Patents

Literature

102 results about "Refined coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refined coal is the product of the application of a coal-upgrading technology that removes moisture and certain pollutants from lower-rank coals such as sub-bituminous and lignite (brown) coals and raising their calorific values. Coal refining or upgrading technologies are typically pre-combustion treatments and/or processes that alter the characteristics of a coal before it is burned. The goals of pre-combustion coal-upgrading technologies are to increase efficiency and reduce emissions when coal is burned. Depending on the situation, pre-combustion technology can be used in place of or as a supplement to post-combustion technologies to control emissions from coal-fueled boilers. A primary benefit of refined coal is the capacity to reduce the net volume of carbon emissions that is currently emitted from power generators and would reduce the amount of emissions that is proposed to be managed via emerging carbon sequestration methodologies. Refined coal technologies have primarily been developed in the United States, several similar technologies have been researched, developed and tested in Victoria, Australia, including the Densified coal technology (Coldry Process) developed to alter the chemical bonds of brown coal to create a product that is cleaner, stable (not prone to spontaneous combustion), exportable and of sufficiently high calorific value to be a black coal equivalent.

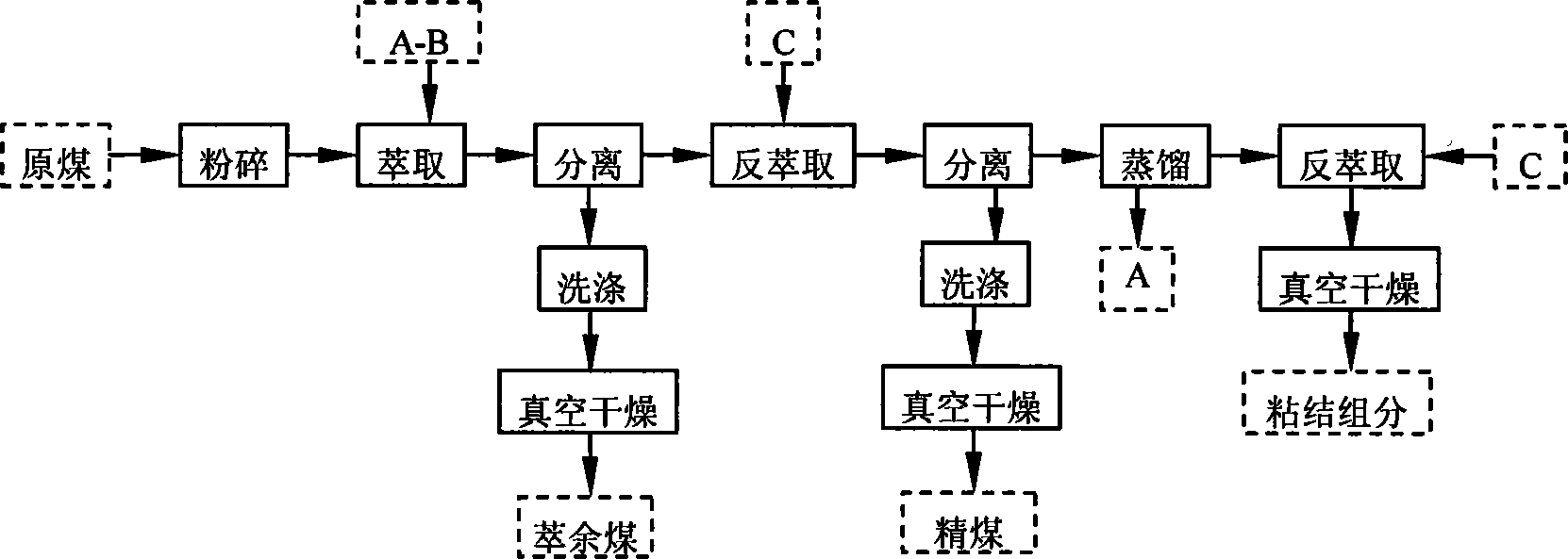

Mild coal-family component separation method based on extraction and back extraction

InactiveCN101070495AEasy to useImprove environmental benefitsSolid fuelsSolid solvent extractionWater useDistillation

Owner:CHINA UNIV OF MINING & TECH

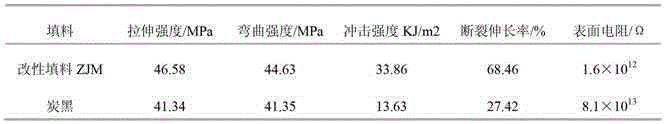

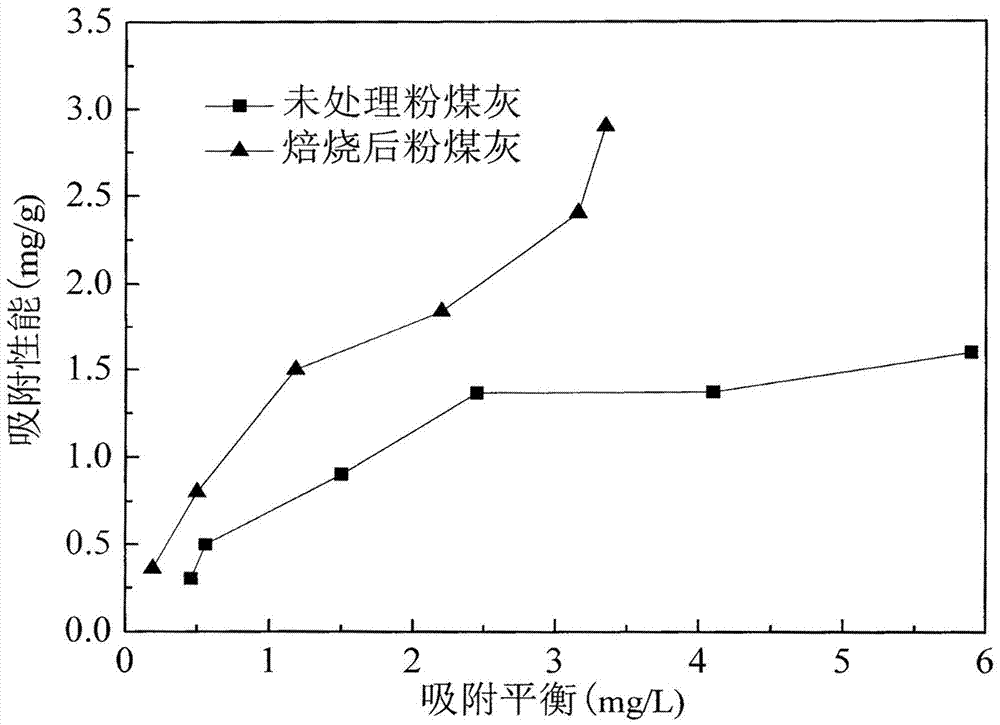

Modified super-fine cool-ash composite plastic

InactiveCN101024712AQuality is not affectedDoes not affect the production processPolymer sciencePolystyrene

The invention relates to modified refined coal compound plastic. It includes plastic 100 portions, polyvinyl chloride and the matched plasticizer 1-95 portions, stabilizer 2-7 portions; plastic 100 portions and polyethylene, polypropylene, ethane acetic acid ethylene copolymer, polystyrene or ABS, and bulk additive 5-90 portions. The physical and chemical indexes are: carbon content >=90%, 18um screenings <=1%, dispersant and coupling agent 0.5-6 portions. The parent material carbon content of the invention could be over 70%. When being used in polyethylene and polyvinyl chloride cable material, it could make cable material ageing resistance, reinforcing action and equally black.

Owner:JIANGSU JINKEN TECH IND

Biomass fuel and processing method thereof

InactiveCN101747975AIncrease the calorific value of combustionTimely consumptionBiofuelsSolid fuelsCombustionAnimal feces

Owner:吉林省崯田农业科技有限公司

Biomass composite solid forming fuel and preparation method thereof

The invention relates to biological complex shaped fuel and the preparation method. The comprised components of fuel and their proportion are as follows: straw 80- 95 uints, refined coal 5- 20 units and sulfur- fixing agent 0.5- 1uints. The production method comprises following steps: (1) disintegrating straw with water content being 13- 17% into particles with size being smaller than 5mm; (2) disintegrating refined coal with water content being 13- 17% to particles with size smaller than 1mm; (3) mixing said straw, refined coal and sulfur- fixing agent according to said proportion; (4) feeding said mixture into shaping machine, extruding at 110- 150 Deg. C and 105- 120 Mpa, getting granular or block- shaped fuel with density being 1.2- 1.4 g / cm3 and water content being 10- 12%; (5) cooling temperature of got shaped fuel to room temperature, and packing. The fuel is characterized by convenient transportation, easy storage and no sulfur product generation, and it is a sustainable new energy.

Owner:北京盛昌绿能科技股份有限公司

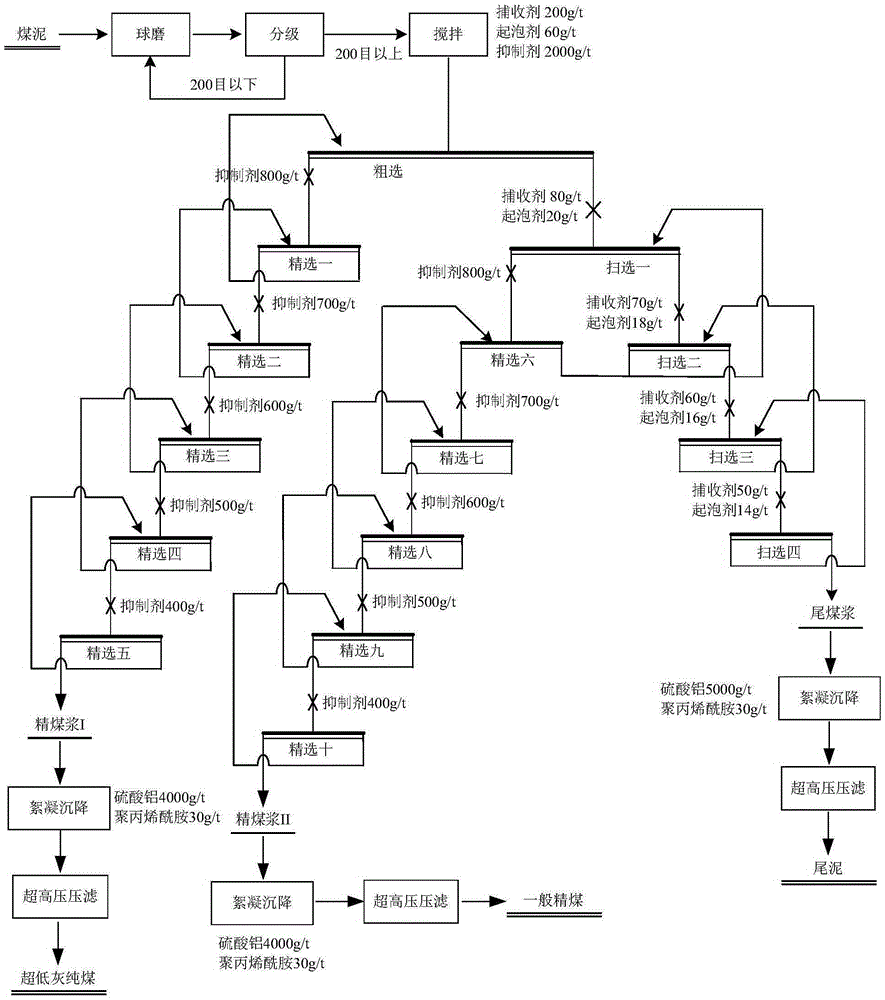

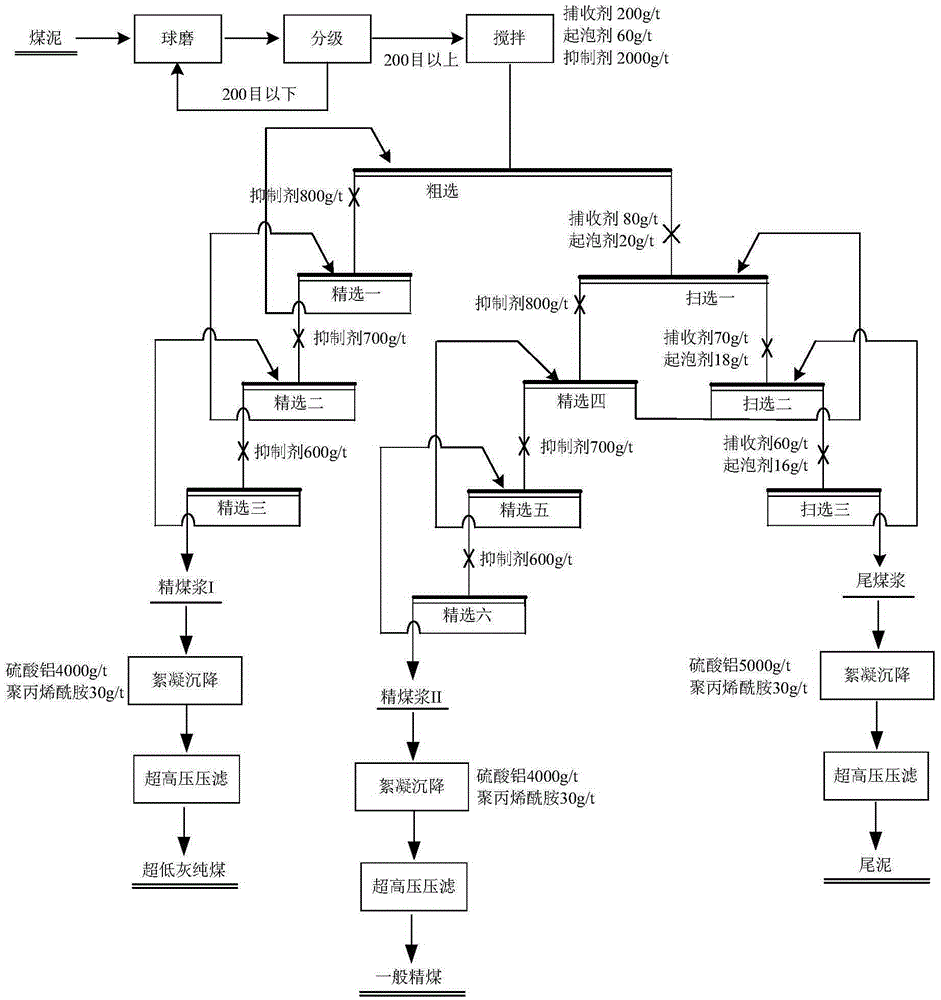

Method for extracting ultra-low-ash-content pure coal from coal slime

InactiveCN105396684ALow recovery rateGood technical effectDifferential sedimentationFlotationFlocculationFoaming agent

