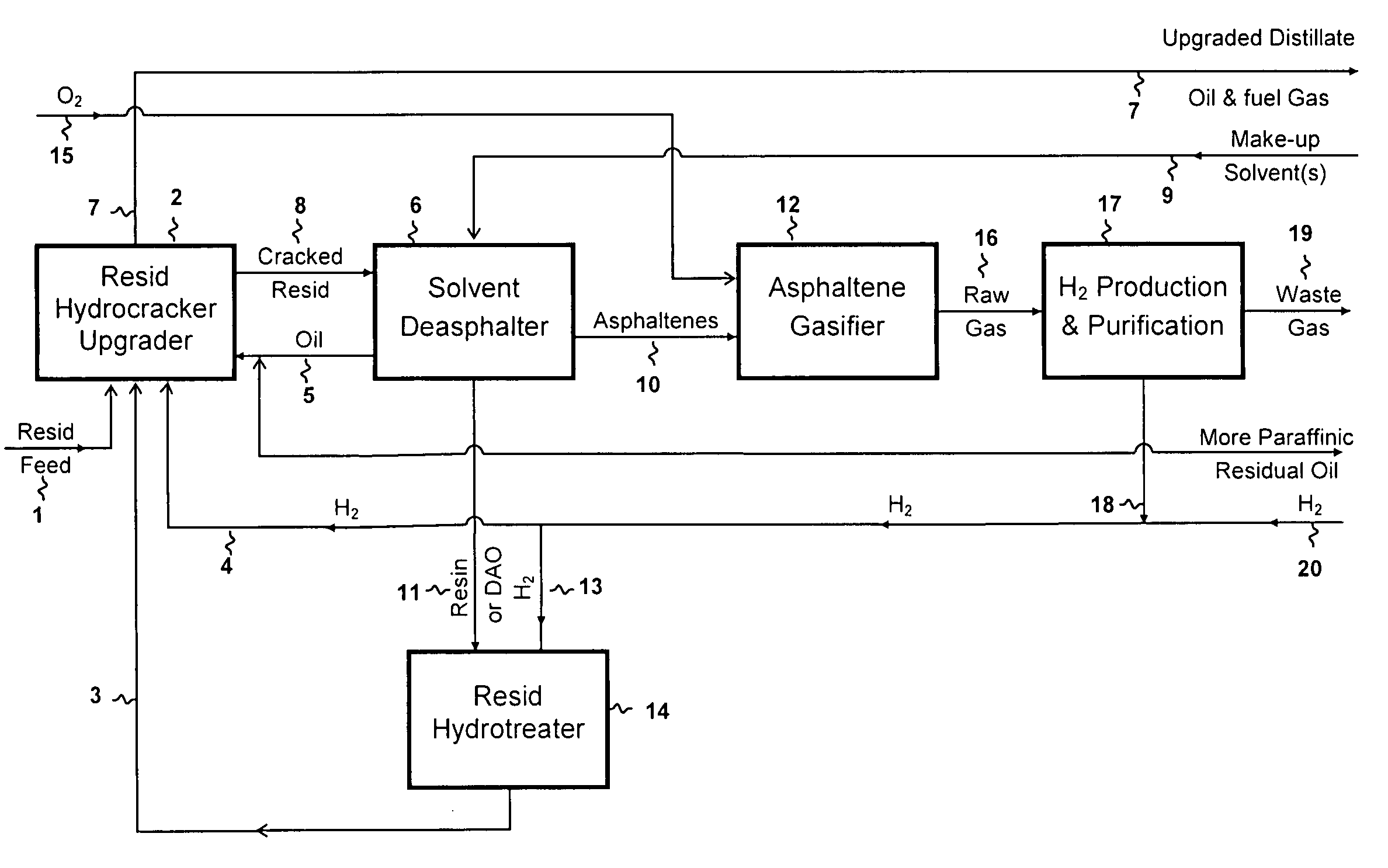

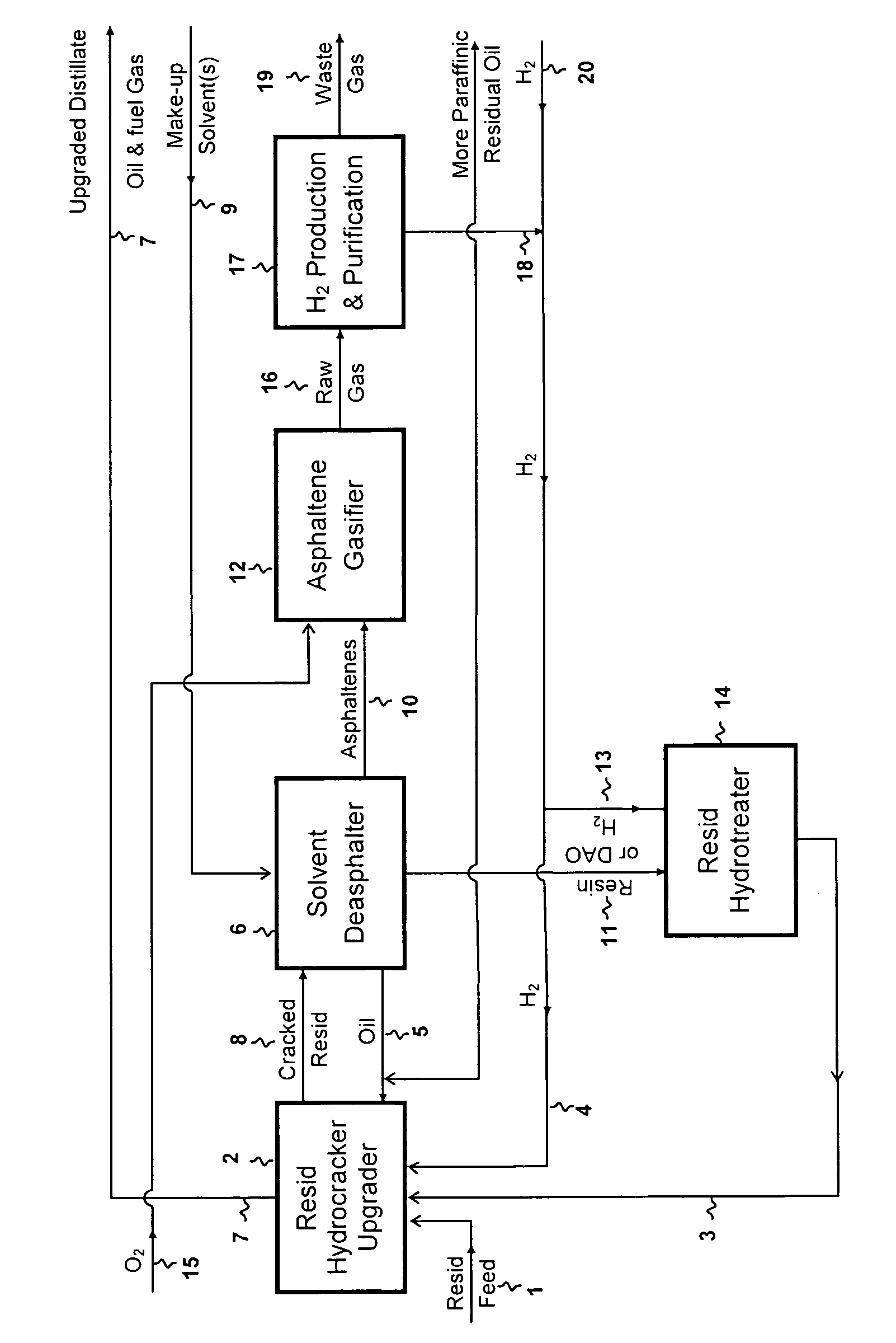

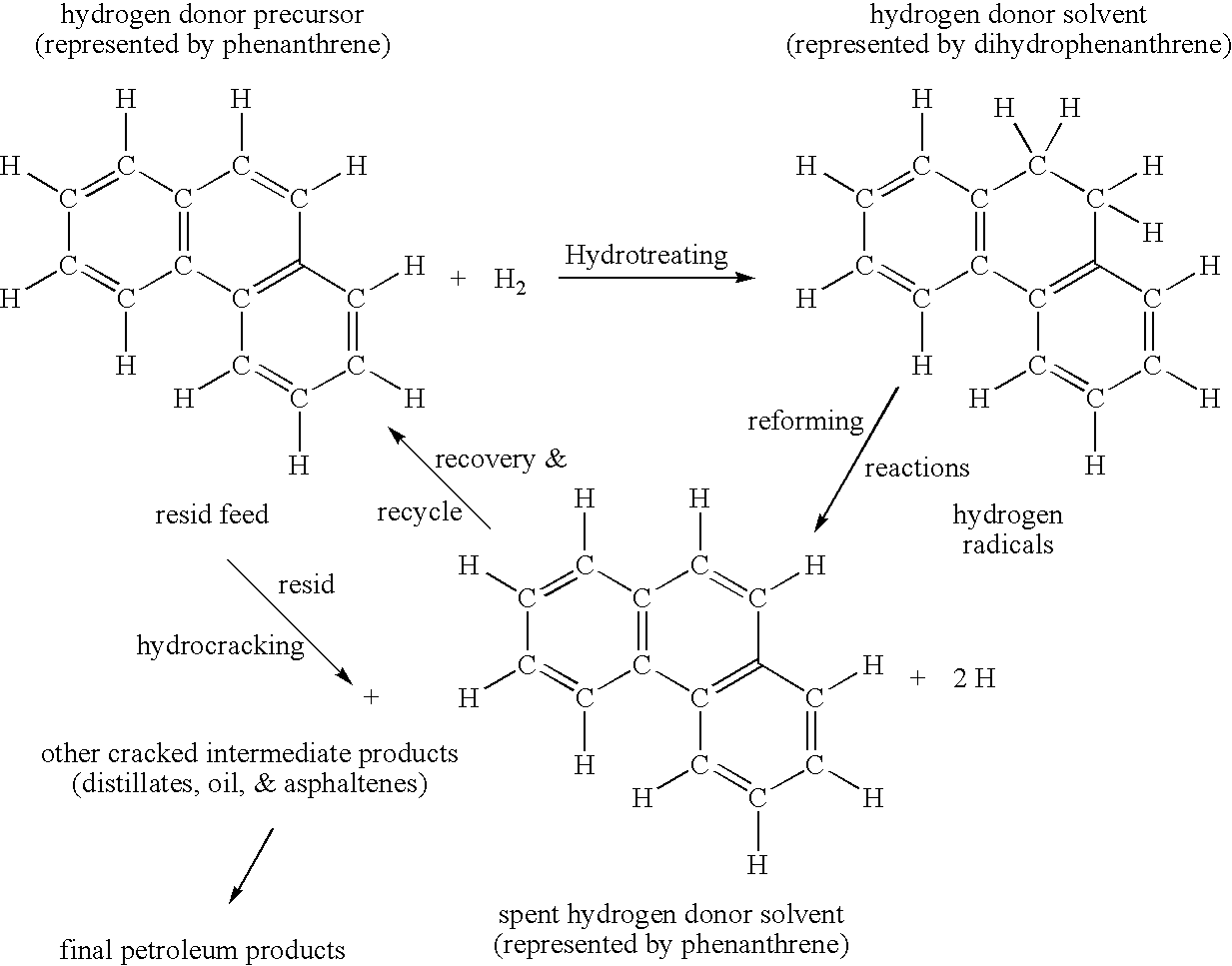

Hydrogen donor solvent production and use in resid hydrocracking processes

InactiveUS20070108100A1Treatment with plural serial cracking stages onlyCoke ovensHydrogenBoiling point

A process derived hydrogen donor solvent is used to increase the maximum resid conversion and conversion rate in an ebullated bed resid hydrocracker. The hydrogen donor solvent precursor is produced by hydroreforming reactions within the resid hydrocracker, recovered as the resin fraction from a solvent deasphalting unit, regenerated in a separate hydrotreater reactor, and recycled to the ebullated bed resid hydrocracker. The major advantage of this invention relative to earlier processes is that hydrogen is more efficiently transferred to the resin residual oil in the separate hydrotreater and the hydrogen donor solvent effectively retards the formation of coke precursors at higher ebullated bed resid hydrocracker operating temperatures and resid cracking rates.

