Patents

Literature

146 results about "Circulation evaporator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Circulation evaporators are a type of evaporating unit designed to separate mixtures unable to be evaporated by a conventional evaporating unit. Circulation evaporation incorporates the use of both heat exchangers and flash separation units in conjunction with circulation of the solvent in order to remove liquid mixtures without conventional boiling. There are two types of Circulation Evaporation; Natural Circulation Evaporators and Forced Circulation Evaporators, both of which are still currently used in industry today, although forced Circulation systems, which have a circulation pump as opposed to natural systems with no driving force, have a much wider range of appropriate uses.

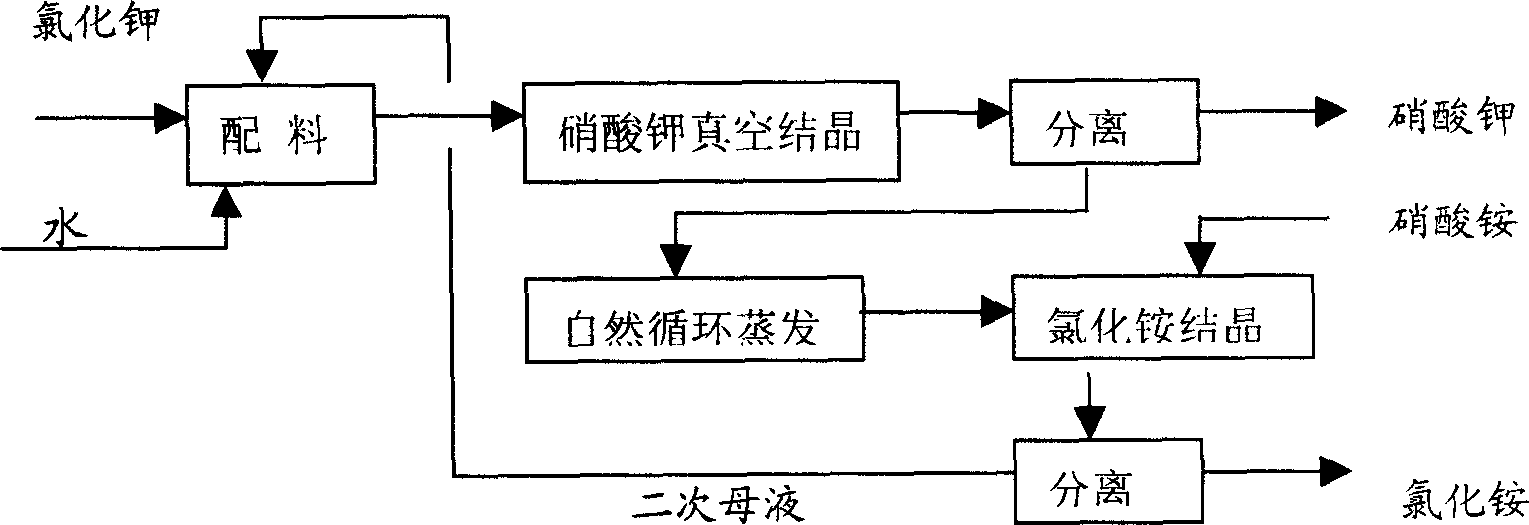

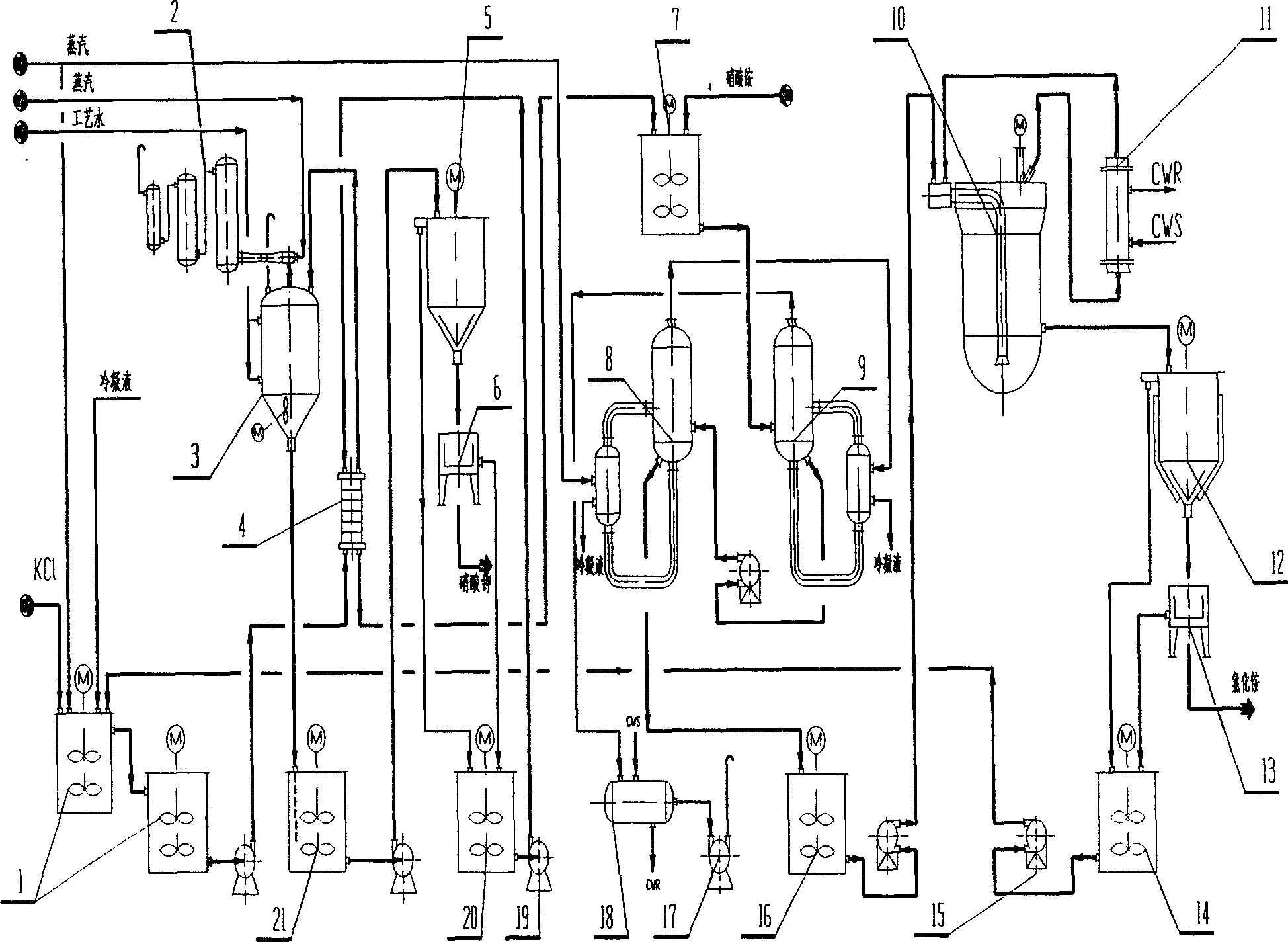

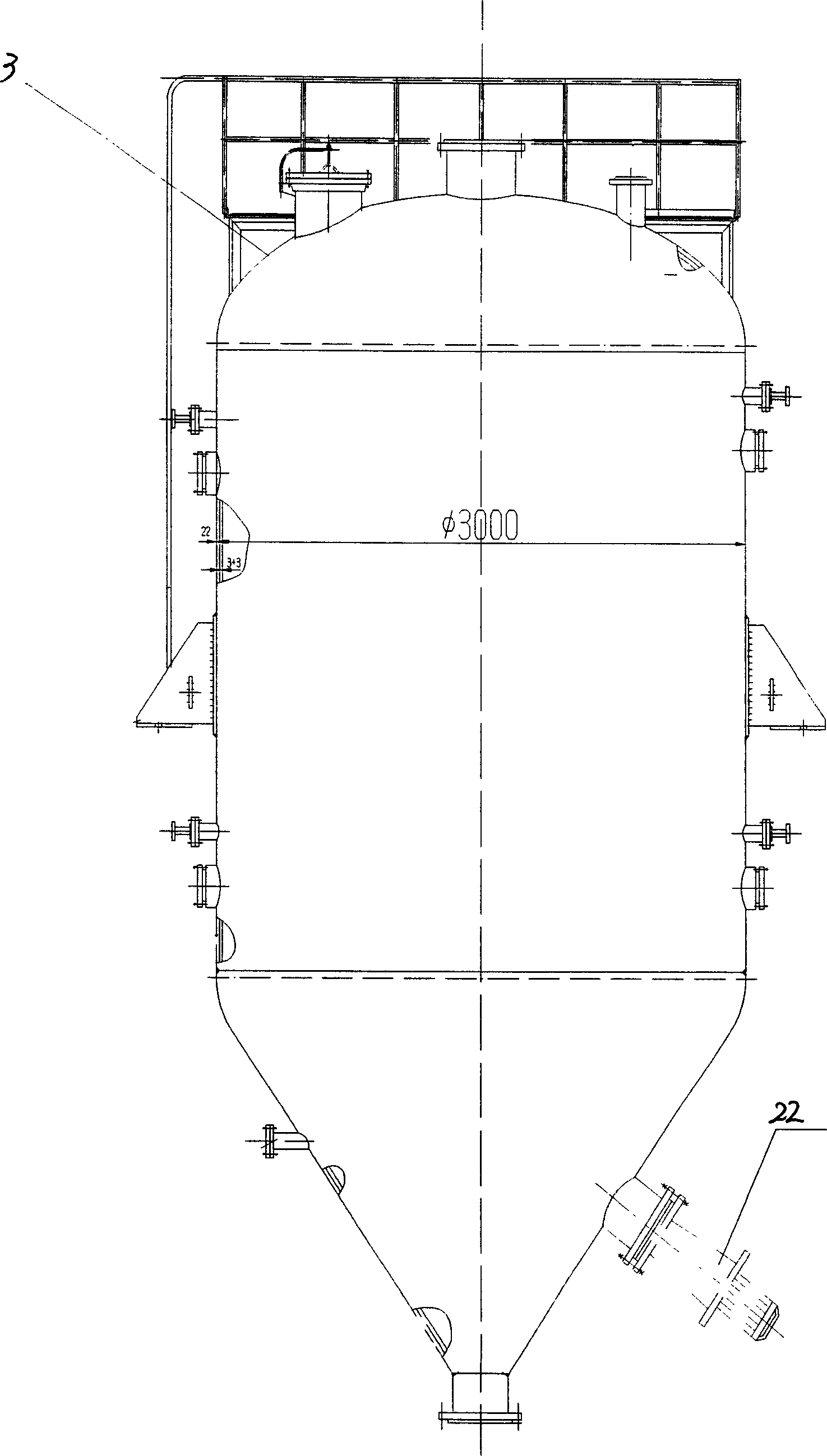

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

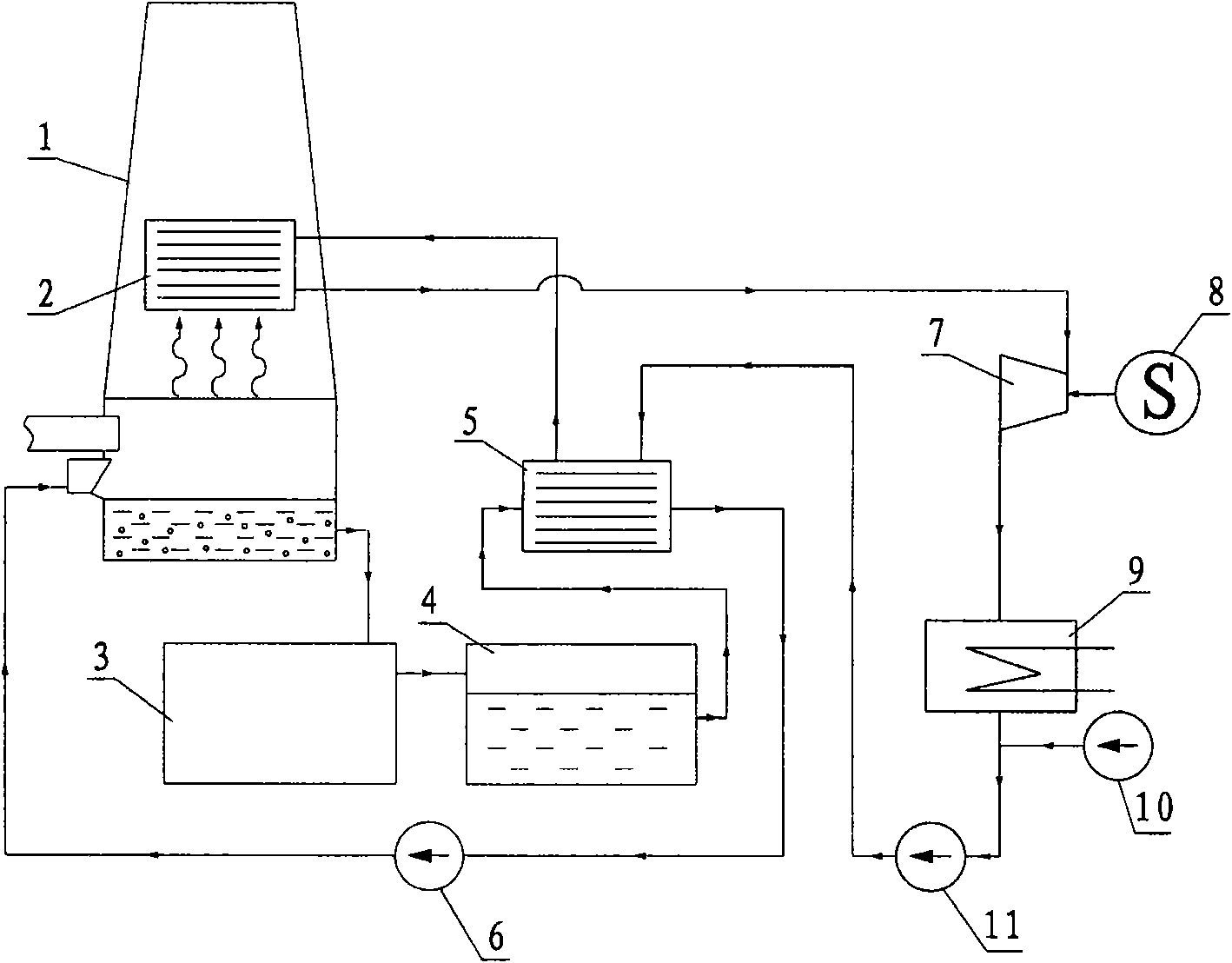

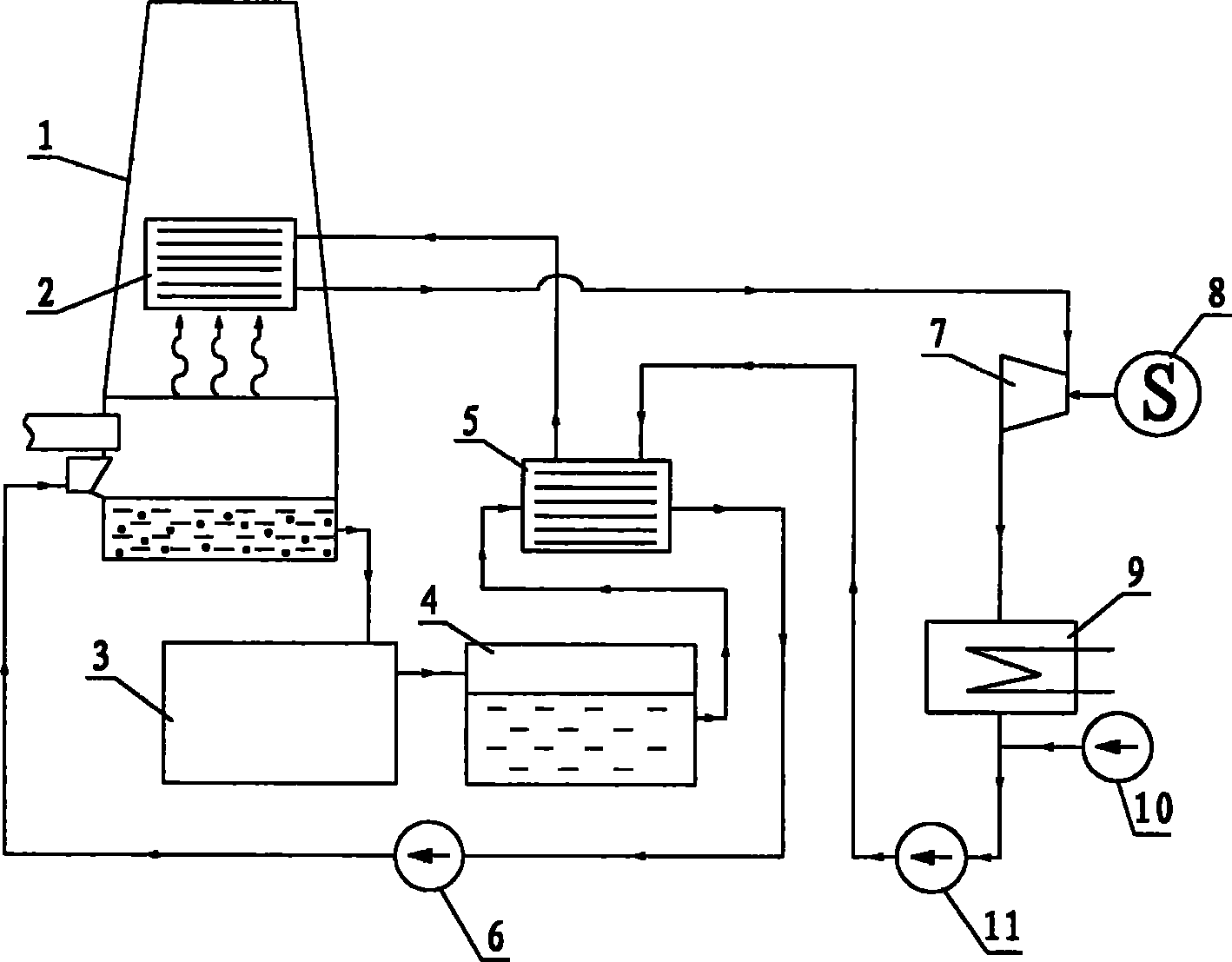

Method and device for collecting steam of flushing cinder and afterheat of hot water in iron-making blast furnace

ActiveCN101792830AAchieve recyclingReduce pollutionSteam generation heating methodsSteam superheatersWater sourceSlag

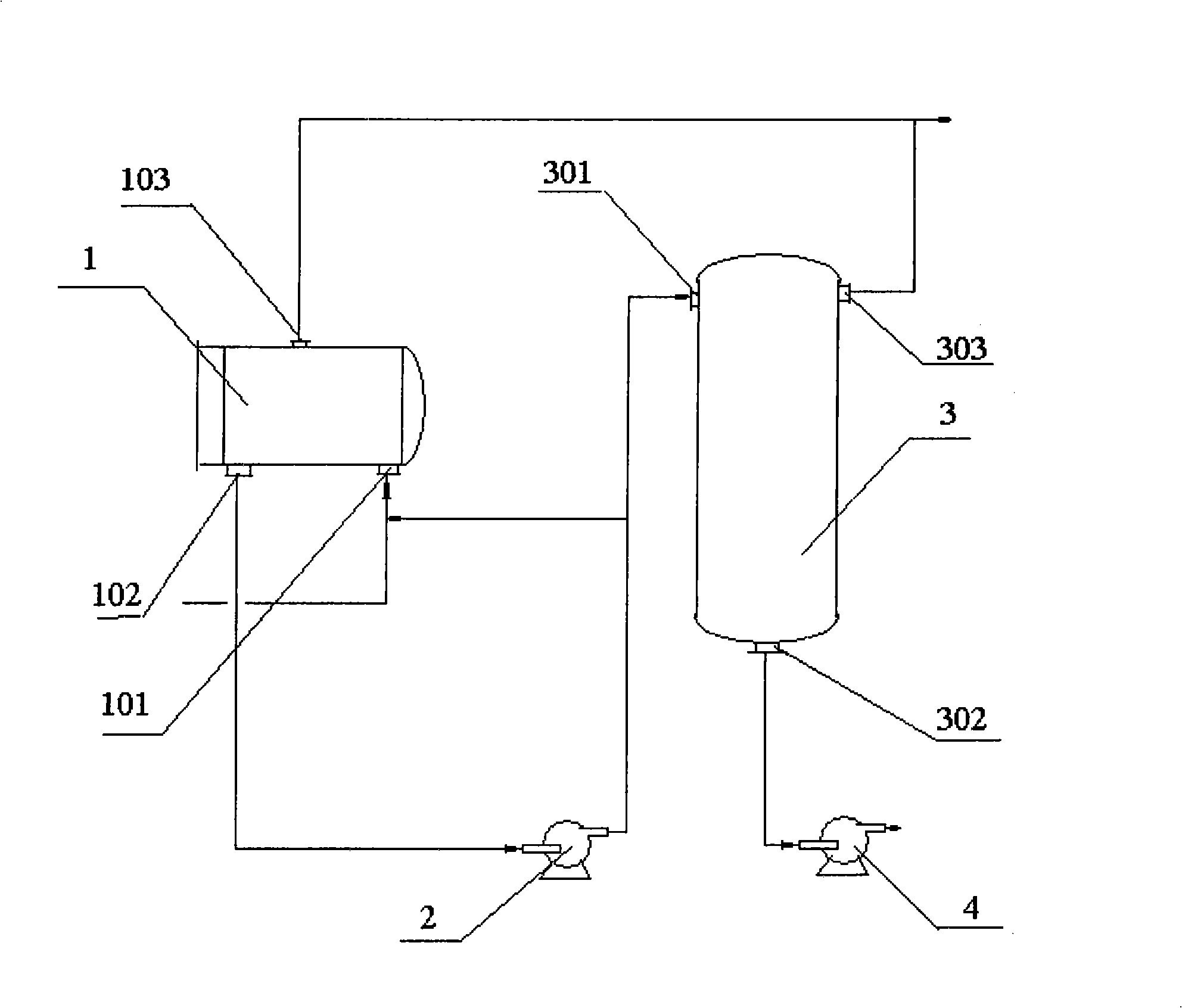

The invention provides a method and a device for collecting the steam of flushing cinder and the afterheat of hot water in an iron-making blast furnace, which belong to the technical field of afterheat recovery. The method comprises the following steps of: delivering the filtered slag quenching water from a conventional blast furnace slag processing system to a circulating pre-heater to heat a working medium, allowing the slag quenching water at a lower temperature from circulating pre-heater to return to the blast furnace to flush slag; introducing the working medium heated by the pre-heater into a circulating evaporator in which the working medium absorbs the heat released in the condensation process of the flushing cinder steam and evaporates and allowing the vaporized steam to drive a steam turbine so as to drive a generator to generate power; and condensing the working medium departing from the steam turbine into liquid, returning the liquid to the circulating pre-heater and evaporator and recycling the liquid by repeated heating and vaporization. The device comprises a flushing cinder steam heat-exchange loop, a slag quenching water heat-exchange circulation loop and a working medium circulation loop. The method and the device have the advantages of maximizing the cyclic utilization of the flushing quenching heat and the water source, reducing the pollution of the flushing cinder steam to the environment and recycling the energy sources and the natural resources.

