Patents

Literature

142results about How to "Unobstructed exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of rapid start-up method of anaerobic ammonium oxidation reactor

ActiveCN102259976AEnsure anaerobic environmentUnobstructed exhaustWaste based fuelTreatment with anaerobic digestion processesChemistrySubstrate concentration

The invention provides a method for quickly starting an anaerobic ammonia oxidation reactor. A small amount of anaerobic ammonia oxidation sludge subjected to enrichment culture successfully is regularly added into a reactor for starting an anaerobic ammonia oxidation process by using non-anaerobic ammonia oxidation sludge (such as nitrification sludge, denitrification sludge, methane-producing sludge and the like) to provide certain growth factors for the reactor, so that the starting condition of the anaerobic ammonia oxidation process is improved, and a part of bacterium sources can be increased to accelerate the enrichment of anaerobic ammonia oxidation bacteria in the sludge in the reactor; and substrate concentration and hydraulic retention time are timely adjusted on the basis to avoid substrate lack and accelerate the growth of the anaerobic ammonia oxidation bacteria and the process of granulating the sludge, so that the starting time of the anaerobic ammonia oxidation reactor is greatly shortened, and the popularization and application of the anaerobic ammonia oxidation process are facilitated.

Owner:江苏清材智能制造有限公司

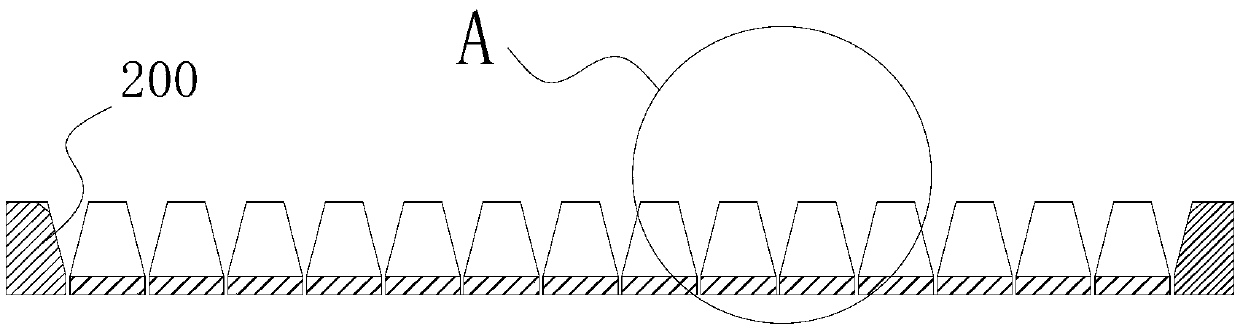

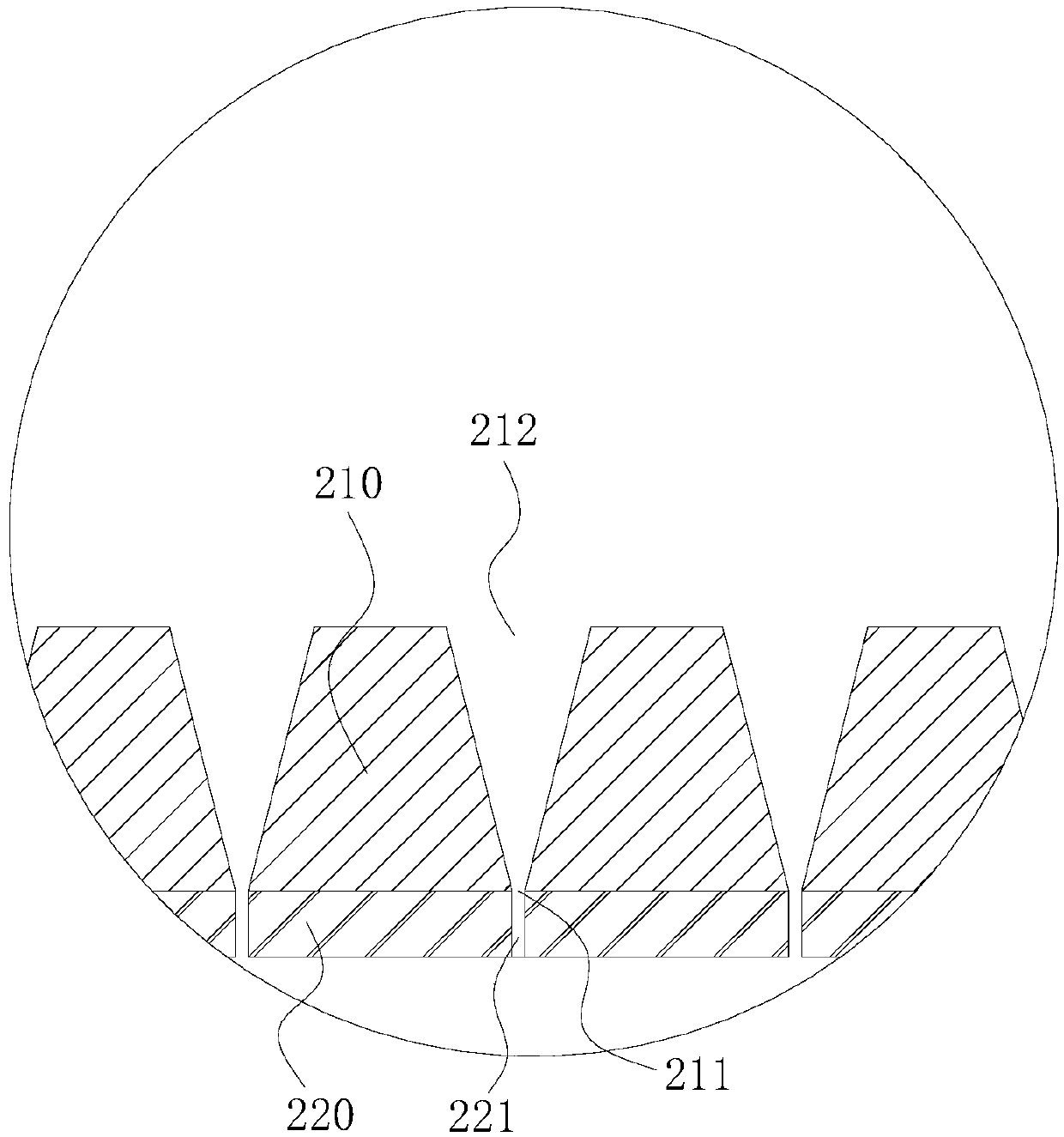

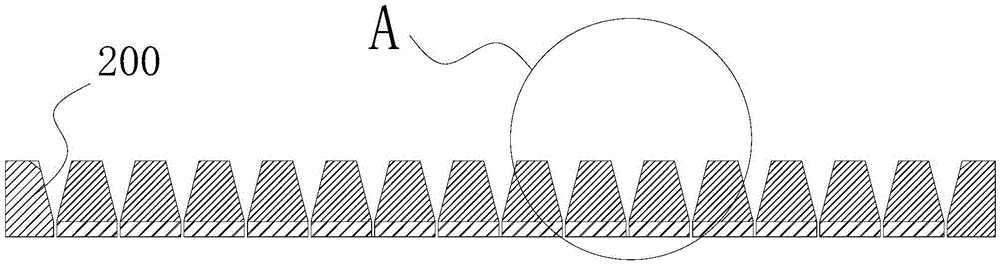

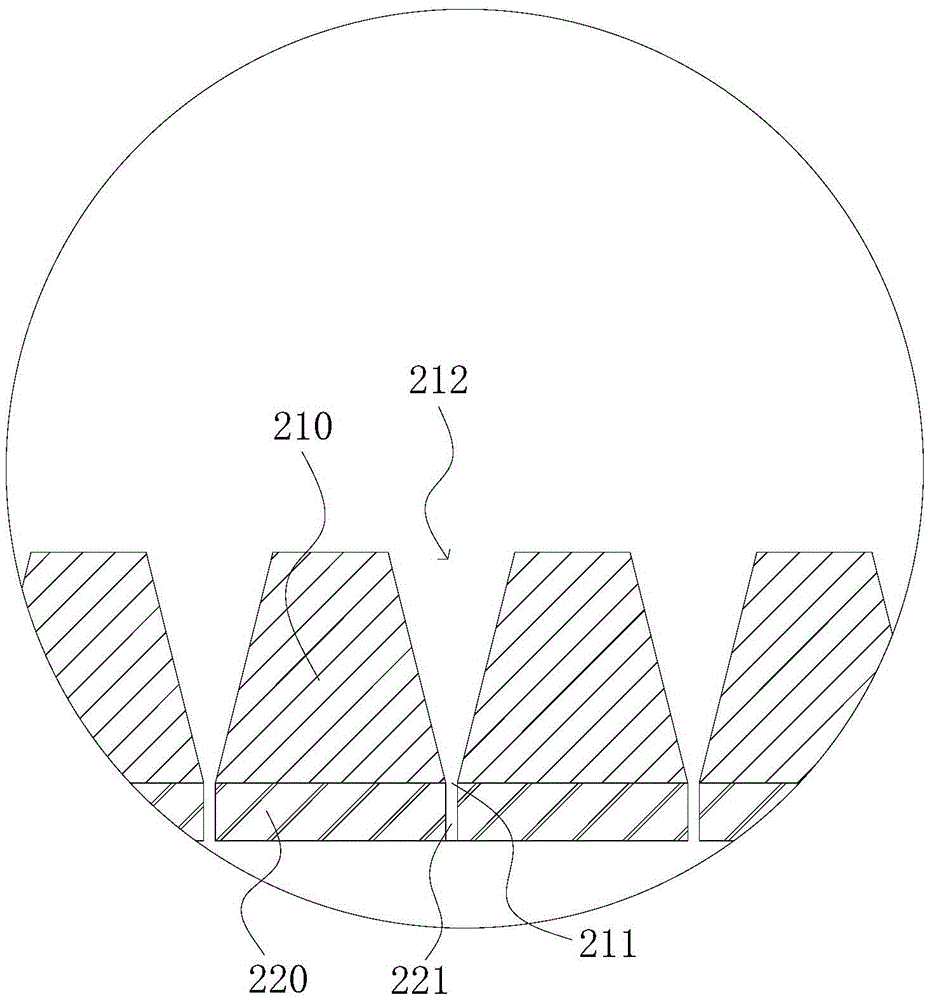

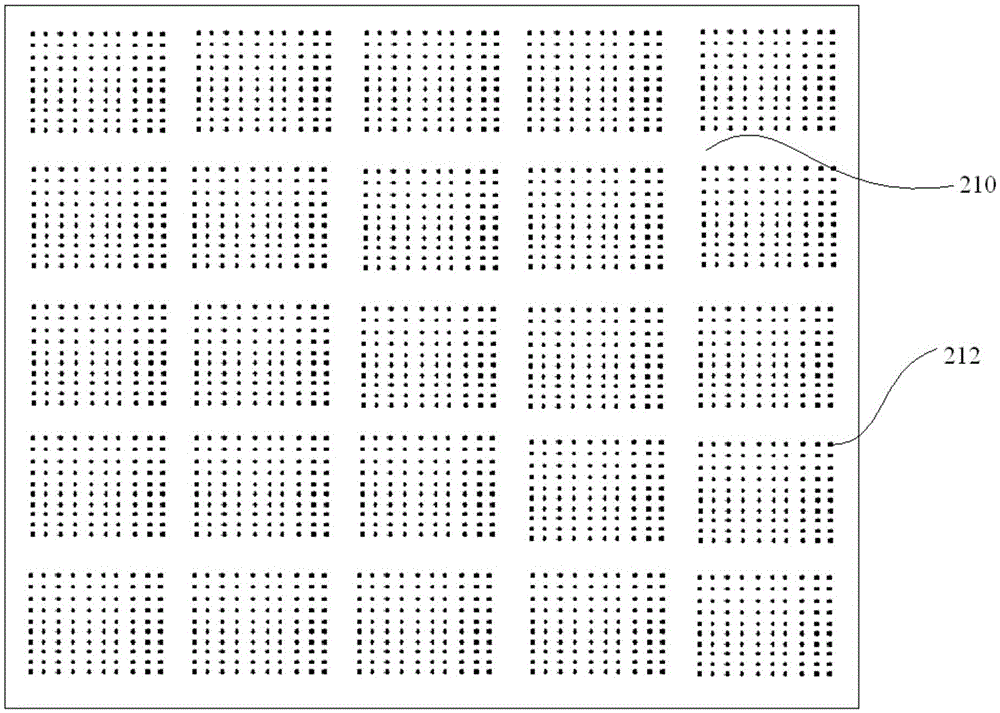

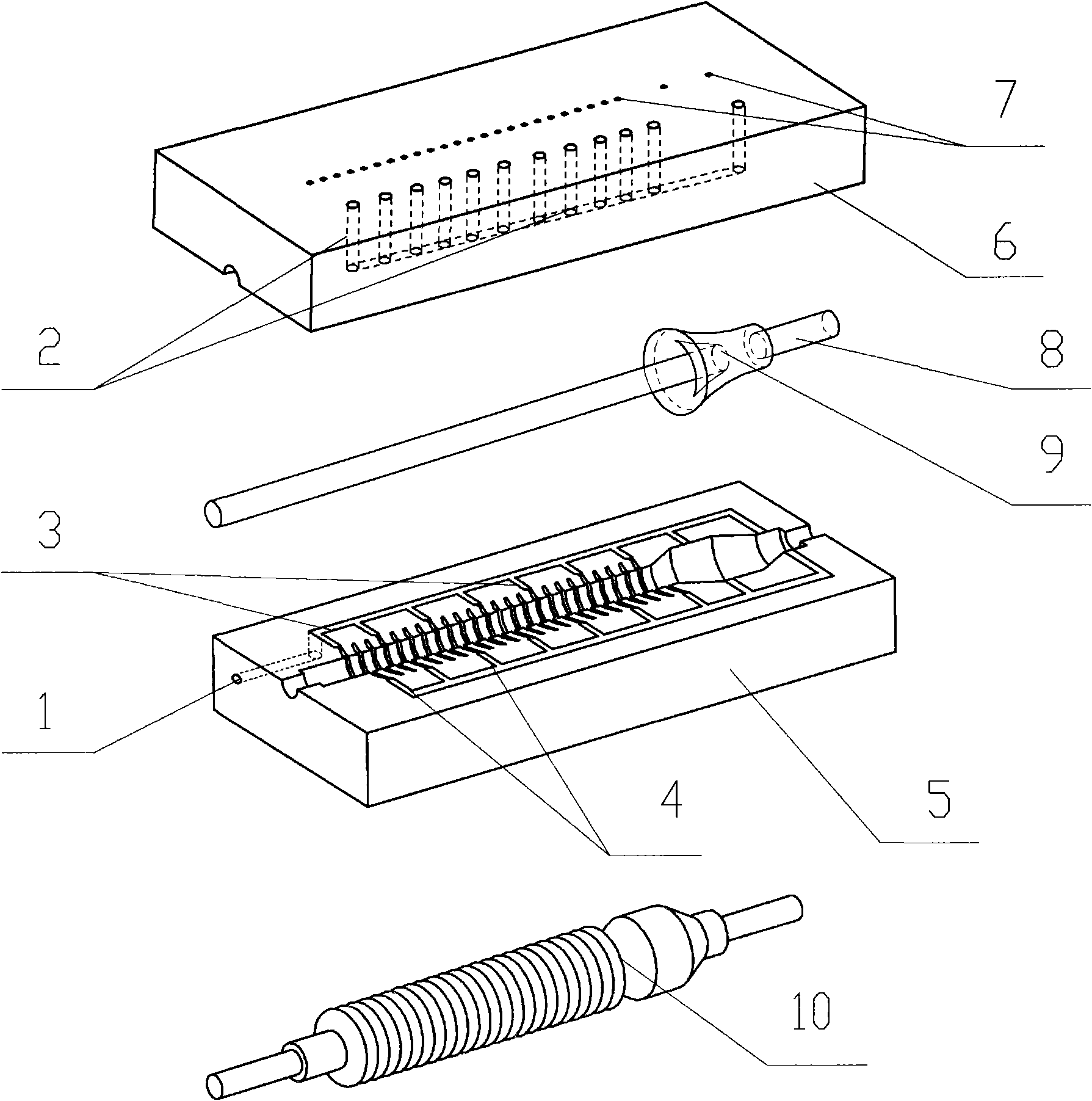

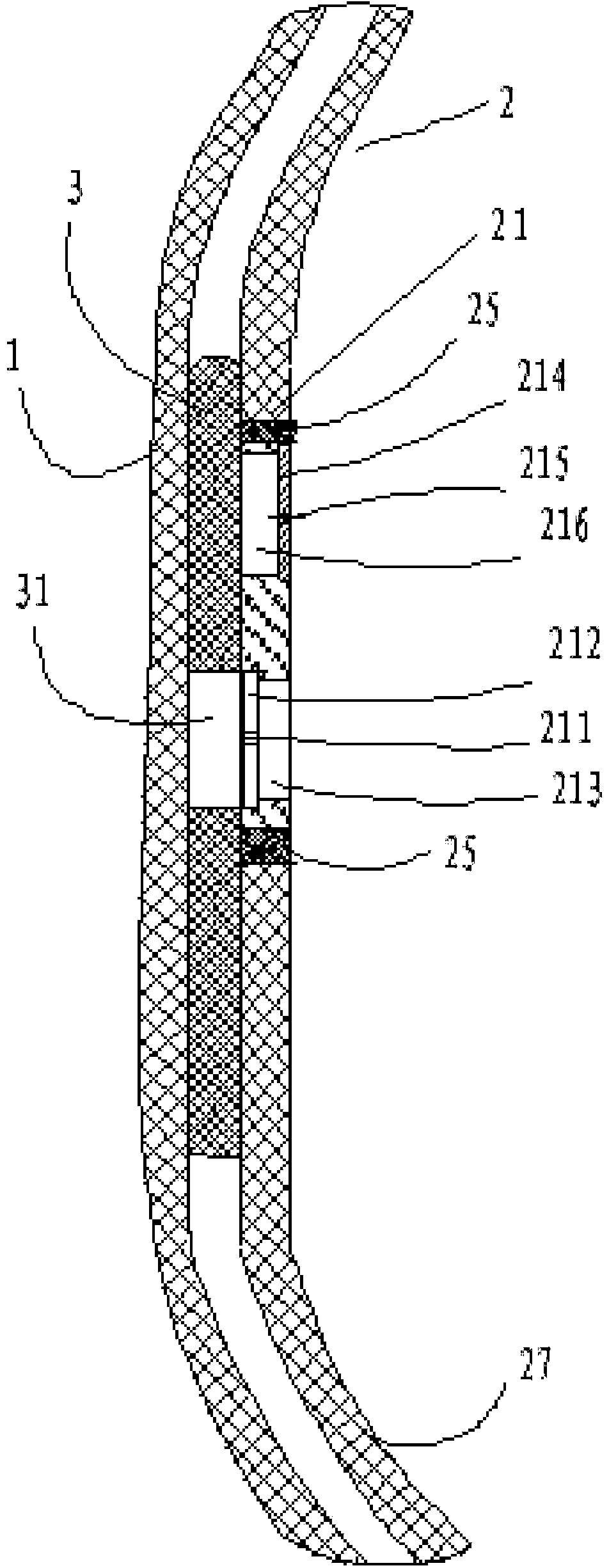

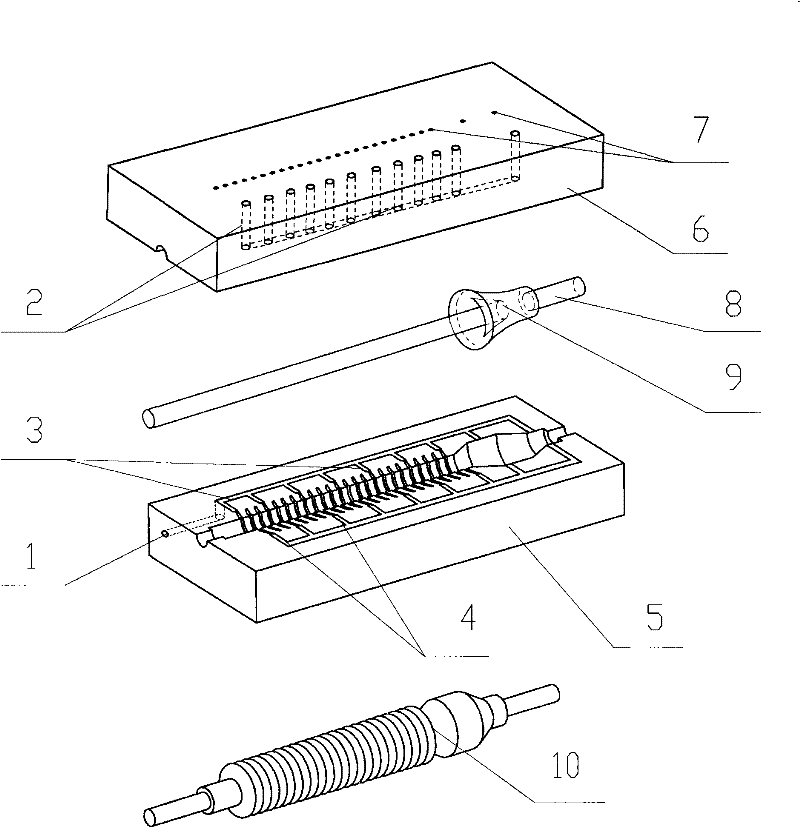

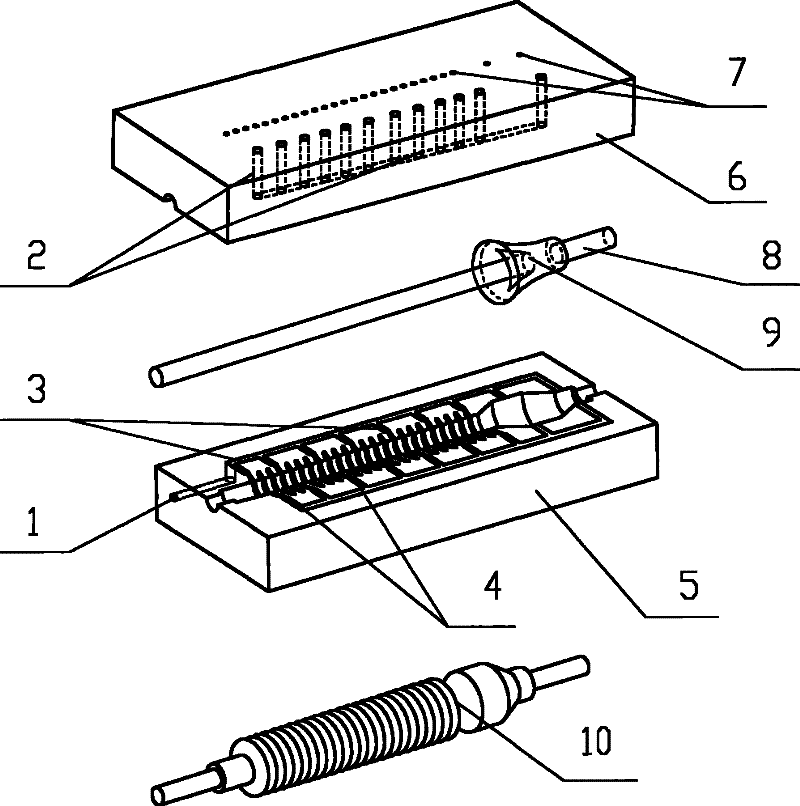

Micro needle chip and preparation method thereof

ActiveCN105498082ARapid perfusionEasy to prepareMicroneedlesMedical devicesCentrifugationProduct gas

