Patents

Literature

301results about How to "Improve palletizing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

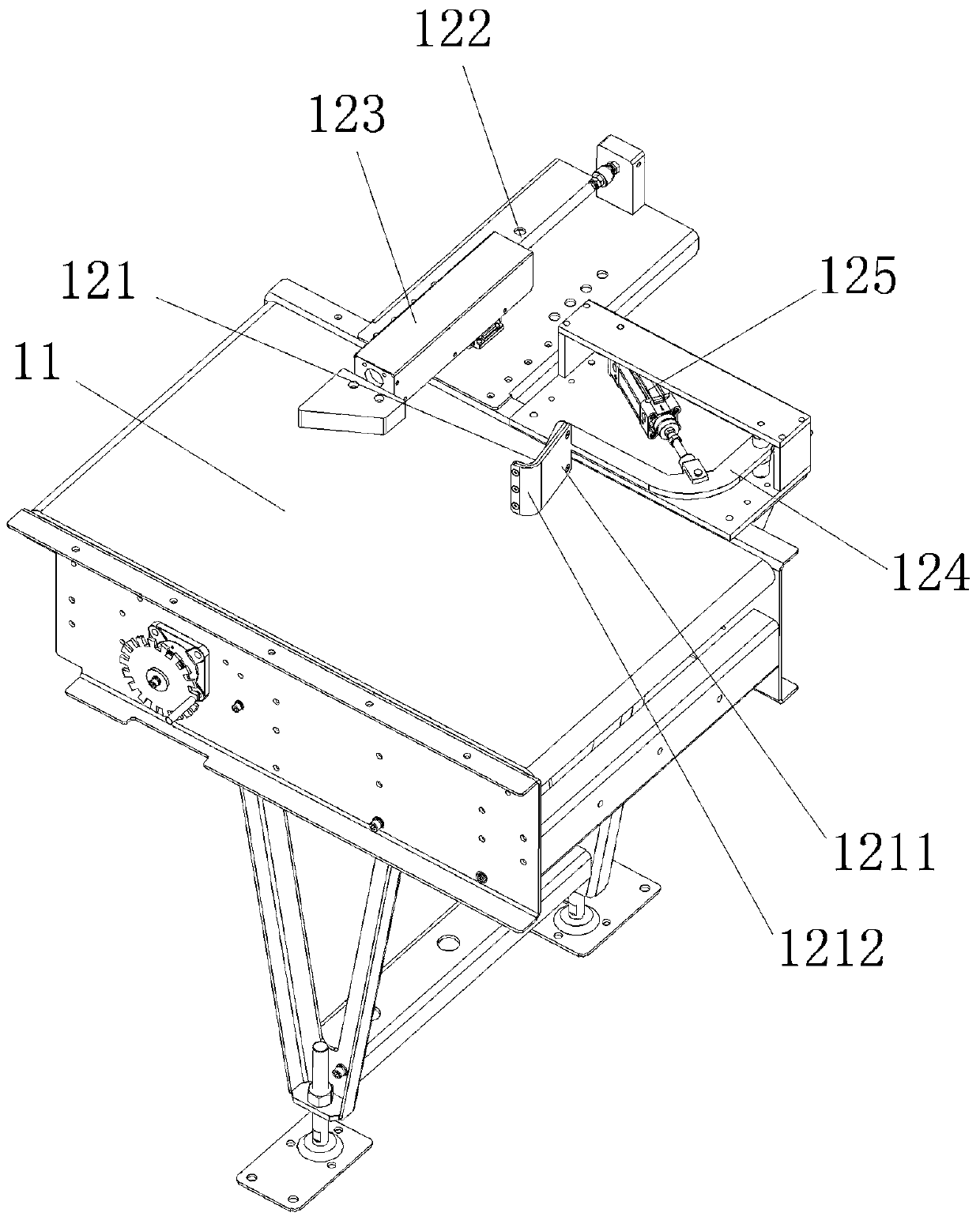

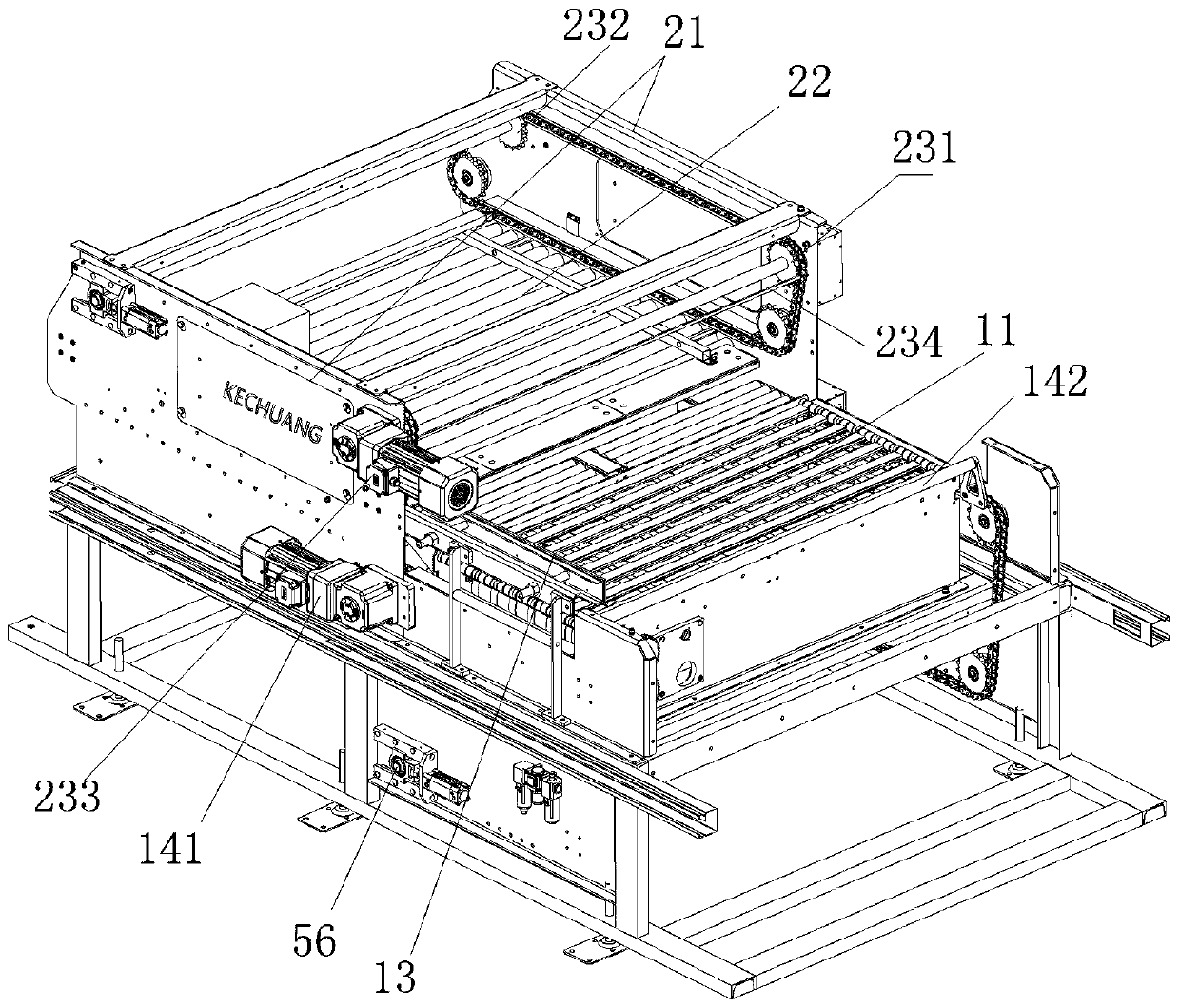

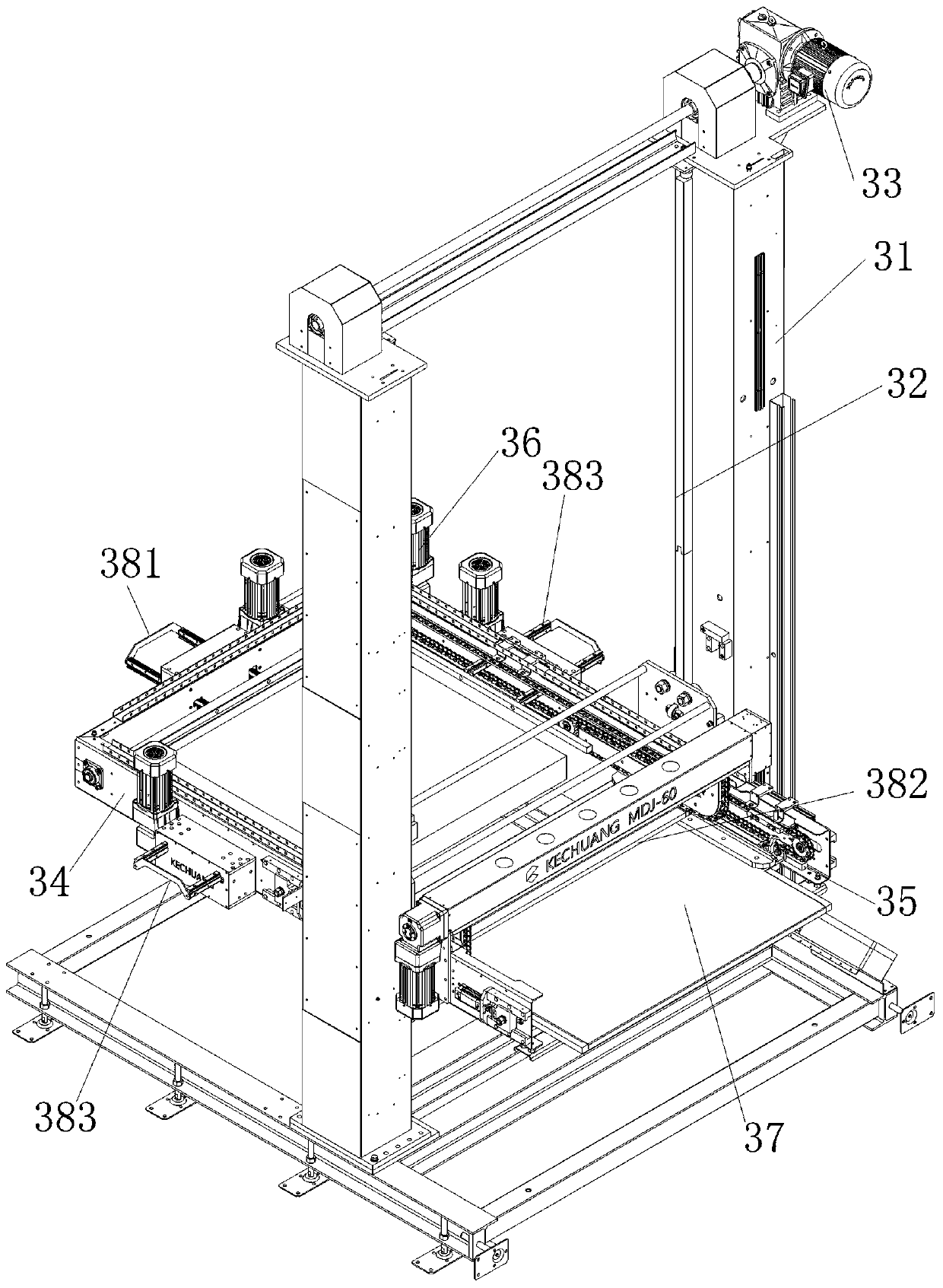

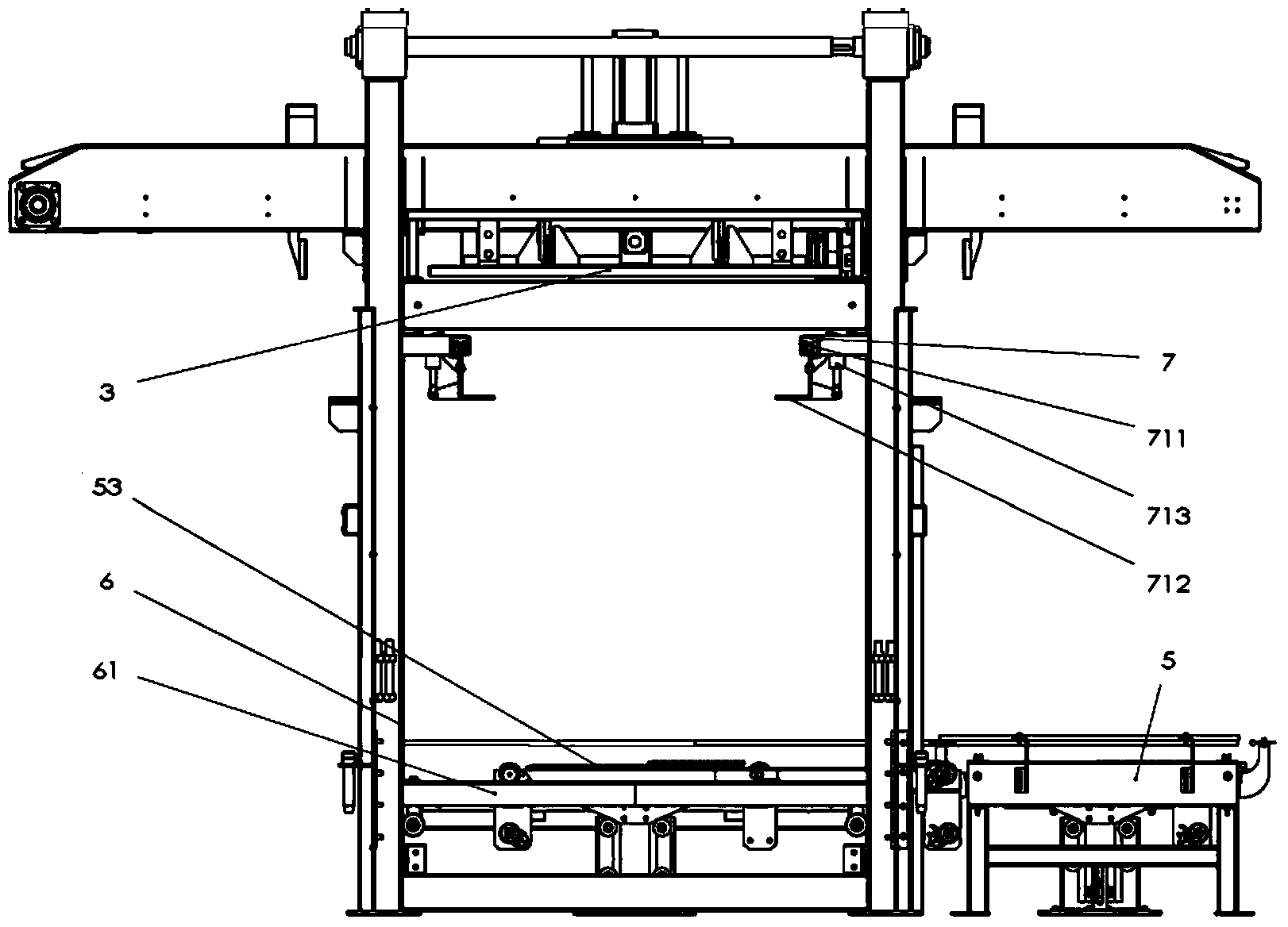

Automatic packaging box stacking machine capable of achieving selective stacking

PendingCN107697646AFacilitated releaseImprove reliabilityStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention discloses an automatic packaging box stacking machine capable of achieving selective stacking, and belongs to the technical field of stacking. The machine comprises an arranging and steering mechanism, a grouping pushing mechanism, a door type stacking mechanism and a matched tray storage supply mechanism which are sequentially arranged on a rack in the packaging box conveying direction. The arranging and steering mechanism comprises a feeding conveying device and a steering device arranged on one side of the feeding conveying device; the machine is characterized in that the steering device comprises a pre-steering baffle and a strengthening check block which are arranged at an interval in the feeding conveying direction, the pre-steering baffle is hinged to a pre-steering air cylinder on the rack through a bending rod and is hinged to the rack to form a swing stretching-out blocking and reset releasing structure, the strengthening check block is connected with a strengthening air cylinder on the rack, and forms a strengthening and resetting releasing structure by means of guidance of a sliding rail and sliding block pair perpendicular to the feeding conveying direction, a packaging box, required to be subject to steering, in the conveying process is subject to rotating and pre-steering operation around the blocked angle by means of blocking of the pre-steering baffle, and pressing strengthening of the blockage angle can be achieved by means of the strengthening check block.

Owner:WEIXIAN KECHUANG LIGHT IND EQUIP

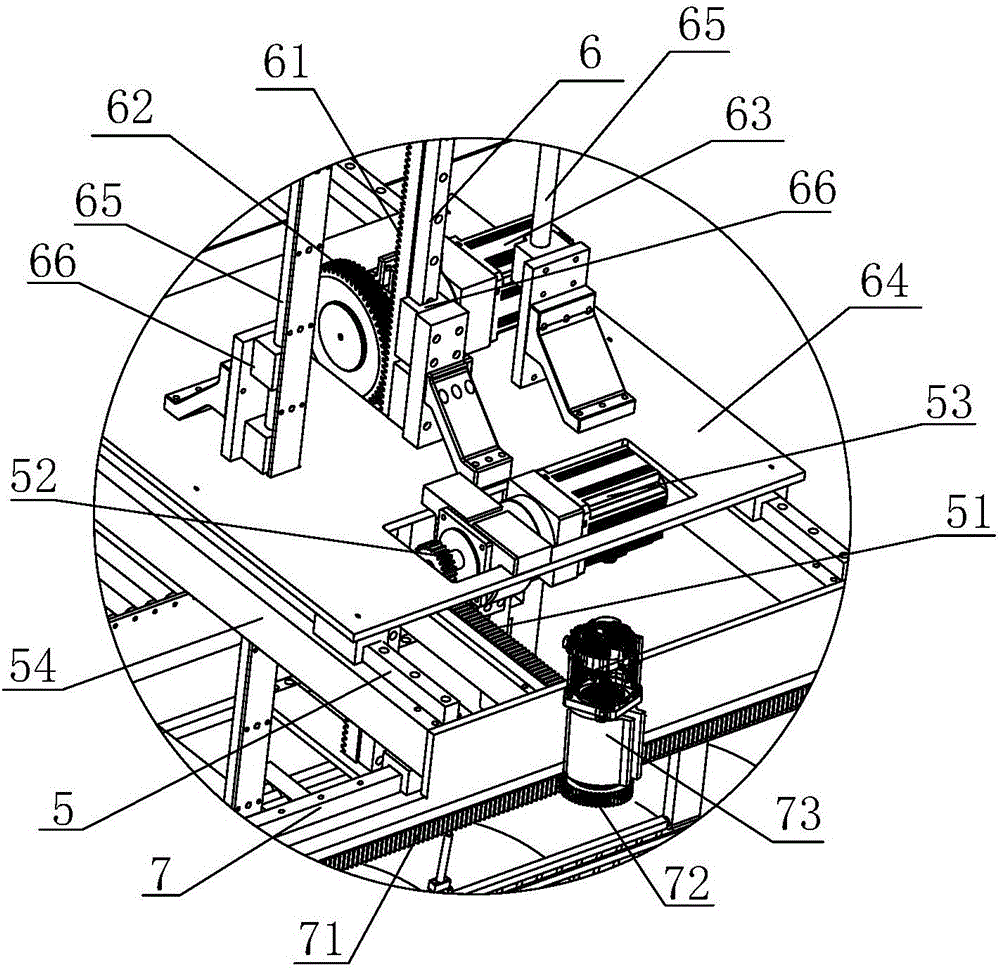

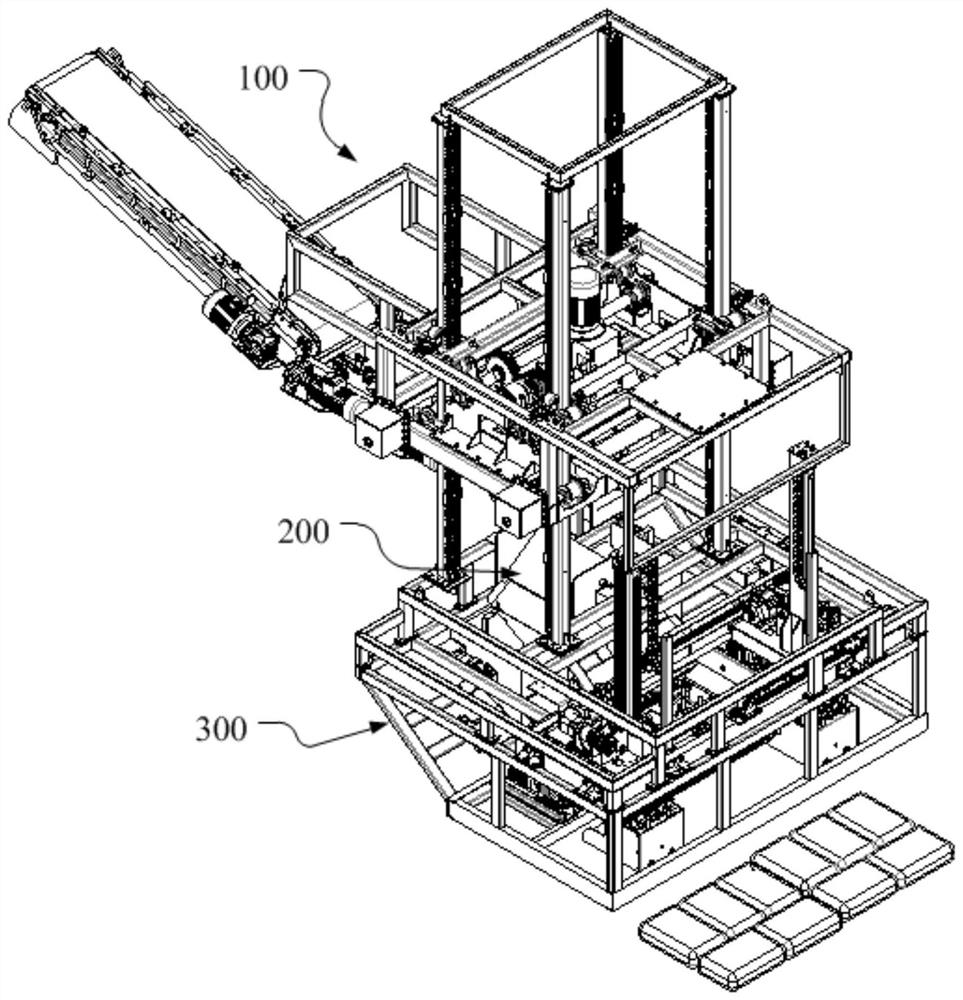

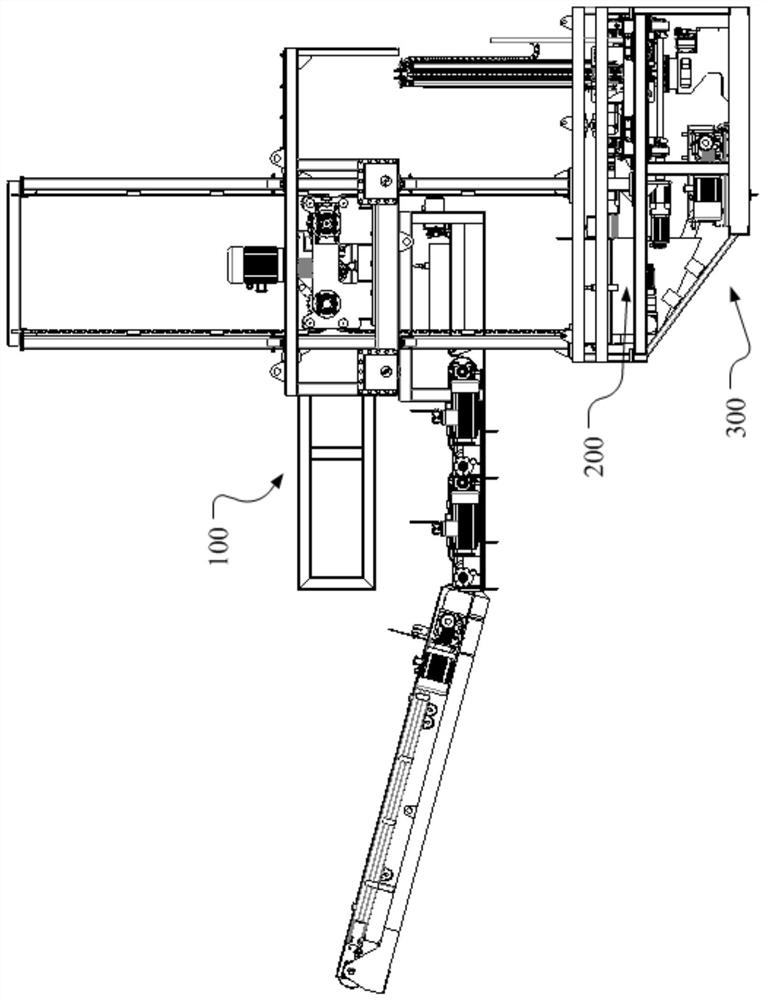

Automatic loading machine for bagged materials

ActiveCN106276323APrecise blanking and palletizingImprove palletizing efficiencyLoading/unloadingEngineeringAutomation

The invention provides an automatic loading machine for bagged materials. The automatic loading machine for the bagged materials comprises supporting frames for being mounted on two sides of a transportation vehicle, an incoming material line for transmitting material bags, a buffer shaping line and a positioning line, and also comprises a Y-direction translation mechanism mounted on the supporting frames, an X-direction translation mechanism mounted on the Y-direction translation mechanism and a Z-direction translation mechanism mounted on the X-direction translation mechanism, wherein a material lifting frame and a material falling frame are mounted at the lower end of the Z-direction translation mechanism; the material lifting frame is used for lifting up the material bags on the positioning line; the material falling frame is used for receiving the material bags which fall off from the material lifting frame and placing the material bags on the transportation vehicle. The automatic loading machine for the bagged materials can precisely control the space position of the material lifting frame and the material falling frame through the three translation mechanisms, so that the materials can fall precisely. The automatic loading machine for the bagged materials realizes high automation without manual participation, so the stacking and loading efficiency of the material bags can be effectively improved.