Owner:BEIJING SHOUGANG INT ENG TECH

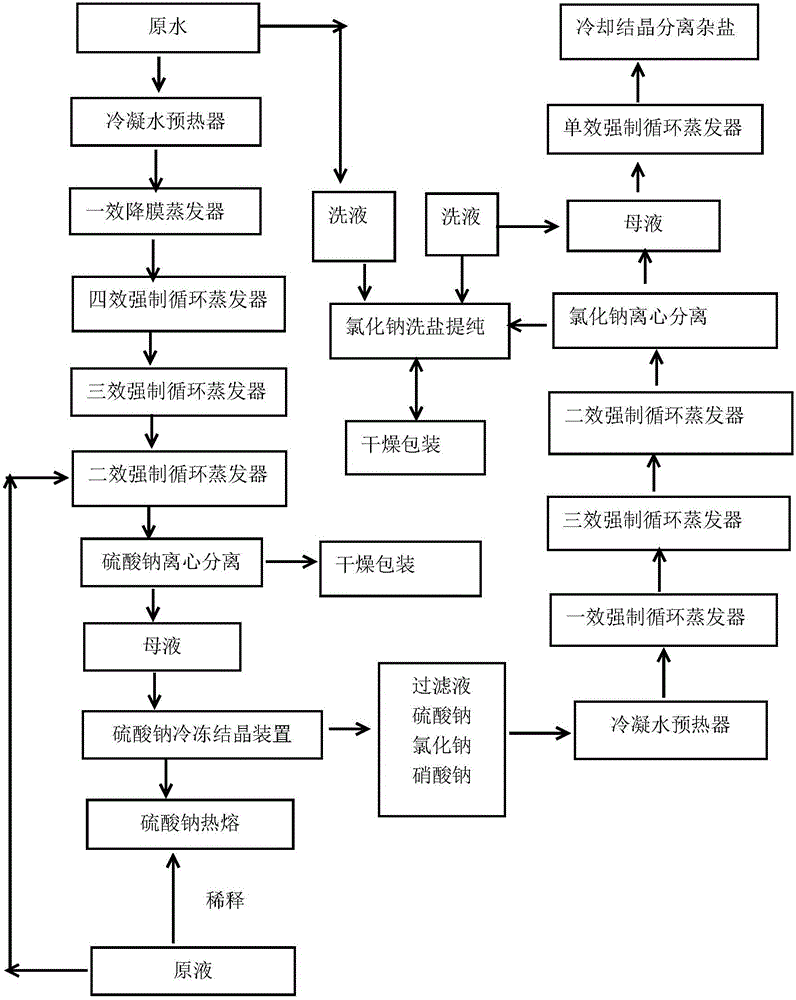

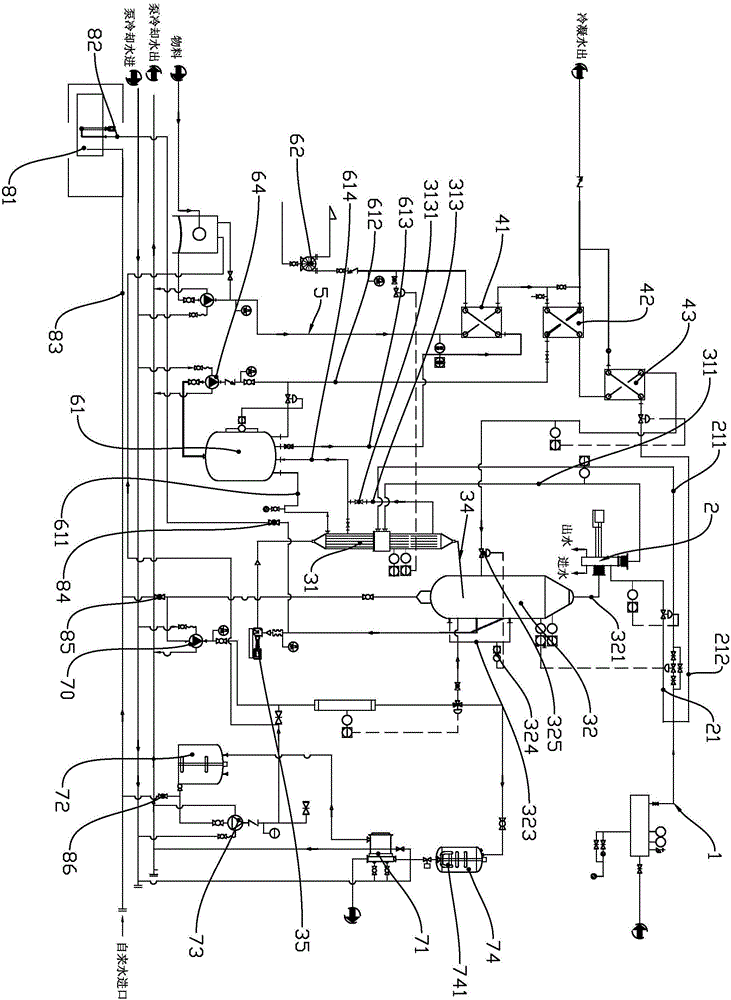

Desulfurization wastewater concentration, evaporation, crystallization and salt separation process

ActiveCN106007133AEfficient separationDissolution inhibitionWater/sewage treatment by centrifugal separationWater contaminantsWastewaterSingle effect

The invention discloses a desulfurization wastewater concentration, evaporation, crystallization, and salt separation process. The process comprises the steps as follows: introducing raw water into a quadruple-effect counter-flow forced circulation evaporator, treating sodium sulfate through evaporating, concentrating and crystalizing, separating sodium sulfate first, and freezing separated mother liquor, wherein most of sodium sulfate in the mother liquor is successfully separated; introducing the frozen mother liquor into a triple-effect evaporator after preheating, evaporating, concentrating and crystalizing sodium chloride, wherein the obtained crystal salt is used as an industrial raw material; introducing the mother liquor produced by a sodium chloride evaporator into a single-effect evaporator to obtain an abraum salt crystal. The process successfully separates the sodium sulfate in the desulfurization wastewater, and the sodium chloride is treated through evaporating, concentrating and crystalizing, the obtained sodium chloride crystal salt is used as the industrial raw material, the mother liquor produced by the sodium chloride evaporator enters the single-effect evaporator to obtain the abraum salt crystal, so that the sodium sulfate and the sodium chloride are effectively separated.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

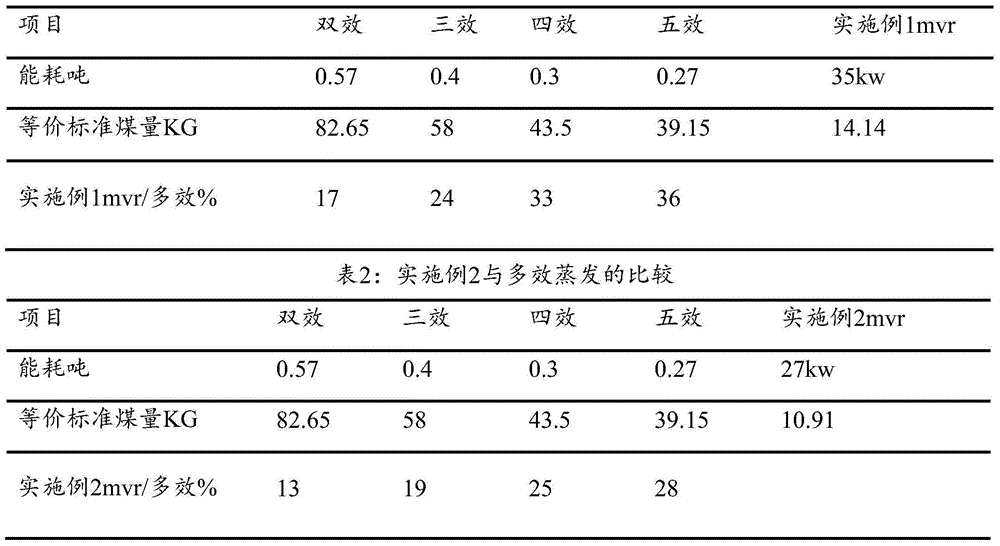

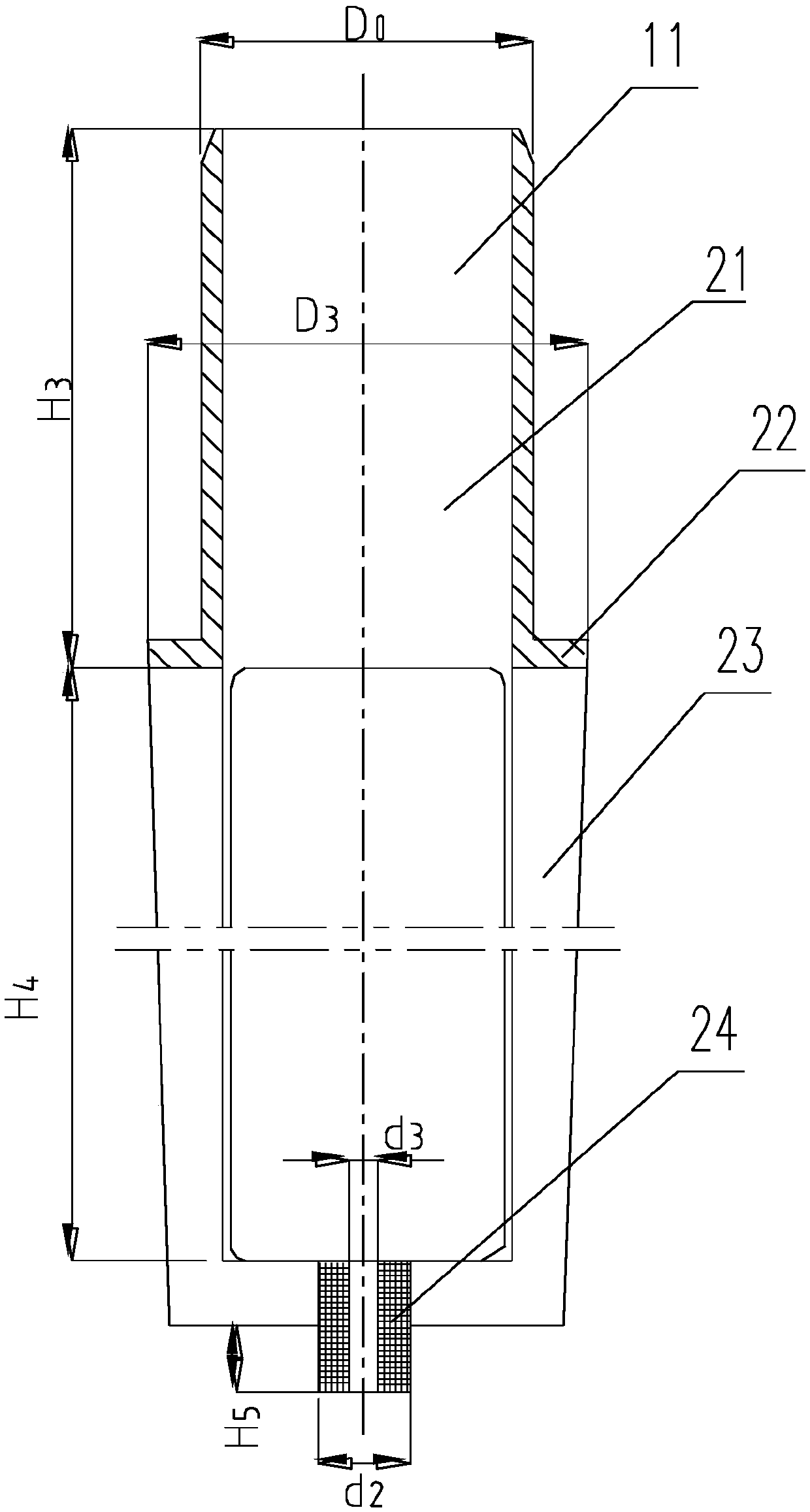

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20110061867A1High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEvaporationEngineering

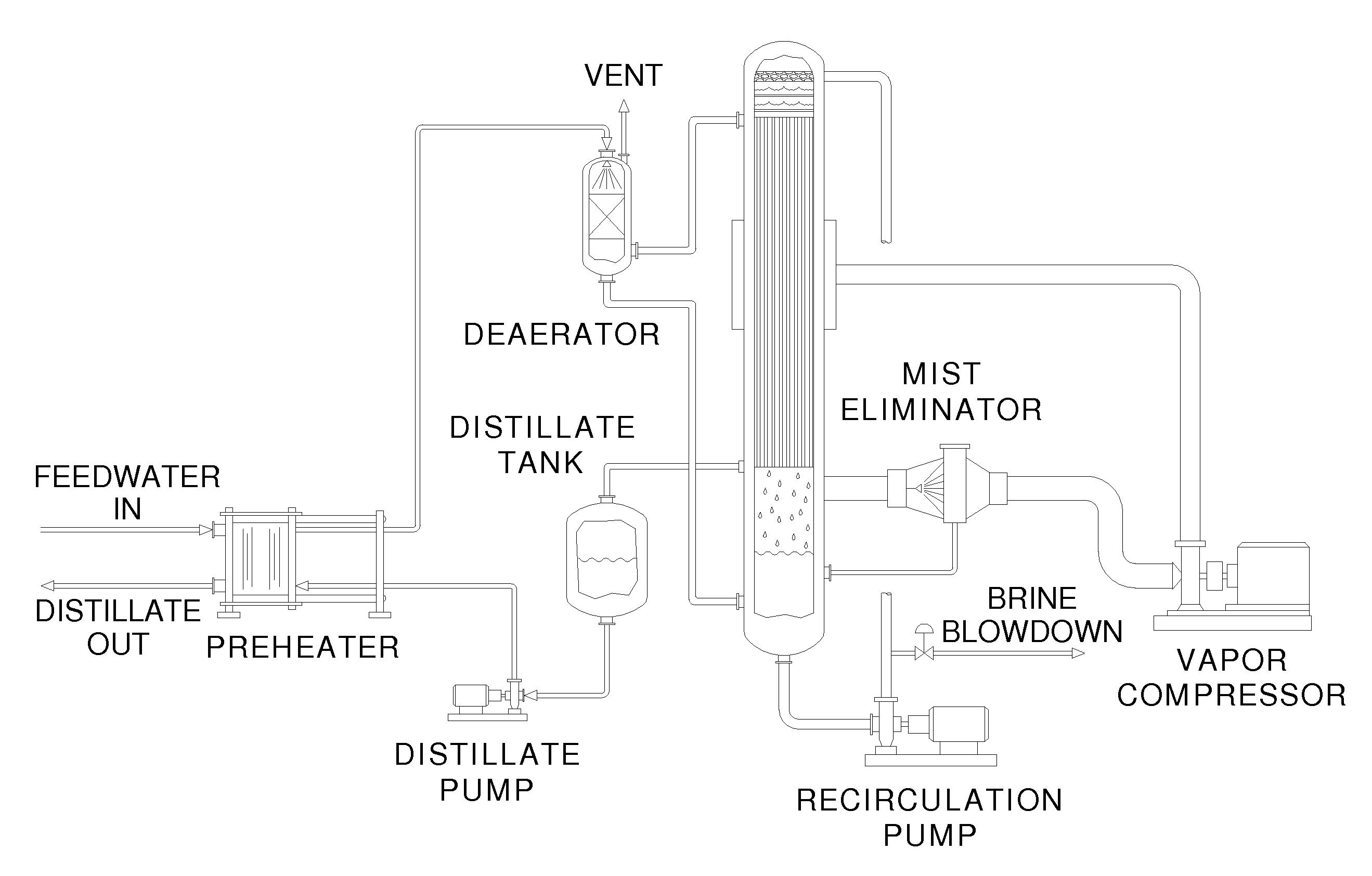

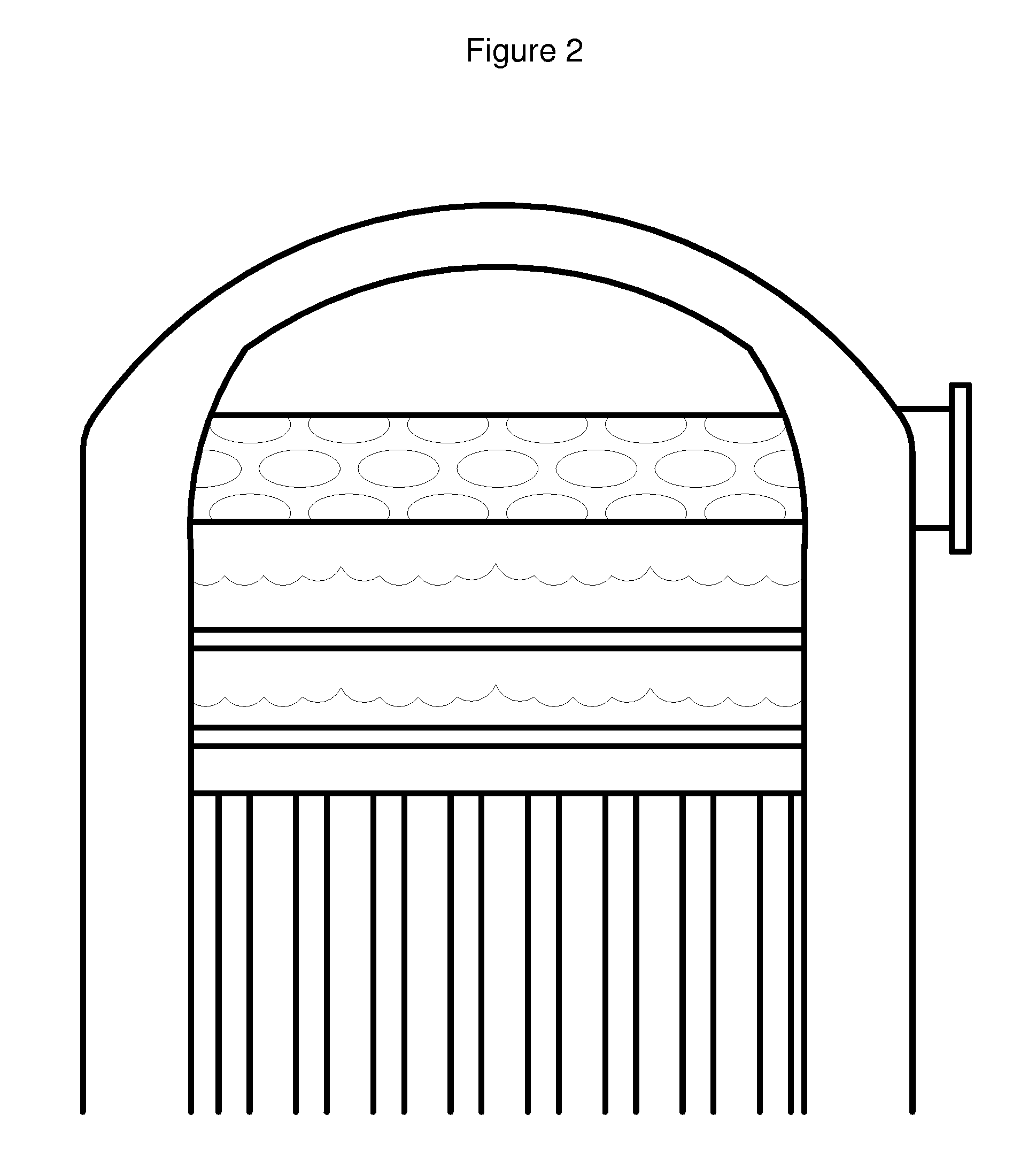

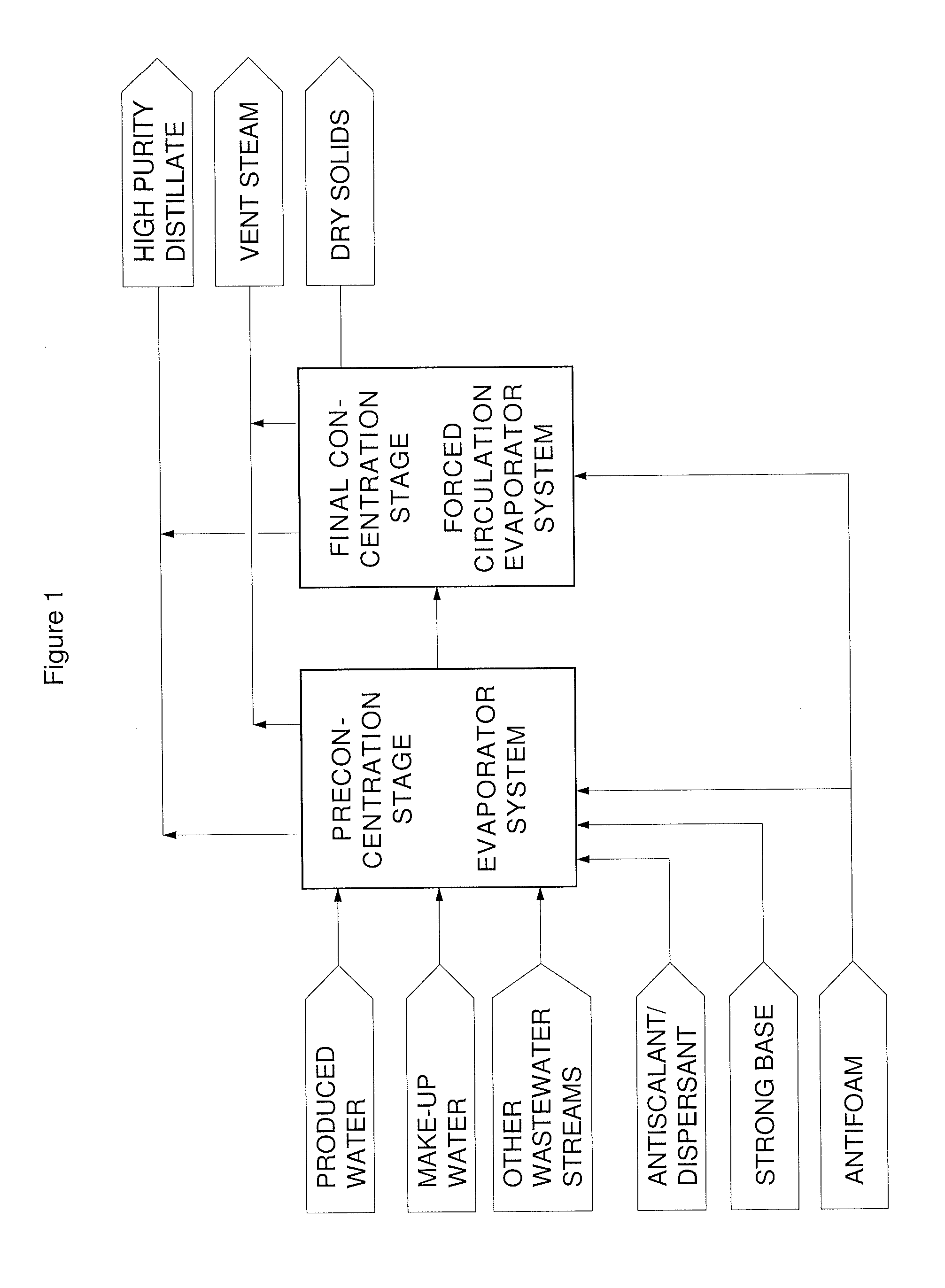

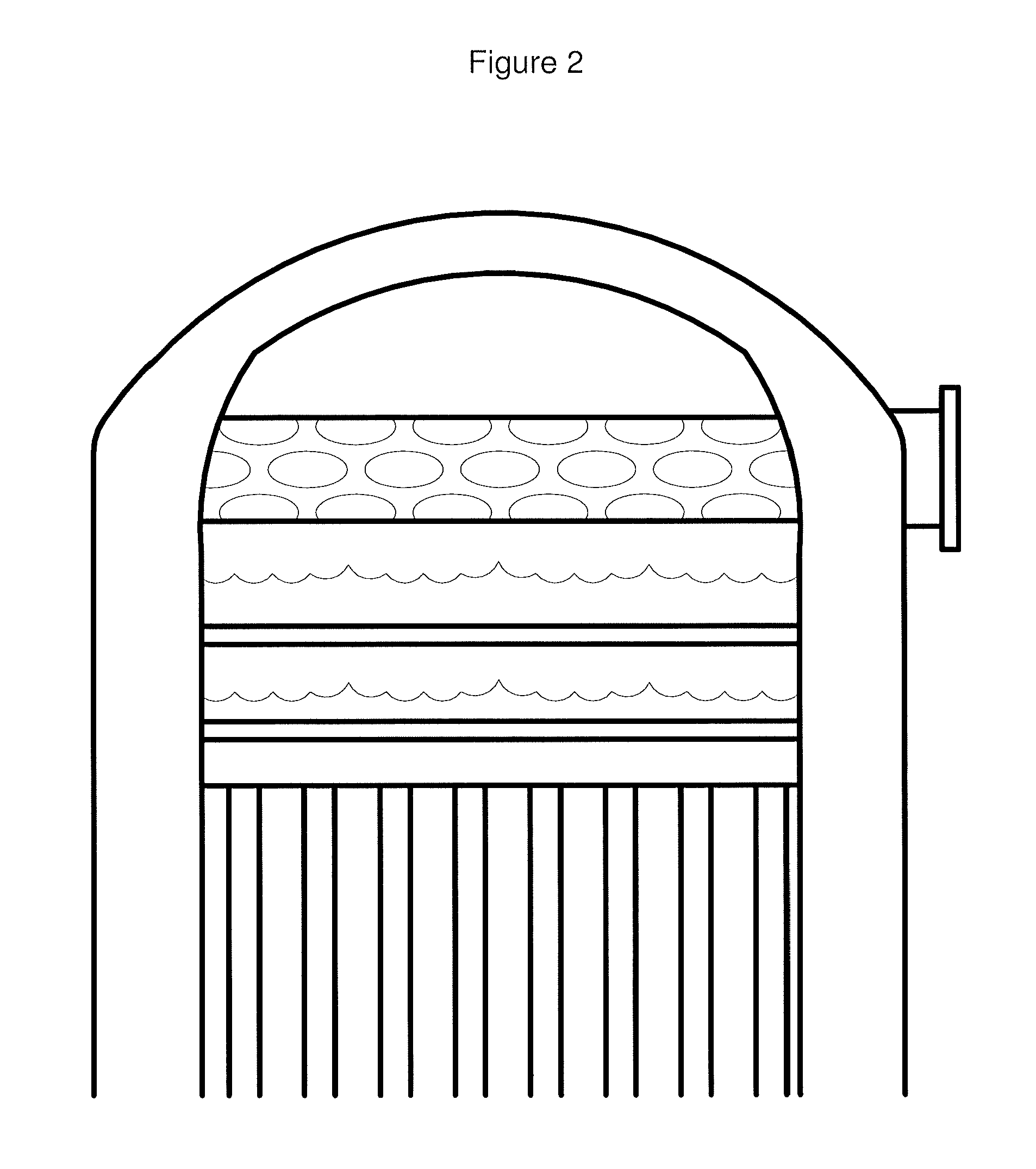

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle>98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