The invention relates to a micro needle chip and a preparation method thereof. The preparation method of the micro needle chip comprises steps: flow injection liquids are injected into a female die, the female die is provided with a plurality of cavities which are adapted to the shapes of needle bodies of micro needle chips to form a cavity array, a plurality of injection inlets are arranged on a side surface of the female die, a plurality of exhaust ports are arranged on the other one surface of the female die to form an exhaust surface, a breathable film is covered on the exhaust surface of the female die, gas penetrates the breathable film and liquid is retained in the cavities when injecting, and the flow injection liquids are demolded after being solidified to form the micro needle chip. Because the exhaust ports and the breathable film are matched, the liquid can be hold back and the gas is discharged at the same time, the micro injection effect is excellent. The preparation method of the micro needle chip does not need processes such as centrifugation which are difficult to achieve in industrial manufacture and the like in technological process, also does not need to use technological means such as high pressure or high temperature with high industrialization cost and the like, has the advantages of simple and convenient operation and low cost, and is suitable for industrialization promotion and use.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

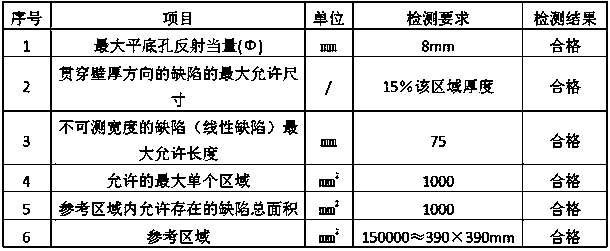

Method for casting aluminum piston with insert ring and cooling coil pipe

The invention provides a method for casting aluminum piston with an insert ring and a cooling coil pipe, comprising steps as follows: (1) preparing aluminum alloy for piston; (2) melting; (3) mould setting of the cooling coil pipe; (4) mould casting of insert ring; (5) mould closing and pouring; (6) mould opening and heat treatment for taking out the casting, processing low temperature melting treatment and ageing heat treatment to obtain the piston blank; (7) post-treatment for carrying out mechanical processing and surface treatment on the piston blank to obtain the aluminum piston finished product. The invention also discloses a method for casting aluminum piston with an insert ring and a cooling coil pipe. Compared with the prior art, the advantages of the invention are as follows: the piston body has compact structure, and the combination between the wear resistant insert ring and the piston body through ultrasonic detection is good, and the position of the cooling coil pipe is precise and the anti-stretching intensity is high.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