Owner:重庆南商机器人科技有限公司

Special-shaped tobacco carton automatic stacking and packing method

InactiveCN106742281AImplement the rotation functionReduce run pathConveyorsControl devices for conveyorsCartonOrder form

The invention discloses a special-shaped tobacco carton automatic stacking and packing method. The method comprises the following steps: 1) order data is read, and a corresponding relation between a stacking manipulator and sorting system real-time orders is set; 2) tobacco cartons are conveyed to the end part of a tobacco carton conveying device and stopped on a baffle plate; 3) a camera and a light source are triggered to shoot; and data of the tobacco cartons is transmitted to the stacking manipulator; 4) according to the orders and the tobacco carton size data, the stacking manipulator grabs the tobacco cartons to stack on a lifting mechanism in sequence; and tobacco stacks are lifted to reach a chain conveyor; 5) the chain conveyor conveys the tobacco stacks to a packing machine for plastic packing; and 6) a labeling machine prints information of the tobacco cartons and labeling time. The method has the following advantages: the method can realize automatic detection, automatic stacking and automatic packing of the special-shaped tobacco cartons according to real-time sorting data; the stacking manipulator can realize the grabbing stability and efficiency; the lifting mechanism shortens the path of the stacking manipulator to improve the stacking efficiency; and the chain conveyor adopts a poking plate form to convey the tobacco stacks, and is provided with multiple poking plates for improving the stacking efficiency.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

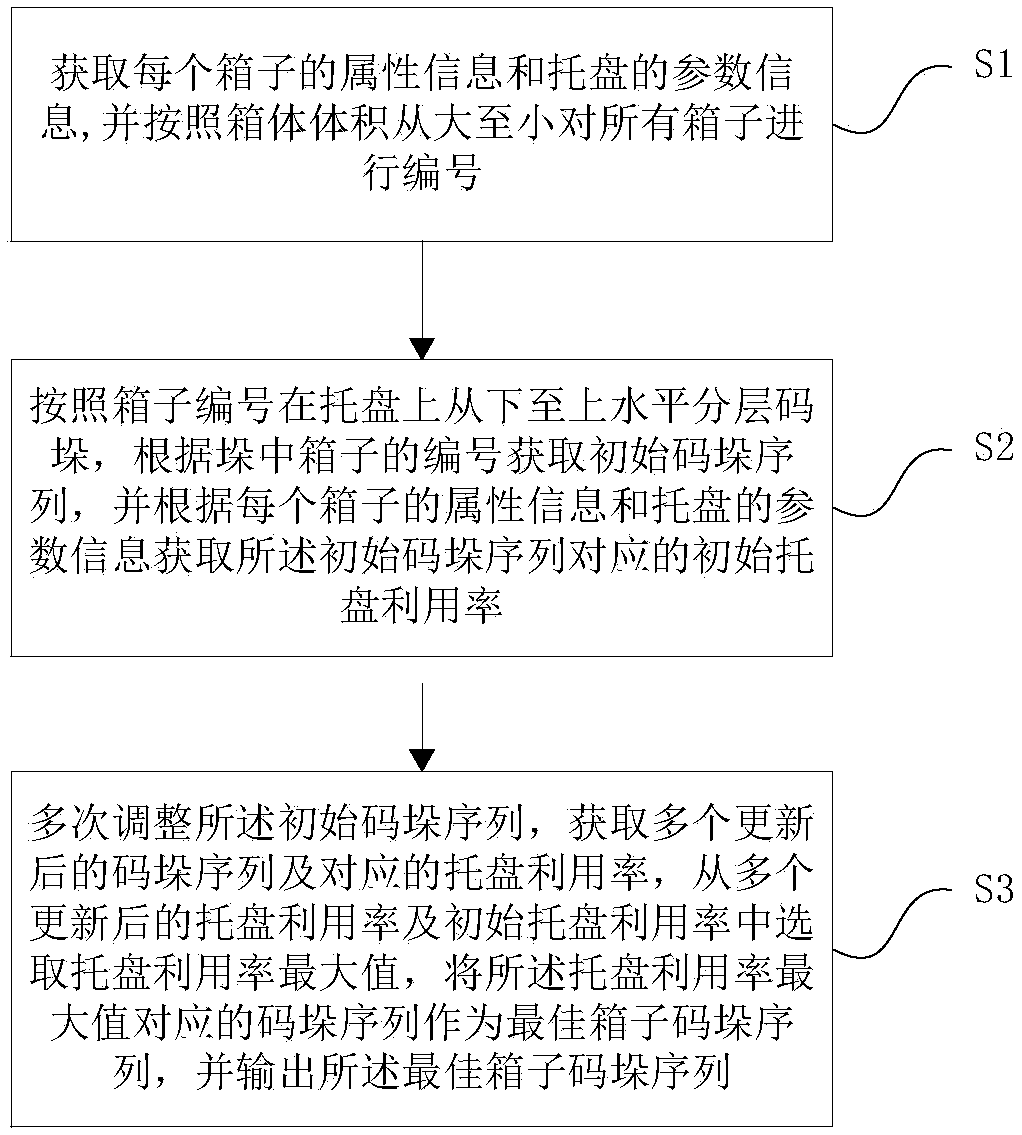

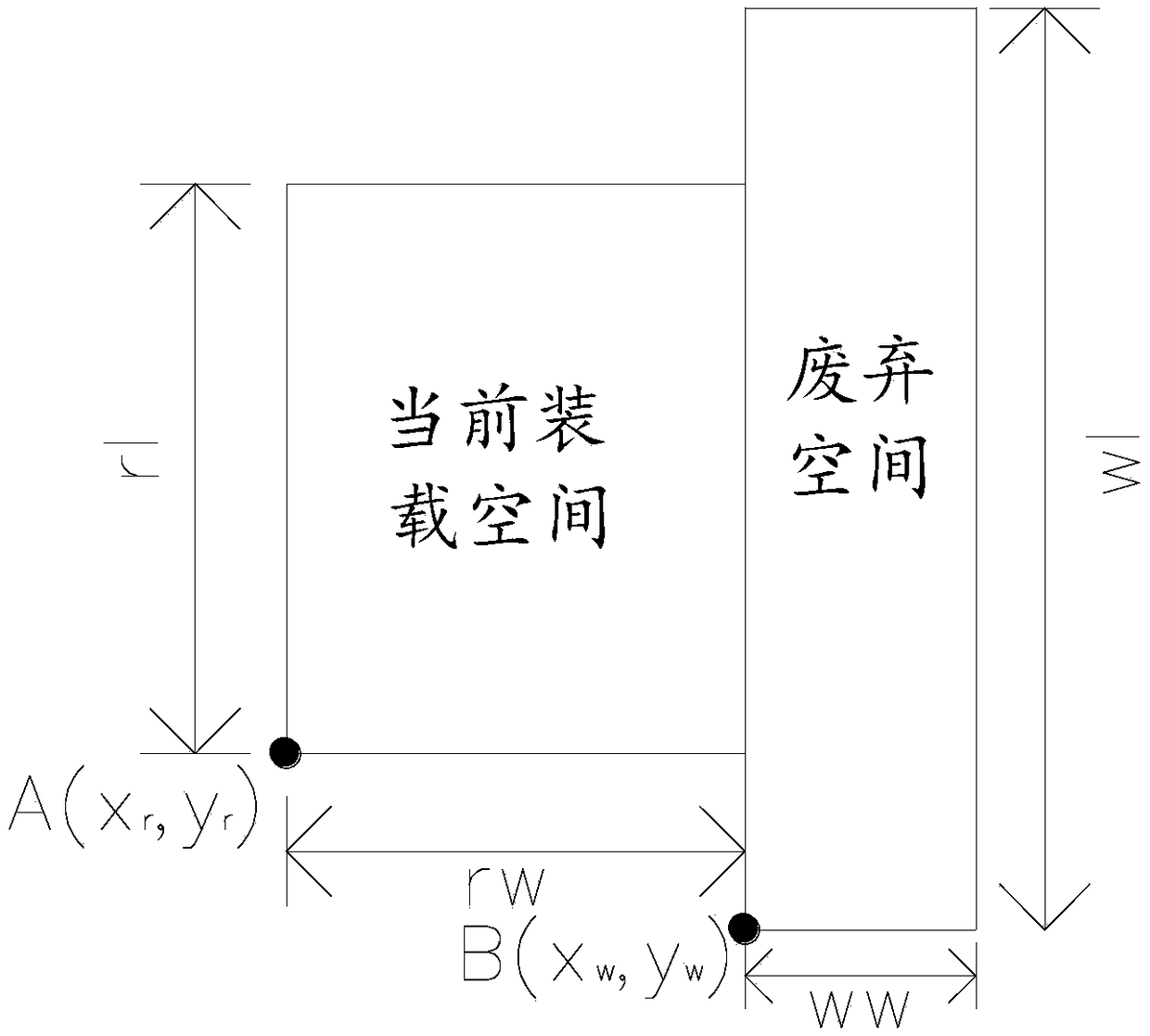

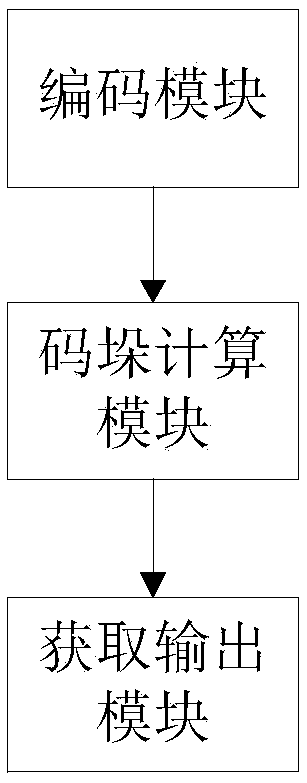

Offline hybrid stacking method and system

ActiveCN108750685AEnsure stack stabilityRealize horizontal layered palletizingConveyorsStacking articlesEngineeringUtilization rate

The invention relates to an offline hybrid stacking method and system. The method comprises the steps of acquiring the attribute information of each box and the parameter information of a tray, and numbering all boxes according to the volumes of the boxes from big to small; stacking the boxes on the tray from bottom to top according to the number of the boxes in a layered manner, and acquiring aninitial stacking sequence and the utilization rate of a corresponding initial tray; regulating the initial stacking sequence for many times, and acquiring the maximum value of the tray utilization rate; and taking the stacking sequence corresponding to the maximum value of the tray utilization rate as the optimal stacking sequence of the boxes, and output the optimal stacking sequence. According to the offline hybrid stacking method, cuboid boxes of different sizes can be stacked in a hybrid manner, and the stacking stability can be ensured; the horizontal layered stacking is achieved, and theoffline hybrid stacking method has the advantages that the stacking stability is high, and the stacking by a robot is facilitated; the utilization rate of the tray is high, etc., and the automation and intelligence of the hybrid stacking process are achieved.

