Patents

Literature

168results about How to "Reduce work stations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cultivation techniques of cost-saving and yield-increasing winter-planted potatoes in southern China

InactiveCN102257917AReduce labor costsSave manpower andSeed and root treatmentFertilising methodsLiquid manureAgricultural engineering

The invention belongs to the technical field of culture of potato, and particularly discloses a cost-saving and yield-increasing culture technique for southern winter planting potato. The technique comprises the following steps of: selecting a land, preparing the land and furrowing; applying a base fertilizer; treating potato seeds; seeding; covering with soil; covering with a film; earthing up the film; managing liquid manure, weeds and insect pests; and harvesting, wherein a method of earthing up the film is that: a layer of smashed soil of 5-8 centimeters is covered on the film by using a machine or a hoe, so that the film on a ridge surface is covered fully. In the technique, an integral water manure furrow application method is used innovatively, so that the labor per acre is saved by 7 persons, and the acre yield is up to 9,136 jin. Due to the adoption of the technique, the increase in of the yield of potato is facilitated, the production cost is lowered, and the economic benefit of potato production is increased. On the aspect of technique, the process flow of potato production is completed, the production time of potato is shortened, and a solid technical foundation is laid for the popularizing scale, standardization and commercial production of the potato industry.

Owner:HUIDONG COUNTY JIUHUA FARMING & TRADING

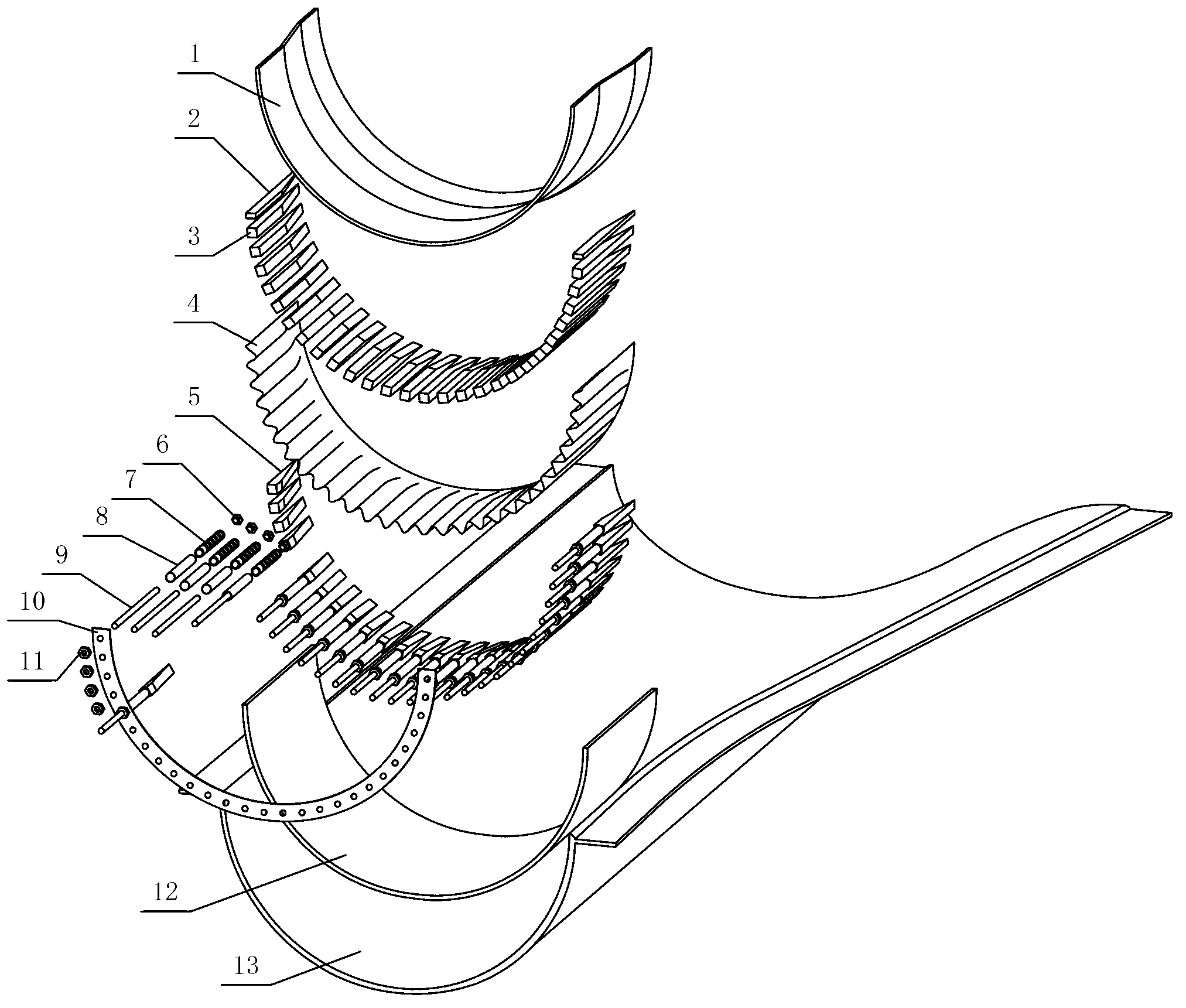

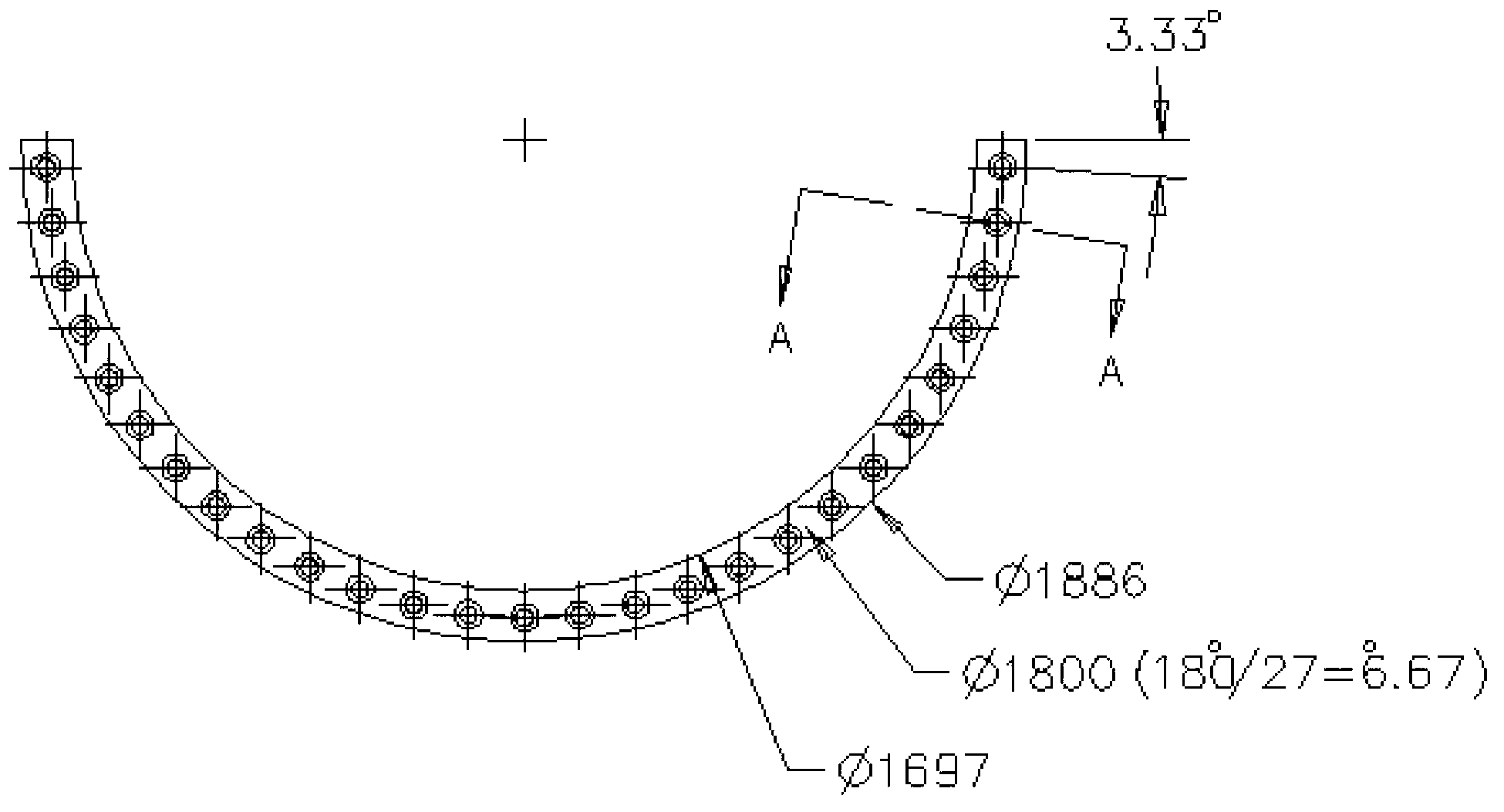

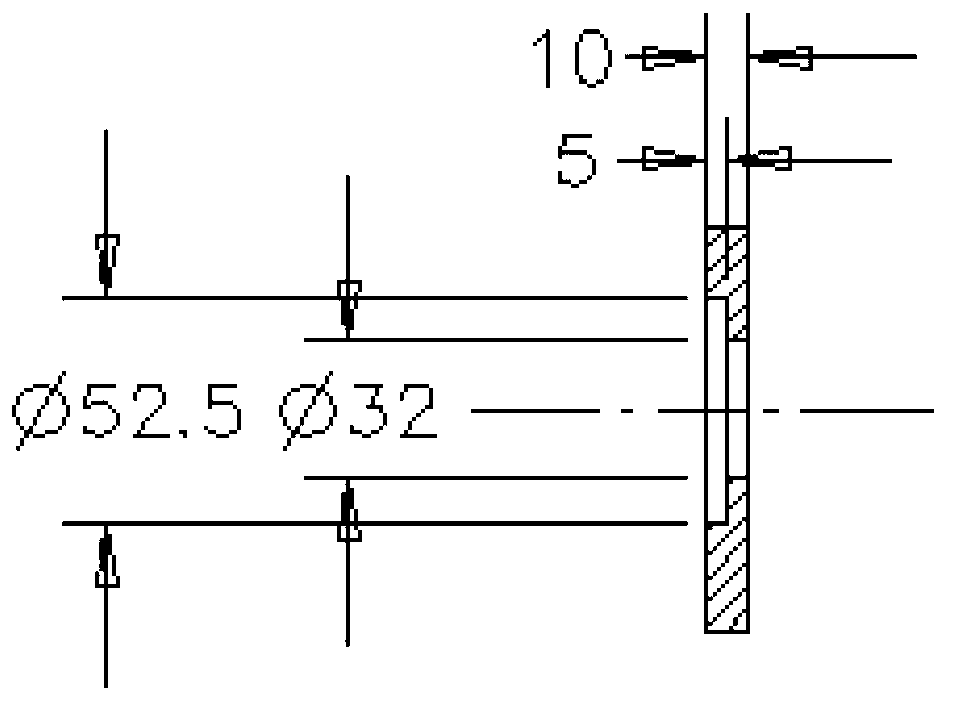

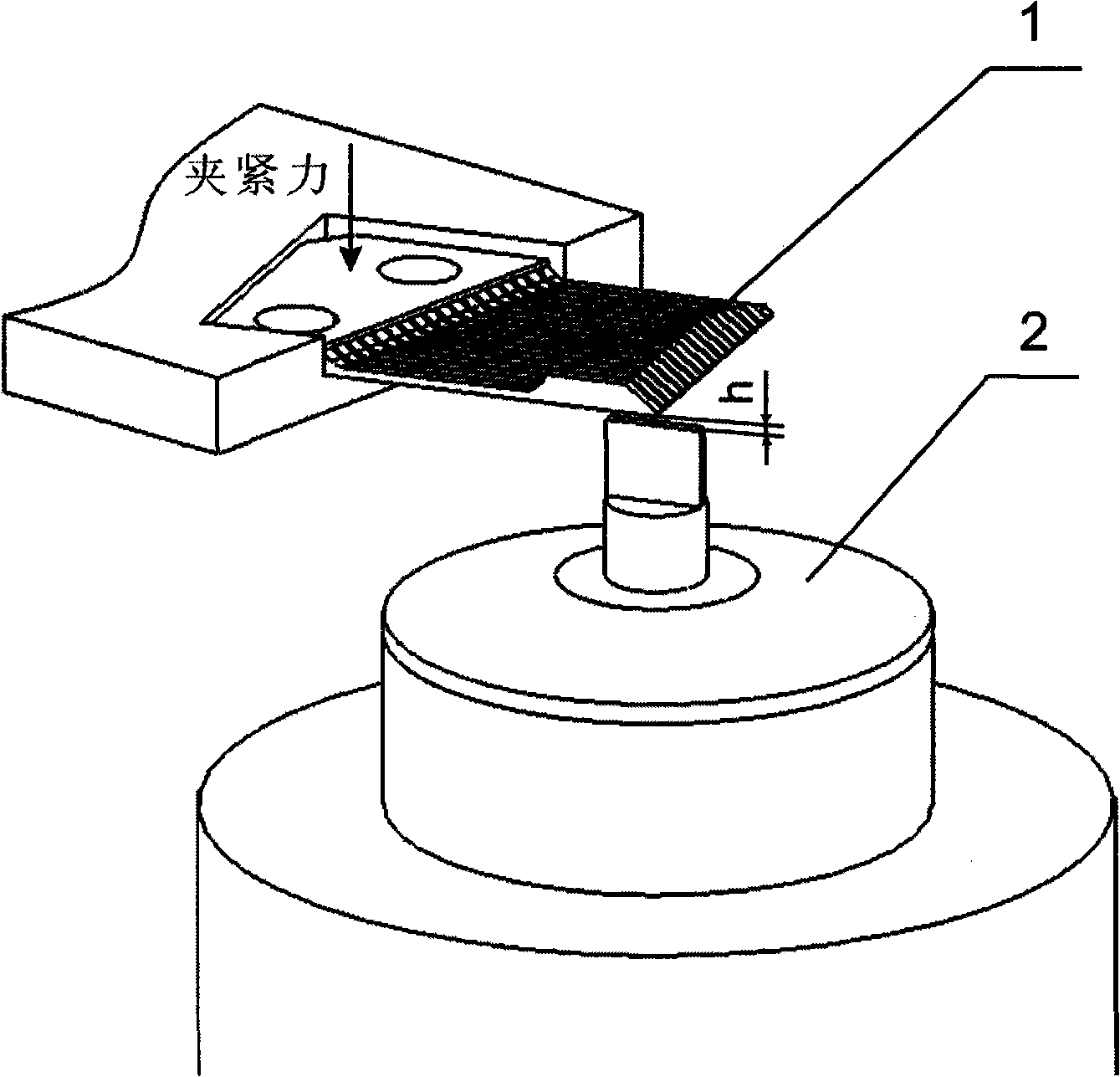

Pre-buried screw processing method for blade roots of Megawatt-level wind turbine generator set

ActiveCN103061995ATightly boundShort processFinal product manufactureWind energy generationElectricityTurbine

The invention provides a method for pre-buried screw processing method for blade roots of Megawatt-level wind turbine generator set. The method includes the steps of aligning the center of each flange hole of a blade root flange plate to corresponding center of each hole of a flange die; penetrating pre-buried screws into the flange holes of the blade root flange plate and fixing the pre-buried screws with nuts; nesting the pre-buried screws with UD sleeves; penetrating bolt sleeves into the UD sleeves; penetrating the pre-buried screws into the bolt sleeves to be tightened; penetrating threaded ends of the bolt sleeves into PVC (Poly Vinyl Chloride) wedges ; clamping the PVC chocks on the lateral sides of the UC sleeves and compacting the UD sleeves and the PVC chocks; and placing UD sticks in the inner sides of the US sleeves, filling the UD sticks between neighboring bolt sleeves, pounding the US sticks tight, and filling clearances among the UC sleeves, the UD sticks and the bolt sleeves with the UD sticks. By the aid of the method, technological process is shortened, rate of finished products is increased, working position is reduced, and production efficiency is improved; and further wind turbine generator set the pre-buried screws and the wind turbine generator set are combined tightly.

