Patents

Literature

1252 results about "Palletizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A palletizer or palletiser is a machine which provides automatic means for stacking cases of goods or products onto a pallet. Manually placing boxes on pallets can be time consuming and expensive; it can also put unusual stress on workers. The first mechanized palletizer was designed, built, and installed in 1948 by a company formerly known as Lamson Corp.

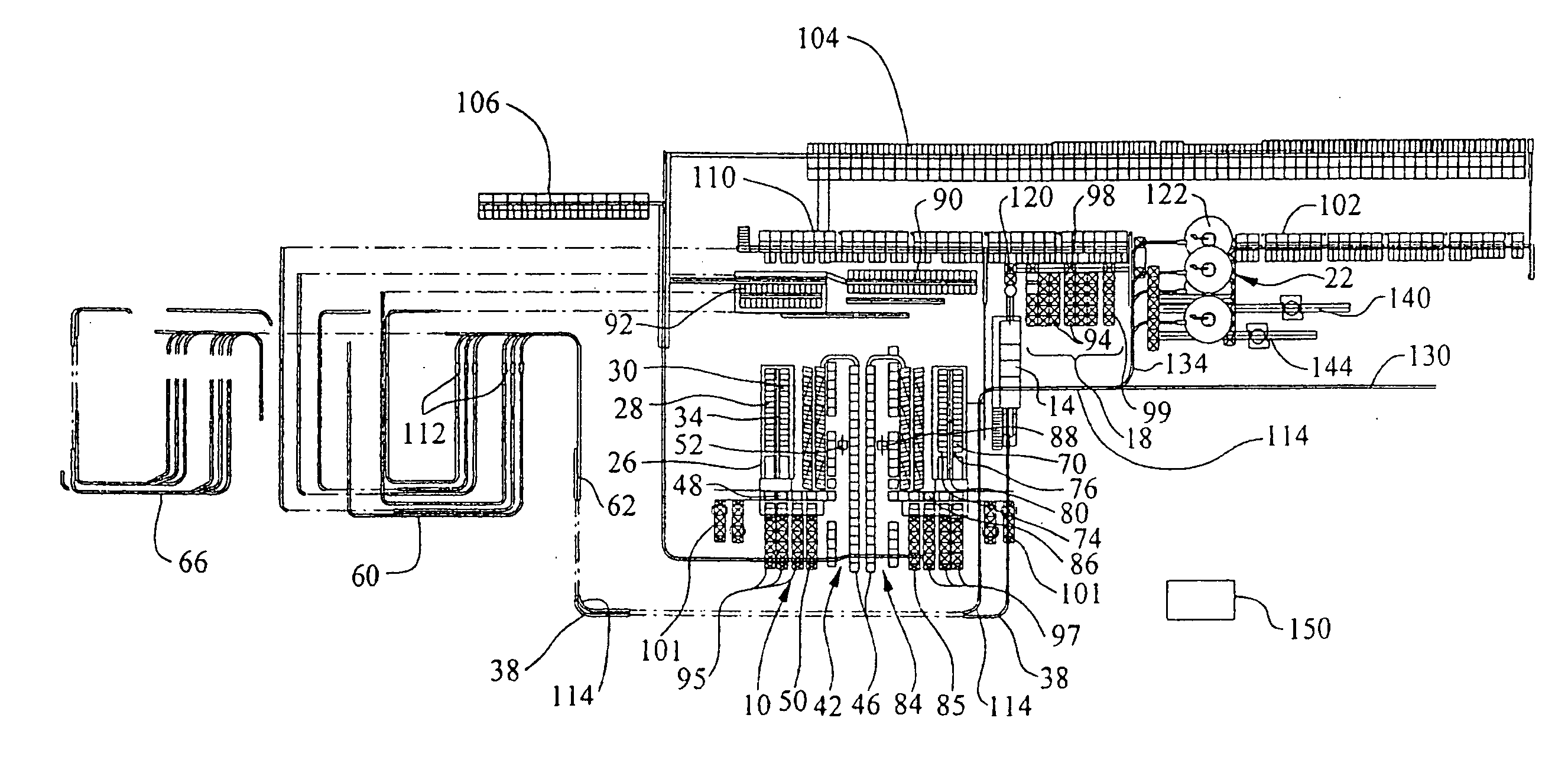

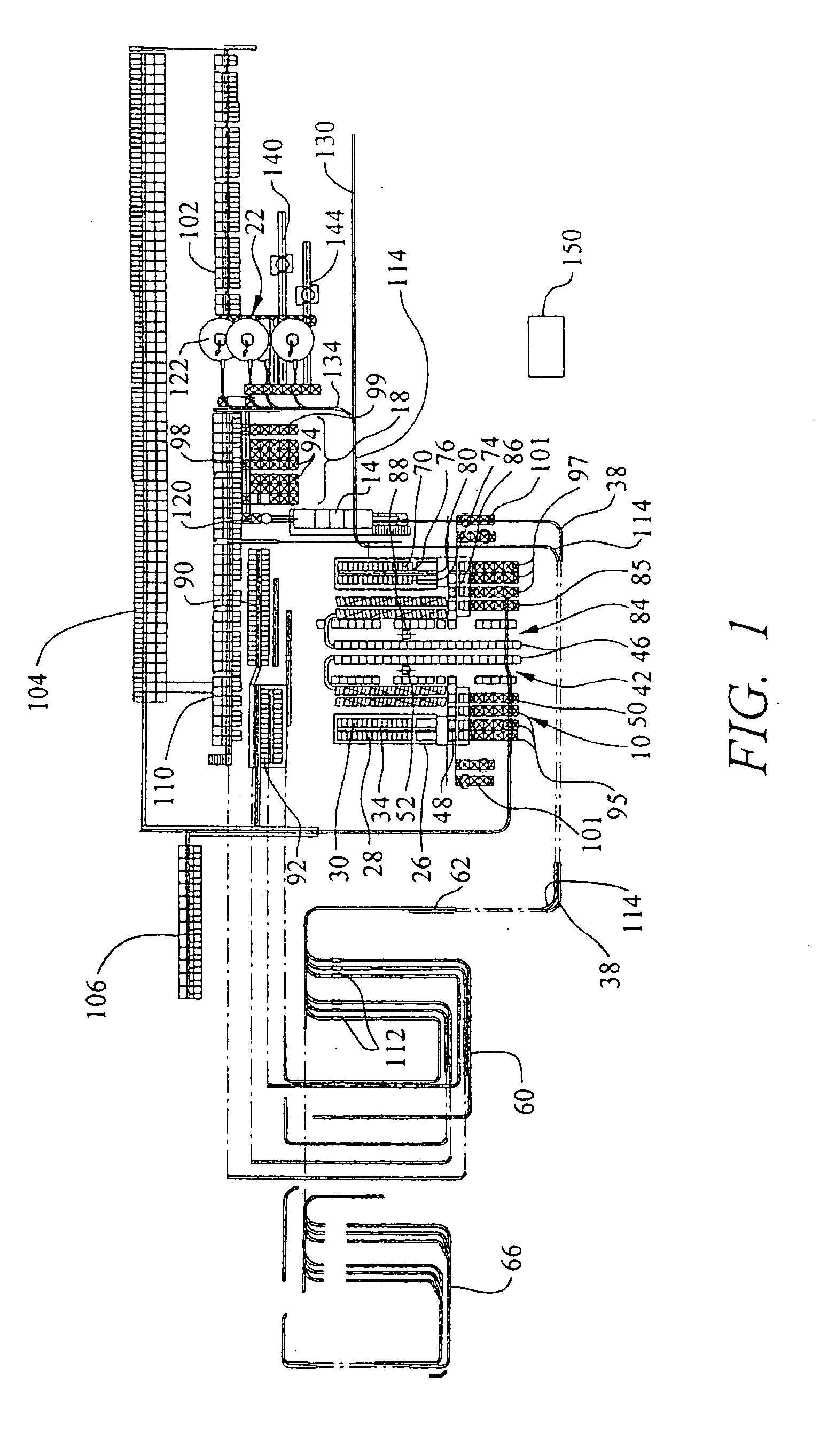

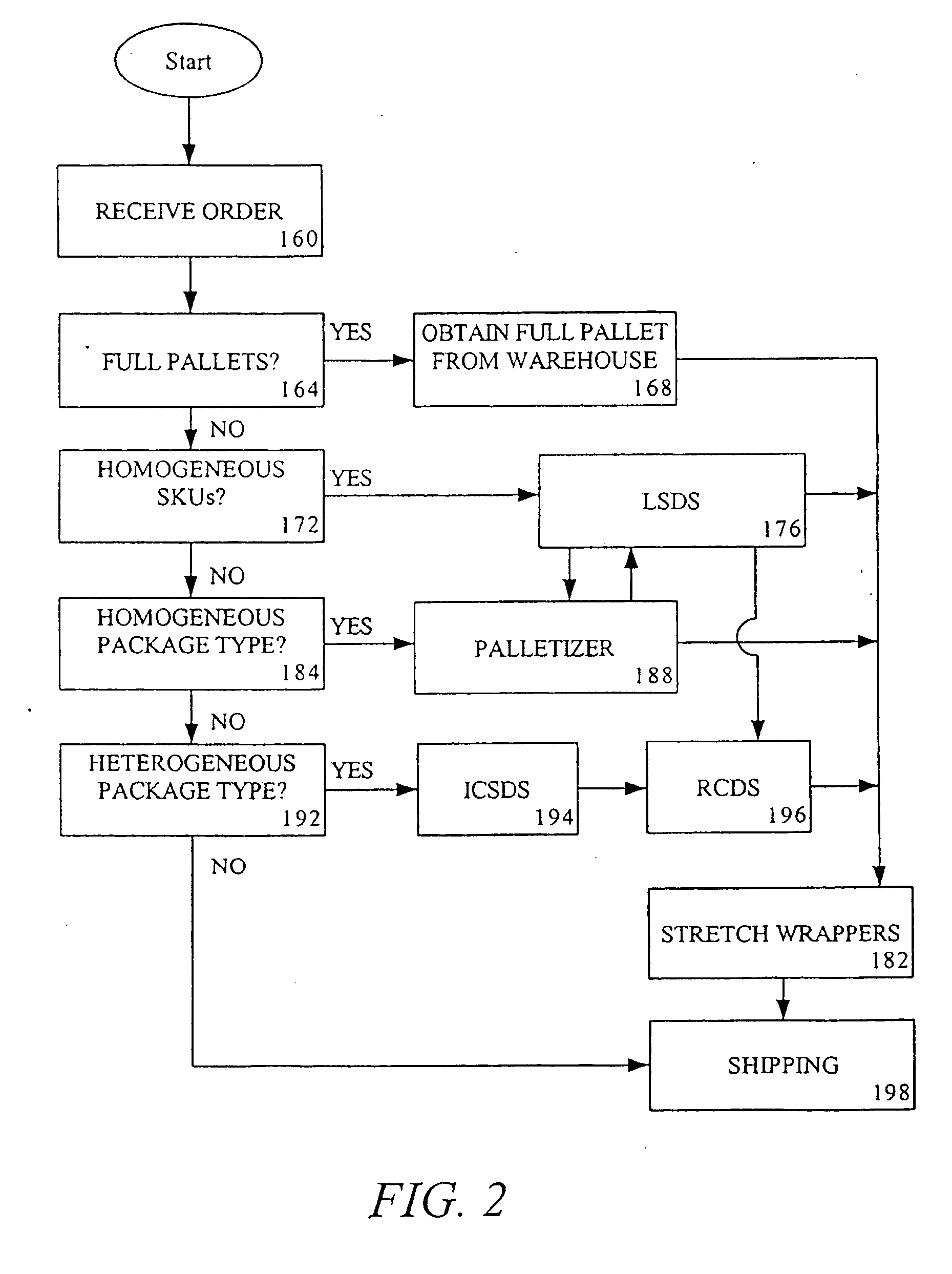

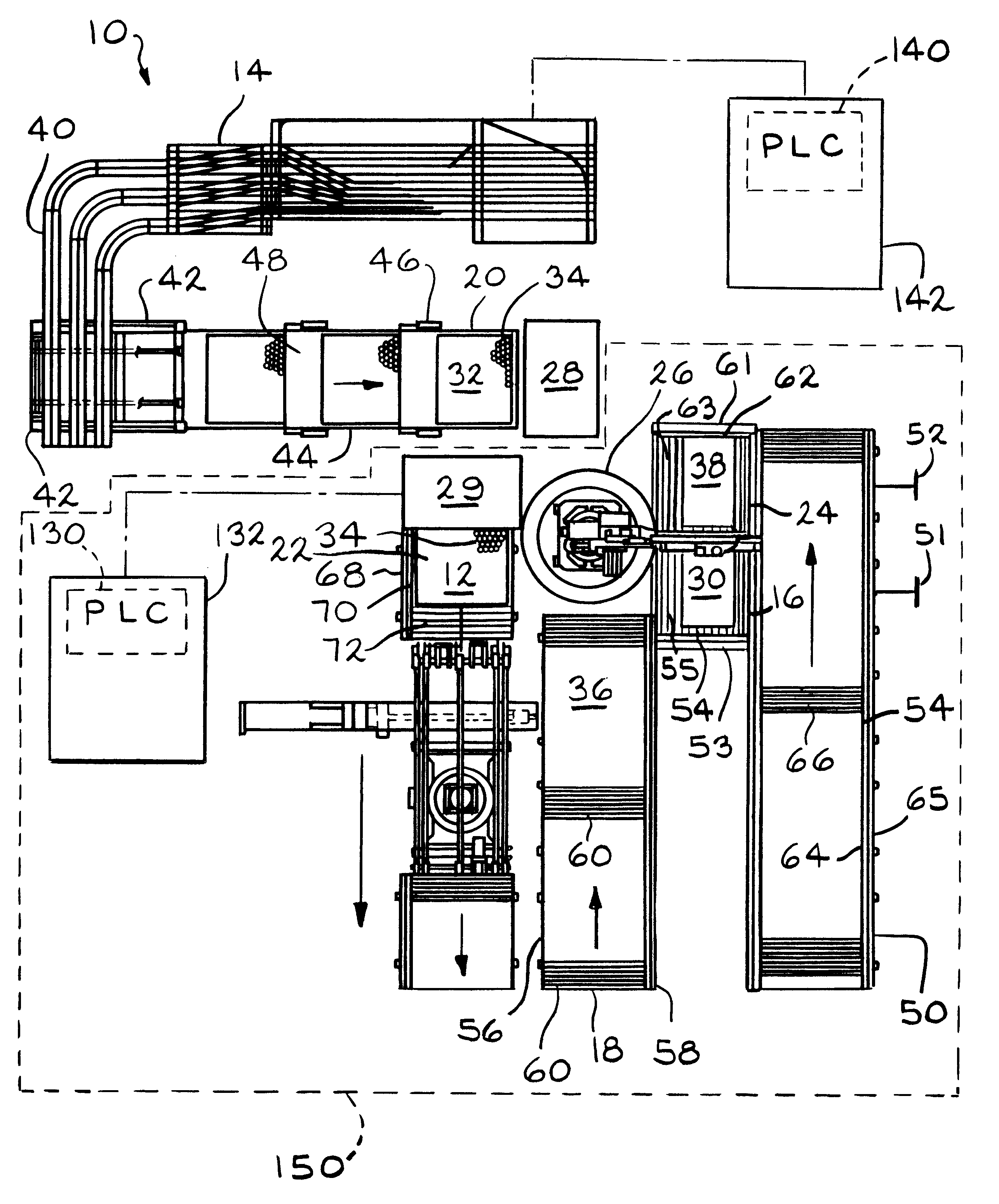

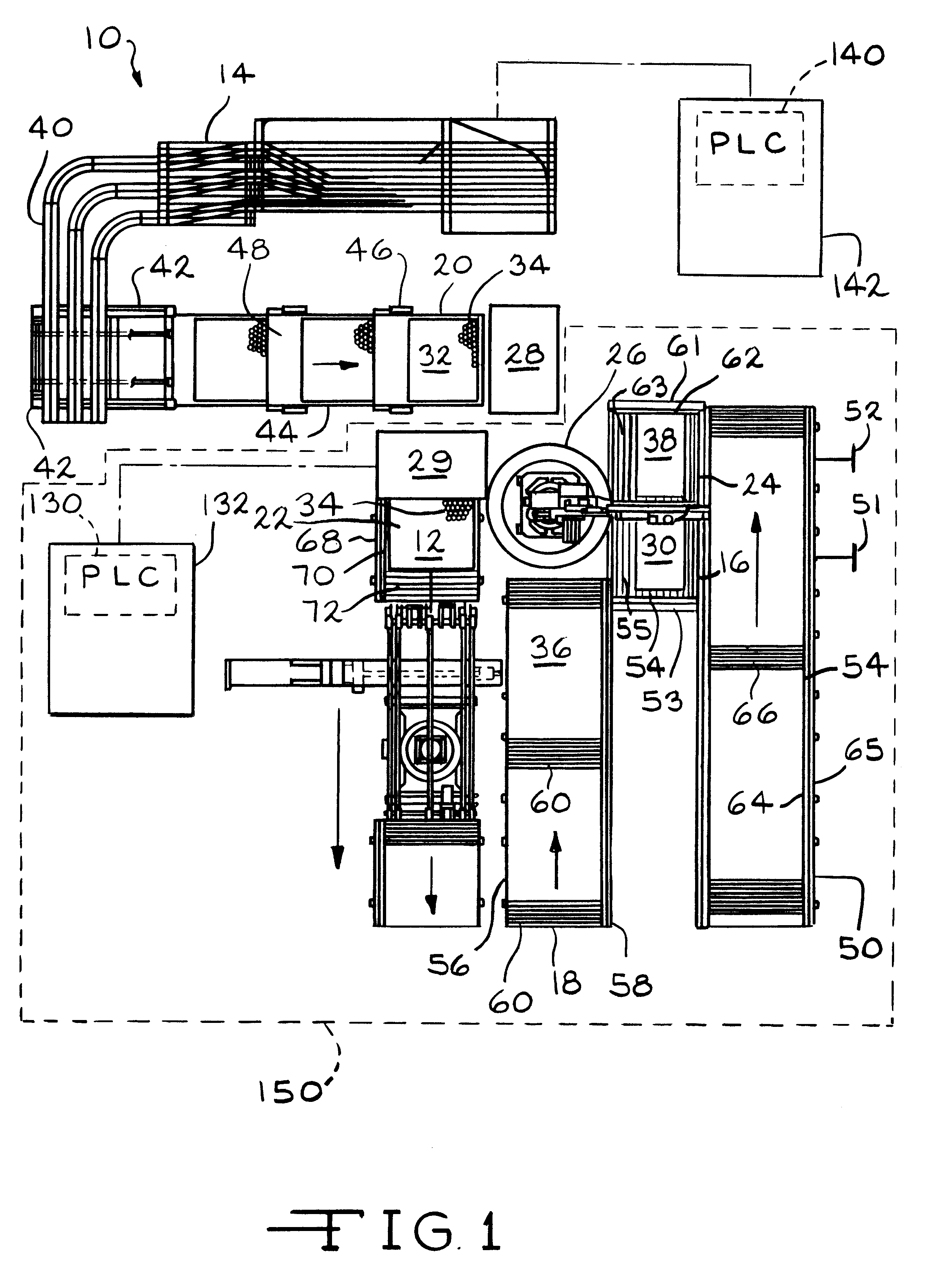

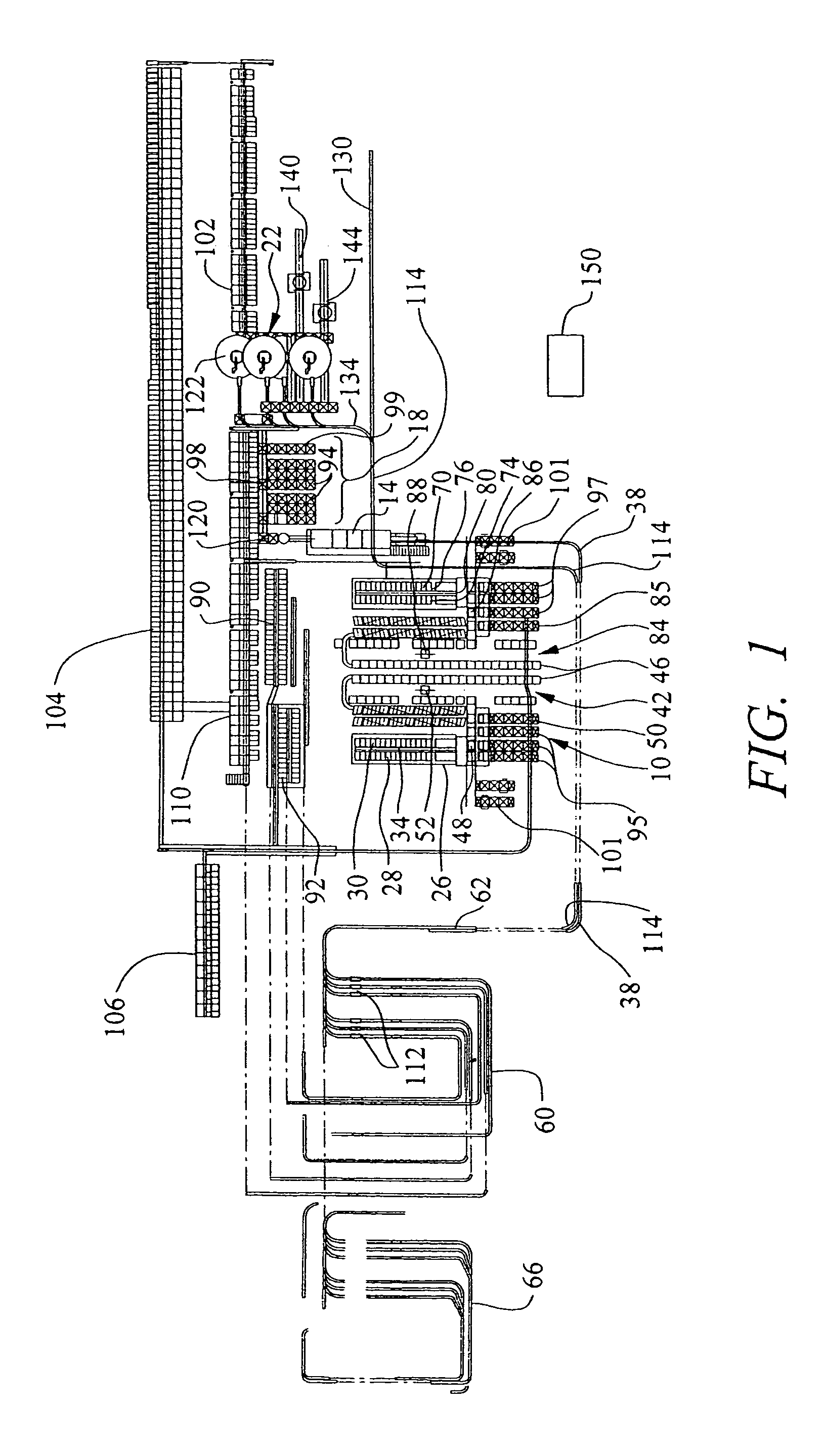

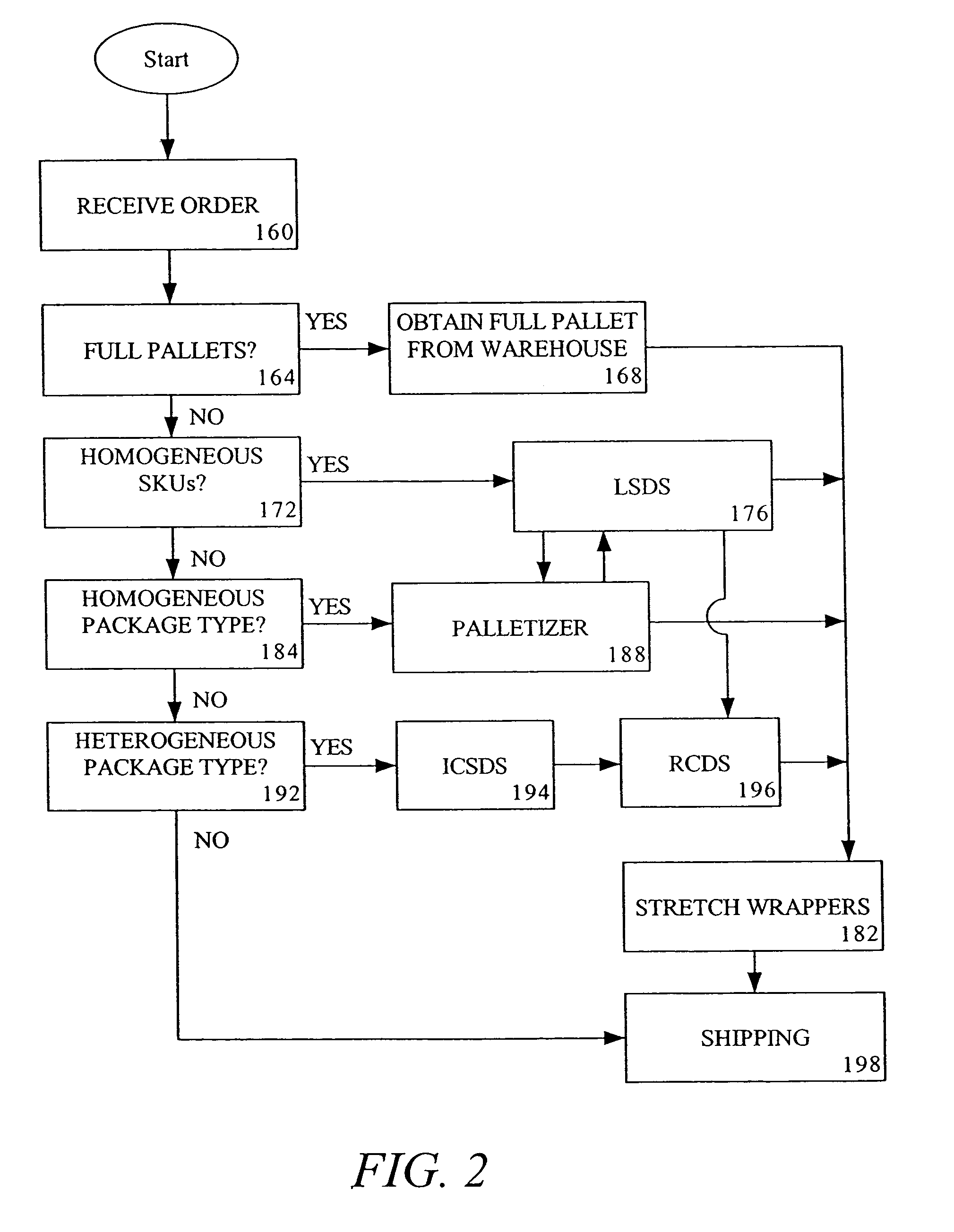

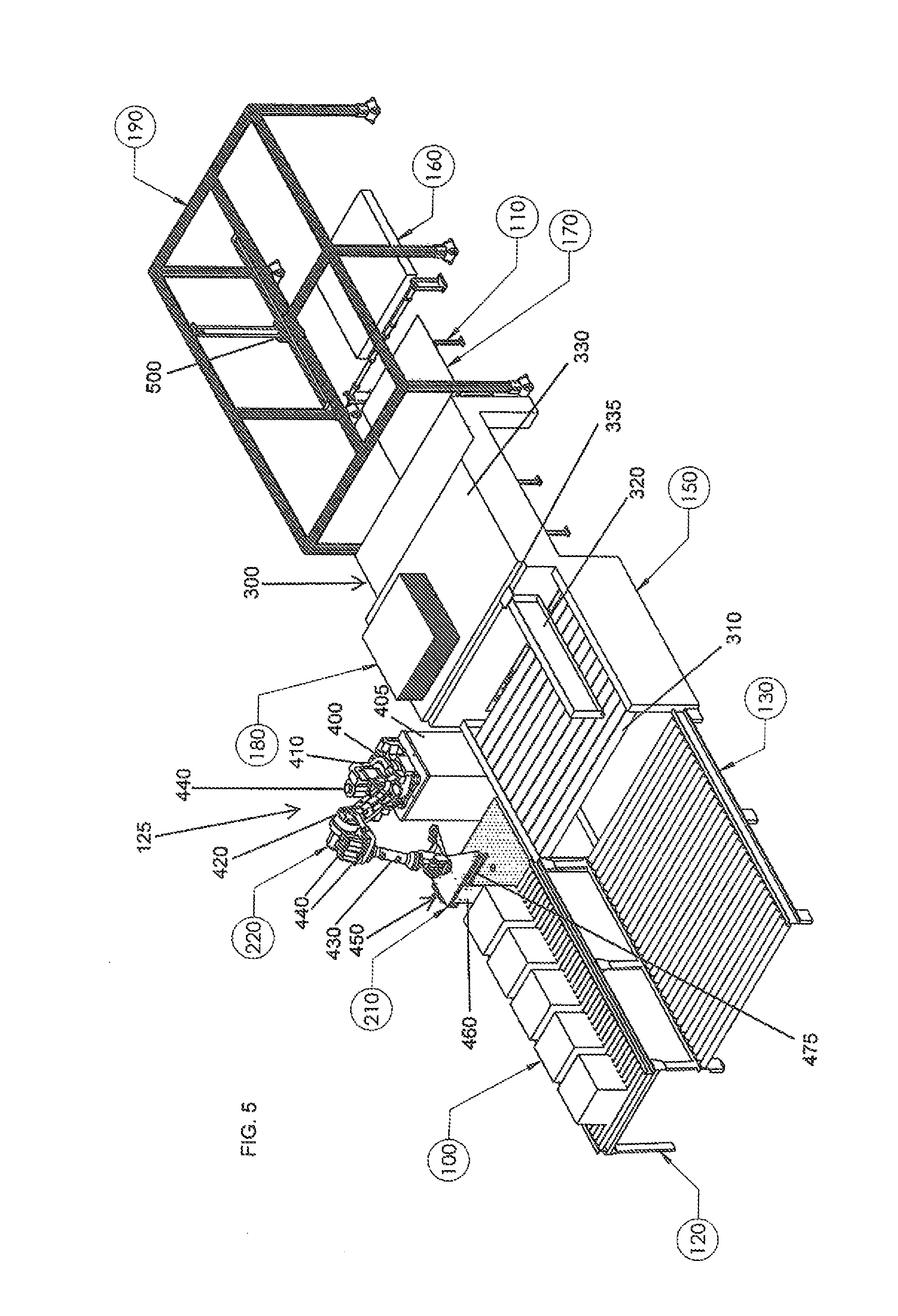

Automated container storage and delivery system

A material storage and delivery system includes an individual container storage and delivery system (ICSDS). A palletizer is provided for placing containers from the ICSDS on a pallet. A layer storage and delivery system (LSDS) places full layers of containers on a pallet. A robotic container delivery system (RCDS) places individual containers on a pallet. A conveyor system conveys containers and pallets between at least two of the ICSDS, the palletizer, the LSDS and the RCDS. A method for storing and delivering containers is also disclosed.

