Patents

Literature

289results about How to "Realize mechanical automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

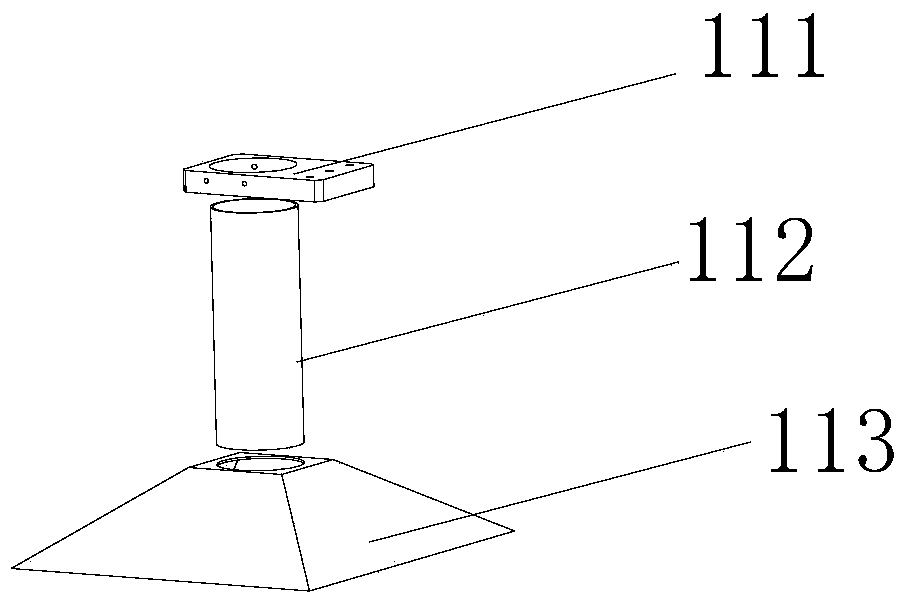

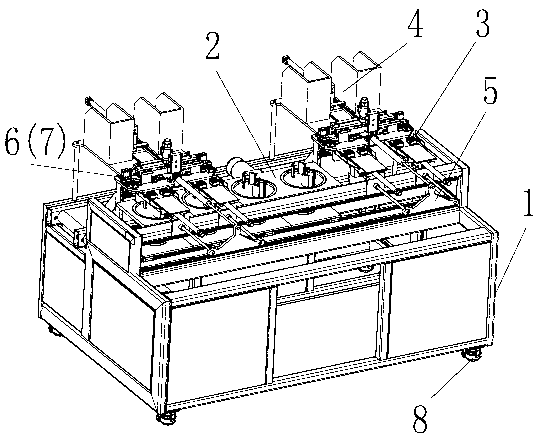

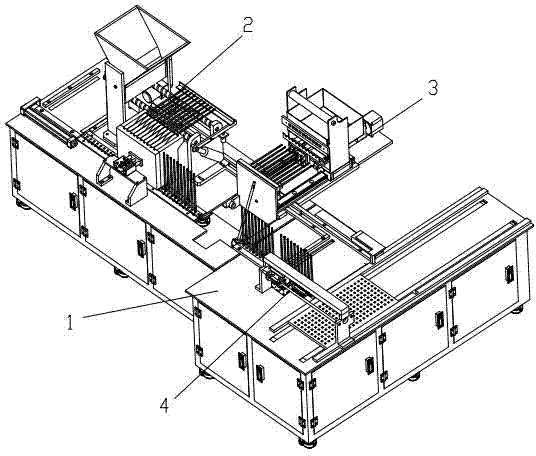

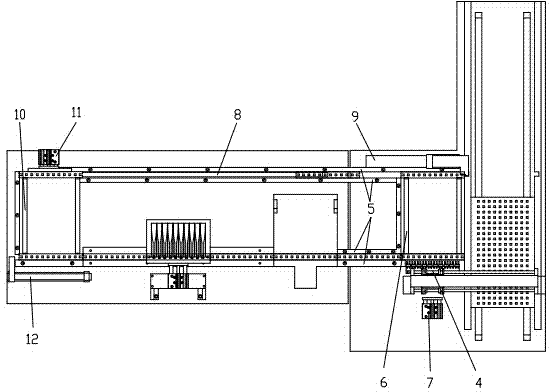

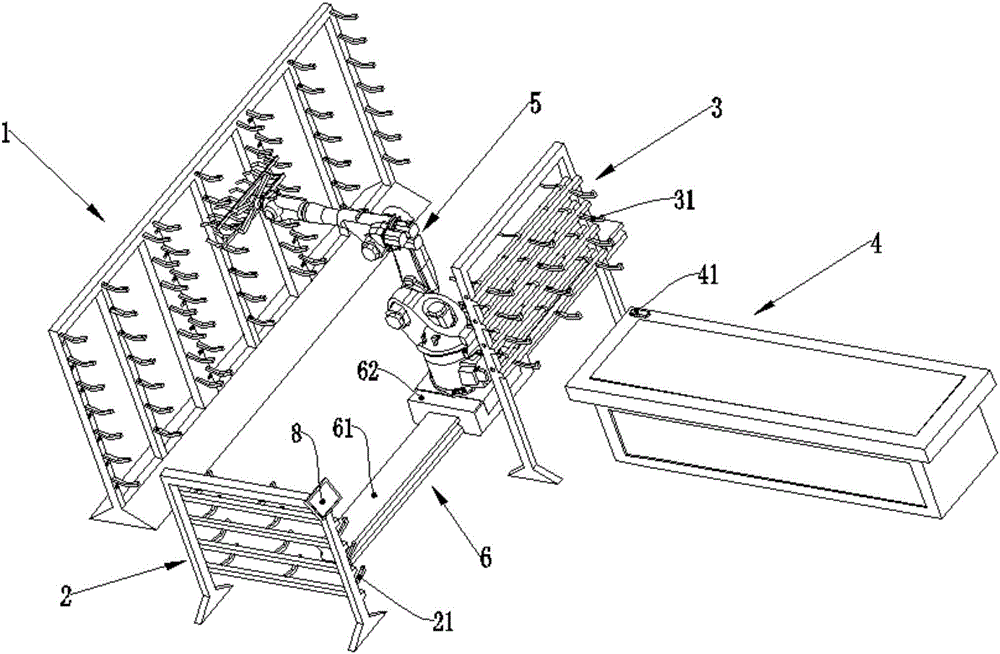

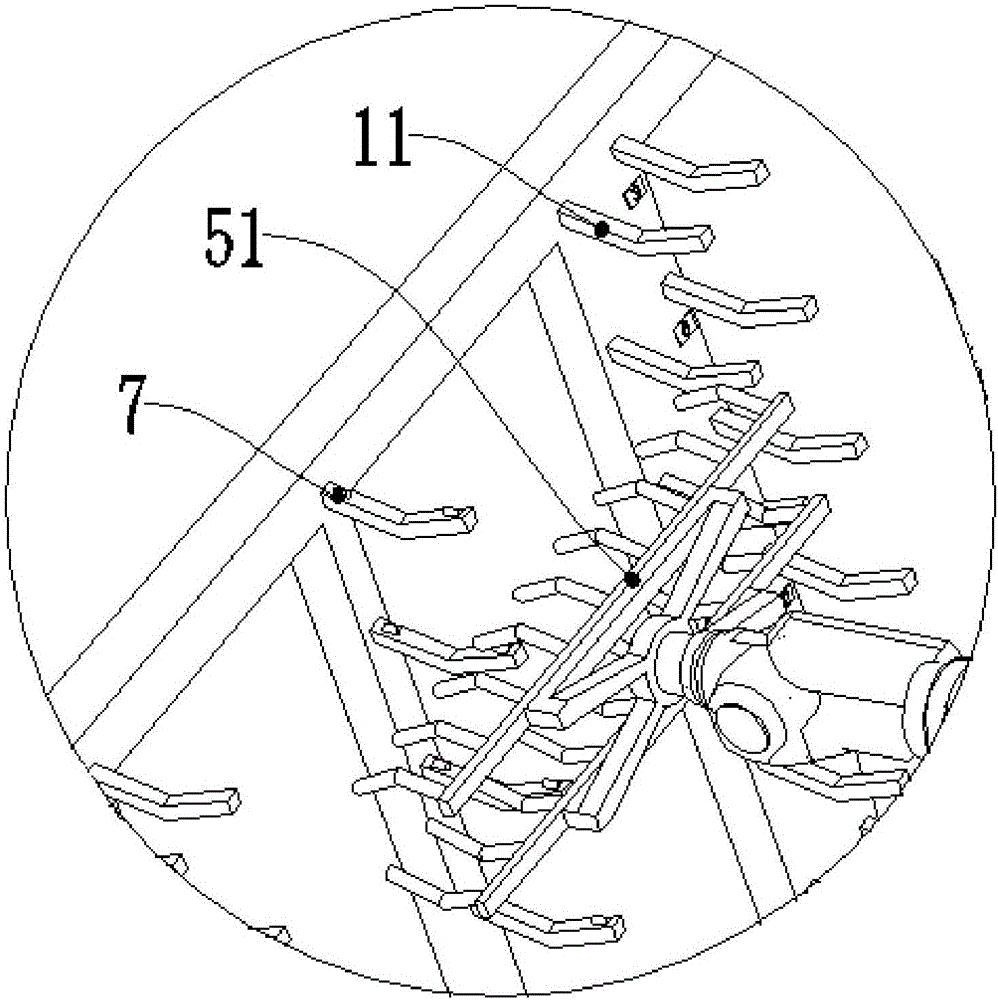

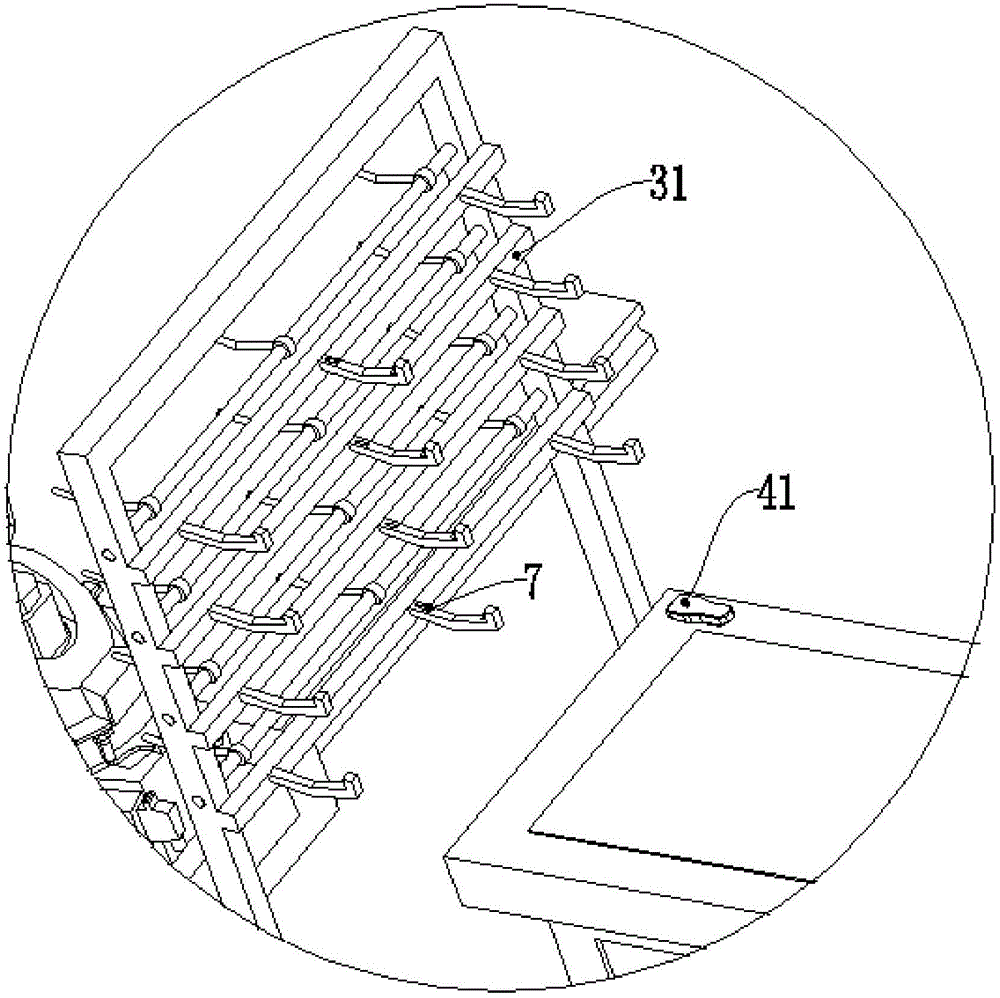

Automatic encasement system for Lilezuan milk bag gift boxes

ActiveCN104828288ASolve the problem that it is difficult to vertically transport automatic packingPrecise movement controlIndividual articlesEngineeringWorkload