Owner:BOC GRP INC

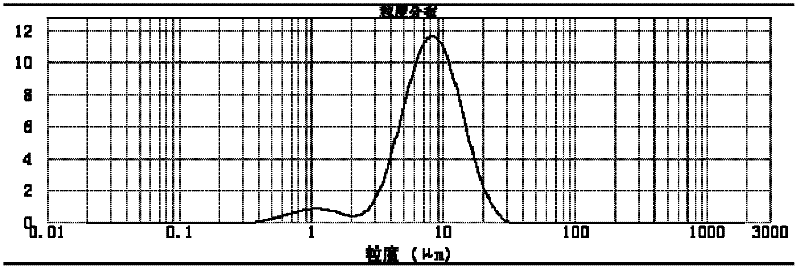

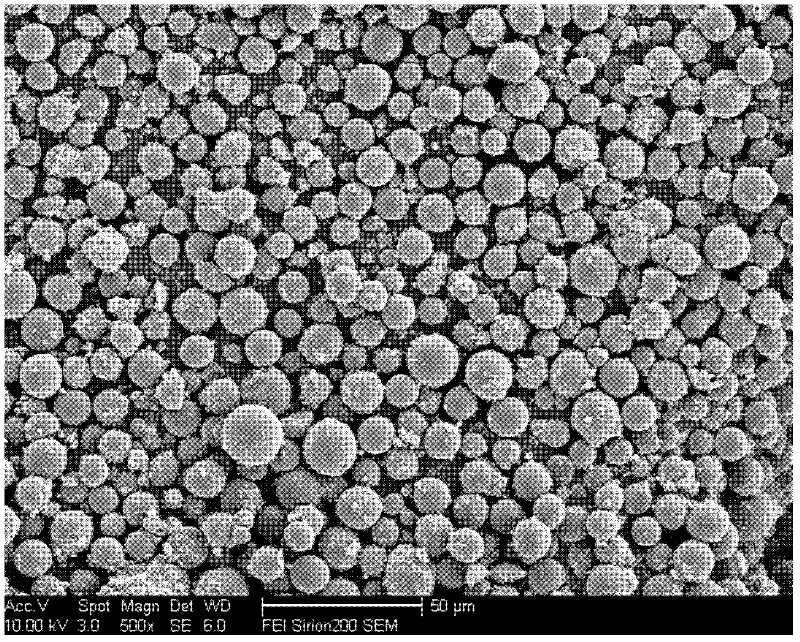

Preparation method of mesophase carbon microspheres from coal liquefaction residues

InactiveCN102225755ANarrow particle size distributionSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereQuinoline

The invention discloses a preparation method of mesophase carbon microspheres from coal liquefaction residues serving as raw materials, which comprises the following steps of: firstly carrying out solvent extraction on the coal liquefaction residues, then carrying out a series of processing to obtain refined asphalt with different contents of quinoline insoluble substances, and carrying out thermal polycondensation reaction on the refined asphalt in the presence of a chemical auxiliary agent and a nucleating accelerator at the temperature of 380-450 DEG C, the pressure of 0-5 MPa and the stirring rotation speed of 40-500 r / min for 1-20 hours to obtain the mesophase microspheres. According to the invention, the chemical auxiliary agent and the nucleating accelerator can be added during theheat treatment process to improve the yield and narrow the particle size distribution of the mesophase carbon microbeads, and the mesophase carbon microspheres are prepared from the coal liquefactionresidues serving as the raw materials and have the advantages of low cost, simple preparation process, high yield (up to 35%), narrow particle size distribution, good sphericity, etc.

Owner:ZIBO MINING GRP

Elastomeric bicomponent fibers comprising block copolymers having high flow

InactiveUS20070004830A1Strong flow abilityIncrease chanceWorking-up pitch/asphalt/bitumen by chemical meansSynthetic resin layered productsElastomerFiber

Bicomponent fibers comprising a thermoplastic polymer and an elastomeric compound are made which can be continuously extruded from the melt at high production rates. The elastomeric compound has high flow and consists essentially of a selectively hydrogenated block copolymer and a tackifier resin, an alpha-olefin copolymer, an alpha-olefin terpolymer, a wax or mixtures thereof. In one embodiment the block copolymer has at least one polystyrene block of molecular weight from 5,000 to 7,000 and at least one polydiene block of molecular weight from 20,000 to 70,000 and having a vinyl content of greater than 60 mol %. In a second embodiment the block copolymer has a vinyl content of less than 60 mol %. The bicomponent fibers are useful for the manufacture of articles such as woven fabrics, spun bond non-woven fabrics or filters, staple fibers, yarns and bonded, carded webs.

Owner:KRATON POLYMERS US LLC

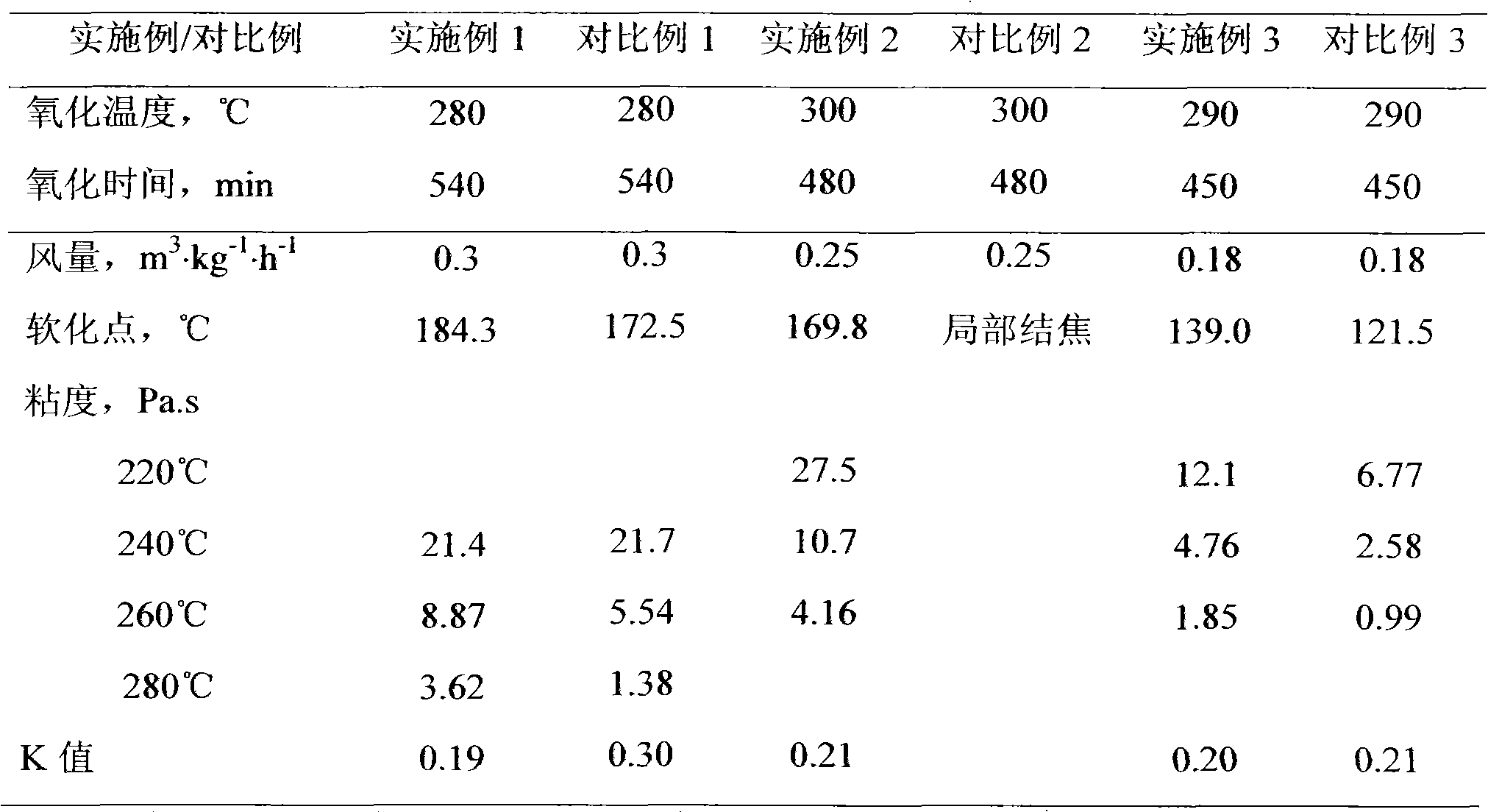

Preparation method of high softening point asphalt

ActiveCN102464989AIncrease profitQuality improvementWorking-up pitch/asphalt/bitumen by chemical meansMolten stateTemperature control

The invention provides a preparation method of high softening point asphalt, and the method comprises: heating an asphalt raw material to a molten state, subjecting the asphalt raw material, reaction additives accounting for 0.01%-5% of the total mass of the asphalt raw material, as well as air to full premixing reaction, with the mixing temperature controlled at 80-180DEG C and the mixing time controlled at 1min-40min; then introducing the mixture to an oxidation reactor for air blowing oxidation at a temperature of 200-340DEG C for 3-10h, with the air blowing rate of an oxidation tower maintained at 0.05-0.5m<3>.kg<-1>.h<-1>, thus obtaining a high softening point asphalt product with excellent high temperature performance and temperature susceptibility resistance. The method of the invention solves the problems of overlong reaction time, nonuniform air distribution, easy coking, short oxidation tower operation cycle, and poor product performance, etc. existing in current high softening point asphalt production processes by oxidation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

