Vacuum pump with auxiliary exhausting mechanism

A technology of exhaust mechanism and vacuum pump, which is applied to components of pumping devices for elastic fluid, rotary piston type/swing piston type pump components, pumps, etc., which can solve the problem of limited placement space, time-consuming and laborious moving of vacuum pump Increase the occupied area of the vacuum pump and other issues to achieve the effect of increasing the installation position, reducing the adjustment probability, and improving the efficiency of oil and gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

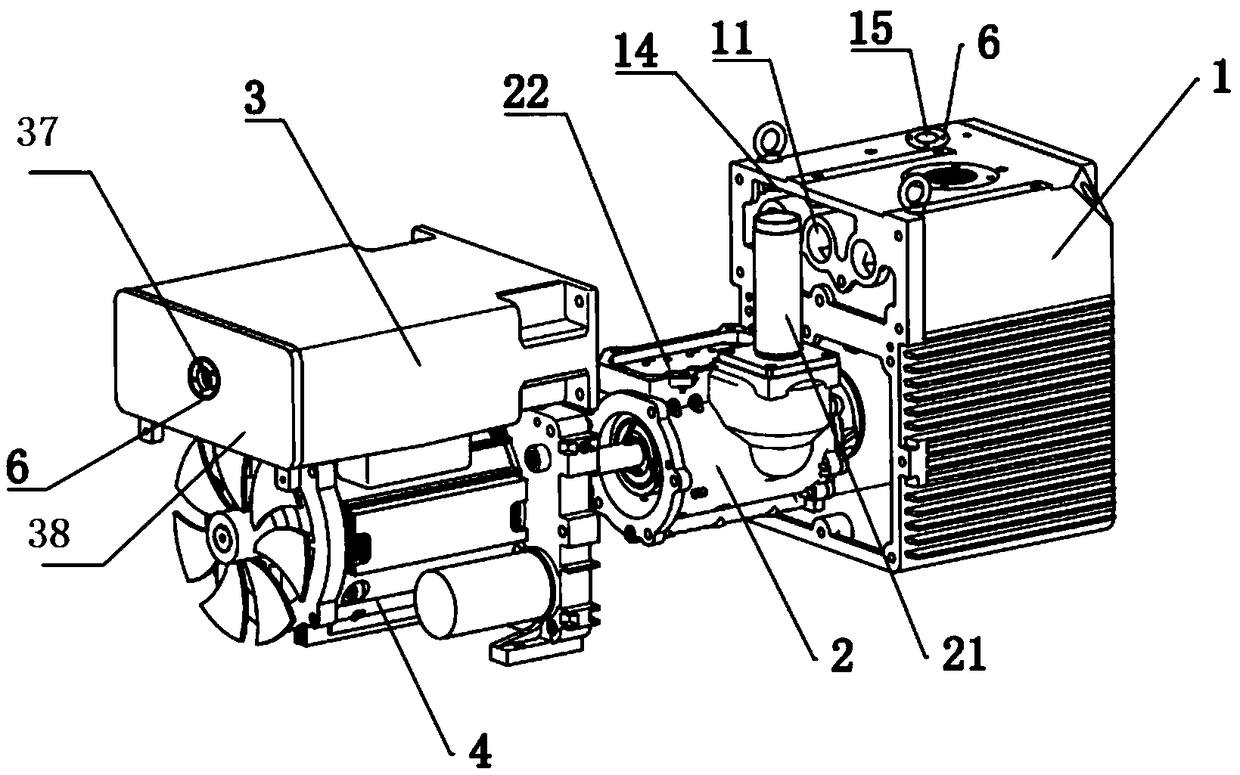

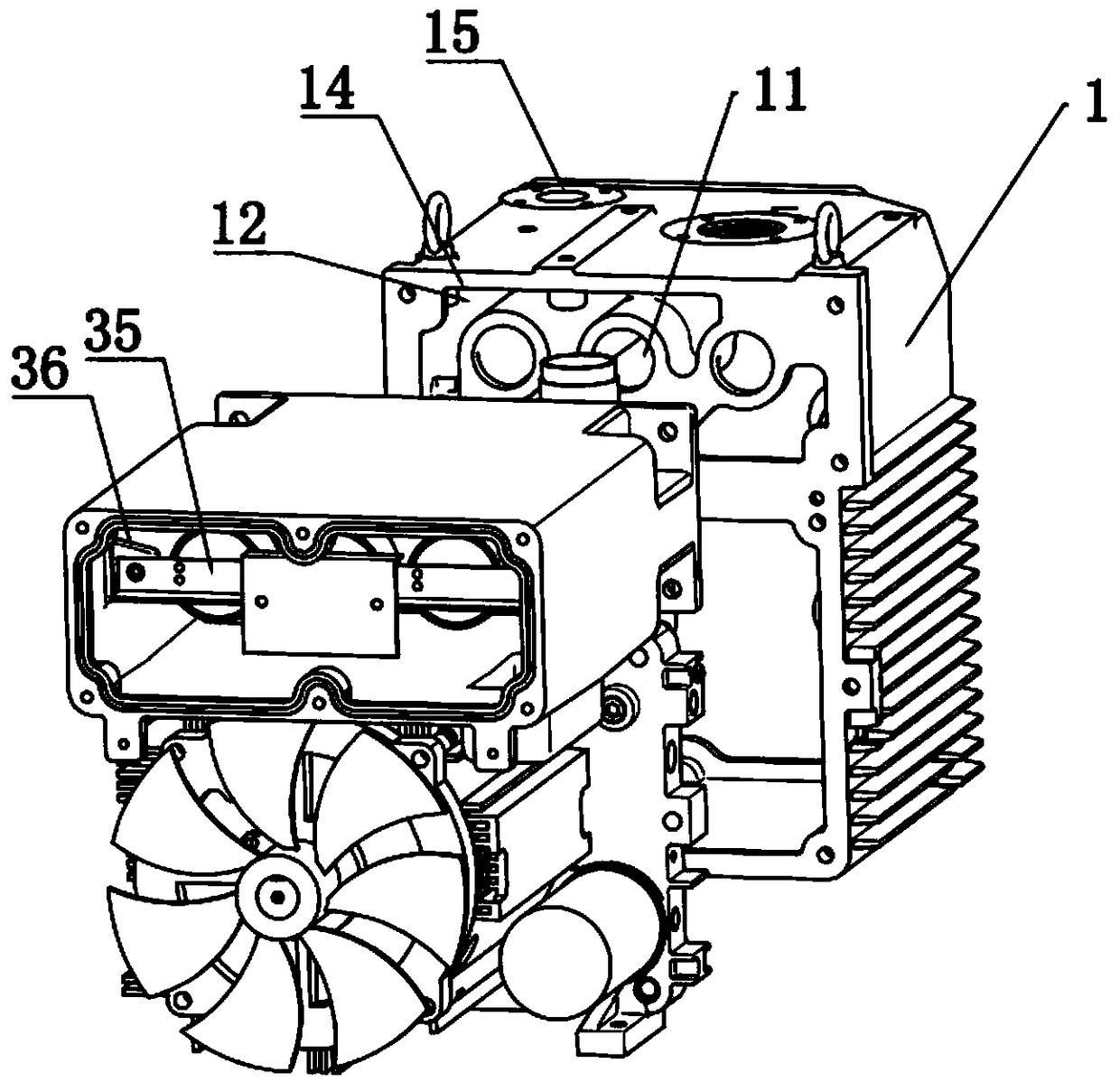

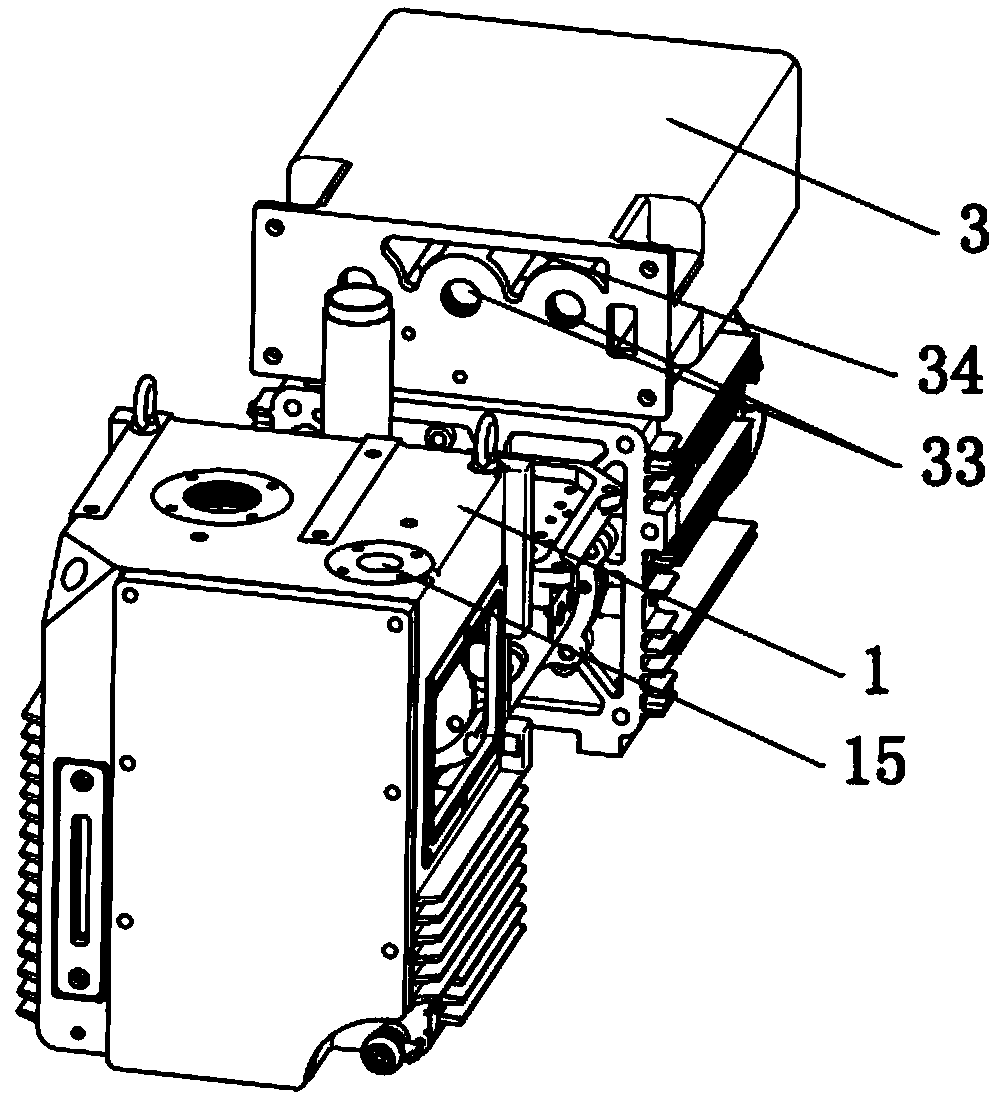

[0034] A vacuum pump with an auxiliary exhaust mechanism, refer to Figure 1-Figure 5 As shown, it includes a fuel tank 1, a pump body 2 arranged in the fuel tank 1, and an oil-gas separator 3 arranged on one side of the fuel tank 1, and a motor 4 for driving the pump body 2 is arranged on the side of the fuel tank 1, and the output shaft of the motor 4 passes through The coupling is connected to the output shaft of the inner rotor of the pump body 2, the oil-air separator 3 is arranged above the motor 4, and the two sides of the top of the pump body 2 are provided with a suction pipe 21 communicating with the inside of the pump body 2 and a first exhaust port 22. The height of the first exhaust port 22 is greater than the maximum liquid level of the fuel tank 1 . The oil-gas separator 3 is arranged on the upper surface of the motor 4 and the upper surface of the oil-gas separator 3 is flat with the upper surface of the oil tank 1 .

[0035] The oil-gas separator 3 includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com