The invention discloses a method for extracting ultra-low-ash-content pure coal from coal slime. The method comprises the following steps: ball-milling slurrying, specifically, milling coal slime until particles with less than 200 meshes occupy more than 90%, and controlling the mass percent concentration of the coal slime slurry to be 10-35%; grading, specifically, conveying the particles with less than 200 meshes to a flotation step; flotation, specifically, adding a collecting agent, a foaming agent and an inhibitor in the obtained coal slime slurry, uniformly mixing, and carrying out one-time rough flotation, two sections of three-to-six-time fine flotation and one section of three-to-six-time scavenging to obtain refined coal slurry I, refined coal slurry II and tailing coal slurry respectively; and dehydration, specifically, adding a flocculant in the refined coal slurry I, the refined coal slurry II and the tailing coal slurry which are obtained through the flotation, carrying out flocculation settling, then dehydrating by virtue of an ultrahigh-pressure pressure filter, and controlling a pressure filter pressure to be 4.5-5.5Mpa, thus obtaining ultra-low-ash-content pure coal products, common refined coal products and tailing coal products. The method disclosed by the invention is simple in process flow, and capable of efficiently extracting the ultra-low-ash-content pure coal products from the coal slime; and moreover, the water contents of the obtained coal products are low and can achieve less than 15%, thus the coal products have remarkable economic benefits and environmental protection value.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

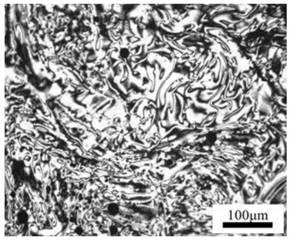

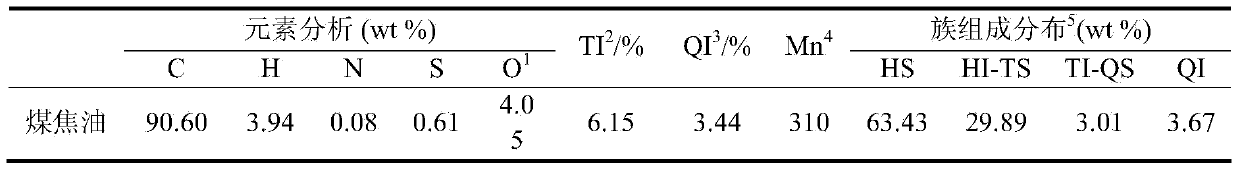

Method for preparing high-quality mesophase pitch by ternary co-carbonization

PendingCN110003932AWide variety of sourcesLow costWorking-up pitch/asphalt/bitumen by chemical meansFiberWide area

The invention discloses a method for preparing high-quality mesophase pitch by ternary co-carbonization, and belongs to the technical field of deep processing of coal tar pitch. The method is characterized in that the high-quality mesophase pitch is prepared from a small amount of graphene and a hydrogen supply reagent as additives and refined coal pitch as a raw material. The method comprises thesteps as follows: firstly, refined coal tar pitch powder and a small amount of graphene are put into a mixer to be evenly mixed, and then the mixed powder and the hydrogen supply reagent are put intoa high temperature and high pressure reactor to be subjected to direct thermal polymerization, and the high-quality mesophase pitch product is obtained. Formation of mesophase pitch in the reactor isobviously accelerated by addition of a small amount of graphene and the hydrogen supply reagent, so that the reaction temperature required for formation of the mesophase pitch from the refined coal pitch is reduced, and time is shortened. The mesophase content of the obtained product is as high as 80% or higher, the optical structure of the product is wide-area streamlined, and the product has low softening point and good spinnability, and can be used for preparing high-end carbon materials such as high-performance carbon fiber and high-heat conducting foam carbon.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing high-strength post-forming biomass charcoal

The invention discloses a production method for producing high intensity post forming biomass charcoal, and belongs to the resource and environment technical field. The invention adopts the material which takes lignin or biomass material as the raw material, the substance containing a great amount of lignin components produced during the product processing process acts as adhesive agent, the powder made by the biomass charcoal with fineness of 40 mesh and mesh residue no more than 20 percent, and the high quality refined coal powder with fineness no less than 60 mesh is used according to the proportion of biomass charcoal powder:refined coal powder:adhesive agent of 55 to 95:0 to 40:5 to 45 (percent, all are converted into dehydrated products), the adhesive agent, the biomass charcoal powder and the refined coal powder are processed to be the post forming biomass charcoal semi-finished products having certain shape and size under the condition that the moisture content percentage is suitable for the molding equipment to be molded, and finally are processed to be the post forming biomass charcoal finished products processed through the heating no less than 350 DEG C and the carbonizing treatment.

Owner:许绍良

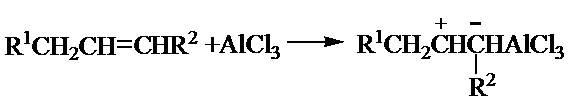

Method for preparing high-quality needle coke raw material by removing QI (Quinoline Insolubles) in coal tar

InactiveCN103740400ALow QI contentImprove responseTreatment with plural serial refining stagesTarAliphatic hydrocarbon

The invention discloses a method for preparing a high-quality needle coke raw material by removing QI (Quinoline Insolubles) in coal tar, and the method comprises the following steps: firstly, separately adding an aromatic hydrocarbon solvent and an aliphatic hydrocarbon solvent into a raw material coal tar or adding a mixture of the aromatic hydrocarbon solvent and the aliphatic hydrocarbon solvent into the raw material coal tar, and carrying out mixing and gravity settling on the obtained mixture, so that an obtained solution is divided into an upper liquid and residues; then, distilling the upper liquid so as to obtain low-QI-content refined coal tar. The QI in coal tar can be removed, and then low-QI-content refined coal tar for preparing needle cokes is obtained; the method is mild in conditions, strong in maneuverability and low in cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Synthetic diesel

InactiveCN101463277ASolution to fossil dieselSolve the technical problems of water emulsificationLiquid carbonaceous fuelsKeroseneOxygen

The invention discloses a synthetic diesel, which is composed of ingredients having the following weight proportions: 20-40 parts of finished diesel, 10-25 parts of 200# solvent diesel, 15-30 parts of refined fatty acid, 15-18 parts of low-temperature refined coal tars, 0.02-0.04 part of 3# aviation kerosene, 0.01-0.03 part of composite modified and catalytic incendiary agent and 0.02-0.05 part of isooctyl nitrate. The invention also discloses a synthesis process for the synthetic diesel. The synthetic diesel comprises oxygen-containing ingredients and in the meantime, uses the catalytic incendiary agent so that the synthetic diesel achieves greater variation in the combustion mode in vehicles than fossil diesel and so that the combustion rate of the synthetic diesel, the output powder and the tail gas emission of the vehicles can all run up to the ideal value, thus realizing dual purposes of energy-saving and emission-reduction.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

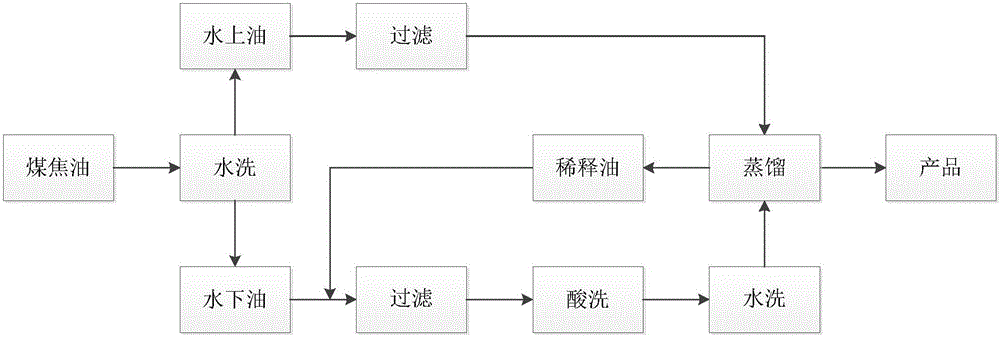

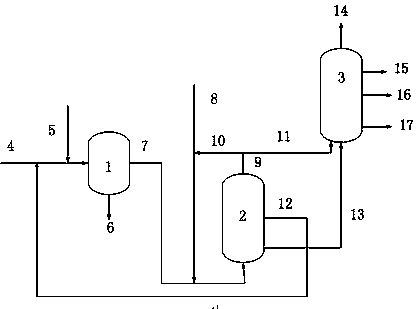

Coal tar pretreatment method

InactiveCN106398735AQuality assuranceHigh selectivityTar working-up by distillationTar working-up by chemical refiningPretreatment methodBoiling point

The invention discloses a coal tar pretreatment method. The method comprises the following steps: 1, fully mixing a coal tar raw material with water, salt and a de-emulsifier A, and using an oil-water separation device to separate the coal tar raw material at 50-200 DEG C under 0.1-5.0 Mpa into oil above water, water and oil under water, wherein the addition amount of water is 5-50% of the weight of the coal tar raw material, the addition amount of the de-emulsifier A is 0.003-0.05% of the weight of the coal tar raw material, and the addition amount of the salt makes the density of the salt in water reach 1.001-1.015 g / cm<3>; 2, treating the oil above water obtained in step 1 to obtain refined coal tar I; 3, treating the oil under water obtained in the step 1 to obtain standing coal tar II; and 4, mixing the refined coal tar I obtained in step 2 with the standing coal tar II obtained in step 3 to obtain refined coal tar, adding the refined coal tar to a distillation system, separating to obtain a fraction with the boiling point being smaller than 150 DEG C and a fraction with the boiling point being greater than 150 DEG C, and mixing a part of the fraction with the boiling point being smaller than 150 DEG C with the fraction with the boiling point being greater than 150 DEG C to obtain pretreated coal tar.