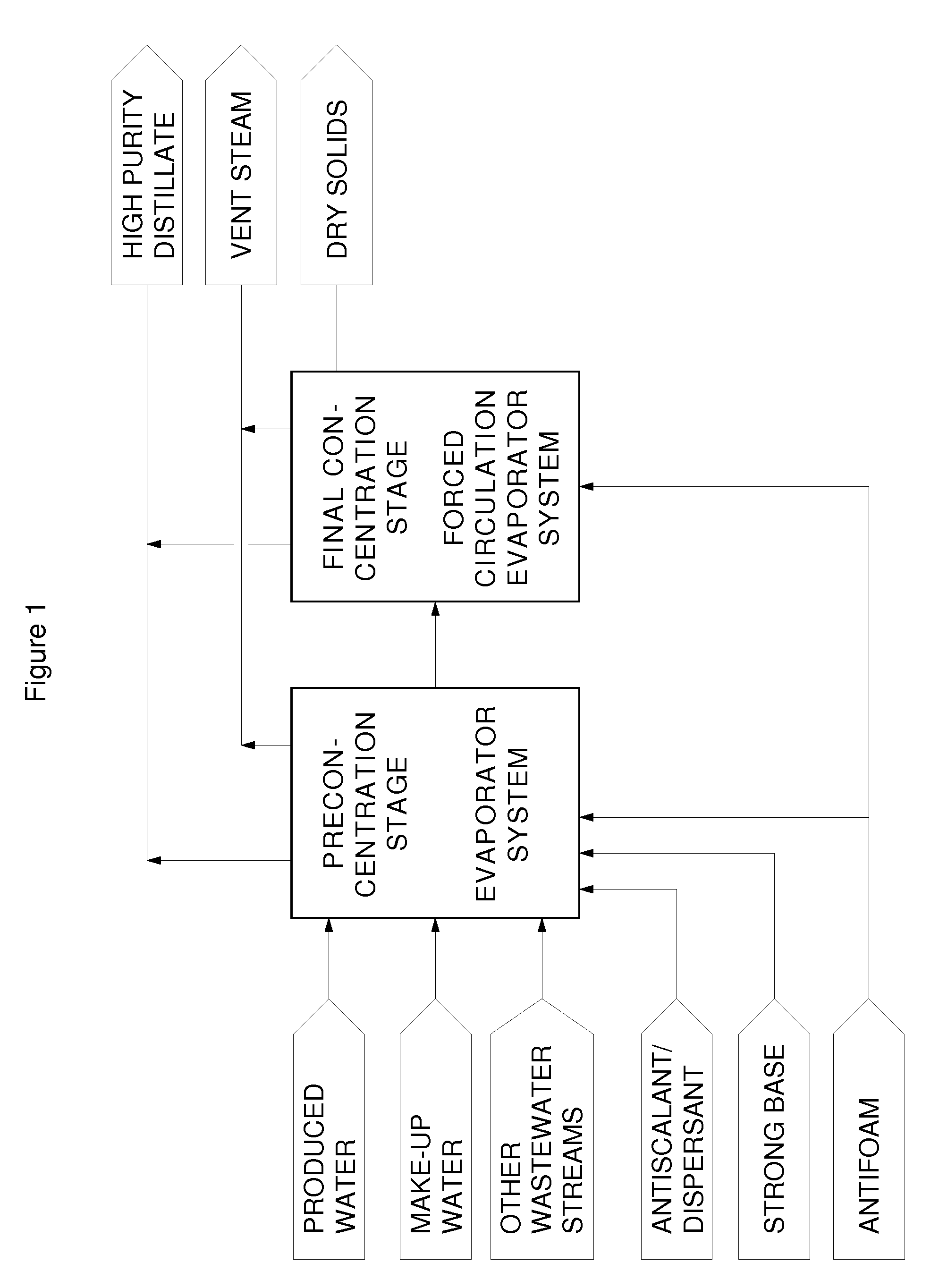

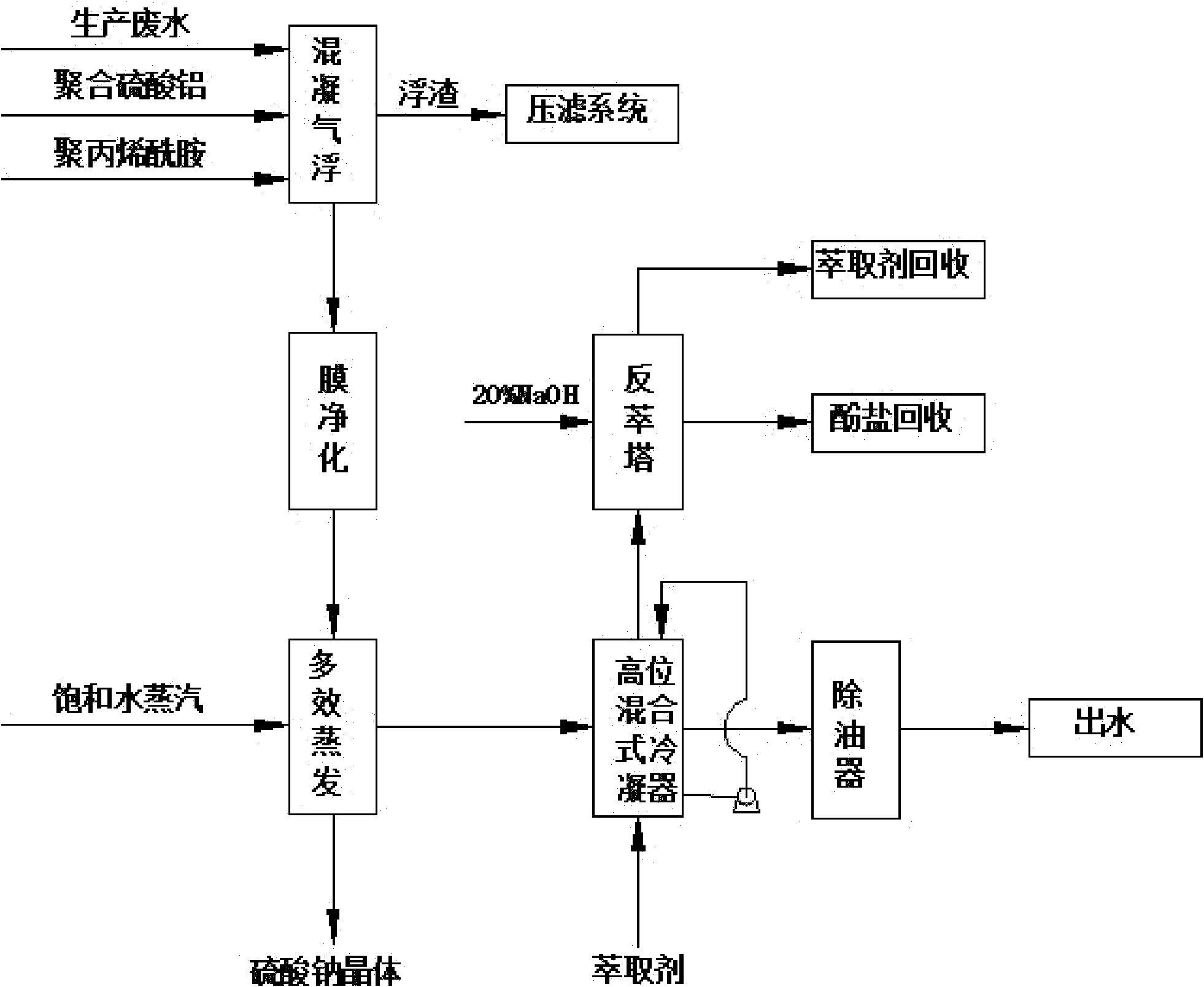

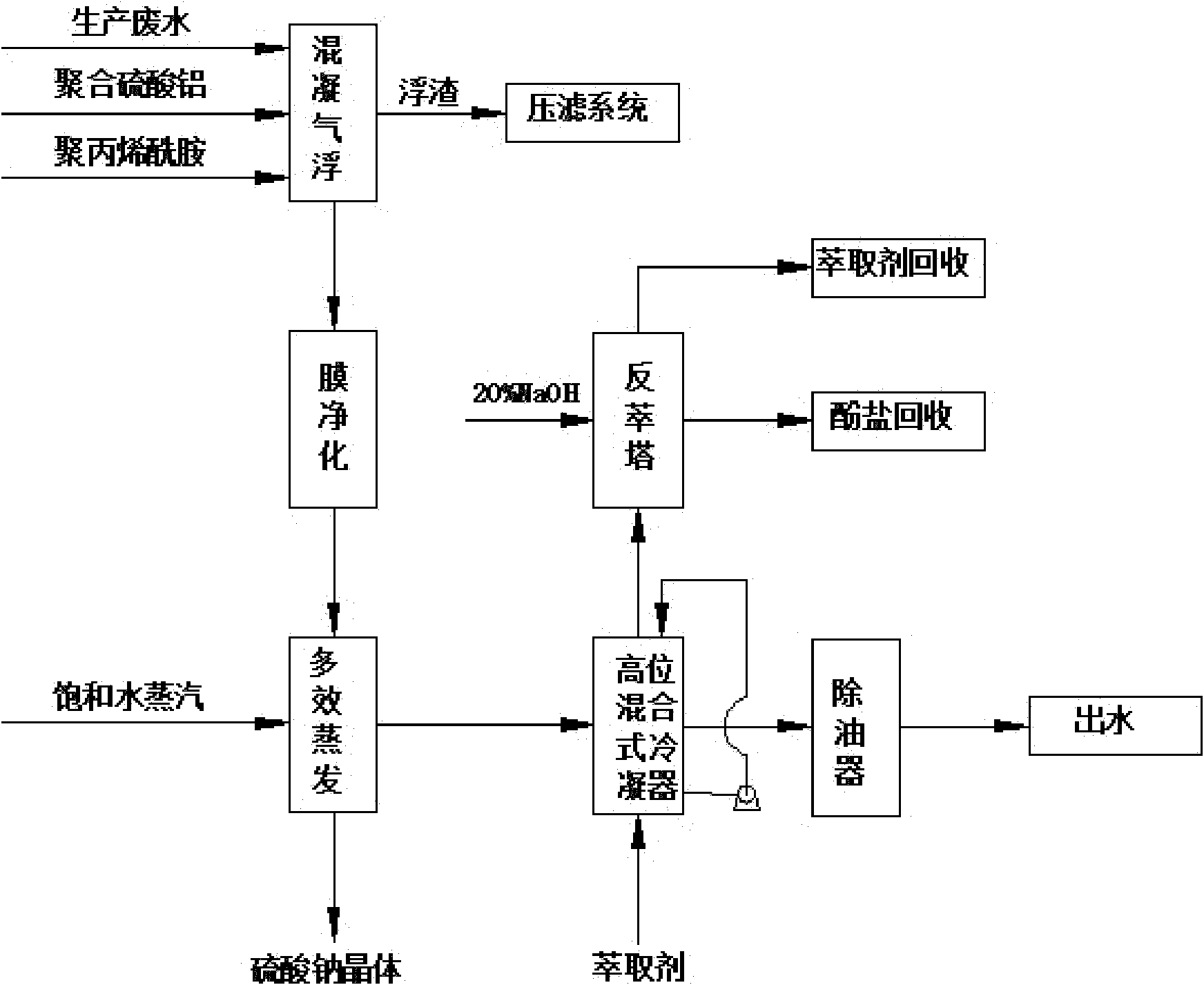

High-concentration organic and inorganic mixed wastewater treatment and recovery method

ActiveCN102079603AEasy extractionOrganic chemistryOrganic compound preparationRecovery methodHigh concentration

The invention discloses a high-concentration organic and inorganic mixed wastewater treatment and recovery method. The method comprises the following steps of: a pretreatment process, namely removing suspended matters in water and partially reducing the chemical oxygen demand (COD) of the wastewater; a membrane purification process, namely filtering by using an organic and inorganic mixed or pure inorganic sintered tube, and removing flocs in the water for further purifying water quality; a multi-effect evaporation process, namely adopting a falling film evaporator or a compulsory external recycling evaporator in a first effect, adopting the compulsory external recycling evaporator in a last effect, generating steam and recovering inorganic salt crystals; an phase inversion extraction / reverse extraction process, namely contacting the steam with an extracting agent directly, making outlet water enter an intermediate water tank and recovering phenate; and a filtering and oil removing process, namely oil carried in water is removed and making the outlet water enter a detection water pool. The method is environmentally-friendly without secondary pollution; an extraction effect is improved by phase inversion extraction; and the inorganic salt crystals and the phenate are recovered by evaporated.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

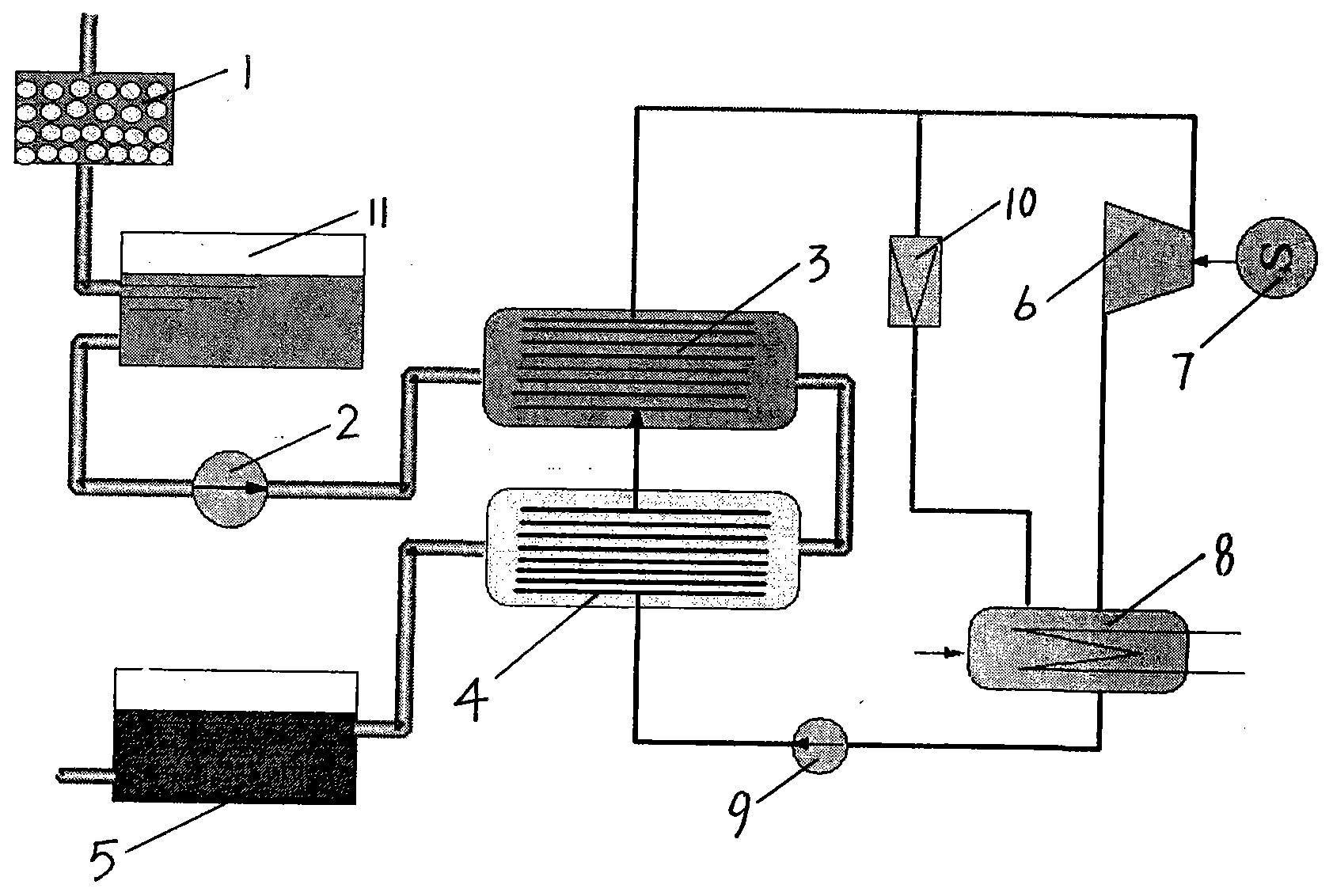

Method and special device for collecting surplus heat of flushing cinder hot water of iron-smelting furnace

The invention relates to a method for collecting surplus heat of flushing cinder hot water of an iron-smelting furnace. Heat of flushing cinder hot water can be collected through the method, the recycling of resources is realized so that the energy is saved and the pollution to environment is lightened, therefore, the invention also provides a special device of the method for collecting the surplus heat of the hot water. The method is characterized in that the flushing cinder hot water is sent to a circulating evaporator after being filtered to be used for heating working medium, the working medium is gasified, gasified steam drives a power machine to drive a generator; the working medium leaving the power machine is condensed to be liquid, the liquid flows back to the circulating evaporator to be gasified for being recycled; the temperature of the flushing cinder hot water leaving the circulating evaporator is reduced, the flushing cinder hot water returns to the iron-smelting furnace to be continuously used for flushing cinder, the working medium is changed into steam after absorbing heat in a heat exchanger, and the steam enters the power machine for applying work. The special device is characterized by comprising a flushing cinder hot water circulating loop and a medium circulating loop, wherein the flushing cinder hot water circulating loop comprises a filtering device, a circulating hot water pump, an evaporating heat exchanger, a water cooling pond and a cinder flushing device; the circulating loop comprises a medium circulating pipe of the evaporating heat exchanger, a power machine, a condenser and an organic working medium pump.