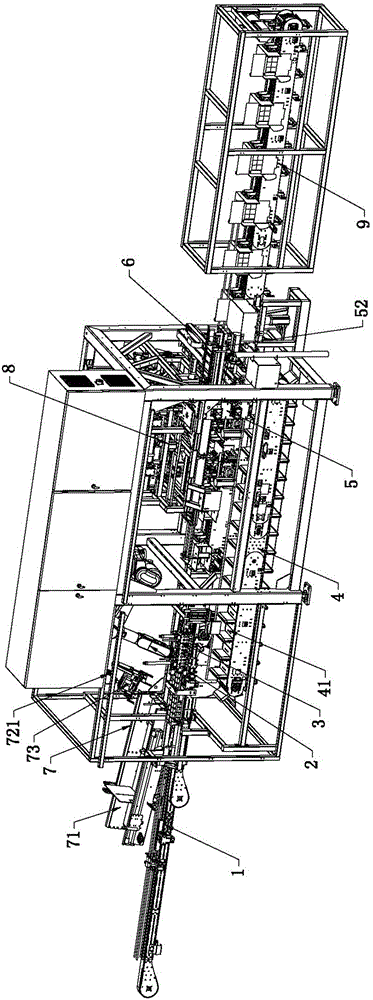

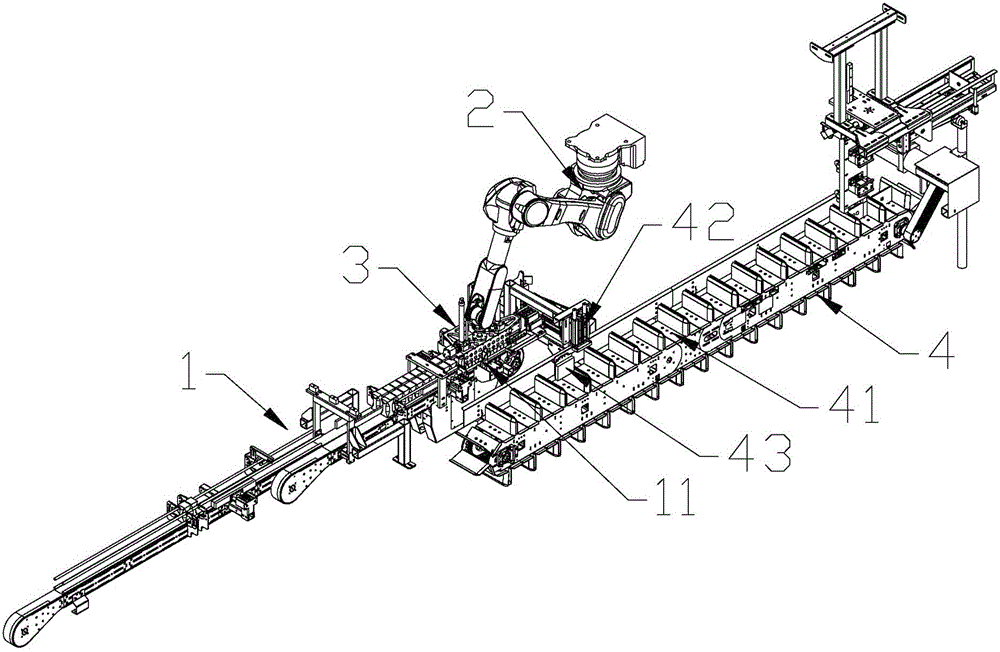

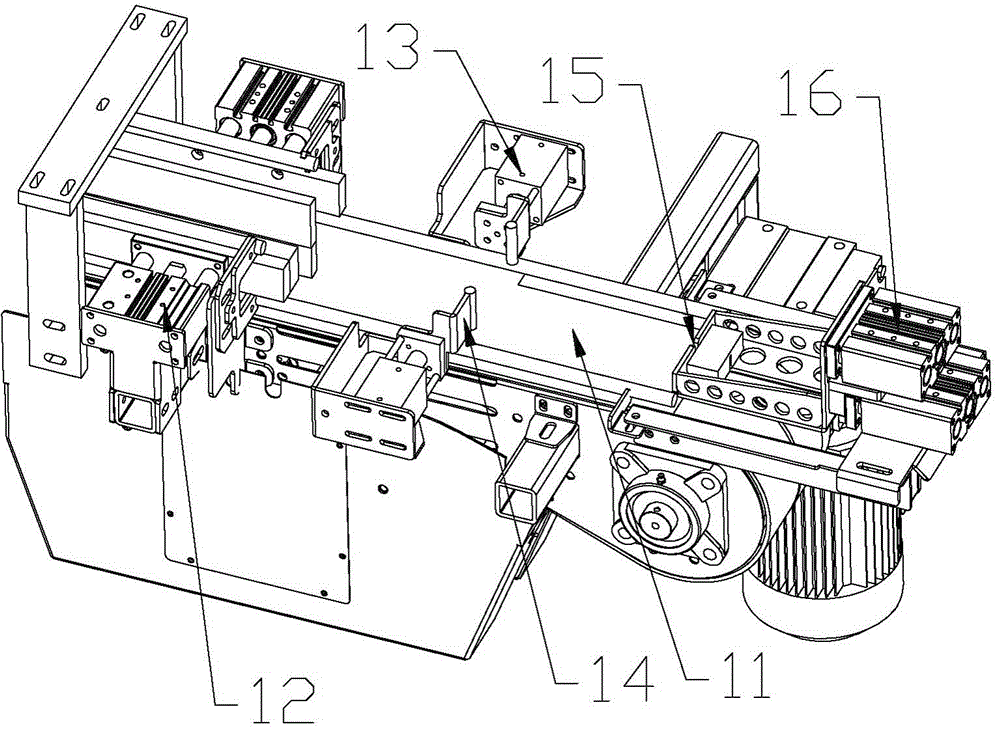

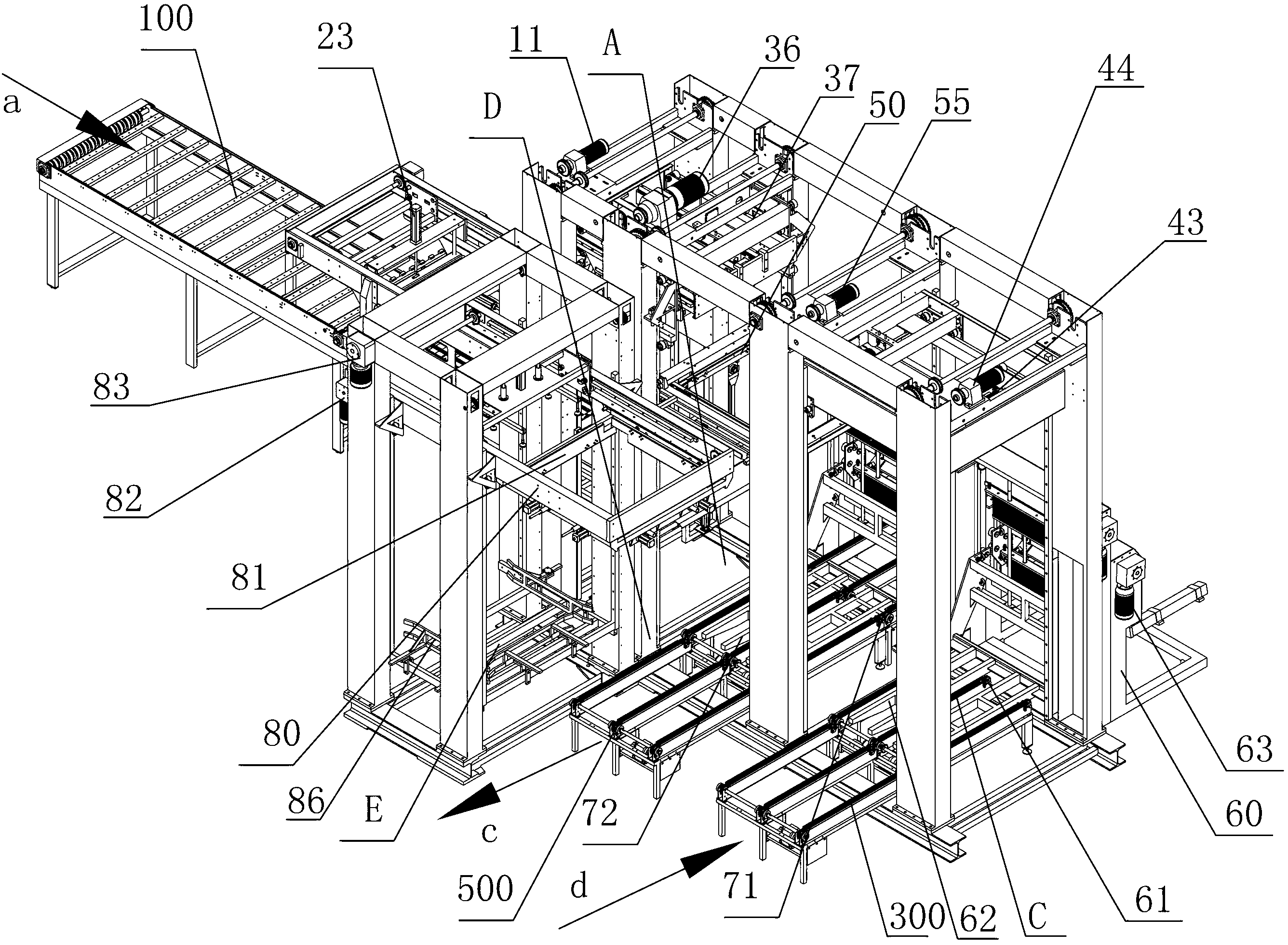

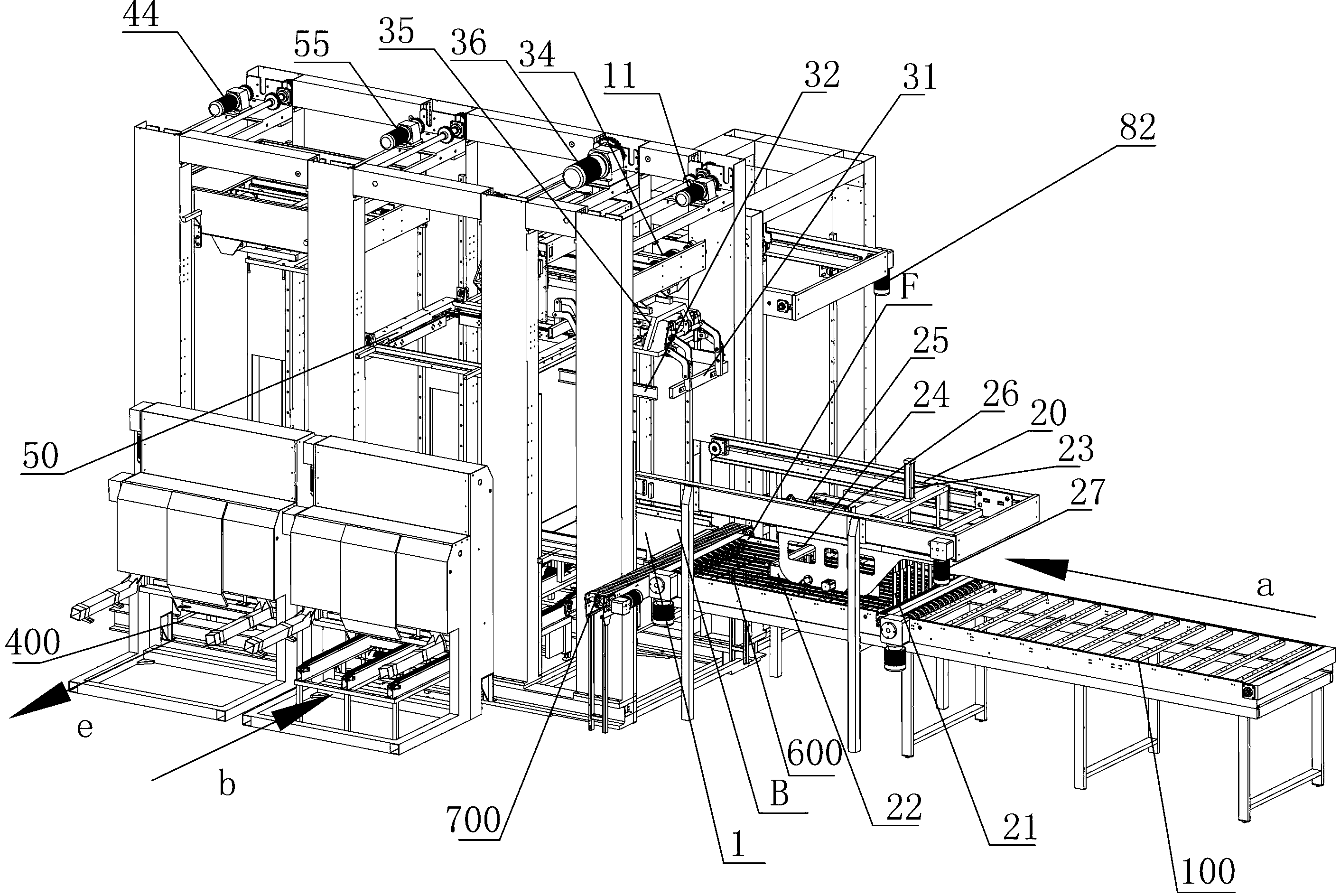

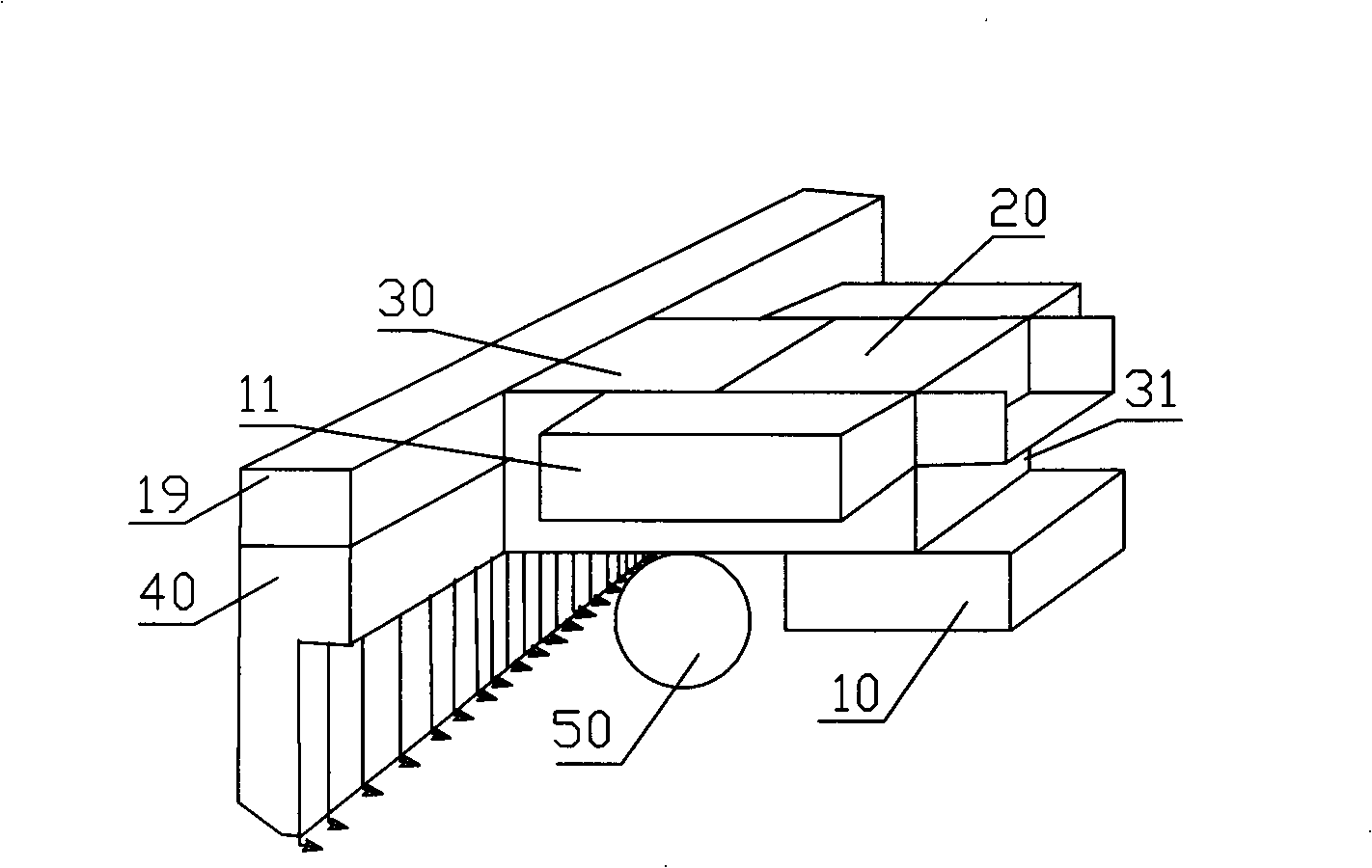

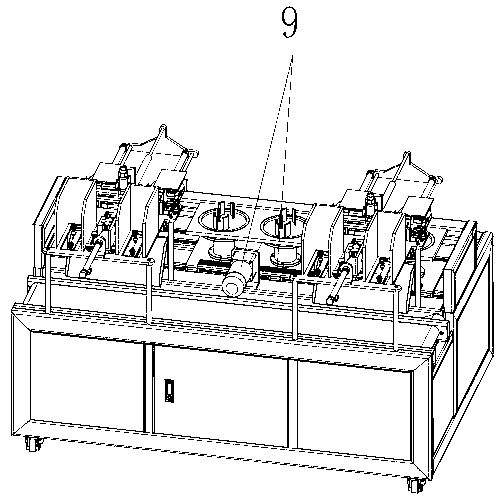

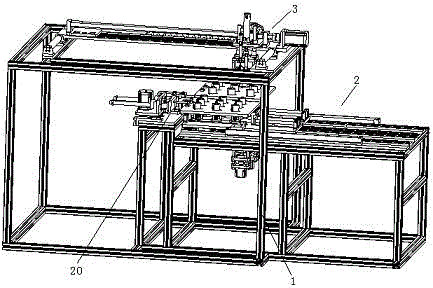

The invention discloses an automatic encasement system for Lilezuan milk bag gift boxes. The automatic encasement system comprises a milk bag integration conveying line (1), a milk bag robot (2) and a milk bag unit conveying line (4), wherein a milk bag clamp (3) at the lower end of a manipulator of the milk bag robot (2) catches a milk bag unit on the milk bag integration conveying line (1) and pushes the milk bag unit into a corresponding milk bag unit separation slot (41) under the condition that the milk bag unit is in a horizontal state; then a small baffle plate insertion machine (5) inserts a small baffle plate into a middle clearance of the milk bag unit, and a horizontal pushing mechanism (6) is used for horizontally pushing the milk bag unit with the inserted small baffle plate into a packaging case already provided with a large lining plate on a packaging case conveying line (9); finally the packaging case already provided with the large lining plate, the small baffle plate and the milk bag unit is covered and encased to finish the whole automatic encasement process. According to the automatic encasement system for the Lilezuan milk bag gift boxes, the milk bag encasement operation is creatively changed from vertical encasement into horizontal encasement, so that the production operation is more stable, the maintenance is easy and convenient, and the workload can be reduced to the maximum extent.

Owner:苏州澳昆智能机器人技术有限公司

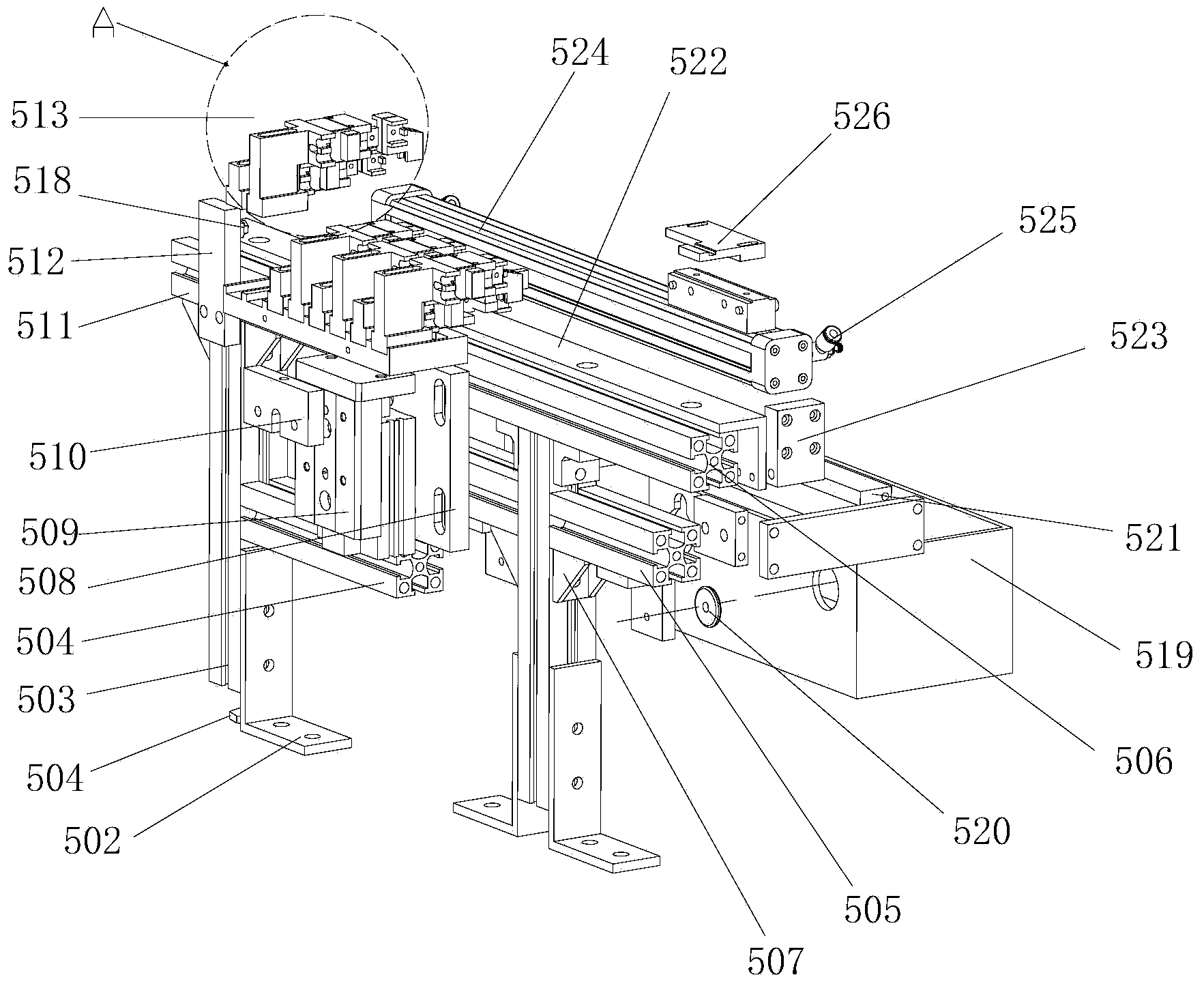

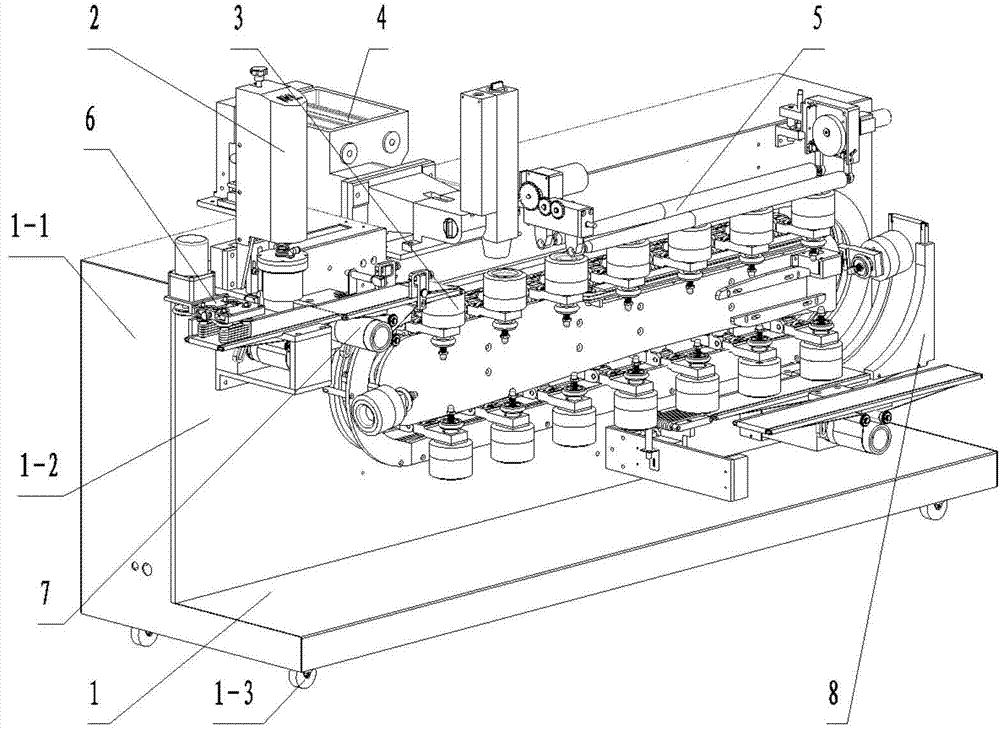

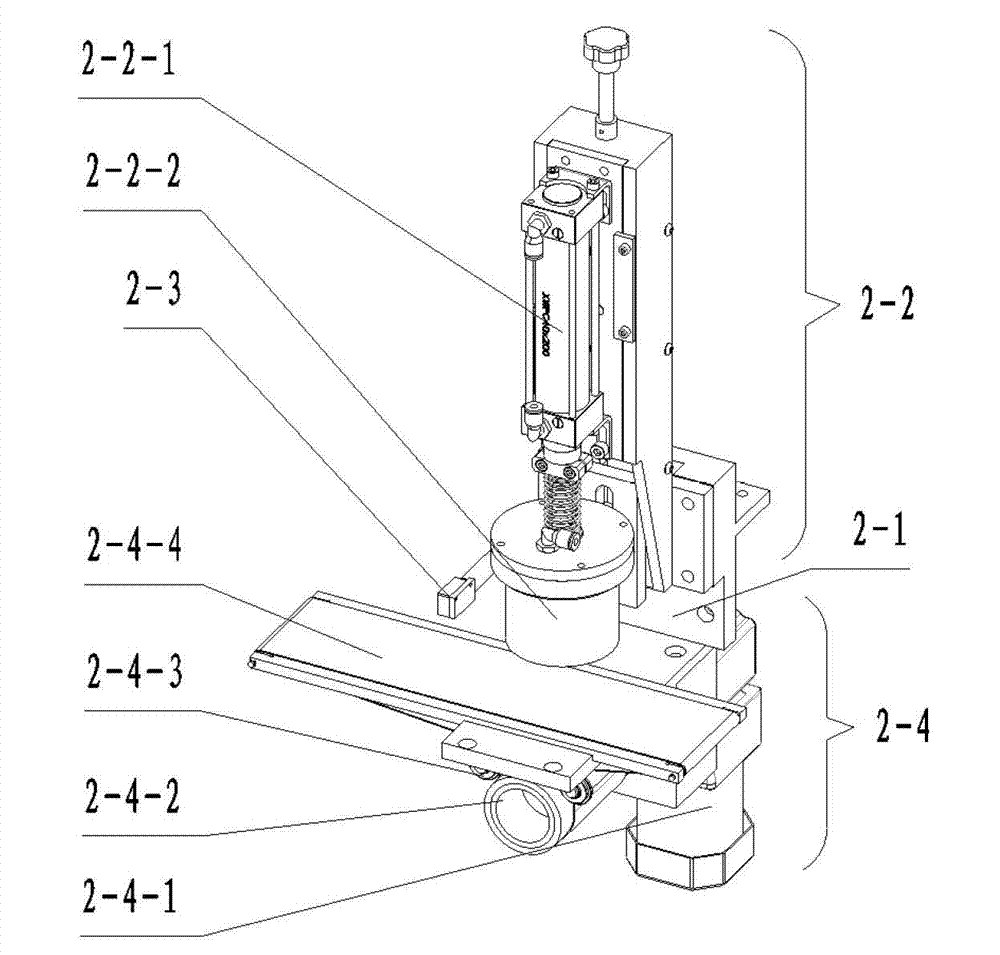

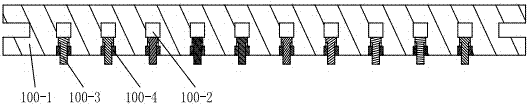

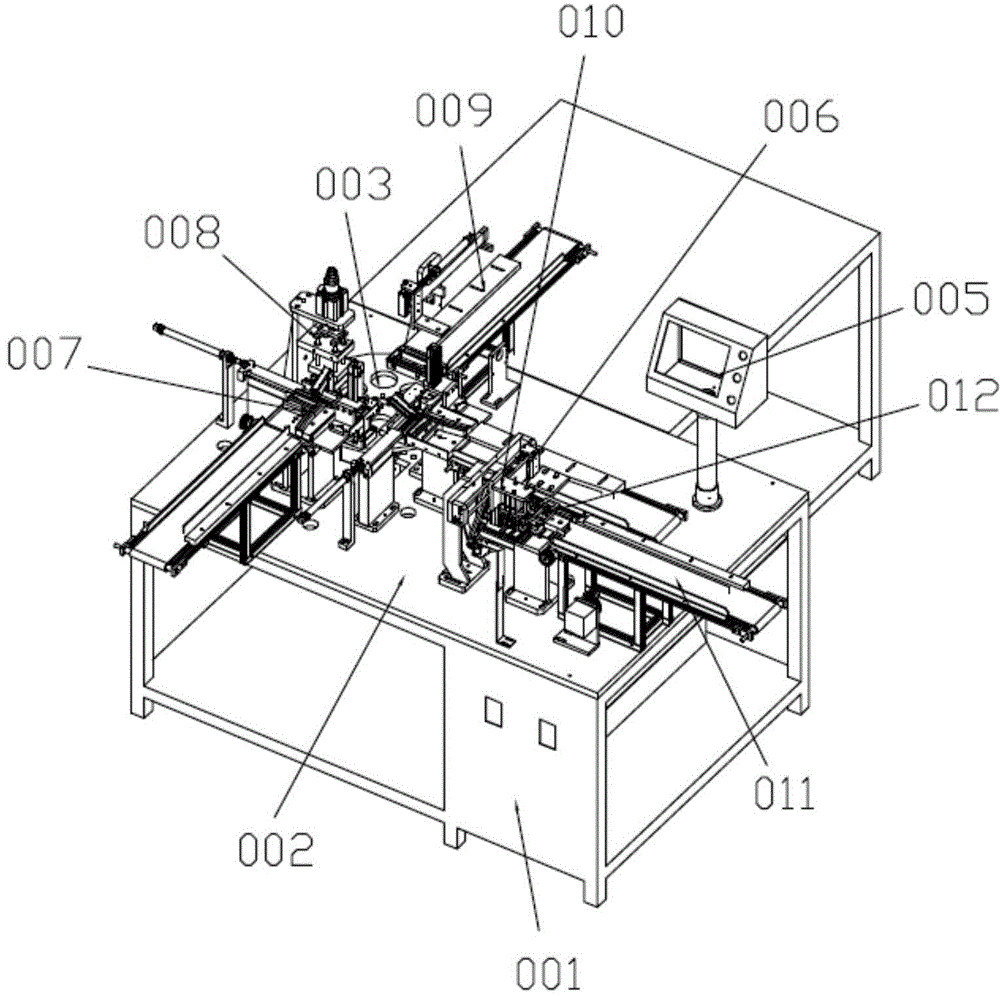

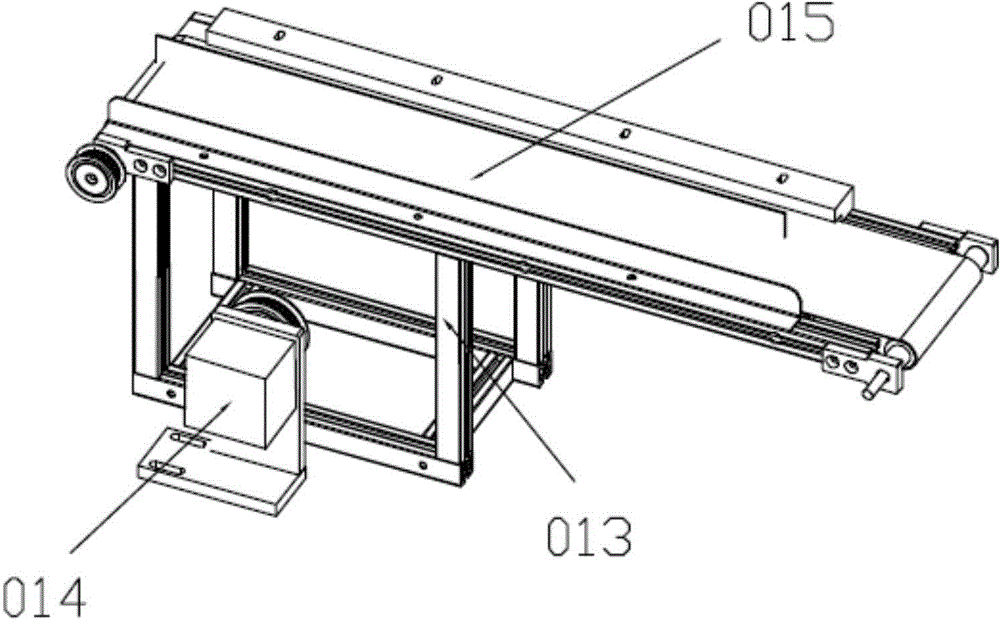

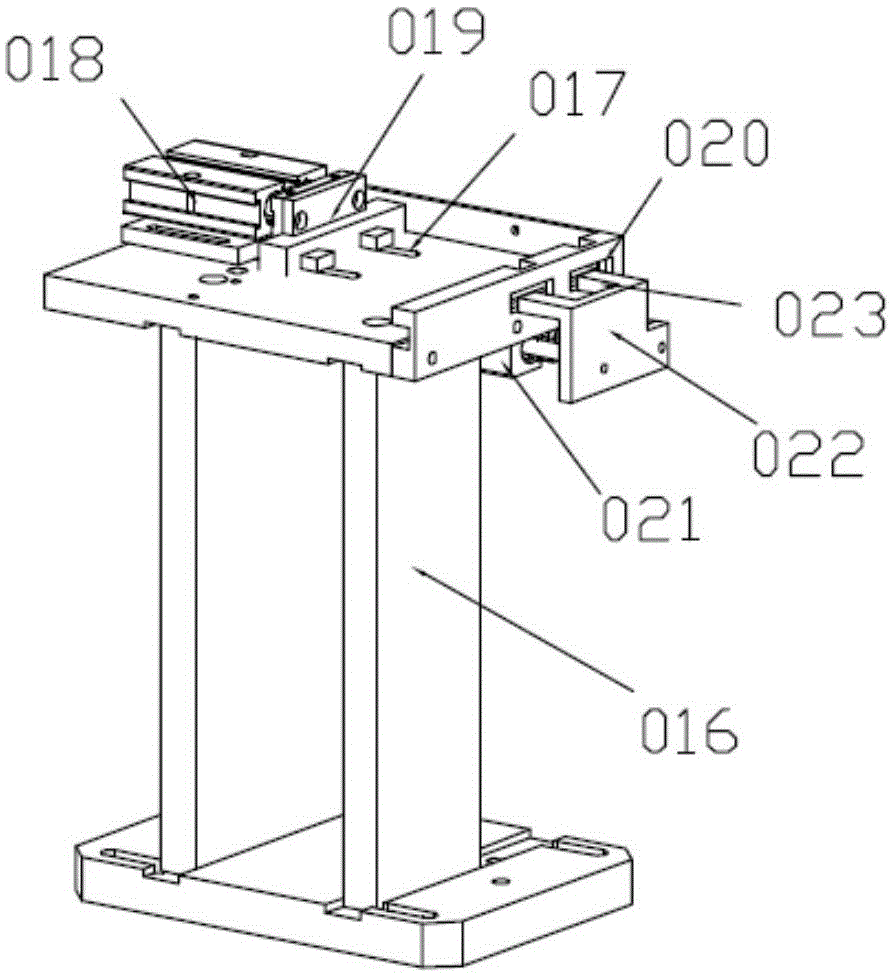

Automatic tin soldering machine

ActiveCN103447649AGuaranteed straightnessRealize mechanical automationMetal working apparatusSolder feeding devicesEngineeringRosin

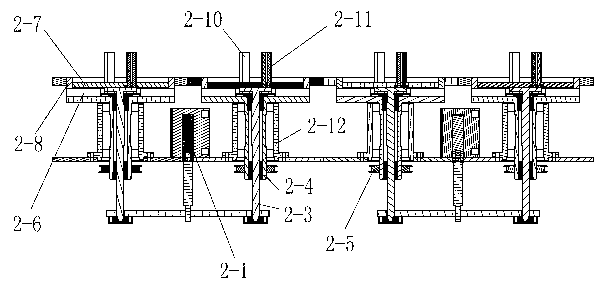

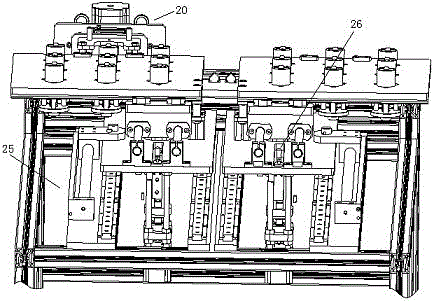

The invention discloses an automatic tin soldering machine. The automatic tin soldering machine comprises a machine base, a soldering tin wire passing mechanism, a control box, an automatic feeding mechanism, a soldering tin assembly mechanism, a soldering tin testing mechanism, a rosin infiltration mechanism, a tin soldering mechanism and a sliding table mechanism, wherein the automatic feeding mechanism, the soldering tin assembly mechanism, the soldering tin testing mechanism, the rosin infiltration mechanism, the tin soldering mechanism and the sliding table mechanism are connected with the control box; the automatic feeding mechanism is connected with the soldering tin assembly mechanism, and the soldering tin wire passing mechanism is connected with the sliding table mechanism; the control box is arranged on the front end face of the machine base; the automatic feeding mechanism, the soldering tin assembly mechanism, the soldering tin testing mechanism, the soldering tin wire passing mechanism and the tin soldering mechanism are sequentially arranged at the top of the machine base from left to right; the sliding table mechanism is arranged at the side edge of the soldering tin wire passing mechanism, a wire material is sequentially conveyed to the soldering tin testing mechanism, the rosin infiltration mechanism and the tin soldering mechanism by the sliding table mechanism after the wire material is conveyed to the soldering tin assembly mechanism by the automatic feeding mechanism, so as to be subjected to an automatic tin soldering process, and automatic discharging is realized. According to the automatic tin soldering machine, mechanical automation for charging, processing and the final discharging can be realized, the production efficiency is increased greatly, and the product quality can be guaranteed.