Owner:特思锐能源科技(北京)有限责任公司

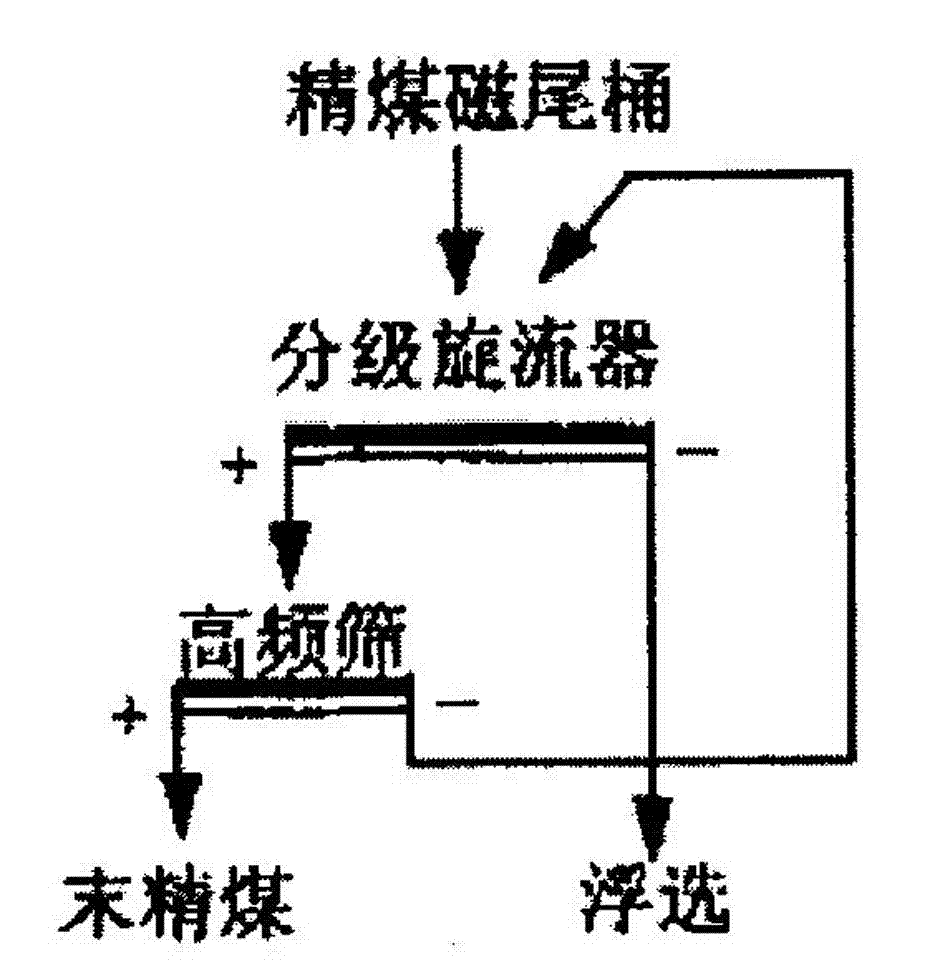

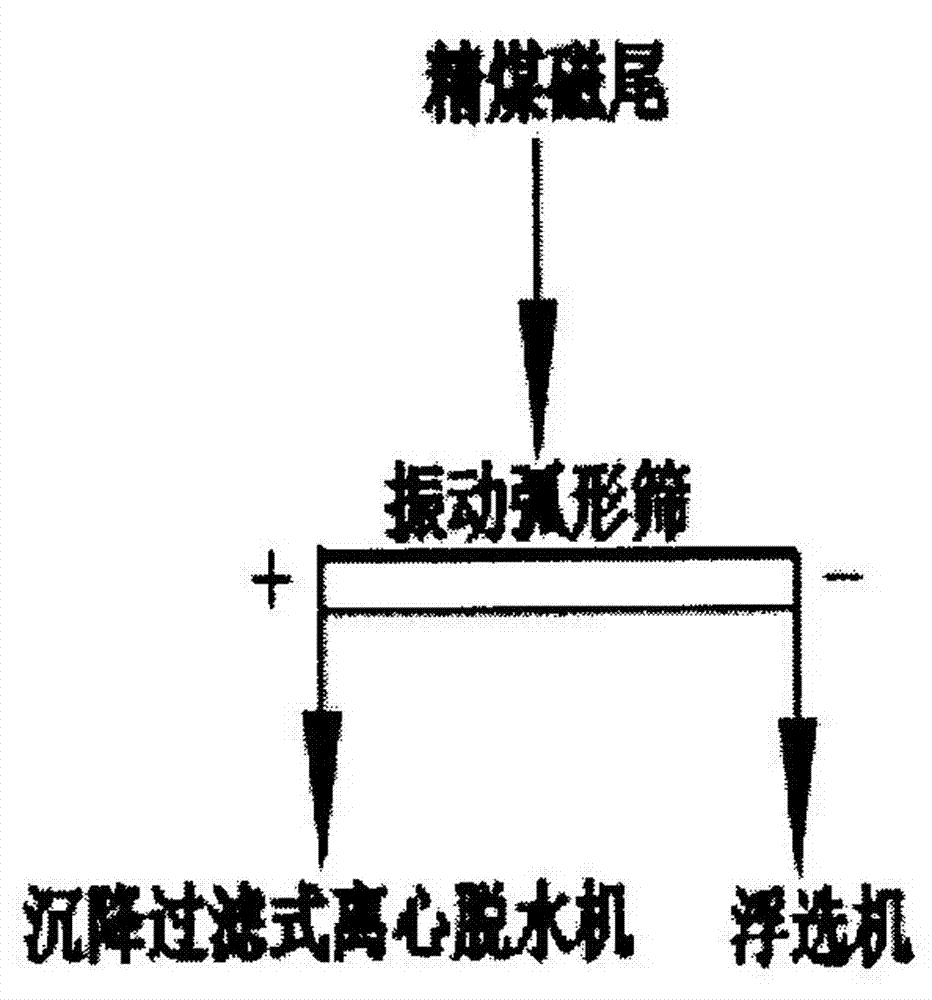

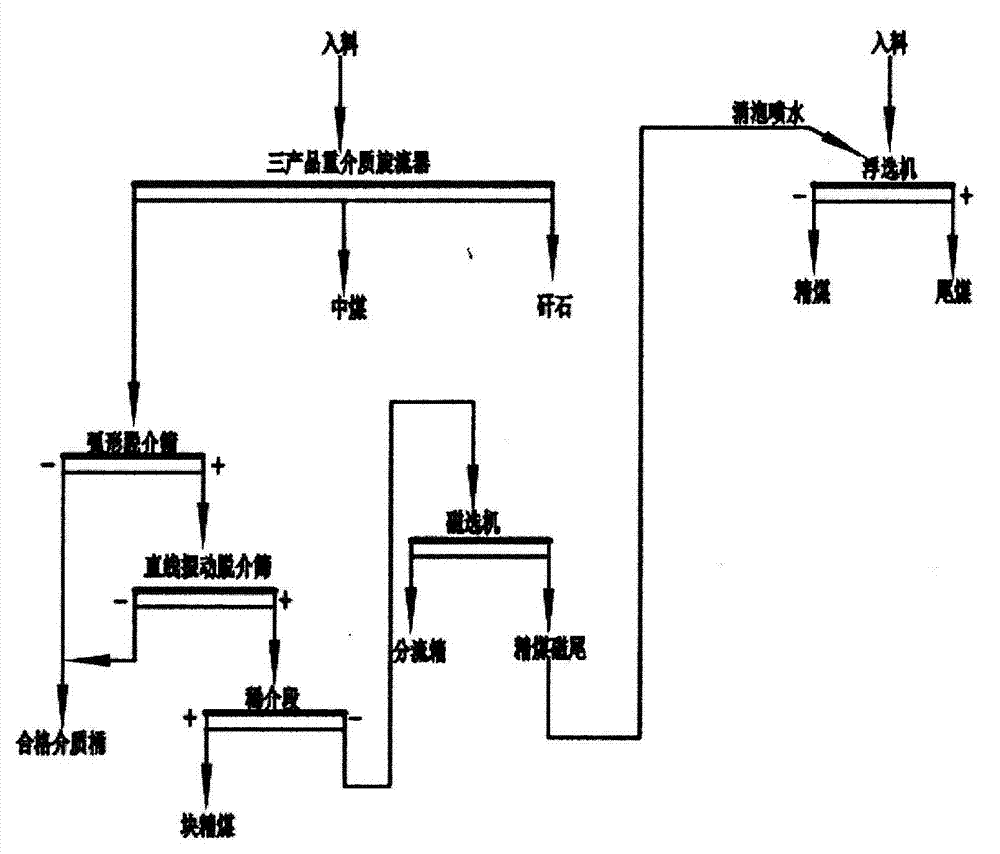

Method for using refined coal magnetic separator tailings for flotation water-spraying foam removal

InactiveCN102824955ALess investment in infrastructureImprove reliabilityWet separationCycloneMagnetic separator

The invention discloses a method for using refined-coal magnetic separator tailings for flotation water-spraying foam removal. The method provides an improvement method aiming at characteristic of first-section overflowing refined coal products of a three-product heavy-medium cyclone, which comprises the following steps of: separating, removing the medium, recycling the medium, and using the refined-coal magnetic separator tailings for the flotation water-spraying foam removal. Therefore, the method is suitable for the characteristic of the refined-coal magnetic separator tailings of the first-section overflowing refined coal products of the three-product heavy-medium cyclone, and is particularly suitable for the technical reform of the refined-coal magnetic separator tailings in a coal preparation plant in which the content of fine granular materials (-0.5mm) is high.

Owner:HENAN POLYTECHNIC UNIV

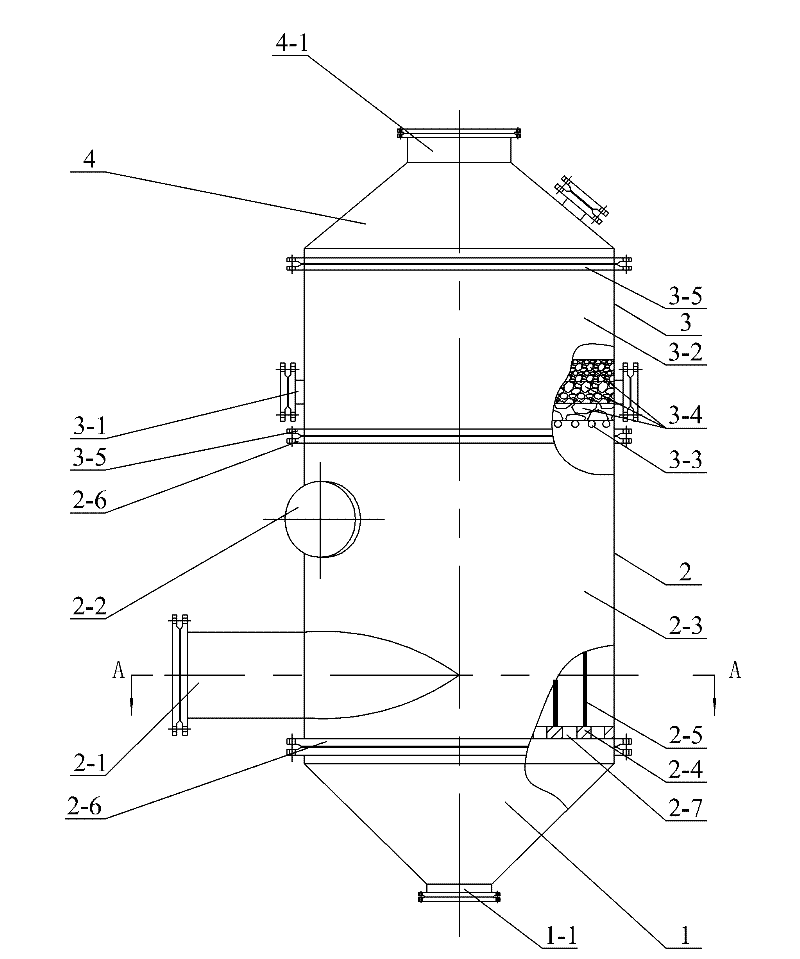

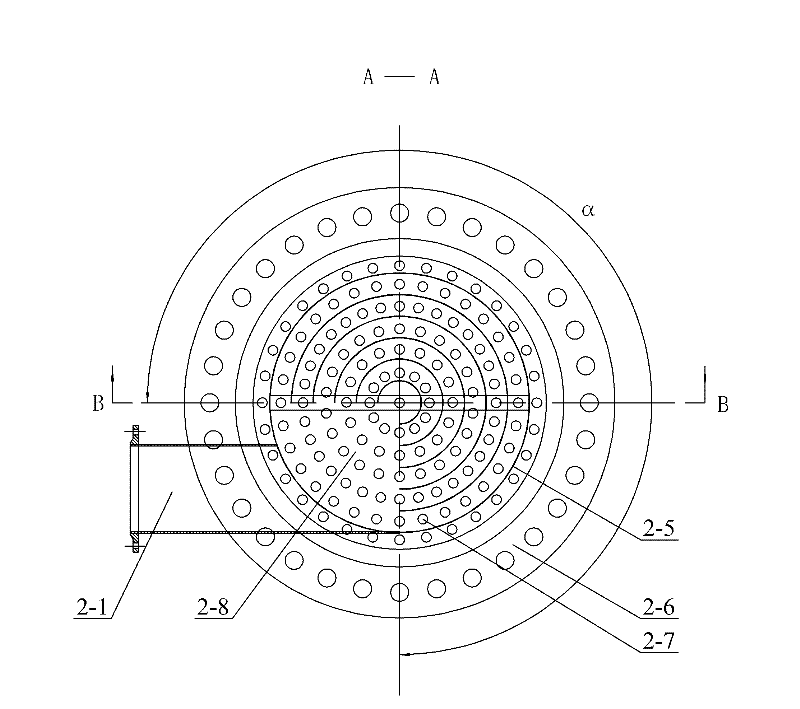

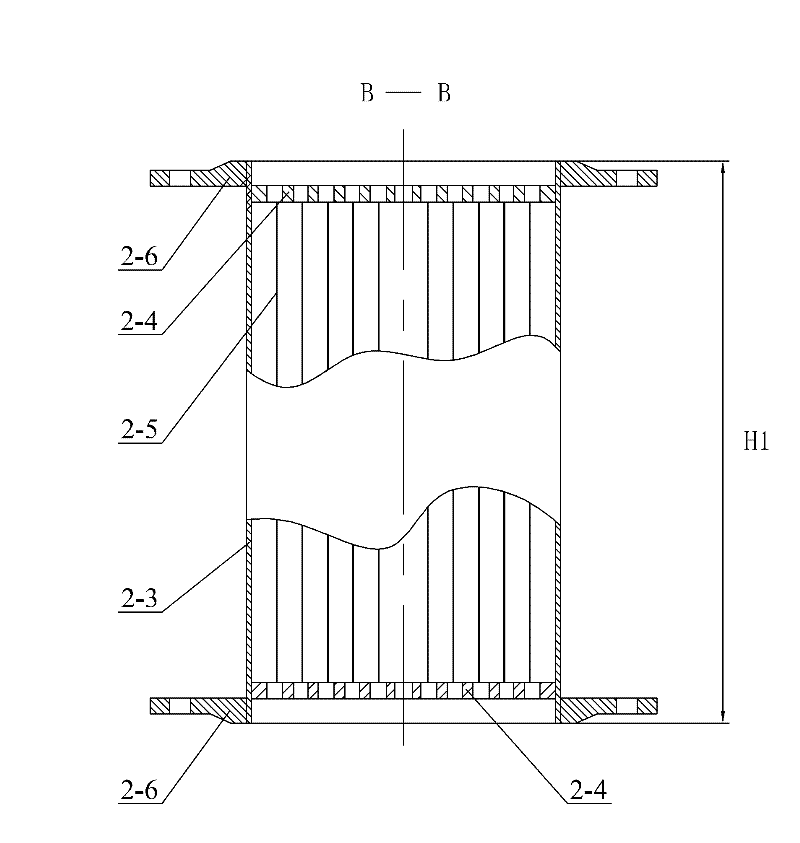

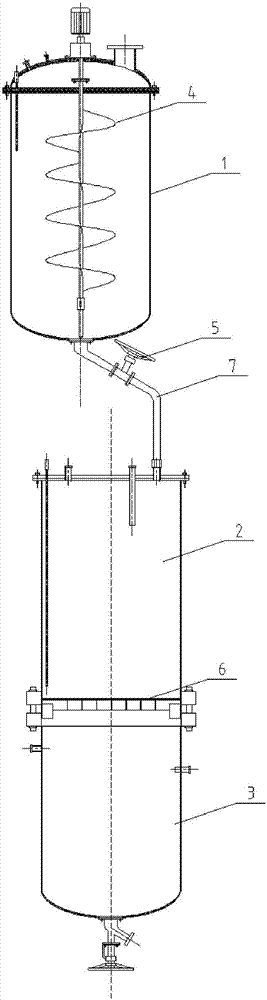

Coke oven coal gas purification apparatus

InactiveCN102344836AImprove purification effectAvoid cloggingGas purification with selectively adsorptive solidsSteelmakingRefined coal

