Coal dressing method

A coal preparation and coal washing technology, applied in chemical instruments and methods, wet separation, lighting and heating equipment, etc., can solve the problems of high-sodium coal desodiumization, boiler hazards, etc., to increase calorific value, reduce hazards, heat The effect of value enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

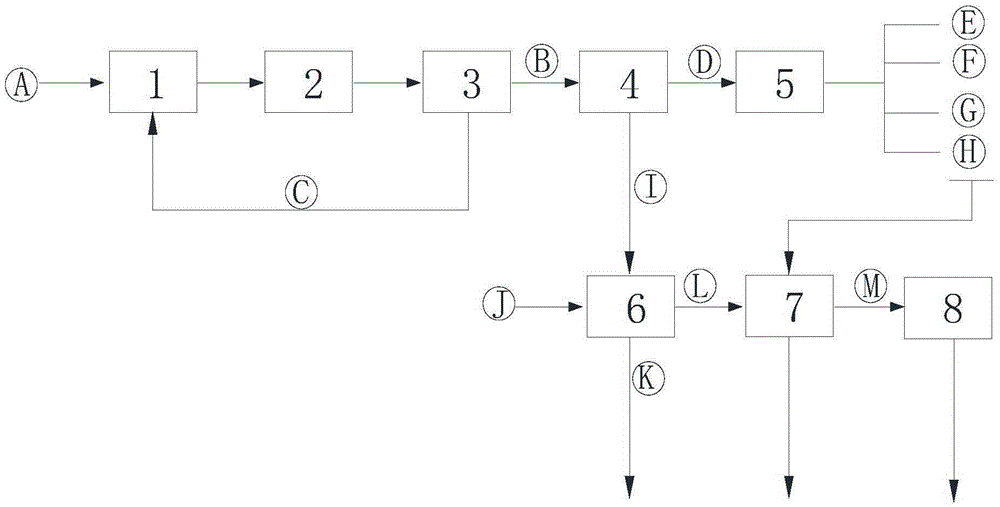

[0053] This embodiment is used to illustrate the coal preparation method provided by the present invention. This embodiment adopts figure 1 device shown.

[0054] The high-sodium raw coal A enters the raw coal crushing unit 2 through the raw coal feeding unit 1, and after being crushed by the raw coal crushing unit 2, it enters the screening unit 3 for screening, and the high-sodium coal C with a particle size greater than 100mm enters the raw coal crushing unit 2 for secondary Broken, the high-sodium coal B with a particle size of no more than 100 mm enters the microwave upgrading and desodiumizing unit 4 . The microwave source located outside the microwave heating chamber with a power of 75kW and a working frequency of 915MHz transmits microwave energy to the energy feed port on the top of the microwave heating chamber through the waveguide to heat the high-sodium coal B in the microwave heating chamber. Wherein, the length of the microwave heating cavity along the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com