Brick stacking system

A stacking system and brick technology, applied in the field of brick processing equipment, can solve the problems of cumbersome and complicated operation process, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

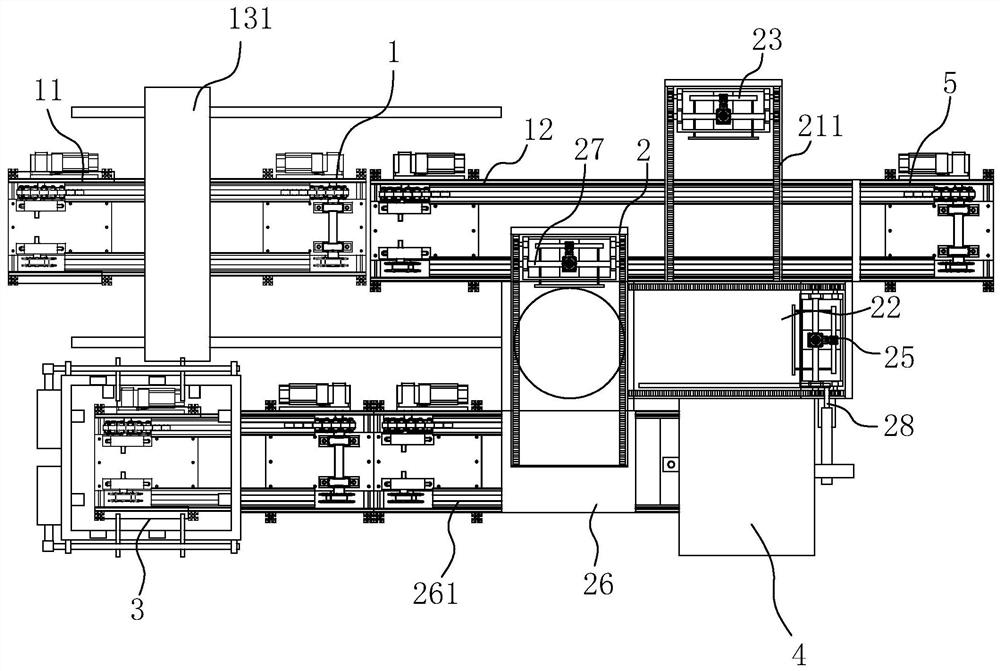

[0080] A brick palletizing system such as figure 1 As shown, it includes: a feeding and transferring mechanism 1 for conveying a curing unit, the curing unit includes a pallet and a layer of bricks laid on the pallet; a mechanism for pushing the bricks away from the pallet for arrangement Material sorting mechanism 2; docking with material sorting mechanism 2, stacking mechanism 4 for palletizing finished bricks; docking with feeding transfer mechanism 1, used for stacking and sorting each pallet pallet disengagement mechanism 5;