The invention discloses a coke oven coal gas purification apparatus, and relates to a coal gas purification apparatus. In the prior art, during the steelmaking producing process, the combustion nozzle of the continuous casting blank cutter and the valve sheet of the continuous casting coal gas pressuring station compressor are generally blocked due to tar and naphthalene carbon deposition, such that the frequencies of stop production and maintenance of the continuous casting coal gas pressuring station compressor and the continuous casting blank cutter are increased. According to the apparatus, a water bucket, a first-order dehydration and decoking assembly, a second-order decoking assembly and an upper cover sequentially form a sealed connection from the bottom to up. A lower end of the water bucket is provided with a water outlet. A side wall of the first-order dehydration and decoking assembly is sequentially provided with an unpurified coal gas inlet and a first manhole from the bottom to up. A side wall of the second-order decoking assembly is provided with a second manhole. The top end of the upper cover is provided with a purified coal gas outlet. The apparatus provided by the present invention is applicable for the users using the refined coal gas and the steelmaking production using the refined coal gas.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Method for preparing high-quality middle phase asphalt by co-carbonization method

ActiveCN108485694AWide variety of sourcesLow costWorking-up pitch/asphalt/bitumen by chemical meansWide areaFiber

The invention provides a method for preparing high-quality middle phase asphalt by a co-carbonization method, and belongs to the technical field of coal tar asphalt deep processing. According to the method, a small amount of middle phase asphalt is used as additives; refined coal asphalt is used as raw materials for preparing high-quality middle phase asphalt. Firstly, the refined coal asphalt anda small number of middle phase asphalt additives are jointly put into a crushing machine to be crushed; uniform mixing is performed; next, the mixture is put into a high-temperature high-pressure reaction kettle for direct hot polymerization so as to obtain the high-purity middle phase asphalt product. The small amount of middle phase asphalt is added, so that the formation of middle phase asphalt products in the kettle is obviously accelerated, so that the temperature required by the forming of the middle phase asphalt by the refined coal asphalt is reduced; the time is shortened. The middlephase content of the obtained product is as high as 98 percent or above; the optical structure is in a wide area flow line shape; the softening point is low; the spinning performance is good. The middle phase asphalt can be used for preparing the high-end carbon materials such as high-performance carbon fiber. The method has the advantages that the process is simple; the energy consumption is low; the product is pure.

Owner:BEIJING UNIV OF CHEM TECH

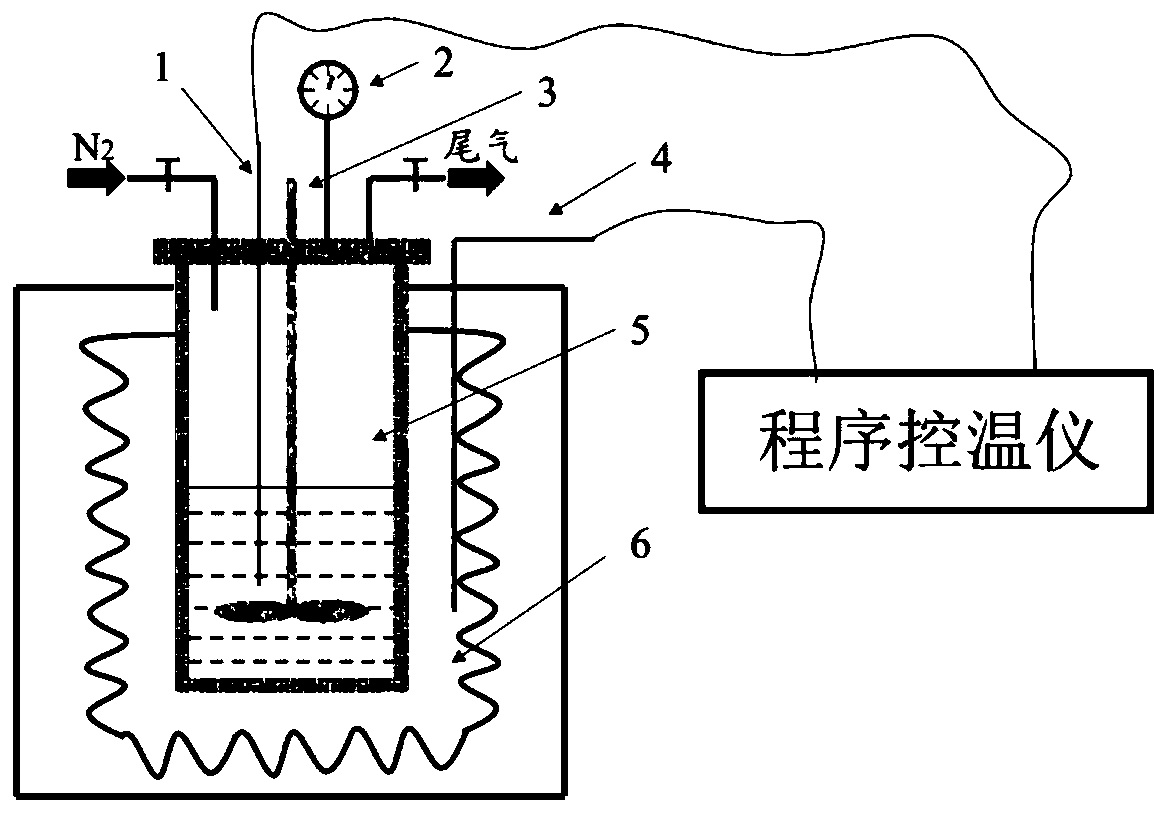

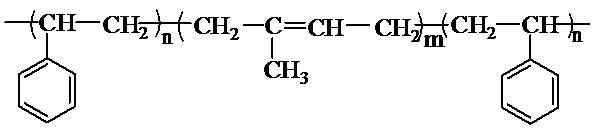

Chemical modification method of coal pitch with unsaturated thermoplastic elastomer

InactiveCN102676195AOvercoming brittlenessHigh softening pointWorking-up pitch/asphalt/bitumen by chemical meansAnti-corrosive paintsEvaporationNitrogen gas

The invention relates to a chemical modification method of coal pitch with an unsaturated thermoplastic elastomer SBS (styrene-butadiene-styrene block polymer), which comprises the following steps: mixing coal pitch and an organic solvent, stirring at room temperature for 3 hours, standing, filtering, concentrating the mother liquor by evaporation, and drying to obtain the refined coal pitch; heating the refined coal pitch to 80 DEG C in a nitrogen atmosphere, and starting stirring; continuing heating to 90-110 DEG C, and adding a 100-mesh styrene unsaturated thermoplastic elastomer, namely SBS of styrene monomer and butadiene monomer; and heating to 130-170 DEG C at the rate of 2 DEG C / minute until granules in the unsaturated thermoplastic elastomer basically disappear in the coal pitch substrate, adding a catalyst, such as boron trifluoride (BF3) or the like, and reacting to obtain the SBS-chemically-modified coal pitch. The modified coal pitch overcomes the brittleness in coal pitch, enhances the softening point of the coal pitch, and basically satisfies the performance requirements for coal pitch for high-grade highways or anticorrosive paint; and thus, the waste coal pitch is changed into valuable substances.

Owner:徐国财

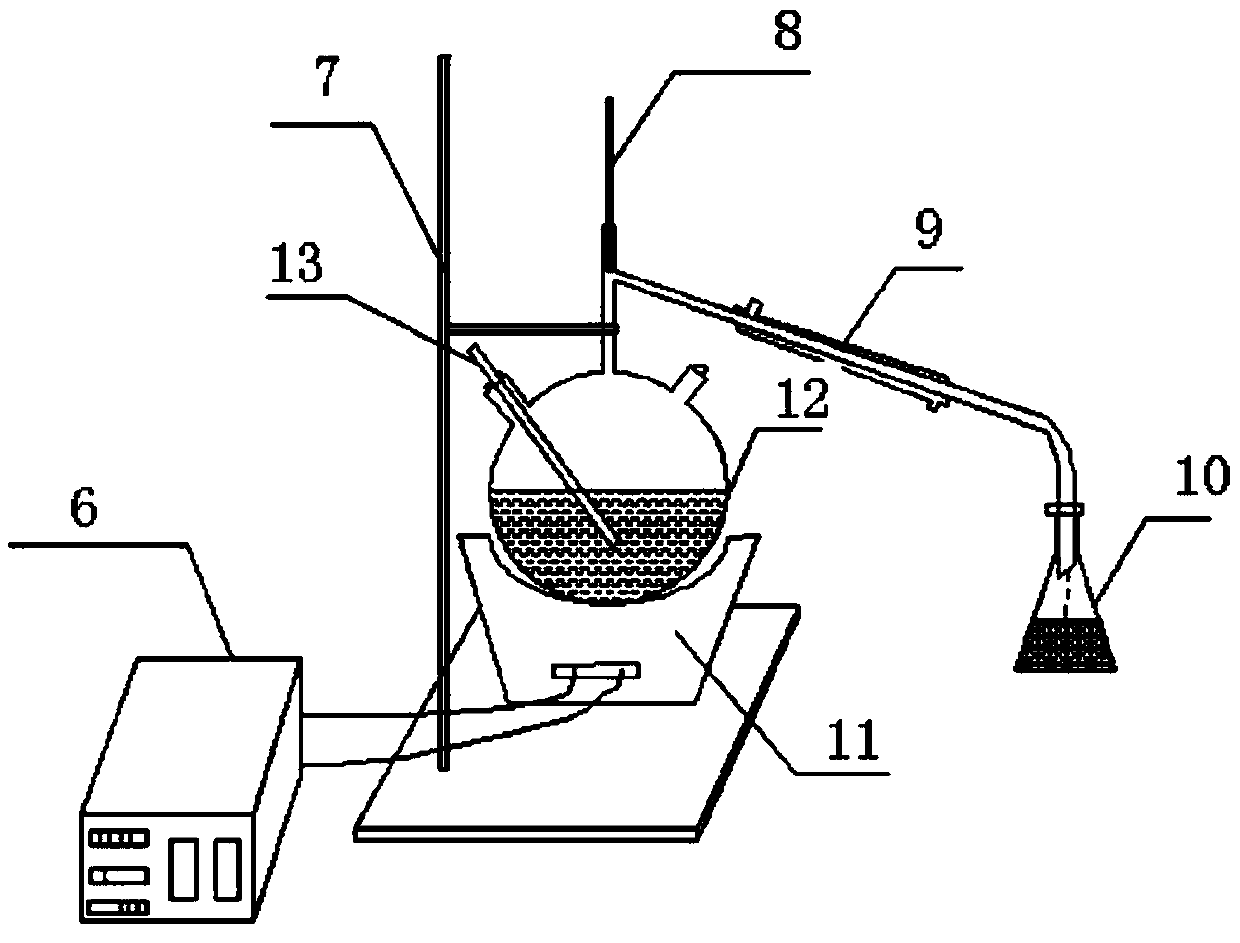

Coal pitch refining method used for synthesizing mesophase pitch

ActiveCN108102679AMolecular weight controllableMeet the requirements of high value-added productsWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingDistillationSolvent

The invention relates to a coal pitch refining method used for synthesizing mesophase pitch. The coal pitch refining method used for synthesizing mesophase pitch comprises following steps: coal pitchis smashed and sieved, a mixed solvent A is added into coal pitch, an obtained mixture is stirred, is allowed to stand, and is subjected to layering so as to obtain an upper layer which is a mixed solution A of the mixed solvent A and coal pitch, and a lower layer which is an impurity mixture containing coal powder coke particles; the upper layer mixed solution A is subjected to filtering and distillation for recovery of the mixed solvent A so as to obtain crude coal pitch; a mixed solvent B is added into the crude coal pitch, and stirring, standing, and layering are carried out so as to obtain an upper layer which is a mixed solution B of the mixed solvent B and refined coal pitch, and a lower layer which is a heavy asphalt impurity mixture; the upper layer mixed solution B is subjected to filtering and distillation for recovery of the mixed solvent B so as to obtain refined coal pitch can be used for synthesizing mesophase pitch. The coal pitch refining method is capable of realizingseparation of coal pitch effective components with impurities such as coal powder coke particles under normal pressure conditions, the obtained refined coal pitch can be taken as a high grade carbonmaterial raw material, and the requirements of subsequent high added value product production are satisfied.

