Preparation method of liners for rolling mills

A liner and rolling mill technology, which is applied in the field of preparation of rolling mill liners, can solve the problems that the production efficiency and reliability of the rolling mill cannot be guaranteed, the ideal service life is not reached, and the cost performance is low, and the ideal anti-wear performance and excellent corrosion resistance can be achieved. And anti-fatigue performance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

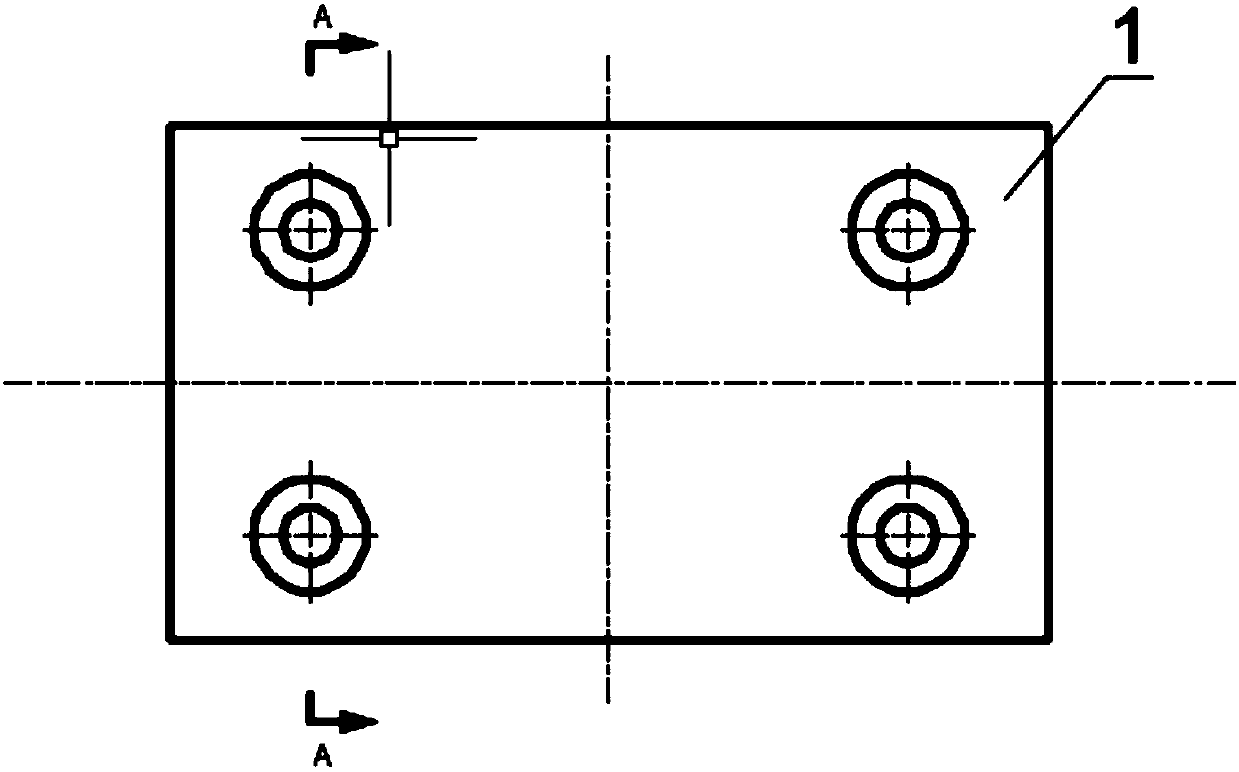

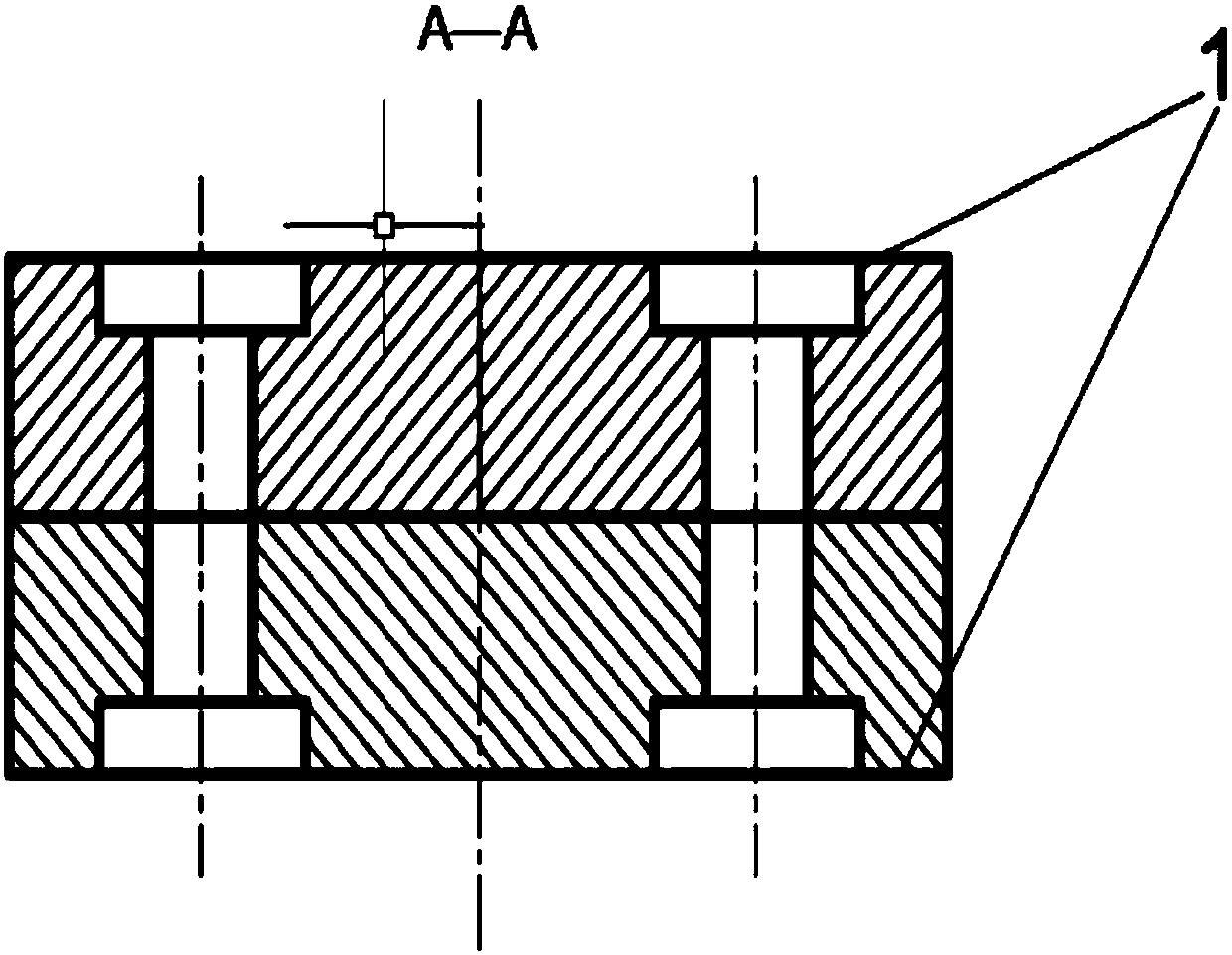

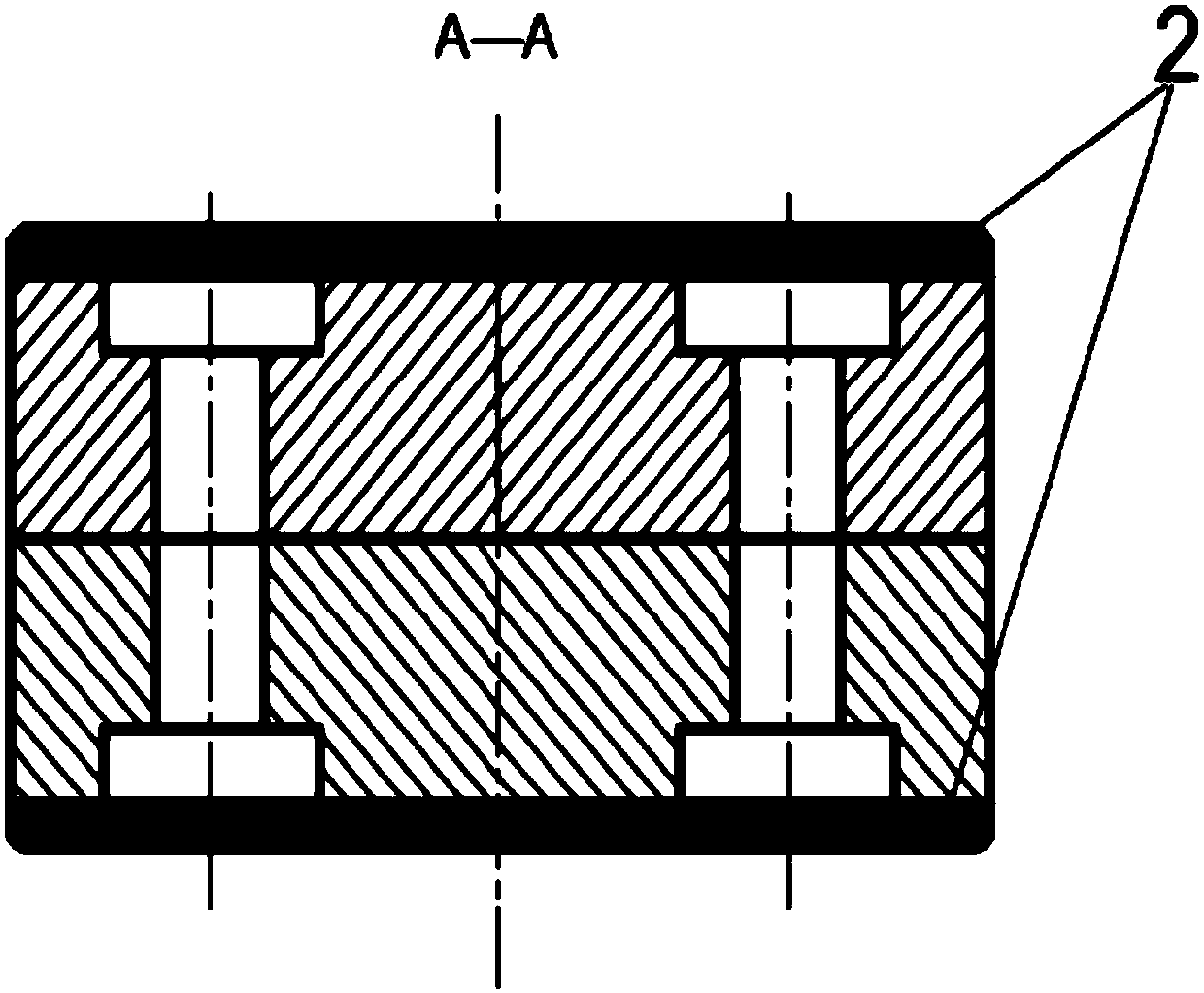

[0025] Such as figure 1 As shown, the 45 steel plate is processed according to the drawing of the lining plate, and the working surface of the lining plate contacting the moving parts is reduced by 1mm according to the size to continue processing. The mass percentage of the chemical composition is: C 0.1%, Si 1.0%, Cr 14%, Co 1.6%, Mn 1.2%, the balance is Fe, and the particle size of the powder is 125-325 mesh; the above alloy powder is mixed with a three-dimensional powder mixer Mix for 3 hours and mix evenly; combine the processed liners of the same size in pairs, and fix the two liners