Additive manufacturing forming inner hole surface polishing and strengthening integrated machining system and method

A technology of additive manufacturing and surface polishing, which is applied in the field of surface treatment and strengthening of metal materials, which can solve the problems of poor surface quality, lack, and surface treatment of the inner wall of holes prone to fatigue cracks, etc., to solve poor surface quality and improve fatigue Effects of lifetime and surface light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

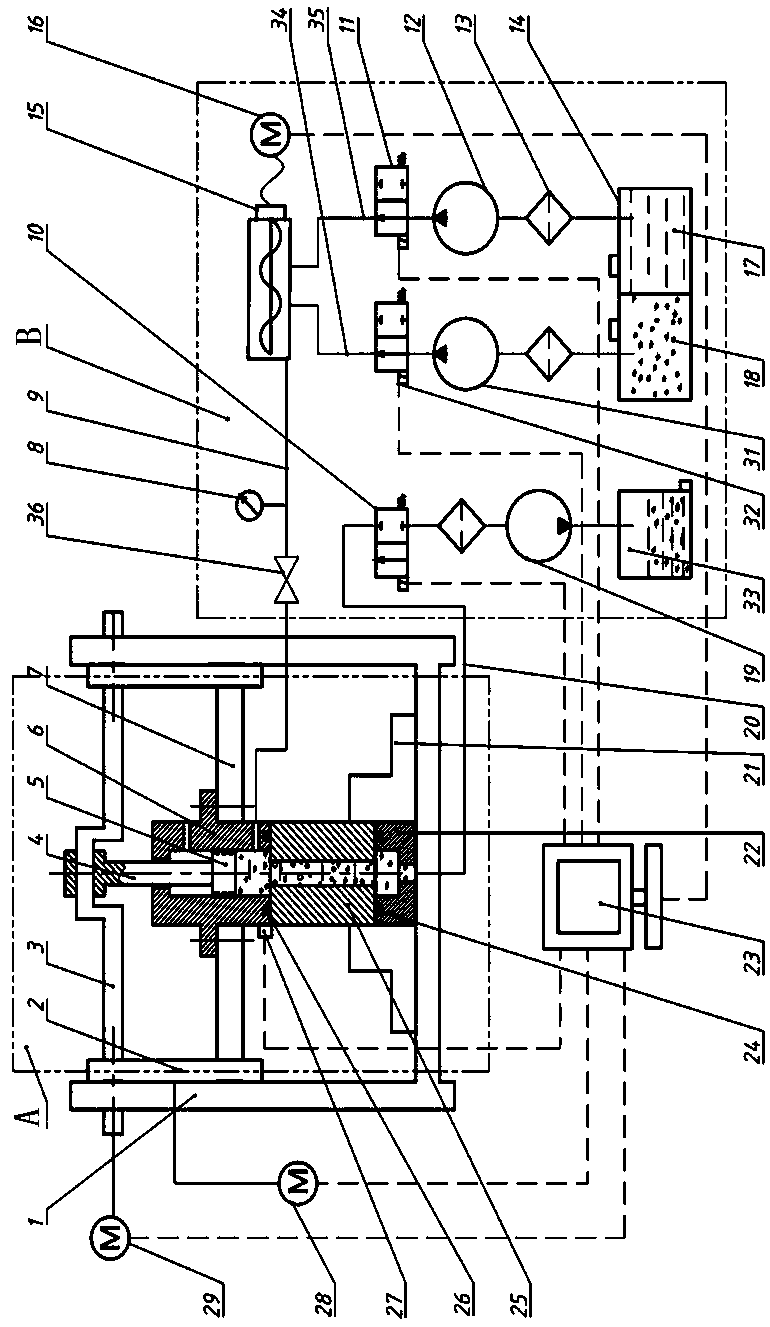

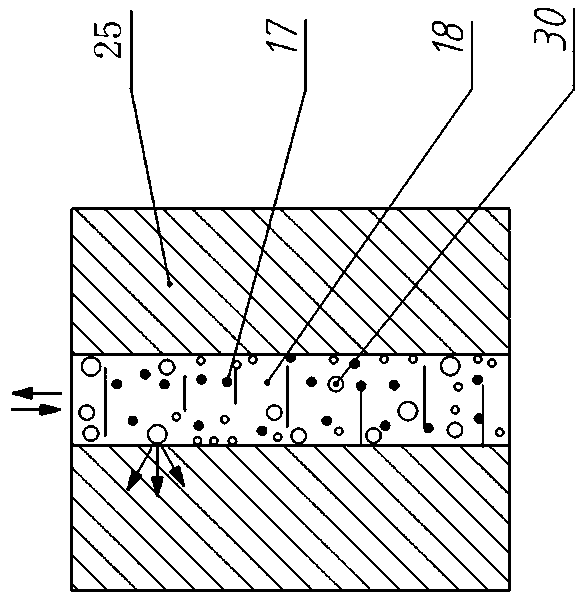

[0024] combine figure 1 and figure 2 , The integrated processing system of additive manufacturing forming inner hole surface polishing and strengthening of the present invention includes a workbench 1, a cavitation generation system A, a liquid supply circulation system B, a controller 23, a photosensitive sensor 27, and the like. The workbench 1 is U-shaped, supporting and connecting the cavitation generating system A, the liquid supply circulation system B provides liquid to the cavitation generation system A, and the controller 23 controls the cavitation generation system A and the liquid supply circulation system B to work.

[0025] Cavitation generation system A includes moving plate 2, crankshaft 3, connecting rod 4, piston 5, piston cylinder 6, vertical moving frame 7, No. 2 drive motor 28, No. 3 drive motor 29, backing plate 22, sealing ring 24 and Position the clamping device 21 .

[0026] On two vertical side walls of workbench 1, chute is set, is used to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com