Automatic double-line palletizer

A line coding and automatic technology, applied in the field of palletizing equipment and automatic packaging, can solve the problem of insufficient palletizing efficiency, achieve the effect of improving efficiency, better appearance, and expanding the scope of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

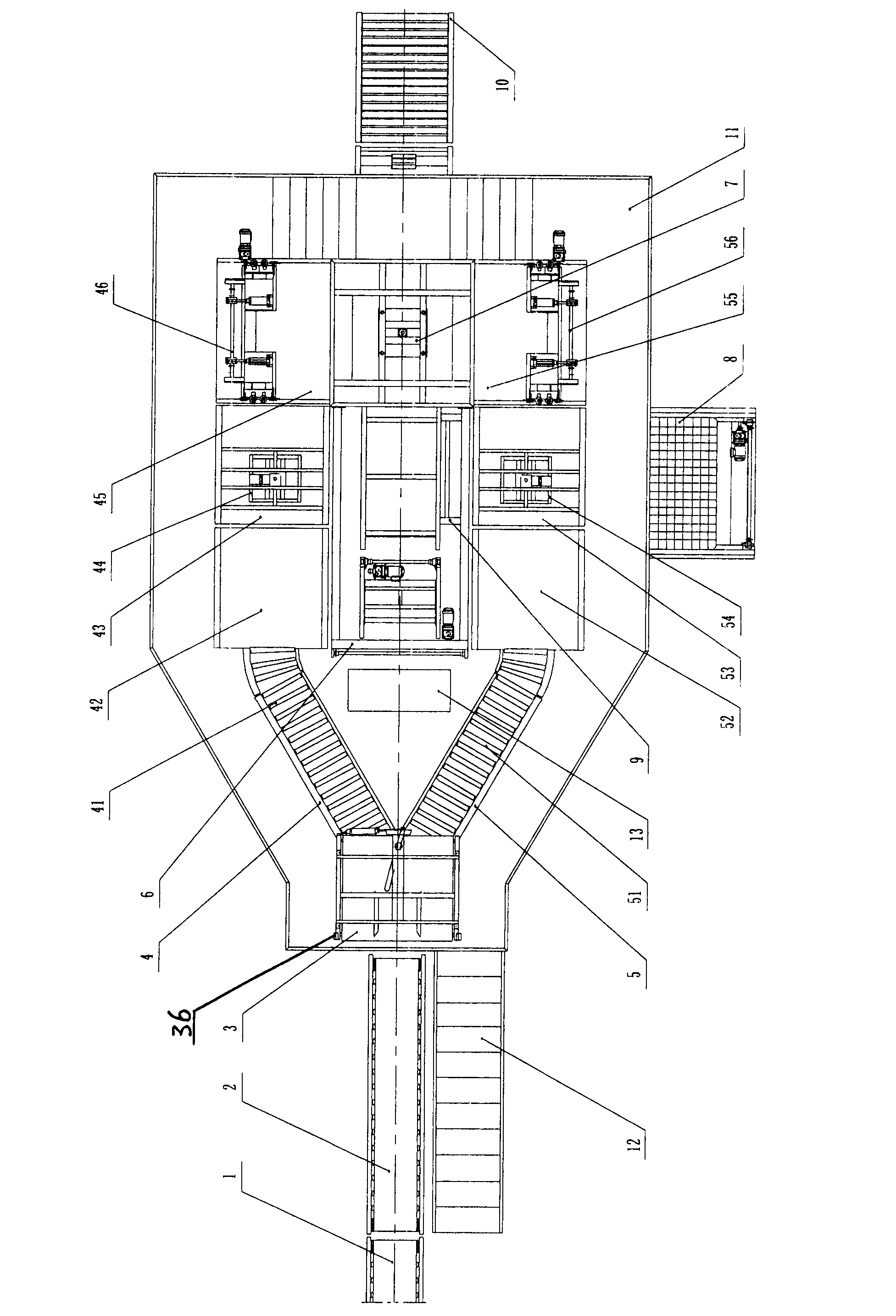

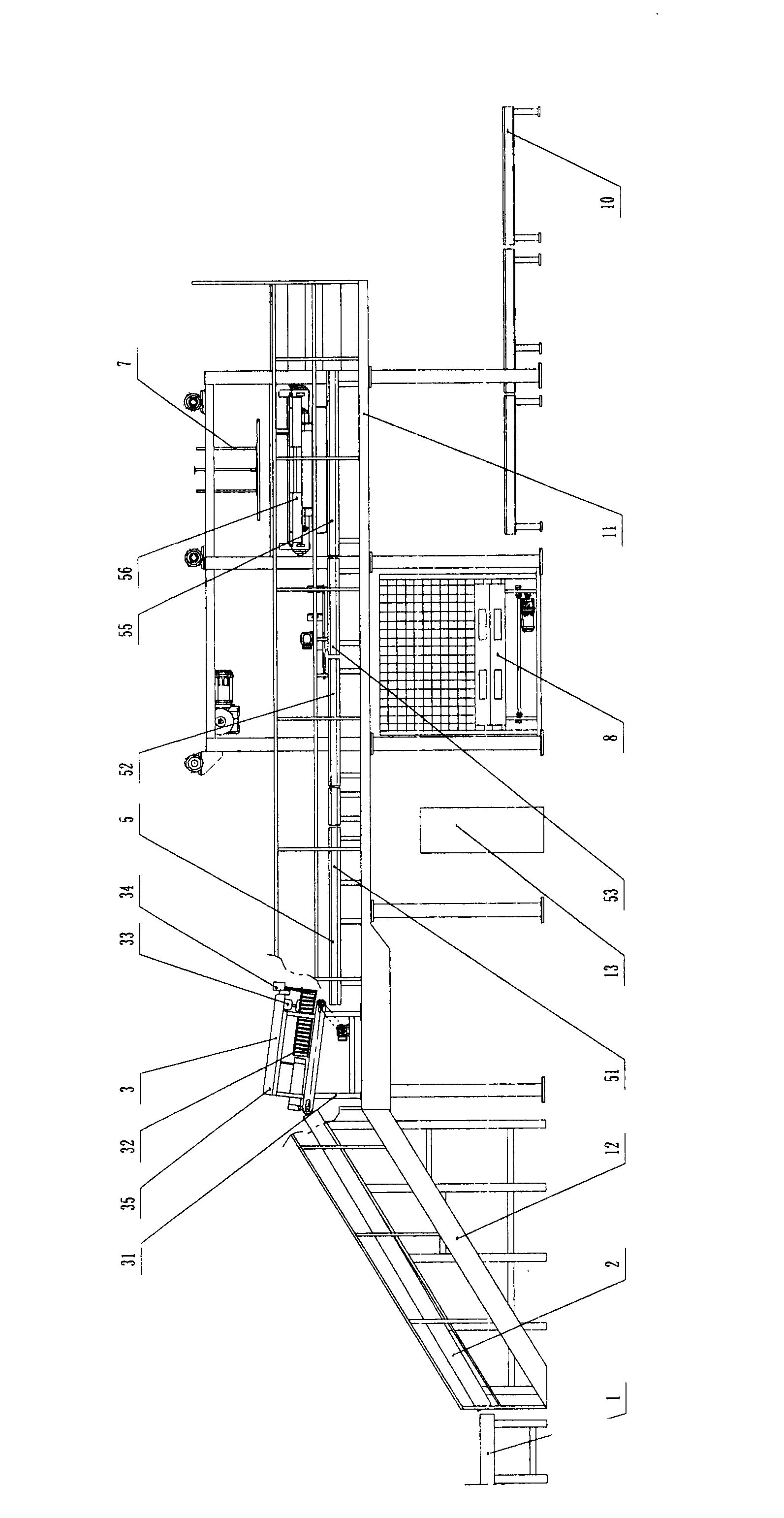

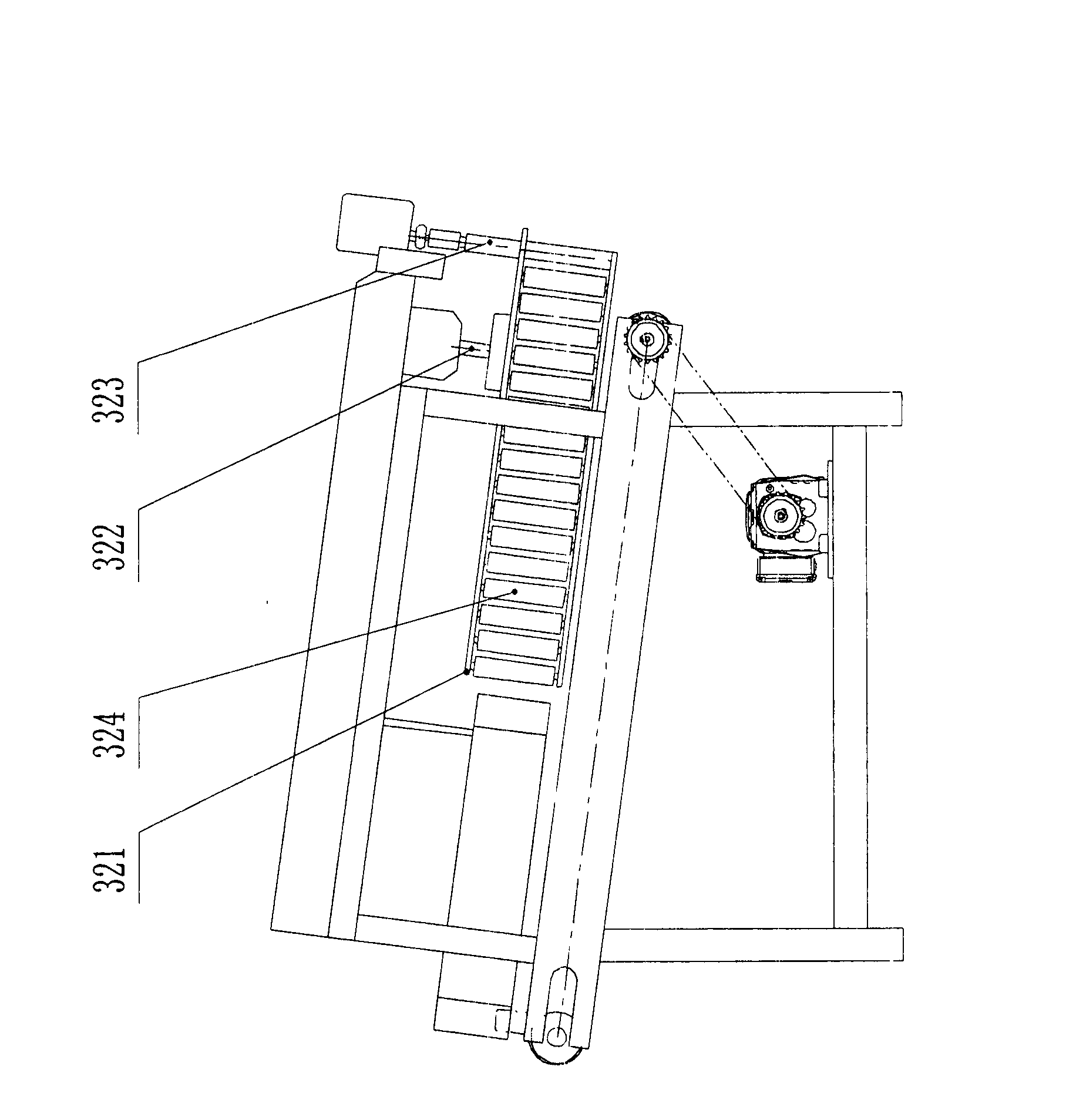

[0024] like figure 1 , figure 2 As shown, the automatic two-line palletizing of the present invention is composed of an entrance conveyor 1, an inclined conveyor 2, an automatic divider 3, a left stacking process line 4, a right stacking process line 5, a sliding door 6, Elevator 7, pallet warehouse 8, pallet conveyor 9, pallet conveyor 10, elevated platform 11, escalator 12, electric control cabinet 13 constitute.

[0025] The left palletizing process operation line 4 is composed of a left ratchet roller conveyor 41, a left slow stop conveyor 42, a left turn bag conveyor 43, a left turn charter machine 44, a left stacking marshalling machine 45, and a left push charter machine 46. , the left ratchet roller conveyor 41, the left slow-stop conveyor 42, the left turn bag conveyor 43, the left stacking and marshalling machine 45 are arranged in sequence from the entran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com