Owner:哈尔滨库柏特科技有限公司

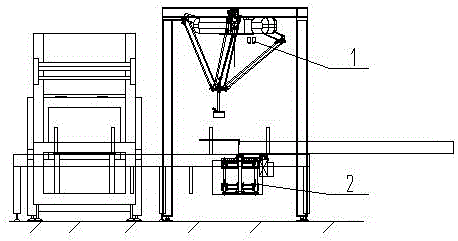

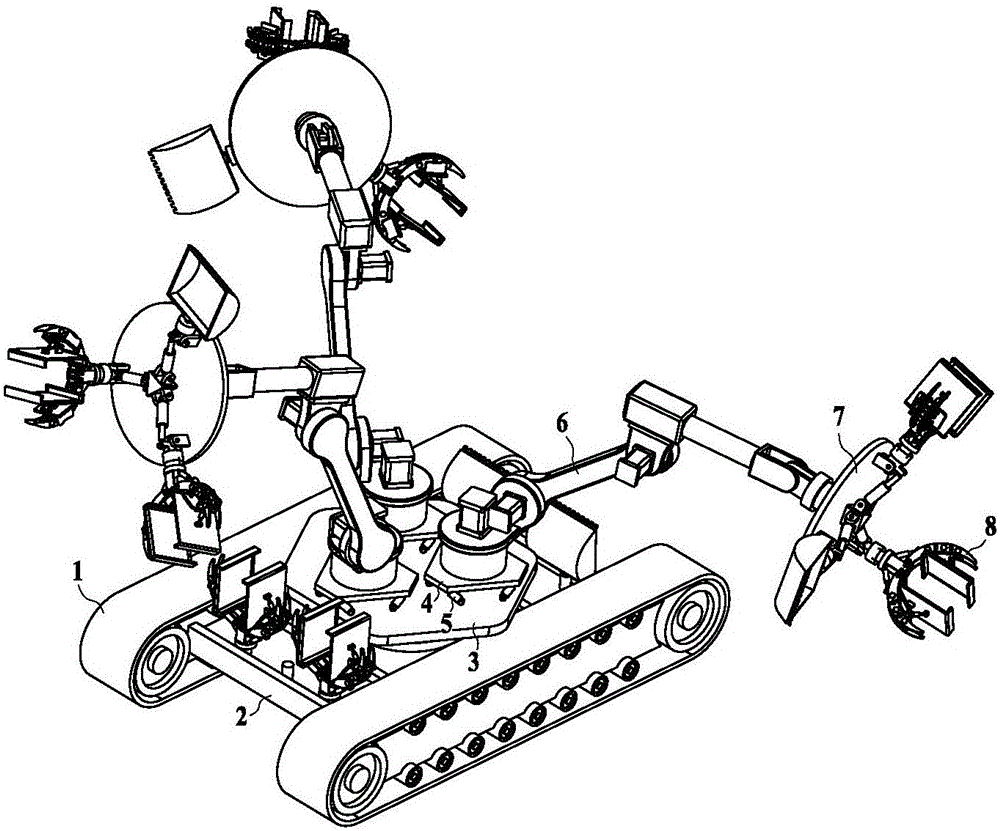

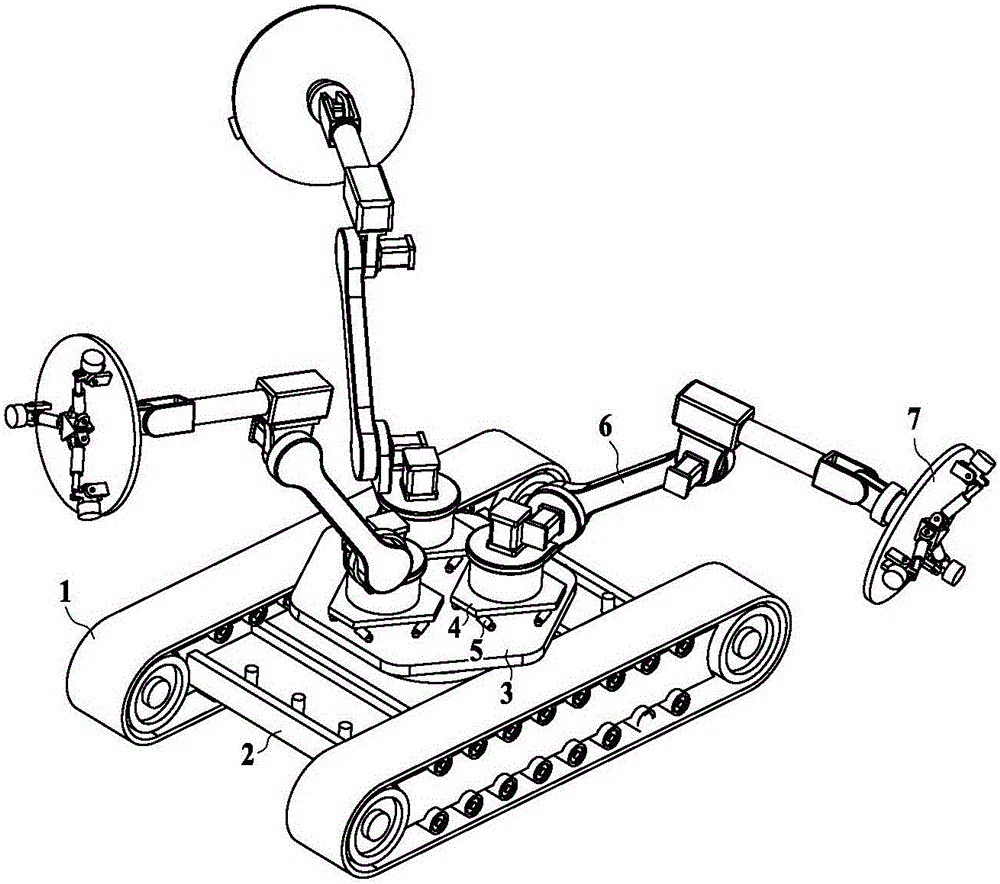

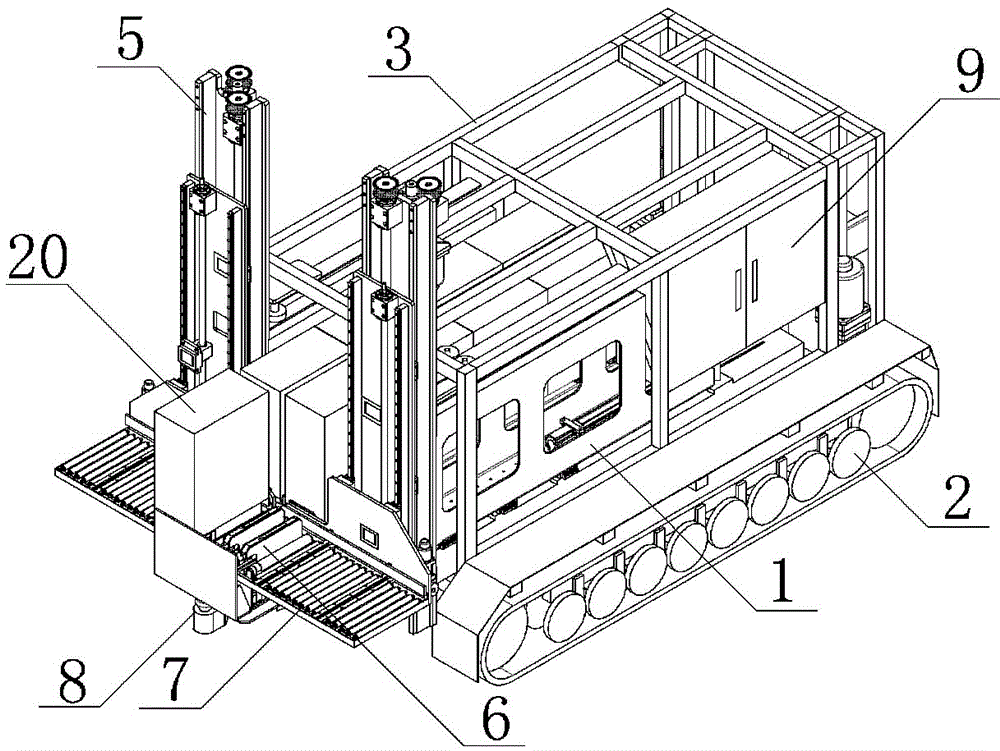

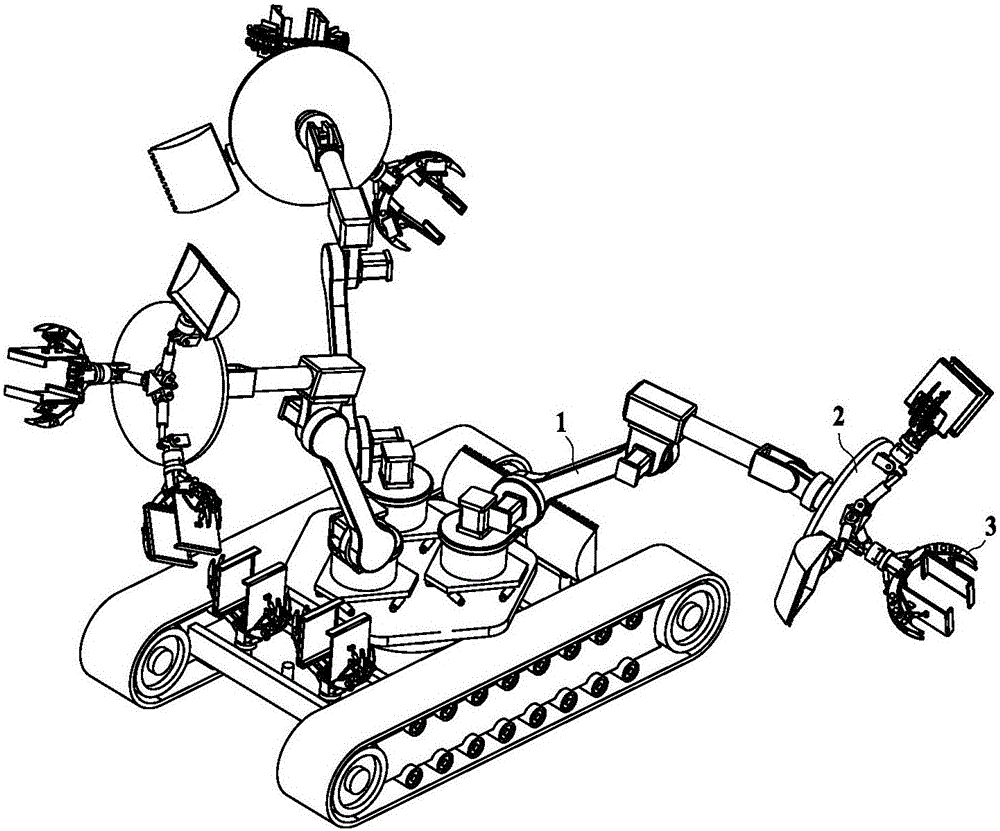

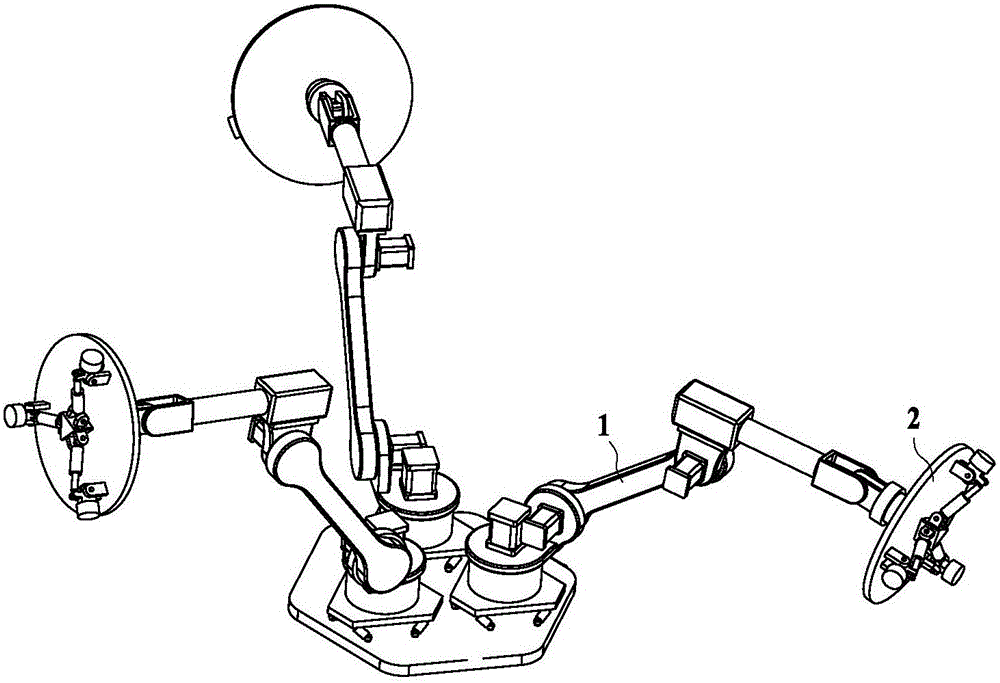

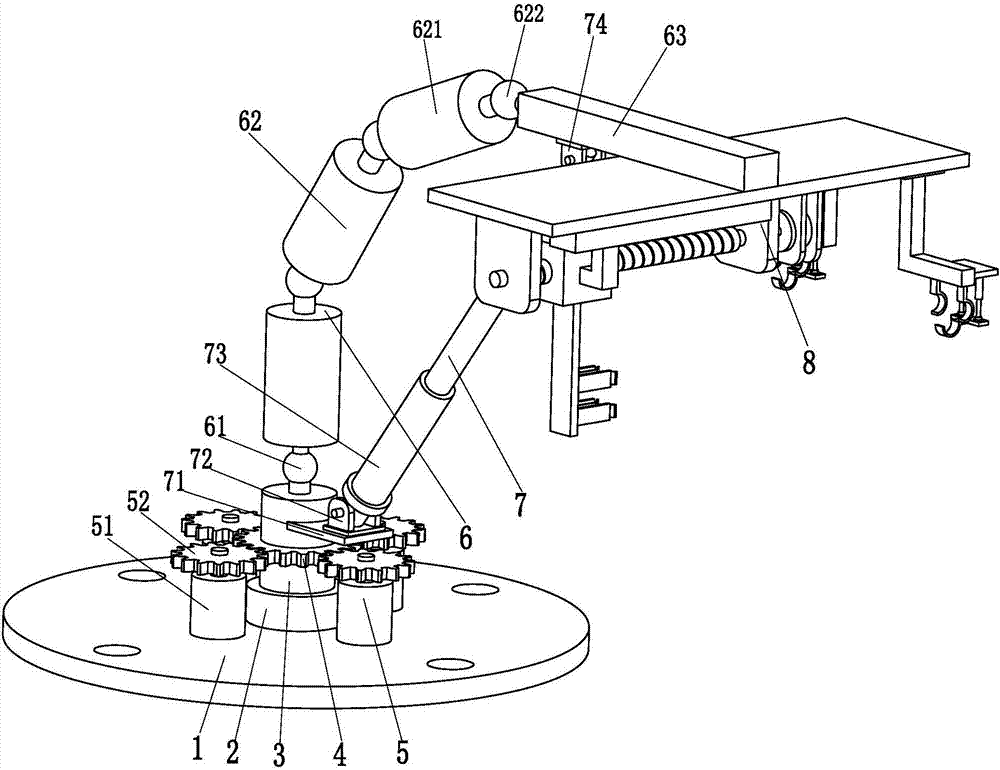

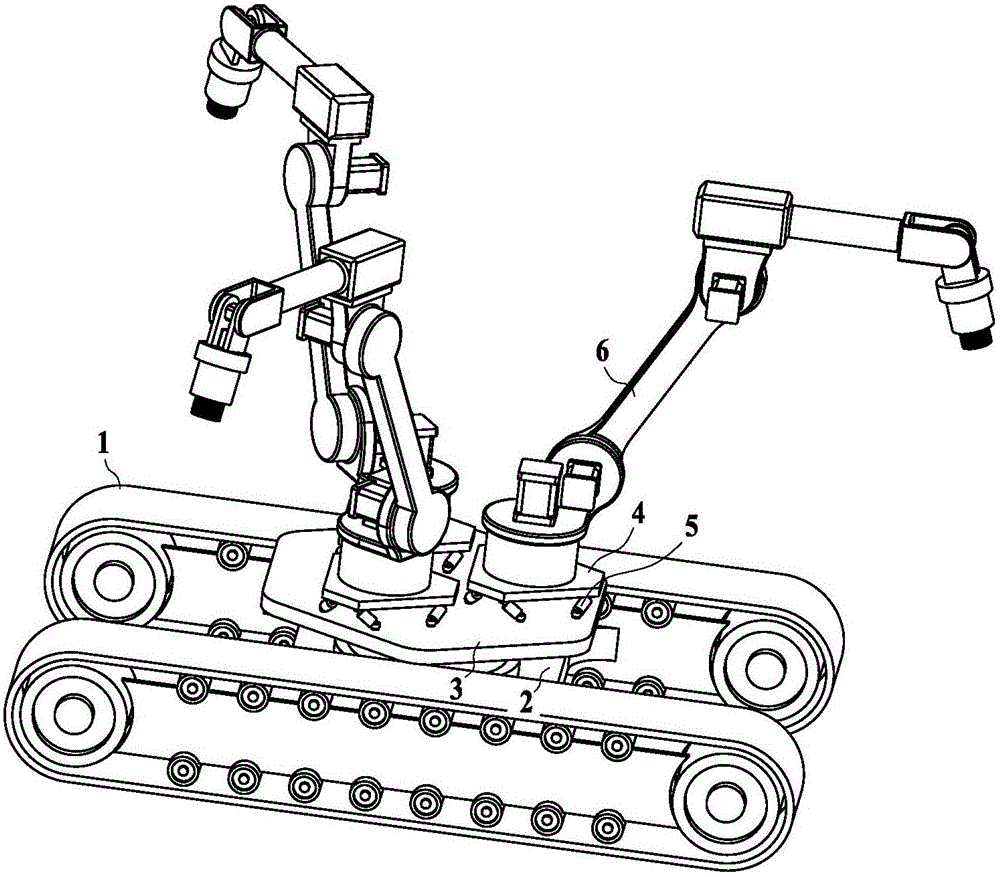

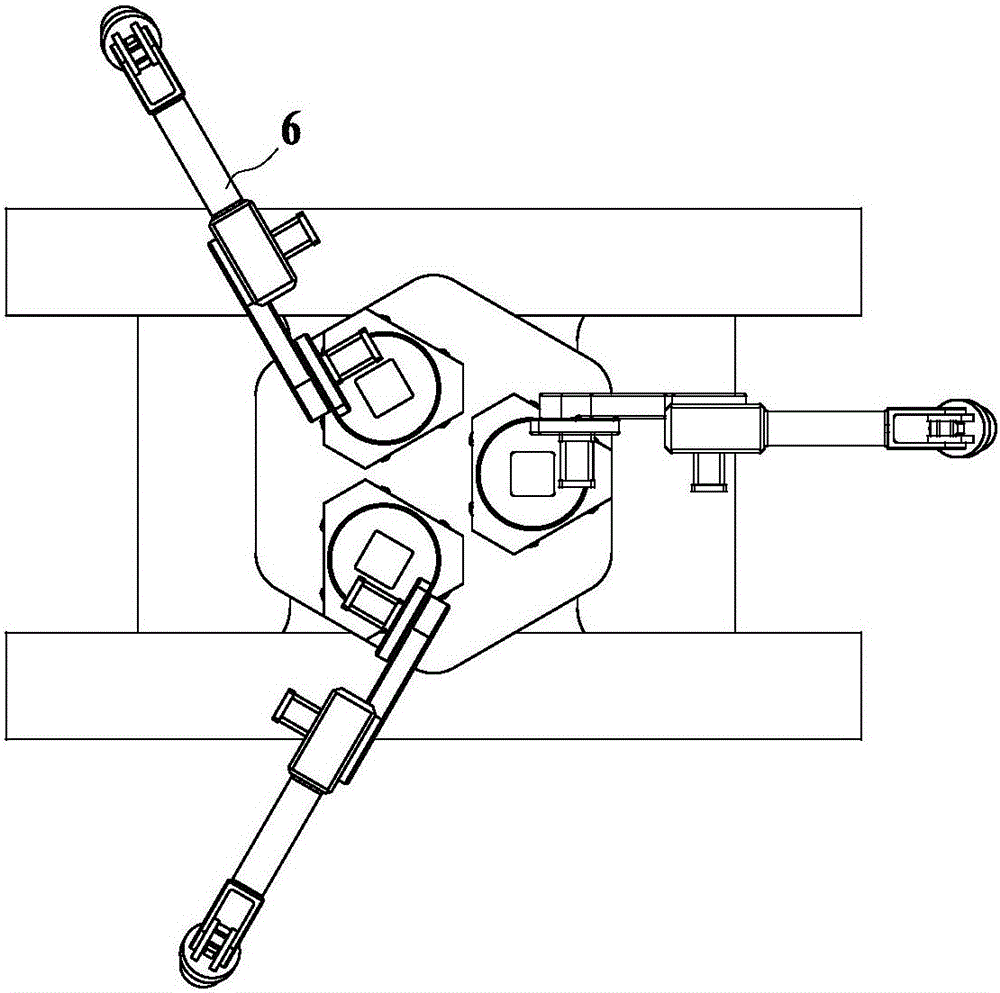

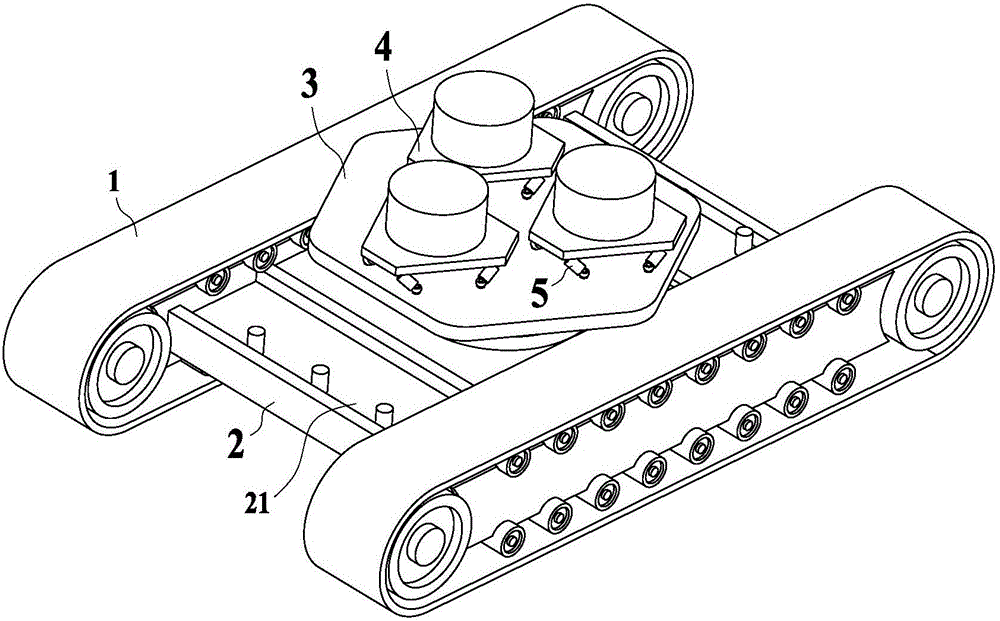

Multifunctional palletizing robot based on Stewart parallel connection platform

ActiveCN105690362AImprove palletizing efficiencyReduce labor intensityProgramme-controlled manipulatorJointsRotary stageEngineering

The invention relates to the field of robots, in particular to a multifunctional palletizing robot based on a Stewart parallel connection platform. The multifunctional palletizing robot comprises caterpillar band travelling mechanisms, a chassis, a rotating table, fine tuning tables, fine tuning air cylinders, mechanical arms, gripping devices and gripping hands; the caterpillar band travelling mechanisms are located on the two sides of the chassis, the rotating table is located in the middle portion of the chassis, the fine tuning tables are located at the upper end of the rotating table, the fine tuning air cylinders are located between the rotating table and the fine tuning tables, the mechanical arms are located at the upper ends of the fine tuning tables, and the gripping devices are located at the ends of the mechanical arms; the rotating table, the fine tuning air cylinders and the fine tuning tables form the Stewart parallel connection platform; and the number of the mechanical arms is three, the number of the gripping devices is three, and the three gripping devices are installed on the three mechanical arms. The multifunctional palletizing robot is high in palletizing efficiency, manual gripping hand replacement is replaced, and the labor intensity of workers is reduced; and in addition, the accuracy for replacing the gripping hands, gripping objects and palletizing the objects is high, and damage to the objects is greatly reduced.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

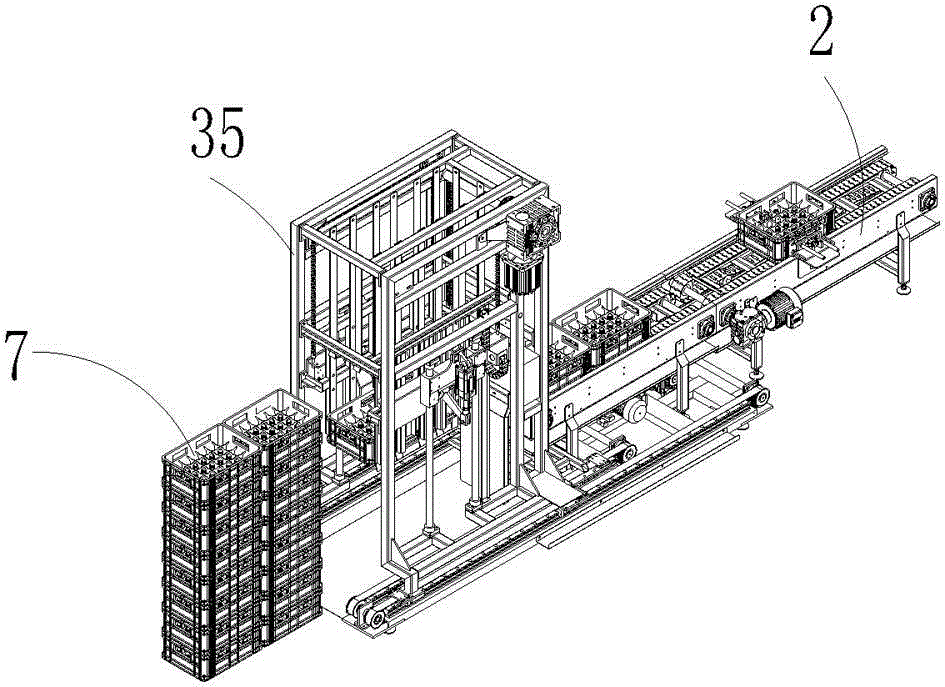

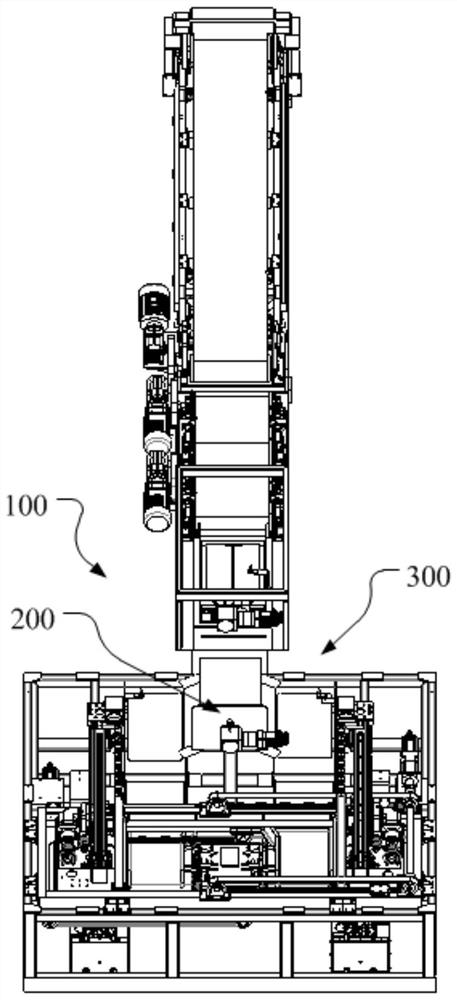

Intelligent automatic stacking equipment and operating method thereof

ActiveCN105000394AImprove palletizing efficiencyIncrease the level of automationStacking articlesProduction lineAutomation

The invention relates to stacking equipment, in particular to intelligent automatic stacking equipment and an operating method thereof. The intelligent automatic stacking equipment is suitable for automatic operation of turnover boxes. The intelligent automatic stacking equipment comprises a conveying mechanism, a stack outlet mechanism and a gripping and lifting mechanism. According to the intelligent automatic stacking equipment and the operating method thereof disclosed by the invention, the intelligent automatic stacking equipment is compact in structure, and capable of greatly improving the turnover box stacking efficiency, reducing the labor cost and improving the automation level of a production line.

Owner:SONGYUAN MACHINERY MFG

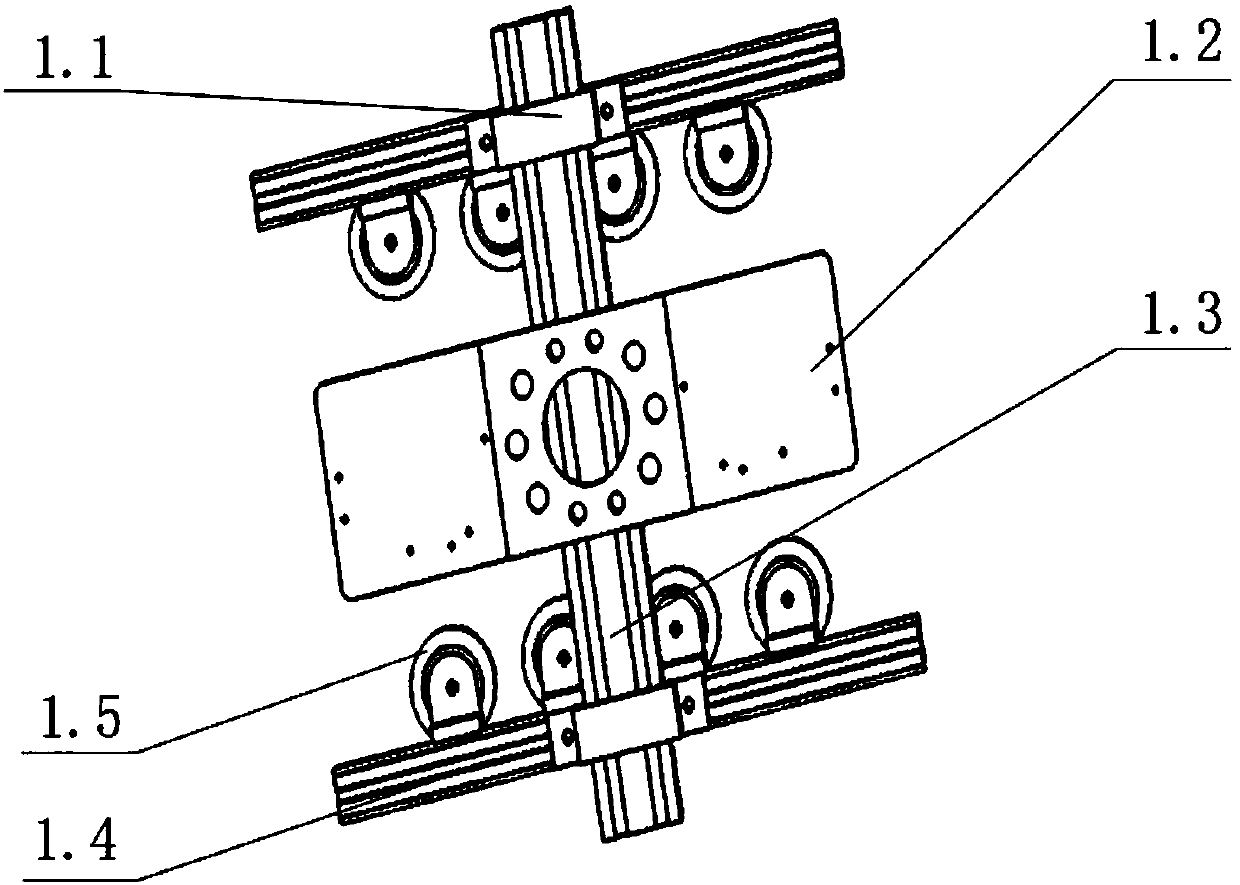

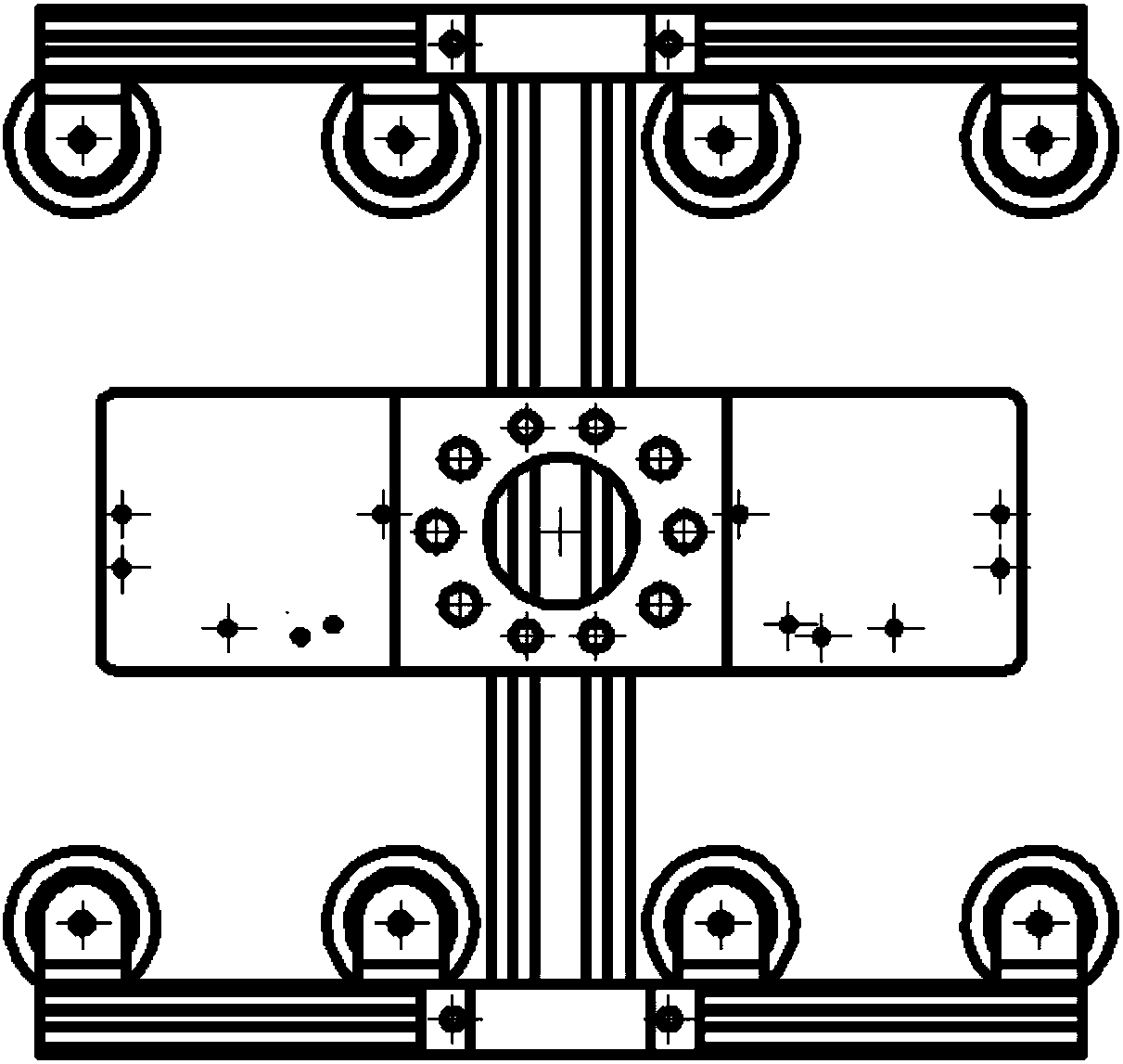

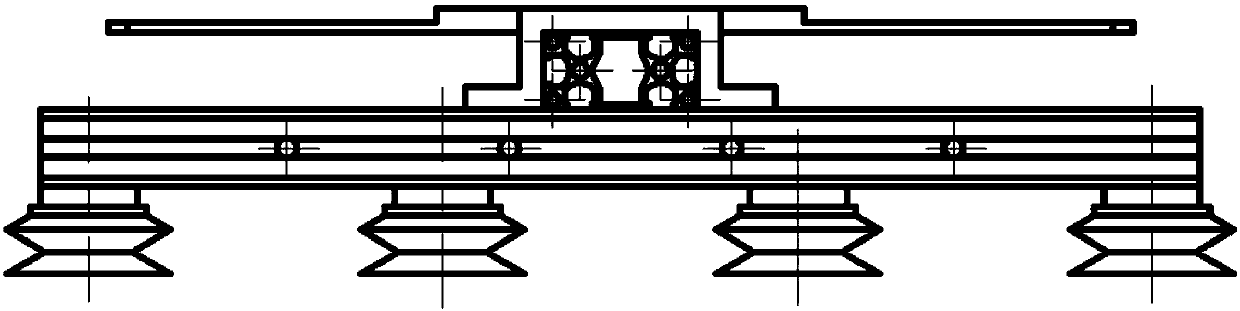

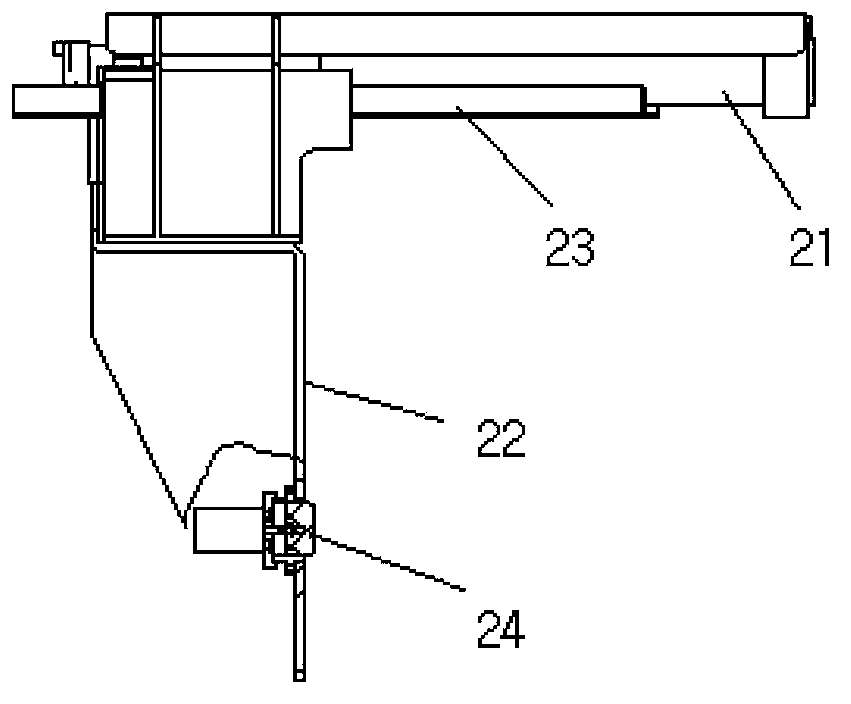

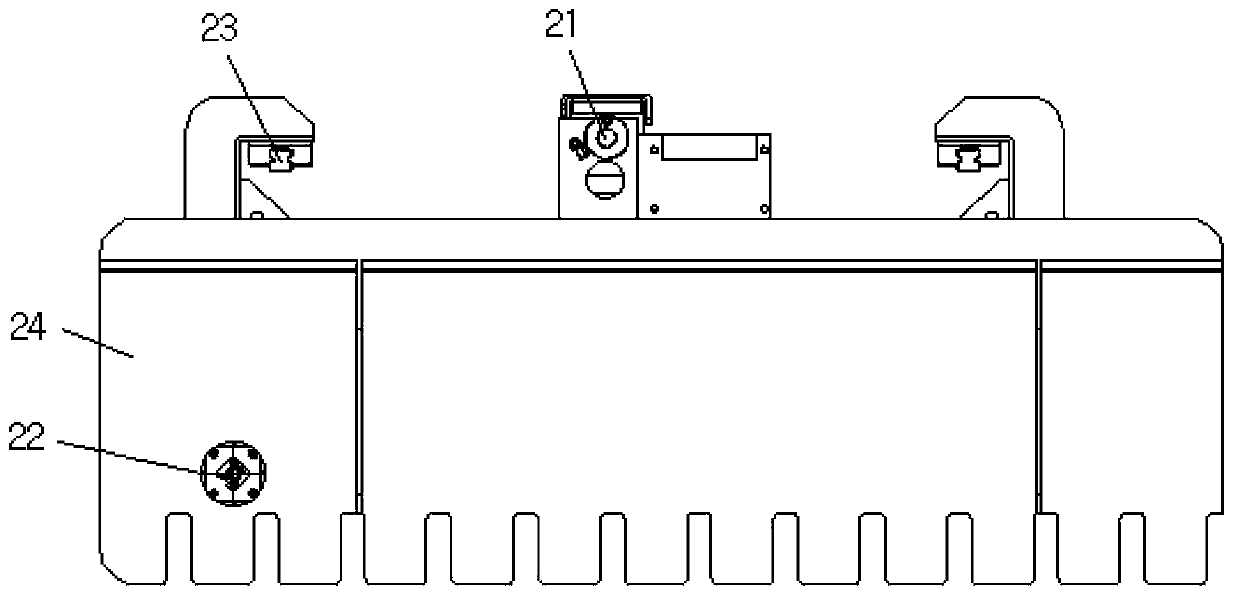

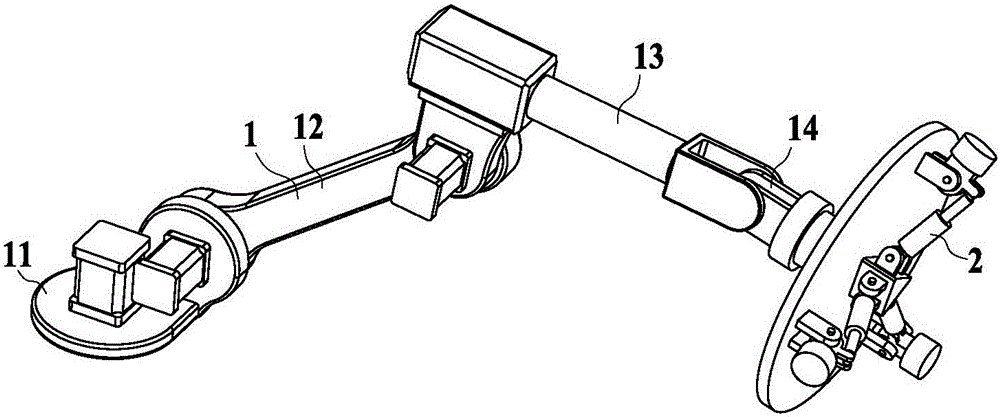

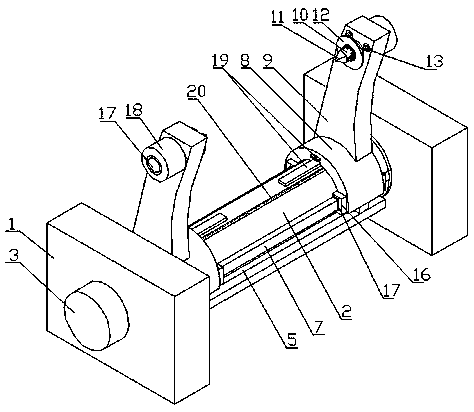

Vacuum adsorption terminal actuator for single-double box grasping

PendingCN107745972ASimple structurePracticalProgramme-controlled manipulatorGripping headsSystem safetyManipulator

The invention relates to a vacuum adsorption terminal actuator for single-double box grasping and relates to the field of intelligent mechanical equipment. The vacuum adsorption terminal actuator comprises an adjustable suction cup mechanism, a vacuum adsorption system and the like. The vacuum suction cup mechanism is used for adjusting the lengths and widths of spaces between suction cups to adapt to different box types. The vacuum system comprises an air source, an air source treatment device, two two-position five-way valves, two vacuum generators, the eight suction cups and a programmablelogic controller (PLC). The PLC presets the opening and closing sequence of the two two-position five-way valves and controls the eight suction cups correspondingly to enable the four suction cups inthe middle to achieve effects or the eight suction cups to achieve effects simultaneously. Pneumatic driving and PLC control are adopted, and thus the vacuum adsorption terminal actuator can be suitable for stacking of different products; and the vacuum adsorption system is safe and reliable, stacking of single-double boxes is accurately completed, the application range of a manipulator is enlarged, and the stacking efficiency is improved.