Owner:甘肃重通成飞新材料有限公司

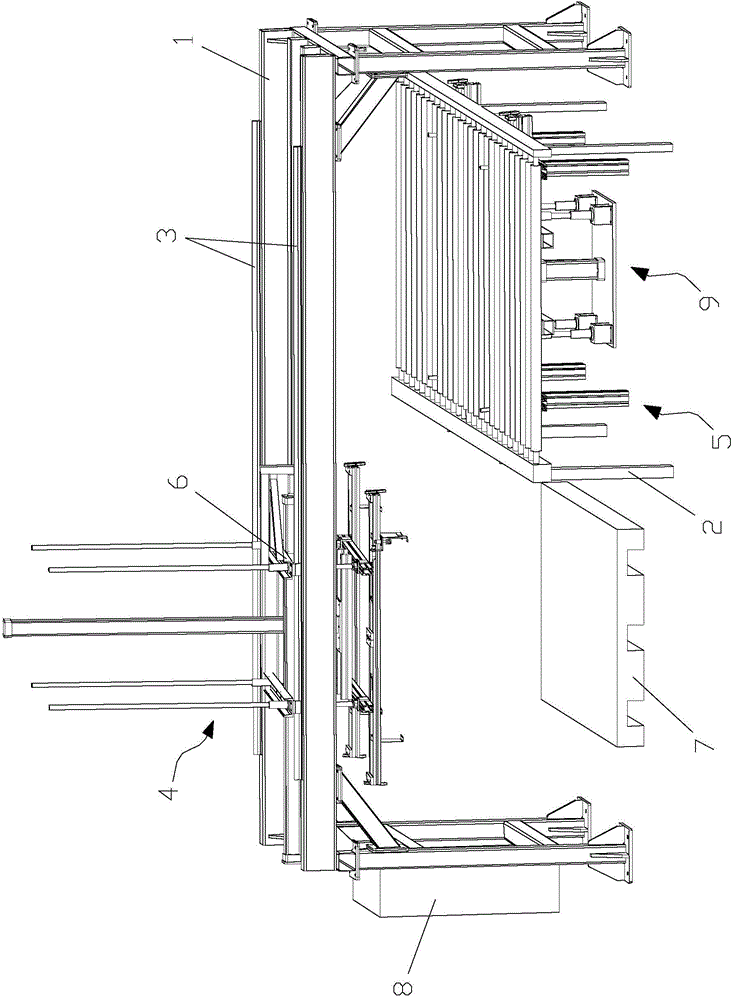

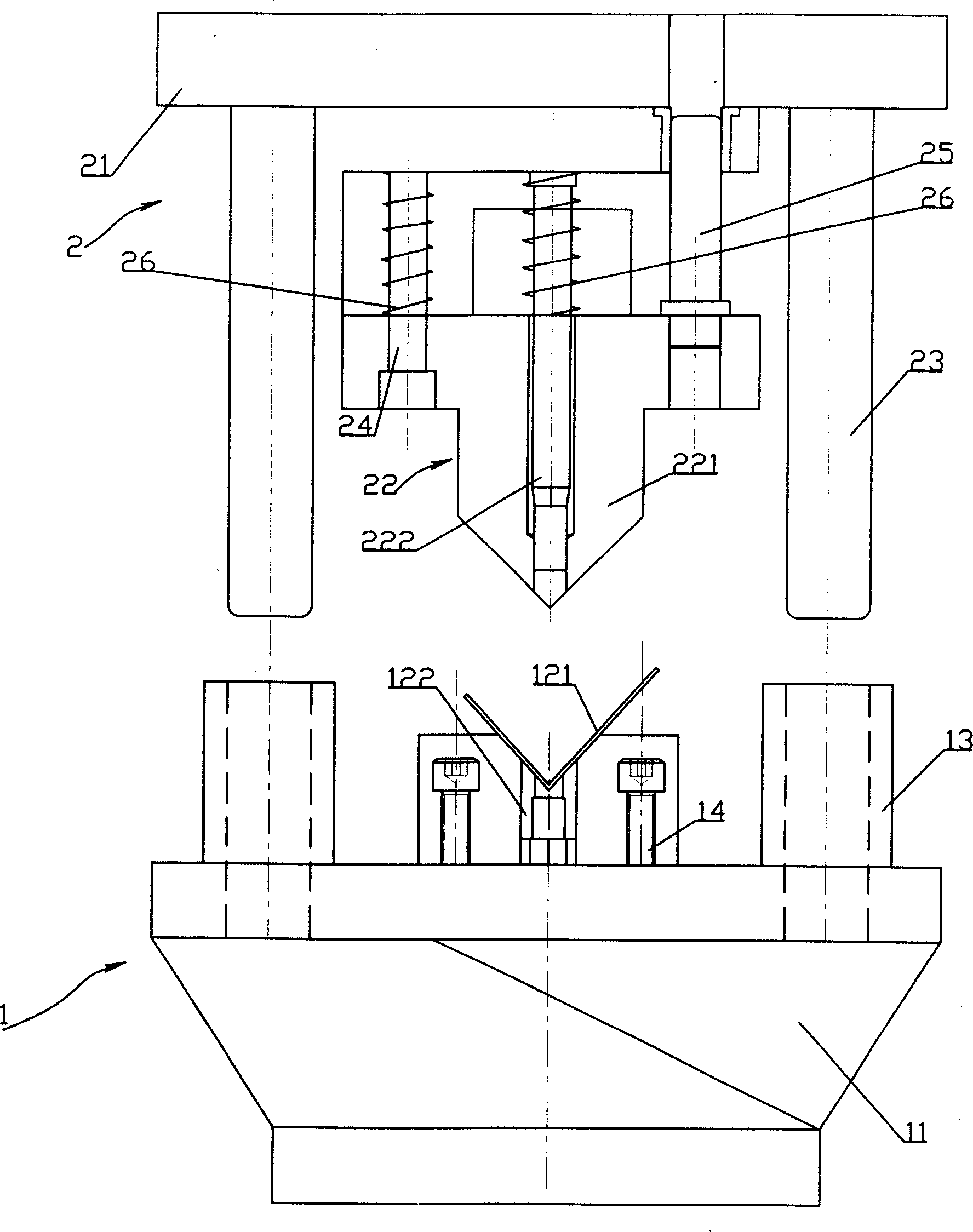

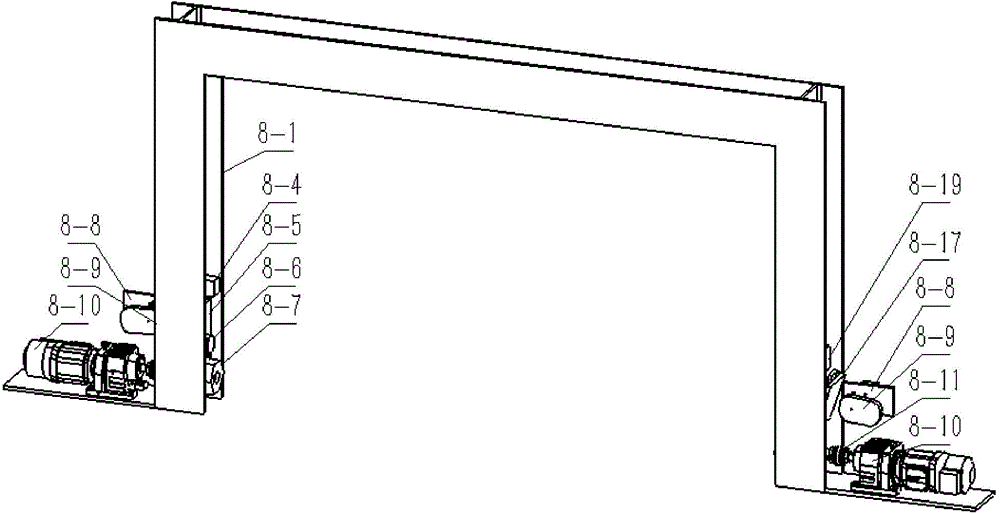

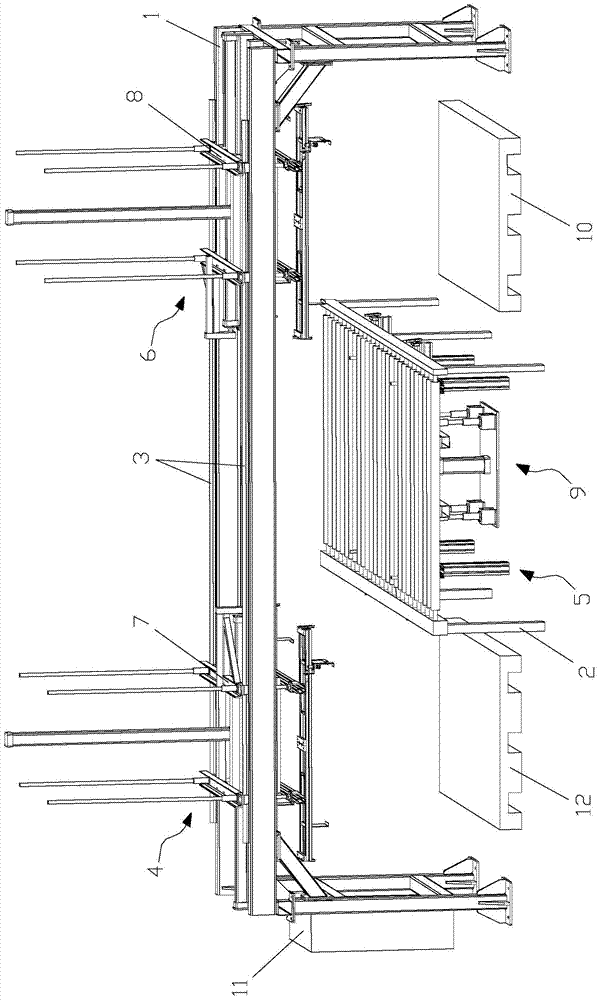

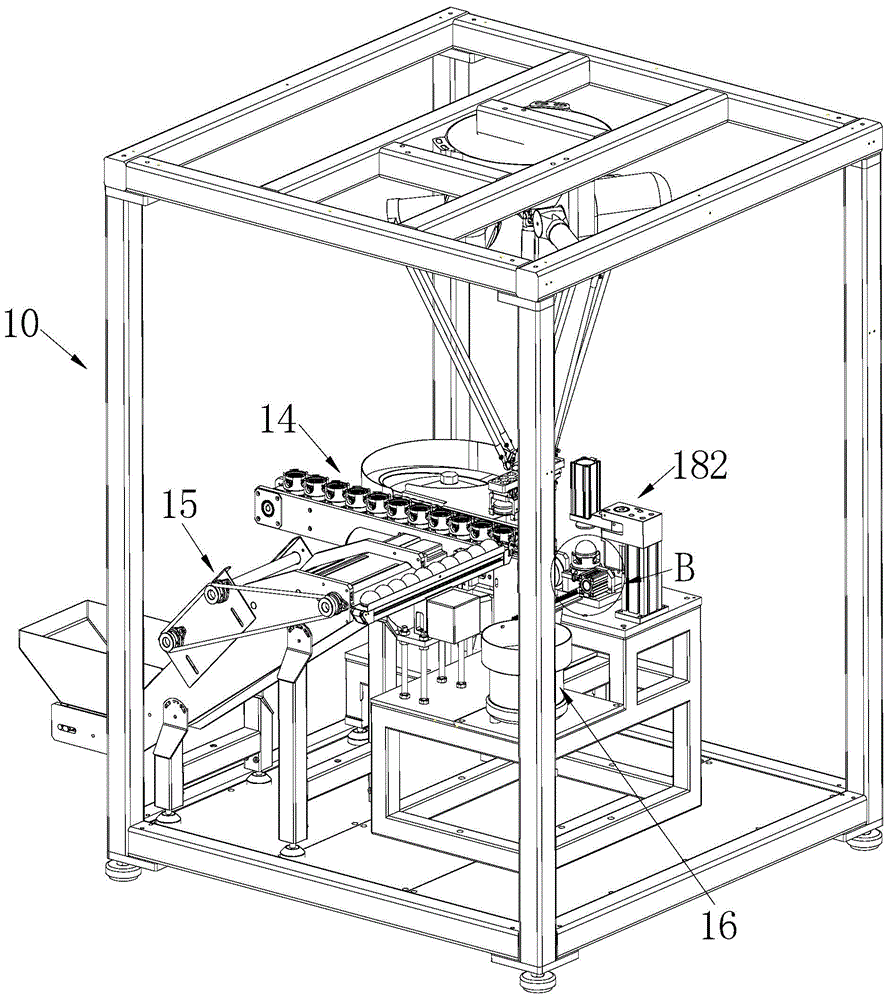

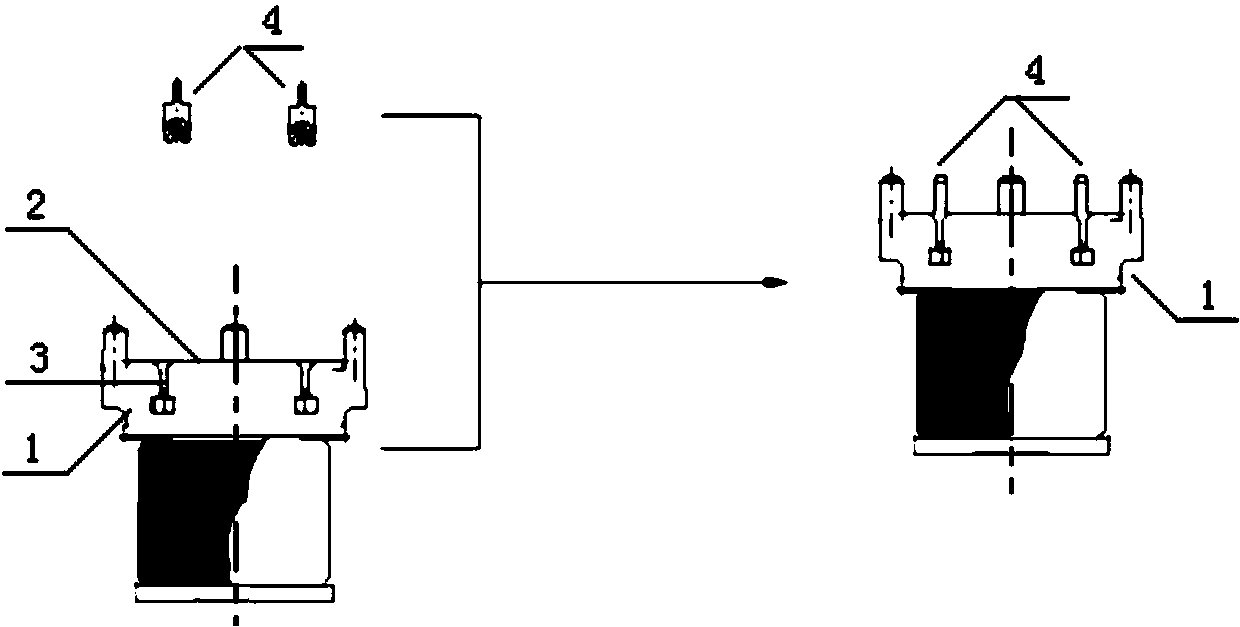

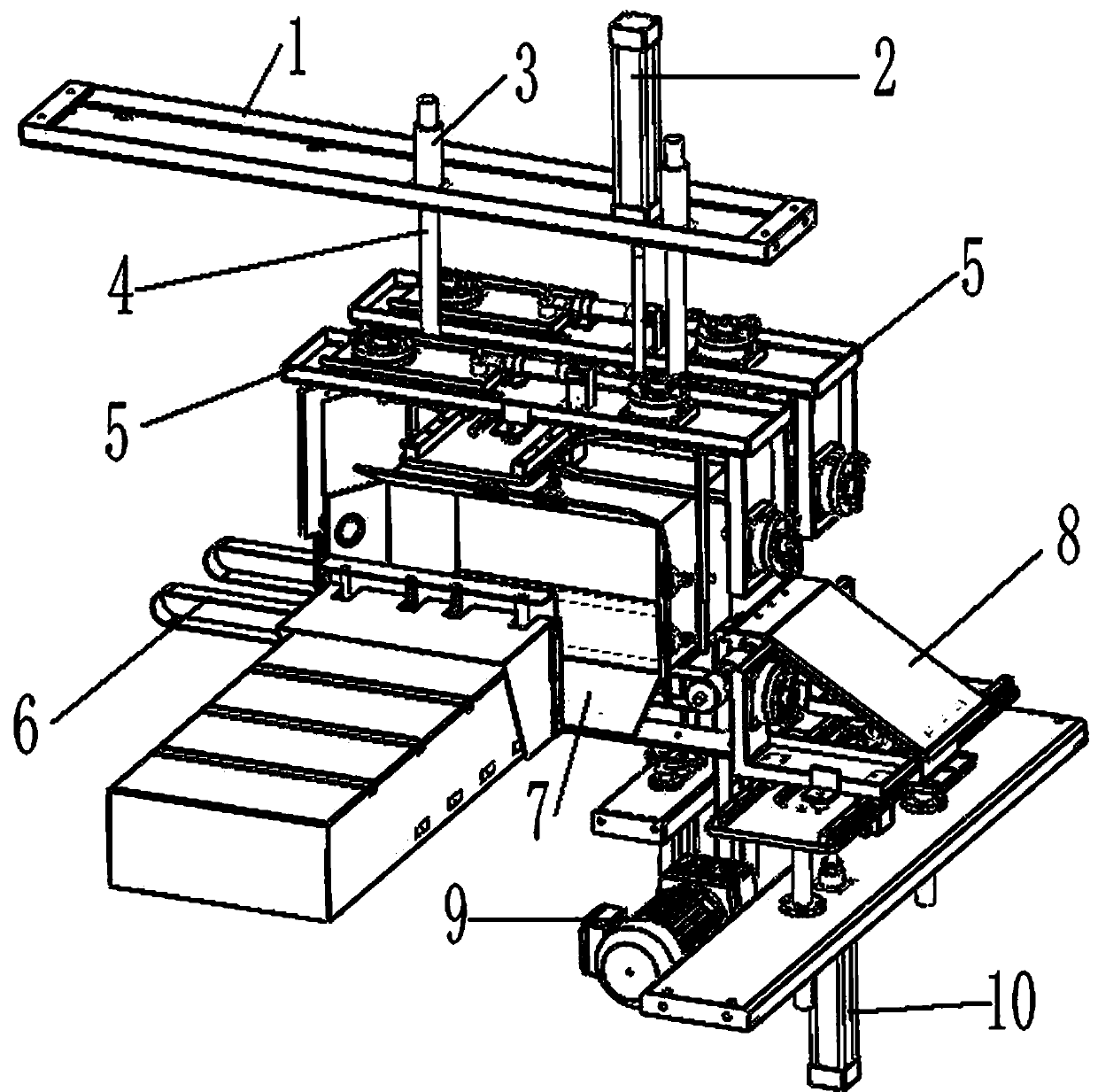

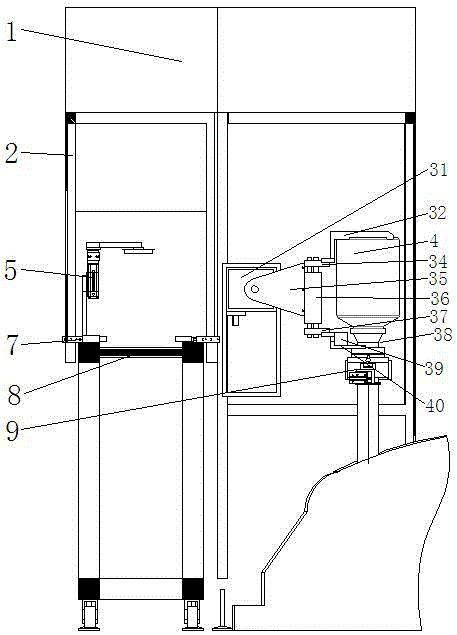

Stacker crane with automatic delivery of single station for flat plate collector

InactiveCN104649023APrecise positioningPrecise handlingConveyorsStacking articlesProduction linePalletizer

The invention discloses a stacker crane with automatic delivery of a single station for a flat plate collector. The stacker crane comprises a portal frame and a production line support arranged under the portal frame, wherein a guide rail is arranged on the portal frame; a collector transporting and clamping mechanism in sliding connection with the guide rail is also arranged on the portal frame; a collector locating mechanism is arranged under a transporting area of the production line support; the collector enters into the transporting area along with a production line; the collector locating mechanism can locate the collector on the transporting area; the collector transporting and clamping mechanism moves to the position above the collector through a sliding seat along the guide rail and downwards moves to clamp the collector, so that the clamped collector is transported and placed on a transferring area along the guide rail. The safety of collector transporting is ensured, the reliability of production is ensured, the limitation on the width of a production line and the influence on the safe operation of the transporting mechanism can be eliminated, and the application range is wide. In addition, manual handling is replaced, so that the labor intensity is greatly reduced, the labor used is reduced, and the labor cost is reduced.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

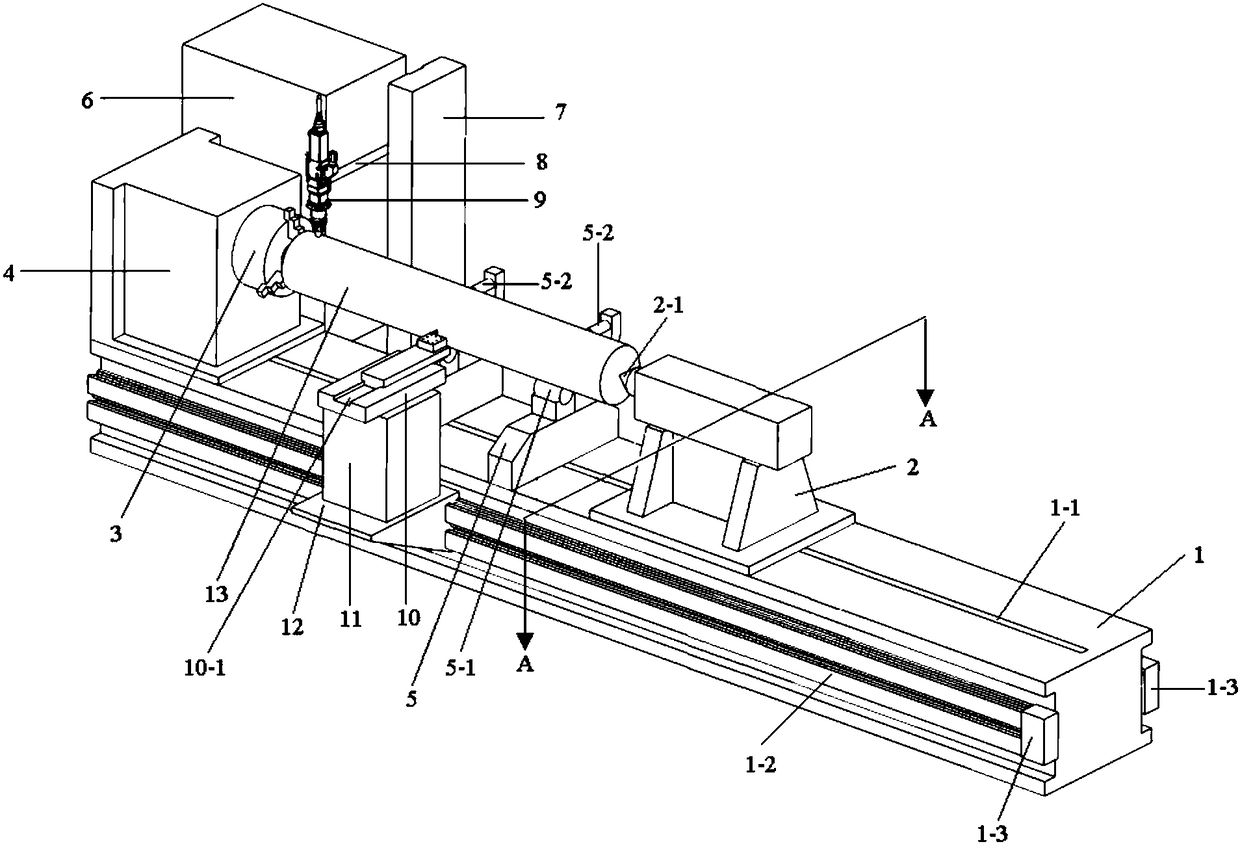

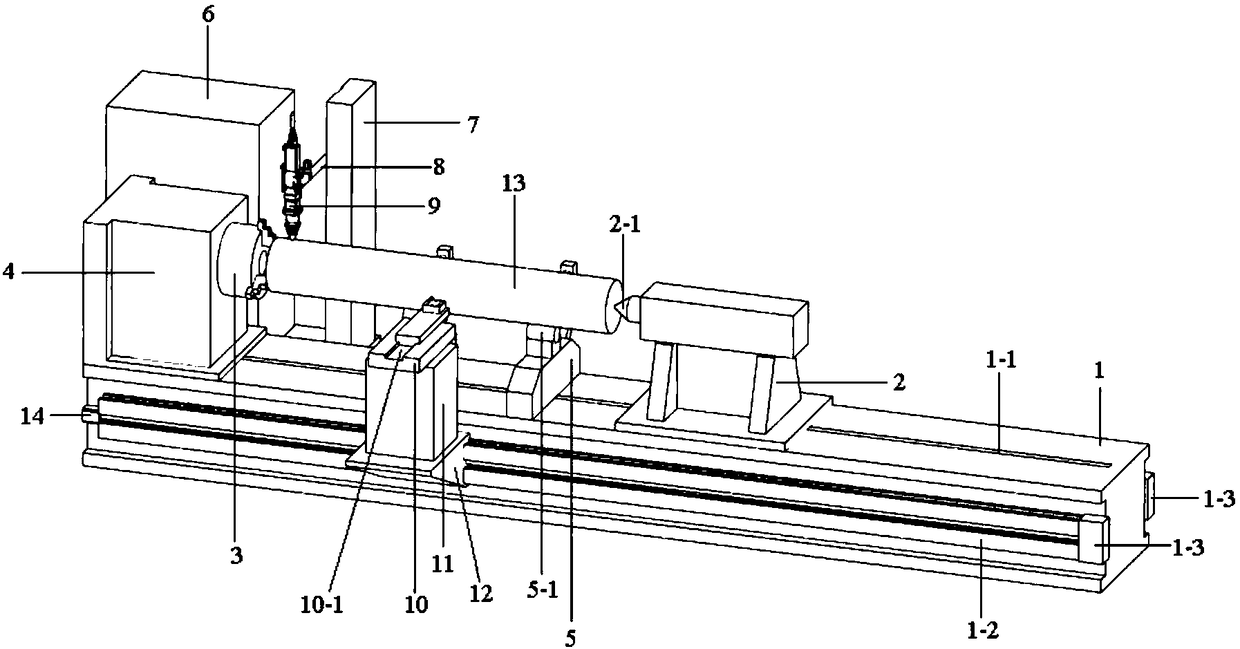

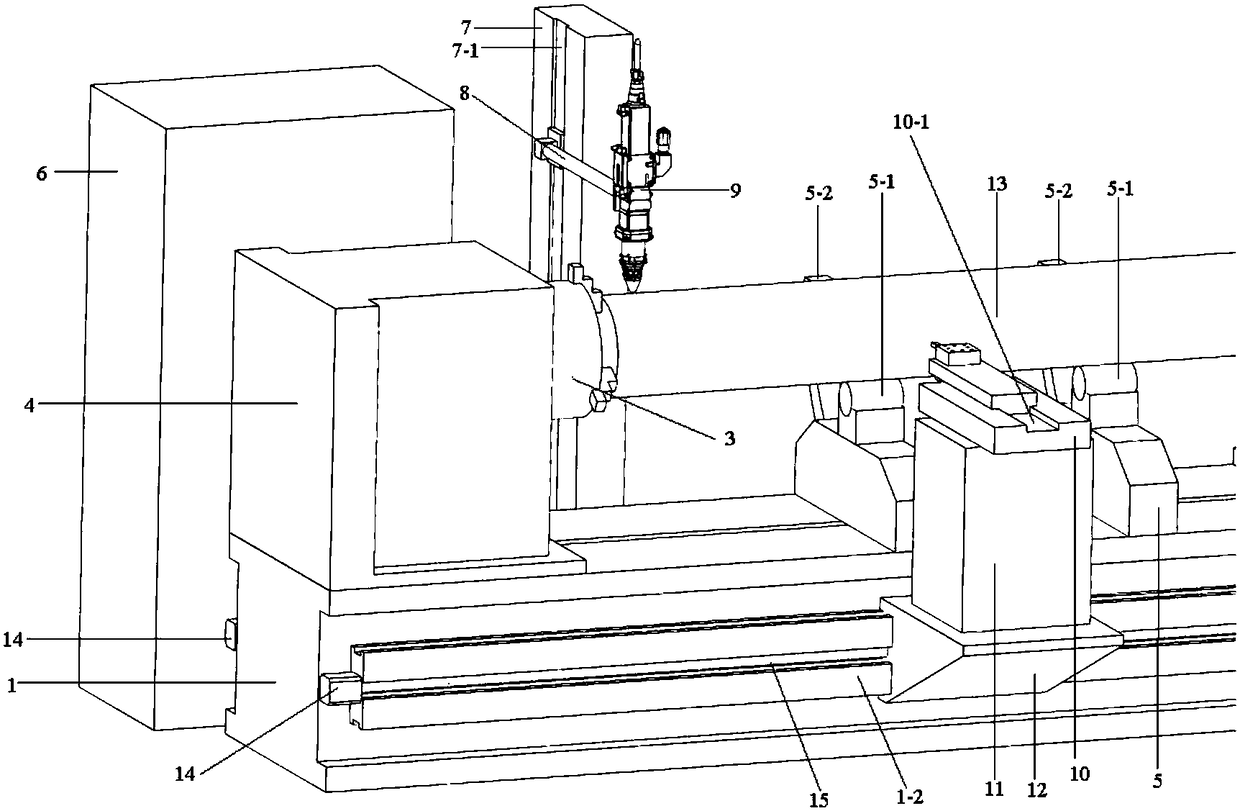

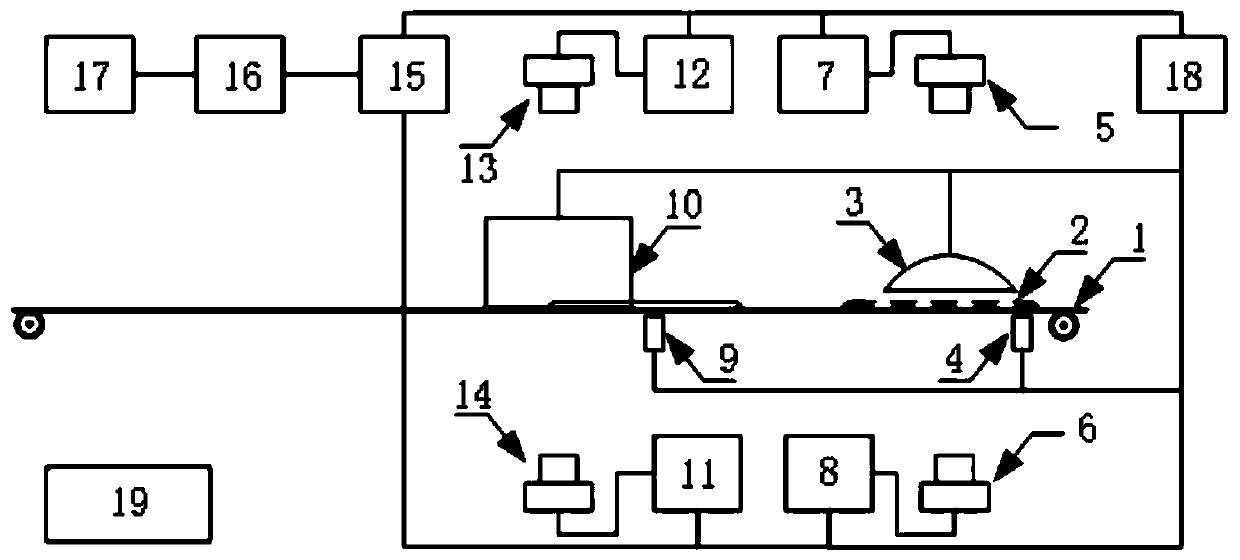

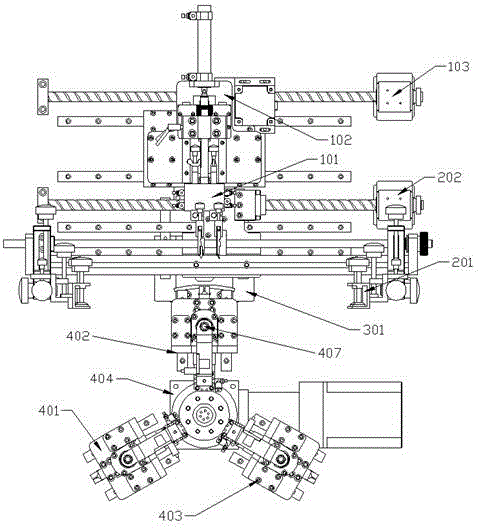

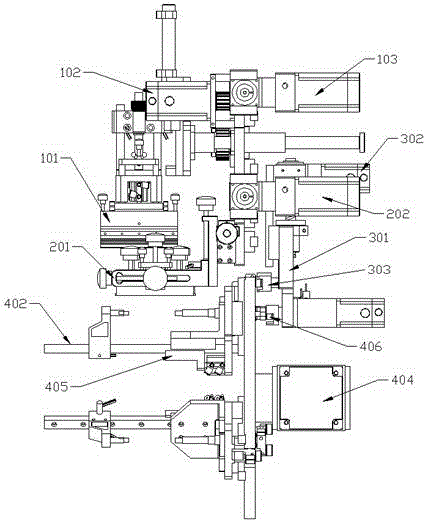

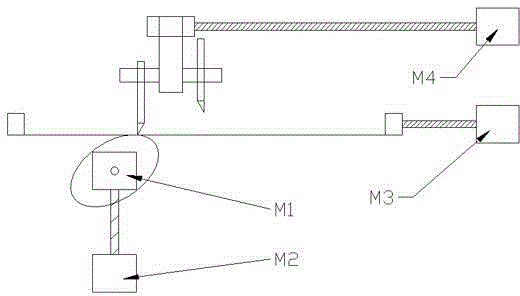

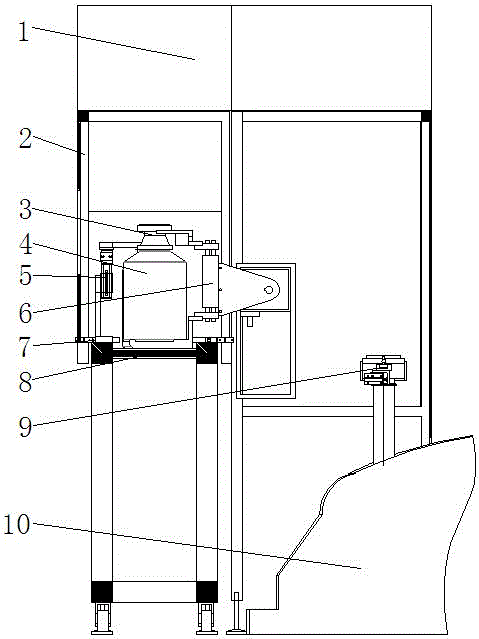

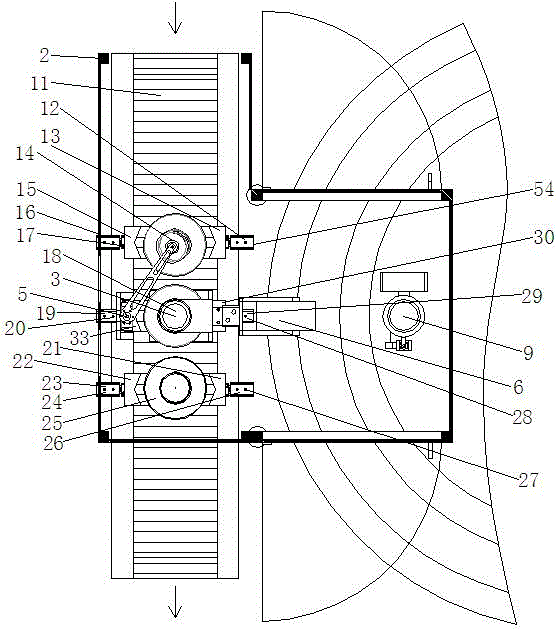

High-speed laser cladding and turning integrated machine device

PendingCN108544238APrevent deviationGuaranteed uniformityOther manufacturing equipments/toolsIncreasing energy efficiencyNumerical controlEngineering

The invention discloses a high-speed laser cladding and turning integrated machine device, and relates to a laser cladding device. The high-speed laser cladding and turning integrated machine device aims to solve the technical problem that before high-speed laser cladding of existing shaft parts, the parts in front and back processes often deviate from the axis due to multiple-times disassembling,assembling and clamping during turning. The high-speed laser cladding and turning integrated machine device is composed of a machine tool, a tail seat, a head seat, a supporting seat, a tool holder,a tool holder sliding table and a laser head fixed body sliding table. Slideways are separately arranged on the two side faces of the machine tool, and the tool holder sliding table and the laser headfixed body sliding table are separately arranged on the two slideways. A tool holder base is fixed to the upper end face of the tool holder sliding table, and a laser head fixed body is fixed to theupper end face of the laser head fixed body sliding table. The tail seat and the head seat are arranged at two ends of the upper end face of the machine tool, and the supporting seat is arranged between the head seat and the tail seat. According to the high-speed laser cladding and turning integrated machine device, two processes of numerical control turning and laser cladding are arranged in onestation and carried out simultaneously to improve production efficiency, and at the same time, the condition of axial deviation caused by repeated clamping of the parts is avoided.

Owner:ACUNITY TIANJIN CO LTD

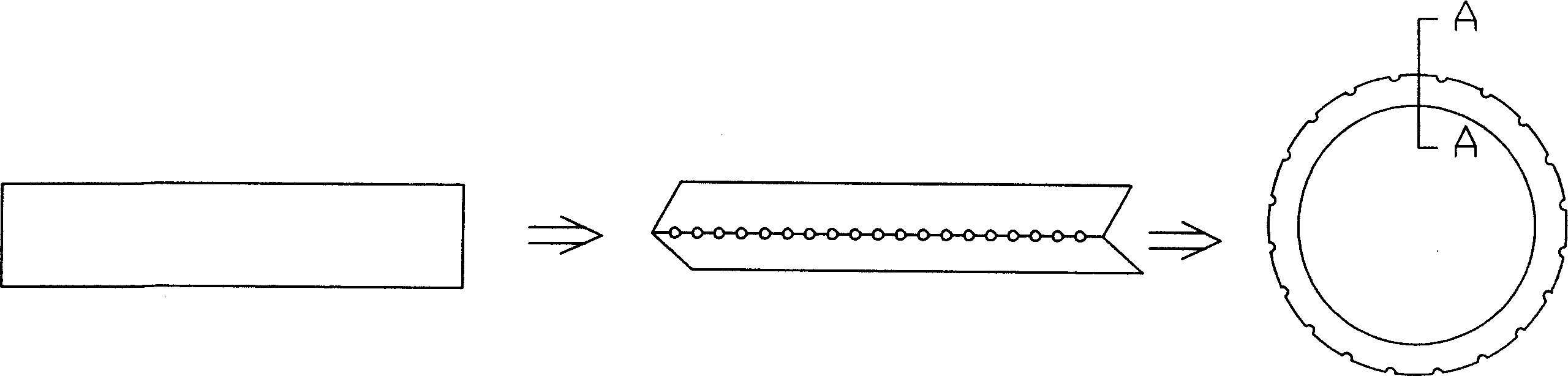

Composite process for bending and punching external protecting ring of steel reel and moulds thereof

A technology for bending the protecting ring of coiled steel and punching holes on it includes such steps as decoiling steel band, shearing to become steel strip, bending to become angular strip while punching 20 holes, and rounding. Its die set is composed of a female die unit consisting of lower die holder and combined bending and punching female die, and a male die unit consisting of upper die holder, bending male die, punching male die, and guide rods.

Owner:上海宝钢工贸实业有限公司

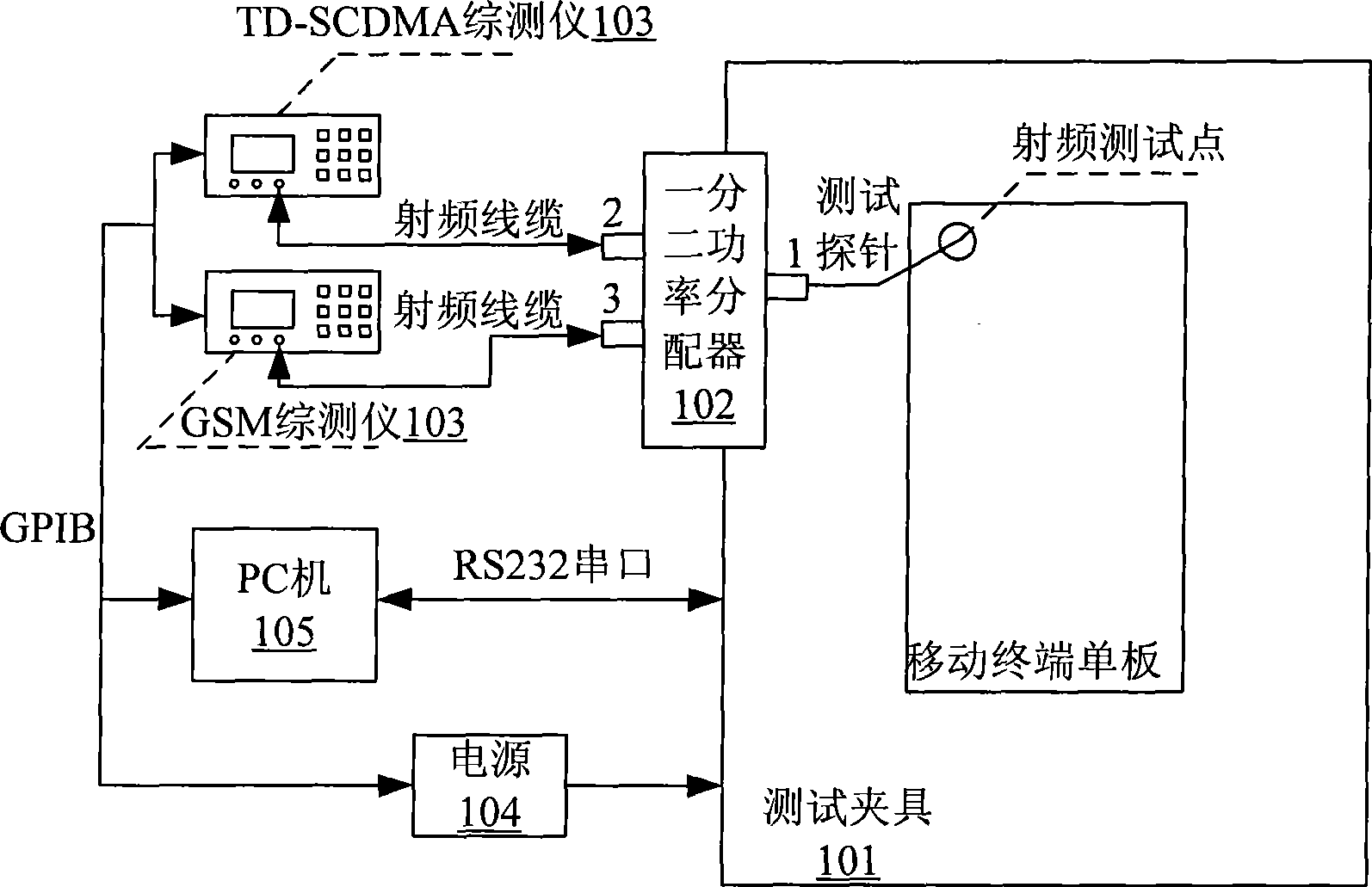

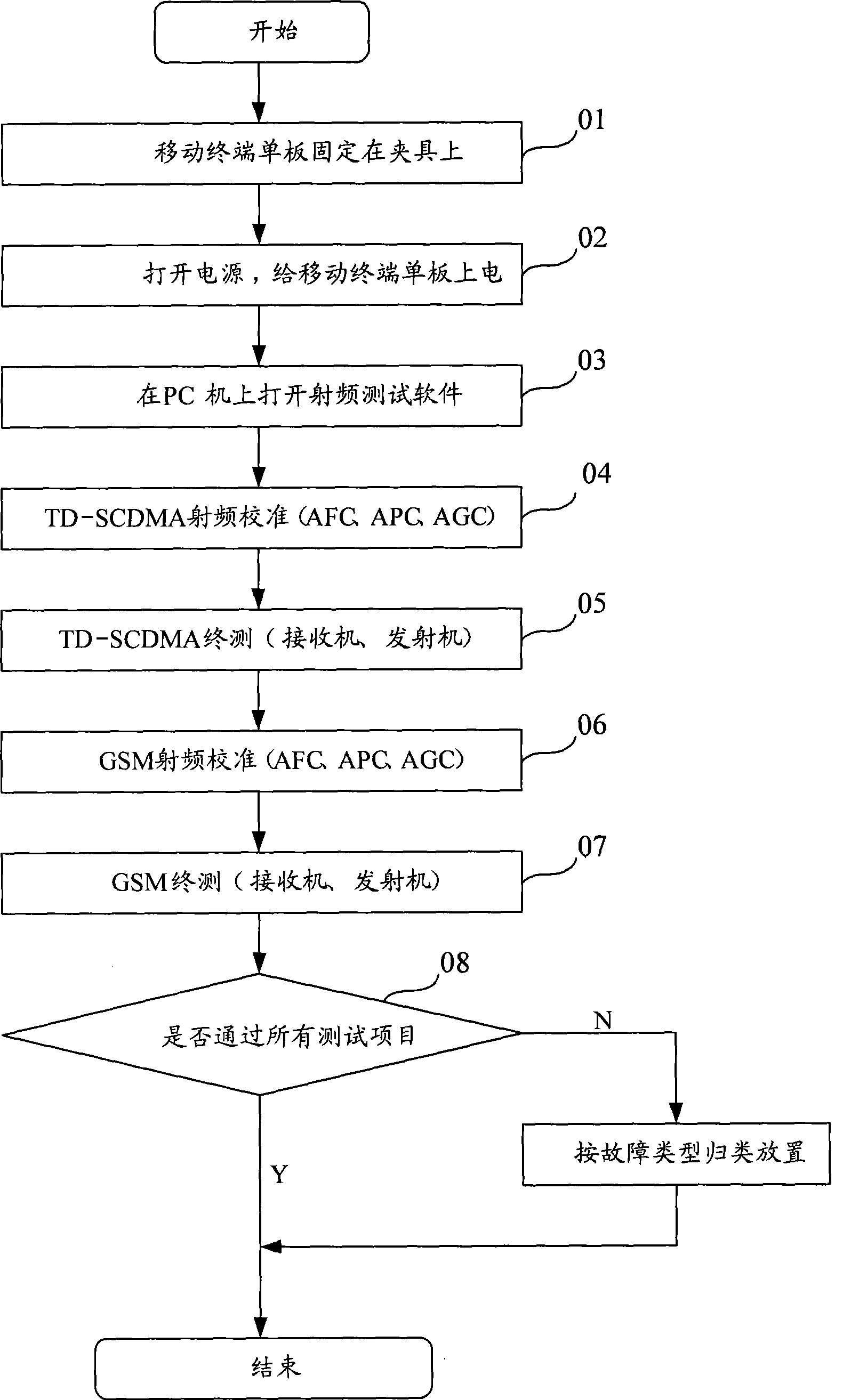

Veneer radio frequency test system for dual-mode single-standby mobile terminal

ActiveCN101374317ASave time for manual switchingReduce work stationsRadio/inductive link selection arrangementsRadio frequencyEngineering

The invention provides a single-board RF testing system of double-mode single-standby terminal, which includes: a testing clamp for fixing single-board; a power divider of one dividing into two, which is equipped on the testing clamp and is connected with an integrated testing instrument, for converting between the RF index calibration and final test under various types of systems; an integrated testing instrument, which is connected with single-board testing interface through the power divider of one dividing into two and the testing clamp, for carrying out RF index calibration and final test of the single-board with every kinds of modes; a power, which is connected to the testing clamp and a computer, for supplying power for the single-board through the computer control and the testing clamp; and a computer, which is used for connecting the integrated testing instrument group to the power supply, and controlling operation of the integrated testing instrument group and the power supply of the power to the single-board, and connecting to the testing clamp, thereby transmitting data to the single-board through the testing clamp. Thereby, the automation of TD-SCDMA / GSM double-mode single-standby mobile terminal RF testing process is realized, and the testing time is shortened, and the work efficiency is improved.