Owner:SHANDONG RUICHENG AEROSPACE CARBON MATERIAL CO LTD

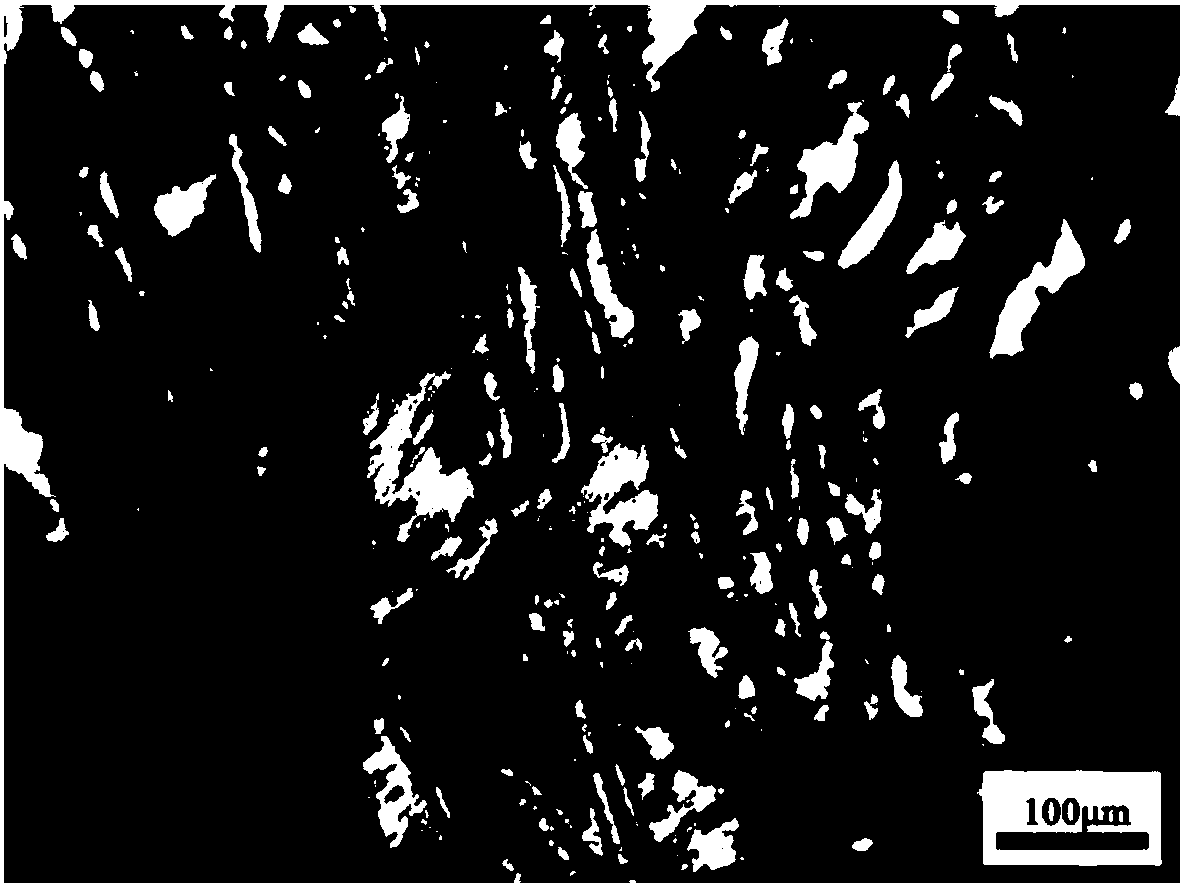

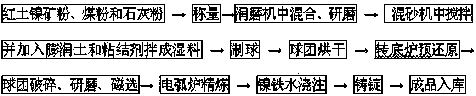

Method for producing high quality ferronickel

The invention relates to ferronickel, and particularly relates to a method for producing high quality ferronickel. According to the method, red soil nickel mineral powder, refined coal dust and lime powder are taken as the main raw materials, and the high quality ferronickel is prepared through a series of steps of burdening, weighing, mixing, adding adhesive, pressing into pellets, drying, sieving, pre-reducing in a rotary hearth furnace, cooling metallized pellets, crushing, ball milling, magnetic separating, briqutting, smelting in an electric-arc furnace, slagging and dephosphorizing, desulfurizing and pouring. The detection shows that the ferronickel comprises 20-30wt% of Ni, 0.2-0.5wt% of C, less than or equal to 0.015wt% of S, less than or equal to 0.03wt% of P, and less than or equal to 0.3wt% of Si, thus being the high quality raw material for producing stainless steel, wear-resistant steel and heat-resisting cast iron.

Owner:JIANGSU UNIV

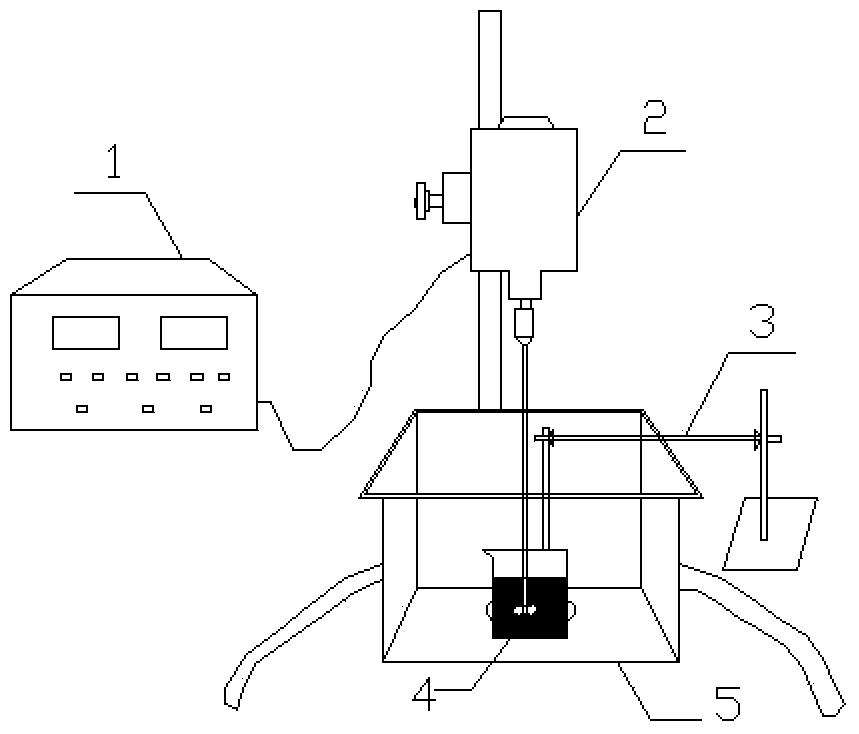

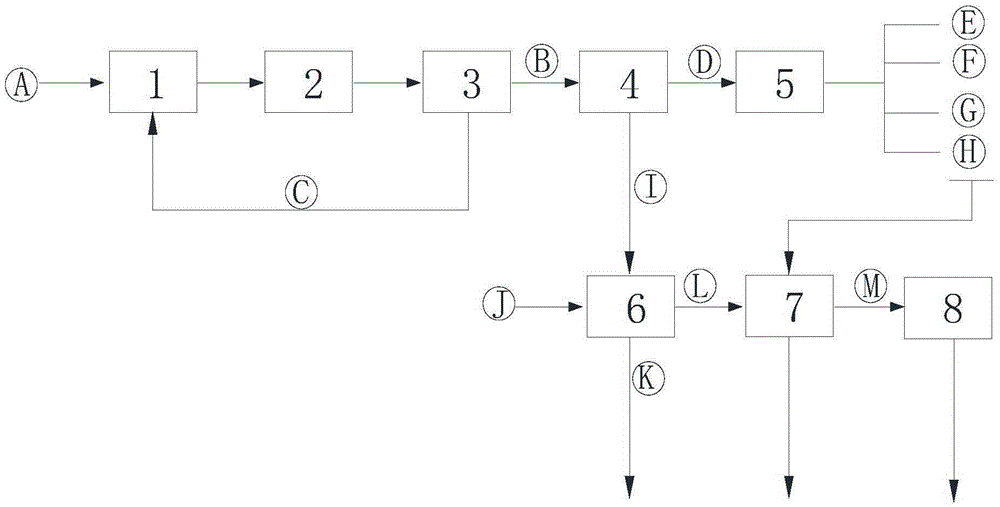

Method for preparing mesophase pitch by utilizing mesotherm coal pitch

ActiveCN107163969ALow ash contentSimple structureWorking-up pitch/asphalt/bitumen by chemical meansTar working-up by chemical refiningMetallurgyReaction temperature

The invention discloses a method for preparing mesophase pitch on the basis of mesotherm coal pitch used as a raw material. The method comprises the following steps: firstly, performing preheating polycondensation reaction, precise heat filtering and cutting light component treatment on the mesotherm coal pitch, thereby acquiring refined coal pitch with ultralow quinoline insoluble content, and then performing heating polycondensation reaction for 1-10h on the refined coal pitch under the reaction temperature of 400-460 DEG C, pressure of 3-5MPa and stirring speed of 50-500r / min, thereby acquiring the mesophase pitch. According to the invention, an integrated device is adopted for simultaneously completing the operations, such as, heating polycondensation and heat filtering and is assisted by simple light component cutting and drying technologies to prepare high-quality mesophase pitch; the production technology is simplified; the production cost is lowered; the yield of the acquired mesophase pitch is within 10-30%; the pitch is low in ash content and has an excellent optical tissue structure.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