Owner:东莞市威元电子科技有限公司

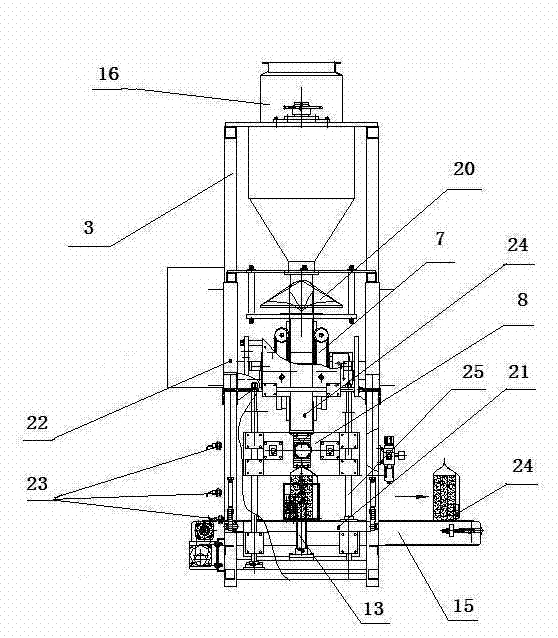

Follow-up stuffing adding twin-cone roller necking-in machine

InactiveCN102894026AOvercome technical difficulties that cannot be fully automatedChange the traditional hand-made processDough-sheeters/rolling-machines/rolling-pinsDough processingPulp and paper industryFully automatic

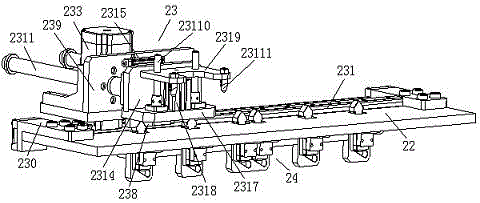

The invention discloses a follow-up stuffing adding twin-cone roller necking-in machine. The equipment comprises a necking-in machine body on which a crisp cake blank stamping device, a rotary mould circulation turning device, a material injection device and a twin-cone roller necking-in device are sequentially arranged, wherein the rotary mould circulation turning device is arranged below the material injection device and the twin-cone roller necking-in device. The follow-up stuffing adding twin-cone roller necking-in machine is special equipment for simultaneously finishing multiple stages before a crisp cake blank is formed and has the effects of solving the technical problem of incapability of fully-automatic production of the traditional crisp moon cake making process, firstly realizing the mechanical automation of the whole production process, reaching the yield of 40-60 / min, greatly increasing the production efficiency, completely changing the traditional manual making process for crisp refreshments and particularly for multilayer stuffed crisp moon cakes, greatly strengthening the standardization and the normalization for the production of the crisp refreshments and obtaining the optimal cost performance. The invention creates a brand new technical field for mechanically and automatically producing crisp foods.

Owner:上海伟隆机械设备股份有限公司

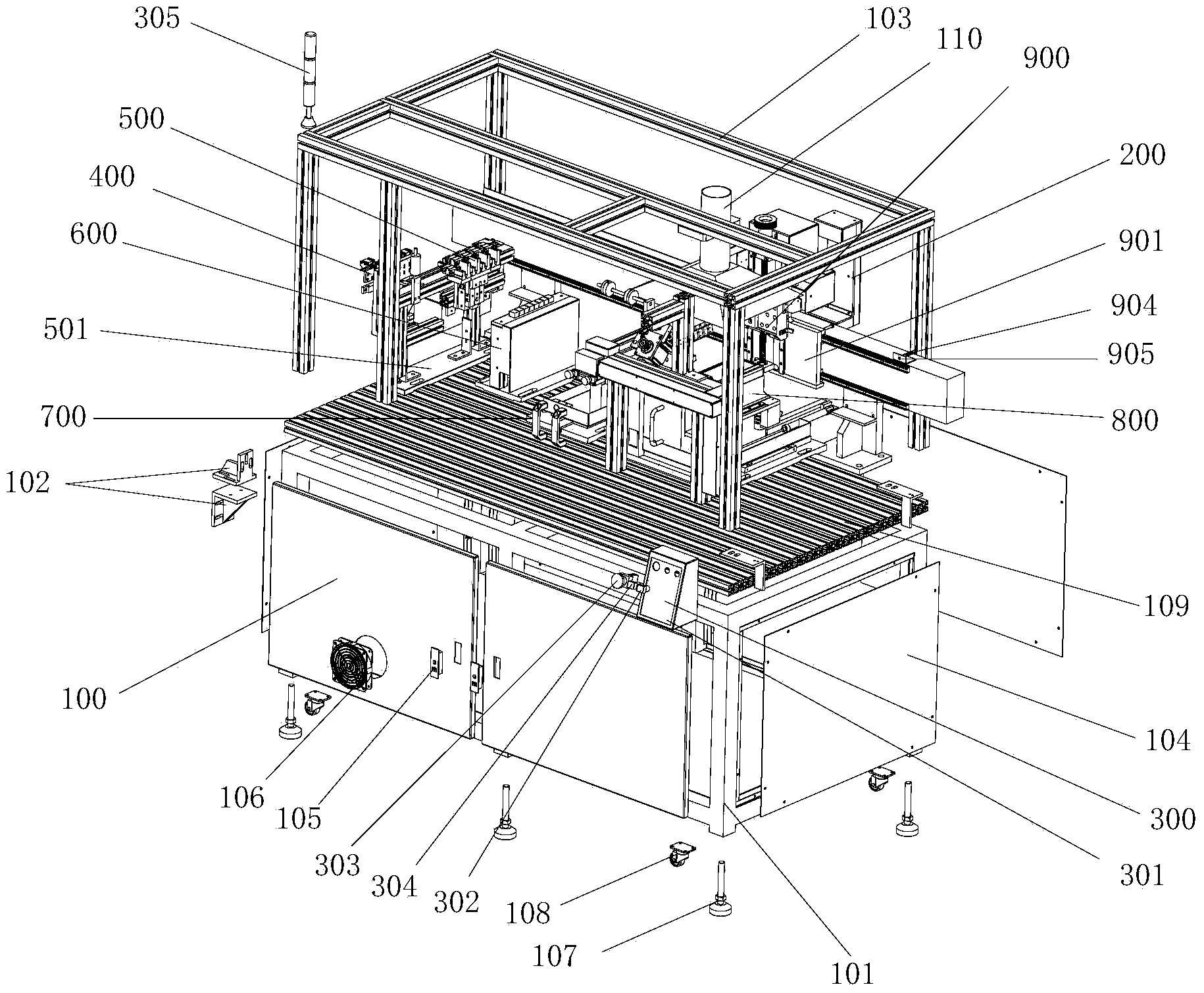

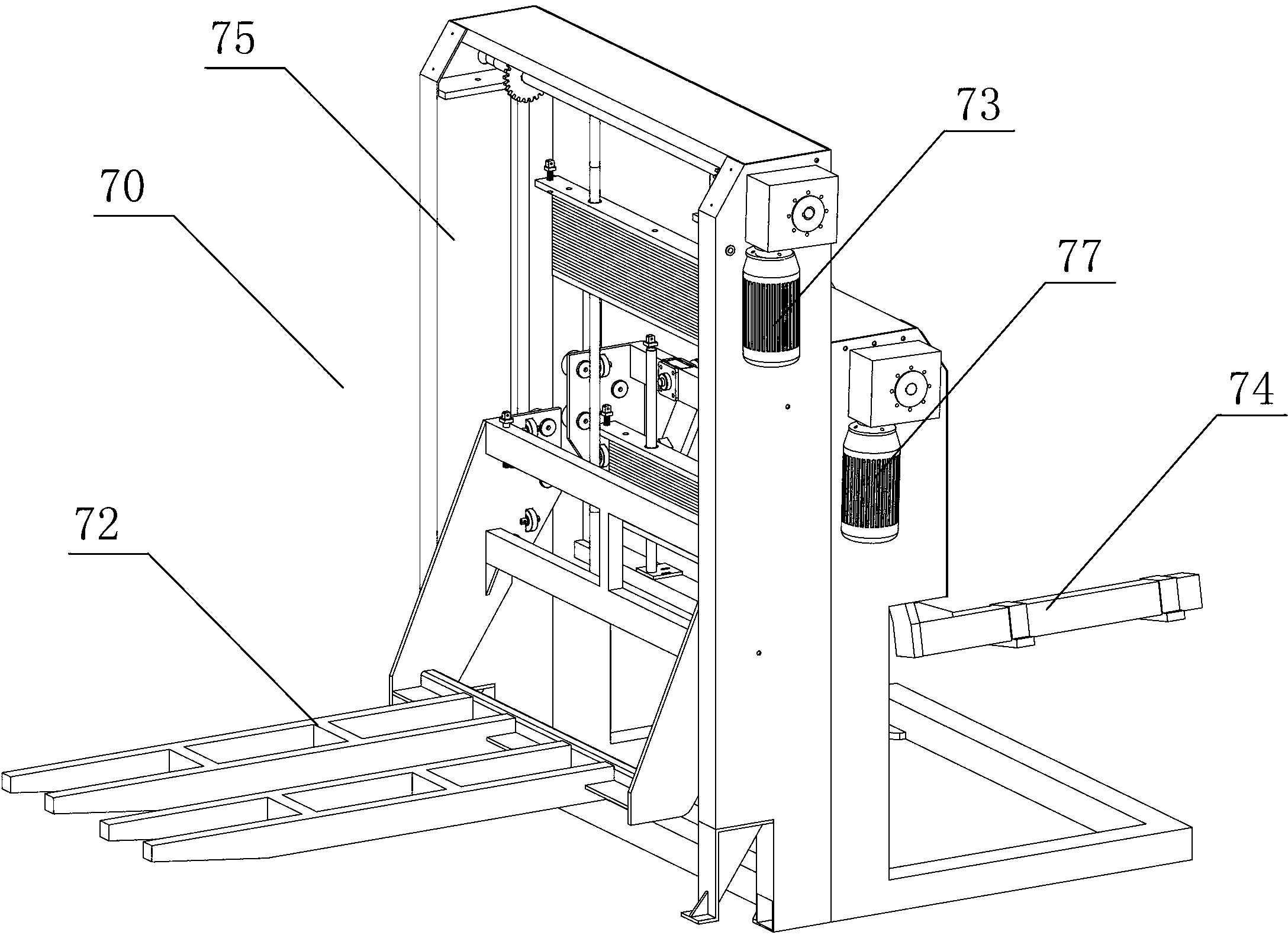

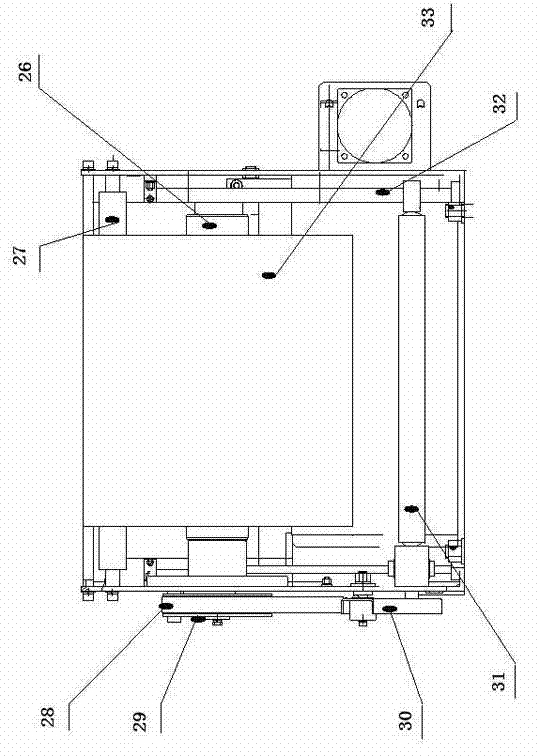

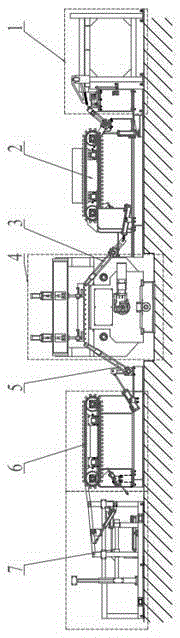

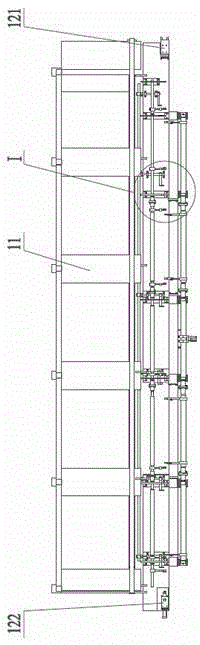

Bottle stacking machine capable of feeding and discharging bottles from low position

ActiveCN102795482ARealize automatic inputLow site requirementsStacking articlesDe-stacking articlesStack machineEngineering

The invention provides a bottle stacking machine capable of feeding and discharging bottles from a low position, which comprises a low-position bottle conveying line, a low-position pallet conveying line, a low-position bottle stack conveying line and a low-position spacer plate conveying line. The bottle stacking machine can feed and discharge bottles from a low position so as to reduce the floor space and the requirements on workshop space, and simultaneously realizes high-speed bottle stacking on the bottle stacking machine. The automatic feeding of a pallet and spacer plates, the automatic discharging of pallet trays and automatic laying of a top plate can be realized on the basis of the bottle stacking machine, and the full mechanical automation during the bottle stacking process is realized. Furthermore, as the bottle stacking machine realizes the mechanical automation during spacer plate taking and laying and is provided with a clamping and positioning mechanism, the bottle stacking machine can adopt spacer plates with bottle positioning baffles, and the quality and the appearance of stacked bottles are greatly improved.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

Film-type automatic bagging machine

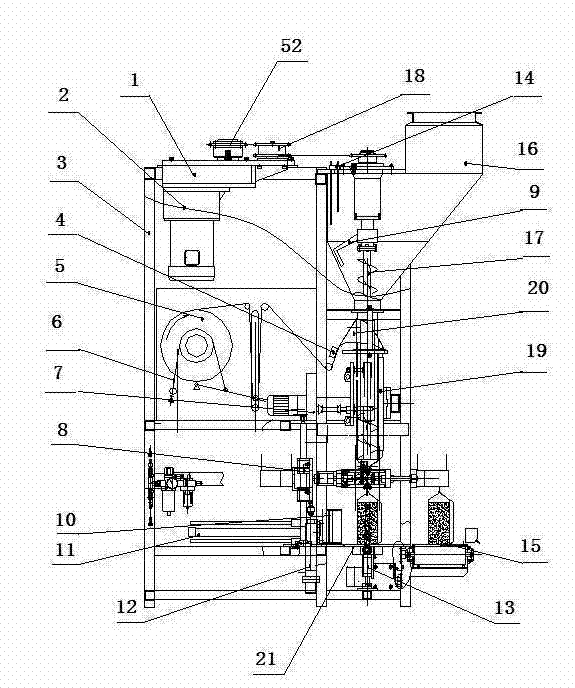

InactiveCN102893810AChange processHigh degree of automationHorticultureElectric machineryDrive motor

The invention provides a film-type automatic bagging machine. The bagging machine comprises a machine frame, the upper part of the machine frame is provided with a drive motor and a storage hopper, and the drive motor is connected with a feed-in screw rod by a positive and negative rotation transmission device; the feed-in screw rod supported by a bearing base is arranged in the storage hopper, and the lower end of the storage hopper is provided with a feeding pipe sleeved outside the feed-in screw rod; the middle part of the machine frame is provided with a film supply device arranged on the machine frame, and the upper part of the feeding pipe is provided with a curved surface forming machine sleeved outside the feeding pipe; and a film-feeding device is arranged between the feeding pipe and the film supply device, the side part of the feeding pipe is provided with a longitudinal edge-sealing device, the lower part of the feeding pipe is provided with a transverse sealing and cutting device, and the side part of a pressure-bearing platform is provided with a bag conveying system. The device thoroughly changes the process flow of the conventional bagging machines, eliminates the operation of manual sealing and filling of breathable materials after manual bagging and packing are performed and frees operators, and one person can operate a plurality of machines, so that the automaticity and the production efficiency are greatly improved.

Owner:徐寿海 +1

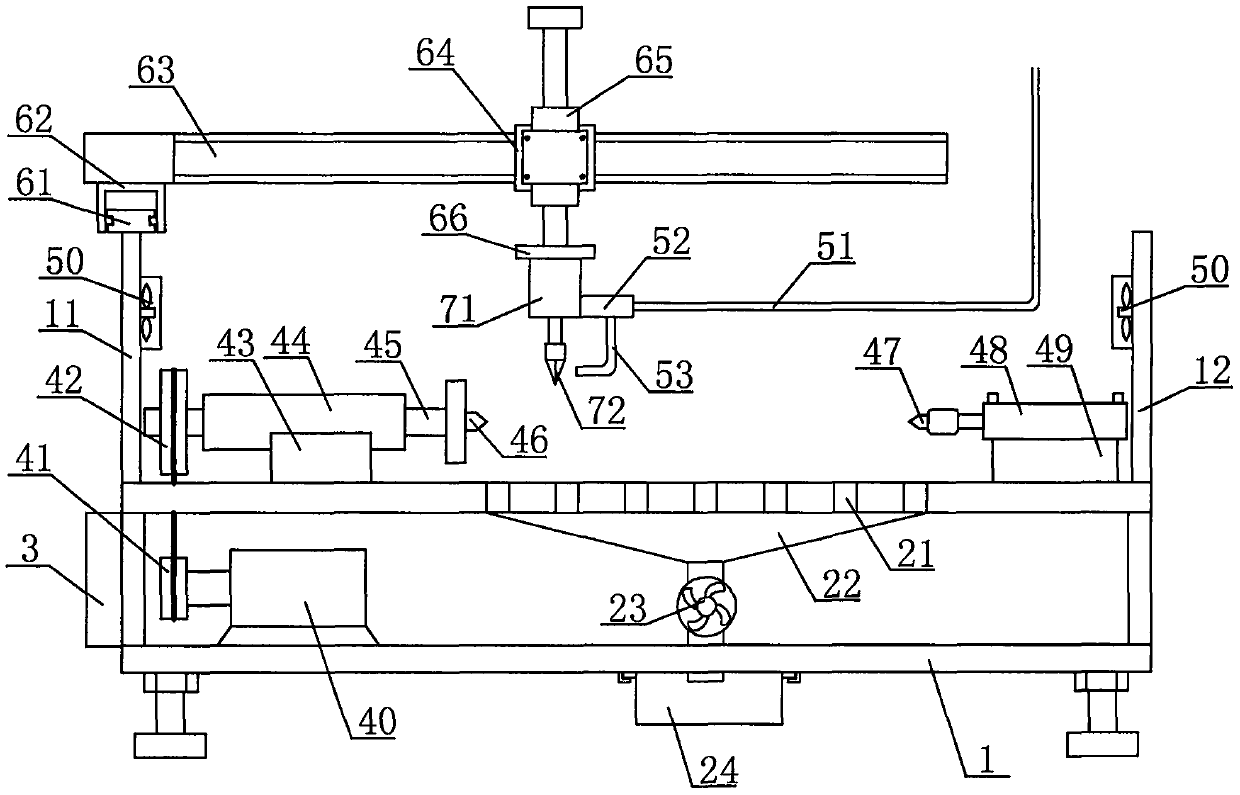

Numerical control laser carving machine

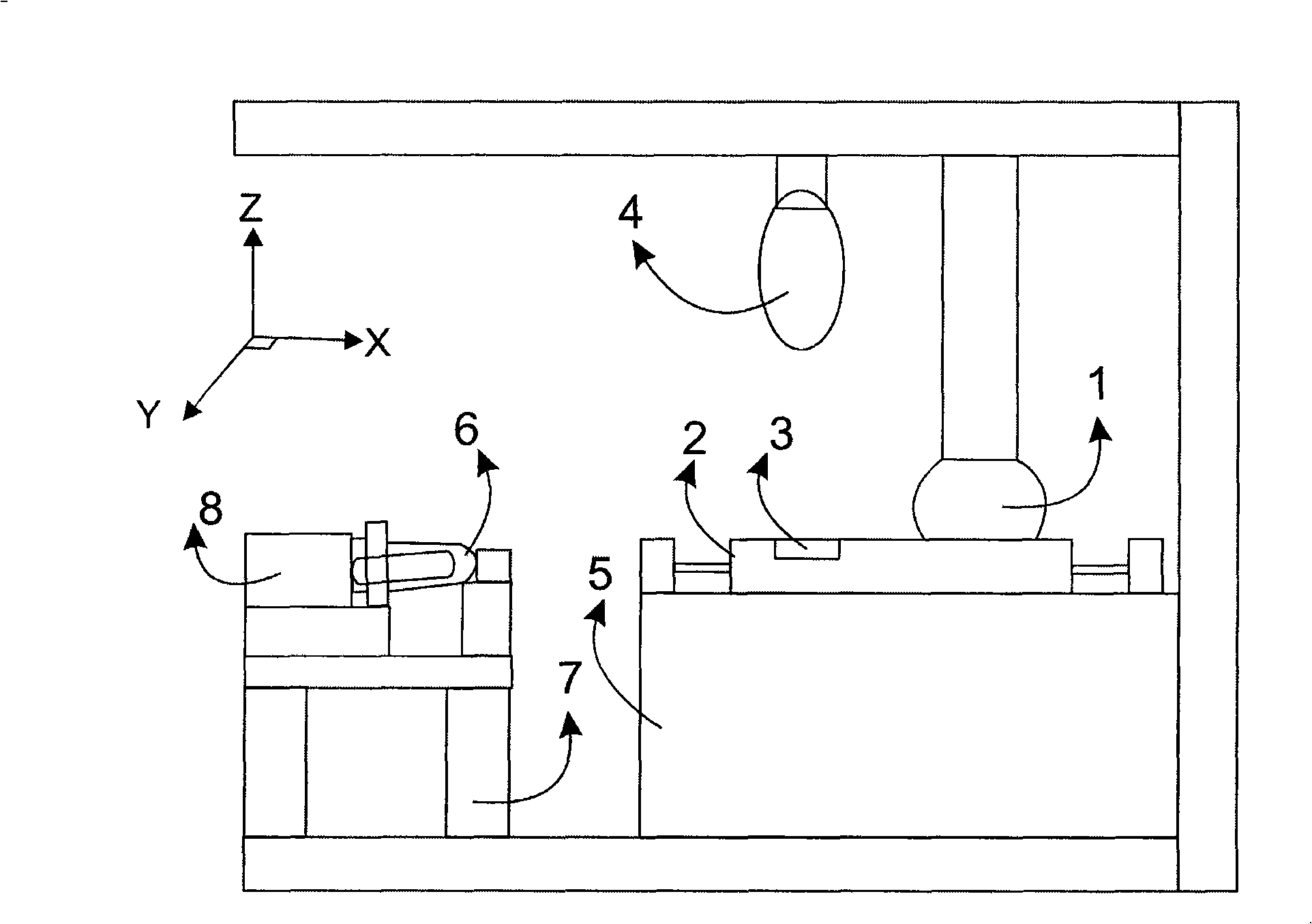

PendingCN107671430ARealize fully automatic engravingRealize mechanical automationLaser beam welding apparatusMaintainance and safety accessoriesNumerical controlStone carving

The invention relates to the field of laser carving machinery, in particular to a numerical control laser carving machine. The numerical control laser carving machine comprises a support table assembly for supporting workpieces, a carving machine head for carving the workpieces according to set programs, a displacement control mechanism for driving the carving machine head to move, a water coolingdevice for cooling a carving cutter, a dust removing device for cleaning dust generated by carving, and a numerical control device. The numerical control laser carving machine can realize full-automatic carving of the workpieces by the carving machine head according to the set programs, needs no person to be on duty in the carving process, can reduce the labor intensity of workers, realizes mechanical automation in the carving operation, greatly improves the working efficiency in stone carving, and can guarantee the workpiece carving product quality through precise program settings. Meanwhile, the numerical control laser carving machine is provided with the dust removing device for cleaning the dust generated by carving, and is provided with the water cooling device for cooling the carving cutter, so that the equipment failure rate can be greatly reduced, and the equipment service life is prolonged.