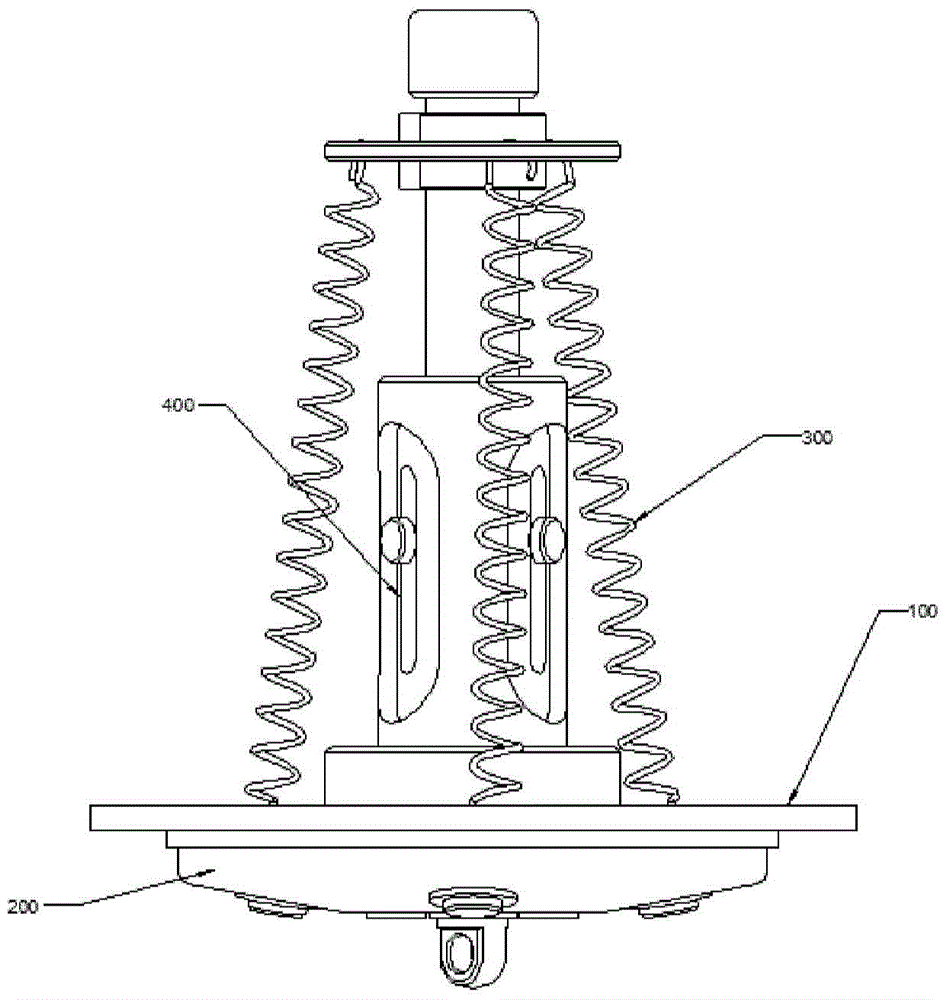

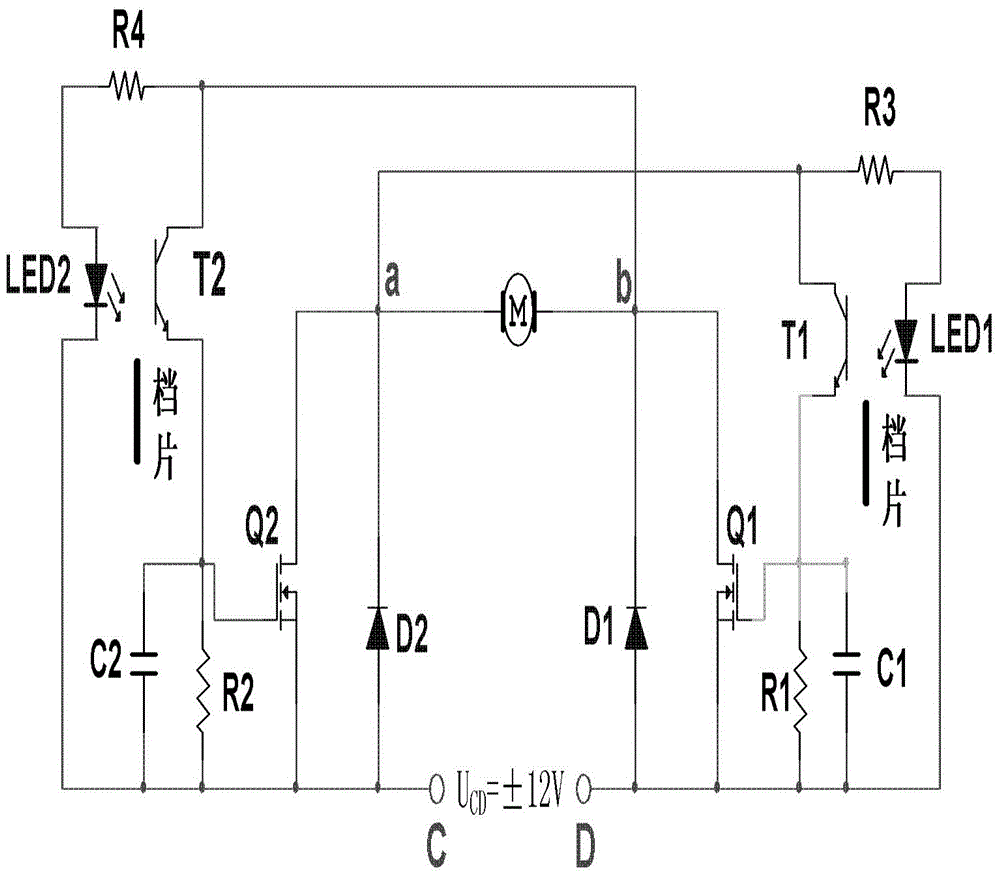

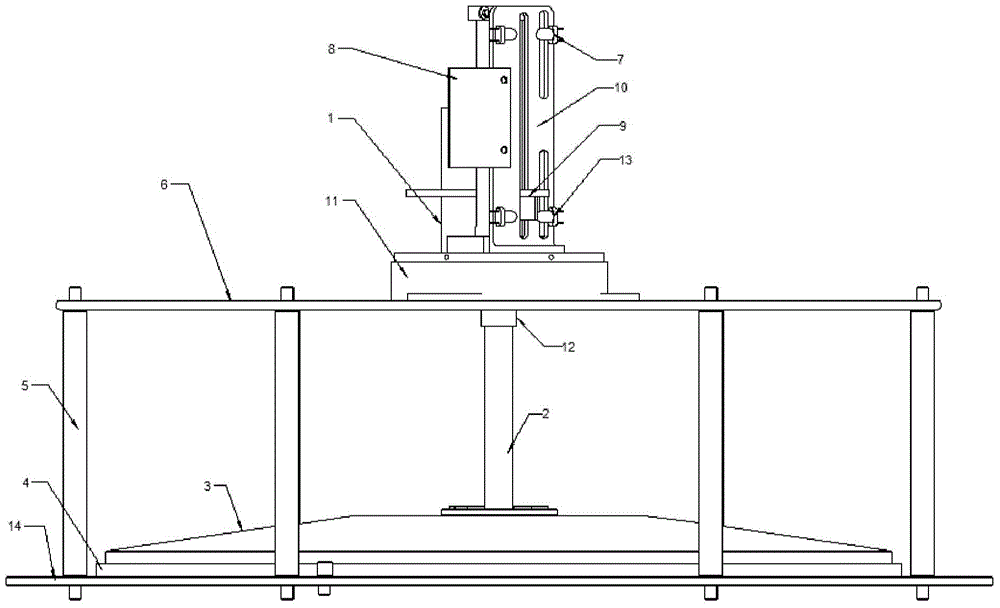

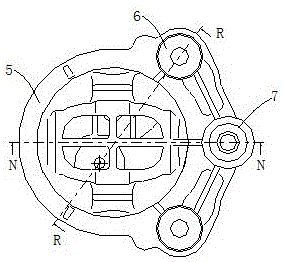

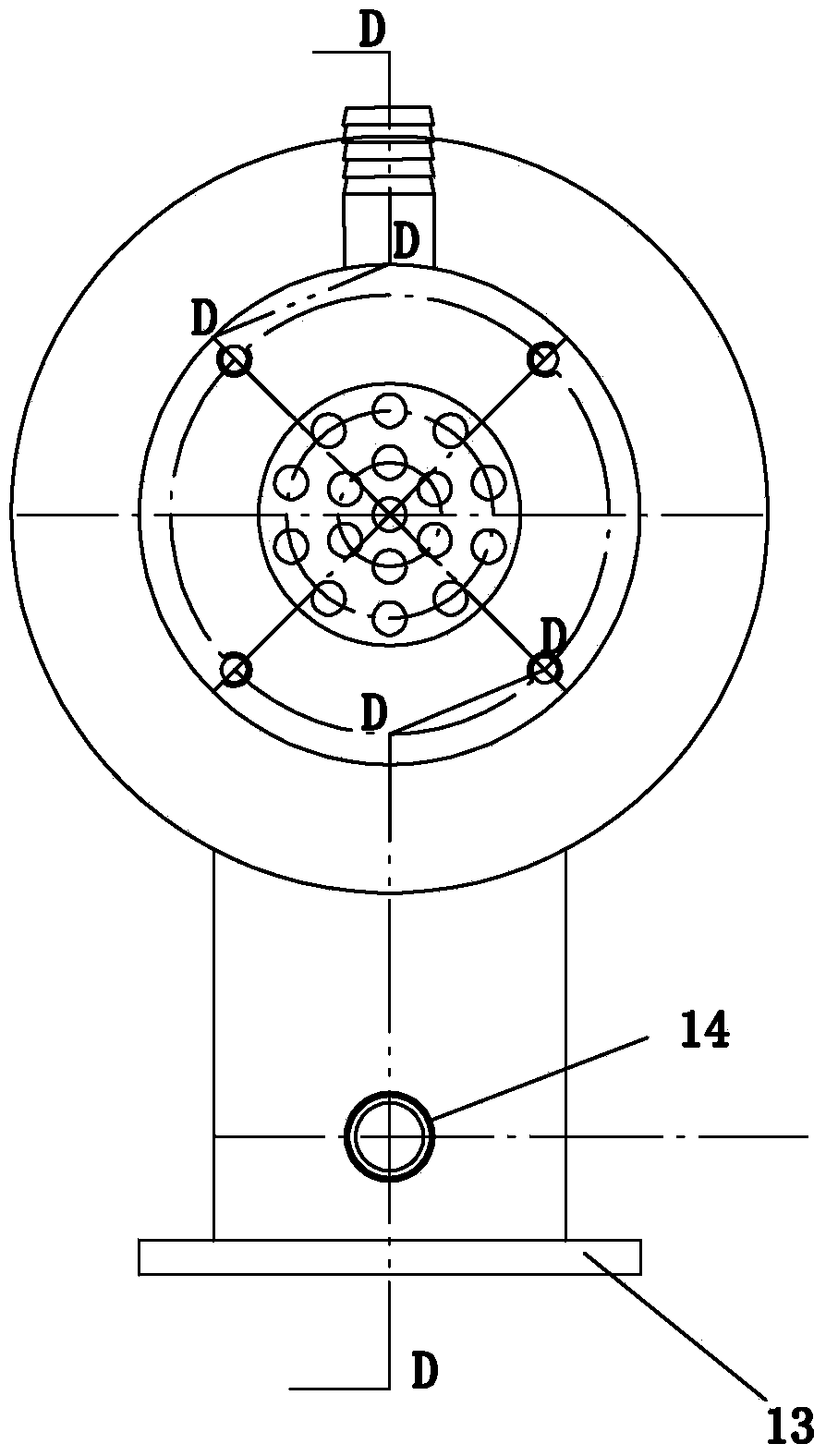

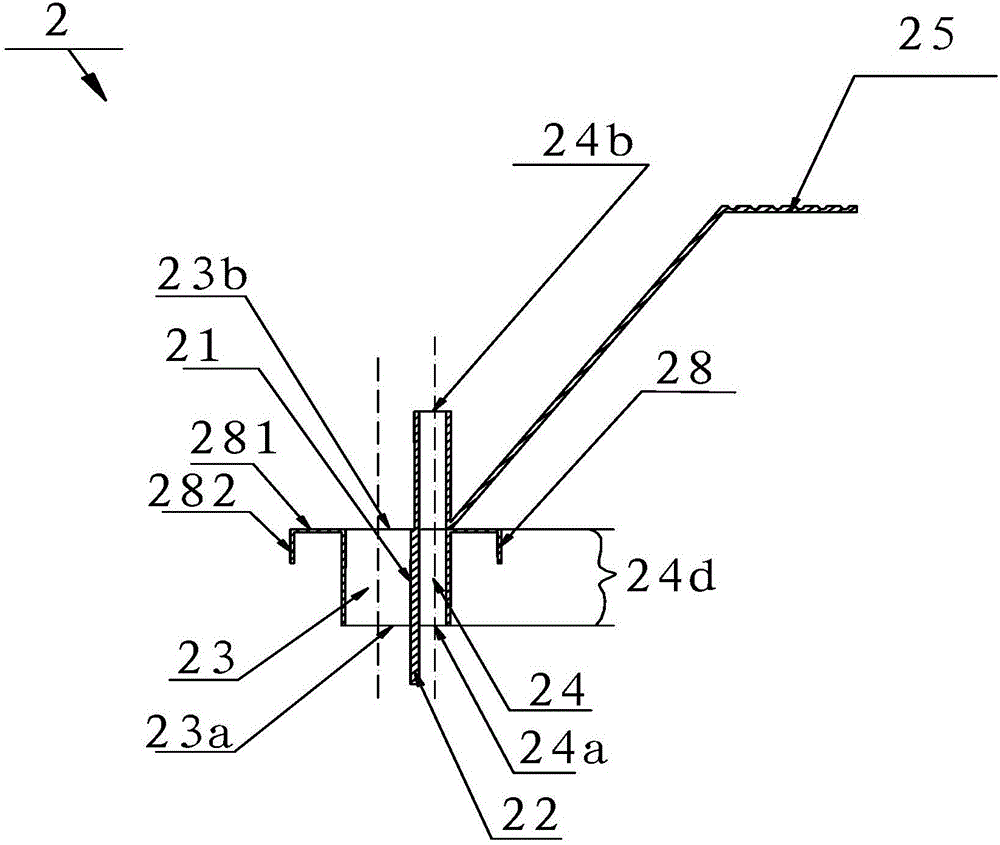

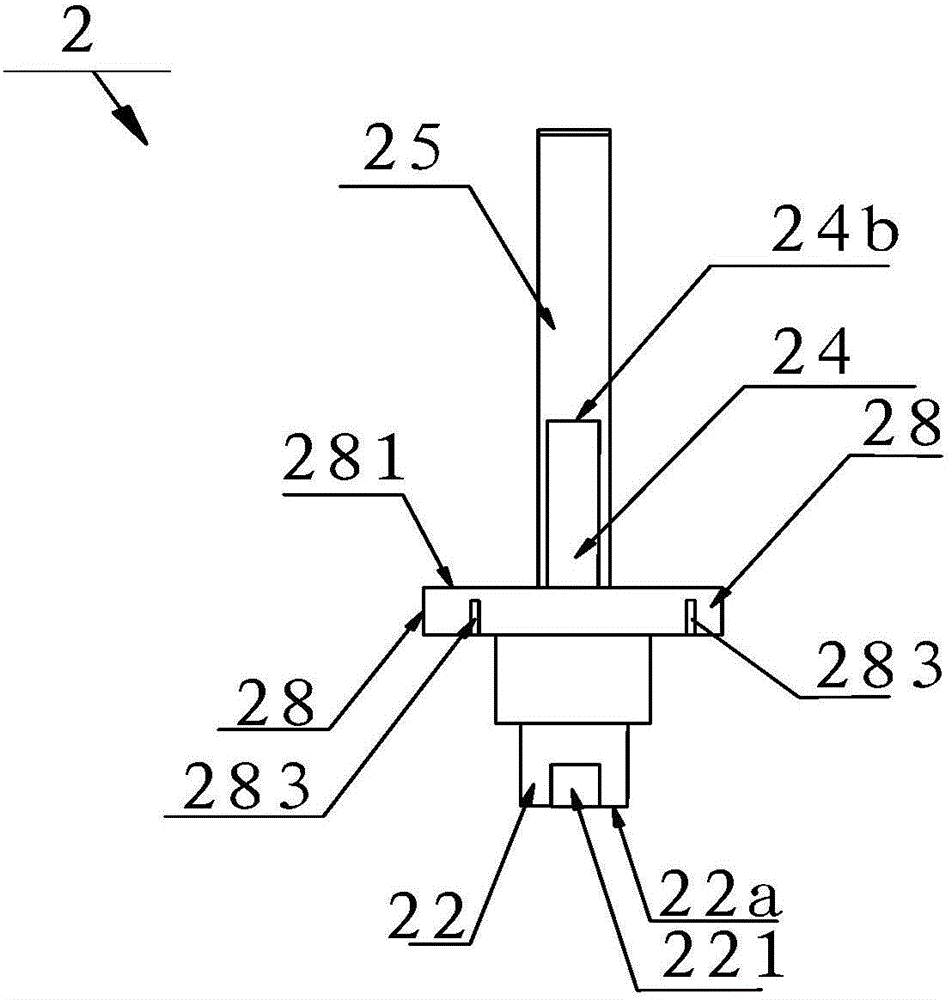

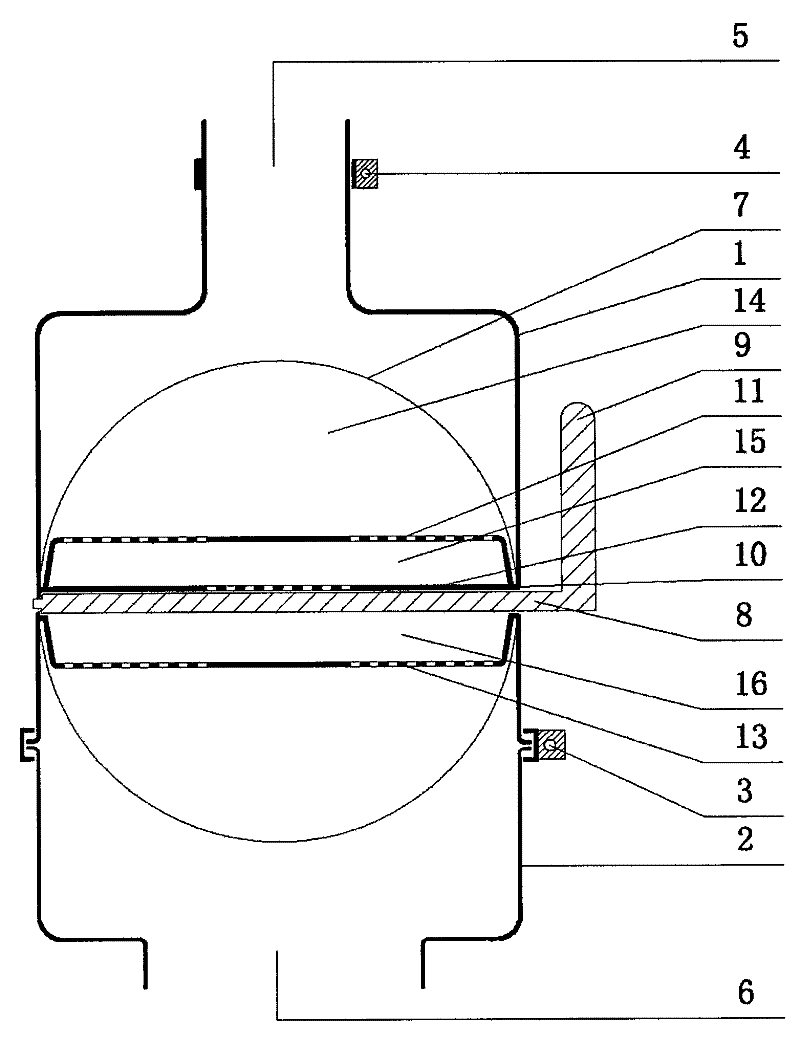

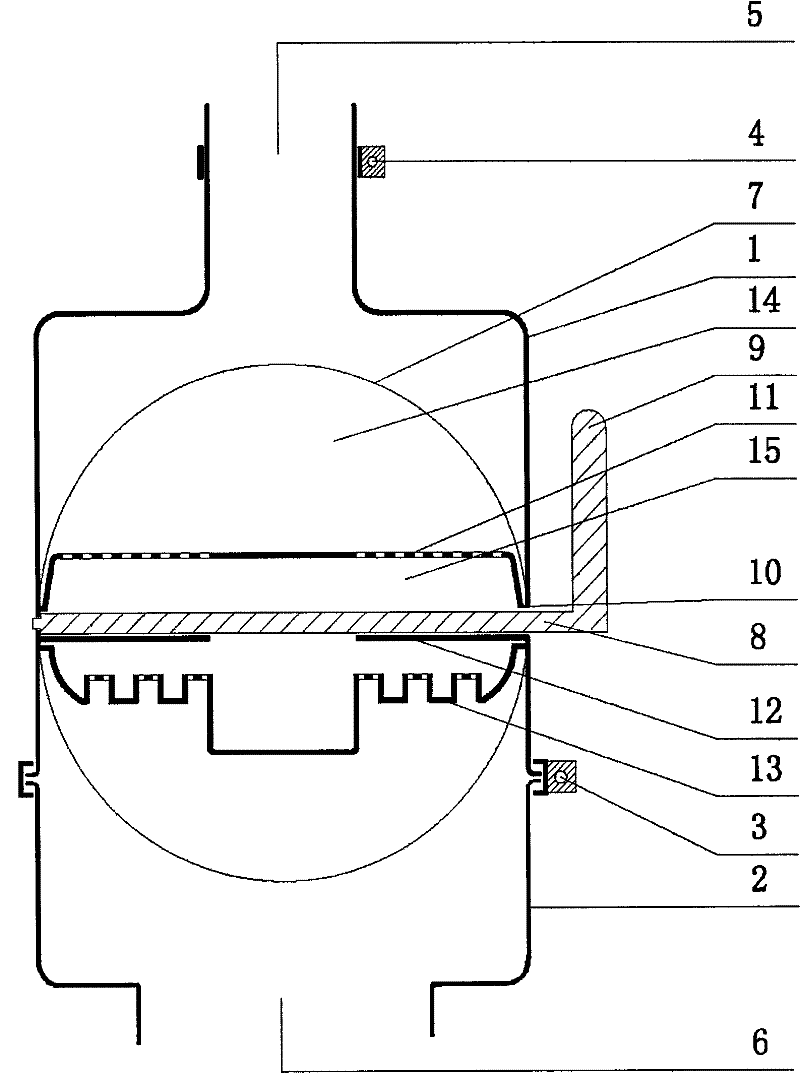

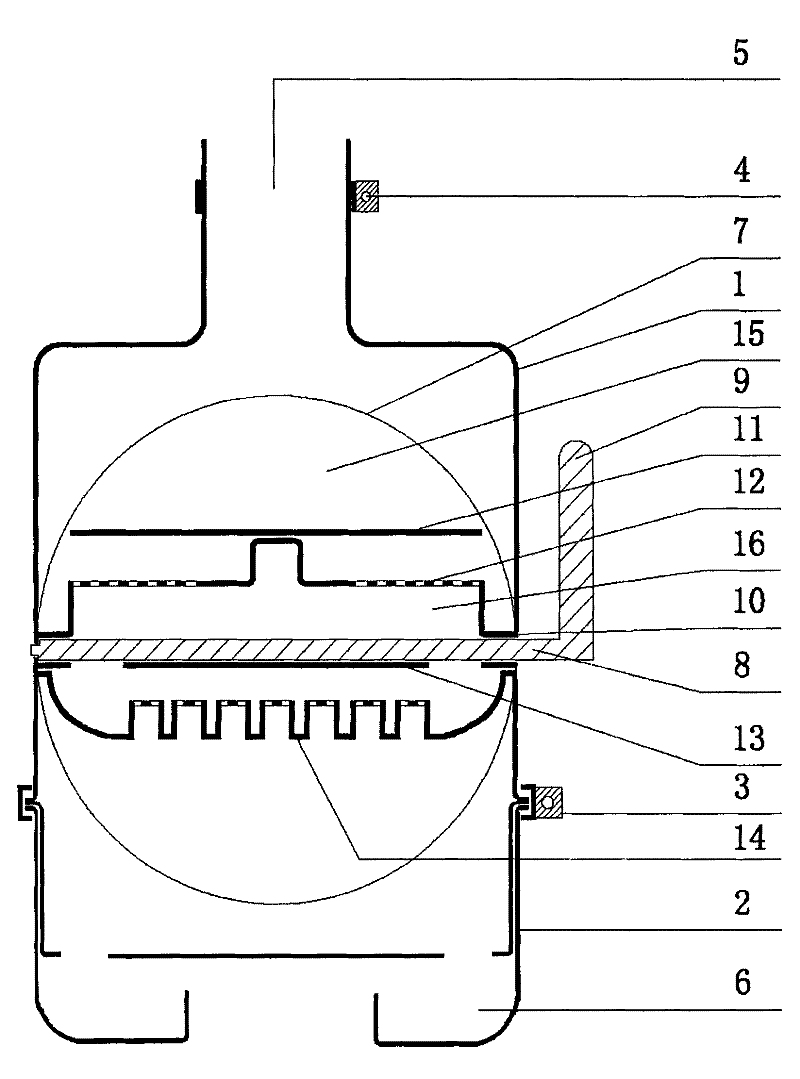

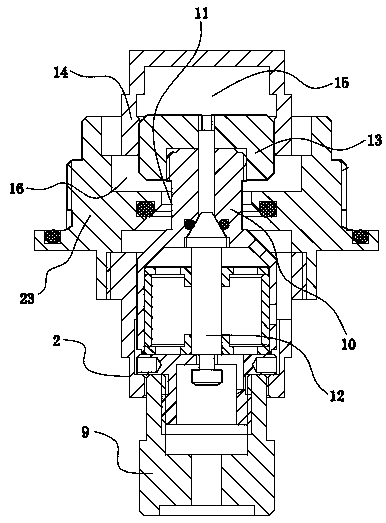

Photoelectric control valve of aerostat

InactiveCN104132176AQuick responseHigh precision of differential pressure controlOperating means/releasing devices for valvesGas-bag arrangementsLower limitEngineering

The invention provides a photoelectric control valve of an aerostat. The photoelectric control valve of the aerostat comprises a valve cover, a seal ring, multiple columns, a base, a control circuit, a valve body, an opening-closing mechanism portion and a limiting mechanism portion, wherein the valve body is arranged on a bag body of the aerostat. The multiple columns are respectively located between the base and the valve body to enable the base and the valve body to be connected. The valve body is provided with a valve port and used for air in an air bag in the aerostat to be discharged out. An outer circle of the valve port is sleeved in an inner hole of the seal ring, and the valve cover covers the seal ring and the valve port and is in a sealed state. A flange structure of the lower end face of a lead screw of the opening-closing mechanism portion is fixed to the valve cover, and the lead screw is used for opening and closing the valve cover and enabling the valve cover to be away from and cover the valve port. A motor of the opening-closing mechanism portion is connected with the control circuit and controls lifting and downward moving of the valve cover in the vertical direction. The lead screw is provided with a threaded hole, a stopping block of the limiting mechanism portion is fixed to the lead screw through the threaded hole, and the stopping block vertically moves with the lead screw to block infrared light emitted by an upper limiting optical coupling assembly and a lower limiting optical coupling assembly of the limiting mechanism portion and cut off the control circuit and accordingly enables the motor to stopping running.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

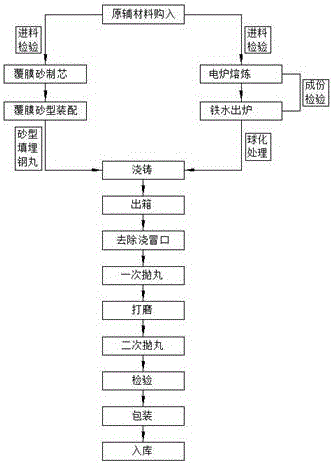

Casting method of main reducer housing

ActiveCN106825438AHigh dimensional accuracyHigh surface finishGearboxesFoundry mouldsPorositySurface finish

The invention relates to a casting method of a main reducer housing. The casting method includes: a precoated sand core forming process, a smelting ball iron process and a casting process, the precoated sand core forming process includes core-making of precoated sand, coated sand type assembly and sand-type steel shot filling; the smelting ball iron process includes electric-furnace smelting and charging of molten iron and treatment; the casting method is characterized by including casting, unboxing, de-gating, one-step shot blasting, grinding, secondary shot blasting and detecting. With the method, exhaust smoothness is guaranteed, generation of hole defects in the casting is avoided from the sand core exhaust process, sand hole and pore defective reject rate is controlled within 1%, shrinkage or porosity defect is avoided, the casting is stable in size and high in surface smoothness, the yield is higher as compared with that with a traditional casting method of the main reducer housing, the production process is easier to control, and production competitiveness has higher advantages.

Owner:抚州市羊易铸业有限公司

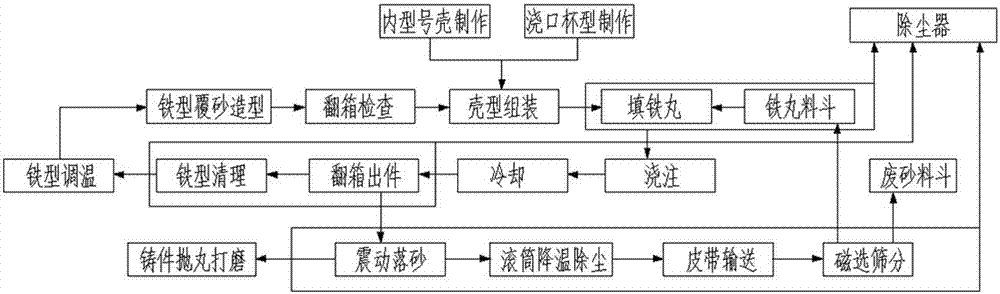

Novel casting technique of semitrailer brake drum

InactiveCN103286279AGuaranteed not to deformBack-off guaranteeCasting plantsFoundry mouldsBrakeDust control

The invention relates to a novel casting technique of a semitrailer brake drum. The novel casting technique of the semitrailer brake drum comprises the following steps of: manufacturing an inner mold shell and a pouring cup; regulating the temperature of an iron mold, covering with sands, and modeling; checking by turning over a mold; assembling a shell mold; filling iron shots; pouring and cooling; turning over the mold, discharging elements, assembling the elements, and recovering; carrying out magnetic separation, and screening; dedusting and cleaning. No deformation of the brake drum is ensured fully; the steel shots are filled in an internal mold sand shell; poured steel liquids generate pressure inward; firstly, because of the 'arch bridge principle', the internal mold sand shell has great support force; and then the steel shots also can block the pressure by steel liquids, and the internal mold sand shell cannot be cracked or deformed absolutely. Before cast elements are condensed and contracted, the internal mold sand shell is scattered, the filled steel shots are at the scattered state, the deformability of the cast elements in contraction is ensured fully, so that free contraction instead of hindered contraction is formed; a bottom-pouring-type pouring mode is adopted, air is discharged smoothly; the cracking possibility at the crossed part is reduced; air holes of the cast elements caused by dampness of a sand mold are prevented; the novel casting technique of the semitrailer brake drum is an environment-friendly casting technique.

Owner:FUDI PRECISION CASTING

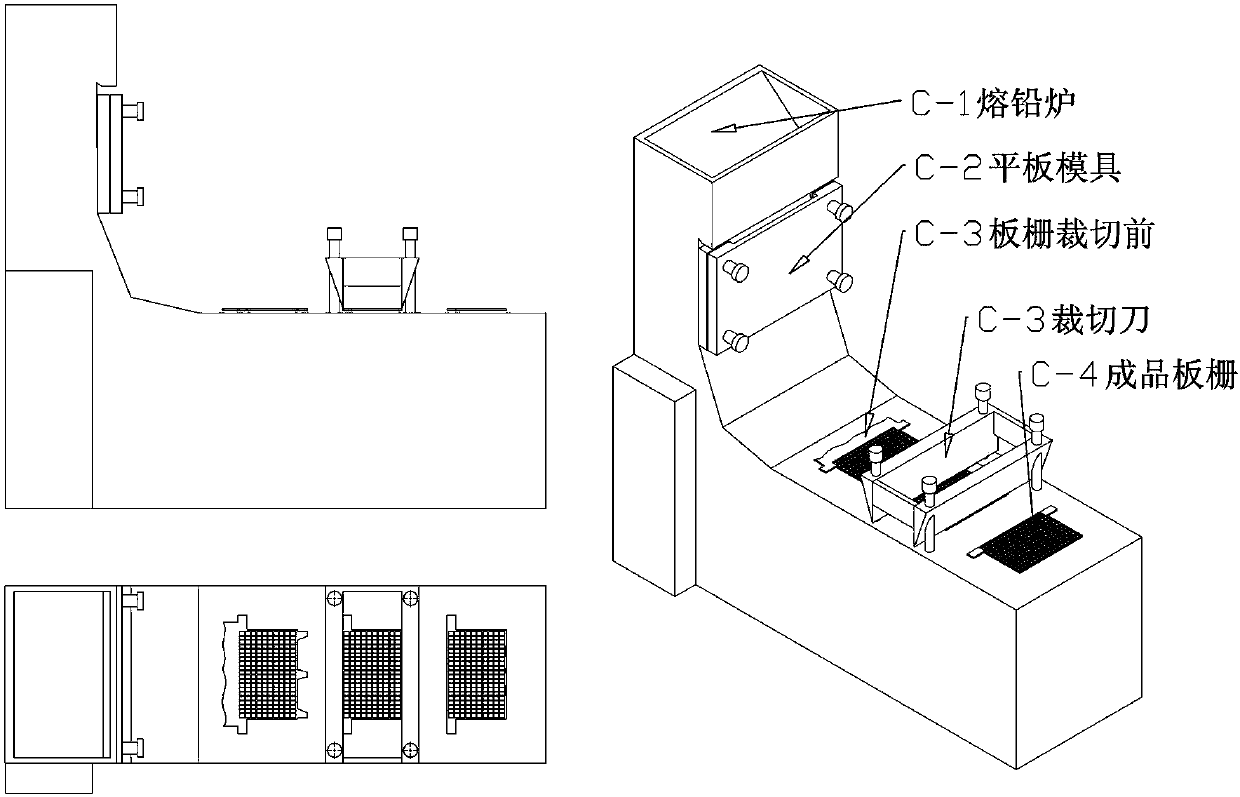

Storage battery grid mold release agent and preparation method thereof

ActiveCN103624211AHeat dissipation fastIncrease productivityFoundry mouldsFoundry coresCell fabricationManufacturing engineering

The invention belongs to the field of storage battery manufacturing technology, and particularly relates to a storage battery grid mold release agent and a preparation method thereof. The storage battery grid mold release agent is prepared from the following raw materials in parts by weight: 0.3-0.7 part of bone glue, 0.4-0.8 part of polyethylene, 0.4-0.8 part of kieselguhr, 0.2-0.5 part of glass water, 0.3-0.7 part of aluminum dihydrogen phosphate, 2-4 parts of cork powder of 200-300 meshes, 2-4 parts of cork powder of 700-800 meshes, and 88.5-94.4 parts of water. The storage battery grid mold release agent is easy to bond, high-temperature-resistant and smooth to exhaust; the prepared grid has fewer pores, thus being easily formed in casting.

Owner:HENAN CHAOWEI POWER SUPPLY

Operation control method of low voltage bypass in thermal power generating set

InactiveCN102261269AGuaranteed uptimeReduce startup timeBoiler controlEngine componentsPressure riseSteam pressure

An operation control method for a low-pressure bypass of a thermal power generating set, characterized in that: according to different operating conditions of the thermal generating set, the set value of the reheat steam pressure of the low-pressure bypass of the thermal generating set is limited. Compared with the prior art, the method provided by the present invention can control the steam pressure of the reheater of the low-pressure bypass according to the different operating stages of the unit, effectively meeting the needs of the high-pressure and medium-pressure cylinders of the gas turbine for combined flushing and ensuring high pressure The cylinder exhaust is unobstructed, which further ensures the smooth rise, stable operation and smooth decline of the main steam pressure of the boiler. At the same time, it can also control the rapid increase of the steam temperature of the boiler so that it can quickly match the metal temperature of the gas turbine cylinder, which is suitable for the constant pressure operation and sliding of the unit. Combined pressure and operation mode, so as to shorten the start-up time of the unit and reduce the discharge of steam to the air, reduce the life loss of the turbine, and realize the optimal start-up of the unit.

Owner:CHINA SHENHUA ENERGY CO LTD +2

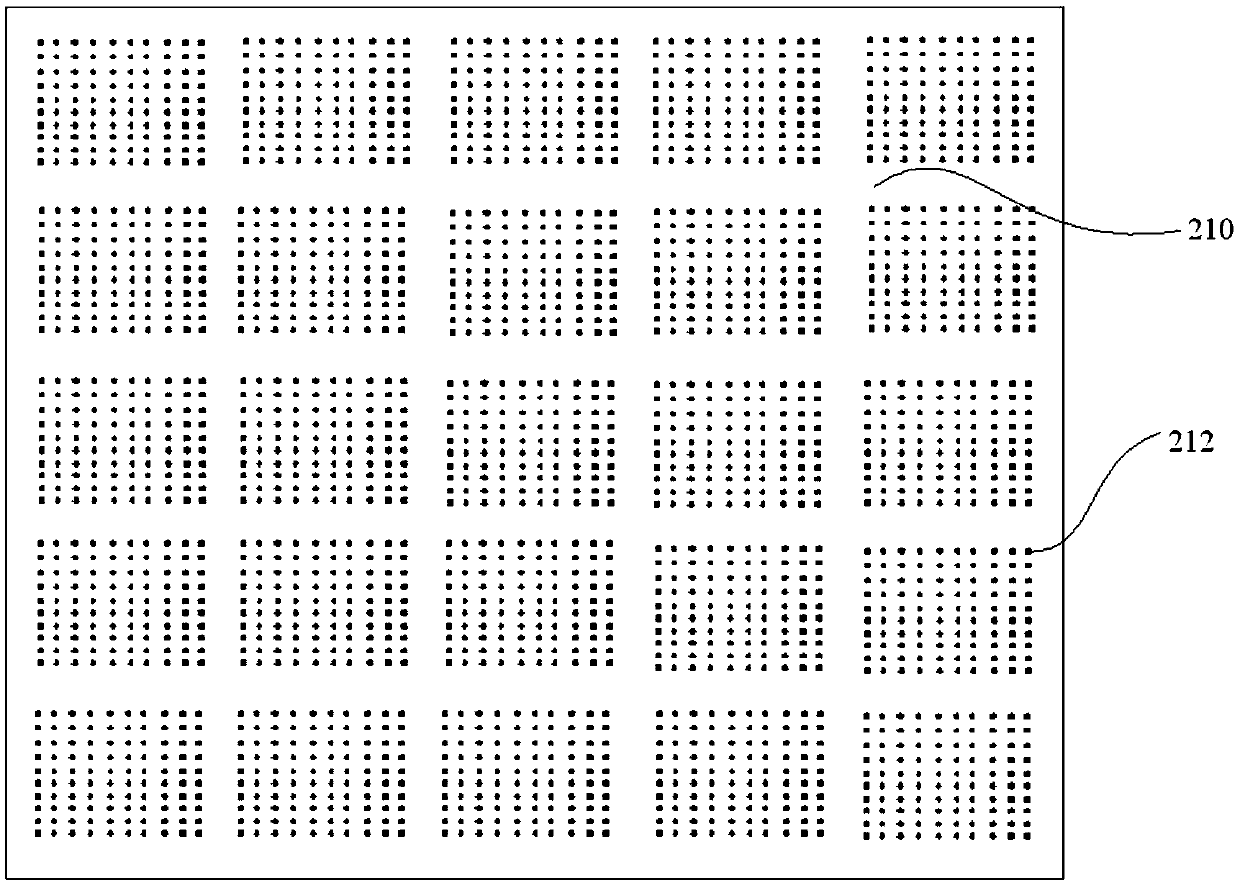

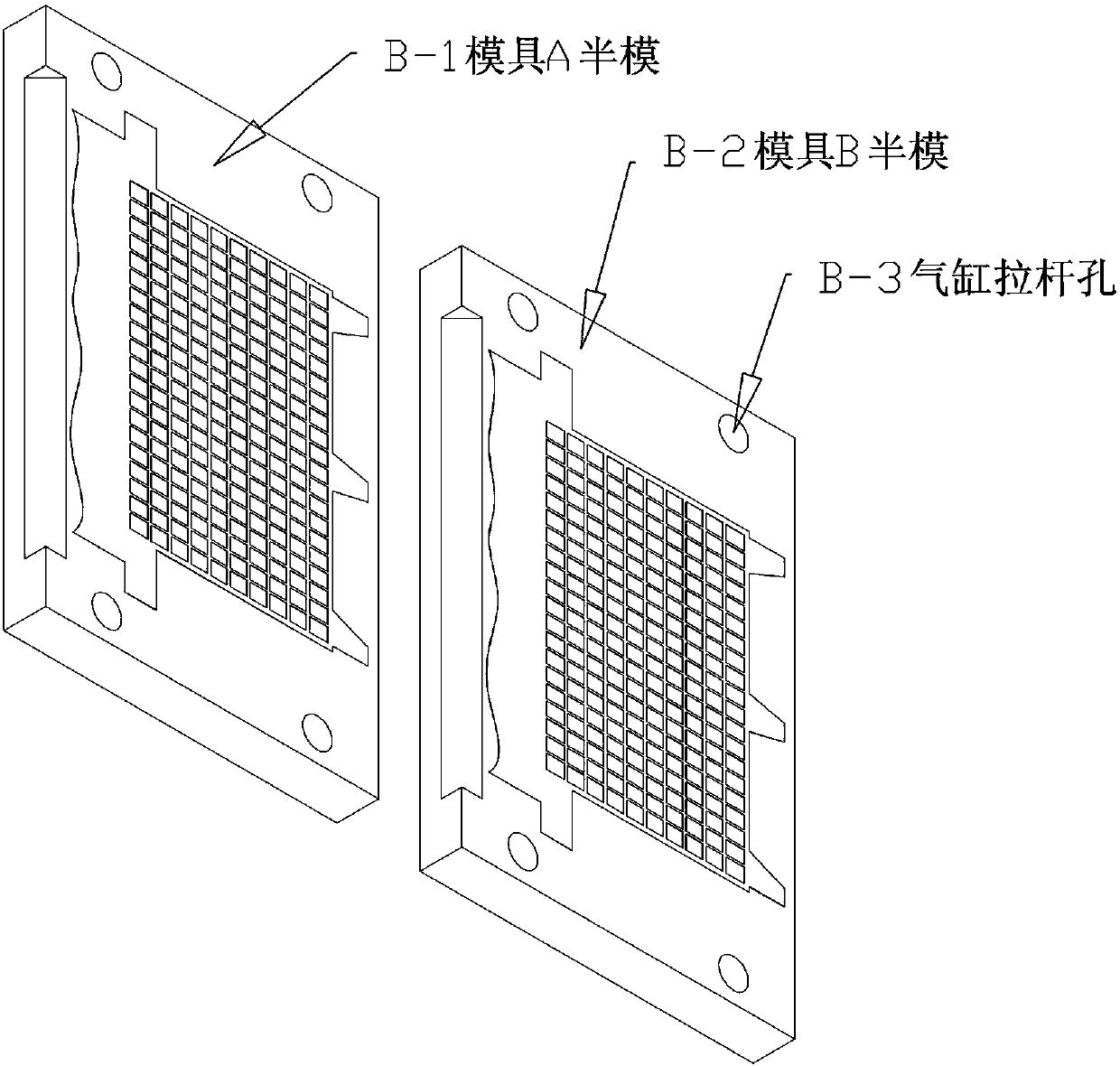

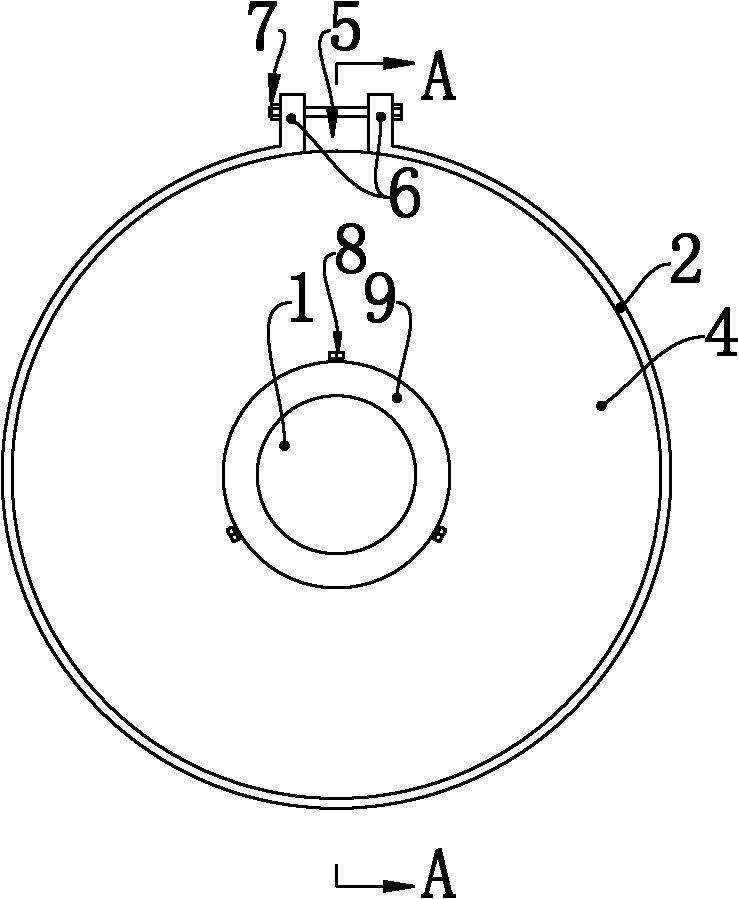

Die used for manufacturing microneedle chip and manufacturing method for microneedle chip