Owner:无锡市东方环境工程设计研究所

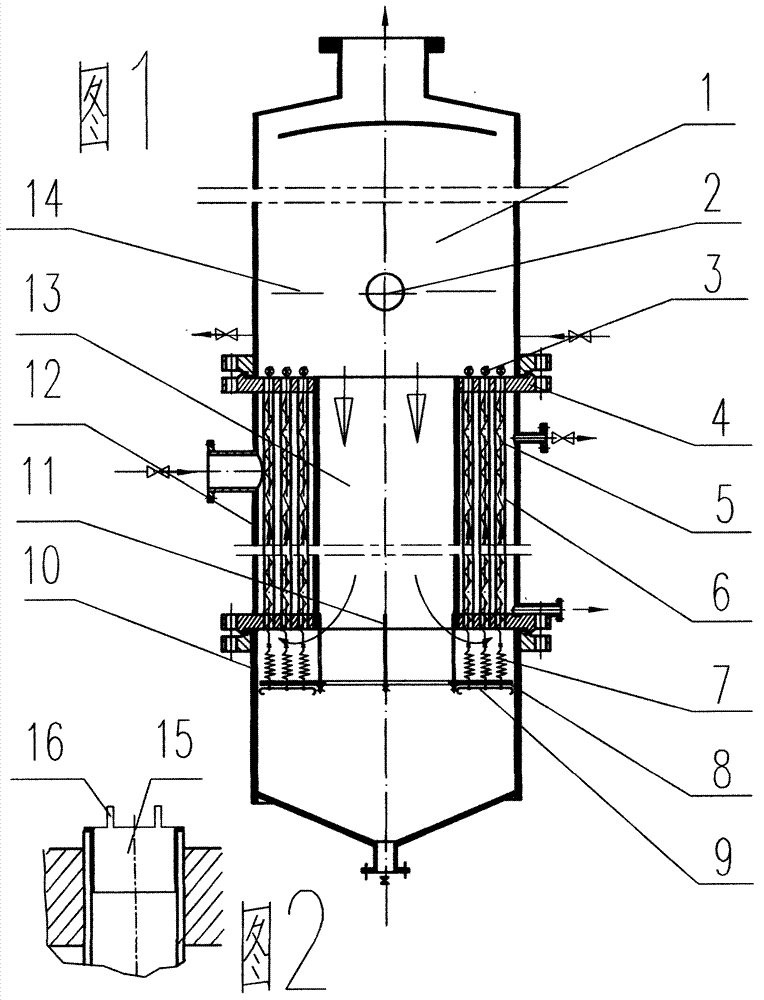

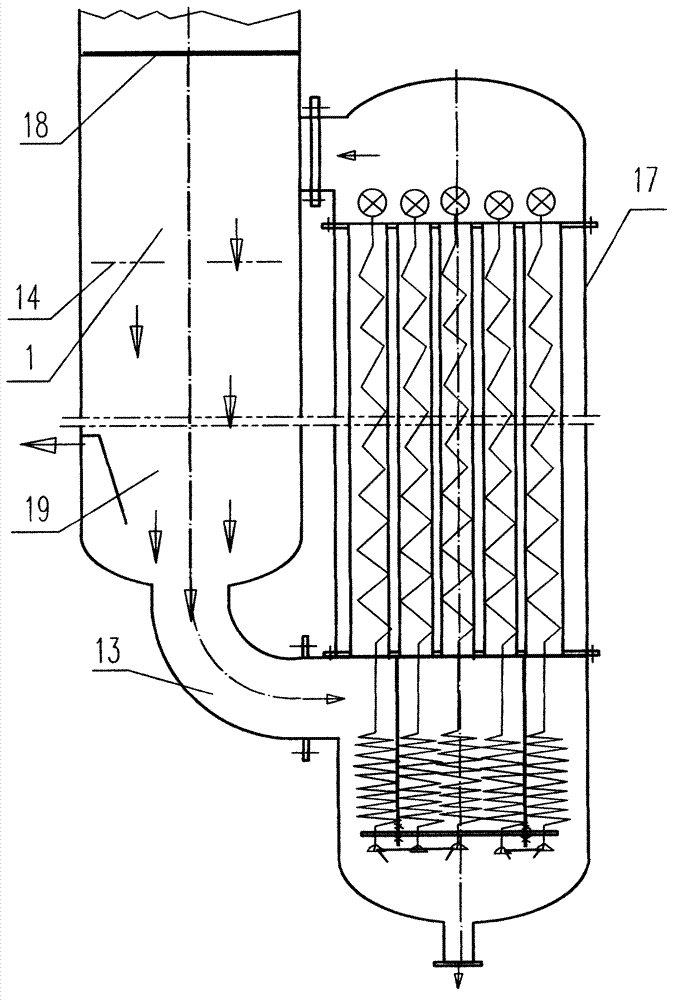

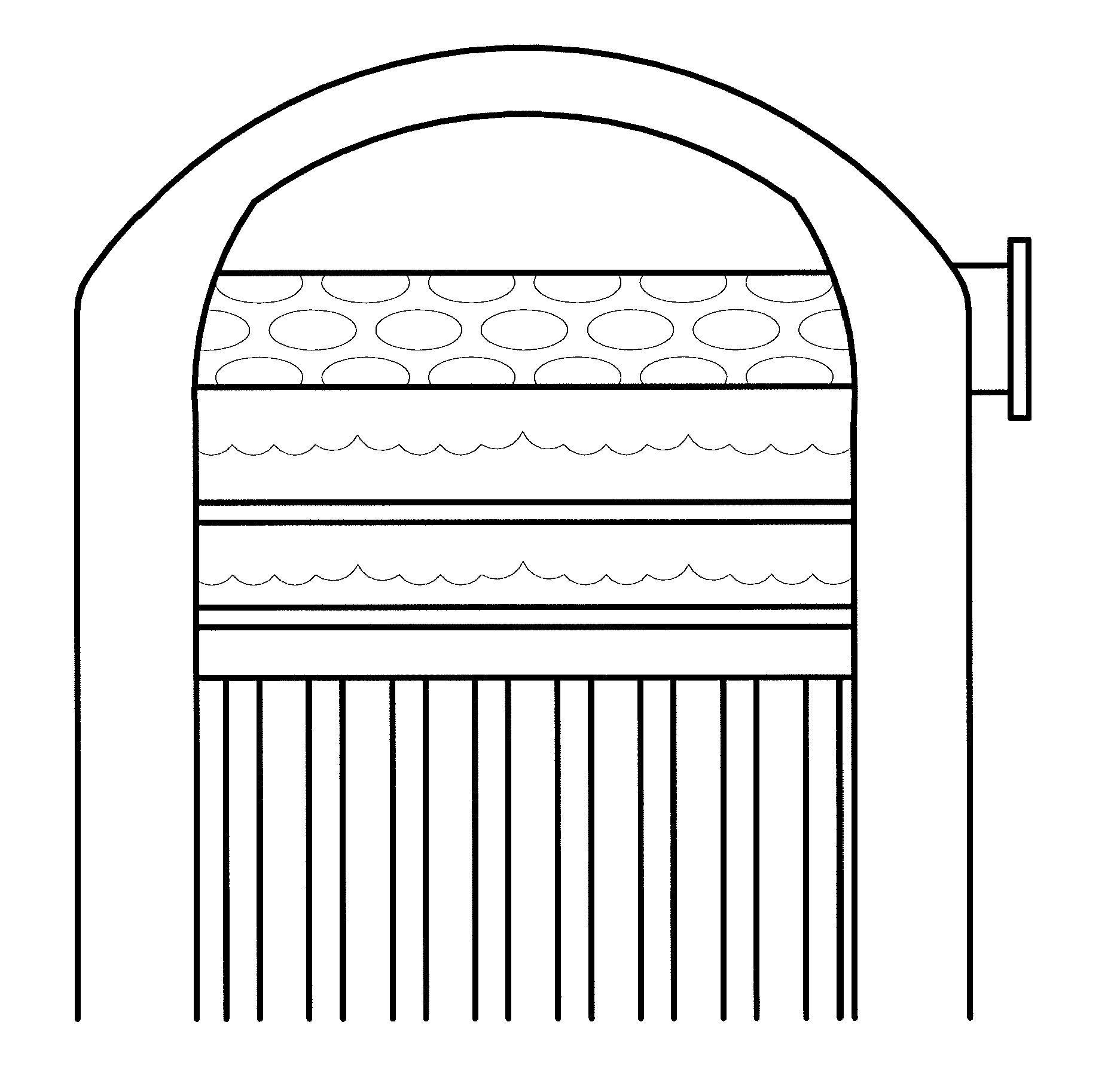

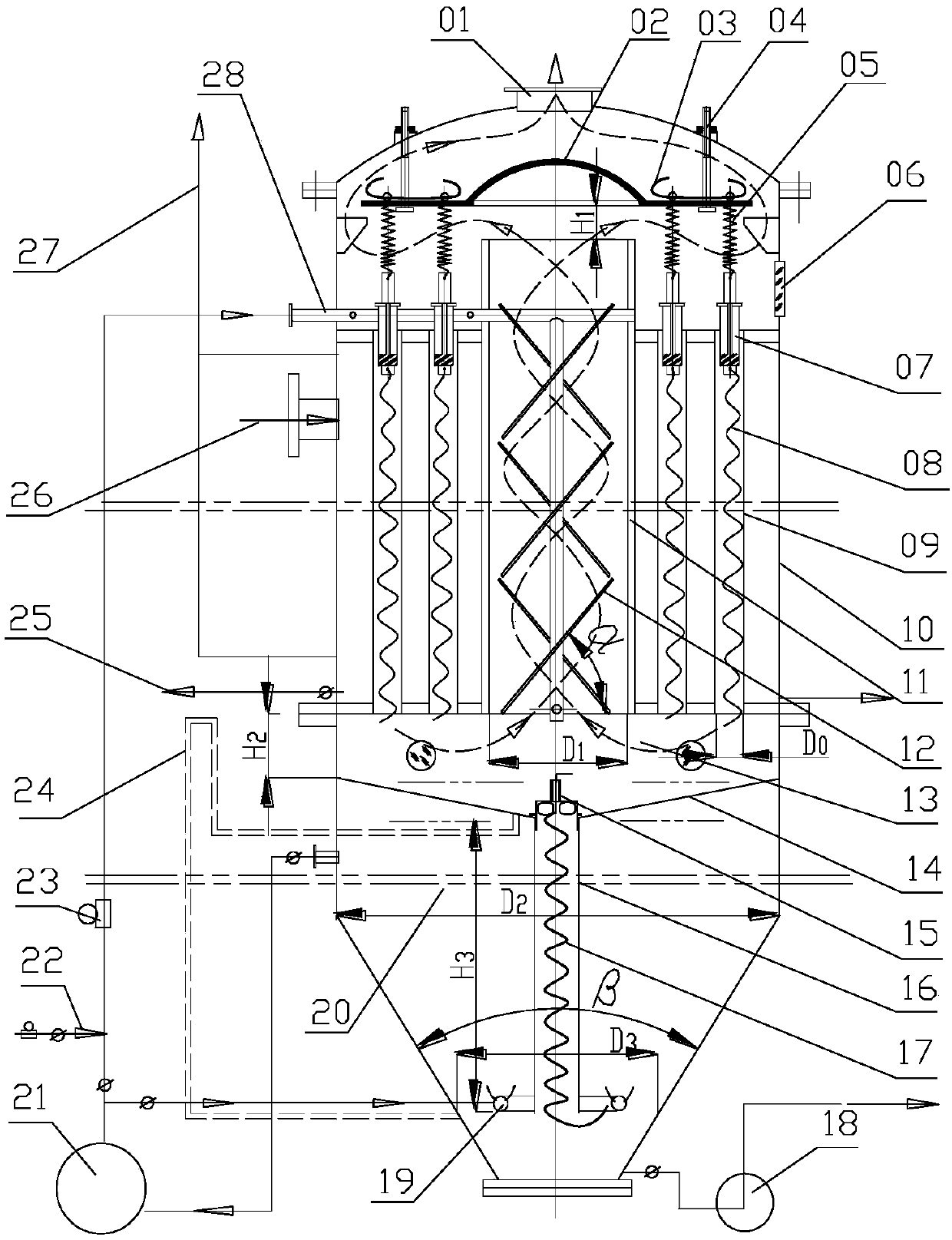

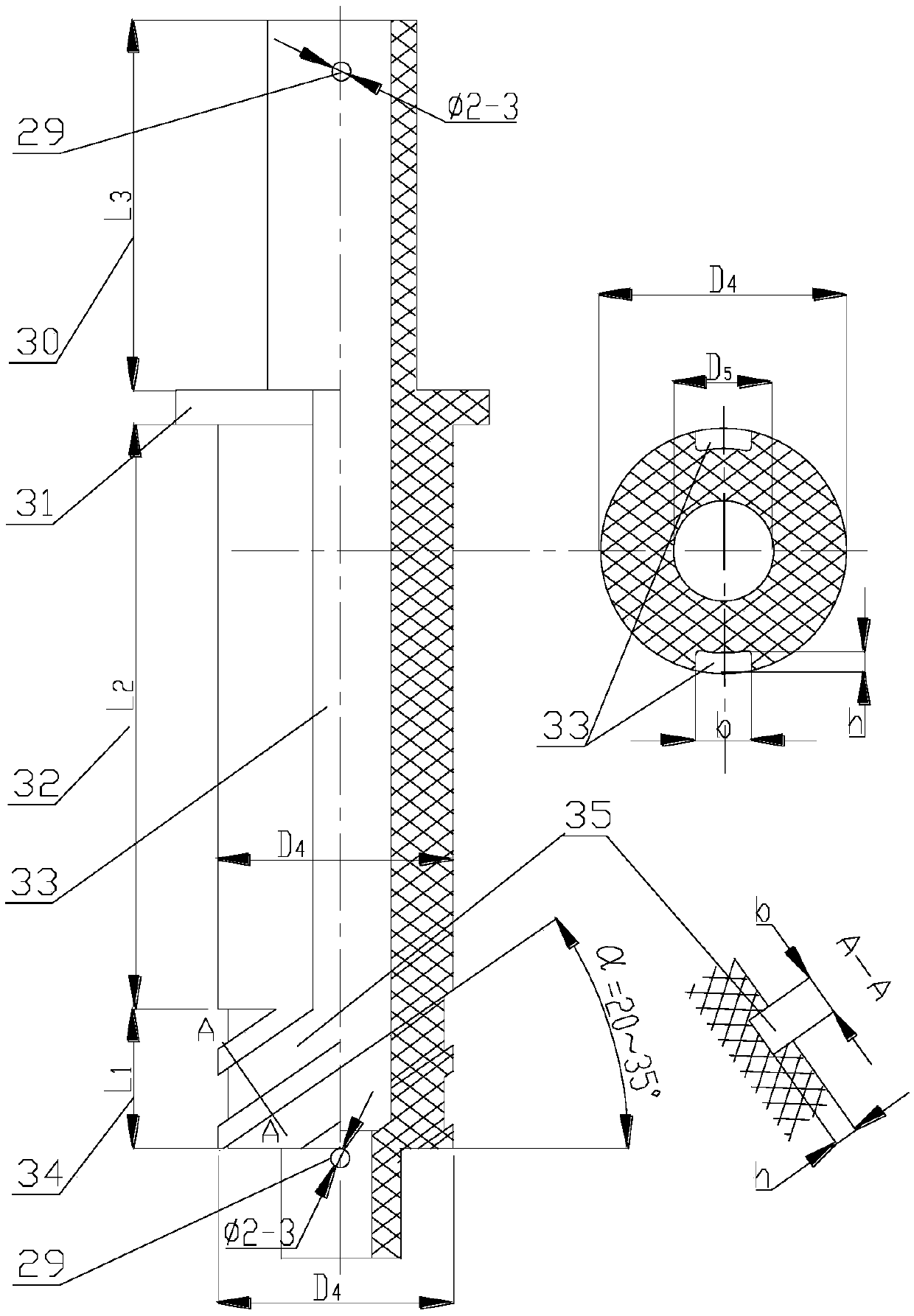

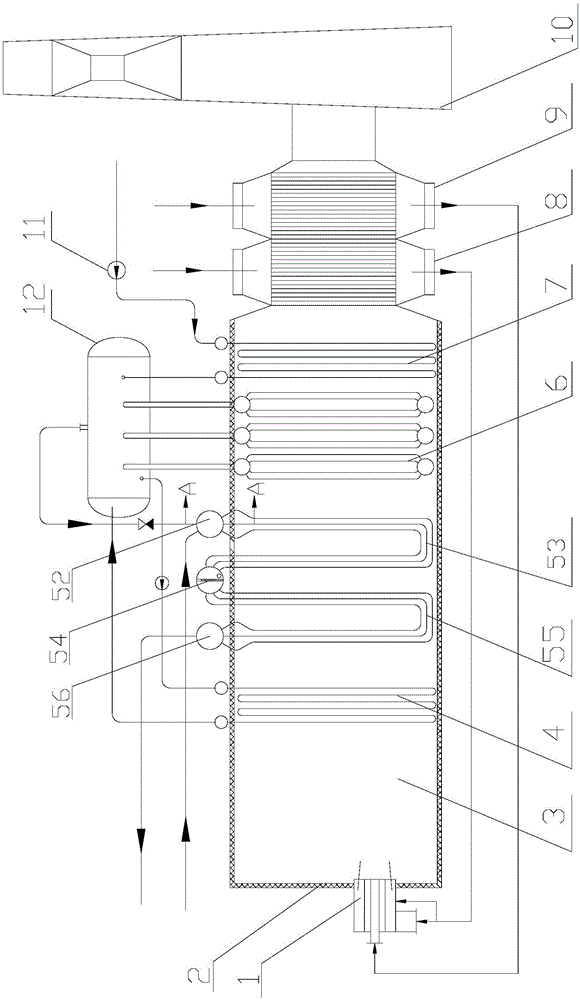

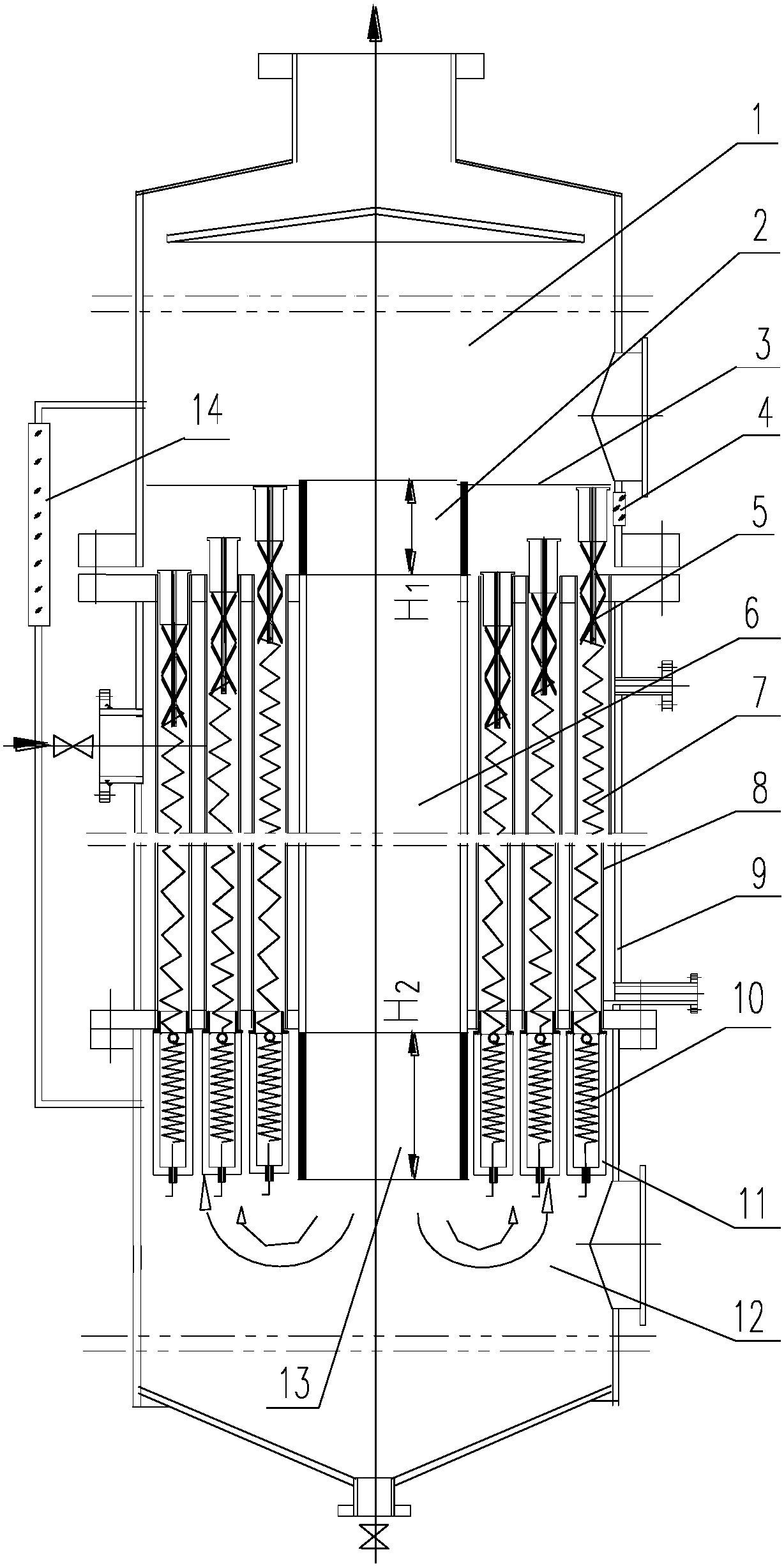

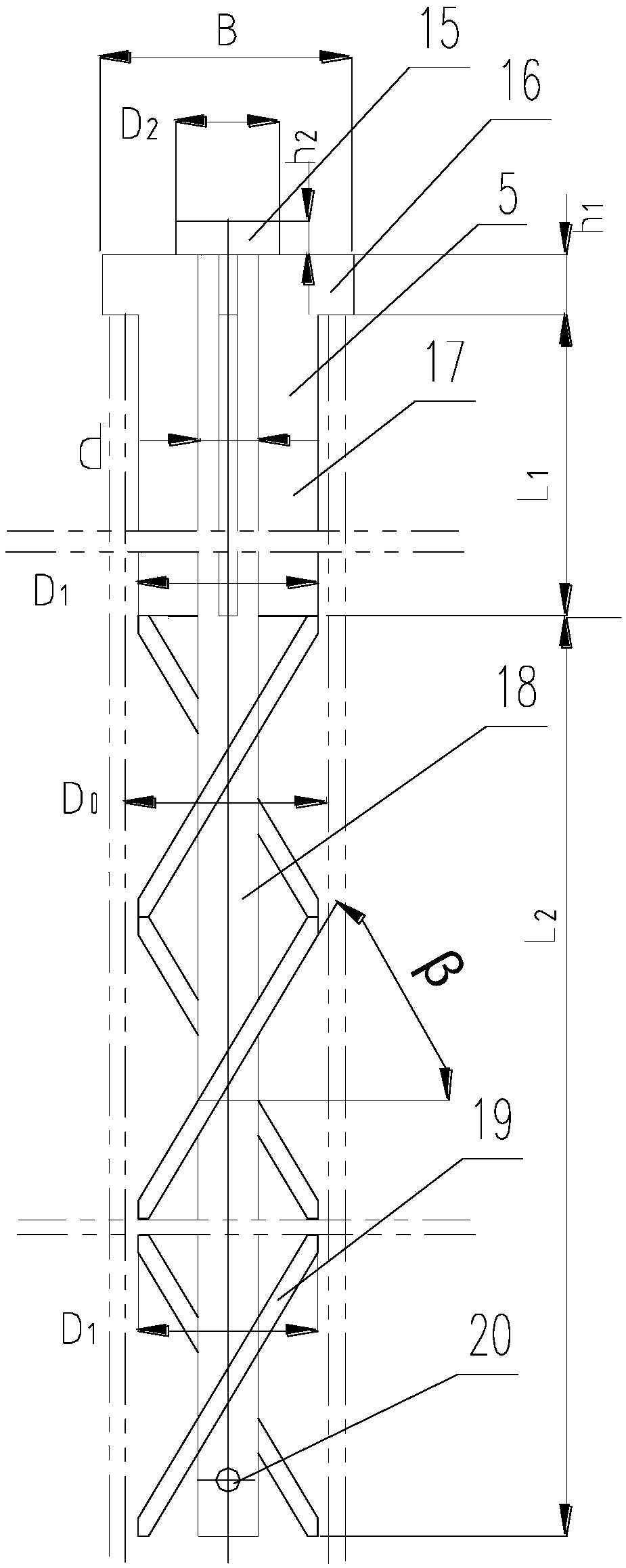

Undulating flow reciprocating screw vibrating cleaning type natural circulating evaporator

InactiveCN103712516ASolve the problem of insufficient cleaning capacitySimple structureCleaning heat-transfer devicesReciprocating motionReboiler

Disclosed is an undulating flow reciprocating screw vibrating cleaning type natural circulating evaporator. An undulating flow reciprocating screw of a steel wire structure is mounted in each heating pipe, the lower end of each undulating flow reciprocating screw is connected with a soft spring which penetrates a fixing plate to be wound and fixed on an assembling plate, and elastic coefficient of the soft springs is low. A fluid dynamic cleaning principle of the undulating flow reciprocating screws includes that high volatility of gas-liquid two-phase flow in the heating pipes is utilized to generate strong radial vibration on self-acting fluid dynamic force and generate axial reciprocating motion with stroke larger than one own screw pitch at the same time, and automatic cleaning of dirt on the inner wall of each pipe and convective heat transfer enhancing are realized. An undulating flow reciprocating screw cleaning mechanism is simple in structure, high in dirt cleaning capability, good in cleaning uniformity, suitable for natural circulating evaporators where dirt is prone to growing, and suitable for outer-heating-chamber natural circulating evaporators and outer-heating-chamber natural circulating reboilers.

