Patents

Literature

455results about How to "To achieve reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene/copper composite material by in-situ catalysis of solid carbon source on surfaces of copper powders

The present invention relates to a method for preparing a graphene / copper composite material by in-situ catalysis of a solid carbon source on surfaces of copper powders. The method comprises the steps of: adding steel balls, the copper powders and polymethyl methacrylate at the mass ratio of 150: 10: (0.1-0.3) into a ball milling tank, and filling argon as protective atmosphere after vacuum pumping; after ball milling, preparing cooper-polymethyl methacrylate powders which are uniformly dispersed; performing reduction treatment in a tubular furnace to catalyze the polymethyl methacrylate into graphene, and obtaining graphene / copper composite powders with graphene in-situ growth; and then preparing a graphene copper-based composite material block. Tensile property of the graphene reinforced copper-based composite material prepared by the method is better than tensile property of that prepared by a traditional adding method, that is a method of adding reduction-oxidation graphene or graphene sheets. Reinforcement of a cooper-based material is achieved, and high-strength copper materials have a better application prospect on electronic devices.

Owner:TIANJIN UNIV

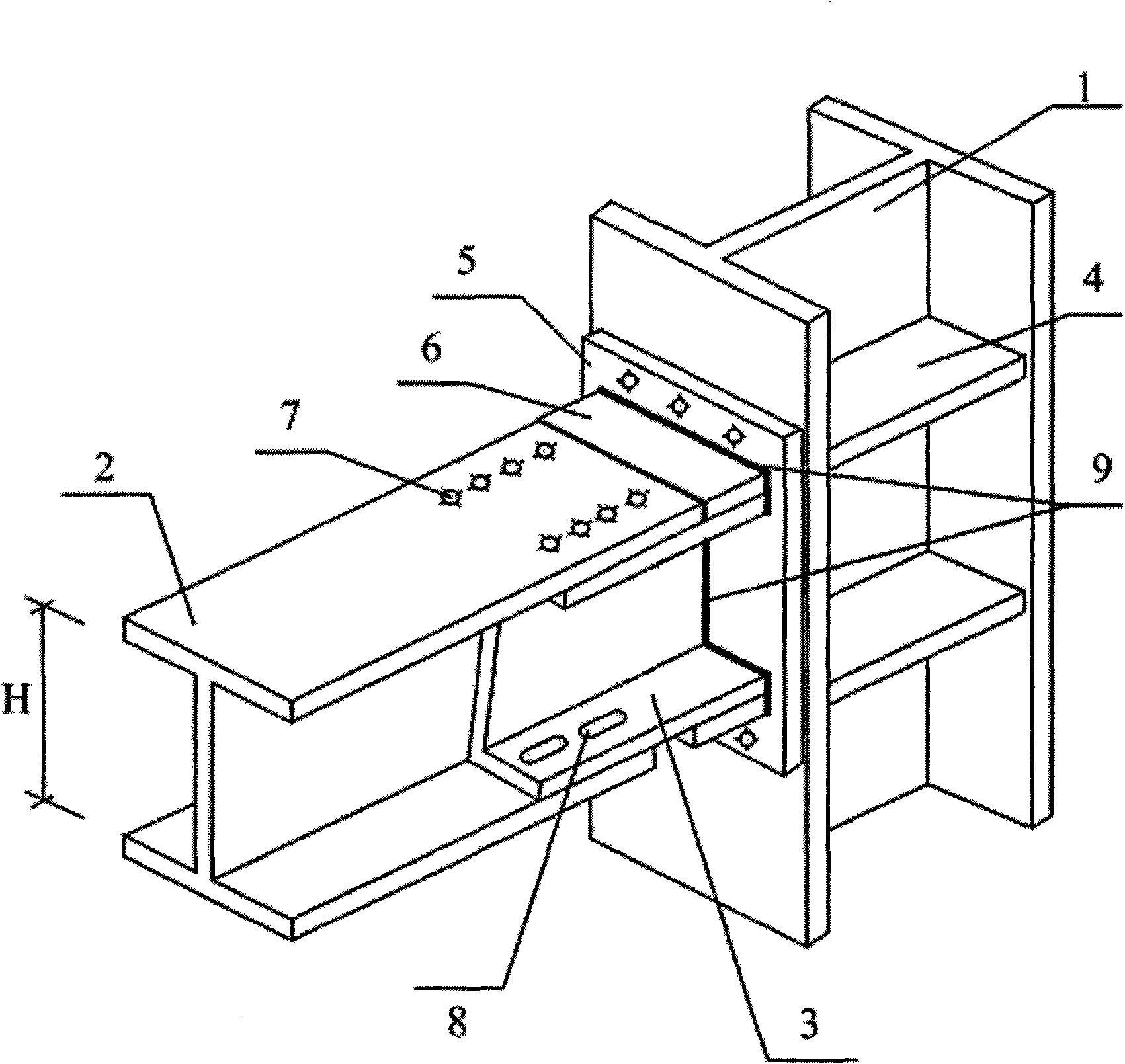

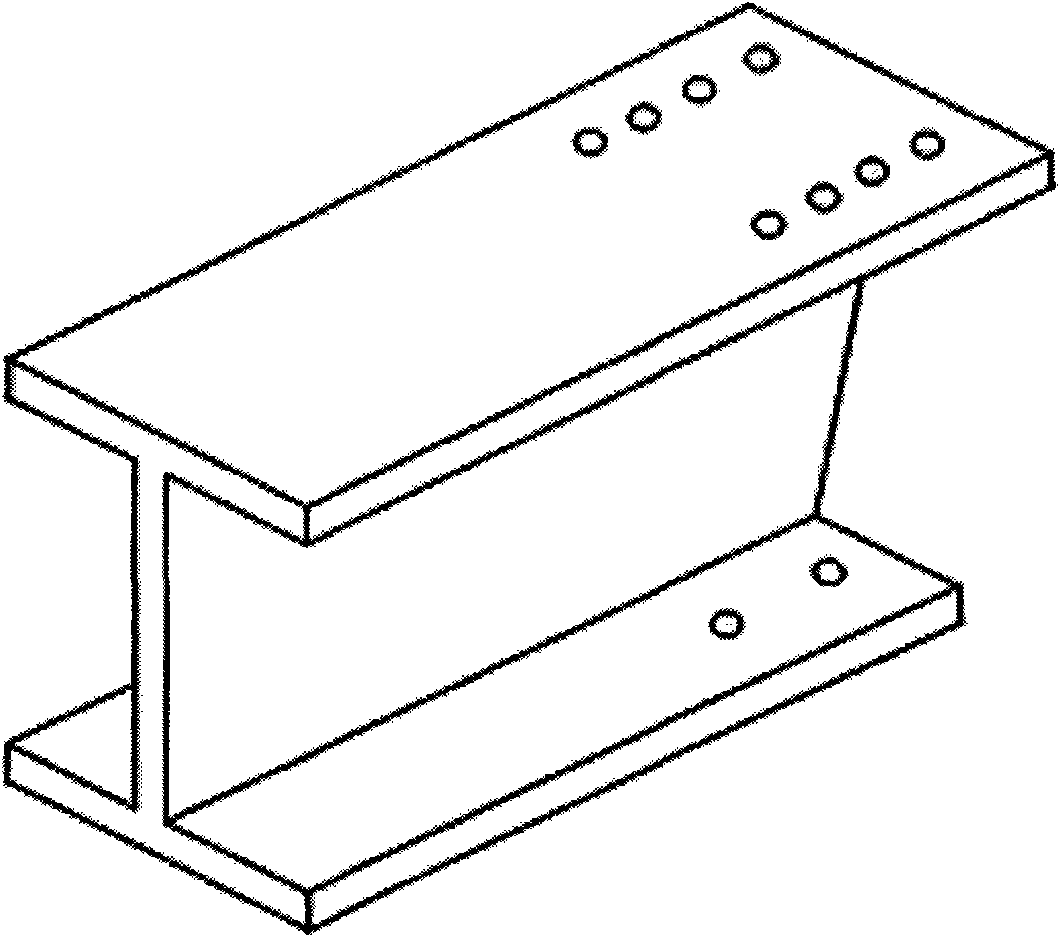

Frame beam column fire-resistant node with catenary effect and construction method thereof

InactiveCN101845854ARelieve thermal expansion stressReduce local bucklingBuilding material handlingFire proofingSteel platesEngineering

The invention relates to a frame beam column fire-resistant node which is formed by increasing a trapezoidal connecting key at the end part of a steel beam, carrying out high-strength bolt anchoring on an upper flange at the beam end and simultaneously carrying out limited anchoring on a lower flange at the beam end, wherein the lower flange at the beam end has the limited telescopic capacity under the environment of a fire disaster. The implementation of the frame beam column fire-resistant node is as follows: cutting the steel beam with the flanges and a web plate and the trapezoidal connecting key, and then respectively assembling a column, the steel beam, the trapezoidal connecting key, a stiffening plate, an end plate and a steel plate through high-strength bolts, ordinary bolts and welding seams. The frame beam column fire-resistant node is applicable to the industry with higher requirements on the fire-resistant performance and the anti-collapse capacity of the structure and a civil steel frame structure. The frame beam column fire-resistant node has the advantages of simple structure, convenient construction and low cost of required materials, and can avoid the local buckling of the beam under the high-temperature environment, form the catenary effect and have the good fire-resistant performance and the anti-collapse capacity.

Owner:BEIJING UNIV OF TECH

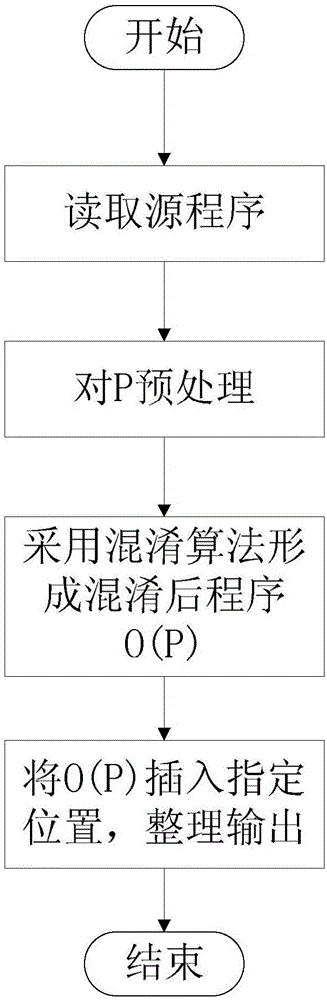

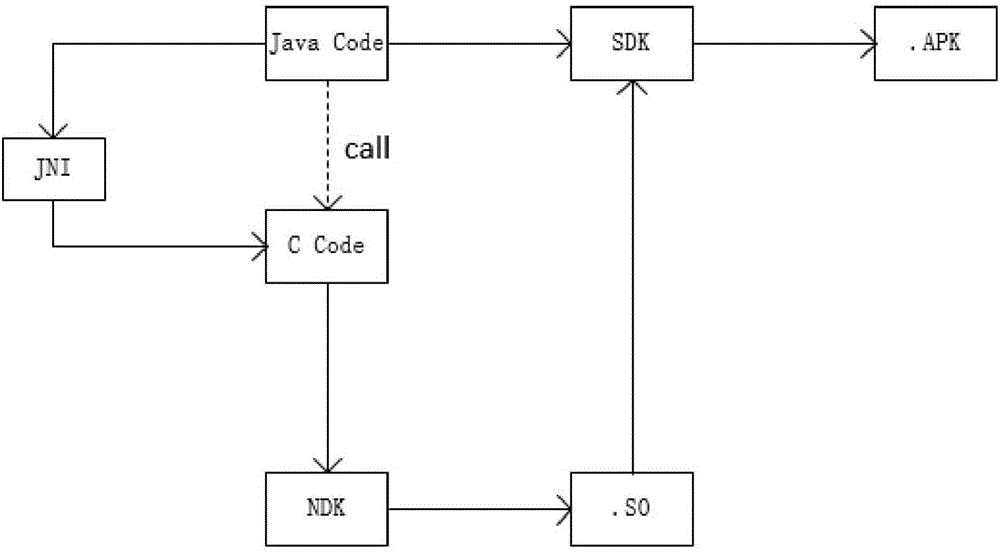

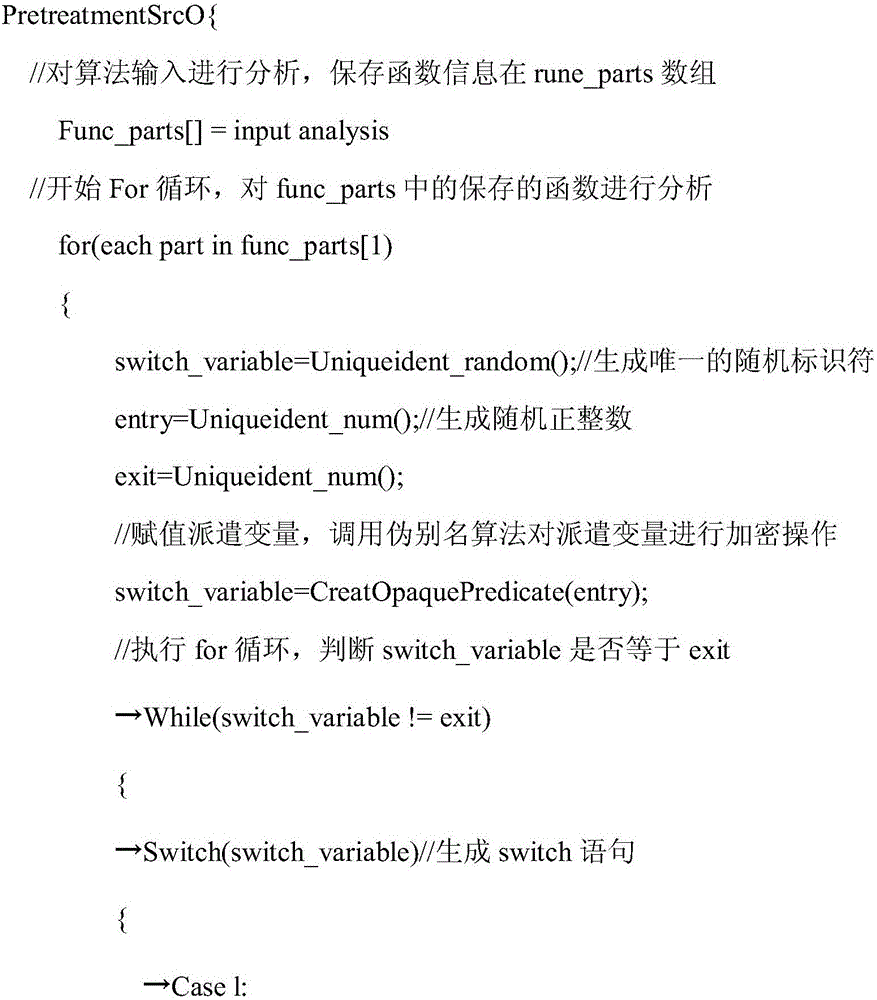

Android application reinforcing method baed on C source code mixing

InactiveCN106326694AImprove reusabilityImprove protectionProgram/content distribution protectionReusabilityC programming language

The invention discloses an Android application reinforcing method based on C source code mixing. The method comprises writing program key codes by using C programming languages and mixing C source codes. The reinforcement of Android application is achieved by mixing the C source codes in the Android application program, and the Android application program codes are protected. The Android application reinforcing method based on C source code mixing specifically includes the steps of writing the key part of the program by using C programming languages, writing programs into .so dynamic-link library file, invoking the dynamic-link library by using JNI technology in Java language, and then mixing the C source codes, so as to achieve the reinforcement of Android application. According to the Android application reinforcing method based on C source code mixing, important codes are saved in the C dynamic-link library by adopting NDK programming, and then the C source codes are mixed, the software protection is improved. At the same time, the important codes are written in a so library, the reusability of the codes are increased, ready-made so library can be directly introduced into other applications, so as to eliminate the troubles of secondary development.