Owner:聊城市沃尔润激光科技有限公司

Full-automatic accurate garlic transplanter and planting method

InactiveCN101347065ASimple priceRealize mechanical automationPotato plantersSeed depositing seeder partsTransplantingEngineering

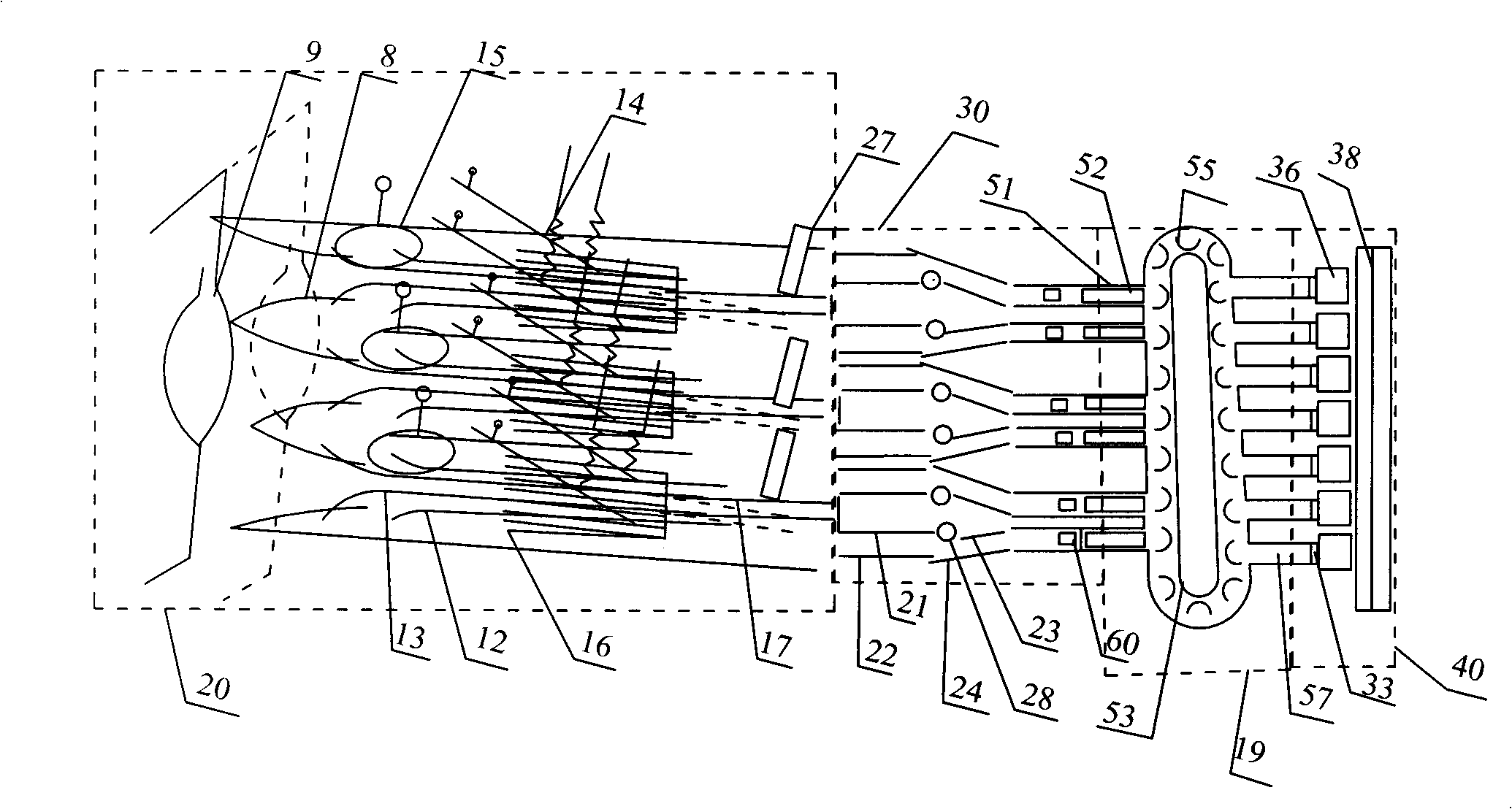

The invention relates to a fully automatic precision garlic transplanting machine and a garlic transplanting method. The fully automatic precision garlic transplanting machine comprises a frame, a running mechanism and a gear box, and further comprises a feed mechanism, a garlic clove peeling mechanism, a dispensing mechanism and a transplanting, hole tracking and detecting and replanting mechanism which are arranged on the frame and connected with each other sequentially; a garlic clove positioning peeling method comprises the following steps: the garlic is delivered to the feed mechanism for cutting off the garlic stem, removing fibrous roots of the garlic and dividing the garlic bulb into two parts, and then the garlic is sent to the garlic clove peeling mechanism for peeling off garlic cloves; the garlic clove peeling mechanism peels off the garlic cloves which are called garlic seeds and deliver the garlic cloves to the dispensing mechanism which distributes the garlic seeds to the transplanting, hole tracking and detecting and replanting mechanism to complete the transplanting, hole tracking and detecting and replanting of the garlic seeds. By adopting the fully automatic precision garlic transplanting machine and the garlic transplanting method, two agronomic requirements that the garlic clove tips face upwards and the garlic clove bellies face the same side can be met, and the transplanting precision is high.

Owner:朱永文

Full-automatic sucker rod forging production line

ActiveCN105397005AReduce manual operationsSave human effortForging/hammering/pressing machinesForging press drivesAutomatic controlEngineering

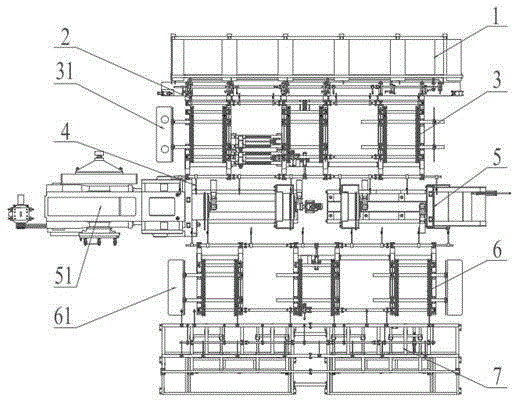

The invention relates to the technical field of machining equipment and automation, in particular to a full-automatic sucker rod forging production line. The full-automatic sucker rod forging production line comprises a mechanical transmission heating system, a pneumatic system, a lubricating system and a control component, wherein the control component controls the pneumatic system to provide power for the mechanical transmission heating system, and controls the lubricating system to lubricate the mechanical transmission heating system; and the whole production line is fully automatically controlled through the control component. During production, field workers only need to place bars on a beginning part of the production line, and transfer finished sucker rods at the tail end of the production line, the bars are not required to be carried manually in a production process, full-automatic operation of the production process is realized, labor and materials are saved, full-automatic production of the sucker rod forging production line is realized, the technical problem that an existing sucker rod forging production line is relatively low in degree of automation and relatively high in labor and material consumption is solved, and the full-automatic sucker rod forging production line is provided.

Owner:DEYANG ZHONGLIAN MACHINERY MFG CO LTD

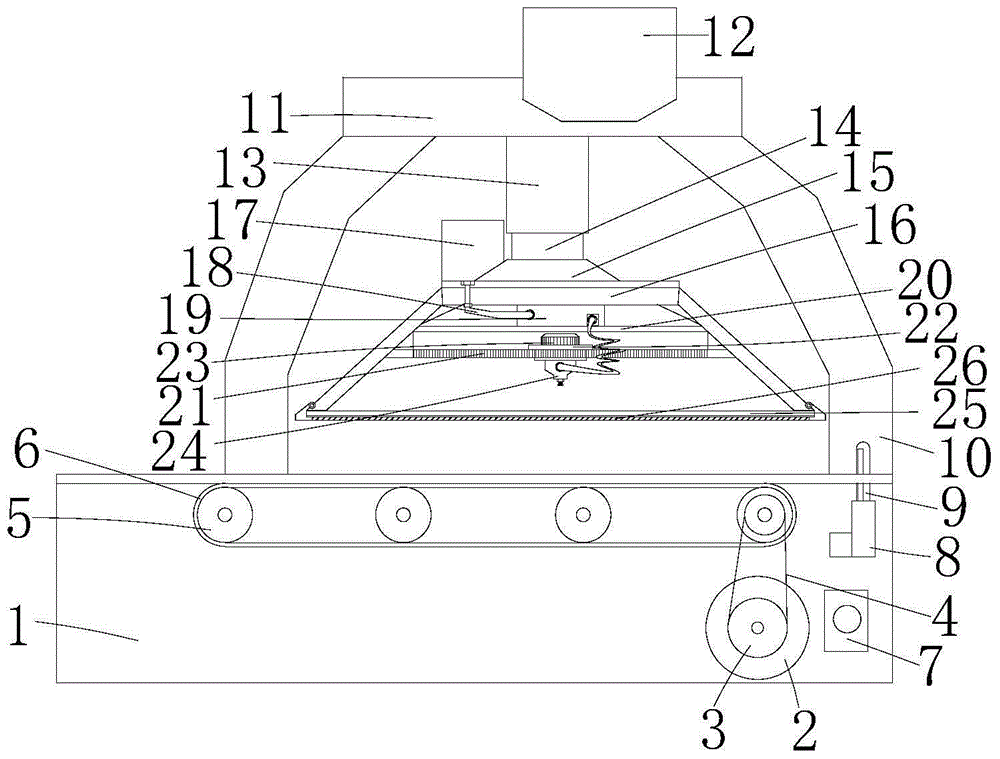

Automatic paint sprayer

ActiveCN104959252AImprove processing efficiencyIncrease handover timeLiquid spraying apparatusEngineeringPressure sensor

The invention discloses an automatic paint sprayer. The automatic paint sprayer comprises a working table, a paint spraying main supporting arm, a paint spraying bearing frame and a paint spraying head, wherein the paint spraying main supporting arm is installed on the top of the working table, the paint spraying bearing frame is installed on the bottom of a connecting block, and the paint spraying head is installed on the bottom of a movable bearing block. The automatic paint sprayer is a feeding, paint spraying and embossing integrated device. Meanwhile, manual paint spraying is effectively replaced, mechanical automation is achieved, and panel processing efficiency is improved greatly; mechanical paint spraying enables the workload of workers to be reduced and machining speed to be increased; a template bearing frame and a template are installed to effectively cover certain parts of a panel during paint spraying so as to achieve embossing; a pressure sensor installed in an inner cavity of a baffle can effectively control the whole device to conduct synchronous paint spraying, and time for replacing one panel with another can be shortened as much as possible.

Owner:TAICANG HONGEN ELECTRONIC TECH CO LTD

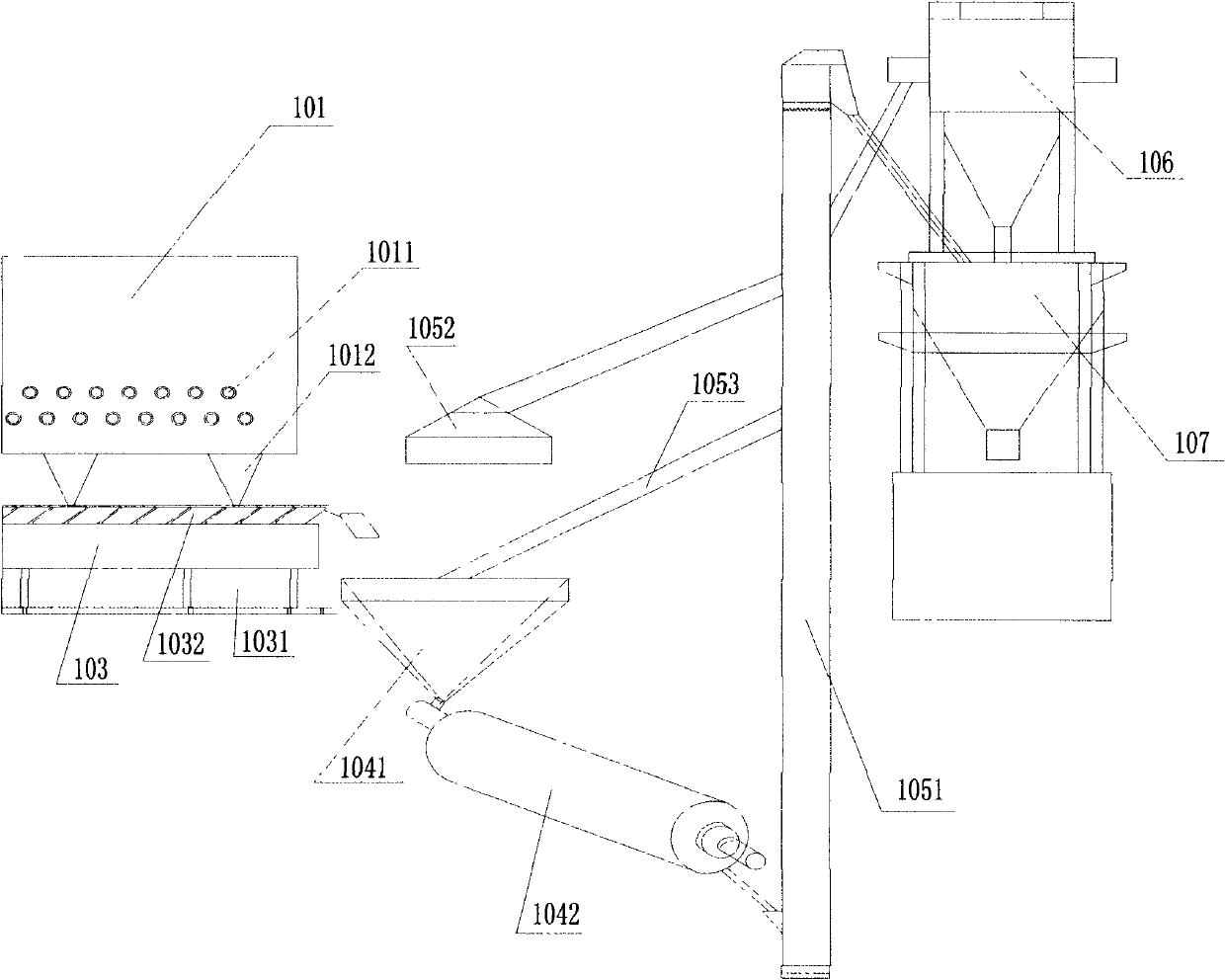

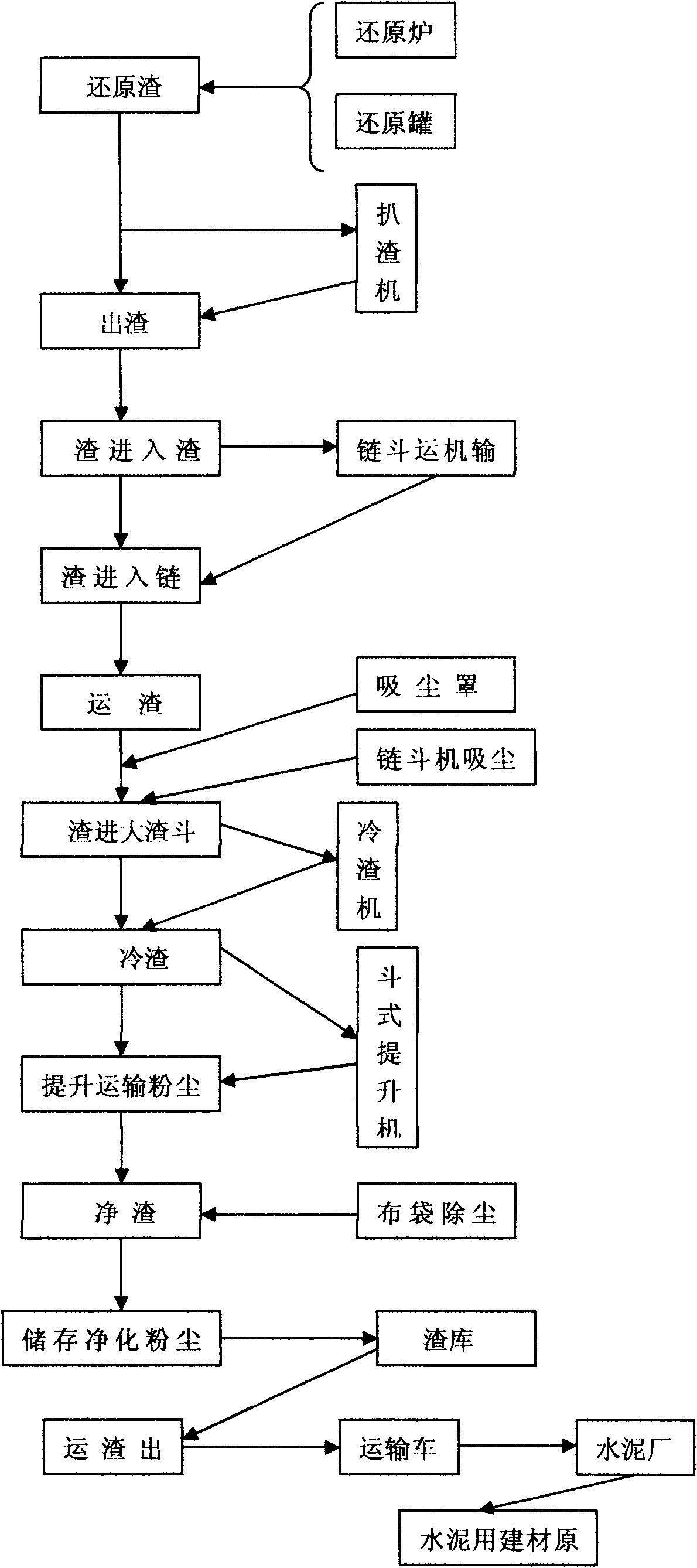

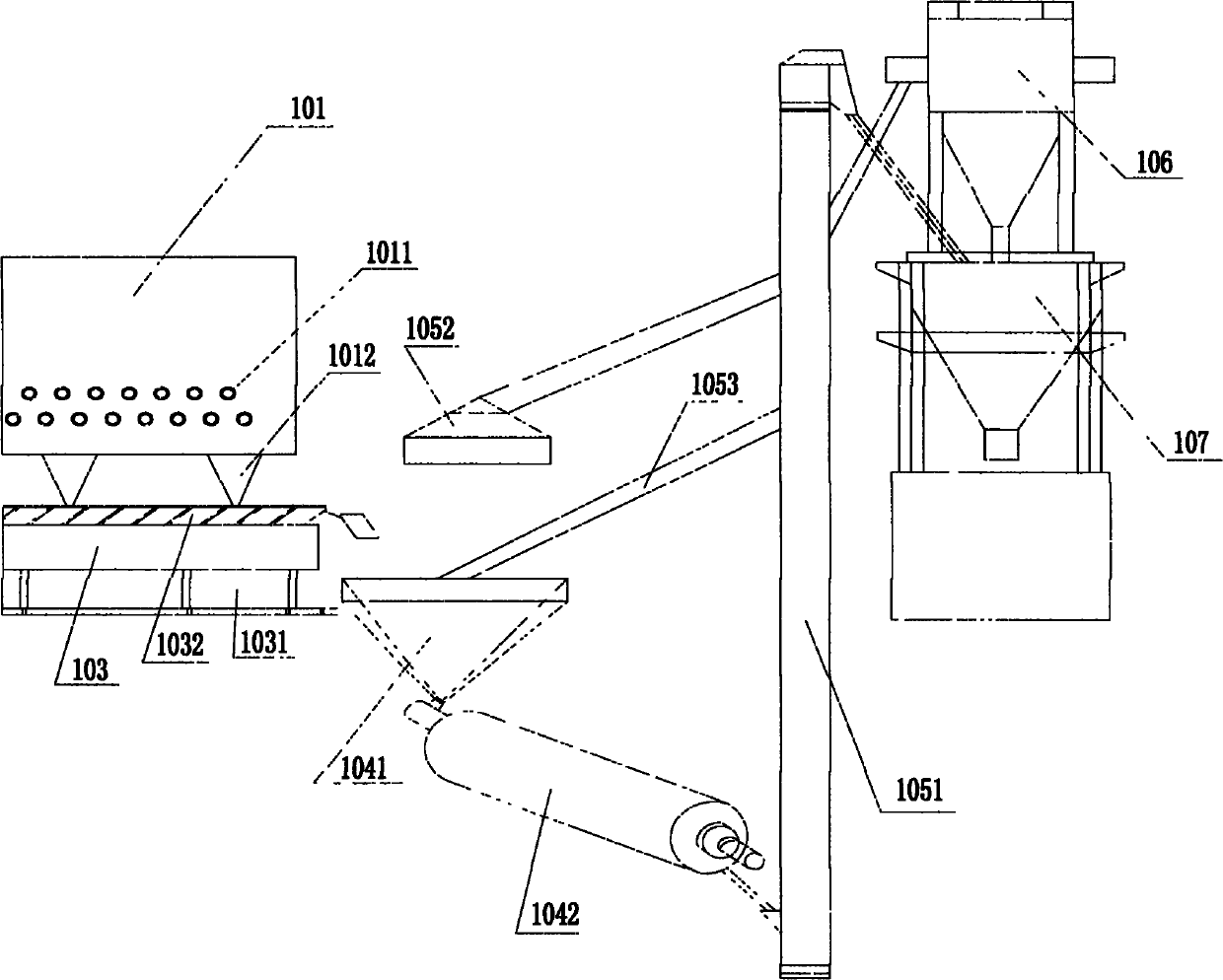

Magnesium smelting reduction deslagging and residual heat recycling device and process

InactiveCN102168186ANo pollution in the processRealize mechanical automationProcess efficiency improvementSlagBaghouse

The invention relates to a magnesium smelting reduction deslagging and residual heat recycling device and process, belonging to the field of metal magnesium smelting, in particular to a magnesium smelting reduction automatic deslagging and residual heat recycling device and technology. The device comprises a reducing furnace, a deslagging machine, a chain bucket conveyor, a slag cooling machine, a bucket elevator, a bag-type dust collector and a slag storeroom; mechanical automation is realized in whole deslagging, transportation, cooling, conveying and storage processes; the waste slag temperature is reduced from 1,000 DEG C or so to below 100 DEG C by the slag cooling machine; the residual heat of the waste slag is effectively recycled, and energy saving and emission reduction are realized; the waste slag does not fall on the ground in the deslagging process and is dry powdery slag after cooled and can be used as a building cement raw material, and the aim of changing waste materialinto things of value is achieved; and operation and storage are basically sealed in the whole process without environmental pollution.