ActiveCN105643839AGood microperfusionRapid perfusionMicroneedlesMedical devicesEngineeringDrug delivery

The invention relates to a die used for manufacturing a microneedle chip and a manufacturing method for the microneedle chip and belongs to the technical field of transdermal drug delivery preparations. The die comprises a female die and a breathable film. The female die is provided with a plurality of cavities which are matched with a needle body of the microneedle chip in shape and arranged in an array manner. Each cavity is provided with a pouring inlet and an exhaust opening. Each pouring inlet is opened in the surface of one side of the female die and is located at the needle base end of the corresponding cavity. Each exhaust opening is opened in the surface of the other side of the female die and is located at the needle point end of the corresponding cavity. An exhaust face is formed on the surface, provided with the multiple exhaust openings, of the female die. The exhaust face is covered with the breathable film, and the breathable film is used for preventing liquid from permeating the exhaust face and enabling gas to permeate the exhaust face. By means of the die, gas is exhausted while liquid is intercepted, and a better micro-pouring effect is achieved. When the die is used for manufacturing the microneedle chip, the centrifuging process and the like which are hard to achieve in industrial production do not need to be conducted, and industrial production of the high-quality microneedle chip becomes possible.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

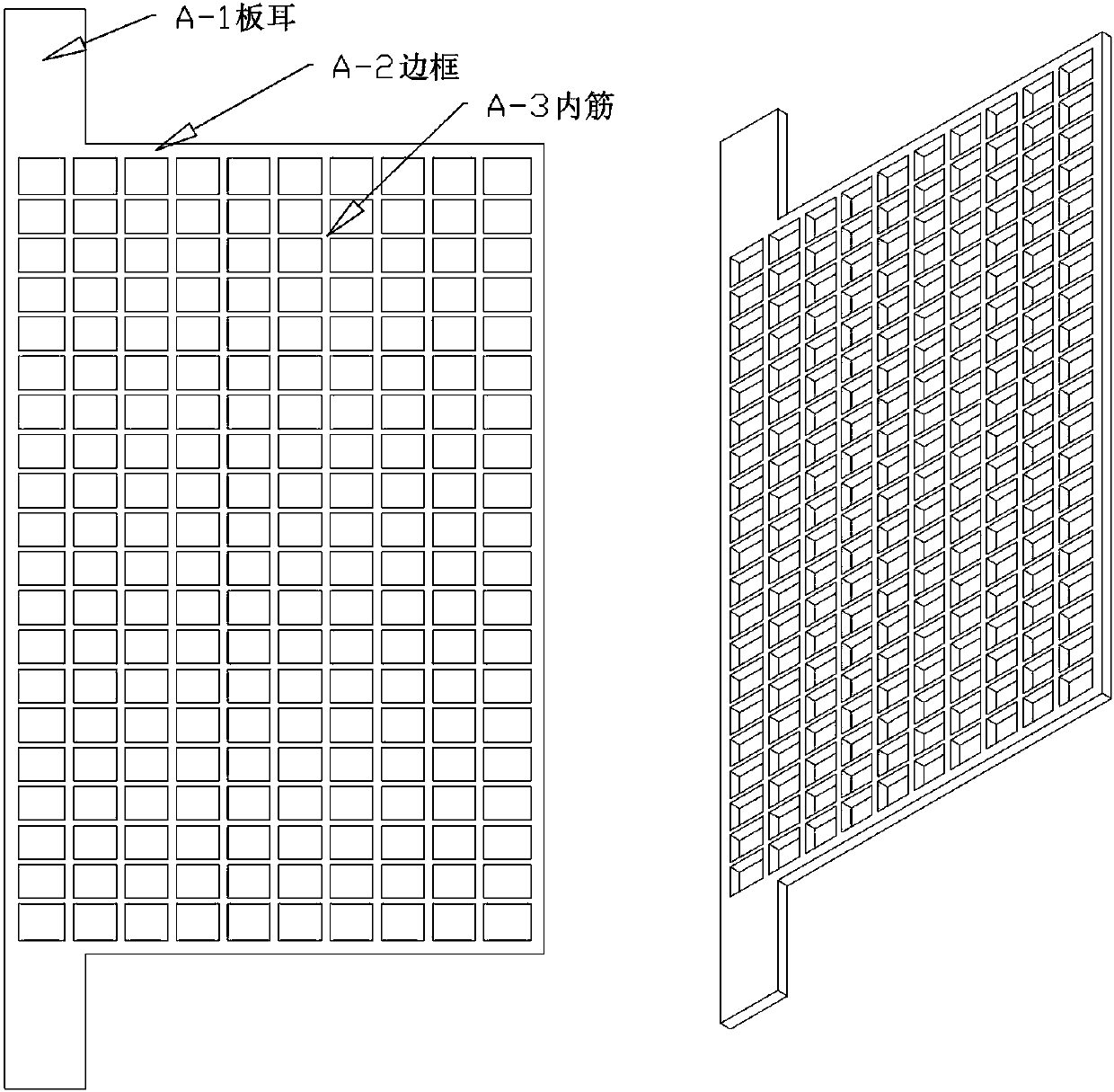

Casting forming process for large wind power planetary carrier

ActiveCN107790641ASmall size deviationEasy to operateFoundry mouldsFoundry coresElectricityEconomic benefits

The invention discloses a casting forming process for a large wind power planetary carrier casting. The planetary carrier casting comprises an upper annular plate and a lower annular plate which are vertically connected with triangular vertical columns, and a parting face of the planetary carrier casting is arranged on the interfaces of the upper annular plate and the triangular vertical columns;a first sand core and a second sand core are arranged between the upper annular plate and the lower annular plate, a triangular air outlet channel is formed in the outer sides of the sand cores, and vertical air outlet channels are formed in the centers of the sand cores; open risers are arranged right above the intersections of the upper annular plate and the triangular vertical columns, blinderrisers are arranged on the lower annular plate, and external chills are arranged under the lower annular plate. Pouring is carried out by adopting combined pouring mode of bottom-back pouring gates and stepped pouring gates. The planetary carrier produced by the method is good in forming and qualified in size, the matric structure of the casting is compact, joint parts of the triangular verticalcolumns and the upper annular plate and the lower annular plate has no crack defect, the other parts only need to undergo modification repair welding, the production cost of the casting is reduced, and higher economic benefits are achieved.

Owner:兰州兰石铸锻有限责任公司

Sand core exhaust method of complicated casting

The invention relates to a sand core exhaust method of a complicated casting, belonging to the casting field. A vent pipe is buried in the heads of an air flue sand core and a water flue sand core during modeling and mould assembling so that the sand cores can be communicated with the external atmosphere through the vent pipe; and the vent pipe as a cast iron casting is made of a steel pipe or as an aluminum alloy casting is made of a glass pipe. The exhaust problem of the sand cores wrapped by metal liquid can be solved by mounting the sand cores on the vent pipe for exhaust; and the invention has the advantages of simplicity and convenience for operation, good exhaust effect, great reduction for generation of air holes in the casting, reduction of casting reject ratio, low price and easiness for purchasing by using the steel pipe or the glass pipe as the vent pipe.

Owner:FAW GROUP

Mold release agent for casting accumulator grids and preparation method of mold release agent

InactiveCN107442740AReasonable ratio of ingredientsImprove spraying effectFoundry mouldsFoundry coresAdhesivePhosphate

The invention discloses a release agent for battery grid casting and a preparation method thereof. The release agent comprises the following raw materials in parts by weight: 0.2-0.6 parts of polytetrafluoroethylene, 0.1-0.3 parts of aluminum dihydrogen phosphate, cork 1-5 parts of powder, 0.2-0.6 parts of sodium silicate, 0.6-1.5 parts of glass fiber powder, 0.1-0.6 parts of attapulgite, 0.6-2.5 parts of nano-silicon dioxide, 3-8 parts of modified aluminum tripolyphosphate, Adhesive 0.1-0.5 parts, stabilizer 0.2-0.8 parts, deionized water 90-120 parts. The preparation method adopts conventional mixing, heating and stirring. The mold release agent of the present invention has good sprayability, adhesion, temperature resistance, small surface tension, high compressive strength, smooth exhaust, can significantly reduce the phenomenon of air holes and cracks in the grid, and can also reduce the number of spray molds , improve production efficiency and save costs.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Casting design method of 38W machine body

InactiveCN109822047AImprove feeding capacityEvenly distributedFoundry mouldsFoundry coresAir cavityDesign methods

The invention discloses a casting design method of a 38W machine body. A main cavity of a casting of the 38W machine body is of a V-shaped structure, the lower part is an air cavity, a plurality of axial baffles are arranged in the middle, the casting design method is sequentially composed of casting design, pouring design and riser design, and optimization is carried out. According to the castingdesign method of the 38W machine body, cracks are reduced, shrinkage porosity is reduced, the size deviation is reduced, sand adherence is reduced, air holes are reduced, the molding quality of the casting is improved, and the production efficiency is improved.

Owner:上柴动力海安有限公司

Horizontal production process of polyurethane rubber roller

The invention belongs to the technical field of rubber chemical industry, and in particular relates to a horizontal production process of a polyurethane rubber roller. The invention aims to provide a horizontal production process of a large polyurethane rubber roller for improving the integral physical properties of the rubber roller. The horizontal production process of the large polyurethane rubber roller comprises the processing steps of: dissolving and mixing raw materials, synthesizing prepolymer, pretreating a rubber roller pouring mold, pouring and forming, vulcanizing and grinding, wherein in the pretreating step of the rubber roller pouring mold, the rubber roller pouring mold is horizontally placed and heated to 80-85 DEG C; and the temperature in the pouring and forming step is kept at 80-85 DEG C for pouring and forming. The method provided by the invention improves the pouring mode, and the product has few defects, good appearance quality and excellent integral properties.