Owner:北京鼎源科技有限公司

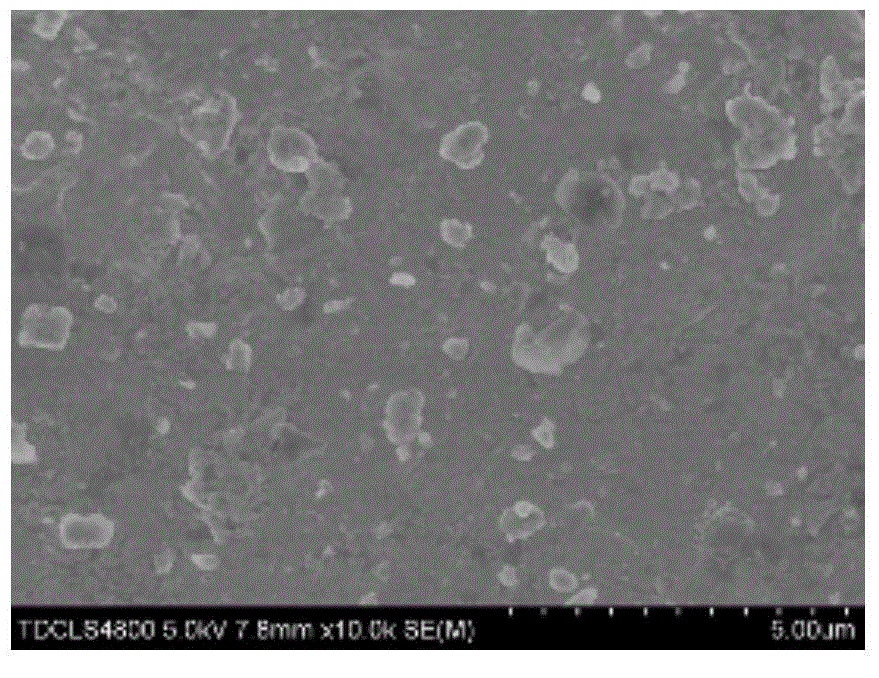

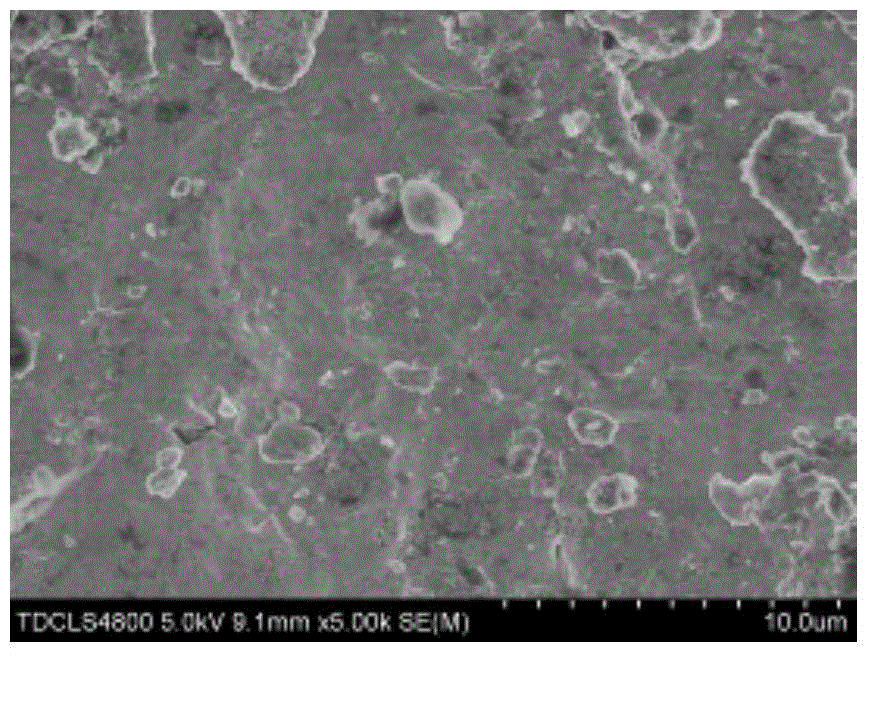

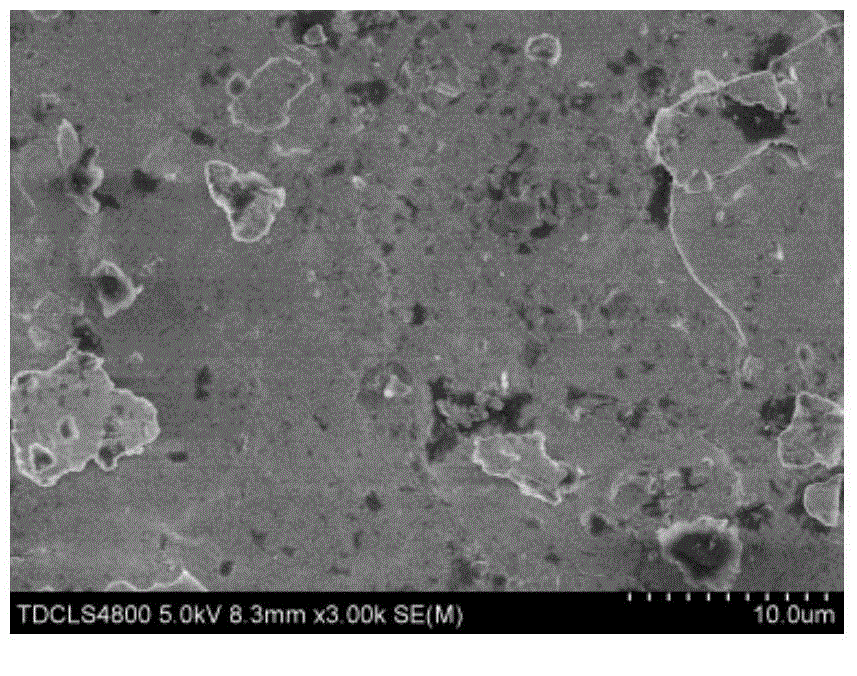

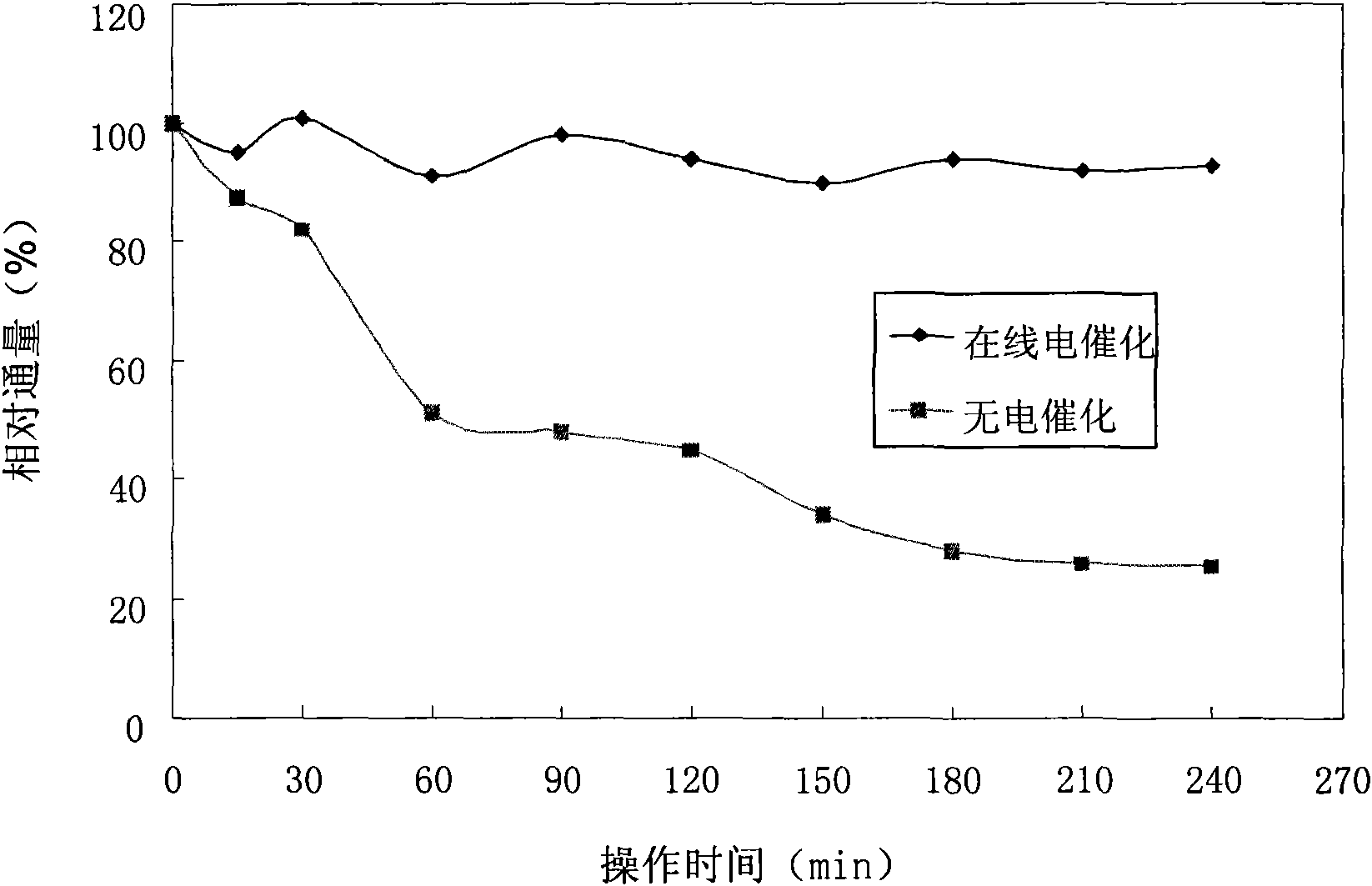

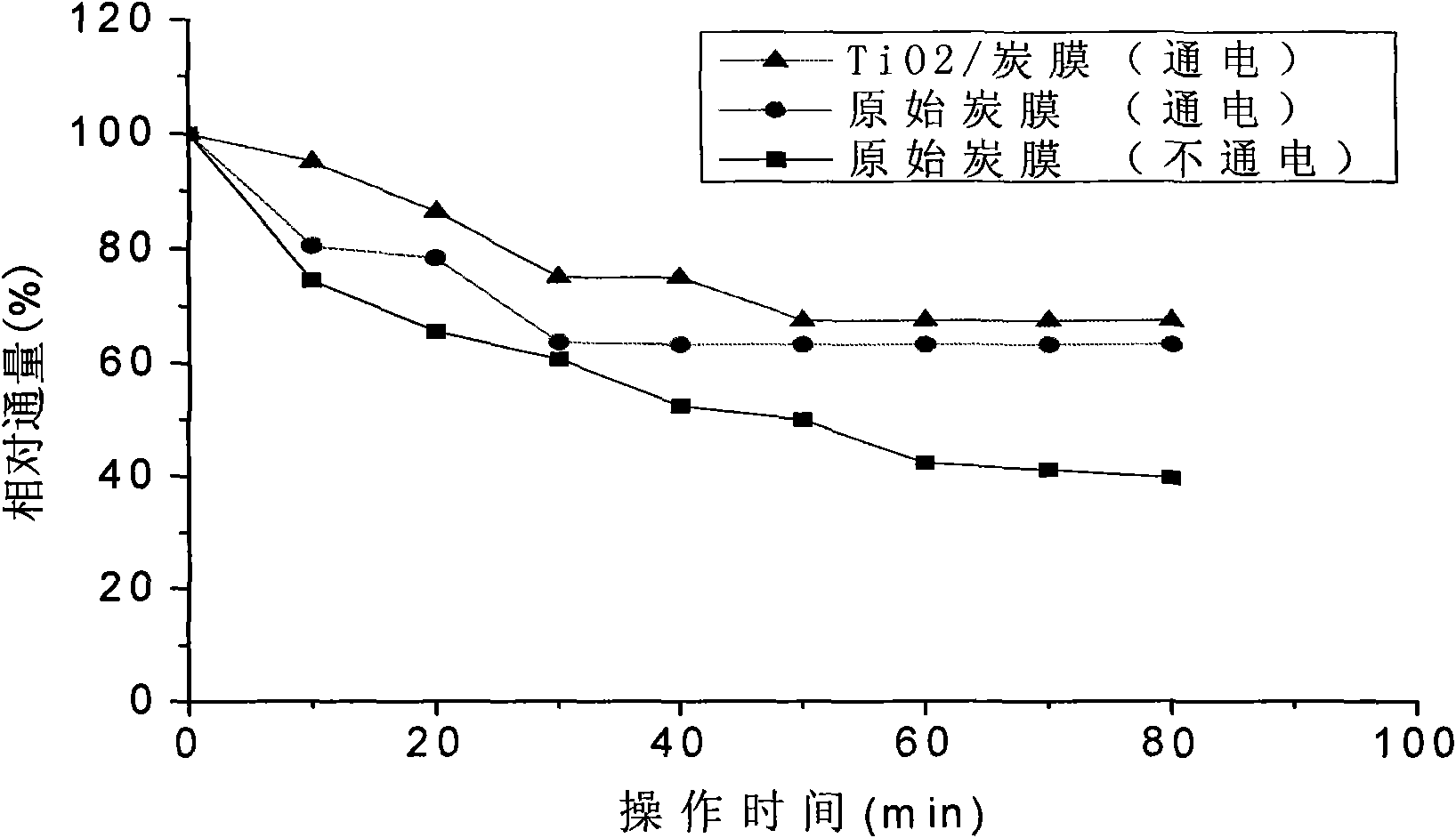

Novel electro-catalytic composite membrane material and preparation method thereof

InactiveCN101559332ATo achieve reinforcementRealize self-cleaningSemi-permeable membranesWater/sewage treatment by electrochemical methodsLow voltageSeparation technology

The invention relates to a novel electro-catalytic composite membrane material and a preparation method thereof. The novel electro-catalytic composite membrane material is characterized in that the material can couple electro-catalytic technology and membrane separation technology. The preparation method comprises the following steps: taking a microporous separation membrane with electric conductivity, namely a carbon membrane, as a substrate, adopting a sol-gel method, mixing a metallic compound, water, a solvent, a catalyst, other additives and the like to be configured into a precursor solution, and obtaining an electro-catalytic composite membrane by sol ageing, film coating, drying and heat treatment; and preparing the composite membrane with superior performances by pretreating a substrate and controlling the mixture ratio of raw materials, the soakage time, the pulling speed, the sintering temperature and the like. The novel electro-catalytic composite membrane material takes the electro-catalytic composite membrane as an anode and a metallic material as a cathode to treat wastewater and realizes the reinforcement of the membrane separation process and the self-cleaning function under the action of a low-voltage electric field. The electro-catalytic membrane material has the advantages of low energy consumption, high separation efficiency, strong antifouling property and the like, and can be widely used for treating and recycling heavily polluted wastewater such as oily wastewater, dye wastewater, paper-making wastewater and the like. The preparation method has the advantages of simple preparation process, cheap equipment, easily-obtained raw materials, convenient operation and suitability for industrialized implementation.

Owner:DALIAN HUAXINYUAN TECHNOLOGY DEVELOPMENT LIMITED COMPANY

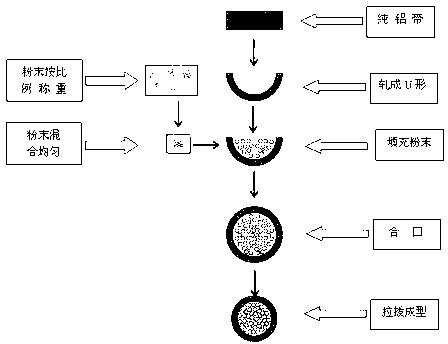

Nano-composite powder core wire

InactiveCN102994936AImprove anti-corrosion, anti-skid and anti-wear performanceExtended service lifeMolten spray coatingMischmetalGranularity

The invention discloses a nano-composite powder core wire. The key points of the technical scheme are that the nano-composite powder core wire consists of a nanometer composite powder core and an outer skin, wherein the nanometer composite powder core accounts for 25-40 percent of the mass of the nano-composite powder core wire; the outer skin is an aluminum strip of which the purity is more than 99.9 percent; the powder core is formed by compounding the following nanometer materials in percentage by weight: 5-24.3 percent of ultrafine aluminum powder of which the granularity is less than 1,000nm, 14.4-18 percent of nanometer titanium dioxide of which the granularity is less than 100nm, 36-45 percent of nanometer alumina powder of which the granularity is less than 100nm, 25-31 percent of ultrafine chromic oxide of which the granularity is less than 100nm and 0.3-1 percent of mischmetal. By the nano-composite powder core wire for coastal equipment with long-acting property, corrosion resistance, skid resistance and abrasion resistance, the coating is prepared by electric arc spraying equipment, so that the nano-composite powder core wire is suitable for coastal areas or offshore equipment, and is suitable for corrosion resistance, skid resistance and abrasion resistance to various steel structures under an atmosphere condition.

Owner:新乡市布瑞林特机械再制造有限责任公司

Grouting reinforcement and rectification method suitable for high-rise building structure

ActiveCN107435346ASolve for uniformityTo achieve reinforcementFoundation engineeringSupporting systemStructure of the Earth

The invention provides a grouting reinforcement and rectification method suitable for a high-rise building structure. The method comprises the steps from S10 to S30, wherein in the step S10, grouting filling reinforcement is conducted on an original cushion layer under an original concrete valve plate, and the original cushion layer and grout are solidified to form a cushion layer reinforcement and strengthening layer; in the step S20, after the cushion layer reinforcement and strengthening layer is formed, grouting filling reinforcement is carried out on an original foundation under the original cushion layer, and the original foundation and grout are solidified to form a foundation reinforcement platform; in the step S30, after the foundation reinforcement platform is formed, a plurality of pile foundation grouting holes are vertically formed in the lower surface of the foundation reinforcement platform at intervals, grout is injected into the pile foundation grouting holes to form an under-column pile foundation. The cushion layer reinforcement layer, the foundation reinforcement platform and the under column pile foundation form a three-dimensional supporting system in the mode that the layers are reinforced layer by layer from top to bottom; the purpose of building foundation reinforcement and lifting rectification integration is achieved, and the problems that a building is not uniform in settlement and a rectification foundation is lifted are successfully solved.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

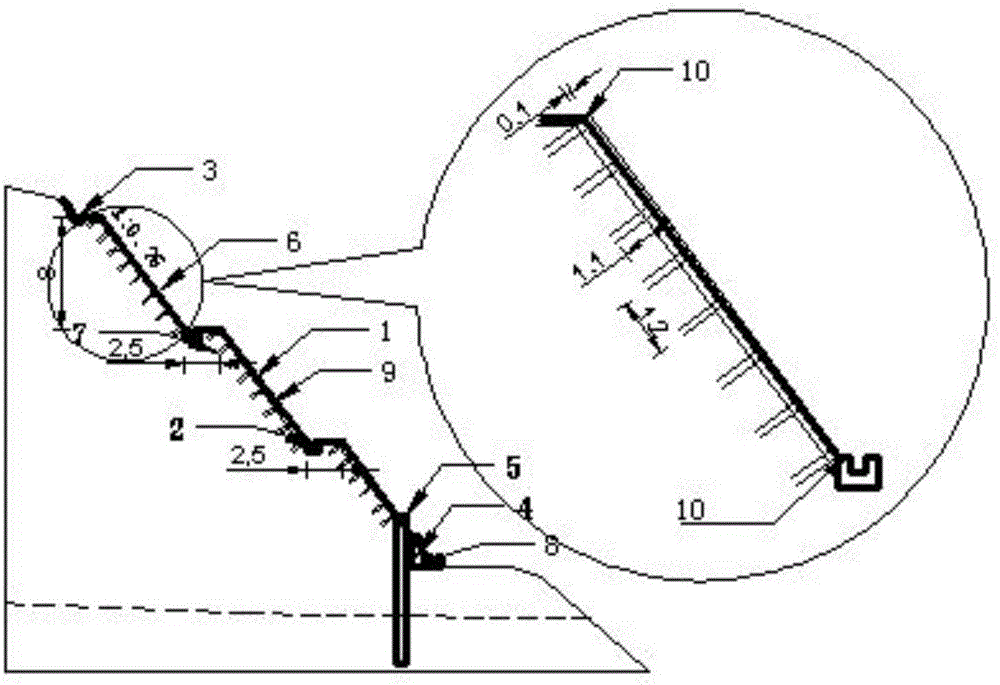

Loess landslide control system based on ecological remediation

InactiveCN106168030AImprove skid resistanceEliminate the effects ofClimate change adaptationExcavationsControl systemEngineering

The invention discloses a loess landslide control system based on ecological remediation. After substep square cutting of a loess landslide mass, the side slope of the loess landslide mass is of a multistep structure, a square-cut side slope is formed, single-row slide-resistant piles are arranged on a slide-resistant section on the front portion of the landslide mass, a retaining wall is constructed at the front edge of the landslide mass, a drainage project is constructed on the slope face and periphery of the landslide mass, and a three-dimensional soil engineering grid grass planting protection slope is laid on the slope face of the square-cut side slope. Cutting, retaining, protection and drainage in landslide treatment are combined, the landslide slide force is reduced to the maximum extent, the landslide skid resisting force is increased to the maximum extent, the influence of rainfall on the slope is eliminated, a slope protection system with an ecological function is constructed through a three-dimensional soil engineering grid, the functions of self washout resistance, slide force resisting reinforcement, ecological restoration and the like of the landslide mass are improved, the overall stability of landslide is effectively improved, and therefore the aim of permanently controlling loess landslide is achieved.