Owner:俞天翔

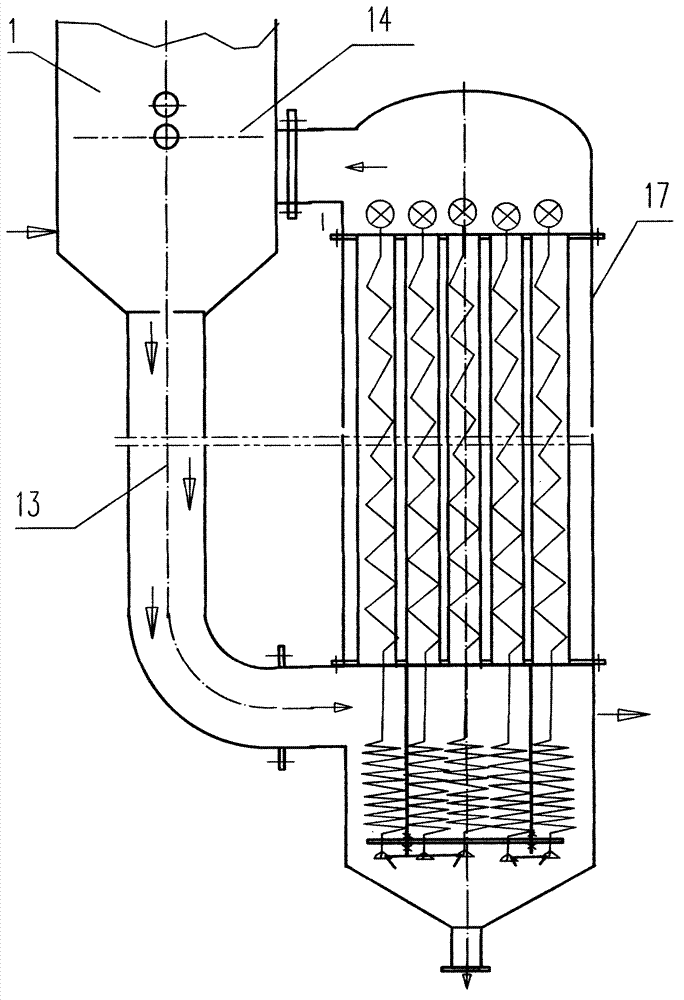

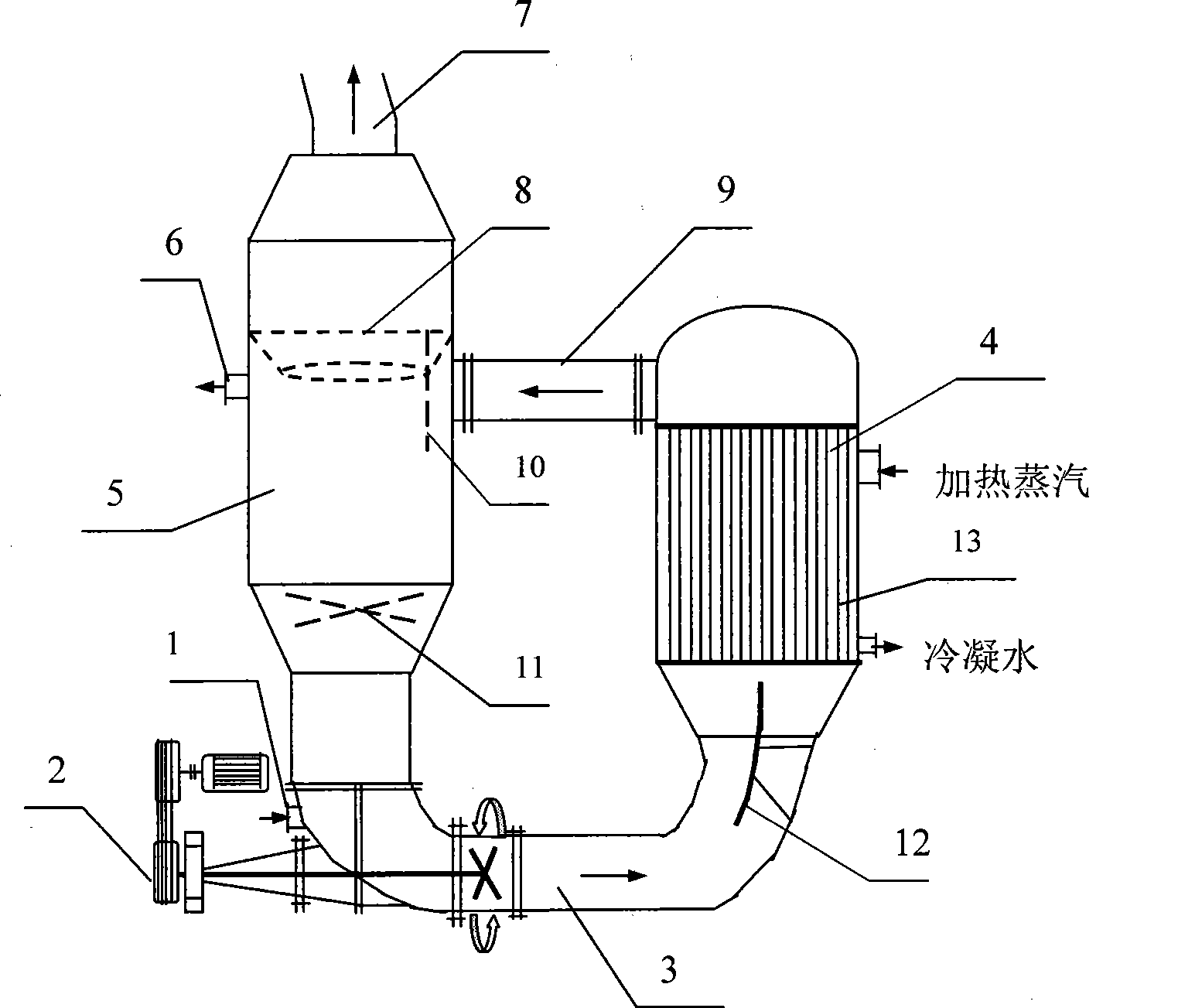

Full forced circulation type evaporator

ActiveCN101391784ALess investmentIncrease production capacityAluminium oxides/hydroxidesEngineeringTubes types

The invention discloses a completely mandatory circulation evaporator which comprises a boiling chamber (5) and a heating chamber (4); the boiling chamber (5) is provided with a feed inlet (1), a feed outlet (2), and a secondary steam export (7); the heating chamber (4) is provided with a heating tube array (13); the upper parts of the boiling chamber (5) and the heating chamber (4) are connected by an upper circulating tube (9), and the lower parts thereof are connected by a lower circulating tube (3); the lower circulating tube (3) at the lower part of the boiling chamber (5) is connected with a forced circulation pump (2); the internal upper part of the boiling chamber (5) is provided with a deflection baffle (8) and a flow around baffle (10); the internal lower part of the boiling chamber (5) is provided with a extinction vortex cross baffle (11); and a guiding plate (12) is arranged in the lower circulating tube (3) which is connected with the lower part of the heating chamber (4). The invention is used for transforming the original external heating type natural circulation (tube type) evaporator (four-effect countercurrent operation), has saved investment and rapid efficiency, as well as high production capacity, and is difficult to cause the heating tube to be fouled and obstructed.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

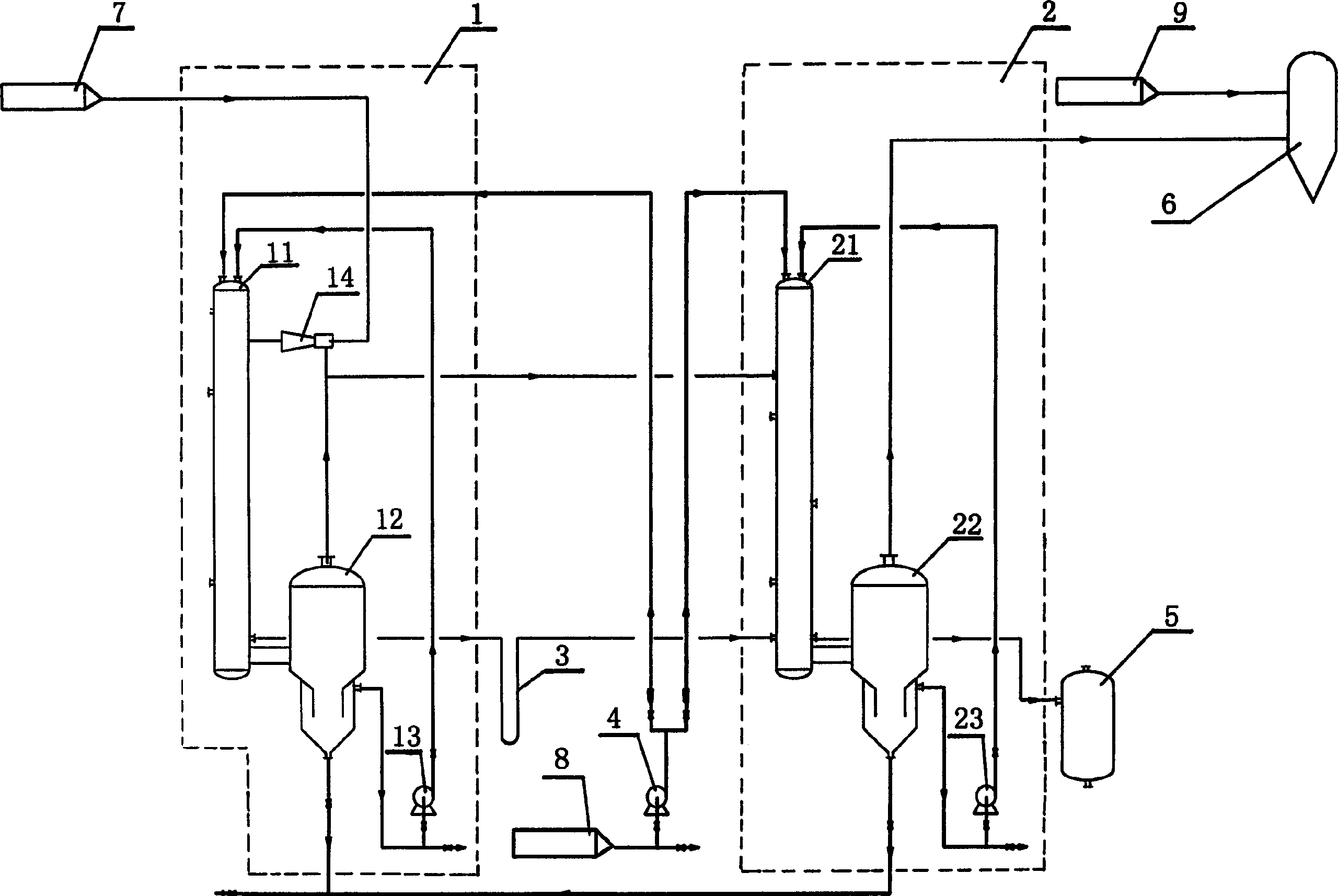

Double-effect evaporating and crystallizing production process of low-solubility, easy-crystallizing and thermosensitive material

InactiveCN1454692ATake advantage ofReduce dosageSolution crystallizationMultiple-effect evaporationSolubilityEngineering

The invention is a double effect evaporation crystal craft for low solubility, easy to crystal, temperature-sensitive material. Parts of the second vapor distilled by the first effect appliance and the heated vapor which is put in continuously are pressed by the heat pump and are transmitted into the shell pass of the first appliance to be used as the heat source, the remanant second vapor distilled b the first effect appliance and the condensate discharged by the first outward circulation evaporator is put in the second outward circulation evaporator shell pass, the distilled vapor are used as the heat source of the second effect outward evaporator. Because that the water of the first effect appliance is used fully, it decreases the quantity of the vapor and the loss of heat energy.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

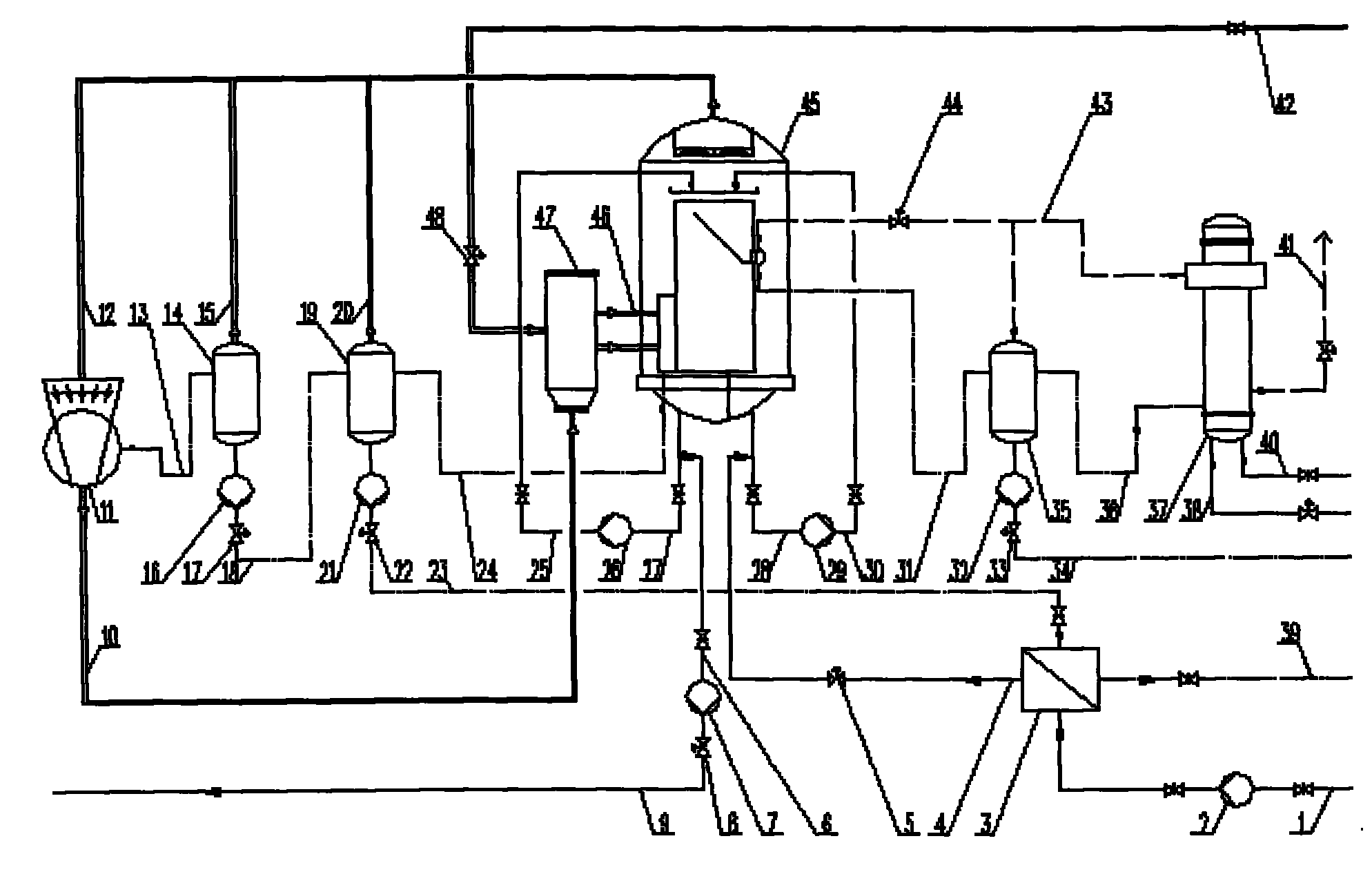

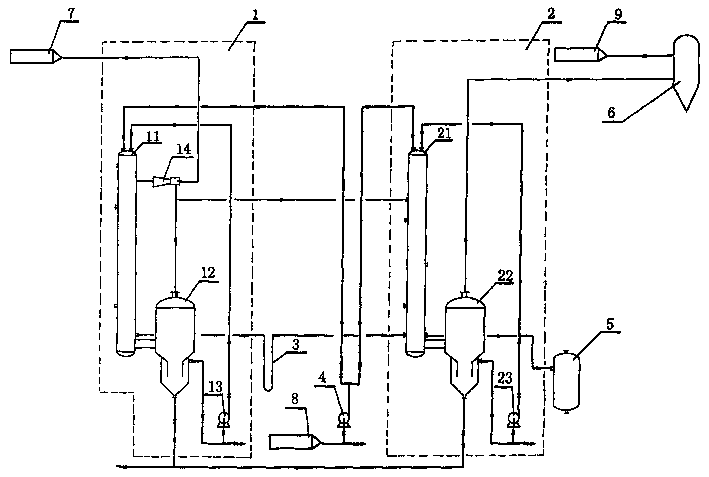

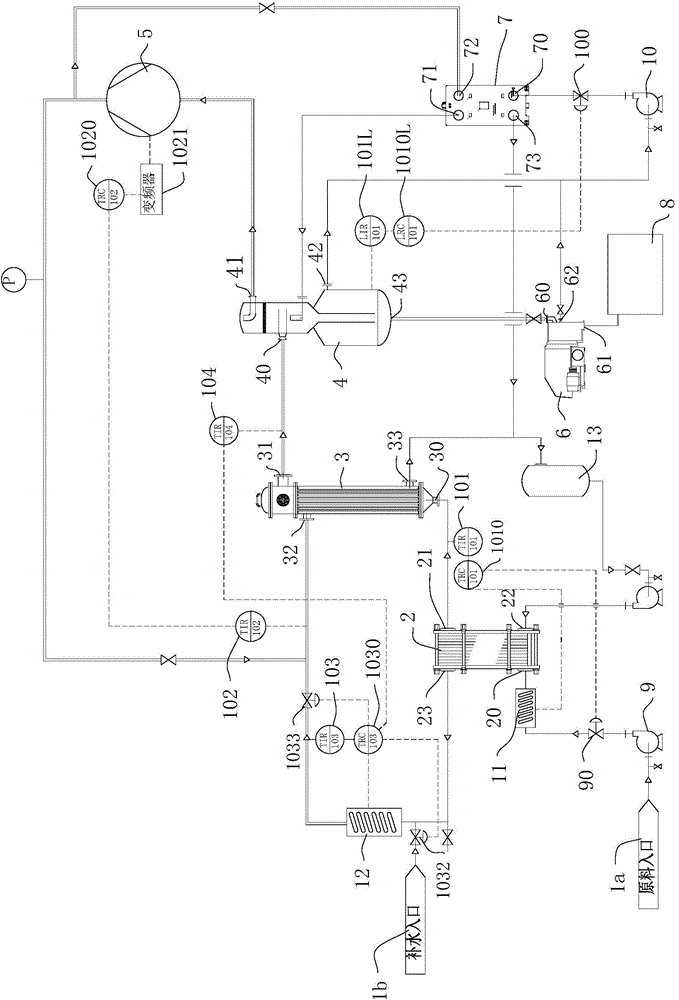

MVR (Mechanical Vapor Recompression) continuous evaporating crystallizing system

ActiveCN104524807AAchieve multi-stage recyclingImprove crystallization efficiencySolution crystallizationMultiple-effect evaporationWater savingVapor–liquid separator

The invention relates to an MVR (Mechanical Vapor Recompression) continuous evaporating crystallizing system. The system comprises a raw material inlet, a water compensating inlet, a preheater, a climbing film evaporator, an air-liquid separator, a compressor, a pipeline heater, a crystallizing separator and four control circuits; an inlet, a first outlet, a second outlet and a third outlet are formed in the air-liquid separator; the preheater is connected with the climbing film evaporator through a pipeline; the climbing film evaporator is connected with the inlet of the air-liquid separator; the compressor is connected between the air-liquid separator and the climbing film evaporator through a steam conveying pipeline; a circulating evaporator is connected between the second outlet and the inlet; cooing water subjected to heat exchange through the climbing film evaporator and cooling water subjected to heat exchange through the circulating evaporator are treated as heat sources of the preheater; the cooling water output end of the preheater and the water supplementing inlet are used for compensating water to the system together; the crystallizing separator is connected with the third outlet of the air-liquid separator; the four control circuits are arranged in the system. The system has optimal and stable parameters, achieves water saving, energy saving and raw-material saving effects and also has a good crystallizing effect.

Owner:CHINA COAL ORDOS ENERGY CHEM COP LTD

Extracting liquid concentrating device

ActiveCN104922974AConcentration free adjustmentLow costFiltration circuitsMultiple-effect evaporationOrganic solventSolvent vapor

The invention discloses an extracting liquid concentrating device, comprising a concentrating system, a solvent recovery system and a concentration adjusting system. The device has the advantages that the principle that solvent vapor generated by organic solvent in an outer circulating evaporating separator and fresh steam are heated in a vapor-steam mode through a secondary heater is utilized; for concentration of aqueous extract, a secondary steam and the fresh steam are subjected to steam-steam mixed heating, and transferred to the outer circulating evaporating separator to serve as a heat source, so as to allow the extracting liquid to maintain a boiling state; part of the steam passing through the heater turns into condensate for preheating the extracting liquid; non-condensable gas of the steam and liquid solvent changing state after heat exchange are recycled properly, the remaining heat thereof is made full use to continue preheating the extracting liquid, and recycling of the organic solvent is realized through a plate heat exchanger; the device is energy-saving, efficient, consumption-reducing, low-cost and low-input during concentration process and concentration process of organic solvent, such as ethanol, and the concentration of the extracting liquid can be adjusted freely during the concentration process.