Owner:TIANJIN UNIV OF COMMERCE

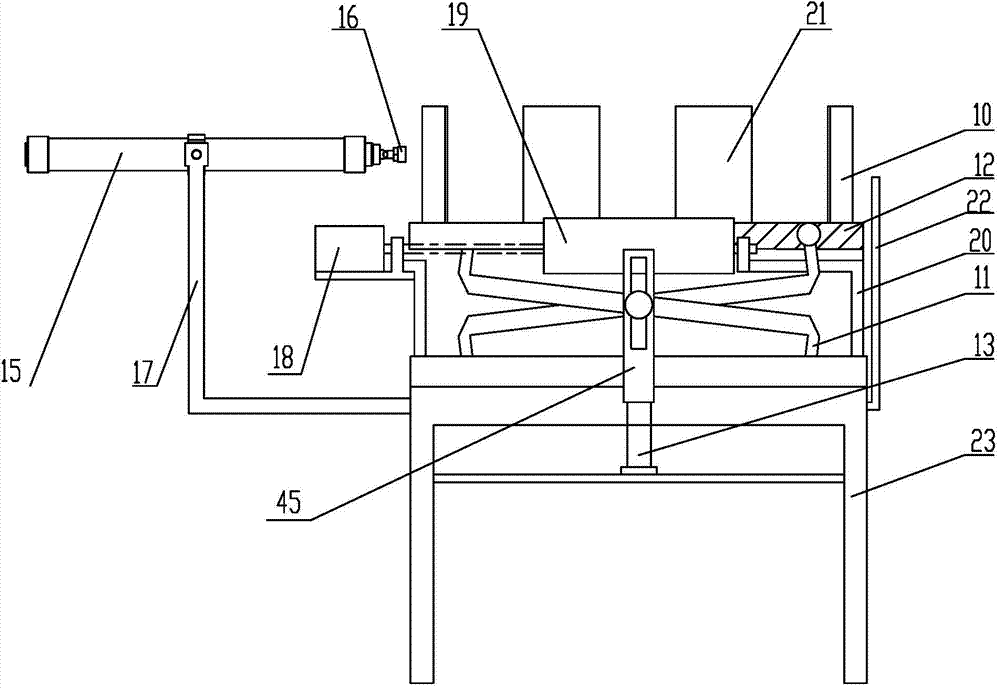

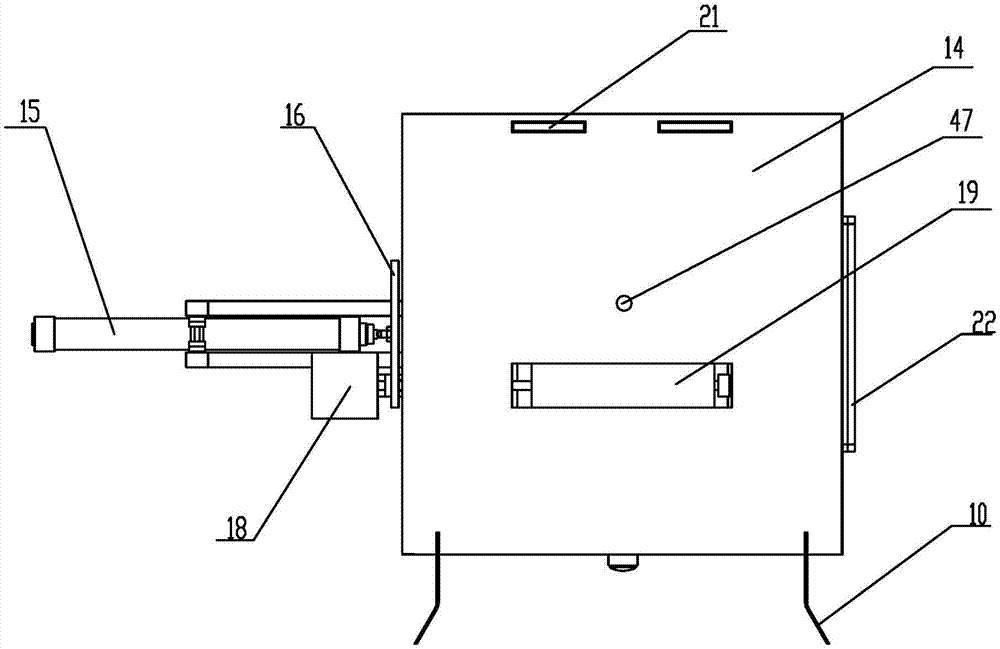

Ceramic tile palletizing apparatus

InactiveCN101397089AEasy to operateImprove palletizing efficiencyConveyor partsMaterials sciencePallet

The invention discloses a ceramic tile stacking device, belonging to the technical field of ceramic manufacturing. The ceramic tile stacking device comprises a vertical frame, a pallet which is used for supporting the ceramic tiles, a turnover device which is used for turning over the pallet from the horizontal direction to the vertical direction, and a rotation device which rotates the pallet in the vertical direction; the bottom of the pallet is provided with a supporting seat which has a supporting function; the supporting seat is movably connected with the upper crossbeam of the vertical frame; the supporting seat is movably connected with the output ends of the turnover device and the rotation device. The invention provides a ceramic tile stacking device which replaces the manual ceramic tile stacking operation with the mechanical device; the ceramic tile stacking device can effectively improve the production efficiency and release the workers from heavy manpower labors at the same time.

Owner:KEDA INDUSTRIAL GROUP CO LTD

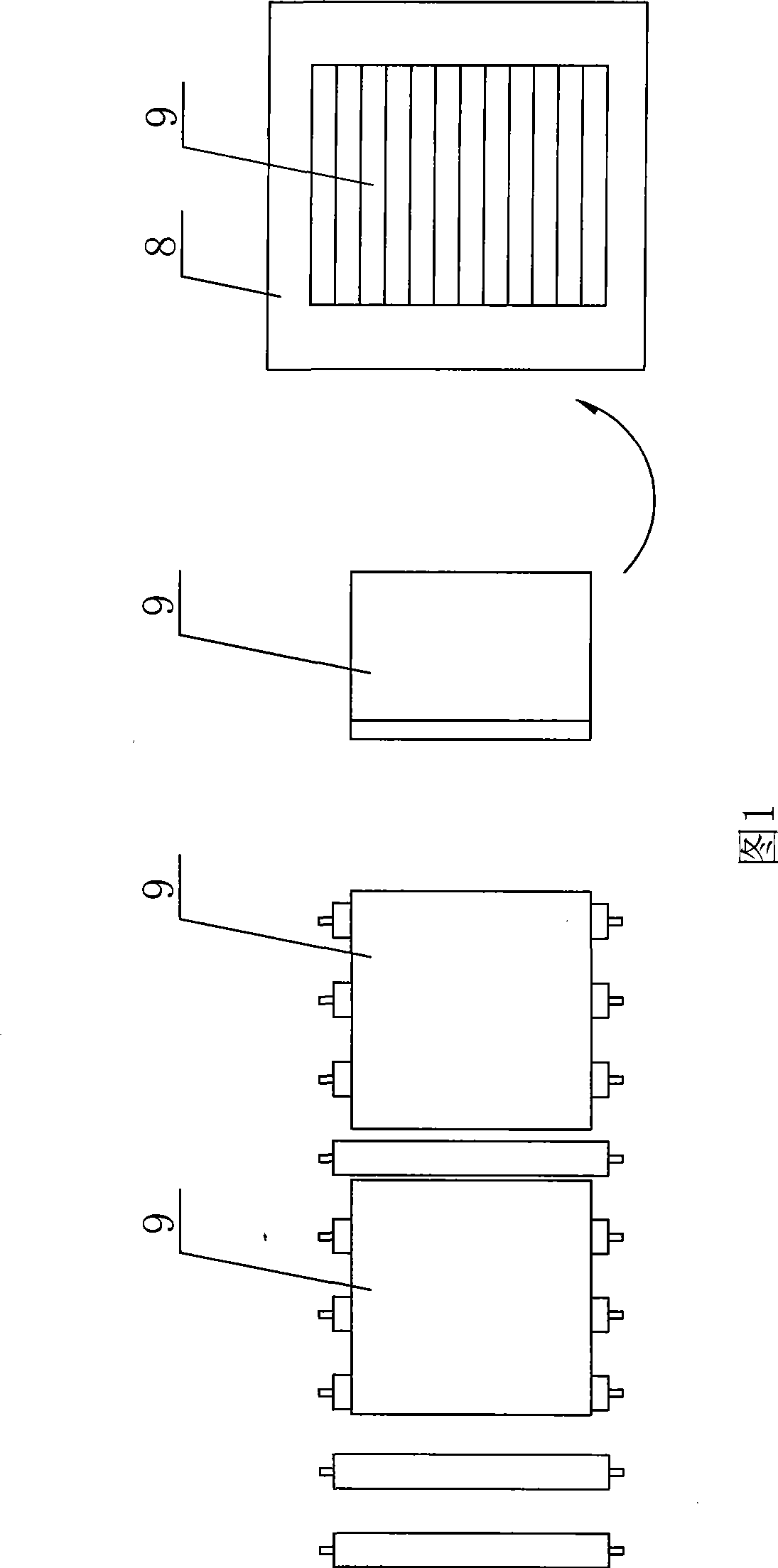

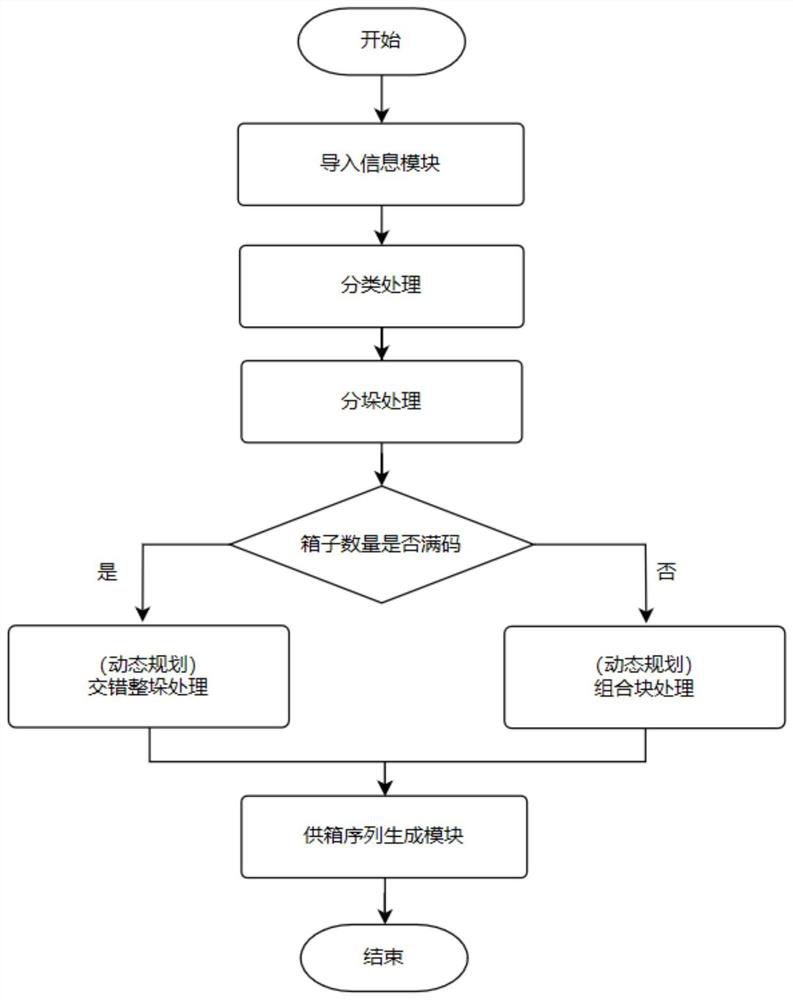

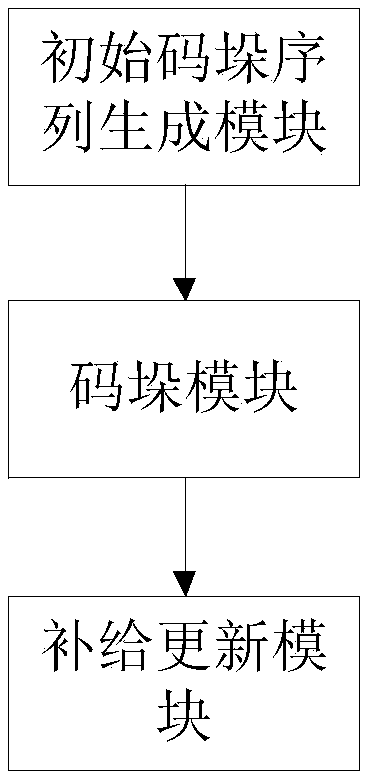

Order-based generation system and method for stable mixed box stack type box supply sequence

PendingCN112085385AFully automatedRealize intelligenceBuying/selling/leasing transactionsResourcesDynamic planningAlgorithm

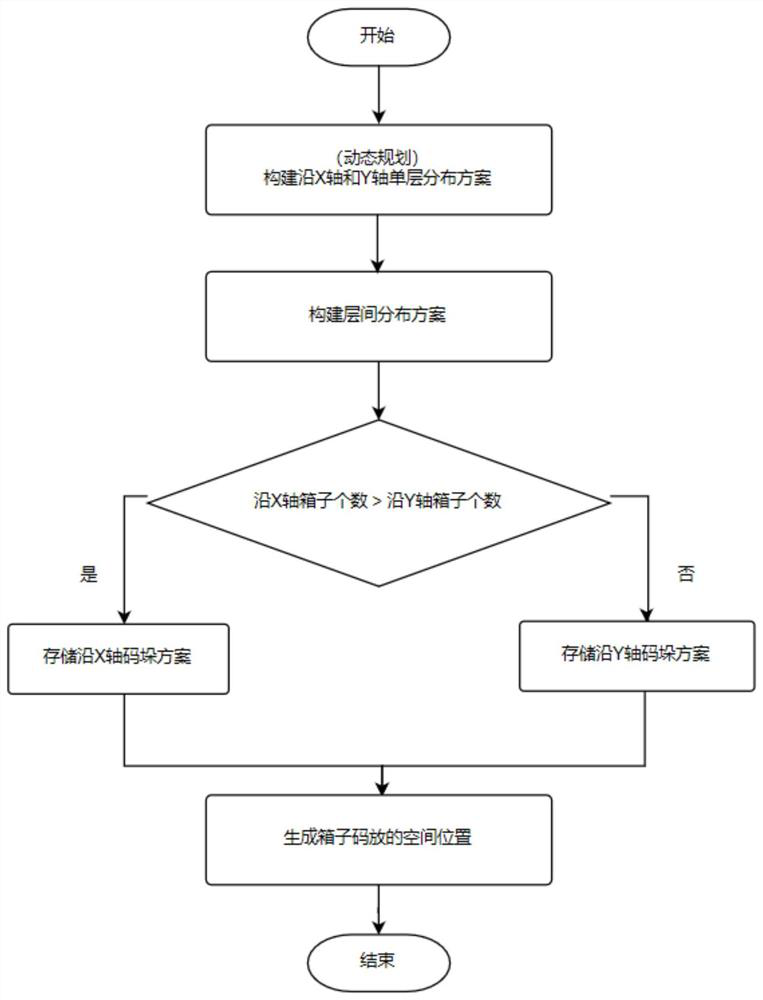

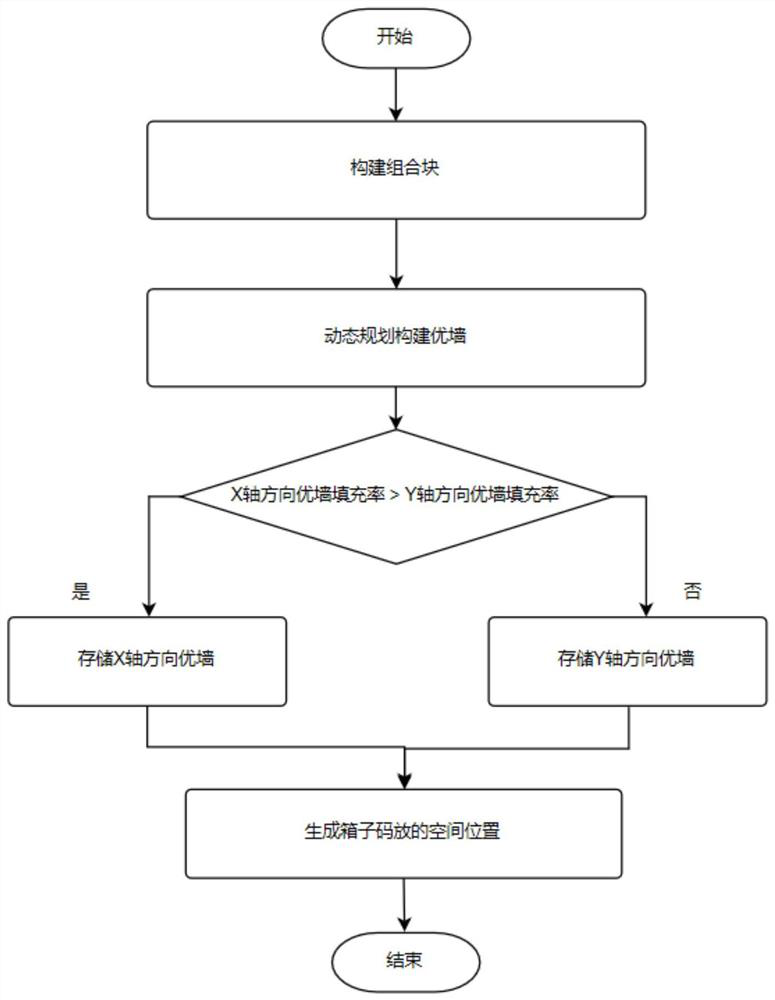

The invention discloses an order-based generation system and method for a stable mixed box stack type box supply sequence. The method comprises the following steps: S1, importing an Excel order and automatically analyzing to obtain quantity information and three-dimensional size data of all articles in the order; S2, according to the three-dimensional size and number of each box in the order, classifying boxes in the order according to the sizes of the boxes, then stacking the boxes according to the number of the boxes, and finally acquiring the stable stack type corresponding to each tray staggered stacking processing or combined block processing based on dynamic planning; and S3, calculating the specific spatial position of each box in each tray according to the stack type generated after the stack dividing treatment, generating a stacking sequence according to a layer-by-layer placement sequence, and generating a box supply sequence containing the stack number, the layer number, thespecific spatial position of the box, the placement direction of the box and the stacking sequence of each stack type.