Owner:NORTHWEST UNIV(CN)

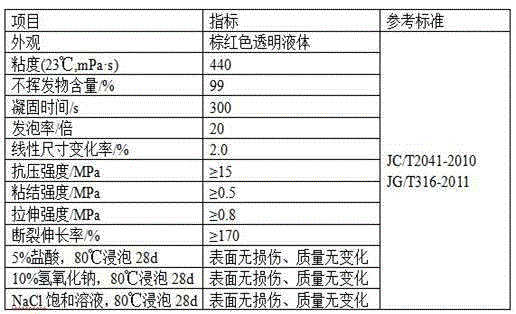

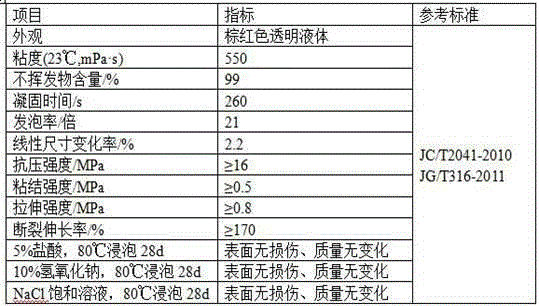

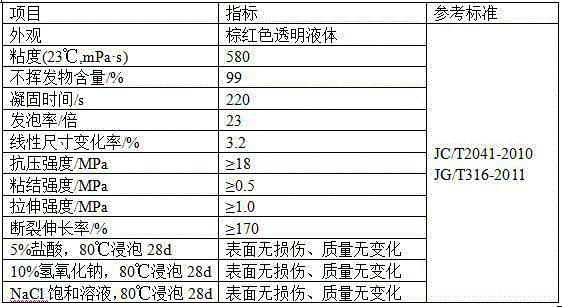

High-performance environment-friendly single-component hydrophobic polyurethane grouting material and preparation method thereof

The invention relates to a high-performance environment-friendly single-component hydrophobic polyurethane grouting material. The high-performance environment-friendly single-component hydrophobic polyurethane grouting material comprises the following substances: 100 parts of a polyurethane prepolymer, 1-10 parts of diatomaceous earth powder, 5-25 parts of polyurethane plasticizer, 5-25 parts of environment-friendly plasticizer, 10-35 parts of an environment-friendly solvent, 2-10 parts of a foam stabilizer, 0.2-2 parts of a catalyst and 0-0.2 part of a storage stabilizer. During construction, the hydrophobic polyurethane grouting material is single liquid grouting, the grouting material is environmentally friendly and free of pollution and can permeate inside various leakage water channels by virtue of grouting pressure and low viscosity, is in contact with water in the leakage gaps to rapidly absorb moisture by virtue of a porous filler and rapidly react with water for foaming. The grouting material and water are rapidly reacted and cured, the more excellent mechanical properties of the grouting material is ensured and the grouting material is high in dimensional stability so that the acid, salt alkali salt corrosion resistance of a product and engineering durability are increased to an utmost extent.

Owner:JIANGSU SOBUTE NEW MATERIALS

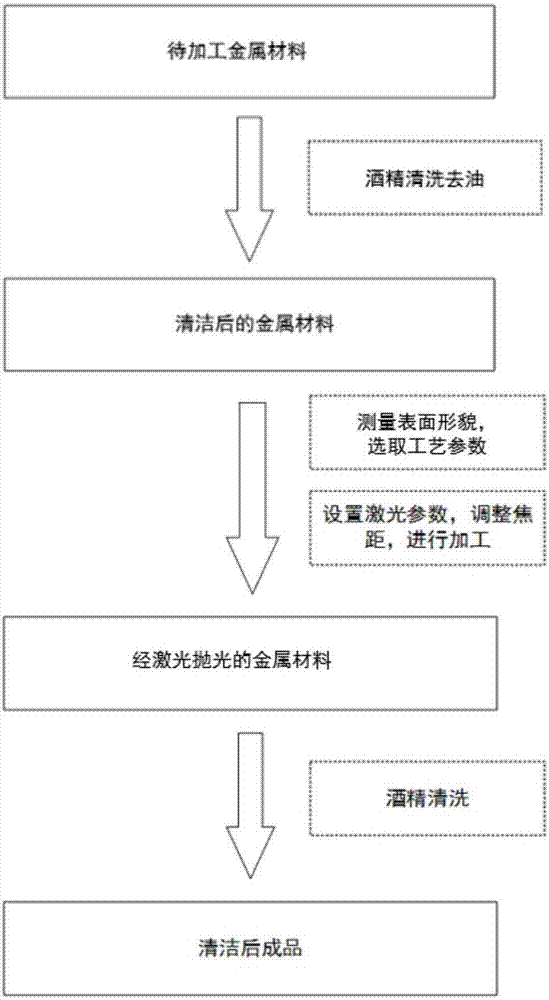

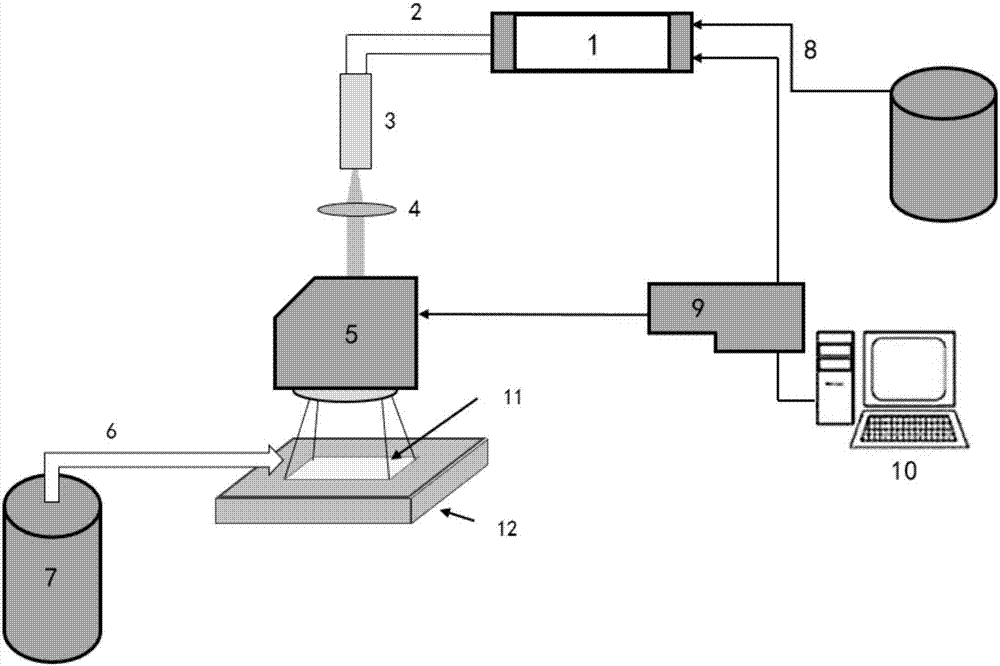

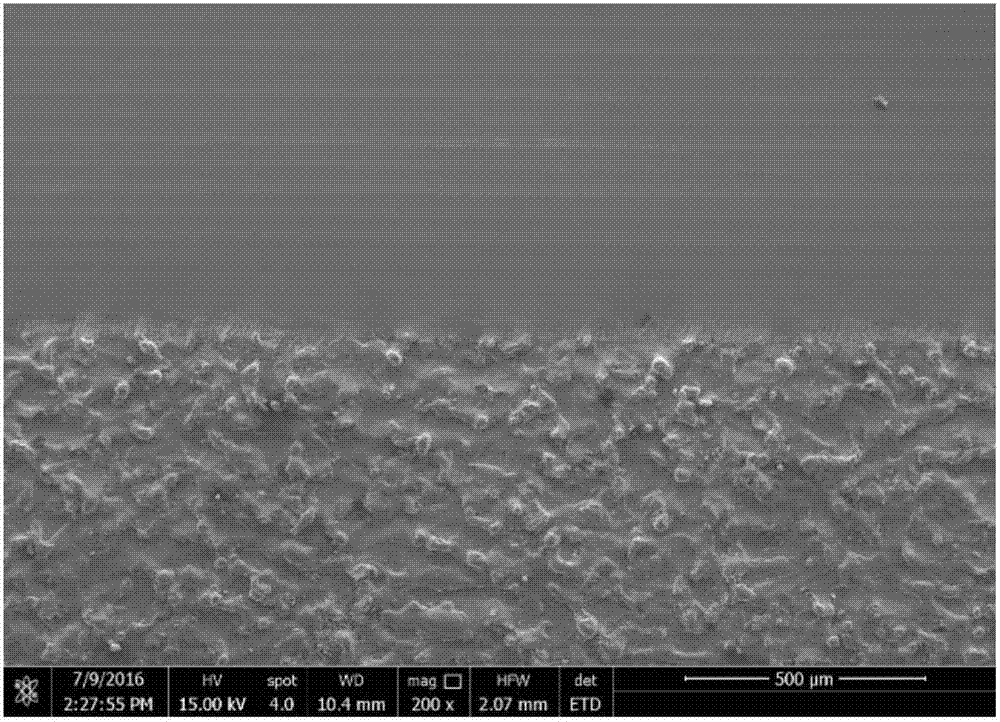

Single-step pulse laser polishing method for metal surfaces

InactiveCN107225328ARapid remeltingTo achieve reinforcementLaser beam welding apparatusElectrochemistryMachining process

The present invention is a single-step pulse laser polishing method for metal surfaces: 1. Simply clean and degrease the surface of the metal material to be processed. 2. Use a three-dimensional profiler to measure the surface to be polished. 3. Place the metal material to be processed on the workbench of the laser processing system, set the laser parameters, start the laser processing system, use the galvanometer to scan the laser at a certain speed and path on the surface of the metal material, and finally obtain remelting on the surface Layer, inert gas is used for protection during processing. 4. Simple cleaning of processed metal materials. Compared with traditional metal surface polishing methods such as mechanical polishing and chemical / electrochemical polishing, the present invention uses laser heating and melting to form a molten pool under the multi-directional action of surface tension and gravity, and the molten material in the molten pool will be redistributed through flow. Around the initial position, the peak-to-valley height difference of most rough surfaces is reduced after rapid solidification, thereby obtaining a polishing effect on the rough surface.

Owner:BEIHANG UNIV

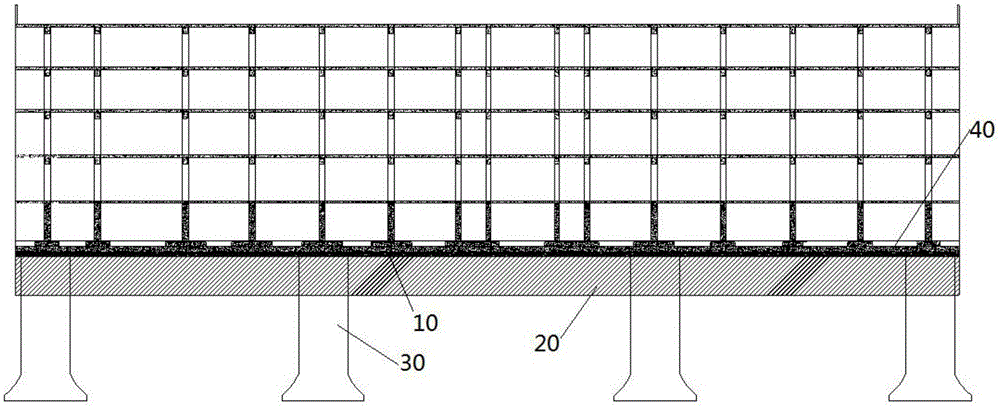

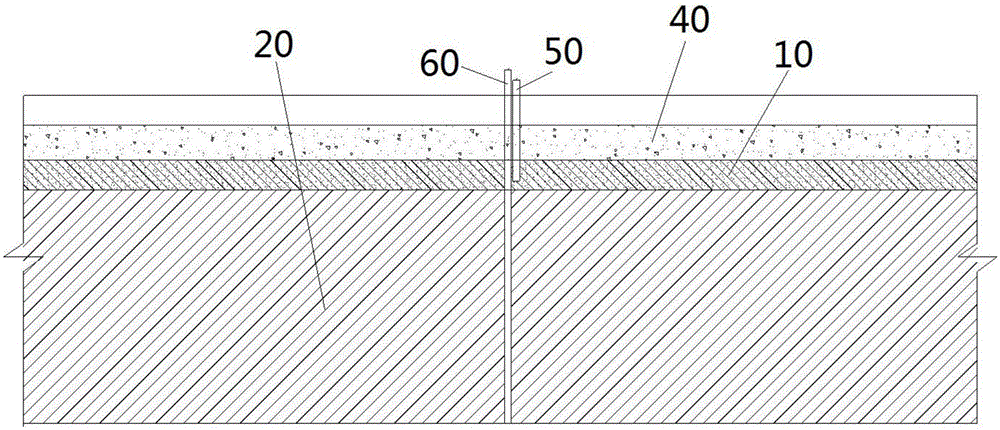

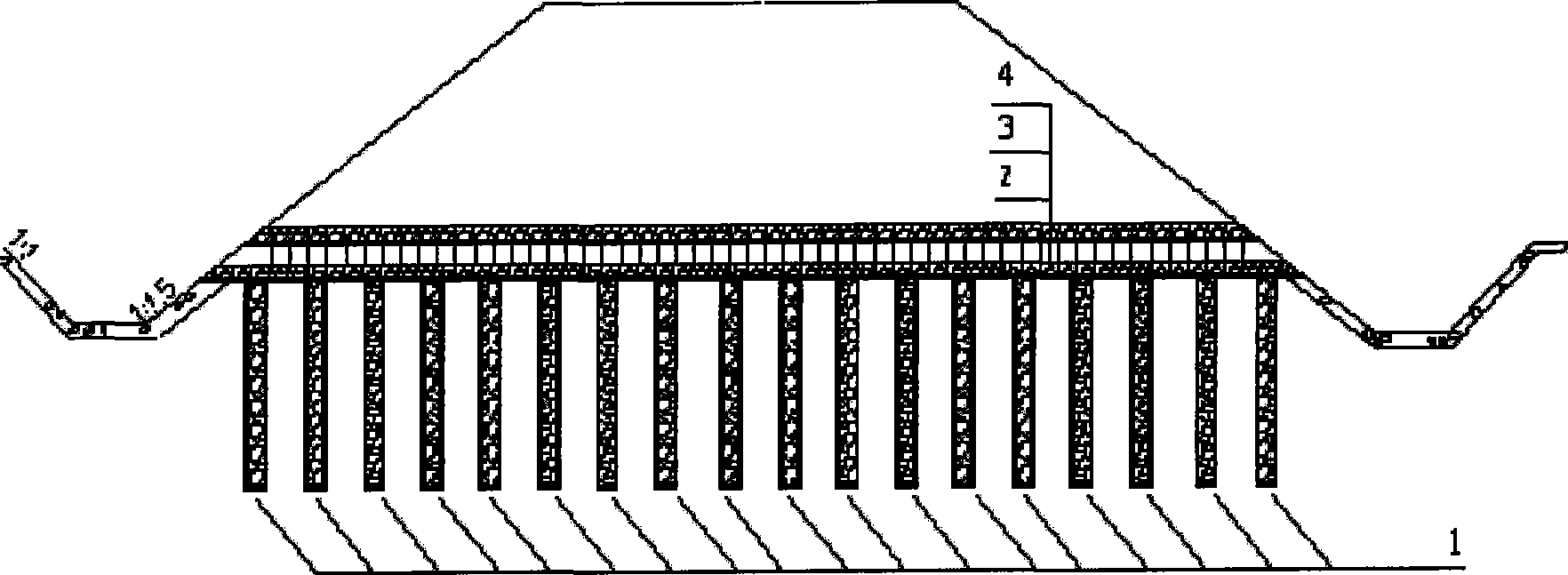

Bidirectional reinforcing and water drainage reinforcing means for highway soft soil foundation

The invention discloses a soft soil foundation two-way reinforcement and drainage reinforcement method for highways. The invention comprises the steps as follows: (1) the site is leveled and the pile positions are set out; (2) the construction is carried out by vibroflotation, hammering method, or vibrating tube sinking method to form a gravel pile; (3) the top of the pile is paved with Geocell coarse sand or gravel hardcore, the main composition body thereof is a Geocell layer with drain holes on the wall, the Geocell is filled with compact coarse sand or gravels, and the upper part and the lower part of the Geocell are respectively paved with drainage layers. By adopting the Geocell coarse sand or gravel hardcore and gravel pile two-way reinforcement and drainage structure, the method can realize a composite action of reinforcement, compaction, replacement and drainage on the soft foundation, effectively improve the strength and stability of the roadbed, reduce the differential settlement of the foundation and satisfy the requirement of traffic load increase on the bearing capacity and deformation of the roadbed.

Owner:HUNAN UNIV

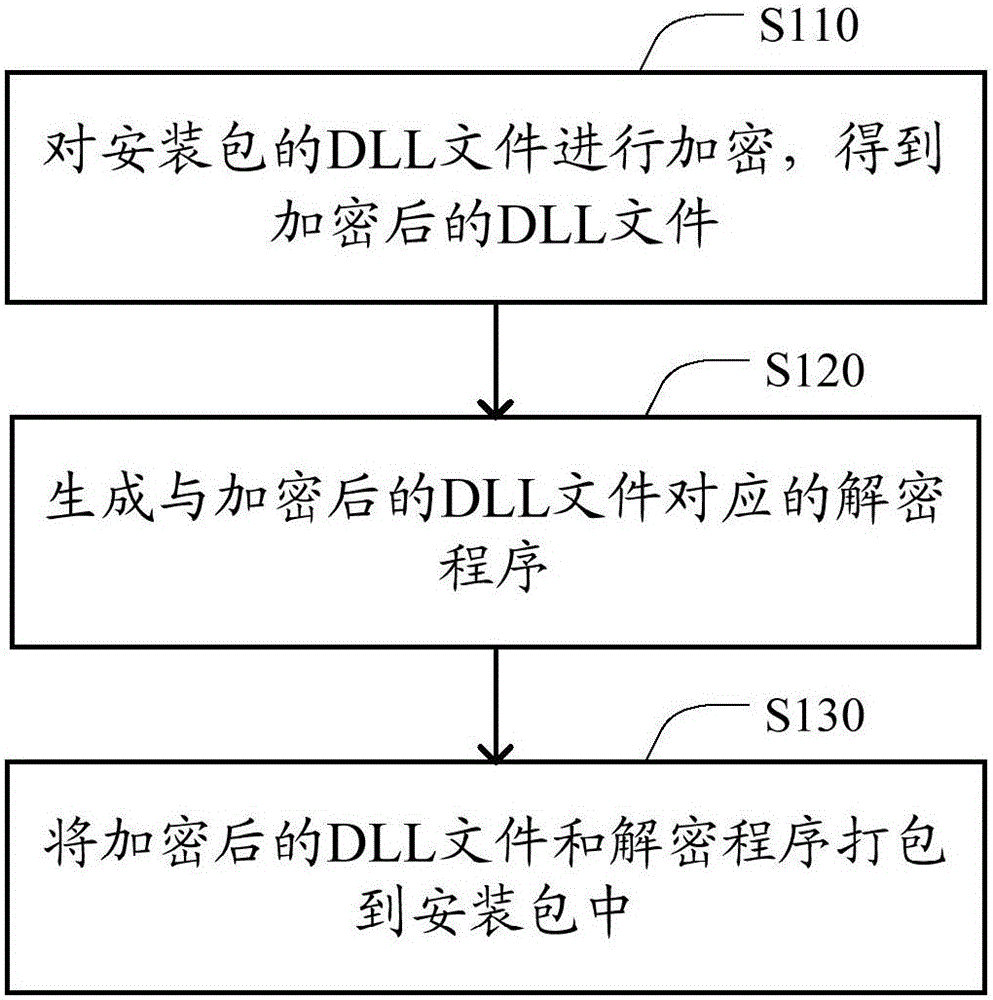

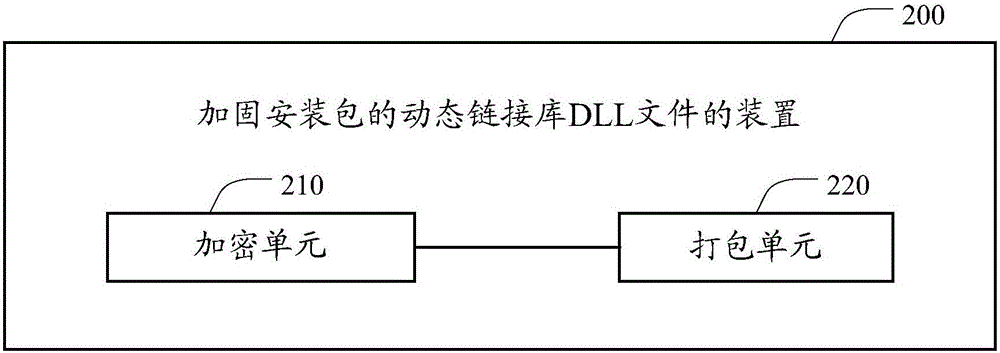

Method and device for reinforcing dynamic link library (DLL) file of installation package

ActiveCN106295370ATo achieve reinforcementEffective protectionDigital data protectionReverse analysisOperating system

The method discloses a method and device for reinforcing a dynamic link library (DLL) file of an installation package. The method includes the steps that the DLL file of the installation package is encrypted, and the encrypted DLL file is obtained; a decryption program corresponding to the encrypted DLL file is generated; the encrypted DLL file and the decryption program are packaged in the installation package. According to the technical scheme, the DLL file is reinforced through the decryption program independent of the DLL file, cracking of the DLL file is difficult to achieve through a reverse analysis method, therefore, the DLL file is effectively protected, and the requirements of a developer for protecting the DLL file are met.