Owner:宁夏惠冶镁业集团有限公司

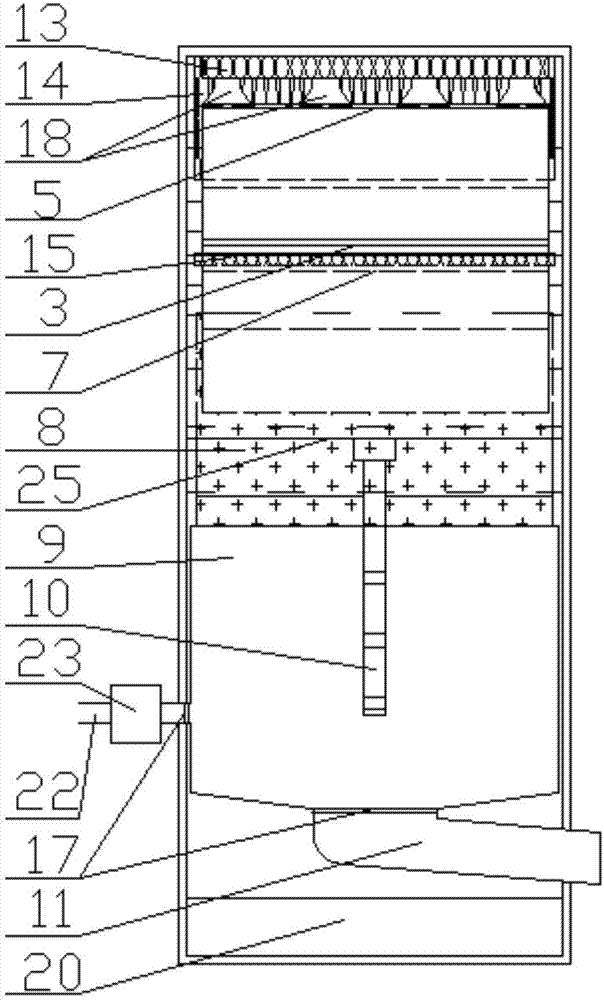

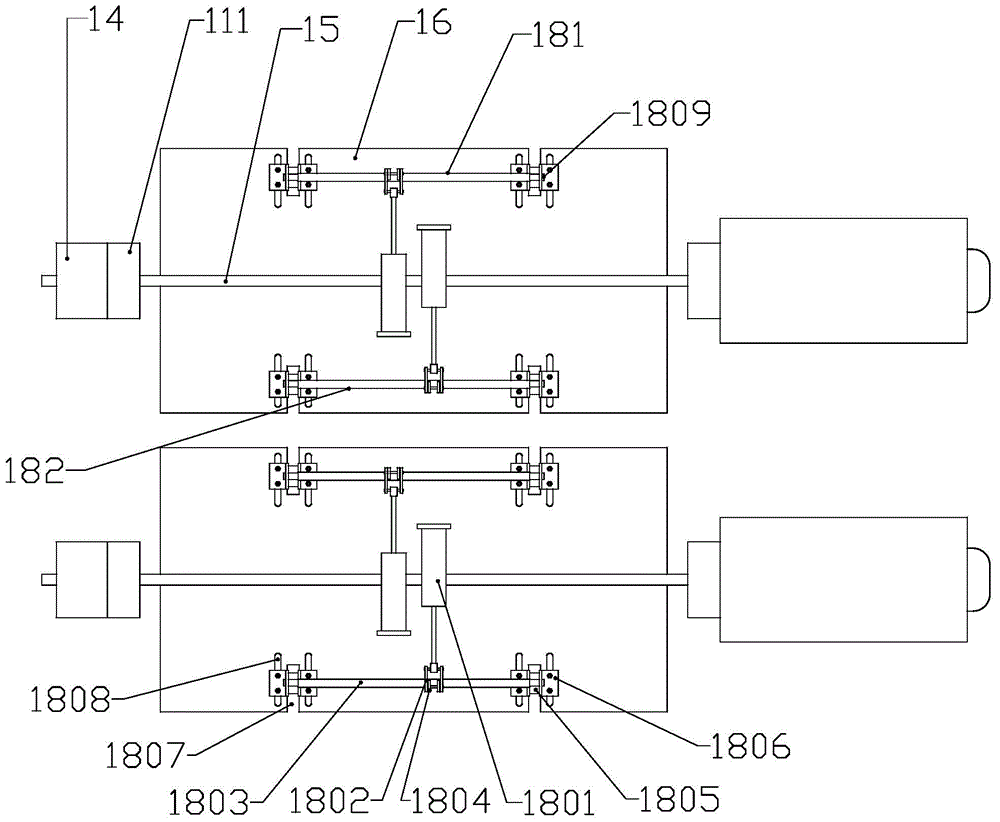

Device and method for packaging infusion tube coiled tube

InactiveCN103318439ARealize mechanical automationReduce labor intensityIndividual articlesEngineeringAutomation

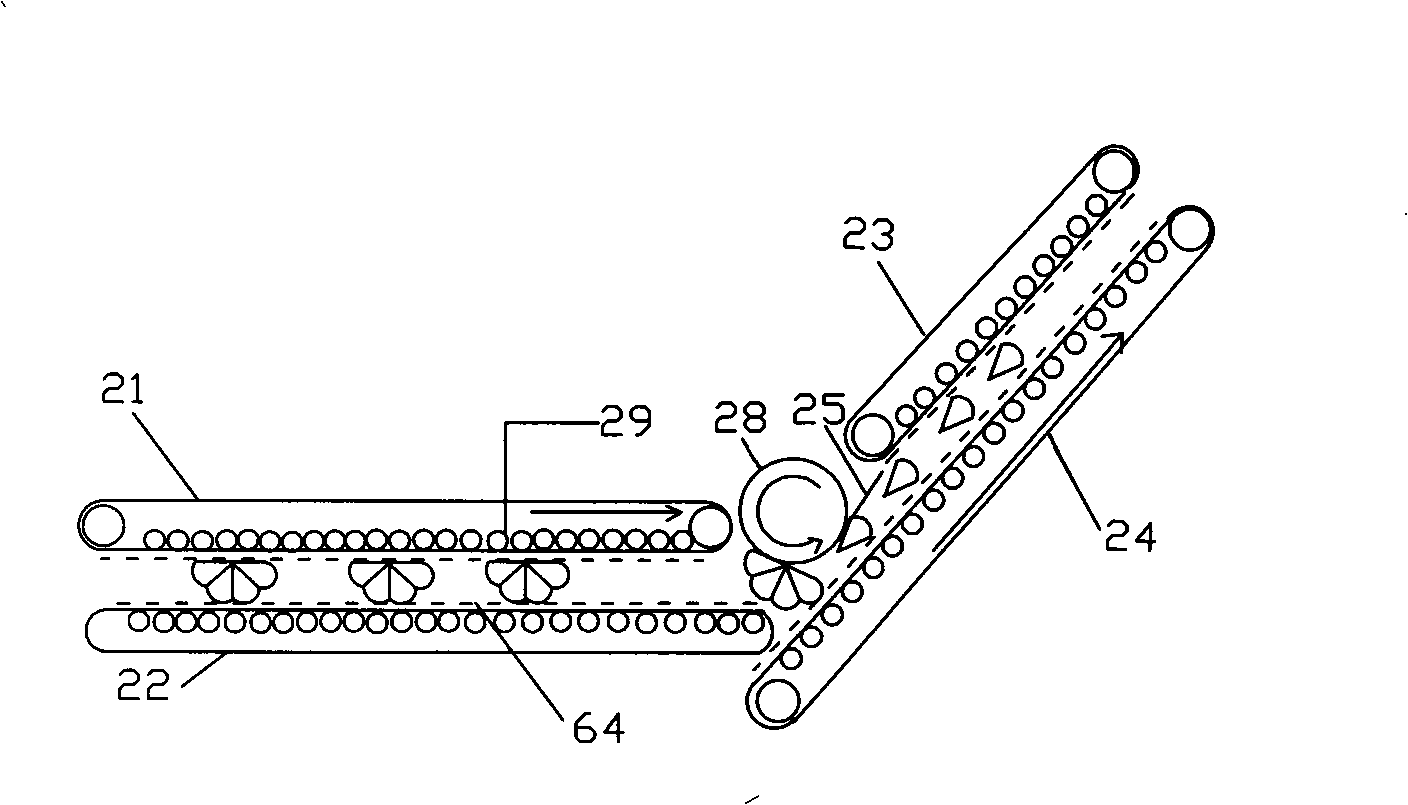

The invention discloses a device for packaging an infusion tube coiled tube. The device comprises a rack. A guiding rail is arranged on the rack. A coiled tube mechanism is movably arranged on the guiding rail. The coiled tube mechanism can move left and right along the guiding rail. A bagging mechanism is fixedly arranged above the guiding rail in an erected mode. When the coiled tube mechanism moves in place, the bagging mechanism is located above the coiled tube mechanism. A bag passing mechanism is arranged on one side of the bagging mechanism. An insertion connecting mechanism is arranged between the bagging mechanism and the coiled tube mechanism. The insertion connecting mechanism is connected with the bagging mechanism. A bag opening mechanism is arranged between the bagging mechanism and the bag passing mechanism. The bag opening mechanism is connected with a bag sealing mechanism. The device for packaging the infusion tube coiled tube can achieve mechanical automation of infusion tube packaging. The invention further discloses a method for packaging the infusion tube coiled tube.

Owner:王华江

Full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike

InactiveCN106968708ASettlement controlReduce distortionUnderground miningSurface miningLithologyMining engineering

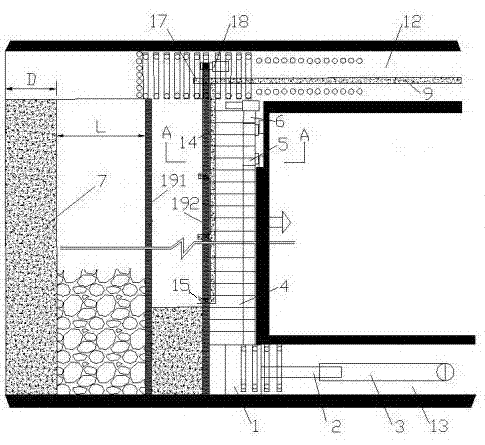

The invention discloses a full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike. According to the principle, the method includes the steps that after a steeply inclined coal seam field is divided into mining areas, a long-wall fully mechanized coal mining face is arranged along the coal seam strike, and after advancing in the coal mining face, a goaf is subjected to sublevel filling along the coal seam strike. According to the rock mechanics principle and the lithology of overlying rock of the coal mining face, the dimensions D and strength of sublevel filling bodies and the limited span L of sublevel filling are determined under the condition that the upper roof of the overlying rock is not broken. A filling-body filling area is divided into inclined sealing filling areas by sublevel small coal pillars and rectangular air bags, and paste filling is conducted in the sealing areas through pipelines. By means of the method, the filling amount can be reduced, the filling cost is lowered, the resource recovery rate is increased, and the safe, environmental-friendly and economical coal mining effects are achieved.

Owner:HUNAN UNIV OF SCI & TECH

Method for preparing oxygen sensor external platinum electrode

InactiveCN101408525AReduce dosageGuaranteed Response SensitivityMaterial electrochemical variablesManufacturing technologyPt element

The invention discloses a method for manufacturing an external platinum electrode of a lambda sensor, comprising the following steps: A. pure platinum electrode sizing agent which has 1-10Mum of grain diameter, 50-80 percent of grain solid content and 40-60kcps of viscosity is confected; B. the pure platinum electrode sizing agent is coated on the surface of a bushing-shaped zirconia basal body by a bat printing device, so as to form an electrode film; C. the bushing-shaped zirconia which is coated with the electrode film is positioned in a high-temperature welding furnace for sintering 4-7 hours under the temperature of 1400-1600 DEG C. The invention basically solves the problems of serious sizing agent waste, uneven coating thickness of the electrode, multifarious manufacturing technologies, and the like, during the traditional preparation of the external platinum electrode and has the advantages of fast speed, good stability, high precision and easy automation realization, and the like, besides, the poriness and thickness of the shaped external platinum electrode are controllable, bonding strength of the substrate is high and the response speed is fast.

Owner:深圳市日理江澍传感材料科学与工程研究院

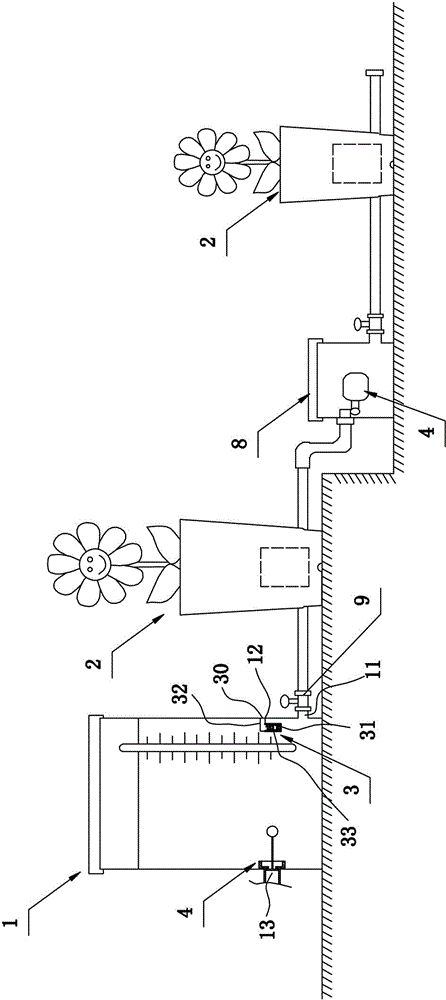

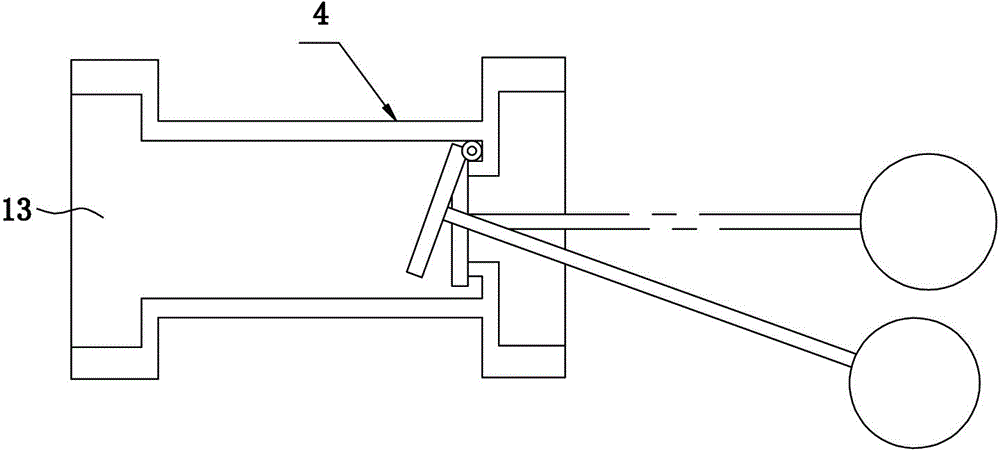

Mechanical pot culture automatic water supply system

ActiveCN104855254AMeet moisture needsRealize automatic watering functionSelf-acting watering devicesWater storageSiphon

A mechanical pot culture automatic water supply system comprises a water supply mechanism and at least one flowerpot communicated with the water outlet end of the water supply mechanism. The water supply mechanism comprises a closed water storage barrel filled with water. Water storage grooves are formed in the flowerpots respectively. A water outlet and an assembling port located above the water outlet are formed in the bottom of the water storage barrel. A check valve used for blocking water in the water storage barrel from flowing outward is arranged at the assembling port of the water storage barrel. The water storage grooves are provided with water inlets communicated with the water outlet through pipelines. An air inlet formed in the outer portion of the water storage barrel is formed in one end of the check valve, an air outlet formed in the water storage barrel is formed in the other end of the check valve, and the air outlet is located in the position flush with the liquid level of the water storage grooves in height. According to the mechanical pot culture automatic water supply system, water can be supplemented to the water storage grooves through the siphon principle, the liquid level height of the water storage grooves is kept constant, and therefore the automatic pot culture watering function is achieved.

Owner:徐州宝美工程机械有限公司

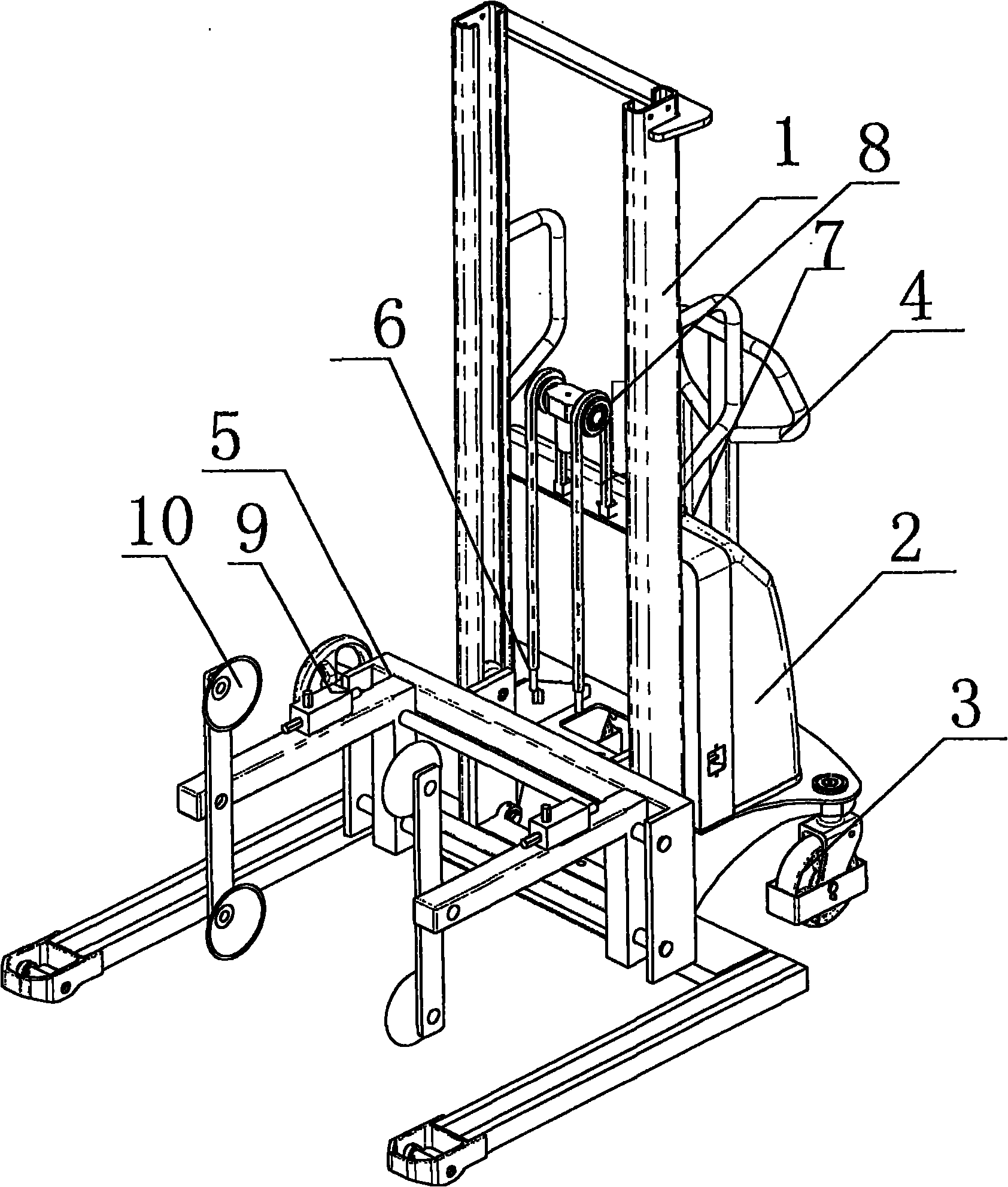

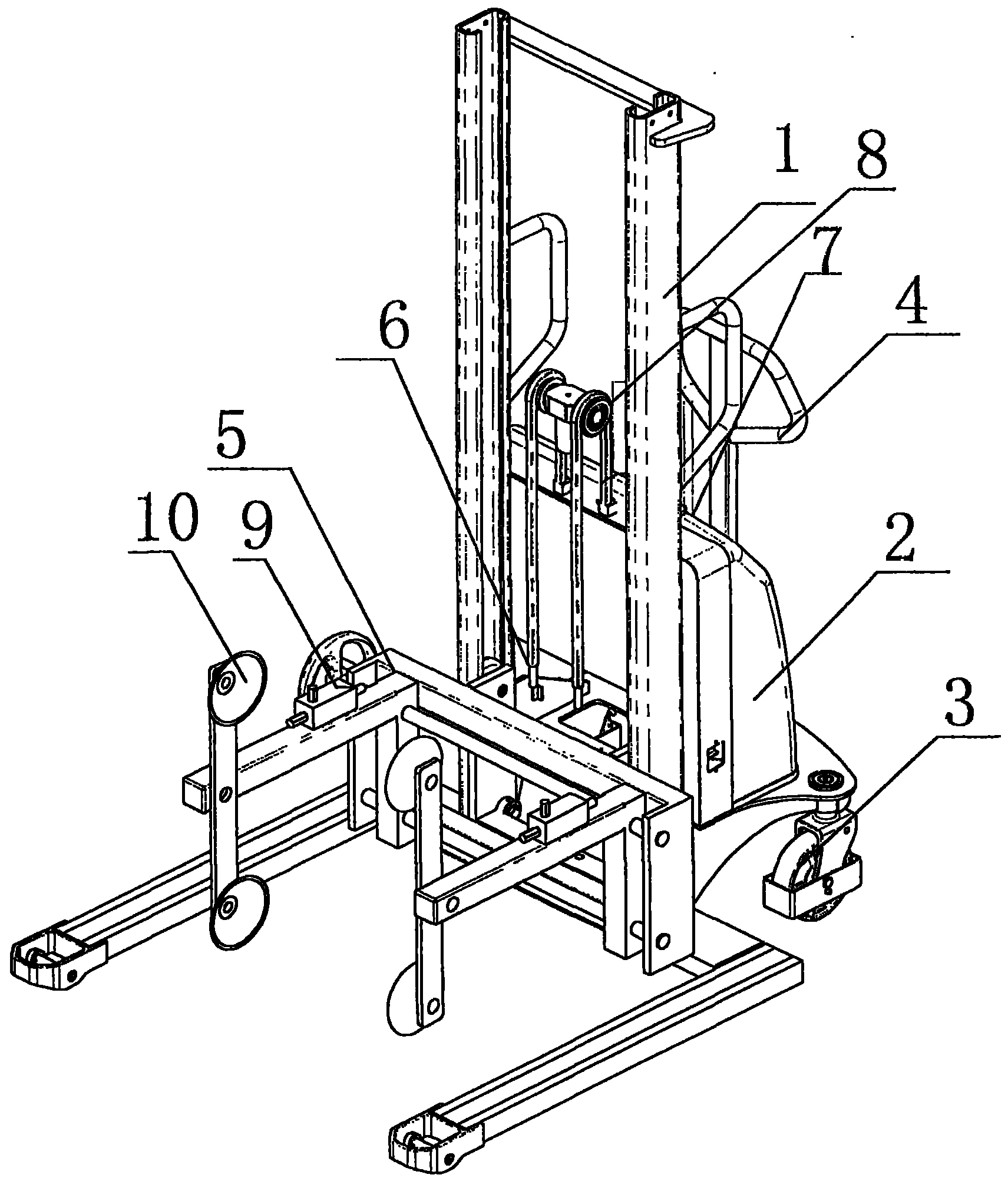

Automatic loading and unloading truck for refrigerators

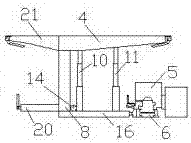

The invention discloses an automatic loading and unloading truck for refrigerators. The automatic loading and unloading truck comprises a frame (1), one side of the frame (1) is provided with a push-pull device, and the other side of the frame (1) is provided with a clamping device; the push-pull device is provided with a box body (2), a roller (3) is arranged at the bottom of the box body (2), a push rod (4) is arranged on the roller (3), and a hydraulic driving device is arranged in the box body (2); the clamping device comprises a lifting clamp (5); the driving device is in transmission connection with the lifting clamp (5) through a conveyor belt (6), and the driving device drives the lifting clamp (5) to ascend or descend through the conveyor belt (6); and the inner surfaces of two clamping arms of the lifting clamp (5) are provided with adsorption devices, the adsorption devices are connected with adsorption control devices, the adsorption control devices control loosening or clamping of the adsorption devices, and the adsorption control devices and the driving device are connected with a control assembly. The automatic loading and unloading truck has high safety performance, realizes loading and unloading automation, and improves the work efficiency.

Owner:陈加朋

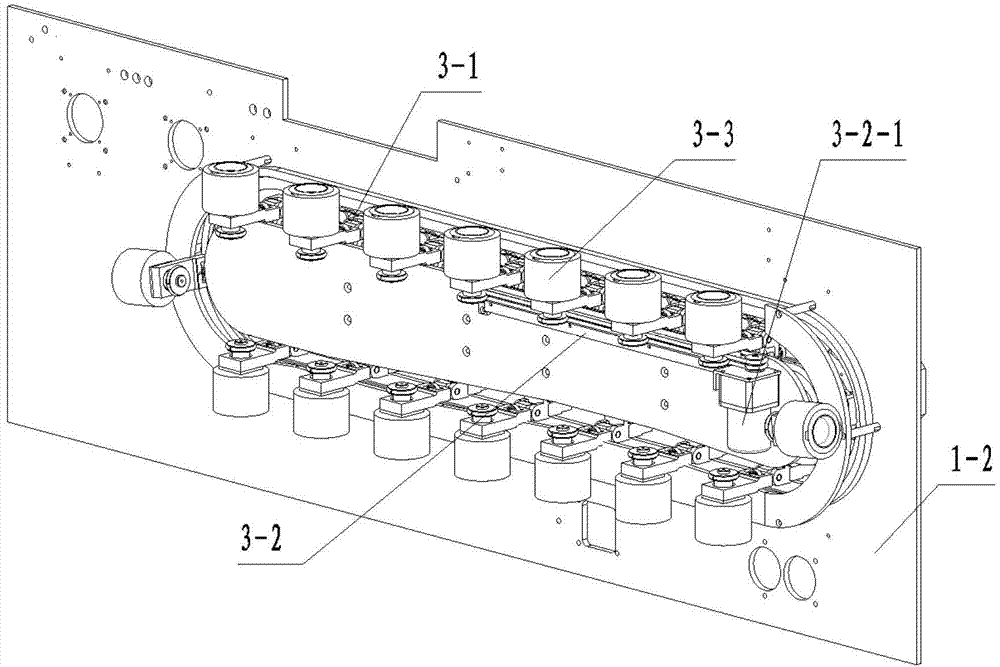

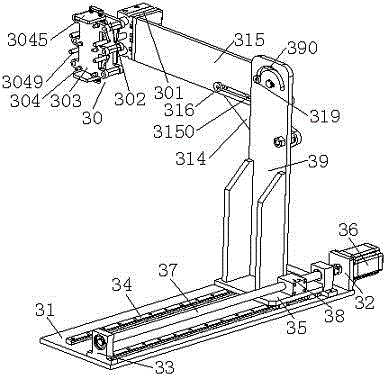

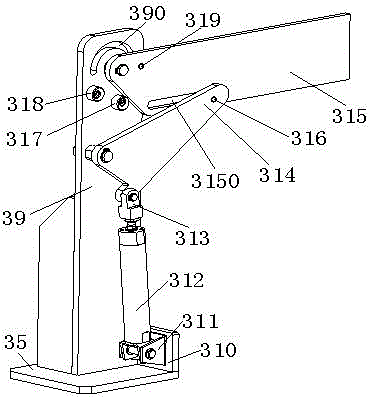

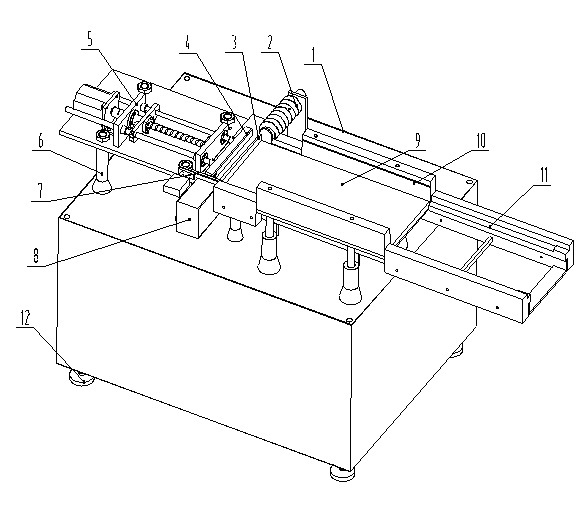

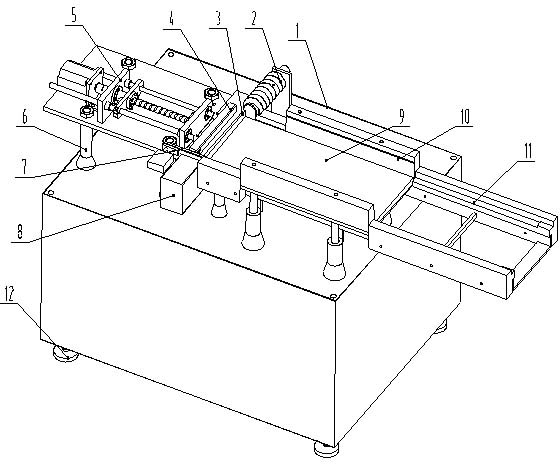

Discharging mechanism of brake pump shell feeder

The invention discloses a discharging mechanism of a brake pump shell feeder. The discharging mechanism of the brake pump shell feeder comprises a discharging mounting plate, a discharging motor mounting plate and two discharging lead screw connection seats are fixed on the upper plane of the discharging mounting plate sequentially, two linear discharging guide rails in parallel are fixed between the two discharging lead screw connection seats and on the upper plane of the discharging mounting plate, a discharging slide plate is fixed on sliders of the two linear discharging guide rails, a discharging motor is transversely fixed on the outer side face of a discharging motor mounting plate, and a rotating shaft of the discharging motor passes through the discharging motor mounting plate to be connected with one end of a discharging lead screw through a coupler. The discharging mechanism of the brake pump shell feeder is novel and simple in structure and capable of discharging workpieces instead of manual operation and achieving quick continuous discharging, so that mechanical automation is achieved.