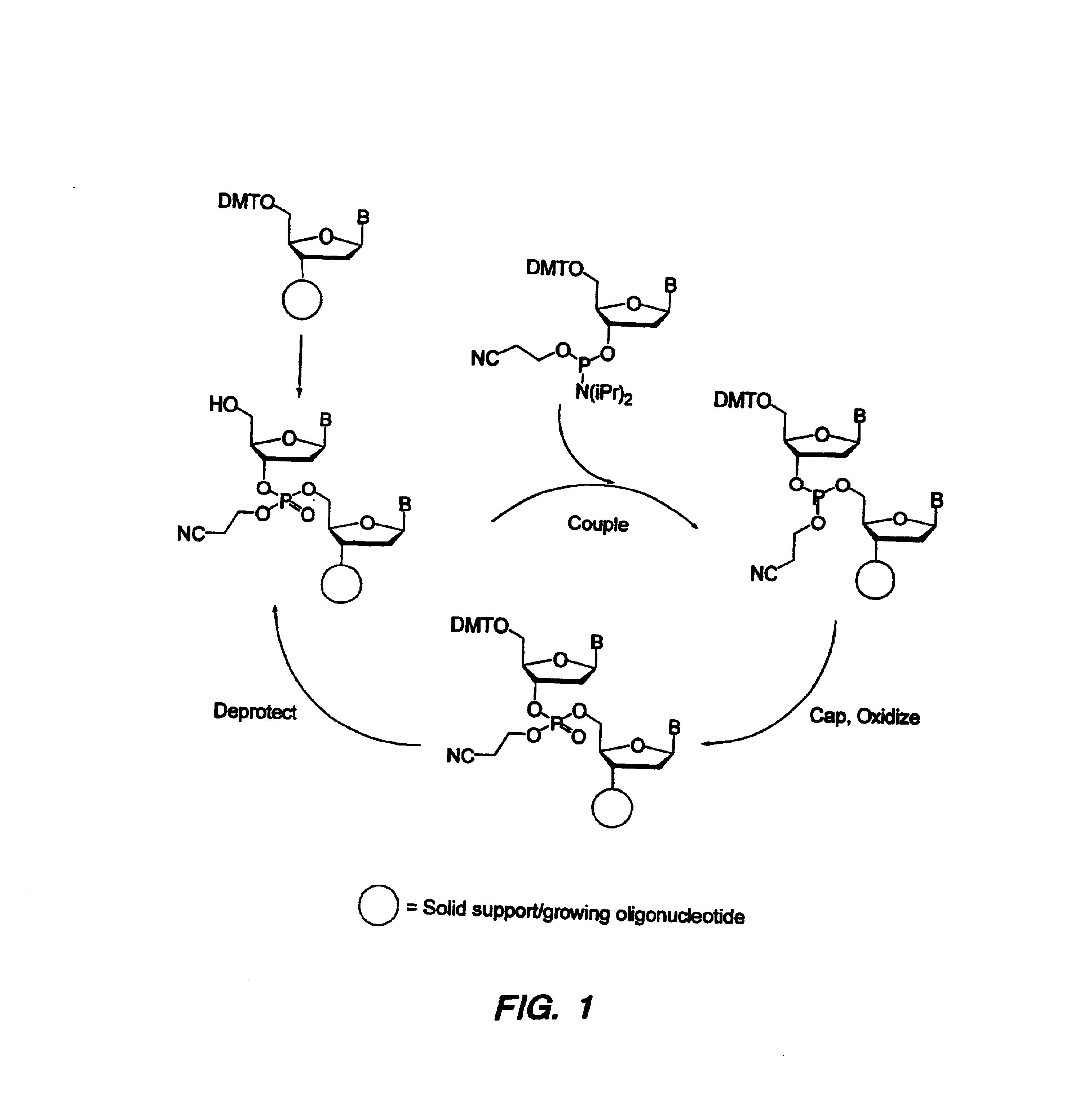

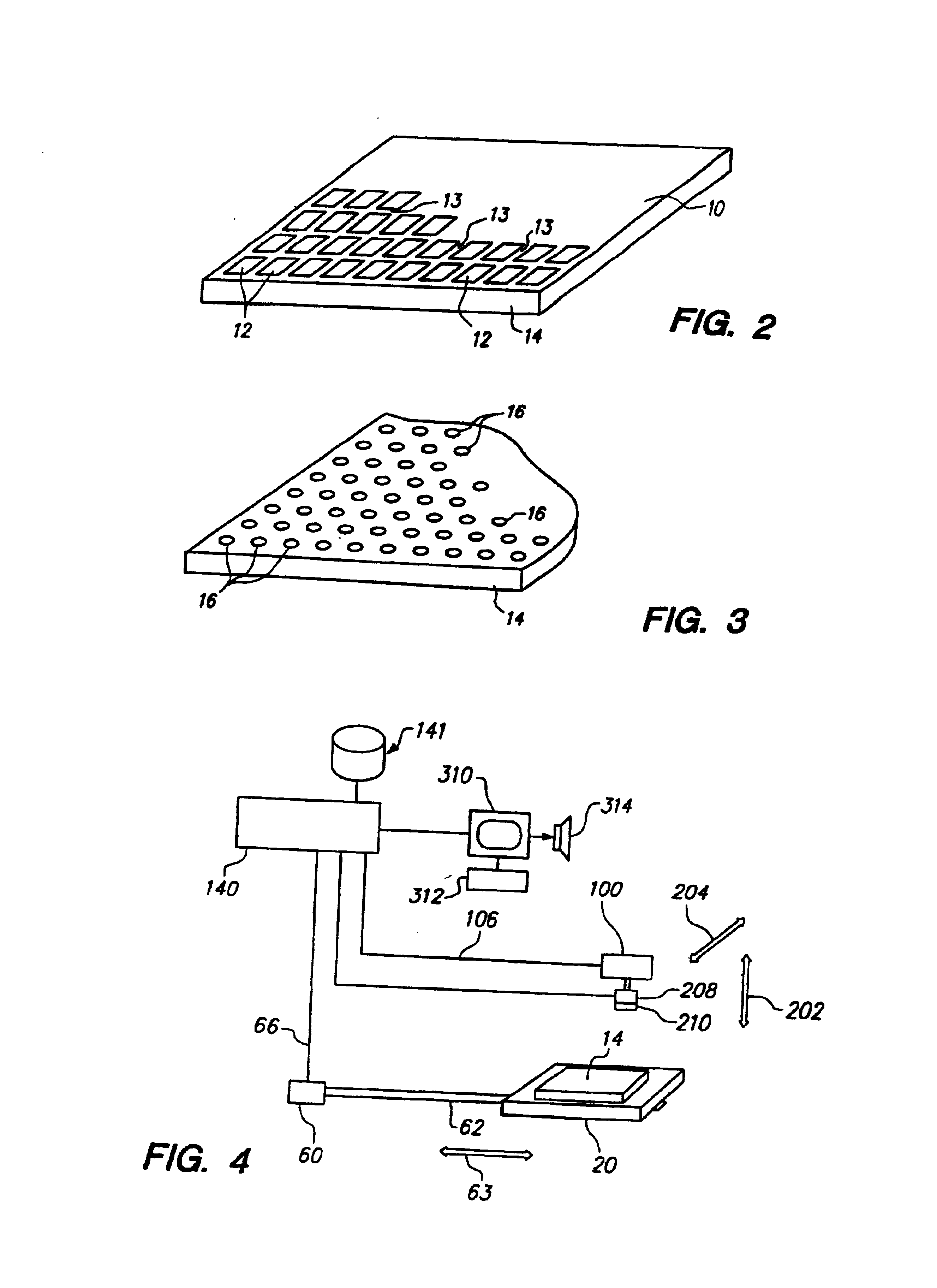

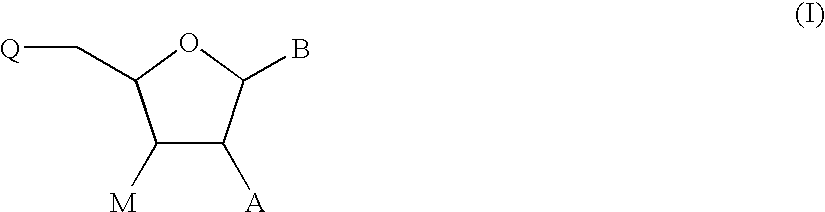

Use of ionic liquids for fabrication of polynucleotide arrays

A method of fabricating polynucleotide arrays includes dissolving a nucleotide monomer, oligonucleotide, or polynucleotide in a solvent containing ionic liquid and depositing the resulting solution on an array substrate. The method has particular application to fabrication of an addressable array of polynucleotides on a substrate that carries substrate bound moieties each with a hydroxyl group. The process may be repeated at specific locations on the array to elongate the polynucleotide deposited on the array.

Owner:AGILENT TECH INC

Asphalt compositions and products comprising tall oil derived materials, and methods for making and using same

InactiveUS8034172B2Working-up pitch/asphalt/bitumen by chemical meansCoatingsSolubilityNeedle penetration

Asphalt compositions and products in which the binder comprises tall oil materials possibly previously subjected to distillation, and / or oxidation, and / or combined with a polymer, the tall oil materials having a softening point in the range of 75 F to 400 F, a Needle Penetration value (0.1 mm) at 25 C of at least 1, a Rotational Viscosity at 275 F in the range of 650 cps to 8,000 cps, and a water solubility of less than 10 percent.

Owner:PVS MERIDIAN CHEM

Asphalt compositions and products comprising tall oil derived materials, and methods for making and using same

InactiveUS20100147190A1Working-up pitch/asphalt/bitumen by chemical meansCoatingsNeedle penetrationSolubility

Asphalt compositions and products in which the binder comprises tall oil materials possibly previously subjected to distillation, and / or oxidation, and / or combined with a polymer, the tall oil materials having a softening point in the range of 75 F to 400 F, a Needle Penetration value (0.1 mm) at 25 C of at least 1, a Rotational Viscosity at 275 F in the range of 650 cps to 8,000 cps, and a water solubility of less than 10 percent.