Owner:江西赫柏康华制药设备有限公司

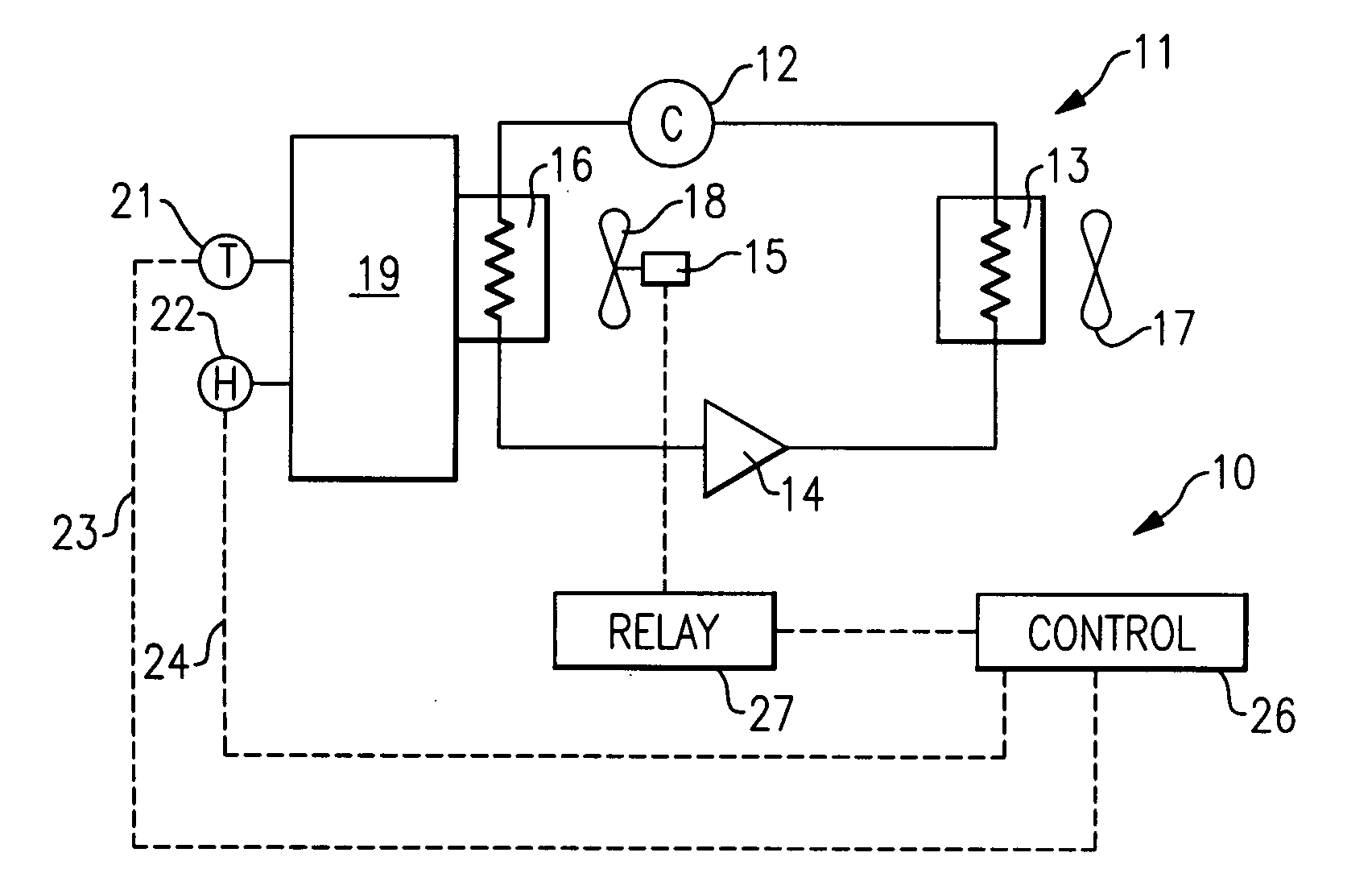

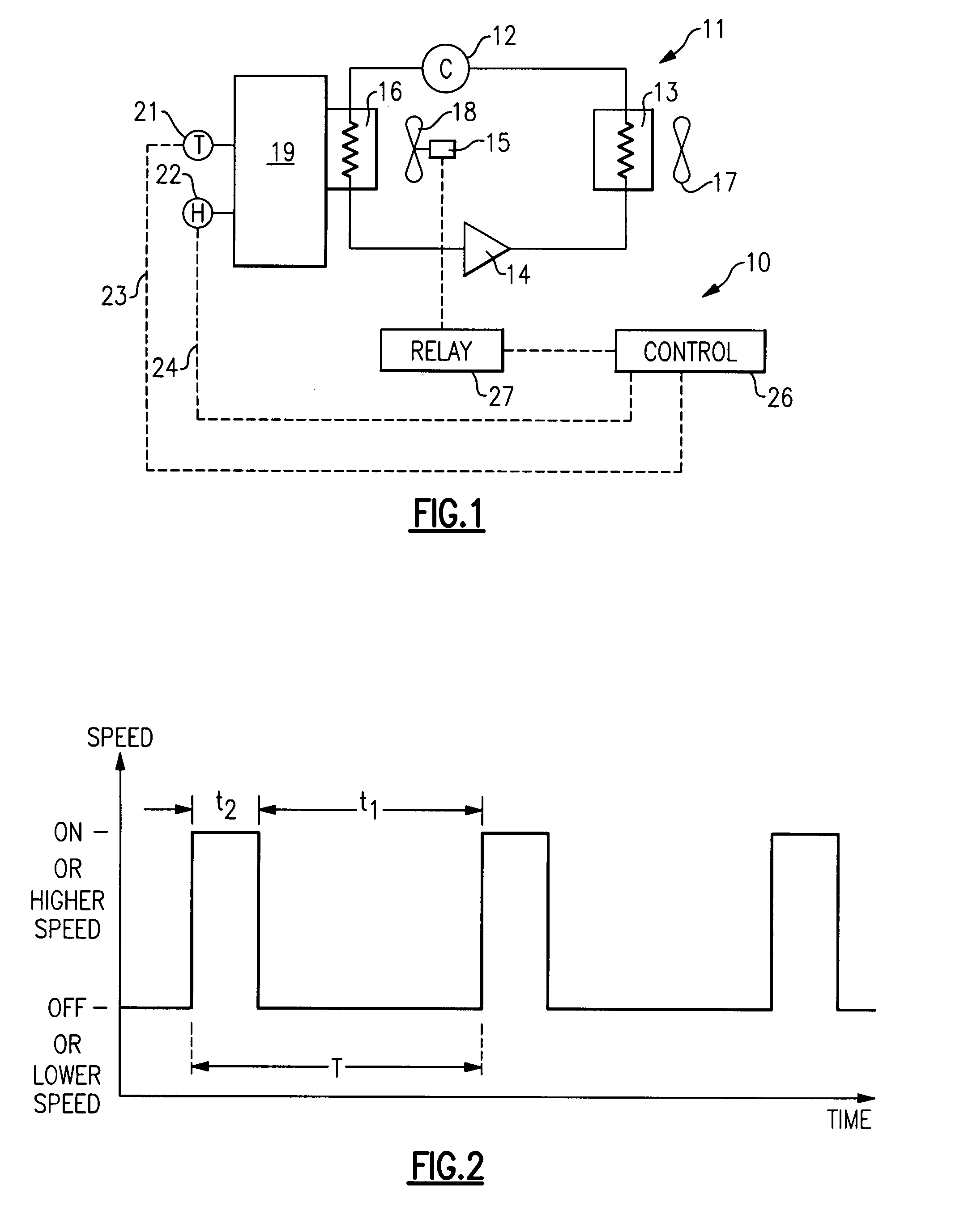

Method and apparatus for improving dehumidification

InactiveUS20100236262A1Improve cooling effectExtension of timeMechanical apparatusSpace heating and ventilation safety systemsLow speedControl theory

Comfort temperature and humidity levels in a conditioned space are controlled by cycling the speed of an evaporator fan motor in such a manner that, during time periods when higher sensible capacity is desired, the time in which the fan motor operates at a higher speed is increased, and during time periods when a higher latent capacity is desired, the time in which the fan motor operates at a lower speed is increased. The fan motor may be a single speed motor that is switched between on and off positions, or it may be a multiple speed motor that is cycled between a higher speed and a lower speed.

Owner:CARRIER CORP

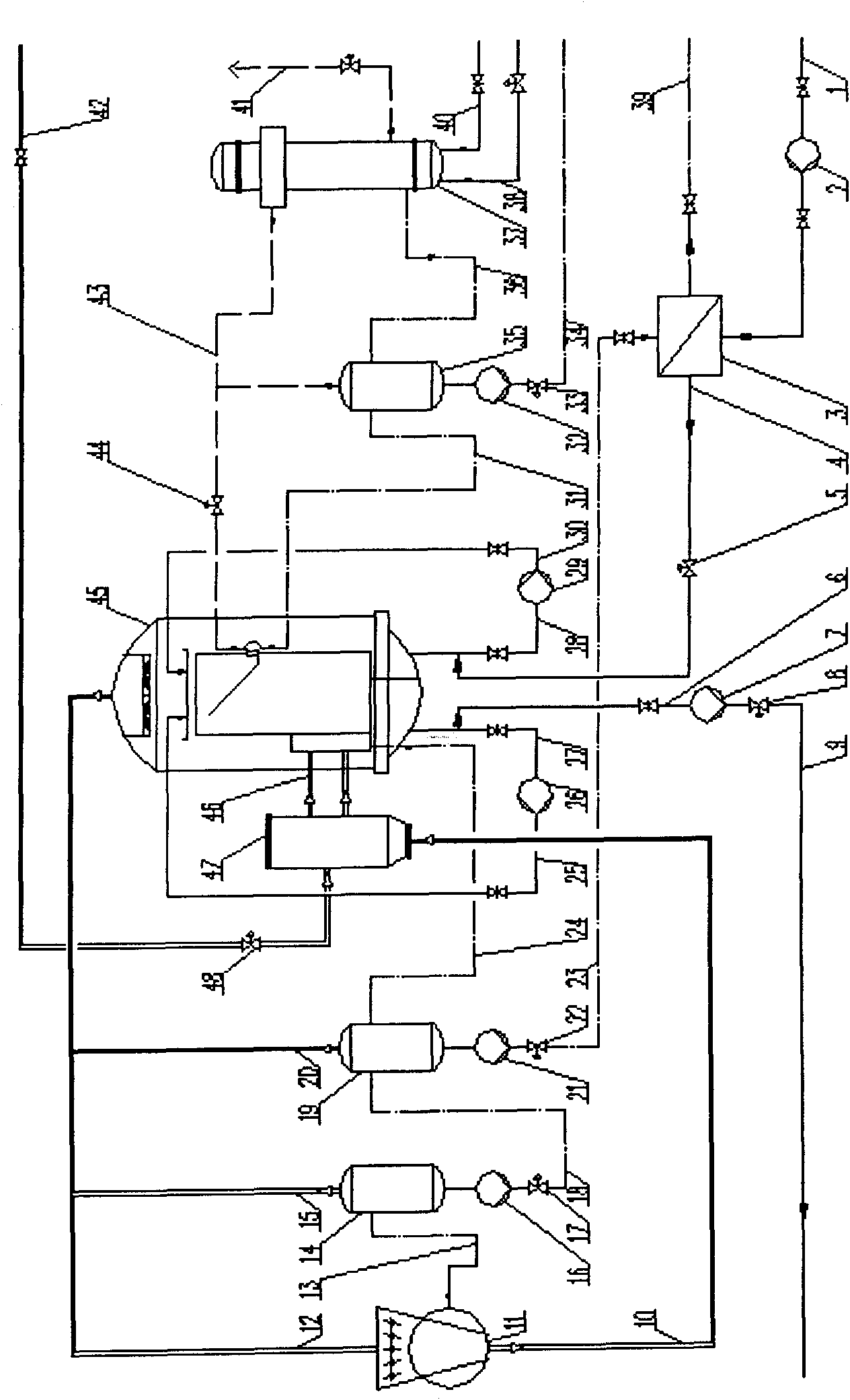

MVR continuous evaporative crystallization system

InactiveCN105879426AIncrease profitImprove energy savingEvaporator accessoriesSolution crystallizationEngineeringVacuum pump

The invention relates to a MVR continuous evaporative crystallization system which comprises a heating system, an evaporative crystallization system, a crystallization separation system and a condensation system. The heating system comprises a live steam compensation pipeline, a steam compressor and a material preheating device. The evaporative crystallization system comprises a circulation evaporator and a crystallizer. The crystallization separation system comprises a centrifugal machine. The condensation system comprises a condensate collection tank. The circulation evaporator comprises is connected with the condensate collection tank through a condensate water inlet pipe. The material preheating device comprises a primary preheater, a secondary preheater and a tertiary preheater. A second branch pipe, used for conveying live steam, connected to the steam compressor is connected into the tertiary preheater. The condensate collection tank is connected with the secondary preheater through a condensate water outlet pipe. The condensate collection tank is connected with the primary preheater through a non-condensation gas pipe. A non-condensation gas outlet of the primary preheater is connected with a vacuum pump. The MVR continuous evaporative crystallization system has the advantages of being high in heat utilization rate, good in energy-saving performance, low in pollution, high in efficiency and stable in work.

Owner:WENZHOU TAIKANG EVAPORATOR

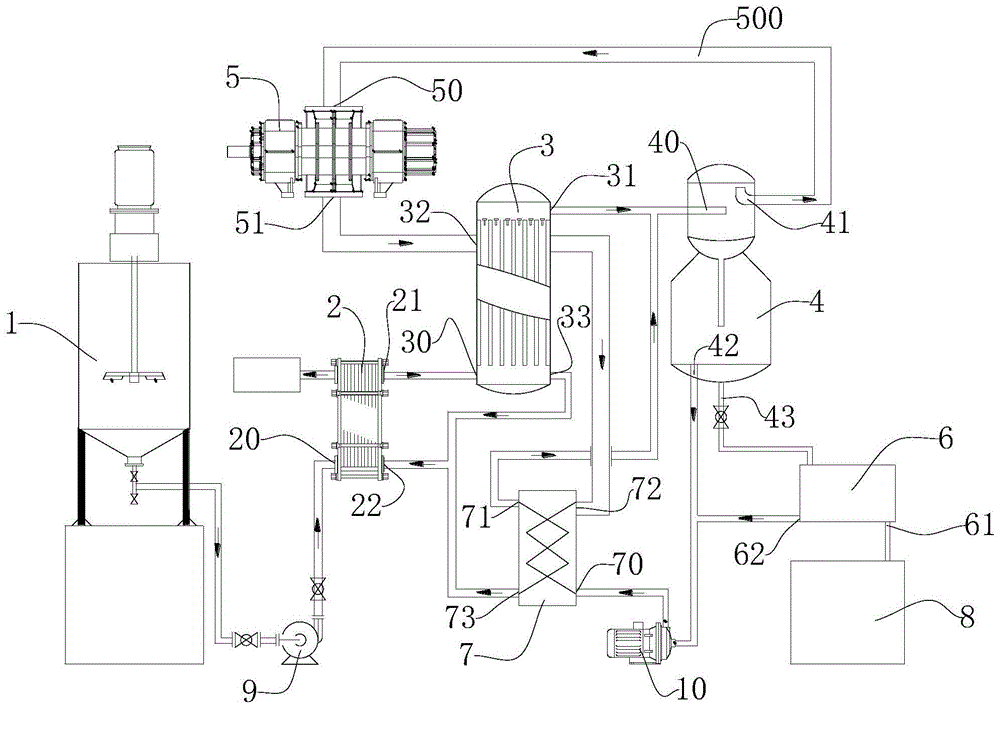

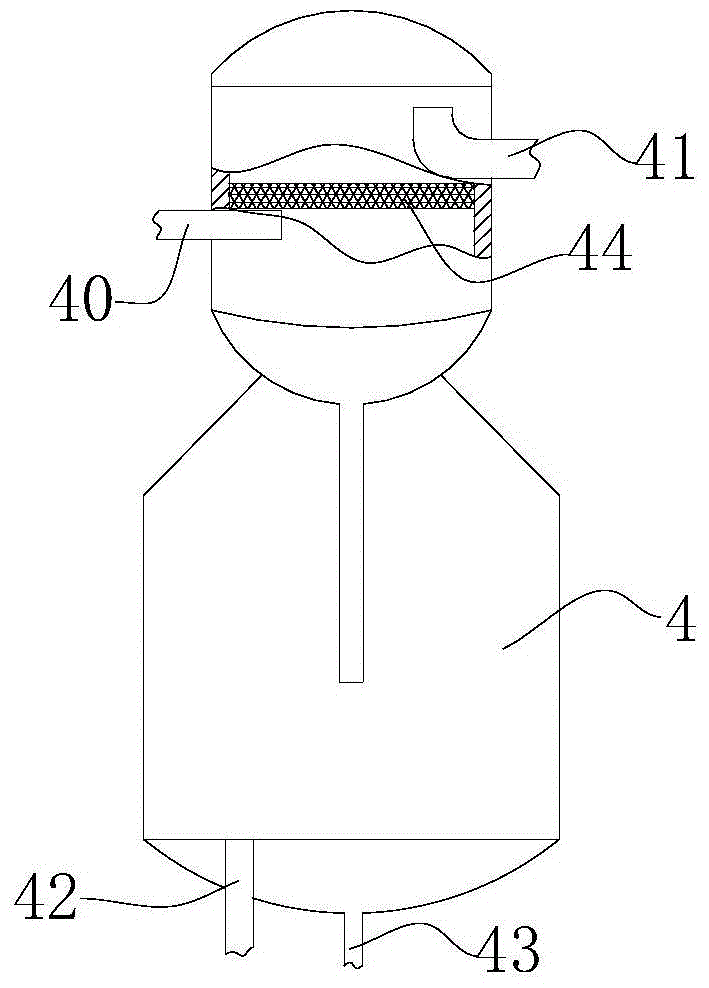

Continuous evaporation and crystallization device and method capable of saving energy by mechanical steam recompression

ActiveCN104524798AConducive to continuous crystallizationHigh crystallinityEvaporator accessoriesSolution crystallizationVapor–liquid separatorEngineering

The invention relates to a continuous evaporation and crystallization device and method capable of saving energy by mechanical steam recompression. The continuous evaporation and crystallization device comprises a preheater, a film-rising evaporator, a compressor, a circulating evaporator, a gas-liquid separator and a crystallization separator, wherein the gas-liquid separator is provided with an inlet, a first outlet, a second outlet and a third outlet; the preheater is connected with the film-rising evaporator by a pipeline, and the film-rising evaporator is connected with the inlet of the gas-liquid separator; the compressor is connected between the gas-liquid separator and the film-rising evaporator by a steam conveying pipeline; the circulating evaporator is connected between the second outlet and the inlet by a pipeline; cooling water after heat exchange of the film-rising evaporator and cooling water after heat exchange of the circulating evaporator are used as heat sources of the preheater, and are fed into the preheater for performing supplement heating on materials flowing through the inner part of the preheater; and the crystallization separator is connected with the third outlet in the gas-liquid separator. The continuous evaporation and crystallization device and method have the advantages that the cost is low, the materials are not wasted, the continuity is good and the energy-saving effect is good.

Owner:山西凤霖板业有限公司

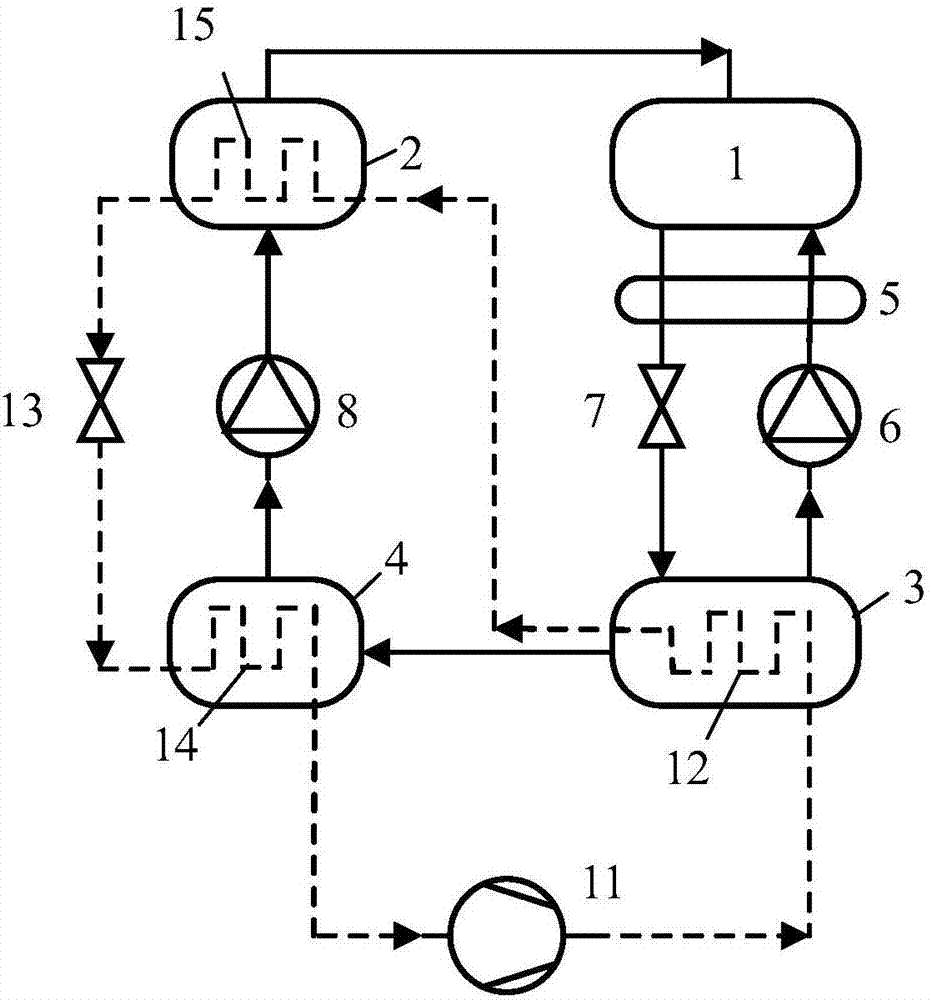

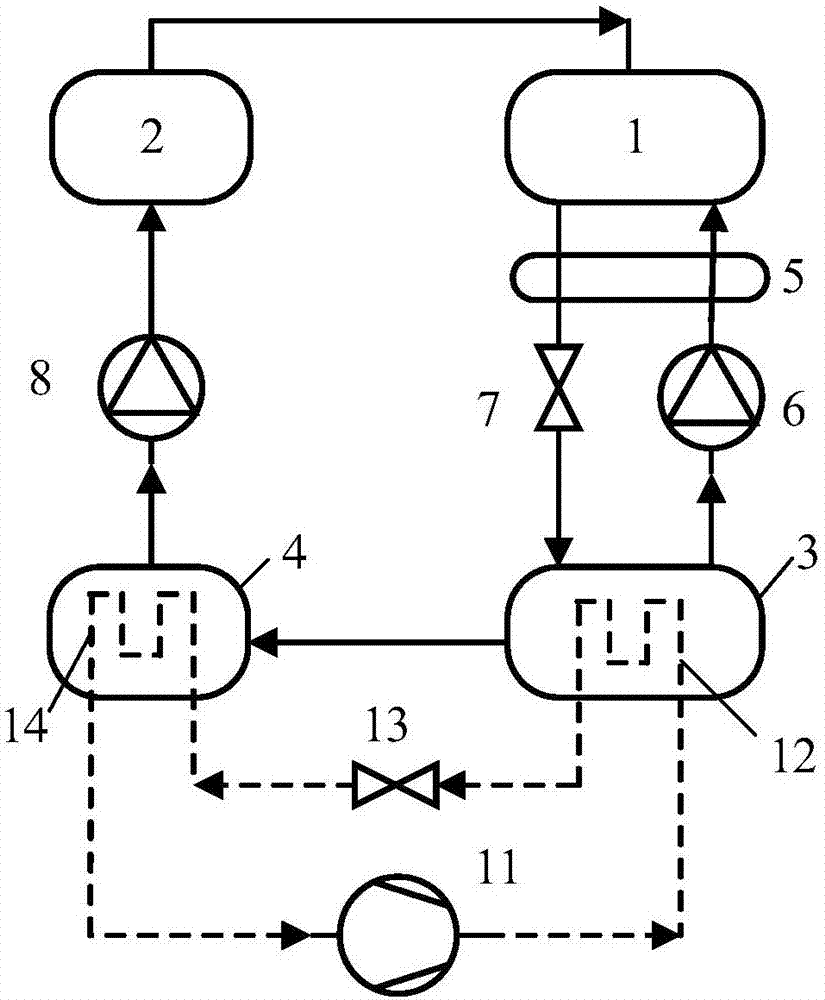

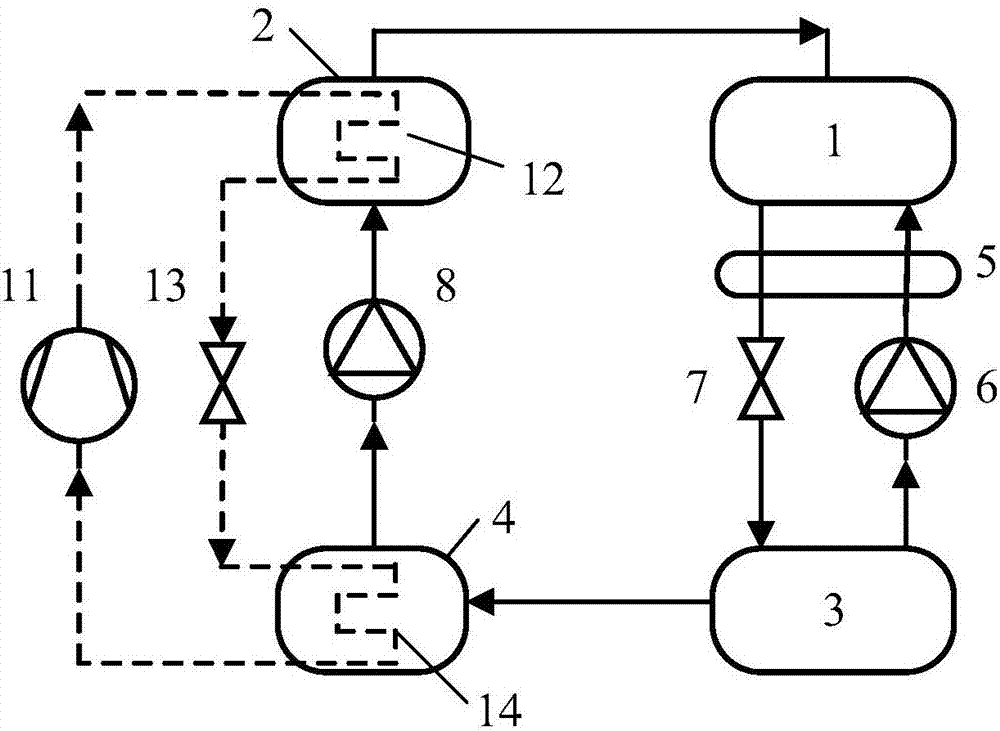

Heat coupling compression absorption type waste heat recovering type heat pump circulation system and method

The invention provides a heat coupling compression absorption type waste heat recovering type heat pump circulation system. The heat coupling compression absorption type waste heat recovering type heat pump circulation system comprises a compression heat pump subcycle system and an absorption heat pump subcycle system; the compression heat pump subcycle system comprises a compression machine (11), a first compression circulation condenser (12), a second compression circulation condenser (15) and a compression circulation evaporator (14); the absorption heat pump subcycle system comprises an absorber, a generator (3), a solution pump (6), a cooling medium pump (8), an absorption circulation condenser (4), an absorption circulation evaporator (2) and a solution heat recovery device (5). The invention further provides a heat coupling compression absorption type waste heat recovering type heat pump circulation method. A solution for improving compression heat pump temperature rise capacity and the absorption heat pump efficiency is provided, and an efficiency circulation manner is provided for waste heat recovering.