Owner:ZTE CORP

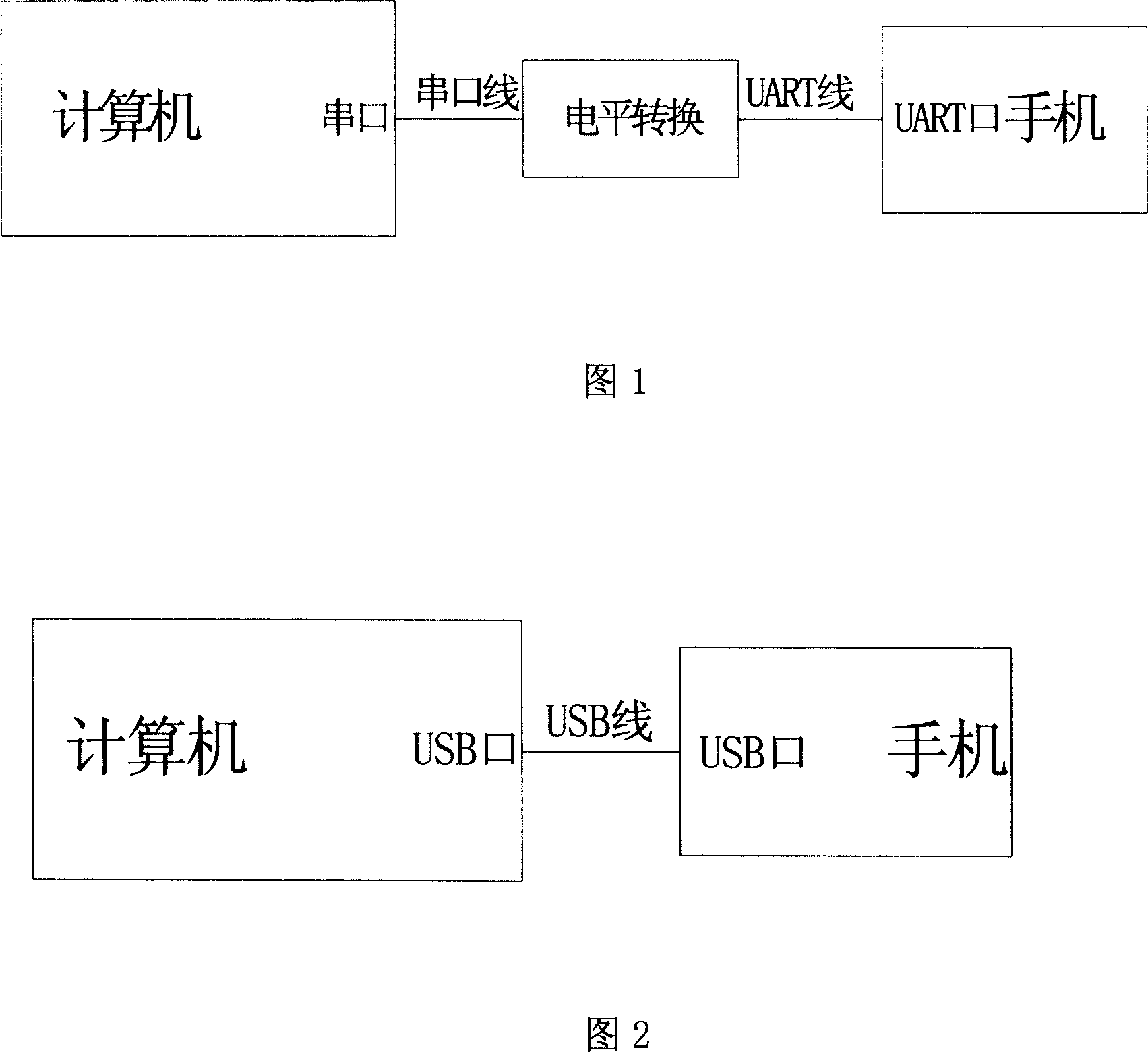

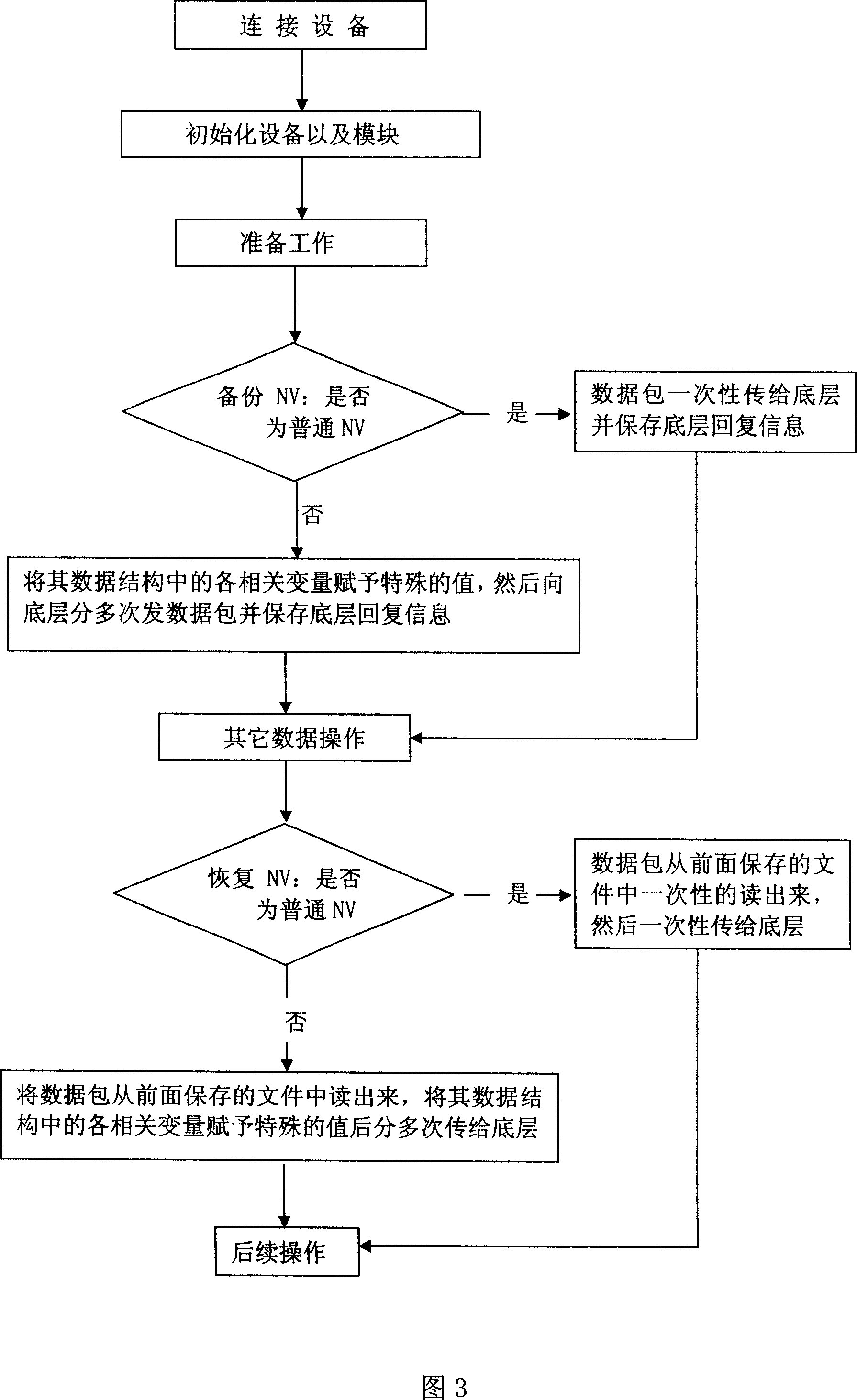

Terminal NV parameter backup recovering method

InactiveCN101137140AReduce labor costsReduce work stationsEnergy efficient ICTRadio/inductive link selection arrangementsNetwork packetBackup

This method includes steps: Step A. Transfer the data pack with NV_ITEM number (NN) to the bottom layer device (BLD). Step B. store the reply data pack sent from BLD into the file. Step C. Read the data pack with NN from the file and transfers it to BLD. Step D. BLD restores NV parameter. This invention can backup and restore any number of NV items, no matter it is the common NV or the special NV. Therefore, depending on different requirement of each project, this invention can backup and restore corresponding standard NV and save many working position, which is needed to execute the NV operation during the re-doing process before. This invention raises the production efficiency and saves lot of manpower cost for the company and the project.

Owner:ZTE CORP

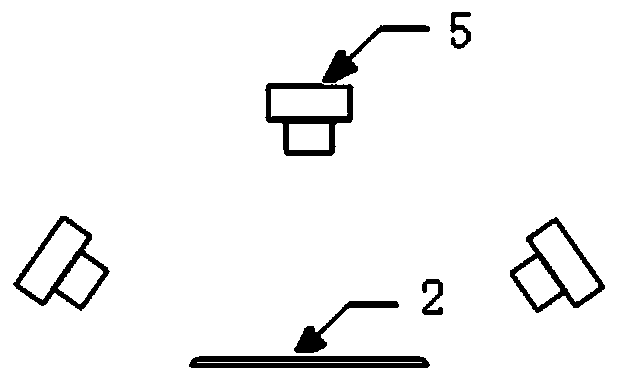

Curved glass defect detection system and method

PendingCN110567977AReduce work stationsImprove detection efficiencyOptically investigating flaws/contaminationPhysicsBoundary detection

The invention discloses a curved glass defect detection system and method. A linear array camera and an area-array camera which are arranged in a double-station distributed manner are utilized; a first program-controlled three-dimensional multi-light-field light source and a second program-controlled three-dimensional multi-light-field light source which are optimally designed are matched with thelinear array camera and the area-array camera, and therefore, the image acquisition of different parts (plane part, long arc edge, R angle and short arc edge) of curved glass under different illumination environments is realized; a linear array camera data preprocessing platform and an area-array camera data preprocessing platform based on an embedded system are used to carry out filtering, boundary detection, defect detection and other preprocessing on images; and preprocessed image data are transmitted to a data processing terminal through a program-controlled switch so as to be subjected to defect identification and classification. The curved glass defect detection system has the advantages of simple structure, stability, efficient detection, accurate defect recognition and easiness inmanagement.

Owner:湖南讯目科技有限公司

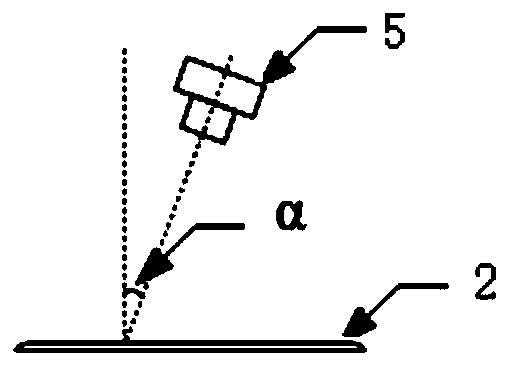

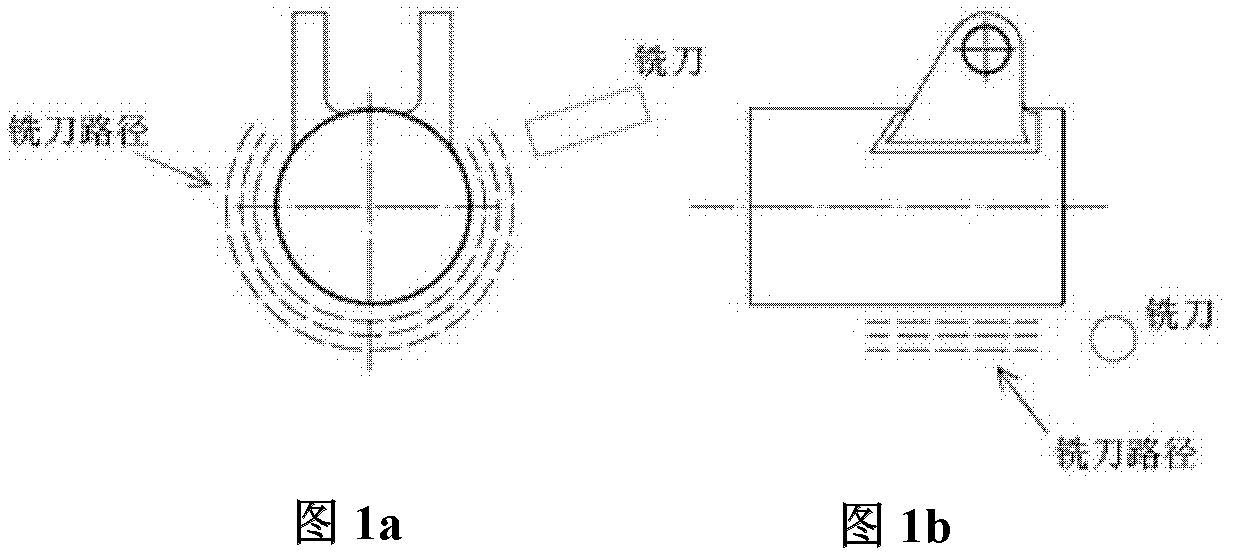

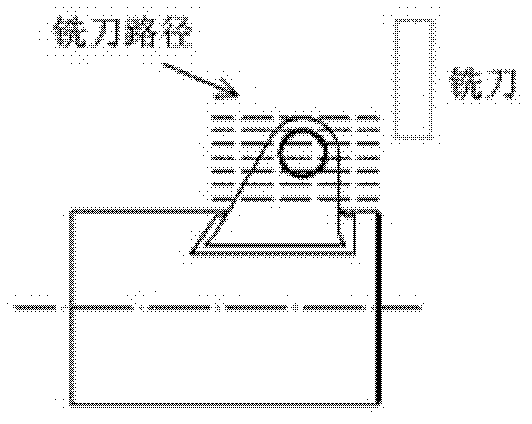

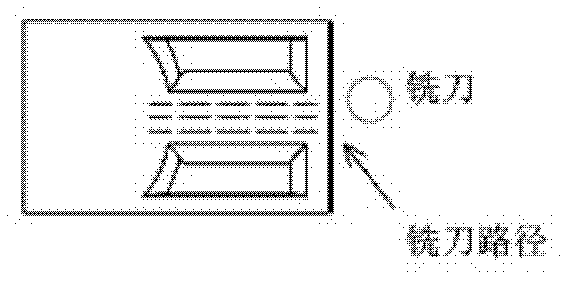

Method for turning and milling to realize typical characteristics of aircraft landing gear

InactiveCN102581620AShorten the time for clamping and positioningHigh clamping precisionOther manufacturing equipments/toolsMilling equipment detailsAircraft landingMachining process

A method for turning and milling to realize typical characteristics of an aircraft landing gear includes the steps: firstly, orthogonal turn-milling for rough machining; secondly, milling to remove intermediate allowance of a lug; thirdly, fine trimming of the bottom of the lug; fourthly, milling of the periphery of the lug; fifthly, fine trimming of the top of the lug; sixthly, semi-finish machining of the inner wall of the lug; seventhly, semi-finish machining and finish machining of the outer wall of the lug; eighthly, finish machining of the inner wall of the lug; and ninthly, finish machining of an outer cylindrical surface. The method mainly aims to realize the common lug characteristics of parts of the landing gear to solve problems in machining the parts. The technological method has the advantages that machining efficiency and the quality of surfaces of workpieces can be effectively improved, and simultaneously, machining is lowered. In addition, the method has an actual reference value in the field of machining process.

Owner:BEIHANG UNIV +1

Multi-station full-automatic screen printing machine

InactiveCN104527216ANo need to adjust the mechanical structurePoor positioningScreen printersScreen printingEngineering

The invention discloses a multi-station full-automatic screen printing machine. The multi-station full-automatic screen printing machine comprises screen printing equipment, a scraper system, a screen frame system, a floating shaft system and a manipulator system, wherein the scraper system, the screen frame system, the floating shaft system and the manipulator system are arranged on the screen printing equipment; movement of the screen printing screen frame, movement of a scraper, rotation and surface change of a product, pre-positioning actions and actions of feeding and discharging manipulators are all controlled through a servo motor and a high-precision screw-nut pair, and movement control is accurate; the multi-station full-automatic screen printing machine can perform double-surfaced screen printing on round bottles and oval bottles and perform multi-surface screen printing on square bottles and special-shaped bottles; besides, the bottles are convenient to replace, the cycle is short, efficiency is high, and workers can easily master the skills.

Owner:无锡柳川智能装备有限公司

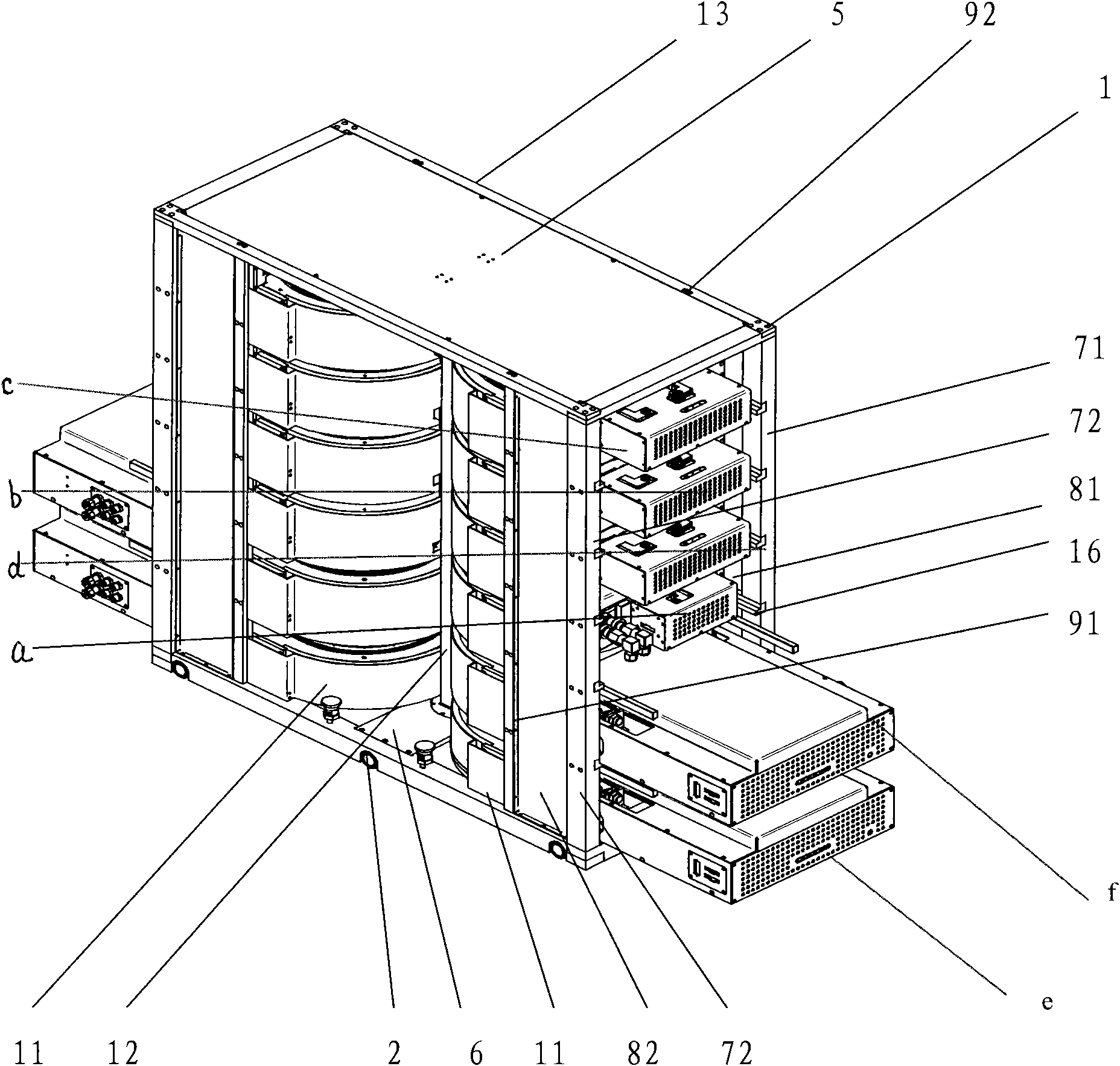

Wafer buffering apparatus in semiconductor device

ActiveCN105321858AReduce the burden onThe downside of reducing exercise time increasesSemiconductor/solid-state device manufacturingConveyor partsPower semiconductor deviceEngineering

The present invention belongs to the field of wafer processing in the semiconductor industry, and specifically a wafer buffering apparatus in a semiconductor device. The wafer buffering apparatus in the semiconductor device includes a first wafer box, a second wafer box, a first air cylinder, a second air cylinder and a bottom plate. The first air cylinder and the second air cylinder are mounted on the bottom plate separately. The first wafer box and the second wafer box are connected with input ends of the first air cylinder and the second air cylinder respectively, and are driven by the first air cylinder and the second air cylinder respectively to alternately move to the position that a manipulator picks up and delivers wafers, namely, the first wafer box or the second wafer box move to the position that the manipulator picks up and delivers wafers, and the second wafer box or the first wafer box locate on a vacancy position. The wafer buffering apparatus in the semiconductor device has simple structure, is convenient to operate. A plurality of wafer boxes provide the function that the manipulator picks up and delivers wafers at the same position through a linear guide way so as to ease the burden of the manipulator, reduce the defect of movement time increasing of the manipulator due to more positions, shorten the time required by processing, and improve the working efficiency.

Owner:SHENYANG KINGSEMI CO LTD

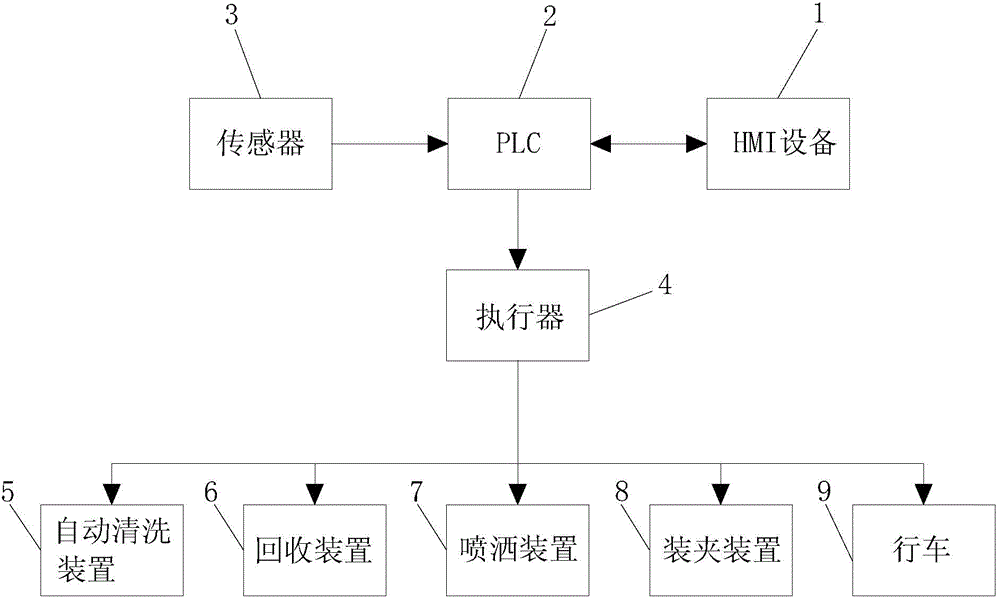

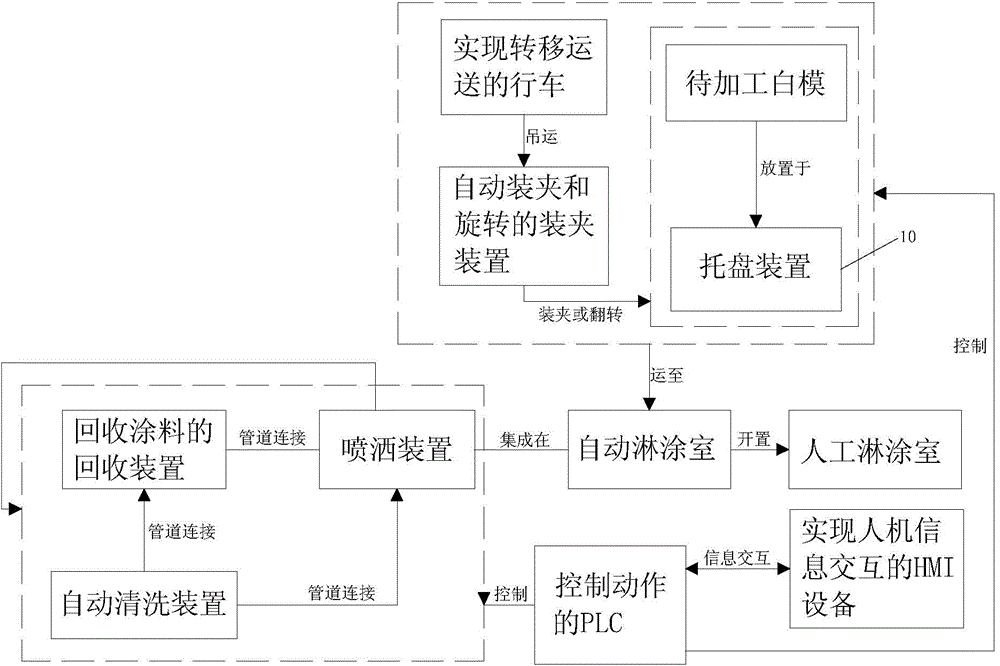

Automatic curtain-coating system for lost foam casting

ActiveCN104588250AHigh degree of automationImprove efficiencyLiquid surface applicatorsLiquid spraying apparatusDevice formControl system

The invention relates to an automatic curtain-coating system for lost foam casting. The system comprises a control system, a curtain-coating-recovery-cleaning system, a clamping device, a pallet device and a traveling crane, wherein the curtain-coating-recovery-cleaning system is formed by integrating an automatic cleaning device, a recovery device and a spraying device through a pipeline and a reversing valve; the automatic cleaning device, the recovery device, the spraying device, the clamping device and the traveling crane are connected with the control system through cables; the curtain-coating-recovery-cleaning system is distributed in the conveying direction of the traveling crane; the clamping device is connected to the traveling crane through a steel cable; the pallet device is connected with the clamping device; the recovery device and the spraying device form curtain-coating equipment. The system has the advantages of high automation degree, high efficiency, low production cost and the like, safety in a production process can be improved, curtain-coating quality can be ensured, manpower is saved, and working efficiency is improved.