Owner:BEIJING QIHOO TECH CO LTD +1

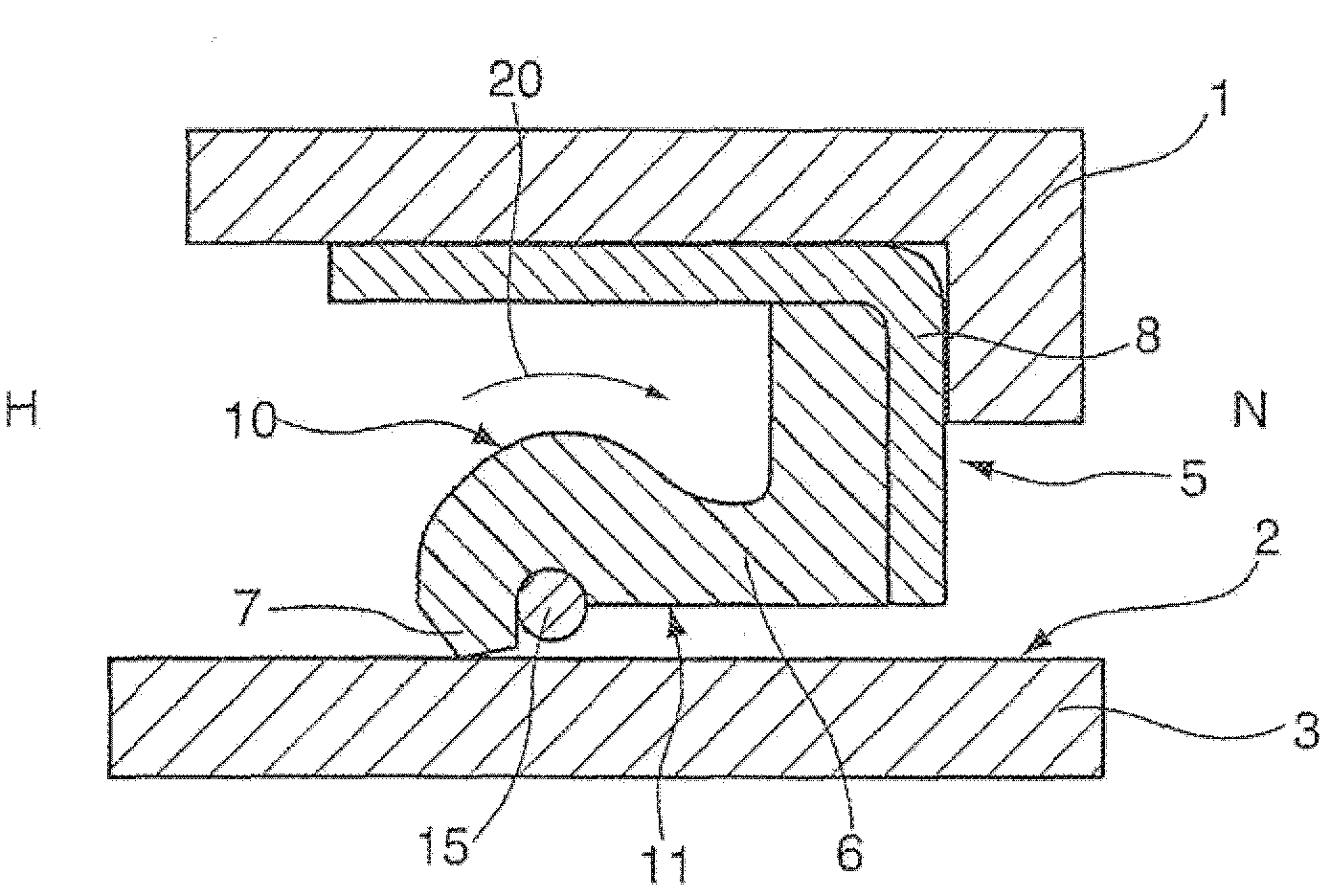

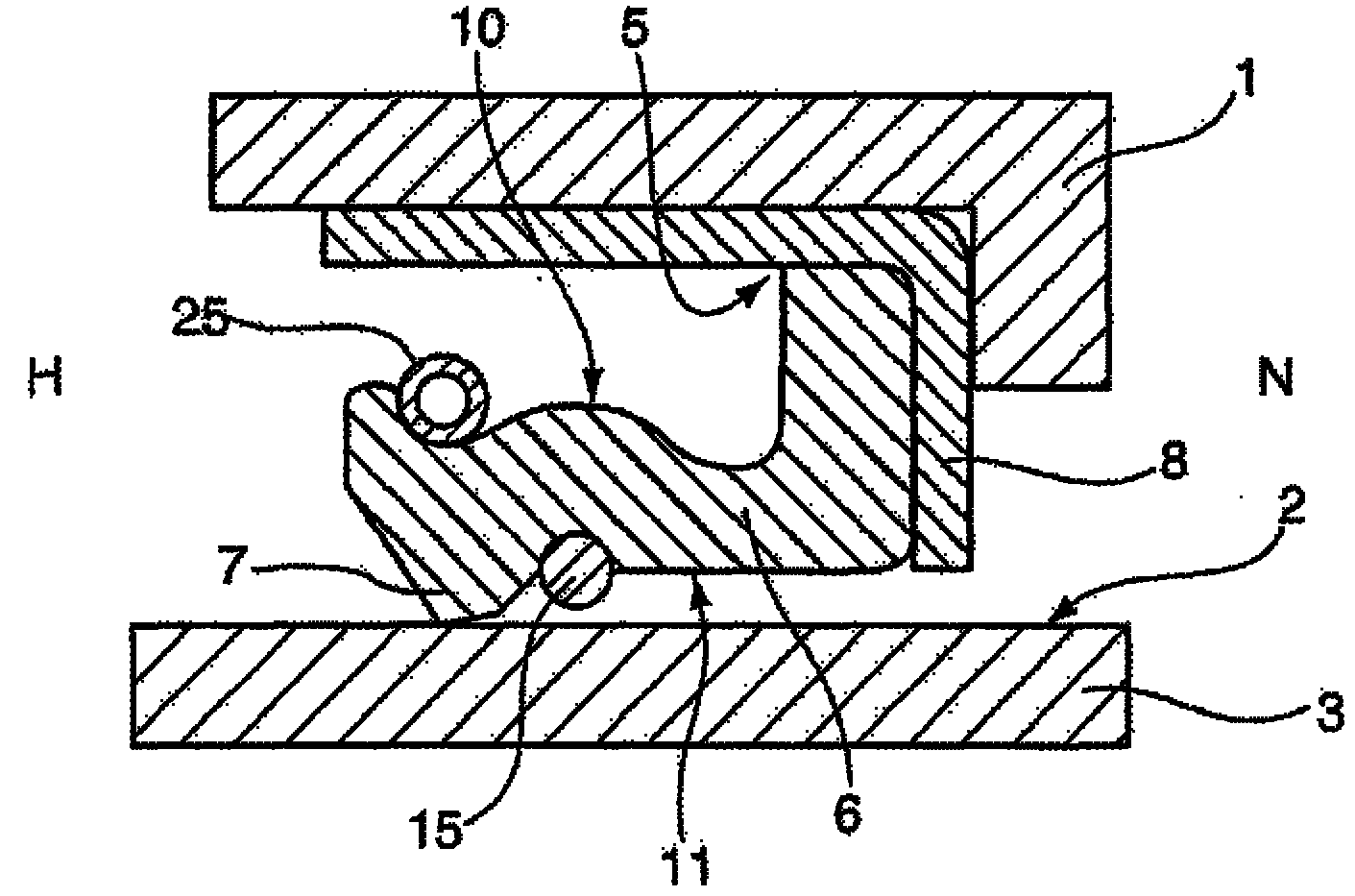

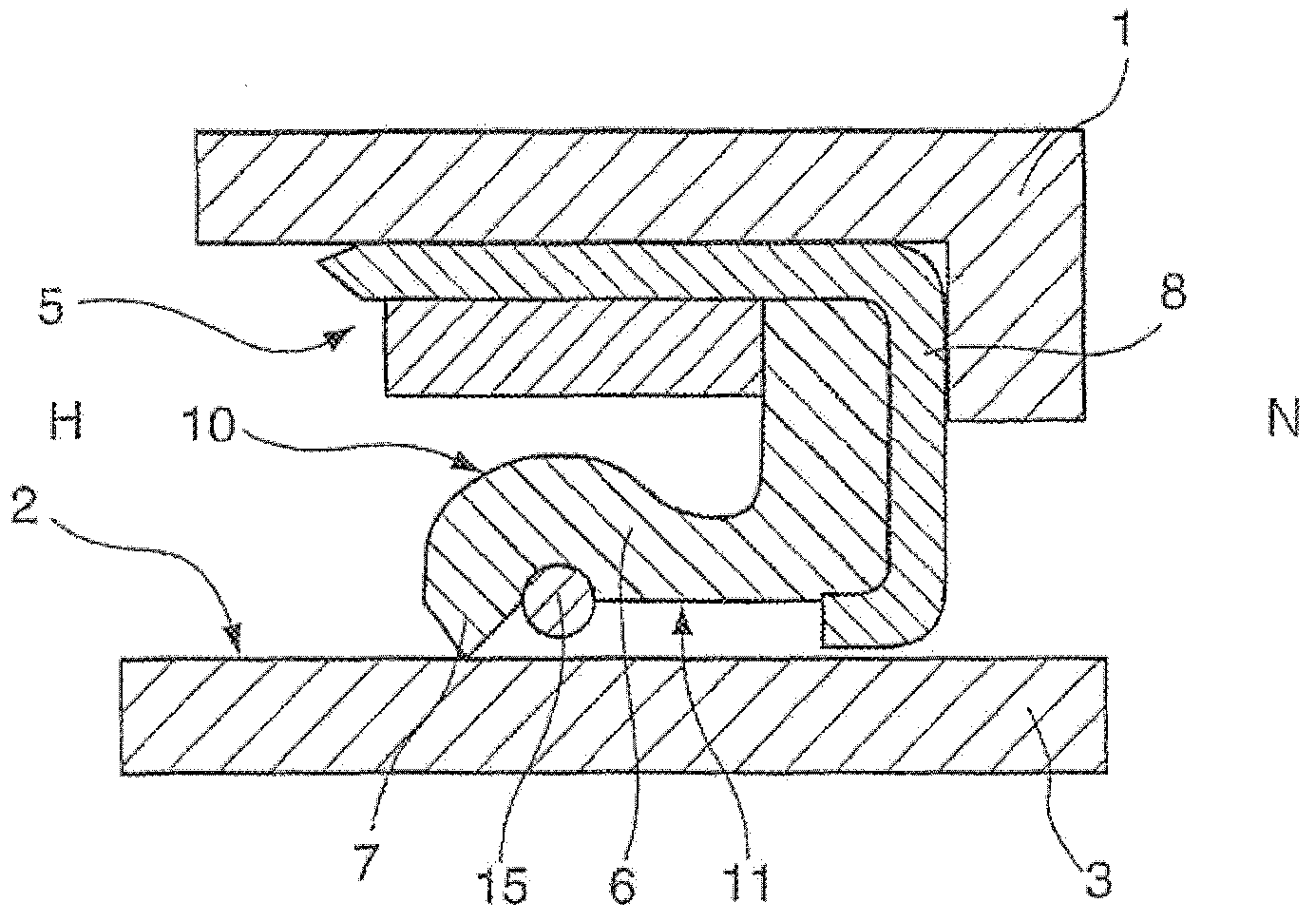

Seal And Seal Arrangement

The invention relates to a seal for sealing a sealing surface (2) between a first machine part (1) having a seal accommodating structure, preferably a groove, and a second machine part (3), which can be moved relative to the first machine part (1) and which has the sealing surface (2), wherein a high-pressure area between the machine parts (1, 3) can be sealed off from a low-pressure area by the seal, comprising - a retaining element (5) for fixing the position of the seal in the seal accommodating structure, and - a sealing lip (6) made of an elastomer material formed on the retaining element (5) and having a sealing edge (7) formed on a free end of the sealing lip (6) for contacting the sealing surface (2), wherein the sealing lip (6) has a high-pressure surface area (10) that adjoins the high-pressure area and a low-pressure surface area (11) that adjoins the low-pressure area. The seal has a supporting element (15), wherein the supporting element (15) forms a support of the sealing lip (6), the support of which is on the low-pressure surface side and extends substantially parallel to the sealing edge (7), and wherein the support is arranged between the sealing edge (7) and the retaining element (5).

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

Cold-hot compound stamping forming method for steel plate with ultrahigh strength

InactiveCN102728708AGuaranteed dimensional accuracySubsequent assembly went smoothlyHot stampingCold formed

The invention discloses a cold-hot compound stamping forming method for a steel plate with an ultrahigh strength, belonging to the field of hot stamping forming. Working procedures of trimming, punching and the like for sheet metal are finished for the steel plate via a cold forming process at first, and the cold-formed-stamped part completely has the shape, structure and dimensional accuracy of drawing requirements. The cold-formed-stamped part is heated to be completely austenitized, and then purposes of keeping the original dimensional accuracy and quenching are achieved via a hot forming mould. The cold-hot compound stamping forming method disclosed by the invention successfully solves the problems of low accuracy and high cost of laser trimming and punching for the traditional hot-formed-stamped part; and compared with the traditional hot forming process, the cold-hot compound stamping forming method disclosed by the invention fundamentally improves the dimensional accuracy of the stamped part, increases production efficiency, decreases production cost, and plays an important role in promoting production practice.

Owner:JILIN RUIHENG MACHINERY

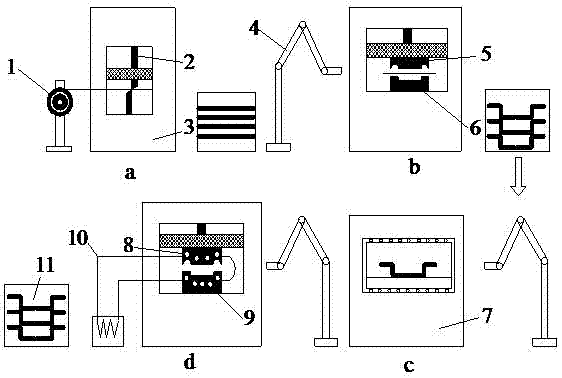

Method and device for strengthening underwater laser micro shot blasting of fastener hole

InactiveCN103233105ADeep and high amplitude residual compressive stressTo achieve reinforcementFastenerHigh amplitude

The invention discloses a method and a device for strengthening underwater laser micro shot blasting of a fastener hole. The fastener hole is placed in water, small light spots are irradiated on an absorption layer of the inner wall of the fastener hole through a laser beam of the small light spots with high power reflected by a full reflecting mirror and arranged inside the fastener hole, and the energy of an impact wave finally generated directly acts on the wall of the hole, so that a high-temperature and high-pressure plasma is generated, and a high-pressure impact wave is generated after the explosion of the plasma for strengthening the inner wall of the fastener hole. The device for using the method comprises a laser, a laser control device, a water tank, a five-shaft working table, a clamping apparatus I, a clamping apparatus II, a feeding device, a total reflecting mirror and a digital control system which are connected in sequence. The method and the device can form deep high-amplitude residual compressive stress layer so as to be suitable for bad working environment with large alternating load, and can be applied for strengthening underwater laser micro shot blasting of the fastener hole.

Owner:JIANGSU UNIV

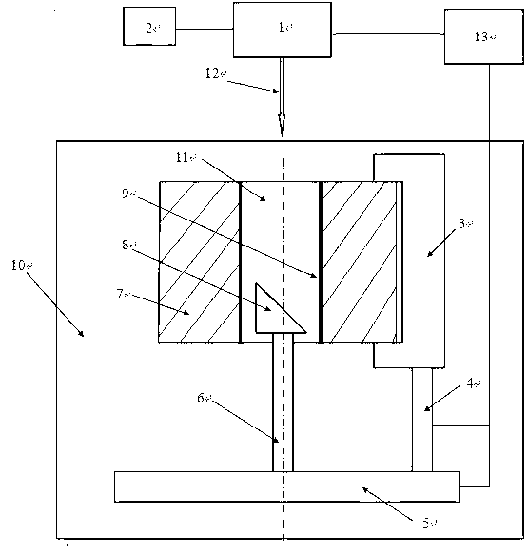

Laser real-time dynamic cladding repair and stress control system and method of damaged gears

ActiveCN107150175ACladding achievedTo achieve reinforcementMetal working apparatusLaser beam welding apparatusImpact systemControl system

The invention discloses a laser real-time dynamic cladding repair and stress control system of damaged gears. The system comprises an optical-infrared coupled dynamic monitoring and measuring system, a laser cladding system, a laser impact system and a clamping table respectively connected with a center control system; the cladding of cladding materials is realized through the heat effect of cladding laser; and impact waves generated by impacting on laser radiated materials are acted on the material surface of a laser cladding layer to realize reinforcement of the laser cladding layer and to eliminate such defects as air holes and loose structures generated in the cladding layer in the laser cladding process. The repair method is suitable for such failure forms as gear fatigue cracks, pitting, gear breakage and gear surface wear, and quickly realizes the shape recovery of gears through laser cladding repair without wasting classing materials; and through laser impact stress control, the defects generated in the laser cladding process are eliminated, the mechanical performances of the repaired gears are guaranteed, subsequent complicated machining is not needed, the repair efficiency is improved, and the gear repair cost is reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