together with bolts through the countersunk holes on the liners so that the non-working surfaces of the liners are in contact (such as figure 1 and figure 2 shown in the figure); the countersunk holes of the installed bolts are covered with good quick-drying powder and dried to ensure that the countersunk holes and bolts are not damaged when the laser cladding alloy powder is applied; the f...

Embodiment 2

[0027] Process the 45-steel plate according to the drawing of the liner plate, and continue to process the working surface of the liner plate in contact with the moving parts according to the size reduced by 1mm. The mass percentage is: C 0.13%, Si 1.5%, Cr 16%, Co 1.7%, Mn 1.6%, the balance is Fe, the particle size of the powder is 125-325 mesh; use a three-dimensional powder mixer to mix the above alloy powder for 3 hours , mixed evenly; combine the processed liners of the same size in pairs, and use bolts to fix the non-working surfaces of the two liners together through the countersunk holes on the liners; in the countersunk holes of the installed bolts Coat with good quick-drying powder and dry to ensure that the countersink holes and bolts are not damaged during laser cladding alloy powder; place the fixed two combined liners on a high-power semiconductor laser processing machine tool, and use preset powder coating method, evenly spread the alloy powder on the working su...

Embodiment 3

[0029] Process the 45-steel plate according to the drawing of the liner plate, and continue to process the working surface of the liner plate in contact with the moving parts according to the size reduced by 1mm. The mass percentage is: C 0.12%, Si 1.3%, Cr 16%, Co 1.7%, Mn 1.6%, the balance is Fe, and the particle size of the powder is 125-325 mesh; use a three-dimensional powder mixer to mix the above alloy powder for 3 hours , mixed evenly; combine the processed liners of the same size in pairs, and use bolts to fix the non-working surfaces of the two liners together through the countersunk holes on the liners; in the countersunk holes of the installed bolts Coat with good quick-drying powder and dry to ensure that the countersink holes and bolts are not damaged during laser cladding alloy powder; place the fixed two combined liners on a high-power semiconductor laser processing machine tool, and use preset powder coating method, evenly spread the alloy powder on the workin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com