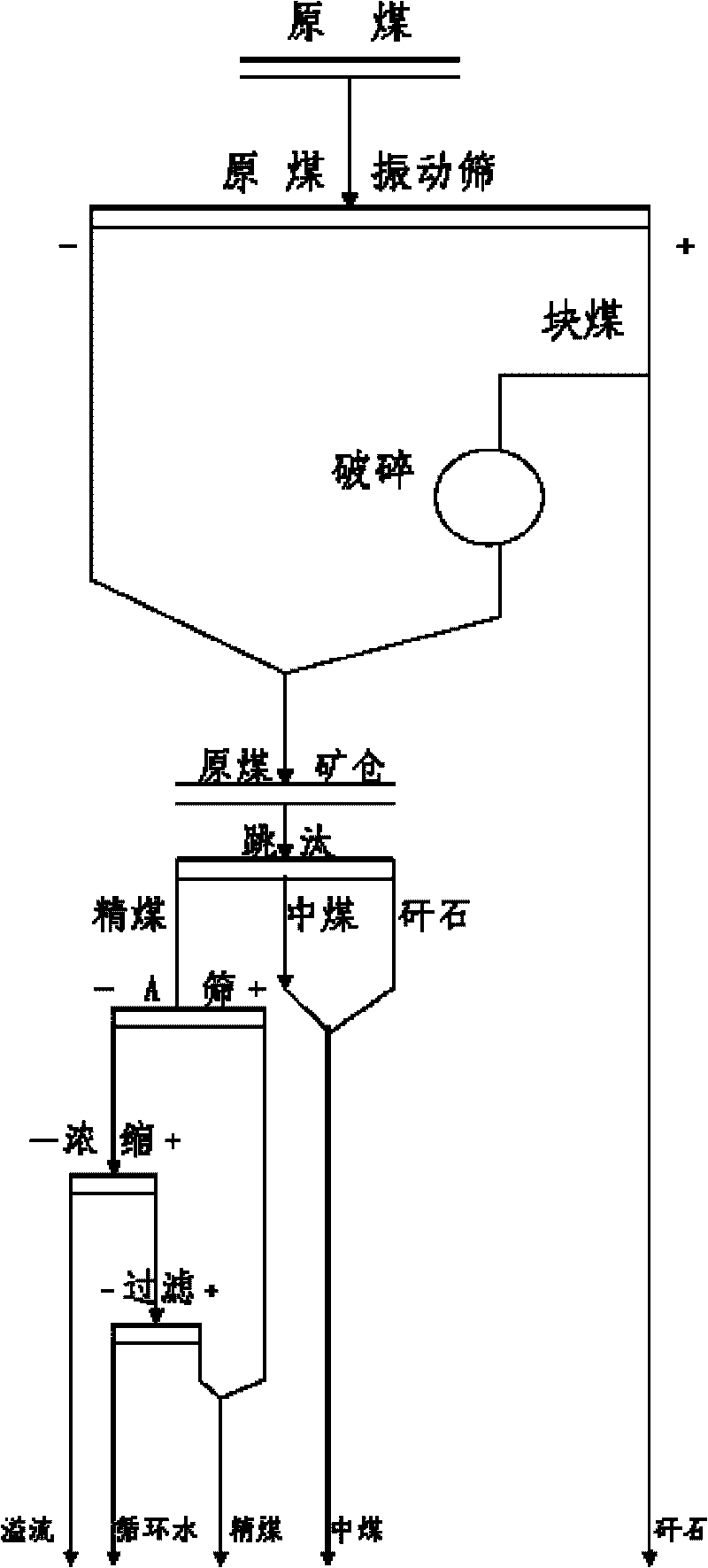

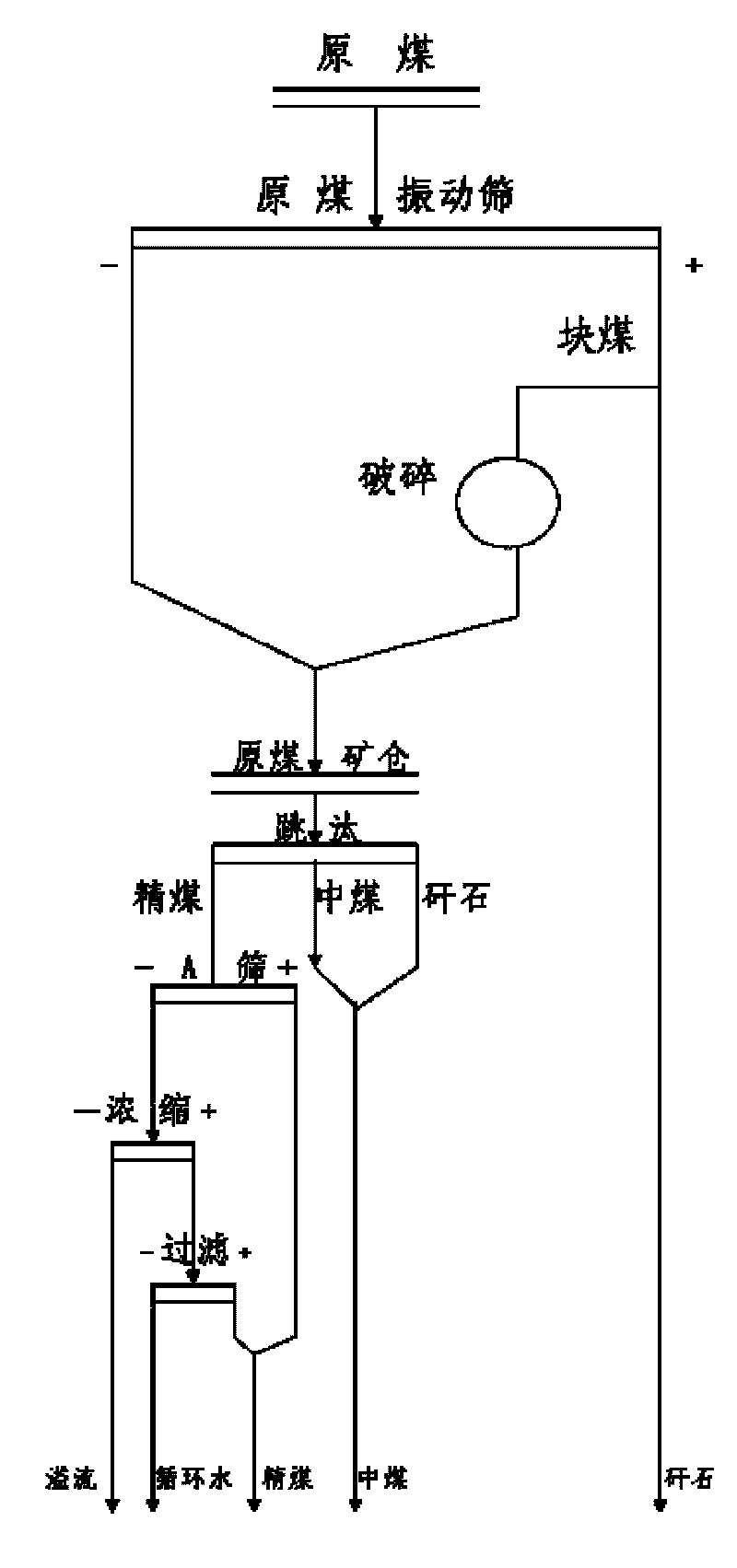

Coal dressing method

ActiveCN105402998AHigh calorific valueReduce sodiumDrying solid materials with heatGranular material dryingHigh sodiumCombustion

The invention relates to the field of coal upgrading and discloses a coal dressing method. The method comprises the following steps: sending high-sodium coal to a microwave upgrading and sodium removing unit (4) for removing sodium; outputting sodium-removed coal by using the microwave upgrading and sodium removing unit (4); sending the microwave upgrading and sodium removing unit (4) to a coal washing unit (5) for dressing by washing; sending refined coal output by the coal washing unit (5) to a refined coal bunker (7); supplying hot air to the refined coal bunker (7) by air and dehumidified steam which comes from the microwave upgrading and sodium removing unit (4) after the air and the dehumidified steam pass through a condensing heat exchanger (6); drying the refined coal by using the hot air. By adopting the coal dressing method provided by the invention, sodium in the coal can be removed, water in the coal can also be removed, harms caused by combustion of sodium element in the coal can be reduced, and the calorific value of the coal is increased as well.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Combined technological method for producing needle coke from coal tar

ActiveCN108102708AImprove performanceImprove natureTreatment with hydrotreatment processesLiquid productGasoline

The invention provides a combined technological method for producing needle coke from coal tar. The combined technological method comprises following steps: coal tar after a coal tar raw material is pretreated enters a boiling-bed reactor, after a reaction, a liquid product obtained through separation is subjected to fractional distillation, a light component and a heavy component are obtained, and the light component is mixed with the coal tar raw material; the heavy component enters a coking device and is subjected to a coking reaction, and after separation, gas, coked gasoline, coked diesel, coked gas oil and needle coke are obtained. The refined coal tar raw material obtained with the method has the advantages of low quinoline insoluble content, low S and N impurity content and the like, and the produced needle coke has the advantages of low coefficient of thermal expansion, low sulfur content, low ash content and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

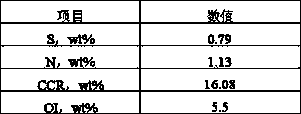

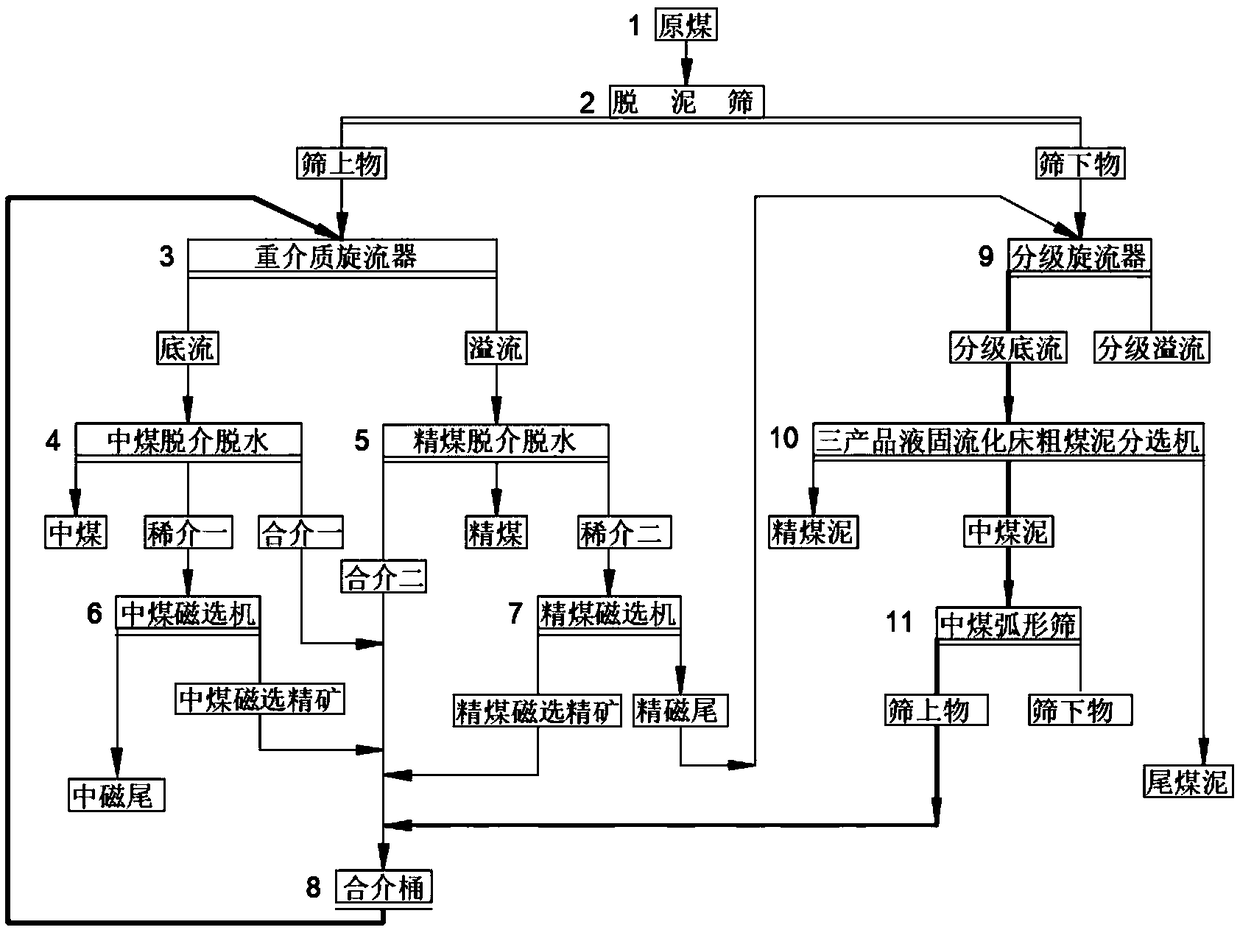

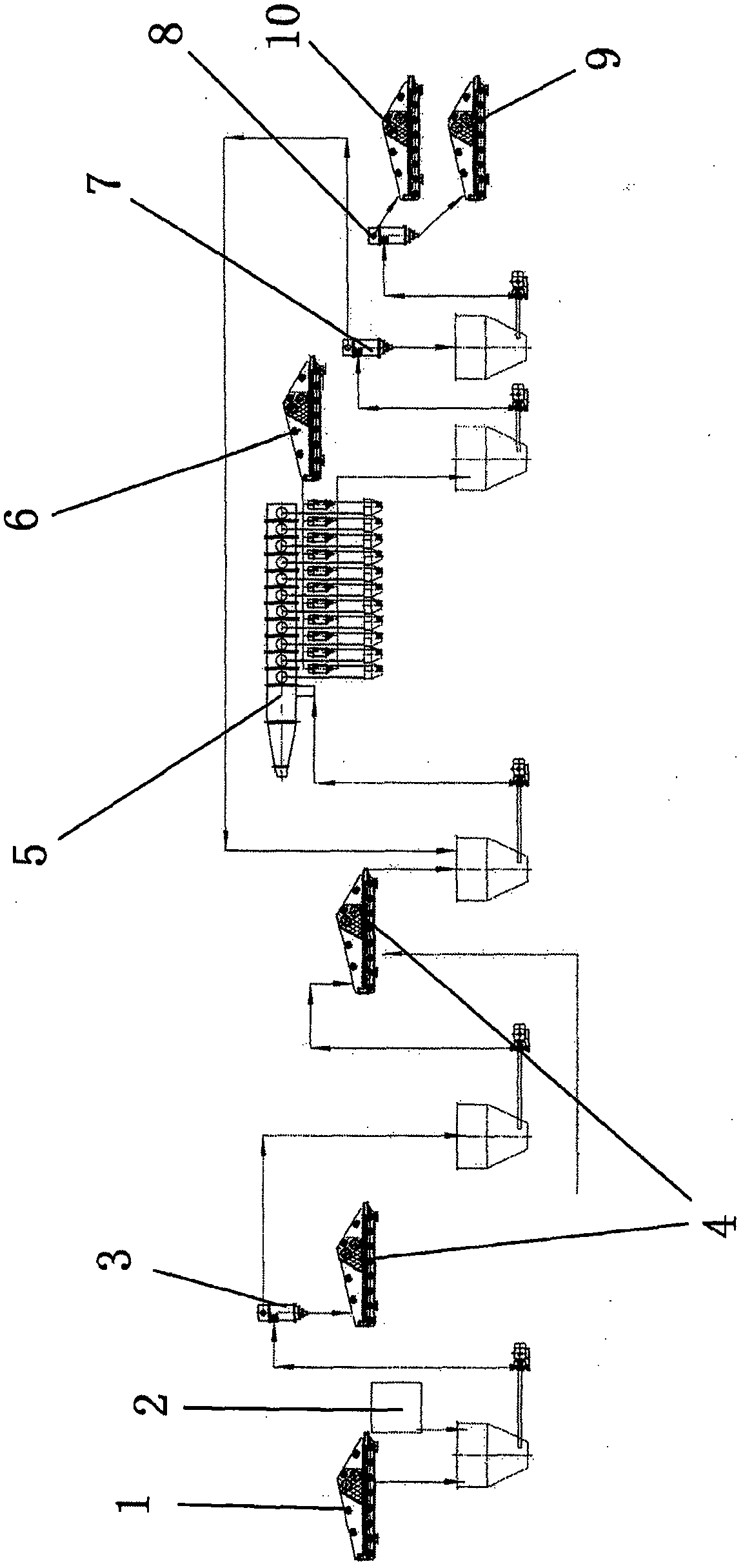

Liquid-solid fluidizing bed coarse slime sorting system of three products and process of system

ActiveCN109225611AHigh recovery rateThe solution cannot be guaranteed at the same timeWet separationCycloneProcess engineering

The invention discloses a liquid-solid fluidizing bed coarse slime sorting system of three products and a process of the system. An object screened out by a desliming screen enters a classified cyclone device, a bottom stream of the classified cyclone device enters a liquid-solid fluidizing bed coarse slime sorting machine of the three products for sorting, refined coal slime, tail coal slime andintermediate coal slime are generated after sorting, dewatering of the intermediate coal slime is completed through an intermediate coal slime sieve, an object screened out by the intermediate coal slime sieve enters a medium combining barrel, and a material in the medium combining barrel is pumped into a heavy medium cyclone device for sorting. By means of the process, the coarse coal slime whichis difficult to sort can be sorted, and meanwhile, the feeding grain size range can be expanded. The problem that the quality of the refined coal slime and tail coal slime in existing coarse coal slime sorting processes cannot be ensured at the same time is solved, and by pumping the intermediate coal slime into the heavy medium cyclone device with high sorting precision for resorting, the recovery rate of refined coal is increased.

