crts Ⅲ type slab ballastless track slab automatic intelligent fine adjustment construction device and construction method

A technology of slab ballastless track and construction device, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of heavy equipment, substandard precision adjustment, moving and slow installation, etc., to improve construction quality standards and realize mechanical The effect of automation and ensuring fine-tuning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

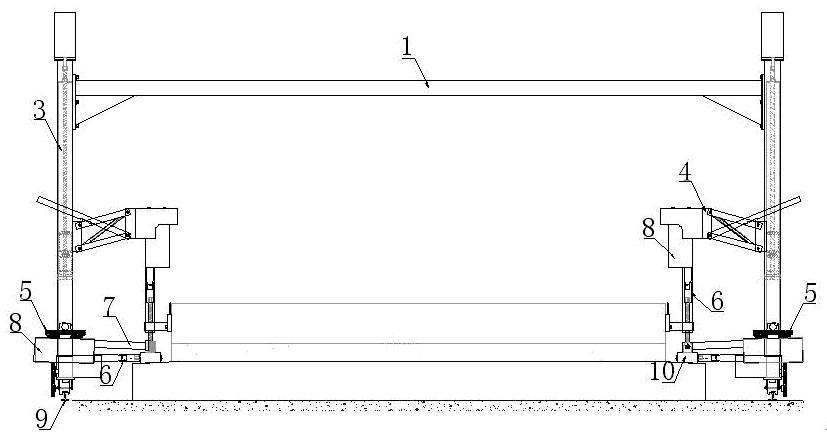

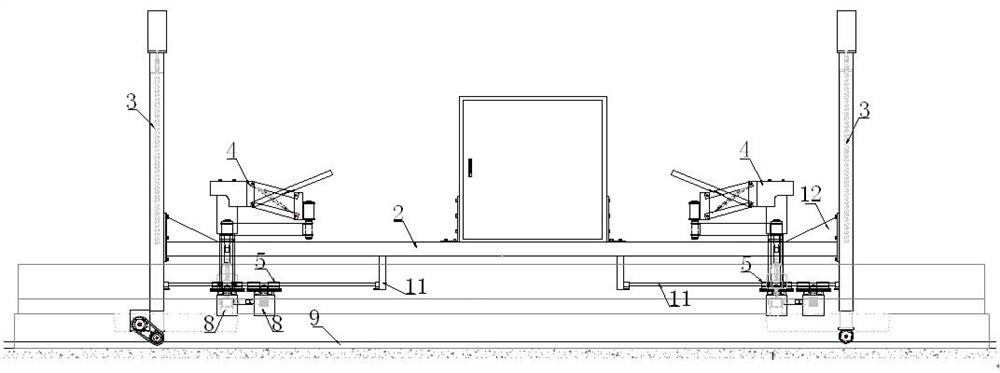

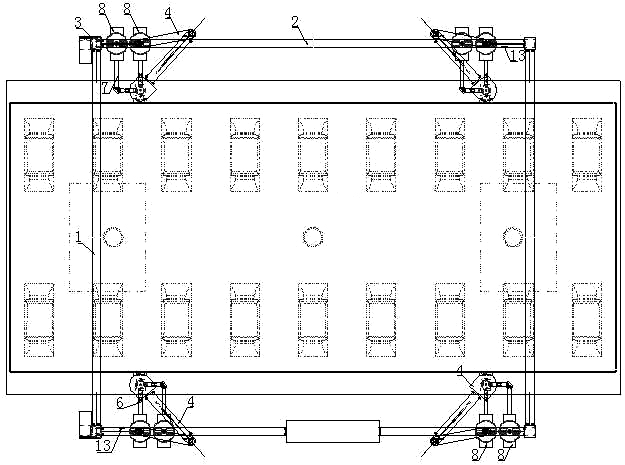

[0055] A CRTSⅢ slab-type ballastless track slab automatic intelligent fine-tuning construction device, including a motor frame device that can automatically walk on the walking light rail 9, the motor frame device straddles the two sides of the ballastless track slab, and the motor frame device is a rectangular frame structure , 4 sets of fine-tuning construction devices are installed on the motor frame device, and 2 sets of fine-tuning construction devices are arranged on each side of the motor frame device. An electric control system is also included, and the electric control system is connected with 8 signals of the fine-tuning servo motor.

[0056] Such as Figure 7 , 8 As shown, the motor frame device includes 4 sets of integral support lifting and walking systems 3 arranged symmetrically on both sides of the ballastless track slab. Bracket lifting and walking system 3 includes bracket lifting servo motor 3.1, connecting steel plate 3.2, lifting external rectangular tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com