Owner:SICHUAN GUOXIN MACHINERY MFG CO LTD

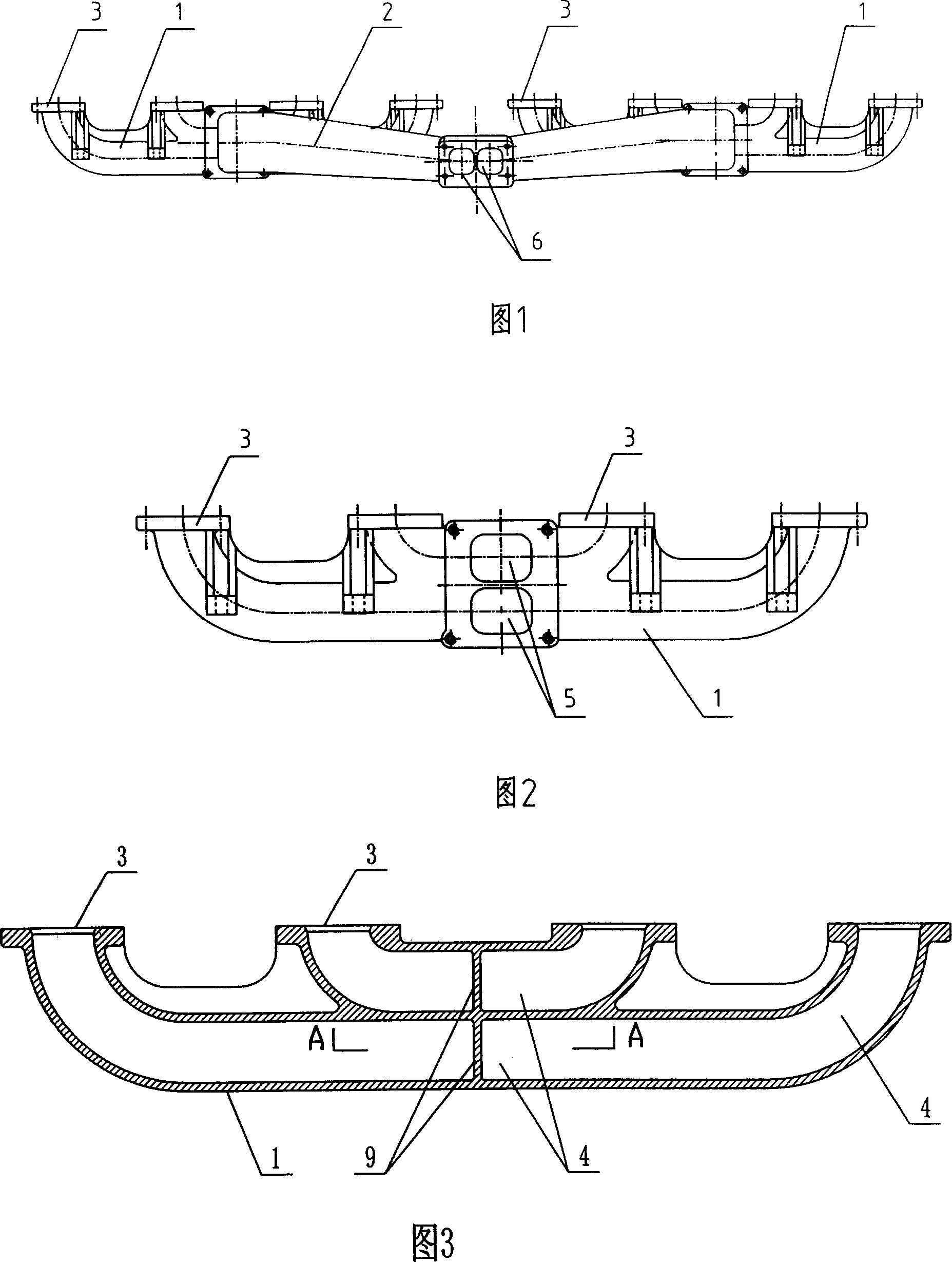

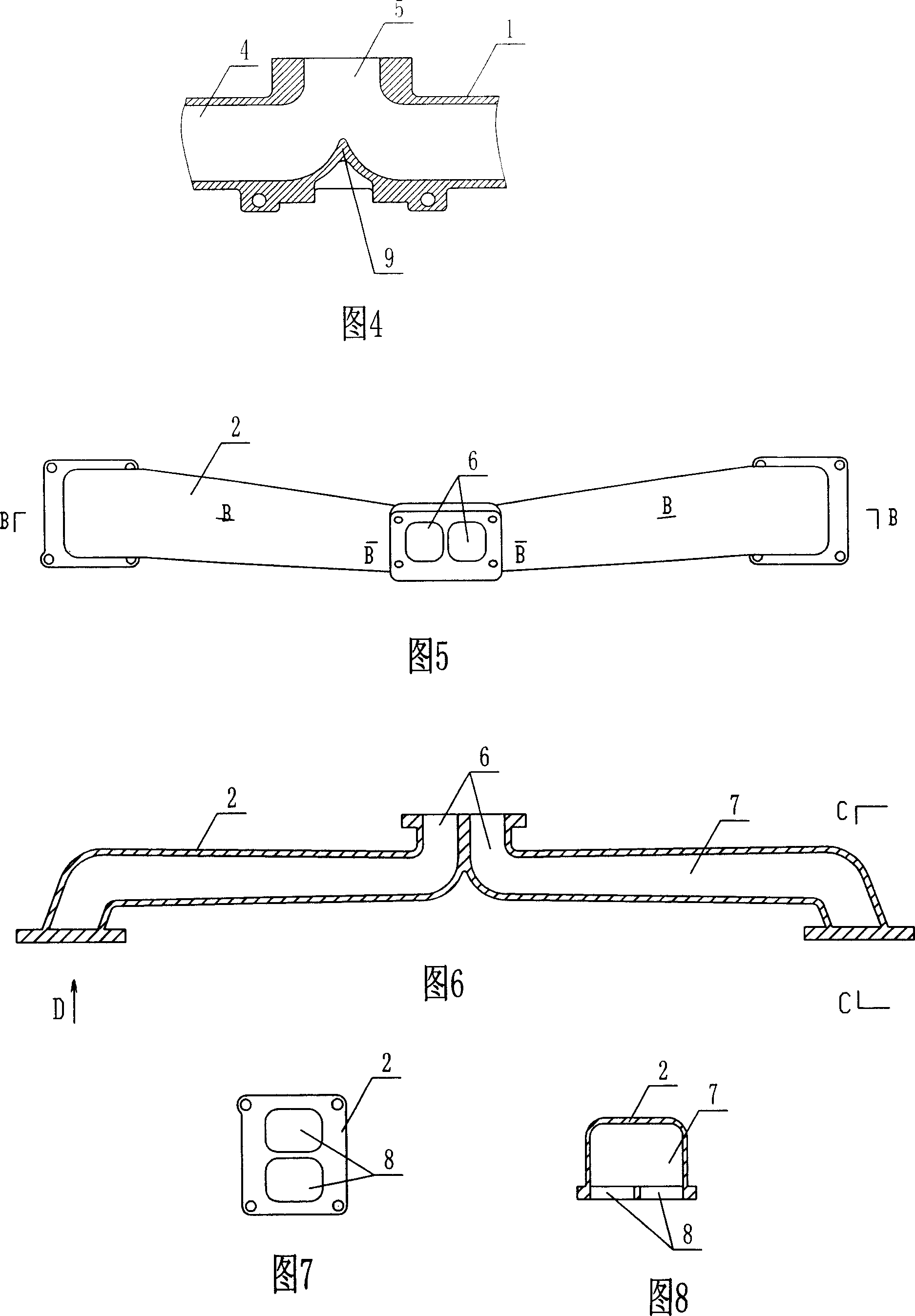

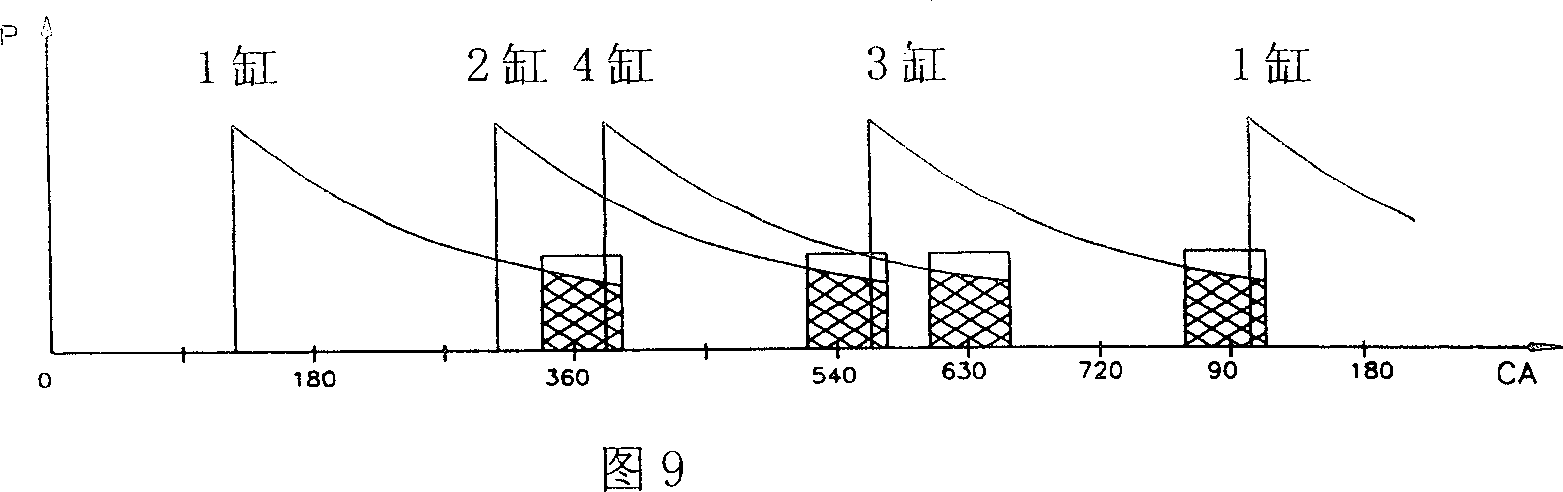

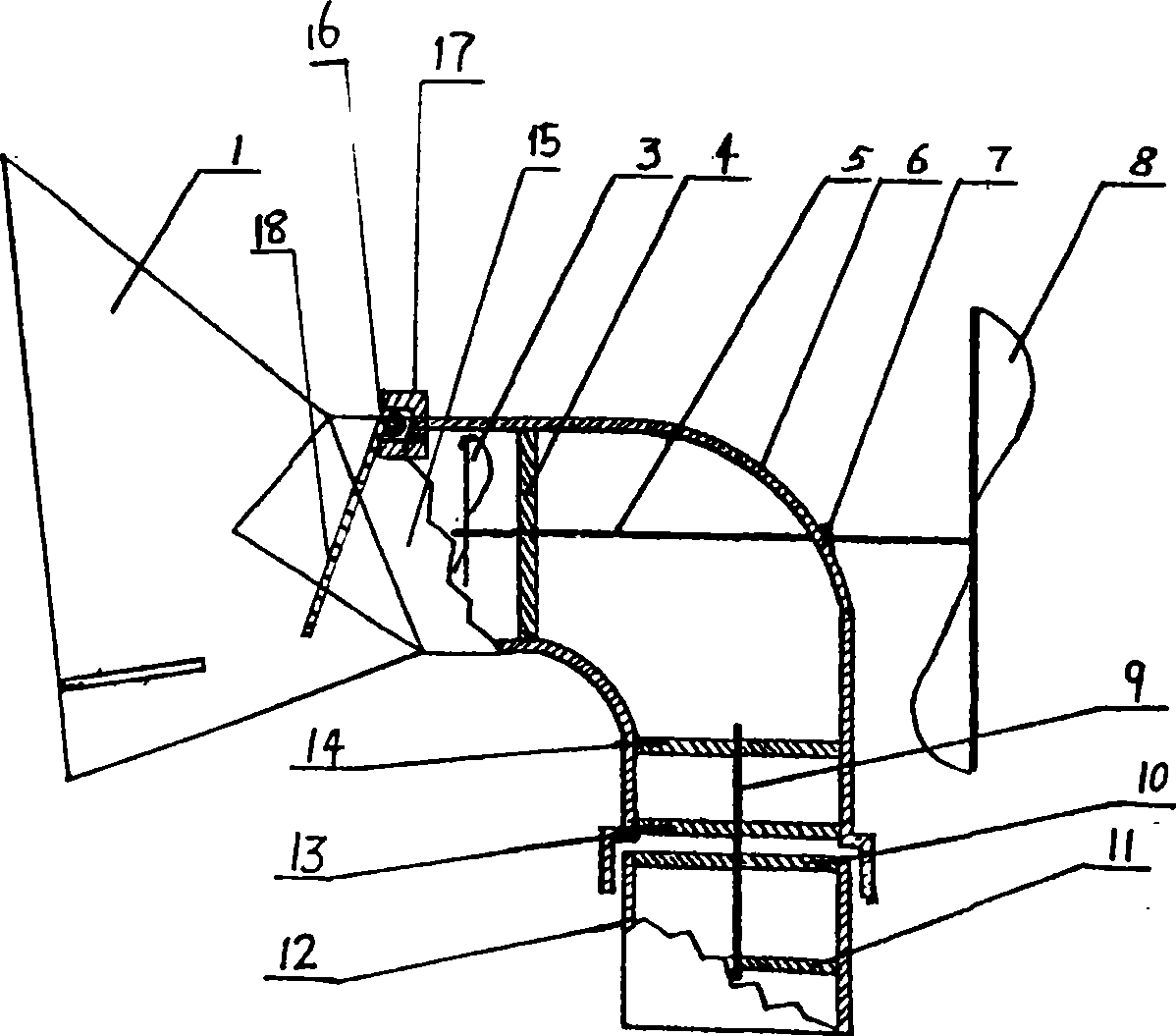

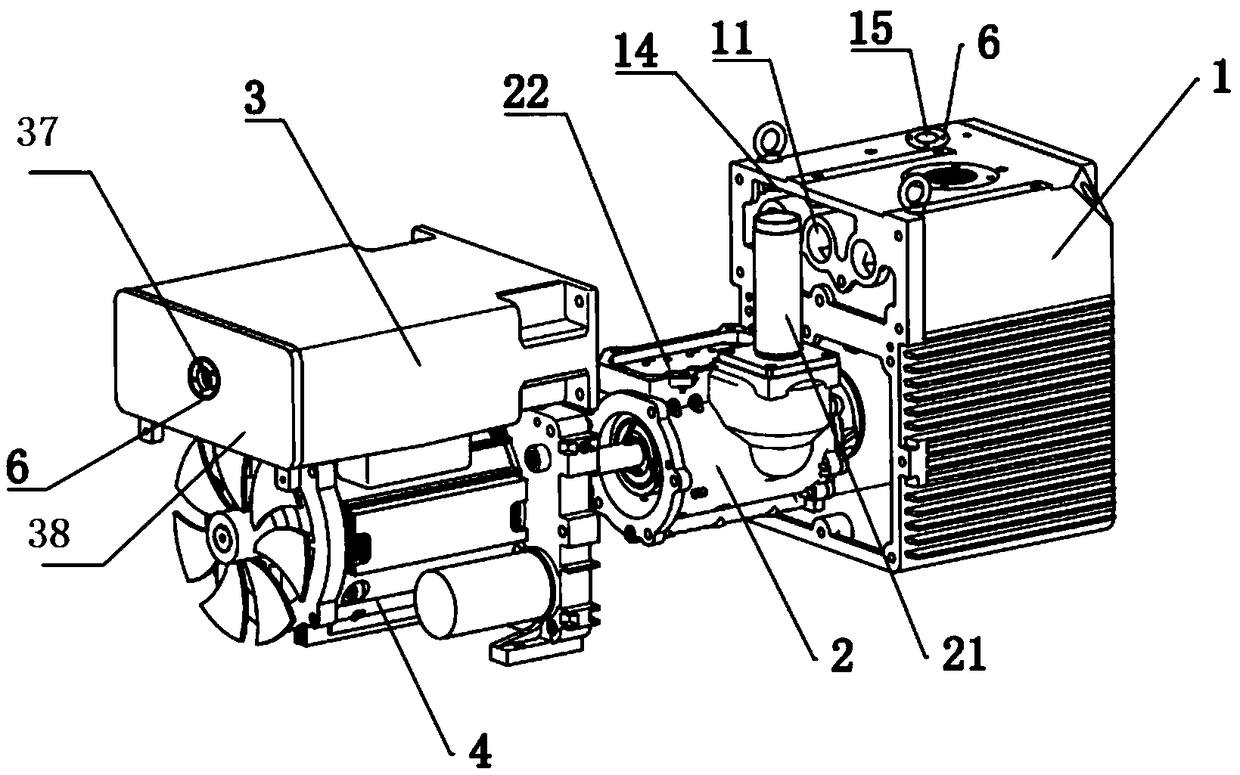

Multi-pulse conversion exhausting device of 8-cylinder straight-row diesel engine

InactiveCN101070776ASimple preparation processSimplify the assembly processExhaust apparatusSilencing apparatusOutgassingTurbocharger

The invention discloses a multi-pulse converter exhauster in 8-cylinder in-line diesel engine , including an exhaust pipe connected with the cylinder in-line diesel engine . The exhaust pipe of a diesel engine were connected to the cylinder inline on the inlet, So-call exhaust pipe is divided into two same structure, each exhaust pipe has four inlet and two outlet, within each exhaust pipe has two parallel flow, which of the two adjacent inlet share a outlet and flow channel A relative of the two sides a common inlet flow channel and a Outgassing mouth, the two Outgassing are set side-by-side in each exhaust pipe inlet side and the adjacent side of the centra. The inlet in two sections of the exhaust pipe installs an exhaust pipe of pulse converter connected a turbocharger in diesel engine. The exhauster that manufacturing and assembing process is simple, is small size, low cost, solved the cylinder exhaust mutual interference problems, so that the engine exhaust flow and have a good engine performance.

Owner:WEICHAI POWER CO LTD

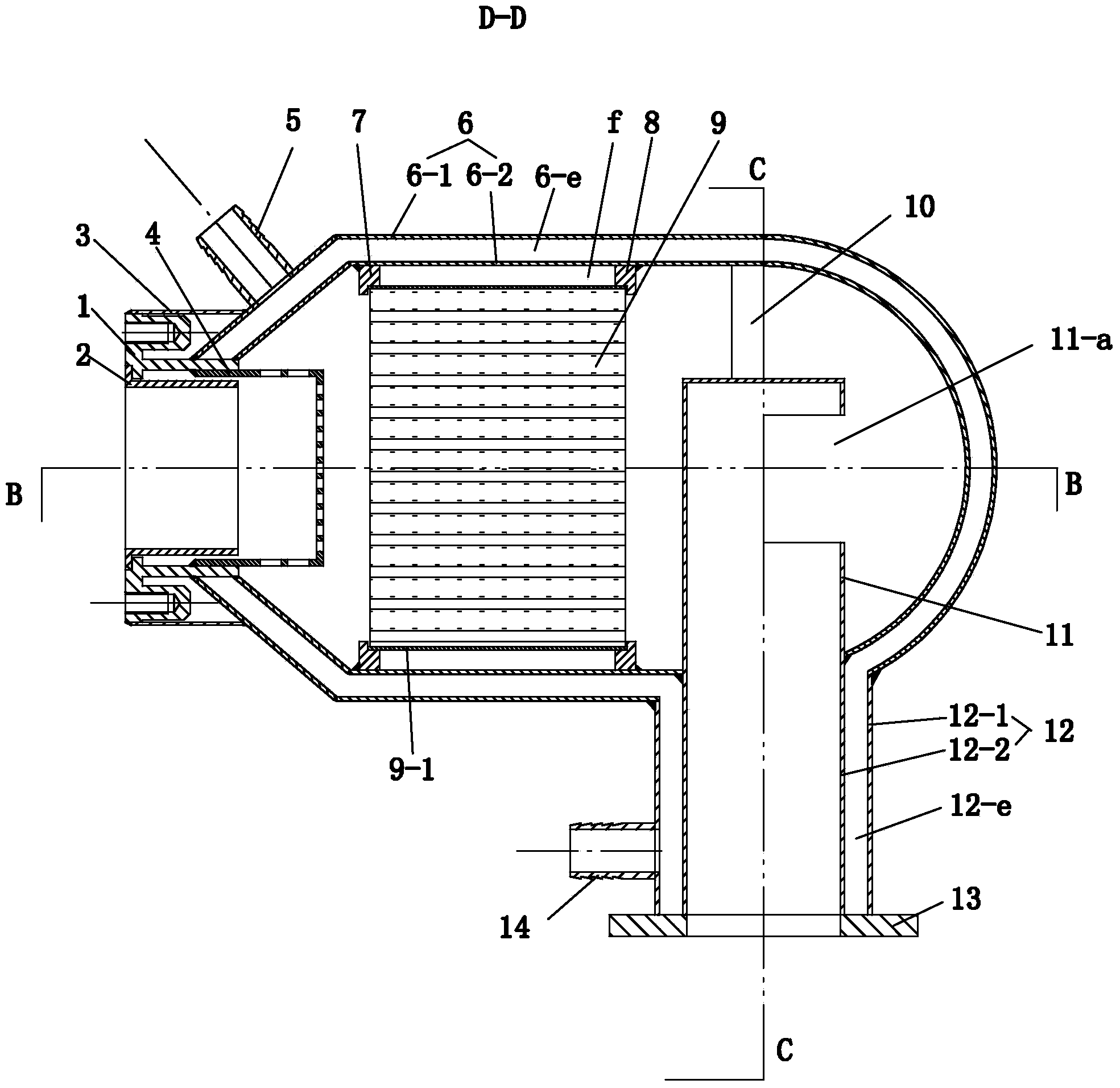

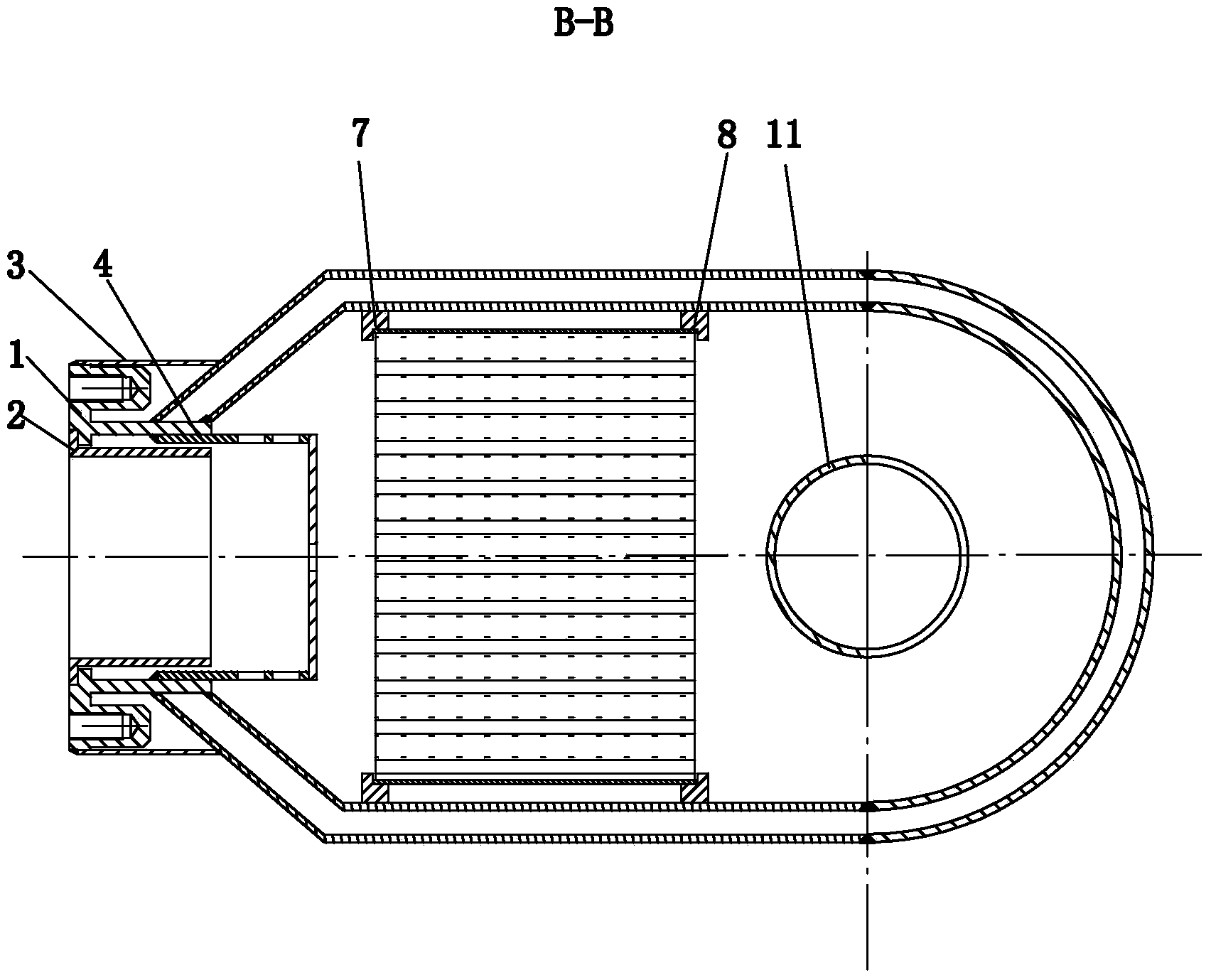

Water-cooling-type tail gas cleanup device of explosion-proof diesel engine

ActiveCN104005815AReduce surface temperatureGuaranteed reaction temperatureExhaust apparatusSilencing apparatusThermal insulationWater cooling

A water-cooling-type tail gas cleanup device of an explosion-proof diesel engine is provided with a front flange, a rear flange, a shell and a DOC core. The front flange is fixed to the front end of a main body shell, a thermal-insulation flange is arranged in the front flange, the rear half portion of the front flange is connected with a flow guide cover, the rear of the flow guide cover goes deep into the main body shell, a front space ring and a rear space ring are arranged on the inner wall of the middle of the main body shell, the DOC core is clamped between the front space ring and the rear space ring, an annular area outside the cylindrical surface of the DOC core between the front space ring and the rear space ring is an air isolation area, an inner shell of a lower shell extends upwards to form a flow guide pipe, an air outlet hole is formed in the cylindrical surface, facing the wall of a hemispheroid cavity, of the flow guide pipe, and the rear flange is installed at the lower end of the lower shell. Through the water-cooling-type tail gas cleanup device, not only is the surface temperature of the diesel engine made to reach the standards, but also high conversion efficiency of the DOC core can be guaranteed.

Owner:CHANGZHOU DEV & MFR CENT

Casting method of high-powered engine box casting

PendingCN111451444AQuality improvementImprove yieldFoundry mouldsFoundry coresTemperature controlIndustrial engineering

The invention discloses a casting method of a high-powered engine box casting. The casting method comprises the steps of preparing moulding sand, performing modeling and core making to obtain a sand mould, preparing pouring iron liquid, taking pig iron, foundry returns and waste steel as raw materials to be fed into a smelting furnace to be smelted, carrying out in-package inoculation and spheroidization on the smelted iron liquid, carrying out stream inoculation before tapping, then carrying out tapping, pouring the iron liquid into the sand mould, carrying out stream inoculation, adopting acold iron riser process for feeding and temperature control, forming a casting after pouring is finished, and carrying out treatment on the formed casting. The obtained casting is good in quality, andquality problems of core clamping, shrinkage, cracks and the like are not prone to happening.

Owner:宜宾普什联动科技有限公司 +1

Fluid extractor for closed body fluid retention devices

ActiveCN106669869ALow costIncrease productivityFluid transfer labwareBody fluid retentionEngineering

The invention relates to the field of medical appliances, particularly a collecting device for collecting the body fluid. The fluid extractor for closed body fluid retention devices comprises an annular side wall and a channel assembly, wherein the annular side wall forms a channel; the channel assembly is arranged in the channel and positioned on the lower part of the channel; the channel assembly and annular side wall form a split fit; the channel assembly is provided with a through hole; the upper part of the channel is used for collecting the fluid; and the lower part of the channel is matched and connected with the channel assembly. The fluid extractor is capable of lowering the cost and enhancing the production efficiency; and when the excess fluid is poured out of the fluid extractor, the fluid in the test tube can be prevented from being poured out from the diversion channel or exhaust channel.

Owner:WUXI KAISHUN MEDICAL DEVICE MFG CO LTD

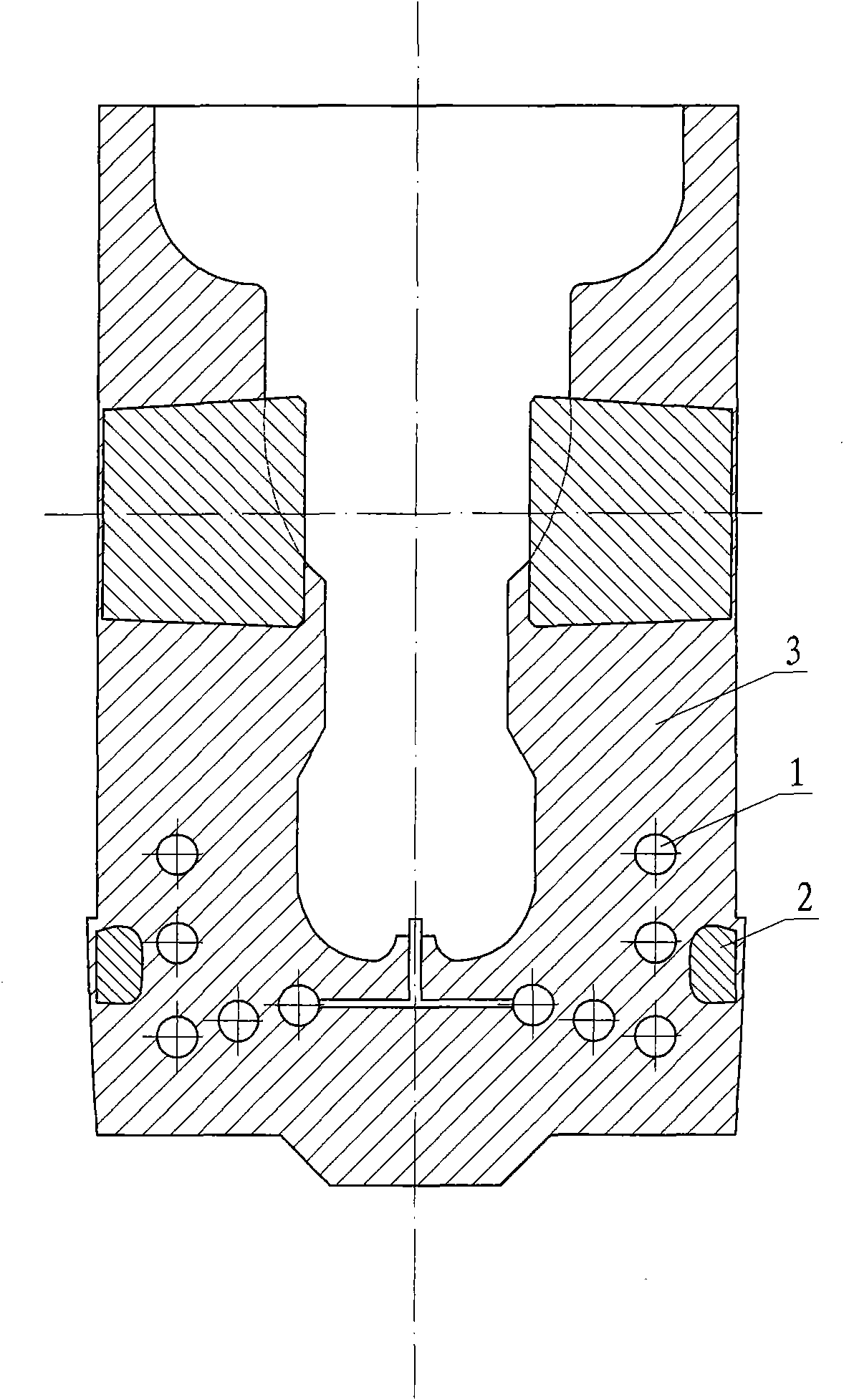

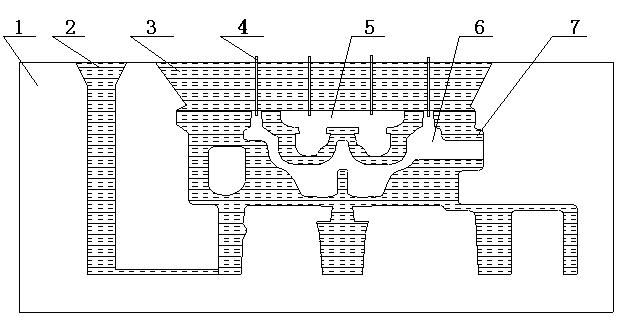

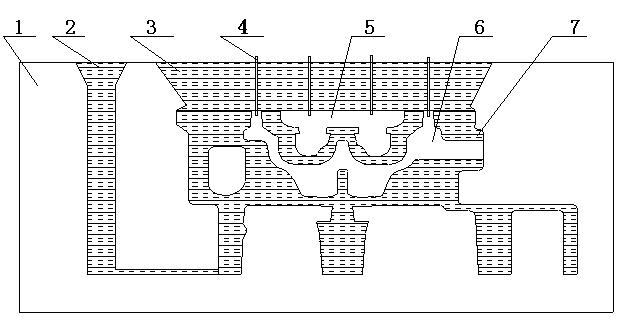

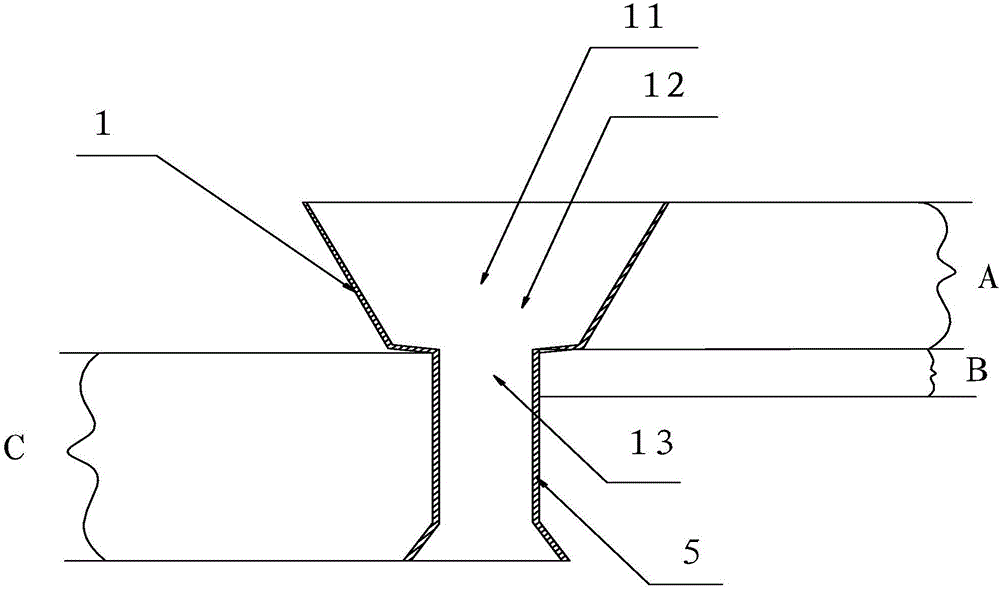

Moulding method for insulating part manufacture of high-voltage cable accessory and moulding mold