Owner:DONGGUAN LISHENG MACHINERY EQUIP +1

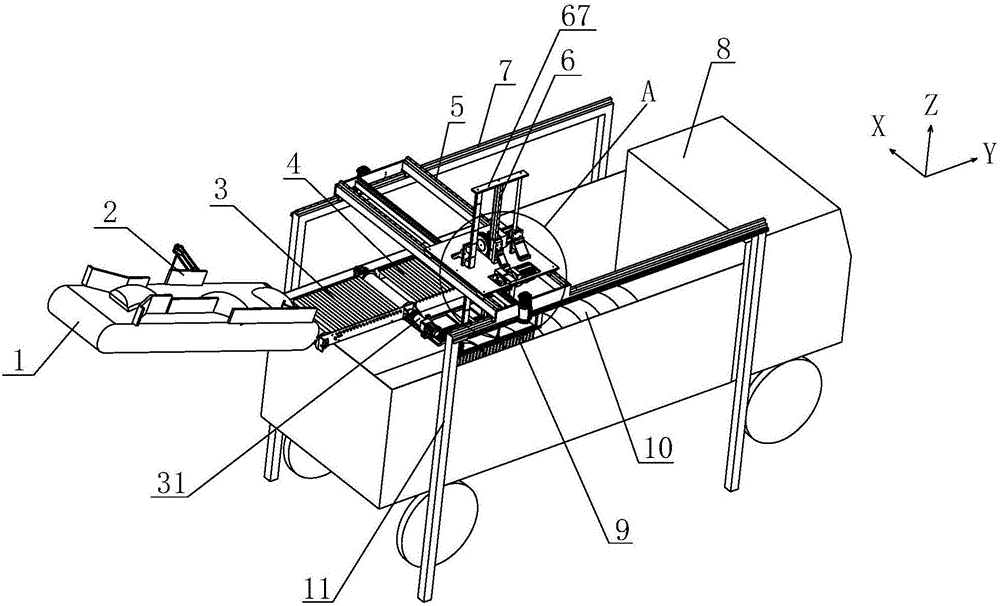

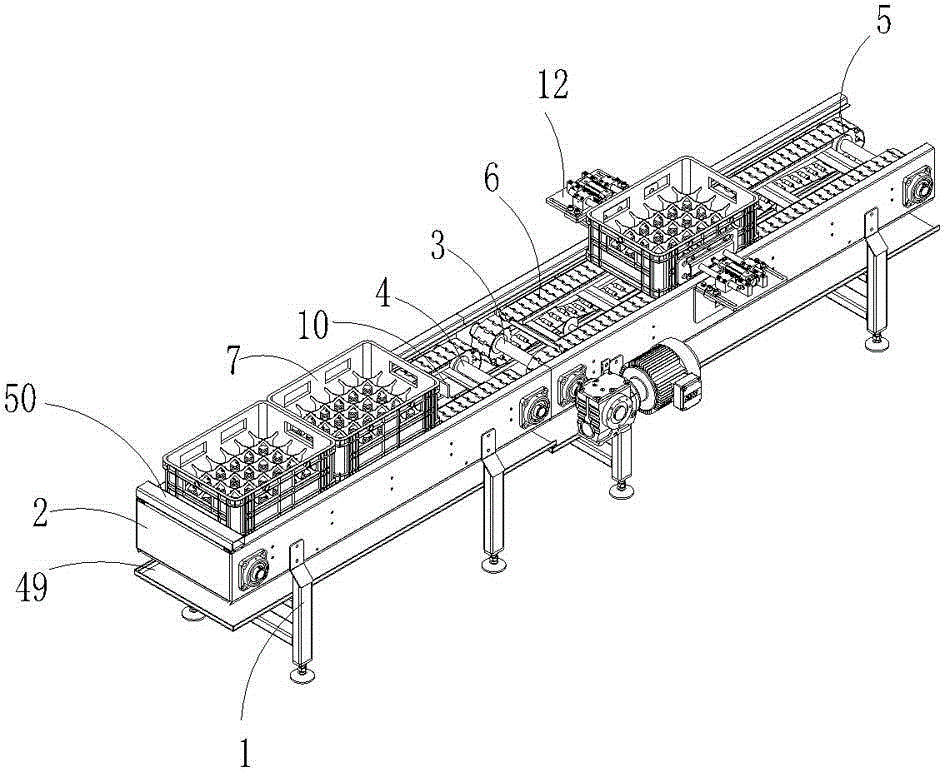

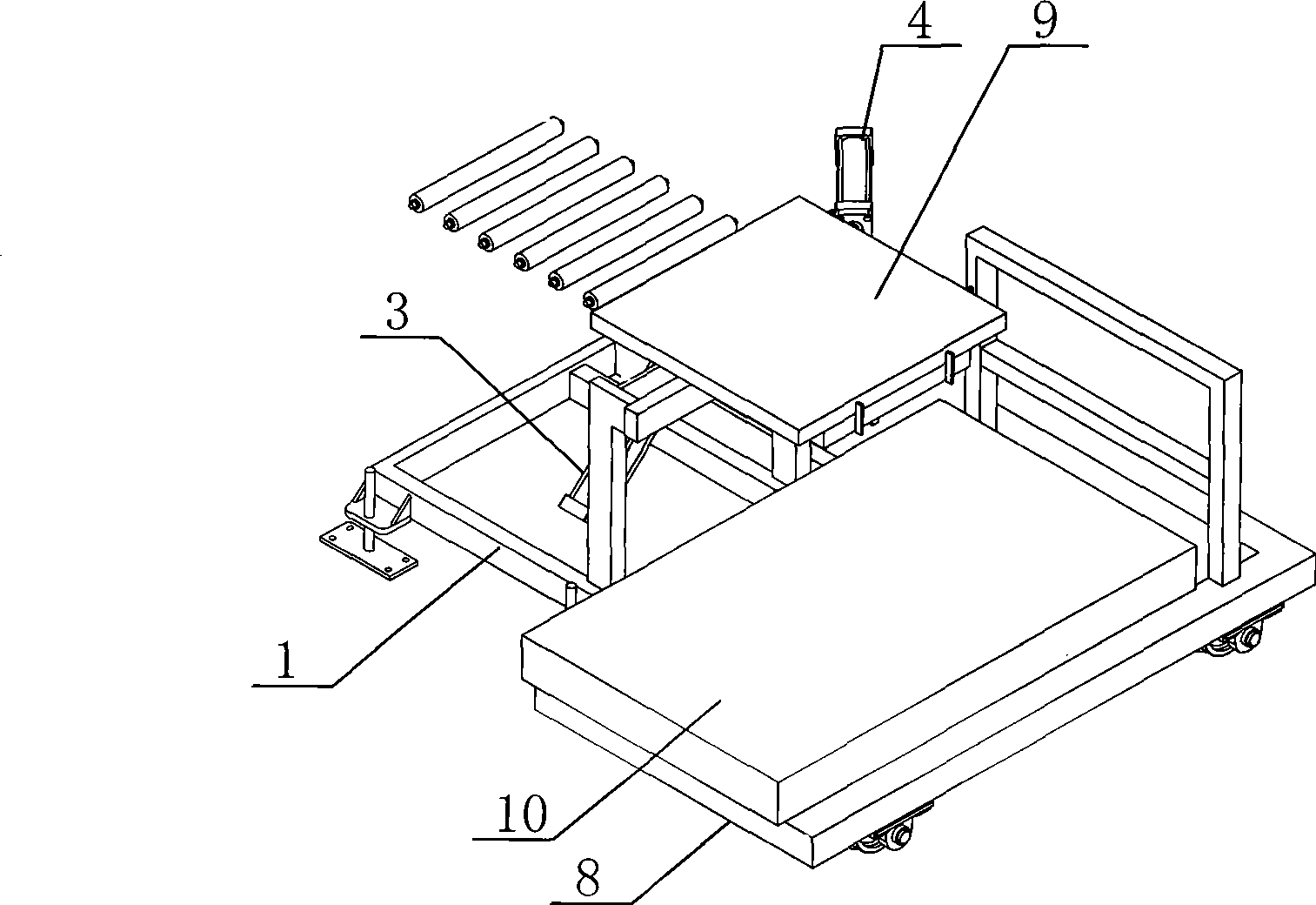

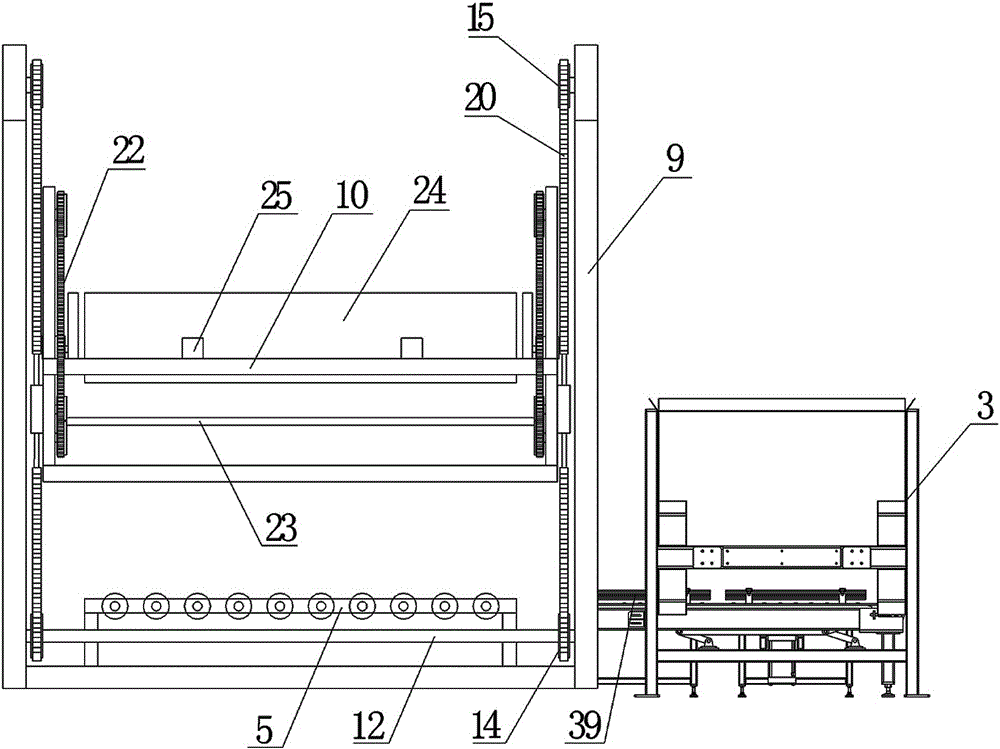

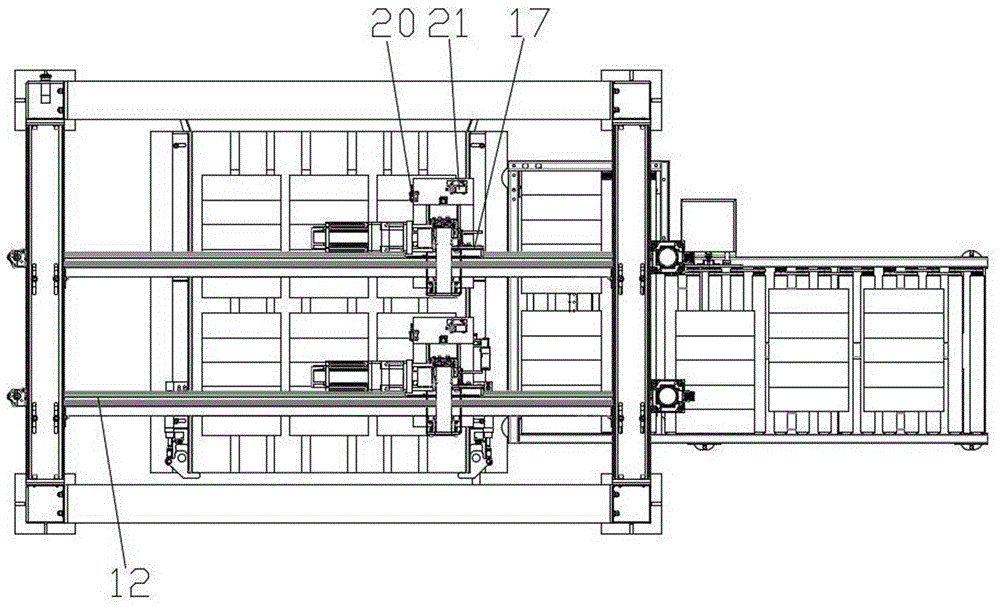

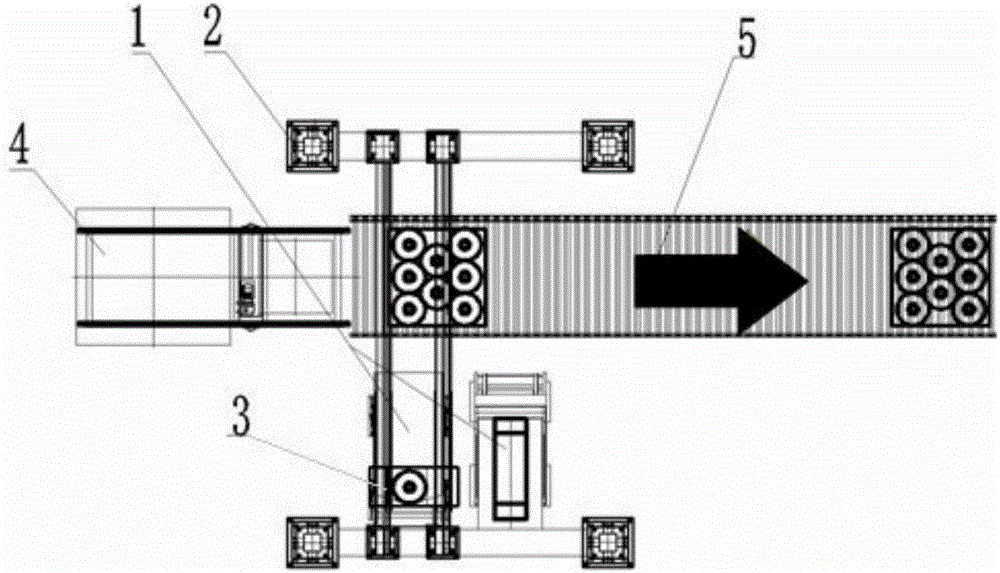

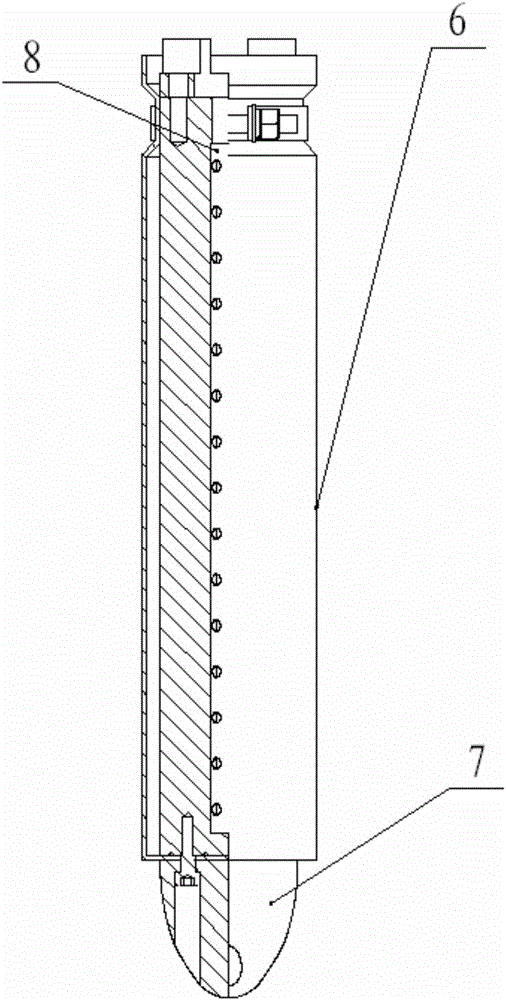

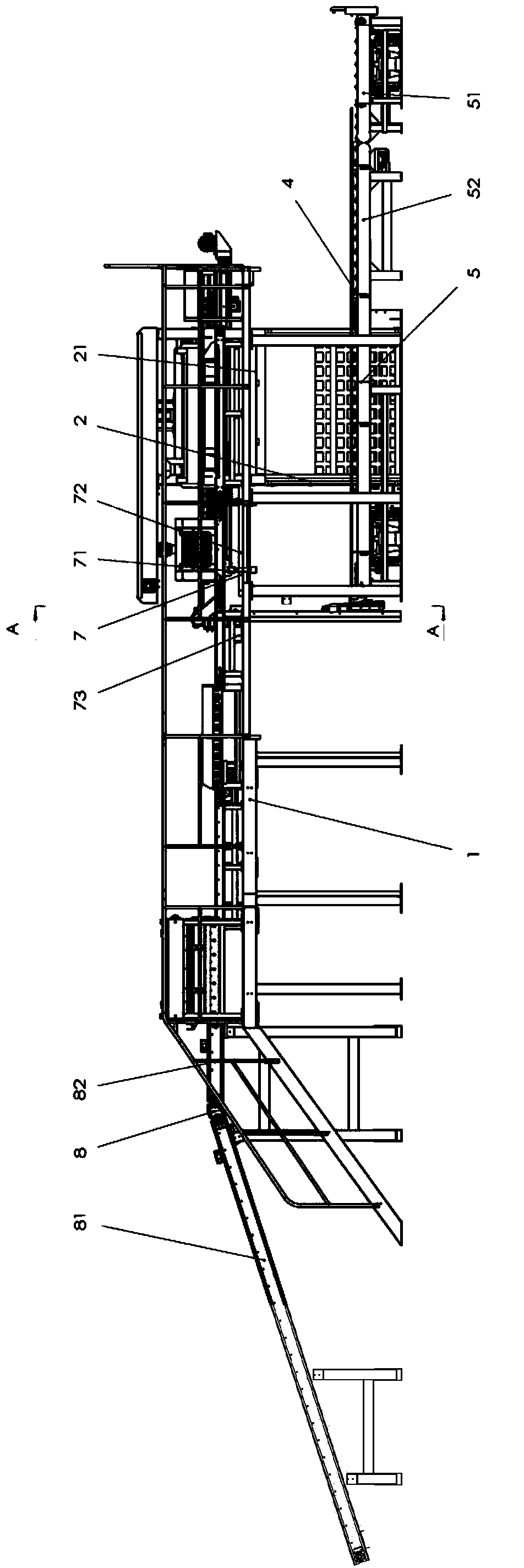

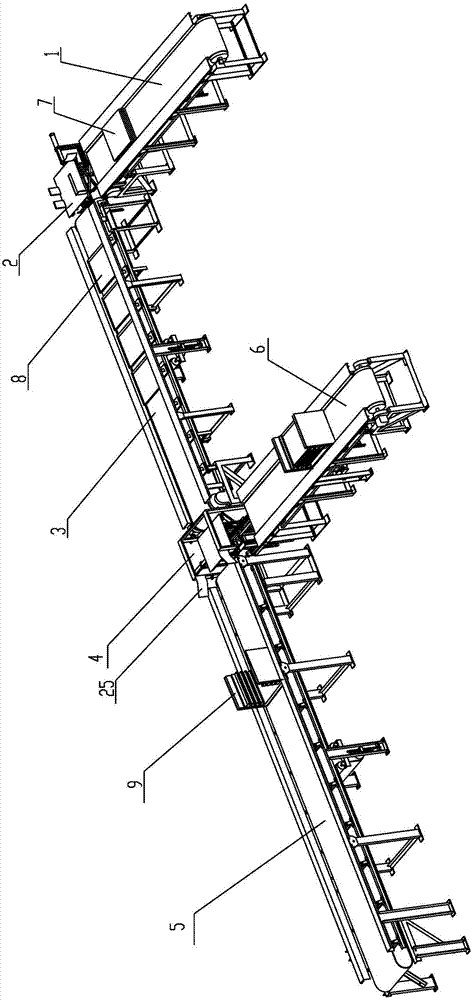

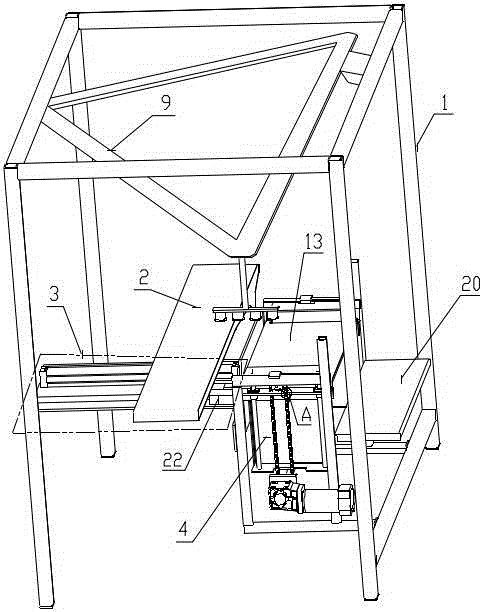

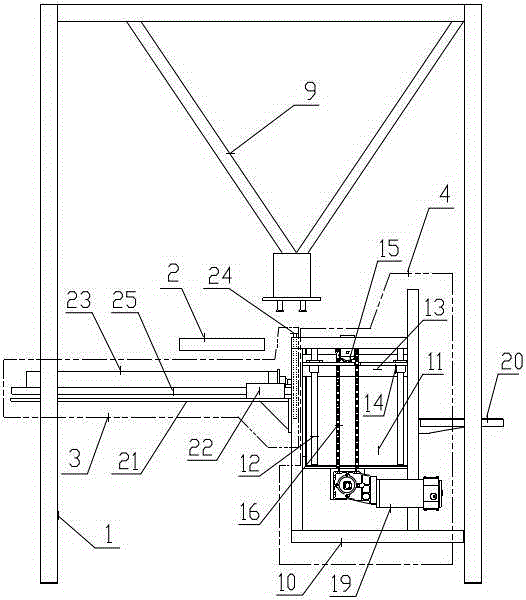

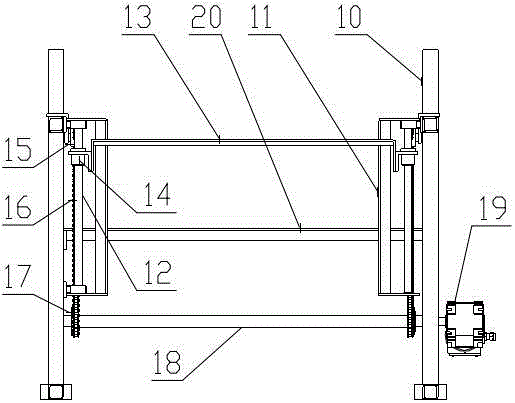

Full-automatic carton stacking production line

ActiveCN105800321AGuaranteed flatnessImprove efficiencyStacking articlesDe-stacking articlesEngineeringProduction line

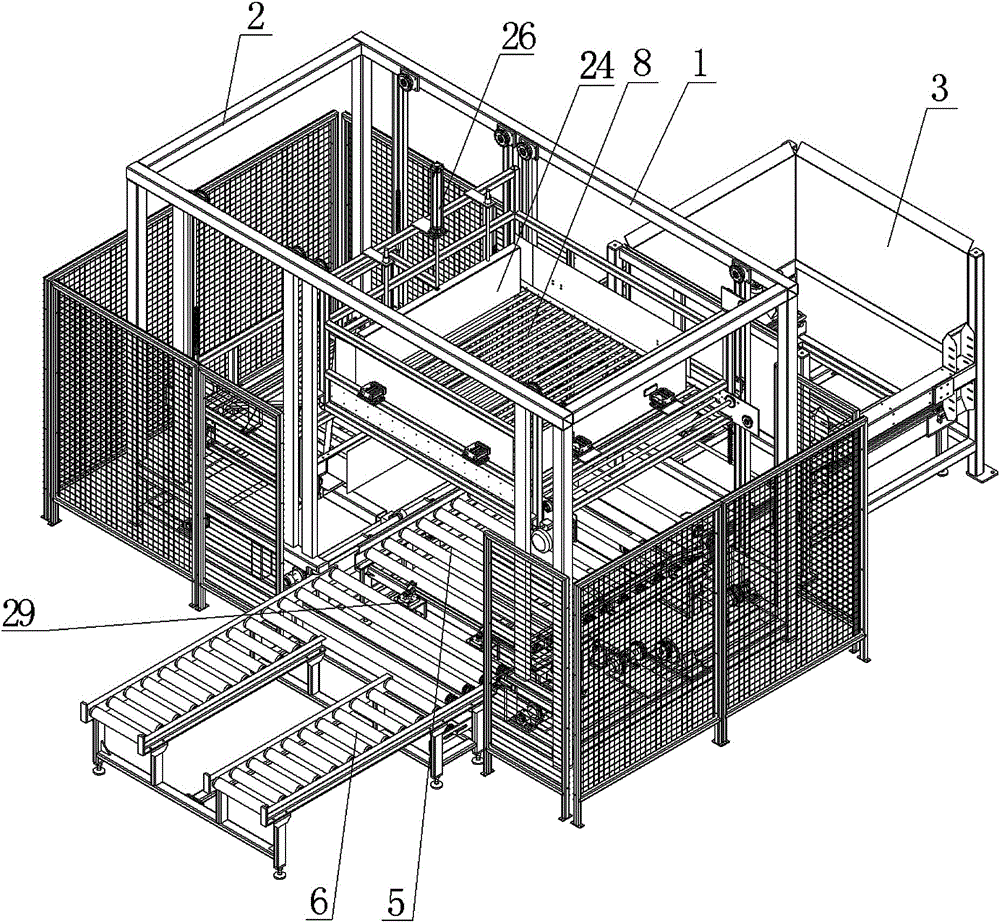

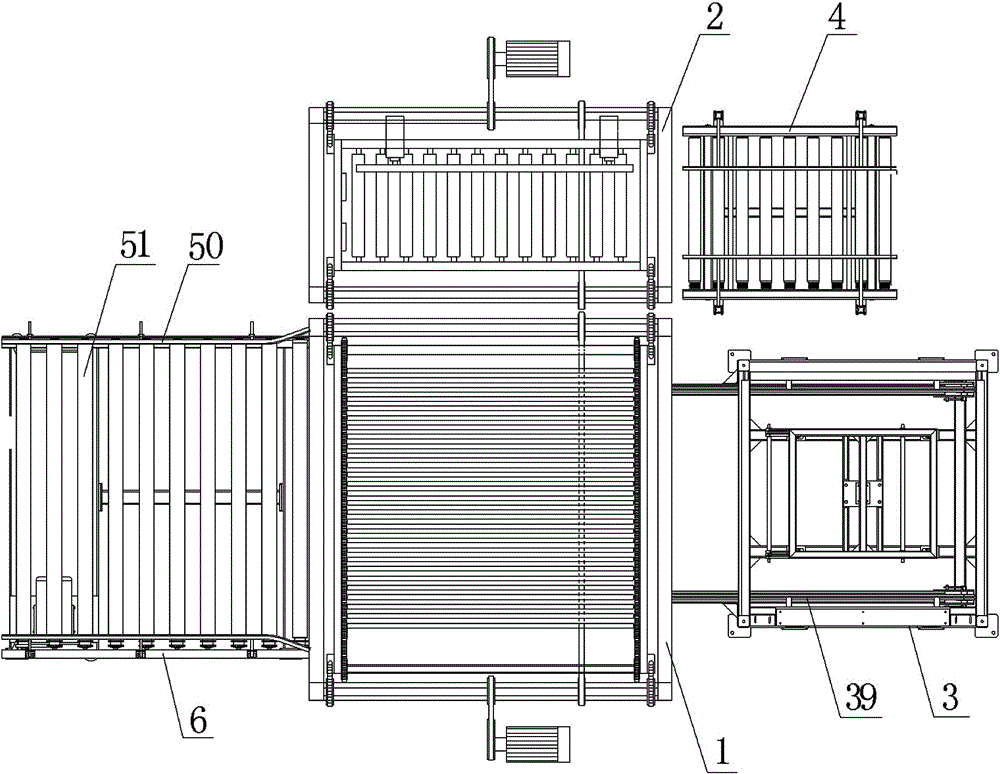

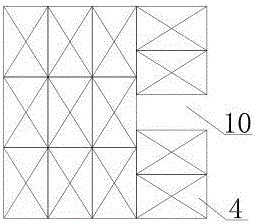

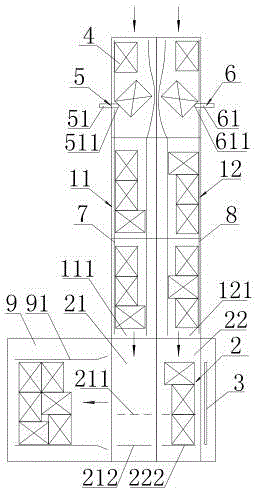

The invention discloses a full-automatic carton stacking production line which comprises a stacking machine (1), a carton pushing machine (2), a tray room (3), a carbon feeding roller way (4), a stack conveying mechanism (5) and a finished product stack conveying device (6), wherein the stacking machine (1) consists of a lifting mechanism I (7) and curtain drawing mechanisms (8); the stack conveying mechanism (5) is arranged below an auxiliary rack (10); the carton pushing machine (2) is arranged on the rear side of the stacking machine (1); the tray room (3) is arranged on the right side of the stack conveying mechanism (5); the carton feeding roller way (4) is arranged on the rear side of the tray room (3); the finished product stack conveying device (6) is arranged on the left side of the stack conveying mechanism (5). The full-automatic carton stacking production line has the beneficial effects of low manufacturing cost, high carton stacking efficiency, low maintenance cost and high stacking quality, and guarantees the carton stacking tidiness.

Owner:成都经纬机械制造有限公司

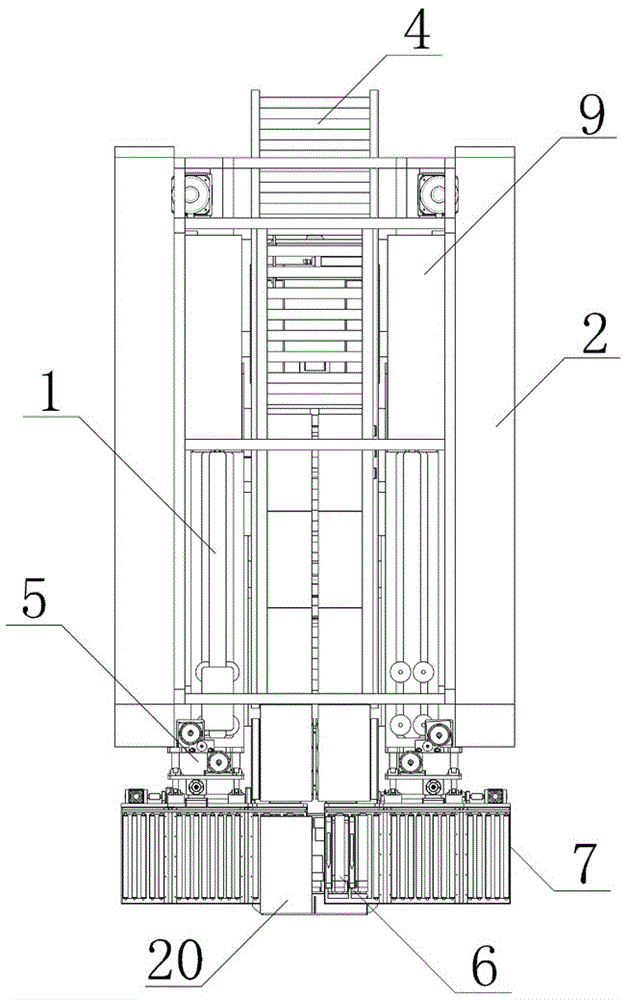

Stacker with wide application range and high stacking efficiency

ActiveCN105564996AEnhance the ability to adapt to complex logistics environmentsImprove material transportation efficiencyConveyorsStacking articlesTransfer mechanismLogistics management

The invention discloses a stacker with the wide application range and high stacking efficiency. The stacker comprises a base, a multi-level retractable transferring mechanism, a traveling mechanism, a frame-shaped support, an orderly arranging mechanism, a multi-level lifting transferring mechanism, a distribution mechanism, a push mechanism, a positioning device and a control device. According to the stacker with the wide application range and high stacking efficiency, the multi-level retractable transferring mechanism can pass over ground obstacles to perform stacking, the problem that a common traveling stacker cannot pass over the ground obstacles is solved, and the stacker adapts to complex logistics environments; the orderly arranging mechanism guarantees that materials are orderly and stably conveyed so as to be stacked and meanwhile the materials are divided into two columns to be conveyed, so that the conveying efficiency is improved; the lifting space of the materials can be greatly improved by the aid of the multi-level lifting transferring mechanism, so that the height of material stacking is effectively increased and the application range of the stacker is widened; and the distribution mechanism, the multi-level lifting transferring mechanism and the push mechanism mutually cooperate so that the two columns of materials can be stacked simultaneously and accordingly the stacking efficiency of the stacker can be greatly improved.

Owner:YUNNAN KELAIZHONGCHENG INTELLIGENT EQUIP CO LTD

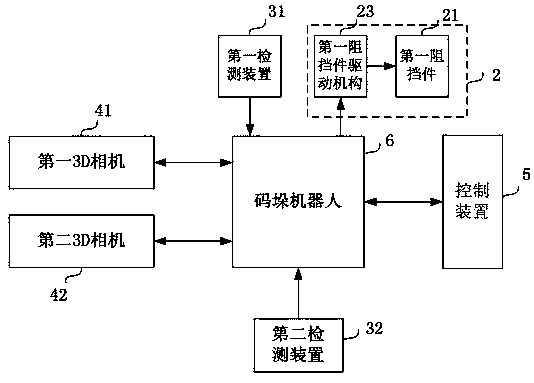

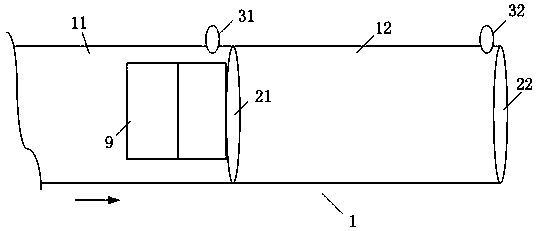

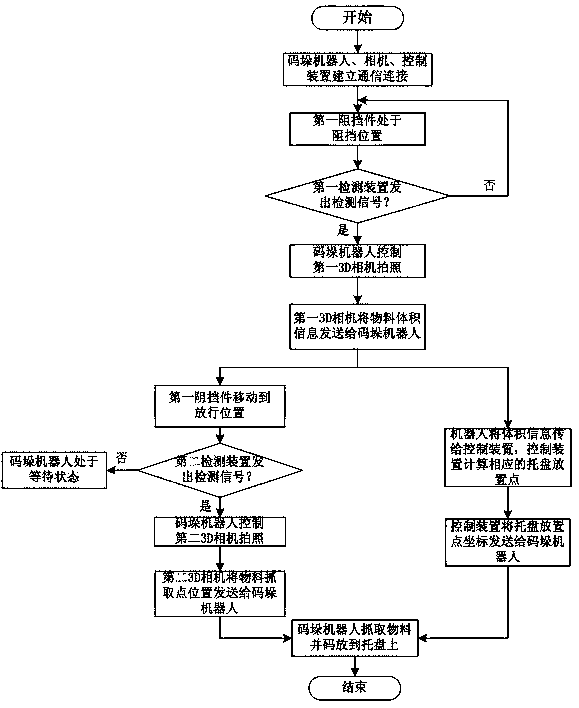

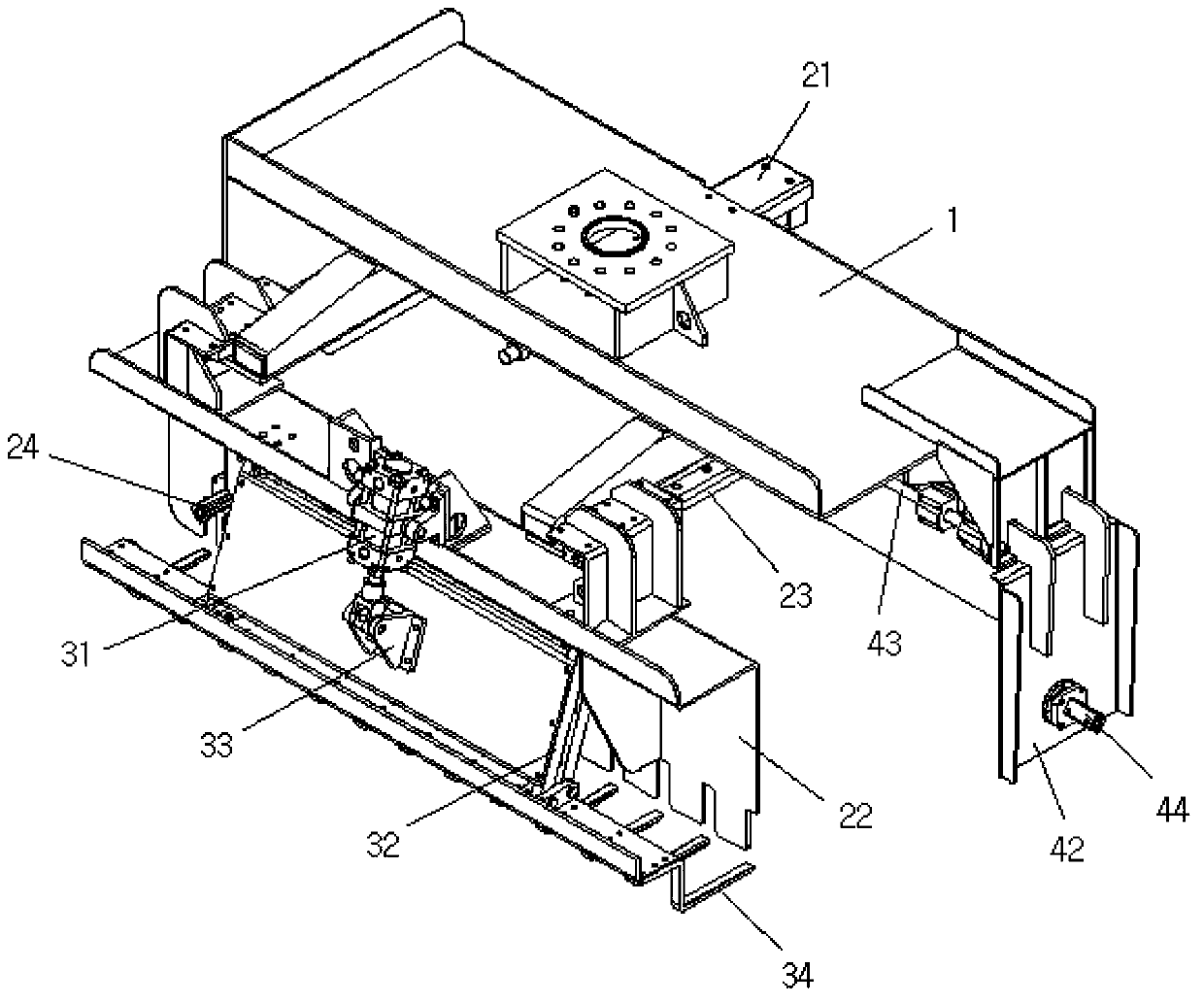

Robot stacking system and stacking method thereof

ActiveCN109625986ARealize automatic identificationImprove palletizing efficiencyStacking articlesEngineering3d camera

The invention provides a robot stacking system which comprises a conveying mechanism, a first blocking mechanism, a first detecting device, a first 3D camera, a second detecting device, a second 3D camera, a control device and a stacking robot. The conveying mechanism is provided with a main conveying area and a temporary storing conveying area. The first blocking mechanism comprises a first blocking part and a first blocking part drive mechanism. The first blocking part is arranged between the main conveying area and the temporary storing conveying area. The first detecting device is used fordetecting whether materials reach the edge position of the main conveying area. The first 3D camera is used for shooting material images of the main conveying area and obtaining material size information. The second detecting device is used for detecting whether the materials reach the preset position of the temporary storing conveying area. The second 3D camera is used for shooting material images of the temporary storing conveying area to determine the material grabbing point position. The control device is used for determining the tray placing point position of the materials according to the size information of the materials. The stacking robot is used for stacking the materials on trays according to the grabbing point of the materials and the tray placing point position. The inventionfurther discloses a stacking method of the robot stacking system. The robot stacking system can stack the materials of different sizes.