Owner:WUHU ANPU ROBOT IND TECH RES INST

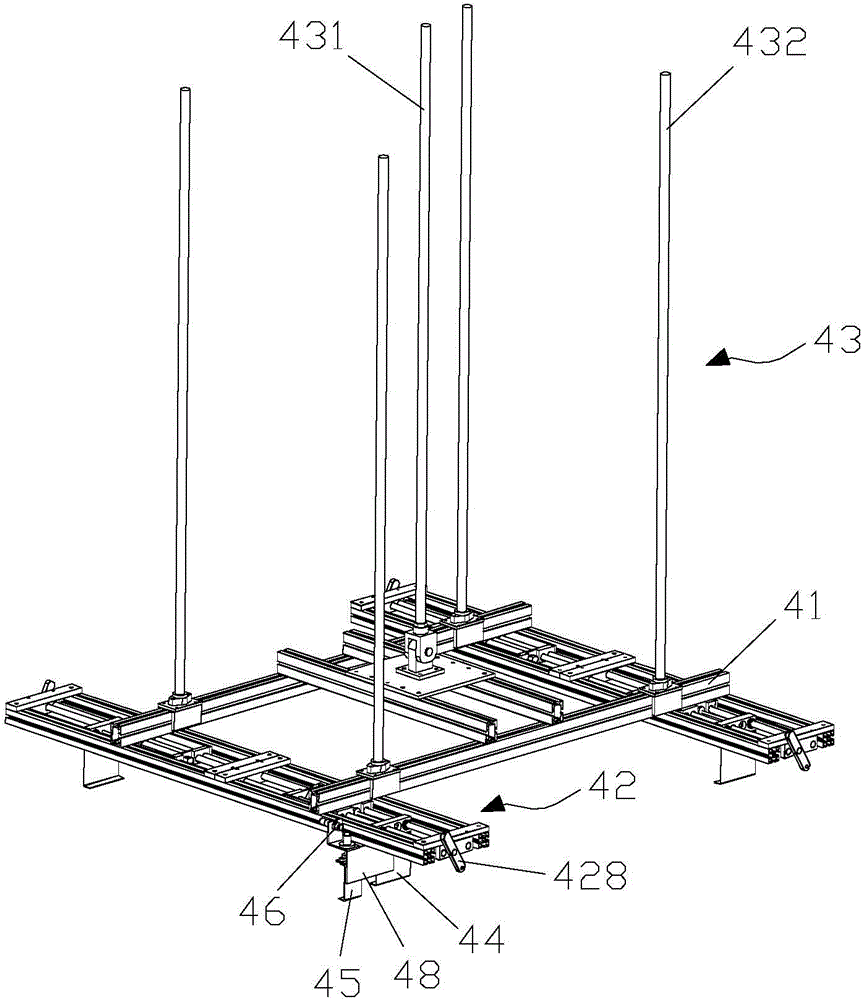

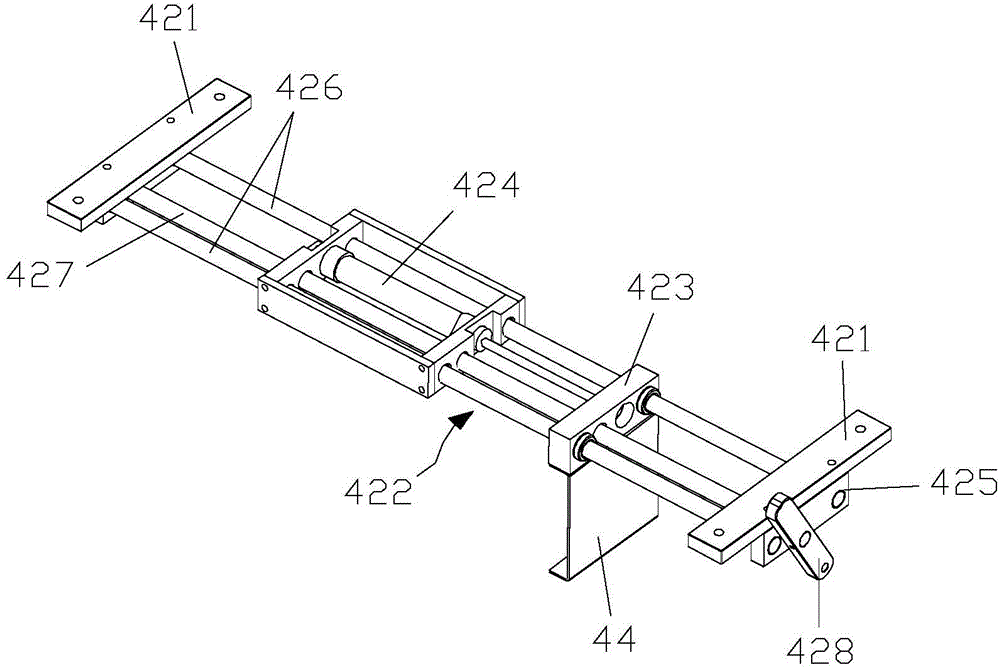

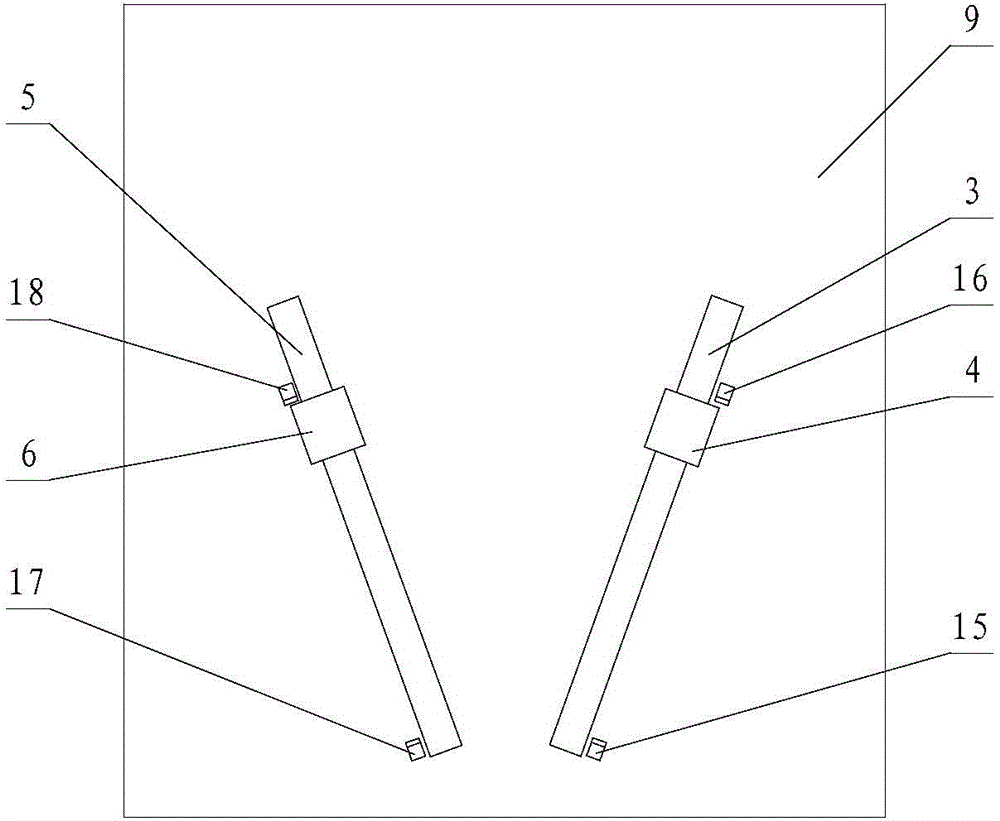

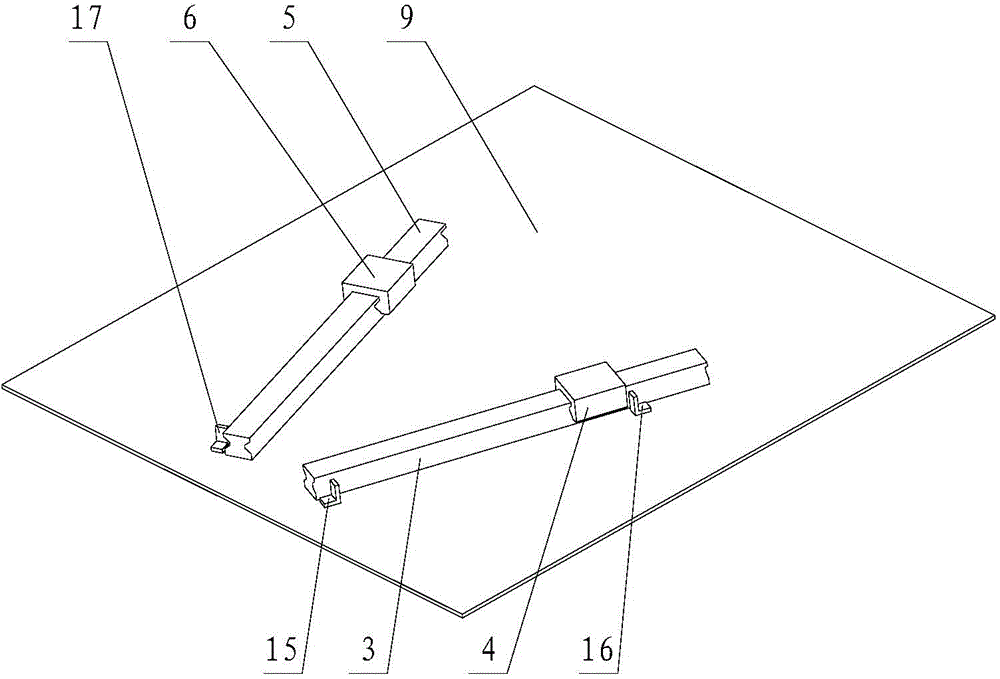

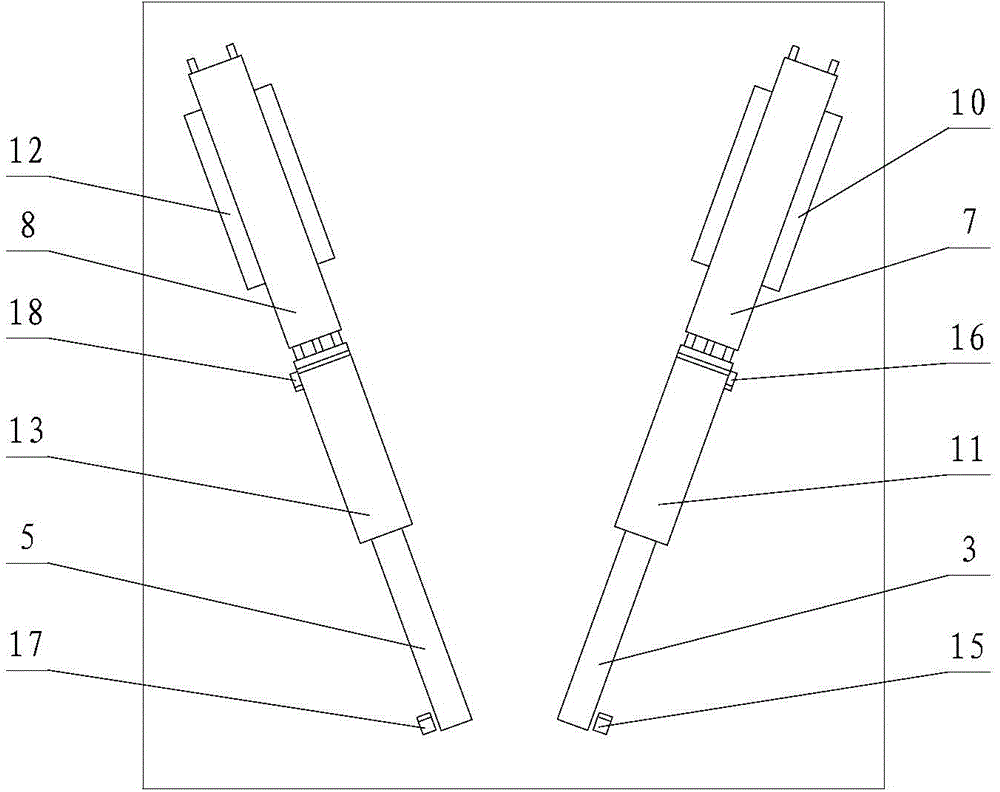

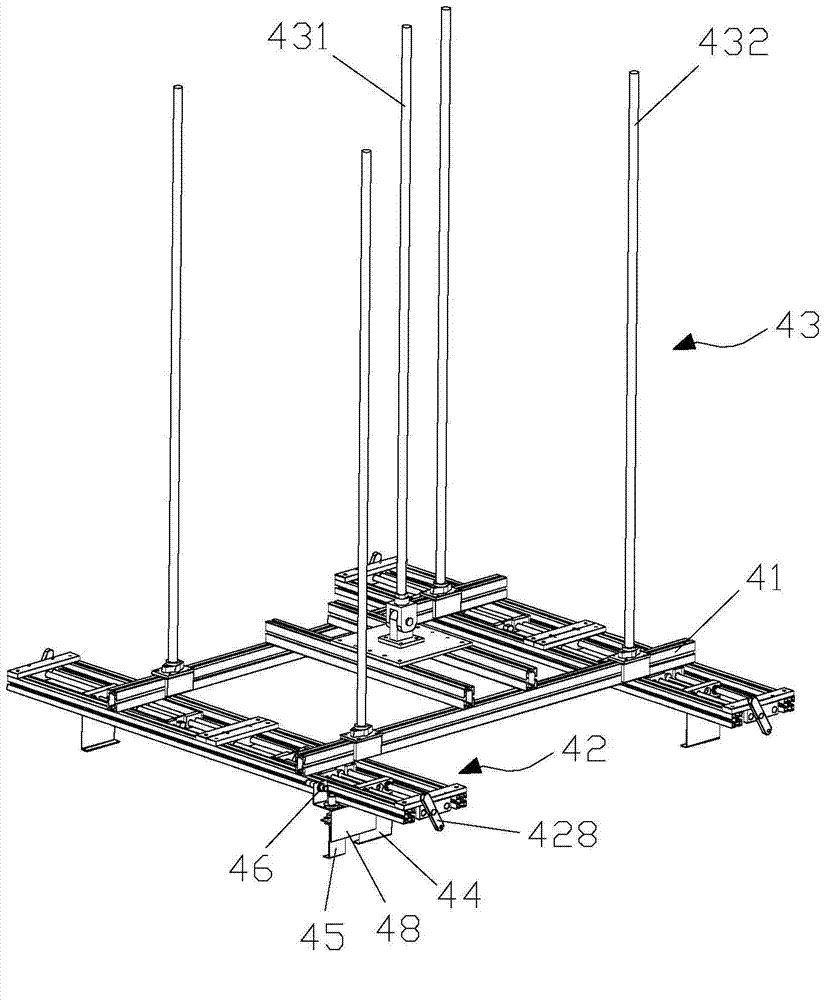

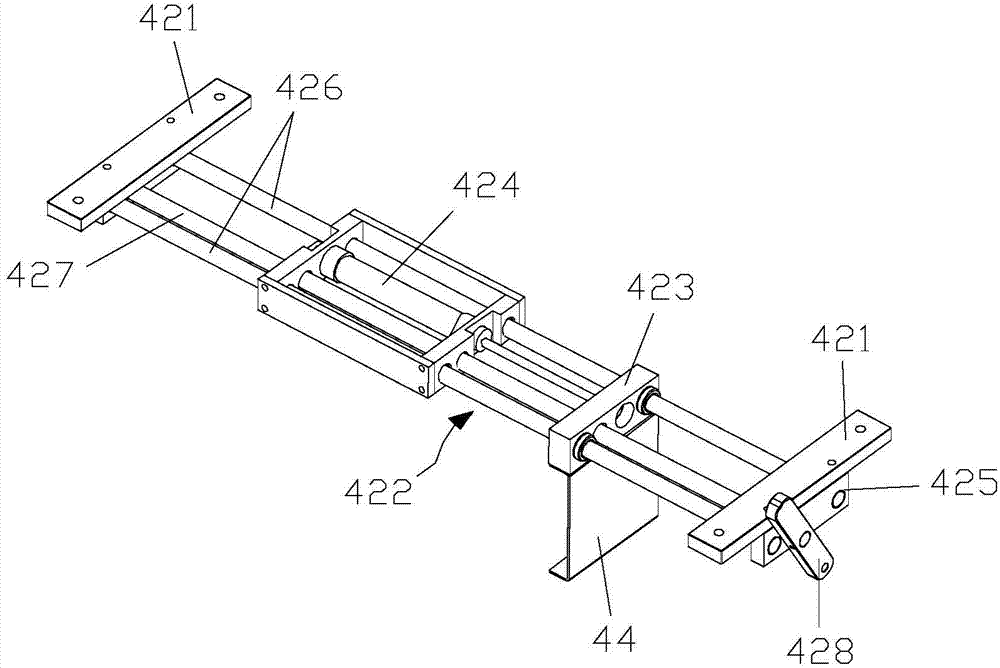

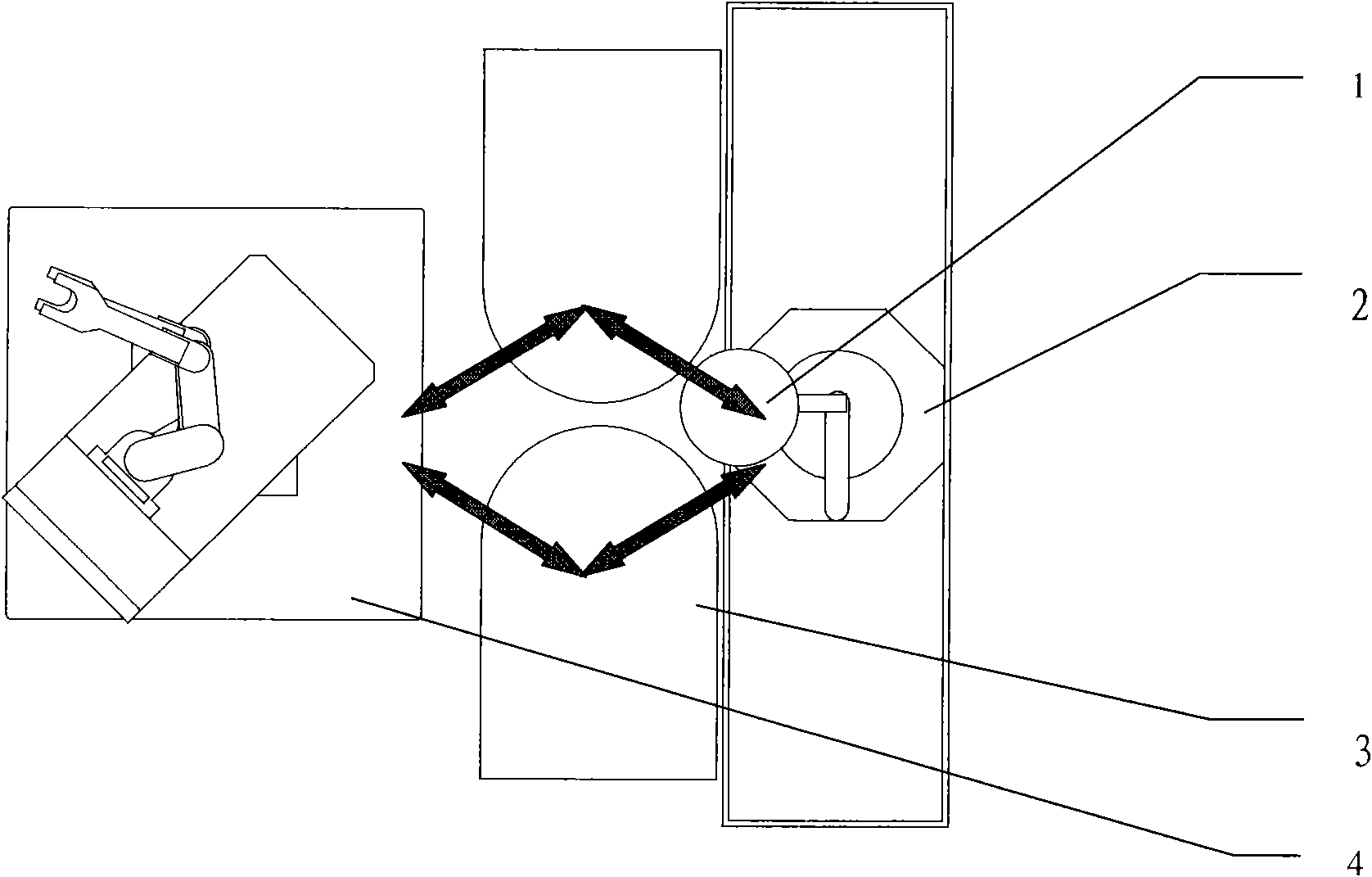

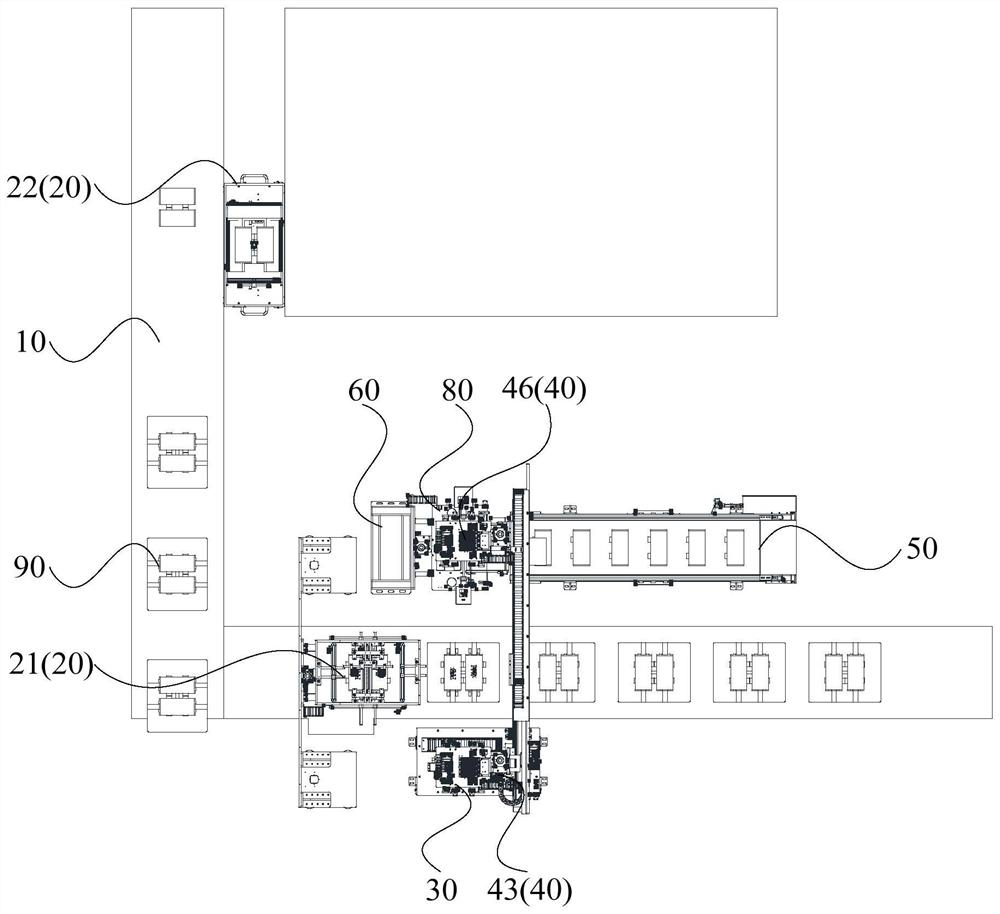

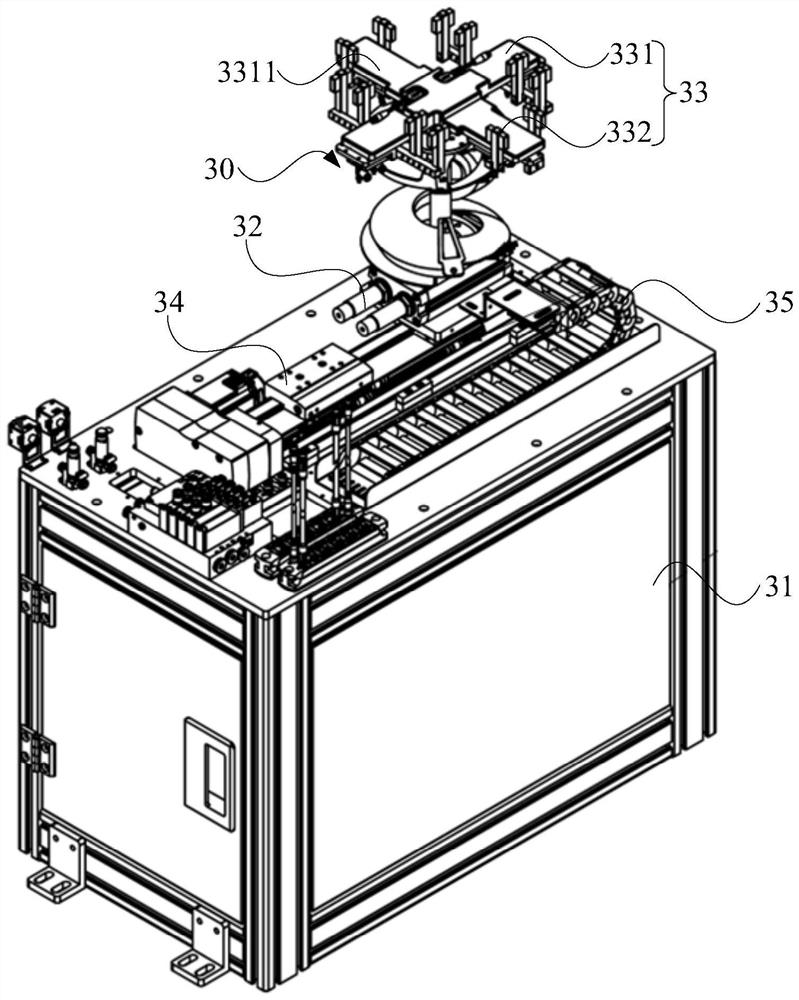

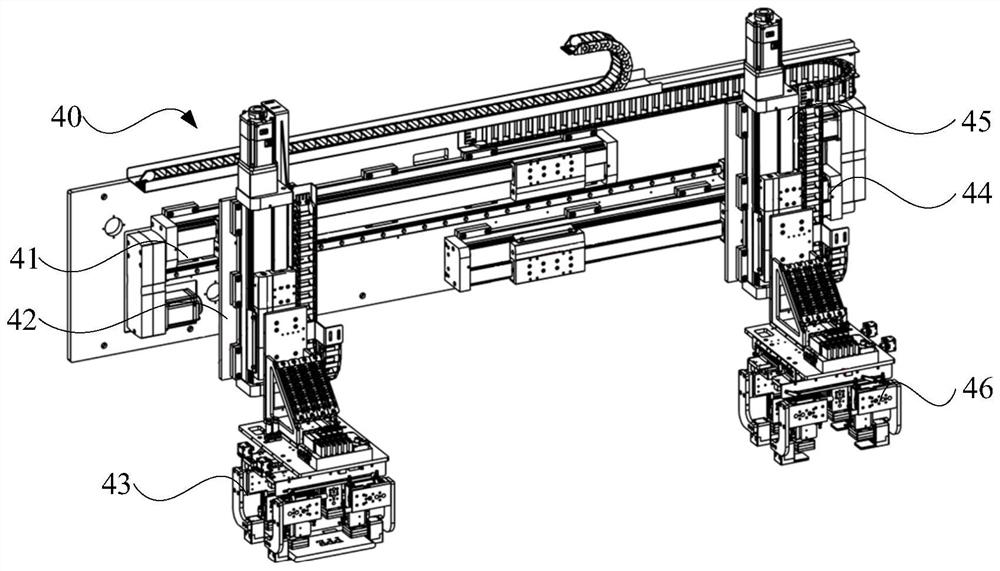

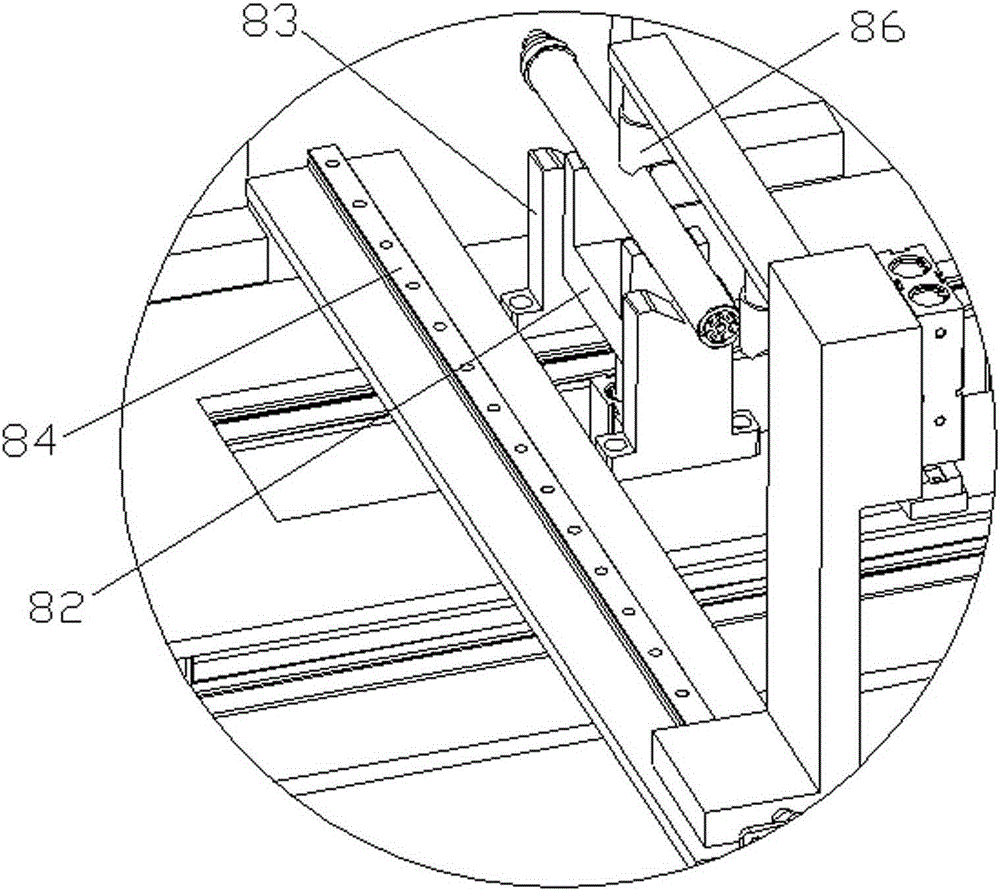

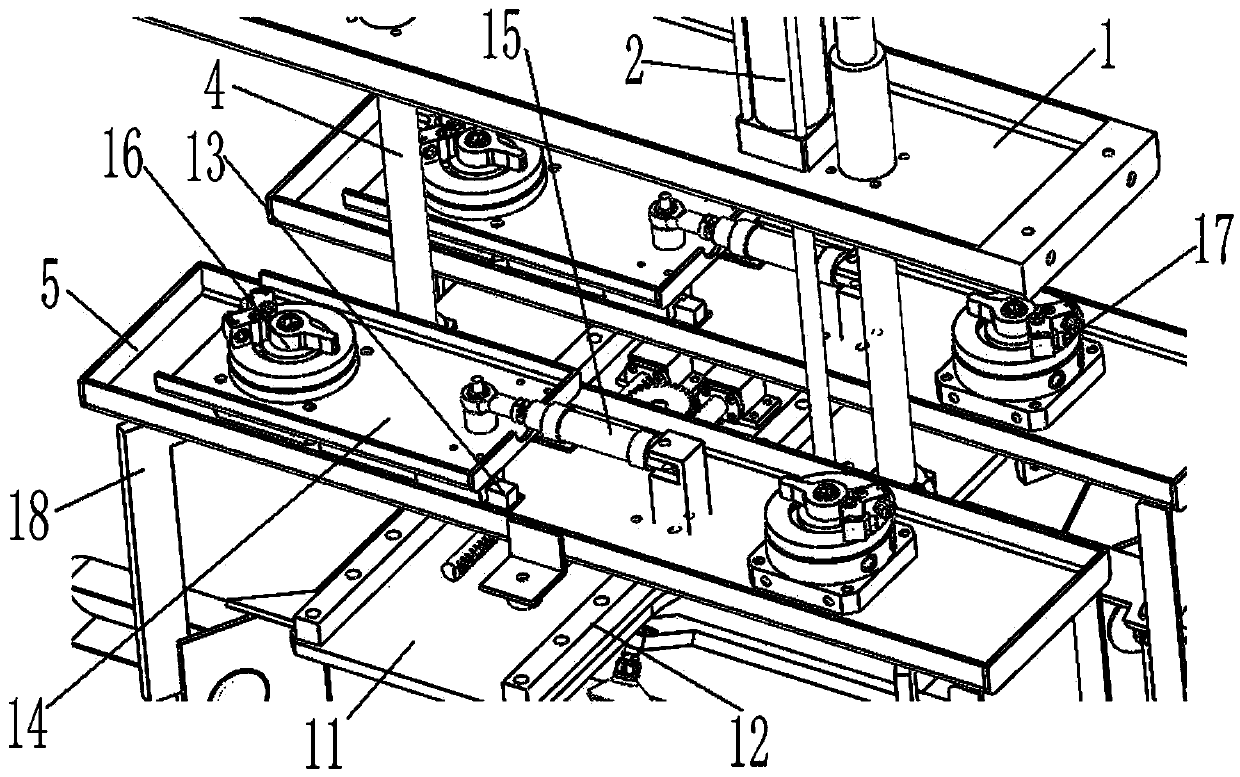

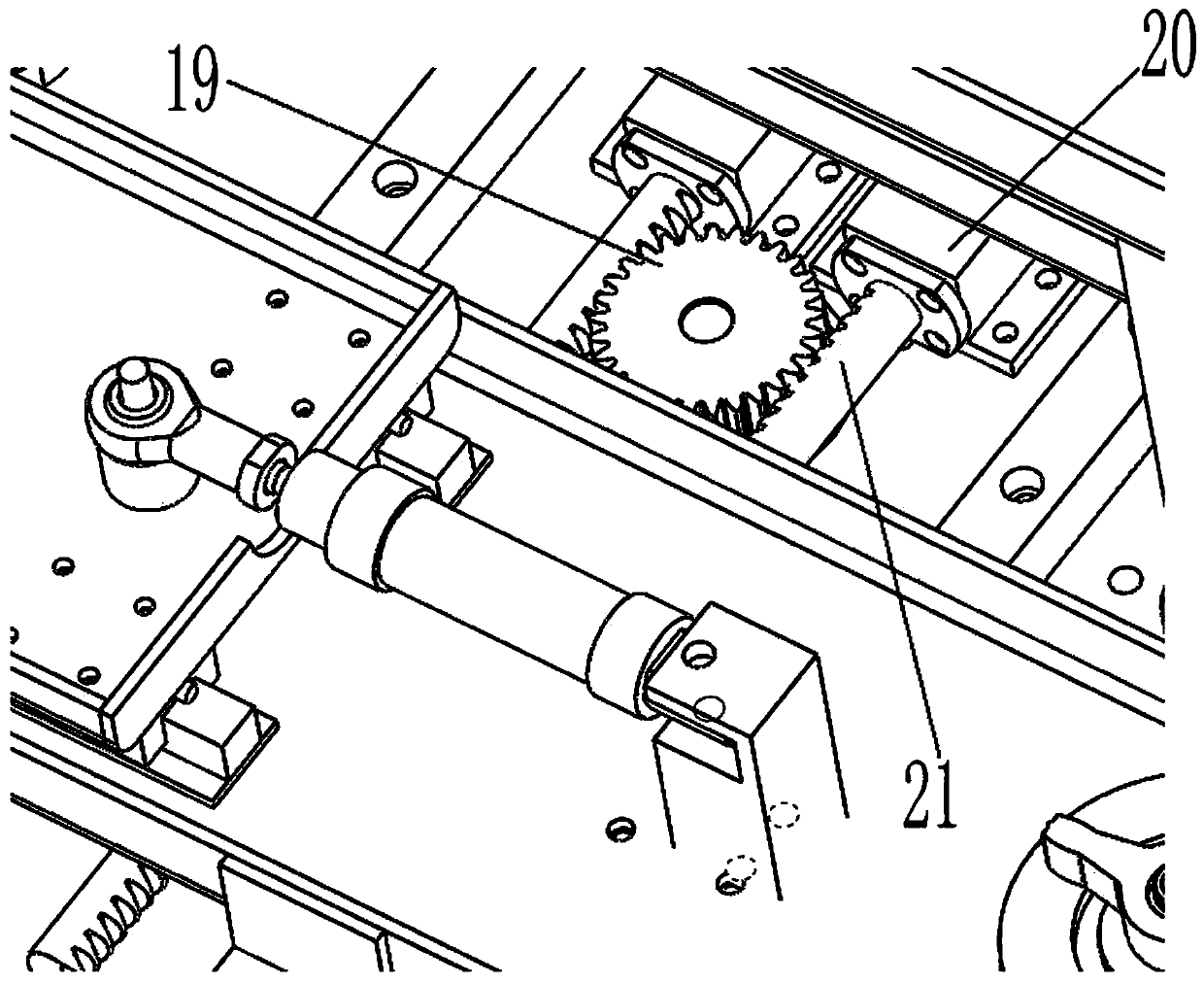

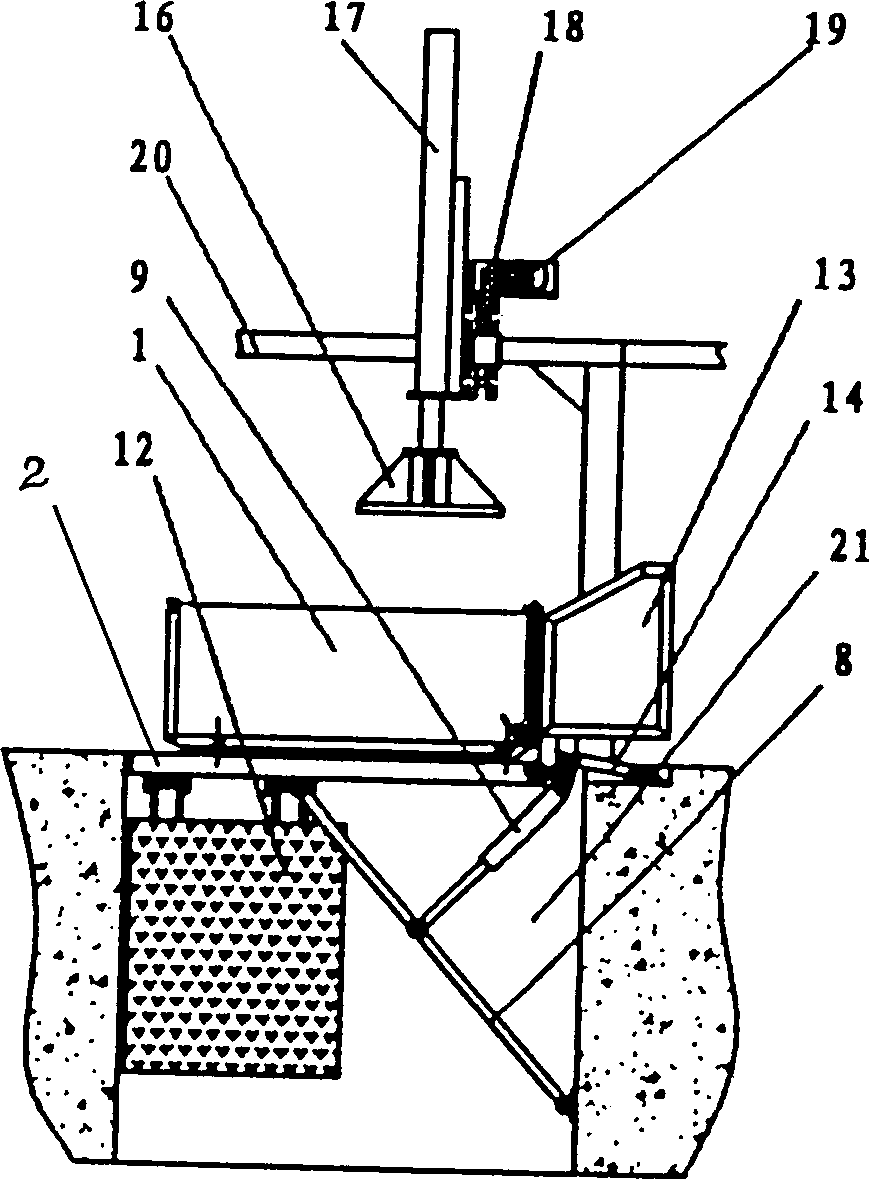

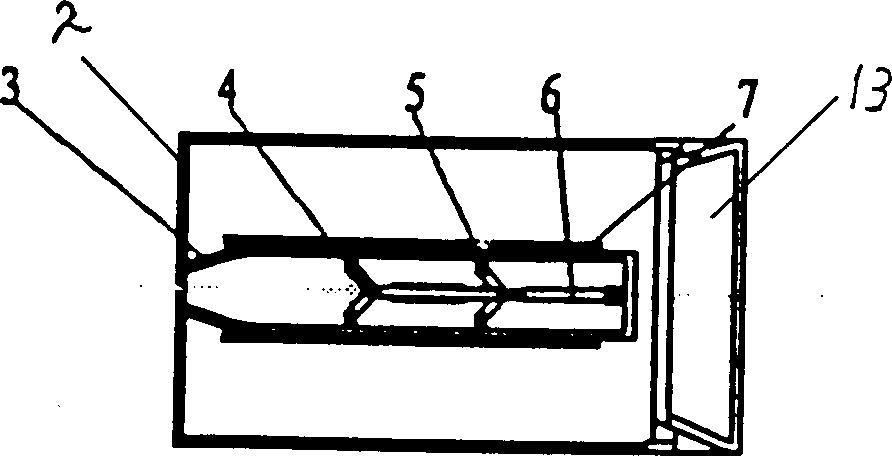

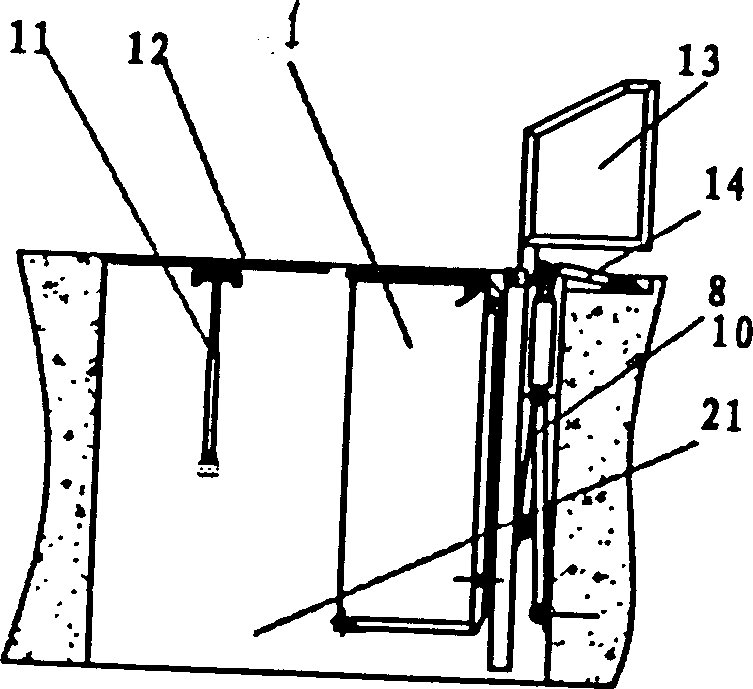

Flat plate heat collector double-station automatic discharging stacker

InactiveCN104709718APrecise positioningPrecise handlingConveyorsStacking articlesProduction lineSoftware engineering

The invention discloses a flat plate heat collector double-station automatic discharging stacker which comprises a portal frame, a production line support, a guide rail, a first heat collector carrying and clamping holding mechanism, a second heat collector carrying and clamping holding mechanism and a heat collector positioning mechanism, the heat collector positioning mechanism can conduct positioning on a heat collector in a carrying area, the first heat collector carrying and clamping holding device moves to the position above the production line support through a first sliding block seat and moves downward to clamp and hold the heat collector, and the heat collector is carried and placed in a transshipment area; meanwhile, the second heat collector carrying and clamping holding mechanism moves to the position above the production line support through a second sliding block seat and moves downward to clamp and hold the next heat collector which is carried and placed in another transshipment area. According to the flat plate heat collector double-station automatic discharging stacker, the safety and the reliability of the carrying of the heat collectors are guaranteed, the limitation of the width of the production line can be eliminated, the influence on the safe operation of the carrying mechanism can be eliminated, and the application range is wide. By means of the double-station carrying mechanism, higher productivity is achieved, and the production efficiency is greatly improved.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

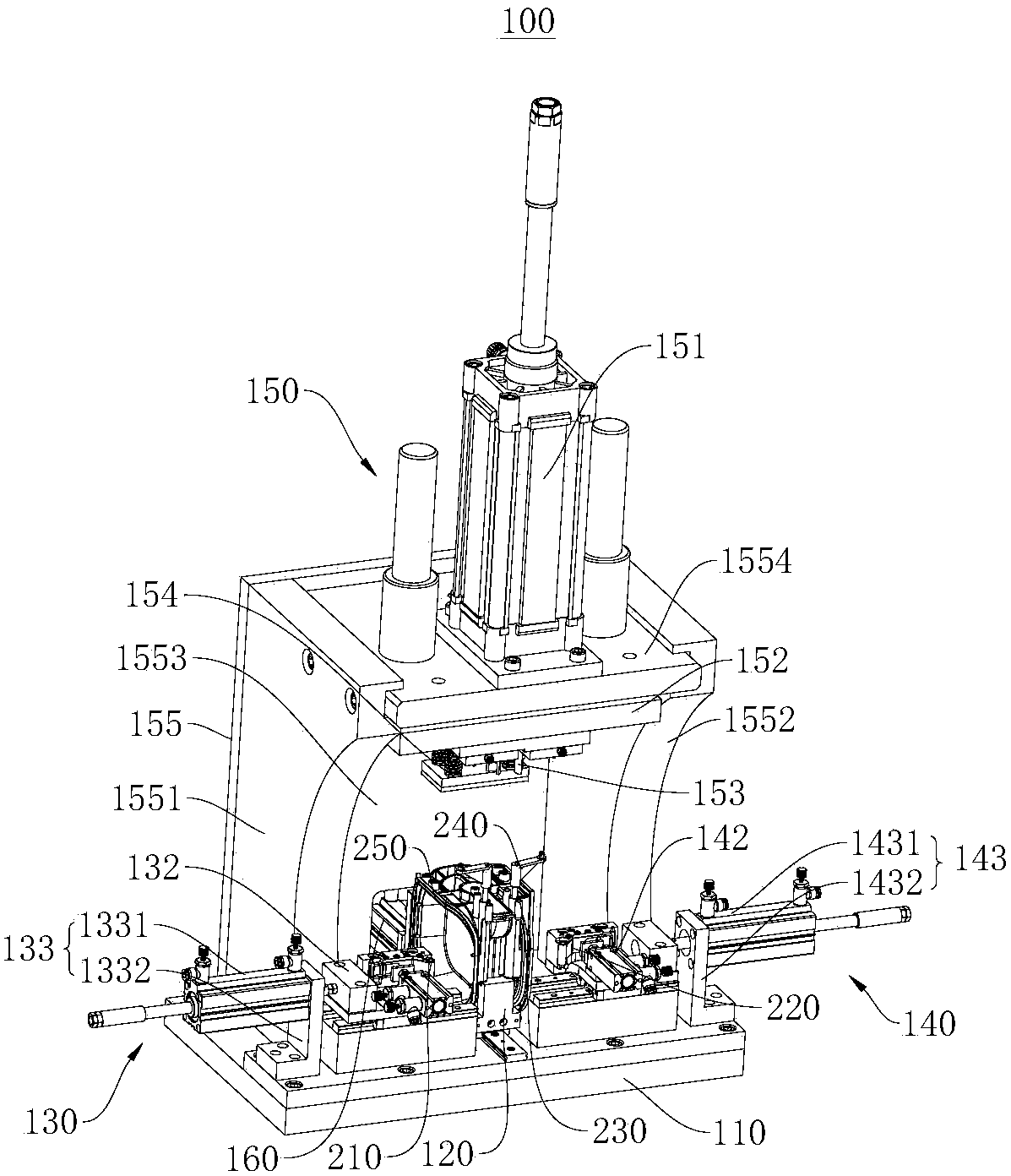

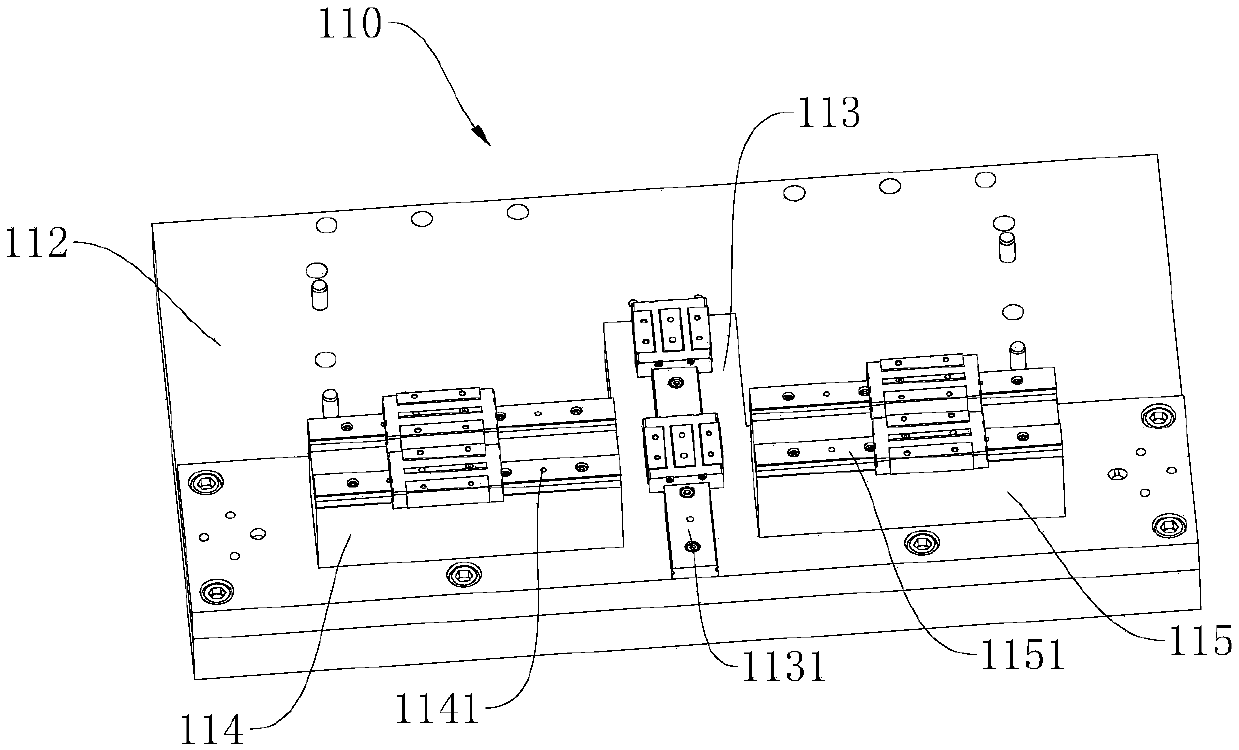

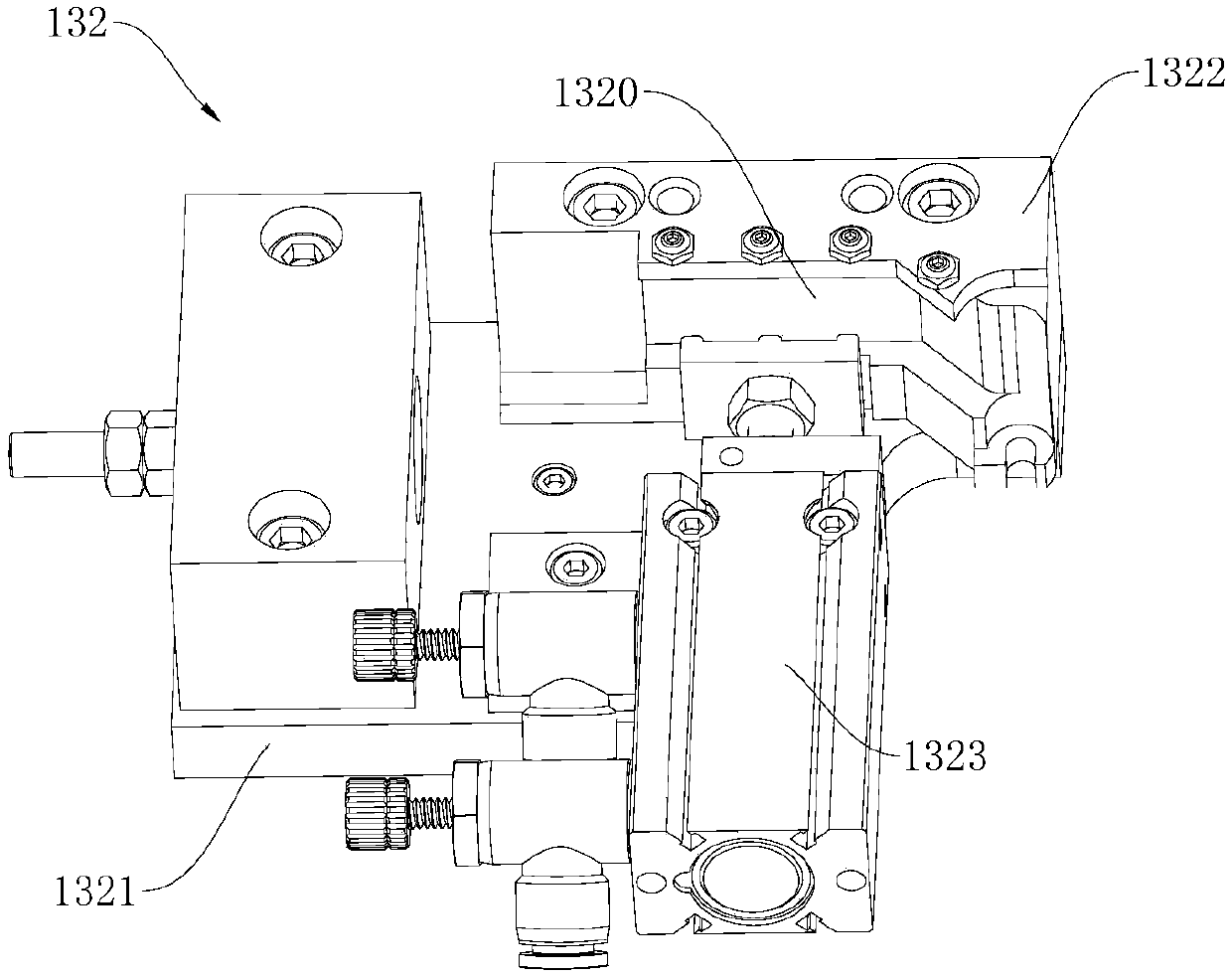

Press fitting equipment

ActiveCN107627104AReduce work stationsSave human effortAssembly machinesEngineeringMechanical engineering