The invention can cause that an insulating part of a high-voltage cable accessory is integrally molded in one step; a set of mold can simultaneously use two materials which are liquid and solid, each part is uniformly molded and smooth in exhausting and a feeding hole is small and evenly heated, thus increasing the stability of the technique; simultaneously, as the structure is simple, the mold design is relatively simple, thereby a vacuum-pumping device can be omitted; in addition, as the integral molded accessory has few inlets, generated flashing and coffin corner residual material are few, thus reducing the cost.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

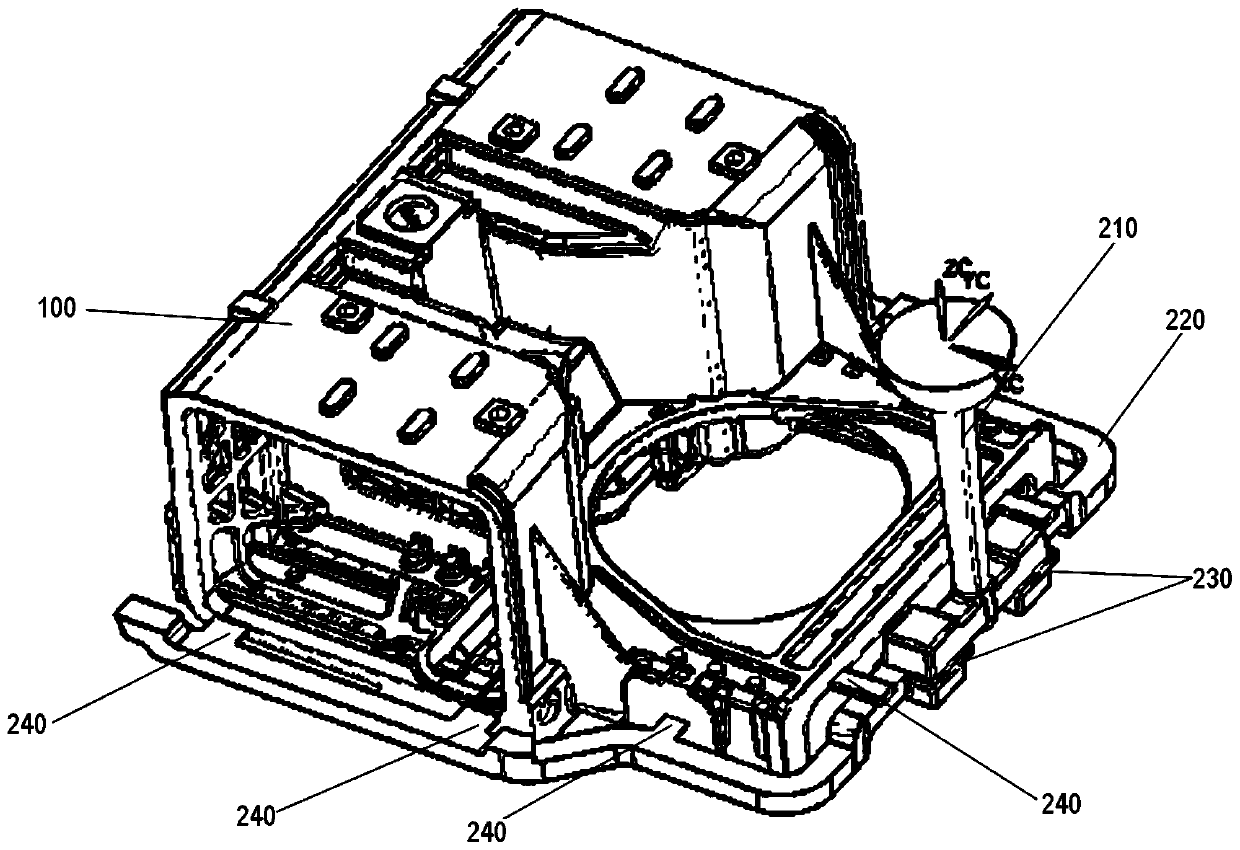

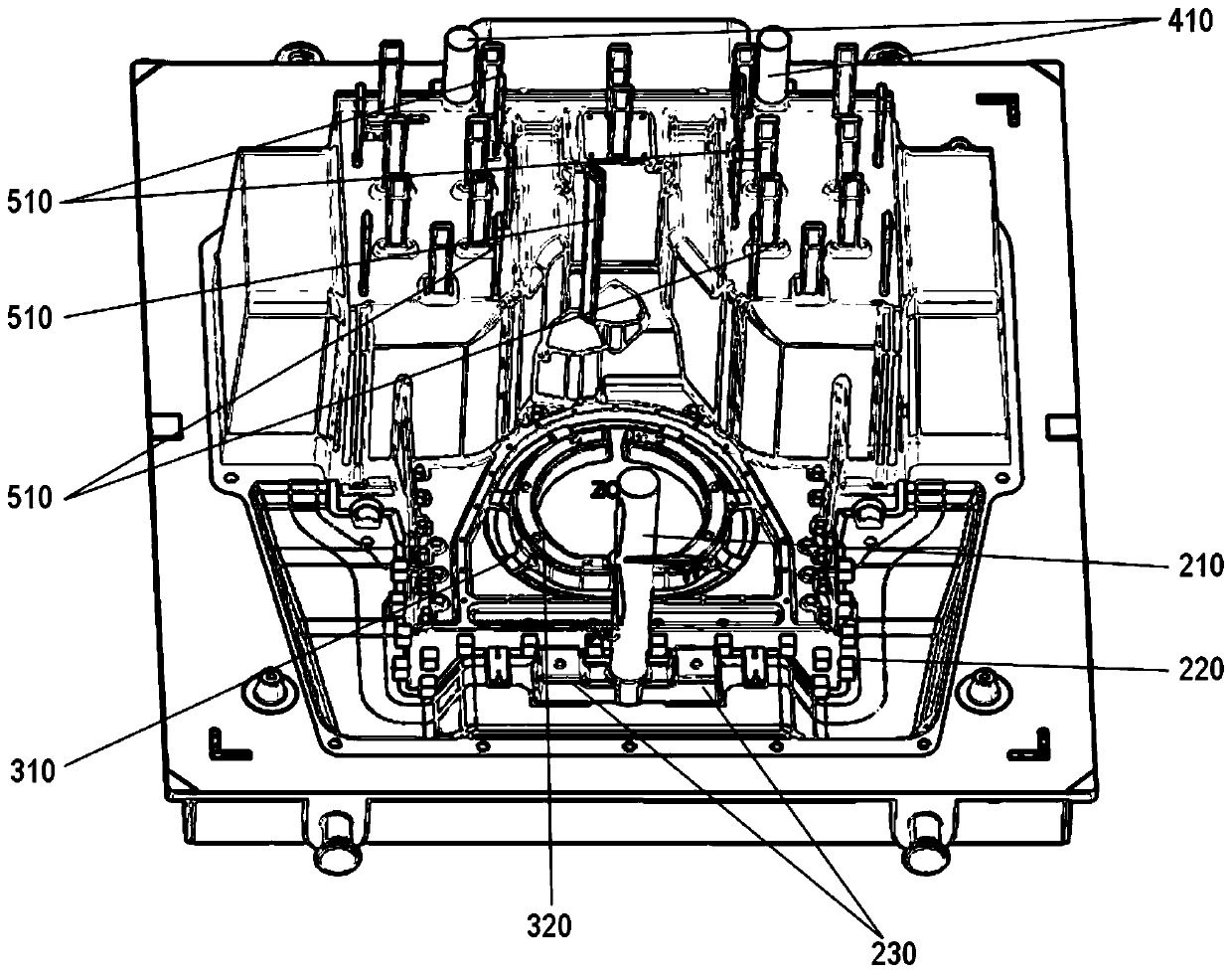

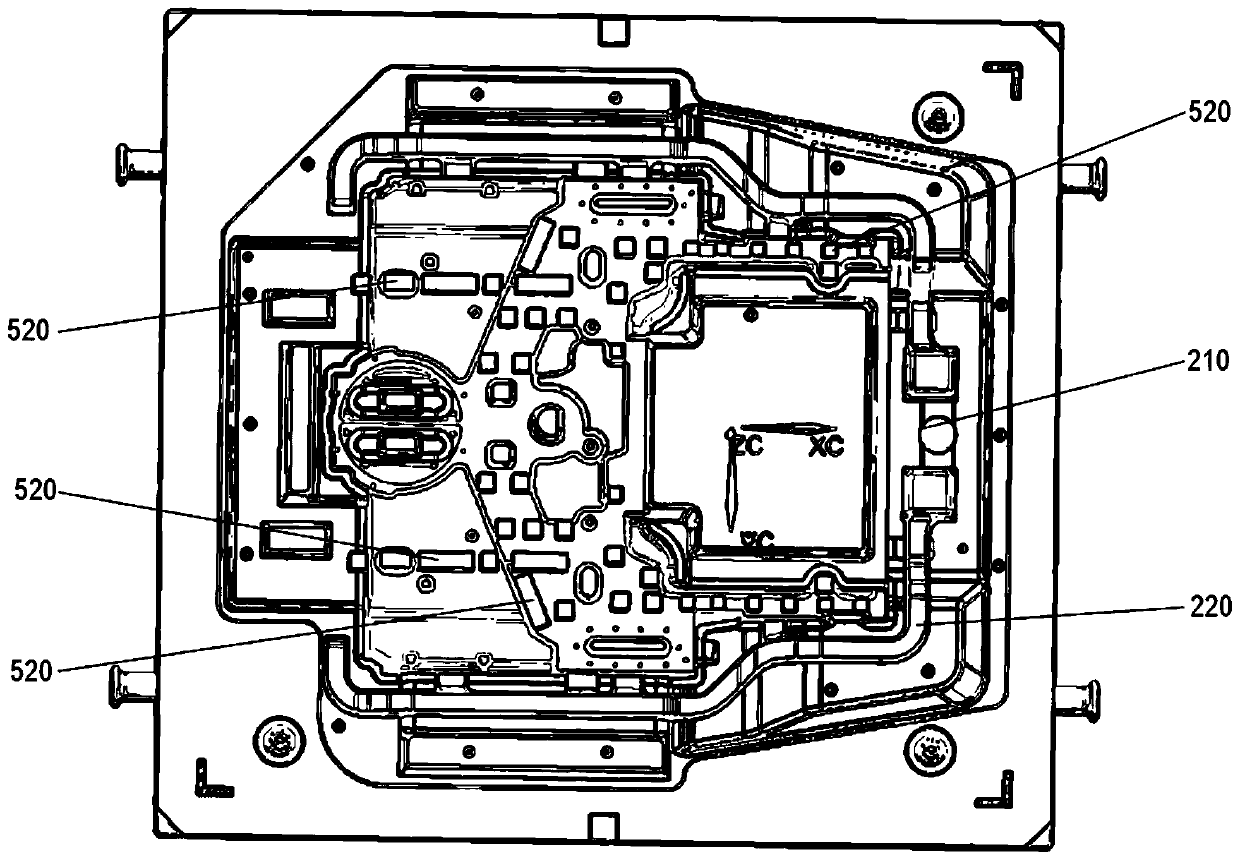

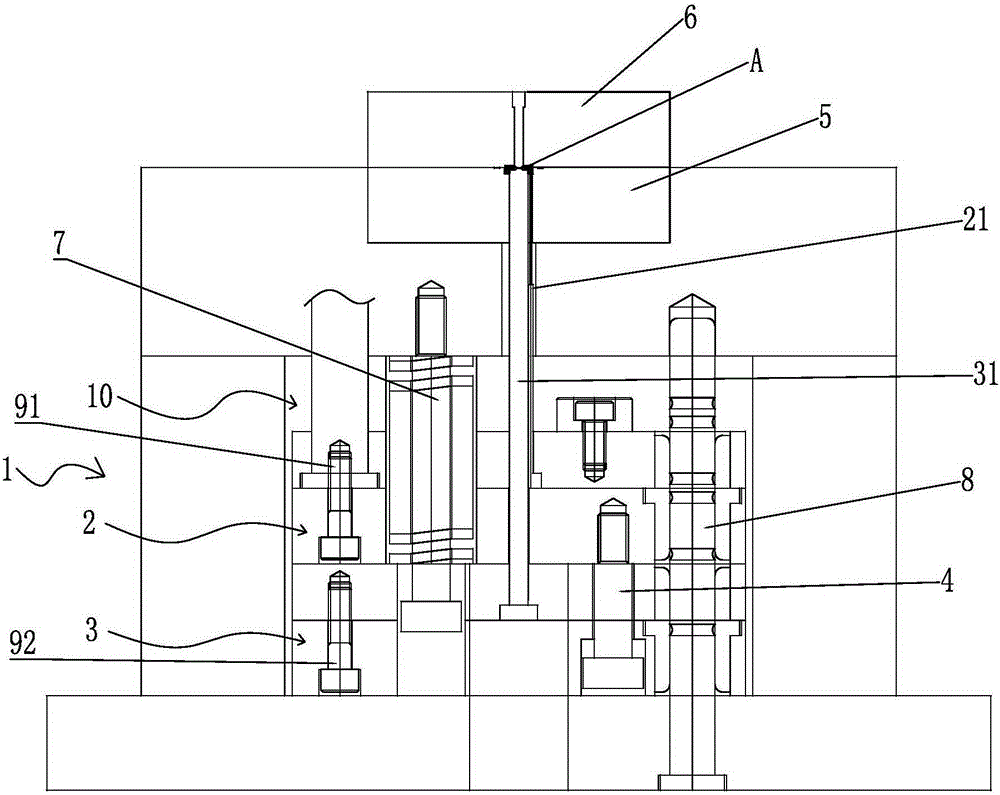

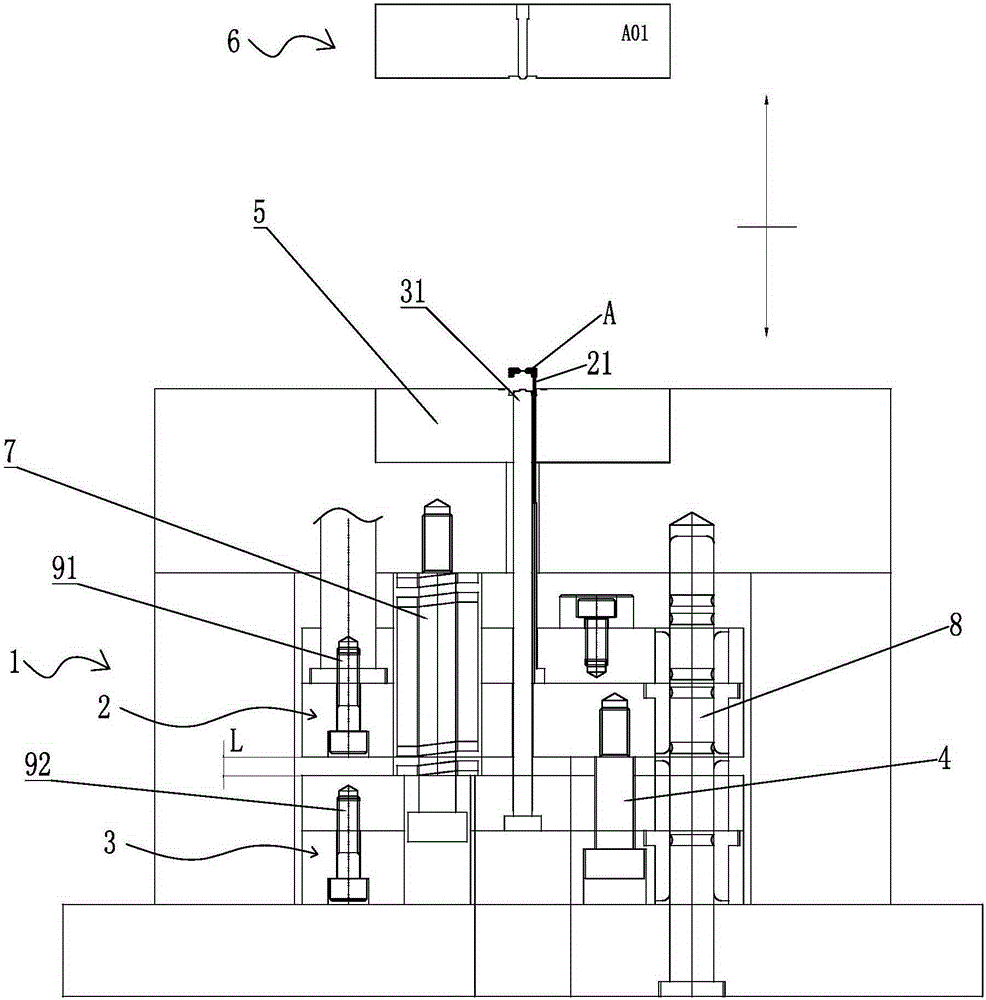

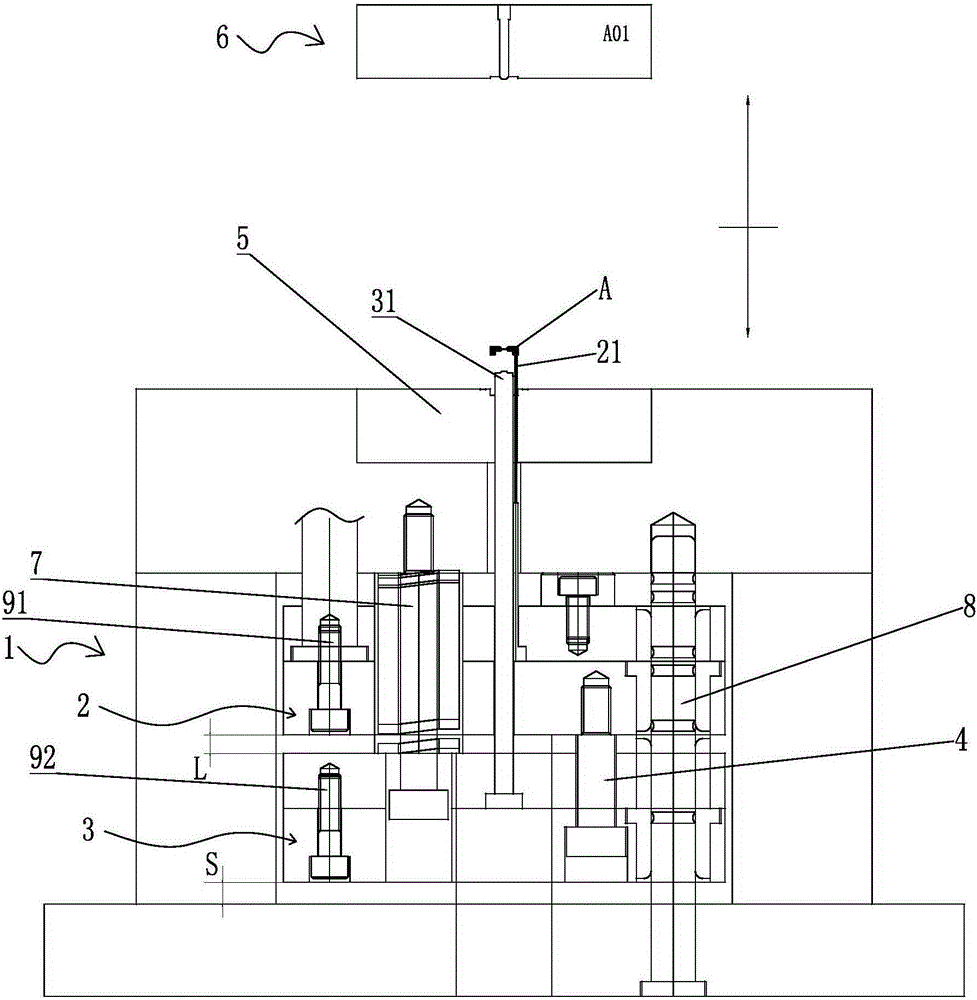

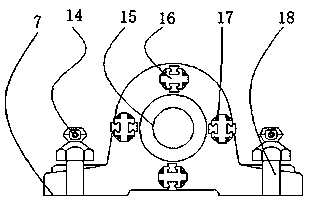

Die structure

ActiveCN105172045AUnobstructed exhaustReduce cleaning and maintenance timesEngineeringInjection molding machine

The invention relates to a die structure comprising a die carrier, wherein a cavity is arranged in the die carrier; an opening communicated with the cavity is formed in the die carrier; the cavity is internally provided with a first ejector retainner plate and a second ejector retainner plate which are movable; the first ejector retainner plate is provided with a central die core which extends to the upper surface of the die carrier after passing through the first ejector retainner plate and the opening; the first ejector retainner plate is provided with an ejector pin for ejecting a molded product at the top end of the central die core; a limiting screw for regulating the positions of the first ejector retainner plate and the second ejector retainner plate is arranged between the first ejector retainner plate and the second ejector retainner plate; a lower die core is arranged at the outer side of the upper end of the central die core; and an upper die core is arranged on the lower die core. Through improving the die structure, the die core part can be directly cleaned and scrubbed on an injection molding machine, so that exhaust is kept smooth, the cleaning and maintaining frequency of a lower die is reduced, the production efficiency is increased, the cost is reduced, and the quality of an injection molded product is greatly improved.

Owner:UNION OPTECH

Switchable spiral-flow type exhaust gas spark arrester for automotive vehicle

InactiveCN102410067AUnobstructed exhaustImprove efficiencyExhaust apparatusSilencing apparatusExhaust gasAir current

The invention discloses a switchable spiral-flow type exhaust gas spark arrester for an automotive vehicle, which relates to an engine exhaust gas processing device for extinguishing spark and combines spiral-flow centrifugal seperation trapping and filter screen barrier seperation trapping. A rotary type spiral-flow valve core and a diversion cover are assembled into an organic whole body of thespark arrestor, wherein the rotary type spiral-flow valve core is opened, an air current chamber is formed to discharge exhaust gas smoothly, and when the rotary type spiral-flow valve core is closed, a diversion chamber and a spiral-flow chamber are formed to carry out multistage composite seperation trapping extinguishment combining spiral-flow centrifugal seperation trapping and filter screen barrier seperation trapping on spark particles. The switchable spiral-flow type exhausting spark arrester is suitable for meeting two special requirements that after the spark arrester is arranged once for all, the valve core is opened when the spark arrester operates in a safety environment and the valve core is closed when the spark arrester operates in a flammable and explosive environment, thereby the complexly repeated dismantling is eliminated, and the transportation efficiency is improved.