Owner:STINGEL FREDERICK J III +2

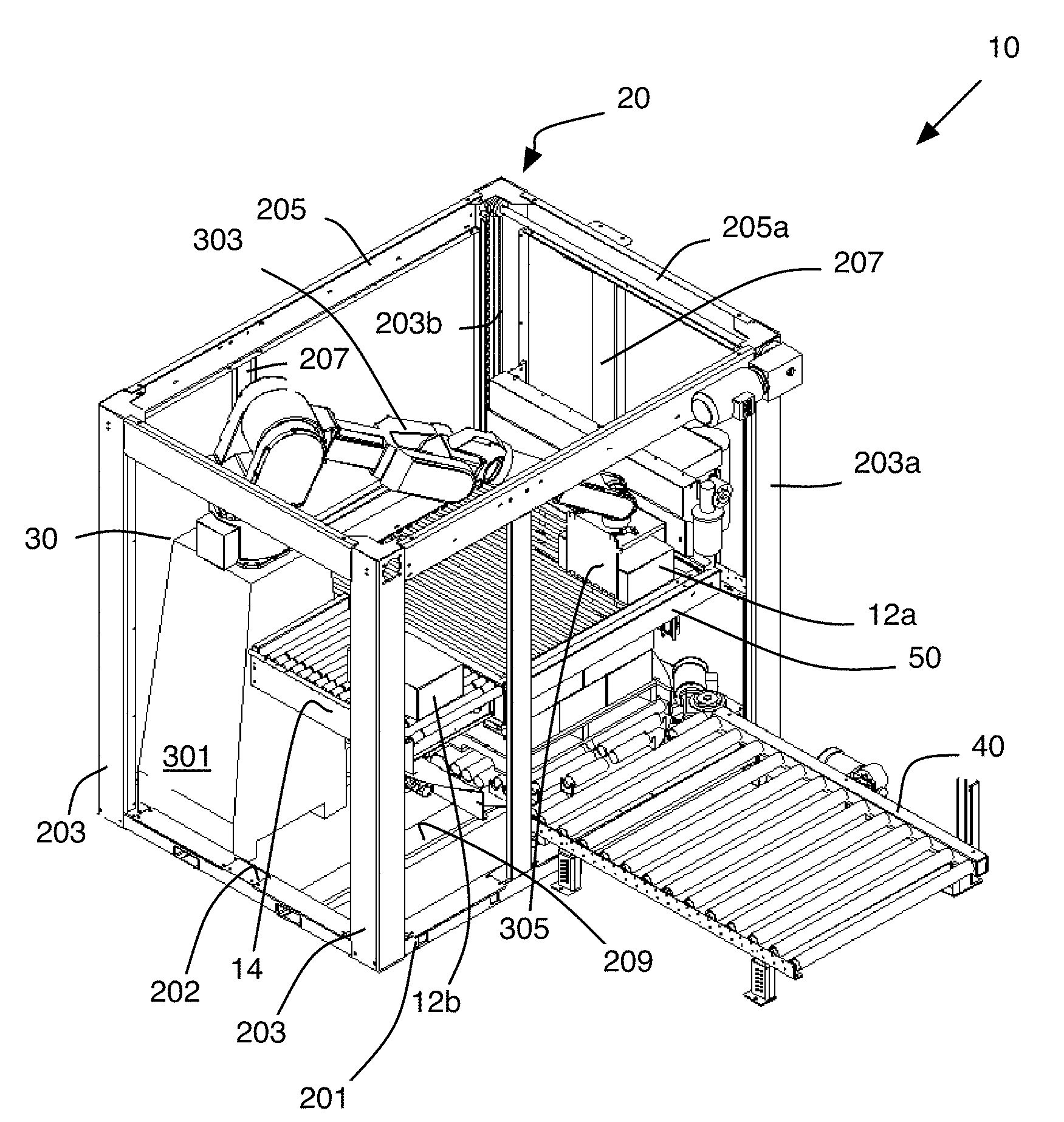

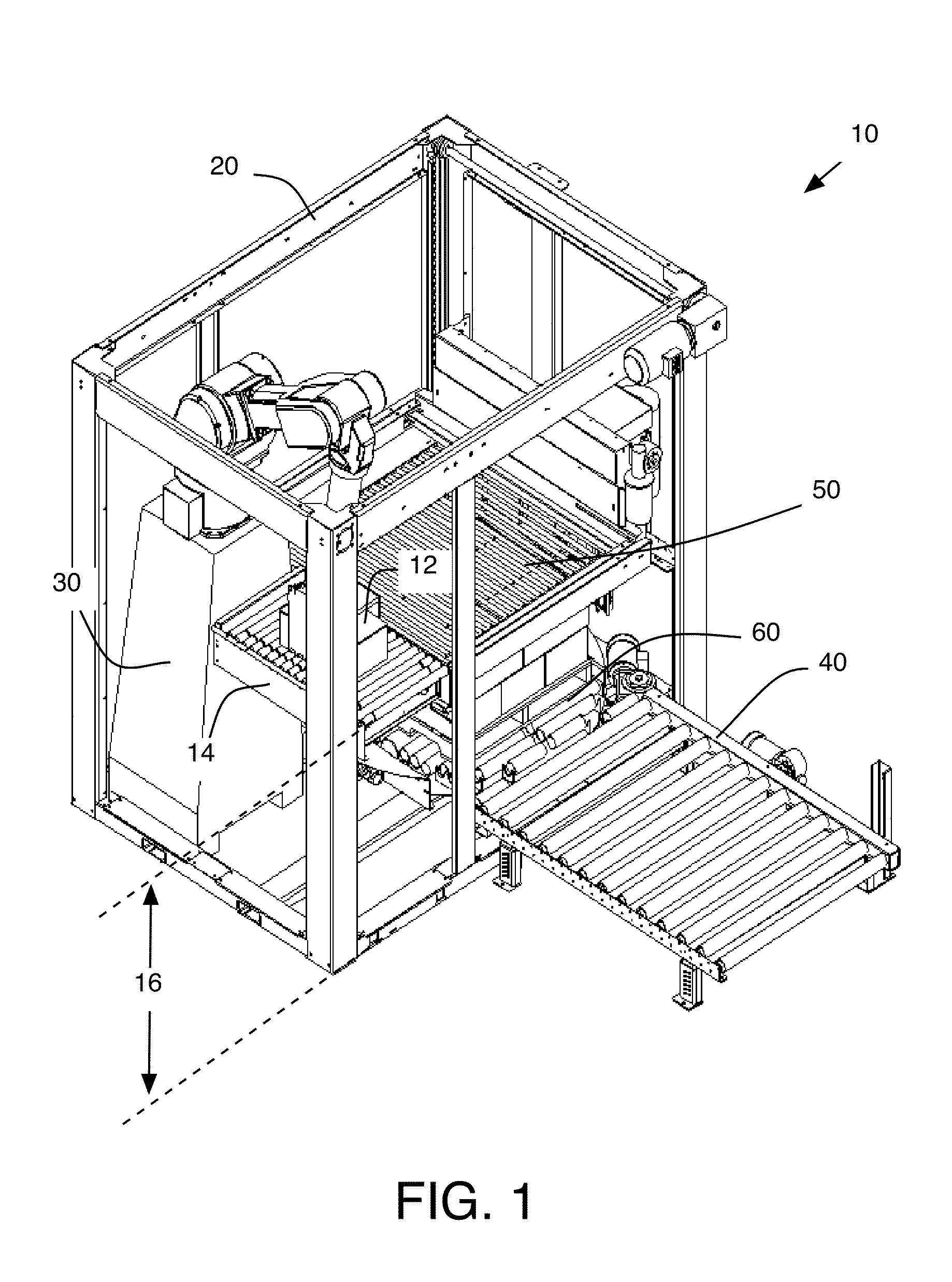

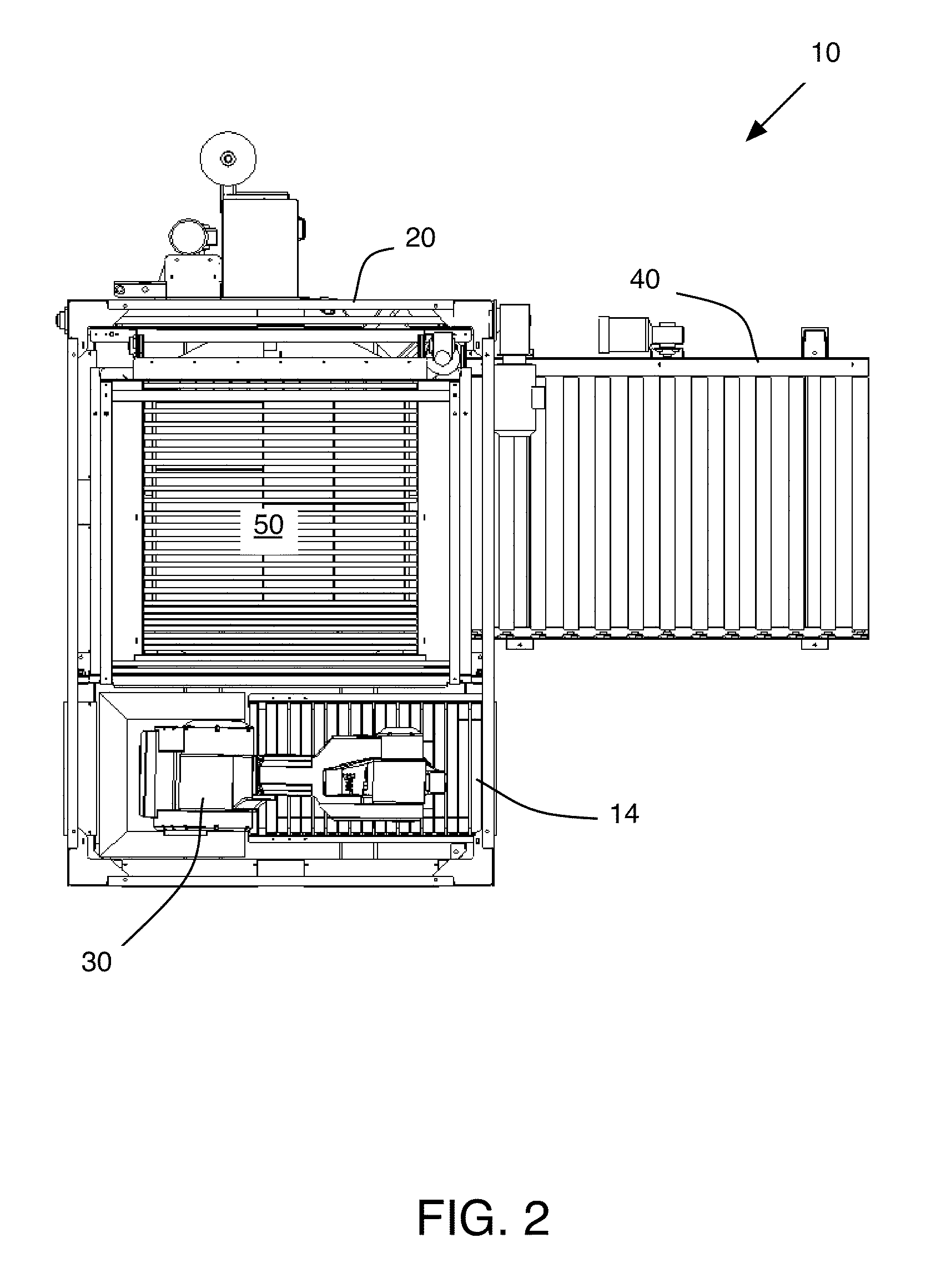

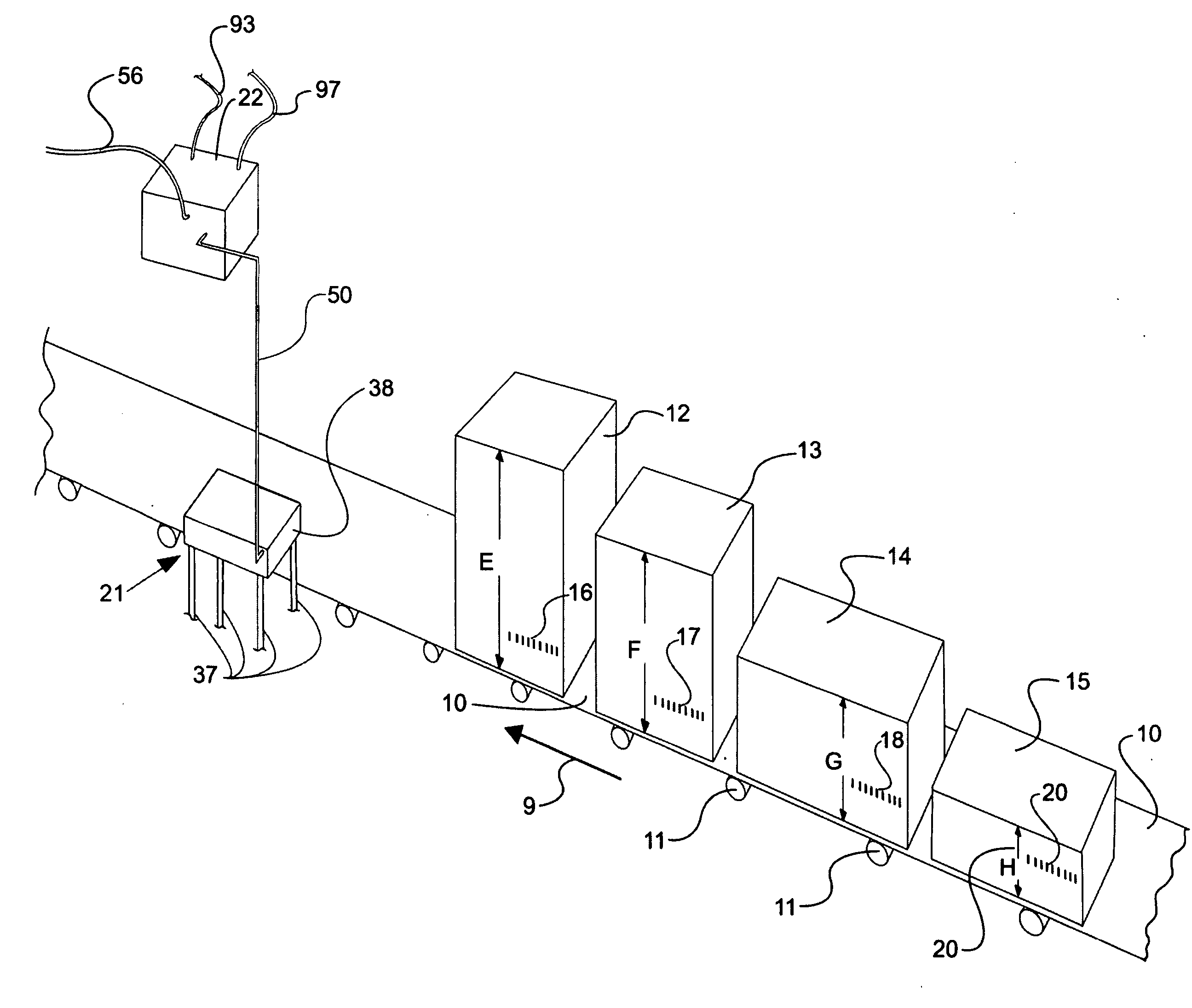

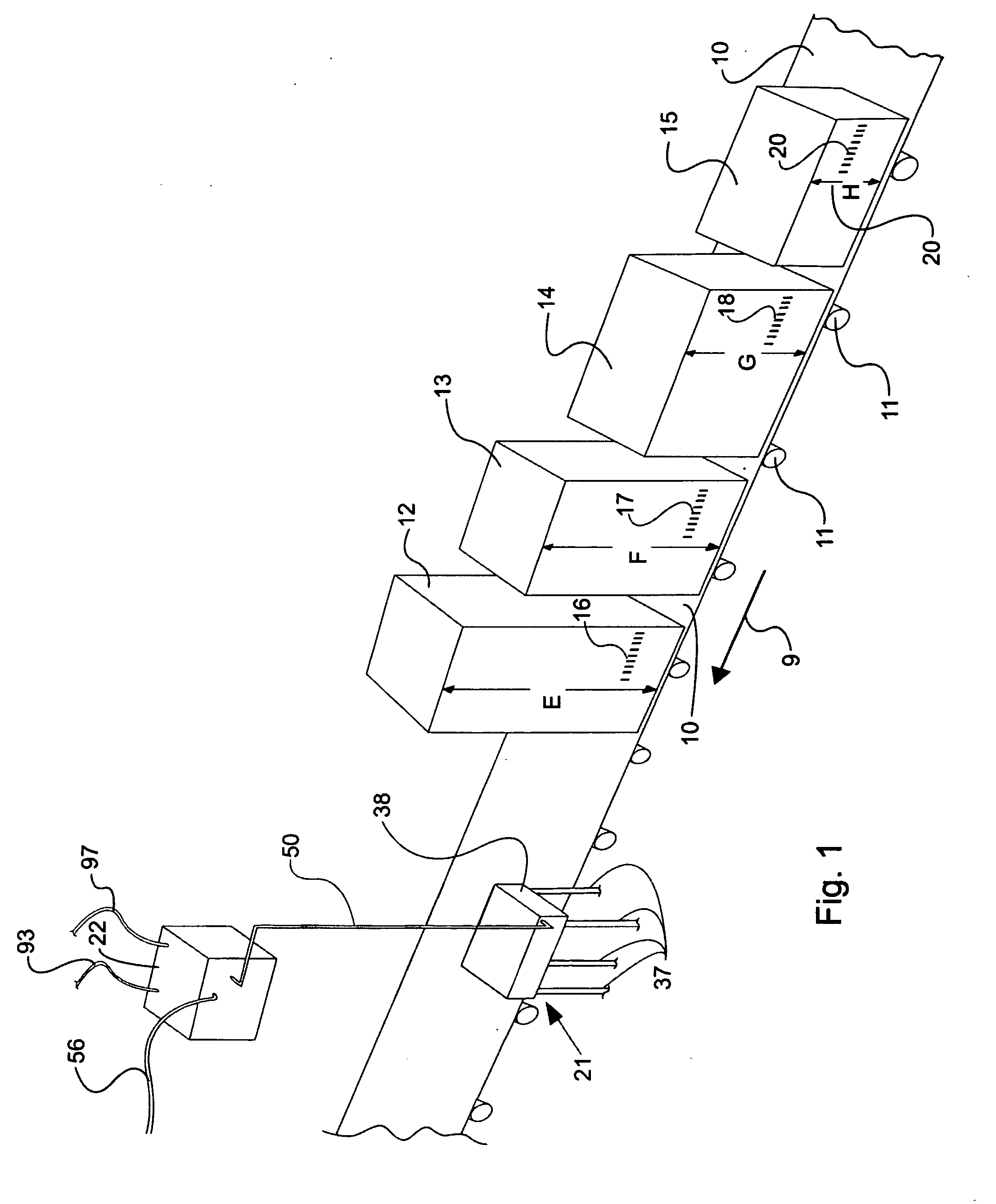

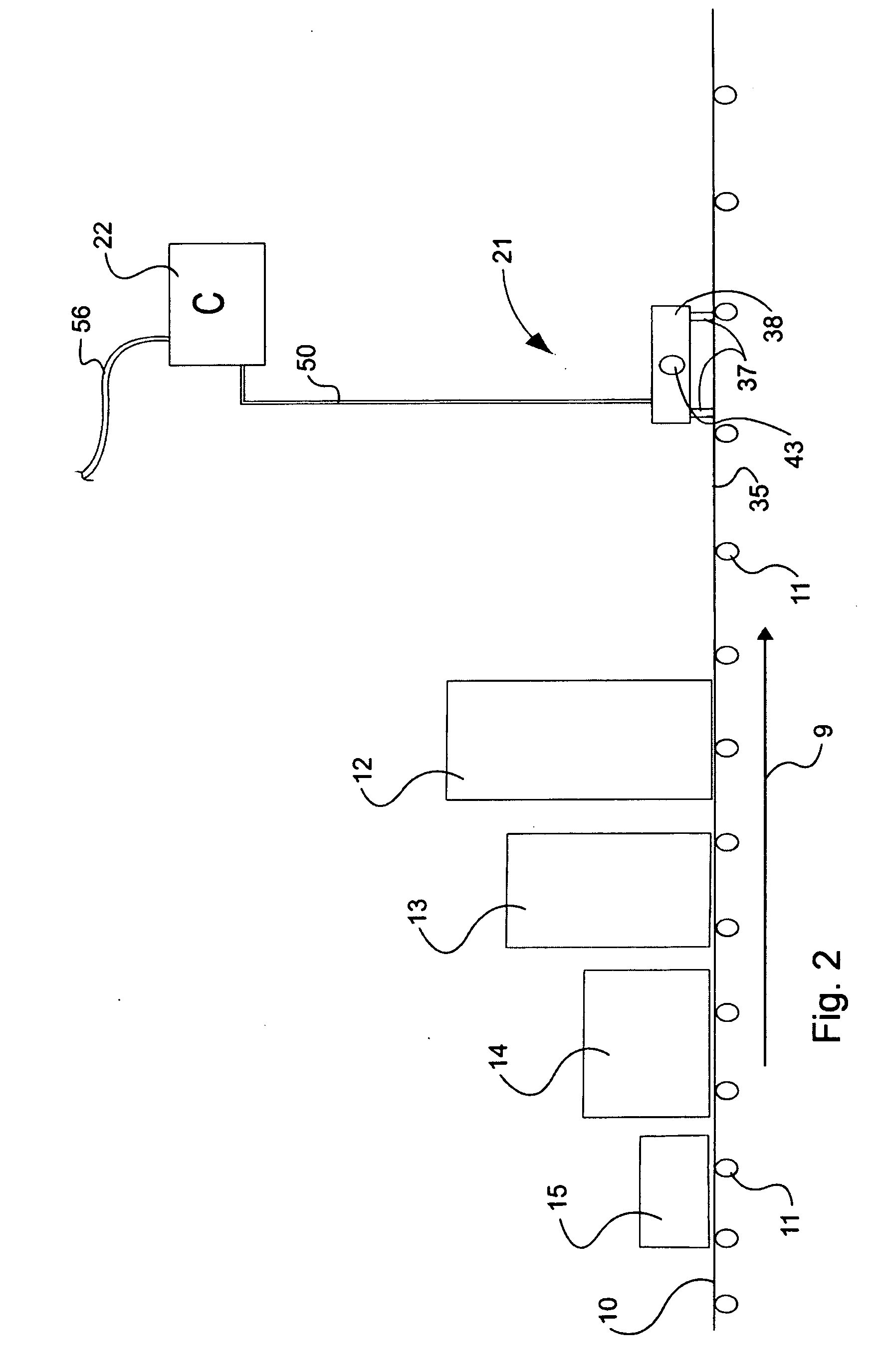

Hybrid palletizer

ActiveUS8074431B1Increase speedShorten the timeWrappers shrinkageSolid materialIndividual itemRobotic arm

The present invention relates to compact palletizers that include a stretch-wrap operation as the pallet is built. Specifically, the present invention uses a robot to place items from a fixed infeed elevation either above or, alternatively, below the height of the finished load. A four-sided compression mechanism compresses the rough-built load to the final pallet size and then the entire layer is released to the pallet.Individual items or group of items are picked and placed onto a layer support device in a loose orientation. The loose orientation enables a much faster palletizing operation because the robotic arm that pick-and-places the item, the items, or the row of items, can travel much faster as it does not have to precisely locate the item, items, or row of items. During the time that a layer is being loosely constructed on the layer support device concurrent wrapping can occur.

Owner:TOP TIER

Bulk palletizer system

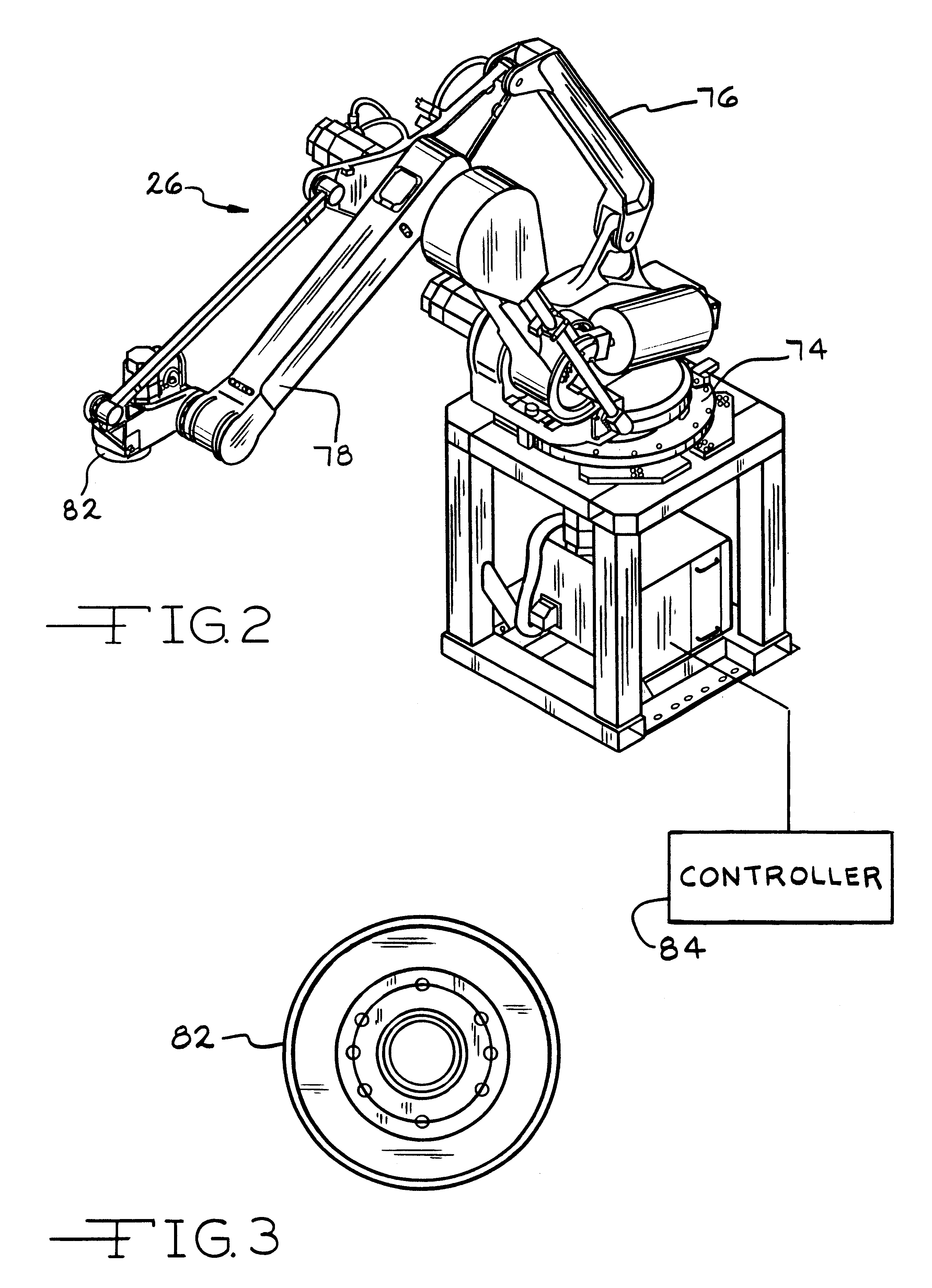

This machine is a cell for bulk palletizing a load such as the packaging of containers (bottles). The machine comprises a tier building system, a bulk load and dunnage supply systems. The cell also includes a programmable robot with cantilevered arm including an effector for transferring pallets, tiers of bulk product, tier sheets and top frames to the load build area. The effector includes an inverted drawer, suction means, pallet gripper means and top frame grippers for doing the transferring.

Owner:KAUFMAN ENGINEERED SYST

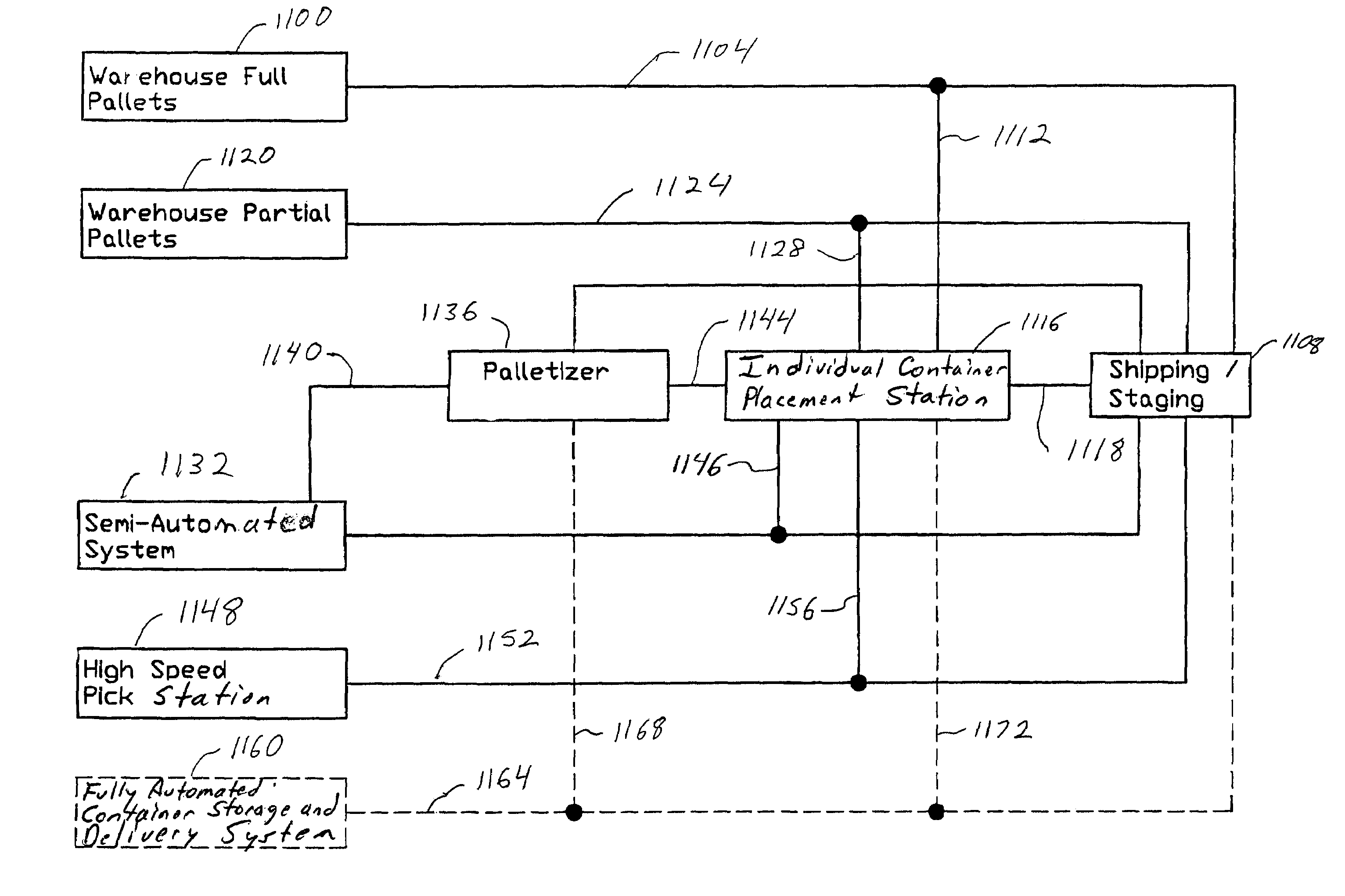

Automated container storage and delivery system

A container storage and delivery system includes an individual container storage and delivery system. A palletizer is provided for forming a group of containers from the individual container storage and delivery system into a layer or a partial layer, and placing this layer or partial layer onto a pallet. A high speed pick station provides access for manual retrieval of high throughput case types from each storage location. An individual container placement station is also provided for placing individual containers onto a pallet. A conveyor system conveys containers and pallets from the individual container storage and delivery system, the palletizer, the high speed pick station, and the individual container placement station.