The invention provides press fitting equipment, and relates to the field of press fitting equipment. By the press fitting equipment, a front pin, a rear pin, a stand column and a rocker are assembledon a film box. The press fitting equipment comprises a film box seat assembly, first press fitting devices, second press fitting devices and third press fitting devices. The film box seat assembly isused for mounting the film box. The first press fitting devices are arranged on one side of the film box seat assembly at intervals and are used for clamping the front pin, and the front pin is assembled on the film box by the first press fitting devices. The second press fitting devices are arranged on the side, which is opposite to the first press fitting devices, of the film box seat assembly at intervals, and are used for clamping the rear pin, and the rear pin is assembled on the film box by the second press fitting devices. The third press fitting devices are arranged at one end of the film box seat assembly at intervals, by the third press fitting devices, the stand column is assembled on the film box, and the rocker is clamped and is assembled on the stand column. By the press fitting equipment, the problems of low yield, low efficiency, waste of materials, high rework rate and the like of a gas meter angle assembly in a production process due to repeated assembly can be avoided effectively, the production efficiency is improved, and the cost is reduced.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

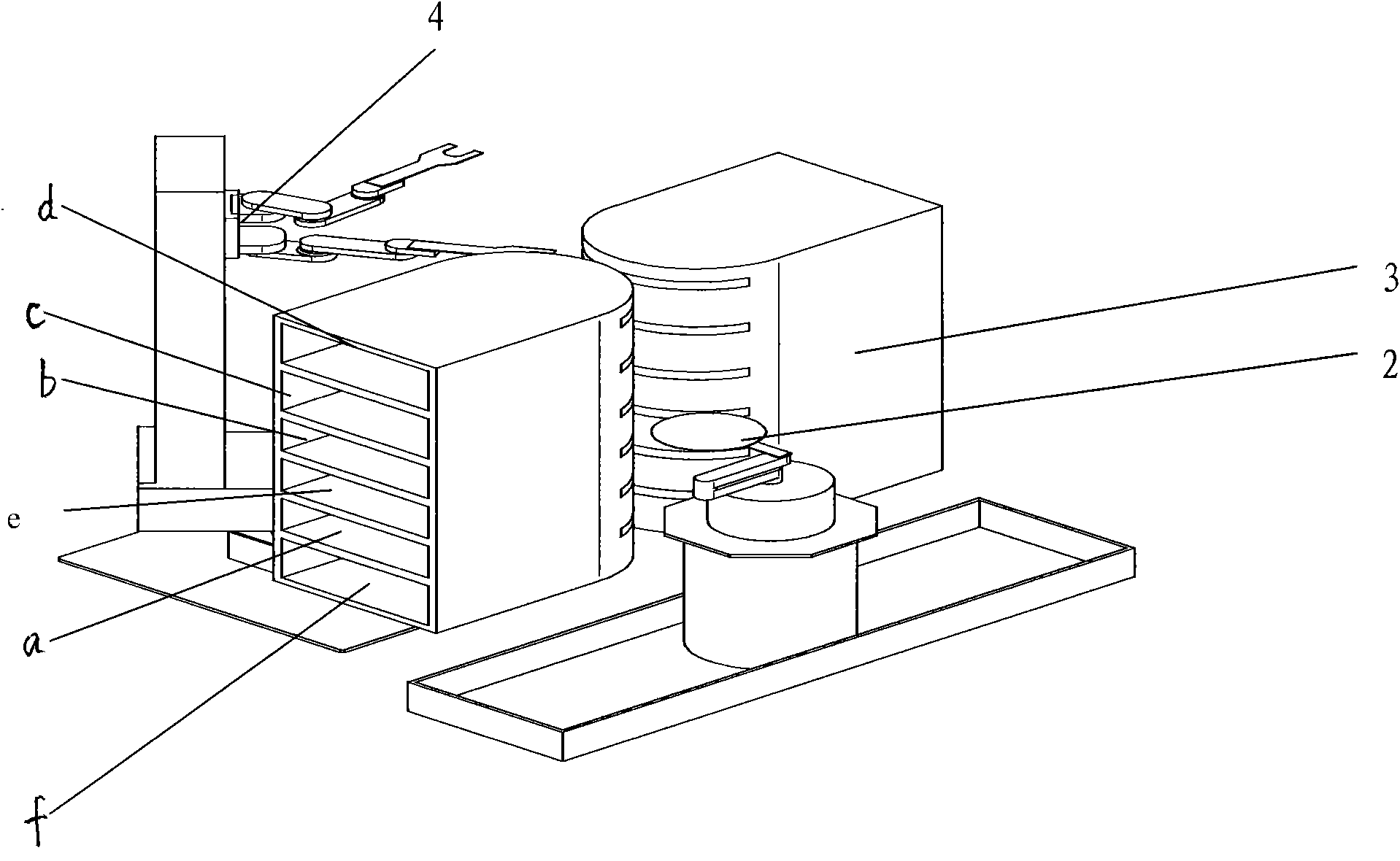

Process wall for glue spreading development equipment

ActiveCN101615561AReduce bottlenecksReduce work stationsPhotomechanical apparatusSemiconductor/solid-state device manufacturingTransfer procedureEngineering

The invention discloses a process wall for glue spreading development equipment, which belongs to the technical field of glue spreading development of semiconductor wafers. Various process units of the process wall are parallelly arranged; the units of the process wall are provided with a wafer inlet and outlet end respectively; and the wafer inlet and outlet end has an arc-shaped run-through structure. The process wall has the advantages that the arc-shaped structures of inlets and outlets of the units of the process wall ensure that the wafer transmission forms a process mode of permeation transmission, break through the prior wafer transmission mode of the glue spreading development equipment, reduce the bottleneck in a wafer transmission path, also reduce the working position of a robot of a process section, and ensure that the effective utilization rate of the process units of the whole process wall is improved. The process wall meets the production requirement of a large-scale and high-productivity glue spreading development process. The application of the structural equipment has small land occupation area, and effectively reduces the pollution of the environment to wafers during the transmission; and the investment cost for the equipment is effectively reduced, and the production efficiency is improved.