Owner:SHANGHAI JIAO TONG UNIV

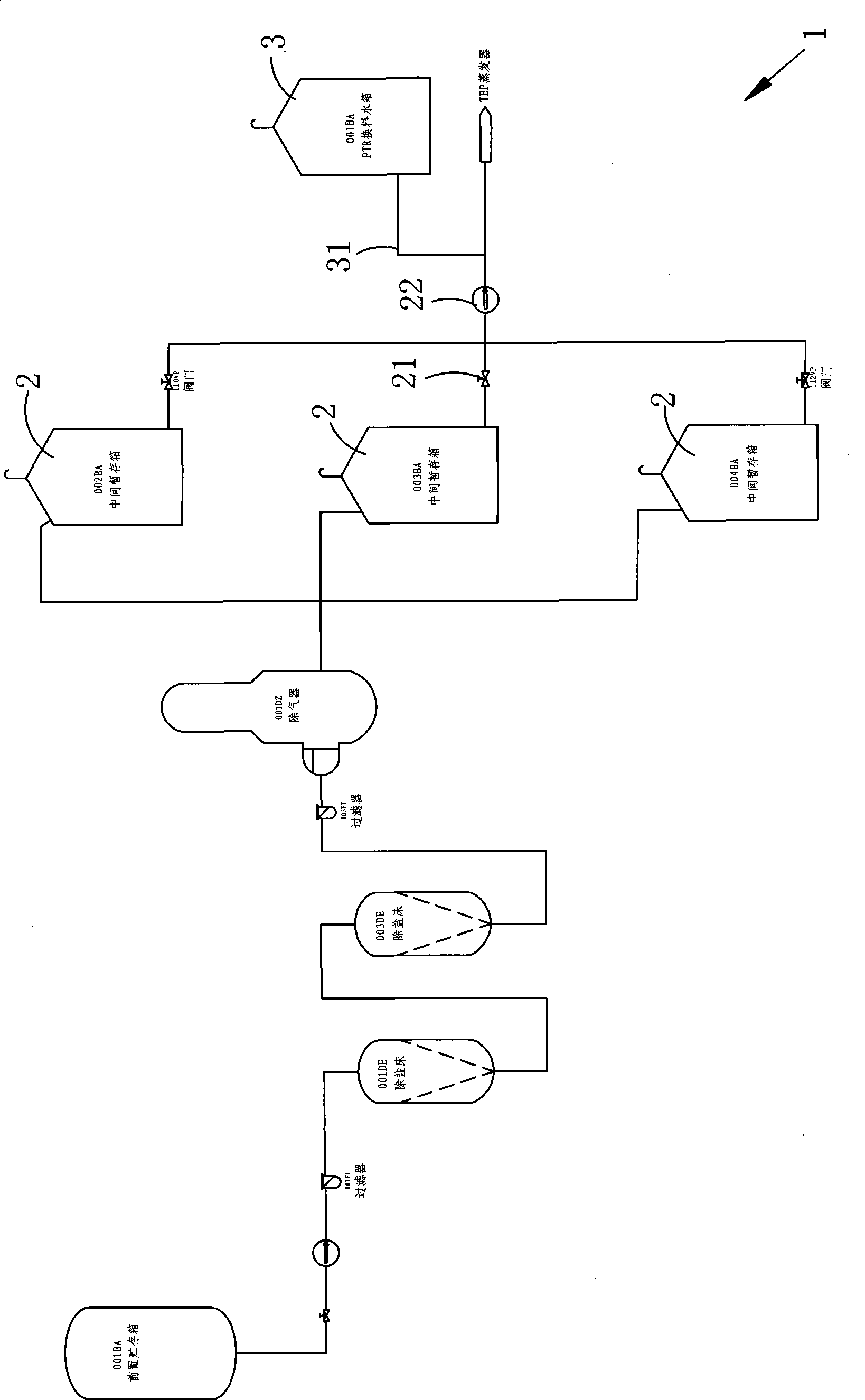

Method for connecting and controlling pipelines of boron recovery system during overhaul

InactiveCN101521050AReduce workloadLow running costNuclear energy generationBoron-oxygen compoundsNuclear engineeringPre treatment

The invention provides a method for connecting and controlling pipelines of boron recovery system during overhaul. The boron recovery system comprises an intermediate register, wherein pretreated reactor coolant is arranged in the intermediate register; the lower reach of the intermediate register is provided with a material-change water tank; and the material-change water tank is connected with the intermediate register. During overhaul, the characteristic that the reactor coolant is low in radioactivity level after pretreatment is fully utilized; the intermediate register is directly connected with the material-change water tank; and by controlling a valve switch, the reactor coolant can be directly sent into the material-change water tank to be reused without being decomposed into boric acid and stack-level make-up water through the treatment of a circulation evaporator. Therefore, the technical proposal has the advantages of reducing the workload of a recycling evaporator in the boron recovery system, saving treatment time and reducing operation cost.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

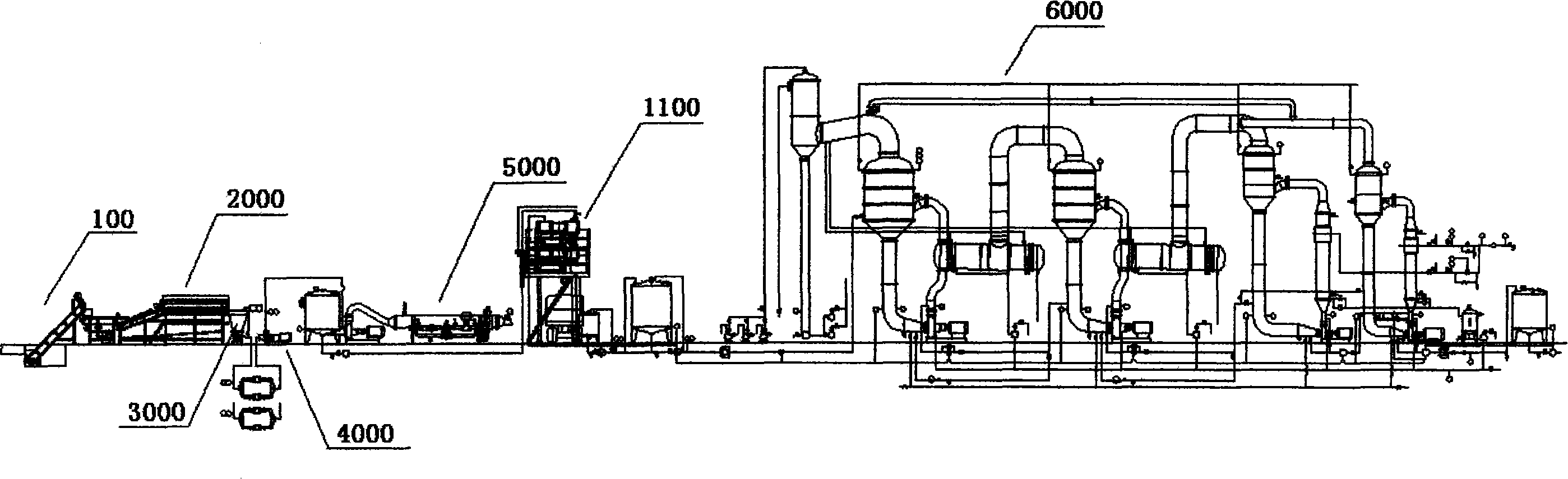

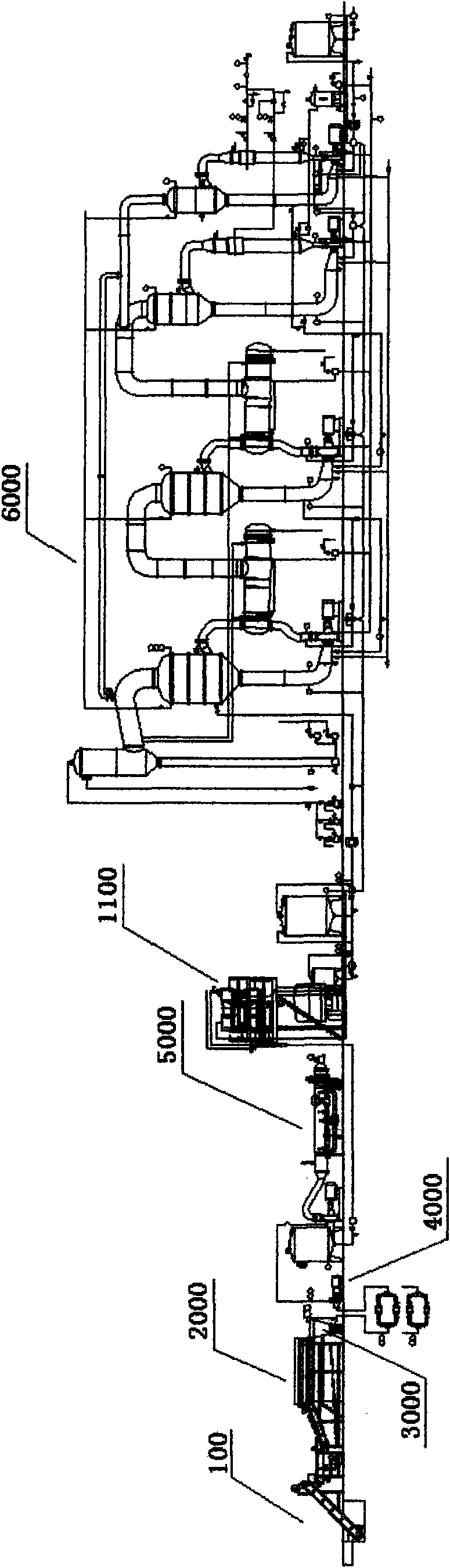

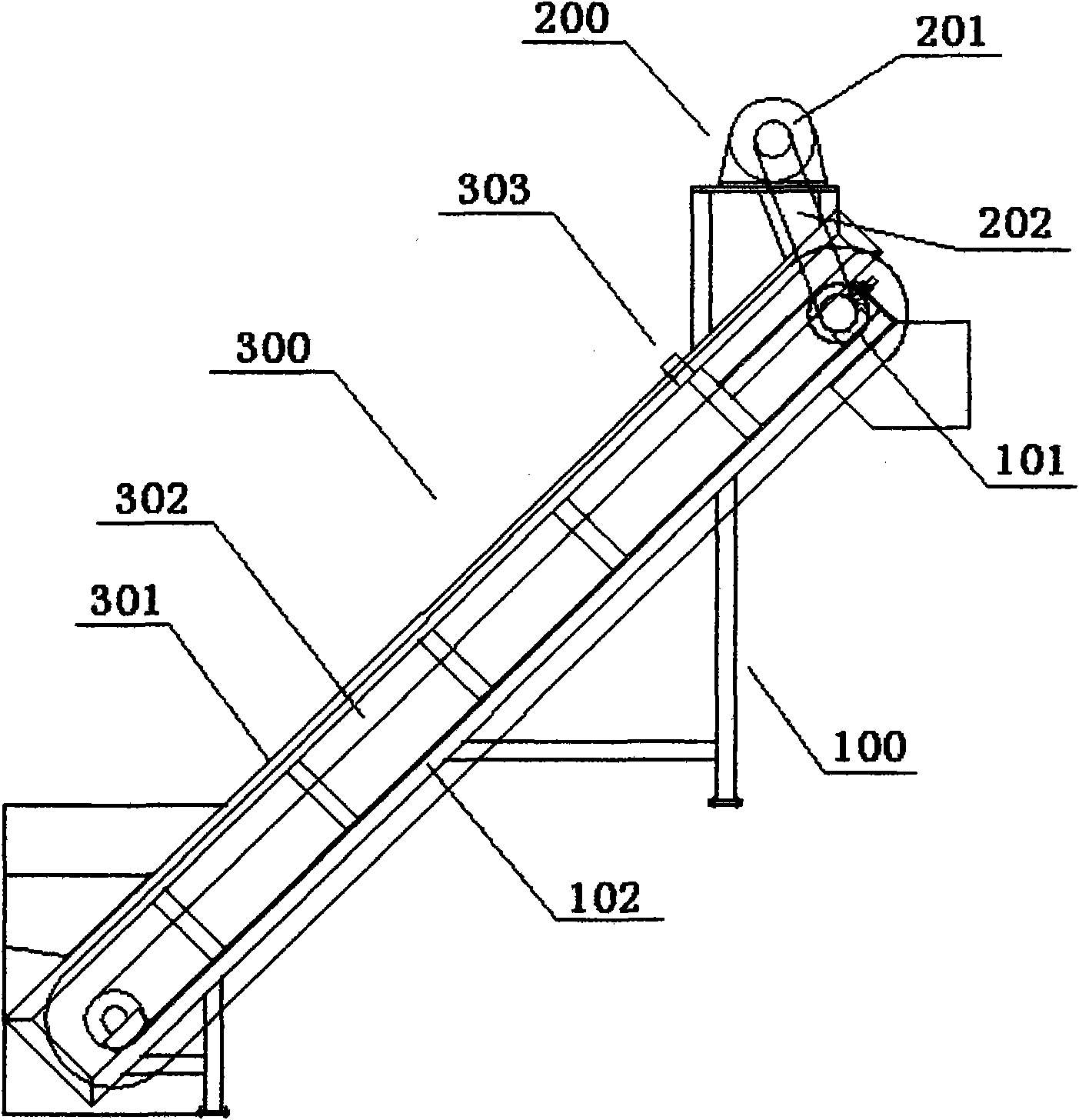

Complete production equipment for tomato sauce

ActiveCN101889675AReasonable structureLarge amount of processingFood preparationFood treatmentEngineeringForced circulation

The invention discloses complete production equipment for tomato sauce, comprising a scraper lifting machine, a floatation machine, a crushing screw rod pump, a crushing pump, a pre-heater, a beating machine, a beating storage tank and a triple-effect four-section forced-circulation evaporator; one end of the floatation machine is connected with a scraper lifting machine and the other end is connected with the crushing screw rod pump; the crushing screw rod pump is connected with the crushing pump by a fixed-cutter weed extractor; the crushing pump is connected with the pre-heater for preheating the tomato sauce via the crushing storage tank; the discharge end of the pre-heater is connected with the beating machine of which one end is provided with the beating storage tank; the pipeline of the beating storage tank is connected with the triple-effect four-section forced-circulation evaporator; and the scraper lifting mechanism is aslant and fixedly installed on the frame and transmitted by a transmission device. The complete production equipment for tomato sauce of the invention has the advantages of advanced design, reasonable structure, high treatment capacity, high efficiency, convenient operation and easy maintenance.

Owner:上海神农节能环保科技股份有限公司

Device for producing hydrated lithium hydroxide on basis of MVR and production method thereof

InactiveCN108298569ASmall amount of lithiumReduce fouling frequencyEvaporation with vapour compressionEvaporator accessoriesLithium hydroxideForced circulation

The invention discloses a device for producing hydrated lithium hydroxide on the basis of MVR. The device includes a raw material tank, a condensate water preheater, a vapor preheater, a forced circulation evaporator, a thickener, a centrifugal machine, a compressor and a vapor separating bag. Raw materials in the raw material tank are conveyed into the condensate water preheater through a feedingpump, and the condensate water preheater is communicated with the vapor preheater through a pipe; the raw materials in the vapor preheater are conveyed into the forced circulation evaporator througha pipe, and the forced circulation evaporator comprises a first heater, a second heater and a crystal separator. The device has the advantages that the interior of a heat exchanging pipe of a forced circulation heater is polished, the adhesive force of crystals adhering to a wall in a solution can be effectively reduced, it is ensured that the flow velocity of the solution in the heat exchanging pipe can reach 2.5 m / s or above, and meanwhile the pipe wall is flushed to further reduce the scaling frequency in the heat exchanging pipe; at the same time, the superheat degree of an outlet of the heater is lowered, flash evaporation and pipe blockage are effectively prevented from occurring in the pipes, and a pipe blockage situation caused by locally massive crystallization due to an excessively high superheat degree is reduced.

Owner:SHANGHAI ZHONGTENG ENVIRONMENTAL PROTECTION TECH CO LTD

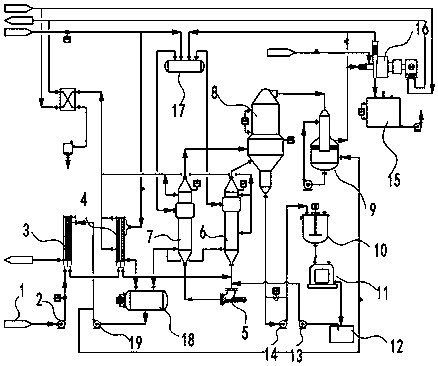

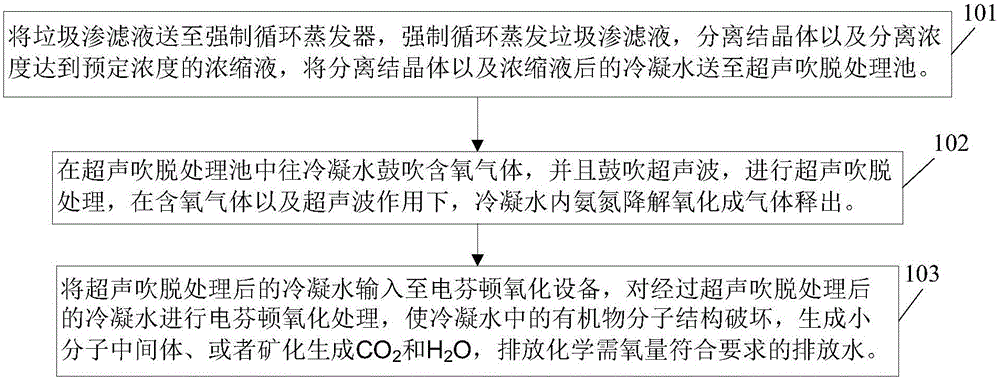

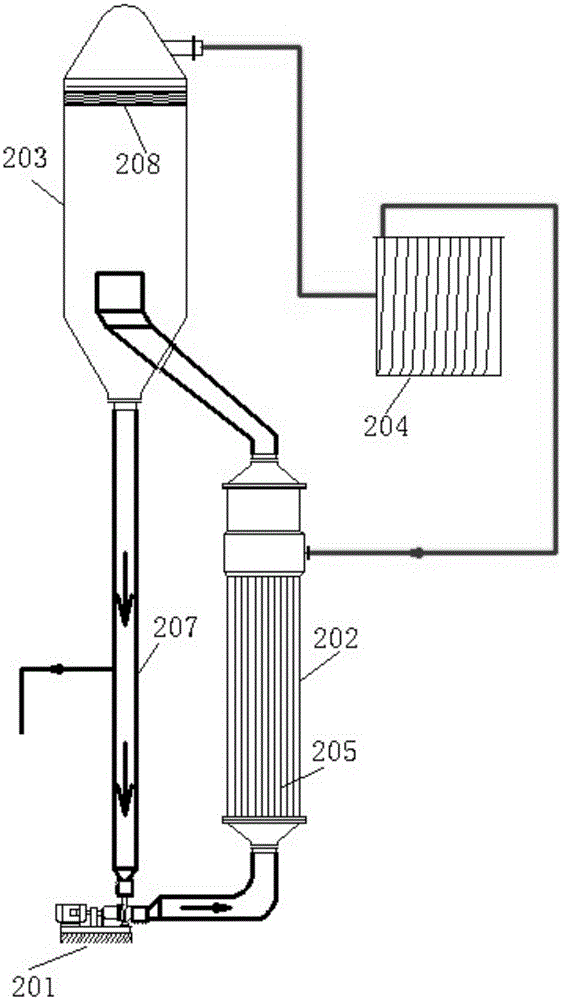

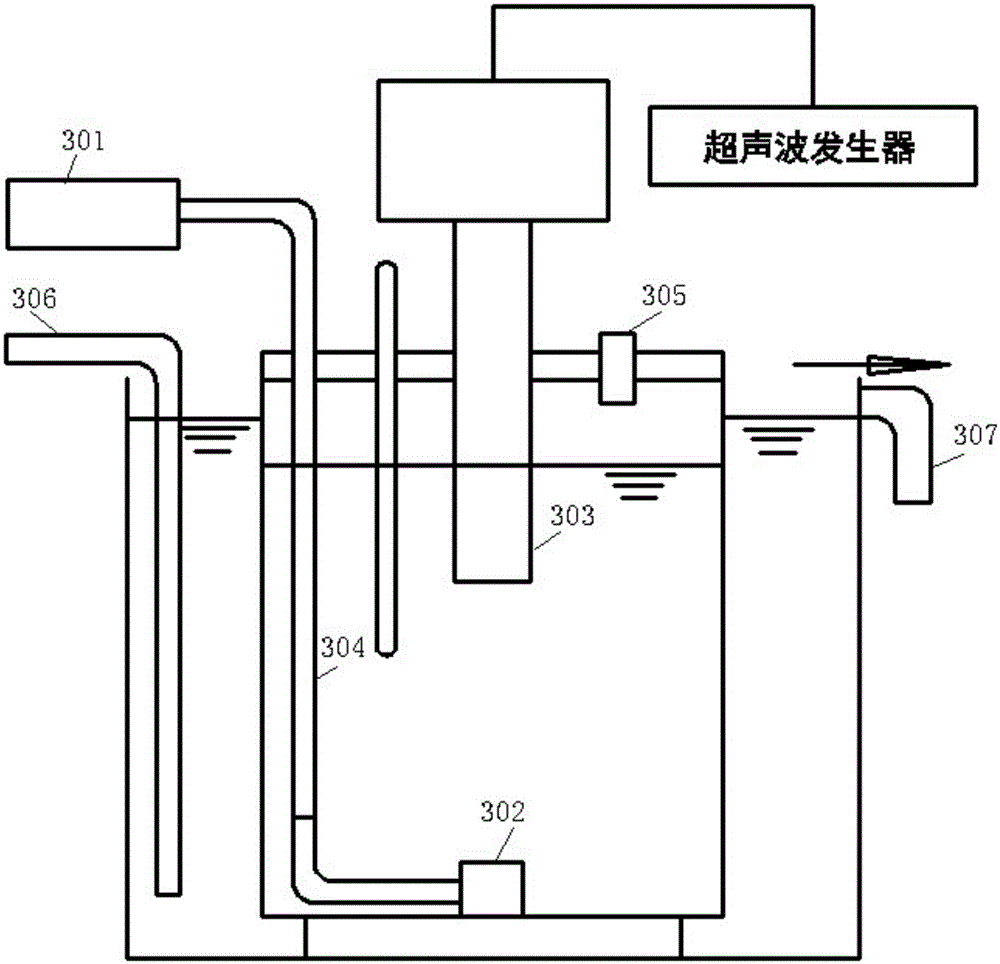

Garbage leachate treatment process and system

PendingCN105000740AReduce processing costsGood removal effectWater contaminantsMultistage water/sewage treatmentUltrasound - actionChemical oxygen demand

A garbage leachate treatment process and system are provided. The process includes the steps: sending a garbage leachate to a forced circulation evaporator, carrying out forced circulation evaporation of the garbage leachate, separating a crystal and separating a concentrated solution with the concentration reaching a preset concentration; sending condensed water discharged after the crystal and the concentrated solution of the garbage leachate are treated and separated in the step 1 to an ultrasonic blowoff treatment tank, blowing oxygen-containing gas to the condensed water, blowing ultrasonic waves, carrying out ultrasonic blowoff treatment, under the action of the oxygen-containing gas and the ultrasonic waves, allowing ammonia nitrogen in the condensed water to be degraded and oxidized into gas, and releasing; and inputting the condensed water after ultrasonic blowoff treatment to an electro-fenton oxidation device, carrying out electro-fenton oxidation treatment on the condensed water, destroying molecular structures of organic matters in the condensed water, generating small molecule intermediates, or mineralizing to form CO2 and H2O, and discharging discharged water having the chemical oxygen demand meeting requirements. The method has the advantages of energy-saving and environmental-protection application, and high processing efficiency.