Owner:SYST LOGISTICS CORP

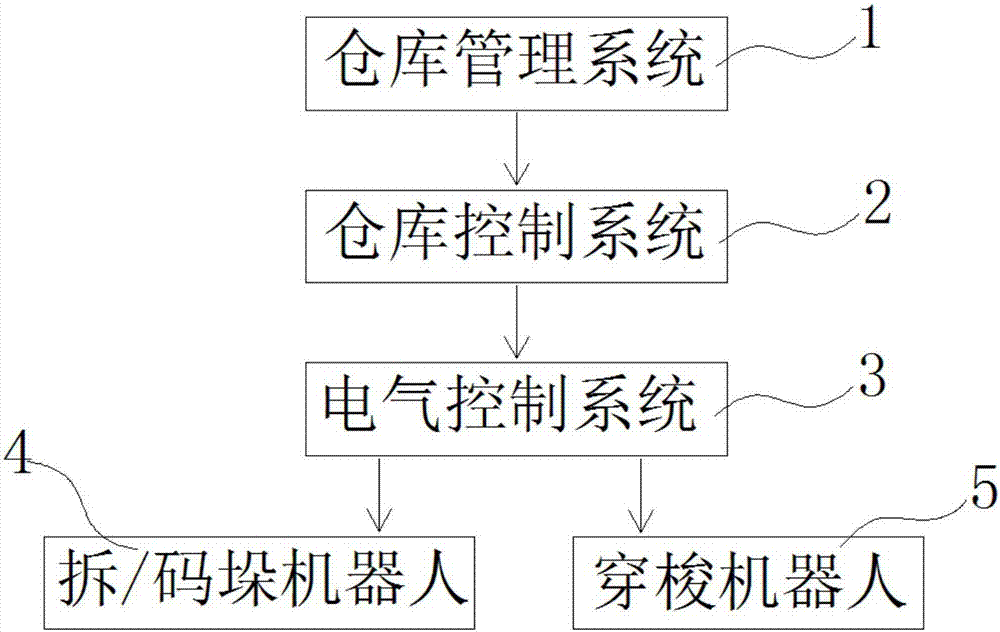

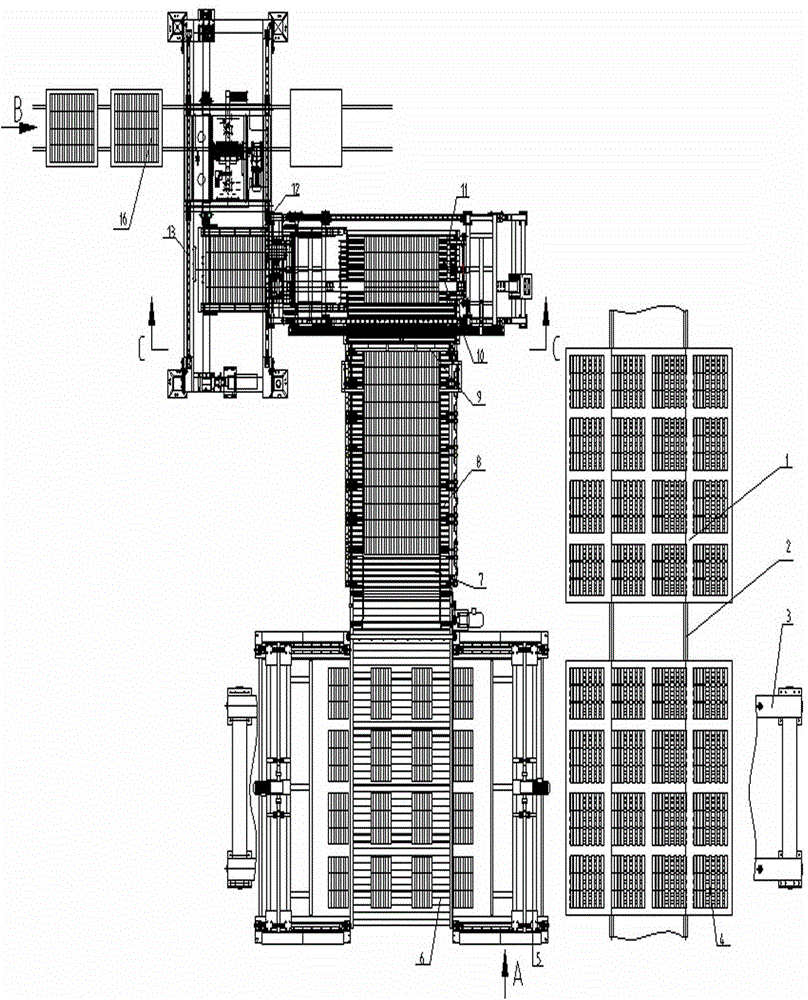

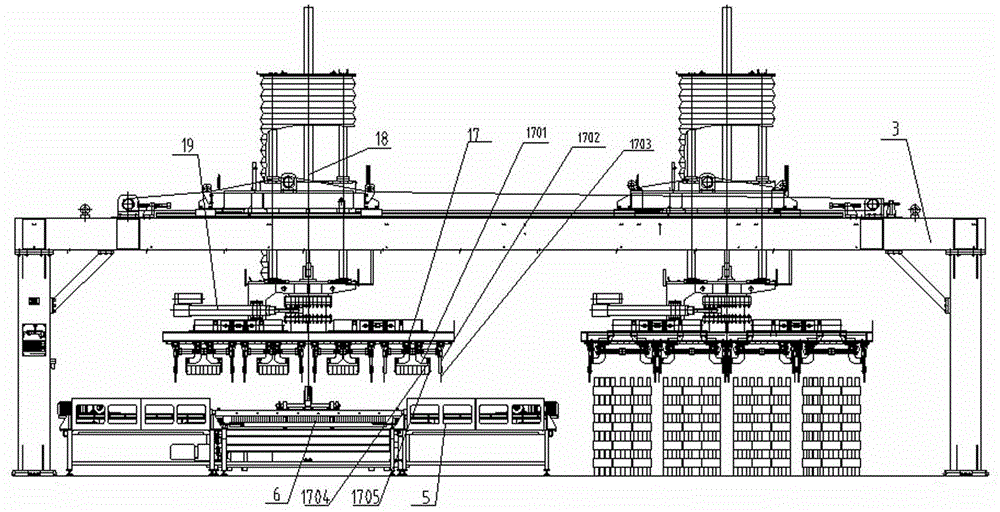

Unmanned intelligent intensive storage managing method and storage system

Owner:南京萨菲机器人系统有限公司

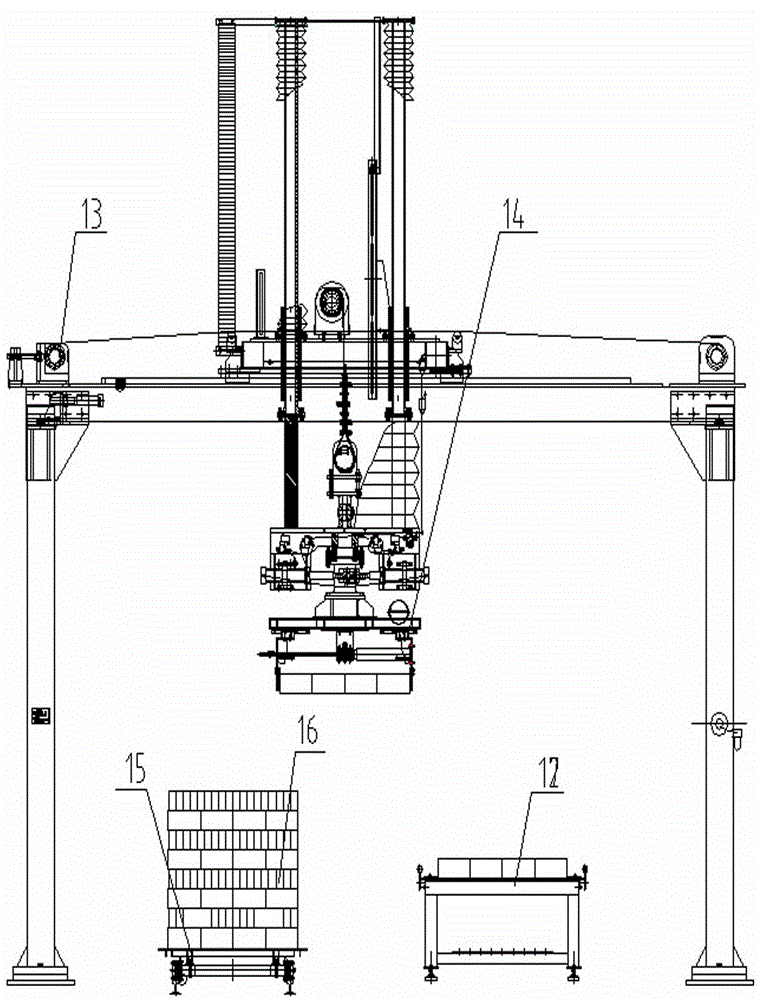

Brick unloading and stacking unit and brick unloading and stacking method for sintered bricks

ActiveCN103552832ASolve bonding problemsReduce labor intensityStacking articlesDe-stacking articlesBrickPalletizer

The invention discloses a brick unloading and stacking unit and a brick unloading and stacking method for sintered bricks. The brick unloading and stacking unit comprises a brick unloading machine for unloading the sintered bricks from a kiln car layer by layer and a pushing mechanism for gathering the bricks transversely; a first roller way conveying platform which is connected behind the brick unloading and stacking unit is provided with a brick collimating device capable of gathering the bricks longitudinally; the first roller way conveying platform is used for grouping the bricks and conveying the bricks onto a second roller way conveying platform which is connected with the first roller way conveying platform under the control of a controller; a conveying device for conveying the grouped bricks along a direction vertical to the conveying direction of the first roller way conveying platform forward is arranged above the second roller way conveying platform; a brick gathering platform is arranged at the tail end of the second roller way conveying platform; a stacking machine for stacking the bricks on the brick gathering platform by clamping in groups is arranged above the brick gathering platform. According to the brick unloading and stacking unit, a full mechanical process from unloading to stacking is realized, the problem of bonding caused by deformation of sintered bricks is solved effectively, the requirement of automatic production is met, and the labor force of workers and production cost are greatly reduced.

Owner:洛阳曜辰自动化科技有限公司

RFID product identification and tracking system

InactiveUS20070185613A1Digital data processing detailsControl devices for conveyorsPalletizerComputer science

Apparatus for RFID tagging of packages is provided, including a conveyor, along which tags having microchips and antennae are applied to packages, with the tags being encoded via radio waves, to contain information about packaged identification and other information, with the encoding being done upstream of a palletizer system, and with the palletizer system being provided for receiving encoded packages from the conveyor.

Owner:HERSHEY CHOCOLATE & CONFECTIONARY CORP

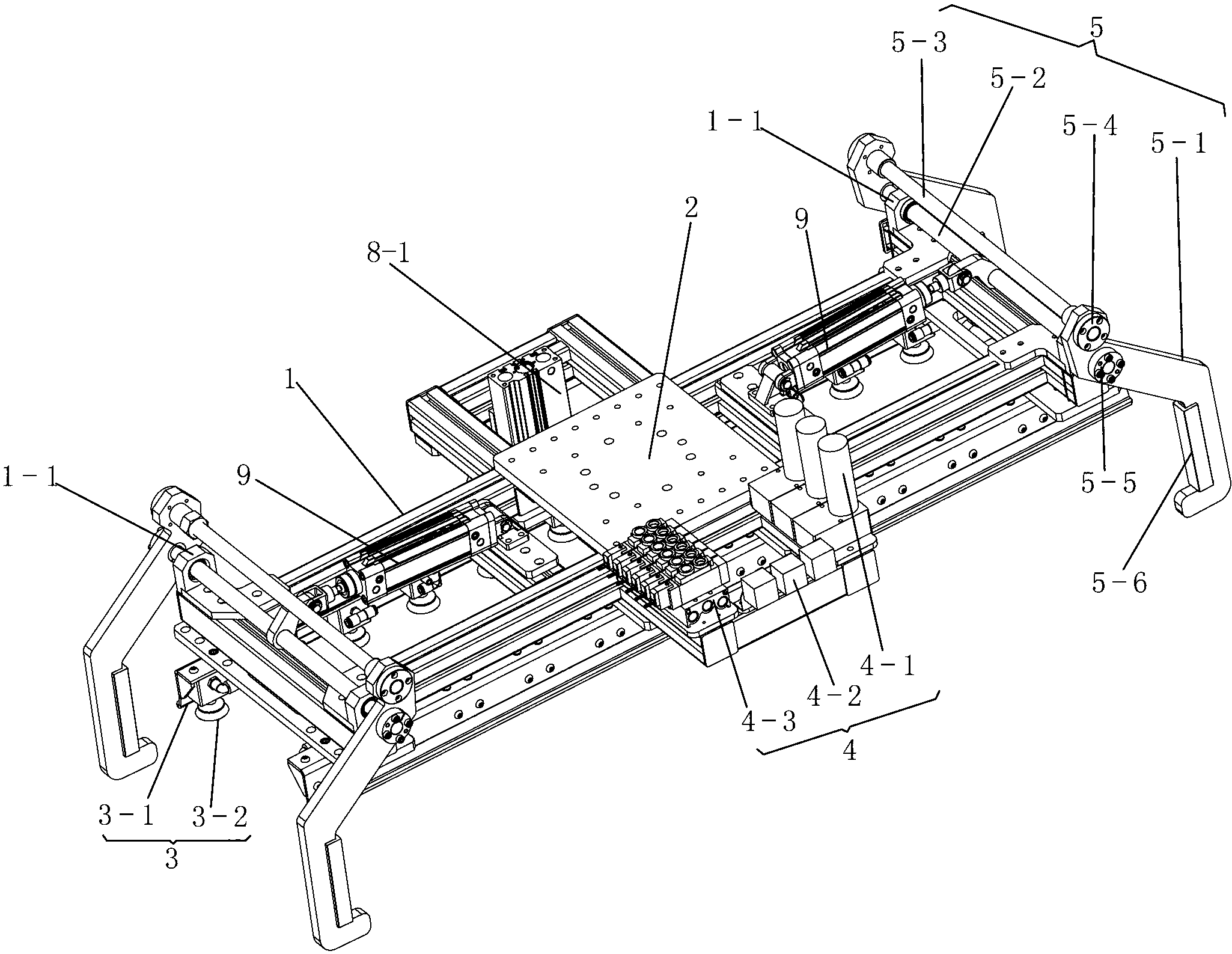

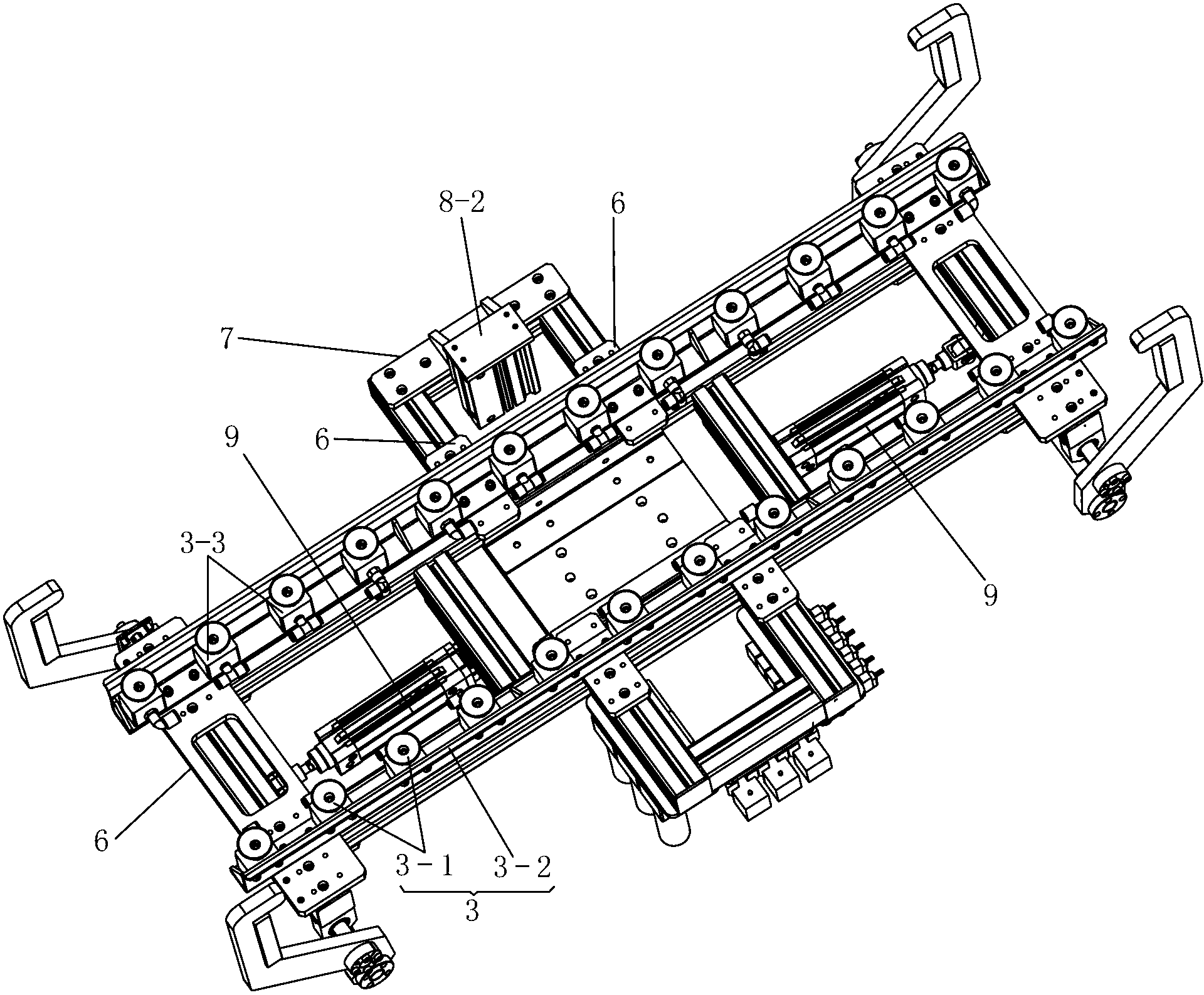

Mechanical arm paw for robot palletizer and manufacturing method of mechanical arm paw

ActiveCN103318652AImprove general performanceImprove versatilityStacking articlesDe-stacking articlesPalletizerEngineering

The invention relates to a mechanical arm paw for a robot palletizer. The mechanical arm paw comprises a connecting flange, an installing frame, supports, a sucker device, a vacuumizing control device, a height detecting device, grabbing devices and an air cylinder driving device. The connecting flange is connected with a mechanical arm of the robot palletizer, the installing frame which is in a rectangular shape is connected with the bottom surface of the connecting flange, the supports are arranged on the two sides of the middle of the installing frame, the sucker device is connected to the installing frame through a plurality of installing plates, the vacuumizing control device is arranged on one support, the height detecting device is arranged on the other support, the grabbing devices are symmetrically installed at the two ends of the installing frame, and the air cylinder driving device is installed on the installing frame. Compared with the prior art, the mechanical arm paw has the advantages of being strong in universality, high in transporting and stacking efficiency and the like, and grabbed objects cannot be damaged.

Owner:JIANGSU ZHONGKE YOUTE ROBOT TECH

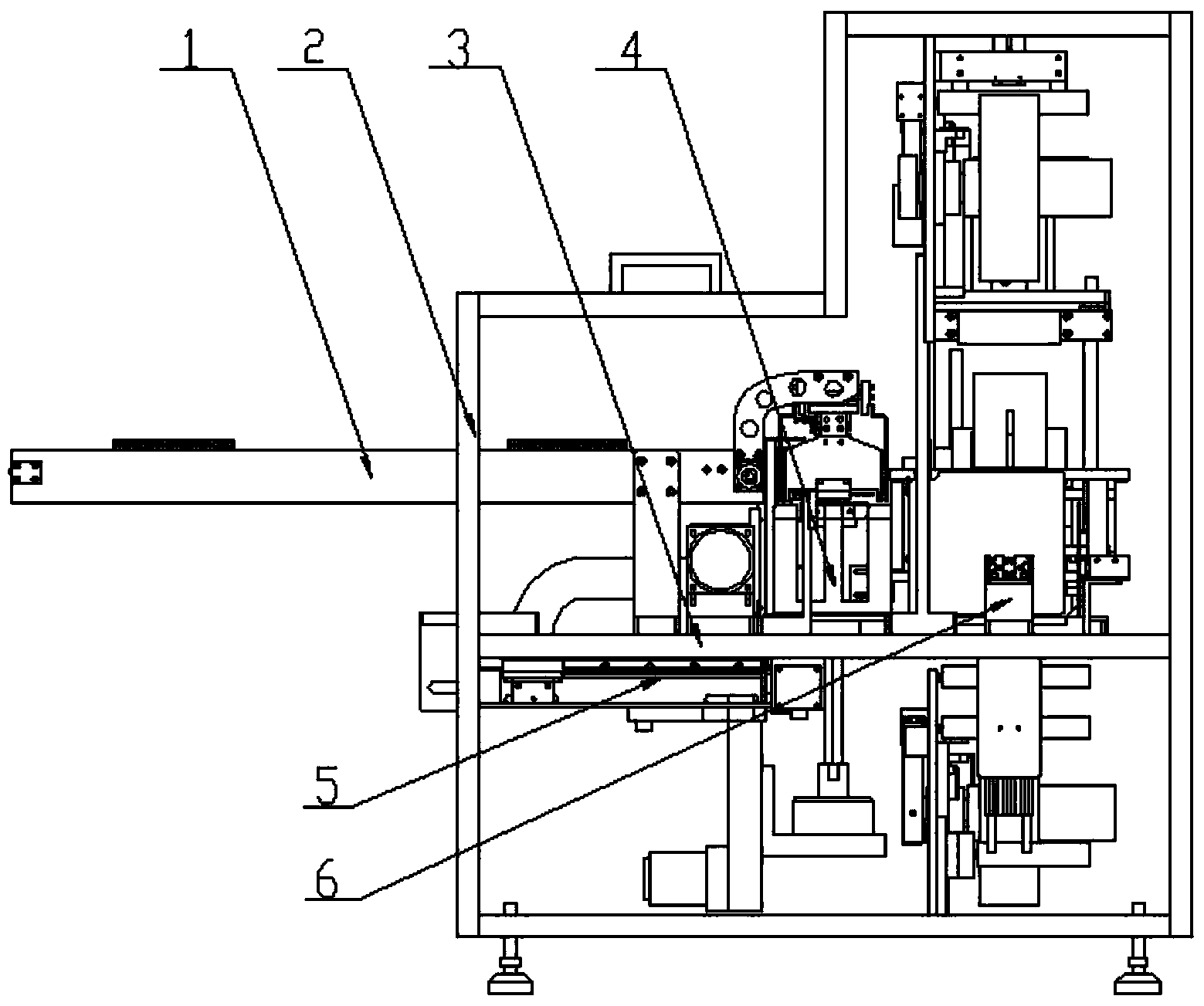

Automatic paper currency stacking and binding integrated machine

ActiveCN103625678AGuaranteed CompatibilityCompact structurePaper article packagingBundling machine detailsHeat sealerControl system

The invention discloses an automatic paper currency stacking and binding integrated machine for packing paper currency with different face values in the financial system. The machine comprises a conveying mechanism, a frame, a supporting base plate, an automatic stacking mechanism, a primary pushing mechanism, an arranging and jacking mechanism, a film packing mechanism, a secondary pushing mechanism, a heat-seal mechanism, a paper currency bundle turnover mechanism and a PLC (programmable logic control) control system, wherein paper currency is sorted and bound, and is fed into the conveying mechanism; the paper currency is fed into the automatic stacking mechanism by the conveying mechanism, and is subjected to pre-arrangement, counting, 5-bundle direction change and stacking; 10 bundles of paper currency is pushed into the arranging and jacking mechanism by the primary pushing mechanism after the paper currency bundles are stacked; the paper currency bundles are jacked to the secondary pushing mechanism after being arranged; the flat arranged paper currency bundles are pushed into the heat-seal mechanism by the secondary pushing mechanism, and are packaged; the paper currency bundles are moved out by the paper currency bundle turnover mechanism after the paper currency bundles are packaged. The automatic paper currency stacking and binding integrated machine has the advantages that paper currency can be automatically treated when the machine is used jointly with a sorting machine and a sealant shrinker, and the machine is compact in structure, stable and reliable, easy to operate and convenient to maintain.