Owner:SHENYANG KINGSEMI CO LTD

Appearance defect detection equipment

The invention relates to appearance defect detection equipment. The appearance defect detection equipment comprises a conveying line, a visual detection device, transfer transition devices and a sorting device; the conveying line is used for conveying to-be-detected products; the visual detection device is arranged in the mode of corresponding to the conveying line and is used for detecting the appearance of the to-be-detected products so as to sort out good products and defective products; the transfer transition devices are arranged on at least one side of the conveying line and provided with transfer stations; and the sorting device comprises a pairing grabbing mechanism and a removing grabbing mechanism, the removing grabbing mechanism is used for removing the defective products in trays, and the pairing grabbing mechanism is used for grabbing and transferring the good products in the trays after the defective products are removed to the transfer stations, and grabbing and transferring the good products in the transfer stations into the trays after the defective products are removed. Therefore, subsequent repairing stations can be omitted, the number of equipment is reduced, and space is saved.

Owner:GUANGZHOU EHOLLY MACHINERY CO LTD

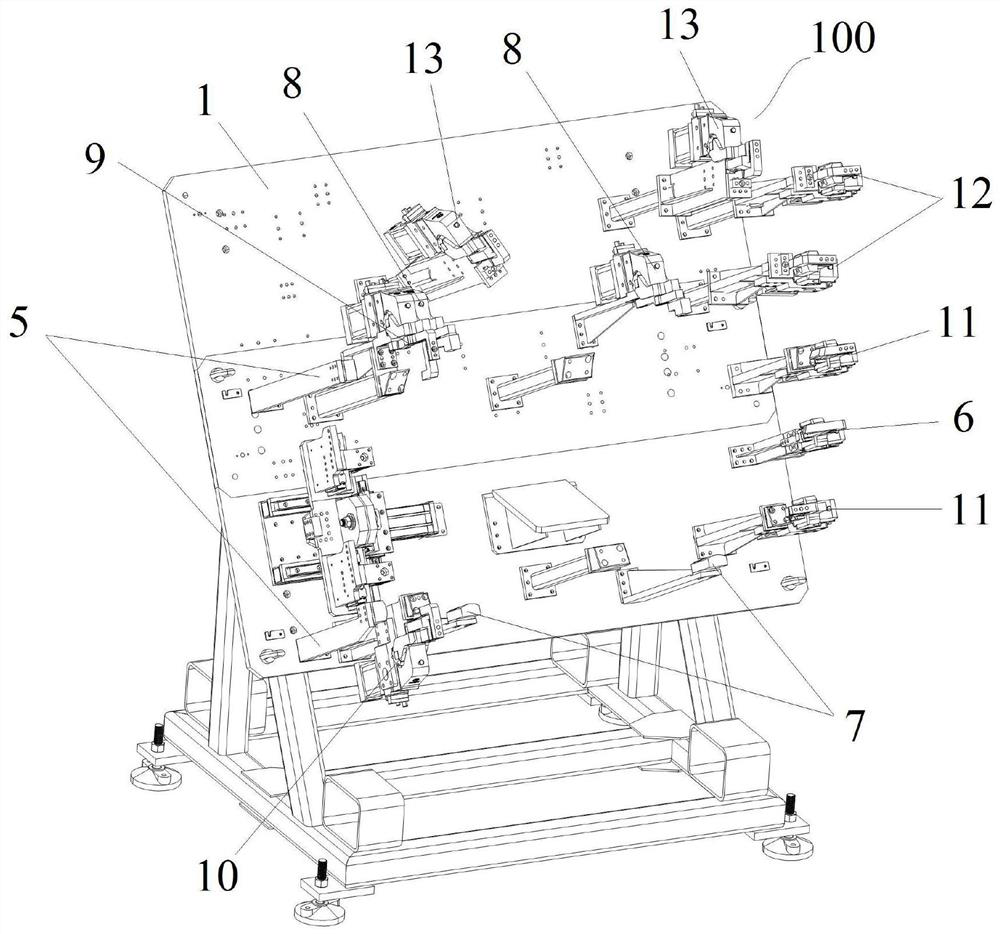

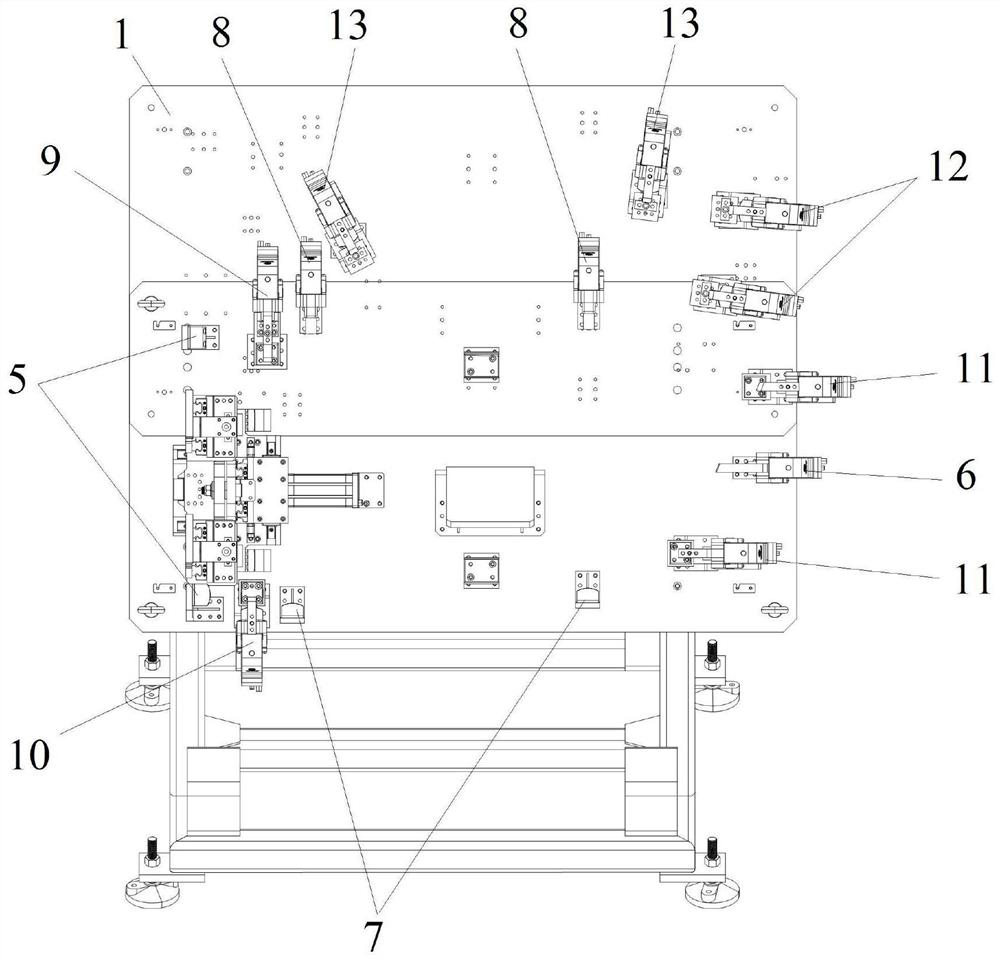

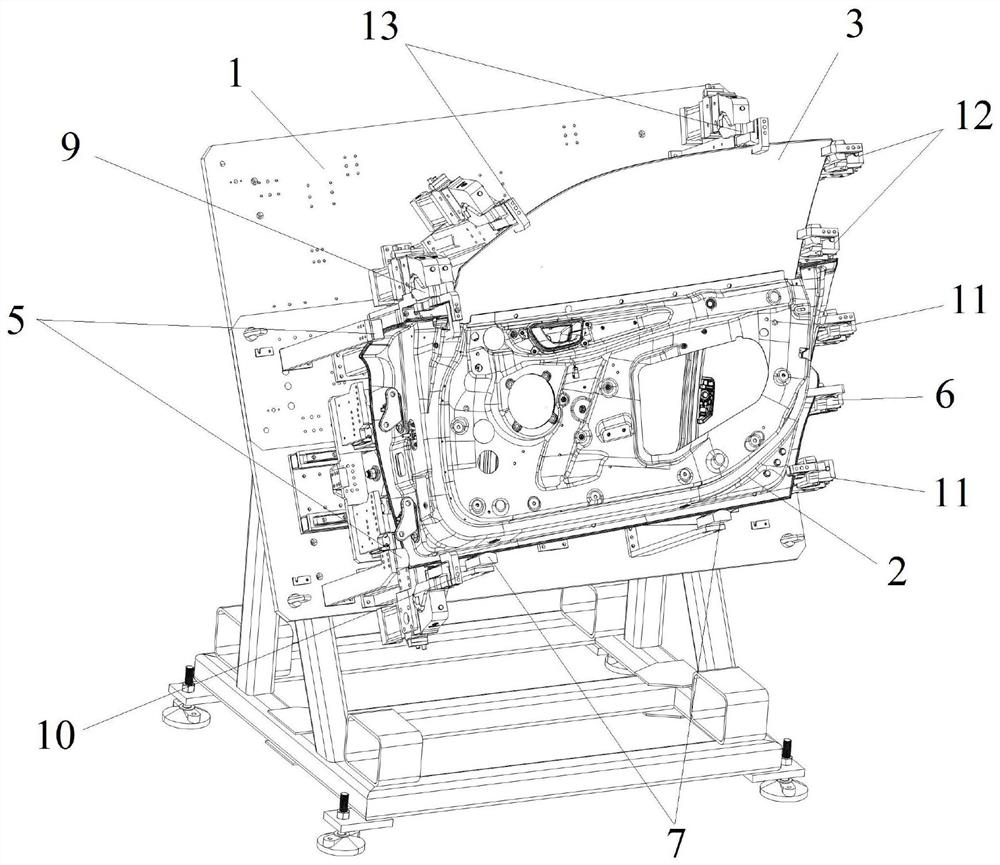

Window glass adjusting device of frameless vehicle door

The invention discloses a vehicle window glass adjusting device of a frameless vehicle door, and relates to the field of tools. The vehicle window glass adjusting device comprises a tool support, a vehicle door fixing mechanism and a vehicle window glass fixing mechanism, the vehicle door fixing mechanism comprises a vehicle door X-direction limiting assembly, a vehicle door Y-direction limiting assembly and a vehicle door Z-direction limiting assembly which are arranged on the tool support; the vehicle door X-direction limiting assembly is used for abutting against the left side and the rightside of the vehicle door outer plate, the vehicle door Y-direction limiting assembly is used for clamping the inner side face and the outer side face of the vehicle door outer plate, and the vehicledoor Z-direction limiting assembly is used for abutting against the upper side and the lower side of the vehicle door outer plate. The vehicle window glass fixing mechanism comprises a vehicle windowglass X-direction limiting assembly and a vehicle window glass Z-direction limiting assembly which are arranged on the tool support, the vehicle window glass X-direction limiting assembly is used forabutting against the right side of vehicle window glass, and the vehicle window glass Z-direction limiting assembly is used for abutting against the upper side of the vehicle window glass. According to the device, the length of the dimension chain is shortened, so that the matching precision between the vehicle window glass and the vehicle door outer plate is higher.

Owner:欧恩科(北京)自动门科技有限公司

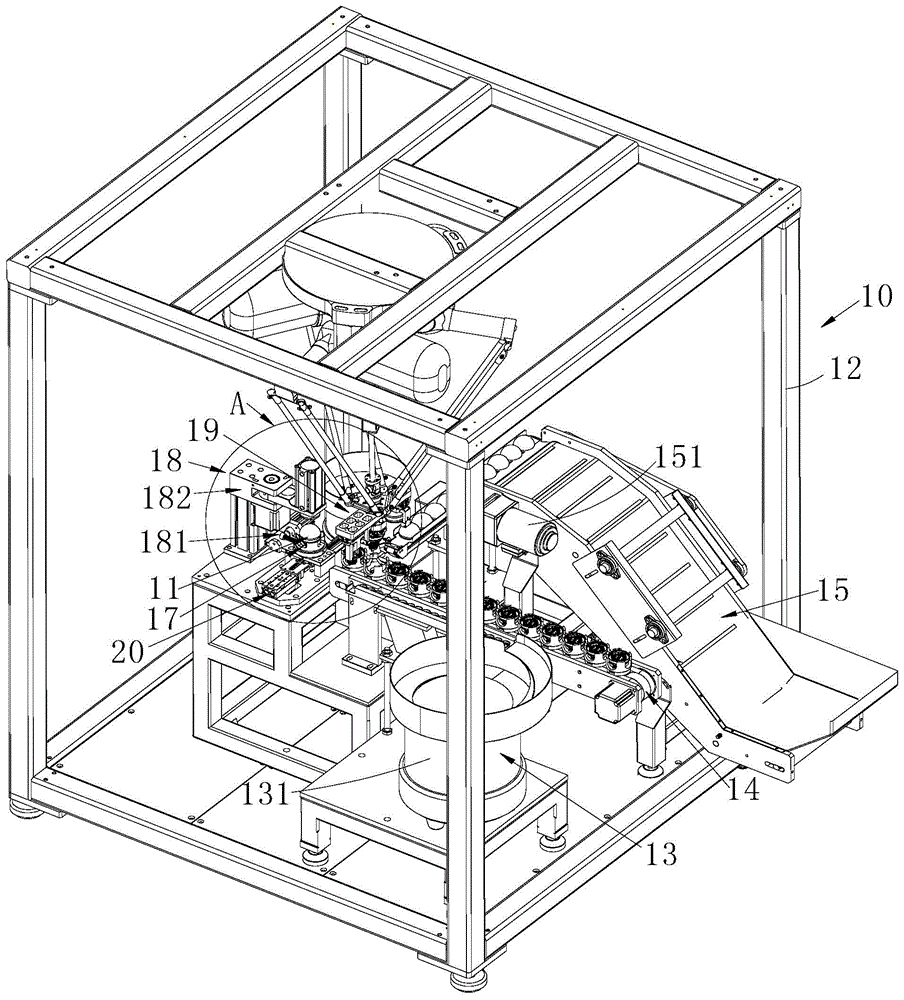

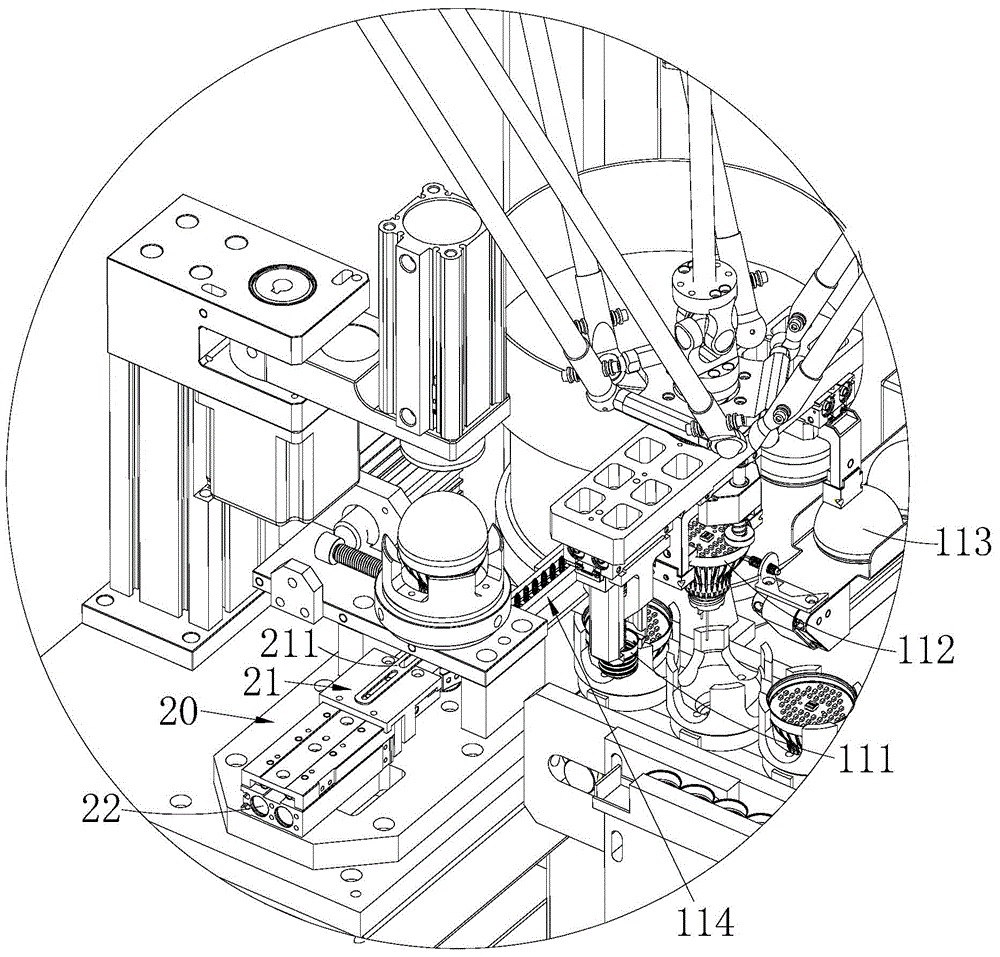

Automatic assembling machine for LED bulb lamp

The invention relates to the technical field of LED lamp production equipment and provides an automatic assembling machine for an LED bulb lamp; the automatic assembling machine comprises a frame; a lamp cap conveying mechanism, a lamp holder conveying mechanism, a lampshade conveying mechanism, a rivet conveying mechanism, a set-up part and an assembling component; a clamping mechanism and a rivet extracting mechanism are arranged on the frame; and the assembling component comprises a cap pressing mechanism, a shade pressing mechanism and a rivet pressing mechanism. A lamp cap, a lamp holder and a lampshade are sequentially put into the set-up part by the clamping mechanism; the lamp cap is pressed into the lamp holder by the cap pressing mechanism; the rivet extracting mechanism and the rivet pressing mechanism match with each other to press rivets into the lamp cap; the shade pressing mechanism is used for pressing the lampshade into the lamp holder to finish assembling. The automatic assembling machine for the LED bulb lamp realizes the function of automatically assembling the lamp cap, the lamp holder and the lampshade into a whole one on one working station without overturning the lamp holder for 180 degrees and additionally arranging the structures such as a mechanical arm and has the advantages of being low in labor cost, simple in structure and operation, stable in products, high in efficiency and satisfactory in market requirements.

Owner:深圳市三一联光智能设备股份有限公司

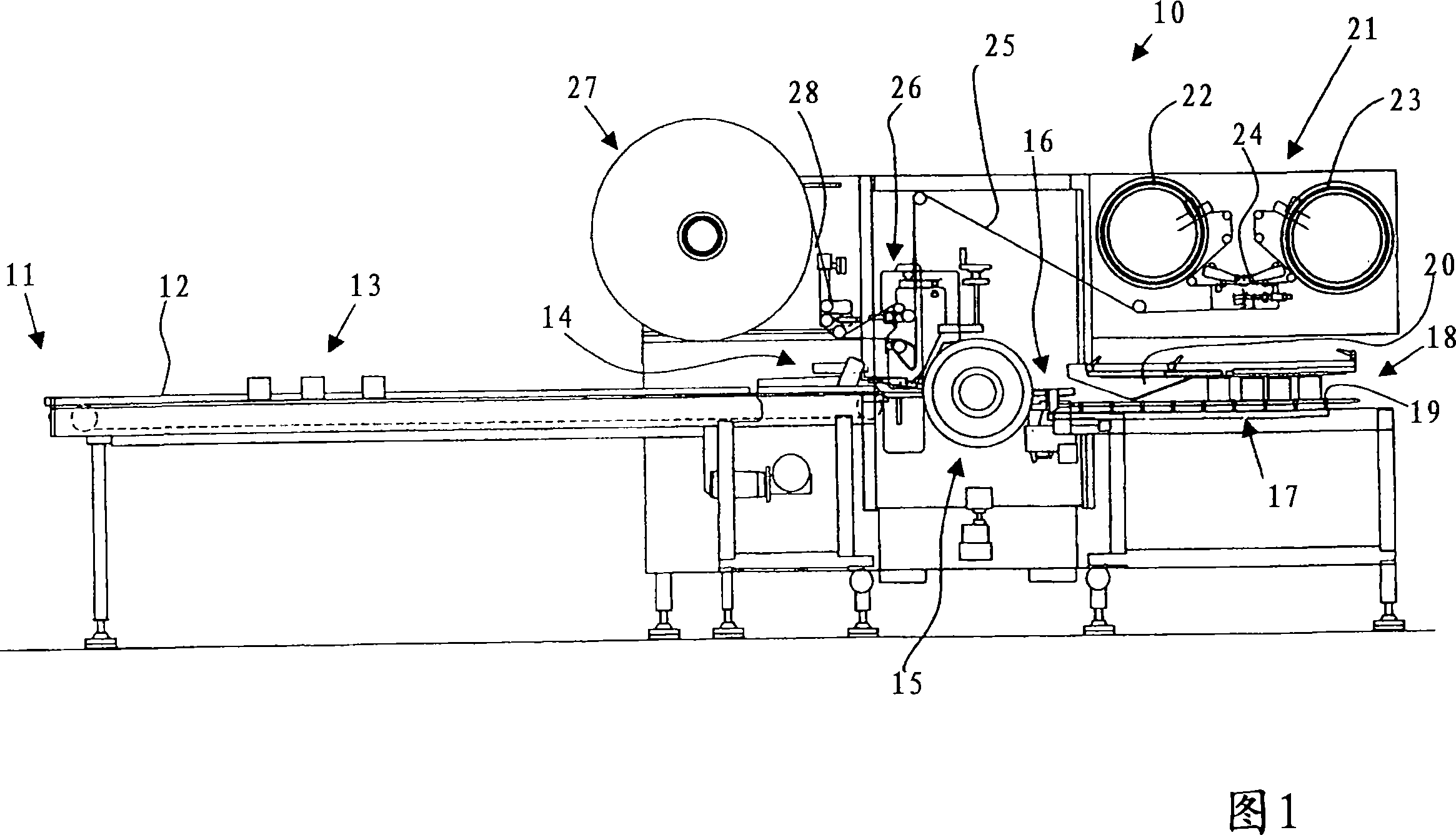

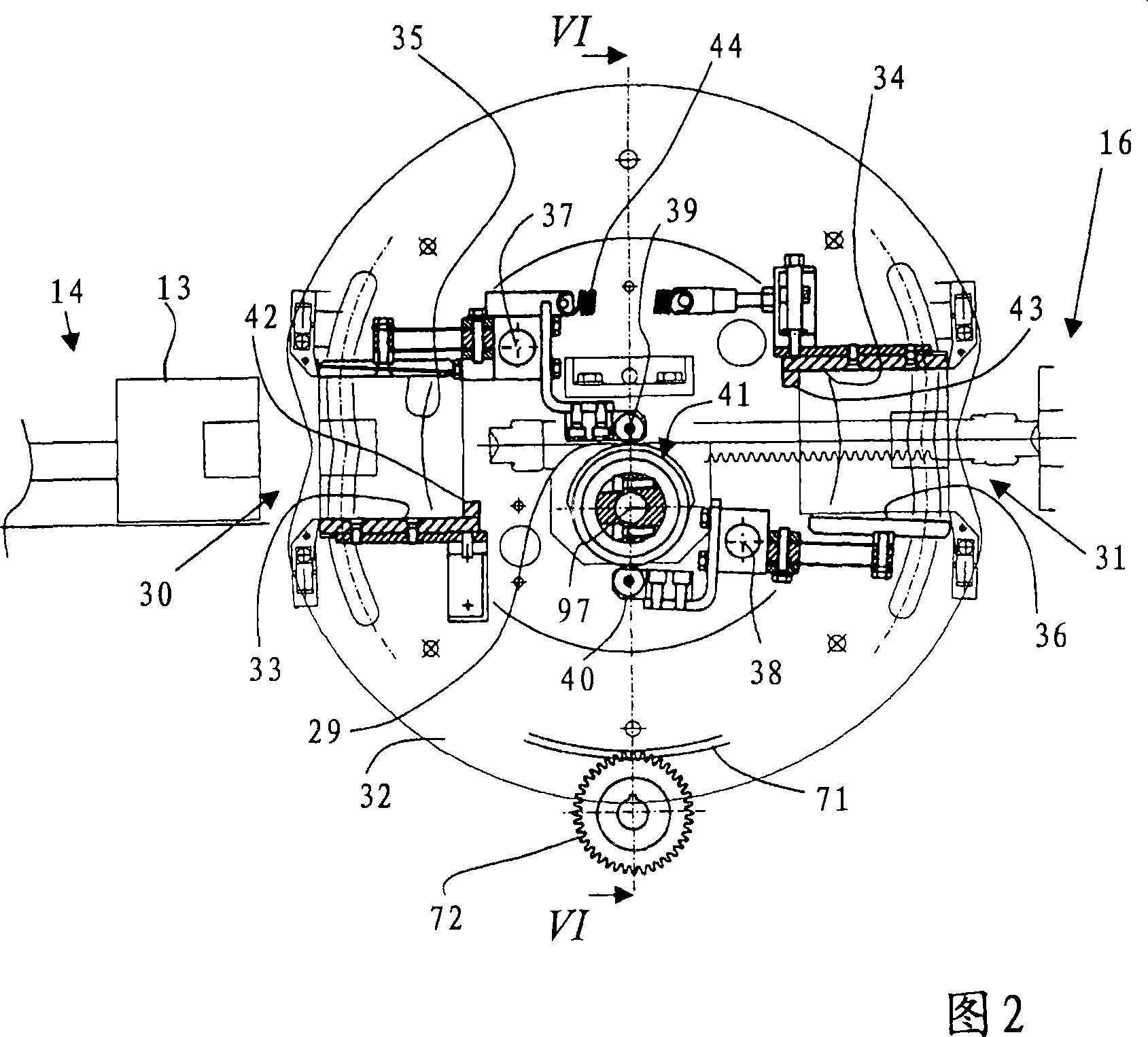

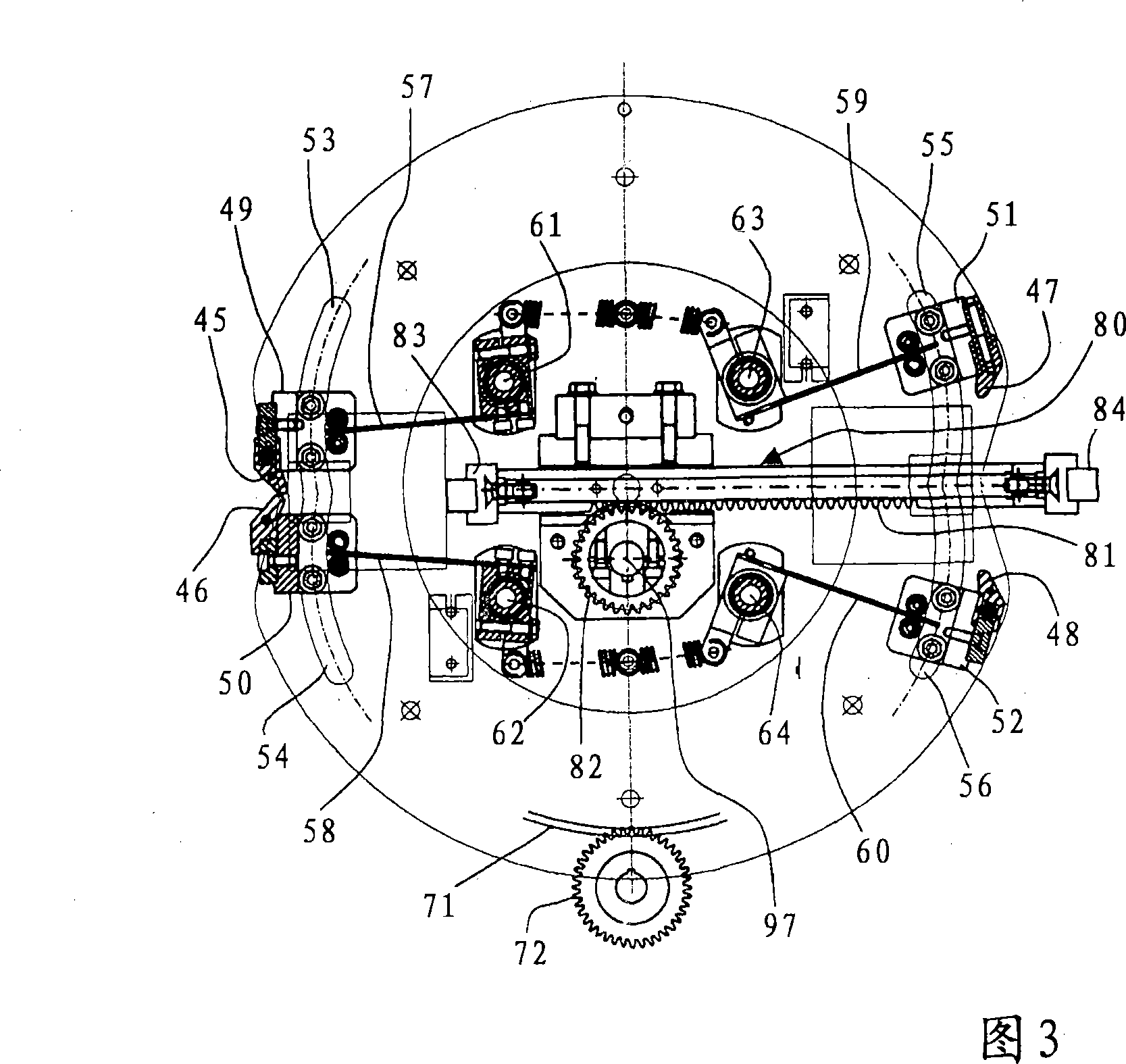

Rotating-head machine for packaging products in sealed film

InactiveCN101160238AReduce work stationsWrapper folding/bending apparatusConveyor wrappingEngineeringMechanical engineering

A machine for packaging products (13) in sealed film (25), comprises a product inlet feeding bench (12), a rotating head (15) for receiving and conveying products arriving sequentially from the feeding bench to a loading station (14) in the head and an outlet bench (17) that receives the products conveyed by the rotating head (15) to an unloading station (16) to evacuate them from the machine. The rotating head (15) comprises peripherally seats (30, 31) for receiving products and sealing means (45, 46, 47, 48) that rotates with these seats (30, 31) to achieve sealing of a film wound around the product in a seat (30, 31) whilst the head rotates to take the seat (30, 31) from the loading station (14) to the unloading station (31).