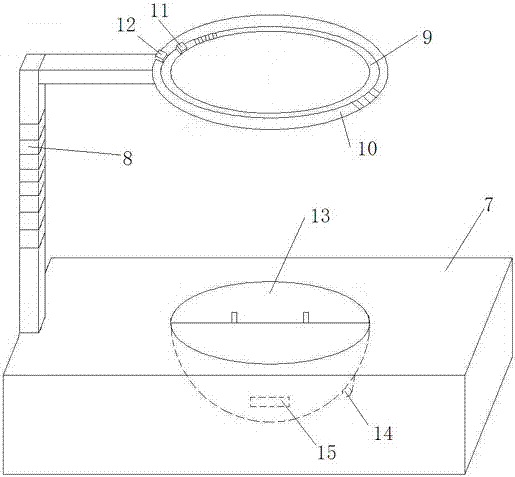

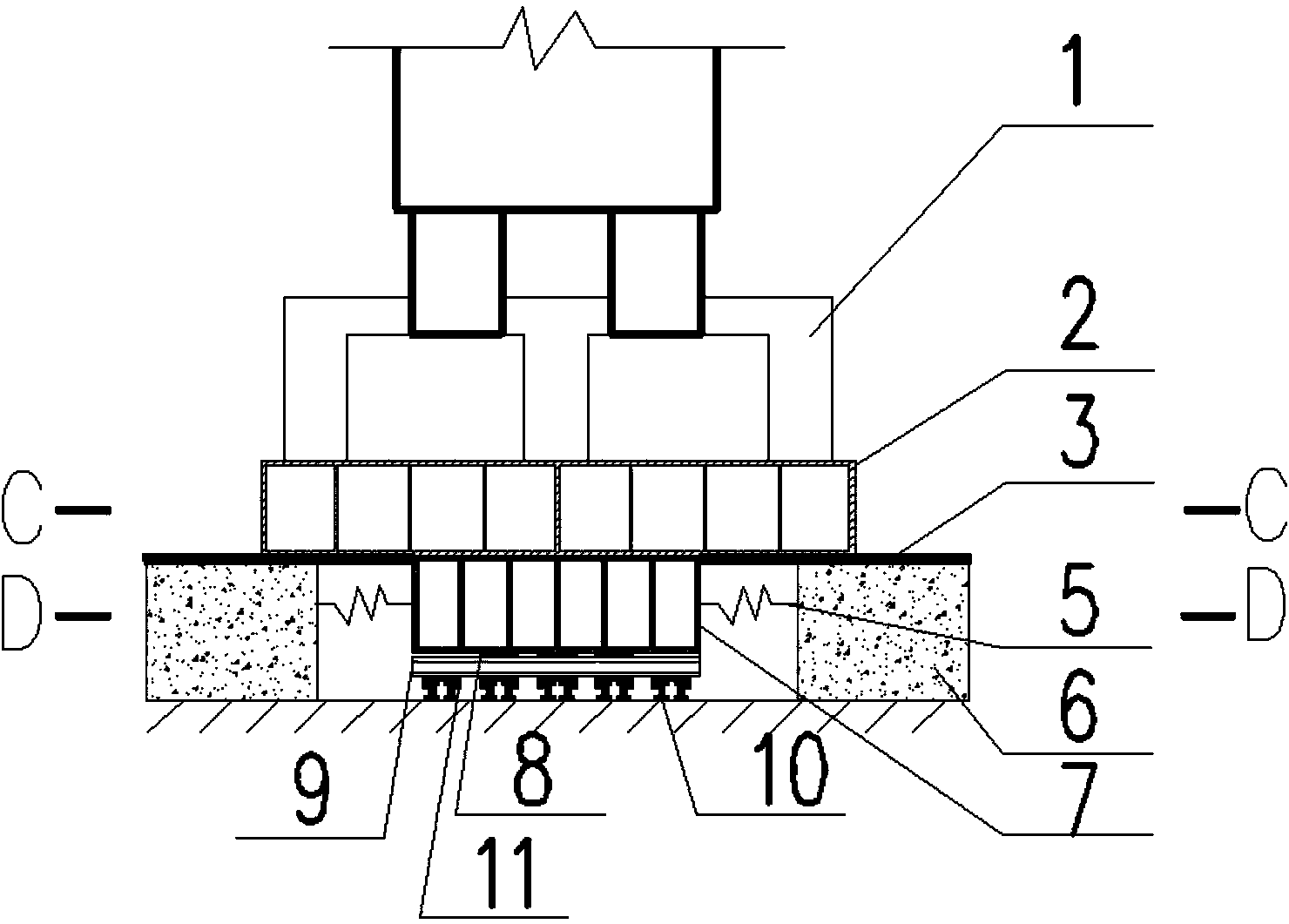

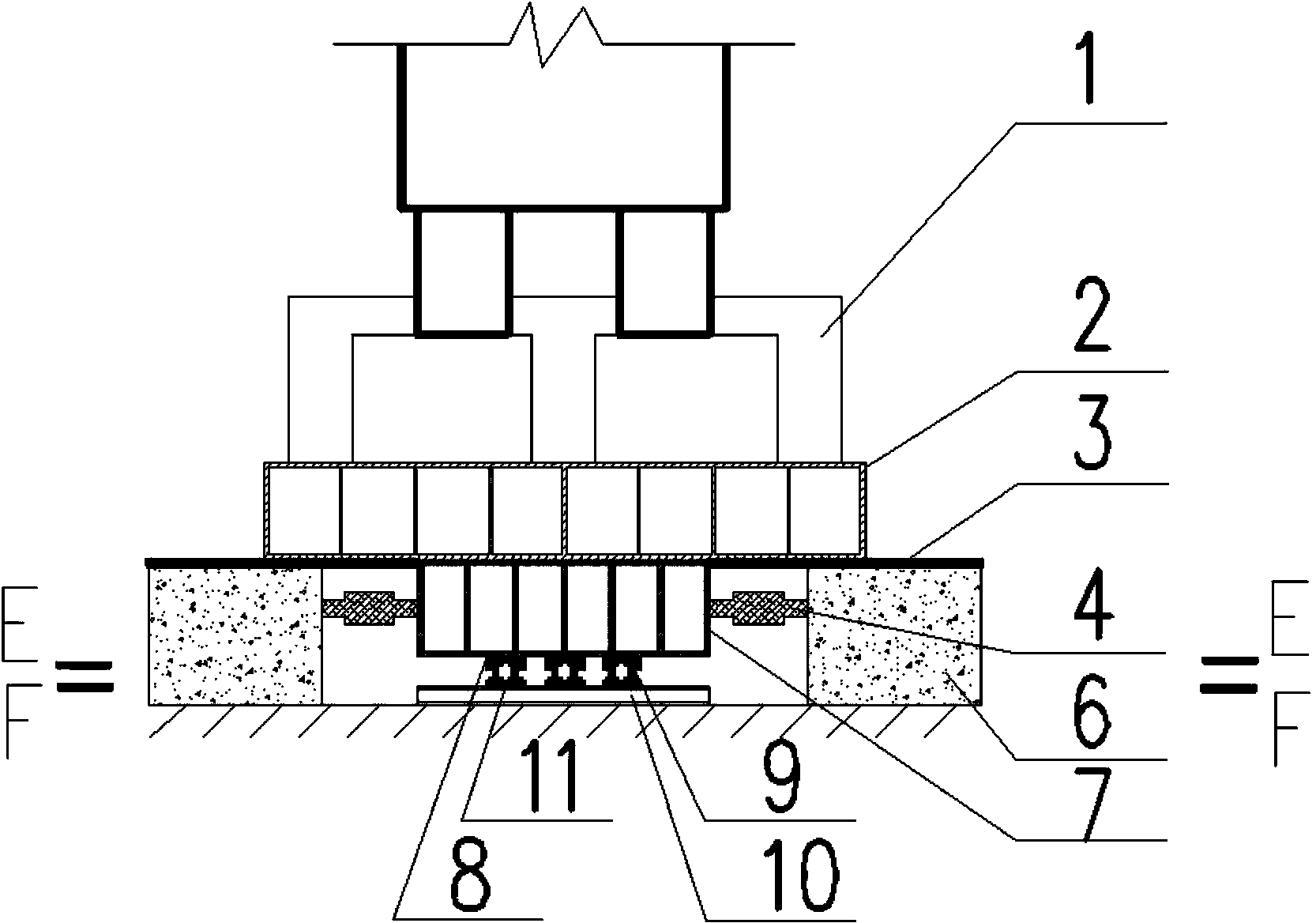

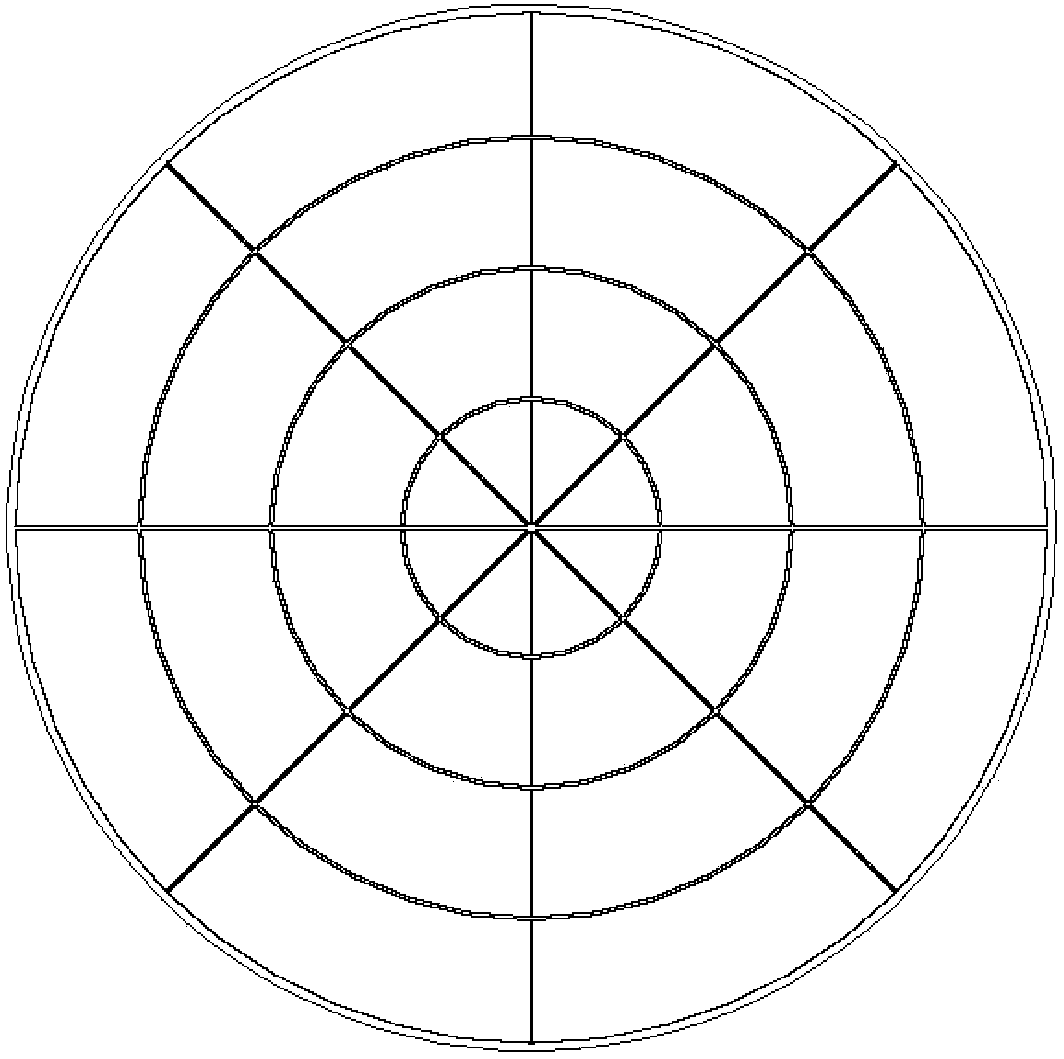

Shock insulating device resistant to pulling and twisting

InactiveCN103669633AWide range of stiffness adjustmentSignificantly prolonged periodShock proofingShock resistanceHigh rise

The invention discloses a shock insulating device resistant to pulling and twisting and belongs to the technical field of building shock resistance. The shock insulating device is mainly composed of a high-rise structure (1), an upper-portion rigid pedestal (2) with high rigidity and bearing capability, a base heat-insulating layer (3), viscous dampers (4), damping springs (5), springs, a damper supports (6), a lower-portion rigid pedestal (7) with high rigidity and bearing capability, horizontal limiting sliders (8), bottom horizontal shock-insulating linear guide rails (9), bottom longitudinal shock-insulating linear guide rails (10) and longitudinal limiting sliders (11). The shock insulating device is low in cost, simple in structure, convenient to construct, high in pulling resistance and twisting resistance and obvious in shock-insulating effect.

Owner:BEIJING UNIV OF TECH

Environment-friendly acrylate grouting material as well as preparation method and application thereof

InactiveCN104177554AImprove water resistanceImprove aging resistancePolymer science(Hydroxyethyl)methacrylate

The invention provides an environment-friendly acrylate grouting material, as well as a preparation method and an application thereof. The material mainly comprises the following components in parts by weight: a main agent, namely 100 parts of methacrylic acid-beta-hydroxyethyl ester, a crosslinking agent which includes 5-30 parts of hydrophilic compound containing a diallyl ether functional group, 1-5 parts of initiator and 0.5-3 parts of accelerant, 0-20 parts of an adjuvant, and a solvent, namely 2-1,000 parts of water. The method comprises the following steps: firstly, mixing the main agent, the crosslinking agent, the accelerant, the adjuvant and a part of solvent evenly to form a solution A in use; then dissolving the initiator into a residual solvent to form a solution B; and finally mixing the solution A with the solution B evenly, and solidifying at room temperature. According to the grouting material disclosed by the invention, the technical problem that the existing organic grouting material cannot be grouted once after being mixed with an inorganic grouting material, and the technical problem that the existing grouting material has poor durability, low strength, poor water solubility, low water expansion rate and high toxicity are solved.

Owner:湖南博旺水电建设有限公司

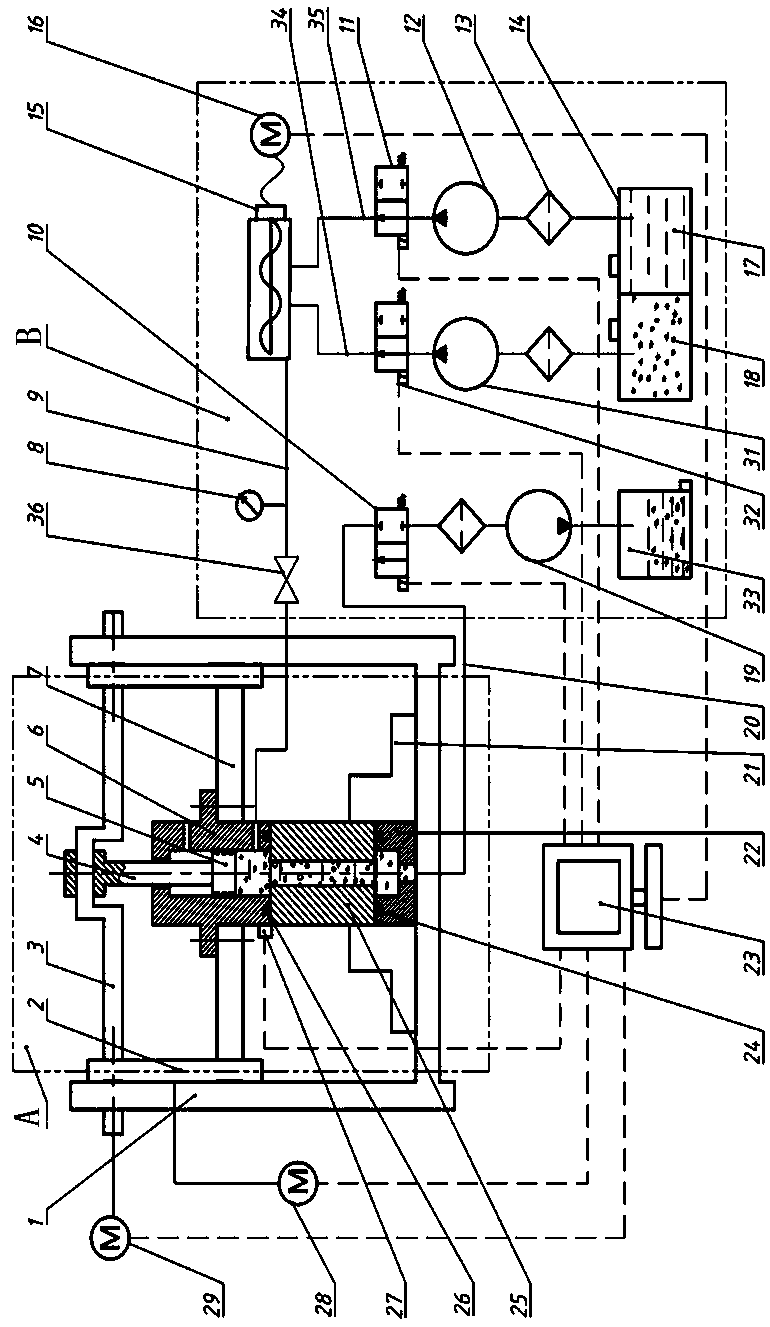

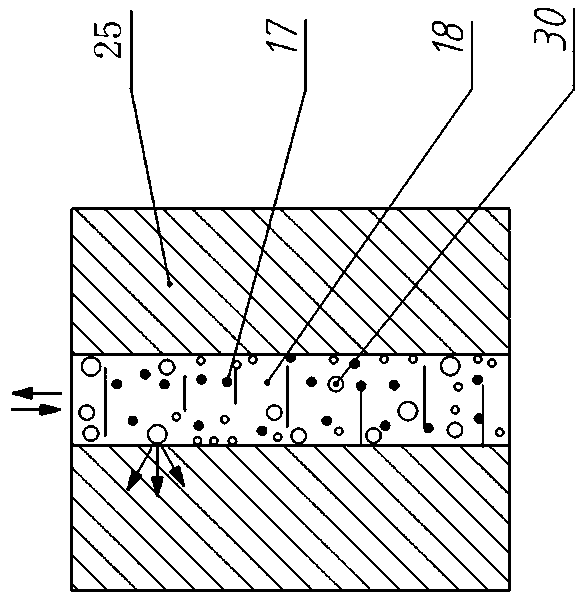

Additive manufacturing forming inner hole surface polishing and strengthening integrated machining system and method

The invention discloses a workpiece inner hole surface polishing and strengthening integrated machining system and a method adopting additive manufacturing forming. The system comprises a workbench, an cavitation generation system, a liquid supply circulation system and a controller, the volume alternating mode is adopted to change the volume of liquid in an inner hole of the additive manufacturing forming workpiece to be changed by virtue of the rapid reciprocating motion of a piston, so that the pressure is changed, a hollow bubble group is formed at the inner part of the liquid and an innersurface of the inner hole, and the hollow bubble group is killed along with further compression, so that shock waves and high-speed water jet flows are generated in the liquid medium; a nano-colloidin the inner hole makes full contact with the inner surface of the hole, ultra-fine polishing of the inner surface of the hole is realized, the shock waves and the high-speed water jet flows on an inner wall of the hole, so that a certain amount of plastic deformation is generated on the inner wall of the inner hole, and the reinforcing of the inner surface of the inner hole is realized. The cavitation technology and the nano colloid polishing technology are organically combined, the fatigue life and the surface smoothness of the inner surface of the inner hole are remarkably prolonged, and the requirements on the ultra-smooth surface are reaches.