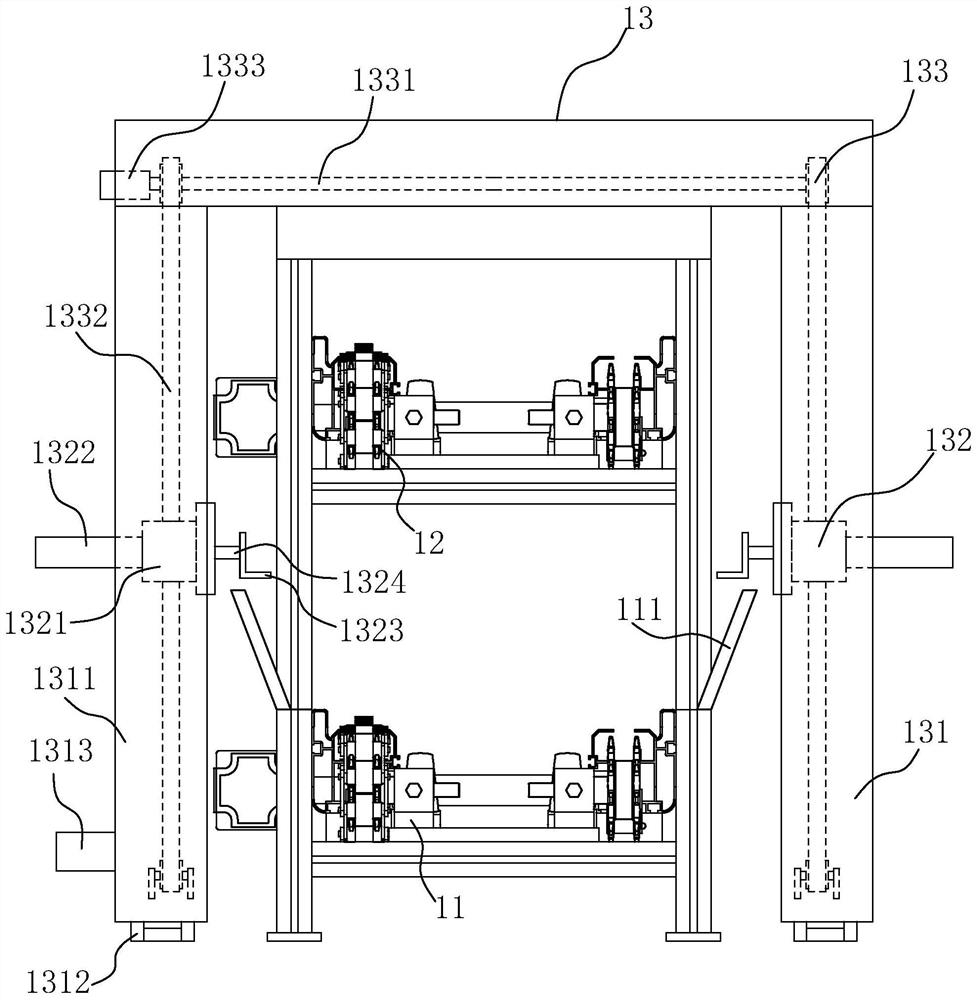

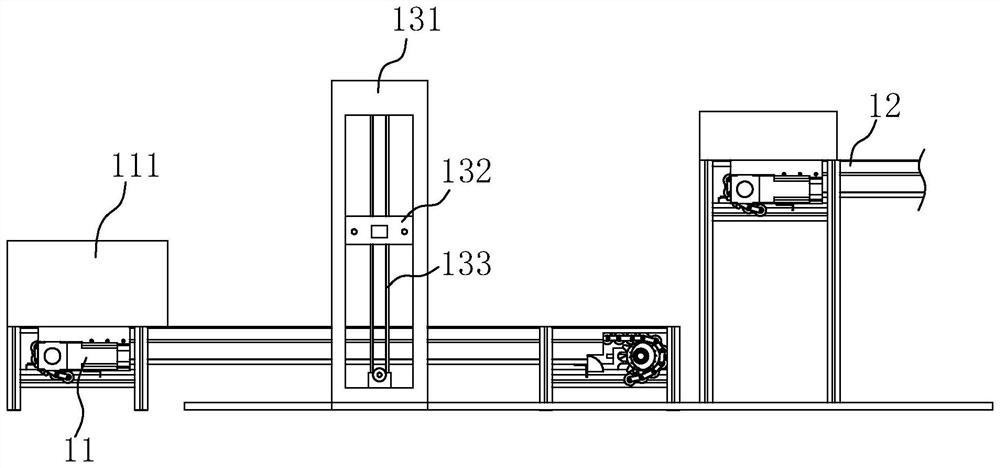

[0081] Specifically, such as figure 2 with image 3 As shown, the feeding and transferring mechanism 1 includes: a first conveying line 11 for transporting several stacked curing units; a second conveying line 12 for conveying the curing units forward one by one, and the second conveying line 12 is higher than The first conveying line 11 ; the clamping and shifting mechanism 13 for transferring the curing units from the first conveying line 11 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com