Owner:PVS MERIDIAN CHEM

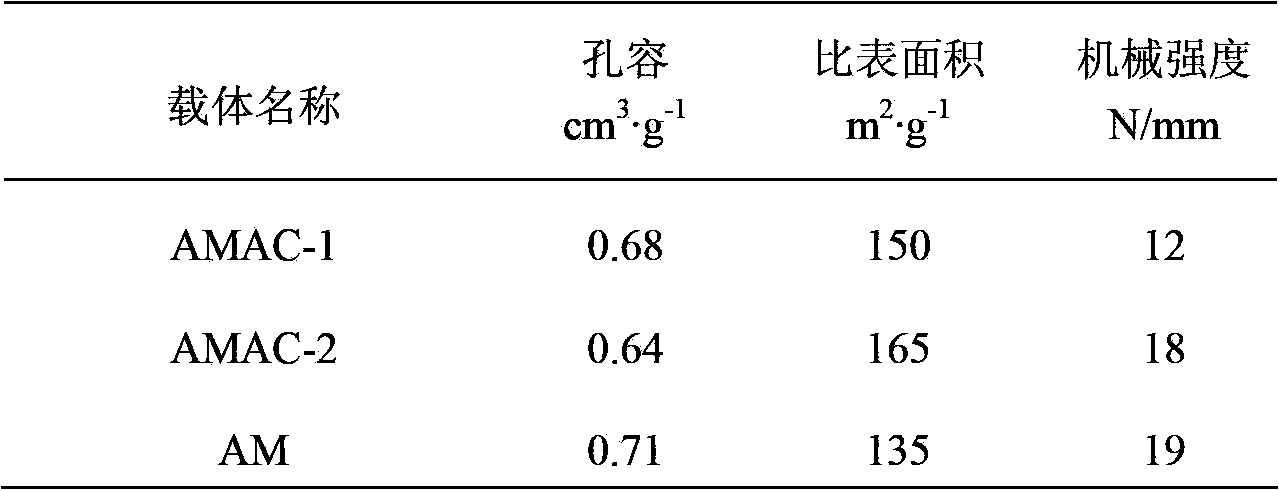

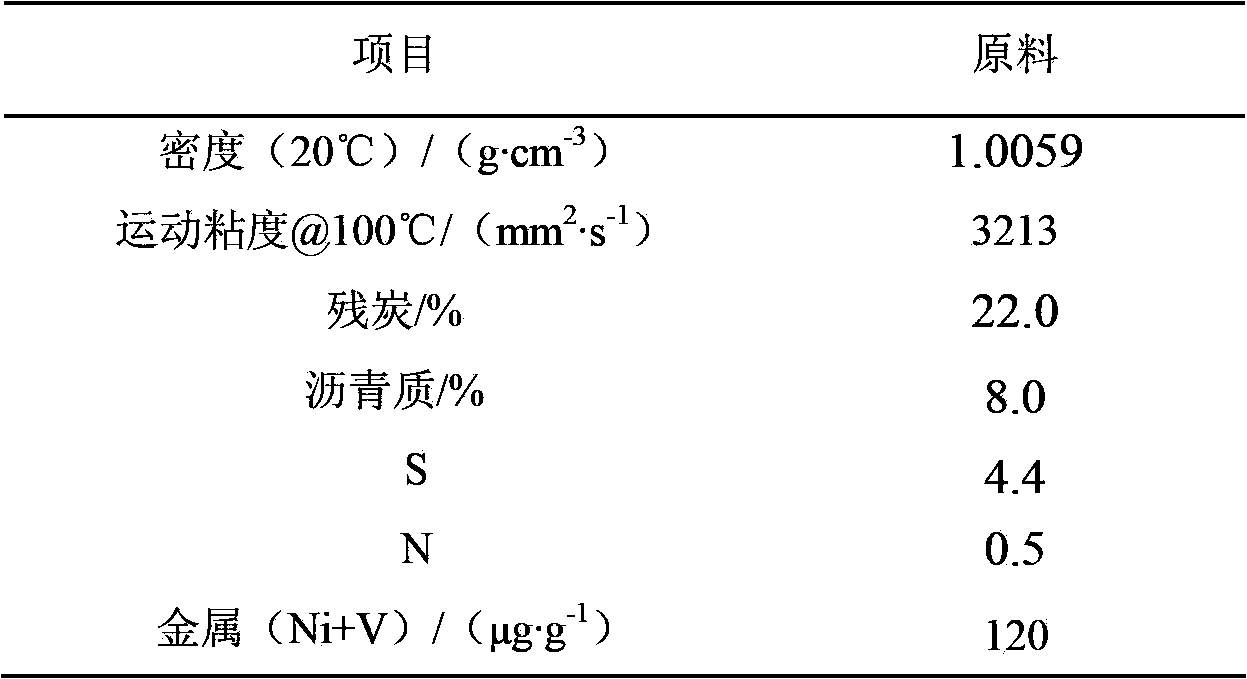

Activated carbon/aluminum oxide composite type catalyst carrier and preparation method and application of activated carbon/aluminum oxide composite type catalyst carrier

InactiveCN103657736ALarge specific surface areaHigh mechanical strengthCatalyst carriersWorking-up pitch/asphalt/bitumen by chemical meansActivated carbonFixed bed

The invention relates to an activated carbon / aluminum oxide composite type catalyst carrier and a preparation method and application of the activated carbon / aluminium oxide composite type catalyst carrier. The preparation method comprises the steps of washing circularly with 20-35% hydrochloric acid in a boiling state, wherein the mass ratio of hydrochloric acid to activated carbon is (5-20):1, performing oxidation with 10-50% nitric acid, wherein the mass ratio of an oxidizing agent to activated carbon is (20-40):1, kneading the activated carbon, aluminium oxide and an assistant into cakes in a kneading machine, extruding the kneaded cakes through an extruding machine, drying the extruded carrier, and roasting in nitrogen protection atmosphere to prepare the activated carbon / aluminum oxide composite type catalyst carrier. The activated carbon / aluminum oxide composite type catalyst carrier is suitably used as a residual oil hydrogenation catalyst carrier of a fixed bed, and is particularly used as the residual oil hydrodemetallization catalyst carrier. The activated carbon / aluminum oxide composite type catalyst carrier has high desulfurization rate up to 86.4-88.3%, high denitrification rate up to 58.3-60.5% and high demetalization rate up to 87.2-90.4%.