Owner:GUANGZHOU SCHIN TECH IND CO LTD

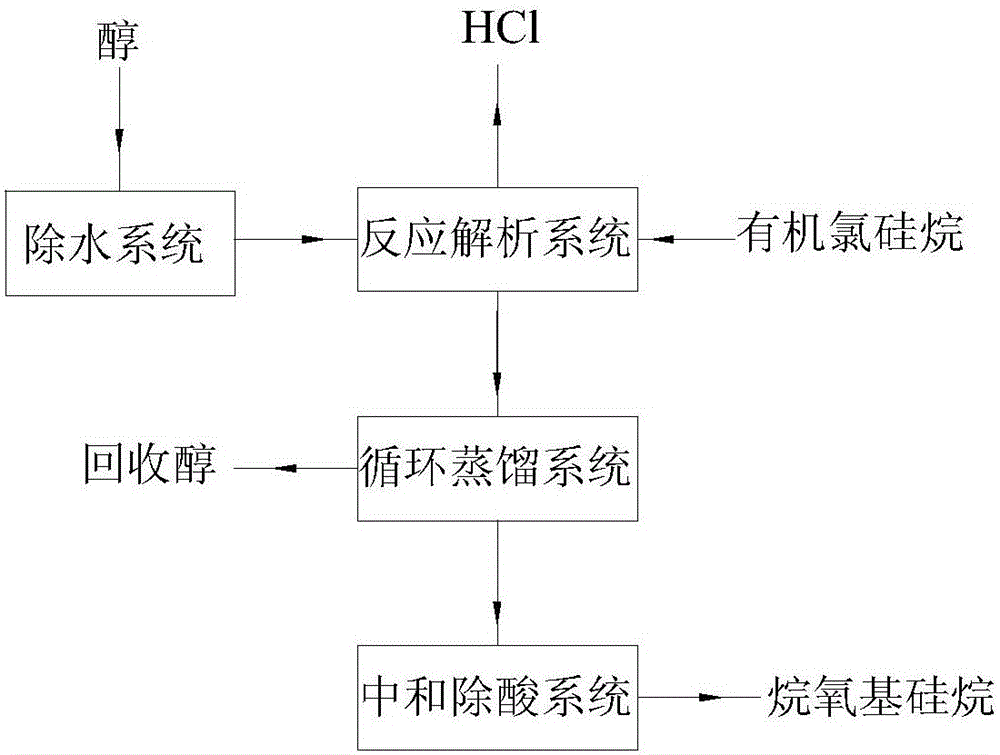

Production process of alkoxy silane

Owner:LUZHOU NORTH CHEM IND

Lithium deposition wastewater treatment system based on MVR (mechanical vapor recompression) evaporative crystallization and treatment method of system

InactiveCN108439685ASmall amount of lithiumSmall sodium sulfate contentWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentLepidoliteSodium sulfate

The invention discloses a lithium deposition wastewater treatment system based on MVR (mechanical vapor recompression) evaporative crystallization. The lithium deposition wastewater treatment system comprises a raw material tank, a condensate preheater, a vapor preheater, a forced circulation evaporator, a thickener, a centrifuge, a compressor and a vapor distribution drum, wherein raw materials in the raw material tank are input into the condensate preheater through a charging pump, and the condensate preheater is communicated with the vapor preheater through a pipeline; the raw materials inthe vapor preheater are input into the forced circulation evaporator through a pipeline, and the forced circulation evaporator comprises a heater I, a heater II and a crystallization separator, and the heater I and the heater II are mounted in a series connection manner. The lithium deposition wastewater treatment system has the following beneficial effects: in the actual production process, lithium carrying amount of anhydrous sodium sulfate is smaller than or equal to 0.08%; meanwhile, secondary steam condensate contains no lithium salt, content of sodium sulfate is smaller than or equal to100 PPm, and the system mainly applies to treatment of sodium sulfate wastewater generated by production of industrial-grade and battery-grade lithium carbonate from lepidolite and spodumene as raw materials.

Owner:SHANGHAI ZHONGTENG ENVIRONMENTAL PROTECTION TECH CO LTD

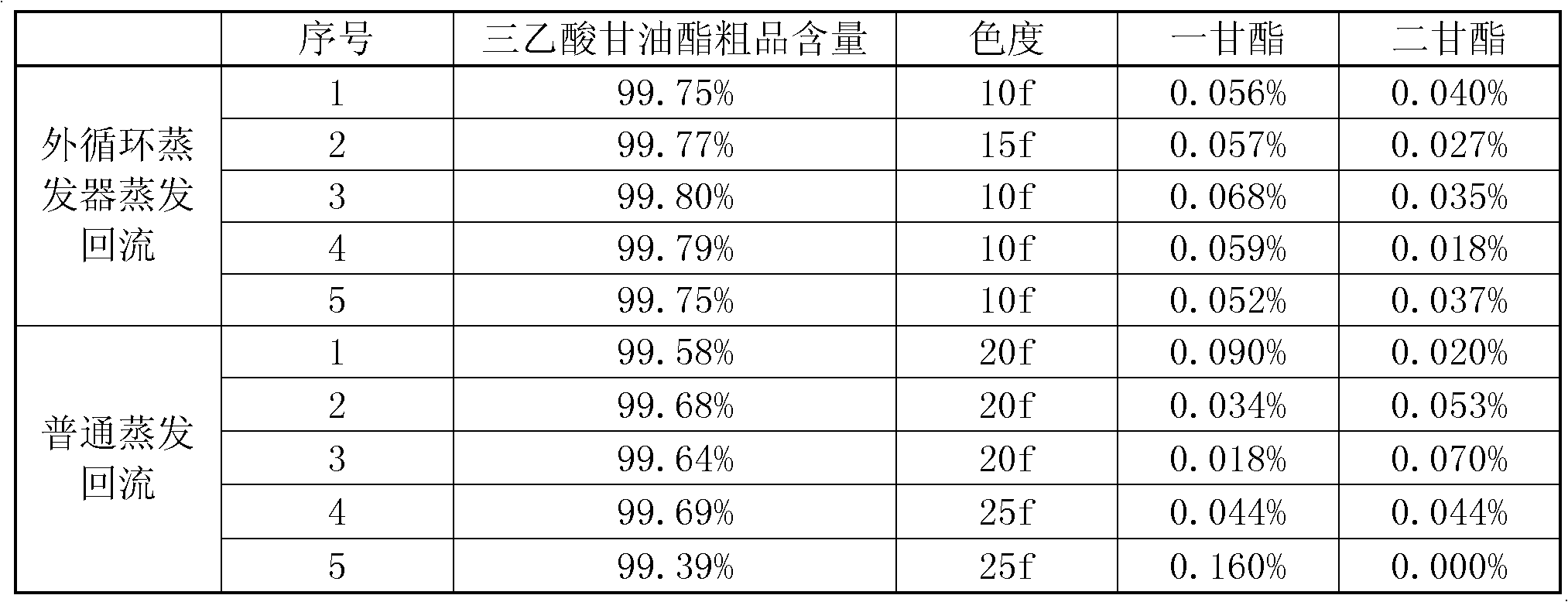

Method for preparing glycerol triacetate

ActiveCN101973877AAddressing Inadequate ContactAddress reactivityOrganic compound preparationCarboxylic acid esters preparationFiltrationSide reaction

The invention discloses a method for preparing glycerol triacetate, which aims to make completer esterification, shorten reaction time, reduce side reaction, increase the yield of product and product content and improve the chromaticity of the product. The method comprises the following steps of: performing the esterification, acylation and deacidification on glycerol and a glacial acetic acid toprepare a glycerol triacetate crude product, wherein water distribution is performed in the esterification process by adopting an external circulating evaporator; and de-coloring the glycerol triacetate crude product obtained by the acylation and deacidification by adopting activated carbon, separating a head fraction, and performing cooling and circulating filtration to form the high-content glycerol triacetate. The invention discloses the economic and environmentally-friendly method for preparing the glycerol triacetate, which greatly improves the quality of product, reduces the post-treatment steps of the product, reduces energy consumption and brings the dual effects of process optimization, and energy saving and consumption reduction.

Owner:湖南先伟阳光生物科技有限公司

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20130269934A1High work pressureIncrease vaporization rateEnergy industryFluid removalFuel oilProcess engineering

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

Automatic-cleaning type evaporative crystallization device

InactiveCN108671566AGet rid of clogging problemsRealize reciprocating automatic cleaningEvaporator accessoriesSolution crystallizationReciprocating motionEngineering

The invention discloses an automatic-cleaning type evaporative crystallization device. A falling film evaporator is arranged at the upper part, the center of the falling film evaporator is provided with a demister, a crystal bottom tank is arranged at the lower part, and a circulation system of the evaporative crystallization device and metering and pipe valve systems for entering and existing offeed liquid are arranged at the outside. The automatic-cleaning type evaporative crystallization device is structurally characterized in that the falling film evaporator, the crystal bottom tank, andthe demister are of three-in-one. An automatic cleaning mechanism of a heating tube of the falling film evaporator consists of a soft spring, a reciprocating motion film distributor capable of movingup and down, and a cleaning spiral; the soft spring is mounted on a fixing plate of a top chamber, and is connected with the cleaning spiral through the reciprocating motion film distributor; the softspring is used for high-power amplification of undulating flow in the heating tube of the falling film evaporator to realize spiral reciprocating automatic cleaning of crystallized salt fouling on the inner wall of the tube. The evaporator of the device is automatically cleaned, the crystal bottom tank is anti-blocking, the advantages of high efficiency, large energy saving, reliability and compact structure are realized, and the device is especially suitable for technical upgrading of small falling film evaporators and current natural circulation evaporators.

Owner:HUNAN UNIV OF TECH

Gas-fired boiler for overheating foreign steam

ActiveCN105157012AIncrease pressureIncrease temperatureEnergy industrySteam superheatersAir preheaterCombustion chamber

The invention relates to a gas-fired boiler for overheating foreign steam. The gas-fired boiler comprises a pot part composed of a steam pocket, a front forced-circulation evaporator, a composite overheater, a rear natural circulation evaporator and a coal economizer, and a furnace part composed of a combustor, a combustion chamber, an air preheater, a gas preheater, a furnace body and a chimney. The combustor is arranged at the front end of the furnace body, the chimney is arranged at the tail end of the furnace body, the front forced-circulation evaporator, the composite overheater, the rear natural circulation evaporator and the coal economizer are sequentially arranged in the furnace body from front to back, and the steam pocket is arranged above the outside of the furnace body. Middle-pressure steam generated by the gas-fired boiler and foreign low-pressure steam are mixed in a steam ejector, then enter the composite overheater, and are overheated to the needed overheating temperature, the steam can adapt to the change of the load of the foreign steam, continuous stable high-quality overheated steam is provided for a steam turbine generator unit for power generation or other heat users, efficient utilization of energy is achieved, and the aims of energy saving and emission reduction are achieved.

Owner:CHANGZHOU UNIV

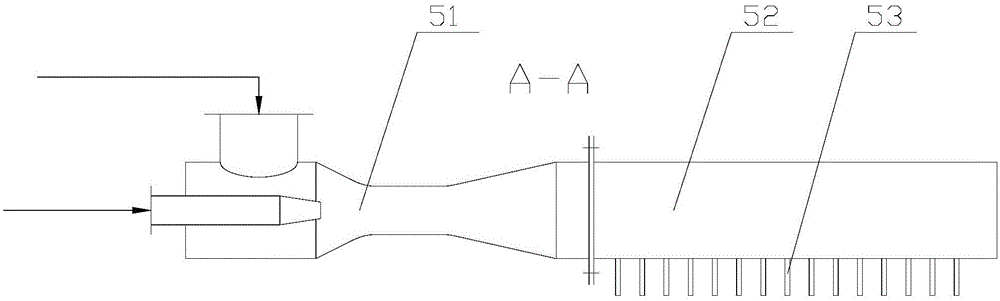

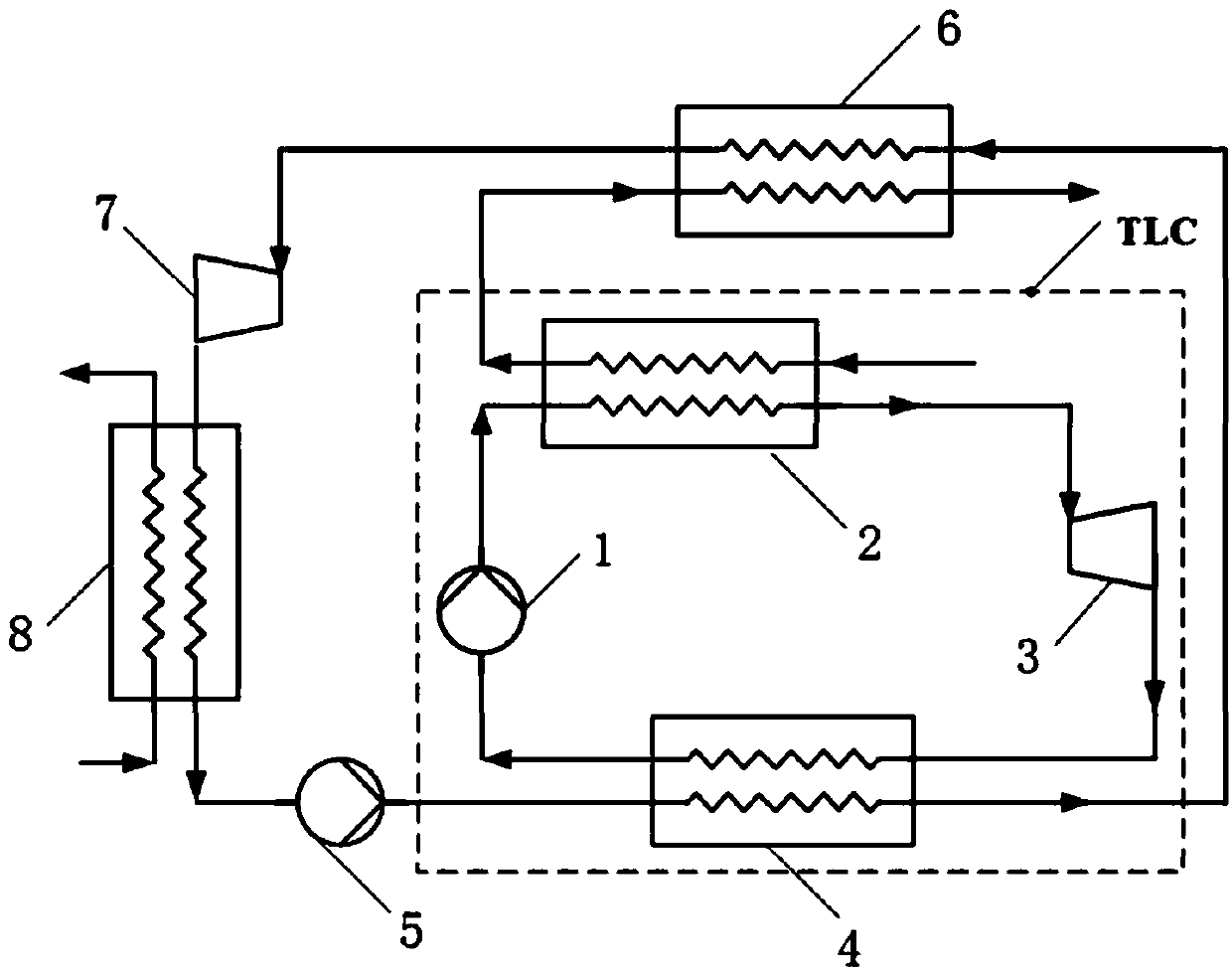

Triangular cycle and Rankine cycle combined waste heat recovery system and method thereof

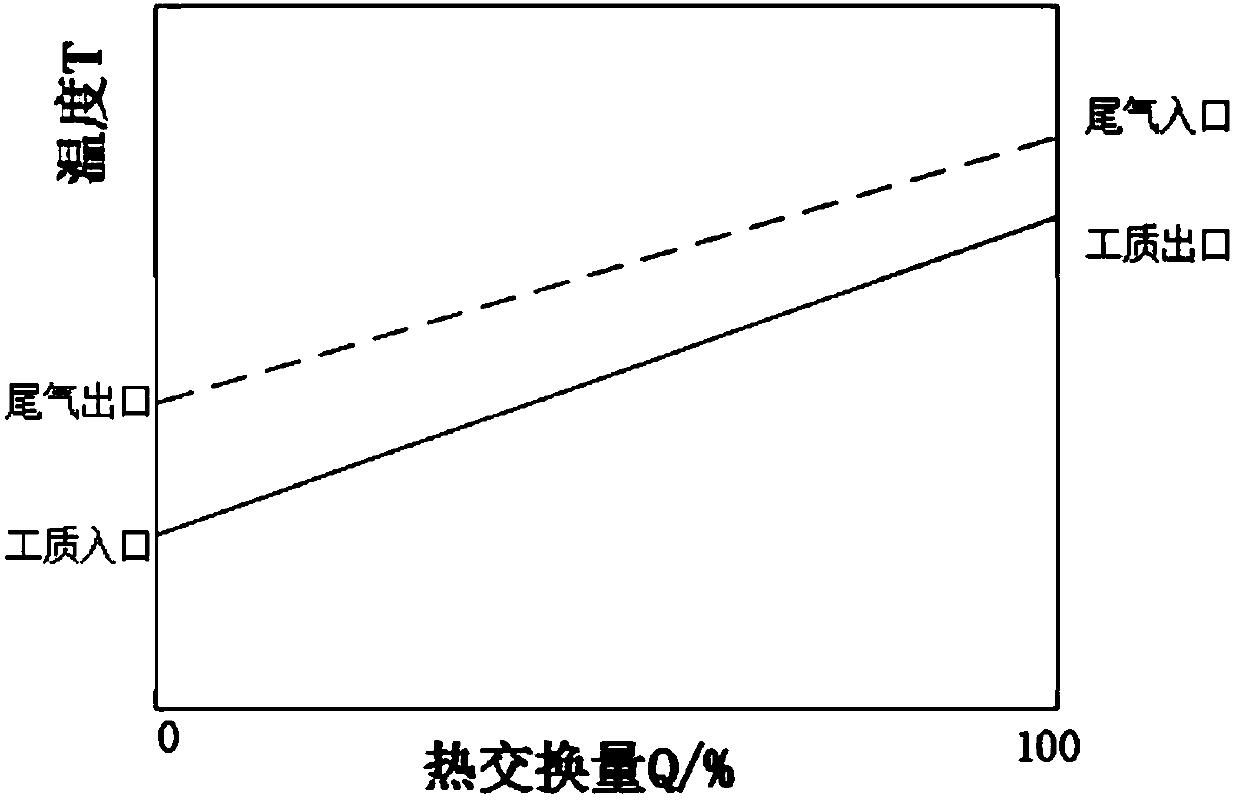

ActiveCN108049924ASimple structureGood temperature matchingInternal combustion piston enginesExhaust apparatusLiquid stateCirculation evaporator

The invention discloses a triangular cycle and Rankine cycle combined waste heat recovery system and a method thereof. The waste heat recovery system comprises working medium pumps, evaporators, expansion machines and condensers. In a triangular cycle, a working medium enters the high-temperature cycle evaporator, absorbs heat, always maintains a liquid state, and then, enters the expansion machine to act, and waste steam after acting preheats a low-temperature working medium in a Rankine cycle in the high-temperature cycle condenser; and in the Rankine cycle, the working medium enters the high-temperature cycle condenser, is in heat exchange with waste steam in the triangular cycle, then, enters the low-temperature cycle evaporator, is in counterflow heat exchange with low-temperature tail gas which is already in heat exchange with the high-temperature working medium in the high-temperature cycle, and then, enters the low-temperature cycle expansion machine to act. According to the triangular cycle and Rankine cycle combined waste heat recovery system, the working medium isothermal heat absorption process in the traditional Rankine cycle in the high-temperature cycle evaporator can be eliminated in the triangular cycle, the temperature matching problem between a heat source and the working mediums is solved, energy loss of the system is reduced, and efficient recycling of waste heat of automobile tail gas is facilitated.

Owner:ZHEJIANG UNIV

Evaporation method and device easy for polymerizing hydrocarbon solution

ActiveCN101337131AGuaranteed uptimeEasy to updateDistillation purification/separationEvaporationPolymer scienceCirculator pump

The present invention provides an evaporation method and apparatus for an easily polymerizing hydrocarbon solution, said evaporation method includes processes that: the easily polymerizing hydrocarbon solution is fed into a main evaporator(1),the evaporated hydrocarbon gas is discharged from the top of the main evaporator(1), the evaporated liquid components are drawn out via a cycle pump(2) from the bottom of the main evaporator(1), part of them being circularly fed into the main evaporator(1) and part of them being fed into a film evaporator(3). The evaporated hydrocarbon gas is then discharged from the top of the film evaporator(3) and the remnant liquid after evaporation is forced to be discharged from the film evaporator(3). The forced circulation evaporator and the film evaporator in this invention combines to realize the evaporation process, the polymeric monomer in the easily polymerizing hydrocarbon solution is not subject to polymerization, thereby improving the evaporation efficiency, maintaining the steady operation, lowering the consume of source and energy.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

Total saponin of American ginseng and injection liquid thereof

ActiveCN1903242AGuaranteed stabilityHigh extraction ratePowder deliveryMetabolism disorderAlcoholPurified water

An American ginseng saponin and its injection is prepared from the root, stem and leaf of American ginseng through cutting short, immersing in warm purified water, cyclic counter-current ultrasonic extracting, concentrating, depositing in alcohol, cold storage, filtering, evaporating for recovering alcohol, filtering, purifying by macroreticular resin column, analyzing by flushing with purified water, decoloring, vacuum recovery to obtain concentrated liquid, spray drying to obtain saponin, and dissolving it in the water for injection to obtain injection.

Owner:李彦群

Coupling spiral cleaning type natural circulation evaporator

ActiveCN107702587ARealize automatic cleaningEffective automatic cleaningFlush cleaningSalt depositReciprocating motion

The invention discloses a coupling spiral cleaning type natural circulation evaporator. The coupling spiral cleaning type natural circulation evaporator is characterized in that a coupling helix cleaning mechanism composed of cleaning heads, helixes, coupling springs and spring supports is mounted on heating pipes of the natural circulation evaporator. During evaporation production, liquid-vapor two-phase flow at the port section of the heating pipes impacts the cleaning heads to drive the helixes to radially and powerfully vibrate, rotate in 5-20 revolutions per minute and do up-down reciprocating motion in 5-20 times of 30-180 mm per minute so as to effectively and automatically clean salt deposit on the inner walls of the heating pipes. Meanwhile, convection heat transfer of natural circulation liquid flow is enhanced. A forced circulation pump is omitted. The coupling spiral cleaning type natural circulation evaporator is simple in structure and has the automatic cleaning capacityto meet the engineering requirements for long-period continuous and high-efficiency production of the majority of saline solution natural circulation evaporators.

Owner:浙江建装工程技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com