Owner:欧洲司马股份公司

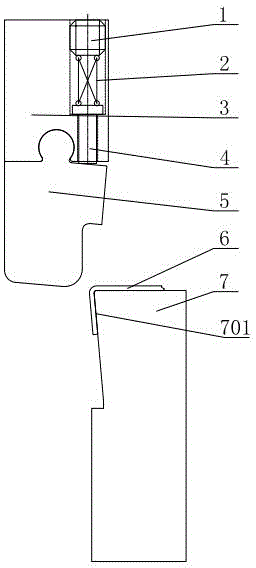

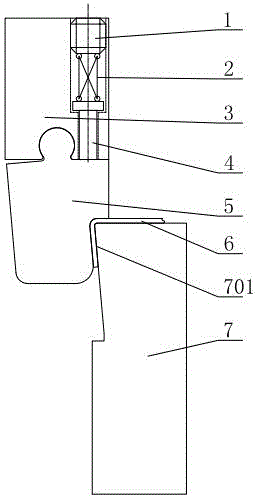

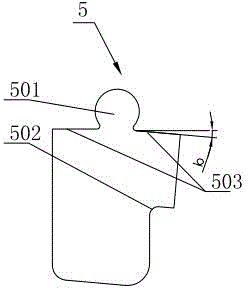

Progressive die 90-degree outward-opening adjustment and acute-angle bending structure

InactiveCN104438856AEasy to processReduce work stationsShaping toolsEjection devicesAcute angleNotching

The invention relates to a progressive die 90-degree outward-opening adjustment and acute-angle bending structure which comprises a fixing insert. A counter bored hole is formed in one end of the fixing insert, an ejection pin is installed at the lower portion of the counter bored hole, and a set screw is arranged at the top end of the counter bored hole and is connected with the ejection pin through a spring. A swing punch is installed under the fixing insert and is structurally that an outwards-protruding puncher pin is arranged in the middle of the upper top face of the swing punch, the upper top faces on two sides of the swing punch are oblique planes, a right-angle gap is formed in the right side of the lower end of the swing punch, and a transition circular arc is arranged at the position of the right-angle gap. The progressive die 90-degree outward-opening adjustment and acute-angle bending structure further comprises a lower die insert core, wherein a bending structure matched with the right-angle gap of the swing punch is arranged at the left end of the lower die insert core. The progressive die 90-degree outward-opening adjustment and acute-angle bending structure is low in machining difficulty and cost, simple and convenient to assemble, good in forming stability and high in forming accuracy and facilitates die repair.

Owner:WUXI MICRO RES

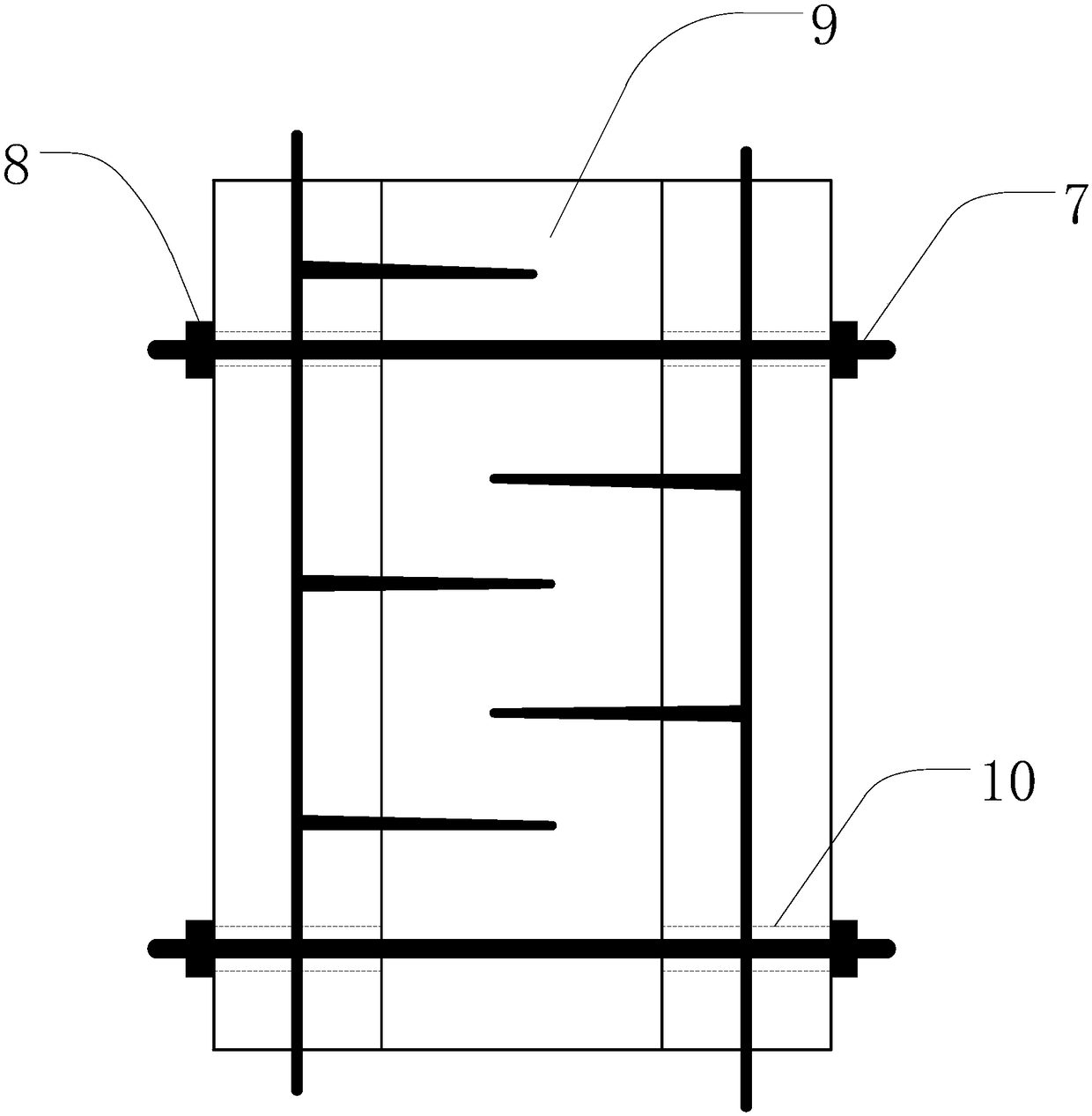

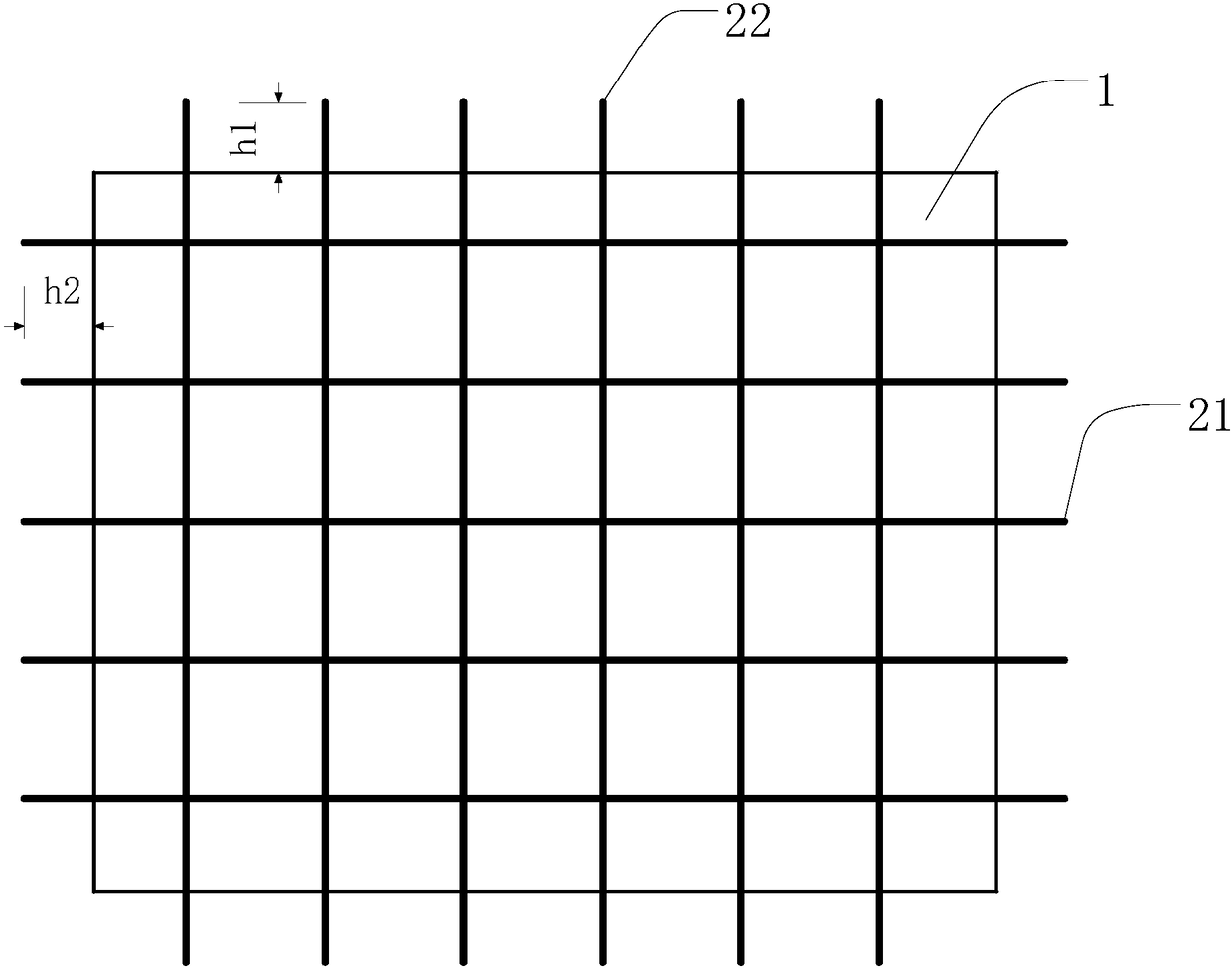

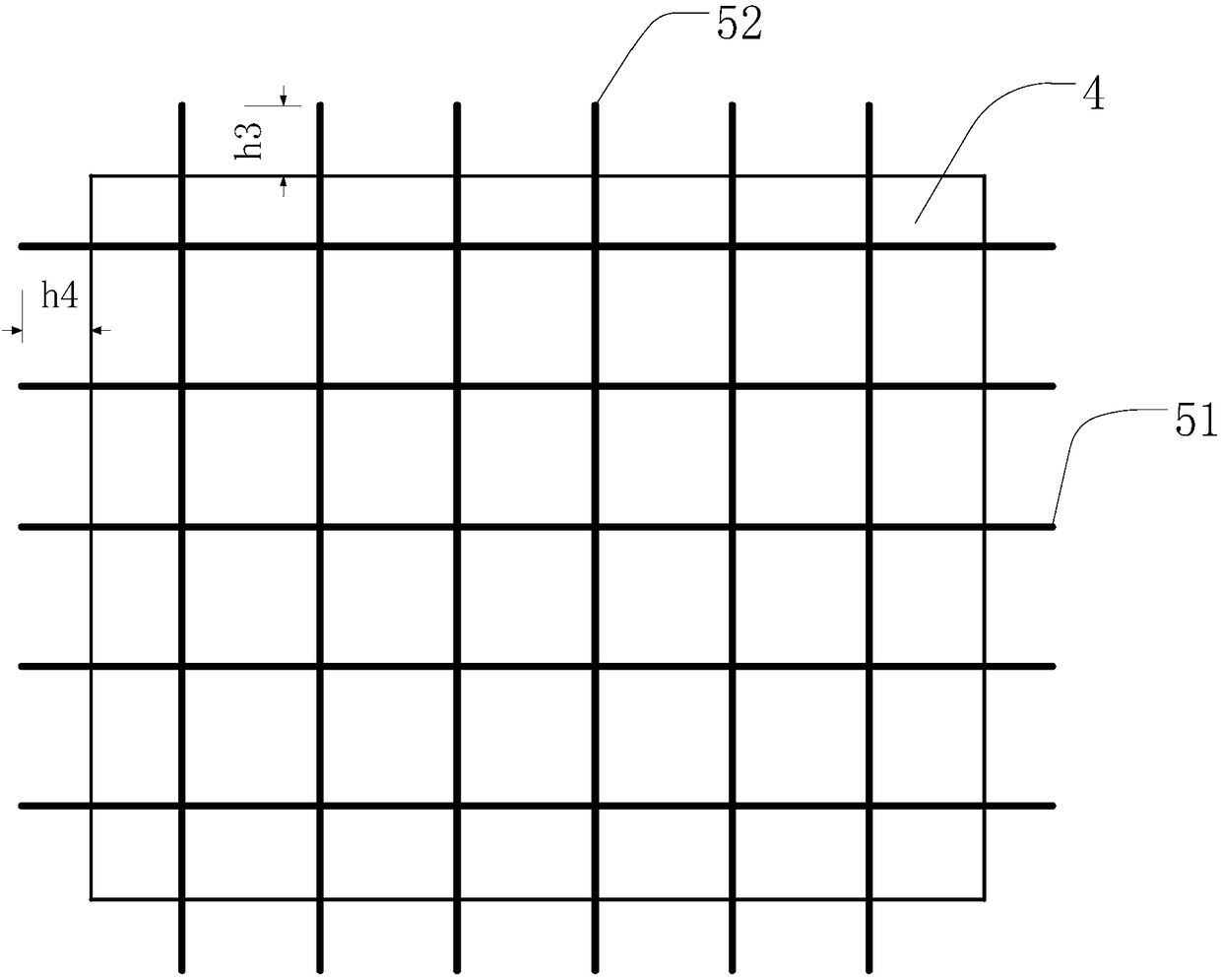

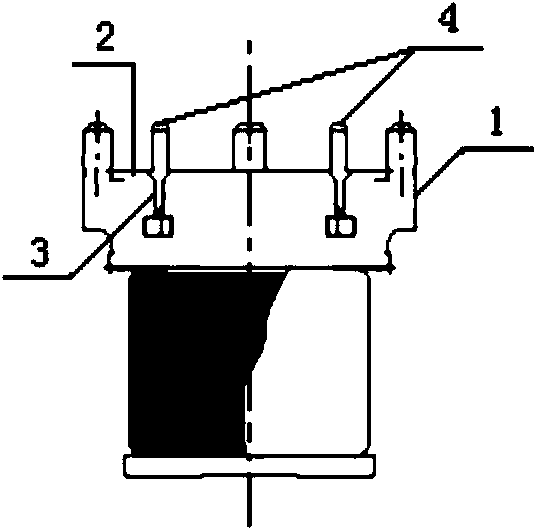

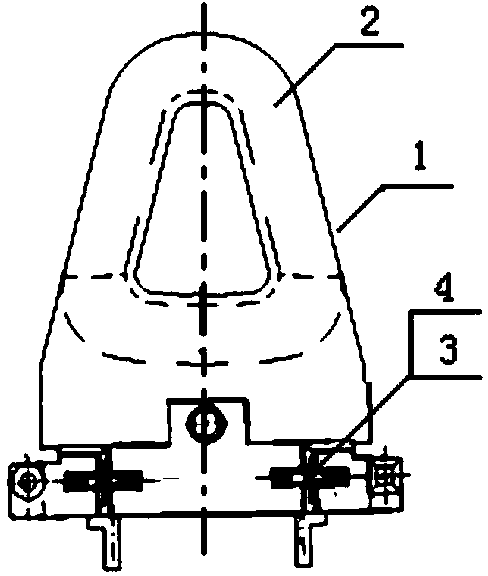

Assembled monolithic two-sided overlapped shear wall structure and construction technology thereof

The invention discloses an assembled monolithic two-sided overlapped shear wall structure. The assembled monolithic two-sided overlapped shear wall structure comprises a first overlapped template, a second overlapped template and cast concrete, wherein the first overlapped template comprises a first concrete body, a first rebar net framework and multiple first truss bars; the second overlapped template comprises a second concrete body, a second rebar net framework and multiple second truss bars; the cast concrete is arranged between the first concrete body and the second concrete body, and isintegrated with the first concrete body and the second concrete body; the first truss bars are arranged at the portion beyond the first concrete body, the second truss bars are arranged at the portionbeyond the second concrete body, and the first truss bars and the second truss bars are overlapped and spaced. The assembled monolithic two-sided overlapped shear wall structure is maintained and formed at a time, the energy consumption is low, locating bolts are reusable, reserved holes are easy to process, two-sided overlapped template plane production is conducted, vertical pairing is conducted, the standardization degree is higher, bars are produced from sides and peripheries, connection of the bars with surrounding components is facilitated, and the applicable range is larger.

Owner:HENAN ZHENGDA BUILDING MATERIALS CO LTD

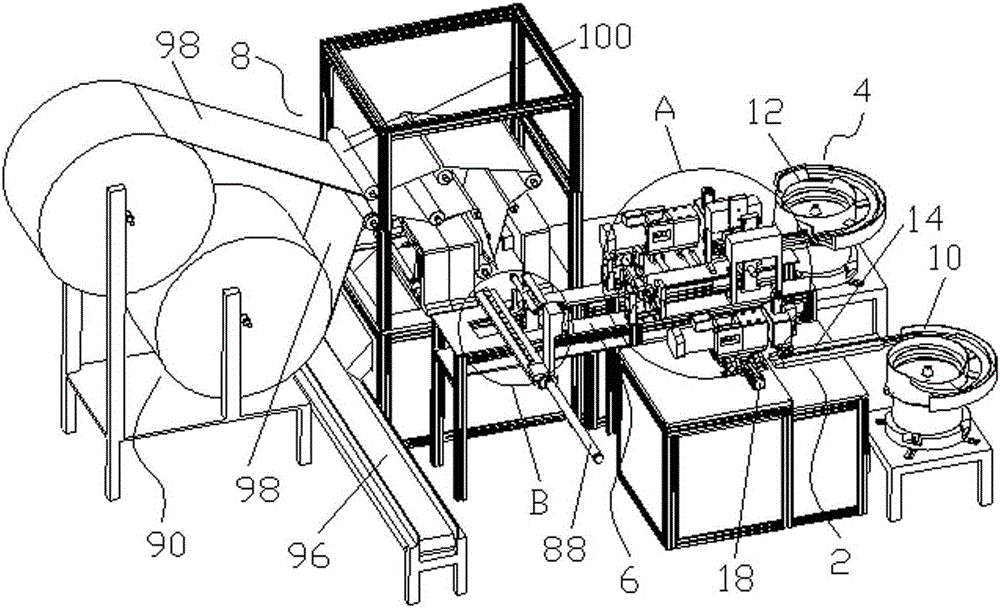

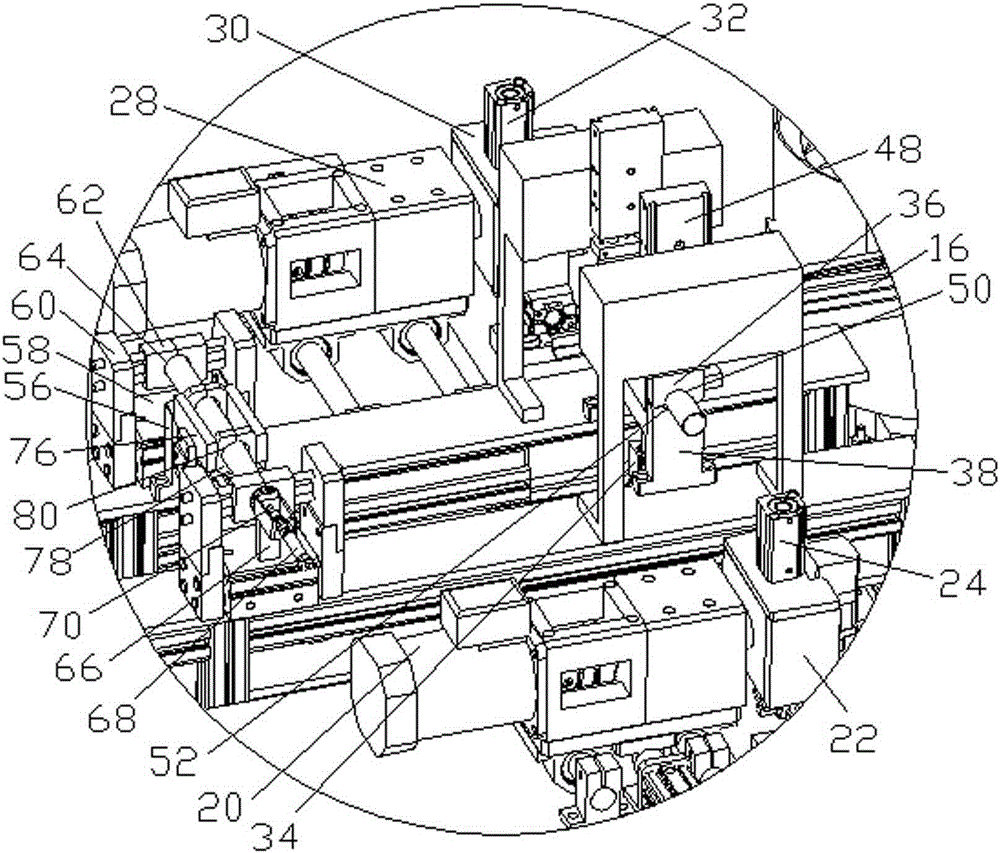

Technology and equipment for arranging wiring terminals on motor coil framework

ActiveCN103475167AReduce intensityRelieve stressManufacturing dynamo-electric machinesAutomatic controlEngineering

The invention relates to a technology and equipment for arranging wiring terminals on a motor coil framework. The technology comprises the processes of inserting the terminals on the coil framework and pressing and fixing the terminals onto the coil framework. The equipment is provided with an automatic online process control device, functional air cylinders, and functional fixtures. The automatic online process control device controls all operation functions according to an order in the whole process, wherein the operation functions comprise pushing the coil framework in place, pushing the terminal into rails, guiding the terminals into the fixtures, inserting the terminals in place, and pressing and fixing the terminals onto the coil framework. The functional air cylinders are distributed in order to execute the operation in each step. The functional fixtures are controlled to work in cooperation with the air cylinders synchronously. A traditional double-station technology which is low in efficiency and needs the operation of multiple persons is simplified to be completed in one procedure which is controlled by the automatic online process control device and operates automatically according to the order in the whole process, therefore, stations are reduced, operation personnel and occupied space are reduced, the assembling effect and the product quality reliability are guaranteed, the operation intensity is lowered, the working efficiency is greatly improved, the production cost is lowered, and basic guarantee is provided for meeting the high-efficiency motor large-scale market requirements.

Owner:上海合愉电机有限公司

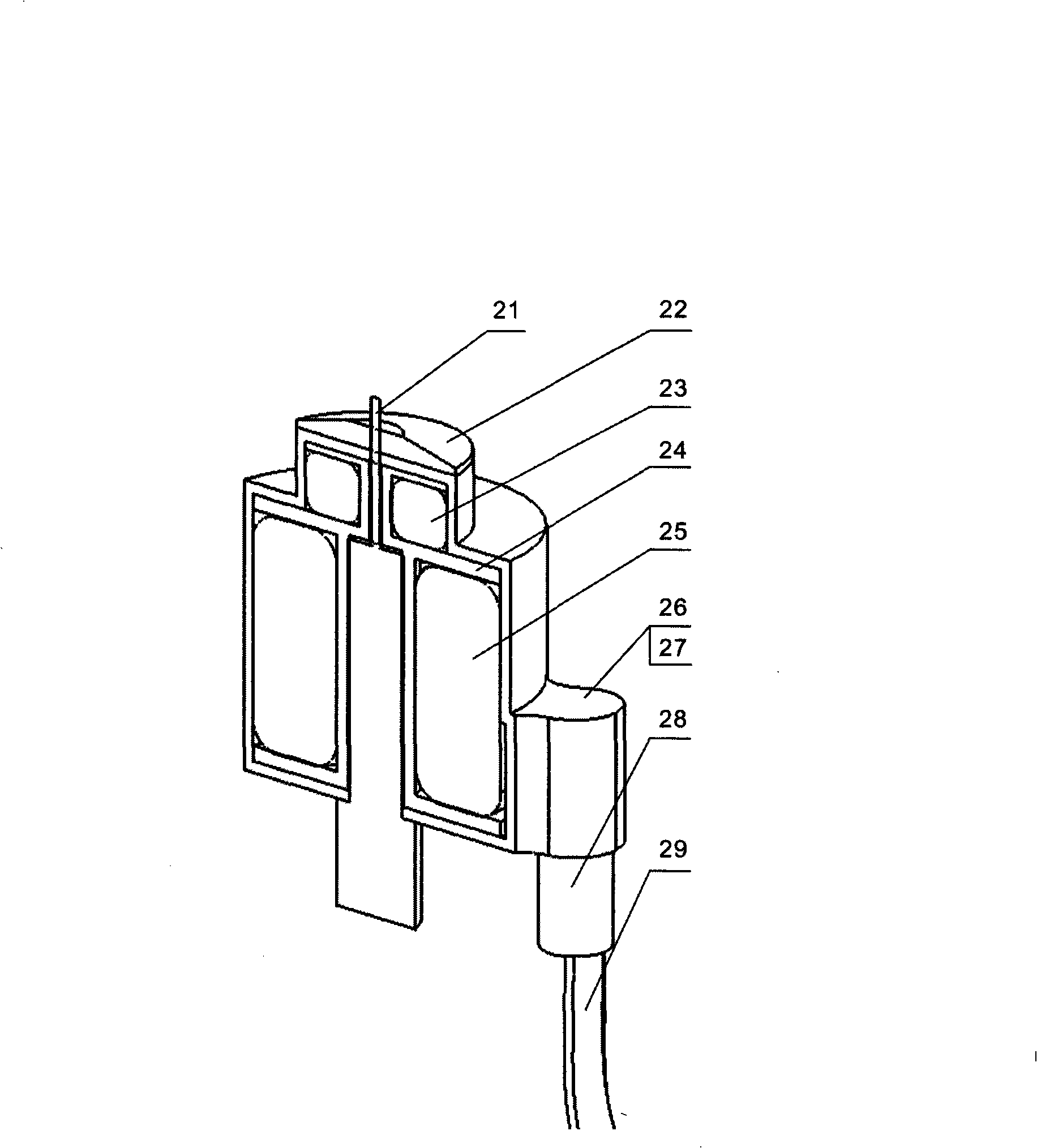

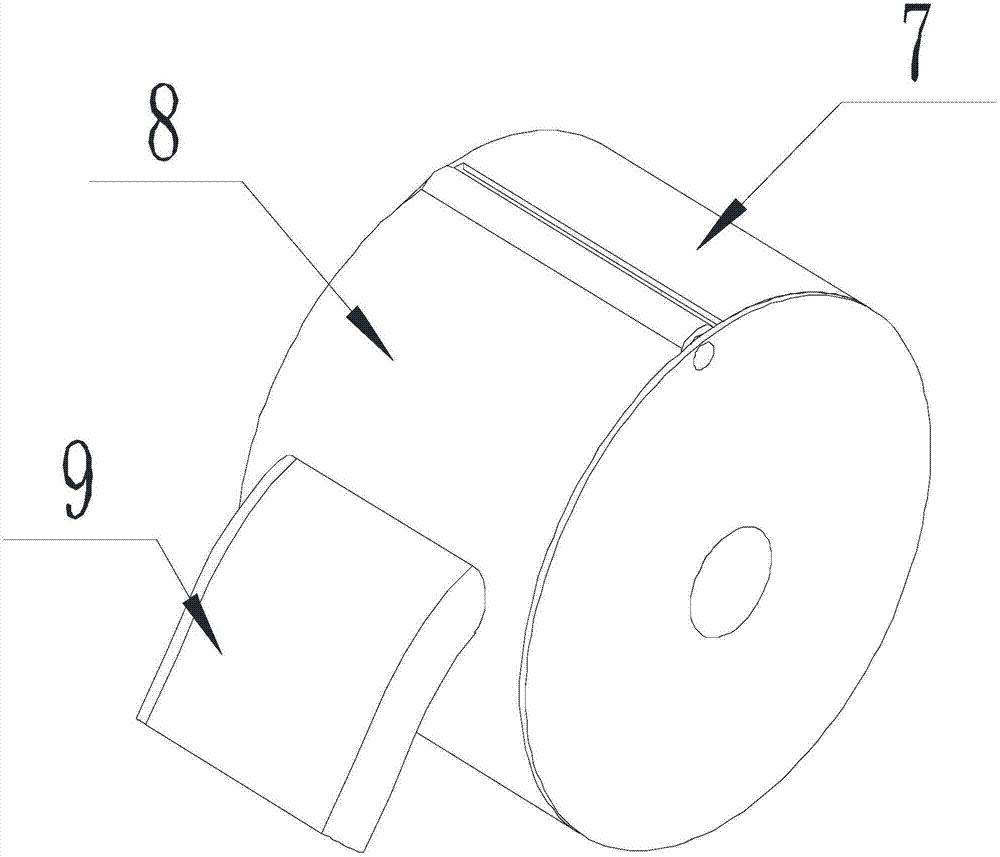

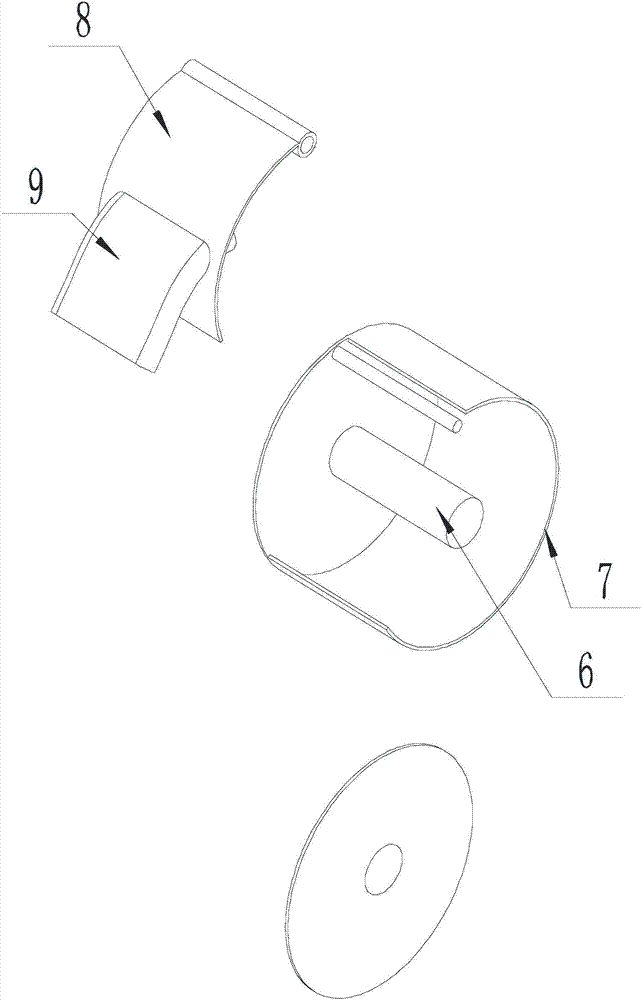

Sensor and test device for testing tone key of musical box

ActiveCN101324462AImprove test accuracyImprove stabilitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansSignal processing circuitsEngineering

A sensor for testing keys of a music box comprises a housing, a vibration detecting coil, a coil rack, an actuating coil, a wire, and an iron core with flat head section, wherein the coil rack is arranged at the middle of the housing; the iron core is inserted in the center of the coil rack; the vibration detecting coil and the actuating coil are respectively wound on the upper and the lower parts of the coil rack; the vibration detection coil is connected with a signal processing circuit; and the actuating coil is connected with a power line. The invention also provides a music box key testing device including the sensor. The sensor has the advantages that the sensor is integrated with vibration excitation and test and can be used for providing the vibration source and testing with high test accuracy and good stability. The sensor and the testing device can achieve vibration excitation and test of keys in one work position to obviate the respective arrangement of vibration excitation positions and test positions in the prior art, thus reducing the number of work positions, reducing the size of the testing device, improving the work efficiency and prolonging the service life.