Owner:PETROCHINA CO LTD

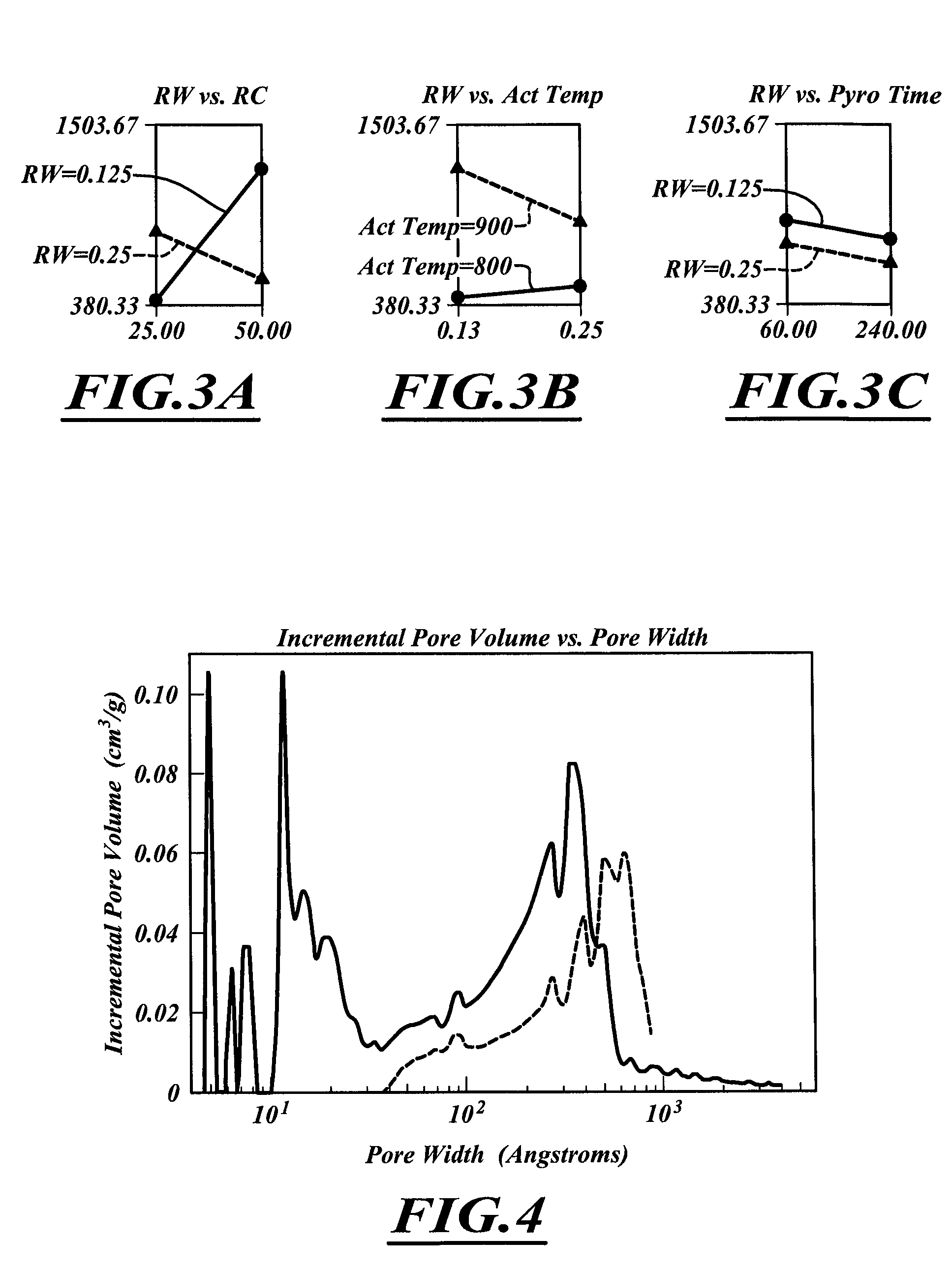

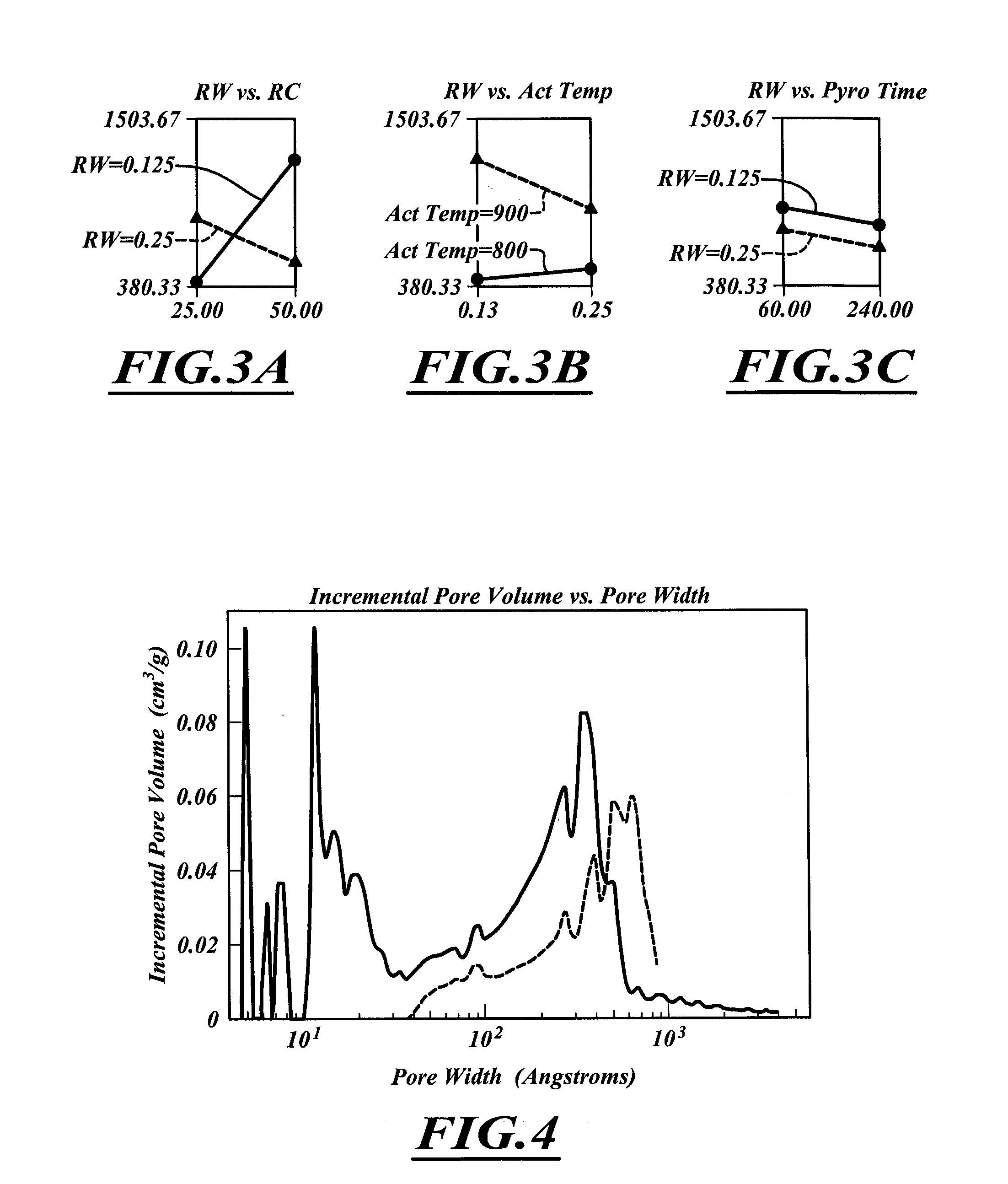

Manufacturing methods for the production of carbon materials

The present application is generally directed to activated carbon materials and methods for making the same. The disclosed methods comprise rapidly freezing synthetically prepared polymer gel particles. The methods further comprise drying, pyrolyzing, and activating steps to obtain an activated carbon material of high porosity. The disclosed methods represent viable manufacturing processes for the preparation of activated carbon materials.

Owner:BASF AG

Hydrotreated hydrocarbon tar, fuel oil composition, and process for making

InactiveUS20140174980A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansBoiling pointTar

Provided is a hydrocarbon tar. The tar has 75 wt % or more of aromatics of 10 carbons to 75 carbons based on the total weight of the tar. The aromatics exhibit 40% to 80% aromaticity. The tar has a boiling point of from 300° F. to 1350° F. There is also a fuel oil composition having the tar therein. There are also processes for making the hydrocarbon tar.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing hydrophilic silica gels with high pore volume

InactiveUS6239243B1High porosityReduce hydrophobicitySilicaWorking-up pitch/asphalt/bitumen by chemical meansSilica gelHydrophobe

A method for the preparation of hydrophilic silica gels with high pore volume. In the preferred method a hydrophilic silica hydrogel treated with an organosilicon compound to effect hydrophobing of the silica hydrogel is heated in the presence of an oxidizing atmosphere to a temperature sufficient to reduce the hydrophobicity imparted by the surface treatment thereby producing a hydrophilic silica gel having high pore volume.

Owner:DOW CORNING CORP

Recovery and transportation of heavy crude oils

InactiveUS6402934B1Low viscosityWorking-up pitch/asphalt/bitumen by chemical meansLiquid carbonaceous fuelsHeavy crude oilSequestering Agent

Owner:ROHM & HAAS CO

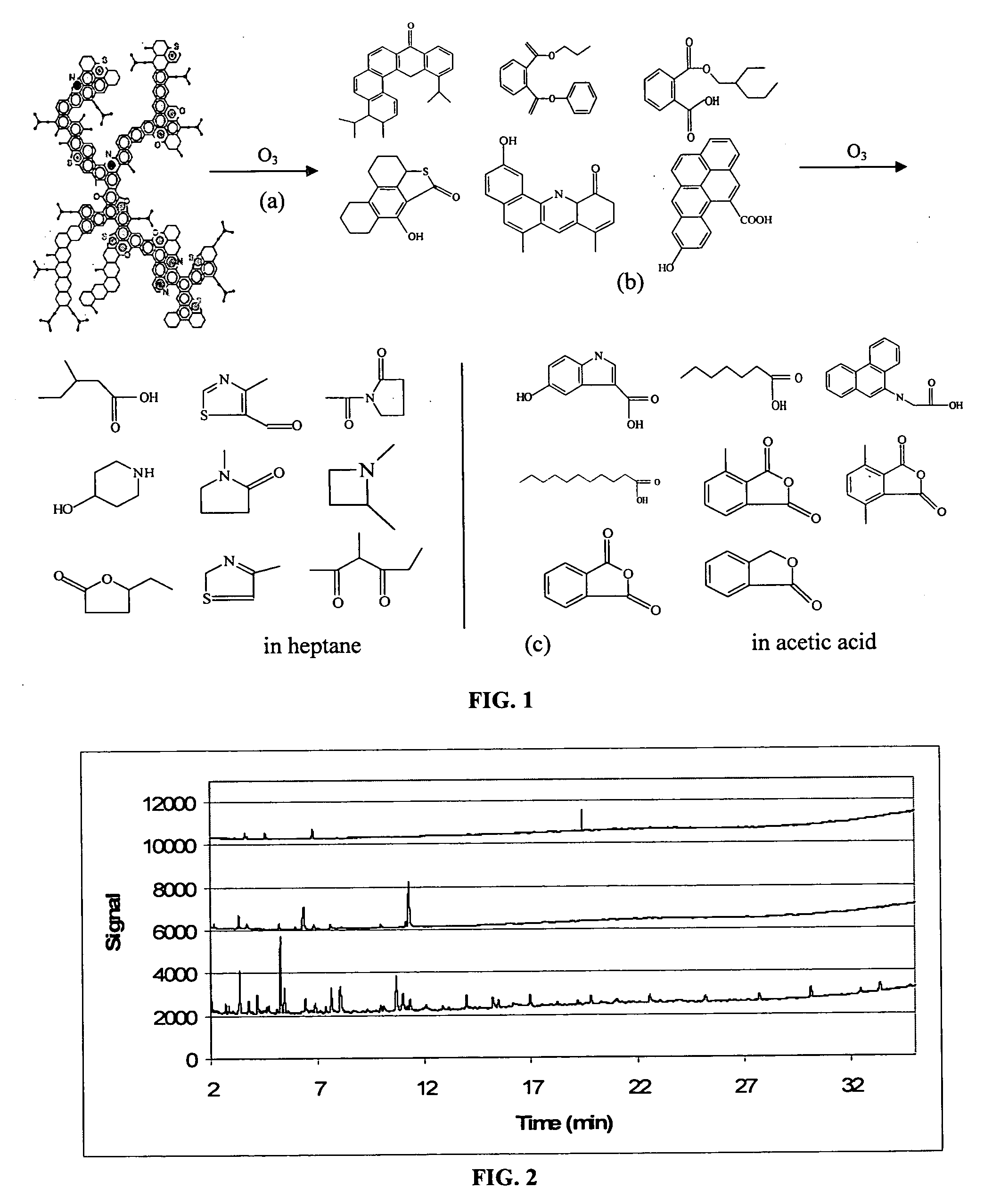

Fragmentation of heavy hydrocarbons using an ozone-containing fragmentation fluid

InactiveUS20060163117A1Thermal non-catalytic crackingCatalytic crackingChemical speciesChemical compound

A method for recovering valuable chemical products from heavy hydrocarbons such as tar sand or petroleum waste products is disclosed and described. Heavy hydrocarbons can be contacted with a fragmentation fluid which includes ozone and a solvent carrier. The fragmentation fluid can be provided at supercritical conditions. For example, supercritical CO2 can be an effective liquid solvent carrier for ozone. During contact with the fragmentation fluid, the heavy hydrocarbons are reduced in size to form a product mixture of chemical compounds. This product mixture typically includes chemical species which are more suitable than the original heavy hydrocarbons to commercial uses and / or further separation to provide useful starting materials for a wide variety of synthesis and industrial applications.

Owner:MARATHON OIL CANADA

Use of steam cracked tar

ActiveUS20070163921A1Catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansTarPulp and paper industry

Owner:EXXONMOBIL CHEM PAT INC

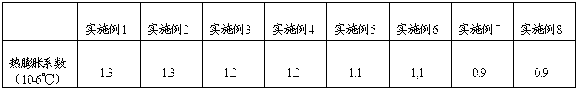

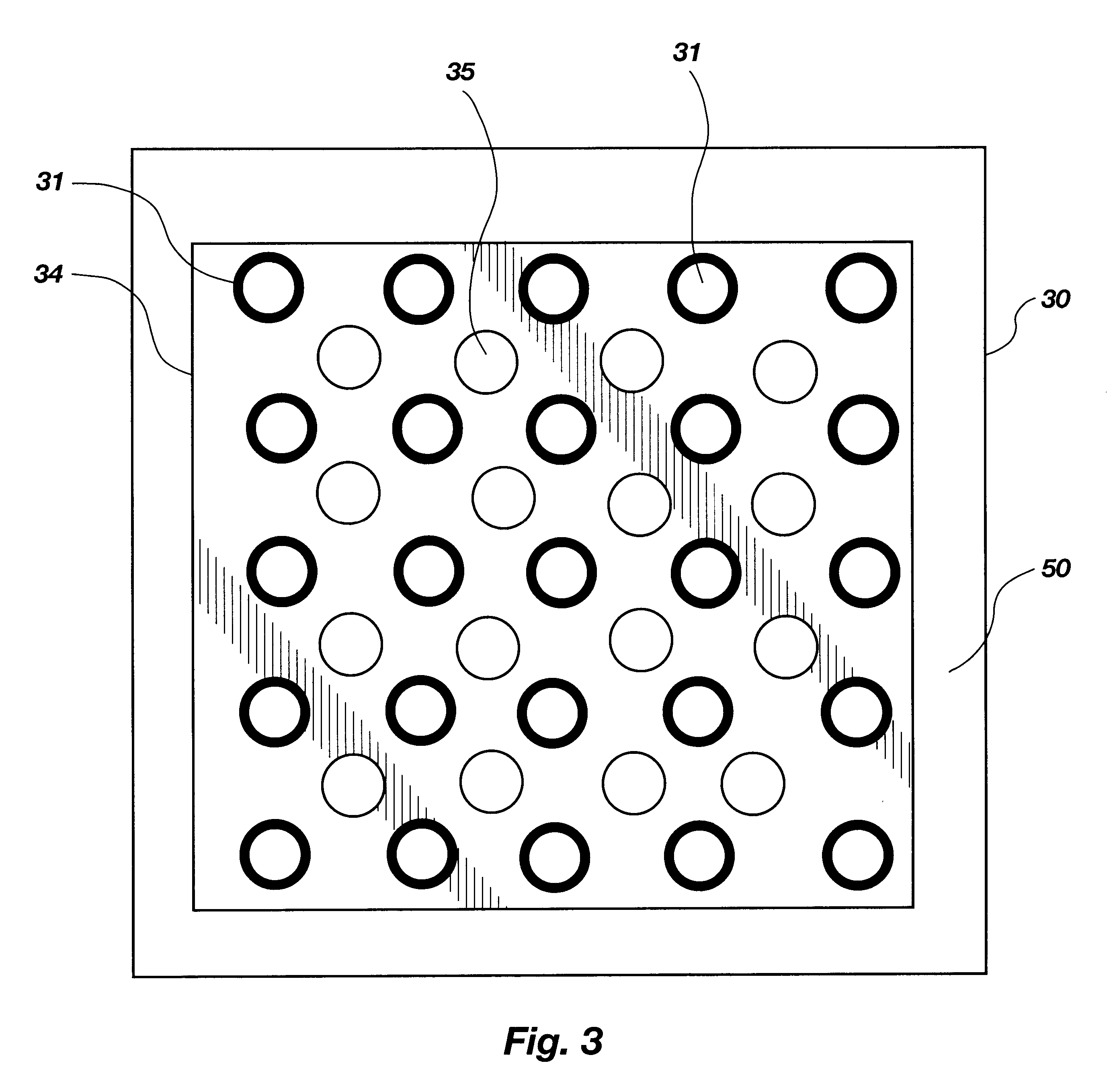

Technology for preparing needle coke raw material from coal-tar pitch

ActiveCN103013566ASuitable for adjusting extraction volumeHigh desulfurization efficiencyWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansPtru catalystCoke