Owner:合肥哈工龙延智能装备有限公司

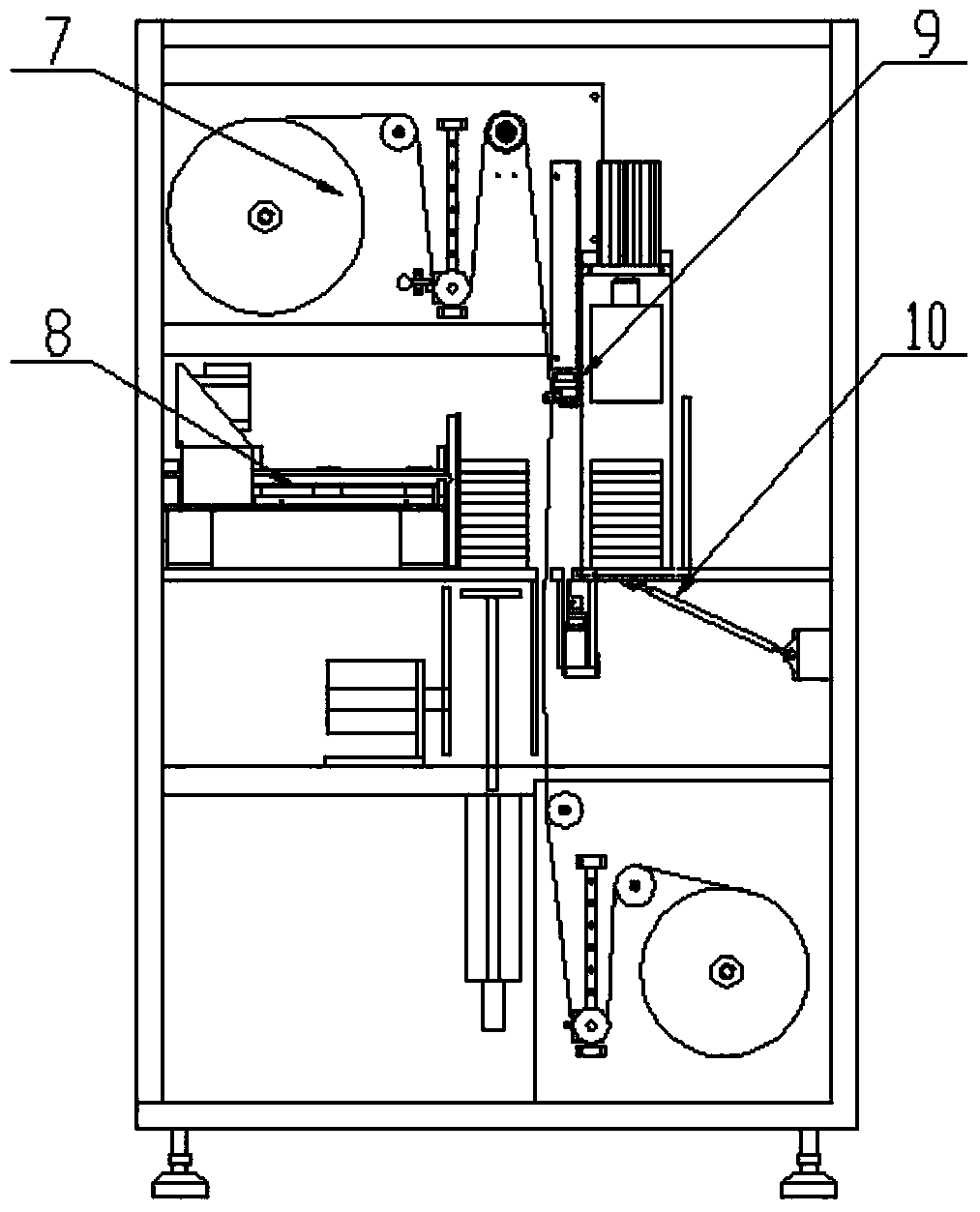

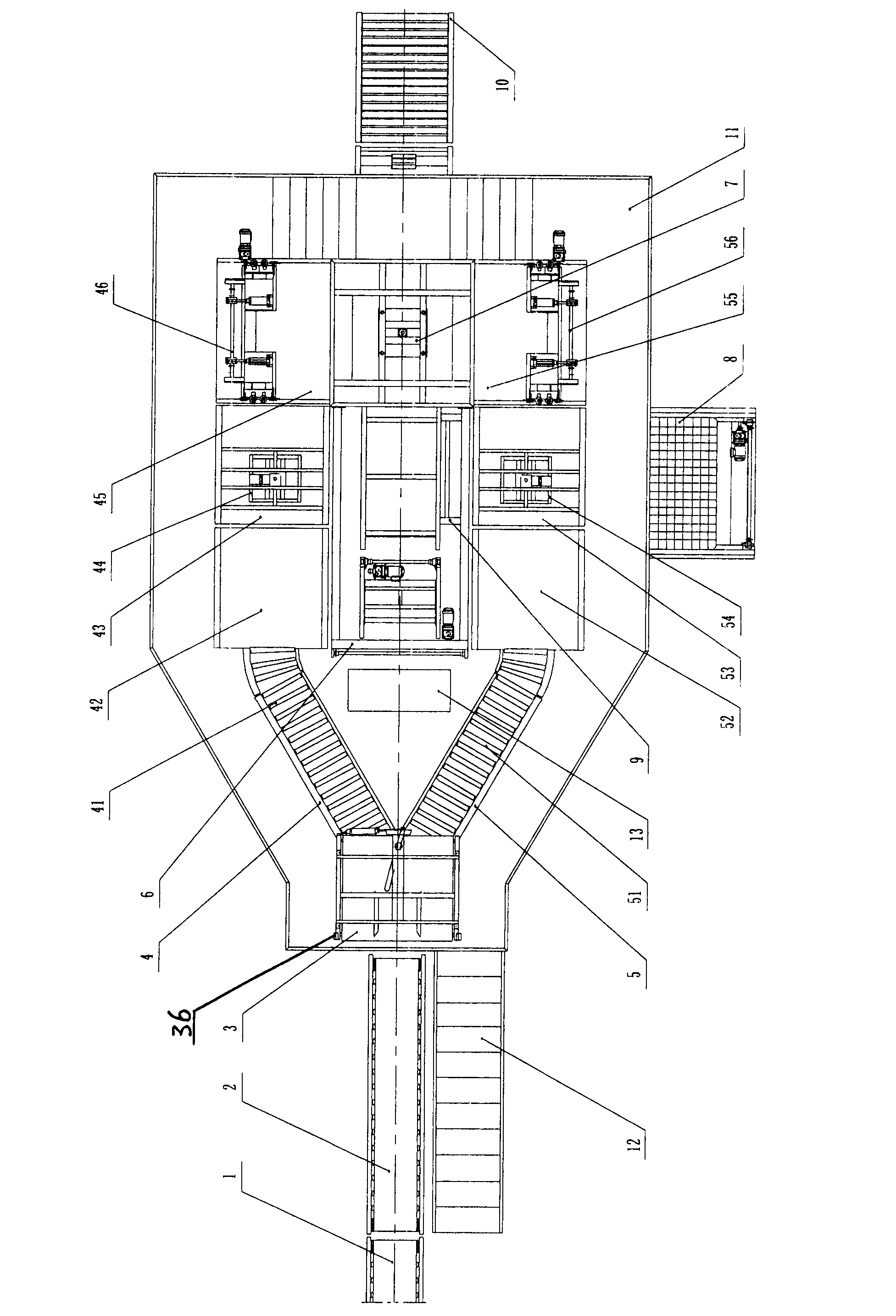

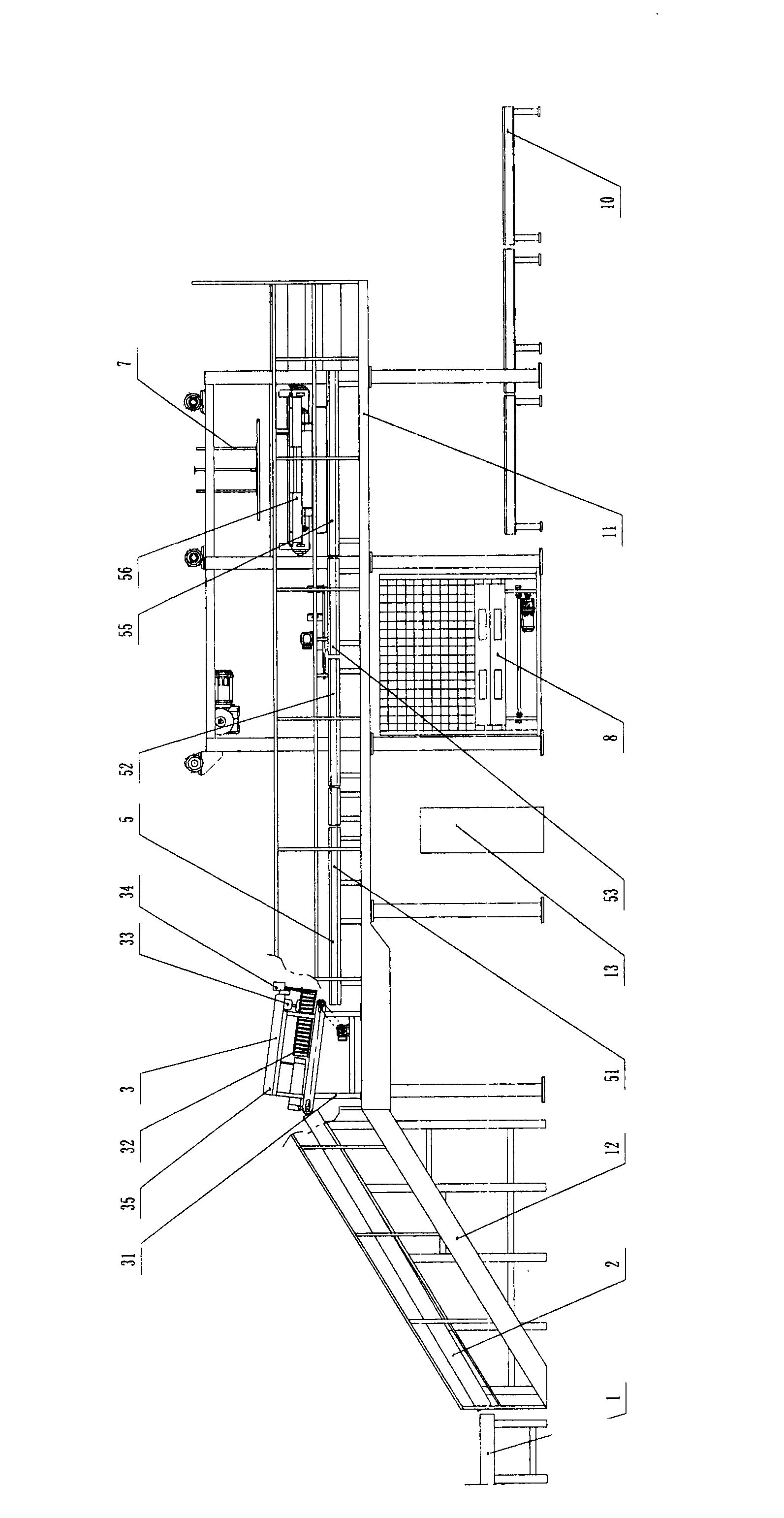

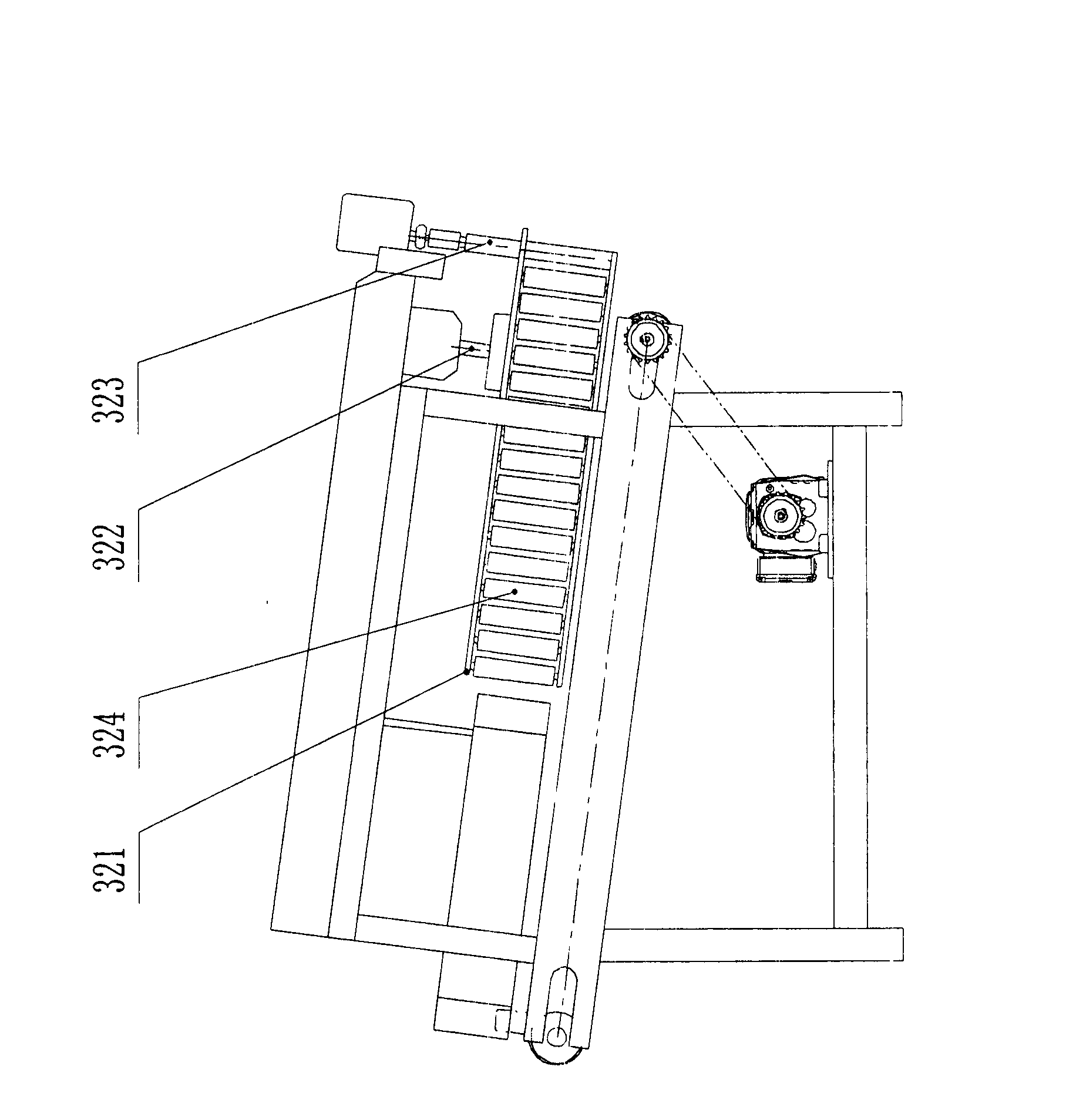

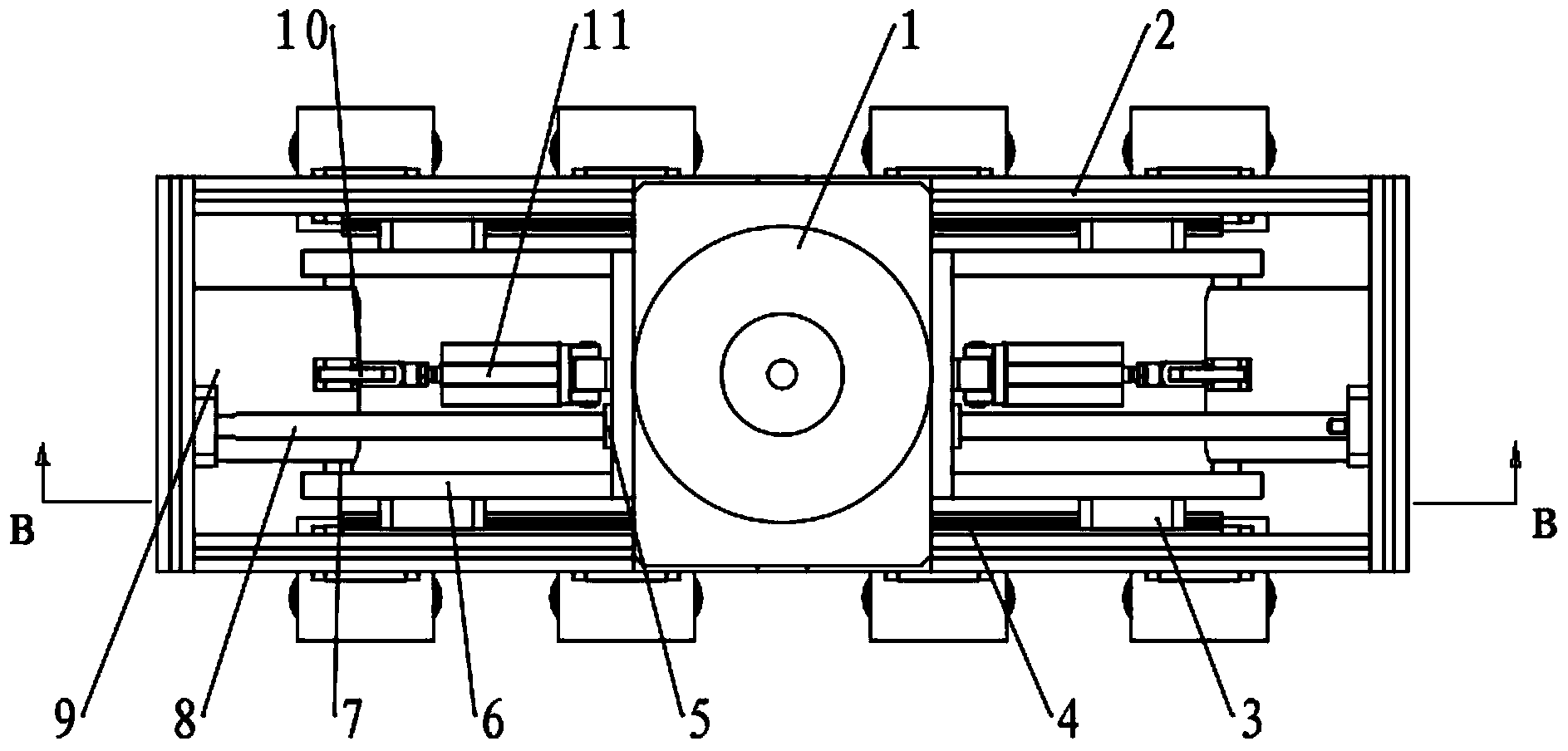

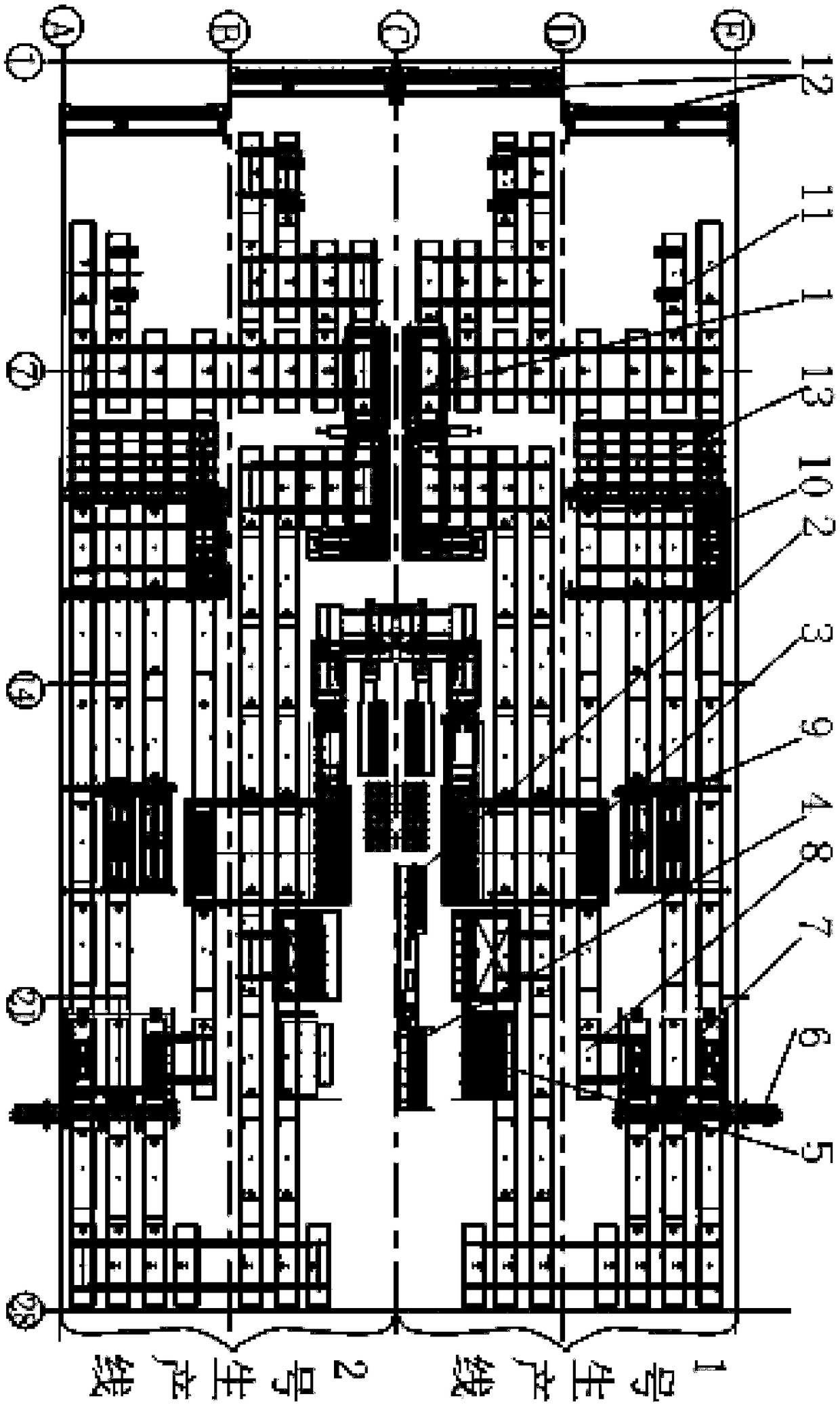

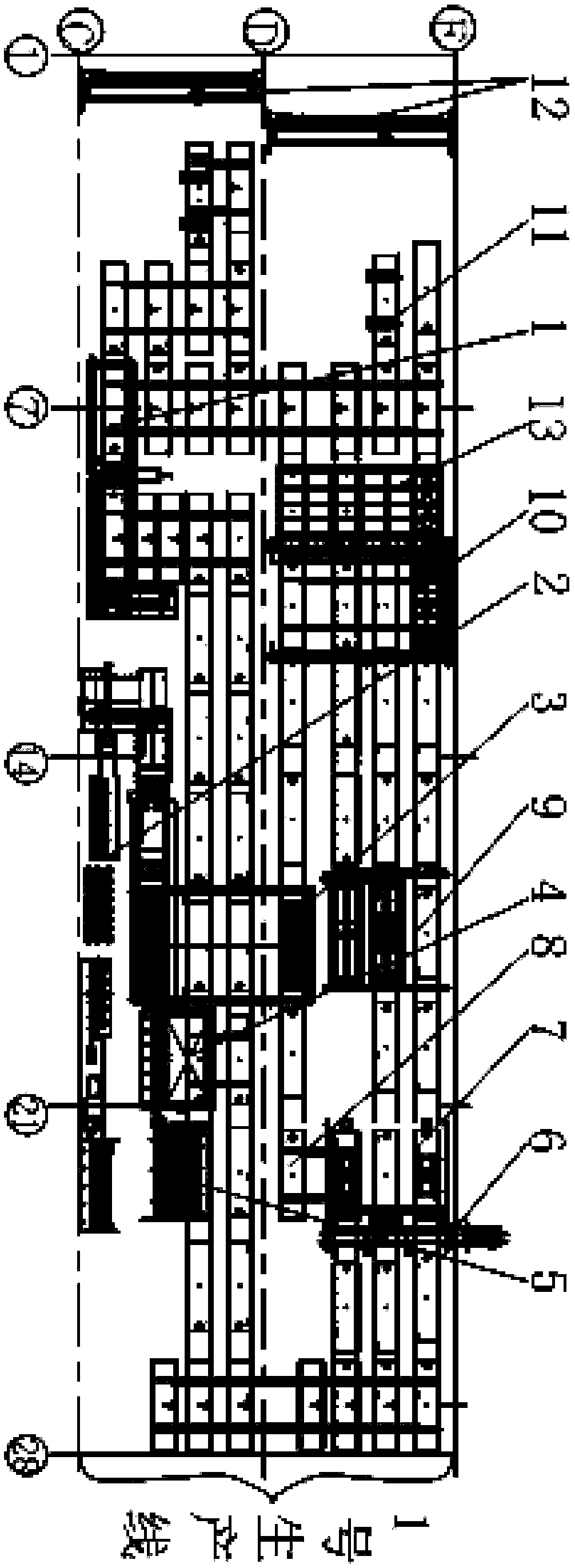

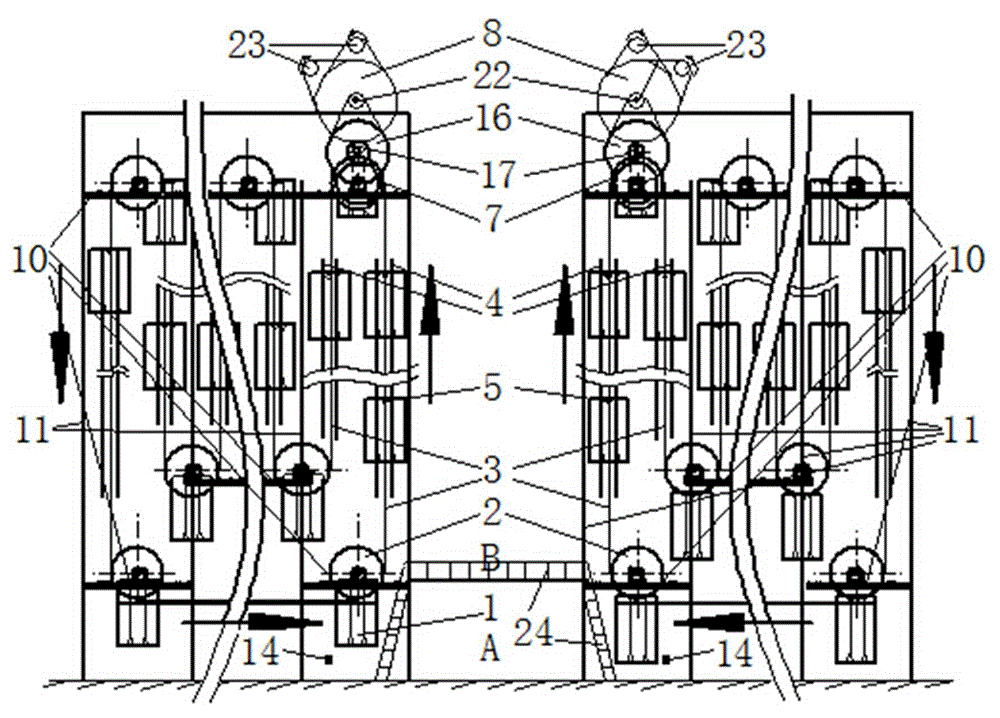

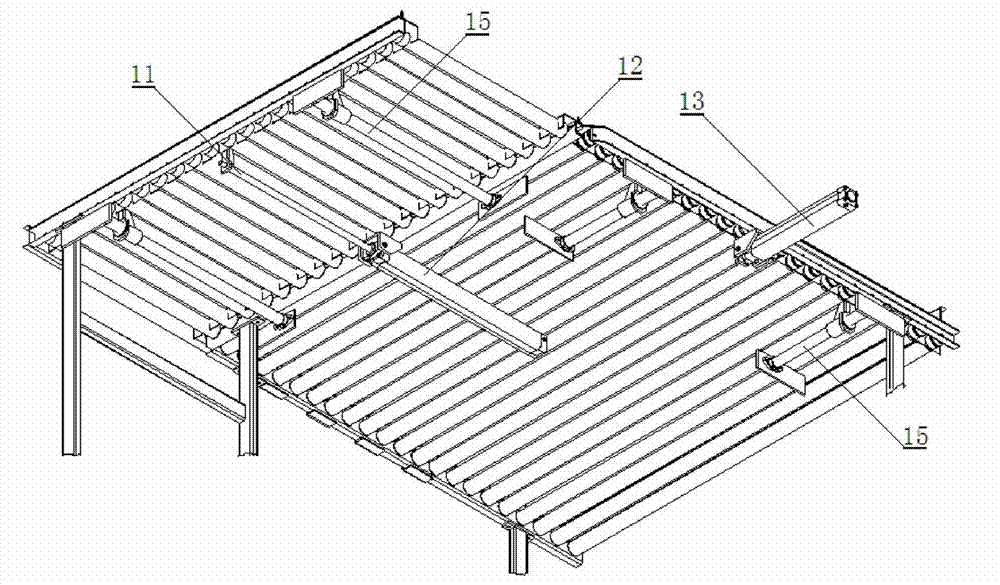

Automatic double-line palletizer

ActiveCN103057944AExpand the scope of promotion and applicationMeet the needs of automatic palletizingStacking articlesConveyor partsPalletizerIndustrial engineering

The invention discloses an automatic double-line palletizer. A left operating line and a right operating line of the palletizer are symmetrically and parallelly arranged on a scaffold, each operating line of the palletizer is provided with a package-turning conveyer, a package-turning machine, a staking grouping machine and a package-pushing machine. The package-turning conveyers, the package-turning machines, the staking grouping machines and the package-pushing machines run independently. The package-turning conveyers and the staking grouping machines are sequentially arranged from entrance to exist, the package-turning machines are mounted above the package-turning conveyers, and the package-pushing machines are mounted above the staking grouping machines. Pallets blow a sliding door which is between the left operating line and the right operating line of the palletizer are used for receiving packages from the package-pushing machines on both sides, and the pallets full of packages are transported to a pallet conveyer through a lift. The automatic double-line palletizer can solve the problem of low stacking efficiency caused by using existing single-line palletizers.

Owner:GUANGXI LIYUANBAO SCI & TECH

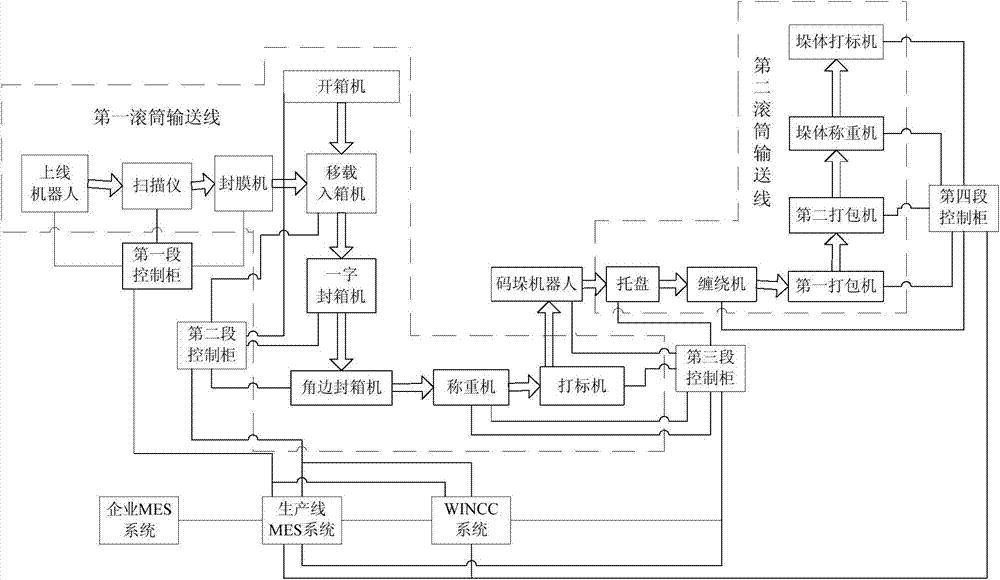

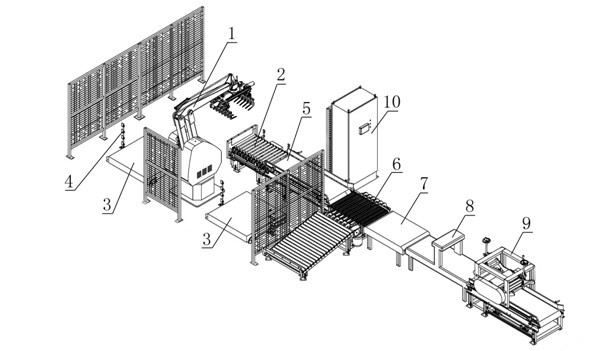

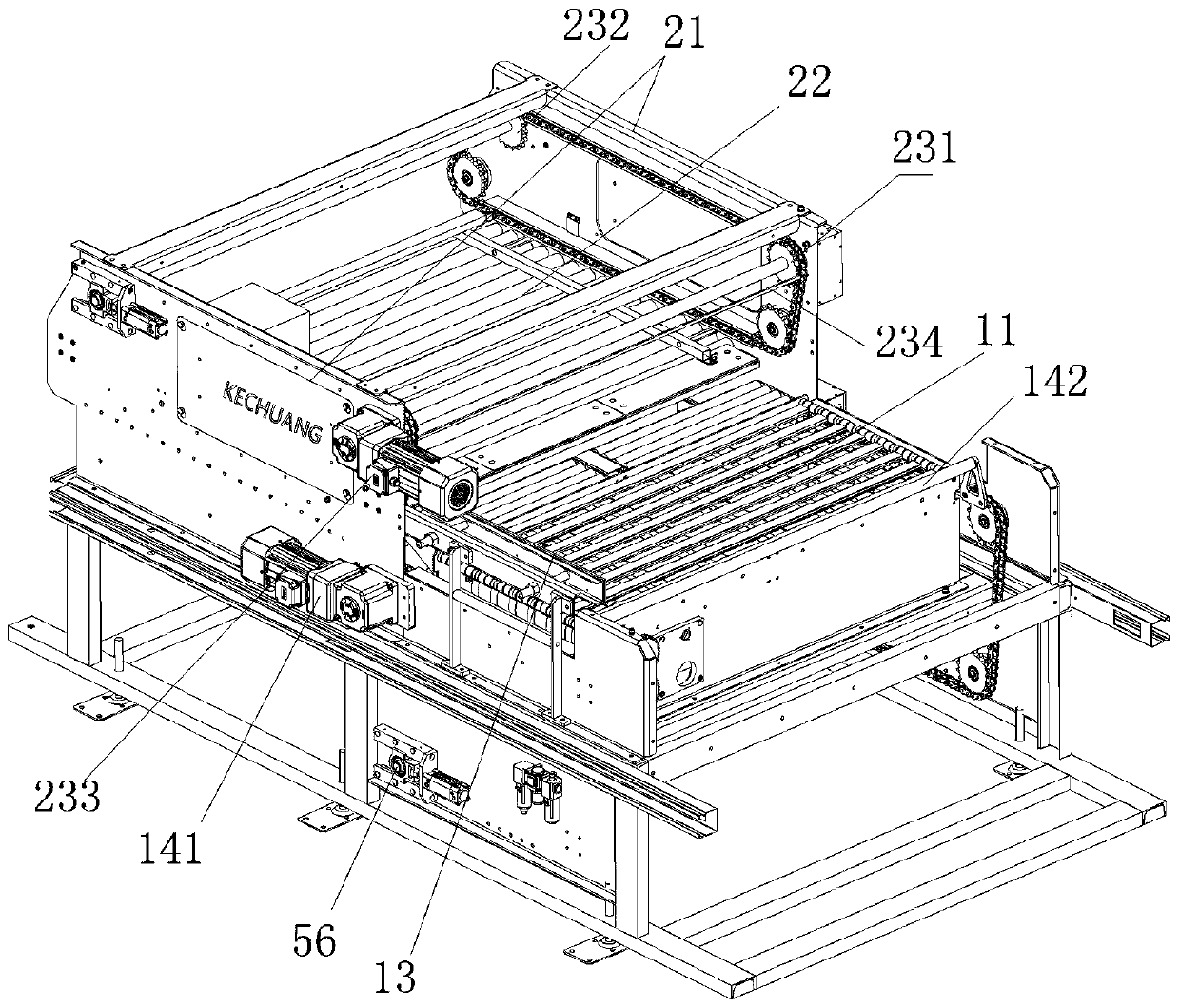

Intelligent flexible packaging production line for box type products

ActiveCN103935568ADynamic adjustment of process parametersWith intelligent line change functionPackaging automatic controlPackaging machinesWinding machineProduction line

The invention discloses an intelligent flexible packaging production line for box type products. The intelligent flexible packaging production line comprises a first roller conveying line, a second roller conveying line, a production line MES system, a WINCC system, a robot palletizer and four control cabinets. A scanner, a film sealing machine, a transferring boxing machine, a linear box sealing machine and a corner and edge box sealing machine are sequentially arranged between the feeding segment and the discharging segment of the first roller conveying line. A box body is arranged between the film sealing machine and the transferring boxing machine. A tray, a winding machine and a first packaging machine are sequentially arranged between the feeding segment and the discharging segment of the second roller conveying line. The robot palletizer is arranged between the feeding segment of the first roller conveying line and the discharging segment of the second roller conveying line. According to the intelligent flexible packaging production line for the box type products, the intelligent flexible packaging production line is compatible with the box type products with different appearances, procedures of feeding, film sealing, vacuum pumping, box opening, box entering, box sealing, weighing, packaging, stacking, marking, discharging and the like can be intelligently finished in a full-automatic mode. The intelligent flexible packaging production line for box type products is wide in application and suitable for packaging of many products in the communication industry.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

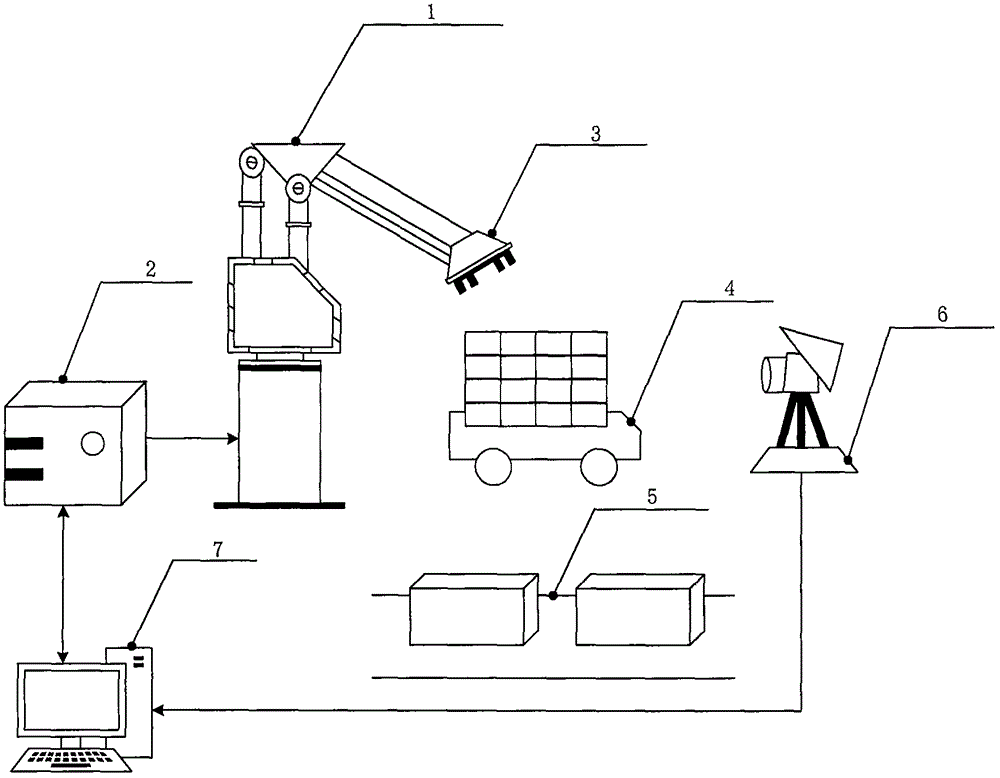

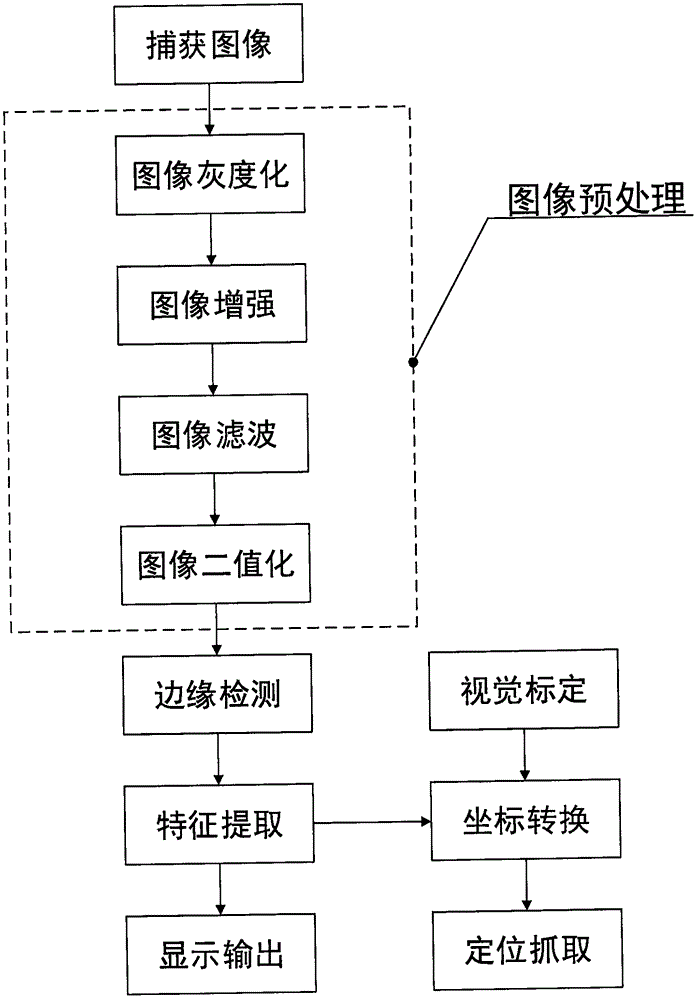

Tracking and monitoring system and method of stacking robot based on machine vision

InactiveCN106695792AInteraction logic is clearImprove flexibilityProgramme-controlled manipulatorComputer monitoringEngineering

The invention discloses a tracking and monitoring system and method of a stacking robot based on machine vision. The tracking and monitoring system comprises the stacking robot, a control cabinet of the stacking robot, a conveyor belt, an automatic guided vehicle (AGV), a vacuum sucker device, and a vision acquisition system, wherein the stacking robot is in communication connection with the control cabinet, and is used for stacking products which are sequentially transferred by the conveyor belt to a cargo loading plane of the AGV; the loaded cargos are transported into a storehouse by the AGV; the vacuum sucker is mounted at the tail end of the stacking robot; the vision acquisition device is used for uploading working video images of the stacking robot to upper computer monitoring software in a real-time manner, and performing image processing on the obtained video, so that real-time monitoring of the stacking process is realized, and abnormal circumstances of dropping of objects during stacking and the like can be analyzed and processed, so that the automated intelligent degree of logistics is increased, acceleration of the working efficiency of the whole plant is facilitated, and the manual cost and the time cost are saved.

