Coupling spiral cleaning type natural circulation evaporator

A technology of natural circulation and evaporator, applied in the direction of flushing, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems that cannot be popularized and applied, the particle external circulation system is complex, and the cleaning capacity is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

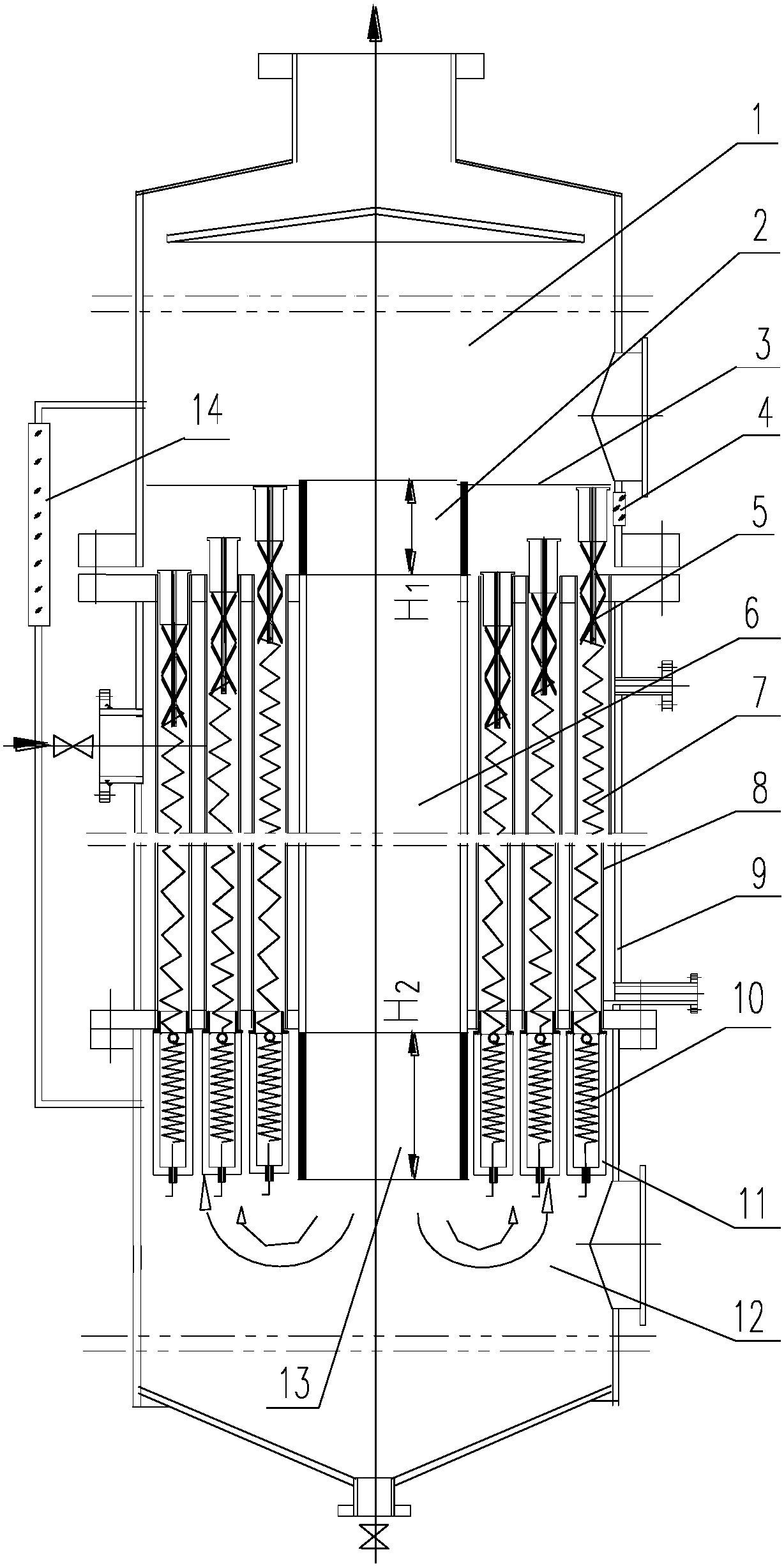

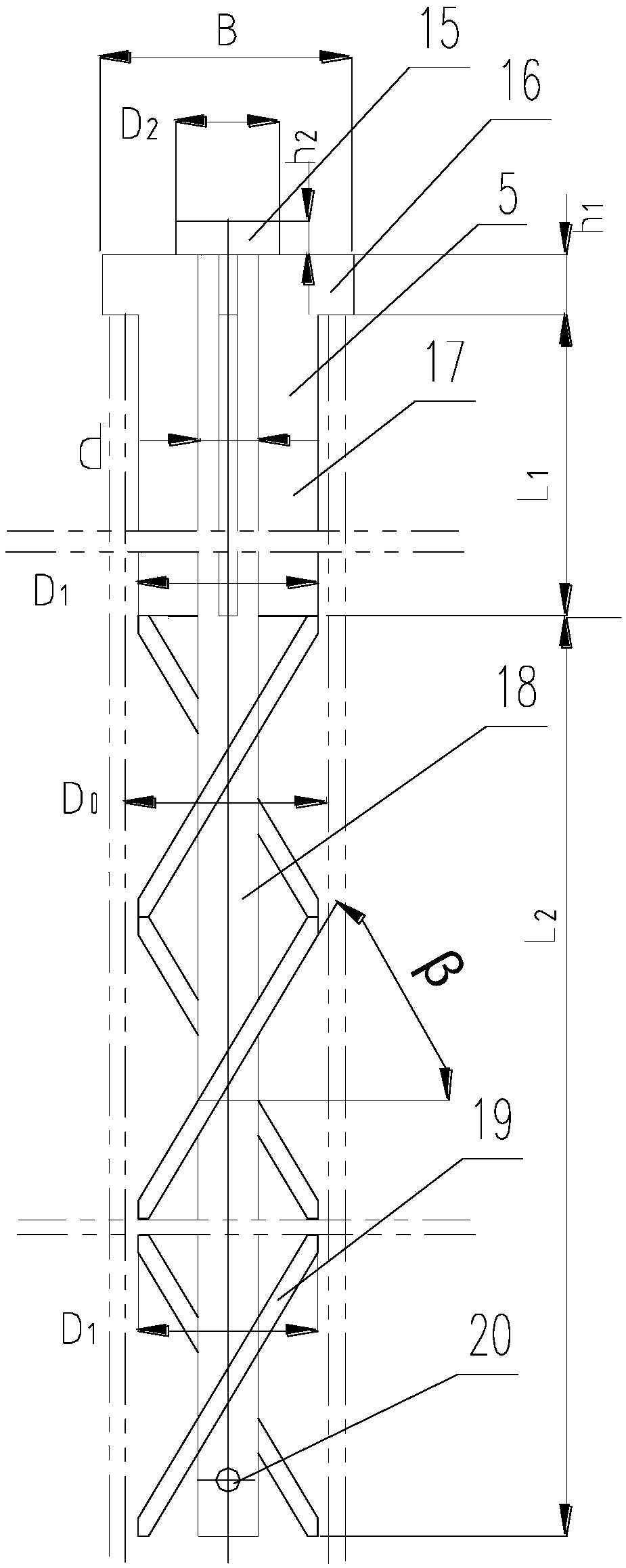

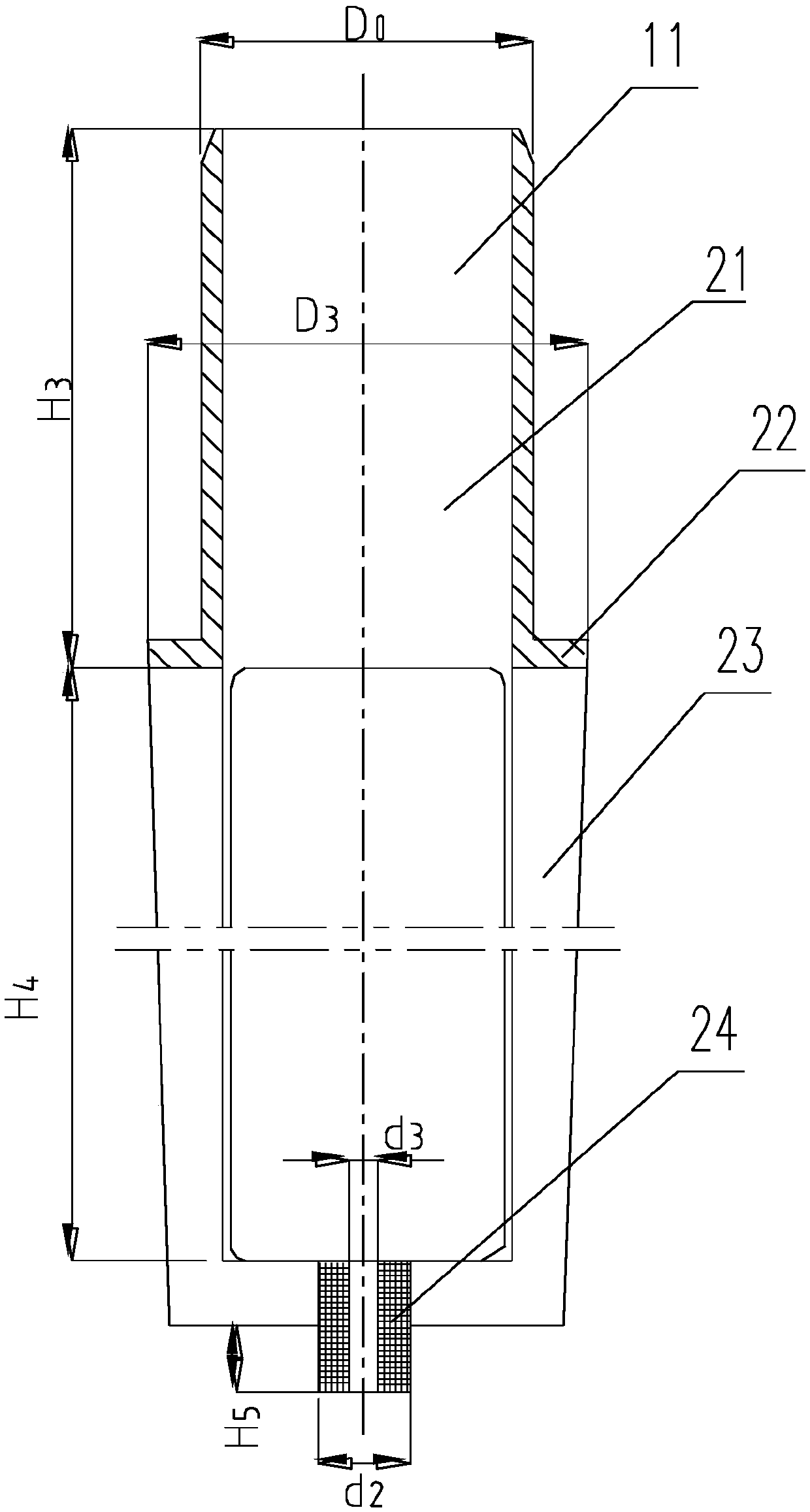

[0012] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

[0013] Attached below figure 1 , figure 2 , image 3 , the present invention is described in further detail.

[0014] In the figure: 1. Evaporation chamber, 2. Super high section, 3. Screen, 4. Sight mirror, 5. Cleaning head, 6. Central circulation pipe, 7. Spiral, 8. Heating pipe, 9. Heating chamber, 10, coupling spring, 11, spring frame, 12, bottom chamber, 13, bottom section, 14, liquid level gauge, 15, top cap, 16, limit hook, 17, straight rib, 18, central axis, 19, oblique Plate tooth, 20, suspension hole, 21, fixed pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com