The invention provides a technology for preparing a needle coke raw material from coal-tar pitch. The technology comprises the following steps of 1, fully mixing asphalt and a solvent, and removing insoluble substances in the mixture by a physical separation method, wherein the solvent is a mixture of coal light oil and coal aromatic oil or is a mixture of BTX and coal aromatic oil; a mass ratio of the coal light oil or the BTX to the coal aromatic oil is in a range of (20: 80) to (95: 5); and a mass ratio of the solvent to the asphalt is in a range of 0.5 to 10, 2, feeding a clear liquor without the insoluble substances into a separator, and separating the light solvent from the clear liquor to obtain a heavy fraction having low QI, and 3, carrying out hydrotreatment on the heavy fraction in the presence of a hydrogenation catalyst at a temperature of 300 to 450 DEG C under the pressure of 5 to 20MPa. The needle coke raw material obtained by the technology has low sulfur content and a small expansion coefficient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Solvent extraction of hydrocarbons from inorganic materials and solvent recovery from extracted hydrocarbons

InactiveUS6207044B1No pollution to the environmentIncrease surface areaLiquid organic insulatorsWorking-up pitch/asphalt/bitumen by chemical meansHydrocarbon solventsSolvent vapor

A process for the solvent separation of hydrocarbons from tar sand or contaminated soils comprises extracting the hydrocarbons from the sand or soil in a solvent extraction means to form a hydrocarbon rich solvent solution. The rich solvent is separated from the hydrocarbon in a process that utilizes flashing of the solvent in a heated flashing column at ambient pressure. The hydrocarbon is withdrawn from the bottom of the column and the flashed solvent vapors are strategicly withdrawn and passed into a condensation column from which the condensed solvent may be recycled. The flashing column is divided by a series of horizontal, vertically aligned apertured trays. The solution is introduced into the top of the column and the flashing operation is facilitated by the increase in the surface area of the solution as it flows by gravity from tray to tray. The column is maintained at a temperature, preferably above the boiling temperature of the solvent. The process is particularly adapted to the use of chlorinated hydrocarbon solvents and most particularly to the use of methylene chloride.

Owner:LUCENT TECH INC

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Roofing coating asphalt composition

ActiveUS20110197785A1Excellent stain indexGood storage stabilityRoof covering using tiles/slatesWorking-up pitch/asphalt/bitumen by chemical meansWaxViscosity

