Sewage-refuse treatment clean-production system at the center of generating plant

A water treatment system and technology of a treatment system, applied in the fields of magnetic field/electric field water/sewage treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as low filtration rate, difficult to decompose, limited heat absorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

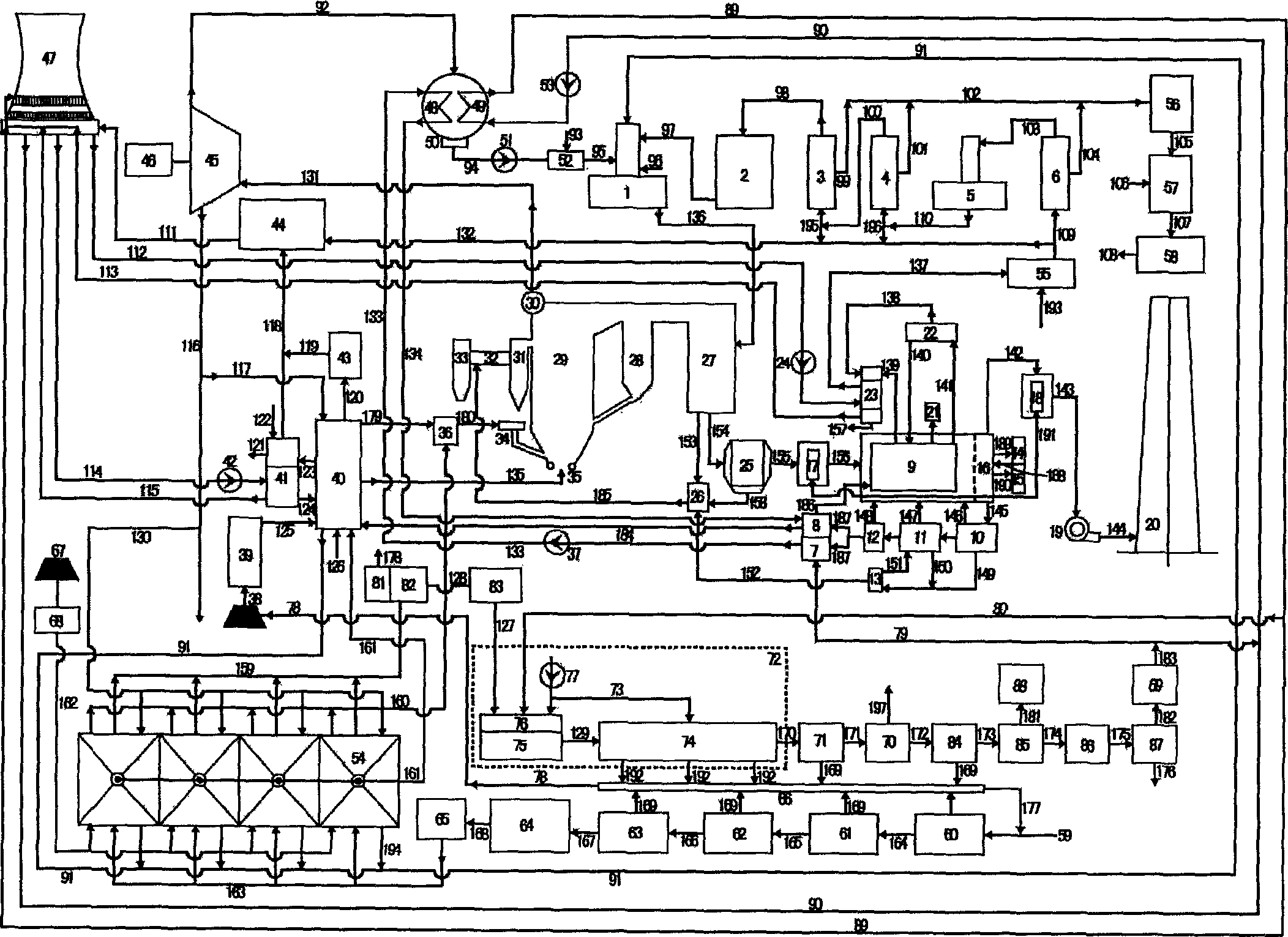

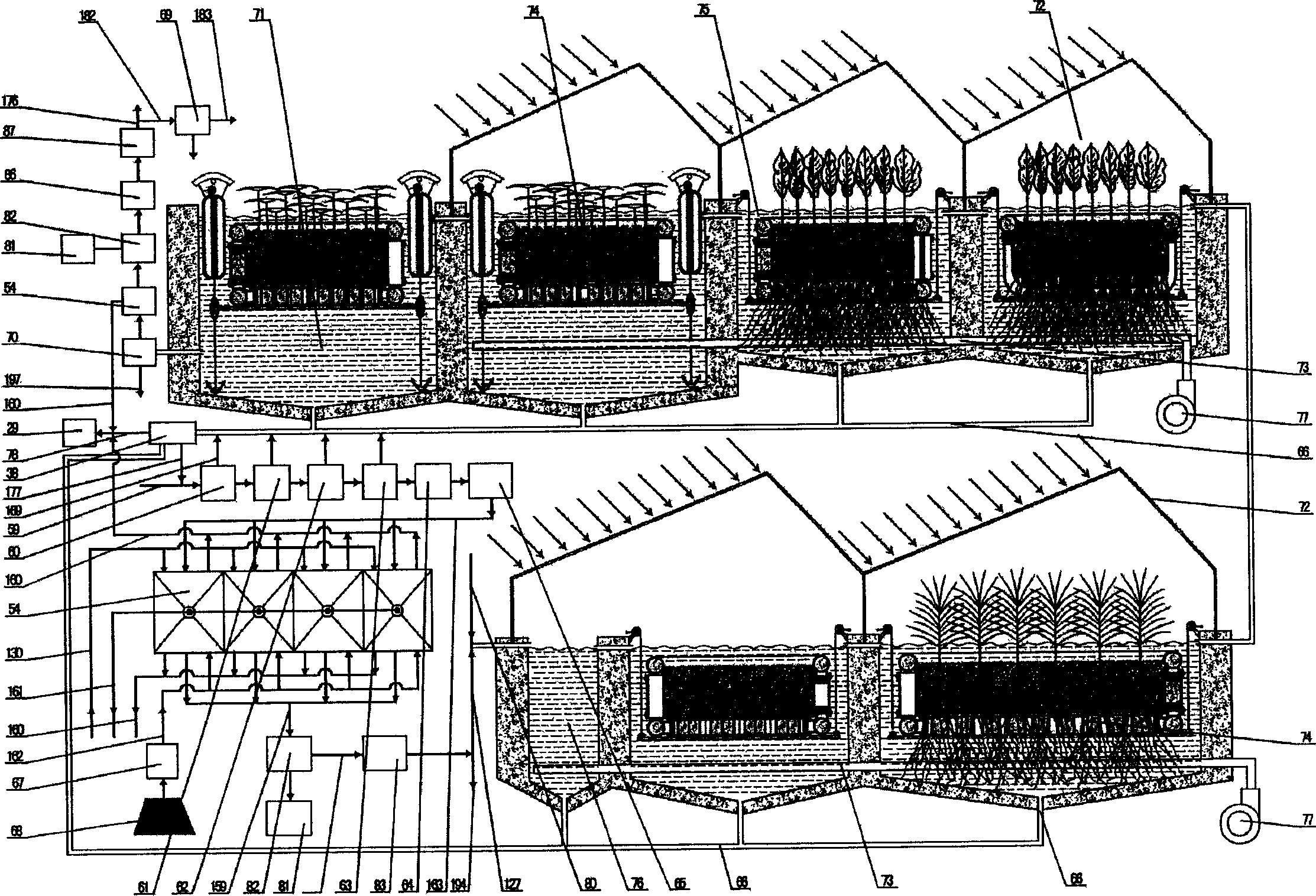

[0097] exist figure 1In the middle, the sewage enters the coarse grid 60, the fine grid 61, the sedimentation tank 62, the sedimentation tank 63, the pretreatment anaerobic storage tank 64, and the pump room 65 after being merged by the sewage water supply pipe 59 and the sludge dewatering device drainage pipe 177 , after being treated, it enters into the coal sewage filter 54 as a filter material through the pretreatment sewage transportation and distribution pipeline 163, and the sludge enters the sludge discharge pipe 66 through the sludge discharge pipeline 169, is dried by the sludge dehydration device, and passes through The conveying device 78 outputs and enters in the refuse storage tank 38 . The sewage that enters the coal as filter material sewage filter 54 is confluenced through the coal filtered sewage outlet pipe 159 and then input to the magnetic filter device 82 . The effluent from the magnetic filter device 82 enters the ultraviolet disinfection device 83 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com