Owner:寇志鹏 +1

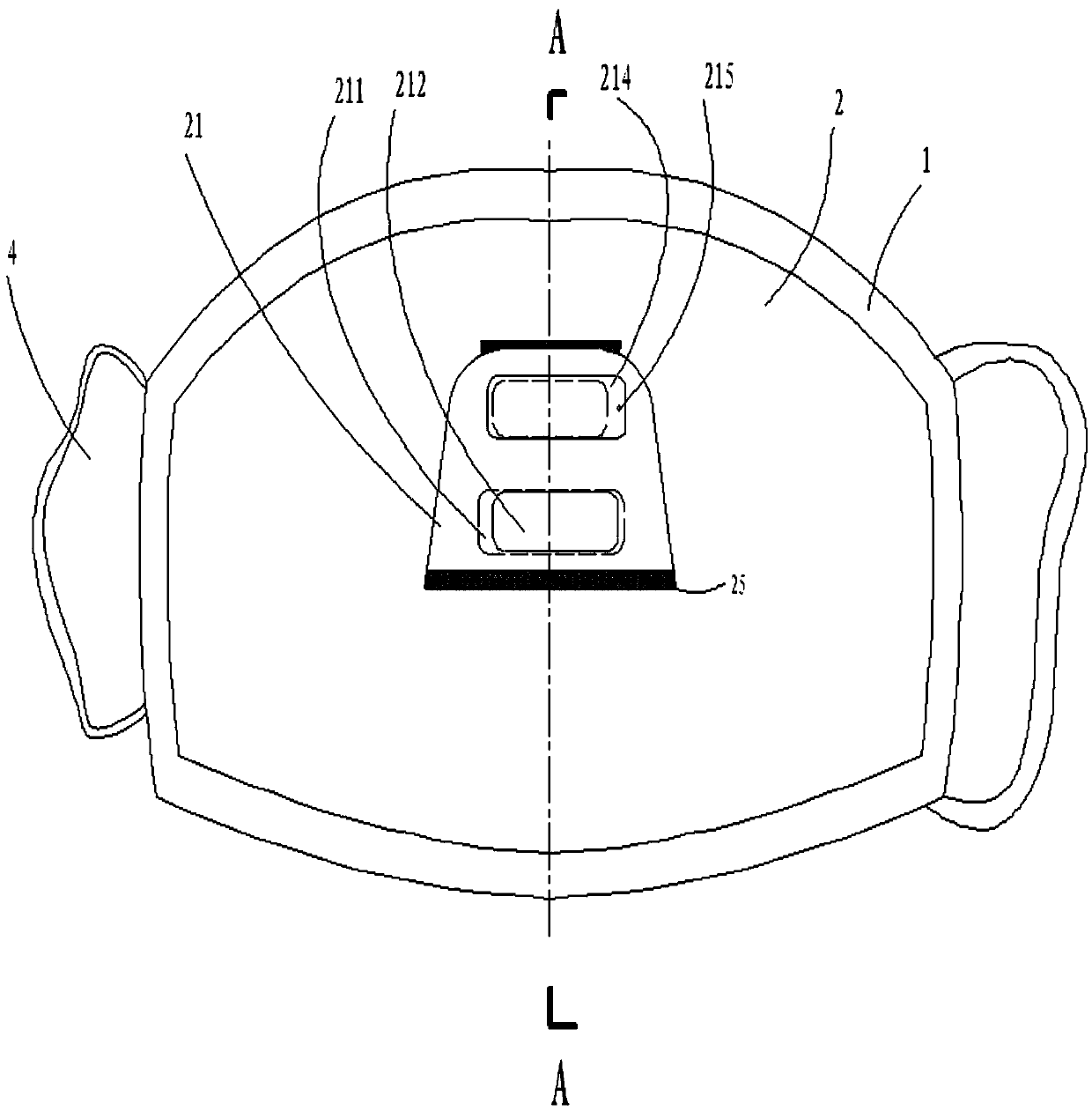

Dust-proof filter mask

InactiveCN103585722AKeep healthyCompact structureFire rescueRespiratory apparatusInhalationRespirator

The invention discloses a dust-proof filter mask which comprises a mask body and fixing bands. The mask body and the fixing bands are connected. The mask body comprises a breathable outer layer, a filter layer and an inner layer, the breathable outer layer, the filter layer and the inner layer are connected in sequence from outside to inside, the inner layer comprises an edge part and a middle part which are connected with each other, the middle part comprises an upper flat plate body, the upper flat plate body corresponds to the position of the nostrils, a nostril air inlet one-way valve is arranged on the upper portion of the upper flat plate body, and a nostril air outlet one-way valve is arranged on the lower portion of the upper flat plate body. The nostril air inlet one-way valve comprises a nostril air inlet valve groove and an air inlet rectangular hole which are matched with each other, the air inlet rectangular hole is covered with a nostril air inlet valve sheet, the nostril air outlet one-way valve comprises an air outlet valve groove and an air outlet rectangular hole, the air outlet rectangular hole is covered with a nostril air outlet valve sheet, and the air outlet valve sheet is connected with the air outlet valve groove in the left side or the right side of the air outlet rectangular hole. The dust-proof filter mask is low in inhalation and exhalation resistance and suitable for being used by a wearer requiring the mask with a plurality of layers and the large inhalation resistance of the mask, and guarantees the body health of a user.

Owner:张秀霞

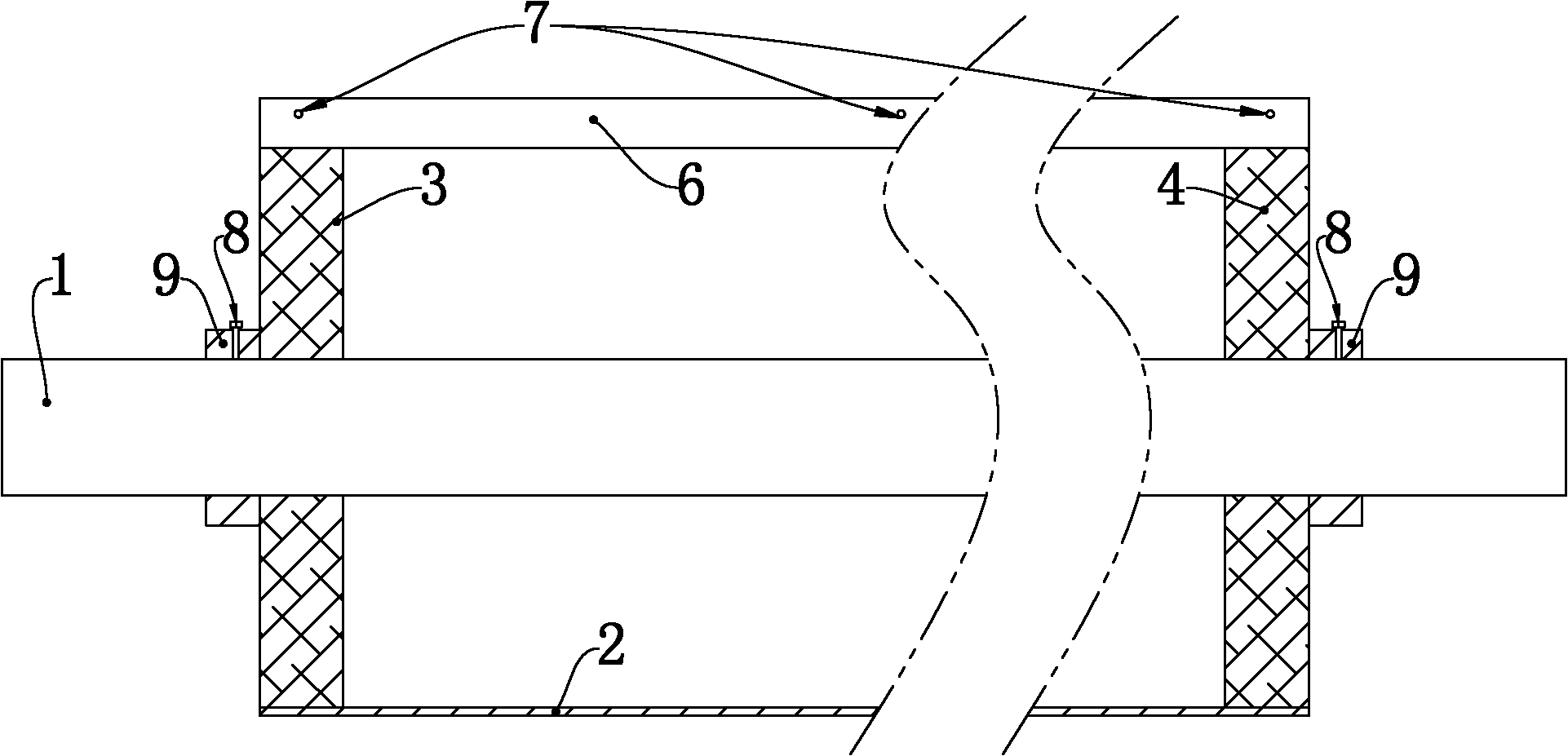

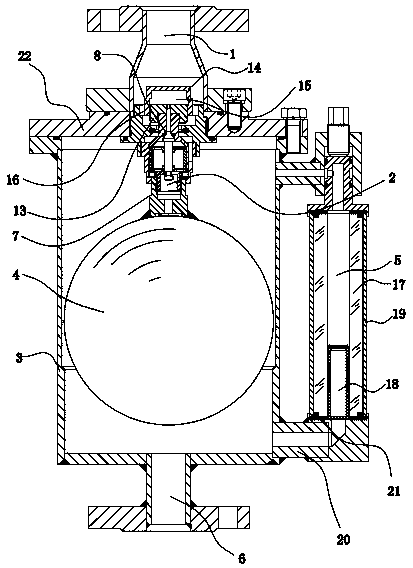

Oil pump vehicle evacuation oil-gas separator

InactiveCN103357201ATurn on high sensitivityImprove separation efficiencyLiquid degasificationExhaust valveEngineering

The invention relates to a vehicle-mounted oil-gas separator, and especially relates to an oil pump vehicle evacuation oil-gas separator. The oil-gas separator comprises a shell, an oil gas entrance channel arranged at the bottom of the shell, and an exhaust channel arranged at the top of the shell, the oil gas entrance channel and the exhaust channel are respectively communicated with the inner cavity of the shell, and a floating ball is arranged in the inner cavity of the shell; an exhaust valve is fixed at the top of the floating ball, and comprises a main valve and a guiding valve; the valve core of the main valve is coupled with the valve port at the top of the shell to make the floating ball float up and down to drive the valve core to open or close the valve port in order to realize the communication or closure between the exhaust channel and the inner cavity of the shell; and the balance valve core of the guiding valve is fixed in the inner cavity of the body of the guiding valve, the piston of the guiding valve is fixed at the top of the valve core, and a separation board is sleeved outside the piston to form a reverse thrust cavity between the piston and the separation board. The oil pump vehicle evacuation oil-gas separator having the above structure has the advantages of thorough exhaust, increase of the oil-gas separation efficiency, and reduction of the use cost.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