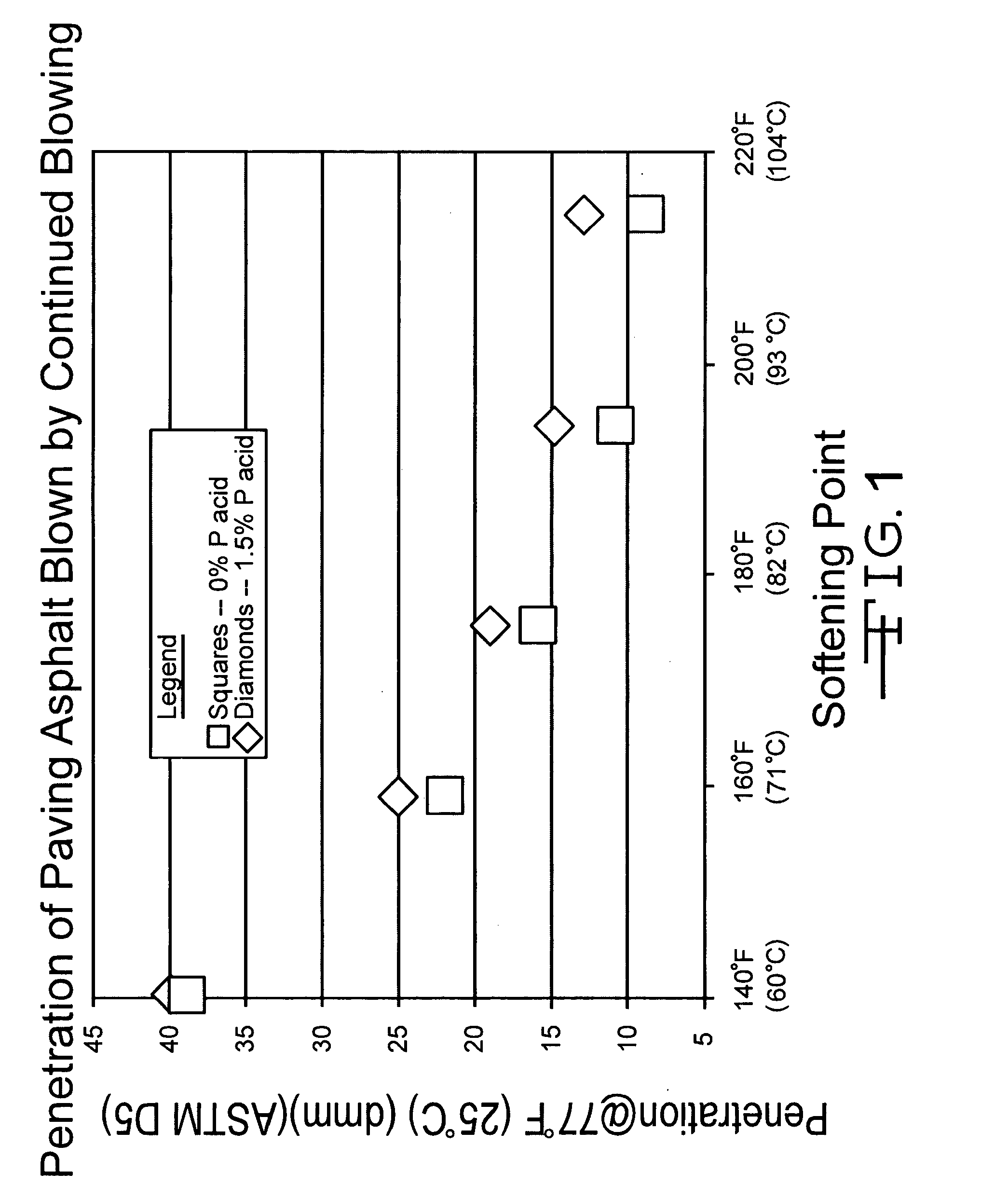

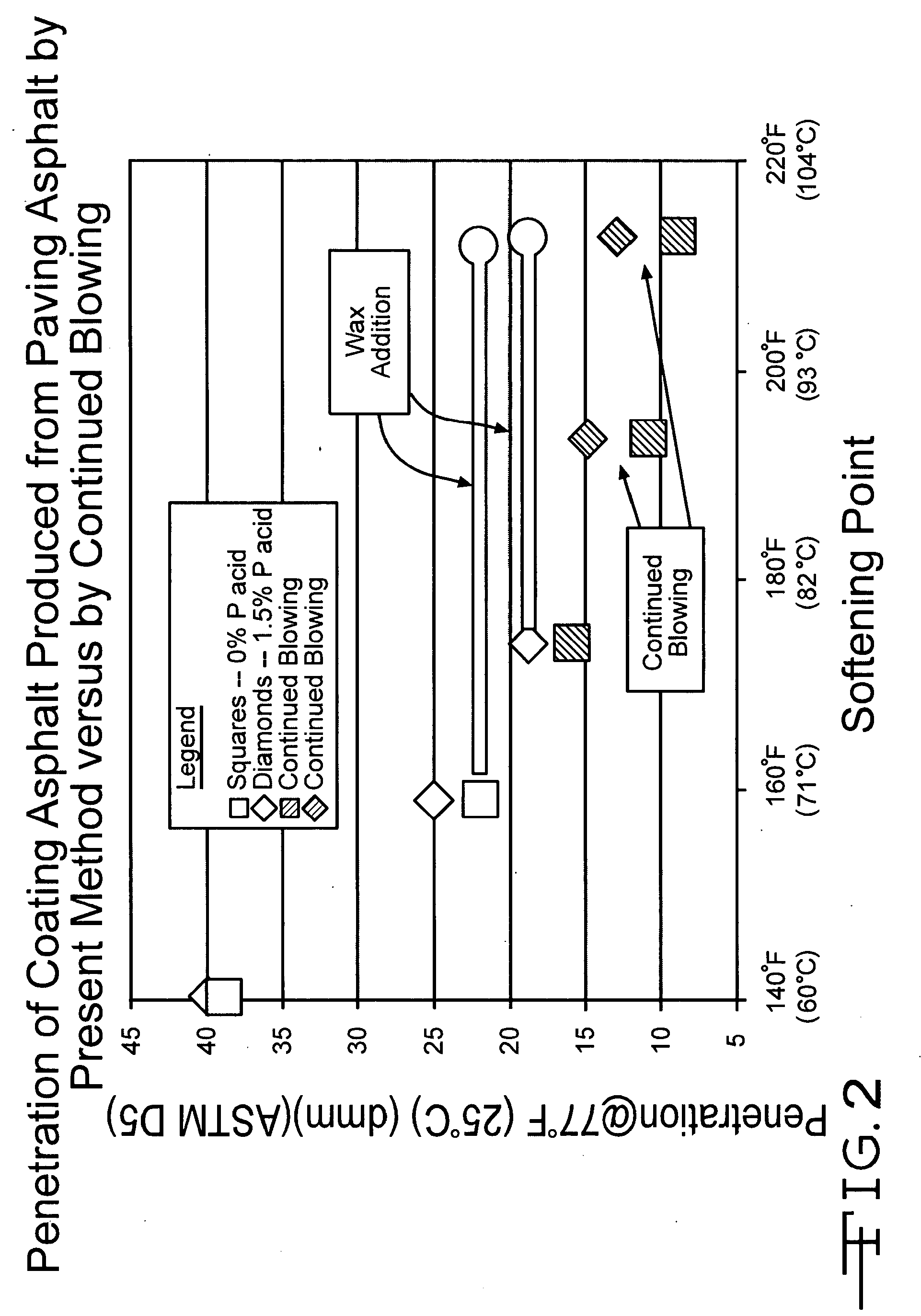

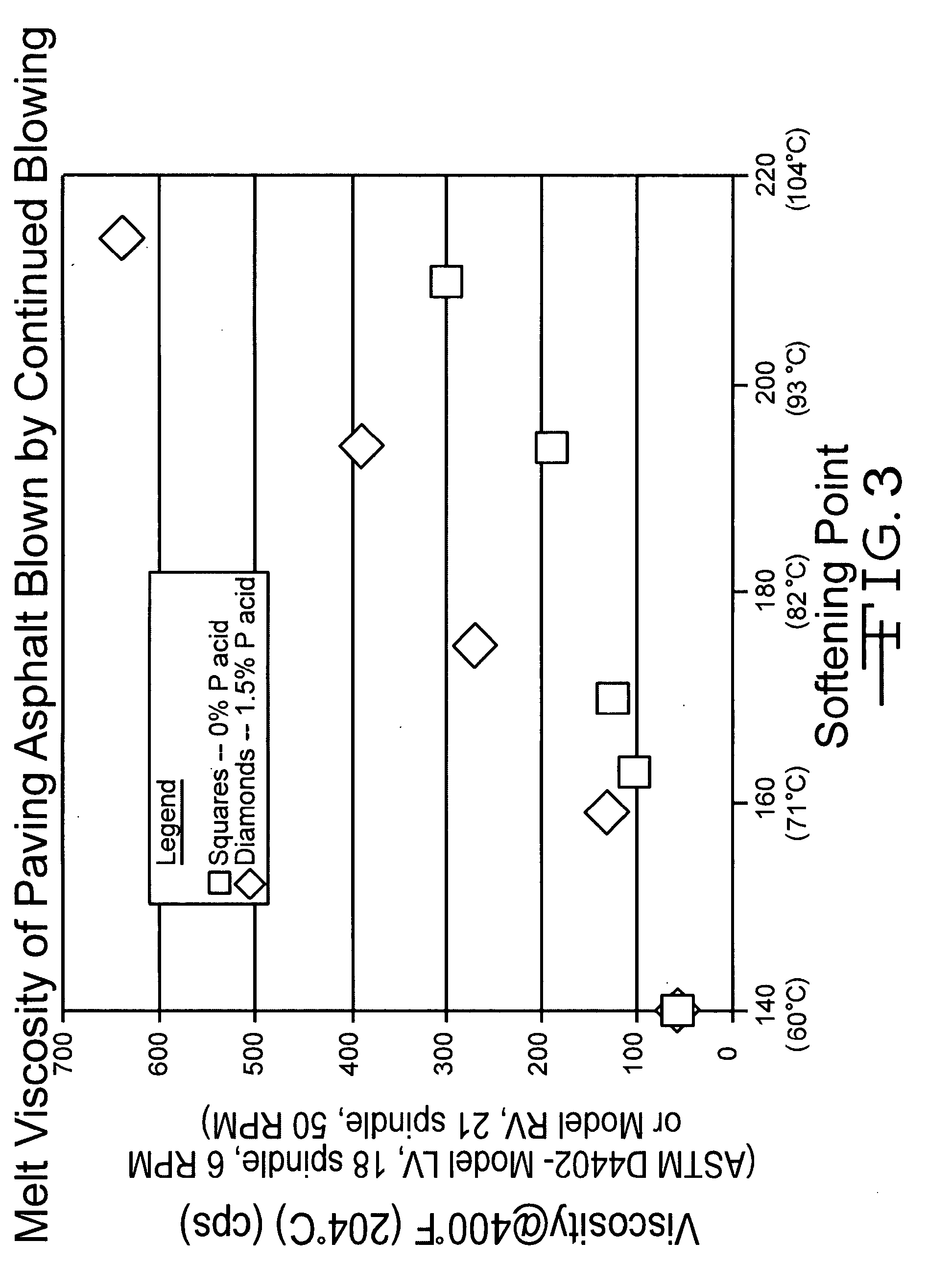

A method of producing a roofing shingle coating asphalt from a non-coating grade asphalt feedstock includes the following steps. The non-coating grade asphalt feedstock is partially blown to lower its penetration to a first penetration that is within or close to a target penetration range of the coating asphalt, and to raise its softening point to a first softening point that is lower than a target softening point range of the coating asphalt. A wax is added to the partially blown non-coating grade asphalt to further raise its softening point to a second softening point that is within the target softening point range to produce the coating asphalt. The wax may also be added during the blowing process. Resulting roofing coating asphalt compositions may comprise a paving grade asphalt and a wax, and yet still has desirable penetration, softening point and viscosity.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Preparation method of intermediate-phase asphalt

ActiveCN102181299AImprove liquidityPromote generationWorking-up pitch/asphalt/bitumen by chemical meansCarbon compositesFiber

The invention relates to a preparation method of intermediate-phase asphalt, in particular to the preparation method of the intermediate-phase asphalt in a coal system or a petroleum system, and the method comprises the following two steps: 1) selecting coal asphalt or petroleum asphalt as raw material, and adding olefin and a friedel-crafts alkylation catalyst for alkylation of the raw material asphalt; and 2) performing pyrocondensation polymerization on the alkylated asphalt for getting a finished product. By adopting the preparation method, the technical problems that the intermediate-phase asphalt prepared by the existing method is high in softening point and can not meet the requirements for preparing high-grade carbon materials can be solved, the intermediate-phase asphalt preparedby the preparation method can be used for manufacturing various important carbon materials, such as needle coke, intermediate-phase asphalt-based carbon fiber, intermediate-phase asphalt-based carbonnegative pole material, intermediate-phase asphalt-based carbon / carbon composite material, intermediate-phase asphalt-based foam carbon, high-temperature lubricant, catalyst carriers and the like.

Owner:CHANGZHOU HEIMA NEW CARBON TECH

Elastomer-modified bituminous compositions

InactiveUS6429241B1Narrow rangeHigh propertyIn situ pavingsWorking-up pitch/asphalt/bitumen by chemical meansCross-linkElastomer

Owner:POLYPHALT

Stabilized bitumen compositions

InactiveUS6100317AReduce the amount presentSame elastic recoveryIn situ pavingsWorking-up pitch/asphalt/bitumen by chemical meansPolyolefinButadiene-styrene rubber

PCT No. PCT / CA94 / 00174 Sec. 371 Date Aug. 13, 1996 Sec. 102(e) Date Aug. 13, 1996 PCT Filed Mar. 28, 1994 PCT Pub. No. WO94 / 22957 PCT Pub. Date Oct. 13, 1994Two or more different polymeric materials are stably incorporated into bitumen by effecting steric stabilization of a polyolefin, such as polyethylene, and by dispersing the other polymer, such as a styrene-butadiene-styrene copolymer, an ethylene-vinyl acetate copolymer or an EPDM copolymer in the stabilized polyethylene-bitumen composition. The ability to incorporate different polymeric materials in bitumen permits desirable modifications to the properties of the composition to be effected. In addition, different properties can be attained by modifying processing parameters.

Owner:POLYPHALT

Method for removing asphaltene deposits

InactiveUS20080020949A1Reduce and prevent formationPreventing and reducing precipitationWorking-up pitch/asphalt/bitumen by chemical meansFlushingKeroseneFuel oil

Compositions comprising at least one C4-C30 olefin or oxidation product thereof and kerosene or an aromatic solvent are particularly effective for use in removing asphaltene and asphaltene-containing organic deposits and in preventing or reducing the precipitation and deposition of asphaltenes from hydrocarbon fluids. When added to heavy oils comprising asphaltenes, alone or in combination with dispersants and further inhibitors, the invented compositions lower viscosity and pour point, and aid in preventing asphaltene precipitation during transport and in combustion.