Owner:苏州迈邻物业管理有限公司

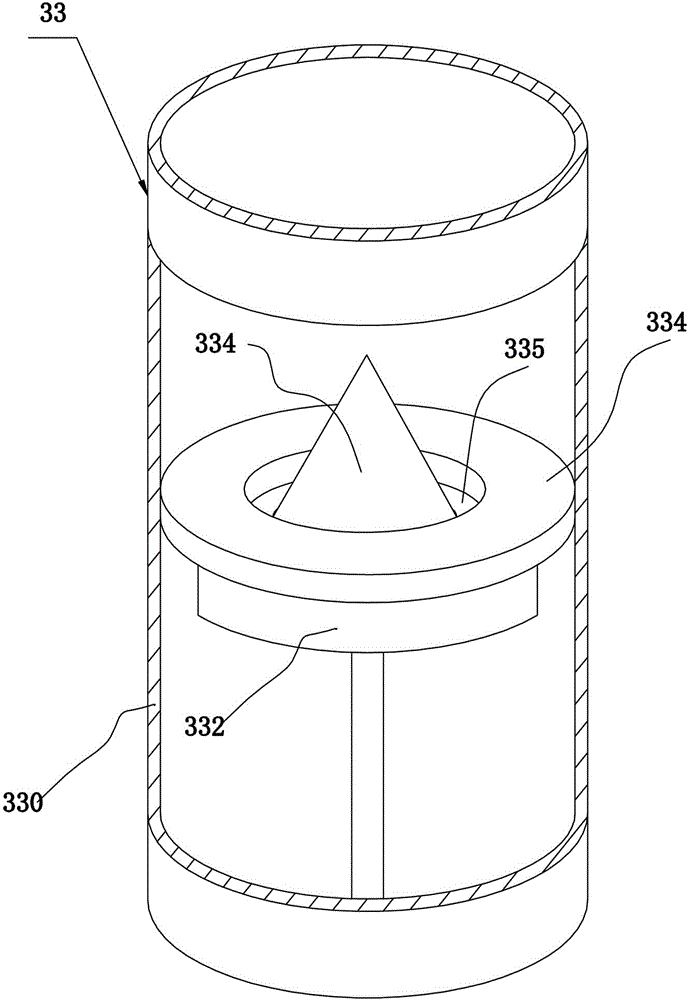

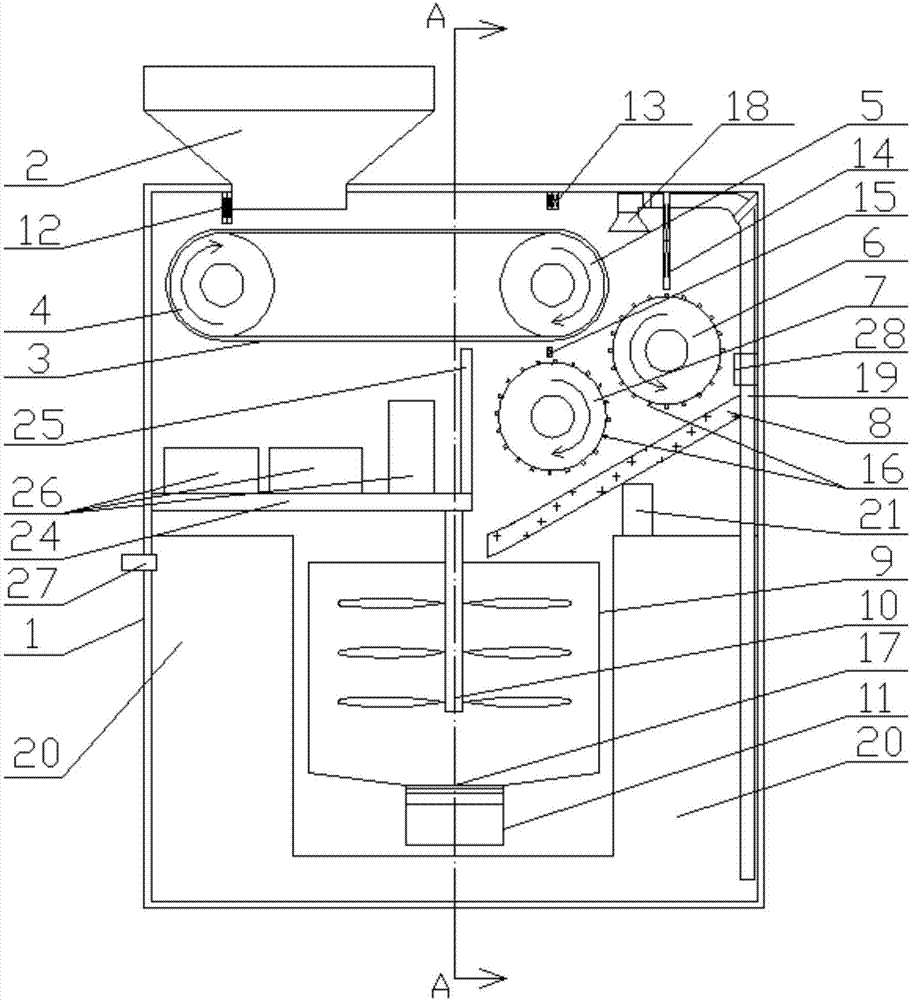

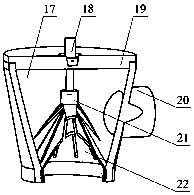

Separating device for pulp and seeds of taxus chinensis

ActiveCN107439088ARealize mechanical automationHigh degree of automationSeed and root treatmentCentrifugesIsoetes triquetraEngineering

The invention discloses a separating device for pulp and seeds of taxus chinensis and belongs to the field of a fruit processing separating device. The separating device comprises a feeding hopper, a separating box, a fruit residue output pipe and a seed output pipe, wherein a conveying belt mechanism, a roller mechanism and a separating mechanism are successively arranged in the separating box from top to bottom; the roller mechanism comprises a slide rail and a right driving wheel, a first roller shaft and a second roller shaft which are distributed in the form of equilateral triangle; the right driving wheel matches with the first roller shaft for extruding the fruit and also is used for driving the conveying belt; the first roller shaft and the second roller shaft match with each other for extruding the fruit; the slide rail is matched with the second roller shaft for extruding the fruit and also is used for conveying the extruded fruit; and the separating mechanism is used for respectively outputting the fruit and the seeds. The separating device for pulp and seeds of taxus chinensis has an excellent working effect and high working efficiency; the separating device also can directly acquire the pulp and the seeds, can promote the degree of automation and can further save labor force; and the structure is compact, the structure design is reasonable and smart, the inner space of the device is fully utilized and the area occupied by the device is reduced.

Owner:陕西天行健生物工程股份有限公司

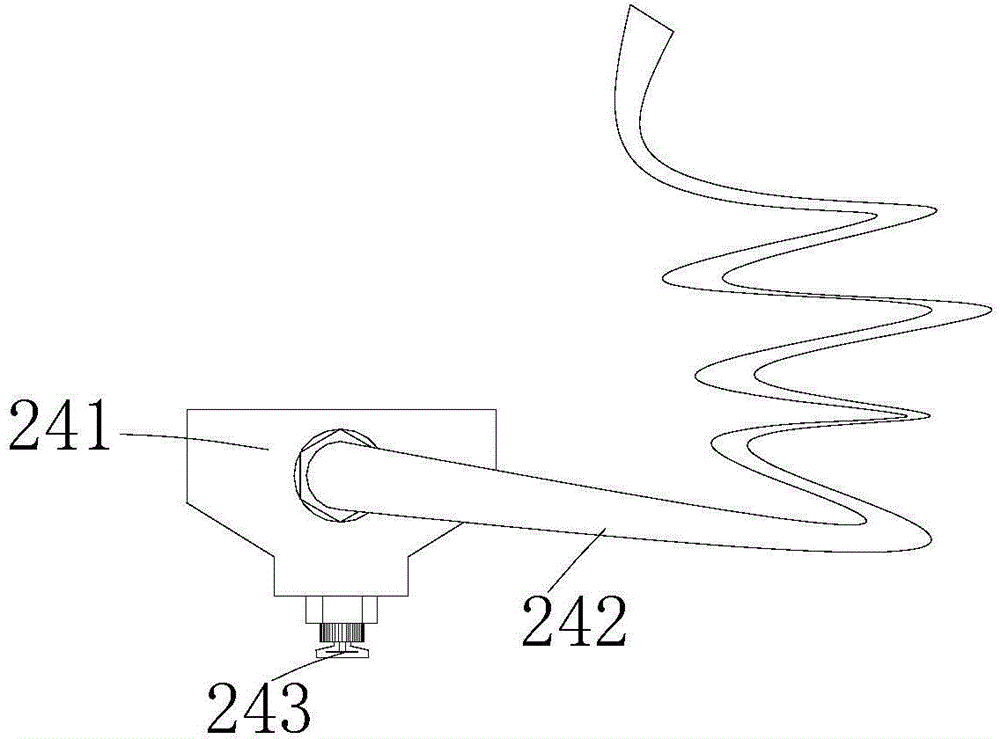

Chopstick varnishing mechanism of automatic chopstick varnishing device

ActiveCN104722441ARealize mechanical automationImprove work efficiencyLiquid surface applicatorsCoatingsReciprocating motionLacquer

The invention discloses a chopstick varnishing mechanism of an automatic chopstick varnishing device. The chopstick varnishing mechanism comprises a first guide rail, wherein the first guide rail is movably provided with a varnishing mechanism support which can be driven by a servo motor to horizontally reciprocate; and the varnishing mechanism support comprises two support side plates and a support baseplate, and a varnish storage barrel is fixedly arranged between the two support side plates; the support baseplate is fixedly connected with a sliding block of the first guide rail; the bottom of the varnish storage barrel is connected with a first air cylinder by which the varnish storage barrel can be inclined for a certain angle; and the support baseplate is fixedly provided with a second guide rail on which a push plate is movably arranged, and the push plate is connected with a second air cylinder capable of driving the push plate to horizontally move. By using the chopstick varnishing mechanism, the mechanical automation of chopstick varnishing can be realized, not only is the work efficiency increased, but also a paint layer with uniform thickness can be formed on the surface of each chopstick.

Owner:王华江

Manufacturing technology of diodes

ActiveCN103681319AHigh consistency of reliability and performanceIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologySurface mounting

The invention relates to a manufacturing technology of diodes. The manufacturing technology of the diodes mainly comprises the operation steps that firstly, a left frame strip, a right frame strip, a core granule and a bridge sheet are assembled together through the gumming technology, and then welding, cleaning, drying, packaging, cleaning, drying, detection, tinning on the exposed parts of the frame strips, drying and packaging are carried out. The diodes manufactured according to the manufacturing technology of the diodes are in the straight angle and surface mounting mode, processes such as bent angles forming a hidden danger for the diodes do not exist in the whole production process, and the consistence of the reliability performance of the diodes is high; the bridge connection technology is adopted, and the performance of the diodes is improved. Mechanical automation can be achieved for all the steps, and the manufacturing technology of the diodes is high in production efficiency, stable and reliable.

Owner:CHANGZHOUSR SEA ELECTRONICS

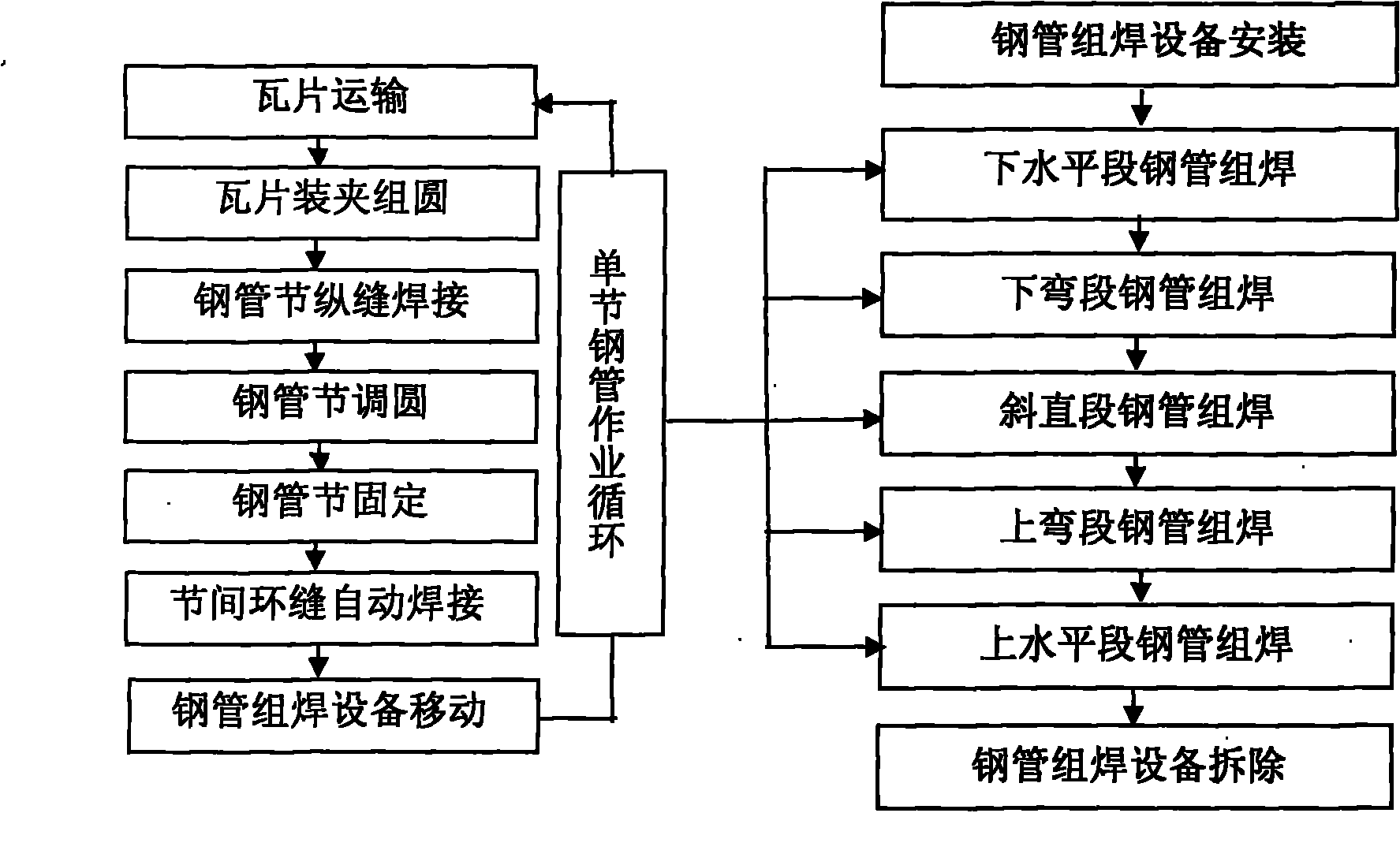

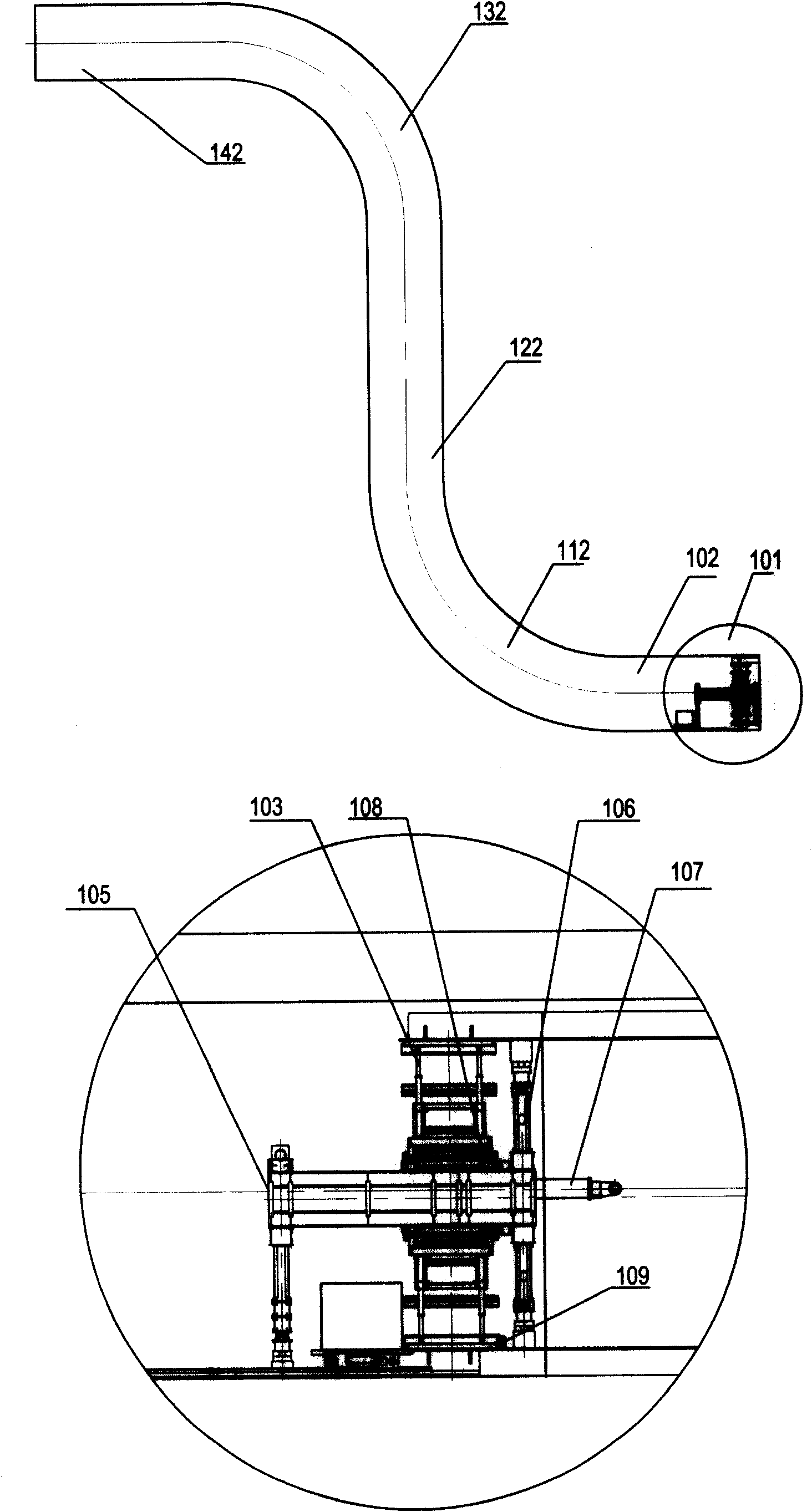

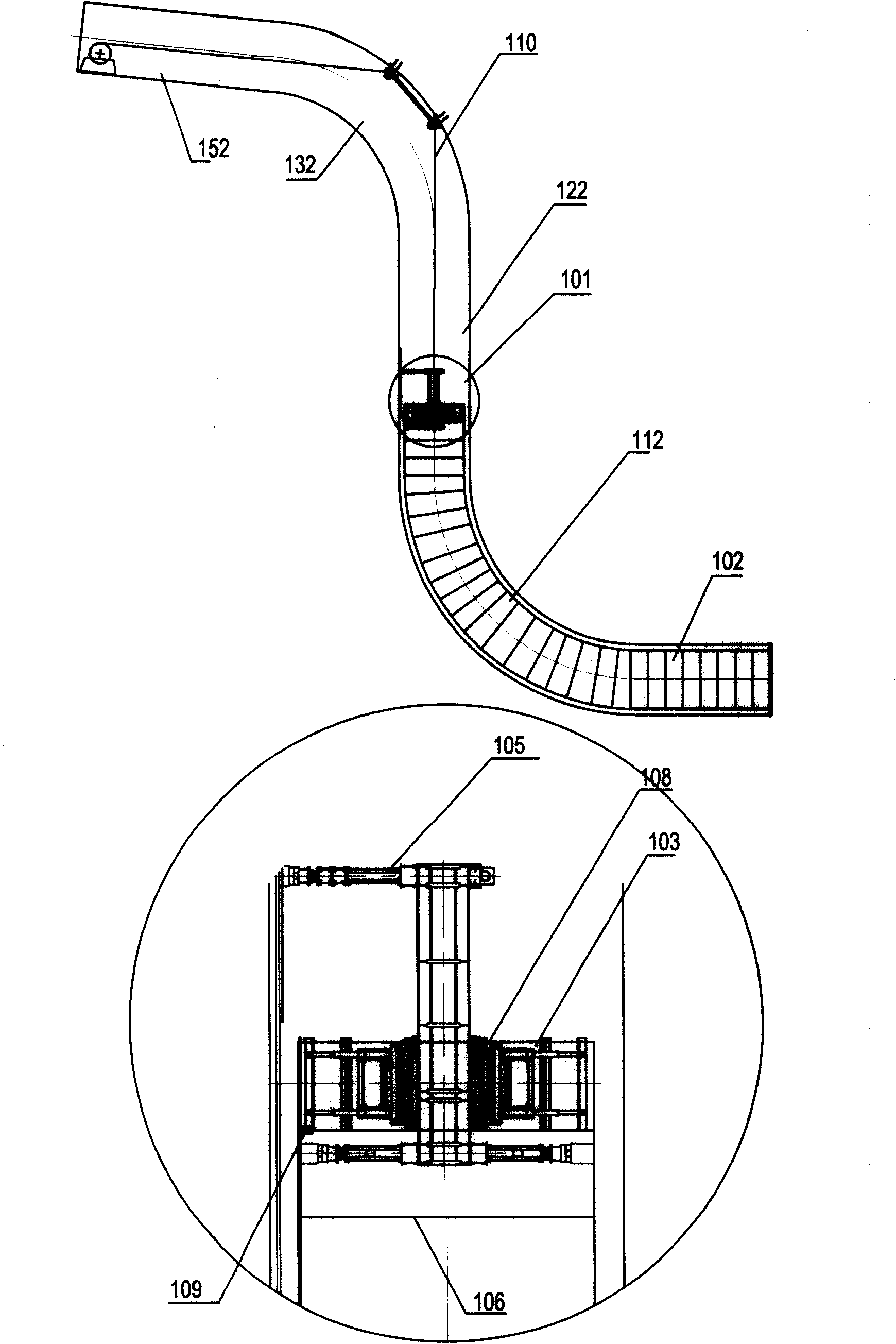

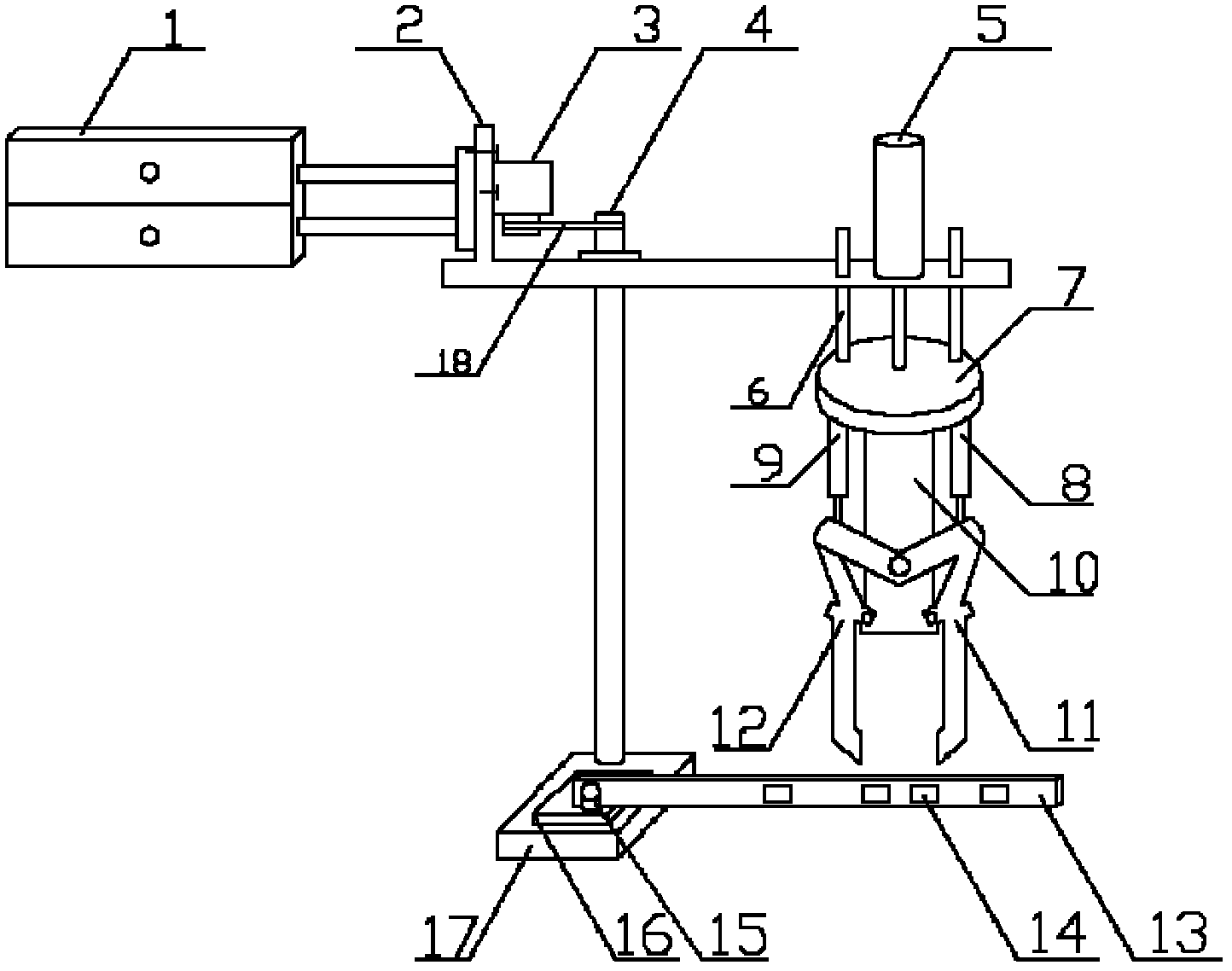

Large steel tube technology and equipment

InactiveCN101774092AIncreased automation level of manufacturing and installation machineryReduce the difficulty of hoisting and transportationWelding/cutting auxillary devicesAuxillary welding devicesUnit structureSteel tube