Owner:JIANGSU UNIV

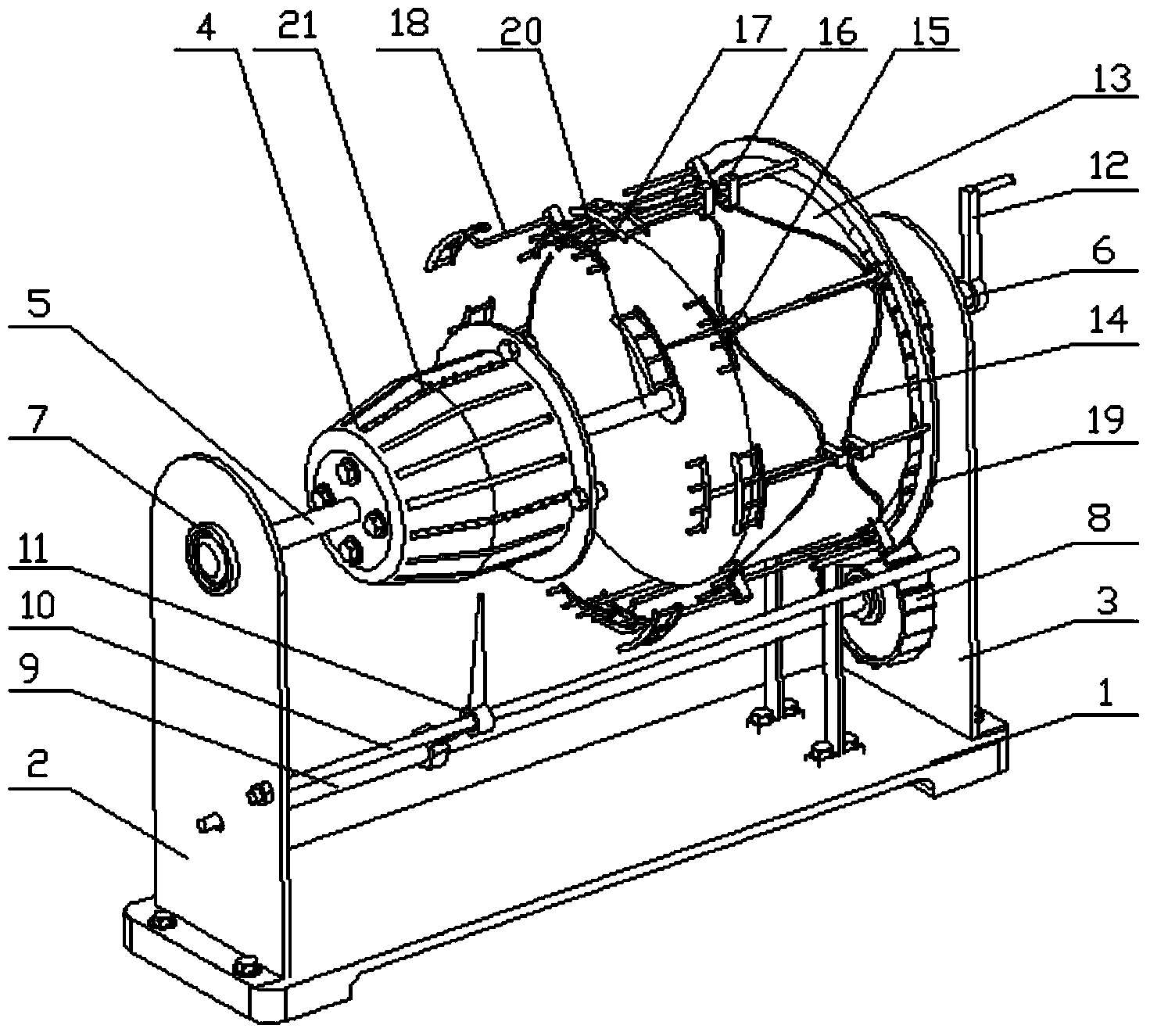

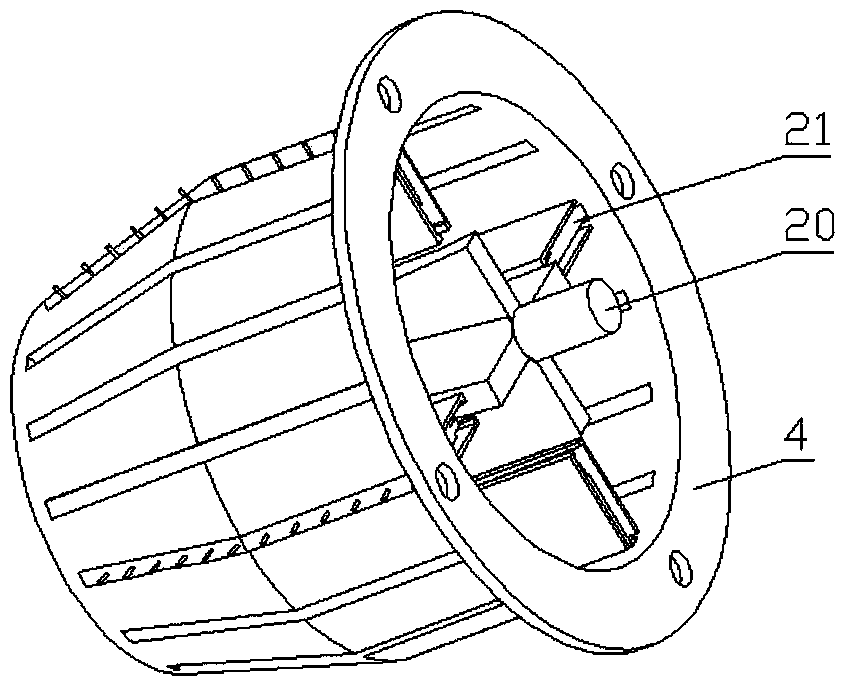

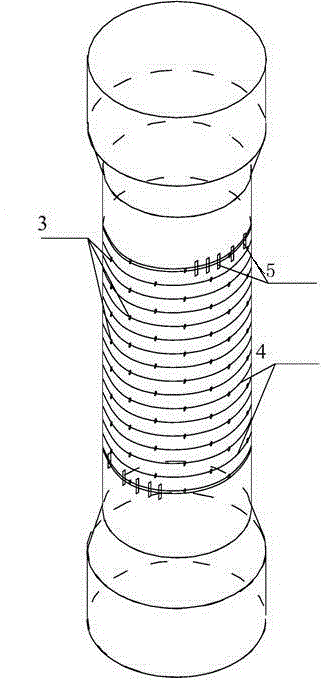

Device and method for forming variable cross-section thin-wall conical carbon fiber perform

ActiveCN103707521ATo achieve reinforcementReduce molding difficultyFiberCarbon fiber reinforced composite

The invention discloses a device and a method for forming variable cross-section thin-wall conical carbon fiber perform and aims at solving the technical problem of a complex method for forming a variable cross-section thin-wall conical carbon fiber perform by using a current carbon fiber perform forming device. Due to the design of a winding die and design philosophies of paving along with the die, winding and shaping, locating a core die, sewing locally, weaving and reinforcing, the forming device is capable of low-cost continuous preparation of a carbon fiber reinforced composite conical variable cross-section thin-wall part perform body; the method is simple; according to the forming method, four processes of paving, winding, sewing and weaving the fiber are continuously performed on the same device, so that the forming difficulty of the variable cross-section thin-wall conical carbon fiber perform is prominently reduced; in the preparation process, process parameters with influence on reinforced body forming quality and the wall thickness of the perform can be controlled in real time. Compared with the background art, no special expensive equipment is needed in the method; the method is capable of forming freely according to the shape of the needed perform.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

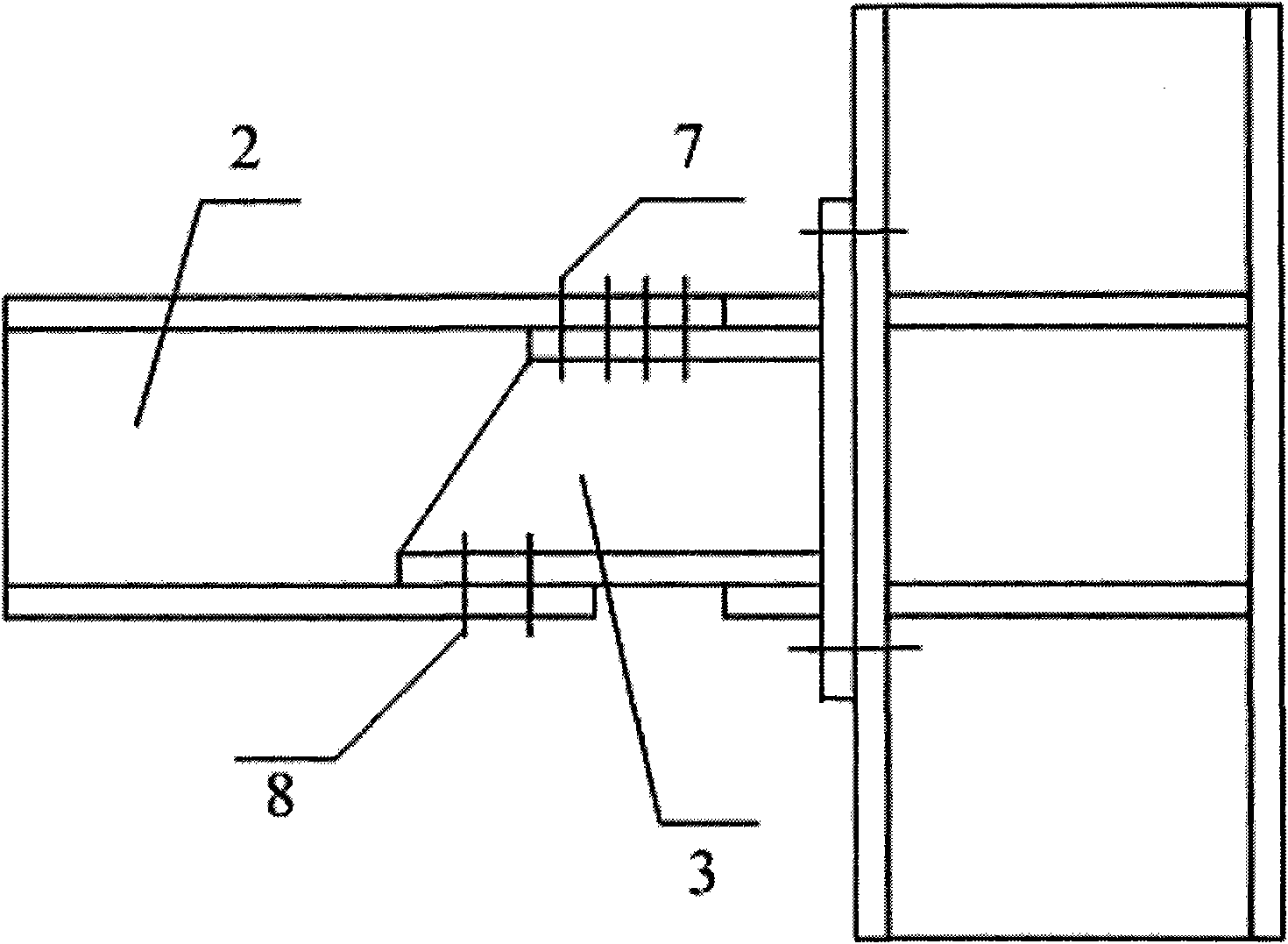

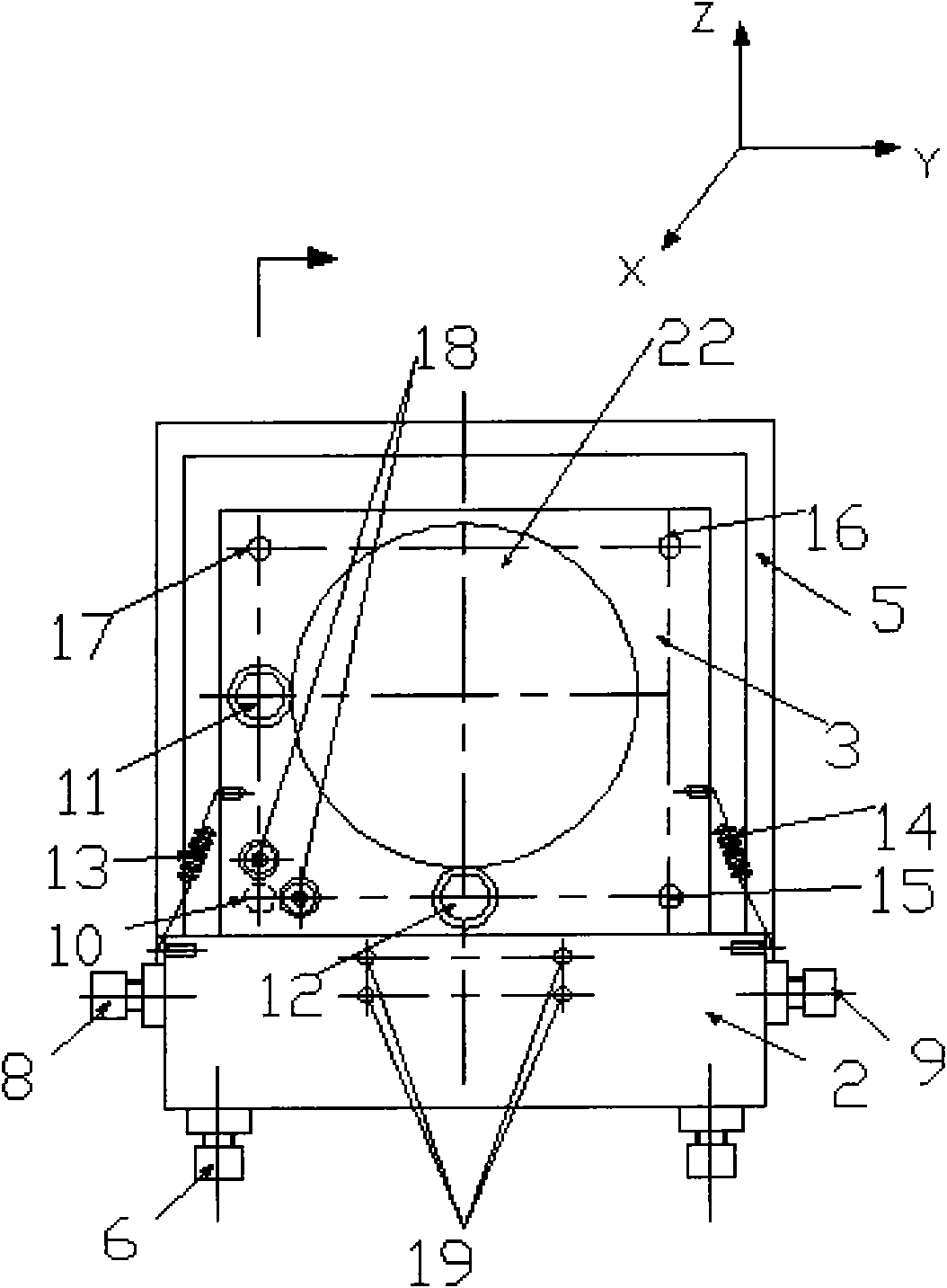

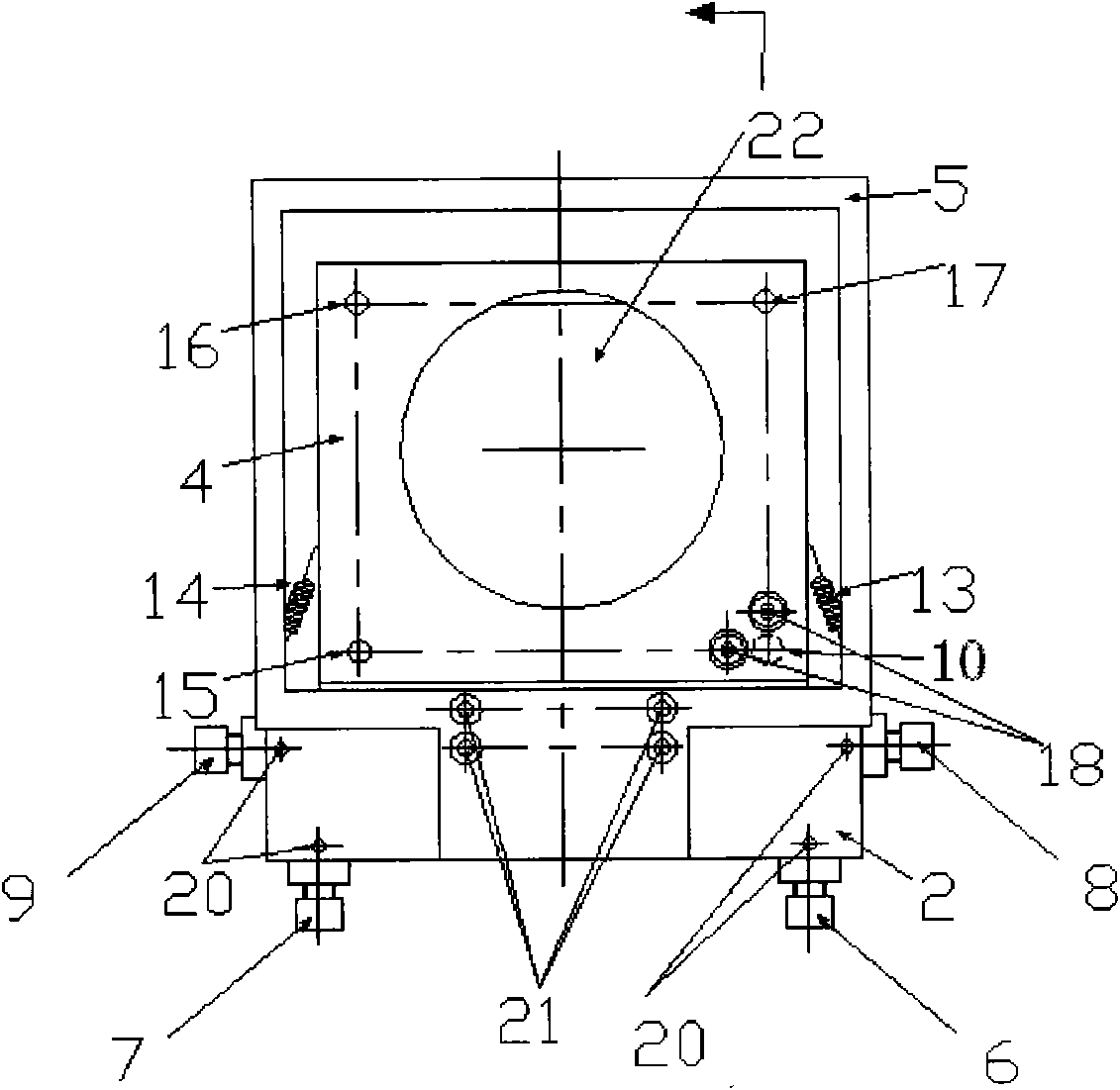

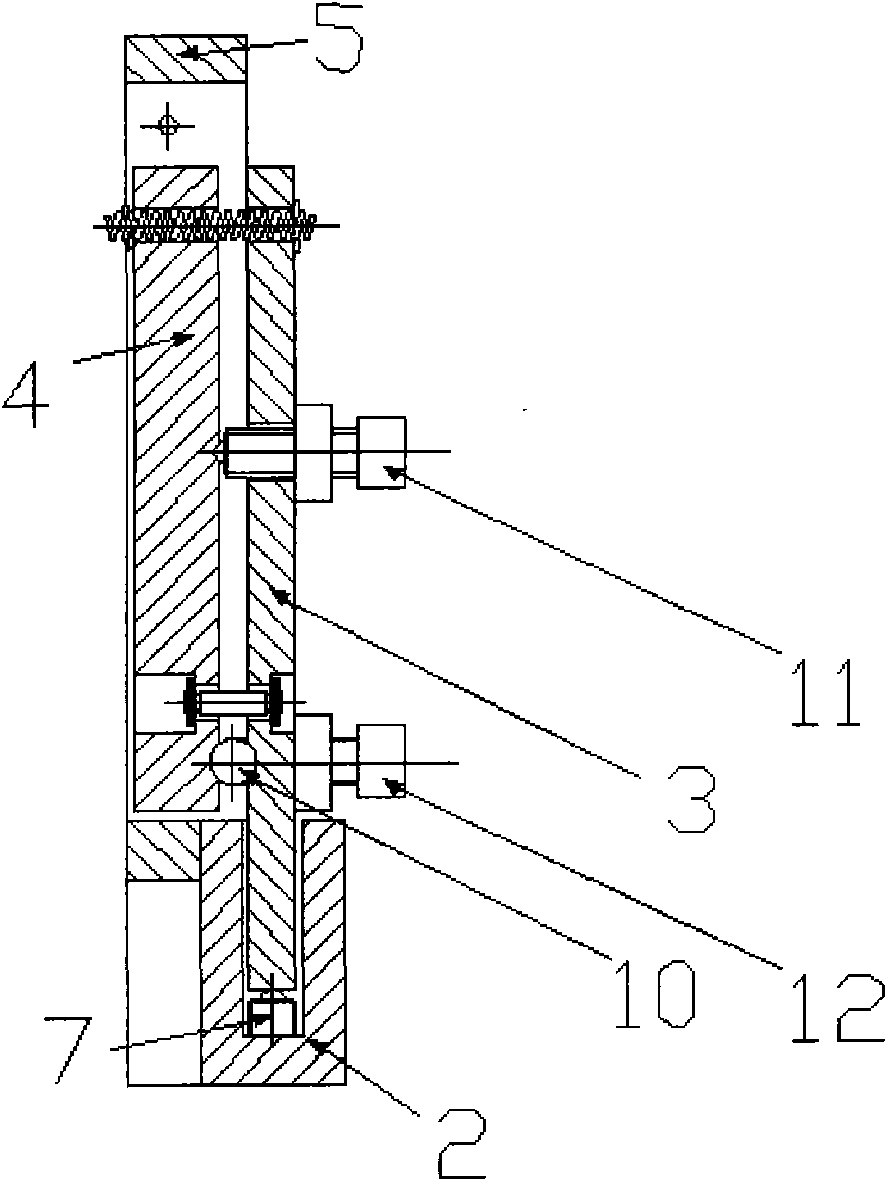

Optical tool regulator for excimer laser micromachining system

InactiveCN101859009AStable jobTo achieve reinforcementMountingsLaser beam welding apparatusEngineeringLaser excimer