Owner:CHINA JILIANG UNIV

Steel angle sectional bar stacking machine and stacking method

InactiveCN104444388AMeet the requirements of angle steel palletizingRealize fully automatic palletizingStacking articlesPalletizerStructural engineering

The invention discloses a steel angle sectional bar stacking machine which comprises a feeding rack, a material distribution mechanism, a feeding trolley, an obverse stacking mechanism, a reverse stacking mechanism, a stacking lifting platform and a stack moving rack. The invention also discloses a steel angle sectional bar stacking method. According to the specific technical scheme, the method includes the first step of enabling each mechanism to be in a work preparation state, the second step of utilizing the feeding trolley to perform feeding, the third step of stacking steel angle sectional bars and the fourth step of completing operation. The steel angle sectional bar stacking machine and the steel angle sectional bar stacking method can satisfy the stacking requirements of various types and shapes of steel angle, achieve full-automatic stacking, reduce production and labor intensity, improve stacking efficiency and are low in equipment cost and operation cost and high in reliability.

Owner:ANHUI ZHONGHANG GROUP

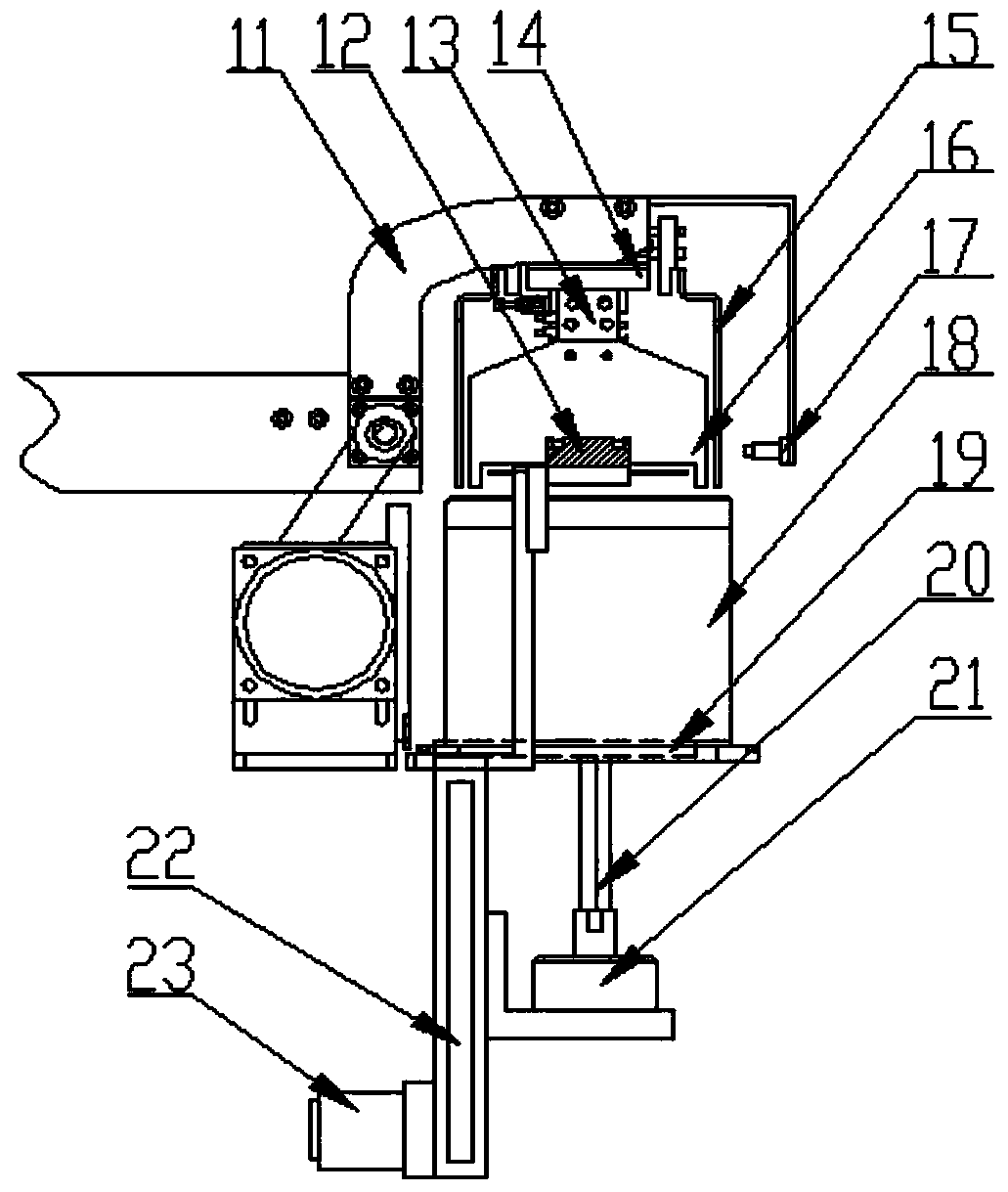

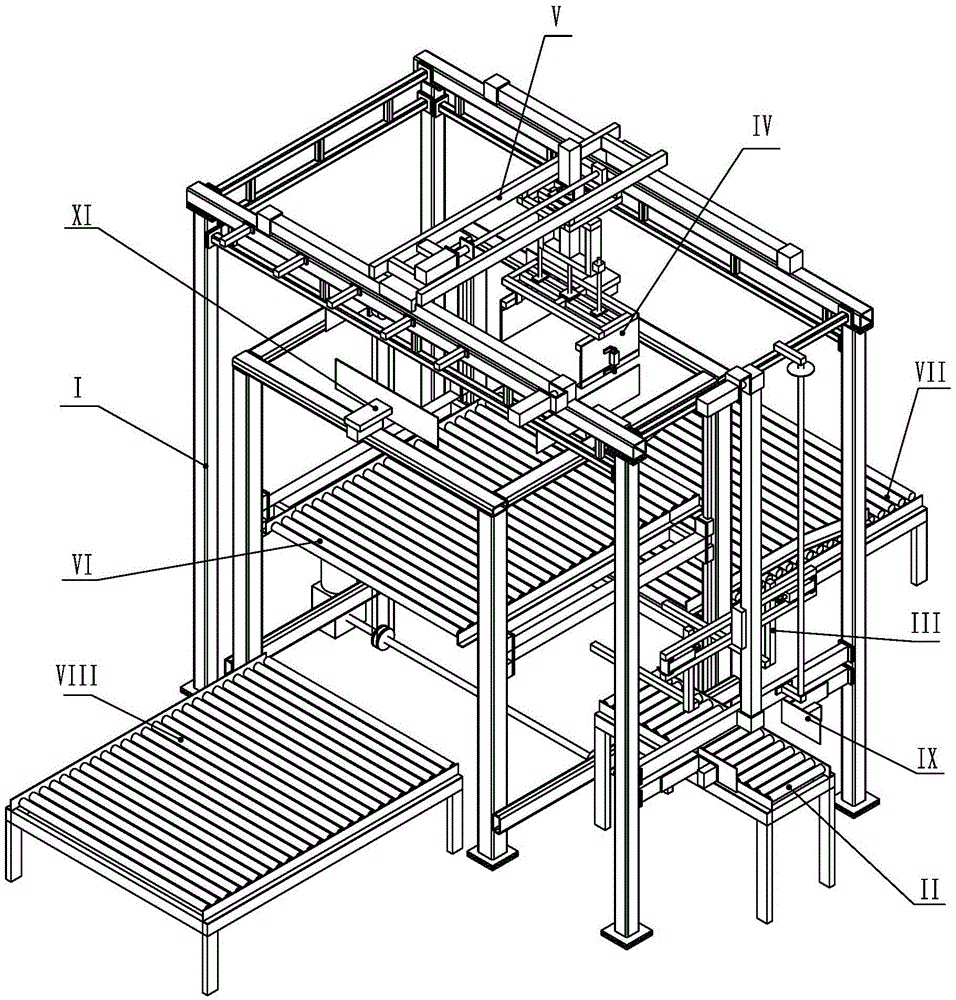

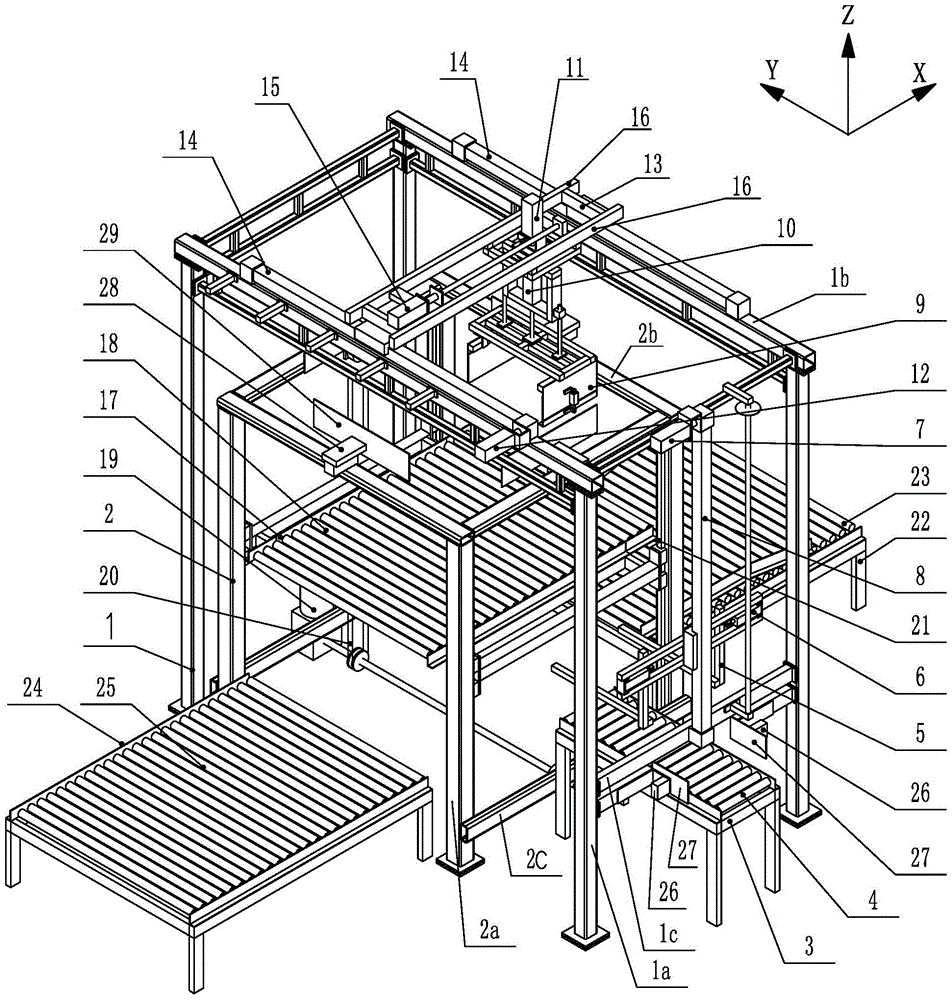

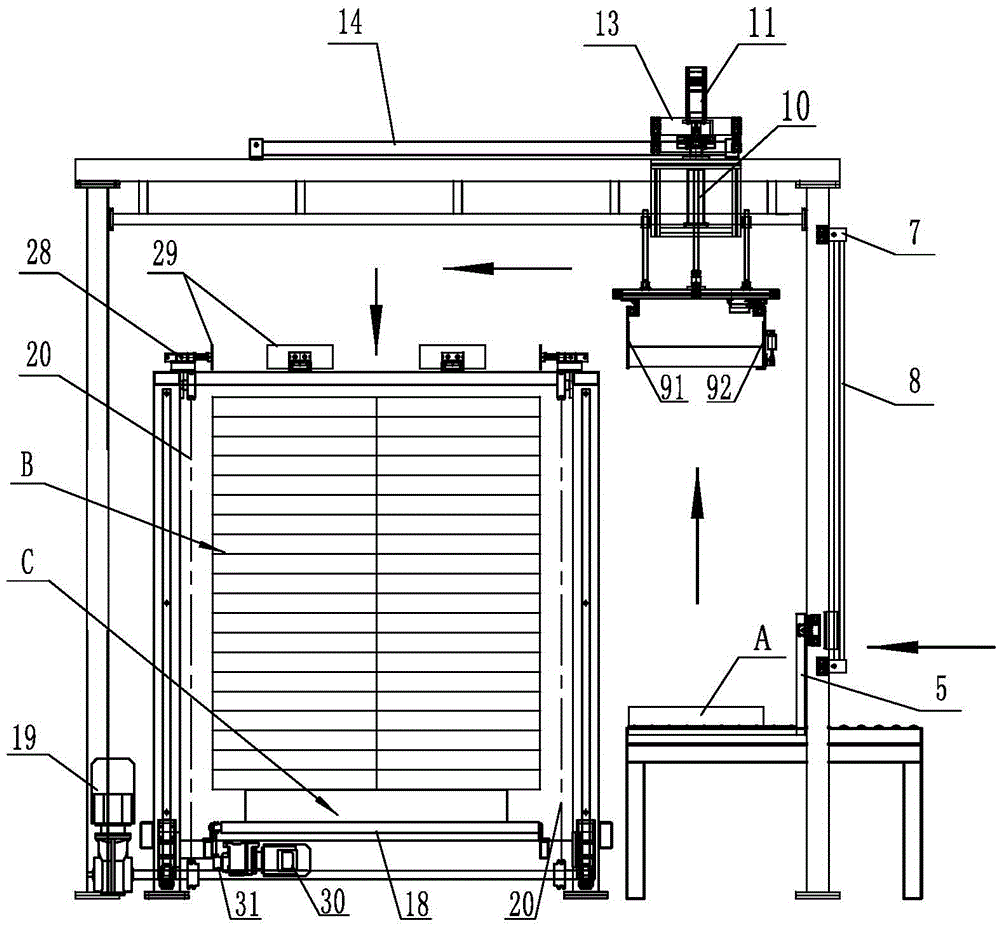

Paperboard stacking device and paperboard stacking machine

ActiveCN105565017ARealize automatic feedingAutomate operationPile receiversArticle feedersCardboardStack machine

The invention discloses a paperboard stacking machine and a paperboard stacking device. The paperboard stacking machine comprises a paperboard stacking device, a paperboard feeding mechanism, a tray feeding mechanism and a paperboard output mechanism; the paperboard stacking device comprises a main body frame; the main body frame comprises an outer frame and an inner frame; a paperboard lifting mechanism is arranged at one side of the outer frame; a gripper mechanism and a gripper translation mechanism are arranged on a top beam of the outer frame; a paper feeding normalizing mechanism is arranged on a stand column of the outer frame; a tray lifting output mechanism is arranged on the inner frame; and a stacking normalizing mechanism is arranged on a top beam of the inner frame. The paperboard stacking machine realizes automation of automatic feeding and paperboard feeding, paper feeding normalizing, lifting, grabbing, translation, rotating, releasing, stacking normalizing, paper stack descending and paper stack output of the tray, and can trimly stack packaged corrugated paperboards or cartons according to predetermined putting positions and rules, thus realizing automatic operation, being good in stacking quality and high in stacking speed, and saving manpower.

Owner:SHANDONG CENTURY MACHINERY

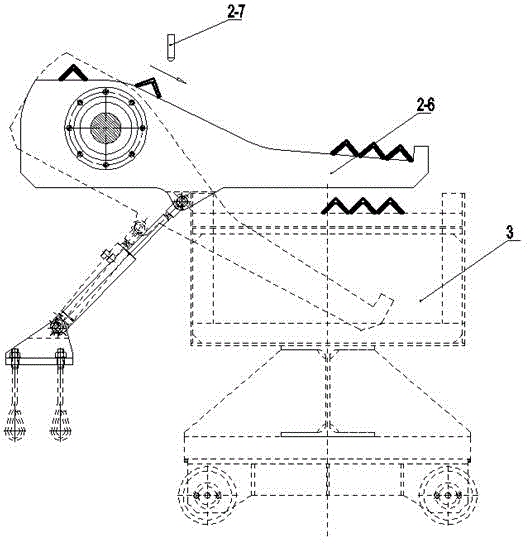

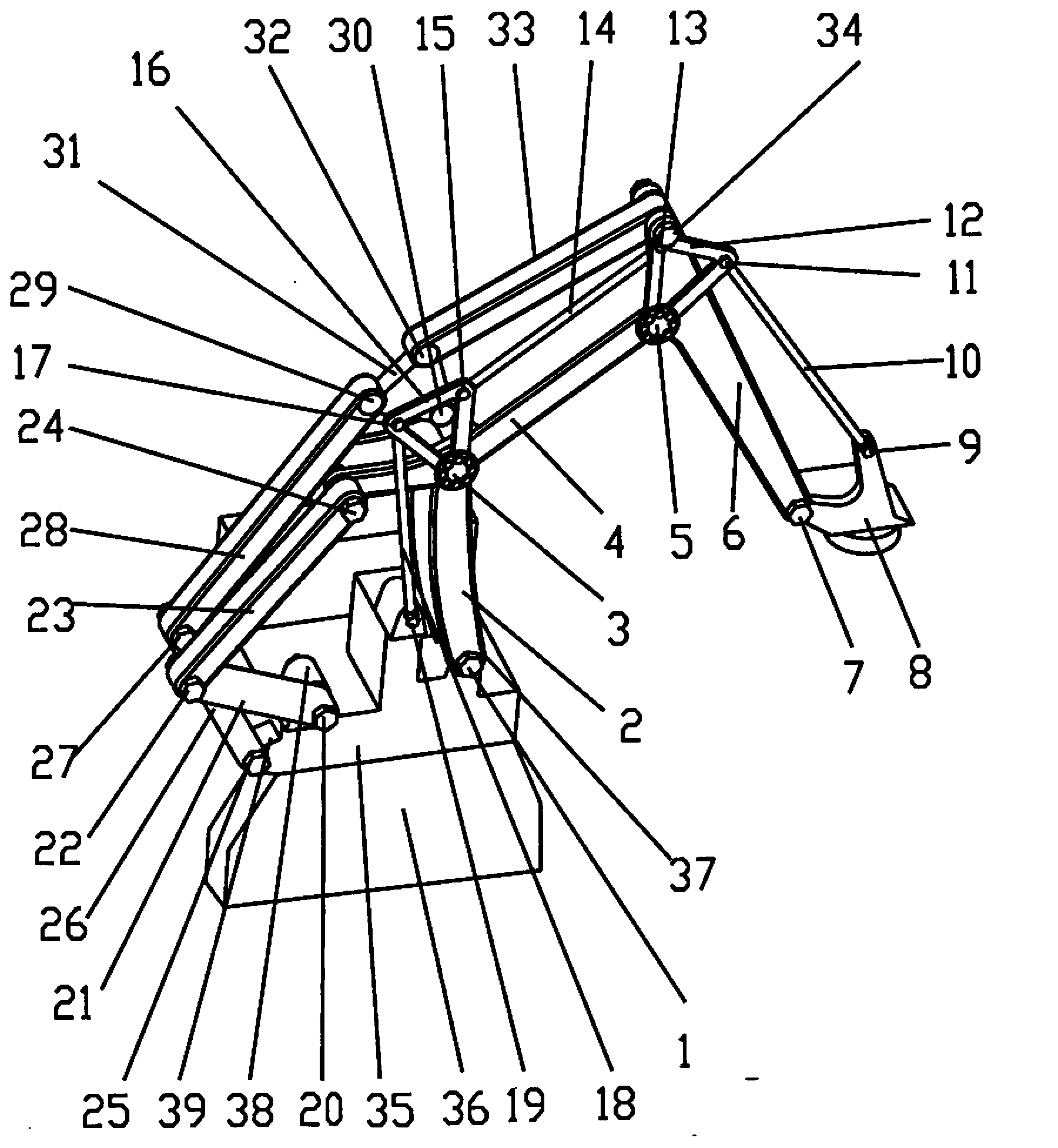

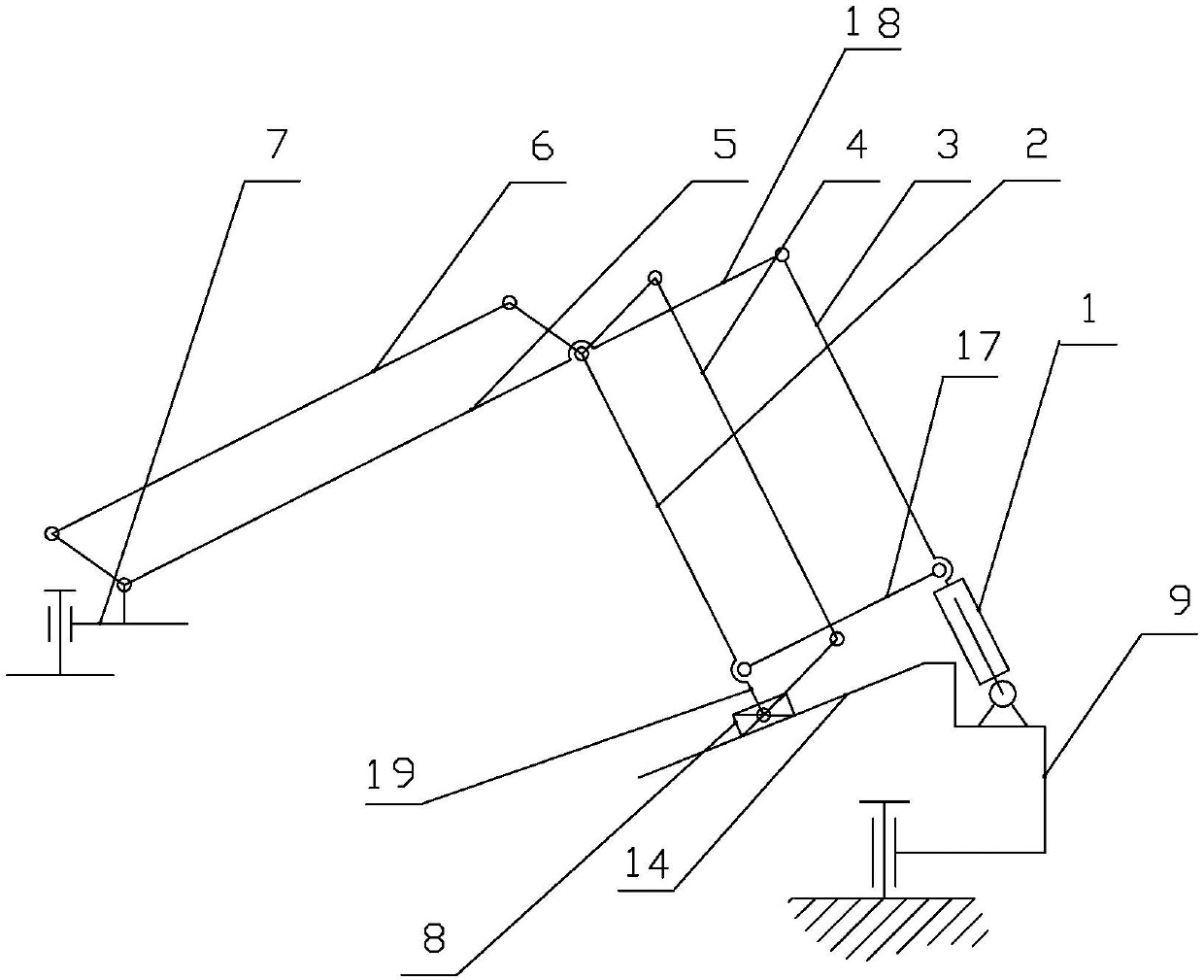

Large-work-space controllable-mechanism stacker crane

InactiveCN103056875AStrong flexible outputLarge working spaceProgramme-controlled manipulatorStacking articlesPalletizerEngineering

The invention relates to a large-work-space controllable-mechanism stacker crane. The stacker crane comprises a large-arm swing branch chain, a mid-arm swing branch chain, a small-arm swing branch chain, a posture keeping branch chain, an end executor and a rack. A robot completes carrying stacking operations with large work space and flexible changeable track output through the combined movement of the large-arm swing branch chain, the mid-arm swing branch chain and the small-arm swing branch chain. Three groups of parallelogram structures of the posture keeping branch chain can guarantee that the end executor keeps a horizontal state constantly in a working process, and all servo motors are mounted on the rack, bars can be made into light bars, the robot moving inertia is small, the dynamic performance is good, and requirements for high-speed and heavy-duty carrying and stacking can be well met. According to the stacker crane, a novel connection rod mechanism is utilized, so that the carrying and stacking work space is large, the connection rod transmission mechanism is simple, stresses on the bars are improved, and the manufacture of large stacker crane is applicable.

Owner:GUANGXI UNIV

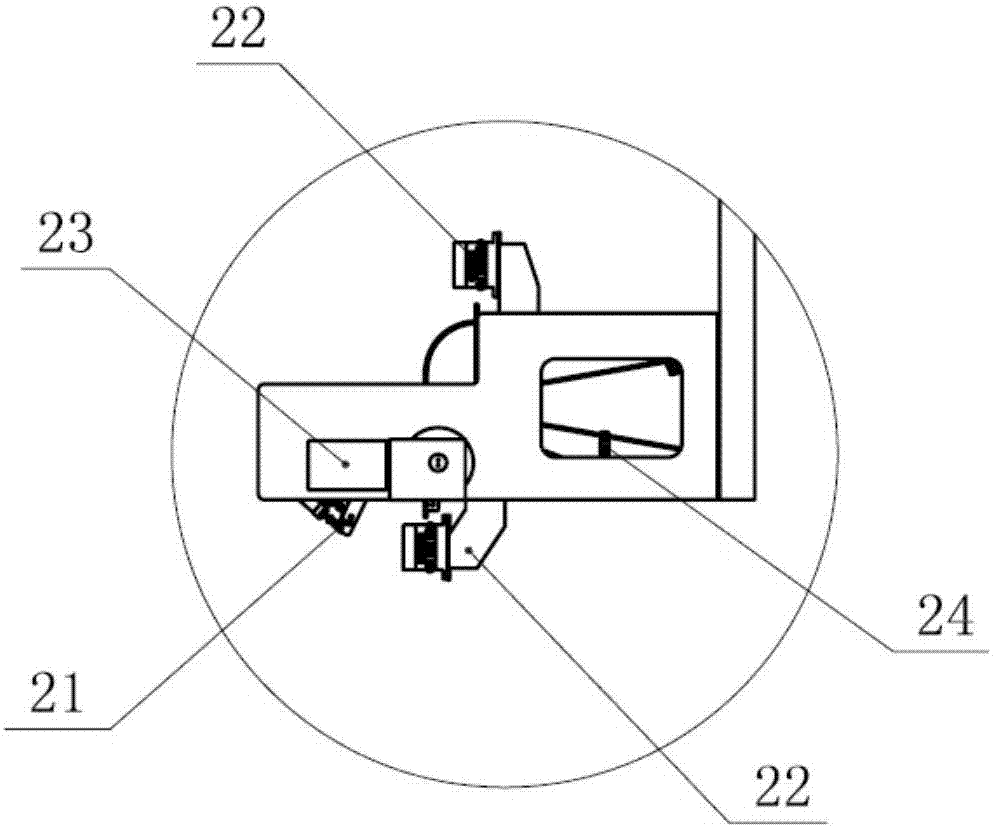

Sucking disc tongs device of robot palletizer

ActiveCN103481290AThere will be no random swinging phenomenonProgramme-controlled manipulatorGripping headsPalletizerEngineering

The invention discloses a sucking disc tongs device of a robot palletizer. The sucking disc tongs device comprises a connecting flange, a main body frame, a clamping plate mechanism, a width adjusting mechanism and a sucking unit, wherein the clamping plate mechanism comprises a clamping plate air cylinder slide rail, a clamping plate air cylinder slide block, a clamping plate air cylinder, a clamping plate support, a clamping plate air cylinder rotating shaft and a clamping plate air cylinder swing arm; the clamping plate air cylinder slide rail is fixed on the main body frame; the clamping plate air cylinder slide block is fixed on the clamping plate air cylinder slide rail; a clamping plate is fixed on the clamping plate air cylinder rotating shaft; the clamping plate air cylinder rotating shaft is fixedly connected with the clamping plate air cylinder by the clamping plate air cylinder swing arm. The adopted sucking unit can be moved on a sucking plate slide block, the position of the sucking unit can be changed according to the size of a box material, a box or a plurality of boxes of materials can be sucked at one step according to needs, and the blocking distance of the clamping plate is changed synchronously through changing the position of the sucking disc and adjusting a screw rod.