Owner:上海新时达机器人有限公司

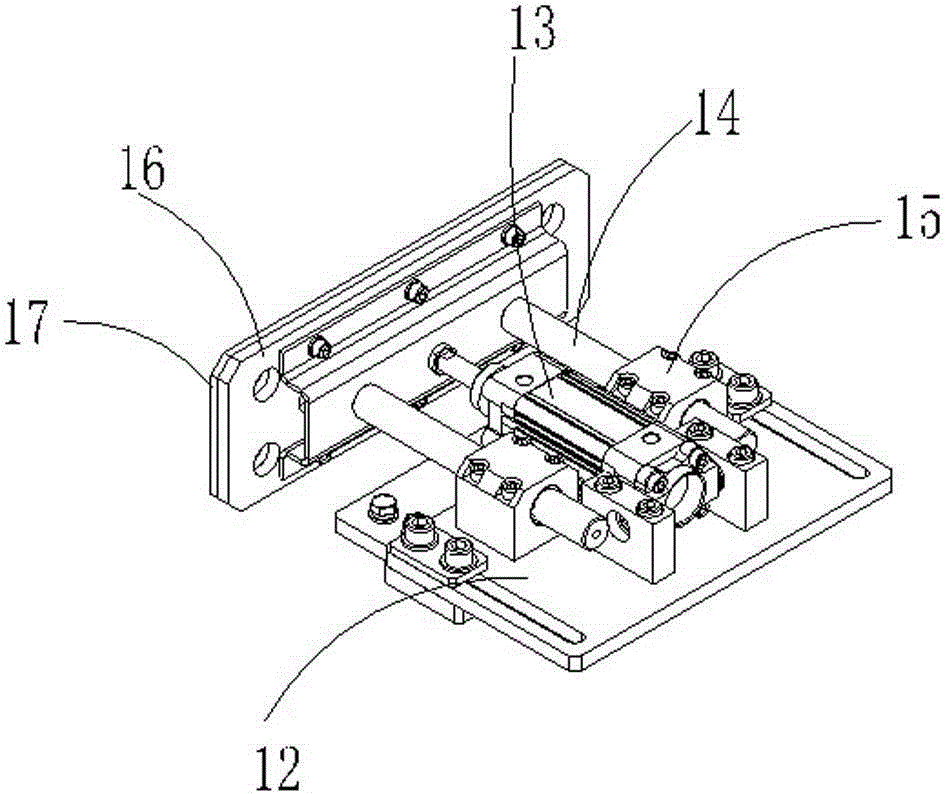

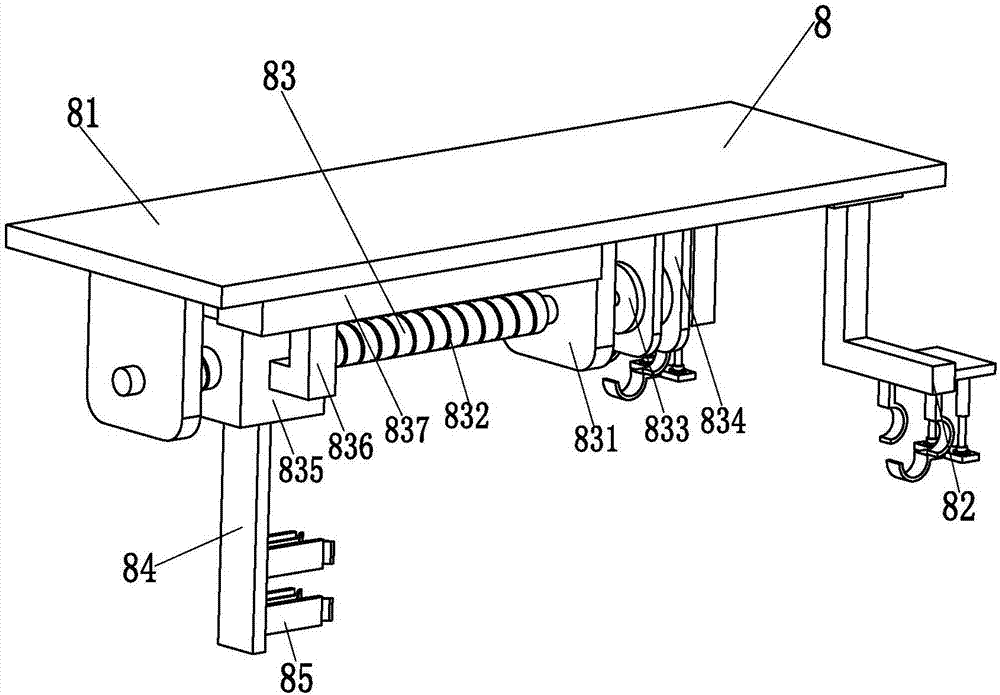

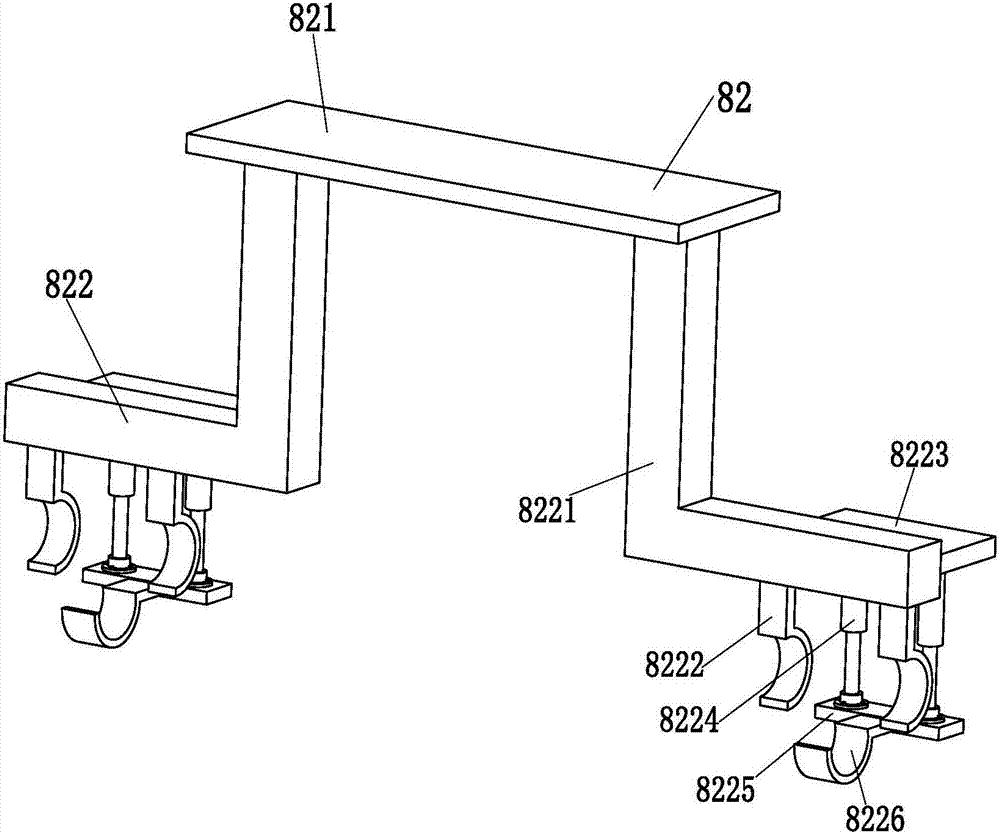

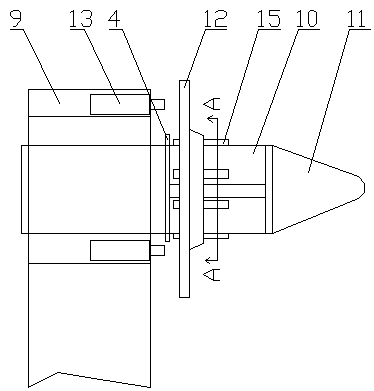

Robot self-adaptation hand grab for stacking box piece

The invention relates to the technical field of stacking equipment, in particular to a robot self-adaptation hand grab for stacking box pieces. Stacking efficiency is improved. The hand grab comprises a base body, a clamping-moving device, a bottom supporting device and a side moving device. The clamping-moving device comprises a clamping-moving air cylinder and a clamping-moving guiding track which are arranged on the base body, and a clamping-moving frame arranged on the clamping-moving guiding track. The clamping-moving frame is fixedly connected with a power arm of the clamping-moving air cylinder. An approaching sensor is arranged on the clamping-moving frame. The bottom supporting device comprises a swinging air cylinder which is arranged on the clamping-moving frame, a swinging arm arranged on the clamping-moving frame in a pivoting mode, and a pushing frame fixedly arranged on the swinging arm. The pushing frame is connected with a power arm of the swinging air cylinder in a pivoting mode. A bottom supporting hooking plate is fixedly arranged at the lower end of the pushing frame. The side moving device comprises a side moving guiding rod and a side moving air cylinder which are arranged on the base body, and a side pressing plate arranged on the side moving guiding rod. The side pressing plate is fixedly connected with a power arm of the side moving air cylinder. The side pressing plate is provided with an approaching sensor. The hand grab is suitable for stacking the box pieces.

Owner:SHANGHAI XINGLU MACHINERY EQUIP +2

Stacking machine and stacking method

InactiveCN106672635AHigh precisionImprove palletizing efficiencyStacking articlesStack machineEngineering

The invention discloses a stacking machine and a stacking method. The stacking machine comprises a frame, a conveying roller way I, a conveying roller way II and N vacuum suckers; the N vacuum suckers fixedly absorb and transfer N goods arranged in an X-axle direction on the conveying roller way II into a goods bearing device correspondingly one to one. The conveying roller way I conveys the goods packed with plastic films by a plastic film packing machine onto the conveying roller way II in a Y-axle direction, and the conveying roller way II arranges N goods in the X-axle direction, so that N sets of vacuum suckers in the frame 1 can correspondingly suck N goods to realize multi-station synchronous operation under the conditions of matching a transverse moving mechanism with a longitudinal moving mechanism. The sucked goods are stacked on the goods bearing device under the effect of the transverse moving mechanism and the longitudinal moving mechanism. The stacking machine and the stacking method replace a traditional manual stacking mode, greatly improve the stacking efficiency, and meanwhile, greatly improve the stacking precision.

Owner:SHANDONG LOGISTIC TECH CO LTD

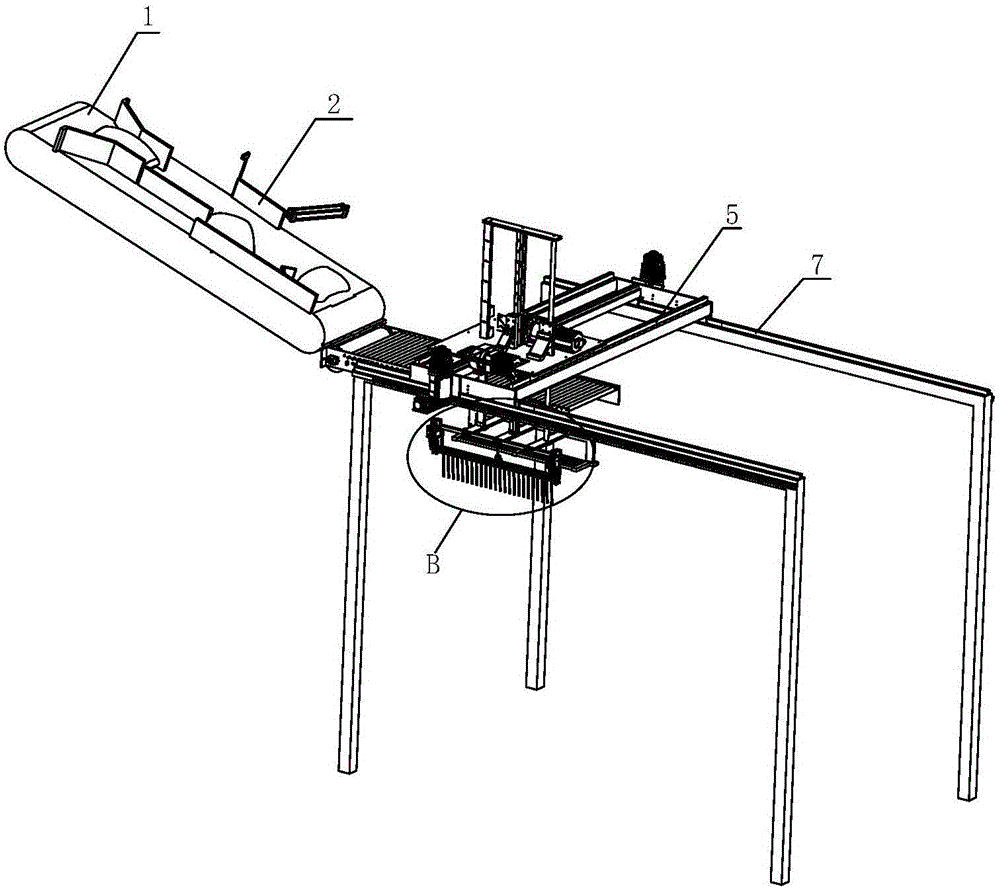

Automatic polyester film roll palletizing system system with pneumatic shaft gripper

ActiveCN106276173AImprove palletizing efficiencyIncrease job securityConveyorsStacking articlesPolyesterCartesian coordinate robot

The invention provides an automatic polyester film roll palletizing system system with a pneumatic shaft gripper. The automatic polyester film roll palletizing system system comprises a tilter, a Cartesian coordinate robot, a conveyor line, a pneumatic shaft gripper, and a depalletizer. The automatic polyester film roll palletizing system system with the pneumatic shaft gripper according to the present invention can allow a great improvement in the polyester film roll palletizing efficiency and an increase in the operating safety factor, and has important technical progress significance and economic value.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

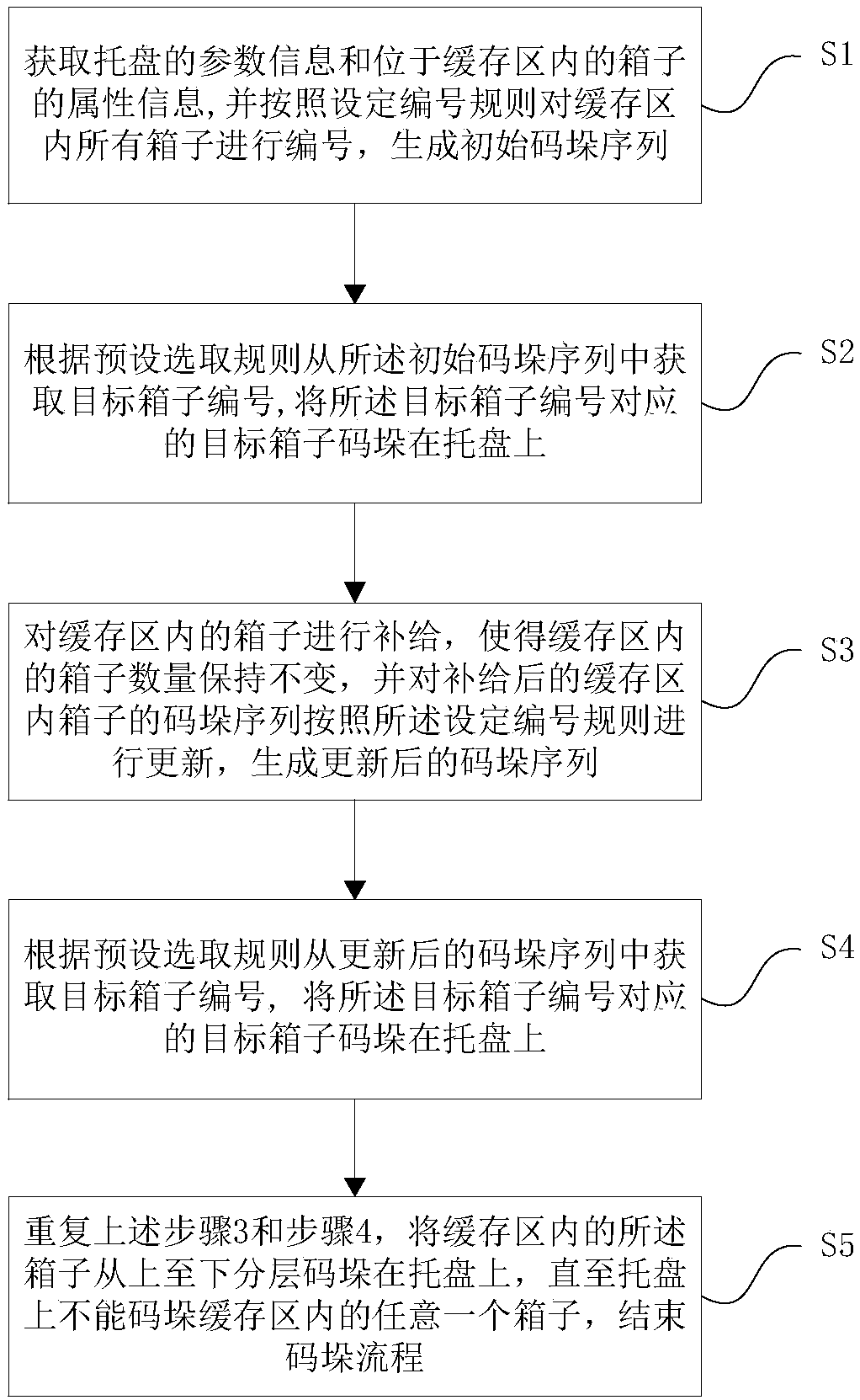

Half-offline mixed stacking method and system as well as robot

ActiveCN108861619AImprove stabilityIncrease profitStacking articlesLogistics managementComputer science

The invention relates to a half-offline mixed stacking method and system as well as a robot. The method comprises the following steps of: obtaining parameter information of a tray and attribute information of boxes in a cache region, and coding all boxes in the cache region to generate an initial stacking sequence; obtaining serial number of the target box from the initial stacking sequence according to a pre-selecting rule, and stacking the target box on the tray; supplementing the boxes in the cache region, keeping number of the boxes in the cache region unchanged, updating a stacking sequence of the boxes in the supplemented cache region according to a set numbering rule to generate an updated stacking sequence and the serial number of the target box, and stacking the target box on thetray. The stacking method disclosed by the invention can solve the online mixed stacking problem of the logistics industry, can perform mixed stacking on rectangular boxes of different dimensions, canguarantee stacking stability, realizes horizontal and layered stacking, and has the advantages of being good in stacking stability, convenient for robot stacking, relatively high in tray utilizationrate and the like.

Owner:武汉库柏特科技有限公司

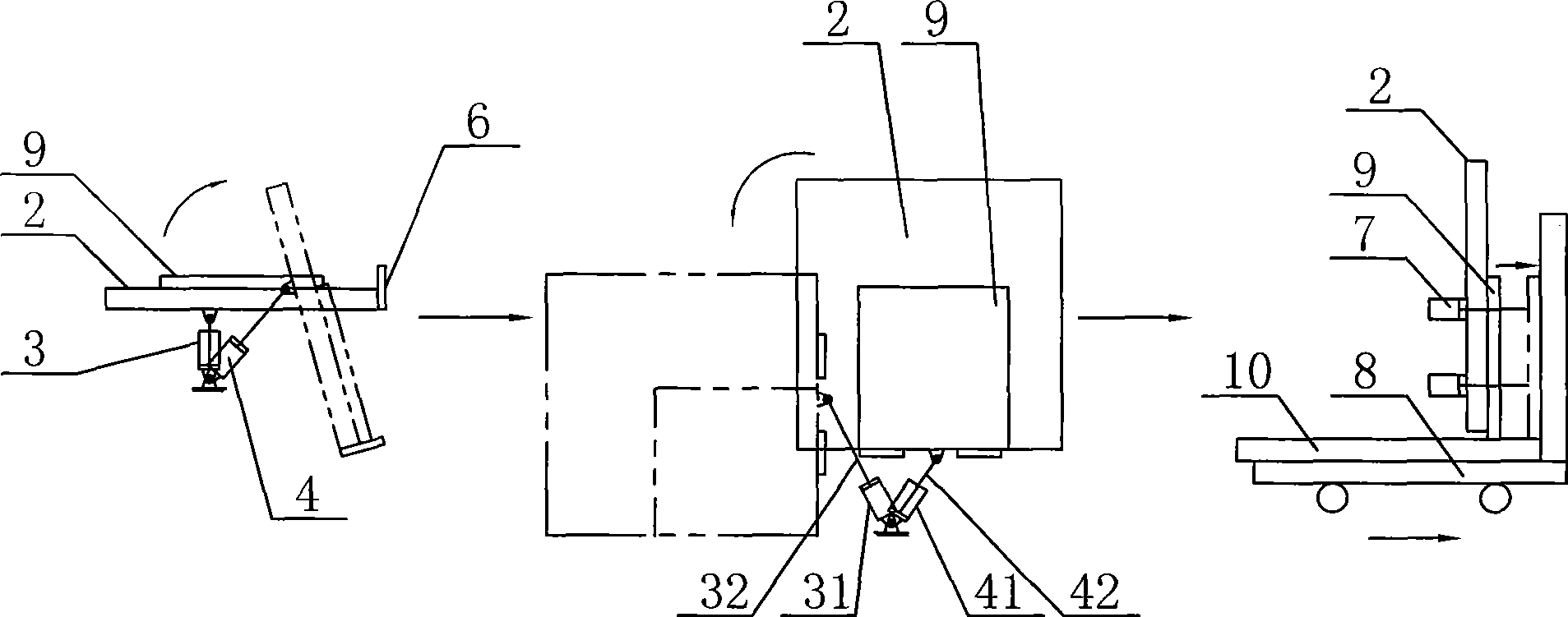

Acoustic board stacking production line and method used for high-speed rail

InactiveCN106927076AImprove palletizing efficiencyReduce labor intensityBinding material applicationStacking articlesSound barrierProduction line

The invention provides an acoustic board stacking production line and method used for a high-speed rail. The acoustic board stacking production line comprises a conveyor, a packaging machine, an overturning machine, an adjusting position worktable, a finished product conveyor, a stacking device and a control system. The conveyor is used for conveying pallets with acoustic boards. The packaging machine is in butt joint with a delivering area of the conveyor. The overturning machine is in butt joint with the delivering end of the packaging machine. The adjusting position worktable is used for stacking small stacks of acoustic boards with the designated number into neat semi-finished product stacks. The finished product conveyor is attached to one side of the adjusting position worktable and is used for stacking the semi-finished product stacks with the designated number into finished product stacks, and the finished product stacks are conveyed to a designated position. The stacking device is used for clamping and stacking the acoustic boards, the small stacks of the acoustic boards and the semi-finished product stacks. The control system is used for controlling the conveyor, the packaging machine, the overturning machine, the adjusting position worktable, the finished product conveyor and the stacking device. By means of the acoustic board stacking production line and method used for the high-speed rail, the stacking efficiency of the acoustic boards can be greatly improved, the production cost is reduced, the product quality is ensured, the labor intensity of workers is lowered, and the requirement for large-batched automatic stacking of concrete sound barrier acoustic boards can be completely met.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

Wood floor stacking machine and floor cutting production line

ActiveCN108582266AIncrease heightEasy to useFeeding devicesPile receiversProduction lineStack machine

The invention relates to a wood floor stacking machine. The front end of a floor conveying mechanism serves as a conveying end, and the rear end of the floor conveying mechanism serves as an output end. A floor bearing mechanism is located on the front side of the output end of the floor conveying mechanism, and a stacking mechanism is located above the output end of the floor conveying mechanism.The floor bearing mechanism comprises a bearing platform frame, a first alignment device and a front bearing platform. The first alignment device and the front bearing platform are installed on the bearing platform frame, and the front bearing platform and an alignment push plate A push device are installed on the upper surface of the bearing platform frame. A first alignment baffle lifting device which is vertically arranged is installed on one side of the bearing platform frame, and a first alignment baffle is arranged on the first alignment baffle lifting device. An alignment push plate Ais arranged on the alignment push plate A push device. The invention further discloses a floor cutting production line. The wood floor stacking machine and the floor cutting production line have the following beneficial effects that the wood floor stacking machine is beneficial to increase the stacking speed and improve the stacking effect; and by the adoption of an upper-and-lower multifunctionaladjustable seamless saw, the saw cutting efficiency is improved, and the labor intensity of workers is reduced.

Owner:SHANDONG ZHONGXIN MACHINERY

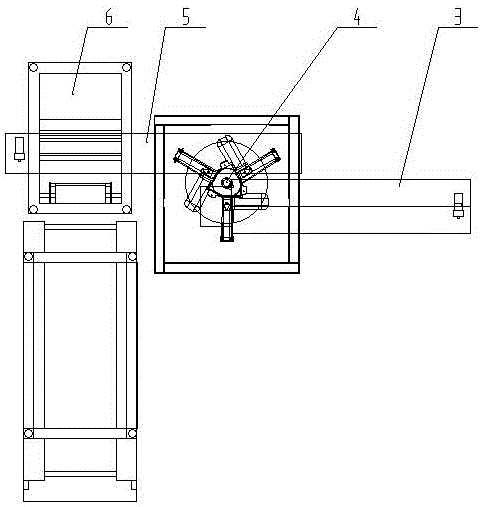

Multifunctional stacking manipulator capable of cooperative work

ActiveCN105773571AImprove palletizing efficiencyReduce labor intensityProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention relates to the field of robots, in particular to a multifunctional stacking manipulator capable of cooperative work. The multifunctional stacking manipulator comprises three mechanical arms, three gripping devices and a hand grab, wherein the mechanical arms are located on an external walking mechanism; the gripping devices are located on the end parts of the mechanical arms; the three gripping devices are respectively mounted on the three mechanical arms. The multifunctional stacking manipulator is high in stacking efficiency, the hand grab is changed by the multifunctional stacking manipulator in place of manual work, the work intensity of workers is alleviated, the multifunctional stacking manipulator has high precision in changing the hand grab, gripping objects and stacking the objects, thus the damage of the objects is greatly reduced.

