Stacker crane with automatic delivery of single station for flat plate collector

A flat plate collector and line palletizer technology, applied in the field of palletizers, can solve the problems of potential safety hazards, high labor costs, low daily production capacity, etc., and achieve the effects of reducing management difficulty, reducing labor intensity, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is the best example of the single-station automatic off-line palletizer for the flat plate heat collector of the present invention, which does not limit the protection scope of the present invention.

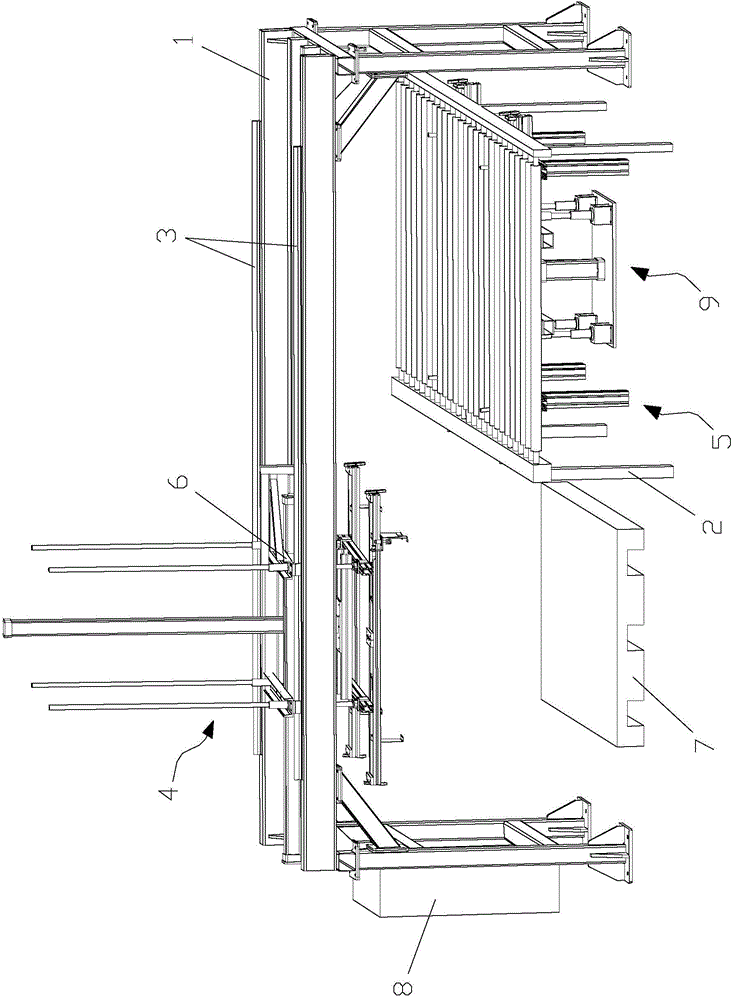

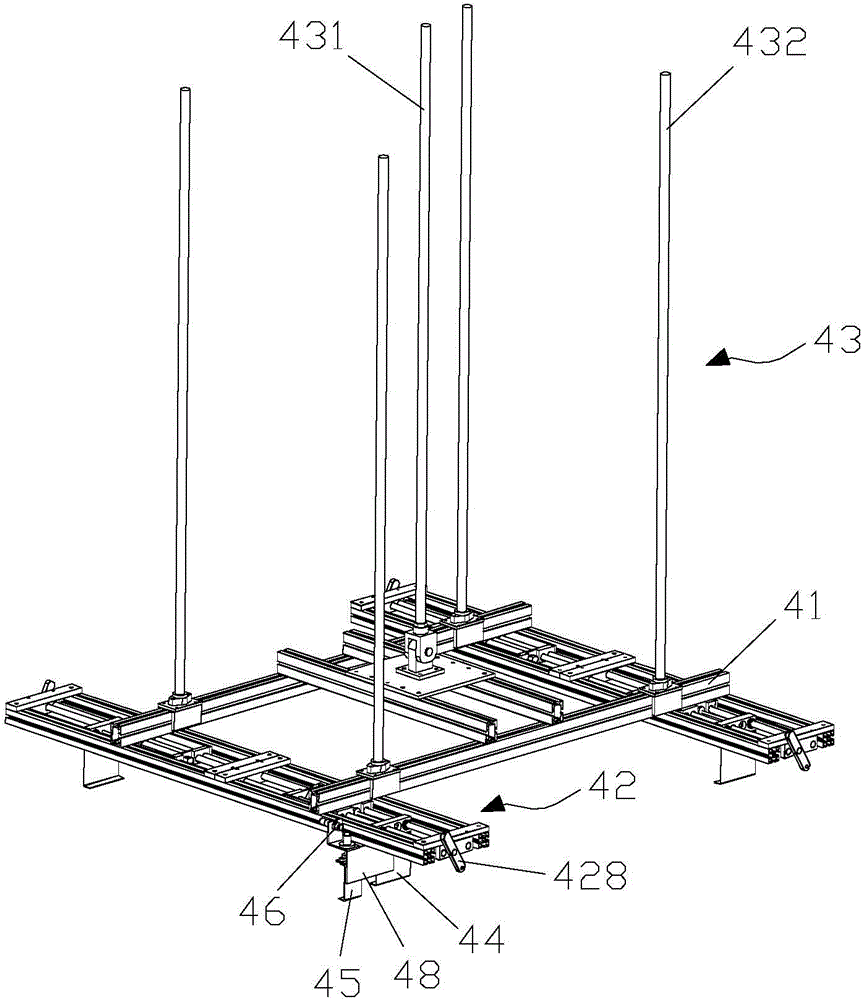

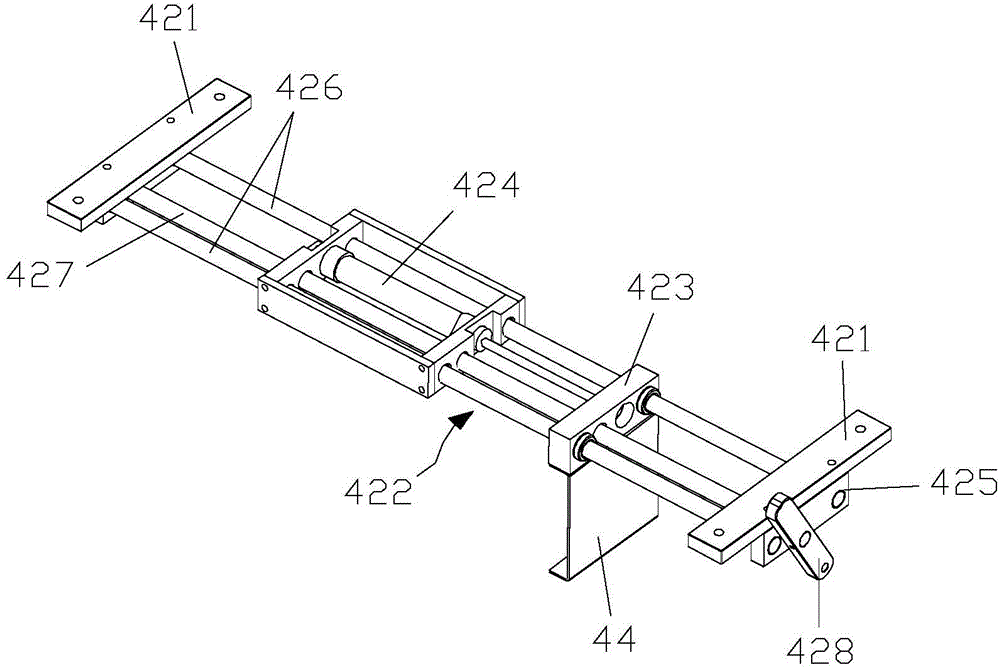

[0029] Please refer to figure 1 , the figure shows a single-station automatic off-line palletizer for flat plate heat collectors, including a gantry 1 and a production line support 2 arranged below the gantry 1, and two guide rails 3 are installed on the gantry 1, The gantry 1 is also equipped with a heat collector handling and clamping mechanism 4 slidingly connected with the guide rail 3, and a heat collector positioning mechanism 5 and a heat collector holding mechanism 9 are arranged below the handling area of the production line support 2, and a heat collector holding mechanism 9 is installed on the gantry. A transfer tray 7 is arranged under the frame 1, and the transfer tray 7 is close to the heat collector positioning mechanism 5. In addition, an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com