Owner:HEFEI EAGLE AUTOMATION ENG TECH

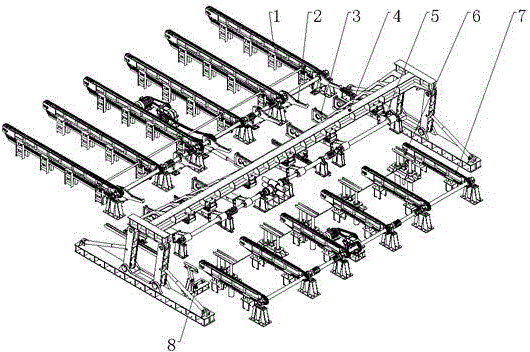

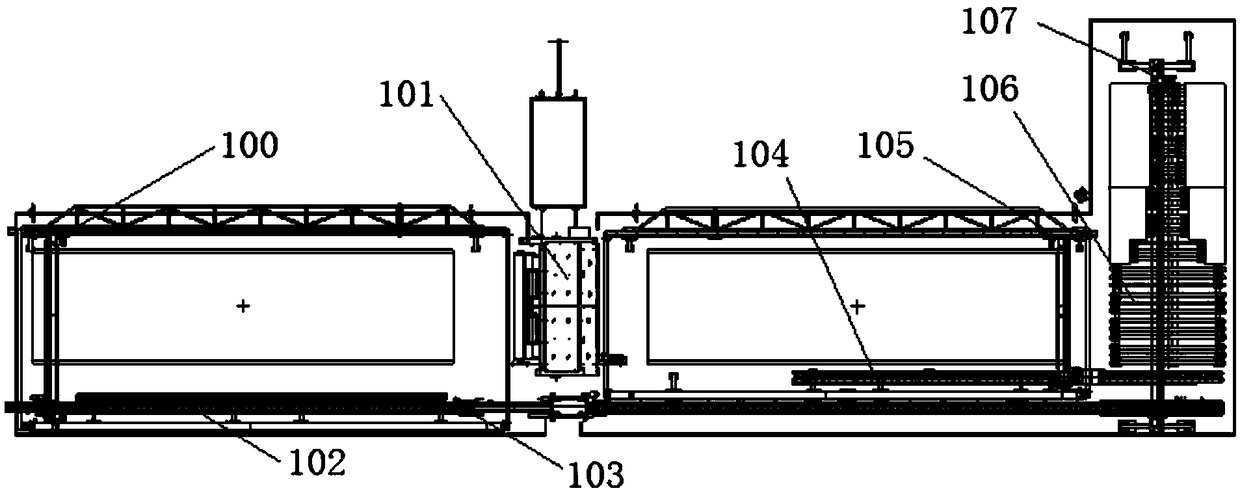

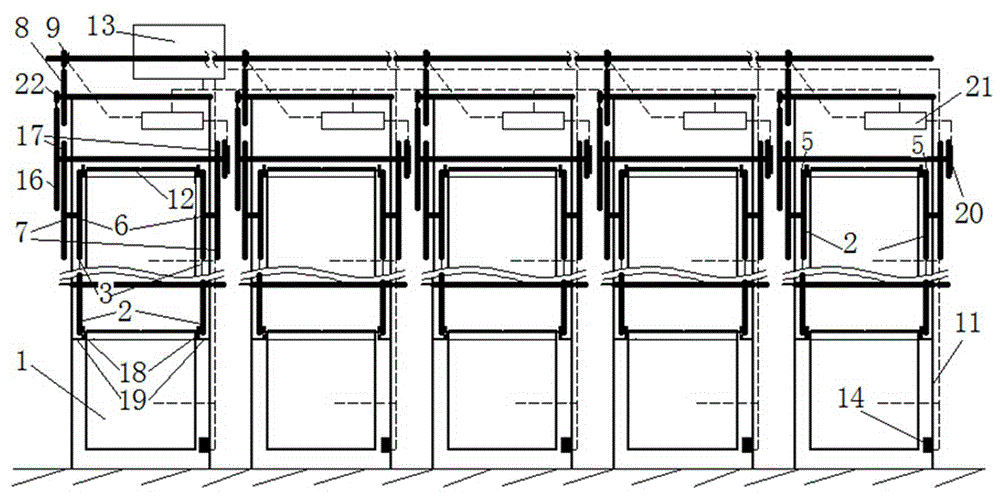

Intelligent production lines capable of producing standard PC components of multiple species and production process

ActiveCN108890850ARealize diversified productionReduce manufacturing costDischarging arrangementCeramic shaping plantsProduction lineMaterial distribution

The invention provides an intelligent production lines capable of producing standard PC components of multiple species and production process. Two intelligent production lines are arranged between anA shaft to a C shaft and between the C shaft to an E shaft respectively, are symmetric relative to the C shaft, and are installed between 1-28 axis of each span; each production line comprises a moldplacing device, a mesh bar processing device, a truss bar processing device, a material distribution machine, a turnover machine, a curing kiln, a stacker and a tipper. According to the production lines, three kinds of standard PC components of laminated slabs, superposed shear walls with no heat preserving function and superposed shear walls with a heat preserving function can be produced simultaneously by a single production line, and an information system is utilized to achieve whole process control of designing, producing and transporting to further reduce labor force. Only eighteen workers are needed to work on the intelligent production line in a working time period, the number of the workers is only one fourth of that of a traditional PC production line, current worker shortage is prevented, the labor intensity is reduced, the product quality and production efficiency are improved, and the production cost of enterprises is reduced.

Owner:美好建筑装配科技有限公司

Multifunctional robot palletizing system

InactiveCN102616578ASimple structureReduce manufacturing costStacking articlesDe-stacking articlesForeign matterControl system

The invention discloses a multifunctional robot palletizing system which comprises components such as a robot palletizer host, wherein palletizing trays are arranged on two sides of the robot palletizer host, a light inductive switch is used for detecting height of palletized materials on the palletizing trays, a palletizing conveyor is used for conveying materials to a fixed gripping position of the robot palletizer host, a conveying buffer mechanism is used for buffering the materials, a screening mechanism is arranged between the conveying buffer mechanism and a weighing mechanism and is used for picking out unqualified materials, the weighing mechanism is used for weighing the materials, a metal foreign matter detecting mechanism is used for detecting metal foreign matters, materials with metal foreign matters are picked out by the scanning mechanism, a bag flattening conveying mechanism is used for flattening and shaping bagged irregular materials so that the materials are palletized by a robot palletizer, electric control systems such as the robot palletizer host coordinate in a centralized manner to finish the whole palletizing flow. The multifunctional robot palletizing system is simple in structure and low in manufacturing cost and has multiple functions of shaping, detecting, weighing, screening and palletizing.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

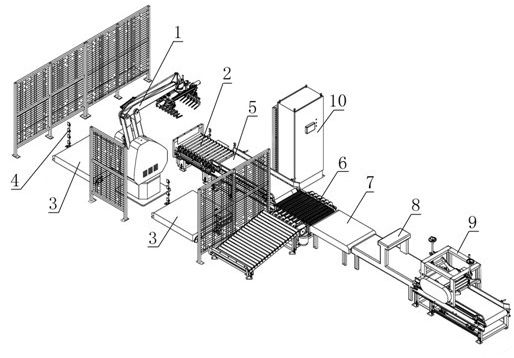

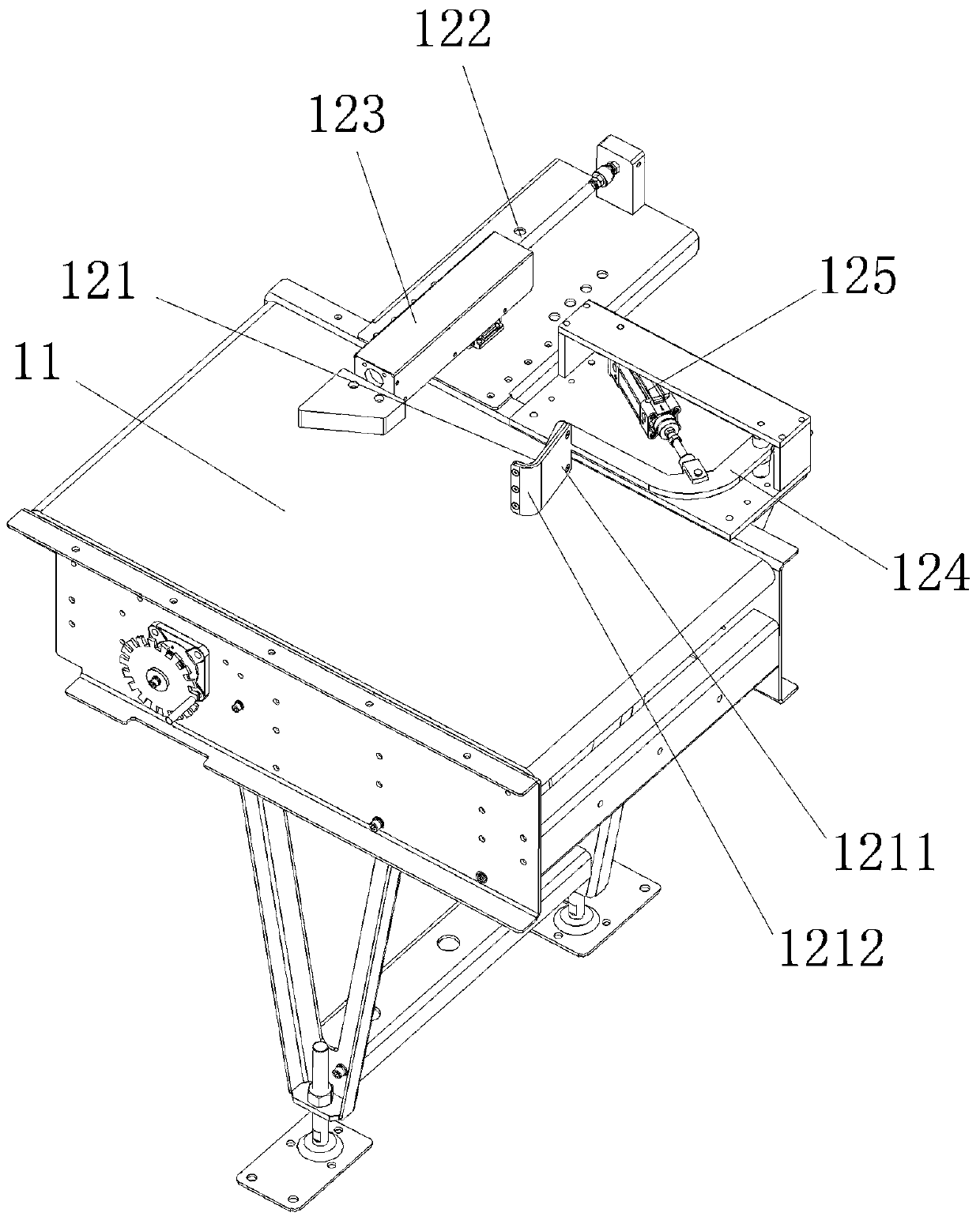

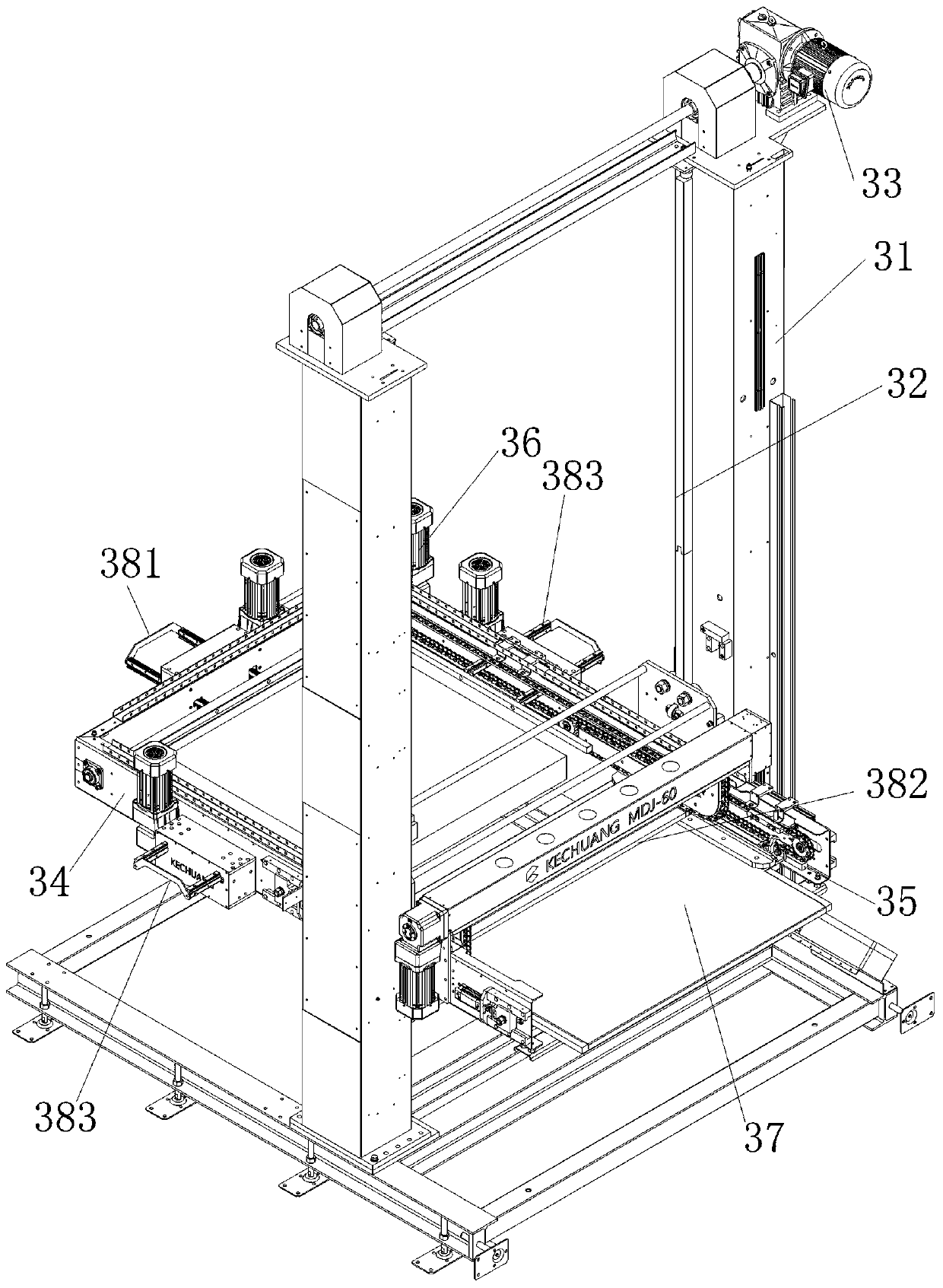

Automatic packaging box stacking machine capable of achieving selective stacking

PendingCN107697646AFacilitated releaseImprove reliabilityStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention discloses an automatic packaging box stacking machine capable of achieving selective stacking, and belongs to the technical field of stacking. The machine comprises an arranging and steering mechanism, a grouping pushing mechanism, a door type stacking mechanism and a matched tray storage supply mechanism which are sequentially arranged on a rack in the packaging box conveying direction. The arranging and steering mechanism comprises a feeding conveying device and a steering device arranged on one side of the feeding conveying device; the machine is characterized in that the steering device comprises a pre-steering baffle and a strengthening check block which are arranged at an interval in the feeding conveying direction, the pre-steering baffle is hinged to a pre-steering air cylinder on the rack through a bending rod and is hinged to the rack to form a swing stretching-out blocking and reset releasing structure, the strengthening check block is connected with a strengthening air cylinder on the rack, and forms a strengthening and resetting releasing structure by means of guidance of a sliding rail and sliding block pair perpendicular to the feeding conveying direction, a packaging box, required to be subject to steering, in the conveying process is subject to rotating and pre-steering operation around the blocked angle by means of blocking of the pre-steering baffle, and pressing strengthening of the blockage angle can be achieved by means of the strengthening check block.

Owner:WEIXIAN KECHUANG LIGHT IND EQUIP

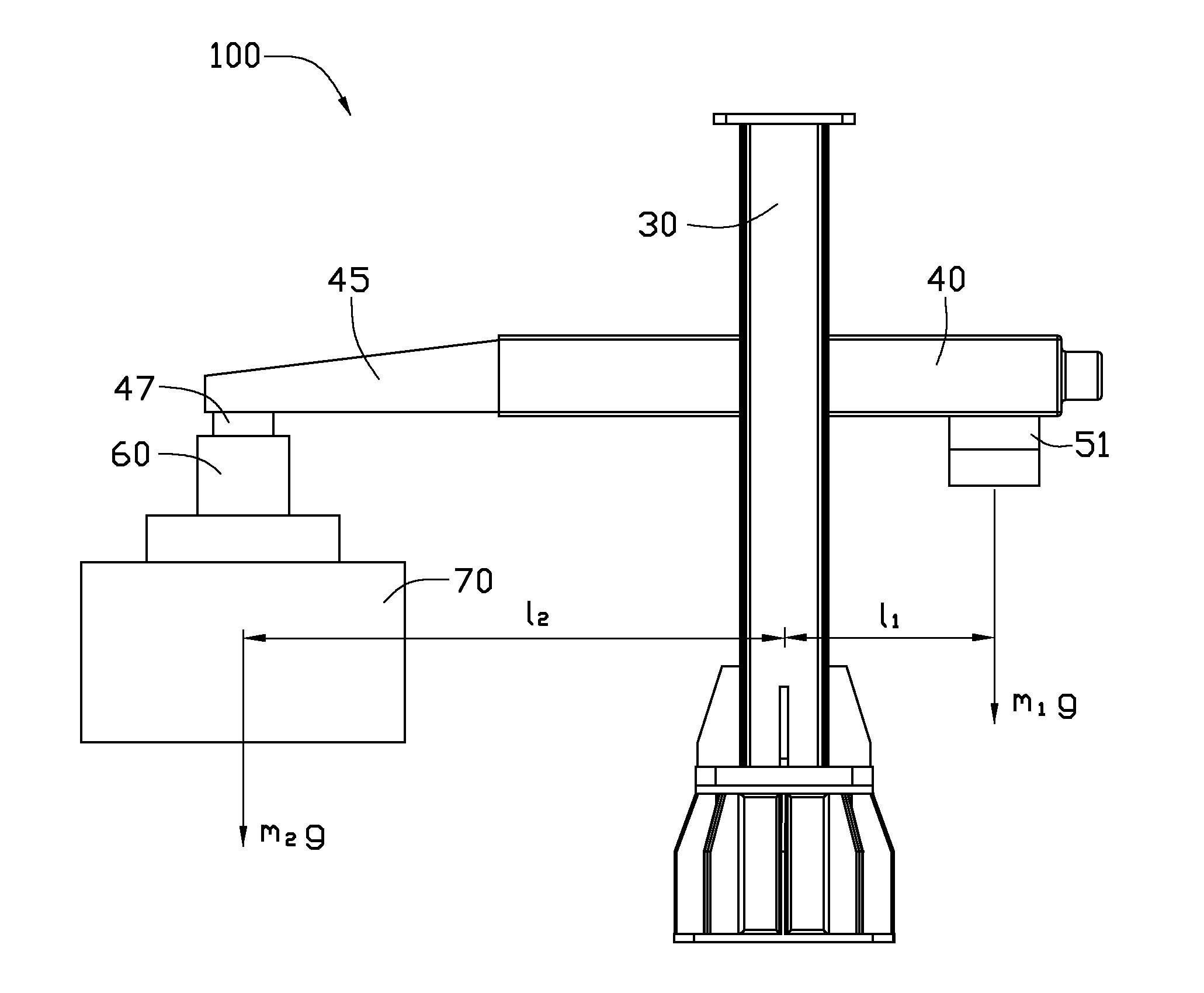

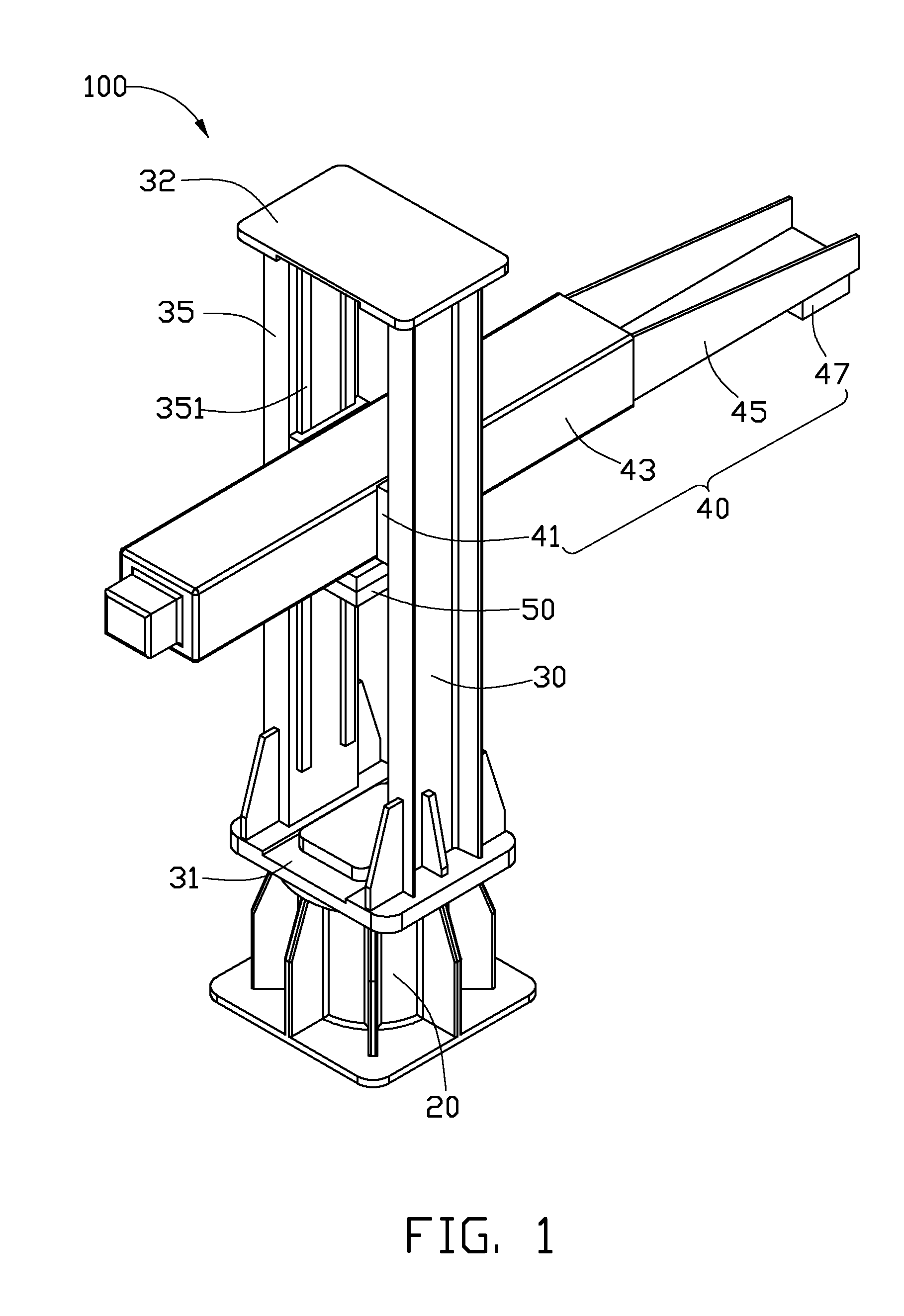

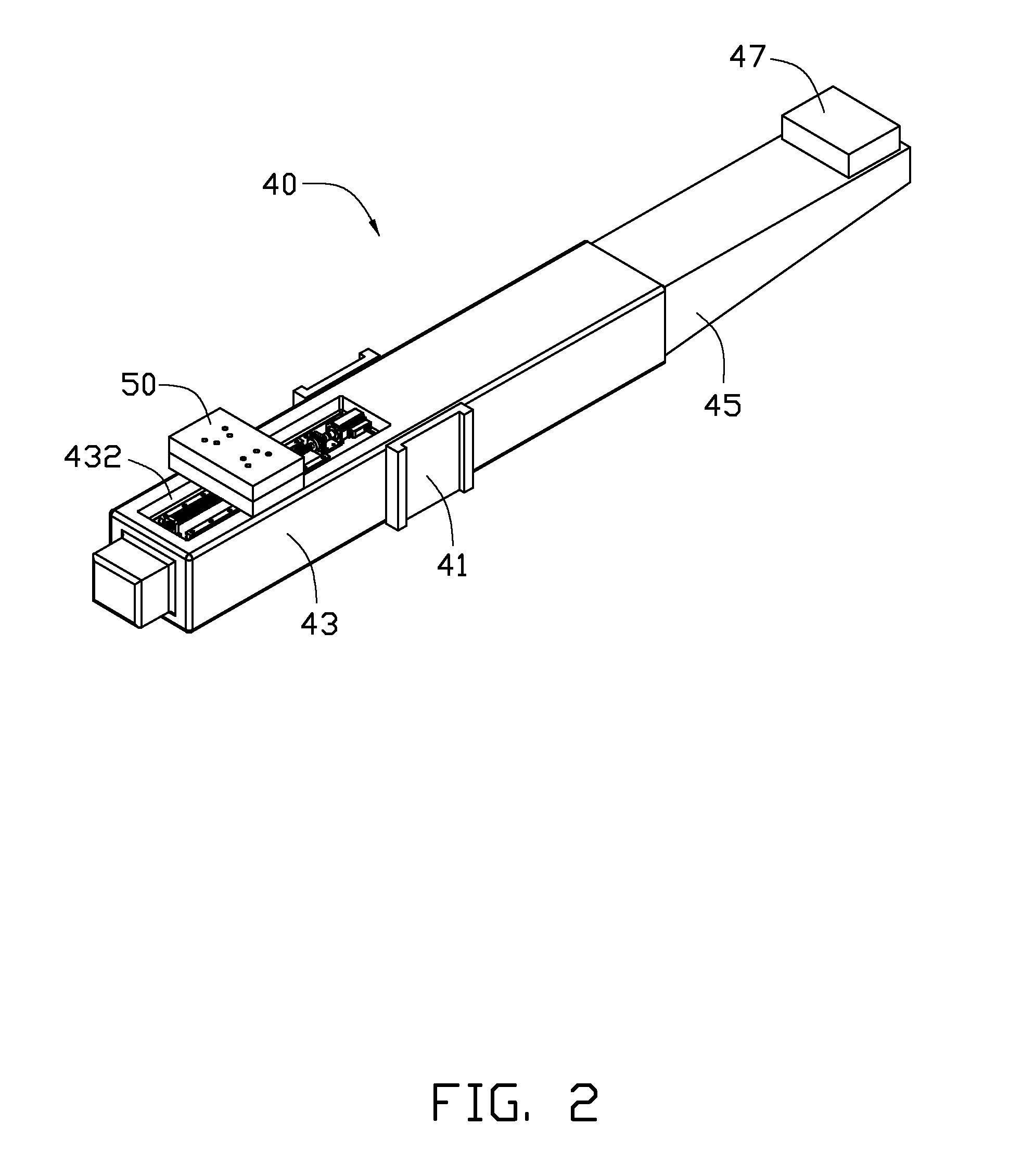

Palletizing robot

InactiveUS20110268549A1Low balanceProgramme-controlled manipulatorMechanical apparatusEngineeringActuator

A palletizing robot includes a lifting frame, an end-effector, an extensible mechanical arm, and a balancing mechanism. The extensible mechanical arm is rotatably connected to the lifting frame. The balancing mechanism and the end-effector are located on opposite ends of the extensible mechanical arm. The balancing mechanism includes a threaded rod, a sliding member, a driving member, and a counterweight. The threaded rod is located on the extensible mechanical arm. The sliding member receives the threaded rod. The driving member is fixed on an end of the threaded rod. The counterweight is fixed on the sliding member. The driving member rotates the threaded rod such that the sliding member slides relative to the threaded rod.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