Owner:广东大市智能装备有限公司

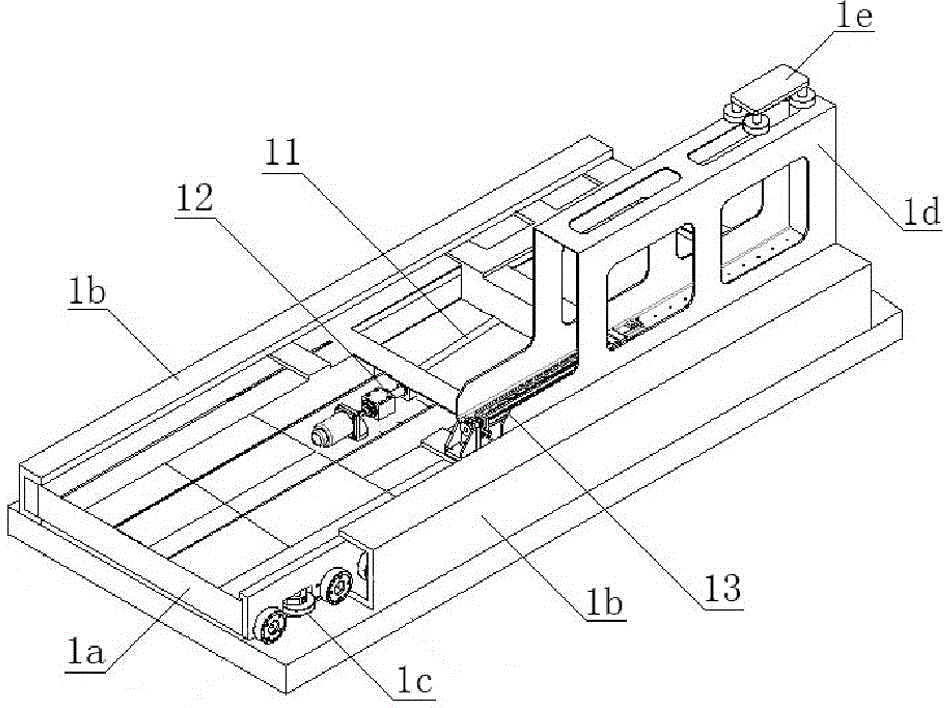

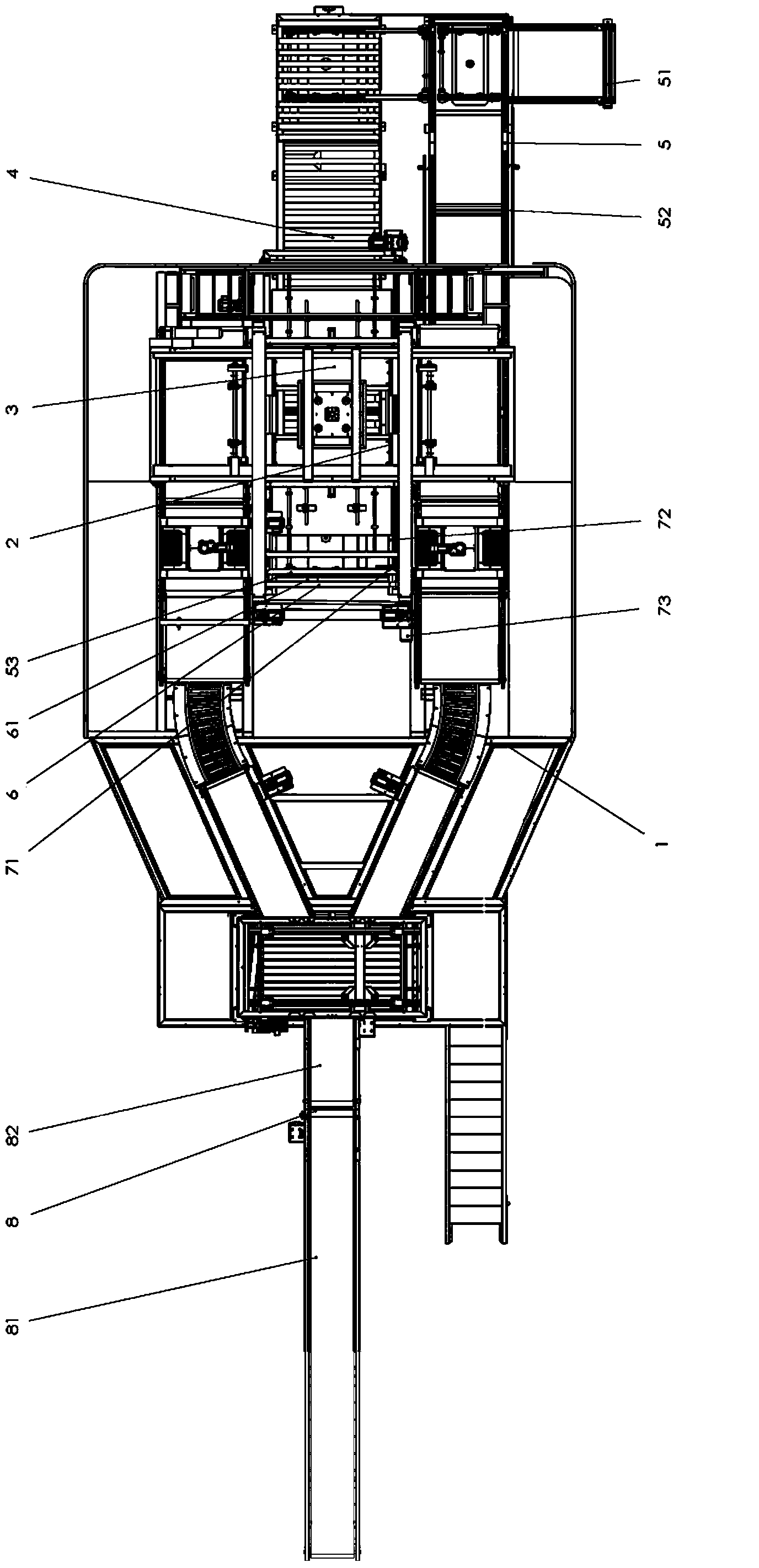

Tray stacking machine achieving high-position replacement

ActiveCN103964212AChange the replacement processMeet palletizing efficiency requirementsStacking articlesDe-stacking articlesMechanical engineeringStack machine

The invention discloses a tray stacking machine achieving high-position replacement. The machine comprises a high platform, a stacking lifting machine, a stacking layering door, a stacked tray conveying machine, a tray low-position conveying device, a tray lifting machine and a tray high-position transferring device, wherein the tray lifting machine is installed on the lower portion of the high platform and is connected with the high platform and is located behind the stacking lifting machine and above the tray low-position conveying device; the tray high-position transferring device is installed on the upper portion of the tray lifting machine and below the stacking layering door; when the stacking machine works, trays sequentially pass the tray lifting machine and the tray high-position transferring device to be conveyed from the tray low-position conveying device to below the stacking layering door, so that high-position replacement is achieved. Accordingly, the stacking machine can accelerate the replacement speed of the trays, shortens replacement time of the trays and improves stacking efficiency.

Owner:GUANGXI LIYUANBAO SCI & TECH

Pallet supplying and stacking system of automatic firework production line

InactiveCN104495270AImprove palletizing efficiencySmooth runningStacking articlesDe-stacking articlesProduction lineStack machine

The invention provides a pallet supplying and stacking system of an automatic firework production line. The system comprises a first conveyor, a second conveyor, a third conveyor, a fourth conveyor, a pallet supplying machine and a stacking machine, wherein the first conveyor is used for receiving and transmitting dried pallet groups; the second conveyor is used for transmitting single pallets; the third conveyor is used for transmitting storage racks; the fourth conveyor is used for transmitting the storage racks with the pallets to a next procedure; the pallet supplying machine is located between the first conveyor and the second conveyor, and is used for receiving the pallet groups transmitted by the first conveyor, and for transferring the single pallets in the pallet groups to the second conveyor; the stacking machine is located among the second conveyor, the third conveyor and the fourth conveyor, and is used for placing the single pallets transmitted by the second conveyor onto the storage racks transmitted by the third conveyor, and then sending the storage racks with the pallets onto the fourth conveyor. The system has the advantages of high stacking efficiency, safety, reliability, stability in transfer, equipment firmness and durability, long service life and the like through the procedures of dried pallet group transmission, pallet supplying, chemical filling, storage rack transmission, stacking and the like after the completion of pelleting.