Owner:CHINA UNIV OF MINING & TECH

Integrated process technology of whitening, shaping and modifying natural powdery quartz

InactiveCN107033633AGood effectSignificant energy savingsChemical industryPigment treatment with macromolecular organic compoundsSodium carbonateRefined coal

The invention discloses an integrated process technology for whitening, shaping and modifying natural powdery quartz, and belongs to the technical field of nonmetallic mineral further processing. The technology includes the steps that after raw powdery quartz ore is preliminarily selected, coarsely crushed, pulverized, graded, doped, calcined, scattered and modified, super-white and superfine active torispherical silica micro powder products are obtained. Dopant is composed of charcoal (or refined coal) and sodium chloride (or sodium carbonate), the dosage of charcoal (or refined coal) is 1-3% of the weight of power materials, the dosage of sodium chloride (or sodium carbonate) is 0.5-2% of the weight of the power materials, the calcination temperature is 900-1300 DEG C, and the heat-insulation time is 1-6 hours. By the adoption of the integrated process technology for whitening, shaping and modifying the natural powdery quartz, the white degrees of the products reach 92-98%, the content of SiO2 is 99.0-99.9%, the content of Fe2O3 is smaller than 0.1%, the fitness reaches 325-3000 mesh, and the shapes of granules is torispherical. The super-white and superfine active torispherical silica micro powder products can be massively used in the industrial fields of electronic and electrical materials, interior and exterior wall paint, fire resistant materials, polishing materials, plastic, rubber, adhesives and the like.

Owner:HUNAN JINMA NEW MATERIAL TECH CO LTD

Grading method for recovering refined coal from coal slime

The invention relates to a method for recovering refined coal from coal slime, in particular to a grading method for recovering the refined coal from the coal slime. The method has the technical key points that by using a spiral classifier and the principle that 'sedimentation velocity in the liquid is different due to different particle sizes and specific gravities' of solid particles, the method realizes the separation between relatively high ash component and relatively low ash component by gravity classification; and 25-35% of plus sieve low ash refined coal with larger particle size can be recovered from the relatively high ash component, and 30-40% of minus sieve high ash coal slime with smaller particle size can be removed from the relatively low ash component. Through twice classification, the aim of 'removing the relatively high ash component in the coal slime' can be achieved. The embodiment of the invention can be used for recovering the refined coal from the coal slime, thus achieving the aim of reducing the ash content of the refined coal and meeting the demand of the user.

Owner:ZIBO WANGZHUANG COAL MINE

Method for selecting coal by using water medium swirler

The invention relates to a method for selecting coal by using a water medium swirler. Raw coal is classified by a grading sieve, materials above 3 mm are crushed to be less than 3 mm through a crusher, the raw coal is subjected to water injection mixing under the grading sieve of 3 mm or less, and enters a high-frequency linear vibrating screen for desliming and grading, and after grading, materials which are larger than 0.063 mm enter a water medium gangue discharge cyclone to remove gangue, the underflow materials enter the gangue dewatering screen, the oversize products are gangue, are conveyed into a gangue field, and then enter an inner circulating water system to be recycled again, the overflow materials enter a final coal coarse slime grading sorting unit, the separated overflow materials enter a clean coal dewatering screen, the oversize products are refined coal and enter a clean coal field, the sieved water enters the inner circulating water system to be recycled again, the separated overflow materials enter the tail coal coarse coal slime unit to be sorted again, and the overflow materials of the waste rock swirler in the water medium is dehydrated through a middling coal dewatering screen; and the materials on the sieve are middling coal and are sent into a middling coal field, and the sieved water enters an inner circulation water system to be recycled.

Owner:山西世纪新龙腾科技有限公司

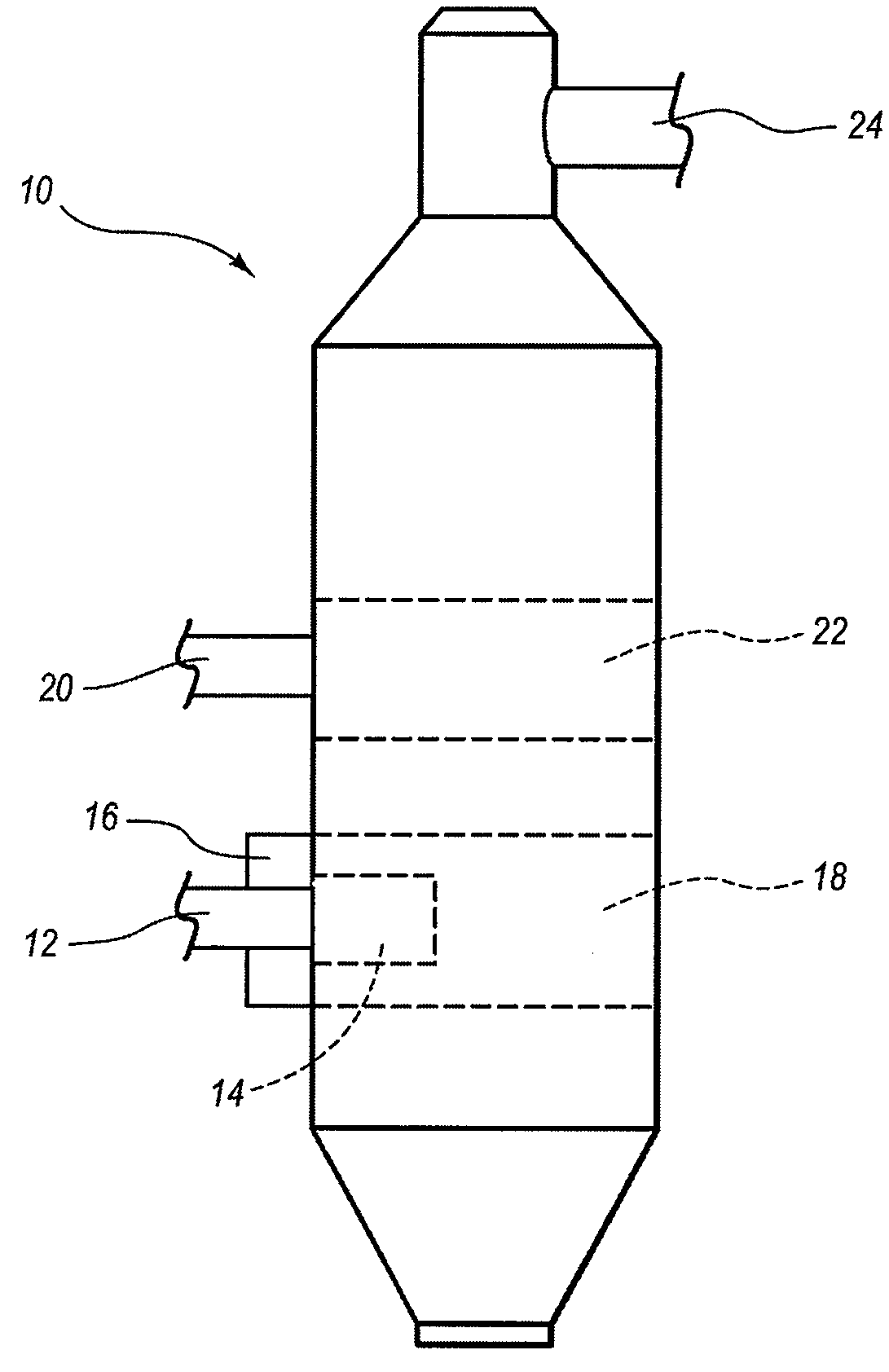

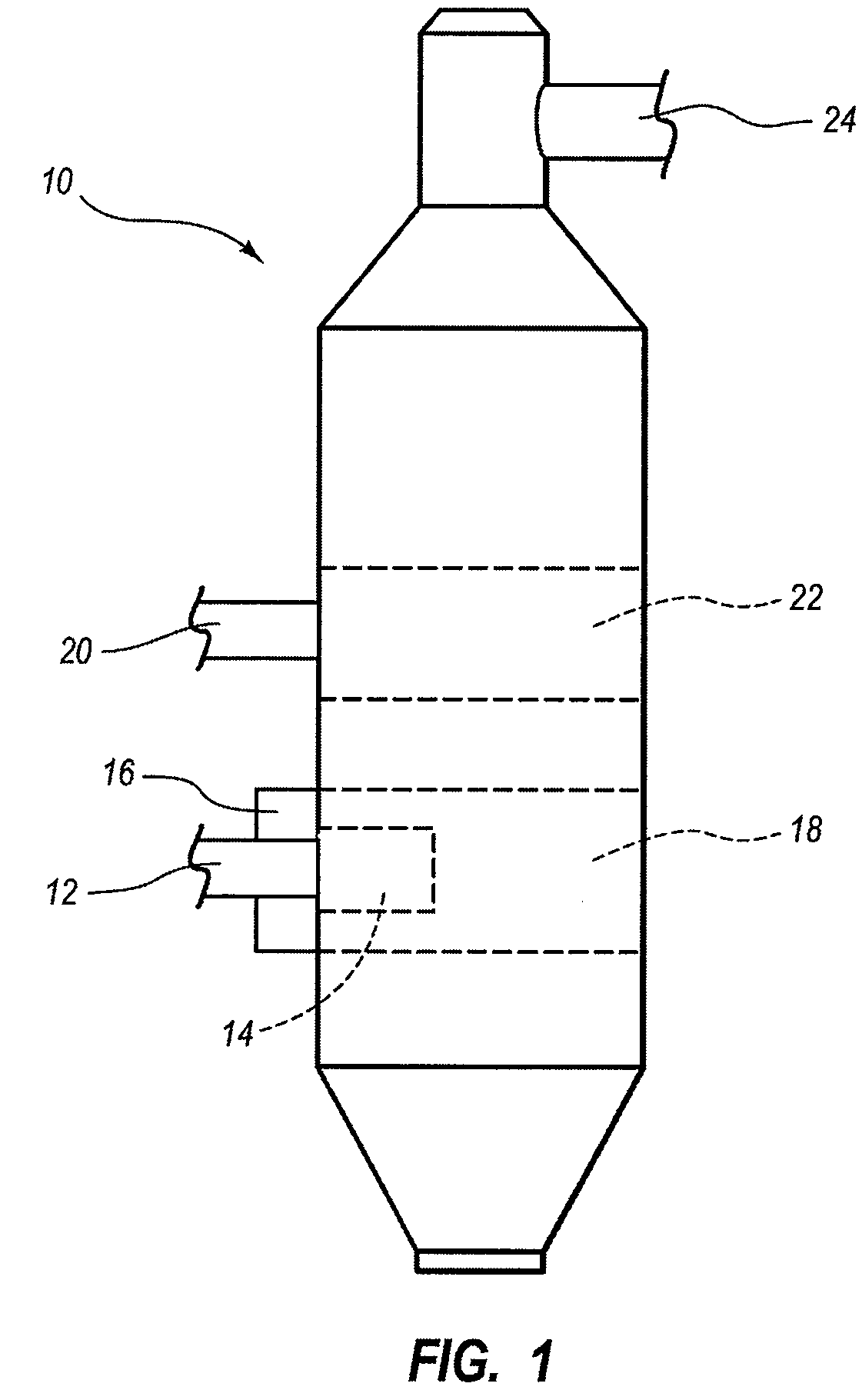

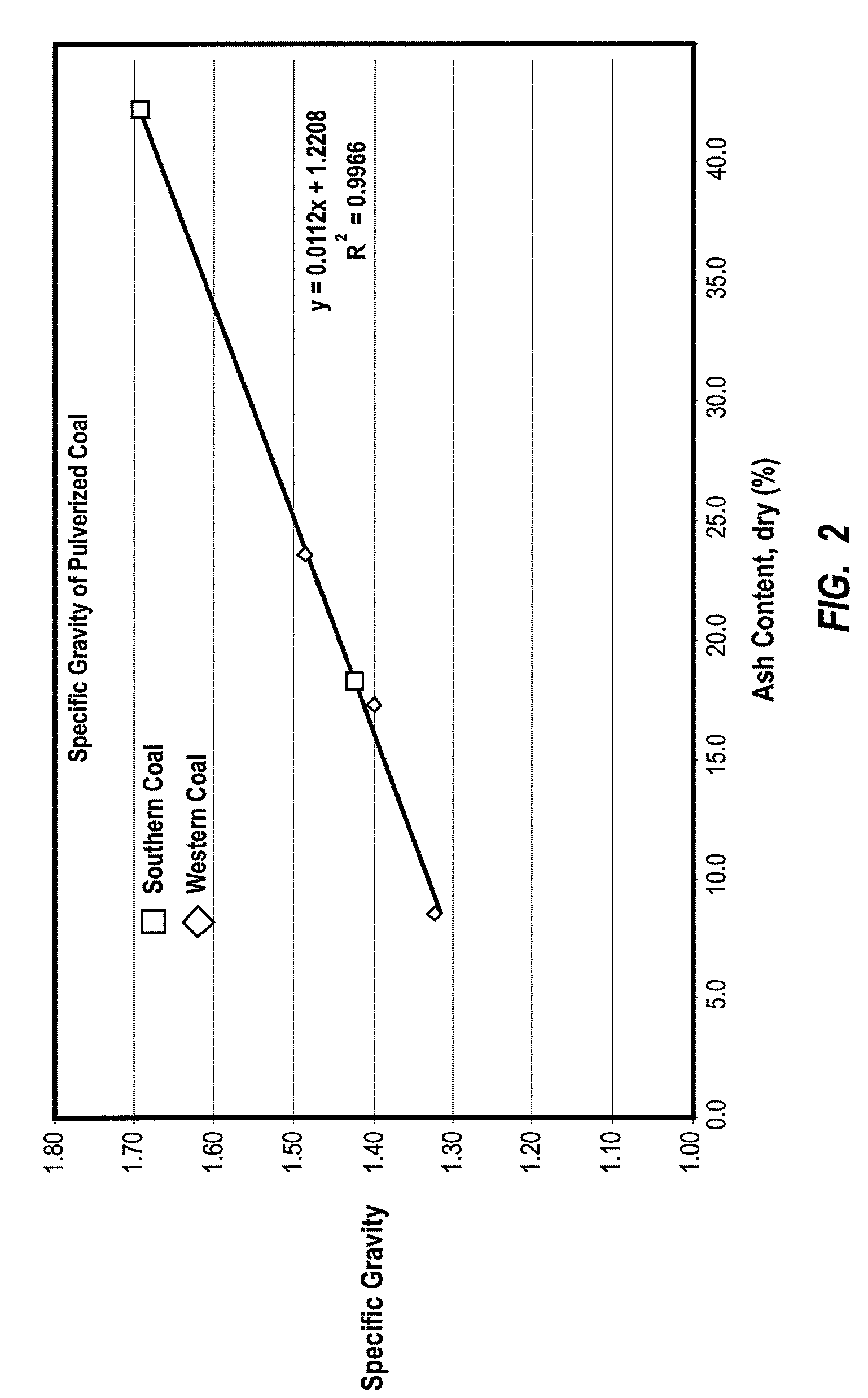

METHOD FOR REDUCING NOx DURING COMBUSTION OF COAL IN A BURNER BY OPTIMIZING COMBUSTION AIR FLOW

InactiveUS20100024698A1Reduce outputLow ash contentAir supply regulationSolid fuelsCombustorNitrogen

An initial coal feedstock comprised of primary or second coal is cleaned so as to reduce its ash content by at least about 20% in order to yield a refined coal product that produces fewer NOx emissions. The reduced NOx emissions result primarily from the ability to use less primary combustion air in order to maintain the pulverized refined coal in a suspended condition within the feeder pipes of a coal burner compared to the minimum quantity of air required to maintain pulverized coal from the initial coal feedstock in a suspended condition within the feeder pipes. Reducing the primary combustion air reduces the amount of oxygen in the primary combustion zone that would otherwise be available for converting fuel nitrogen into NOx. Instead, more of the fuel nitrogen is converted into N2. Reducing the primary combustion air also reduces the temperature of the core flame, reducing thermal NOx formation. Increasing the amount of secondary and / or tertiary combustion air to compensate for the reduced primary combustion air results in an overall decrease in NOx formation, as thermal NOx formation is reduced as combustion is completed in the cooler secondary and / or tertiary combustion zones.