The invention relates to an optical tool regulator for an excimer laser micromachining system, which belongs to the technical field of micro-nanoscale science and is used for MEMS machining. In the optical tool regulator, a sliding seat (1) is arranged on an optical guide rail; a regulating seat (2), a supporting plate (3), a mirror bracket (4) and a tight positioner (5) are sequentially arranged on the sliding seat (1); the mirror bracket (4) is provided with an optical tool hole (22) capable of accommodating a circular optical element with heavy caliber; and a square optical element regulator (23) arranged in the optical tool hole (22) and a light-reflecting inclined frame seat (32) capable of converting light paths are arranged. The optical tool regulator can realize five-dimensional fine adjustment in the X direction, Y direction, Z direction, pitching direction and the direction of left and right rotation, and also can convert the light paths by 90 degrees and is provided with square optical elements. The tight positioner (5) is directly connected with the regulating seat (2), and coats the periphery of the mirror bracket (4), a plurality of screw holes are uniformly formed at the periphery of the lateral surface of the tight positioner, and the tight positioner butts against the mirror bracket (4) fixedly through bolts, so that the optical elements work reliably and stably for a long time.

Owner:BEIJING UNIV OF TECH

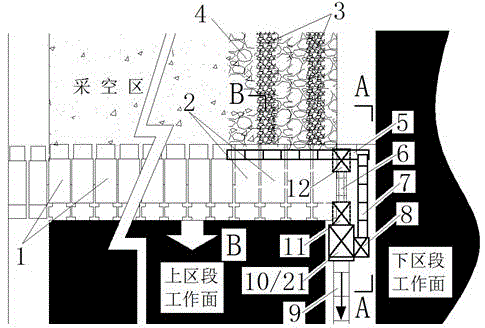

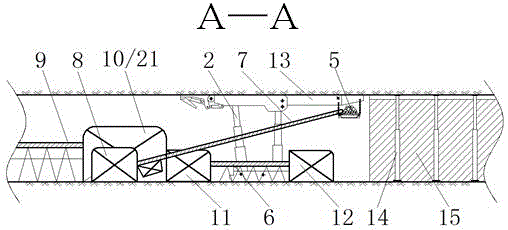

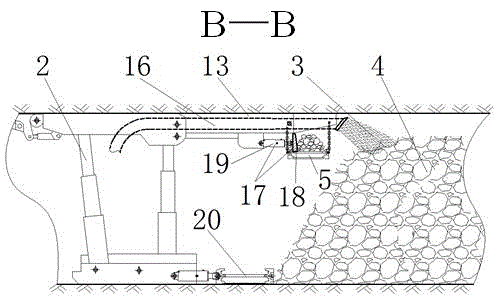

Gob-side entry retaining method for putting top waste rock down to achieve roadway side packing

InactiveCN104453994ASimple support processTake advantage ofMaterial fill-upResource recoveryFilling materials

The invention relates to a gob-side entry retaining method for putting top waste rock down to achieve roadway side packing. The method is mainly applied to the gob-side entry retaining technical field. In the advancing process of a working face, a top coal caving support is directly adopted to put waste rack above a goaf down, the waste rock is transported to the end of the working face and is simply crushed, transferred and transported back, the processed waste rock is stacked, the goaf on one side of a retained roadway is filled with the processed waste rock to form a waste rock wall serving as a roadway side support, and a rear top beam is arranged at the position, needing roadway side packing, of hydraulic supports of the working face, so that a waste rock back transportation device is conveniently installed and the waste rock is stacked to the enough height. Meanwhile, when the waste rock is stacked or after the waste rock is stacked, cemented filling materials are sprayed to the stacking position of the waste rock to achieve airtightness and reinforcement along the roadway side support of the gob-side entry retaining. The method is of great importance in ensuring gob-side entry retaining stability of the thick seam working face, especially the fully mechanized caving face, improving the resource recovery rate and simplifying the roadway side support process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

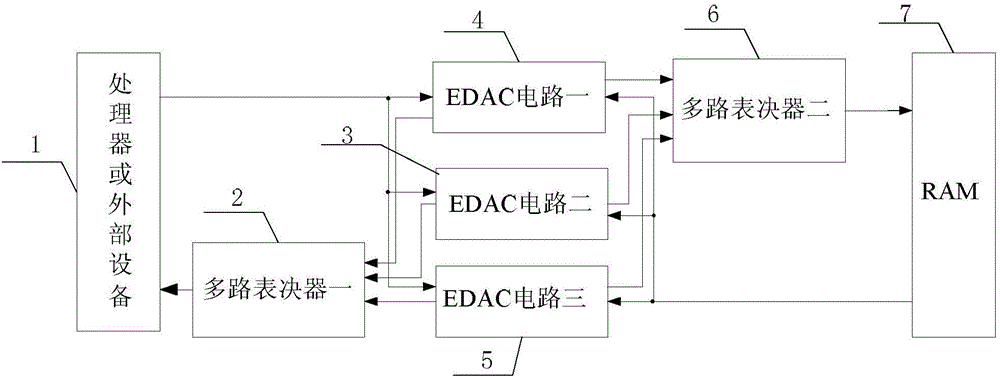

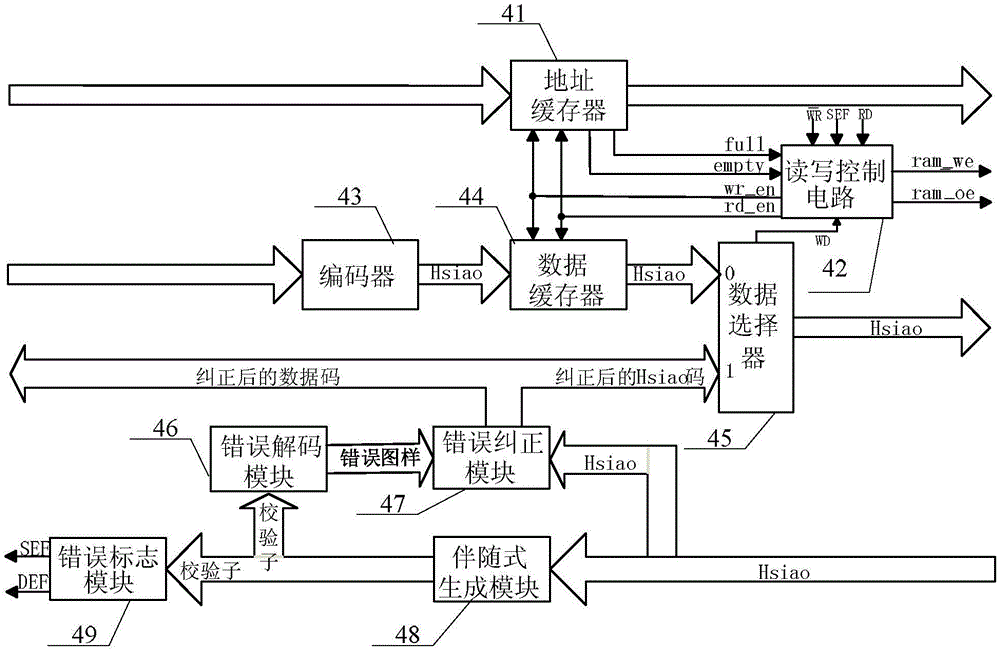

SRAM type FPGA-based RAM data reliability reinforcement apparatus and method

ActiveCN106531224AImprove coding efficiencyReduce error correction costsStatic storageData reliabilityRadiation process

Owner:HARBIN INST OF TECH

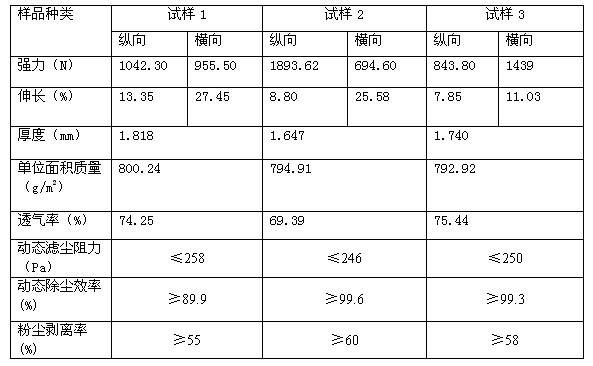

Production process for spunlace composite high temperature-resisting and corrosion-resisting filtering material

ActiveCN102580400AGood strengthStrong chemical resistanceSynthetic resin layered productsNeedling machinesCorrosion resistantFilter material

The invention relates to a production process for a spunlace composite high temperature-resisting and corrosion-resisting filtering material and belongs to the technical field of a textile filtering material. The production process comprises the following steps that: taking polyphenylene sulfide fibers and fiberglass fabrics as raw materials; checking, weighing and charging the polyphenylene sulfide fibers; charging the polyphenylene sulfide fibers into a long curtain, a horizontal opener, a big-cabin cotton blending box and a refined opener successively; and then carding by using a carding machine I and a carding machine II in a layering mode; placing into a cross lapping machine I and a cross lapping machine II to lap; clamping the fiberglass fabrics between the raw materials delivered by the cross lapping machine I and the cross lapping machine II and performing superposition; and performing the processes of pre-wetting, hydroentangling, dehydrating, drying and taking-up. The production process for the spunlace composite high temperature-resisting and corrosion-resisting filtering material provided by the invention has the advantages of excellent mechanical performance, filtration performance, high temperature-resisting performance, and chemical corrosion-resisting performance and size stability.

Owner:ZHEJIANG BAOREN NONWOVEN CO LTD

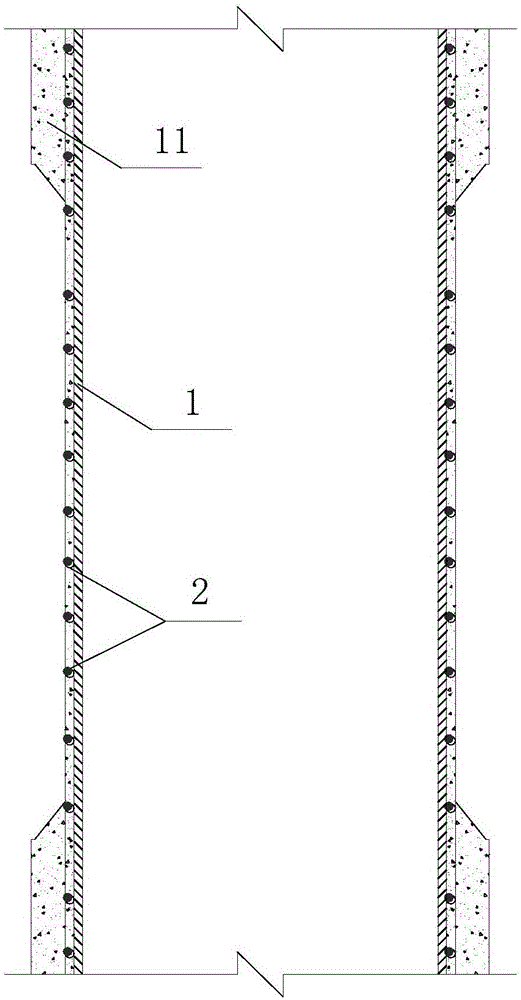

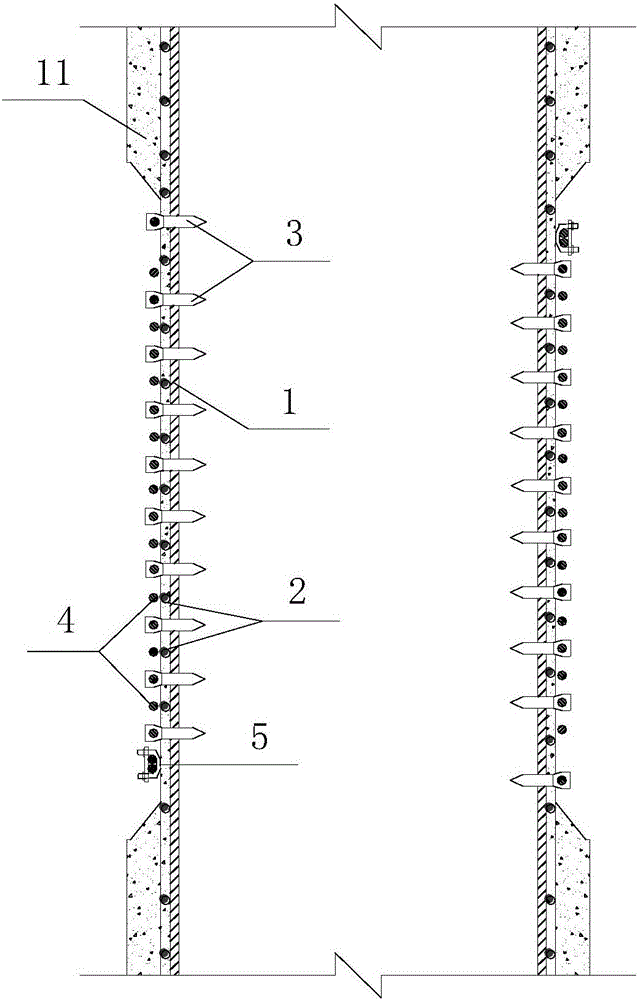

Reinforcing method for winding thermal excitation embedded shape memory alloy wires on concrete column

The invention discloses a reinforcing method for winding thermal excitation embedded shape memory alloy wires on a concrete column, and belongs to the field of concrete structure reinforcing. According to the force-bearing requirement of a reinforcing member, the to-be-reinforced zone is determined, and a protection layer of the to-be-reinforced zone is wholly or partially chipped away; according to the force-bearing requirement of the reinforcing member, the winding range, interval and diameter of the thermal excitation embedded shape memory alloy wires are further determined, the size and position of positioning screws are determined; the shape memory alloy wires are positioned through the positioning screws and fixed through anchorage device finally; the shape memory alloy wires are heated to the reverse change finish temperature or above of the shape memory alloy wires so that the shape memory alloy wires can generate restoring force; and heating is stopped, after the shape memory alloy wires are naturally cooled, the protection layer is repaired with epoxy-cement mortar, and the surface of the repaired concrete column is coated with fireproof paint. The reinforcing material is buried in the protection layer, so that the corrosion resistance is good, no anchorage device is exposed, the reinforced structure is good in durability, finished product protection is easy, the structure is consistent with an original structure after being reinforced, and the appearance is not influenced.

Owner:DALIAN UNIV OF TECH

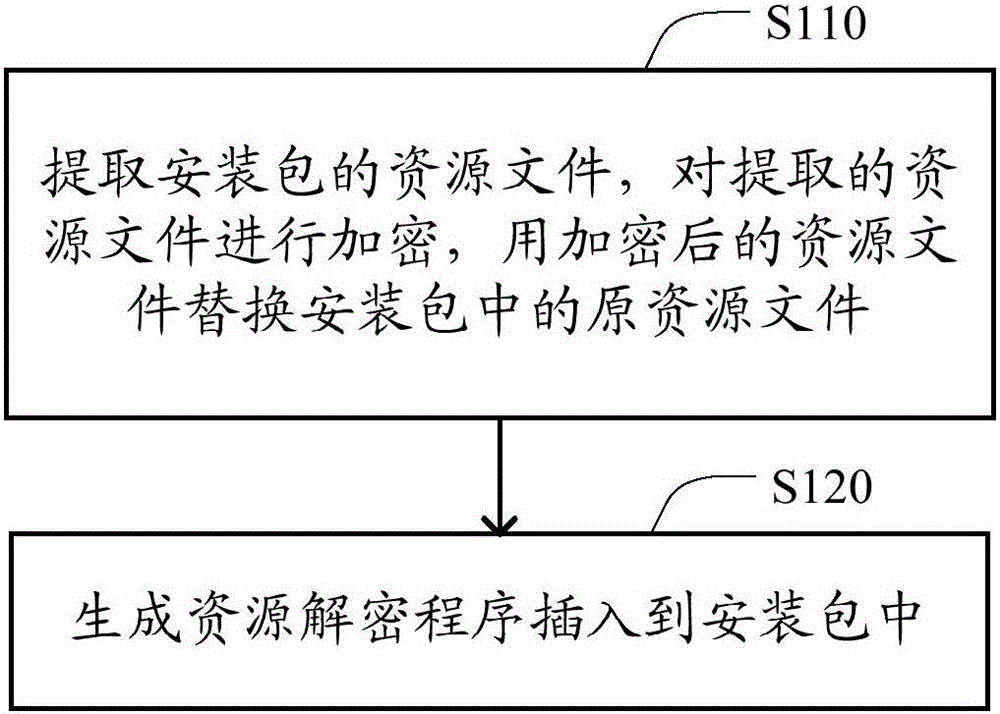

Method and device for reinforcing resource file of installation package

InactiveCN106293852ATo achieve reinforcementEffective protectionDigital data protectionProgram loading/initiatingOperating systemResource file

The invention discloses a method and device for reinforcing a resource file of an installation package. The method includes the steps of extracting the resource file of the installation package, encrypting the extracted resource file, replacing an original resource file in the installation package with the encrypted resource file, and generating a resource decrypting program to be inserted in the installation package. The technical scheme is only aimed at the resource file in the installation package, other files in the installation file are not influenced, the resource file can be effectively protected, the resource file in the installation package can hardly be decrypted even when the installation package is unpackaged, and the requirement of a developer for protecting the resource file is met.