The invention aims to provide a new large steel tube manufacturing and installation technology and equipment. A unit structure taking tiles as the basis is adopted to transport large space steel tubes as well as install and weld on spot; installing and welding equipment adopts a steel tube positioning method and moves in the mode of flexible boosting or winching lifting of an axial cylinder; steel tube installation girth welding adopts rotation driving to drive an automatic welding device to finish the automatic welding of a space girth; mechanical operation can be realized when the steel tube is horizontal or is in an inclined, upper elbow or lower elbow state to form a set of large steel tube engineering center capable of multi-angle omnibearing moving. The invention replaces a traditional large space steel tube construction technology, is favorable for improving engineering safety, quality and efficiency, protects environment, lowers the integrated manufacturing cost of the steel tube and is especially suitable for large intake steel tube engineering in the cavity or dam of hydropower stations.

Owner:彭智祥

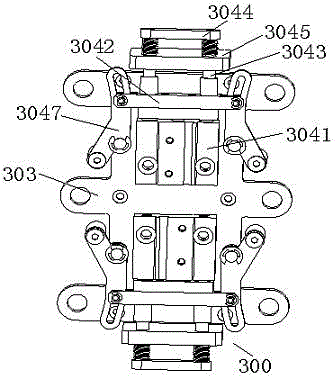

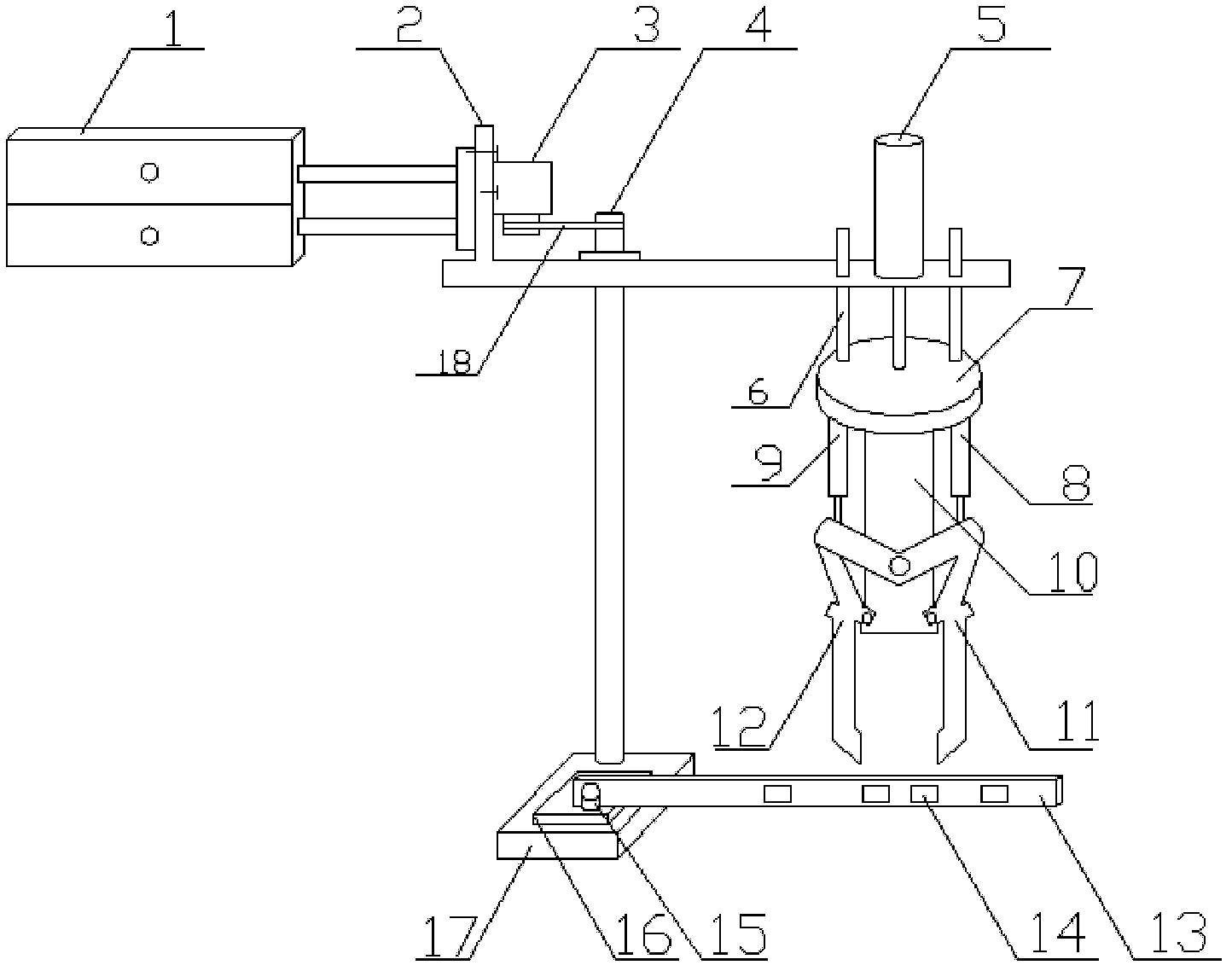

Pneumatic manipulator

The invention discloses a pneumatic manipulator which comprises a base, a rotating shaft, a fixed plate, a rotating mechanism and a claw mechanism, wherein one end of the rotating shaft is connected with the base, and the other end of the rotating shaft is connected with the fixed plate; the fixed plate is L-shaped, the L end is connected with the rotating mechanism, and the other end is connected with the claw mechanism; a stepper motor on the rotating mechanism is connected with the rotating shaft through a conveyor belt; the claw mechanism comprises a pneumatic cylinder II, a plurality of support columns, a fixed table, a pneumatic cylinder III, a pneumatic cylinder IV, a support plate, a left finger and a right finger; a telescopic shaft of a hydraulic cylinder II and the support columns penetrate through holes on the fixed plate and are connected with the upper end surface of the fixed table, and the lower end surface of the fixed table is connected with the support plate, a hydraulic cylinder III and a cylinder body of a hydraulic cylinder IV; and the left finger and the right finger are respectively connected with the lower end of the support plate, the right finger is connected with a telescopic shaft of the pneumatic cylinder III, and the right finger is connected with a telescopic shaft of the pneumatic cylinder IV. The invention has the advantages of simple debugging, convenience for installation and use, reliable performance and high production efficiency and realizes mechanical automation.

Owner:申超

Laminator for automatically tearing film on lower cover

InactiveCN104553239AAvoid lossRealize mechanical automationLamination ancillary operationsLaminationEngineeringTransfer mechanism

The invention discloses a laminator for automatically tearing a film on a lower cover. The laminator comprises a base, wherein a working platform is arranged at the upper end part of the base; a graduator is arranged on the working platform; the graduator is provided with a jig for loading materials; a control device, an aluminum box feeding mechanism, a film feeding mechanism, a pressing mechanism and a discharging mechanism are sequentially arranged round the graduator; a release paper tearing transfer mechanism is arranged on a side edge of the aluminum box feeding mechanism, an aluminum box automatic loading mechanism is arranged in front of the release paper tearing transfer mechanism, and a first positioning mechanism is arranged between the aluminum box feeding mechanism and the release paper tearing transfer mechanism. The laminator disclosed by the invention realizes mechanical automation and is high in precision. Positioning mechanisms arranged for feeding aluminum boxes and films can automatically lift up and down and longitudinally translate and are accurate to position. Moreover, the loss of raw materials is avoided to the maximum extent, and the whole machine is simple in structure, reasonable in layout, easy to manufacture and convenient to operate.

Owner:东莞信宏五金制品有限公司

C type retaining ring feeding device

ActiveCN106516699ARealize mechanical automationReduce manufacturing costConveyor partsEngineeringRetaining ring

The invention discloses a C type retaining ring feeding device. The C type retaining ring feeding device comprises a rack installed on the ground; the rack is provided with a C type retaining ring supplying mechanism and a C type retaining ring discharging mechanism; the C type retaining ring discharging mechanism is located above the C type retaining ring supplying mechanism; the C type retaining ring supplying mechanism comprises a tray transposition device and a C type retaining ring supplying device which are arranged on the rack, and the C type retaining ring supplying device is located on one side of the tray transposition device; the tray transposition device comprises an installing plate fixed to the rack; the installing plate is provided with a tray displacement assembly and a positioning assembly; and the positioning assembly is arranged on the lower plane of the installing plate. Due to the above manner, the C type retaining ring feeding device can replace manual work to perform automatic feeding on C type retaining rings.

Owner:李帅

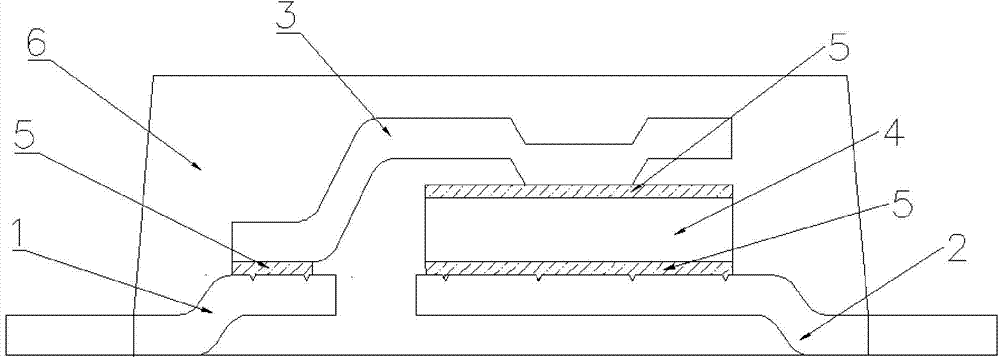

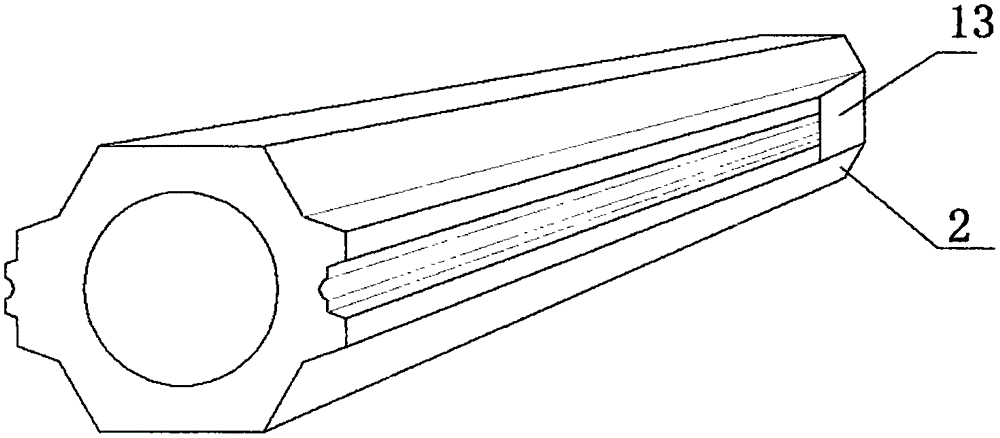

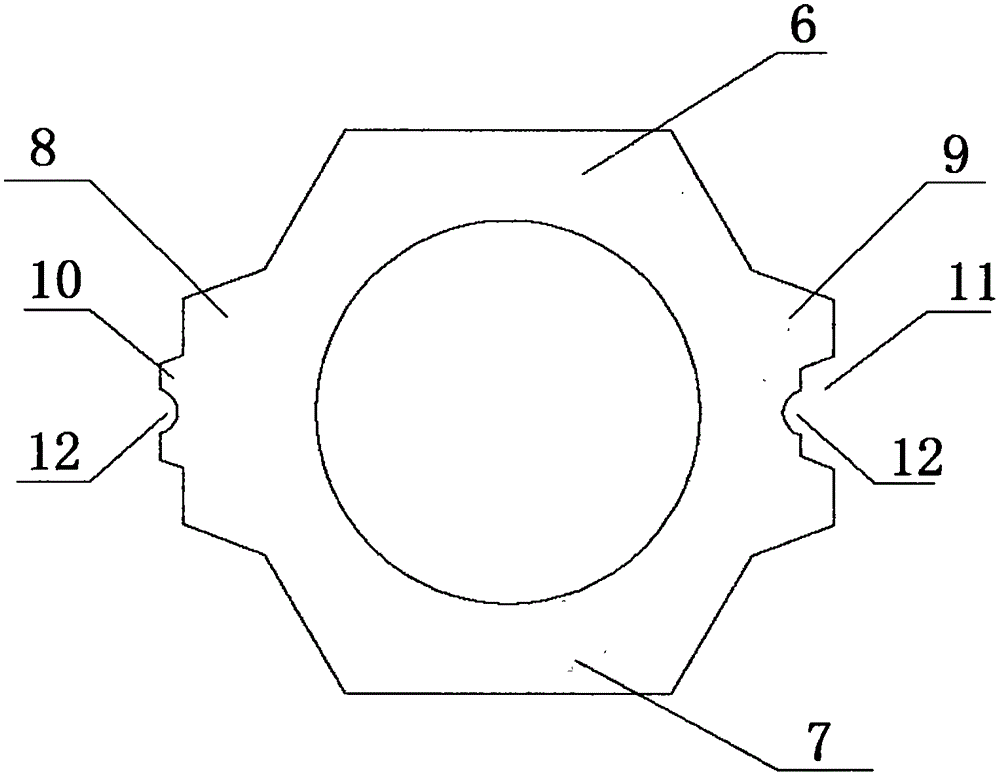

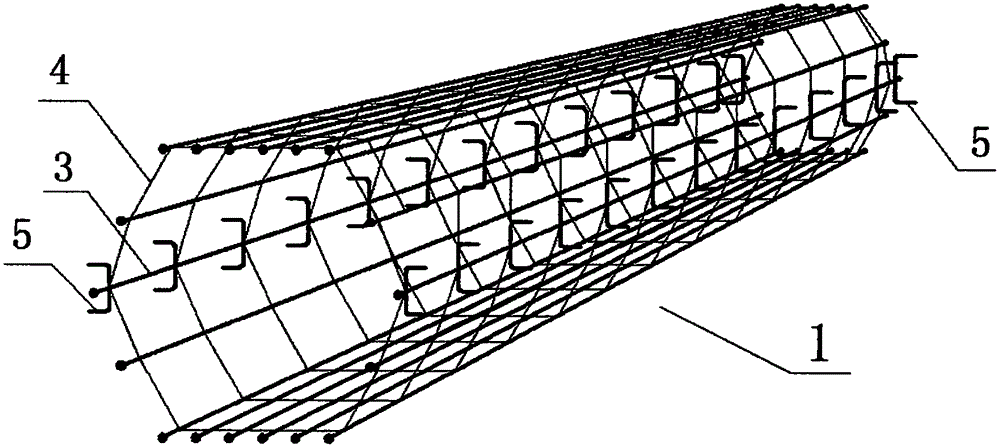

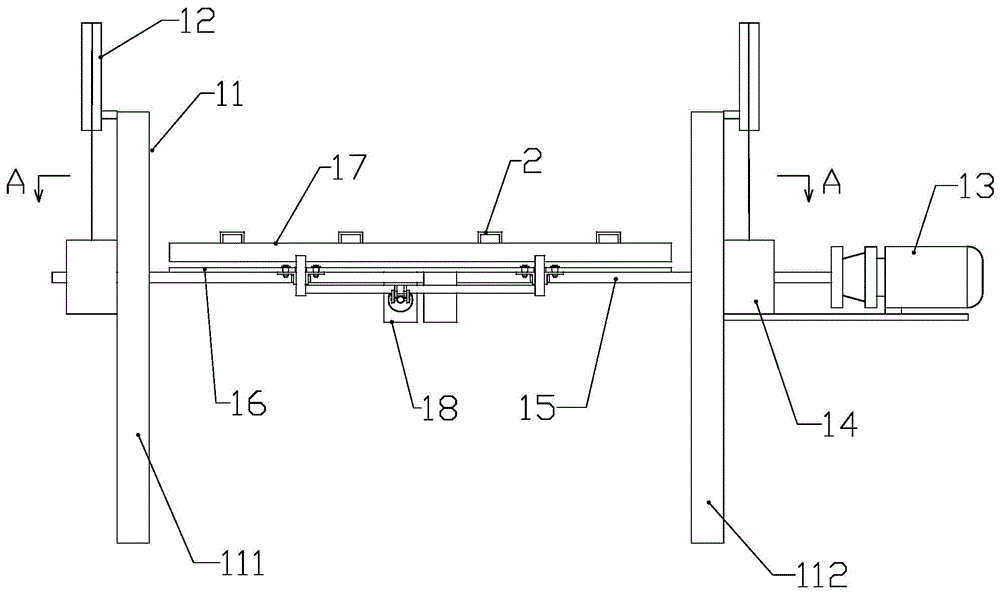

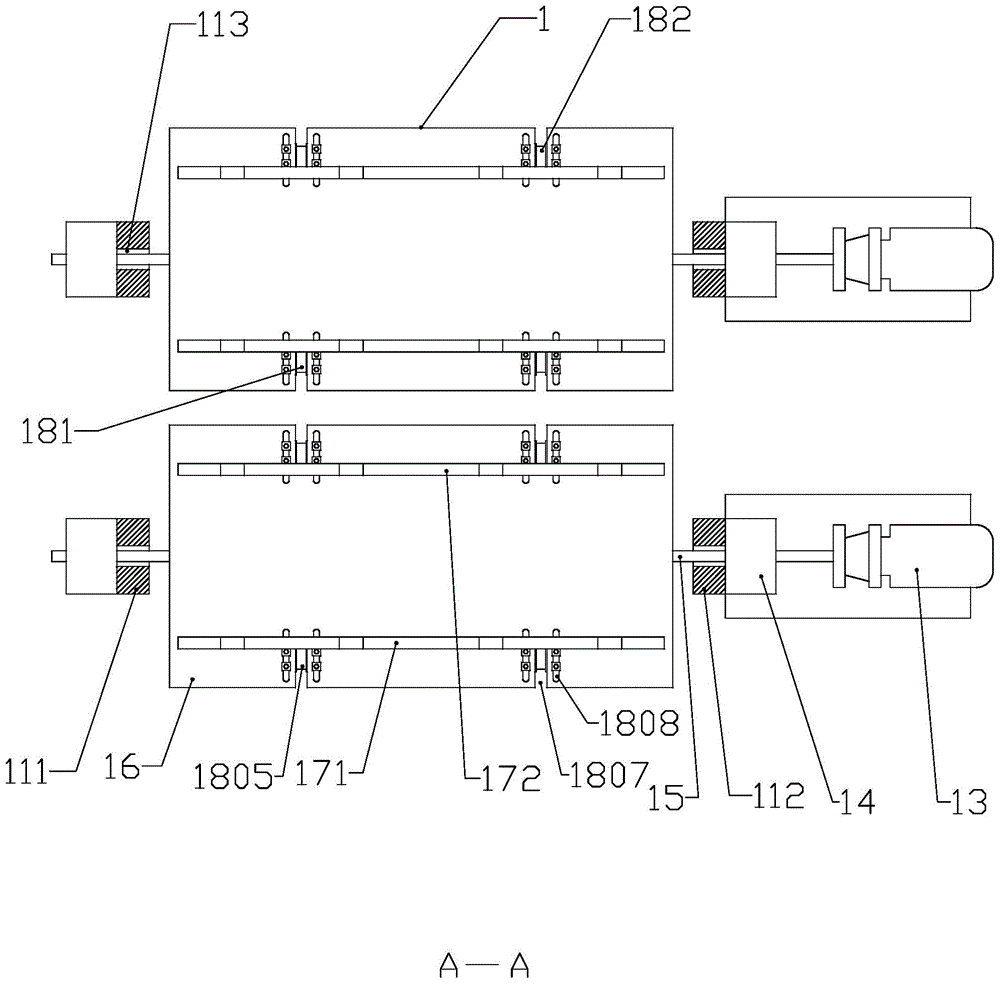

Prestressed high-strength concrete hollow support pile and manufacturing method thereof

InactiveCN105544531AGuaranteed stabilityBeautiful seamsCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention provides a prestressed high-strength concrete hollow support pile and a manufacturing method thereof. The prestressed high-strength concrete hollow support pile comprises a reinforcement cage framework and a concrete pile body. The cross section of the prestressed high-strength concrete hollow support pile is of a polygonal hollow pipe shape. The prestressed high-strength concrete hollow support pile comprises an upper pile body flange plate, a lower pile body flange plate, a left pile body supporting leg, a right pile body supporting leg, a pile body tenon and a pile body mortise, wherein the upper pile body flange plate and the lower pile body flange plate are arranged symmetrically; each pile body flange plate is formed by welding two or more longitudinal prestress main ribs and two or more hoop ribs in a crossed mode; hoop ribs are evenly distributed between the upper pile body flange plate and the lower pile body flange plate in a surrounding mode; the pile body tenon is located on one side of the left pile body supporting leg, the pile body mortise is located in one side of the right pile body supporting leg, and the pile body tenon and the pile body mortise are in engaged fit; reserved grouting slots are formed in the middle of the pile body tenon and the middle of the pile body mortise symmetrically. The prestressed high-strength concrete hollow support pile is firm in structure, good in soil conserving and water stopping effect, easy and convenient to construct and low in project cost, and by adoption of the mechanical and automatic producing and processing procedures, the construction period is short and efficiency is high.