Owner:HEADWATERS ENERGY SERVICES CORP

Waterless separator of high-sulfur coal and low-sulfur coal gangue blocks and sulfur blocks

InactiveCN101934274AHigh recovery rateReduce energy consumptionSortingLow energy photonsDelivery system

The invention belongs to the technical field of coal separation, and particularly relates to a waterless separator of high-sulfur coal and low sulfur coal gangue blocks and sulfur blocks. The waterless separator comprises a raw coal screening graded feed system, an elastic double-flange coal conveyor, a high-sulfur coal gangue block and sulfur block separating system, a low-sulfur conveying electronic weighing scale, a high-sulfur coal gangue block and sulfur block conveying system, an electric variable frequency speed regulating system, a programmable control type electric appliance interlocking device, a photoelectric conversion and electronic pulse filter, a detecting head shielded chamber, a 238 Pu low-energy photon source and a probe. The photoelectric conversion and electronic pulsefilter, the probe and the 238 Pu low-energy photon source form an online recognition separation detecting system of 238 Pu type coal sulfur and ash to waterlessly separate the high-sulfur coal blocks, the gangue blocks and the sulfur blocks in raw coal blocks and obtain low-sulfur low-ash refined coal, and no slime water is generated to pollute the environment, thereby greatly reducing the coal separation energy consumption and the coal separation cost.

Owner:HUNAN BILV EP IND DEV

Method for removing metal from coal tar at low pressure

ActiveCN103725324ARaw materials are simpleHigh metal capacityTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a method for removing metal from coal tar at low pressure, which mainly solves the problem that the content of metal in all fraction of coal tar is generally higher than 200mu g / g, which highly restricts the operational cycle of a main hydrogenation unit. The method comprises steps of firstly mixing coal tar with hydrogen; then allowing the mixture to enter a fixed bed hydrogenation reactor from the top for hydrorefining reaction, wherein the fixed bed hydrogenation reactor is at least filled with a hydrogenation protective catalyst, which comprises a first protective catalyst, a second protective catalyst and a third protective catalyst which are sequentially filled from top to bottom, the reaction pressure for hydrorefining reaction is 2.8-8.5MPa; then carrying out gas-liquid separation on effluent of the fixed bed hydrogenation reactor so as to obtain the refined coal tar containing less than 2mu g / g of total metal. According to the method, the reaction is carried out at lower operation pressure, and the refined coal tar containing less than 2mu g / g of total metal is produced through hydrogenation at low pressure.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

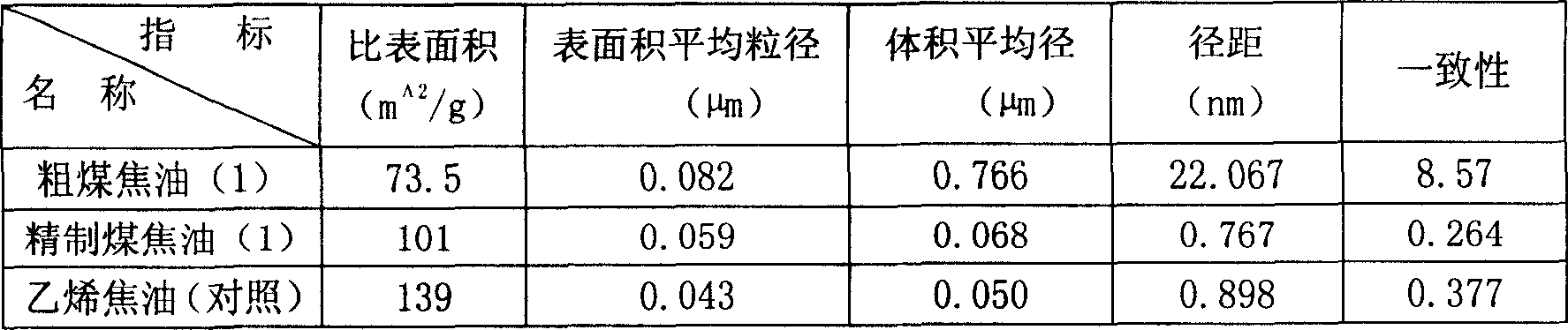

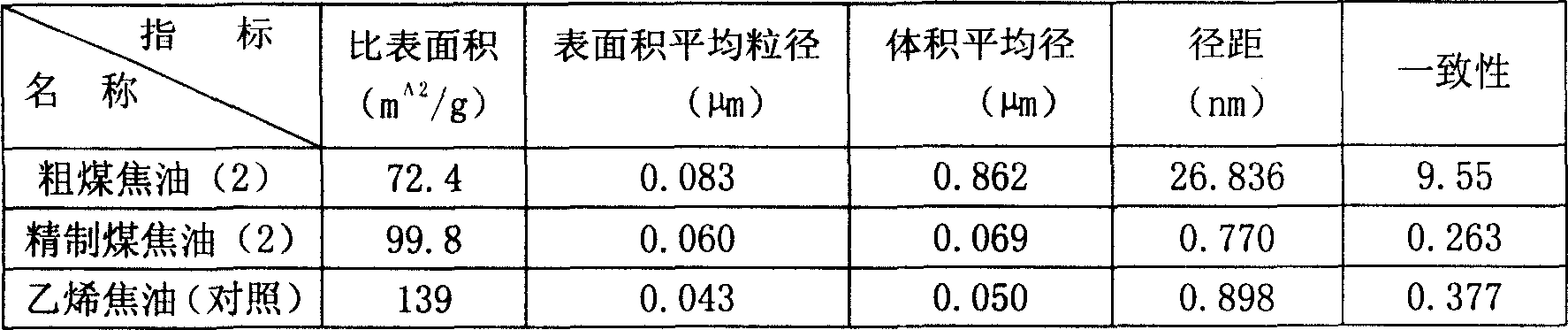

Process for purifying feedstocks of carbon black

The invention discloses a process for purifying feedstocks of carbon black which mainly comprises, charging forward dissolvent comprising benzene, toluene and alpha-methylnaphthalene or beta-methylnaphthalene into crude coal tar, wherein the weight ratio of the crude coal tar and the forward dissolvent is 1:0.1-3, after 0.5-1 hour, charging backward dissolvent comprising aminoethyl alcohol, propanone, alcohol isopropylicum and phenylethene into the miscible liquid of the crude coal tar and the forward dissolvent, wherein the weight ratio of the crude coal tar and the backward dissolvent is 1:0.05-0.5, at the temperature of 10-60 deg. C, pressure 0.1-0.1Mpa, sustaining 0.5-2 hours, carrying out solid-liquid separation to obtain the refined coal tar.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Preparation method of rubber and plastic filling agent

The invention discloses a preparation method of a rubber and plastic filling agent. The preparation method comprises the steps of 1) refining coal dust; 2) configuring a modifier; and 3) preparing the rubber and plastic filling agent: mixing the refined coal dust and the modifier, stirring and drying to obtain the rubber and plastic filling agent. According to the filling agent prepared by the processes of mixing, drying and the like, the preparation process is simple, the operation is easy, the filling agent can replace carbon black in common industries, and is superior to common carbon black in the aspects of electrical property, impact property, processing property and the like.

Owner:XIAN UNIV OF SCI & TECH +1

Asphalt resin binder

The invention discloses an asphalt resin binder which is prepared by condensation of refined coal tar and phenolic aldehyde under the catalysis action of an inorganic acid. Compared with an existing asphalt resin binder, the asphalt resin binder has the advantages the used raw materials are low in price and easy to available, the softening point of the asphalt resin binder is low, and the content of a quinoline insoluble is low; compared with phenolic resin, the asphalt resin binder is higher in carbon residue; and the specific surface area of the carbon residue is smaller, and thus the asphalt resin binder is an excellent carbon material binder.

Owner:SHAANXI NORMAL UNIV

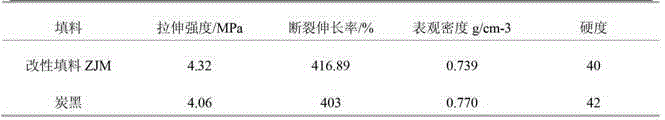

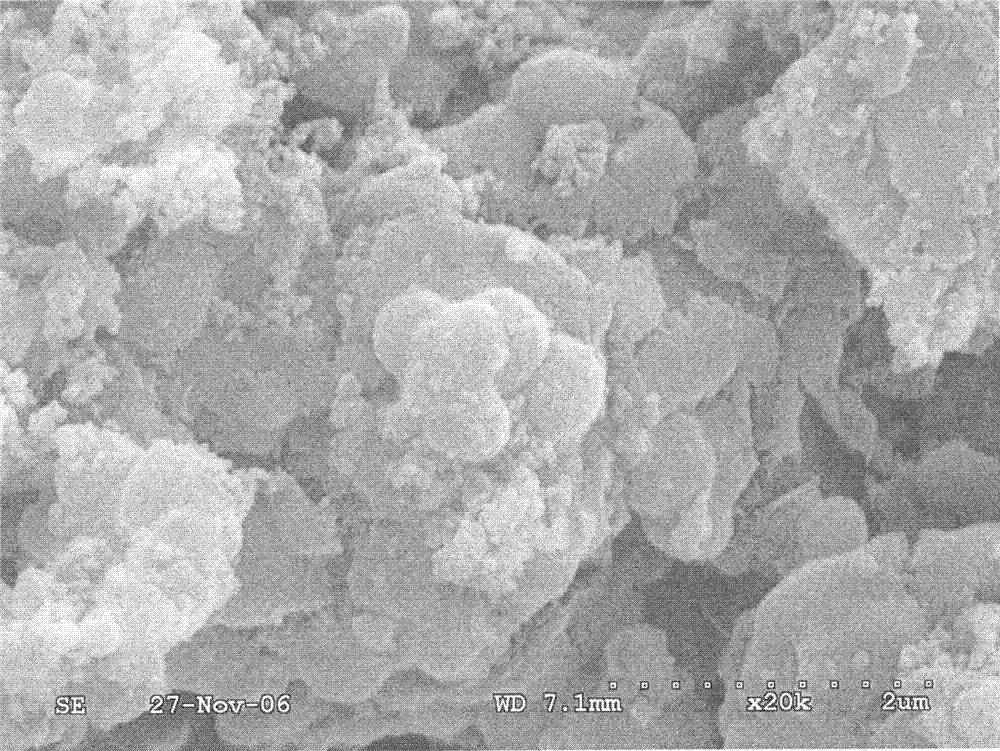

Preparation method for nanometer titanium dioxide/coal ash composite material

InactiveCN106861606ASolve processing problemsImprove adsorption capacityWater/sewage treatment by irradiationOther chemical processesWater bathsMuffle furnace

The invention discloses a preparation method for a nanometer titanium dioxide / coal ash composite material. The method comprises the following steps: purifying by performing thermal treatment and acid treatment on raw material coal ash, thereby acquiring refined coal ash; under a water bath condition, weighting a certain amount of refined coal ash and distilled water and putting into a four-opening flask and stirring, adding less concentrated hydrochloric acid and then dropping a certain amount of TiCl4 solution; standing by for a while, and then dropping an aqueous solution containing ammonium sulfate and concentrated hydrochloric acid into the TiCl4 solution, mixing and stirring for a period of time, increasing the temperature of the mixture and then keeping the temperature; dropping an ammonium carbonate solution in a certain concentration, adjusting pH value, reacting for a period of time and then filtering, washing and drying, and then placing a sample into a muffle furnace for roasting, thereby acquiring the coal ash loaded TiO2 composite material. According to the invention, the waste coal ash of the power plant is used as a raw material and TiO2 is loaded onto the surface of the waste coal ash, so that a photo-catalysis compound material is prepared. The material is capable of effectively degrading the waste gas and waste water and can achieve the effect of treating the waste with the waste.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com