Owner:BEIJING QIHOO TECH CO LTD +1

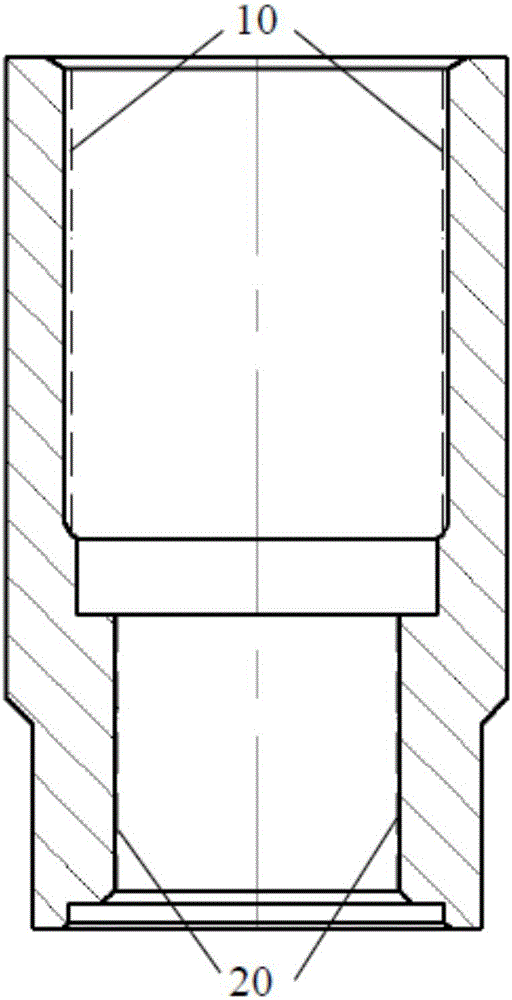

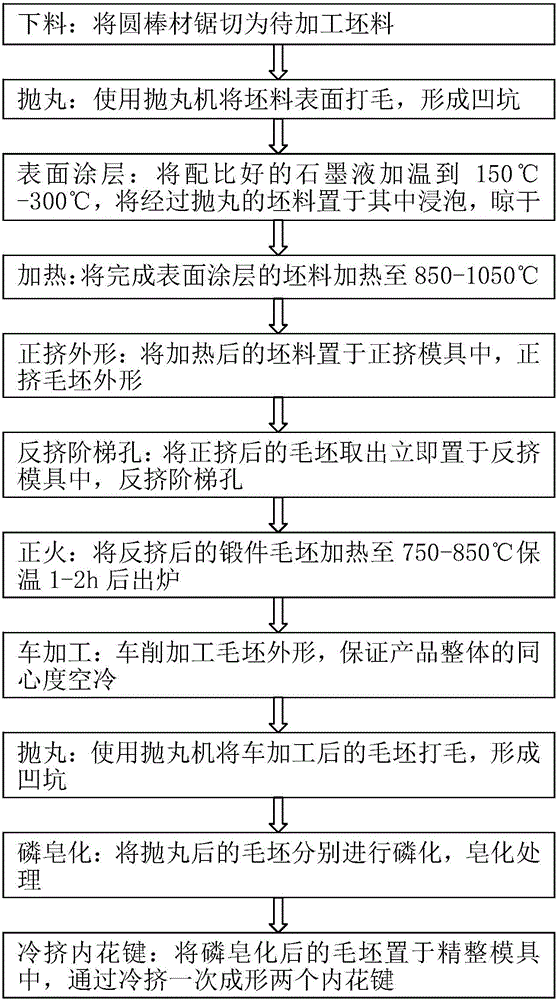

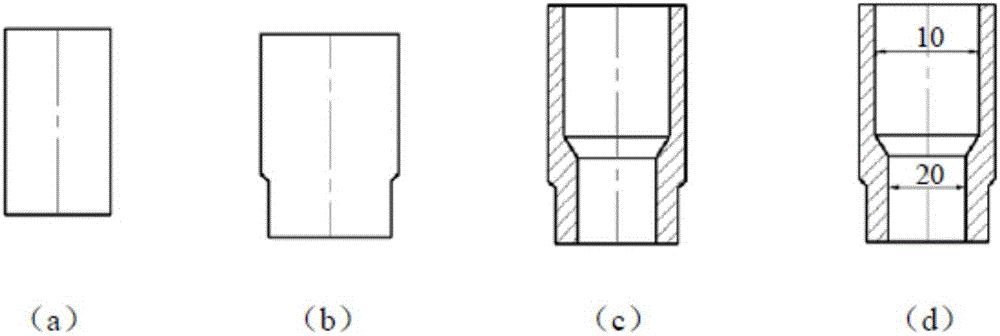

Machining technology for engine drive sleeves

InactiveCN105729067ATo achieve reinforcementImprove mechanical propertiesManufacturing technologyEngineering

The invention provides an improved machining technology for engine drive sleeves. The machining technology comprises the steps of blanking, shot blasting, surface coating forming, heating, forward extruding of appearances, reverse extruding of step holes, normalizing, turning, shot blasting, phosphorus saponifying and cold extruding of internal splines for forming two internal splines at a time. The machining technology avoids subsequent cutting processes such as hole drilling and gear broaching and belongs to chip-less machining methods; by adopting the solid forging technology, a lot of metal flow lines are prevented from being cut, and the whole mechanical property is better; two internal splines can be formed simultaneously through the cold extruding technology, and therefore the raw material and the machining time can be saved to a great extent, the manufacturing technology can be simplified, the manufacturing cost can be lowered, and the surfaces of the internal splines are reinforced in the cold forming process of the internal splines. The machining technology has the advantages that the production efficiency is high, the manufacturing cycle of products is short, and the whole competitiveness of the products is improved.

Owner:JIANGSU HAIYU MACHINERY

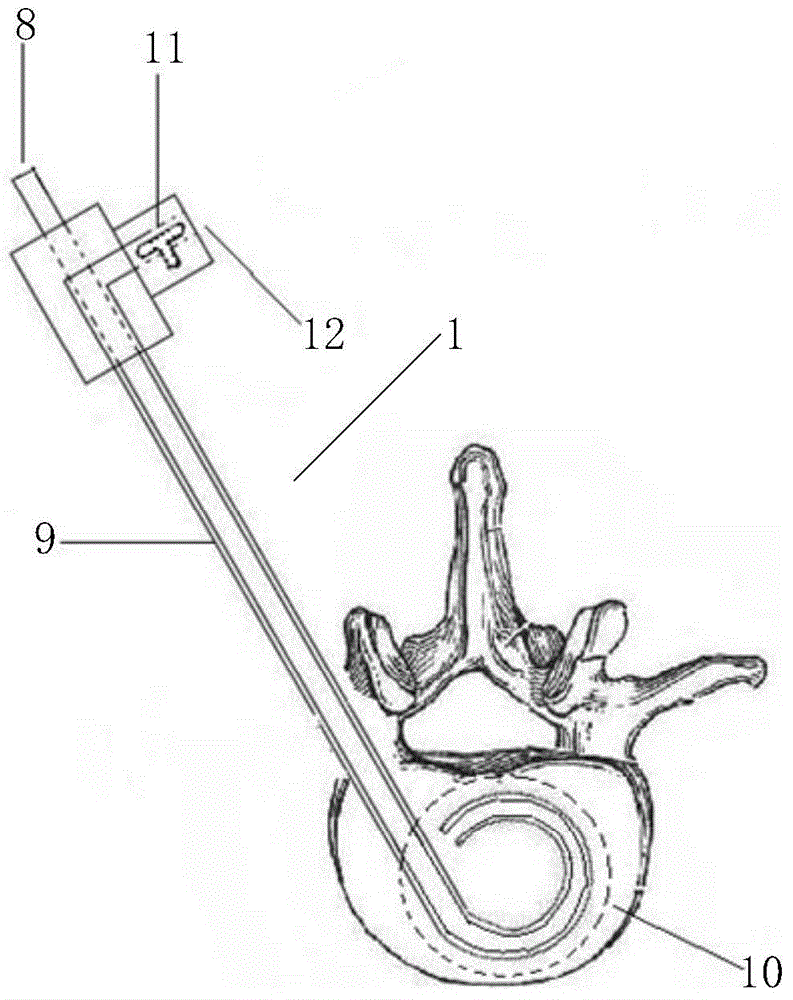

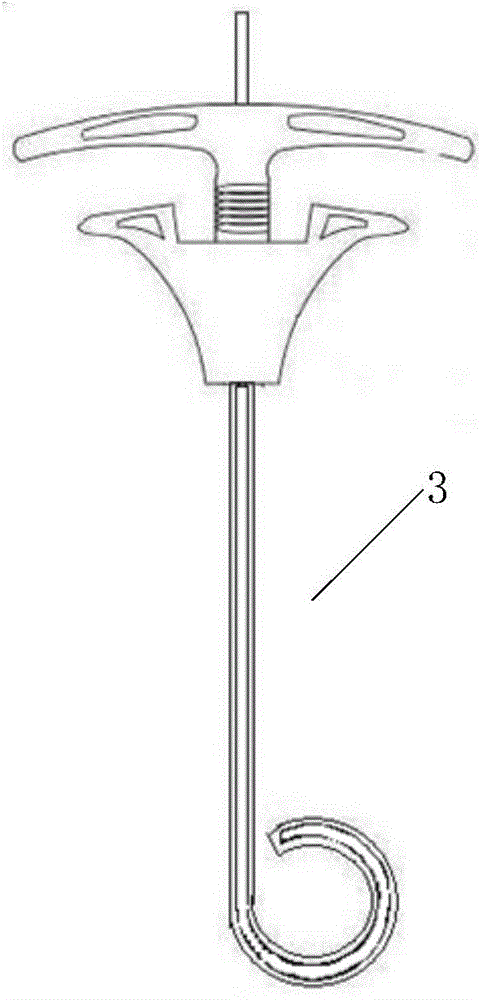

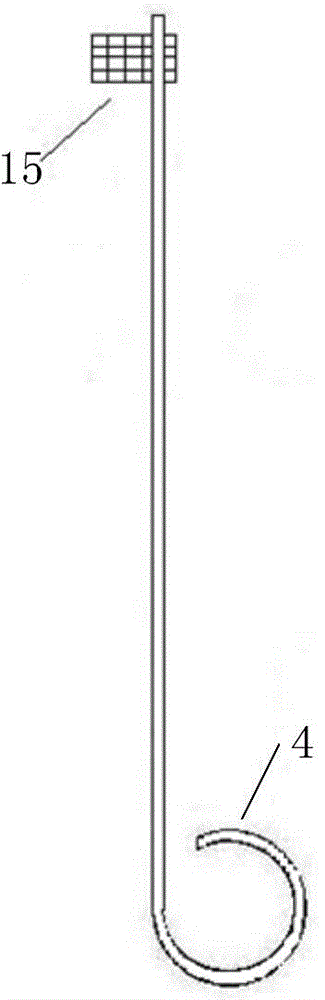

Vertebral body kyphose forming system

InactiveCN104783880ATo achieve reinforcementEasy resetBalloon catheterInternal osteosythesisBalloon dilatation catheterGynecology

The embodiment of the invention discloses a vertebral body kyphose forming system. The vertebral body kyphose forming system comprises a balloon dilatation tube (1) and a bone cement injector (3), wherein the balloon dilatation tube (1) and the bone cement injector (3) are cooperatively used; a free end of the balloon dilatation tube (1) is arranged inside the vertebral body, and the balloon dilatation tube (1) in the vertebral body is a circular balloon (10); the balloon dilatation tube (1) comprises an inner tube (8) and an outer tube (9), wherein the inner tube (8) and the outer tube (9) are of hollow structures; a port formed between the inner tube (8) and the outer tube (9) in the circular balloon (10) is sealed; and the port of the inner tube (8) is opened. By adopting the vertebral body kyphose forming system provided by the embodiment, the problem of pleurocentrum restoration in the vertebral body kyphose process plasty is solved.

Owner:GENERAL HOSPITAL OF THE NORTHERN WAR ZONE OF THE CHINESE PEOPLES LIBERATION ARMY

High-toughness non-heat treatment strengthened die-casting aluminum alloy and preparation method thereof

The invention discloses a high-toughness non-heat treatment strengthened die-casting aluminum alloy and a preparation method thereof. The aluminum alloy comprises, by weight: RE: 7-10%, Mg: 0.05-0.5%,Ti: 0.05-0.1%, inevitable impurity elements: less than or equal to 0.1%, and the balance Al. The component of RE is one or any combination of Ce and La. A pure aluminum ingot, a pure magnesium ingot,Al-Ti master alloy, Al-Ce master alloy and Al-La master alloy are used as raw materials, the preparation process of the aluminum alloy is pressure casting, and the alloy does not need to be subjectedto subsequent heat treatment; the yield strength is more than 150 MPa, the tensile strength is more than 200 MPa and the elongation rate is more than 10% in an as-cast state; and the high-toughness non-heat treatment strengthened die-casting aluminum alloy can be used for structural members with high requirements on mechanical properties in the industries of automobiles and the like, steel structural members are replaced, and the light weight development requirements of automobiles are met.

Owner:江苏双梦源精密成型科技有限公司

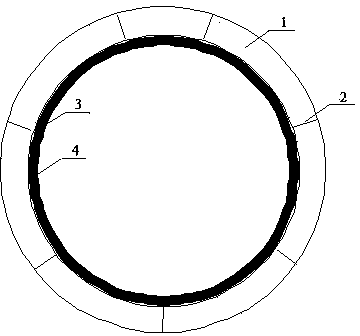

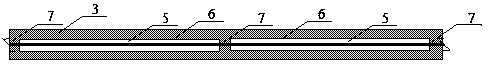

Circumferential intelligentized reinforcement structure and method of shield tunnel

ActiveCN104389621ATo achieve reinforcementRealize monitoringMining devicesUnderground chambersCircumferential strainEngineering

The invention discloses a circumferential intelligentized reinforcement structure and method of a shield tunnel. A reinforcing and monitoring integrated structure is formed through intelligent fiber composite ribs with built-in distributed optical fiber sensors, circumferentially arranged along the inner side surface of the tunnel. The method comprises the following steps: bonding intelligent FRP (fiber reinforced plastic) ribs with the inner side of the tunnel through bonding materials to form a structure layer with good mechanical property; calculating the circumferential convergence of the structure by monitored circumferential strain, and judging the performance change of the reinforced structure. According to the circumferential intelligentized reinforcement structure and method, facilities are simple, the engineering construction is convenient, the difficult problem of reinforcing and monitoring integration of the conventional shield tunnel can be solved, the market competitiveness is high, and large-scale popularization is facilitated.

Owner:SOUTHEAST UNIV +2

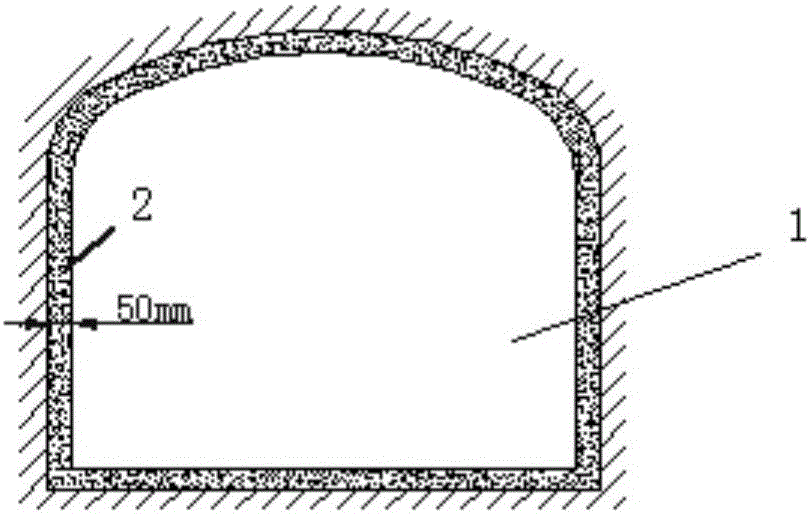

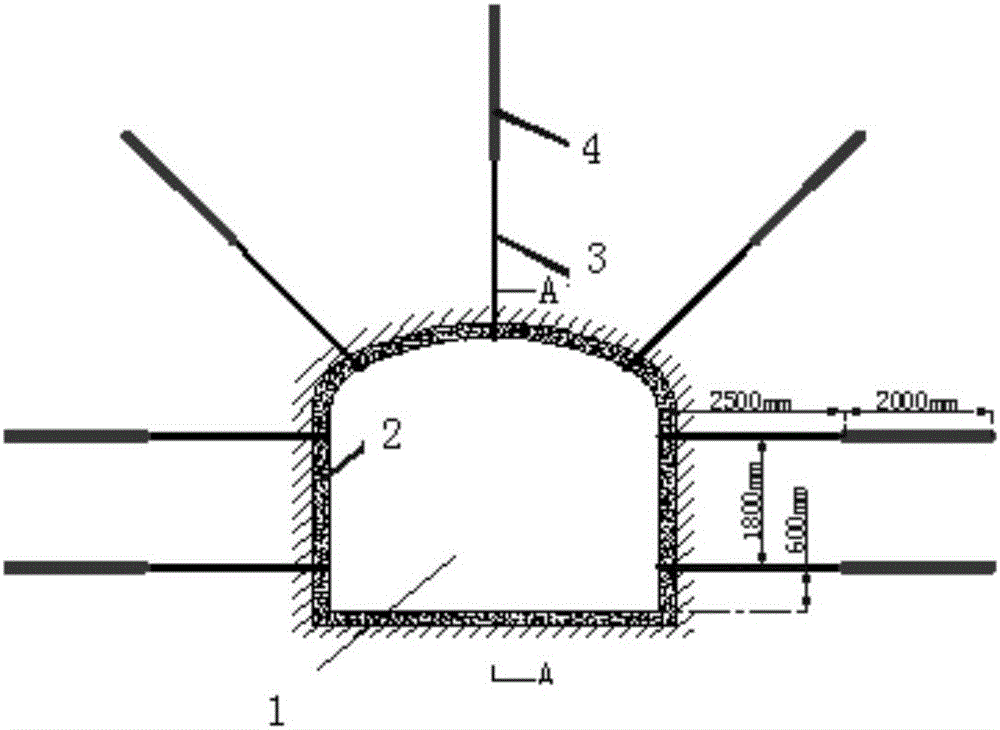

Deep mine hard rock roadway stress adsorption layer structured support method

ActiveCN105781572ARealize synergy and unificationTo achieve reinforcementUnderground chambersBlastingShotcreteStructure of the Earth

The invention discloses a deep mine hard rock roadway stress adsorption layer structured support method. In the initial stage after a deep roadway is excavated, concrete is sprayed to form a concrete flexible support layer. 4.5 m-5.0 m blastholes are drilled in the two sides of the roadway and an arch top, the spaces in the range of 2 m-2.5 m of the bottoms of the blastholes are filled with explosive for conducting soft fragmentation explosion to construct an arch broken rock stress adsorption layer. Grouting conduit anchor rods are driven in through the blastholes, cement paste is poured into the grouting conduit anchor rods to reconstruct structure support bodies. Paste is poured into the blastholes so as to fix the grouting conduit anchor rods, so that a rockburst prevention support structure formed by the arch broken rock stress adsorption layer, the structure support bodies, an isolation rock body, the concrete flexible support layer and the grouting conduit anchor rods of the high-stress deep hard rock roadway in a cooperative mode is achieved. Through the stress adsorption layer formed by the support technology, high stress and gathering of stress energy of surrounding rock of the isolation rock body can be effectively reduced, rockburst is restrained, and tunneling safety and efficient construction of the deep hard rock rockburst type roadway can be well achieved.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com