Owner:湖南卓工建材科技有限公司

Automatic component overturning demolding machine

ActiveCN104149186ASo as not to damageReduce labor intensityDischarging arrangementElectric machineryEngineering

The invention discloses an automatic component overturning demolding machine, and belongs to demolding machines. The automatic component overturning demolding machine structurally comprises two sets of overturning demolding mechanisms. Each set of overturning demolding mechanism comprises a support, upper-down moving cylinders, an overturning motor, sliding blocks, a rotating shaft, an overturning plate, a mold fixed clamping plate and a clamping plate movable driving mechanism. Each support comprises a left support body and a right support body, the outer side of the left support body and the outer side of the right support body are respectively provided with one upper-down moving cylinder, and cylinder rods of the upper-down moving cylinders are connected with the sliding blocks respectively. One rotating shaft is arranged between the sliding block on the outer side of each left support body and the sliding block on the outer side of the corresponding right support body, each rotating shaft is movably connected with the two corresponding sliding blocks, and one end of each rotating shaft is connected with a motor shaft of the corresponding overturning motor. Each overturning plate is arranged on the upper portion of the corresponding rotating shaft, each mold fixed clamping plate is arranged on the upper portion of the corresponding overturning plate, and each mold fixed clamping plate is connected with the corresponding clamping plate movable driving mechanism. The automatic component overturning demolding machine has the advantages that mechanical automation is achieved in component demolding, manual operation is avoided, time and labor are saved, the labor intensity of workers is lowered, the mechanical action is simple, and the working efficiency is high.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

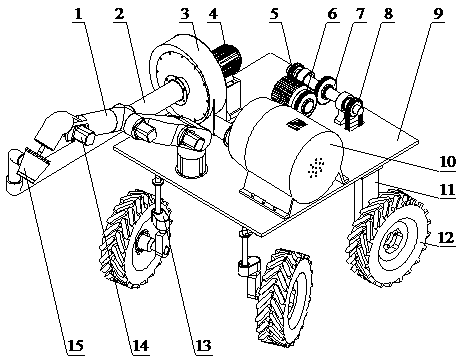

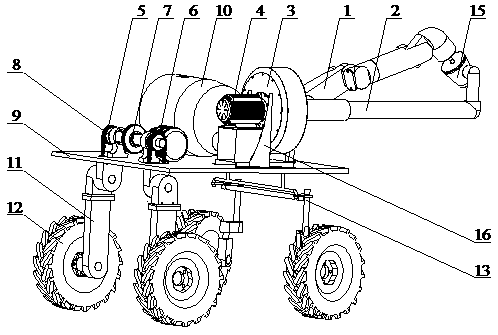

Safflower picking robot

PendingCN108391507ARealize mechanical automationImprove environmental adaptabilityPicking devicesSimulationManipulator

The invention relates to a safflower picking robot. The robot comprises a vehicle body, a mechanical arm and a collecting device; the robot is characterized in that the mechanical arm and a collectingdevice are installed on the vehicle body and located on the upper portion of the vehicle body, and the mechanical arm is located in front of the collecting device. The robot can replace a person forpicking safflower, mechanical automation is achieved, the environmental suitability is high, and the robot has the advantages of being low in labor intensity, capable of liberating the labor force andsaving the manpower resource and the like.

Owner:SHIHEZI UNIVERSITY

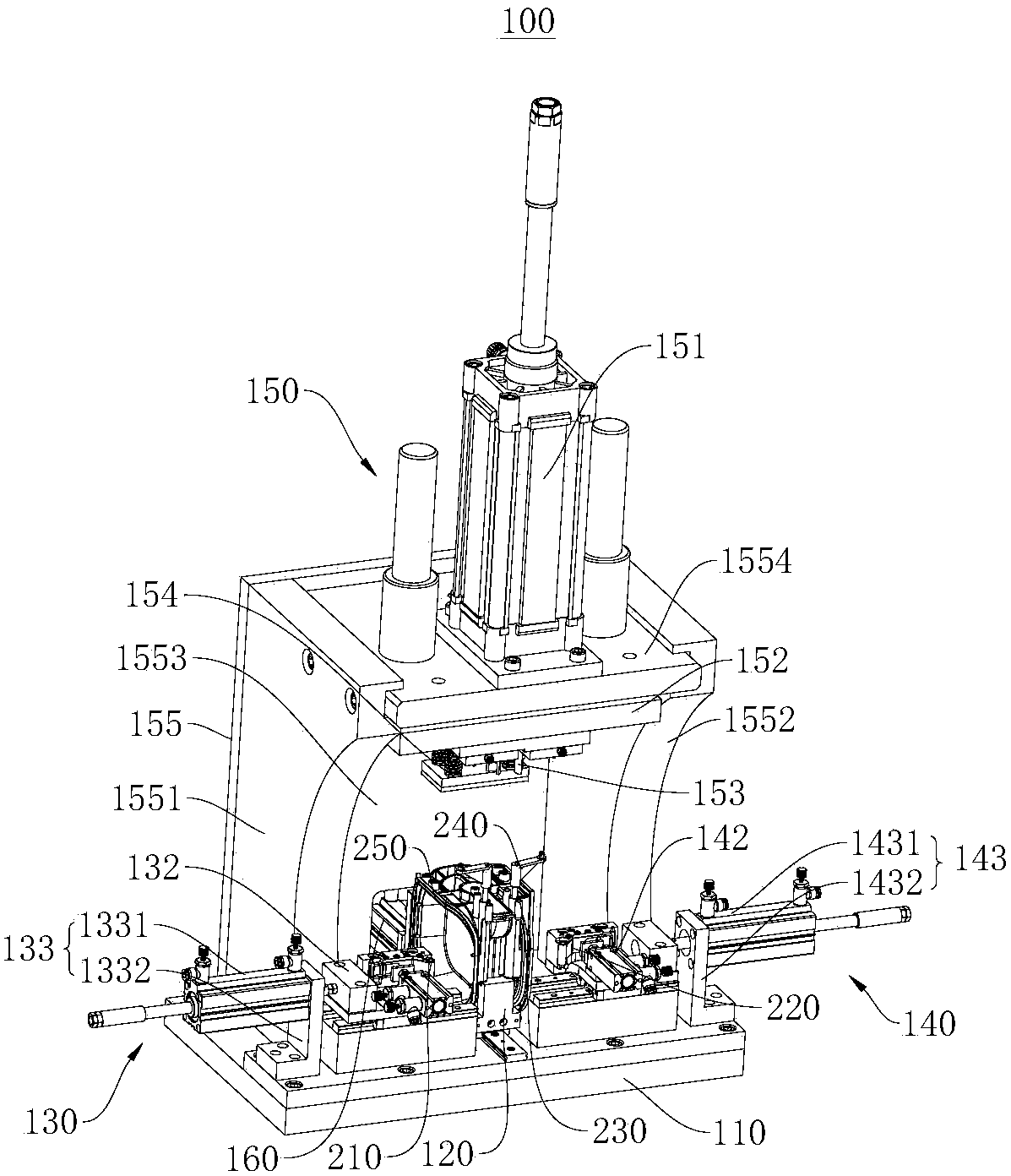

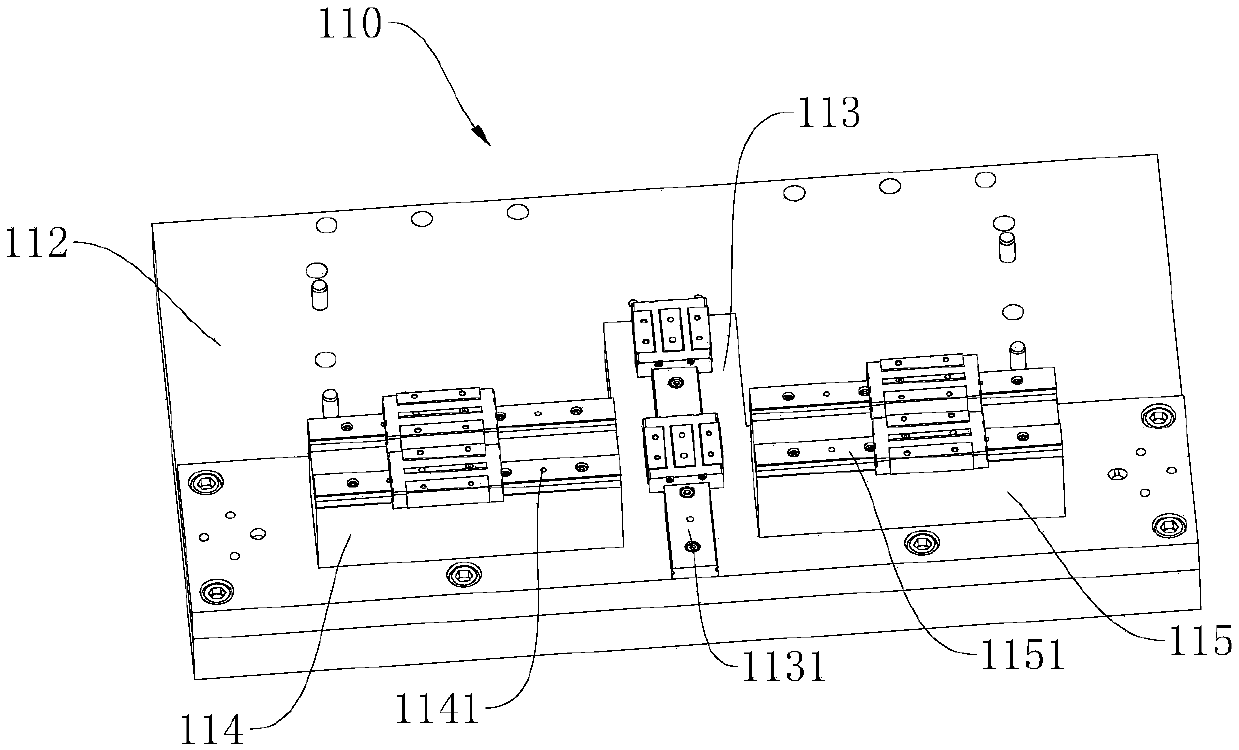

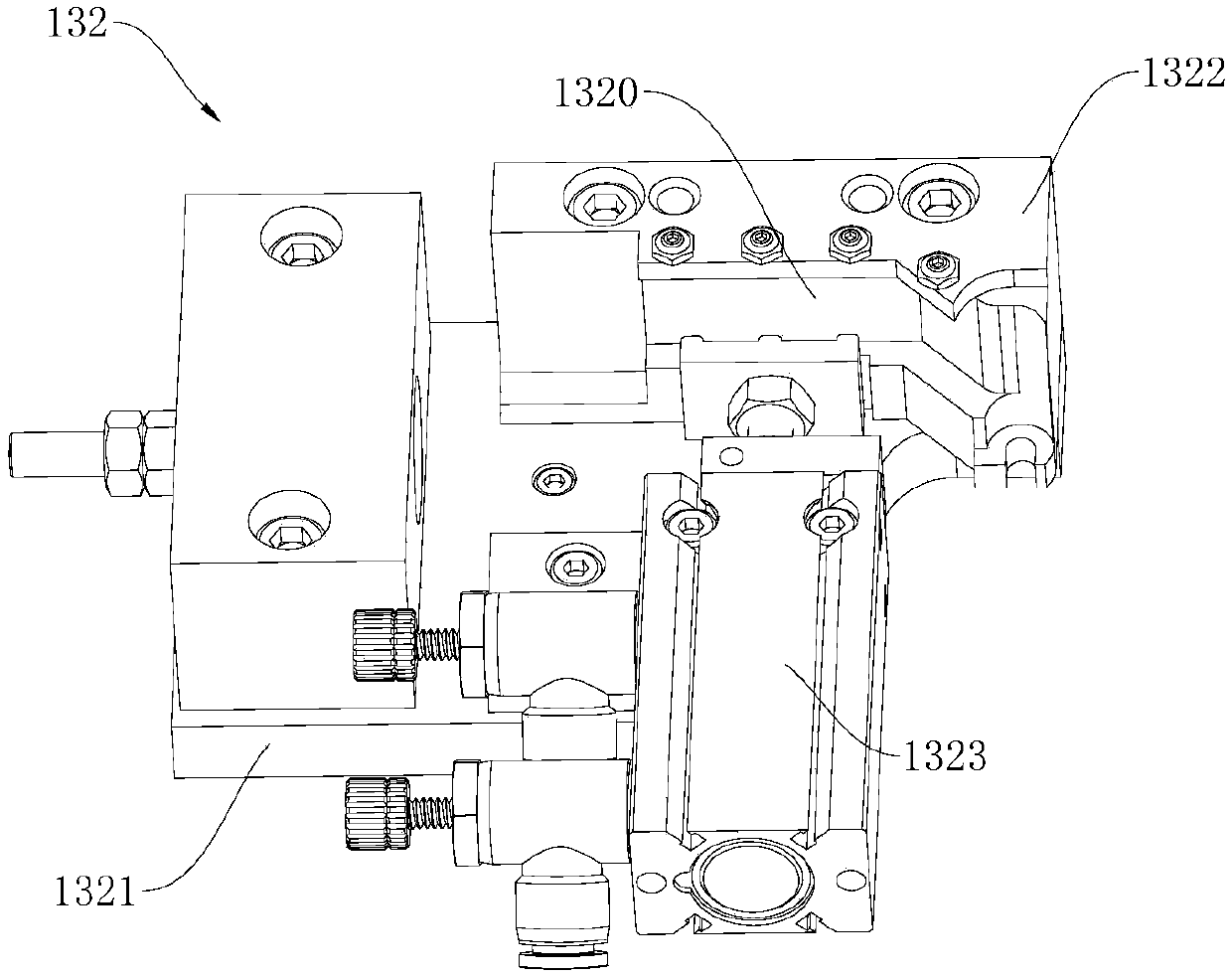

Press fitting equipment

ActiveCN107627104AReduce work stationsSave human effortAssembly machinesEngineeringMechanical engineering

The invention provides press fitting equipment, and relates to the field of press fitting equipment. By the press fitting equipment, a front pin, a rear pin, a stand column and a rocker are assembledon a film box. The press fitting equipment comprises a film box seat assembly, first press fitting devices, second press fitting devices and third press fitting devices. The film box seat assembly isused for mounting the film box. The first press fitting devices are arranged on one side of the film box seat assembly at intervals and are used for clamping the front pin, and the front pin is assembled on the film box by the first press fitting devices. The second press fitting devices are arranged on the side, which is opposite to the first press fitting devices, of the film box seat assembly at intervals, and are used for clamping the rear pin, and the rear pin is assembled on the film box by the second press fitting devices. The third press fitting devices are arranged at one end of the film box seat assembly at intervals, by the third press fitting devices, the stand column is assembled on the film box, and the rocker is clamped and is assembled on the stand column. By the press fitting equipment, the problems of low yield, low efficiency, waste of materials, high rework rate and the like of a gas meter angle assembly in a production process due to repeated assembly can be avoided effectively, the production efficiency is improved, and the cost is reduced.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

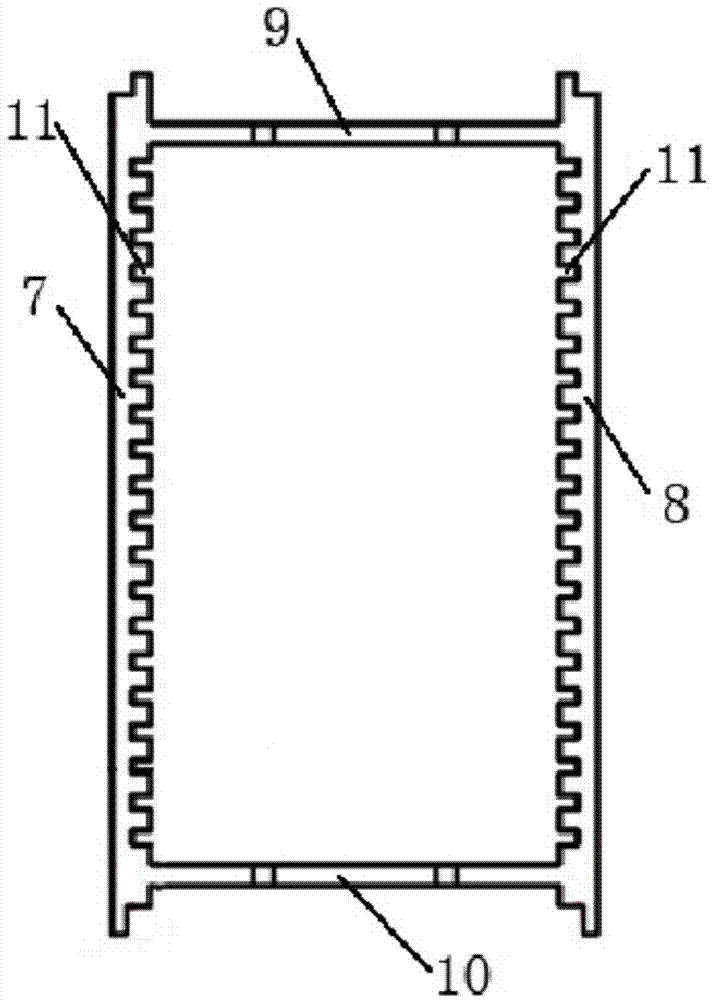

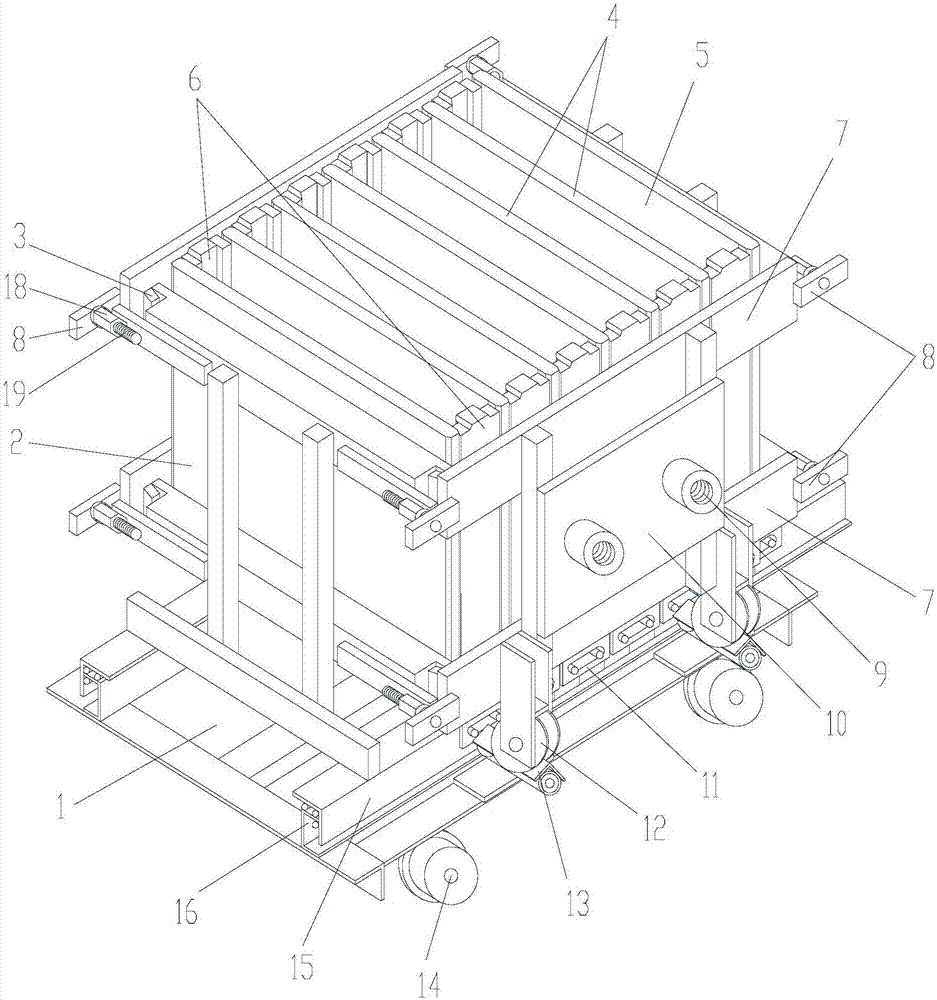

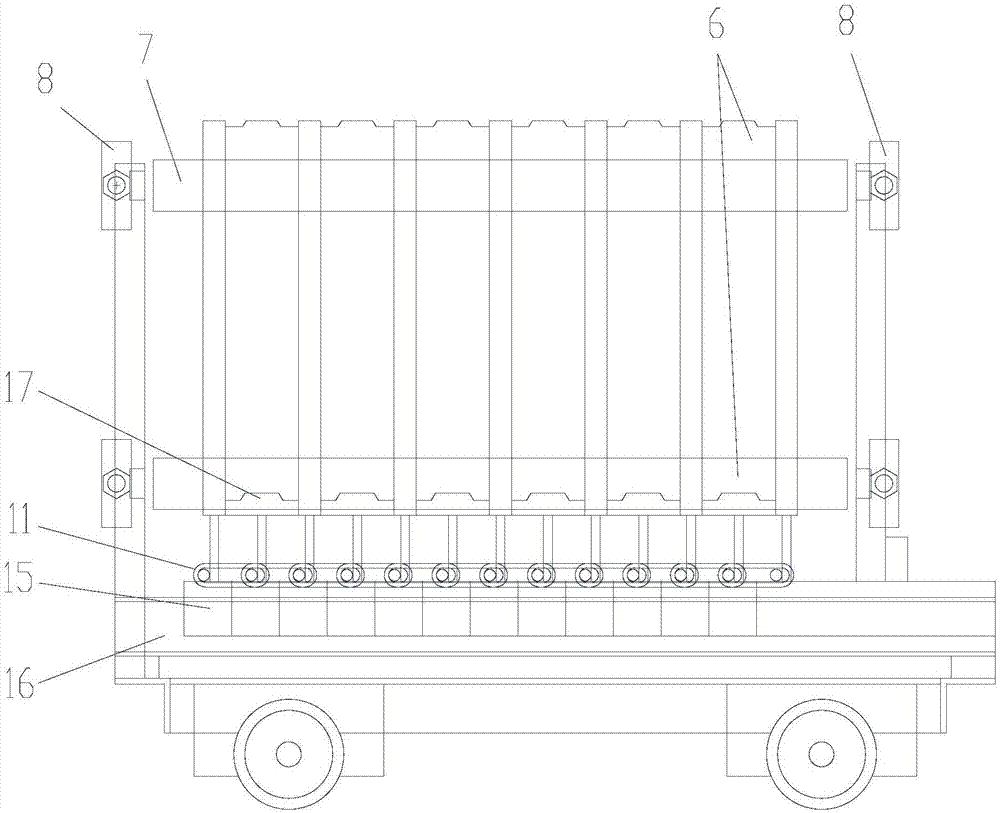

Building material forming mould box

PendingCN107486928ARealize mechanical automationImprove yieldMouldsCeramic shaping mandrelsBuilding productBrick

The invention discloses a building material forming mould box. The building material forming mould box comprises a mould box which operates on railways; a front side mould plate and a rear side mould plate which are oppositely arranged on an underframe of the mould box; the space between the front side mould plate and the rear side mould plate is divided into a plurality of mould cavities; end moulds are arranged on the left side and the right side of each mould cavity; a bottom mould is arranged at the bottom of each mould cavity; front-back guide rails and sliding pieces are also arranged on the underframe; the front side mould plate, the bottom mould, partition moulds, and the rear side mould plate are respectively connected with the sliding pieces; adjacent two sliding pieces are movably connected with each other; the rear side mould plate is fixed to the underframe; the end moulds can move horizontally; mechanical automation of mould opening and mould closing is realized through a locking mould of the mould box; and the building material forming mould box disclosed by the invention is applicable to automatic assembly line production of building products, such as bricks, blocks, plates and prefabricated parts.

Owner:胡云模

Cutting system capable of charging and discharging intelligently and charging and discharging method of cutting system

ActiveCN106044200AReduce labor intensityRealize mechanical automationMetal working apparatusStorage devicesEngineeringUltimate tensile strength

The invention discloses a cutting system capable of charging and discharging intelligently and a charging and discharging method of the cutting system. The cutting system comprises a material storage cabinet, a cutting bed, and a charging cabinet arranged between the material storage cabinet and the cutting bed. The cutting system further comprises a charging and discharging robot, wherein the charging and discharging robot is arranged between the material storage cabinet and the charging cabinet; the material storage cabinet comprises a plurality of material storage racks; the material storage racks are arranged at one side, facing the charging and discharging robot, of the material storage cabinet; the charging cabinet comprises a plurality of charging racks; and the charging racks are arranged at the two sides of the charging cabinet. The cutting system capable of charging and discharging intelligently is used to carry and cut a flexible material, so that mechanical automation of charging and discharging is realized, the labor intensity of workers is reduced greatly, the layout is reasonable, the charging and discharging are orderly and efficient, and the production efficiency is improved greatly.

Owner:FOSHAN SHIKE INTELLIGENT TECH CO LTD +2

Arranging machine

The invention relates to an arranging machine, which comprises a frame, a bottle pushing mechanism, a bottle storage area and a frame lifting device, wherein the bottle pushing mechanism comprises a bottle pushing rod and a bottle pushing power mechanism; the bottle storage area is formed on the frame; the bottle pushing mechanism is arranged at one end of the bottle storage area, and the frame lifting device is arranged at the other end of the bottle storage area; a conveyer belt mesh is arranged below the bottle pushing mechanism; the side face of the bottle storage area close to the bottle pushing rod is provided with a bottle feeding screw mechanism; the bottle storage area is provided with a bottle stopping rod and a bottle retaining bar; and air cylinders are arranged on the bottle stopping rod and the bottle retaining bar. The arranging machine has an automatic counting function, and ensures that the bottle feeding is quicker and more stable and the counting is more accurate, so that the automatic operation without human interference can be carried out and all production of products to be packaged or finished products in a batch is recorded.

Owner:南京固延制药设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com