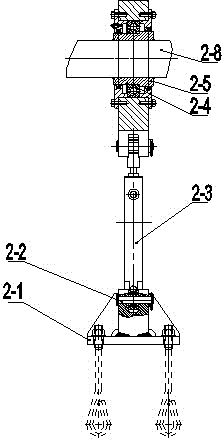

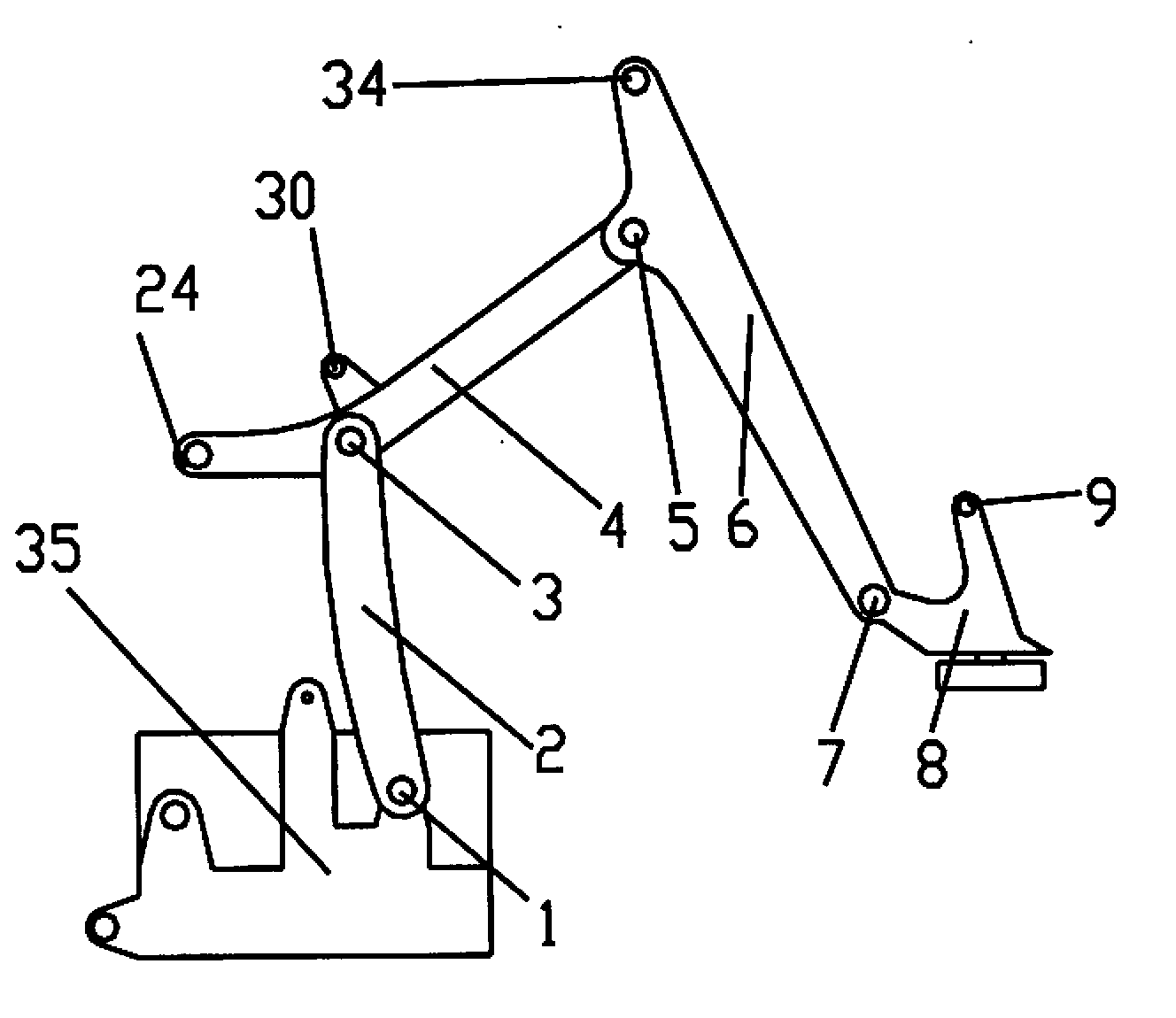

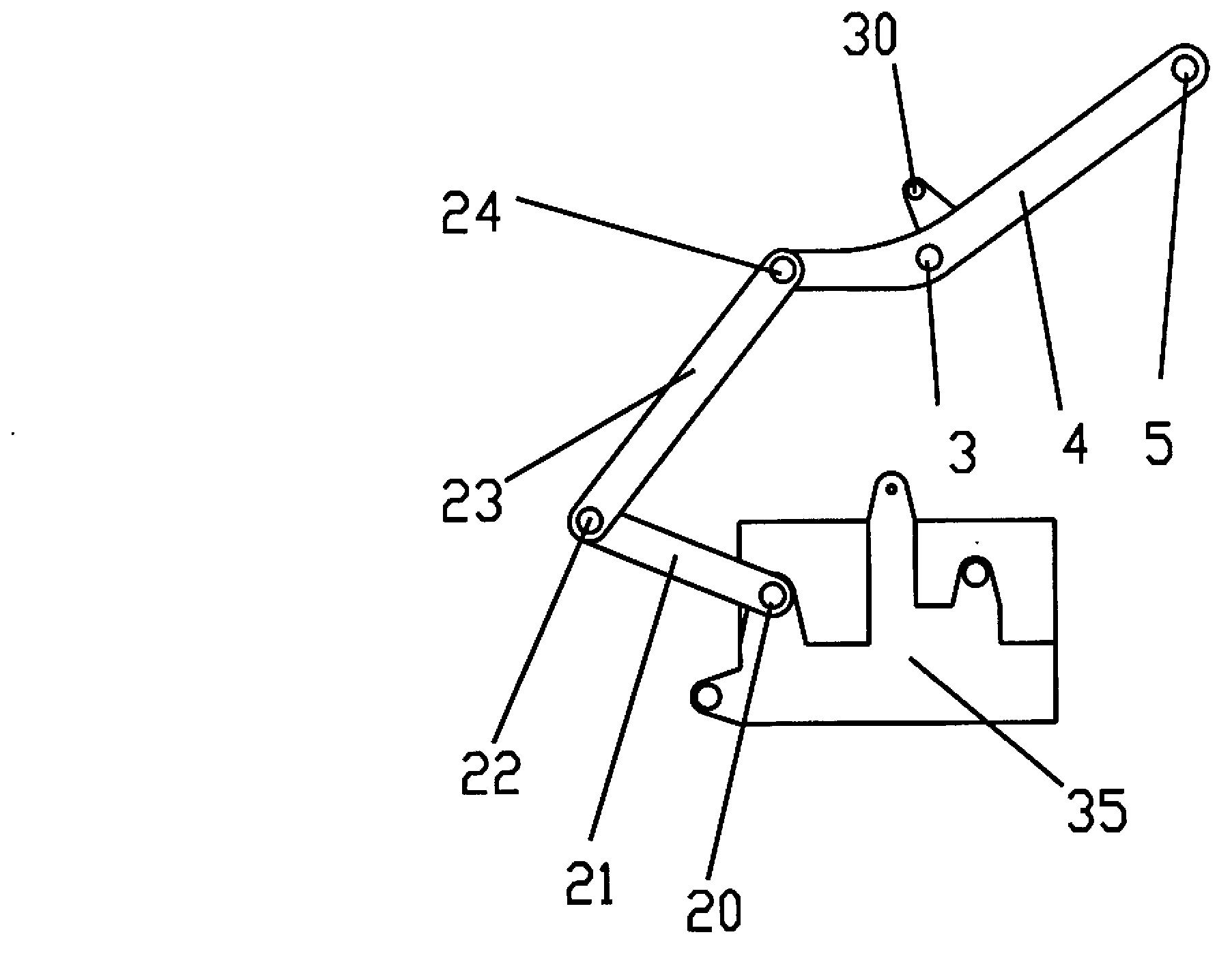

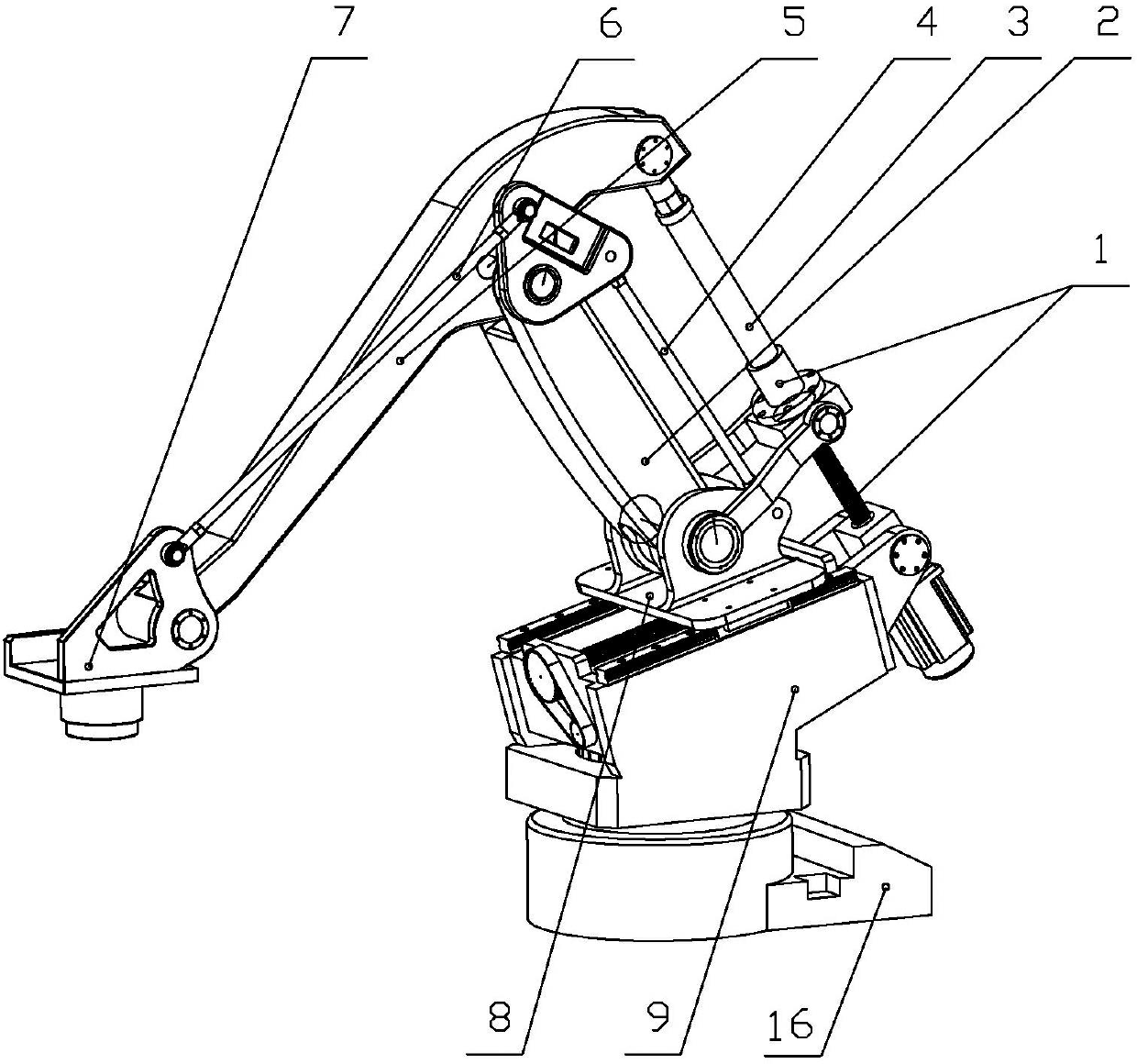

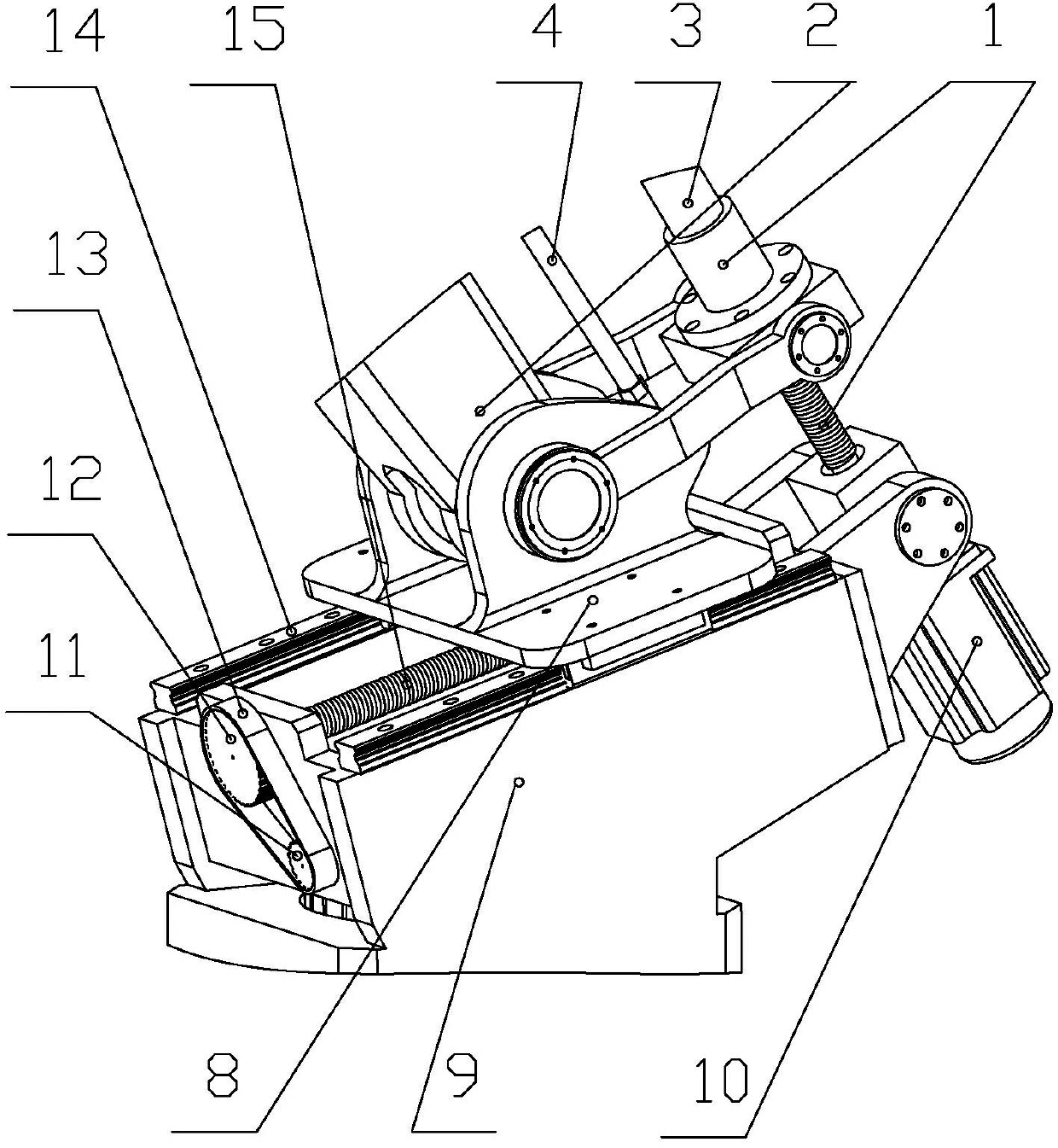

Robot palletizer for carrying

InactiveCN102602708AReduce energy consumptionSimple mechanical structureStacking articlesDe-stacking articlesPalletizerEngineering

The invention relates to a robot palletizer for carrying. The robot palletizer comprises a base, a rotary rack, a large arm parallelogram mechanism, a wrist horizontal posture keeping parallelogram mechanism, an arm parallelogram mechanism, a wrist and an inclined guide rail, wherein the rotary rack is arranged on the base, the large arm parallelogram mechanism is arranged on the rotary rack, the arm parallelogram mechanism is connected with the large arm parallelogram mechanism and the wrist horizontal posture keeping parallelogram mechanism, the wrist is connected with the arm parallelogram mechanism, the inclined guide rail is arranged on the rotary rack, a sliding block driven by a linear driving element is arranged on the inclined guide rail and is movably connected with a fixed connecting piece at the lower end of a large arm below the wrist horizontal posture keeping parallelogram mechanism, the lower end of a large arm above the large arm parallelogram mechanism is coaxially connected with the upper end of the linear driving element, and the lower end of the linear driving element is connected with the rotary rack by a rotary hinge. According to the robot palletizer, the machinery structure of the robot palletizer is simplified, and the stress mode of the mechanism is optimized, so that the structure is compact, the energy loss is saved, and the manufacturing cost is low.

Owner:GUANGDONG UNIV OF TECH

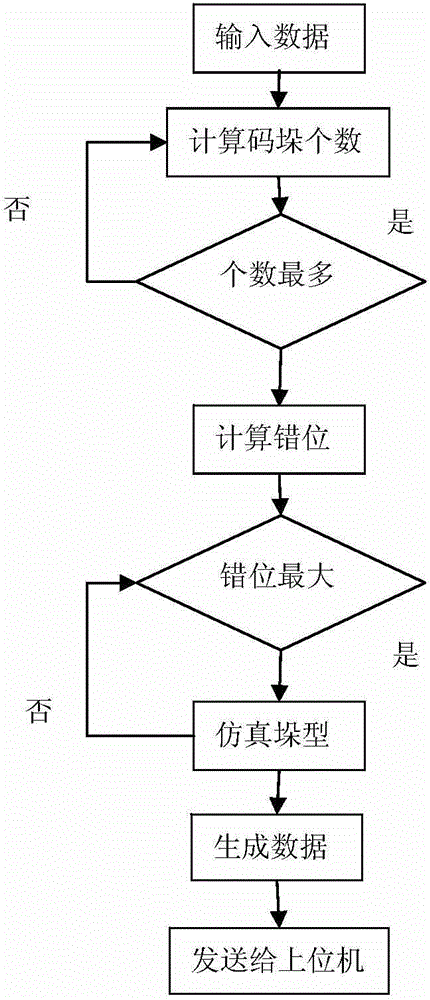

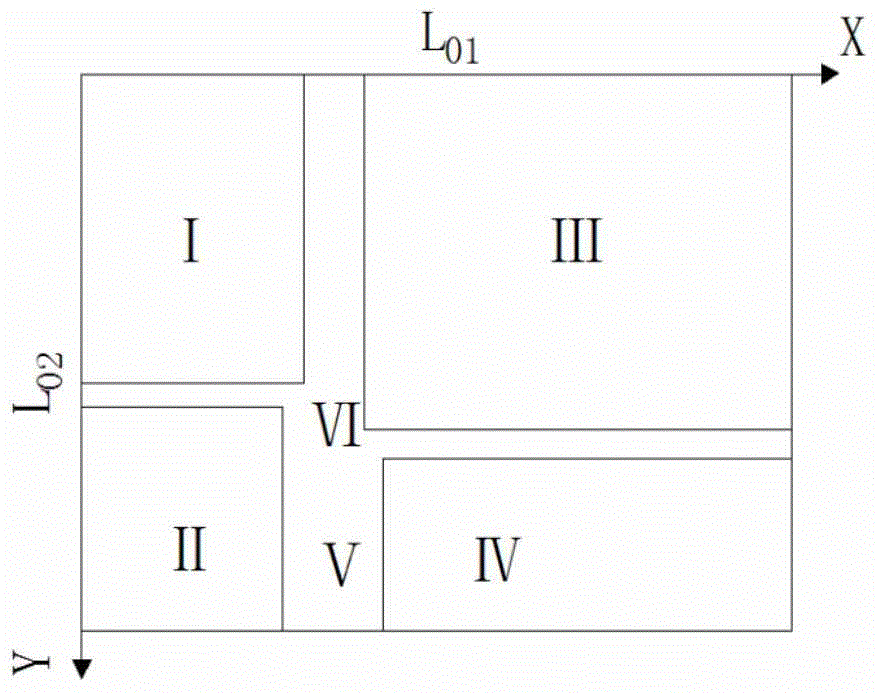

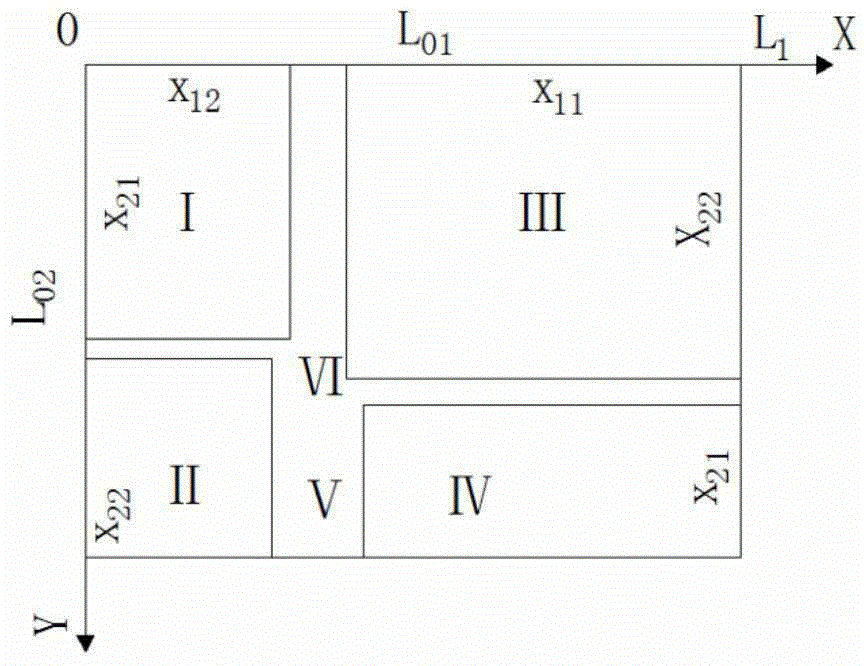

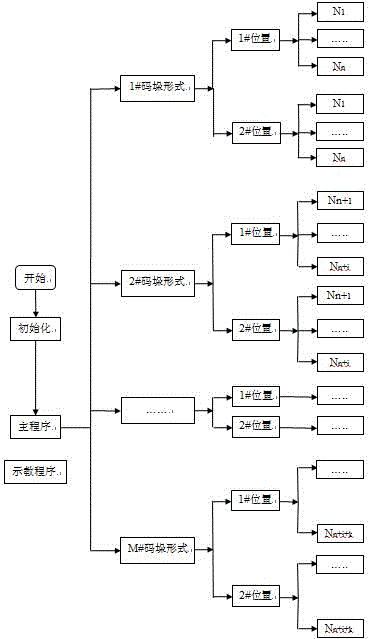

Dislocation palletizing programming method

InactiveCN104528389AIncrease profitObserve intuitivelyConveyorsStacking articlesPalletizerSoftware engineering

The invention discloses a novel dislocation palletizing programming method. The novel dislocation palletizing programming method comprises the steps that cargo information, pallet information, palletizing layer number and dislocation information in a palletizing process are integrated to generate a TXT format file which is convenient to save, read and modify; according to a TCP / IP protocol, a palletizing information text document is submitted to an upper computer; after the upper computer receives data, the upper computer judges the reasonability of the data firstly, and then analyzes the data to be the data needed in the palletizing of a robot palletizer. According to the dislocation palletizing programming method, the optimal pile type can be quickly figured out, the pile type can be simulated, and the existence or inexistence of interference problems can be visually judge out; not only can the optimal pile type be provided, but also the dislocation between odd layers and even layers can be formed to enable the pile type to be the most stable.

Owner:TIANJIN UNIV OF COMMERCE

Aligning and stacking palletizing machine

InactiveUS9126770B1Limit in costTimely controlProgramme-controlled manipulatorRobotRobotic armEngineering

A device for engaging and aligning items moving along a conveyance line that are to be positioned on a pallet is provided. The device includes a robotic arm positioned adjacent the conveyance line and having a manipulator thereon. The manipulator includes a number of fingers that extend downwardly from the manipulator in order to engage the items on the conveyance line. The fingers operate to stop and align the items to form a well-defined stack in the shape defined by the position of the fingers on the manipulator. The manipulator can rotate while the fingers are in engagement with the stack of items in order to reposition the items as desired for placement on the pallet by sliding the items along the various surfaces of the system and without lifting the items off of the conveyance line, thereby limiting the cost and time associated with the operation of the device.

Owner:AUTOMATAN LLC

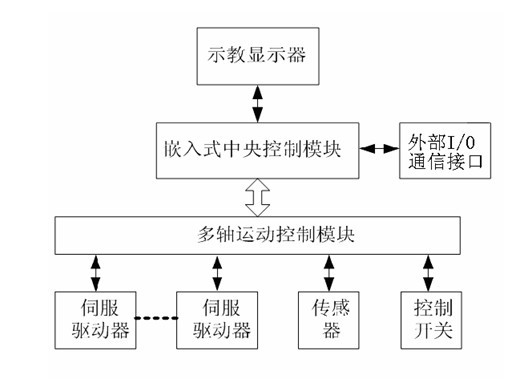

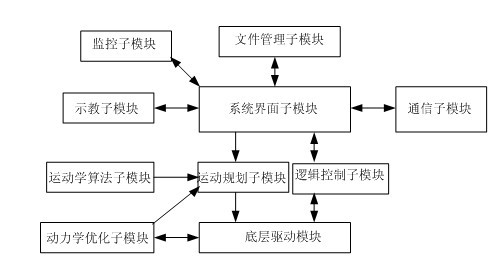

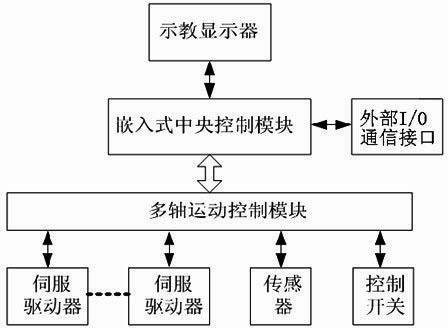

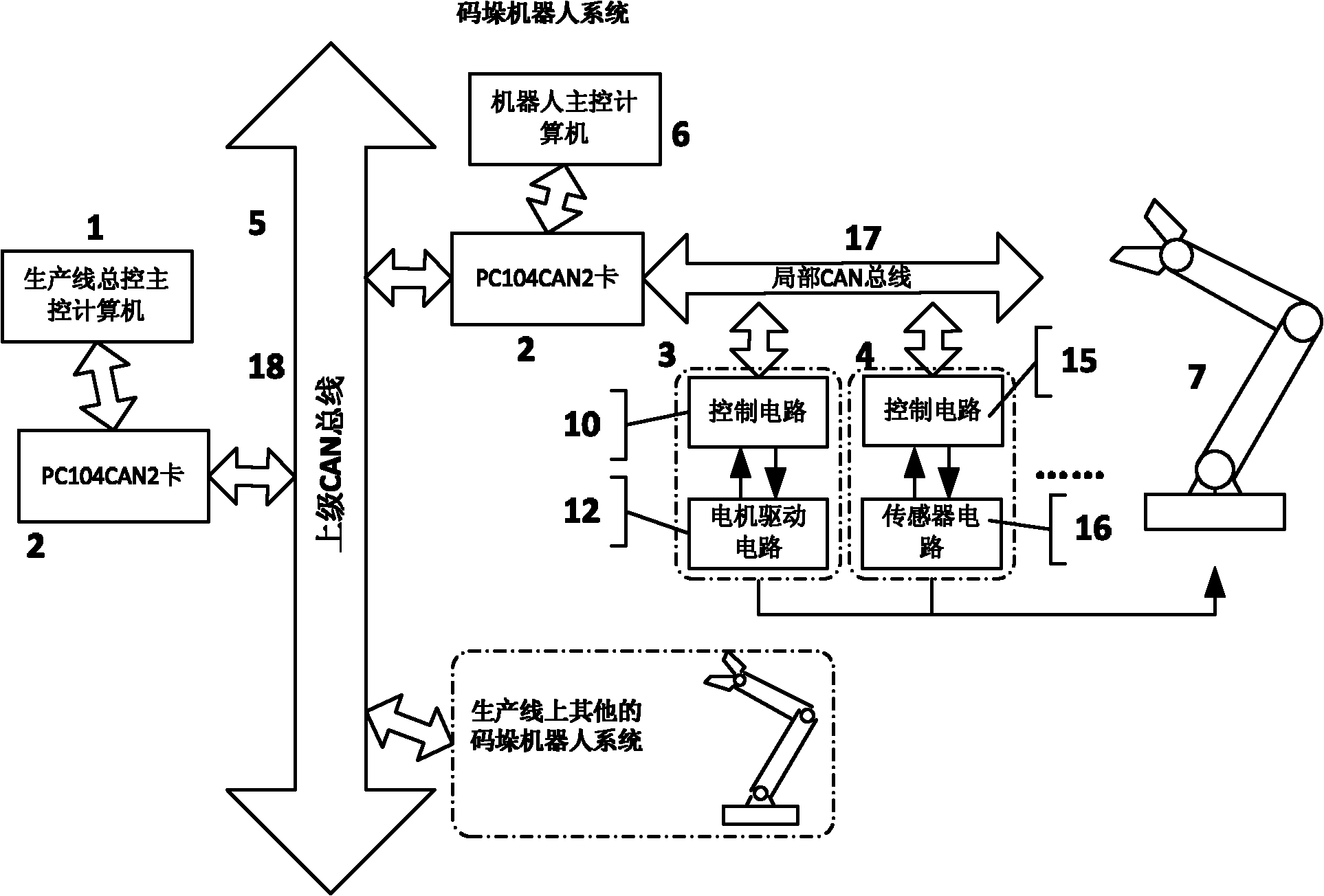

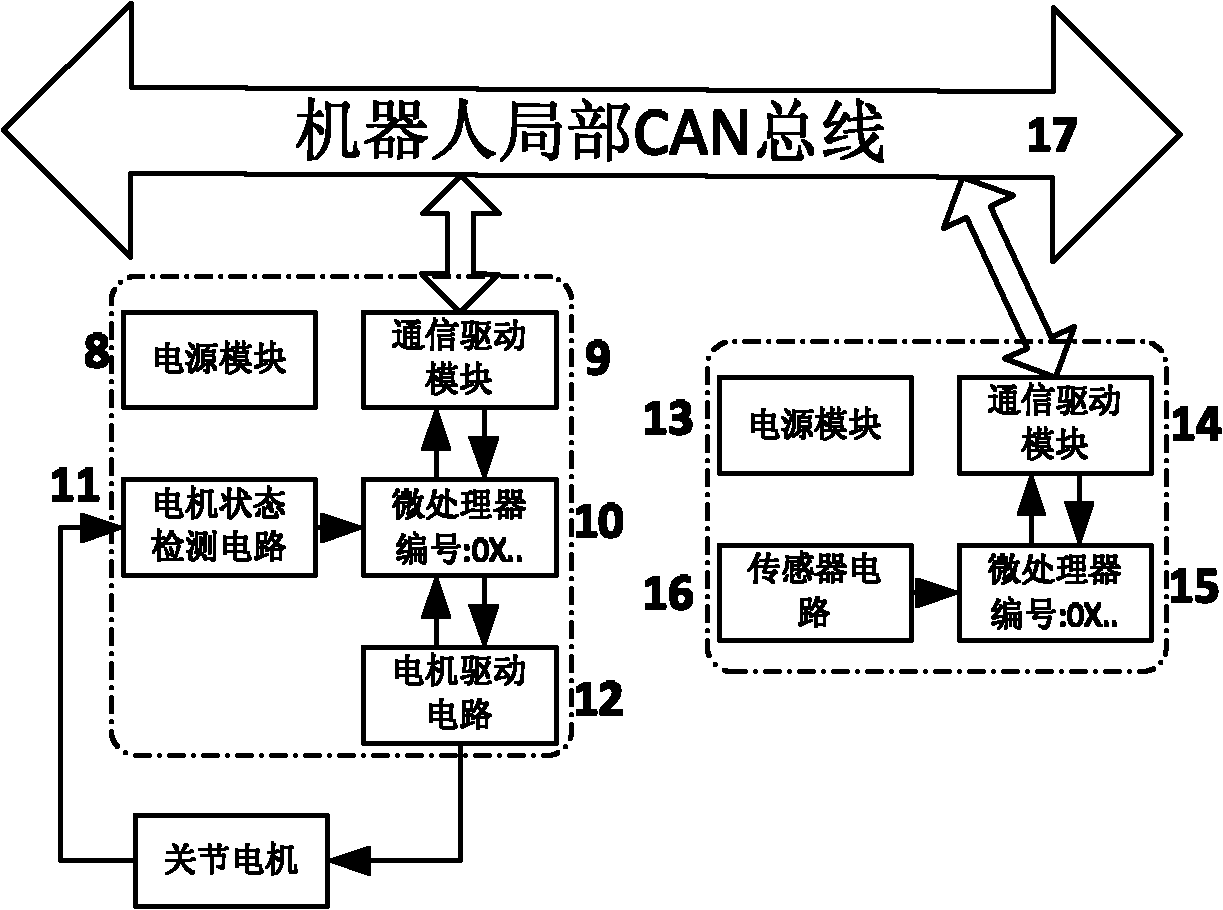

Control system for robot palletizer

InactiveCN102616577AImprove scalabilityHigh degree of automationStacking articlesDe-stacking articlesCommunication interfaceControl system

The invention discloses a control system for a robot palletizer. The control system is characterized by comprising an embedded central control module, a multi-shaft movement control module, a servo driver, a demonstration display, an external I / O (input / output) communication interface, a sensor and a control switch, wherein the embedded central control module and the multi-shaft movement control module are connected by a PCI (Peripheral Component Interconnect) bus, the embedded central control module and the demonstration display are connected by a special communication cable, the embedded central control module and the external I / O communication interface are connected, the multi-shaft movement control module is connected with the servo driver, the sensor and the control switch through digital I / O interfaces, and the embedded central control module controls the robot palletizer to complete the palletizing operation. The control system is convenient to operate and a user can perform demonstration and parameter input operations just by the handheld demonstration display.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

Control method of palletizing robot based on formula

ActiveCN106239512AAddress labor costsRealize automatic palletizingProgramme-controlled manipulatorStacking articlesCardboardControl system

The invention relates to a control method of a palletizing robot based on formula comprising a teaching step of teaching a robot with key teaching points; an inputting step of inputting palletizing form data, palletizing position data and palletizing formula data in a robot control system; a selecting step of selecting palletizing positions, palletizing forms and palletizing formula from the control system; a step of obtaining actual palletizing positions by means of a palletizing algorithm according to the data obtained from the above steps. The invention has the advantages that the palletizing system pre-develops several kinds of palletizing forms, and then customers only need to select the required palletizing forms according to the actual production process, meanwhile, the size of the products, the number of products to be grabbed, the cardboard placement and the number of palletizing layers are input into the control system so that corresponding palletizing of products can be fulfilled; the degree of automation and ease of operation of the robot palletizing system reduce labor costs.

Owner:NANTONG UNIVERSAL MACHINERY

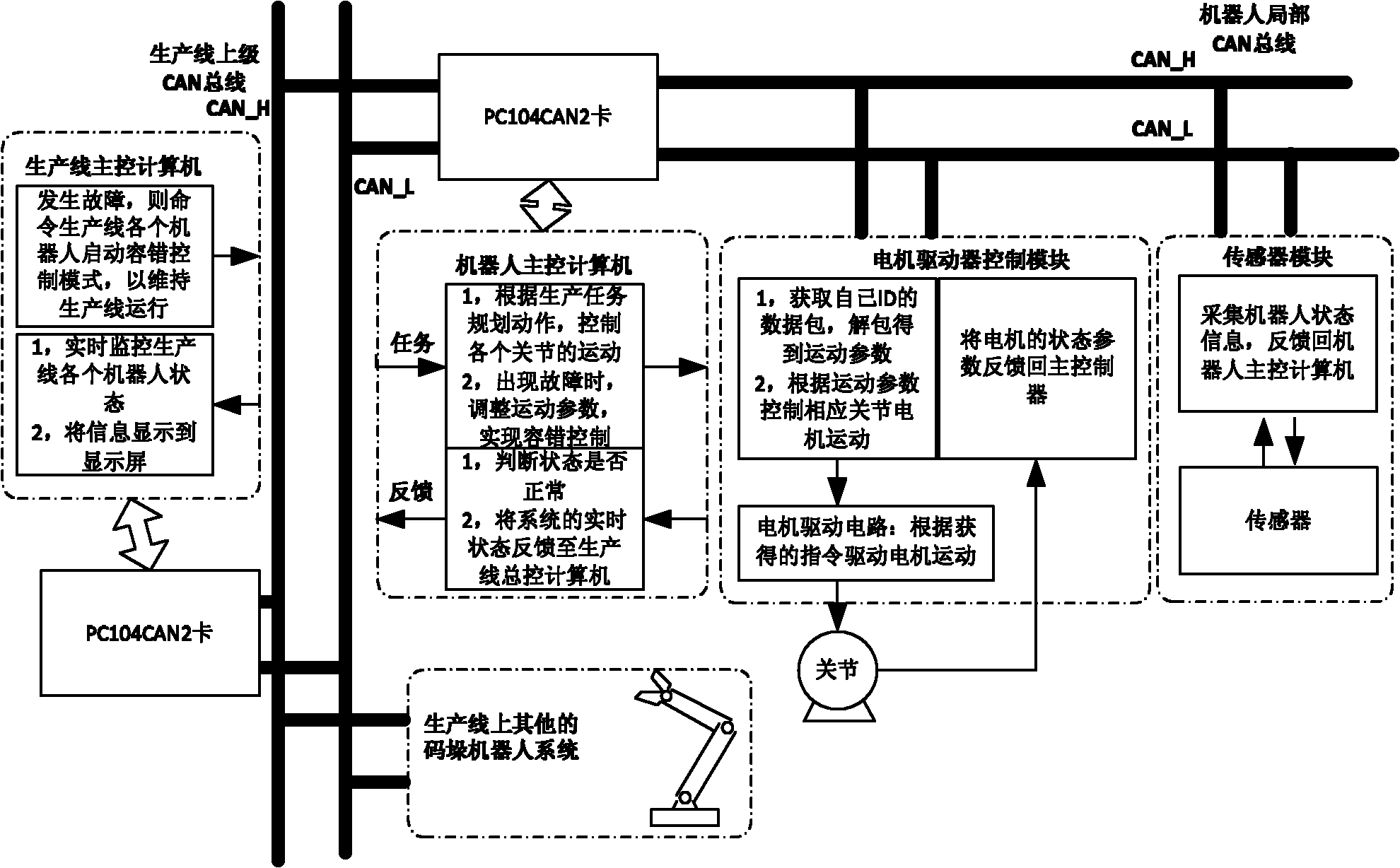

Control system for robot palletizer with self-maintenance function

InactiveCN102139486AGuaranteed uptimeImplement fault-tolerant controlManipulatorProduction lineSelf maintenance

The invention relates to a control system for a robot palletizer with the self-maintenance function, belonging to the technical field of automation control. The control system comprises a production line master control module, a bus interface module, a motor driver module, a sensor module, a communication bus, a robot master control module and a robot palletizer. The control system not only can control the movement of corresponding machine joints of the robot palletizer, but also can monitor the movement state of the robot palletizer in real time, can carry out the automatic adjustment when in malfunction so as to realize fault-tolerant control and simultaneously feeds back the fault information to a master control system. The master control system gives an alarm, displays the fault information and controls other robots on the same production line to take measures, so as to coordinate the robot with malfunction and maintain the normal operation of the production line.