Owner:INEOS USA LLC

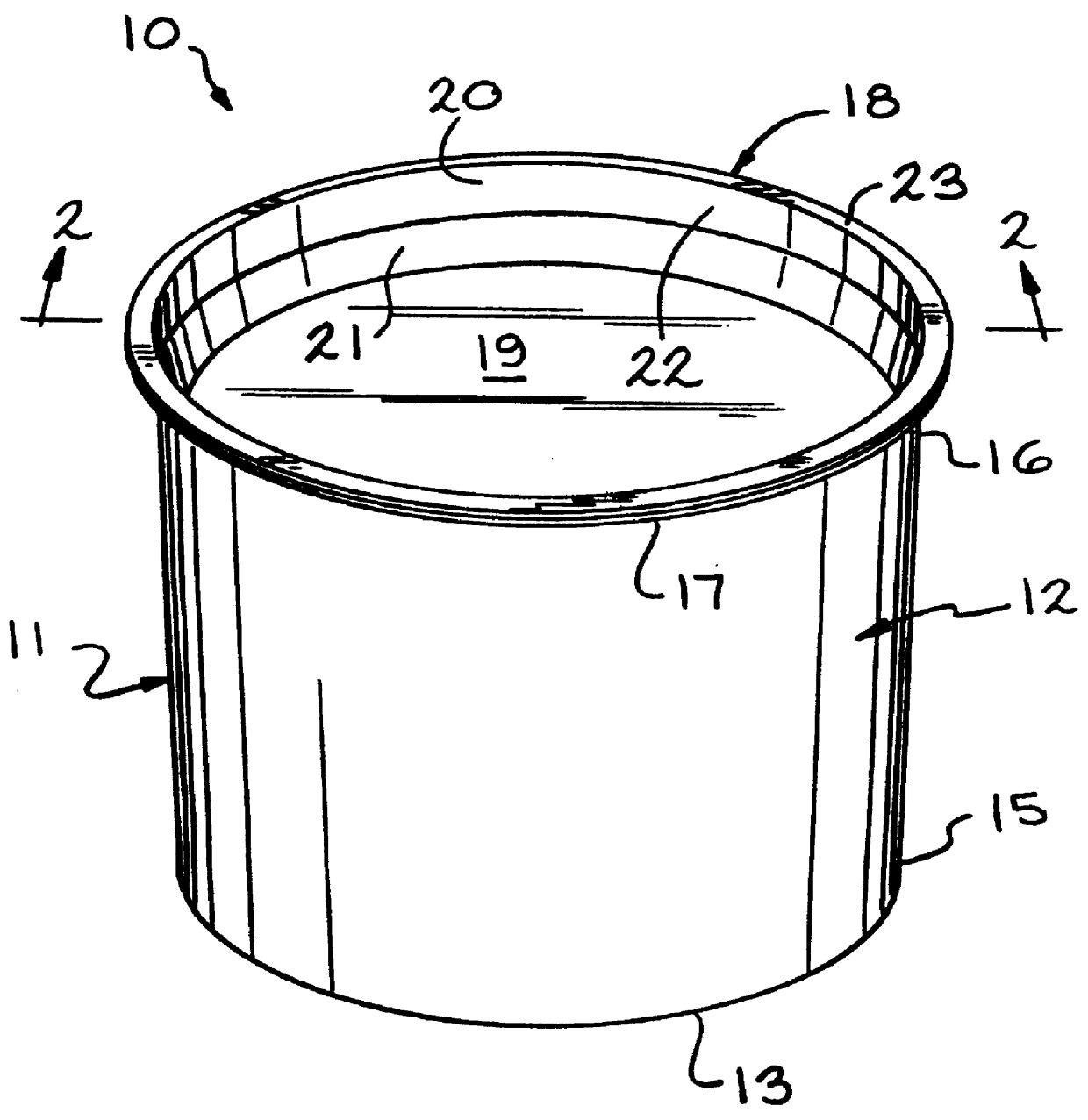

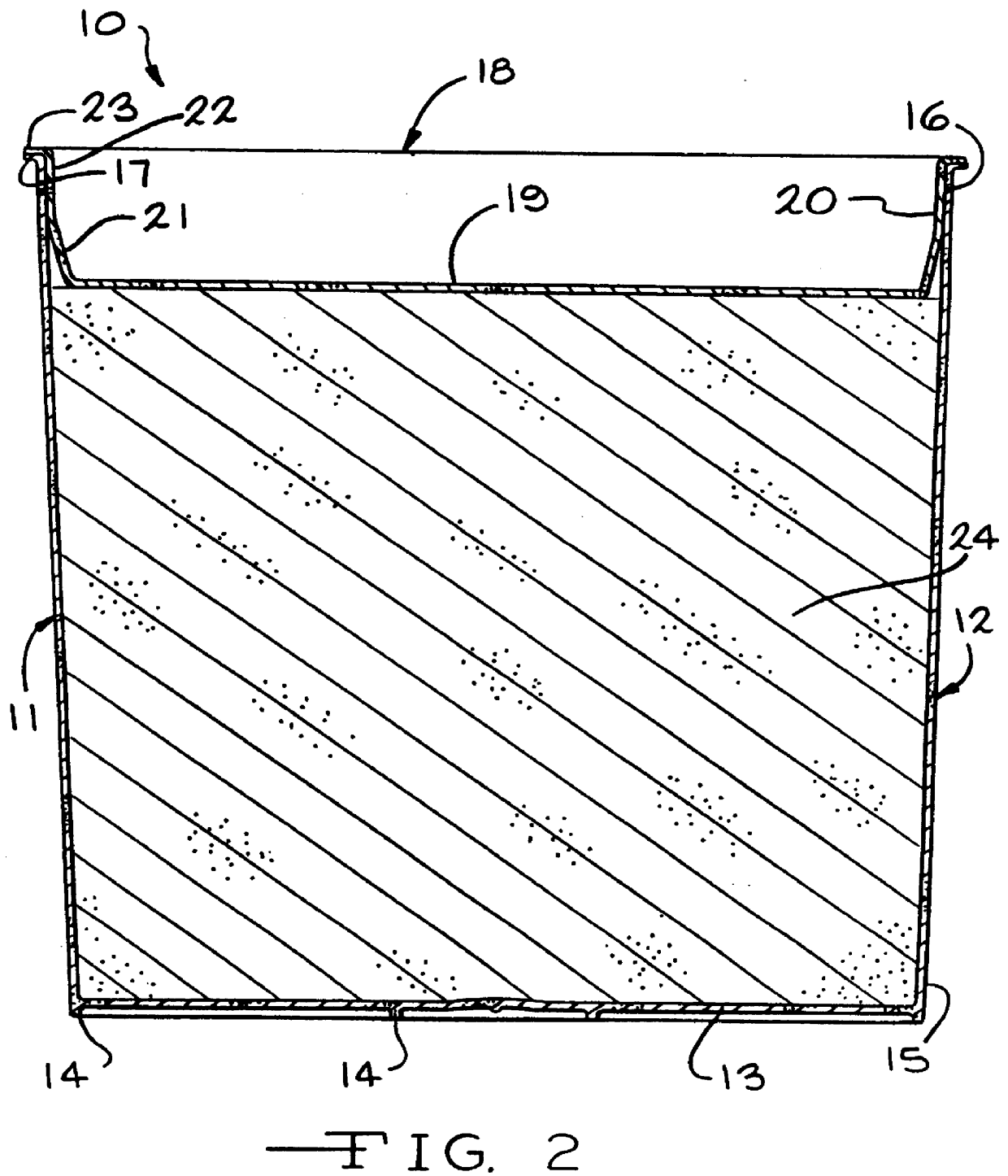

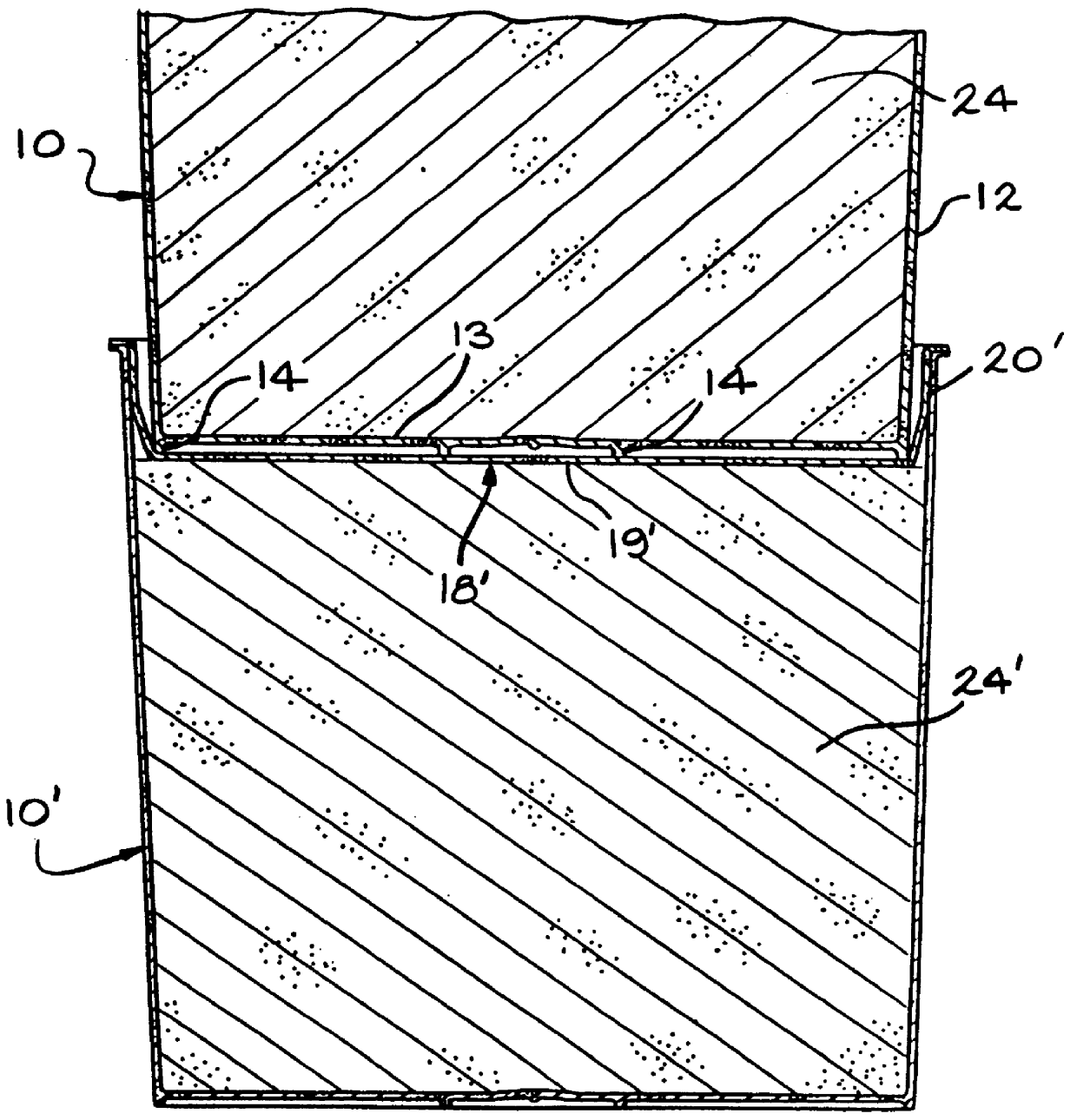

Consumable asphalt containers and method of reducing fumes from a kettle of molten asphalt

InactiveUS6107373AAvoid problemsReduce fumingFlexible coversIn situ pavingsParticulatesAdditive ingredient

A consumable container is molded from a composition comprising 40 to 90 weight % of an asphalt and 10 to 60 weight % of a polymer material, which advantageously can include a first polymer such as PP that imparts heat resistance and a second polymer such as EVA that imparts toughness and impact resistance. This molded asphalt / polymer material preferably has an unnotched Izod impact strength of at least 2 joules. The container is consumable-it can be melted along with roofing asphalt held in the container without adversely affecting the properties of the asphalt and without requiring undue mixing. The composition also can be used to reduce fumes normally emitted from a kettle of molten asphalt, e.g., as measured by a reduction of the visual opacity of the fumes by at least 25%, a reduction of the hydrocarbon emissions of the fumes by at least 20%, or a reduction of the total suspended particulates emissions of the fumes by at least 15%. The container may be used, e.g., to hold roofing or paving asphalt or a recyclable petroleum-derived material, such as used motor oil. In one embodiment, the container composition may include one or more ingredients to improve the quality of paving-grade asphalt

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for producing environment-friendly rubber softening oil

InactiveCN101560330ANo pollutionNo or only pollutionWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansPolycyclic aromatic hydrocarbonFiltration

The invention relates to a method for producing environment-friendly rubber softening oil. The method is characterized by comprising the following steps: decompressing and distilling mineral oil; adding a catalyst into cut fraction at a temperature of between 280 and 340 DEG C to carry out a high-pressure hydrogenation reaction; adding the obtained product into carclazyte to be refined, and carrying out vacuum filtration to obtain refined mineral oil; treating bottom oil of a vacuum tower by the conventional propane deasphalting process to obtain an asphalt solution; distilling the asphalt solution under reduced pressure, taking cut fraction at a temperature of between 270 and 330 DEG C to be oxidized to obtain oxidized asphalt; mixing and stirring the obtained refined mineral oil and the oxidized asphalt in proportion by weight of 2.5-3.5:1.2-1.5 at a temperature of between 50 and 80 DEG C. The environment-friendly rubber softening oil has the advantages that the softening property, the compatibility and the intermiscibility are the same as or similar to the prior product high aromatic oil, but as the rubber softening oil does not contain or contains trace polycyclic aromatic hydrocarbon, so the rubber softening oil does not have carcinogenicity, does not pollute human body and environment, and meet the requirement of environment-friendly rubber extending oil.

Owner:SHANGHAI FUWODI LUBRICANT

Popular searches

Direct heating destructive distillation Catalytic naphtha reforming Biofuels Solid fuels Liquid hydrocarbon mixture production Tar working-up by chemical refining Metal/metal-oxides/metal-hydroxide catalysts Refining with oxygen compounds Hydrocarbon distillation Treatment with plural serial stages only

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com