Owner:TANGSHAN COLLEGE

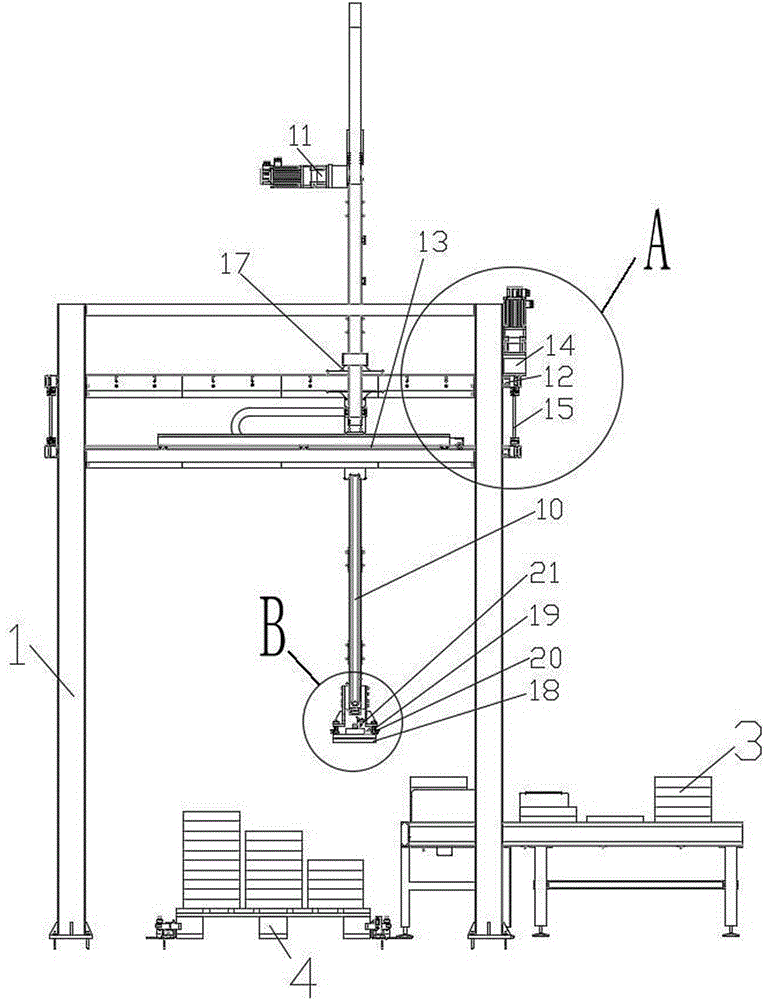

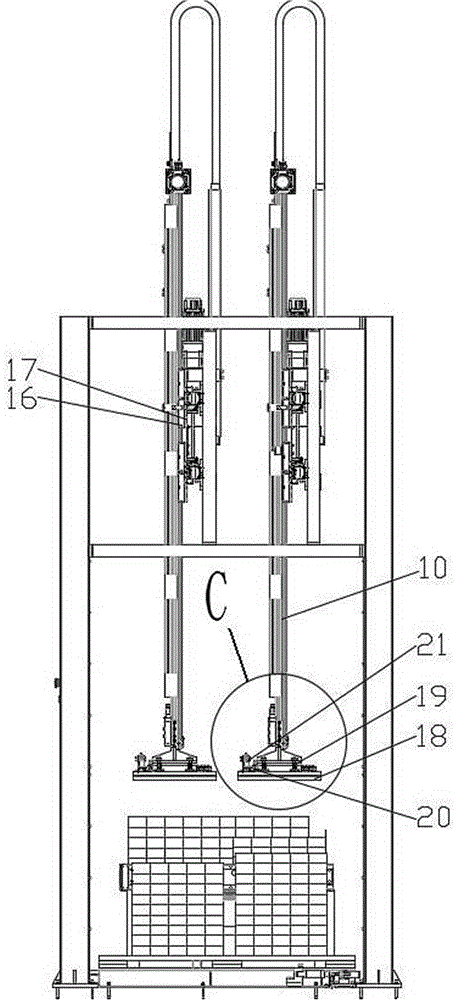

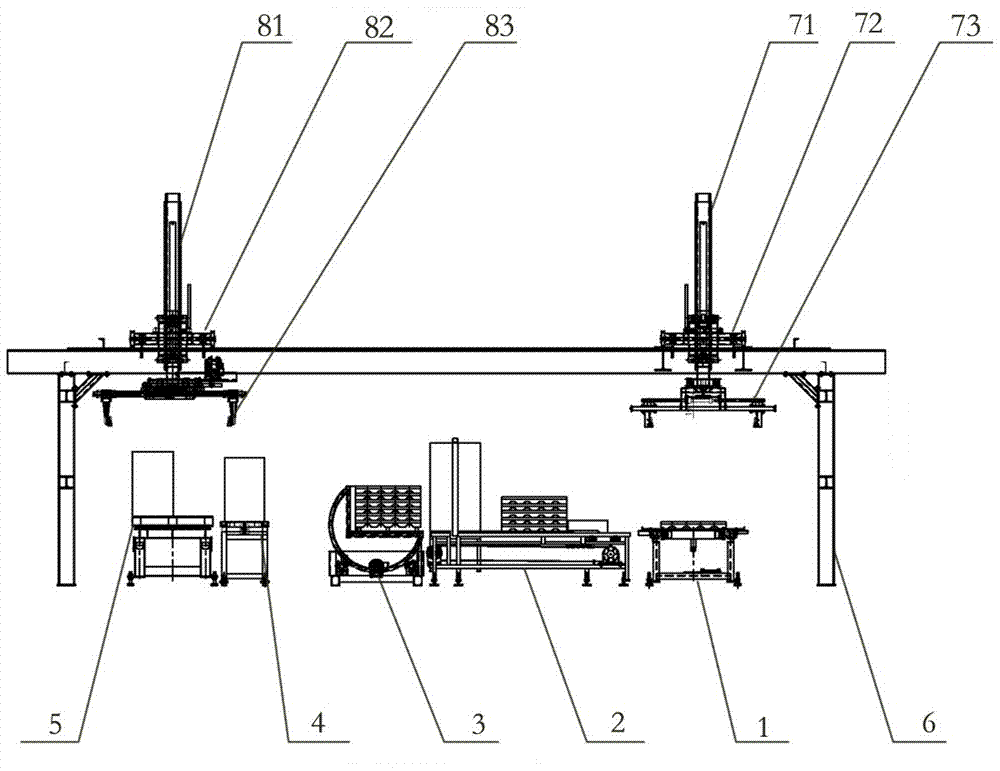

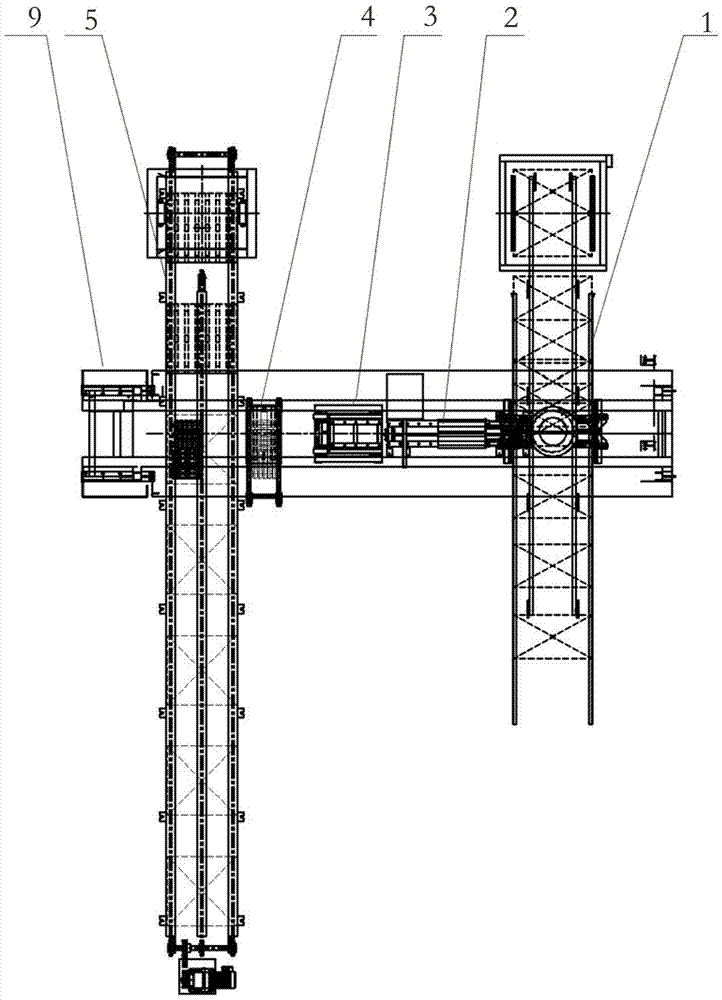

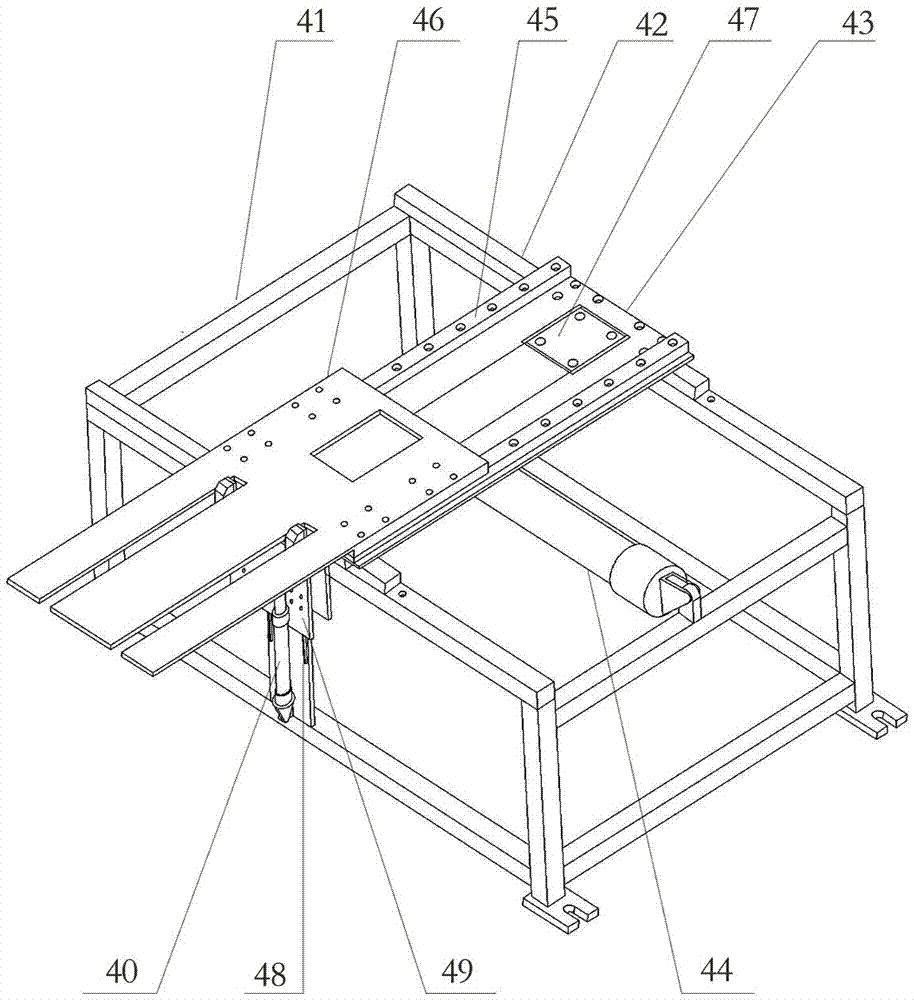

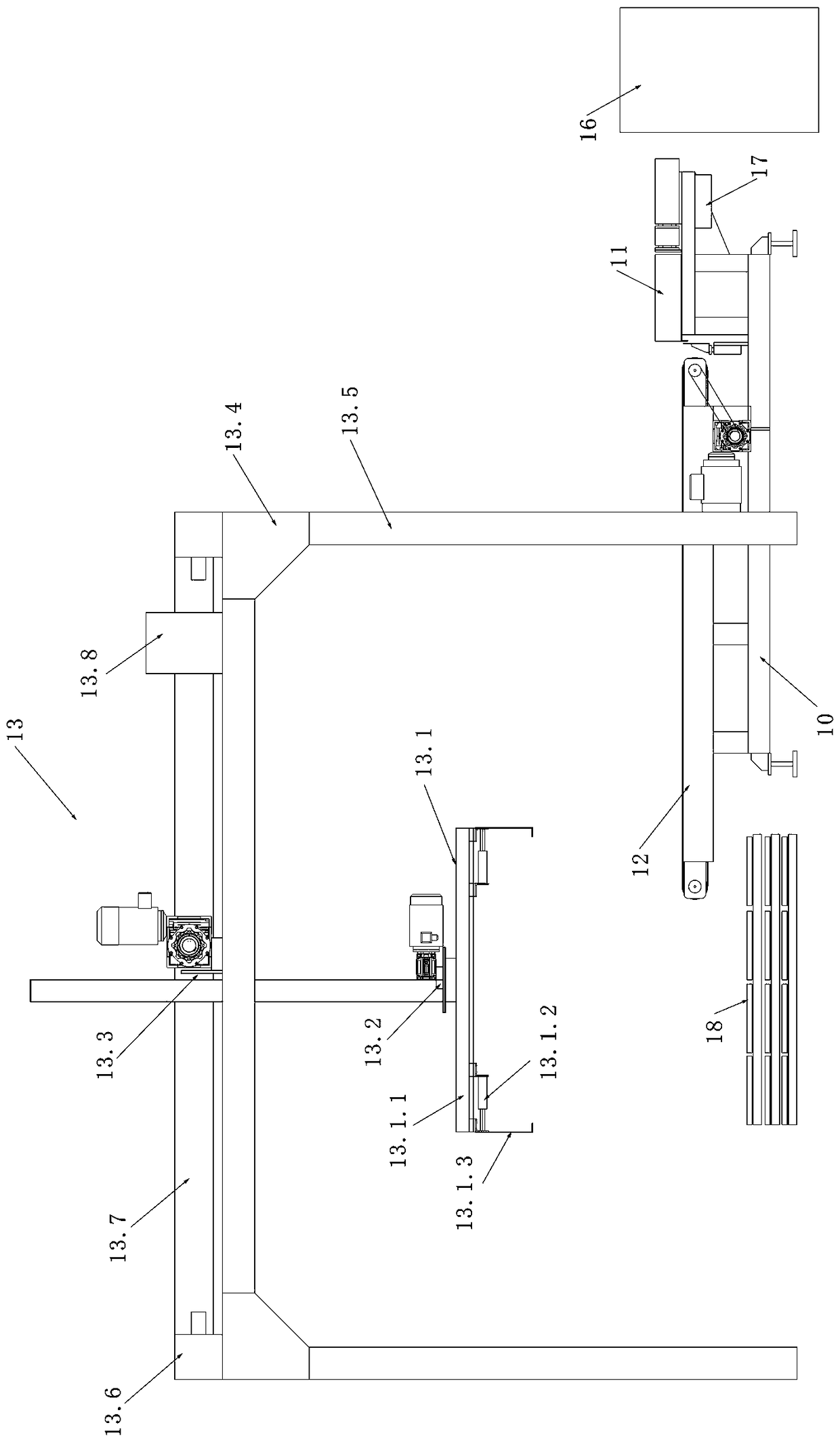

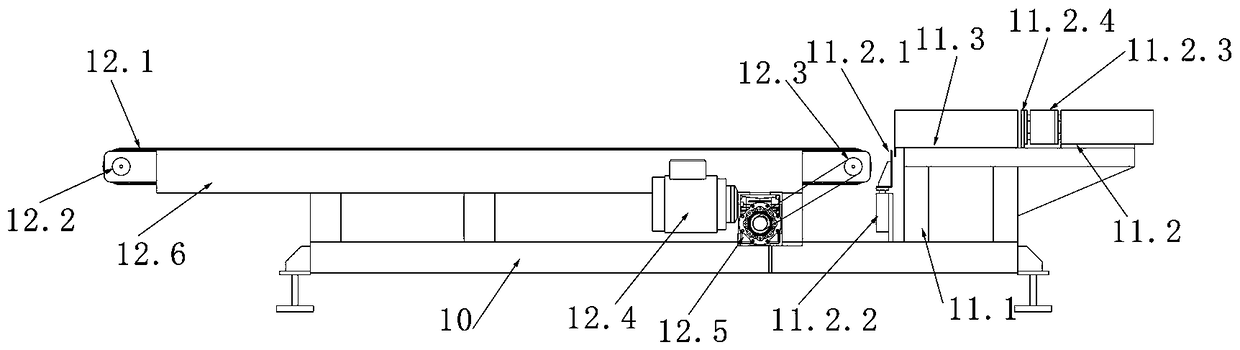

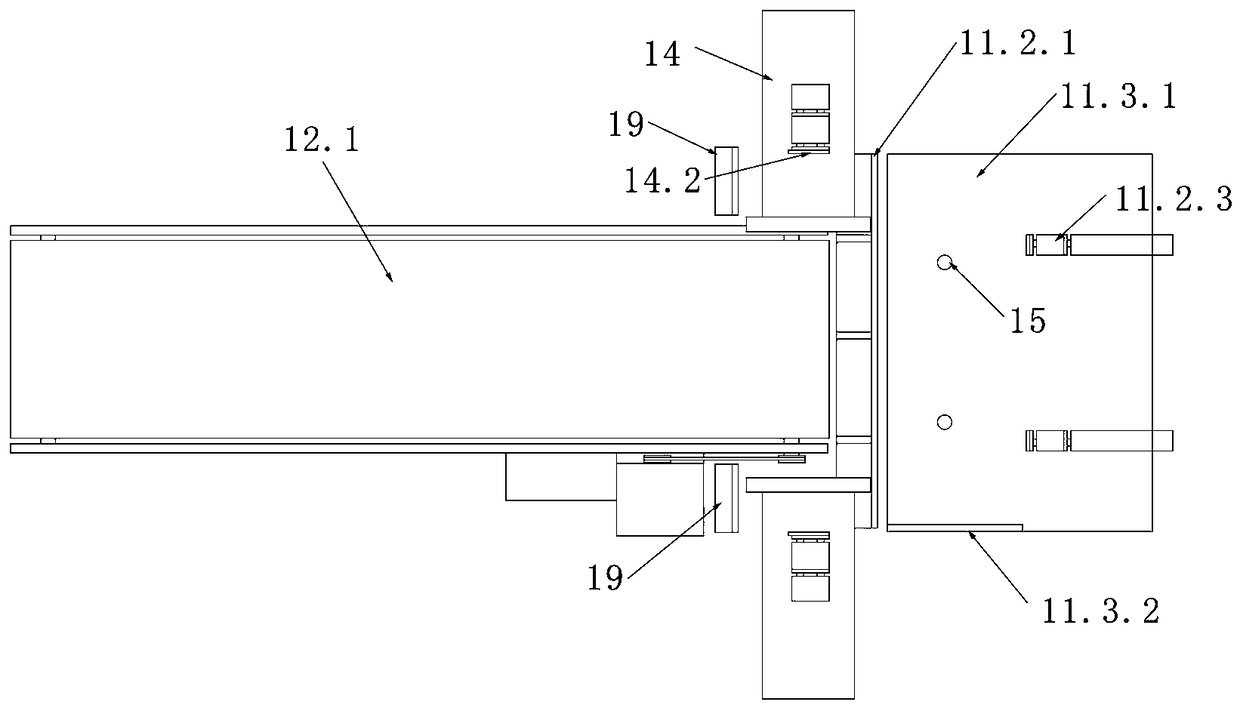

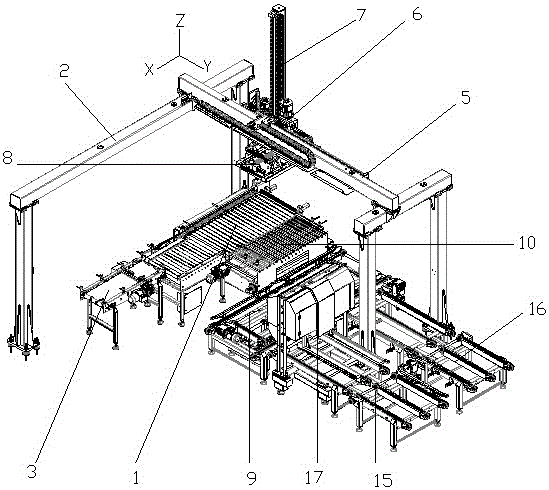

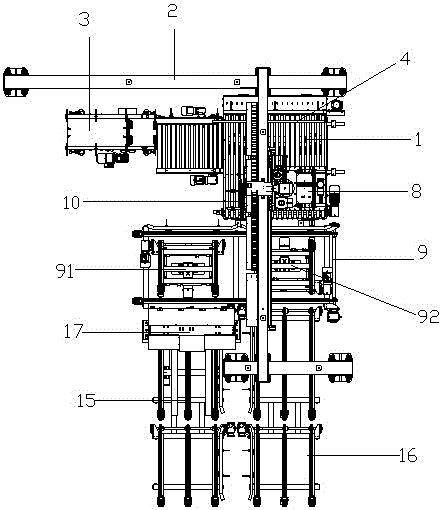

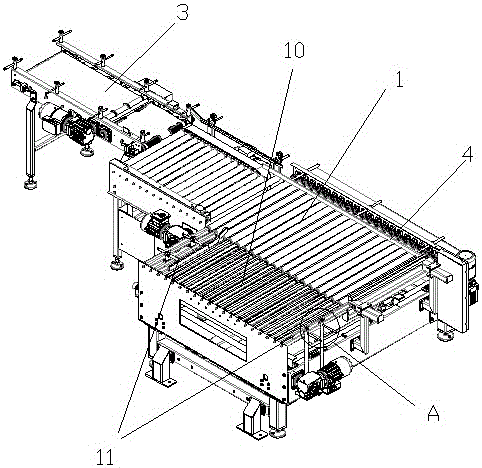

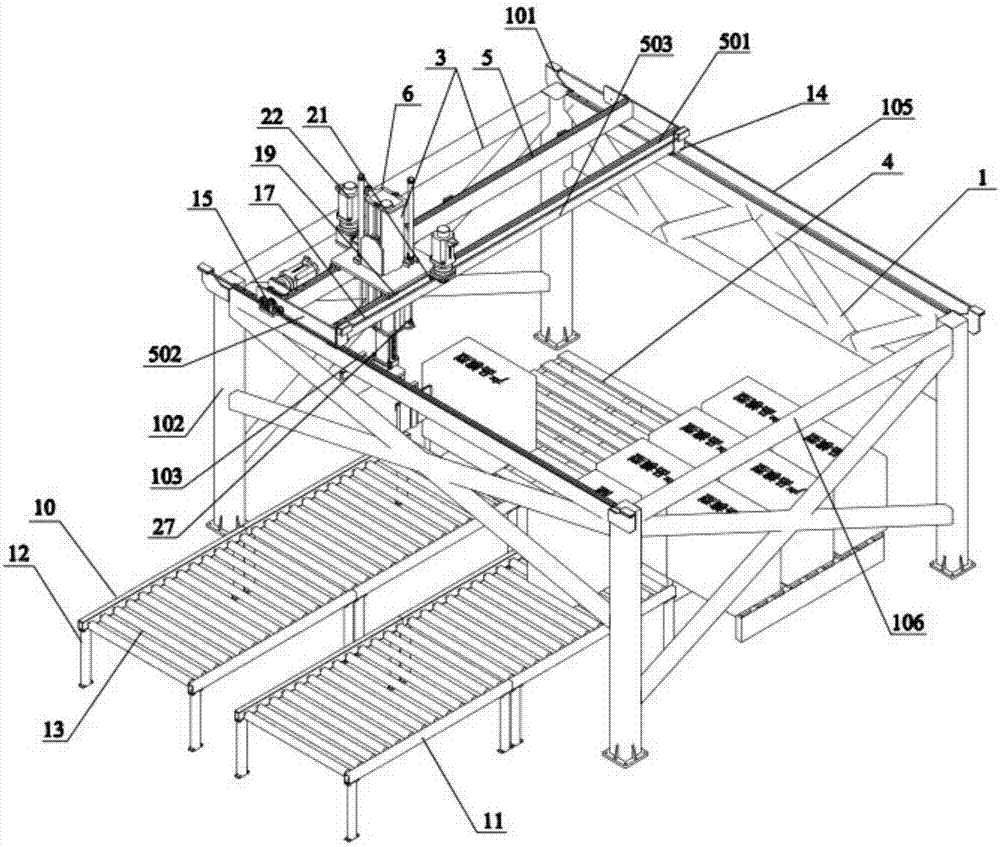

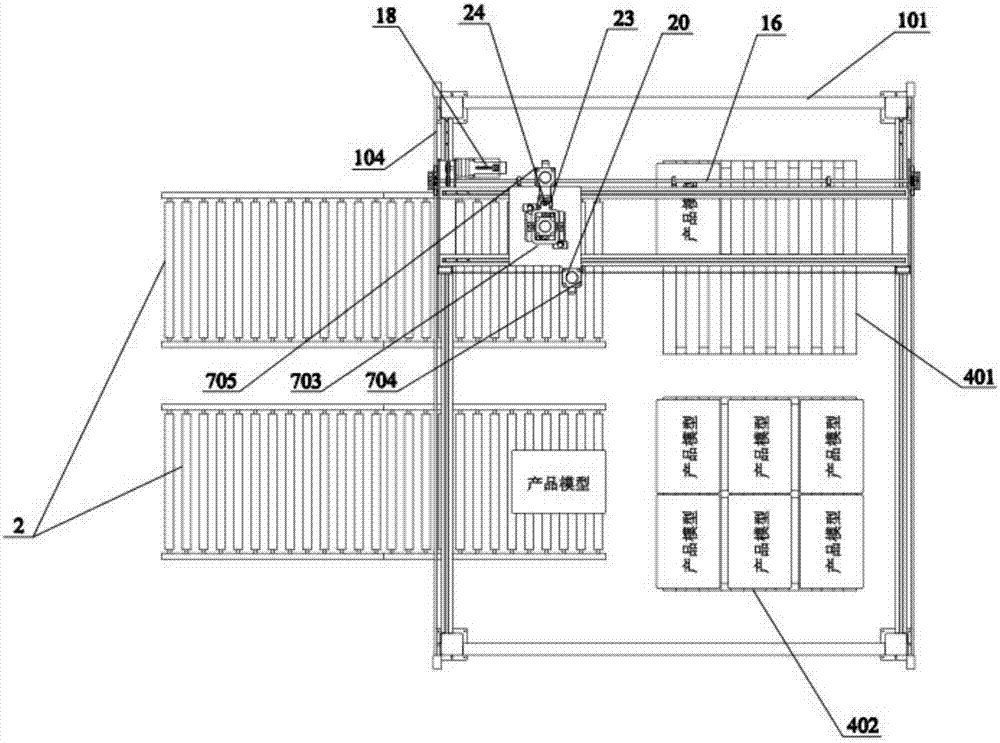

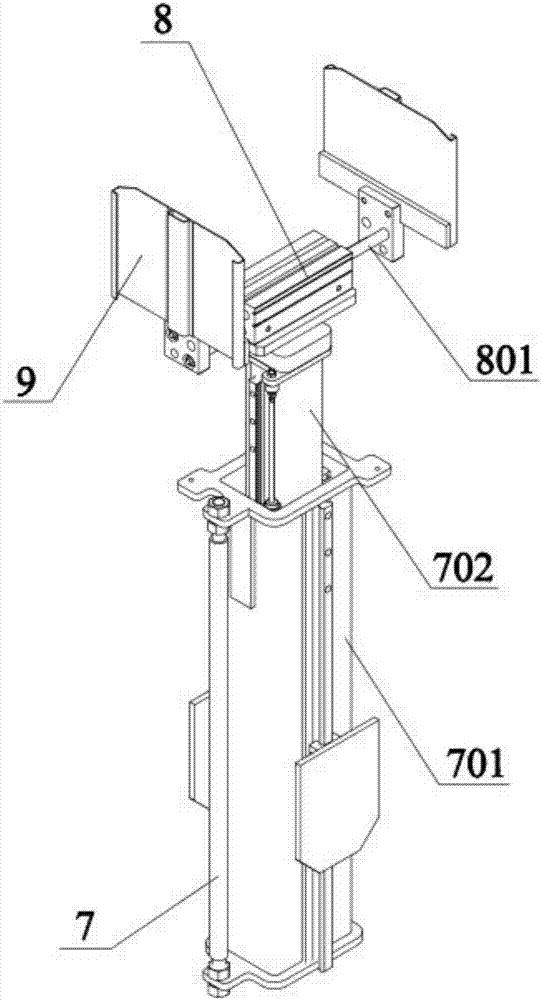

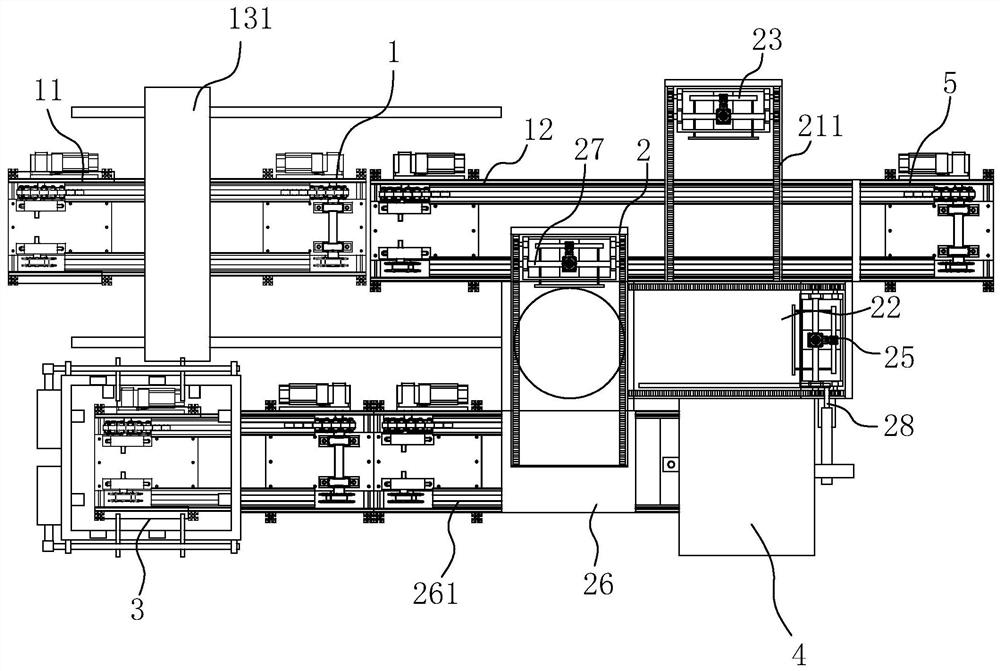

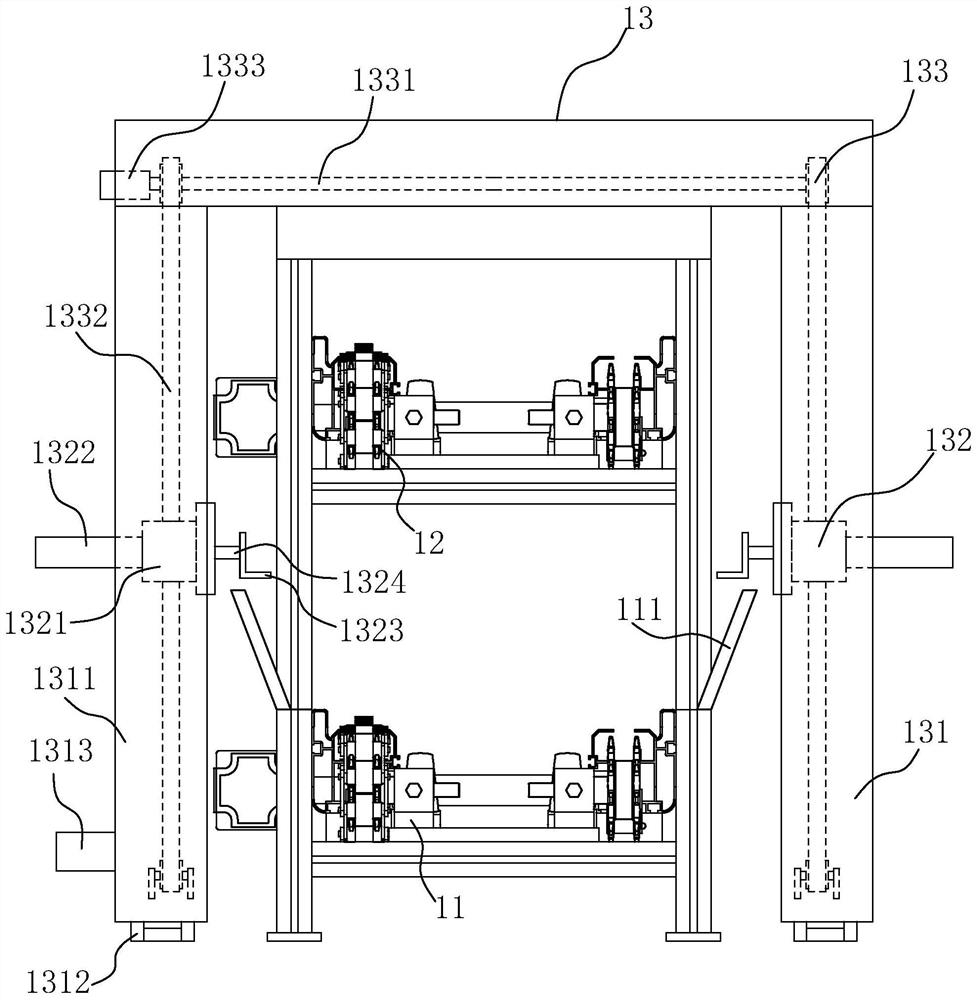

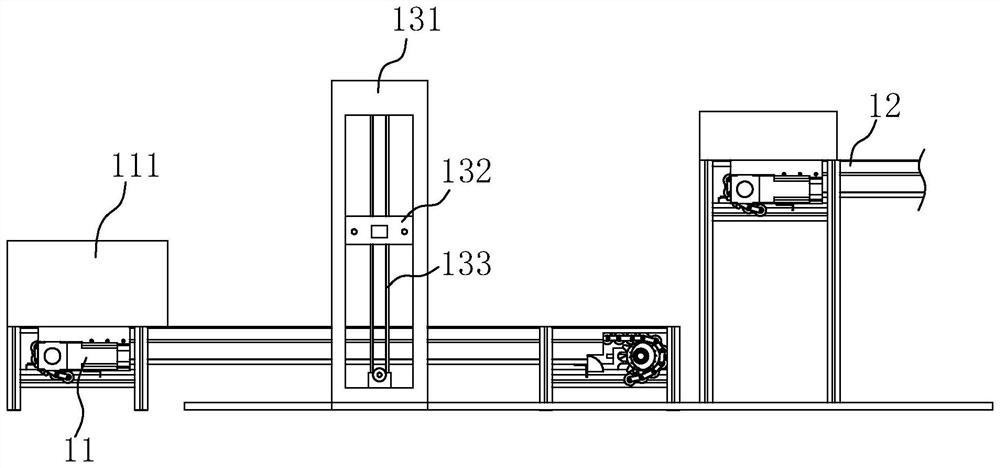

Truss robot stacking work station structure and use method thereof

ActiveCN106629088AHigh degree of automationImprove palletizing efficiencyStacking articlesDe-stacking articlesAssembly lineManipulator

The invention relates to the technical field of pallet stacking, and discloses a truss robot stacking work station structure. The work station comprises a material conveyor belt and a truss. The material feeding inlet end of the material conveyor belt is interfaced to an assembly line. The material conveyor belt is a roller conveyor belt. One side of the material conveyor belt is provided with a push rod. The bottom of the material conveyor belt is provided with a push rod translation mobile mechanism. The other side of the material conveying belt is provided with a container body pre-positioning platform. The truss is provided with a horizontal beam which is perpendicular to the moving direction of the material conveyor belt. The horizontal beam is provided with a slide base. The slide base is provided with a lifting base. The lower end of the lifting base is provided with a machine hand. The inner side of the container body pre-positioning platform is abutted on one side of the material conveying belt. The outer side of the container body pre-positioning platform is provided with a pallet adjustment support platform. The truss robot stacking work station structure and use method thereof have the advantages of being high in automation level, and high in stacking efficiency.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

Feeding car loader

PendingCN111807081AImprove palletizing efficiencyConveyorsControl devices for conveyorsProduction lineAutomotive engineering

The invention discloses a feeding car loader. The feeding car loader comprises a feeding device, a receiving and distributing device and a stacking device. When the feeding car loader is used, after material bags enter the receiving and distributing device through the feeding device, under the distributing action of the receiving and distributing device, the material bags enter a corresponding stacking line through one distributing outlet and enter another corresponding stacking line through another distributing outlet. Thus, by the adoption of the feeding car loader, the material bags fed bythe feeding device can be distributed into the multiple stacking lines for stacking operation, and only one front-end production line conveying device needs to be arranged to be connected with the feeding device. Thus, on the premise that the stacking efficiency of the feeding car loader is improved, the occupied space of the feeding car loader is reduced, and the equipment cost is reduced.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

Industrial stacking robot special for sharing bicycle flow line production

ActiveCN107176469AIncrease the scope of applicationImprove work efficiencyGripping headsStacking articlesManipulatorSingle vehicle

The invention relates to an industrial stacking robot special for sharing bicycle flow line production. The industrial stacking robot comprises a bottom plate. A fixed seat is installed in the middle of the upper end of the bottom plate. A rotary table is installed on the fixed seat through a bearing. An outer gear is installed on the outer wall of the rotary table. Four driving mechanisms mesh with the outer gear symmetrically and are installed on the bottom plate. Driving force of the four driving mechanisms on the outer gear is large and uniform. A flexible arm which can be adjusted by multiple angles is installed on the rotary table. An adjusting mechanism is installed between the lower end of the flexible arm and the outer wall of the rotary table. A manipulator is installed on the lower side of the tail end of the flexible arm, and the driving mechanisms, the adjusting mechanism and the flexible arm are matched with the manipulator to complete the sharing bicycle automatic stacking process. The industrial stacking robot can achieve a full-automatic flow line stacking function of sharing bicycles, manual stacking is not needed, and the industrial stacking robot has the advantages of being simple and convenient to operate, and high in stacking speed, stacking efficiency and work efficiency and the like.

Owner:JIAYING UNIV

Special-shaped cigarette stacking device and stacking method

ActiveCN105173749AShorten the vertical lifting strokeConvenience to workStacking articlesDe-stacking articlesUltimate tensile strengthMechanical engineering

Owner:GUIZHOU HUILIAN TECH LIMITED

Movable high-altitude lifting operation platform used for stacking automobile parts in warehouse

The invention provides a movable high-altitude lifting operation platform used for stacking automobile parts in a warehouse. The movable high-altitude lifting operation platform comprises a rack, a conveying device, a grabbing device and two stacking pallets. The grabbing device comprises a rectangular moving mechanism and a manipulator. The manipulator comprises a first air cylinder, a second air cylinder and two pneumatic claws. Two short plates of the rectangular moving mechanism are arranged on first sliding rails in a striding mode correspondingly, and second sliding rails are arranged on two long plates of the rectangular moving mechanism correspondingly. The first air cylinder comprises a shell and an inner core, wherein the shell is arranged on the second sliding rails in a striding mode through a fixing plate, and the inner core is connected with the second air cylinder. The second air cylinder comprises two piston rods, and the two piston rods are connected with the two pneumatic claws correspondingly. The conveying device comprises a part feeding mechanism and a part discharging mechanism, and the part feeding mechanism and the part discharging mechanism are arranged side by side. The stacking pallets comprise the first pallet matched with the part feeding mechanism and the second pallet matched with the part discharging mechanism. By adoption of the movable high-altitude lifting operation platform used for stacking the automobile parts in the warehouse, the problem that existing stacking equipment is low in stacking efficiency and high in labor intensity is solved.

Owner:宁波天伟汽车部件有限公司

Multi-channel stack pattern forming device

ActiveCN106477310AShorten molding timeImprove palletizing efficiencyConveyorsStacking articlesMechanical engineeringMulti channel

Owner:JIANGSU NEWAMSTAR LIQUID PACKAGING ENG TECH RES CENT CO LTD

Brick stacking system

The invention relates to a brick stacking system. The brick stacking system comprises a feeding and transferring mechanism used for conveying a maintenance unit, a tidying mechanism used for pushing bricks away from supporting plates to tidy and arrange the bricks, a stacking mechanism being in butt joint with the tidying mechanism and used for stacking the arranged bricks, a supporting plate separating mechanism being in butt joint with the feeding and transferring mechanism and used for stacking and arranging the supporting plates and a pallet feeding mechanism being in butt joint with the stacking mechanism and used for conveying pallets to the stacking mechanism. The stacking mechanism comprises a stacking frame, a lifting and stacking mechanism, a blocking assembly, a clamping and arranging assembly and a pressing and stacking assembly. When in use, the feeding and transferring mechanism conveys the maintenance unit, the pallet supply mechanism supplies the pallets to the stackingmechanism, the tidying mechanism tidies the bricks, so that the bricks are arranged orderly and tightly, then the bricks are transferred to the lifting and stacking mechanism, limiting and stacking of the bricks are achieved, and the stacking efficiency is improved.

Owner:徐州凯润环保科技股份有限公司

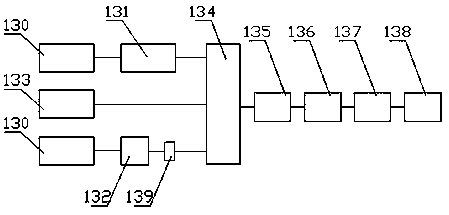

Corrugated paper board production line

PendingCN109551825AHeating fastHeating is fast by electromagnetic heatingMechanical working/deformationPile receiversProduction lineCardboard

The invention provides a corrugated paper board production line. The corrugated paper board production line comprises a pair of body paper frame lifting arms (130), a surface paper preheating mechanism (131), an inner paper preheating mechanism (132), a single corrugated machine (133), a draping machine (134), a dryer (135), a slitting machine (136), a transverse cutting machine (137) and a stacking machine (138). The corrugated paper board production line has the advantages that 1, the body paper frame lifting arms can generate power in the process of paper roll rotating, and recycling and reusing of energy consumption are achieved; 2, surface paper is heated to enable a semi-circular heating plate to generate heat through an electromagnetic heating module, heating is quick, the temperature control is precise, the heating quality of the surface paper is improved, the semi-circular heating plate is convenient and quick to be assembled and disassembled, and the working efficiency is improved; 3, halt is not required when single exchanging is carried out on single and double surfaces of corrugated paper boards, single exchanging is carried out through an automatic cutting and connecting device, and the working efficiency is greatly improved; and 4, the paper boards are batched and stacked in a dislocation mode through a moving batch-wise working section, so that the stacking efficiency and quality are obviously improved.

Owner:HUBEI JINGSHAN LIGHT INDAL MACHINERY

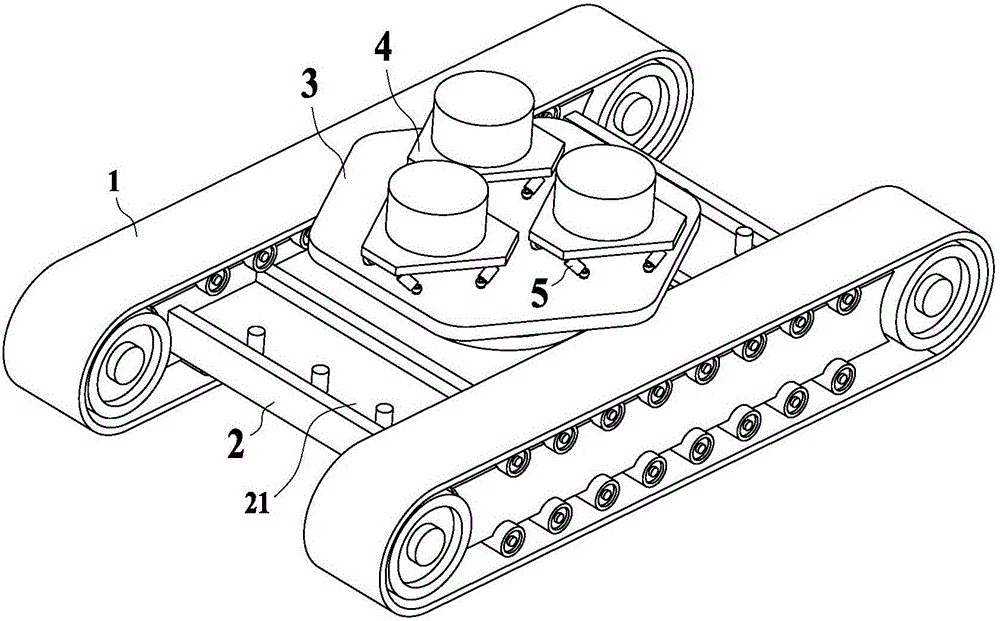

Multi-manipulator-cooperating robot palletizer

The invention relates to the field of robots and particularly relates to a multi-manipulator-cooperating robot palletizer. The multi-manipulator-cooperating robot palletizer comprises crawler travel mechanisms, a chassis, a rotating table, fine-adjustment tables, fine-adjustment air cylinders and three manipulators; the crawler travel mechanisms are located at the two sides of the chassis, the rotating table is located at the middle part of the chassis, the fine-adjustment tables are located at the upper end of the rotating table, the fine-adjustment air cylinders are located between the rotating table and the fine-adjustment tables, the manipulators are located at the upper ends of the fine-adjustment tables, and claws are separately mounted at the end parts of all the manipulators; the rotating table, the fine-adjustment air cylinders and all the fine-adjustment tables form a Stewart parallel platform; three identical or different claws can be mounted at the end parts of the three manipulators. According to the multi-manipulator-cooperating robot palletizer, the palletizing efficiency is high, the labor intensity for workers is lightened, and different goods can be palletized simultaneously; the accuracy of grabbing and palletizing the goods is high, so that the damage to the goods is greatly reduced.

Owner:南京创翼少儿科教技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com