Owner:宁波韵声机芯制造有限公司

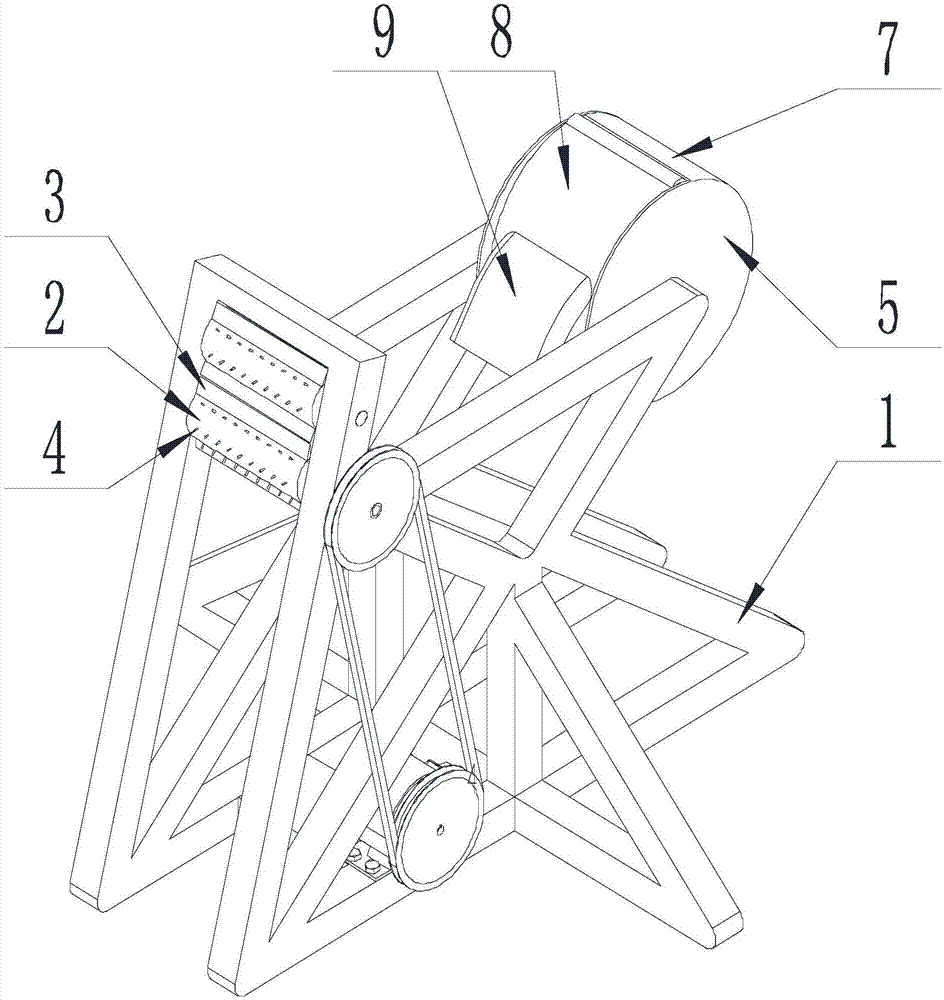

Foamed net conveying equipment for apple packing

ActiveCN107512419AReduce work stationsSimple packaging processWrapping material feeding apparatusPackaging fruits/vegetablesEngineeringSupport plane

The invention discloses foamed net conveying equipment for apple packing. The equipment comprises a cutting module, a driving device and a support frame; the cutting module is supported on the ground by the support frame; the cutting module comprises a pair of mounting shafts with parallel axes; cutters and clamping rods are respectively arranged on the mounting shafts; edges of the cutters are parallel to the axes of the mounting shafts; two ends of the mounting shafts are rotationally connected with the support frame; the driving device drives the mounting shafts to rotate around self axes, and enables the edges of the cutters to contact with each other; and the rotating directions of the mounting shafts are opposite. The cutoff and the expanding of foamed nets are realized through the equipment, so that the cutting of the foamed nets and the packing of apples are consecutive; and compared with a traditional packing mode, the equipment reduces stations, simplifies the packing process, and improves the working efficiency.

Owner:硕睿(重庆)企业服务有限公司

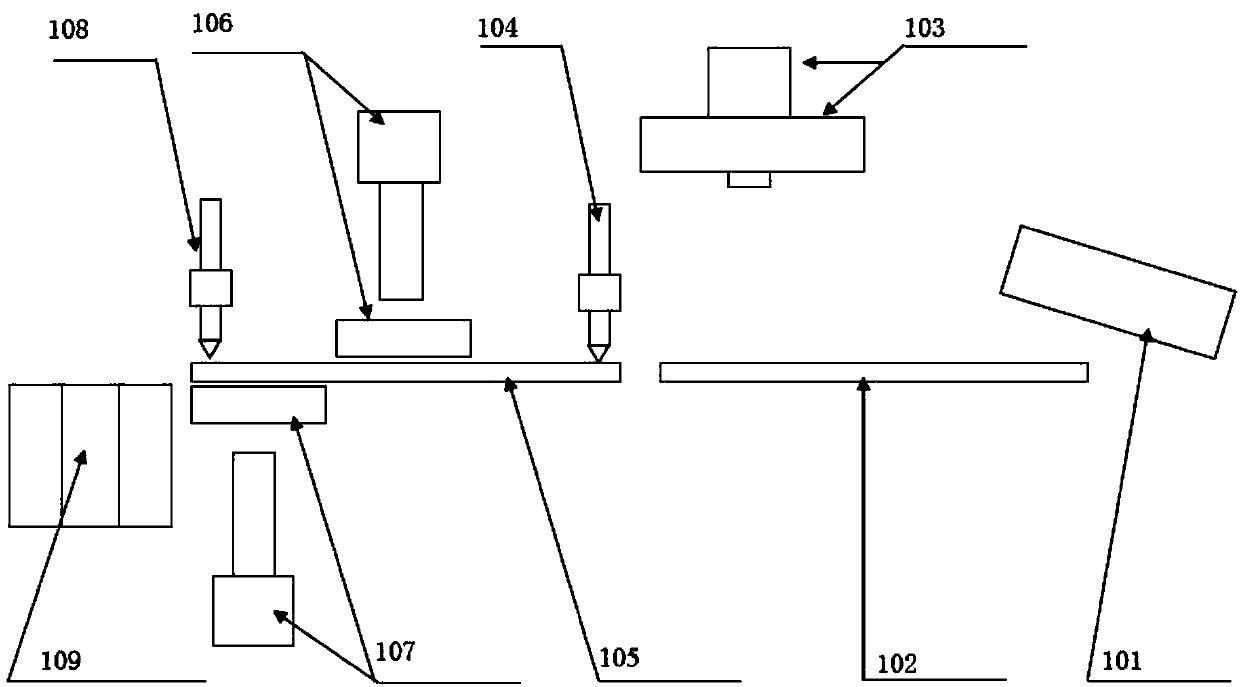

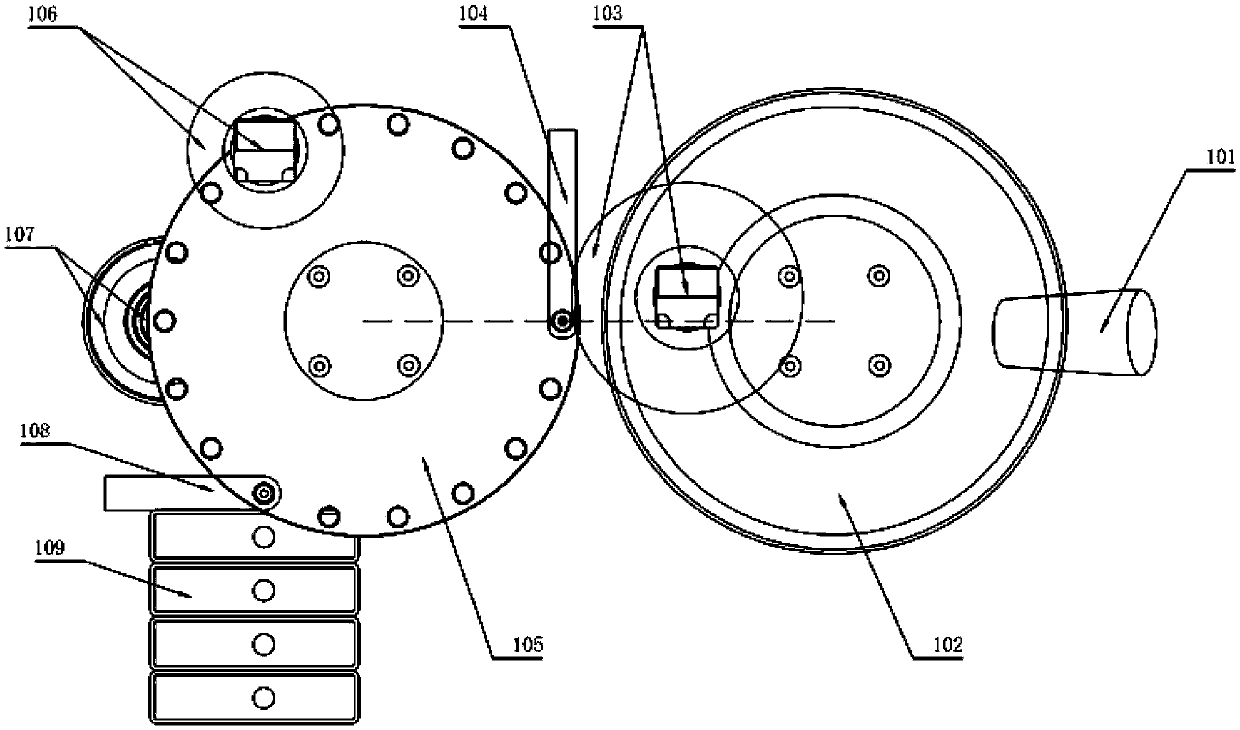

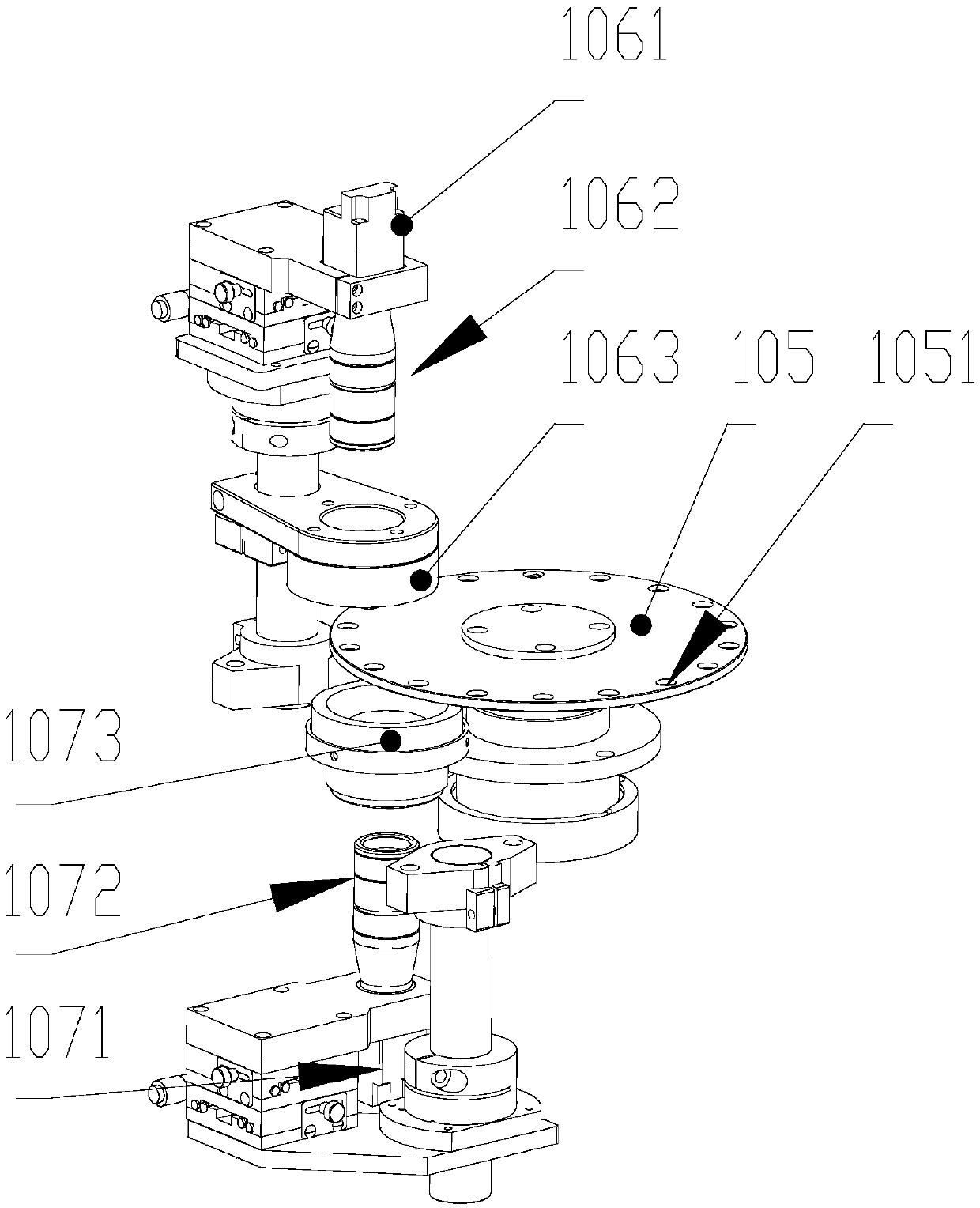

Toner cartridge ink cylinder component assembler for printer

ActiveCN105196051AIncrease productivityGuaranteed assembly accuracyAssembly machinesPacking procedureEngineering

The invention relates to a toner cartridge ink cylinder component assembler for a printer The toner cartridge ink cylinder component assembler comprises a first assembling device, a second assembling device, a transfer device part of which is arranged between the first assembling device and the second assembling device and a packing device arranged outside the transfer device; the assembler is also provided with a first vibration disc and a second vibration disc, wherein a first rail is arranged between the first vibration disc and the first assembling device, and a second rail is arranged between the second vibration disc and the second assembling device. Large ends and small ends can be assembled at the same time, production efficiency is improved, charging of the small ends and large ends is recognized by adopting a CCD (charge coupled device) mechanism, thus ensuring assembling precision; the transfer carrying adopts three manipulators for charging and discharging, and the second manipulator comprises a clasping manipulator to ensure a precise direction of a workpiece in a stamping procedure; the stamping procedure and detection procedure are integrated to reduce work stations; the packing procedure adopts a manner of sealing three sides plus pre-sealing the next, and sealing and charging can be favorably performed at the same time.

Owner:JIANGSU BVM INTELLIGENT TECH

Special-shaped cigarette box opening machine

PendingCN107934103ACompact structureReduce work stationsBinding material removalEngineeringConveyor belt

A special-shaped cigarette box opening machine comprises a rack, a lower sliding base, an upper sliding base, two lower box cover opening mechanisms, two upper box cover opening mechanisms, two side box cover opening mechanisms, a distance adjusting mechanism I and a distance adjusting mechanism II; and after a sealing adhesive tape of a packaging box is cut off and is conveyed in place by a conveying belt, a lower sliding base driving mechanism drives the lower sliding base to move upwards, and then the lower box cover opening mechanisms act to open a lower box cover downwards in an overturning manner. After the lower box cover is opened in the overturning manner, an upper sliding base driving mechanism drives the upper sliding base to move downwards, and the upper box cover opening mechanisms act to upwards open an upper box cover upwards in an overturning manner. Finally, two side box covers are opened to the outer side by the side box cover opening mechanisms in an overturning manner. Due to the fact that opening of the upper box cover, the lower box cover and the side box covers is achieved on one station, the whole special-shaped cigarette box opening machine is compact in structure, stations are saved, and efficiency is improved. The special-shaped cigarette box opening machine conveniently adapts to specification of special-shaped cigarette packaging boxes in differentlengths and heights, and the application range of the special-shaped cigarette box opening machine is widened.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Vertical tilting transport apparatus for domestic refuse

InactiveCN1339391AImprove the efficiency of transshipment workReduce work stationsRefuse transferringLoading/unloadingLocking mechanismEngineering

At the mouth to a silo, one platform is installed and hinged to one edge, and the bottom of the platform is drawn by one hydraulic pull rod to turn by 90 deg from the silo mouth to the bottom. The center of the platform has two positioning edges with a locking mechanism in between. On one side of the garbage can, there are two positioning tracks slide fitted with the positioning edge of the platform and with positioing pin holes for locking by the said locking mechanism. On one edge of the silo, there is one hydraulic elevating and compressing mechanism to compress garbage inside the garbage can and turn the platform with locked garbage by 90 deg. The present invention can reduce working sites and covered area and raise garbage transport efficiency.

Owner:上海市环境工程设计科学研究院

Device and method of detecting polished quartz wafer shallow scratch

PendingCN110006919AImprove efficiencyImprove stabilityOptically investigating flaws/contaminationTurn angleEngineering

The invention discloses a device and a method of detecting a polished quartz wafer shallow scratch. The device comprises a material feed cylinder, a wafer taking tray, a positioning module, a wafer taking sucking head, a detection tray, a front detection module, a back detection module, a wafer placing sucking head and a wafer accommodation box, wherein the material feed cylinder is used for scattering polished wafers onto the wafer taking tray based on certain vibration frequency under control of a main procedure, the wafer taking tray is designed to turn by a small angle clockwise and anticlockwise precisely, so as to distribute the polished wafers onto the wafer taking tray uniformly disorderly to be taken up one by one layer, the positioning module comprises a positioning camera, a lens and a light source, is above the wafer taking tray, and is used for positioning and imaging the polished wafer on the wafer taking tray, so as to calculate coordinates of the polished wafer, whereinthe coordinates comprise a step size and a turning angle.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Automatic feeding device for powder mixing machine

The invention provides an automatic feeding device for a powder mixing machine. The automatic feeding device comprises a rack provided with a conveying channel. A cap opening station, a turnover station and a cap falling station are arranged on the rack in the advancing direction of the conveying channel sequentially. Positioning and clamping devices are arranged on the two sides, corresponding to the cap opening station, the turnover station and the cap falling station, of the rack. A cap taking and placing device matched with a raw material barrel on the cap opening station and the cap falling station is arranged on one side of the rack; a barrel turning device is arranged on the other side, corresponding to the turnover station, of the rack. The automatic feeding device for the powder mixing machine is capable of achieving full automation, reasonable in whole structure and high in working efficiency; the requirement of the pharmaceutical production process can be met.

Owner:SHINVA MEDICAL INSTR CO LTD

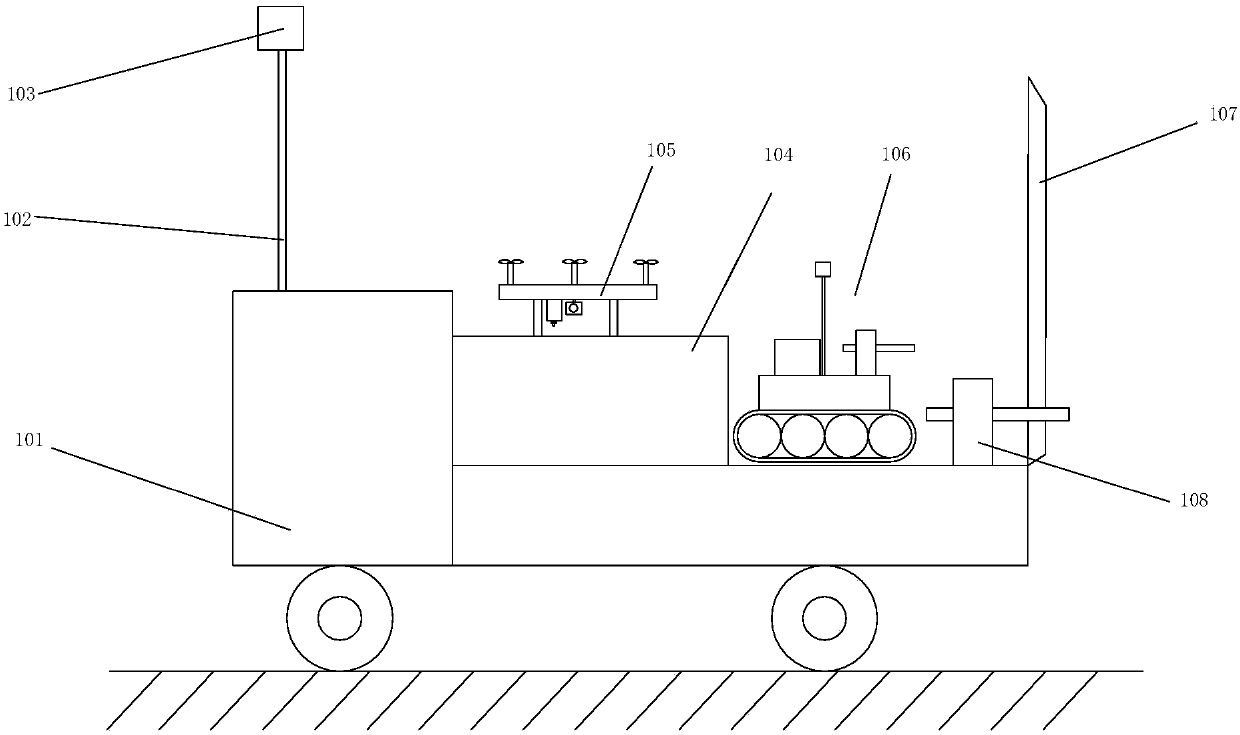

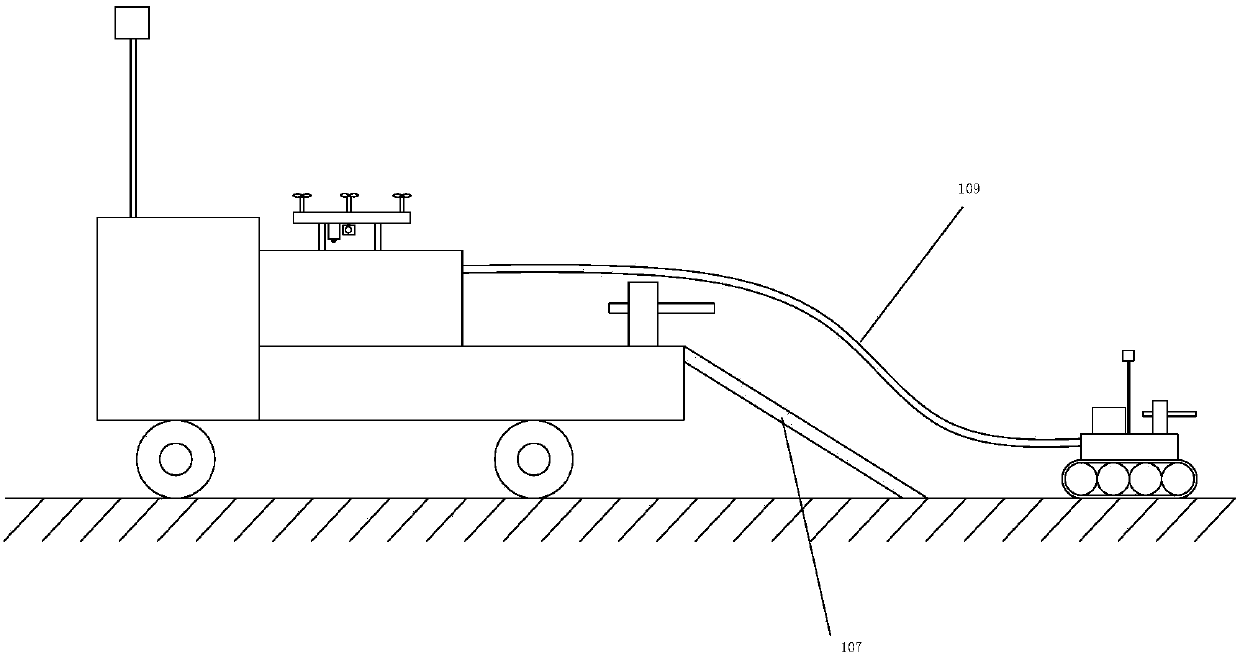

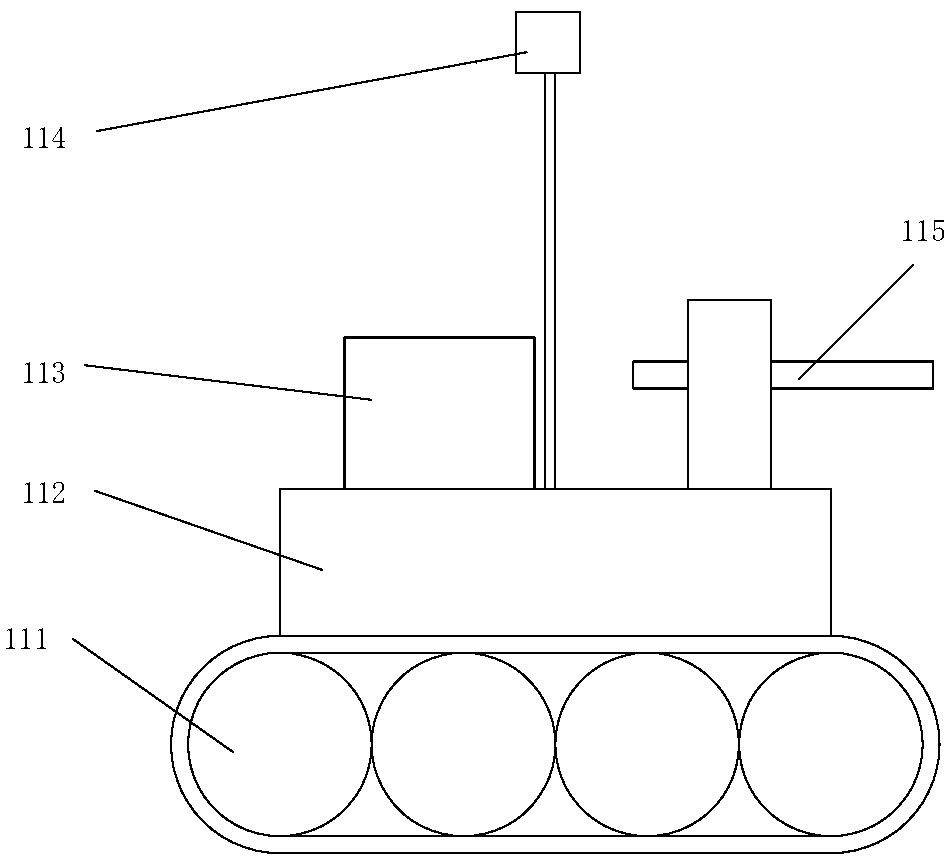

Automatic liquid spraying control method

InactiveCN108012825AAvoid homeworkReduce work stationsWatering devicesCultivating equipmentsFlight vehicleAgricultural engineering

The invention discloses an automatic liquid spraying control method. Water spraying is conducted in at least one of the four modes, wherein according to the first mode, water is sprayed through a mainspraying gun on a vehicle-mounted platform; according to the second mode, under the surveillance of an aircraft, the water is sprayed through the main spraying gun or a crawler-type walking vehicle;according to the third mode, in the absence of the aircraft, the water is sprayed through the crawler-type walking vehicle; according to the fourth mode, the water is sprayed through the aircraft. Bymeans of the automatic liquid spraying control method, automatic spraying can be achieved, and the spraying operation efficiency is high.

Owner:长沙修恒信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com