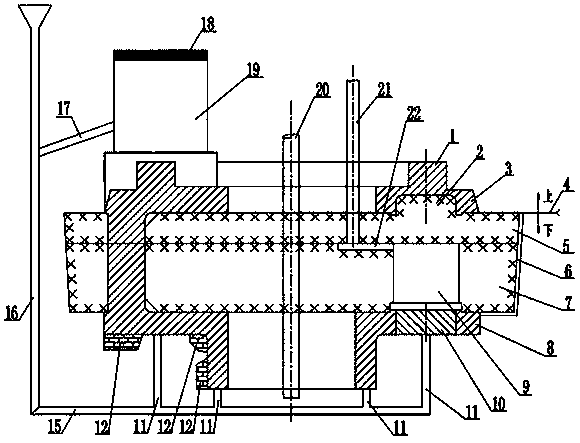

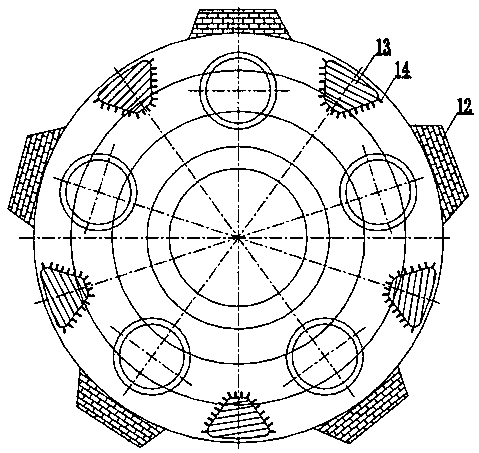

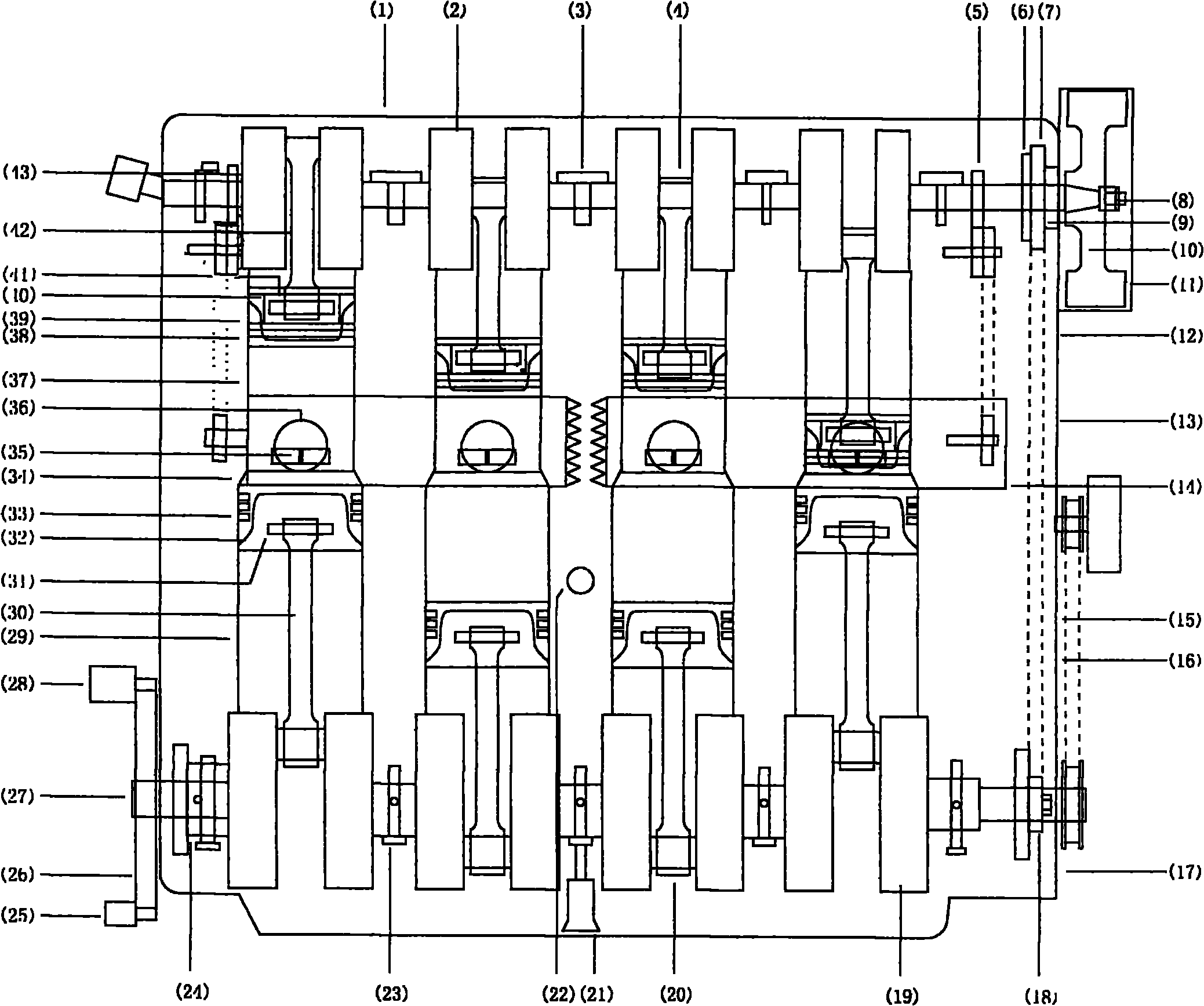

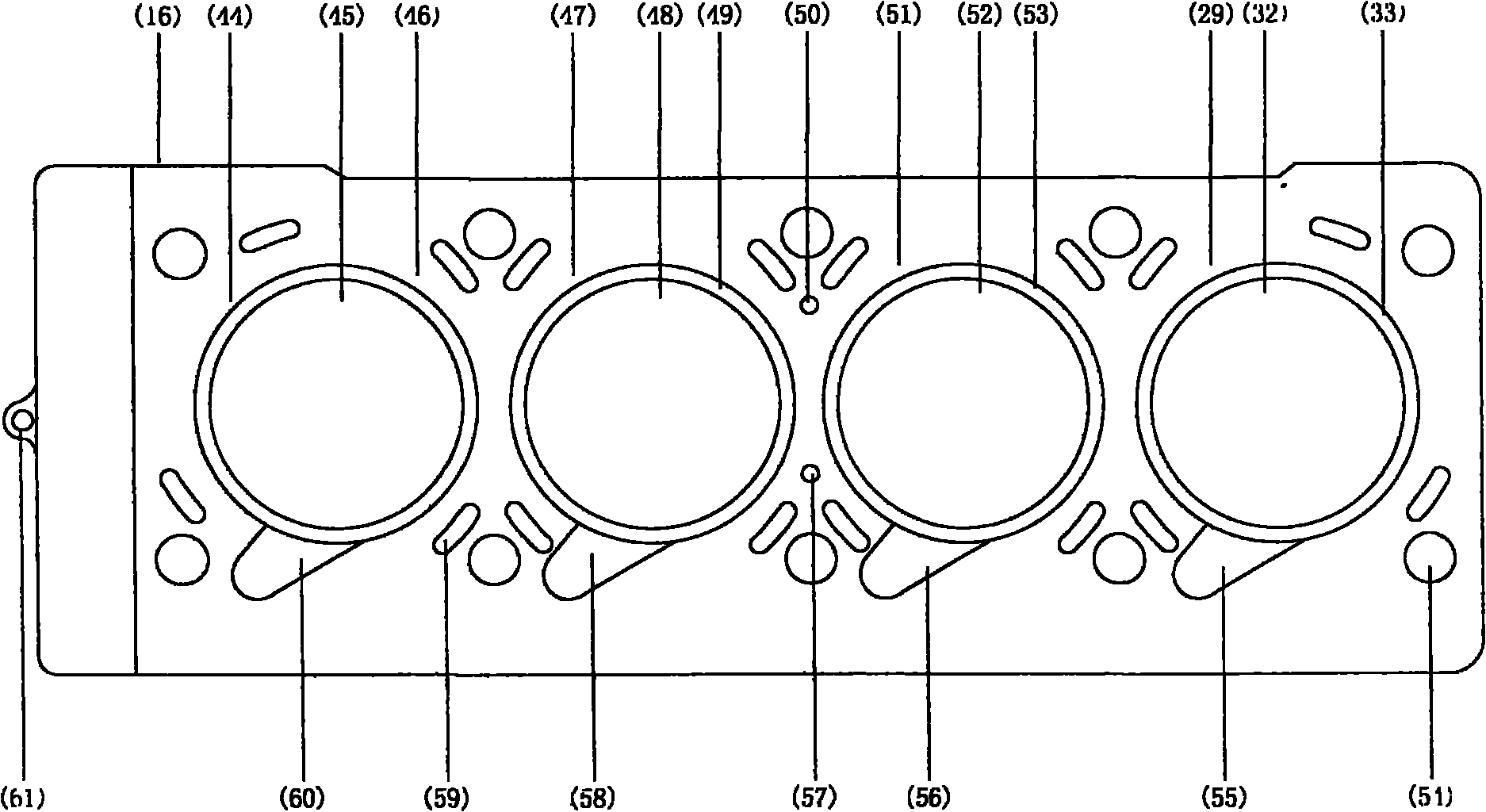

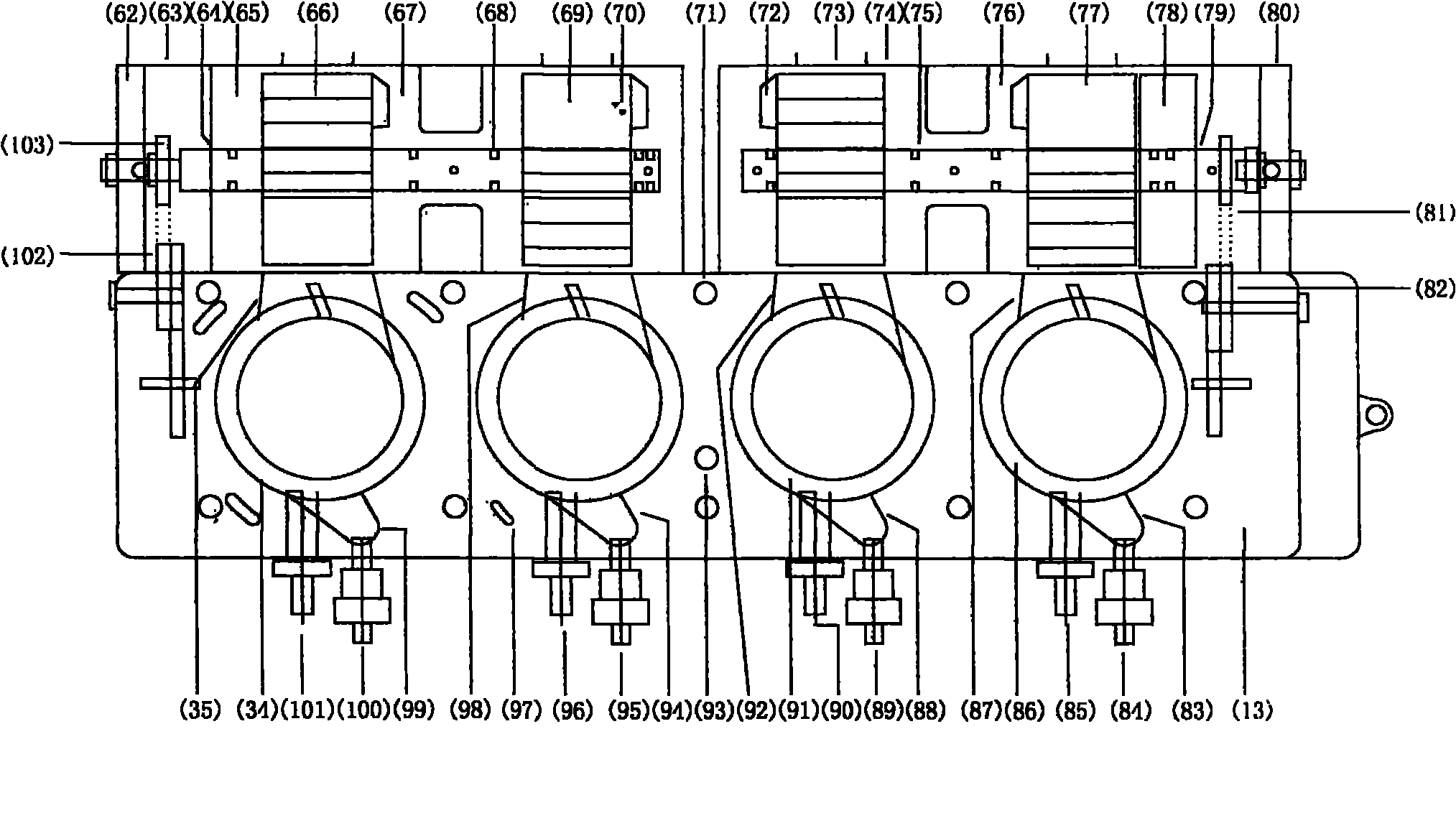

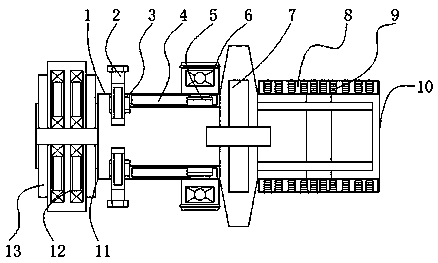

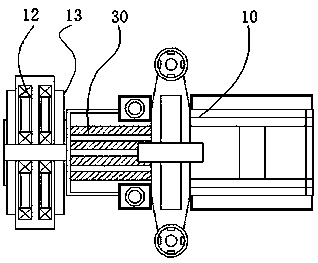

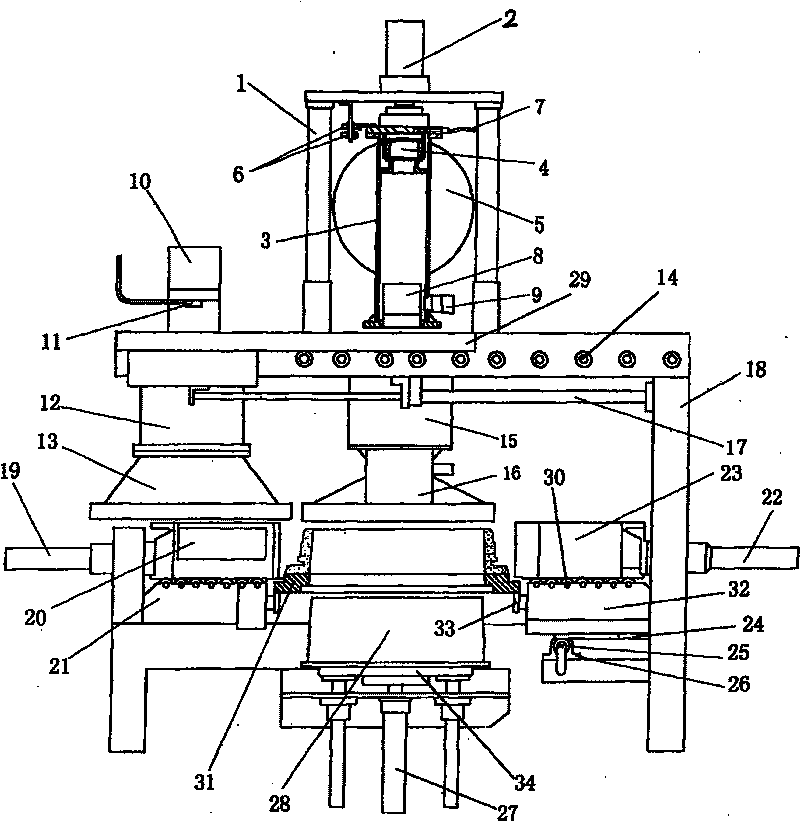

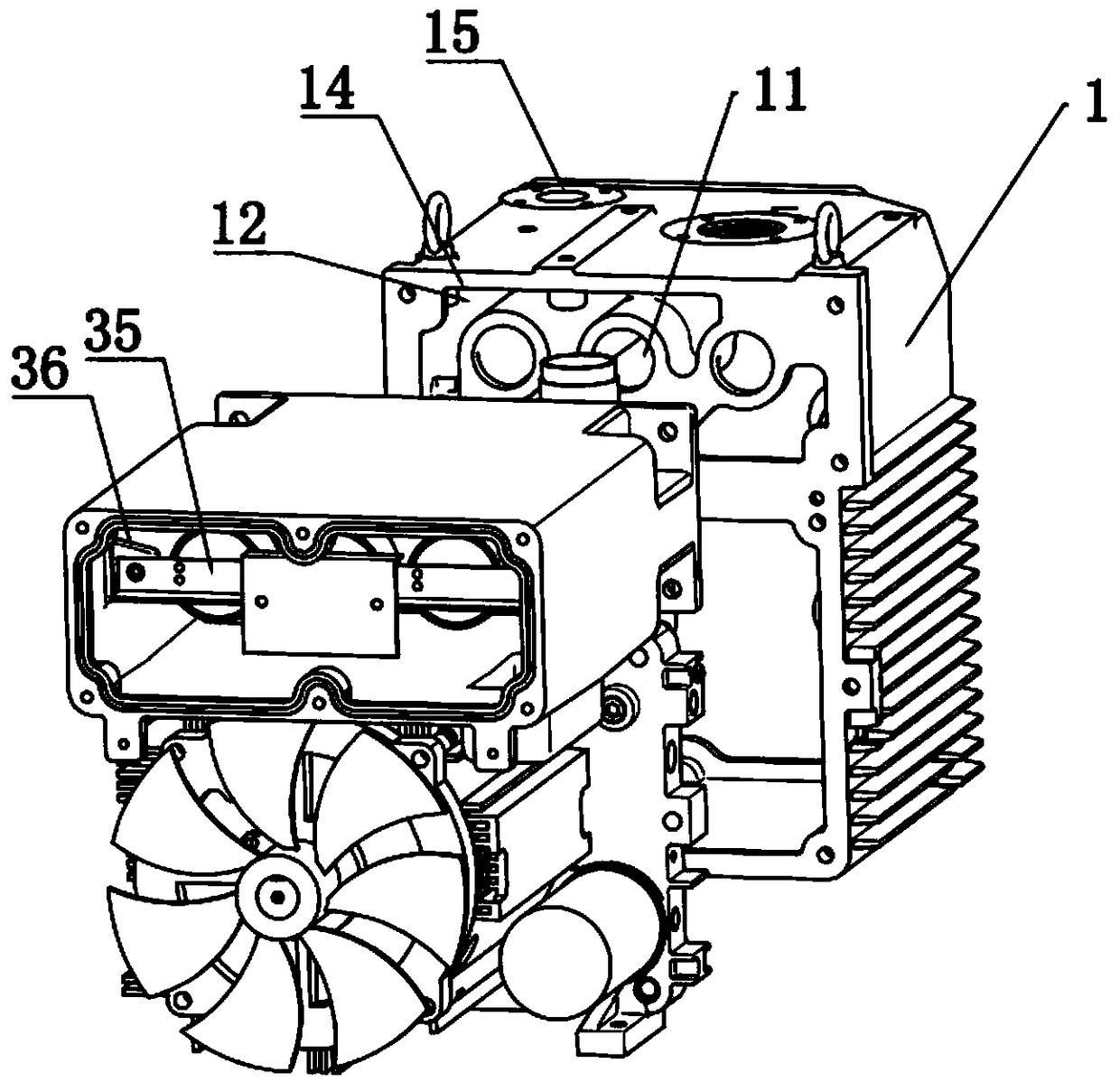

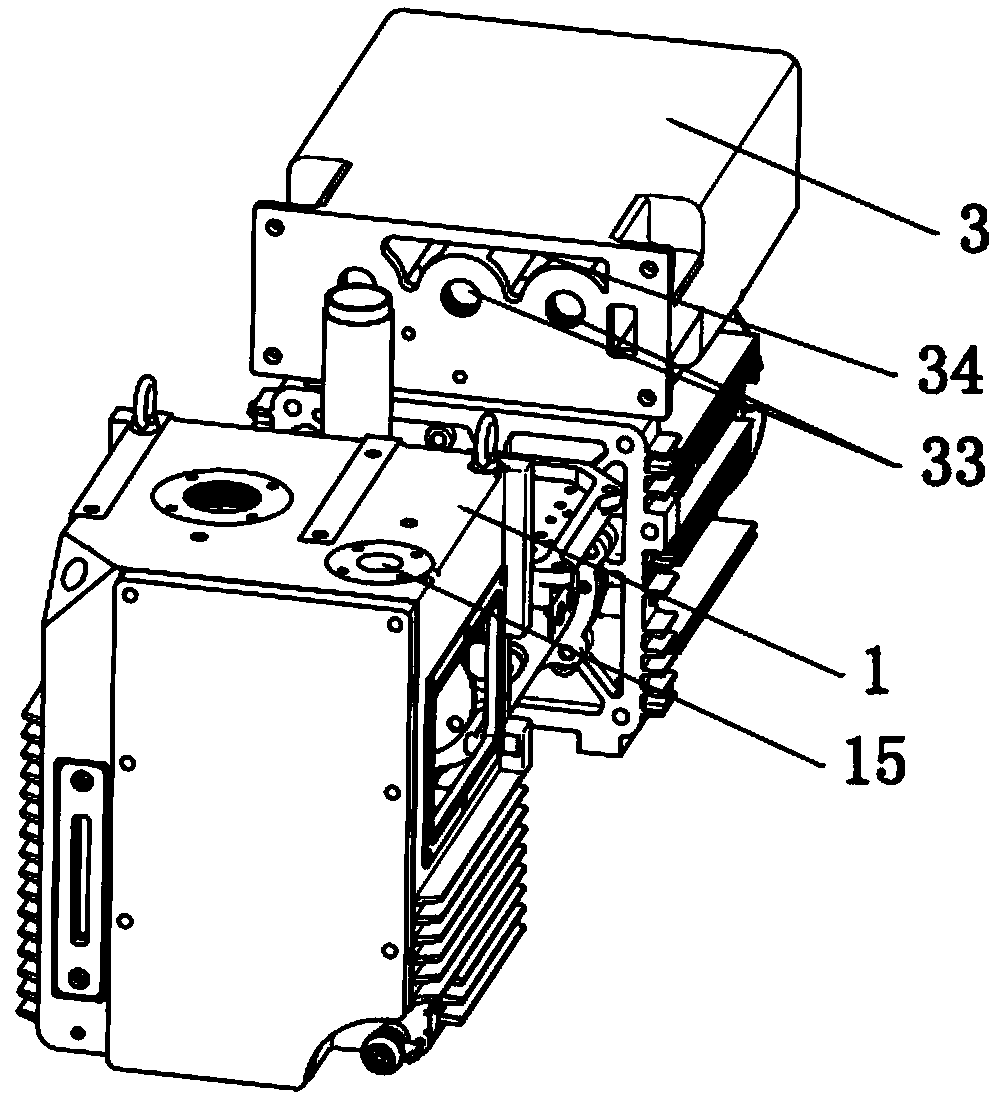

Novel four-stroke four-cylinder layered dual-vortex combustion energy-saving internal combustion engine with new gas distribution mechanism

ActiveCN102155285AImprove lubrication conditionsPowerfulInternal combustion piston enginesCylinder headsPistonEngineering

The invention provides a novel four-stroke four-cylinder layered dual-vortex combustion energy-saving internal combustion engine with a new gas distribution mechanism. In the internal combustion engine, four cylinder nozzle gaskets (14) and four small cylinder heads (13) with the new gas distribution mechanisms are arranged on four cylinders (28) of the conventional four-stroke vertical four-cylinder double overhead camshaft gasoline engine, and four small cylinders (37) are arranged inversely; two ports (35) are arranged in the front of the wall of each small cylinder (37); gas enters and is exhausted by up and down sliding of a small piston (39); and when big and small pistons (32, 45, 48, 52, 39) apply work simultaneously, gas exhaust is to push each small piston (39) and intake and exhaust turbines (66, 69, 73, 77) to apply work. The internal combustion engine has the advantages of simple structure, good lubricating condition, stable work, realizes that fuel vortex performs layered dual-vortex combustion in hot air interlayer, thereby having larger high-power output, saving fuel by about 50 percent, and reducing emission by 85 percent.

Owner:NANTONG YATAI ENG TECH

Vehicle exhaust pipe facilitating internal cleaning for energy conservation and emission reduction

InactiveCN109555579AAvoid stickingUnobstructed exhaustExhaust apparatusSilencing apparatusParticulatesEngineering

The invention relates to a vehicle exhaust pipe facilitating internal cleaning for energy conservation and emission reduction. The vehicle exhaust pipe convenient to internal cleaning for energy conservation and emission reduction comprises a main body and baffles, interface grooves are connected to the left side of a main body frame, the inner wall inside the main body and theinner wallsinside theinterface grooves are in close fit, clamping plates are installed on the left side inside the main body in the up-down direction, the main body and the clamping plates are in flexible connection, connecting columns are arranged at the top ends of the clamping plates, and sliding grooves are fixed to the right sides of the clampingplates. The vehicle exhaust pipe facilitating internal cleaning forenergy conservation and emission reduction has the beneficial effects that clamping plates can be clamped in the main body by manually moving the connecting columns, the interface grooves can be fixed to the main body, the interface grooves and the an exhaust pipe can be mounted in the main body through the connecting columns and the clamping plates, thus dust between the exhaust pipe and the interface grooves can be cleared by manually moving the connecting columns and the clamping plates, exhaust particulate matter can be prevented from being clamped between the exhaust pipe and the interfacegrooves, and thus the particulate matter of the vehicle exhaust pipe can be cleared.

Owner:王佩洁

Pneumatic air exhaust system

InactiveCN101418979AEfficient dischargeDischarge fullyLighting and heating apparatusAir-flow control membersEngineeringProduct gas

The invention relates to the technical field of air exhaust, in particular to a wind-powered exhaust system. The invention solves the problem that the prior exhaust system can not achieve on-time and overall exhaust and ventilation by providing a wind-powered exhaust system capable of preventing exhausted air from being recharged. The wind-powered exhaust system comprises a fixed air passage, an exhaust fan and air outlet, wherein an upper end of the fixed air passage is connected with a rotary air passage, and an air door is arranged at the air outlet. The wind-powered exhaust system has the advantages of no secondary pollution, environmental protection, simple maintenance and reduced labor cost, economization and practicality, effective and complete discharge of dirt air in the air passage, prevention of air-flow recharge, and ensured smooth air discharge and freshness of air.

Owner:北京恩湾科技有限公司

Method for quickly starting anaerobic ammonia oxidation reactor

ActiveCN102259976BEnsure anaerobic environmentUnobstructed exhaustWaste based fuelTreatment with anaerobic digestion processesStart timeSubstrate concentration

The invention provides a method for quickly starting an anaerobic ammonia oxidation reactor. A small amount of anaerobic ammonia oxidation sludge subjected to enrichment culture successfully is regularly added into a reactor for starting an anaerobic ammonia oxidation process by using non-anaerobic ammonia oxidation sludge (such as nitrification sludge, denitrification sludge, methane-producing sludge and the like) to provide certain growth factors for the reactor, so that the starting condition of the anaerobic ammonia oxidation process is improved, and a part of bacterium sources can be increased to accelerate the enrichment of anaerobic ammonia oxidation bacteria in the sludge in the reactor; and substrate concentration and hydraulic retention time are timely adjusted on the basis to avoid substrate lack and accelerate the growth of the anaerobic ammonia oxidation bacteria and the process of granulating the sludge, so that the starting time of the anaerobic ammonia oxidation reactor is greatly shortened, and the popularization and application of the anaerobic ammonia oxidation process are facilitated.

Owner:江苏清材智能制造有限公司

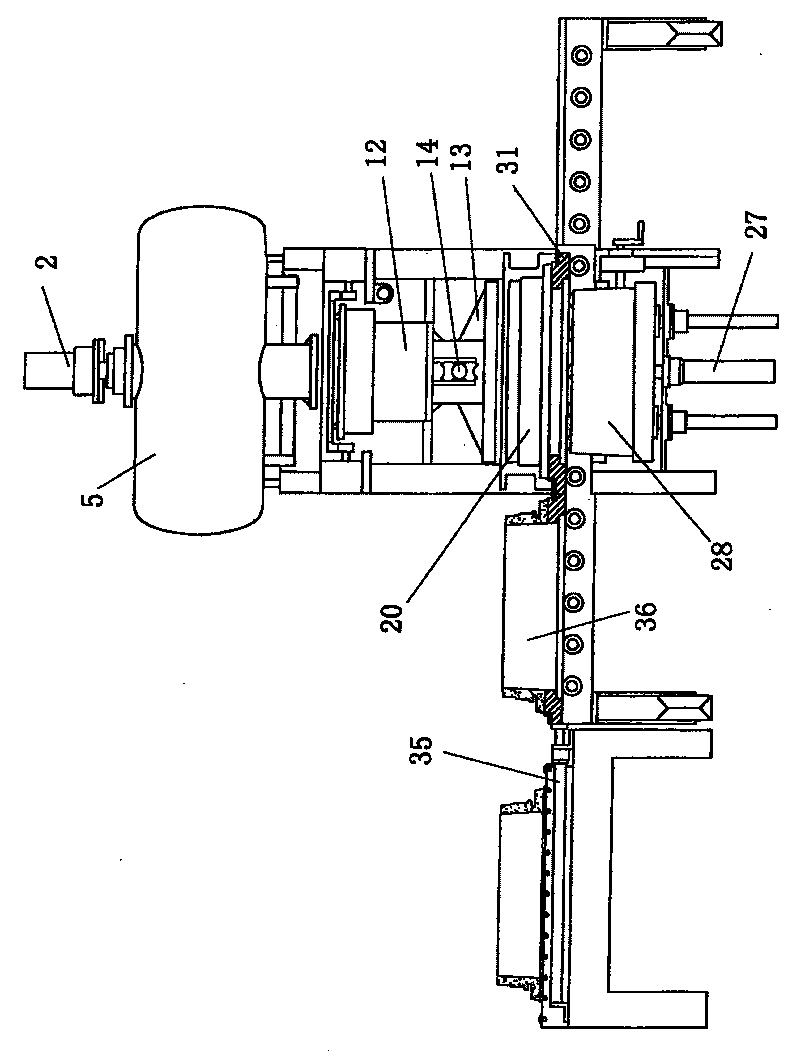

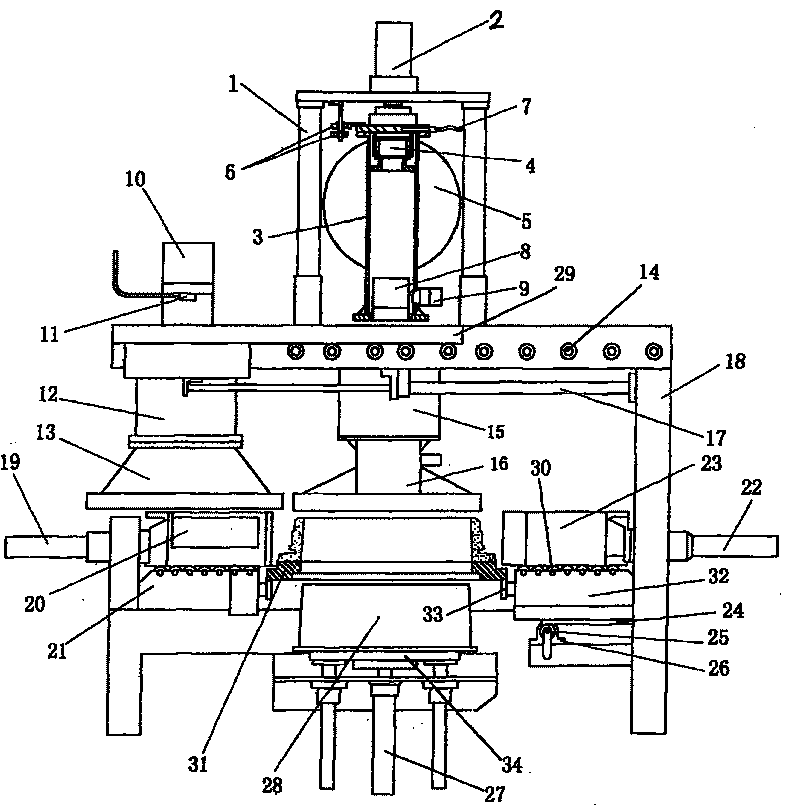

Cold-box core blower

InactiveCN101352752BAvoid damageImprove pass rateFoundry mouldsMoulding machine componentsAir compressionEngineering

Owner:冯新林

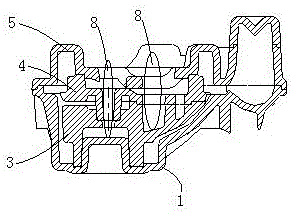

Moulding method for insulating part manufacture of high-voltage cable accessory and moulding mold

A forming die for producing an insulation part of a high-voltage cable accessory is formed by an upper die (6), a lower die (5) and a die core (8). The shape of a die cavity is the shape of the insulation part of the high-voltage cable accessory and is characterized in that: a group of vertical opens (2) are arranged near an end part of the upper die (6), a plurality of vent holes (7) are arranged on a vertical axis of the surface of the upper die (6); a group of transverse opens (4) corresponding to the vertical opens (2) are provided on the lower die (5), the transverse opens are communicated with the die cavity, the lower die (5) is also provided with a group of transverse opens (3) and the vertical opens (1) communicated with the lower die (5), and the transverse opens are communicated with the die cavity. The invention can integrally mold the insulation part of the high-voltage cable accessory in one step. One set of dies can simultaneously use liquid and solid materials. Each part molds uniformly and the exhaust is unblocked. A feed open is small and the heating is uniform. Thus the process stability is improved, the die design is relatively simple. A vacuum-pumping device is omitted, and the materials are saved, thus the cost is reduced.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

Vacuum pump with auxiliary exhausting mechanism

InactiveCN108661905AAdd connection locationIncrease the installation locationPumpsRotary/oscillating piston pump componentsButt jointFuel tank

The invention relates to a vacuum pump with an auxiliary exhausting mechanism. The vacuum pump comprises an oil tank, a pump body arranged in the oil tank and an oil-gas separator disposed on one sideof the oil tank; the pump body comprises a first exhausting opening formed in the top of the pump body; the oil-gas separator comprises a shell and an exhausting filter element which is fixed into the shell; a second exhausting opening is formed in the shell; a passing opening which is in butt joint with an inlet of the exhausting filter element is formed in one side, close to the shell, of the oil tank and located above the first exhausting opening; the auxiliary exhausting mechanism which communicates with the interior of the shell is disposed on the oil tank and comprises a flow guiding wall which protrudes inwards from the inner wall of the oil tank, and an exhausting cavity is formed between the inner wall of the oil tank and the flow guiding wall; and a third exhausting opening which communicates with the exhausting cavity is formed in the outer wall of the oil tank. The vacuum pump is good in oil-gas separation effect, and the mounting position selectivity of externally-connected exhausting pipes is diversified.

Owner:ULVAC NINGBO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com