Owner:SHANGHAI JIAO TONG UNIV

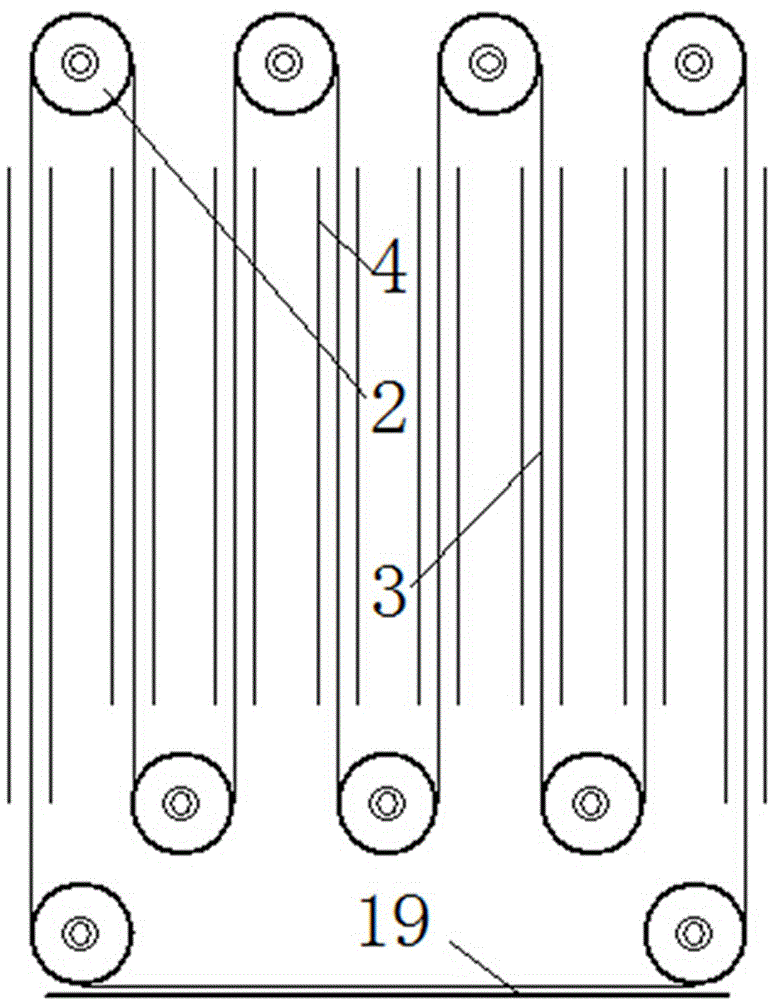

Integral-type mesh welding machine

ActiveCN107253053AMeet development needsIncrease productivityOther manufacturing equipments/toolsMetal working apparatusPunchingMesh reinforcement

The invention belongs to the field of steel bar mesh welding devices and discloses an integral-type mesh welding machine. The integral-type mesh welding machine is sequentially provided with a longitudinal bar conveying mechanism, a welding mechanism, a transverse bar blanking mechanism, a mesh pulling mechanism, a shearing mechanism, a conveying mechanism, a packaging machine, a stacking mechanism and a tray travelling mechanism according to the steel bar mesh machining sequence. A punching mechanism and / or a wire reversing mechanism and / or a mesh wiping mechanism capable of being selectively started are further arranged between the mesh pulling mechanism and the shearing mechanism. According to the integral-type mesh welding machine, through arrangement of all the mechanisms, welding, punching, wire welding and reversing, bending, stacking and packaging of a mesh piece can be automatically and integrally completed, and therefore a steel bar mesh with special requirements is machined; and the current development demands of machining industries are effectively met, and the production efficiency is improved.

Owner:TJK MACHINERY TIANJIN

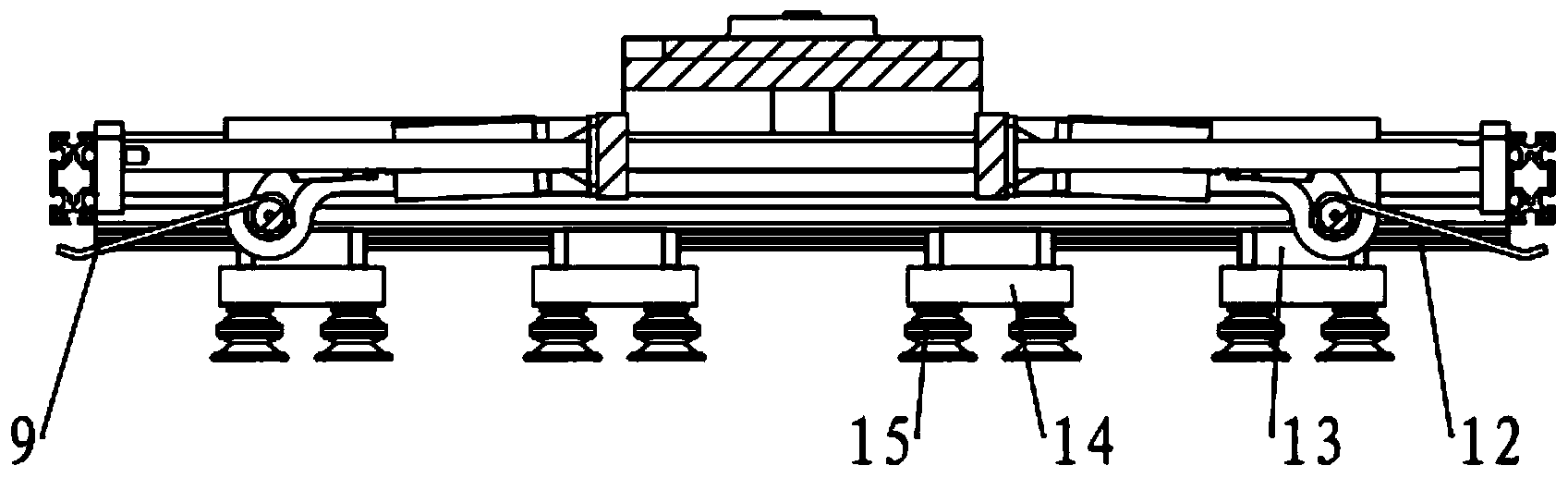

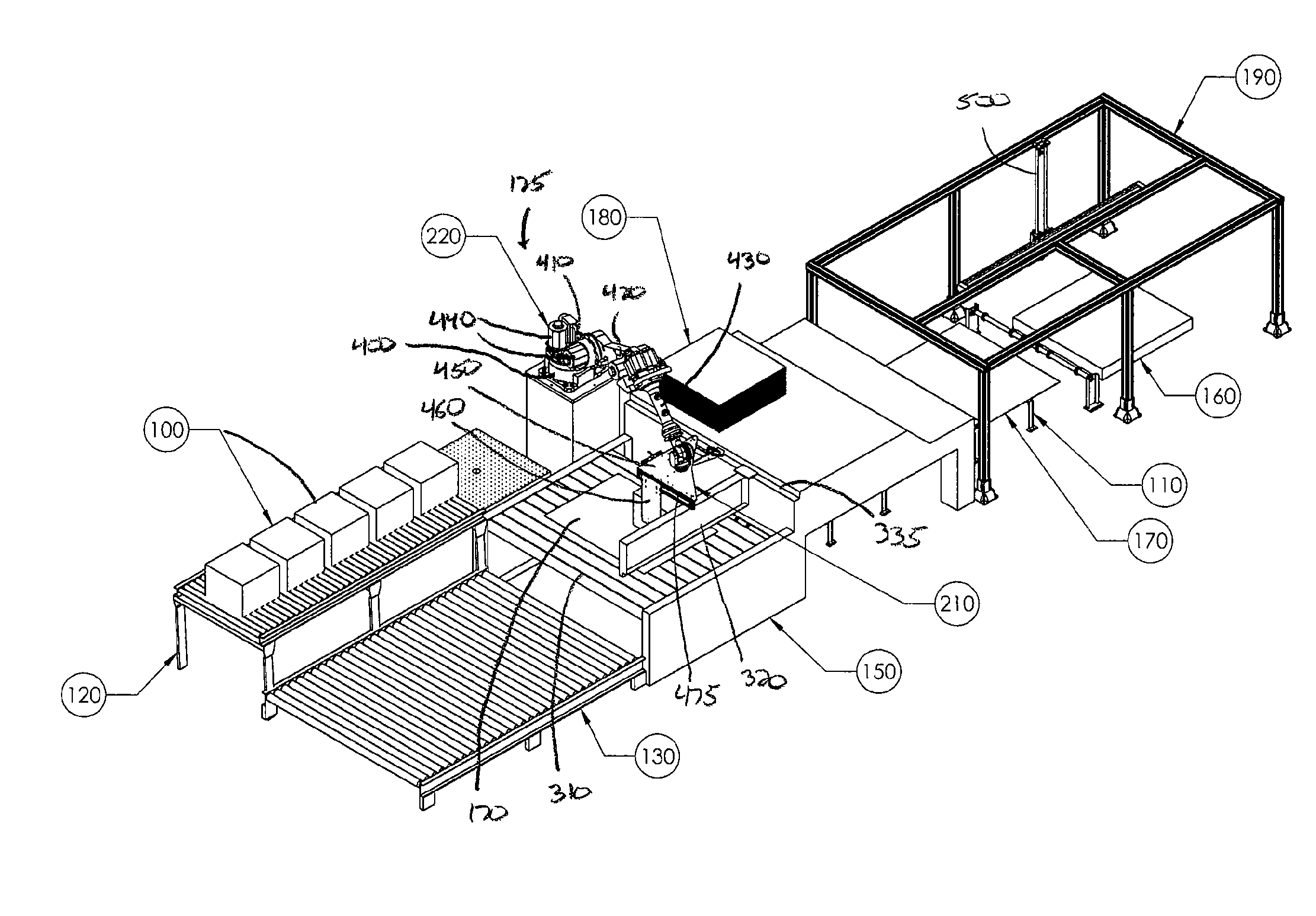

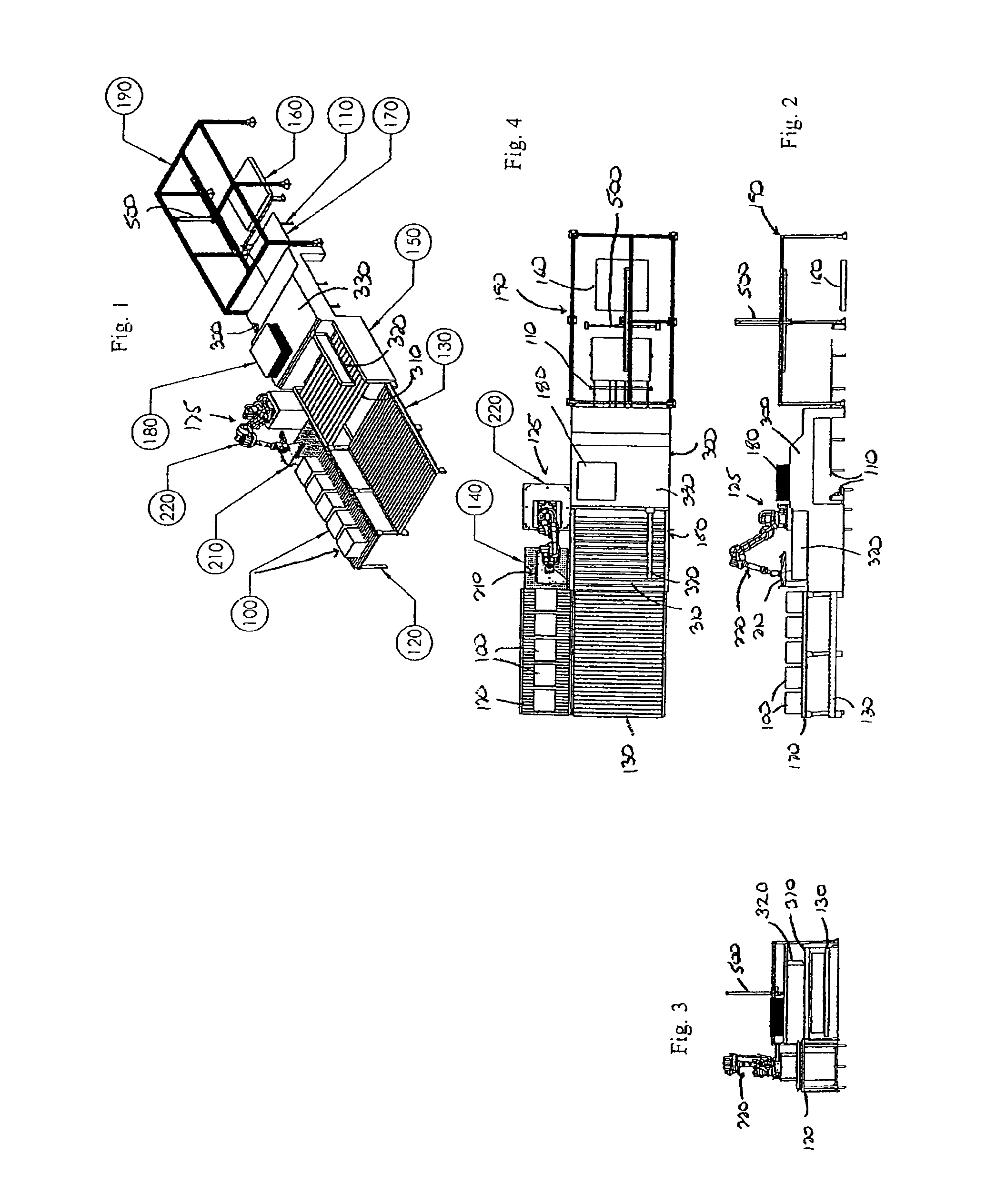

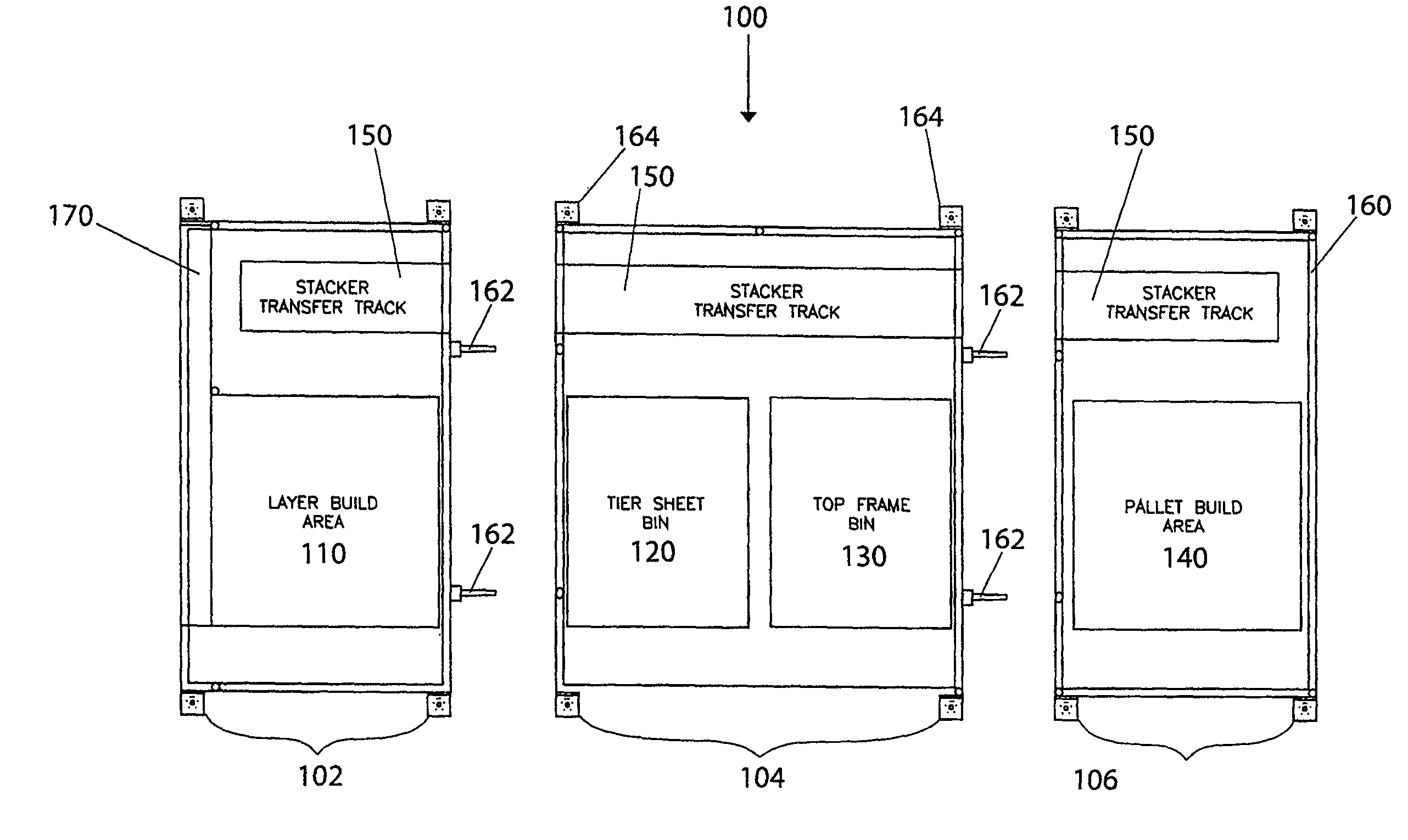

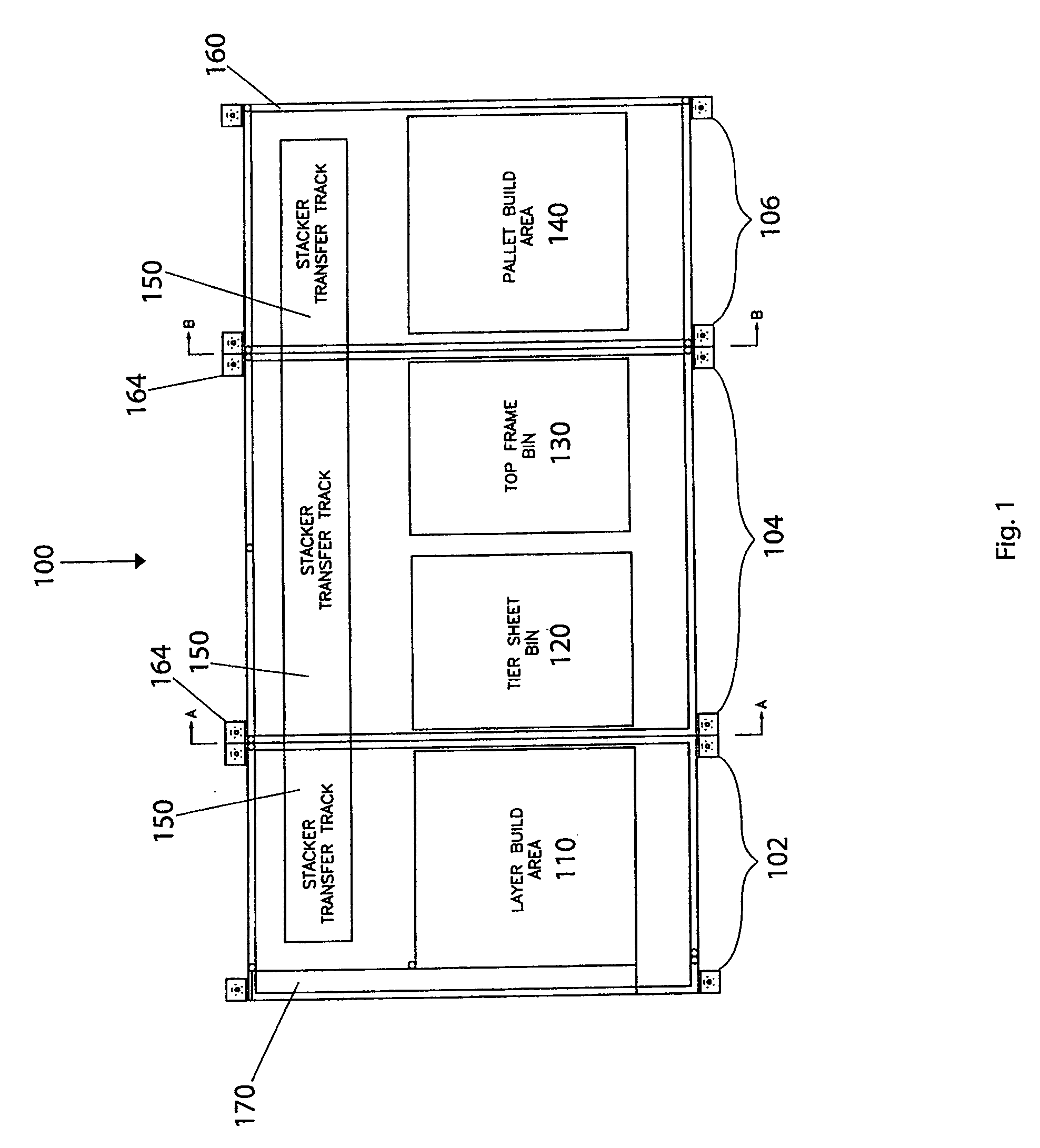

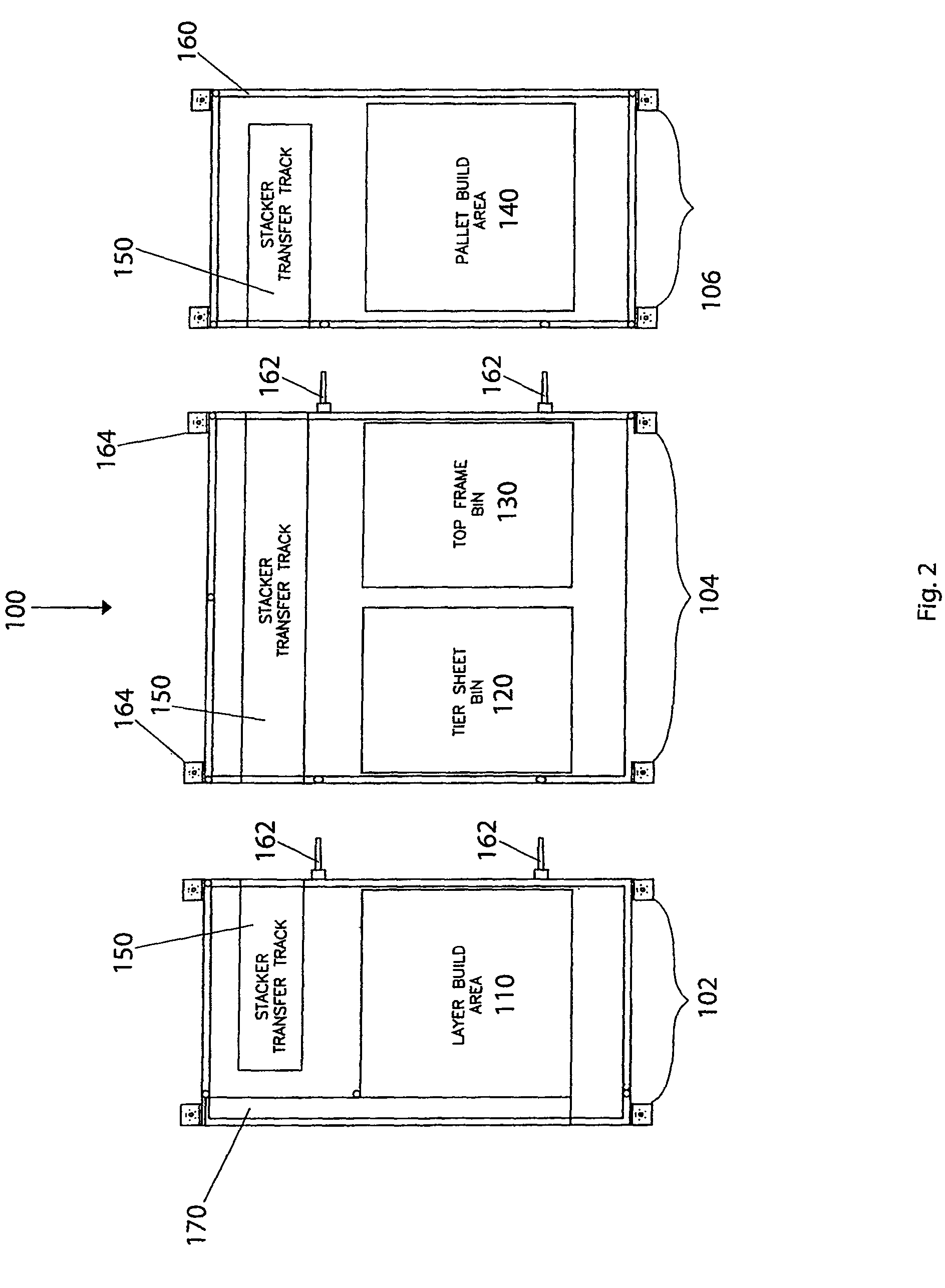

Mobile split palletizer

A modular split palletizer for loading layers of articles on stackable pallets. The palletizer has a frame supporting first, second, and third sections. The first section includes a layer build area and a first portion of a stacker transfer track. The second section includes a tier sheet bin, a top frame bin, and a second portion of the track. The third section includes a pallet build area and a third portion of the track. Each of the first, second, and third sections can be disassembled, moved individually and independently, and re-assembled at a new location to form the complete palletizer. Also disclosed is a method of relocating the modular split palletizer. With the palletizer at one location, the utilities connected to the palletizer are disconnected, the fasteners holding the sections together are released, and the sections are separated. The disassembled sections are moved to the new location and reassembled.

Owner:GRAHAM PACKAGING CO LP

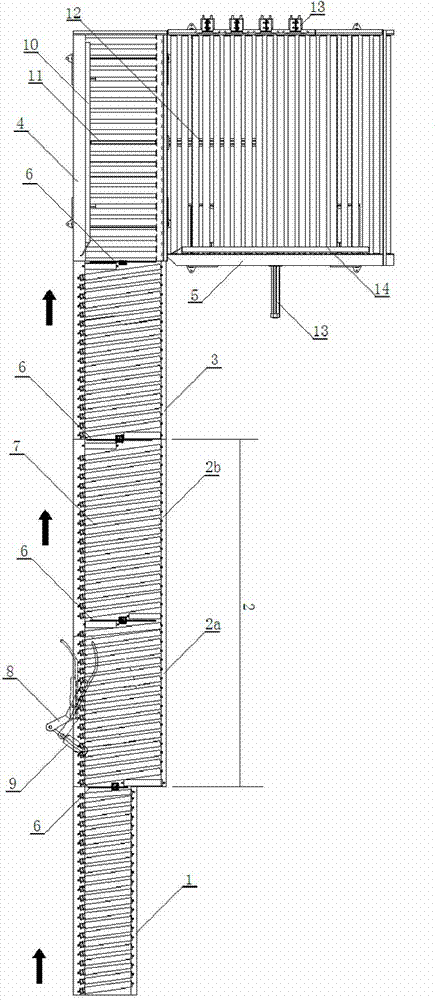

Suspension rotation type overhead stereoscopic warehouse system

The invention discloses a suspension rotation type overhead stereoscopic warehouse system which comprises stand columns, beams, closed-loop chains, chain wheels, a plurality of suspension cargo basket hanging frames, electric control devices, power devices, a main power source, a sample recognition device and a control center. The suspension cargo basket hanging frames are connected to the equal-perimeter closed-loop chains inside the symmetric planes on the left side and the right side in series at intervals, wherein the symmetric planes are composed of the stand columns and the beams. Each closed-loop chain and the corresponding chain wheels are meshed to form a chain wheel set. The closed-loop chains are driven by the chain wheels to reciprocate, and then the suspension cargo basket hanging frames are made to move. An overhead warehouse which is provided with two vertical rows of multi-layer fixed platform overhead cargo cabins and achieves storage and delivery through a high-position stacking machine is changed into the overhead stereoscopic warehouse which is provided with 4K vertical rows of multi-layer perpendicular multi-arc suspension cargo basket hanging frame overhead cargo cabins which are arranged on the horizontal multi-line closed-loop combination line and can move horizontally, the unit space cargo storage capacity is greatly improved, and the suspension rotation type overhead stereoscopic warehouse system has the functions of automatic cargo storage and delivery and automatic production and sampling sample supply.

Owner:浙江永金生物科技有限公司

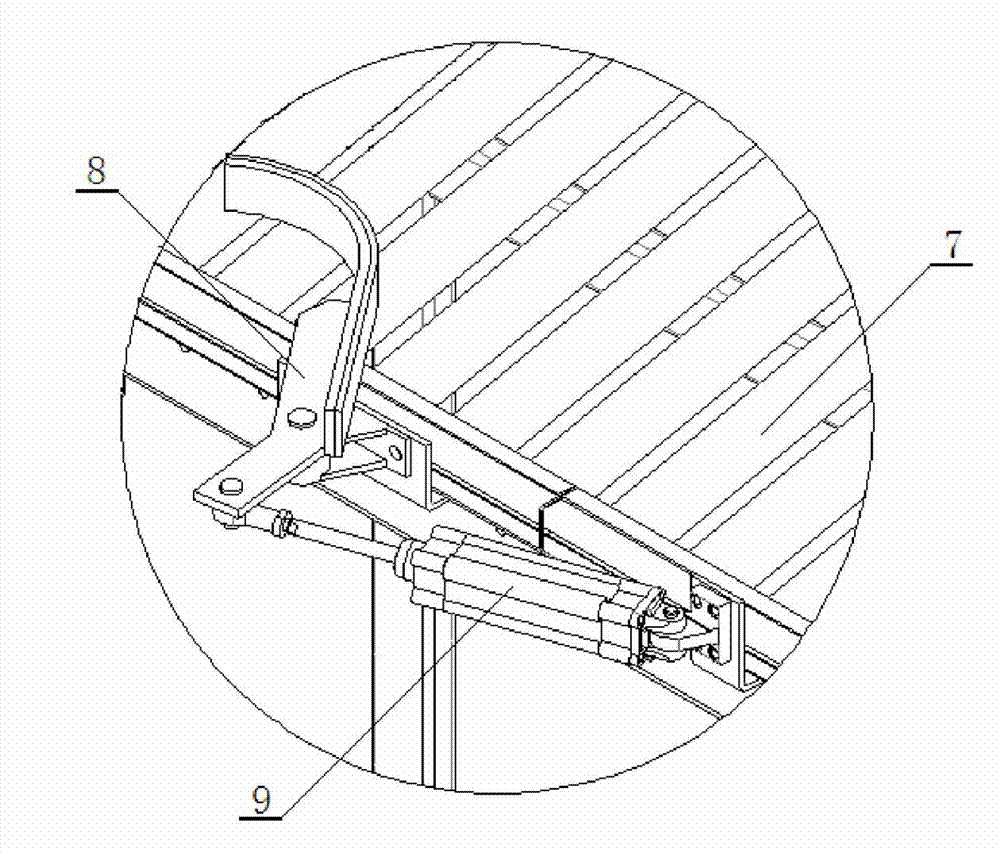

Stacking device suitable for layered staggered superposition of goods of stacking machine

The invention provides a stacking device suitable for layered staggered superposition of goods of a stacking machine. The stacking device comprises a direct conveying section, a steering conveying section, a conveying cache section, a push box transfer section and a goods-taking conveying section, wherein the direct conveying section coordinates with the steering conveying section, the conveying cache section, the push box transfer section and the goods-taking conveying section sequentially; the steering conveying section is provided with a steering driving device; and the push box transfer section is provided with a push box transfer device. The stacking device is provided with an inclined roller steering conveying section, so that goods steering can be automatically realized when the goods need to be steered. The stacking device is provided with push box, so that the goods can be pushed transversely and steered stably. The goods-taking conveying section is provided with a correcting device which can stack the goods tidily in groups, so that grabbing of a mechanical arm is facilitated. The stacking device adopts layered stacking formation, so the goods are put in order and easy to grab. The stacking device is low in driving power, low in braking inertia, high in safety of the conveyed goods and high in practicability, and contributes to improving the production efficiency and increasing the economic benefit of enterprises.

Owner:云南众诚士德柔性自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com